Patents

Literature

2941results about How to "Reduce spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

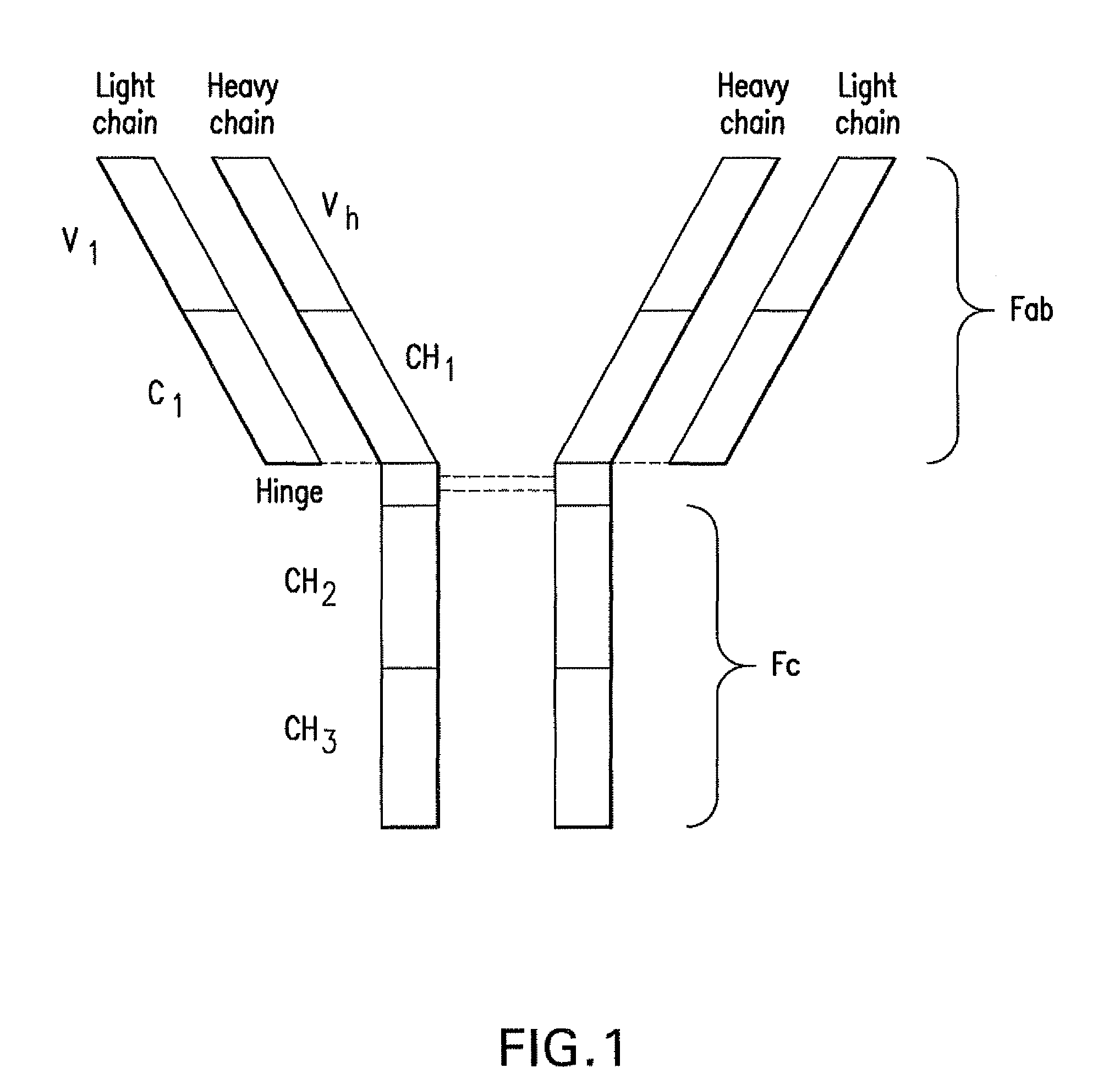

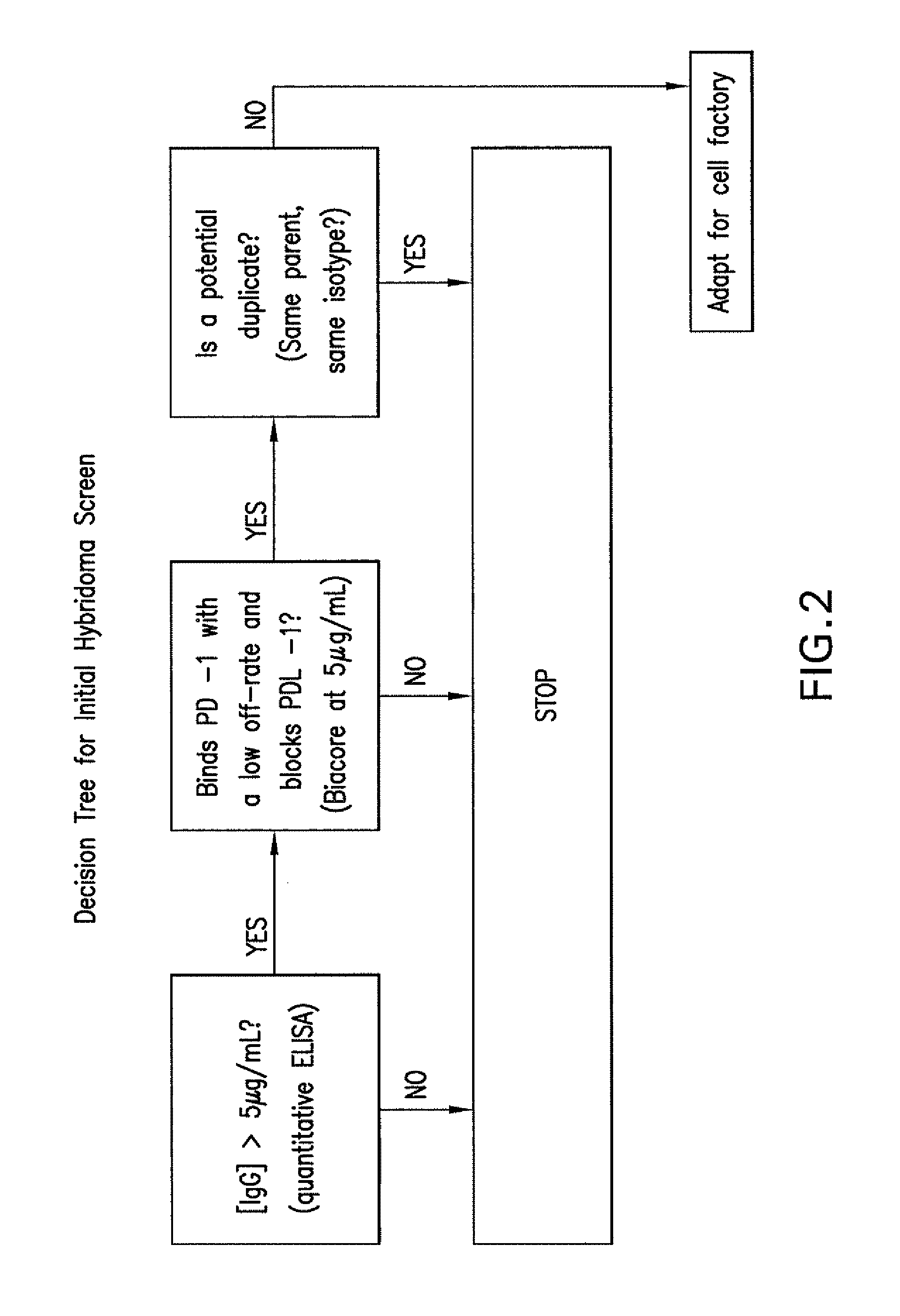

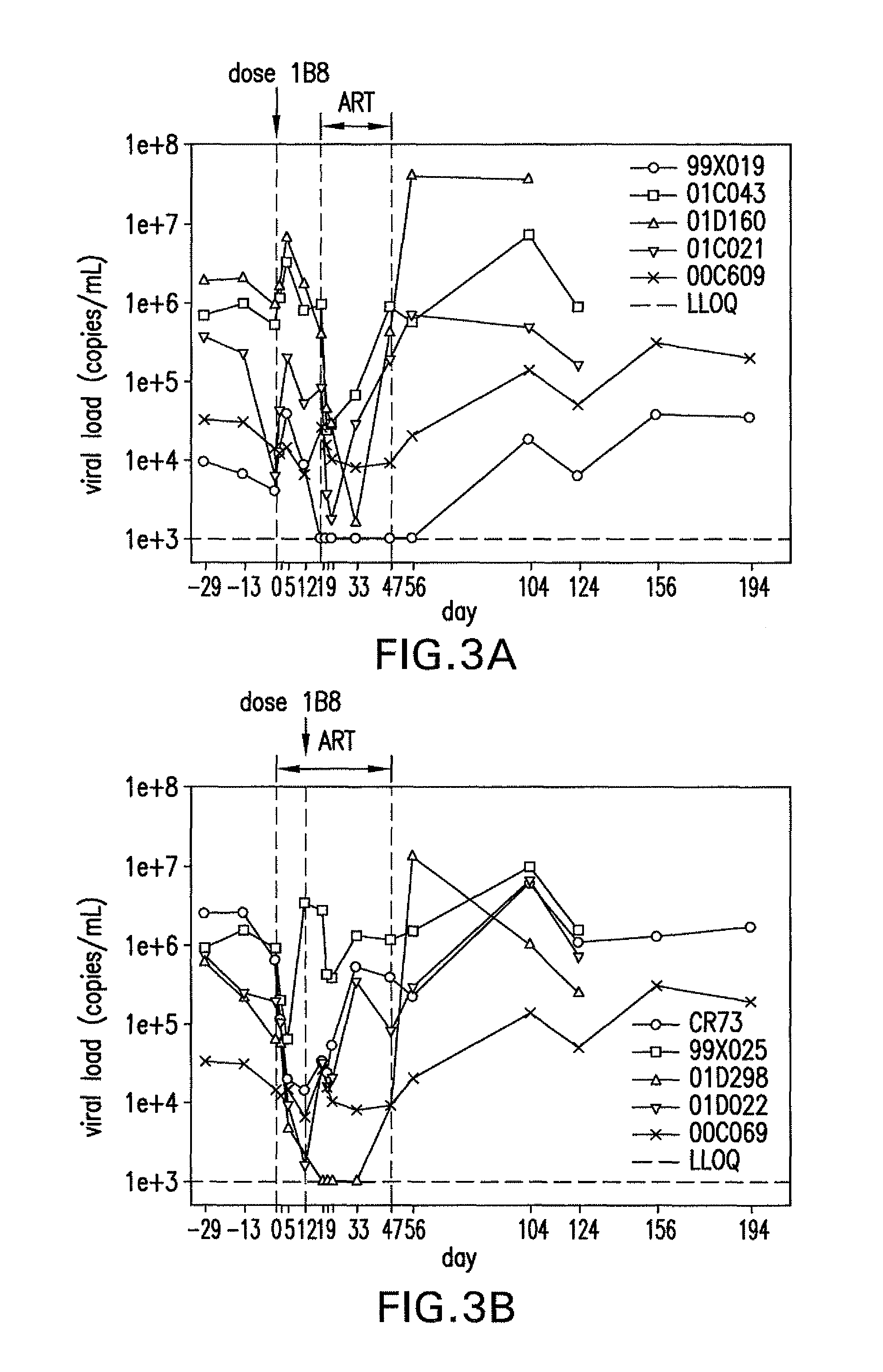

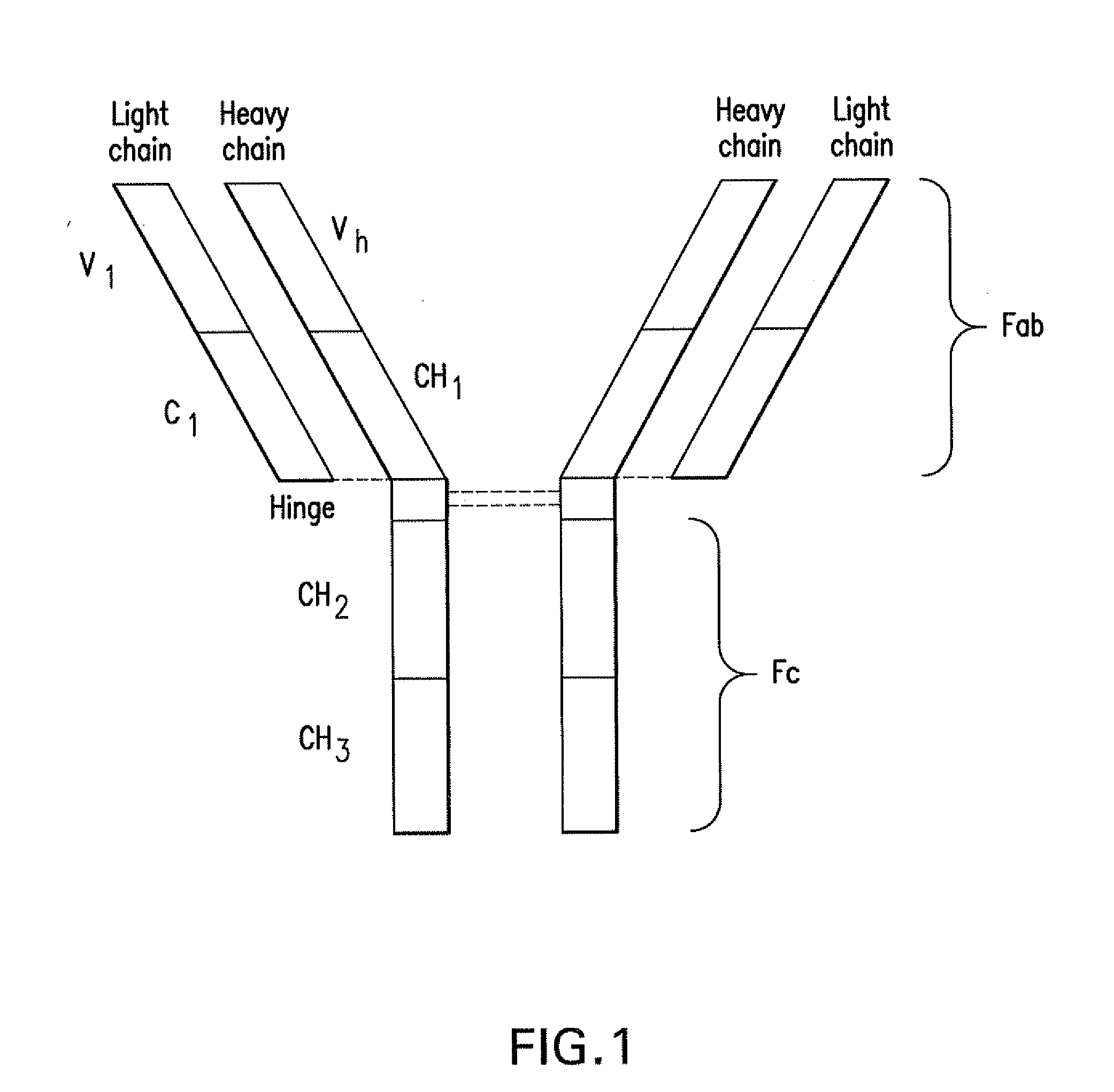

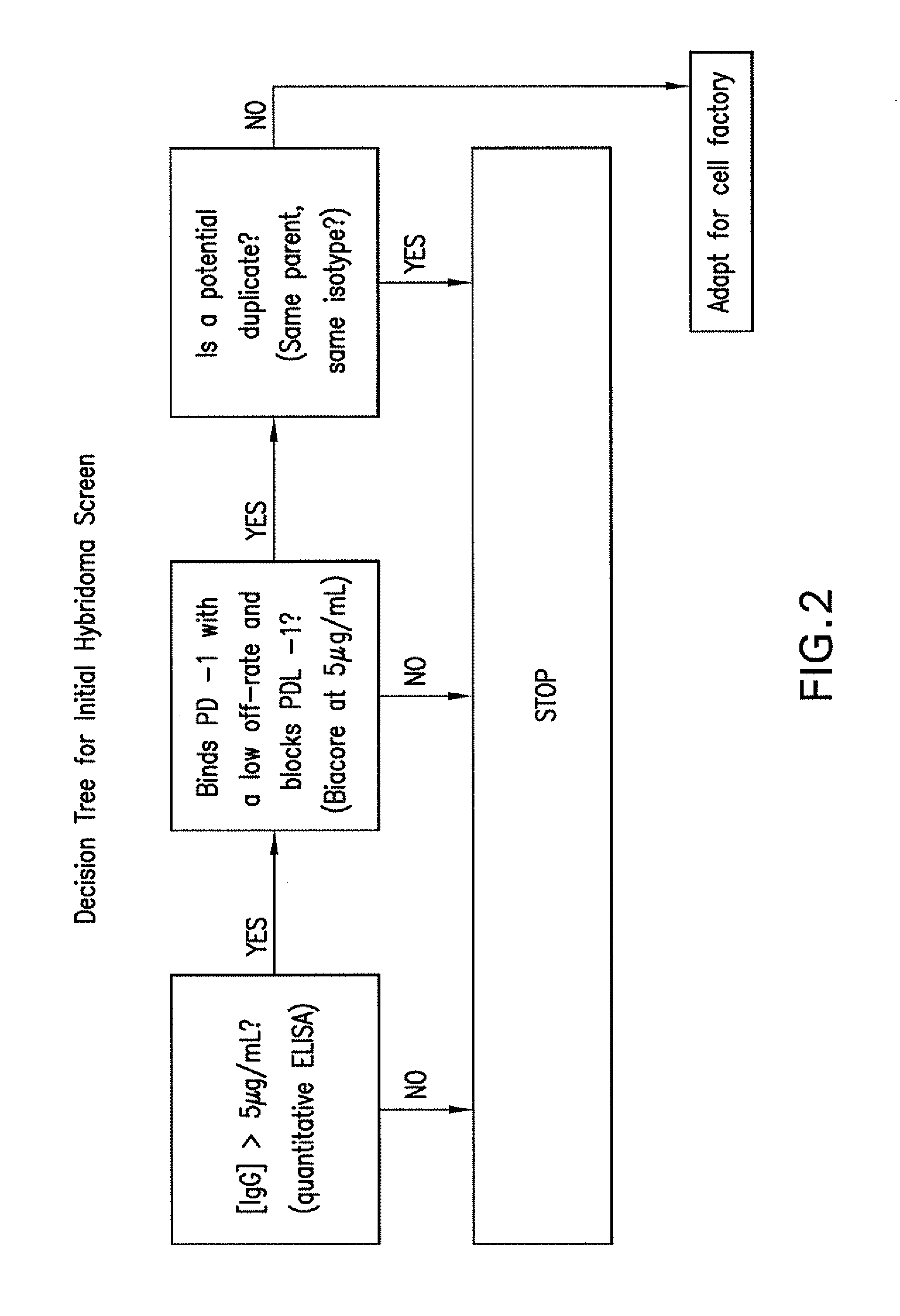

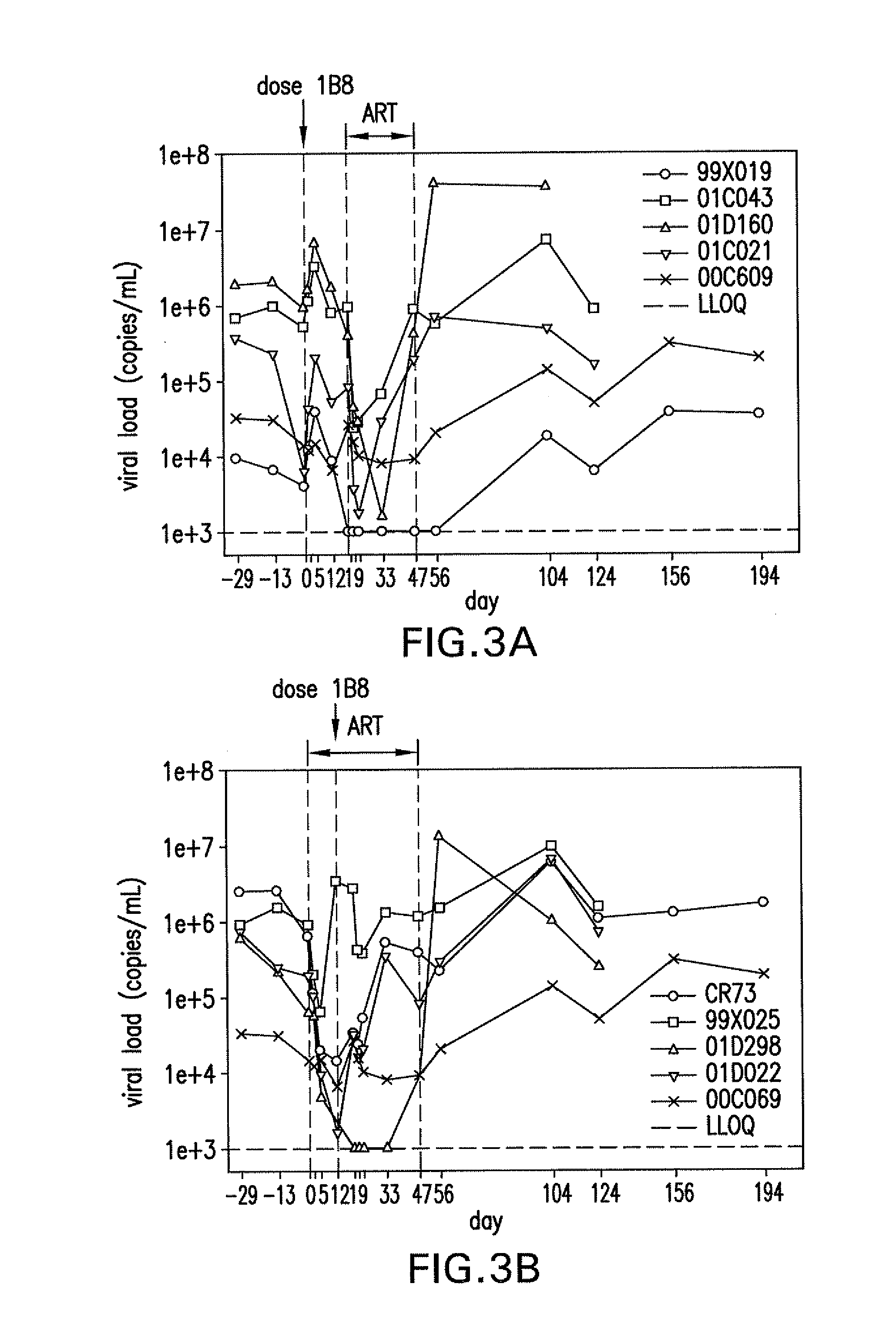

PD-1 binding proteins

ActiveUS8168757B2Regulating T cell responsesImprove immunityAntibody mimetics/scaffoldsAntibody ingredientsHost immunitySignalling pathways

The present invention features PD-1 binding proteins, a subset of which inhibits binding of PD-L1 to the PD-1 receptor. These binding proteins can be employed to modulate the immune system through the manipulation of the PD-1 signaling pathway, enhancing host immunity to treat infections and cancer.

Owner:MERCK SHARP & DOHME LLC

Pd-1 binding proteins

ActiveUS20110008369A1Enhance host anti-microbial immunityImprove immunityAntibody mimetics/scaffoldsImmunoglobulins against animals/humansPD-L1Host immunity

The present invention features PD-1 binding proteins, a subset of which inhibits binding of PD-L1 to the PD-1 receptor. These binding proteins can be employed to modulate the immune system through the manipulation of the PD-1 signaling pathway, enhancing host immunity to treat infections and cancer.

Owner:MERCK SHARP & DOHME LLC

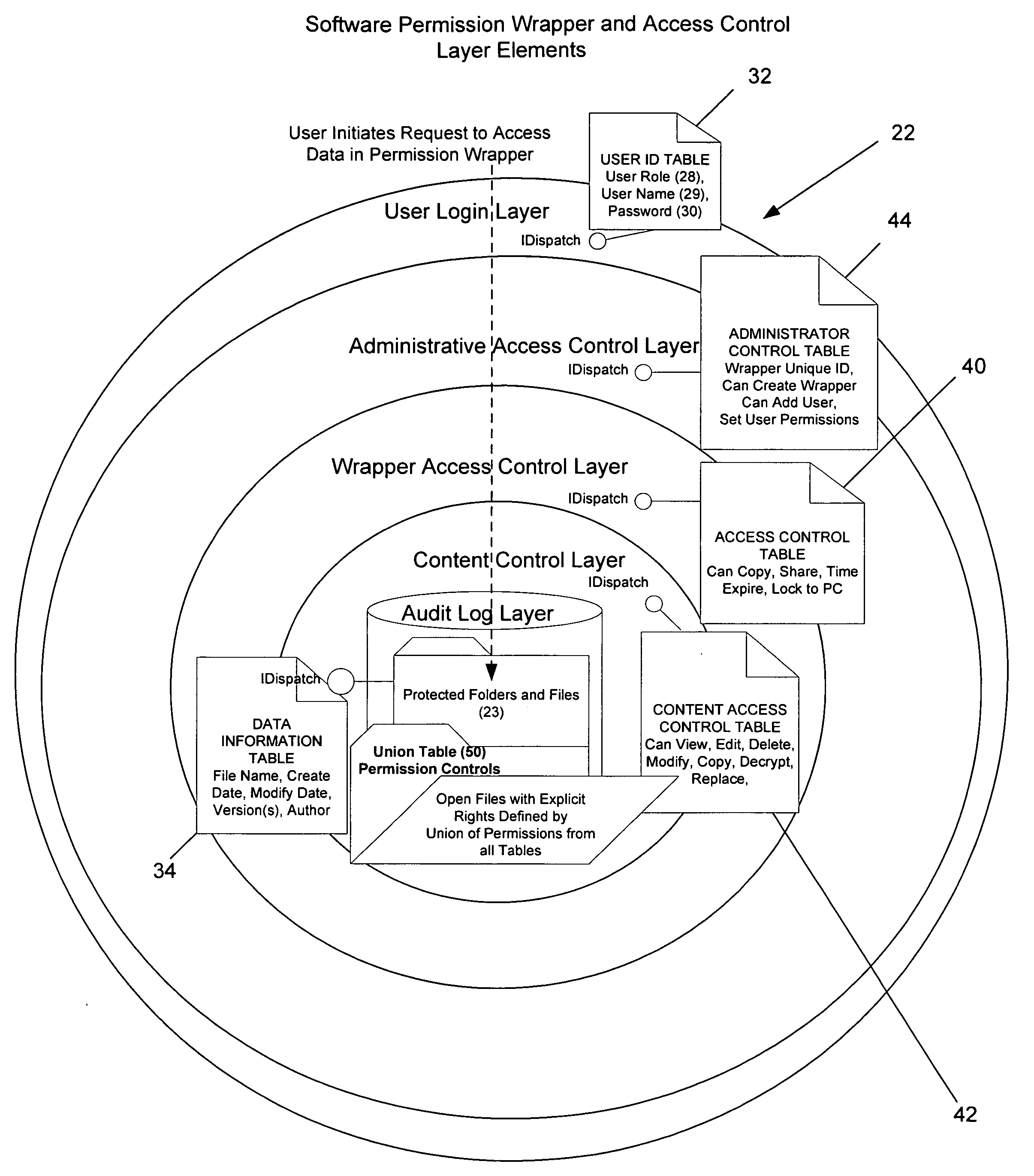

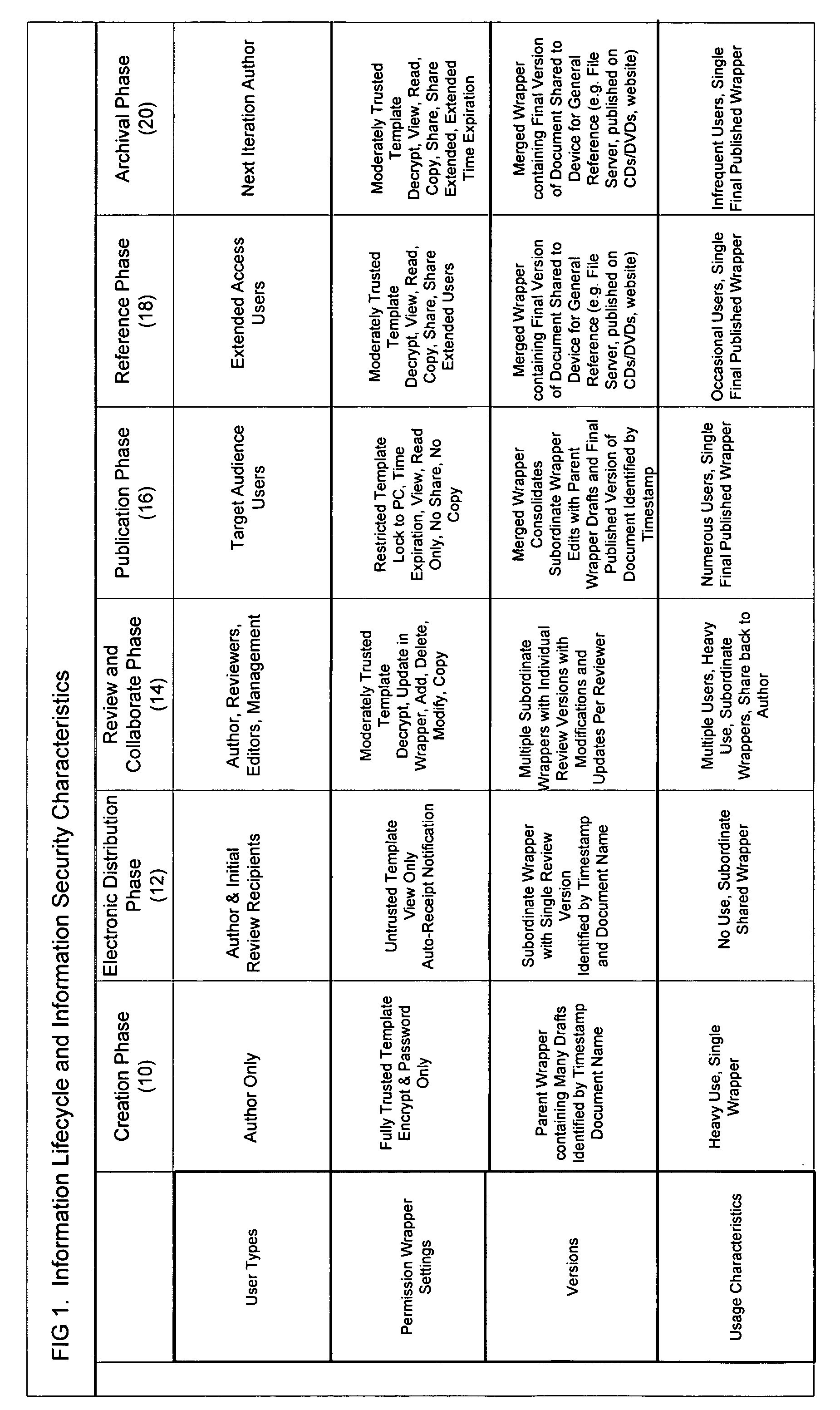

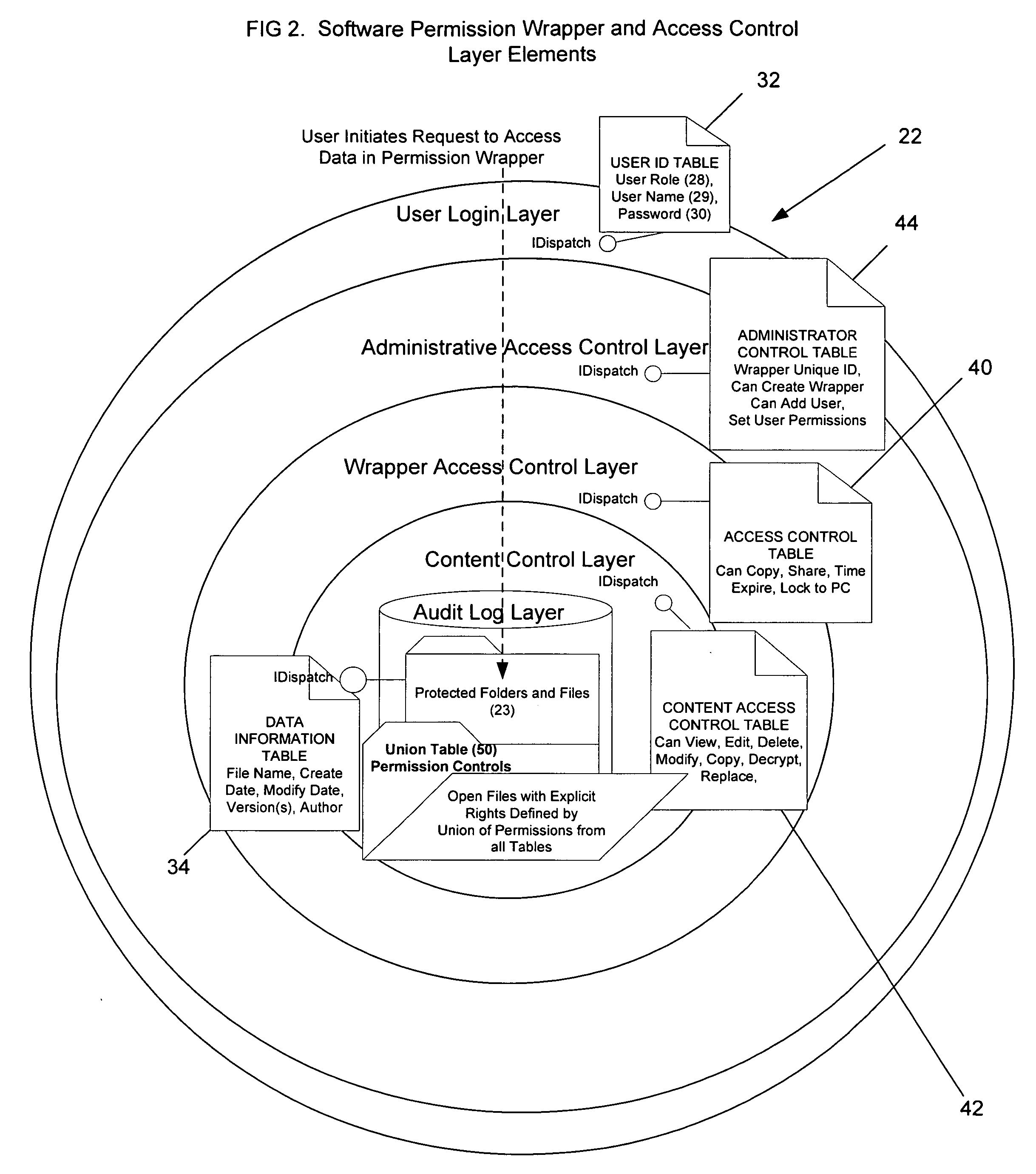

Method and apparatus for automatically detecting sensitive information, applying policies based on a structured taxonomy and dynamically enforcing and reporting on the protection of sensitive data through a software permission wrapper

InactiveUS20060048224A1Reduce spreadMemory loss protectionError detection/correctionInformation controlAutomatic control

The present invention relates to the automatic detection of sensitive digital information, and the identification methods, application and enforcement of information security policies for digital information controlled through a software permission wrapper throughout the useful life of the information. This invention includes a unique taxonomy that defines the policies and rules regarding how the information is controlled automatically throughout its useful lifecycle based on the type of information, the stage of the information lifecycle, the user / group role accessing the information, the locality of the information, and the expected threats to the information. The taxonomy is maintained in a database that associates information security control policies and actions to sensitive data. These policies are enforced through a software permission wrapper that is used to encapsulate sensitive digital information. The software permission wrapper is used to control access and enforce digital rights to the information based on the taxonomy based policies for that information. The permission wrapper can automatically change the protection of the information based on pre-defined protection states that can automatically enforce discretionary access control rights to the sensitive information controlled in the permission wrapper. The changes to the level of protection occur dynamically based on changes in user locality, stage of information lifecycle, and user / group role and the detection of threats. In addition, there is provided an internal audit capability describing what actions the user has performed, where the data is located, with whom and how the data has been shared.

