Patents

Literature

335 results about "Low Mass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Mass (called in Latin, Missa lecta, which literally means "read Mass") is a Tridentine Mass defined officially in the Code of Rubrics included in the 1962 edition of the Roman Missal as Mass in which the priest does not chant the parts that the rubrics assign to him. A sung Mass in turn is a ‘High’ or Solemn Mass if celebrated with the assistance of sacred ministers (deacon and subdeacon); without them it is a Missa Cantata.

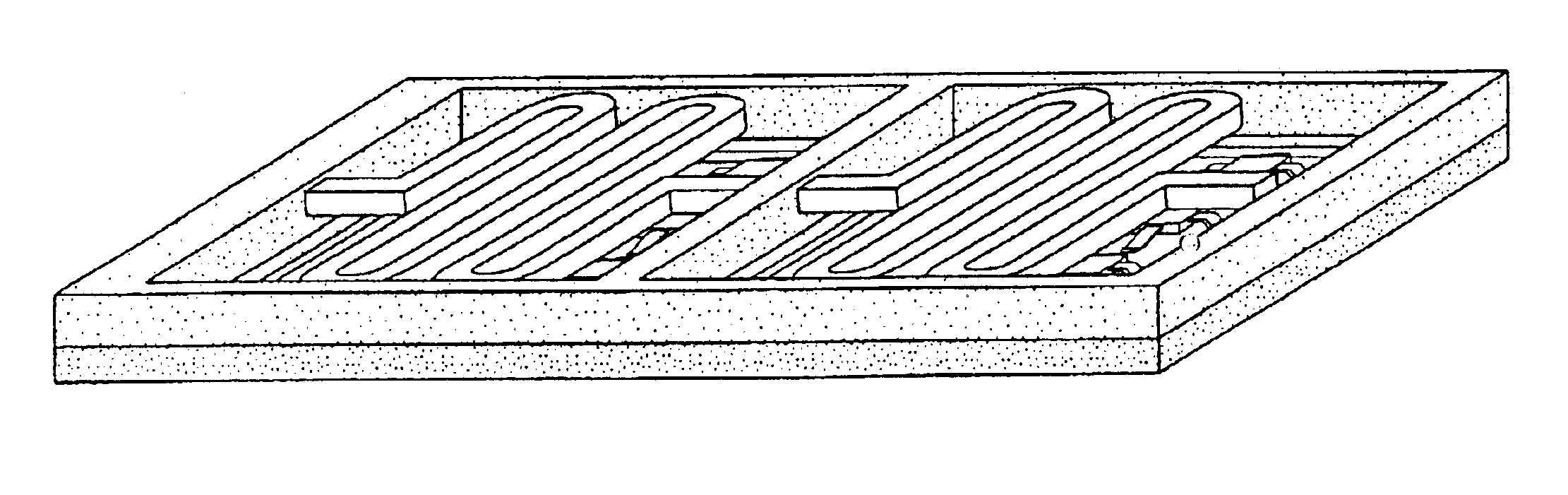

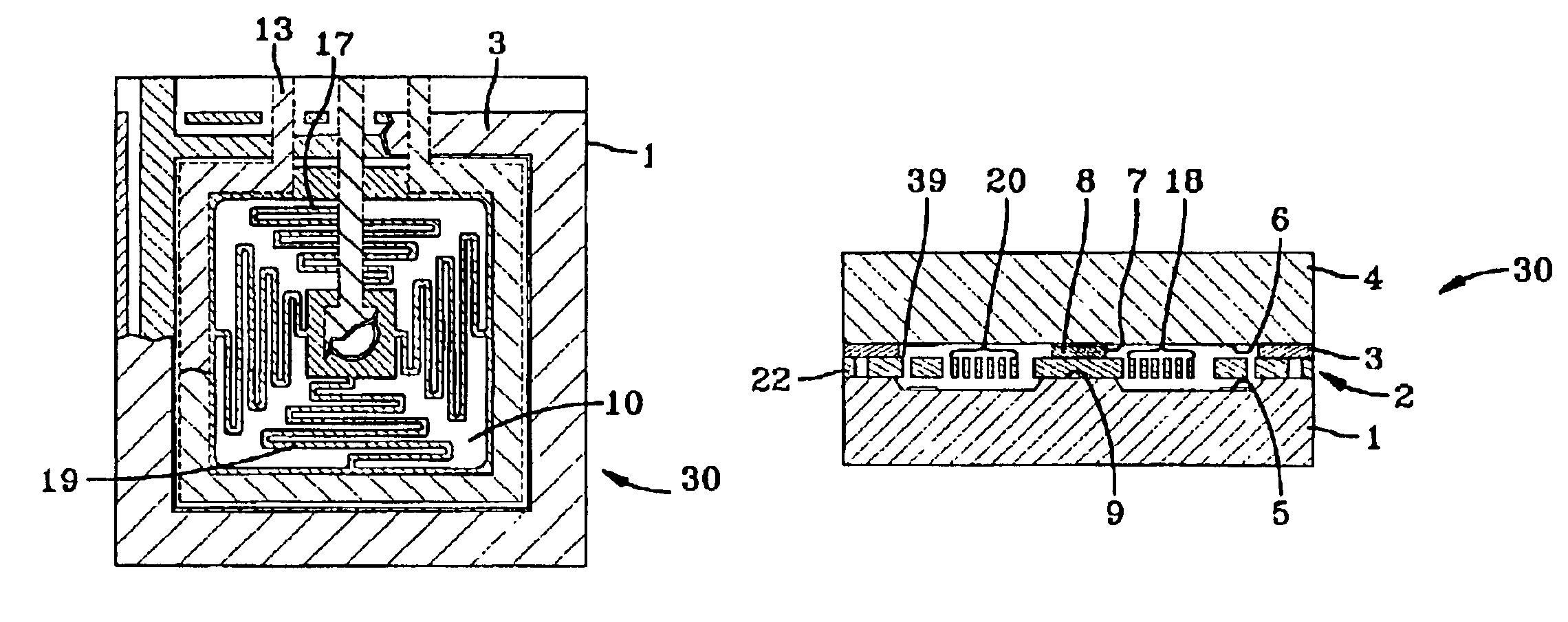

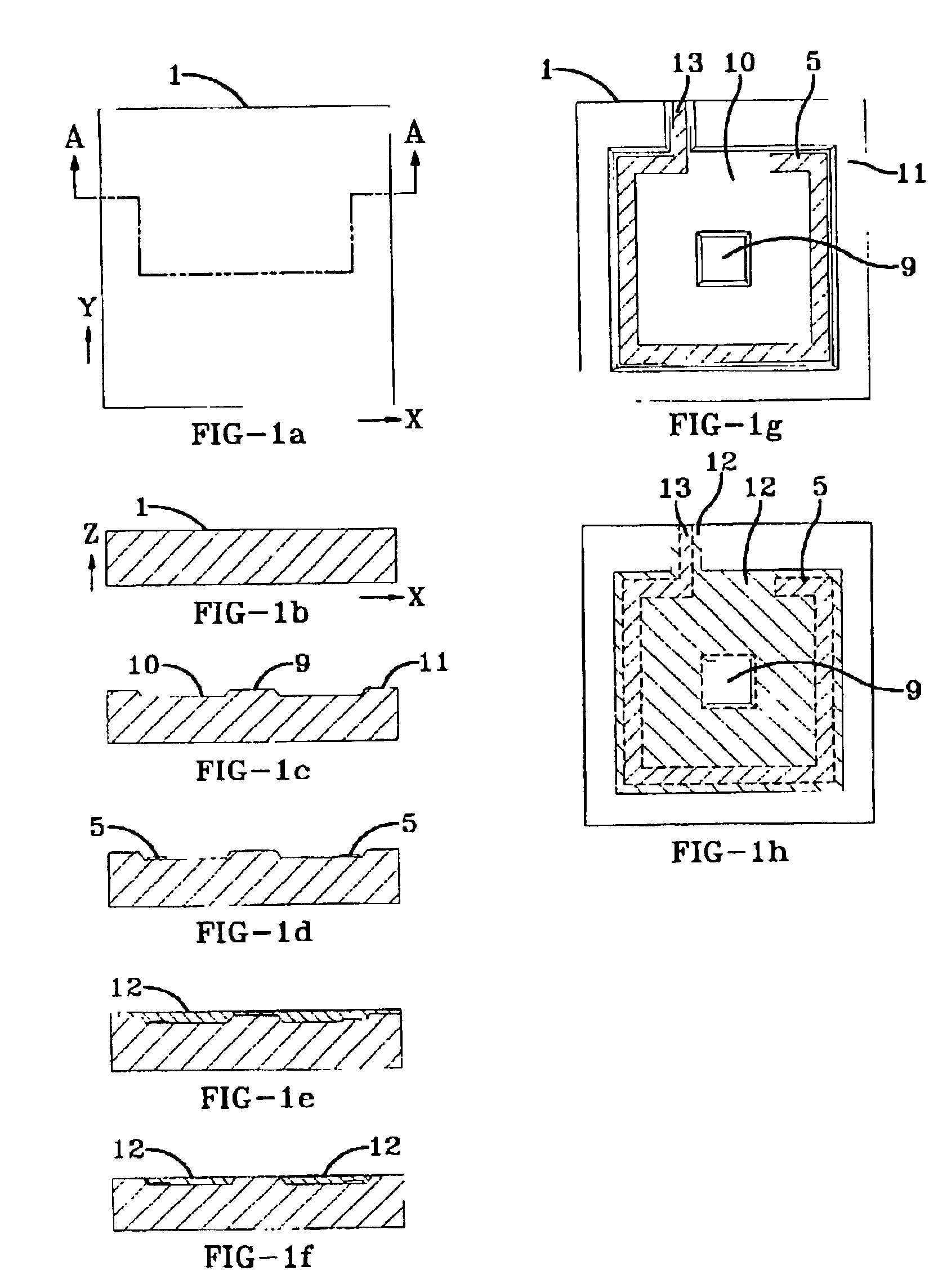

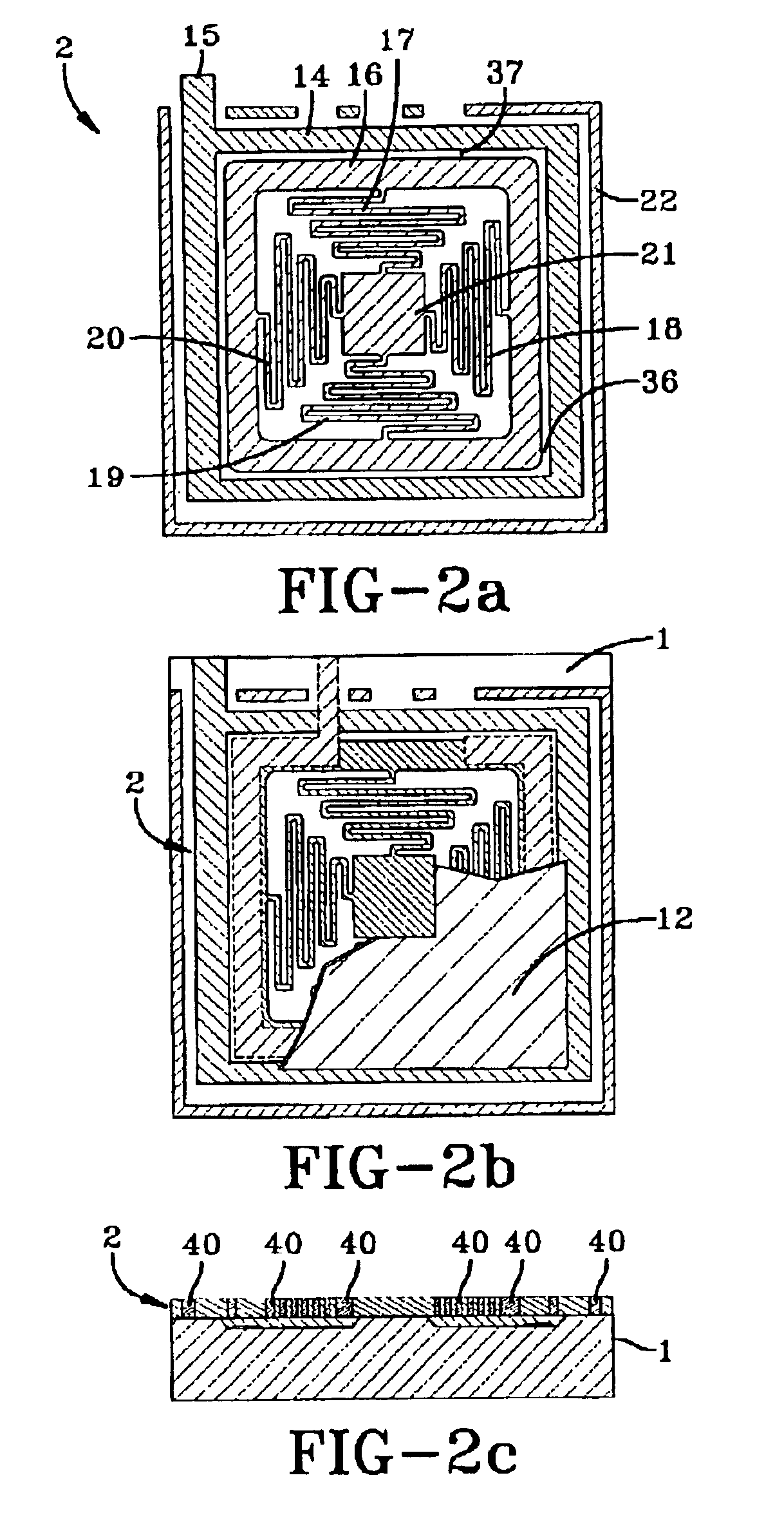

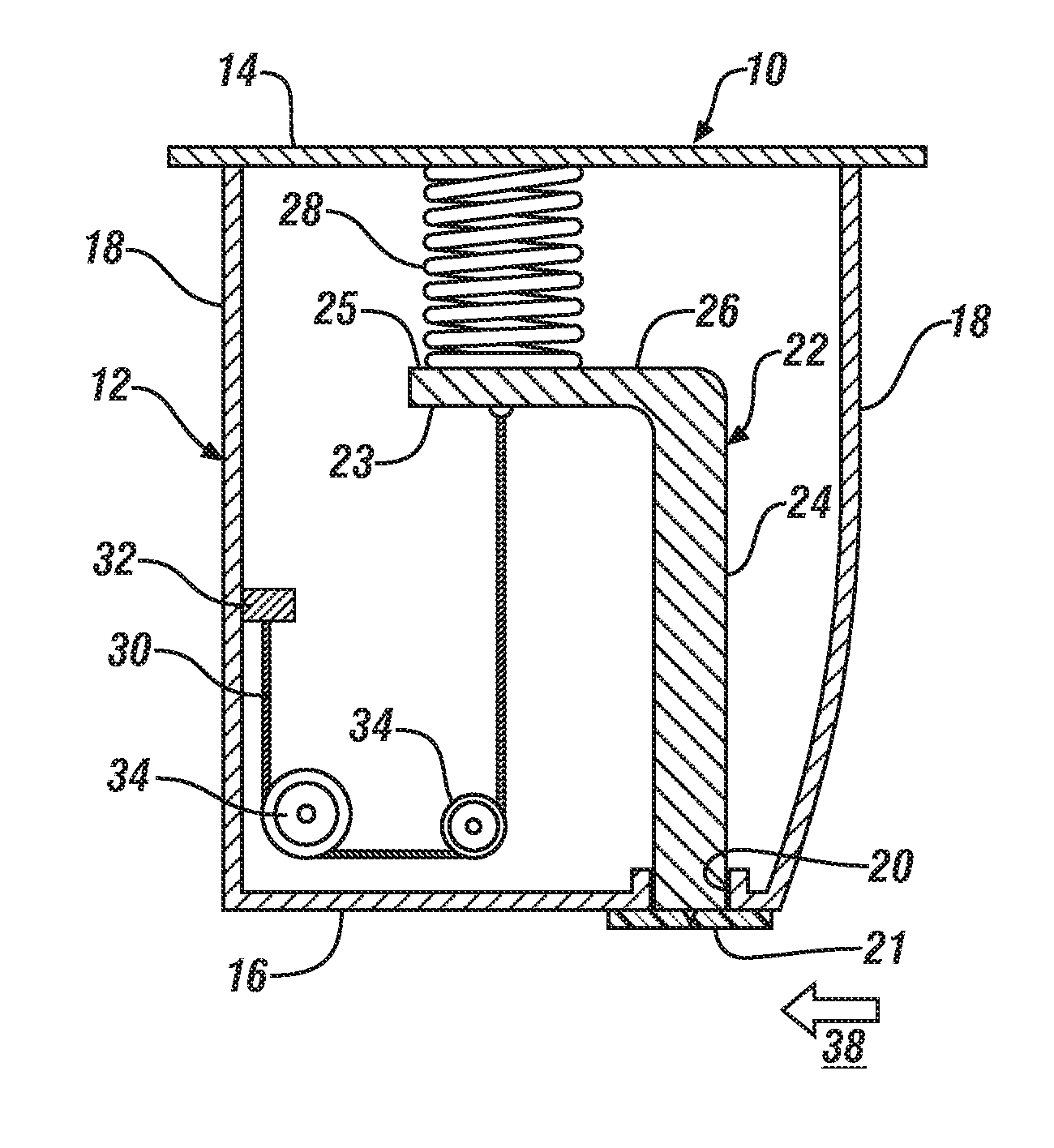

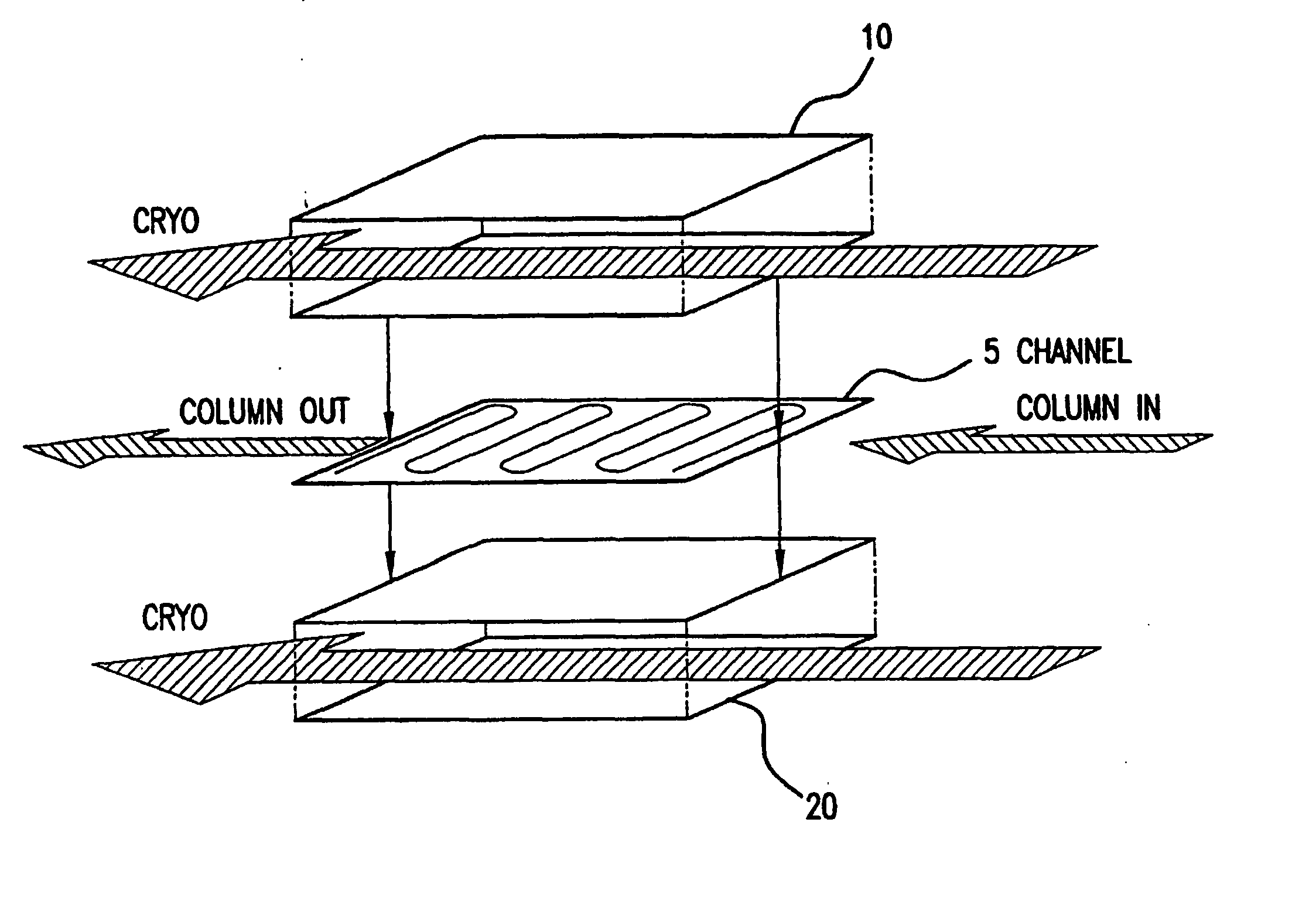

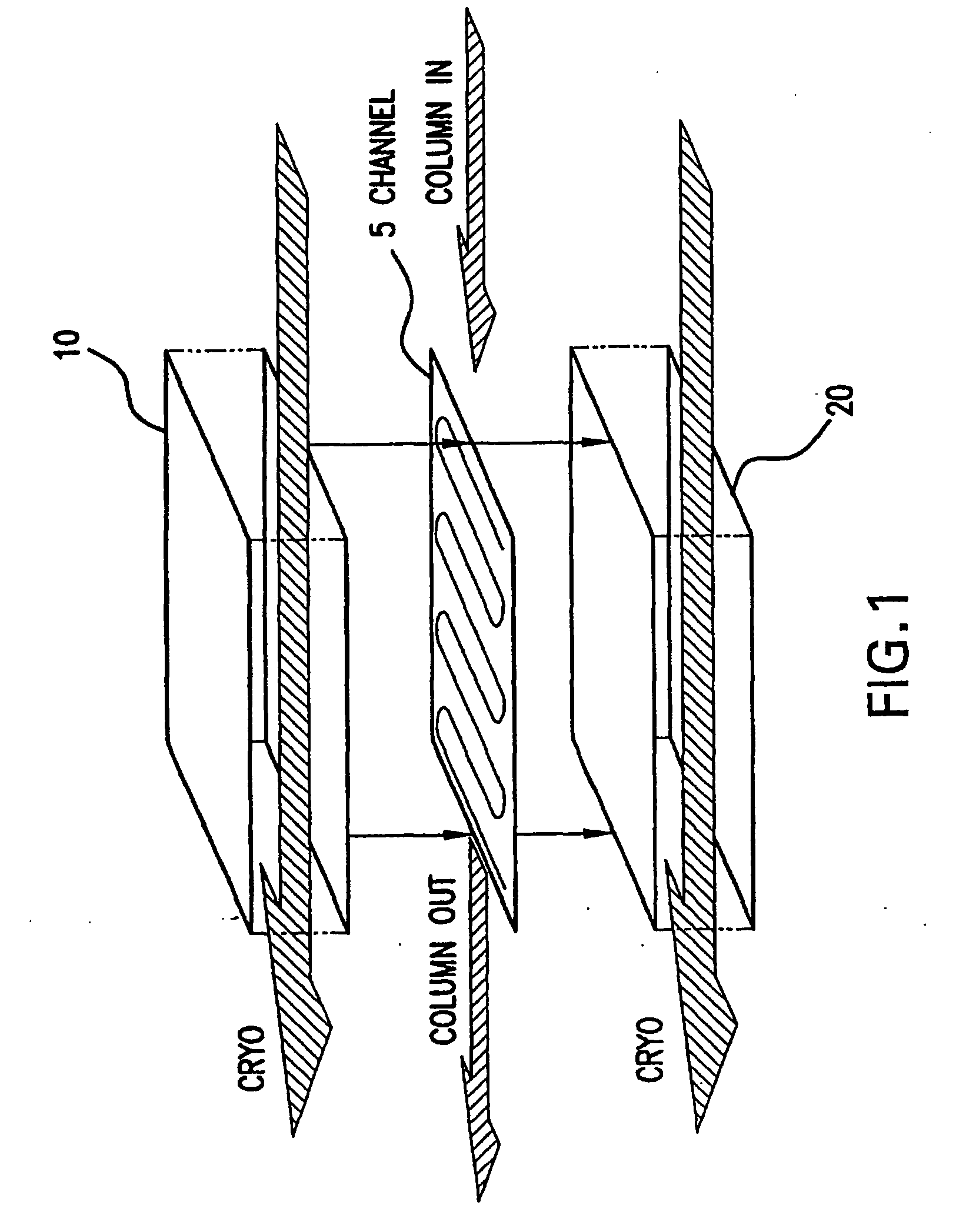

Separation microcolumn assembly for a microgas chromatograph and the like

InactiveUS6838640B2Easy to separateComponent separationDispersed particle separationTemperature controlMicro column

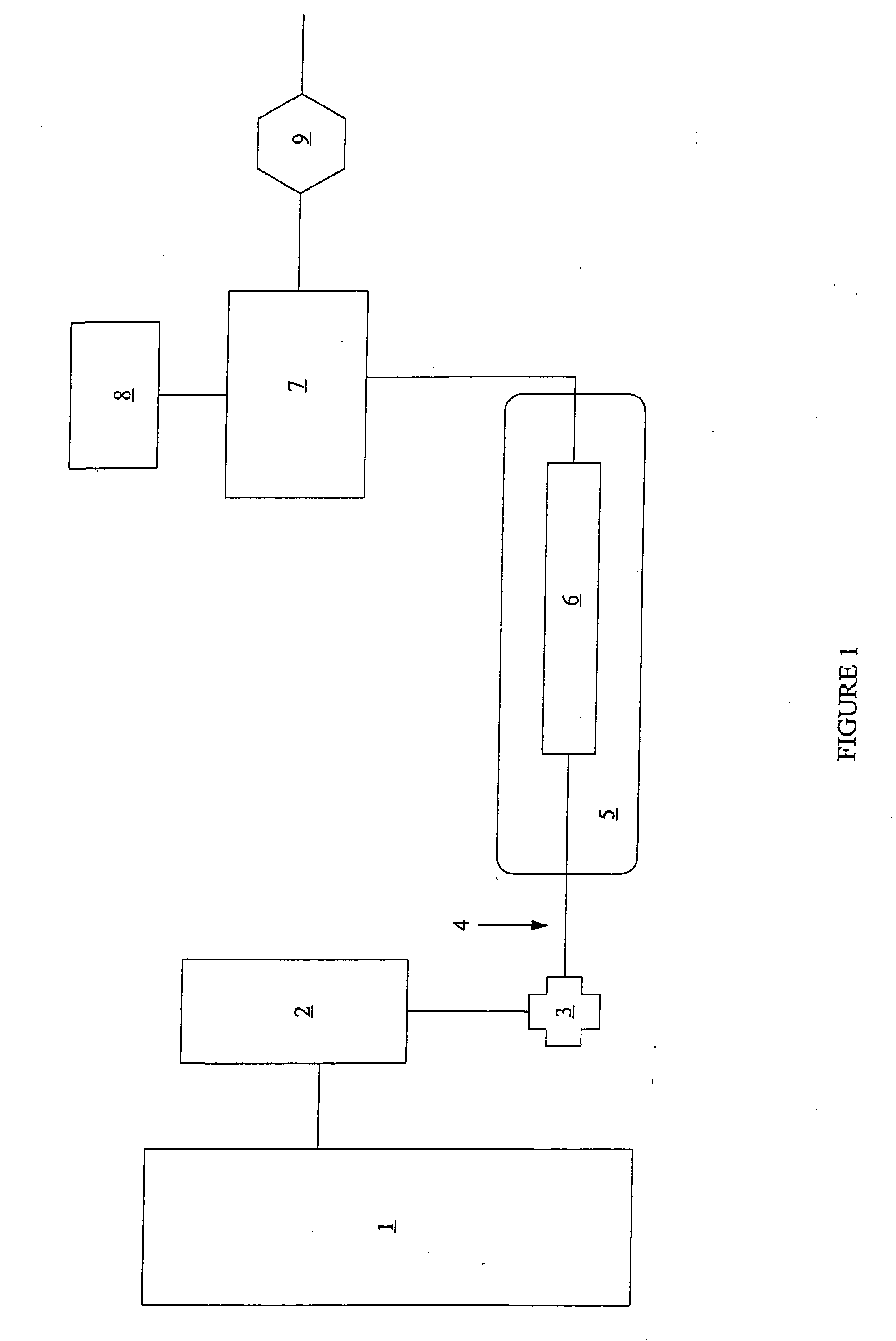

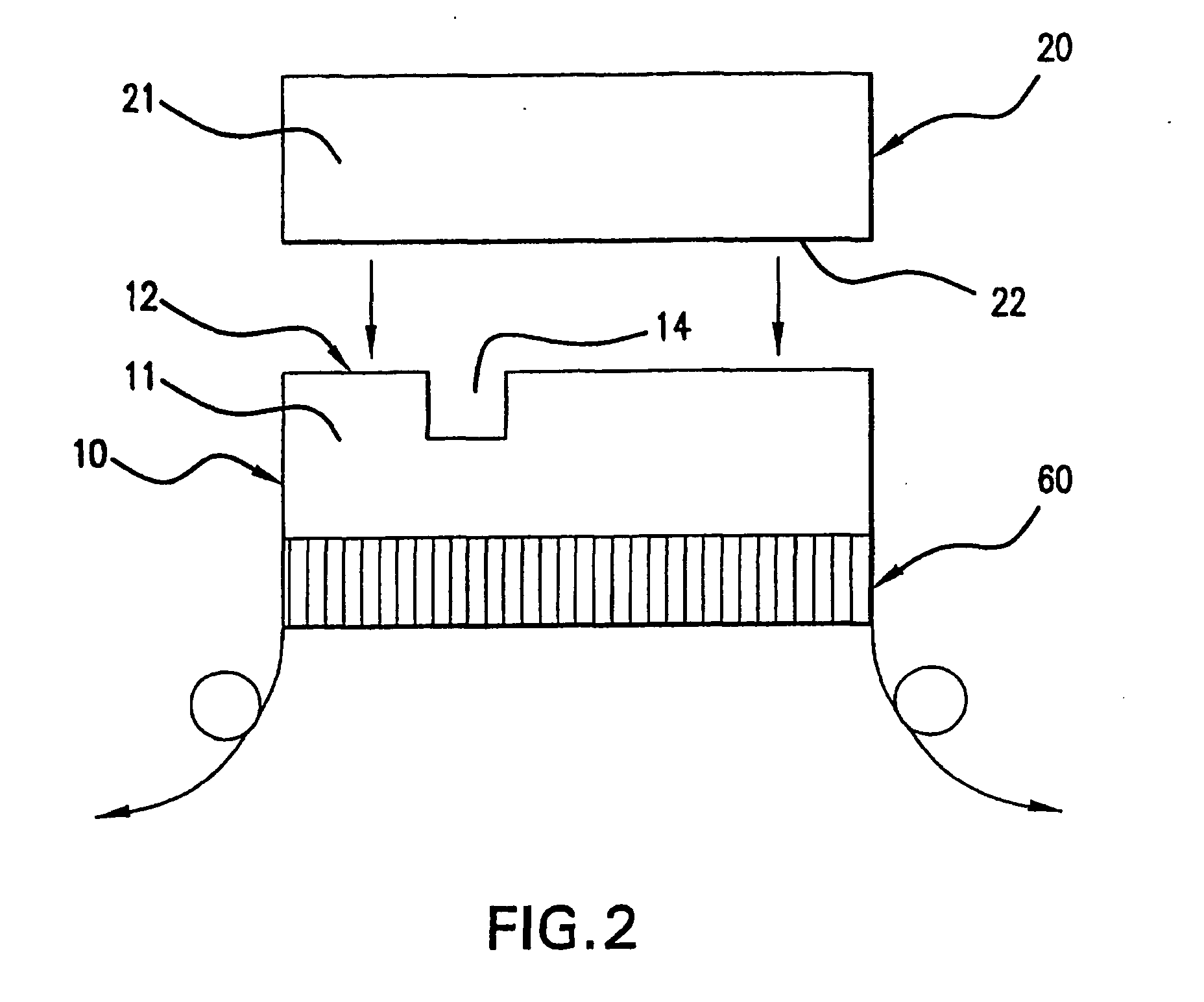

A high-sensitivity, separation microcolumn assembly for a microgas chromatograph and the like is provided. The assembly has an ultra-low mass complete with integrated heaters. The assembly uses multiple zones for temperature control, and microstructures that permit very rapid heating and cooling of the microcolumn.

