Patents

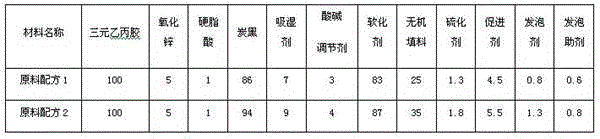

Literature

85results about How to "Improve anti-collapse performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

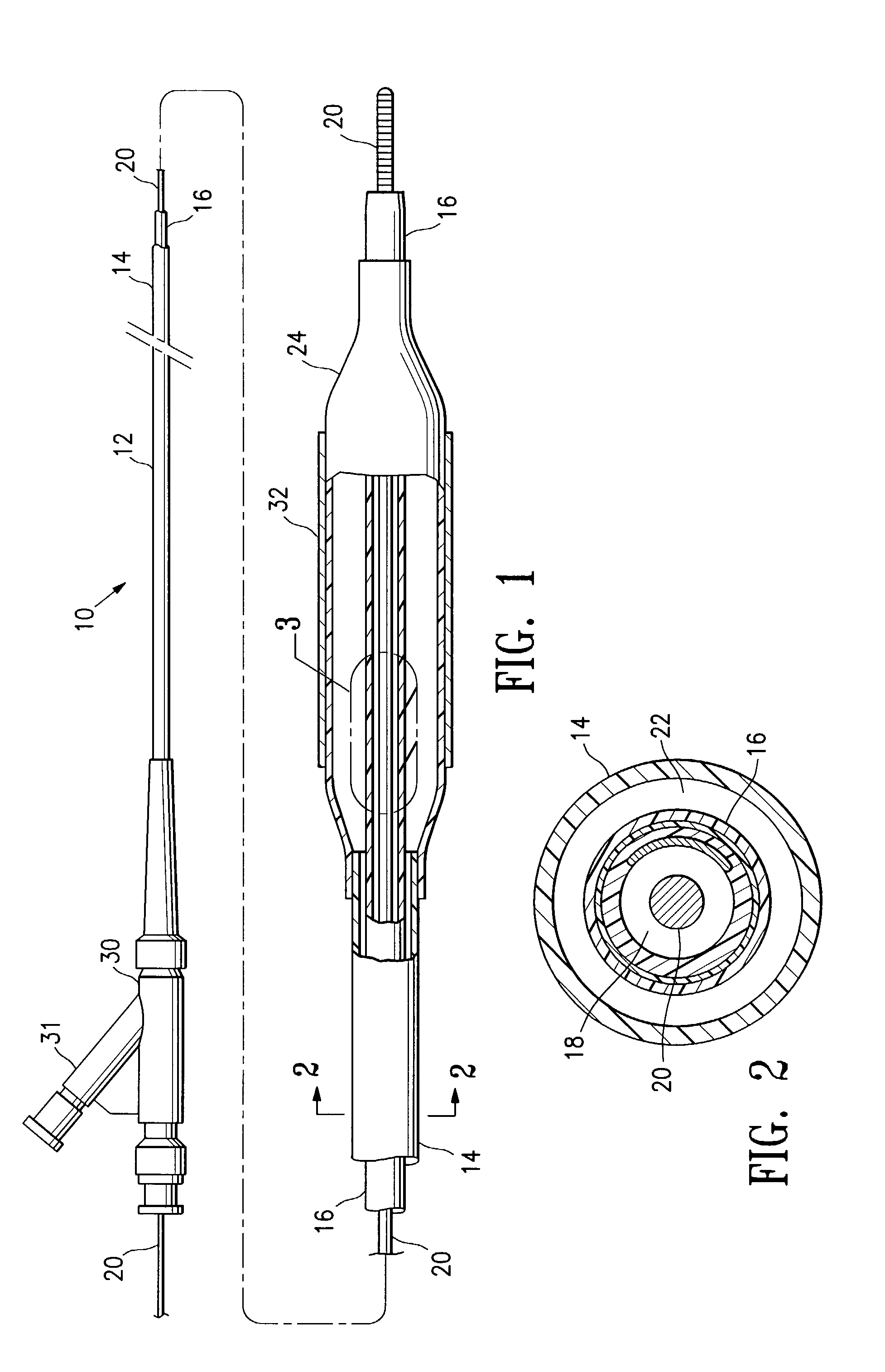

Coil reinforced multilayered inner tubular member for a balloon catheter

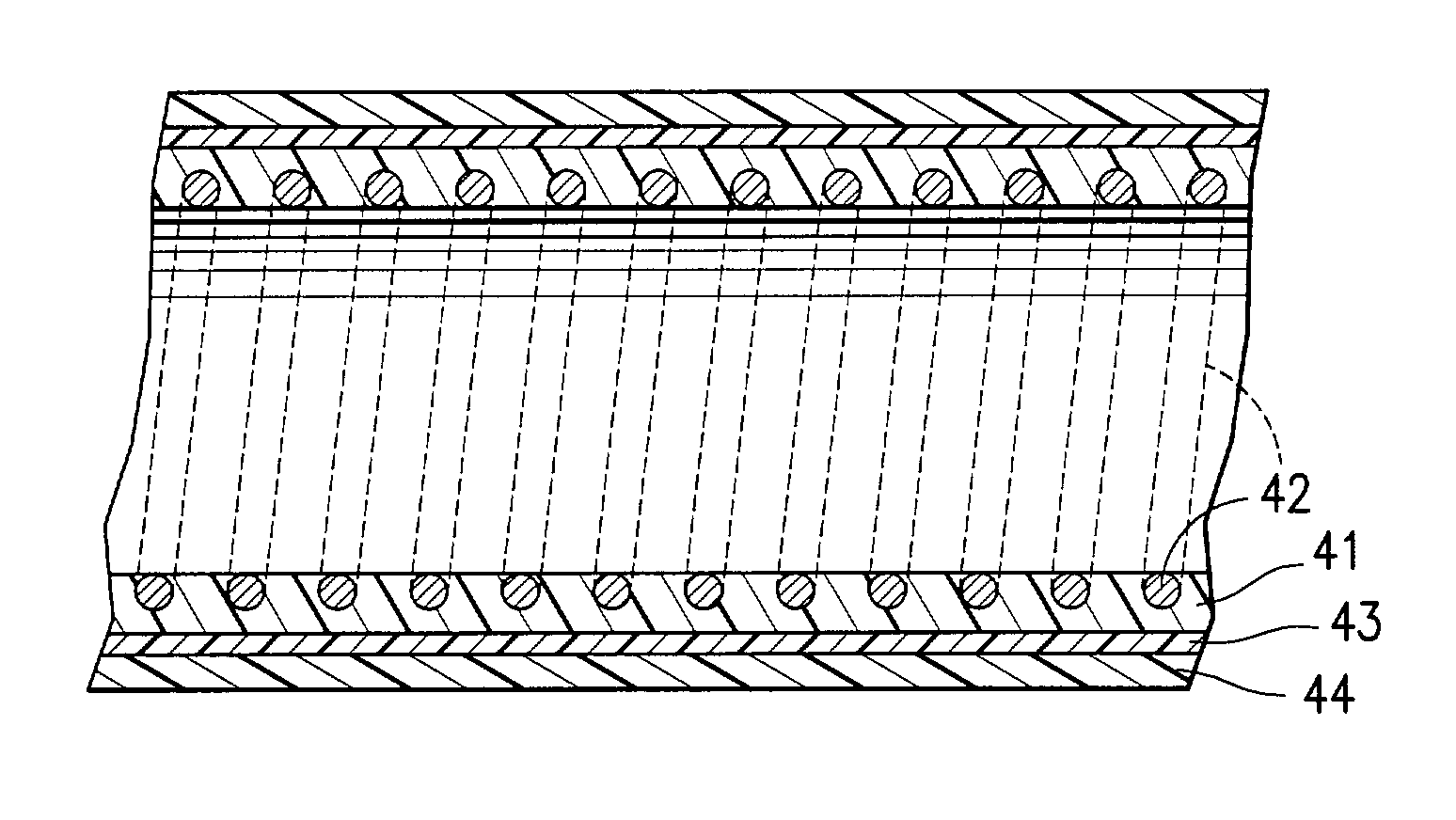

A catheter having an elongated shaft formed of a polymeric tubular member with at least a section having a lubricious inner layer defining the guidewire lumen, a coiled support member at least partially embedded in the lubricious inner layer, and an outer layer on an outer surface of at least a distal portion of the lubricious inner layer. In a presently preferred embodiment, the coil supported polymeric tubular member forms an inner tubular member of a balloon catheter.

Owner:ABBOTT CARDIOVASCULAR

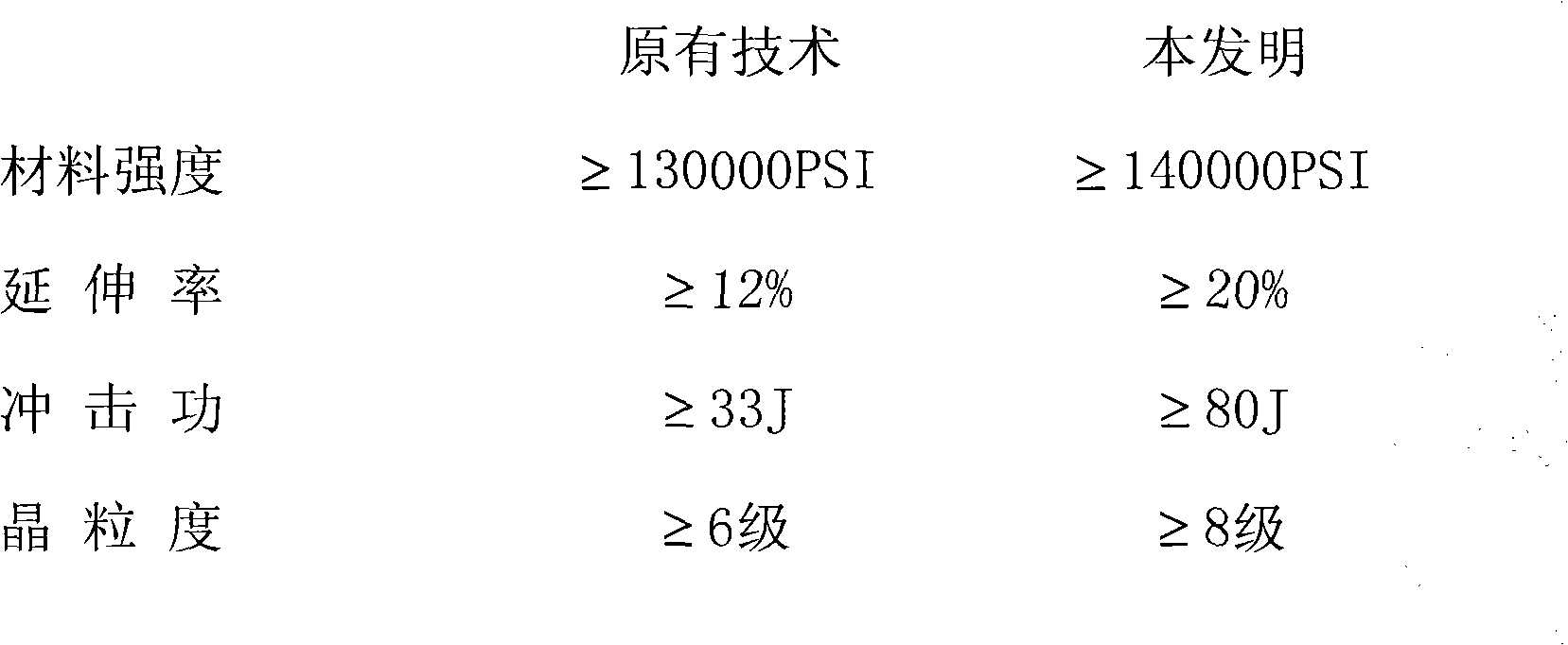

Rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and production method thereof

InactiveCN102251180ALow elemental contentReduce residual stressDrilling rodsProcess efficiency improvementRare earthFlame cutting

A rare-earth-containing ultrahigh strength collapse-resistant petroleum casing and a production method thereof belong to the technical fields of ferrous metal smelting and metal press working. The petroleum casing comprises the following raw materials by weight percent: 90% of blast furnace molten iron and 10% of high quality steel scrap. The casing blank comprises the following chemical components by weight percent: 0.18-0.35% of C, 0.10-0.35% of Si, 0.55-1.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.020% of S, 0.60-1.10% of Cr, 0.15-0.50% of Mo, 0.01-0.03% of Al, 0.0005-0.0100% of RE ( RE is the mixed rare earth metals of Ce and La and the weight percents of Ce and La are 67% and 33% respectively), less than 0.10% of Cu, less than 0.10% of Ni and the balance of Fe and trace elements. The process flow of the production method is as follows: pretreating molten iron, smelting in a top-bottom blowing converter, refining in a ladle furnace (LF), performing VD vacuum treatment, performing continuous casting of round billets, performing flame cutting, heating the casing blanks, boring, performing continuous rolling, performing sizing and diameter reducing, cooling, performing saw cutting, performing heat treatment, straightening, performing flaw inspection and lathing screw threads. The mechanical properties of the petroleum casing are as follows: the strength is no less than 140000PSI, the residual stress is no more than 80MPa, the impact power is no less than 80J and the grain size is no less than the grade 8. The product is characterized in that the residual stress is low, the content of harmful elements is low, the impact toughness is high, the grains are small, and the product resists extrusion and is difficult to damage.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

