Anti-dripping transparent flame-retardant TPU material and preparation method thereof

An anti-dripping and anti-dripping agent technology, applied in the field of polymer materials, can solve the problem of TPU resin not being transparent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

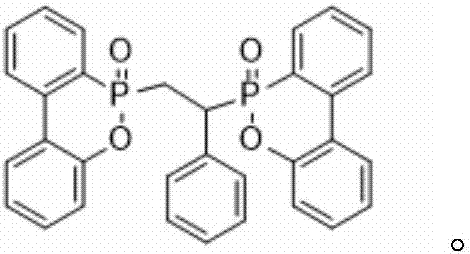

[0014] Embodiment 1 of the present invention: anti-dripping transparent flame-retardant TPU material, calculated in parts by mass, including 94 parts of thermoplastic polyurethane elastomer, 6 parts of flame retardant DIDOPO, 0.2 part of anti-dripping agent, 0.5 part of antioxidant and 0.1 part of transparent flame retardant synergist is the raw material for preparation; the anti-dripping agent is anti-dripping agent PTFE; the antioxidant is antioxidant 1010; the transparent flame retardant synergist is organic silicon Flame retardant synergist; the flame retardant DIDOPO is a phenylethyl bridged chain 9'10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide; the melting temperature of DIDOPO is 180°C, The decomposition temperature is 360°C, and the structural formula of DIDOPO is:

[0015]

[0016] The preparation method of anti-dripping transparent flame-retardant TPU material, according to the above-mentioned parts by weight, take thermoplastic polyurethane elastomer, DIDOPO, ...

Embodiment 2

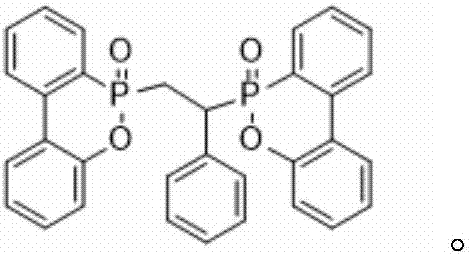

[0017] Embodiment 2 of the present invention: anti-dripping transparent flame-retardant TPU material, calculated in parts by mass, including 92 parts of thermoplastic polyurethane elastomer, 8 parts of flame retardant DIDOPO, 0.25 part of anti-dripping agent, 0.5 part of antioxidant and 0.1 part of transparent flame retardant synergist is the raw material for preparation; the anti-dripping agent is anti-dripping agent PTFE; the antioxidant is antioxidant 1010; the transparent flame retardant synergist is organic silicon Flame retardant synergist; the flame retardant DIDOPO is a phenylethyl bridged chain 9'10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide; the melting temperature of DIDOPO is 180°C, The decomposition temperature is 360°C, and the structural formula of DIDOPO is:

[0018]

[0019] The preparation method is the same as in Example 1.

Embodiment 3

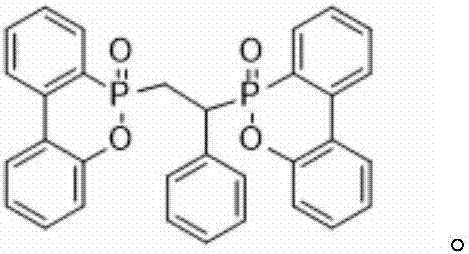

[0020] Example 3 of the present invention: an anti-dripping transparent flame-retardant TPU material, calculated in parts by mass, including 94 parts of thermoplastic polyurethane elastomer, 6 parts of flame retardant DIDOPO, 0.2 part of anti-dripping agent and 0.5 part of antioxidant; The anti-dripping agent is anti-dripping agent PTFE; the antioxidant is antioxidant 1010; the flame retardant DIDOPO is phenylethyl bridge chain 9'10-dihydro-9-oxa -10-phosphaphenanthrene-10-oxide; the melting temperature of DIDOPO is 180°C, the decomposition temperature is 360°C, and the structural formula of DIDOPO is:

[0021]

[0022] The preparation method is the same as in Example 1, but no transparent flame retardant synergist is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com