Patents

Literature

236 results about "Paint stripper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paint stripper, or paint remover, is a chemical product designed to remove paint, finishes, and coatings while also cleaning the underlying surface. The product's material safety data sheet provides more safety information than its product labels.

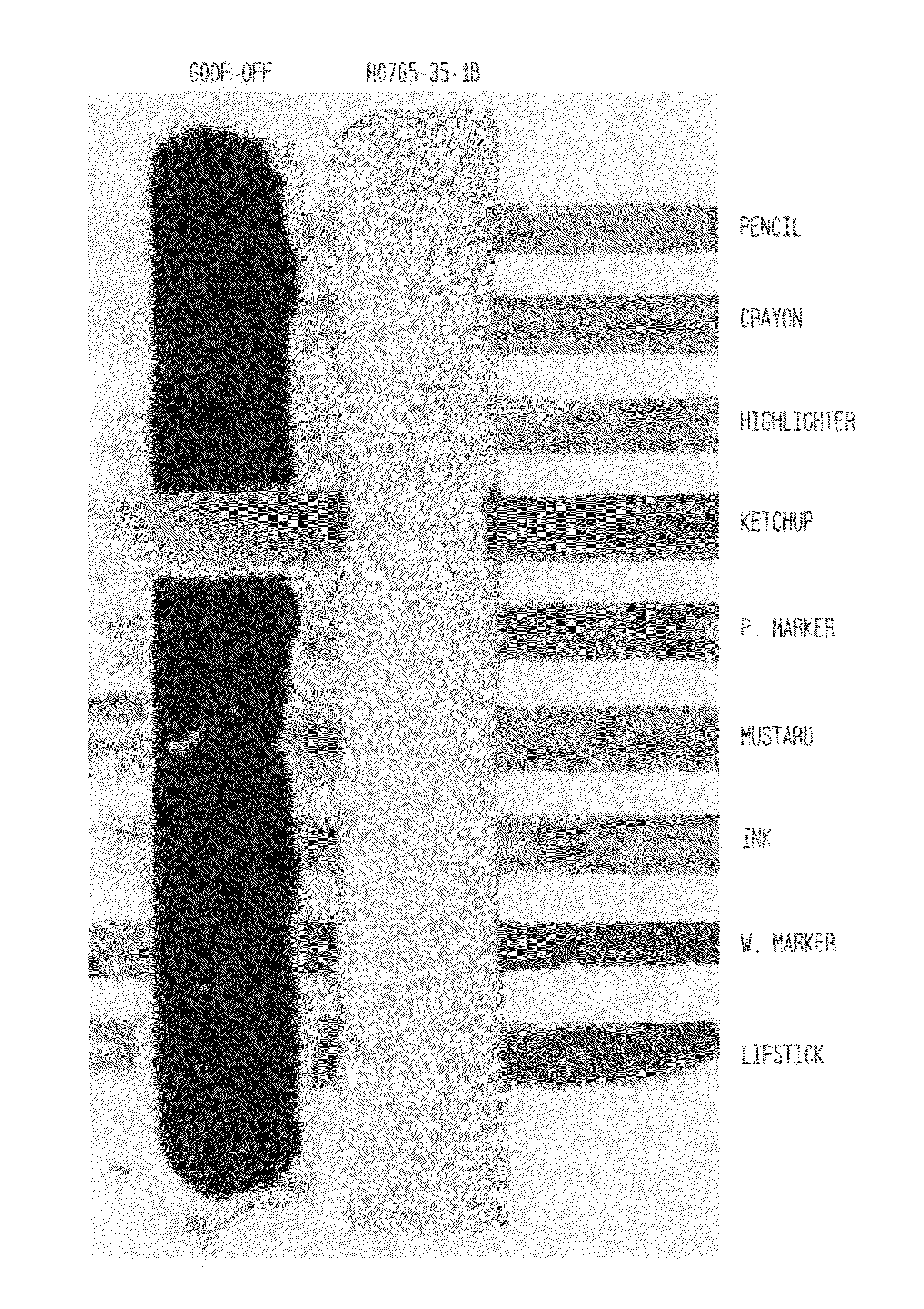

Cleaning compositions incorporating green solvents and methods for use

ActiveUS20090281012A1High flash pointLow vapor pressureOrganic detergent compounding agentsDetergent mixture composition preparationGlutaric acidActive agent