Owner:RGT UNIV OF MICHIGAN

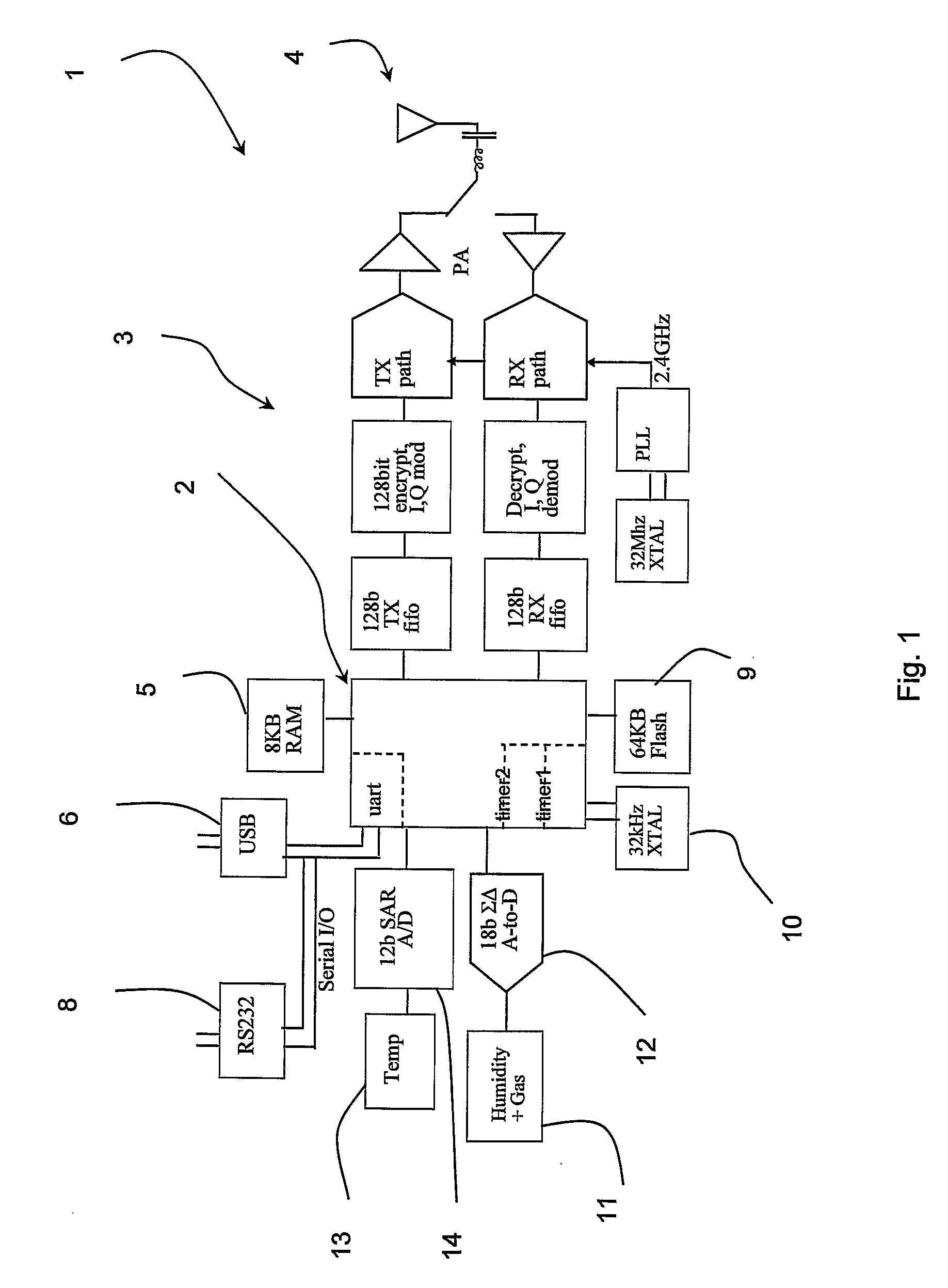

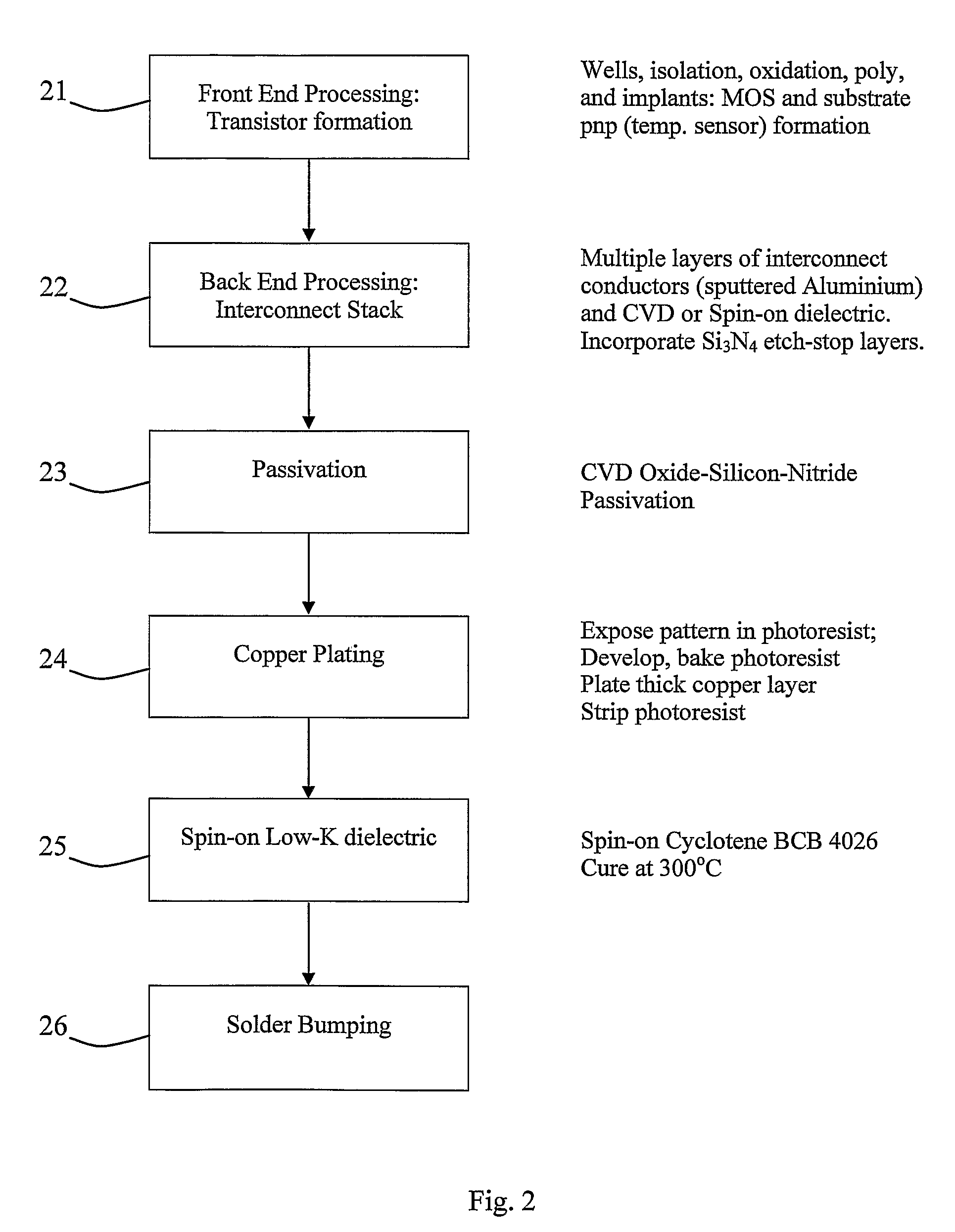

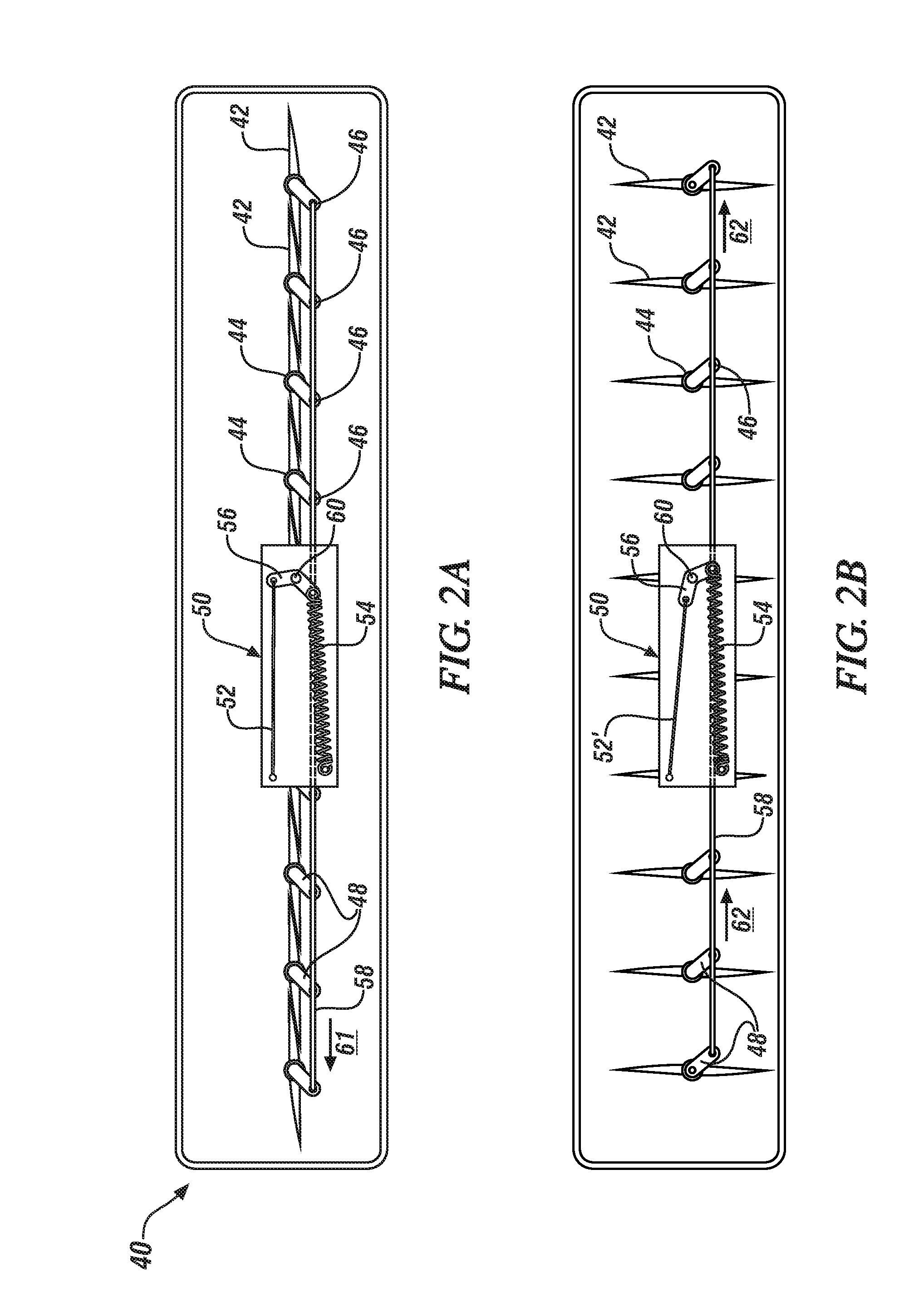

Integrated Electronic Sensor

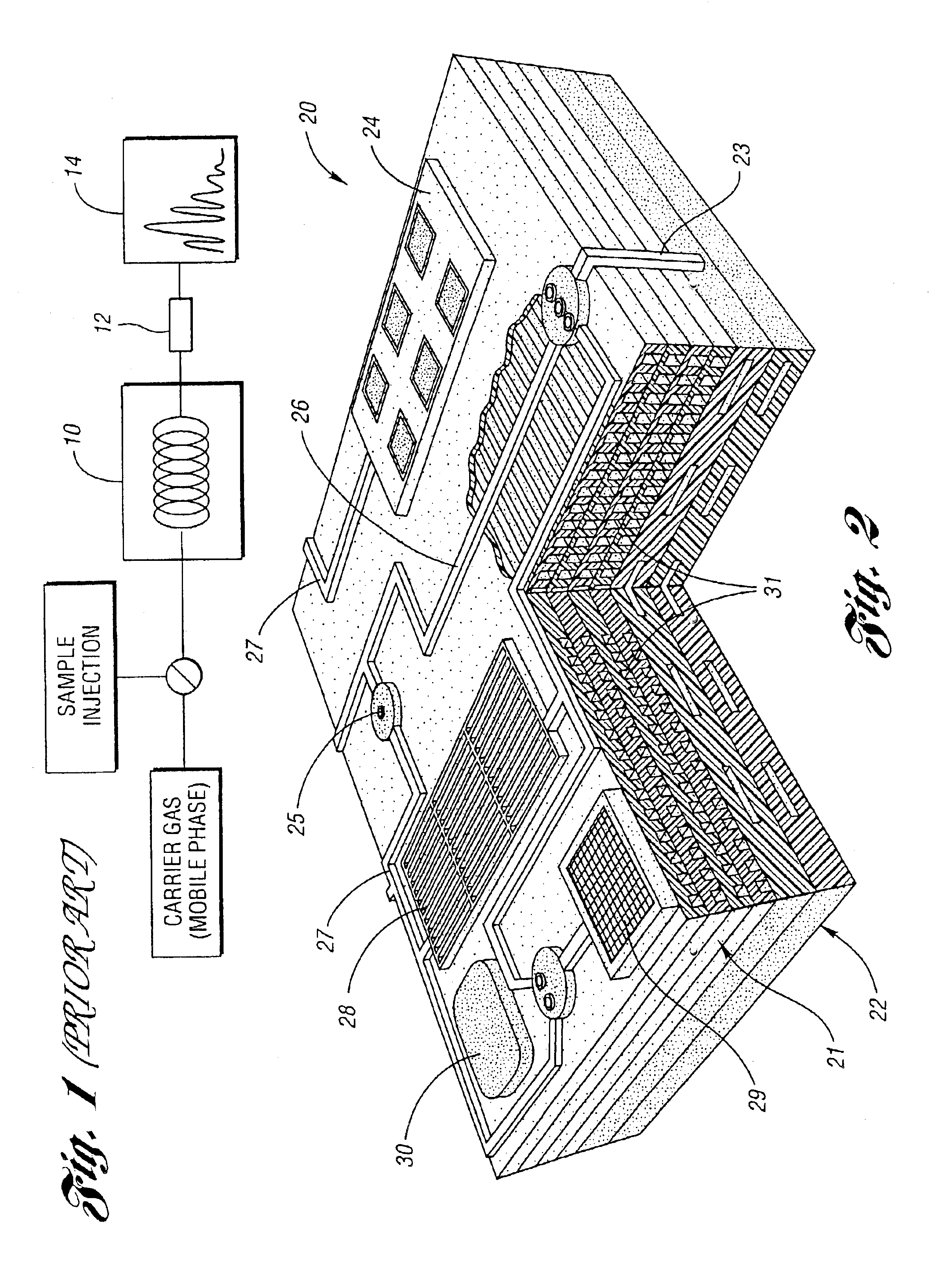

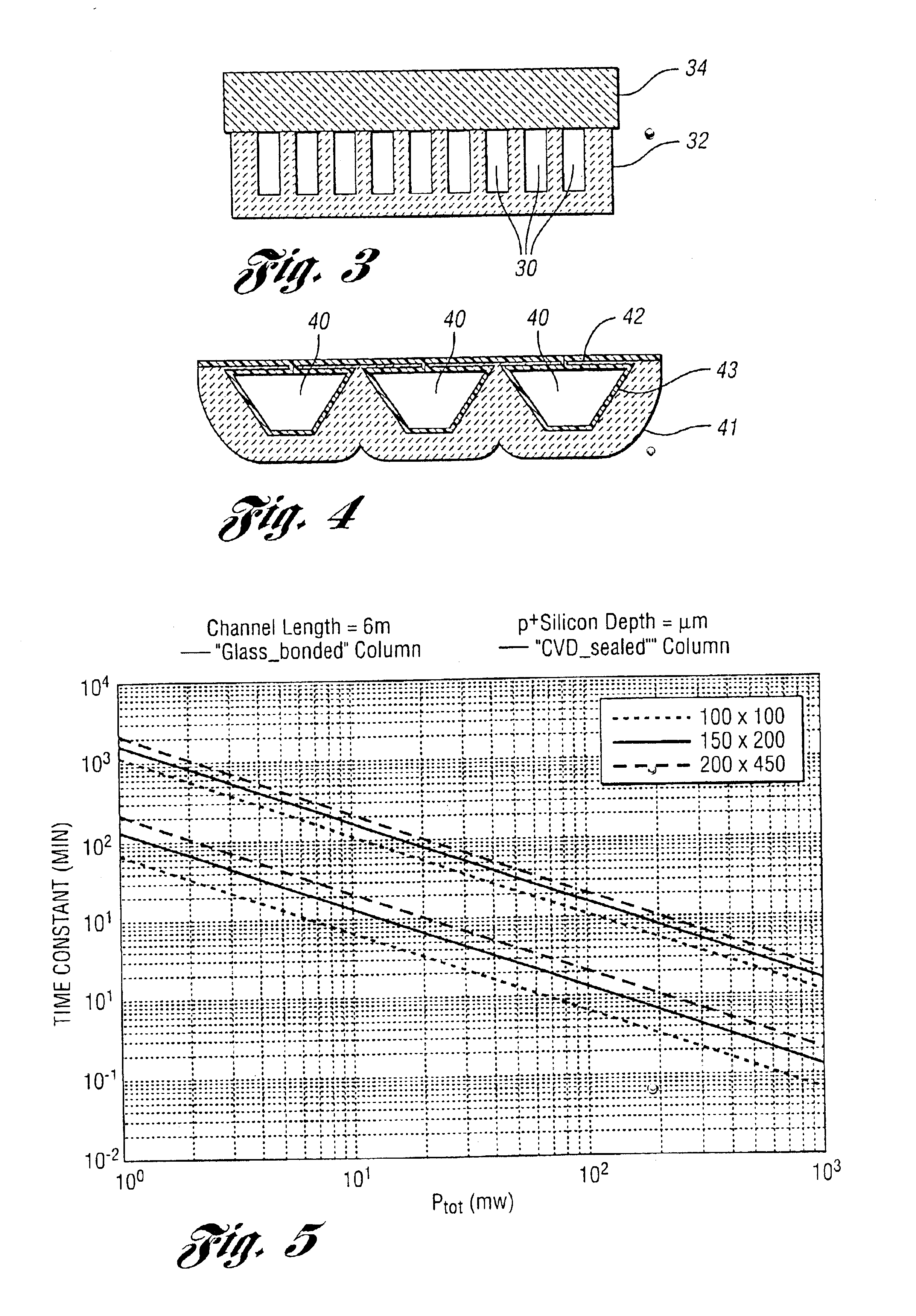

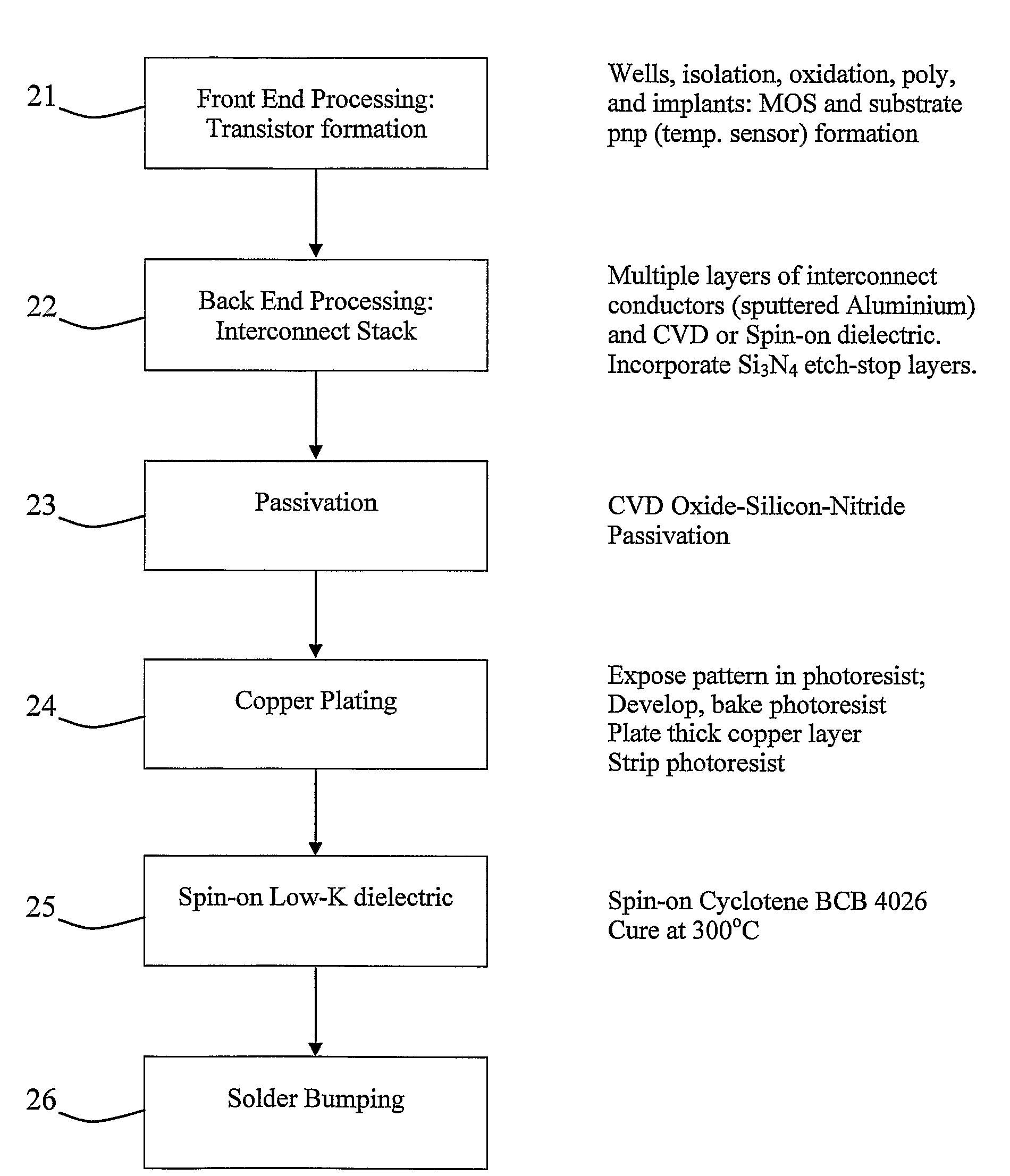

ActiveUS20090141767A1Improve response characteristicsSufficient free space volumeThermometer detailsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMicrocontrollerLine sensor

A single chip wireless sensor (1) comprises a microcontroller (2) connected to a transmit / receive interface (3), which is coupled to a wireless antenna (4) by an L-C matching circuit. The sensor (1) senses gas or humidity and temperature. The device (1) is an integrated chip manufactured in a single process in which both the electronics and sensor components are manufactured using standard CMOS processing techniques, applied to achieve both electronic and sensing components in an integrated process. A Low-K material (57) with an organic polymer component is spun onto the wafer to form a top layer incorporating also sensing electrodes (60). This material is cured at 300° C., which is much lower than CVD temperatures. The polyimide when cured becomes thermoset, and the lower mass-to-volume ratio resulting in K, its dielectric constant, reducing to 2.9. The thermoset dielectric, while not regarded as porous in the conventional sense, has sufficient free space volume to admit enough gas or humidity for sensing.

Owner:SILICON LAB INC

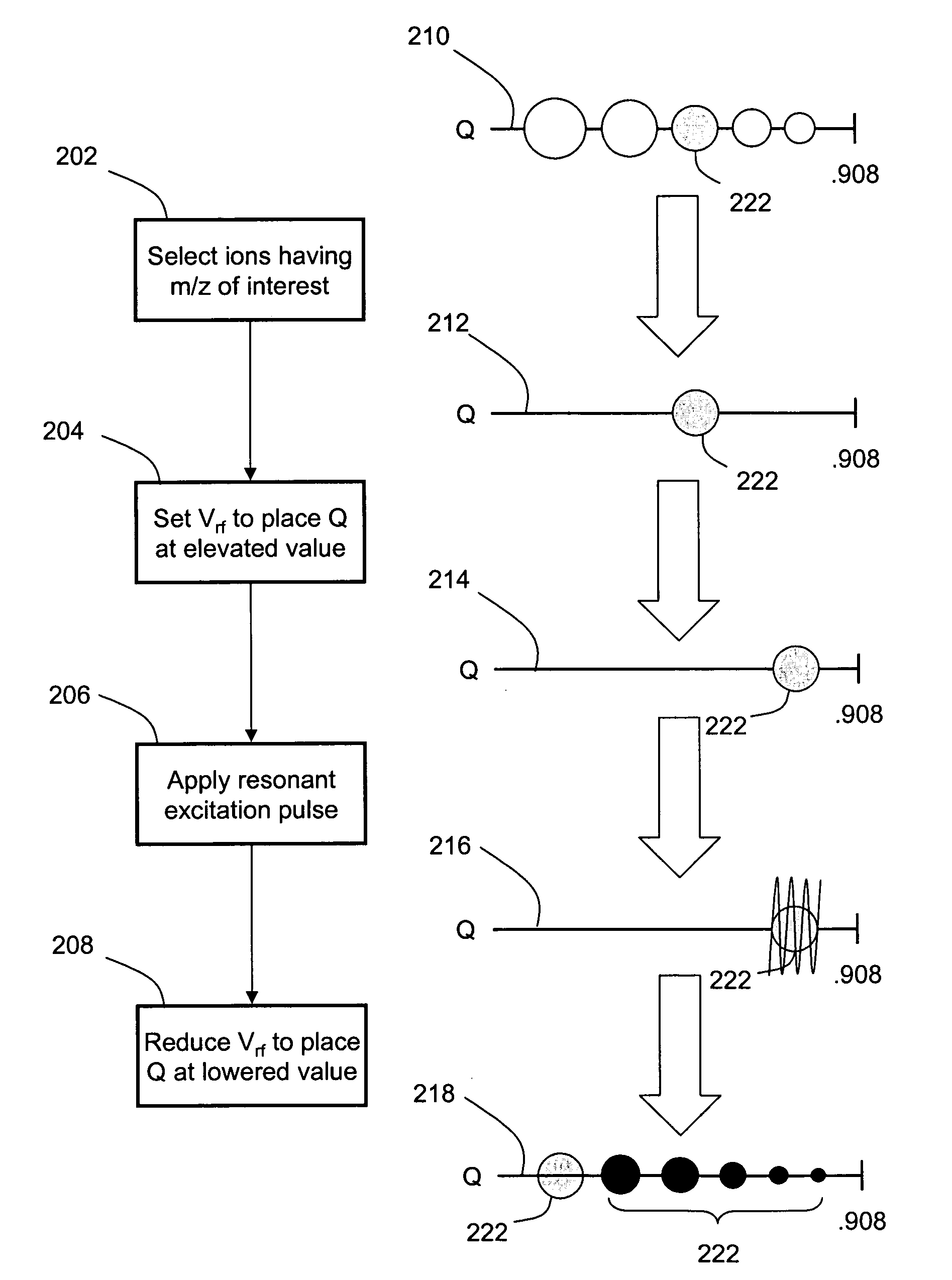

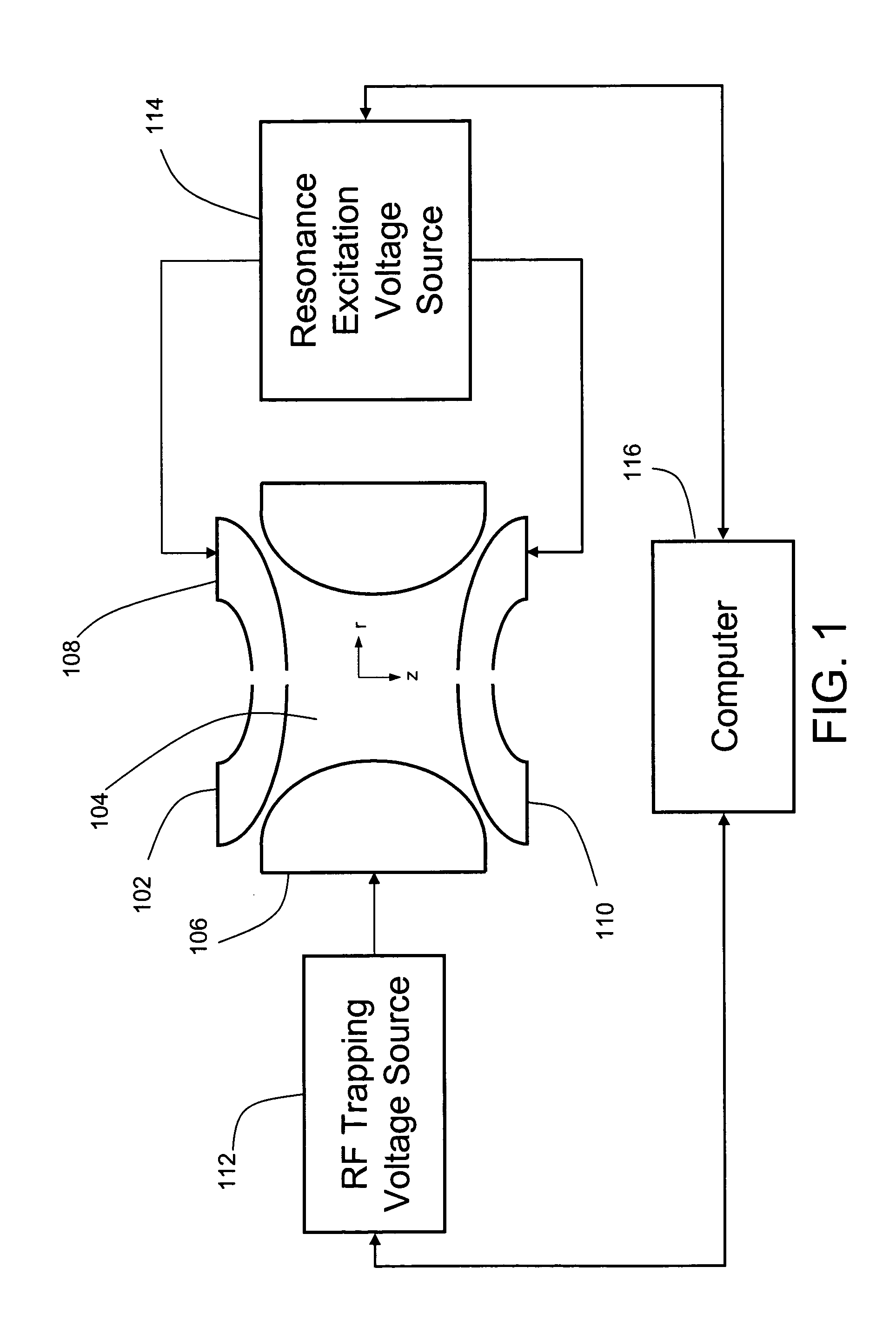

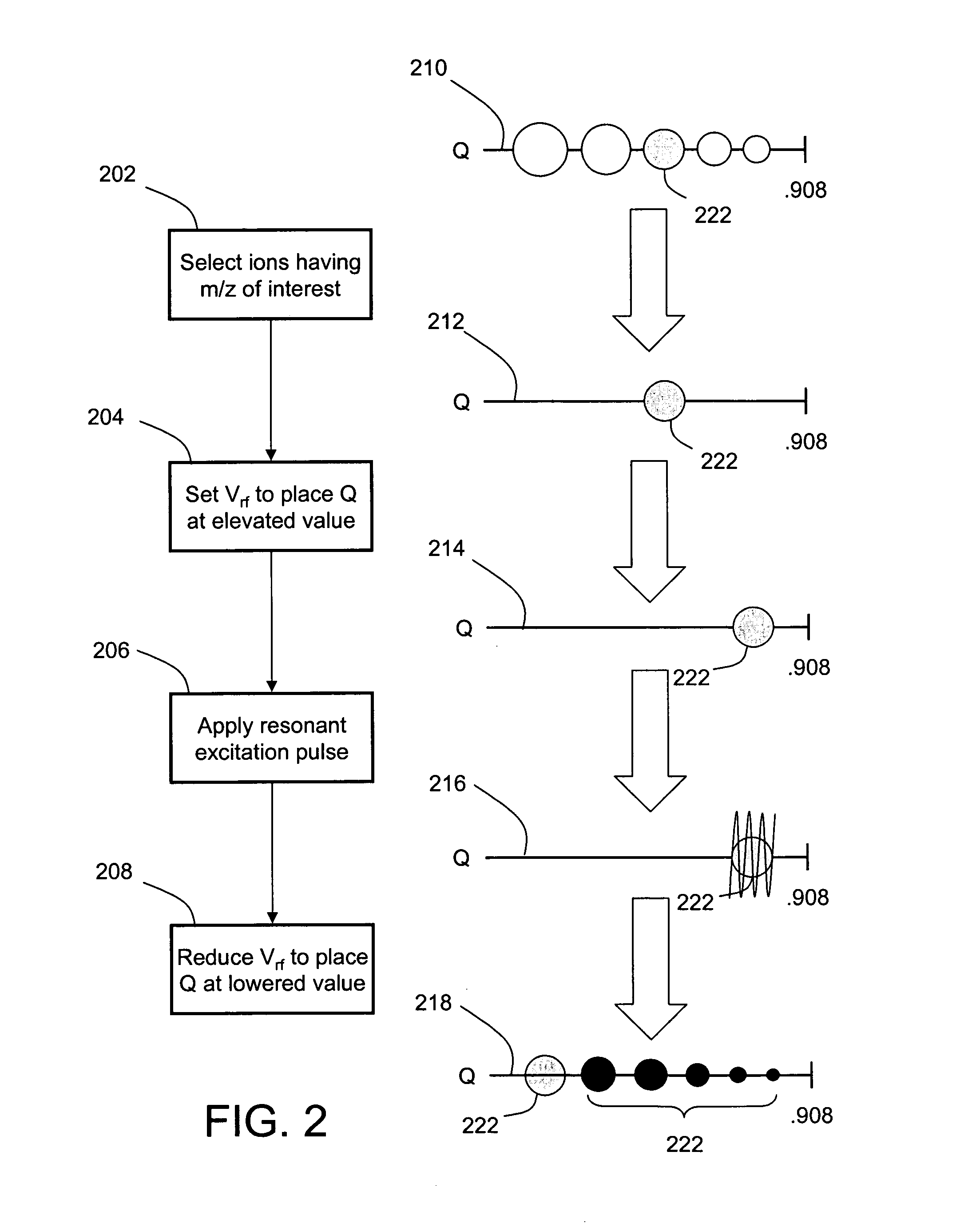

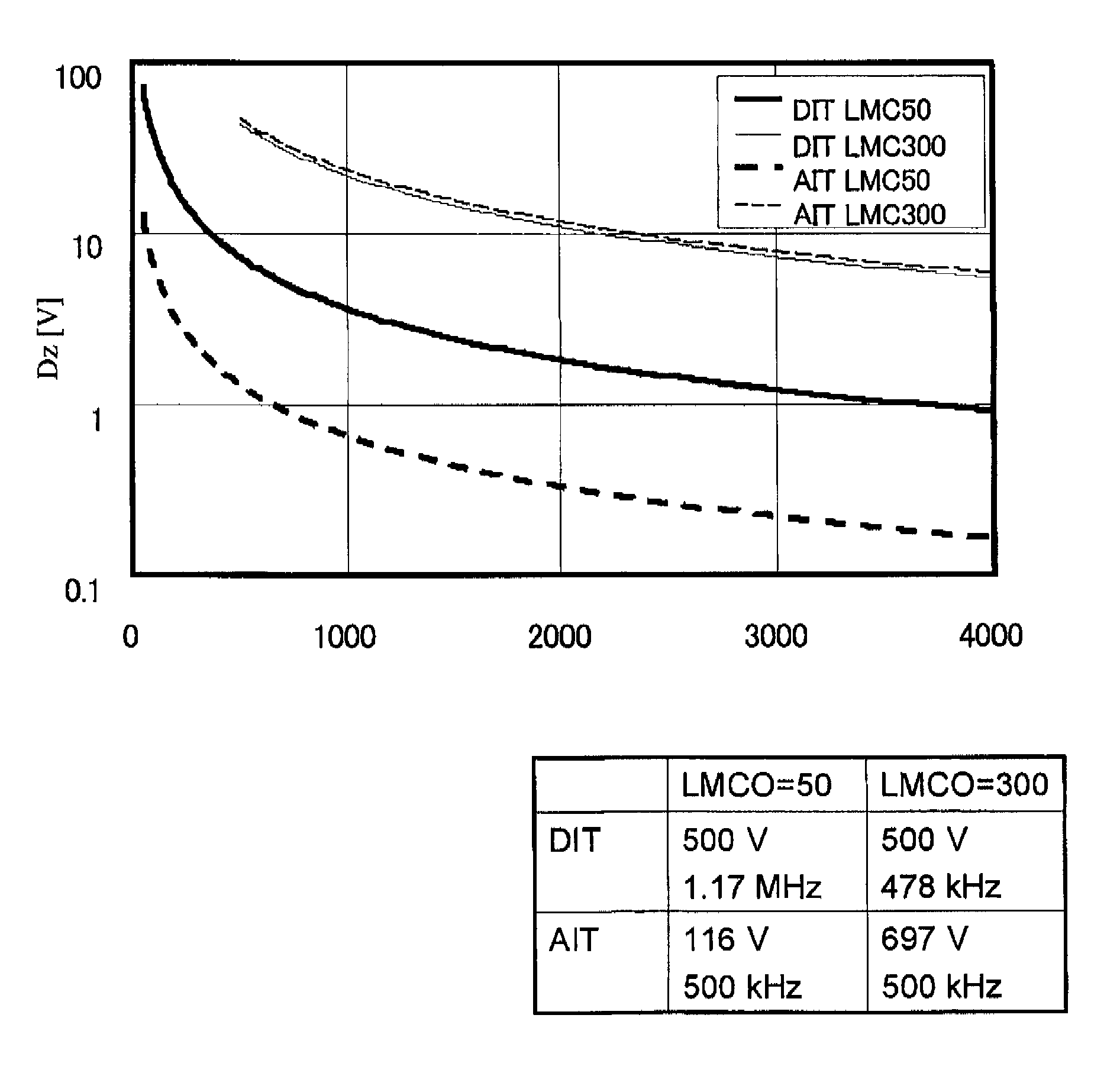

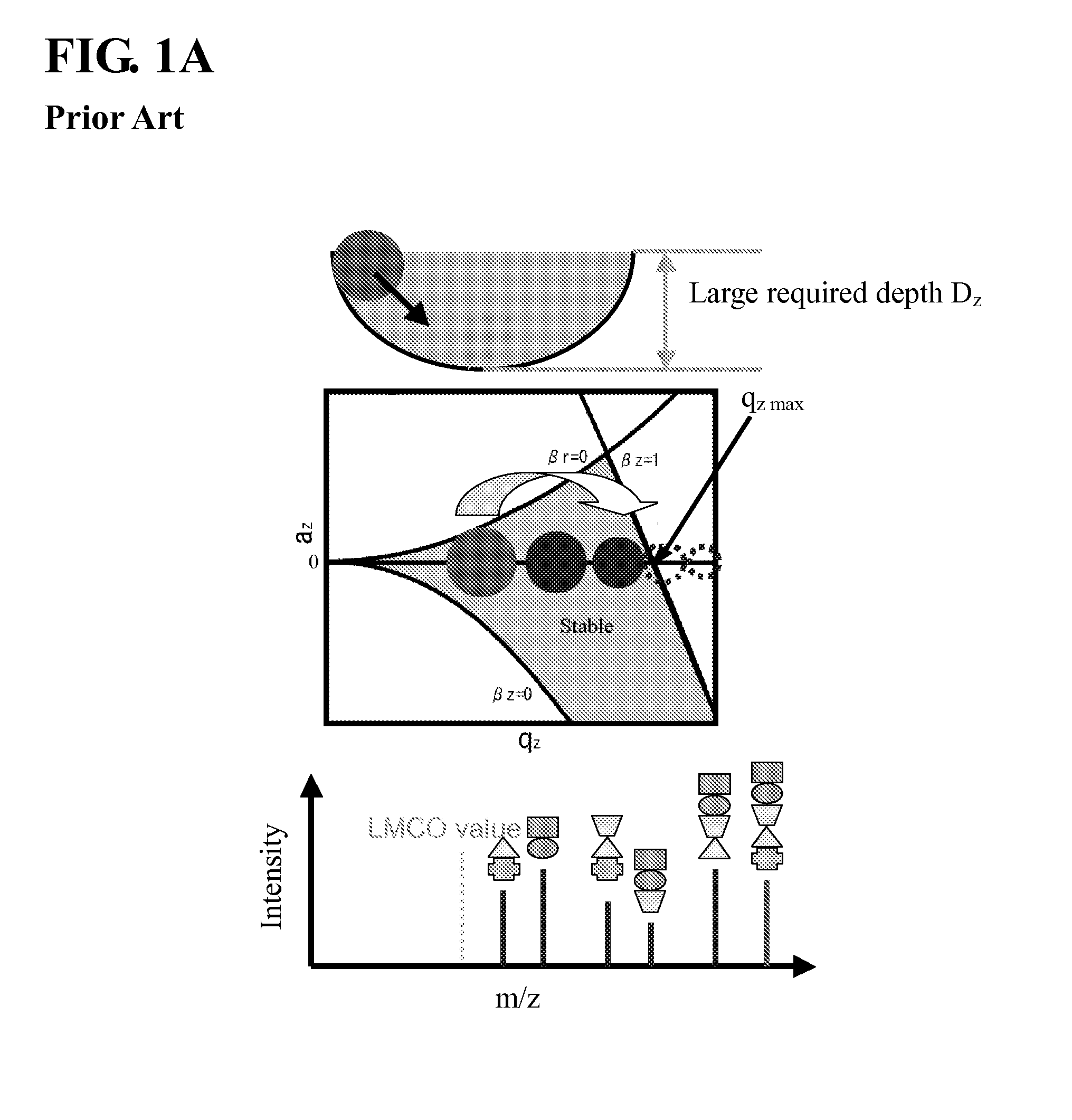

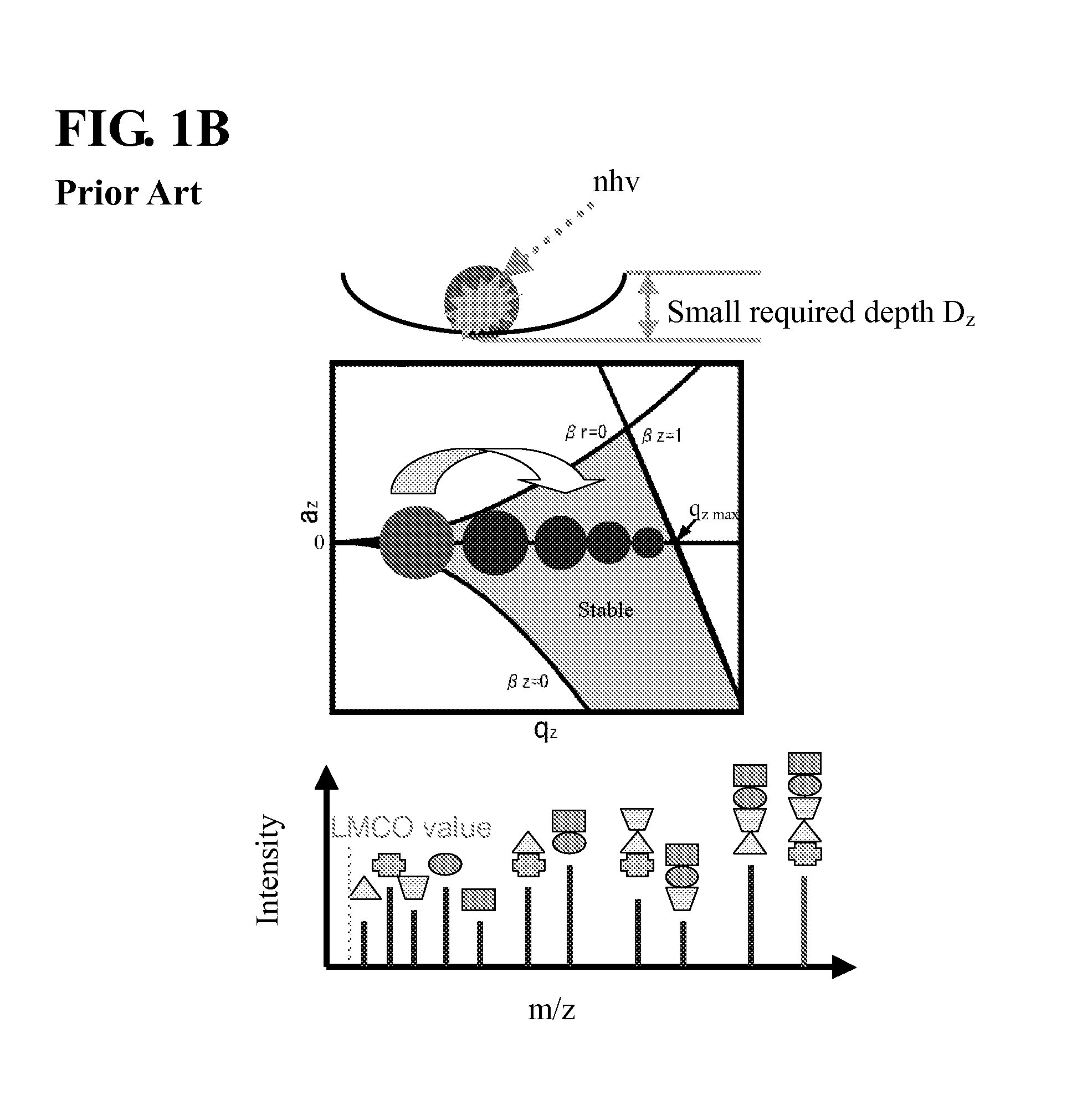

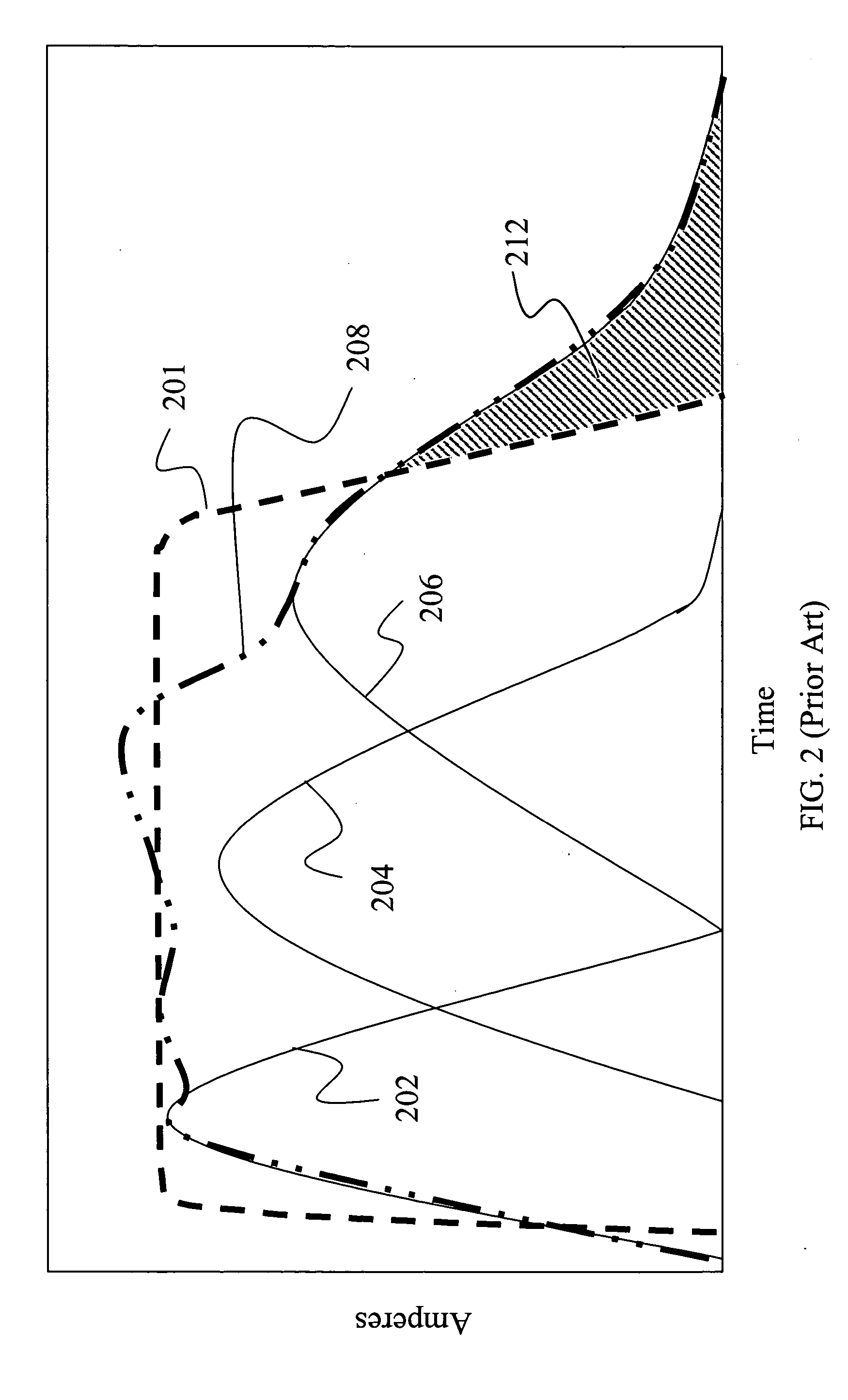

High-Q pulsed fragmentation in ion traps

ActiveUS6949743B1Low QLower LMCOStability-of-path spectrometersIsotope separationElevated valueIon trap mass spectrometry

