Copper welding paste for braze welding and preparation method thereof

A copper solder paste and brazing technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as inappropriate copper solder paste, and achieve high joint strength, collapse resistance, good fluidity, and low corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

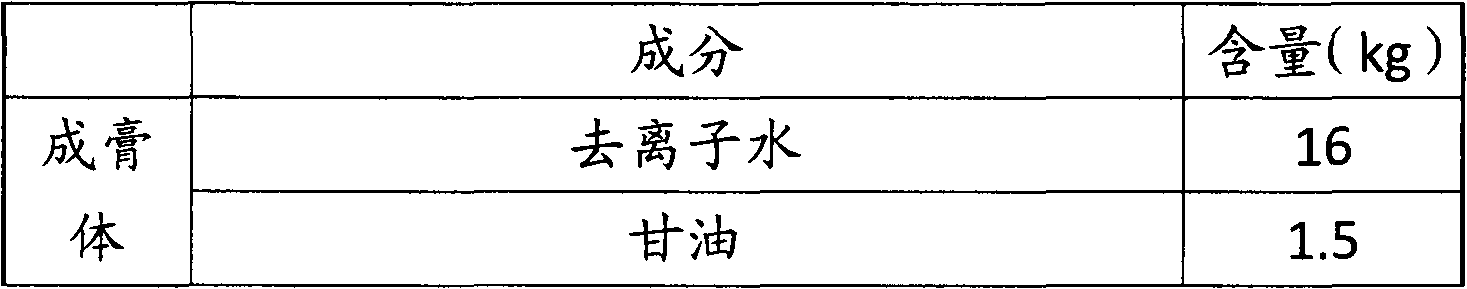

[0046] First, prepare the raw materials according to the following components:

[0047]

[0048]

[0049] Thereafter, the specific preparation steps include:

[0050] 1. Mix Cu powder and Fe powder in proportion in the mixer evenly;

[0051] 2. Add KF to a blender filled with deionized water and stir for 10 minutes;

[0052] 3. Add hydroxyethyl cellulose, xanthan gum and gum arabic to the above aqueous solution in proportion, stir for 120 minutes, then add glycerin, hydrogenated castor oil, silicone oil and N, N, N', N'-tetrakis-(2 Hydroxypropyl) ethylenediamine, stirred for 10 minutes to form a paste mixed with brazing flux;

[0053] 4. Add the mixed Cu powder and Fe powder into the paste, and stir for 45 minutes to make a copper solder paste.

[0054] The copper solder paste prepared according to Example 1 is mainly used for welding low-carbon steel parts. There is no residue on the surface of the parts after welding, the weld seam is fine and dense, and it has very...