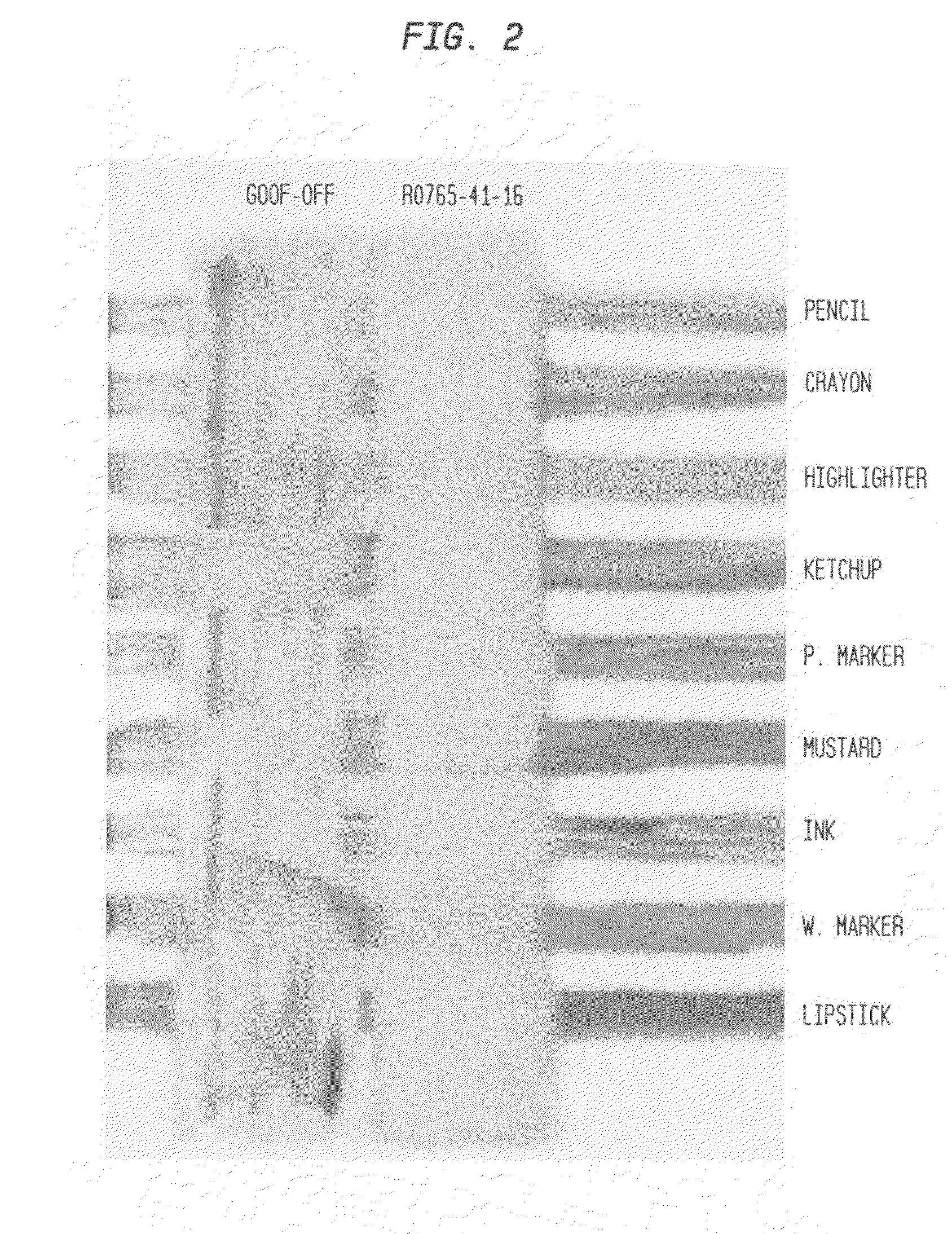

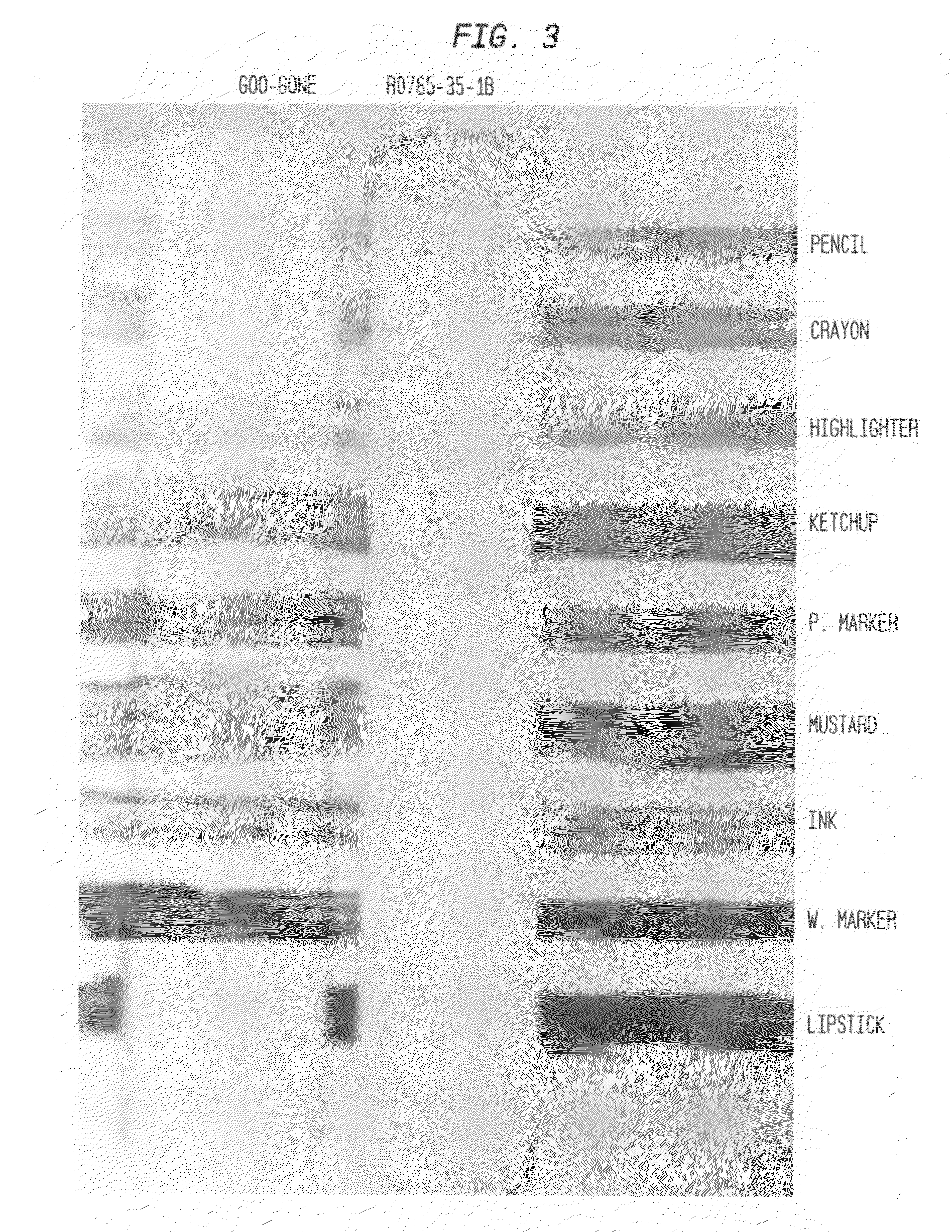

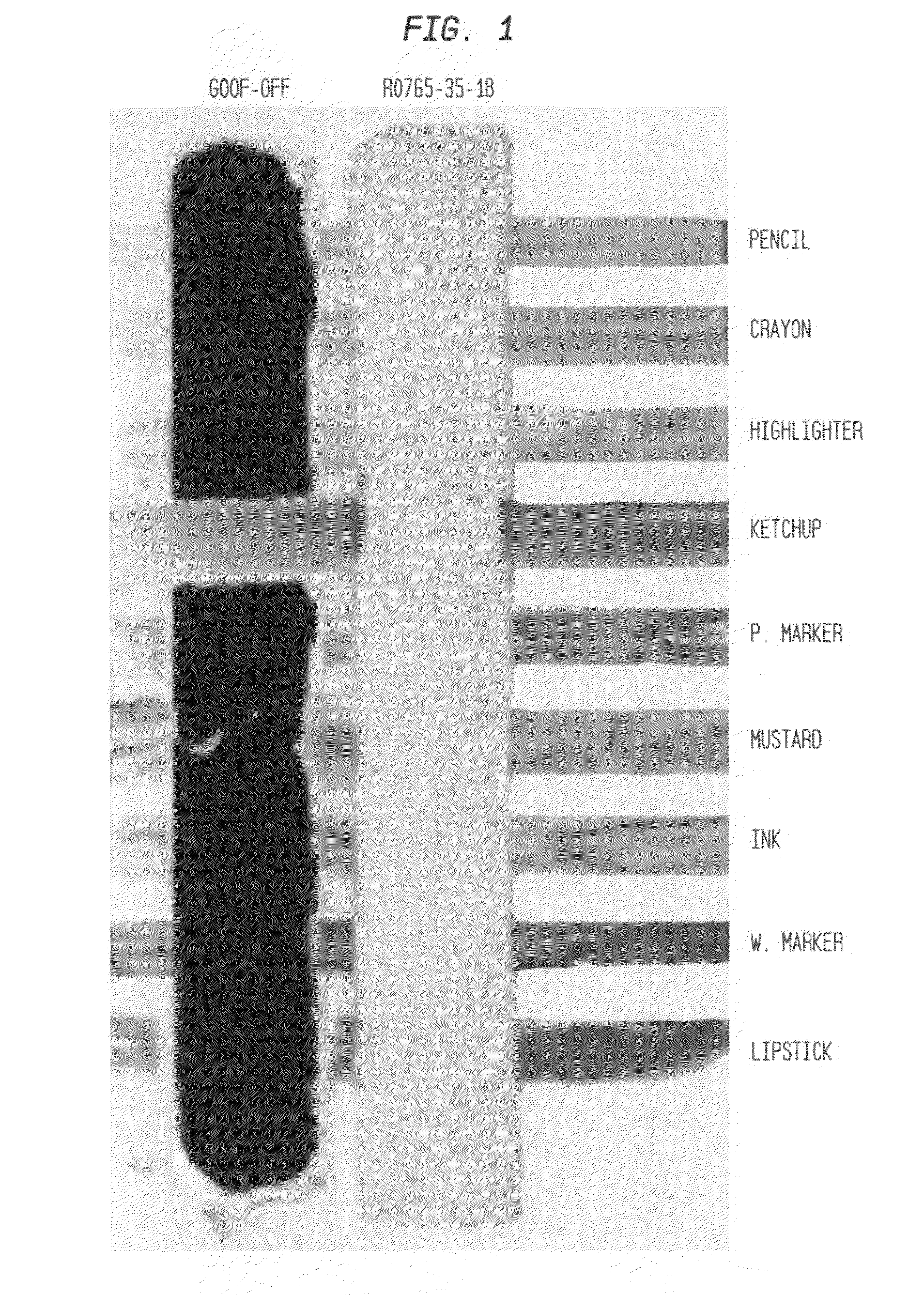

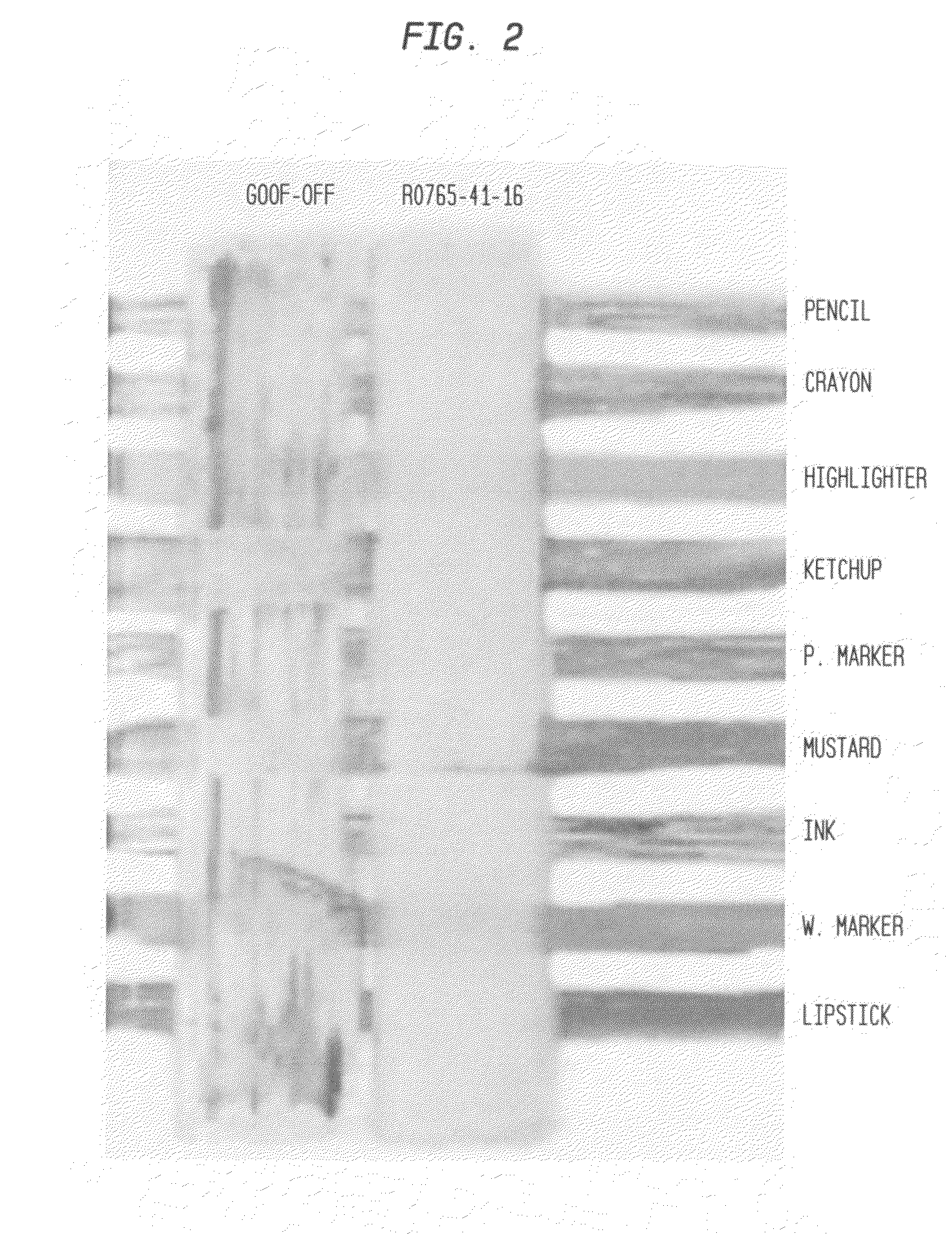

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Multifunctional chorine-free and benzene-free compound paint stripper and production method thereof

InactiveCN101684213ANo pollution in the processNot corrosiveChemical paints/ink removersSolventSealant

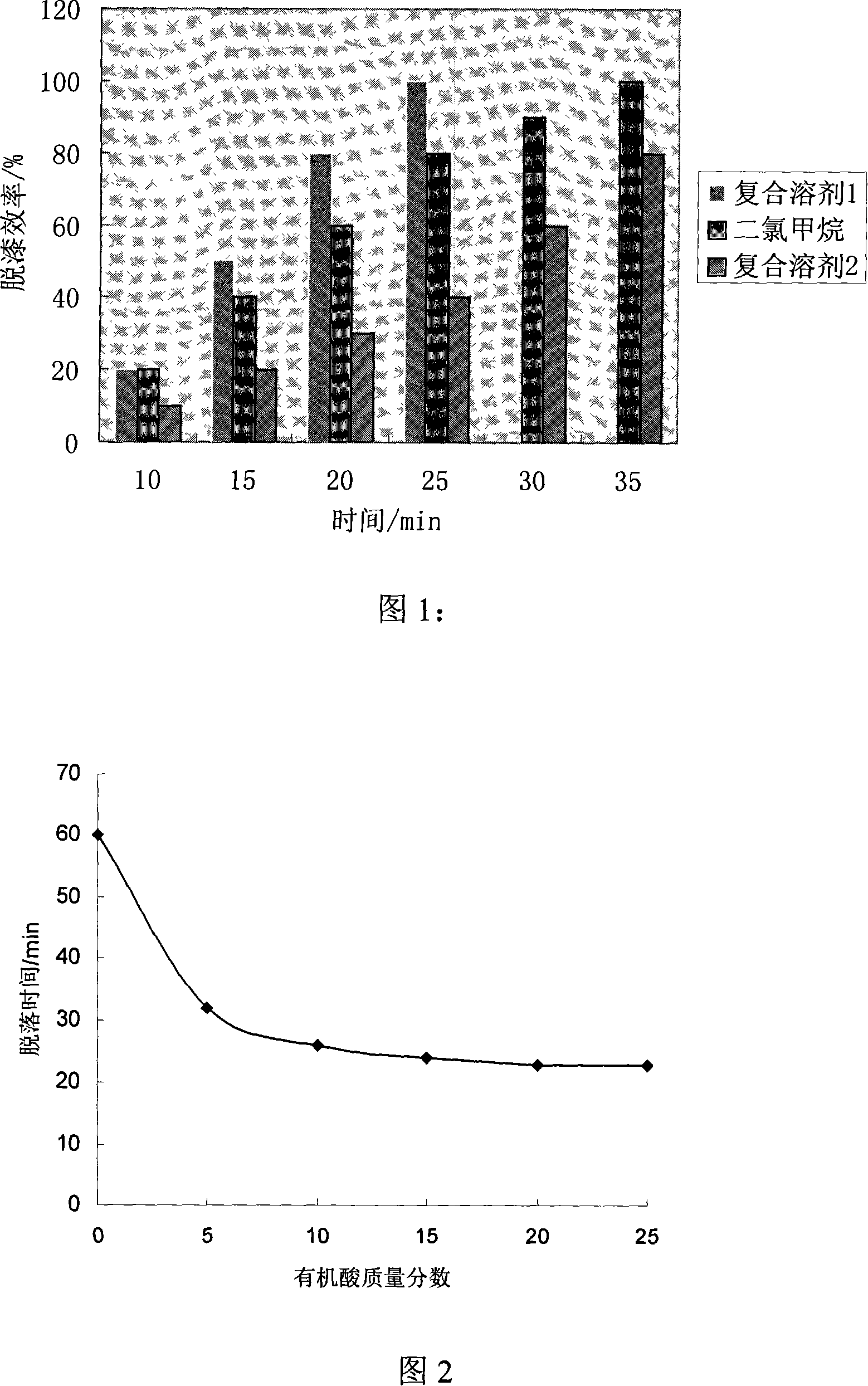

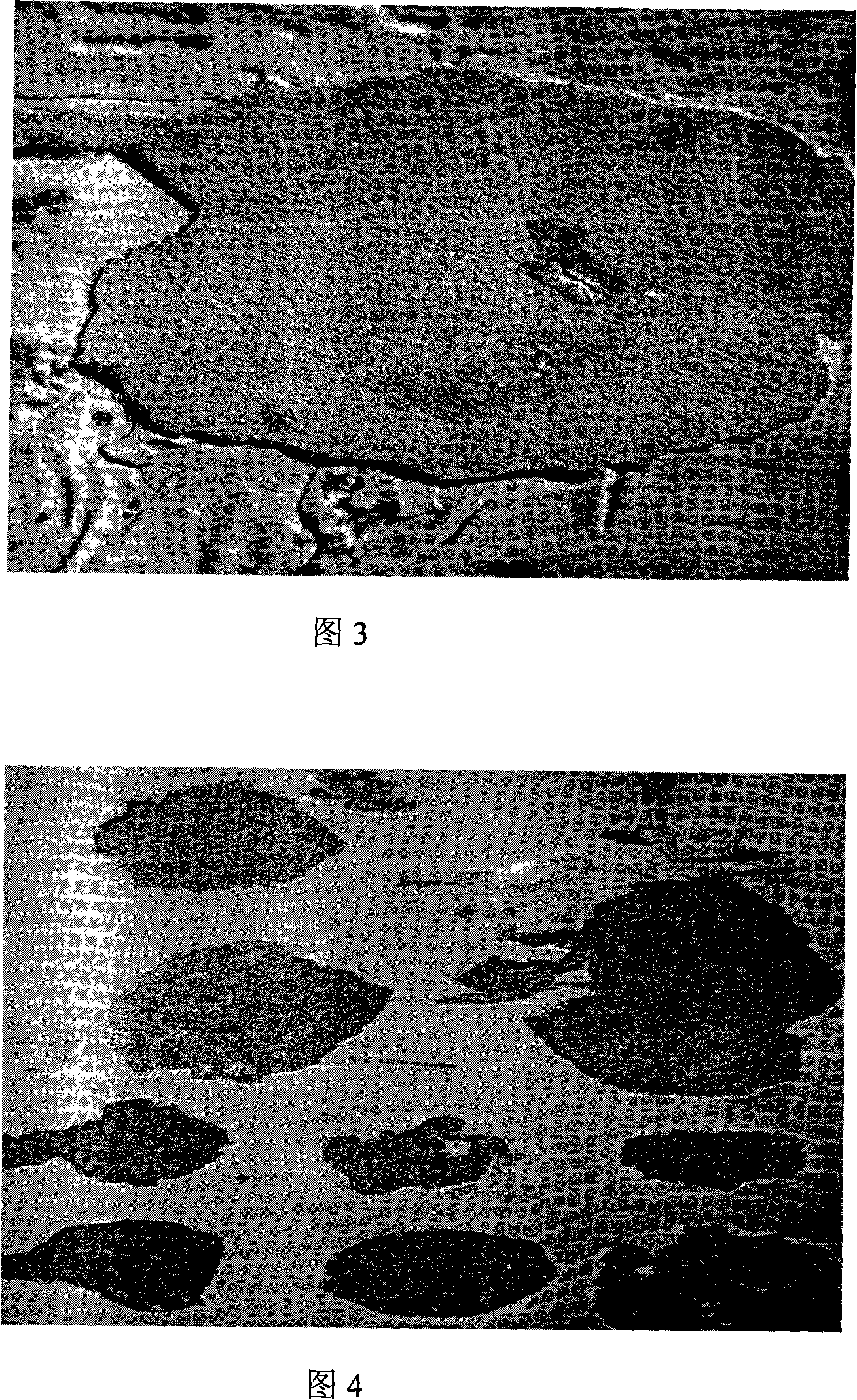

The invention discloses a multifunctional chorine-free and benzene-free compound paint stripper and a production method thereof. The multifunctional chorine-free and benzene-free compound paint stripper is a composition, which is characterized in that: the composition comprises the following components in part by weight: 30 to 60 parts of main solvent, 5 to 30 parts of latent solvent, 5 to 30 parts of solubilizer, 2 to 15 parts of accelerant, 2 to 15 parts of activating agent, 1 to 6 parts of osmotic agent, 0.5 to 2.5 parts of inhibitor, 1 to 8 parts of sealant, and 0.1 to 0.6 parts of thickening agent. The production method comprises the following steps: adding the main solvent in a reaction kettle; adding the latent solvent, the activating agent and the accelerant to the main solvent dropwise with stirring; stirring the mixture until the mixture is dissolved completely; adding the thickening agent and stirring the mixture until the thickening agent is dissolved; adding the thickeningagent to the mixture again and mixing with the solubilizer; and finally, adding the sealant and the inhibitor and stirring the mixture uniformly. The pain stripper in the invention avoids harm to a human body, environmental pollution and causticity, and has a large foaming area, a short paint stripping time, little dosage and high frequency when demoulding. The production method in the inventionis simple in process, less in device investment, rich in raw material resource and low in product cost.

