Patents

Literature

391 results about "Microfabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

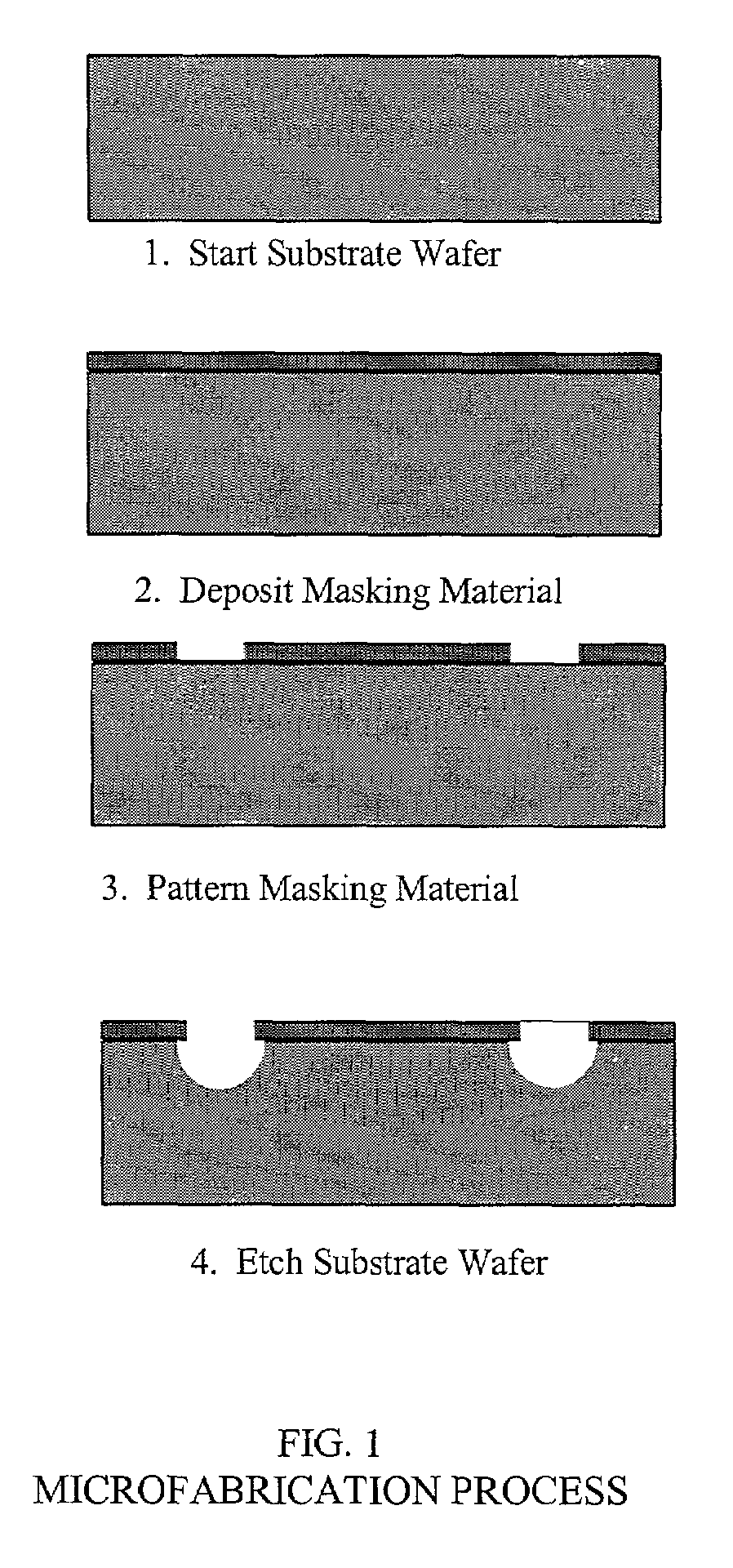

Microfabrication is the process of fabricating miniature structures of micrometre scales and smaller. Historically, the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device fabrication". In the last two decades microelectromechanical systems (MEMS), microsystems (European usage), micromachines (Japanese terminology) and their subfields, microfluidics/lab-on-a-chip, optical MEMS (also called MOEMS), RF MEMS, PowerMEMS, BioMEMS and their extension into nanoscale (for example NEMS, for nano electro mechanical systems) have re-used, adapted or extended microfabrication methods. Flat-panel displays and solar cells are also using similar techniques.

Integrated active flux microfluidic devices and methods

InactiveUS20040248167A1Increase speedImprove accuracyBioreactor/fermenter combinationsFlow mixersAntigenHybridization probe

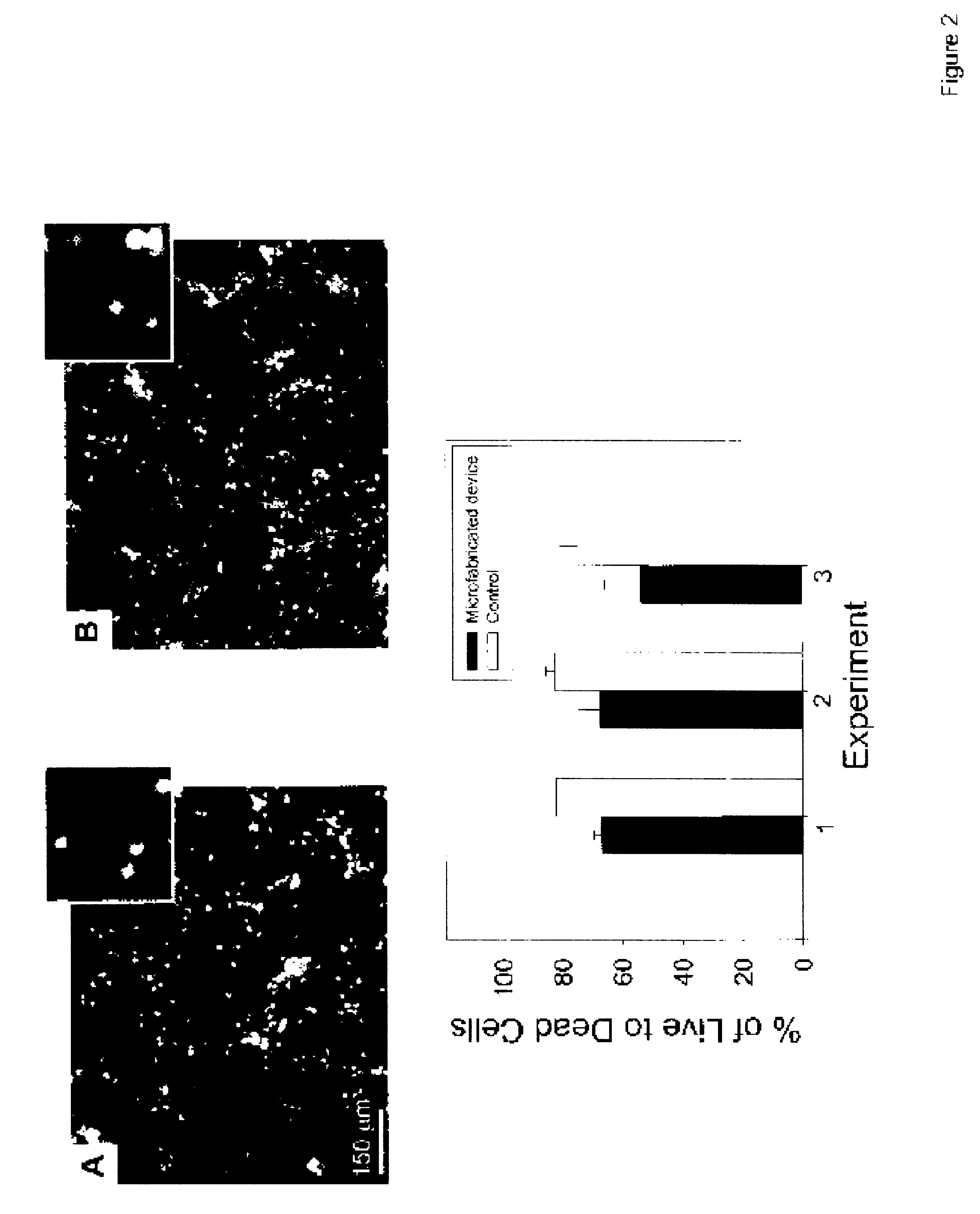

The invention relates to a microfabricated device for the rapid detection of DNA, proteins or other molecules associated with a particular disease. The devices and methods of the invention can be used for the simultaneous diagnosis of multiple diseases by detecting molecules (e.g. amounts of molecules), such as polynucleotides (e.g., DNA) or proteins (e.g., antibodies), by measuring the signal of a detectable reporter associated with hybridized polynucleotides or antigen / antibody complex. In the microfabricated device according to the invention, detection of the presence of molecules (i.e., polynucleotides, proteins, or antigen / antibody complexes) are correlated to a hybridization signal from an optically-detectable (e.g. fluorescent) reporter associated with the bound molecules. These hybridization signals can be detected by any suitable means, for example optical, and can be stored for example in a computer as a representation of the presence of a particular gene. Hybridization probes can be immobilized on a substrate that forms part of or is exposed to a channel or channels of the device that form a closed loop, for circulation of sample to actively contact complementary probes. Universal chips according to the invention can be fabricated not only with DNA but also with other molecules such as RNA, proteins, peptide nucleic acid (PNA) and polyamide molecules.

Owner:CALIFORNIA INST OF TECH

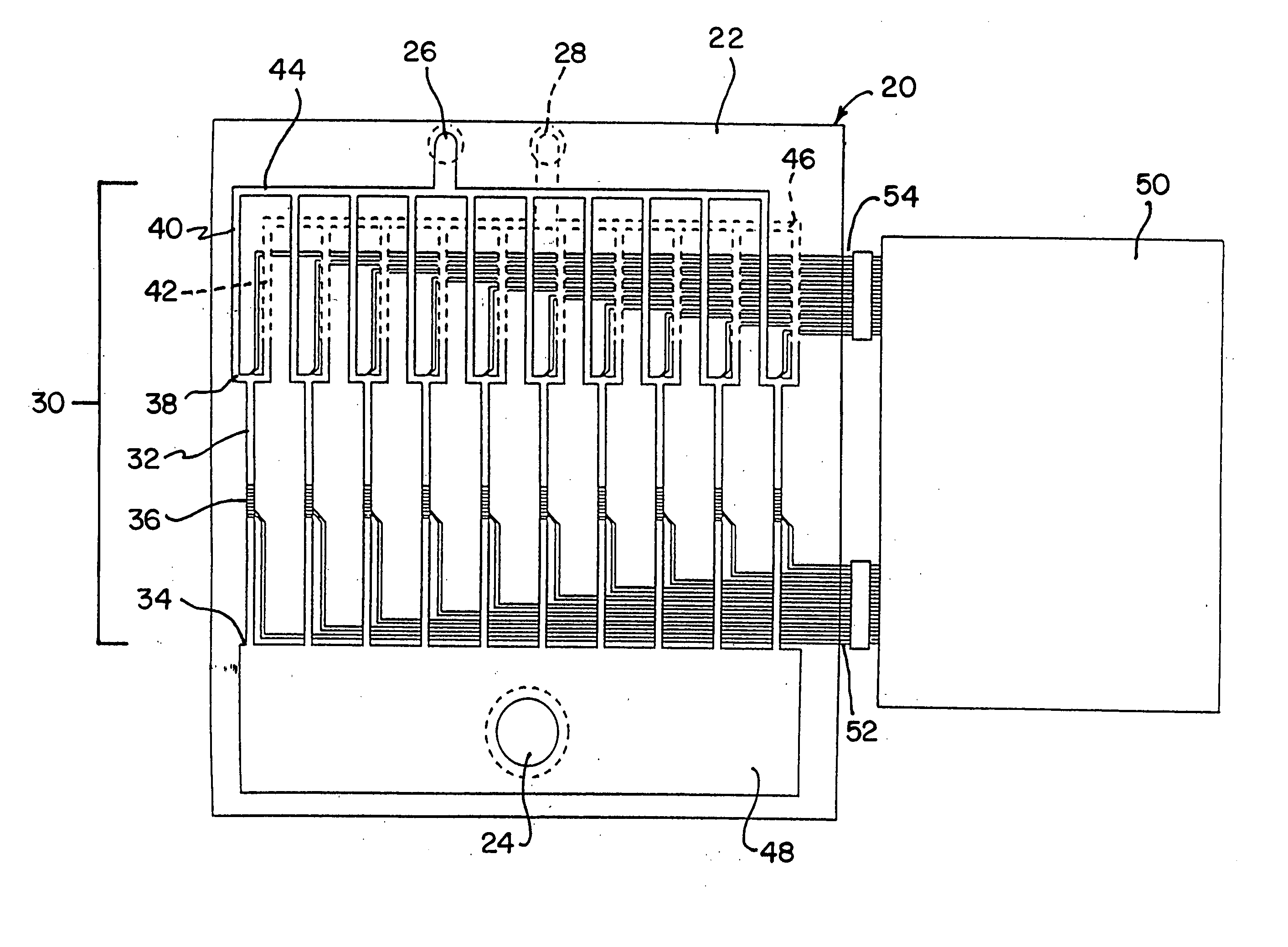

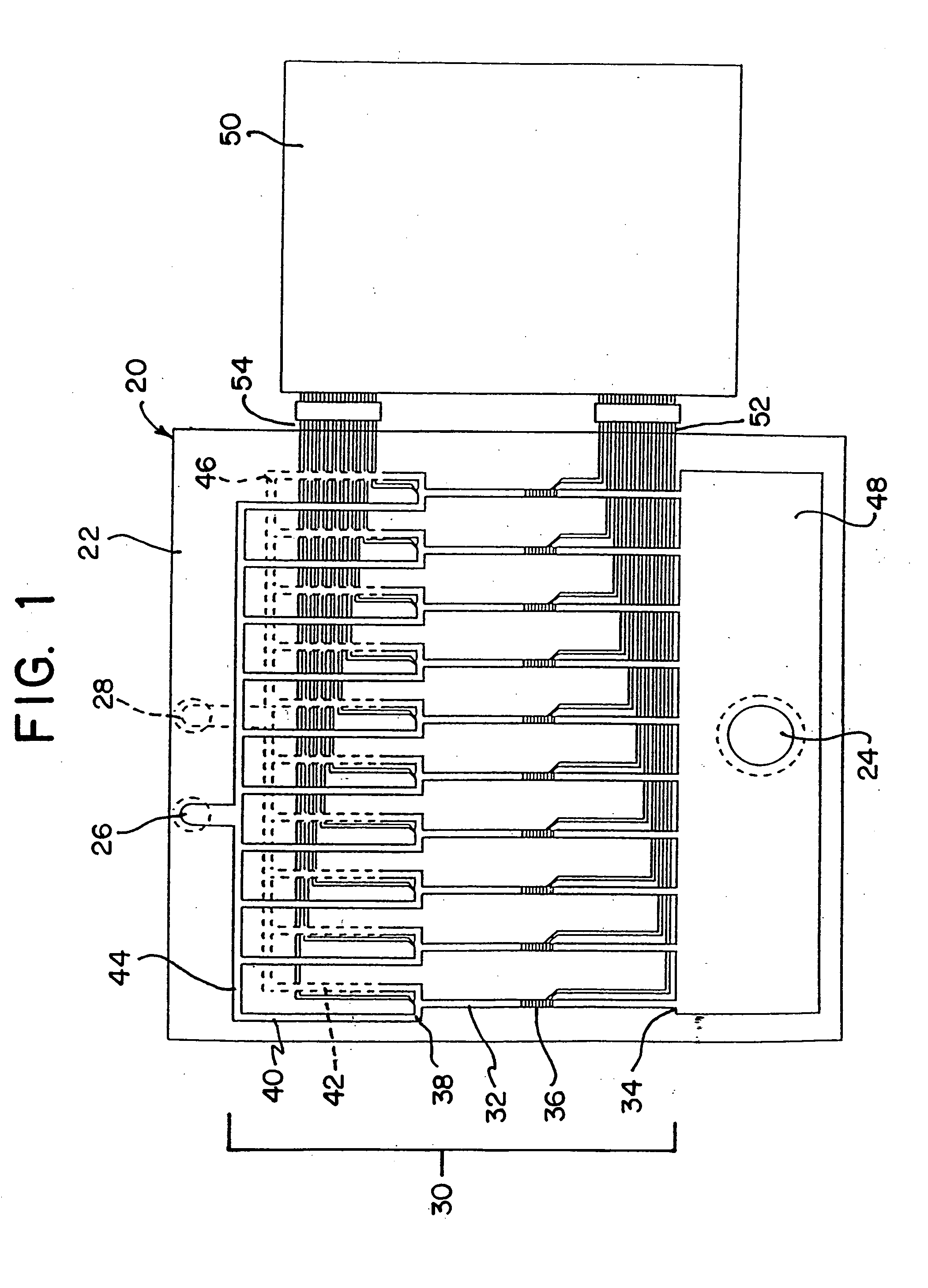

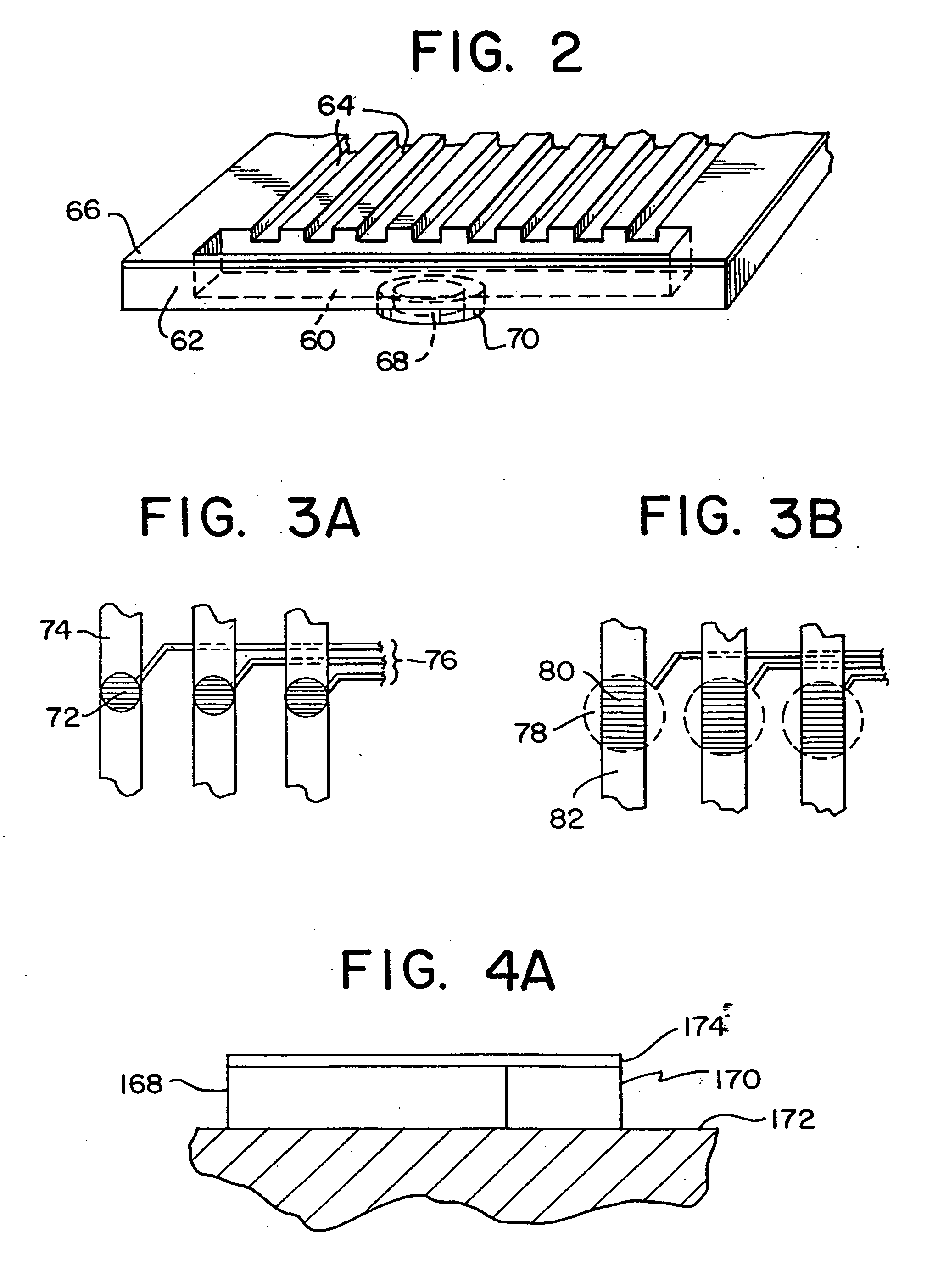

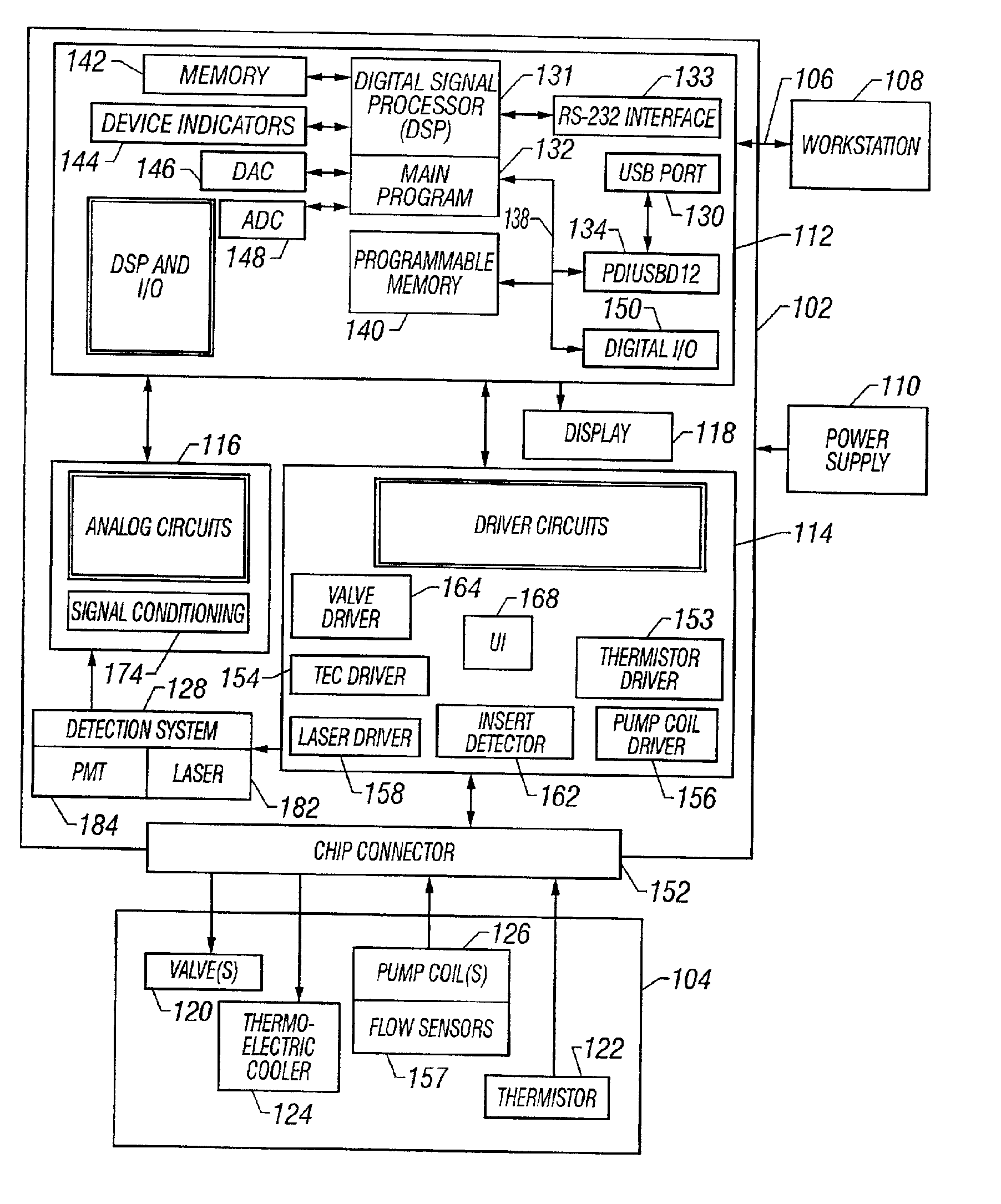

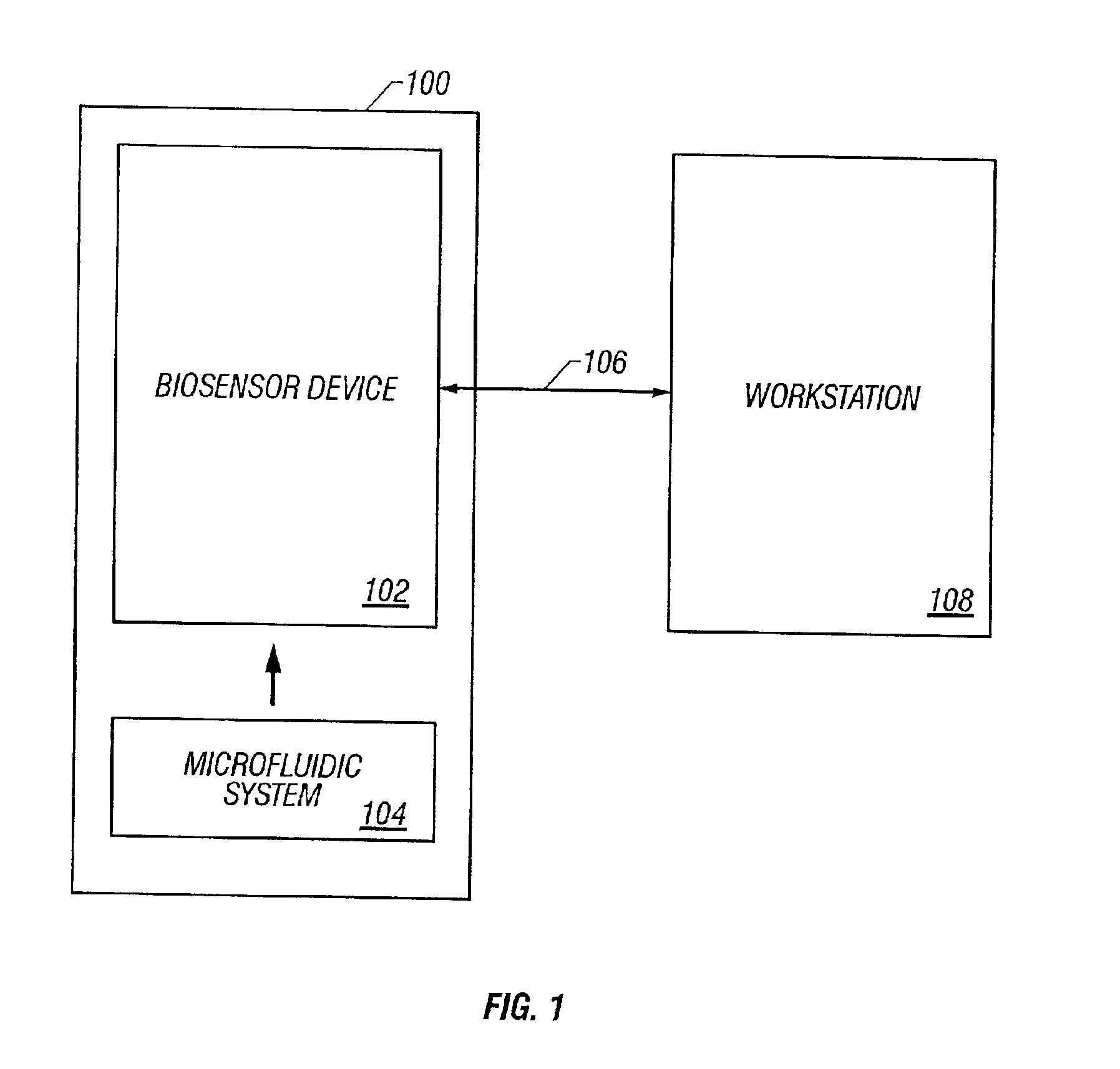

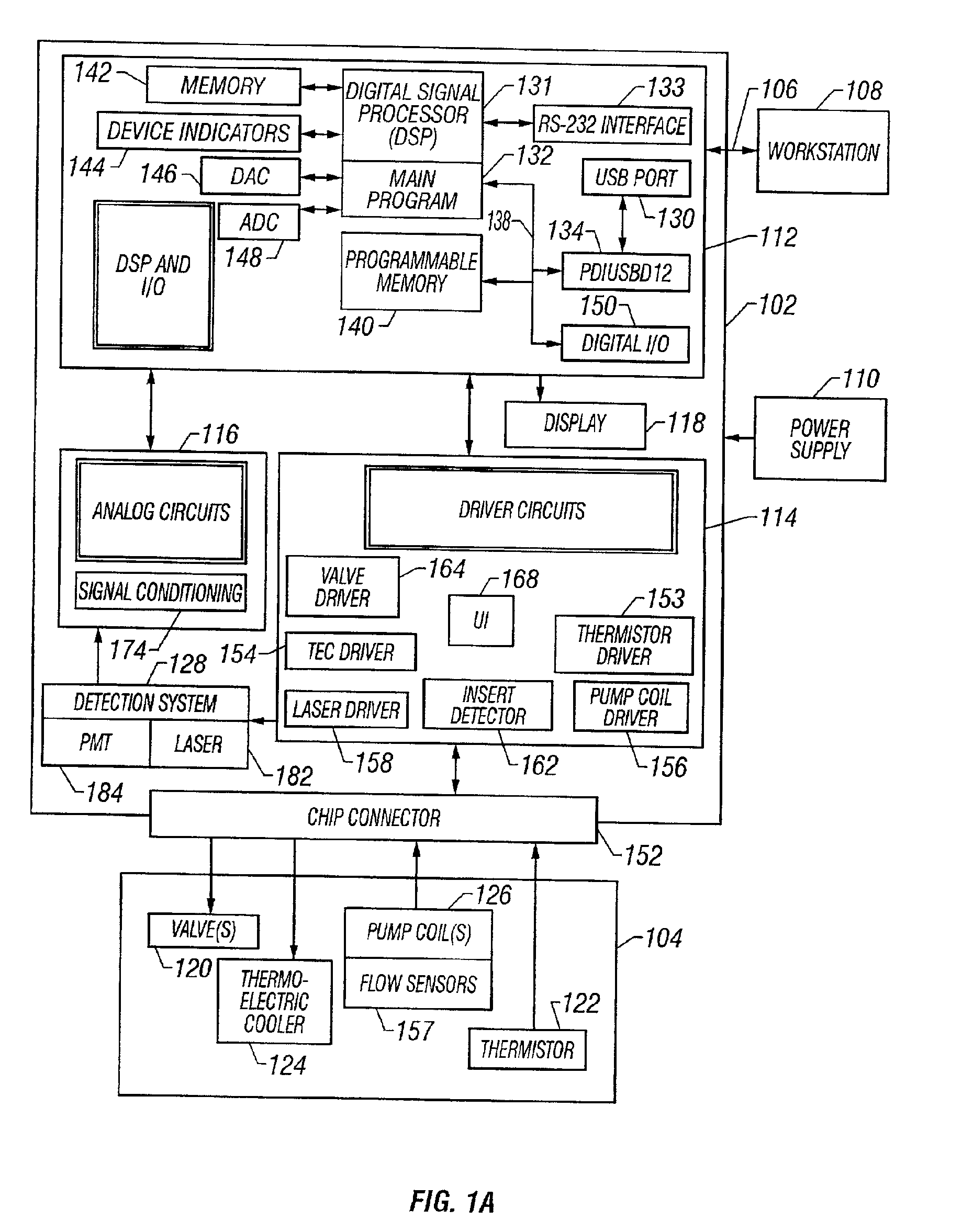

Automated microfabrication-based biodetector

InactiveUS6878755B2Reduce riskHeating or cooling apparatusMicrobiological testing/measurementInformation processingChannel coupling

