Patents

Literature

120results about "Nanostructure assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

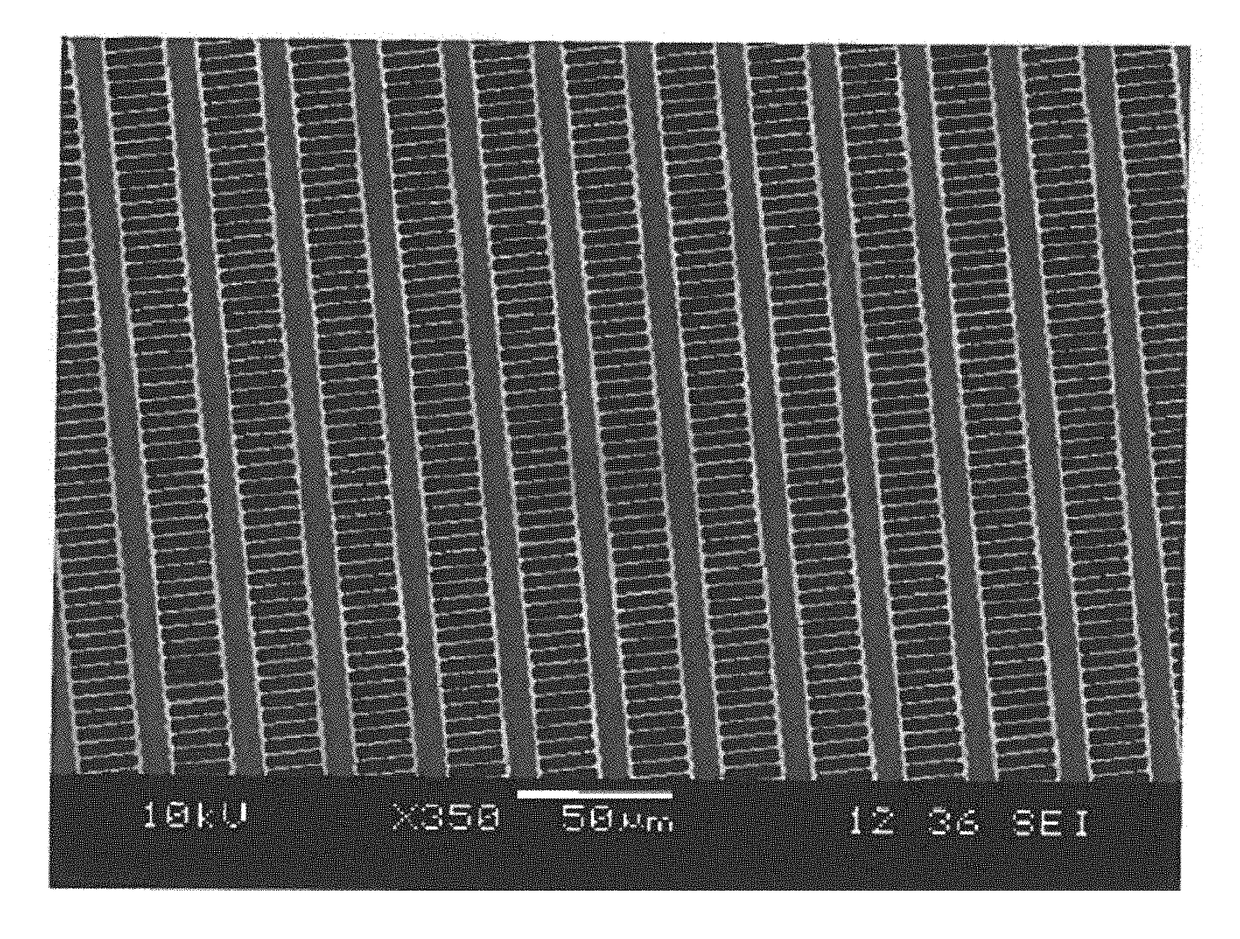

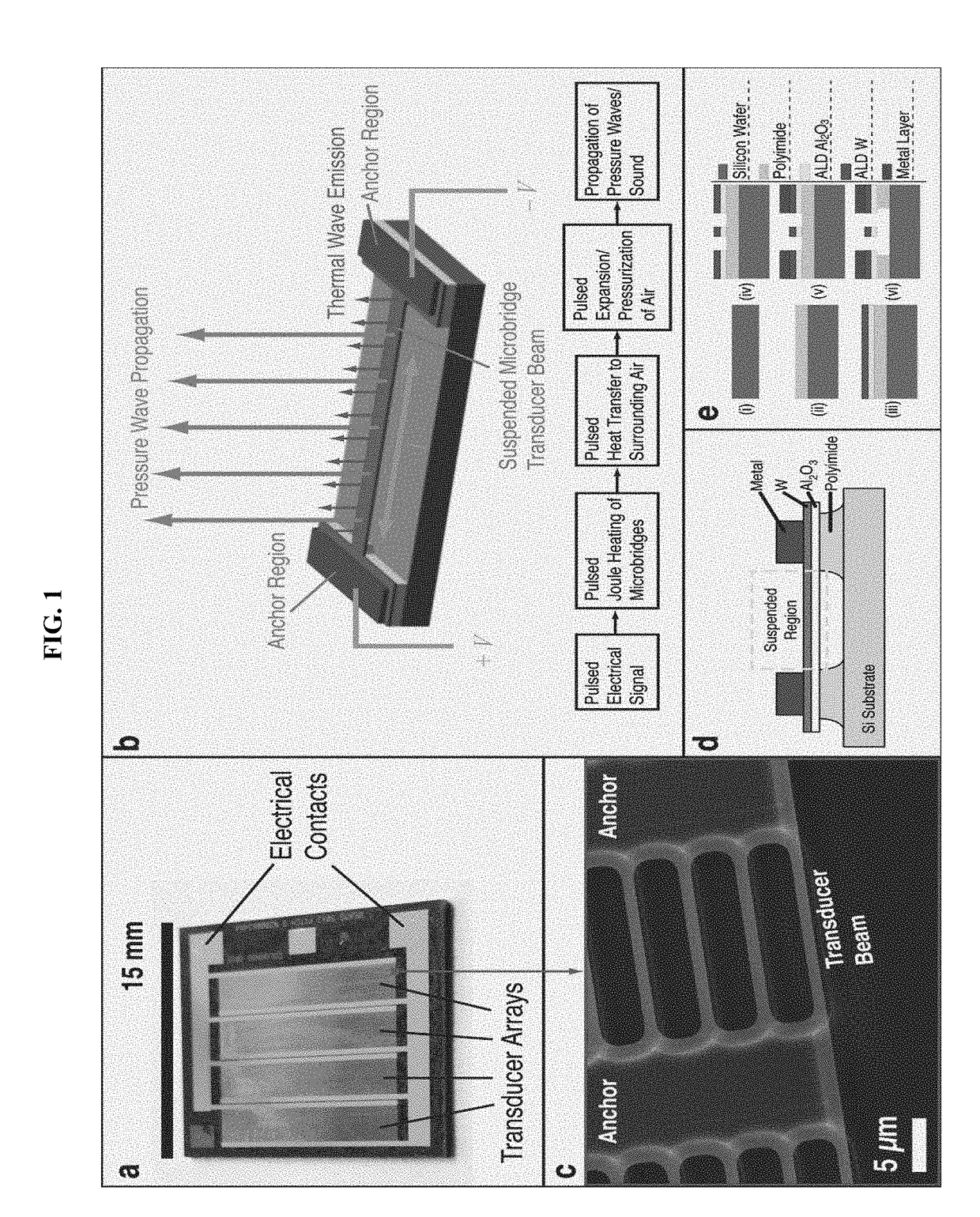

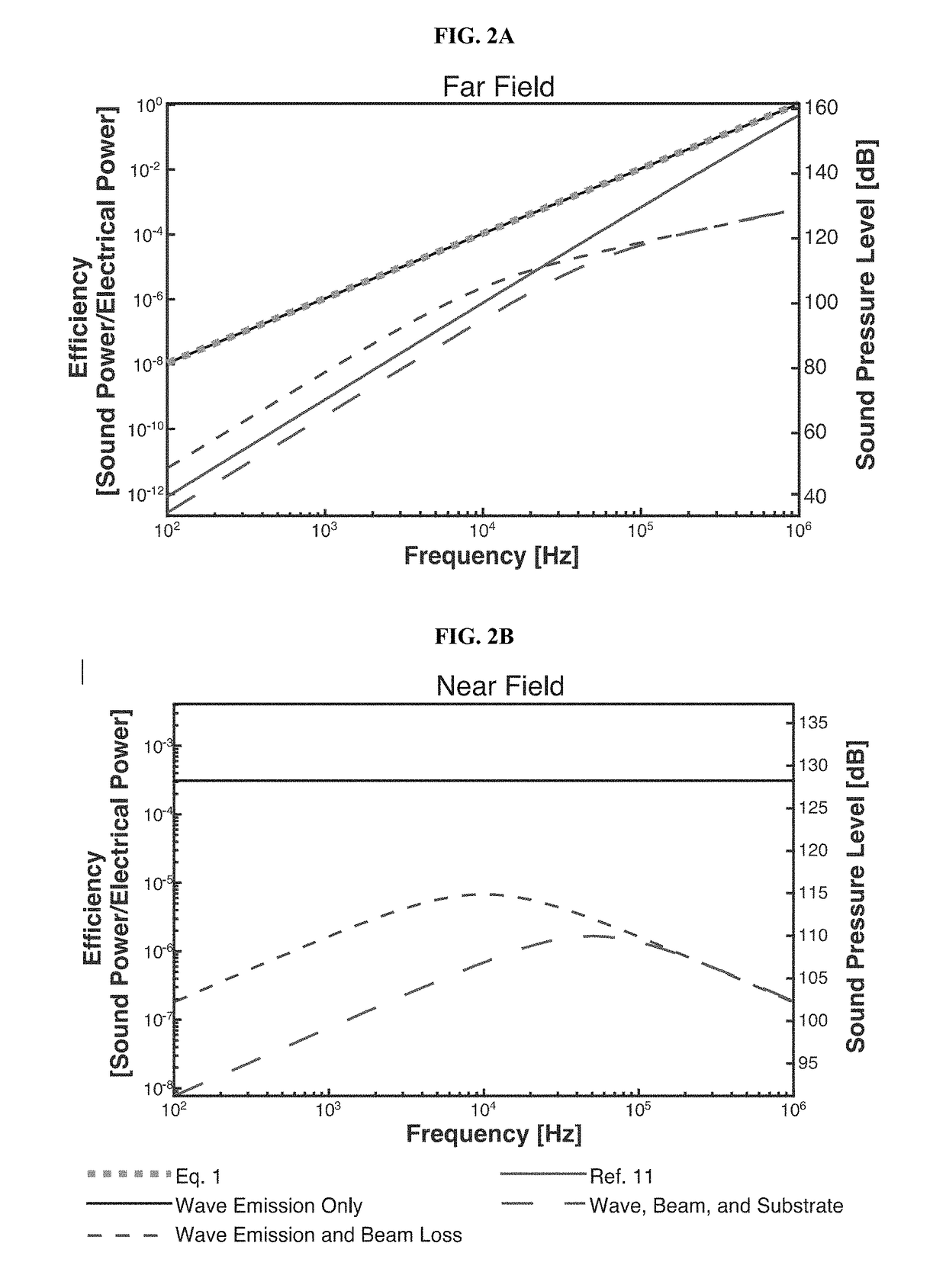

Thermal and thermoacoustic nanodevices and methods of making and using same

ActiveUS20170332179A1Avoid dependenceSpecific nanostructure formationNanostructure assemblyThermoacousticsEngineering

In one aspect, the present invention provides nano-scale heaters, such as nano-scale thermoacoustic loudspeakers comprising suspended metal nanobridges prepared using atomic layer deposition (ALD). The loudspeakers of the invention are capable of producing audible sound when stimulated with an electrical current or other energetic stimulus. In another aspect, the present invention provides methods of preparing and using such nanodevices.

