Patents

Literature

572results about "Specific nanostructure formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

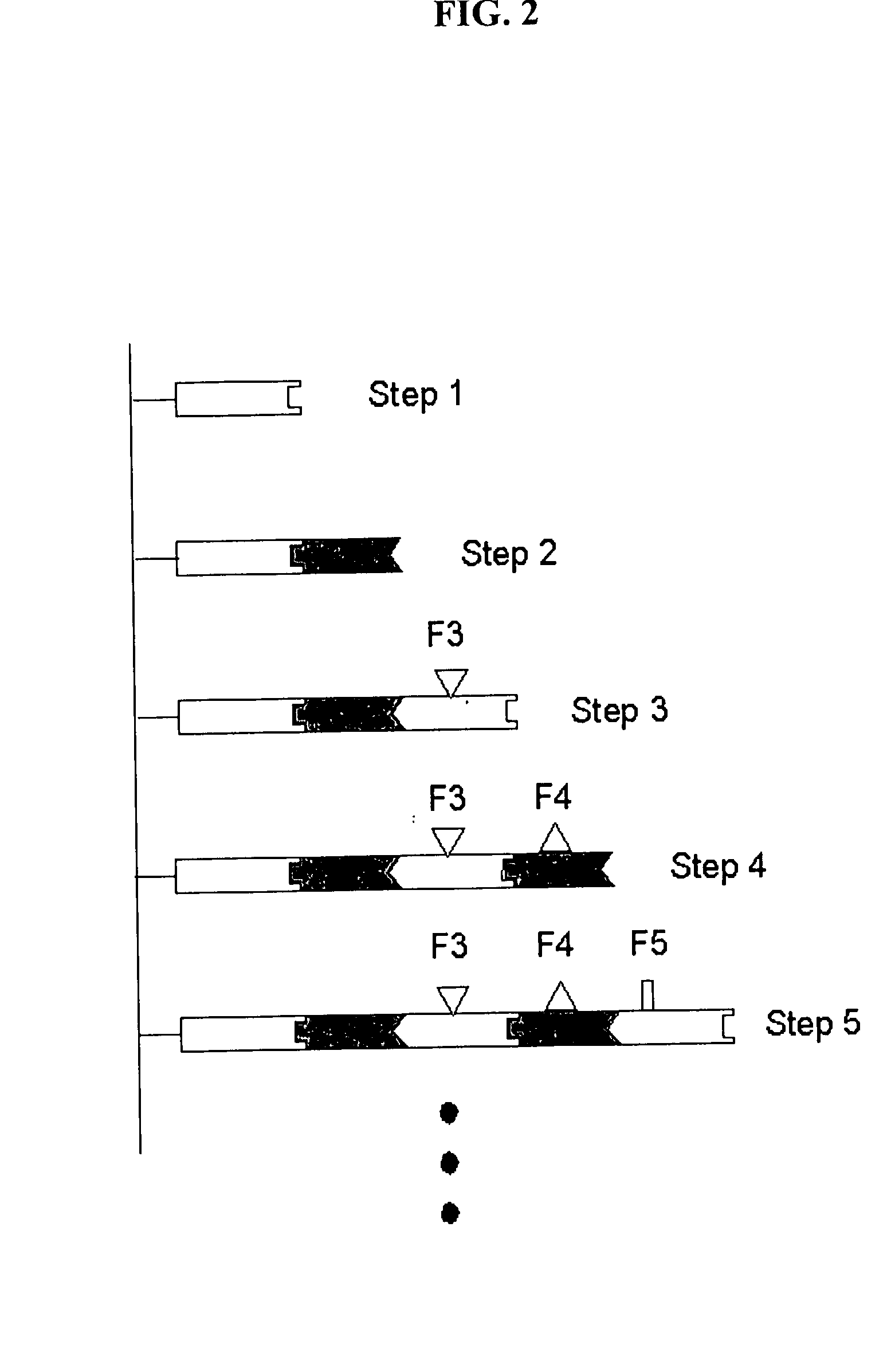

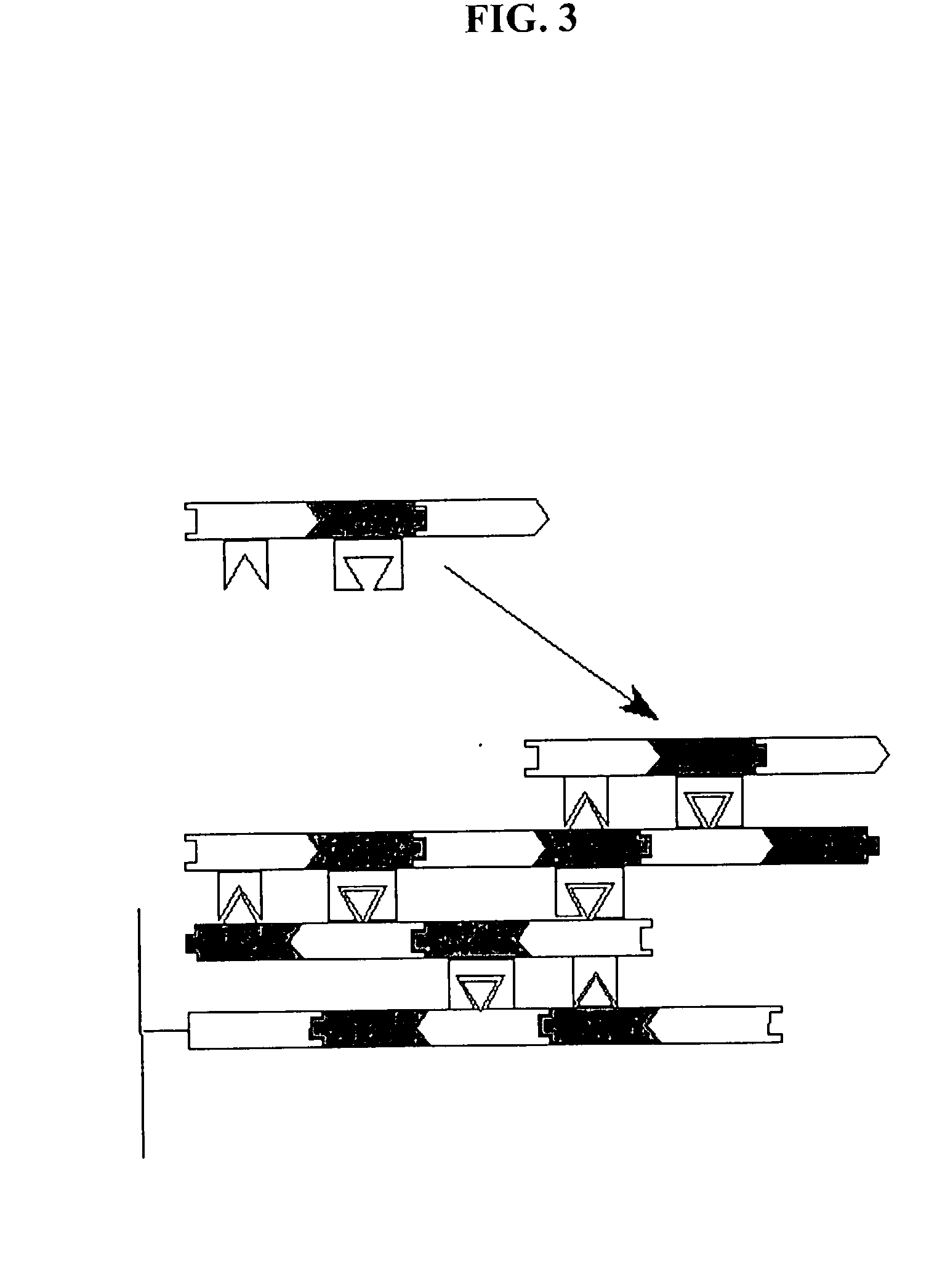

Staged assembly of nanostructures

The present invention provides methods and assembly units for the construction of nanostructures. Assembly of nanostructures proceeds by sequential, non-covalent, vectorial addition of an assembly unit to an initiator or nanostructure intermediate during an assembly cycle, a process termed "staged assembly." Attachment of each assembly unit is mediated by specific, non-covalent binding of a single pre-determined joining element of one assembly unit to a complementary joining element on a target initiator or nanostructure intermediate. Each interaction of a joining element is designed such that the joining element does not interact with any other joining element of the assembly unit. Self-association of the assembly unit is therefore obviated: only one assembly unit can be added at a time to a target initiator or nanostructure intermediate.

Owner:NANOFRAMES

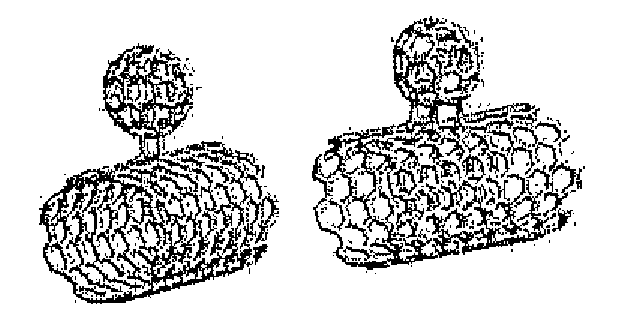

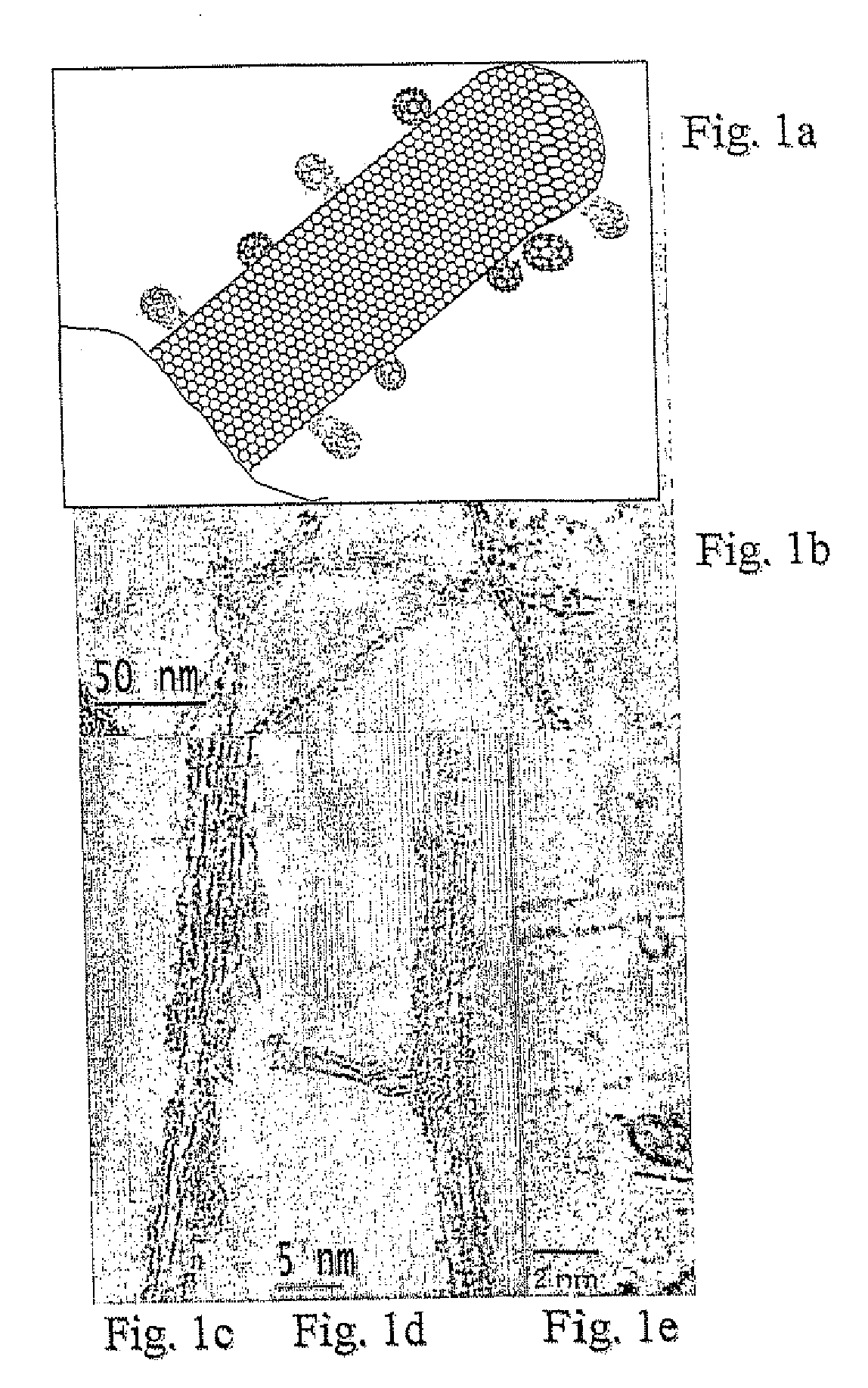

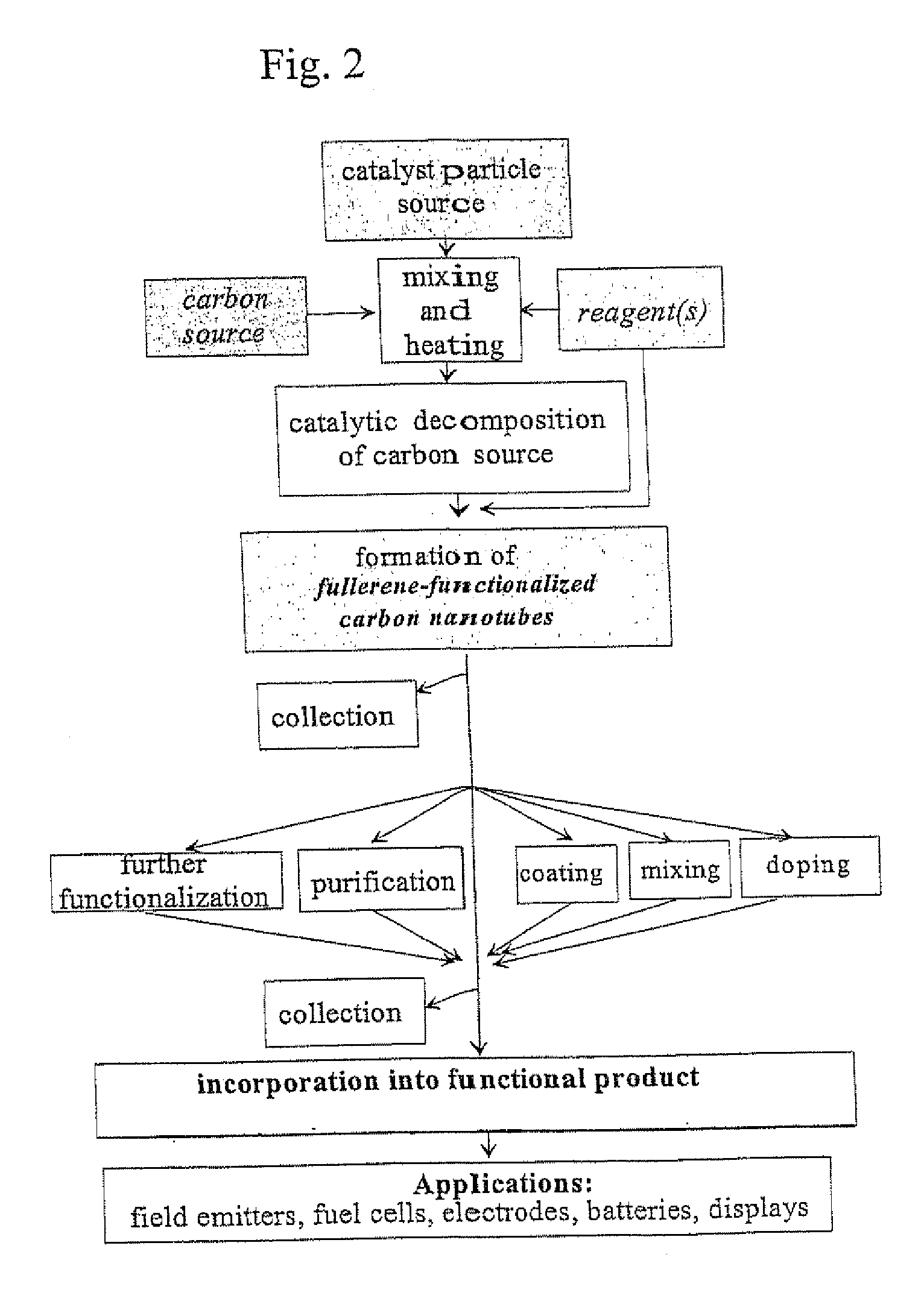

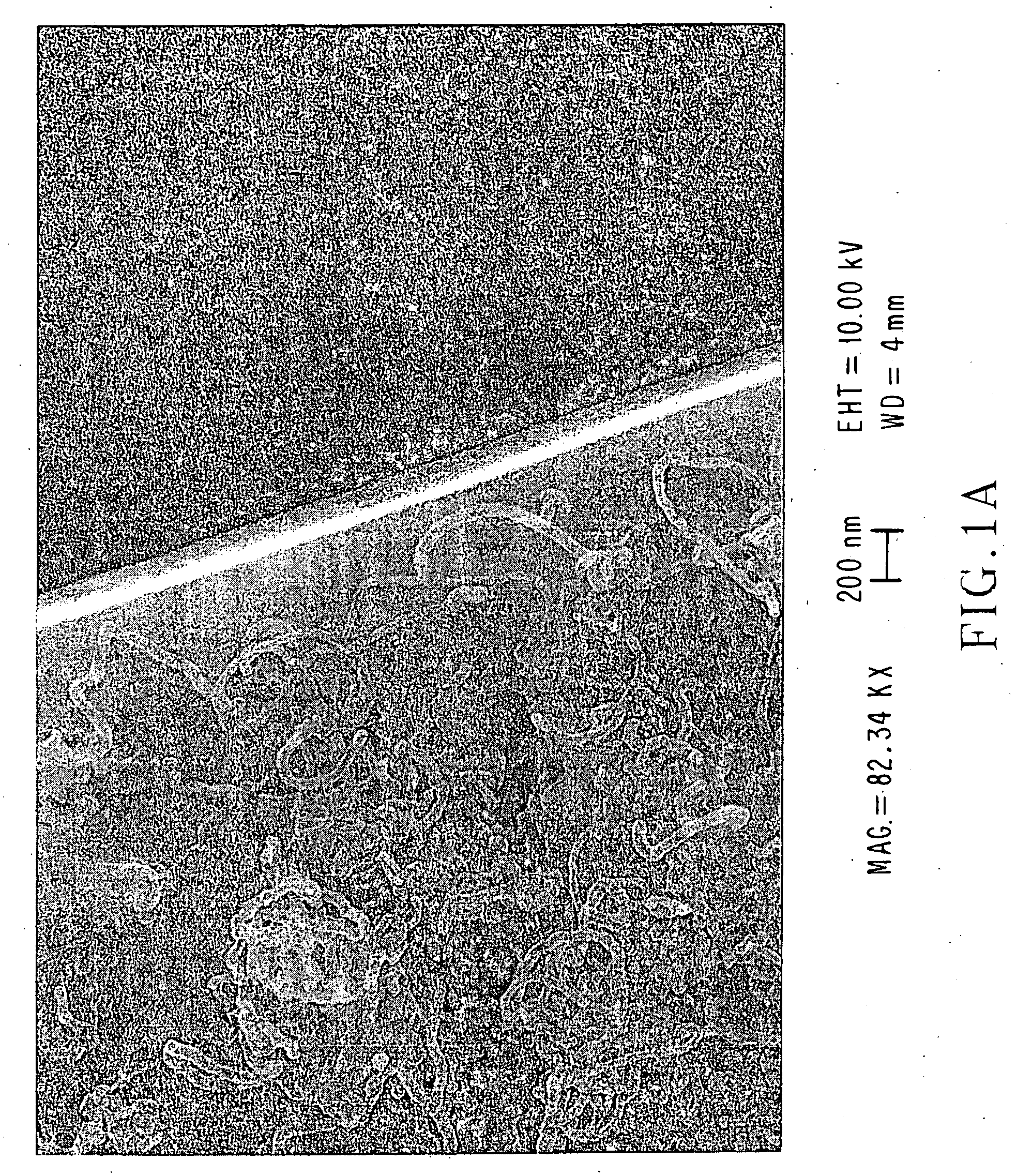

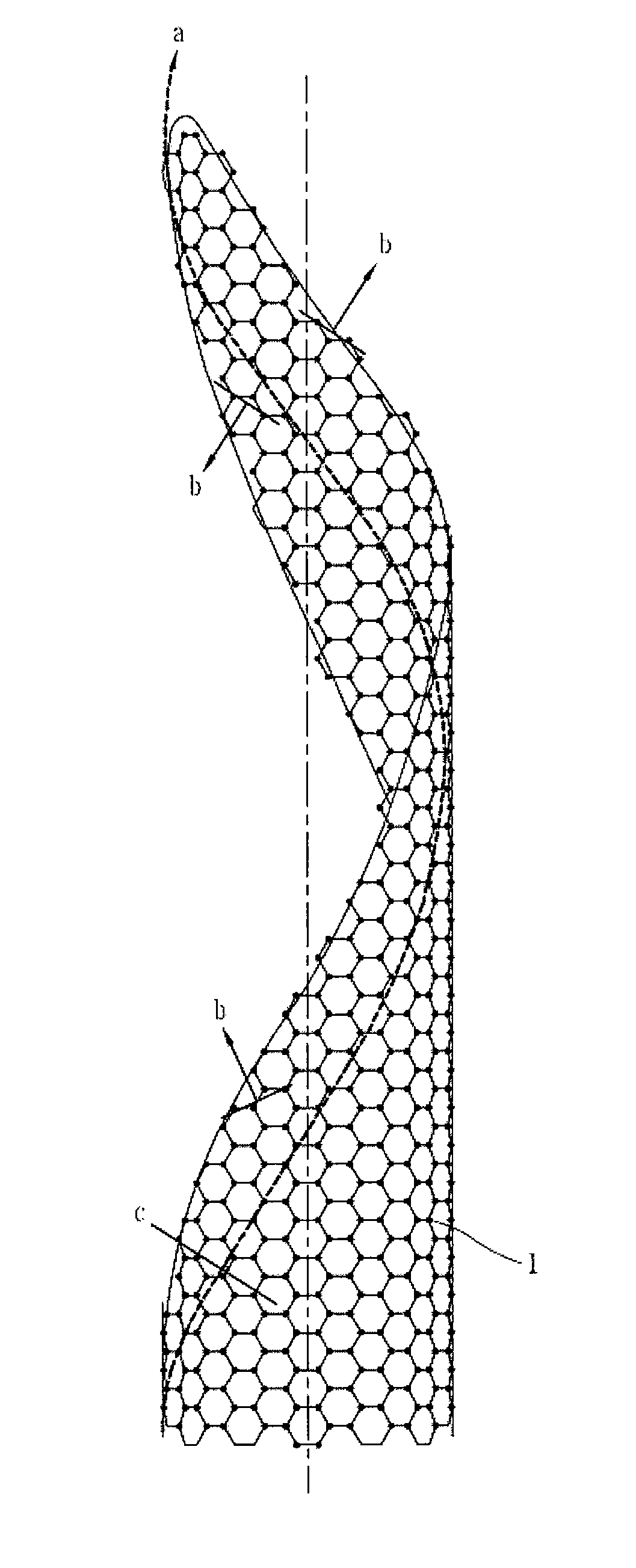

Carbon nanotubes functionalized with fullerenes

InactiveUS20090226704A1Enhancement in cold electron field emissionImprove mechanical propertiesSpecific nanostructure formationMaterial nanotechnologyC60 fullereneNanotube

The present invention relates to covalently bonded fullerene-functionalized carbon nanotubes (CBFFCNTs), a method and an apparatus for their production and to their end products. CBFFCNTs are carbon nanotubes with one or more fullerenes or fullerene based molecules covalently bonded to the nanotube surface. They are obtained by bringing one or more catalyst particles, carbon sources and reagents together in a reactor.