Owner:ENCRYPTX CORP

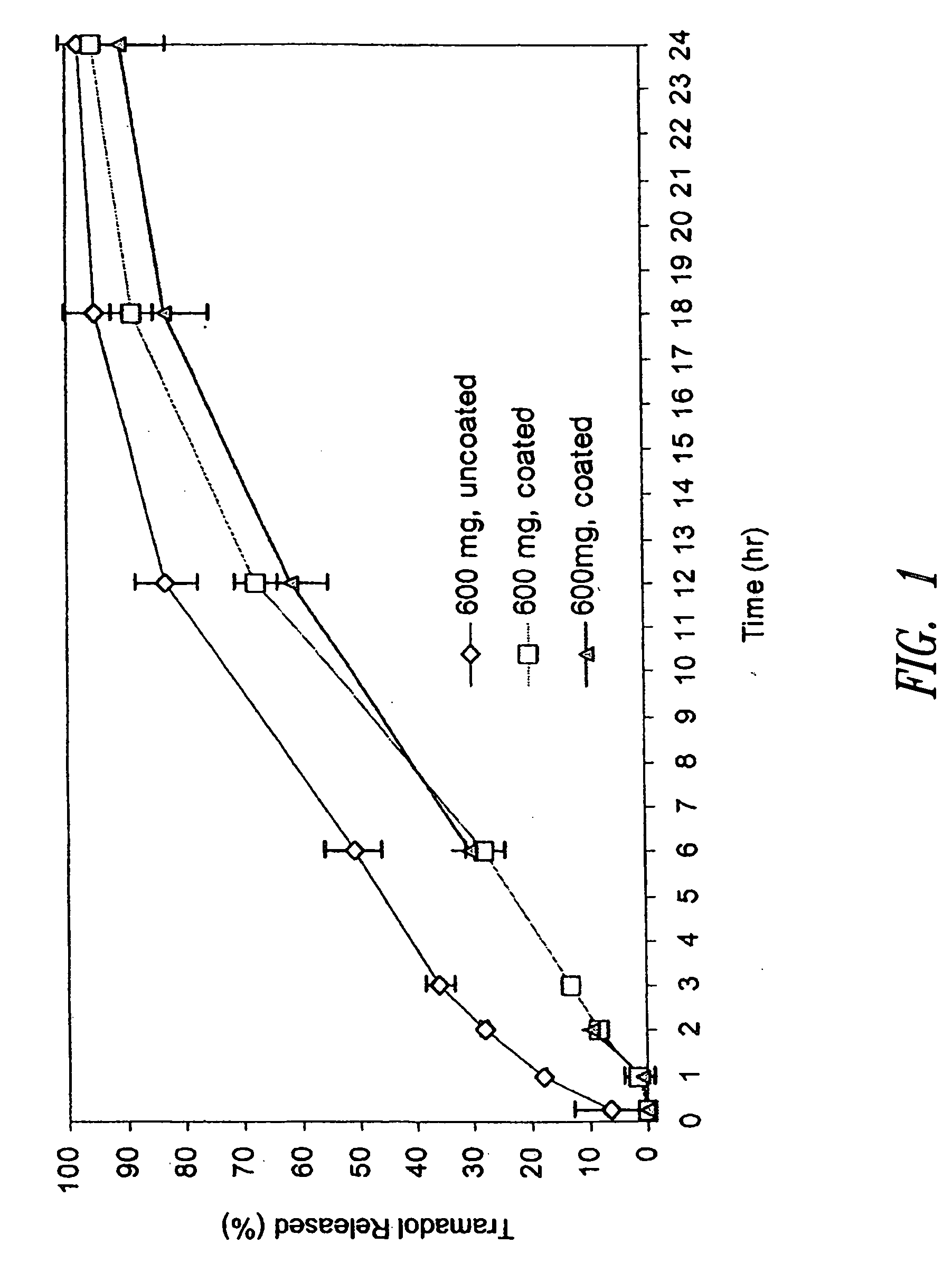

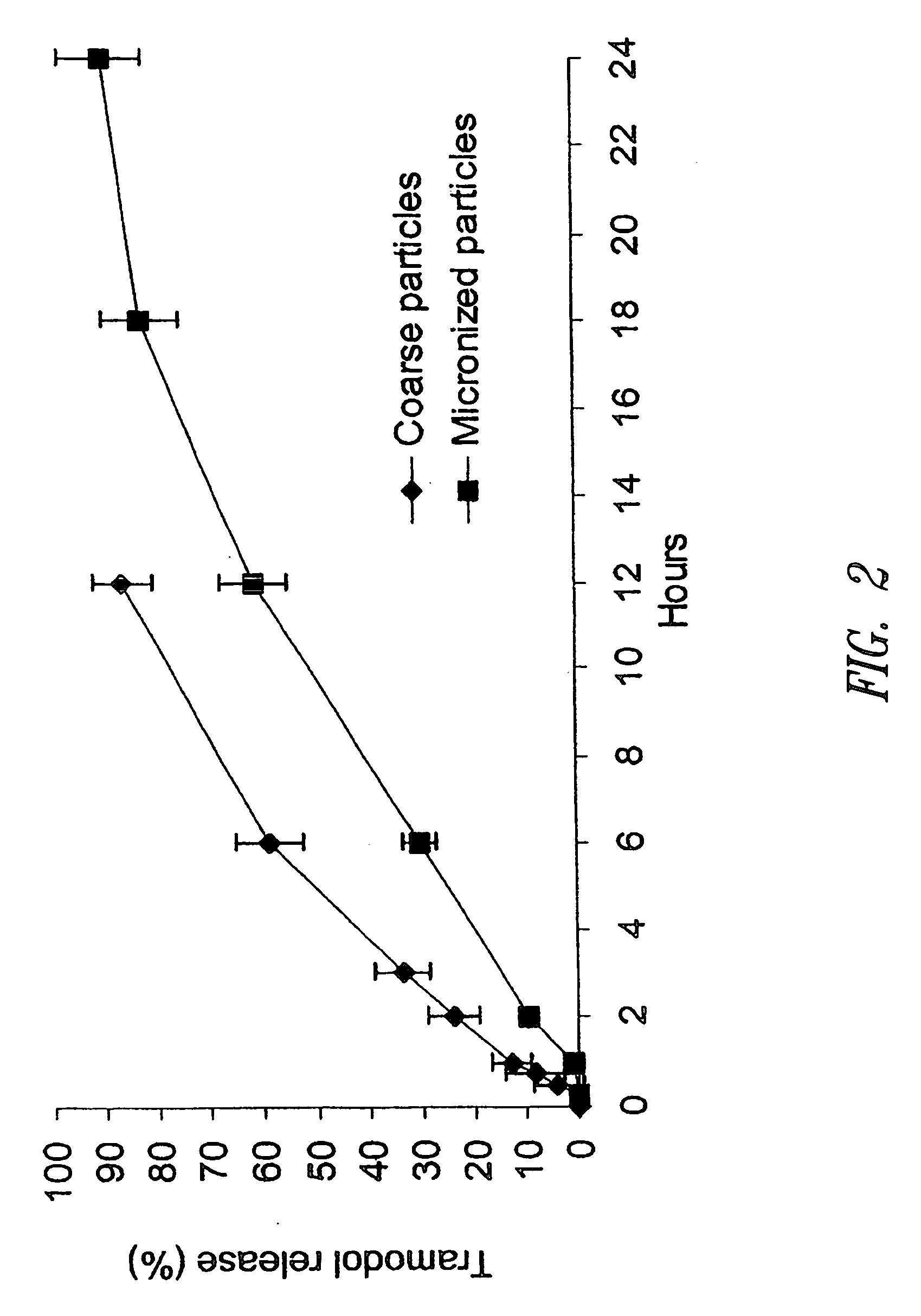

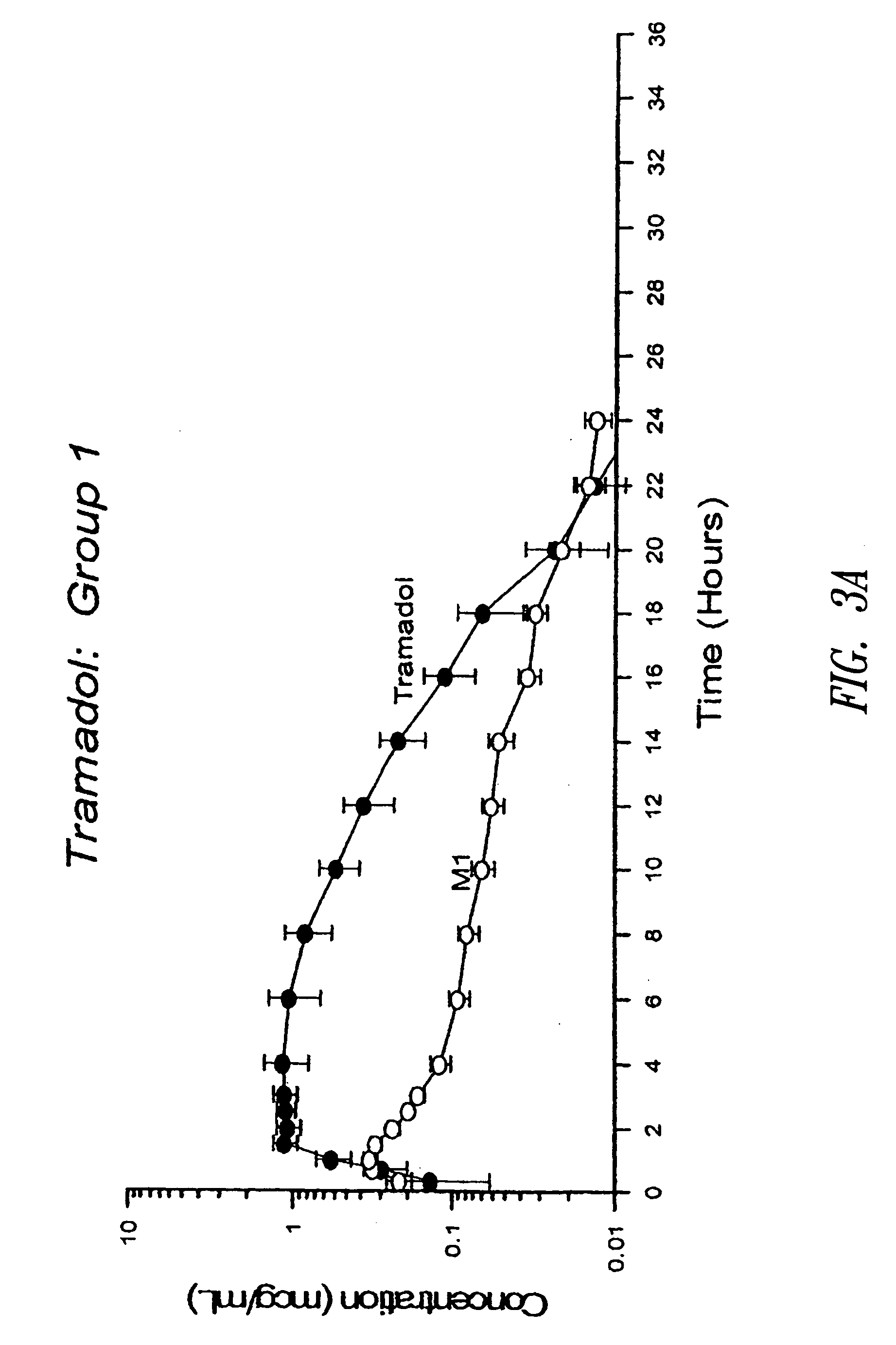

Sustained release pharmaceutical compositions for highly water soluble drugs

ActiveUS20070020335A1Reduce spreadReduce erosionPowder deliveryOrganic active ingredientsControlled releaseActive agent

The present invention provides pharmaceutical compositions for controlled release of pharmaceutically active agents, especially those with a high water solubility, high dose, and / or short half-life. In addition, the present application provides methods for preparing and using such pharmaceutical compositions.

Owner:FARNAM +1

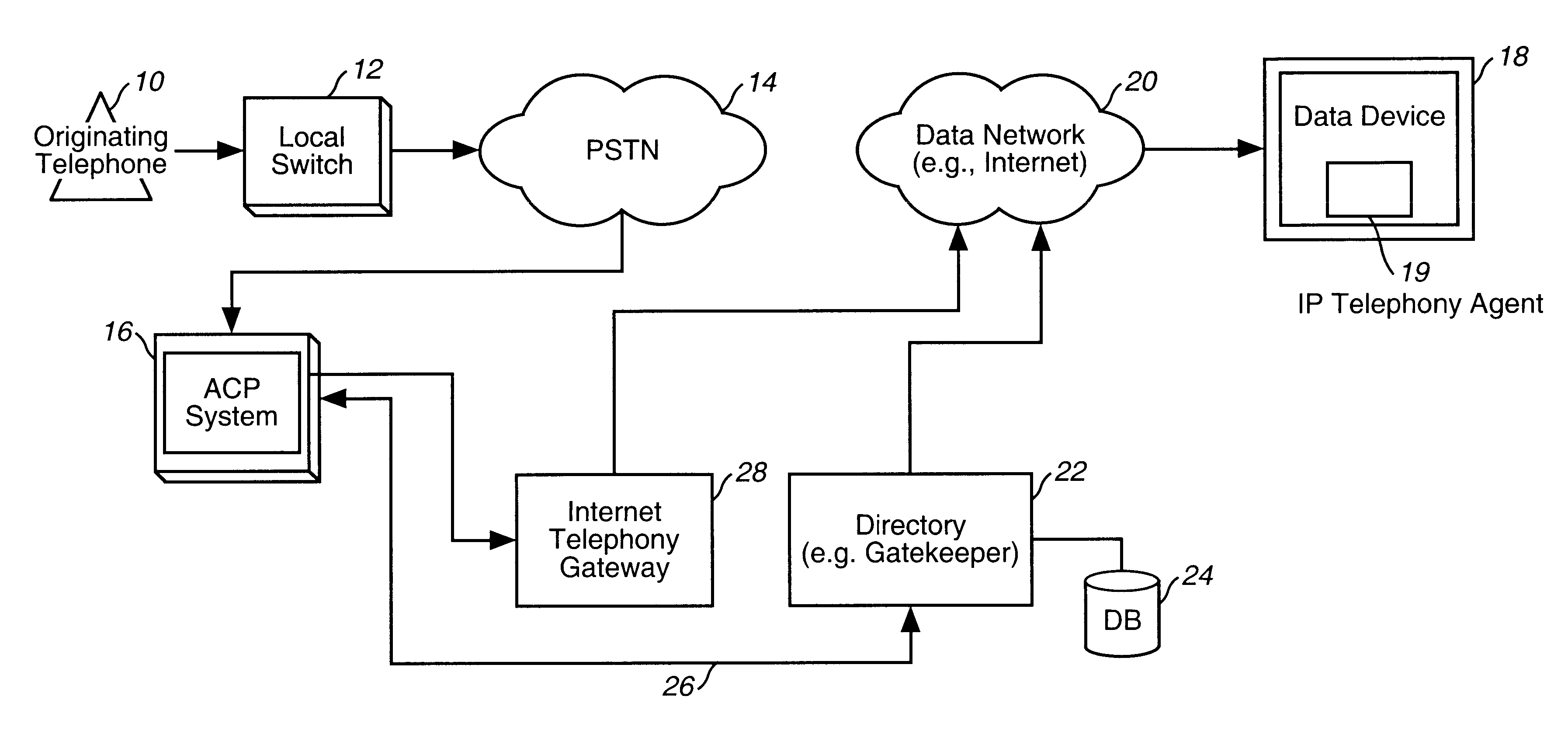

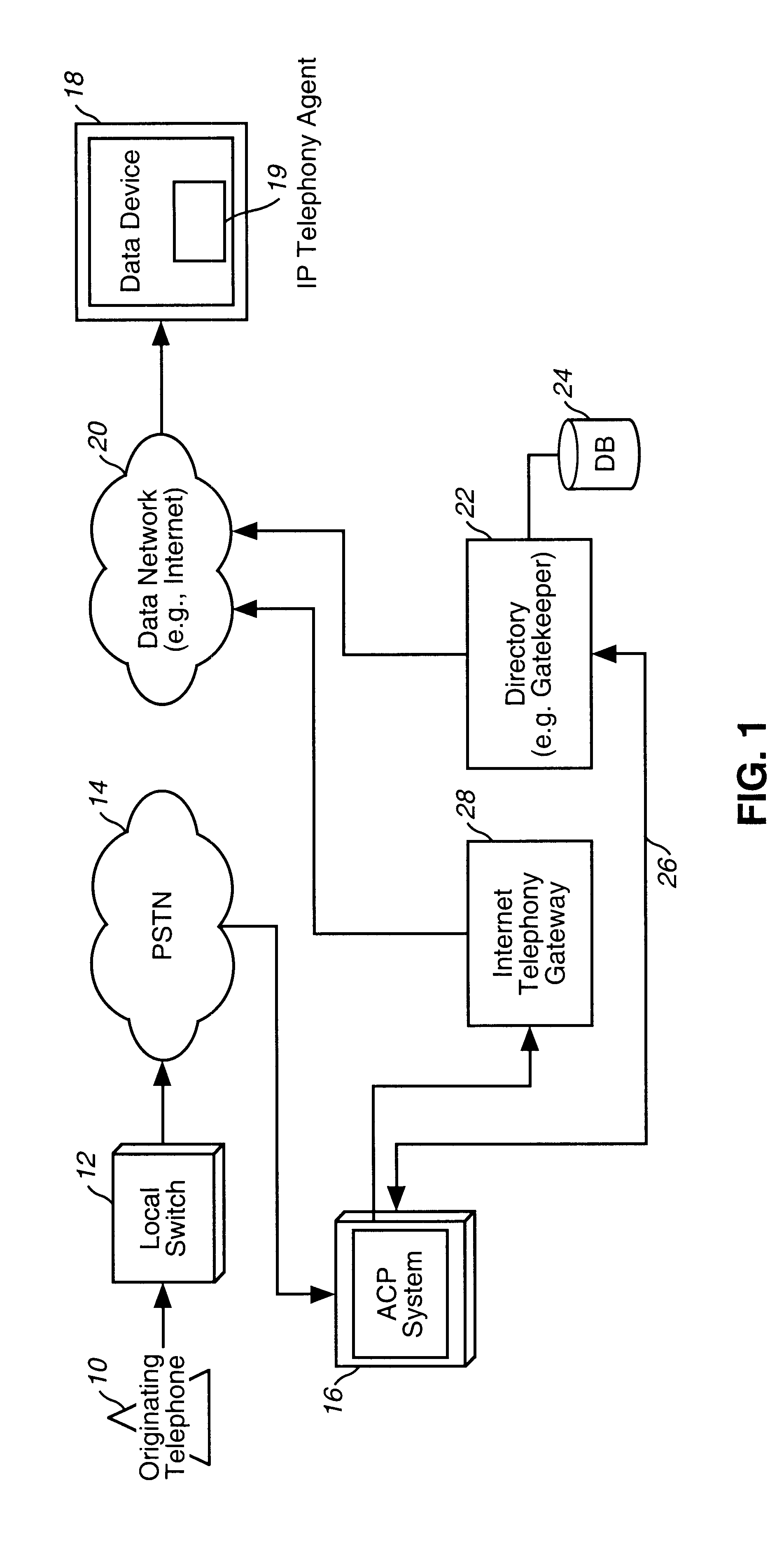

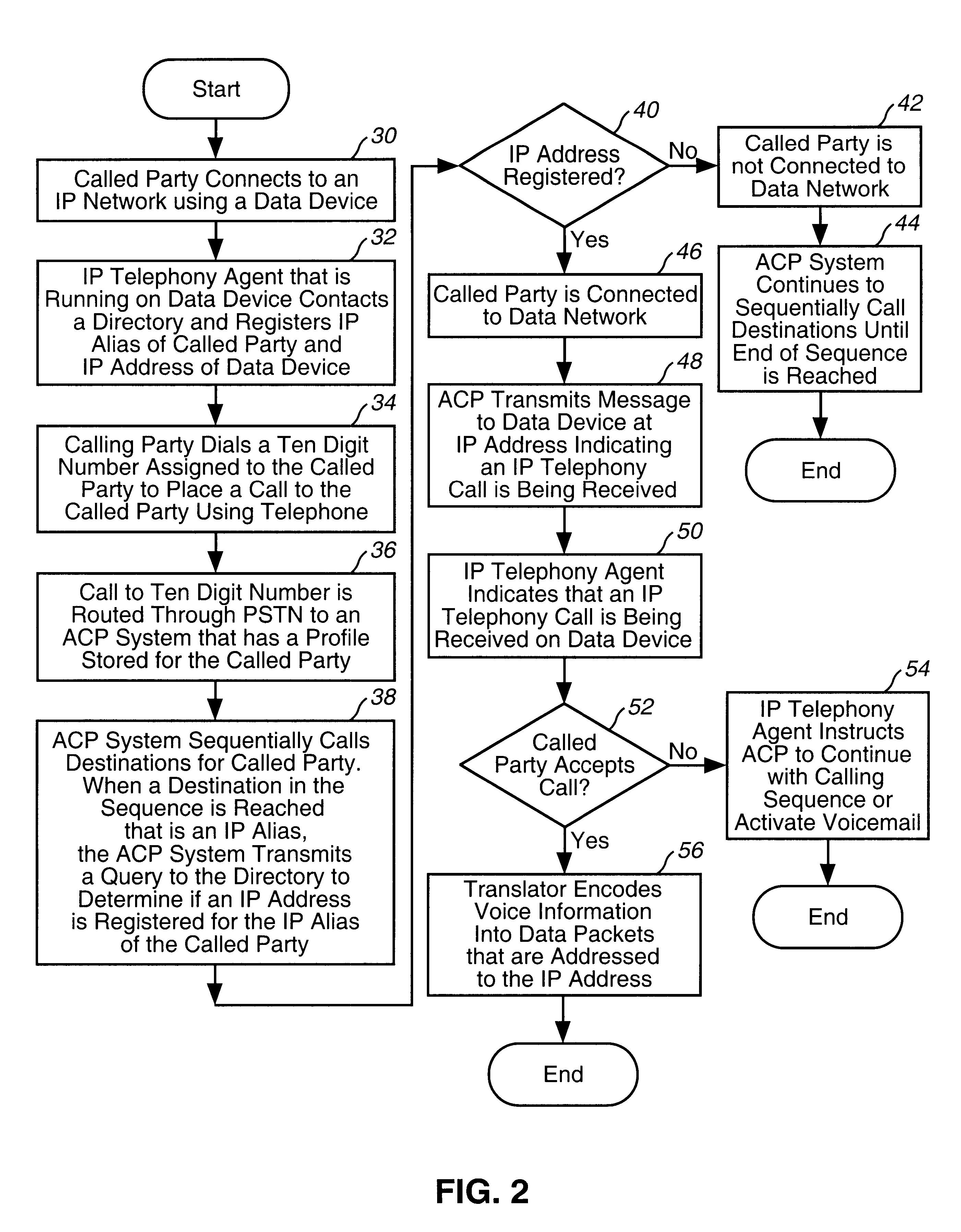

Virtual second line hybrid network communication system

InactiveUS6351464B1Reduce cost and inconvenienceReduce spreadInterconnection arrangementsSpecial service for subscribersMix networkIp address

A system and method for routing a telephone call on a PSTN network to a data device. The present invention utilizes an automatic call processing system that has a one number location service. A called party provides a calling profile that is stored in the automatic call processing (ACP) system. When a call is placed to a telephone number that is assigned to the called party, the call is routed to the ACP system. The ACP system calls each of the numbers of the calling profile for that called party until that party is reached. At least one of the destinations in the calling profile is a logical address for a data network. The automatic call processing system recognizes the logical address and queries a directory to determine if an IP address has been registered in the directory for the logical address of the called party. If the called party is using a data device that is logged on the Internet, an IP telephony agent, such as an IP telephony client running on the data device, registers the IP address of the data device together with the logical address of the caller. If the ACP system determines if an IP address is registered with the directory, the ACP system will direct the call to an Internet telephony gateway. The Internet telephony gateway encodes and packetizes the voice information for transmission over the data network to the data device.

Owner:VERIZON PATENT & LICENSING INC

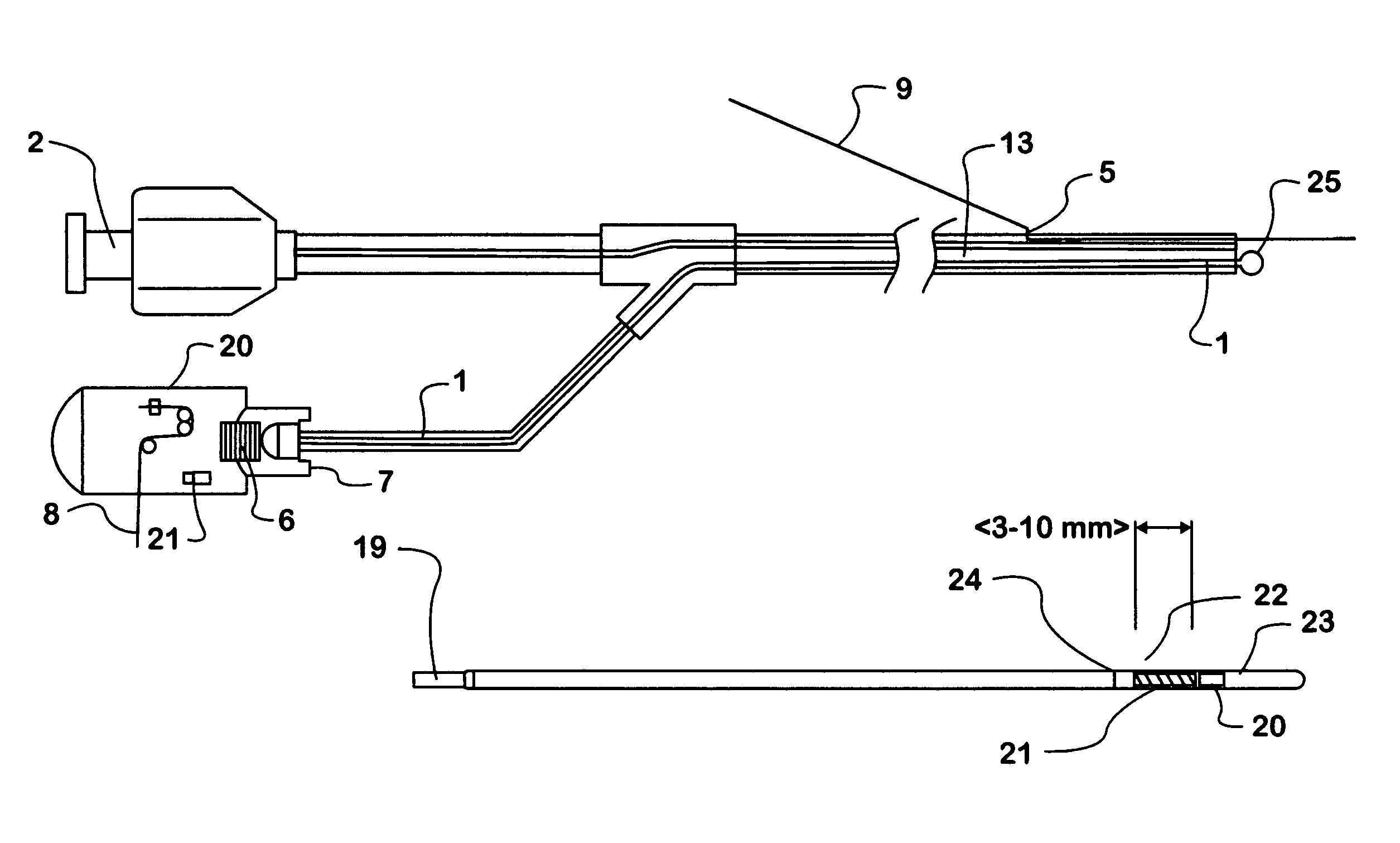

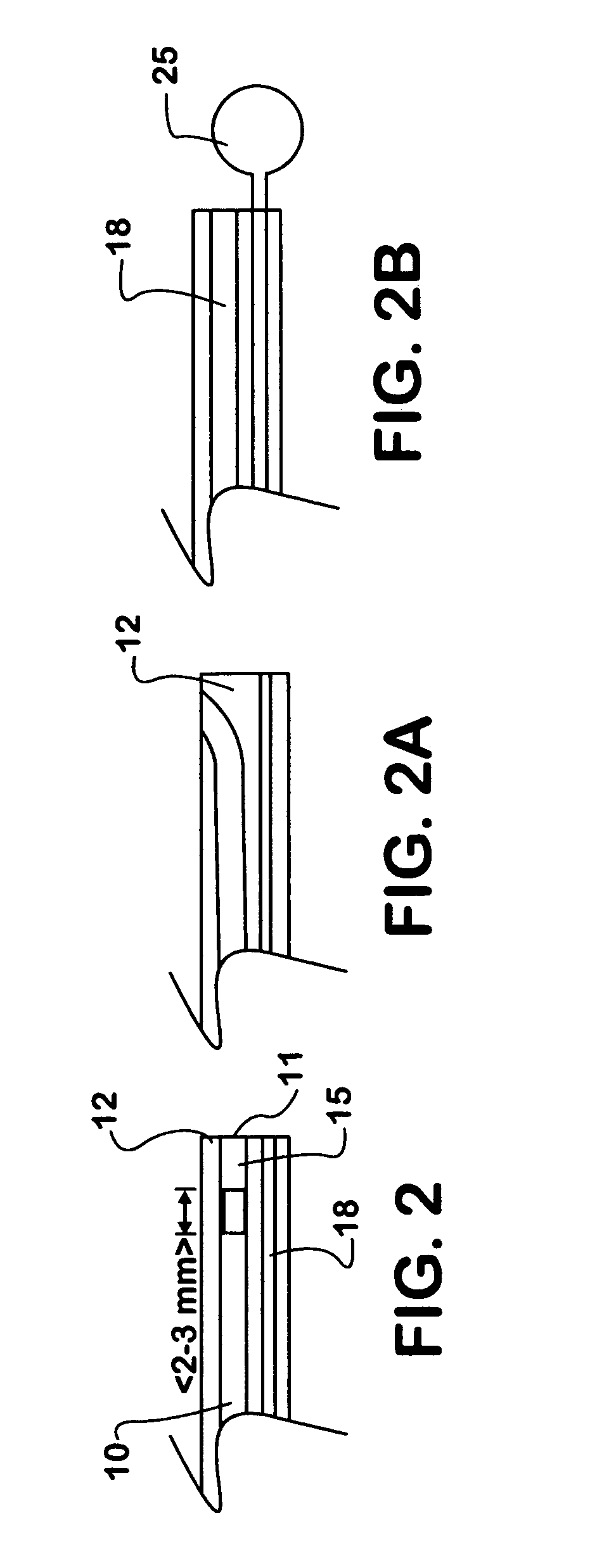

Electromagnetic photonic catheter for reducing restenosis

InactiveUS6962584B1Reduce spreadImprove scalabilitySurgical instrument detailsCatheterPhotonicsPercent Diameter Stenosis

The method of vascular treatment for restenosis or vulnerable plaque after an invasive procedure, such as for example angioplasty, stenting with or without drug coating, or drug delivery, comprises: inserting a catheter or hollow guide wire to the treatment location; delivering light through the catheter in the wavelength range of about 700–2500 nm; and moving the light to treat the affected region.

Owner:STONE GREGG W +5

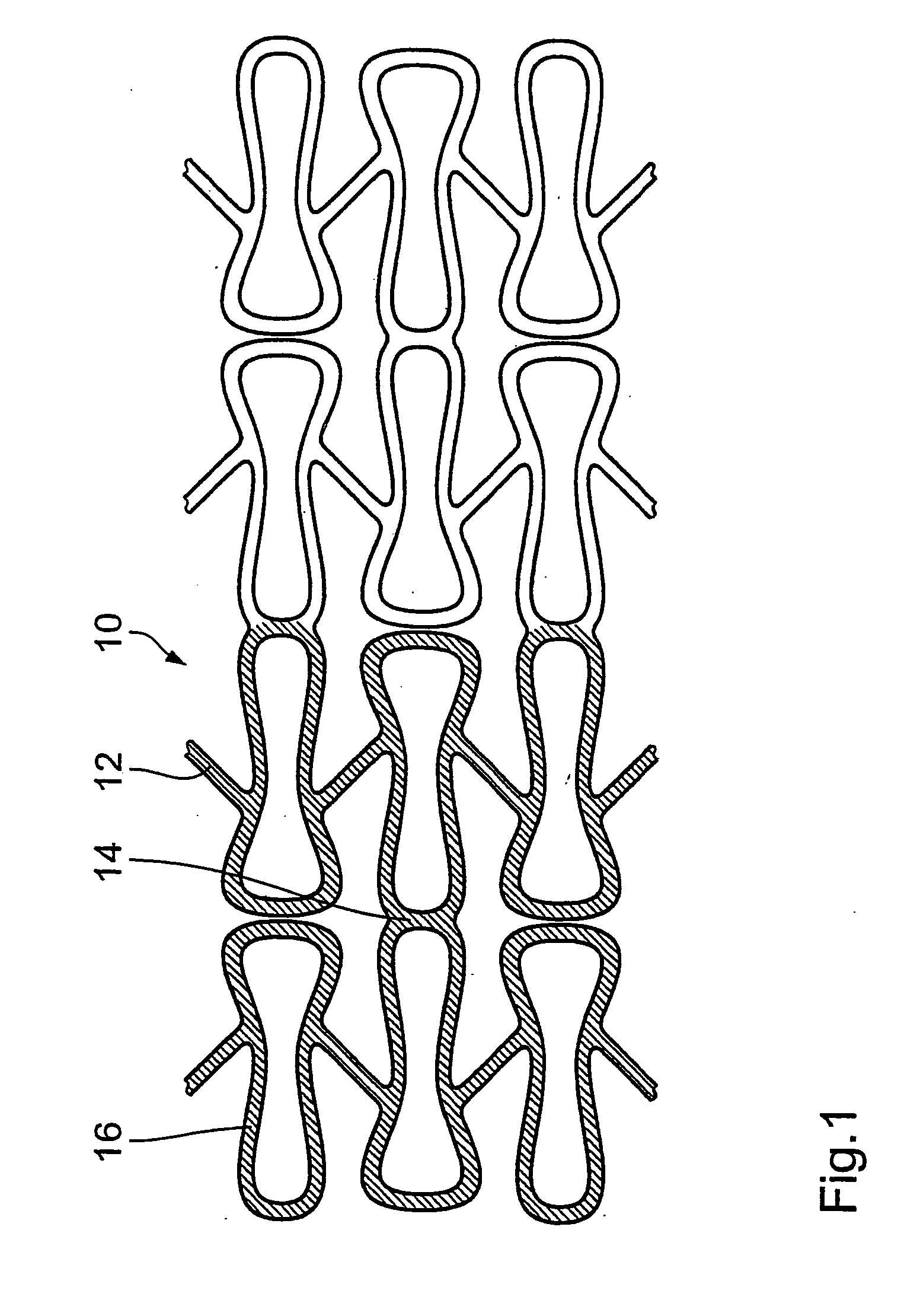

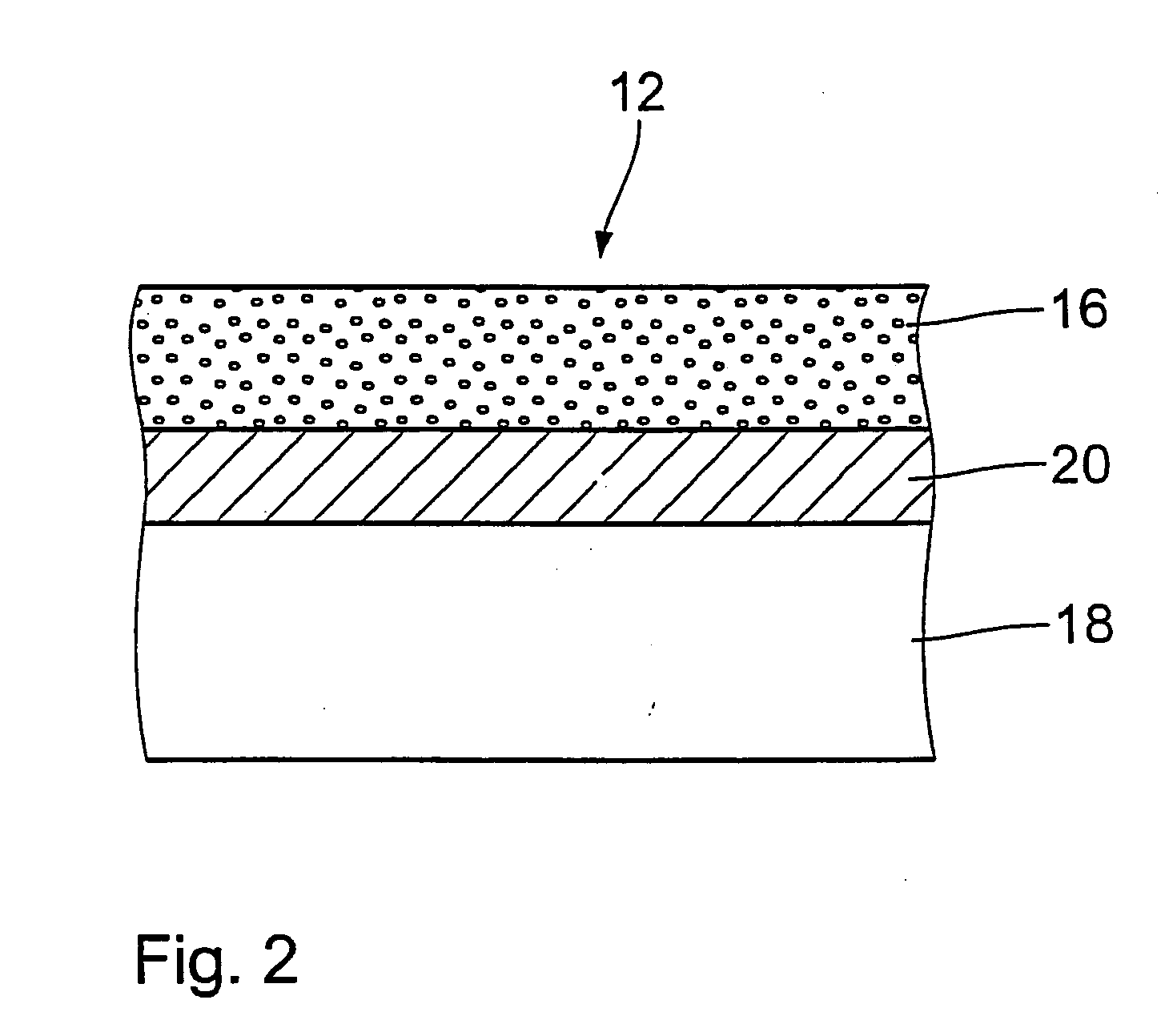

Stent with polymeric coating

InactiveUS20040034409A1Effectively suppress the restenosis-triggering factorsReduce spreadPharmaceutical containersPretreated surfacesPercent Diameter StenosisPolymer

The invention concerns an implantable stent (10) with an at least portion-wise polymeric coating (16). The coating material is admittedly intended to bond to known materials but by virtue of its properties it is intended to enjoy improved compatibility and reduce inflammatory and proliferative processes which can lead to restenosis. That is achieved in that the polymeric coating (16) in the implantable condition after production and sterilization contains poly-L-lactide of a mean molecular weight of more than 200 kDa.

