Patents

Literature

217results about How to "Improve collapse resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

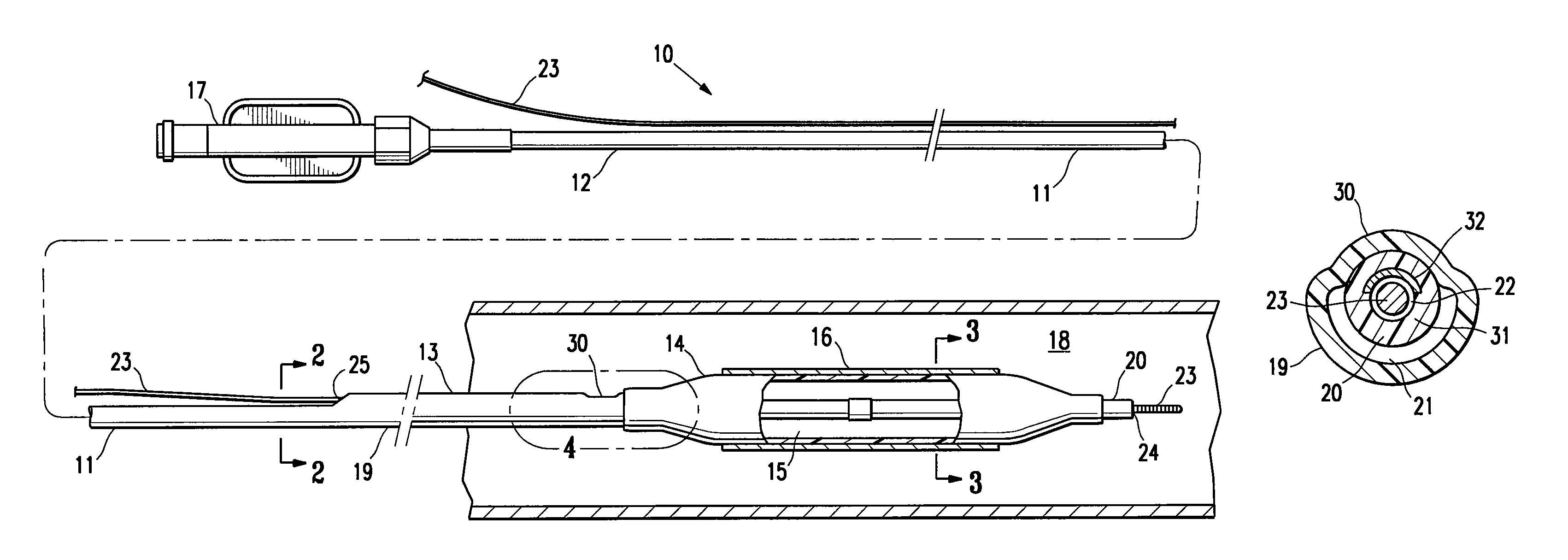

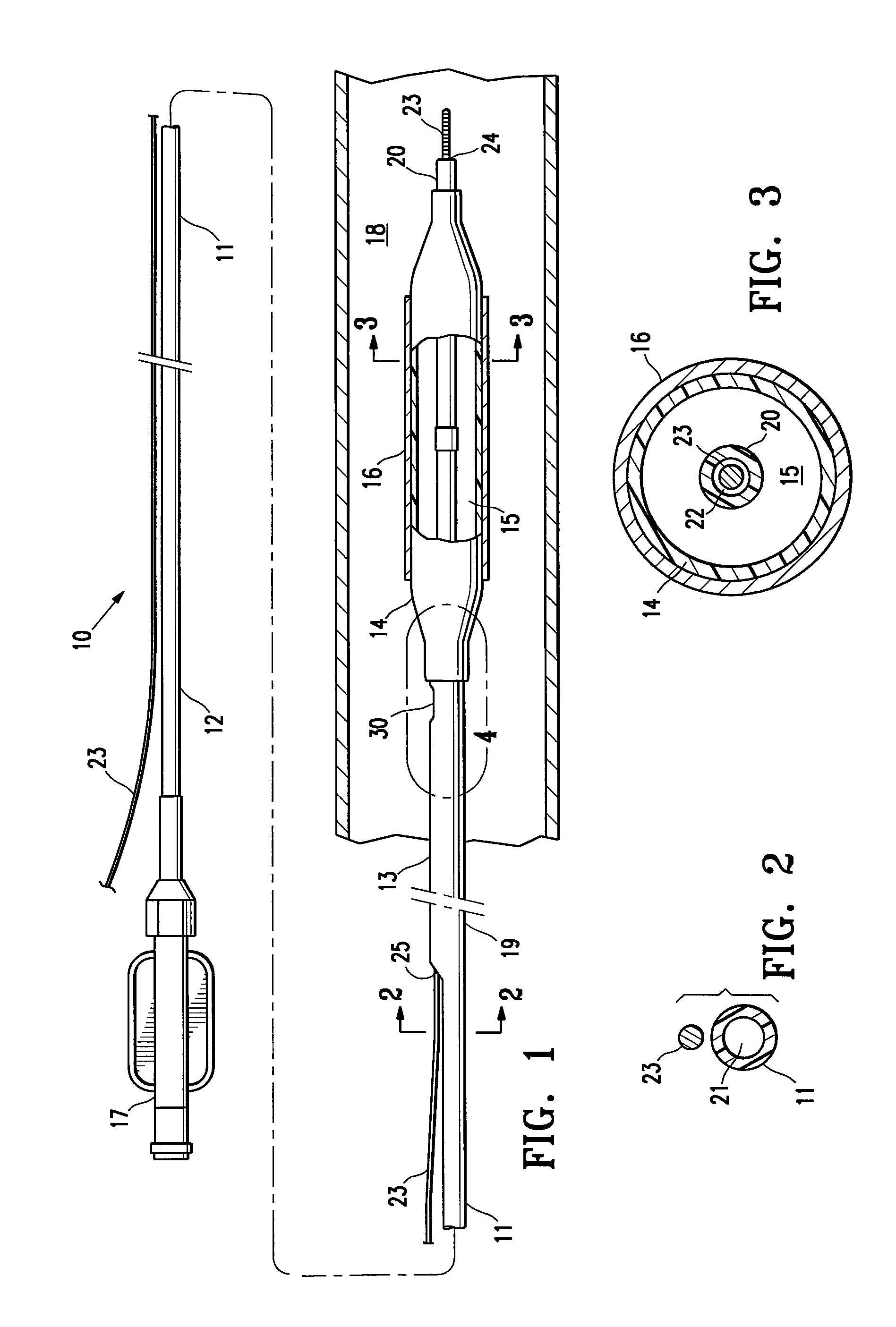

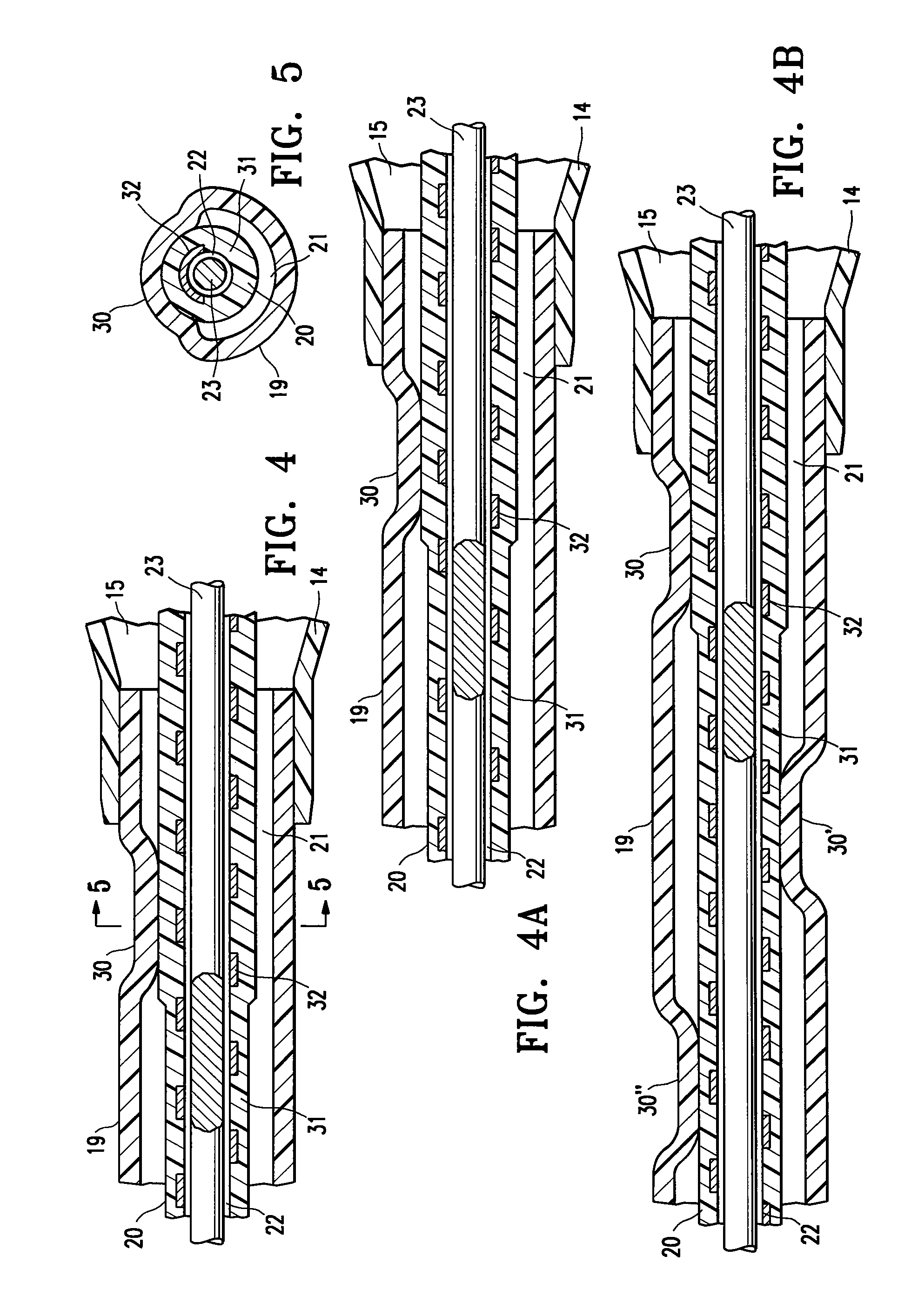

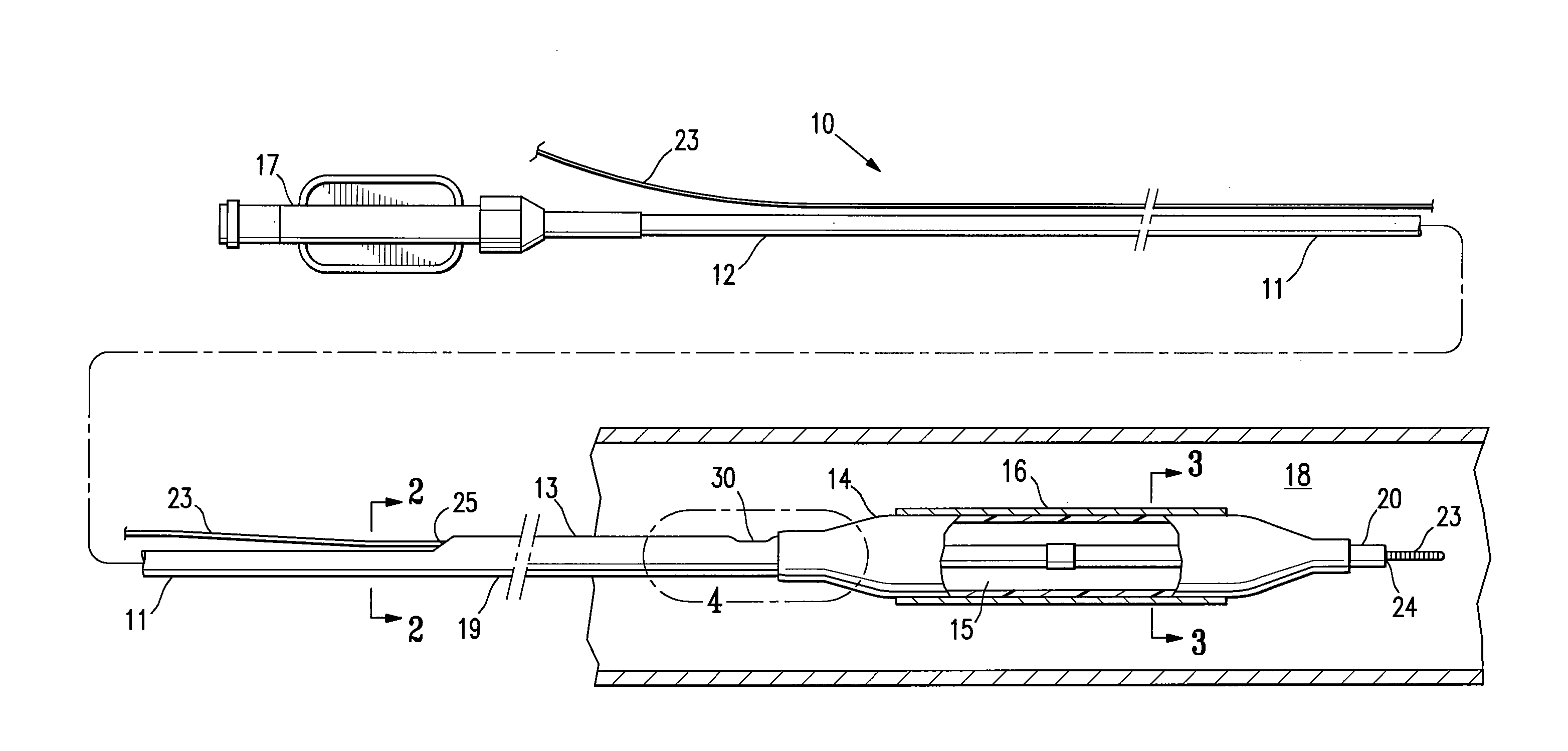

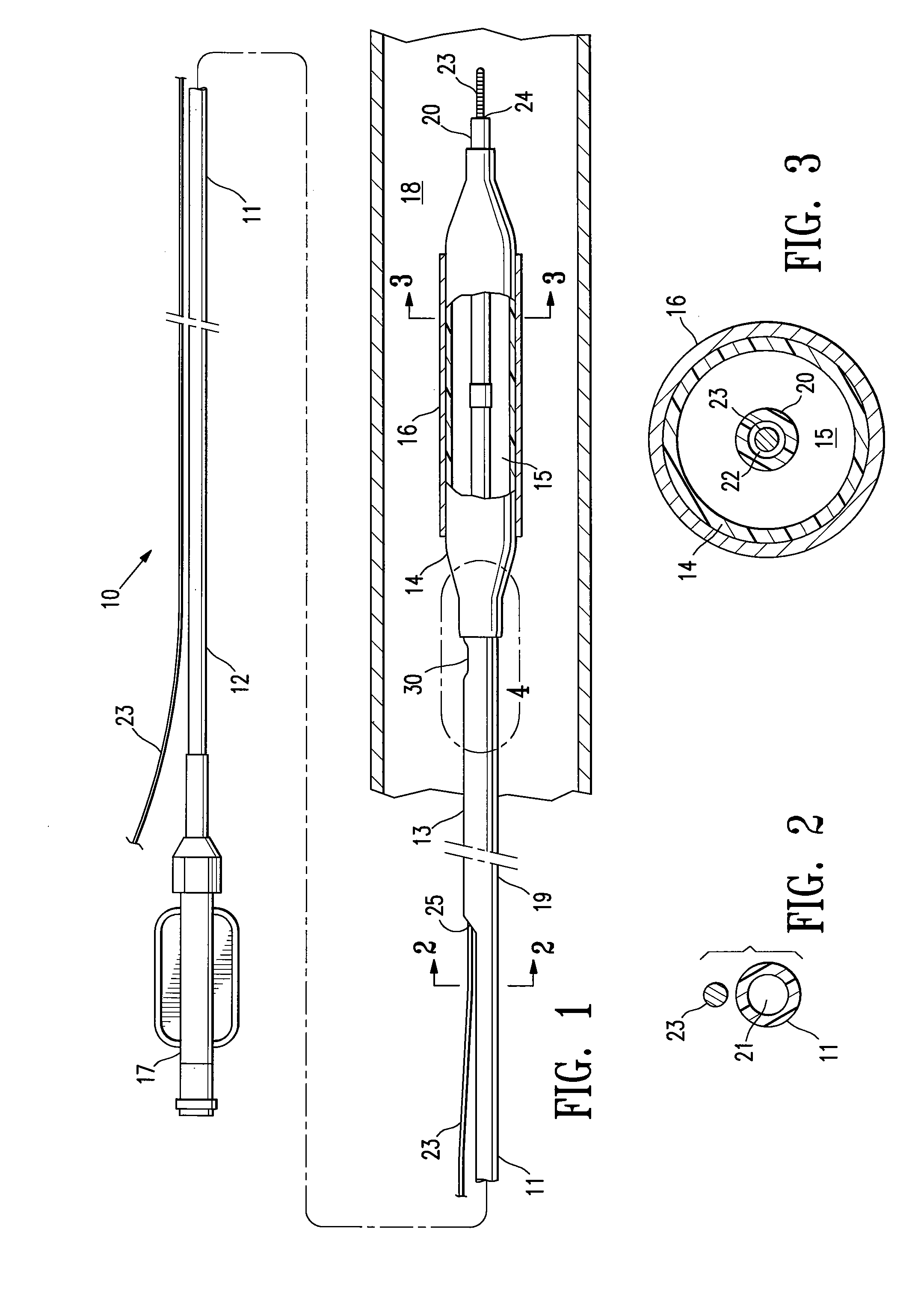

Balloon catheter having a shaft with a variable stiffness inner tubular member

ActiveUS7273485B2Reduce wall thicknessIncrease wall thicknessStentsBalloon catheterVariable stiffnessAxial compression

A catheter having an elongated shaft and a balloon on a distal shaft section, the elongated shaft comprising an outer tubular member, and an inner tubular member which has a bonded portion along which an outer surface of the inner tubular member is bonded to an inner surface of the outer tubular member. The inner tubular member has a proximal portion proximal to the bonded portion, and a distal portion distal to the bonded portion with higher axial compression stiffness and column strength than the proximal portion thereof. The catheter has improved traceability, axial collapse resistance, pushability, and crossability, for improved ability to position the balloon at a desired location in a patient's body lumen.

Owner:ABBOTT CARDIOVASCULAR

Balloon catheter having a shaft with a variable stiffness inner tubular member

InactiveUS20080045895A1High axial compression stiffness and column strengthImproved crossabilityStentsBalloon catheterVariable stiffnessDistal portion

A catheter having an elongated shaft and a balloon on a distal shaft section, the elongated shaft comprising an outer tubular member, and an inner tubular member which has a bonded portion along which an outer surface of the inner tubular member is bonded to an inner surface of the outer tubular member. The inner tubular member has a proximal portion proximal to the bonded portion, and a distal portion distal to the bonded portion with higher axial compression stiffness and column strength than the proximal portion thereof. The catheter has improved trackability, axial collapse resistance, pushability, and crossability, for improved ability to position the balloon at a desired location in a patient's body lumen.