Owner:CANATU OY

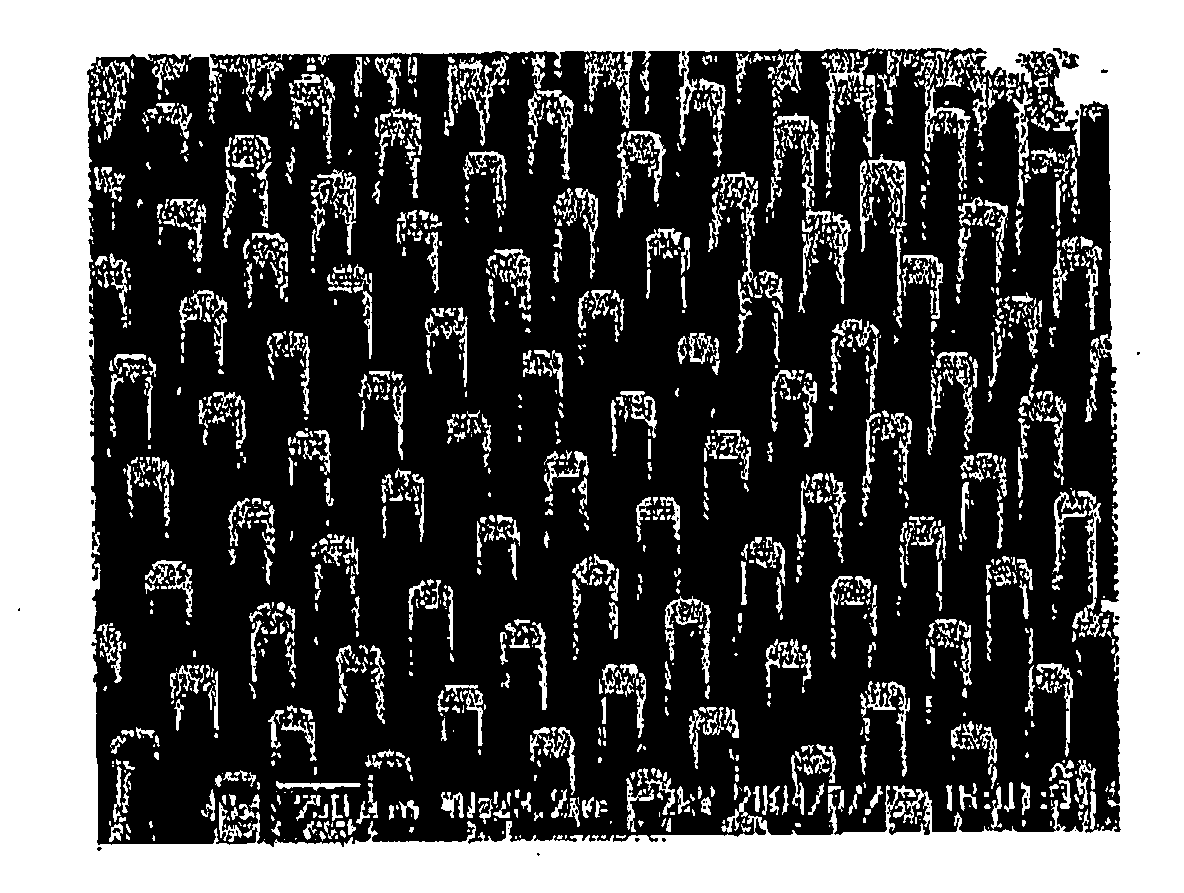

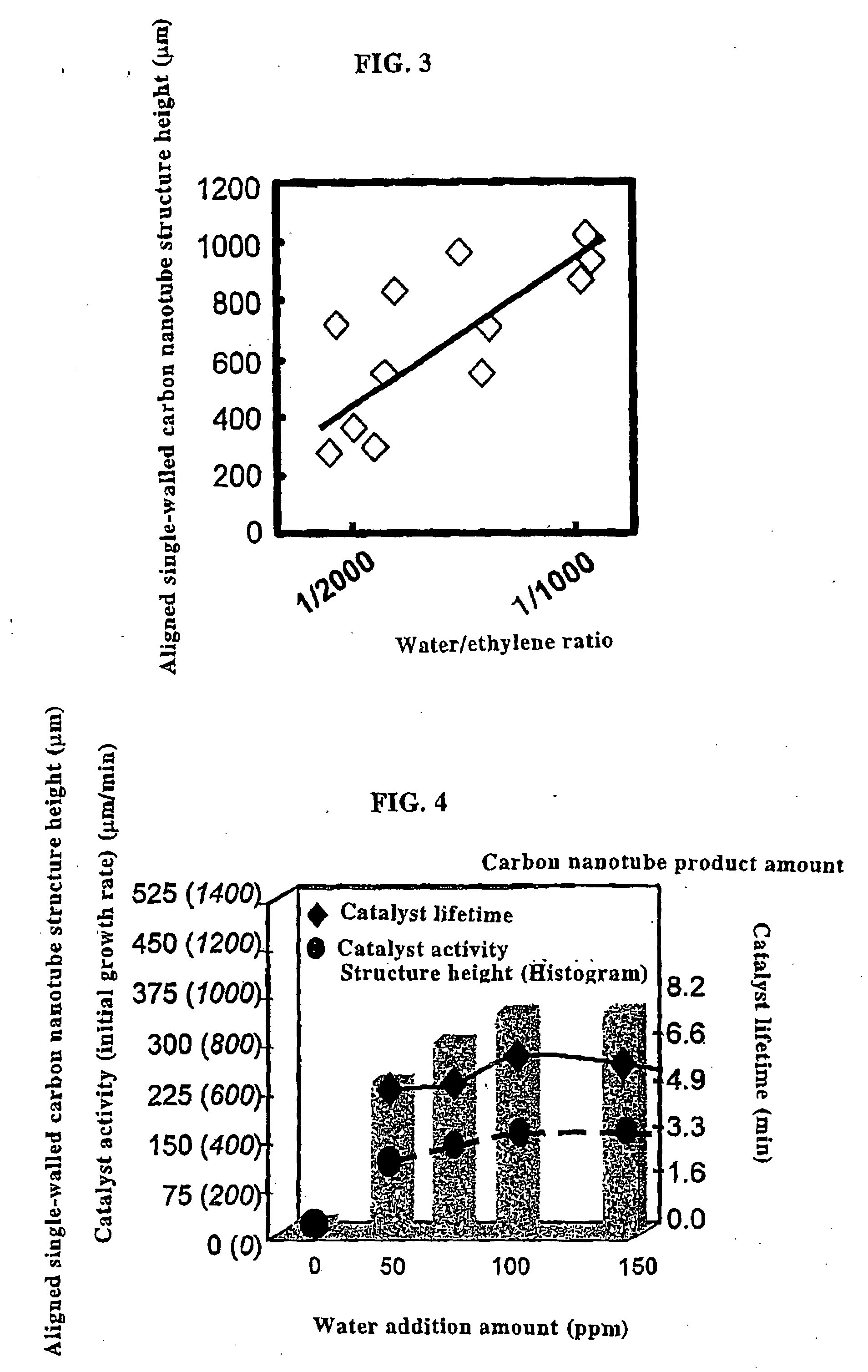

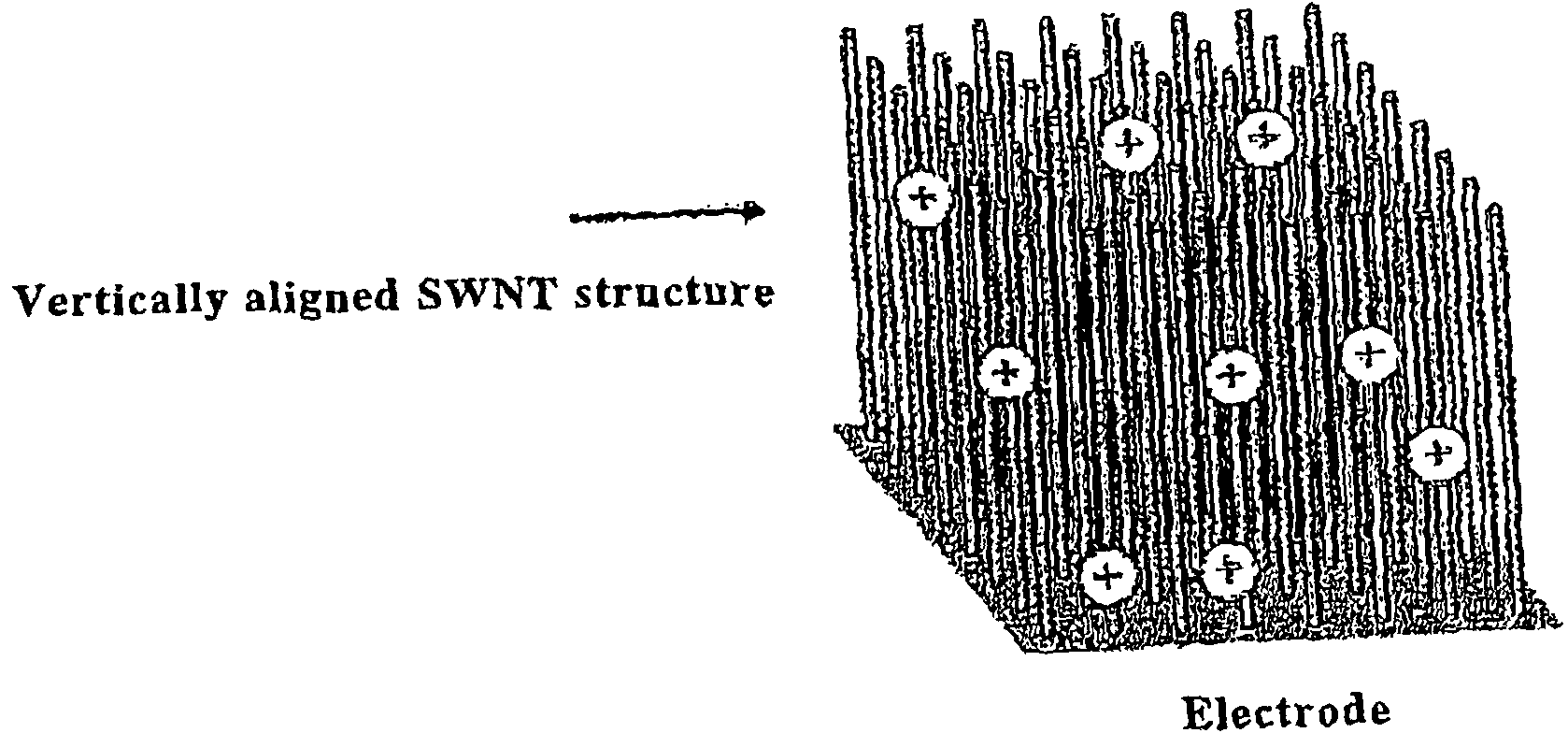

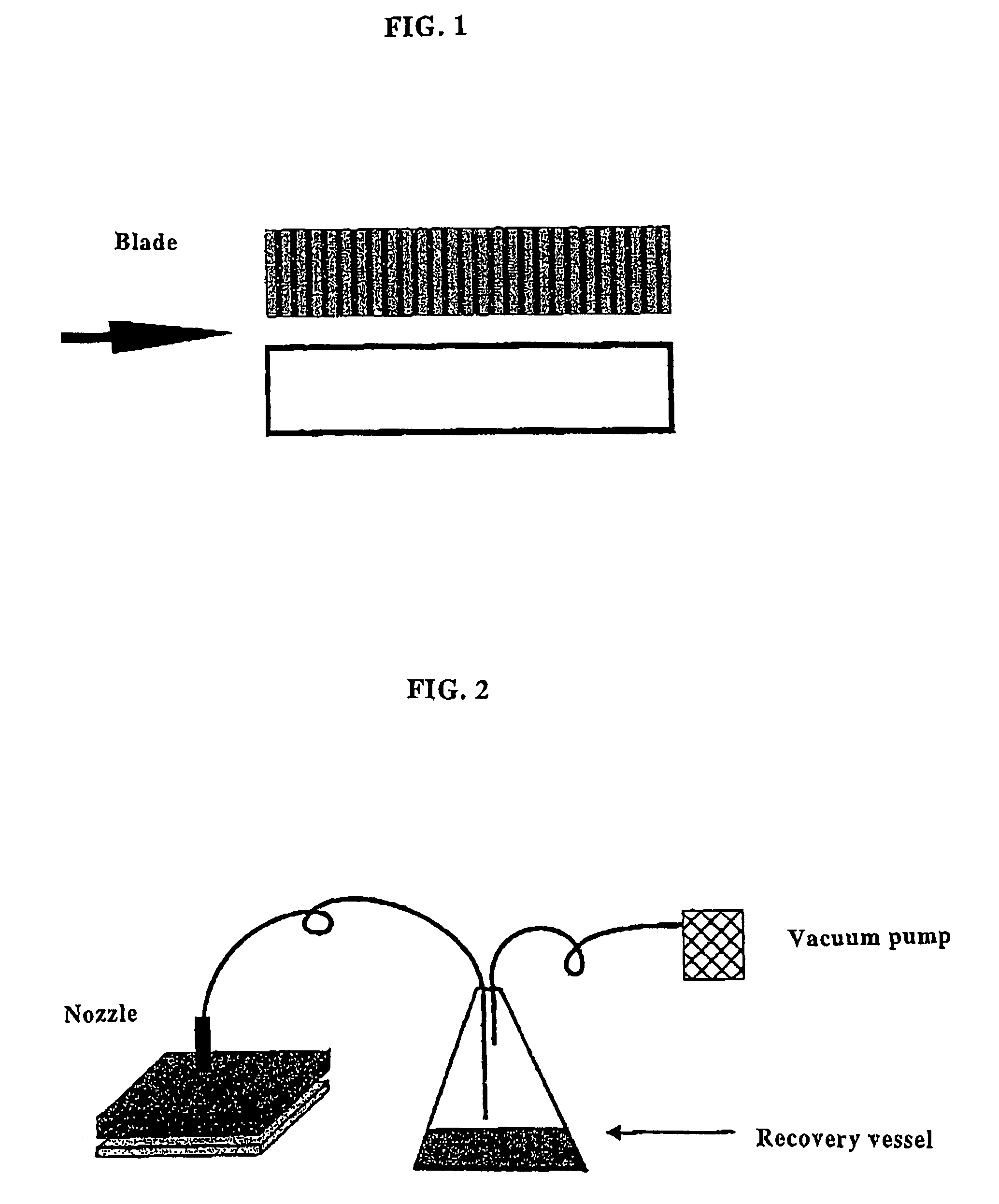

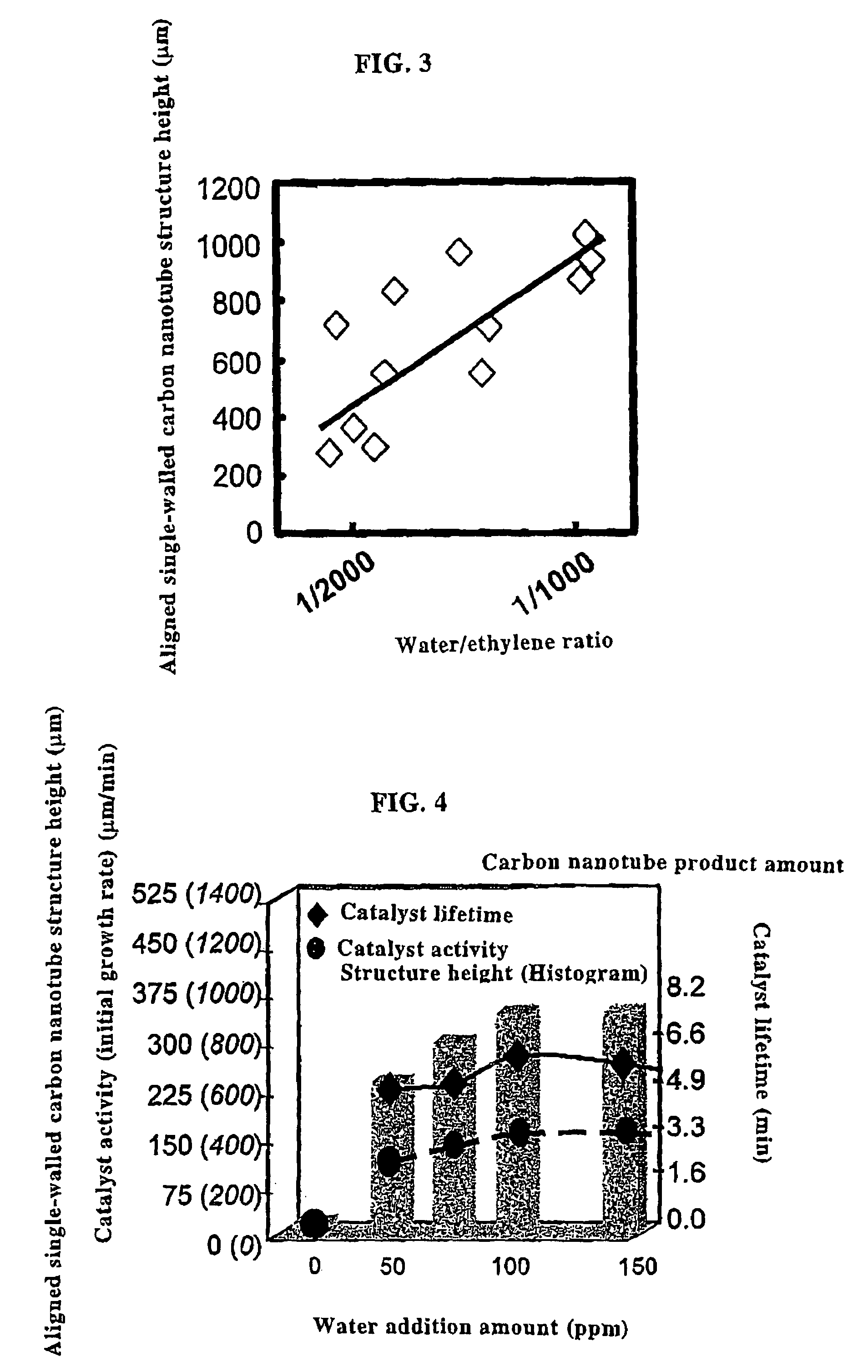

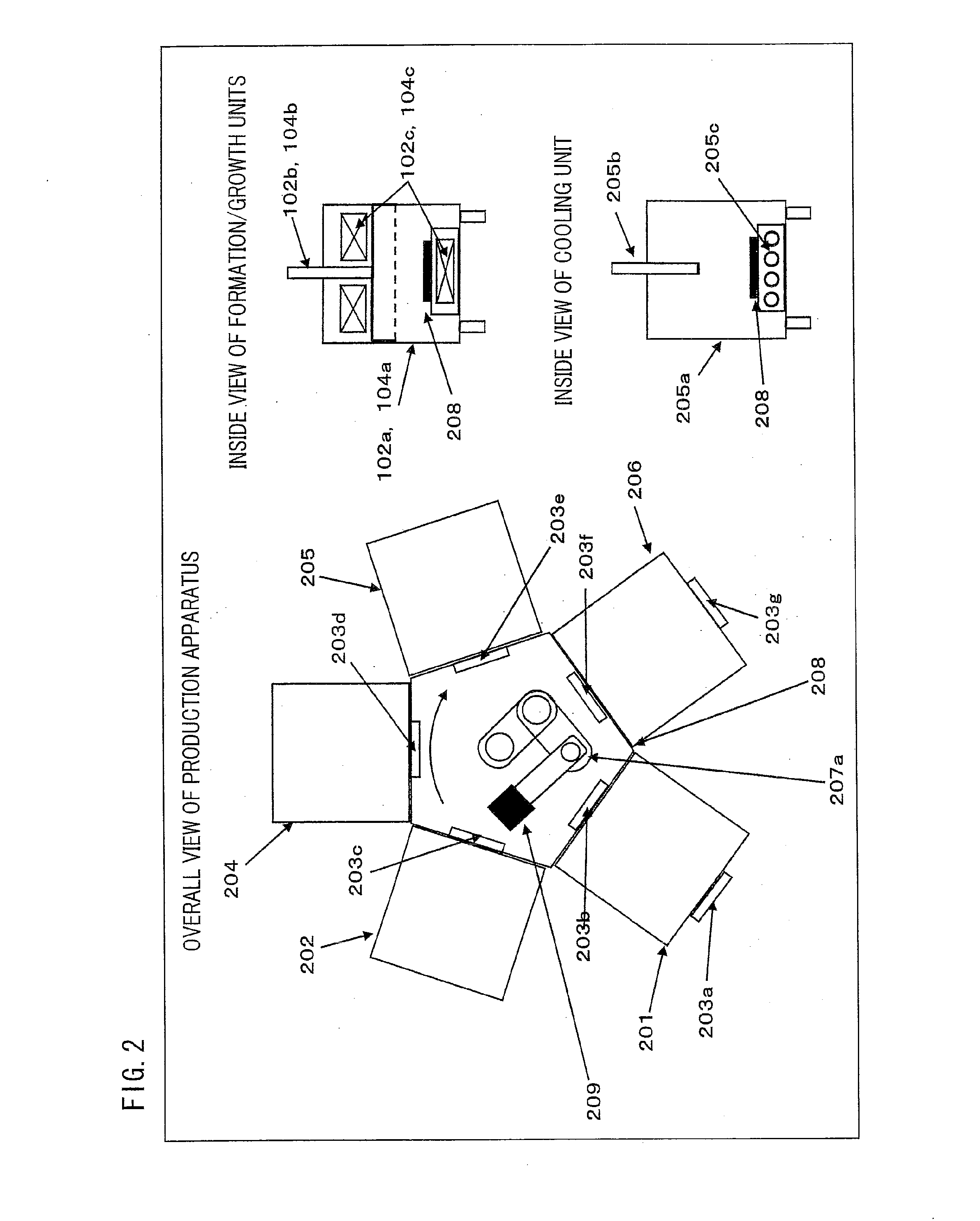

Single-Walled Carbon Nanotube and Aligned Single-Walled Carbon Nanotube Bulk Structure, and Their Production Process, Production Apparatus and Application Use

ActiveUS20080318049A1Efficient productionIncrease freedomMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Single-walled carbon nanotube and aligned single-walled carbon nanotube bulk structure, and their production process, production apparatus and application use

ActiveUS7854991B2Prolong lifeIncrease probabilityMaterial nanotechnologyCell electrodesMetal catalystCarbon nanotube

This invention provides an aligned single-layer carbon nanotube bulk structure, which comprises an assembly of a plurality of aligned single-layer carbon nanotube and has a height of not less than 10 μm, and an aligned single-layer carbon nanotube bulk structure which comprises an assembly of a plurality of aligned single-layer carbon nanotubes and has been patterned in a predetermined form. This structure is produced by chemical vapor deposition (CVD) of carbon nanotubes in the presence of a metal catalyst in a reaction atmosphere with an oxidizing agent, preferably water, added thereto. An aligned single-layer carbon nanotube bulk structure, which has realized high purify and significantly large scaled length or height, its production process and apparatus, and its applied products are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