Rapid and efficient fragmentation of ions in an ion trap for MS / MS analysis is achieved by a pulsed fragmentation technique. Ions of interest are placed at an elevated value of Q and subjected to a relatively high amplitude, short-duration resonance excitation pulse to cause the ions to undergo collision-induced fragmentation. The Q value of the ions of interest is then reduced before significant numbers of ion fragments are expelled from the ion trap, thereby decreasing the low-mass cutoff and allowing retention and subsequent measurement of lower-mass ion fragments.

Owner:THERMO FINNIGAN

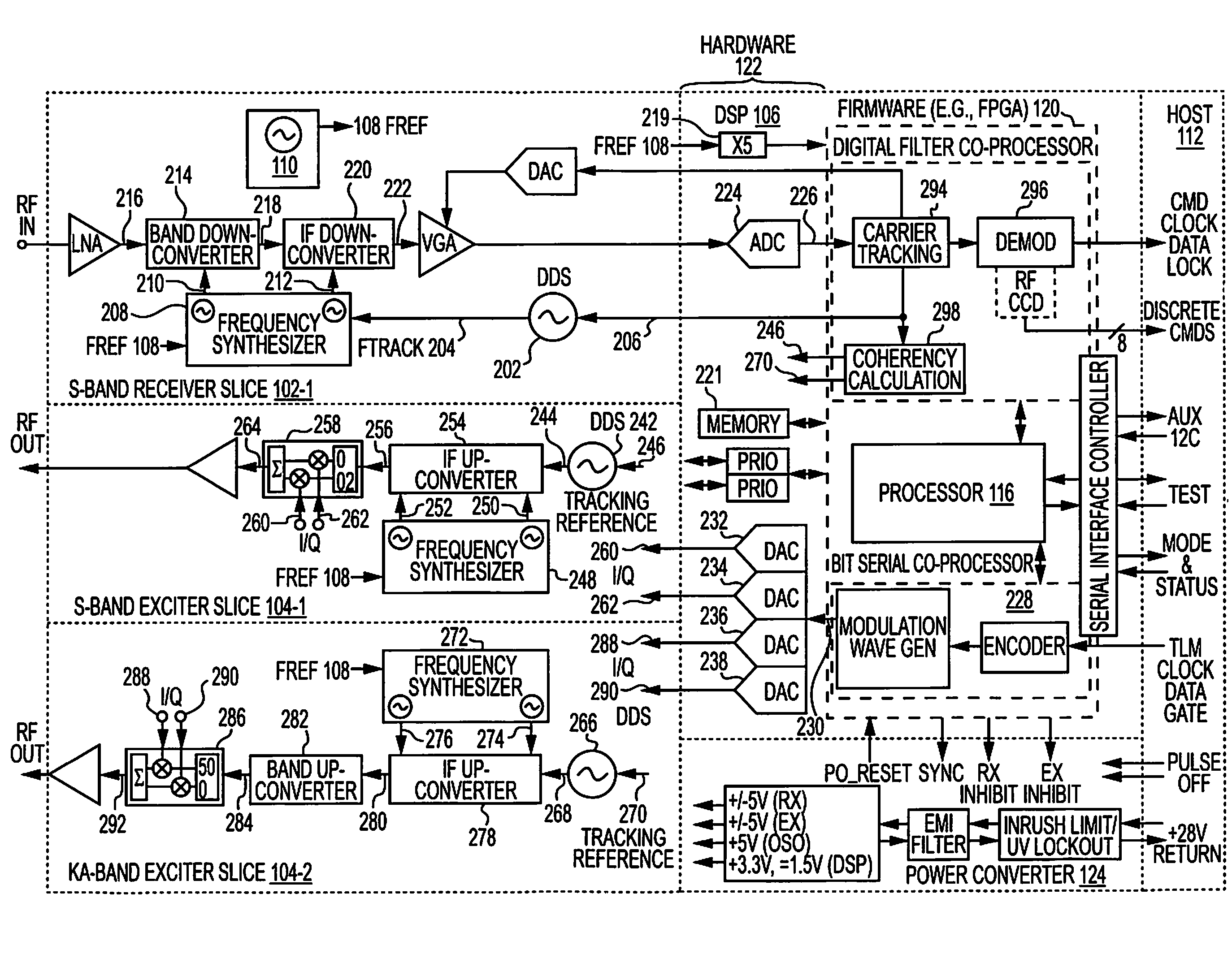

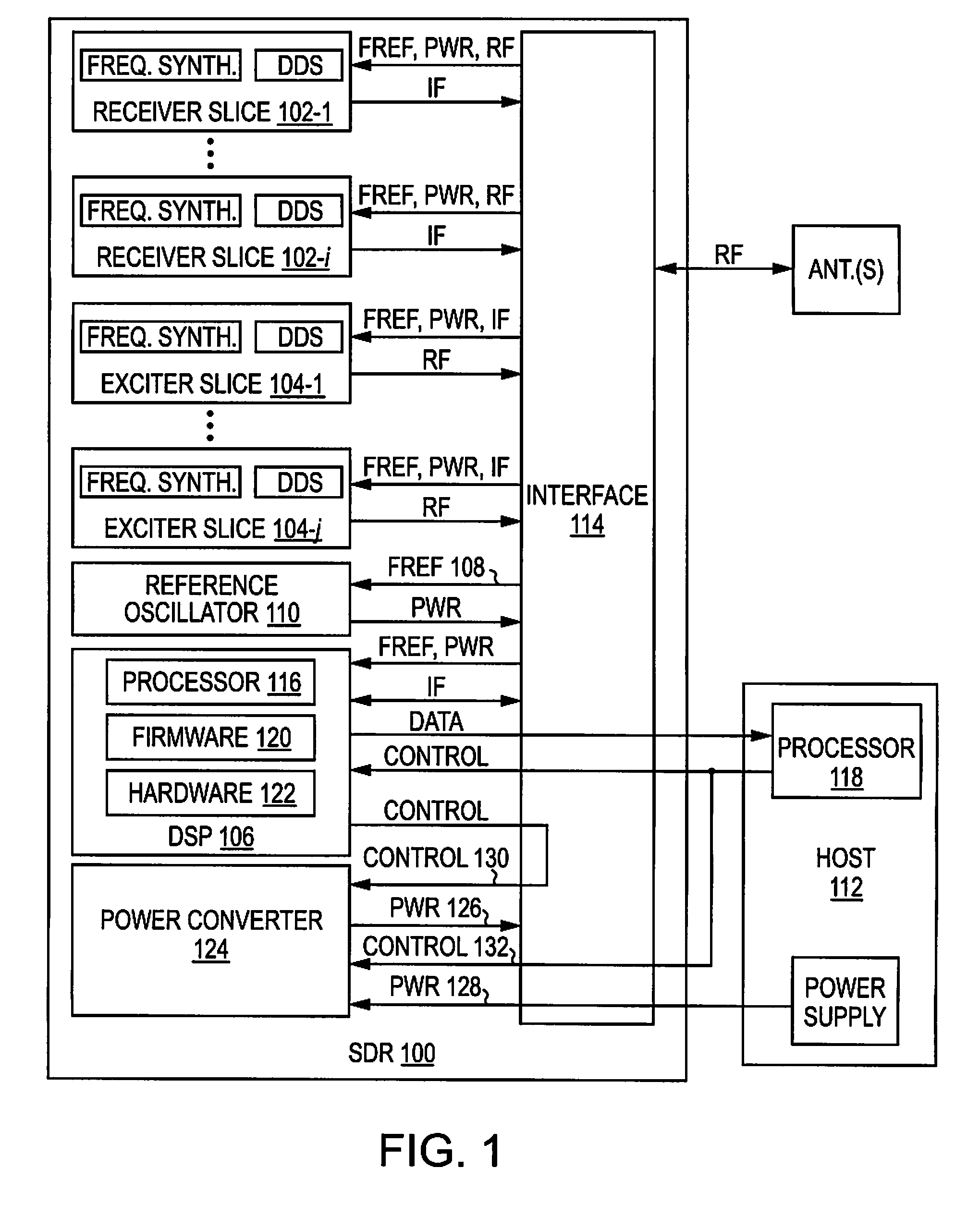

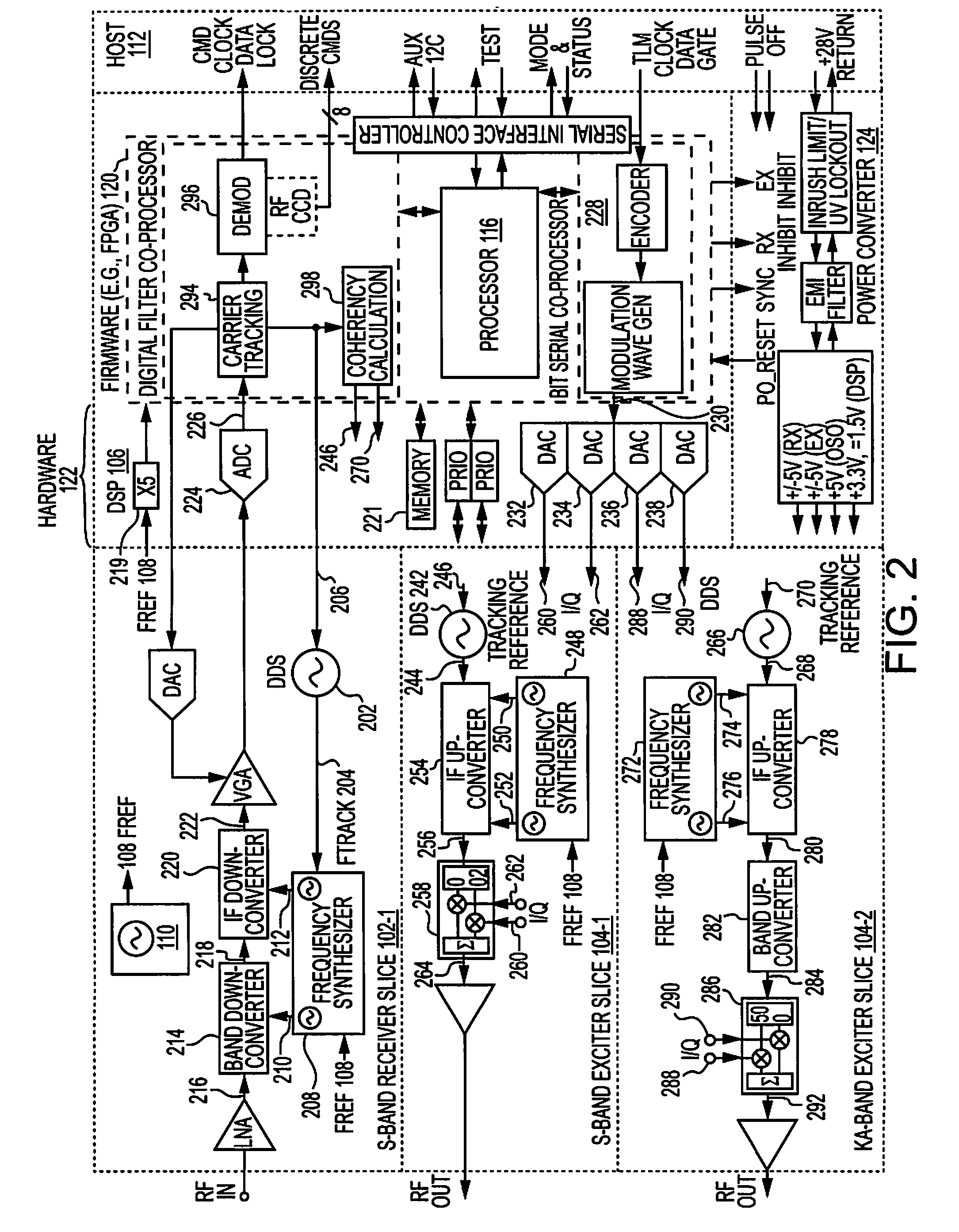

Low Power, Low Mass, Modular, Multi-Band Software-Defined Radios

ActiveUS20120252387A1Low spuriousHigh precisionPulse automatic controlRadio transmissionMulti bandLow noise

Methods and systems to implement and operate software-defined radios (SDRs). An SDR may be configured to perform a combination of fractional and integer frequency synthesis and direct digital synthesis under control of a digital signal processor, which may provide a set of relatively agile, flexible, low-noise, and low spurious, timing and frequency conversion signals, and which may be used to maintain a transmit path coherent with a receive path. Frequency synthesis may include dithering to provide additional precision. The SDR may include task-specific software-configurable systems to perform tasks in accordance with software-defined parameters or personalities. The SDR may include a hardware interface system to control hardware components, and a host interface system to provide an interface to the SDR with respect to a host system. The SDR may be configured for one or more of communications, navigation, radio science, and sensors.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

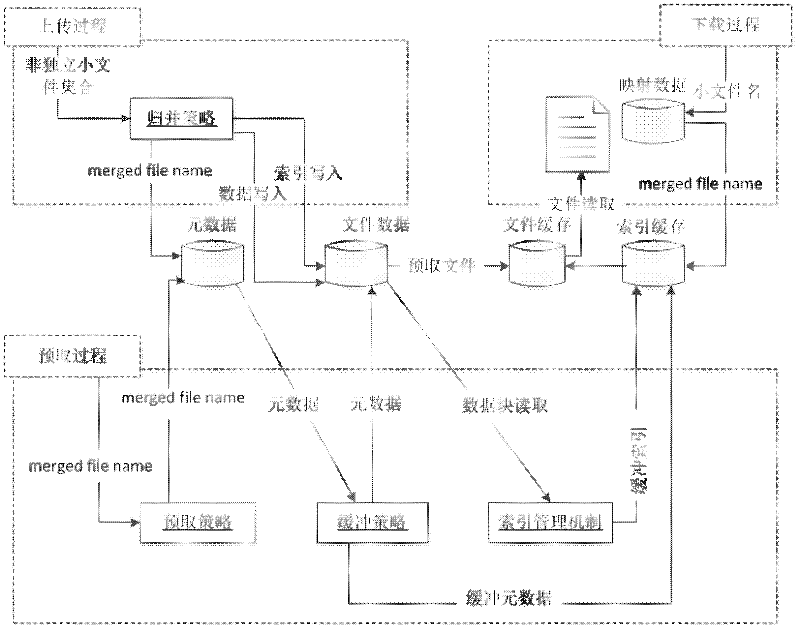

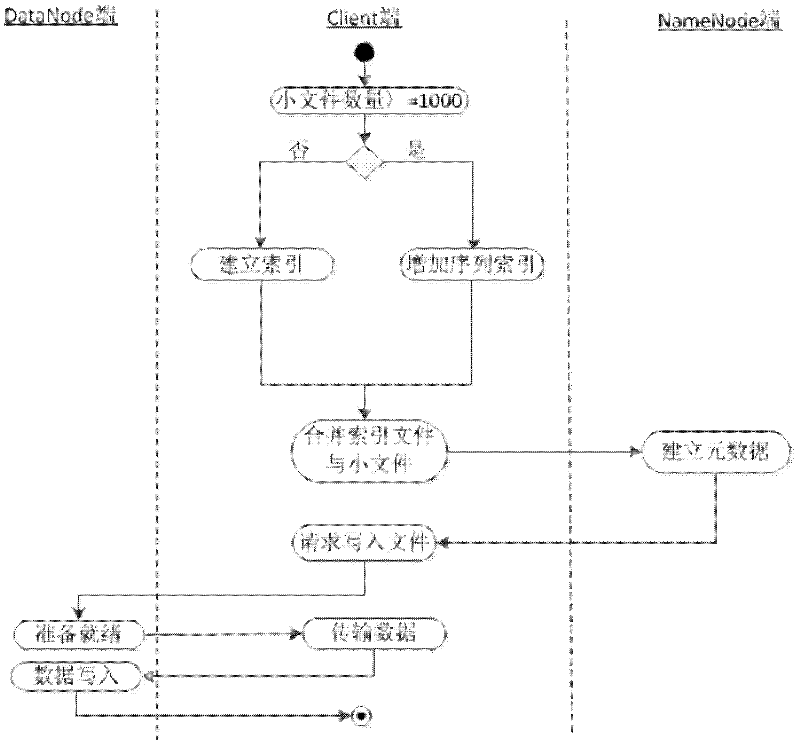

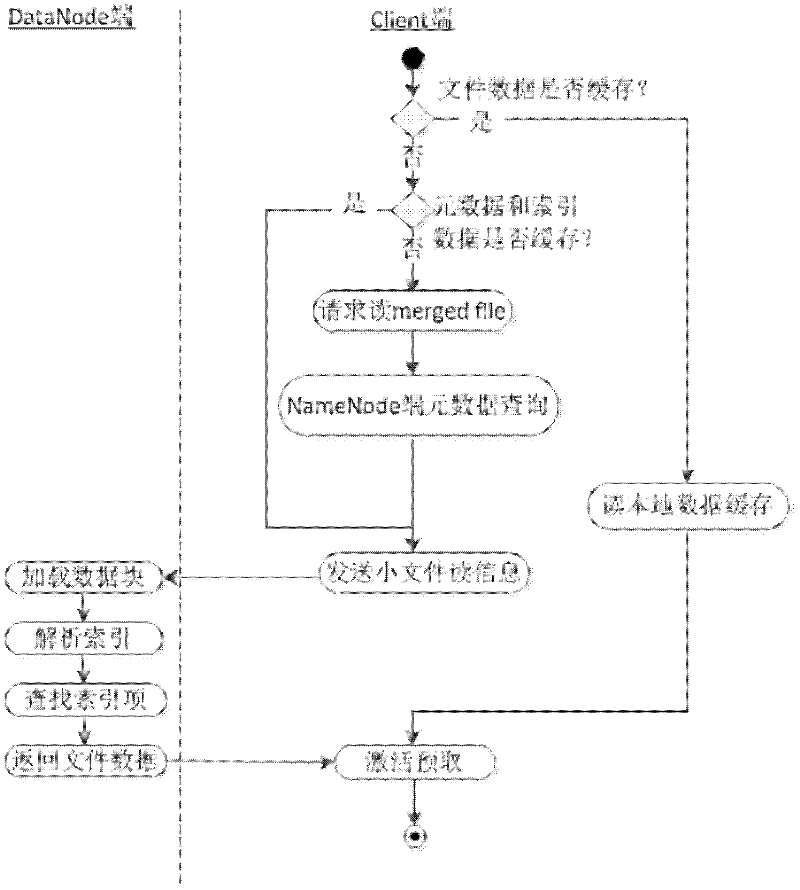

Mass non-independent small file associated storage method based on Hadoop

InactiveCN102332027AReduce interactionImprove storage efficiencySpecial data processing applicationsData nodeSmall files

The invention discloses a mass non-independent small file associated storage method based on Hadoop. The method is mainly used for solving the problem of low mass non-independent small file access and reading efficiency and aims at a plurality of small files, namely non-independent small files obtained by cutting a big file. The method is characterized by comprising the following steps: (1) merging all the small files of the big file into one file which is named merged file; (2) establishing a local index for each merged file, and storing a local index file and a file entity onto a Data Node of a Hadoop system while updating; and (3) when the non-independent small files are read, improving the file reading efficiency by adopting metadata cache, local index file pre-fetching and associated file pre-fetching. By utilizing the method provided by the invention, the efficiency of the existing Hadoop system for storing and reading small files is improved. The method is suitable for the storage and management of the mass non-independent small files in universal scenes.