Owner:ABBOTT CARDIOVASCULAR

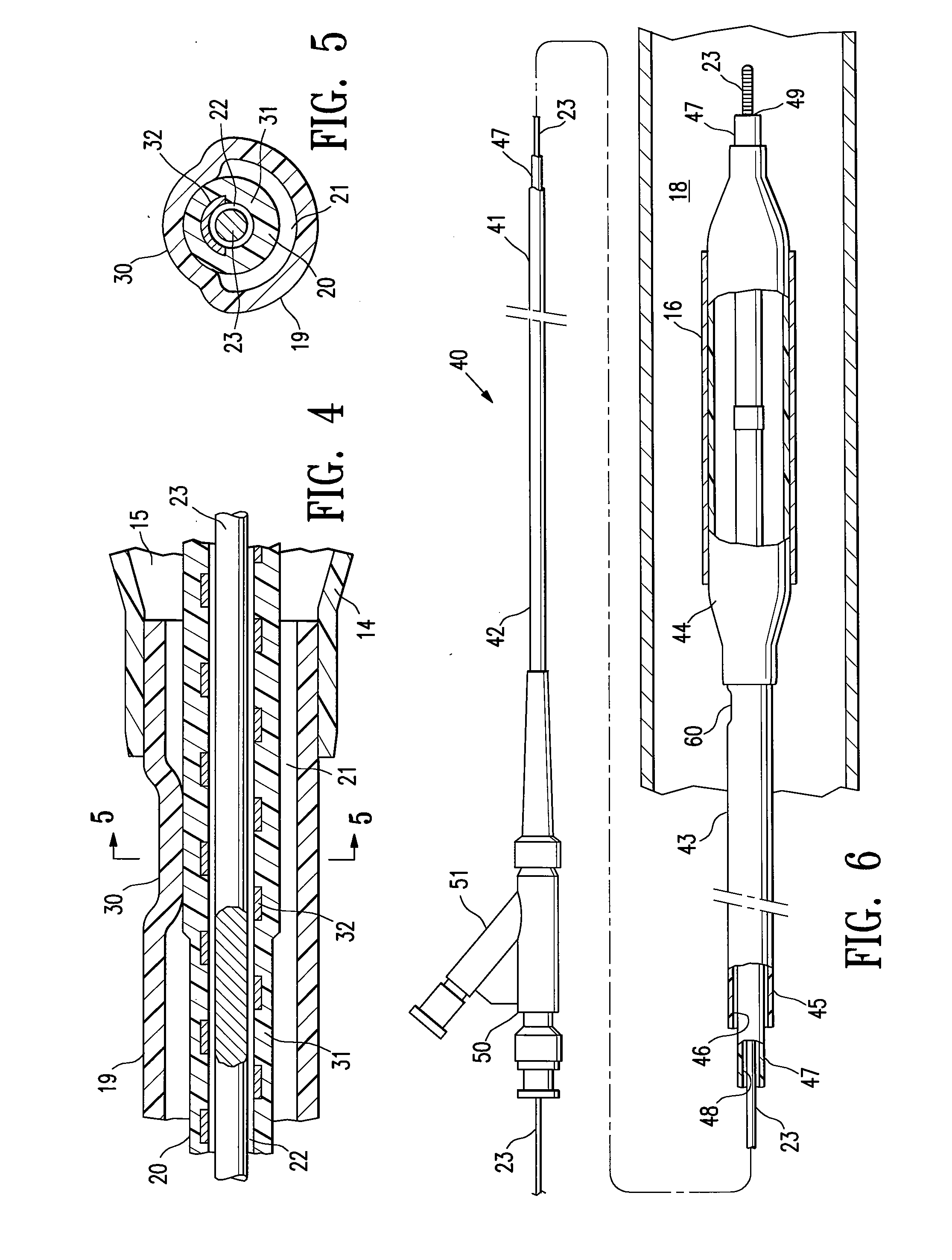

Filtrate reducer for oil field well drilling fluid

ActiveCN101054512AImprove anti-slump inhibitionImprove collapse resistanceDrilling compositionFragilityMonomer

The invention relates to an oil field fluid loss additive for drilling liquid and its producing method and the application of the treating agent in the process of producing drilling liquid system. The treating agent utilizes the cation monomer dimethyl diallyl ammonium chloride can make the sodium lignin sulfonate and the sulfonated-methyl brown coal graft induced by FeCl3 so as to produce a new fluid loss agent with the resistance to salt and collapse at high temperature. The composed product integrates the brown coal and lignin. The cation introduction improves the resistance to collapse. The weak crosslinking function of the Fe3+ makes the heat resistance improved further based on the brown coal. Therefore, the product can be widely applied in different complicated conditions such as high temperature deep well, gypsum / slat bed, stratum with a bad water sensitivity, fragility stratum and etc. and has a good prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Brazing aluminium alloy multilayer composite board material and method for producing the same

InactiveCN101372161APrevent proliferationHigh strengthAuxillary arrangementsMetal rolling arrangementsHeat exchangerAluminium alloy

The invention relates to a braze-welding aluminum alloy multilayer composite material used in a heat exchanger main board of an automobile. The braze-welding aluminum alloy multilayer composite material is composed of AA4045 alloy, AA3003 alloy and Mod6060 alloy. A method provided by the invention is as follows: the three alloys are produced and are welded together by a sub-arc weld after the surfaces of the three alloys are cleaned in sequence that the AA4045 alloy is at the external layer, the AA3003 alloy is at the two middle layers and the Mod6060 alloy is at the internal layer. Then hot rolling and cold rolling are carried out. The alloys are processed to obtain the preset thickness which is 1.5mm to 2.5mm according to 20 percent to 30 percent of the cold processing rate, recrystallization and annealing are carried out at the thickness with the annealing temperature of 405 DEG C to 415 DEG C, heat preservation is carried out for 2 hours to 3 hours, and a finished product can be obtained by leveling and shearing after the alloys are sent out of a furnace. During the production process, each layer of the alloys plays the following functions respectively: the AA4045 alloy is mainly used for welding, the AA3003 alloy is used for isolating and the Mod6060 alloy is used for aging strengthening, strength reinforcing and collapse resisting.

Owner:南通华特铝热传输材料有限公司

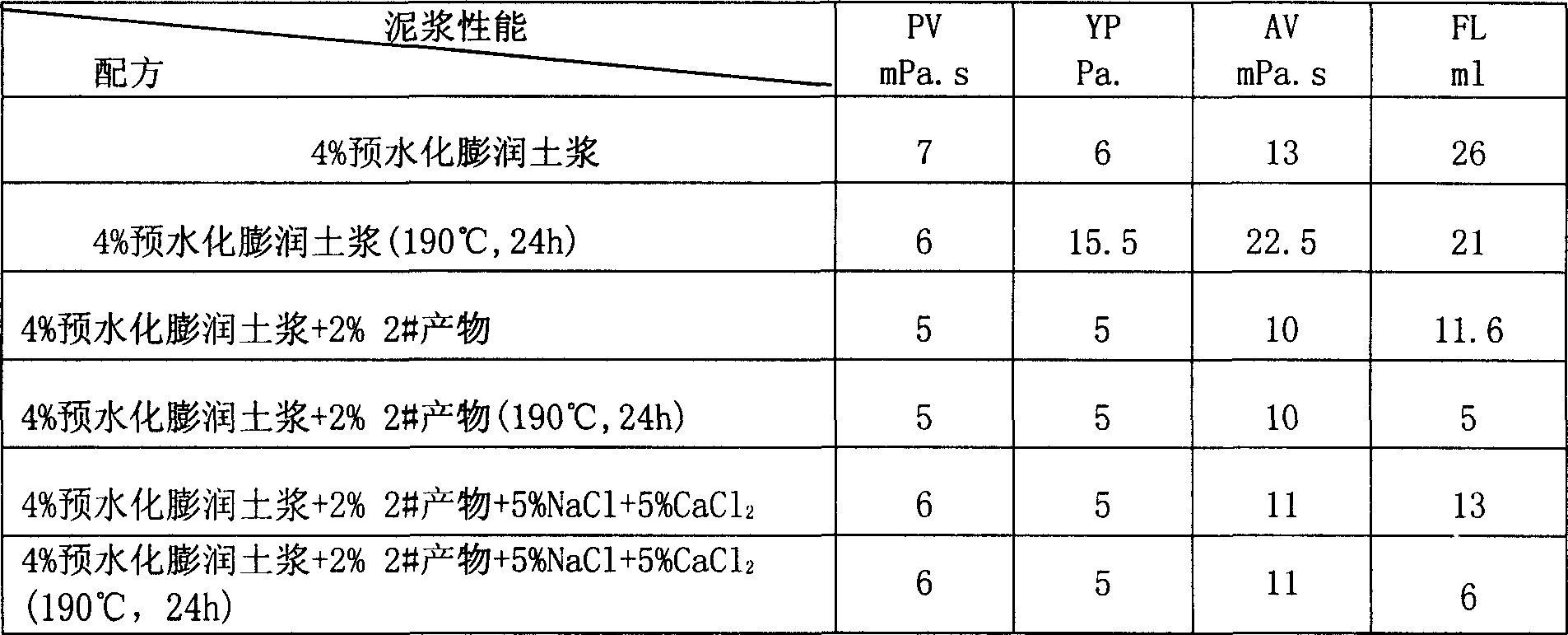

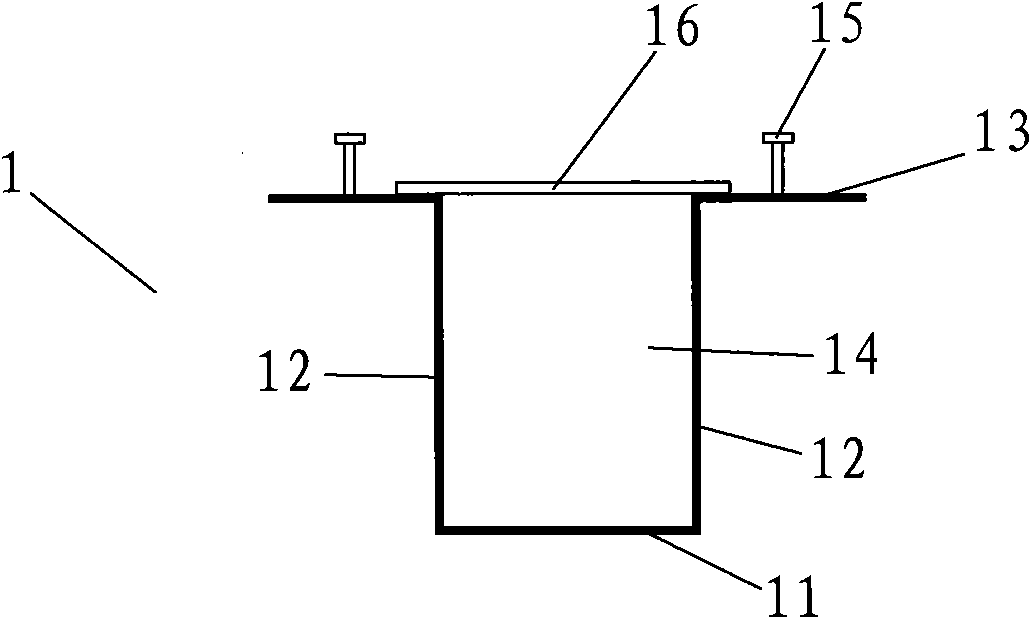

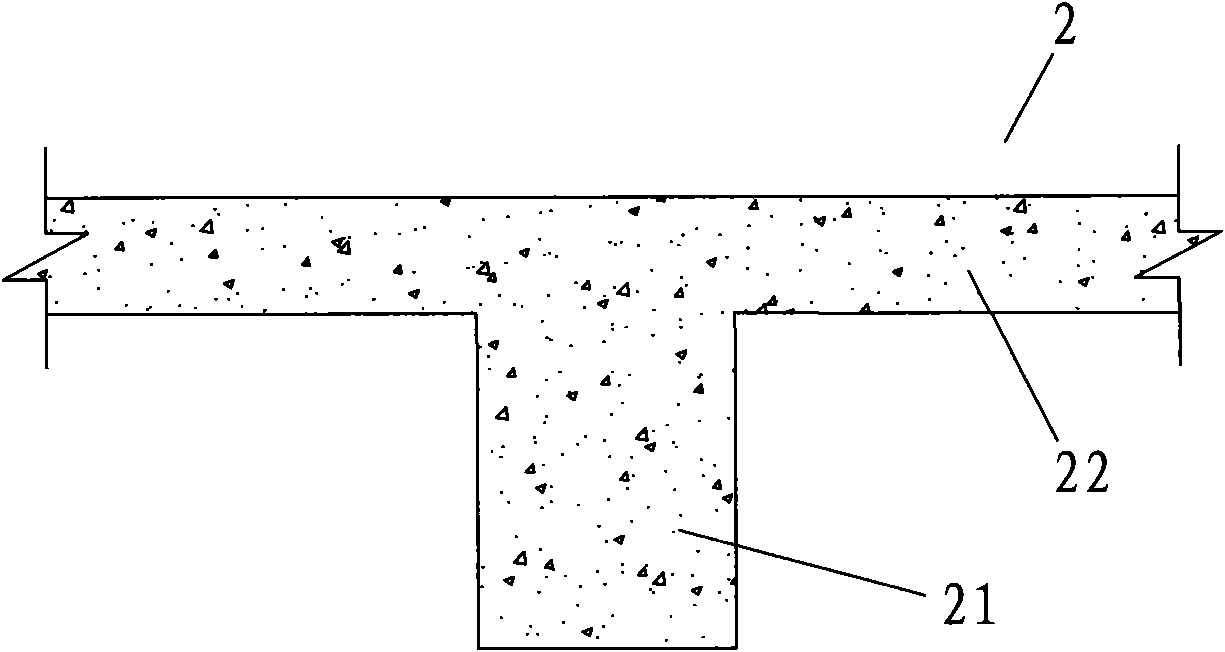

Template-free U-shaped steel concrete combination beam

InactiveCN101851983AOvercoming the Shortcomings of Single AdoptionSave materialLoad-supporting elementsConcrete beamsEngineering

Owner:HUAQIAO UNIVERSITY

Needle cylinder injection type leadless solder paste for heat radiator welding

InactiveCN101301705ACoating is effectiveNo wasteWelding/cutting media/materialsSoldering mediaActive agentGlycerol

The invention discloses a needle cylinder injection-typed lead-free solder paste used for the welding of radiators; the lead-free solder paste contains a tin-bismuth-rare earth lead-free solder mixed with a soldering flux. The soldering flux comprises 40 to 45 percent of resin (such as hydrogenation resin glycerol and alkyd resin), 10 to 15 percent of active agent (such as alkyl poly-glycosides and monoethanolamide sulfosuccinate), 2.1 to 3.1 percent of thixotropic agent (such as amide modified hydrogenated castor oil and Ethylene bis stearamide stearic amide), 0.8 to 1.2 percent of special additive (such as release agent, antioxidant and resist), and residual quantity of solvent (such as glycol dipropionate ether acetate and 1,3-propanediol). The needle cylinder injection typed lead-free solder paste of the invention has low welding temperature, comparatively low viscosity, better rheological property under the action of the pressure, and better anti-collapse performance after the solder paste is coated, and is especially applicable to the welding of the radiators, and is beneficial to precisely controlling the dosage of the welding paste and saving the cost.

Owner:PERFECTION SCI & TECH DONGGUAN

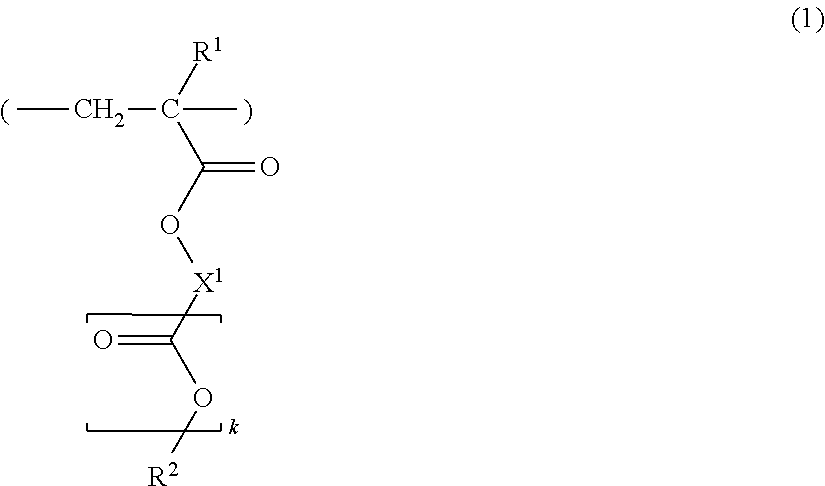

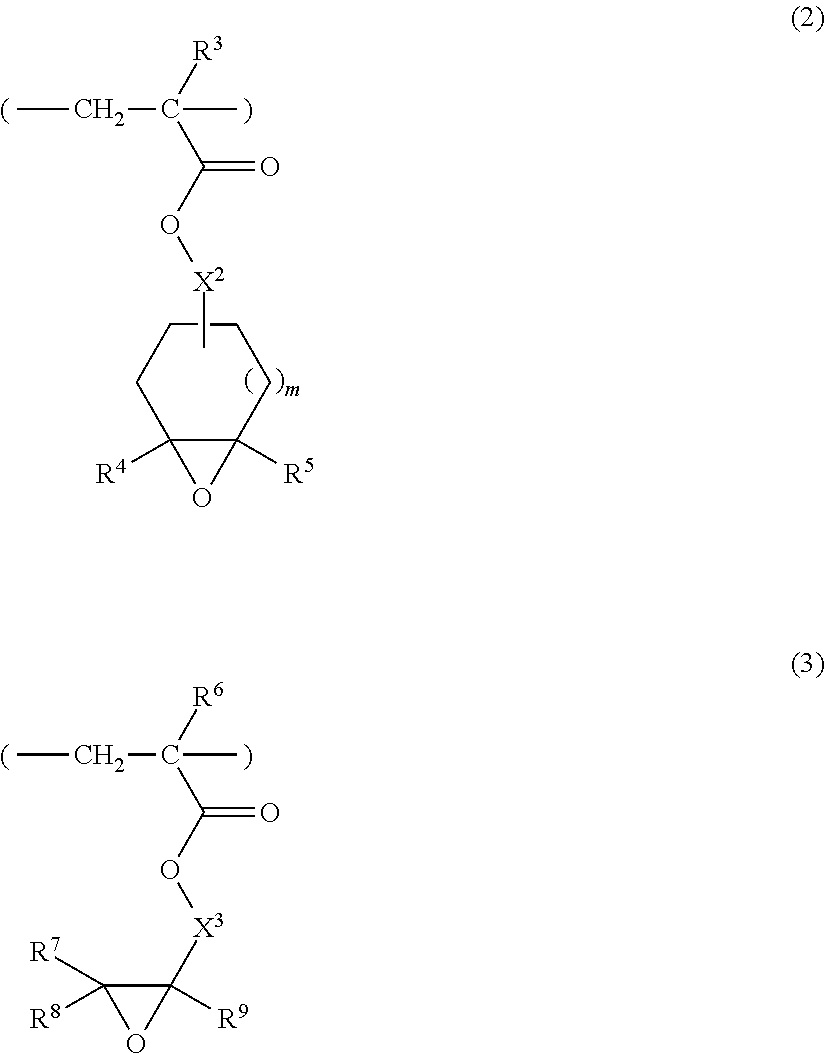

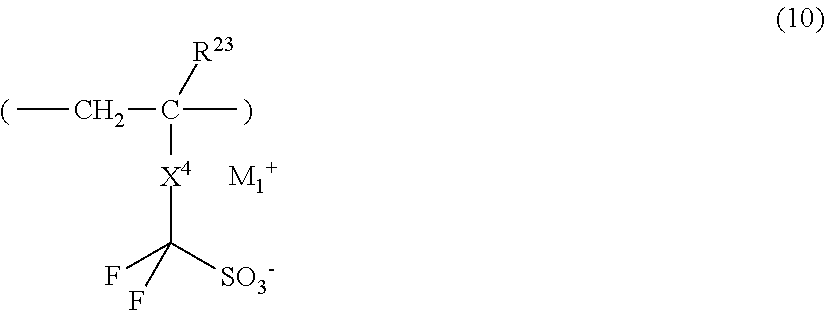

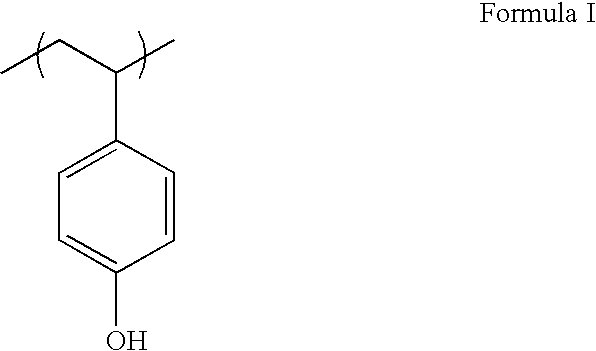

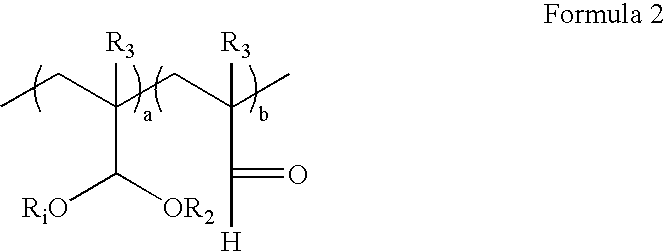

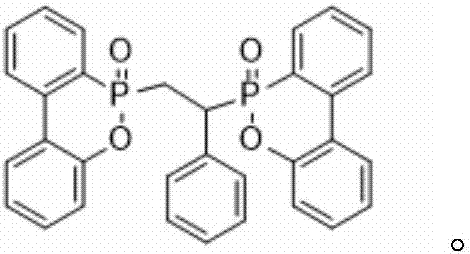

Positive resist composition and patterning process

InactiveUS20130101936A1Improve collapse resistanceMinimal LWRPhotosensitive materialsSemiconductor/solid-state device manufacturingEthylene oxideDissolution

A positive resist composition comprising (A) a polymer comprising recurring units containing an acid labile group, recurring units having a lactone ring, and recurring units having an oxirane ring, the polymer being adapted to increase alkaline dissolution under the action of an acid, (B) a photoacid generator, and (C) a solvent forms a fine pattern with improved LWR, improved MEF, rectangular profile, and collapse resistance.