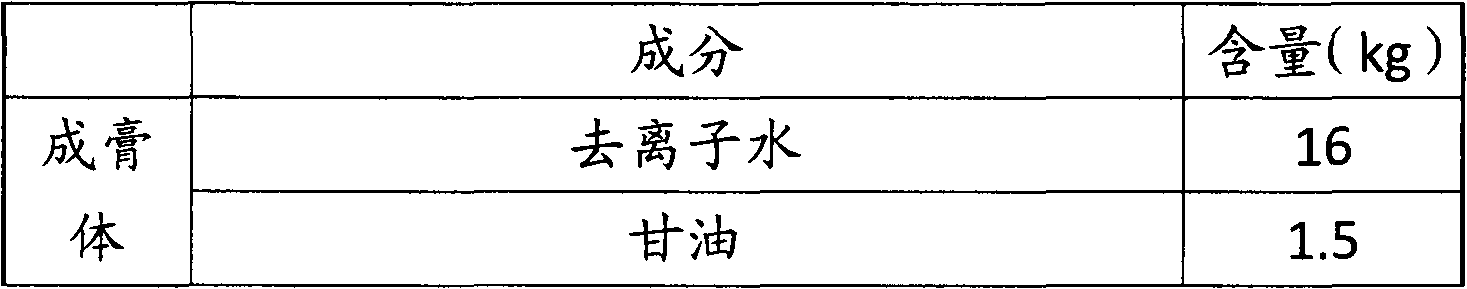

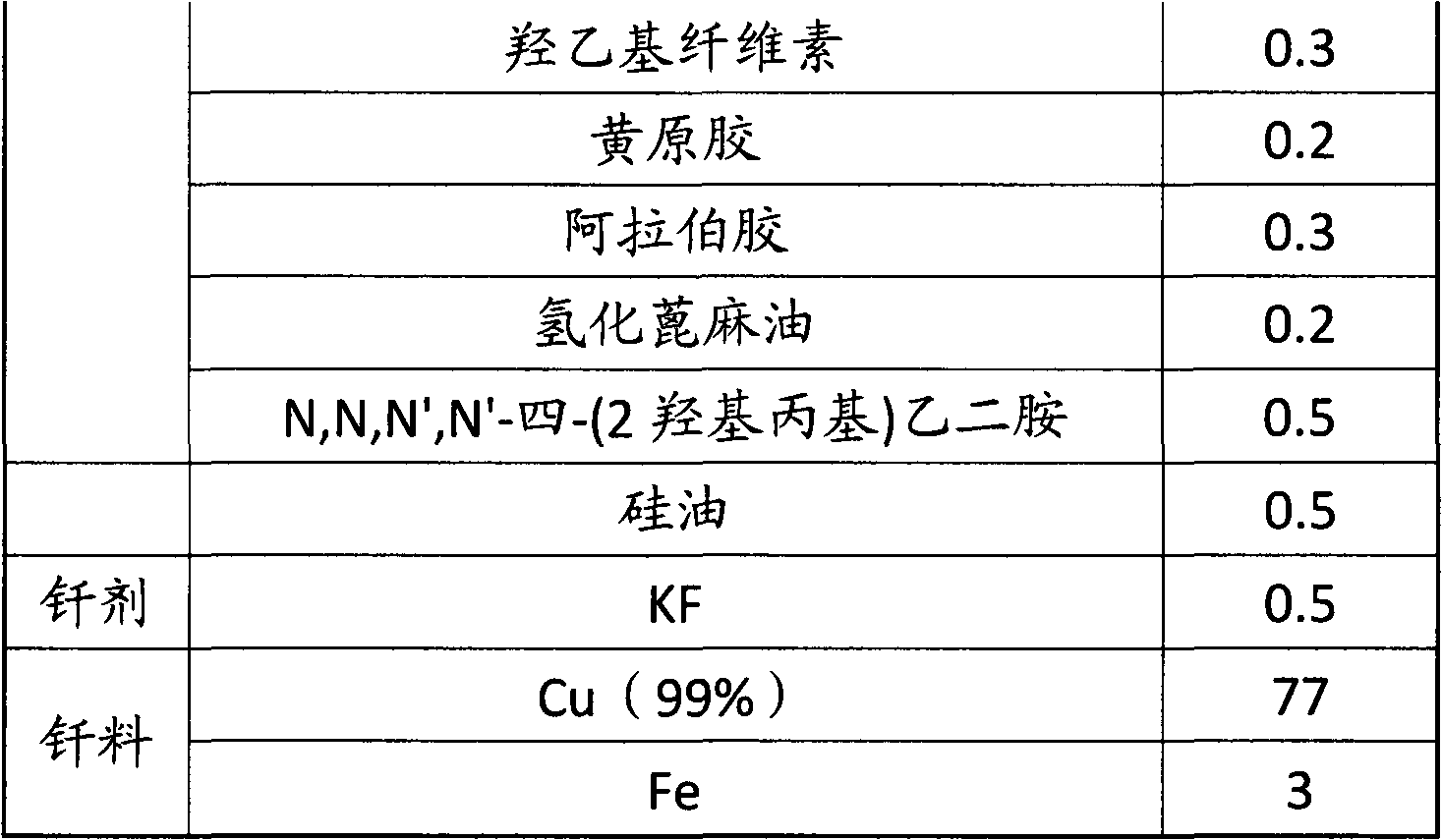

Copper welding paste for braze welding and preparation method thereof

ActiveCN103659053ALess corrosiveAvoid cleaningWelding/cutting media/materialsSoldering mediaPipe fittingSuccinic acid

The invention discloses copper welding paste for braze welding, a preparation method of the copper welding paste for braze welding and the application of the copper welding paste for braze welding. The copper welding paste for braze welding comprises 67wt%-92wt% of brazing filler metal, 8wt%-33wt% of pasty fluid and brazing flux of which the mass is 0-5% that of the brazing filler metal, wherein the brazing filler metal comprises Cu and / or one or more types of Cu alloy, the brazing flux comprises any one or more than two components of CaF2, KF, NaF, BaF2, sebacic acid, succinic acid, lauric acid and boric acid, and the pasty fluid comprises a solvent, a thickening agent, a rheological agent, an antifoaming agent and an activating agent. When the copper welding paste prepared through the method is applied before braze welding, the copper welding paste has good thixotropy, collapse resistance and fluidity; after braze welding, a part has high joint strength, a weld joint is plump and free of residues, and the part does not need cleaning; the copper welding paste can be widely applied to welding automobile pipe fittings, copper-based heat dissipation assemblies and stainless steel parts.

Owner:SUZHOU CUBRAZING MATERIALS CO LTD

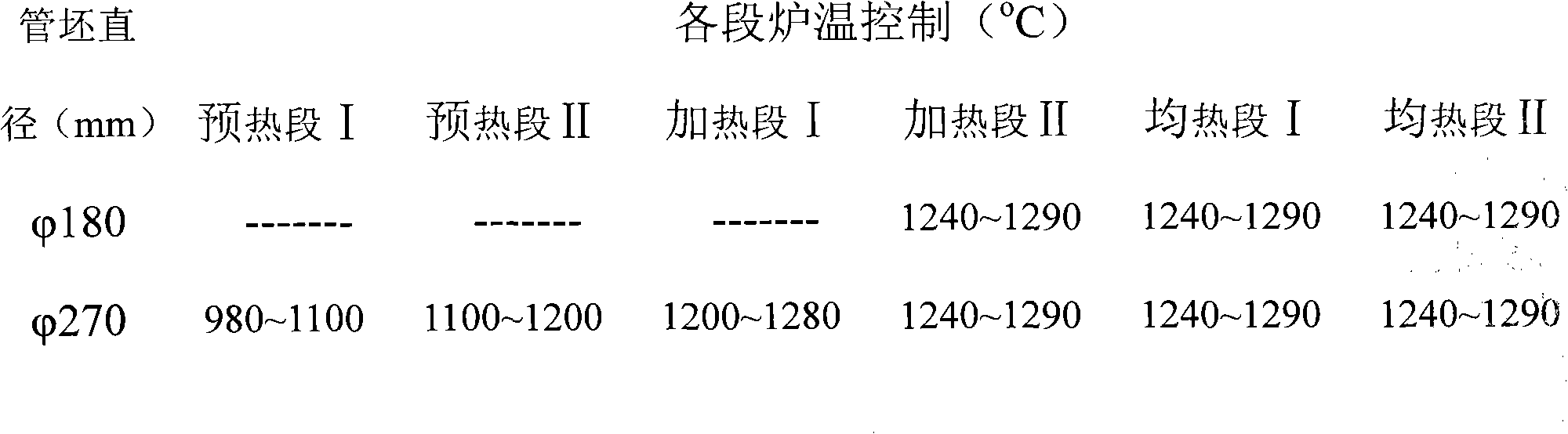

High collapse-resistance and hydrogen sulphide-corrosion-resistant low alloy petroleum case pipe and method of manufacturing the same

ActiveCN101245437AImprove toughnessImprove anti-collapse performanceTemperature control deviceFurnace typesAlloyPetroleum

The invention relates to a low-alloyed petroleum casing pipe with high anti-collapse and high hydrogen sulfide corrosion resistance and a production method. The weight percentages of the chemical components of the low-alloyed petroleum casing pipe are: 0.24-0.34 percent of C, 0.35-1.0 percent of Mn, 0.20-0.50 percent of Si, 0.4-1.1 percent of Cr, 0.2-0.7 percent of Mo, 0.007-0.07 percent of Al, 0.005-0.05 percent of Ti, 0.01-0.05 percent of Nb, 0.05-0.15 percent of V, 0-0.6 percent of Ni, 0-0.2 percent of Cu, less than 0.003 percent of B, less than 0.015 percent of P, less than 0.005 percent of S and less than 0.01 percent of Ca and the rest of Fe and inevitable impurities. The production method comprises: external refining and vacuum degassing, and then Ca treatment, smelting, continuous casting to form round blocker and pipe making, soaking, air cooling after rolling, sawing, and then quenching and tempering heat treatment, heating to 880-900 DEG C, water quenching after heat preservation for 30-60 min, tempering and heat preservation under 680-710 DEG C and hot sizing under 550-650 DEG C, the temperature of hot straightening is more than 450 DEG C. The low-alloyed petroleum casing pipe has better anti-collapse performance and hydrogen sulfide corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Bone cement containing calcium citrate and preparation method of bone cement

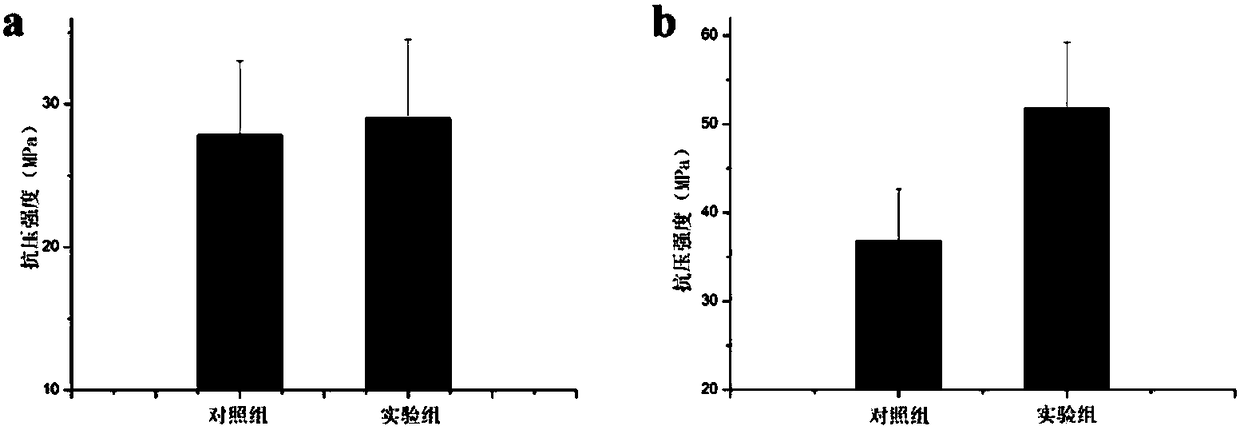

ActiveCN105396175AImproved ability to resist collapseStrong plasticityTissue regenerationProsthesisSolid phasesOrthopedic department

The invention belongs to the field of bone damage repair medicinal materials and particularly relates to a preparation method and application of bone cement containing calcium citrate. The bone cement containing calcium citrate is composed of a solid phase part and a liquid phase part, the solid phase part is formed by compounding the calcium citrate and calcium phosphate salt, and the mass ratio of the calcium citrate to the calcium phosphate salt is (2-5):1; the liquid-solid ratio is (0.5-1.5):1. The bone cement containing the calcium citrate has comprehensive biomedical properties such as good plasticity, bone guidance, bone induction activity, cell activity and good degradation rate and is applicable to the orthopedics department, the thoracic surgery department and shaping and restoration of skull and jaw surfaces.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

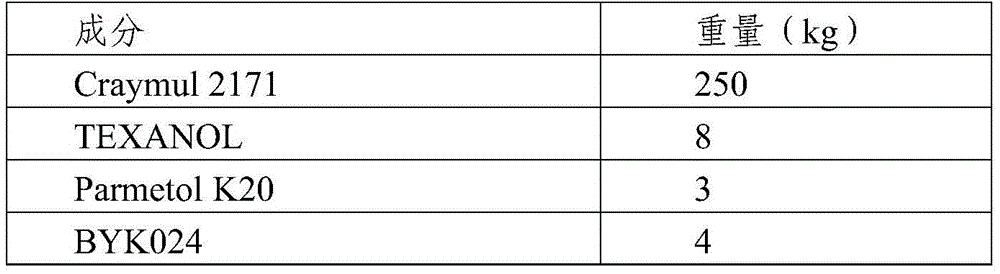

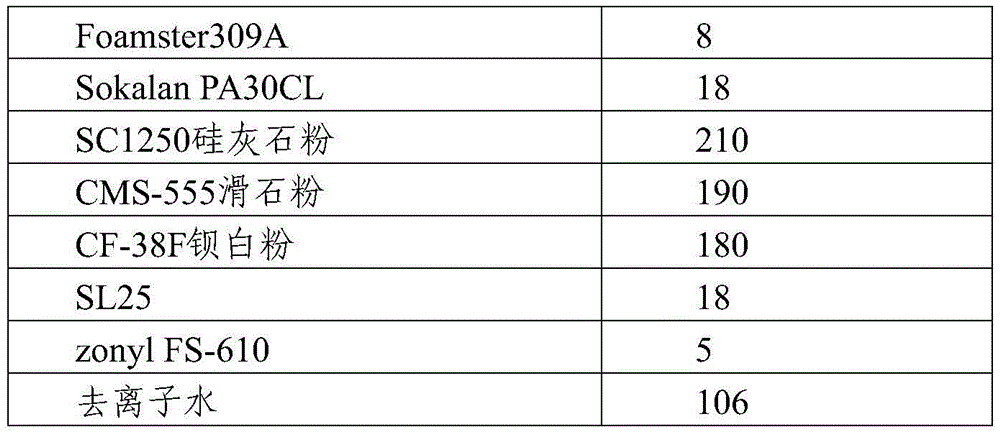

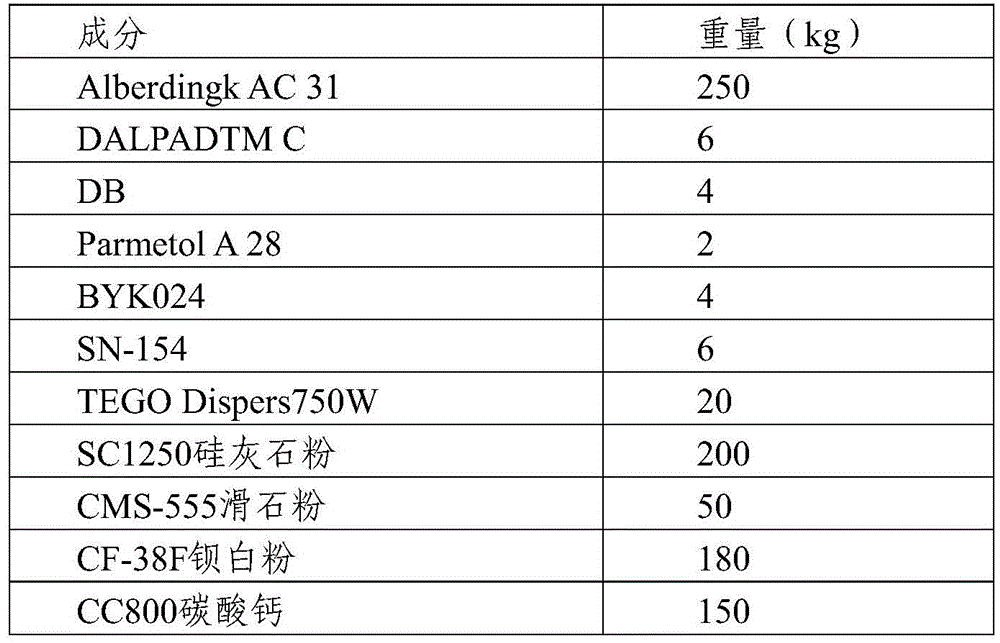

Water-based bi-component white primer and preparation method thereof

InactiveCN105482586AGood solvent resistanceNo bottoming problemAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention provides a water-based bi-component white primer. The water-based bi-component white primer comprises two components A and B, wherein the component A comprises the following components in parts by weight: 200-300 parts of water-based hydroxy acrylic resin, 1-4 parts of an in-tank fungicide, 10-25 parts of a wetting dispersant, 4-15 parts of a defoaming agent, 5-15 parts of a film-forming aid, 150-300 parts of wollastonite, 350-500 parts of fillings, 10-30 parts of a rheology controller, 5-10 parts of a base material wetting agent and 50-150 parts of water; the component B is a water-based polyisocyanate curing agent. The dually-curable water-based resin with high solid content and low hydroxyl value is utilized, is matched with the specific water-based polyisocyanate curing agent and is supplemented with the fillings including wollastonite and white barium powder to form a special thixotropic thickening system, so that the storage stability of products is improved, and the special thixotropic thickening system is excellent in construction performance, environmentally friendly and ultralow in VOC content and further has the characteristics of ultrahigh solid content, high drying speed and hardness, good collapse resistance, high crosslinking density, good solvent resistance and the like.