Owner:CHANGSHU NANJING NORMAL UNIV DEV RES INST

Alkali paint remover and its preparing and using method

InactiveCN1775871AReduce corrosionReduce poisonChemical paints/ink removersAqueous solutionSodium hydroxide

The invention relates to alkaline paint remover and the method to manufacture that belongs to paint remover technology field. It is made up of sodium hydroxide solution, surface activator and assistant additive. The consistency of sodium hydroxide solution is 2-15%, surface activator hexadecyl trimethyl bromized amine 0.05-5%, and assistant additive 0.1-5%, and the other is water. Manufacturing method is that: making 2-15% consistency of sodium hydroxide solution; adding CTMAB 0.05-5%, and assistant additive 0.05-5%; dissolving fully under the temperature of 50-80 degree centigrade to gain paint remover. The advantages of the invention are low cost, low toxicity, fast paint removing, etc.

Owner:UNIV OF SCI & TECH BEIJING

Ink cleaning composition and methods for use

ActiveUS20100273695A1High flash pointLow vapor pressureDetergent mixture composition preparationChemical paints/ink removersDibasic esterGlutarates

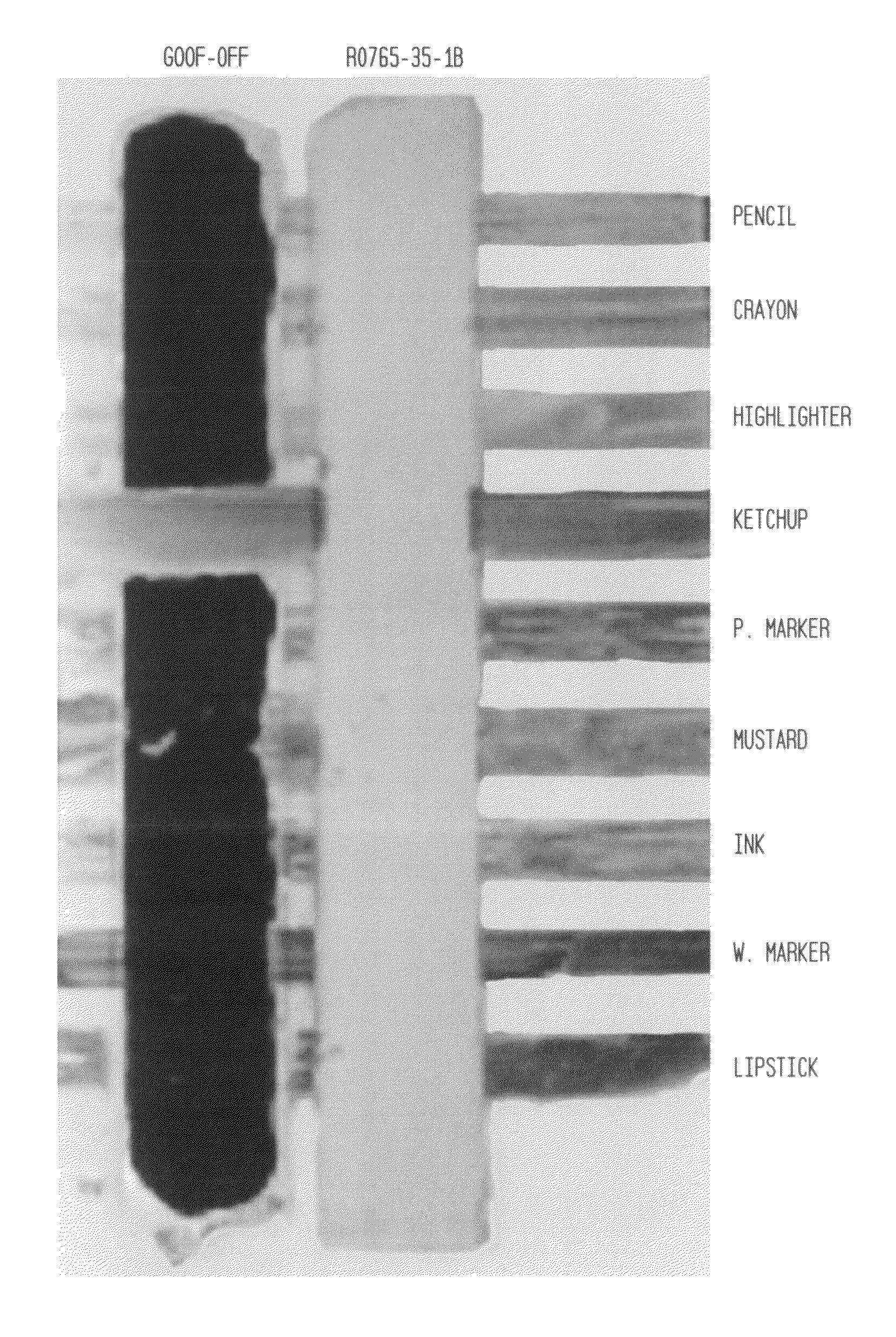

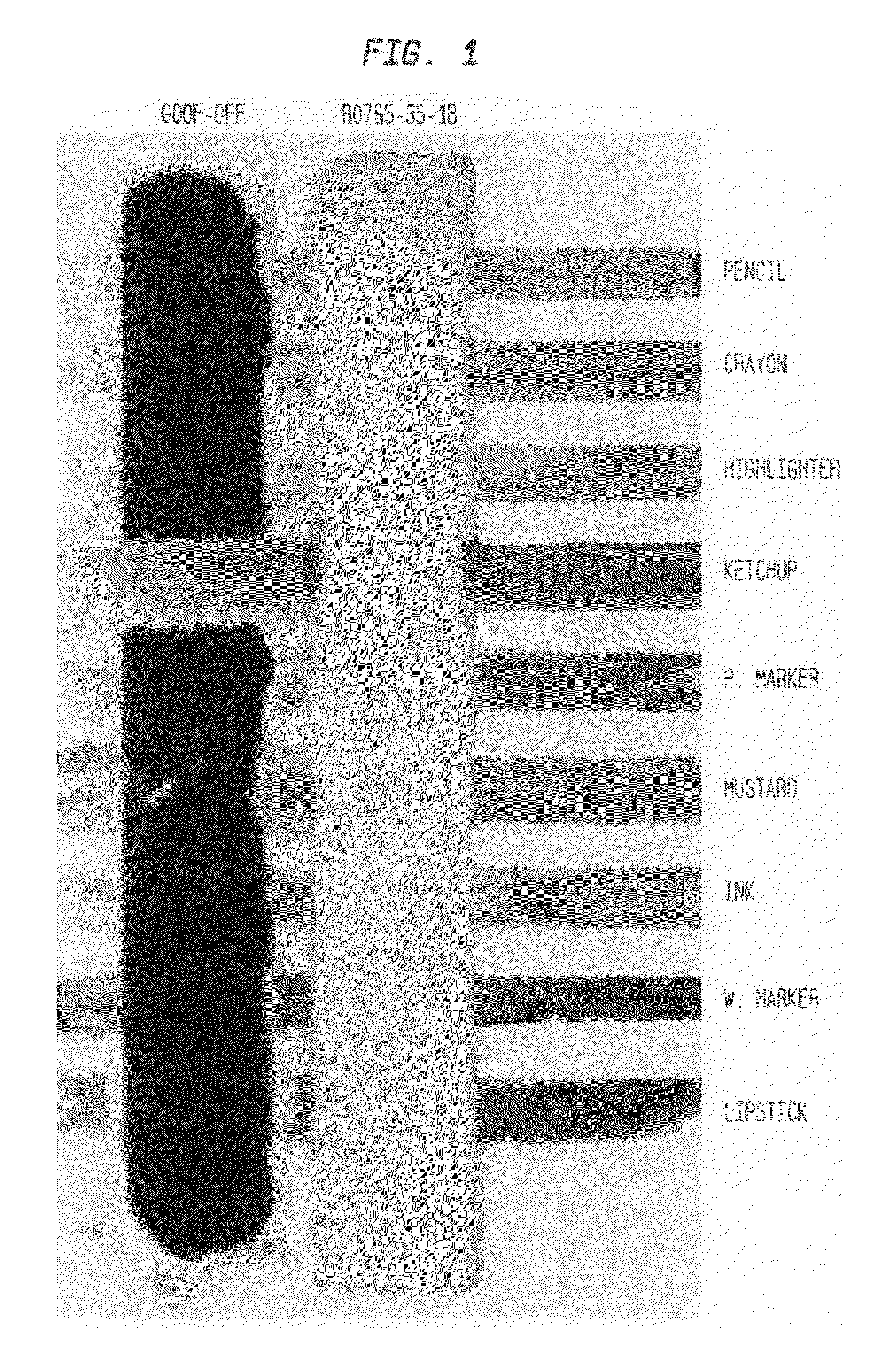

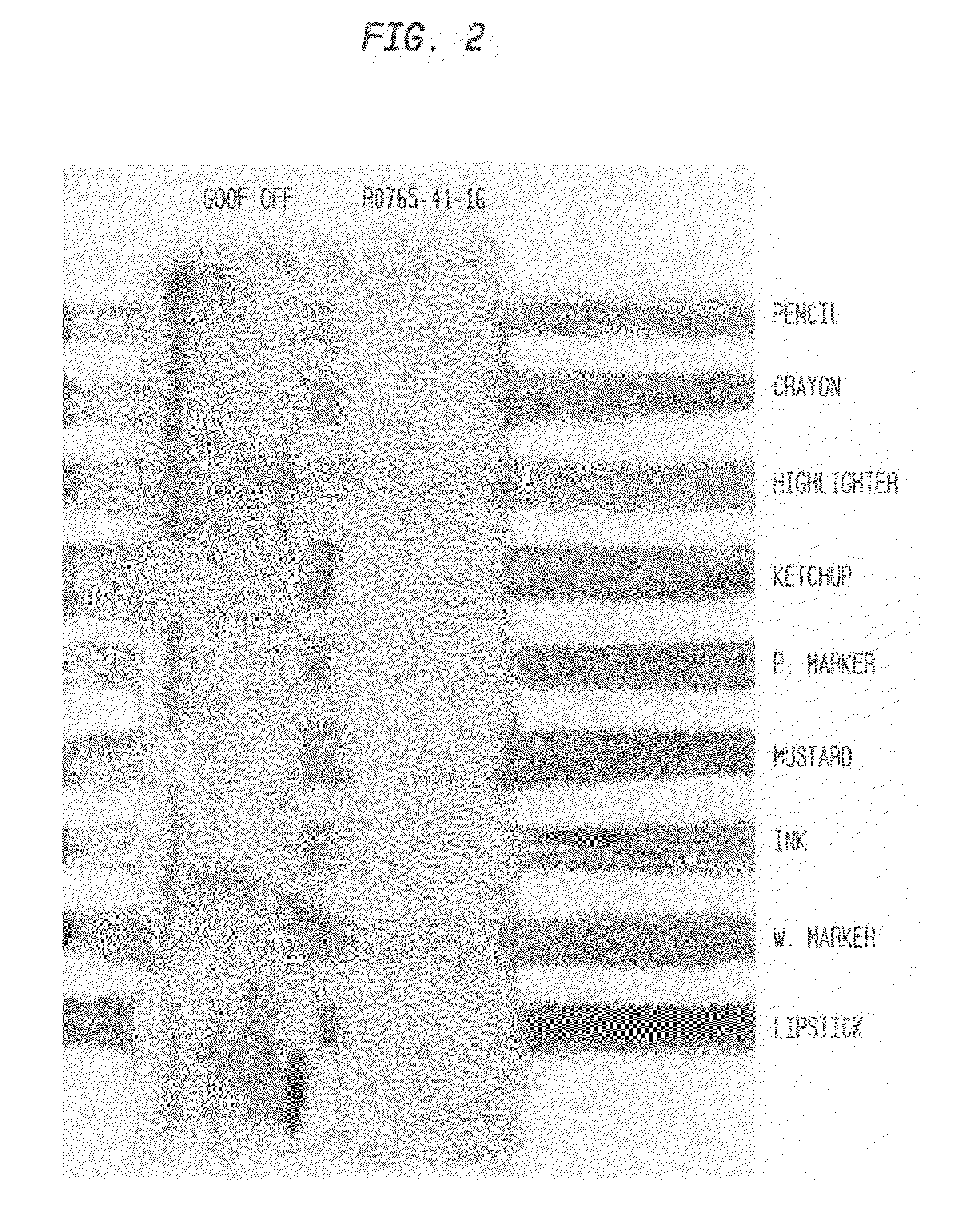

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Paint and coating remover

InactiveUS6369009B1Improve efficacyLow toxicityChemical paints/ink removersDetergent solventsPolymer scienceDibasic ester

This invention concerns a composition useful as a paint remover, comprising: alkylene carbonate such as propylene carbonate or ethylene carbonate, hydrogen peroxide, and water, and optionally an alcohol such as benzyl alcohol. In another broad respect, this invention concerns a process for removing paint, comprising: applying a composition containing alkylene carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. In another broad respect, this invention is a composition useful as a paint remover, comprising: dialkyl carbonate, hydrogen peroxide, and water, optionally containing an alcohol, optionally containing a glycol ether. In another broad respect, this invention is a process for removing paint, comprising: applying a composition containing dialkyl carbonate, hydrogen peroxide, and water to a painted surface for a time and under conditions effective to cause blistering or bubbling of the paint. Advantageously, the composition of this invention may include a dibasic ester (DBE).