Owner:SHIN ETSU CHEM IND CO LTD

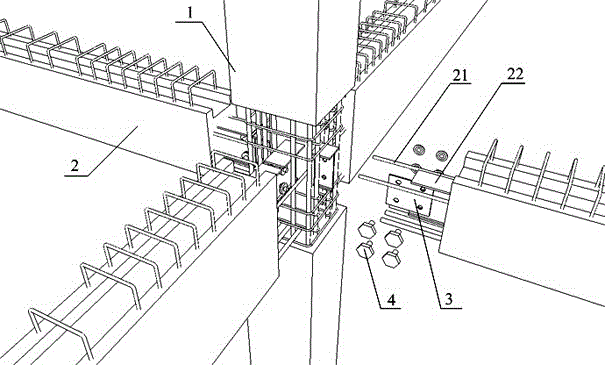

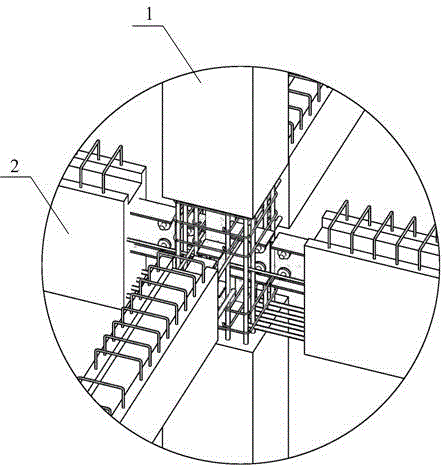

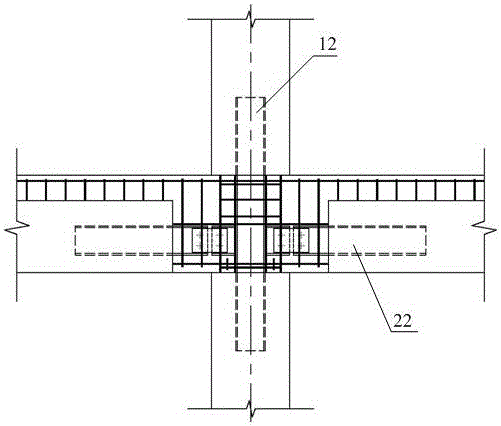

Prefabricated concrete frame structure and manufacturing method thereof

ActiveCN106149873AEnsure continuityEnsure integrityBuilding constructionsShear capacityAgricultural engineering

The invention discloses a prefabricated concrete frame structure which comprises prefabricated columns and prefabricated beams. Each prefabricated column is connected with one end of the corresponding prefabricated beam, a node area is formed at a joint of each prefabricated column and the corresponding prefabricated beam, each prefabricated beam is divided into an upper-layer column body and a lower-layer column body by the corresponding node area, each upper-layer column body and the corresponding lower-layer column body are connected through longitudinal reinforcing steel embedded in the prefabricated column in the corresponding node area, and column body longitudinal rebars are embedded in each prefabricated column and are continuous in the corresponding node area; beam end reinforcing steel is embedded at one end, connected with the corresponding prefabricated column, of each prefabricated beam, and the longitudinal reinforcing steel and the beam end reinforcing steel are connected through bolts. The invention further discloses a manufacturing method of the prefabricated concrete frame structure. Nodes of the prefabricated concrete frame structure are equivalent to cast-in-place concrete frame nodes in anti-seismic performance and energy dissipating capacity, anti-seismic concept design of 'strong nodes and weak components', 'strong shear capacity and weak bending capacity' and 'strong columns and weak beams' is realized, and construction process and difficulty can be reduced.

Owner:FOSHAN ELECTRIC POWER DESIGN INST +1

Magnesium-based bone filling adhesive and preparation method and application thereof

InactiveCN102274543AHigh strengthImprove adhesionSurgical adhesivesO-Phosphoric AcidMagnesium phosphate

The invention discloses a magnesium-based bone filling adhesive and its preparation method and application. The adhesive material is composed of a solid phase component and a liquid phase component, wherein the solid phase component is composed of basic oxide, Calcium phosphate, hydrogen phosphate, magnesium phosphate, and starch are mixed evenly; the liquid phase component is prepared by dissolving sugar and hydrogen phosphate in aqueous phosphoric acid. Mix the above-mentioned solid phase components and liquid phase components evenly to form a pasty cement slurry, which is used for filling and repairing bone tissue trauma and treating osteoporosis, especially for the adhesion of bones, tendons, ligaments and prostheses. Bonding and fixing, avoiding the disadvantages of the existing calcium phosphate cement, such as low early strength, non-viscosity, easy collapse, poor biodegradability and magnesium phosphate cement containing ammonium salt, and achieved good results. And it has the characteristics of low raw material cost, simple preparation method, high strength, strong cohesiveness, good collapse resistance, good biodegradability, no ammonia gas, etc., and can be directly injected into the lesion with a syringe or filled into the body after curing and molding. It is very convenient to use, and it can also be used for bonding and fixing building materials such as metal, ceramics, and plastics.

Owner:天津美基生物医药科技有限公司

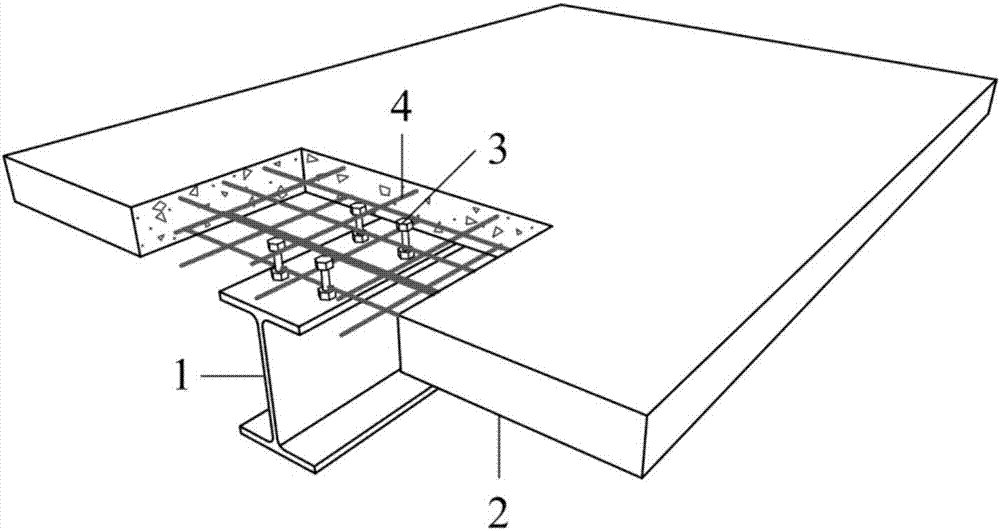

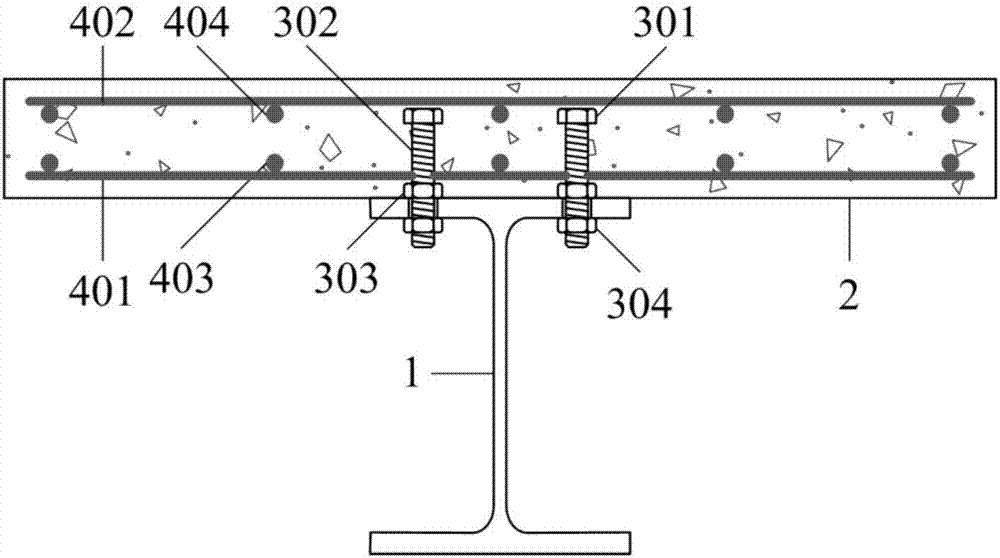

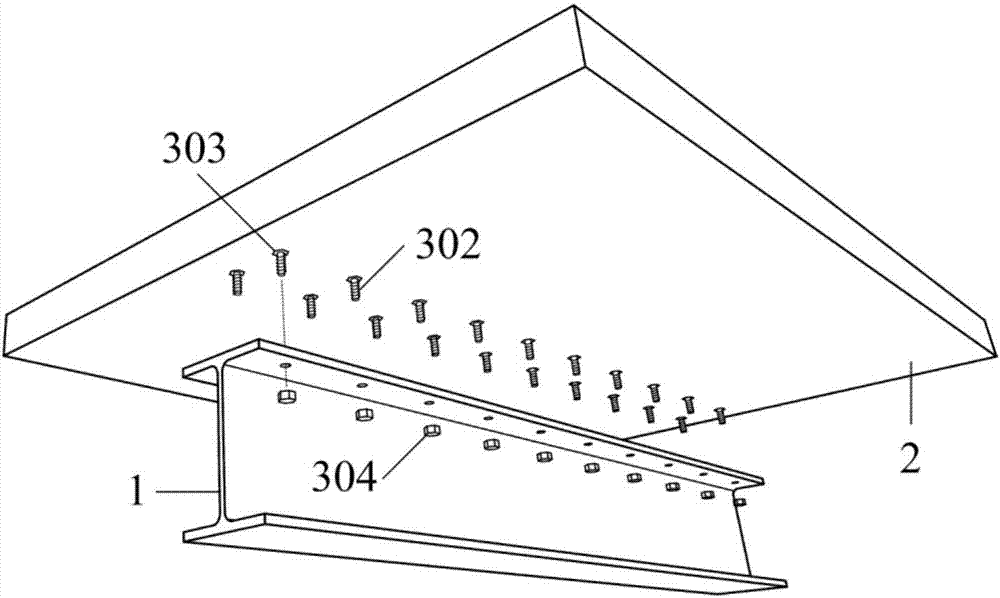

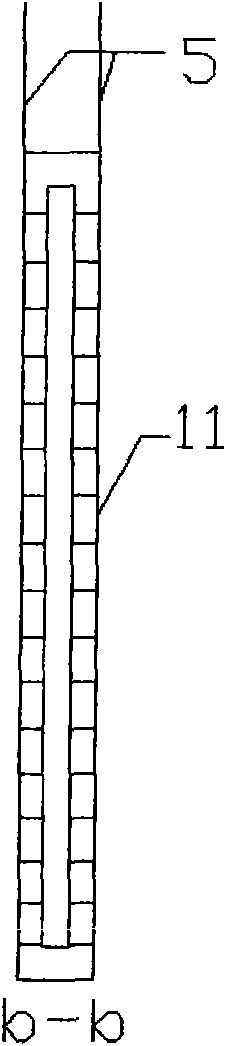

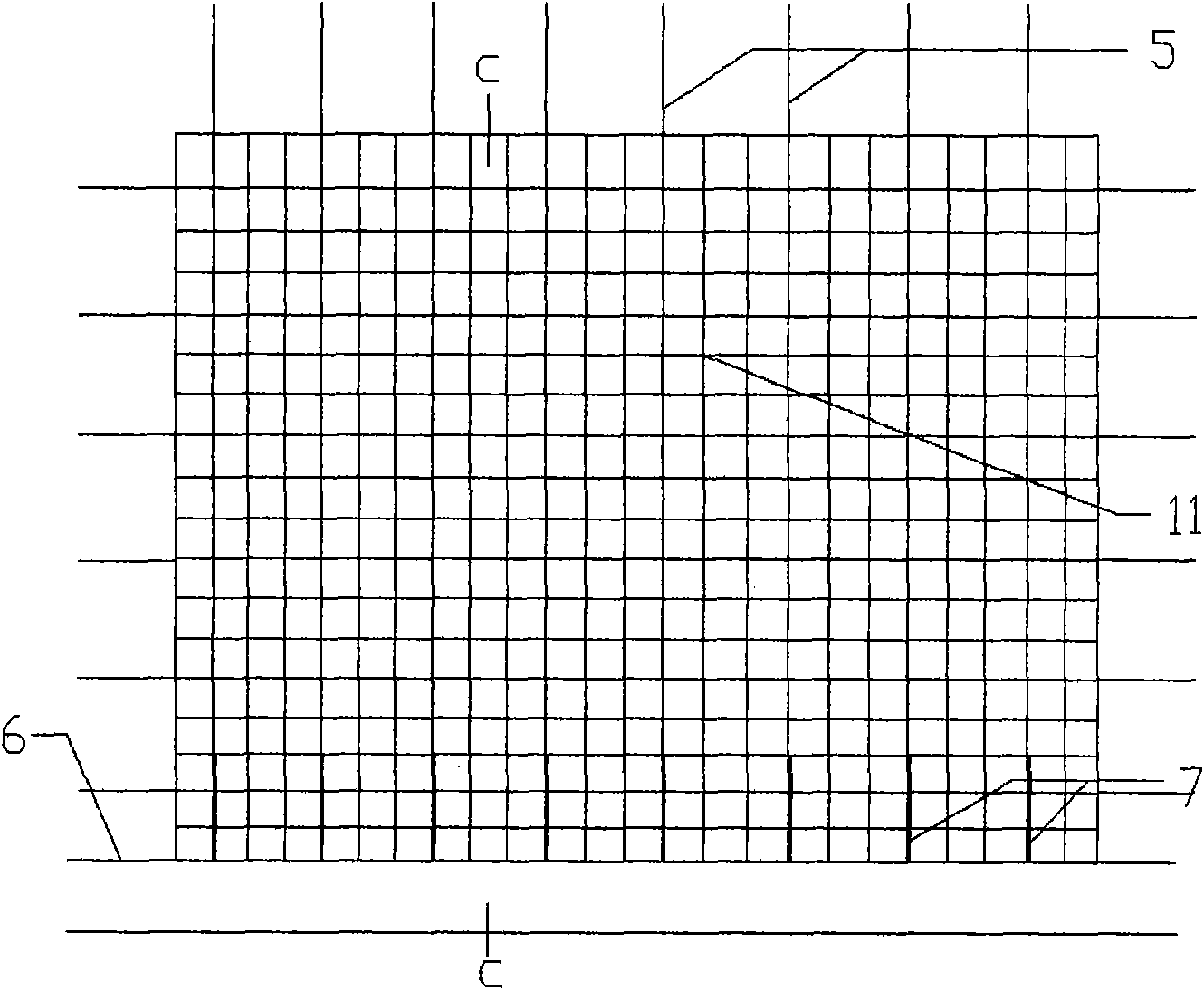

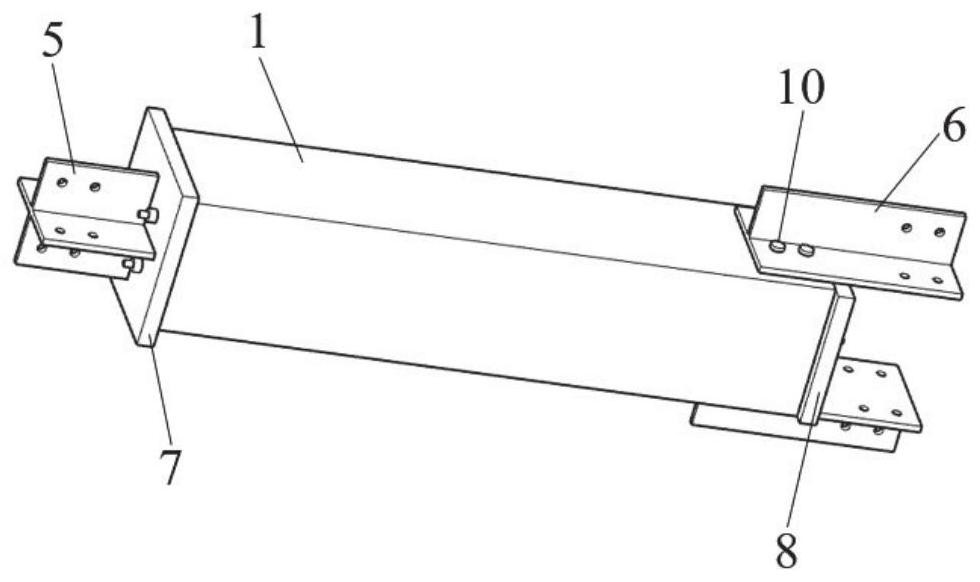

Detachable assembled high-ductility steel-concrete composite beam

InactiveCN107447921AHigh degree of industrializationEasy to processLoad-supporting elementsEngineeringRebar

The invention discloses a detachable assembled high-ductility steel-concrete composite beam and belongs to the technical field of steel structures of structural engineering. A steel beam and a precast concrete floor are assembled through bolts. Bolt holes are reserved in the upper wing edge of the I-shaped steel beam, the bolts are pre-buried at the bottom of the precast concrete floor and welded or mechanically connected with transverse steel bars at the bottom, so that the ductility and the anti-collapse capability of the structure are improved under the action of a strong shock. During assembly, the precast concrete floor is built at the top of the upper wing edge of the I-shaped steel beam, the bolts pre-buried at the bottom of the precast concrete floor penetrate the bolt holes reserved at the upper wing edge of the steel beam, and then the steel beam and the floor are fastened by nuts. When the service life of the structure is up, the bolts are unscrewed and the precast floor and the steel beam are separated to realize disassembly. The novel composite beam has the advantages of a traditional cast-in-place composite beam, is simple in assembly construction, high in speed and low in cost, and can effectively prevent dust raising on a construction site; post-earthquake repair and replacement of damaged members are facilitated; and the detachable assembled high-ductility steel-concrete composite beam can be detached in the service period or after service termination, and has a wide engineering application prospect.