Embodiment 2

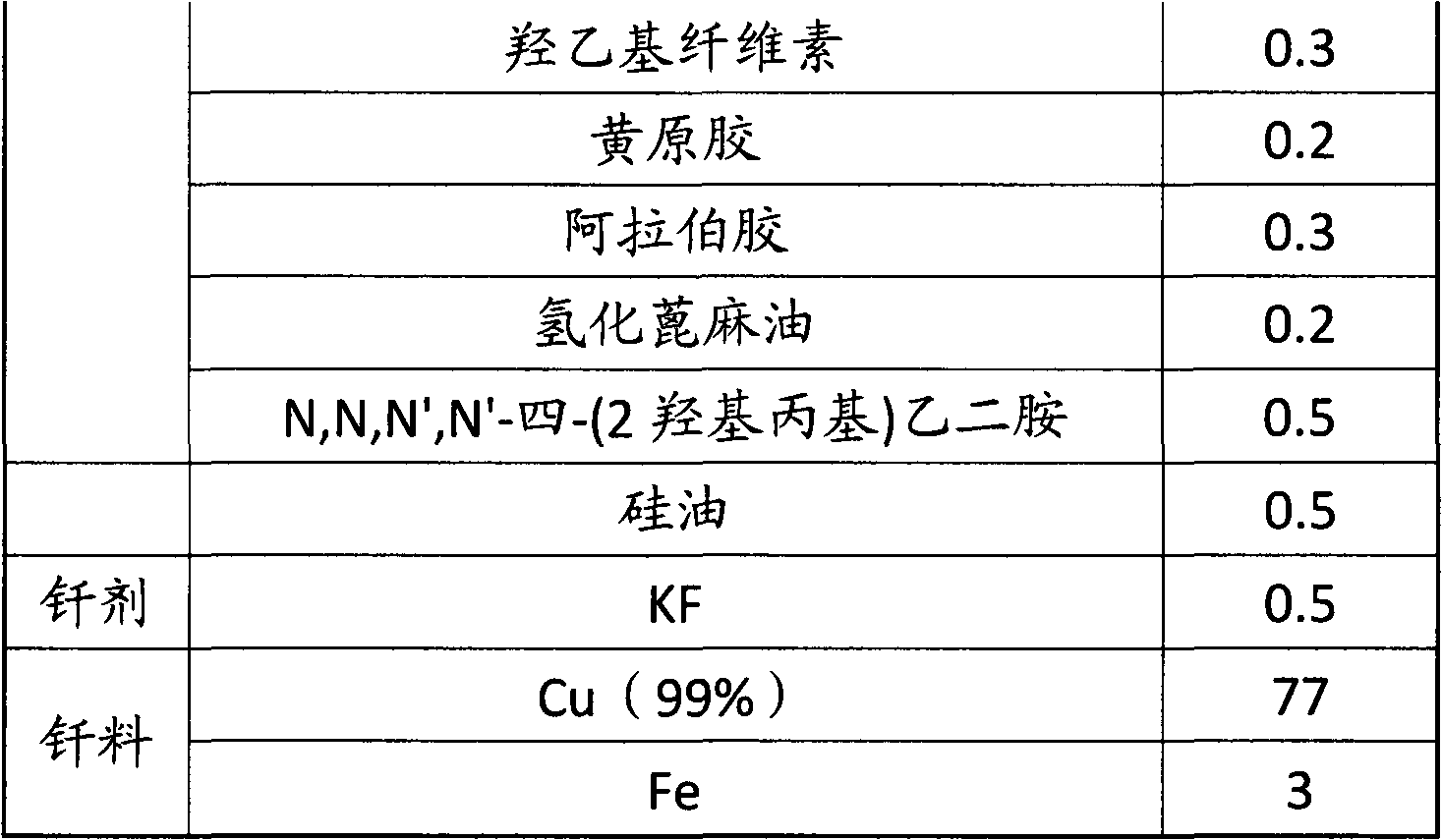

[0056] First, prepare the raw materials according to the following components:

[0057]

[0058]

[0059] Thereafter, the specific preparation steps include:

[0060] 1. Add Cu 余量 sn 10 Ni powder and Ni powder are mixed evenly in the mixer in proportion;

[0061] 2. Mix dipropylene glycol monomethyl ether and 1,2-propanediol in a mixer for 10 minutes;

[0062] 3. Add sebacic acid and lauric acid to the above solvent;

[0063] 4. Add hydroxyethyl cellulose and methyl acrylate to the above solution in proportion, stir for 90 minutes, then add modified castor oil and acetylene glycol, and stir for 10 minutes to form a paste mixed with flux;

[0064] 5. The mixed Cu 余量 sn 10 Ni powder and Ni powder were added to the paste and stirred for 45 minutes to make a brazing paste. The copper solder paste prepared according to Example 2 is used for welding stainless steel components. After welding, the surface of the part is consistent with the color of the weld seam, and the ...