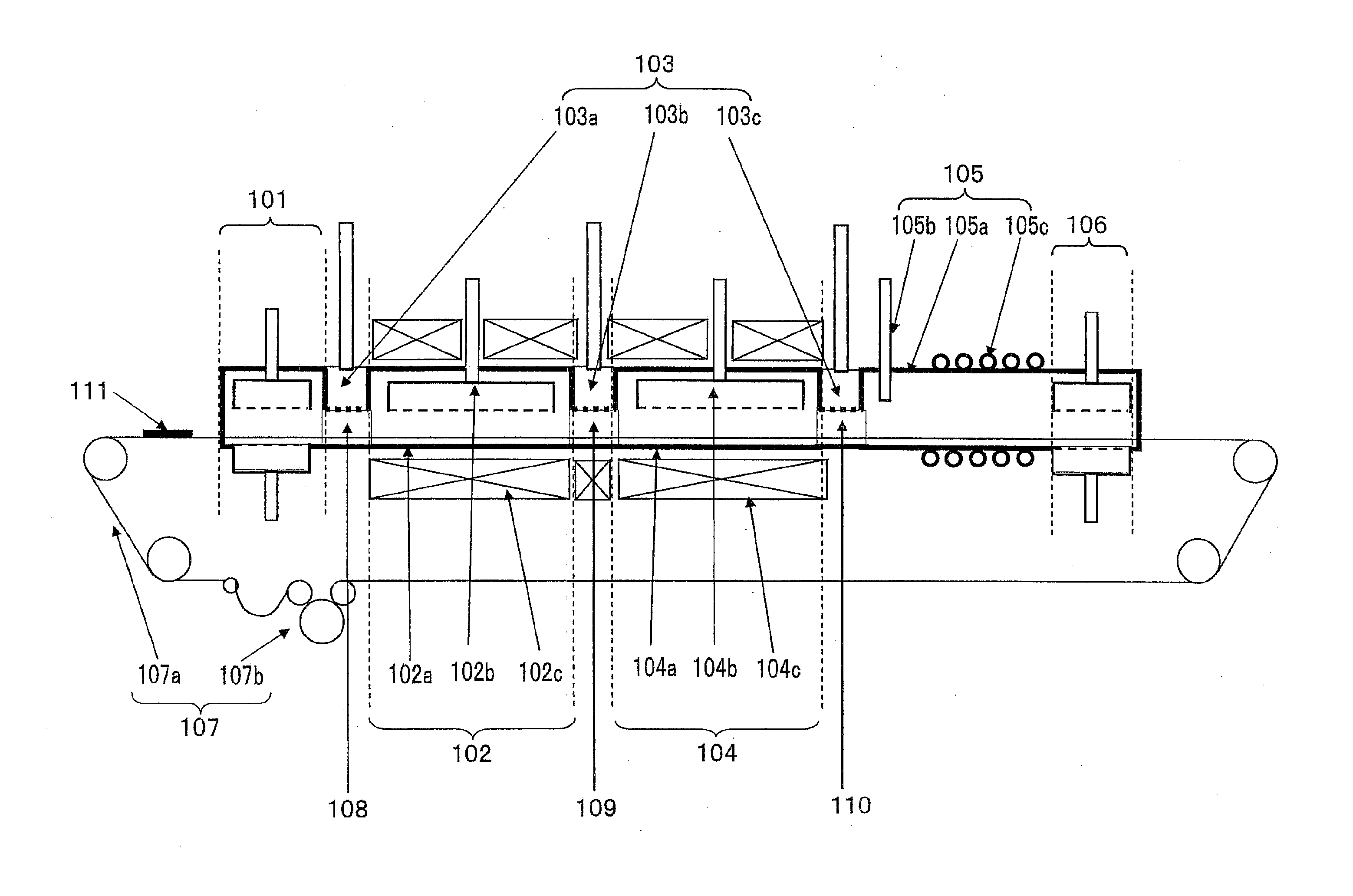

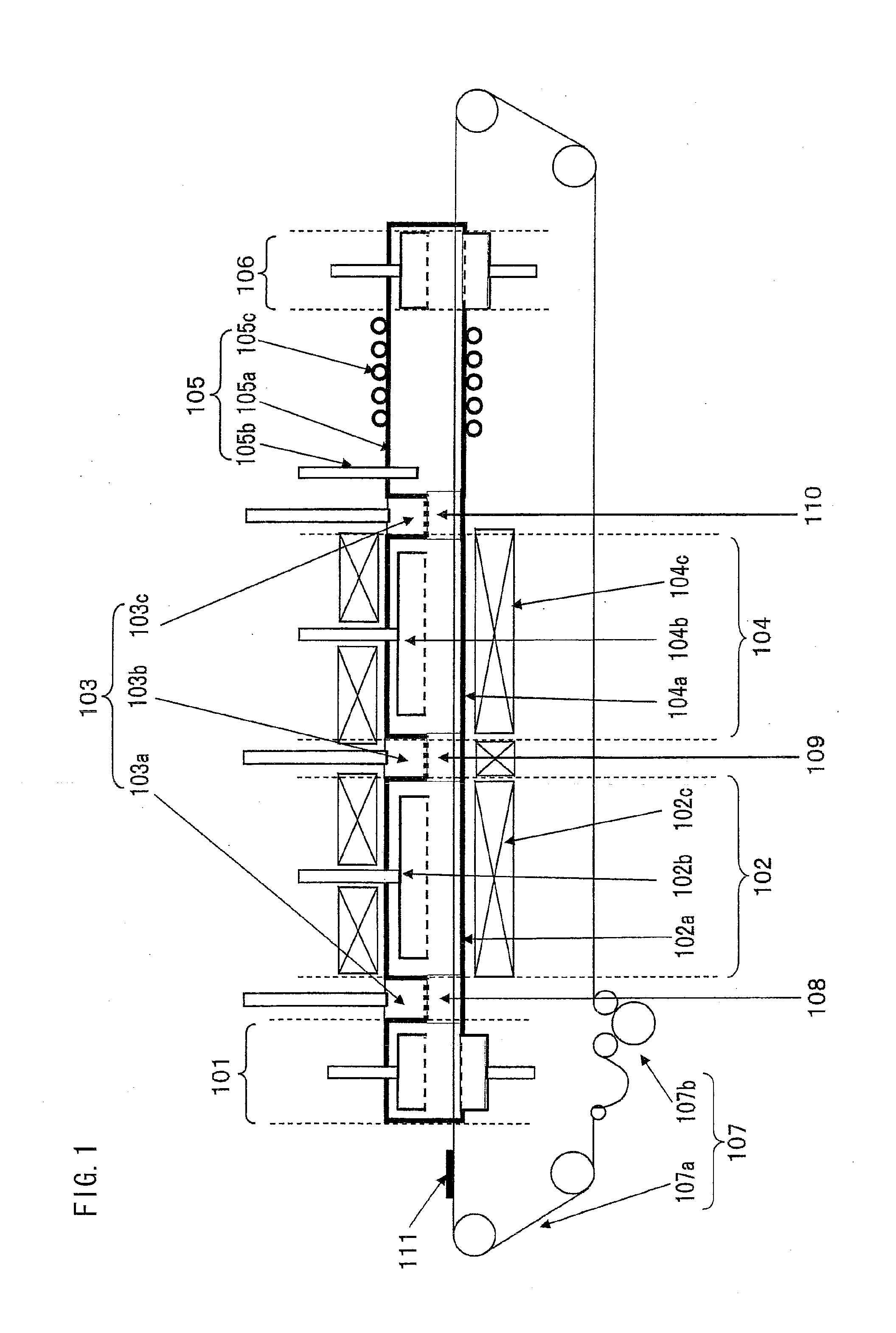

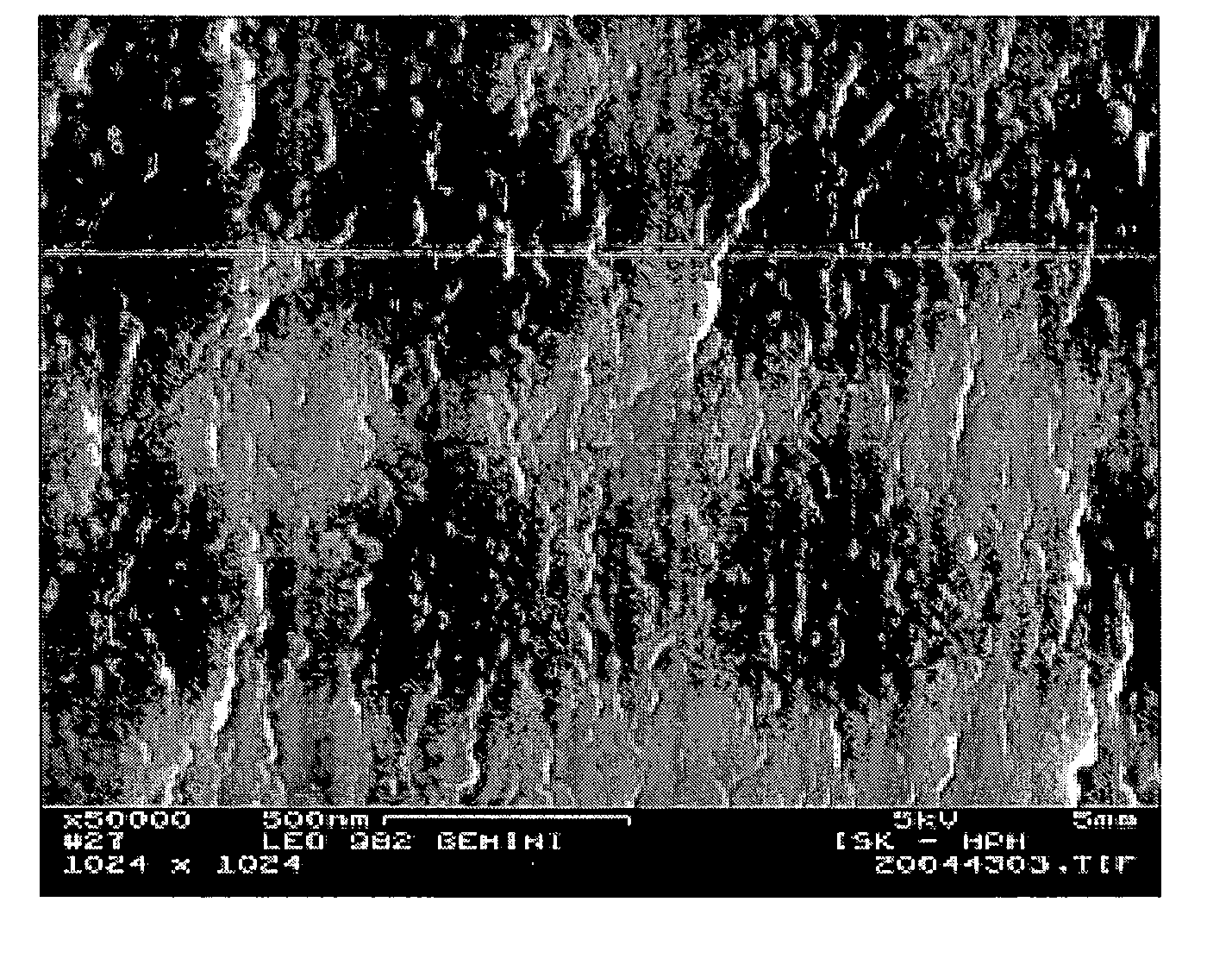

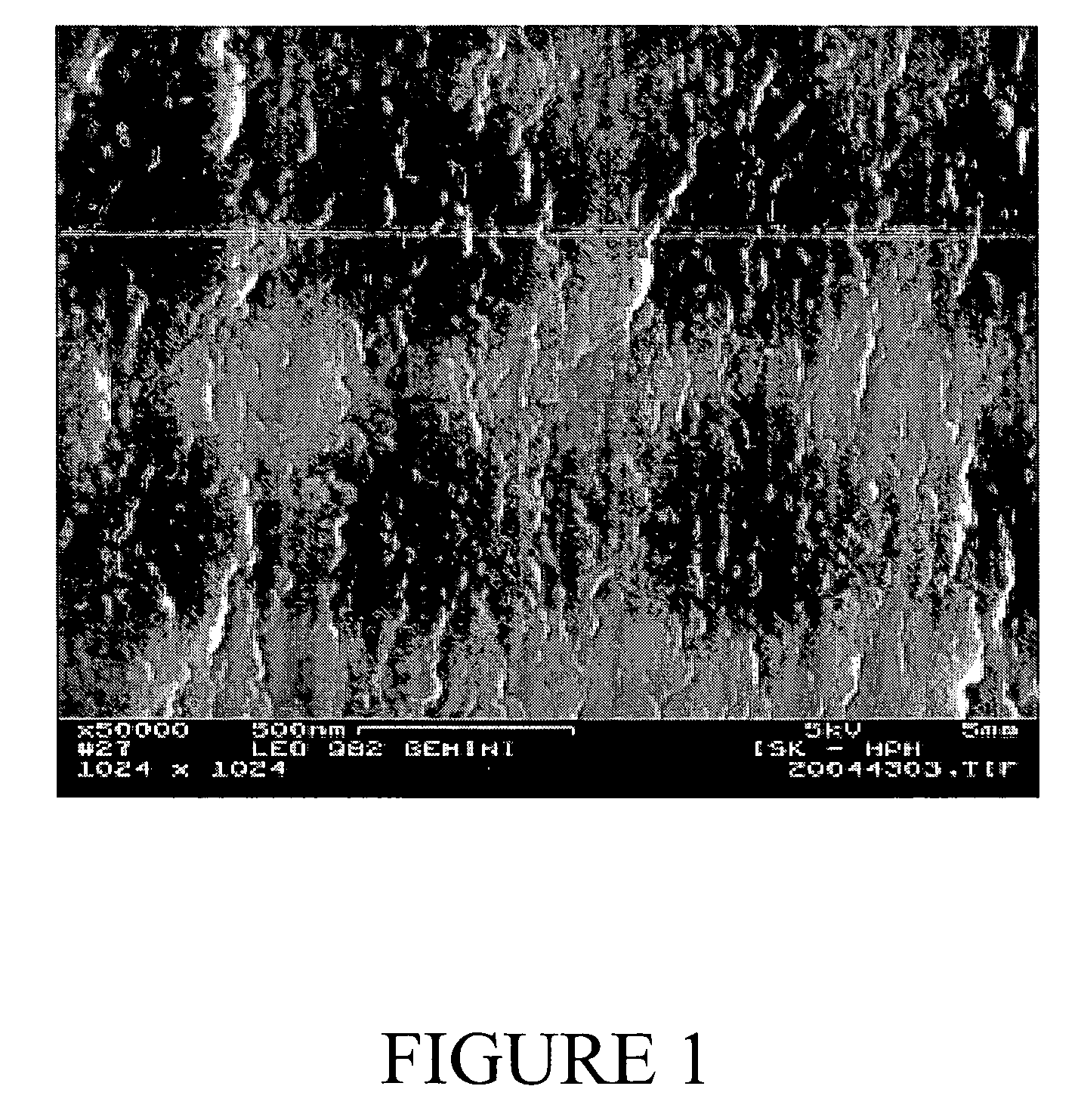

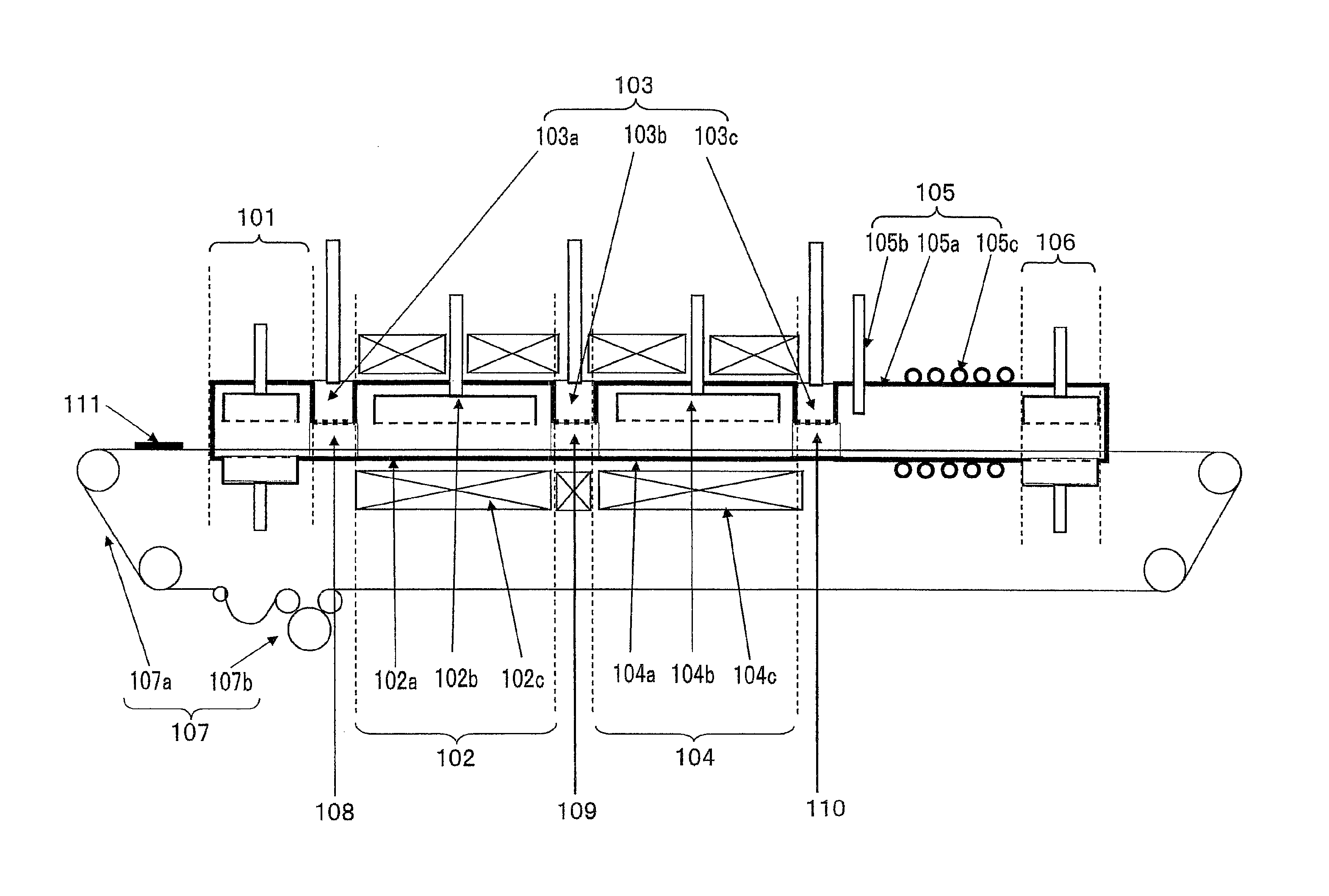

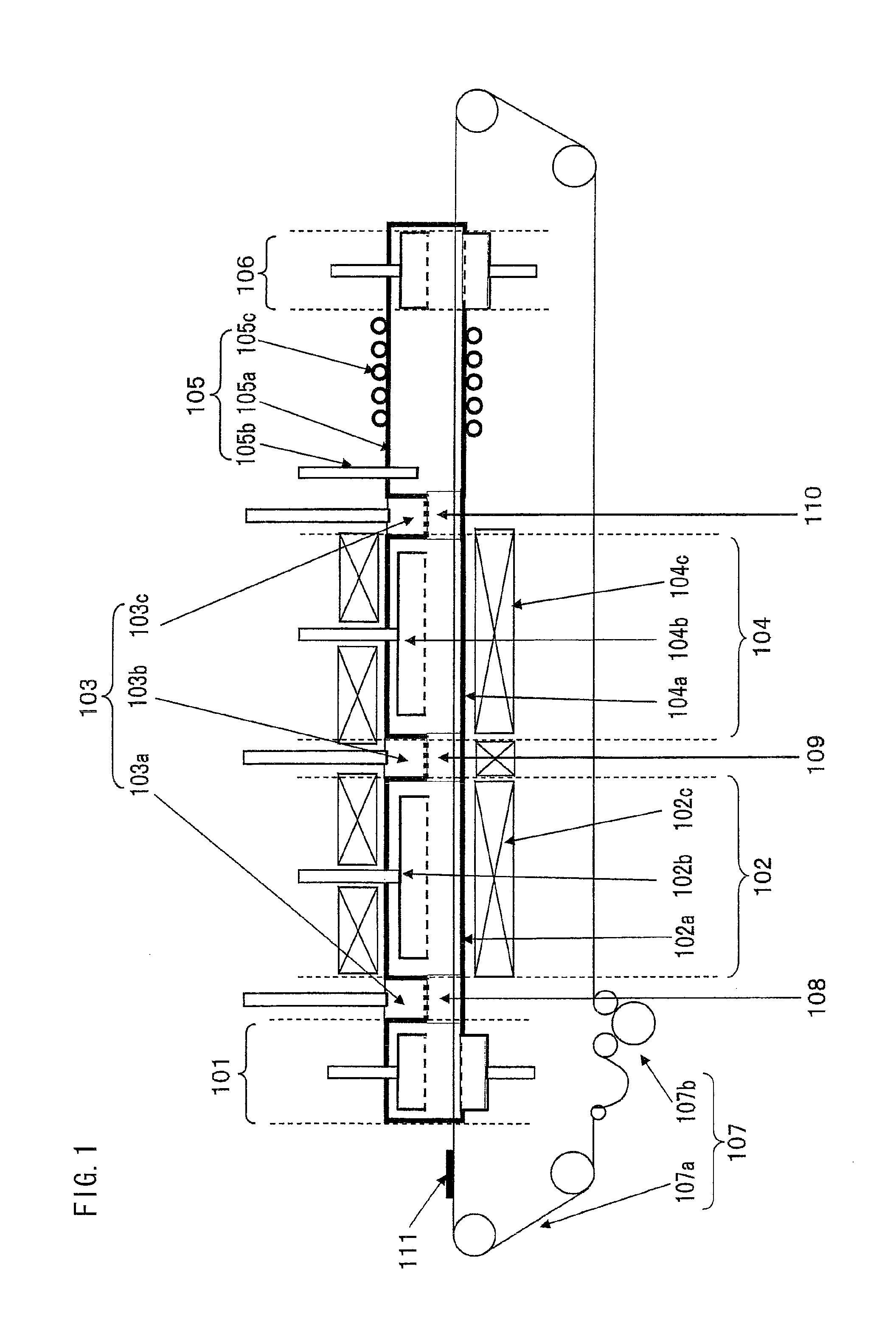

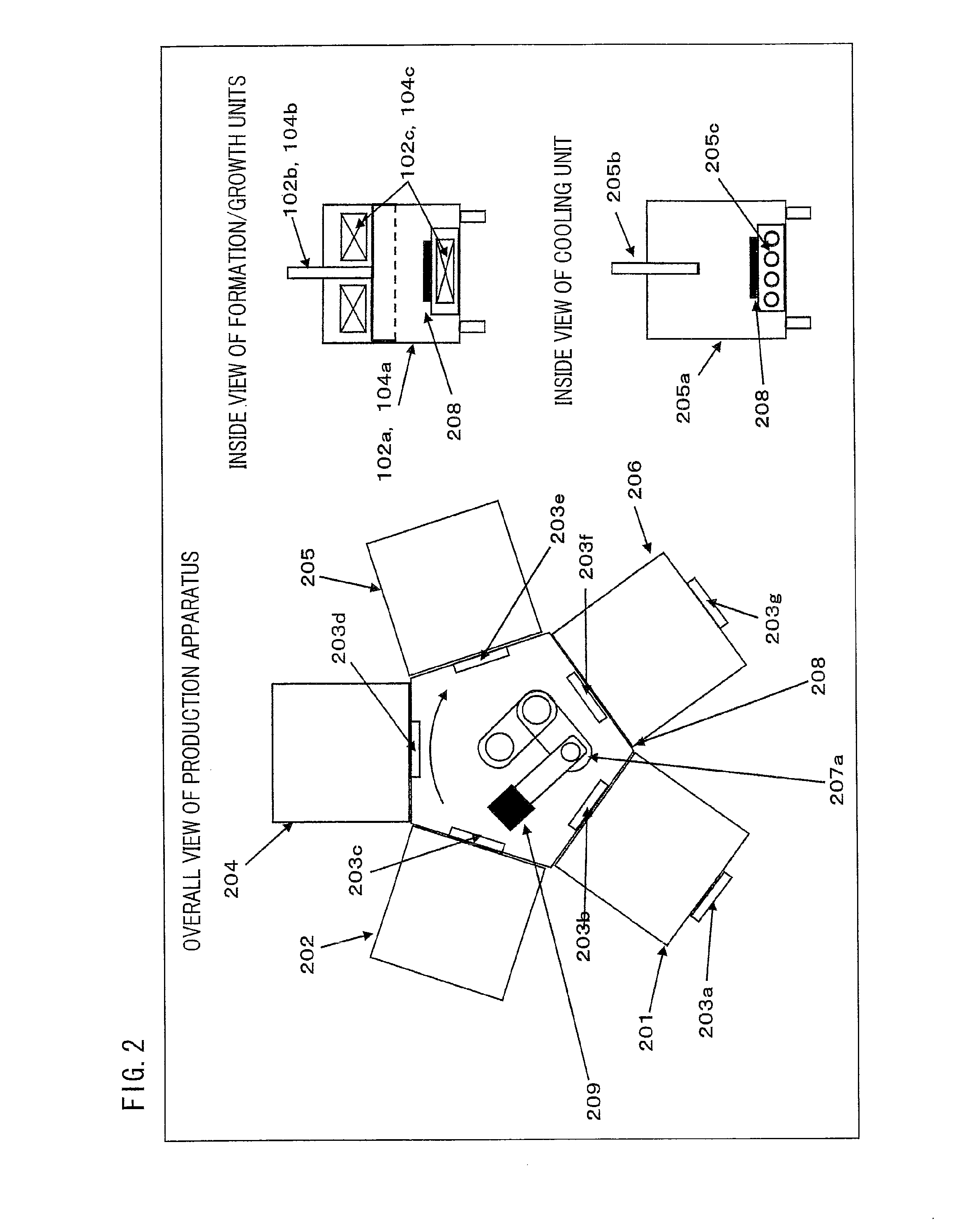

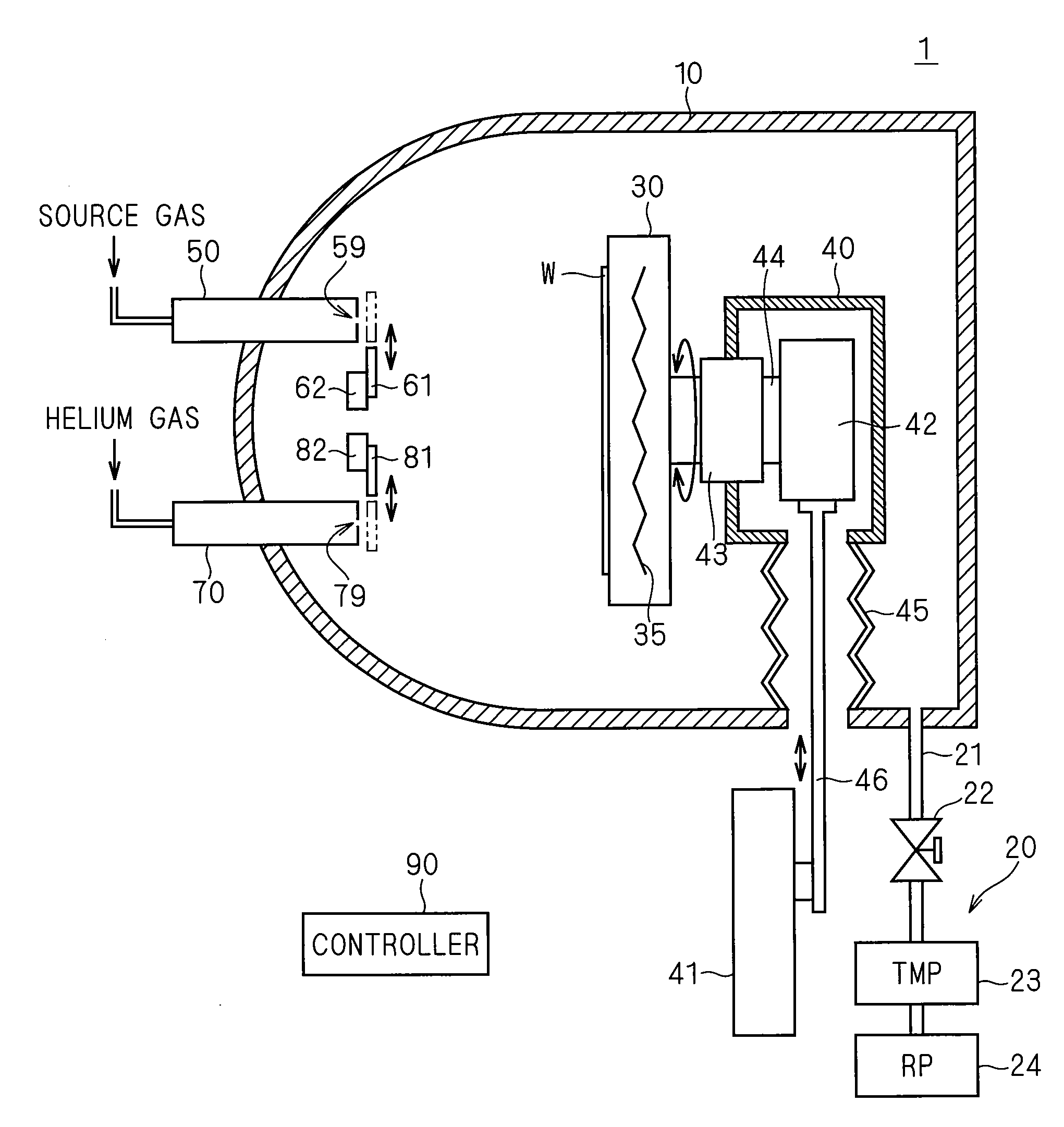

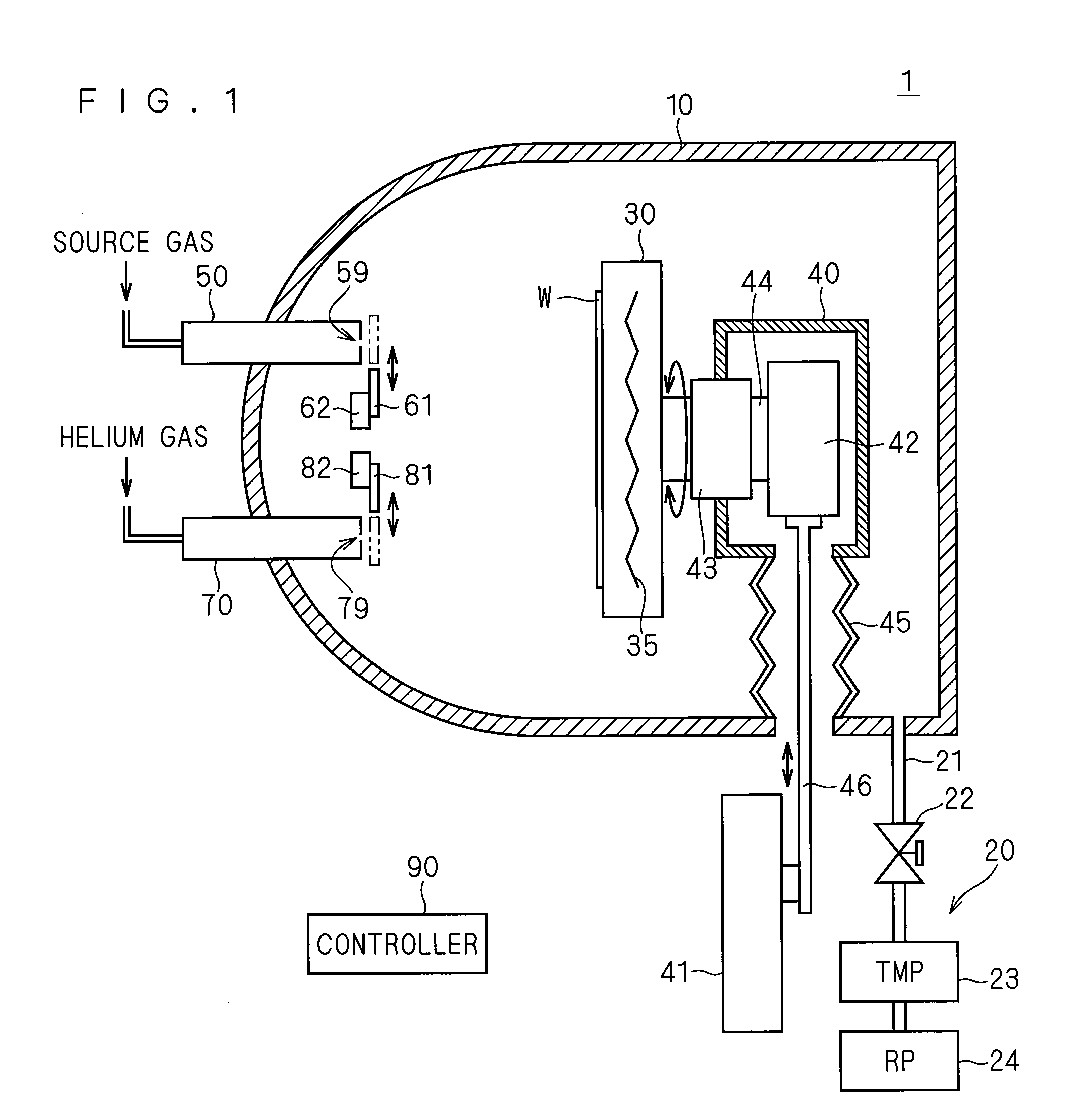

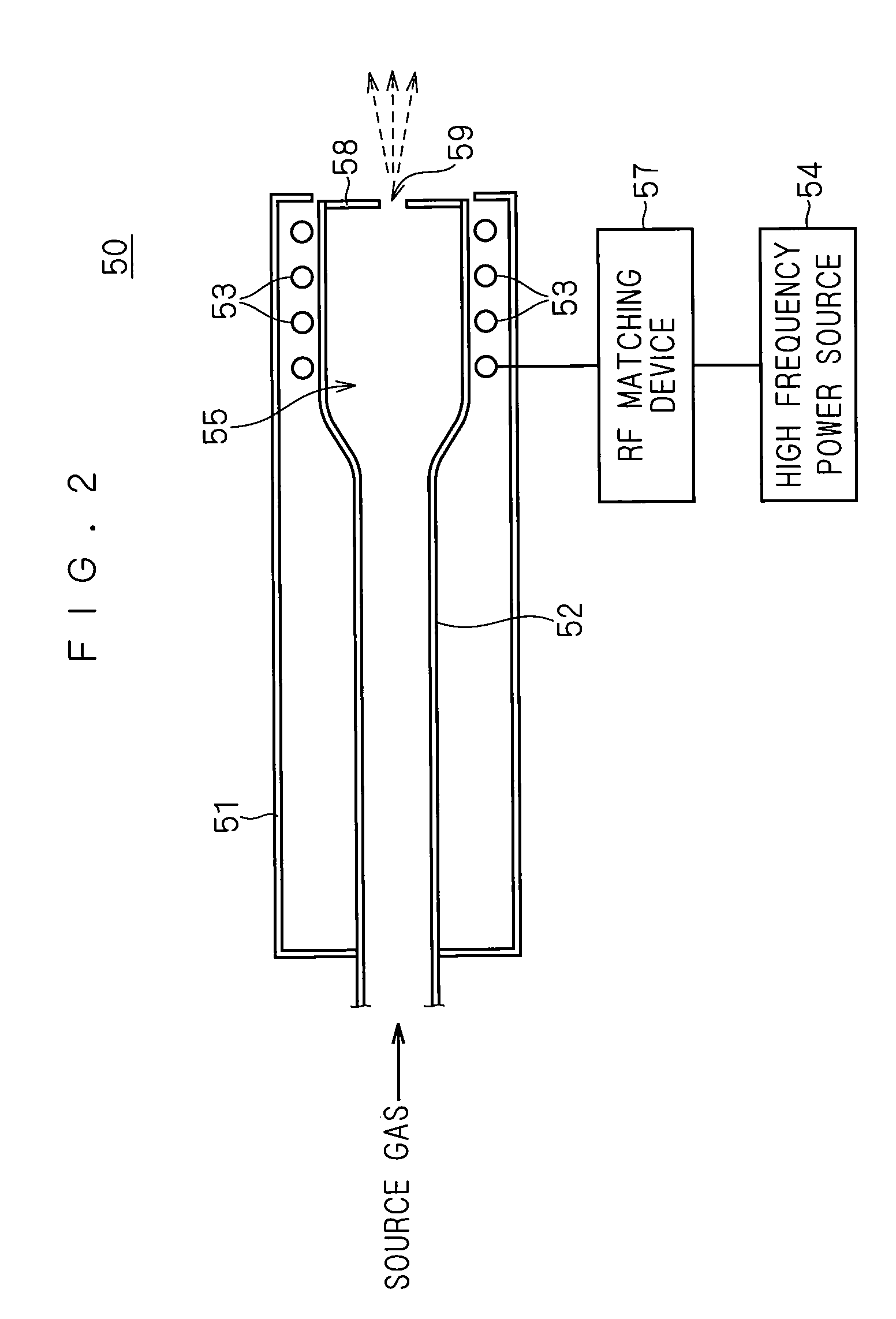

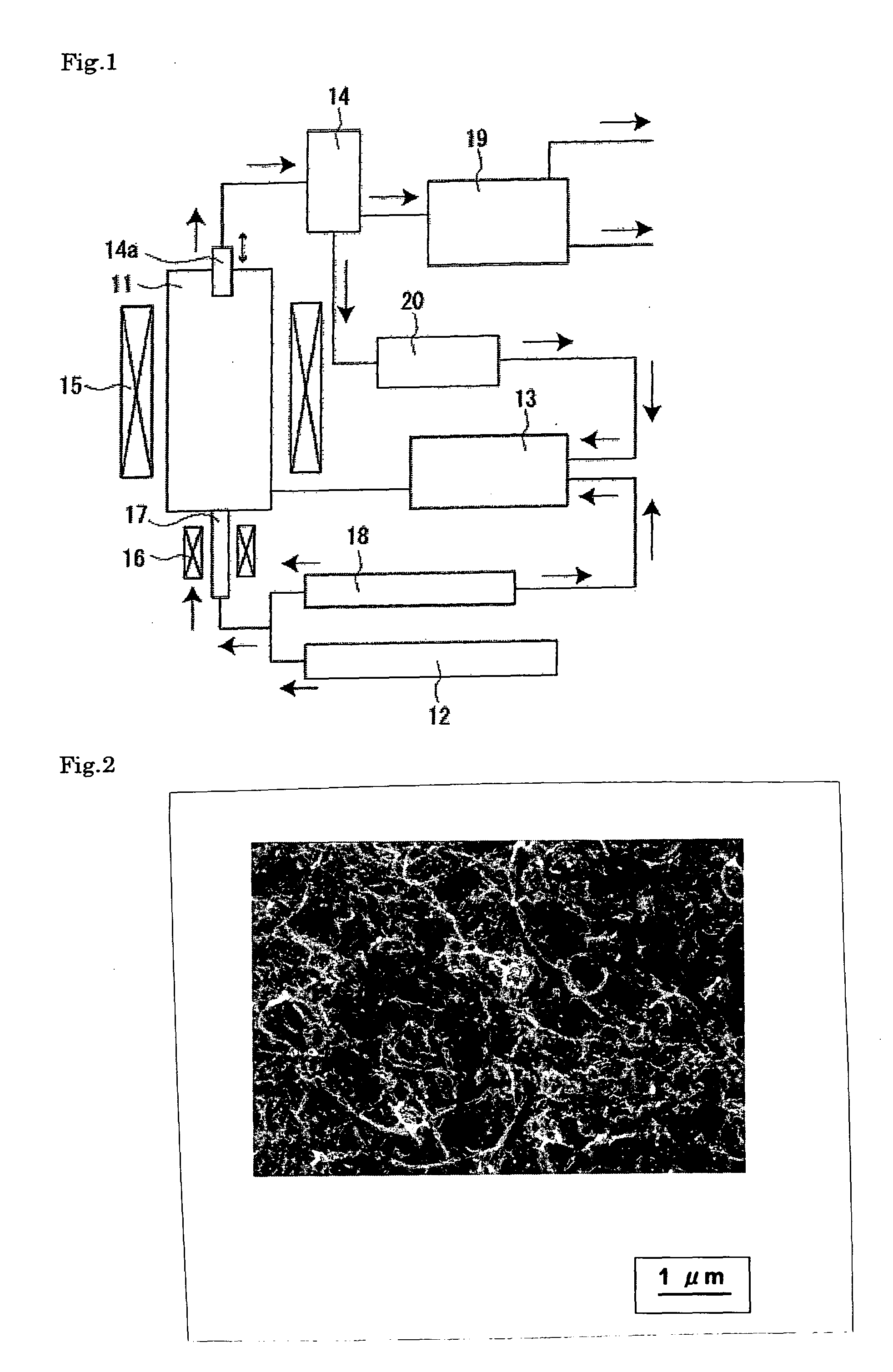

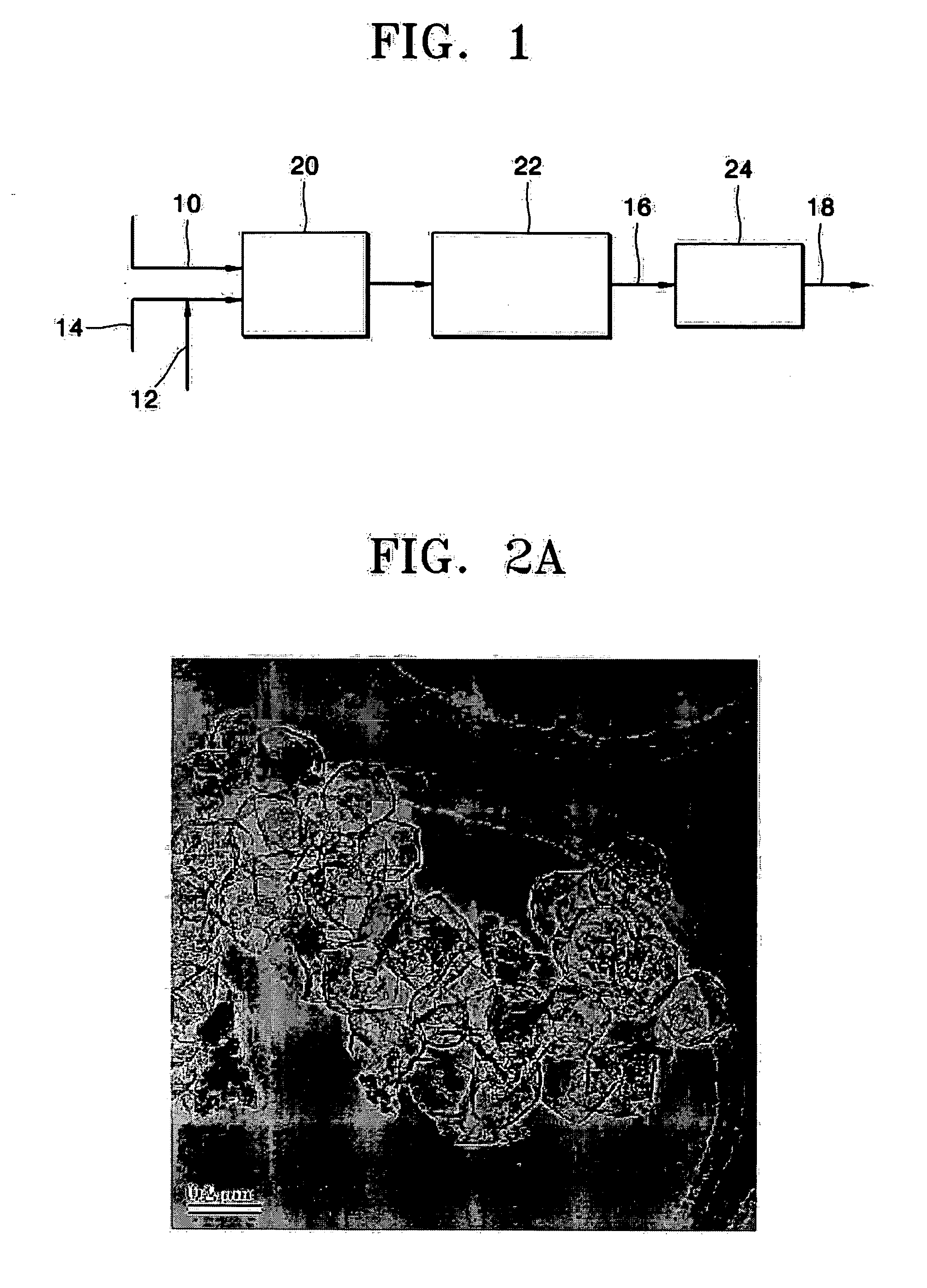

Apparatus and method for producing aligned carbon-nanotube aggregates

ActiveUS20100196600A1Deterioration in quality can be preventedAvoid stickingSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProduct gas

An apparatus of the present invention for producing an aligned carbon-nanotube aggregate is an apparatus for producing an aligned carbon-nanotube aggregate by synthesizing the aligned carbon-nanotube aggregate on a base material having a catalyst on a surface thereof, the apparatus including: a formation unit that processes a formation step of causing an environment surrounding the catalyst to be an environment of a reducing gas and heating at least either the catalyst or the reducing gas; a growth unit that processes a growth step of synthesizing the aligned carbon-nanotube aggregate by causing the environment surrounding the catalyst to be an environment of a raw material gas and by heating at least either the catalyst or the raw material gas; and a transfer unit that transfers the base material at least from the formation unit to the growth unit. Thus provided is a production apparatus and a production method that are capable of improving efficiency in the production of aligned CNT aggregates by preventing a decrease in production volume and deterioration in quality of aligned CNT aggregates in serial production and by making it easy to increase the size of the apparatus.

Owner:ZEON CORP +1

Control of carbon nanotube diameter using CVD or PECVD growth

The diameter of carbon nanotubes grown by chemical vapor deposition is controlled independent of the catalyst size by controlling the residence time of reactive gases in the reactor.

Owner:GLOBALFOUNDRIES US INC

Composite materials containing carbon nanoparticles

InactiveUS20060155376A1Adversely affecting the physical and chemical stabilityMaterial nanotechnologyPigmenting treatmentCarbon NanoparticlesOrganic polymer

The present invention relates to a process of producing composite materials by a sol / gel-process, comprising carbon nanoparticles and organic polymer material. The invention further relates to composite materials, which are manufactured with the use of said sol / gel technology.

Owner:CINVENTION AG

Apparatus and method for producing aligned carbon-nanotube aggregates

ActiveUS7897209B2Deterioration in quality can be preventedAvoid stickingSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProcess engineering

An apparatus of the present invention for producing an aligned carbon-nanotube aggregate is an apparatus for producing an aligned carbon-nanotube aggregate by synthesizing the aligned carbon-nanotube aggregate on a base material having a catalyst on a surface thereof, the apparatus including: a formation unit that processes a formation step of causing an environment surrounding the catalyst to be an environment of a reducing gas and heating at least either the catalyst or the reducing gas; a growth unit that processes a growth step of synthesizing the aligned carbon-nanotube aggregate by causing the environment surrounding the catalyst to be an environment of a raw material gas and by heating at least either the catalyst or the raw material gas; and a transfer unit that transfers the base material at least from the formation unit to the growth unit. Thus provided is a production apparatus and a production method that are capable of improving efficiency in the production of aligned CNT aggregates by preventing a decrease in production volume and deterioration in quality of aligned CNT aggregates in serial production and by making it easy to increase the size of the apparatus.

Owner:ZEON CORP +1

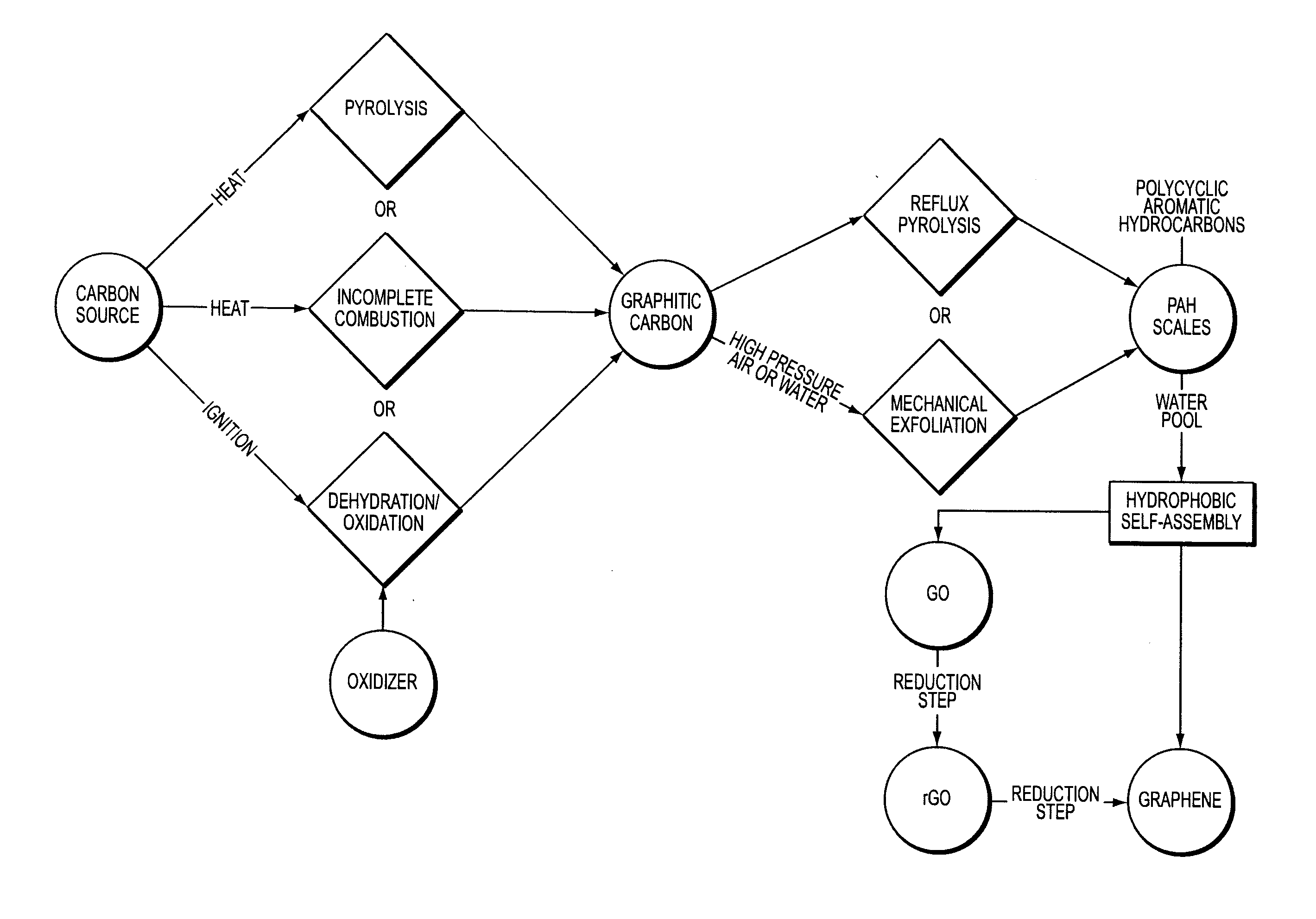

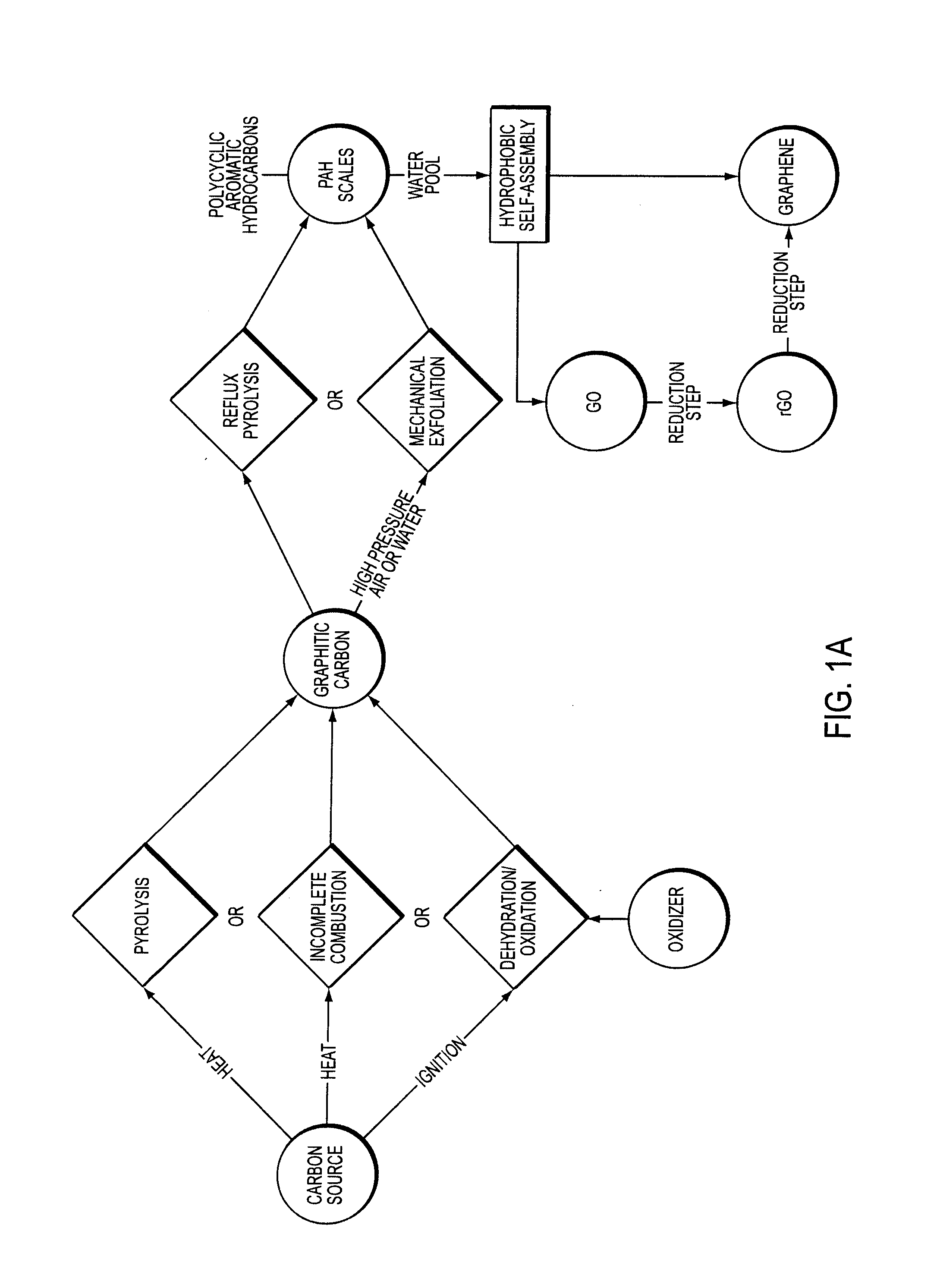

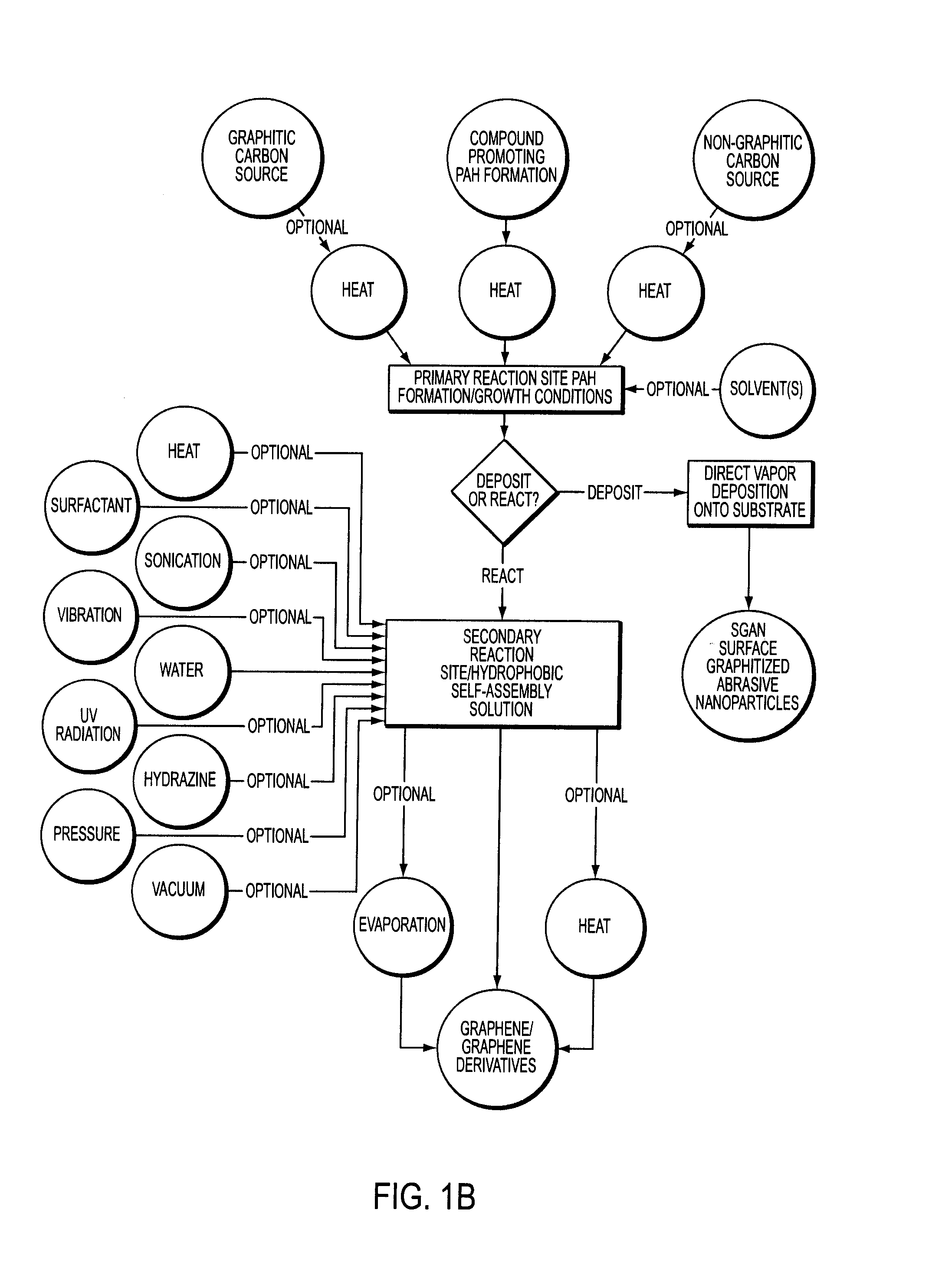

Facile synthesis of graphene, graphene derivatives and abrasive nanoparticles and their various uses, including as tribologically-beneficial lubricant additives

ActiveUS20140134092A1Reduce frictionImprove smoothnessMaterial nanotechnologyCosmetic preparationsNanoparticleGraphene derivatives