Owner:TSINGHUA UNIV

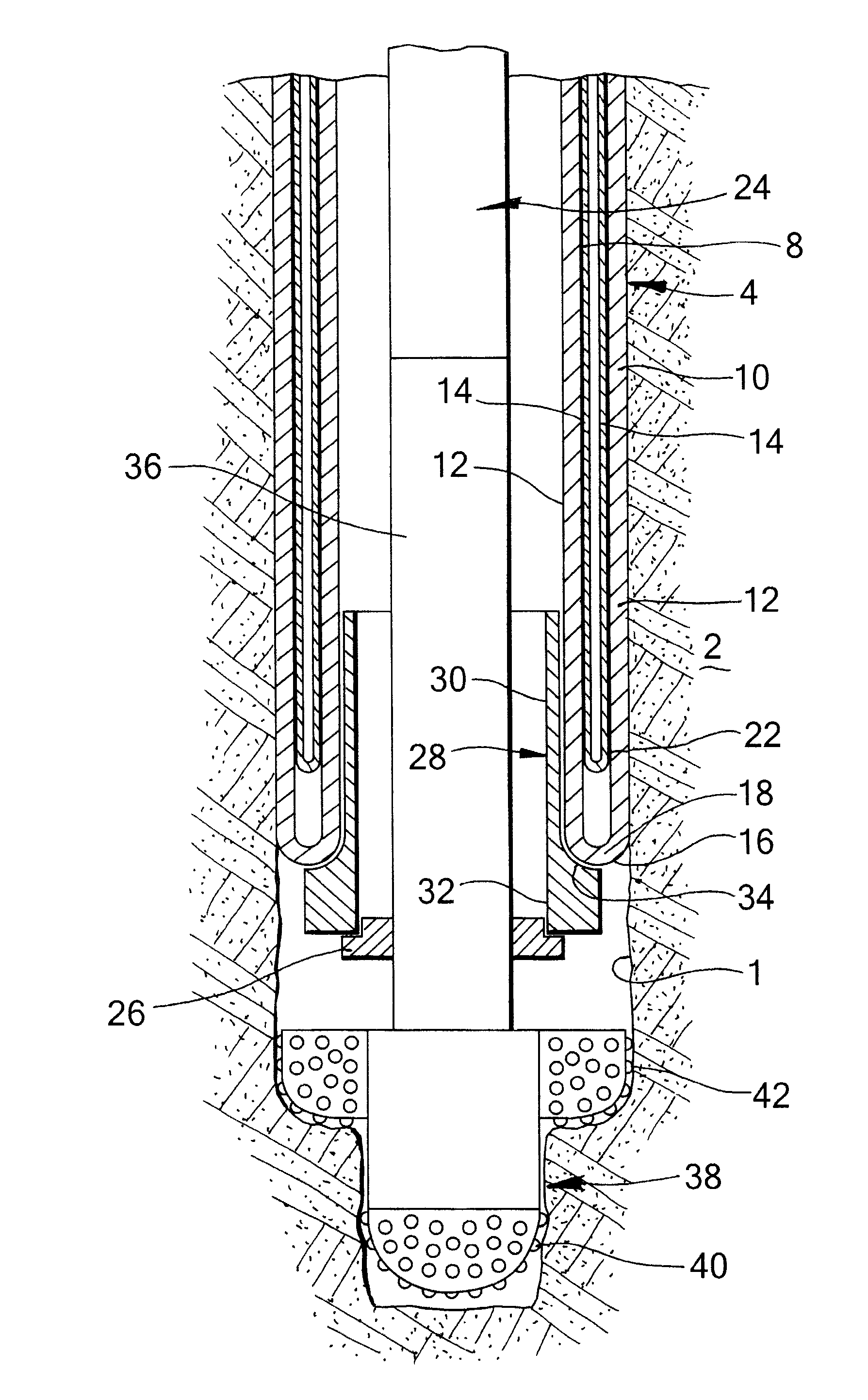

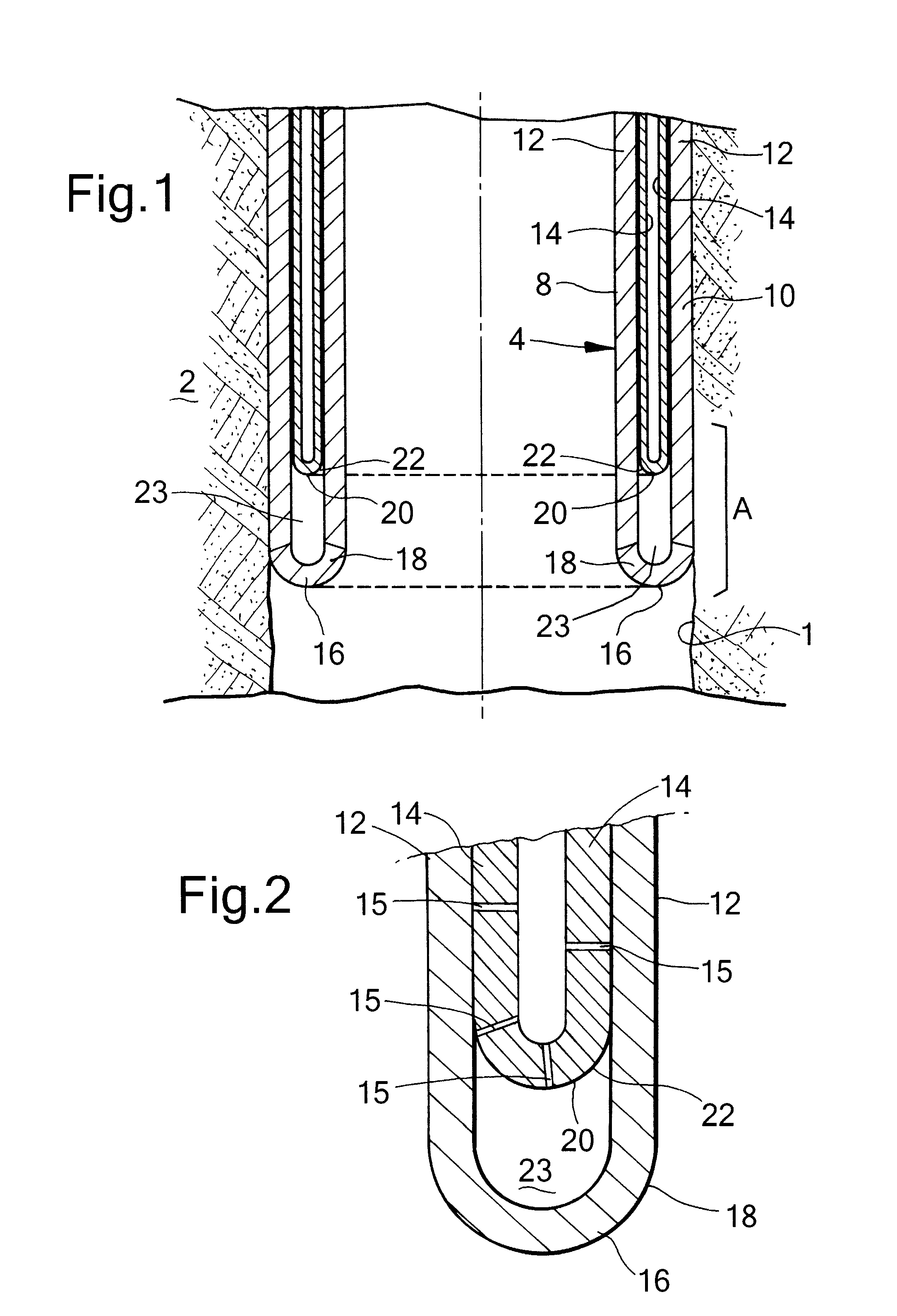

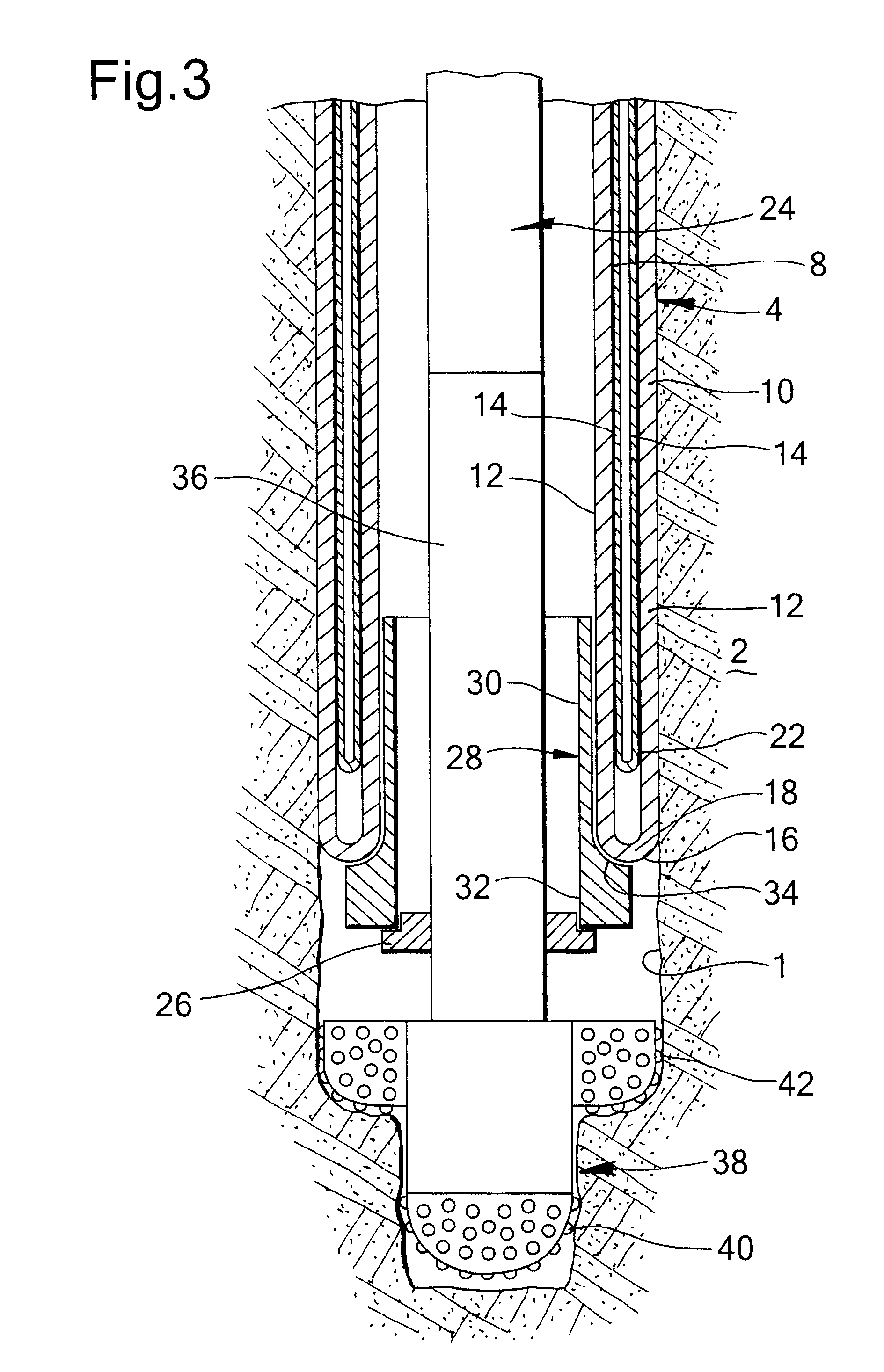

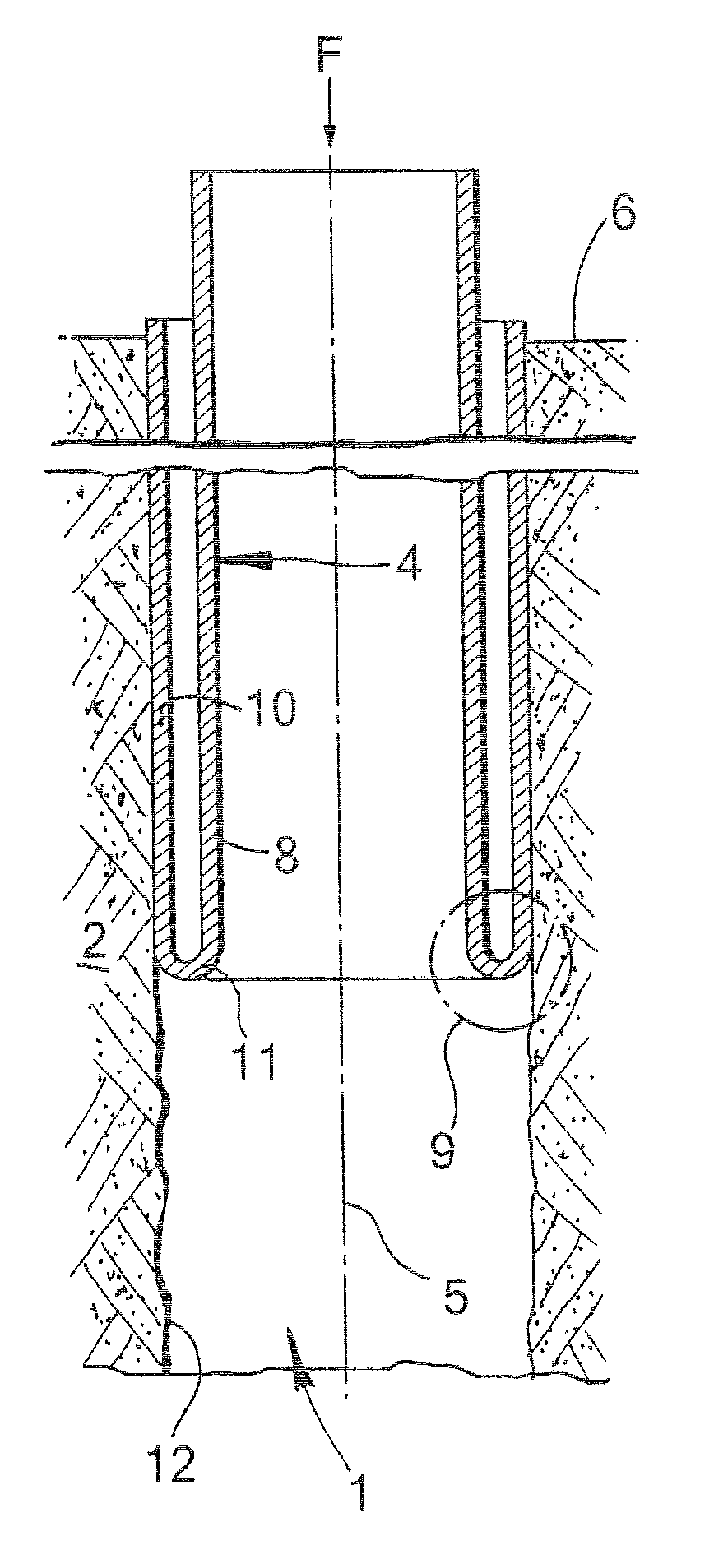

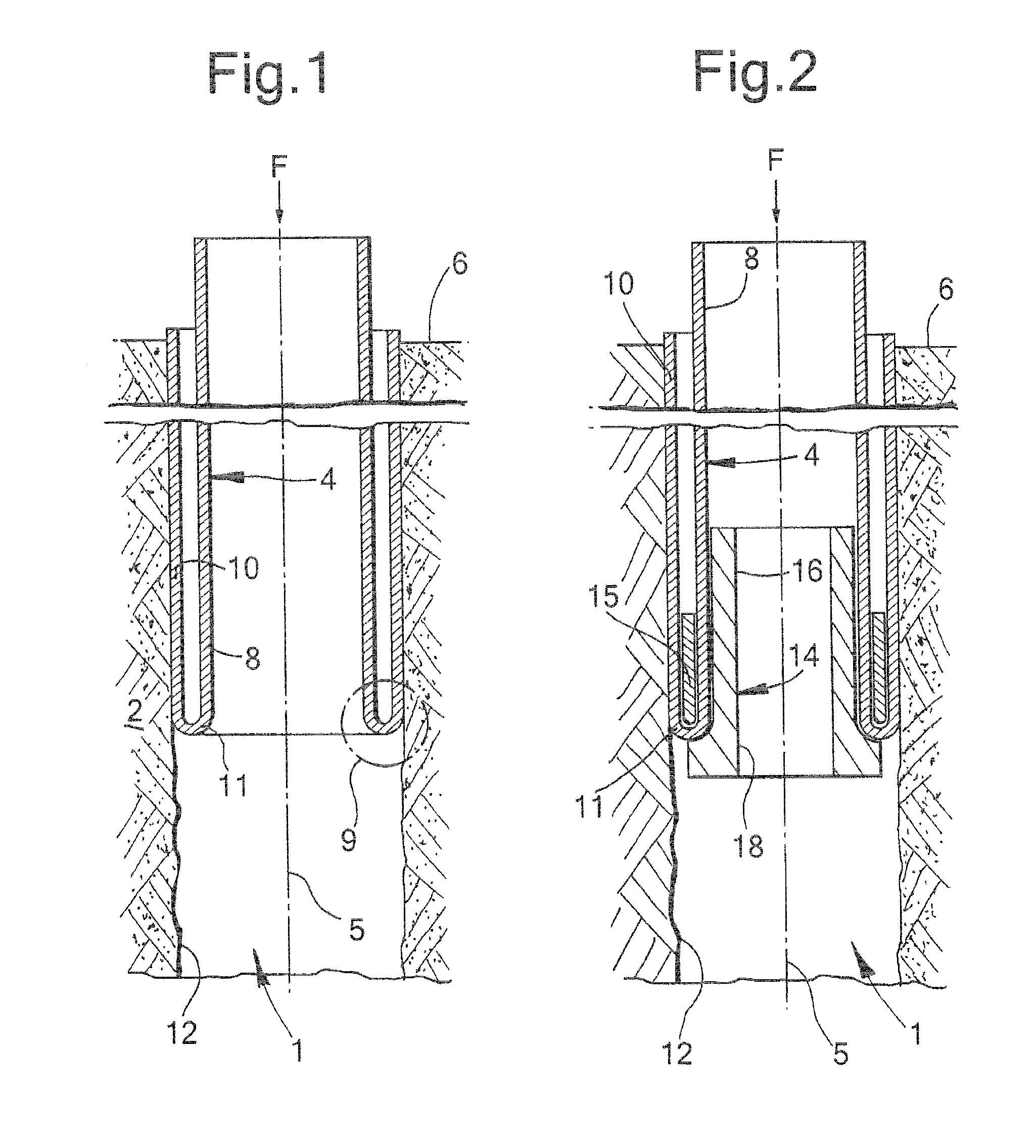

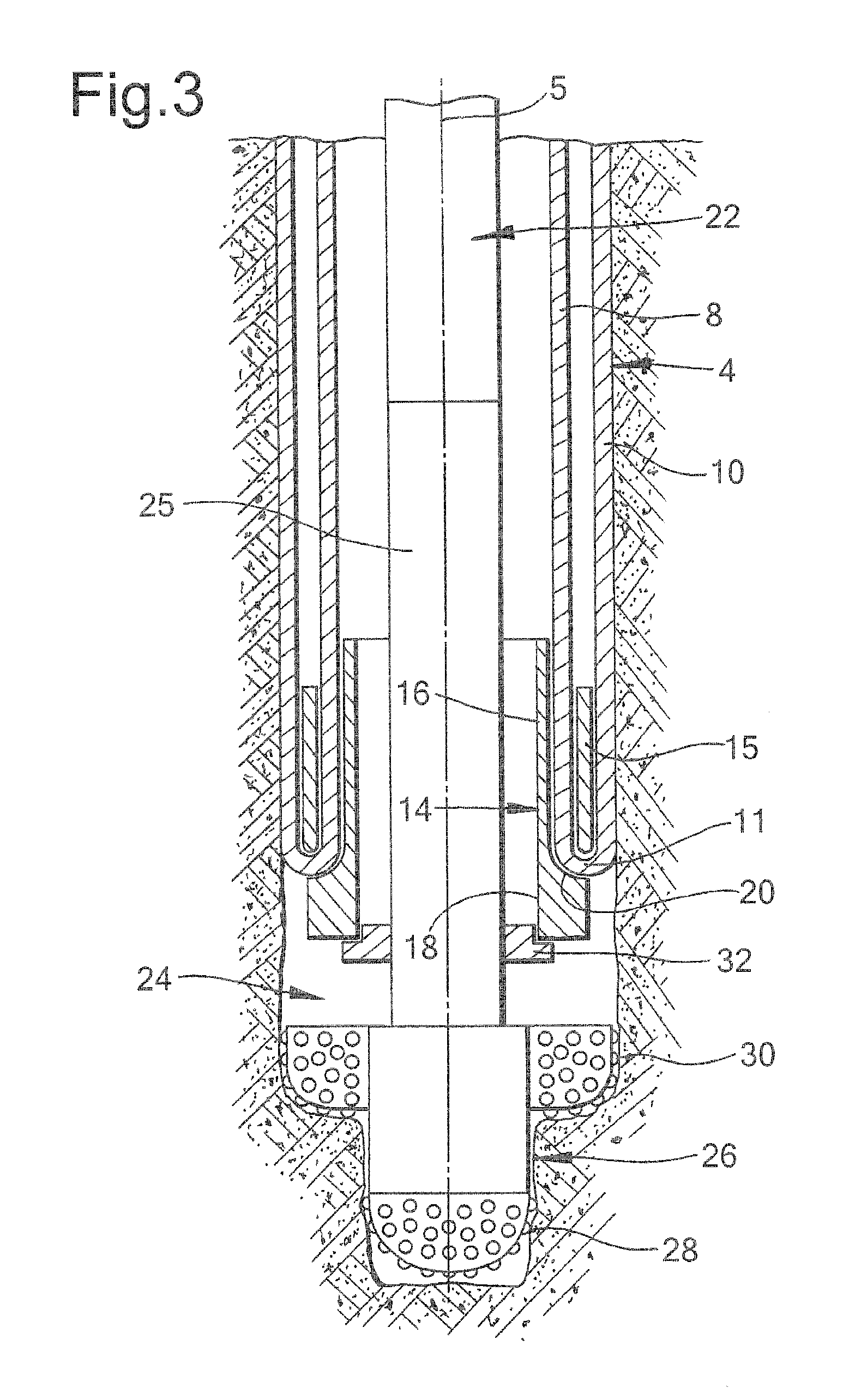

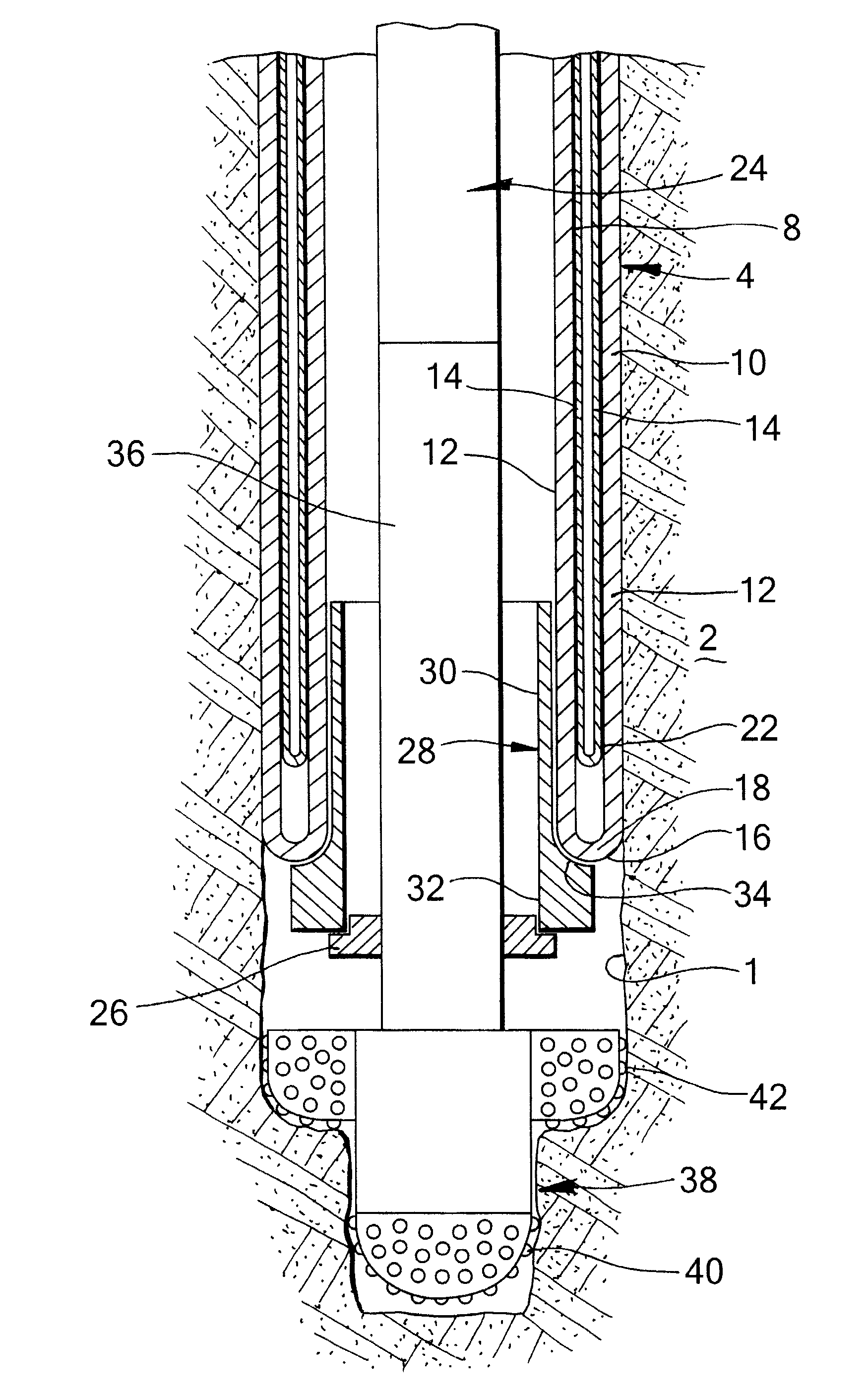

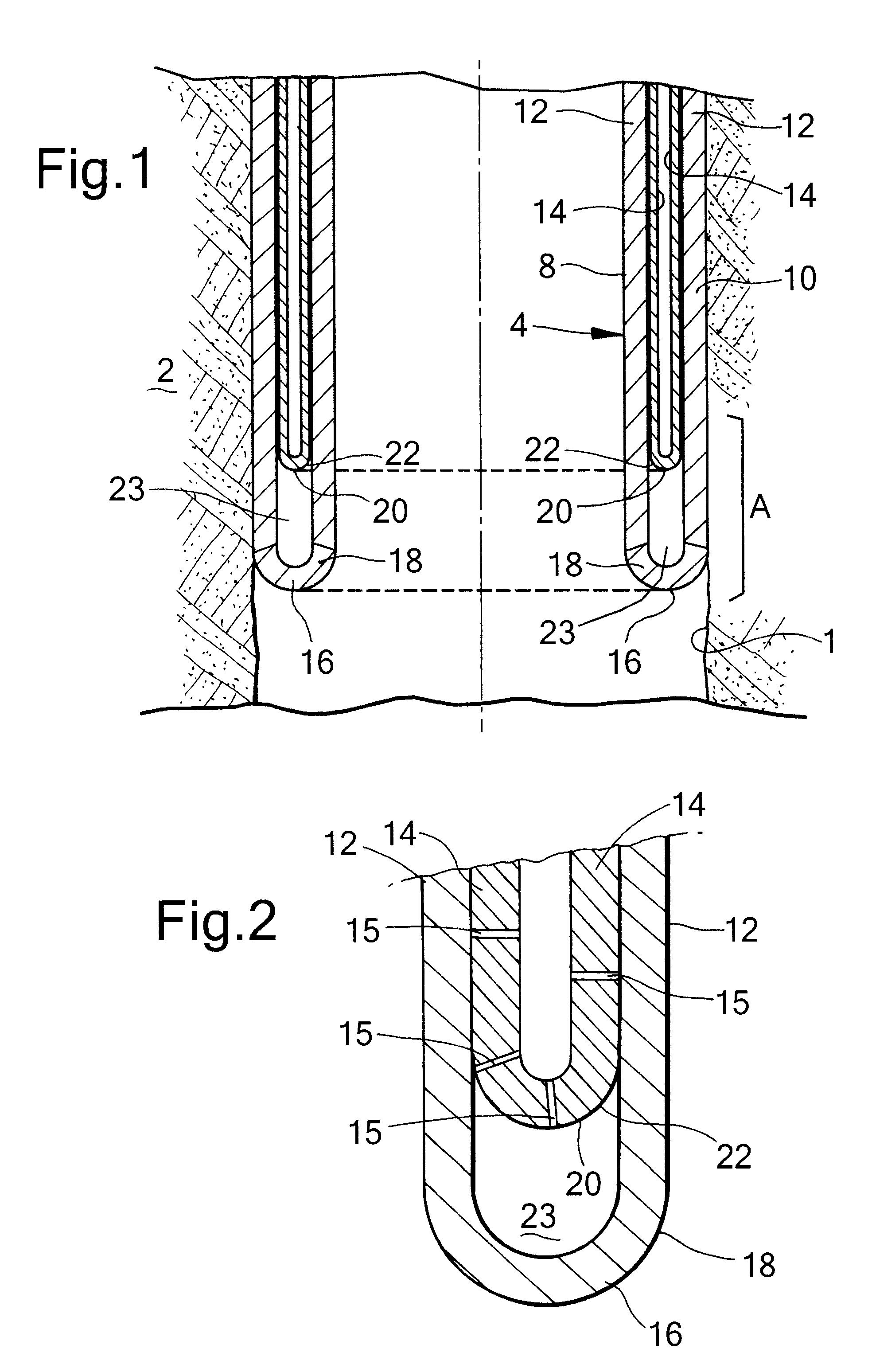

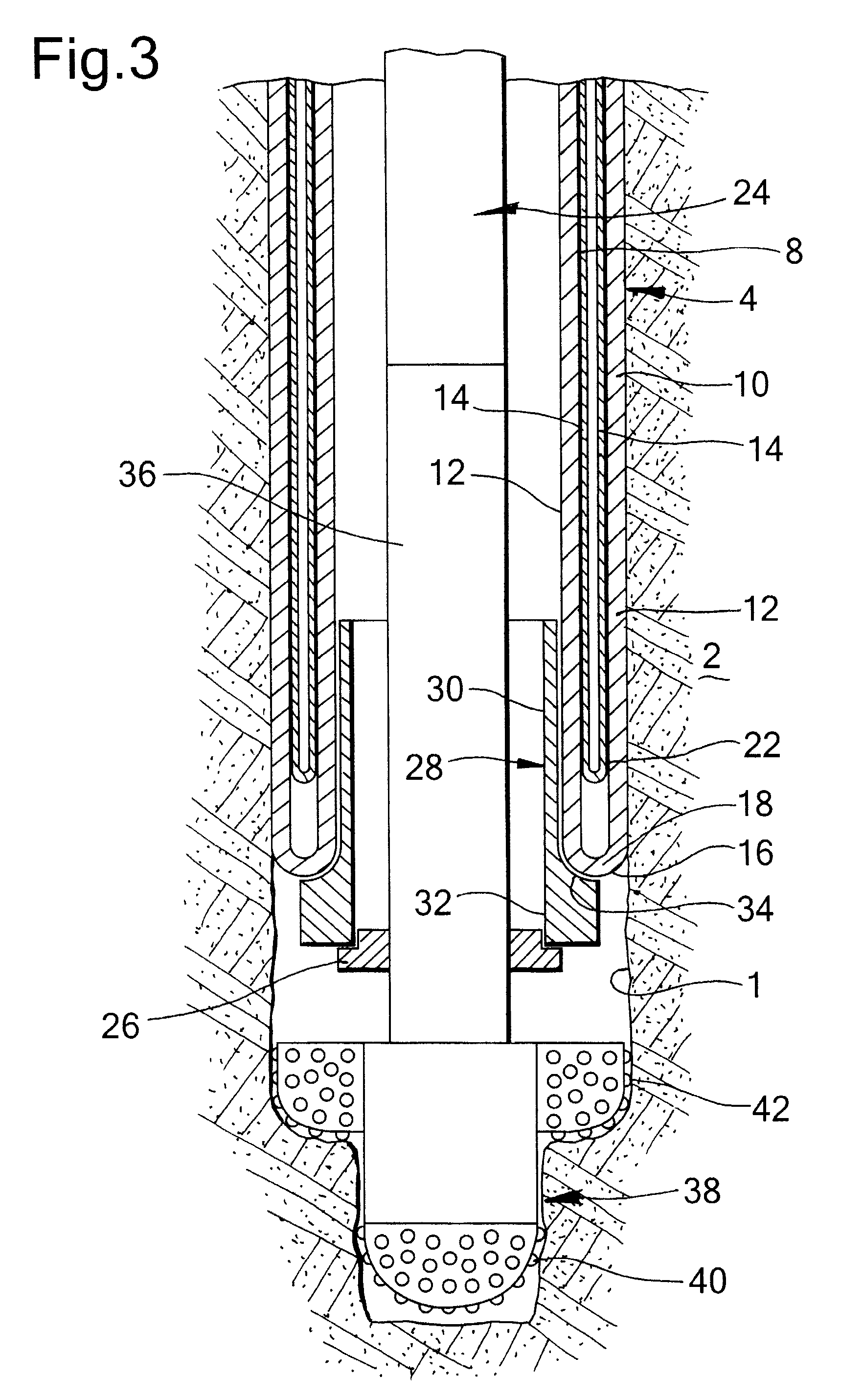

Method of radially expanding a tubular element

The invention relates to a method of radially expanding a tubular element extending into a wellbore formed in an earth formation, the tubular element including a first layer and a second layer extending around the first layer, said layers being separable from each other. The method comprises inducing each layer to bend radially outward and in an axially reverse direction so as to form an expanded tubular section extending around a remaining tubular section of the tubular element, wherein each layer has a respective bending zone in which the bending occurs, and increasing the length of the expanded tubular section by inducing the respective bending zones of the layers to move in an axial direction relative to the remaining tubular section. The layers in the respective bending zones are separate from each other so as to define an axial space between the layers.

Owner:SHELL OIL CO

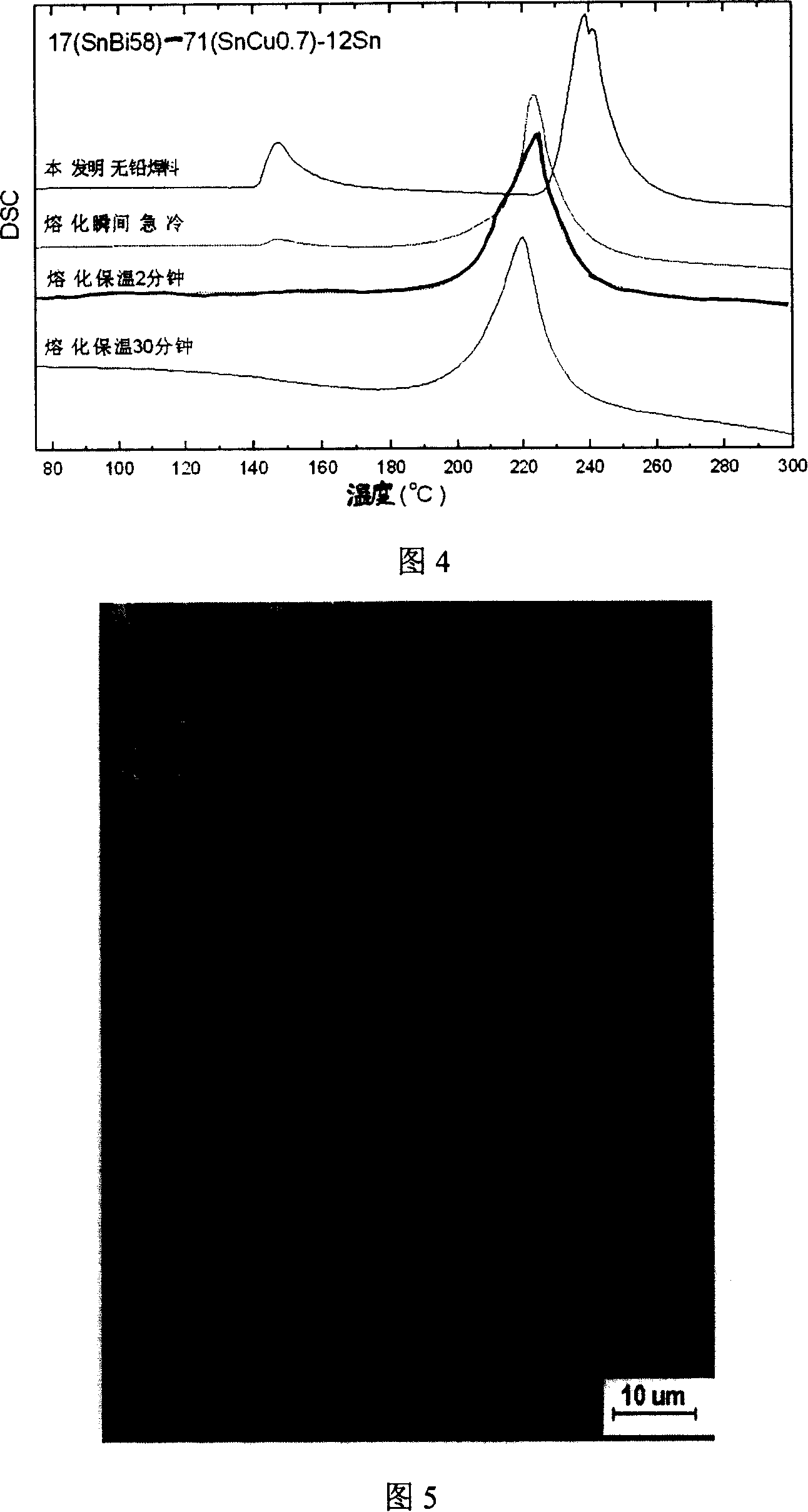

Home position alloying type lead-free solder and preparation method thereof

ActiveCN101138812AHas an occlusal effectReduce high temperature side effectsMixing methodsWelding/cutting media/materialsSingle substanceAlloy

The present invention, which belongs to the electronic soldering technology field, discloses an in-situ alloying lead-free solder and a preparation method thereof. The present solder consists of two or more alloy powders or single-substance metal powders, which are mixed mechanically and uniformly. In welding and application processes, the solder has the advantages of a strong anti-collapsing ability, a bright co-center circles of the solder joint, a good spreading effect, a simple preparation technique and low cost and the optimal advantages are that the welding with the use of a unified SMT welding technique and without changing the welding technique line and parameters of the previous solder is convenient. The medium / high temperature solder can be welded under a low temperature or gradient temperatures so that the medium / high temperature application of the low temperature solder is realized and the service life of the solder joint is prolonged.