Owner:BIOTRONIK

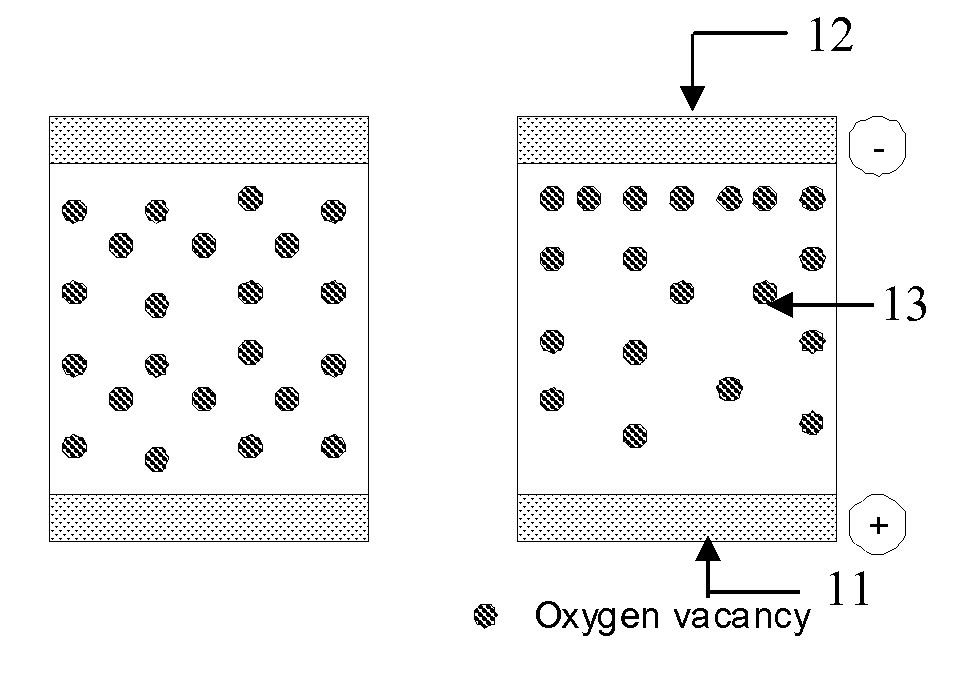

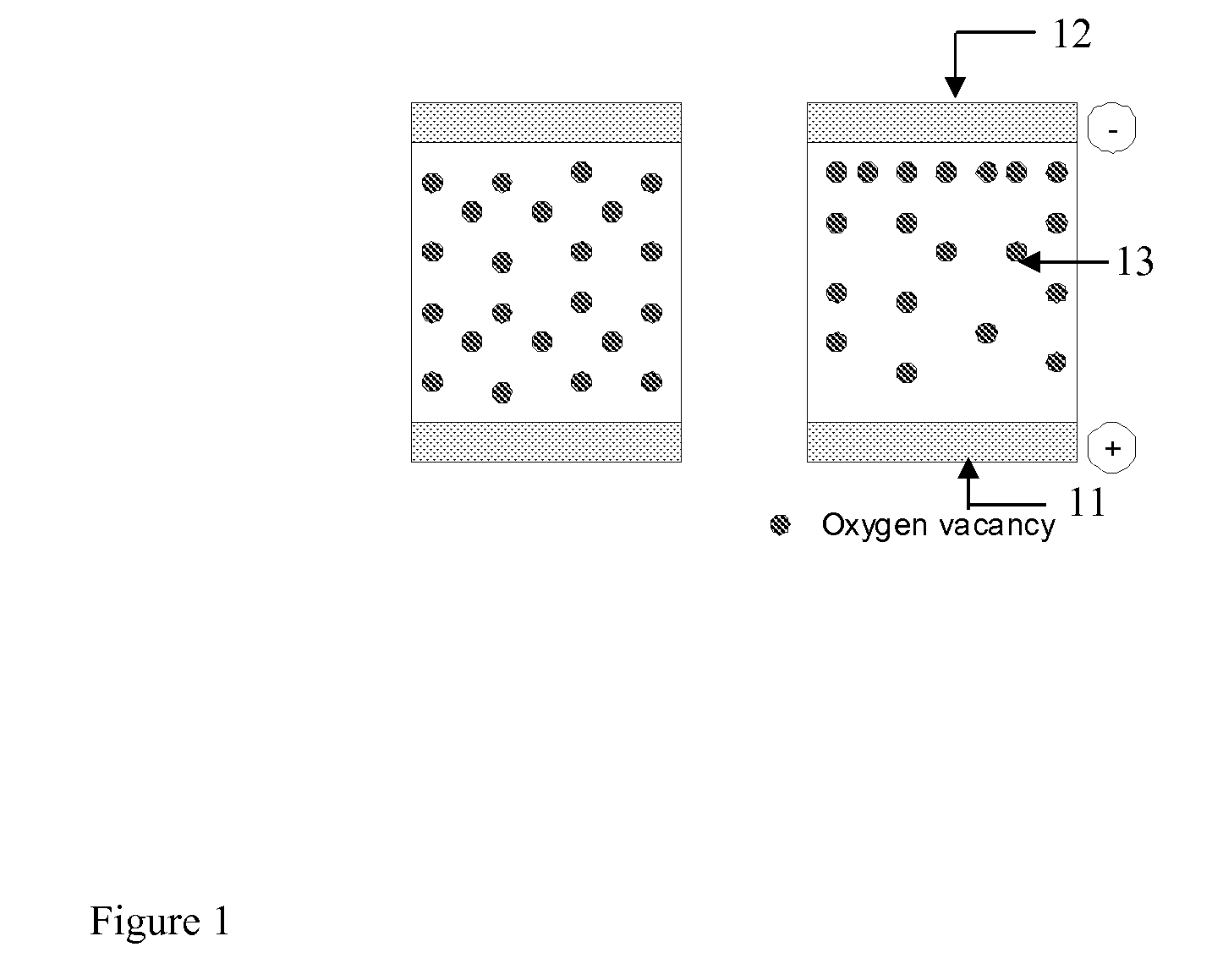

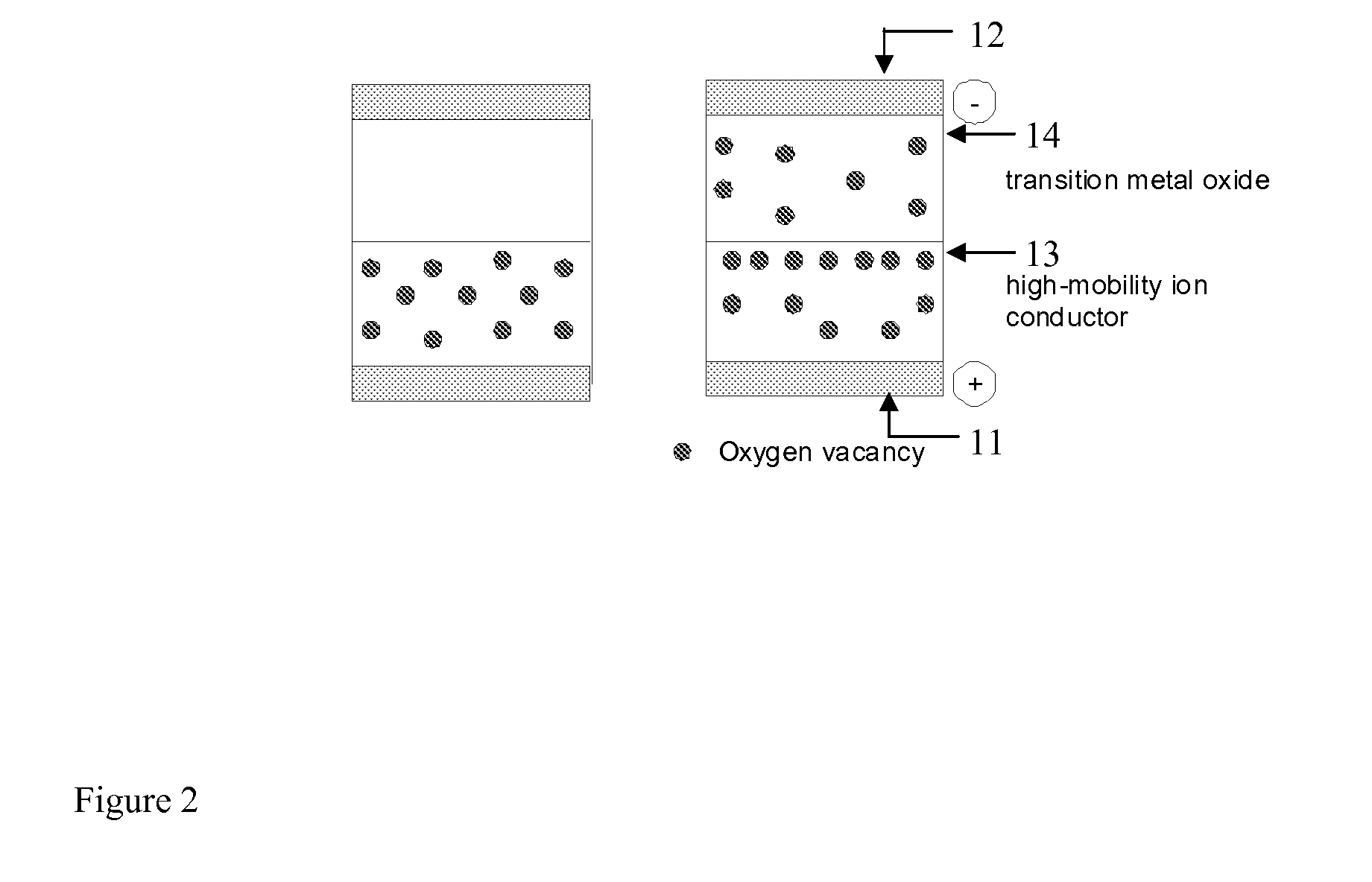

Nonvolatile programmable resistor memory cell

InactiveUS20080001172A1High oxygen ion mobilityImprove response timeSemiconductor devicesPhysicsOxide

A nonvolatile programmable resistance memory cell comprising a high-mobility ion conductor and a method for fabricating the same are provides. The memory cell comprises of a first and second electrode and a reversible and persistent programmable resistance structure connecting the first and second electrode. The resistance is modifiable by altering the ionic distribution of a high-mobility oxygen ion conductor region. As an alternate embodiment, the memory cell further includes a transition-metal oxide region.

Owner:IBM CORP

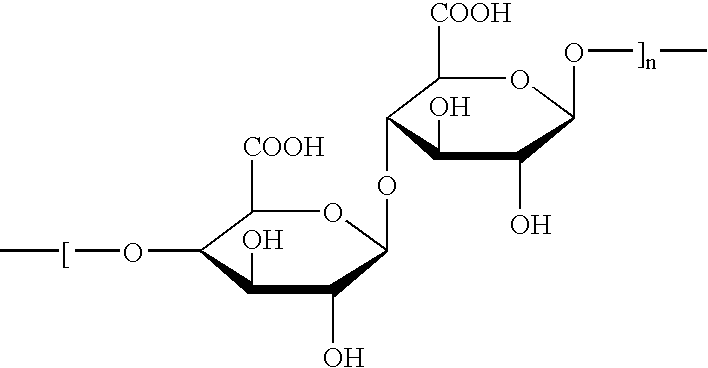

Microcapsules and processes for making the same using various polymers and chitosans

InactiveUS6733790B1Improve stabilityReduce partial pressurePowder deliveryBiocideAnionic polymersAlginic acid

A microcapsule having a mean diameter of from about 0.1 to about 5 mm, a membrane and a matrix containing at least one active principle wherein the microcapsule is the product of the process comprising the steps of (a) forming an aqueous matrix by heating an aqueous solution comprised of a gel former, an anionic polymer selected from the group consisting of a salt of alginic acid and an anionic chitosan derivative and active principle; (b) adding the aqueous matrix to an aqueous solution of chitosan.

Owner:COGNIS IP MANAGEMENT GMBH

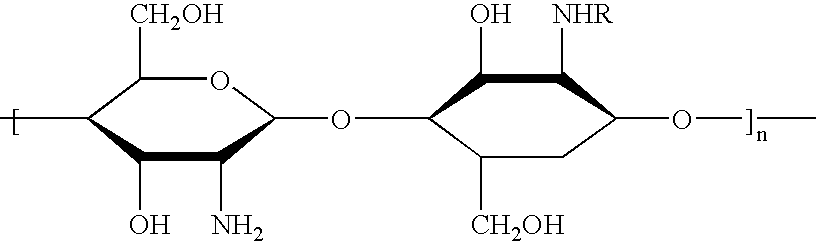

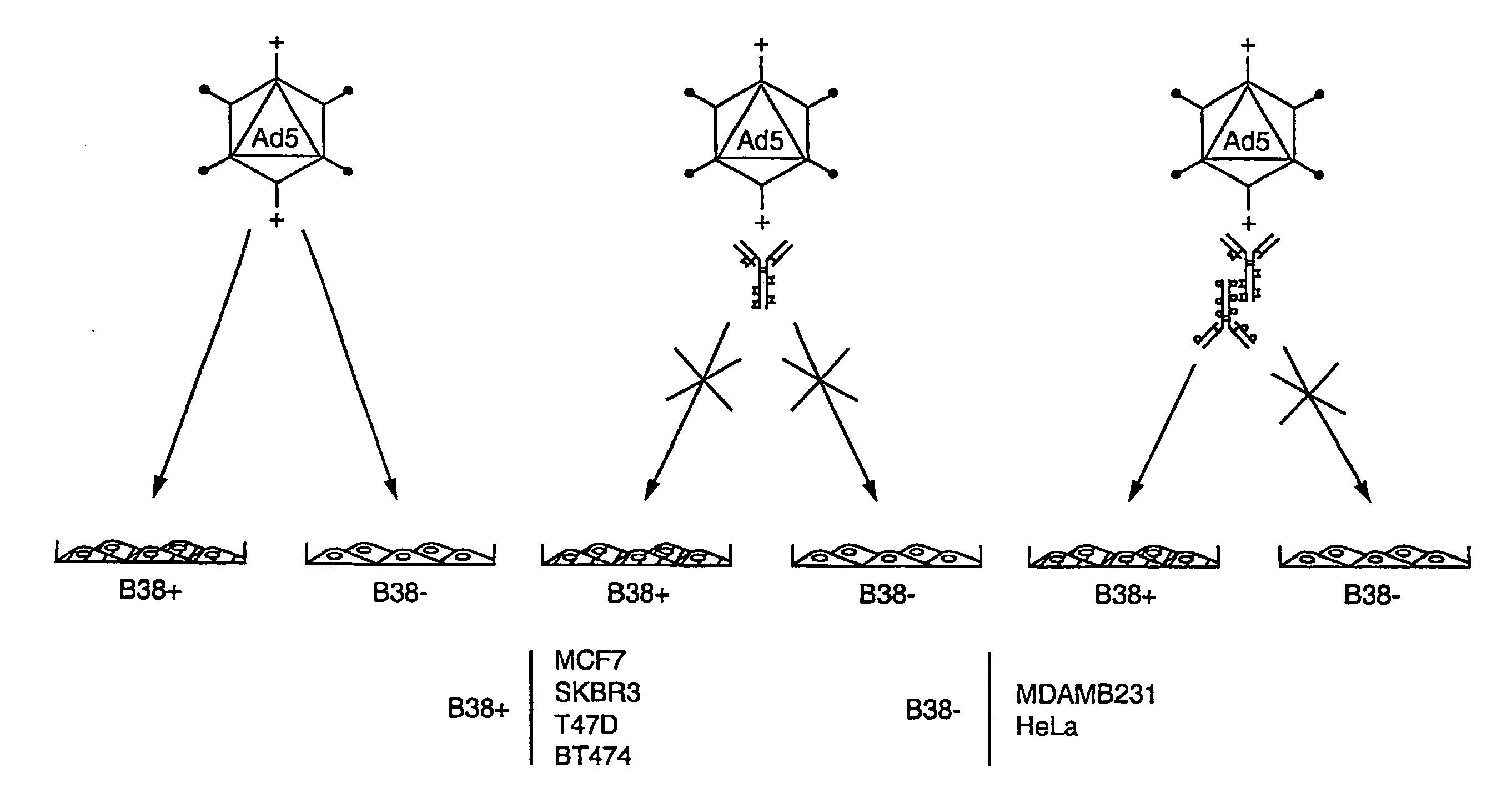

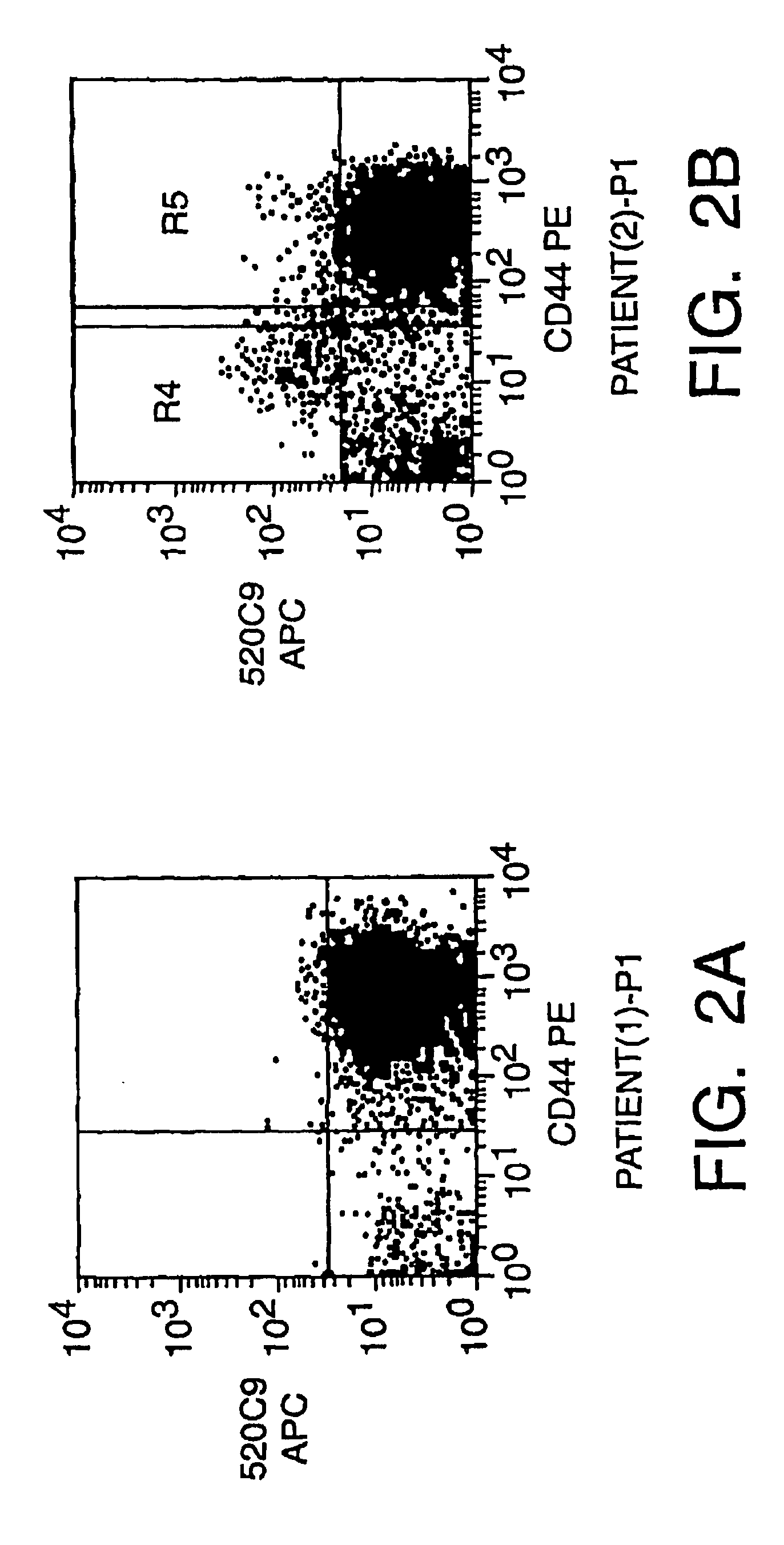

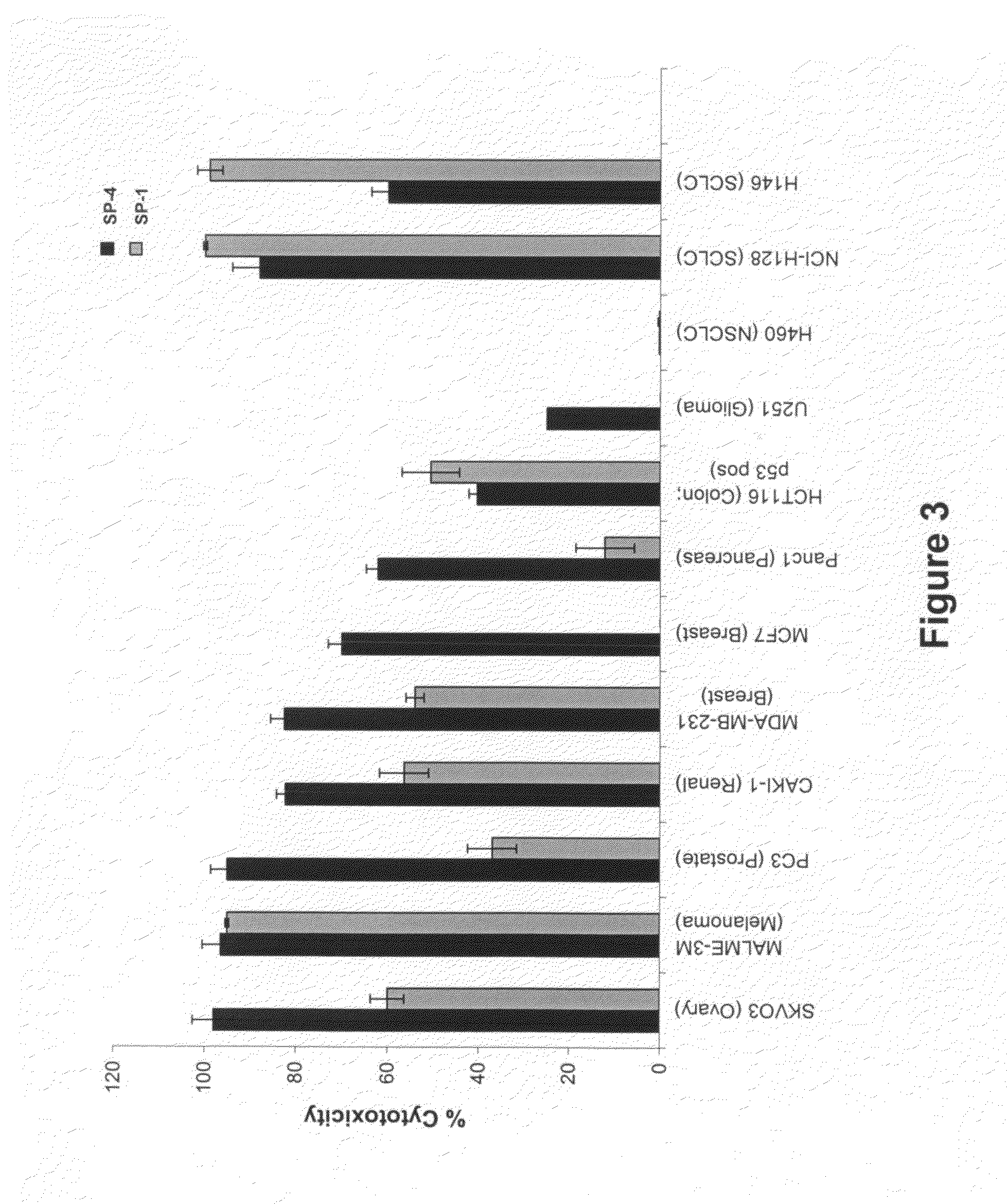

Isolation And Use Of Solid Tumor Stem Cells

InactiveUS20080178305A1Reduce spreadIncreased proliferationMaterial nanotechnologyMicrobiological testing/measurementAbnormal tissue growthMammary gland structure

A small percentage of cells within an established solid tumor have the properties of stem cells. These solid tumor stem cells give rise both to more tumor stem cells and to the majority of cells in the tumor that have lost the capacity for extensive proliferation and the ability to give rise to new tumors. Thus, solid tumor heterogeneity reflects the presence of tumor cell progeny arising from a solid tumor stem cell. We have developed a xenograft model in which we have been able to establish tumors from primary tumors via injection of tumor cells in the mammary gland of severely immunodeficient mice. These xenograft assay have allowed us to do biological and molecular assays to characterize clonogenic solid tumor stem cells. We have also developed evidence that strongly implicates the Notch pathway, especially Notch 4, as playing a central pathway in carcinogenesis.