Owner:UNIV OF COLORADO THE REGENTS OF

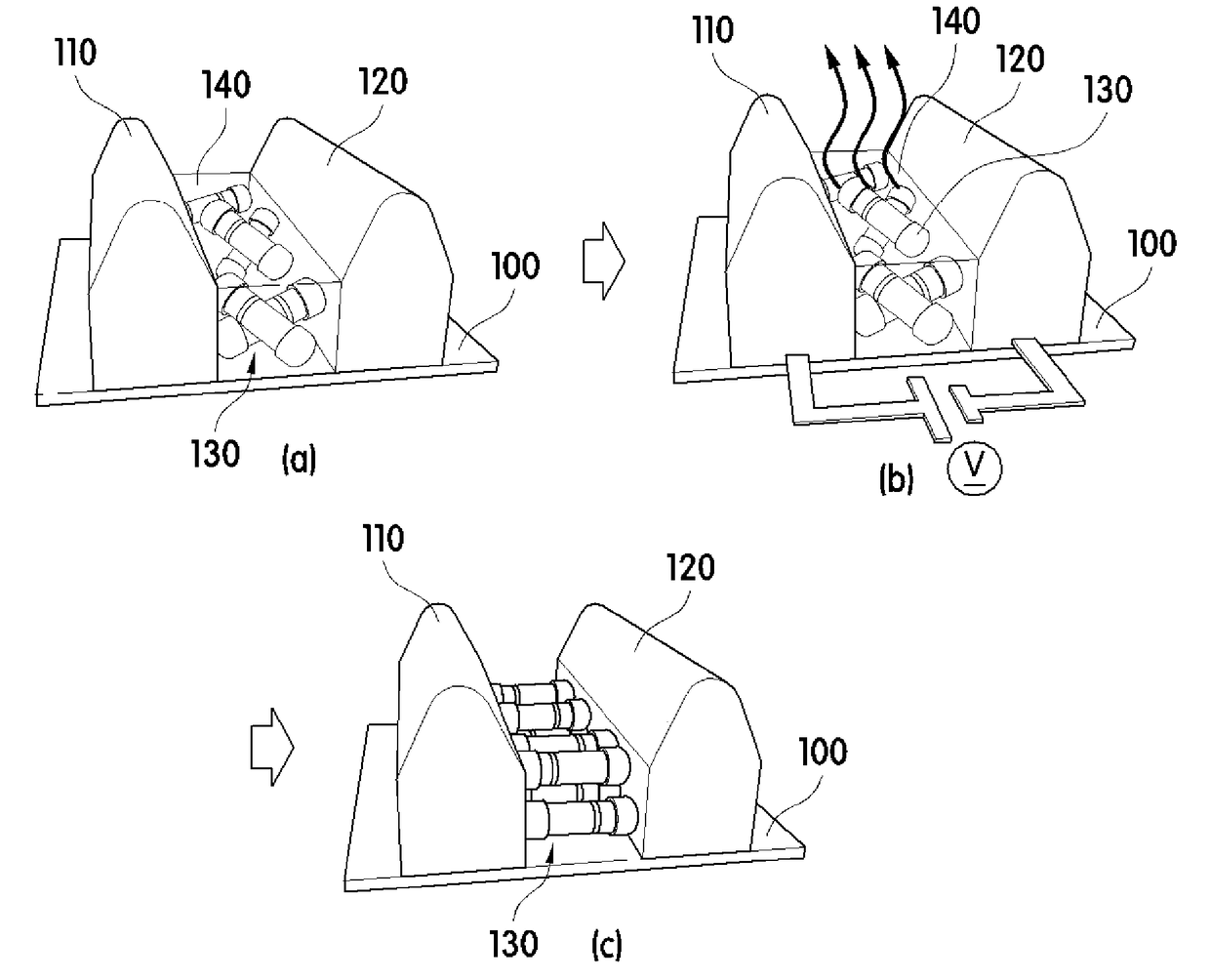

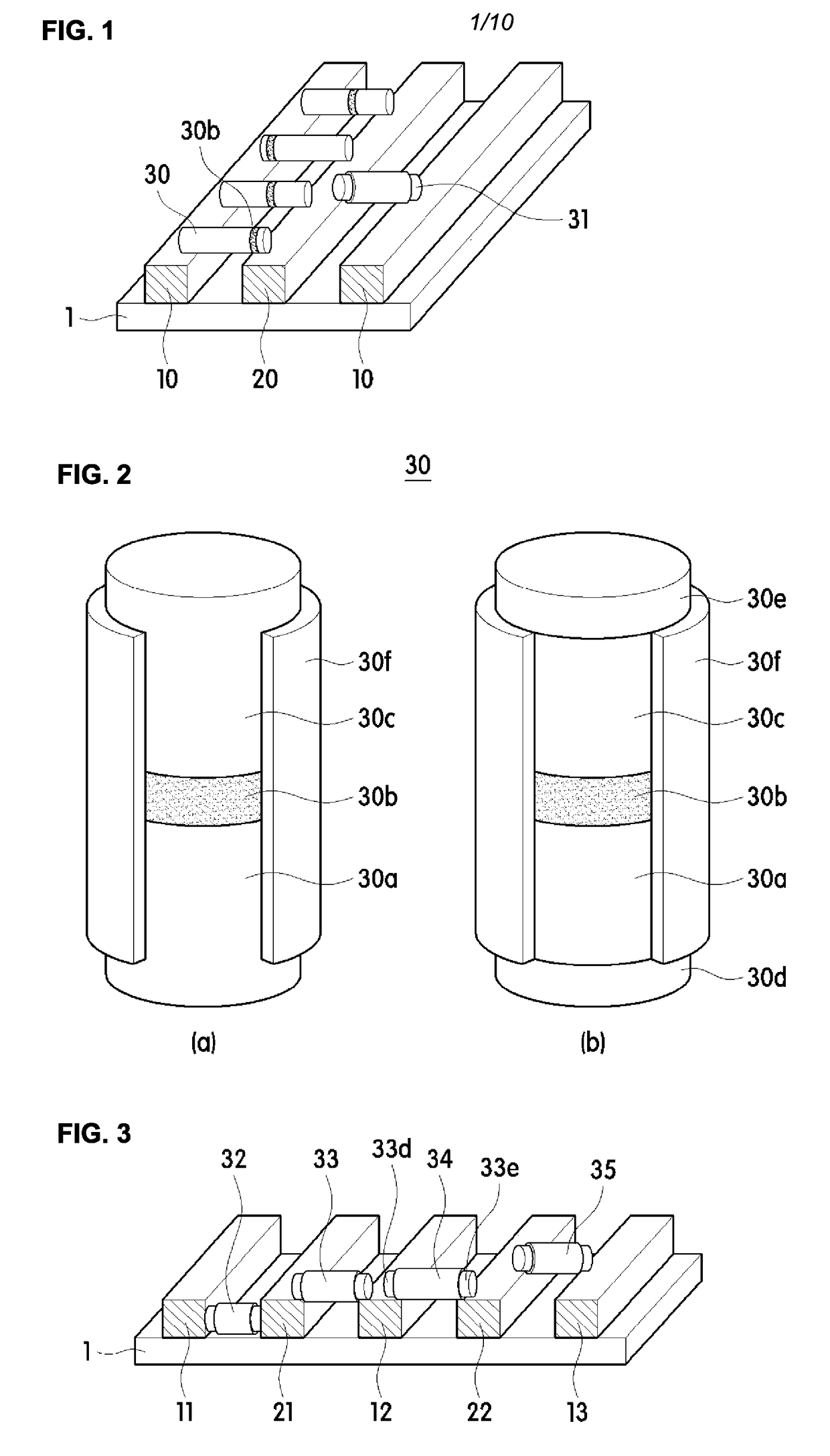

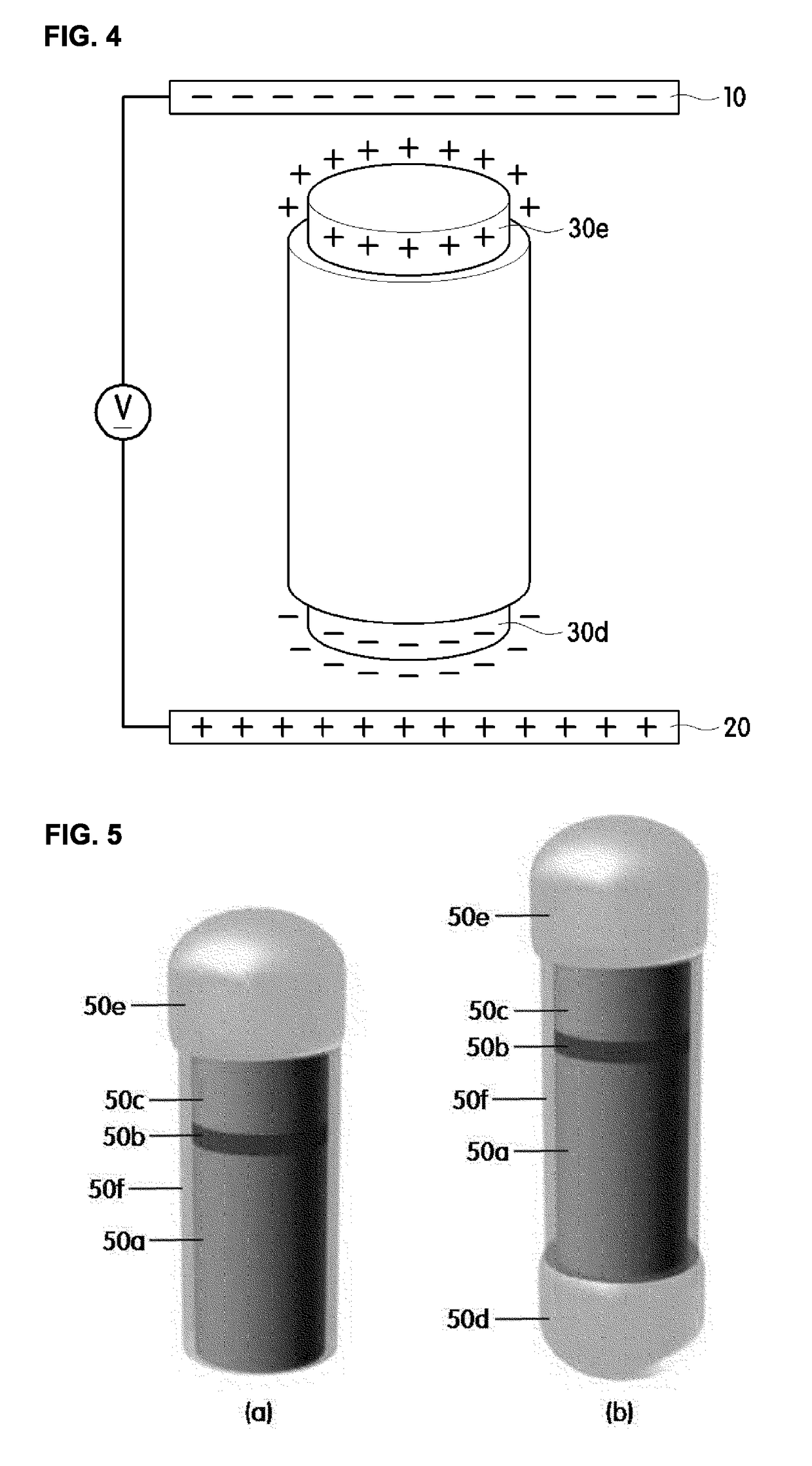

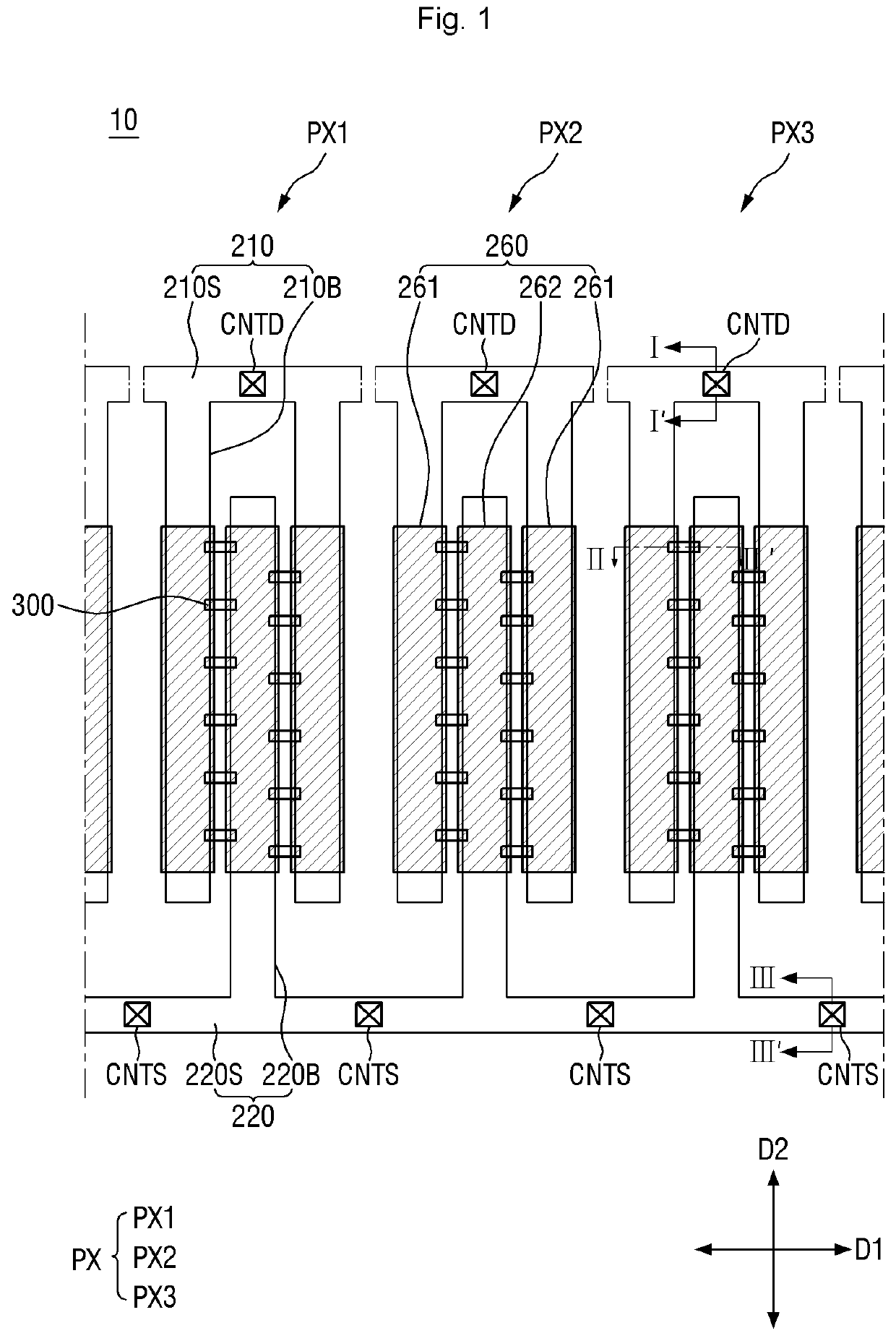

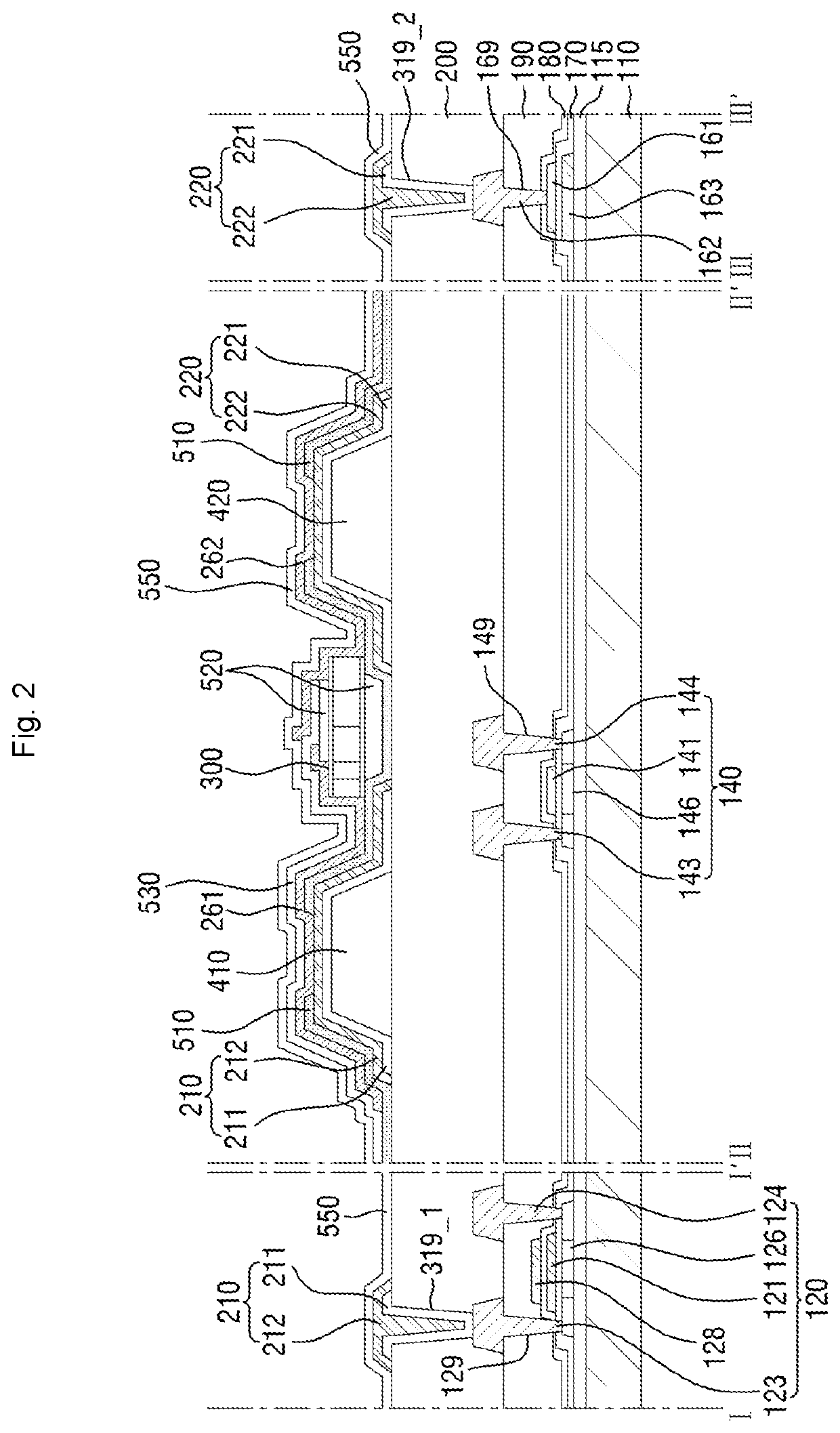

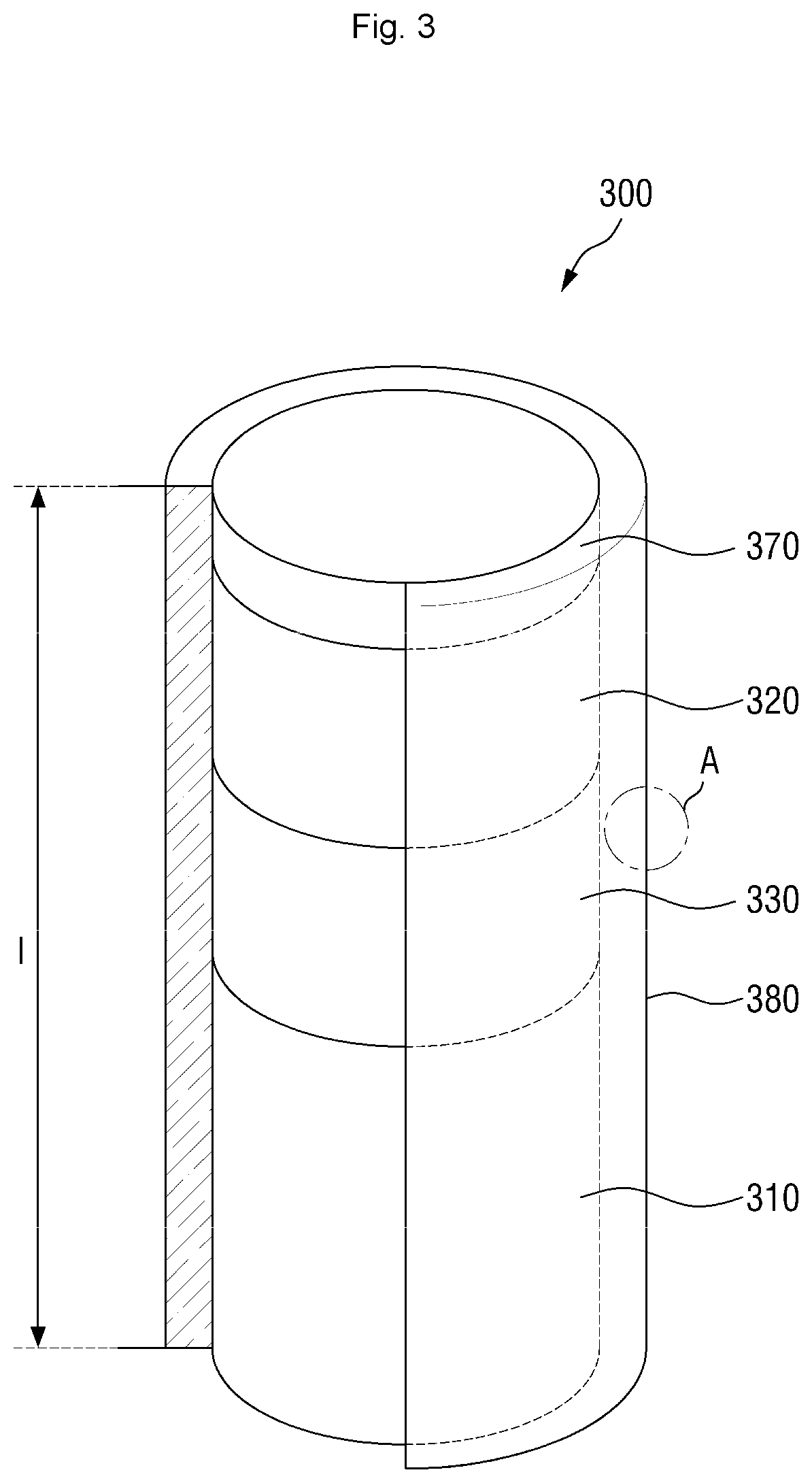

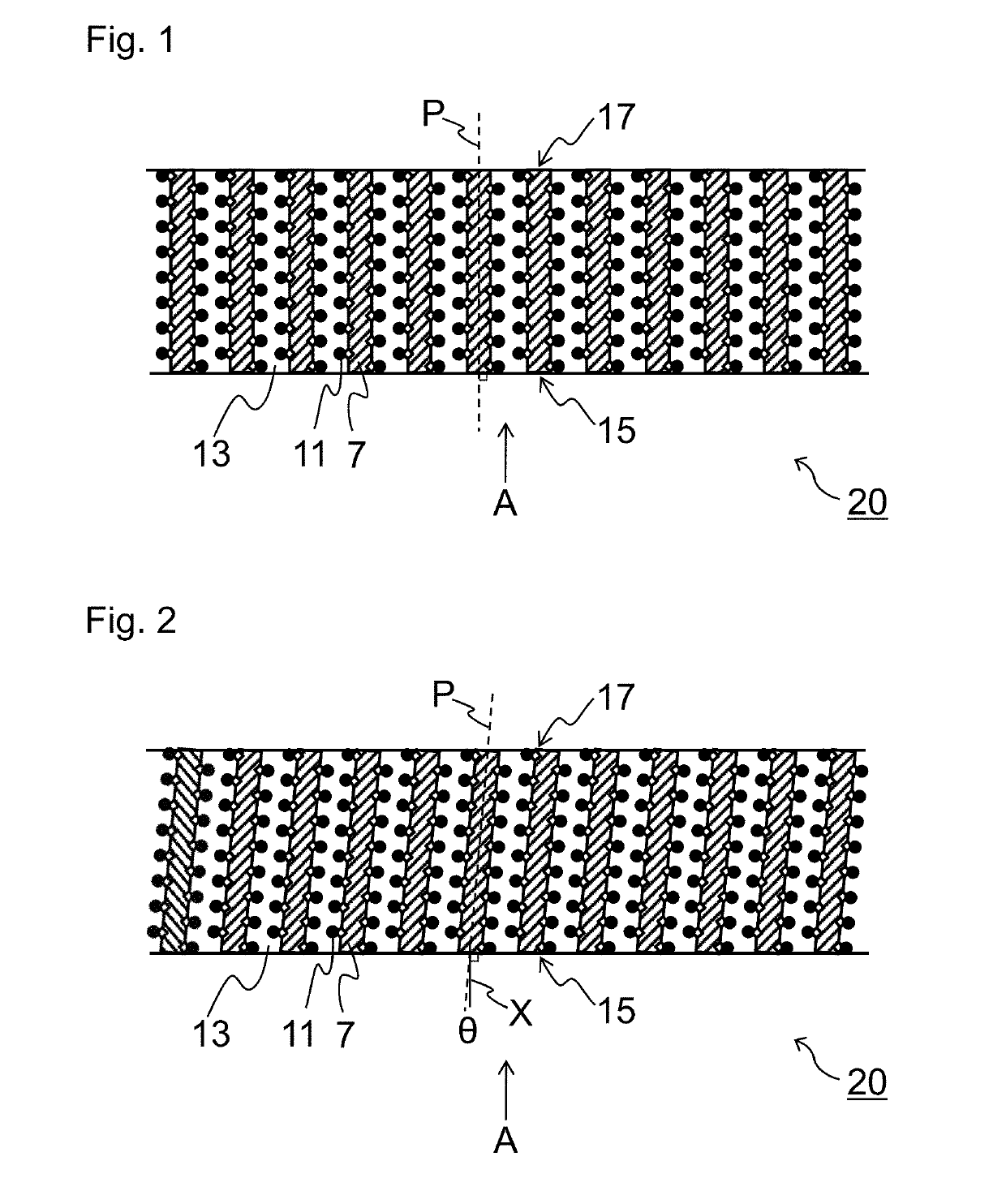

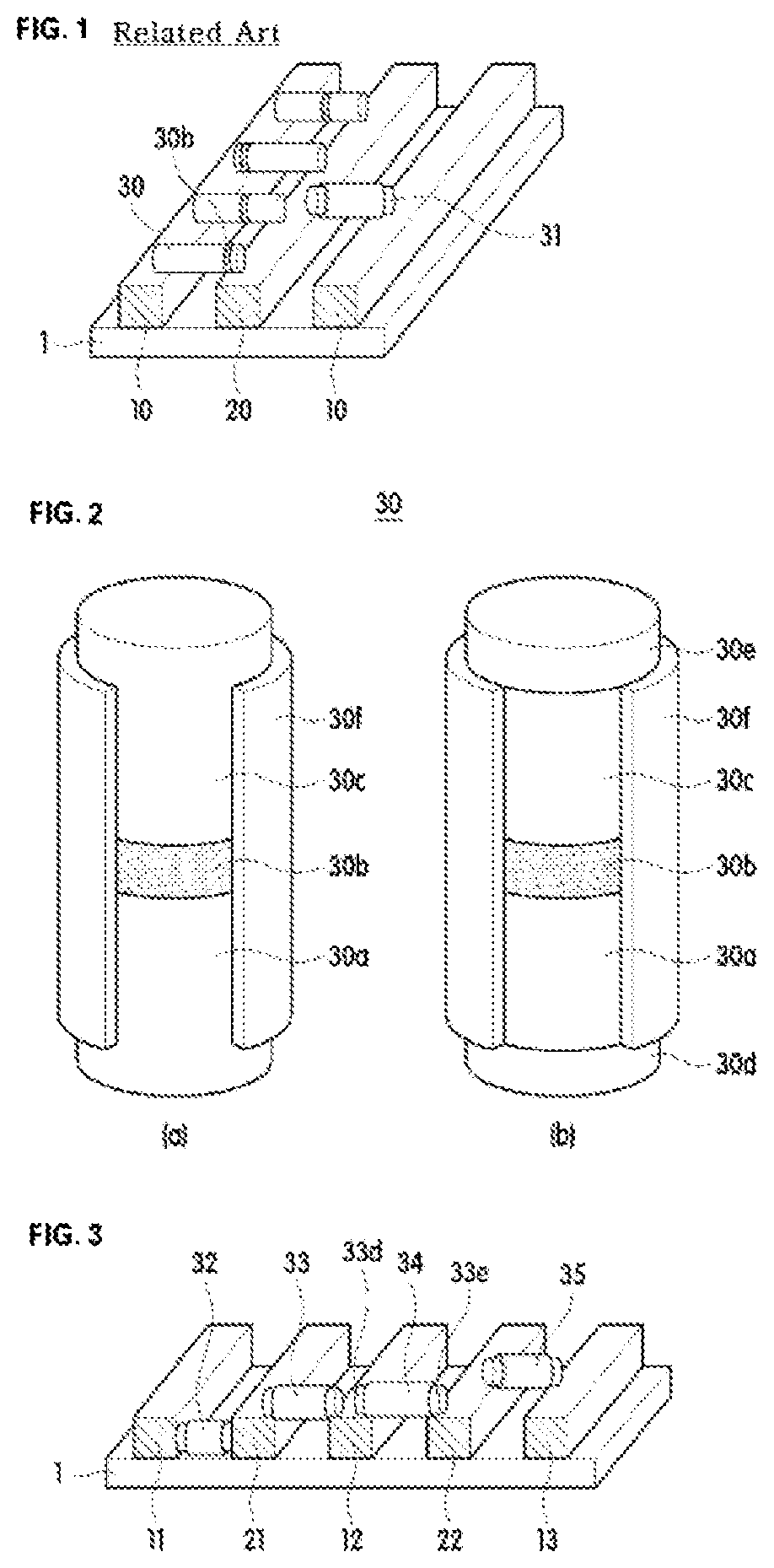

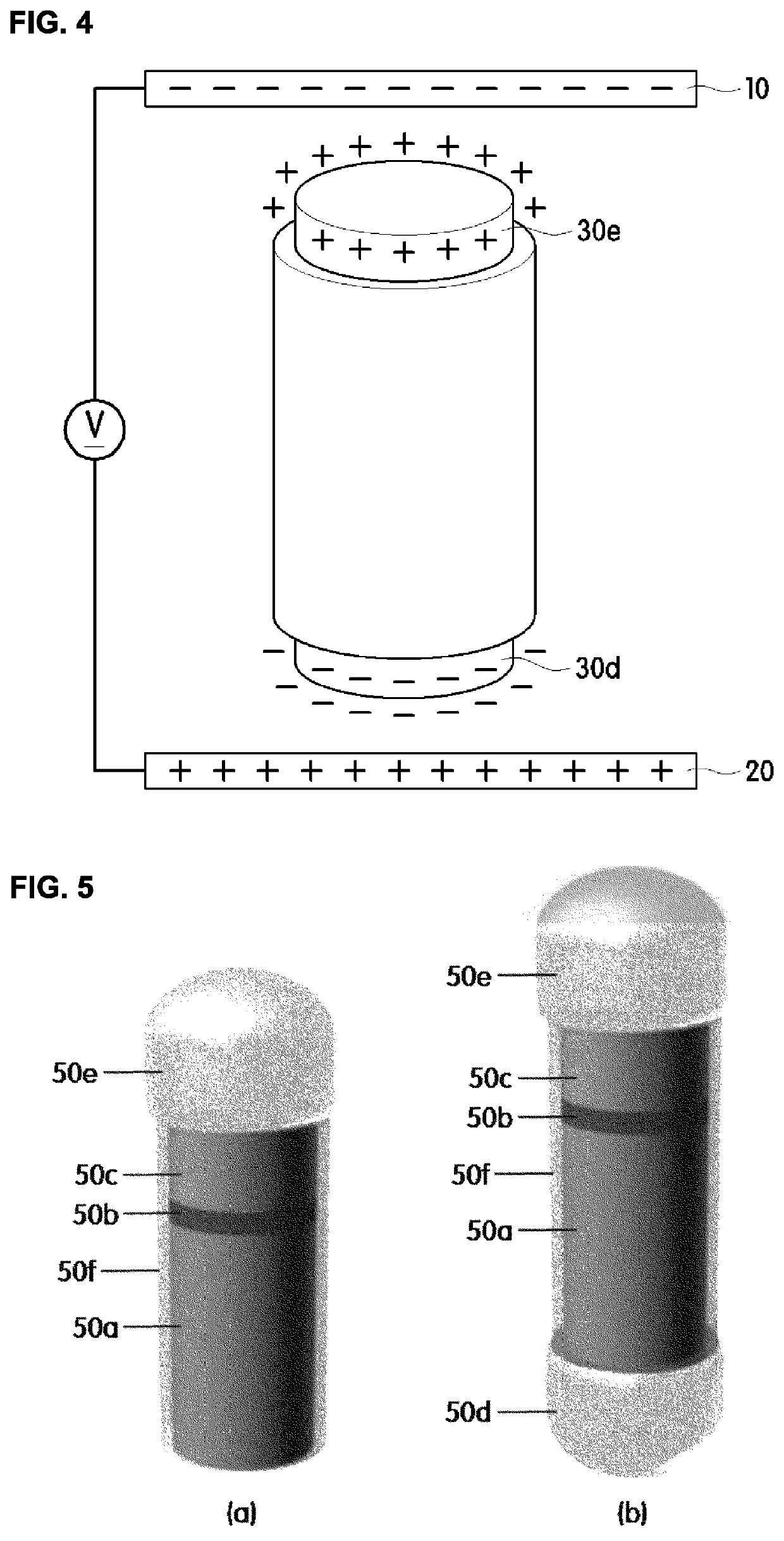

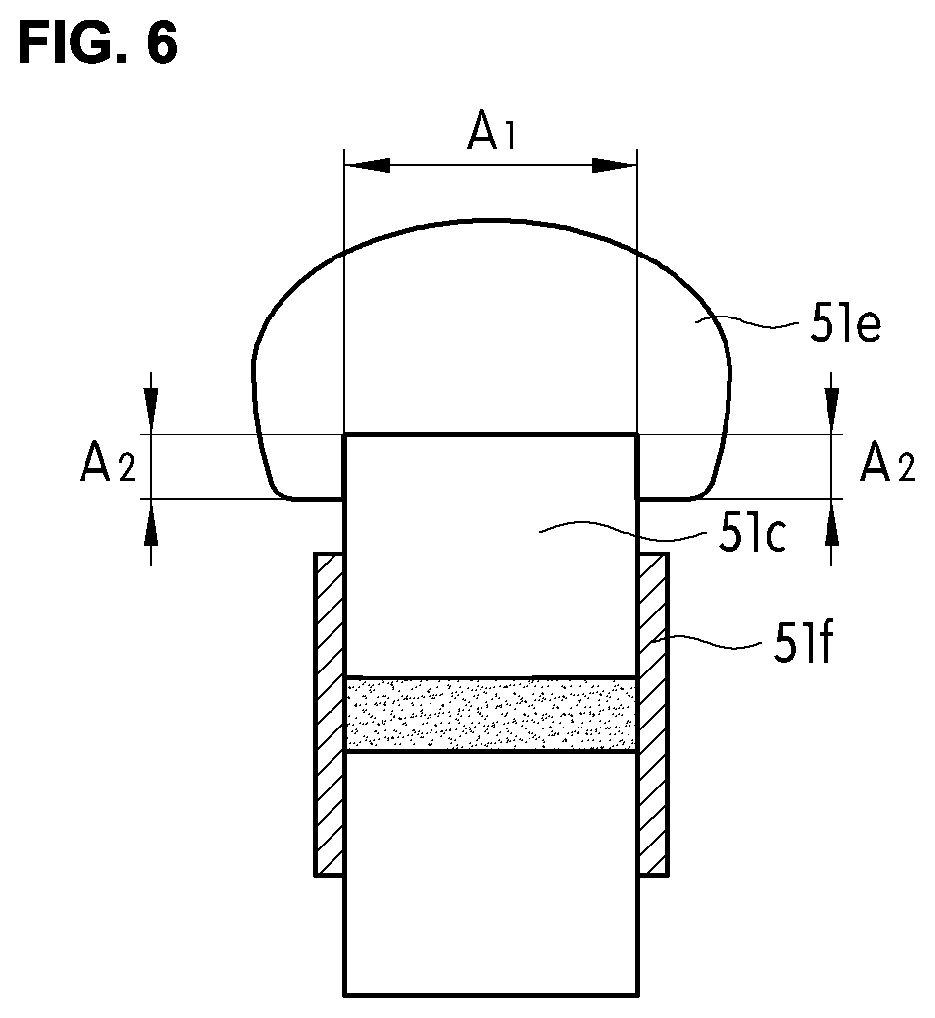

Micro-led element for horizontally-aligned assembly, method for manufacturing same, and horizontally-aligned assembly comprising same

ActiveUS20170317228A1Easy to layEasy alignmentNanostructure assemblySolid-state devicesElectricityEngineering

The present invention relates to a nano-scale light-emitting diode (LED) element for a horizontal array assembly, a manufacturing method thereof, and a horizontal array assembly including the same, and more particularly, to a nano-scale LED element for a horizontal array assembly that can significantly increase the number of nano-scale LED elements connected to an electrode line, facilitate an arrangement of the elements, and implement a horizontal array assembly having a very good electric connection between an electrode and an element and a significant high quantity of light when a horizontal array assembly having the nano-scale LED elements laid in a length direction thereof and connected to the electrode line is manufactured, a manufacturing method thereof, and a horizontal array assembly including the same.

Owner:SAMSUNG DISPLAY CO LTD

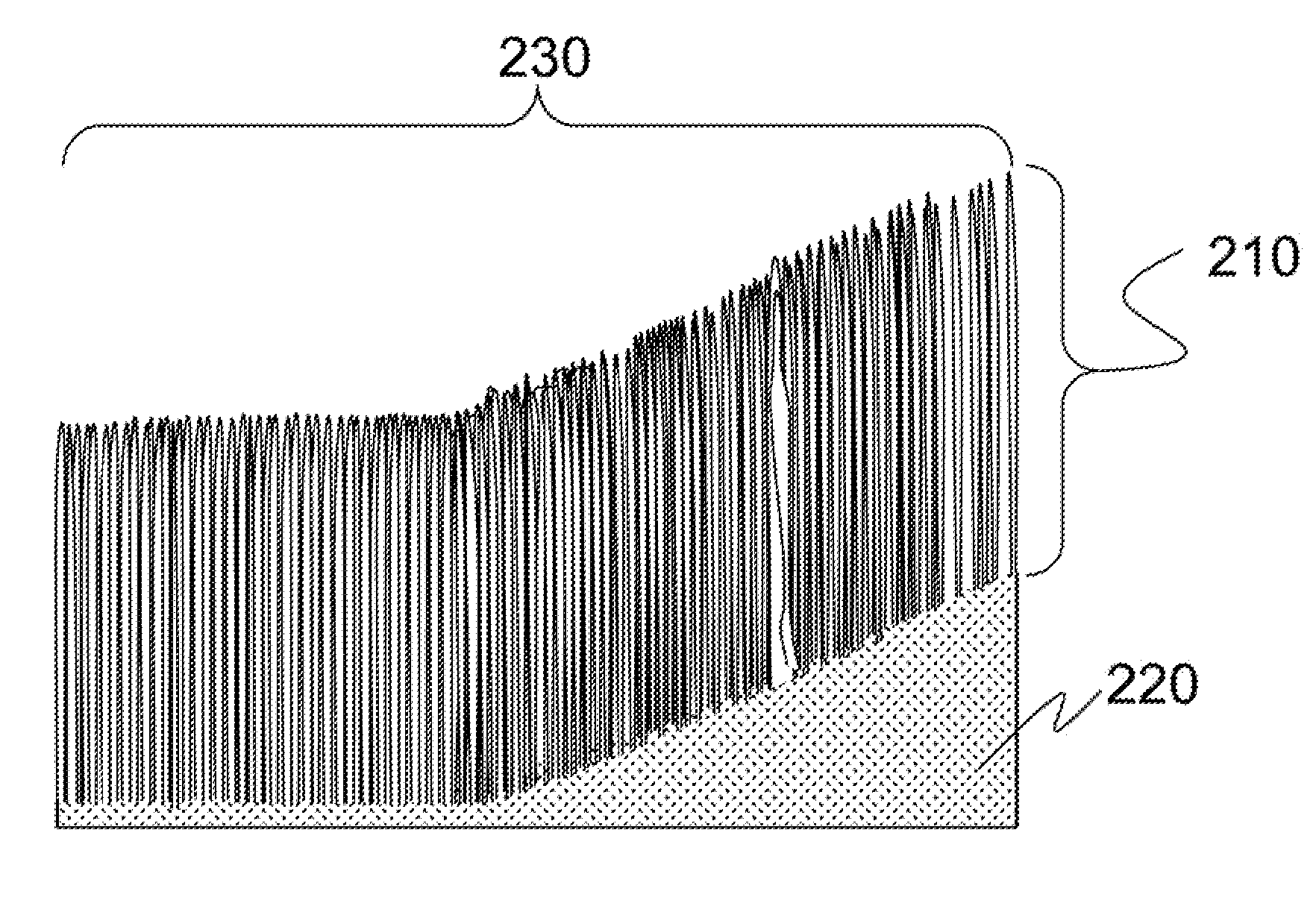

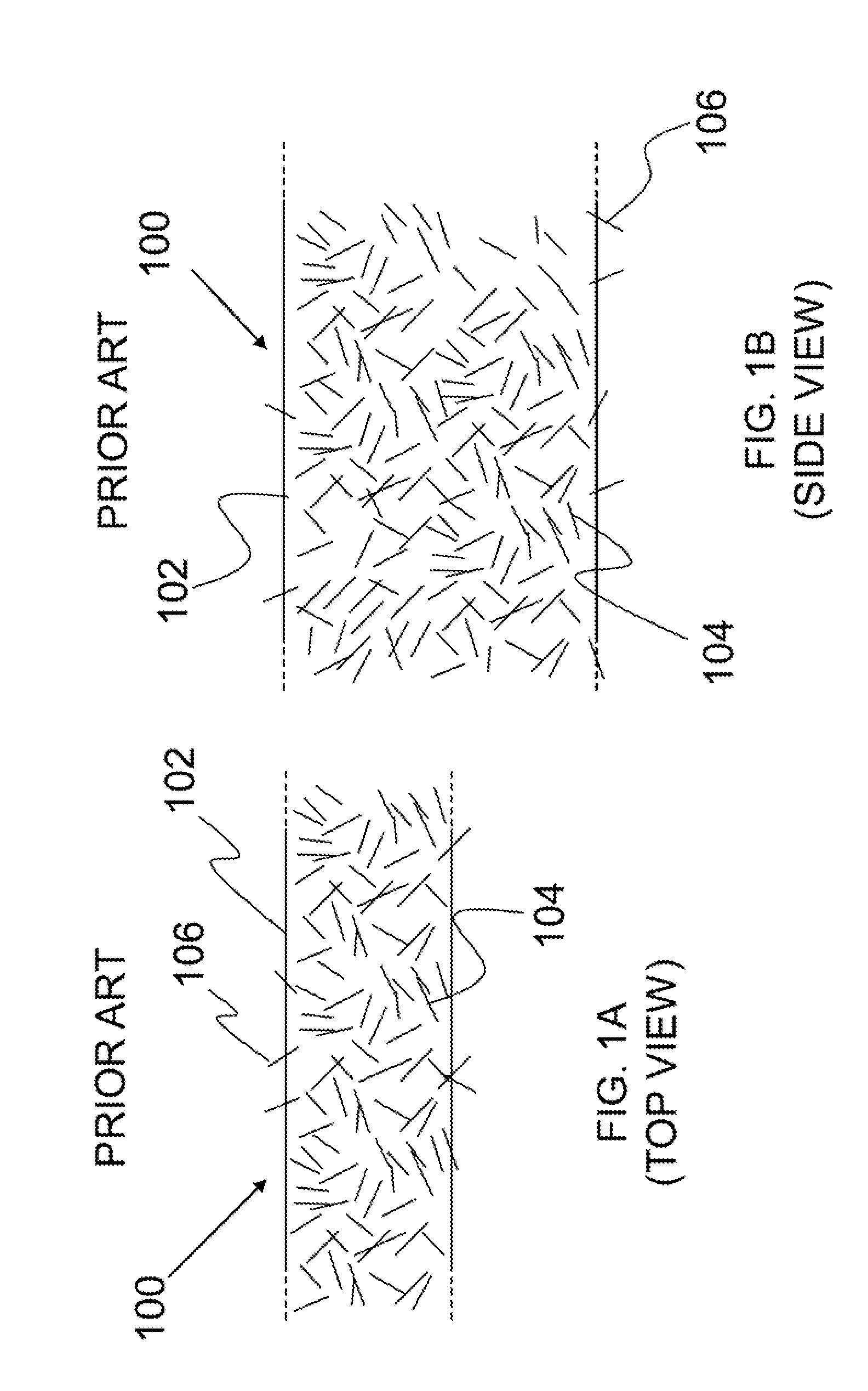

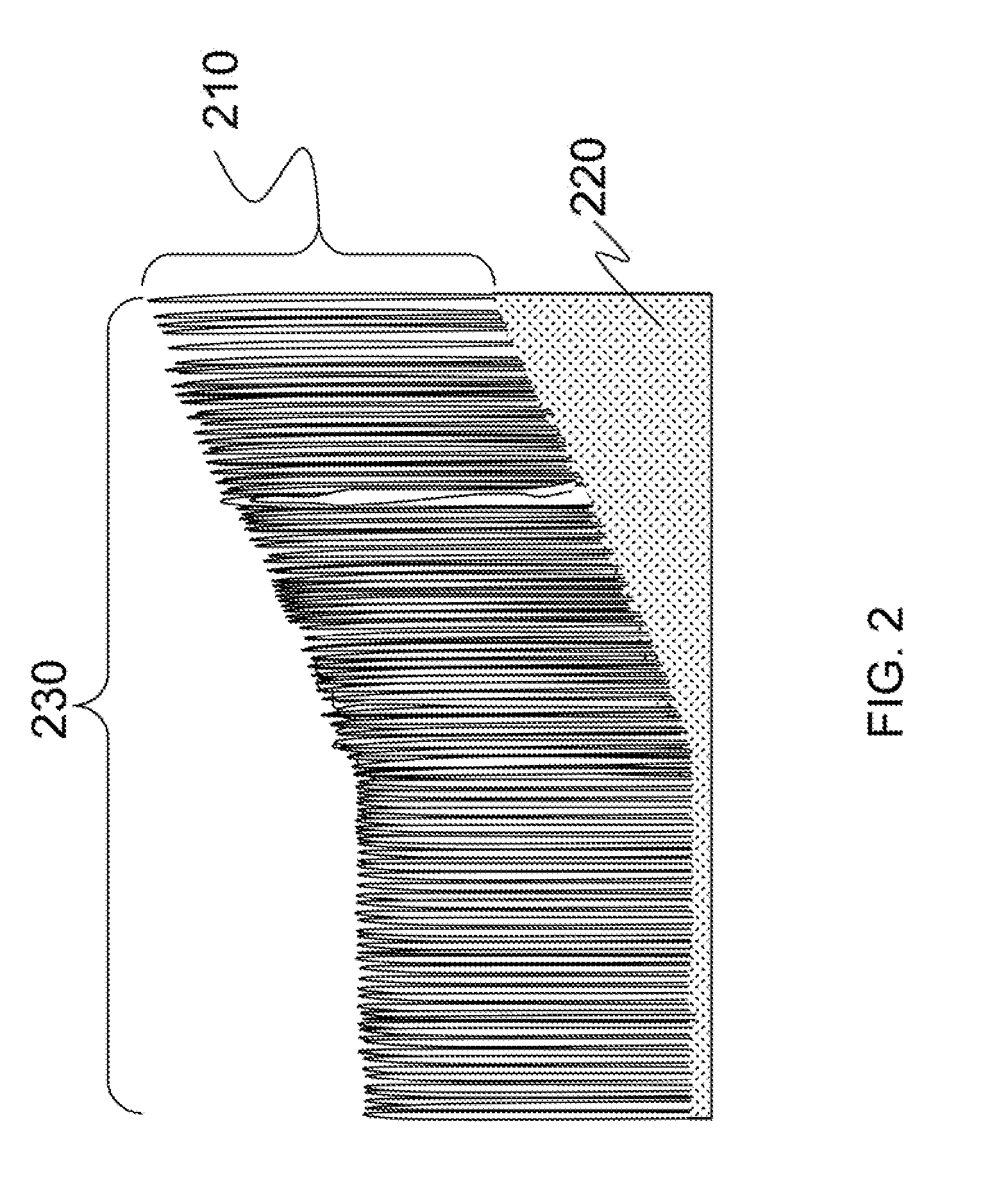

Method for selectively anchoring and exposing large numbers of nanoscale structures

Methods for fastening nanoscale structures within an anchoring structure to form a nanostructure composite and nanostructure composites formed therefrom. A primary fluid layer is formed on an anchoring substrate. Nanostructures are provided on an initial substrate, the nanostructures having a defined height and orientation with respect to the initial substrate. The nanostructures are introduced to a desired depth in the primary fluid layer, such that the orientation of the nanostructures relative to the growth substrate is substantially maintained. The primary fluid layer comprises one or more fluid layers. Ones of multiple fluid layers are selected such that when altered to form an anchoring structure, a portion of the anchoring structure can be removed, permitting exposure of at least a portion of the nanostructures from the anchoring structure in which they are affixed. The growth substrate is removed. Ends or other parts of nanostructures may be exposed from the anchoring structure.

Owner:CALIFORNIA INST OF TECH

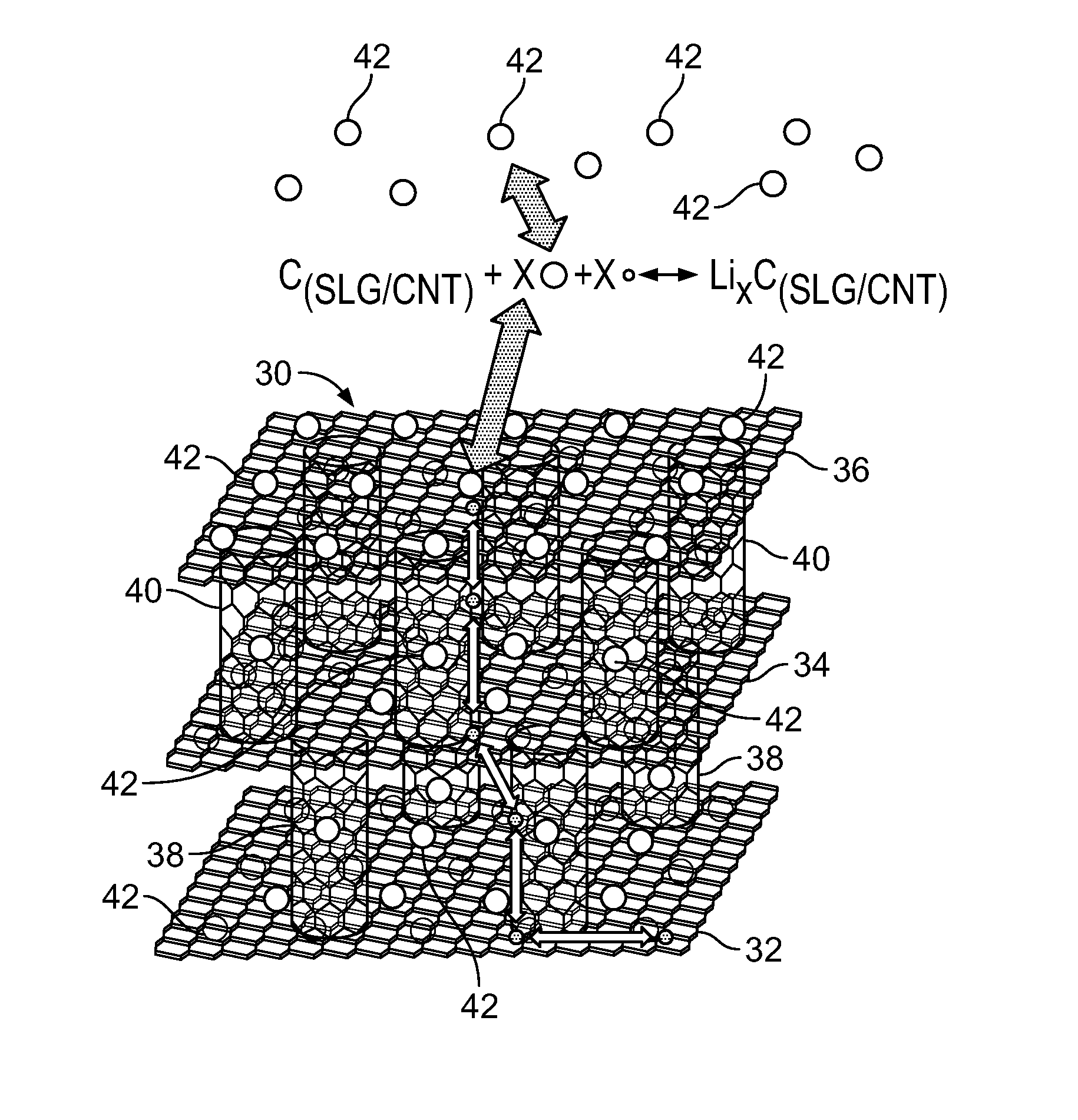

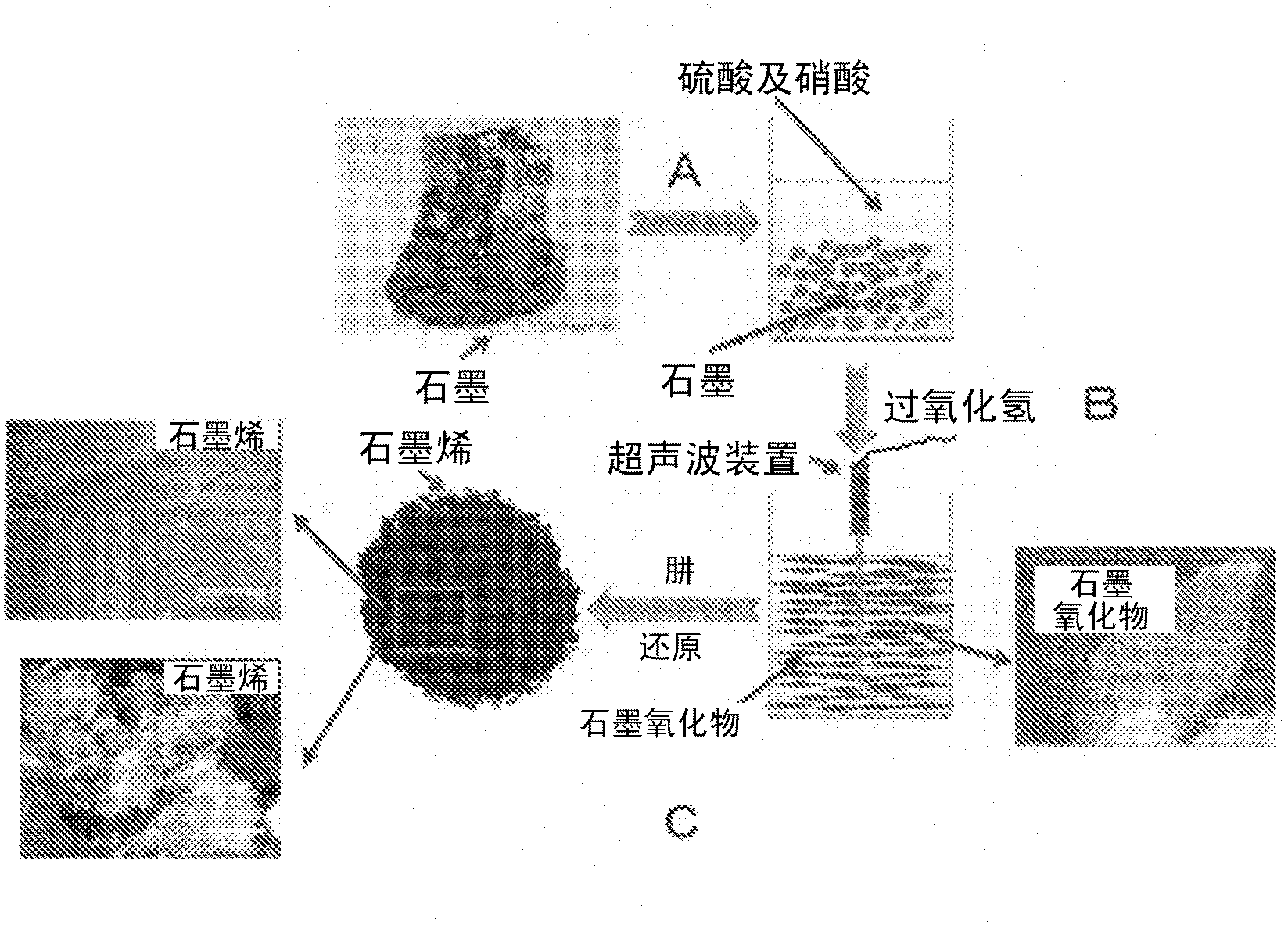

Popcorn-like growth of graphene-carbon nanotube multi-stack hybrid three-dimensional architecture for energy storage devices

Graphene-carbon nanotube multi-stack three-dimensional architectures (graphene-CNT stacks) are formed by a “popcorn-like” growth method, in which carbon nanotubes are grown throughout the architecture in a continuous step. Alternating layers of graphene and a transition metal are grown by a vapor deposition process. The metal is fragmented and etched to form an array of catalytic sites. Carbon nanotubes grow from the catalytic sites in a vapor-solid-liquid process. The graphene-CNT stacks have applications in electrical energy storage devices, such as supercapacitors and batteries. The directly grown carbon nanotube array between graphene layers provides ease of ion diffusion and electron transfer, in addition to being an active material, spacer and electron pathway.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

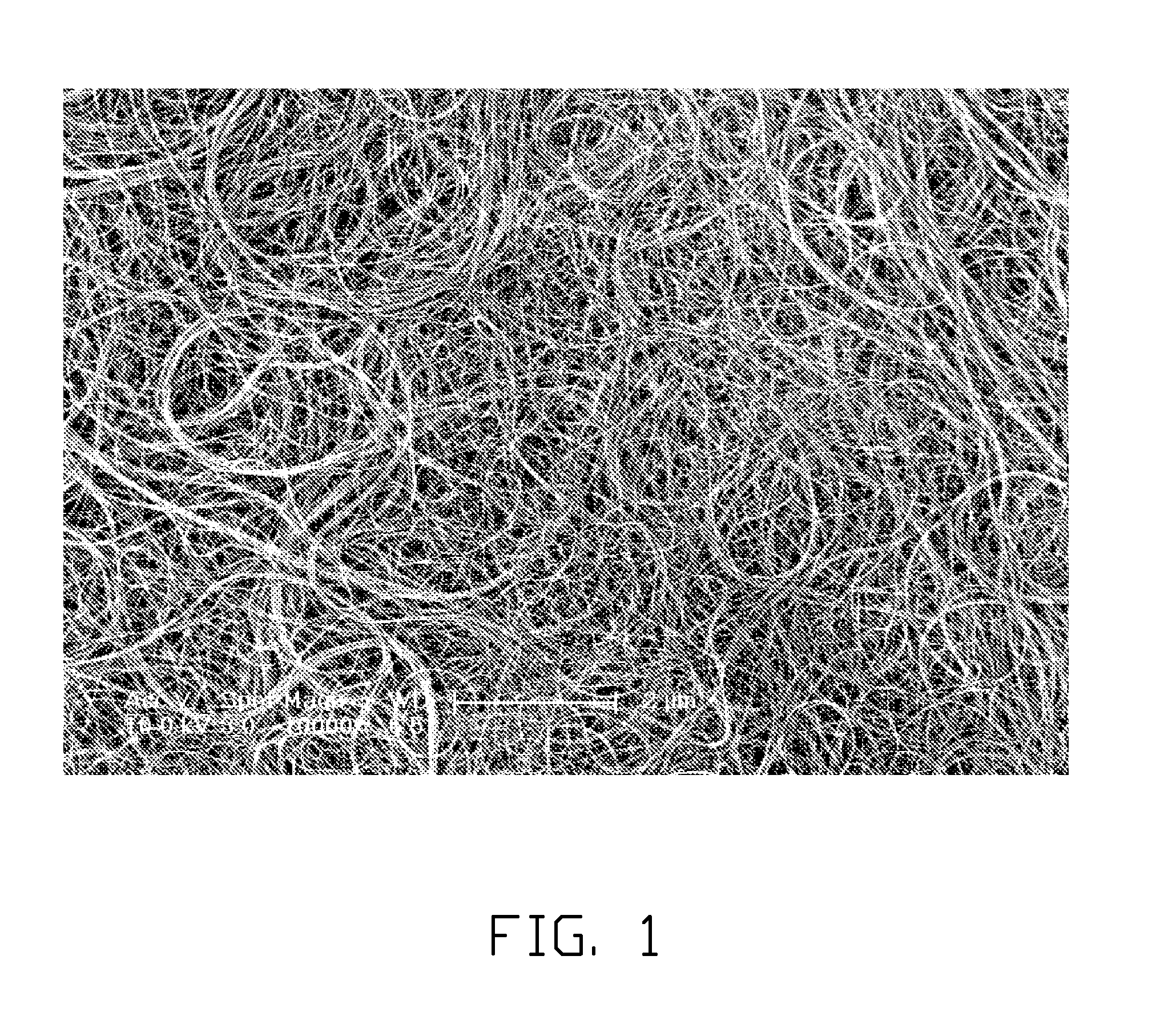

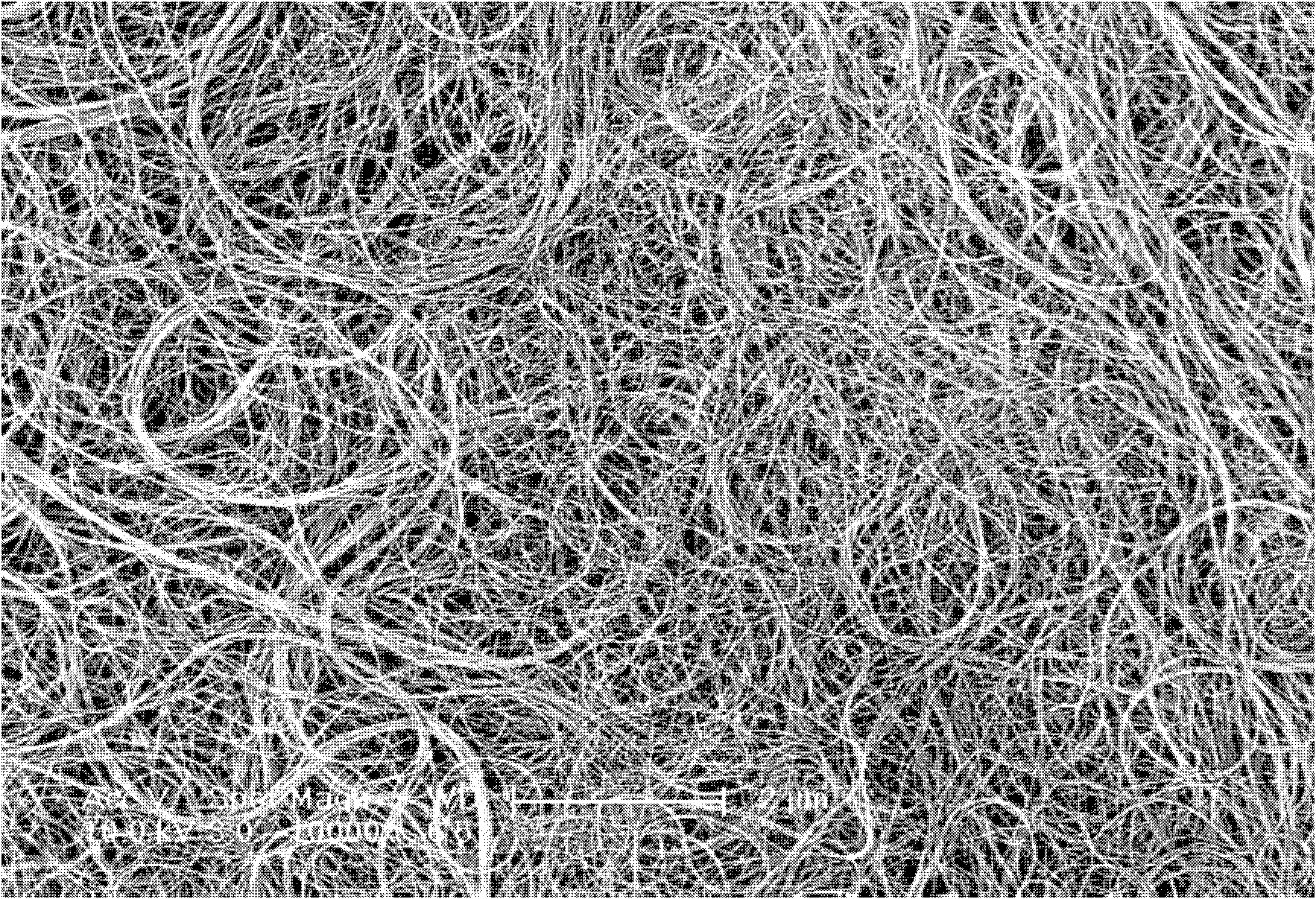

Carbon nanotube structure

A carbon nanotube structure includes a number of carbon wires and a number of second carbon nanotubes. Each of the carbon nanotube wires includes a number of first carbon nanotubes joined end to end by the carbon-carbon bonds therebetween. The carbon wires and the carbon nanotubes are joined by van der Waals attractive force therebetween.