Owner:BEIJING COMPO ADVANCED TECH

Injectable self-cured calcium phosphate bone-rehabilitating material and its preparing process

The invention discloses an injectable self-solidifying calcium phosphate bone-repairing material and making method, which consists of solid phase and liquid phase, wherein the solid phase contains 0.2-2.0% degeneration starch, 0-15% beta-dicalcium silicate powder, 0-15% strontium and bismuth compound and 0-30% macromolecular microball or microcapsule; the liquid phase is composed of one or more composition of deionized water, diluted phosphoric acid, physiological saline, blood, soluble phosphate solution and organic acid; the rate of liquid phase and solid phase is 0.3-1.2ml / g.

Owner:SOUTH CHINA UNIV OF TECH

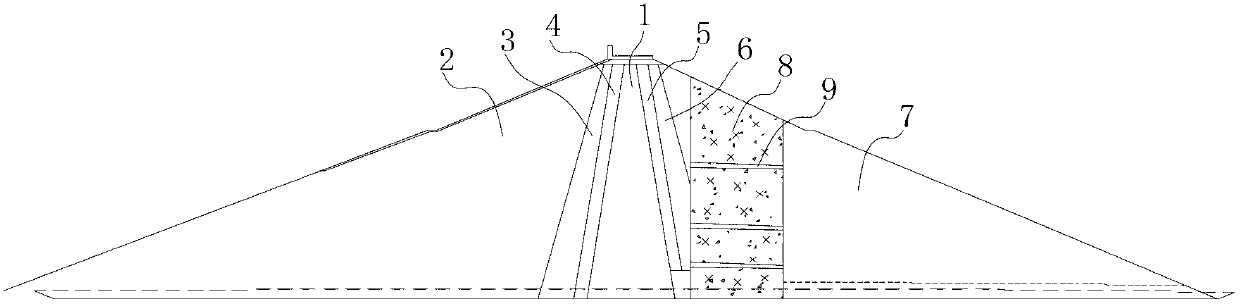

Soil-core-wall rock-fill dam and construction method thereof

ActiveCN102995608AImprove collapse resistanceWon't crashEarth-fill damsRock-fill damsFilling materialsEngineering

The invention discloses a soil-core-wall rock-fill dam with better burst resistance and a construction method thereof. The soil-core-wall rock-fill dam comprises a soil core wall, wherein one side of the upstream of the soil core wall is provided with an upstream rock-fill material area, an upstream transition material area and an upstream refiltering material area which are arranged in sequence along the water-flowing direction; one side of the downstream of the soil core wall is provided with a downstream refiltering material area, a downstream transition material area and a downstream rock-fill material area which are arranged in sequence along the water-flowing direction; and the downstream rock-fill material area is internally provided with a concrete burst-resistant wall. The soil-core-wall rock-fill dam disclosed by the invention has the advantages that since the concrete burst-resistant wall is arranged in the downstream rock-fill material area, the burst resistance of a dam body can be greatly improved, and even though the flood is over the top or the dam top is opened to cause discharge of water in a reservoir due to the external-force factor, the whole burst of the dam also can not be caused due to the existence of the concrete burst-resistant wall. The soil-core-wall rock-fill dam disclosed by the invention is suitable for being promoted and applied in the field of rock-fill dams.