Embodiment 3

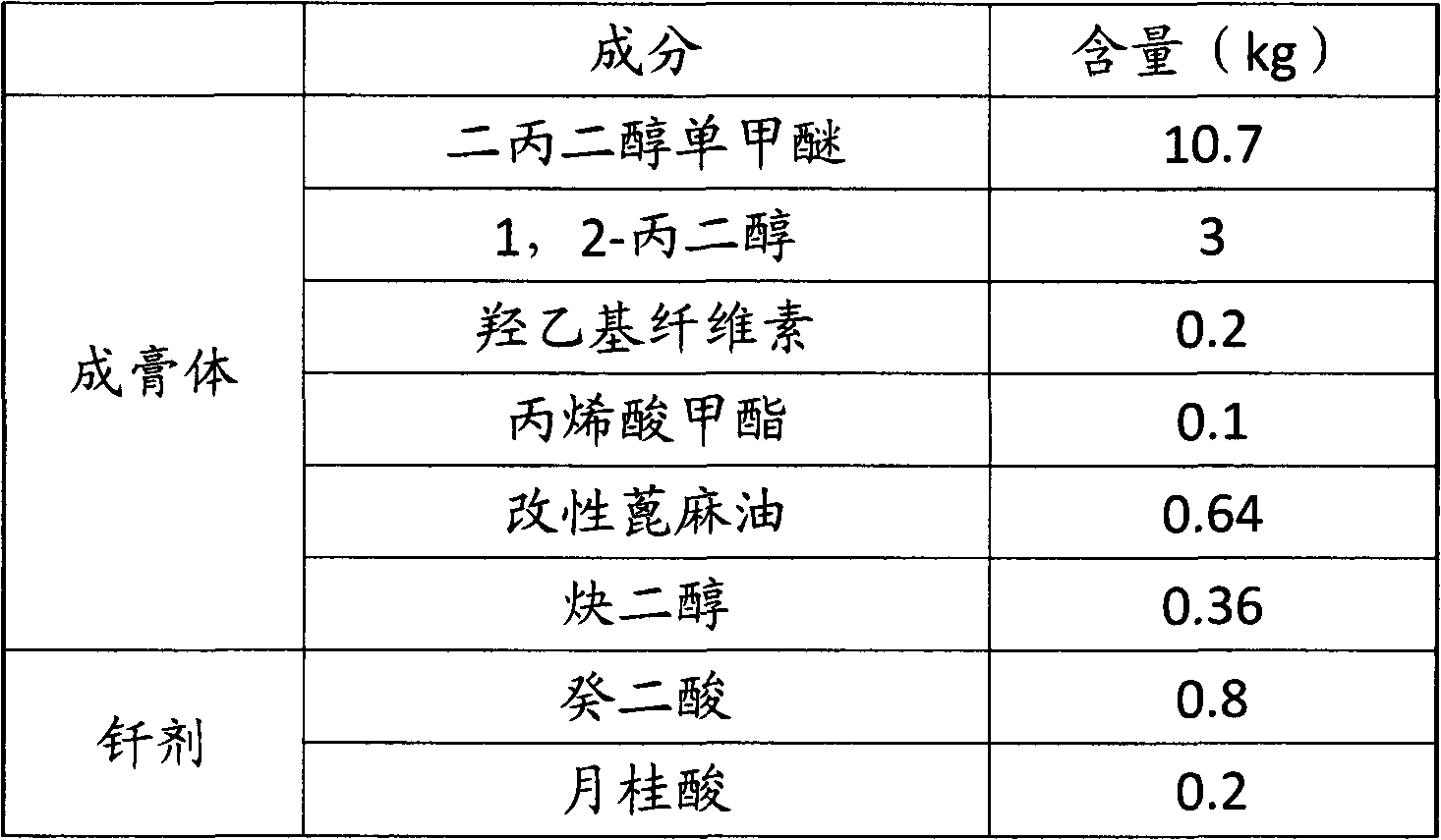

[0066] First, prepare the raw materials according to the following components:

[0067]

[0068] Thereafter, the specific preparation steps include:

[0069] 1. The Cu balance Sn 14 Ni 5 P 5 Powder and Cu 余量 sn 50 The powder is mixed evenly in the mixer according to the proportion;

[0070] 2. Mix diethylene glycol monoethyl ether and ethyl carbitol in a mixer for 10 minutes;

[0071] 3. Add hydroxypropyl starch, ethyl hydroxyethyl cellulose, hydroxypropyl cellulose and locust bean gum to the above solution in proportion, stir for 120 minutes, then add deionized salicylic acid amide and mineral oil, stir for 10 minutes Minutes to form a paste;

[0072] 4. The mixed Cu balance Sn 14 Ni 5 P 5 Powder and Cu 余量 sn 50 Add the powder into the paste and stir for 45 minutes to make a brazing paste.

[0073] The copper solder paste prepared according to Example 3 is used for low-temperature welding of low-carbon steel components, and better welding strength can be obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com