Owner:ONCOMED PHARMA +1

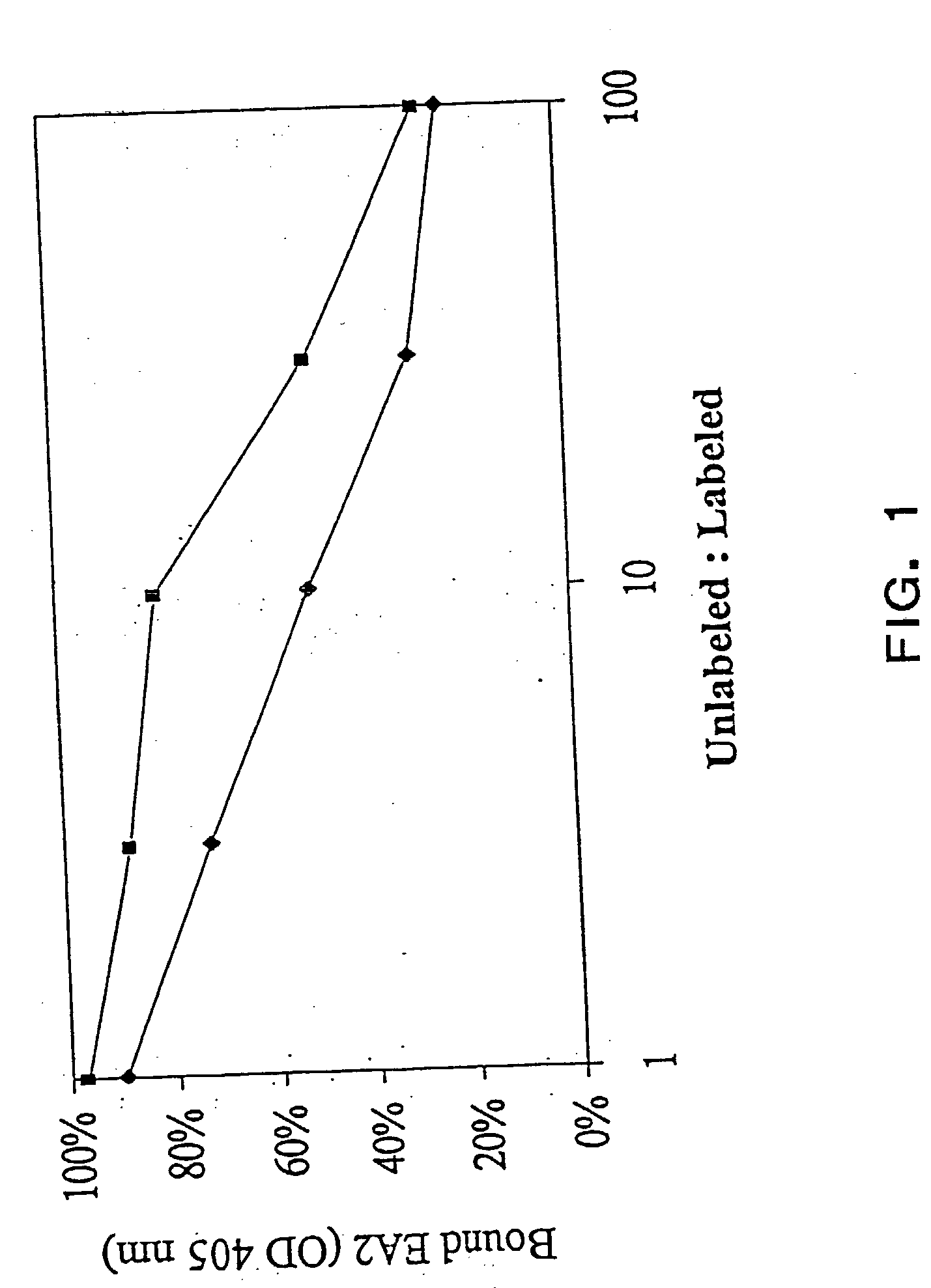

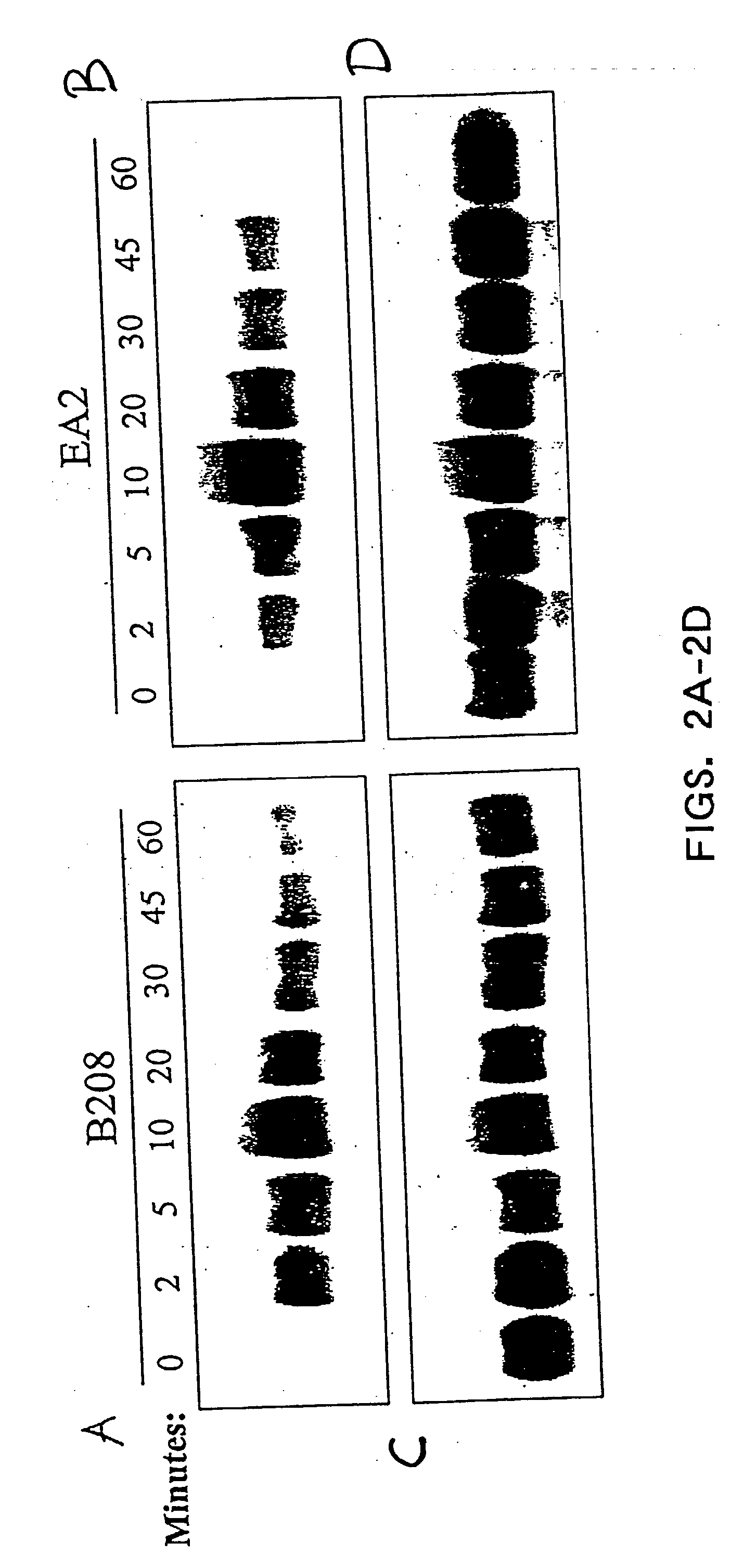

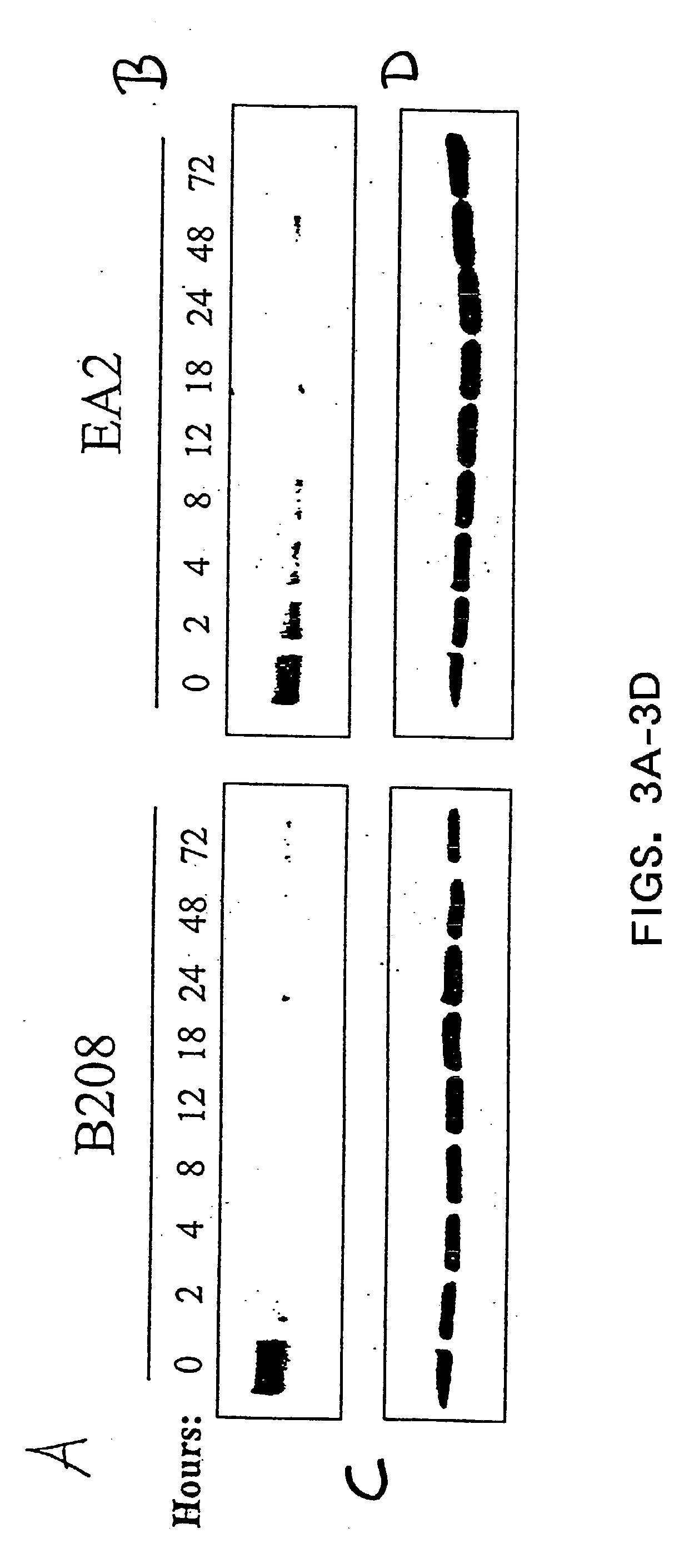

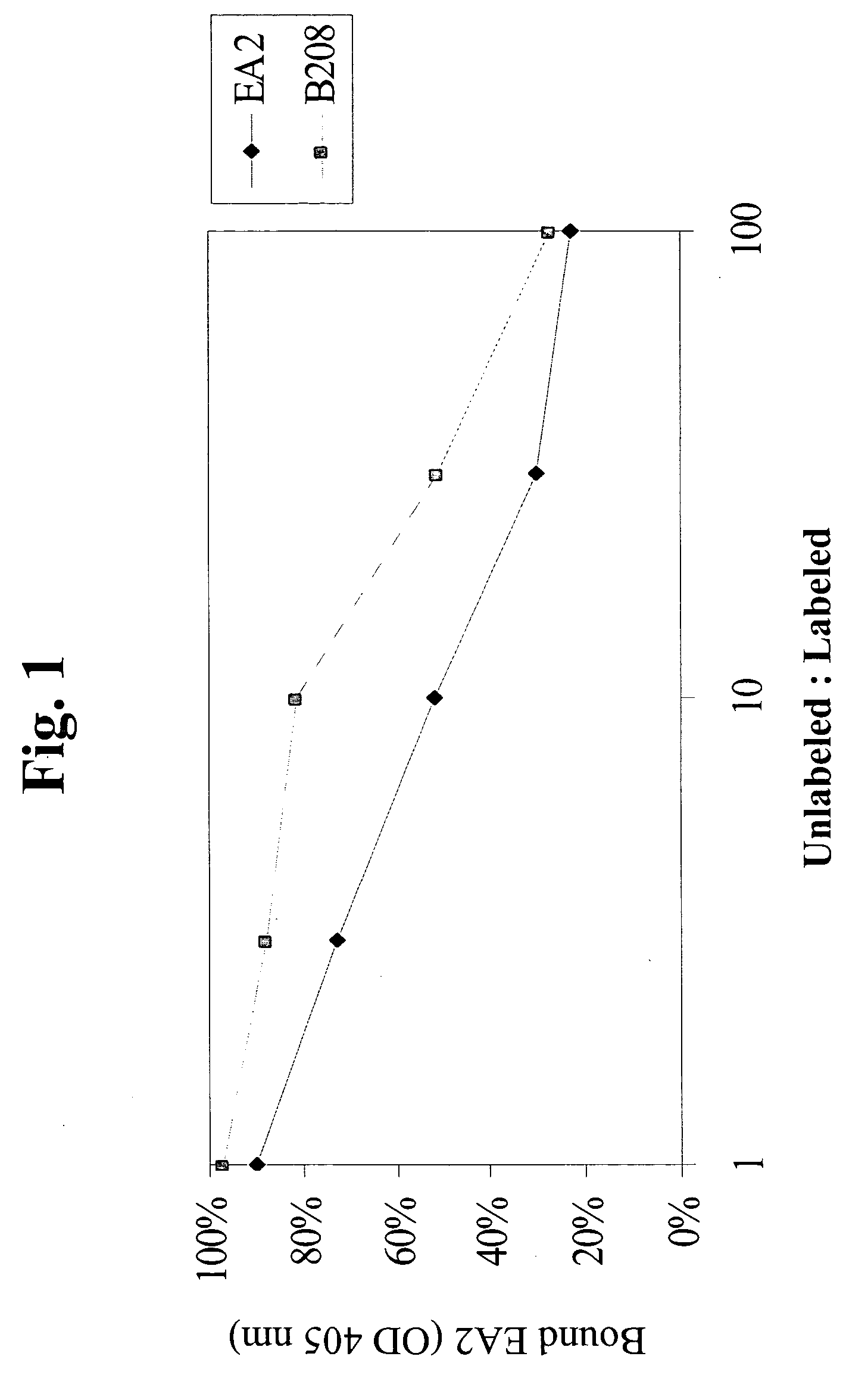

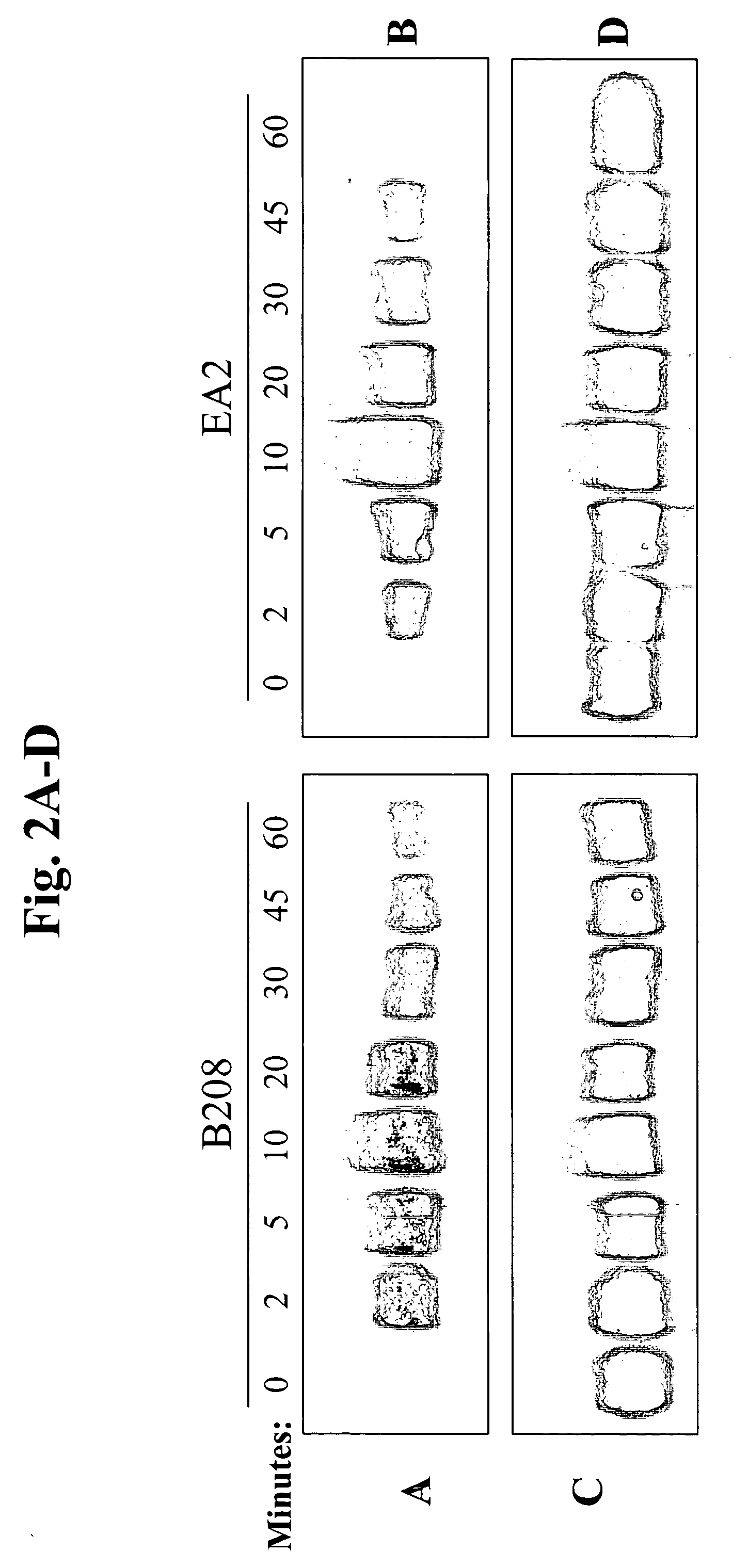

EphA2 monoclonal antibodies and methods of use thereof

InactiveUS20040028685A1Decrease contactStable interactionOrganic active ingredientsFungiTubular networkLymphatic Spread

The present invention relates to methods and compositions designed for the treatment, management, or prevention of cancer, particularly, metastatic cancer. In one embodiment, the methods of the invention comprise the administration of an effective amount of an antibody that binds to EphA2 and agonizes EphA2, thereby increasing EphA2 phosphorylation and decreasing EphA2 levels. In other embodiments, the methods of the invention comprise the administration of an effective amount of an antibody that binds to EphA2 and inhibits cancer cell colony formation in soft agar, inhibits tubular network formation in three-dimensional basement membrane or extracellular matrix preparation, preferentially binds to an EphA2 epitope that is exposed on cancer cells but not non-cancer cells, and / or has a low Koff, thereby, inhibiting tumor cell growth and / or metastasis. The invention also provides pharmaceutical compositions comprising one or more EphA2 antibodies of the invention either alone or in combination with one or more other agents useful for cancer therapy.

Owner:MEDIMMUNE LLC

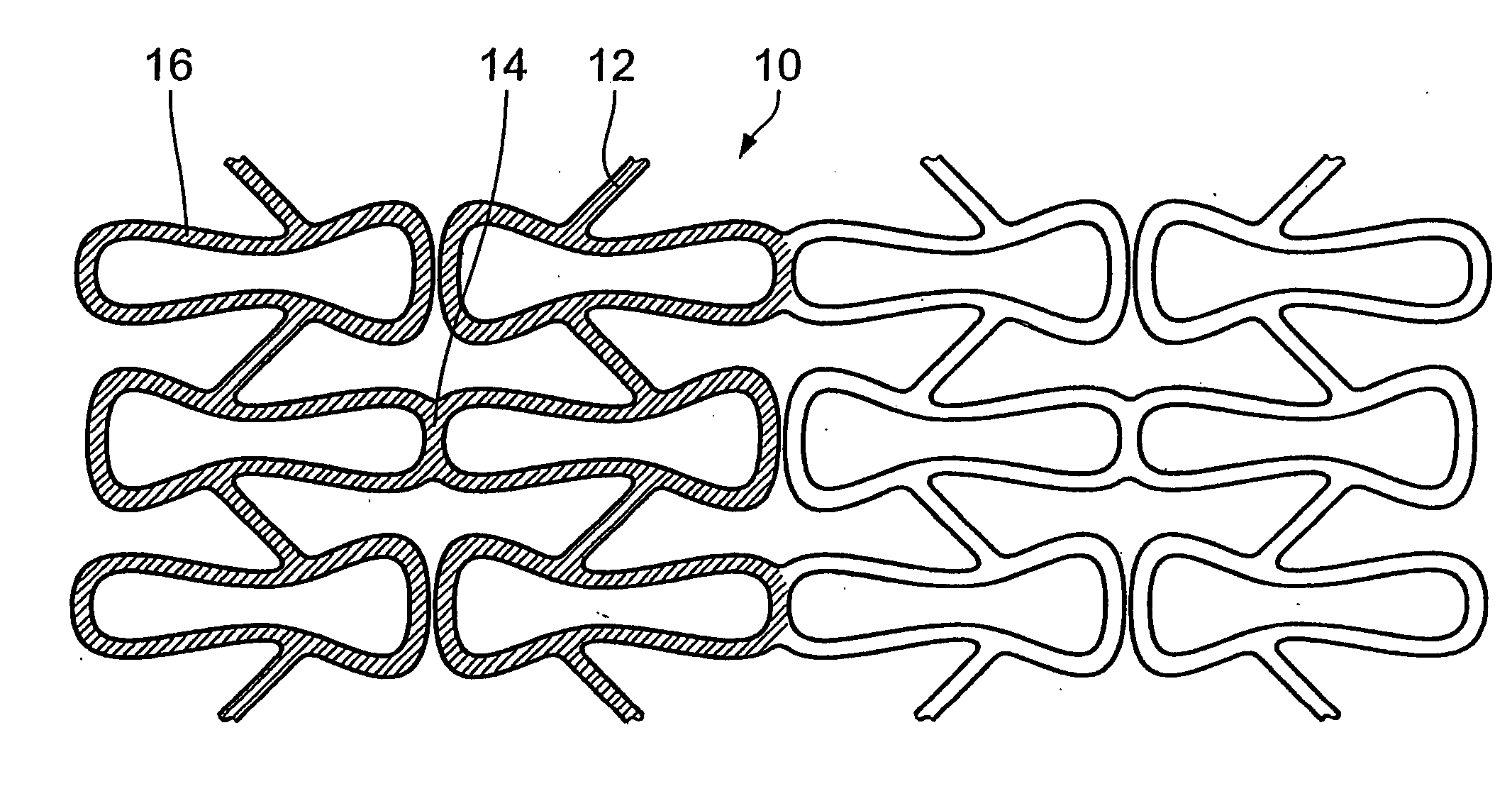

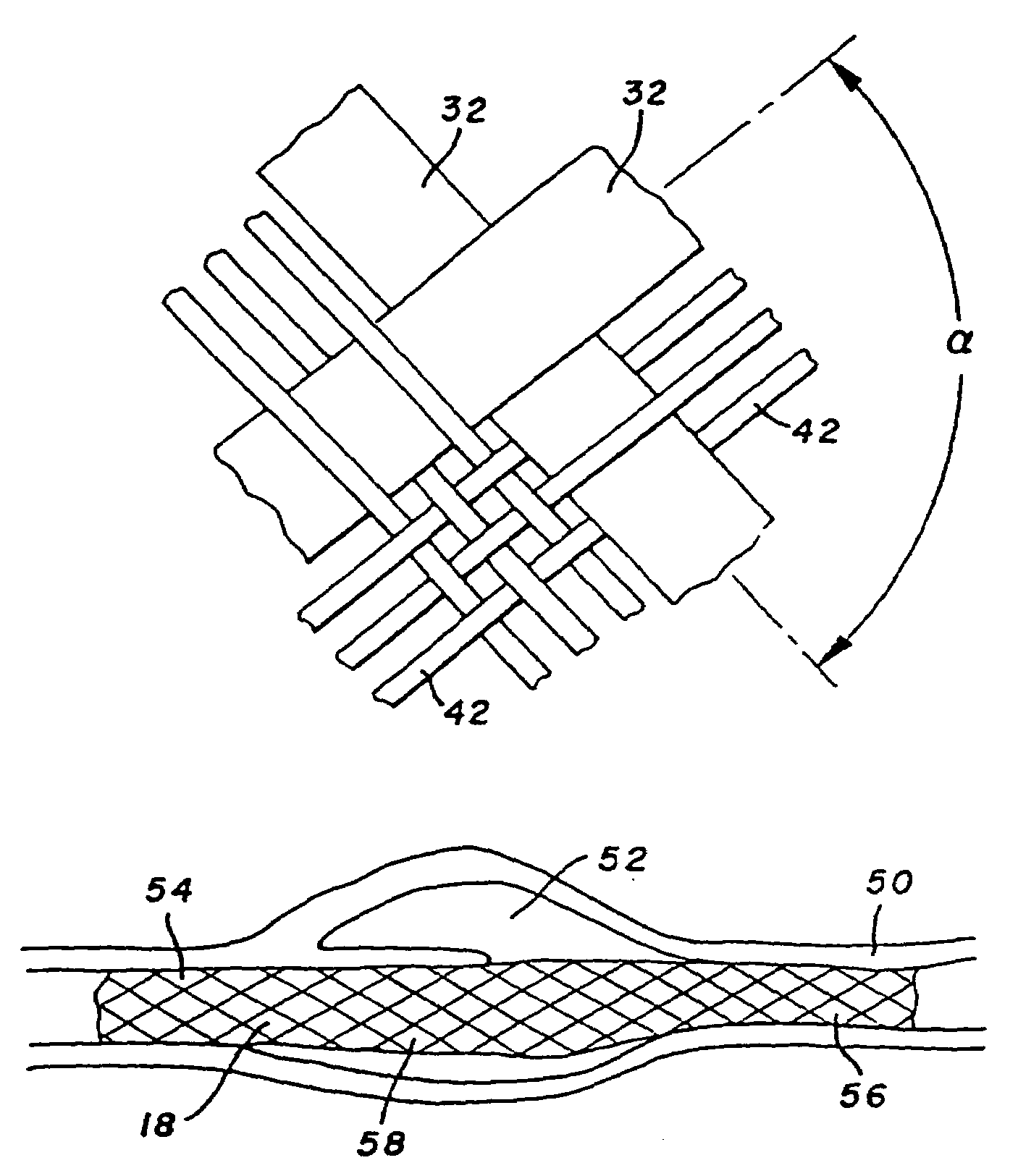

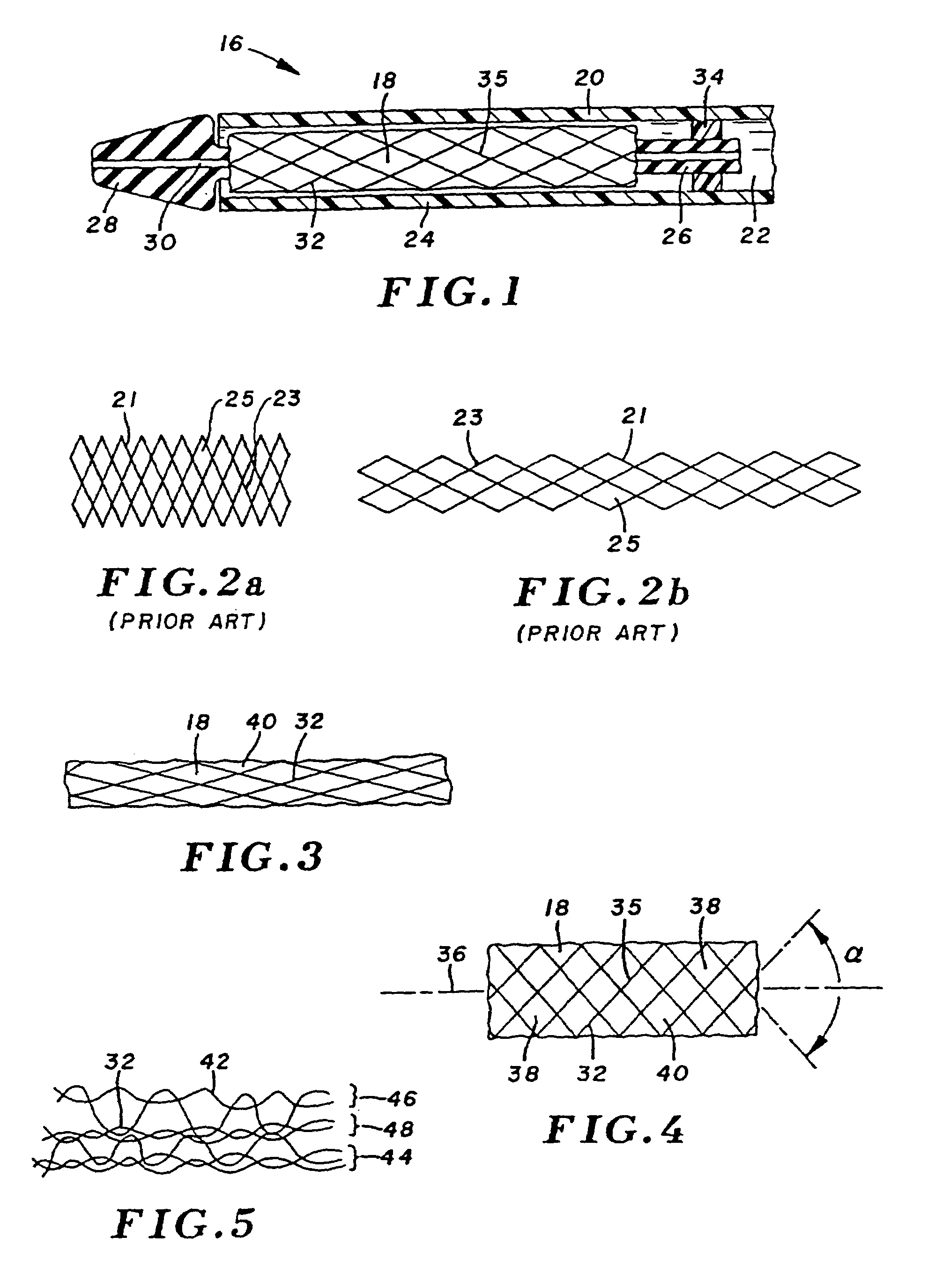

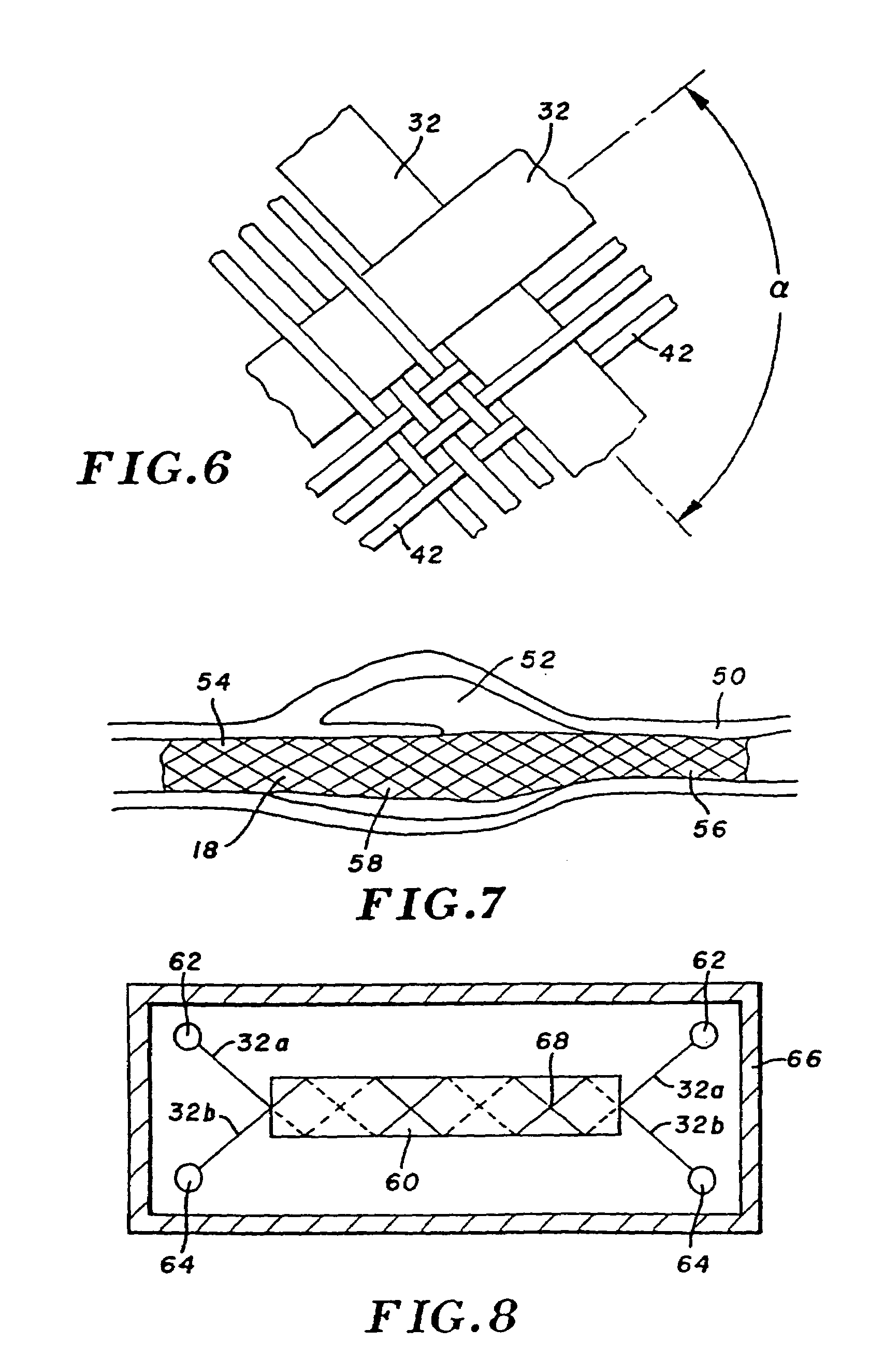

Three-dimensional braided covered stent

InactiveUS7052513B2Reduce manufacturing costSolve the lack of tensionStentsBlood vesselsYarnProsthesis

A prosthesis for transluminal implantation consists of a flexible tubular three-dimensionally braided structure of metal or polymeric monofilaments, and polymeric multifilament yarns. The prosthesis can be elastically deformed to reduce its diameter through axial elongation. The monofilaments and multifilament yarns are arranged in axially spaced apart helices, concentric on a common central axis of the prosthesis. The monofilaments are selectively shaped before their interbraiding with the multifilament yarns, either by an age-hardening or other heat-setting stage, or a cold-working stage that controllably plastically deforms the strands. The shaped structural strands cooperate to impart to the prosthesis its nominal shape and resilience. The textile strands cooperate to provide one or more layers of sheeting that reduce permeability and thereby enhance the utility of the prosthesis as a vascular graft. An alternative embodiment prosthesis includes elastically and plastically deformable structural strands, selectively plastically deformed by cold working, then three-dimensionally braided to form the prosthesis.