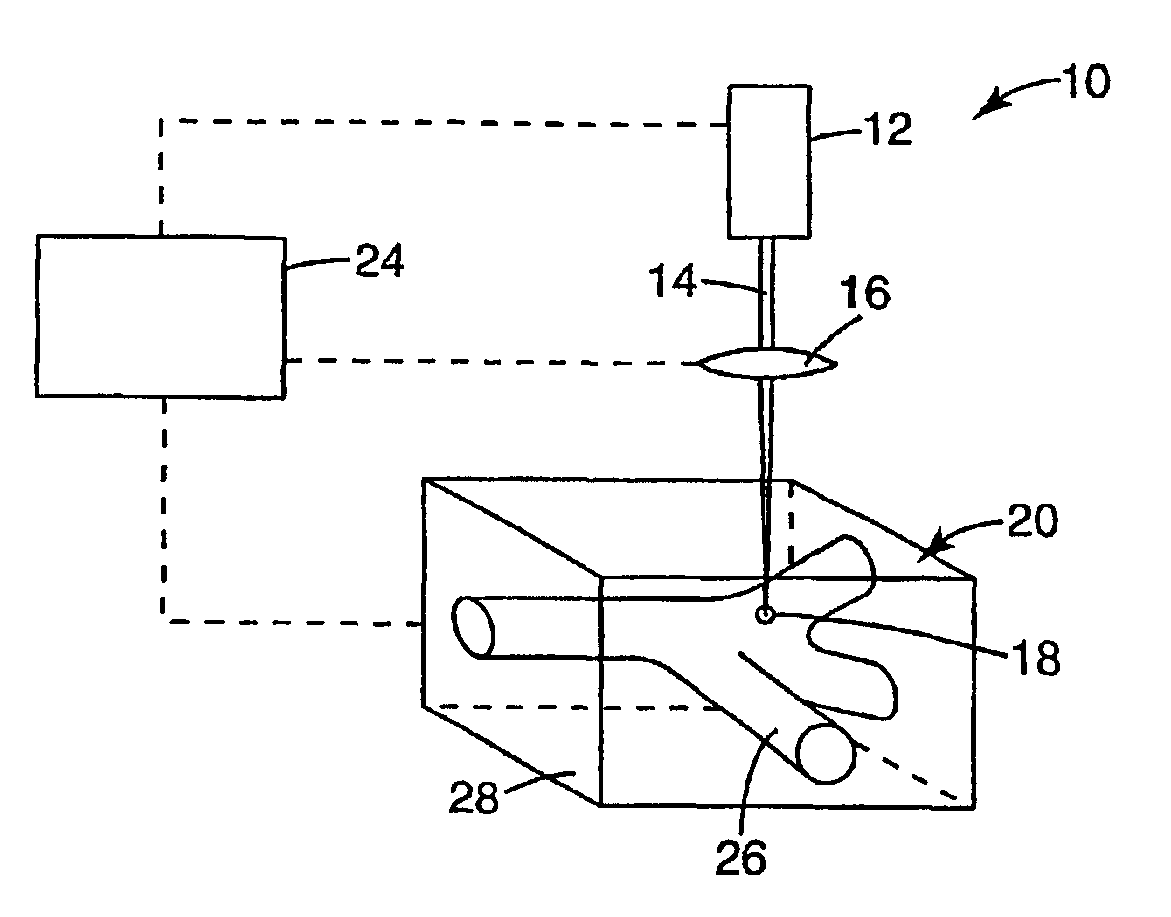

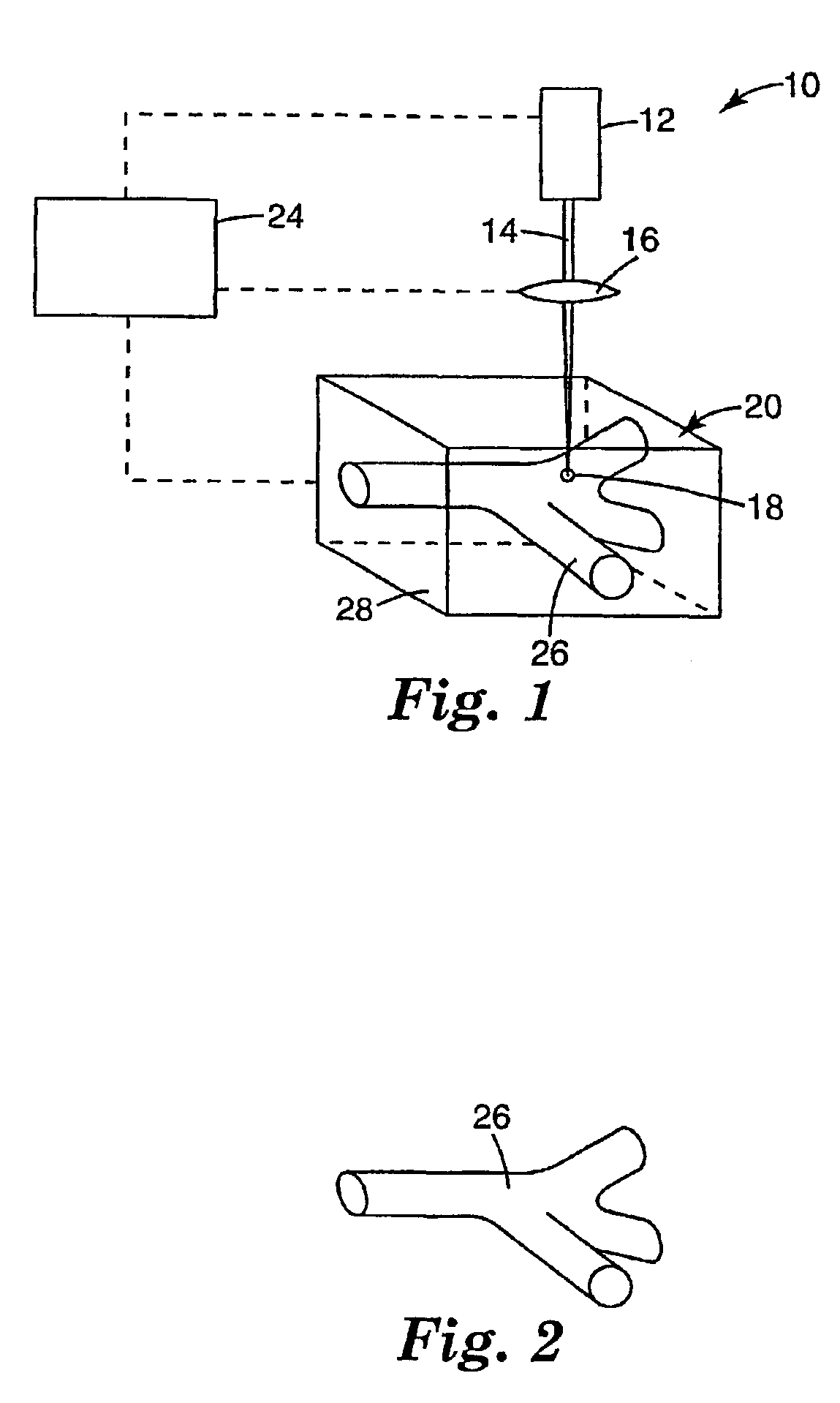

A system, apparatus, and method for processing a sample for chemical and / or biological analysis, and detecting one or more target substances. A first system of microfabricated components includes at least a reservoir and a channel, and a second system of detection components including at least a lens. The lens is focused on a sensing platform of the first system. The sensing platform is coupled to the reservoir by the channel. Various types of detection systems can be utilized with the present invention including fluorescence detection systems with a laser that is positioned to illuminate a sample in the sensing platform. The microfabricated components include one or more pumps, valves, mixers, and filters. A thermoelectric cooler can be positioned to control the temperature of at least one of the microfabricated components. A variety of component configurations can be implemented, and a variety of different processes can be performed, depending on the configuration of components. The device can also be networked with other information processing devices and share data regarding substances detected from the sample.

Owner:MICROGEN SYST

Emboli diverting devices created by microfabricated means

A medical device for interposition between a first flow path and at least one second flow path is provided. The device includes a first surface facing toward the opening of at least one second flow path; and a second surface facing away from the opening of at least one second flow path. When the device is in the operative position, it extends less than the complete circumference of the first flow path and substantially covers the opening of at least one second flow path. The device contains one or more surface features to facilitate chronic implantation. The device further has one or more characteristic porosities. Different configurations are indicated depending on the pathophysiology being treated and dictate the characteristic porosity of the device. In some, cases blood is prevented from reaching the second flow path and in other cases, particulates traveling within the blood are prevented from reaching the second flow path. Methods of preventing emboli or blood flow into the second flow path are also provided. Methods and devices for delivery are also provided.

Owner:GERTNER MICHAEL

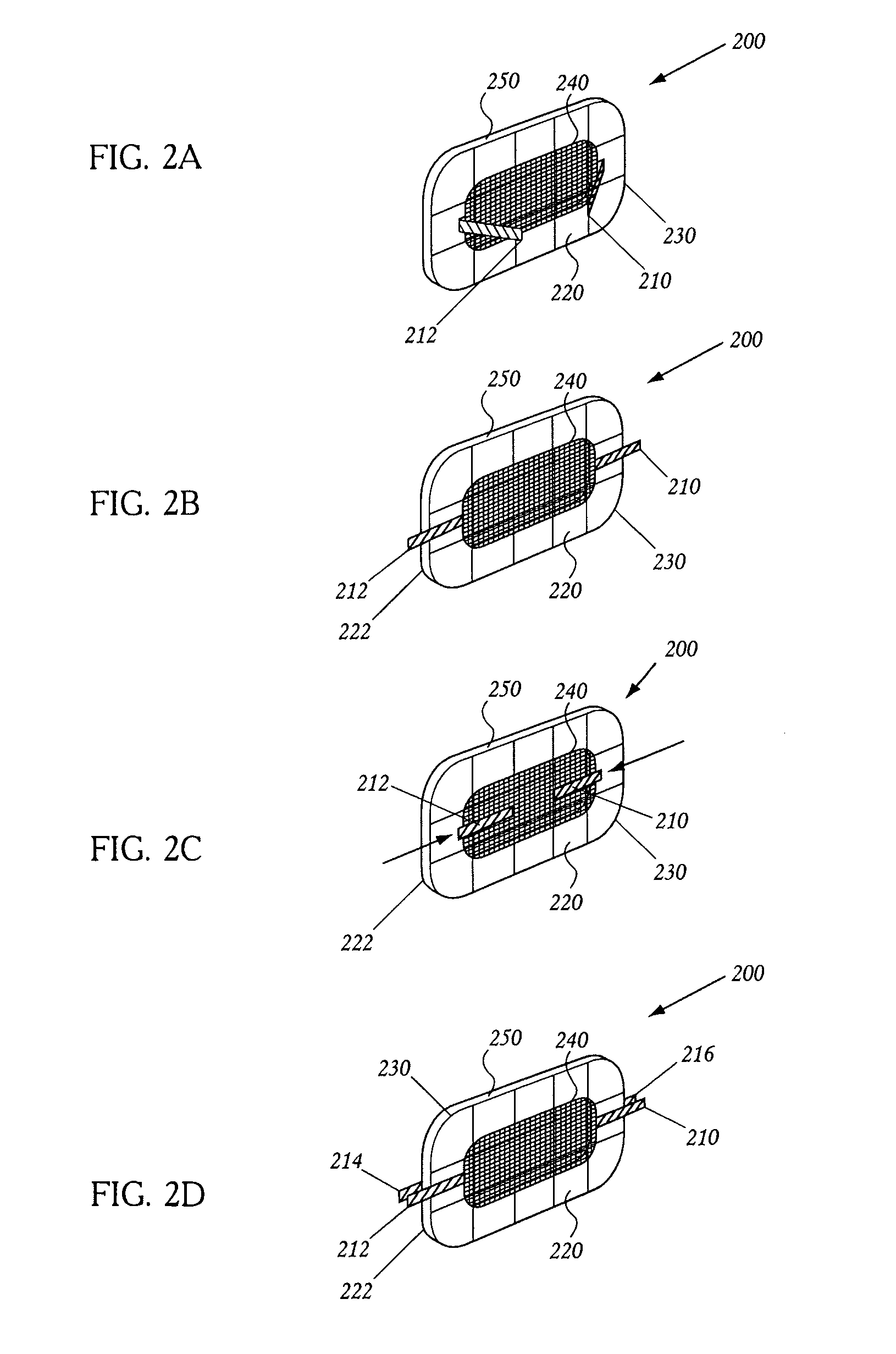

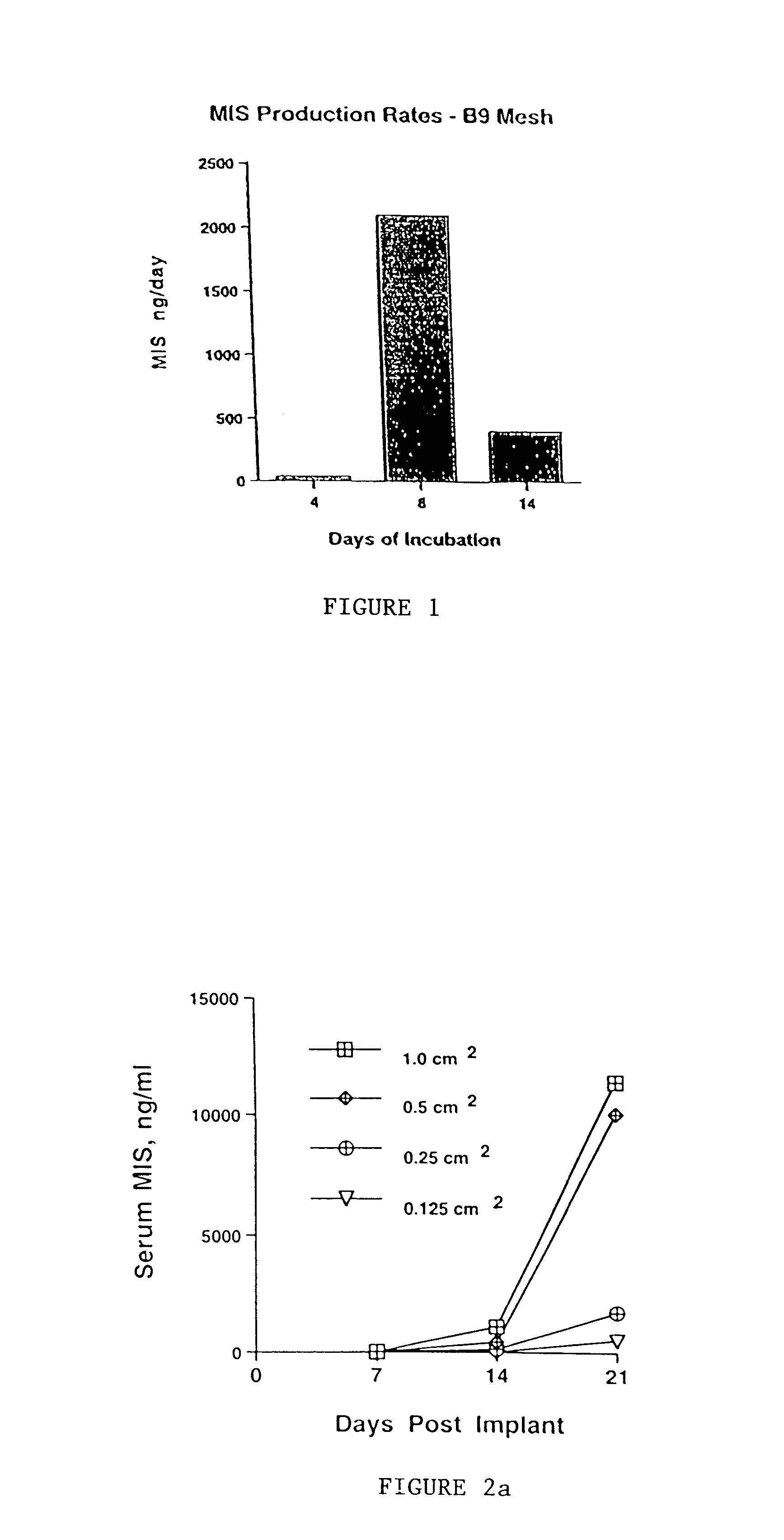

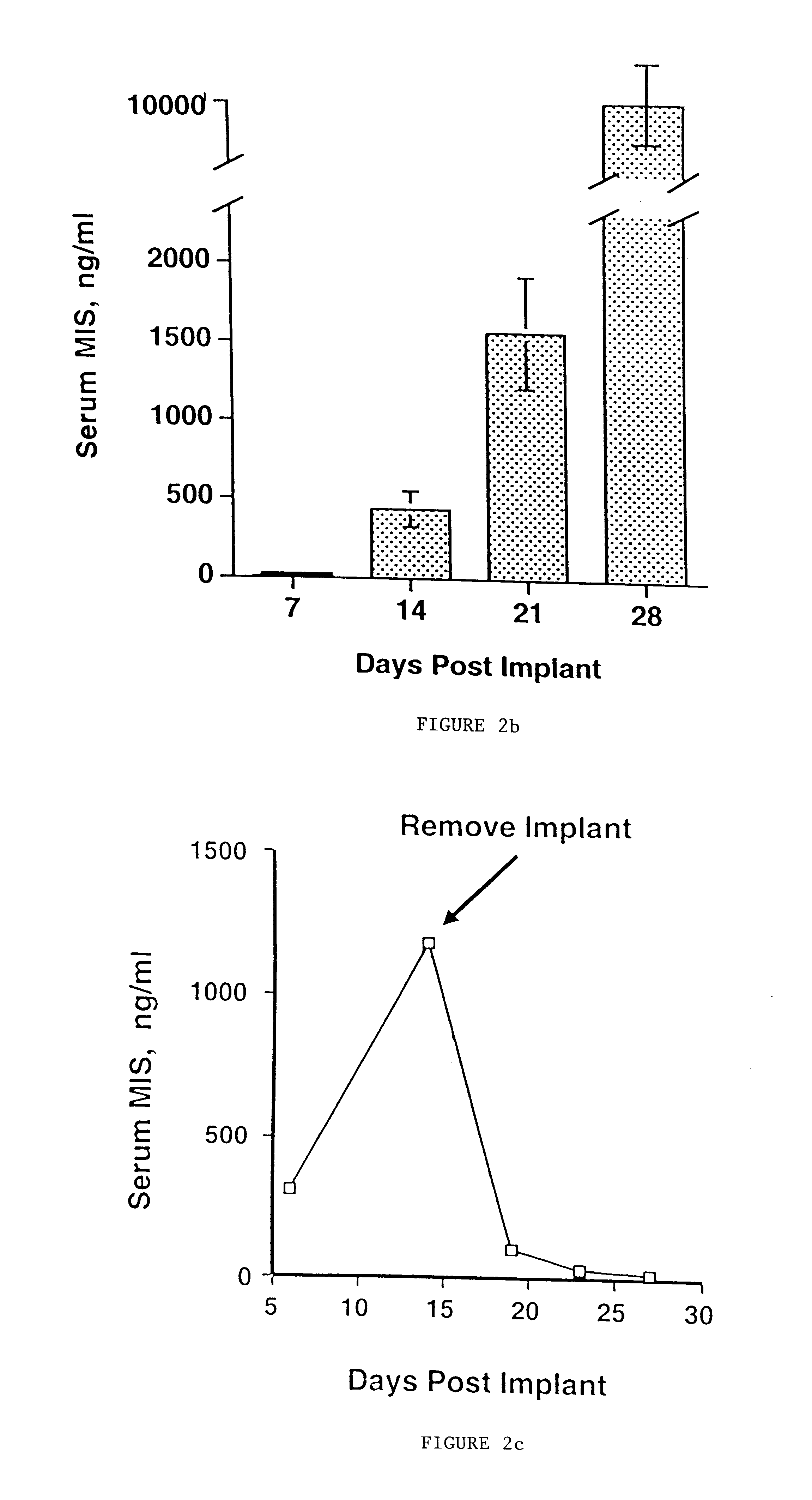

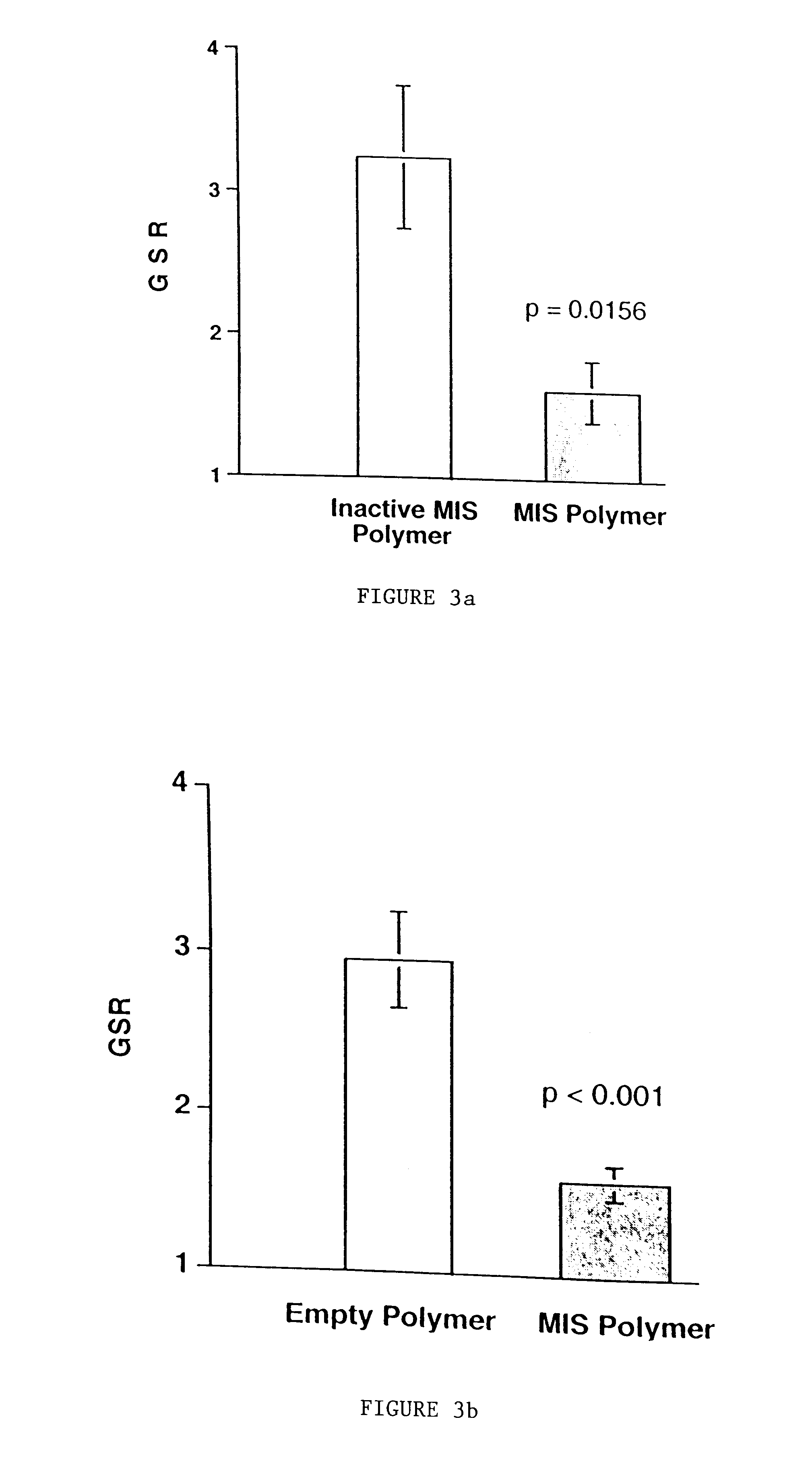

Delivery of therapeutic biologicals from implantable tissue matrices

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

Methods for microdispensing patterened layers

InactiveUS6306594B1Efficient couplingShort response timeMicrobiological testing/measurementBurettes/pipettesAnalyteClinical settings

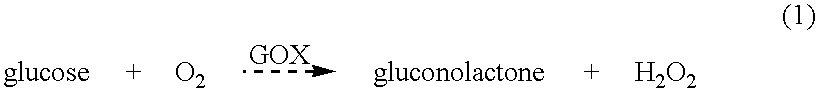

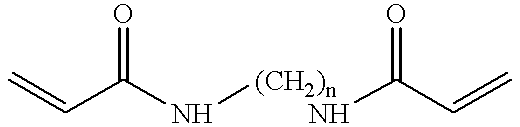

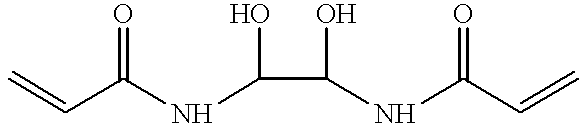

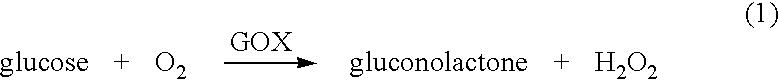

An efficient method for the microfabrication of electronic devices which have been adapted for the analyses of biologically significant analyte species is described. The techniques of the present invention allow for close control over the dimensional features of the various components and layers established on a suitable substrate. Such control extends to those parts of the devices which incorporate the biological components which enable these devices to function as biological sensors. The materials and methods disclosed herein thus provide an effective means for the mass production of uniform wholly microfabricated biosensors. Various embodiments of the devices themselves are described herein which are especially suited for real time analyses of biological samples in a clinical setting. In particular, the present invention describes assays which can be performed using certain ligand / ligand receptor-based biosensor embodiments. The present invention also discloses a novel method for the electrochemical detection of particular analyte species of biological and physiological significance using an substrate / label signal generating pair which produces a change in the concentration of electroactive species selected from the group consisting of dioxygen and hydrogen peroxide.