Owner:PEERLESS WORLDWIDE

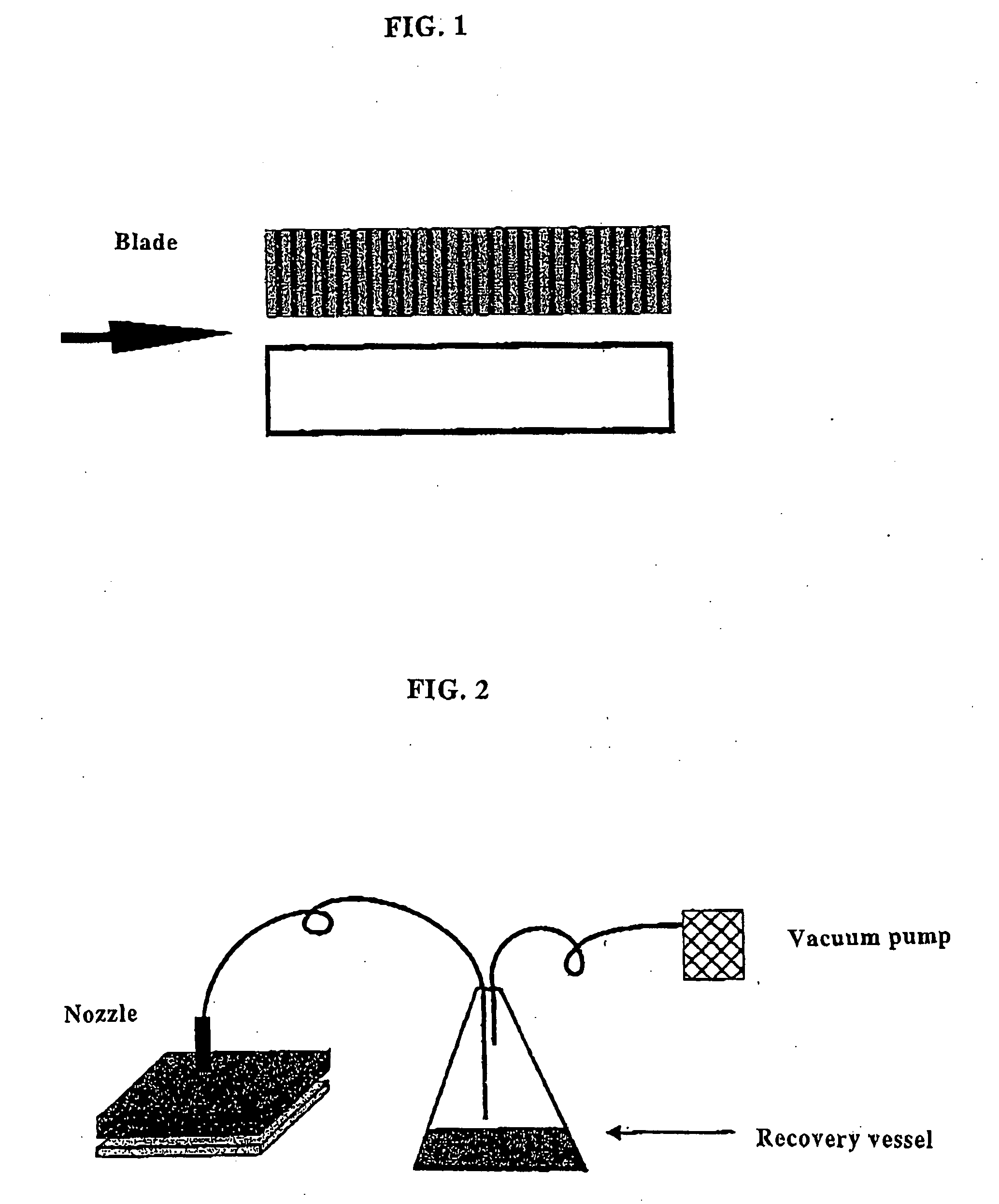

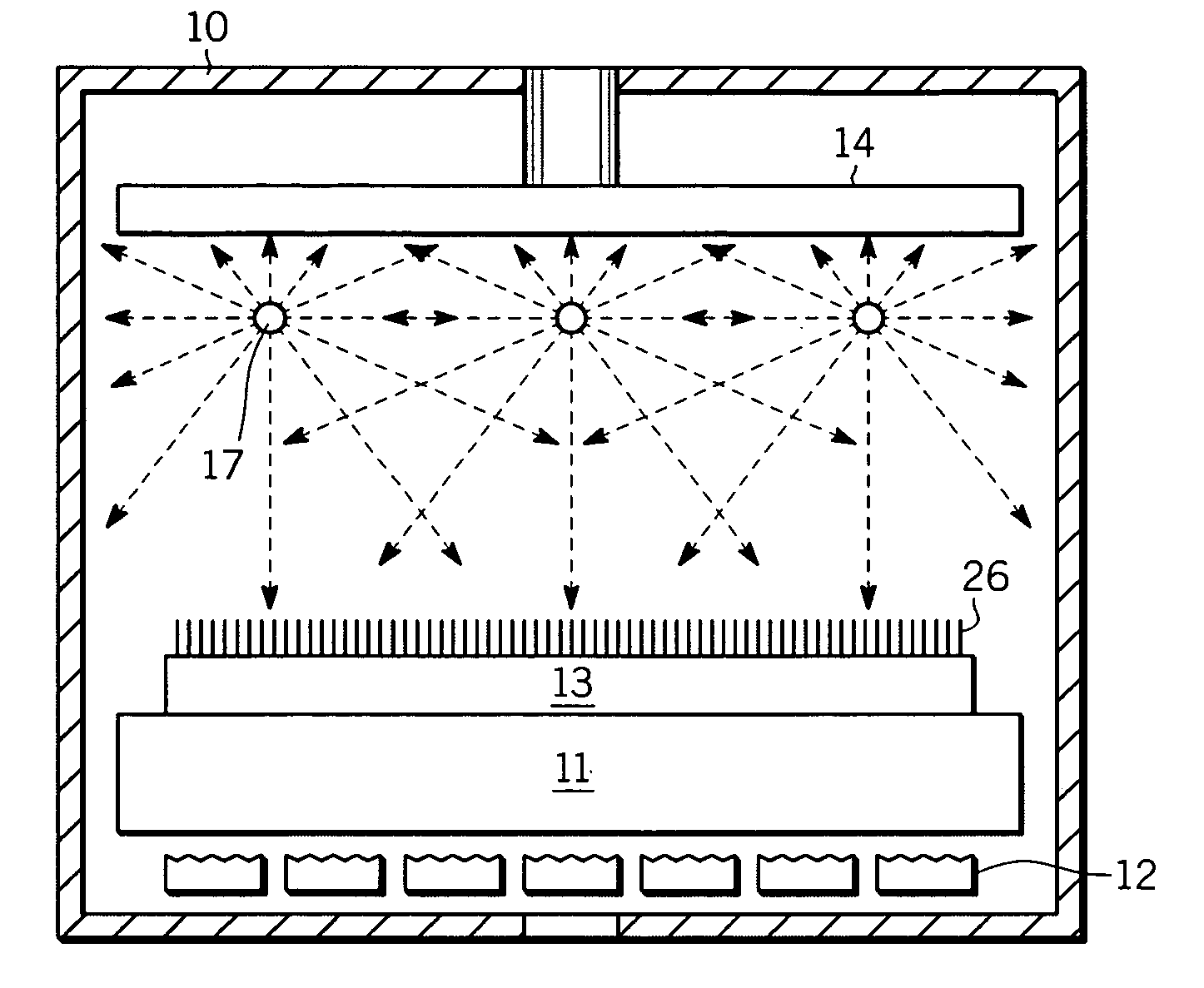

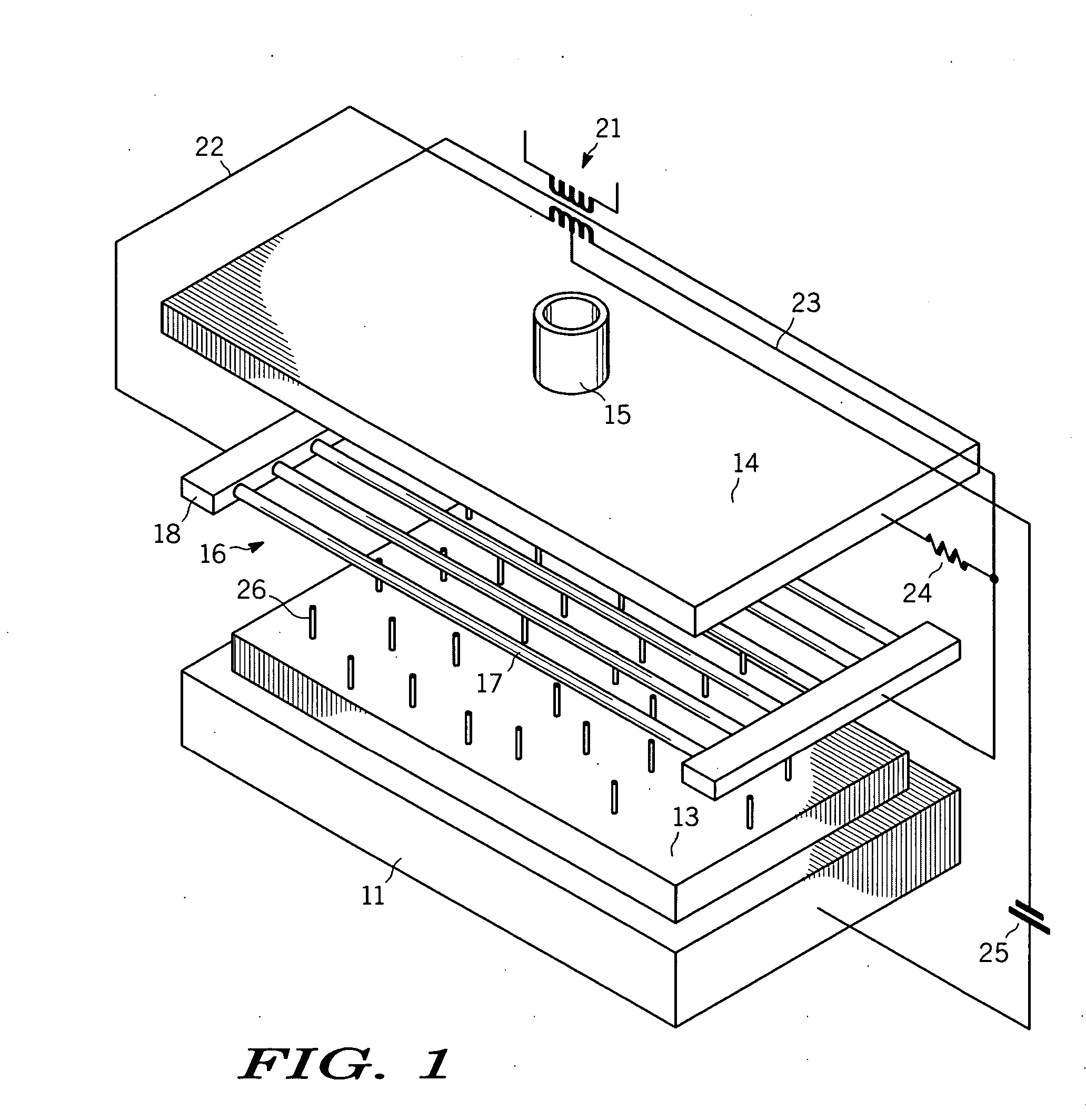

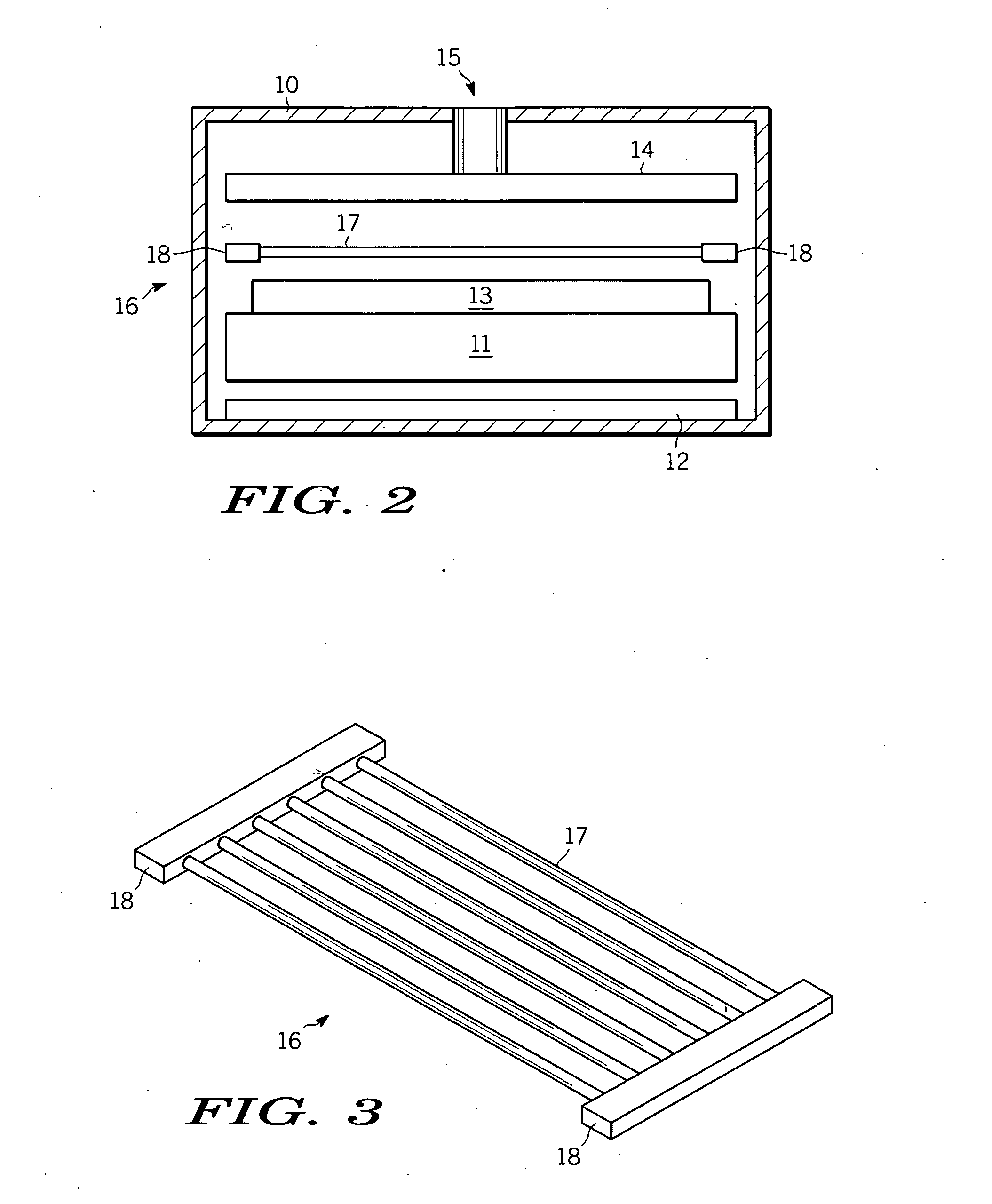

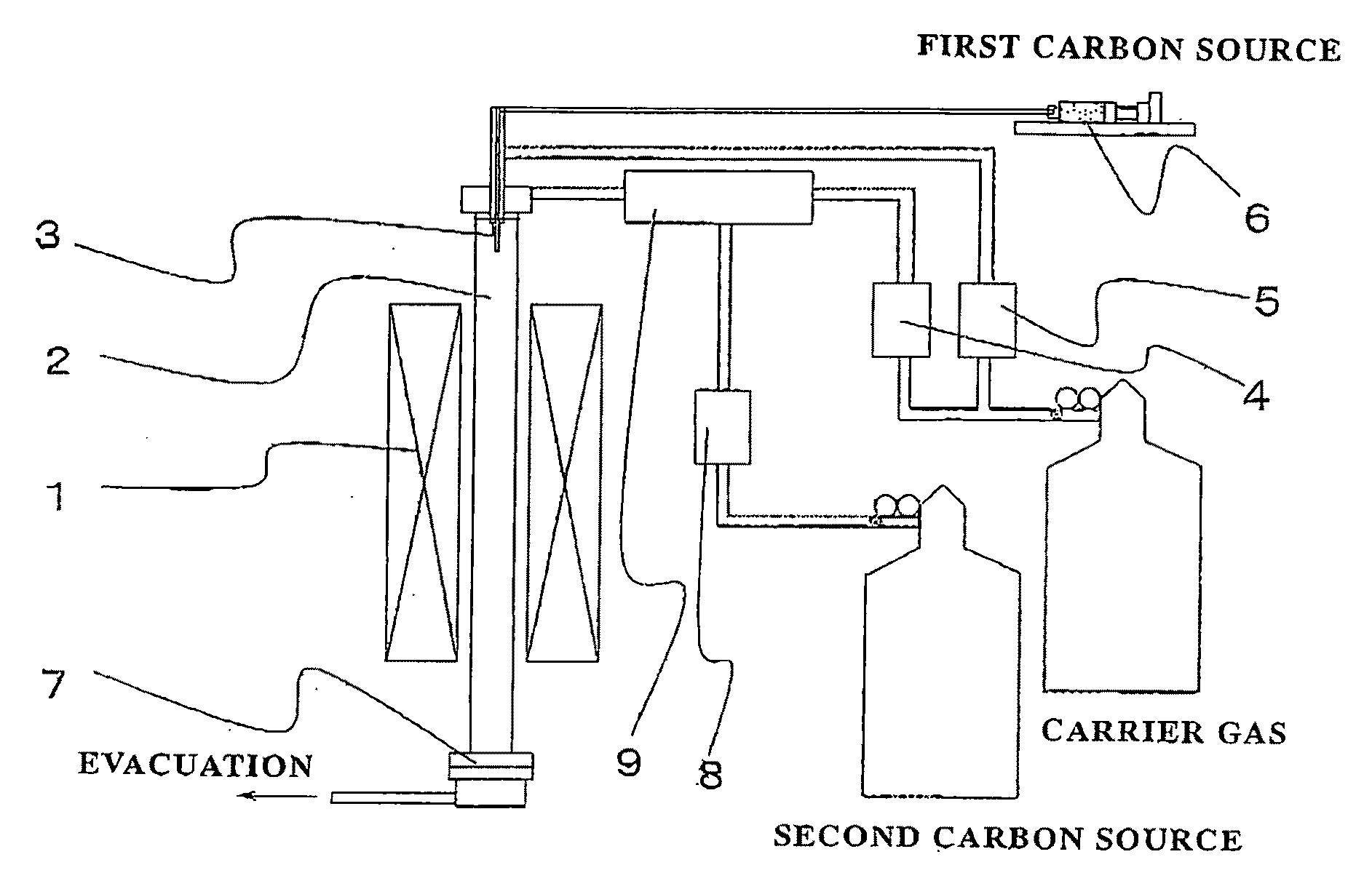

Apparatus and process for carbon nanotube growth

InactiveUS20060185595A1Improve rendering capabilitiesIncreased processing flexibilityMaterial nanotechnologySpecific nanostructure formationCarbon nanotubeAspect ratio

An apparatus is provided for growing high aspect ratio emitters (26) on a substrate (13). The apparatus comprises a housing (10) defining a chamber and includes a substrate holder (12) attached to the housing and positioned within the chamber for holding a substrate having a surface for growing the high aspect ratio emitters (26) thereon. A heating element (17) is positioned near the substrate and being at least one material selected from the group consisting of carbon, conductive cermets, and conductive ceramics. The housing defines an opening (15) into the chamber for receiving a gas into the chamber for forming the high aspect ratio emitters (26).

Owner:MOTOROLA INC

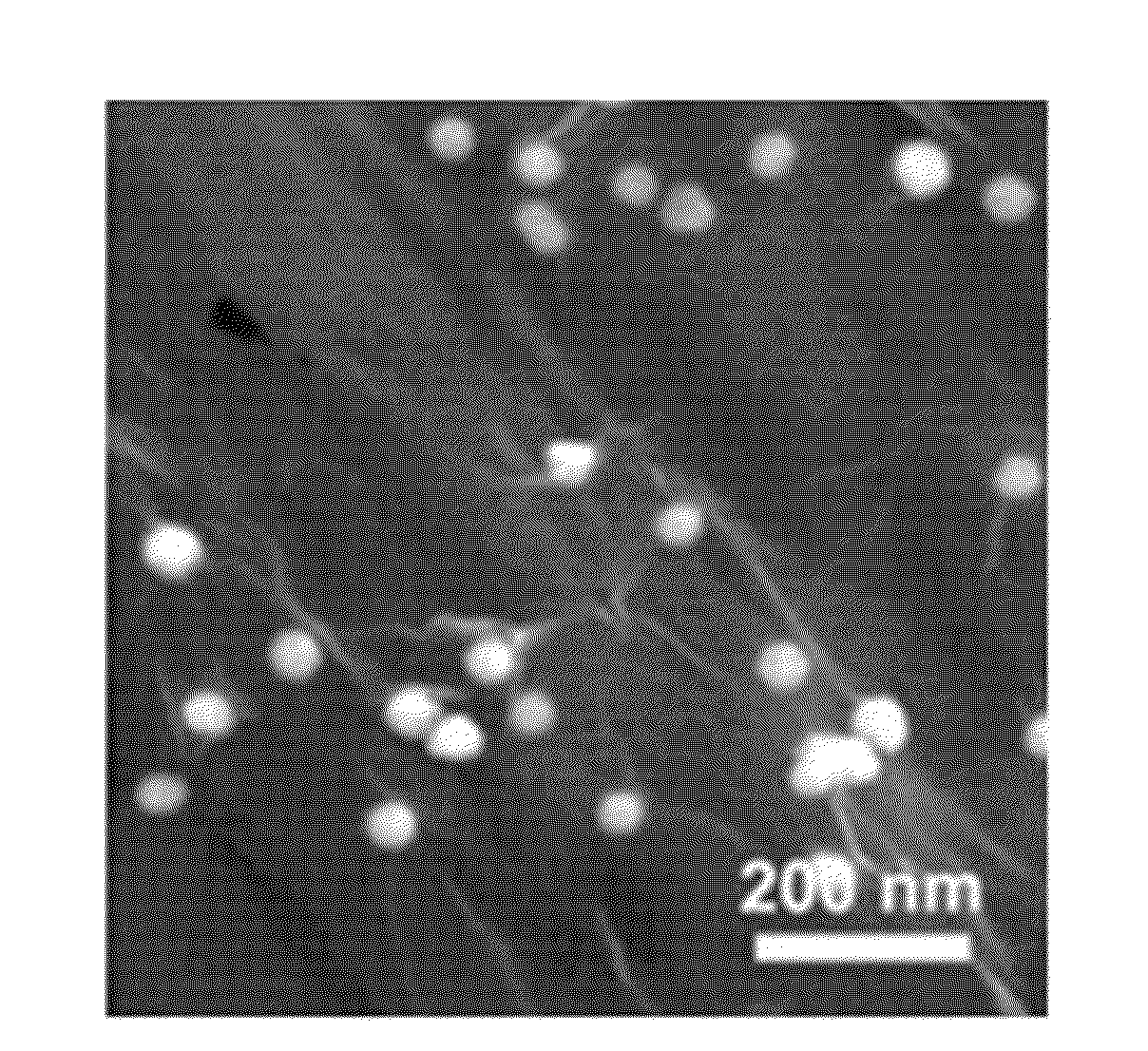

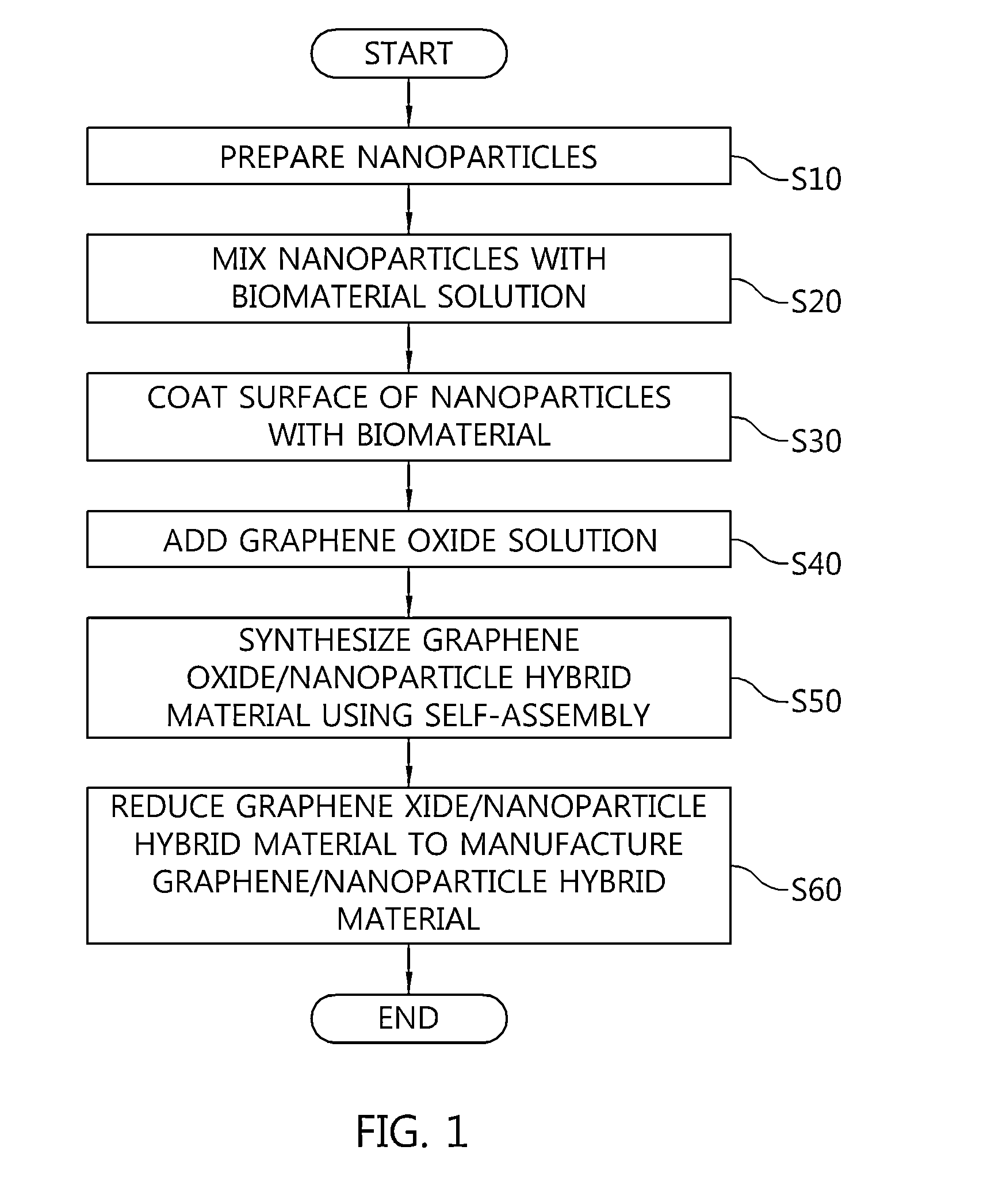

Method of manufacturing graphene hybrid material and graphene hybrid material manufactured by the method

InactiveUS20140346408A1Easily and rapidly and eco-friendly manufacturedUse minimizedNon-metal conductorsSpecific nanostructure formationNanoparticleHybrid material

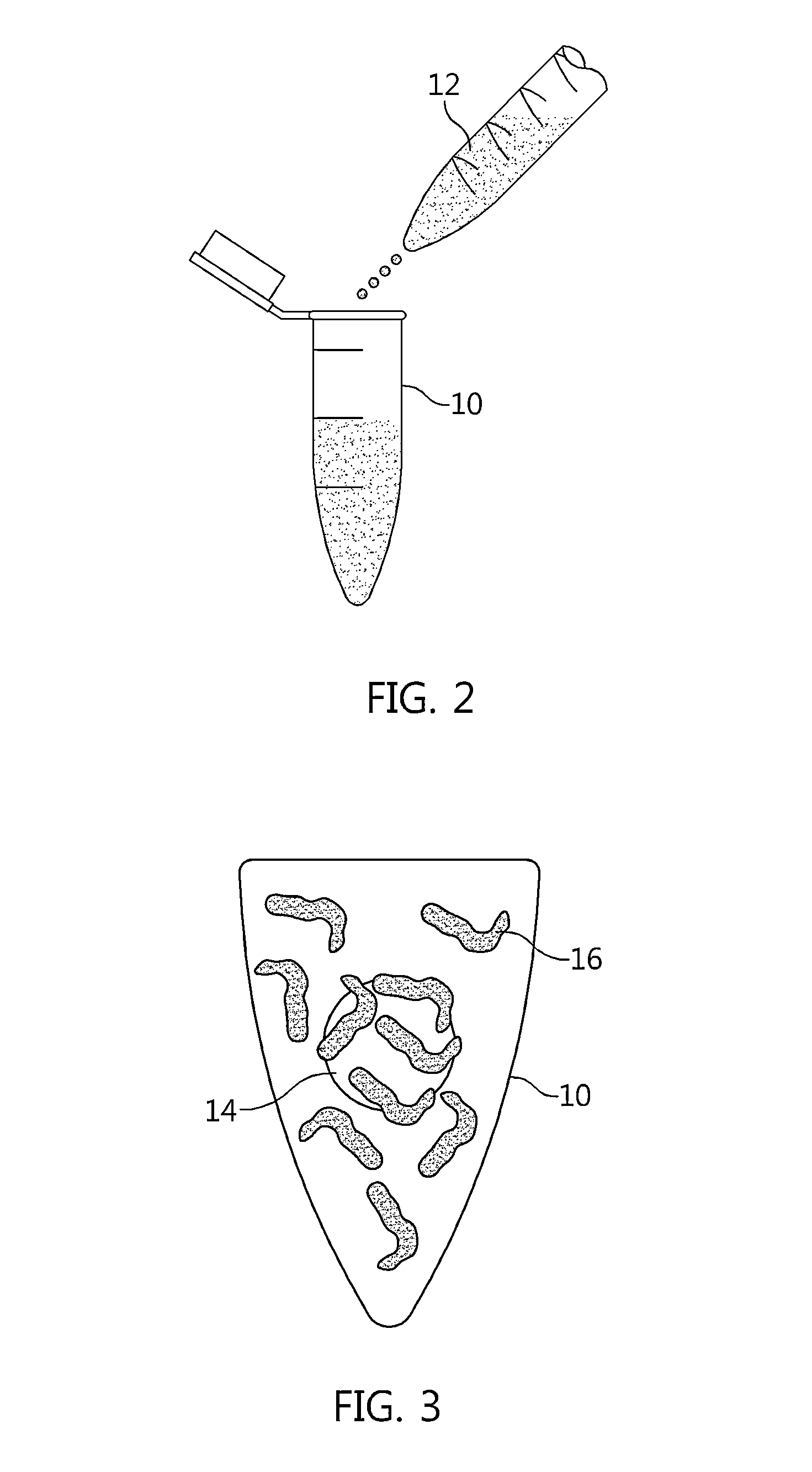

This invention relates to a method of manufacturing a graphene or graphene oxide / nanoparticle hybrid material and a graphene / nanoparticle hybrid material manufactured thereby, wherein the hybrid material can be easily, rapidly and eco-friendly synthesized while minimizing the use of chemicals and thermal treatment because of electrostatic self-assembly properties of a biomaterial. This method includes preparing nanoparticles, a biomaterial solution and a graphene oxide solution, mixing the nanoparticles with the biomaterial solution to form biomaterial-coated nanoparticles, mixing the biomaterial-coated nanoparticles with the graphene oxide solution to obtain a graphene oxide / nanoparticle hybrid material, and reducing the graphene oxide / nanoparticle hybrid material to obtain a graphene / nanoparticle hybrid material.

Owner:ELECTRONICS & TELECOMM RES INST

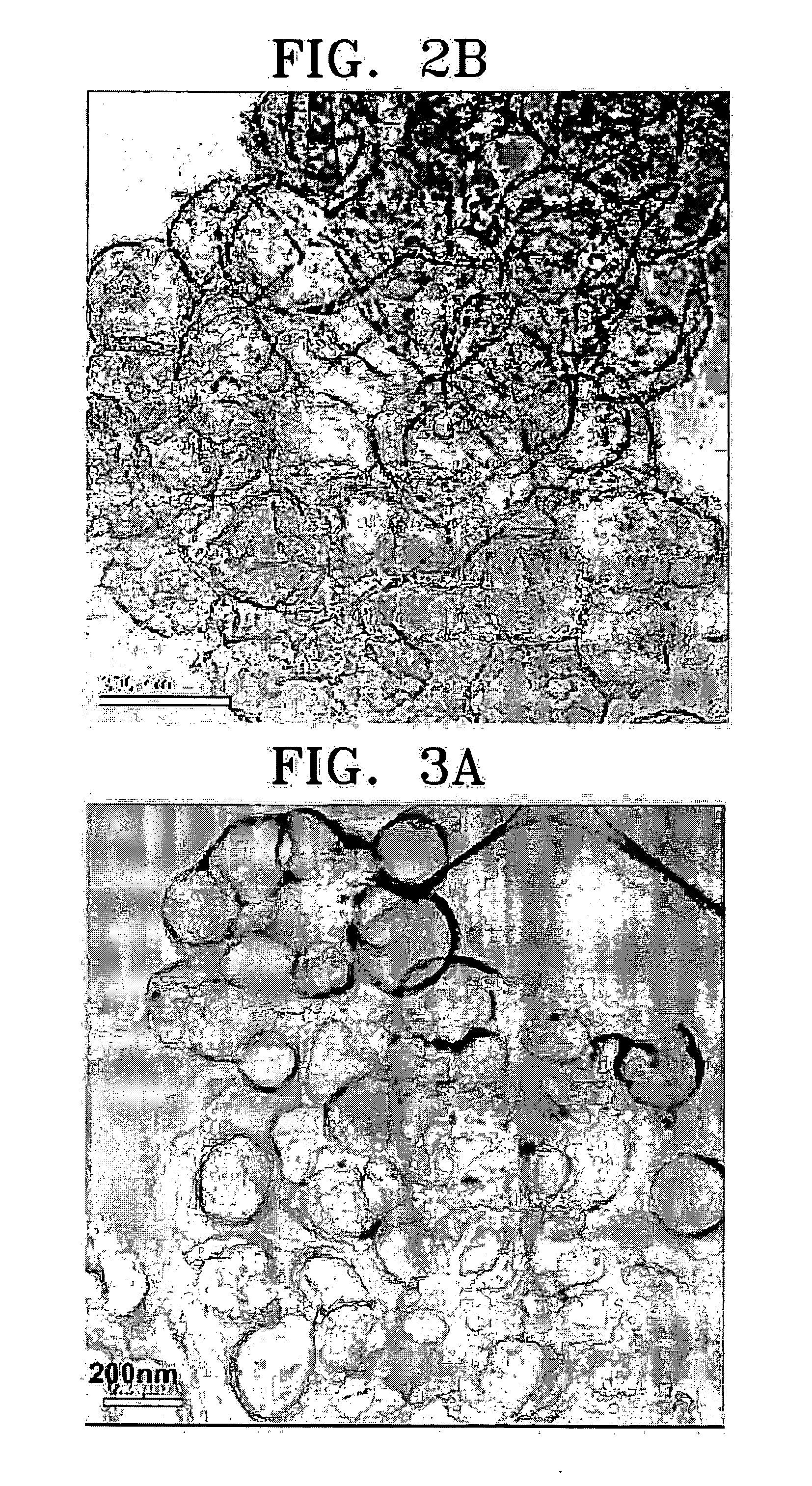

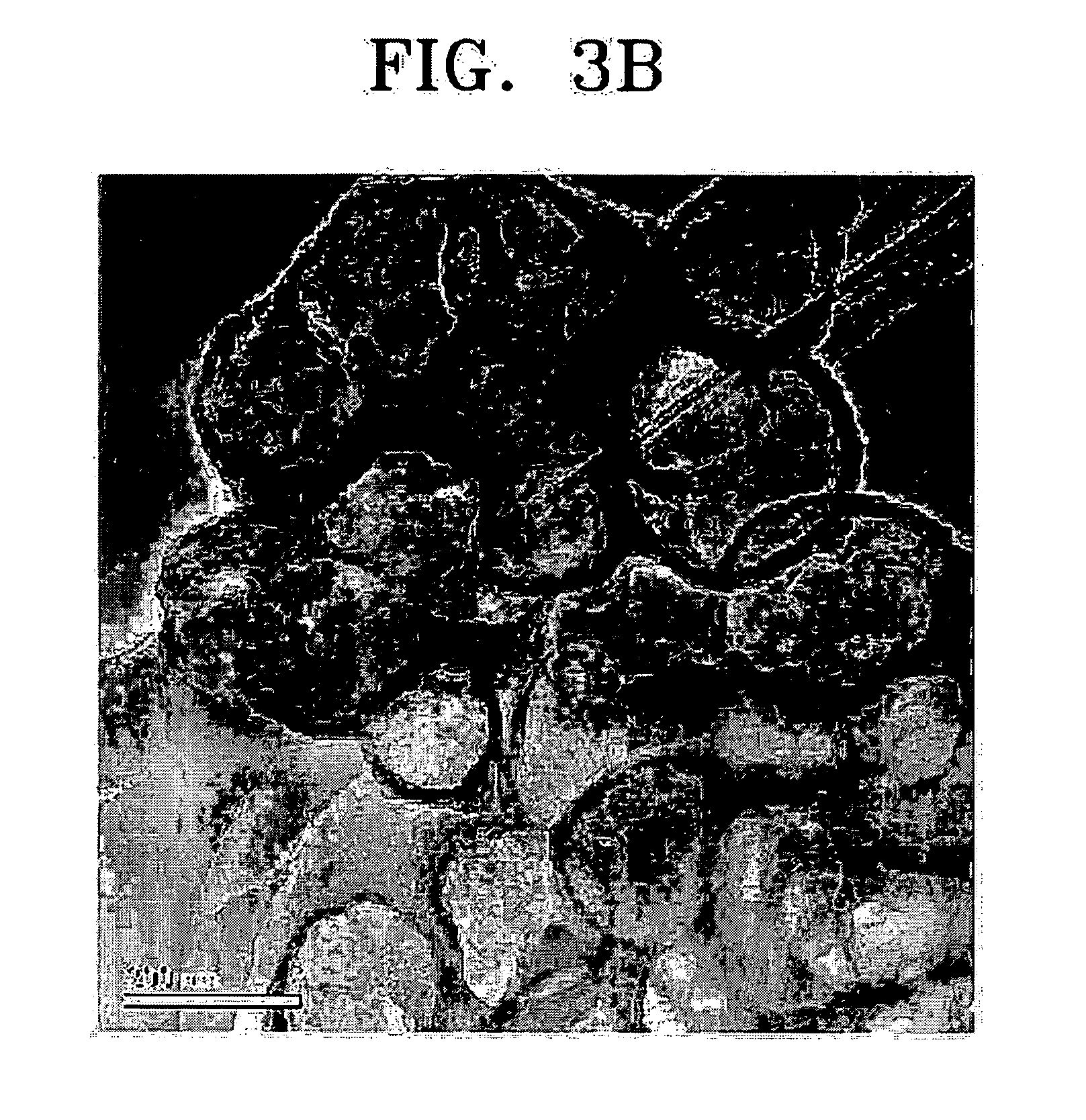

Carbon nanotubes, method of growing the same, hybrid structure and method of growing the hybrid structure, and light emitting device

InactiveUS20090121219A1Promote growthMaterial nanotechnologyRadiation applicationsCarbon nanotubeLight-emitting diode

Owner:SAMSUNG SDI CO LTD

Apparatus for and method of forming carbon nanotube

InactiveUS20090214800A1Quality improvementImprove throughputSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeHigh pressure

A vacuum chamber includes a radical beam irradiation part and a nanoparticle beam irradiation part. A substrate is held by a substrate holding part. The nanoparticle beam irradiation part irradiates the substrate with a beam of metal nanoparticles serving as a catalyst to form the catalyst on the substrate. Thereafter, the radical beam irradiation part generates a plasma from a source gas to irradiate the substrate with a beam of generated neutral radical species to grow a carbon nanotube on the substrate. The provision of an aperture in the radical beam irradiation part allows a relatively high degree of vacuum of 10−5 Torr to 10−3 Torr to be maintained in the vacuum chamber if the generation of the plasma involves a high pressure.

Owner:DAINIPPON SCREEN MTG CO LTD

Process for producing carbon nanomaterial and system for producing carbon nanomaterial

InactiveUS20110158892A1High purityImprove efficiencyMaterial nanotechnologySpecific nanostructure formationFluidized bedMaterials science

A process for producing a carbon nanomaterial, including fluidizing a carbon raw material, a catalyst and a fluidizing material in a fluidized bed reactor to produce the carbon nanomaterial, wherein the fluidizing material is a carbon material. A carbon nanomaterial production system for producing a carbon nanomaterial including a fluidized bed reactor for fluidizing a car-bon raw material, a catalyst and a fluidizing material to carry out the reaction thereof, a carbon raw material feeding device for feeding the carbon raw material to the fluidized bed reactor, a catalyst feeding device for feeding the catalyst to the fluidized bed reactor, and a recovering device for recovering the produced carbon nanomaterial from the fluidized bed reactor, wherein a part of the recovered carbon nanomaterial is transferred to the catalyst feeding device and used as the fluidizing material.

Owner:SHOWA DENKO KK

Method for preparing graphene ribbons where structure is controlled

InactiveUS20110097258A1Good physical propertiesSimple waySpecific nanostructure formationMaterial nanotechnologyCvd grapheneMaterials science

Disclosed is a method for fabricating graphene ribbons which are high-functional carbon materials. Provided a method of fabricating graphene ribbons, including (a) preparing a carbon structure in which a graphene ribbon is spirally grown (a graphene helix), revealing a tube shape, and (b) applying energy to unroll the graphene helix into the graphene ribbons.

Owner:KOREA INST OF SCI & TECH

Carbon nanosphere with at least one opening, method for preparing the same, carbon nanosphere-impregnated catalyst using the carbon nanosphere, and fuel cell using the catalyst

InactiveUS20060239890A1Improve area utilizationReduce mass transfer resistanceMaterial nanotechnologySpecific nanostructure formationHigh current densityFuel cells

A carbon nanosphere has at least one opening. The carbon nanosphere is obtained by preparing a carbon nanosphere and treating it with an acid to form the opening. The carbon nanosphere with at least one opening has higher utilization of a surface area and electrical conductivity and lower mass transfer resistance than a conventional carbon nanotube, thus allowing for higher current density and cell voltage with a smaller amount of metal catalyst per unit area of a fuel cell electrode.