Owner:XI AN JIAOTONG UNIV

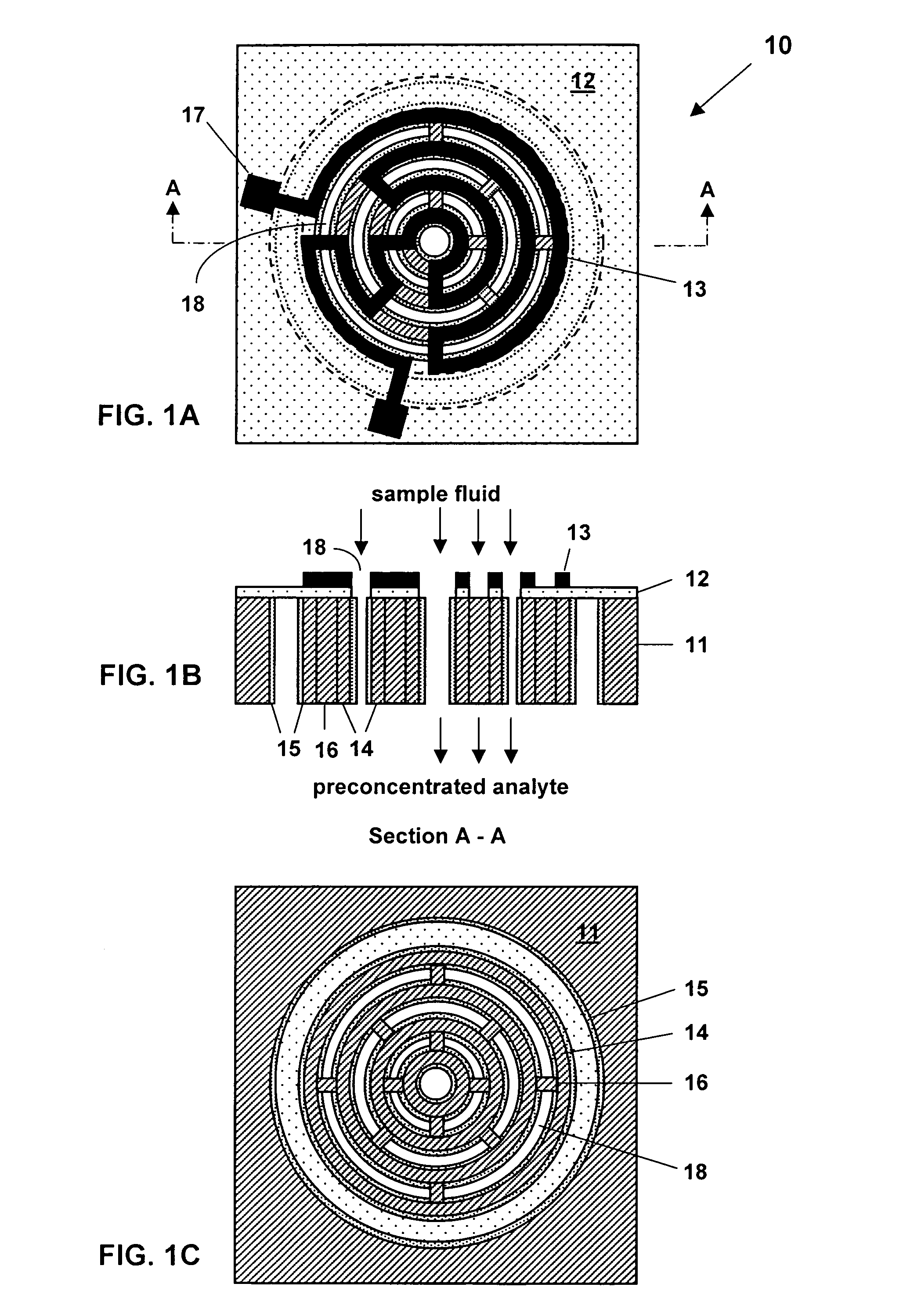

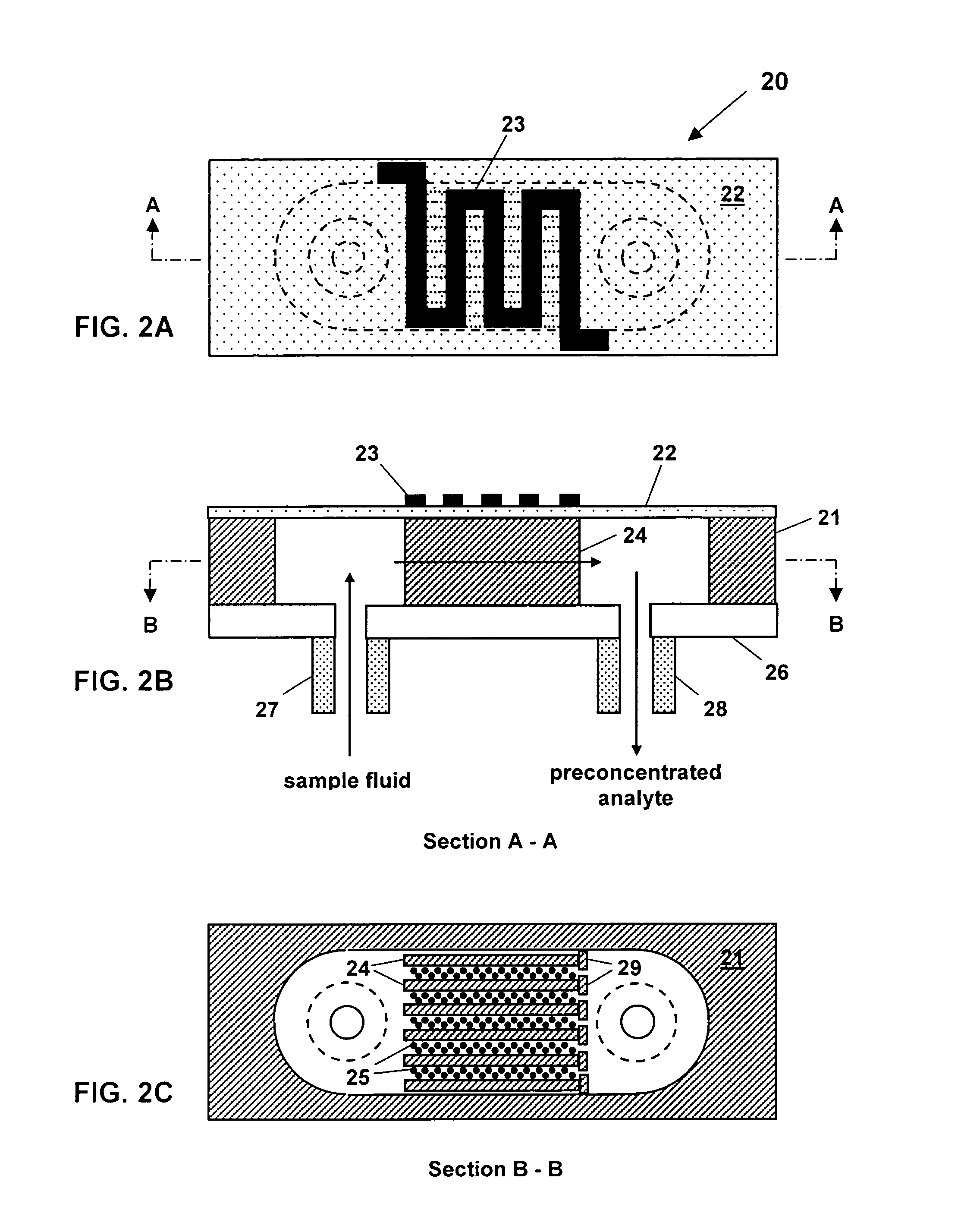

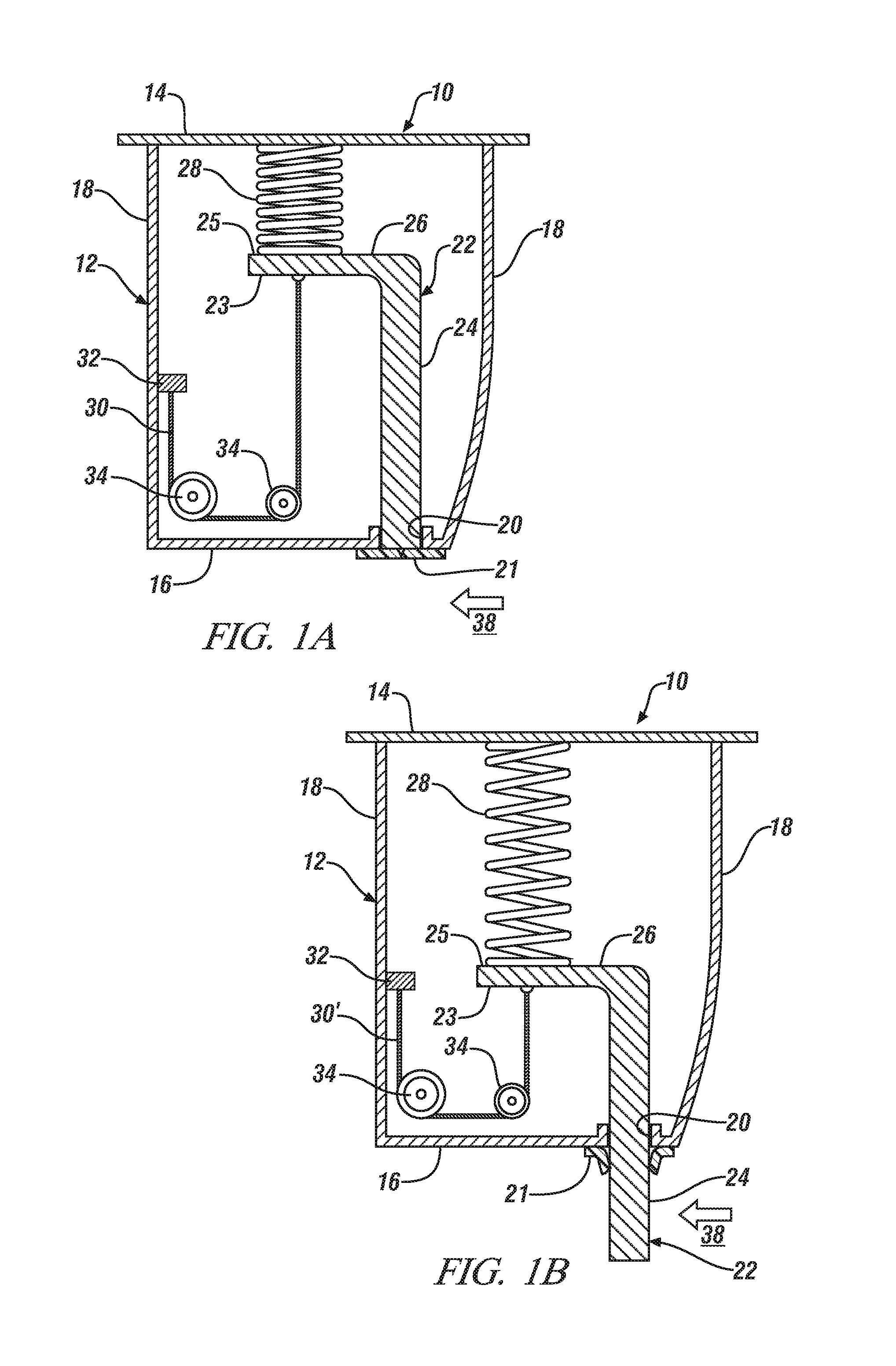

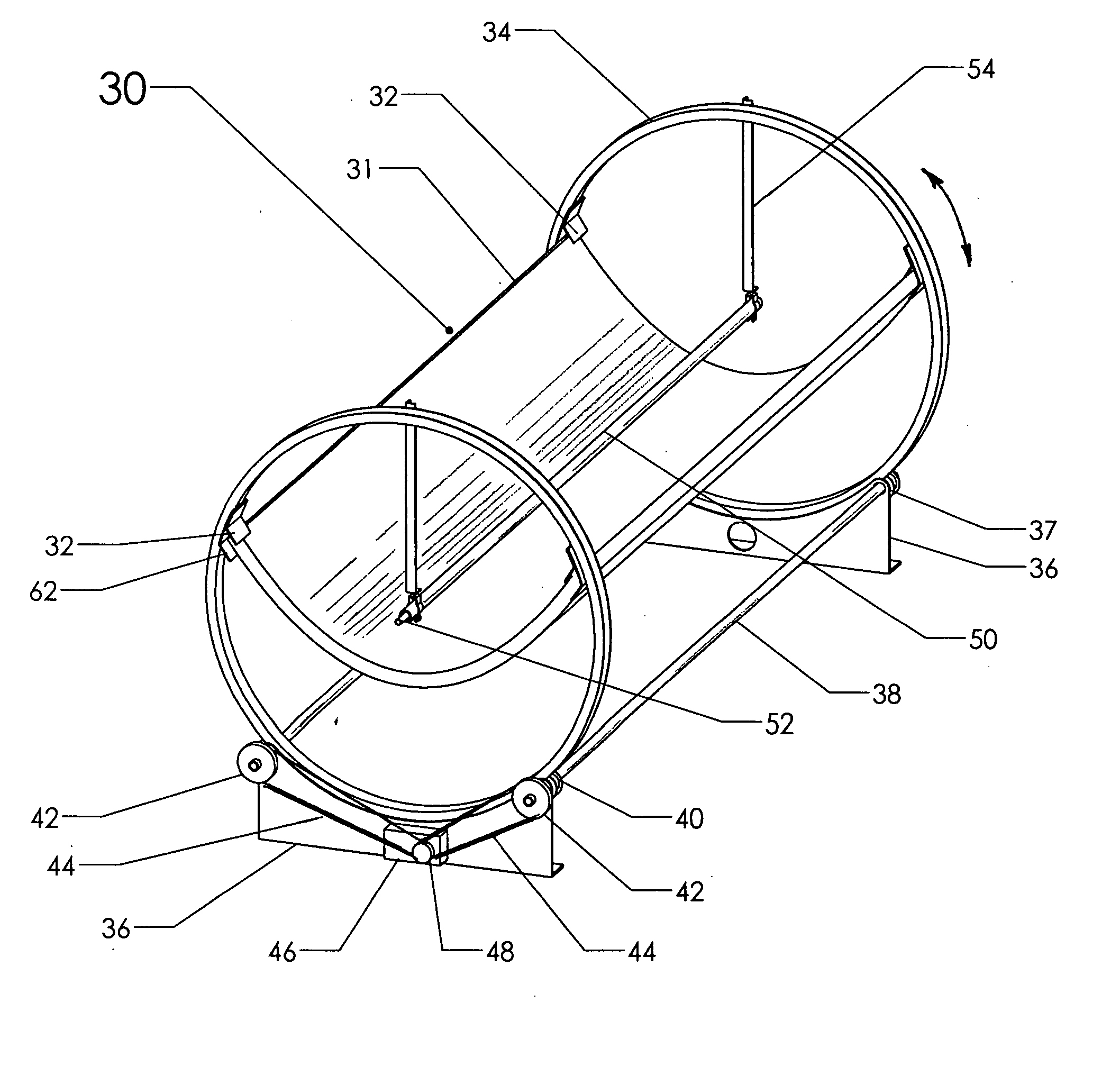

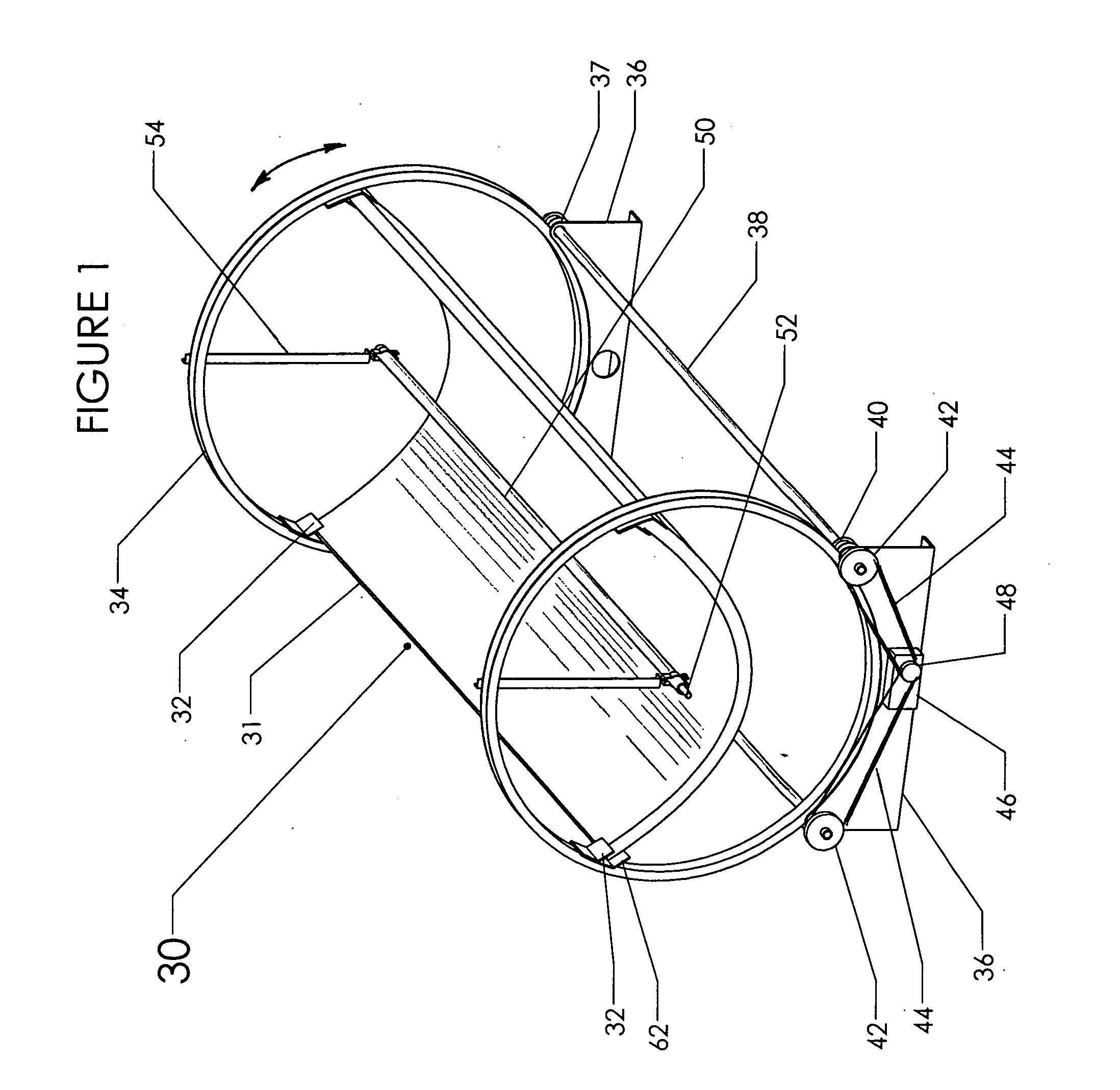

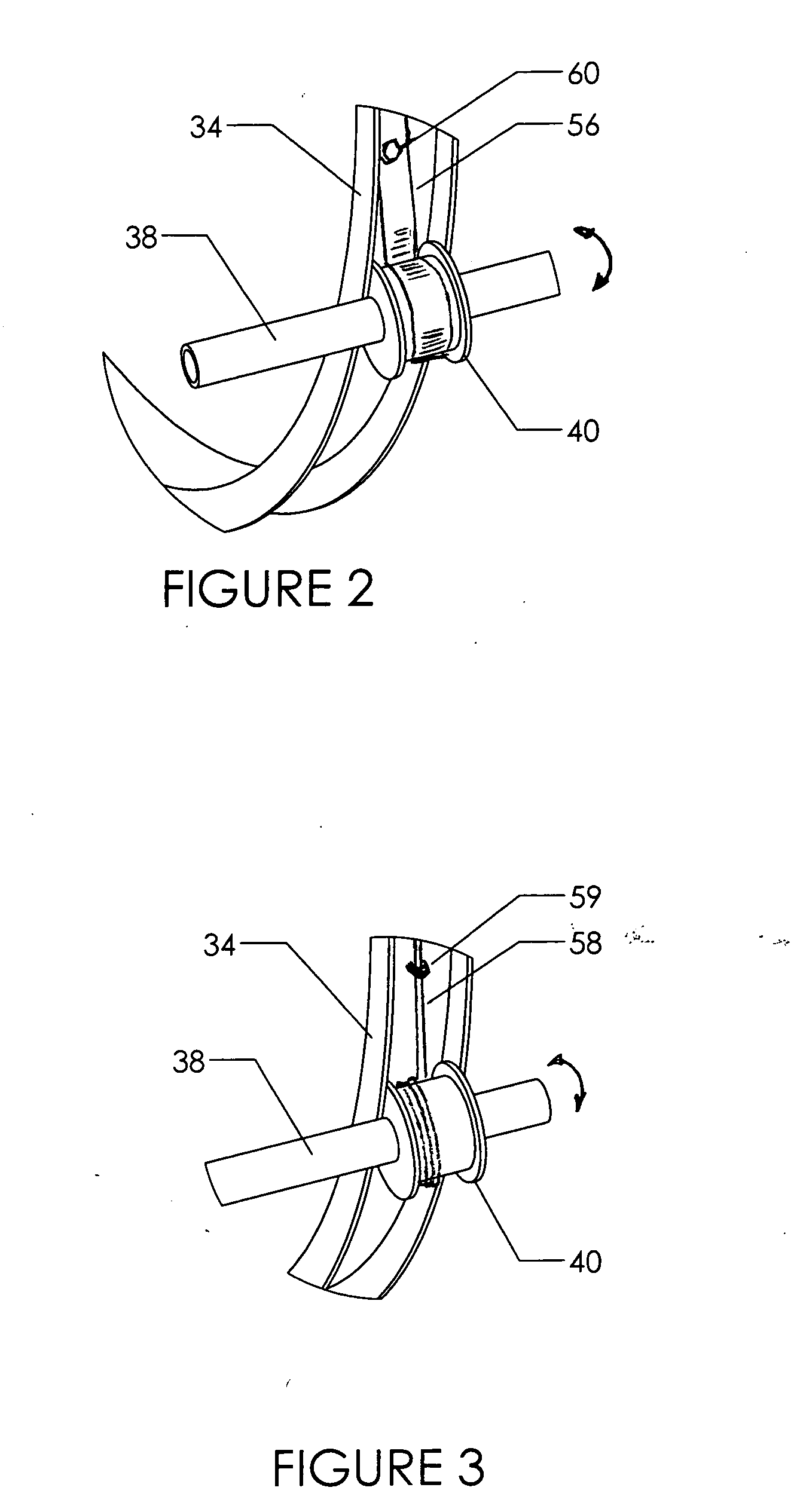

Non-planar chemical preconcentrator

ActiveUS7118712B1Quick releaseComponent separationWithdrawing sample devicesAnalyteCompound (substance)

A non-planar chemical preconcentrator comprises a high-surface area, low mass, three-dimensional, flow-through sorption support structure that can be coated or packed with a sorptive material. The sorptive material can collect and concentrate a chemical analyte from a fluid stream and rapidly release it as a very narrow temporal plug for improved separations in a microanalytical system. The non-planar chemical preconcentrator retains most of the thermal and fabrication benefits of a planar preconcentrator, but has improved ruggedness and uptake, while reducing sorptive coating concerns and extending the range of collectible analytes.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

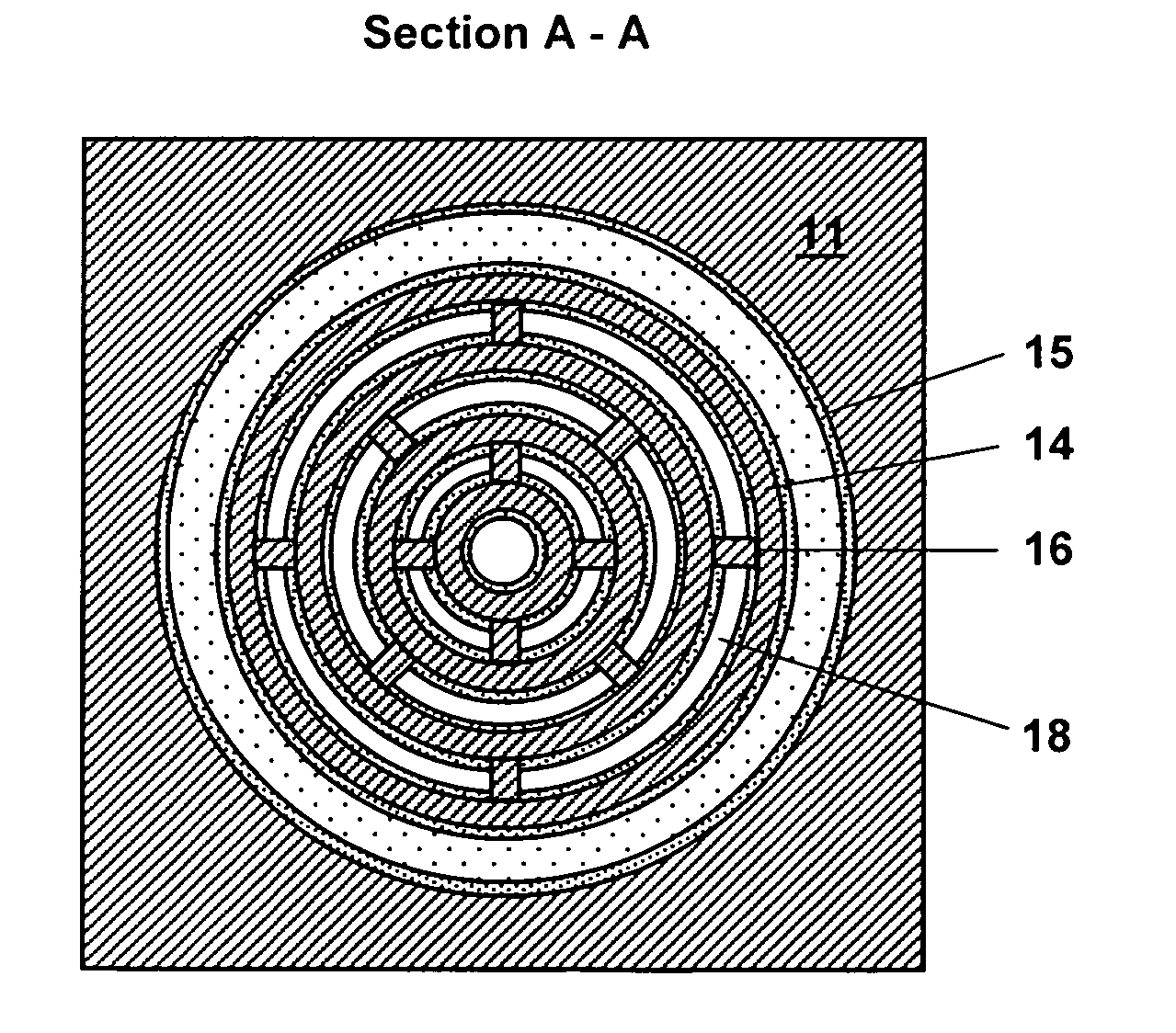

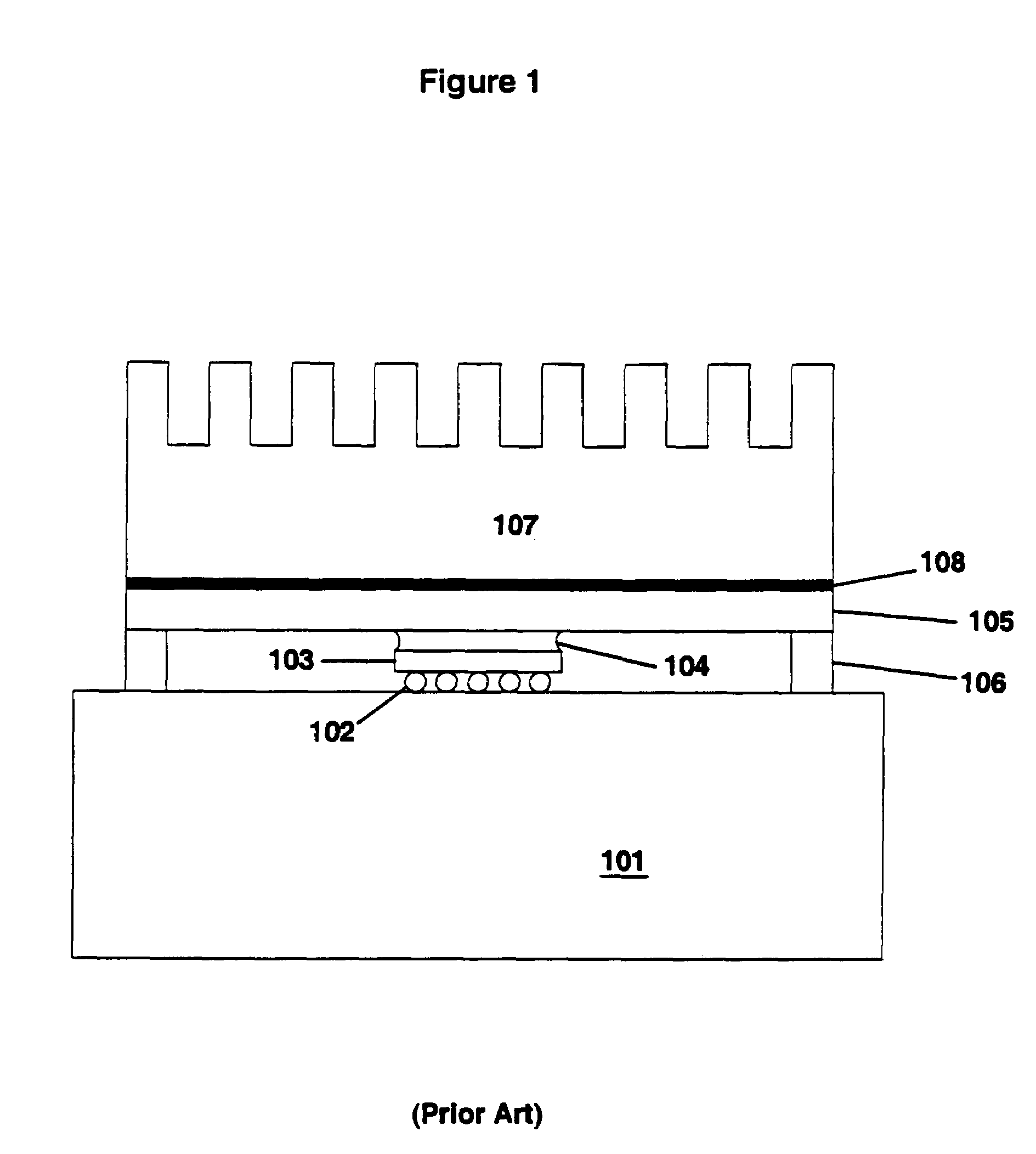

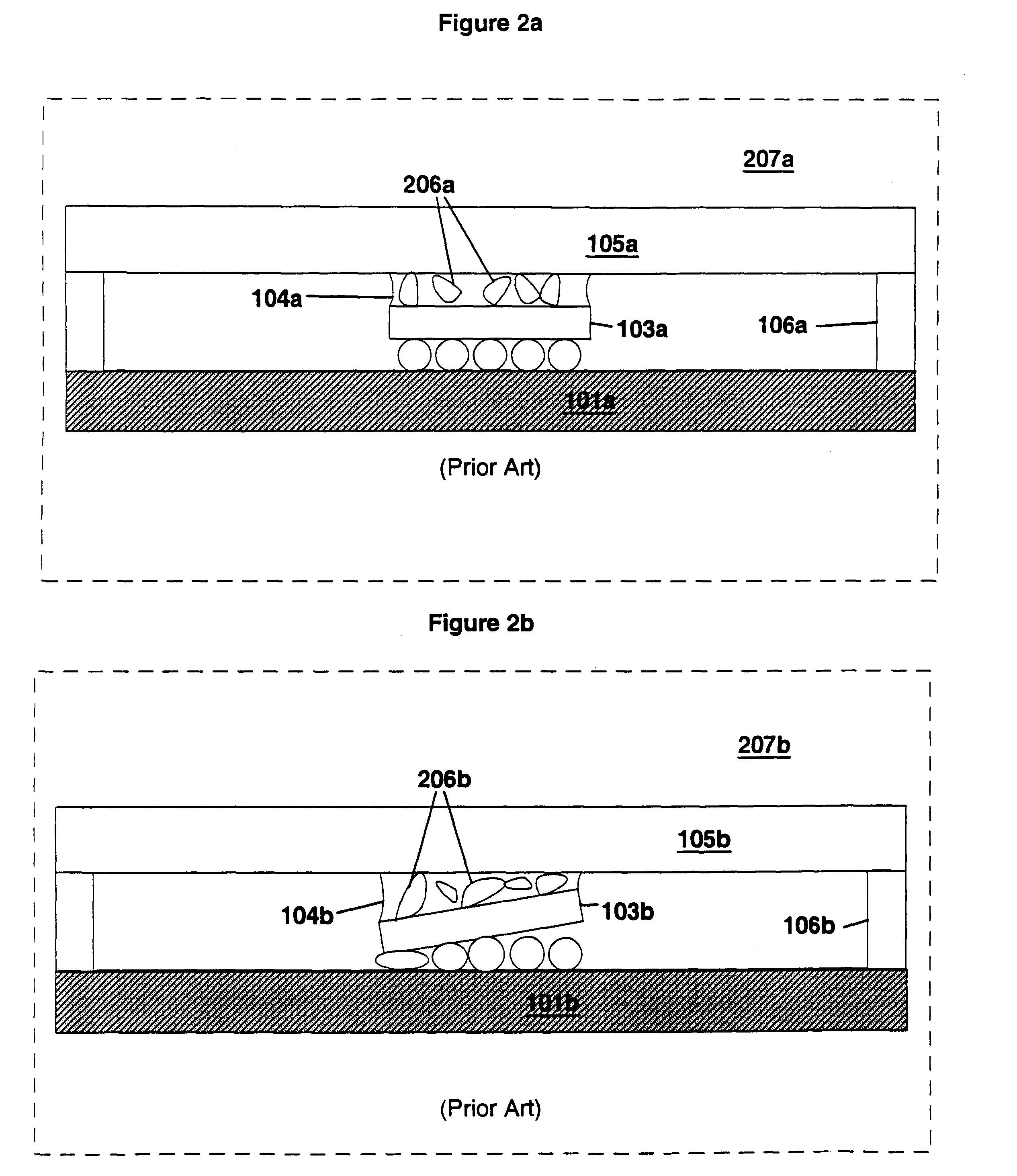

Stiffener for flip chip BGA package

ActiveUS7459782B1Improve package reliabilityLess bowingSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Provided are semiconductor die flip chip packages with warpage control and fabrication methods for such packages. A package includes a heat spreader that is attached to a die and a stiffener, which are in turn attached to a package substrate. In general, the stiffener is made of a material that has a relatively low CTE value. For example, the stiffener material may have a CTE value less than 12 ppm / ° C. The material may also have a relatively low mass density value of less than 8.9 g / cm3. Such a material may include natural graphite or some composite form of it. The result is a package with less bowing and so improved co-planarity (e.g., in compliance with industry specifications) with the surface to which it is ultimately bound; thereby, improving the reliability of the package. Moreover, a package that is relatively lighter and more robust than conventional semiconductor die flip chip packages can be realized.

