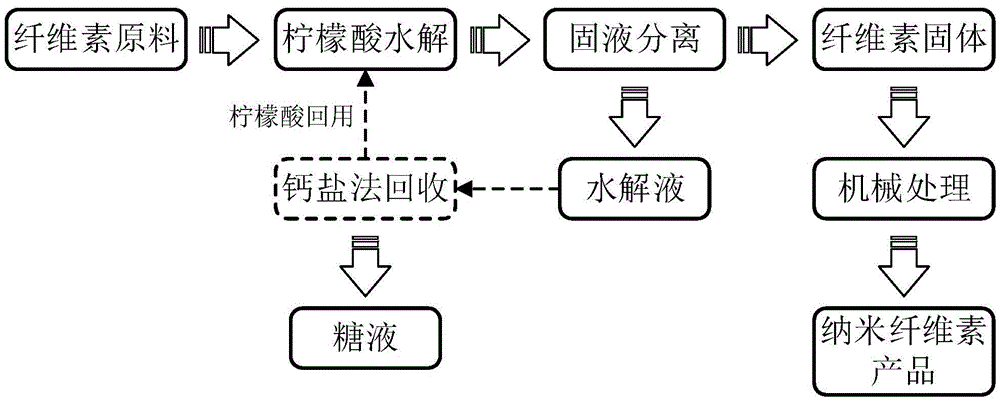

Preparation method of nanocellulose fibrils

A nanocellulose and cellulose technology, which is applied in the field of natural polymer material preparation, can solve the problems of expensive TEMPO catalyst, expensive ionic liquid, difficult industrial production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In step 1) of the method for preparing nanocellulose fibrils according to the present invention: the weight ratio of the added cellulose raw material to the added citric acid solution is 1:6-100, when the weight ratio is less than 1:6, that is, lemon The amount of added acid solution is insufficient, stirring is difficult, and the reaction is not uniform; and when the weight ratio is greater than 1:100, that is, too much citric acid solution, it is not economical. If the reaction temperature exceeds 175°C and the reaction time is too long, the citric acid will be decomposed and too many side reactions will occur, resulting in a decrease in the yield.

[0043] One of the advantages of the method for preparing nanocellulose fibrils according to the present invention is that the hydrolyzate reacted in step 1) can be directly recycled without adding citric acid or after adding a small amount of citric acid, which greatly reduces the process cost. However, due to the loss of...