Owner:JPMORGAN CHASE BANK N A AS COLLATERAL AGENT

Paint stripper

The invention discloses a paint stripper to remove epoxy paint film, in particular to a paint stripper for paint film of bilge paint and ship surface paint, which comprises the following parts: main solvent, thickener, acid component and random solutizer.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method to increase flash points of flammable solvents

The present invention relates to a method to decrease the flammability of normally flammable alcohols and solvents. The additive is Alpha Terpineol, which will increase the flash point of flammable alcohols or solvents, by blending the Terpineol into the flammable solvent or alcohol. Solvents such as acetone, methanol, ethylacetate, ethanol and xylene, to name a few, increases flash points by 50° C. to 60° C., by addition of 12-14% terpineol. The said solvent can then be blended with other organic solvents to produce performance solvents, such as paint strippers with flash points greater than 140° F. and meet Federal and state Volatile Organic Compound regulations.

Owner:TARKSOL INT

Preparation and application method of water-based paint remover

InactiveCN103013221ATake off quicklyReduce corrosionChemical paints/ink removersSodium lactateActive agent

The invention discloses a preparation and application method of a water-based paint remover. The water-based paint remover consists of sodium hydroxide, a surface active agent and a composite additive. The mass fraction of sodium hydroxide is 3%-10% that of the surface active agentis 0.5%-2%, that of the composite additive is 1%-6%, and the rest is water. The surface active agent is octadecyl dihydroxy diethyl betaine; and the composite additive is composed of three of sodium lactate, sodium malate, sodium sarcosinate, natrium aceticum and sodium gluconate. The water-based paint remover disclosed by the invention has the characteristics of being efficient, environmentally-friendly, safe, nontoxic, barely corrosive and hard to volatilize, can be used for removing the paint from common metal and plastic base materials, and is simple and easy to prepare and use.

Owner:GUANGDONG UNIV OF TECH

Method for removing paint from enameled wire and paint remover

InactiveCN102558940AWon't hurtDoes not affect the organizationChemical paints/ink removersPolyesterCrucible

The invention belongs to a paint removing technology and relates to a method for removing paint from an enameled wire and a paint remover. The method comprises the following steps: weighing sodium hydroxide and potassium hydroxide by using a scale or an electronic scale, mixing, pouring the mixture into a nickel crucible and heating, so that the mixture is melted; soaking one end, needing paint removal, of the enameled wire into the paint remover, removing paint, and taking out the enameled wire after the paint-removing reaction stops; soaking one paint-removed end of the enameled wire into clear water, washing for not less than 15 seconds, neutralizing the residual alkaline liquid by using a glacial acetic acid solution and performing subsequent cleaning; and after cleaning, wiping, detecting and storing in the drying environment. The invention is simple in operation, low in cost, can remove paint from polyimide copper enameled wires, polyimide nickel enameled wires, polyester copper enameled wires and polyester nickel enameled wires in a wide temperature range, does not damage the metal materials of the enameled wires, and is very applicable to small-diameter enameled wires which cannot be depainted by a mechanical grinding method.

Owner:SUZHOU CHANGFENG AVIATION ELECTRONICS

Cleaning compositions incorporating green solvents and methods for use

ActiveUS8222194B2Point becomes highLow vapor pressureSoap detergents with organic compounding agentsOrganic detergent compounding agentsGlutaric acidActive agent

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a C1-C12 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d-limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:SPECIALTY OPERATIONS FRANCE

Powerful paint stripper

ActiveCN101629036AConvenient flaw detectionEasy to repaintChemical paints/ink removersParaffin waxLacquer

The invention relates to a powerful paint stripper comprising the following components by weight percent: 0-5 percent of surface active agent, 72-78 percent of dichloromethane, 0-3 percent of ethylacetate, 0.78-0.8 percent of thickener, 0.6-0.7 percent of ceresin wax, 4.85-10 percent of phenol, 5-9 percent of alcohol, 0-6 percent of methanoic acid, 0-6 percent of ammonia water and 0-1 percent of sodium nitrite. The invention can effectively remove paint on the metal surface of planes and on the train wheel surface so as to perform flaw detection and repaint on the metal materials without damaging metal and wood surfaces, and has excellent depainting performance, low use amount and low depainting cost.

Owner:长沙艾森设备维护技术有限公司

Ink cleaning composition and methods for use

InactiveCN102428165ANon-ionic surface-active compoundsDetergent mixture composition preparationDibasic esterPhenol

An environmentally-friendly cleaning composition for industrial and consumer applications comprising (a) a blend of dibasic esters, (b) one or more surfactants (c) and, optionally, (d) water or a solvent. The dibasic esters are be derived from a blend of adipic, glutaric, and succinic diacids, and, in one particular embodiment, the blend comprises dialkyl adipate, dialkyl methylglutarate and dialkyl ethylsuccinate, wherein the alkyl groups individually comprise a Q- Ci2 hydrocarbon group. The one or more surfactants are typically chosen from alcohol alkoxylate, an alkyl phenol ethoxylate, a terpene, a terpene alkoxylate or any derivates thereof. Optionally, additional components or additives including delaminates such as pinene and d- limonene, fragrances, whiteners, stabilizers, thickeners and the like can be added to the composition. The industrial or consumer application selected from the group consisting of a graffiti cleaner, a painted-substrate cleaner, an ink cleaner, a metal substrate cleaner, a plastic substrate cleaner, an environmentally friendly cleaner, a stain-spot cleaner, an industrial hand cleaner, a resin cleaner, a tar resin cleaner, a textile cleaner, a paint stripper and any combination thereof.

Owner:RHODIA OPERATIONS SAS

Environment-friendly removing agent of covering paint as well as preparation method and application of environment-friendly removing agent

ActiveCN103351703AVolatile fastOperational securityChemical paints/ink removersEnvironmental resistanceOrganic solvent

The invention belongs to the field of environment-friendly paint removers, and discloses an environment-friendly removing agent of a covering paint as well as a preparation method and using method of the environment-friendly removing agent. The environment-friendly removing agent of the covering paint contains the following components in percentage by mass: 5-45% of an alkali compound, 0.5-15% of an inorganic auxiliary agent, 5-30% of an organic auxiliary agent, 0.5-5% of a surfactant, and the balance of water. The environment-friendly removing agent of the covering paint is in the form of a water aqua, is safer and lower in toxicity and VOC (volatile organic compound) compared with the conventional dichloroethane type removing agent, and is safe to operators; the removing time of a preferred plan is only 5 minutes, so that the advantage of an organic solvent removing agent on removing time is not obvious anymore. Compared with an acidic system removing agent, the environment-friendly removing agent does not generate pungent smells, and is safe to a base material to ensure that the base material can not be corroded and generate rusts. Compared with a conventional alkali system removing agent, the environment-friendly removing agent is safer and more efficient.