Owner:SAMSUNG SDI CO LTD

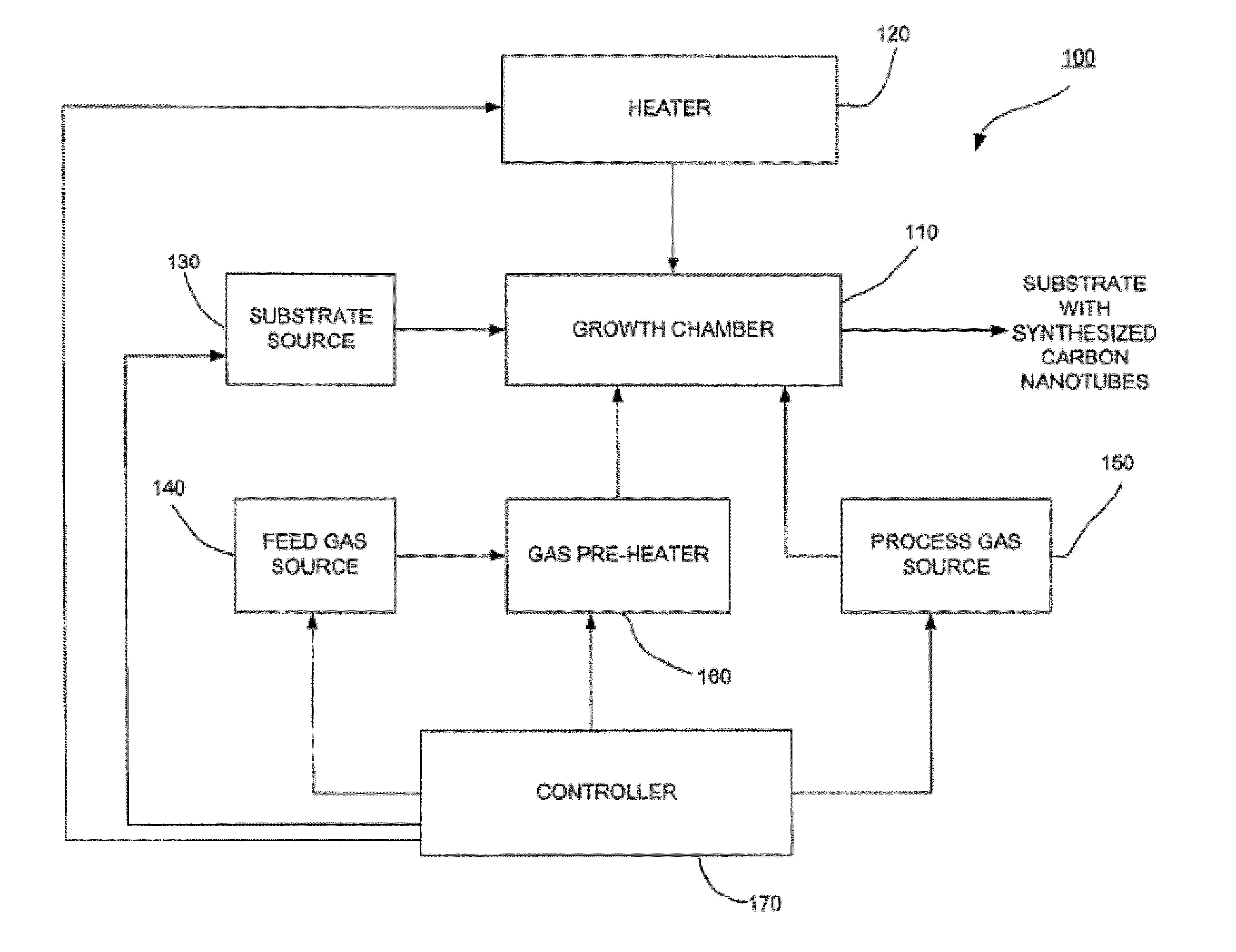

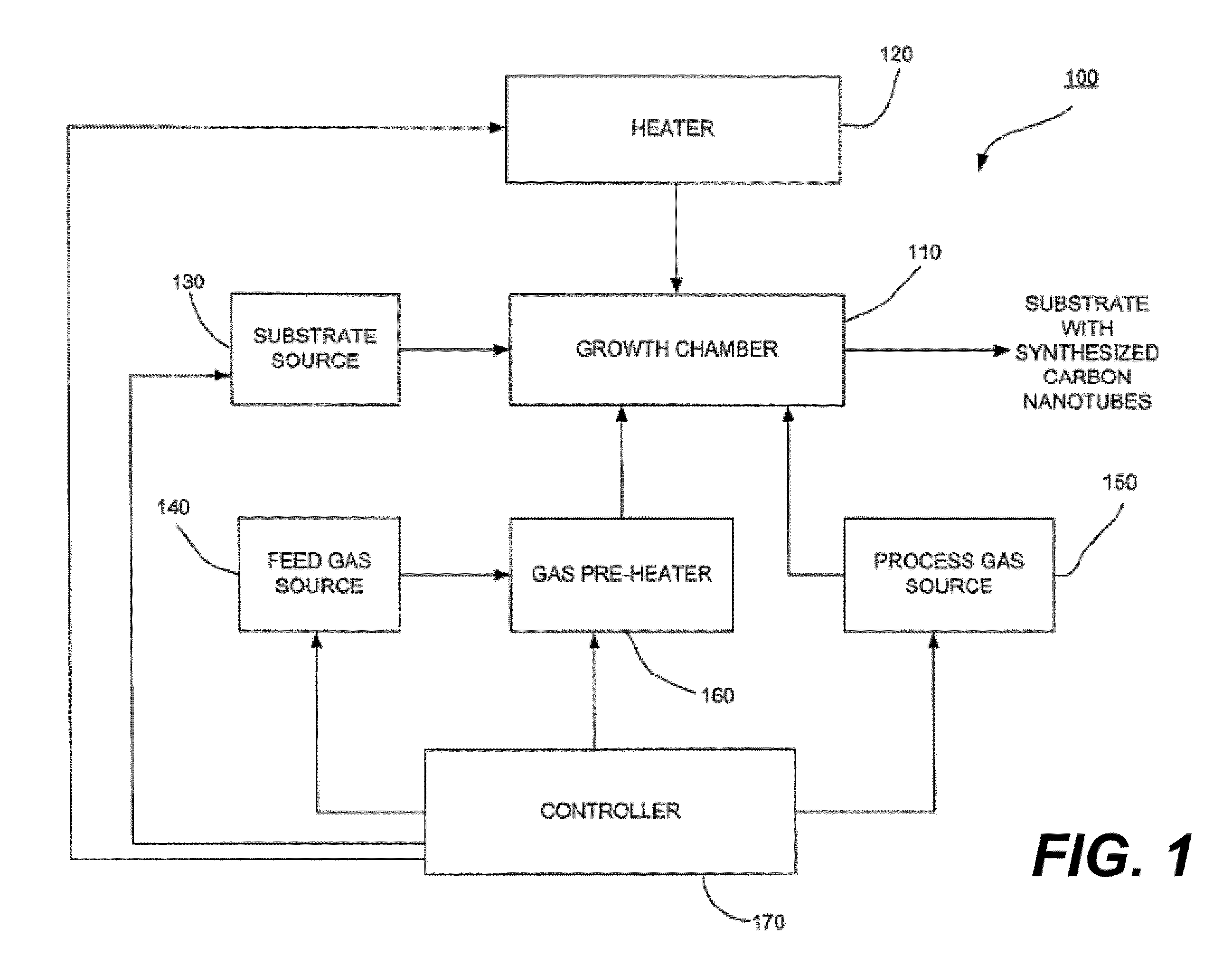

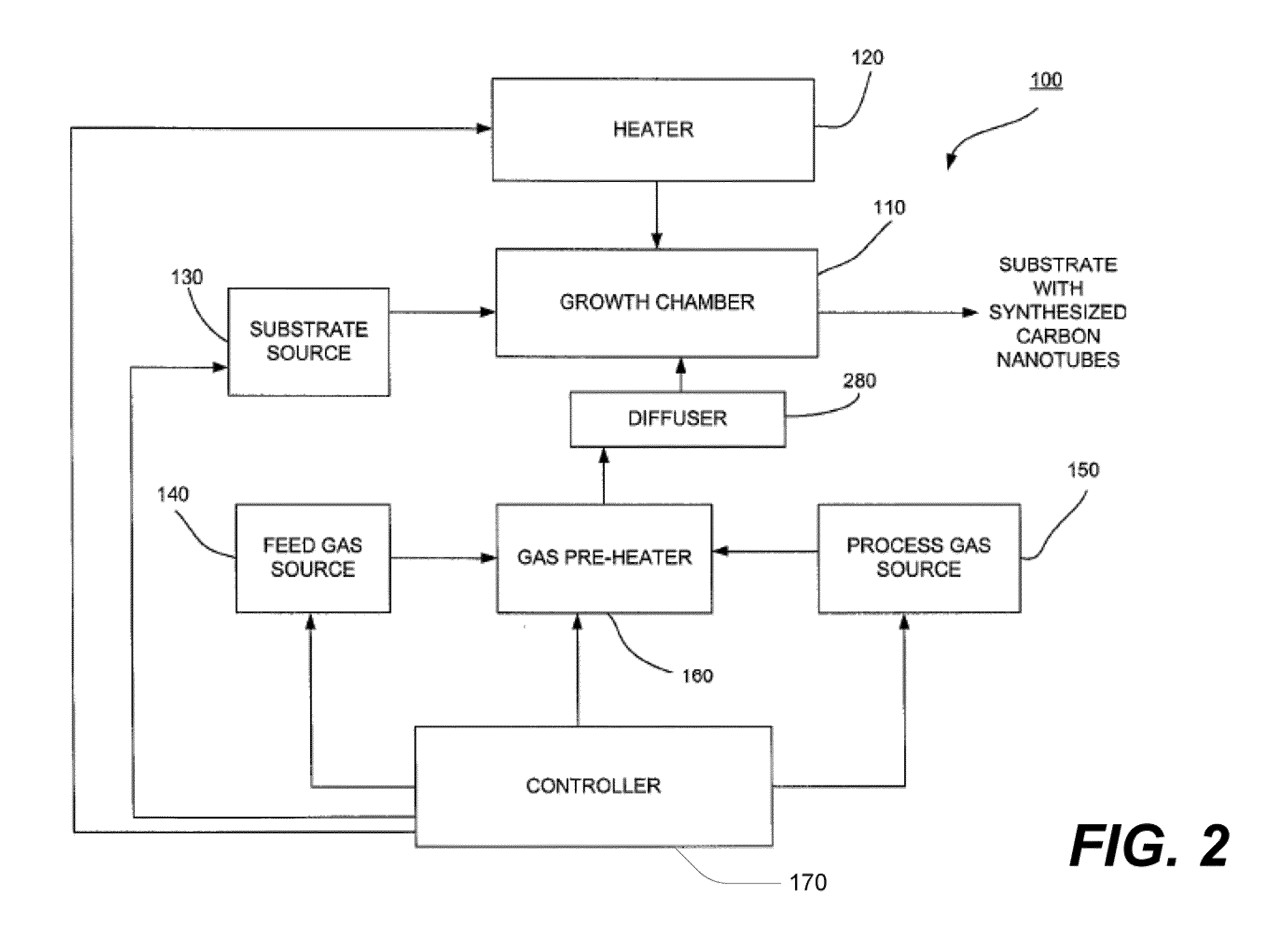

Low temperature cnt growth using gas-preheat method

ActiveUS20100221424A1Promote growthSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProduct gas

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

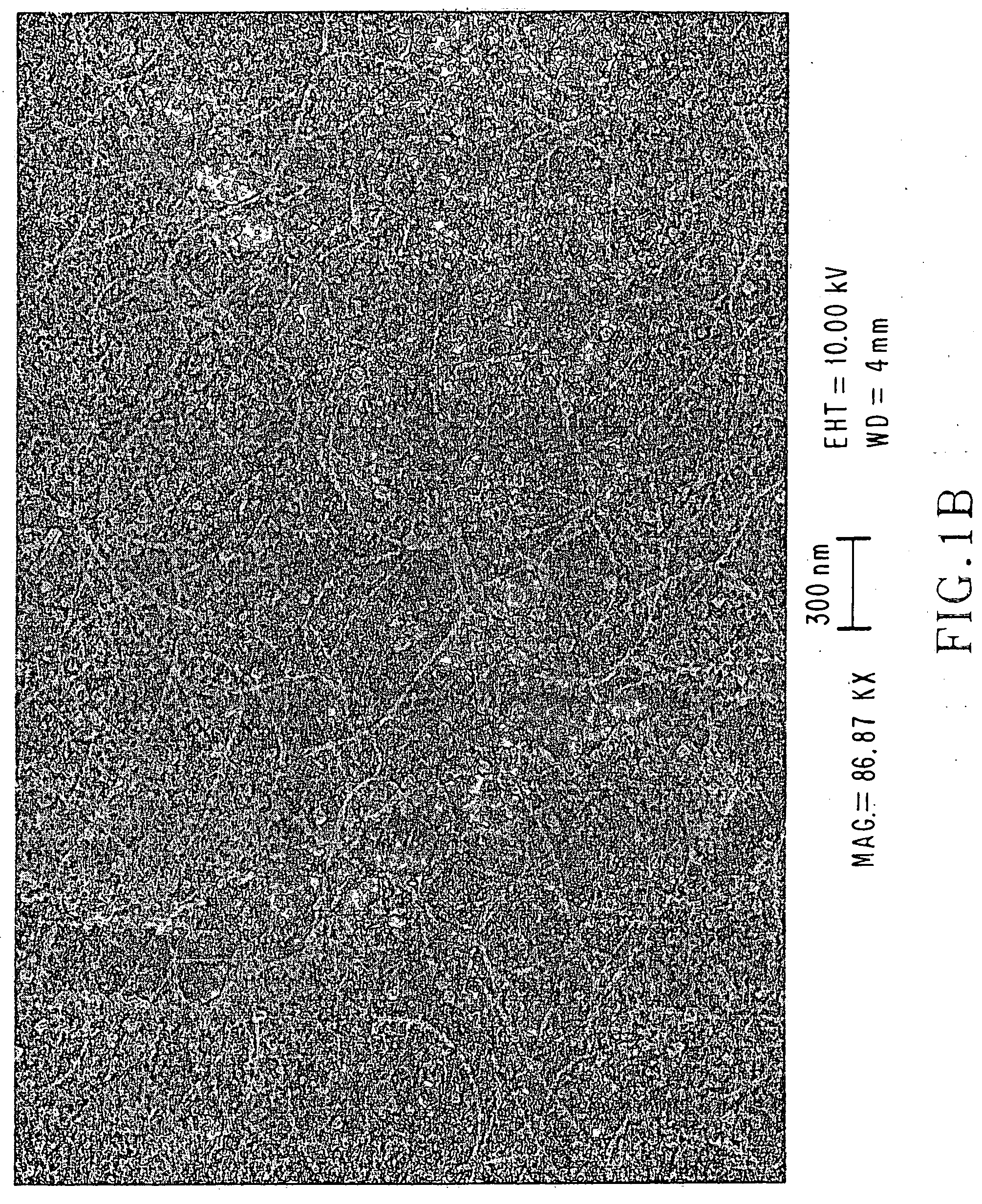

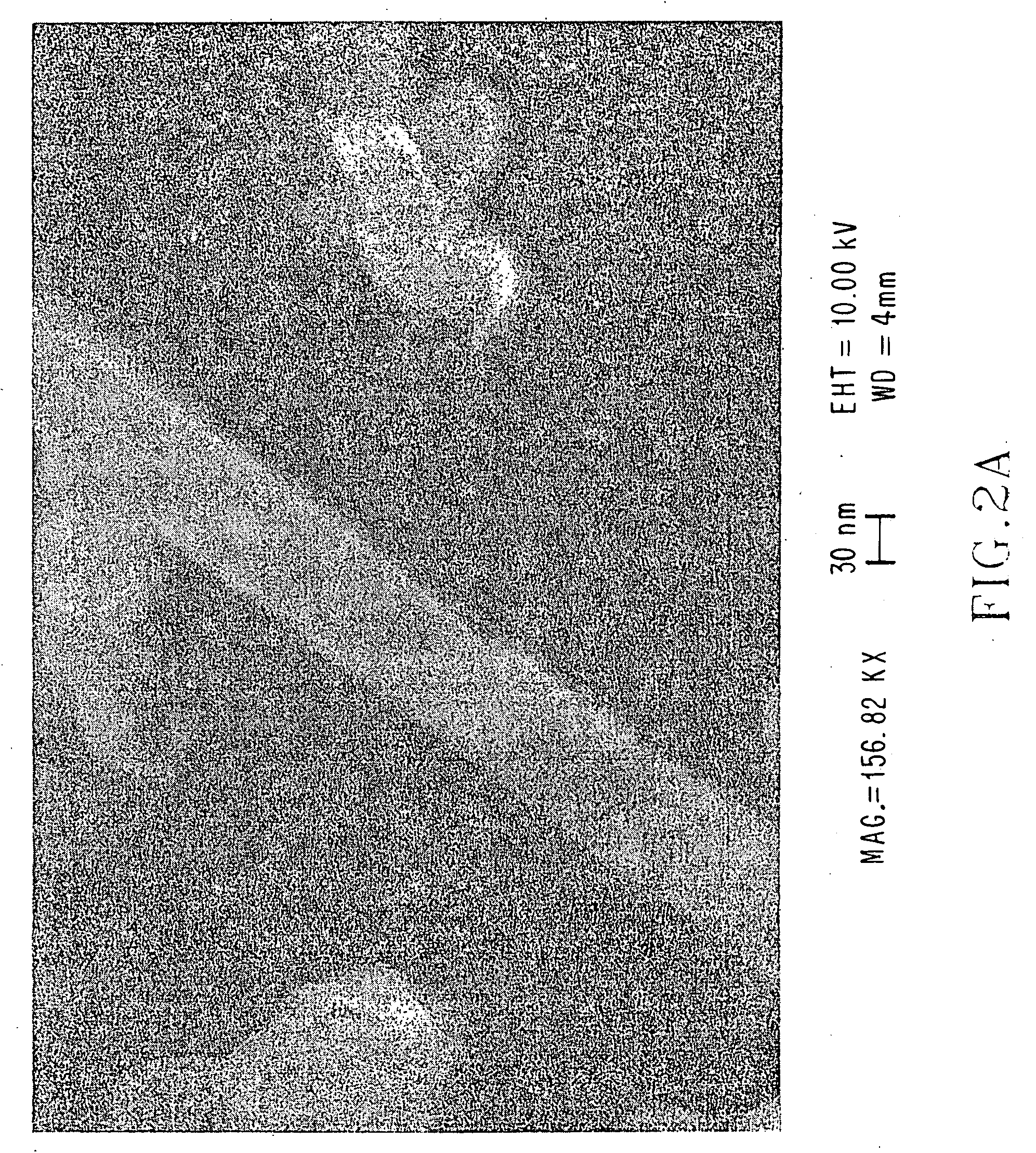

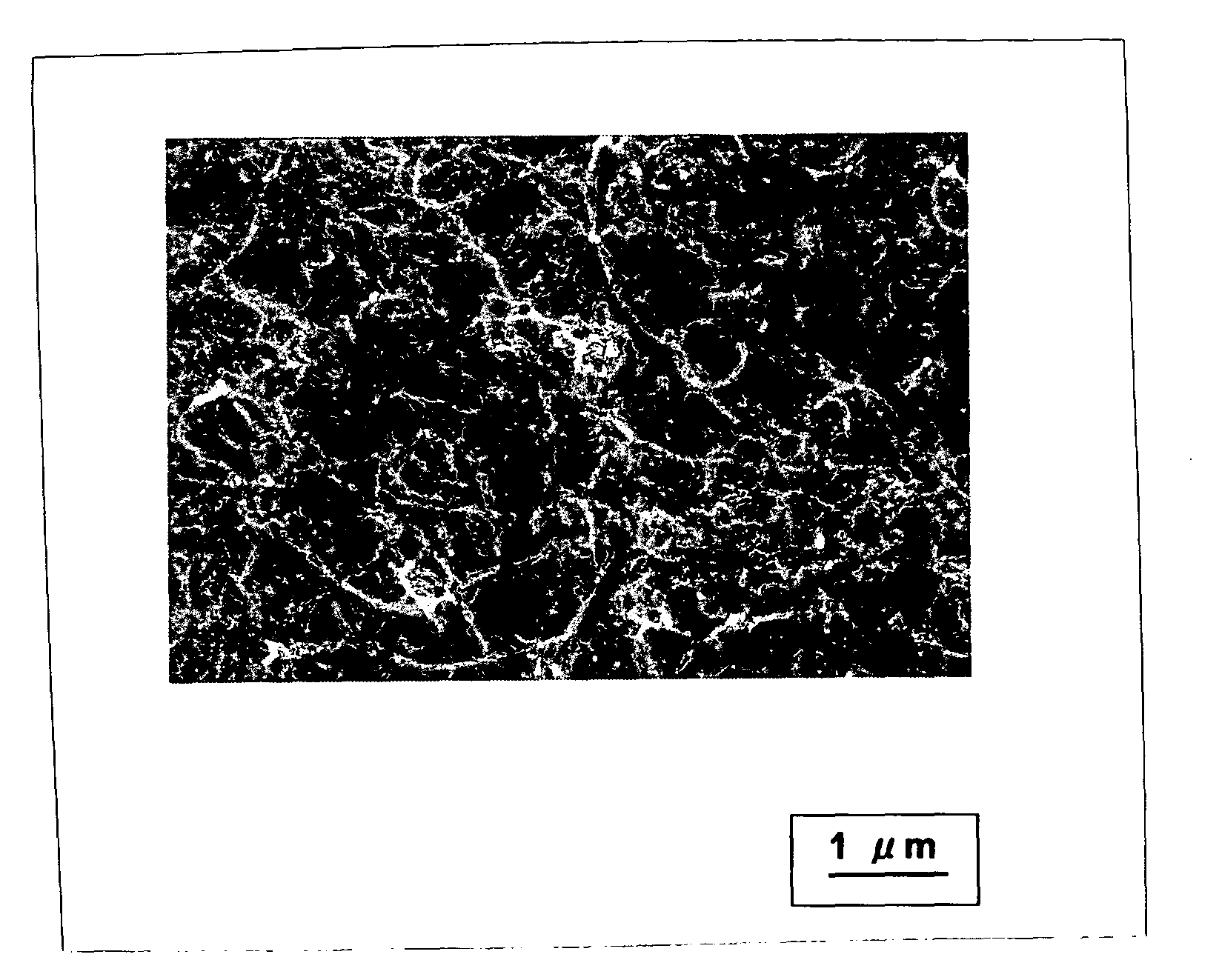

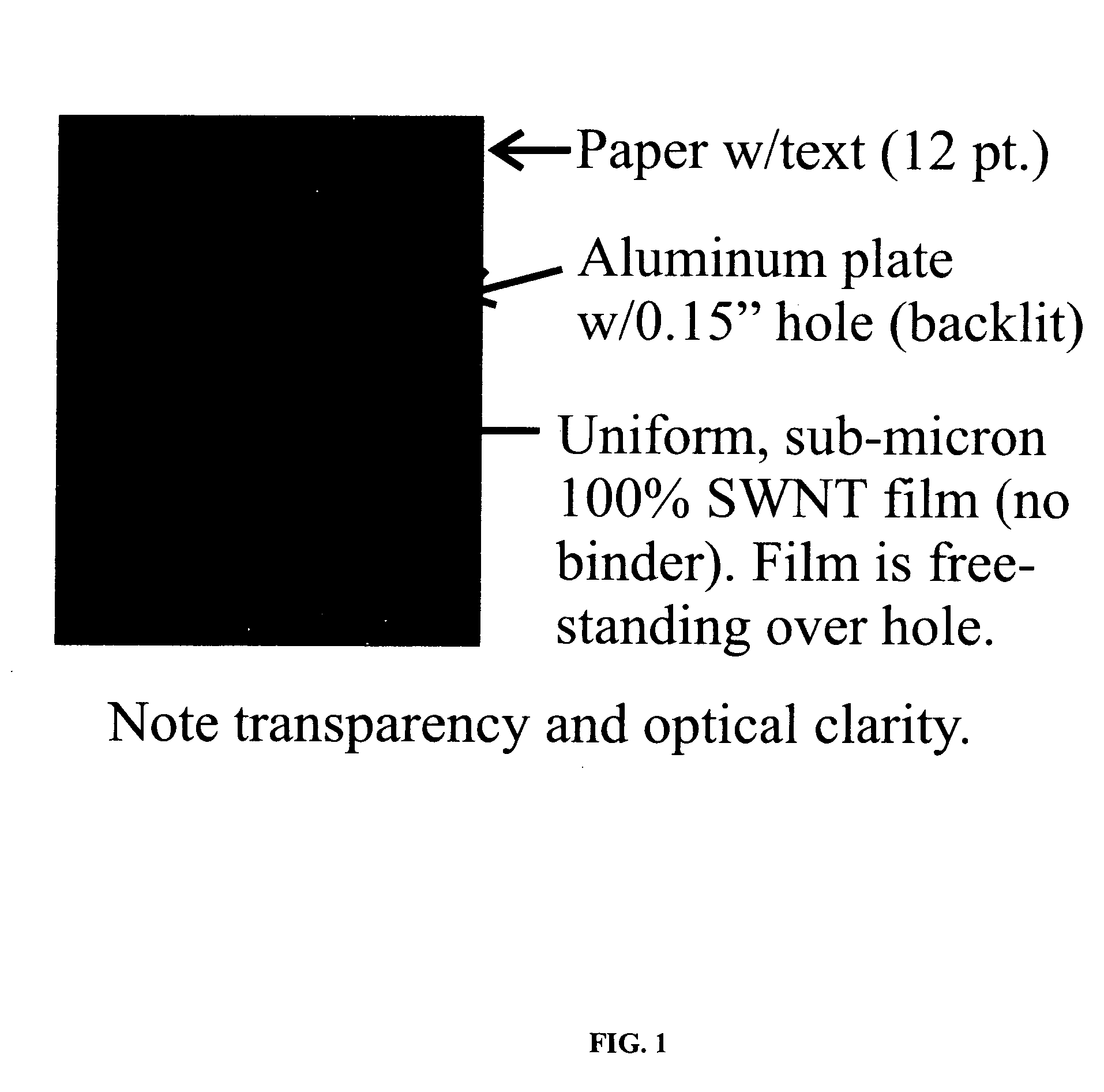

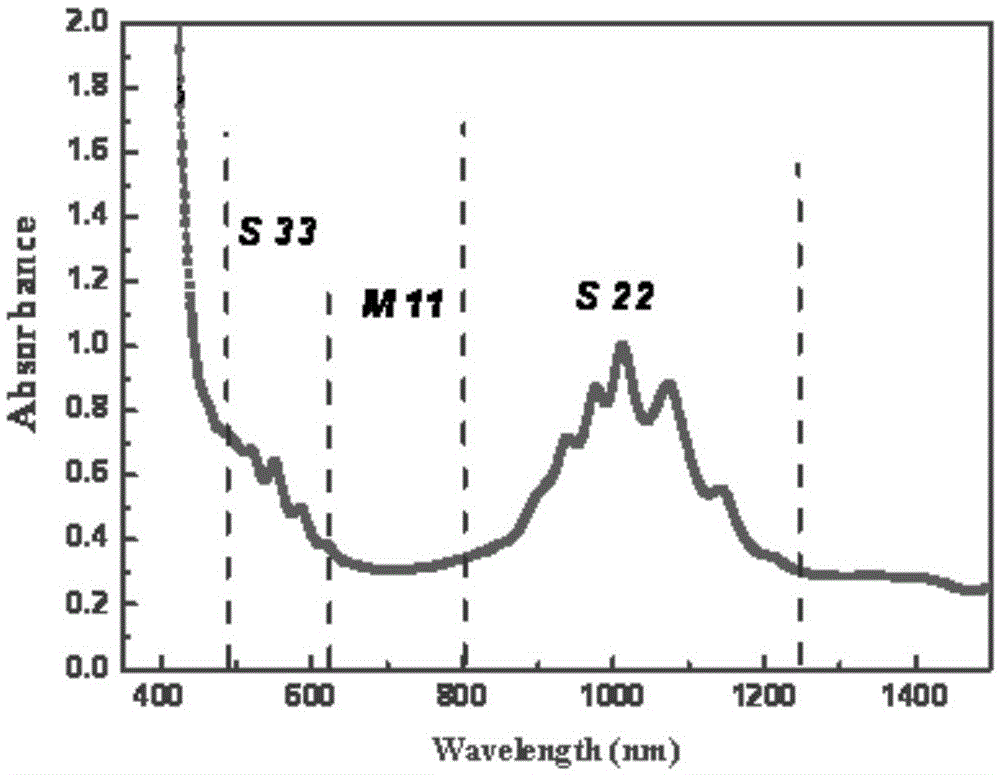

Transparent and electrically conductive single wall carbon nanotube films

InactiveUS20070141345A1Uniform optical densityHigh light transmittanceSpecific nanostructure formationMaterial nanotechnologyElectrical resistance and conductanceTransmittance

An optically transparent and electrically conductive single walled carbon nanotube (SWNT) film comprises a plurality of interpenetrated single walled carbon nanotubes, wherein for a 100 nm film the film has sufficient interpenetration to provide a 25° C. sheet resistance of less than 200 ohm / sq. The film also provides at least 20% optical transmission throughout a wavelength range from 0.4 μm to 5 μm.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

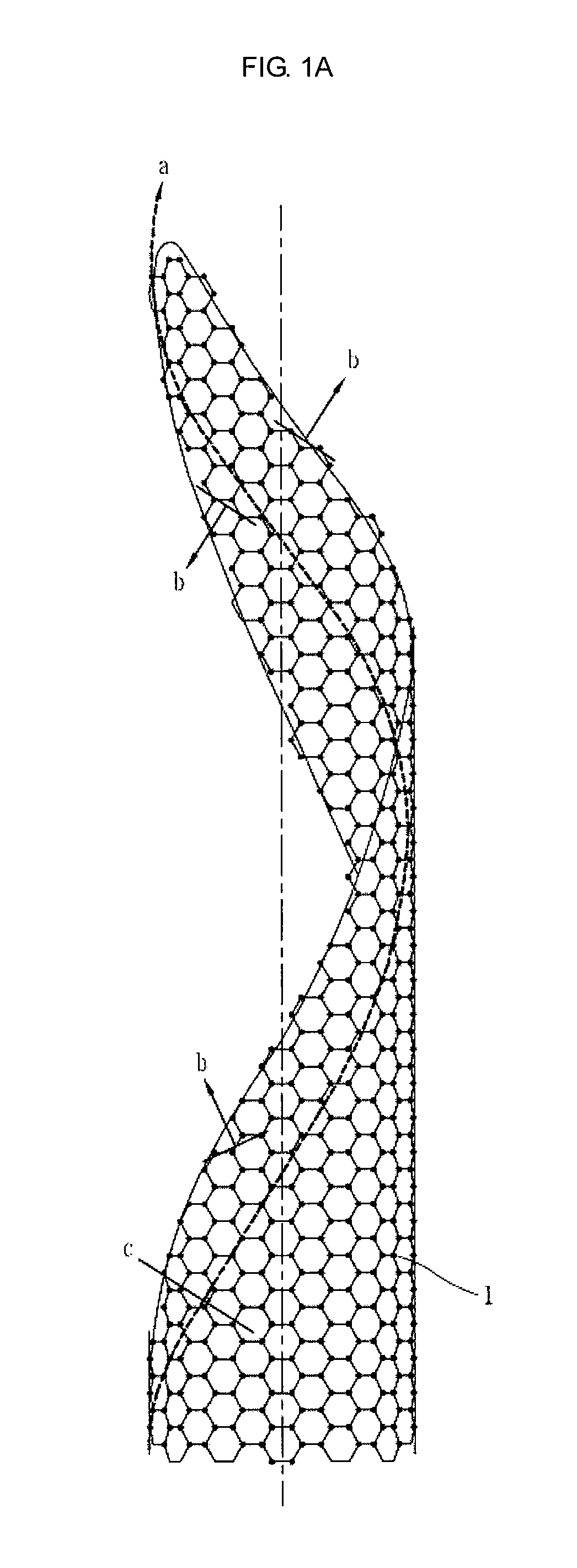

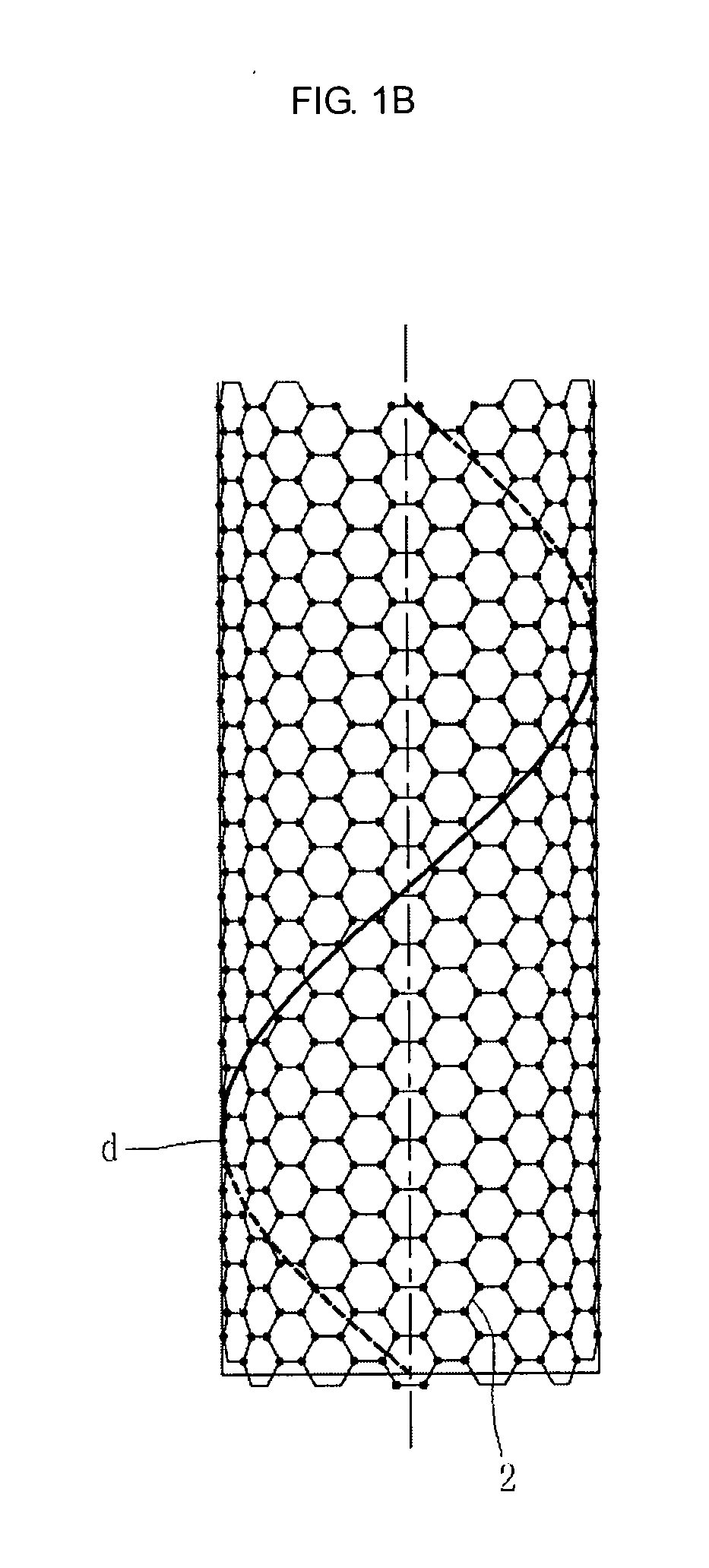

Simple tool for positional diamond mechanosynthesis, and its method of manufacture

InactiveUS7687146B1Specific nanostructure formationLayered productsMechanosynthesisDiamond deposition

A method is described for building a mechanosynthesis tool intended to be used for the molecularly precise fabrication of physical structures—as for example, diamond structures. An exemplar tool consists of a bulk-synthesized dimer-capped triadamantane tooltip molecule which is initially attached to a deposition surface in tip-down orientation, whereupon CVD or equivalent bulk diamond deposition processes are used to grow a large crystalline handle structure around the tooltip molecule. The large handle with its attached tooltip can then be mechanically separated from the deposition surface, yielding an integral finished tool that can subsequently be used to perform diamond mechanosynthesis in vacuo. The present disclosure is the first description of a complete tool for positional diamond mechanosynthesis, along with its method of manufacture. The same toolbuilding process may be extended to other classes of tooltip molecules, other handle materials, and to mechanosynthetic processes and structures other than those involving diamond.