Owner:TSINGHUA UNIV +1

Method

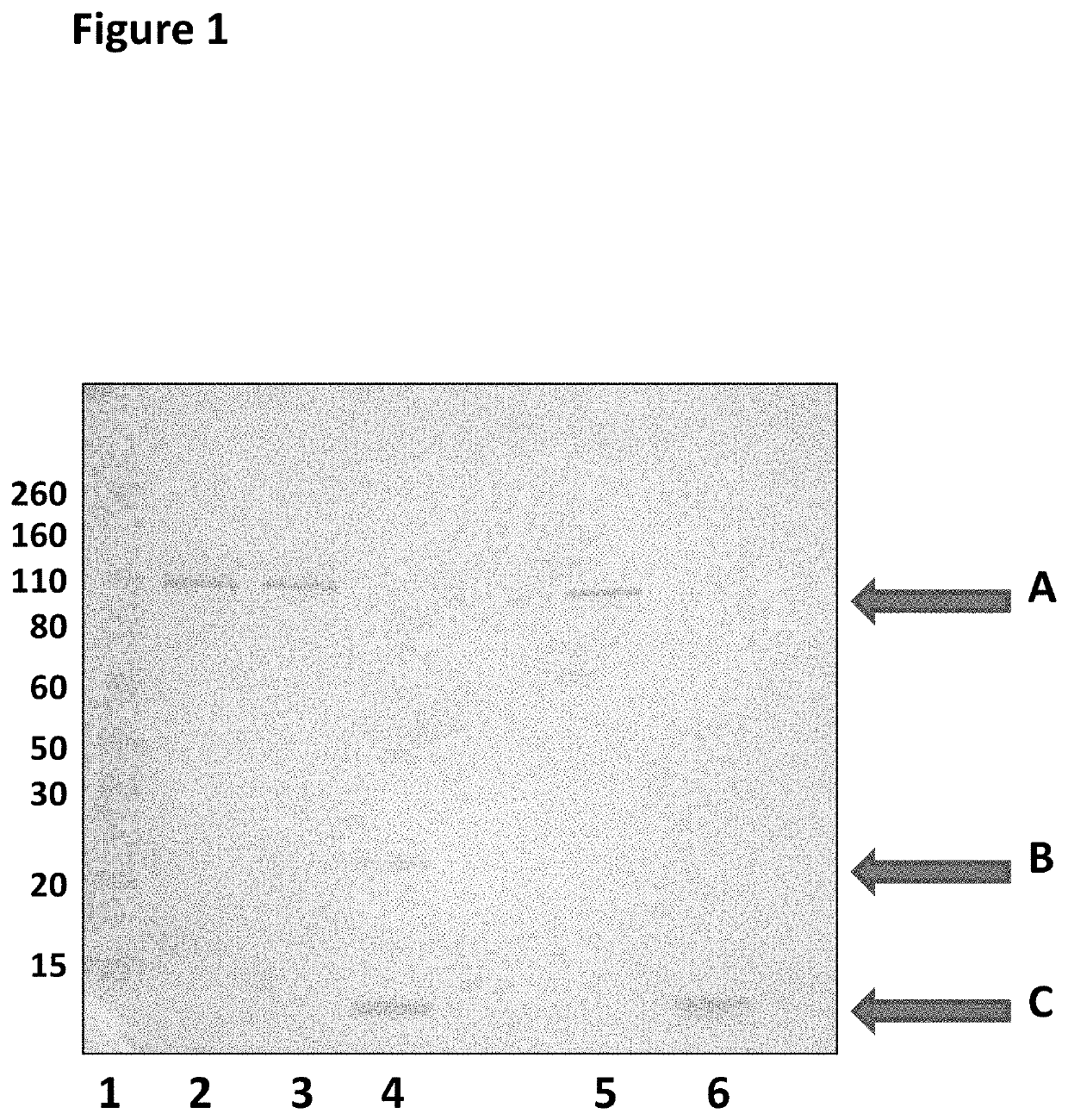

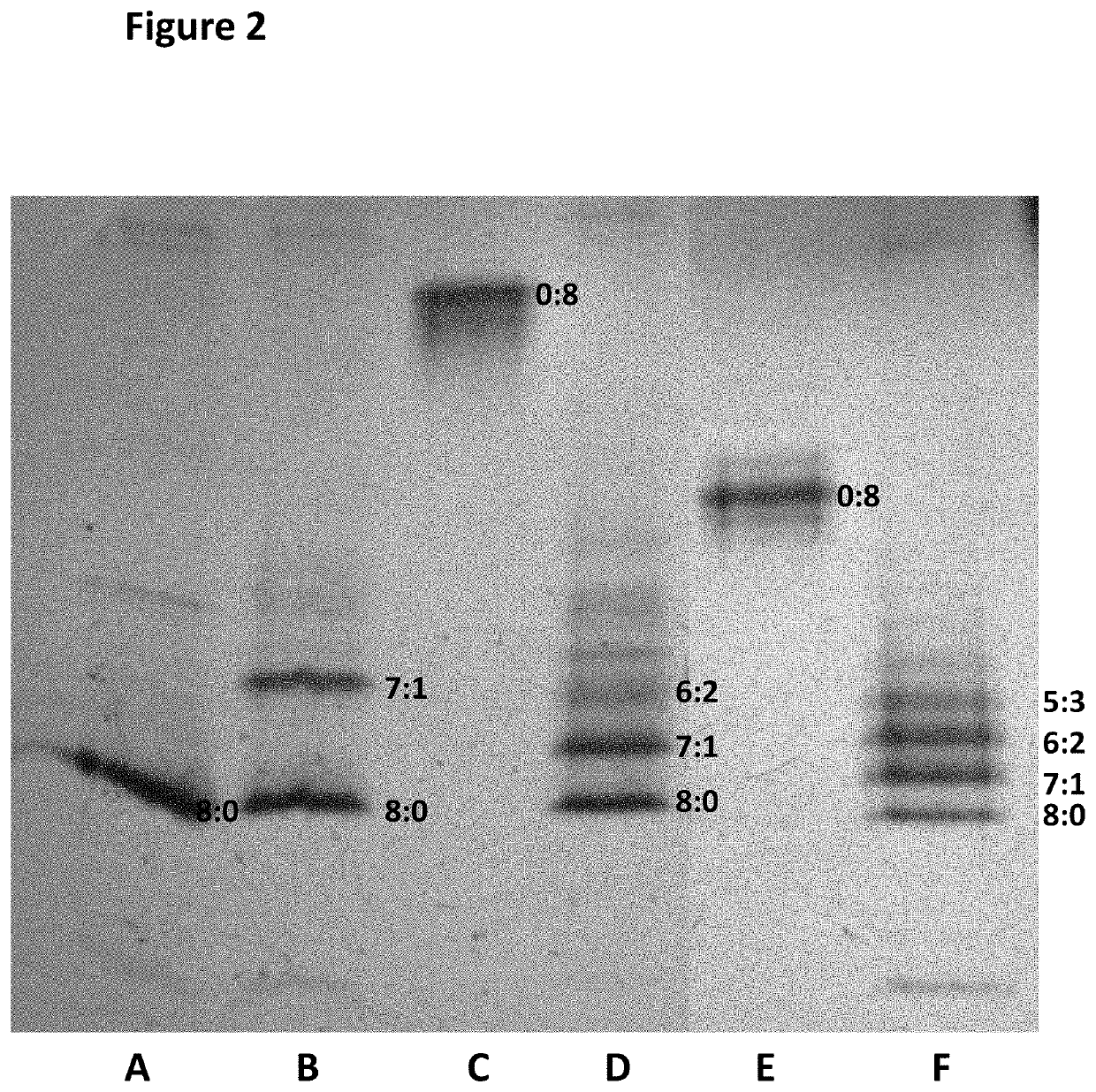

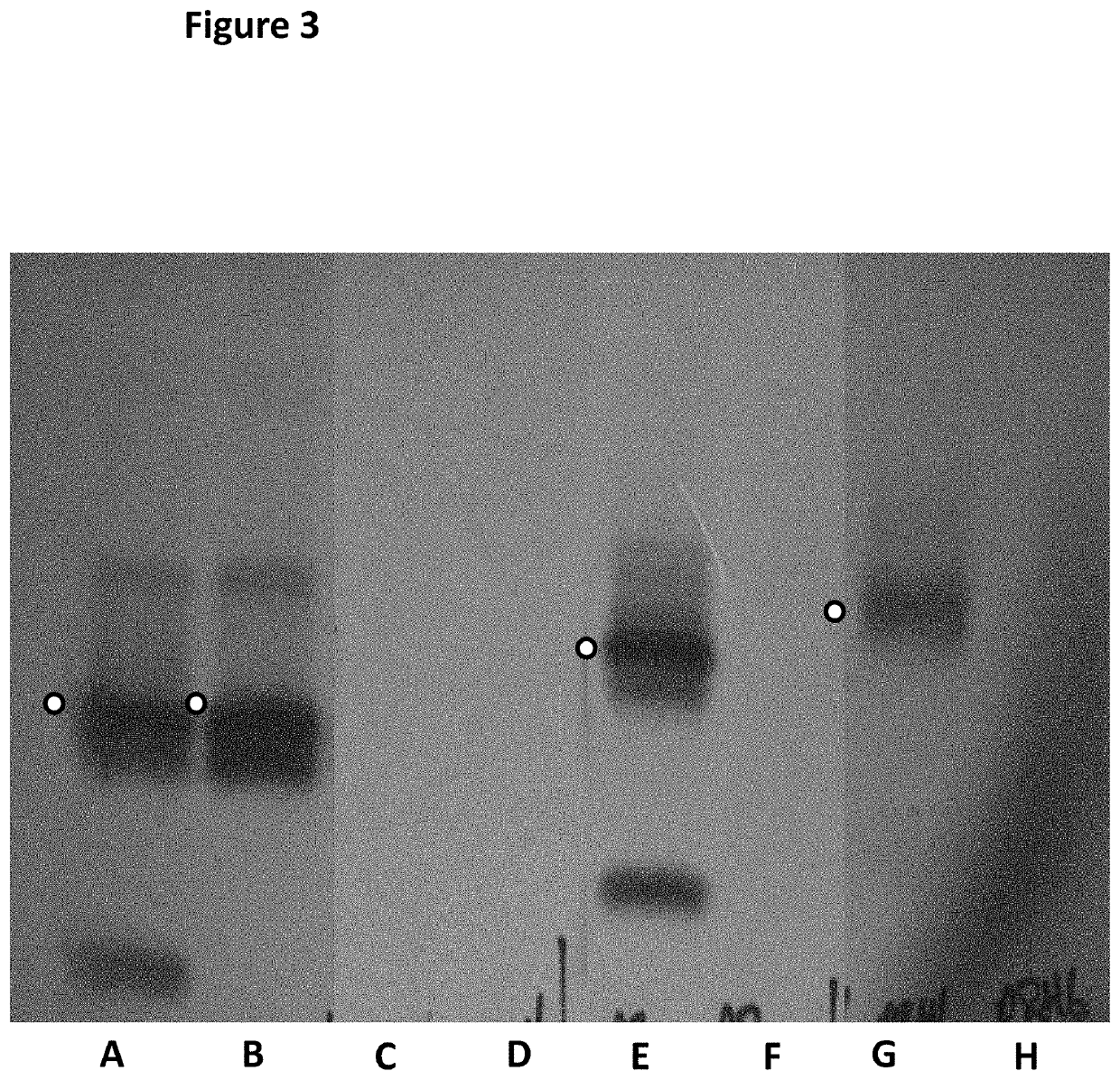

ActiveUS20180095066A1Nanostructure assemblyMicrobiological testing/measurementPolynucleotideChemistry

The invention relates to a novel method of producing hetero-oligomeric pores. The invention also relates to hetero-oligomeric pores produced using the method and polynucleotide characterisation using the hetero-oligomeric pores.

Owner:OXFORD NANOPORE TECH LTD

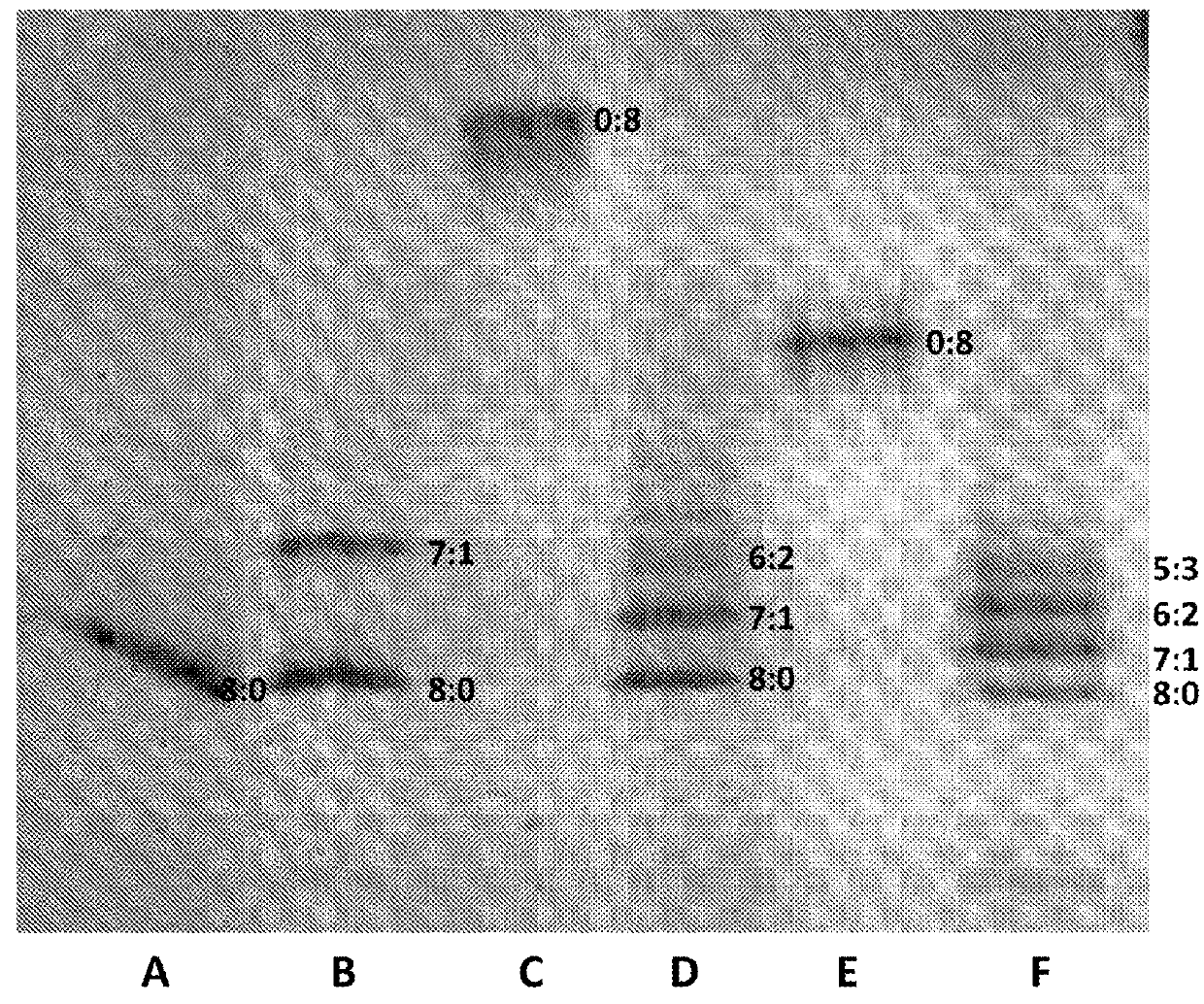

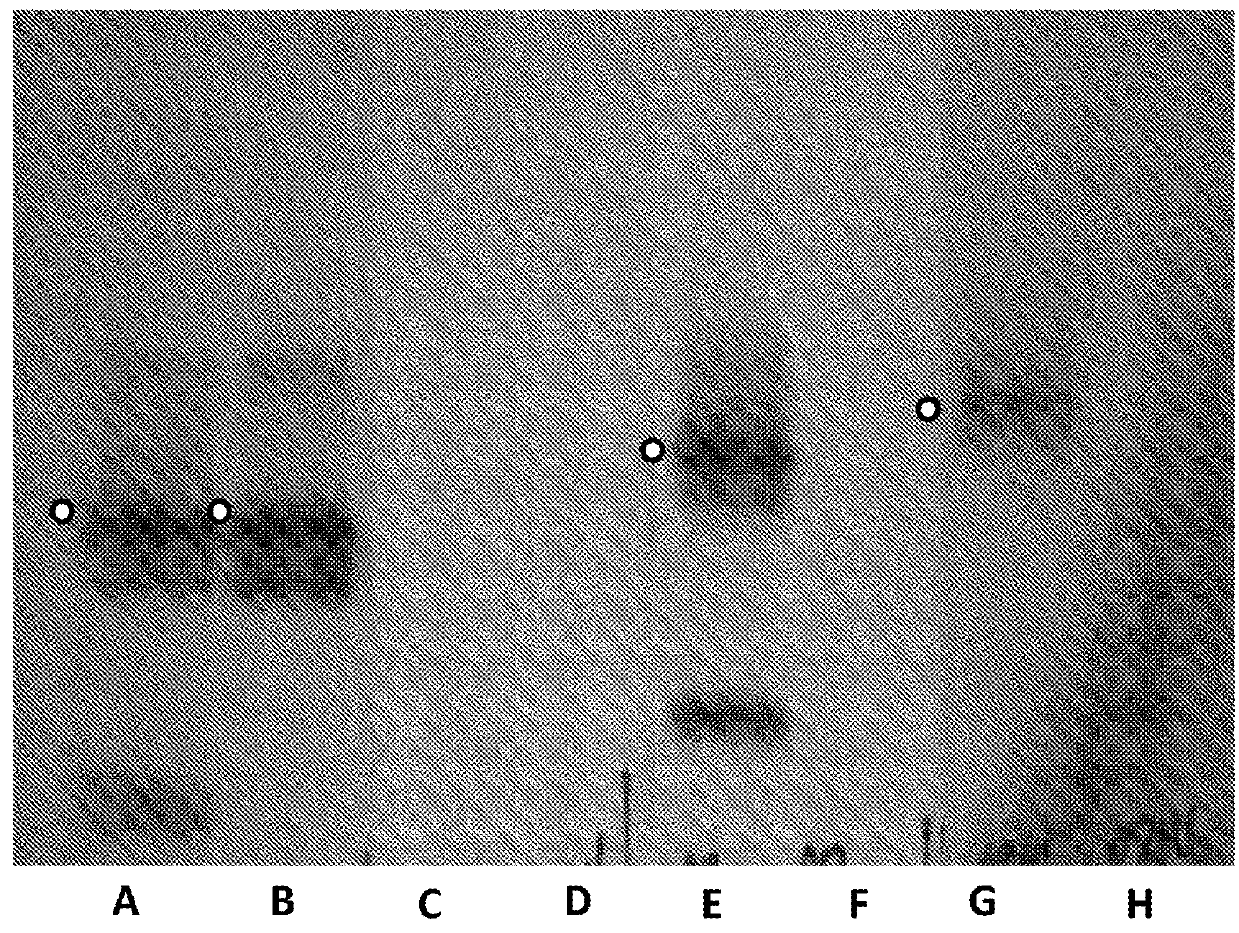

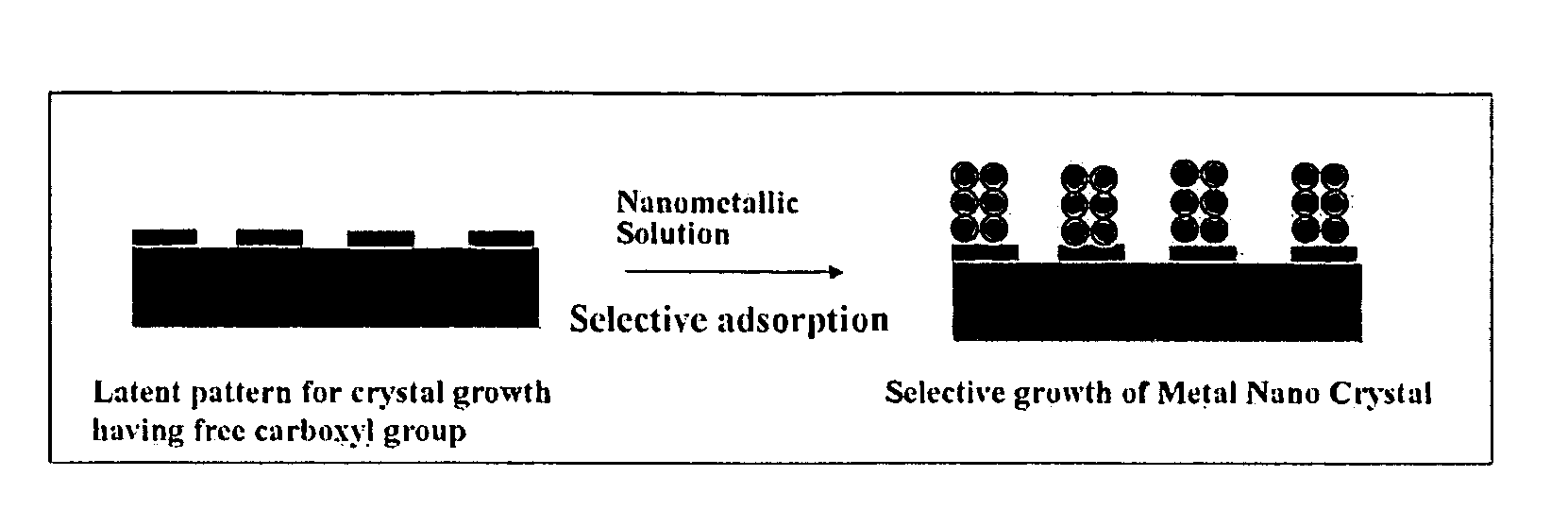

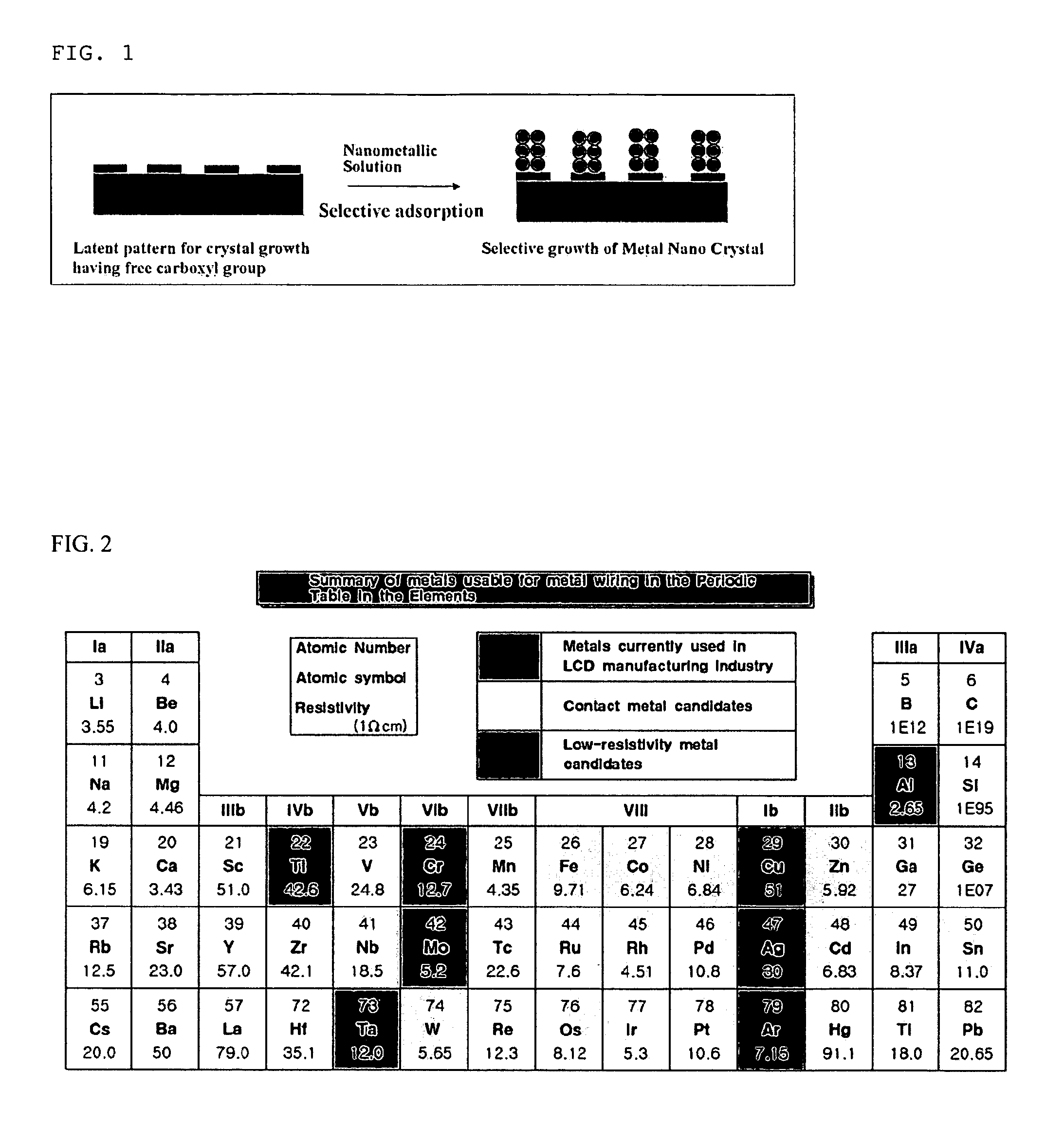

Method for forming metal pattern by using metal nanocrystals

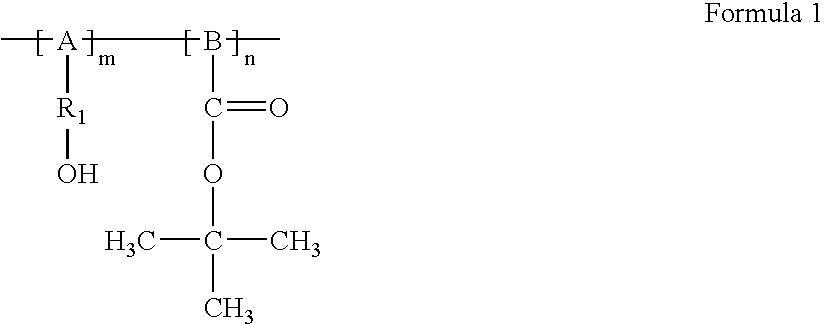

ActiveUS7205096B2Superior in metal wiring propertySimplifies photolithographyRadiation applicationsPhotomechanical apparatusLatent imagePhotoacid generator

Disclosed herein is a method for forming a metal pattern by using metal nanocrystals. The method comprises the steps of: (i) coating a photosensitive compound having a substituent, which is converted into a free carboxyl group by light exposure, on a substrate to form a photosensitive film; (ii) selectively exposing the photosensitive film to light in the presence of a photoacid generator to form a latent pattern for crystal growth having a free carboxyl group; and (iii) treating the latent pattern for crystal growth with a nanometallic solution in which metal nanocrystals can be formed to grow the metal nanocrystals on the latent pattern. According to the method, a metal wiring pattern can be formed in a cost-effective and relatively simple manner. Further, the metal pattern formed by the method can be useful in the manufacture of an electromagnetic interference filter for flat panel display devices or an electrode, and can thus be applied to devices, e.g., organic light-emitting devices (OLED) and organic thin-film transistors (OTFT).

