Method for recycling N-methylformamide and diethylene glycol monomethyl ether in paint remover waste liquid

A technology of methyl formamide and diethylene glycol, which is applied in the field of recycling N-methyl formamide and diethylene glycol monomethyl ether in paint remover waste liquid, to save energy consumption, save equipment investment, and reduce energy consumption. The effect of consumption and equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

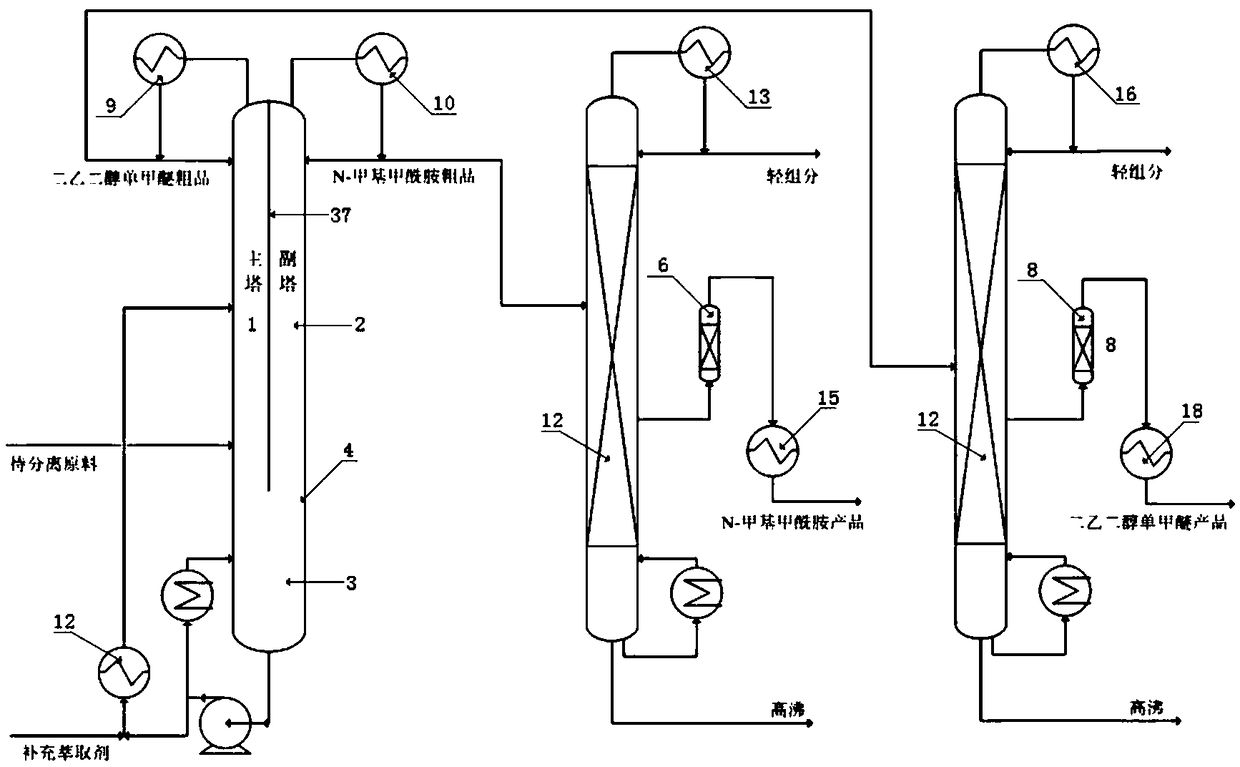

[0033] according to figure 1 Shown: The extraction partition distillation tower 4 is a packed tower with a tower diameter of 60mm. The tower body and packing are made of 304 stainless steel. The packing type is φ3mm×3mm θ ring packing. The tower height is 5m. The number of theoretical plates in the rectification section of sub-column 2 is 25, the number of theoretical plates in common stripping section 3 is 26, and the cross-sectional area ratio between the stripping section of sub-column 2 and the rectification section of main column 1 is 0.5. N-methylformamide refining tower 5 is a packed tower with a tower diameter of 40mm. The tower body and packing are made of 304 stainless steel. The packing type is φ3mm×3mm θ ring packing. The tower height is 3m. The number of theoretical plates in the rectification section is 12, and the number of theoretical plates in the stripping section is 20. N-methylformamide demetallization tower 6 is a packed tower with a tower diameter of 20m...

Embodiment 2

[0037] The extraction partition distillation column 4 is a packed column with a tower diameter of 60 mm. The tower body and packing are made of 304 stainless steel. The packing type is φ3mm×3mm θ ring packing. The tower height is 5m. The number of theoretical plates in the rectifying section is 25, the number of theoretical plates in the common stripping section 3 is 26, and the cross-sectional area ratio of the stripping section of the sub-column 2 to the rectifying section of the main column 1 is 0.5. N-methylformamide refining tower 5 is a packed tower with a tower diameter of 40mm. The tower body and packing are made of 304 stainless steel. The packing type is φ3mm×3mm θ ring packing. The tower height is 3m. The number of theoretical plates in the rectification section is 12, and the number of theoretical plates in the stripping section is 20. N-methylformamide demetallization tower 6 is a packed tower with a tower diameter of 20mm. The tower body and packing are made of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com