Owner:BEIJING ZHANCHEN CHEM +5

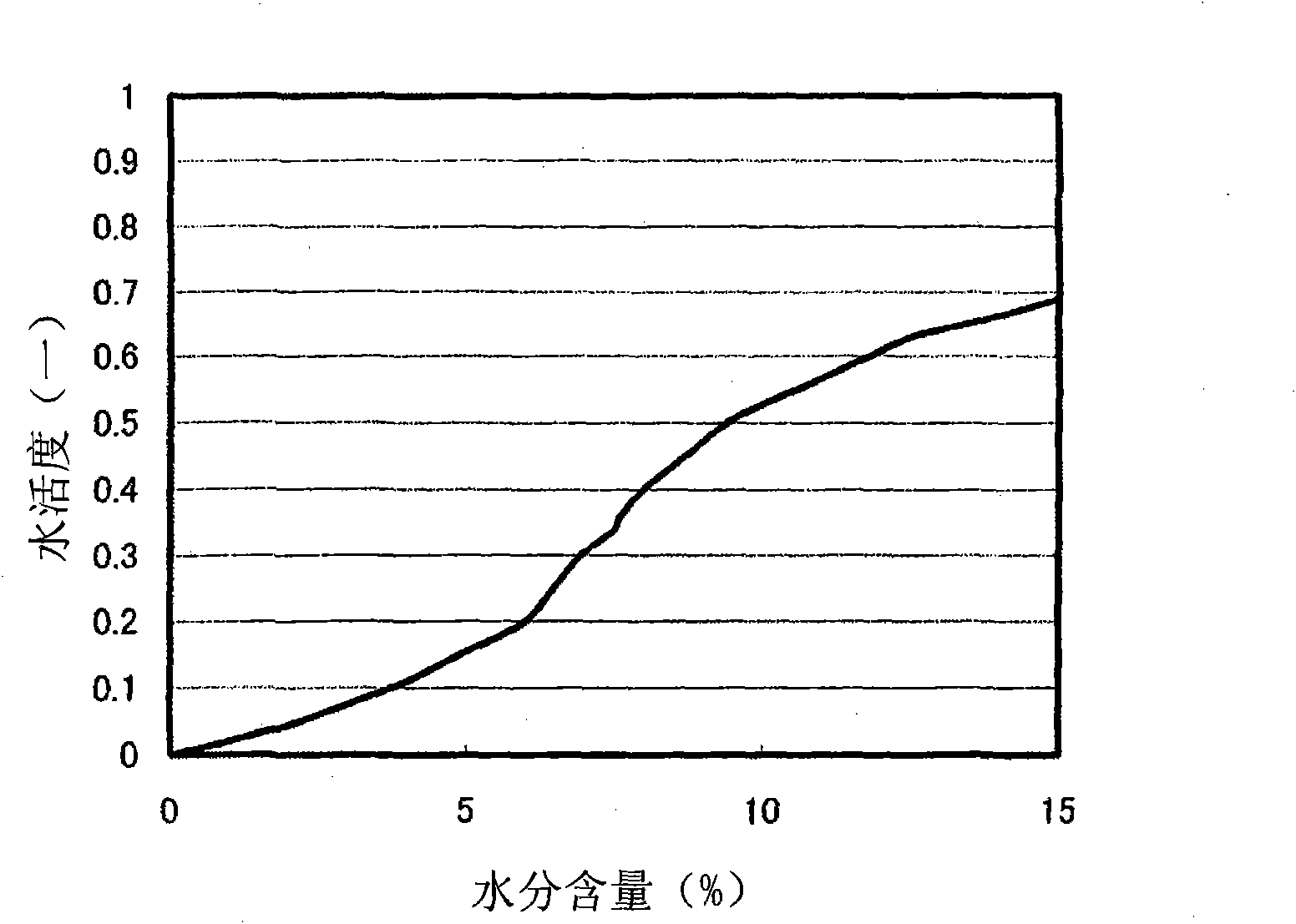

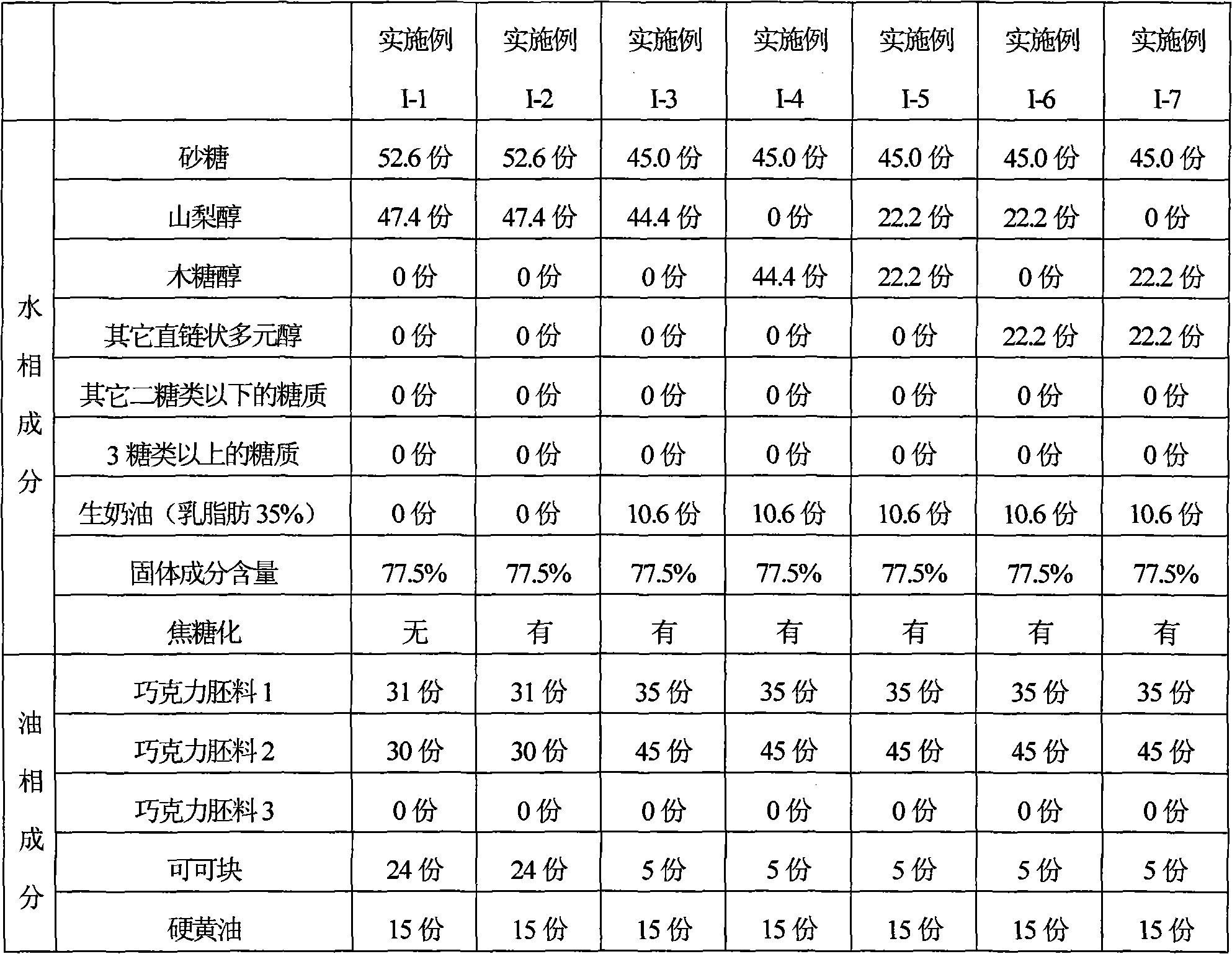

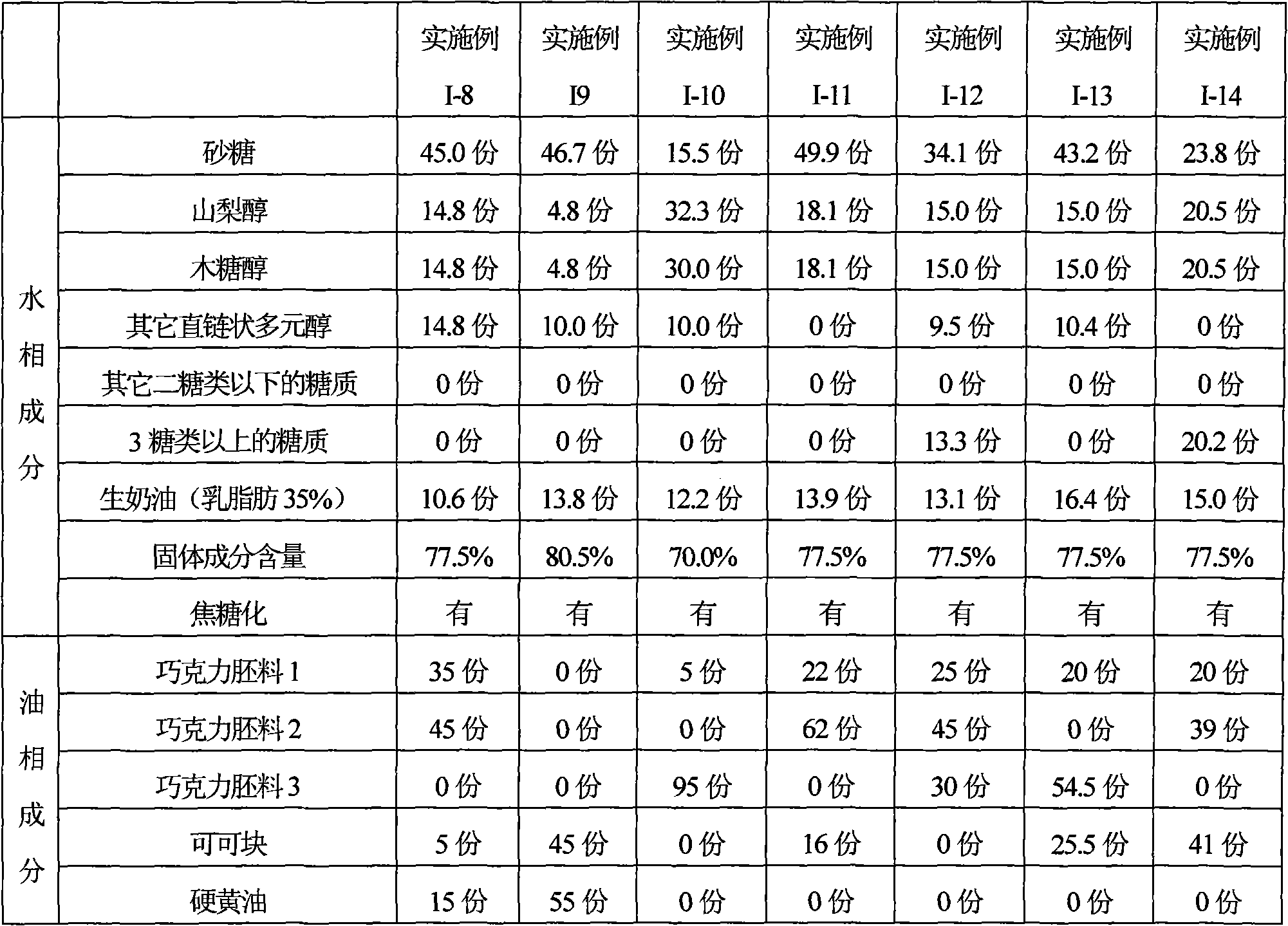

Crude chocolate sample composition, manufacturing method thereof and dessert using the same

The invention provides a crude chocolate sample composition, a method for manufacturing the crude chocolate sample composition effectively and a novel dessert for using the crude chocolate sample composition with above advantages. The crude chocolate sample composition has the flavor and taste of the crude chocolate sample; and the crude chocolate sample composition can maintain the better flavor and taste when circulated for around one year. The above problem is solved by a crude chocolate sample composition, wherein the crude chocolate sample composition comprises the following components in percentage by weight: 40-70% of sugar comprising disaccharide or below, 5-25% of hard butter and 8-18% of moisture; the water activity is lower than 0.600; and the content of the straight chain polyatomic alcohol in the disaccharide is 5-25% by weight.

Owner:UHA MIKAKUTO CO LTD

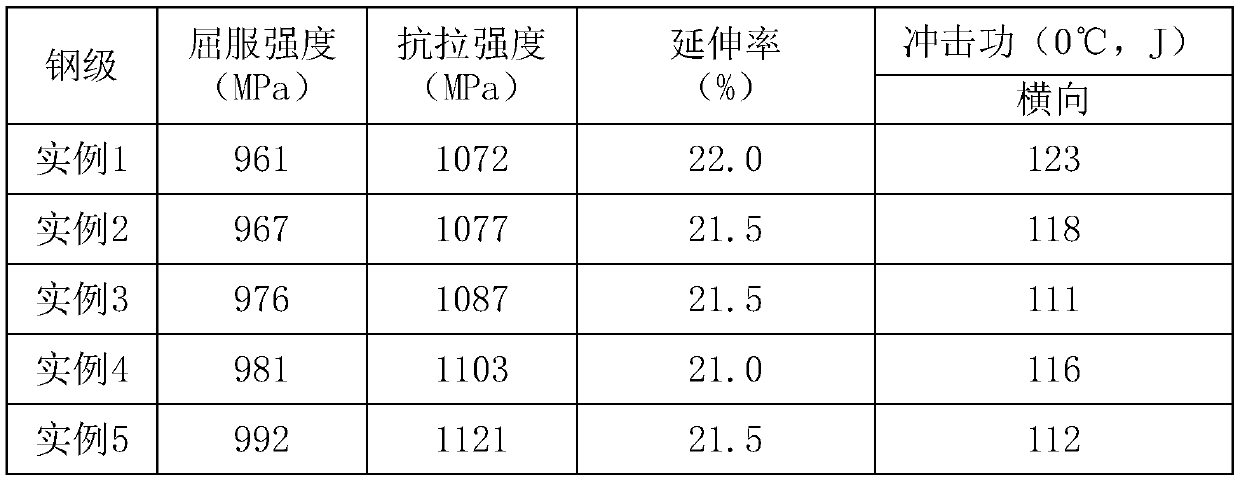

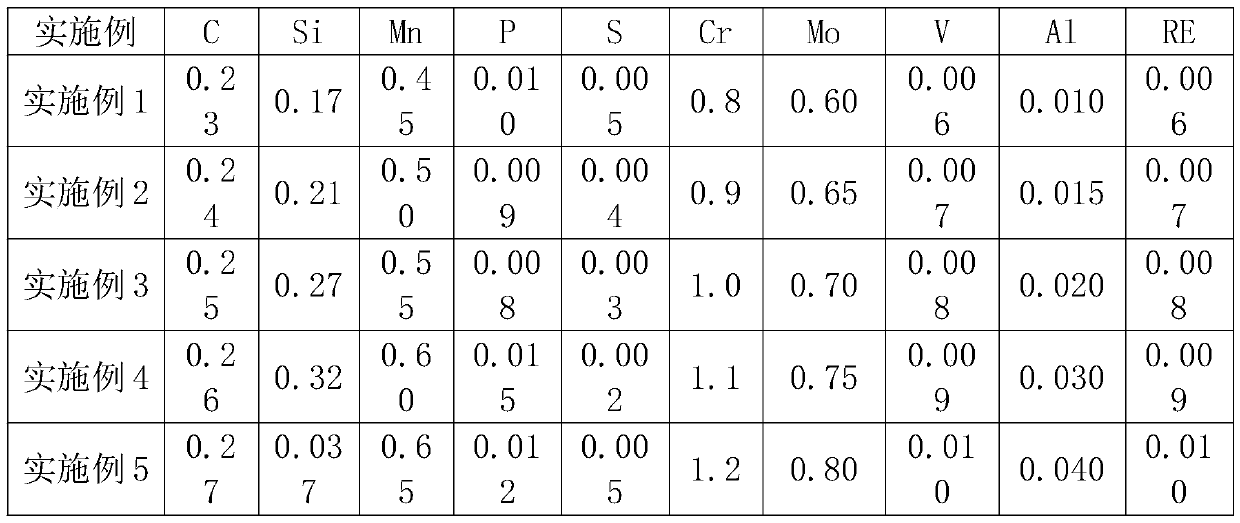

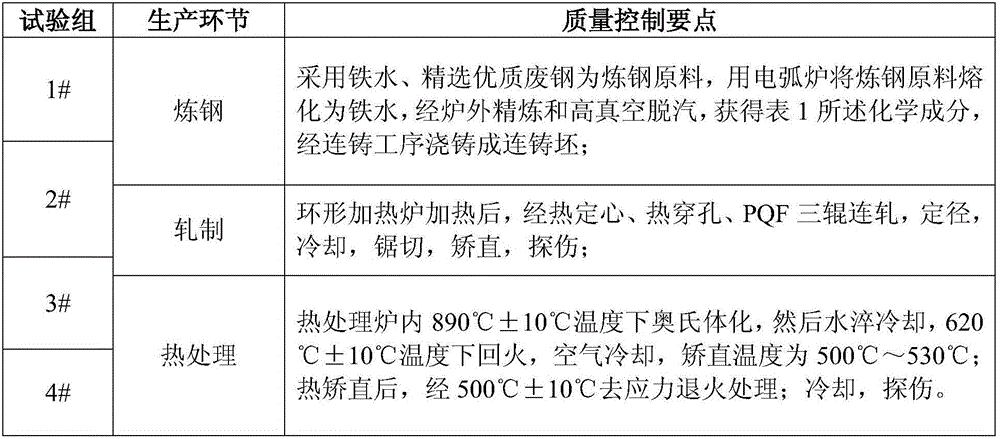

Rare-earth-containing high-strength high-toughness seamless steel tube for shale gas and preparation method thereof

InactiveCN110004357AImprove toughnessImprove lateral impact toughnessRare-earth elementChemical composition

The invention discloses a rare-earth-containing high-strength high-toughness seamless steel tube for shale gas. The seamless steel tube is prepared from, by mass, 0.23%-0.27% of C, 0.17%-0.37% of Si,0.45%-0.65% of Mn, 0.8%-1.2% of Cr, 0.60%-0.80% of Mo, 0.06%-0.10% of V, 0.01%-0.04% of Al, less than or equal to 0.015% of P, less than or equal to 0.005% of S and 0.006-0.010% of RE. The invention discloses a preparation method. According to the rare-earth-containing high-strength high-toughness seamless steel tube for shale gas, rare earth elements are added into the Cr-Mo series steel, the modification and microalloying of the rare earth elements not only makes the steel have high strength and crush resistance but also has high toughness, especially high transverse impact toughness, and the seamless steel tube can meet the working condition requirements of shale gas exploitation and has good popularization value.