Owner:I STAT CORP

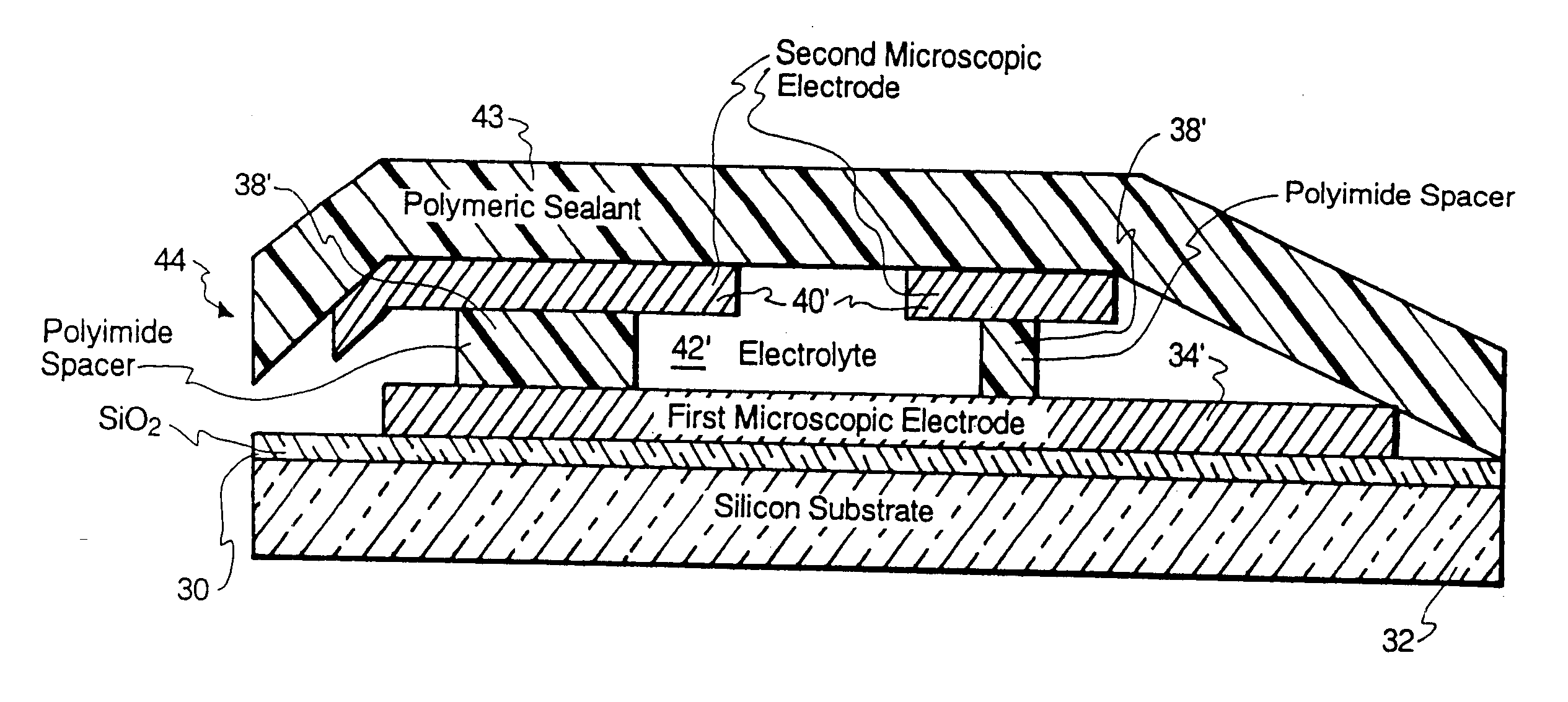

Microscopic batteries for MEMS systems

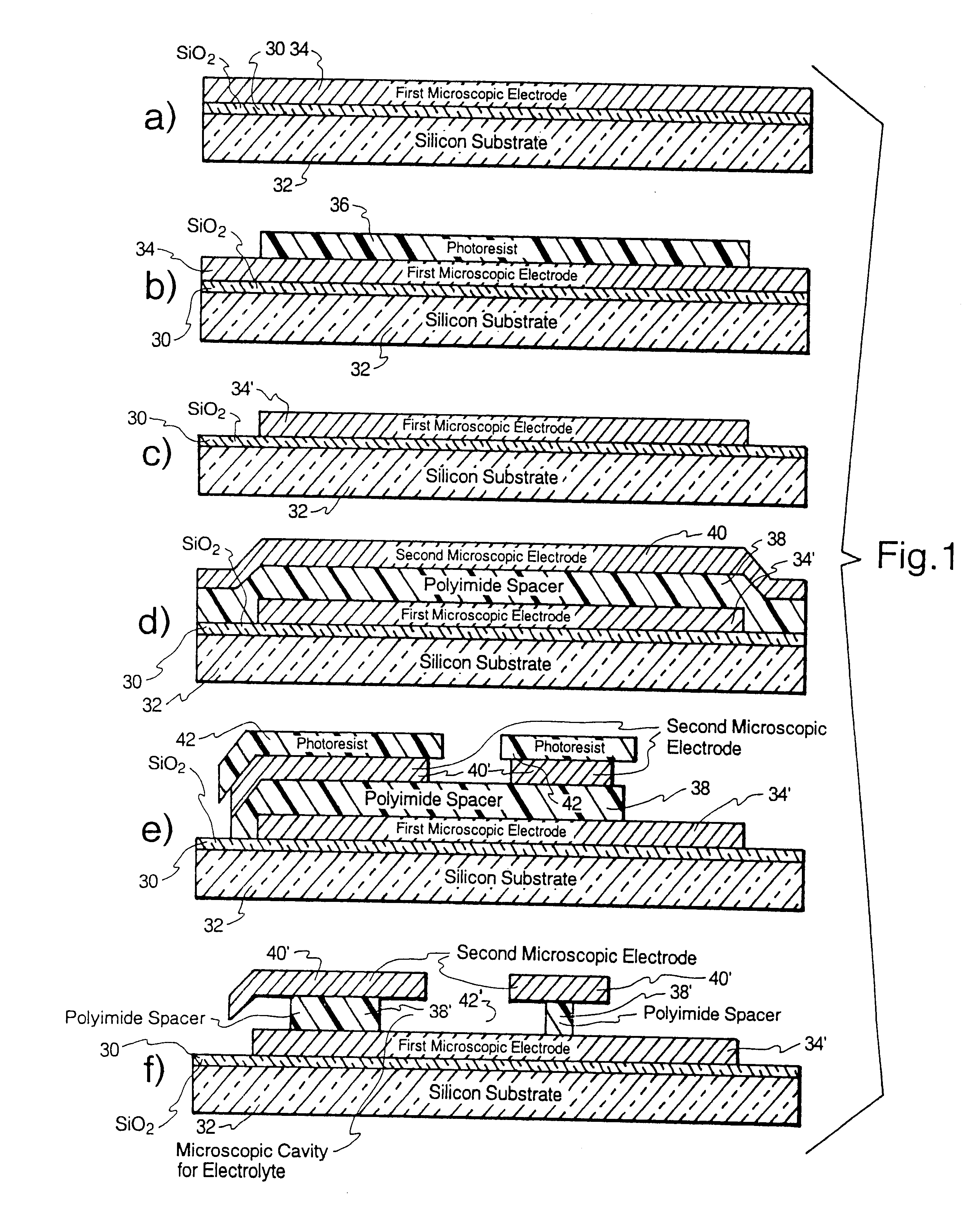

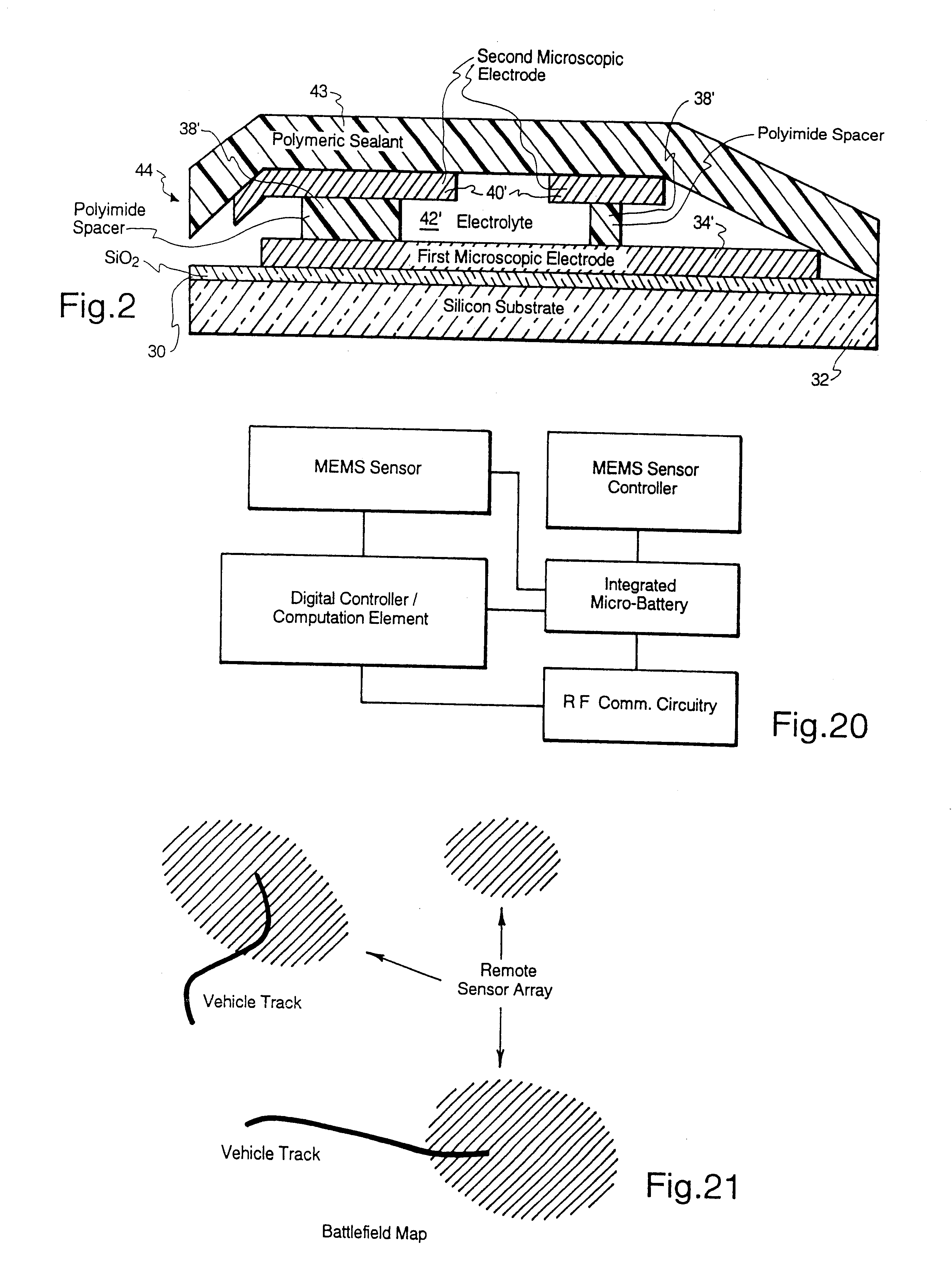

InactiveUS6610440B1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureElectricityMicrofabrication

Microscopic batteries, integratable or integrated with microelectromechanical systems or other microscopic circuits, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed, among which comprise closed system microscopic batteries for internal storage of electricity using interval reactants only, which comprise microscopic electrodes, electrolyte and reservoir for the electrolyte.

Owner:BIPOLAR TECH

System and method of microdispensing and arrays of biolayers provided by same

InactiveUS20020090738A1Bioreactor/fermenter combinationsBiological substance pretreatmentsReal time analysisClinical settings

Owner:ABBOTT POINT CARE

Photoacid generator compounds and compositions

InactiveUS7824839B2Appropriate mobilityHomogeneous distribution of in resistOrganic chemistryOrganic compound preparationResistMicrofabrication

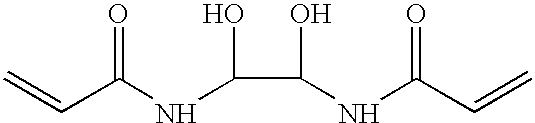

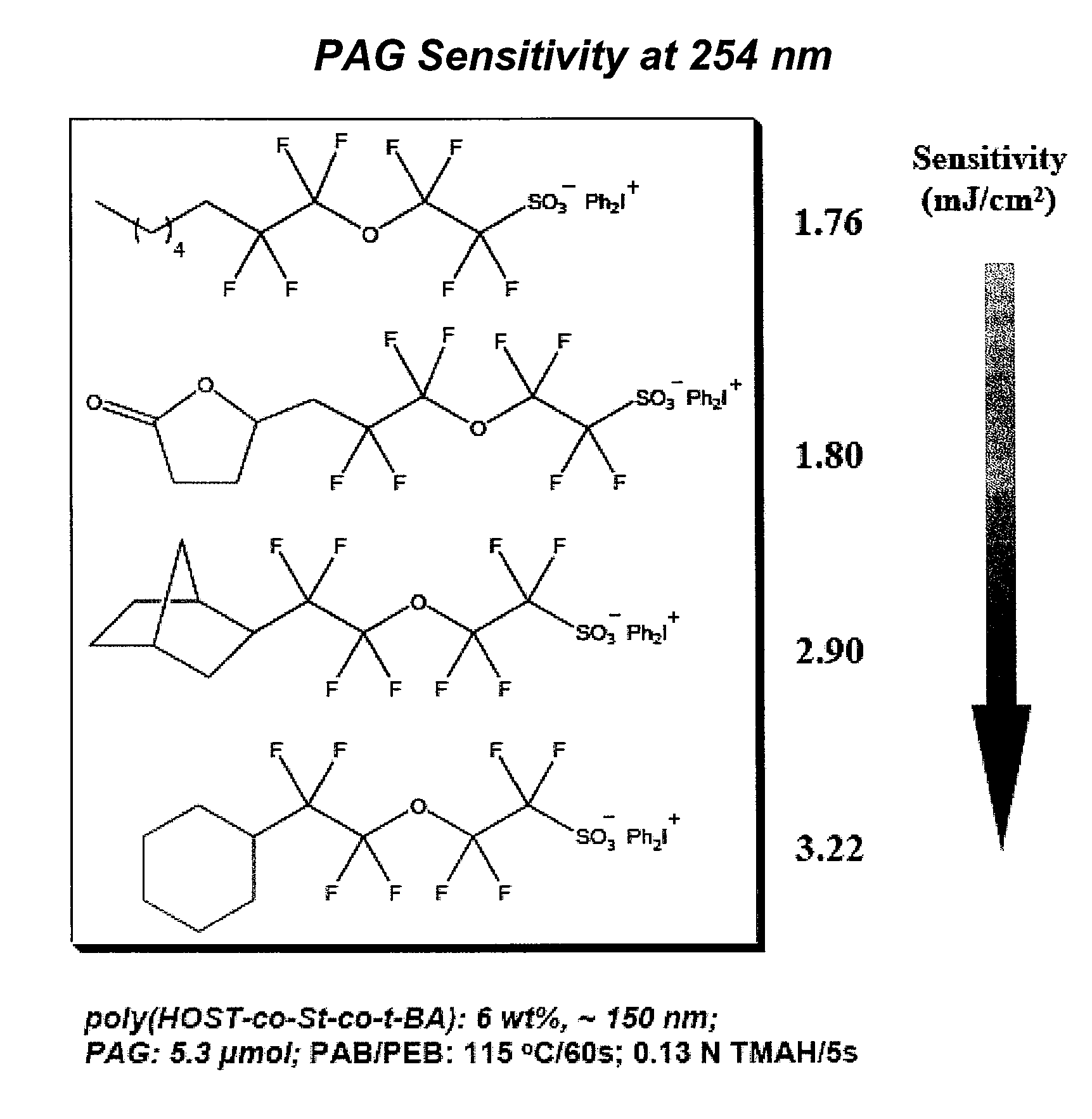

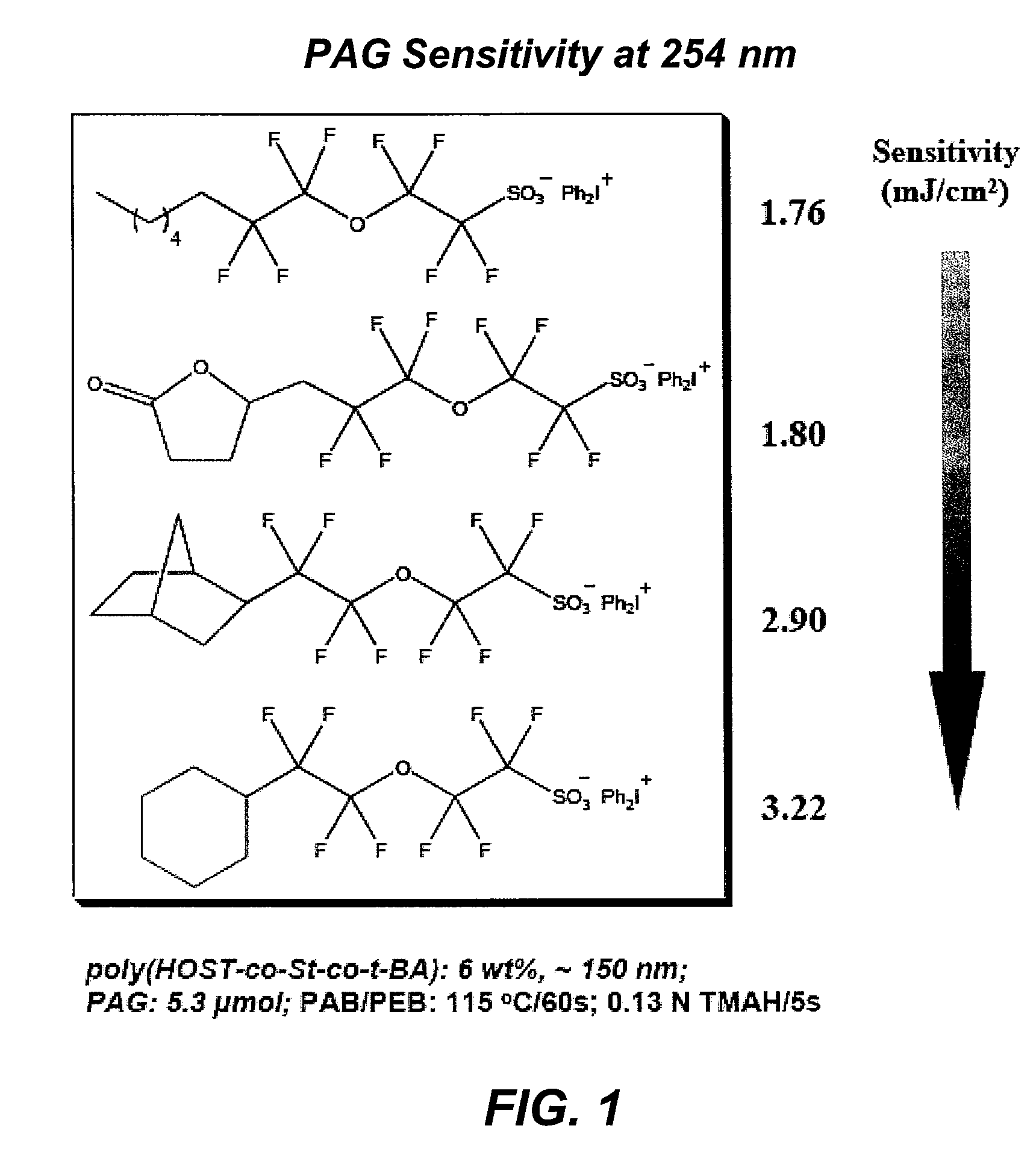

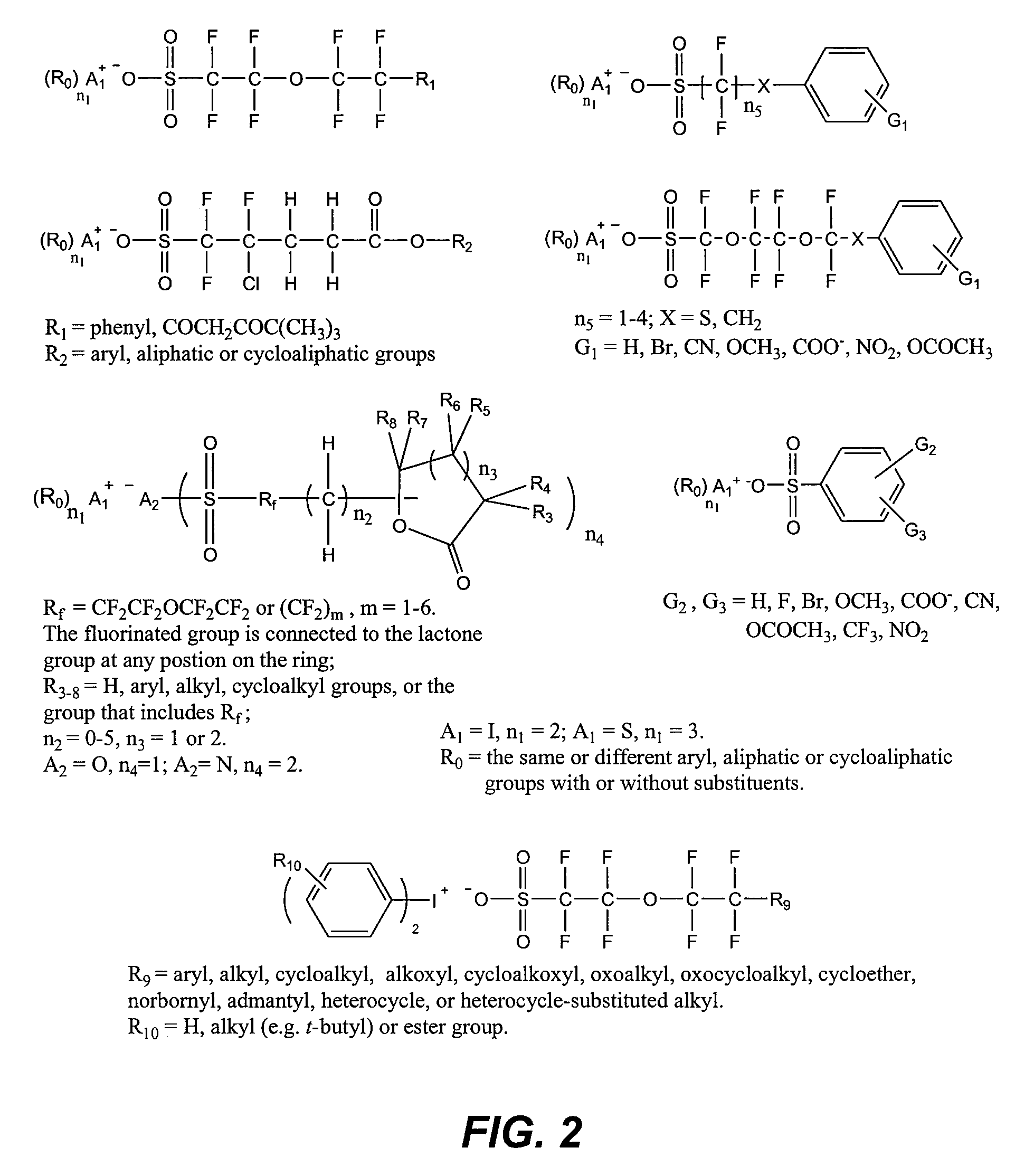

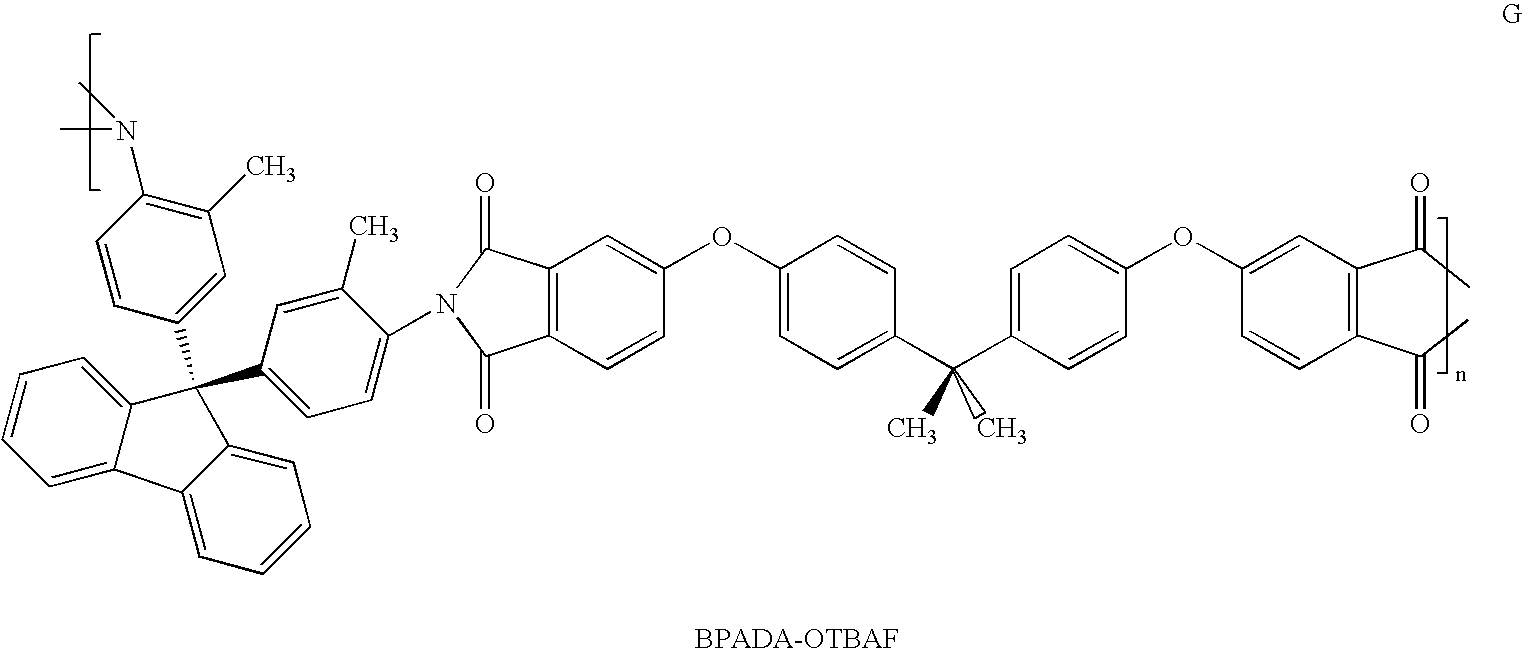

The invention provides various ionic and non-ionic photoacid generator compounds. Photoresist compositions that include the novel ionic and non-ionic photoacid generator compounds are also provided. The invention further provides methods of making and using the photoacid generator compounds and photoresist compositions disclosed herein. The compounds and compositions are useful as photoactive components in chemically amplified resist compositions for various microfabrication applications.