Owner:POWERCHINA CHENGDU ENG

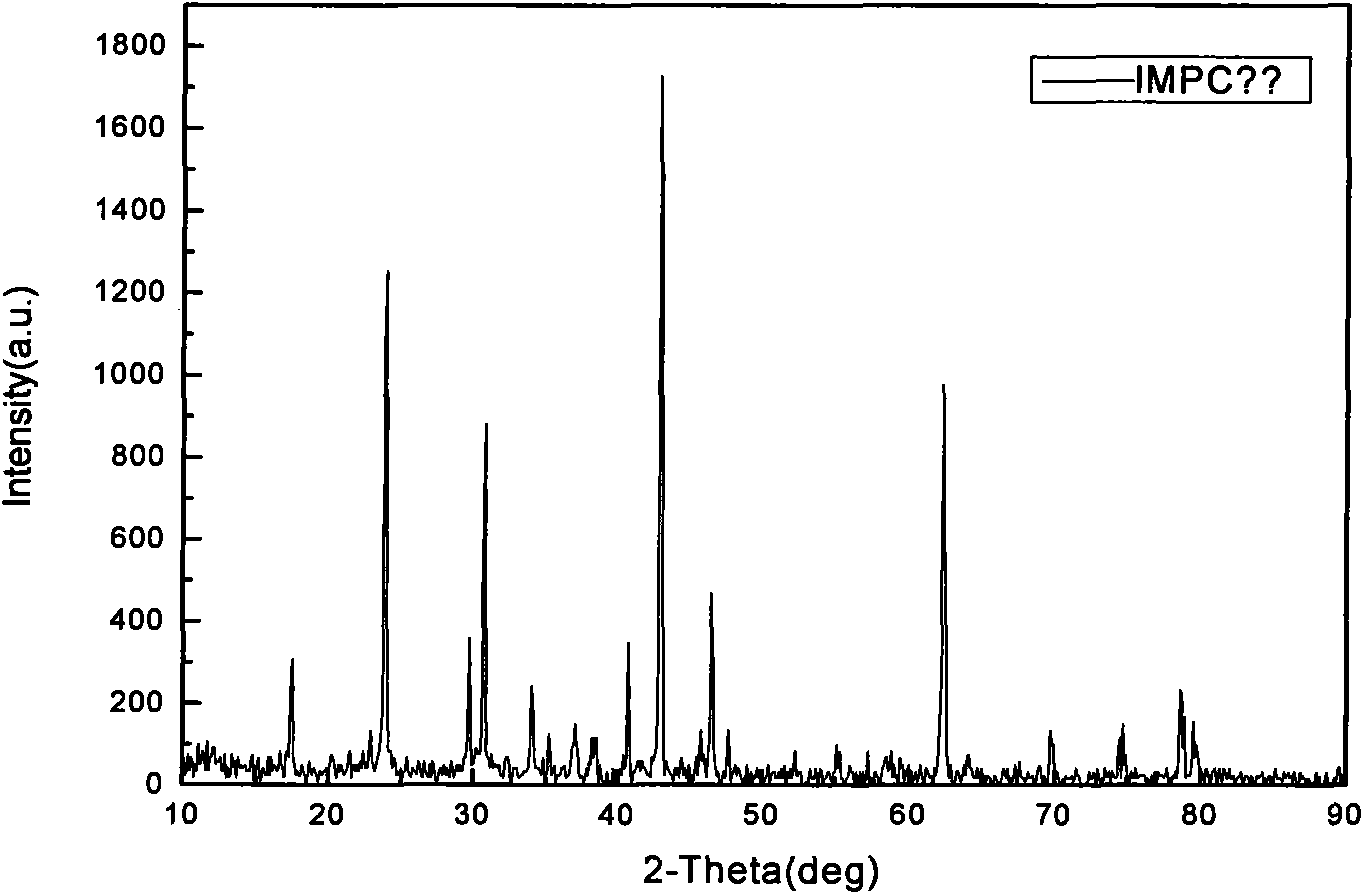

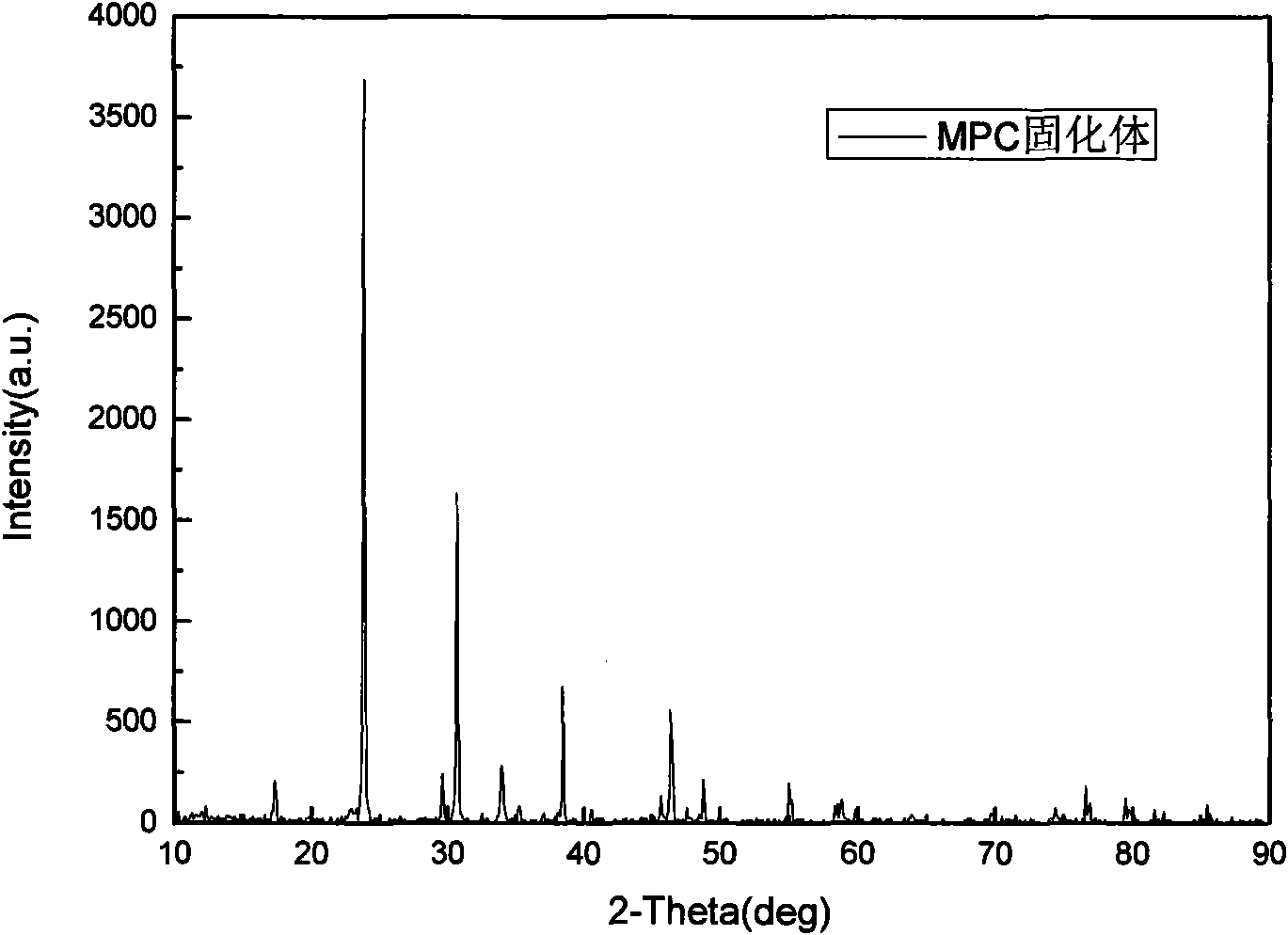

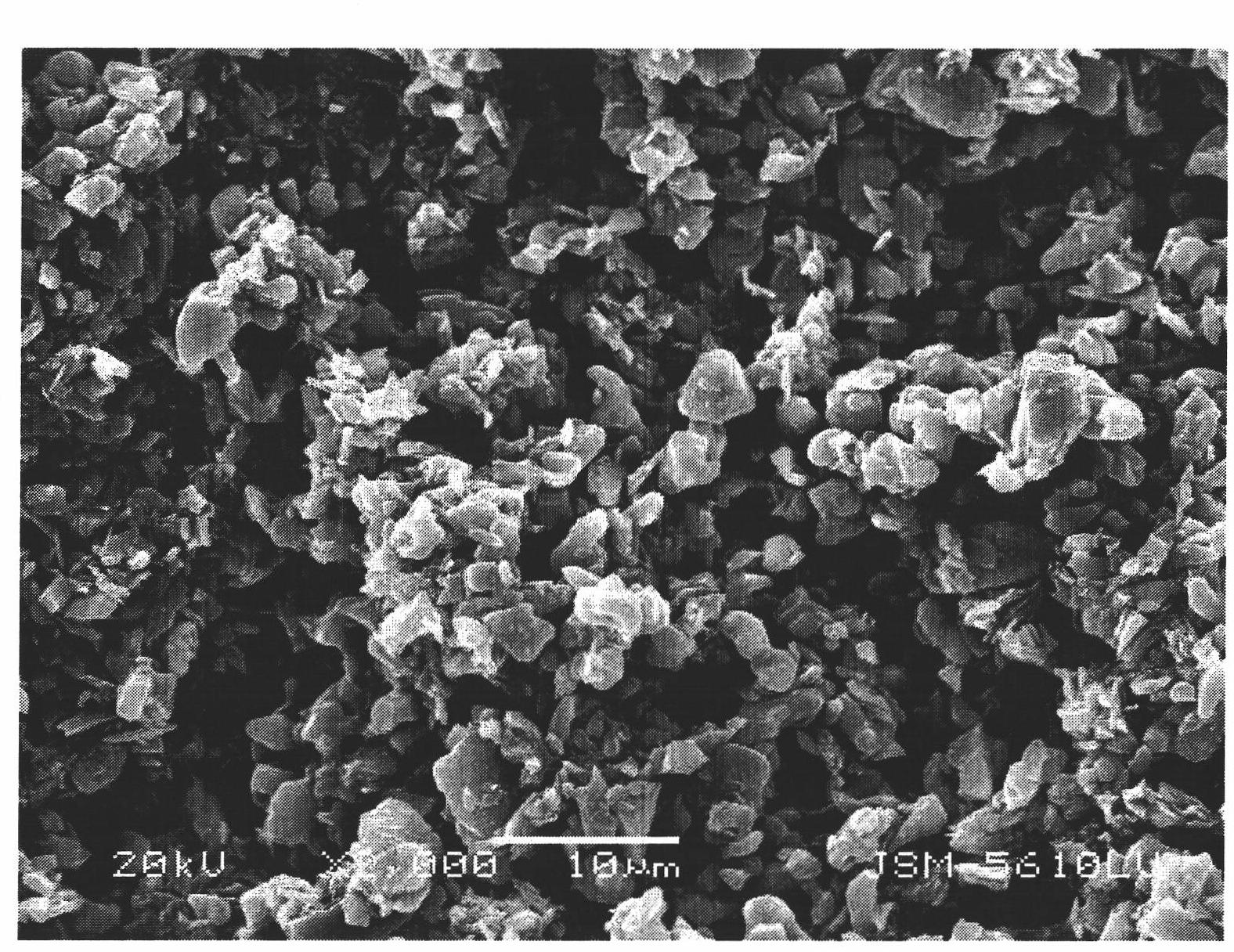

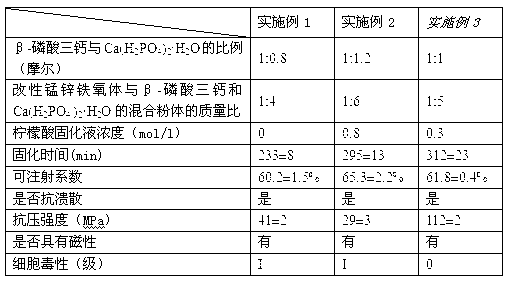

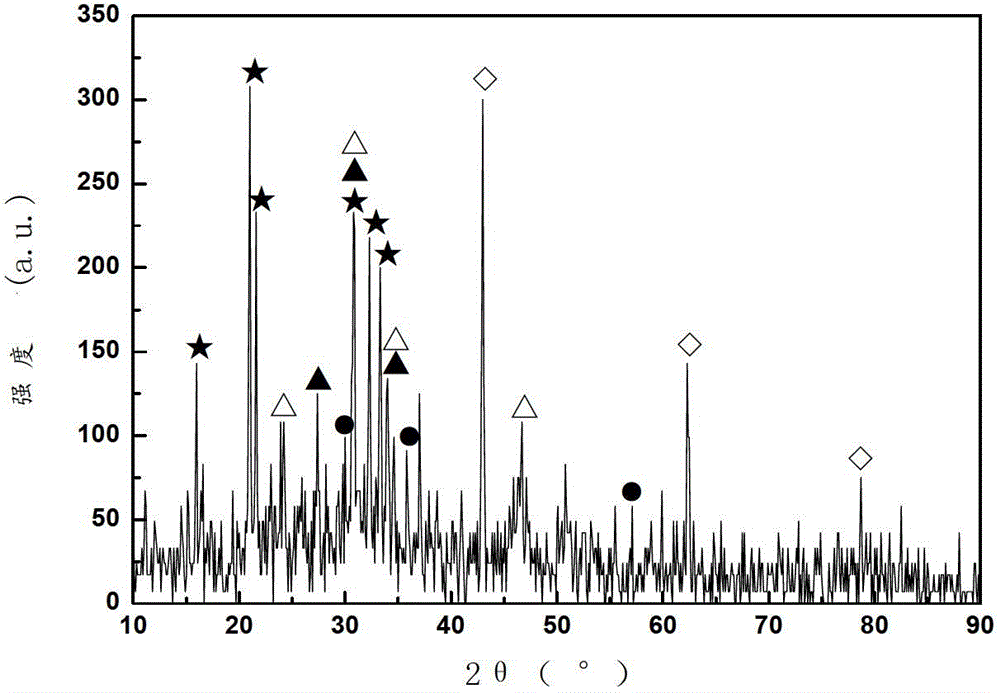

High-strength magnetic calcium-phosphate-based bone cement and preparation method thereof

InactiveCN103058645ALow preparation temperatureReduce energy consumptionProsthesisTri calcium phosphateMixed materials

The invention relates to high-strength magnetic calcium-phosphate-based bone cement which is obtained by blending a solid-phase mixed material and a liquid phase before use. The ratio of the solid-phase mixed material to the liquid phase when blending is that every 2.8-3.2g of the solid-phase mixed material requires 1mL of liquid phase. The liquid phase is a citric acid solution with a concentration of 0-0.8mol / L. The solid-phase mixed material is composed of the raw materials of beta-tricalcium phosphate, Ca(H2PO4)2.H2O, and Mn-Zn ferrite with a chemical composition of Mn0.4Zn0.6Fe2O4. The molar ratio of beta-tricalcium phosphate to Ca(H2PO4)2.H2O is 1:0.8-1.2. The weight ratio of Mn-Zn ferrite to the mixture of beta-tricalcium phosphate and Ca(H2PO4)2.H2O is 1:4-6. According to the invention, beta-tricalcium phosphate, Ca(H2PO4)2.H2O, and modified Mn-Zn ferrite with the chemical composition of Mn0.4Zn0.6Fe2O4 are adopted as solid-phase raw materials. With the three substances, preparation temperature is low, energy consumption is low, quenching is not needed, and operation is safe. The compressive strength of the bone cement can reach 112MPa, which is greatly higher than that of existing calcium-phosphate-based bone cement. The bone cement has good injectable performance, anti-collapsing performance, and low cytotoxicity.

Owner:HENAN UNIV OF SCI & TECH

Method of radially expanding a tubular element in a wellbore provided with a control line

ActiveUS8056641B2Increase the lengthRetain its shapePipe laying and repairDrilling rodsControl lineEngineering

Owner:SHELL OIL CO

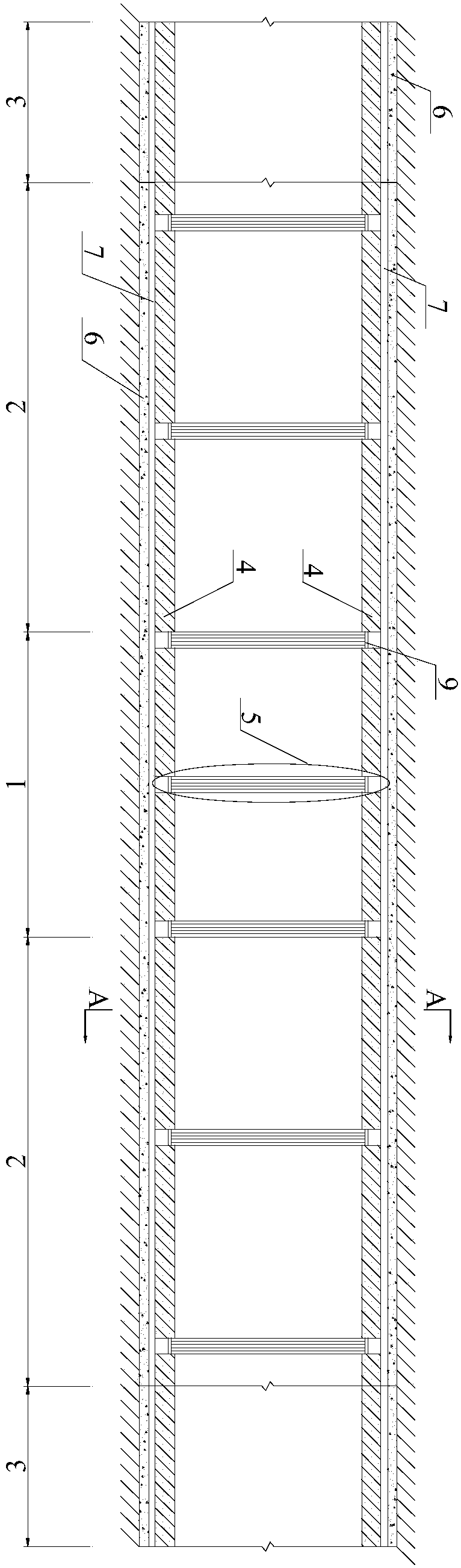

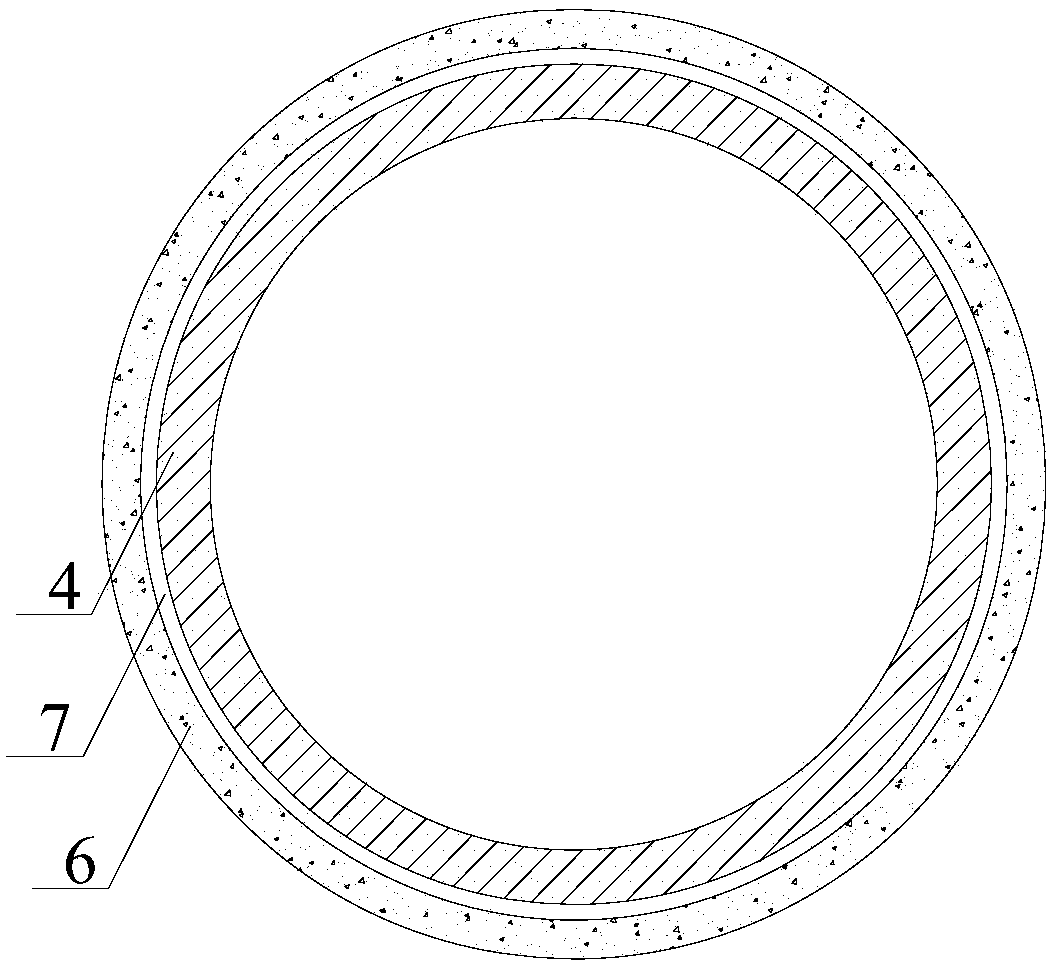

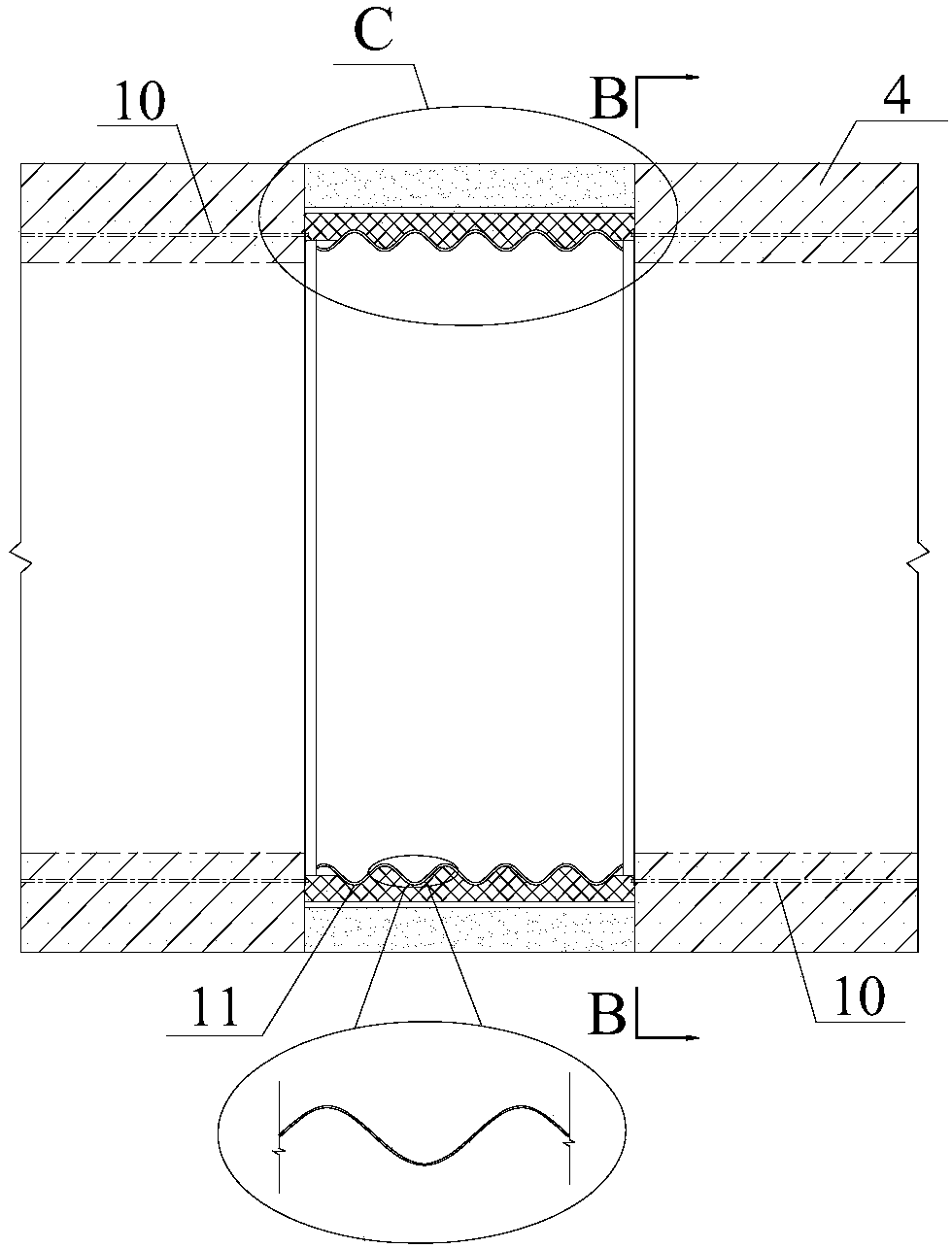

Anti-crack-type hinged tunnel used for crossing movable fault zone and application thereof

ActiveCN108252721AImprove ductilityImprove collapse resistanceUnderground chambersTunnel liningGeomembranePre stress

The invention provides an anti-crack-type hinged tunnel used for crossing a movable fault zone and application thereof. The tunnel structure comprises a primary lining, section inner linings and annular flexible hinges between the adjacent section inner linings, and the annular flexible hinges are arranged at different intervals in a fault broken zone section and a fault broken zone affected section. Prestress steel bars are annularly arranged in the section inner linings of the tunnel, the annular flexible hinges are composed of corrugated steel pipes, rubber cushion layers, steel bar nets and flexible anti-crack concrete layers from the inner wall of a tunnel lining outwards. The corrugated steel pipes and the section inner linings are connected through the prestress steel bars. The tunnel waterproof effect is ensured through multi-layer waterproof measures, and PVC waterproof plates, geomembranes and back-attached-type water stop straps are included. An ultrahigh-toughness cement-based composite material is selected for the flexible anti-crack concrete layers and has good anti-permeability and durability. A diastrophism quantity generated by a movable fault is met, the safety ofthe tunnel crossing the movable fault is ensured, local damage to the annular flexible hinges is easy to rapidly repair, and the normal using function of the tunnel can be ensured after diastrophismof the movable fault.