Owner:广东山之风环保科技有限公司

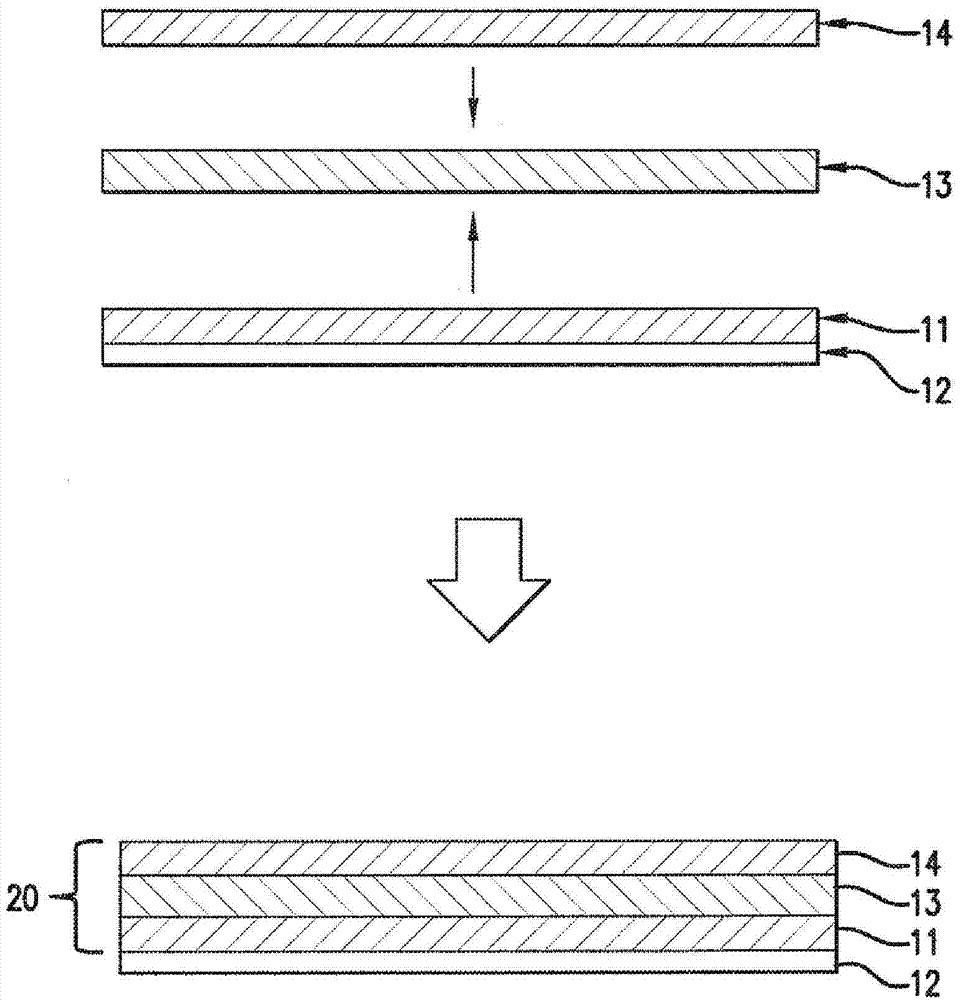

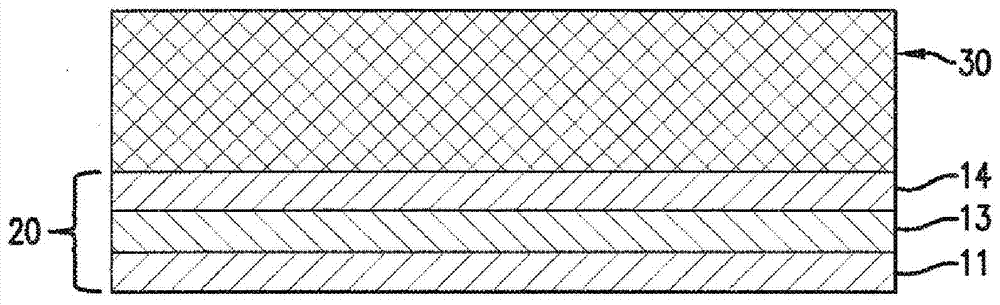

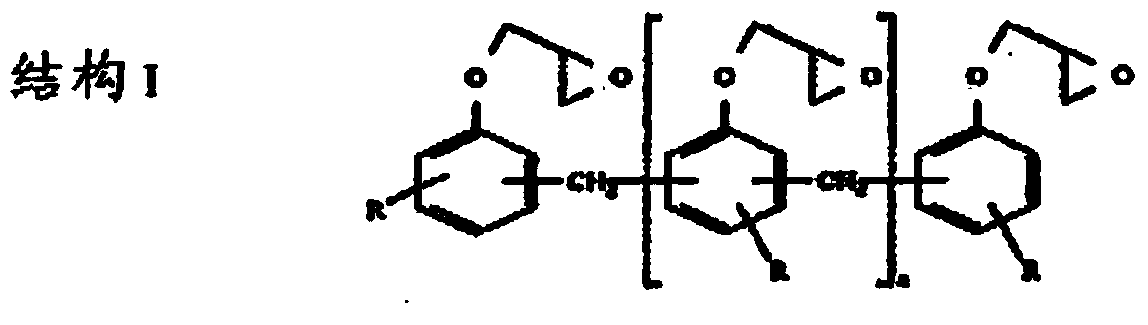

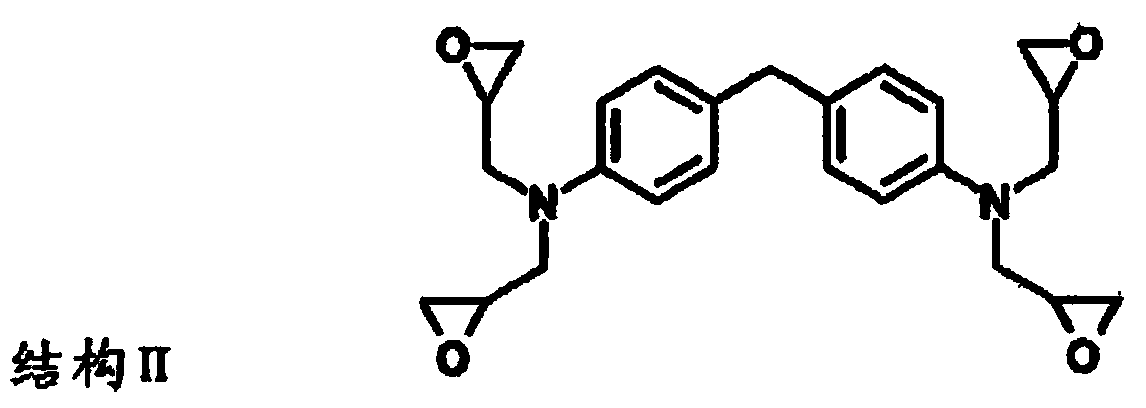

Conductive surfacing material for composite structures

An electrically conductive surfacing material capable of providing sufficient conductivity for lightning strike protection (LSP) and / or electromagnetic interference (EMI) shielding is disclosed. The conductive surfacing material is a multi-layered structure having a very thin conductive layer (e.g. solid metal foil) and a resin film formed on at least one surface of the conductive layer. The resin film is formed from a curable resin composition containing an epoxy novolac resin, a tri-functional or tetra-functional epoxy resin, ceramic microspheres, a latent amine-based curing agent, particulate inorganic fillers; and a toughening component. Optionally, the resin film further includes conductive additives to increase electrical conductivity of the surfacing material. The resin film exhibits high Tg as well as high resistance to paint stripper solutions. Furthermore, the conductive surfacing material is suitable for co-curing with fiber-reinforced resin composite substrates.

Owner:CYTEC IND INC

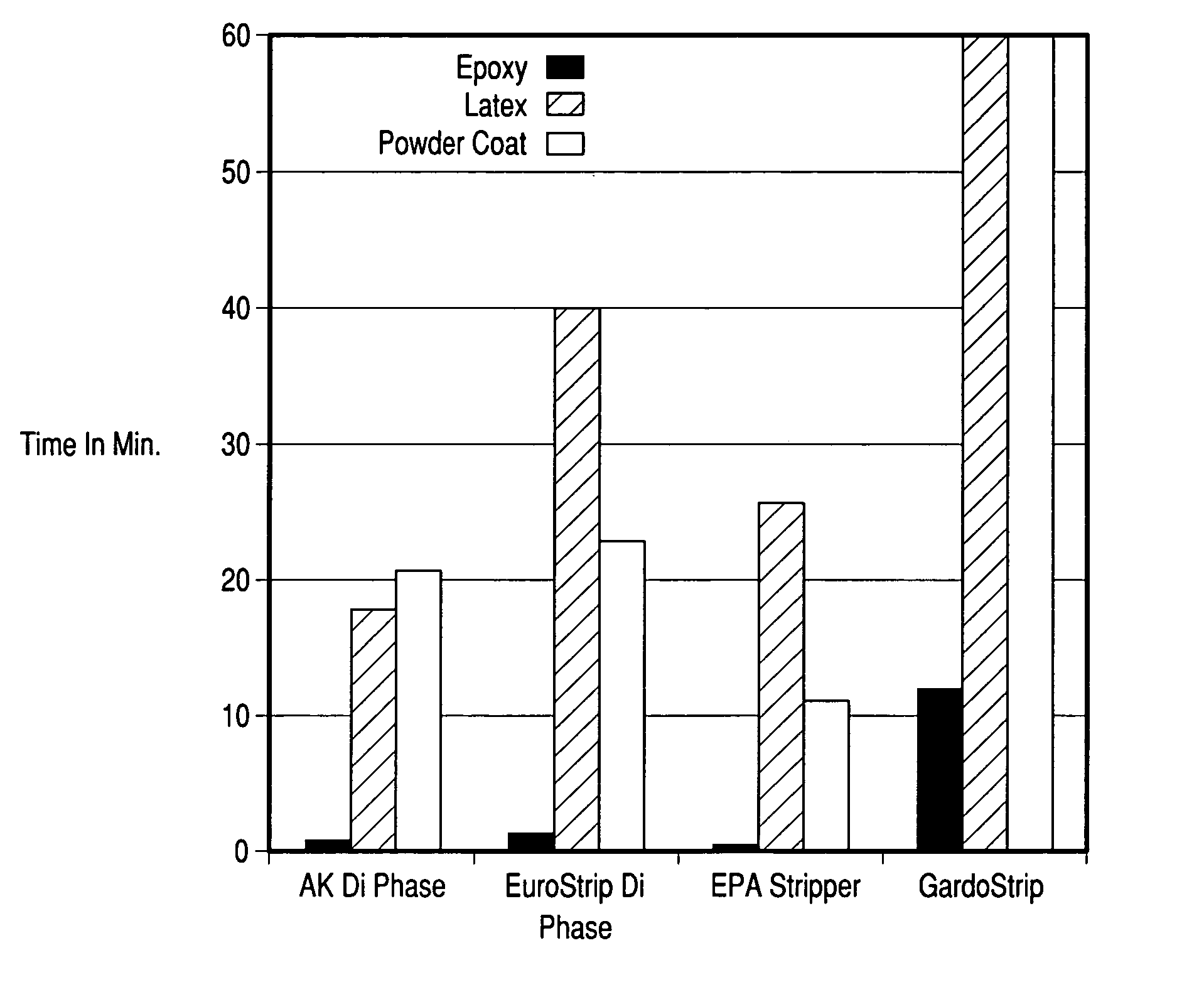

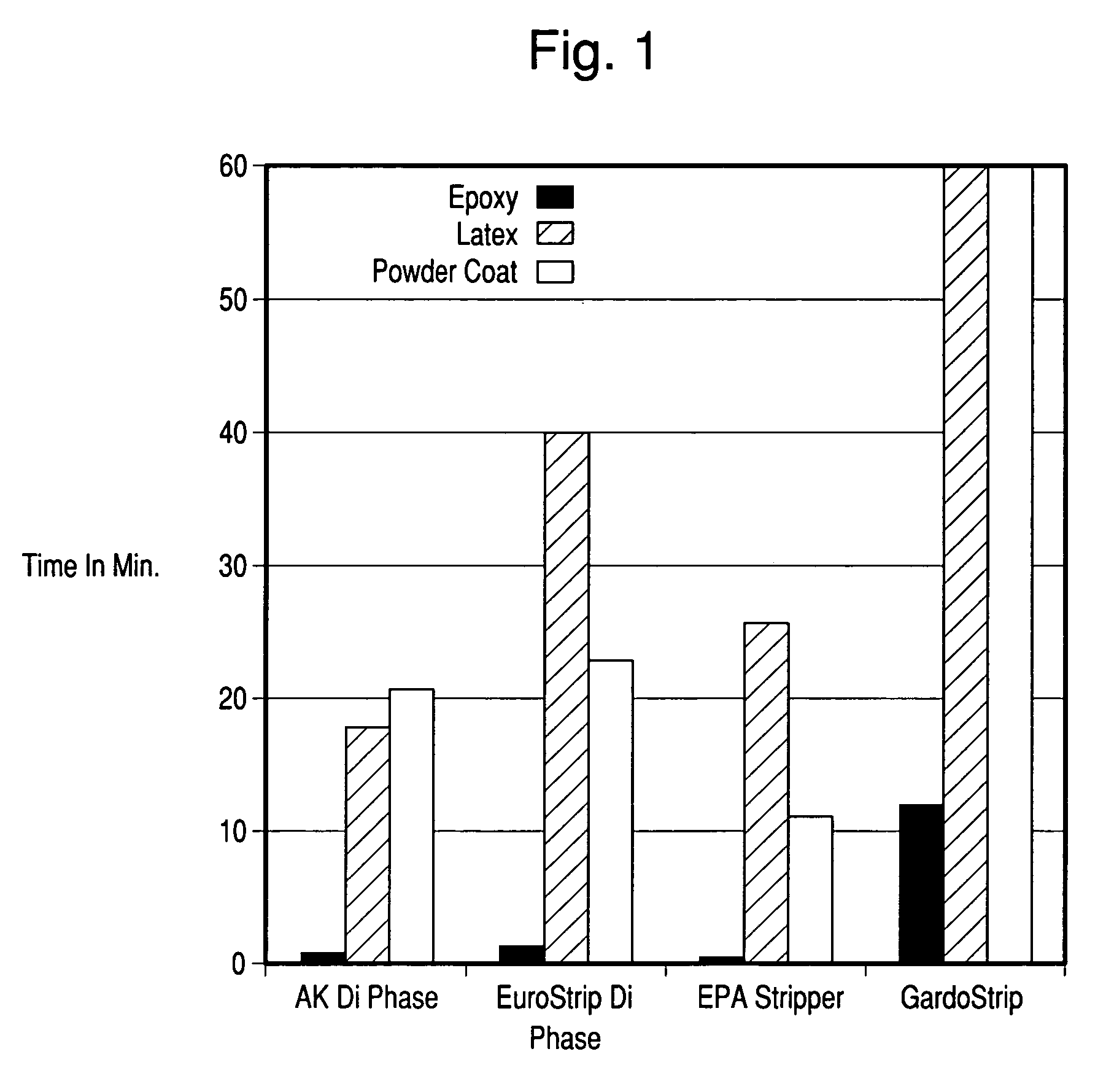

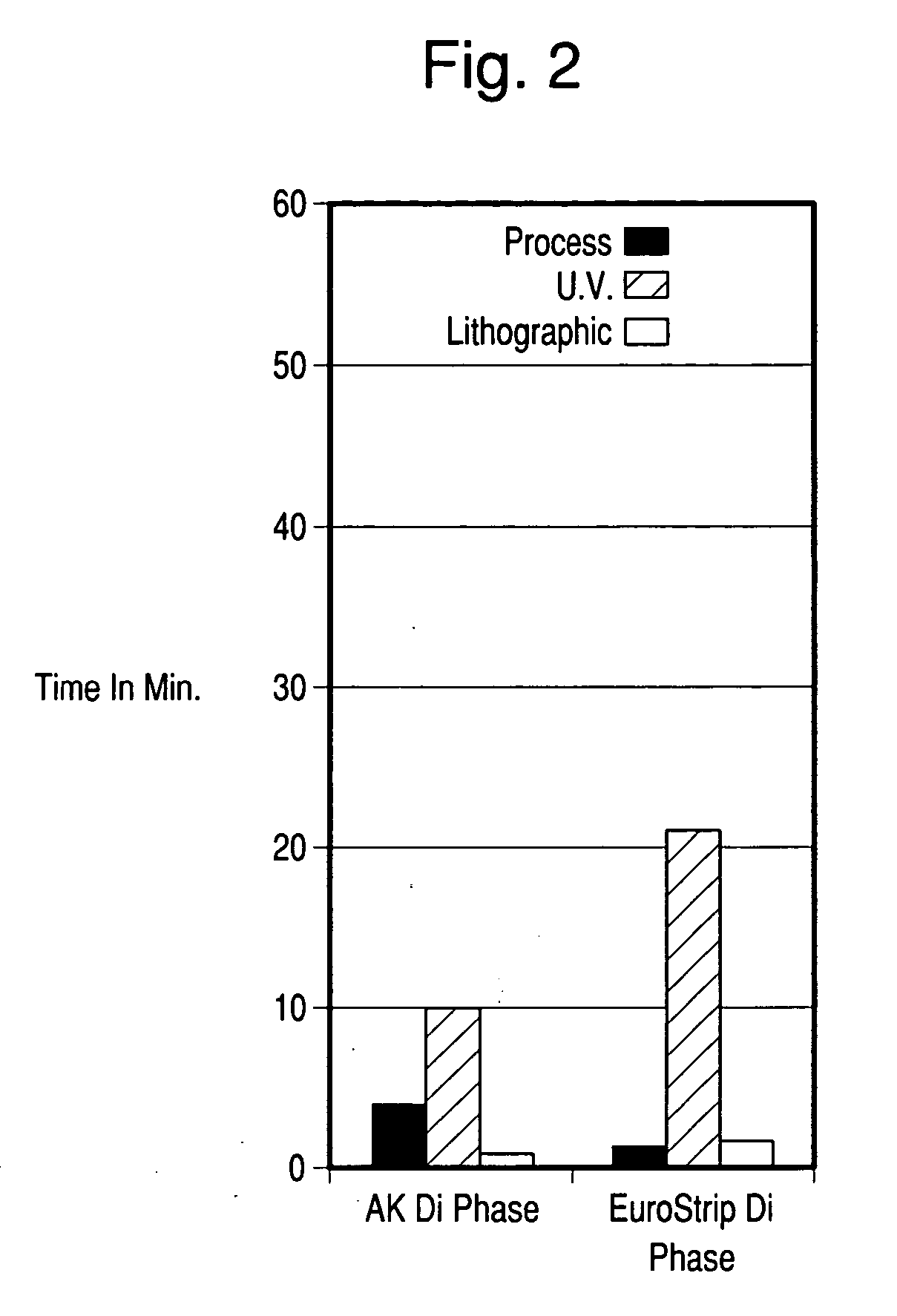

Paint & ink remover two-phase system

InactiveUS20060058208A1Chemical paints/ink removersCleaning processes and apparatusOrganic solventChloride

A two-phase paint and ink stripper composition comprises an aqueous phase containing a basic activator in the form of an amino-alkyl-alkanol and an organic phase which contains an alkylene carbonate and organic solvents. The paint stripper composition of the present invention is free from methylene chloride and does not contain monoethanol amine.