Owner:ZYVEX LABS LLC

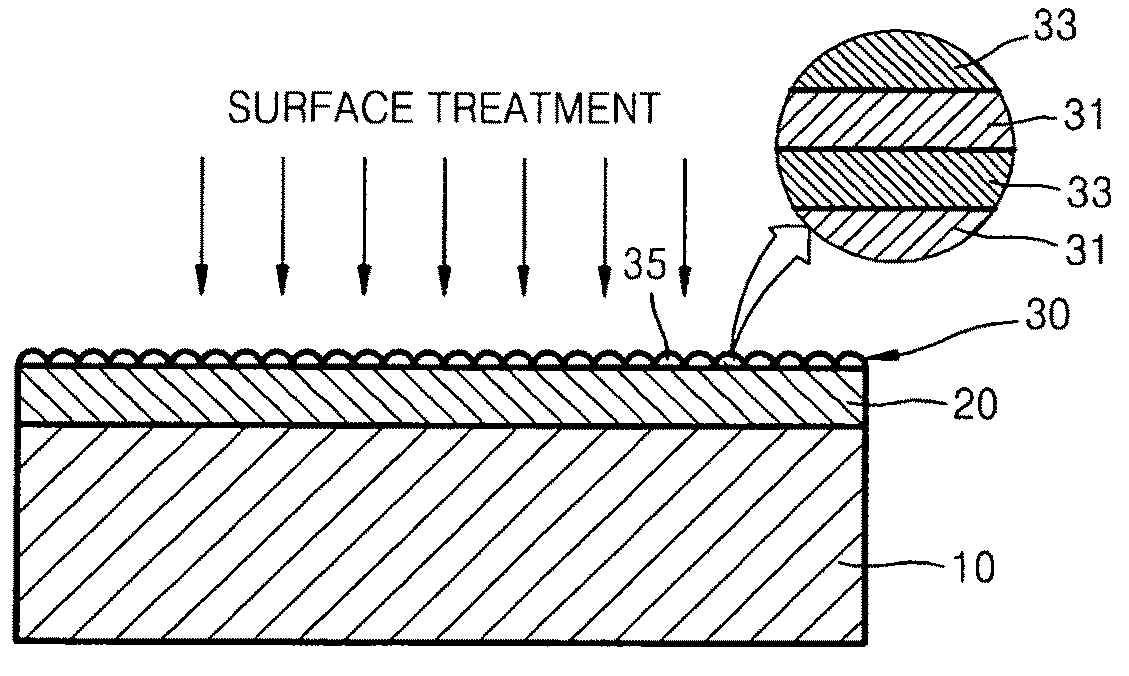

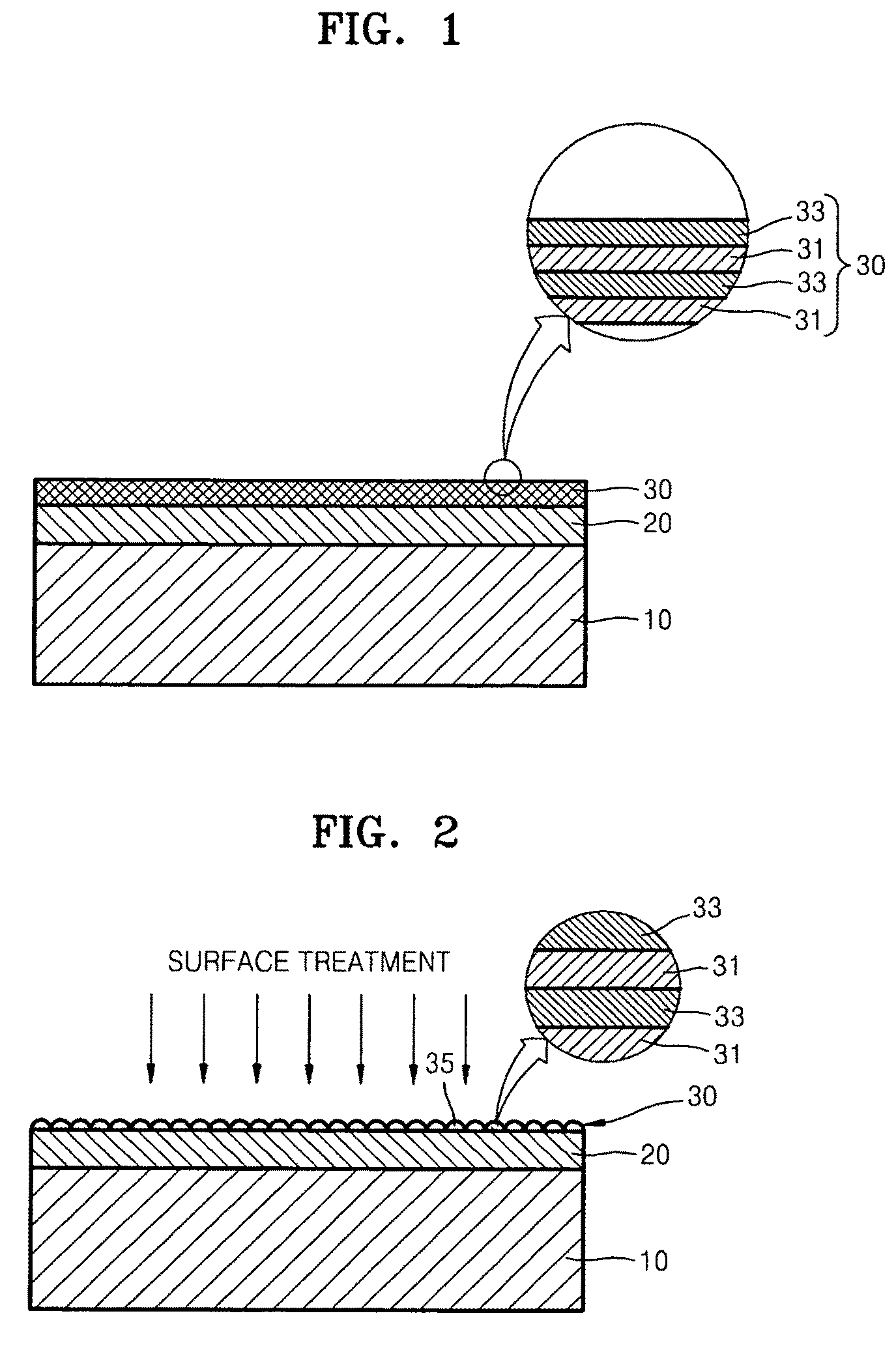

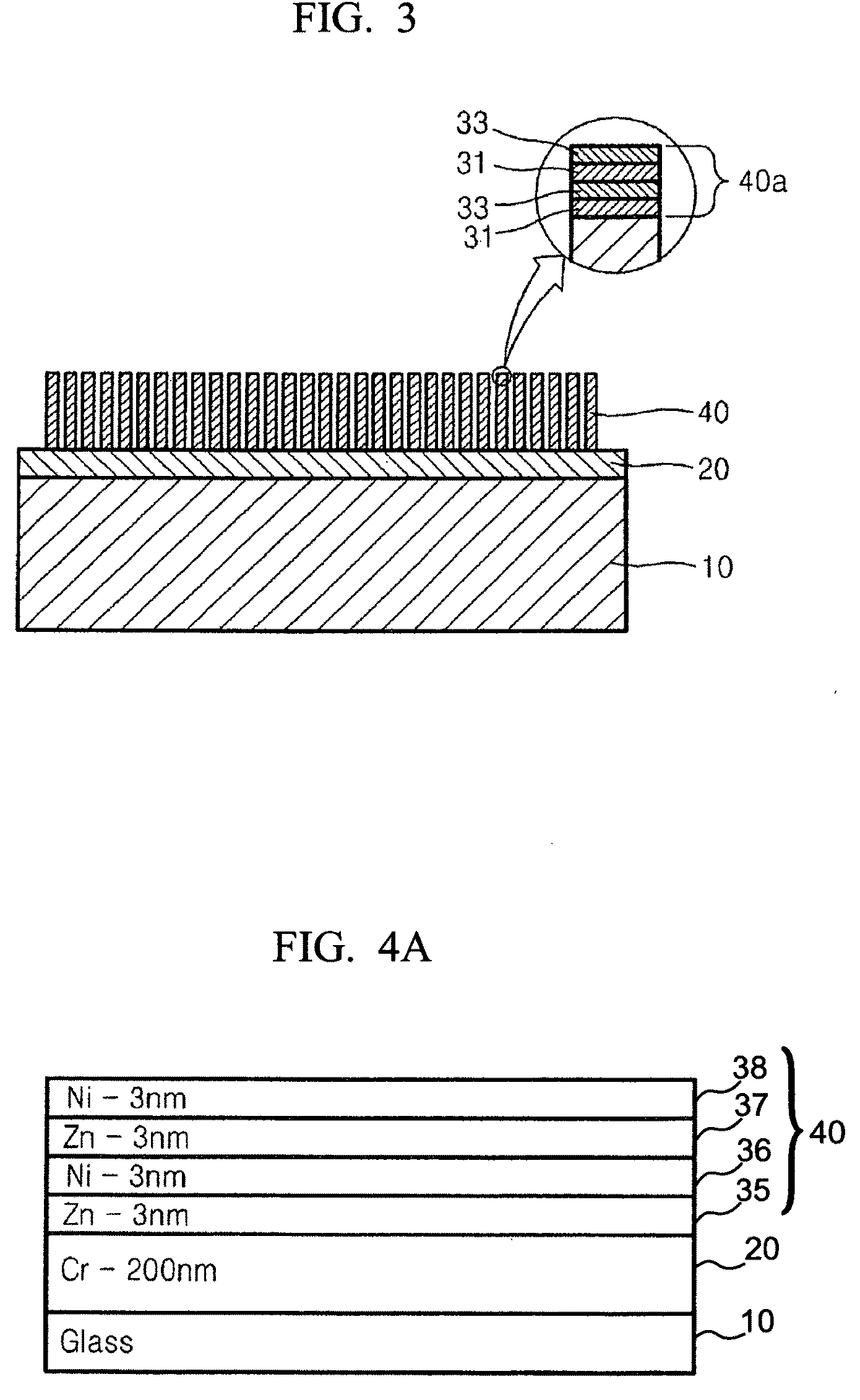

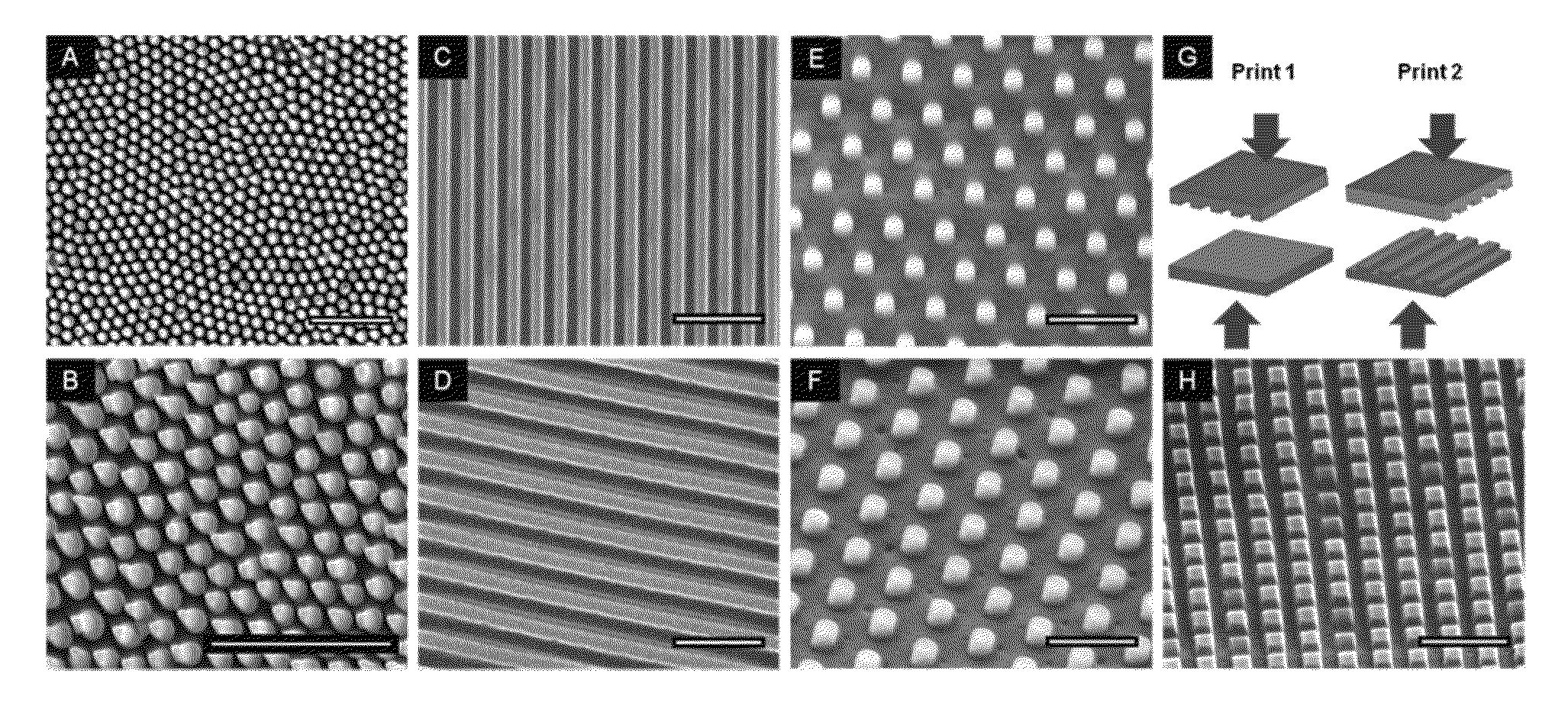

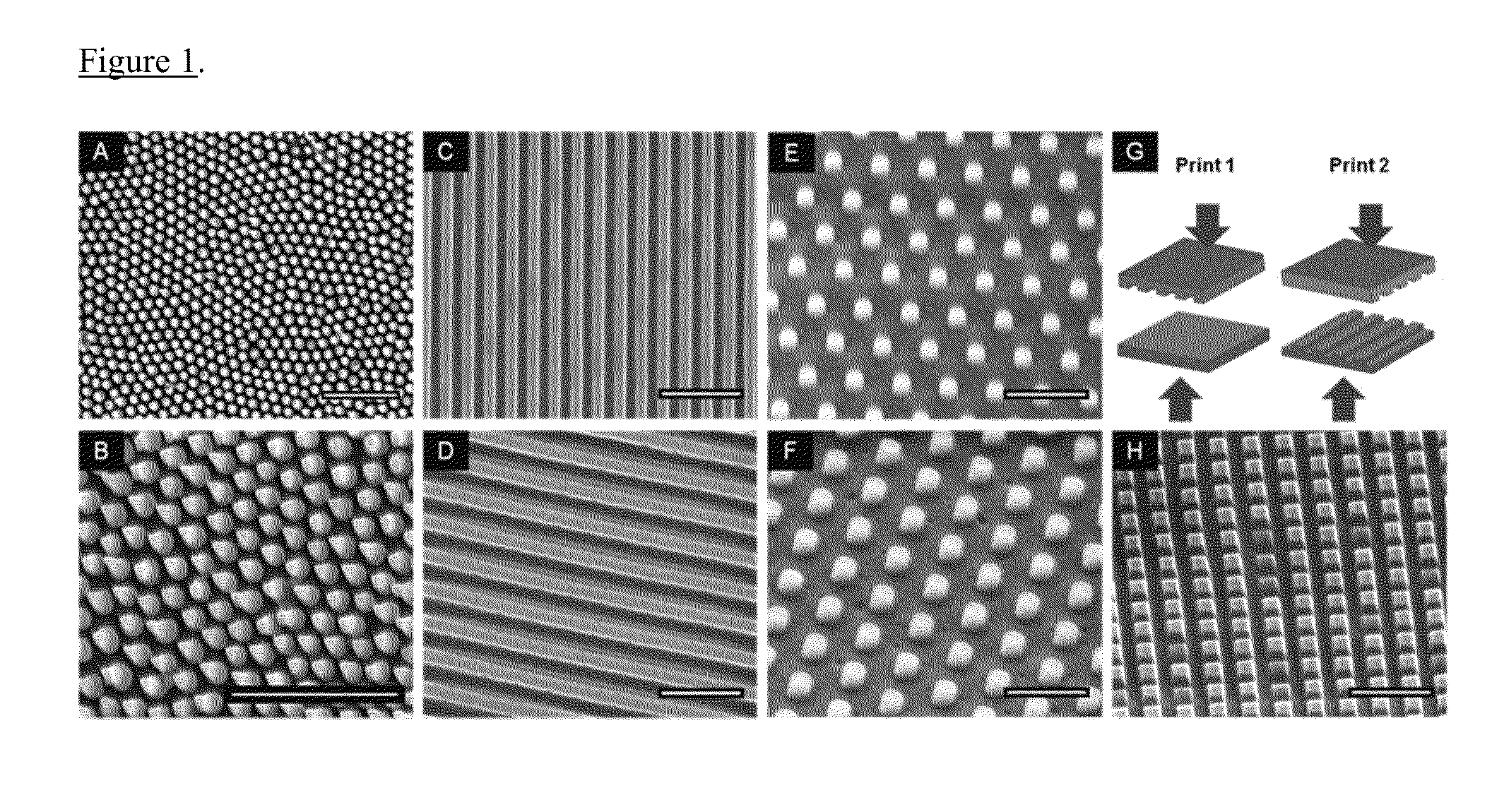

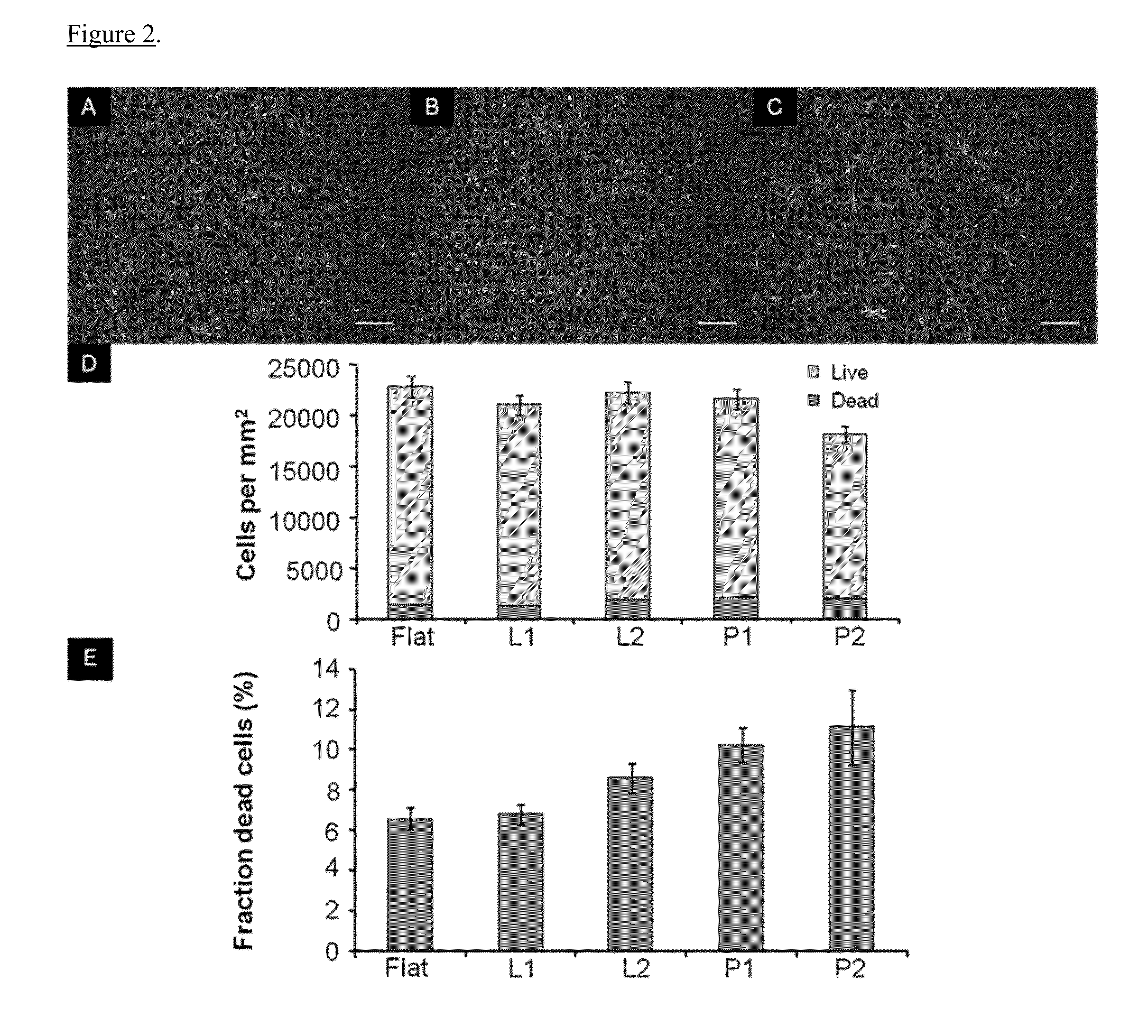

Bactericidal surface patterns

ActiveUS20150273755A1Specific nanostructure formationLayered productsPolymeric surfaceSurface pattern

The invention relates to imparting surfaces with nanometer sized structures that provide bactericidal properties to the surface and devices. In one embodiment, the present invention provides a bactericidal surface with nanometer sized pillars created by imprinting a softened polymer surface with a mold. In another embodiment, the nanometer sized pillars are part of a medical device with antibacterial properties.

Owner:RGT UNIV OF CALIFORNIA

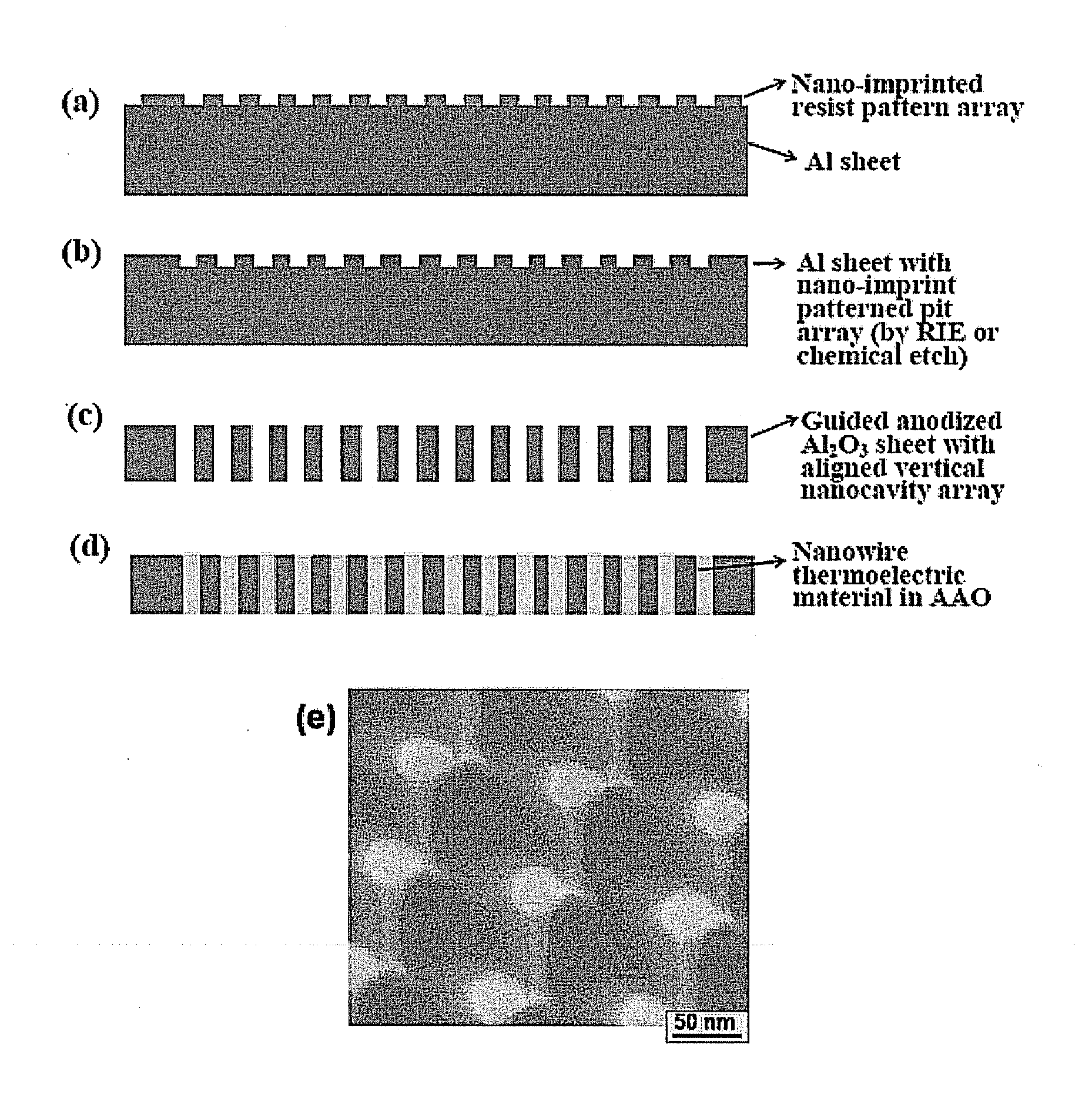

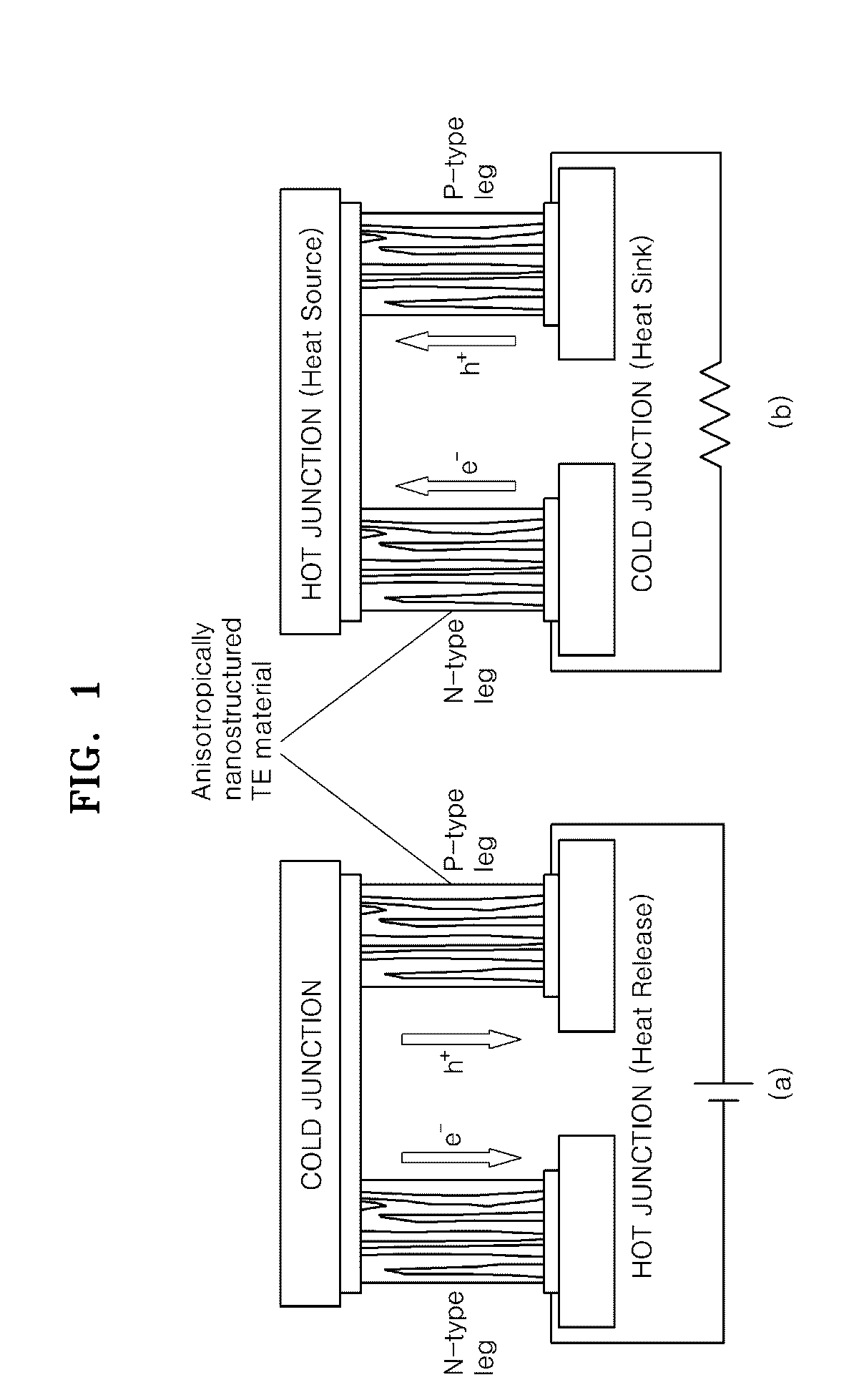

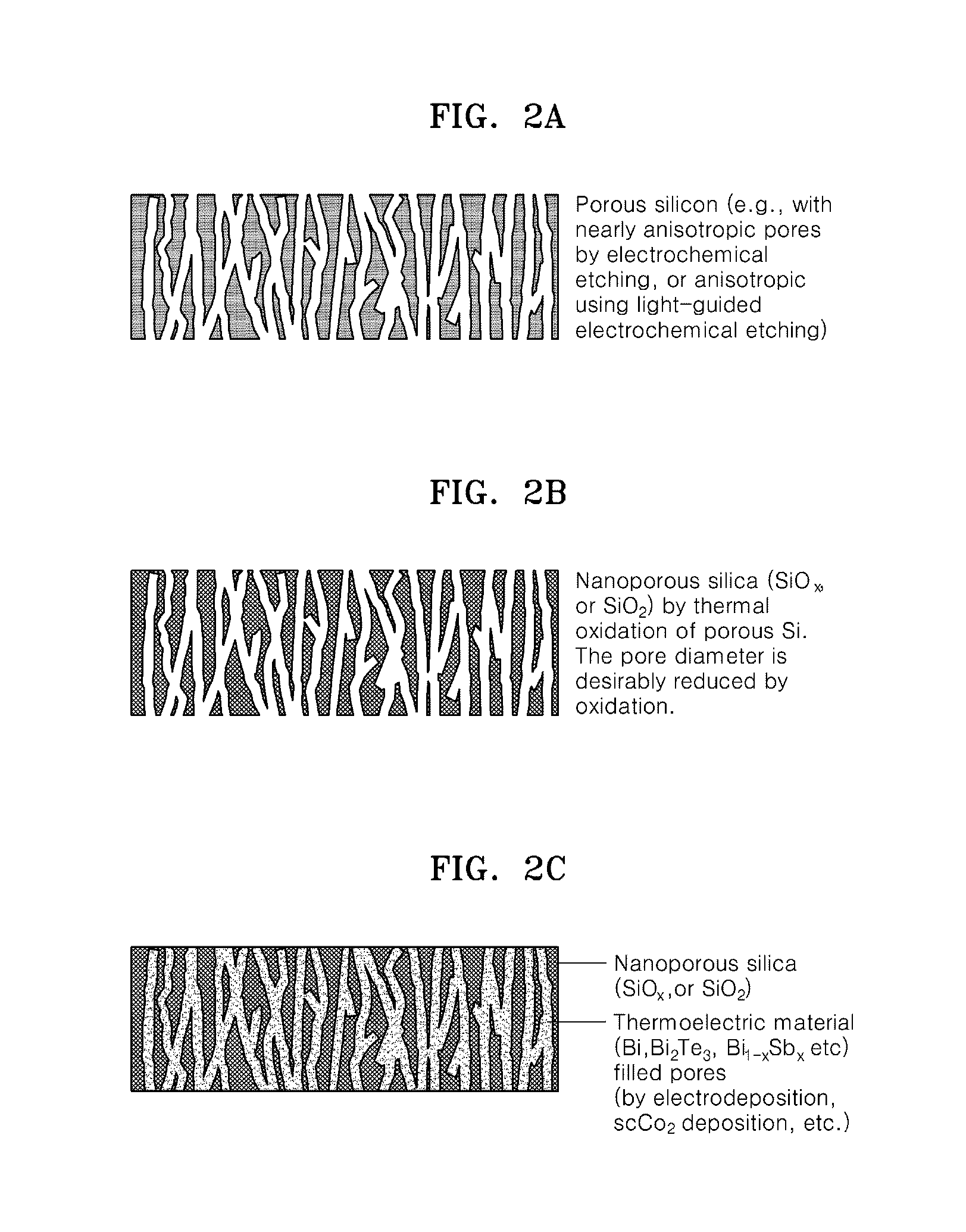

Anisotropically elongated thermoelectric material, process for preparing the same, and device comprising the material

InactiveUS20100236596A1Material nanotechnologySpecific nanostructure formationThermoelectric materialsNanometre

Owner:SAMSUNG ELECTRONICS CO LTD +2

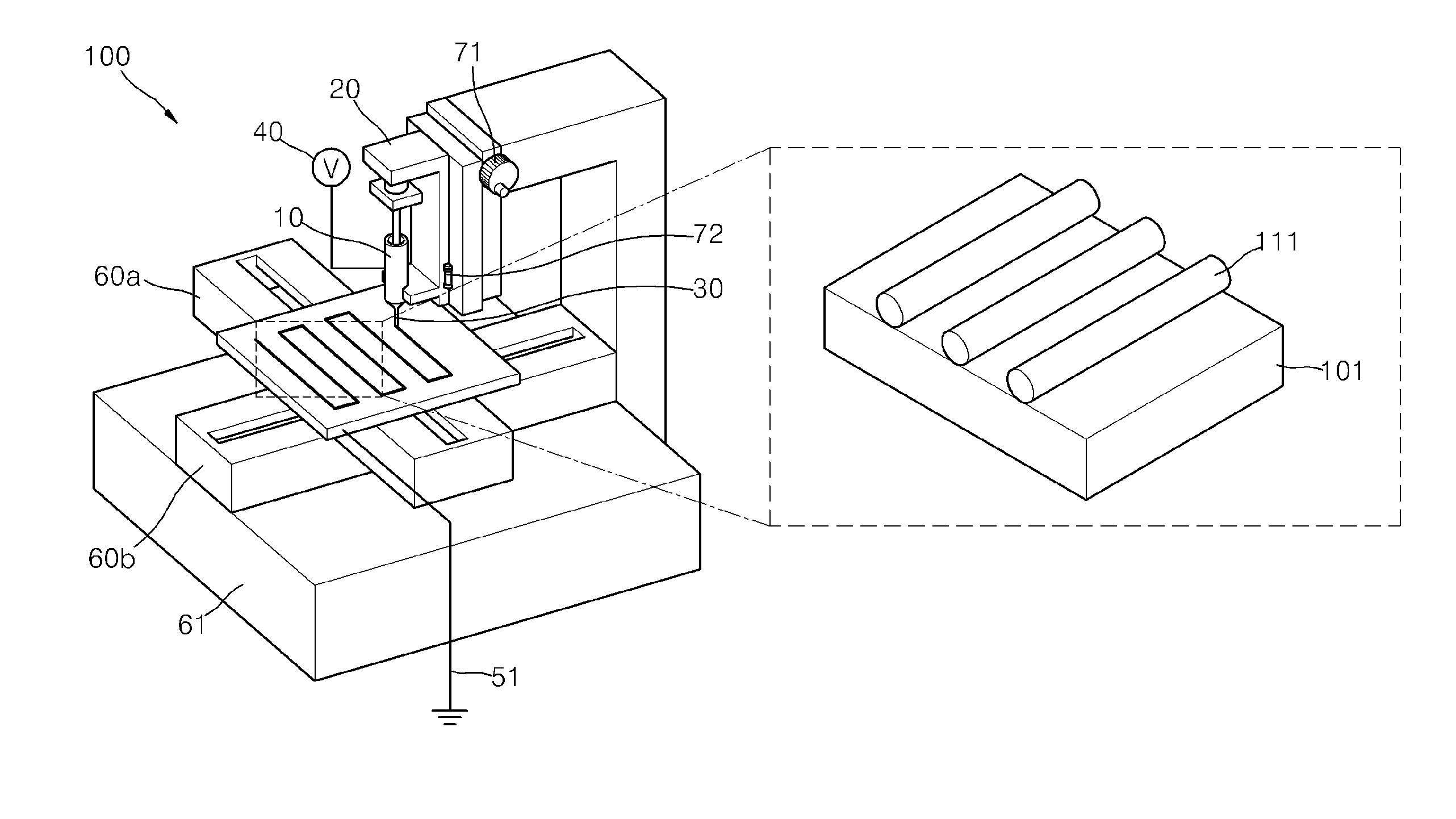

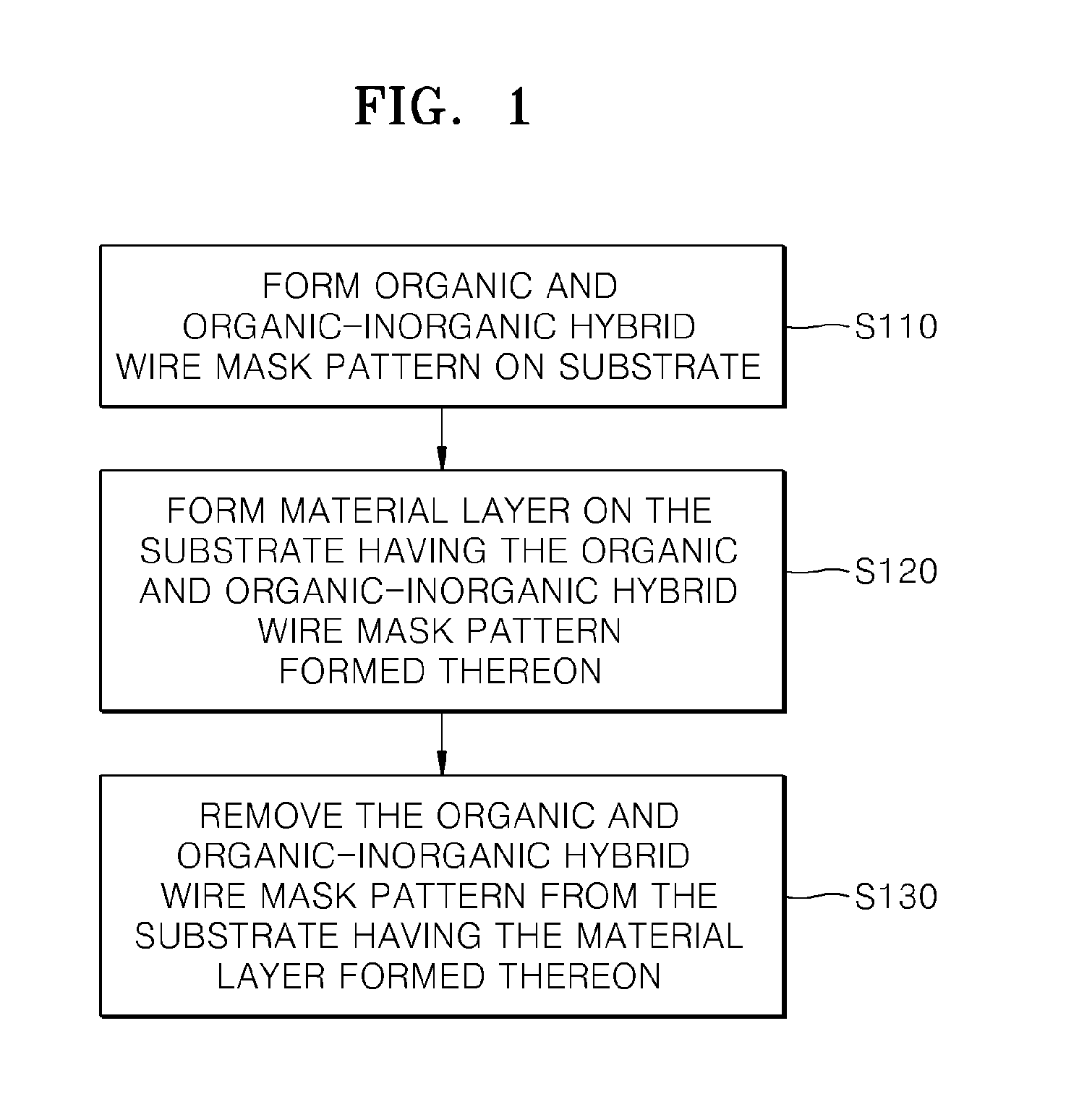

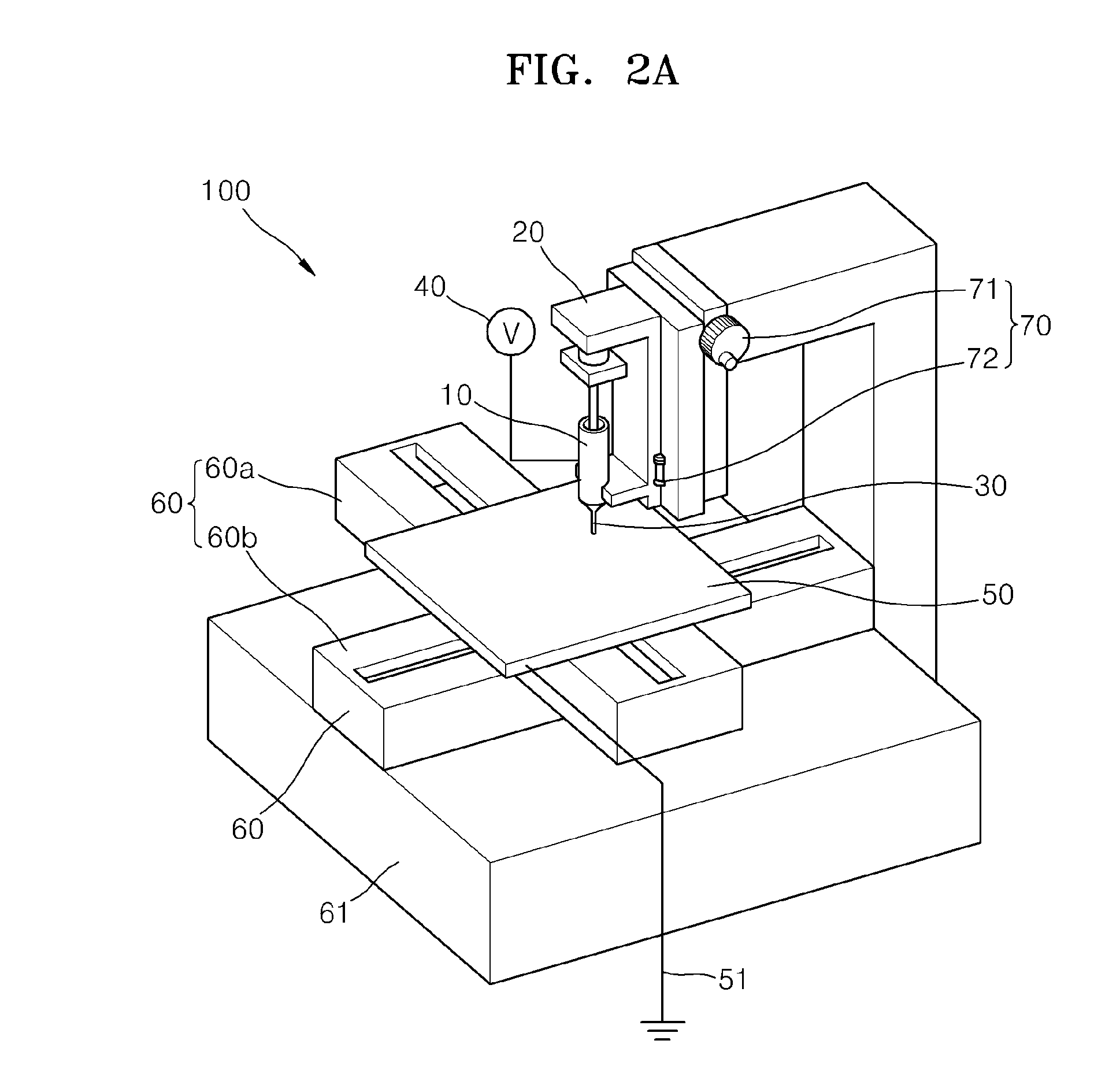

Micro-Pattern Forming Method, and Micro-Channel Transistor and Micro-Channel Light-Emitting Transistor Forming Method Using Same