Owner:BAOTOU IRON & STEEL GRP

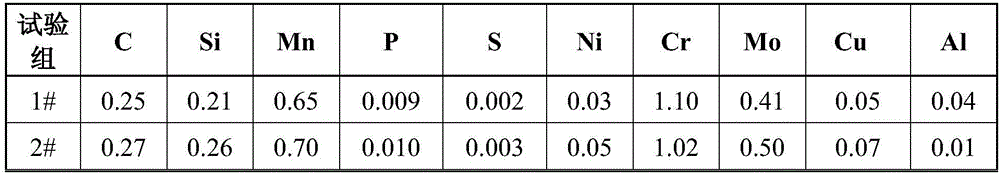

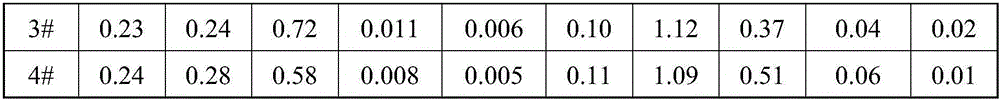

125 ksi high-strength and high-toughness petroleum casing pipe for exploring thickened oil through SAGD method and manufacturing method thereof

The invention provides a 125 ksi high-strength and high-toughness petroleum casing pipe for exploring thickened oil through the SAGD method and a manufacturing method thereof. The casing pipe comprises, by weight, 0.23-0.28% of C, 0.17-0.30% of Si, 0.56-0.75% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.007% of S, smaller than or equal to 0.20% of Ni, 1.0-1.20% of Cr, 0.35-0.55% of Mo, smaller than or equal to 0.15% of Cu, smaller than or equal to 0.01-0.04% of Al and the balance Fe. The manufacturing method includes the steps of selecting raw steel-making materials; adjusting steel compositions through external refining, vacuum degassing and argon stirring; lowering the out-of-roundness of the outer diameter and the unevenness of the wall thickness of a steel pipe by carrying out high-precision rolling through a PQF unit; and carrying out heat treatment to obtain high-strength and high-toughness matching and lowering the residual stress of the steel pipe by increasing the thermal straightening temperature and through the stress relief annealing technology. The casing pipe and the manufacturing method thereof have the beneficial effects that the heat stability is good, the yield strength is not lower than 800 MPa at 350 DEG C, the external extrusion deformation resistance is high, the actual anti-collapse property is higher than the API calculation value by more than 56%, and the requirements of exploring the thickened oil through the SAGD method are met.

Owner:TIANJIN PIPE GROUP CORP

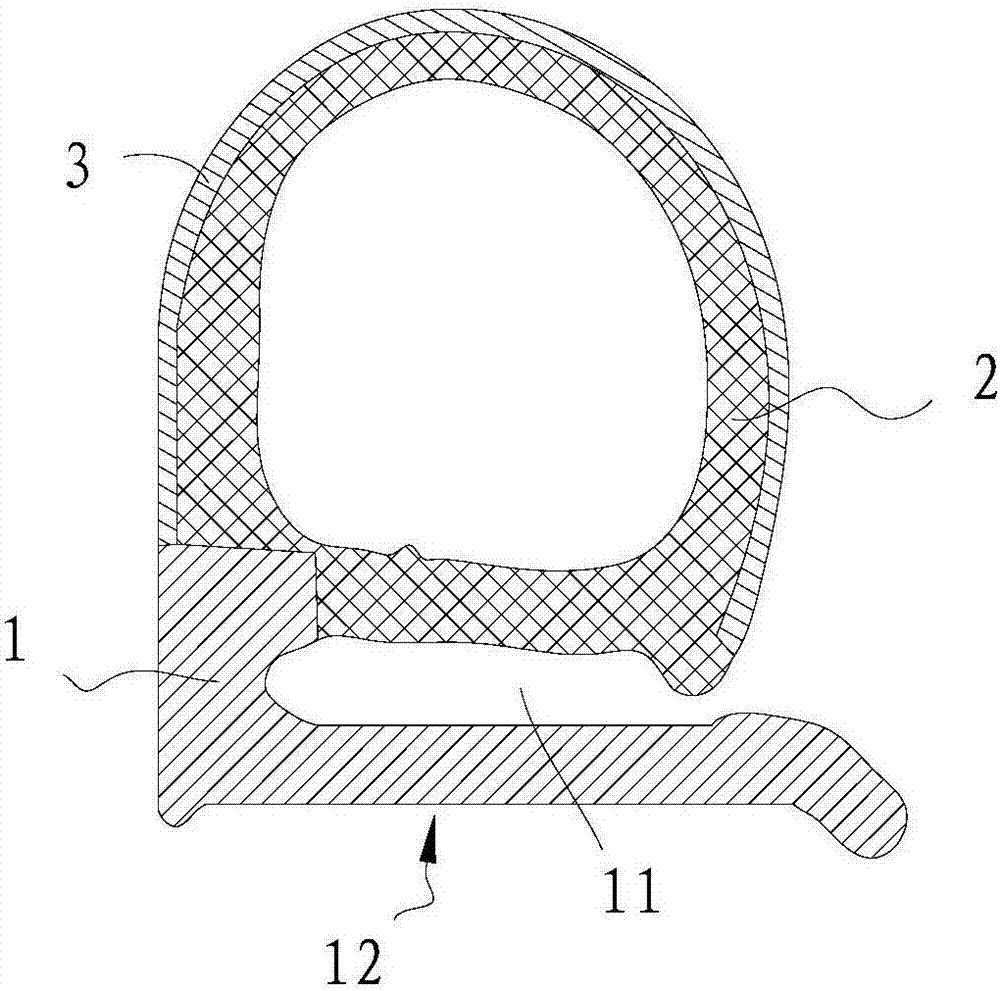

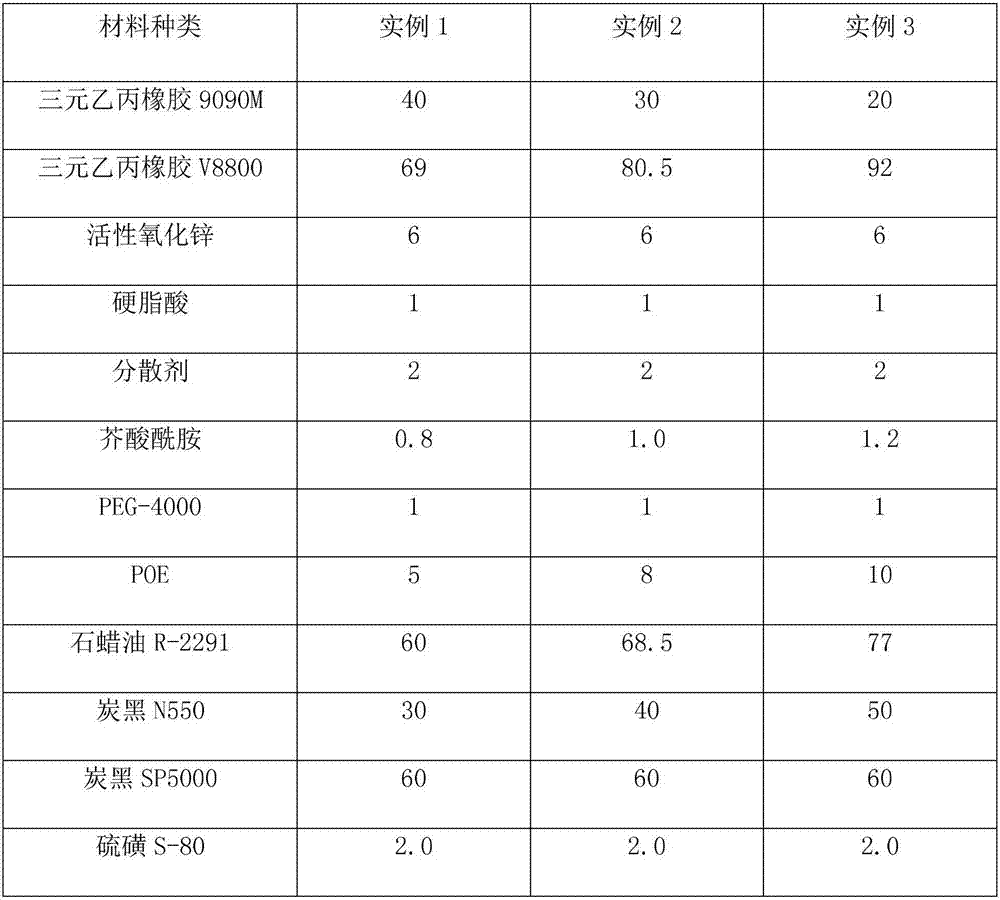

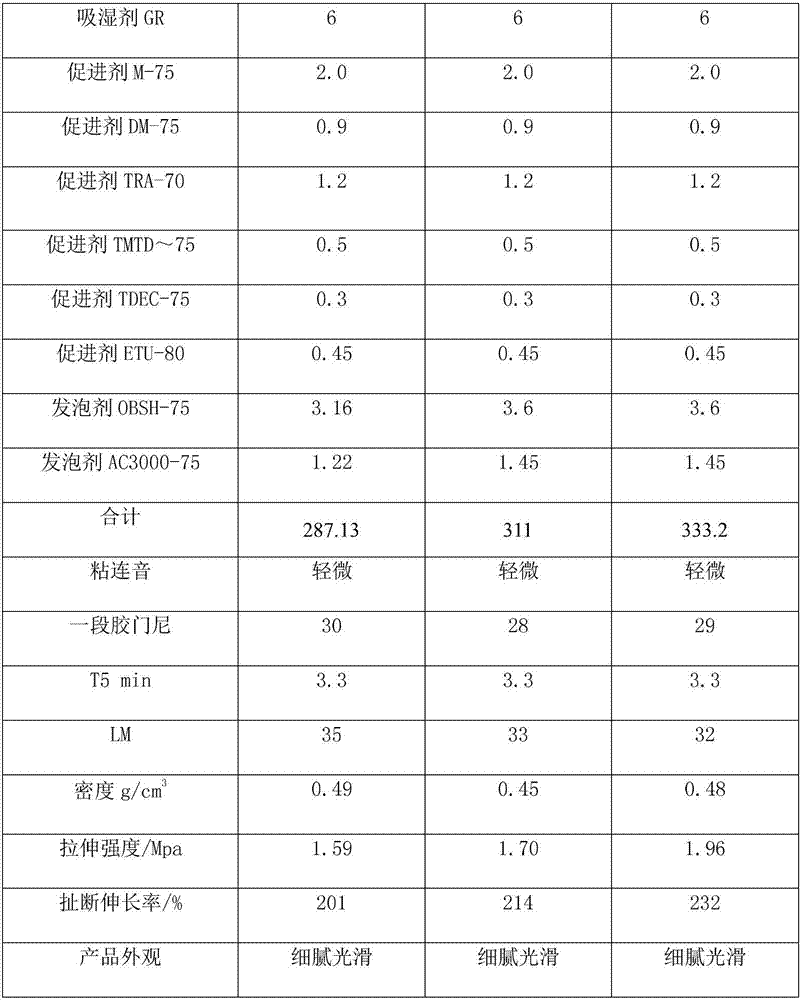

Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

InactiveCN107418061ALow viscosityConducive to lightweight designEngine sealsVehicle sealing arrangementsElastomerPolyolefin

The invention provides sponge foaming rubber for a car door sealing strip and a preparation method thereof, a car door sealing strip and a preparation method thereof. The sponge foaming rubber for the car door sealing strip, provided by the invention, is prepared from the following components in parts by weight: 20 to 40 parts of ethylene-propylene-diene monomer 9090M, 69 to 92 parts of ethylene-propylene-diene monomer V8800, 5 to 7 parts of active zinc oxide, 1 to 2 parts of stearic acid, 1 to 3 parts of a dispersant, 0.8 to 1.4 parts of erucamide, 1 to 2 parts of PEG-4000 (Polyethylene Glycol-4000), 5 to 10 parts of POE (Polyolefin Elastomer), 60 to 77 parts of paraffin oil R-2291, 30 to 50 parts of carbon black N550, 50 to 70 parts of carbon black SP5000, 1.5 to 2.5 parts of sulfur S-80, 6 to 10 parts of a moisture absorbent GR, 3 to 6.4 parts of an accelerant, 3 to 3.6 parts of a foaming agent OBSH-75 (Oxydibenzenesulfonyl Hydrazide-75) and 1.1 to 1.5 parts of a foaming agent AC3000-75. By adopting a formula of the sponge foaming rubber for the car door sealing strip, provided by the invention, the prepared sponge rubber has relatively low density and can meet a lightweight design; meanwhile, the obtained rubber also can have relatively good physical performance, so that the utilization quality of the car door sealing strip utilizing the sponge foaming rubber can also be improved.

Owner:NUOBO RUBBER PRODION

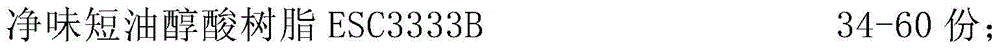

Transparent odor-removing anti-collapse polyurethane primer paint for furniture and preparation method of transparent odor-removing anti-collapse polyurethane primer paint

ActiveCN104559729AImprove anti-collapse performanceImprove toughnessPolyurea/polyurethane coatingsCyclohexanonePolymer science

The invention discloses transparent odor-removing anti-collapse polyurethane primer paint and a preparation method thereof. The transparent odor-removing anti-collapse polyurethane primer paint consists of components A, B and C, wherein the component A is a transparent polyurethane primer paint composition; the component B is a polyurethane curing agent; the component C is a diluent. When the transparent odor-removing anti-collapse polyurethane primer paint is used, the weight ratio of a main agent to the curing agent to the diluent is 1:(0.5-1):(0.5-0.6); the component A, that is, the transparent polyurethane primer paint composition of the transparent odor-removing anti-collapse polyurethane primer paint comprises the following main components: odor-removing short oil alkyd resin ESC3333B, castor oil alkyd resin 1234, stearic acid zinc powder TV-A, 1000-mesh talcum powder, a defoaming agent BYK052, bentonite anti-sinking slurry, n-butyl acetate and the like; the component B, that is, the curing agent comprises the following main components: toluene diisocynate trimer Bayer1351, a toluene diisocynate affixture L75, n-butyl acetate and the like; the component C, that is, the diluent comprises the following main components: n-butyl acetate, dimethylbenzene, cyclohexanone and propylene glycol monomethyl ether acetic ester. On the basis that the property of ordinary transparent polyurethane primer paint is maintained, the problem that a paint film is collapsed is solved, odor can be rapidly removed, and the primer paint is free of paint film collapse and generally free of odor after 24 hours after construction.