Owner:CHURCH & DWIGHT CO INC

Method to increase flash points of flammable solvents

The present invention relates to a method to decrease the flammability of normally flammable alcohols and solvents. The additive is Alpha Terpineol, which will increase the flash point of flammable alcohols or solvents, by blending the Terpineol into the flammable solvent or alcohol. Solvents such as acetone, methanol, ethylacetate, ethanol and xylene, to name a few, increases flash points by 50° C. to 60° C., by addition of 12-14% terpineol. The said solvent can then be blended with other organic solvents to produce performance solvents, such as paint strippers with flash points greater than 140° F. and meet Federal and state Volatile Organic Compound regulations.

Owner:TARKSOL INT

Paint remover and its preparing method and using method

InactiveCN1944547AGood paint removal effectEasy to prepareChemical paints/ink removersVegetable oilOrganic solvent

The present invention relates to one kind of paint remover and its preparation process and usage. The paint remover consists of organic base 30-55 wt %, organic solvent 40-65wt %, and corrosion inhibitor 0.5-7wt %, and during storage and use, its surface is covered with oil sealer. The organic base is alcohol amine with boiling point not lower than 160deg.c and molecular weight smaller than 200; the organic solvent has point not lower than 200deg.c; the corrosion inhibitor is saccharide; and the oil sealer is vegetable oil or mineral oil with density lower than the paint remover and insoluble in the paint remover. The paint remover has simple preparation process, convenient use and environment friendship, and may be used to remove several kinds of paint film in high speed and no corrosion to most of the substrate.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Paint remover used for polyester, poly esterimine paint capper covered round wire paint film

Owner:GUANGDONG RONSEN SUPER MICRO WIRE CO LTD

Preparation and application of environmental-protective aqueous paint remover

InactiveCN104513519AEnvironmentally friendlyEasy constructionChemical paints/ink removersPotassium hydroxideBENZYL ALCOHOL/WATER

A preparation and an application of an environmental-protective aqueous paint remover are disclosed. The environmental-protective aqueous paint remover is prepared from following raw materials, by weight, 22-25% of benzyl alcohol, 15-18% of sodium p-toluene sulfonate, 3.0-4.0% of potassium hydroxide, 0.8-1.4% of sodium gluconate, 4-8% of a cosolvent and 45-55% of tap water. The paint remover is prepared by following steps: (1) adding the sodium p-toluene sulfonate, the sodium gluconate, the potassium hydroxide to the tap water to obtain a mixture and stirring the mixture to enable the sodium p-toluene sulfonate, the sodium gluconate and the potassium hydroxide to be completely dissolved; and (2) adding the benzyl alcohol, triethanolamine and ethanol to obtain a mixture and stirring the mixture for dissolving the benzyl alcohol, the triethanolamine and the ethanol to obtain a transparent liquid product with a color from white to yellow. The paint remover is alkaline and is subjected to a paint removing experiment during a use process with a heating temperature being 50-70 DEG C. The environmental-protective aqueous paint remover is advantaged in that: (1) the paint remover is water-soluble and is environmental-protective when being used for replacing a volatile solvent paint remover; (2) the paint remover is free of toxic chemical products; (3) the paint remover is suitable for removing various paints; (4) the paint remover is alkaline and is free of damaging a base material; and (5) the paint remover is not liable to volatilize, can be used repeatedly and is low in comprehensive cost.

Owner:SHANGHAI LICHANG ENVIRONMENTAL ENG

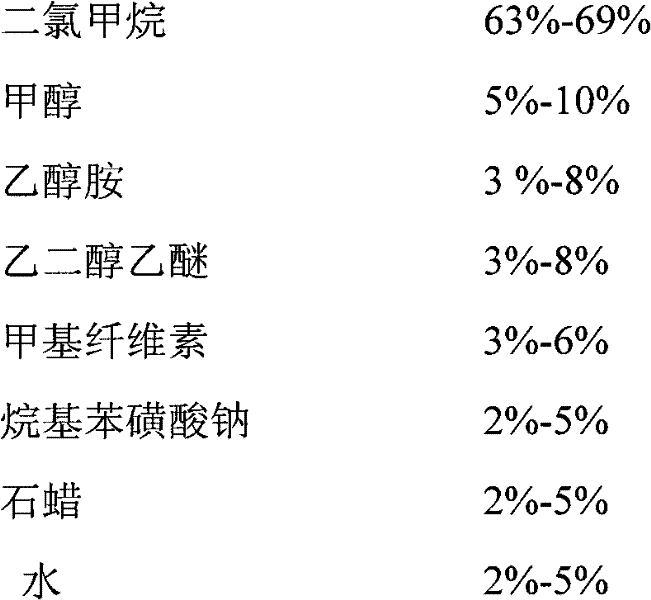

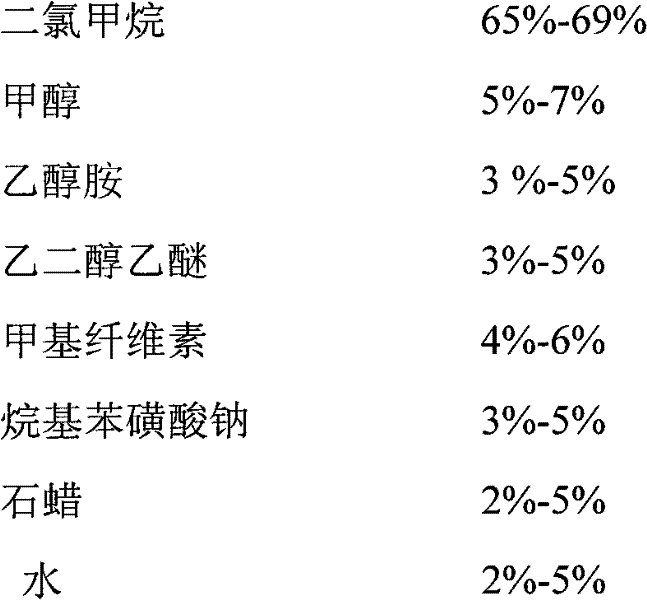

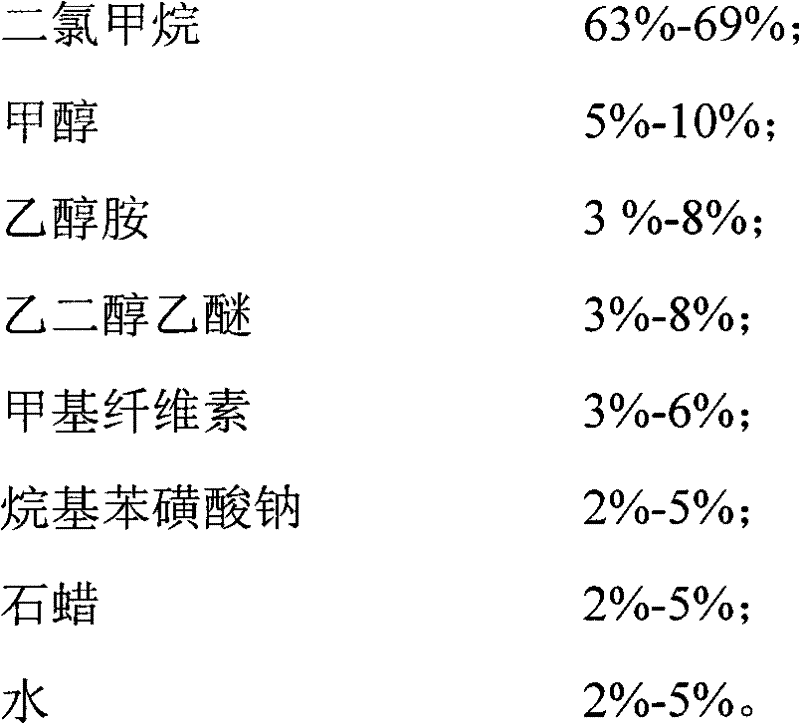

Neutral paint stripper

InactiveCN102337053ALess corrosiveHigh stripping timeChemical paints/ink removersCarboxymethyl celluloseParaffin wax

The invention relates to a neutral paint stripper which can be widely used in the paint strippers of various primer films. The neutral paint stripper mainly comprises dichloromethane, methanol, ethanolamine, 2-ethoxyethanol, carboxymethyl cellulose, sodium alkyl benzene sulfonate, paraffin wax and water.

Owner:宁波英科特精工机械股份有限公司

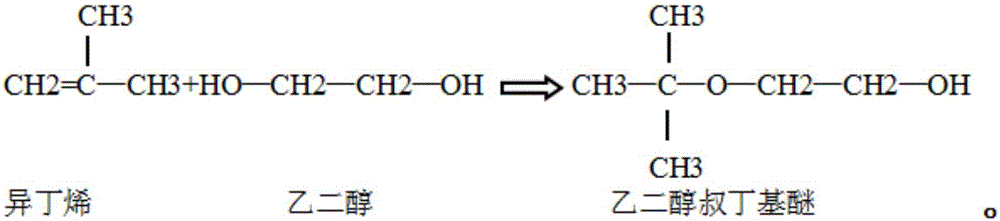

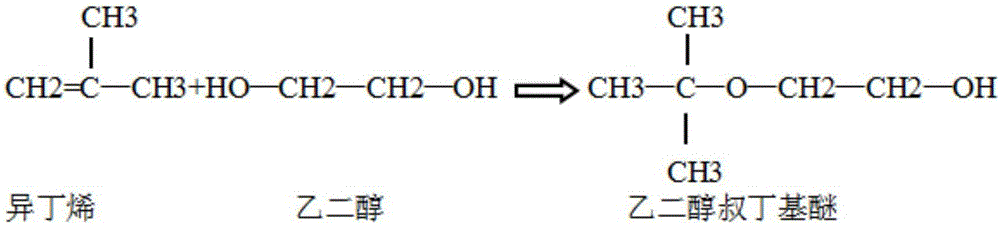

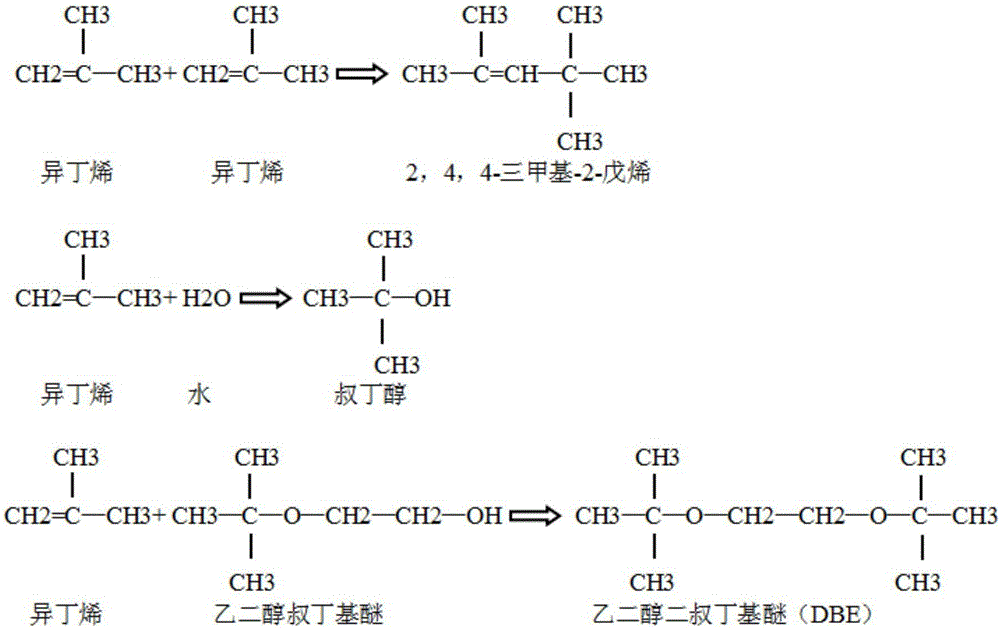

Ethylene glycol tertiary butyl ether and production technology thereof

InactiveCN106748668ASmall smellLow toxicityEther separation/purificationEther preparation by compound additionFiberDispersion stability

The invention relates to ethylene glycol tertiary butyl ether and a production technology thereof and belongs to the field of process production of chemical products. The ethylene glycol tertiary butyl ether is generated by reaction between isobutene and glycol in mixed carbon4 under action of solid catalyst. A technological process of the ethylene glycol tertiary butyl ether comprises a reaction unit and a separation unit. The ethylene glycol tertiary butyl ether prepared through the technology disclosed by the invention has the advantages of extremely-low odor, low toxicity, low photochemical reaction, moderate skin irritation, good water intermiscibility, good latex coating dispersion stability, intermiscibility with most resin and organic solvents, good hydrophilia and wide application in the fields of coating, printing ink, cleaning agent, fiber wetting agent, plasticizer, organic synthesis intermediate, paint remover and the like.