ActiveUS20130203198A1Low costForming accuratelySpecific nanostructure formationSolid-state devicesEngineeringOrganic inorganic

Provided is a method of forming a micropattern according to an aspect of the present invention. The method of forming a micropattern may include forming an organic wire or organic-inorganic hybrid wire mask pattern having a circular or elliptical cross section on a substrate, forming a material layer on an entire surface of the substrate having the organic wire or organic-inorganic hybrid wire mask pattern formed thereon, and removing the organic wire or organic-inorganic hybrid wire mask pattern from the substrate to allow only the material layer on a portion of the substrate having no organic wire or organic-inorganic hybrid wire mask pattern formed thereon to be remained.

Owner:POSTECH ACAD IND FOUND

Method for synthesis of carbon nanotubes

ActiveUS7799246B2Material nanotechnologyFrom normal temperature solutionsPtru catalystCarbon nanotube

The present invention relates to a process for preparing CNTs by bringing a carbon source into contact with a multivalent metal and / or metal-oxide-based catalyst deposited on an inorganic substrate having a BET specific surface area of greater than 50 m2 / g. The CNTs obtained may be used as agents for improving the mechanical and electrical conductivity properties in polymeric compositions.

Owner:ARKEMA FRANCE SA

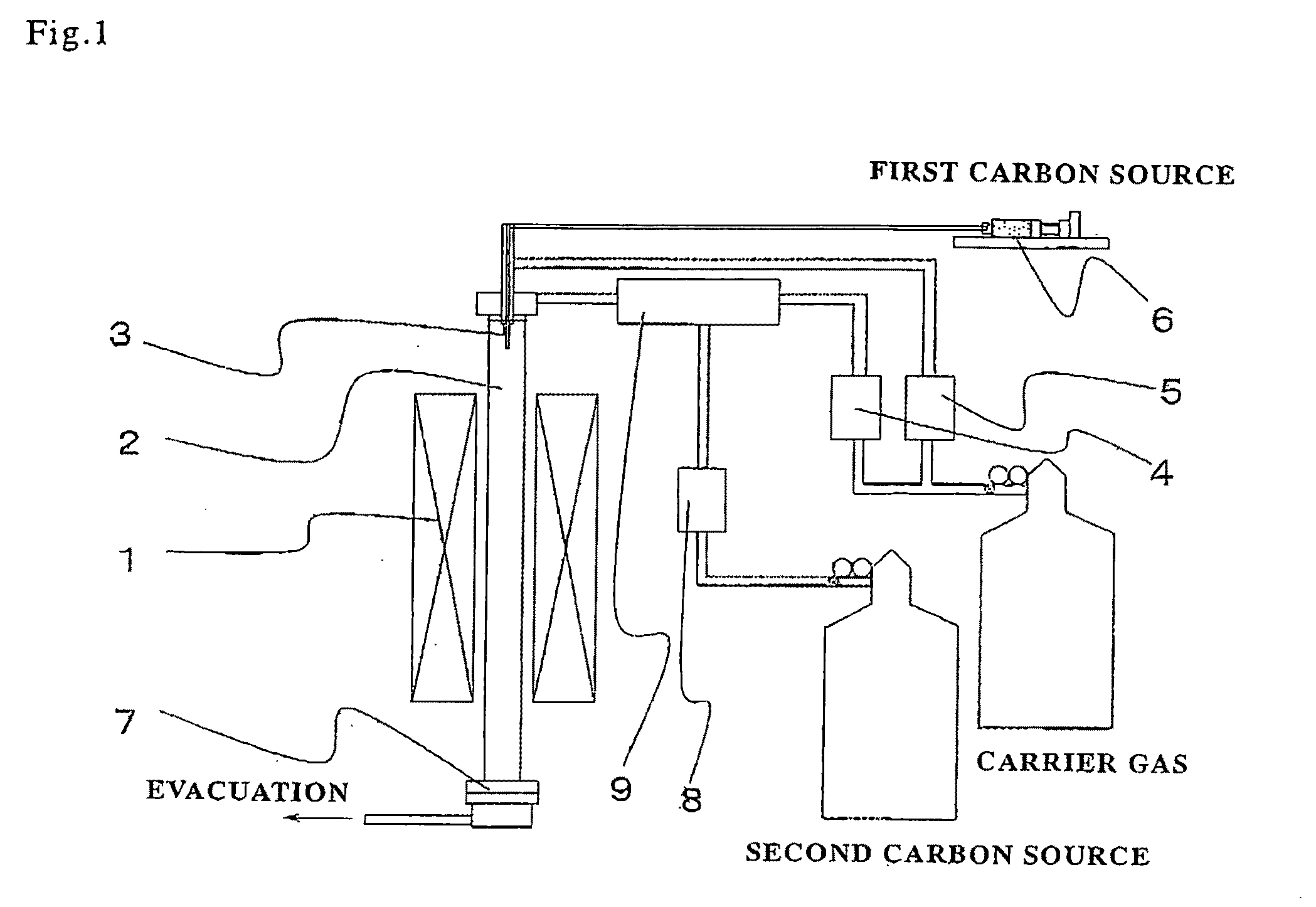

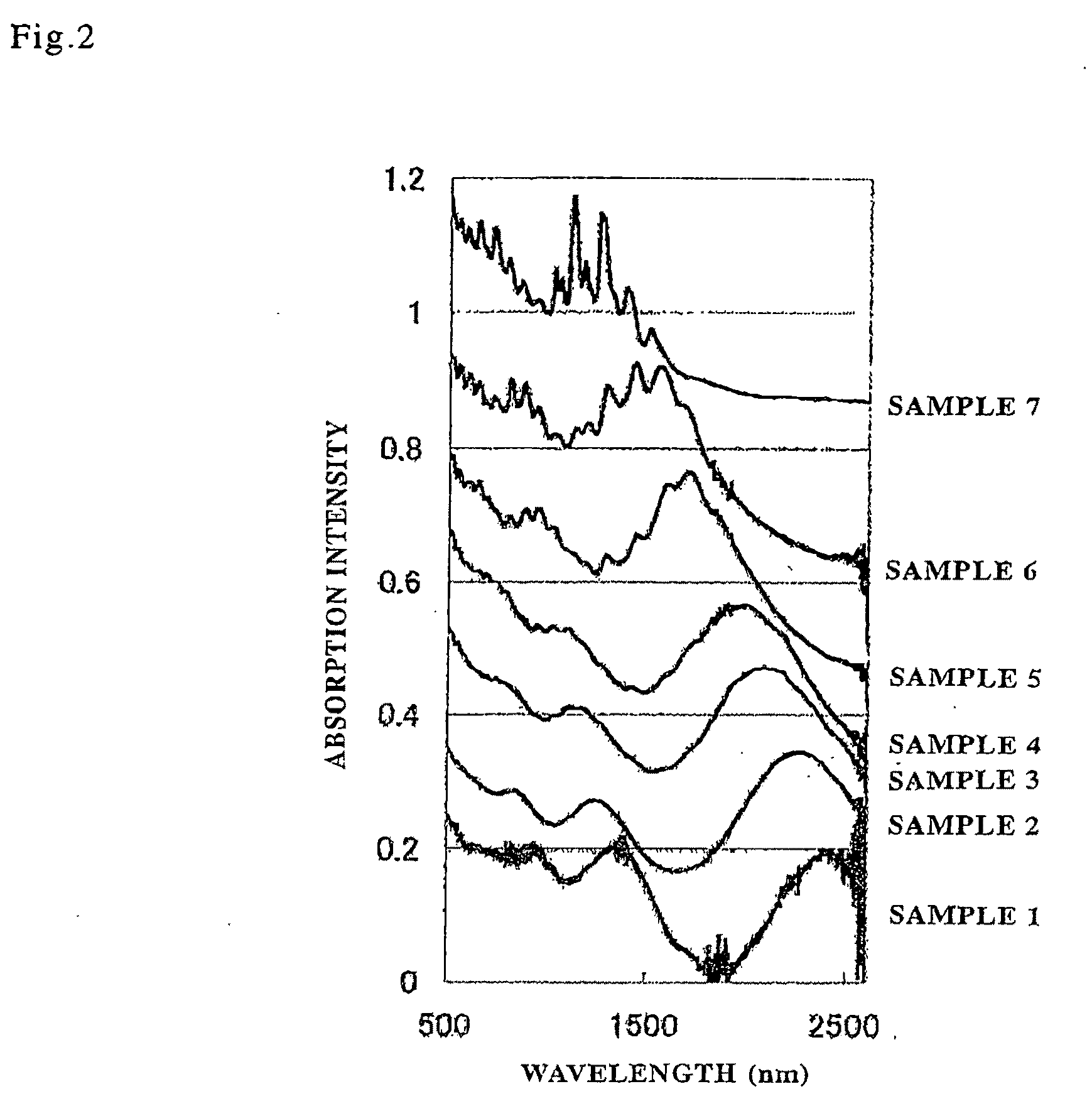

Single-Walled Carbon Nanotubes, Carbon Fiber Aggregate Containing the Single-Walled Carbon Nanotubes, and Method for Producing Those

InactiveUS20090186223A1High purityQuality improvementMaterial nanotechnologyFibre chemical featuresFiberCarbon fibers

It relates to high purity single-walled carbon nanotubes having controlled diameter, useful as industrial materials, including high-strength carbon wire rods, particularly uniform single-walled carbon nanotubes having diameter fallen in a range of from 1.0 to 2.0 nm, and a method for producing the same efficiently, in large amount and inexpensively. The single-walled carbon nanotube obtained is characterized in that its diameter is fallen in a range of from 1.0 to 2.0 nm, and an intensity ratio IG / ID between G-band and D-band in a Raman spectrum is 200 or more. Furthermore, those single-walled carbon nanotubes are synthesized by a gas-phase flow CVD method that uses a saturated aliphatic hydrocarbon which is liquid at ordinary temperature as a first carbon source and an unsaturated aliphatic hydrocarbon which is gas at ordinary temperature as a second carbon source.

Owner:NAT INST OF ADVANCED IND SCI & TECH

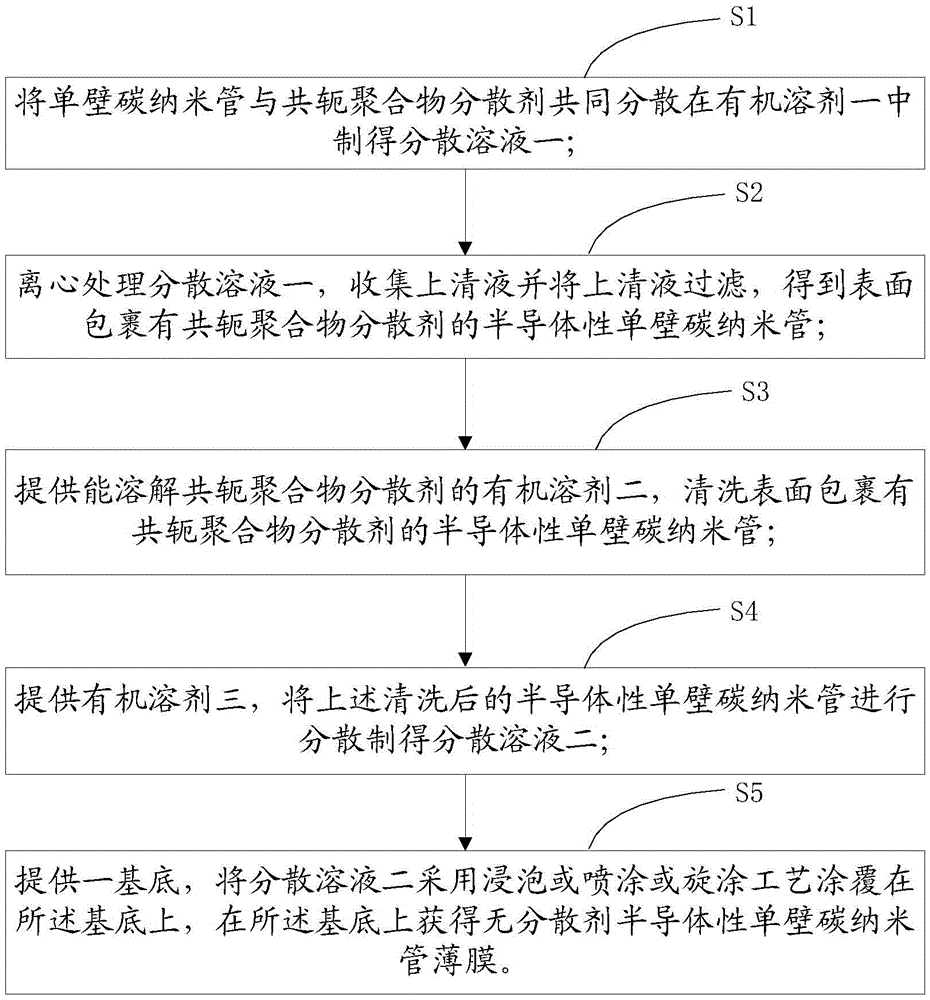

Method for preparing dispersant-free semi-conductive single-walled carbon nanotube film

ActiveCN105585000AIntrinsic performanceIncrease contactSpecific nanostructure formationMaterial nanotechnologyOrganic solventCarbon nanotube

The invention discloses a method for preparing a dispersant-free semi-conductive single-walled carbon nanotube film. The method comprises steps as follows: a single-walled carbon nanotube and a conjugated polymer dispersant are dispersed in an organic solvent I together, and a dispersion solution I is prepared; the dispersion solution I is subjected to centrifugal treatment, supernatant liquor is collected and filtered, and a semi-conductive single-walled carbon nanotube with the surface coated with a dispersant is obtained; an organic solvent II is provided, and the semi-conductive single-walled carbon nanotube with the surface coated with the conjugated polymer dispersant is washed; an organic solvent III is provided, the washed semi-conductive single-walled carbon nanotube is dispersed, and a dispersion solution II is prepared; the dispersion solution II is applied to a substrate I, and the dispersant-free semi-conductive single-walled carbon nanotube film is obtained. Compared with the prior art, the dispersant-free semi-conductive single-walled carbon nanotube film prepared with the method can show intrinsic performance of the single-walled carbon nanotube and is suitable for preparation of a high-performance carbon nanotube film semi-conductor device.

Owner:苏州希印纳米科技有限公司

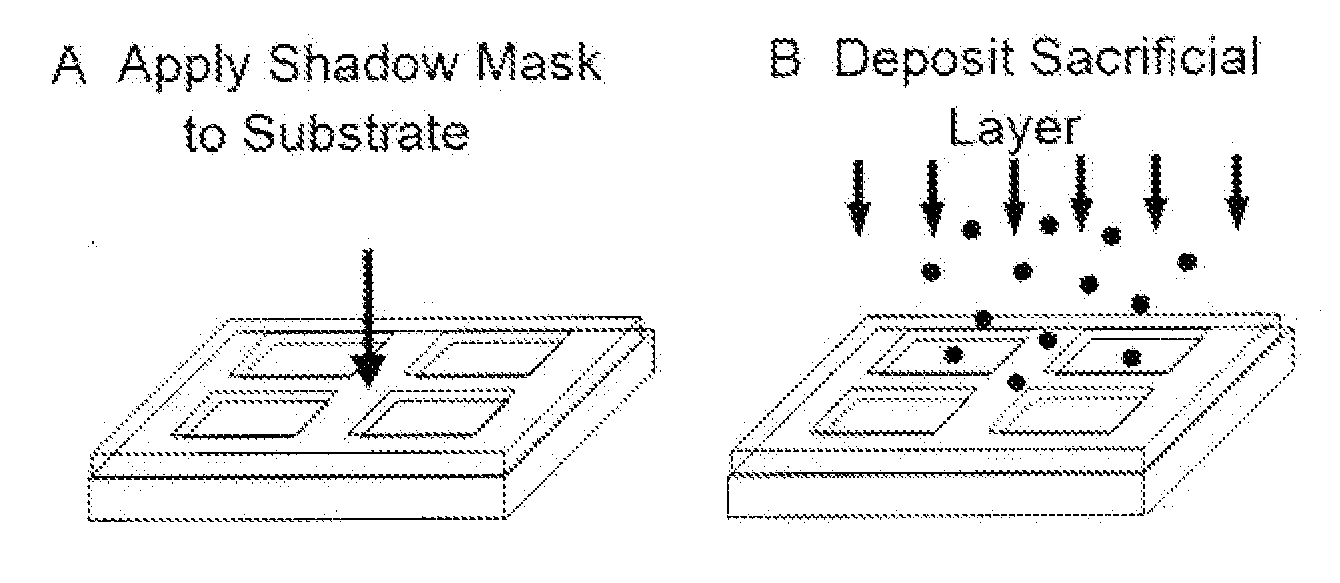

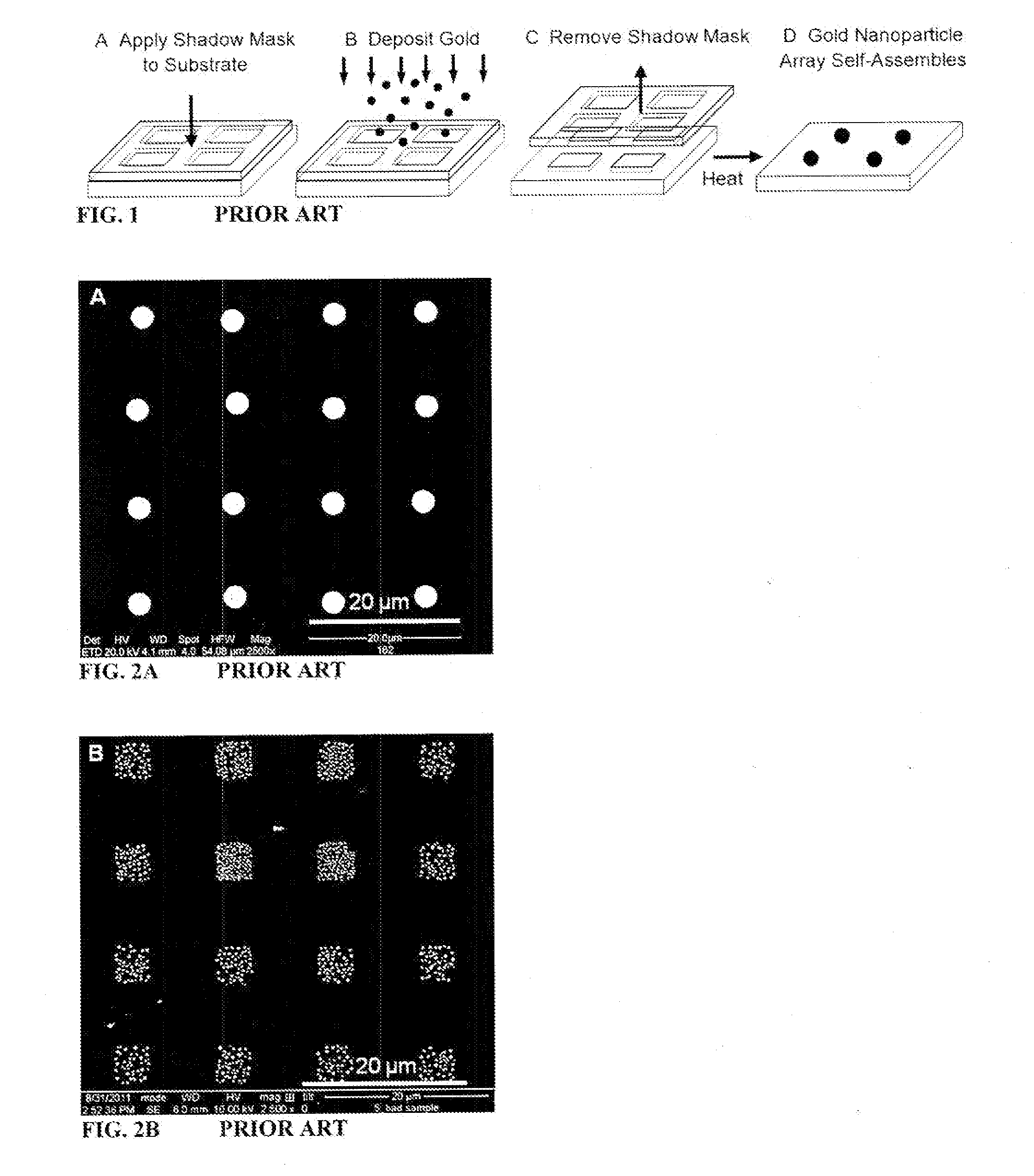

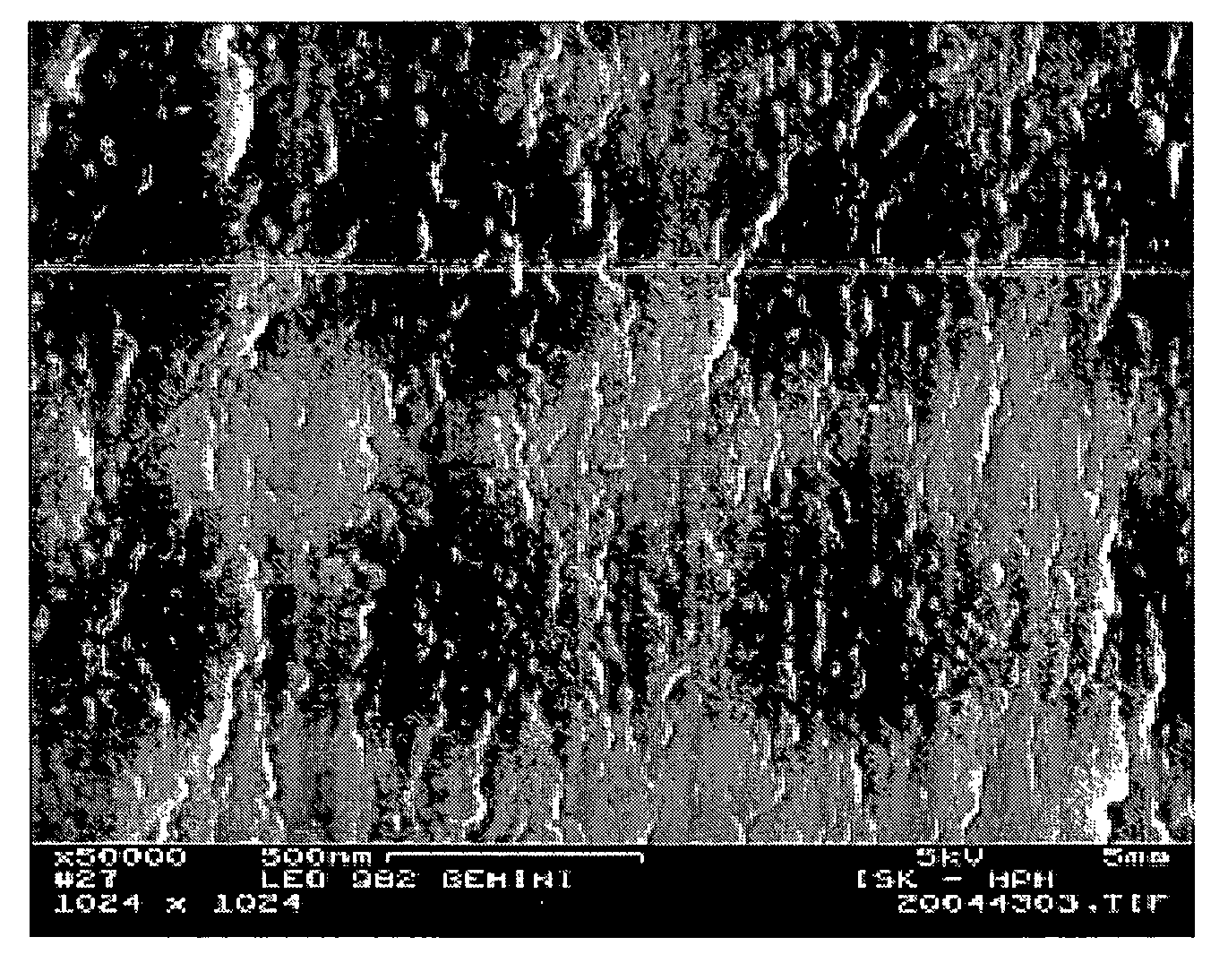

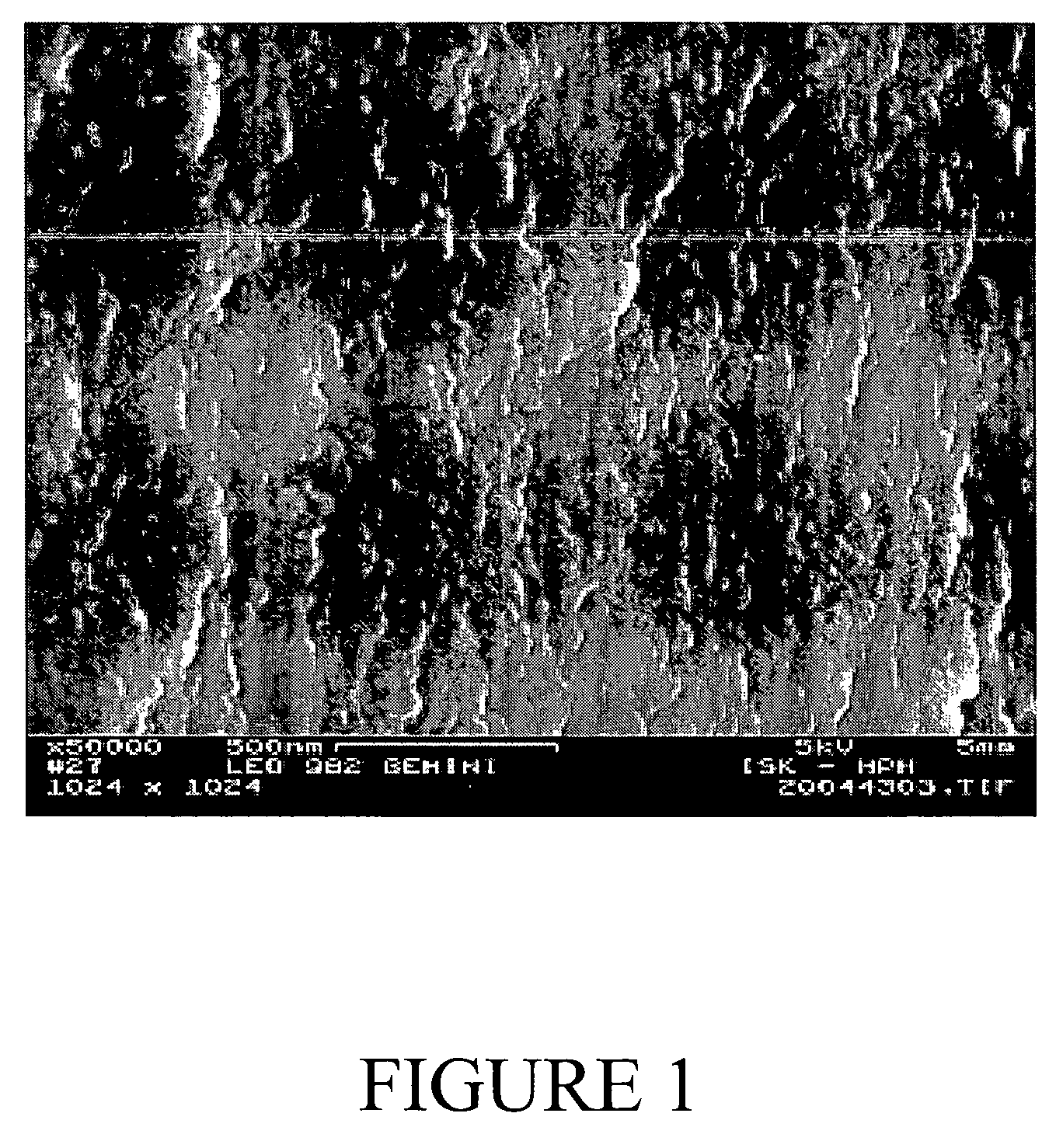

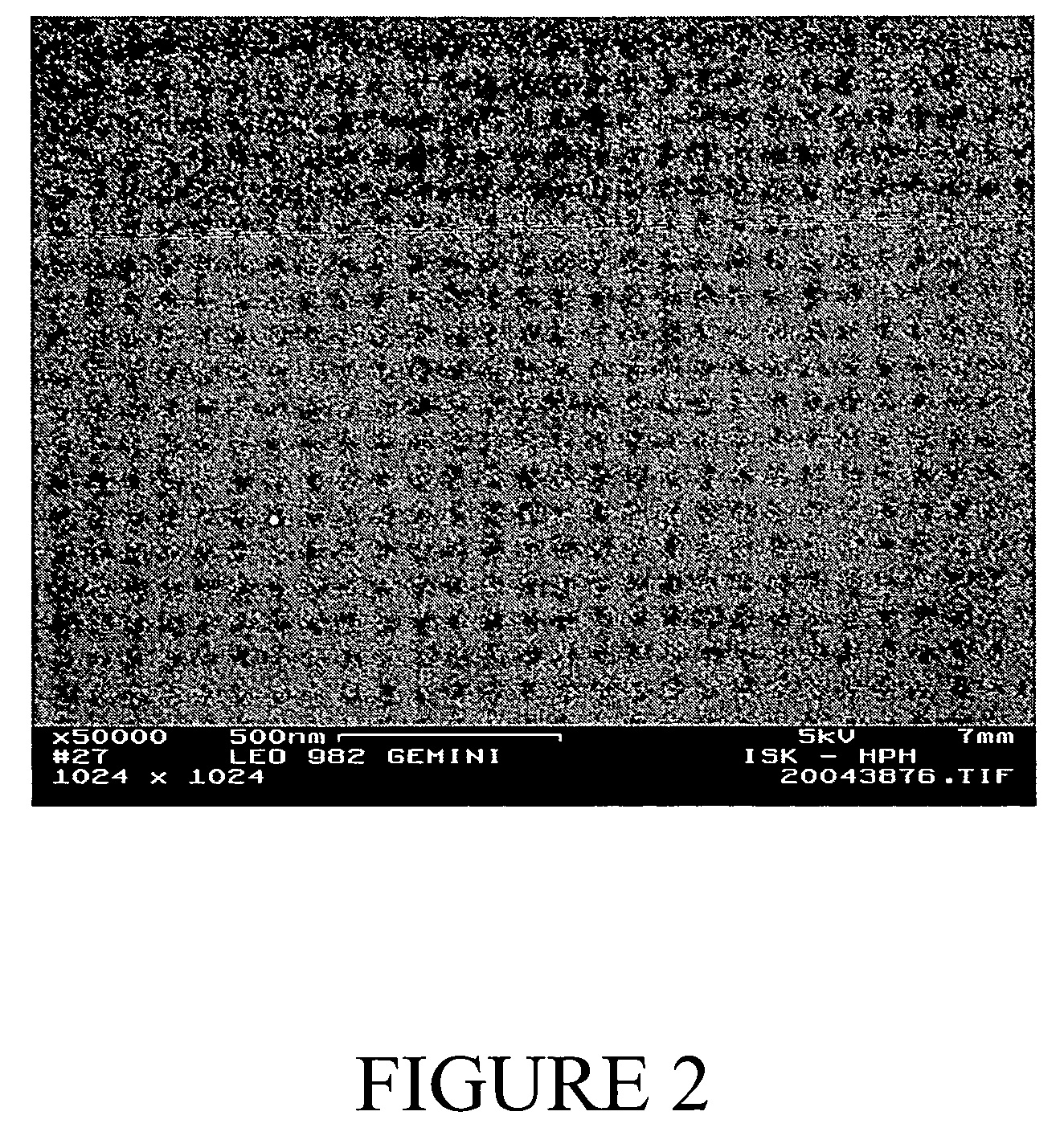

Self-assembly of small structures

ActiveUS20130273340A1Reduce areaMade preciselySpecific nanostructure formationMaterial nanotechnologySelf-assemblyMaterials science

Small structures are formed by applying to a substrate a structural material and a layer of a sacrificial material having a lower surface energy than the structural material, to form an intermediate product. The substrate is then heated to a temperature at which the sacrificial material evaporates or sublimes and the structural material is mobilized. The sacrificial material is permitted to evaporate or sublime, an area of the substrate covered by the sacrificial material to diminish, and the structural material to agglomerate on the remaining sacrificial material to form a structure.