Owner:SHANGHAI CARPOLY PAINT

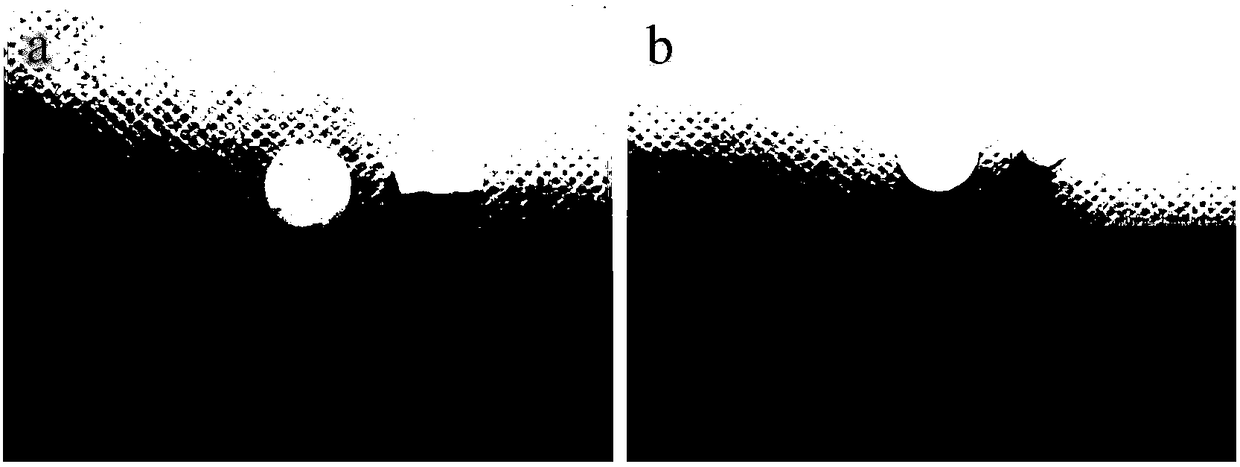

Compound bone cement, preparation method and application of compound bone cement, and bone repair material

ActiveCN108273131APromote differentiationRegulation of adhesionAntibacterial agentsOrganic active ingredientsDiseaseCell adhesion

The invention discloses compound bone cement, a preparation method and application of the compound bone cement, and a bone repair material. The compound bone cement is prepared by mixing the followingraw materials in percentage by mass: 50-80% of solid phase powder and 20-50% of setting liquid, wherein the solid phase powder comprises phosphate and / or acidic salt of phosphoric acid; the setting liquid comprises chitosan, hyaluronic acid, organic acids and water. The compound bone cement has excellent syringeability, biological activity and bone conduction and repair ability, the set bond repair material has an excellent mechanical property, the surface of the material is easy for cell adhesion, and the cell differentiation ability cannot be influenced. The compound bone cement disclosed by the invention can be used for bone defect filling and repairing and serves as a drug carrier to be used for treating orthopedic related diseases.

Owner:深圳市中科海世御生物科技有限公司

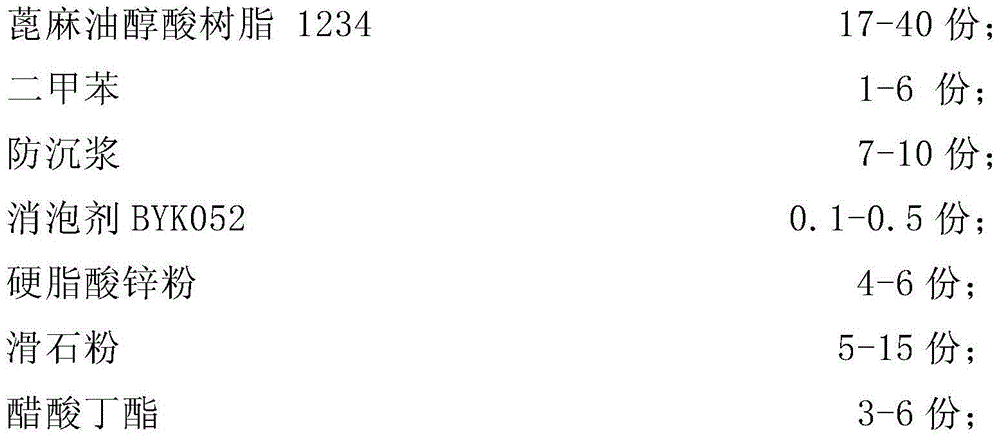

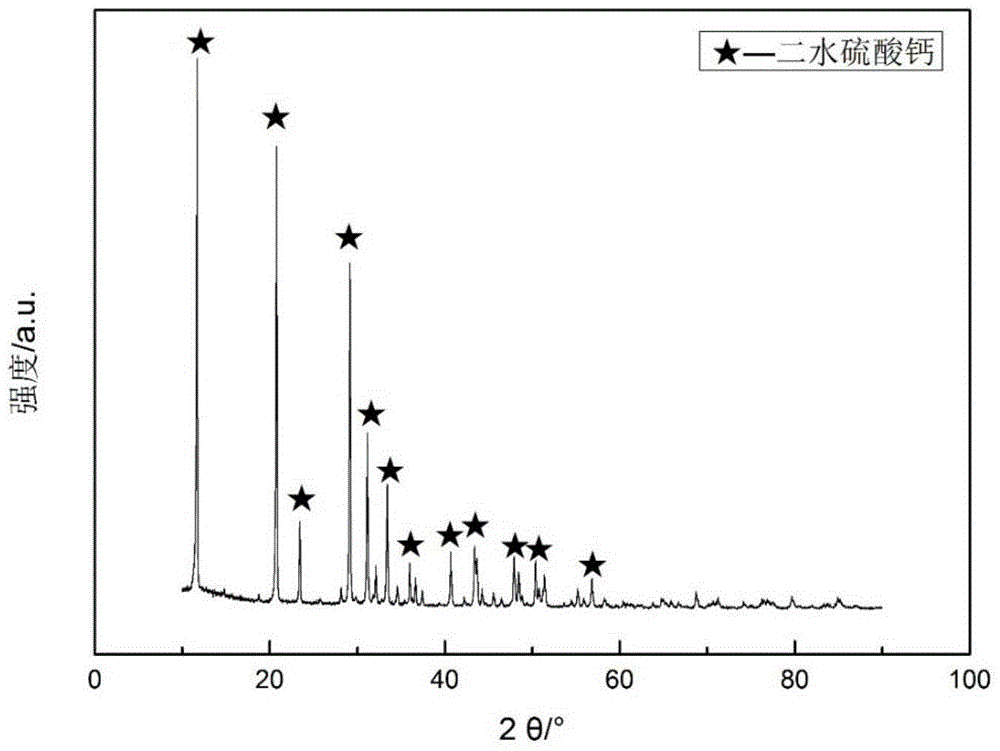

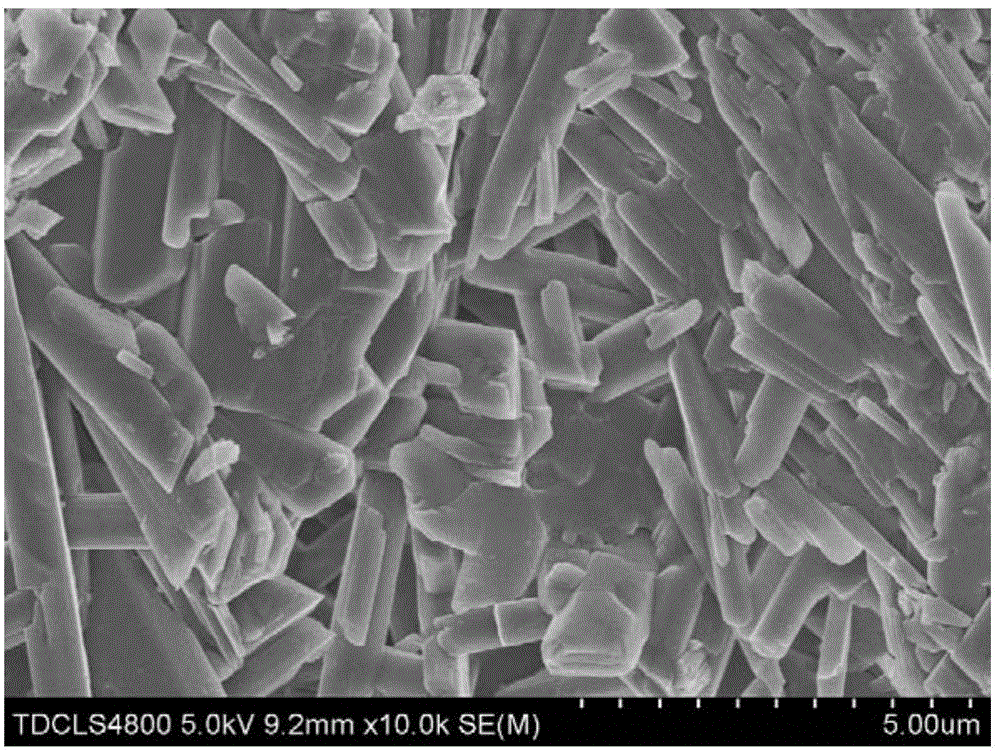

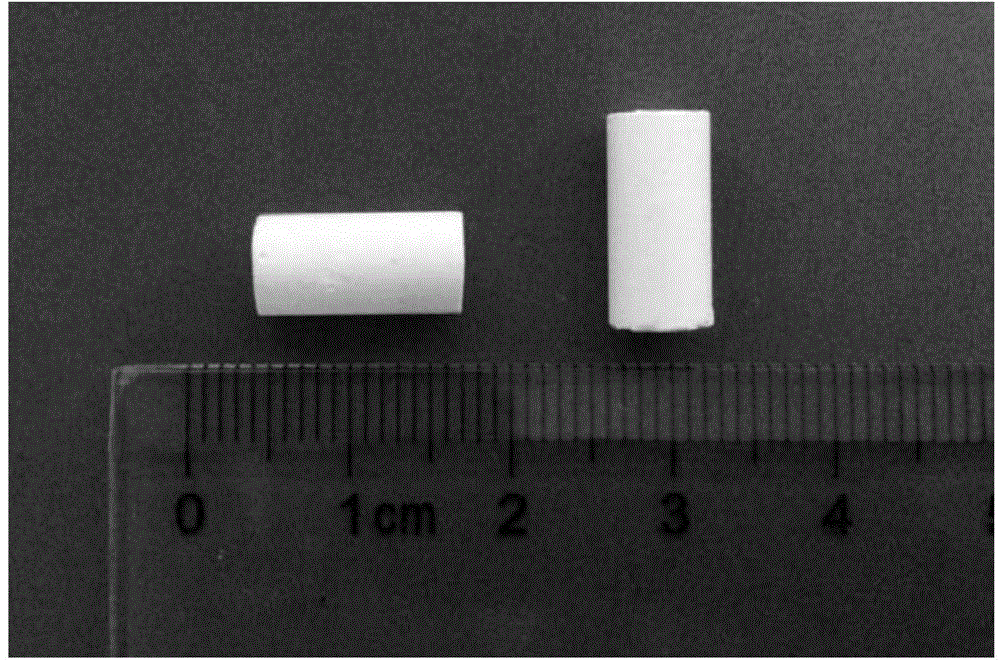

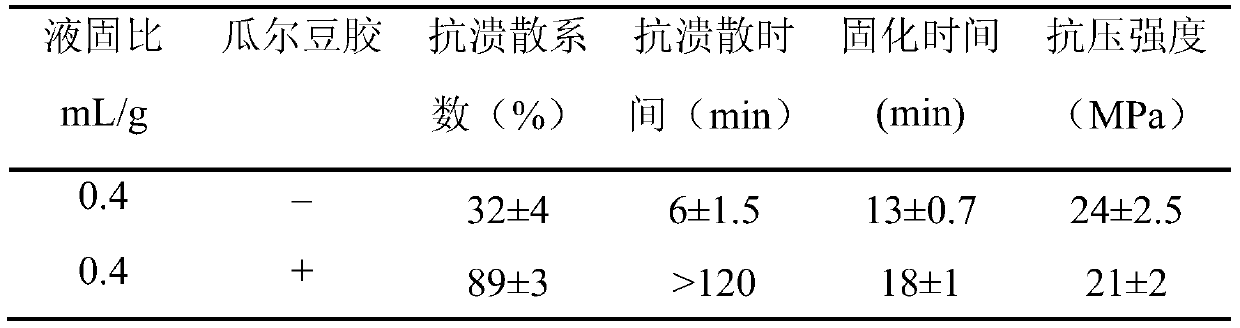

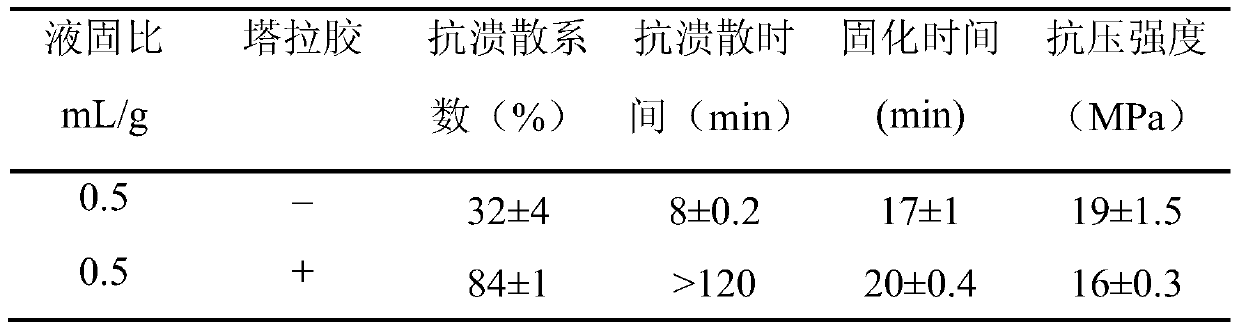

Injectable bone cement and preparation method thereof

InactiveCN104645418AGood injectabilityImprove anti-collapse performanceProsthesisInjectable boneBiocompatibility Testing

The invention relates to an injectable bone cement and preparation method thereof. The injectable bone cement comprises powder and curing liquid, wherein the powder is composited of calcium sulfate hemihydrate and polyethylene glycol diacrylate, and the curing liquid is sulfhydrylated hyaluronic acid aqueous solution or sulfhydrylated chitosan aqueous solution. The preparation method comprises the following steps of: preparing the powder of calcium sulfate hemihydrate and polyethylene glycol diacrylate inproportion; adding the curing liquid according to the liquid-to-solid ratio of 0.4-1.0mL / g, mixing and stirring evenly, and curing at room temperature to form the injectable bone cement. Sulfhydrylated hyaluronic acid and sulfhydrylated chitosan are liable to form intramolecular and intermolecular disulfide bonds under neutral condition and have higher degree of crosslinking and viscoelasticity; thus, injectable property, collapse resistance and mechanical property of the bone cement are improved. Meanwhile, the bone cement provided by the invention also has good biocompatibility and biodegradablity, and can be used for filling and repair for various bone defects. The injectable bone cement and the preparation method thereof are used in the field of tissue engineering and medicine.

Owner:TIANJIN UNIV

Anti-scratching highlight RC printing paper and preparation method thereof

The invention discloses anti-scratching highlight RC printing paper and a preparation method thereof. The preparation method comprises the steps that highlight RC paper is coated with an ink absorption layer coating, and pre-coating RC printing paper is obtained after drying is performed; then, the pre-coating RC printing paper continues to be coated with an anti-scratch glossy layer coating, andthe anti-scratching highlight RC printing paper is obtained after drying; the ink absorption layer comprises nanometer aluminum oxide, an adhesive, a pH regulator, a silane coupling agent, a defoamingagent, a flatting agent and a cross-linking agent; the anti-scratch glossy layer comprises micro transparent powder, nanometer aluminum oxide, an adhesive, a pH regulator, a silane coupling agent, adye fixing agent, a flatting agent and a cross-linking agent. According to the anti-scratching highlight RC printing paper, the glossiness is higher than 50%, the surface hardness reaches up to 4H tothe minimum, the excellent scratch resistance is achieved, and the high glossiness and the imaging effect close to traditional photos are achieved.