Owner:潍坊康顺化工有限公司

Cleaning agent of alkali finishing coat and preparation method

InactiveCN101709175ASimple recipeEasy to manufactureChemical paints/ink removersLacquerWater quality

The invention relates to a cleaning agent of an alkali finishing coat, which combines an alkali paint removing component and an organic depainting component for use, wherein the weight ratio of a total component comprising the alkali component and water to the organic component is from 9:11 to 12:8; the cleaning agent of the alkali finishing coat is prepared by the following method: (1) mixing sodium hydroxide, sodium carbonate and sodium dodecyl benzene sulfonate and stirring; (2) adding ethanolamine and ethylene glycol monobutyl ether; (3) adding ethanol and mixing evenly; and (4) heating. The invention has the advantages that the cleaning agent has simple formula, convenient preparation and very small toxicity and has a very good paint removing action for a finishing coat mobile telephone casing or similarities taking acrylic acid as a main part, a product with disqualified surface spraying or a residual product can be recycled after being processed, the use rate of resources is enhanced, and the fund and energy resources are saved. The used paint remover can be used for the second time, and the original components of the paint remover can also be replenished for use for many times. No special requirement for the water quality exists, and tap water can also be adopted.

Owner:CHINA NAT ACAD NANOTECH & ENG

Ink cleaning composition and methods for use

ActiveUS8440598B2Point becomes highLow vapor pressureSoap detergents with organic compounding agentsDetergent mixture composition preparationDibasic esterAdipate

Owner:SPECIALTY OPERATIONS FRANCE

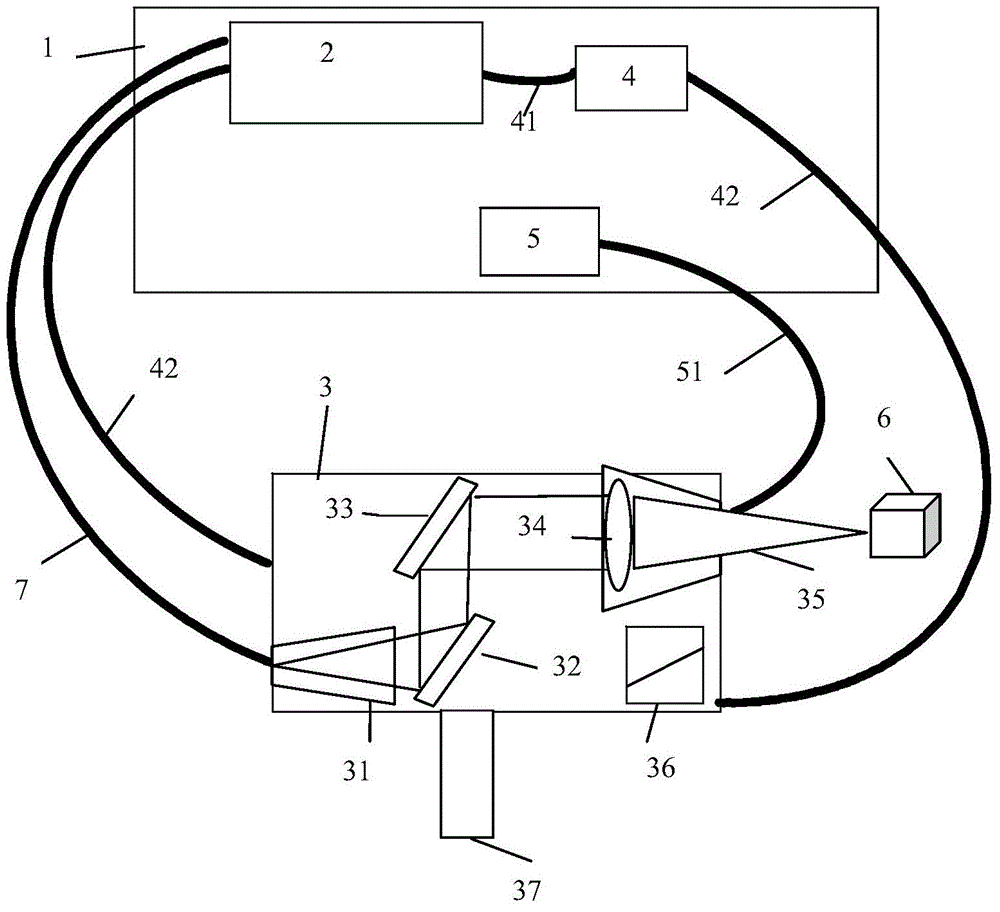

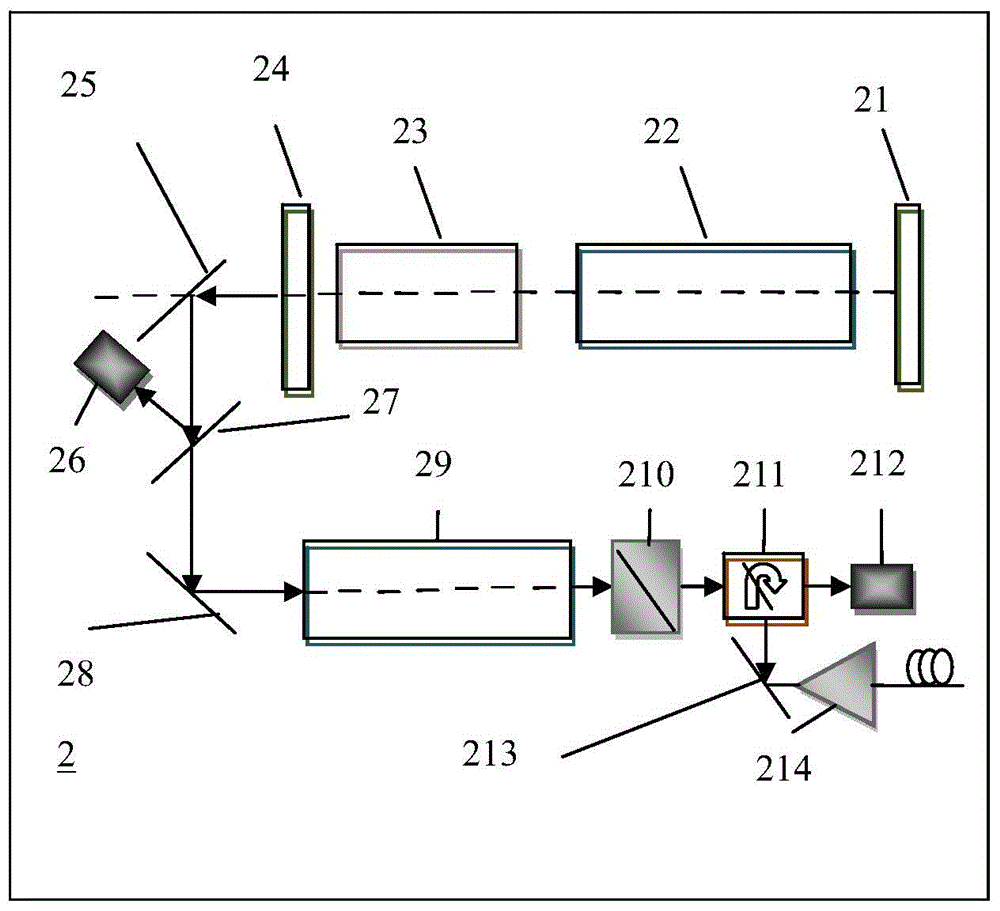

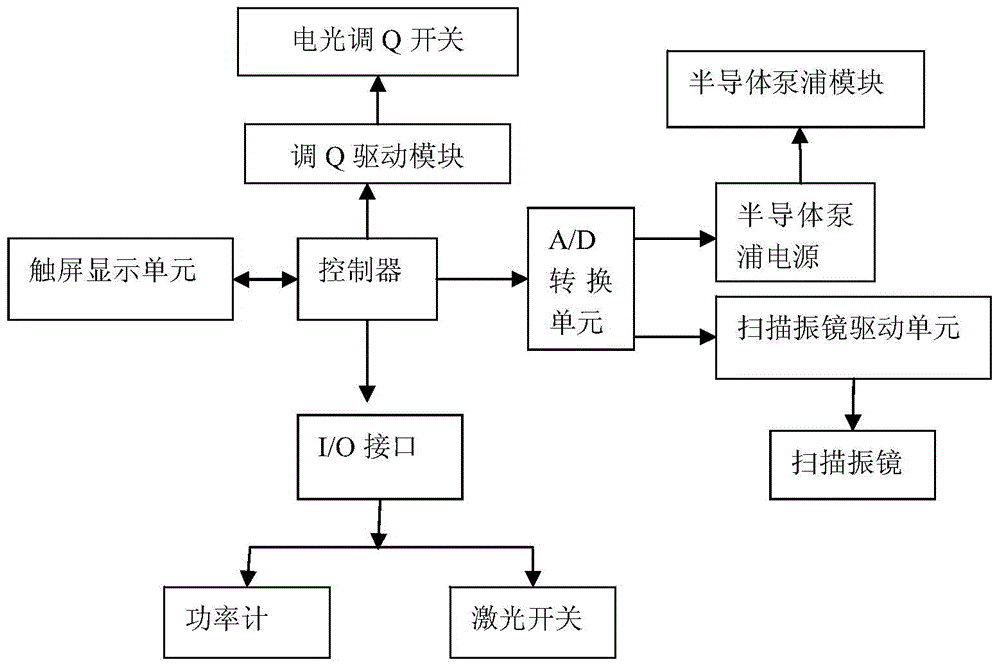

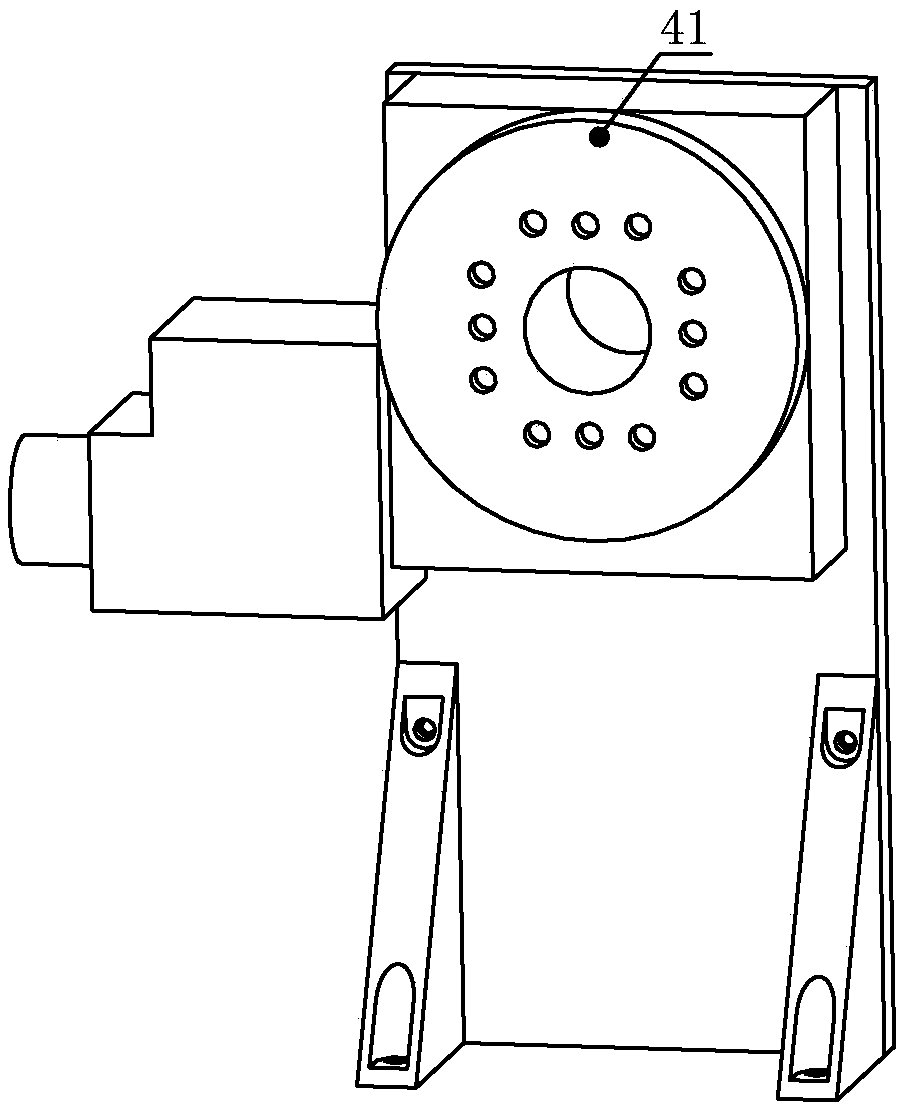

Airplane coated paint laser cleaning equipment

ActiveCN104438227AIncrease laser output powerImprove efficiencyDirt cleaningJet aeroplaneAutomatic control

The invention discloses airplane coated paint laser cleaning equipment which comprises a laser device 2 and a cleaning and processing head 3 connected with the laser device 2. A semiconductor pumping solid pulse laser device is adopted, and laser output power is improved by means of electro-optical modulation Q through an MOPA structure; optical fibers are coupled through a hollow cone, long-distance, large-range, long-time and stable cleaning is realized through optical fiber transmission, and no potential safety hazard is caused to an airplane body, so that cleaning cost is greatly lowered, pollution, of a paint stripper, to environment is reduced, and the airplane coated paint laser cleaning equipment can realize automatic control and is low in using cost and high in efficiency.