Embodiment 1

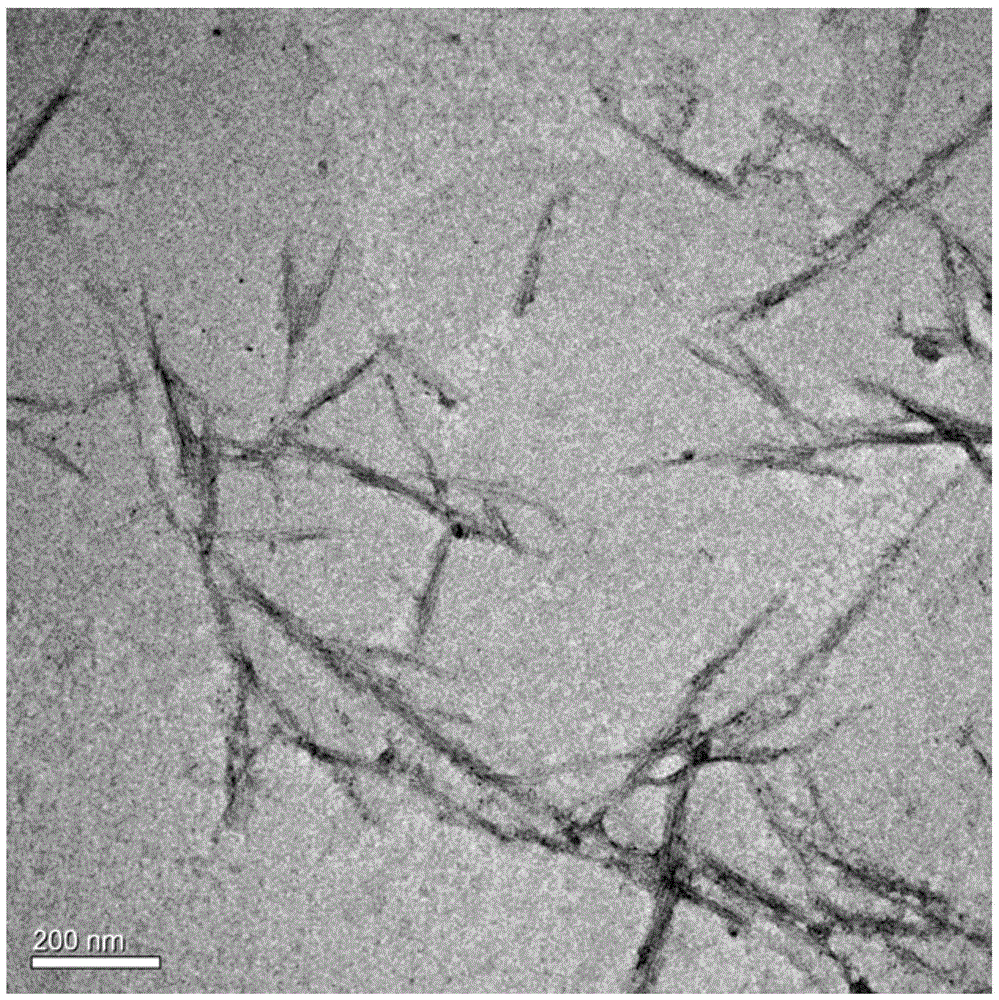

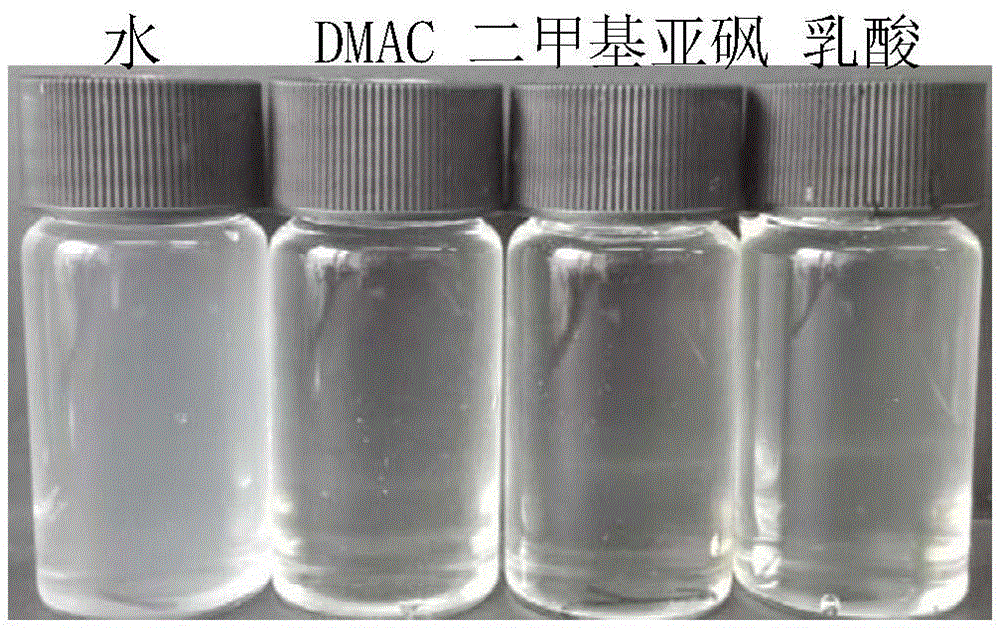

[0046] Weigh 3g of dry bleached eucalyptus pulp into a 250mL round bottom flask, add 100mL of 50wt% citric acid solution, and stir magnetically at 120°C for 5h. After the reaction, the flask was quickly placed in a cold water bath to cool to room temperature, and then the reaction mixture was transferred into a centrifuge tube and centrifuged at 8000 rpm for 5 min. The hydrolyzate can be directly returned to pretreat the next batch of cellulosic raw material. The precipitated colloid was centrifugally washed with distilled water to neutrality, and the centrifuged product was diluted to a concentration of 0.2 wt% with distilled water, and then homogenized 6 times at 50 MPa by a high-pressure homogenizer to obtain a viscous product. The yield of nanocellulose fibrils obtained in this example is 71% (relative to the original dry bleached eucalyptus pulp), and the nanoscale fibrils with good dispersibility are specifically shown in the appendix figure 2 Transmission electron mic...

Embodiment 2

[0048] Weigh 3g of absolute dry furfural residue into a 250mL round bottom flask, add 60mL of 50wt% citric acid solution, and stir magnetically at 150°C for 45min. After the reaction, the flask was quickly placed in a cold water bath to cool to room temperature, and then the reaction mixture was transferred into a centrifuge tube and centrifuged at 8000 rpm for 8 min. The hydrolyzate can be directly returned to pretreat the next batch of cellulosic raw material. The precipitated colloid was washed by centrifugation with distilled water to neutrality, and the product after centrifugation was diluted to a concentration of 5 wt% with distilled water, and then beaten by a PFI mill for 50k times to obtain a viscous product. The yield of nanocellulose fibrils obtained in this example is 81% (relative to the original dry furfural slag), and the width is 10-25nm nanofibrils, specifically see attached Figure 4 Transmission electron microscope pictures in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com