Owner:ALTERA CORP

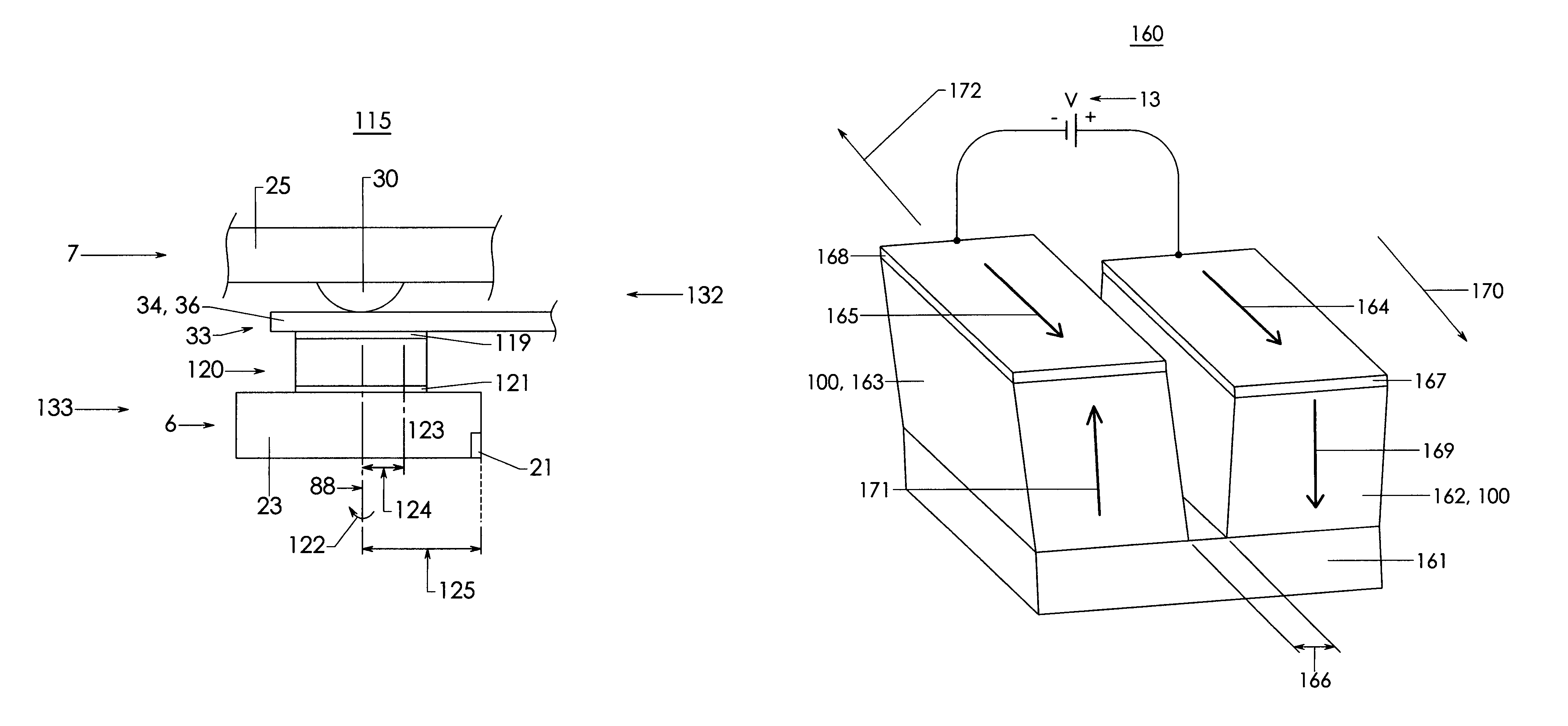

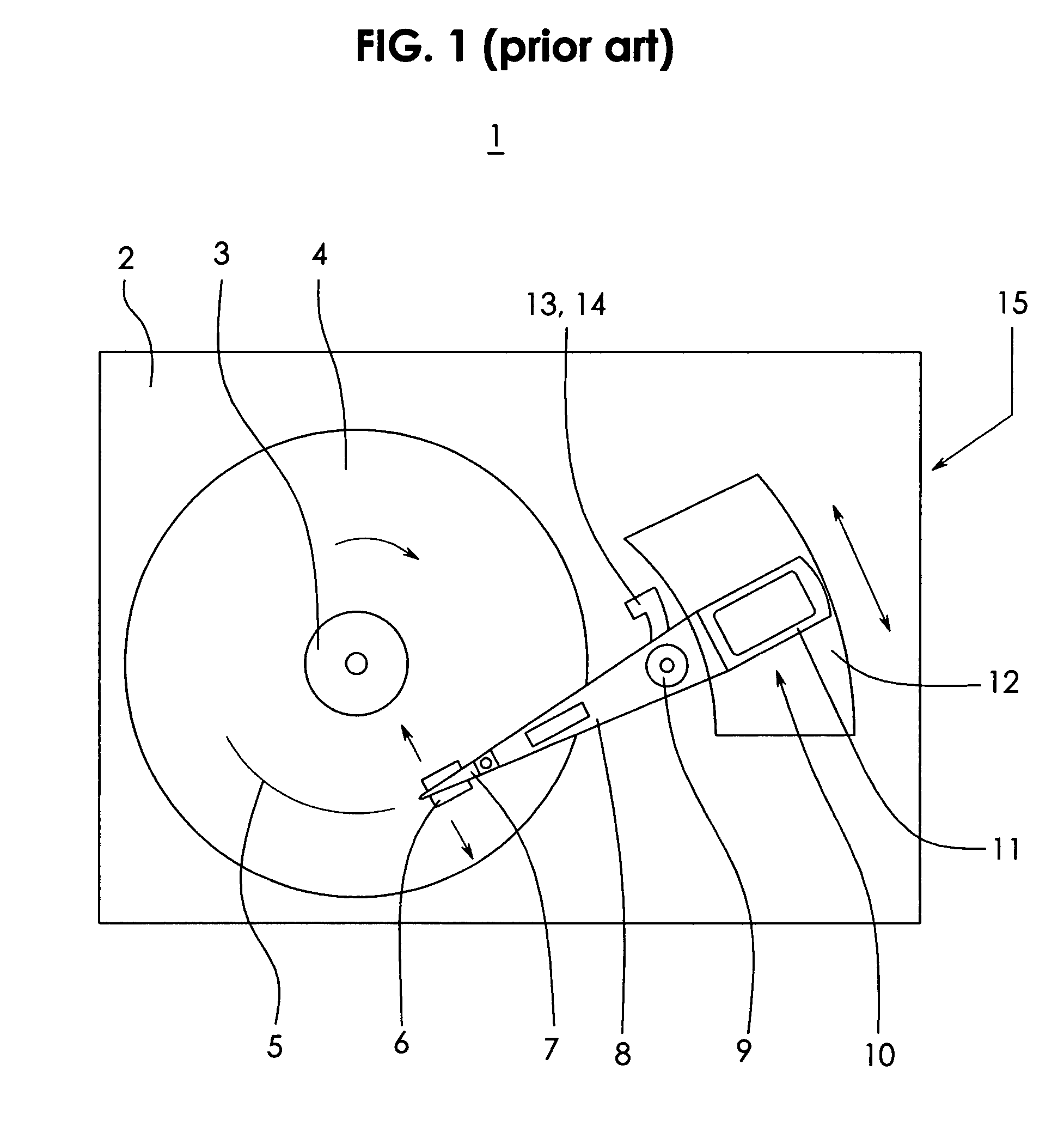

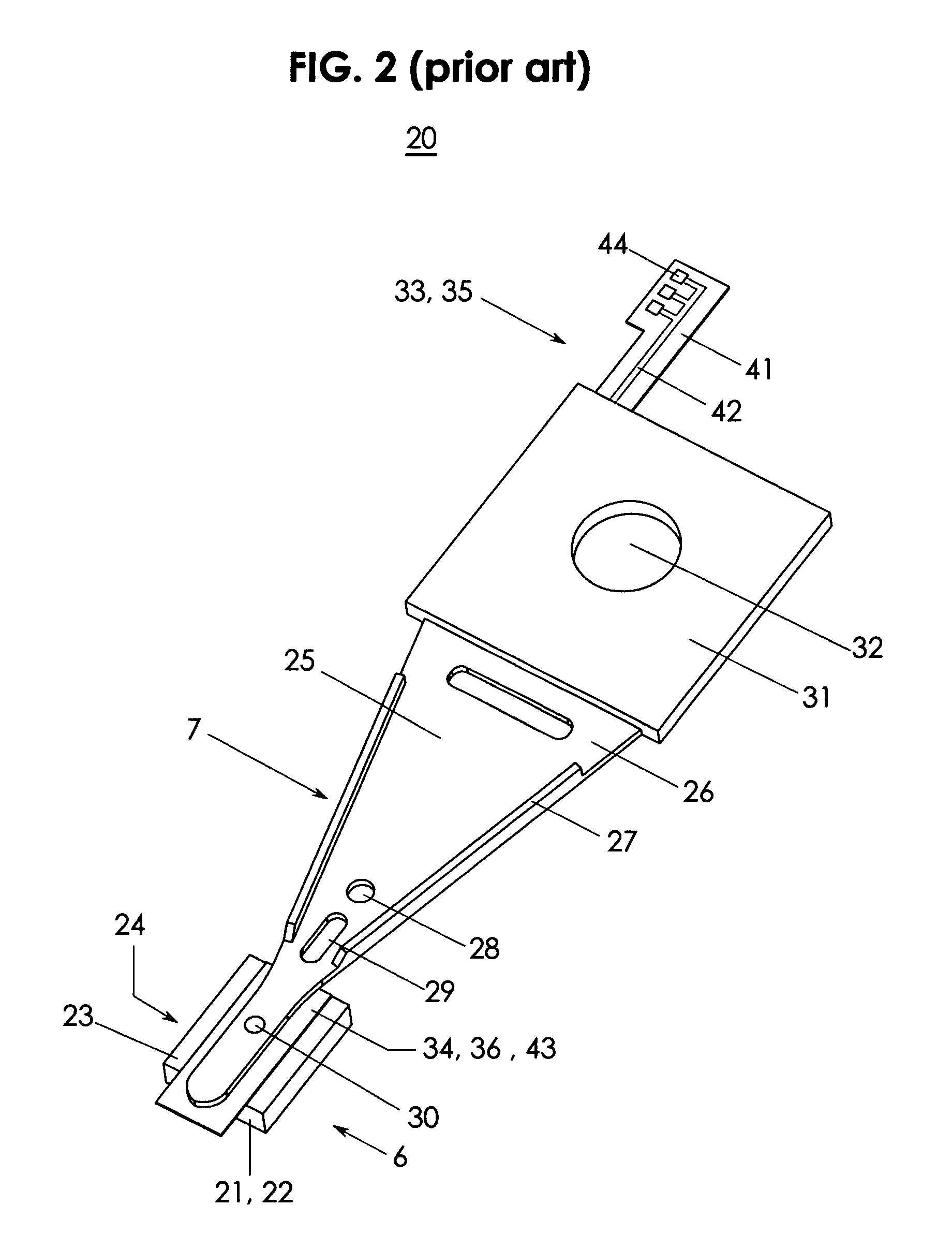

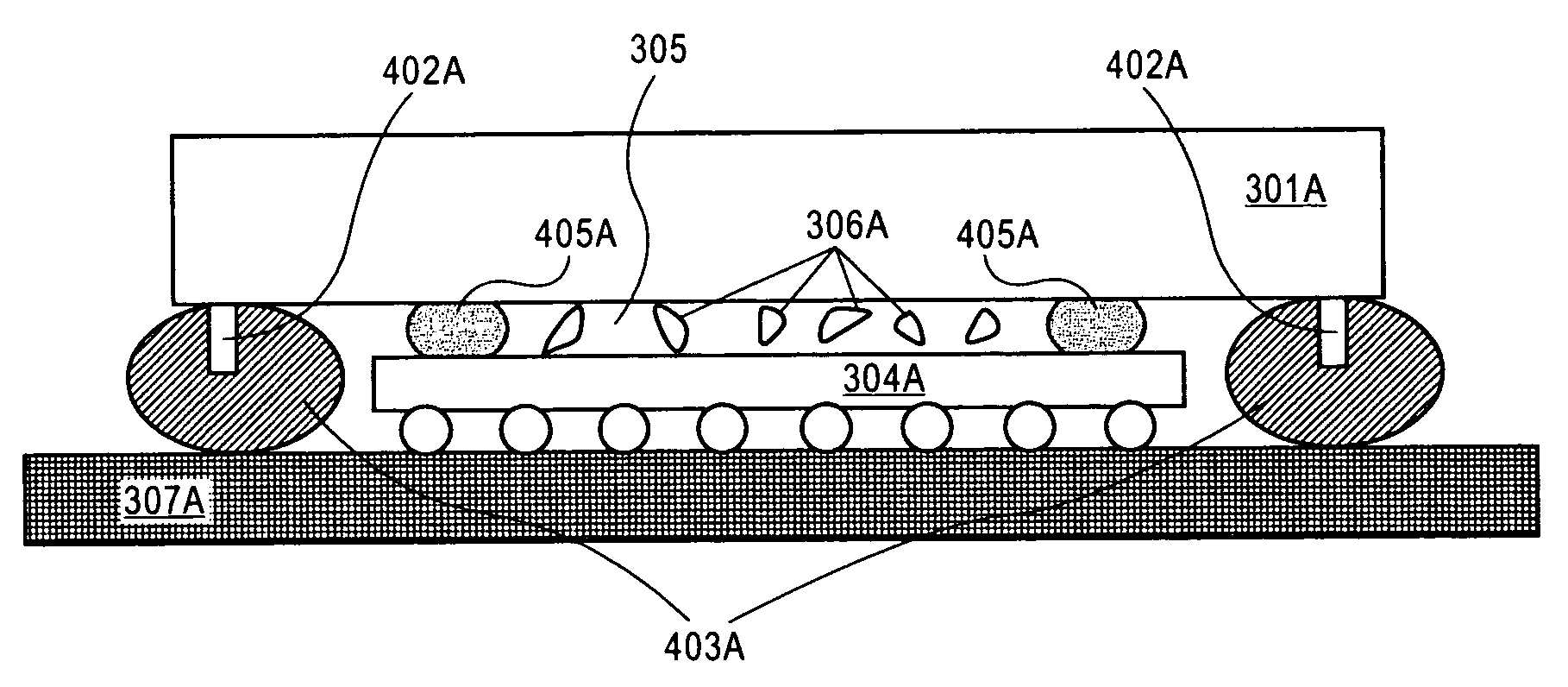

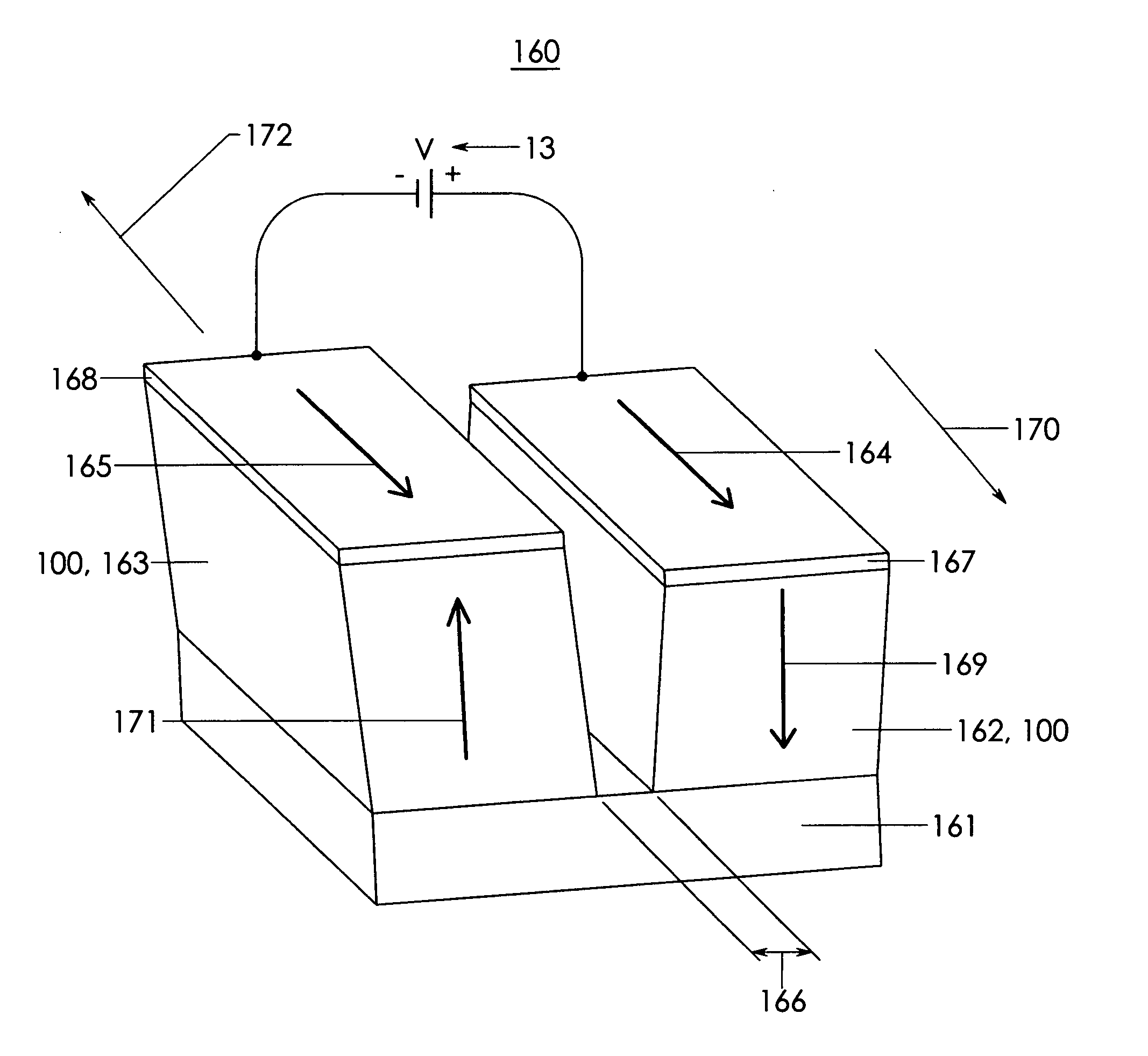

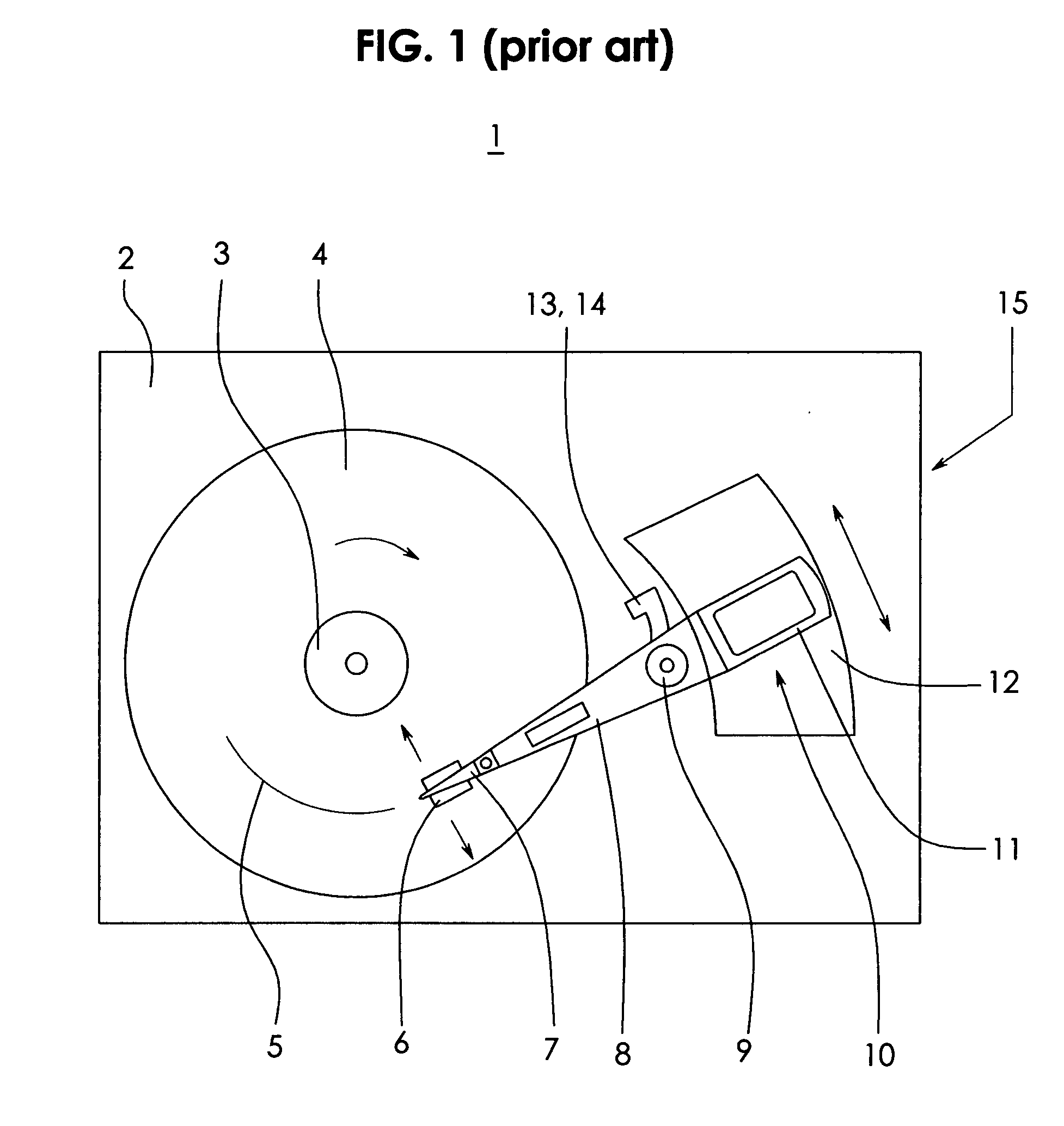

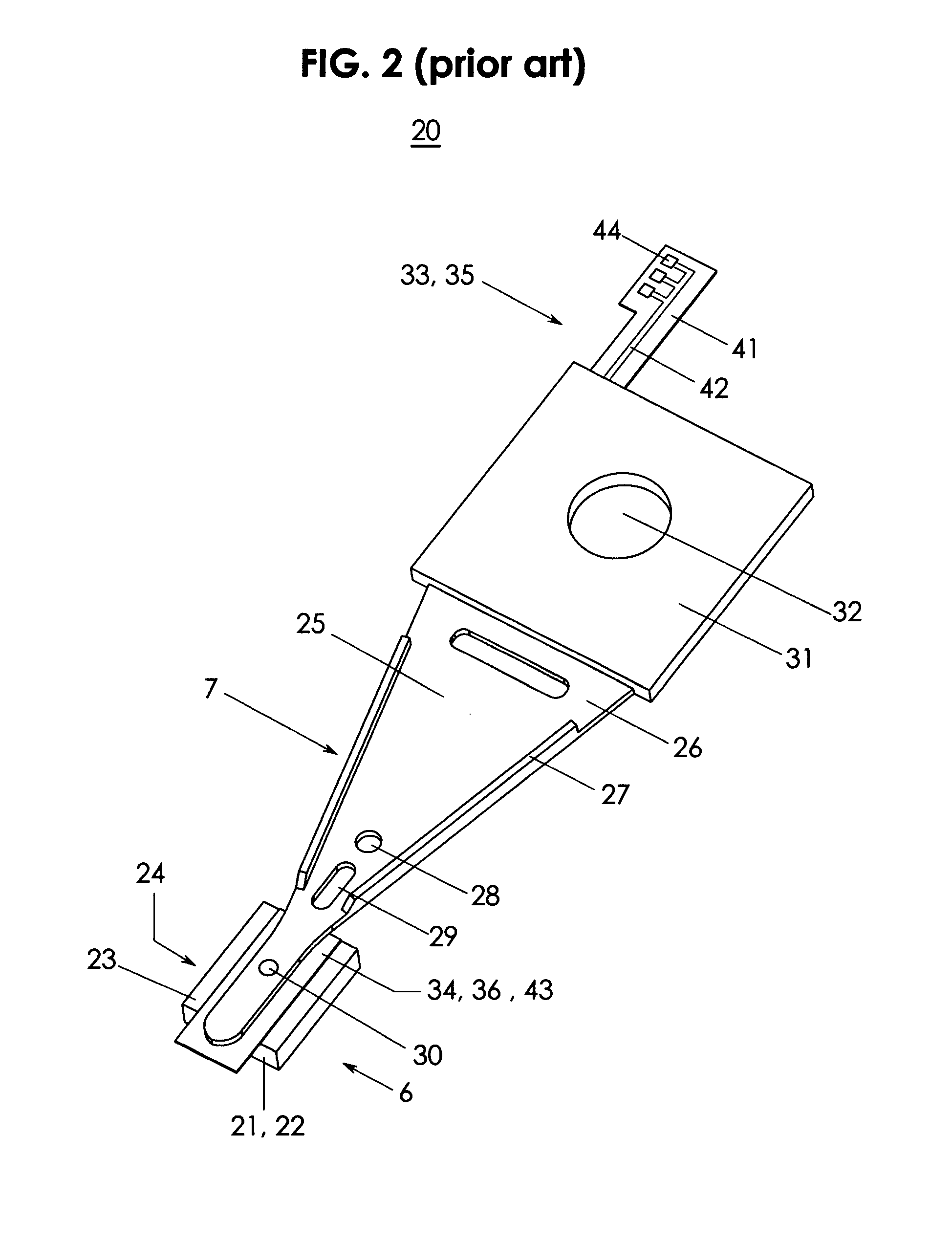

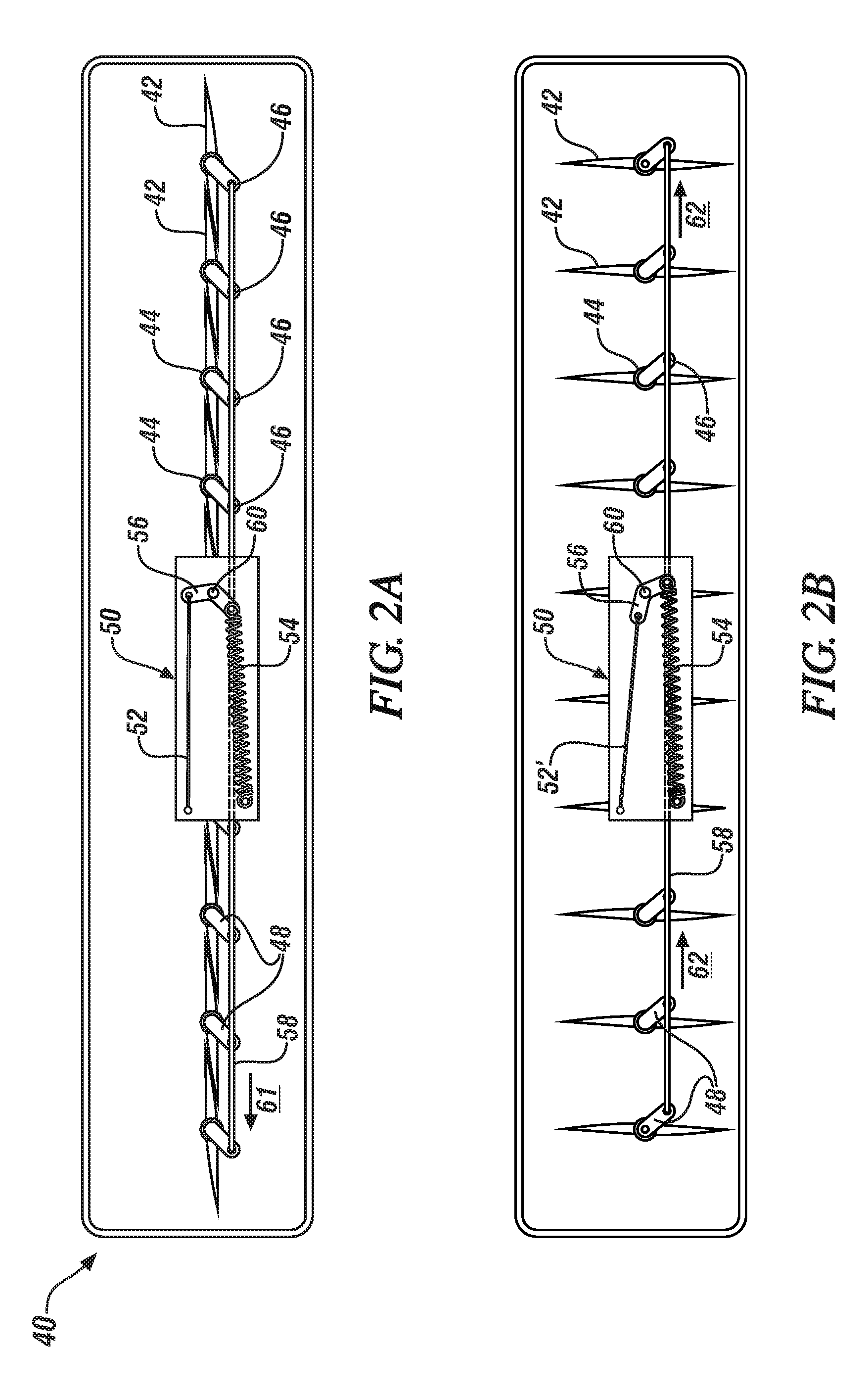

Rotational, shear mode, piezoelectric motor integrated into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head/gimbal assembly for improved tracking in disk drives and disk drive equipment

ActiveUS8125741B2High track densityImprove data storage capacityDriving/moving recording headsArm with actuatorsShock resistanceControl theory

A rotational, shear mode, piezoelectric motor is integrated with a suspension, head or head gimbal assembly (HGA) into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head gimbal assembly (HGA) for use in disk drives and disk drive manufacturing equipment. When excited by a control voltage, the collocated, shear mode, piezoelectric micro-actuated HGA rotates the head enabling high frequency, high resolution track positioning of the read / write element. The motor is integrated with the head and flexure (collocation). The head rotates about a rotation axis that is ideally located at the center of mass of the head. A shear mode piezoelectric motor rotates the head. A collocated, rotational, shear mode, piezoelectric micro-actuated HGA has high stiffness, high frequency response, high positioning resolution, low mass and low internal vibration for improved tracking, increased track density and greater disk drive storage capacity. Furthermore, its solid integration improves shock resistance and reduces micro-contamination.

Owner:MAGNECOMP +1

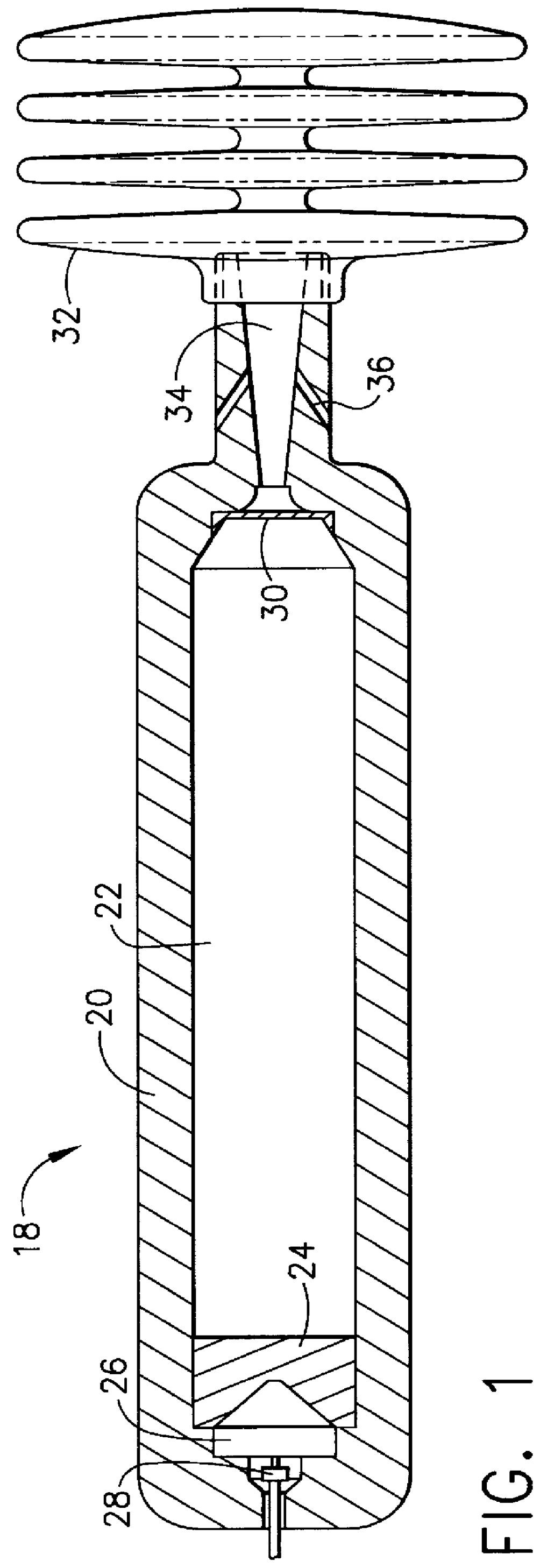

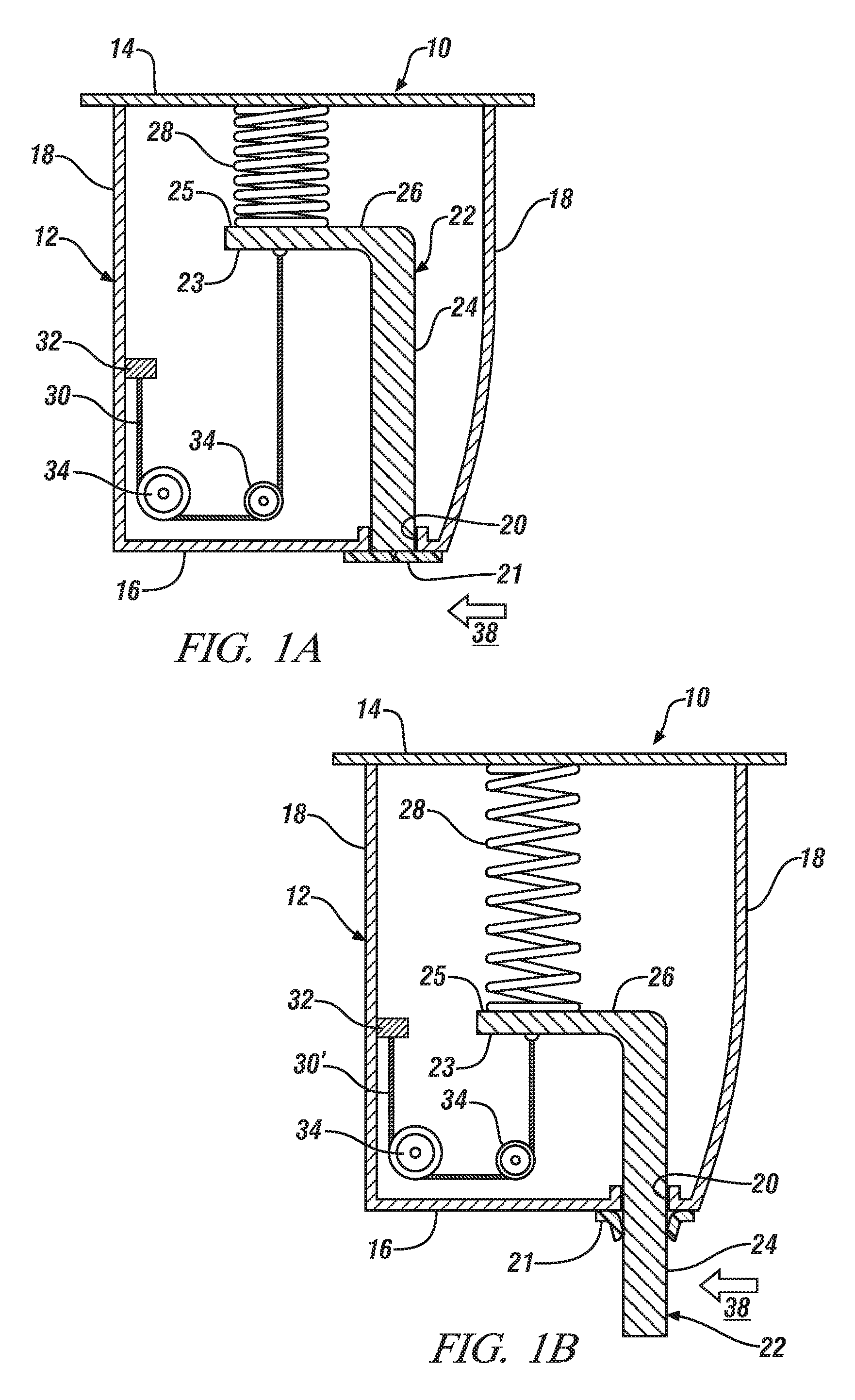

Safety air bag inflation device

InactiveUS6155600AFailure of controlSpeed up the flowPedestrian/occupant safety arrangementLiquid transferring devicesReaction rateGas passing

An air bag inflator providing a source of gas, releasable upon command, to inflate a supplemental inflation restraint (SIR) system commonly known as an automobile air bag. Provided is a pressure vessel containing one or more separate chambers for the purpose of storing gaseous fuel(s) and gaseous oxidizer(s) or liquid fuel(s) and liquid oxidizer(s) under pressure with helium as the primary filler gas. The primary function of the helium gas is to serve as a kinetic damper to modulate and control the reaction rate of the fuel(s) and oxidizer(s). Because of its low mass, high thermal conductivity and high heat capacity for its mass, helium is an excellent filler gas. In the case of the gaseous fuel(s) and oxidizer(s) a single chamber is provided. In the case of liquid fuel(s) and oxidizer(s), two or more separate housings are provided for storing the liquid fuel(s) and oxidizer(s). Along with the liquid fuel(s) and oxidizer(s) housings, two separate chambers containing pressurized helium are provided within the pressure vessel. The first helium chamber rapidly pressurizes upon initiation of a gas producing pyrotechnic igniter. This pressure acts on thin membranes on the first chamber side of the separate liquid storage housings to force the liquid fuel(s) and oxidizer(s) into the second chamber where the materials are atomized and mixed. The mixture is ignited by the arrival of hot gases from the igniter directed into the second chamber via the small diameter tube or orifice. The fuel(s) oxidizer(s) mixture burns to produce gaseous reaction products that are released into the air bag by bursting a controlled rupture burst disc.