Owner:CORNELL RES FOUNDATION INC

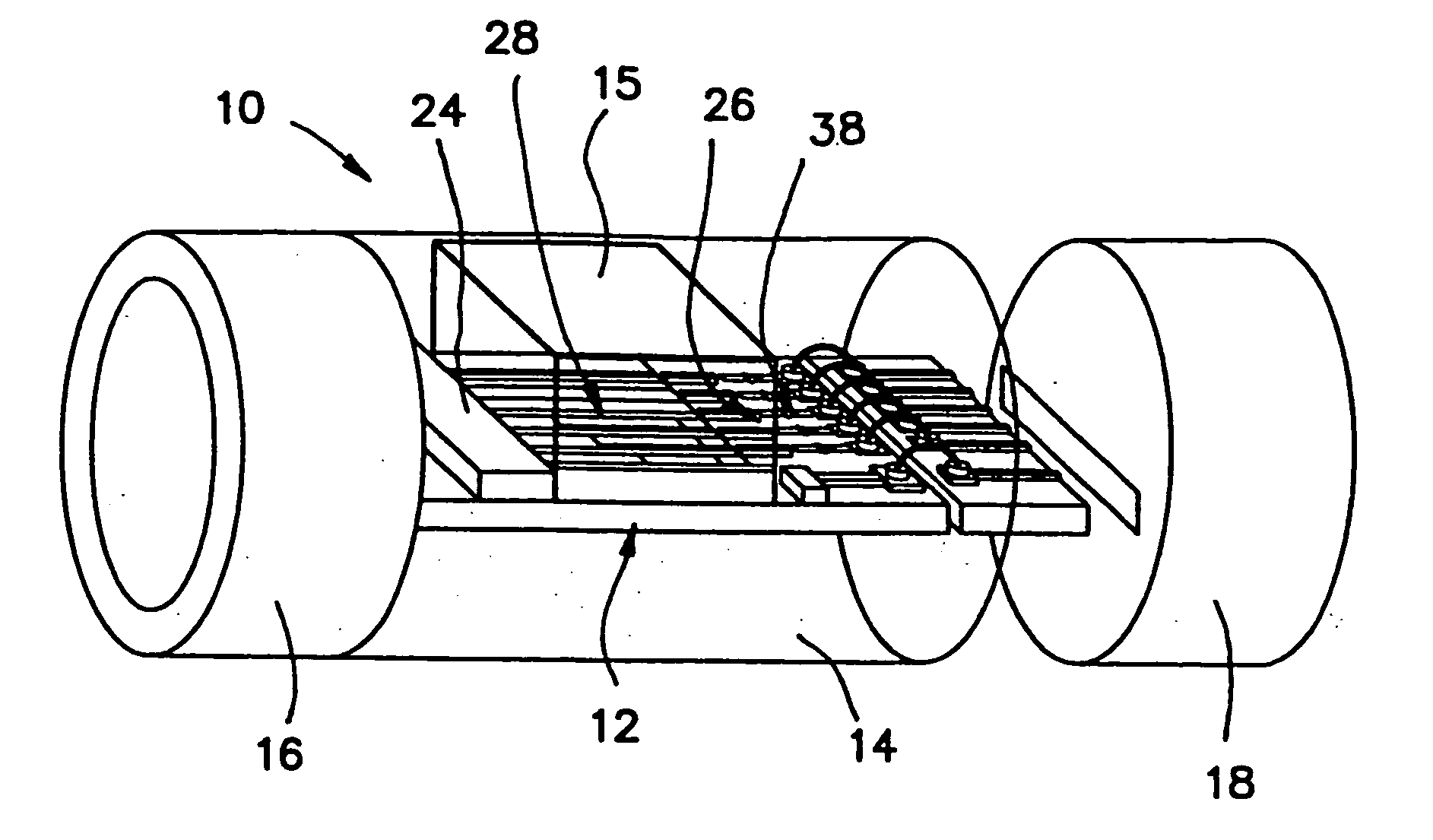

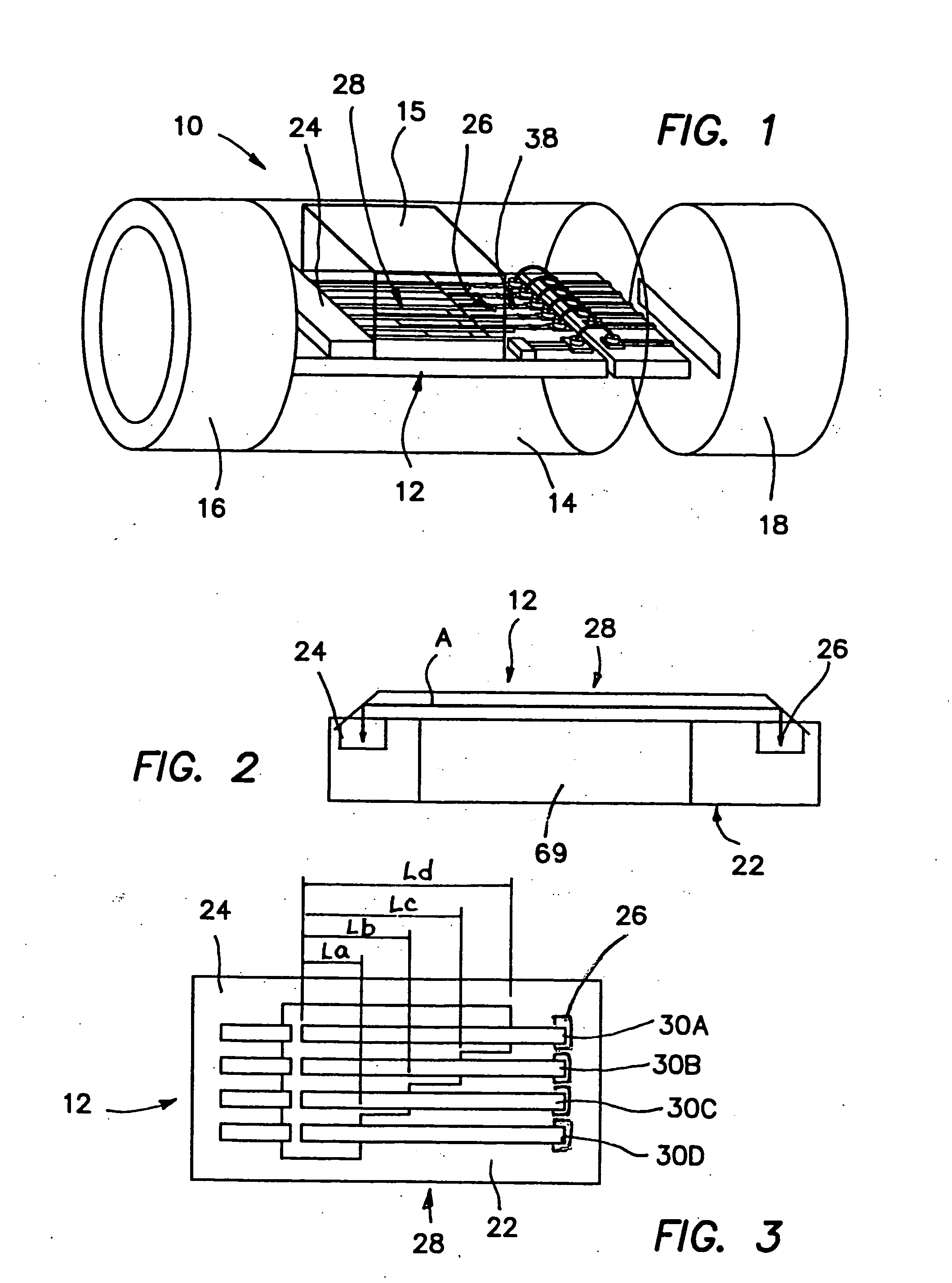

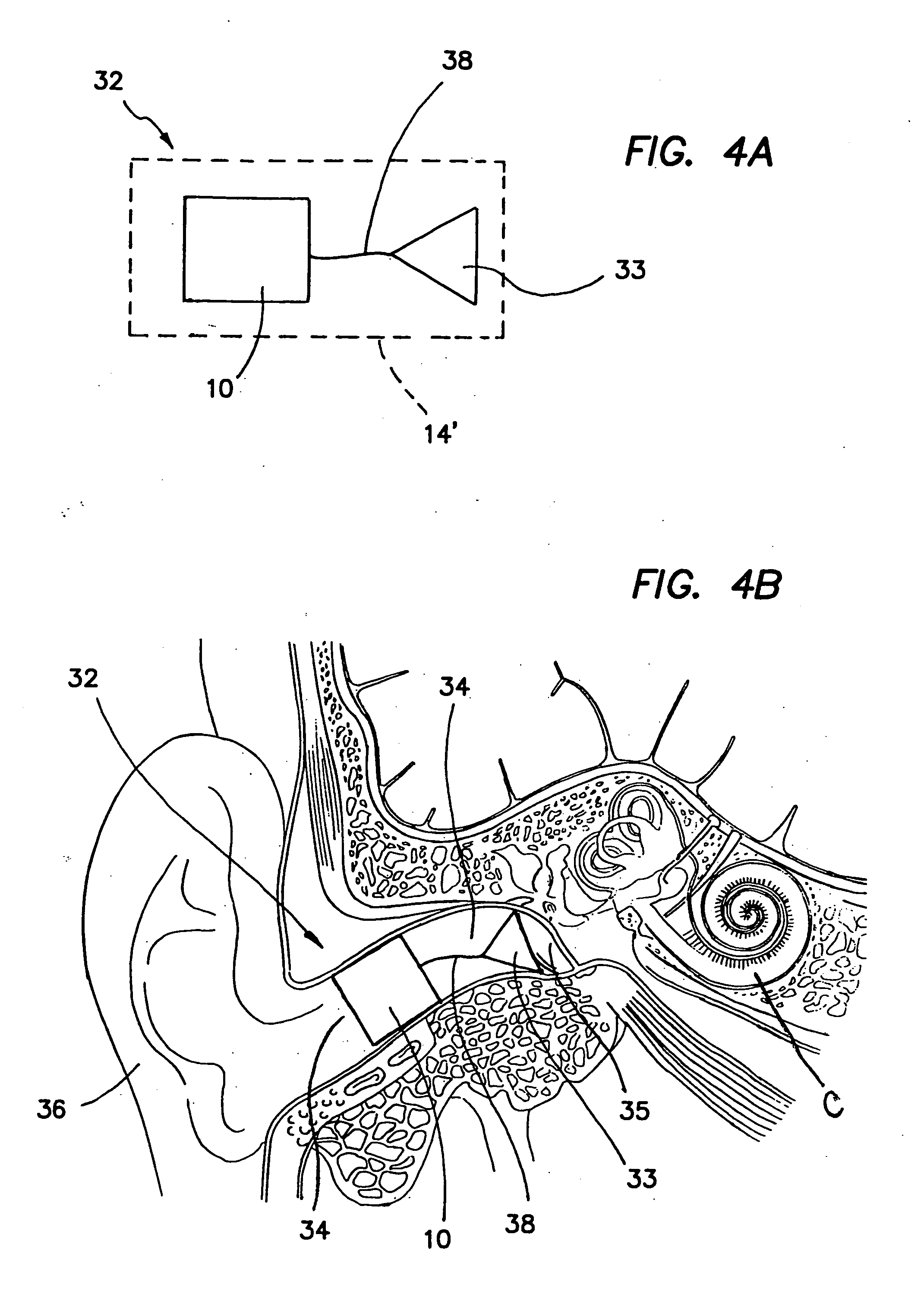

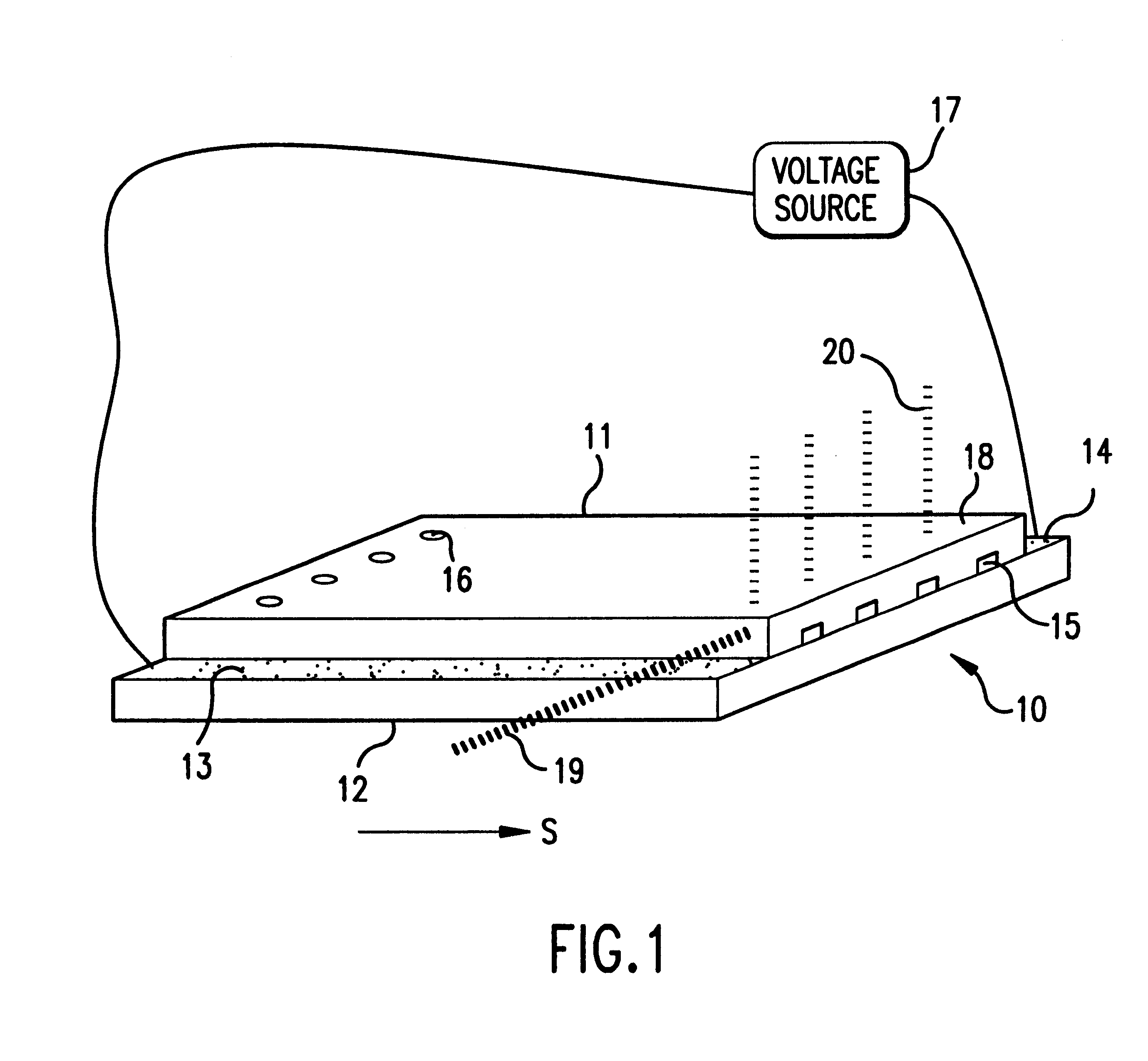

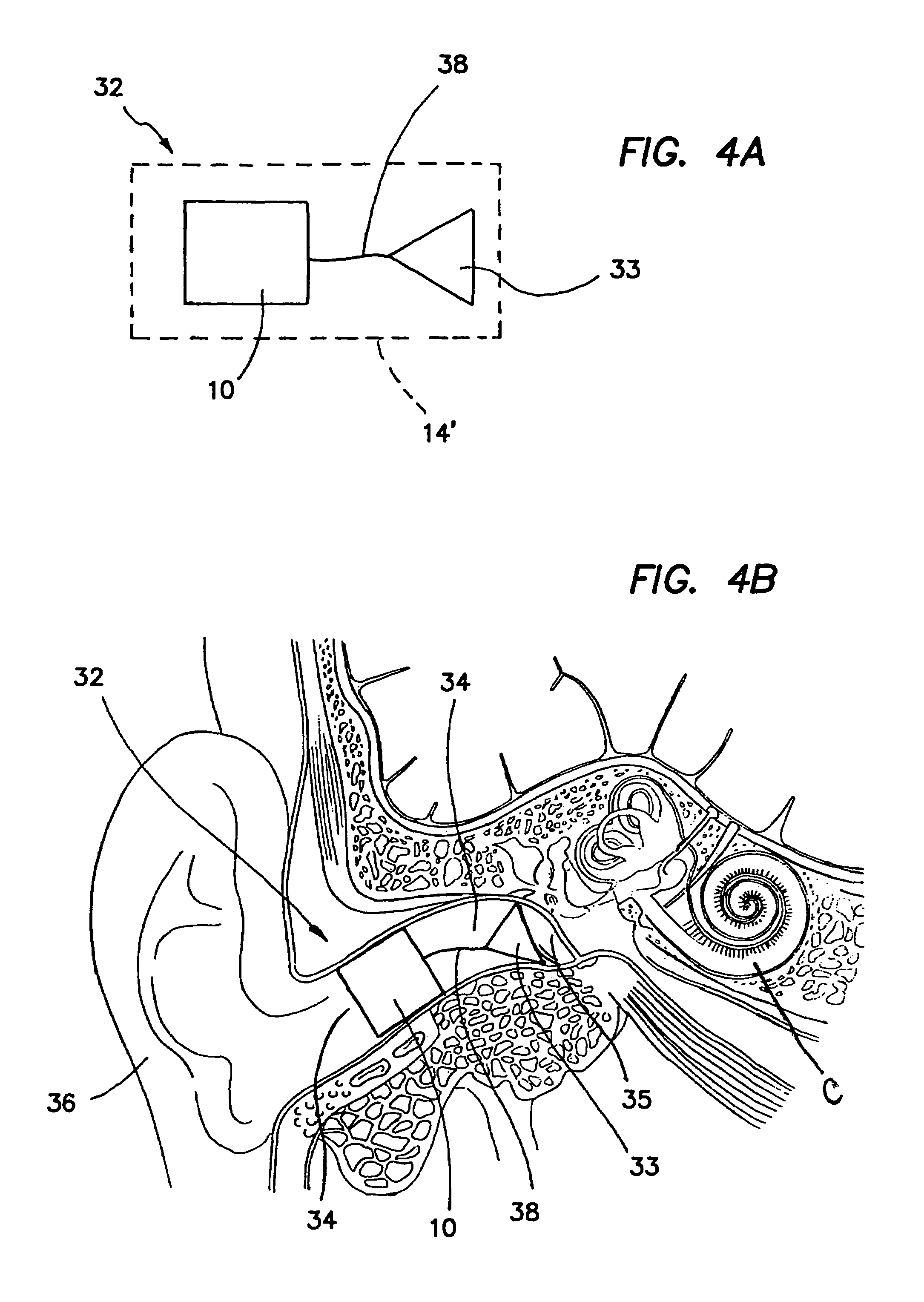

Optical waveguide vibration sensor for use in hearing aid

InactiveUS20060107744A1Improve hearingVibration measurement in solidsRecord carriersPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

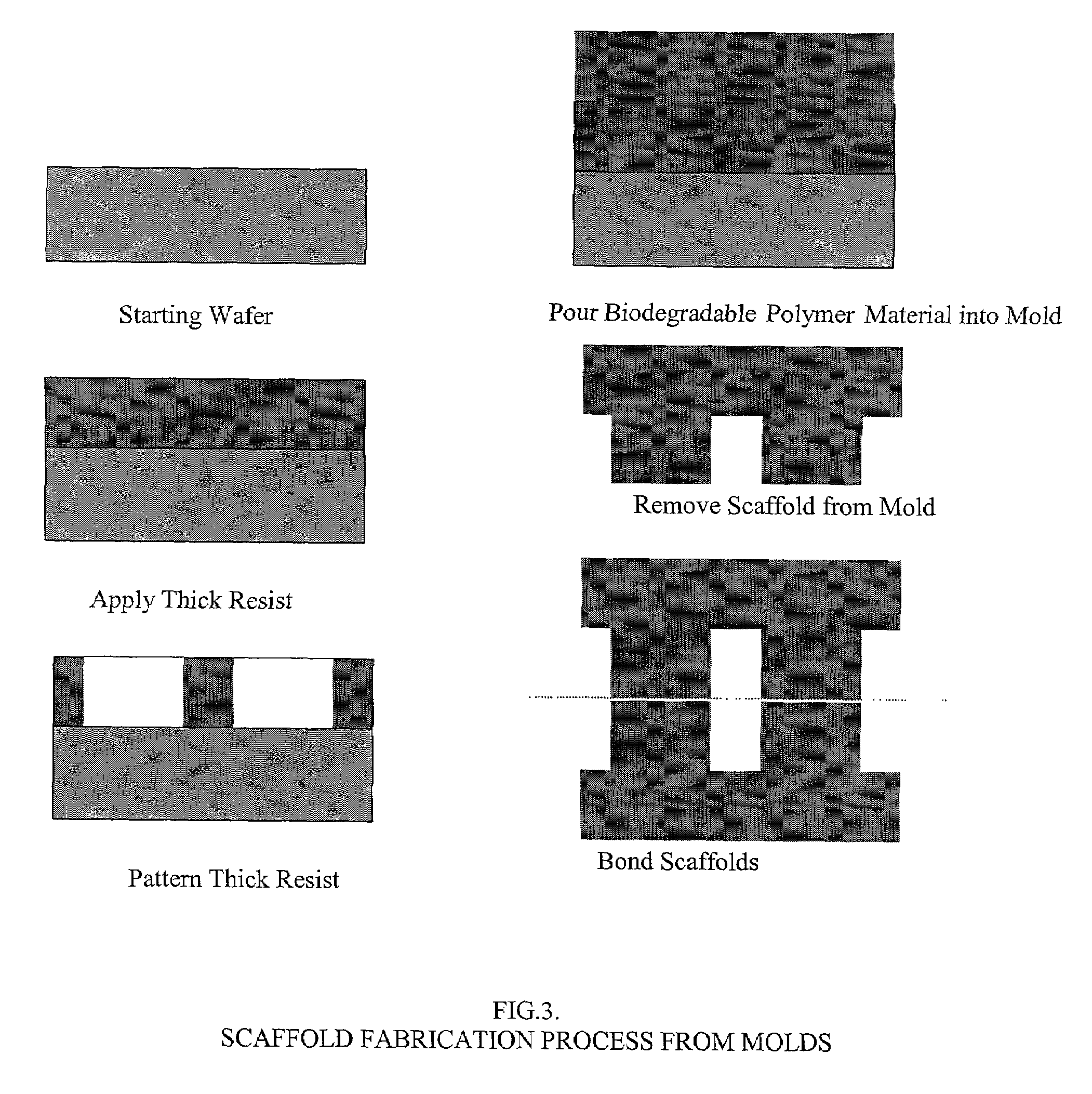

Multilayer device for tissue engineering

InactiveUS7371400B2Good effectImprove viabilityImmobilised enzymesFixed microstructural devicesAdhesion processCell adhesion

The invention provides for translating two-dimensional microfabrication technology into the third dimension. Two-dimensional templates are fabricated using high-resolution molding processes. These templates are then bonded to form three-dimensional scaffold structures with closed lumens. The scaffolds can serve as the template for cell adhesion and growth by cells that are added to the scaffolds through the vessels, holes or pores. These scaffolds can be formed by layering techniques, to interconnect flat template sheets to build up a fully vascularized organ.

Owner:CHARLES STARK DRAPER LABORATORY

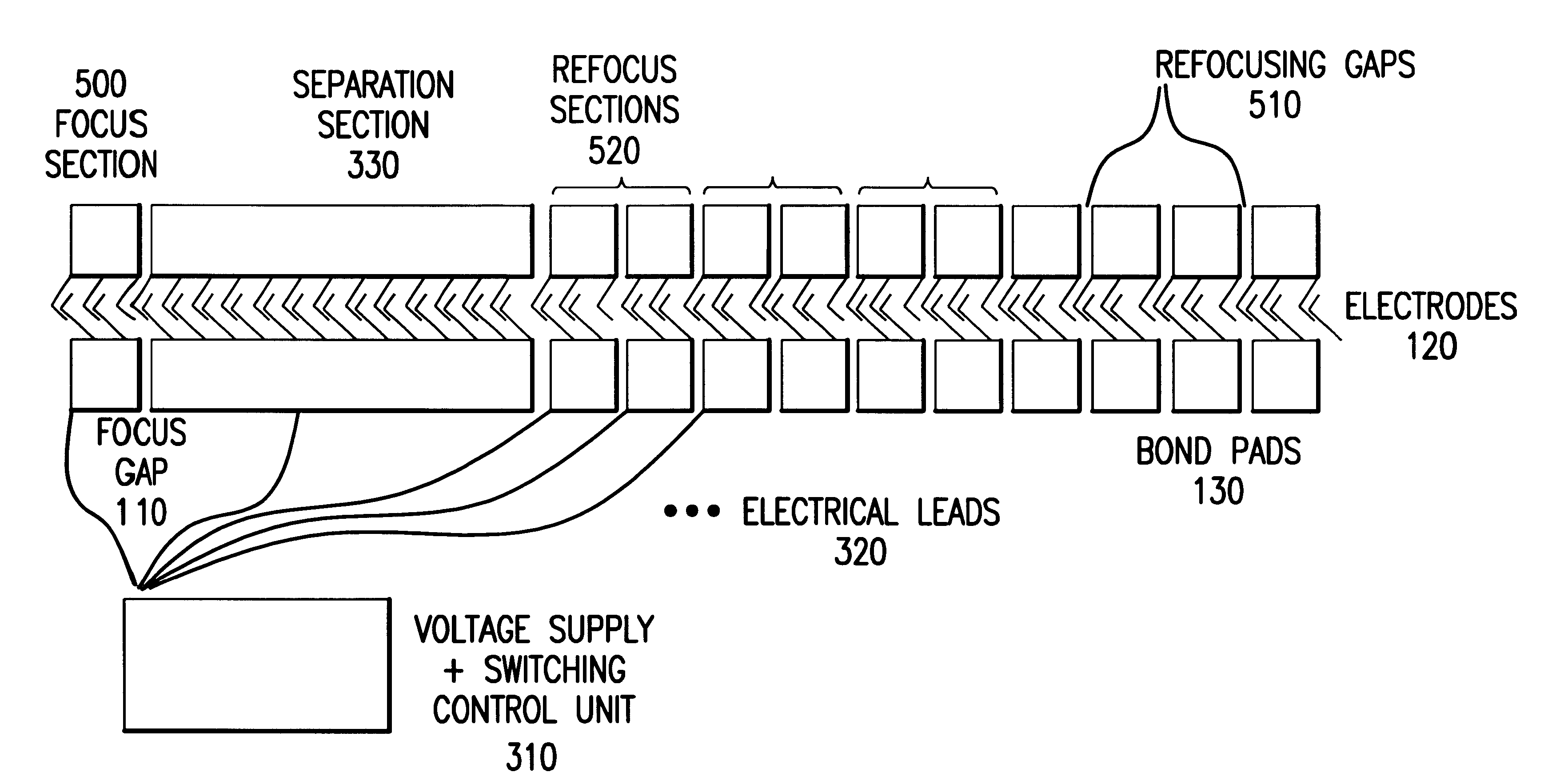

Separation of charged particles by a spatially and temporally varying electric field

InactiveUS6193866B1Strong interactionRapid separationSludge treatmentVolume/mass flow measurementInjection portDNA fragmentation

This invention relates to a method and device for separating charged particles according to their diffusivities in a separation medium by means of a spatially and temporally varying electric potential. The method is particularly suited to sizing and separating DNA fragments, to generating DNA fragment length polymorphism patterns, and to sequencing DNA through the separation of DNA sequencing reaction products. The method takes advantage of the transport of charged particles subject to an electric potential that is cycled between an off-state (in which the potential is flat) and one or more on-states, in which the potential is preferably spatially periodic with a plurality of eccentrically shaped stationary potential wells. The potential wells are at constant spatial positions in the on-state. Differences in liquid-phase diffusivities lead to charged particle separation. A preferred embodiment of the device is microfabricated. A separation medium fills physically defined separation lanes in the device. Electrodes deposited substantially transverse to the lanes create the required electric potentials. Advantageously, injection ports allow sample loading, and special gating electrodes focus the sample prior to separation. The effects of thermal gradients are minimized by placing the device in contact with a thermal control module, preferably a plurality of Peltier-effect heat transfer devices. The small size of a microfabricated device permits rapid separation in a plurality of separation lanes.

Owner:CURAGEN CORP

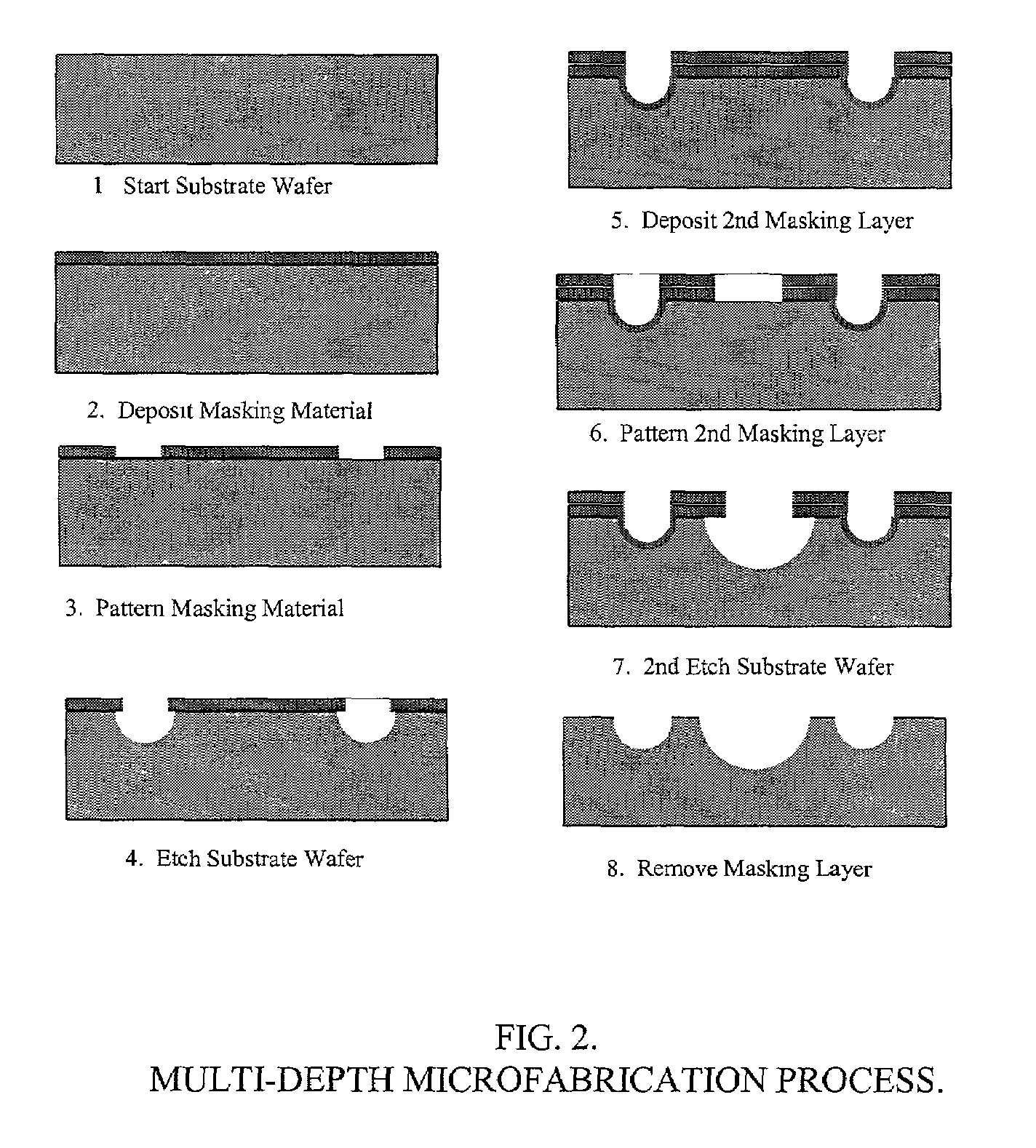

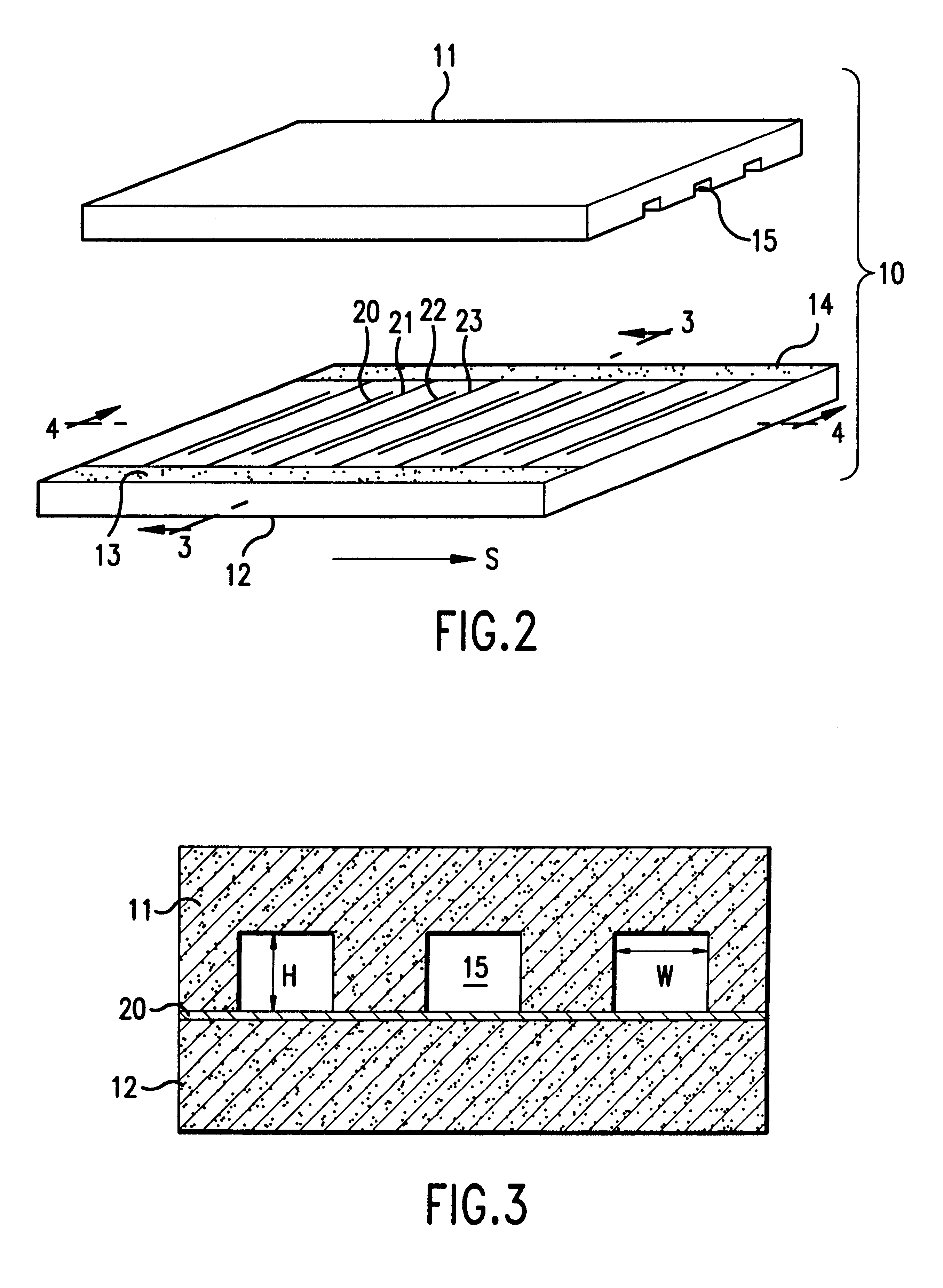

Three dimensional microfabrication

InactiveUS6977223B2Semiconductor/solid-state device manufacturing3D structure electroformingMicrofabricationVoltage

Method for making three-dimensional structures. A template is provided having at least two conductive regions separated by a non-conductive region. The template is disposed in an electrolyte in an electrodeposition cell and a voltage is established between one of the conductive regions and an electrode in the cell. Material is deposited on the one of the conductive regions connected to the voltage and subsequently bridges to the other conductive region with material deposition continuing on both of the at least two regions. The non conductive region may be a gap and the gap dimension is selected to regulate height differences between the at least two conductive regions.