Owner:LIFESHIELD SCI

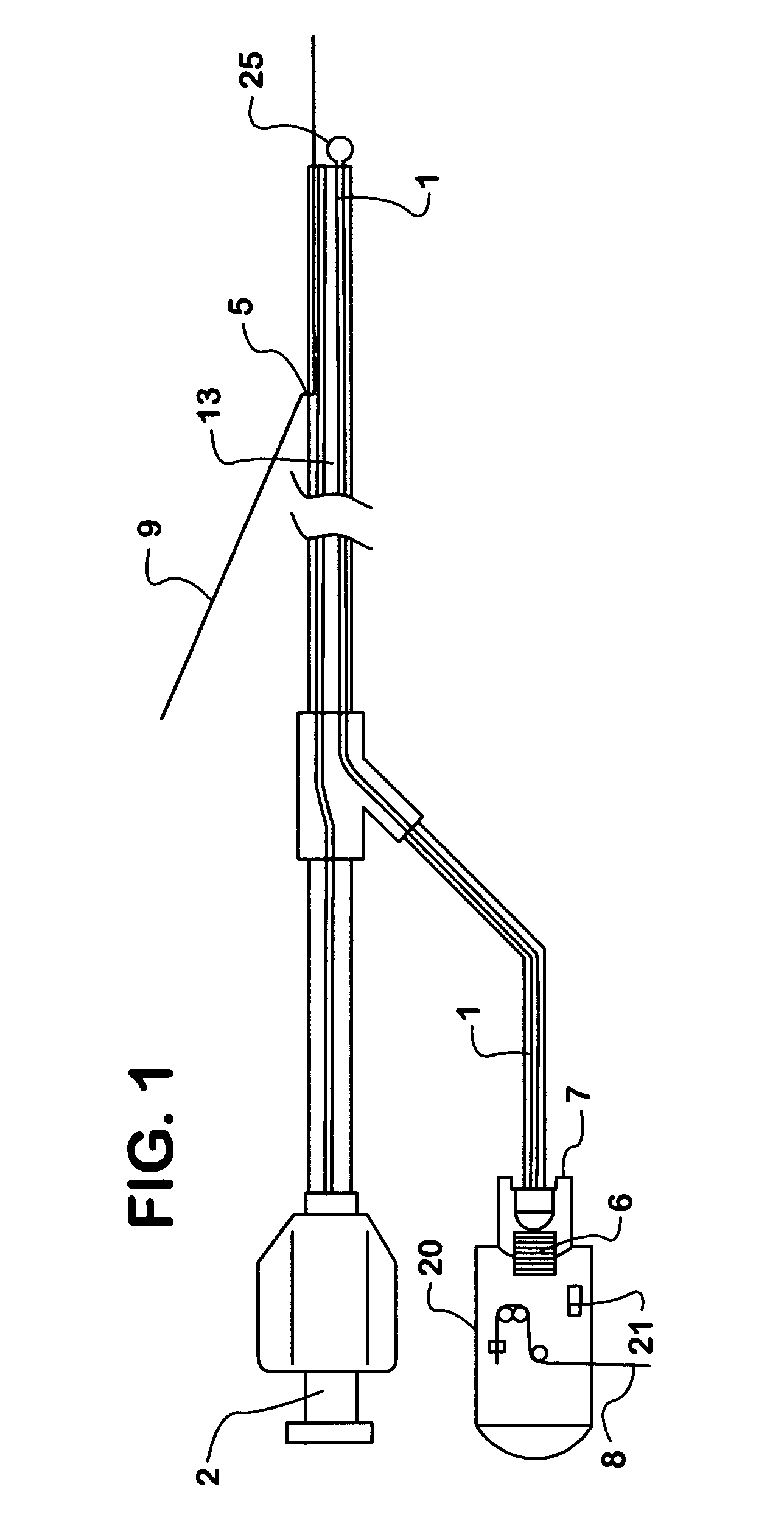

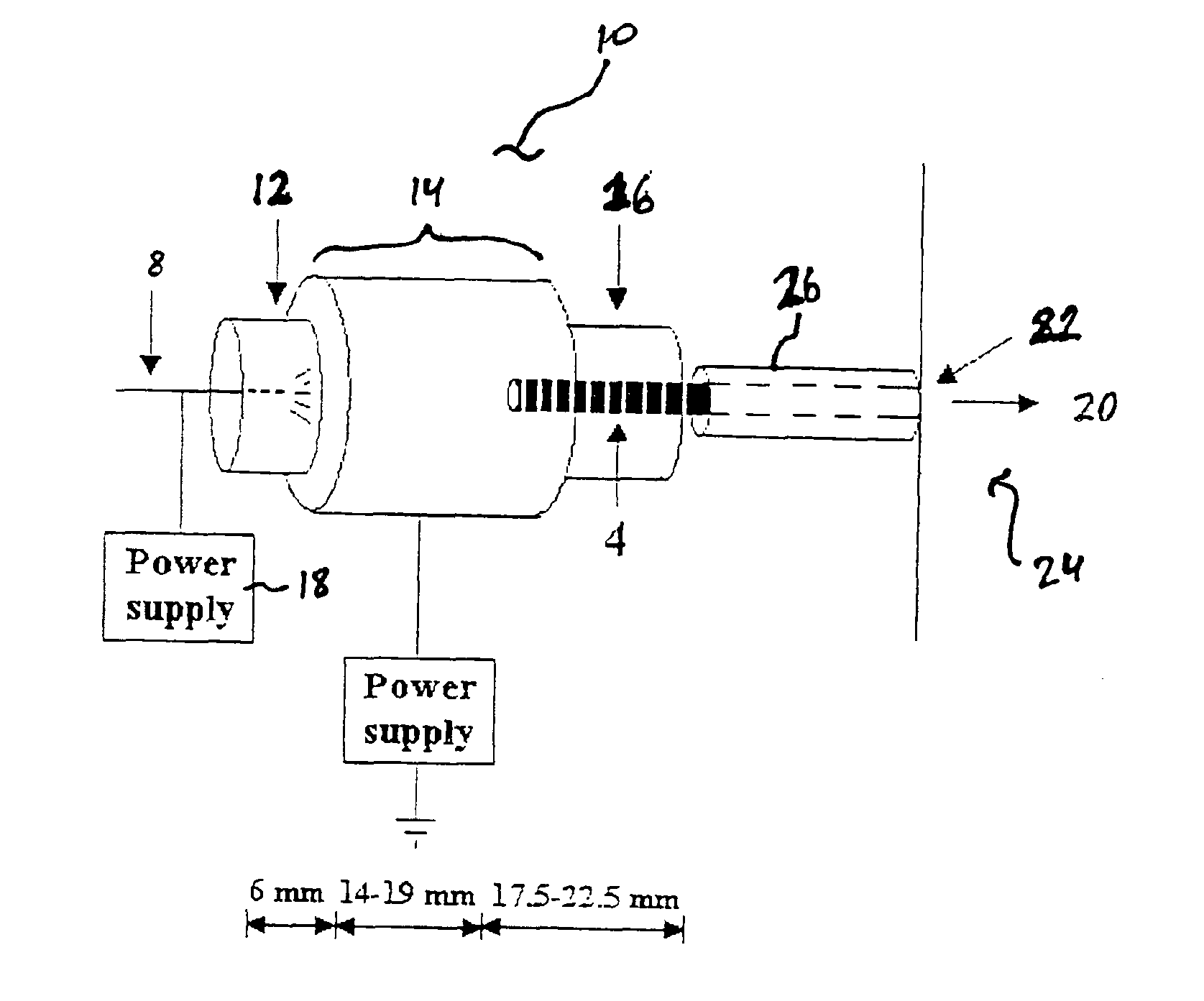

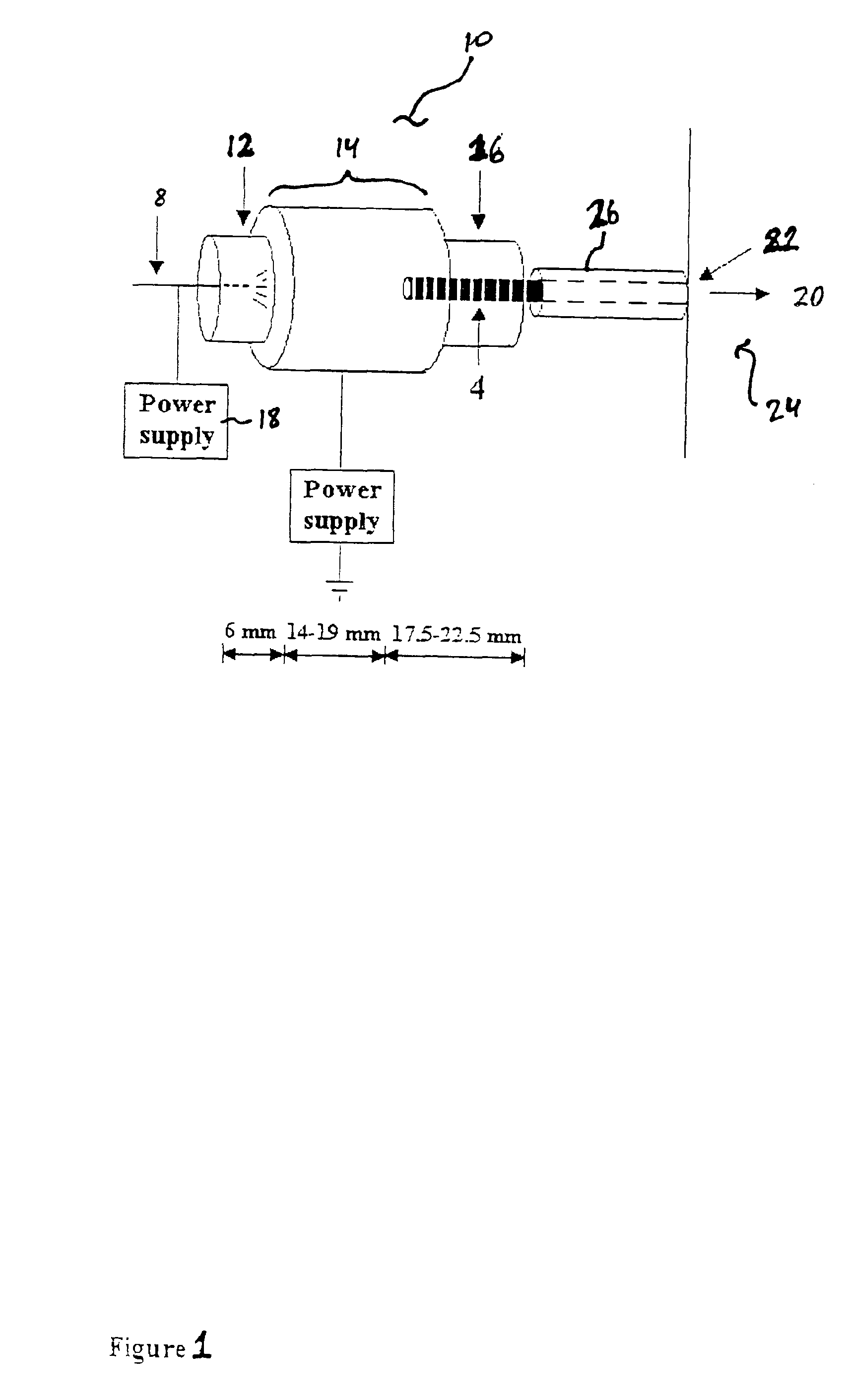

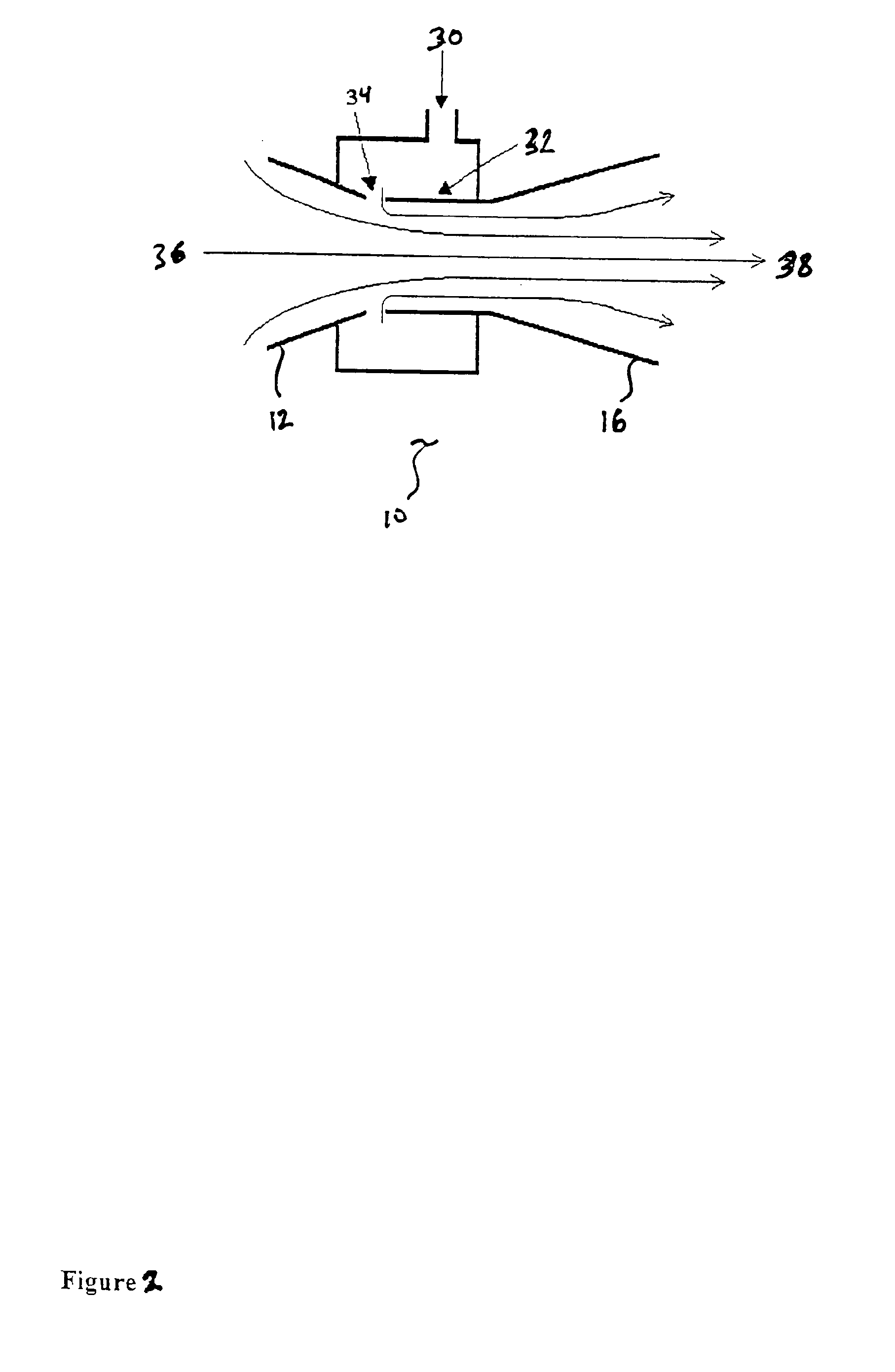

Method and apparatus for aerodynamic ion focusing

InactiveUS6992299B2High sensitivityIncrease the number ofThermometer detailsStability-of-path spectrometersDesolvationHigh velocity

A method and apparatus for focusing ions for delivery to an ion detection device using an aerodynamic ion focusing system that uses a high-velocity converging gas flow at an entrance aperture to focus an ion plume by reducing spreading and increasing desolvation of ions, and wherein a voltage is applied to at least a portion of the aerodynamic ion focusing system to assist in the focusing and delivery of ions to the ion detection device.

Owner:BRIGHAM YOUNG UNIV

Il-17 and il-23 antagonists and methods of using the same

ActiveUS20080095775A1Reduce penetrationInhibit and reduce immune responseSenses disorderNervous disorderCytokineBiology

The present invention relates to blocking, inhibiting, reducing, antagonizing or neutralizing the activity of IL-17, IL-23 via it's p19 subunit or both IL-17 and IL-23 (via p19). IL-17 and IL-23 are cytokines that are involved in inflammatory processes and human disease.

Owner:ZYMOGENETICS INC

Therapeutic peptidomimetic macrocycles

InactiveUS20090275519A1Less treatmentReduce activated hPBL proliferationMetabolism disorderPeptidesMedicineBioactive peptide

The present invention provides biologically active peptidomimetic macrocycles for the treatment of cell proliferative disorders such as cancer and immunoproliferative disease.

Owner:AILERON THERAPEUTICS INC

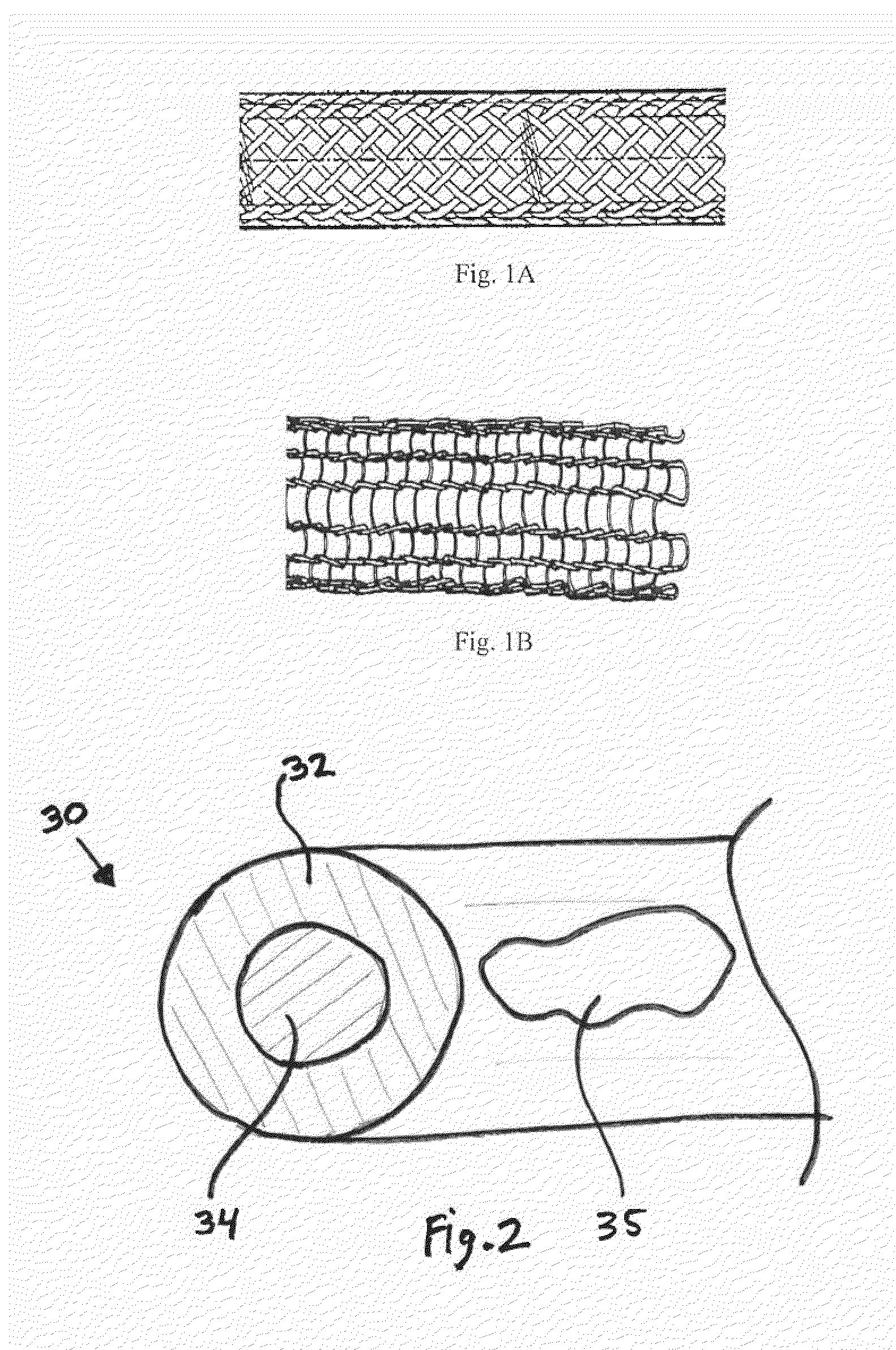

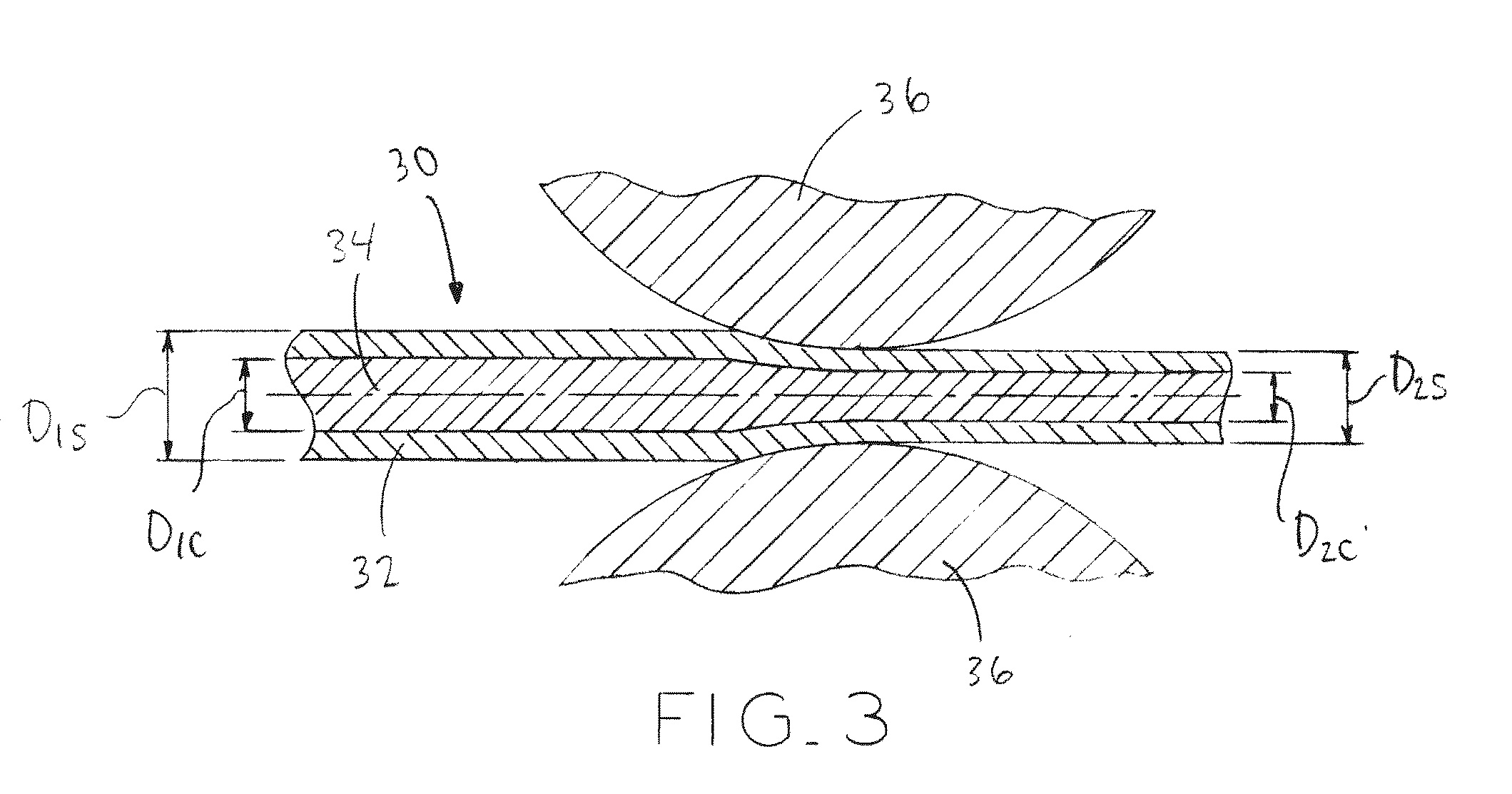

Biodegradable composite wire for medical devices

ActiveUS20110319978A1Vessel patency has been restoredDiffering biodegradation rateStentsSurgeryMechanical integrityPercent Diameter Stenosis

A bimetal composite wire including, in cross-section, an outer shell or tube formed of a first biodegradable material and an inner core formed of a second biodegradable material. When formed into a stent, for example, the first and second biodegradable materials may be different, and may have differing biodegradation rates. In a first embodiment, the first biodegradable material of the shell may degrade relatively slowly for retention of the mechanical integrity of a stent during vessel remodeling, and the second biodegradable material of the core may degrade relatively quickly. In a second embodiment, the first biodegradable material of the shell may degrade relatively quickly, leaving a thinner structure of a second biodegradable material of the core that may degrade relatively slowly. The biodegradation rates may be inherently controlled, such as by selection of materials, and also may be mechanically controlled, such as by material thicknesses and the geometric configuration of the shell, core, or overall device. In any embodiment, the metallic scaffold may also be coated with a drug-eluting, biodegradable polymer, to further inhibit neointimal proliferation and / or restenosis.

Owner:FORT WAYNE METALS RES PROD CORP

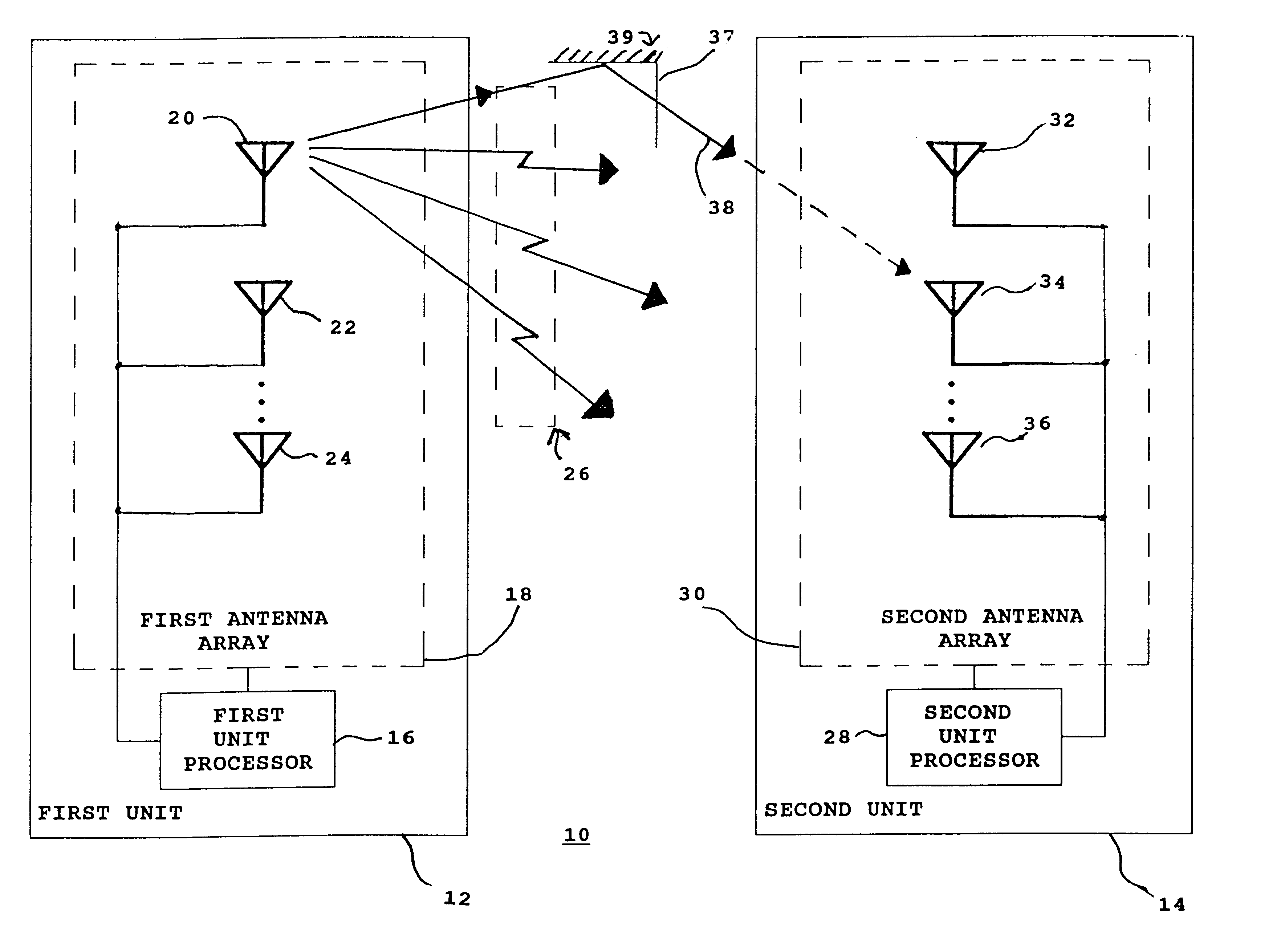

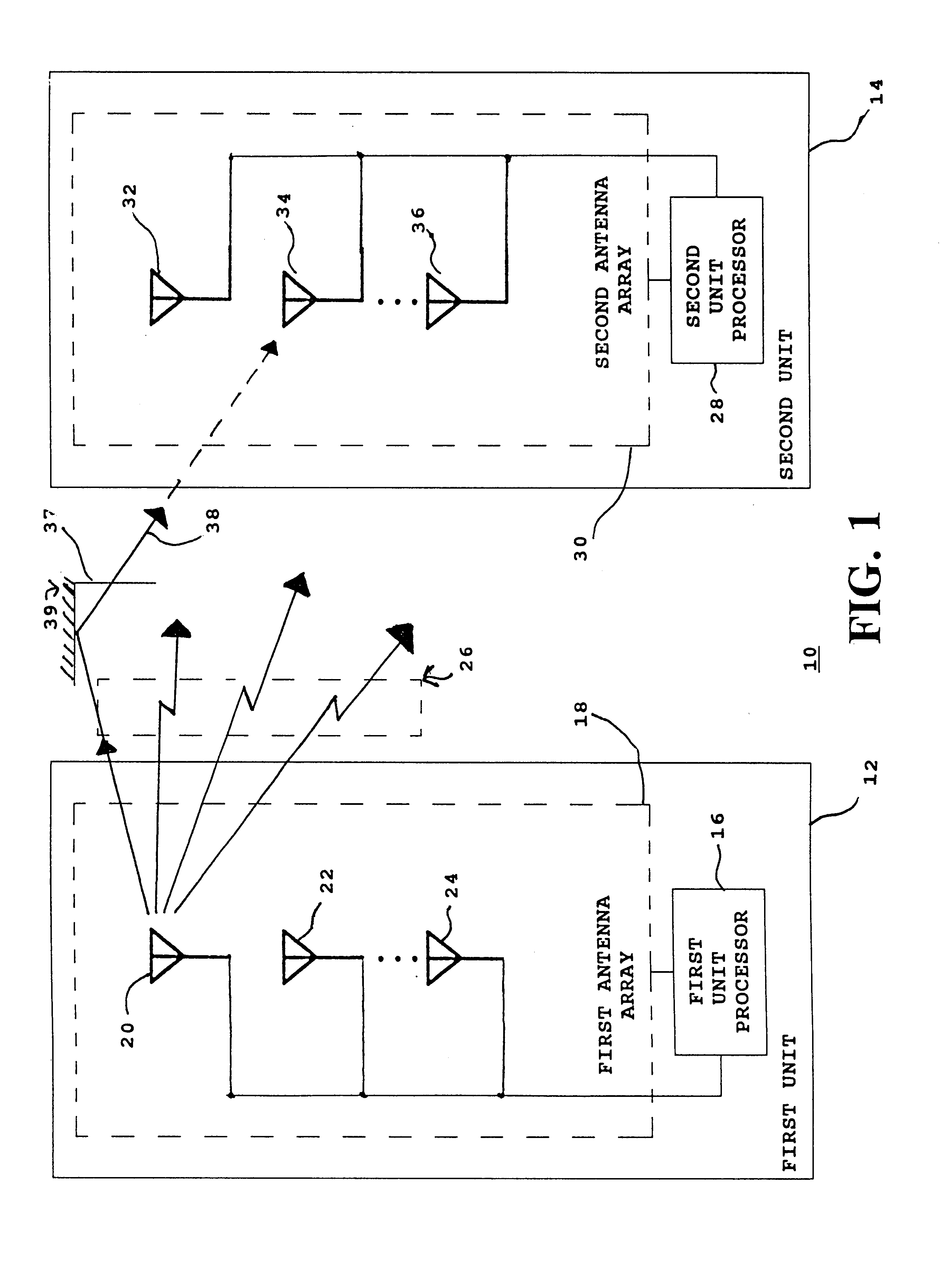

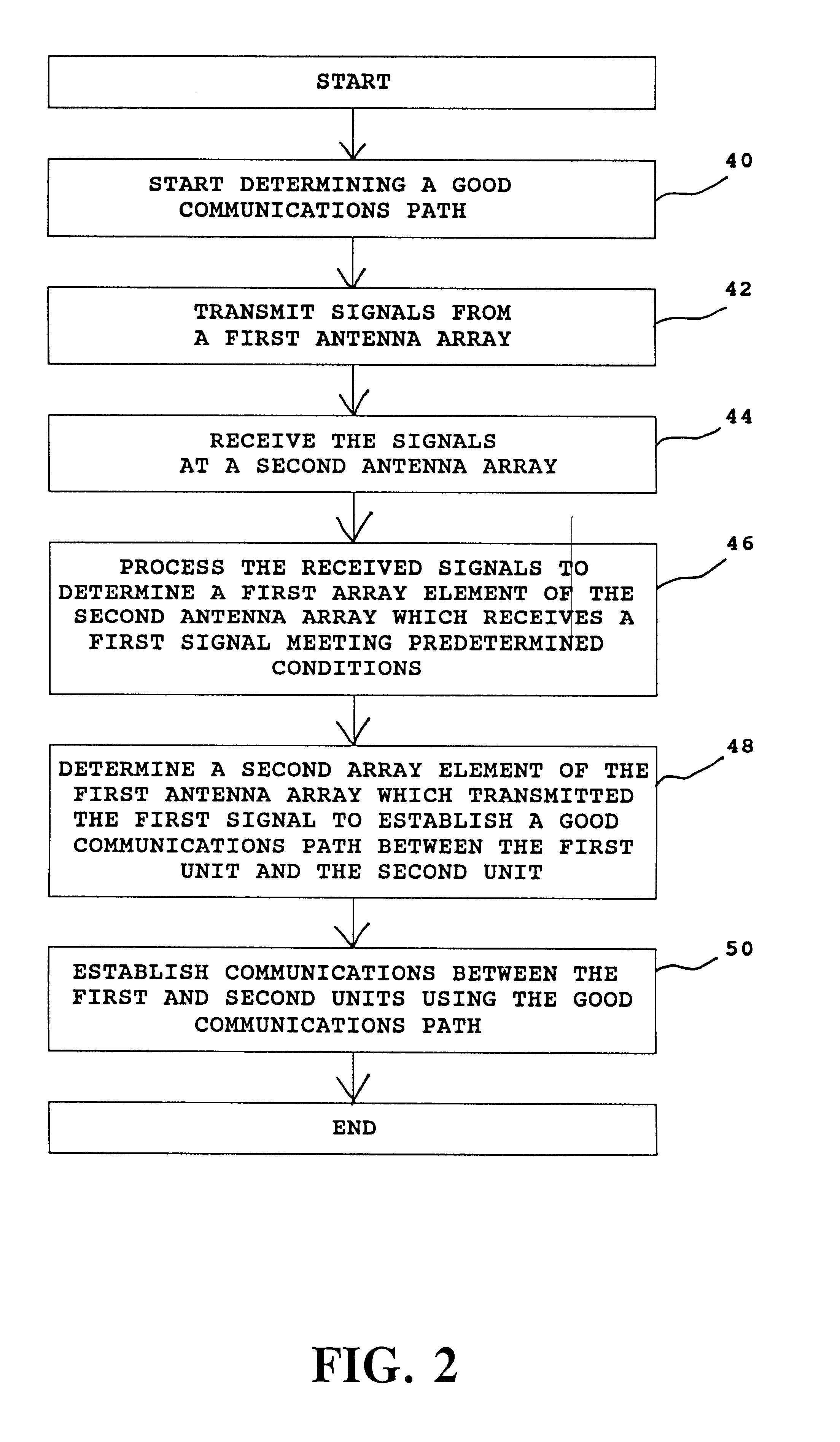

Wireless indoor communications using antenna arrays

InactiveUS6895253B1High data rate communicationIncrease power marginData switching by path configurationDiversity/multi-antenna systemsData transmissionPower margin

A wireless communication system and method includes antenna arrays at both the transmitter and receiver having a plurality of elements for very high data rate communication. Phased array antennas or directive fixed beam antennas are used with a beamwidth in azimuth and elevation less than 30° to increase the power margin and to decrease the delay spread of signals at the receiver to permit wireless data communications at high data rates in closed environments, for example, bursty transmissions and isochronous communications. The wireless communication system is capable of data transmission rates which exceed 1 Gbps with propagation losses of up to at least 60 dB relative to one meter.

Owner:LUCENT TECH INC

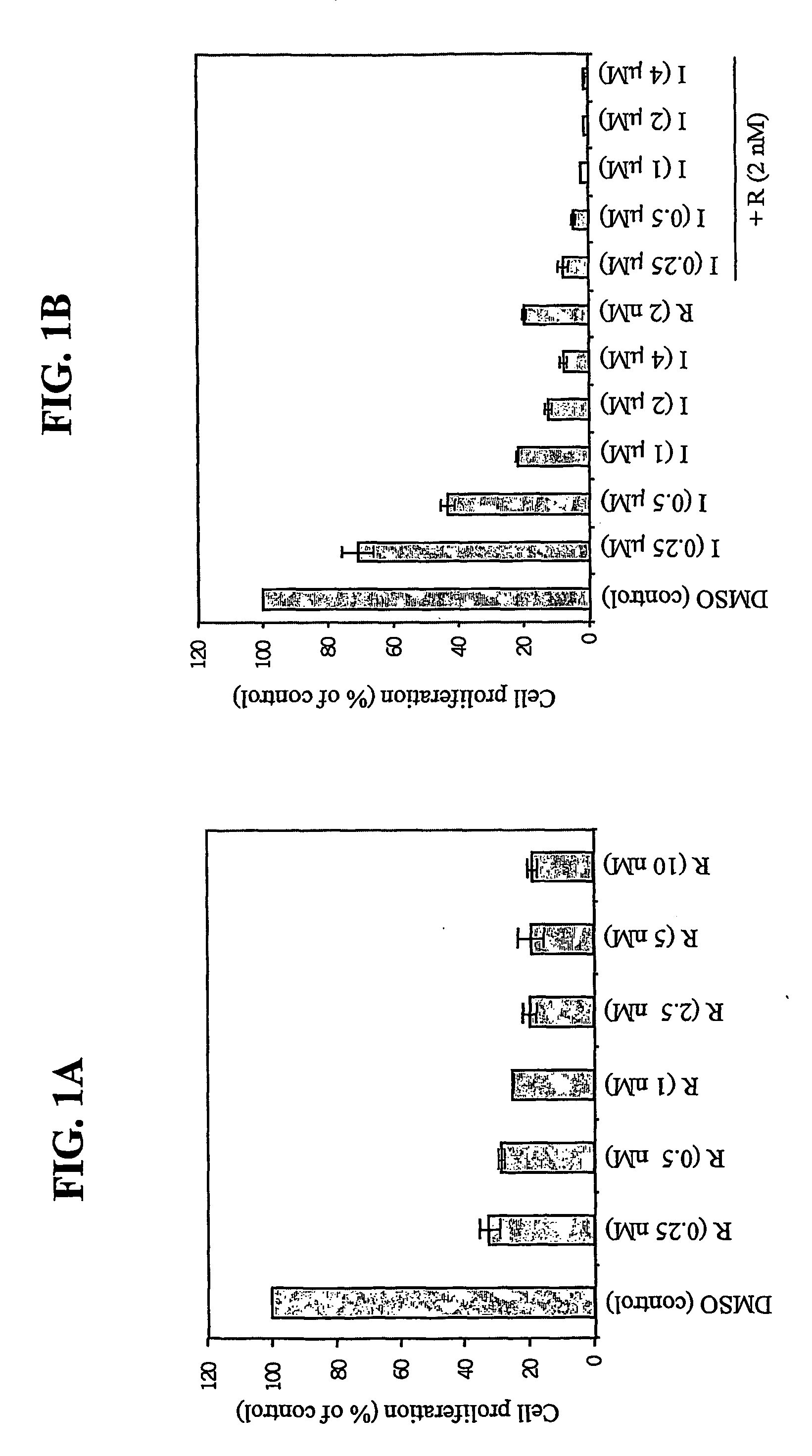

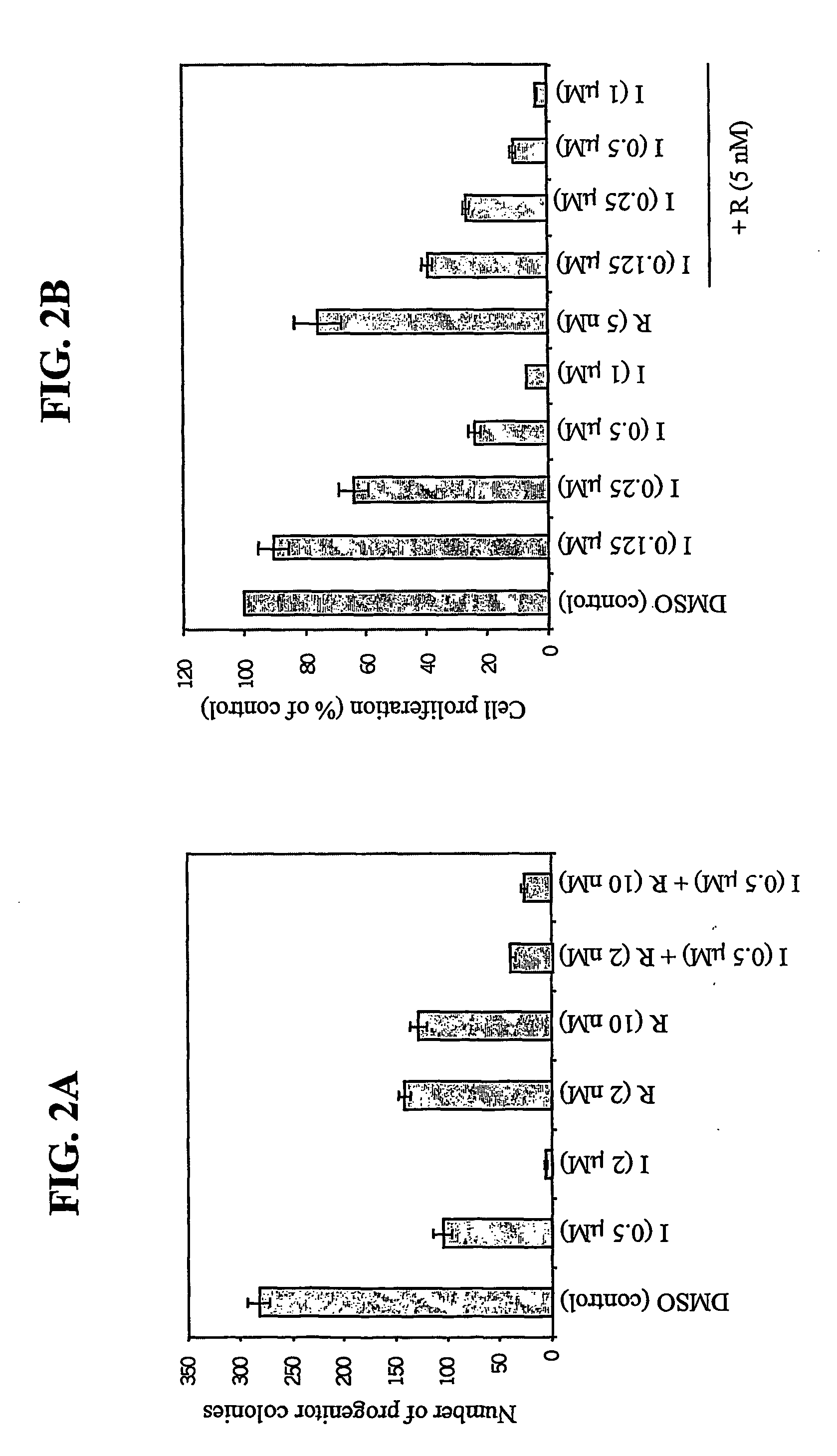

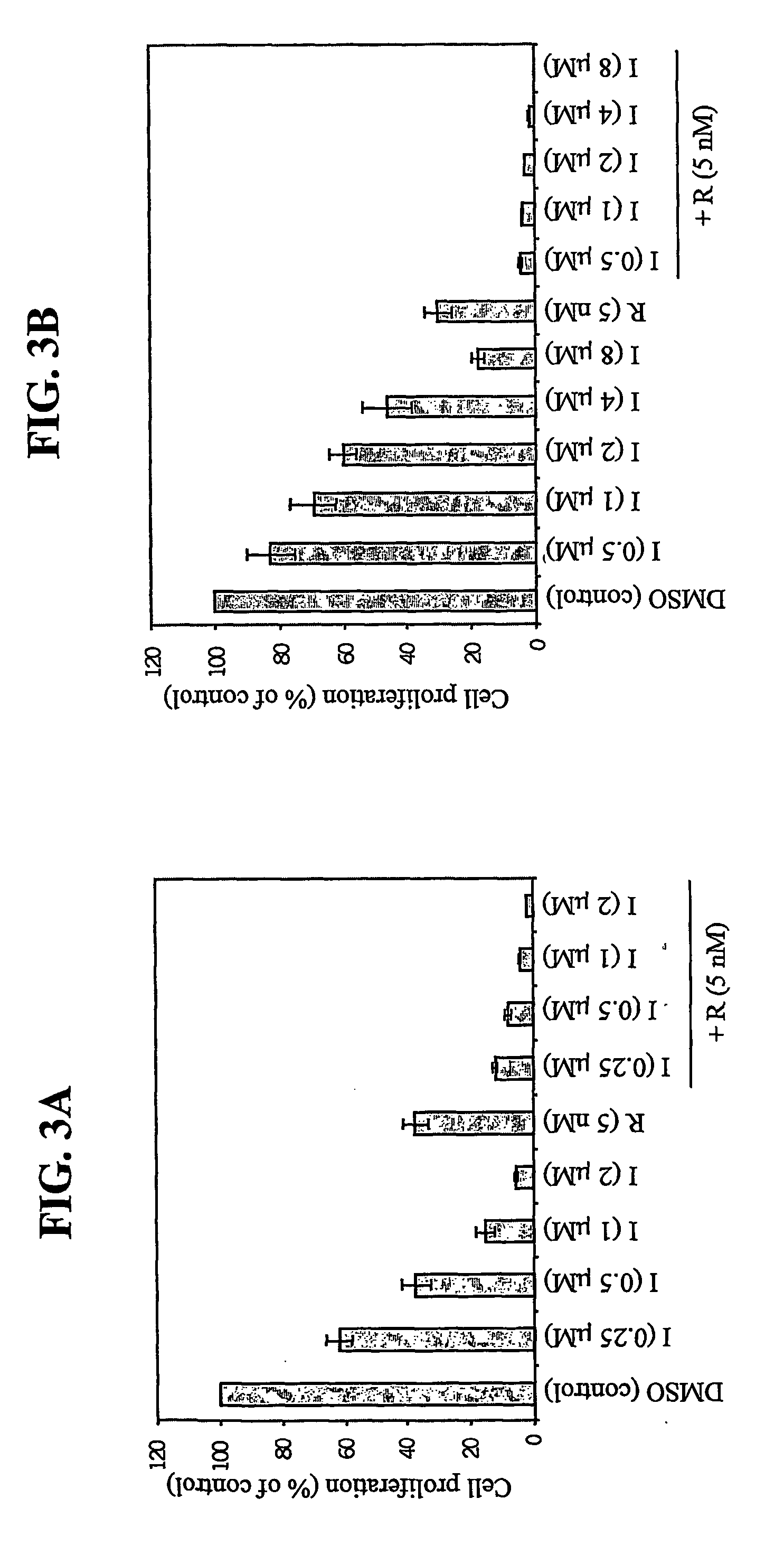

Combination of mtor inhibitor and a tyrosine kinase inhibitor for the treatment of neoplasms

InactiveUS20060094674A1Reduce spreadIncreased apoptosisBiocideGenetic material ingredientsMEK inhibitorTyrosine-kinase inhibitor

The invention features methods and compositions including an mTOR inhibitor and a tyrosine kinase inhibitor for reducing the proliferation of and enhancing the apoptosis of neoplastic cells. The addition of an MEK inhibitor to this combination further enhances the effectiveness of this therapeutic method.