Owner:SAMSUNG ELECTRONICS CO LTD

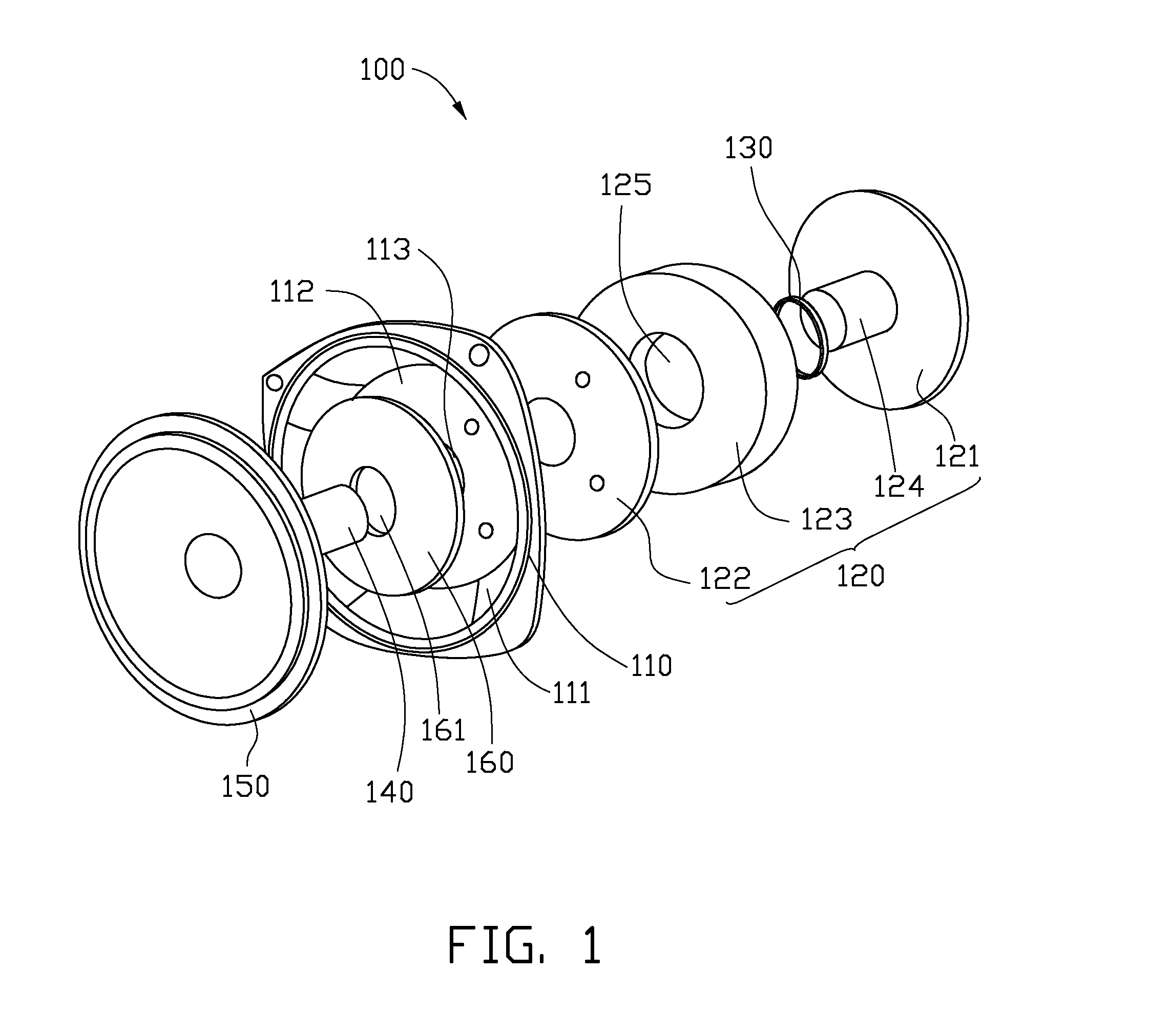

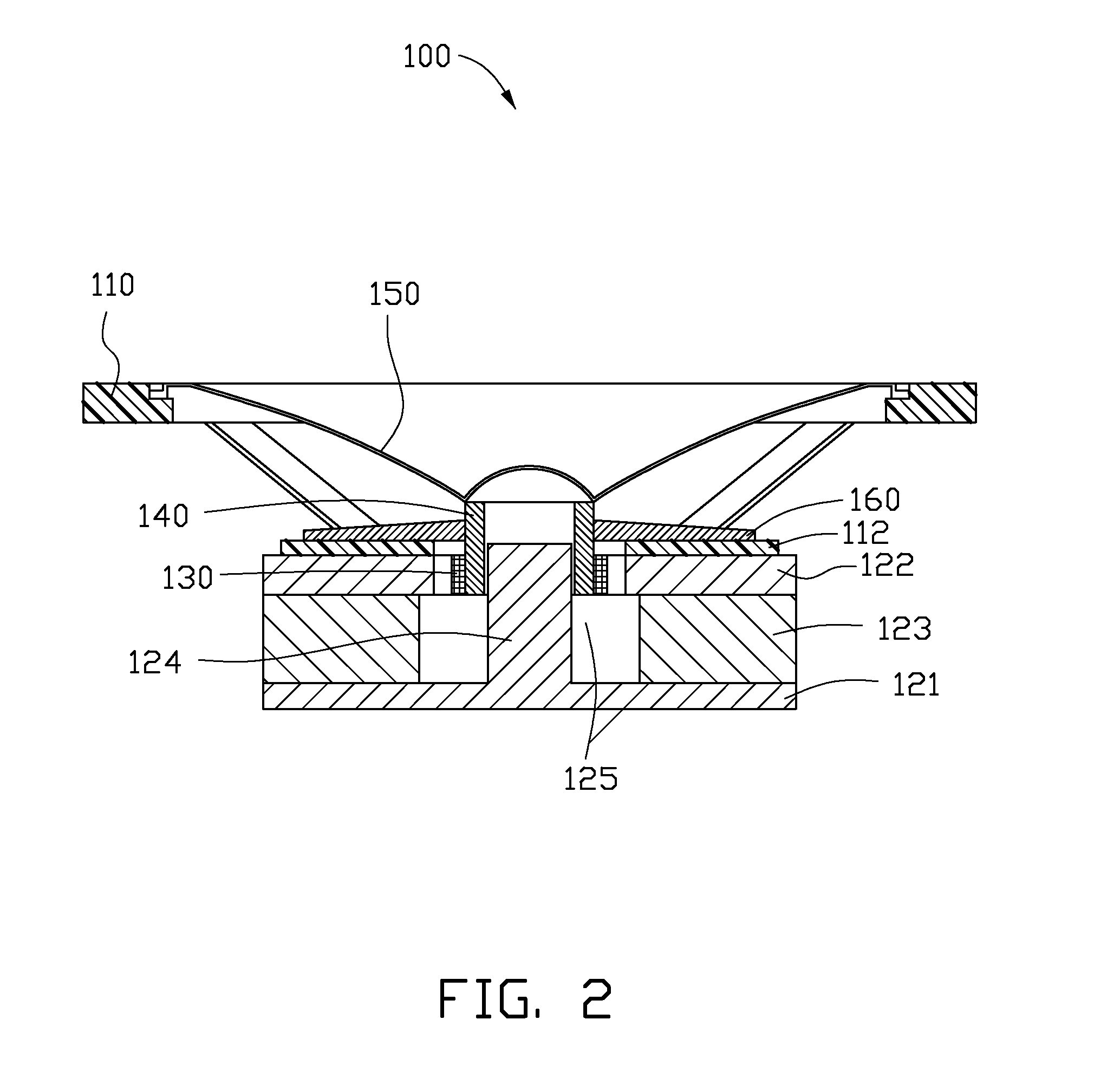

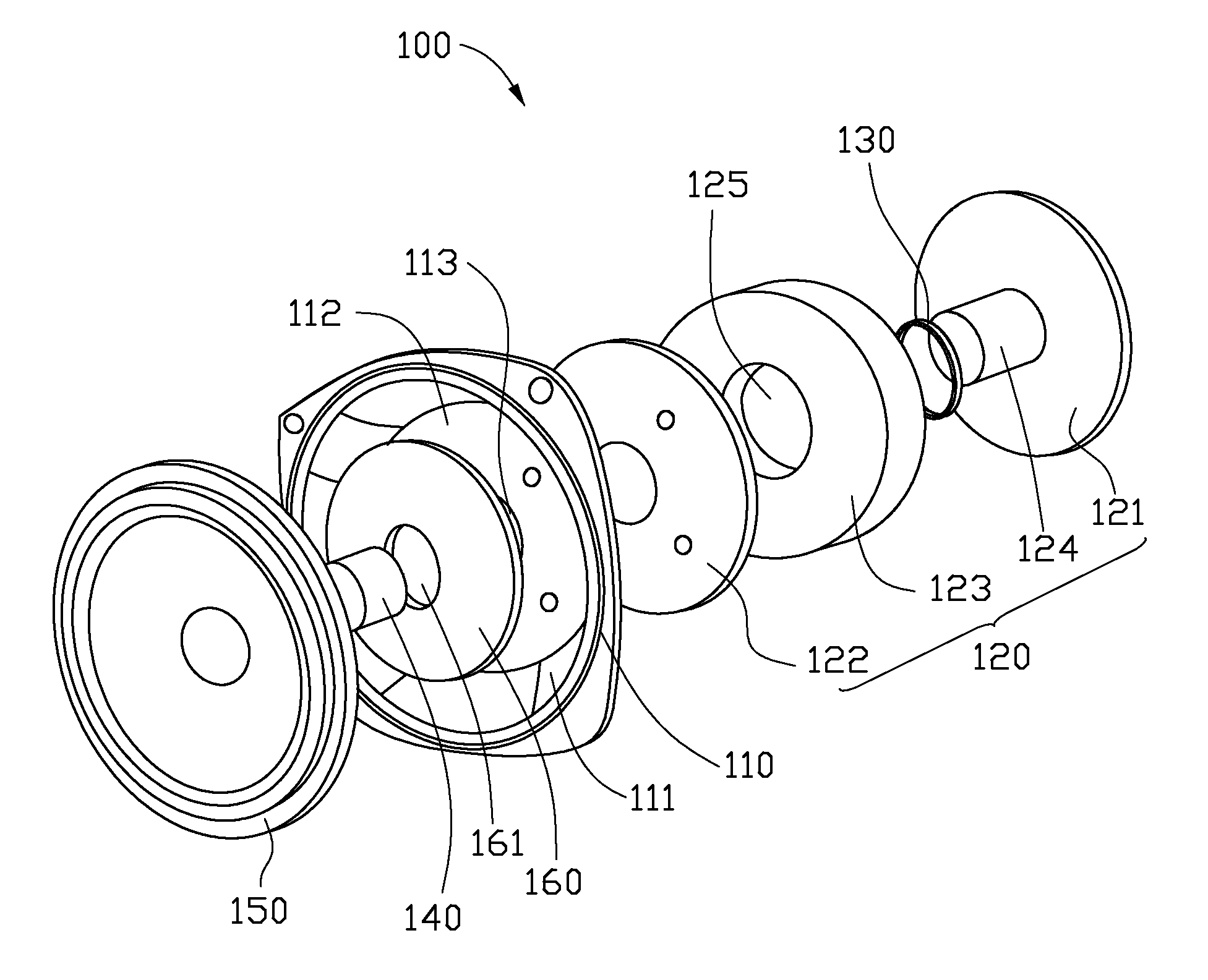

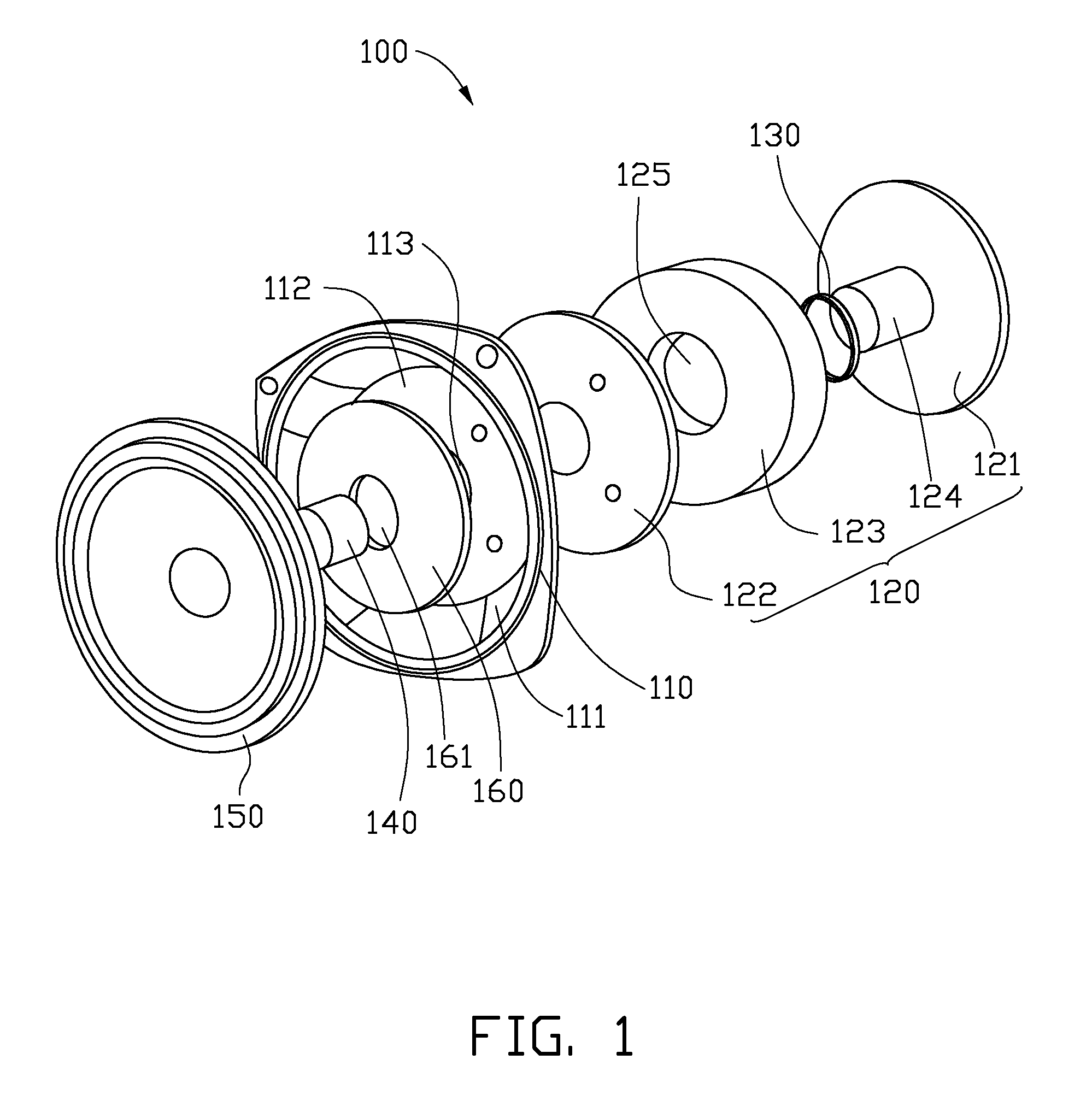

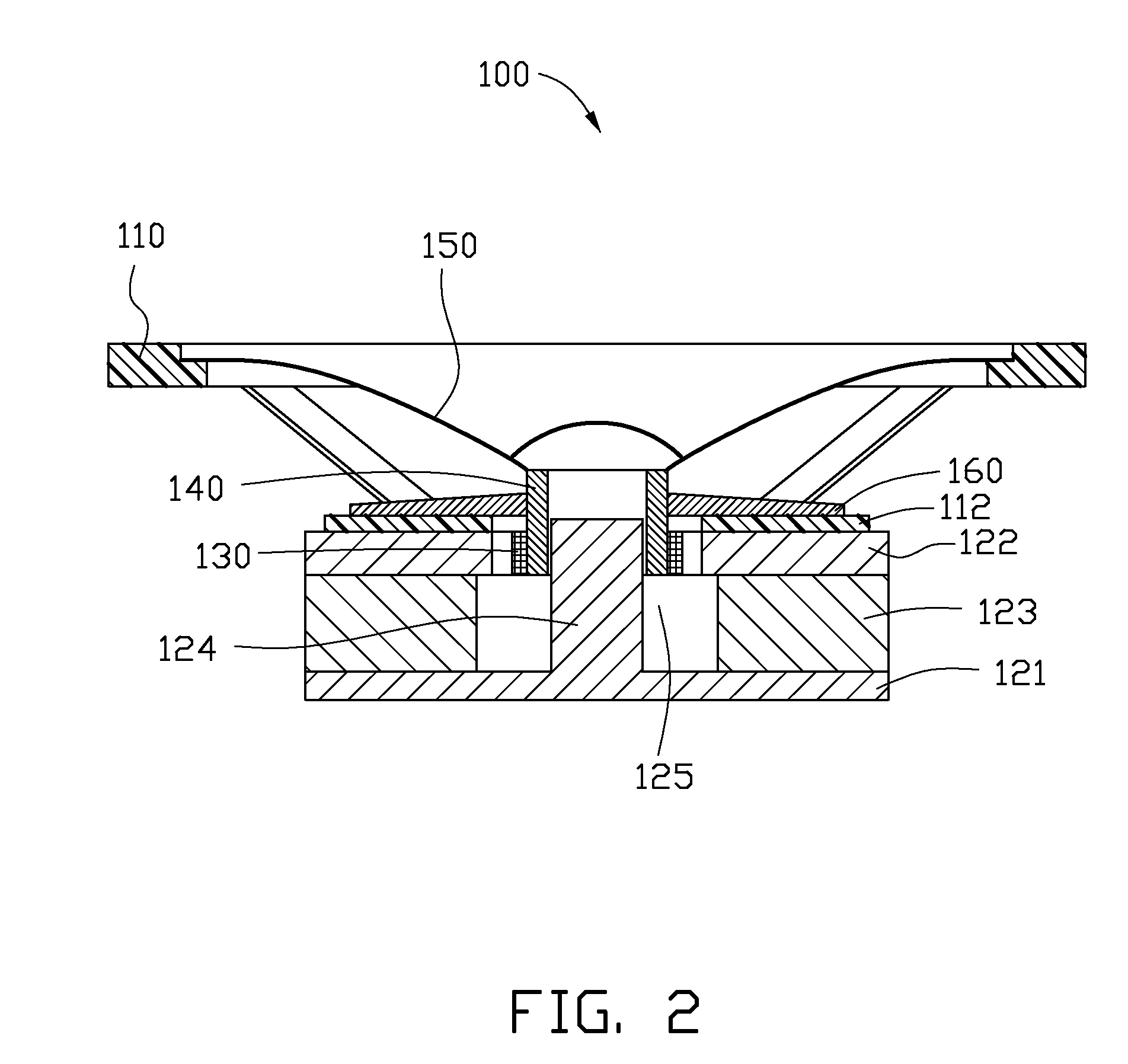

Diaphragm, method making the same and loudspeaker using the same

ActiveUS20110096952A1Envelopes/bags making machineryMaterial nanotechnologyCarbon nanotubeLoudspeaker

A diaphragm includes a carbon nanotube film structure and an amorphous carbon structure composited with the carbon nanotube structure to form a stratiform composite structure. The carbon nanotube film structure defines a plurality of micropores therein. The amorphous carbon structure comprises a plurality of amorphous carbon particles received in the micropores.

Owner:TSINGHUA UNIV +1

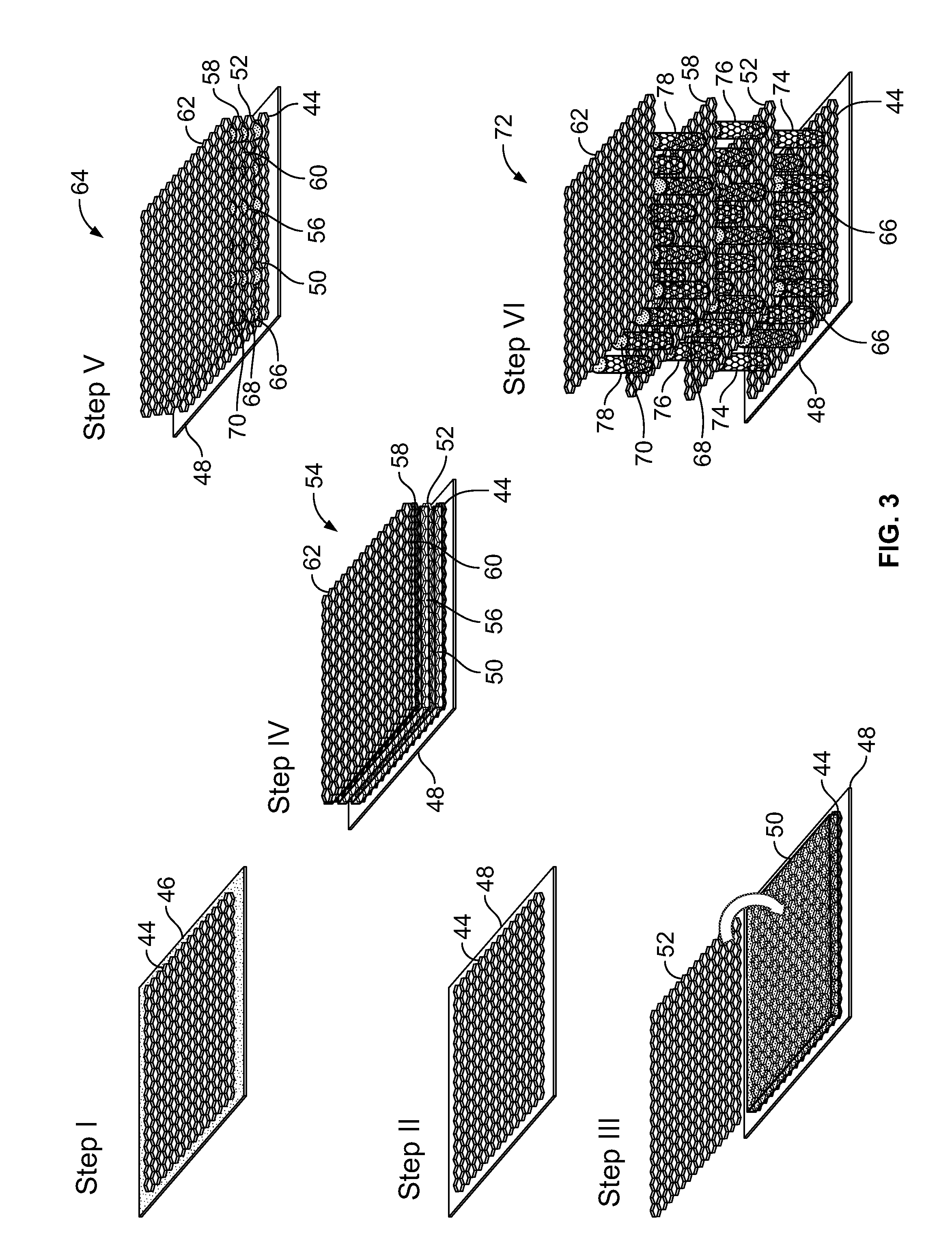

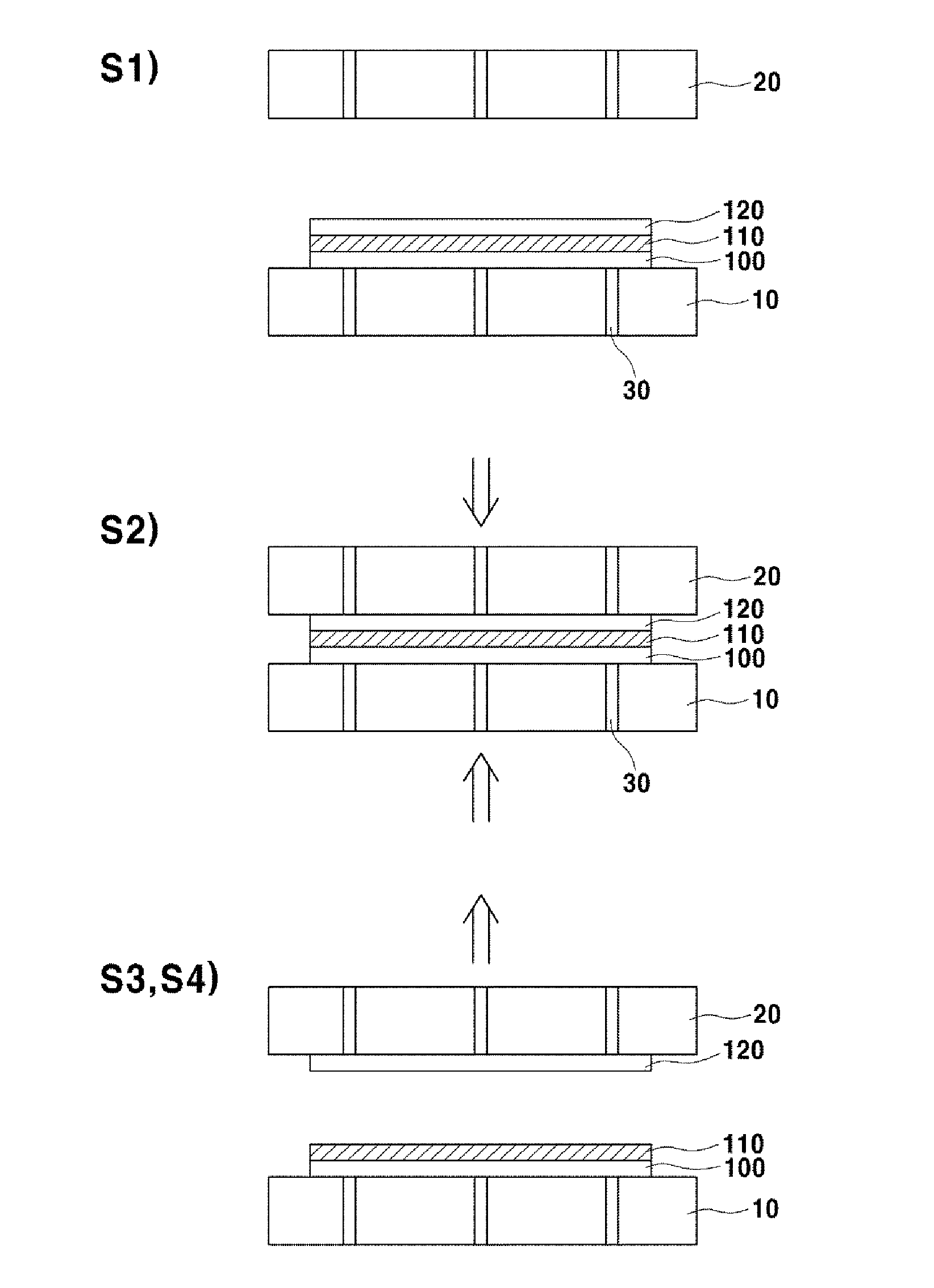

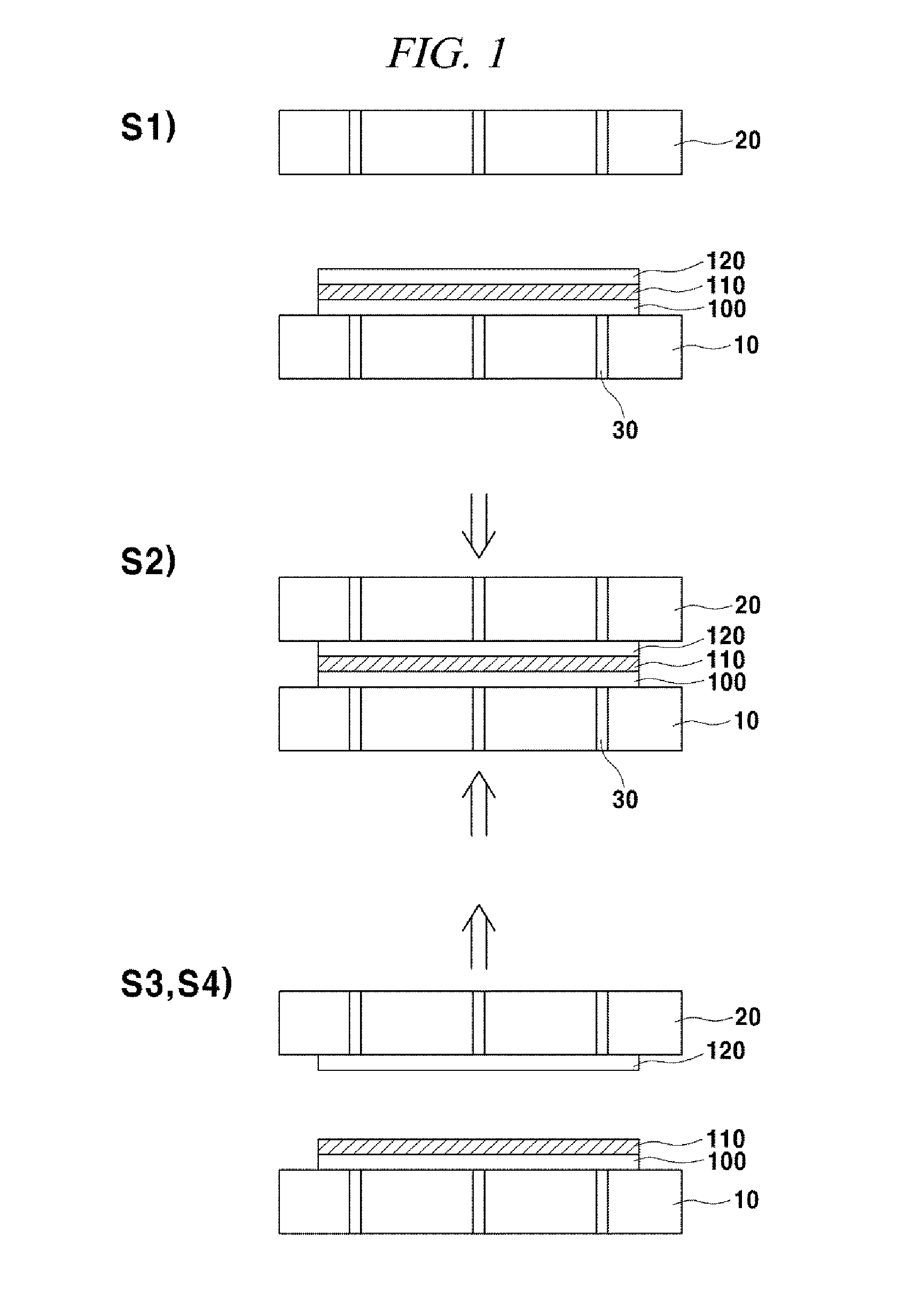

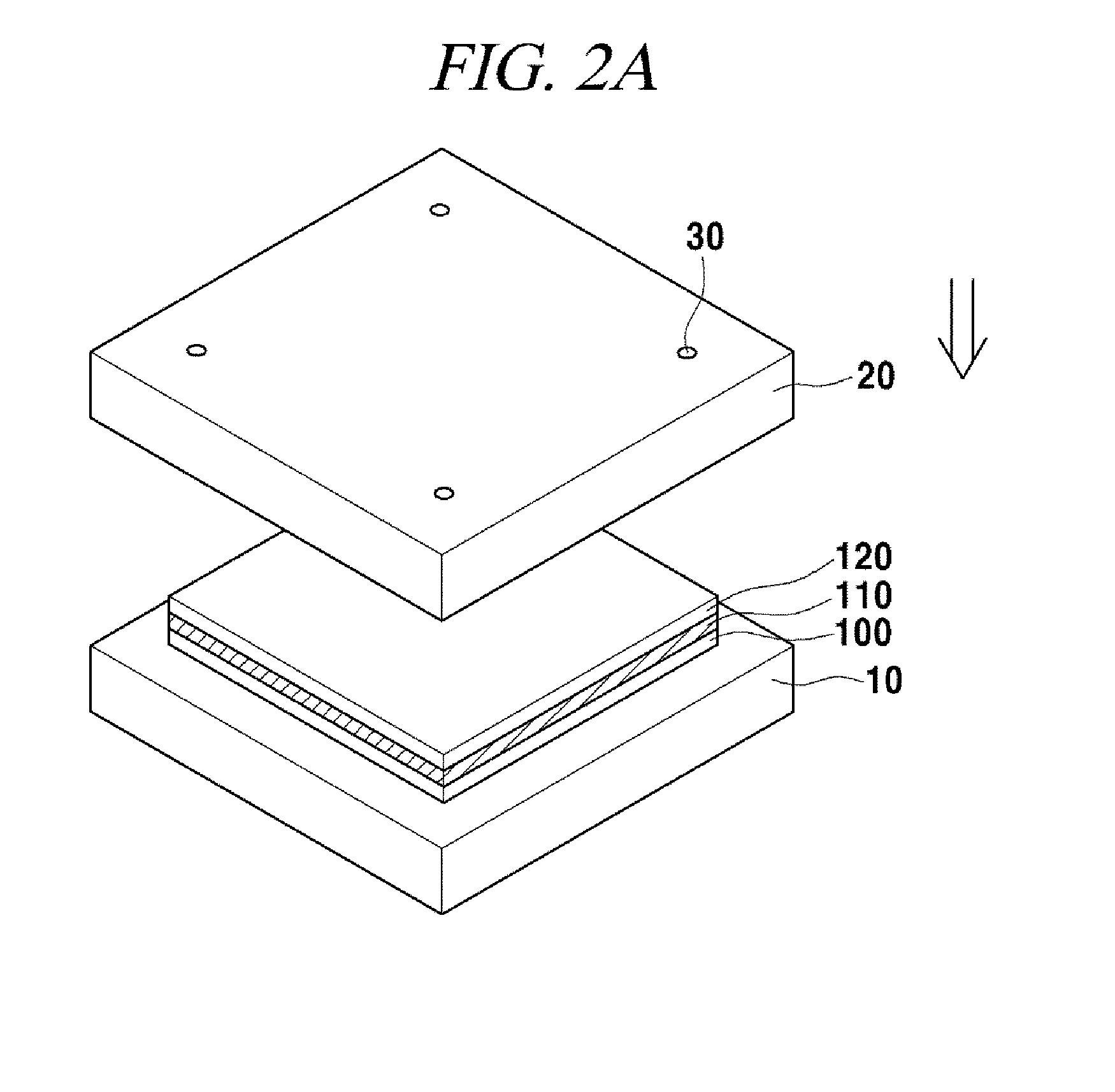

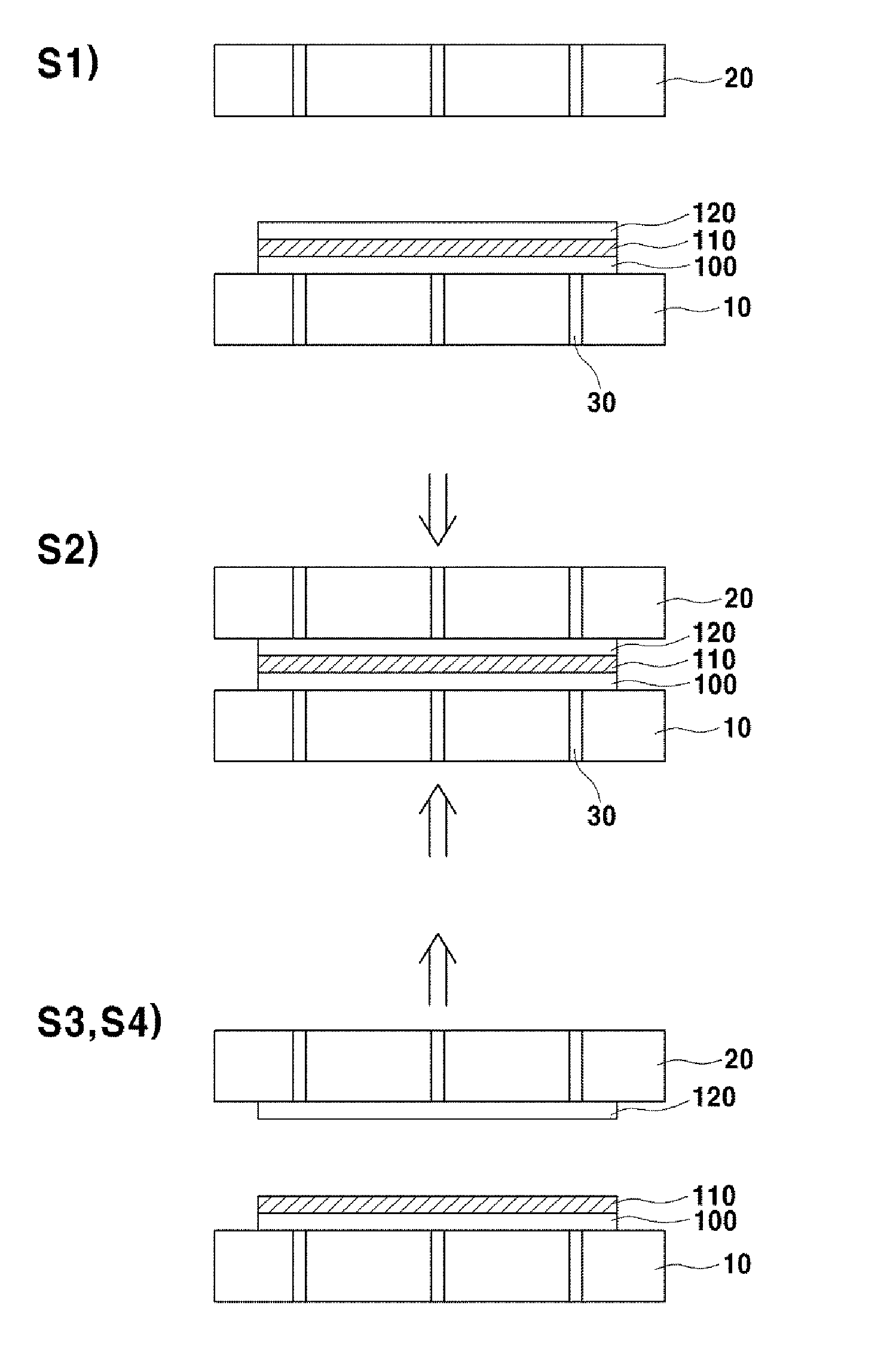

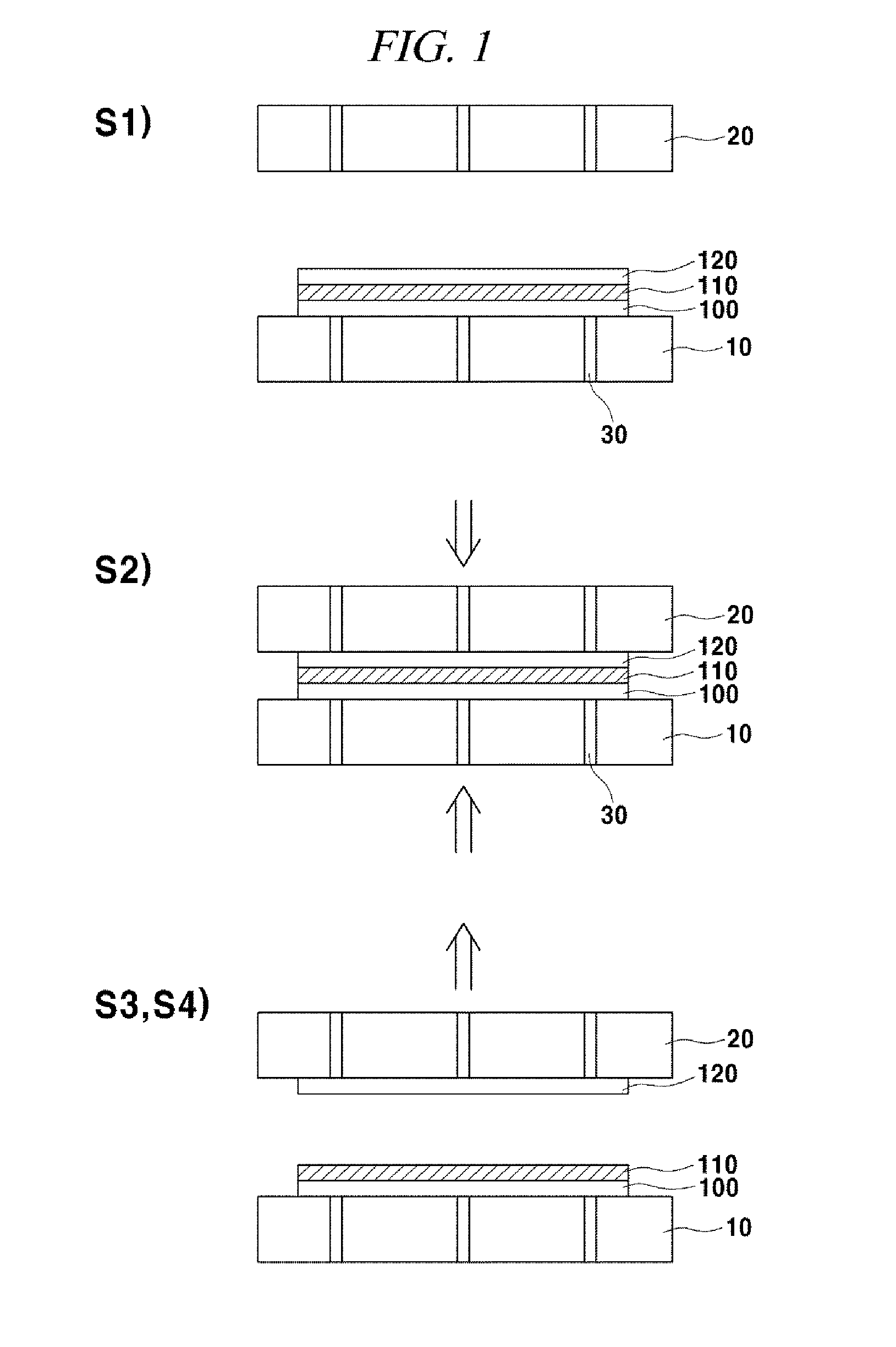

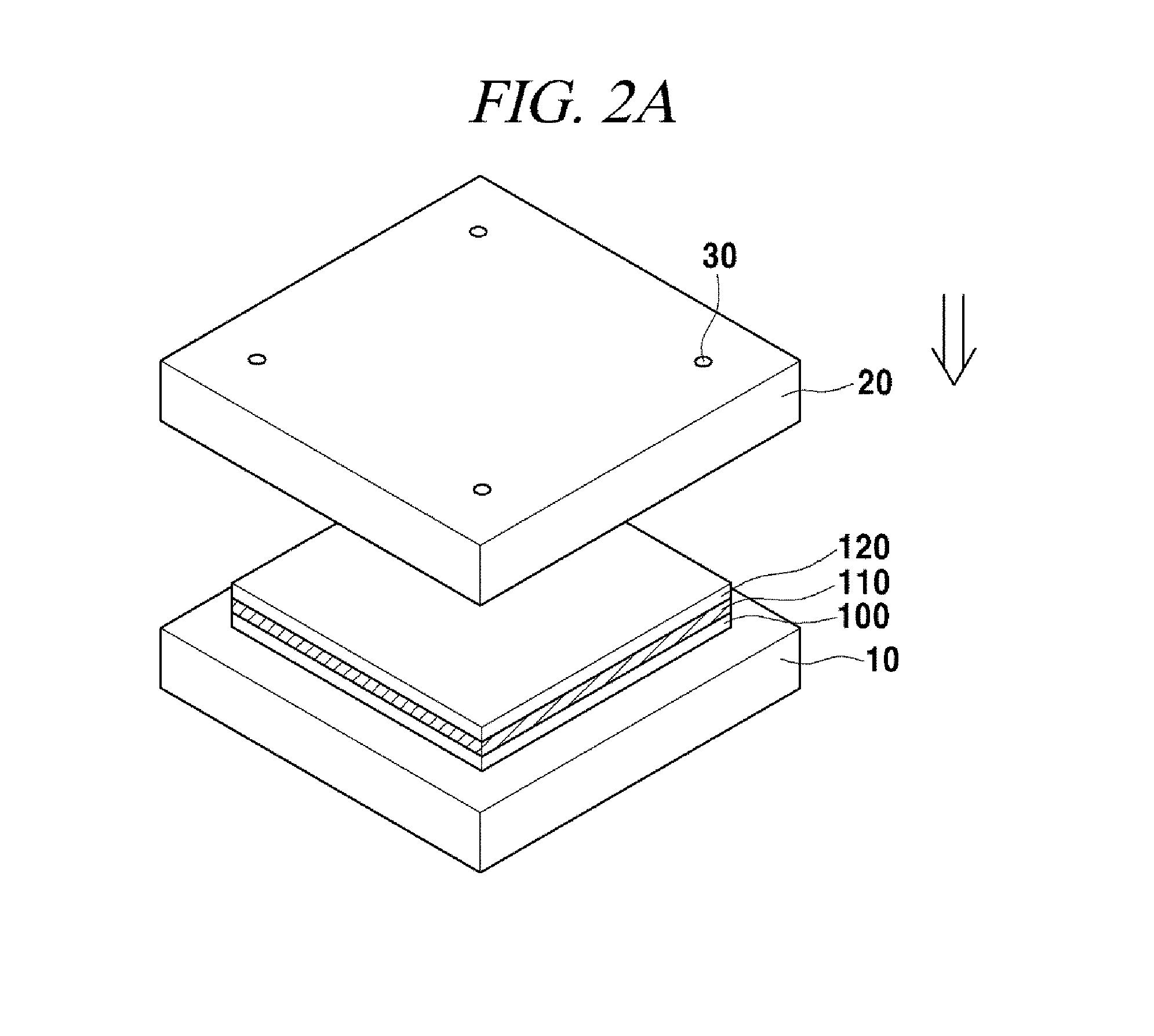

Method for transferring graphene using a hot press

ActiveUS20130299077A1Minimize damageEasy transferNanostructure assemblyLamination ancillary operationsGrapheneMaterials science

The present invention relates to a method for transferring graphene using a hot press, comprising: a step of contacting graphene, having a thermal-releasable sheet attached thereto, with a target substrate; and a step of pressing and heating the graphene having the thermal-releasable sheet attached thereto and the target substrate using the upper press and lower press of a hot press so as to separate the thermal-releasable sheet and the graphene and transfer the separated graphene to the target substrate. The present invention also relates to a graphene-transfer hot press apparatus for said transfer process.