Owner:MASSACHUSETTS INST OF TECH

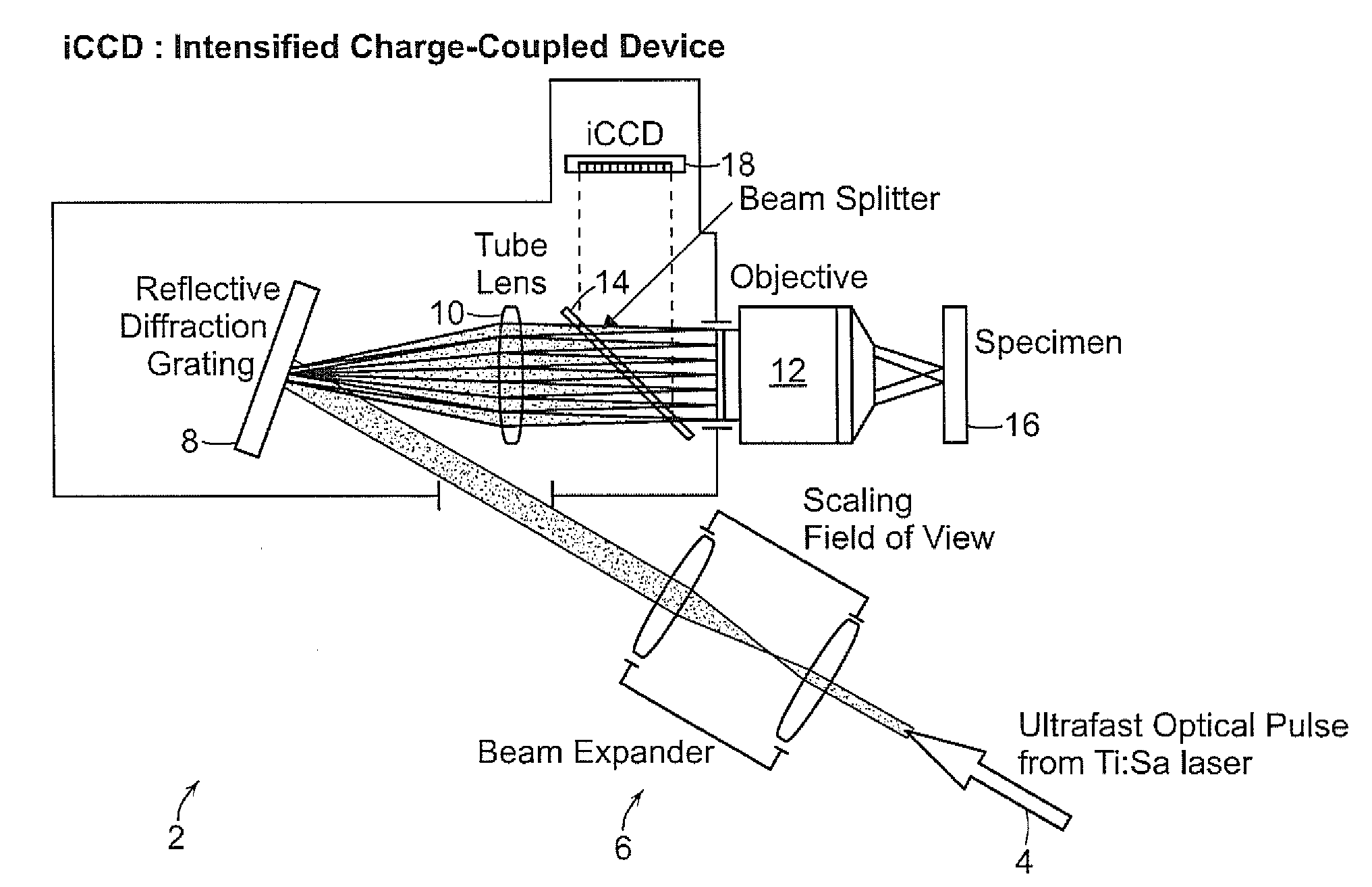

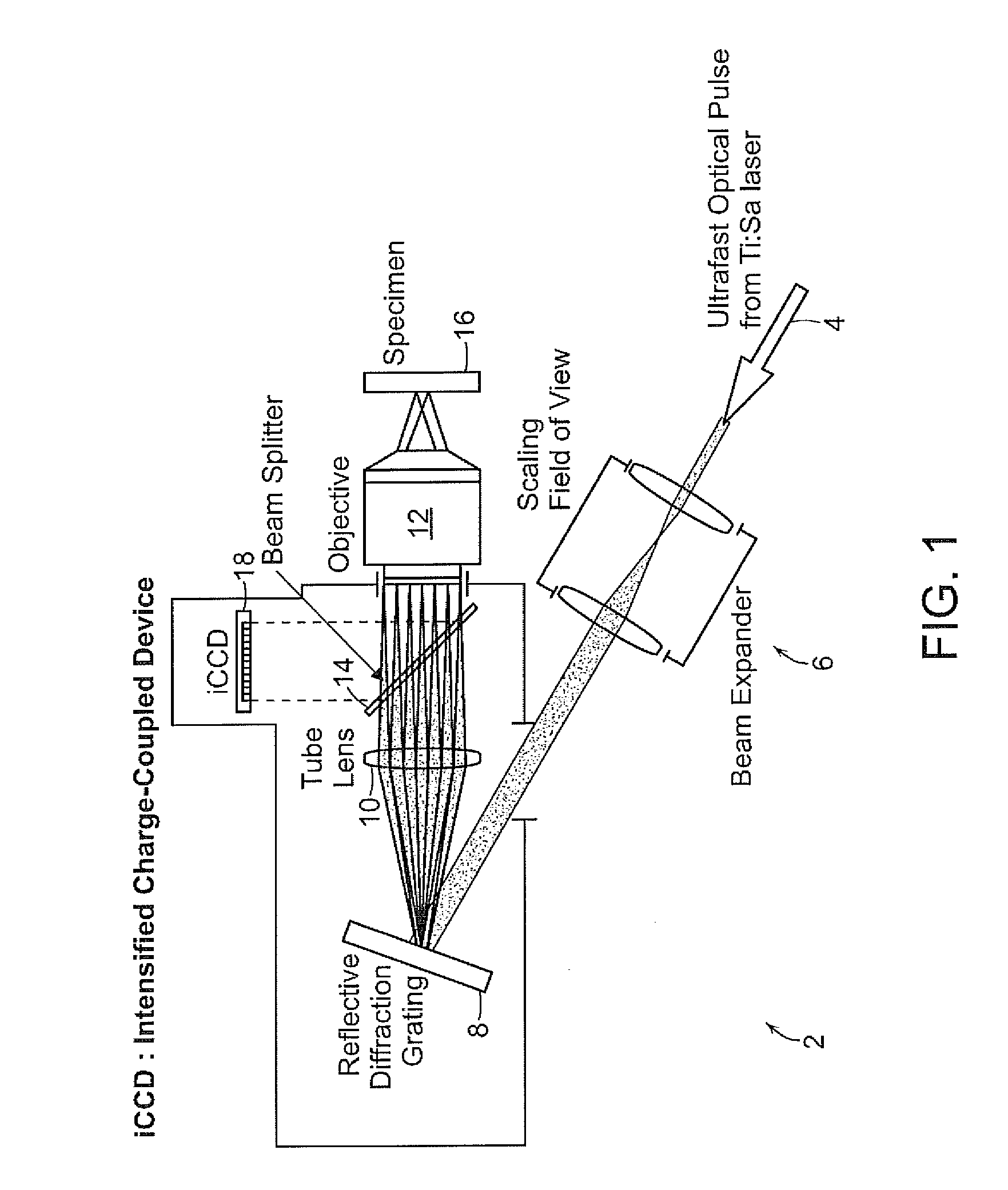

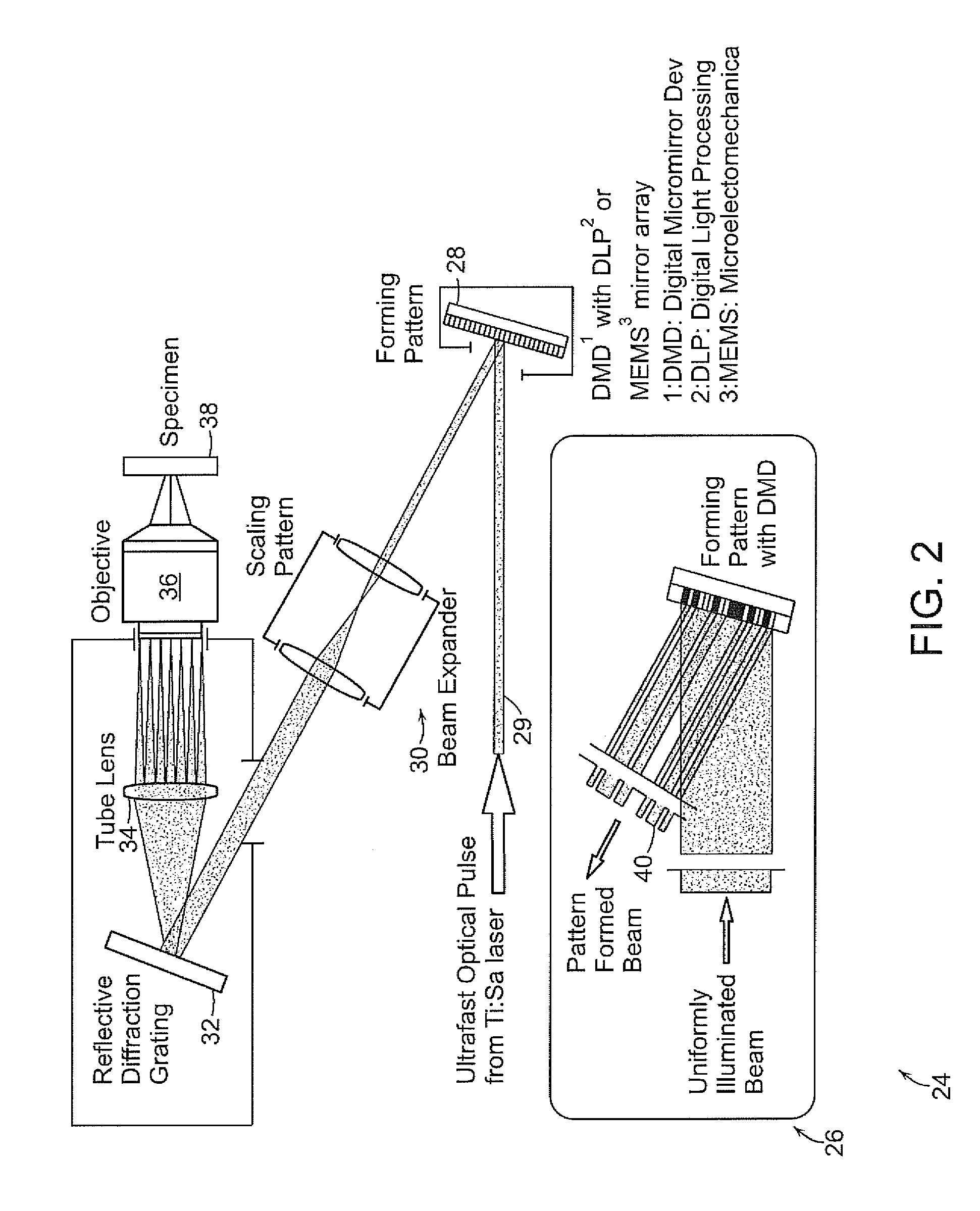

3D two-photon lithographic microfabrication system

InactiveUS7902526B2Wave amplification devicesPhotomechanical apparatusMicrofabricationMonochromatic color

An imaging system is provided that includes a optical pulse generator for providing an optical pulse having a spectral bandwidth and includes monochromatic waves having different wavelengths. A dispersive element receives a second optical pulse associated with the optical pulse and disperses the second optical pulse at different angles on the surface of the dispersive element depending on wavelength. One or more focal elements receives the dispersed second optical pulse produced on the dispersive element. The one or more focal element recombine the dispersed second optical pulse at a focal plane on a specimen where the width of the optical pulse is restored at the focal plane.

Owner:MASSACHUSETTS INST OF TECH

Microfabrication of organic optical elements

InactiveUS6855478B2Good optical stabilityConsistent optical performanceAdditive manufacturing apparatusPhotosensitive materialsMicrofabricationPhotoinitiator

Method of fabricating an optical element. A photodefinable composition is provided that includes (i) a hydrophobic, photodefinable polymer, said photodefinable polymer having a glass transition temperature in the cured state of at least about 80° C.; and (ii) a multiphoton photoinitiator system comprising at least one multiphoton photosensitizer and preferably at least one phtoinitiator that is capable of being photosensitized by the photosensitizer. One or more portions of the composition are imagewise exposed to the electromagnetic energy under conditions effective to photodefinably form at least a portion of a three-dimensional optical element.

Owner:3M INNOVATIVE PROPERTIES CO

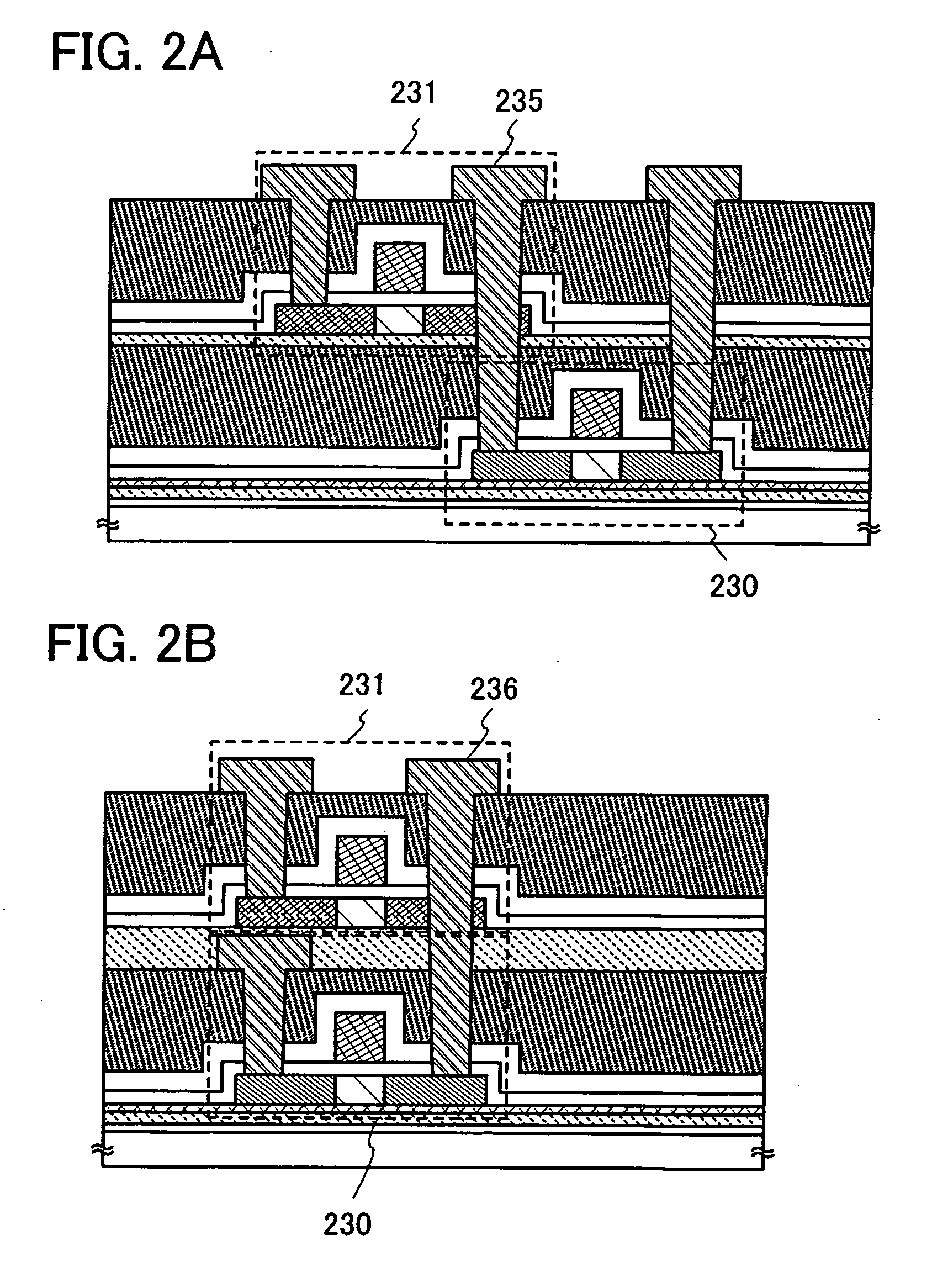

Display device and method for manufacturing the same

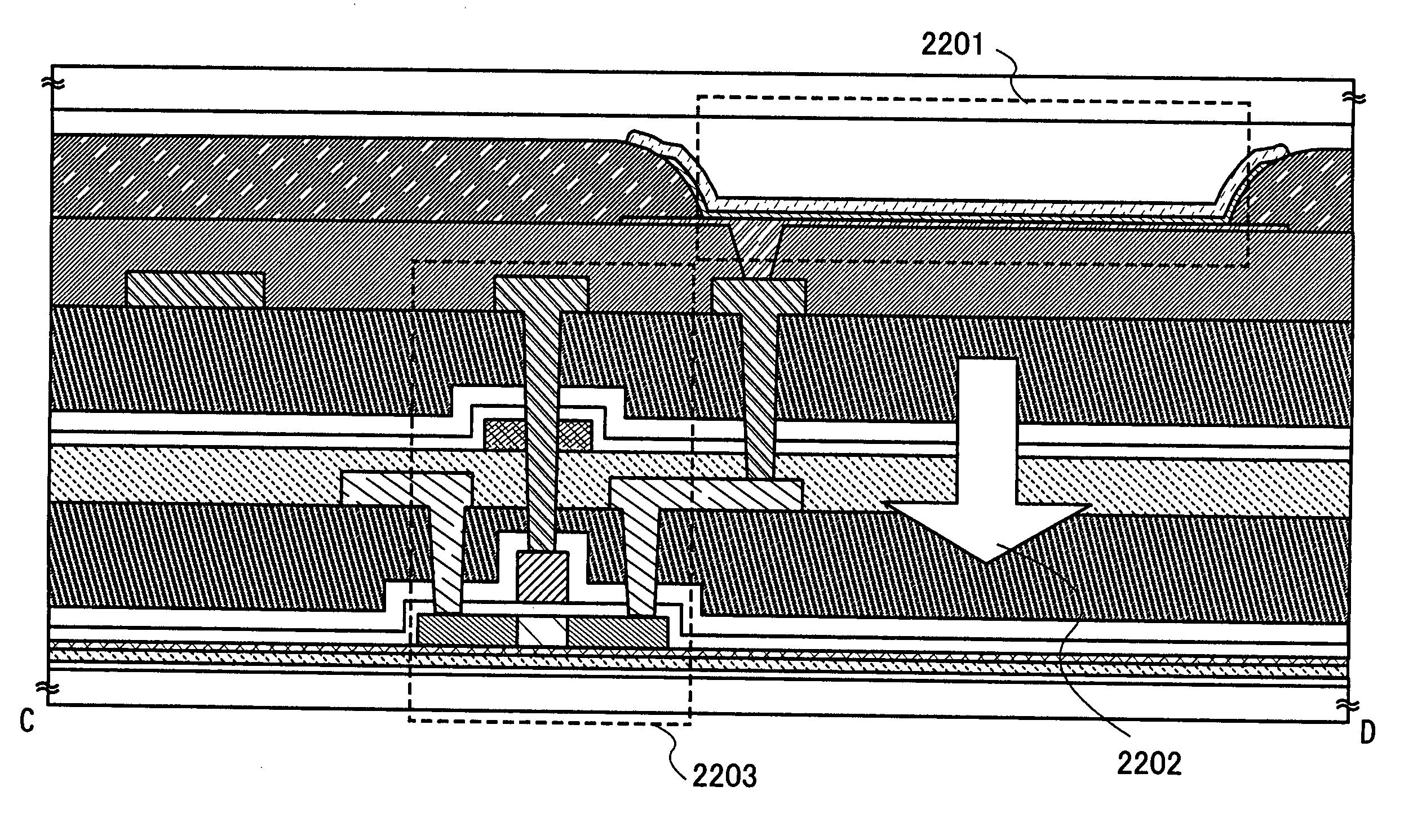

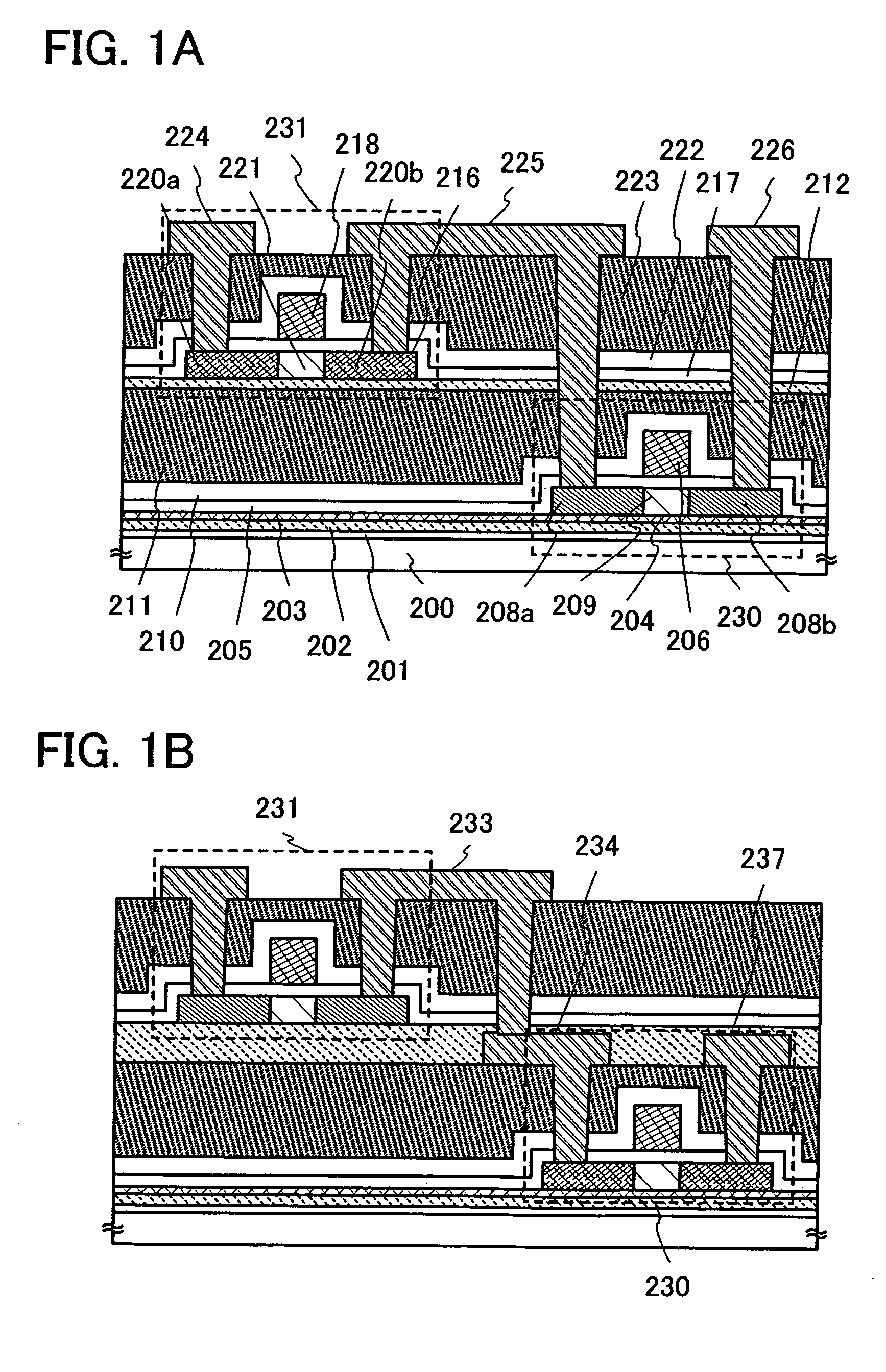

InactiveUS20090078939A1Improve performanceIncrease the aperture ratioTransistorSolid-state devicesMicrofabricationDisplay device

To provide a display device which can realize high performance of a field-effect transistor which forms a pixel of the display device and which can achieve improvement in an aperture ratio of a pixel, which has been reduced due to increase in the number of field-effect transistors, and reduction in the area of the field-effect transistor which occupies the pixel, without depending on a microfabrication technique of the field-effect transistor, even when the number of field-effect transistors in the pixel is increased. A display device is provided with a plurality of pixels in which a plurality of field-effect transistors including a semiconductor layer which is separated from a semiconductor substrate and is bonded to a supporting substrate having an insulating surface are stacked with a planarization layer interposed therebetween.

Owner:SEMICON ENERGY LAB CO LTD

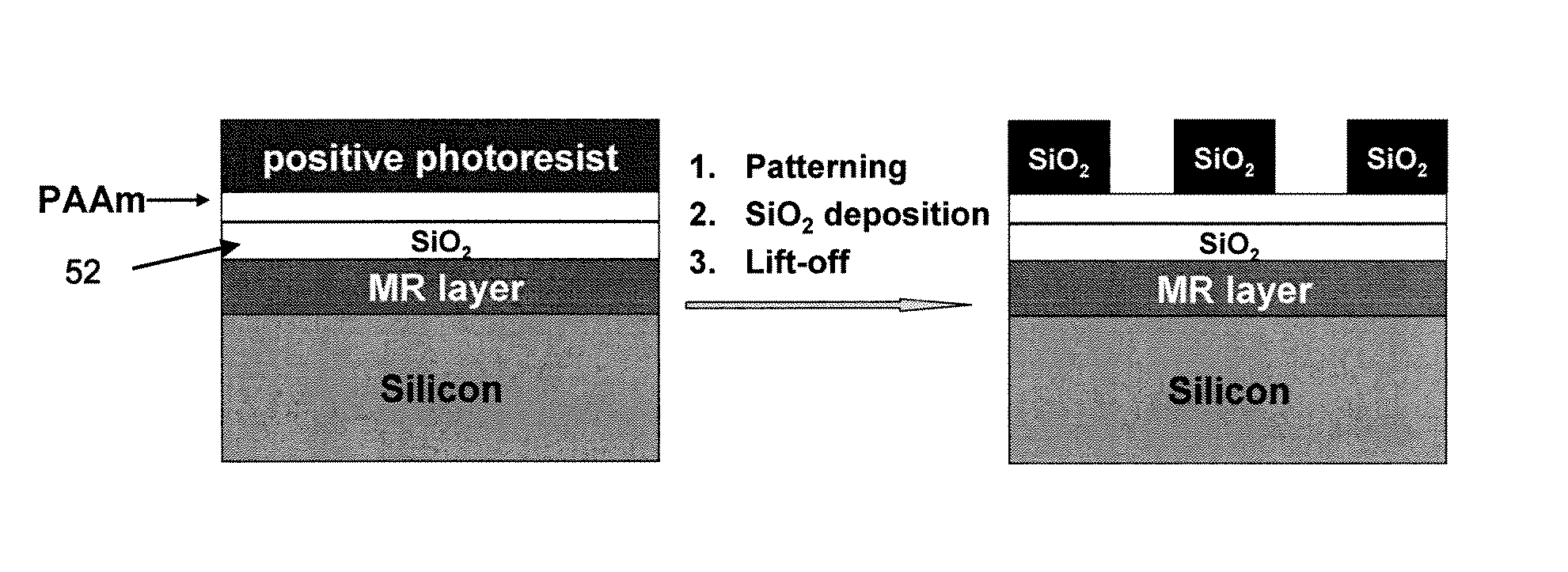

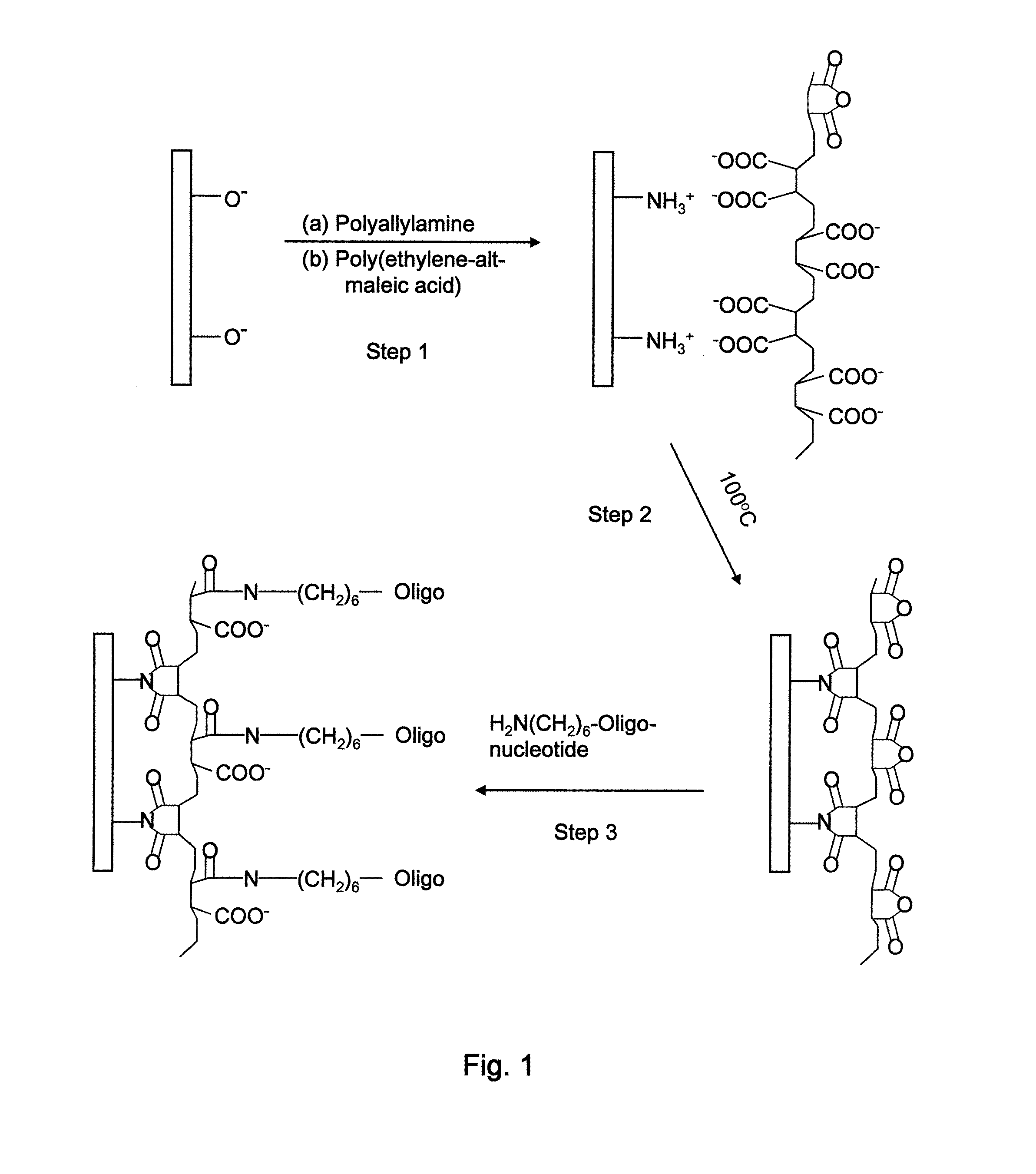

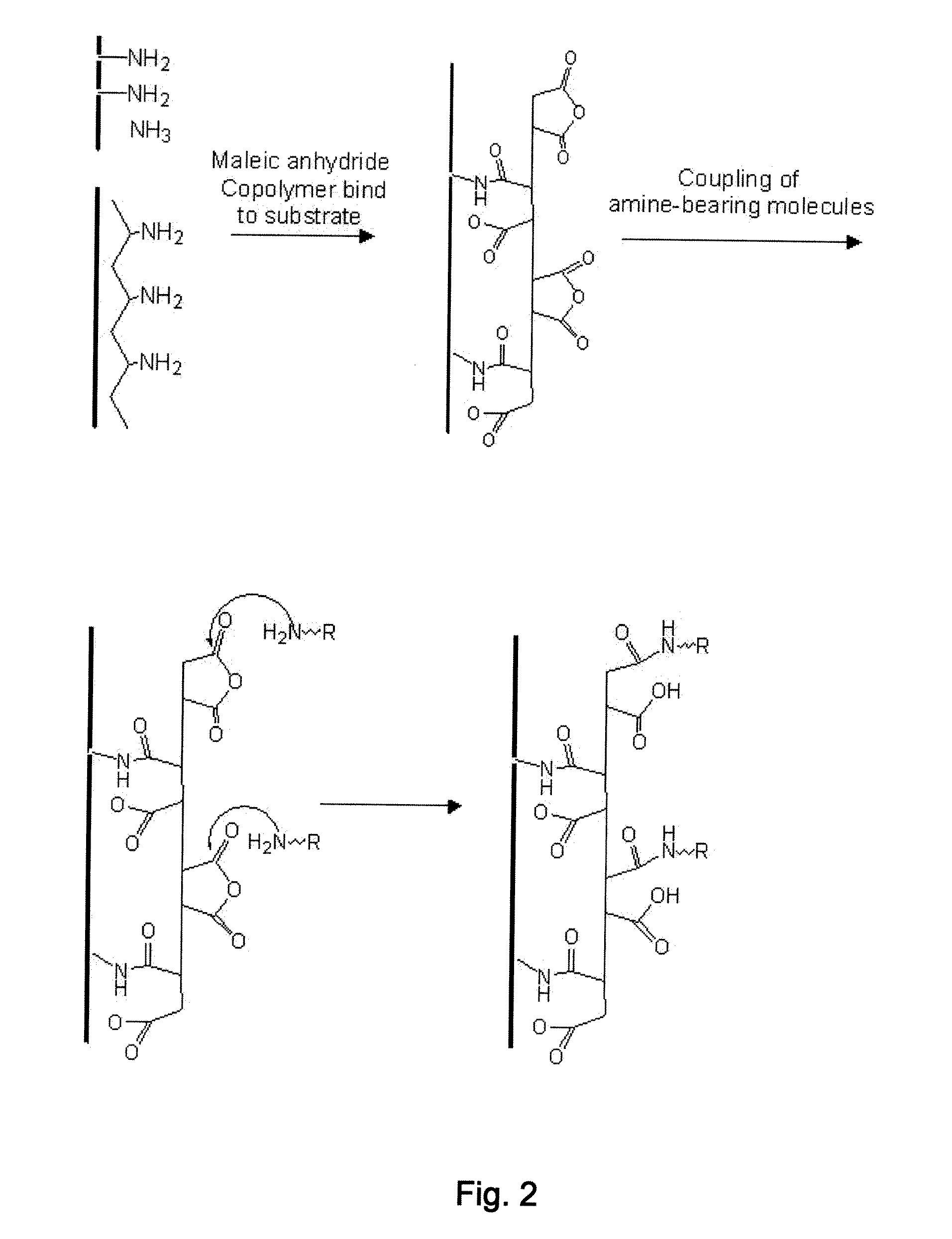

Biomolecule Immobilization on Biosensors

A highly specific and versatile surface chemistry for immobilization of amine-terminated probes is disclosed. A bi-layered polymer thin film serves as the platform for coupling the probes, which are preferably oligonucleotides. The process involves sequentially coating a substrate with polyamine and polyacid anhydride. Hydrolyzed polyacid anhydride groups may be converted to non-hydrolyzed groups at about 100° C. prior to probe attachment. The process of coating the substrate requires no harsh chemical pretreatment of substrates such as RCA or Piranha cleaning. In addition, simple thermal activation of the anhydride groups has a low requirement for storage, leading to a long shelf life of modified surfaces. The disclosed surface chemistry is especially compatible with microfabrication processes, and its effective application to magnetic biosensors is demonstrated.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