Owner:BETH ISRAEL DEACONESS MEDICAL CENT INC

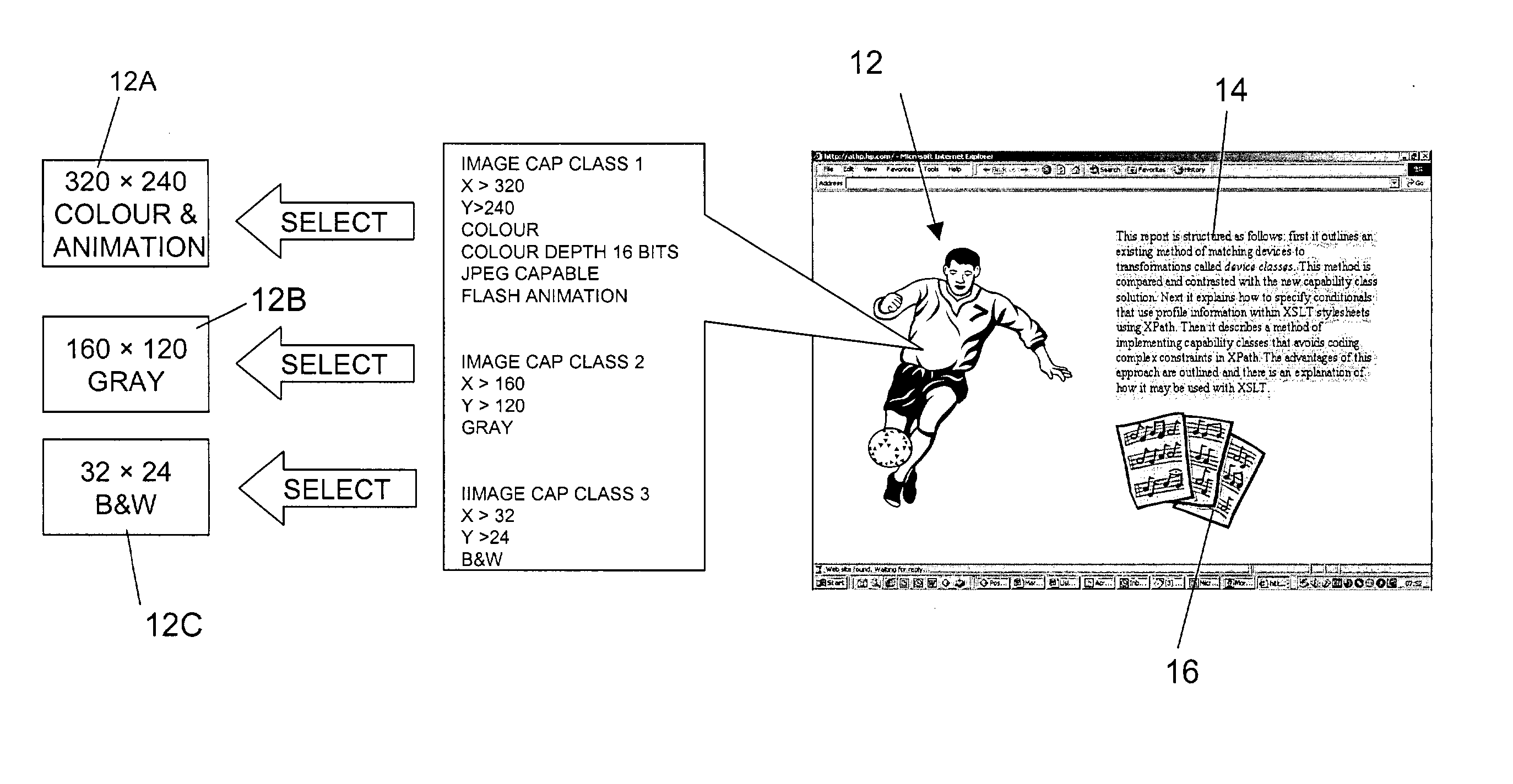

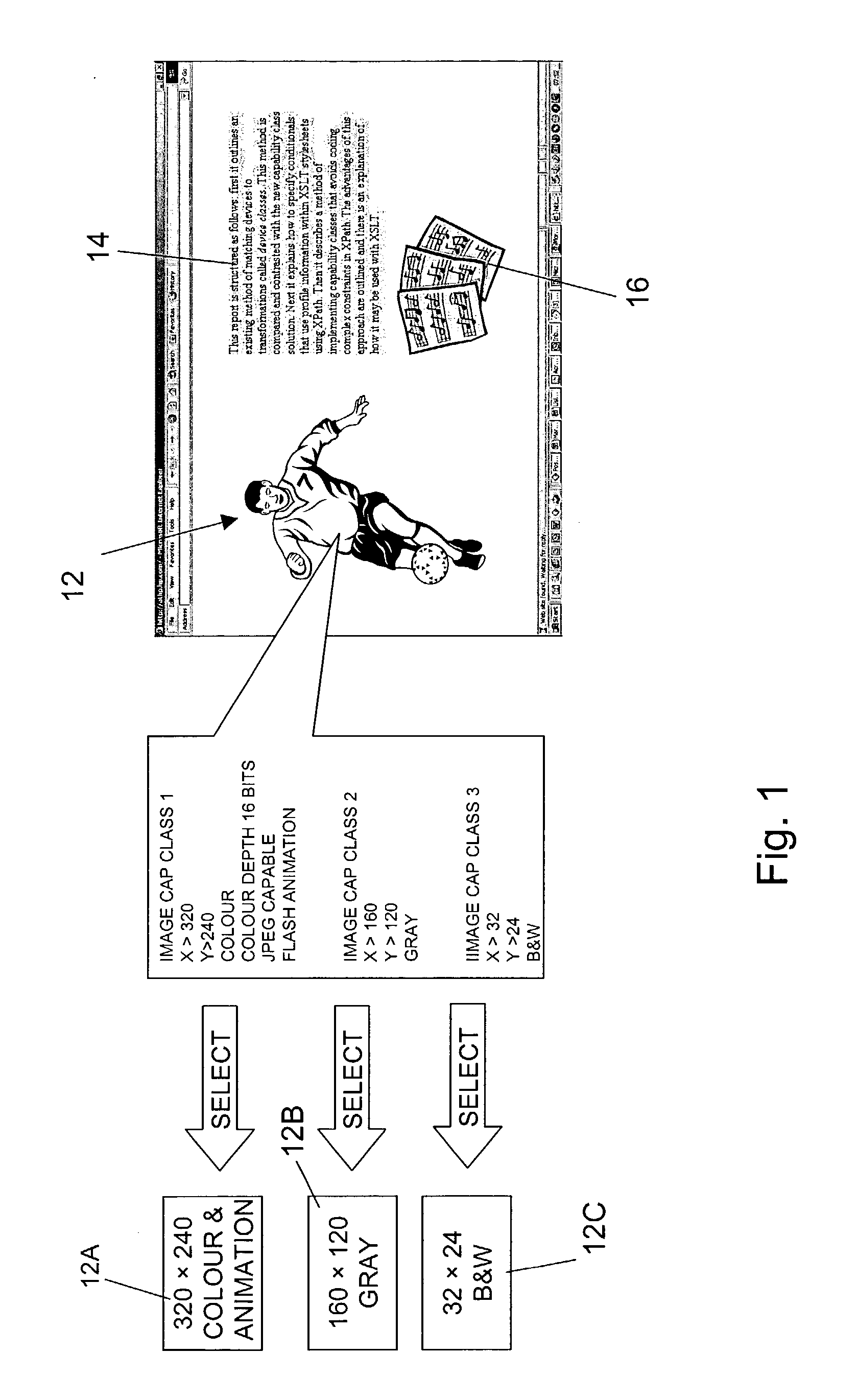

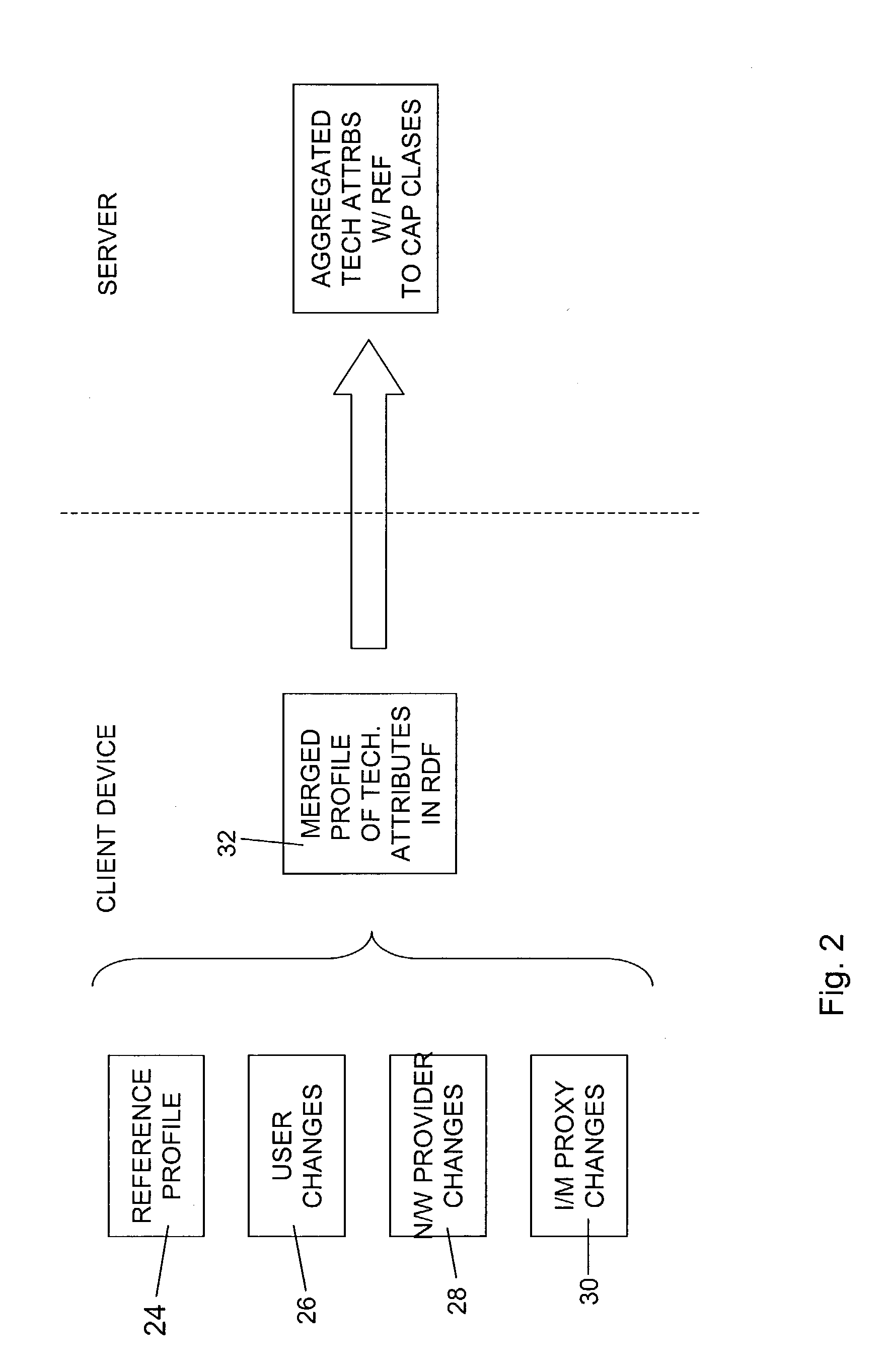

Provision of content to a client device

InactiveUS20030167334A1Reduce spreadMultiple digital computer combinationsSecuring communicationClient-sideWeb page

Content accessible to a variety of client devices from a web page is associated with machine readable labels setting out capabilities required by a client device in order to manifest the content in a meaningful manner. Several versions of the content may be provided by the author, each version of the content being associated with its own specification of client device capabilities required to manifest it. The capabilities required are matched with the technical attributes of a client device, in order to establish which version of the content to provide to a client device.

Owner:HEWLETT PACKARD DEV CO LP

Feed additives for animals: prevention of foot and mouth disease

The present invention relates to feed additives for cloven-hooved animals. The invention provides methods for making a biological compositions comprising yeast cells that can improve the immune functions of such animals such that the incidence of foot and mouth disease is reduced. The invention also relates to methods for manufacturing the biological compositions, and methods of using the biological compositions as feed additives.

Owner:ULTRA BIOTECH

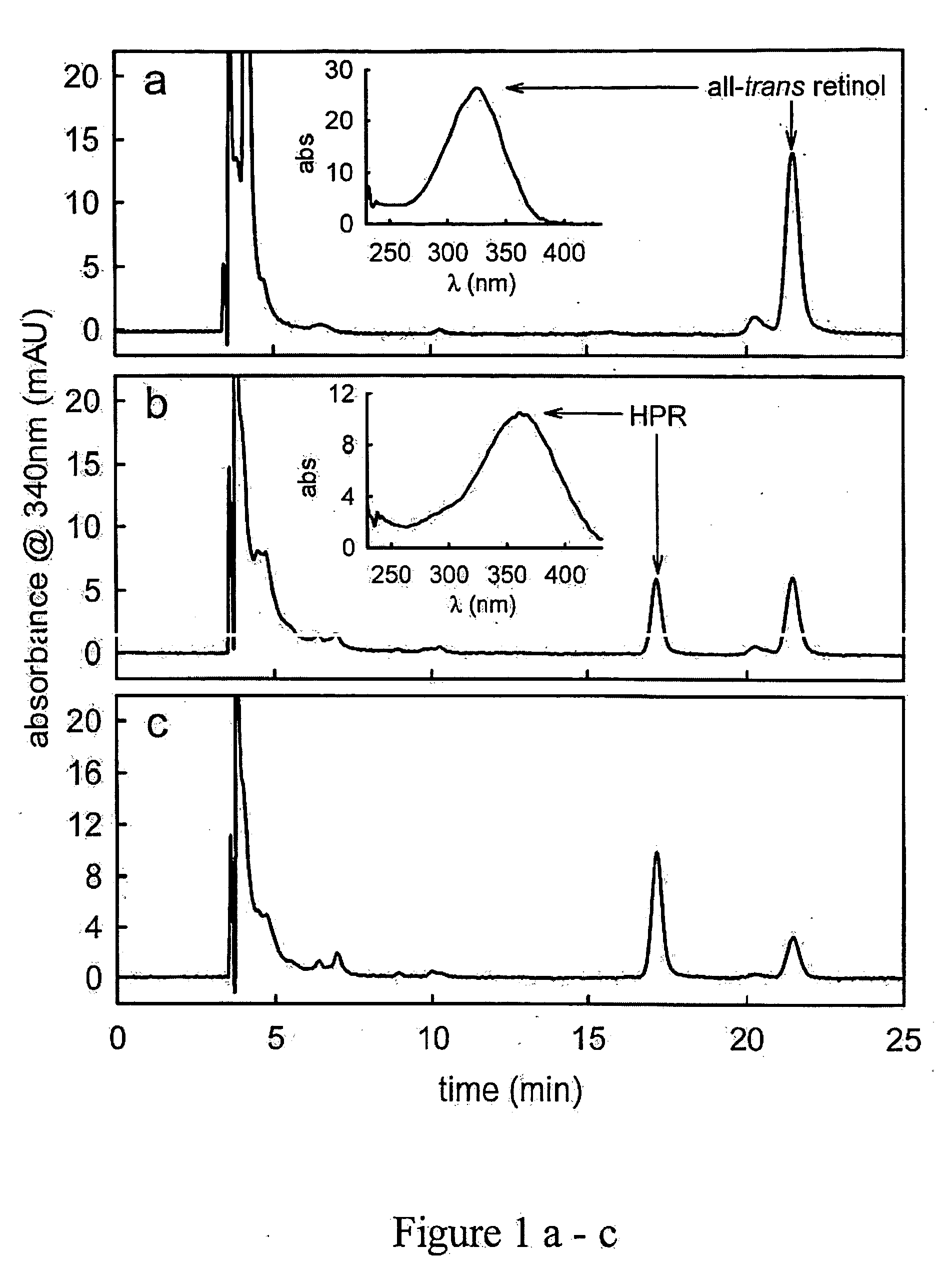

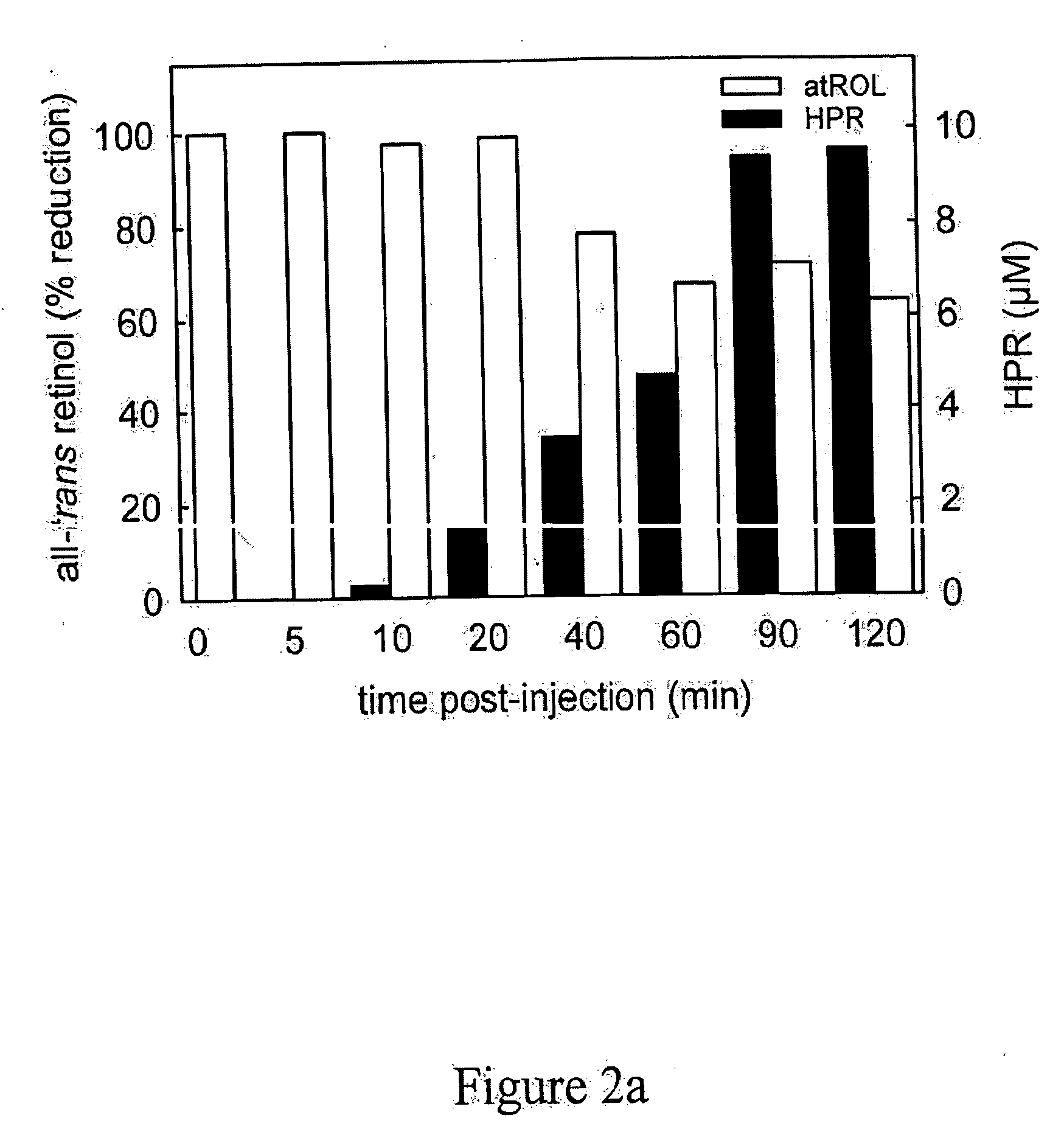

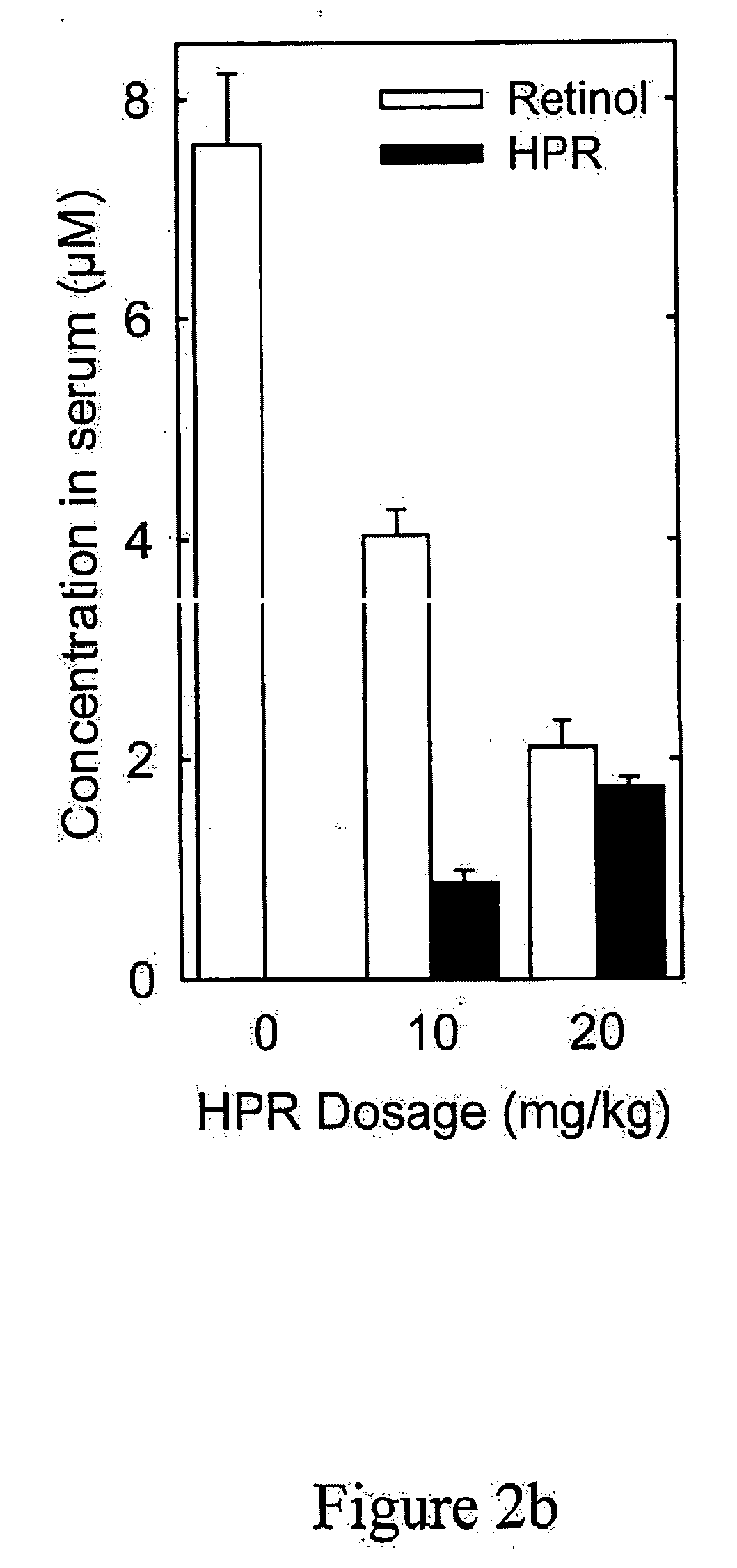

Methods and compositions for treating ophthalmic conditions with retinyl derivatives

Compounds that cause reversible night blindness may be used to treat ophthalmic conditions associated with the overproduction of waste products that accumulate during the course of the visual cycle. We describe methods and compositions using such compounds and their derivatives to treat, for example, the macular degenerations and dystrophies or to alleviate symptoms associated with such ophthalmic conditions. Such compounds and their derivatives may be used as single agent therapy or in combination with other agents or therapies.

Owner:ACUACELA INC

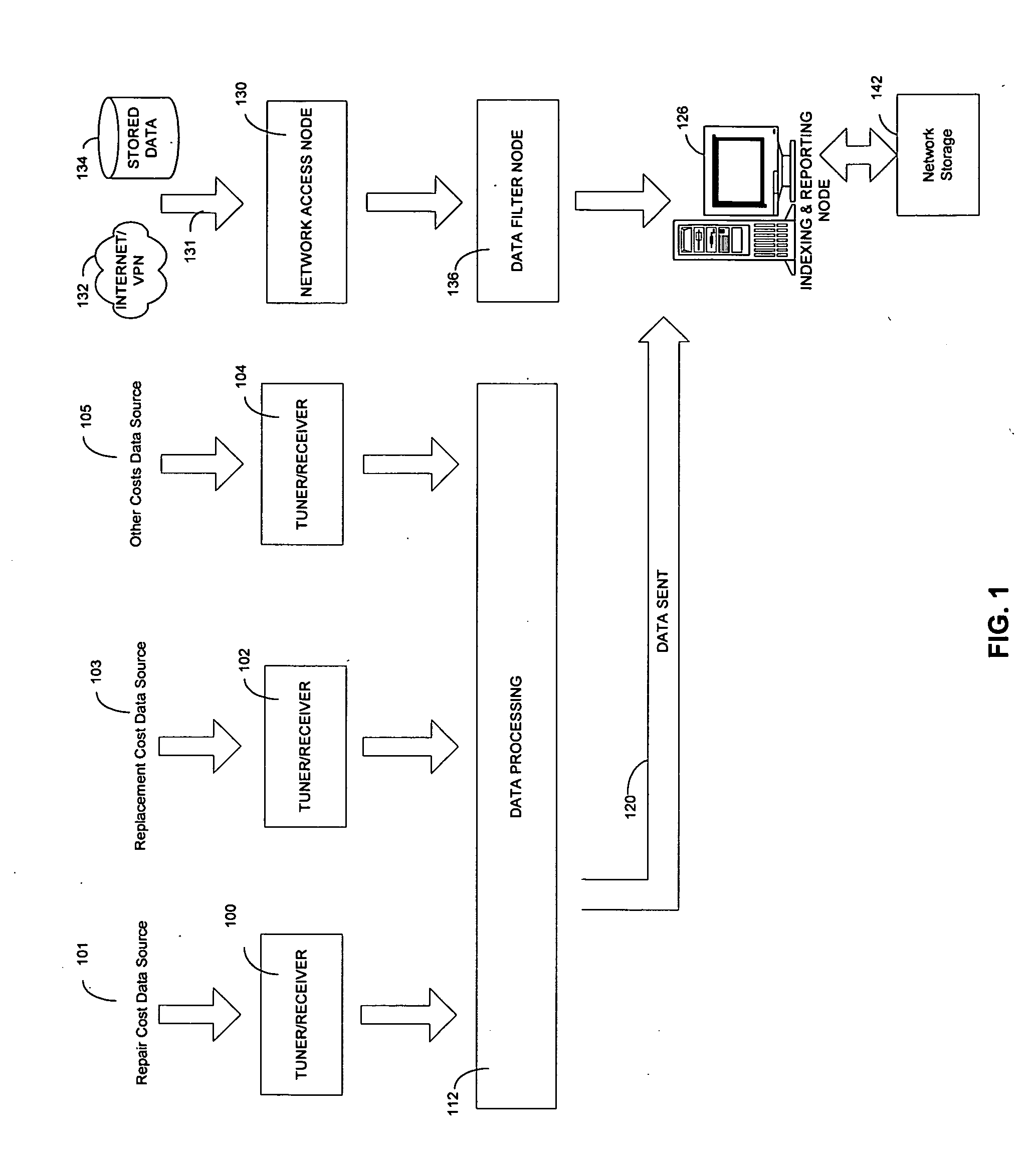

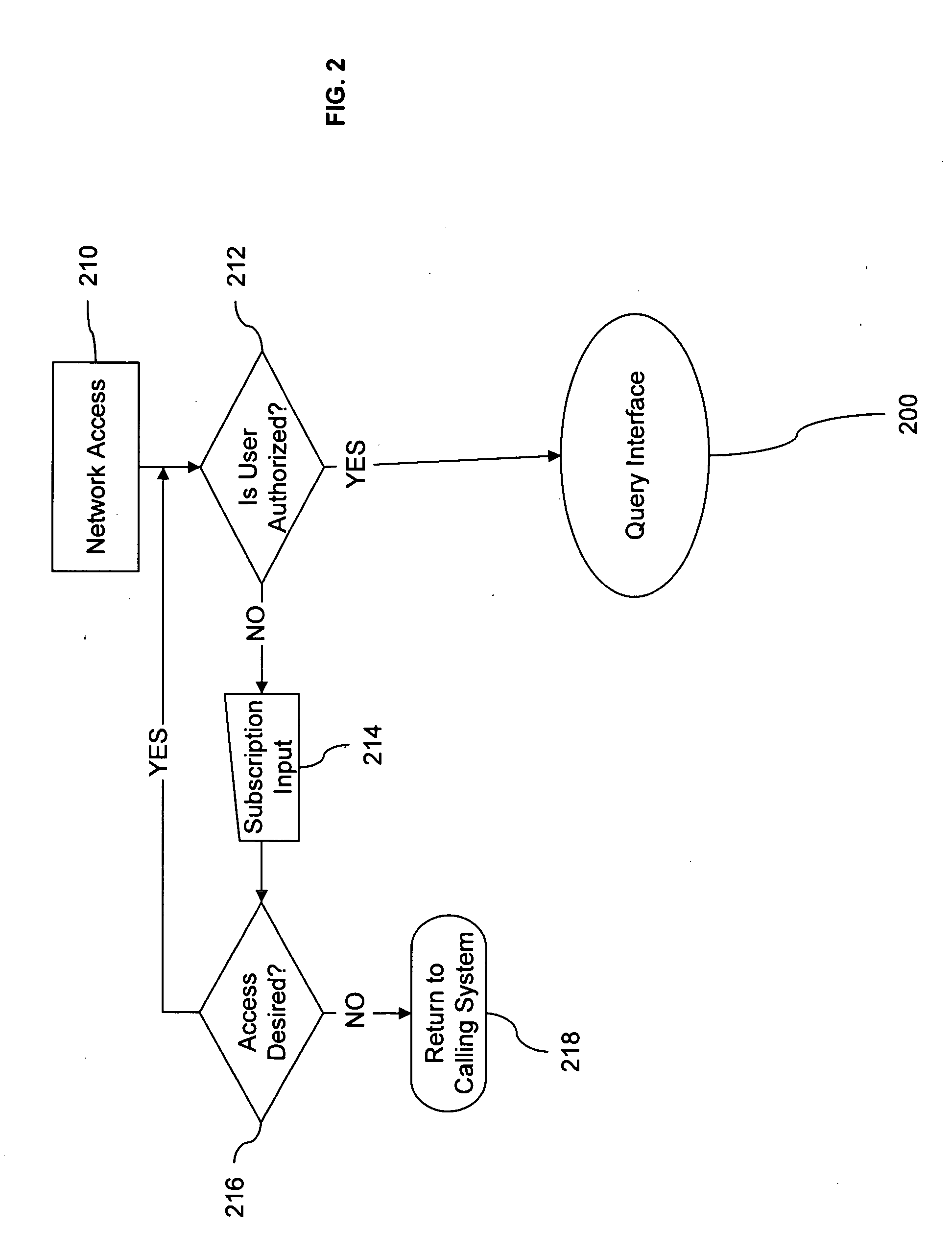

System and method for salvage calculation, fraud prevention and insurance adjustment

InactiveUS20080097796A1Improved claim file documentationReduce frequency and likelihoodFinanceTime informationComputer science

Disclosed is a novel system and method that provides real time information to an insurance adjuster. The system obtains information related to an insured item which has an outstanding claim. Information includes the cost to repair a specific item, the salvage value of the item, and the cost to replace the item. The system then compares the information related to the insured item from an economic perspective to determine whether it should be repaired or replaced. Since the system is objective, it reduces the reliance on subjective human factors such as collusion and lack of expertise. As a result, the system reduces the number of fraudulent and inaccurate transactions related to the specific item.