Owner:HIGO TECH (SUZHOU) CO LTD

Basic paint remover and preparation method thereof

InactiveCN1919939AReduce corrosionImproved paint stripping activityChemical paints/ink removersBenzeneActive agent

Owner:SHANXI UNIV

Water-based paint stripper and preparation method thereof

InactiveCN107286727AImprove solubilityNot volatileChemical paints/ink removersDiethylene glycol monobutyl etherWater based

The invention belongs to the technical field of surface treatment of metal products, and in particular relates to an water-based paint stripper and a preparation method thereof. The preparation method comprises the steps: benzyl alcohol, diethylene glycol monobutyl ether and a promoter are mixed to prepare a mixed solution 1; then a thickener, a corrosion inhibitor and a surfactant are added into the mixed solution 1, and heating and stirring are carried out to obtain a mixed solution 2; then an oxidant is added to the mixed solution 2, heating and stirring are carried out to obtain a mixture, and the mixture is uniformly mixed with deionized water to obtain the water-based paint stripper. The water-based paint stripper obtained by the invention has a higher paint stripping efficiency and a faster paint stripping speed, meanwhile, the paint stripper has small corrosion on metal substrates, the paint stripper does not contain toxic substances such as phenol, and thus the paint stripper does not harm an operating environment and the health of workers, and is an environment-friendly and efficient paint stripping product.

Owner:常州文诺纺织品有限公司

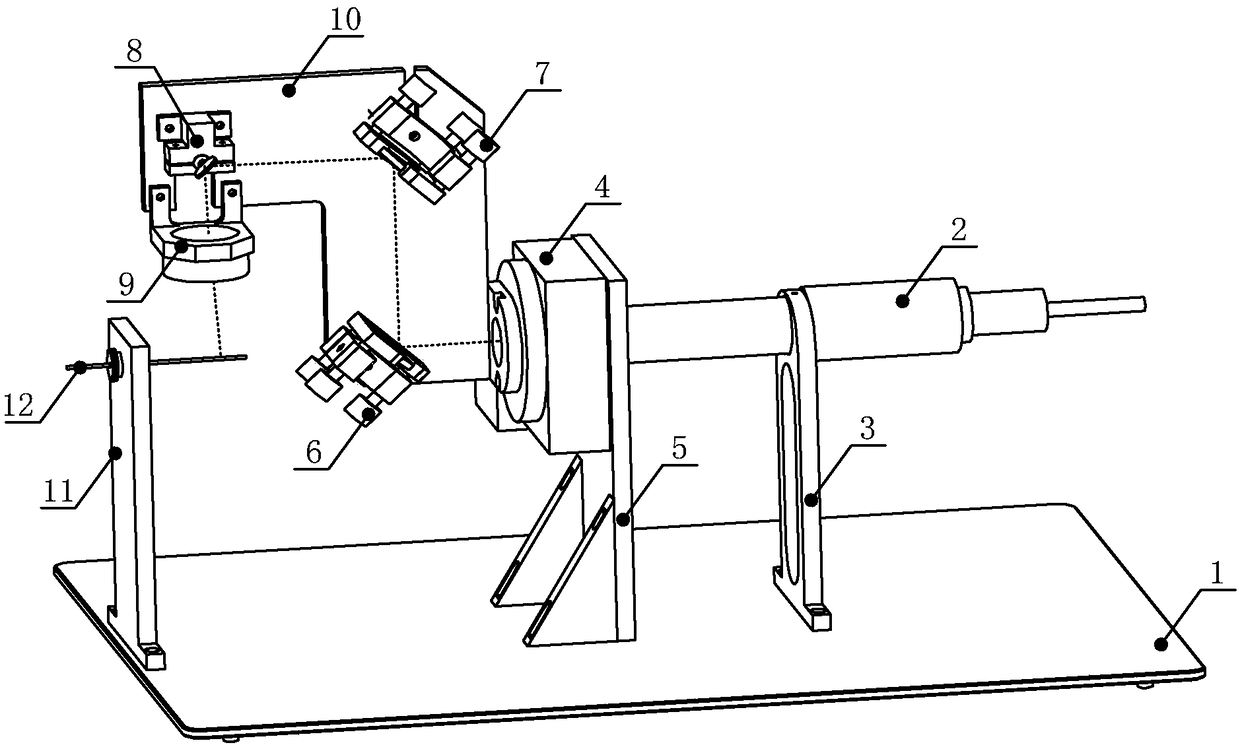

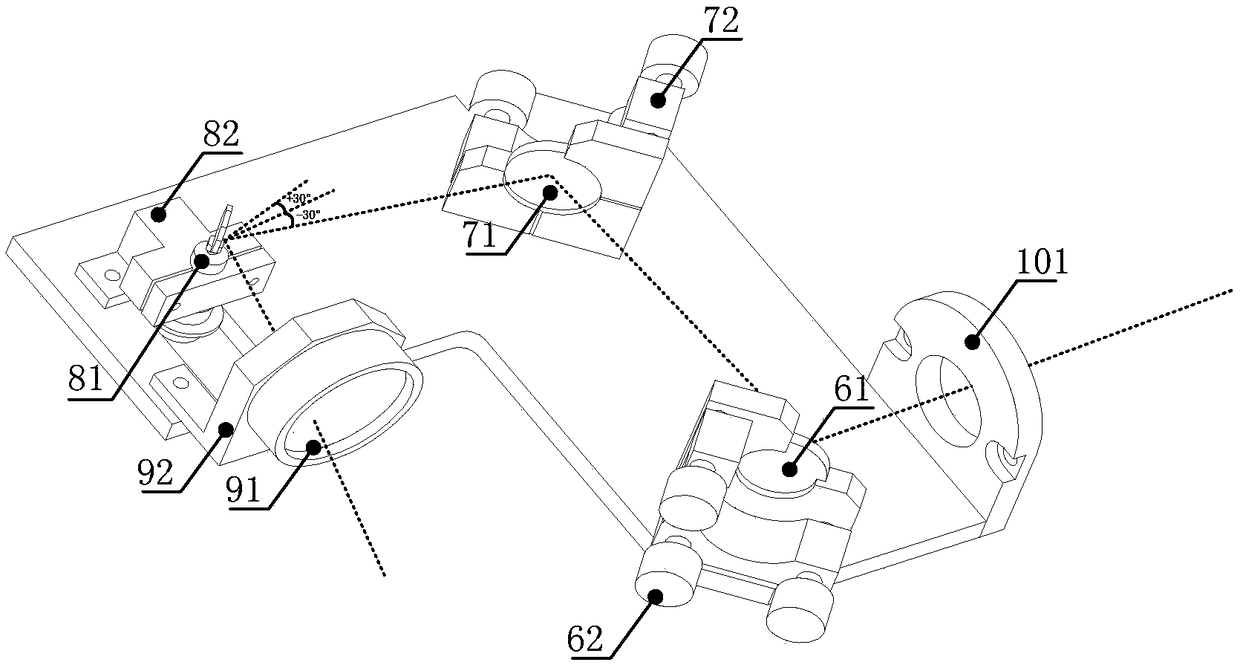

A laser removing device for enamel wire clad layer

ActiveCN109193312AAvoid damageAvoid chemical contaminationLine/current collector detailsLaser beam welding apparatusEngineeringOperation mode

The invention relates to a laser removing device for enameled wire cladding layer. The laser output from a laser output head is focused on the cladding layer of the enameled wire through a transmission optical path assembly. The enameled wire is coaxially arranged with the laser output head and the rotary driver. The rotary actuator rotates the transmission optical path assembly about its axis, removing the enameled wire cladding. A laser removing device for enamel wire clad layer adopts an automatic operation mode and utilizes laser to act on that enameled wire clad layer, which overcomes thedefect that the manual contact operation mode is easy to damage the enameled wire body and improves the working efficiency of removing the enameled wire clad layer compared with the sandpaper polishing mode; Compared with paint stripper, it can effectively reduce chemical pollution and personal hazards to operators.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Paint remover formula

ActiveCN101875796ALow costGood paint removal performanceChemical paints/ink removersParaffin waxO-Phosphoric Acid

The invention relates to a paint remover, in particular to a paint remover formula, which comprises the following compositions in part by weight: 70 to 80 parts of methylene chloride, 3 to 4 parts of acetone, 1.8 to 2.2 parts of pyridine, 1.8 to 2.2 parts of formic acid, 1.8 to 2.2 parts of ceresin wax, 1.4 to 1.6 parts of cellulose acetate, 1.4 to 1.6 parts of alcohol, 1.4 to 1.6 parts of phosphoric acid and 2 to 3.5 parts of aqueous ammonia; meanwhile, the paint remover formula can also be prepared from the following compositions in part by weight: 80 to 85 parts of methylene chloride, 2 to 3 parts of acetone, 1 to 1.5 parts of pyridine, 2 to 3.5 parts of formic acid, 1.5 to 2 parts of ceresin wax, 1.5 to 2 parts of cellulose acetate, 0.8 to 1 parts of phosphoric acid and 3 to 3.5 parts of aqueous ammonia. The paint remover formula is suitable for removing amino paints, ethylene perchloride paints, epoxy paints on aluminum ware, steel ware and copper ware and the films of spurted plastic ware, and has the advantages of excellent paint removing performance, low material cost, and simple and convenient operation and application.

Owner:西安北方光电有限公司

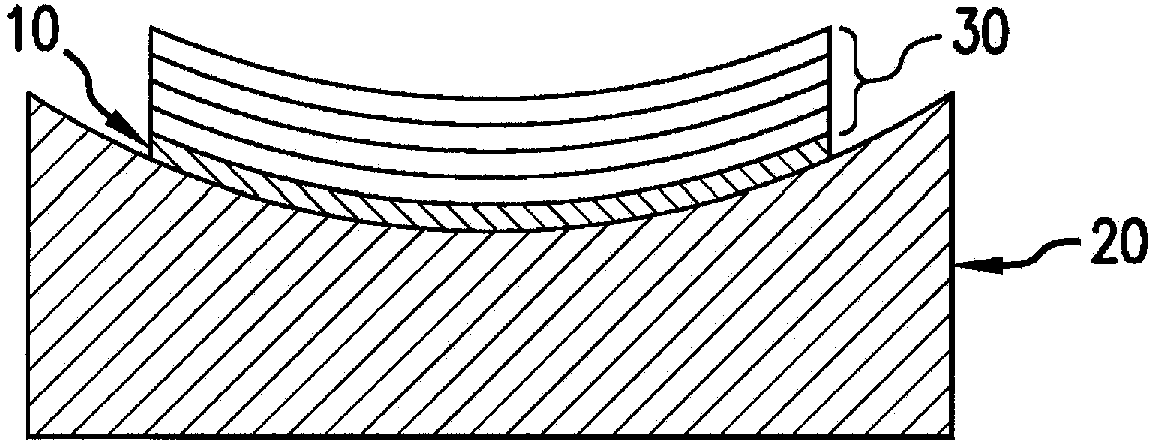

Surfacing film for composite structures and method of making the same

A surfacing film is formed from a curable resin composition. The resin composition comprises an epoxy novolac resin, a tri-functional or tetra-functional epoxy resin, ceramic microspheres, an amine-based curing agent, particulate inorganic fillers and a toughening component. The surfacing film exhibits high Tg and high cross-linked density after curing, as well as high resistance to paint stripper solutions. The surfacing film is suitable for co-curing with fiber-reinforced resin composite materials. The surfacing film may optionally contain electrically conductive additives to provide sufficient conductivity for lightning strike protection (LSP) or electromagnetic interference (EMI) shielding.

Owner:CYTEC TECH CORP

Magnesium-alloy paint-remover composition and its production

A magnesium-alloy paint remover composition consists of halohydrocarbon 50-90wt%, acid 2-15wt%, alcohol 2-20wt%, liquefied hydrocarbon 0.5-10wt%, emulsifier 0.5-10wt% and corrosion inhibitor 0.1-5wt%. It can remove surface paint film shortly and have no secondary spray.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com