Owner:GUANGDONG GLM DIGITAL TECH

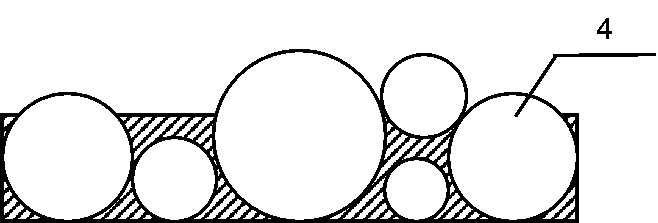

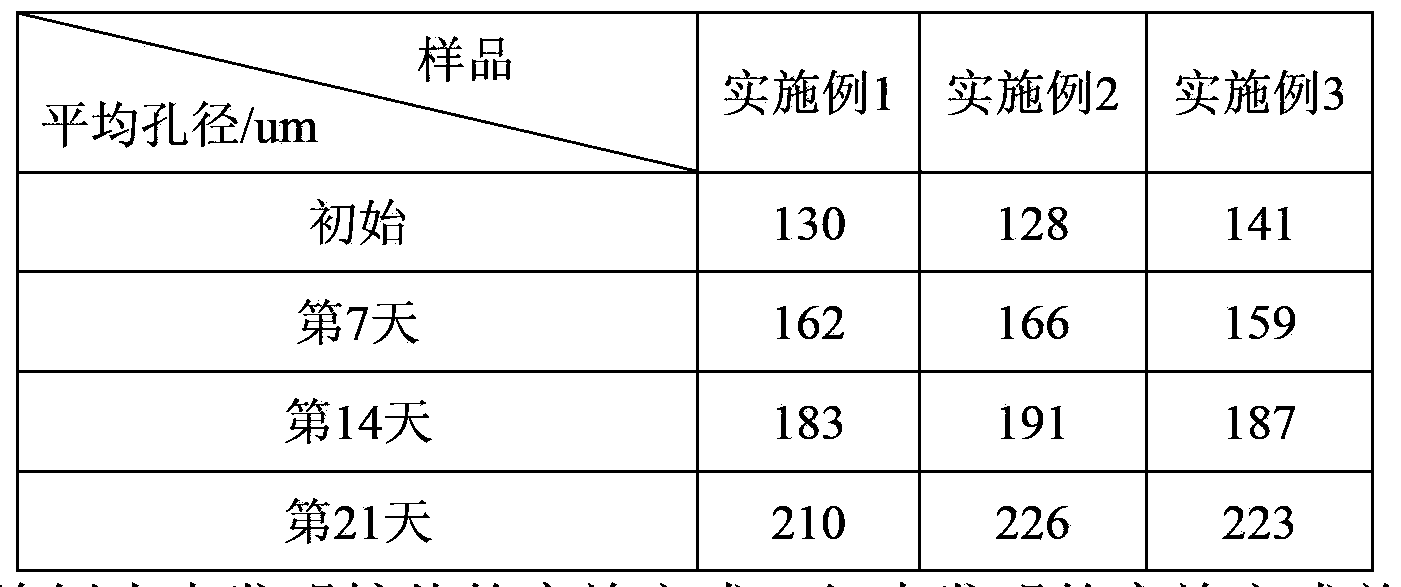

Calcium phosphate-based composite microsphere support and preparation method thereof

The invention discloses a calcium phosphate-based composite microsphere support and a preparation method thereof. The preparation method comprises the following steps of dissolving polyglycollide-lactide in dichloromethane to obtain a polyglycollide-lactide solution; dispersing crystallized calcium phosphate and anhydrous calcium hydrogen phosphate in the polyglycollide-lactide solution to obtain a solution 1; adding Tween-80 to liquid wax to obtain a solution 2: adding the solution 1 to the solution 2 under a stirring state to obtain composite microspheres; pouring the composite microspheres into a mold, adding deionized water, conserving in a constant temperature and humidity chamber after demolding; immersing in cold acetone and freeze drying to obtain the calcium phosphate-based composite microsphere support. The prepared microsphere support has a three-dimensional through pore structure with moderate pore size, and has good mechanical properties and good biocompatibility. The pore size of the support is further enlarged after polyglycollide-lactide is degraded, thereby facilitating the formation of new bones. Besides, the preparation process is simple; raw materials are easily available; cost is low and industrialized production can be easily realized.

Owner:广州智焜生物科技有限公司

Fin material for aluminum alloy heat radiator

The invention provides a fin material for an aluminum alloy heat radiator, which can effectively solve the problems that the conventional fin material for the aluminum alloy heat radiator, which is machined by using the traditional 3003 aluminum alloy, has the defects of low strength and poor collapse resistance. Meanwhile, with the adoption of the fin material for the aluminum alloy heat radiator provided by the invention, the material thickness can be greatly reduced; and the raw material cost is reduced; and a heat radiator pipe can be prevented from being corroded, so that the service life of the entire heat radiator can be prolonged. The fin material for the aluminum alloy heat radiator is characterized by comprising the following materials according to the total parts by weight of 100: 0.5-0.8 parts of silicon (Si), less than or equal to 0.6 parts of ferrum (Fe), less than or equal to 0.1 parts of copper (Cu), 1.4-1.8 parts of manganese (Mn), less than or equal to 0.03 parts of magnesium (Mg), 2.3-2.7 parts of zinc (Zn), 0.05-0.2 parts of zirconium (Zr), and the balance of aluminum (Al) and other unavoidable impurity trace elements.

Owner:YINBANG CLAD MATERIAL

Brushite bone cement preparation method

InactiveCN108283730AGood biocompatibilityImprove anti-collapse performanceAntibacterial agentsOrganic active ingredientsIonChain network

The invention relates to a brushite bone cement preparation method, which belongs to the technical field of a pavement maintenance material. The method takes silk fibroin as a medical carrier, mutualentanglement is realized through a silk fibroin molecular chain, a three-dimensional network is formed, hydroxyapatite is deposited at a network skeleton, so that the scatter-resistant performance ofthe calcium phosphate bone cement is increased, silk fibroin can control medicine release through chemical bond combination and coating modes, the common medicine burst release effect is effectively controlled, during bone tissue restoration and treatment, the local medicine concentration of a treatment dosage is kept, the pharmaceutical effect of the biomaterial is prolonged, the curative effectof lidocaine for alleviating ache can be effectively performed for a long time in human body, a silk fibroin high molecular chain network is taken to provide a hydroxyapatite deposited template, through complexation effect on calcium ions, a solidification reaction is delayed, the effect for prolonging the solidification time is achieved, brushite is taken as flaky crystal, the accumulation is tight, and compressive strength is increased.

Owner:袁杰

Self-repairing injectable bone cement and preparation method

ActiveCN105536059AHigh mechanical strengthImprove anti-collapse performancePharmaceutical delivery mechanismTissue regenerationCross-linkInjectable bone

The invention discloses self-repairing injectable bone cement and a preparation method thereof. Solid powder of the self-repairing injectable bone cement contains inorganic calcium salt and is composited with formylated alginic acid or formylated alginic acid components, cured liquid contains water-soluble lysine-based polymers, and the self-repairing injectable bone cement is obtained by blending the cured liquid and the solid powder according to the liquid-solid ratio of 0.1 mL to 10 g. According to the self-repairing injectable bone cement material, amino groups and formyl groups are introduced to react to form imine bonds, a cross-linked network with the self-repairing property can be established, the mechanical strength and the collapse resistance property are improved, and meanwhile the good injection property can be reserved, so that the product has the good comprehensive property. By means of the good biocompatibility of lysine primitives and the degradability of the water-soluble lysine-based polymers and sodium alginate, adhesion, growth and proliferation of cells are facilitated, bone repair is facilitated, and ingrowth of the cells and blood vessels and bone tissue reconstruction are achieved.

Owner:闫策

Transparent primer dipped with unsaturated polyester and preparation method thereof

InactiveCN106833309AImprove fullnessUniform molecular weight distributionEpoxy resin coatingsPolyester coatingsPolyesterAcrylic resin

The invention discloses a transparent primer dipped with unsaturated polyester. The transparent primer is composed of the following components at a weight ratio: primary paint: a diluent: an initiator: an accelerator=100:150:(1-2):(1.2-2.5); the primary paint is composed of the following components: 70-80% of unsaturated polyester resin, 5% of epoxy acrylic resin, 0.3-0.5% of a defoamer, 0.3-0.5% of a dispersant, 0.5-0.8% of an anti-settling agent, 0.2-0.4% of a flatting agent, 0.1-0.3% of a polymerization inhibitor, 4-6% of a polishing agent and 7-18% of an active solvent. The unsaturated polyester resin is allyl ether modified unsaturated polyester resin, the solid content of which is 72-78% and the viscosity of which is 2000-3000mpa.s; the active solvent is a mixture of styrene and a polyester transparent primer; and the diluent is composed of acetic ether, styrene, methylbenzene and acetone. The transparent primer dipped with unsaturated polyester disclosed by the invention has relatively good defoaming property and sag prevention, and is strong in seepage force, excellent in fillibility, and the sealing effect is obviously superior to that of a PU sealing primer in the market, so that the problem that the film collapses is effectively solved. The transparent primer for firstly dipping woodware is labor-saving and material-saving, energy-saving and environment-friendly, high in construction efficiency and suitable for flow line production.

Owner:CHENGDU YOUPIN CHEM CO LTD

Method for manufacturing improved vehicle radiator aluminum alloy foil material

InactiveCN103509982AHigh strengthGood collapse resistance and heat transfer capacityMetal rolling arrangementsTitaniumCopper

The invention provides a method for manufacturing an improved vehicle radiator aluminum alloy foil material, which contains the following components by weight: 0.03-0.30% of iron, 0.26-1.54% of silicon, 0-0.15% of copper, 1.3-2.8% of manganese, 1.4-1.8% of zinc, 0.10-0.25% of zirconium, 0.01-0.03% of titanium, and the balance aluminum.

Owner:王林海

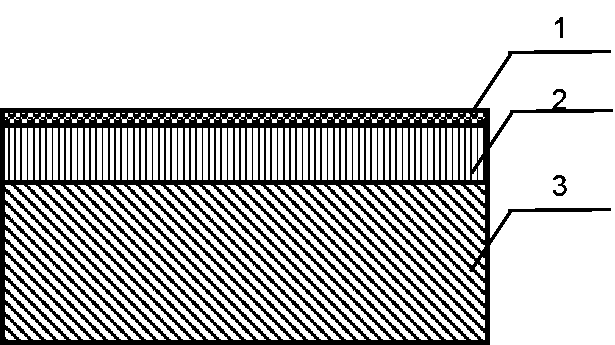

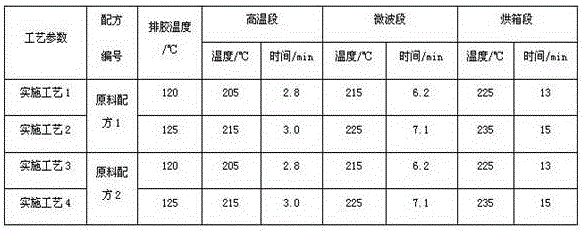

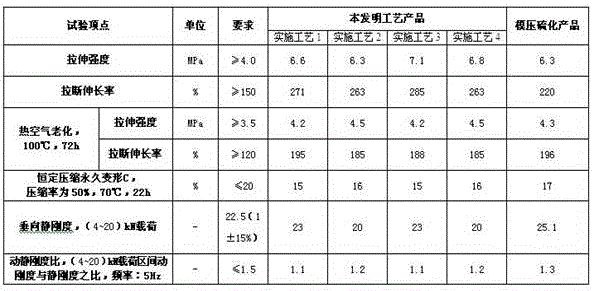

Production process for ethylene propylene diene monomer microporous base plate and product produced by production process

The invention discloses a production process for an ethylene propylene diene monomer microporous base plate. The production process comprises the following steps: adding ethylene propylene diene monomer into a kneading machine to knead, and then adding zinc oxide, stearic acid, carbon black, a moisture absorbent, an acid and alkali regulator, a softening agent and an inorganic filler into the kneading machine to knead, thereby preparing a master batch; adding the prepared master batch into an open mixing machine, adding a vulcanizing agent, a promoter, a foaming agent and a foaming aid, uniformly mixing, regulating roll spacing to 0.8-1.3 millimeters for thin-passing, carrying out triangular packaging for 3-4 times, regulating the roll spacing to 5-6 millimeters for discharging, so as to prepare a rubber compound, and standing the rubber compound for not smaller than 16 hours; putting the rubber compound on a cutter for cutting; feeding prepared rubber strips into a cold feeding extruder to extrude; sequentially feeding the prepared rubber strips into a high-temperature section, a microwave section and an oven section to carry out continuous vulcanizing until complete vulcanizing; and pulling the prepared vulcanized rubber into the cutter through a pulling machine, and cutting the prepared vulcanized rubber into a needed dimension, thereby obtaining a microporous base plate finished product. The invention further provides an ethylene propylene diene monomer microporous base plate.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