Owner:GRAPHENE SQUARE

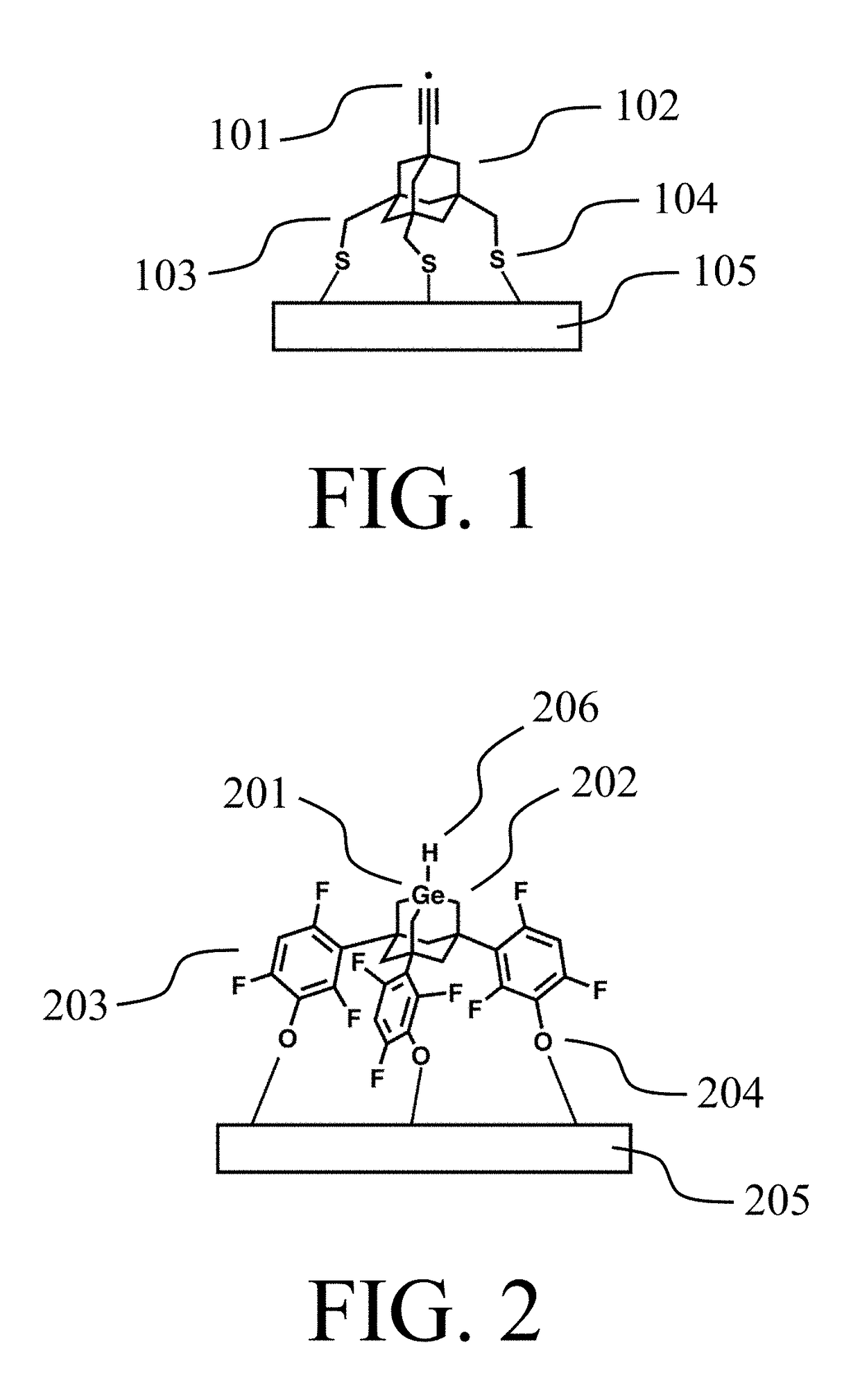

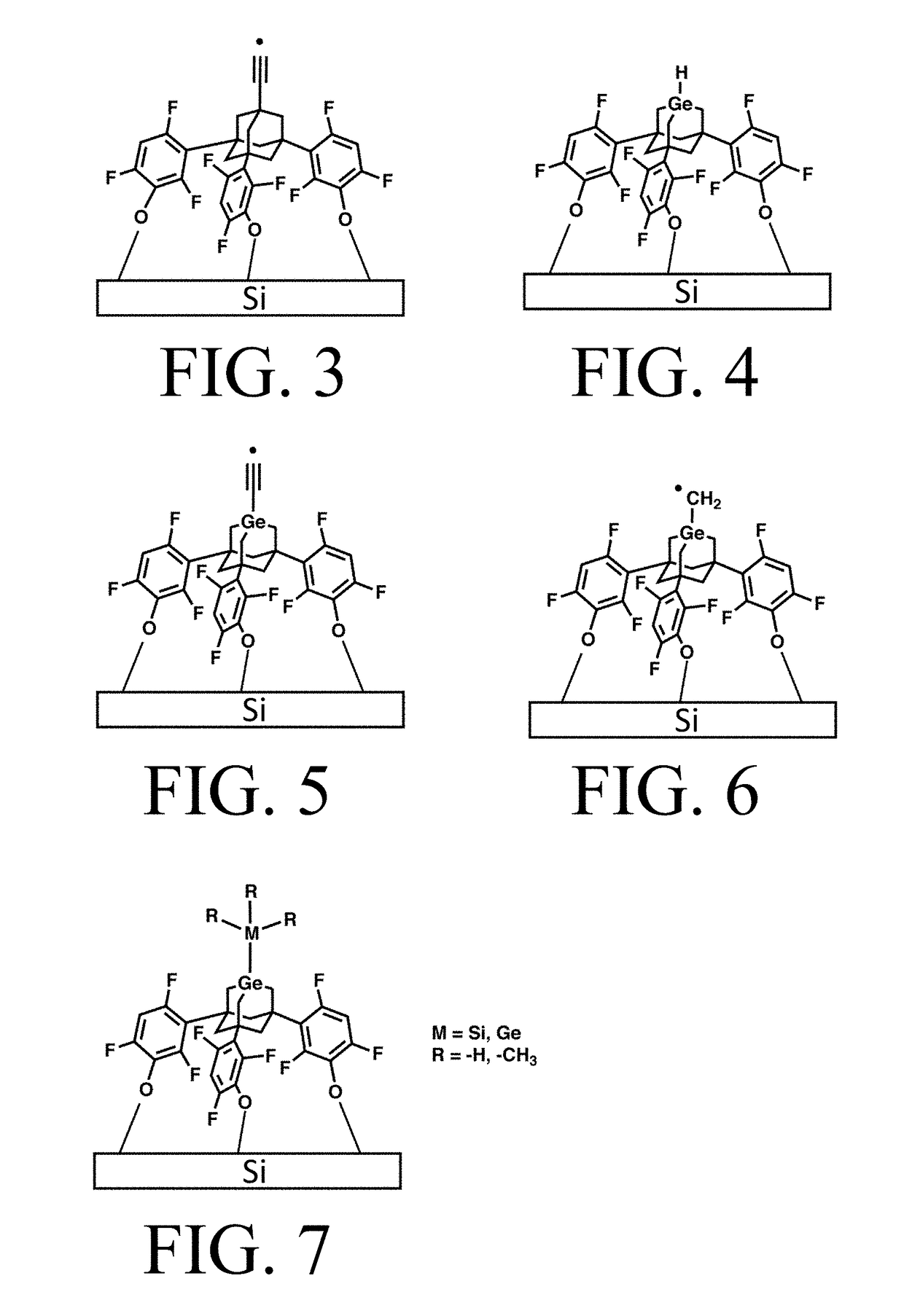

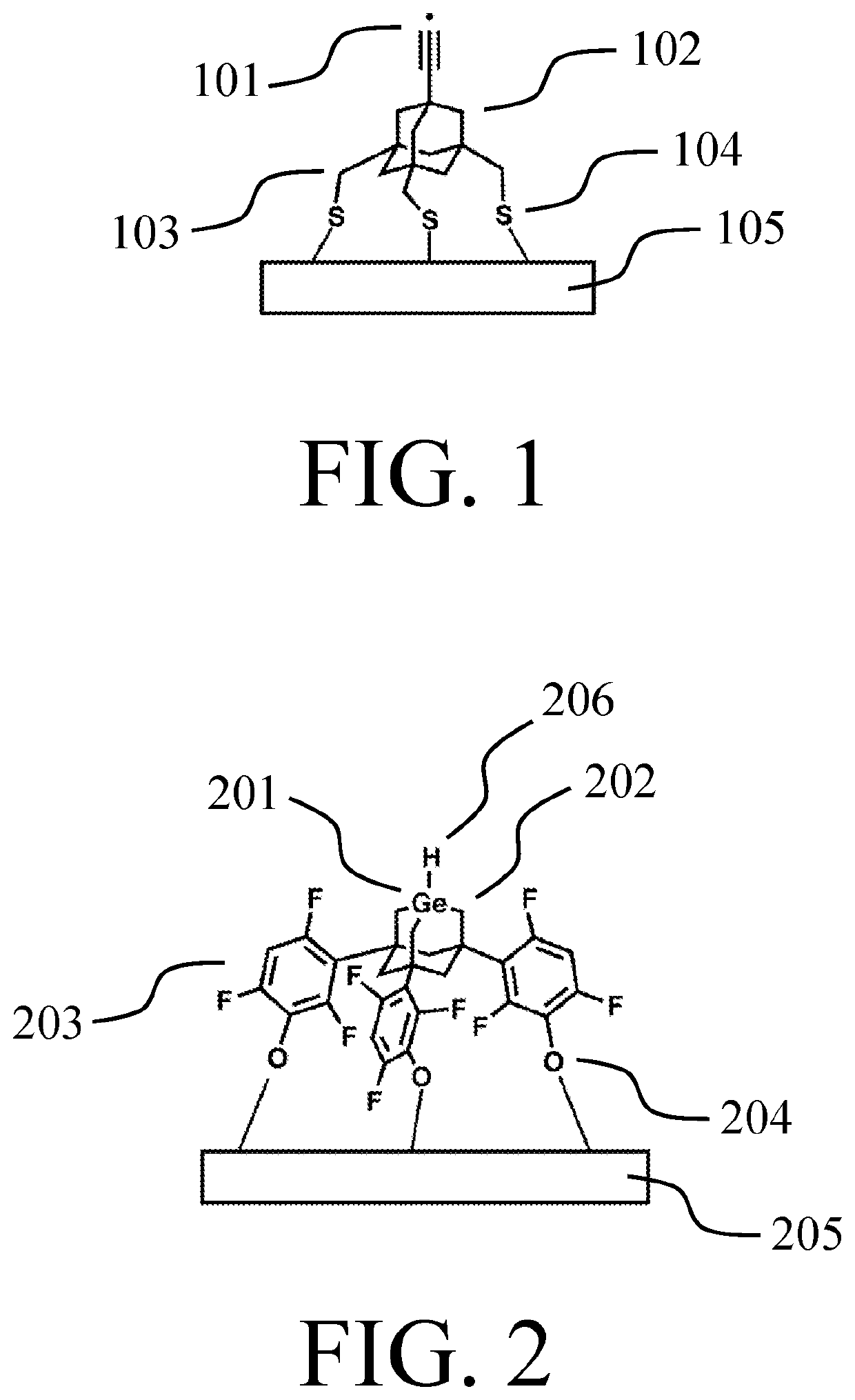

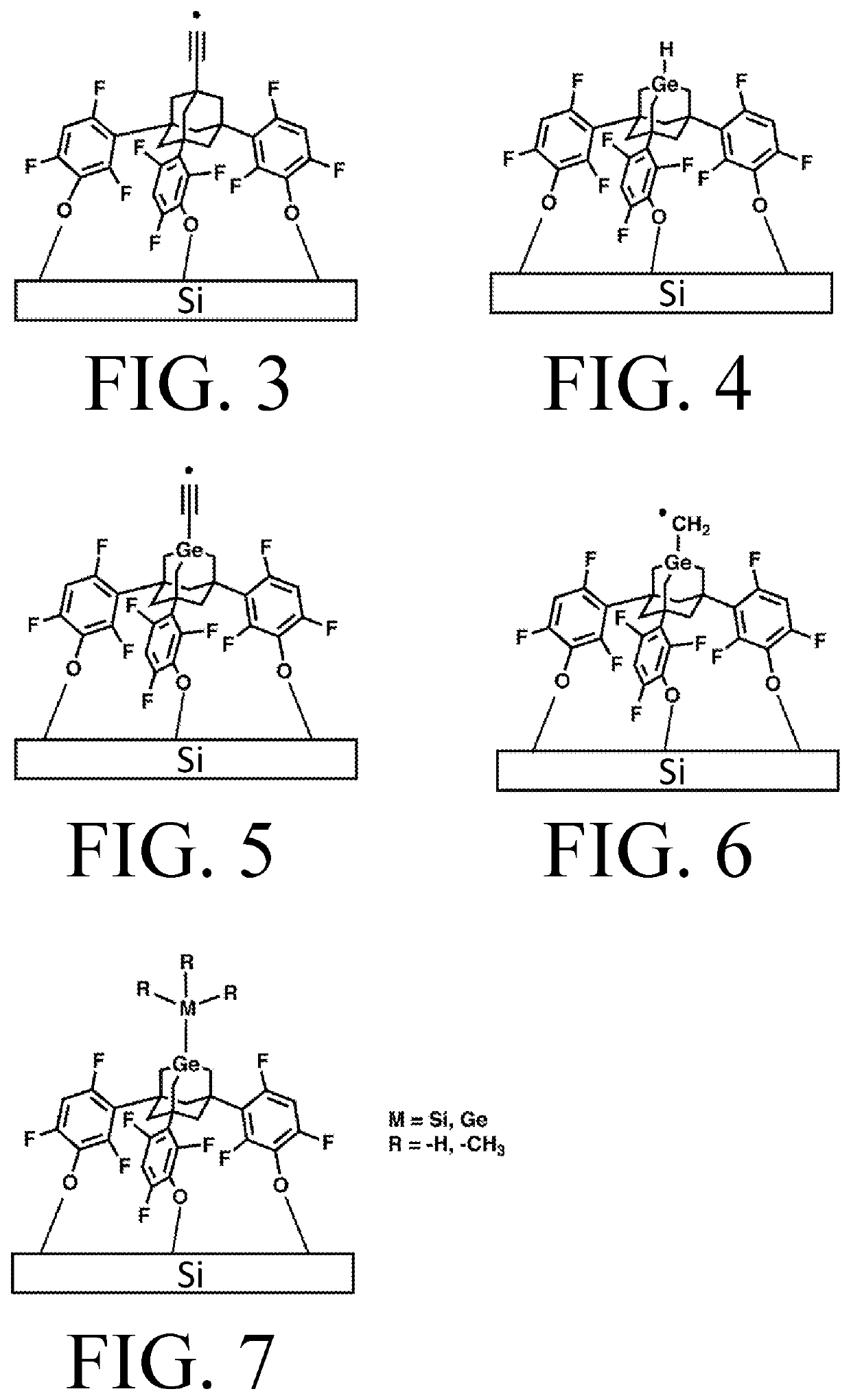

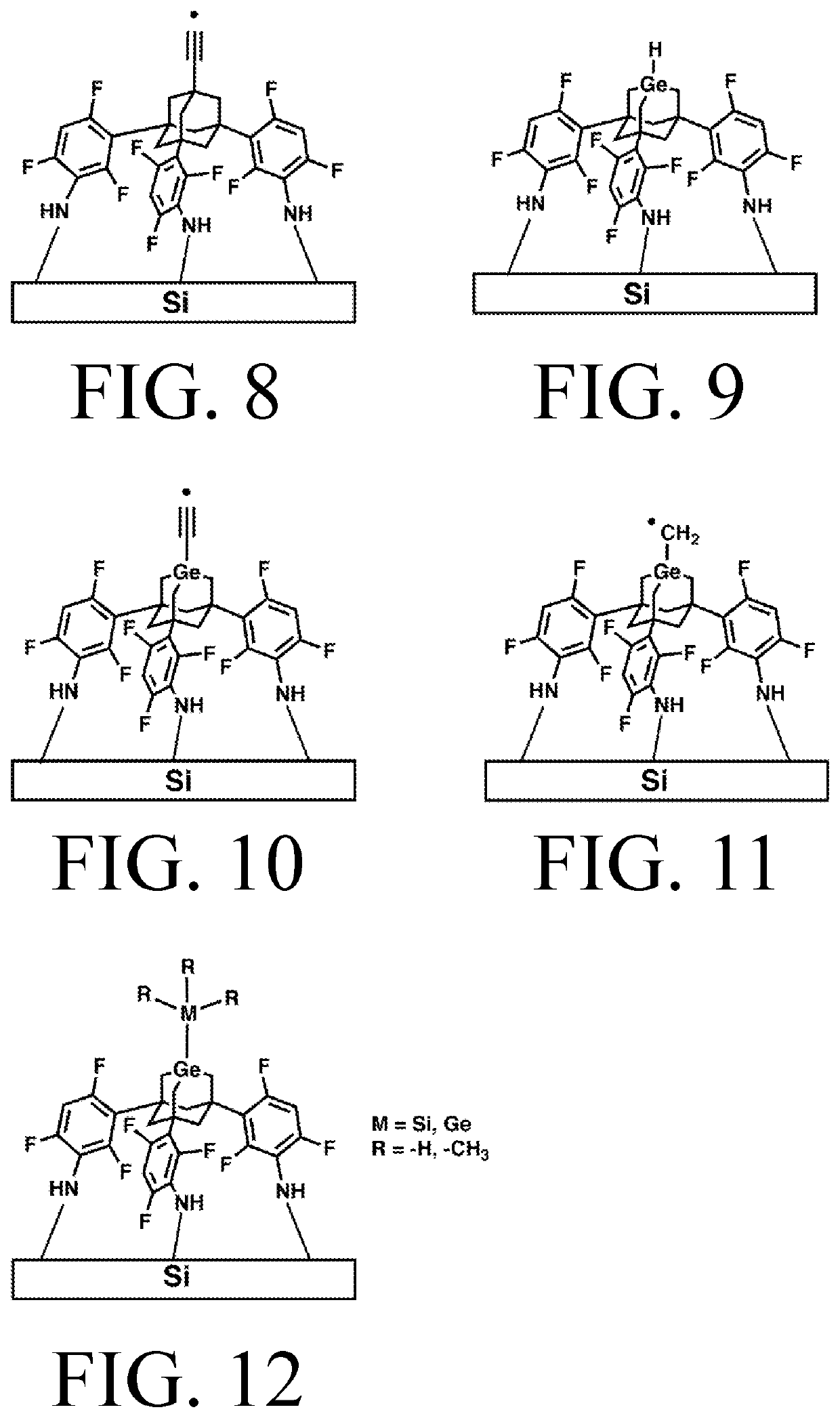

Sequential tip systems and methods for positionally controlled chemistry

ActiveUS10067160B2Improve versatilityReduce complexitySpecific nanostructure formationNanostructure assemblyMechanosynthesisBiomedical engineering

Methods, systems, and devices are described which facilitate mechanosynthesis through the sequential use of a plurality of tips, each of which may have a different affinity for feedstock, thereby allowing tip to tip transfers which enhance system versatility and reduce equipment complexity.

Owner:CBN NANO TECH INC

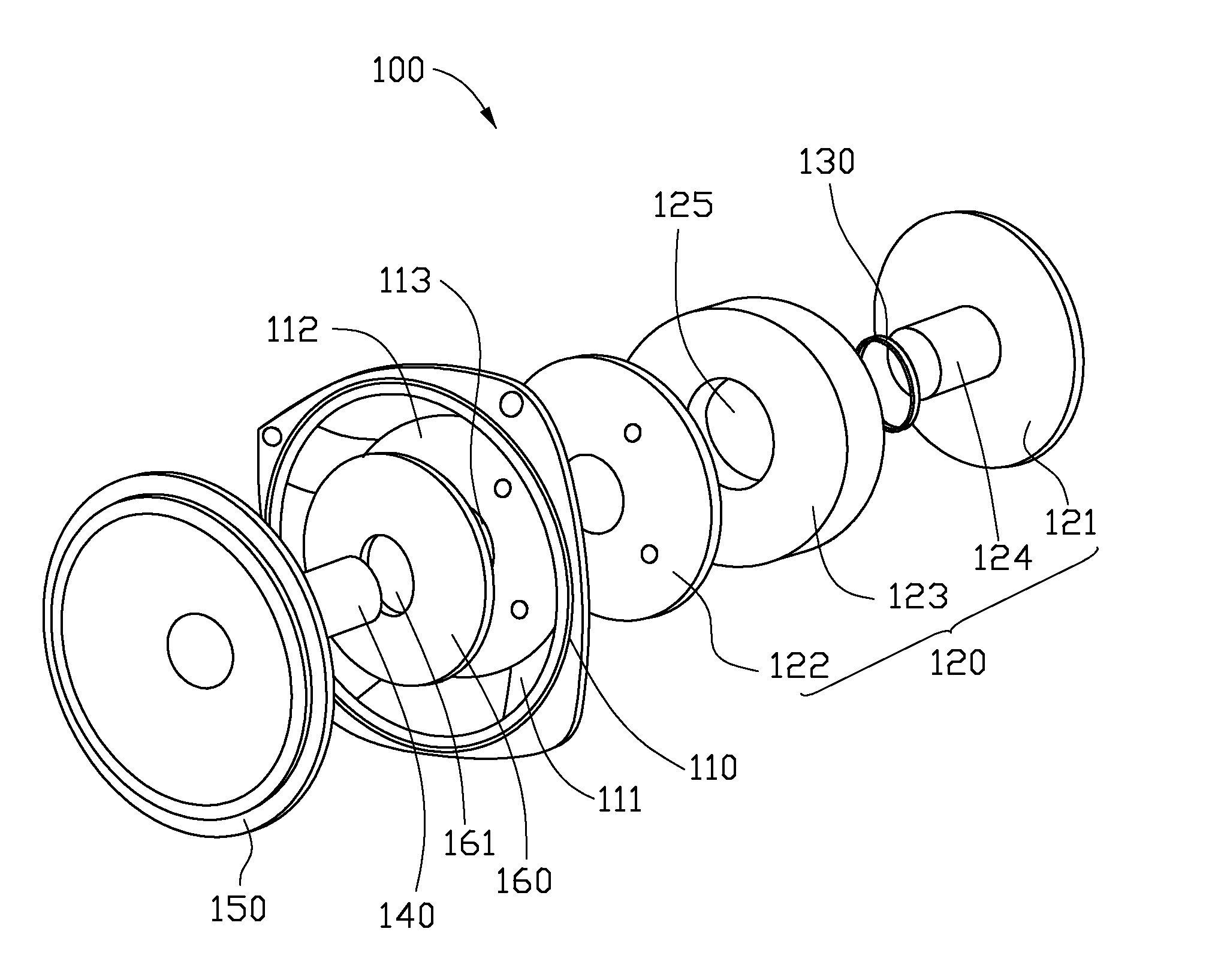

Bobbin and loudspeaker using the same cross-reference to related applications

ActiveUS20110075878A1Solve the power is smallLight weightEnvelopes/bags making machineryMaterial nanotechnologyBobbinCarbon nanotube

A bobbin includes a carbon nanotube film structure and an amorphous carbon structure. The carbon nanotube film structure defines a number of micropores therein. The amorphous carbon structure is composited with the carbon nanotube structure. The amorphous carbon structure comprises a number of amorphous carbon particles received in the micropores.

Owner:TSINGHUA UNIV +1

Carbon nanotube structure

A carbon nanotube structure includes a number of carbon wires and a number of second carbon nanotubes. Each of the carbon nanotube wires includes a number of first carbon nanotubes joined end to end by the carbon-carbon bonds therebetween. The carbon wires and the carbon nanotubes are joined by van der Waals attractive force therebetween.

Owner:TSINGHUA UNIV +1

Systems and methods for the manufacture of atomically-precise products

Owner:CBN NANO TECH INC

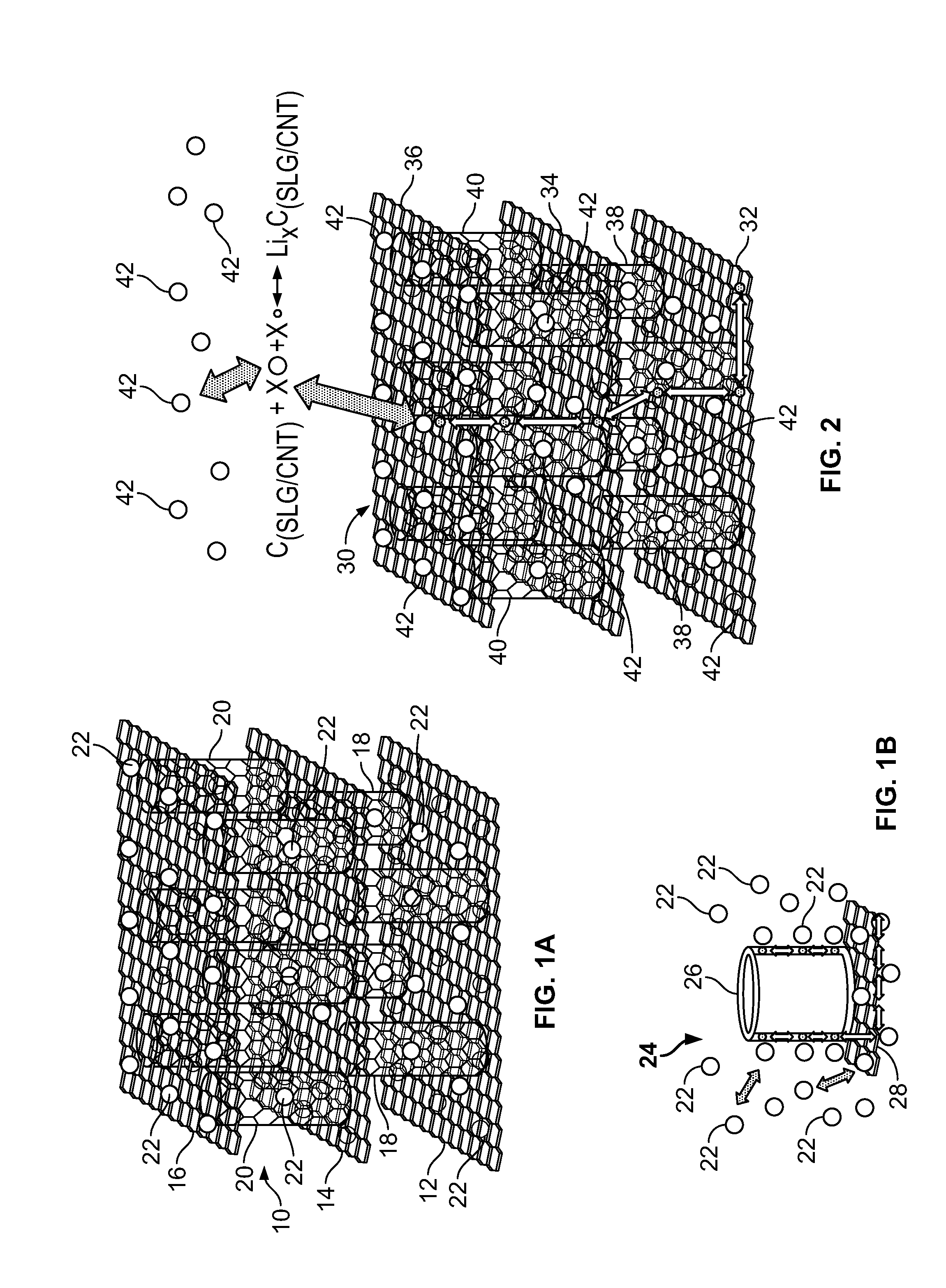

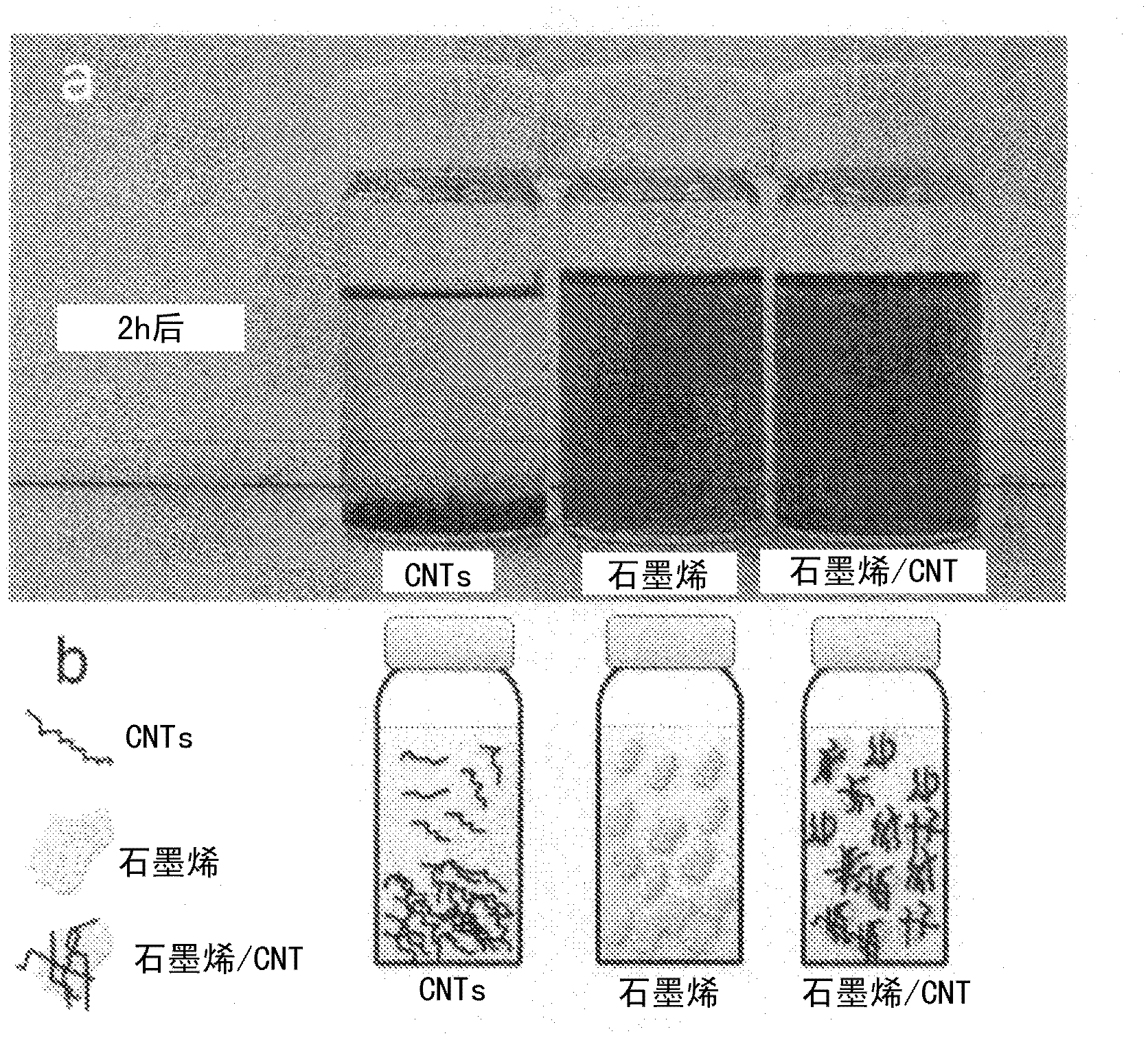

Graphene sheet film linked with carbon nanotubes, method for producing same and graphene sheet capacitor using same

ActiveCN103237755AMassive spreadHigh speed diffusionMaterial nanotechnologyNanostructure assemblySheet filmCarbon nanotube

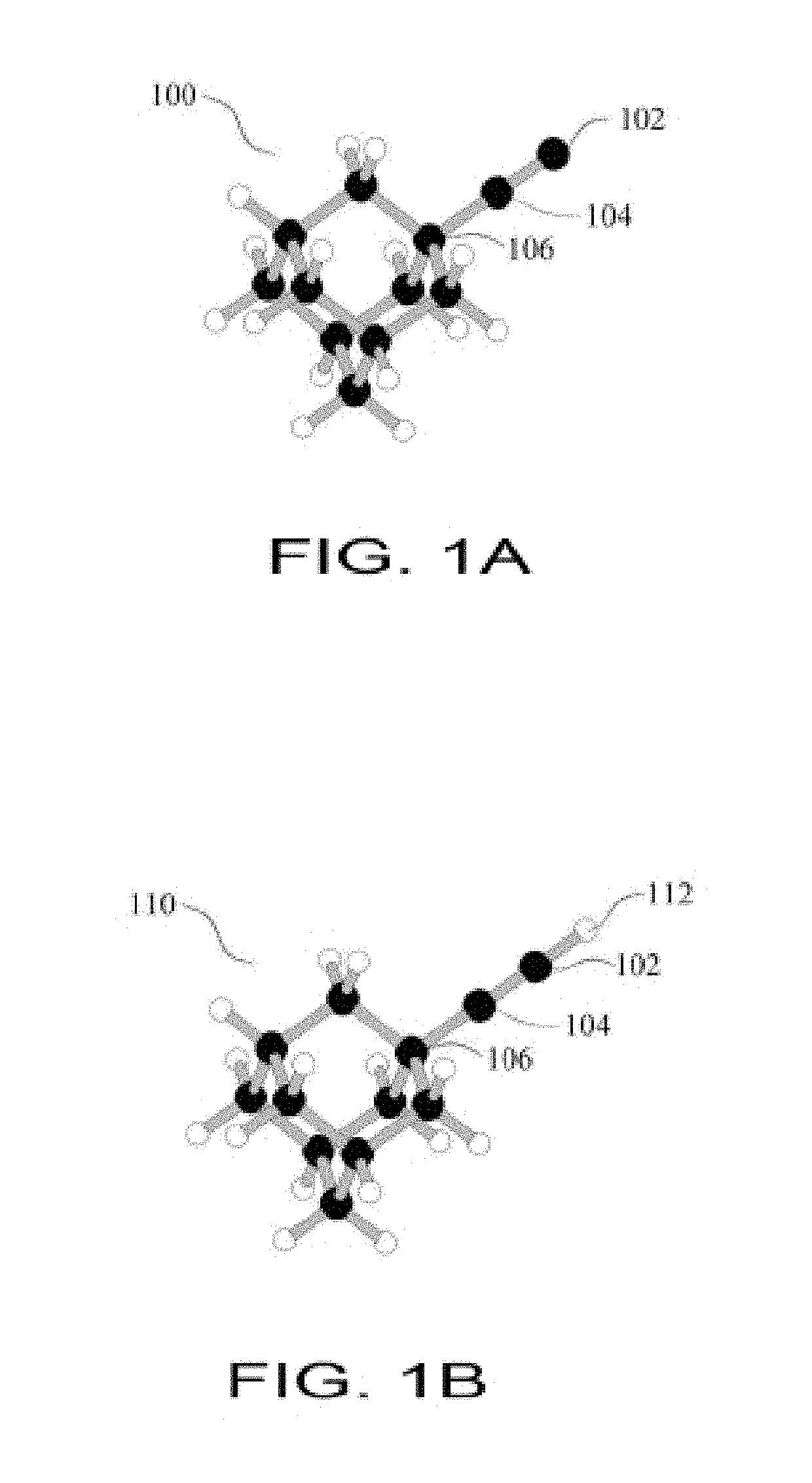

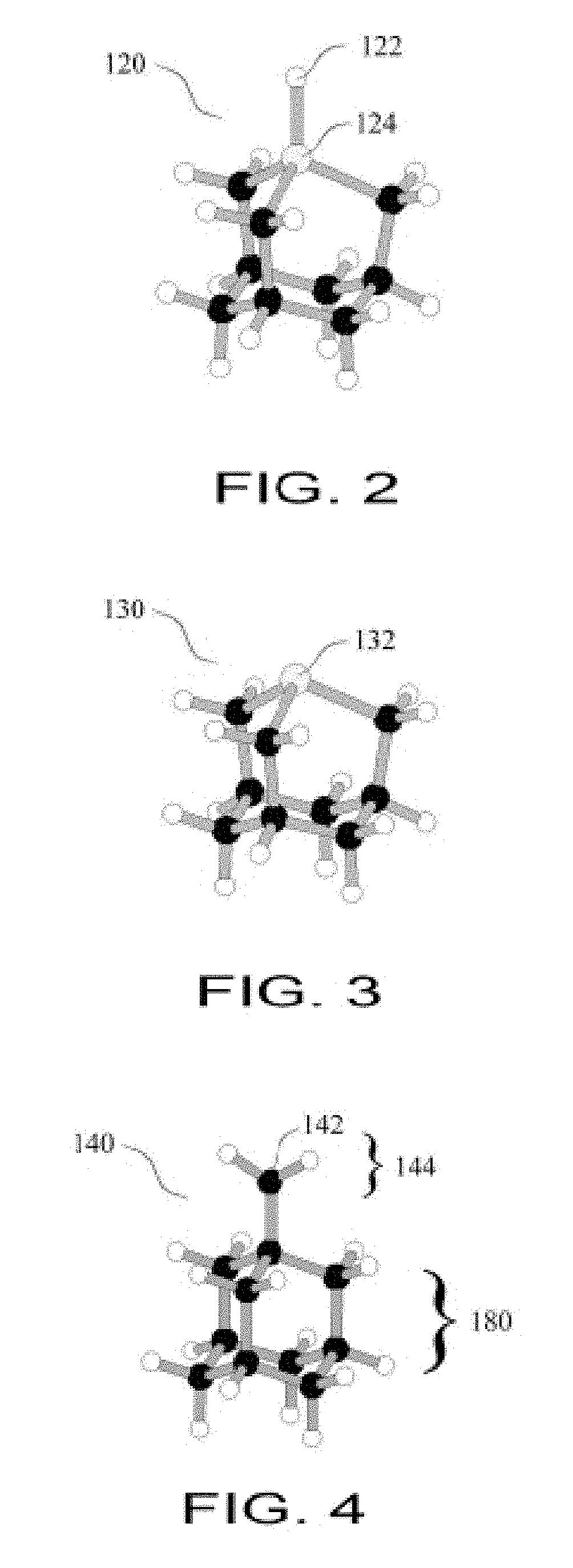

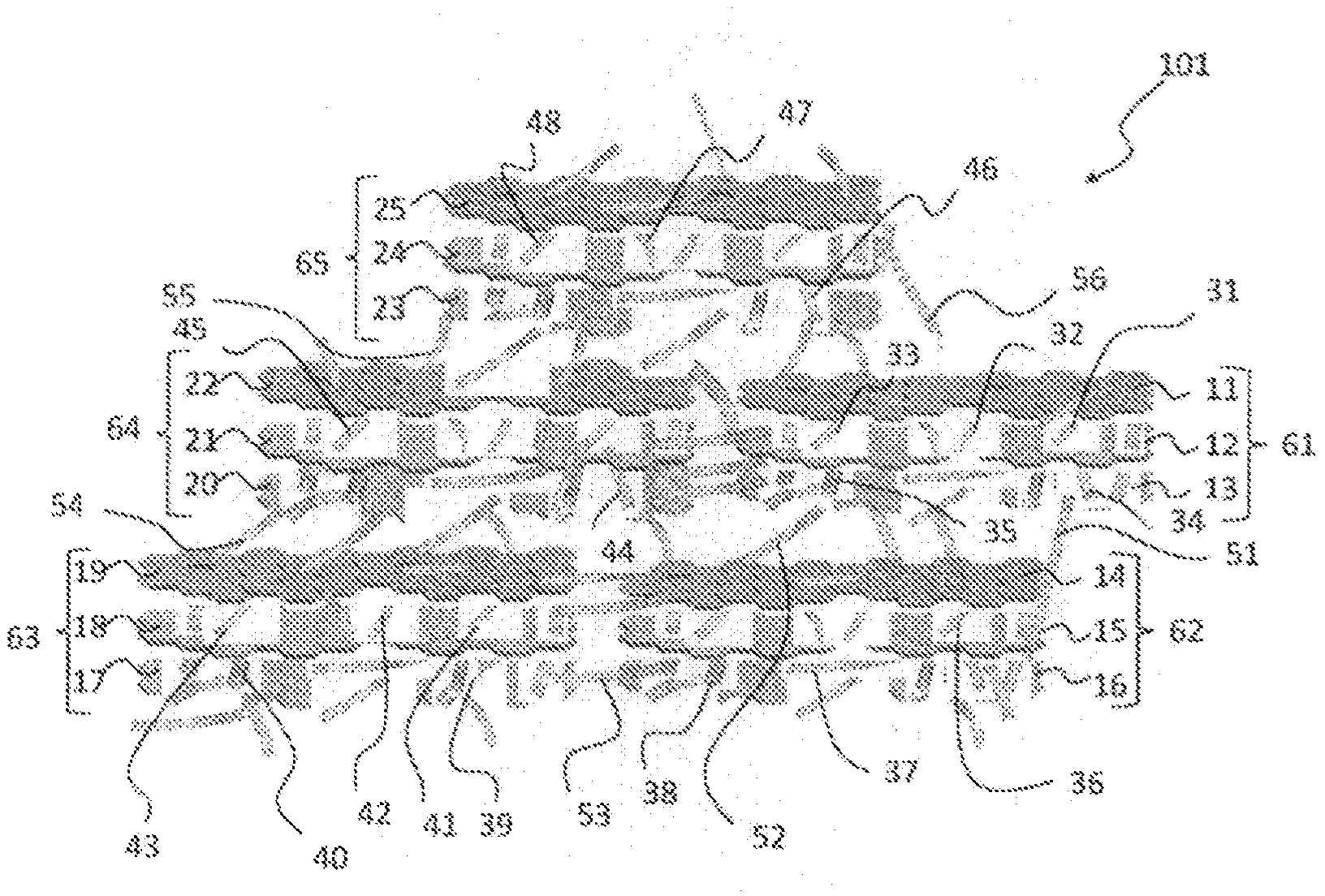

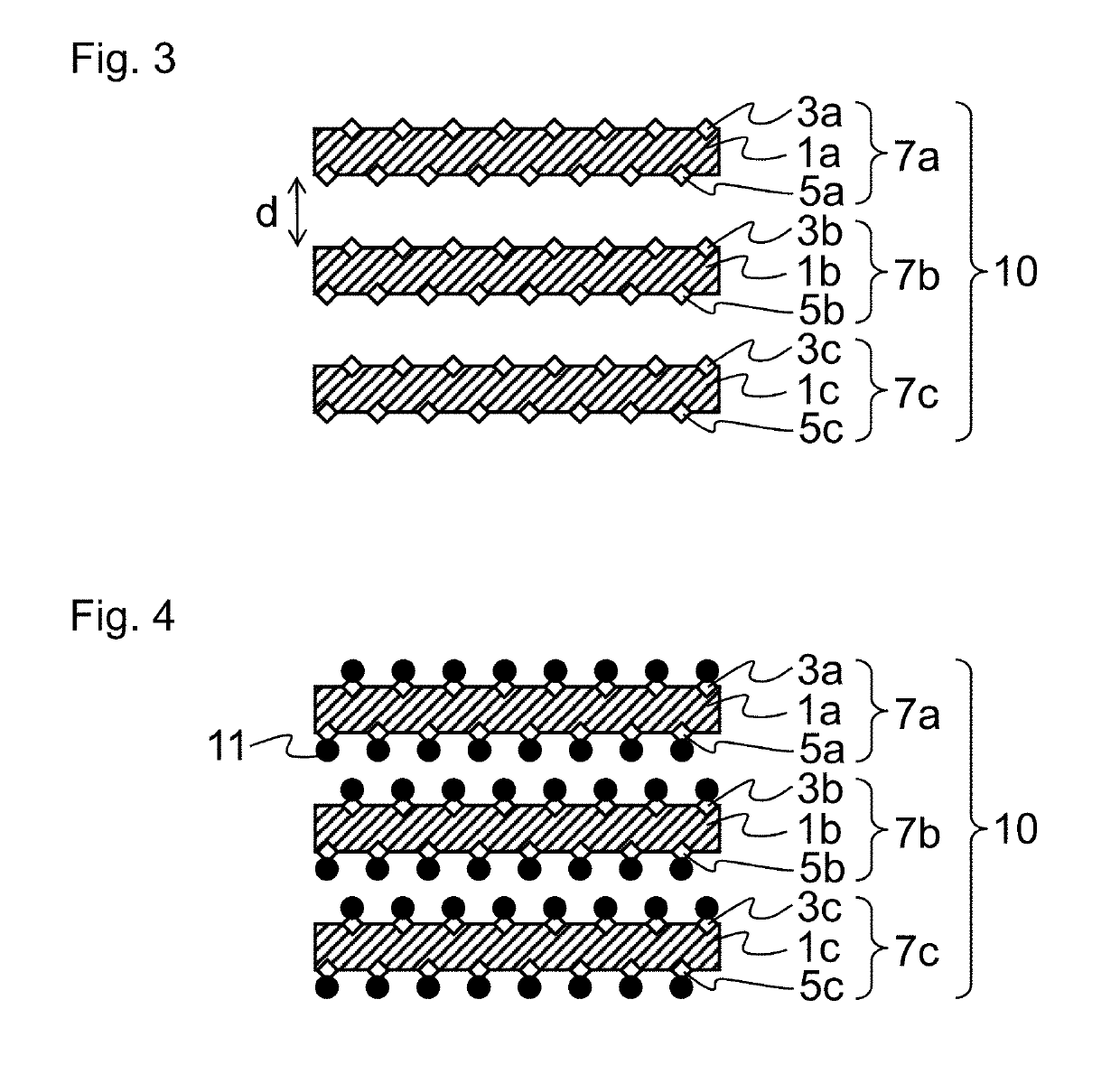

A graphene sheet film in which two or more graphene sheets (11-25) are stacked and the stack is film-shaped, wherein a graphene sheet stack (101) is used which comprises: first carbon nanotubes (31-48) which connect the graphene sheets (11-25) together and which form graphene sheet laminated bodies (61-65) in which the graphene sheets (11-25) are laminated such that the surfaces thereof are parallel with each other; and second carbon nanotubes (51-56) which link the graphene sheet laminated bodies (61-65) together. According to the present invention, a graphene sheet film with high capacitor properties associated with energy density and output density, a method for producing same and a graphene sheet capacitor using same can be provided.