Owner:TEMPLE UNIVERSITY

Composite materials containing carbon nanoparticles

InactiveUS7780875B2Adversely affecting the physical and chemical stabilityMaterial nanotechnologyPigmenting treatmentCarbon NanoparticlesOrganic polymer

The present invention relates to a process of producing composite materials by a sol / gel-process, comprising carbon nanoparticles and organic polymer material. The invention further relates to composite materials, which are manufactured with the use of said sol / gel technology.

Owner:CINVENTION AG

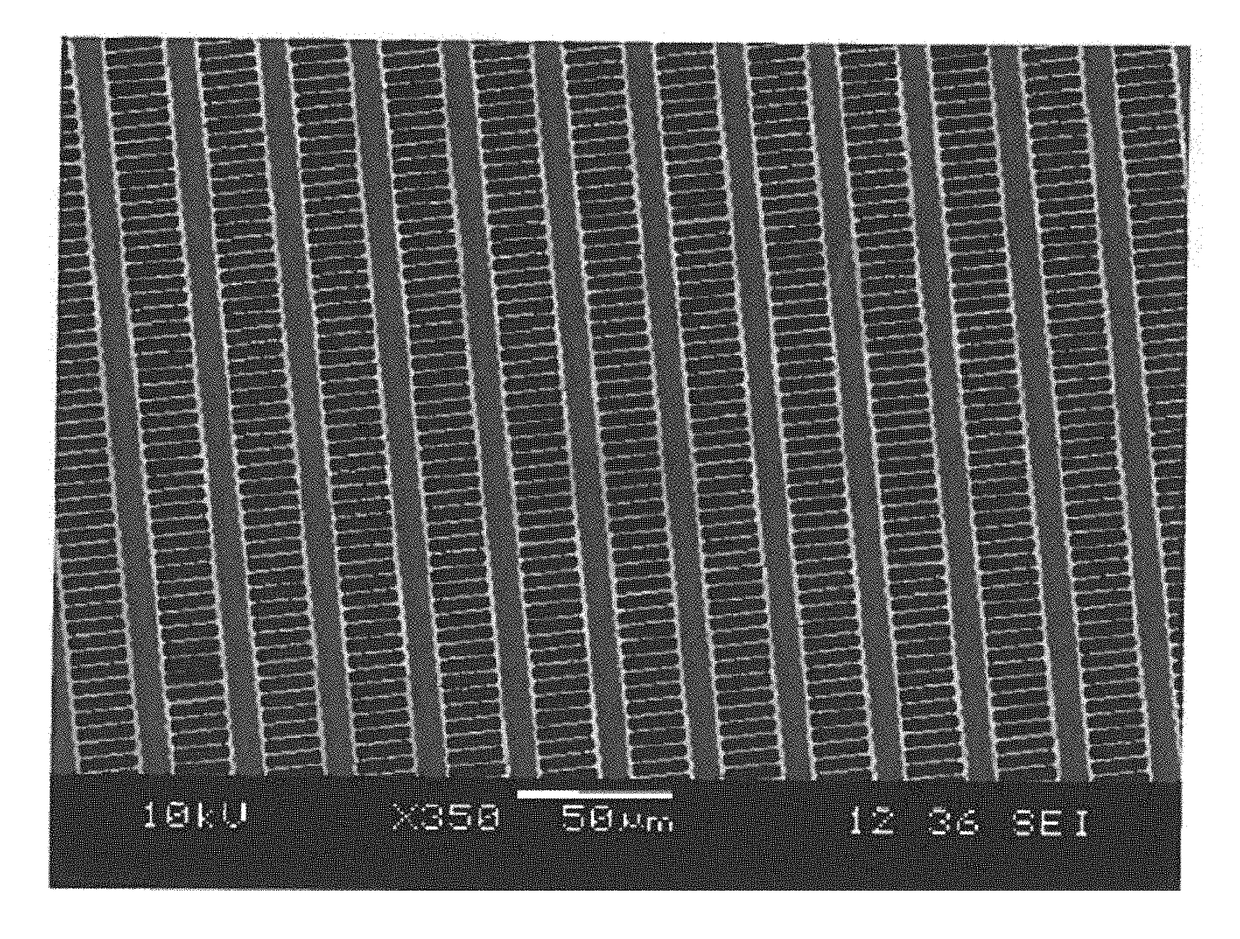

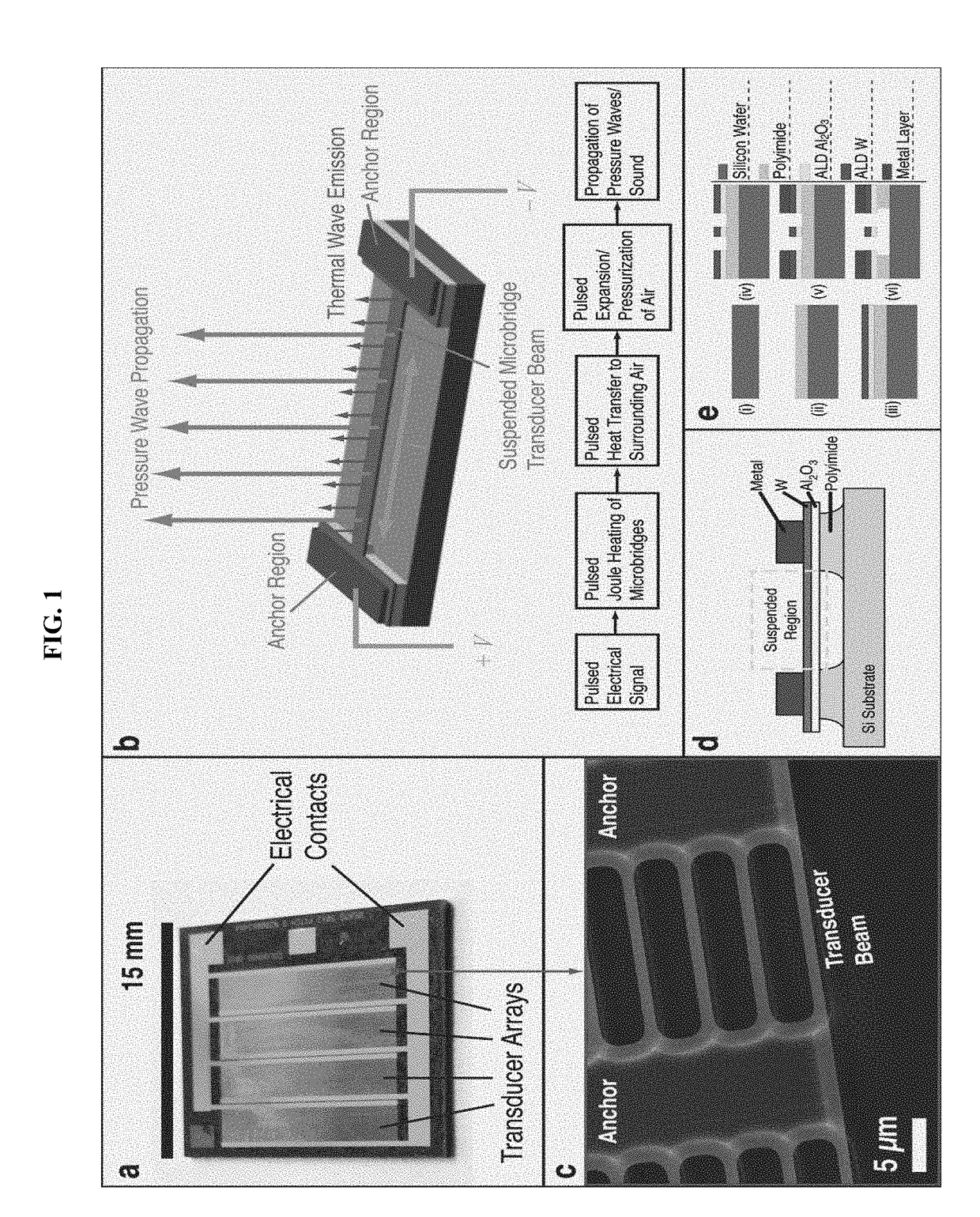

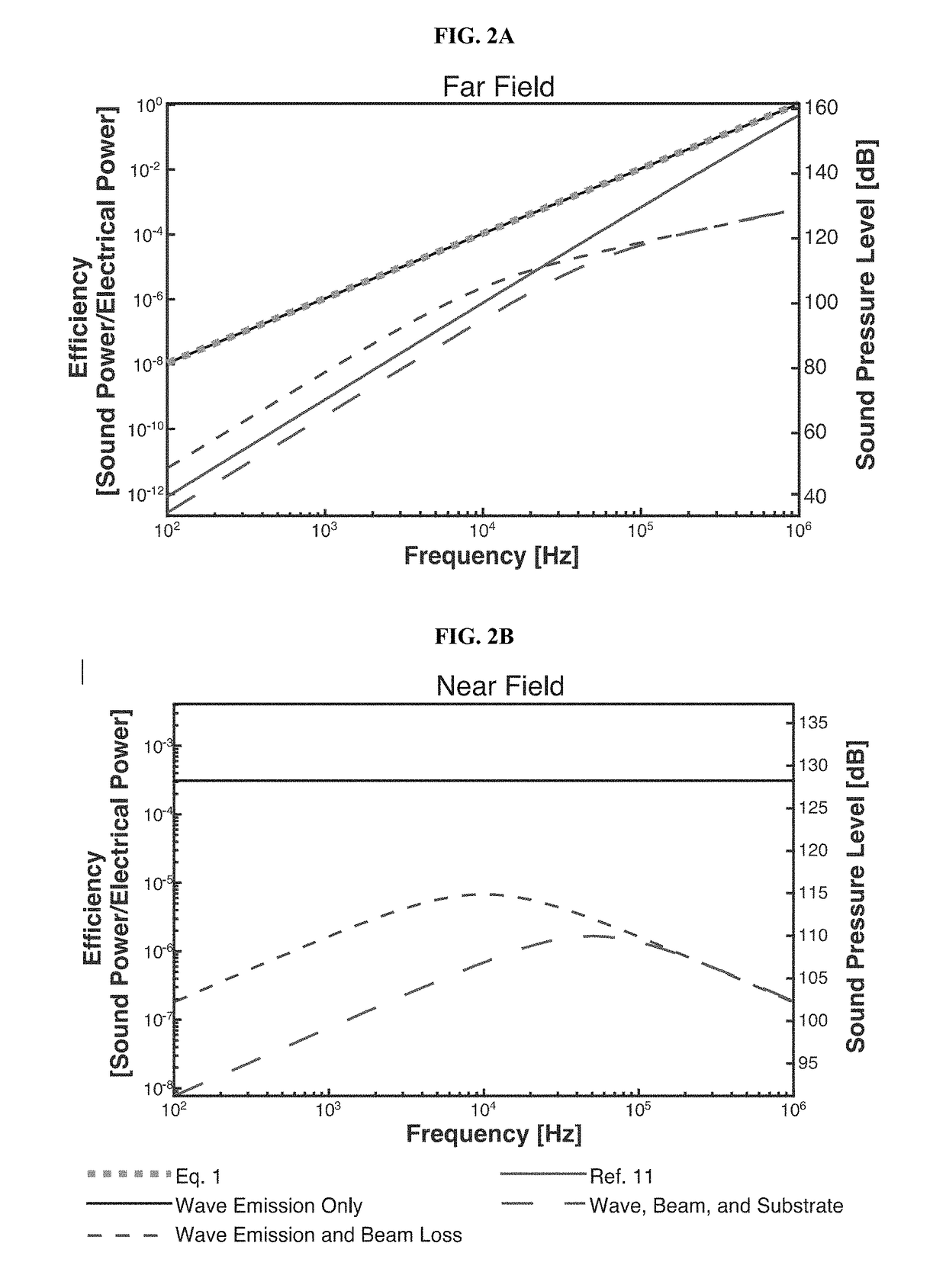

Thermal and thermoacoustic nanodevices and methods of making and using same

ActiveUS20170332179A1Avoid dependenceSpecific nanostructure formationNanostructure assemblyThermoacousticsEngineering

In one aspect, the present invention provides nano-scale heaters, such as nano-scale thermoacoustic loudspeakers comprising suspended metal nanobridges prepared using atomic layer deposition (ALD). The loudspeakers of the invention are capable of producing audible sound when stimulated with an electrical current or other energetic stimulus. In another aspect, the present invention provides methods of preparing and using such nanodevices.

Owner:UNIV OF COLORADO THE REGENTS OF

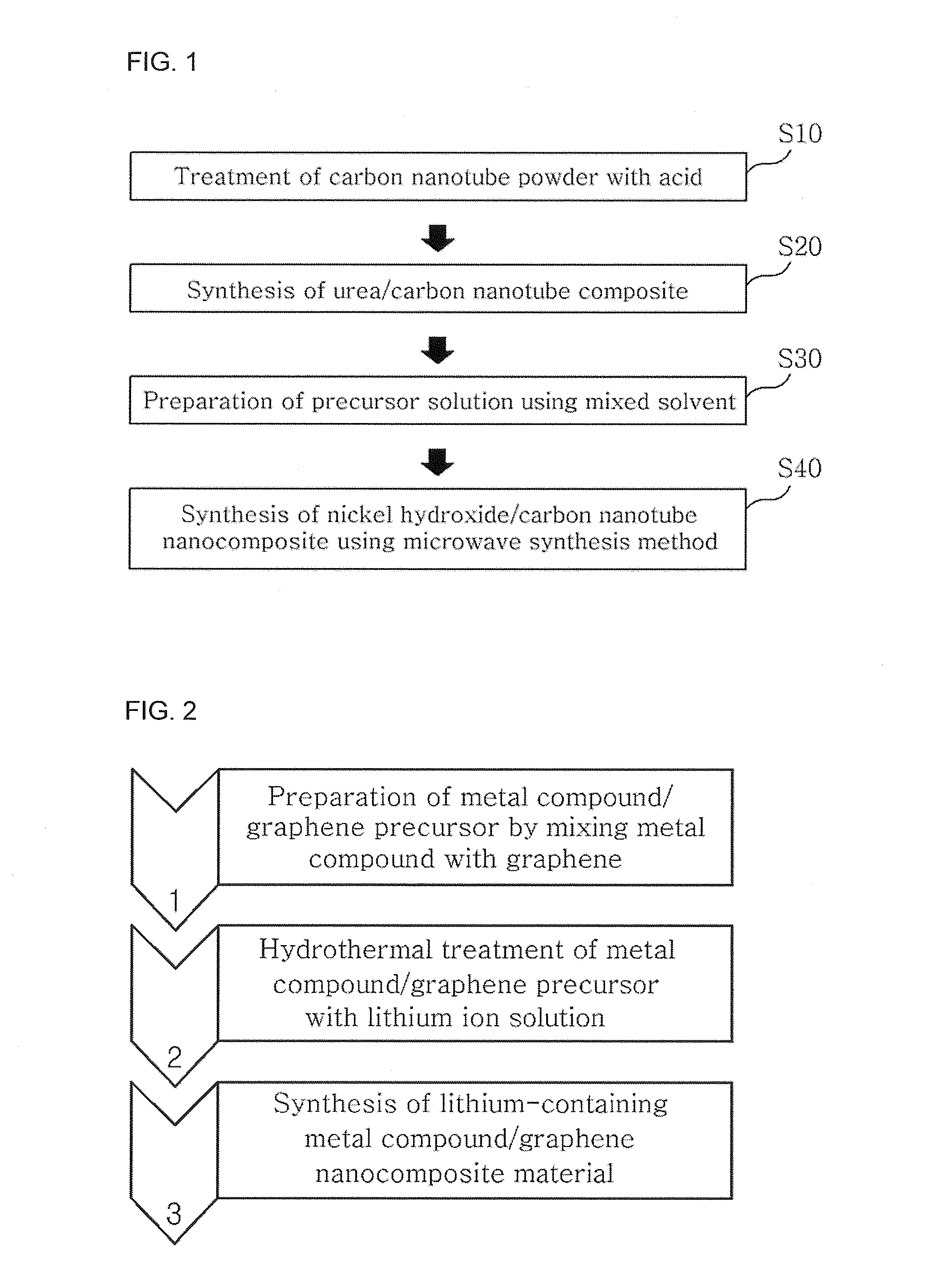

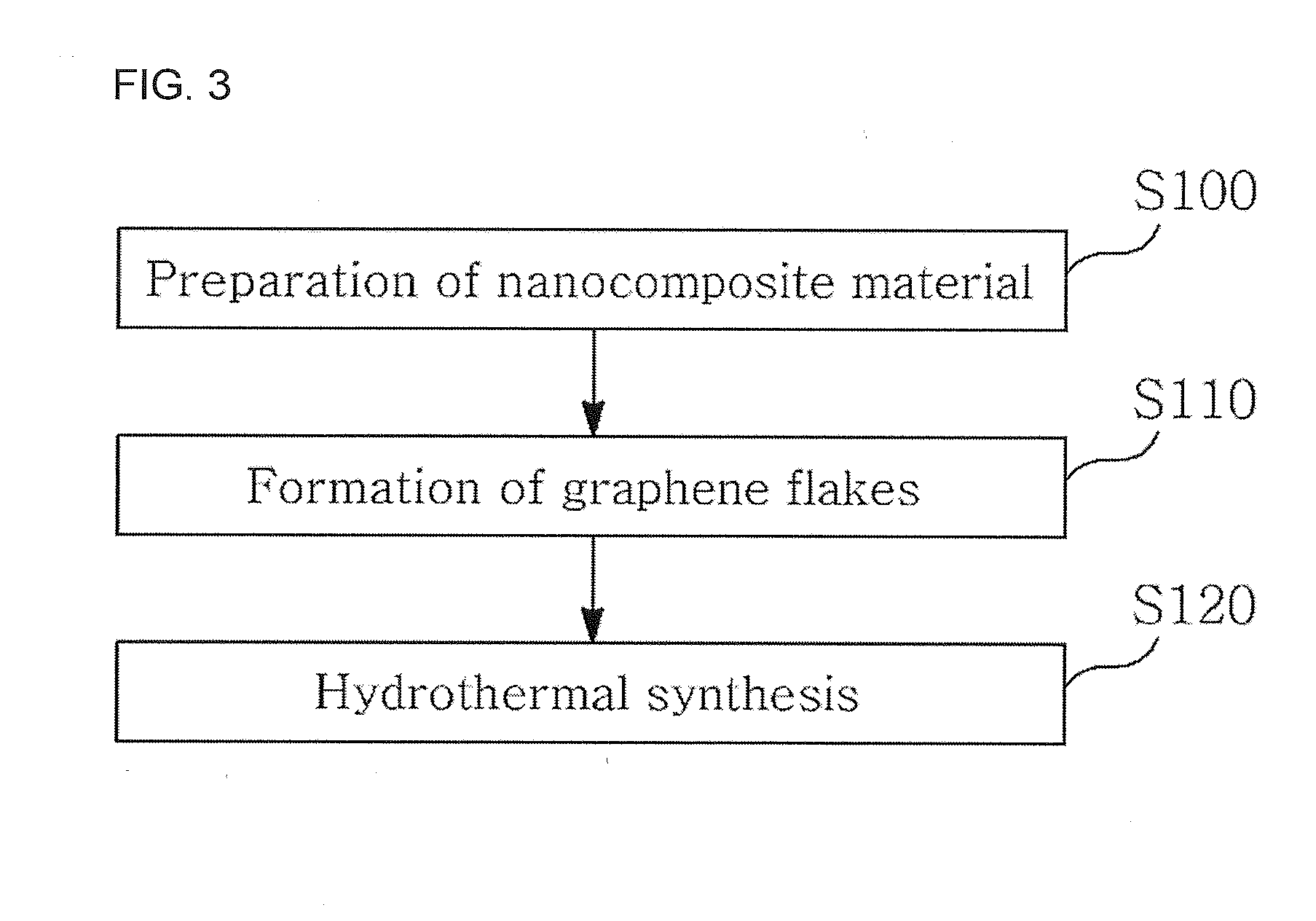

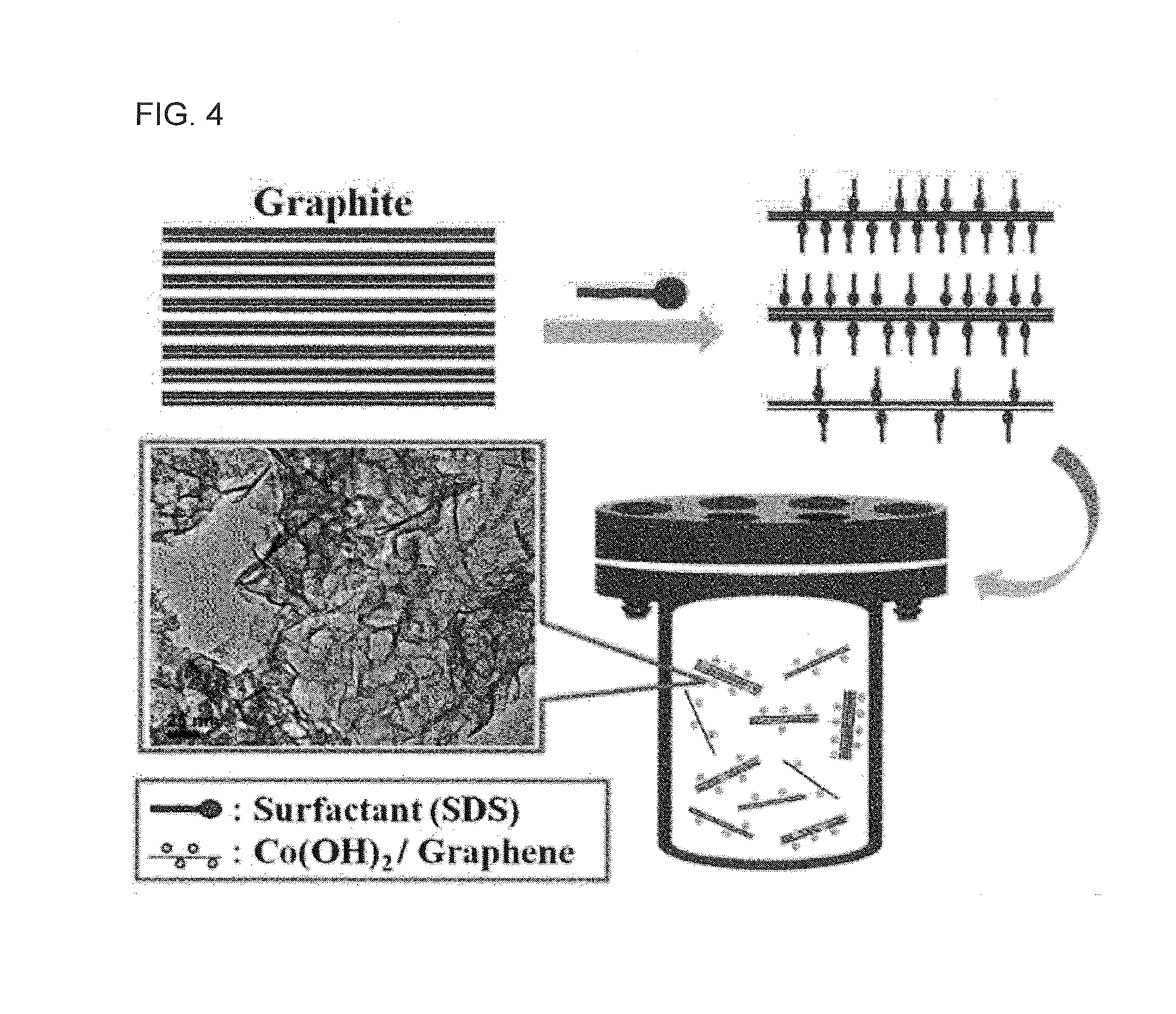

Method for preparing metal oxide-graphene nanocomposite and method for preparing electrode using metal oxide-graphene nanocomposite

InactiveUS20160218353A1Reduce processing stepsReduce processing costsSpecific nanostructure formationHybrid capacitor electrodesGraphene nanocompositesGraphene flake

Disclosed is a method of preparing a metal oxide-graphene nanocomposite, including preparing a nanocomposite material, forming graphene flakes by pretreating the nanocomposite material, and hydrothermally synthesizing the pretreated nanocomposite material. A method of manufacturing an electrode using the metal oxide-graphene nanocomposite is also provided. According to this invention, the metal oxide-graphene nanocomposite is synthesized from inexpensive graphite through one-step processing using only a surfactant, in place of conventional methods using oxidants, reductants and high-temperature heat, thereby lowering the number of processing steps and processing costs. Also, in the fabrication of the electrode, low electrical resistance characteristic of graphene is applied as it is, in place of the conventional use of active material, conductive material and binder, thereby exhibiting desired processing efficiency without the addition of the conductive material. Furthermore, highly pure graphene is prepared in a short time and various metal oxide active materials suitable for use in energy storage devices, for example, unary, binary, and multicomponent metal oxides, is formed through one-step processing, and necessary oxides having desired weight ratios {cobalt oxide (CoO), tricobalt tetraoxide (Co3O4), and cobalt hydroxide [Co(OH)2]} can be easily prepared, and thus very wide application ranges (secondary batteries, gas sensors, etc.) are expected.

Owner:AJOU UNIV IND ACADEMIC COOP FOUND

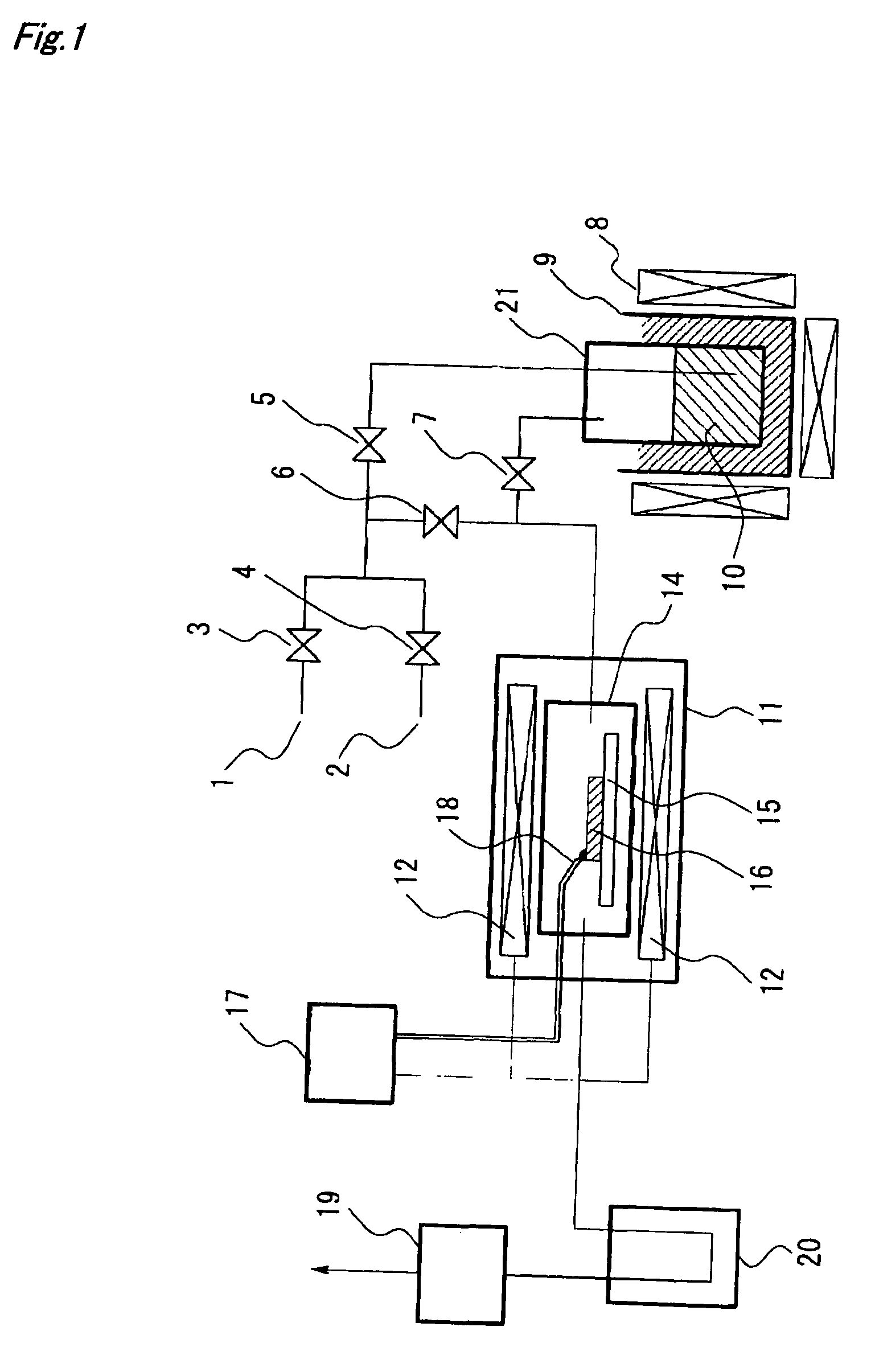

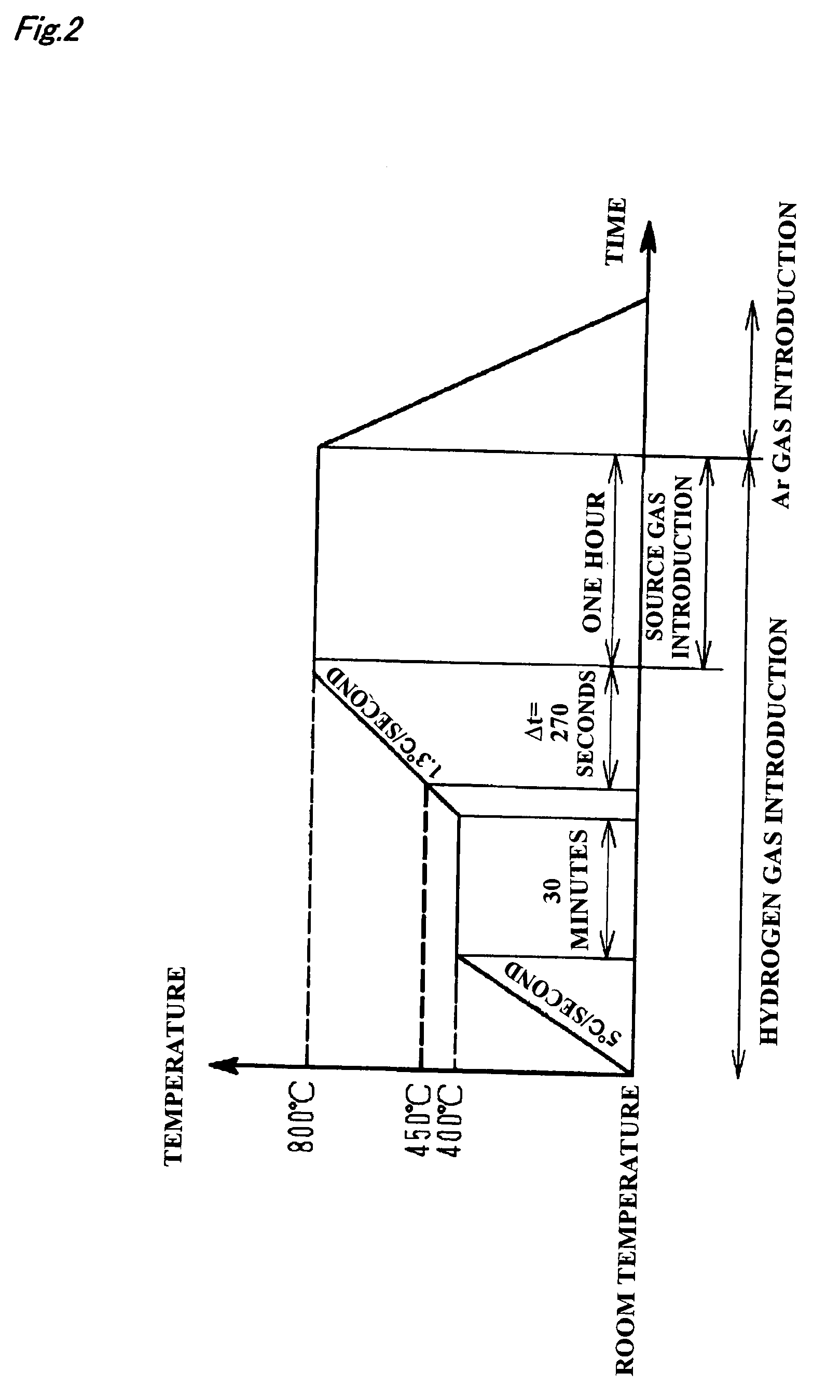

Carbon nanotube assembly and manufacturing method thereof

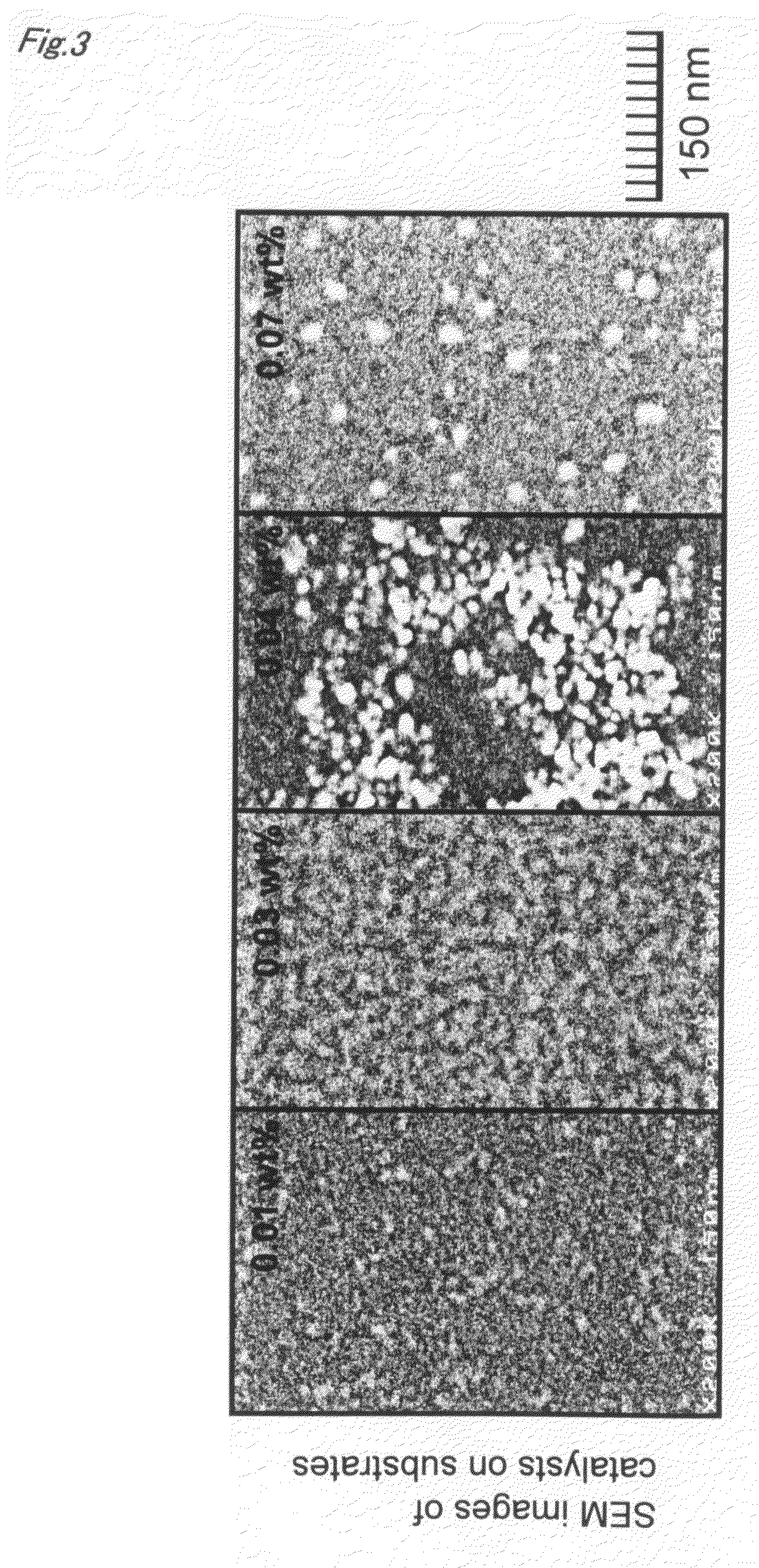

ActiveUS7731930B2Increase deposition densityEasy to optimizeSpecific nanostructure formationMaterial nanotechnologyReaction temperatureCarbon nanotube

A method for manufacturing a carbon nanotube assembly including the steps of: forming metallic fine particles, having a predetermined particle diameter, on a substrate; heating the metallic fine particles to a predetermined temperature of 300° C. to 400° C. in a reducing atmosphere to cause reduction at surfaces thereof; heating the metallic fine particles to a predetermined reaction temperature in a reactor; and introducing an organic compound vapor into the reactor to grow carbon nanotubes on the metallic fine particles in such a way that a time during which the temperature of the metallic fine particles exceeds 450° C. is 600 seconds or fewer for the period of time before the growth of the carbon nanotubes is started after the heating of the metallic fine particles is started.

Owner:NIKON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com