Owner:HARTFORD FIRE INSURANCE

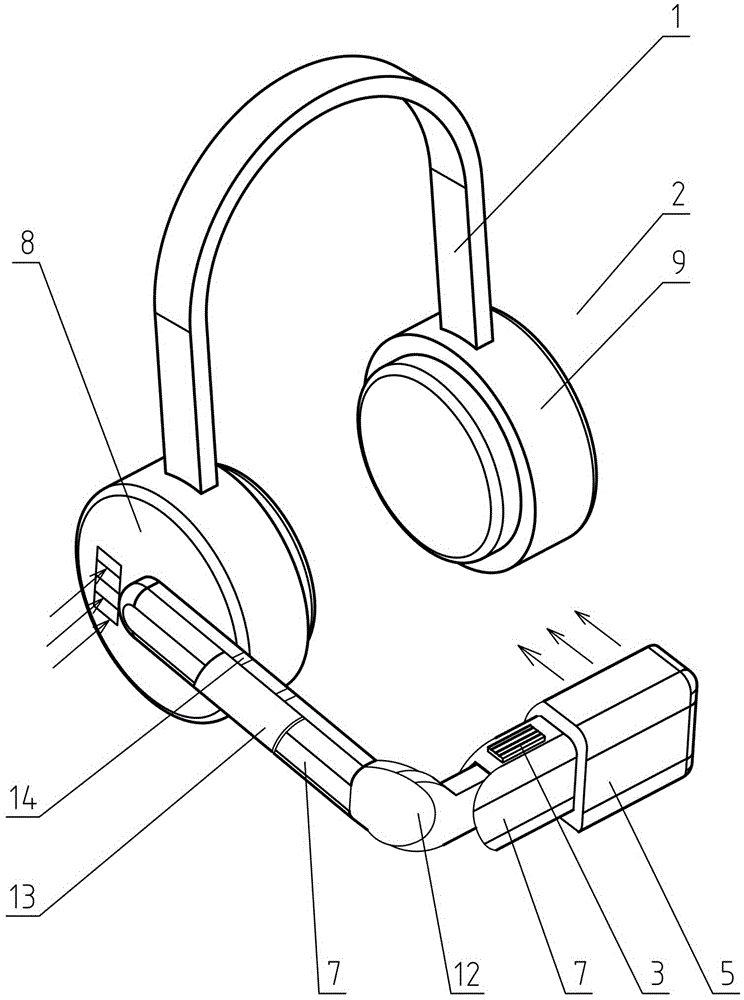

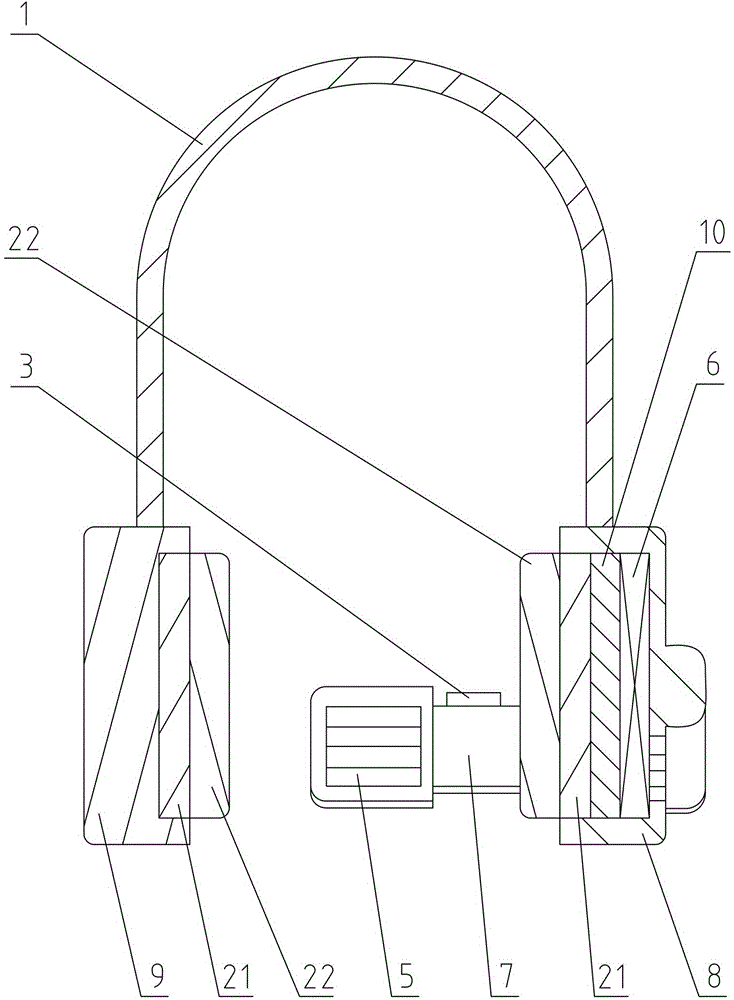

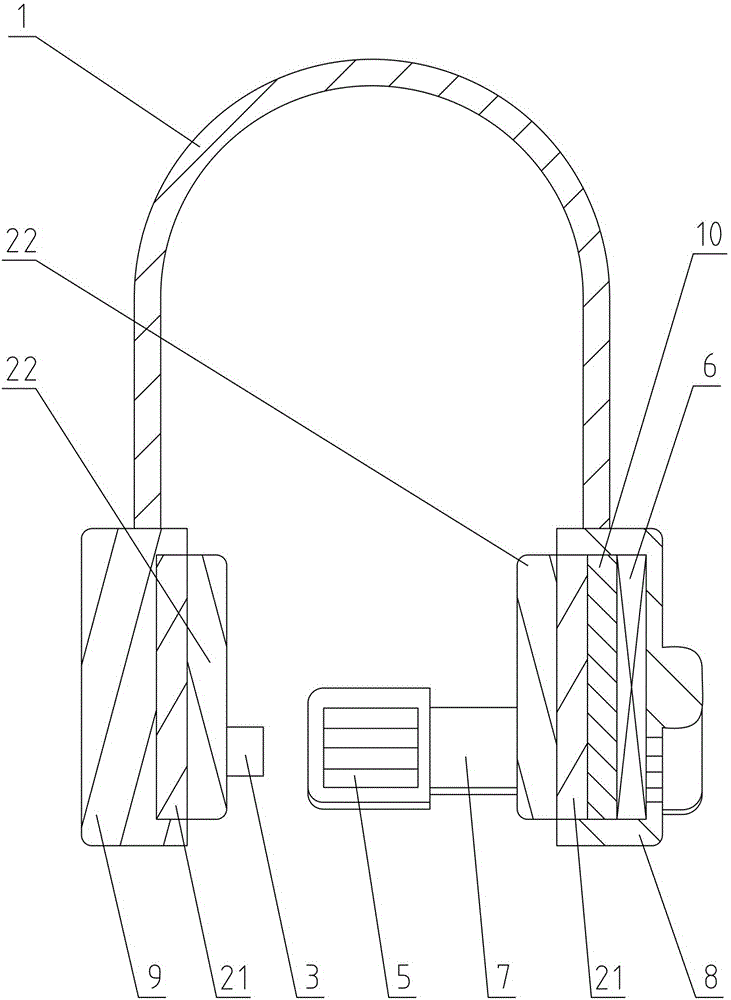

Head-mounted portable air purifier

InactiveCN103949017AReduce breedingReduce spreadFire rescueRespiratory apparatusAir purifiersFresh air

The invention discloses a head-mounted portable air purifier. An air purification assembly is additionally arranged on a lug; the air purification assembly comprises an air purification device, a fan and a connecting air pipe; the fan is mounted on the lug; the top end of the connecting air pipe is connected with the fan, and the tail end of the connecting air pipe is connected with the air purification device; a microphone is arranged at the part, of the connecting air pipe or the lug, close to the air purification device, so that an earphone is combined with the air purifier and a user can breathe fresh air in time when using the earphone. The human health is effectively maintained, the head-mounted portable air purifier is diversified in function and attractive in appearance, and the use comfort of the air purifier is improved. Moreover, a door body capable of being used for opening a pipe cavity is arranged on the connecting air pipe, so that the connecting air pipe is convenient to clean and maintain; wires are tightly attached to the inner wall of the connecting air pipe, so that the wires are effectively protected by the connecting air pipe, and the service quality of the earphone is improved.

Owner:KINGBY PHOTOCATALYSIS SCI & TECH

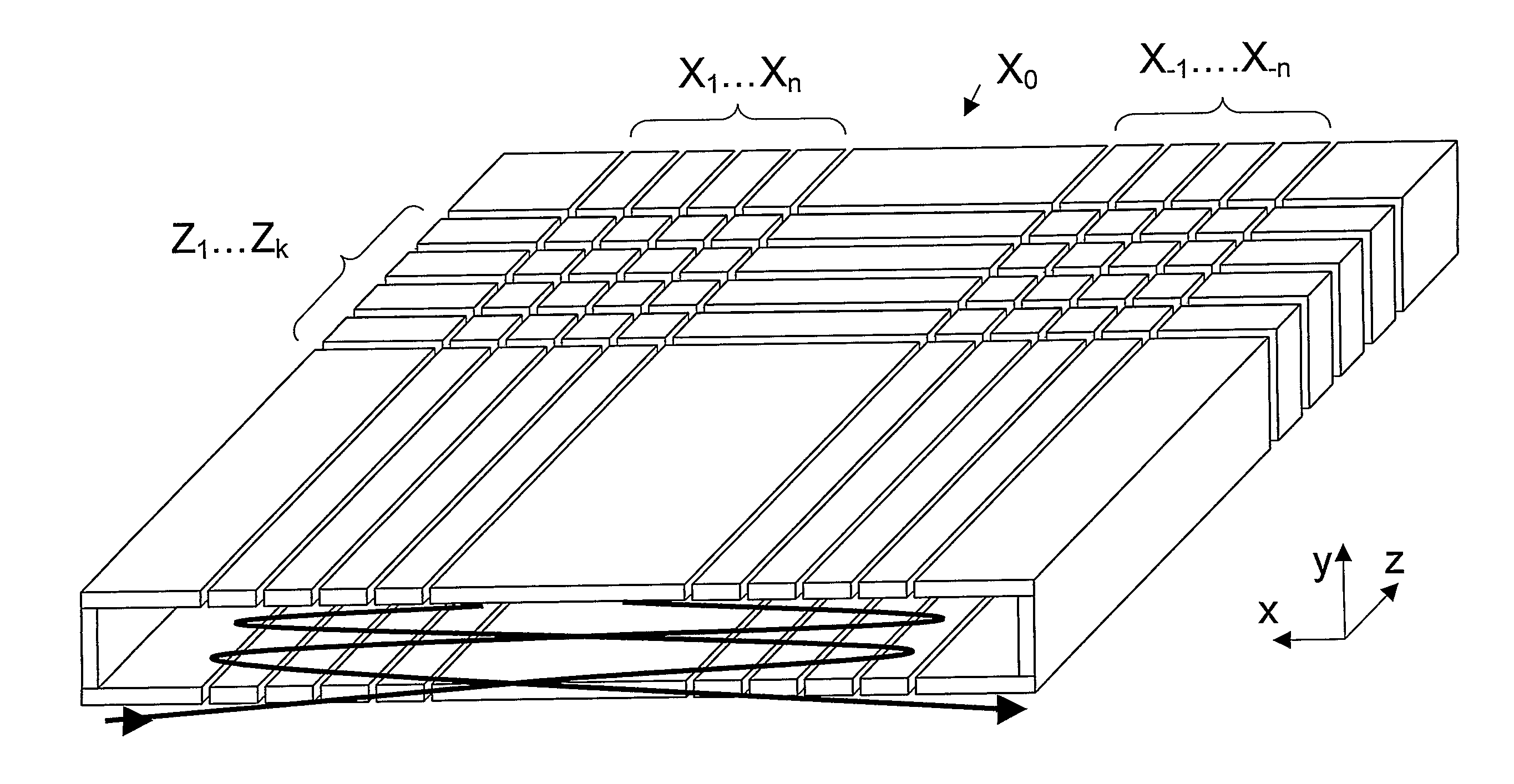

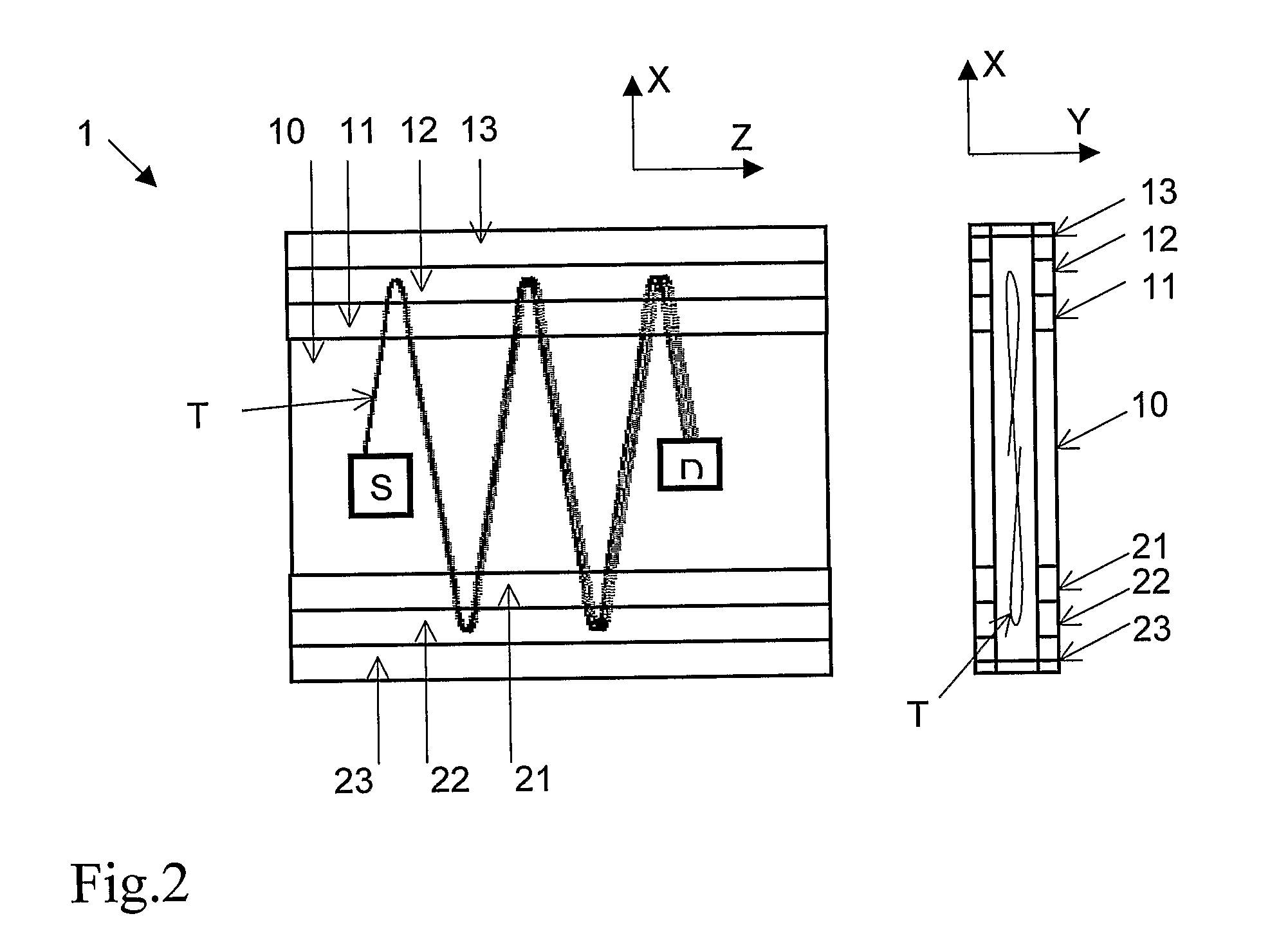

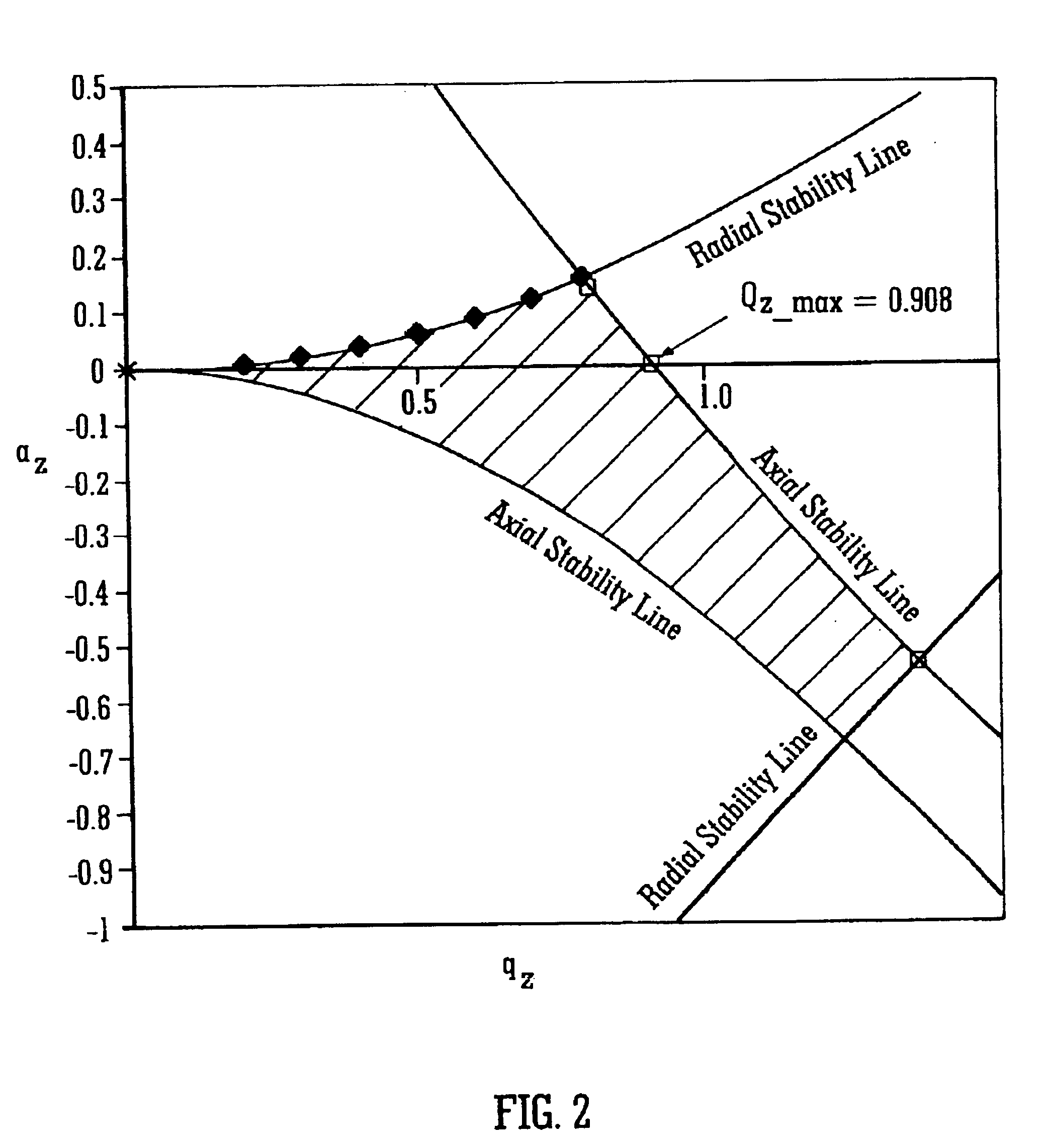

Multi-reflecting time-of-flight mass analyser and a time-of-flight mass spectrometer including the mass analyser

ActiveUS20100044558A1Minimizing beam spreadReducing angular spreadIsotope separationMass spectrometersTime-of-flight mass spectrometryFlight direction

A multi-reflecting TOF mass analyser has two parallel, gridless ion mirrors each having an elongated structure in a drift direction (Z). These ion mirrors provide a folded ion path formed by multiple reflections of ions in a flight direction (X), orthogonal to the drift direction (Z). The analyser also has a further gridless ion mirror for reflecting ions in the drift direction (Z). In operation ions are spatially separated according to mass-to-charge ratio due to their different flight times along the folded ion path and ions having substantially the same mass-to-charge ratio are subjected to energy focusing with respect to the flight and drift directions.

Owner:SHIMADZU CORP

IL-17 and IL-23 antagonists and methods of using the same

ActiveUS7790862B2Reduce penetrationInhibit and reduce immune responseSenses disorderNervous disorderCytokineAntagonist

The present invention relates to blocking, inhibiting, reducing, antagonizing or neutralizing the activity of IL-17, IL-23 via it's p19 subunit or both IL-17 and IL-23 (via p19). IL-17 and IL-23 are cytokines that are involved in inflammatory processes and human disease.

Owner:ZYMOGENETICS INC

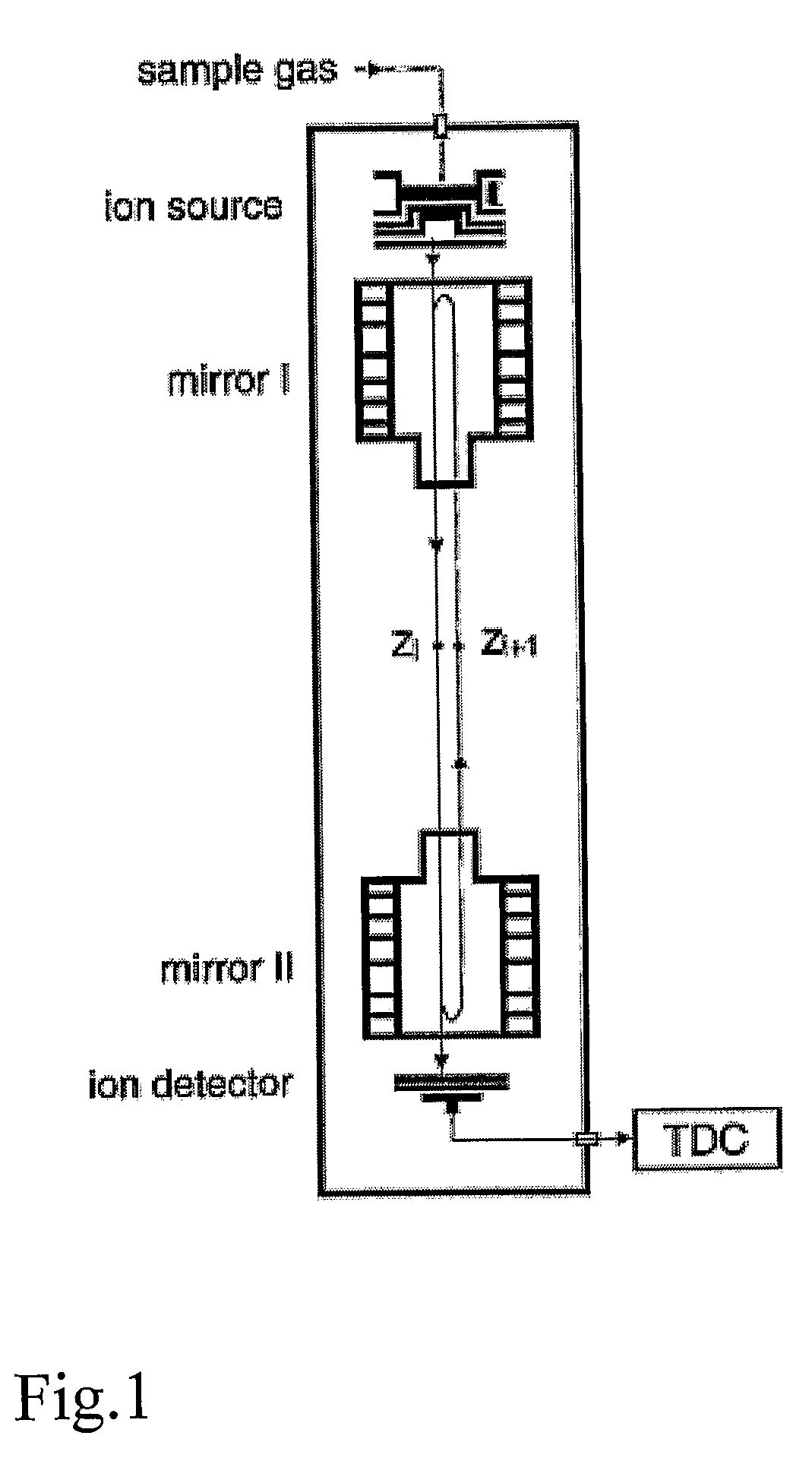

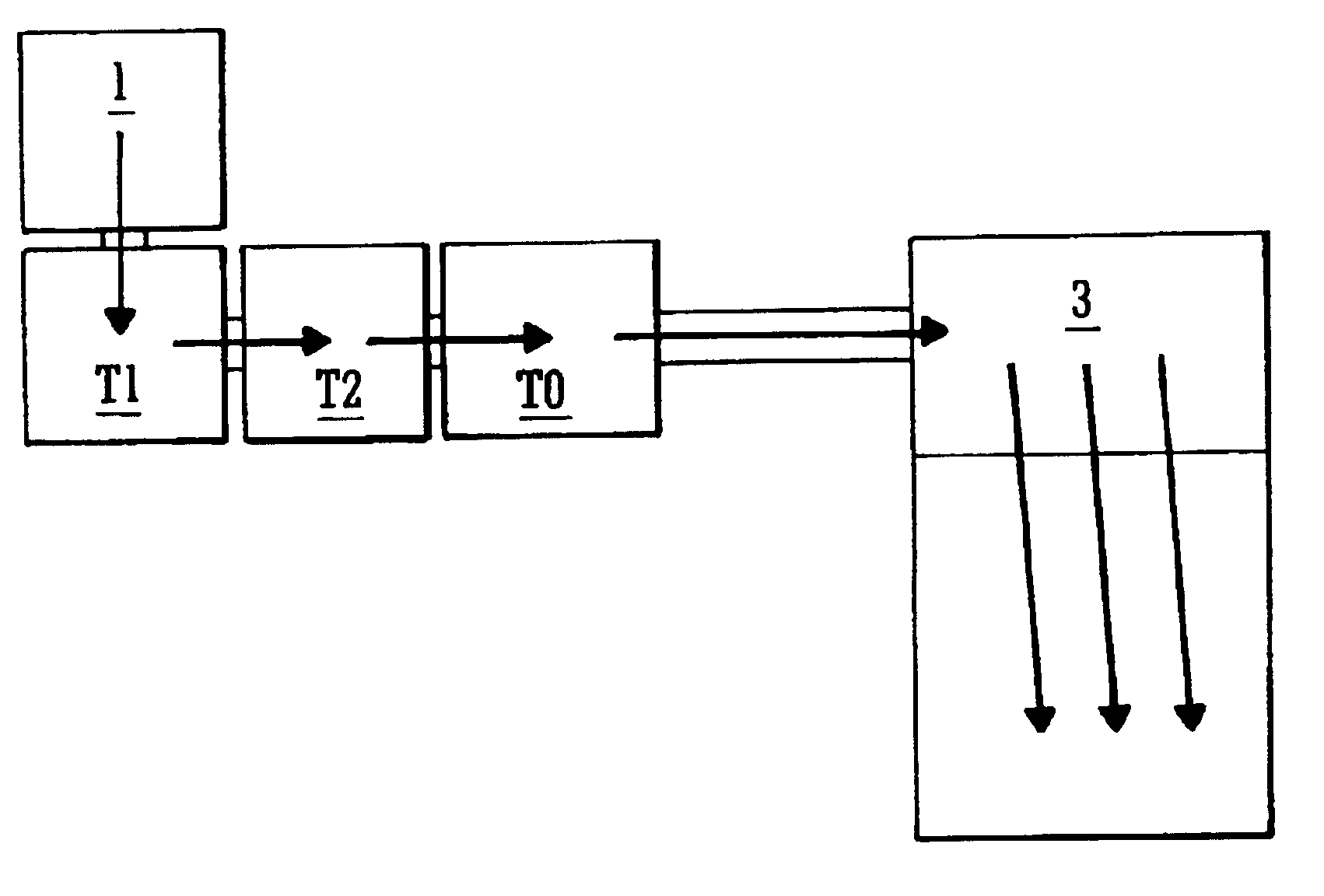

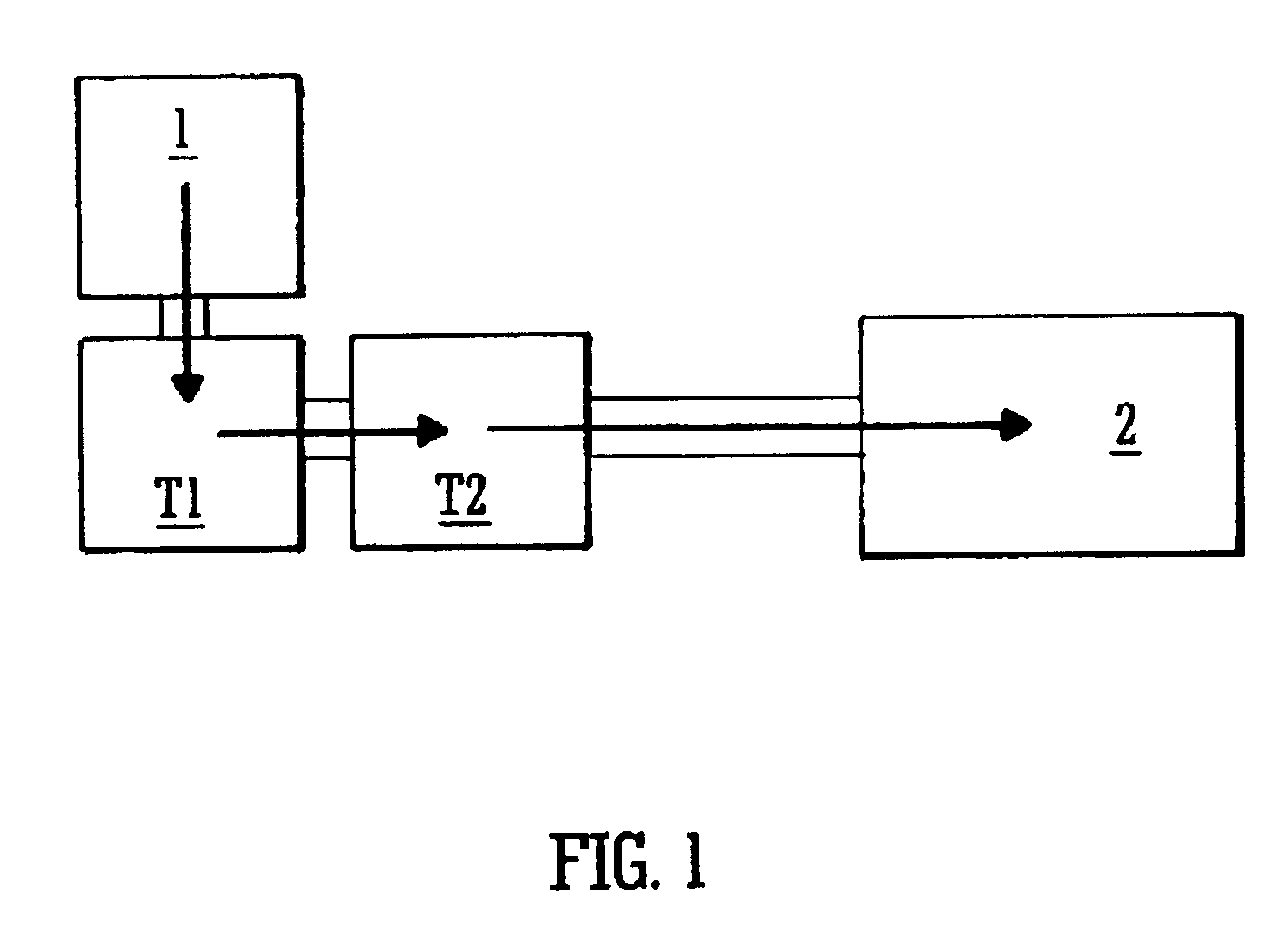

Mass spectrometer

InactiveUS6875980B2Increases ion trapping volumeIncrease capacityStability-of-path spectrometersTime-of-flight spectrometersIon trap mass spectrometryMass analyzer

A mass spectrometer is disclosed wherein a relatively energetic pulse of ions having a relatively narrow spread of mass to charge ratios are ejected from a quadrupole ion trap and received in an ion trap upstream of a Time of Flight mass analyser. The ions are collisionally cooled within the ion trap and are pulsed out of the ion trap and into an extraction region of the Time of Flight mass analyser without substantially exciting the ions. This enables improved operation with the Time of Flight mass analyser. According to another embodiment, parent ions are fragmented and the resulting fragment ions are stored in two ion traps having different low mass cut-offs. The trapping system enables MS / MS experiments to be performed with a very high duty cycle.

Owner:MICROMASS UK LTD

Targeted drug delivery using EphA2 or EphA4 binding moieties

InactiveUS20050153923A1Good curative effectIncreased level of cytokineAntibody mimetics/scaffoldsGenetic material ingredientsDelivery vehicleNucleotide

The present invention relates to methods and compositions designed for the treatment, management, or prevention of a hyperproliferative cell disease, particularly cancer. The methods of the invention comprise the administration of an effective amount of a composition that targets cells expressing an Eph family receptor tyrosine kinase, such as EphA2 or EphA4, for the treatment, management, or prevention of hyperproliferative diseases, particularly cancer. In one embodiment, the method of the invention comprises administering to a subject a composition comprising an EphA2 or EphA4 targeting moiety attached to a delivery vehicle, and one or more therapeutic or prophylactic agents that treat or prevent a hyperproliferative disease, where the therapeutic or prophylactic agents are operatively associated with the delivery vehicle. In another embodiment, the method of the invention comprises administering to a subject a composition comprising a nucleic acid comprising a nucleotide sequence encoding an EphA2 or EphA4 targeting moiety and a therapeutic or prophylactic agent that treats or prevents a hyperproliferative disease. In yet another embodiment, the method of the invention comprises administering to a subject a composition comprising an EphA2 or EphA4 targeting moiety and a nucleic acid comprising a nucleotide sequence encoding an agent that treats or prevents a hyperproliferative disease, where the nucleic acid is operatively associated with the delivery vehicle. Pharmaceutical compositions are also provided by the present invention.