Owner:NAT INST FOR MATERIALS SCI

Method for transferring graphene using a hot press

ActiveUS8916013B2Minimize damageEasy transferNanostructure assemblyLamination ancillary operationsGrapheneMaterials science

The present invention relates to a method for transferring graphene using a hot press, comprising: a step of contacting graphene, having a thermal-releasable sheet attached thereto, with a target substrate; and a step of pressing and heating the graphene having the thermal-releasable sheet attached thereto and the target substrate using the upper press and lower press of a hot press so as to separate the thermal-releasable sheet and the graphene and transfer the separated graphene to the target substrate. The present invention also relates to a graphene-transfer hot press apparatus for said transfer process.

Owner:GRAPHENE SQUARE

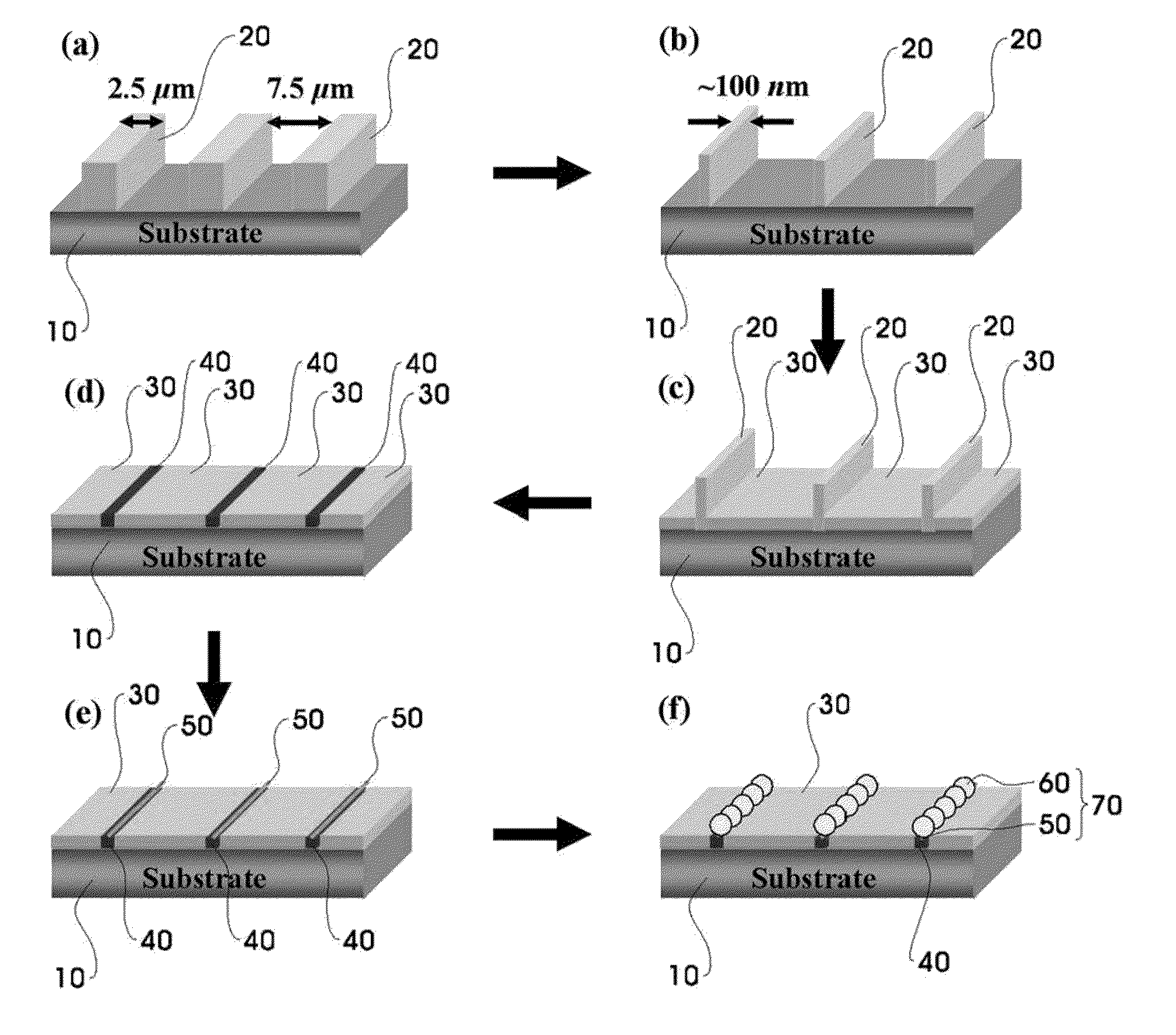

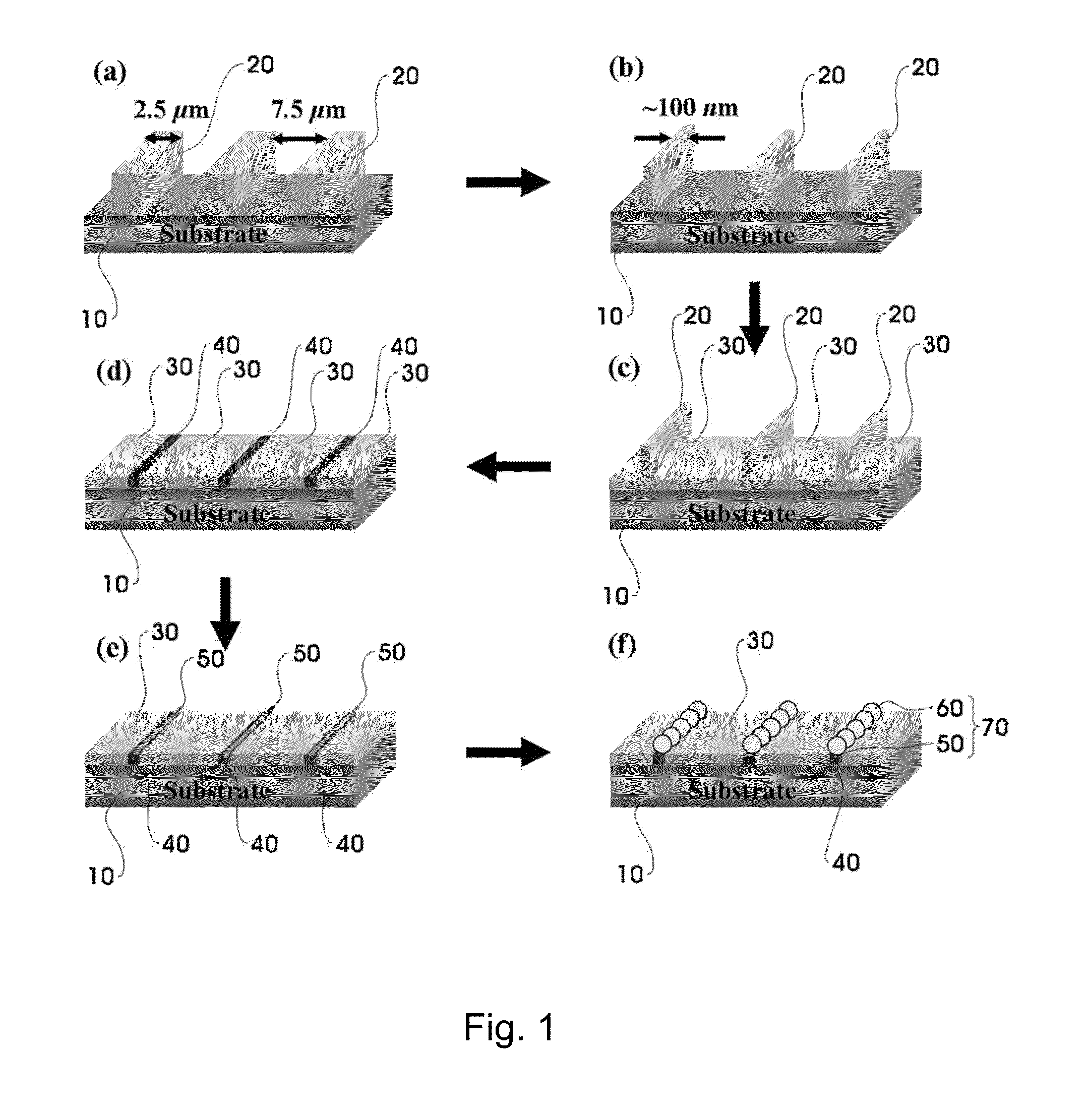

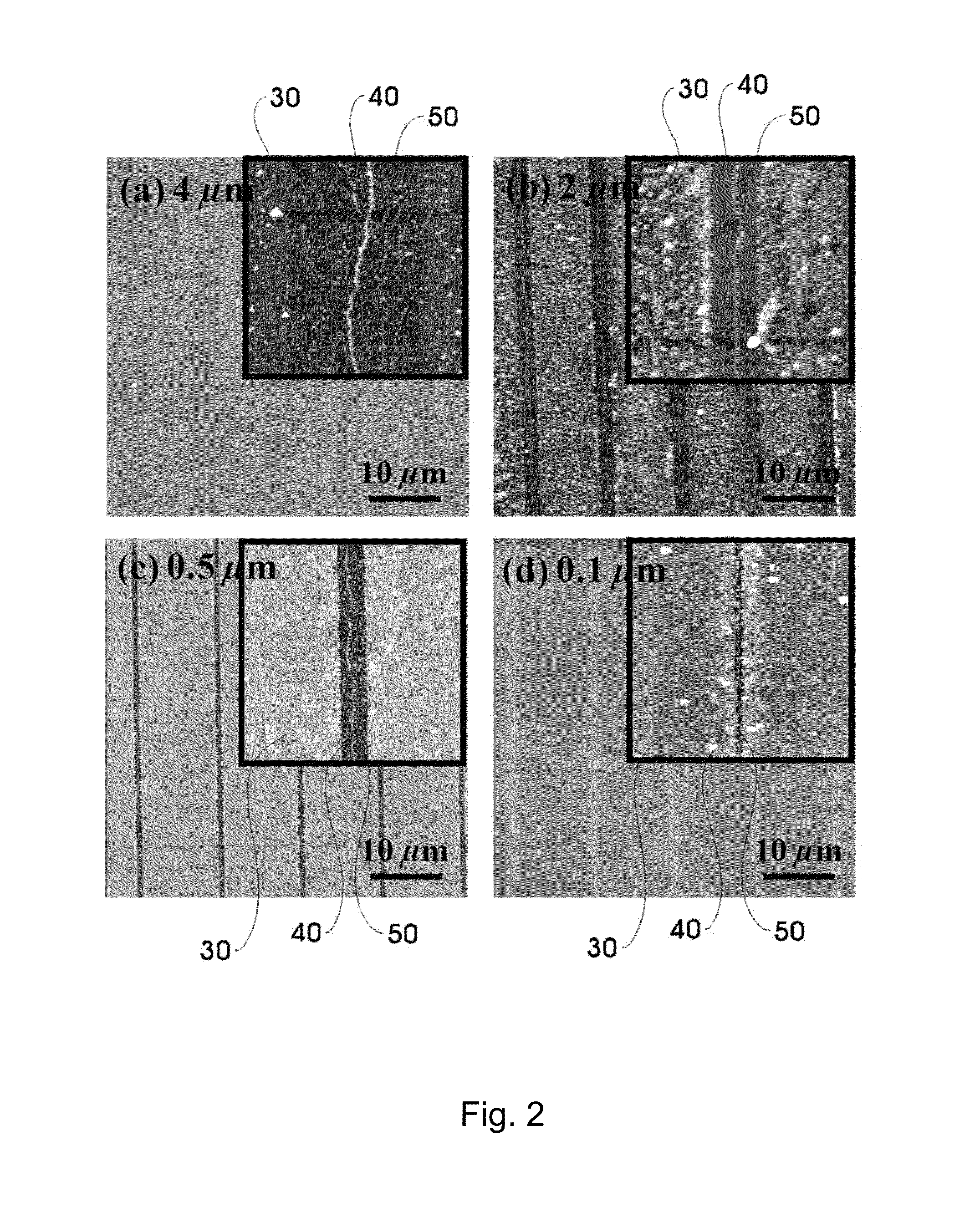

Method to assemble nano-structure on a substrate and nano-molecule device comprising nano-structure formed thereby

ActiveUS20100216076A1Reduce widthSurface potentialMaterial nanotechnologyNanostructure assemblyResistNanolithography

A method of selectively positioning nanostructures on a substrate is provided which includes: a first step of forming a photoresist pattern on the substrate and then control the line width of the photoresist pattern in a nano unit to form a nanometer photoresist layer; a second step of forming a protective layer for preventing adsorption of a nano-material in a patter-unformed area on the substrate on which the nanometer photoresist layer has been formed; a third step of removing the photoresist layer formed on the substrate; a fourth step of forming a positively-charged or negatively charged adsorbent layer in the area from which the photoresist layer has been removed; and a fifth step of applying a nano-material-containing solution charged in the opposite polarity of the adsorbent layer to the substrate on which the adsorbent layer has been formed.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

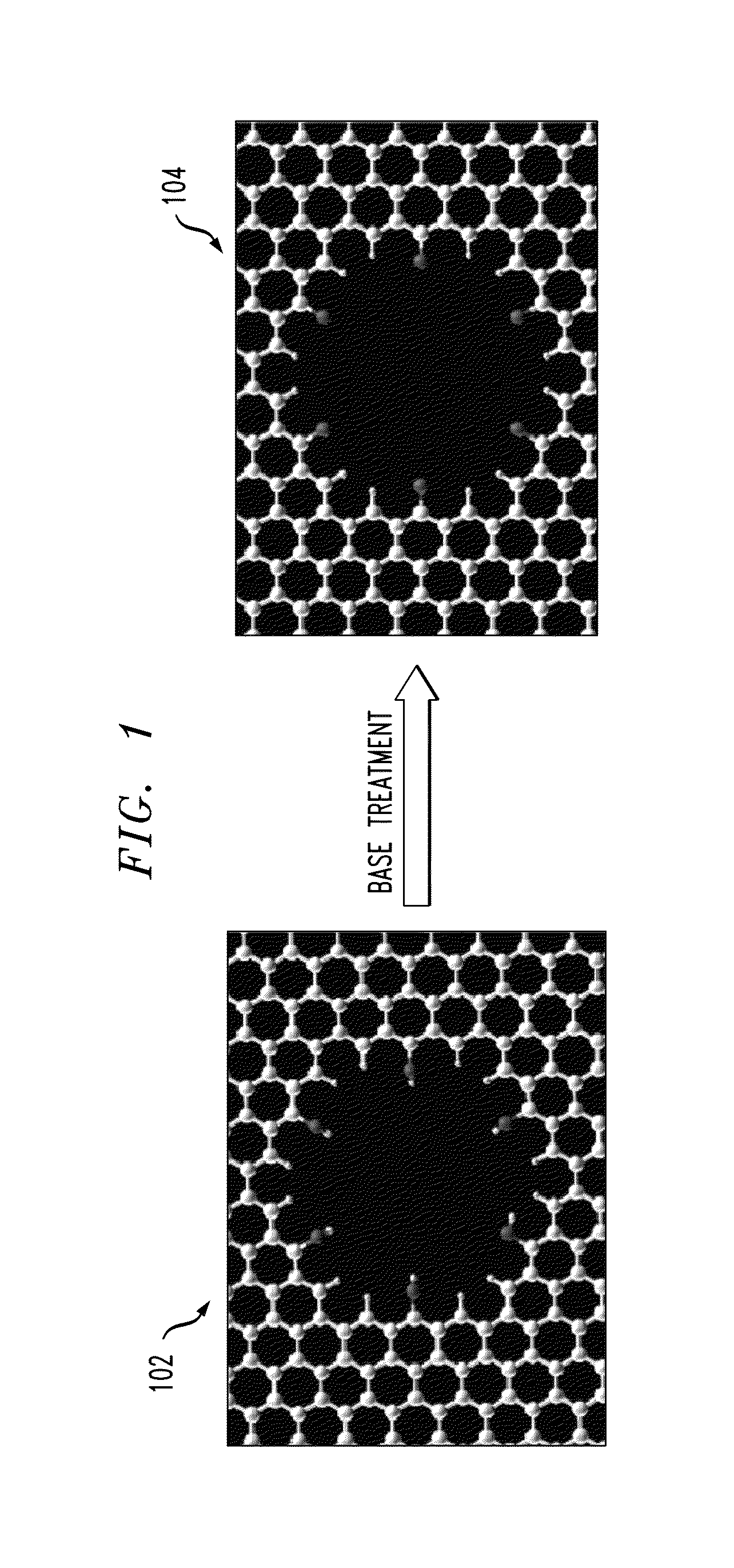

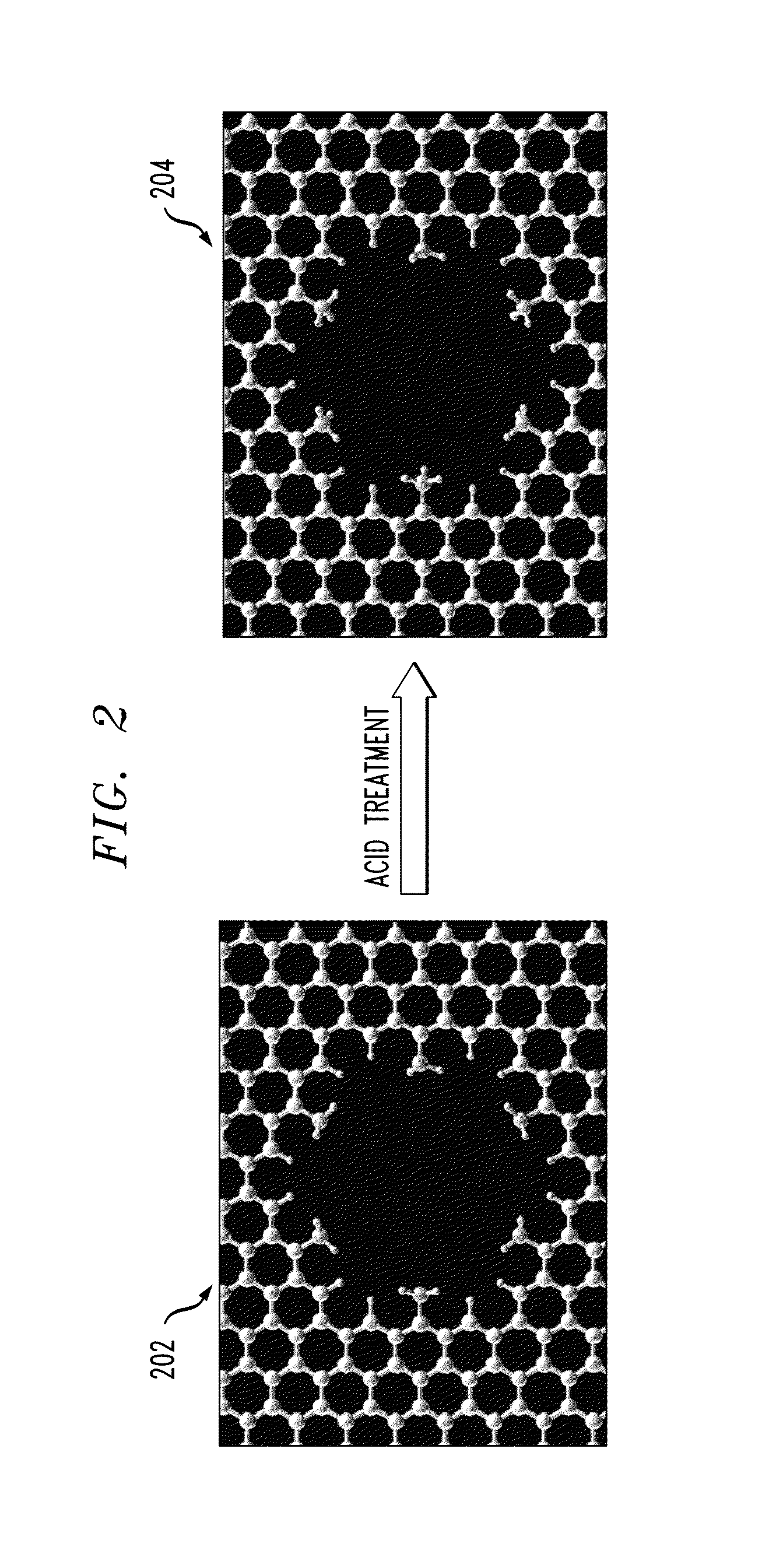

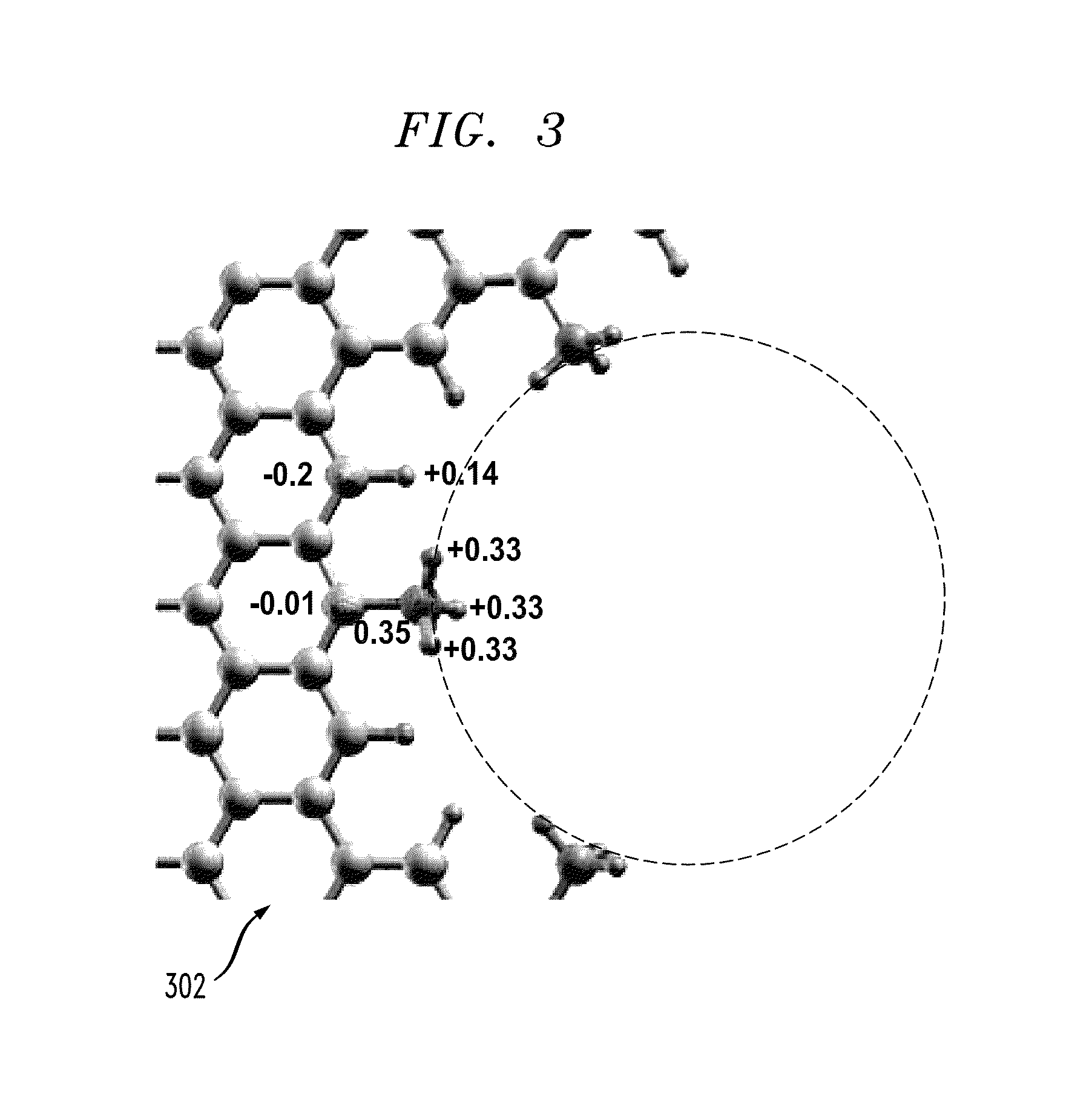

Controlled assembly of charged nanoparticles using functionalized graphene nanomesh

InactiveUS8835686B2Material nanotechnologyNanostructure assemblyChemical treatmentTargeted nanoparticles

A method, an apparatus and an article of manufacture for attracting charged nanoparticles using a graphene nanomesh. The method includes creating a graphene nanomesh by generating multiple holes in graphene, wherein each of the multiple holes is of a size appropriate to a targeted charged nanoparticle, selectively passivating the multiple holes of the graphene nanomesh to form a charged ring in the graphene nanomesh by treating the graphene nanomesh with chemistry yielding a trap with an opposite charge to that of the targeted nanoparticle, and electrostatically attracting the target charged nanoparticle to the oppositely charged ring to facilitate docking of the charged nanoparticle to the graphene nanomesh.

Owner:INT BUSINESS MASCH CORP +1

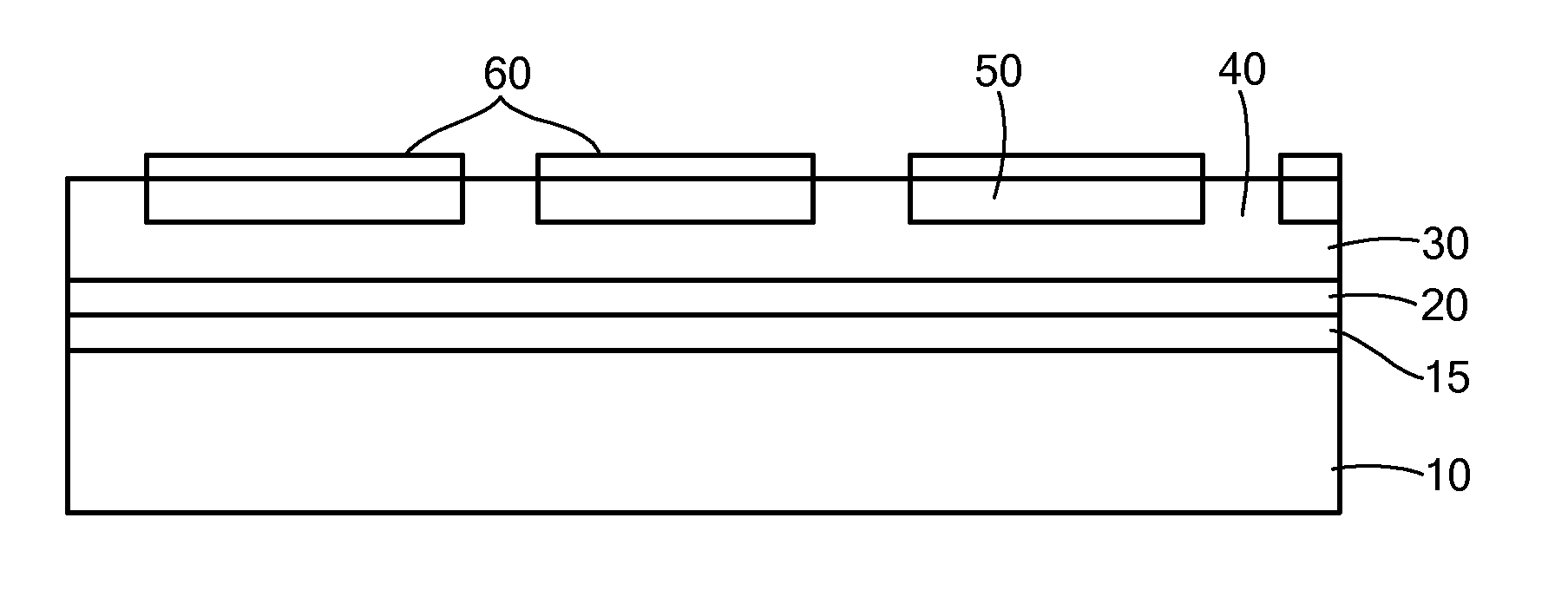

Light emitting element, display device including the same, and method for manufacturing the display device

PendingUS20210202800A1Easy alignmentImprove responseGroup 4/14 element organic compoundsNanostructure assemblyDisplay deviceElectrical polarity

A light emitting device, a display device comprising same, and a method for manufacturing a display device are provided. The light emitting device comprises: a first conductivity type semiconductor doped to have a first polarity, an active layer on the first conductivity type semiconductor, a second conductivity type semiconductor on the active layer and doped to have a second polarity different from the first polarity and an insulating material layer surrounding side surfaces of the first conductivity type semiconductor, the second conductivity type semiconductor, and the active layer, wherein the insulating material layer includes an insulating material film and an element orienter bonded to an outer peripheral surface of the insulating material film.

Owner:SAMSUNG DISPLAY CO LTD

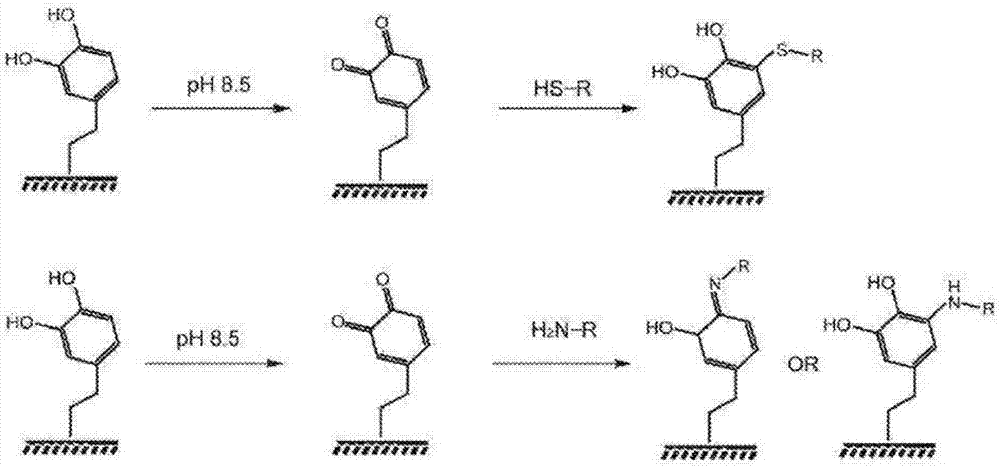

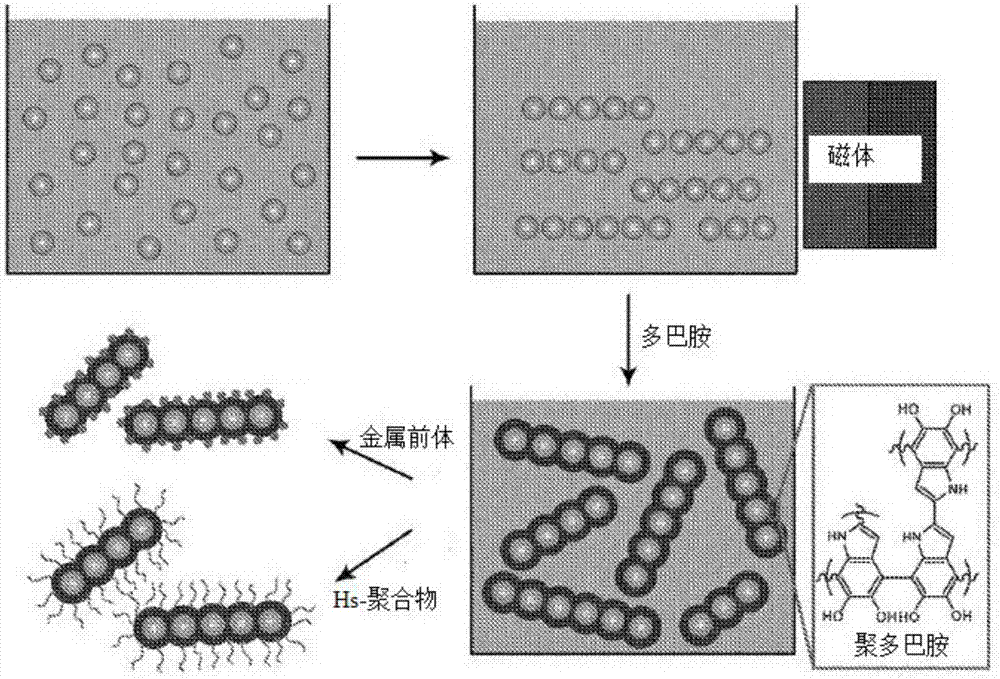

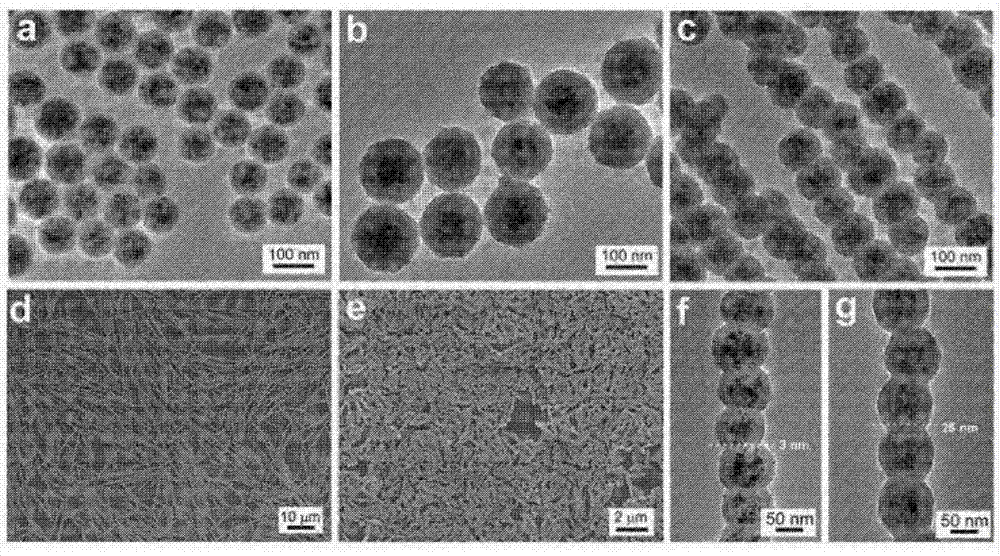

Method for preparing a magnetic chain structure

A method for preparing a magnetic chain structure is provided. The method comprises providing a plurality of magnetic particles; dispersing the plurality of magnetic particles in a solution comprisinga dopamine-based material to form a reaction mixture; applying a magnetic field across the reaction mixture to align the magnetic particles in the reaction mixture; and polymerizing the dopamine-based material on the aligned magnetic particles to obtain the magnetic chain structure. A magnetic chain structure prepared by the method is also provided.

Owner:NANYANG TECH UNIV

Systems and methods for mechanosynthesis

Improved methods, systems and devices for mechanosynthesis, including those that involve the bulk chemical preparation of tips, multiple tips on a presentation surface, and multiple tips used sequentially in a thermodynamic cascade. These improvements can simplify starting requirements, improve versatility, and reduce equipment and process complexity.