Owner:AUTOLIV DEV AB

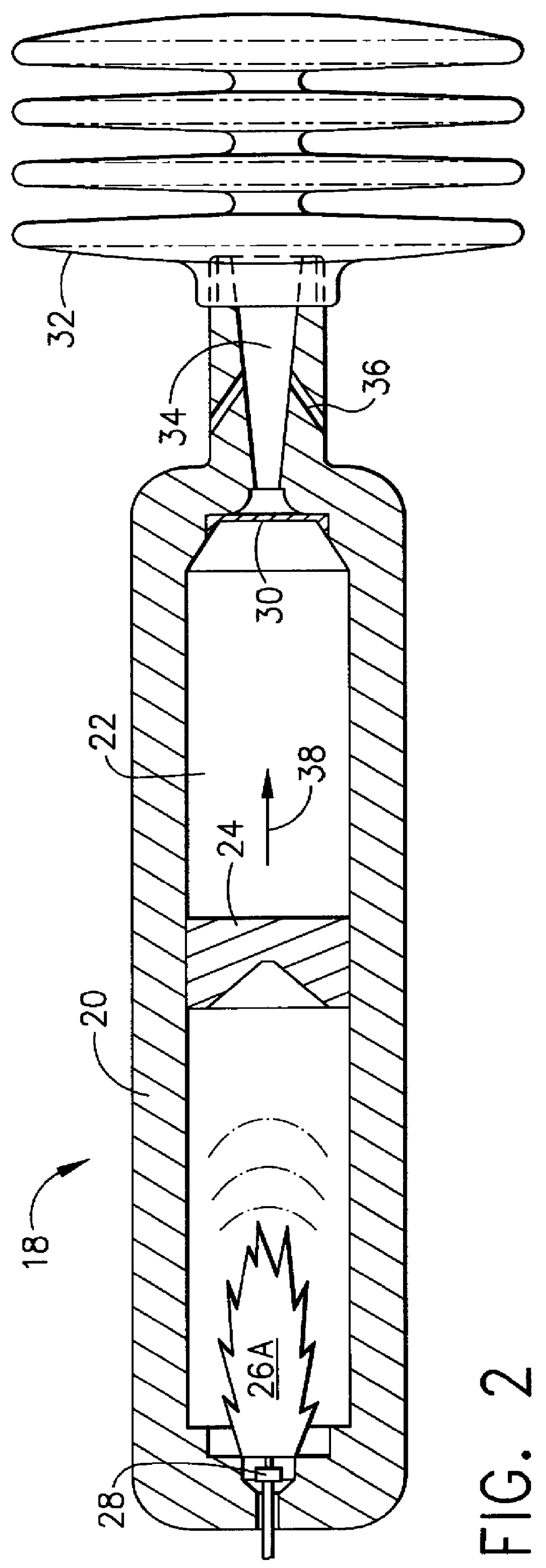

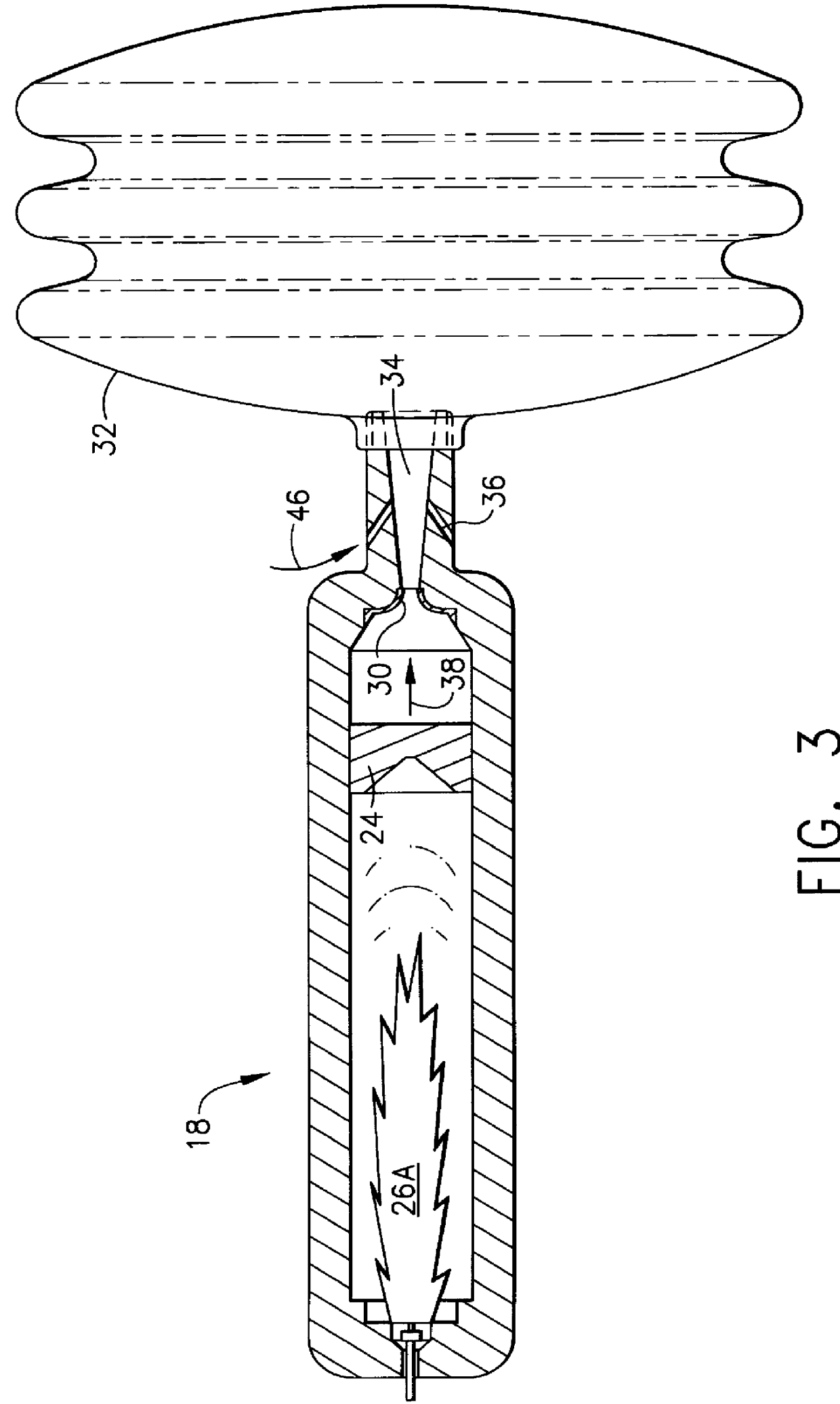

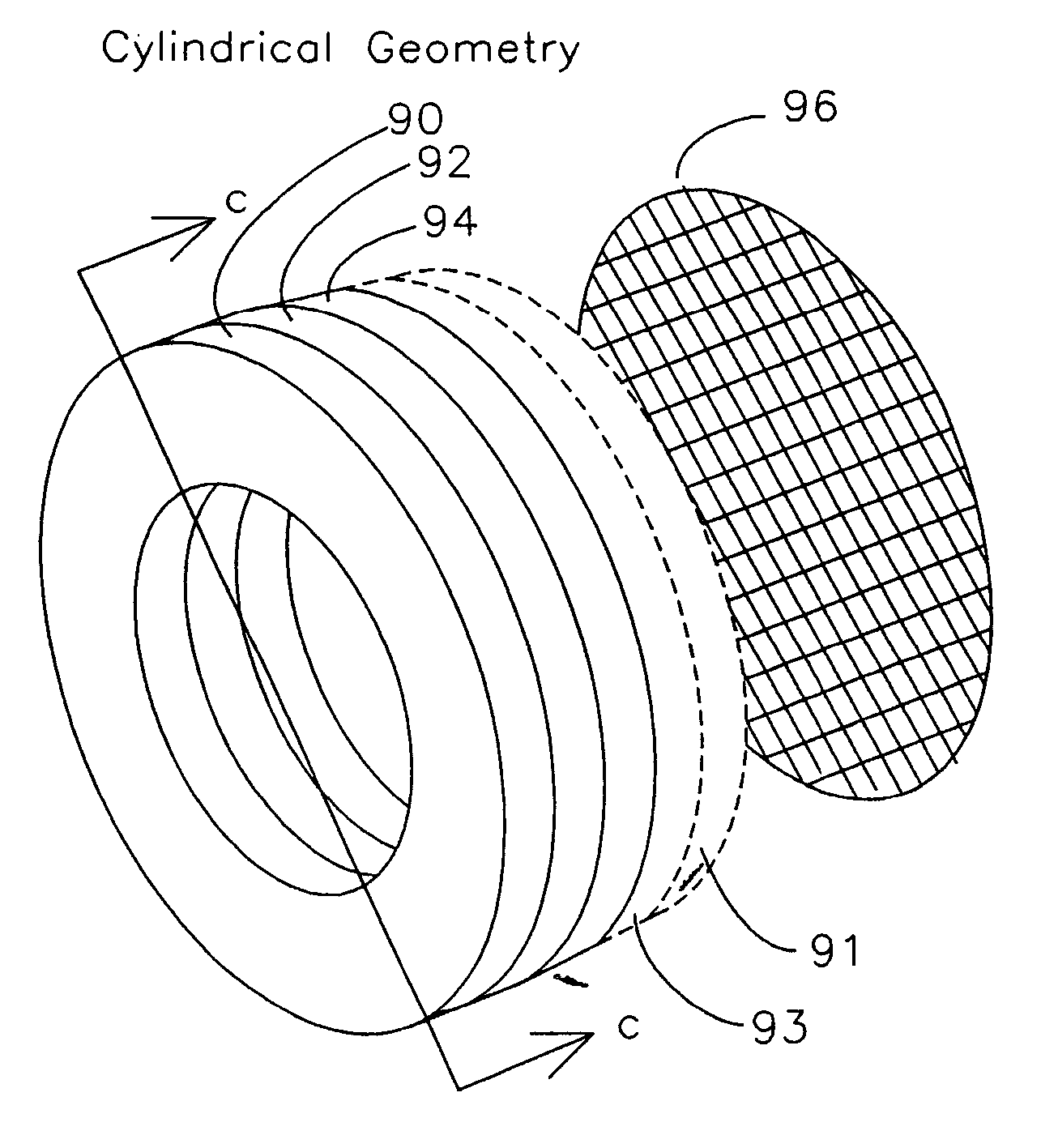

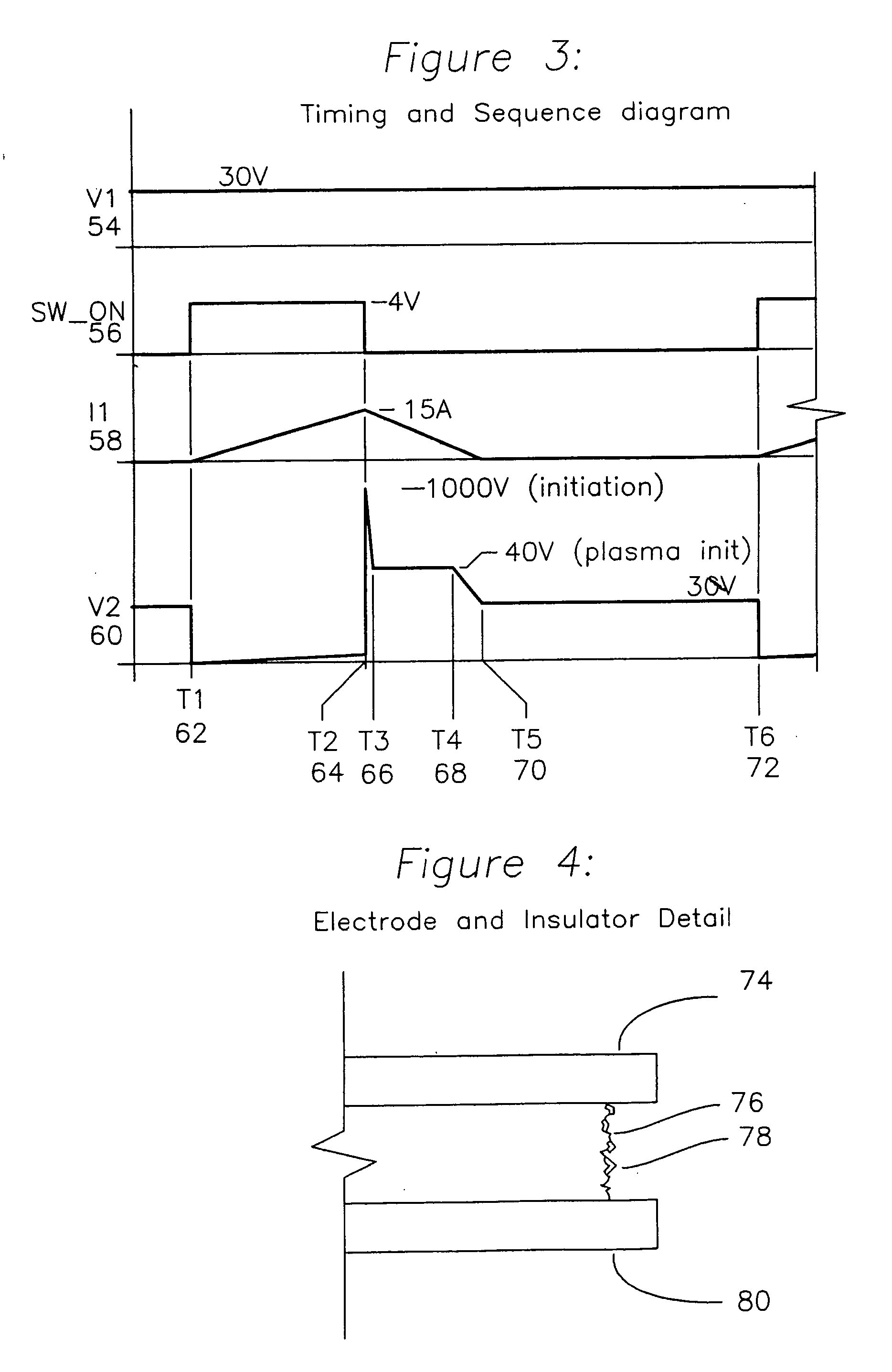

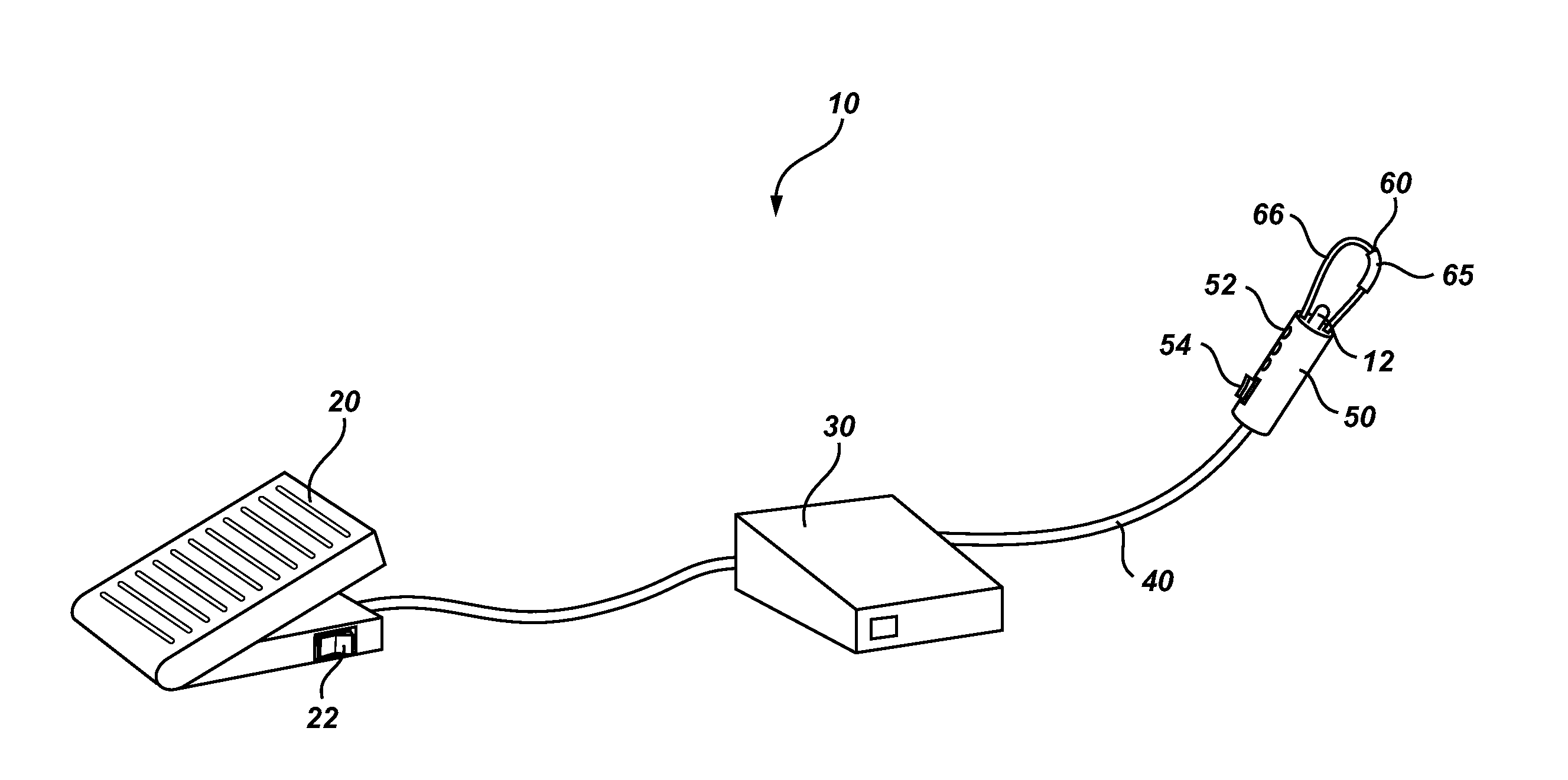

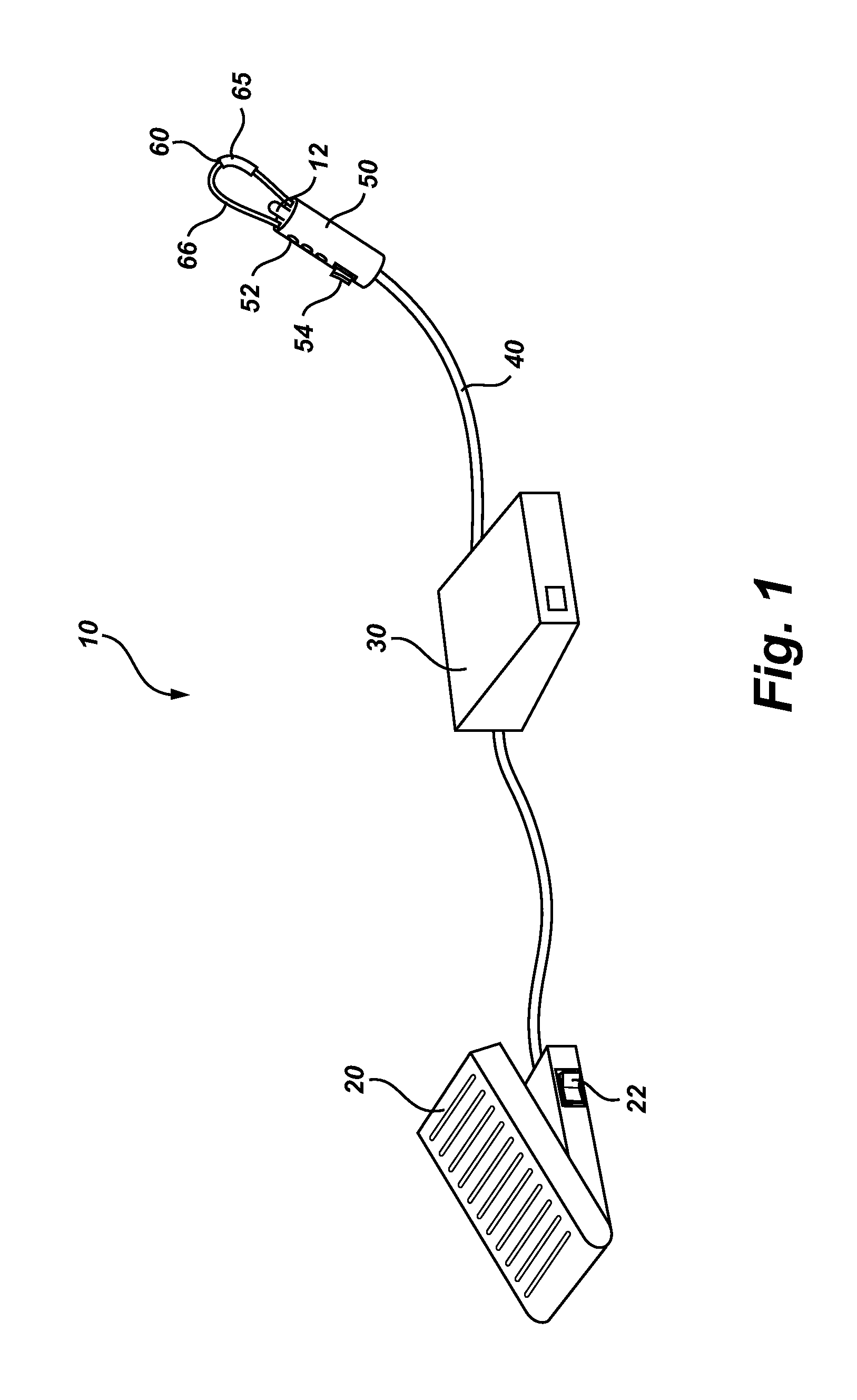

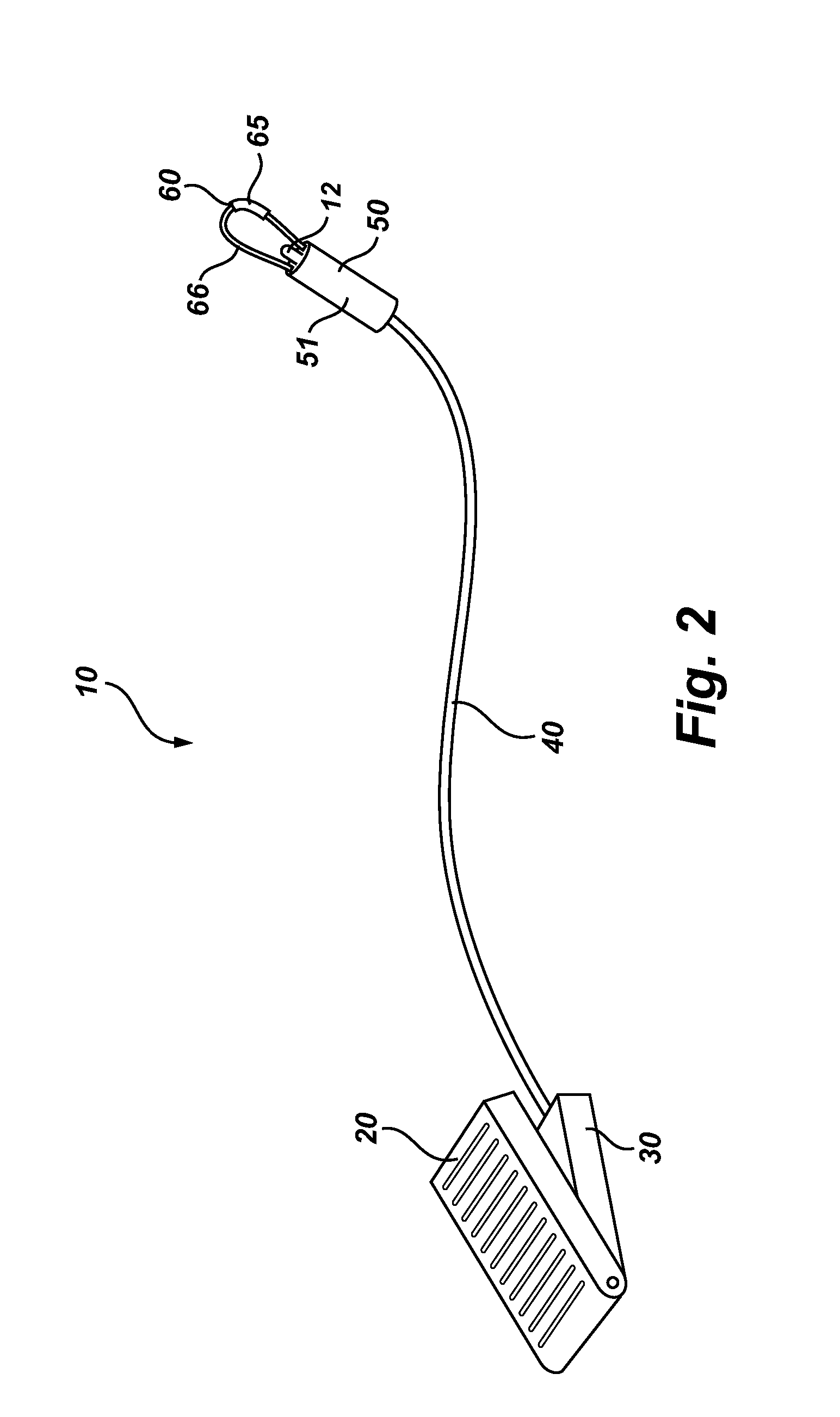

Vacuum arc plasma thrusters with inductive energy storage driver

InactiveUS20070045248A1Effective “ throttle ”High resistivityArc welding apparatusMachines/enginesVoltage spikeLow voltage

An apparatus for producing a vacuum arc plasma source device using a low mass, compact inductive energy storage circuit powered by a low voltage DC supply acts as a vacuum arc plasma thruster. An inductor is charged through a switch, subsequently the switch is opened and a voltage spike of Ldi / dt is produced initiating plasma across a resistive path separating anode and cathode. The plasma is subsequently maintained by energy stored in the inductor. Plasma is produced from cathode material, which allows for any electrically conductive material to be used. A planar structure, a tubular structure, and a coaxial structure allow for consumption of cathode material feed and thereby long lifetime of the thruster for long durations of time.

Owner:KRISHNAN MAHADEVAN

Heated balloon catheter

ActiveUS20120071712A1Consistent temperatureTurn fasterLaproscopesSurgical instruments for heatingElectrical conductorPower flow

Thermally adjustable surgical tools include a conductor and a ferromagnetic material. The ferromagnetic material may be quickly heated when subjected to high frequency alternating current through the conductor. The ferromagnetic material may also cool rapidly because of its relatively low mass and the small thermal mass of the conductor. The thermally adjustable surgical tools may be used to sculpt, melt, break and / or remove biological material. The thermally adjustable surgical tools may also include balloon catheters which can heat fluid to thereby treat biological material.

Owner:DOMAIN SURGICAL

Omnidirectional microscale impact switch

InactiveUS6765160B1Low costEfficient methodAcceleration measurementContactsElectrical and Electronics engineeringLow Mass

The invention is a normally-open, momentary, non-latching, inertial thresholding switch 30, fabricated on a substrate 1 in a planar configuration, using no cylindrical tilt mass, with low mass 16 and small switch gap 36, 37, 38, 39 to allow fast switch action and rapid reset. Of ultra-miniature, rugged construction, its high mechanical frequency limits sensitivity to vibration inputs.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

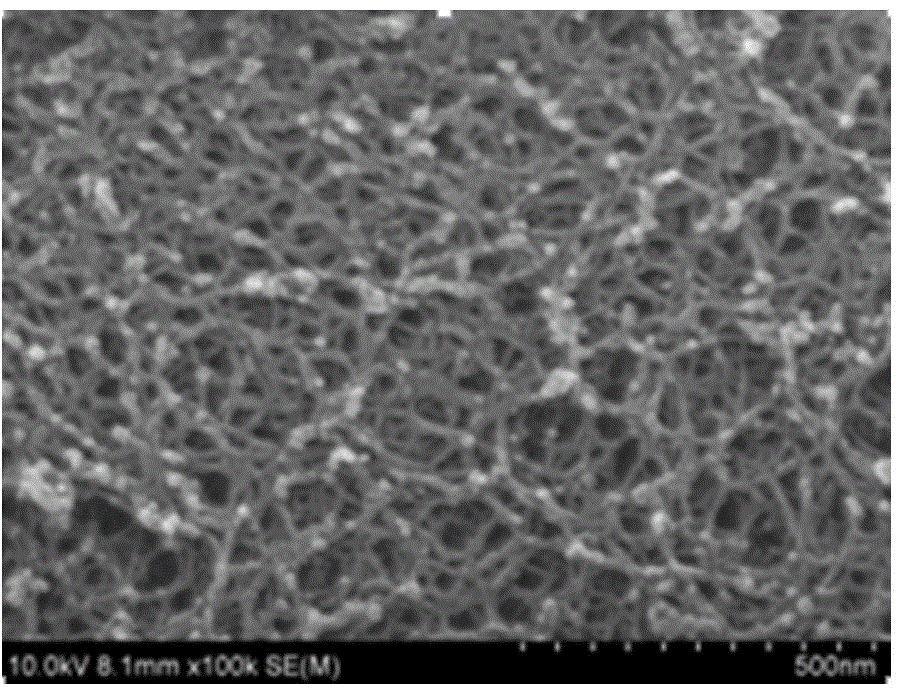

Carbon nanosphere with at least one opening, method for preparing the same, carbon nanosphere-impregnated catalyst using the carbon nanosphere, and fuel cell using the catalyst

InactiveUS20060239890A1Improve area utilizationReduce mass transfer resistanceMaterial nanotechnologySpecific nanostructure formationHigh current densityFuel cells

A carbon nanosphere has at least one opening. The carbon nanosphere is obtained by preparing a carbon nanosphere and treating it with an acid to form the opening. The carbon nanosphere with at least one opening has higher utilization of a surface area and electrical conductivity and lower mass transfer resistance than a conventional carbon nanotube, thus allowing for higher current density and cell voltage with a smaller amount of metal catalyst per unit area of a fuel cell electrode.

Owner:SAMSUNG SDI CO LTD

Ion trap mass spectrometry

InactiveUS7582866B2Solution value is not highSufficient amountStability-of-path spectrometersIsotope separationIon trap mass spectrometryMass Spectrometry-Mass Spectrometry

Owner:SHIMADZU CORP

Biomass quick cracked oil water vapour catforming hydrogen production method

InactiveCN101318622AExtended service lifeSolve the phenomenon of carbon depositionHydrogenCatalytic reformingGas phase

The invention discloses a method by adopting biomass fast pyrolysis oil which carries out two sections of fixed bed reactors and water vapor catalytic reforming for producing hydrogen; the two sections of fixed bed reactors are connected in series, the natural dolomite which is relatively cheap and easily available is taken as catalyst in water vapor reforming reaction at the first section of fixed bed reactor, while the second fixed bed reactor adopts Ni / Mgo as catalyst to further improve the purity and yield of the target product gas. Comparatively high temperature and comparatively high S / C (more than 12) are extremely important for the effective transformation of the biomass pyrolysis oil in the first fixed bed reactor. However, for any temperature point, low mass space velocity can facilitate the increasing of the yield of any gas product and the total gas phase transformation ratio of the biomass oil is increased accordingly. The Ni / MgO catalyst is extremely effective in the purification stage, when S / CH4 is not less than 2 and the temperature is not lower than 800 DEG C, the transformation ratio of methane can reach 100 %. Low mass space velocity can facilitate effective transformation of methane; when mass space velocity is not higher than 3600h<-1>, the potential hydrogen yield can reach 81.1%.

Owner:EAST CHINA UNIV OF SCI & TECH

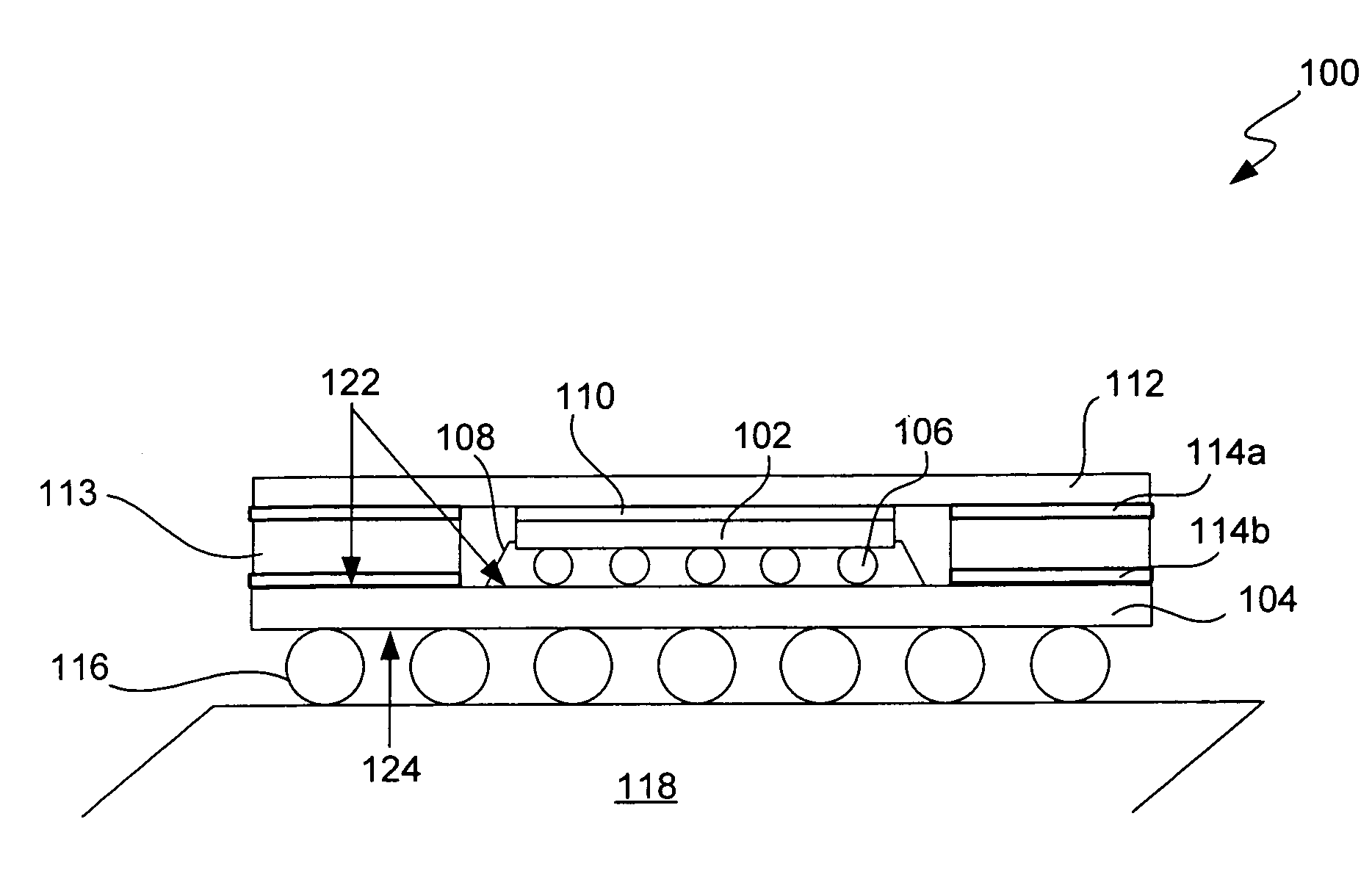

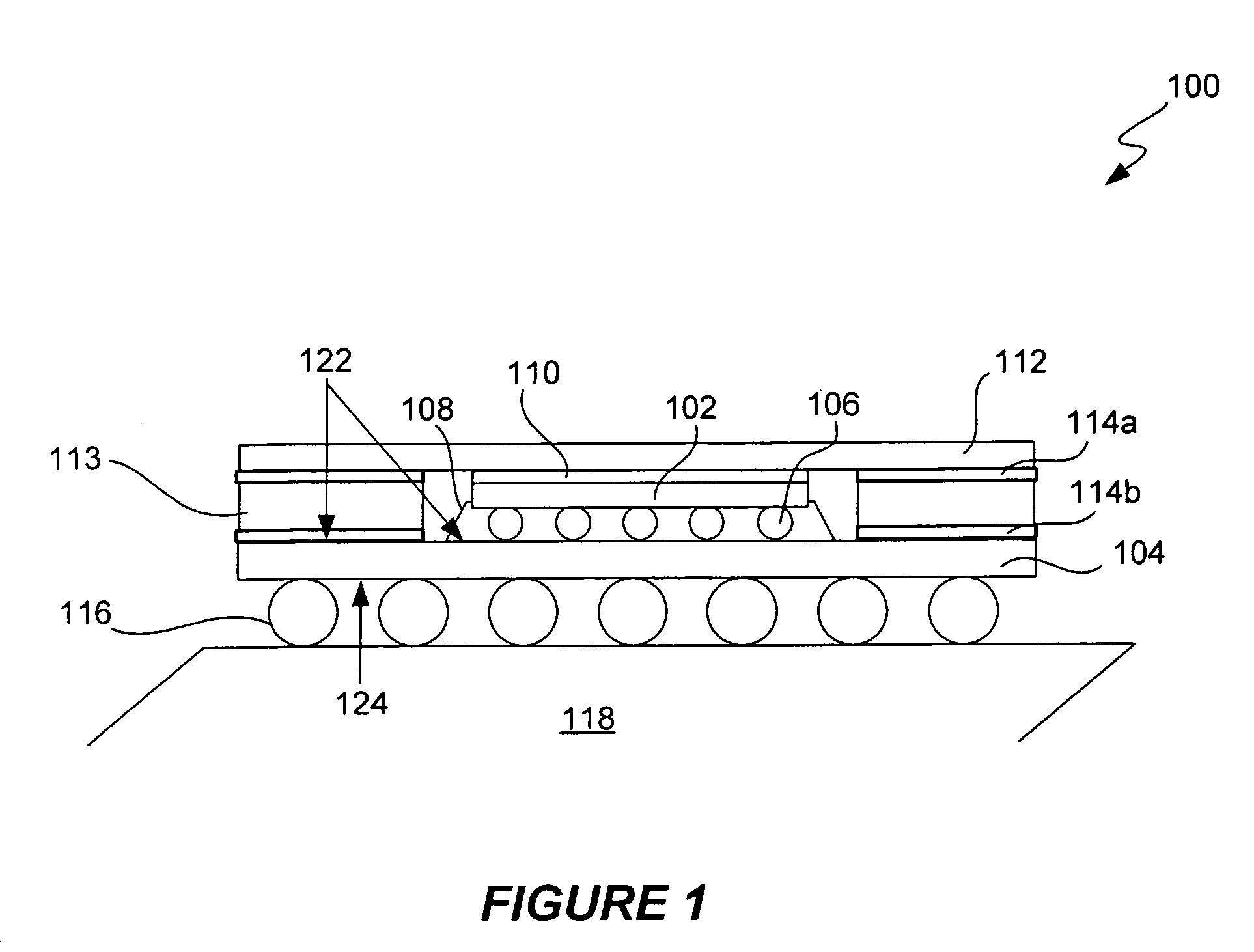

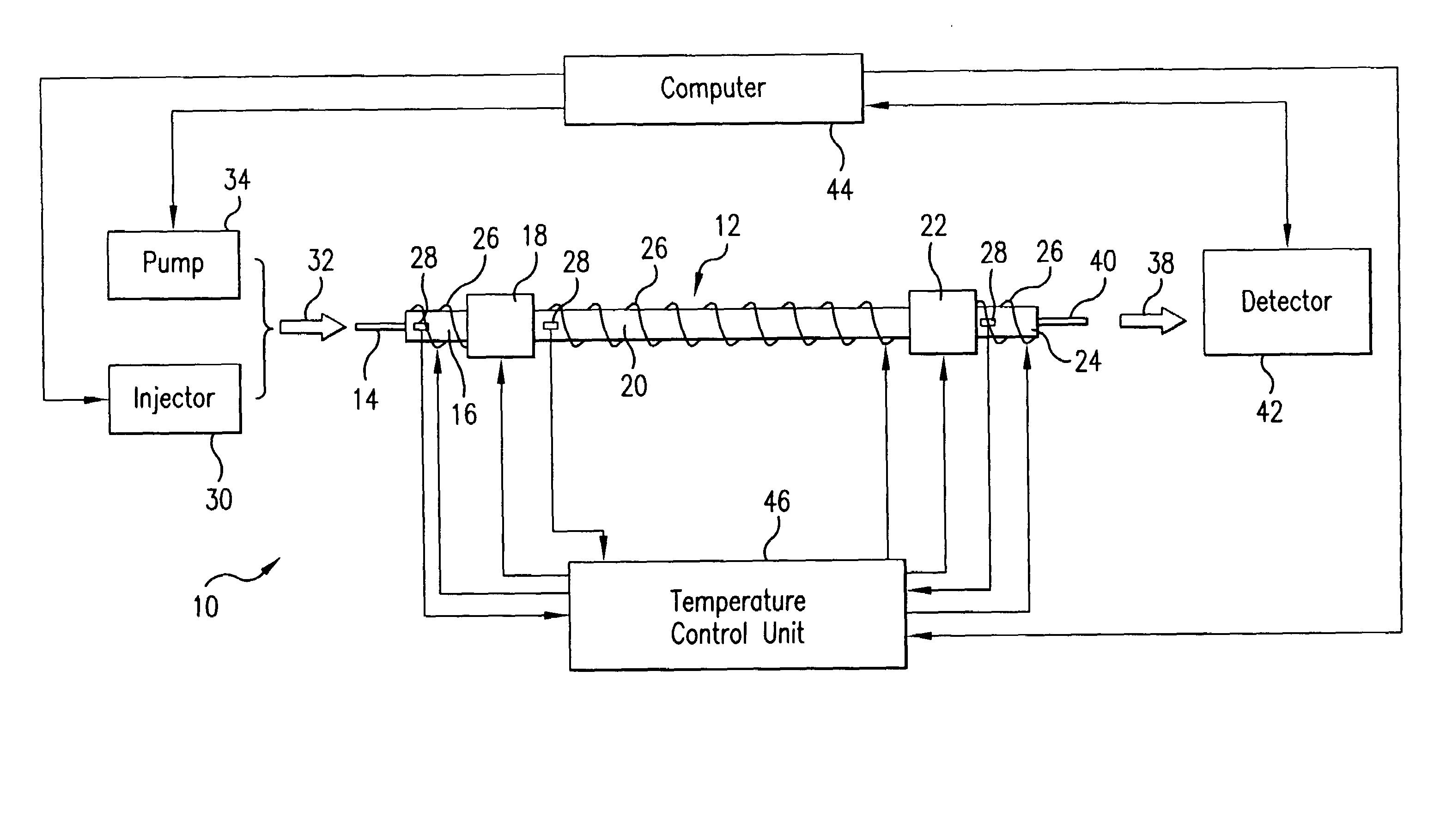

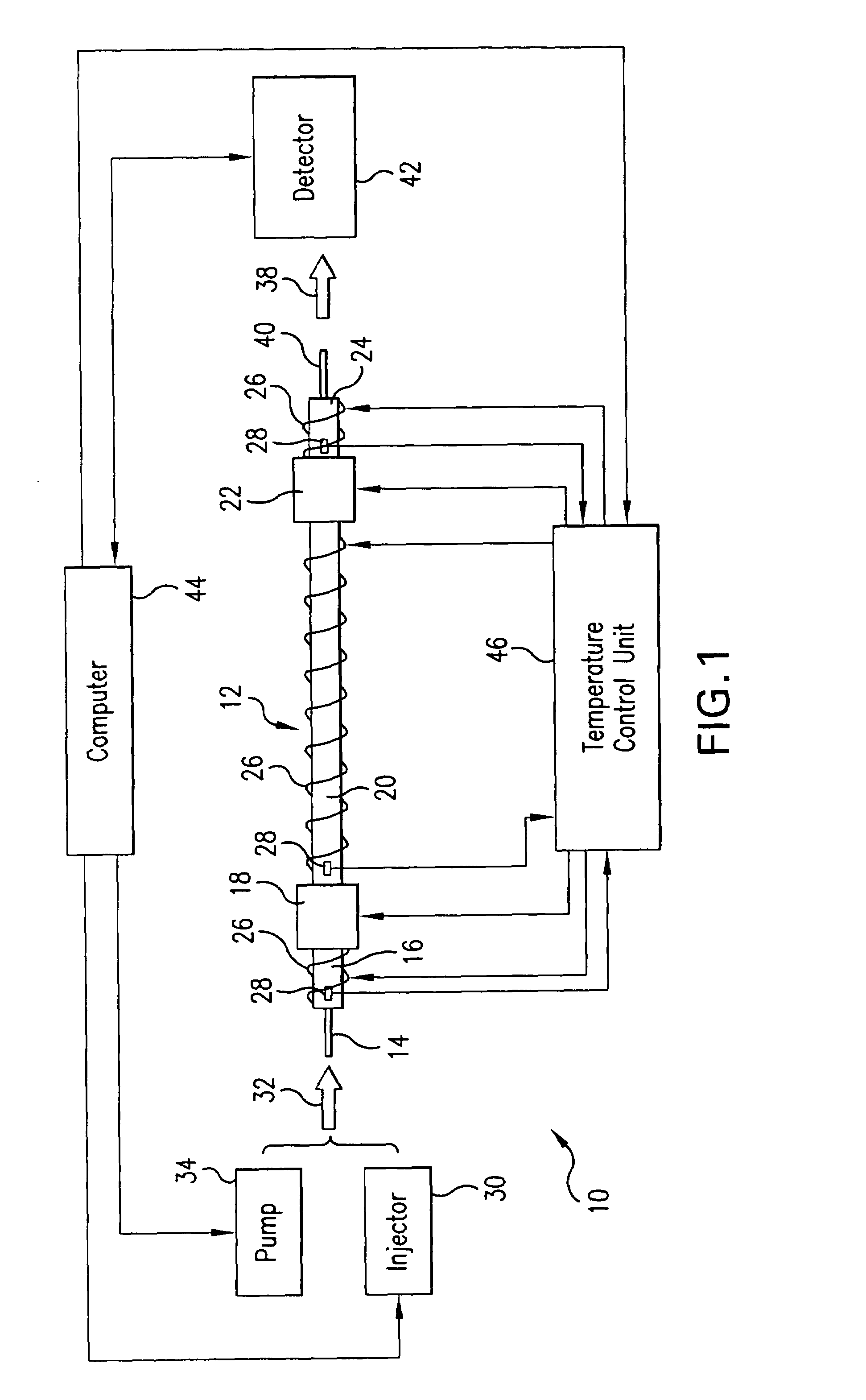

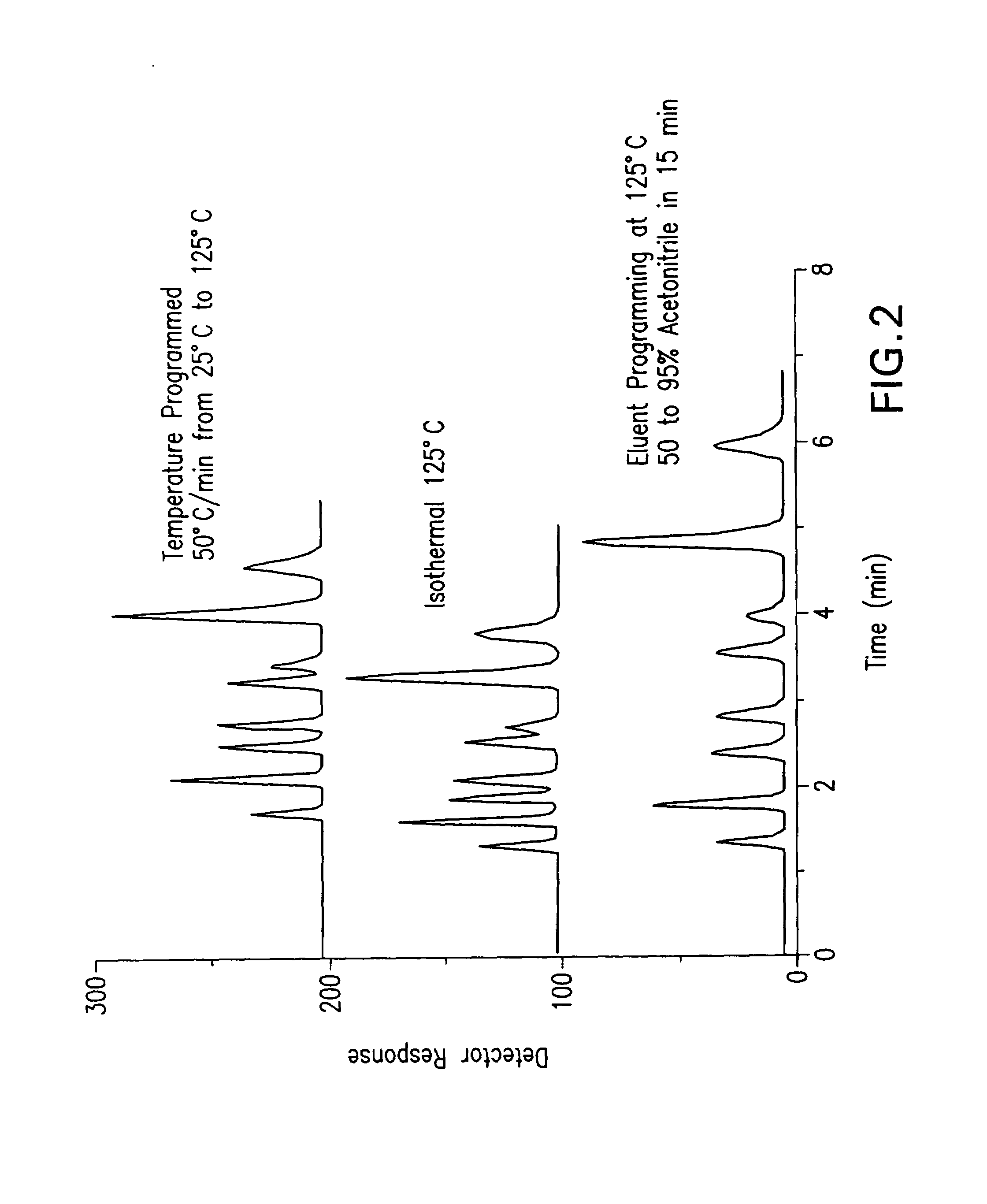

Temperature programmed low thermal mass fast liquid chromatography analysis system

InactiveUS20090173146A1Fast heat exchangeHigh throughput analysis rateComponent separationElectronic temperatureCapillary Tubing

A temperature programmed low thermal mass fast liquid chromatography system capable of high throughput and low power consumption includes a straight or curved short reloadable low-mass tubular heater with a capillary column extending inside. If the capillary column is long enough, it is coiled to form a coiled capillary LC column (the length of which does not exceed 0.2 m-1.0 m) packed in a singular module package with a heating wire and a temperature sensing wire extending along and in proximity to the LC capillary column. A tubular heater, e.g. a steel tubing, incorporates the LC capillary column, along with the heating wire and the temperatures sensor and is coiled to form a miniature power saving LC module which may be attached outside a chromatography oven. Capillary lengths extend inside the oven between the inlet and outlet of the LC column module and mobile phase source and detector, respectively. An electronic temperature control block is positioned outside the oven cavity and controls the heating of the capillary LC column, as well as other heated zones in the system.