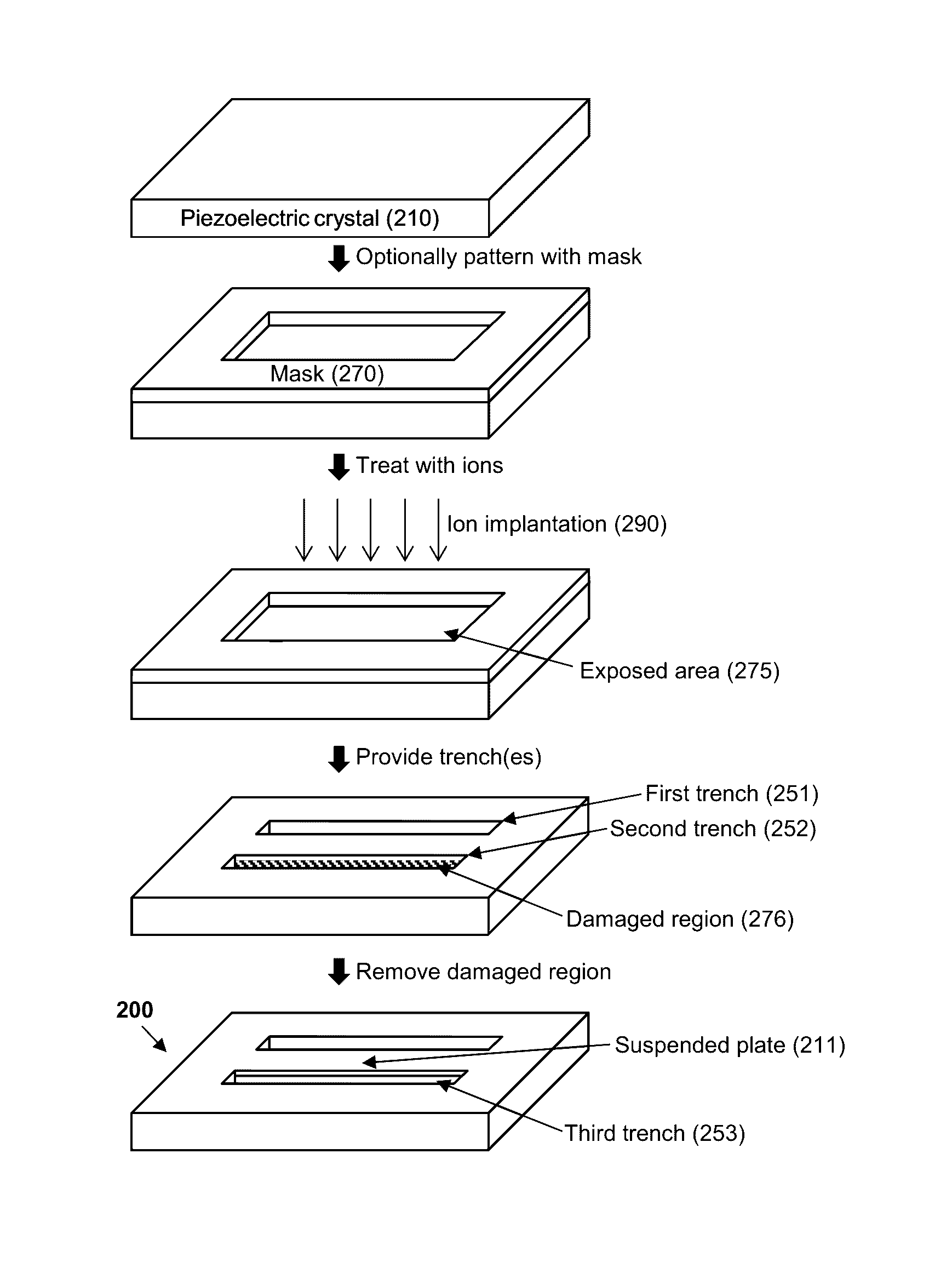

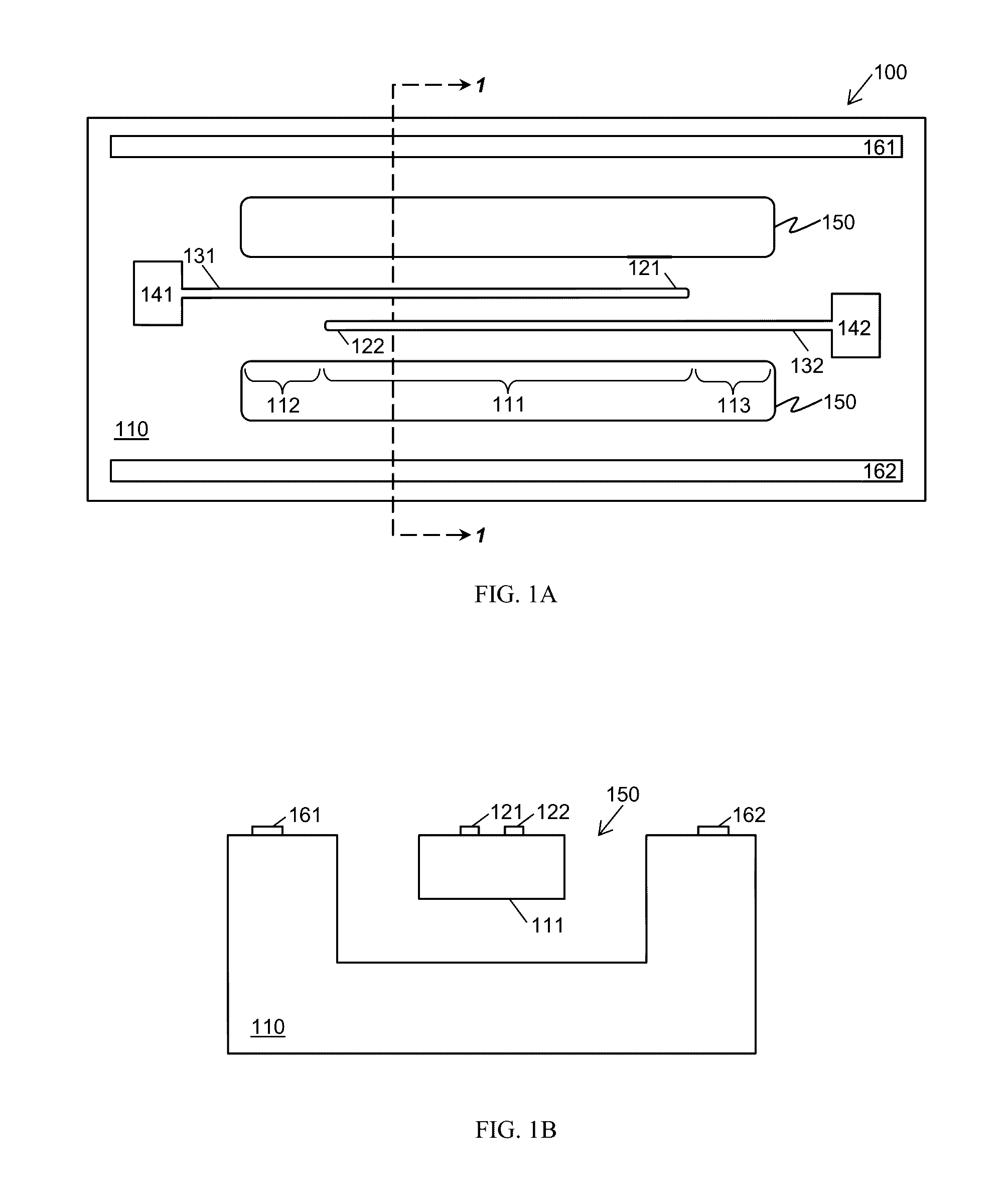

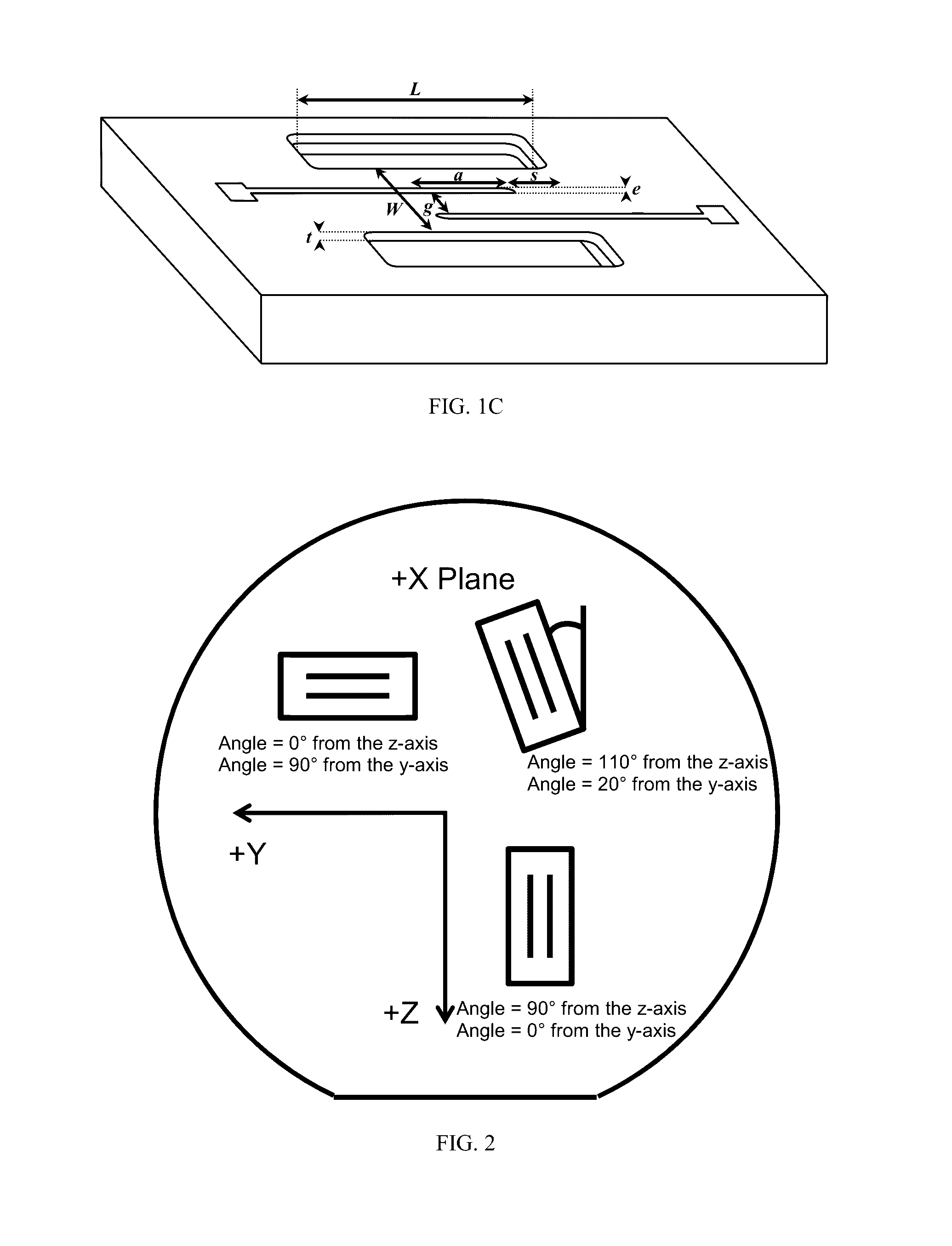

Single crystal micromechanical resonator and fabrication methods thereof

The present invention relates to a single crystal micromechanical resonator. In particular, the resonator includes a lithium niobate or lithium tantalate suspended plate. Also provided are improved microfabrication methods of making resonators, which does not rely on complicated wafer bonding, layer fracturing, and mechanical polishing steps. Rather, the methods allow the resonator and its components to be formed from a single crystal.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

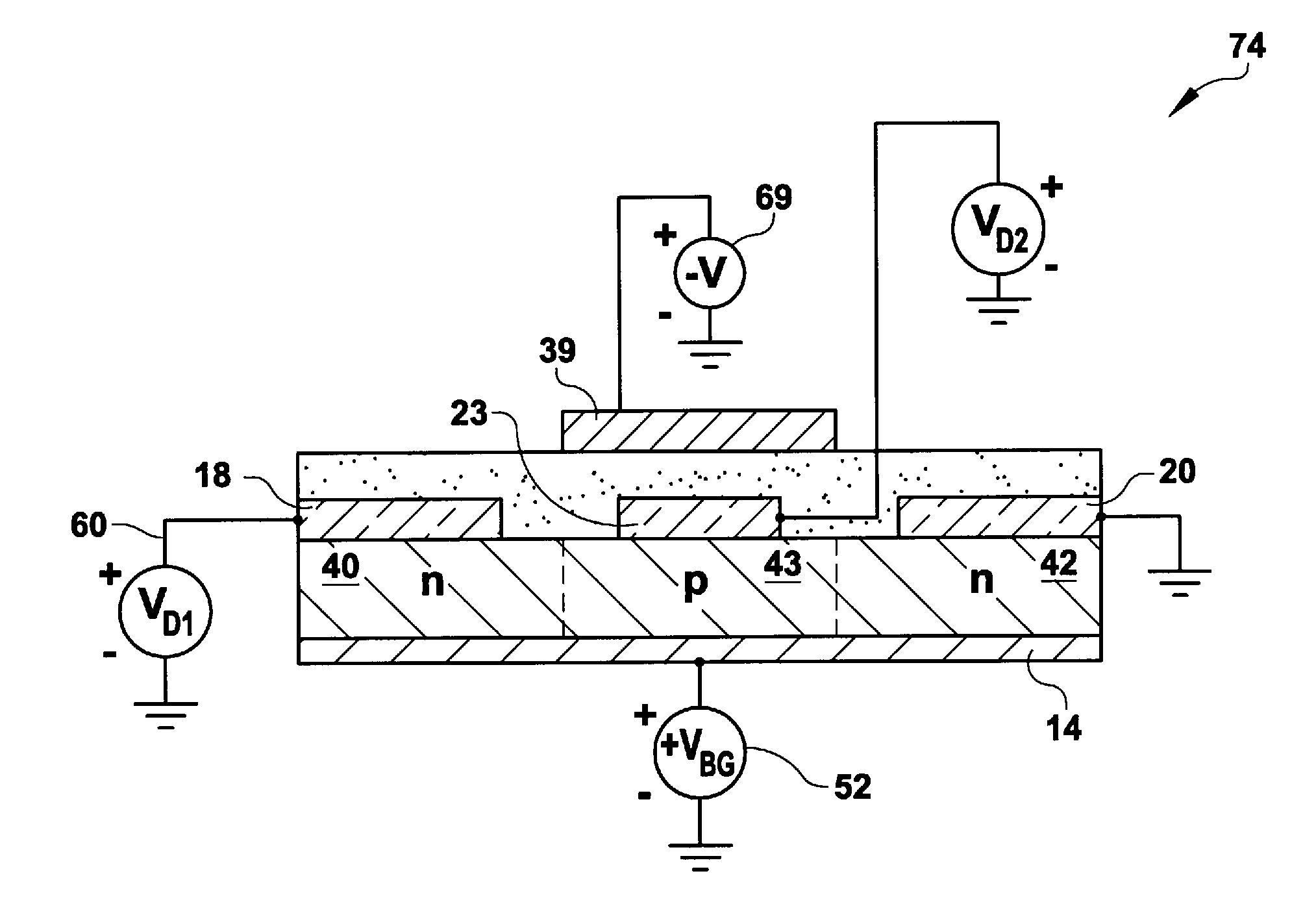

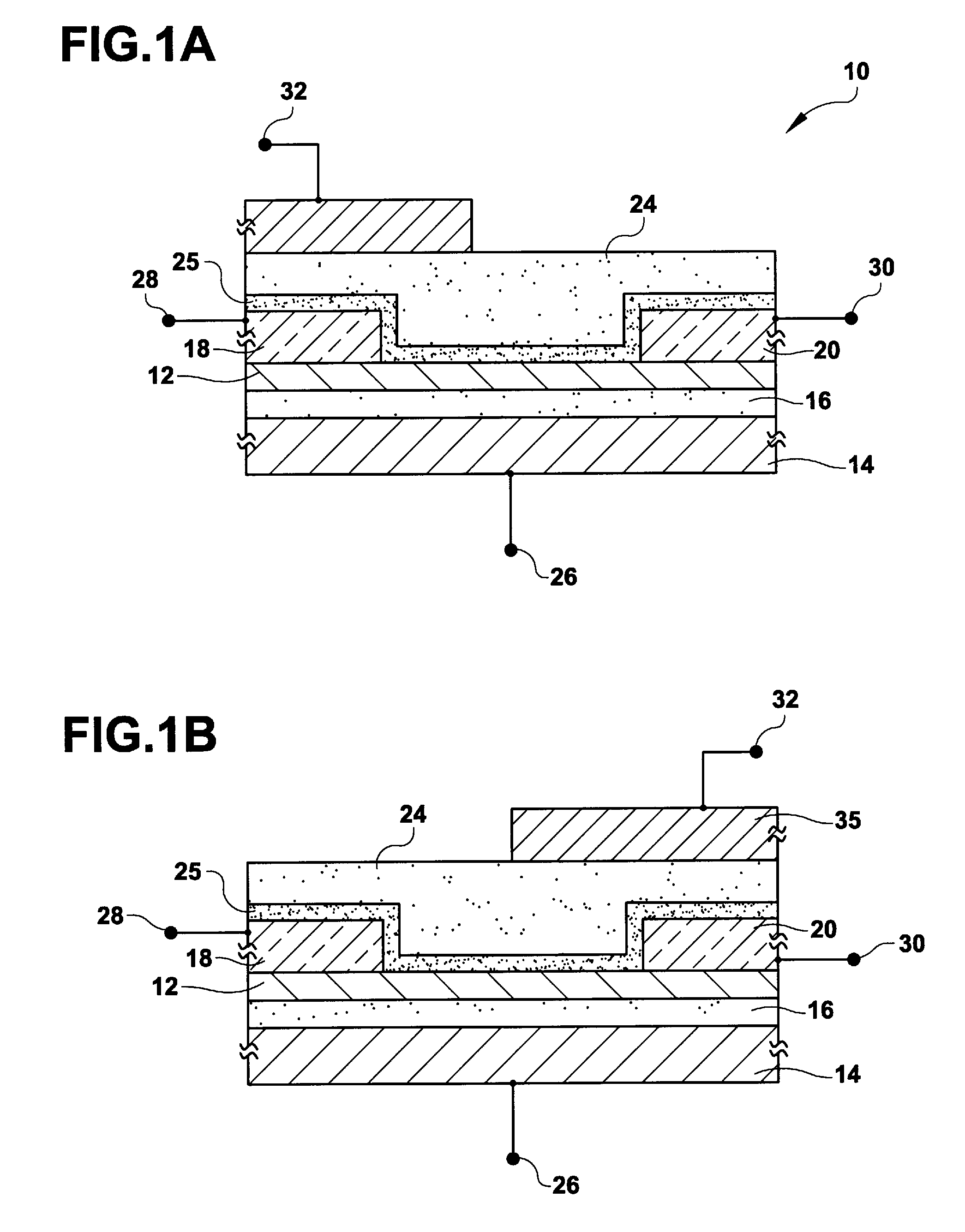

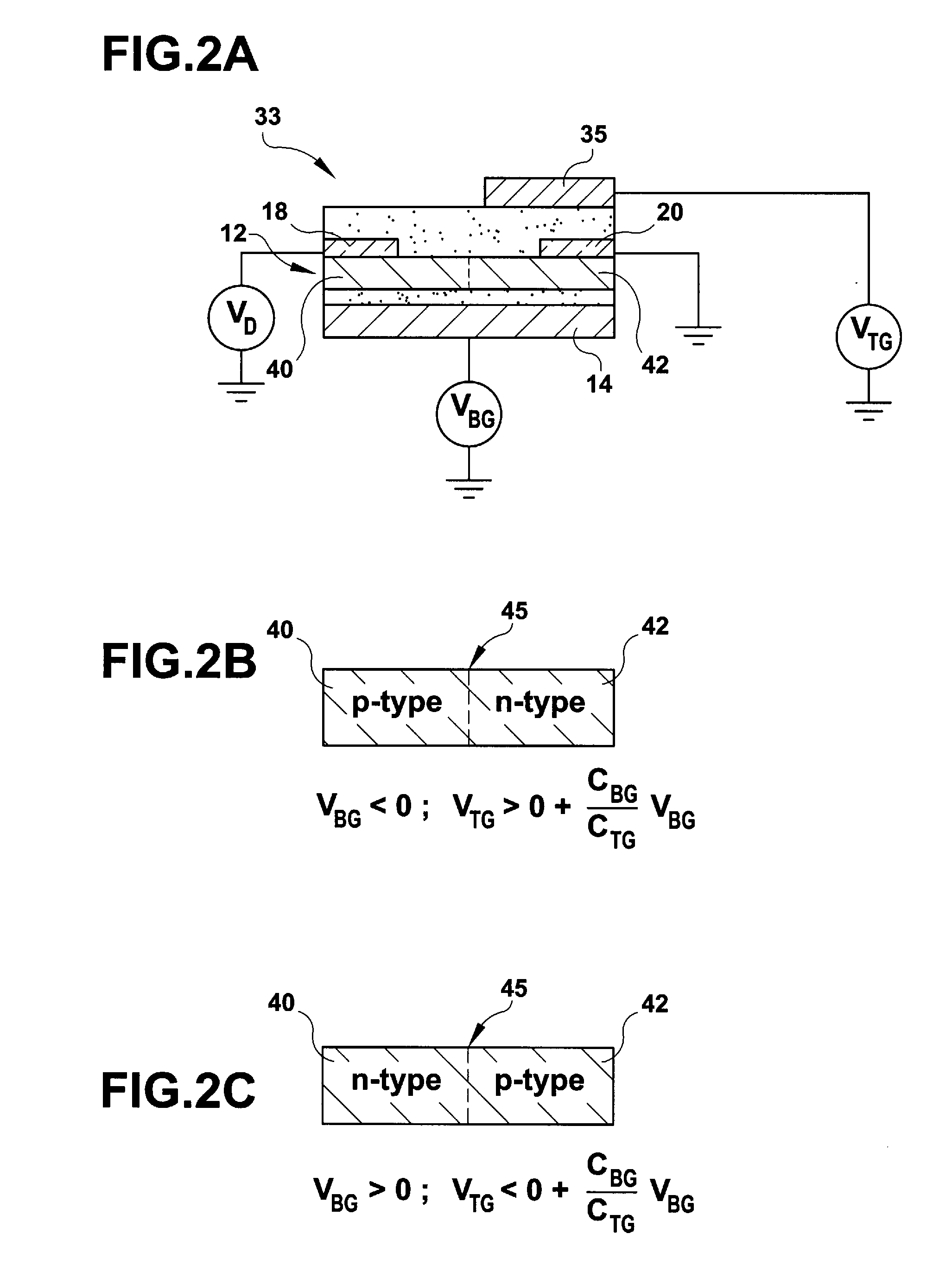

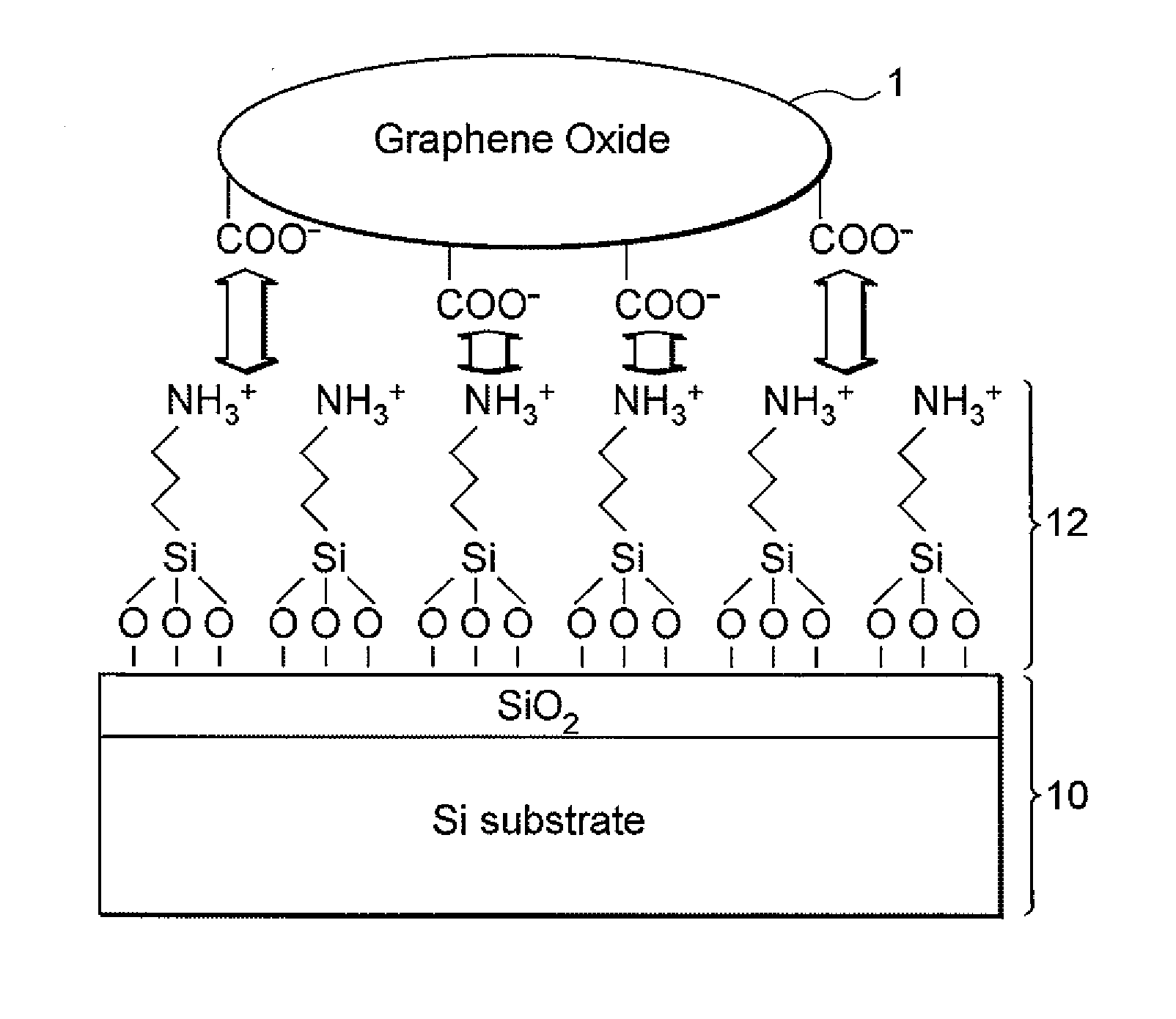

Microfabrication of Carbon-based Devices Such as Gate-Controlled Graphene Devices

A graphene device includes a graphene layer and a back gate electrode connected to apply a global electrical bias to the graphene from a first surface of the graphene. At least two graphene device electrodes are each connected to a corresponding and distinct region of the graphene at a second graphene surface. A dielectric layer blanket-coats the second graphene surface and the device electrodes. At least one top gate electrode is disposed on the dielectric layer and extends over a distinct one of the device electrodes and at least a portion of a corresponding graphene region. Each top gate electrode is connected to apply an electrical charge carrier bias to the graphene region over which that top gate electrode extends to produce a selected charge carrier type in that graphene region. Such a carbon structure can be exposed to a beam of electrons to compensate for extrinsic doping of the carbon.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