Owner:CBN NANO TECH INC

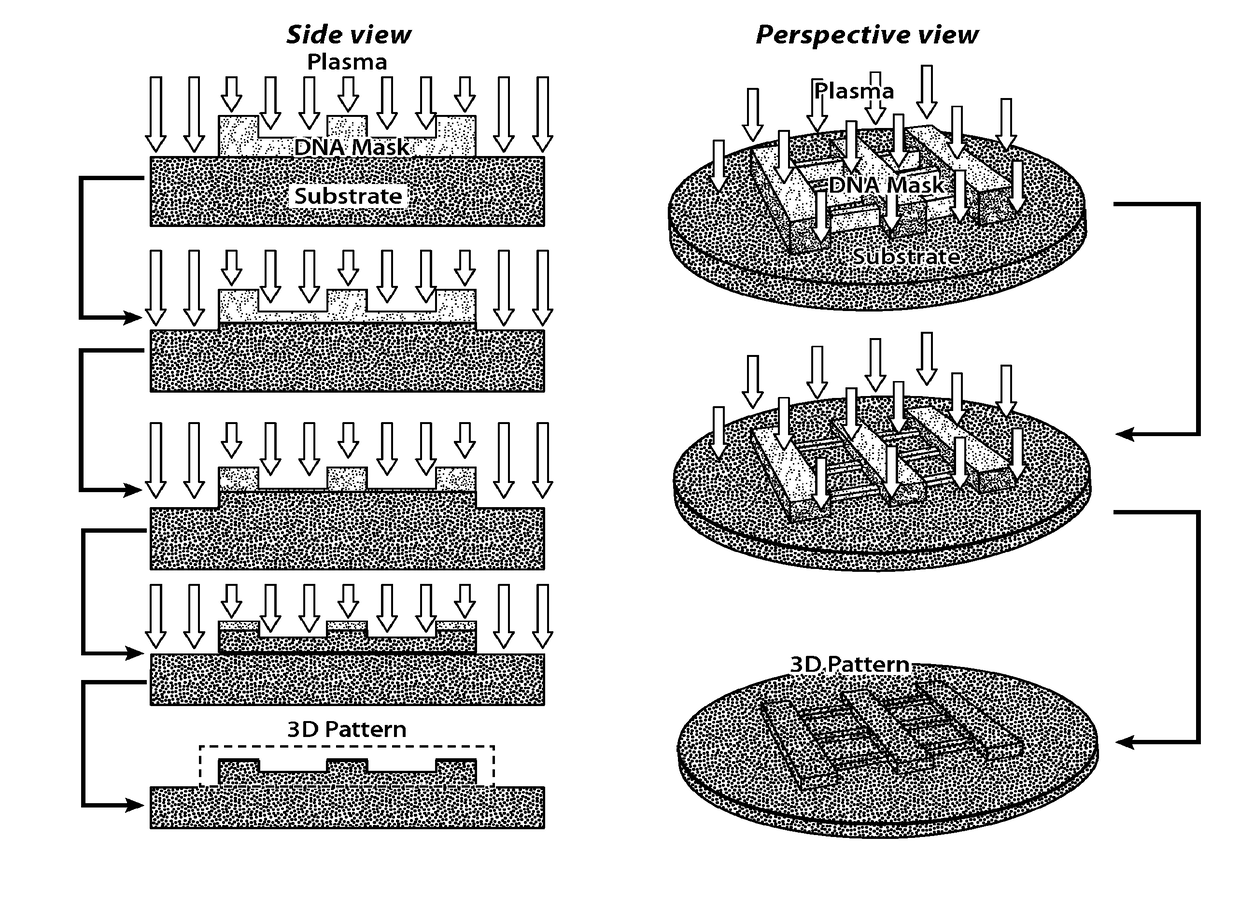

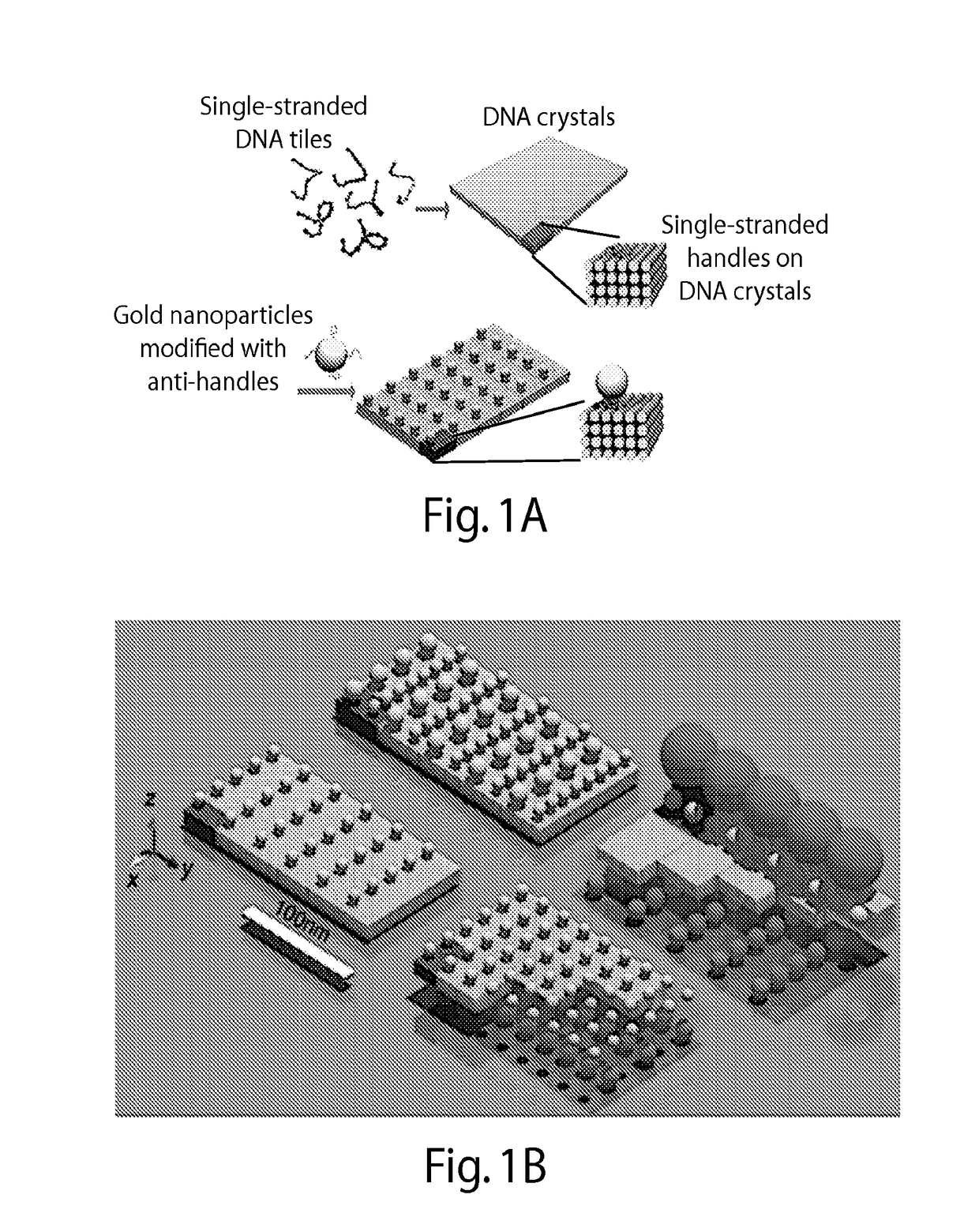

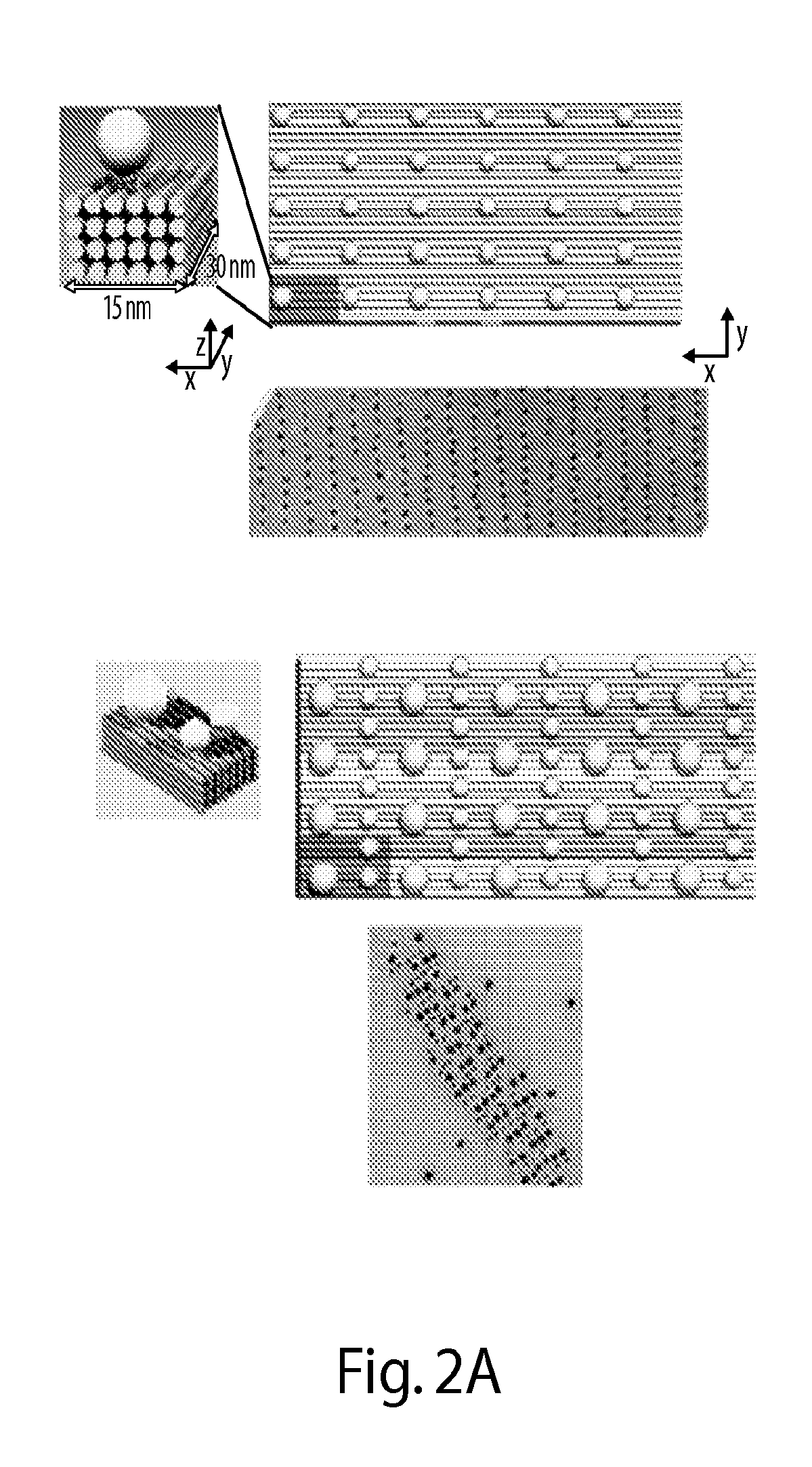

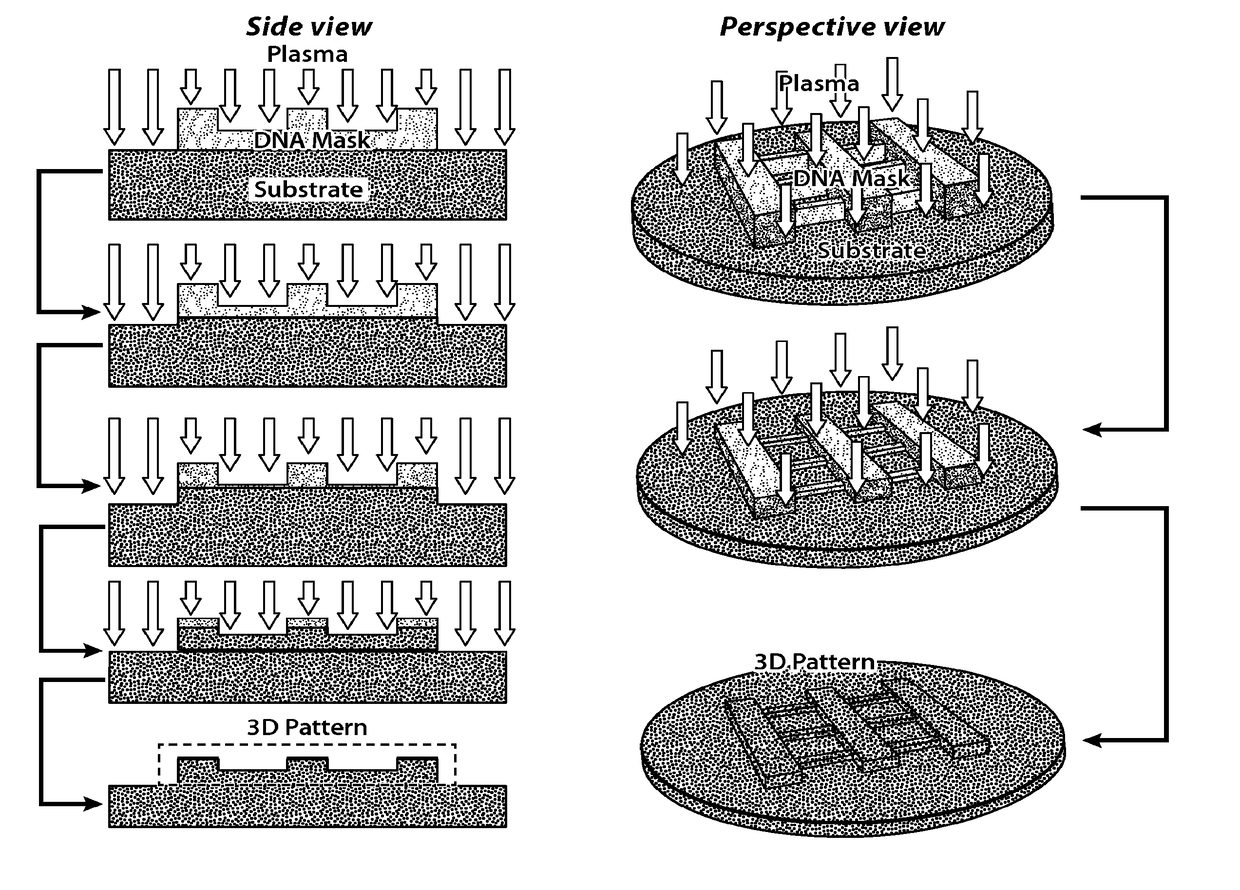

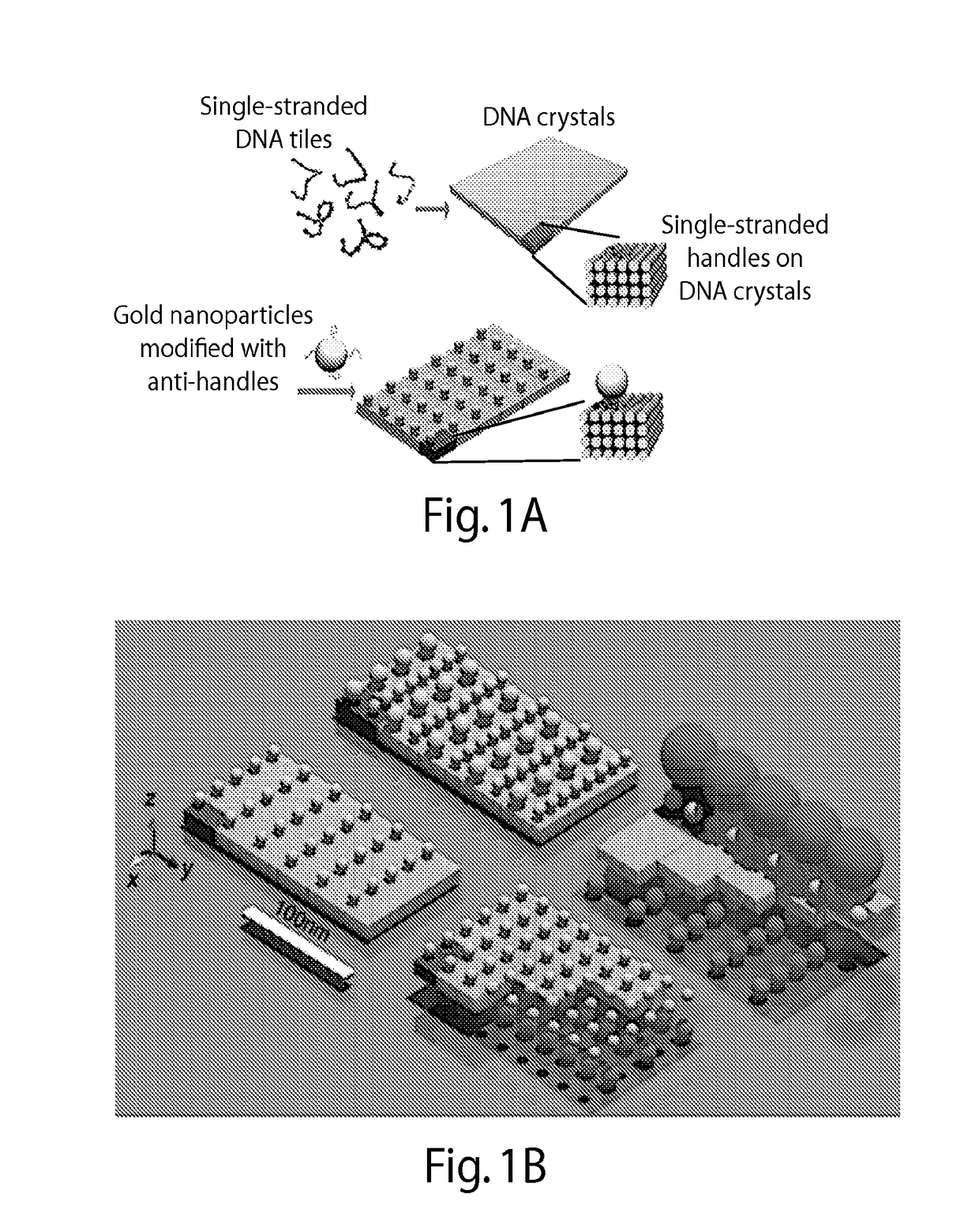

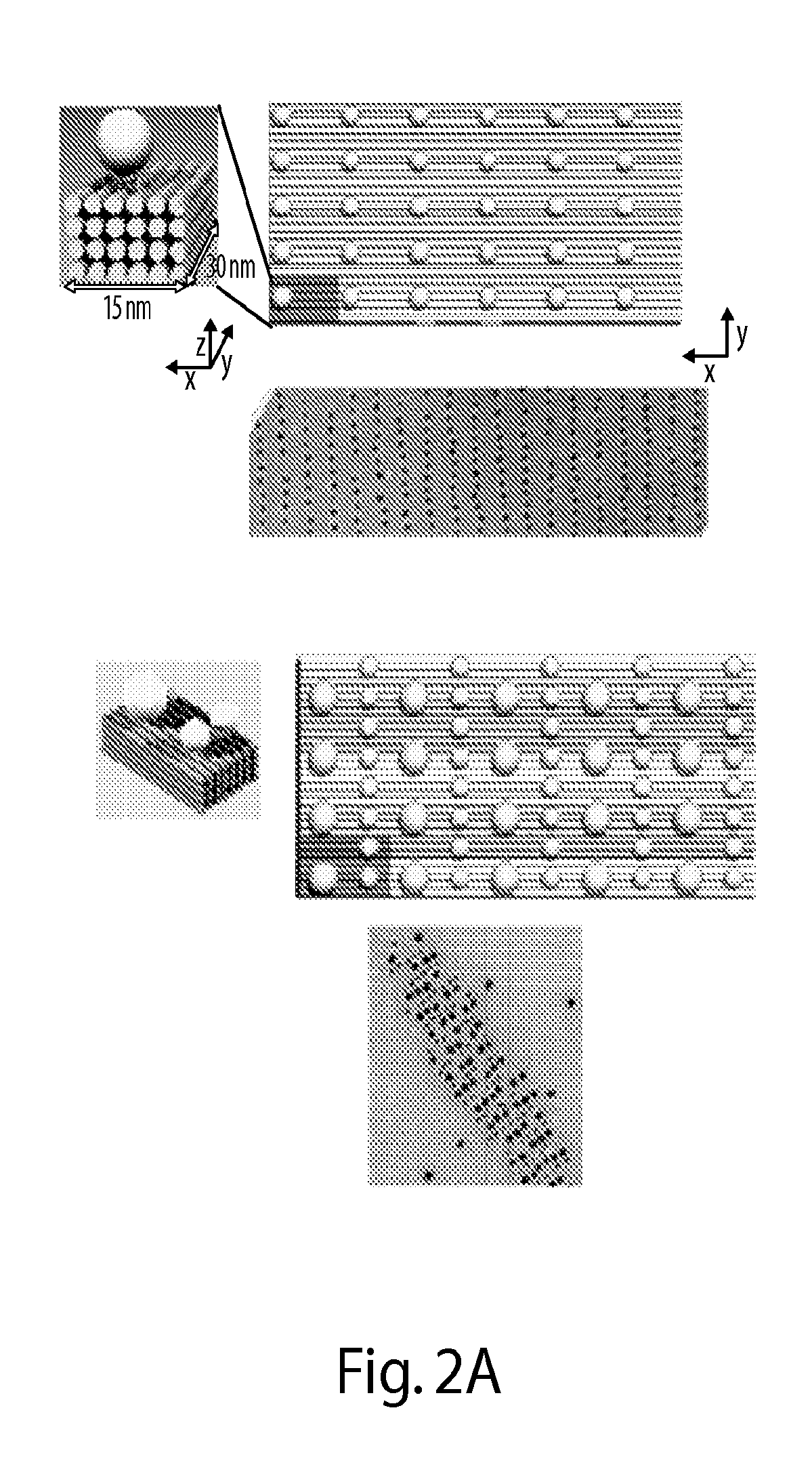

Scalable nucleic acid-based nanofabrication

ActiveUS20170190573A1Minimal feature defectPattern can be very complexMaterial nanotechnologyNanostructure assemblyNanoparticlePatterned substrate

The present disclosure relates to the alignment of moieties (e.g., nanoparticles and / or nanowires) into prescribed architectures on two- and / or three-dimensional substrates (e.g., nucleic acid nanostructures / crystals). The present disclosure also relates to a nucleic acid (e.g., DNA) lithography method that includes, in some embodiments, adsorbing a bare nucleic acid nano-structure onto a surface of a substrate, and etching the surface of the substrate containing the bare nucleic acid nanostructure, thereby producing a patterned substrate.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

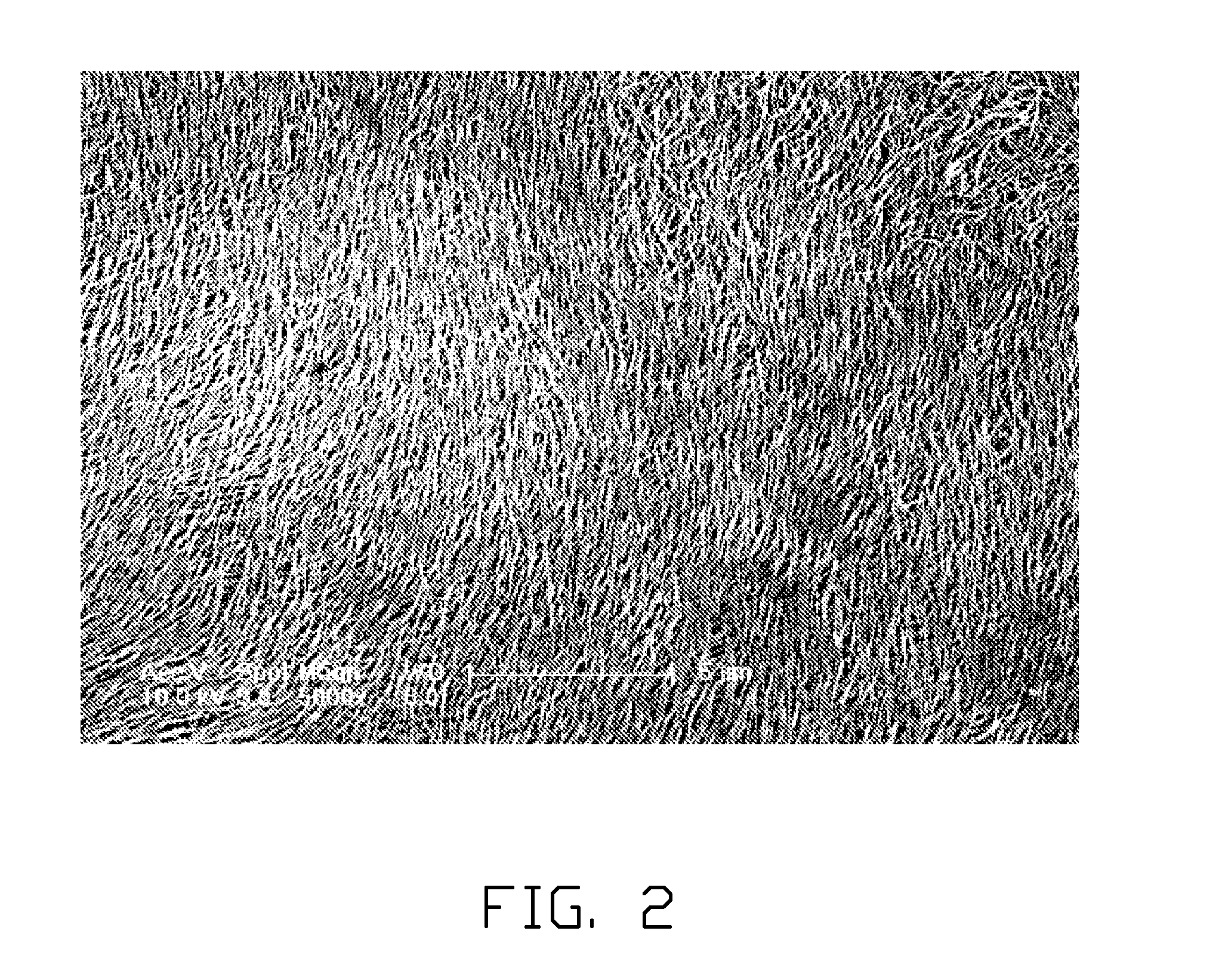

Aligned film and method for producing the same

ActiveUS20190092641A1Increase reflectionImprove reflectivityMaterial nanotechnologyNanomagnetismOctahedronMagnetite Nanoparticles

An aligned film having first and second faces opposed to each other, the aligned film having (a) a plurality of layers aligned non-parallel to the first and second faces between the faces of the aligned film, each layer having a crystal lattice represented by: Mn+1Xn (wherein M is at least one metal of Group 3, 4, 5, 6, or 7; X is a carbon atom, a nitrogen atom, or a combination thereof; and n is 1, 2, or 3), each X is positioned within an octahedral array of M, and at least one of two opposing surfaces of each said layer have at least one modifier or terminal T selected from a hydroxy group, a fluorine atom, an oxygen atom, and a hydrogen atom; and (b) magnetic nanoparticles carried on a layer surface and / or between two adjacent layers of the plurality of layers.

Owner:MURATA MFG CO LTD +1

Composite structure of carbon nano tube

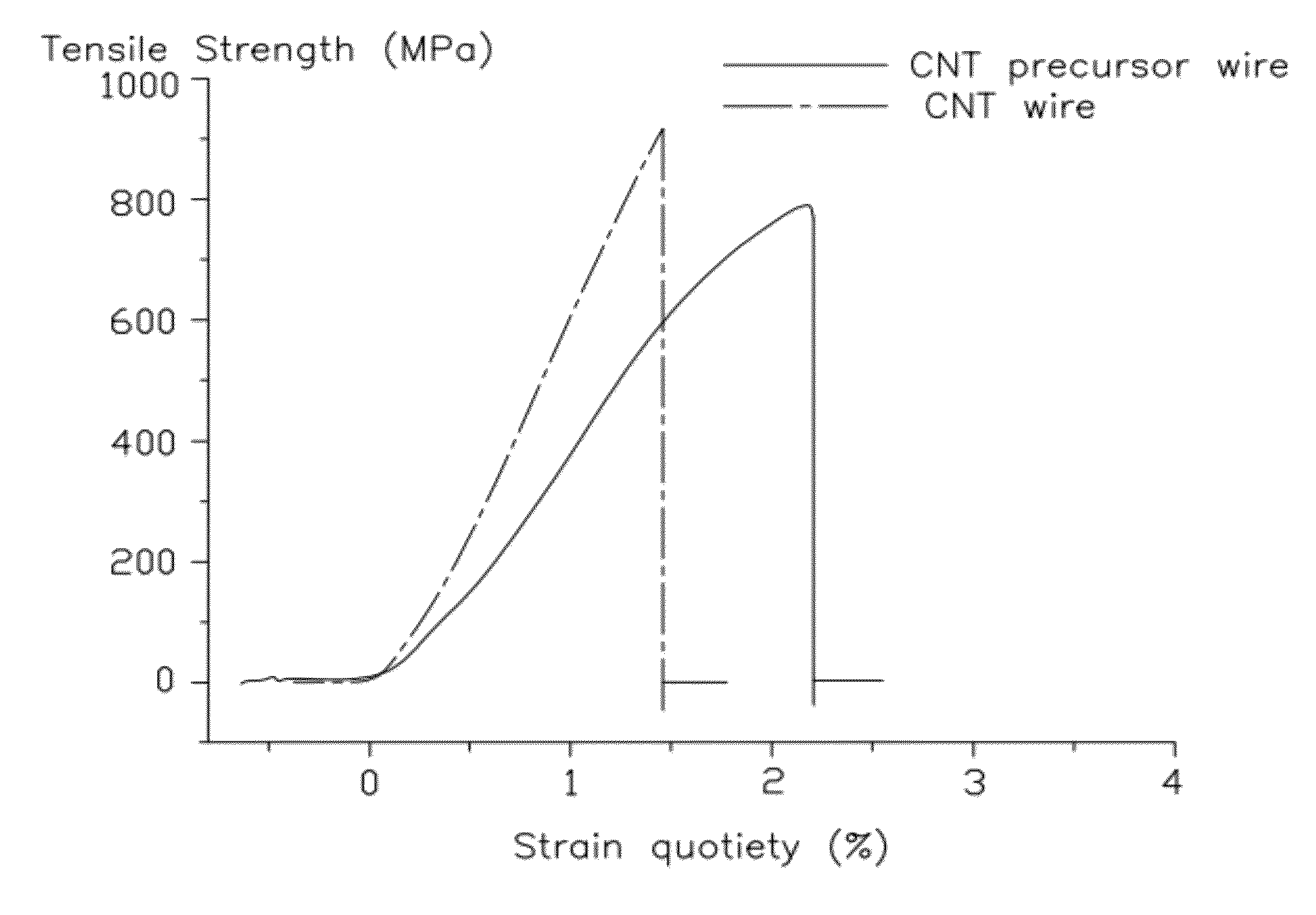

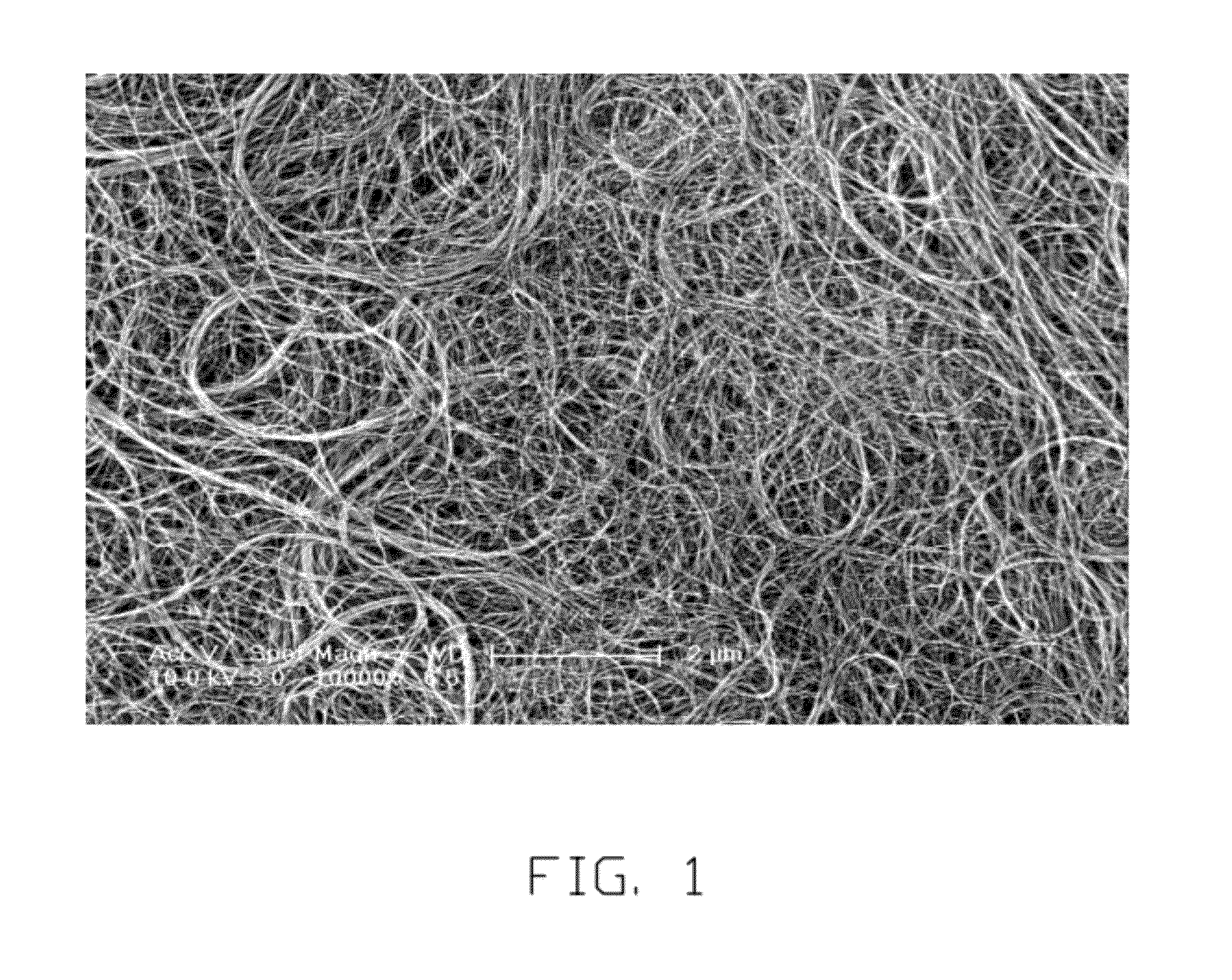

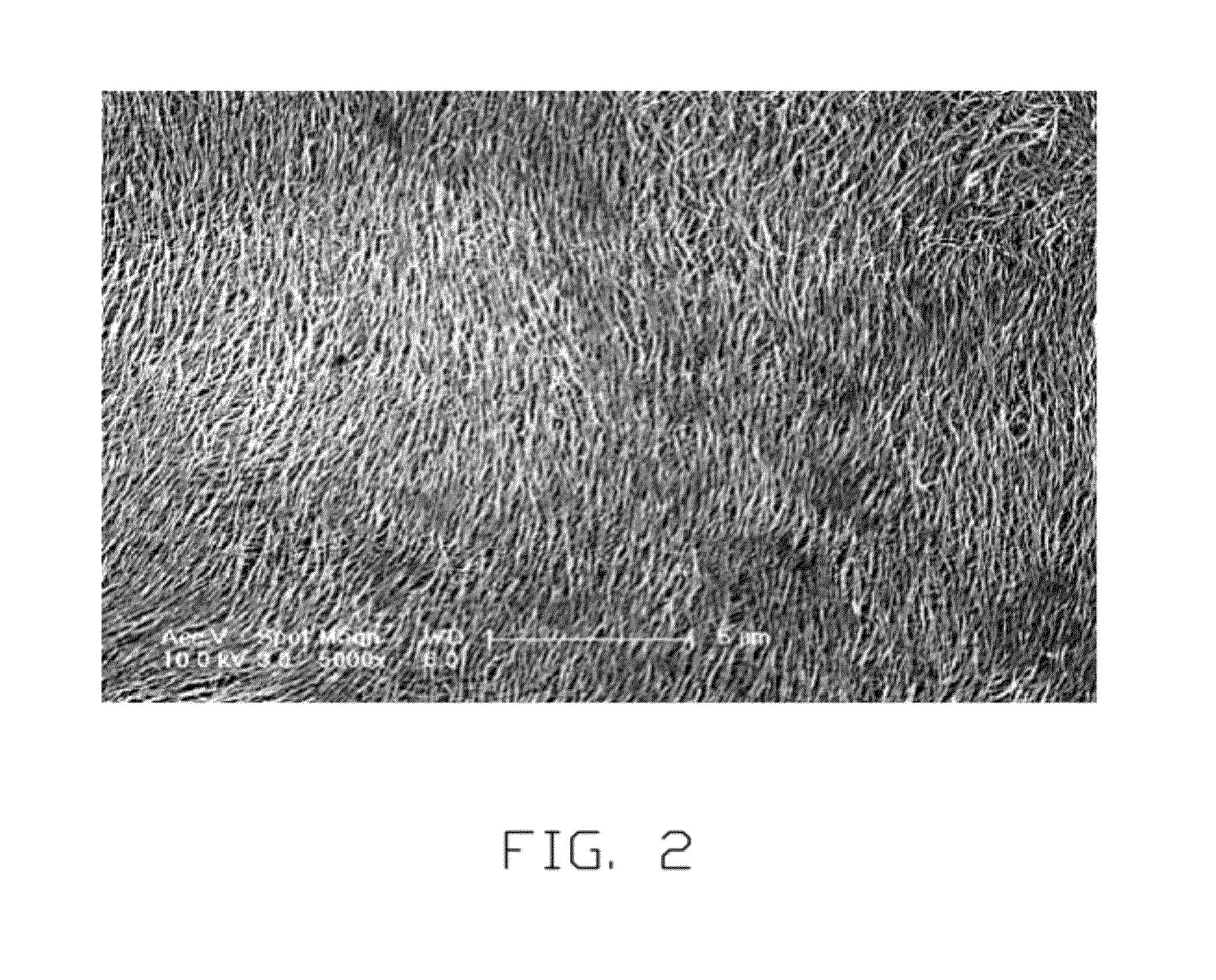

ActiveCN101898758AImprove mechanical propertiesImprove bindingMaterial nanotechnologyNanostructure assemblyCarbon–carbon bondCarbon nanotube

The invention relates to a composite structure of a carbon nano tube, comprising a carbon nano tube structure and a graphite structure which is filled in the carbon nano tube, wherein the carbon nano tube structure comprises a plurality of carbon nano tubes which are mutually connected by Van der Waals force. The graphite structure is compounded with the carbon nano tube structure by a carbon-carbon bond.