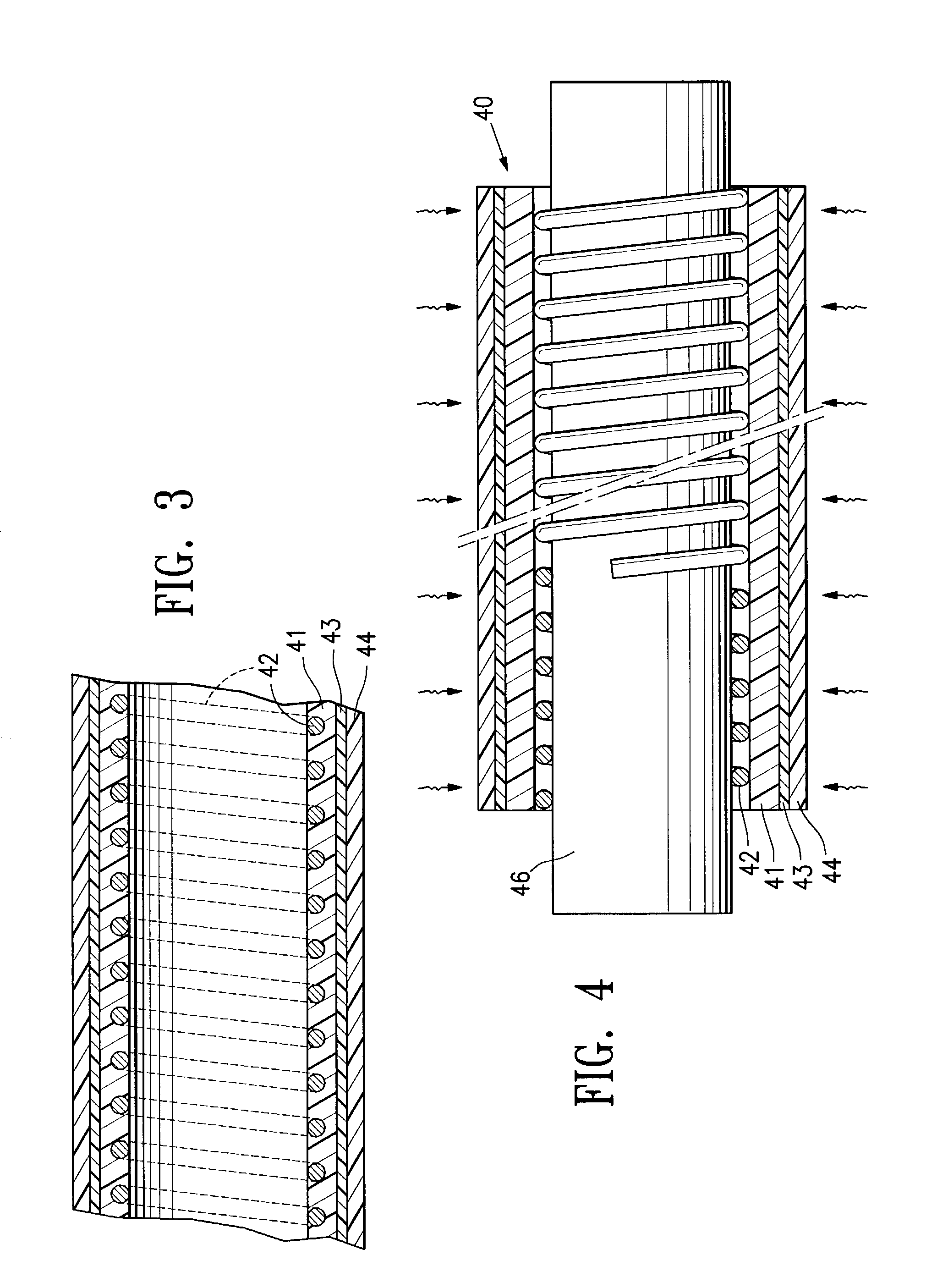

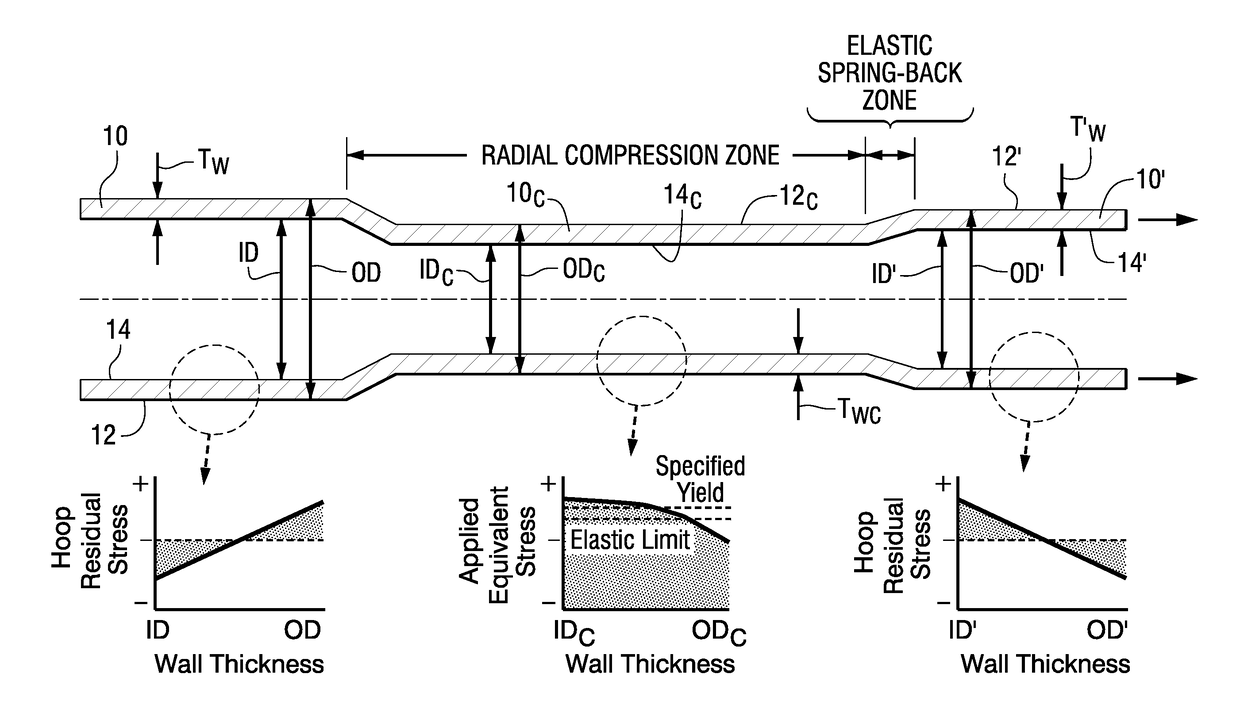

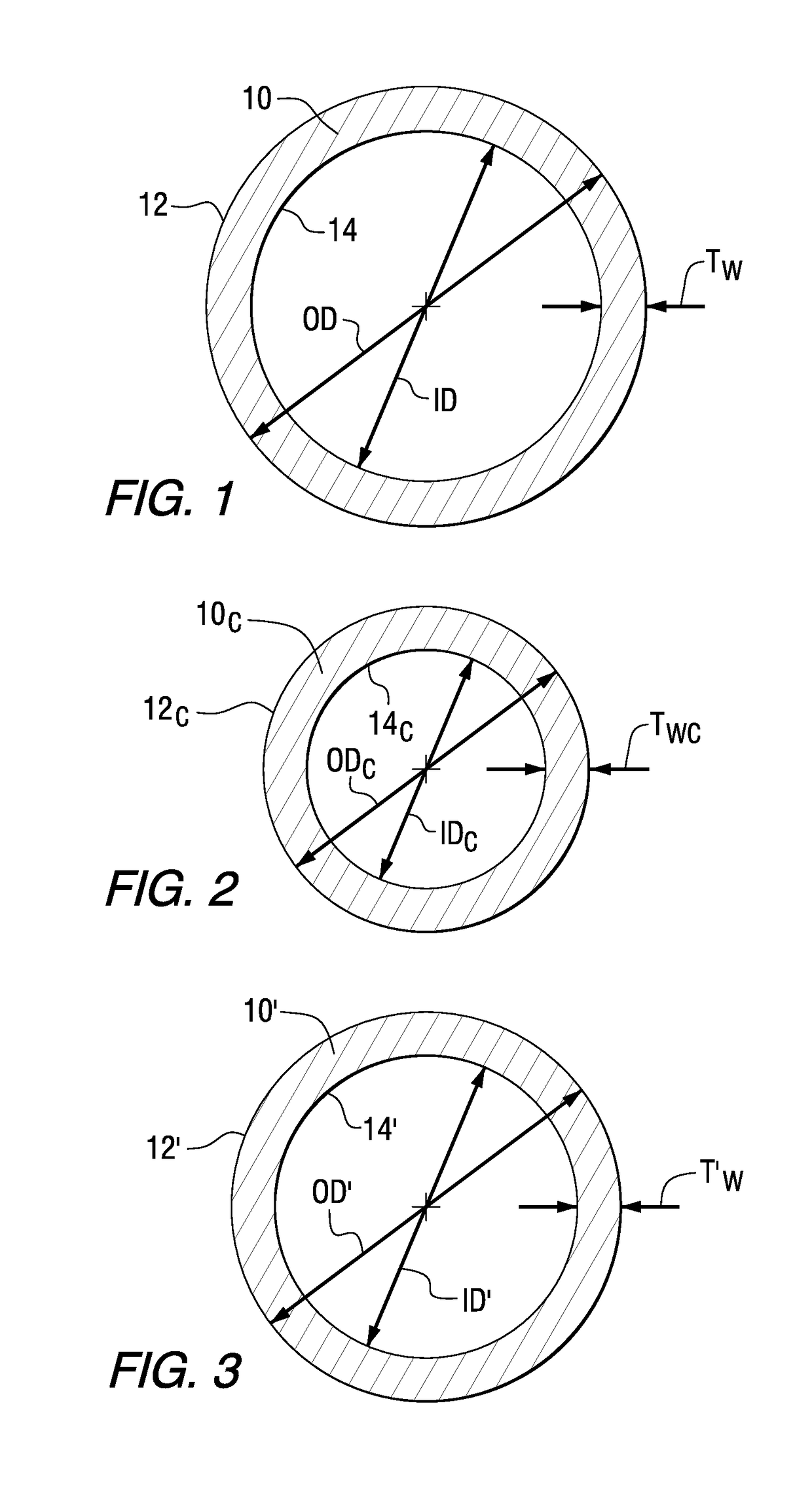

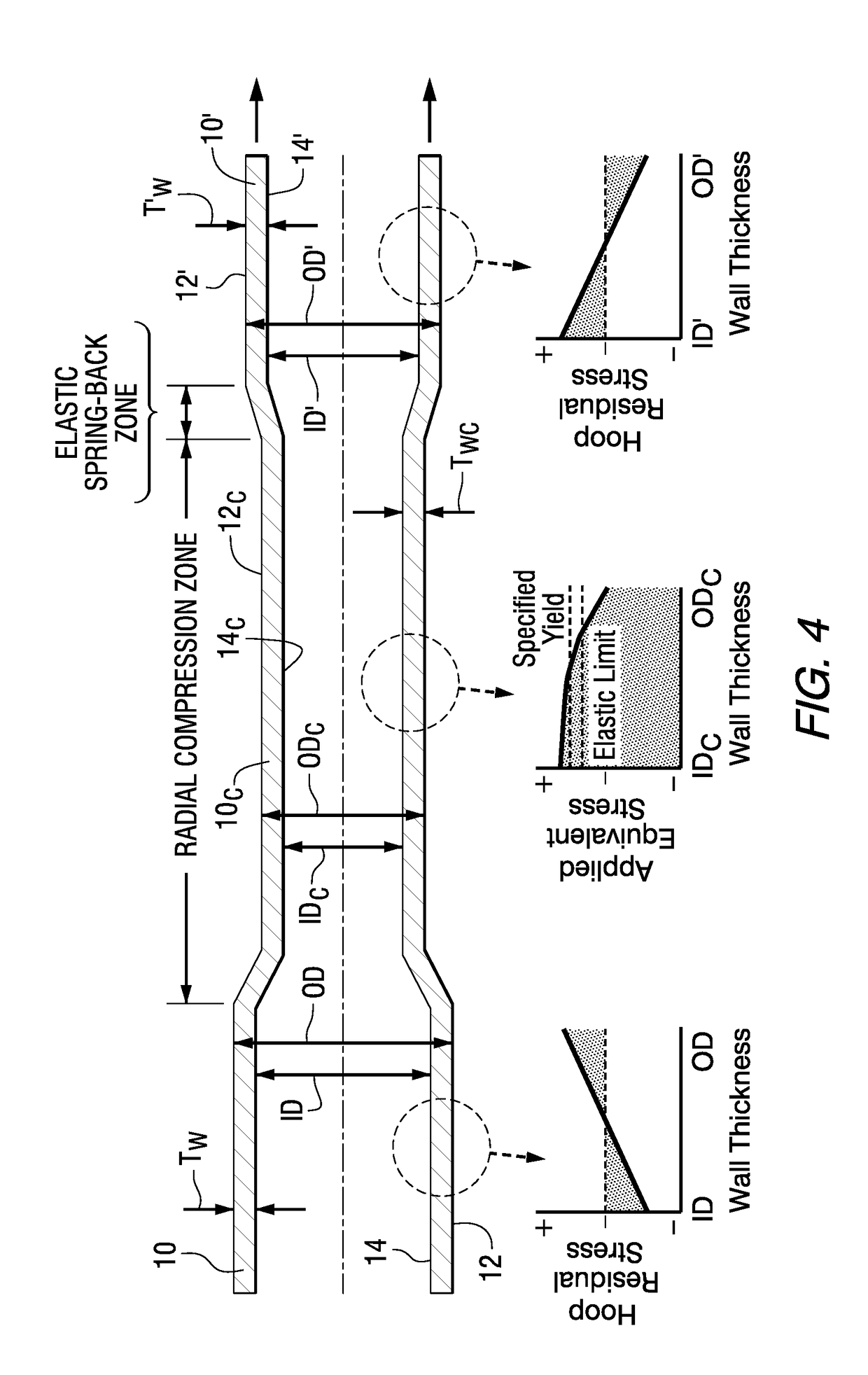

Compressive forming processes for enhancing collapse resistance in metallic tubular products

ActiveUS20180229289A1Improve collapse resistanceReduce compressionCylindersFurnace typesRadial compressionForming processes

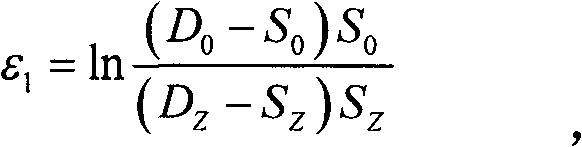

A method to improve the collapse resistance of metallic tubular products is disclosed. The method comprises identifying the types of stress that can be applied in order to change the residual stress profile of metallic tubular products, such as those that have completed a straightening process, and results in a residual stress profile that improves collapse resistance. The metallic tubular product is subjected to radial compression processing to control the residual stress profile and to enhance collapse resistance. The radial compression process may be used after the tubular product has been subjected to a straightening process.

Owner:USX CORP

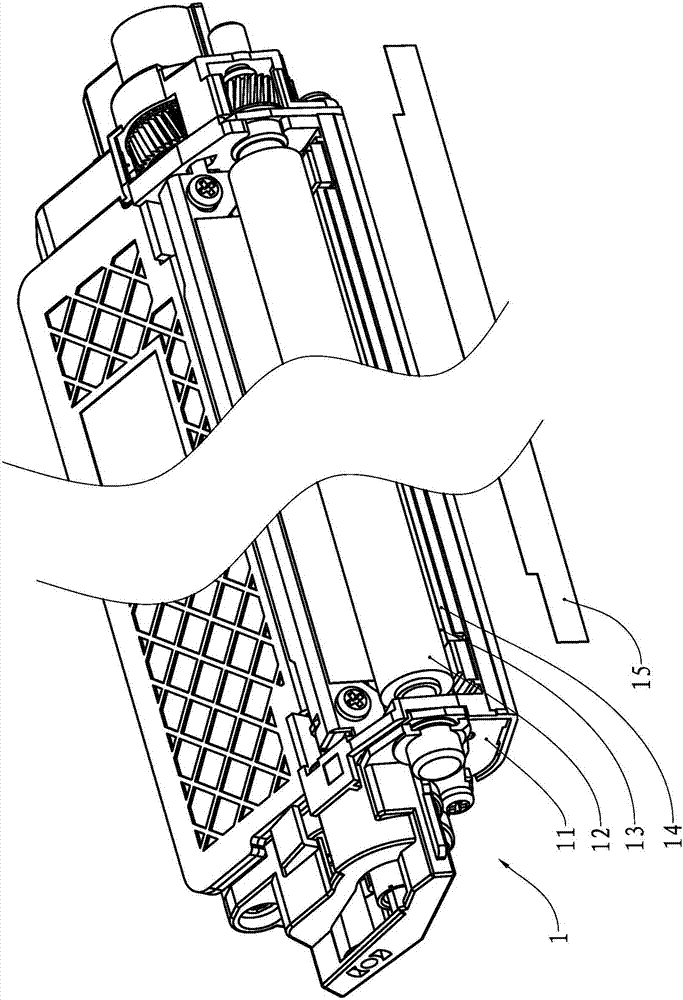

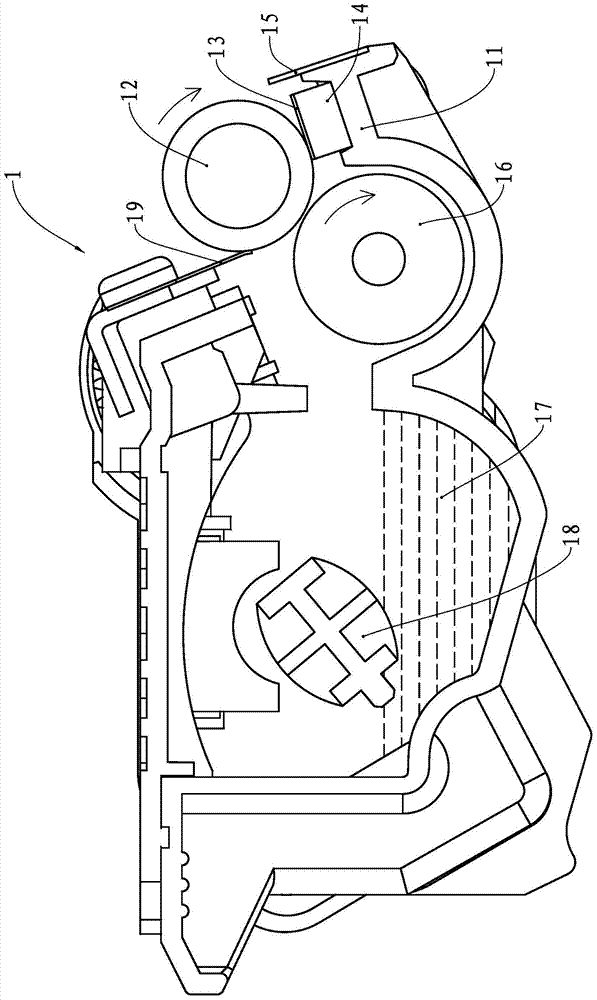

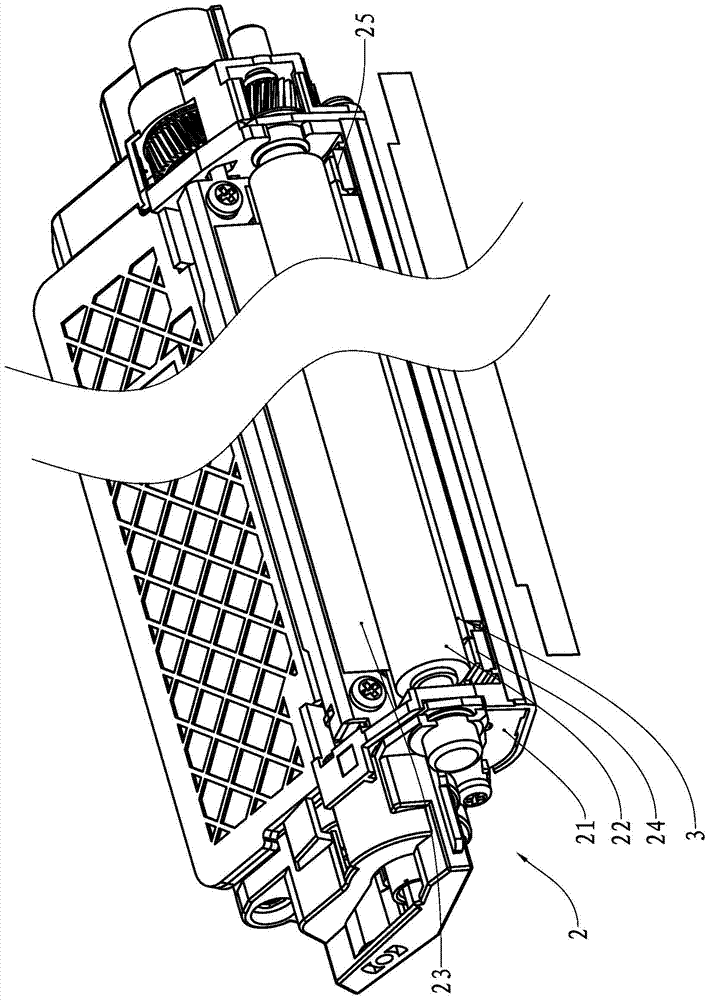

Processing box

ActiveCN103529681AImprove sealingImprove anti-collapse performanceElectrography/magnetographyEngineeringMechanical engineering

