Neutral paint stripper

A paint remover and neutral technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve problems affecting product quality, waste of resources, environmental pollution, etc., and achieve the goal of reducing the amount of pollution treatment and usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

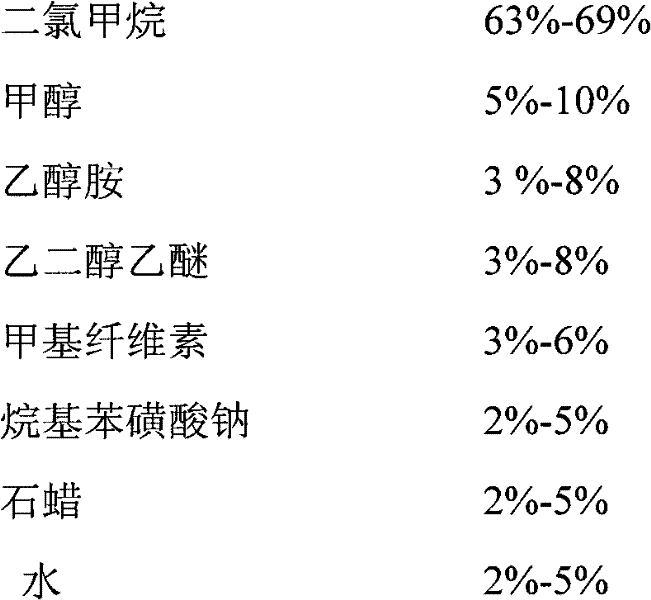

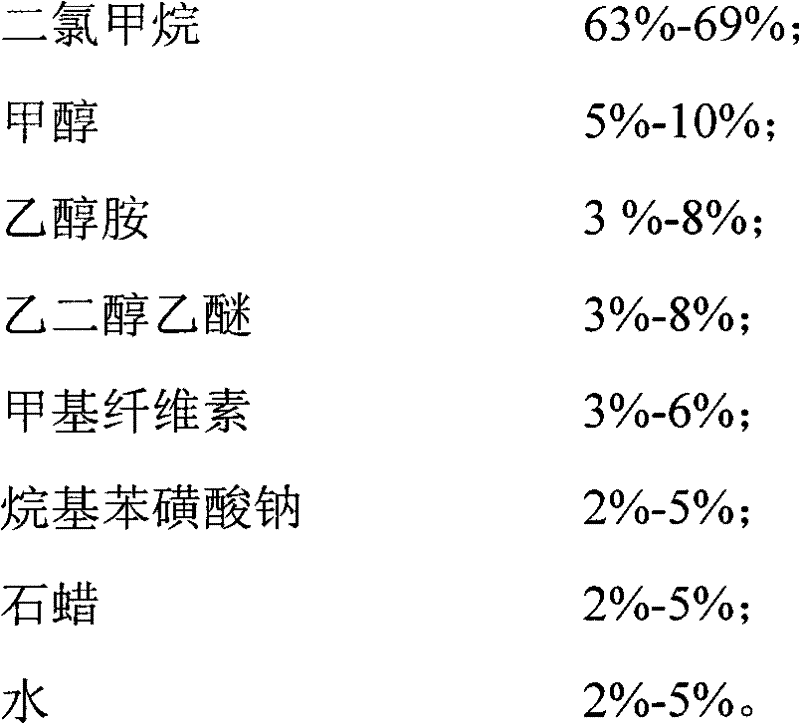

Method used

Image

Examples

Embodiment 1

[0023] Select 63% dichloromethane by weight, 5% methyl alcohol, 8% ethanolamine, 8% ethylene glycol ether, 6% methylcellulose, 5% sodium dodecylbenzenesulfonate, 2 % paraffin, the rest is water, and each component is 100 kilograms in total. The above-mentioned components are added successively in a closed reactor with a stirrer. The order of addition has no effect on product performance. In this embodiment, the selected stirring time 40 minutes, in other embodiments of the present invention also can choose to stir 30 minutes, 35 minutes, 45 minutes, 50 minutes, the time of stirring can be different according to the difference of outside temperature, generally can realize this fully in 40 minutes. The effect of the invention, but when the temperature of the outside is high, the stirring time can be appropriately reduced, such as 30 minutes or 35 minutes, and even less time can also realize the present invention. When the outside temperature is low, a longer stirring time should...

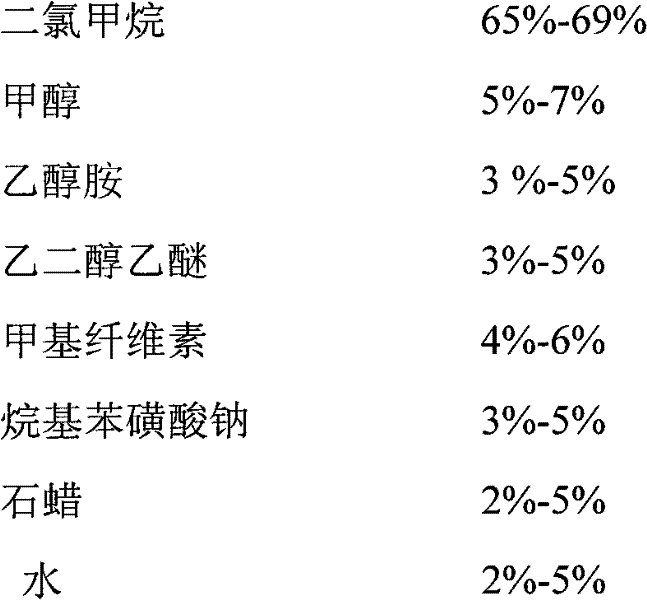

Embodiment 2

[0025] In each embodiment of the present invention, the reaction time and the selected reaction kettle or storage container are all the same or similar, and will not be described repeatedly in the following embodiments. Different only is the weight ratio of each component, in the present embodiment, the weight ratio of each component of paint remover is, the dichloromethane of 69%, the methyl alcohol of 5%, the ethanolamine of 8%, the ethylene glycol of 8% Alcohol ethyl ether, 3% methyl cellulose, 2% sodium dodecylbenzenesulfonate, 2% paraffin, and the rest are water, each component is 100 kg in total. Other implementation conditions are identical with embodiment one.

Embodiment 3

[0027] In the present embodiment, select 65% dichloromethane, 10% methanol, 5% ethanolamine, 5% ethylene glycol ether, 6% methylcellulose, 5% dodecylbenzenesulfonic acid Sodium, 2% paraffin, all the other are water, each component adds up to 100 kilograms, and other implementation conditions are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com