Owner:AGILENT TECH INC

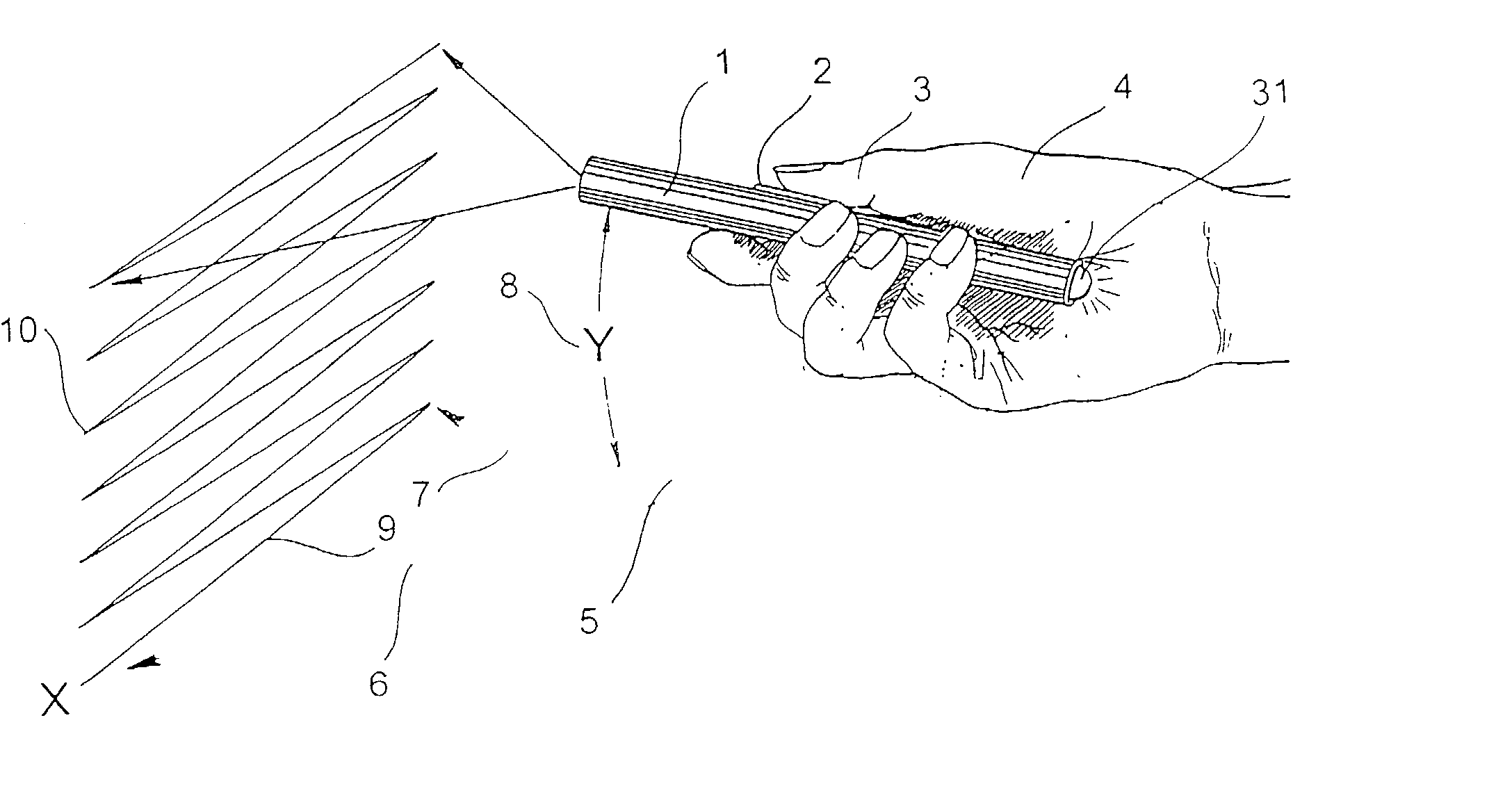

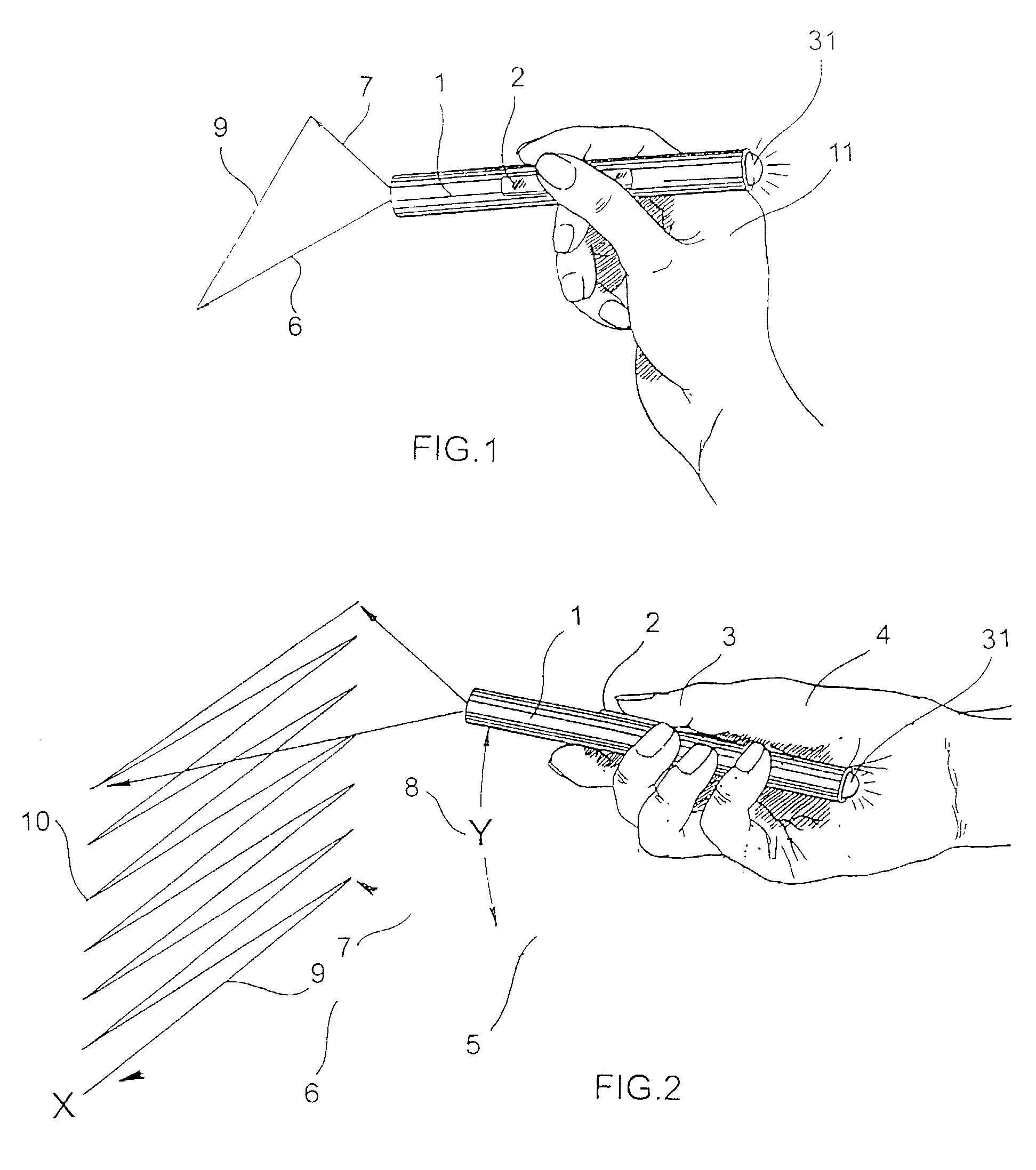

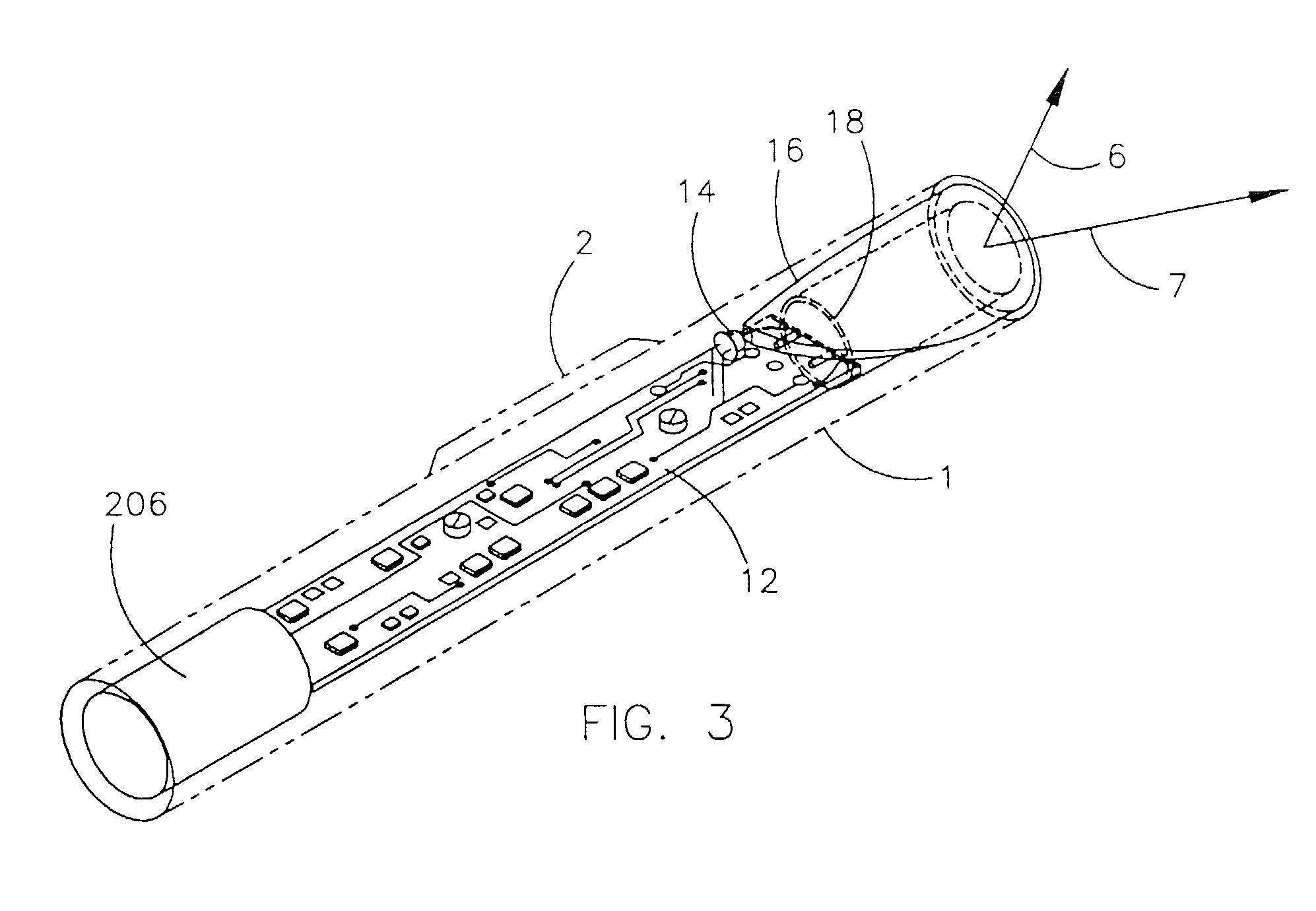

Light beam scanning pen, scan module for the device and method of utilization

Owner:SYMBOL TECH INC

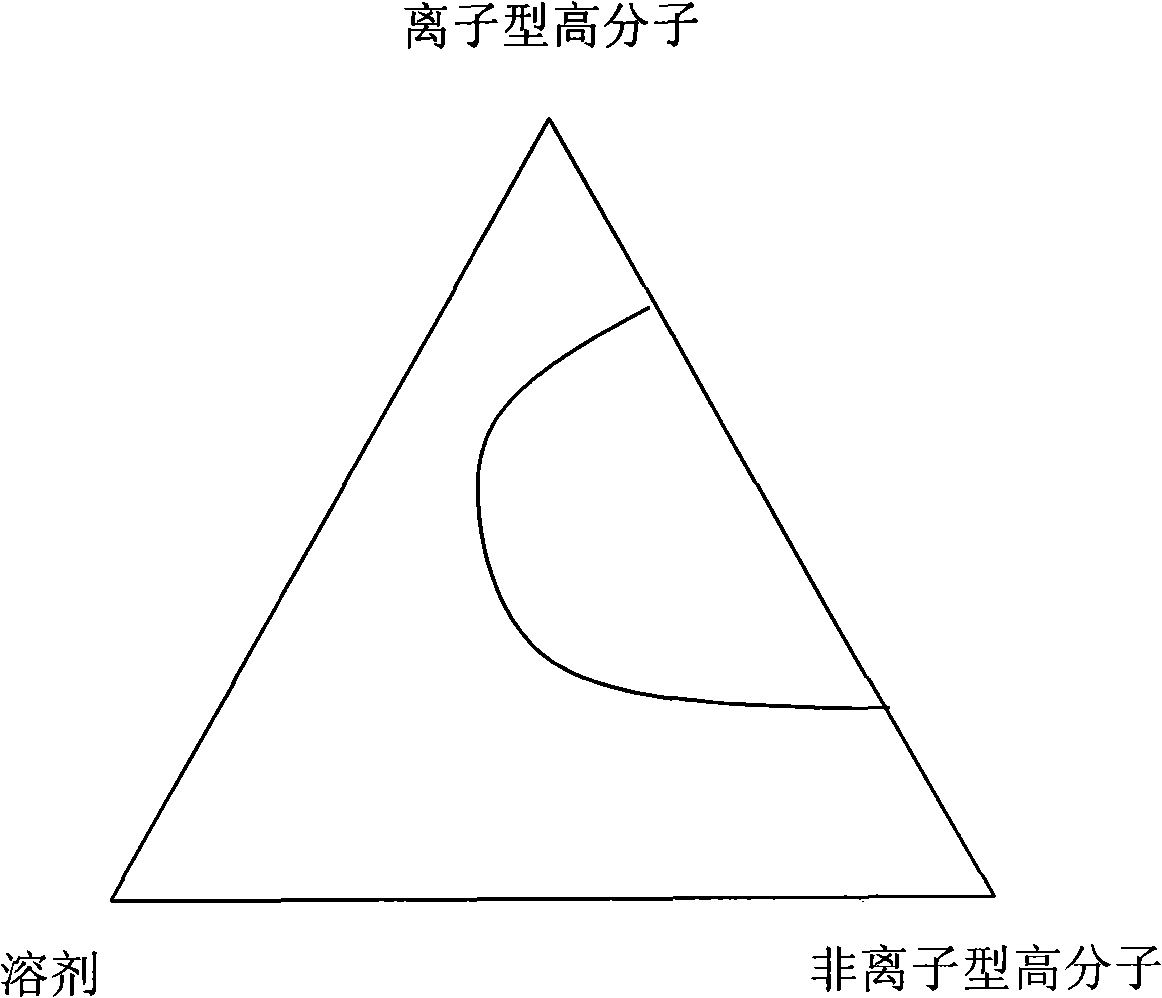

Film material with ionic exchange performance and use thereof

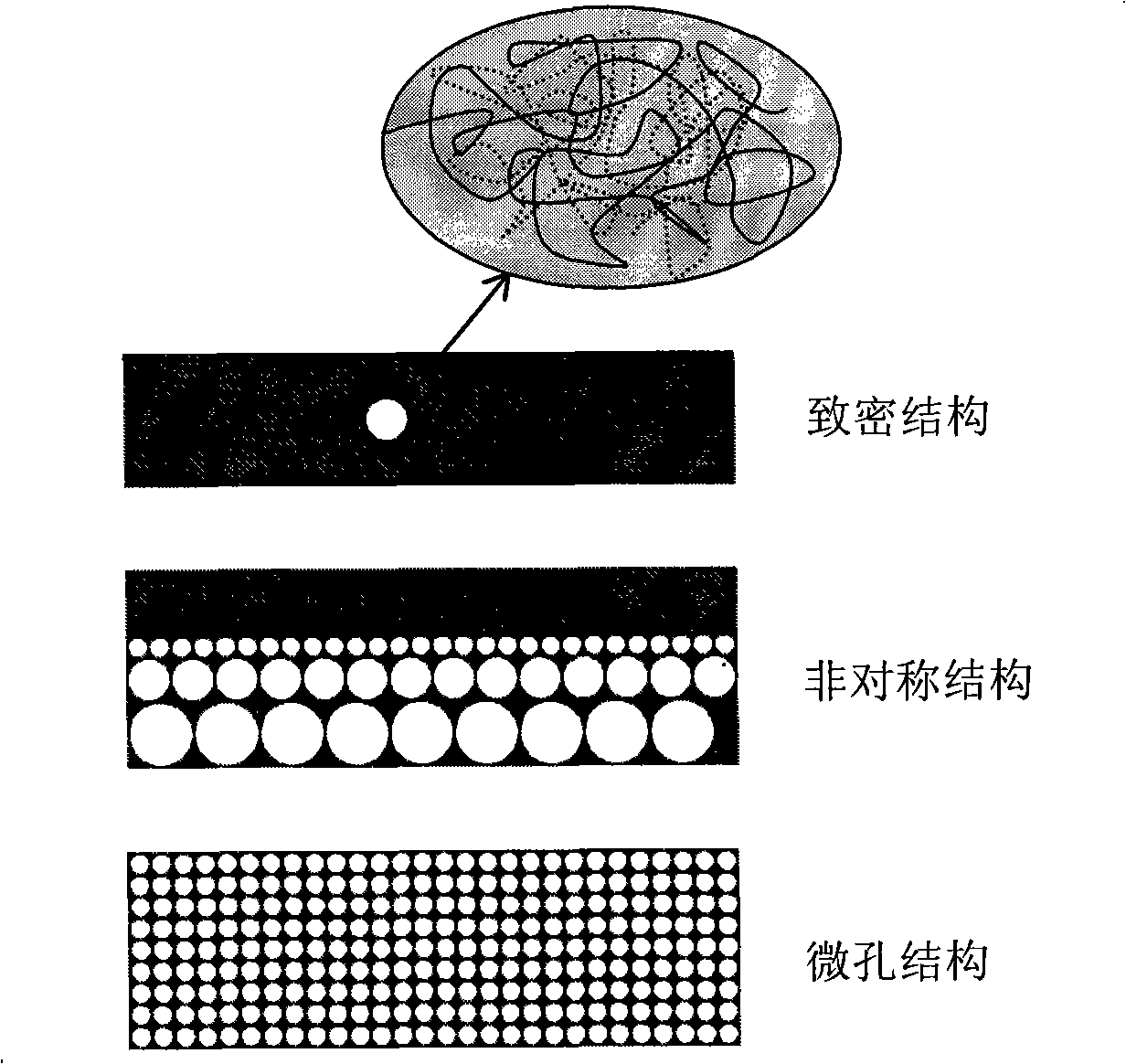

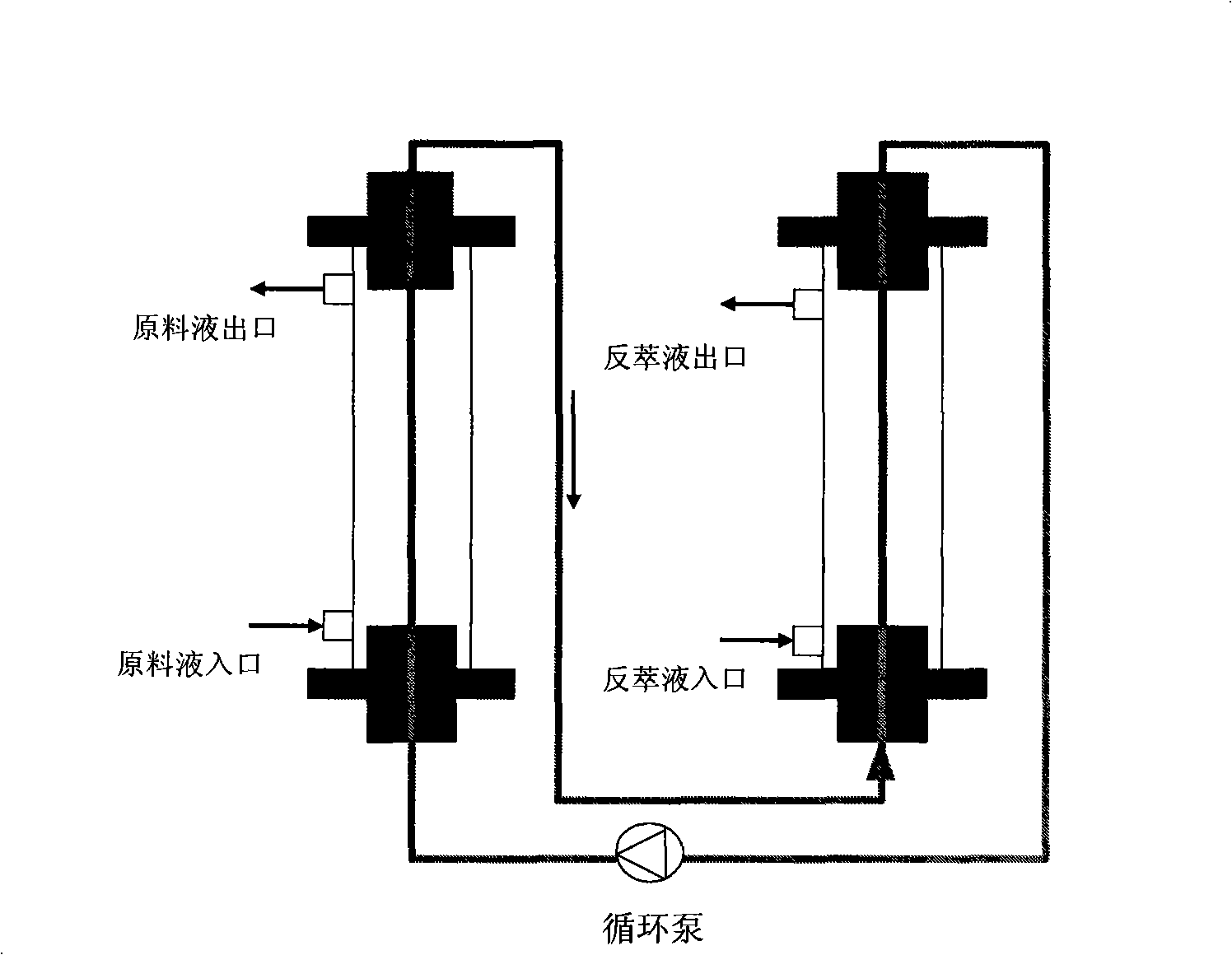

InactiveCN101264427AReduce mass transfer resistanceGood chemical stabilitySemi-permeable membranesSolvent extractionChemical physicsWater vapor

The invention discloses a membrane material with ion exchange performance, which is characterized in that the membrane material is in a compact structure or a millipore structure, and is mixed by the polymer with ion exchange performance and the polymer with nonionic exchange performance; wherein, the weight ratio of the polymer with ion exchange performance to the polymer with nonionic exchange performance is 5 / 95 percent to 95 / 5 percent. The invention also discloses the application of the membrane material in the separation of anion and cation and the recovery membrane extraction, the removal of the vapor in the gas and the desalination of the water system in the process of driving the positive permeation by non-pressure. The membrane material has the advantages of getting rid of the supporting concept of supporting liquid membrane, enjoying high chemical stability, and low mass transfer resistance to ions. The membrane material not only provides a long-time stability in the separation process of the liquid membrane ions, but also finds application points in other separation fields.

Owner:南京奥特高科技有限公司

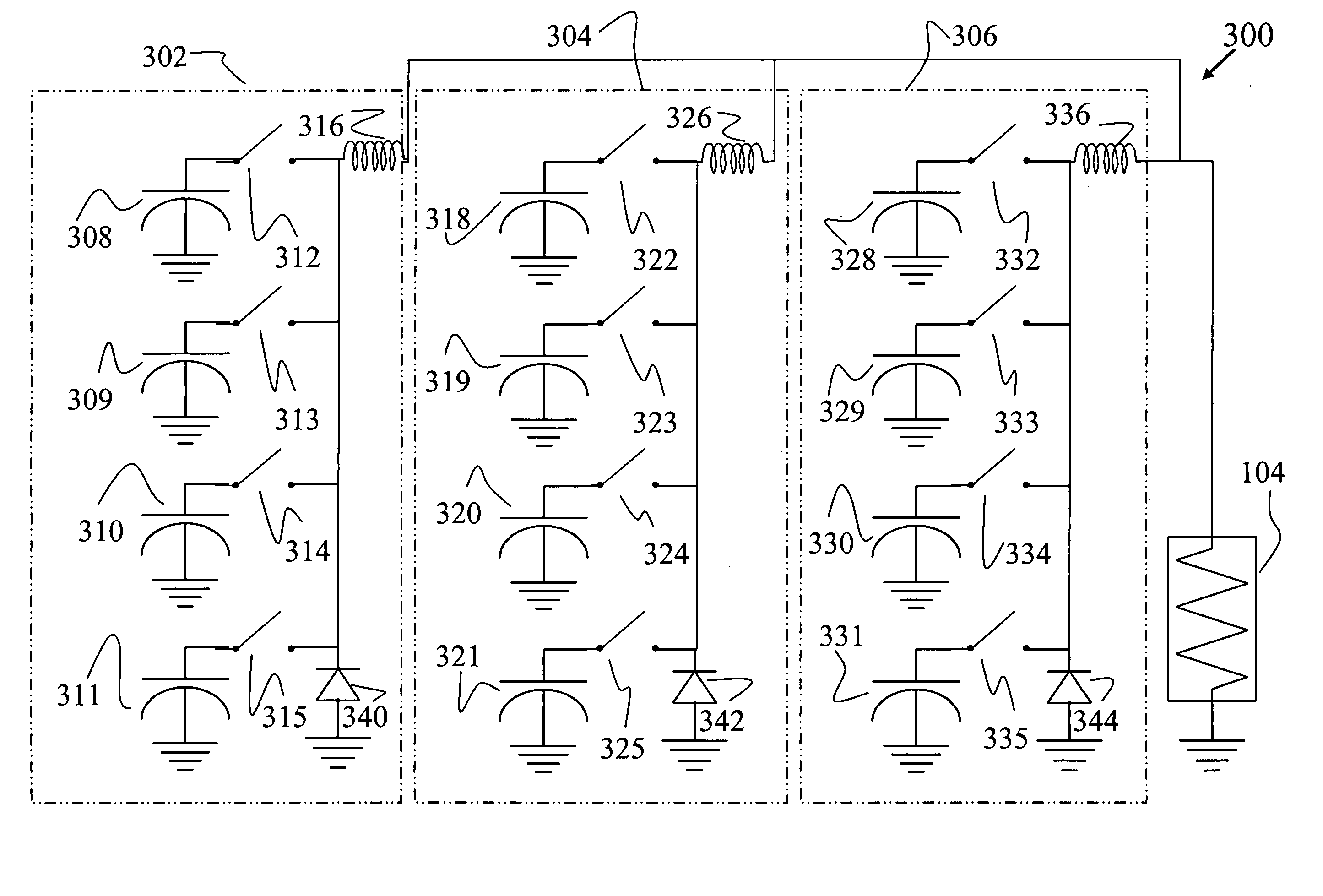

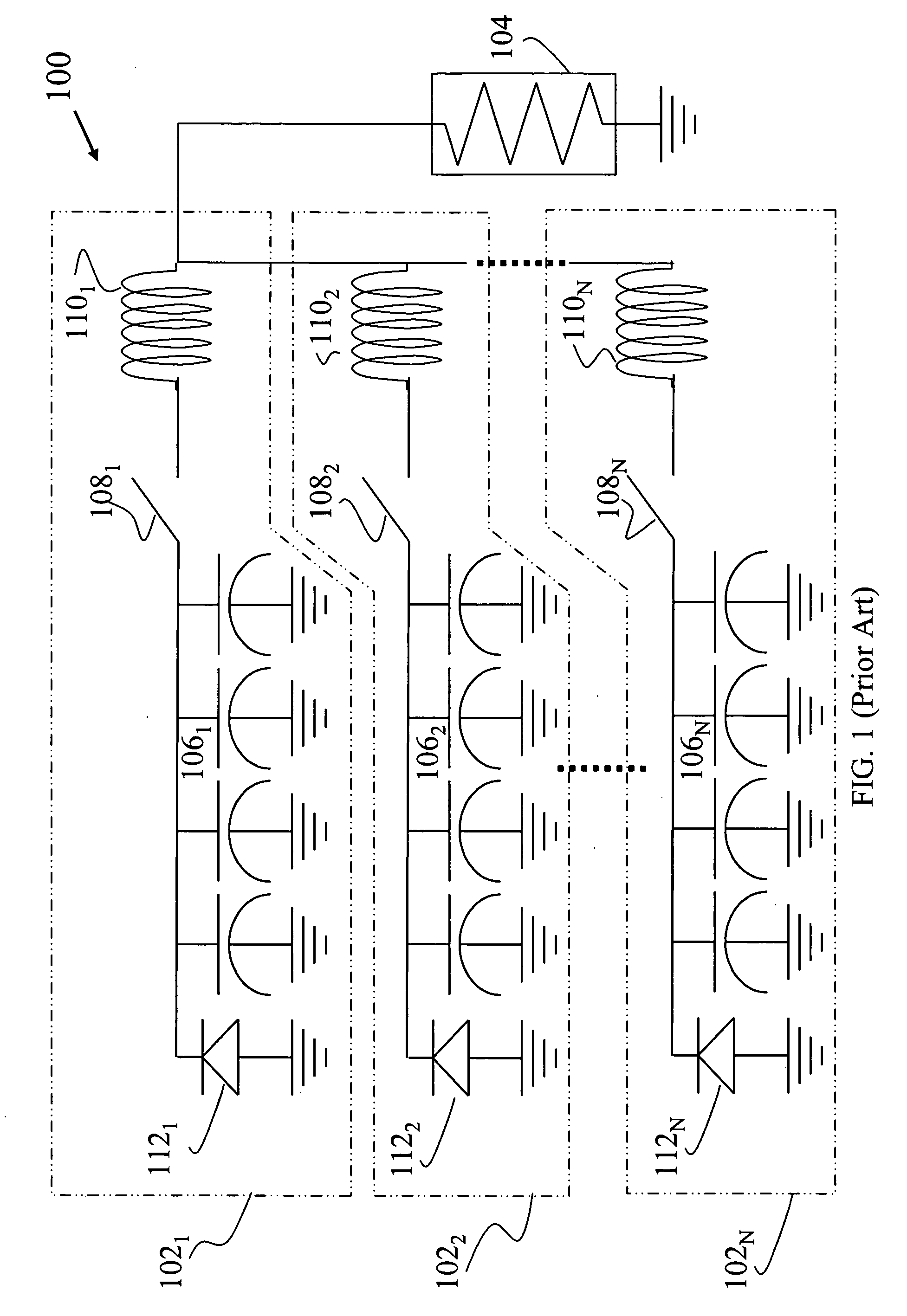

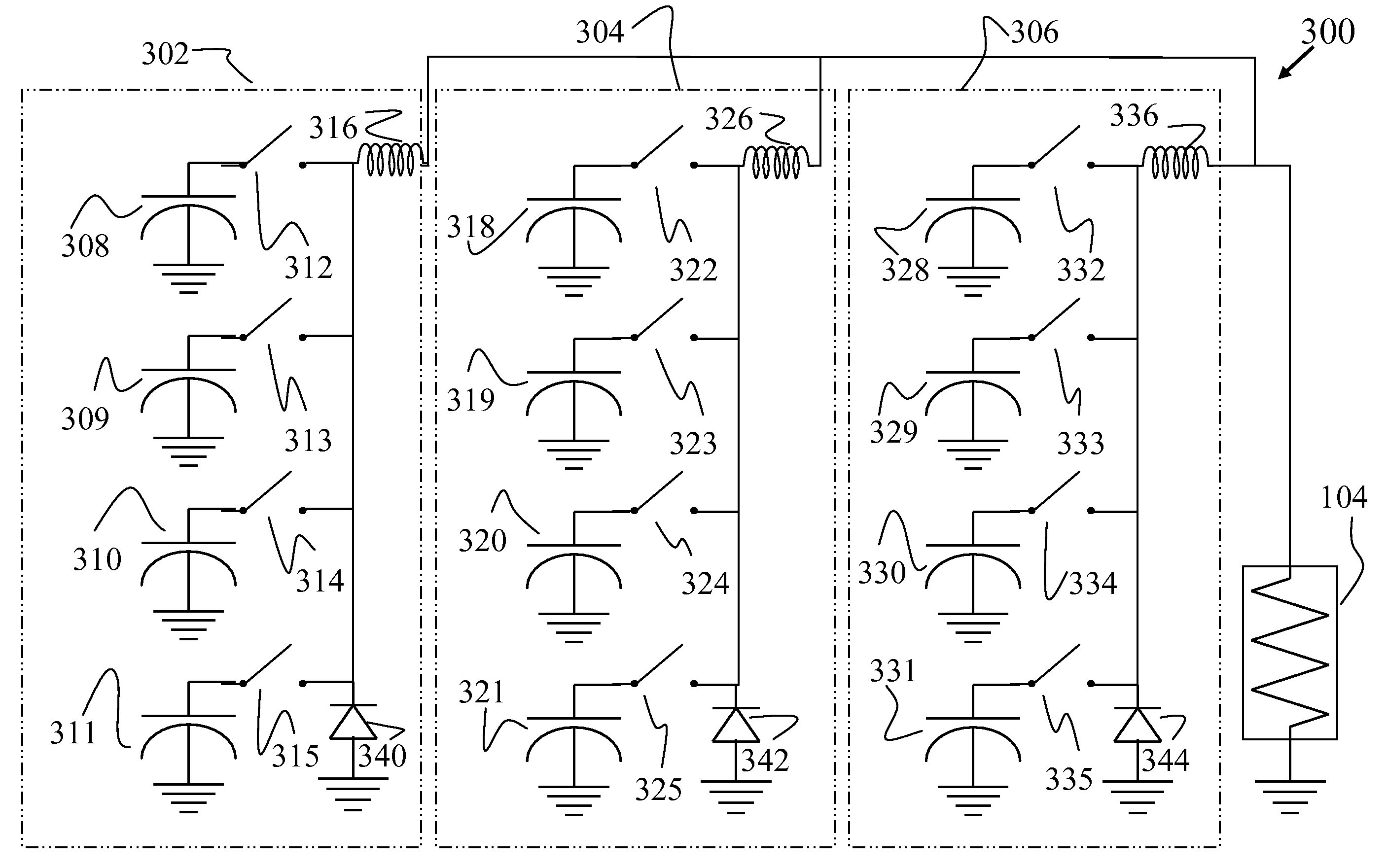

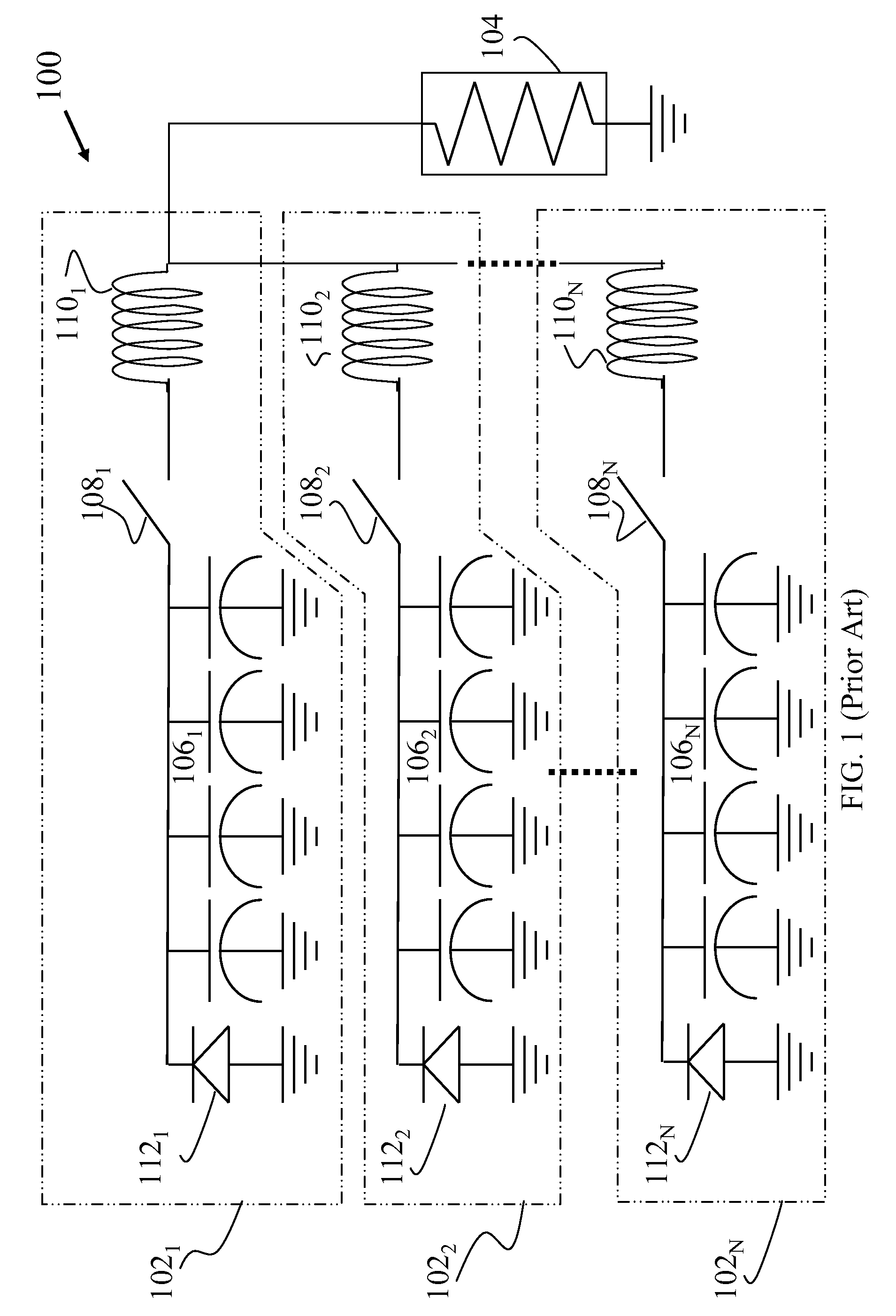

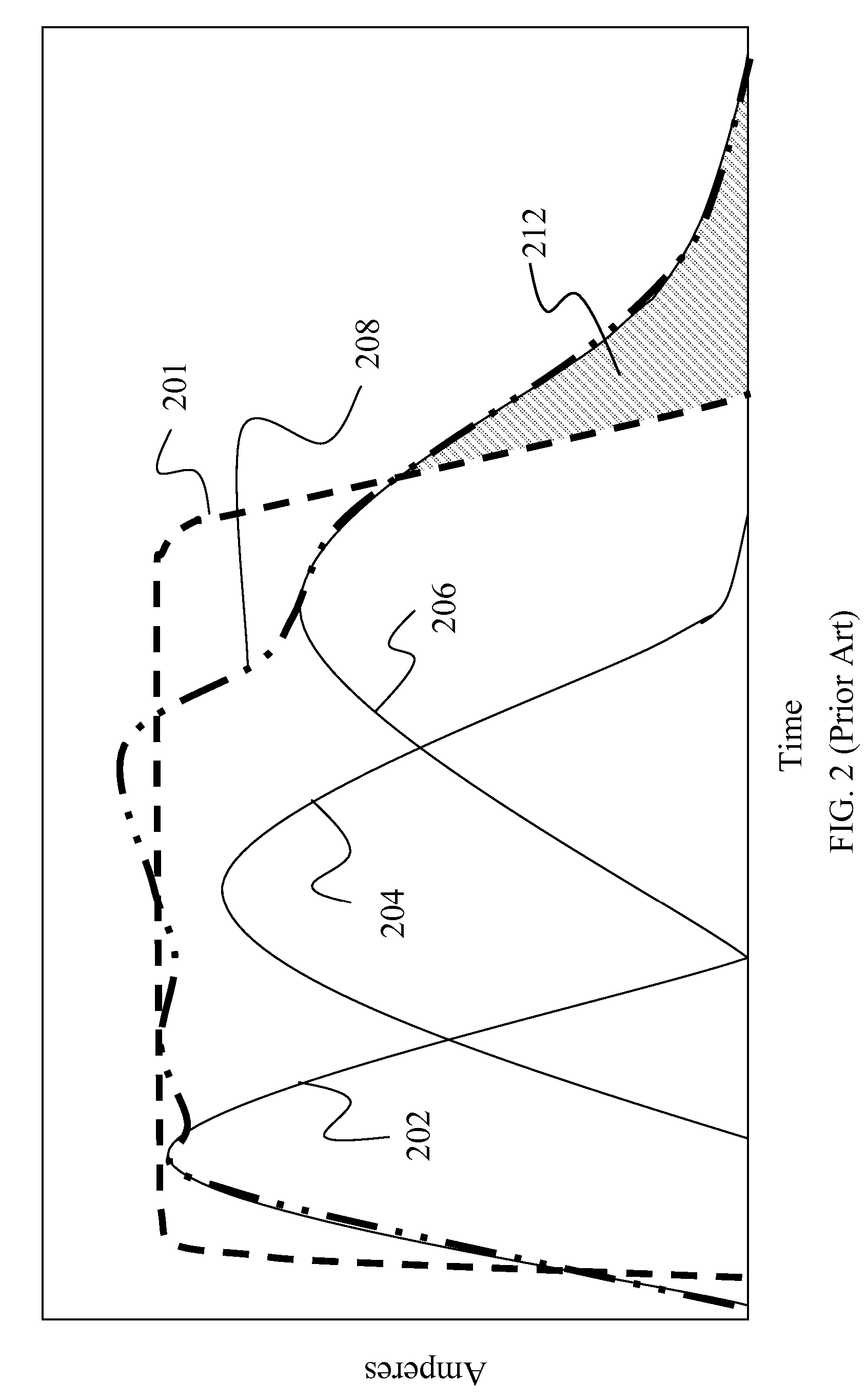

Capacitor pulse forming network with multiple pulse inductors

ActiveUS20050168195A1Shaping characteristicReduce quality problemsDc network circuit arrangementsBatteries circuit arrangementsPulse forming networkEngineering

Capacitor based pulse forming networks and related methods are provided which require fewer inductors are that pulsed more frequently to provide a smaller, lower mass, and lower inductance pulse forming network having better pulse shaping characteristics than conventional pulse forming networks. In one implementation, the invention can be characterized as a capacitor based pulse forming network comprising a plurality of inductors adapted to be coupled to a load, a plurality of capacitor units, and a plurality of switches. Each switch couples a respective capacitor unit to a respective inductor, wherein multiple capacitor units are coupled to each inductor by separate switches. The plurality of switches are adapted to non-simultaneously discharge the multiple capacitor units to provide non-simultaneous pulses through a given inductor to the load and not through other inductors. The non-simultaneous pulses form at least a portion of an output pulse waveform to the load.