Owner:TSINGHUA UNIV +1

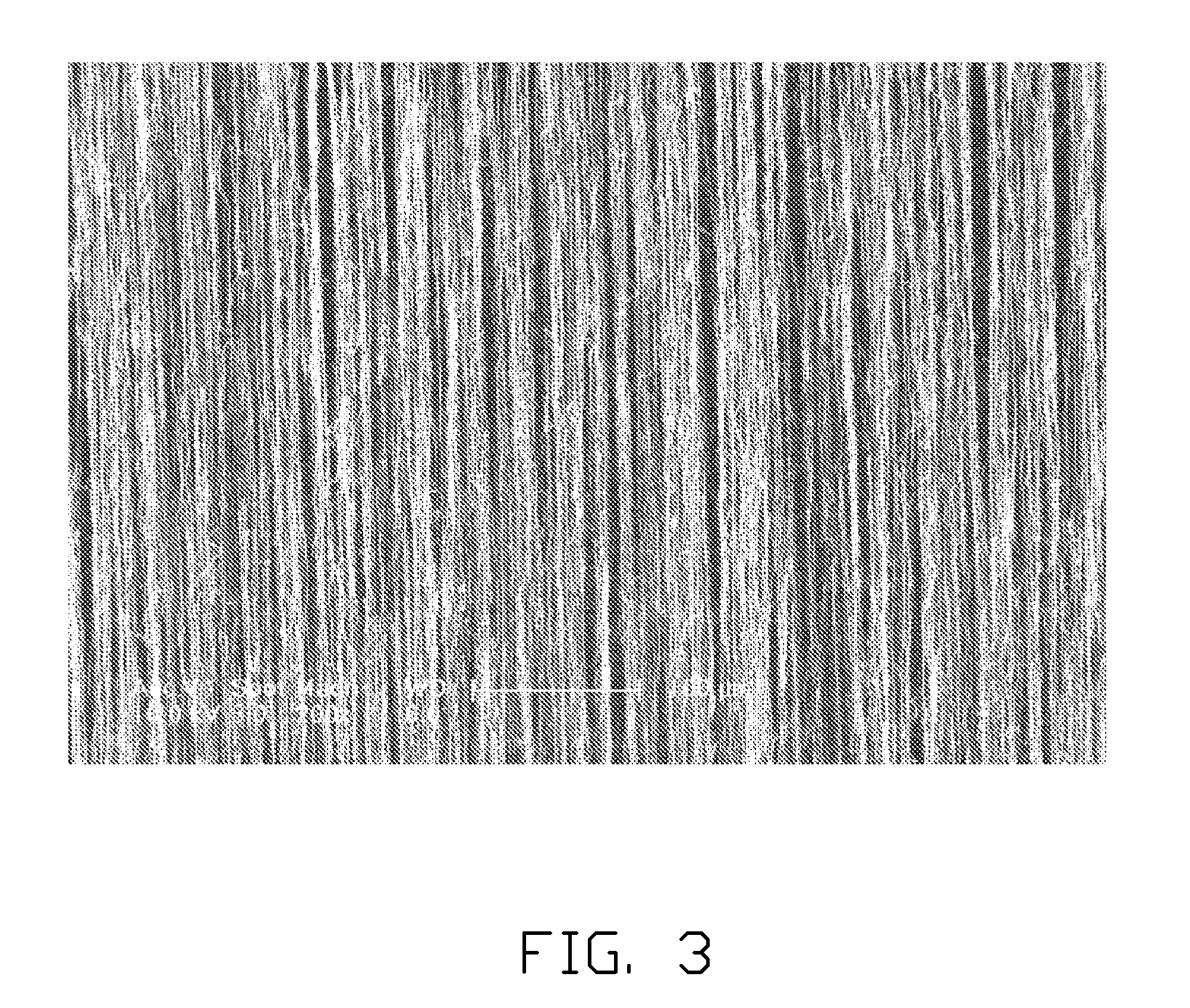

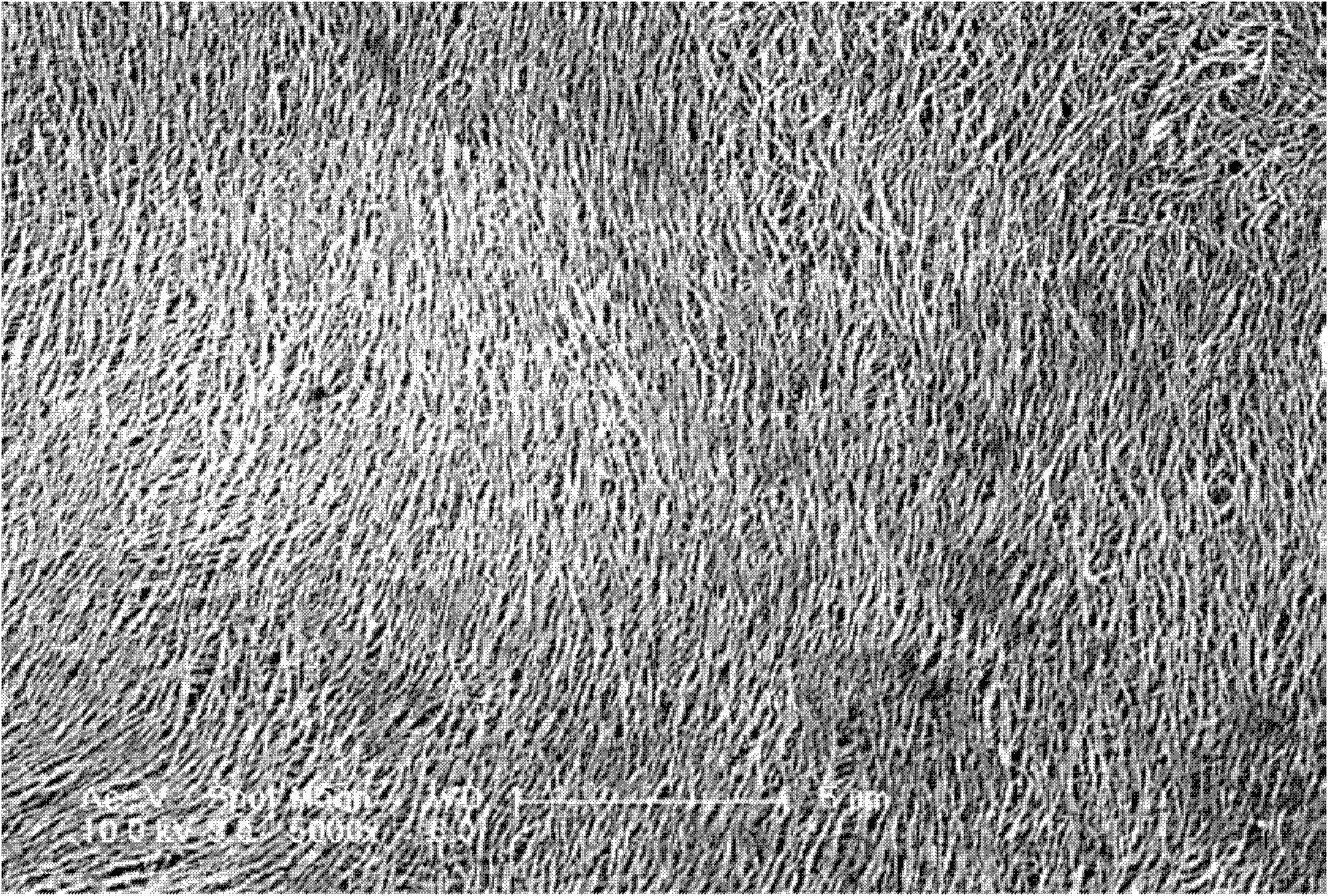

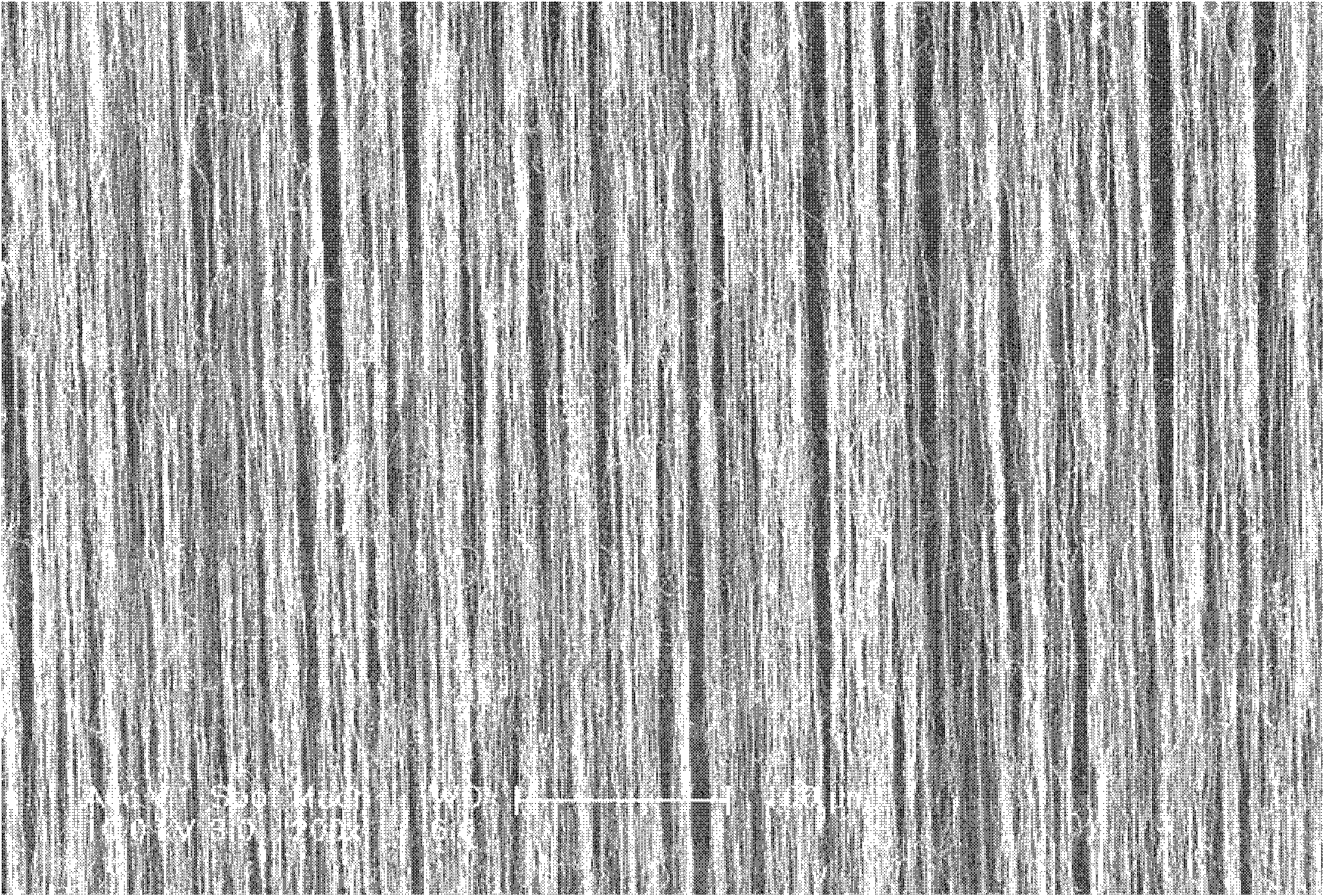

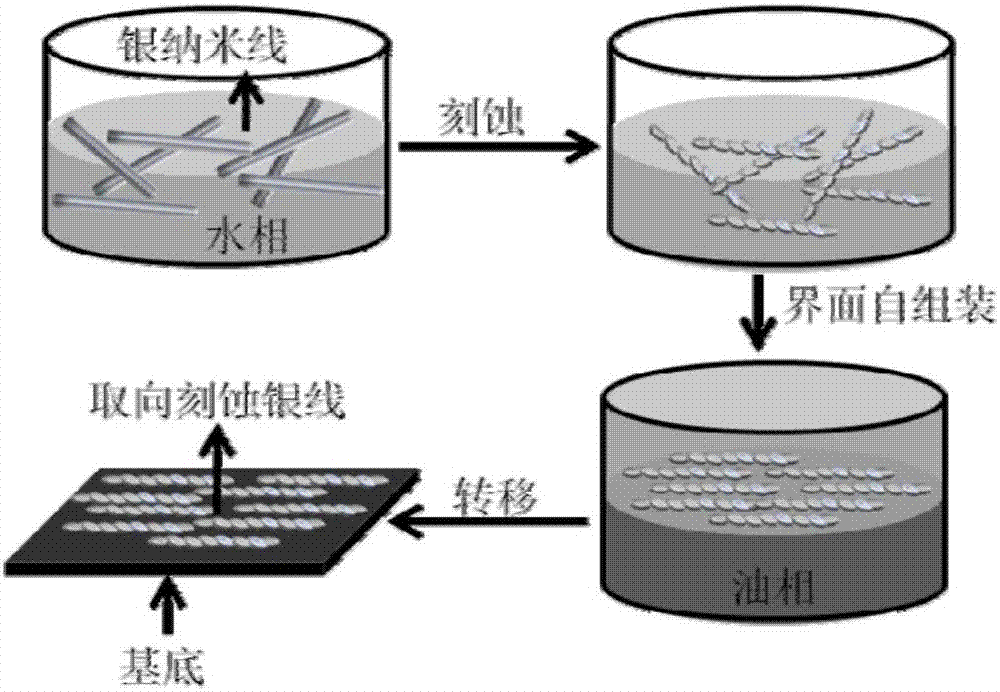

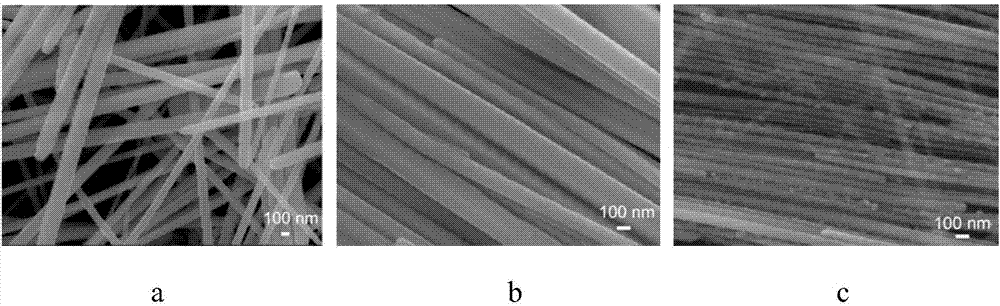

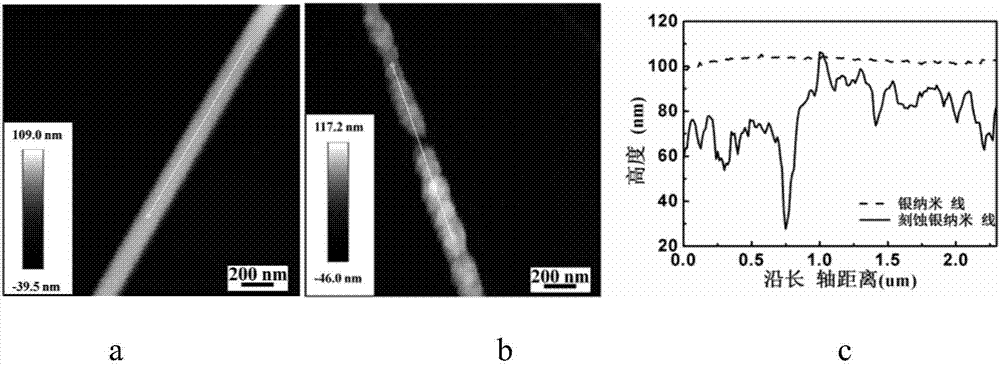

Surface-enhanced Raman scattering substrate, and preparation method and application of surface-enhanced Raman scattering substrate

InactiveCN107235471AEasy to prepareLow costSpecific nanostructure formationMaterial nanotechnologySurface roughnessThree-phase

The invention belongs to the technical field of laser Raman detection, and discloses a surface-enhanced Raman scattering(SERS) substrate and a preparation method and an application of the surface-enhanced Raman scattering substrate. The surface of the substrate is coated by an ordered etched silver nanowire film, and the ordered etched silver nanowire film is formed by ordered arrangement of mutually-parallel etched silver nanowires, the average distance between adjacent etched silver nanowires is 0-15nm, and the surface roughness of one single etched silver nanowire is 0-20nm. The preparation method is as follows: etching is performed on silver nanowire surfaces by adopting a chemical method, the etched silver nanowires are self assembled by a three-phase interface method, and then the etched silver nanowires after self assembling are transferred to the surface of the substrate. The preparation method has the advantages of simplicity, low costs, easy realization and the like. If the substrate is used for SERS detection, the substrate has high detection sensitivity, and when Rhodamine B is used as a probe molecule, the lowest detection limit can reach 10-11M, and therefore the surface-enhanced Raman scattering substrate has an extensive potential application prospect in the fields of foods, environments, medical treatments, biology and the like.

Owner:GUANGDONG UNIV OF TECH

Method of assembling nanoscale and microscale objects into three-dimensional structures

Owner:CHARLES STARK DRAPER LABORATORY

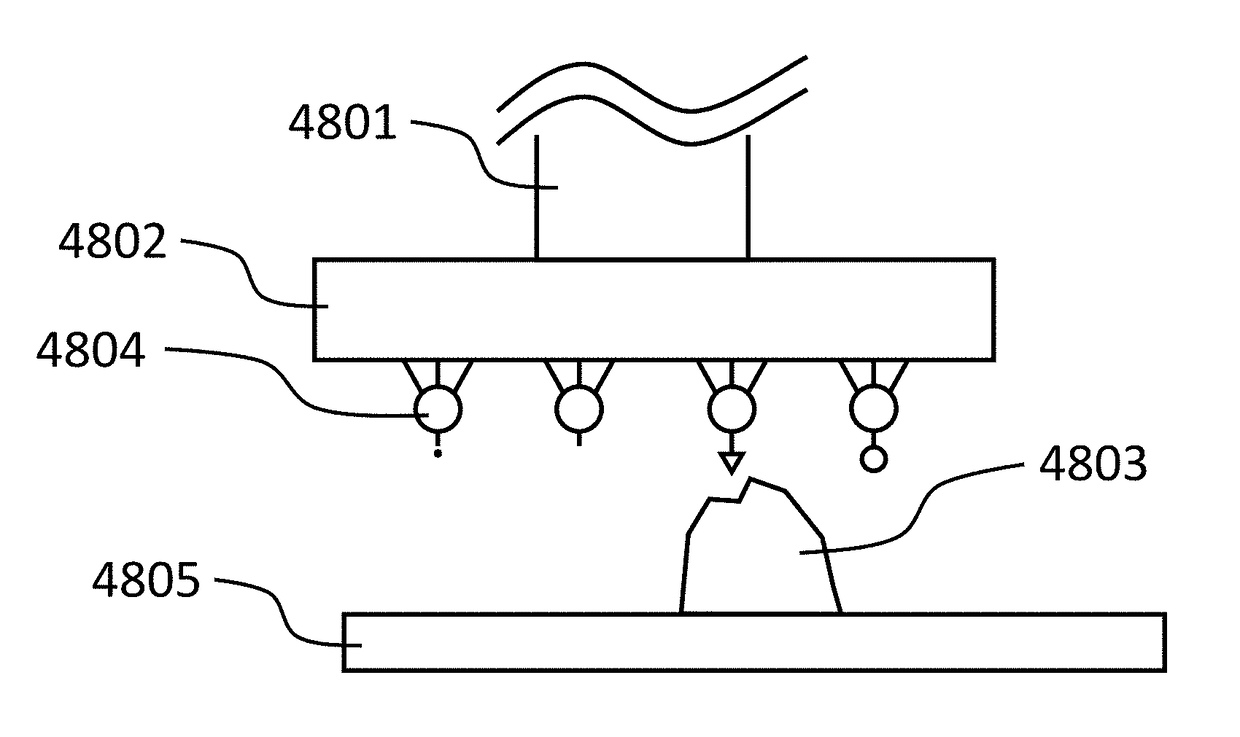

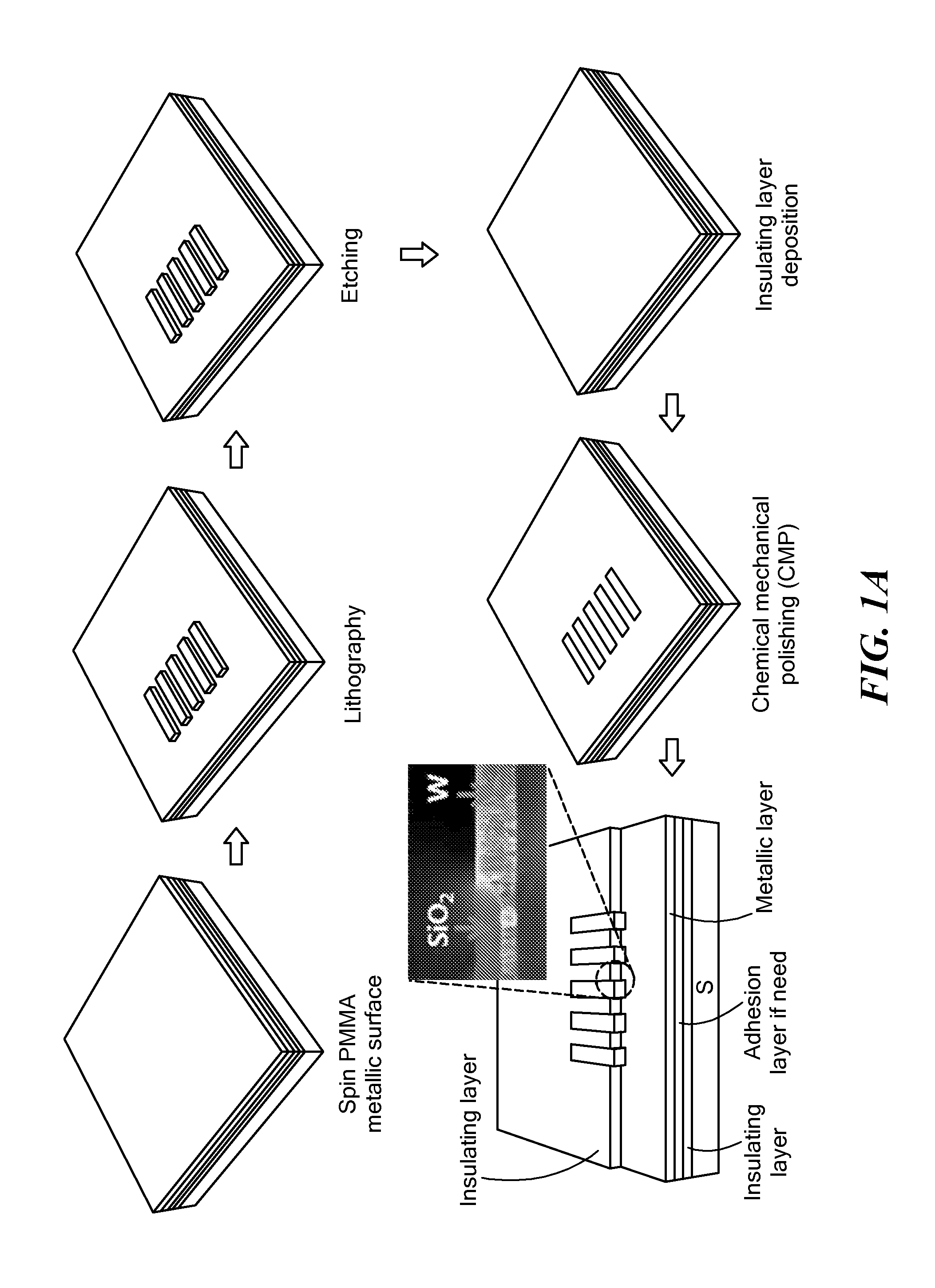

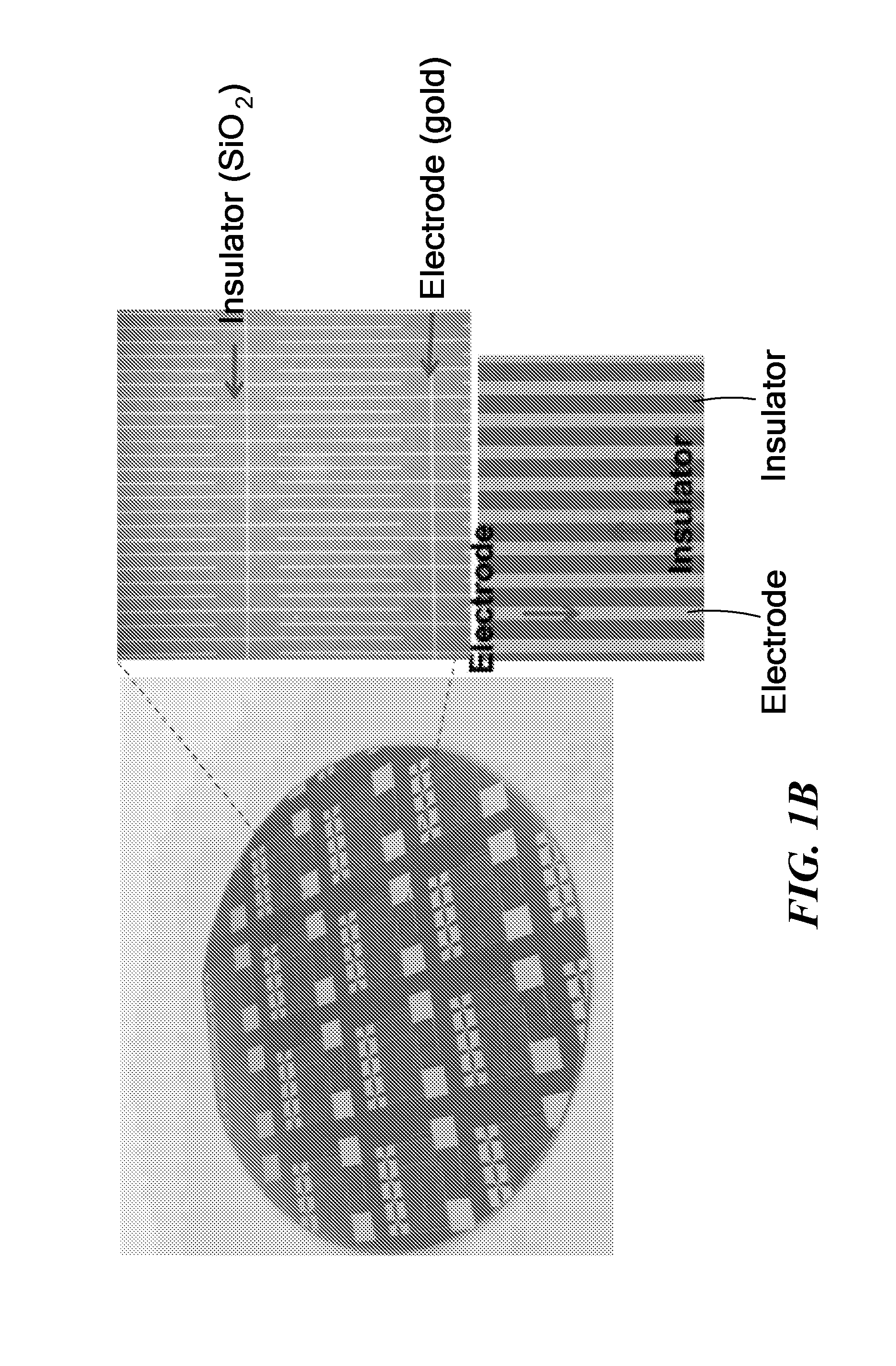

Damascene Template for Directed Assembly and Transfer of Nanoelements

ActiveUS20140318967A1Low costLow productionElectrolysis componentsNanoinformaticsMicron scaleHigh rate

Damascene templates have two-dimensionally patterned raised metal features disposed on an underlying conductive layer extending across a substrate. The templates are topographically flat overall, and the patterned conductive features establish micron-scale and nanometer-scale patterns for the assembly of nanoelements into nanoscale circuits and sensors. The templates are made using microfabrication techniques together with chemical mechanical polishing. These templates are compatible with various directed assembly techniques, including electrophoresis, and offer essentially 100% efficient assembly and transfer of nanoelements in a continuous operation cycle. The templates can be repeatedly used for transfer of patterned nanoelements thousands of times with minimal or no damage, and the transfer process involves no intermediate processes between cycles. The assembly and transfer processes employed are carried out at room temperature and pressure and are thus amenable to low cost, high-rate device production.

Owner:NORTHEASTERN UNIV

Scalable nucleic acid-based nanofabrication

ActiveUS10099920B2Minimal feature defectPattern can be very complexMaterial nanotechnologyNanostructure assemblyLithographic artistNanoparticle

The present disclosure relates to the alignment of moieties (e.g., nanoparticles and / or nanowires) into prescribed architectures on two- and / or three-dimensional substrates (e.g., nucleic acid nanostructures / crystals). The present disclosure also relates to a nucleic acid (e.g., DNA) lithography method that includes, in some embodiments, adsorbing a bare nucleic acid nanostructure onto a surface of a substrate, and etching the surface of the substrate containing the bare nucleic acid nanostructure, thereby producing a patterned substrate.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Nano-scale LED element for horizontally-aligned assembly, method for manufacturing same, and horizontally-aligned assembly comprising same micro-LED

ActiveUS10910512B2Easy alignmentIncrease the number ofNanostructure assemblySolid-state devicesMechanical engineeringMaterials science

The present invention relates to a nano-scale light-emitting diode (LED) element for a horizontal array assembly, a manufacturing method thereof, and a horizontal array assembly including the same, and more particularly, to a nano-scale LED element for a horizontal array assembly that can significantly increase the number of nano-scale LED elements connected to an electrode line, facilitate an arrangement of the elements, and implement a horizontal array assembly having a very good electric connection between an electrode and an element and a significant high quantity of light when a horizontal array assembly having the nano-scale LED elements laid in a length direction thereof and connected to the electrode line is manufactured, a manufacturing method thereof, and a horizontal array assembly including the same.

Owner:SAMSUNG DISPLAY CO LTD

Method

PendingUS20220283141A1Nanostructure assemblyMicrobiological testing/measurementHeterologousPolymer science

The invention relates to a novel method of producing hetero-oligomeric pores. The invention also relates to hetero-oligomeric pores produced using the method and polynucleotide characterisation using the hetero-oligomeric pores.

Owner:OXFORD NANOPORE TECH LTD

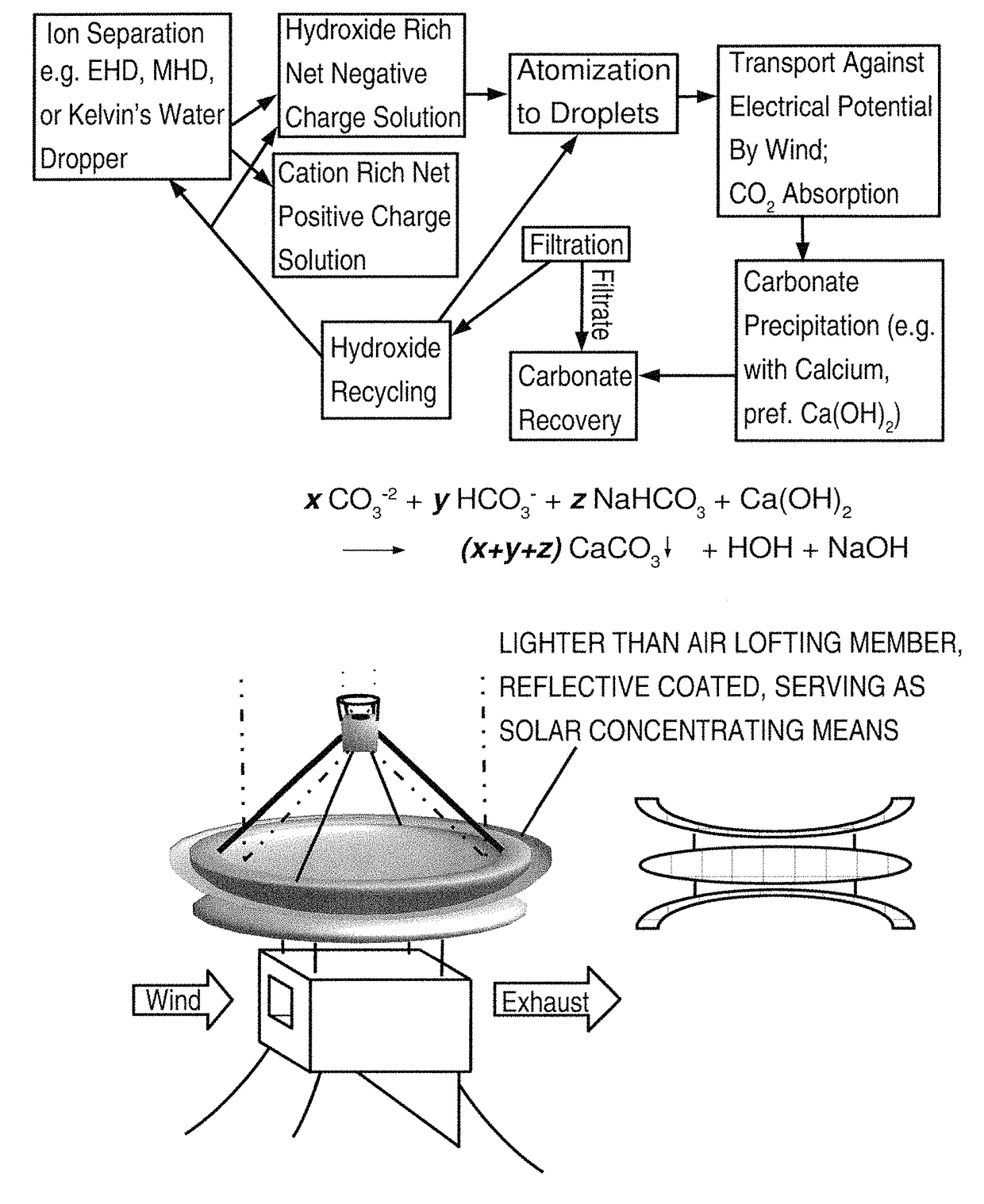

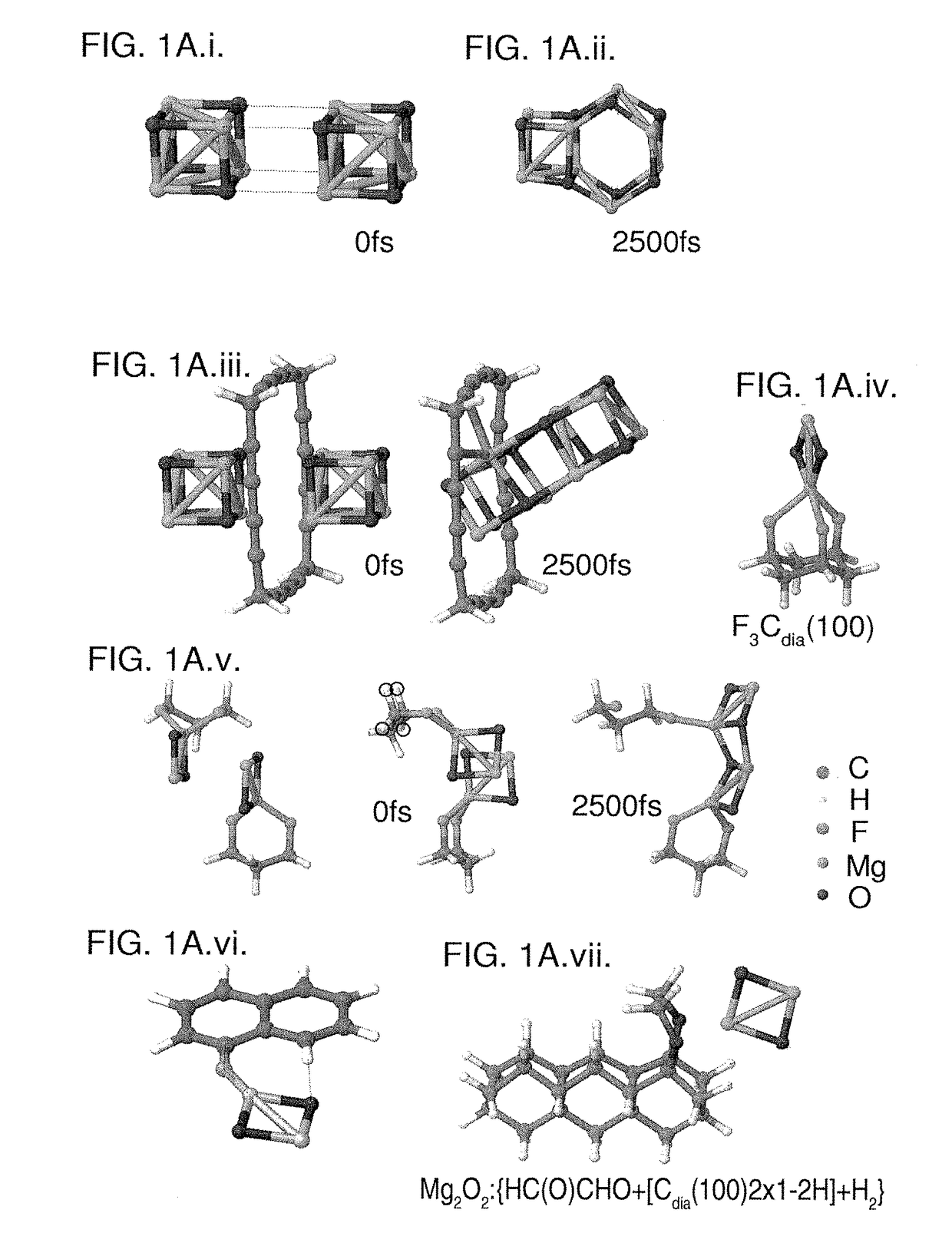

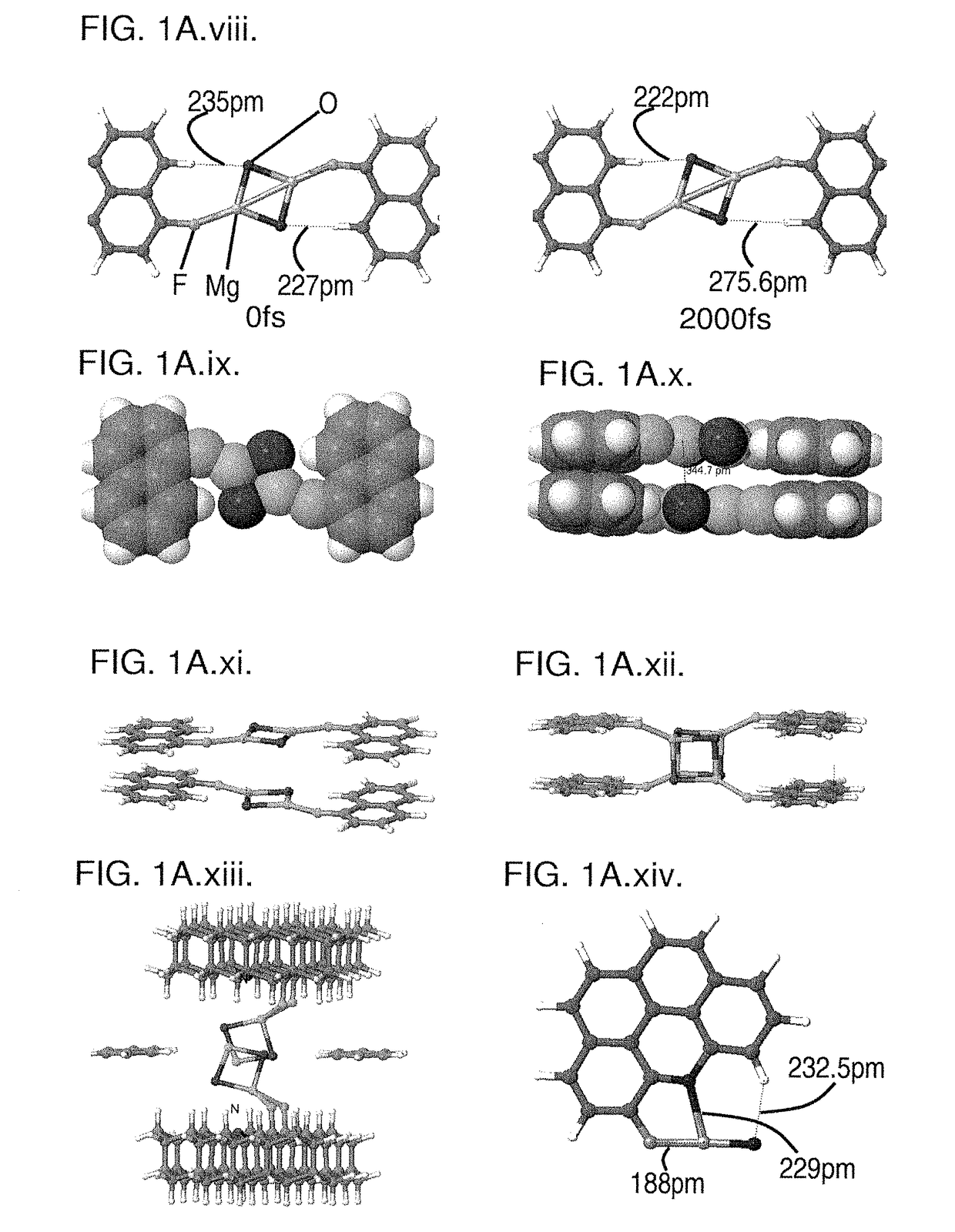

Convergent nanofabrication and nanoassembly methods, means and applications thereof, products and systems therefrom including methods and means for conversion of pollutants to useful products

ActiveUS10106401B1Improve energy efficiencyAvoid wastingSpecific nanostructure formationMaterial nanotechnologyInformation processingNanostructure

Convergent nanofabrication and nanoassembly methods are disclosed. Molecules and / or nanostructures are bound to supported binding tools and manipulated to bond together in desired locations and orientations to yield desired precise structures. Methods for precise fabrication of materials including diamond, graphene, nanotube, β-SiC (and precise modifications thereof, e.g. color centers for quantum computation and information processing and storage), halite structured materials including MgO, MgS, TiC, VN, ScN, precisely Mn doped ScN, NbN, HfC, TaC, HfxTayC, and metals, and graphenoid structures for photovoltaic devices are disclosed. Systems disclosed performing these methods can fabricate systems with similar capabilities, enabling allo- or self-replication, and have capabilities including: conversion and storage of energy; obtainment and processing of matter from abundant environmental sources including on other planets and fabrication of desired articles using same; converting wind power (esp. high altitude wind) to electricity with concurrent capture of CO2 and conversion thereof to useful feedstocks e.g. by reaction with CH4 from oceanic methane clathrates; growth of algae crops including food. Fabrication of arbitrarily long carbon nanotubes enable construction of orbital elevators.

Owner:RABANI ELI MICHAEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com