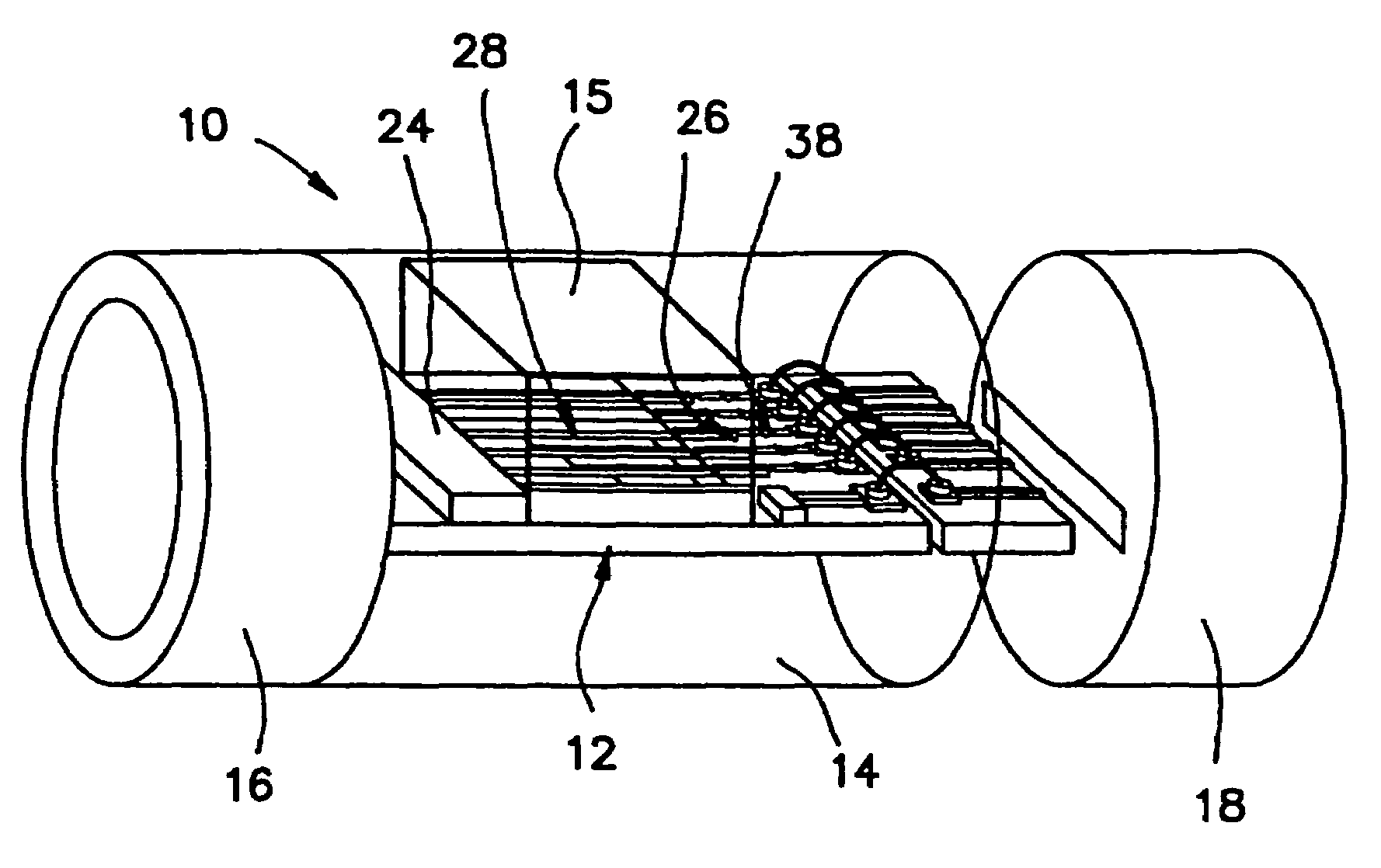

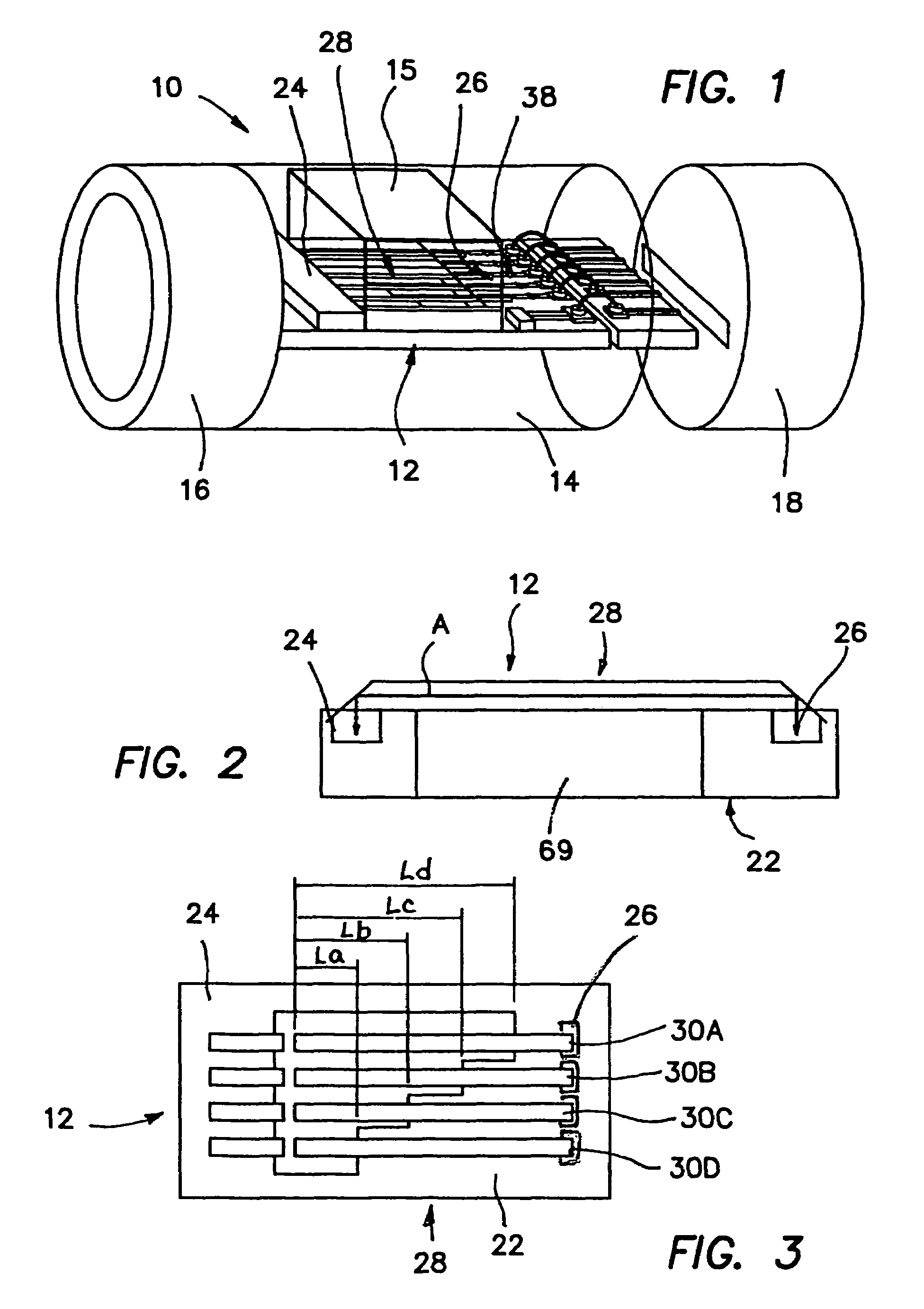

Optical waveguide vibration sensor for use in hearing aid

InactiveUS7444877B2Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesPolymer optical waveguideLoudspeaker

A directionally-sensitive device for detecting and processing vibration waves includes an array of polymeric optical waveguide resonators positioned between a light source, such as an LED array, and a light detector, such as a photodiode array. The resonators which are preferably oriented substantially perpendicularly with respect to incoming vibration waves, vibrate when a wave is detected, thus modulating light signals that are transmitted between the light source and the light detector. The light detector converts the modulated light into electrical signals which, in a preferred embodiment, are used to drive either the speaker of a hearing aid or the electrode array of a cochlear implant. The device is manufactured using a combination of traditional semiconductor processes and polymer microfabrication techniques.

Owner:RGT UNIV OF CALIFORNIA

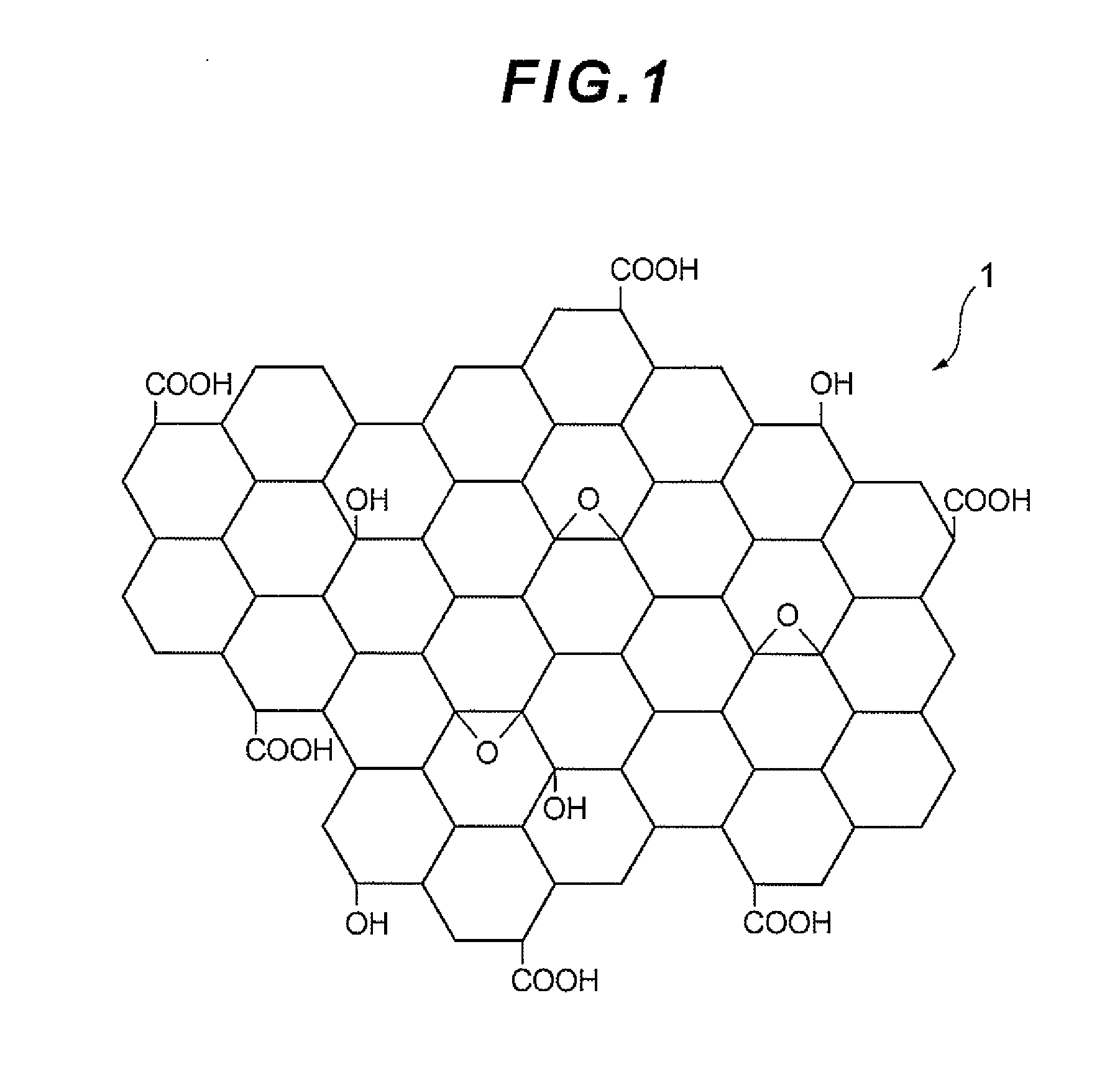

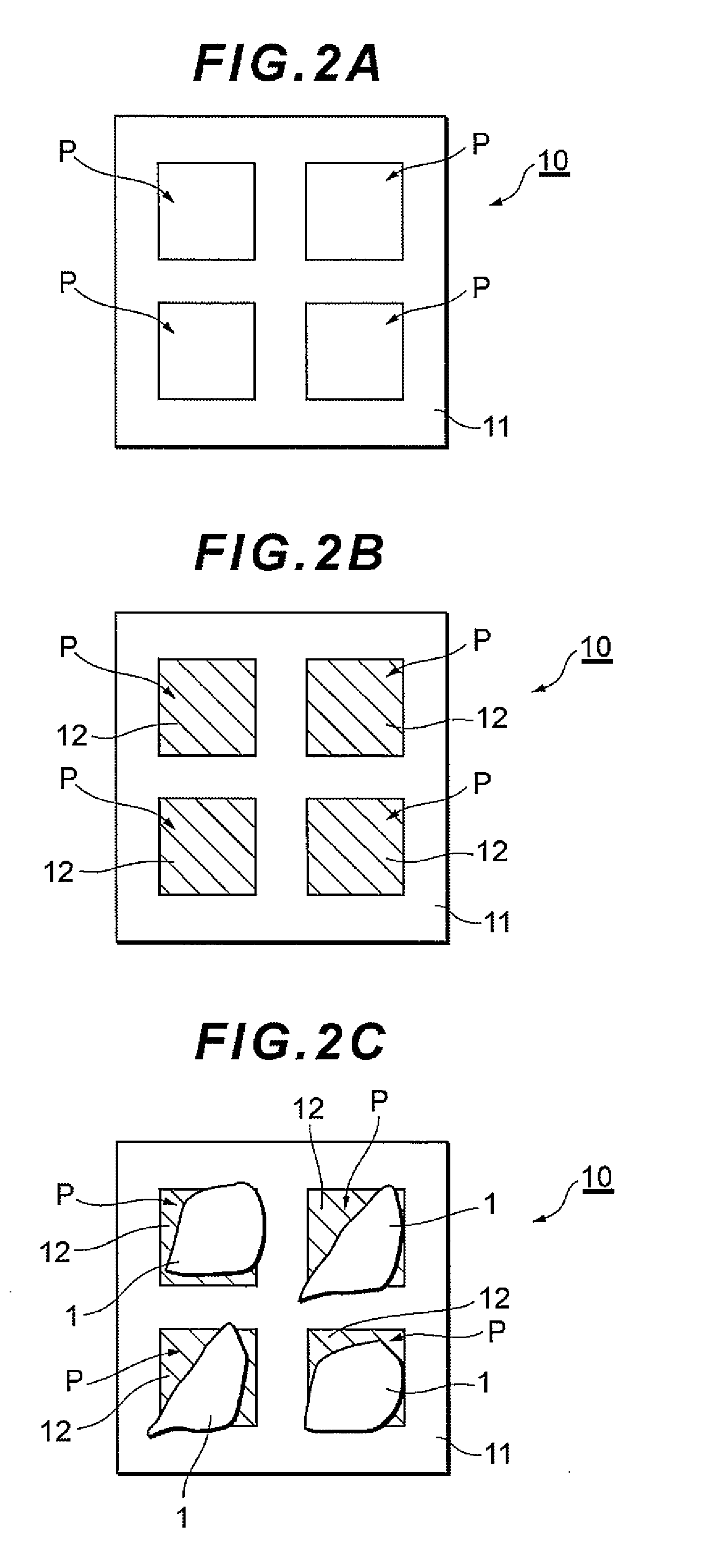

Graphene structure, method for producing the same, electronic device element and electronic device

InactiveUS20110143101A1Low costIncrease the areaMaterial nanotechnologyLayered productsResistHydrophilization

Provided are a graphene structure and a method for producing the same in which graphene can be patterned with high precision, and thereby microfabrication of electronic device elements and electronic devices using graphene is possible and the manufacturing cost can be notably reduced. A resist film is precisely patterned on a substrate, hydrophilized films are formed in openings of the resist film, and then GO is selectively fixed on the portions of the hydrophilized films by a chemical bond utilizing the hydrophilicity of the GO, and the GO is reduced to obtain a graphene structure in which graphene is selectively fixed to only the portions of the hydrophilized films. Thus, the graphene structure is constituted by disposing graphene on a substrate and forming a bond, by hydrophilization treatment, between the hydrophilized portion of the substrate and the graphene and / or between the unhydrophobized portion of the substrate and the graphene.

Owner:EMPIRE TECH DEV LLC

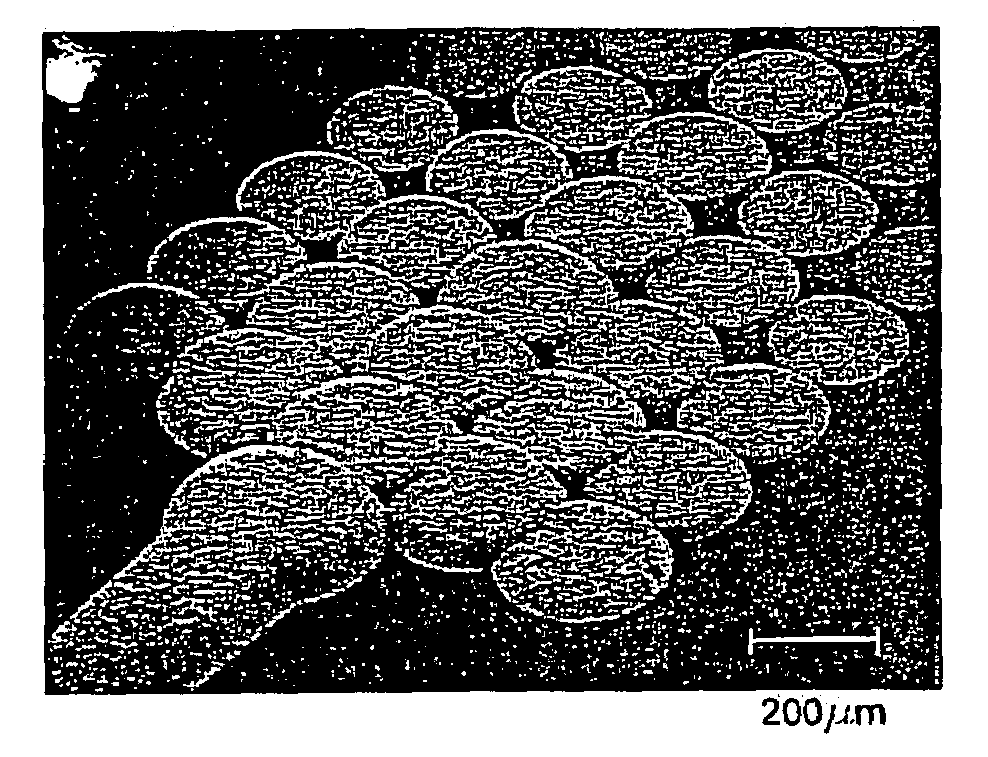

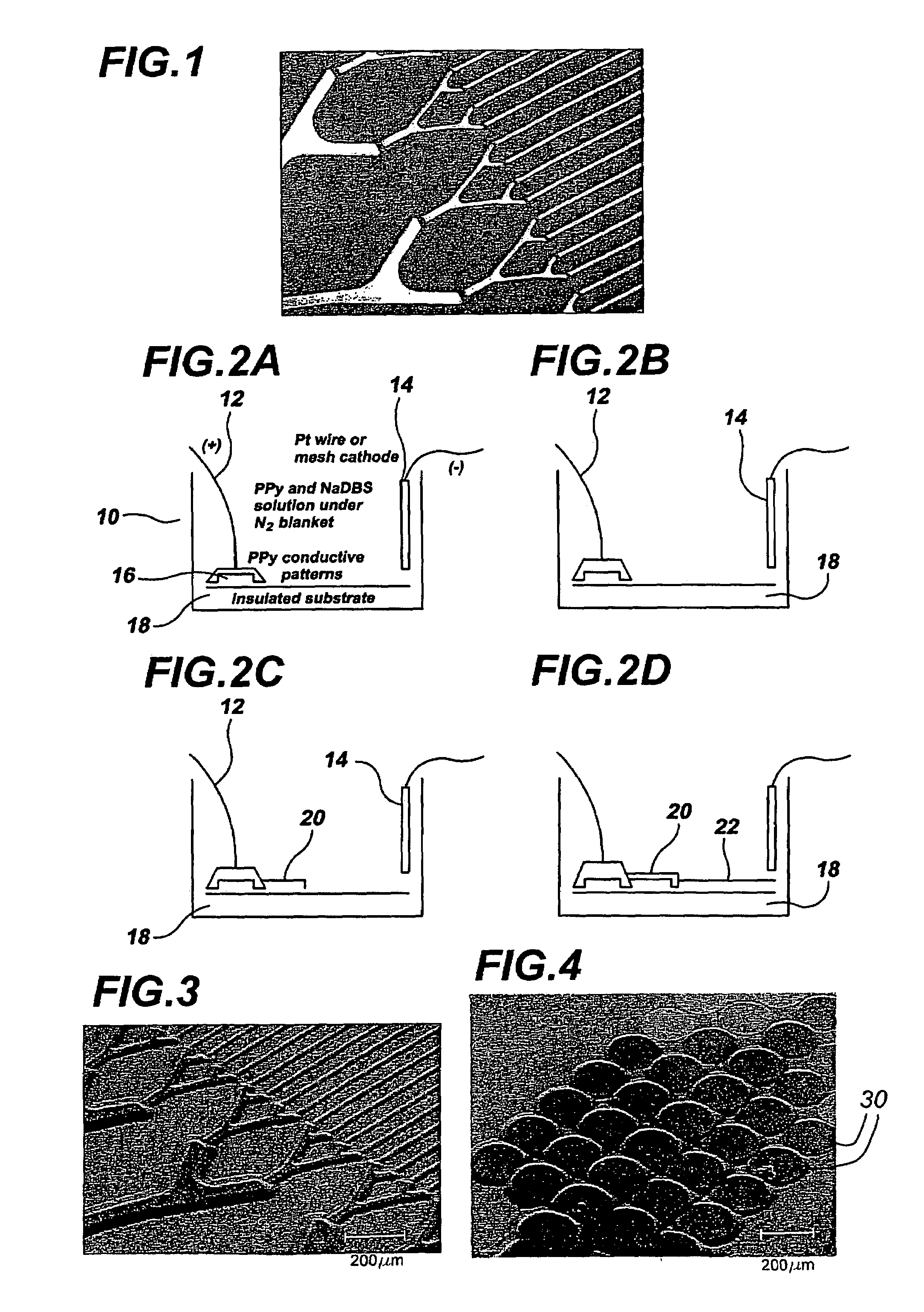

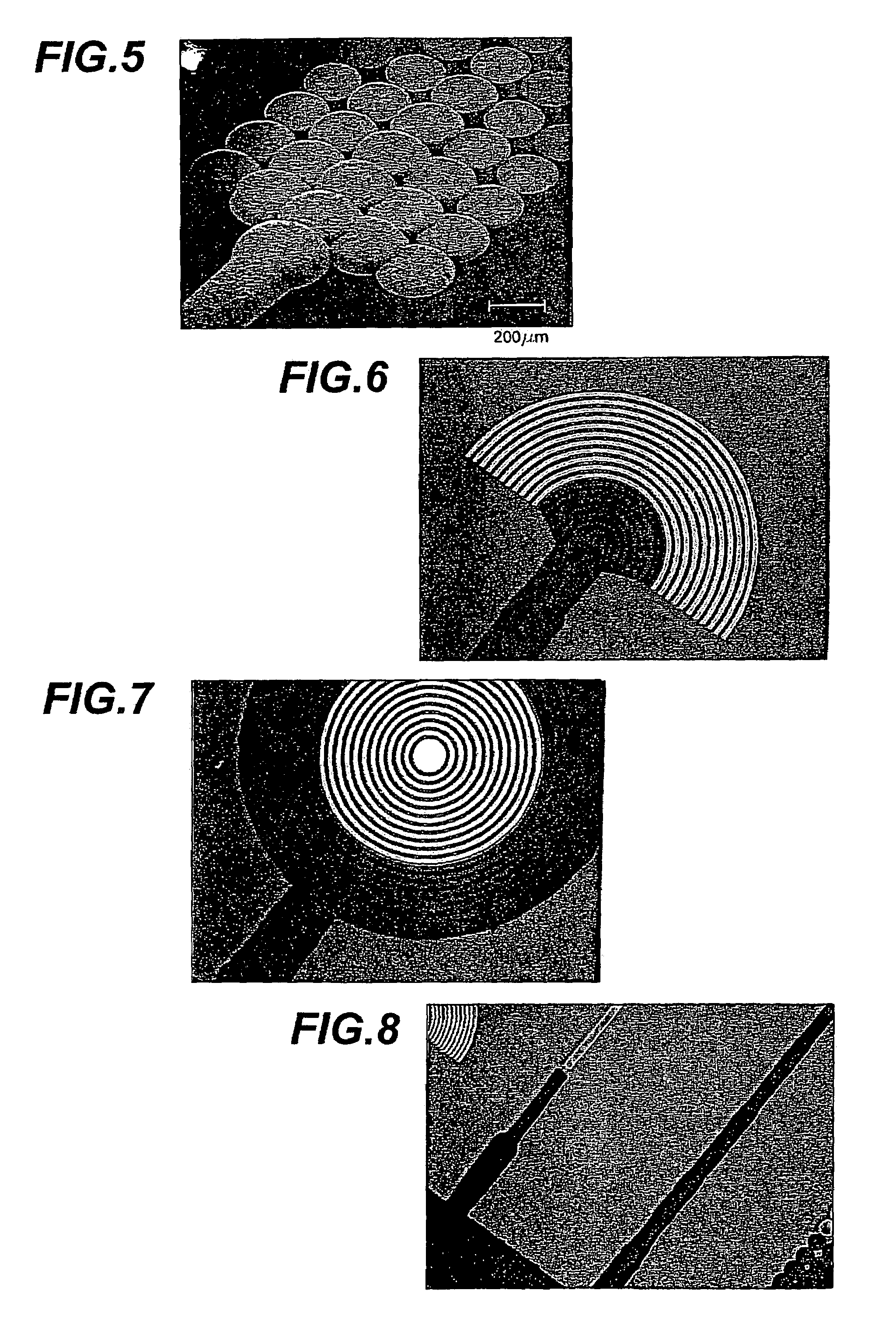

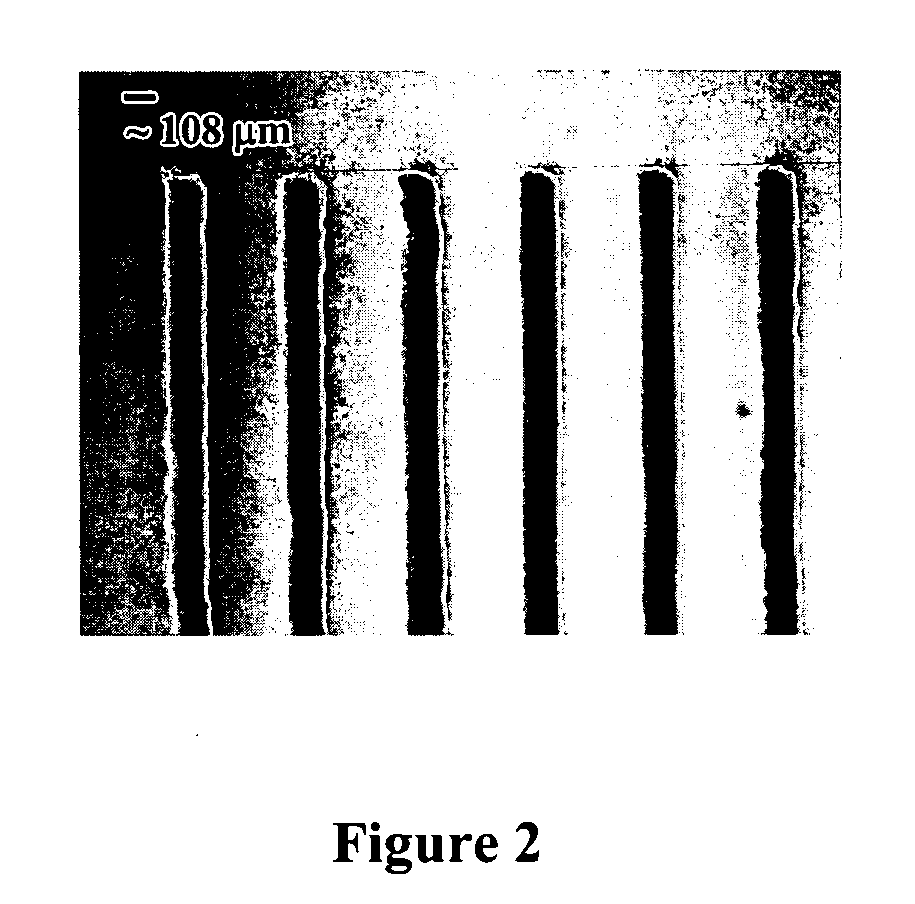

High aspect ratio, microstructure-covered, macroscopic surfaces

InactiveUS6197180B1Improve performanceDecorative surface effectsChemical/physical/physico-chemical microreactorsMicrofabricationLIGA

The performance of many macroscopic structures (those whose dimensions are on the order of centimeters, meters, or even larger) can be greatly improved by covering their surfaces with microstructures. There are several applications in which "large," microstructure-covered sheets are useful. An apparatus and method are disclosed for forming high aspect ratio microstructures ("HARMs") on planar and non-planar surfaces, using a modification of the LIGA microfabrication process. A free-standing polymer sheet is lithographically patterned with through-holes. The polymer sheet is then pressed against, clamped to, or otherwise attached to a conductive substrate in such a way that the patterned holes in the sheet are not blocked. Subsequent electroplating produces well-defined HARM structures on the planar or non-planar surface, in shapes that are complementary to the lithographically patterned through-holes in the polymer. The polymer may then be removed (e.g., by melting, dissolution, or burning). Various planar and non-planar surfaces have been covered with microstructures. Where the metal surface is non-planar, the polymer sheet may be heated or otherwise made sufficiently flexible to conform to the metal surface, preferably by heat-shrinking to assure firm contact. The process may be used to electroplate microstructures directly onto metal surfaces generally-not just onto metal surfaces that have been specially prepared for LIGA processes, as has previously been the case.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

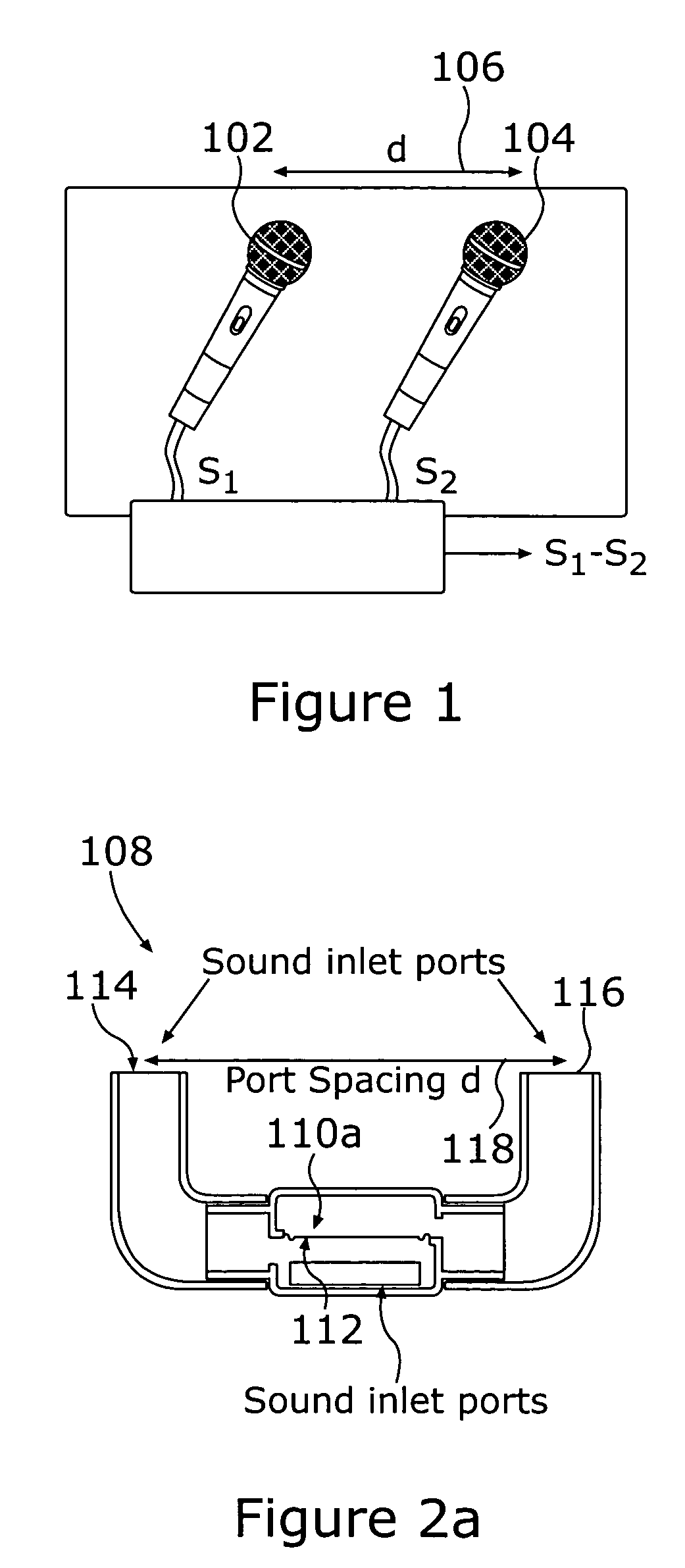

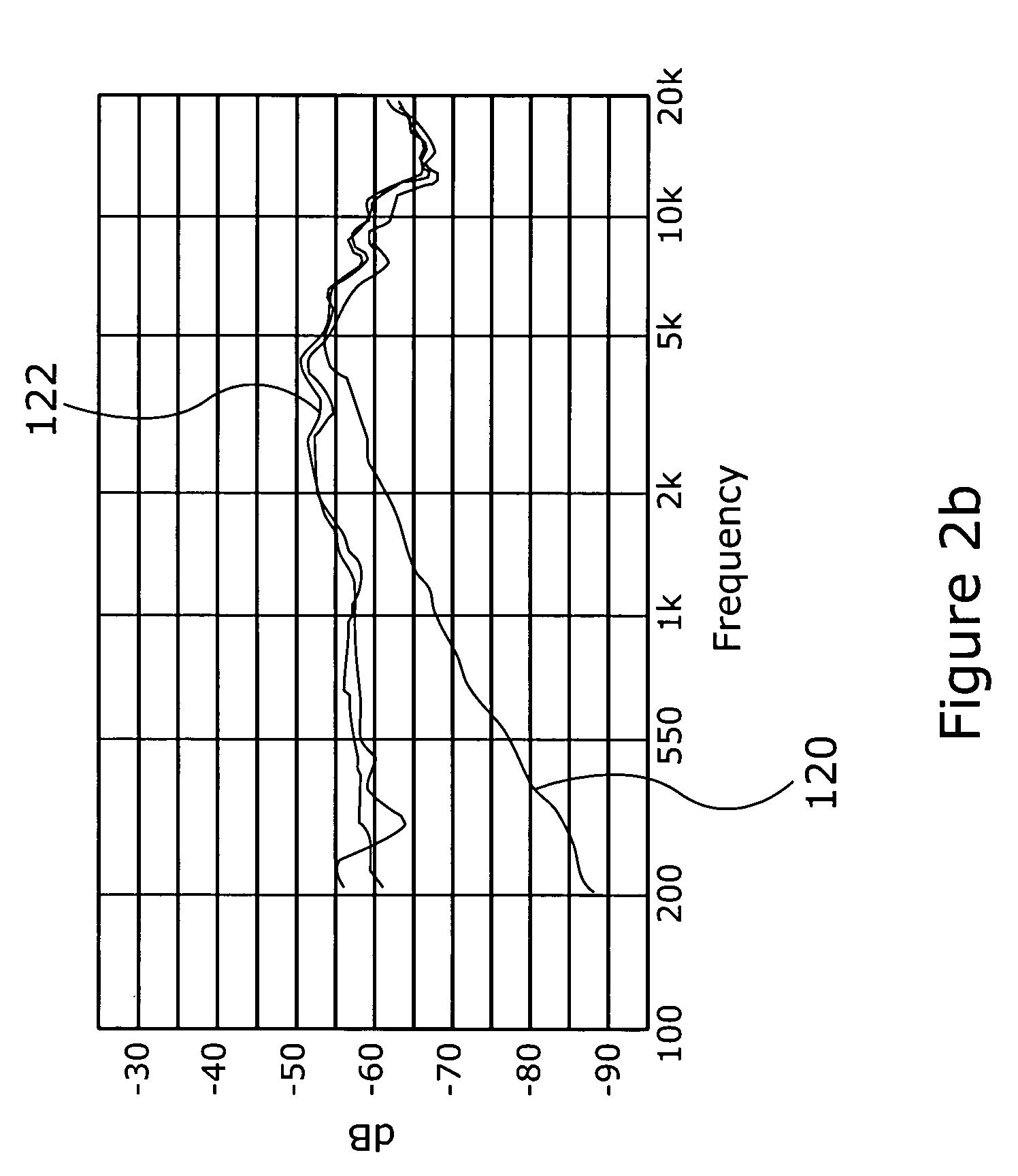

High-order directional microphone diaphragm

InactiveUS6963653B1Good directionWide frequency responseFrequency/directions obtaining arrangementsDeaf-aid setsLow noiseMicrofabrication

The invention features a miniature, second-order, microcrystalline silicon microphone diaphragm formed using silicon microfabrication techniques. The diaphragm is composed of two or more rigid diaphragm elements hinged to one another providing second- or higher-order response depending on the number of diaphragm elements used. The response of the differential diaphragm has a response that is highly dependent on the direction of the incident sound. The diaphragms are useful for constructing highly innovative microphones that have far greater directionality, better sensitivity, wider frequency response, and lower noise than is achievable with current technology.