Owner:BEIJING UNIV OF TECH

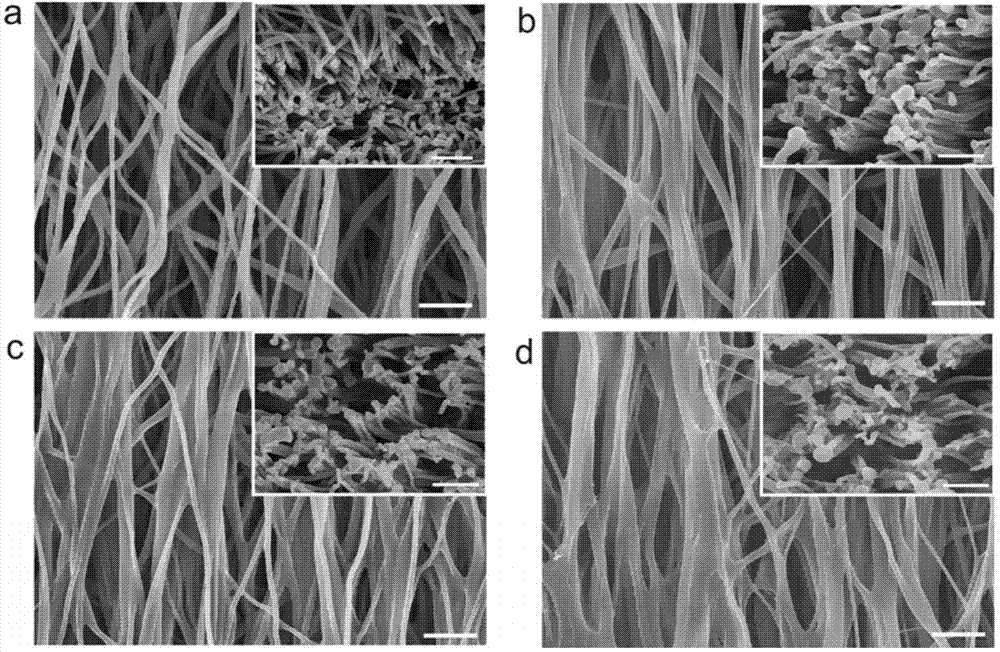

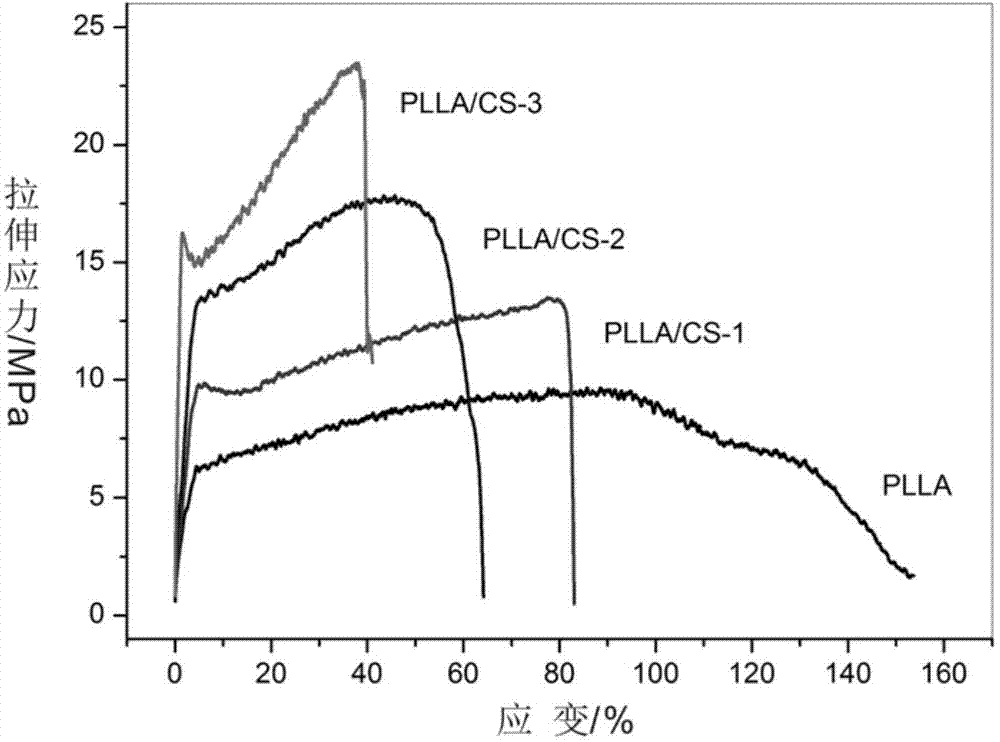

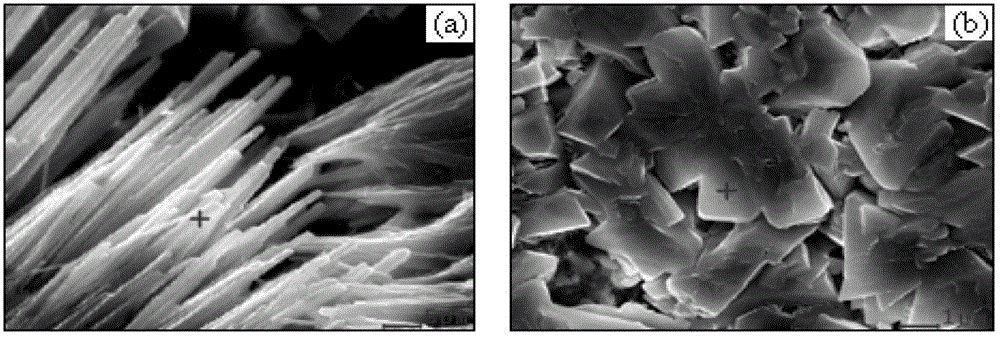

Polylactic acid-chitosan composite nerve conduit and preparation method thereof

InactiveCN103751839AKeep the clock throughHigh tensile strengthFibre typesProsthesisFiberPeripheral neuron

Belonging to the technical field of medical biomaterials, the invention in particular relates to a polylactic acid-chitosan composite nerve conduit. The composite nerve conduit is composed of oriented polylactic acid electrospun fiber and a chitosan layer wrapping the fiber. The invention also provides a preparation method of the polylactic acid / chitosan composite nerve conduit, and application of the nerve conduit in preparation of peripheral nerve defect repair materials. The polylactic acid-chitosan composite nerve conduit prepared by the invention has excellent biomechanical properties and superior hydrophilcity, also has good biological tissue compatibility, can significantly promote the attachment, migration and proliferation of Schwann cells, is easy to cut and preserve, and is simple to operate during clinical use, thus having good clinical application prospects in the peripheral nerve damage repair field.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Industrial construction method for multistory residence system with clamp die frame core wall self-bearing structure

ActiveCN102140842AImprove insulation effectLight weightWallsBuilding material handlingIndustrial constructionEarthquake resistance

The invention relates to an industrial construction method for a multistory residence system with a clamp die frame core wall self-bearing structure. The construction of a bearing wall comprises the following steps of: (1) pre-embedding connecting steel bars on a footing of the bearing wall and a concrete foundation beam; (2) arranging a precast wall plate with a light core material between the connecting steel bars of the foundation beam in an aligned mode; (3) respectively arranging the stressed steel bars of a constructional column and a beam, respectively connecting the connecting steel bars of the constructional column and the beam, and arranging the clamp dies of the constructional column and the beam to ensure that the left and right ends and / or the upper end of the wall plate is coated in the clamp die of the constructional column and / or the clamp die of the beam; and (4) spraying concrete onto surfaces on the two sides of the wall plate, and casting the constructional column and the beam in situ. By the construction method, a large number of templates can be saved, the construction speed is obviously increased, the construction period is shortened, cost is reduced, the strength, impact resistance, earthquake resistance and overall performance of the constructed multistory residence system are obviously improved, the dead weight of the system is reduced, and the systemhas good energy conversation, heat insulation and sound insulation effects.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

Method of radially expanding a tubular element

ActiveUS8056642B2Effectively turned insideLittle strengthDrilling rodsUnderground chambersEngineeringWellbore

Owner:SHELL OIL CO

Calcium phosphate composite material for filling root canal and preparation method thereof

ActiveCN103142418AEasy to operateGood injectabilityImpression capsDentistry preparationsHydration reactionMagnesium phosphate

The invention provides a calcium phosphate composite material for filling a root canal. The composite material consists of a solid-phase component and a liquid-phase component, wherein the solid-phase component is a mixture of calcium phosphate, magnesium oxide, soluble hydrophosphate and iodoform; and the liquid-phase component is an aqueous solution of sugar, hydrophosphate and citric acid. The invention also provides a method for preparing the composite material. In the composite material, the injection property and collapse resistance of the composite material can be improved by the gelation of the sugar in the liquid-phase component and the chelation of inorganic ions in the solid-phase component, the magnesium phosphate generated by a hydration reaction has relatively strong adhesive force, the bonding strength between the root filling material and the root canal wall can be promoted, and leakage is avoided; and the iodoform can be used for enhancing the X-ray opacity and diminish inflammation to improve the curative effect of root canal therapy.

Owner:厦门百美特生物材料科技有限公司

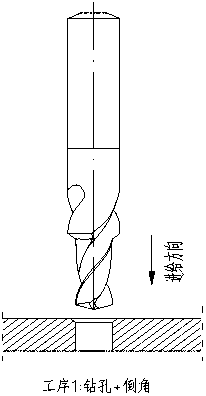

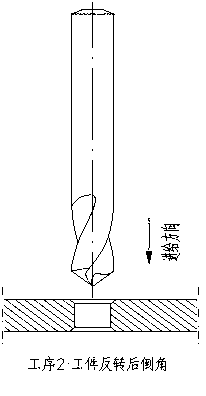

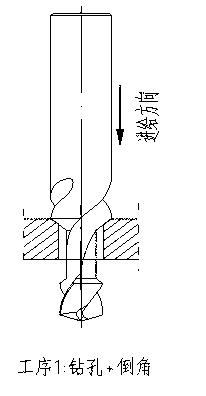

Positive-negative chamfering drilling bit used for processing of plate parts

InactiveCN103157836AImprove processing efficiencyGuaranteed machining accuracyTransportation and packagingTrepanning drillsEngineeringDuring feed

The invention relates to a positive-negative chamfering drilling bit used for processing of plate parts. The positive-negative chamfering drilling bit used for the processing of the plate parts comprises a handle portion, a neck portion and a head portion, the head portion, the neck portion and the handle portion are coaxial cylinder bodies taking the same central axis as the center, scrap discharge grooves are arranged on the head portion and the neck portion, an entity portion except the scrape discharge grooves is a tool back, a main cutting edge, a negative cutting edge and a positive cutting edge are respectively arranged at positions of the head end face, the middle and the tail end face of the scrape discharge grooves, the main cutting edge is used for drilling the plate parts by drilling a hole, the positive cutting edge processes the an inlet chamfer of a through hole during feeding for the first time, and after the inlet chamfer is processed, the tool is retracted to the position of the negative chamfer edge to mill an outlet chamfer of the through hole out. The positive-negative chamfering drilling bit used for the processing of the plate parts achieves composite processing of drilling, chamfering and negative-chamfering.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

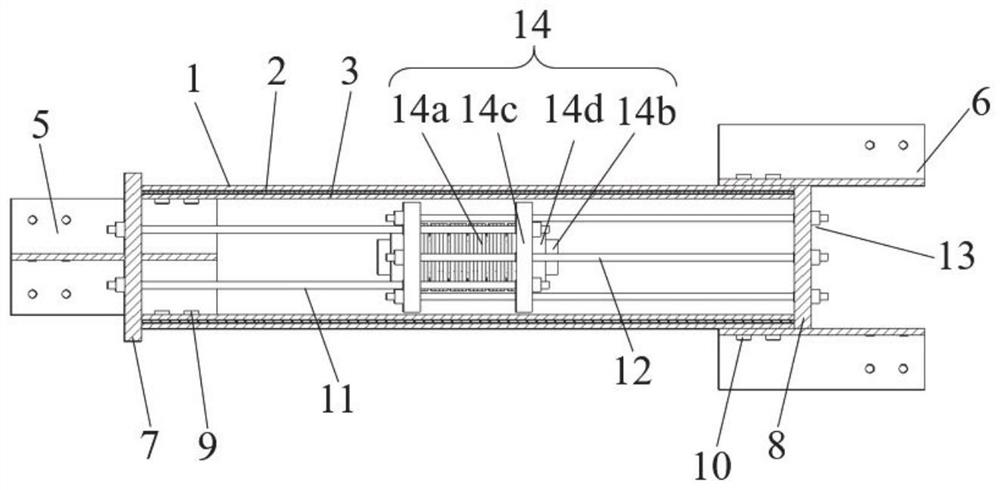

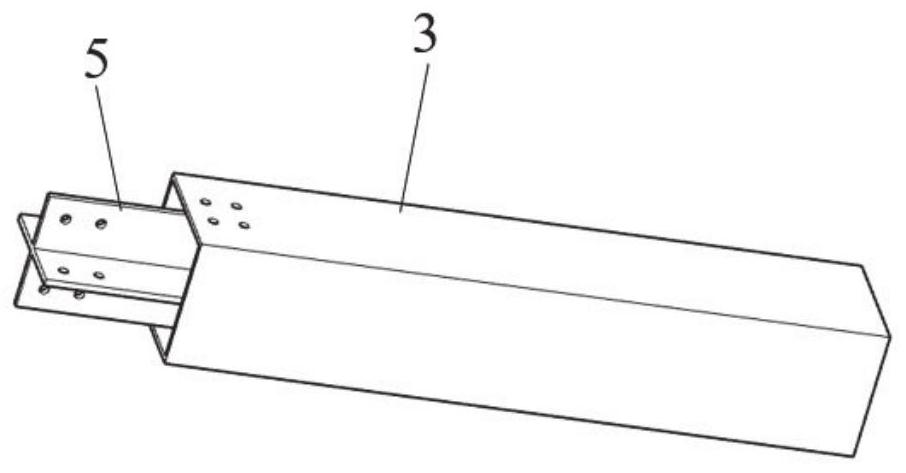

Assembly type self-resetting buckling restrained brace

InactiveCN112982707AReduce dosageStable supportProtective buildings/sheltersShock proofingBuckling-restrained bracePre stress

The invention relates to an assembly type self-resetting buckling restrained brace. The assembly type self-resetting buckling restrained brace mainly comprises an energy-consuming inner core, an inner pipe, an outer pipe, a connecting piece, an end plate, two groups of prestressed steel strands and a disc spring resetting device. The inner pipe and the outer pipe are force transmission parts of a resetting system and are also restraining parts of the energy-consuming inner core, so that the energy-consuming inner core does not need to be independently provided with the restraining parts, and the material consumption is reduced; the energy-consuming inner core is connected with the inner pipe and the outer pipe through self-tapping screws, so that the brace is convenient to assemble and replace after an earthquake; the resetting system is formed by connecting the two groups of prestressed steel strands and the disc spring resetting device in series, so that the deformation capability of the brace is greatly enhanced; after a disc spring combination in the resetting system is pressed under the action of external force, the supporting rigidity is increased, so that deformation concentration among structural layers can be prevented, the deformation among the structural layers is more uniform, and the collapse resistance of the structure under the action of a rare earthquake or even a very rare earthquake is effectively improved.

Owner:TONGJI UNIV

Drilling fluid for drilling of fractured igneous rock formation and preparation method of drilling fluid

The invention relates to a drilling fluid for drilling of a fractured igneous rock formation and a preparation method of the drilling fluid in the field of petroleum drilling. The drilling fluid is prepared from components in parts by weight as follows: 1,000 parts of water, 3-4 parts of drilling fluid bentonite, 2-3 parts of sodium carbonate, 2-3 parts of a polymer coating agent, 2-3 parts of potassium polyacrylate or a metal cation polymer, 5-10 parts of an organic amine inhibitor, 20-30 parts of an anti-sloughing reinforced wall fixation agent, 20-30 parts of sulfonated phenol formaldehyderesin, 5-10 parts of a sulfonate copolymer filtrate reducer, 20-30 parts of walchowite, 10-20 parts of an anti-salt and temperature-resistant fluid loss agent, 20-40 parts of superfine calcium carbonate, 50-70 parts of potassium chloride, 0-10 parts of an organic anti-friction compound and 10-20 parts of a nano-micro blocking agent, and the weight is increased to 1.30-1.85 g / cm<3> with a density weighting agent. The drilling fluid has good temperature resistance and lubricating property and excellent inhibition property and anti-sloughing wall fixation property and can effectively prevent thefractured igneous rock formation from collapsing; the rock carrying capability of the drilling fluid can be substantially improved, repeated grinding of larger falling blocks nearby a drill bit is prevented, the frictional resistance is reduced, the mechanical drilling speed is increased, and underground safety is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Organic anti-reflective coating composition and method for forming photoresist pattern using the same

InactiveUS20050112497A1Effectively and prevent collapseWithout reducing sensitivityX-ray/infra-red processesPhoto-taking processesResistAnti-reflective coating

Disclosed are an organic anti-reflective coating composition and a method for forming a photoresist pattern using the same in order to improve uniformity of the pattern in an ultra-fine pattern formation process of the photoresist. The organic anti-reflective coating composition is able to prevent excessive generation of acid in a portion to be exposed to light caused by a photo acid generator contained in a photoresist film during a photoresist pattern formation process by means of exposure to light, in turn, to inhibit such acid from diffusing up to the other portion not to be exposed to light to lead to damage or collapse of the photoresist pattern.