Owner:GENERAL ATOMICS

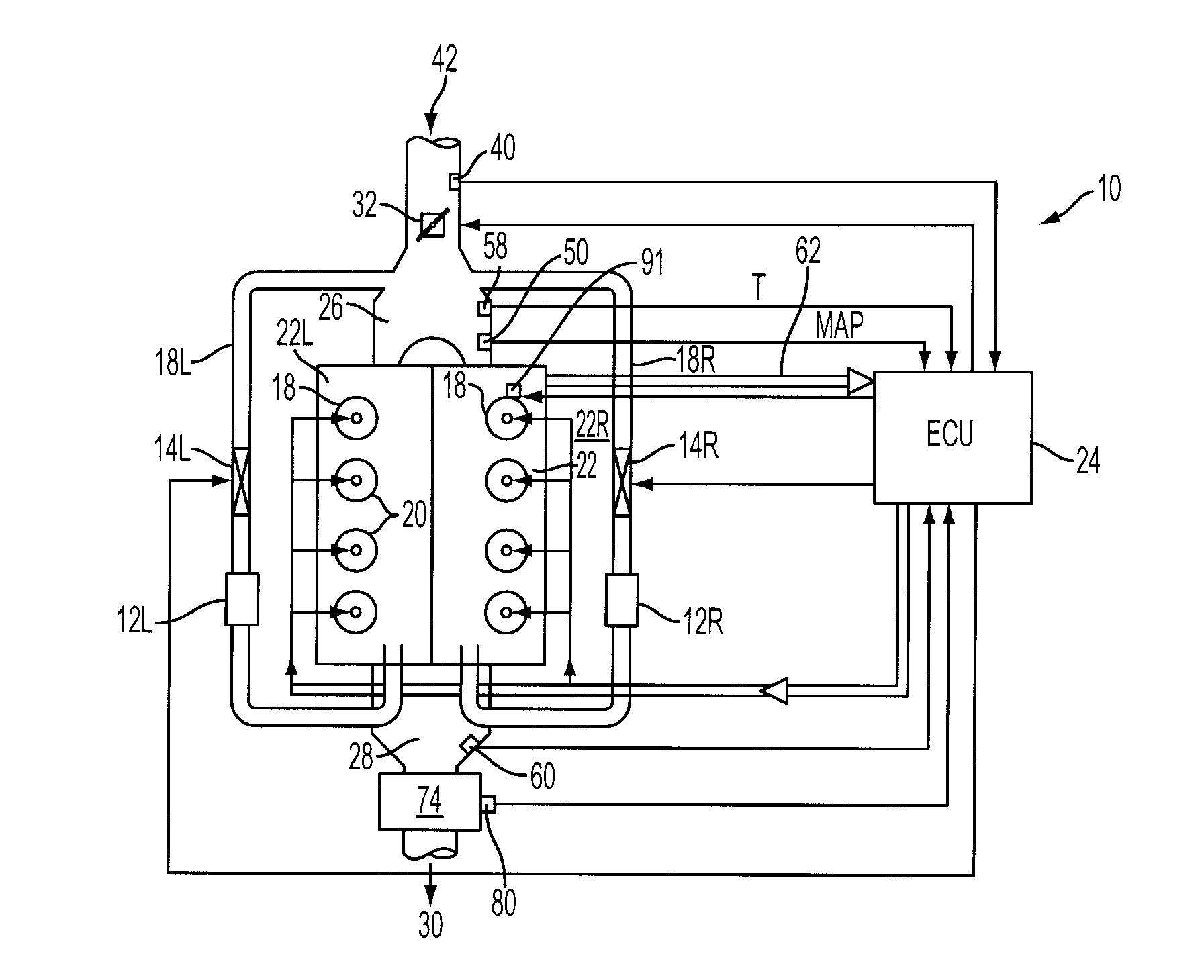

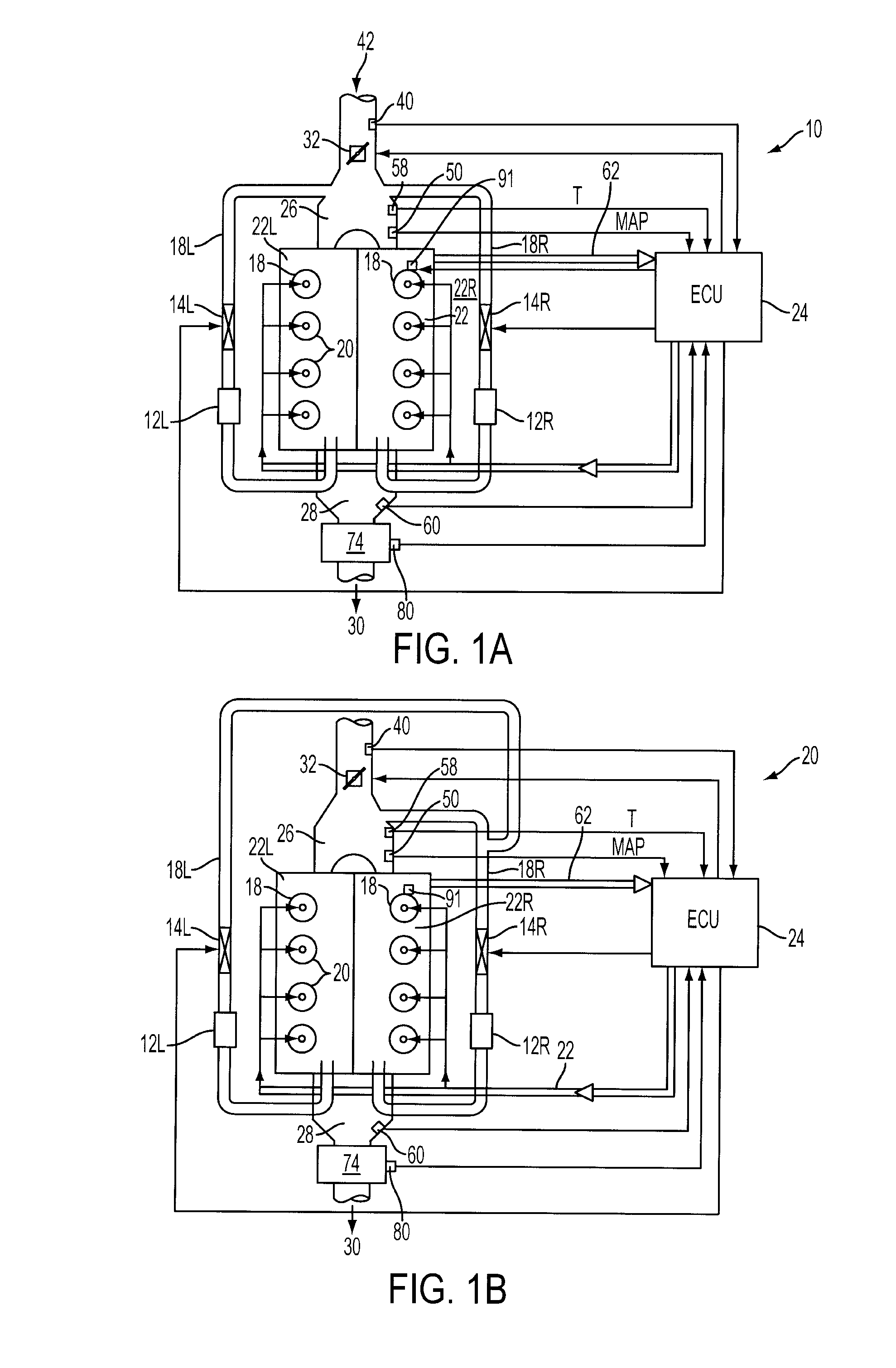

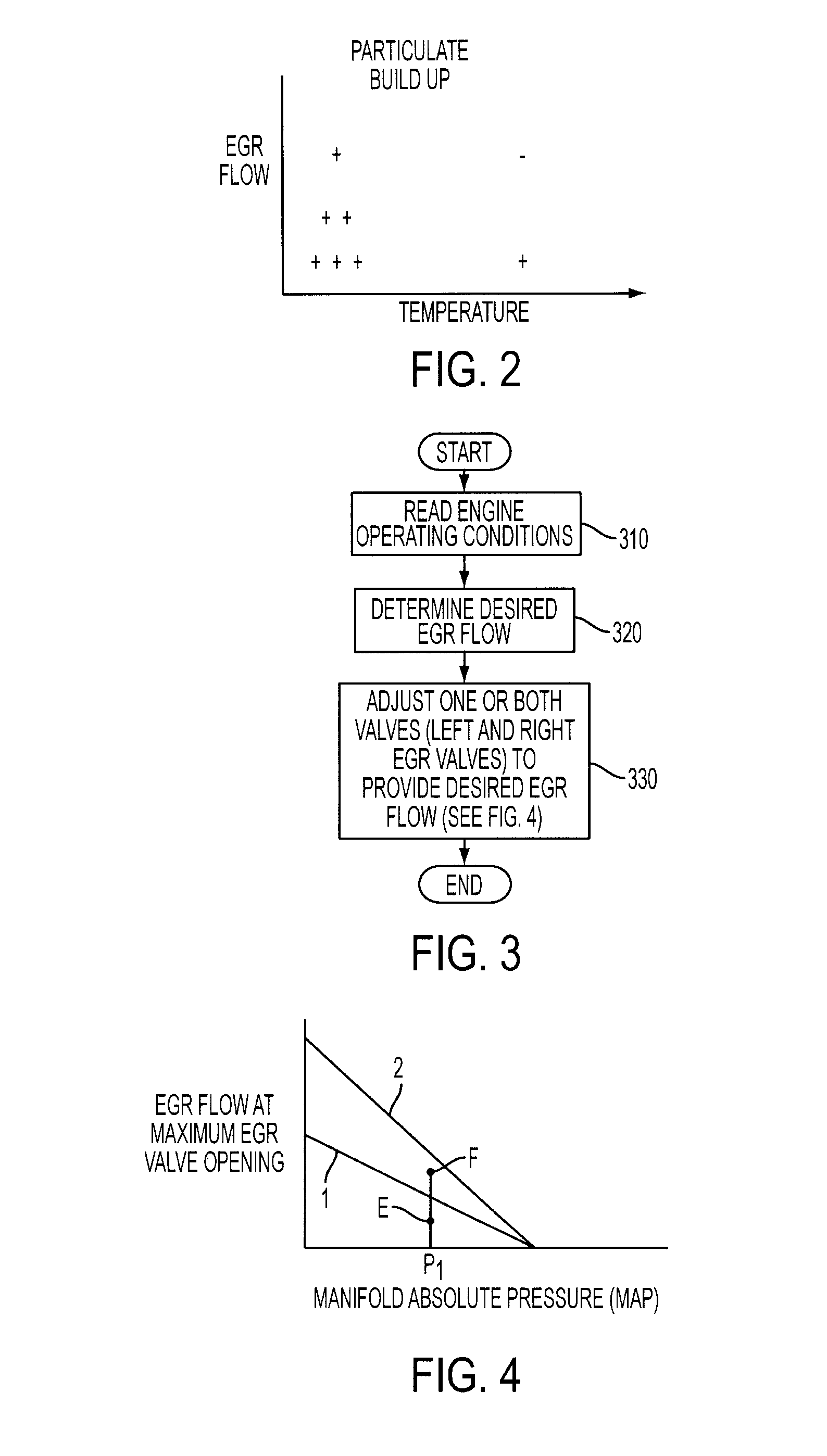

Alternative Left/Right Bank EGR Loop Operation to Improve Fouling Resistance During Low Mass Flow Engine Mode

InactiveUS20080060624A1Reduce formationReduce nitrogen oxide emissionsElectrical controlInternal combustion piston enginesControl systemDiesel engine

A system for a vehicle, comprising of a diesel engine having an intake system and an exhaust system, a first EGR loop coupled between said intake system and said exhaust system and having a first valve and a first cooler located therein, a second EGR loop coupled between said intake system and said exhaust system and having a second valve and a second cooler located therein, and a control system operating the first and second valves in a first condition where both valves provide EGR flow to the engine, and at least temporarily increasing flow in the first EGR loop and decreasing flow in the second EGR loop when EGR flow is decreased to a condition where buildup in one of said coolers is increased.

Owner:FORD GLOBAL TECH LLC

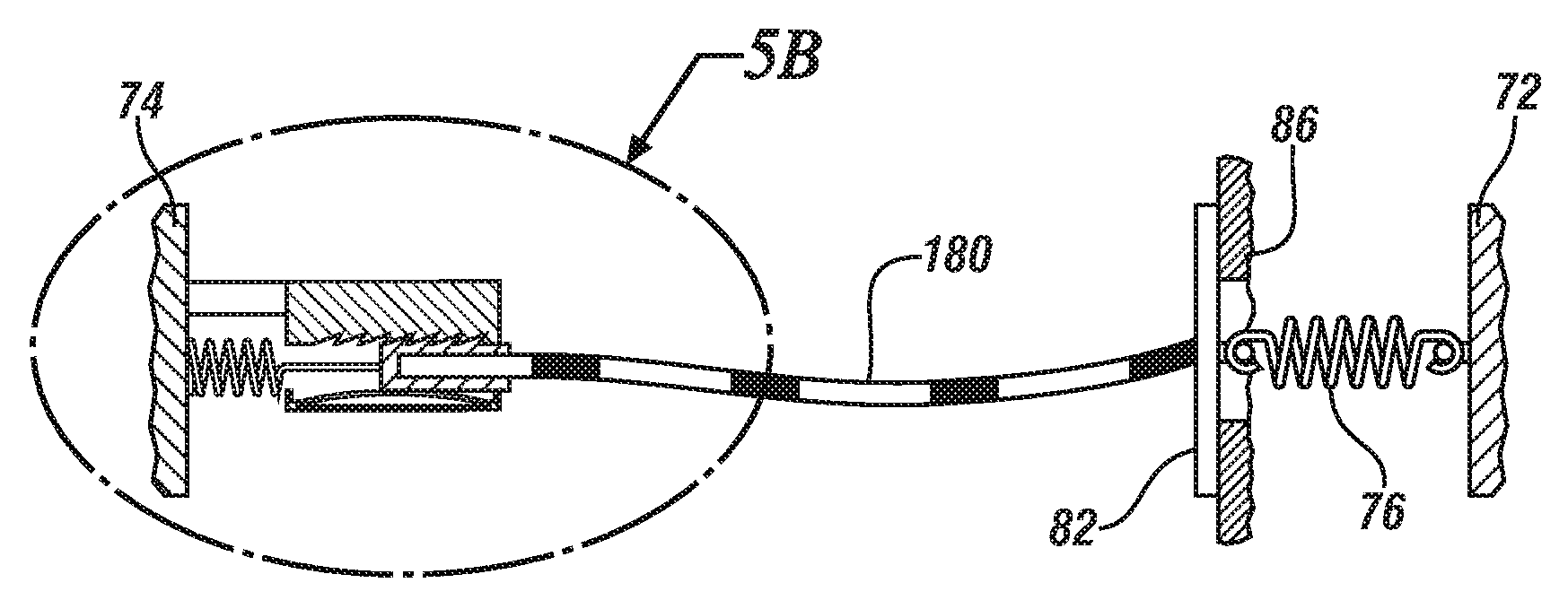

Compensating for incomplete reversal in mechanisms incorporating shape memory alloy wire

InactiveUS20140060036A1Engage with obstructionAvoid relative motionCoolant flow controlMechanical power devicesShape-memory alloyAlloy

Shape memory alloy (SMA) actuating elements are commonly simpler and of lower mass than alternative actuator designs and may find particular application in the transportation industry. Such SMA-powered devices are usually reliable and long-lived but the phase transformations which occur in the SMA alloy and are responsible for its utility are not totally reversible. This irreversibility, a consequence of irrecoverable strain, may progressively degrade the long-term actuator performance as the irrecoverable strain accumulates over many operating cycles. Methods and devices for compensating for these effects and extending the useful cycle life of SMA actuators are described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Mobile phase treatment for chromatography

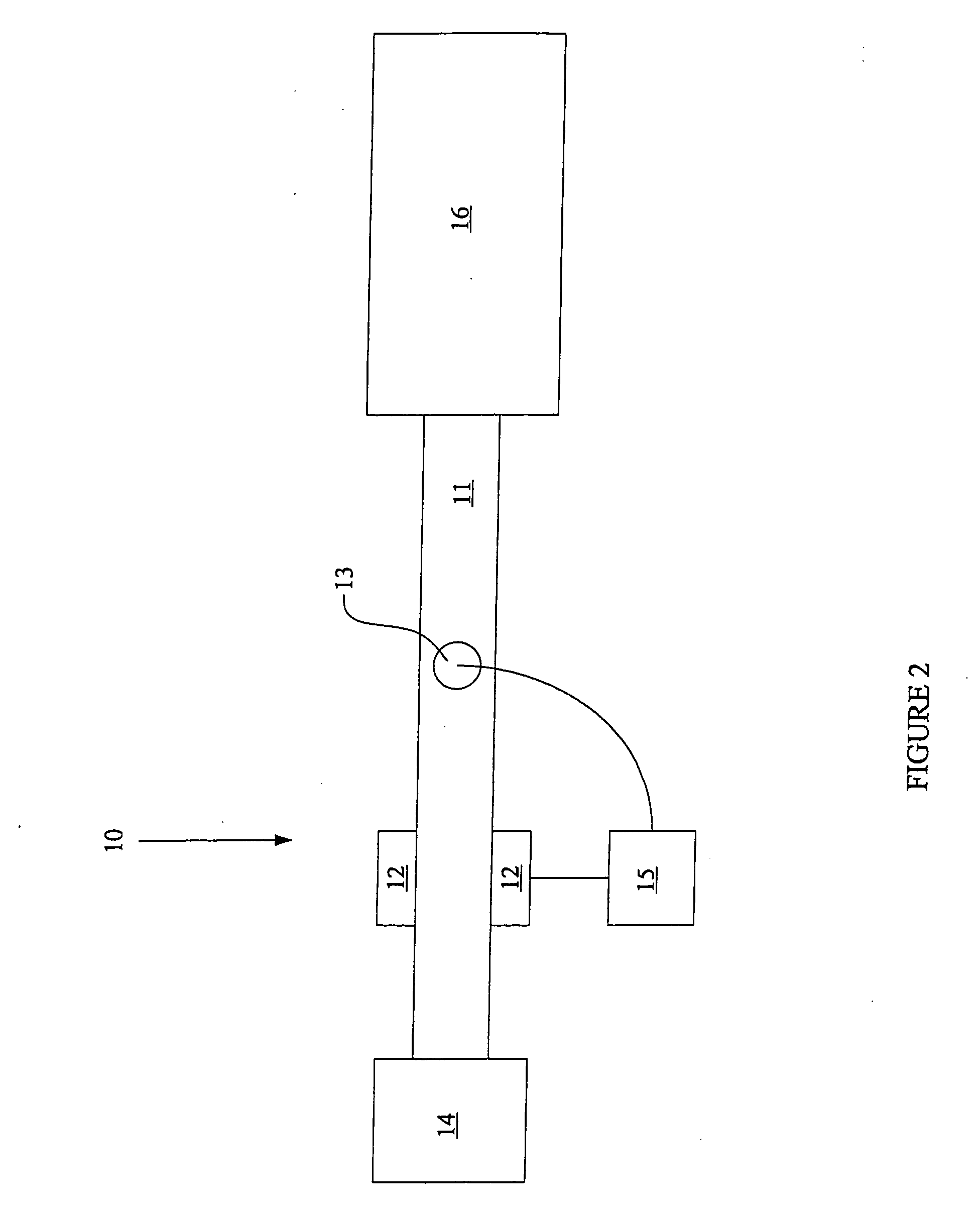

InactiveUS20060054558A1Convenient temperature programmingThe process is convenient and fastIon-exchange process apparatusComponent separationDead volumeContact time

A convenient and efficient method for heating or cooling the mobile phase fluid of a chromatographic system prior to its entry into the chromatographic column is described. The “preheating” or “precooling” process is carried out using an apparatus containing a short length of tubing where the mobile phase is heated or cooled. The heating or cooling is performed using a heating or cooling element that is in intimate thermal contact with the exterior of the tubing. The temperature change of the mobile phase is measured downstream by a non-invasive, low-mass sensing element on the exterior of the tubing. With a low mass heating or cooling element, the device can be very responsive and allows for rapid equilibration and convenient temperature programming of the mobile phase. This configuration also requires only a short mobile phase contact time, is non-invasive, adds no dead volume, and allows for use of columns over a wide range of internal diameter, flow rates and temperatures.

Owner:SELERITY TECH

Capacitor Pulse Forming Network with Multiple Pulse Inductors

InactiveUS20060290399A1Shaping characteristicReduce quality problemsDc network circuit arrangementsSecondary cells charging/dischargingCapacitancePulse forming network

Capacitor based pulse forming networks and methods are provided which require fewer inductors are that pulsed more frequently to provide a smaller, lower mass, and lower inductance pulse forming network having better pulse shaping characteristics than conventional pulse forming networks. In one implementation, the invention can be characterized as a capacitor based pulse forming network comprising a plurality of inductors adapted to be coupled to a load, a plurality of capacitor units, and a plurality of switches. Each switch couples a respective capacitor unit to a respective inductor, wherein multiple capacitor units are coupled to each inductor by separate switches. The plurality of switches are adapted to non-simultaneously discharge at least some of the multiple capacitor units to provide non-simultaneous pulses through a given inductor to the load and not through other inductors. The non-simultaneous pulses form at least a portion of an output pulse waveform to the load.

Owner:GENERAL ATOMICS

Thermal heat spreaders designed for lower cost manufacturability, lower mass and increased thermal performance

InactiveUS7190585B2Semiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionEngineering

A heat spreader, comprising a metal body with attached standoffs located approximately above the integrated circuit, is described. The standoffs should improve bond layer thickness control between the integrated circuit and the heat spreader, leading to a lower cost and lower mass package, as well as a more reliable device with increased thermal performance.

Owner:INTEL CORP

Low Cost Fixed Focal Point Parabolic Trough

InactiveUS20110100358A1Reduce quality problemsImprove rigiditySolar heating energySolar heat devicesEngineeringHeavy equipment

In accordance with one embodiment, a parabolic trough system is disclosed to capture solar heat. It has low mass, high rigidity and precise robust rotational control. The trough does not require massive supports, since it use a “sandwich structure” where the core is lightweight urethane foam and the skin is made of aluminum sheet. The inside skin also functions as the parabolic reflector. The shape minimizes wind loads by centering the receiver in the parabola and by making the center of focus the center of rotation.The system can be rapidly built in the field since there are few parts. Assembly does not require heavy equipment. Support posts are used on both sides of the trough to minimize the anchoring requirements in wind loads.The trough bodies are rotated in a rotational control mechanism that uses circumscribing rings to support a continuous row of troughs that can sustain 120 mile per hour winds. Optical performance is improved with the drive ring design. The structure is continuous and torque is uniformly applied to each ring through two spools supported on drive tubes. A cable is wrapped around each spool as well as around the top part of the ring. As the spools rotate, they pull the cable and rotate the rings and troughs with precision and strength. The spools and cables also restrain the system under high wind loads.

Owner:PERISHO RANDAL JEROME

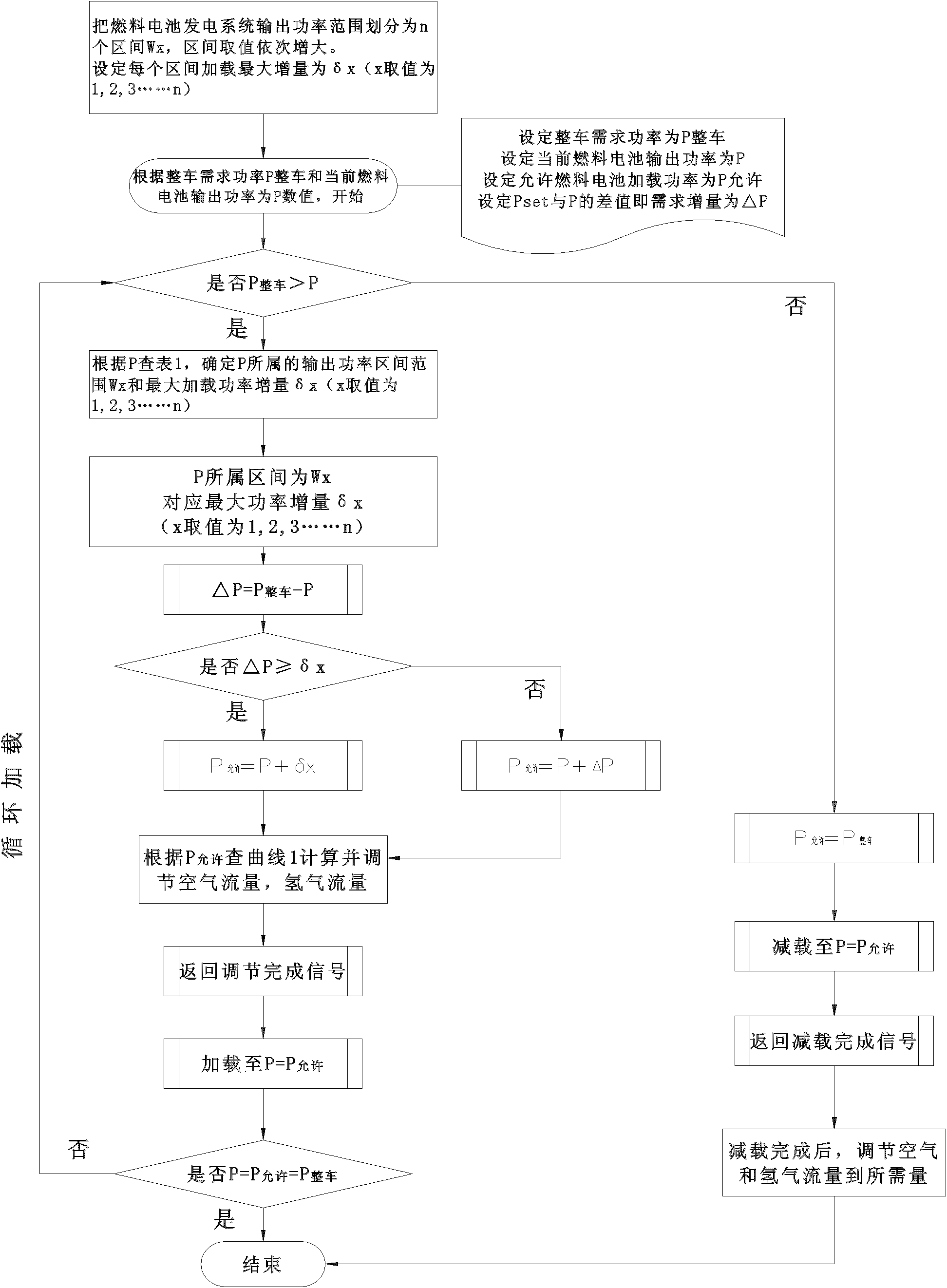

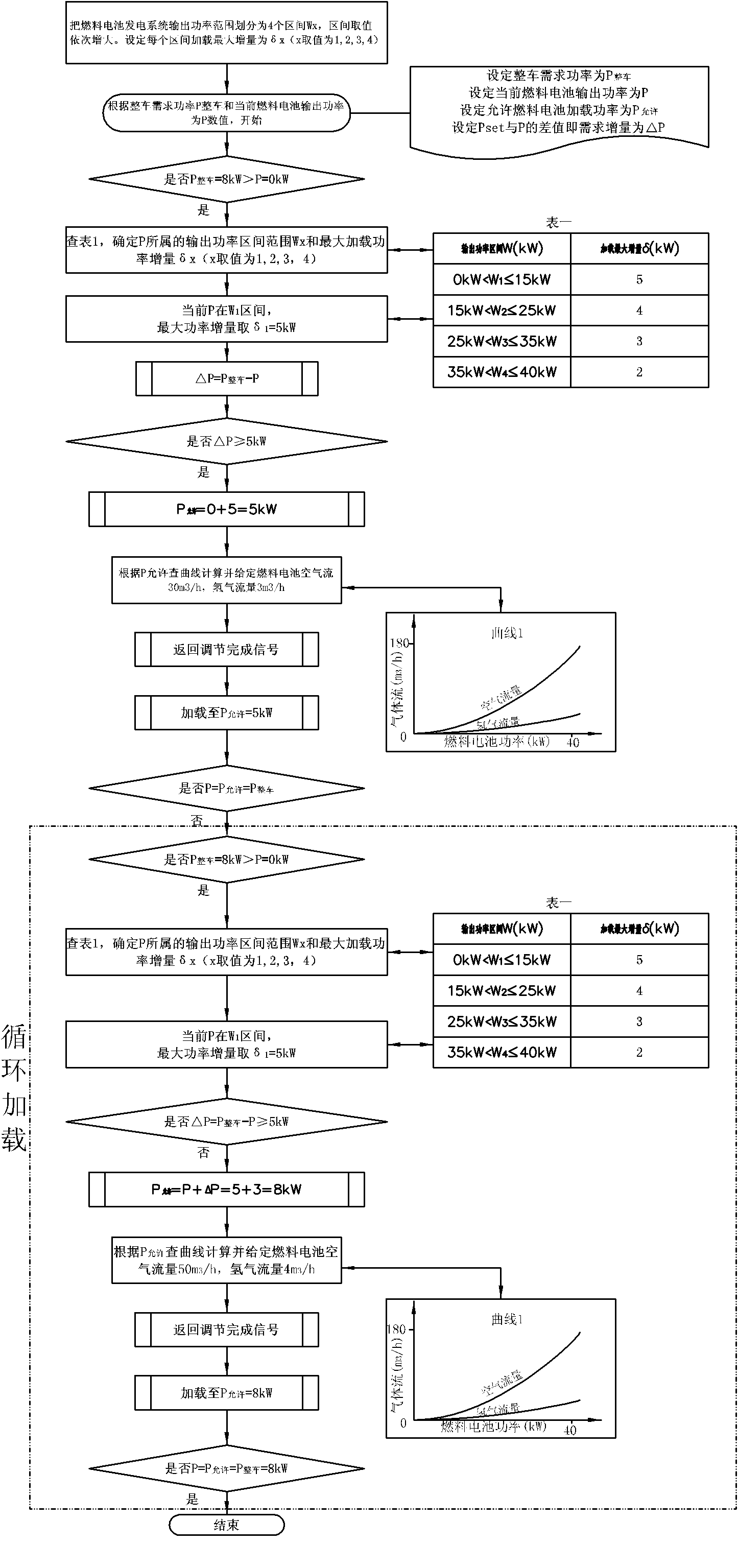

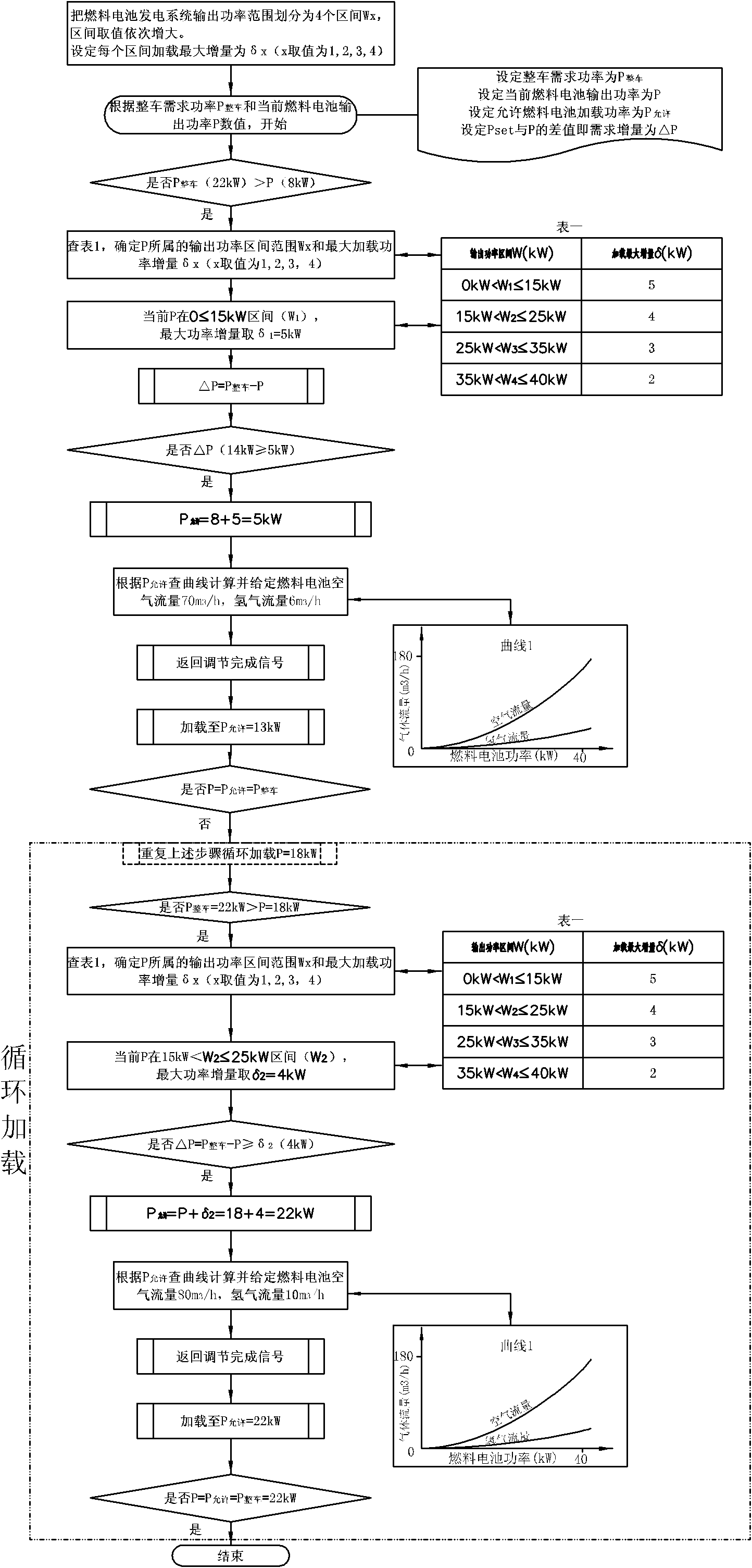

Loading control method for power generation system of automobile fuel cell

ActiveCN102522581AExtended service lifeAvoid polarity reversalFuel cell auxillariesFuel cellsGreek letter sigma

The invention provides a loading and deloading control method for a power generation system of an automobile fuel cell. The method comprises the following steps of: during loading, setting a maximum power gain sigma(x), comparing the maximum power gain sigma(x) with a difference value delta(P) between the power P(whole automobile) required by a whole automobile and the loading power P of the conventional fuel cell to determine a loading amount, and calculating the allowable power P(allowable) to be output by the power generation system of the fuel cell; adjusting corresponding parameters of the power generation system of the fuel cell according to the calculated allowable loading power P(allowable); after the adjustment is finished, returning a finish signal, repeatedly and cyclically loading until the power P(whole automobile) is equal to the power P(allowable), and cyclically loading repeatedly until the power P(allowable) is equal to the power P(whole automobile); during deloading, directly deloading; and after finishing the deloading, adjusting the parameters of the power generation system of the fuel cell. The method has the advantages that: by continuously loading according to low gain, the damage of gas insufficiency, antipole and the like to membrane electrodes, which are caused by low mass transfer because of high-speed large load loading, is reduced; and the service life of the power generation system of the fuel cell is prolonged.

Owner:SUNRISE POWER CO LTD

Focusing device based on bonded plate structures

The invention provides a low mass and size thermal focusing device for a gas phase analytical device. The device has two or more plates bonded together. The device also has at least one channel with an entrance and exit is formed within allowing ingress and egress of a gas stream. The device also has a temperature reduction module in thermal contact with at least one plate of the device. Thermal focusing devices with additional plates and / or channels are also disclosed.

Owner:AGILENT TECH INC

Rotational, shear mode, piezoelectric motor integrated into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head/gimbal assembly for improved tracking in disk drives and disk drive equipment

ActiveUS20090021857A1High track densityImproved fine track positioningDriving/moving recording headsArm with actuatorsShock resistanceControl theory

A rotational, shear mode, piezoelectric motor is integrated with a suspension, head or head gimbal assembly (HGA) into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head gimbal assembly (HGA) for use in disk drives and disk drive manufacturing equipment. When excited by a control voltage, the collocated, shear mode, piezoelectric micro-actuated HGA rotates the head enabling high frequency, high resolution track positioning of the read / write element. The motor is integrated with the head and flexure (collocation). The head rotates about a rotation axis that is ideally located at the center of mass of the head. A shear mode piezoelectric motor rotates the head. A collocated, rotational, shear mode, piezoelectric micro-actuated HGA has high stiffness, high frequency response, high positioning resolution, low mass and low internal vibration for improved tracking, increased track density and greater disk drive storage capacity. Furthermore, its solid integration improves shock resistance and reduces micro-contamination.

Owner:MAGNECOMP +1

Compensating for incomplete reversal in mechanisms incorporating shape memory alloy wire

InactiveUS9021801B2Engage with obstructionMaintain tensionCoolant flow controlMechanical power devicesAlloySma actuator

Shape memory alloy (SMA) actuating elements are commonly simpler and of lower mass than alternative actuator designs and may find particular application in the transportation industry. Such SMA-powered devices are usually reliable and long-lived but the phase transformations which occur in the SMA alloy and are responsible for its utility are not totally reversible. This irreversibility, a consequence of irrecoverable strain, may progressively degrade the long-term actuator performance as the irrecoverable strain accumulates over many operating cycles. Methods and devices for compensating for these effects and extending the useful cycle life of SMA actuators are described.

Owner:GM GLOBAL TECH OPERATIONS LLC

Preparation method for crosslinking type polyimide aerogel

The invention belongs to the technical field of aerogel materials, and particularly relates to a preparation method for a crosslinking type polyimide aerogel. The adopted sol-gel method comprises the steps that acid anhydride and diamine containing a plurality of benzene ring structures are adopted as a precursor body to prepare polyamide acid, then a crosslinking agent is added to form a crosslinking type polyamide acid structure, imidization is performed to form wet gel, and the supercritical drying technology is combined with the wet gel to obtain the crosslinking type polyimide aerogel material with the low mass, high specific surface area and good heat stability. Compared with the prior art, the preparation method has the advantages that raw materials are easy to obtain, the reaction process is simple, the obtained material is of the nanometer level three-dimensional net structure, the density of the material is smaller than 130 mg / cm<3>, the specific surface area can reach more than 500 mg / cm<3>, and the problems that conventional organic aerogel is high in density, low in specific area, poor in heat stability and the like are solved.

Owner:SHANGHAI GRAND SOUND BEYOND NOISE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com