Owner:MEDIMMUNE LLC

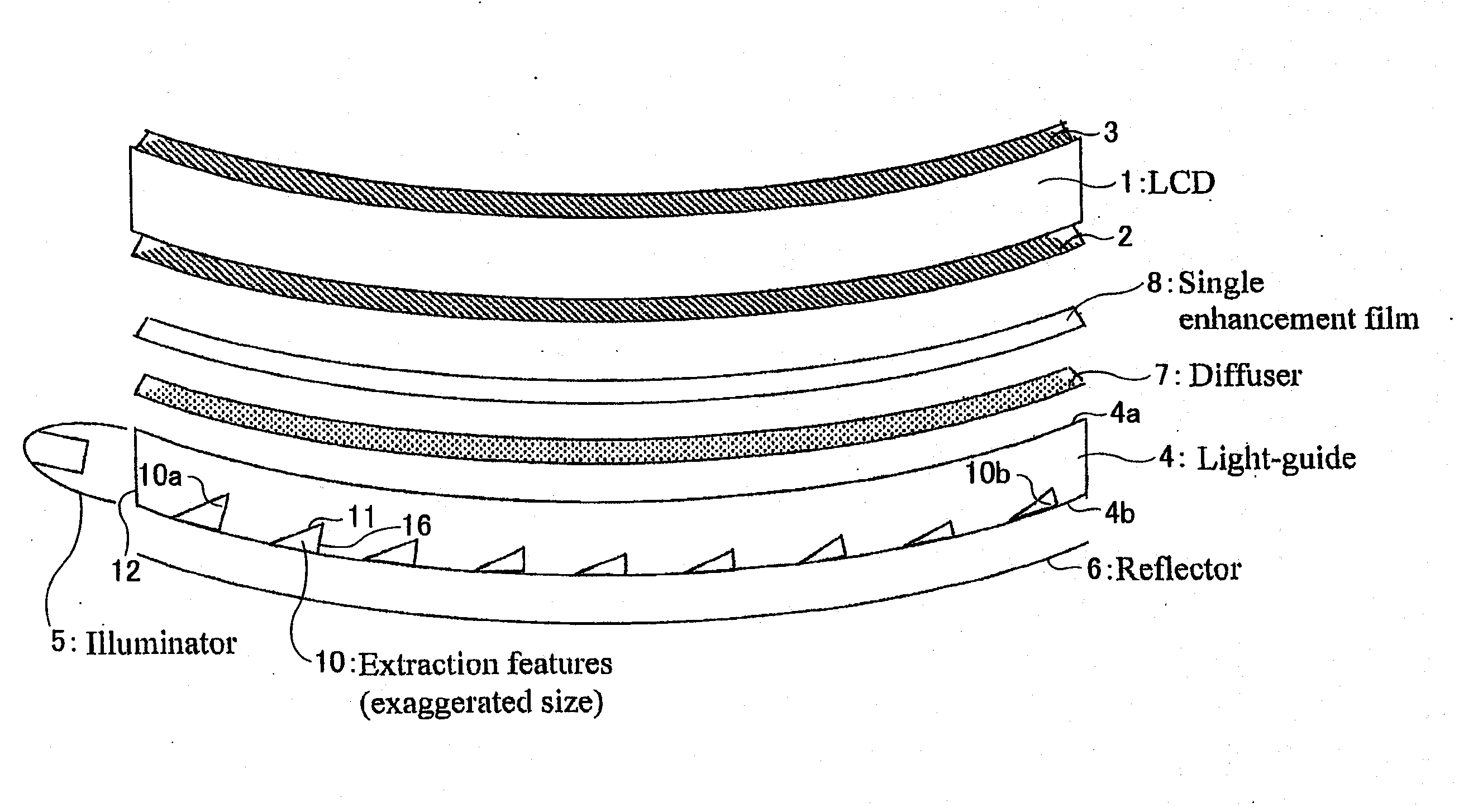

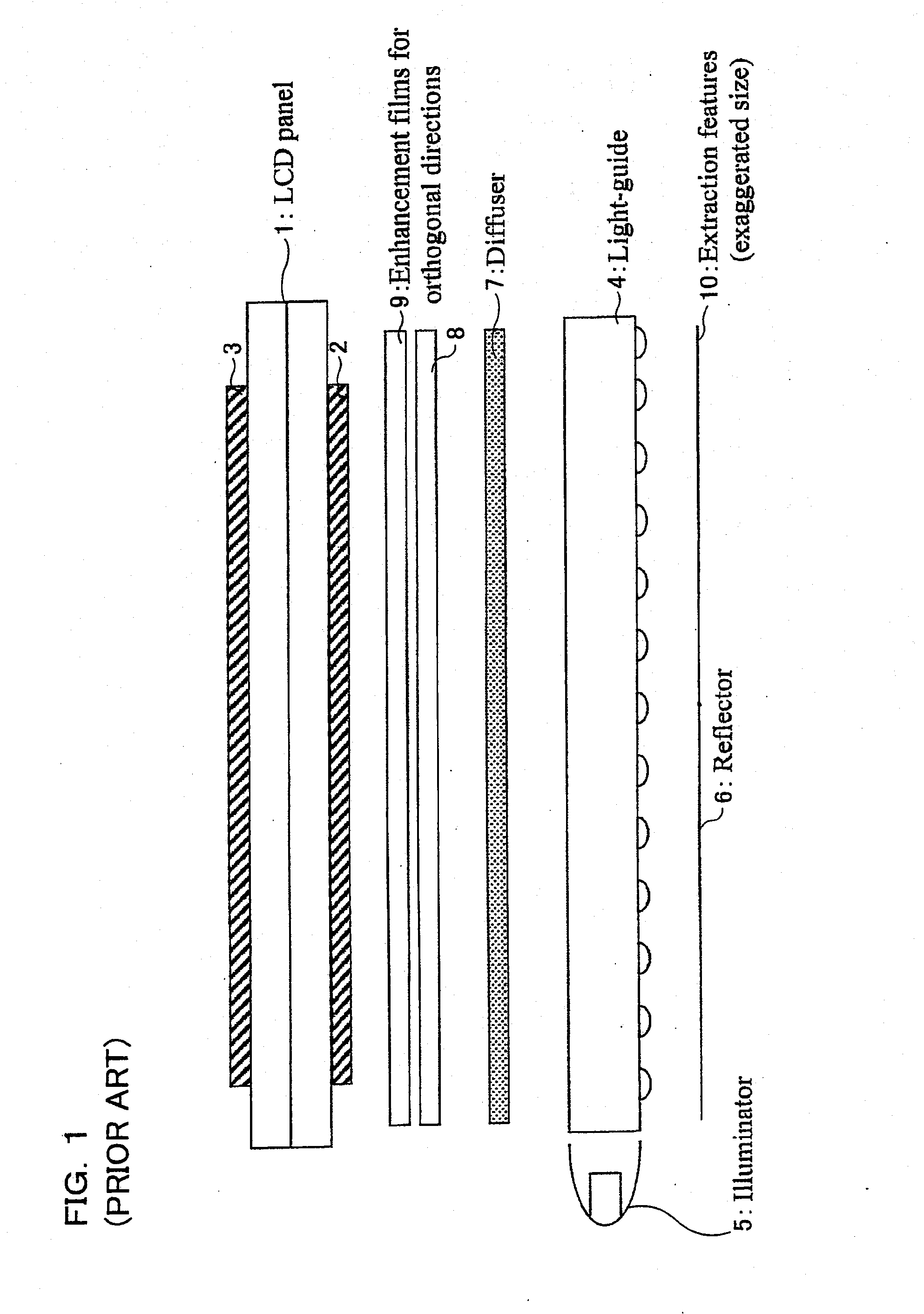

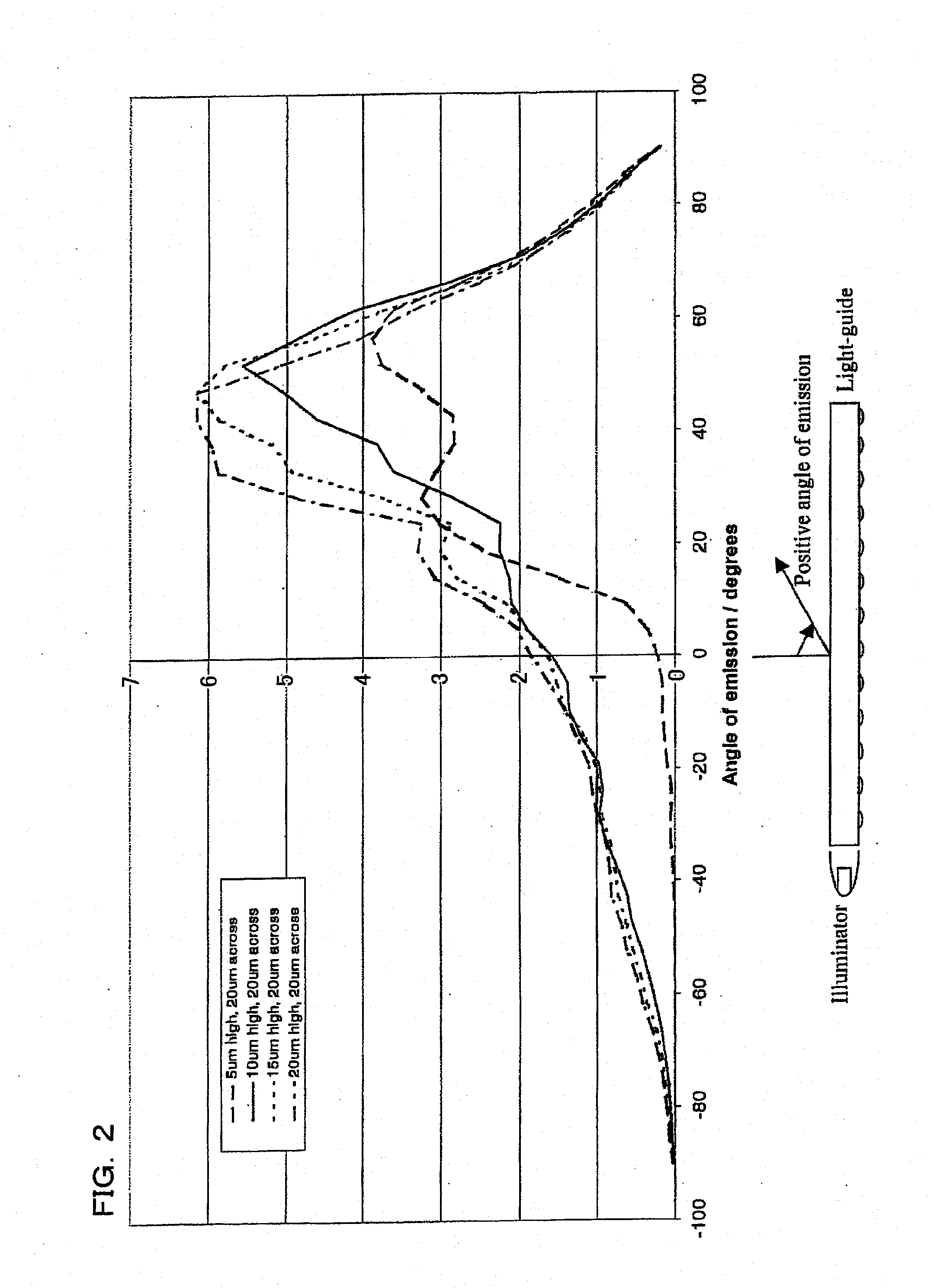

Backlight and display

InactiveUS20100157577A1Expand the range of displayThinner backlightPlanar/plate-like light guidesIlluminated signsSpatial light modulatorEdge surface

A backlight is provided for a transmissive spatial light modulator such as a liquid crystal device (1). The backlight comprises a light source (5), which supplies light through an input edge surface (12) of a non-flat light guide (4) having a front surface (4a) and a rear surface (4b). The rear surface (4b) comprises a plurality of concave features (10), each of which has a surface (11) which faces the input surface (12) and which is oriented so as to direct light towards and out of the front surface (4a). The surfaces (11) have slope angles with respect to a tangent plane to the rear surface (4b) at the feature (10) which vary with distance from the input surface (12) so as to concentrate output light from the light guide (4) into a desired angular output range.

Owner:SHARP KK

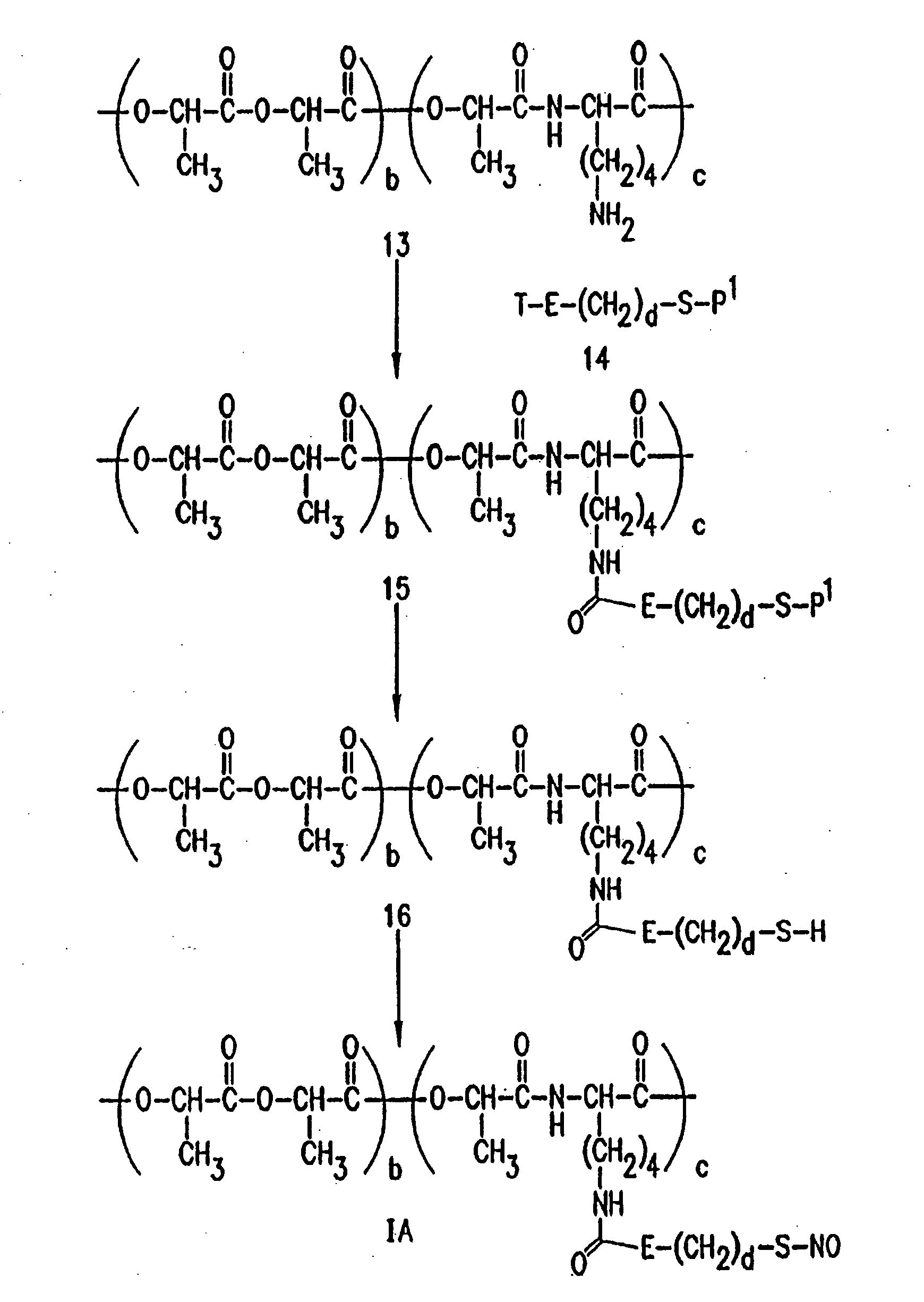

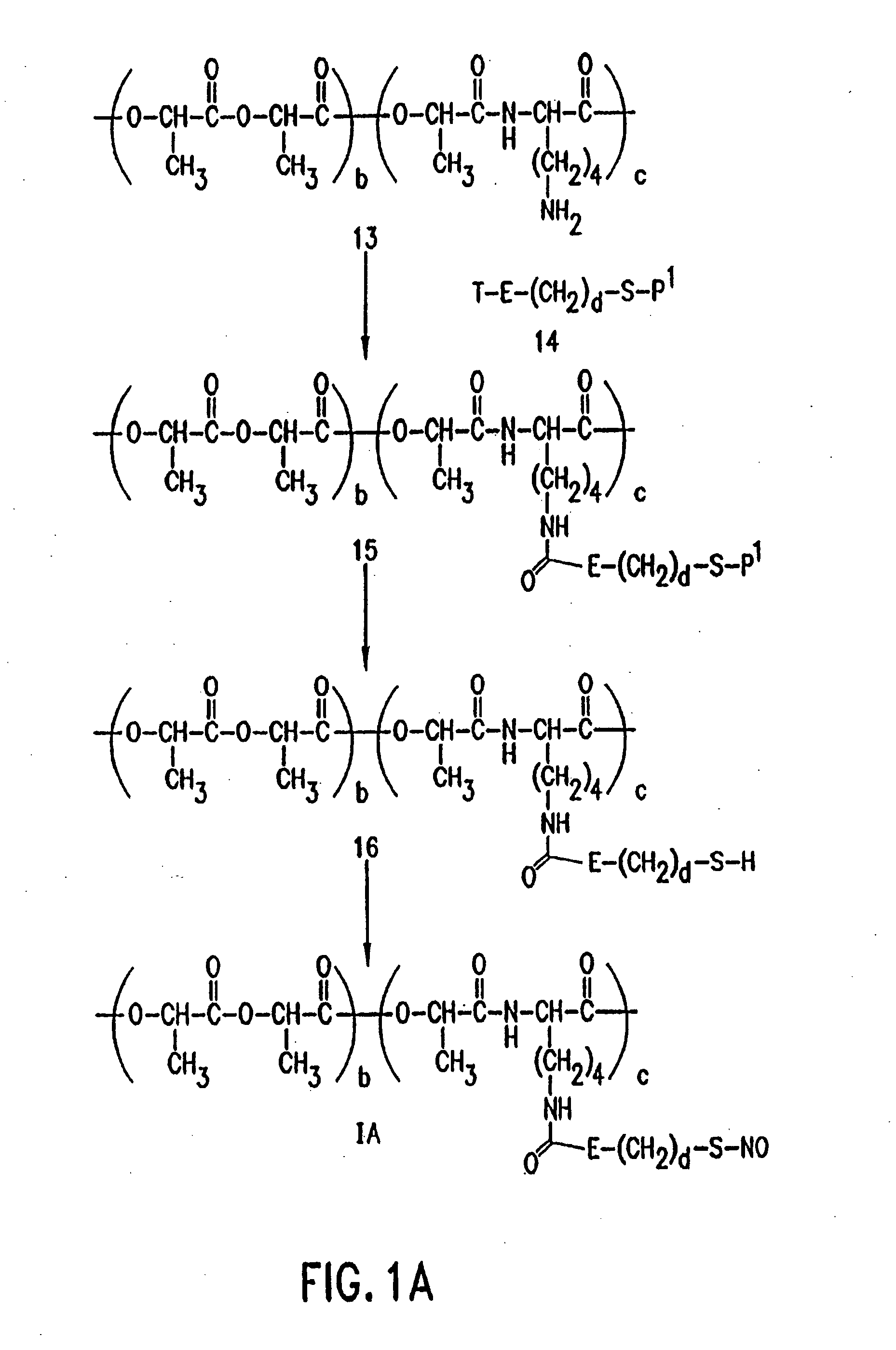

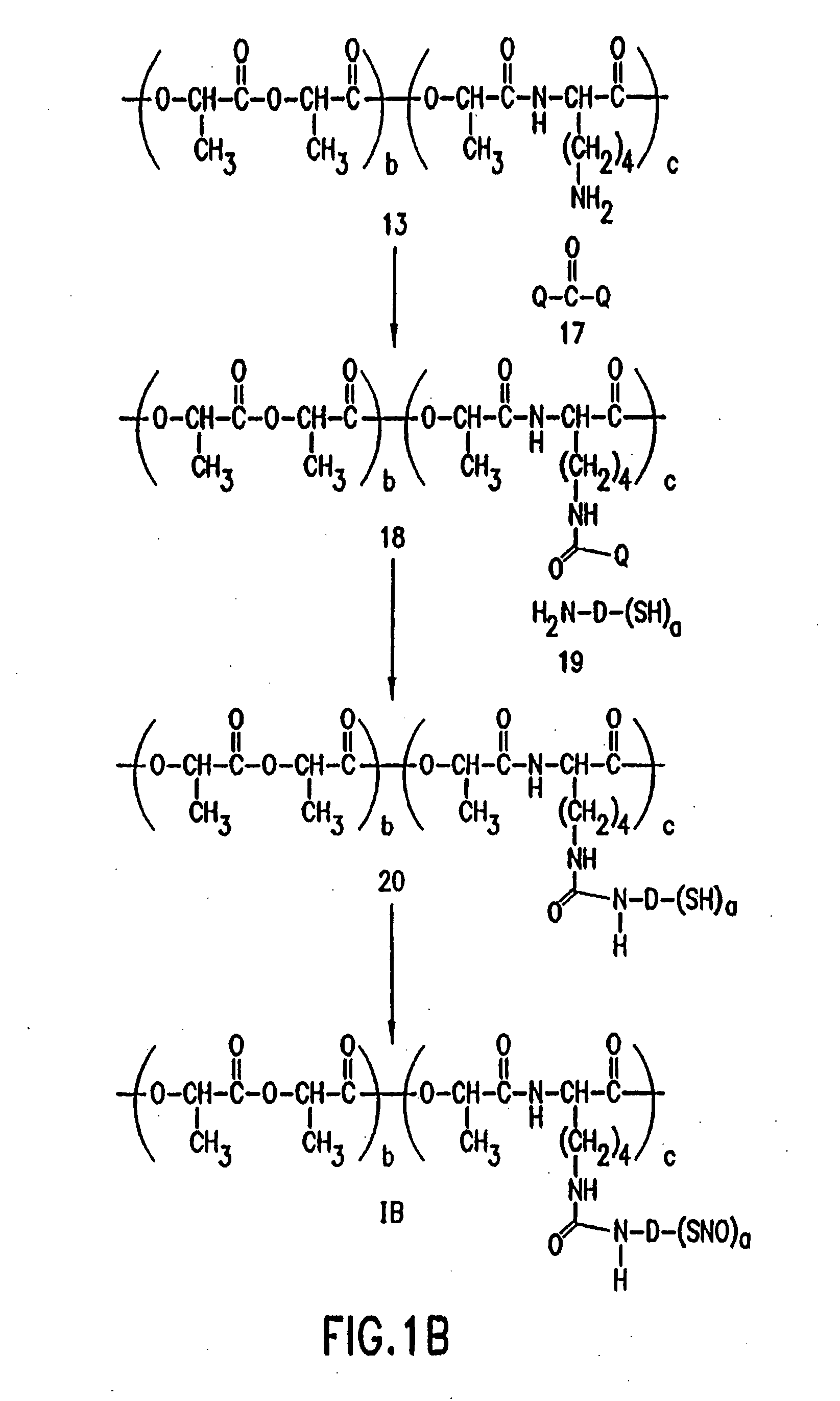

Use of nitric oxide adducts

InactiveUS20070248676A1Modulate effectReduce intimal proliferationPowder deliveryMaterial nanotechnologyReactive siteNitric oxide

The invention provides a method for preventing adverse effects associated with the use of a medical device in a patient by introducing into the patient a device of which at least a portion includes a prophylactic or therapeutic amount of a nitric oxide adduct. The nitric oxide adduct can be present in a matrix coating on a surface of the medical device; coated per se on a surface of the medical device; directly or indirectly bound to reactive sites on a surface of the medical device; or at least a portion of the medical device can be formed of a material, such as a polymer, which includes the nitric oxide adduct. Also disclosed is a method for preventing adverse effects associated with the use of a medical device in a patient by locally administering a nitric oxide adduct to the site of contact of said device with any internal tissue.

Owner:NITROMED

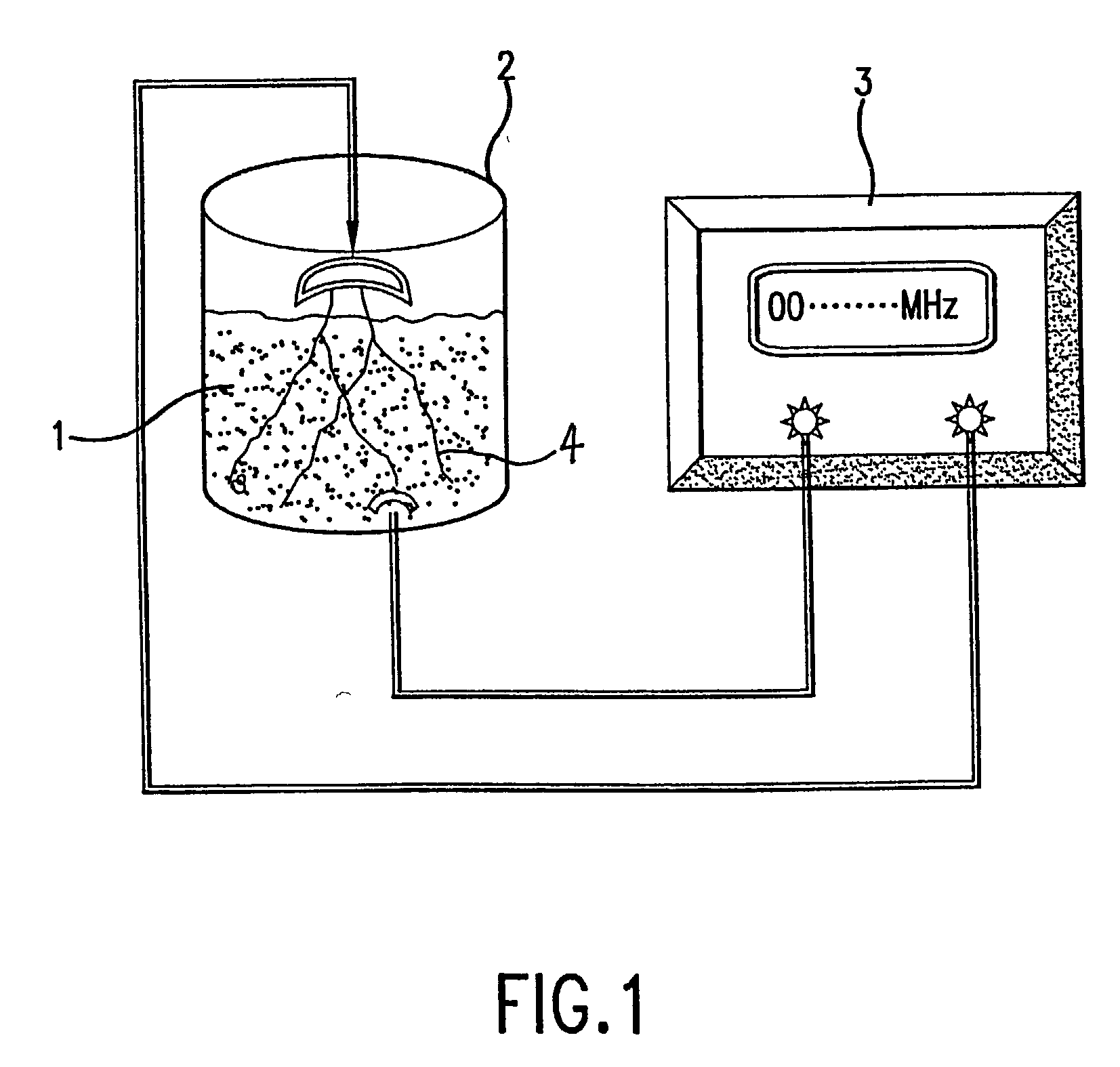

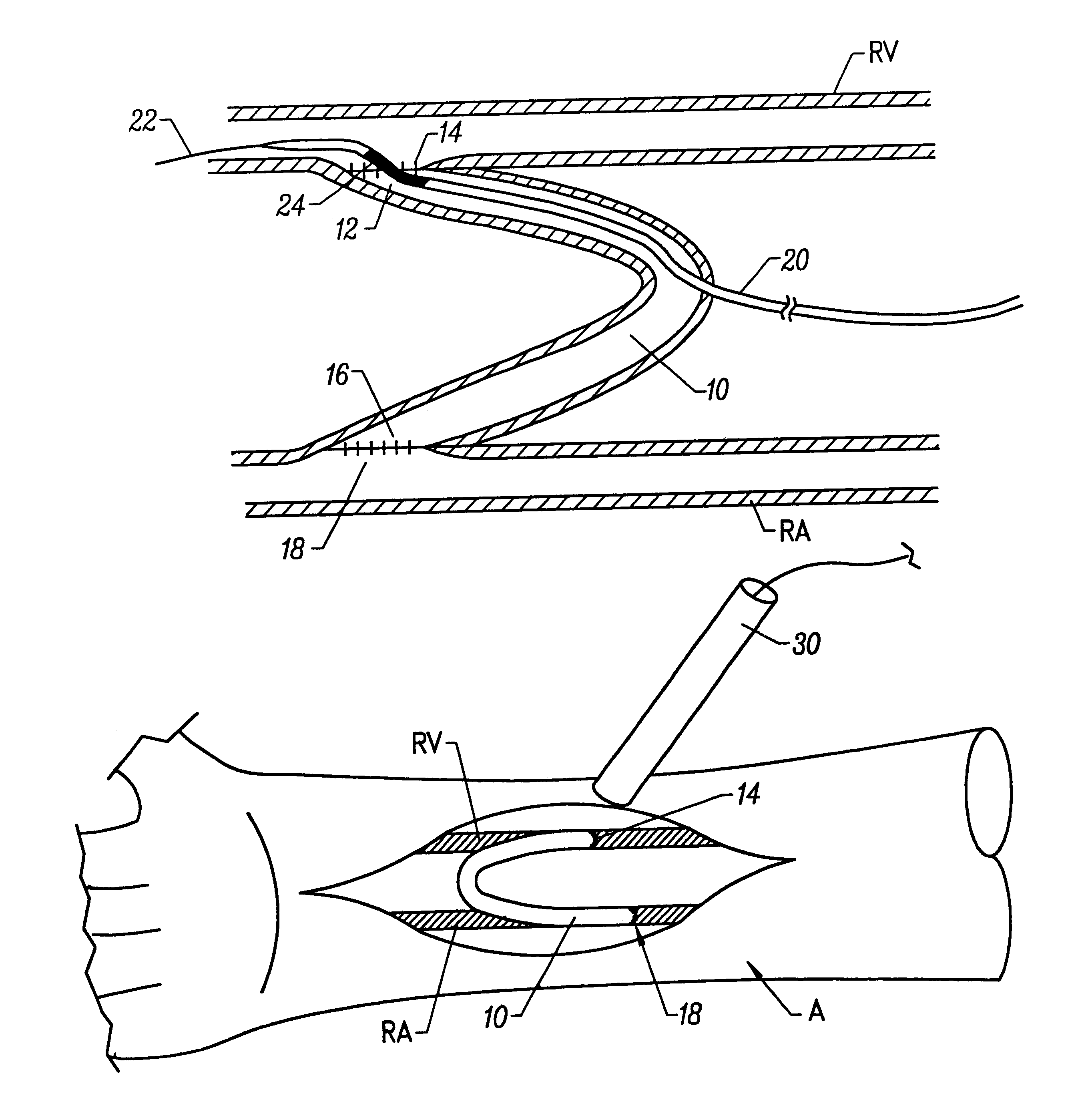

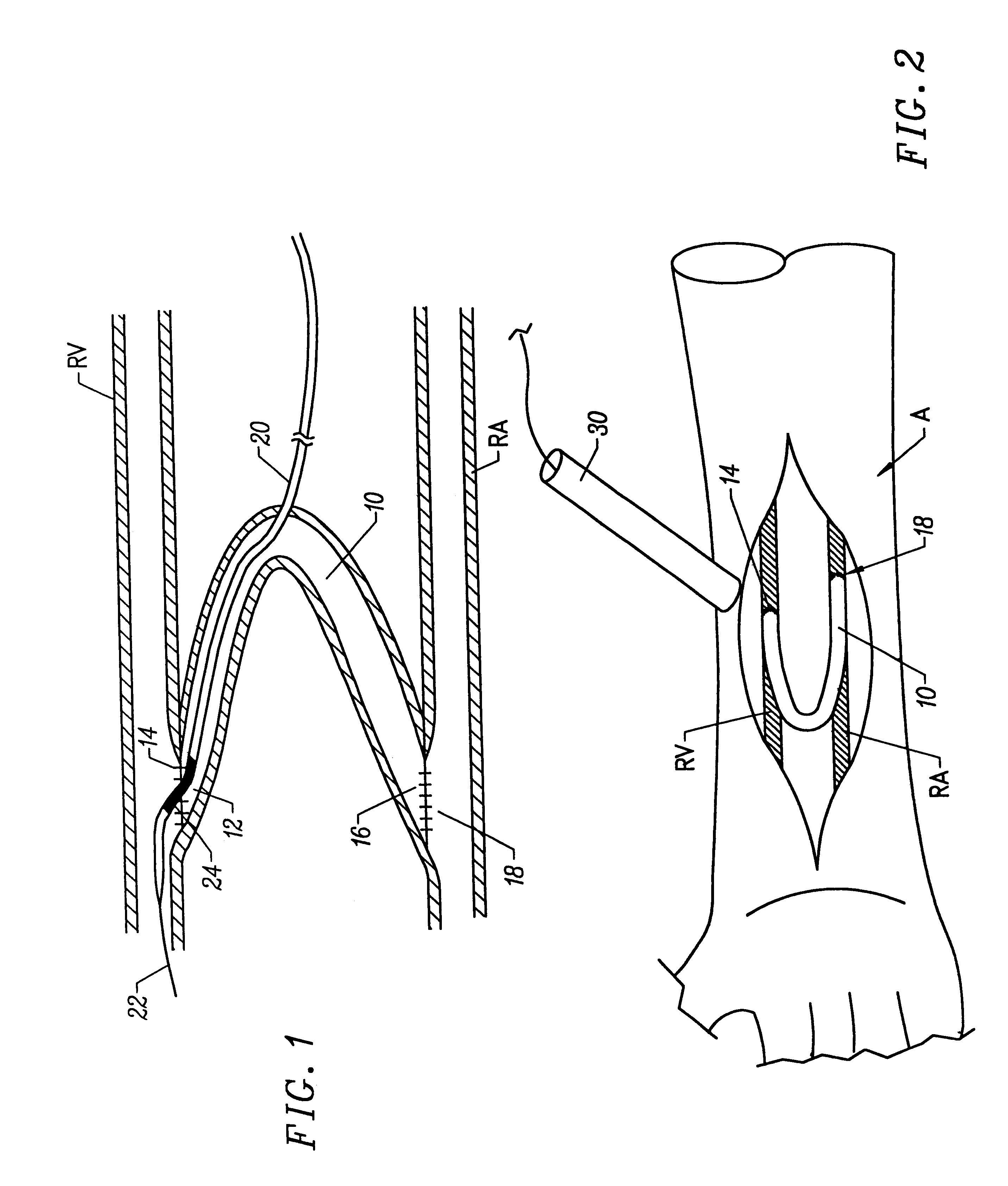

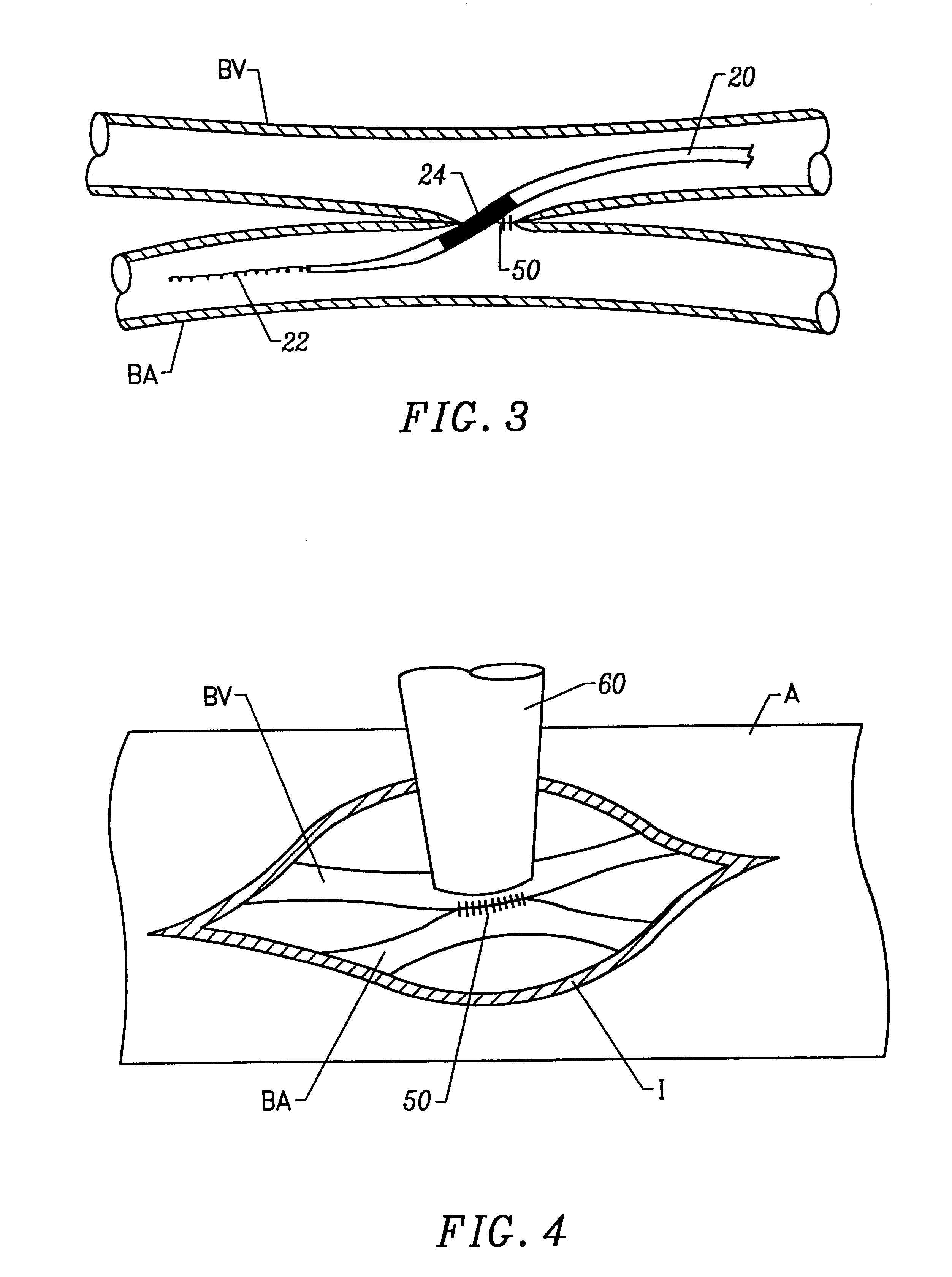

Methods and kits for the inhibition of hyperplasia in vascular fistulas and grafts

InactiveUS6387116B1Inhibit hyperplasiaInhibition is effectiveSurgeryBlood vesselsHaemodialysis machineMechanical index

A method for inhibiting hyperplasia at an anastomotic junction of a vascular fistula or vascular graft comprises exposing the anastomotic junction to vibrational energy at a mechanical index and for a time sufficient to inhibit hyperplasia. Kits are described comprising the catheter or a probe suitable for performing the methods together with instructions for use setting forth the methods. The methods and kits are particularly suitable for treating anastomotic junctions formed to provide vascular access for hemodialysis, hemofiltration, and the like. The methods and kits are also suitable for treating other vascular grafts, such as those formed during cardiac bypass graft surgery, vascular repair, and the like.

Owner:PHARMASONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com