Owner:SK HYNIX INC

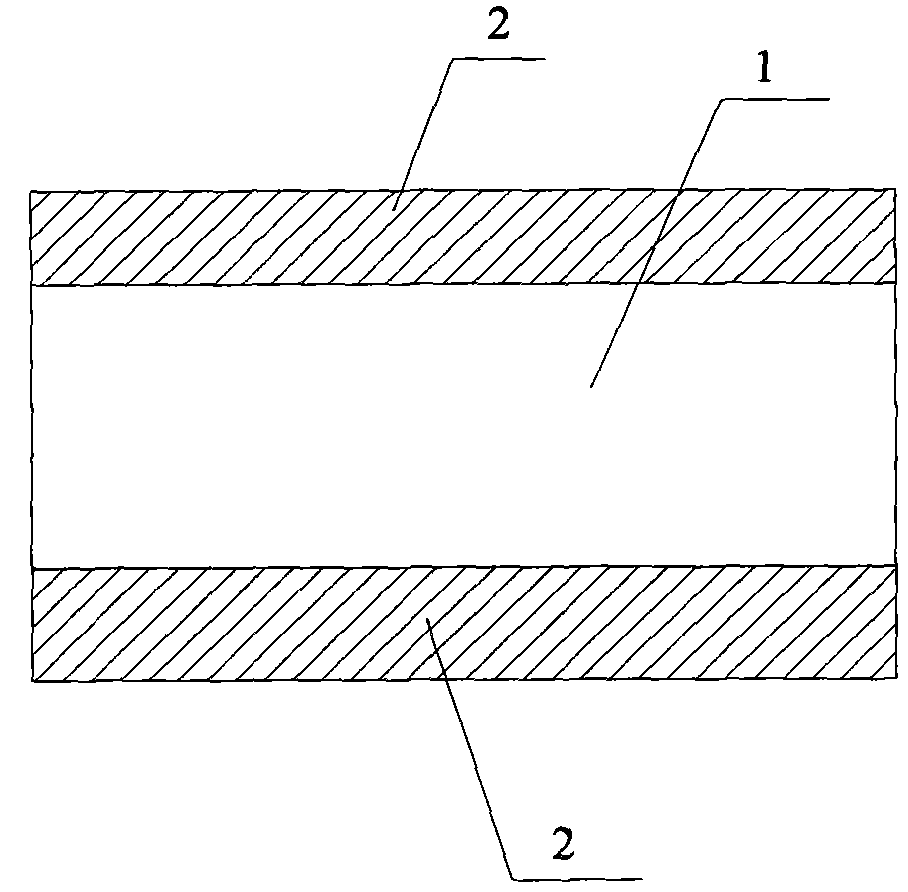

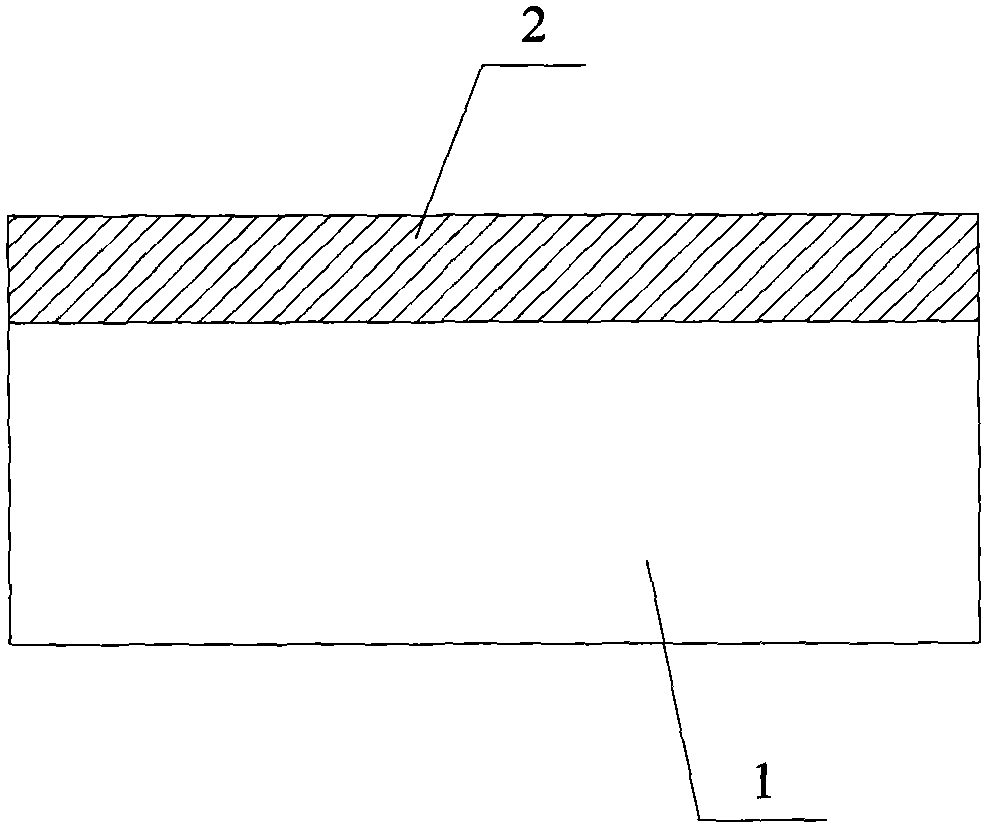

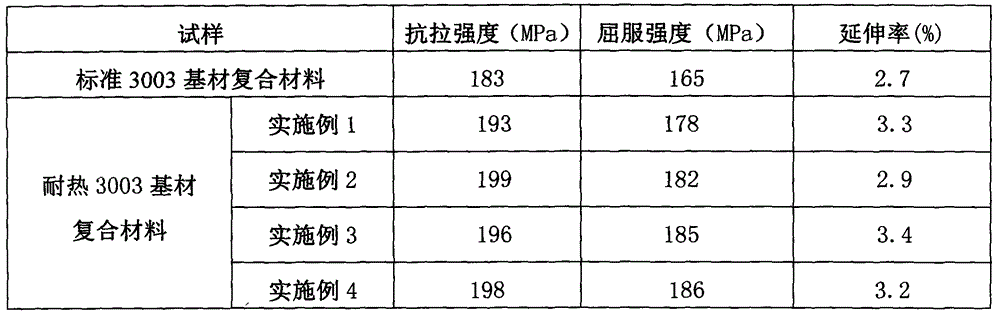

Heat-resistant aluminum alloy soldering composite material and preparation method thereof

InactiveCN105880866AGood molding effectEasy to weldWelding/cutting media/materialsSoldering mediaSolderingMechanical property

The invention discloses a heat-resistant aluminum alloy soldering composite material. The heat-resistant aluminum alloy soldering composite material comprises a core and skin, wherein the core is covered with the skin. The core is 3003 aluminum alloy. The skin is 4343 or 4045 or 4104 or 4004 aluminum alloy. Meanwhile, the invention discloses a preparation method of the heat-resistant aluminum alloy soldering composite material. Compared with an ordinary aluminum alloy soldering composite material, the heat-resistant aluminum alloy soldering composite material prepared through the method is optimized and improved on the aspect of the mechanical property, the formability of ultra-thin composite materials is improved, and the collapse resistance is improved.

Owner:JIANGSU CAIFA ALUMINUM

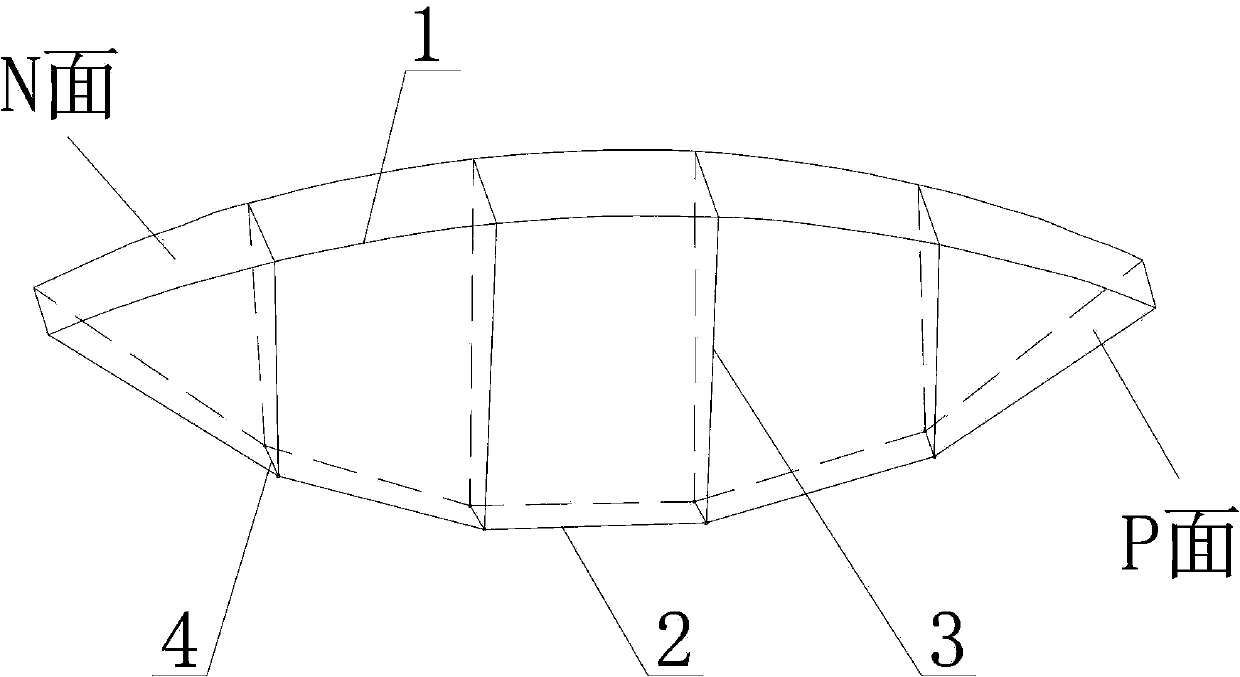

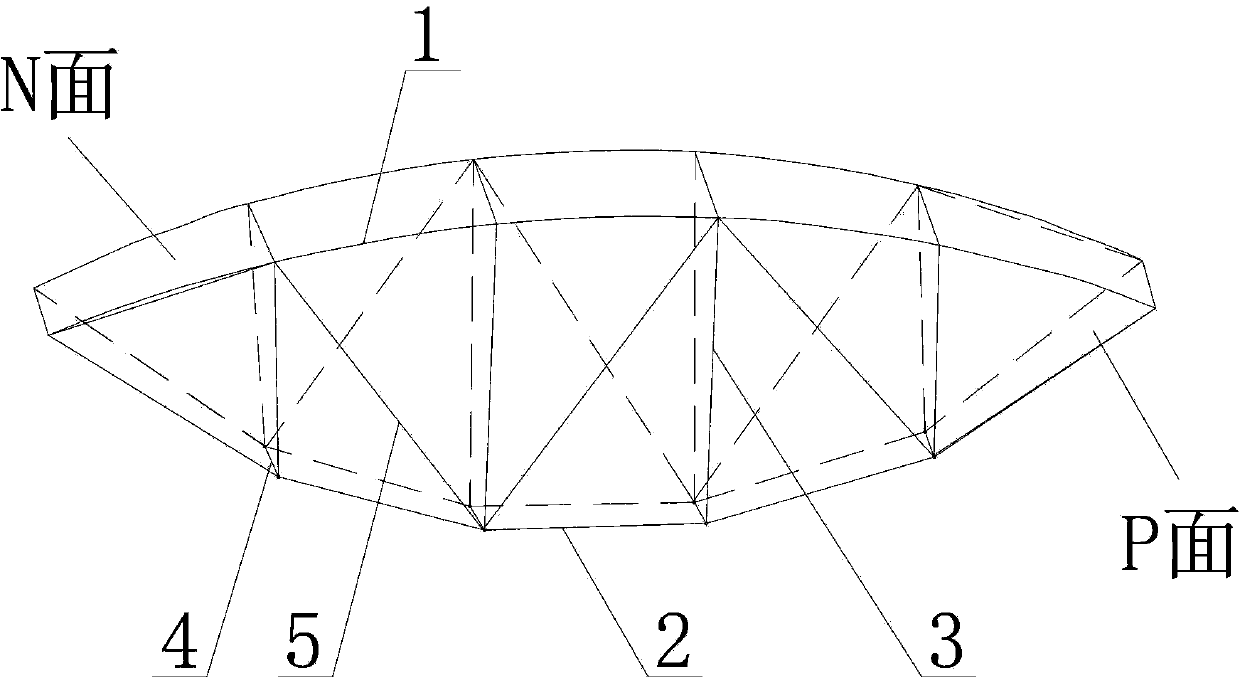

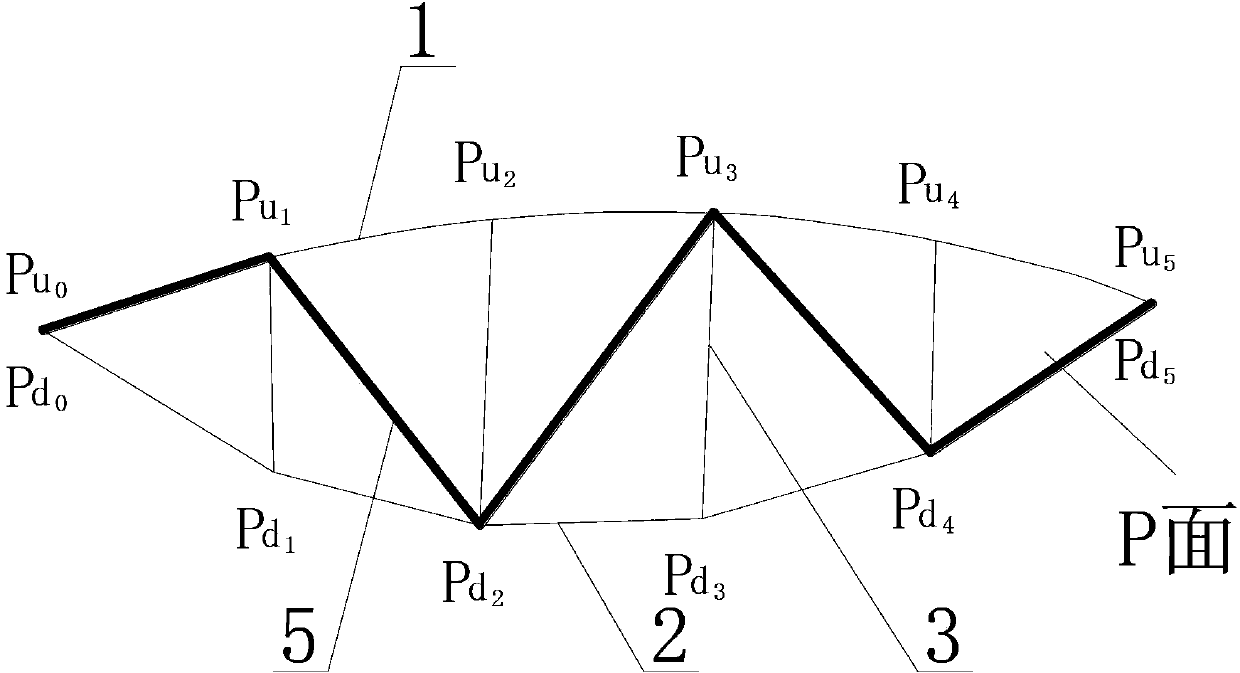

Beam string structure

ActiveCN103362213AImprove collapse resistancePrevent progressive collapseBuilding constructionsEngineeringFace structure

Owner:SOUTHEAST UNIV

Anti-dripping transparent flame-retardant TPU material and preparation method thereof

The invention discloses an anti-dripping transparent flame-retardant TPU material and a preparation method thereof. The effects that halogen-free flame retardants DIDOPO have high flowability; when the DIDOPO is used for achieving flame-retardant effects on the TPU, the TPU / DIDOPO flame-retardant material has excellent flame-retardant performance; the transparency of the TPU / DIDOPO flame-retardant material is not influenced; meanwhile, after the addition of transparent synergists, the flame-retardant synergistic effect is achieved on the TPU / DIDOPO flame-retardant material; meanwhile, the anti-reflection effect is achieved on the TPU / DIDOPO flame-retardant material, but the TPU / DIDOPO flame-retardant material can easily drip and fall are discovered. Therefore, the applicant discovers that the anti-dripping agent PTFE achieves an anti-dripping effect through the heated shrinkage by using the fibrillation of polytetrafluoroethylene polymers in the plastic processing process through the study; the flame spreading is reduced. When the anti-dripping agent PTFE is added into the TPU / DIDOPO flame-retardant material, the melt strength and the collapse resistance performance of the polymers are improved, so that the flame-retardant and anti-dripping performance of the TPU / DIDOPO is improved.

Owner:JIANGLIN GUIZHOU HI TECH DEV CO LTD

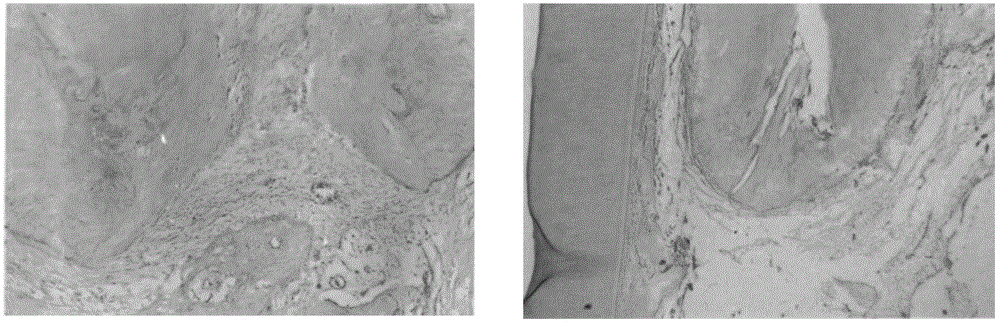

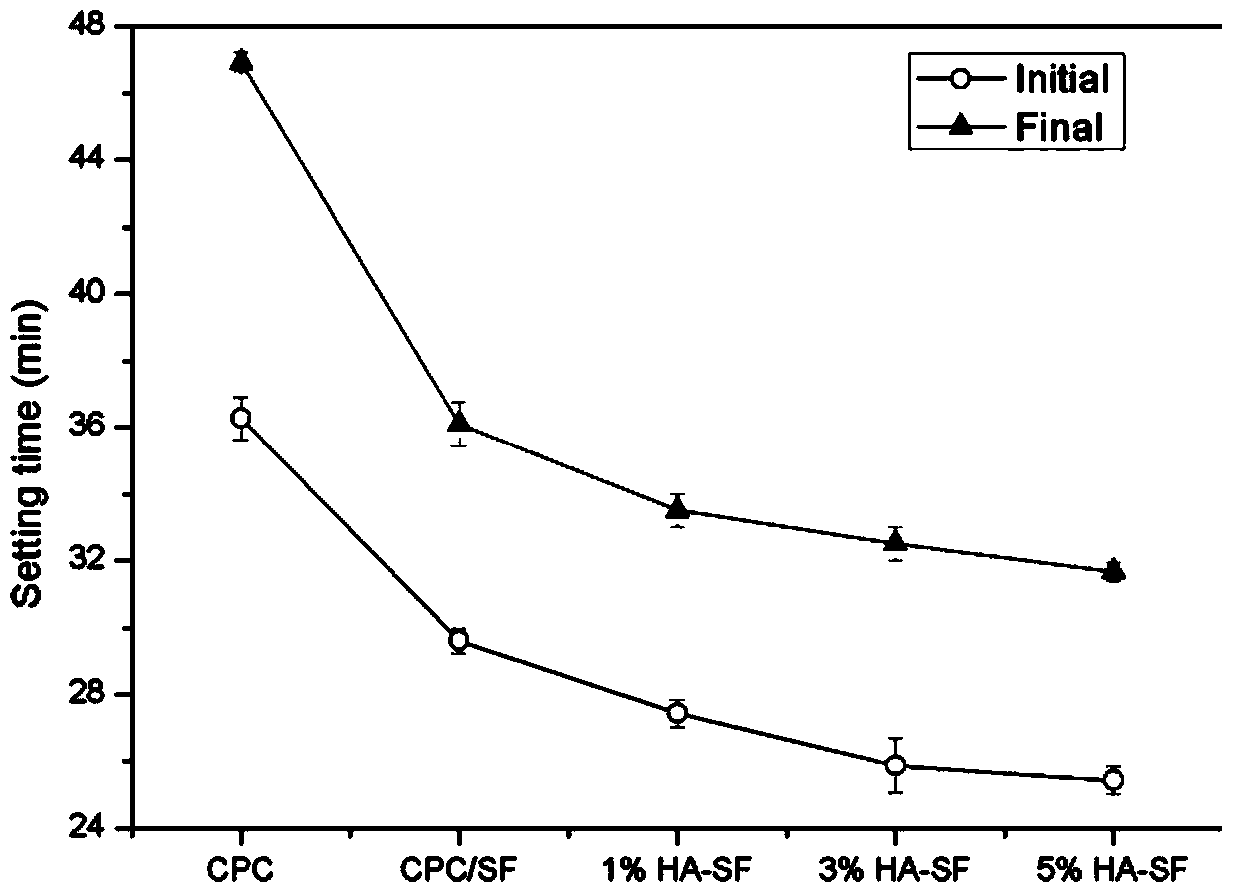

Hydroxyapatite-silk fibroin composite reinforced calcium phosphate bone cement and preparation method thereof

InactiveCN104043149AImprove mechanical propertiesImprove interface compatibilityProsthesisCalcium biphosphateApatite

The invention discloses a hydroxyapatite-silk fibroin (HA-SP) composite reinforced calcium phosphate bone cement and a preparation method thereof. The preparation method comprises the following steps: doping the calcium phosphate bone cement powder with 1-4wt.% of hydroxyapatite-silk fibroin composite, taking a silk fibroin solution as a blending solution and carrying out blending in a liquid-solid ratio L / P=0.33-0.4mL / g, and solidifying to obtain the hydroxyapatite-silk fibroin composite reinforced calcium phosphate bone cement. The hydroxyapatite-silk fibroin composite adopted in the preparation of the calcium phosphate bone cement is capable of effectively improving the interface compatibility of organic and inorganic phases and increasing the interface bonding force in the calcium phosphate bone cement / silk fibroin (CPC / SF) system, and thus capable of improving the mechanical properties of the calcium phosphate bone cement; the silk fibroin solution is taken as the solidifying solution so that the collapse resistance of the calcium phosphate bone cement can be effectively improved; the mechanical properties of the bone cement are improved to meet the basic requirements of clinical application.

Owner:SUZHOU UNIV

Compound bone cement, preparation method and application of compound bone cement, and bone repair material

ActiveCN108273131APromote differentiationRegulation of adhesionAntibacterial agentsOrganic active ingredientsDiseaseCell adhesion

The invention discloses compound bone cement, a preparation method and application of the compound bone cement, and a bone repair material. The compound bone cement is prepared by mixing the followingraw materials in percentage by mass: 50-80% of solid phase powder and 20-50% of setting liquid, wherein the solid phase powder comprises phosphate and / or acidic salt of phosphoric acid; the setting liquid comprises chitosan, hyaluronic acid, organic acids and water. The compound bone cement has excellent syringeability, biological activity and bone conduction and repair ability, the set bond repair material has an excellent mechanical property, the surface of the material is easy for cell adhesion, and the cell differentiation ability cannot be influenced. The compound bone cement disclosed by the invention can be used for bone defect filling and repairing and serves as a drug carrier to be used for treating orthopedic related diseases.

Owner:深圳市中科海世御生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com