The invention provides a processing box. The processing box comprises a shell, a develop roller and a first sealing part. A cavity for containing supplies is defined by the shell, a supply outlet is formed in one end of the cavity, the develop roller is installed at the position, close to the supply outlet, inside the cavity and the first sealing part is installed below the develop roller and fixed onto the supply outlet. The processing box further comprises a sealing doctor blade, the sealing doctor blade comprises a fixed portion and a contacting portion, the fixed portion is fixed onto the supply outlet, the contacting portion comprises a first end portion and a contacting end face, the first end portion is connected with the first sealing part in abutting mode, and the contacting end face is elastically connected with the develop roller in an abutting mode. According to the processing box, the sealing doctor blade makes elastic contact with the develop roller, so that the sealing doctor blade is not prone to deforming, and improvement of the sealing performance and the durability of the processing box is facilitated.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Preparation process of anti-CO2-corrosion oil well pipe with steel grade of less than 150ksi produced by CPE unit

The invention discloses a preparation process of an anti-CO2-corrosion oil well pipe with a steel grade of less than 150ksi produced by a CPE unit. The process comprises the following steps: smelting each component by virtue of a converter according to the mass percentage proportion of each component, and performing continuous casting and continuous rolling on molten steel which is smelted by the converter to prepare a pipe billet, wherein the pipe billet comprises the following components in percentage by mass: 0.13-0.23% of C, 0.11-0.41% of Si, 0.8-1.0% of Mn, 5.0-6.0% of Cr, 0.05-0.45% of Mo, 0.02-0.04% of Al and the balance of Fe and inevitable impurities, and the total mass percentages are 100%. A steel pipe rolled by virtue of the process disclosed by the invention is good in surface quality and high in size precision, the anti-collapse performance of a pipe body can be effectively improved, the improvement of the anti-CO2-corrosion performance of the steel pipe can also be facilitated, the mechanical performance of the steel pipe can reach less than 150ksi, and the steel pipe is suitable for mining application of deep wells and ultra deep wells.

Owner:JIANGSU CHANGBAO STEELTUBE CO LTD

Method for preparing an aqueous dispersion of multistage polymer particles

The present invention relates to a method of preparing an aqueous dispersion of multistage polymer particles comprising contacting under emulsion polymerization conditions and in a staged fashion an aqueous dispersion of carboxylic acid functionalized core polymer particles with first monomers and second monomers. The core comprises structural units of a high Tg hydrophobic monomer and / or the first monomers comprise a high Tg hydrophobic monomer, and the second monomers comprise at least 80 percent styrene. The high Tg hydrophobic monomer is cyclohexyl methacrylate, isobornyl methacrylate, 4-t-butyl methacrylate, t-butylstyrene, or n-butyl methacrylate, or a combination thereof. The multistage polymer particles are useful as opaque polymers, which are used in pigmented coating formulations to reduce the load of TiO2. The particles exhibit excellent collapse resistance and unusually low dry bulk density, and do not require acrylonitrile to achieve this desired combination of properties.

Owner:ROHM & HAAS CO

Aluminum alloy material used for processing air-cooling fin in power station

InactiveCN102719711AIncreased copper contentReduce manufacturing costPower stationUltimate tensile strength

The invention provides an aluminum alloy material used for processing an air-cooling fin in a power station. According to the aluminum alloy material, the problem in the prior art that the air-cooling fin in the power station, which is processed from conventional 3003 aluminum alloy, is low in strength can be solved, the anti-collapse performance of fin material under high-temperature brazing condition is improved effectively, and the service life of the fin material is prolonged, and furthermore, due to the adoption of the aluminum alloy material used for processing the air-cooling fin in the power station provided by the invention, the thickness of the fin material is reduced effectively, and the production cost is lowered. The aluminum alloy material is characterized by comprising the following materials being 100 parts in total weight: Si being smaller than or equal to 0.3 part, Fe being smaller than or equal to 0.5 part, 0.5 -0.7 part of Cu, 0.65-1 part of MN, 0.08 -0.1 parts of Ti and the balance of Al and other inevitable impurity elements.

Owner:YINBANG CLAD MATERIAL

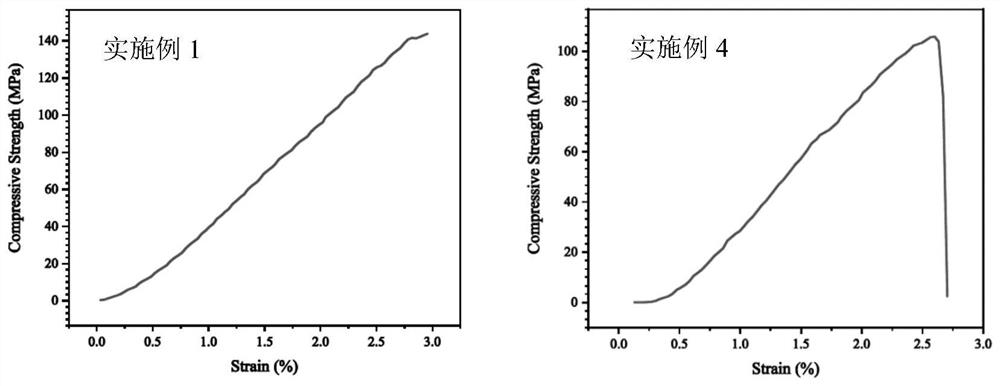

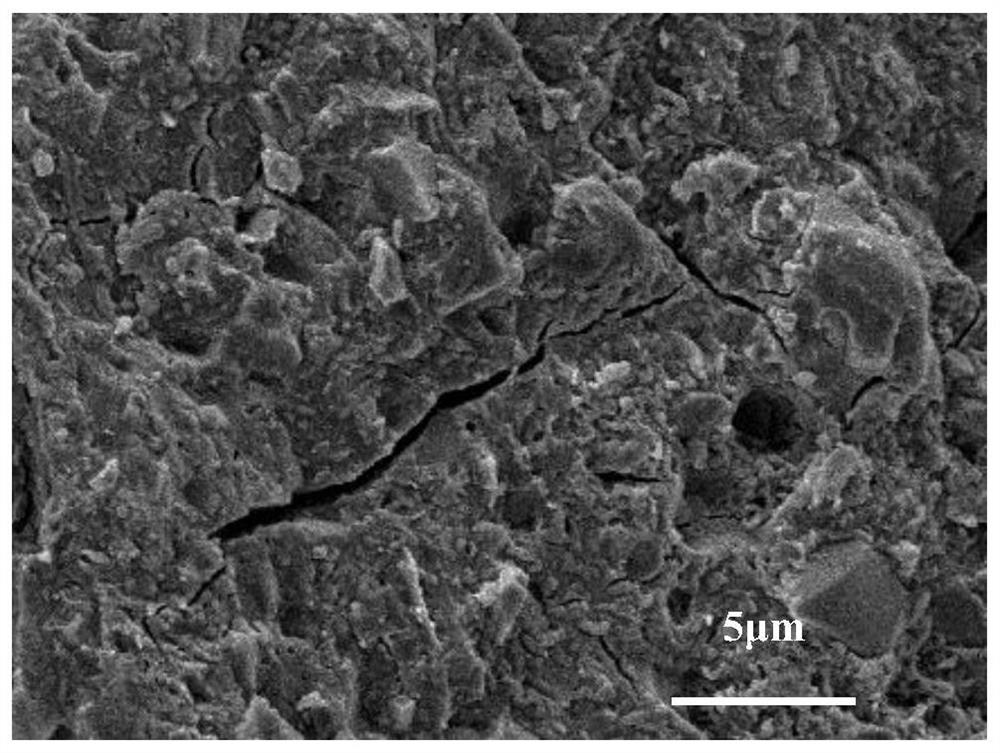

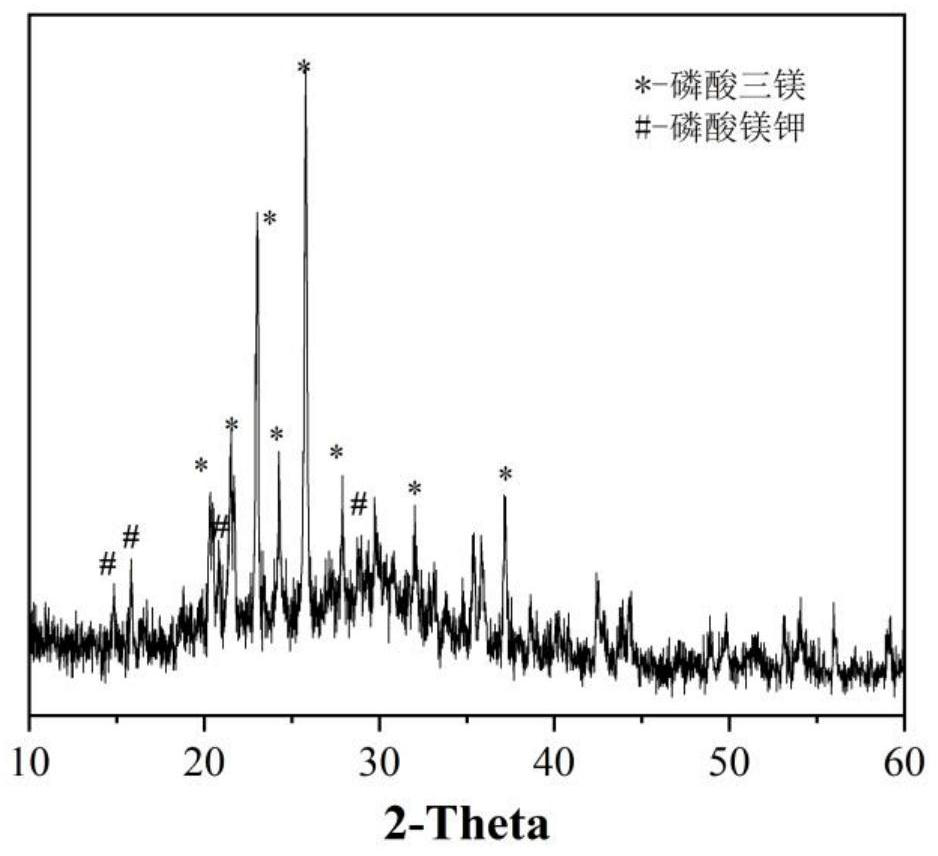

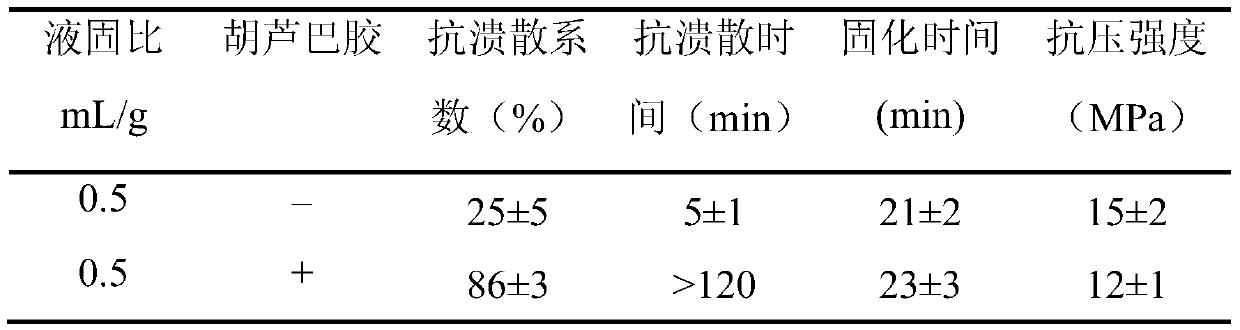

High-strength injectable magnesium phosphate bone cement and preparation method thereof

PendingCN113880474AHigh strengthHigh compressive strengthSurgical adhesivesProsthesisMagnesium phosphateMagnesium orthophosphate

The invention discloses high-strength injectable magnesium phosphate bone cement and a preparation method thereof. The high-strength injectable magnesium phosphate bone cement comprises solid-phase powder and curing liquid, wherein the ratio of the solid-phase powder to the curing liquid is (1.5-3.5) g: 1mL; the solid-phase powder comprises the following components in parts by weight: 50-90 parts of magnesium phosphate salt and 10-50 parts of hydrophosphate, wherein the magnesium phosphate salt comprises trimagnesium phosphate, and the hydrophosphate salt comprises monopotassium phosphate; and the curing liquid is an aqueous solution. The solid-phase powder and the curing liquid are directly mixed to prepare the high-strength injectable magnesium phosphate bone cement. The bone cement has high compressive strength, good injectability and collapse resistance, can prolong the curing time and reduce heat release in the reaction process, and is suitable for being applied to the fields of osteoporosis vertebral compression fracture, spinal fusion and bone repair of other bearing parts.

Owner:WUHAN UNIV OF TECH

A kind of anti-collapse calcium phosphate bone cement and its preparation method and application

ActiveCN105233334BImprove anti-collapse performanceNo collapse requirementProsthesisCalcium biphosphateBone cement

Owner:SOUTH CHINA UNIV OF TECH

Rubber wear-resisting tire tread

The invention relates to the technical field of tires, in particular to a rubber wear-resisting tire tread. The rubber wear-resisting tire tread is characterized by being prepared from the following raw materials in parts by weight: 26-30 parts of butadiene rubber, 26-30 parts of natural rubber, 5-7 parts of organic fiber, 4-5 parts of zinc oxide, 10-12 parts of carbon black, 4-5 parts of silicon dioxide, 2-3 parts of isoprene, 2-3 parts of microcrystalline wax, 3-5 parts of a plasticizer and 1-2 parts of sulphur. According to the rubber wear-resisting tire tread, the early groove crack of a tread groove can be effectively prevented; the abrasive resistance, the tear resistance and the anti-cracking and anti-dropping properties of the tire tread are improved; and the service cycle of the tire is prolonged.

Owner:招远市东晟橡胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com