Owner:RES FOUND OF STATE THE

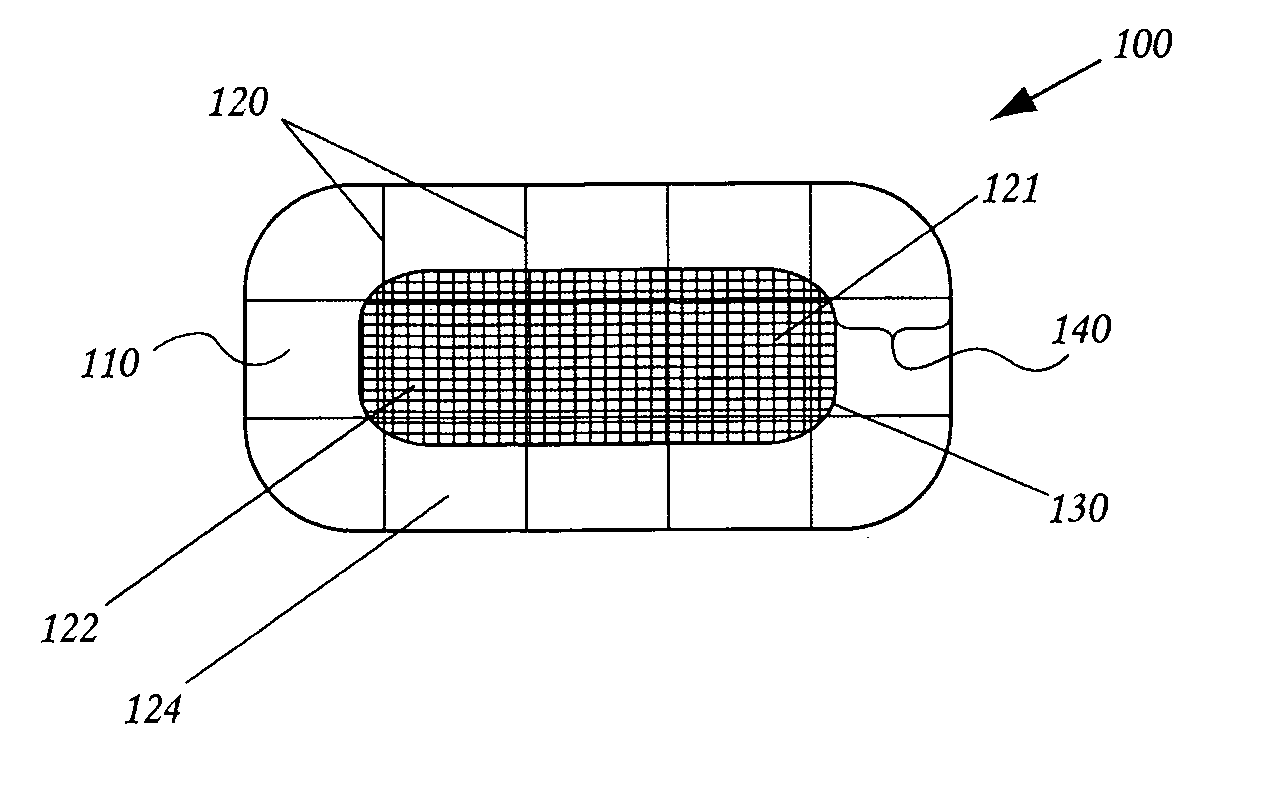

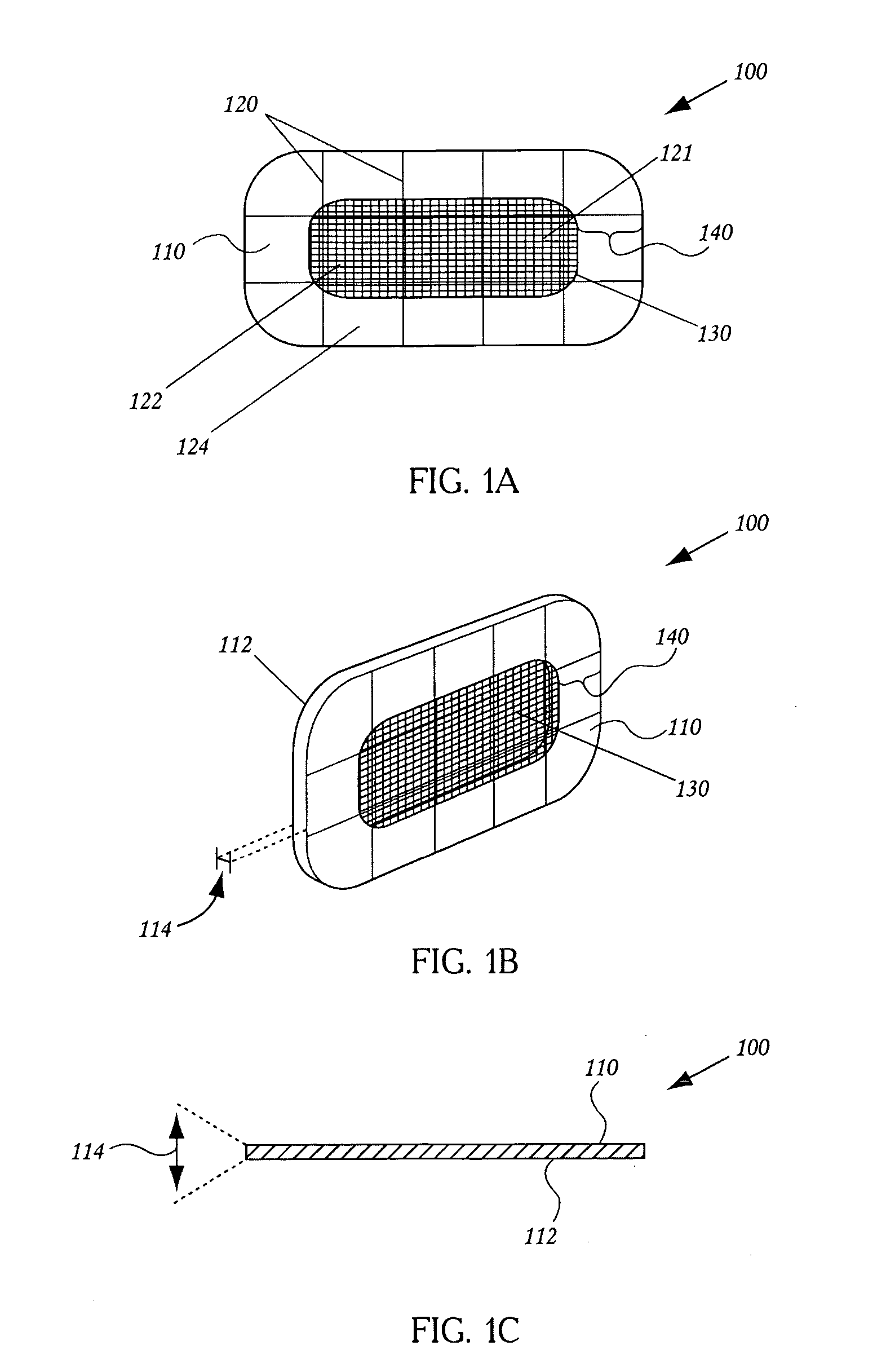

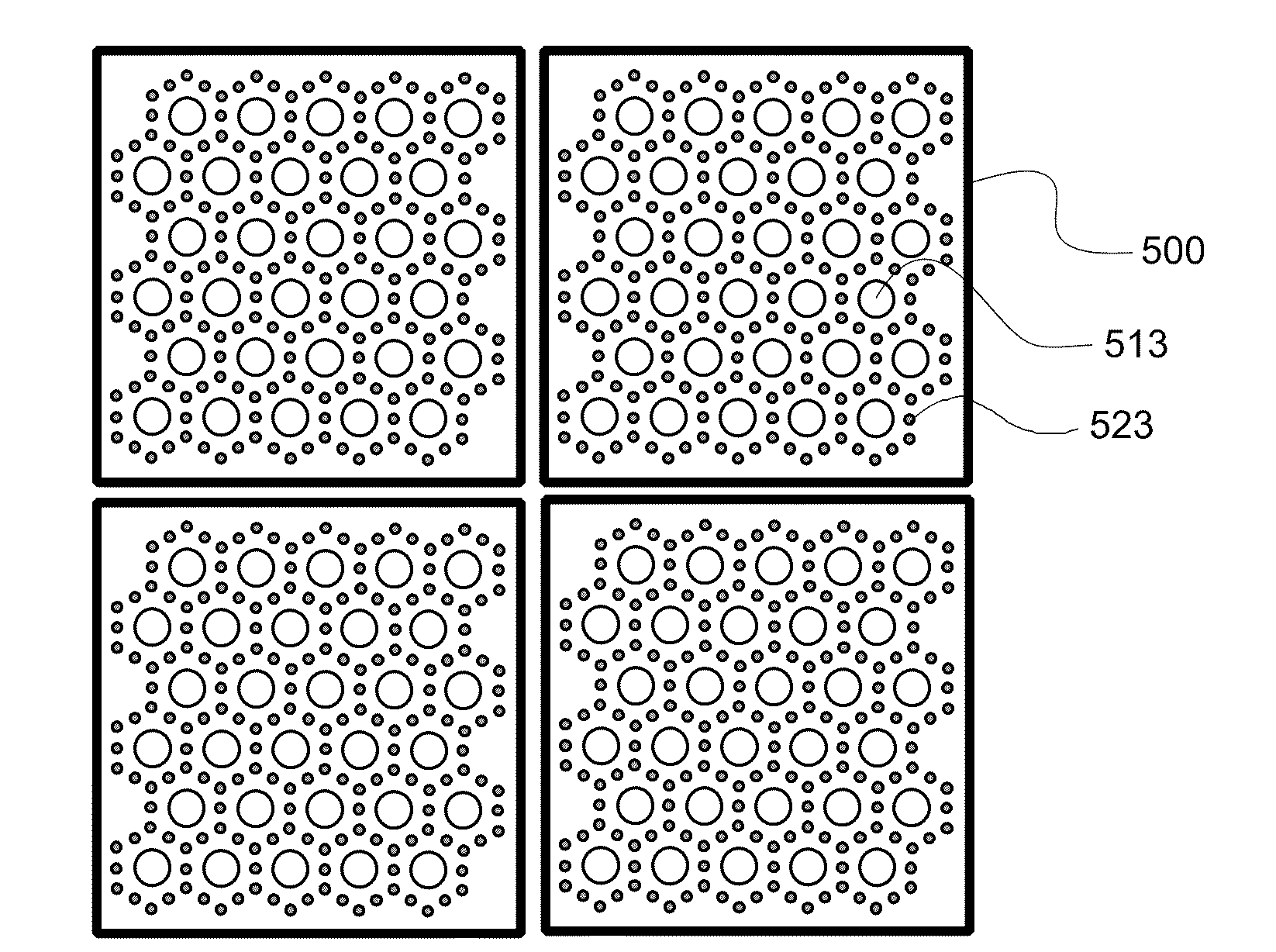

Method and apparatus for microfiltration to perform cell separation

ActiveUS20090188864A1Laborious and expensiveMembranesDecorative surface effectsParyleneMicrofabrication

A microfiltration apparatus and method for separating cells, such as circulating tumor cells, from a sample using a microfiltration device having a top porous membrane and a bottom porous membrane. The porous membranes are formed from parylene and assembled using microfabrication techniques. The porous membranes are arranged so that the pores in the top membrane are offset from the pores in the bottom membrane.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

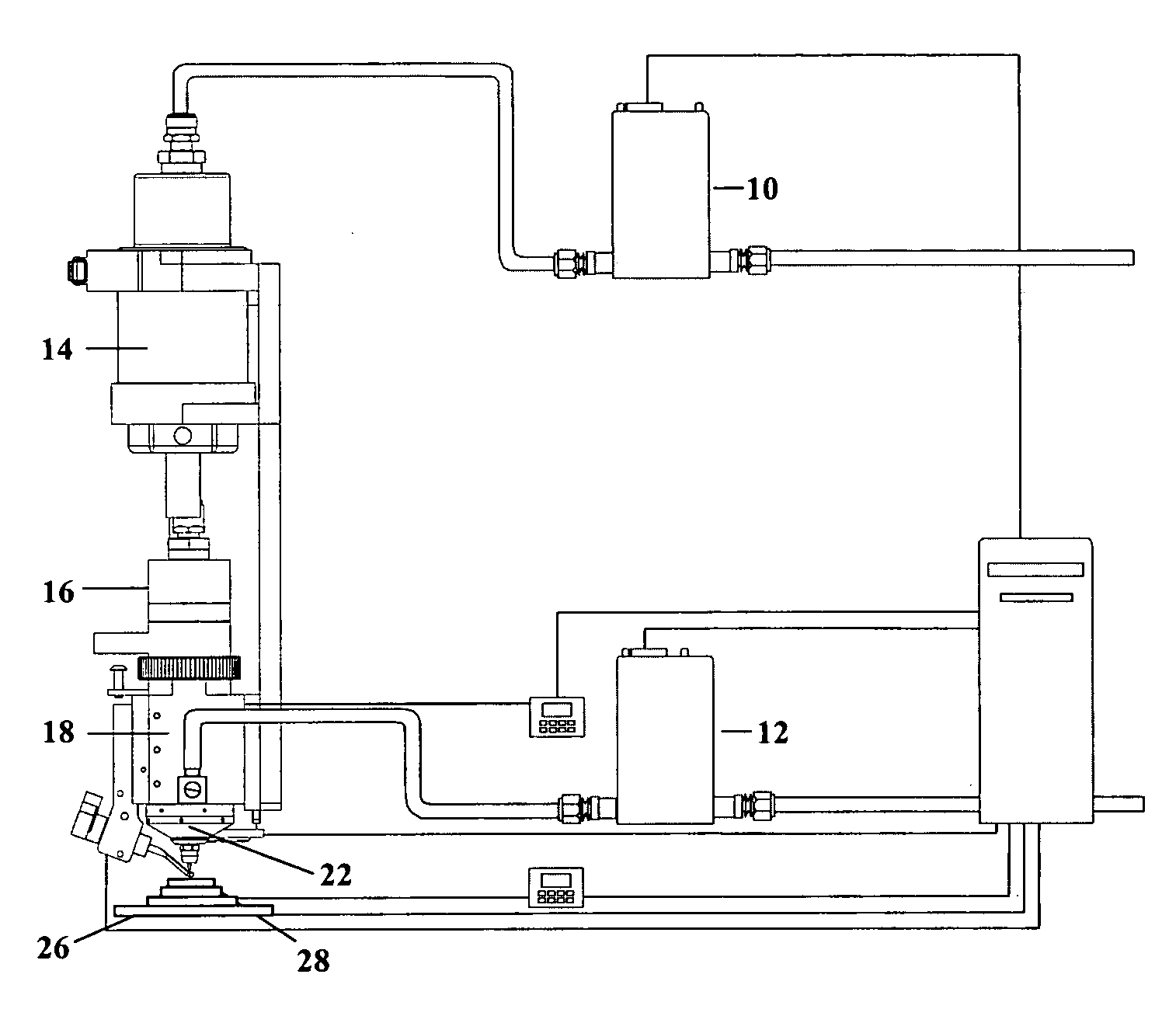

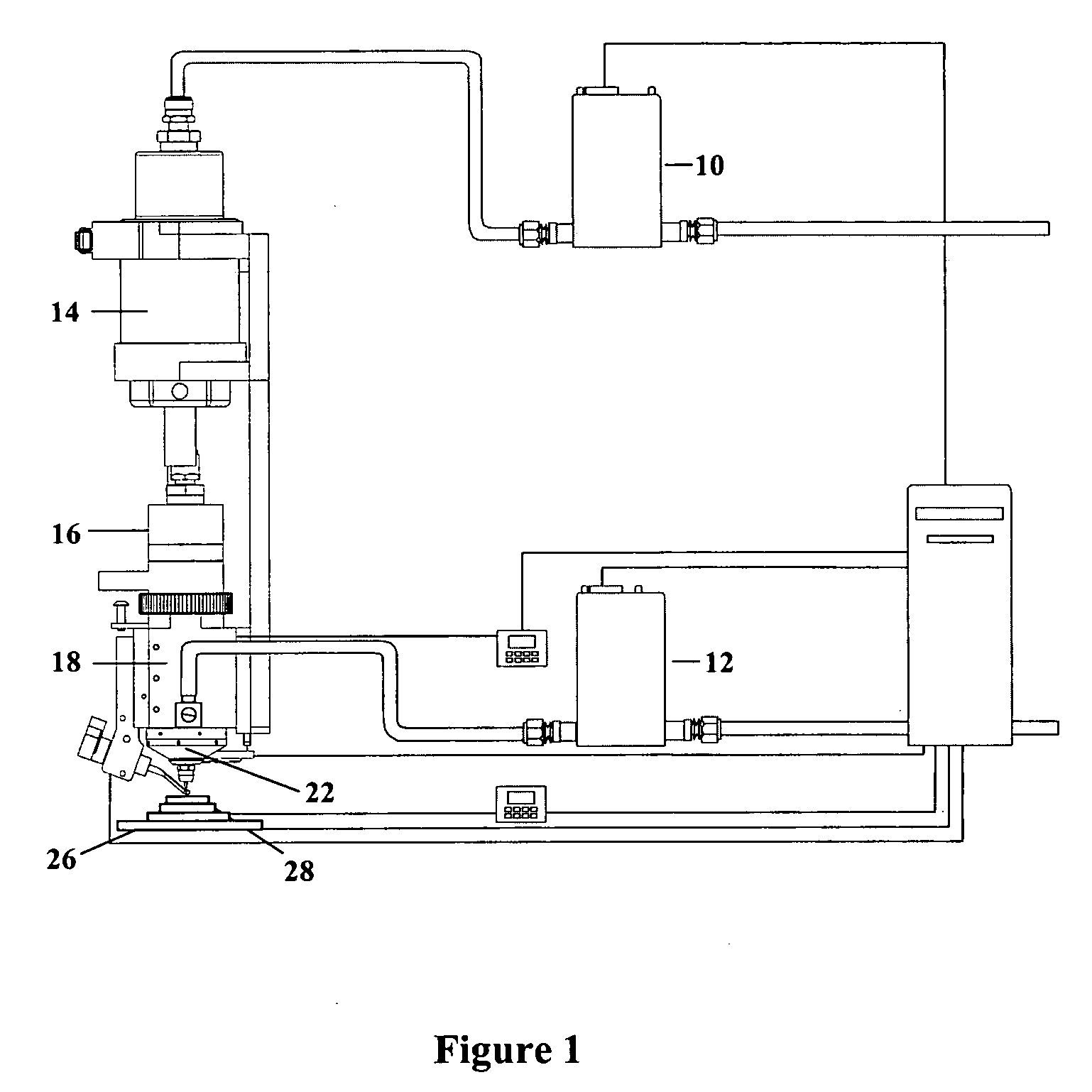

Method and apparatus for mesoscale deposition of biological materials and biomaterials

InactiveUS20060280866A1Wide viscosity rangeMicrobiological testing/measurementPharmaceutical containersDielectricEngineering

Methods and apparatus for the direct deposition or patterning of biological materials and compatible biomaterials. The method is capable of depositing biological materials and biomaterials in a computer defined pattern, and uses aerodynamic focusing of an aerosol stream to deposit mesoscale patterns onto planar or non-planar targets without the use of masks or modified environments. The aerosolized compositions may be processed before deposition (pre-processing) or after deposition on the target (post-processing). Depositable materials include, not are not limited to conductive metal precursors, nanoparticle metal inks, dielectric and resistor pastes, biocompatible polymers, and a range of biomolecules including peptides, viruses, proteinaceous enzymes, extra-cellular matrix biomolecules, as well as whole bacterial, yeast, and mammalian cell suspensions. The targets may be planar or non-planar, and are optionally biocompatible. Applications include biosensor rapid prototyping and microfabrication, lab-on-chip manufacturing, biocompatible electroactive polymer development (ambient temperature bio-production of electronic circuitry), and various additive biomaterial processes for hybrid BioMEMS, Bio-Optics, and microfabrication of biomedical devices.

Owner:OPTOMEC DESIGN CO

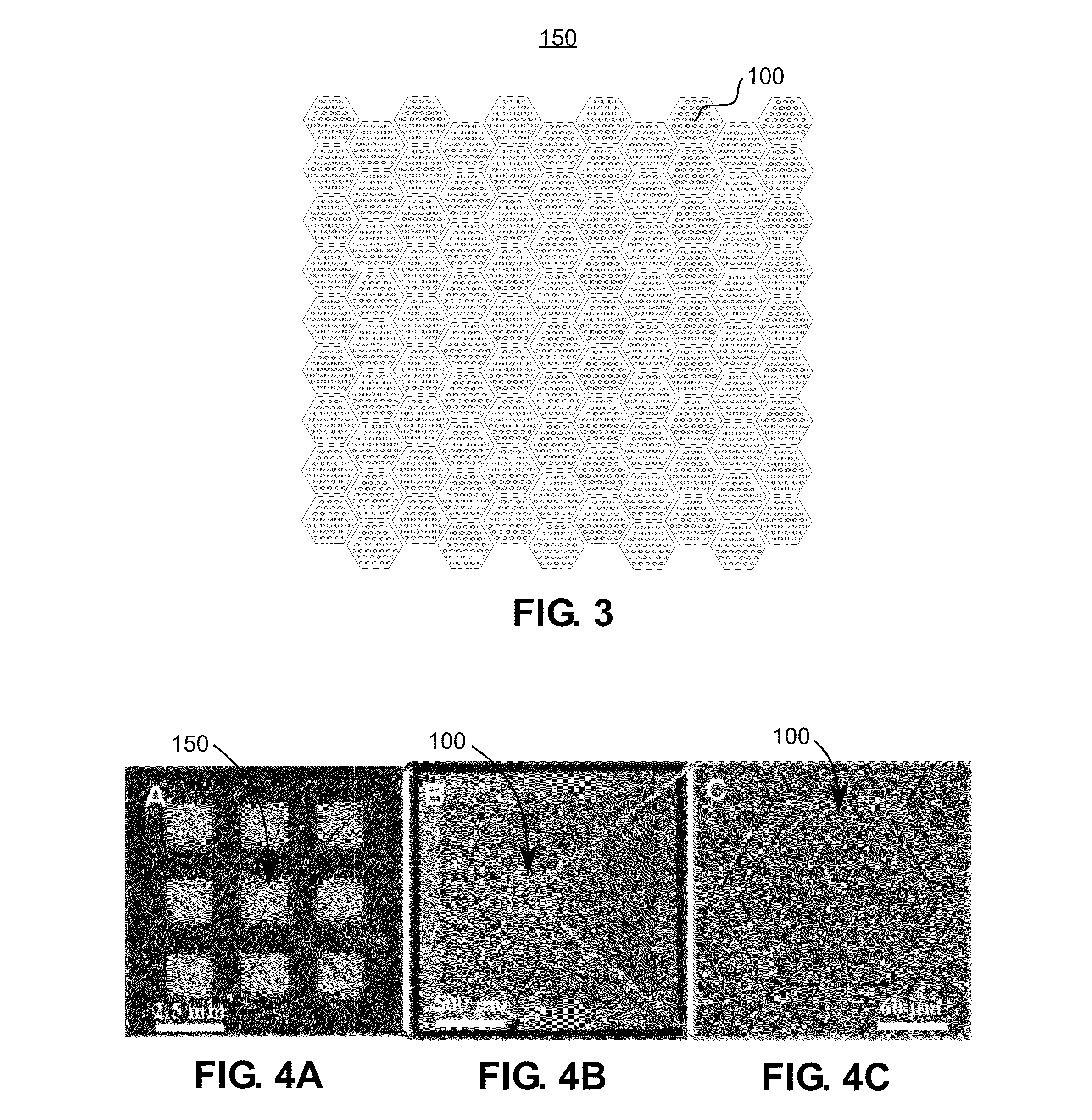

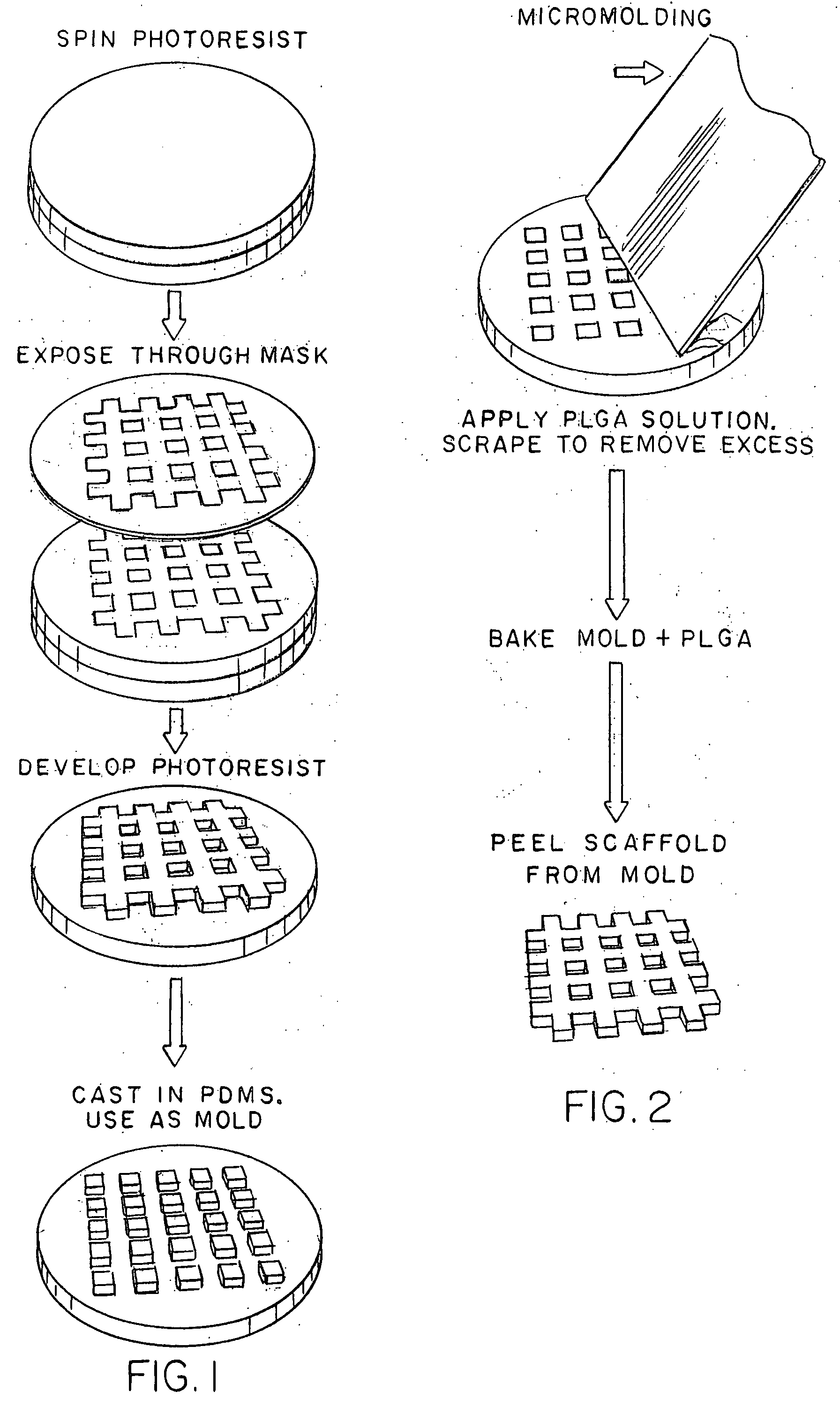

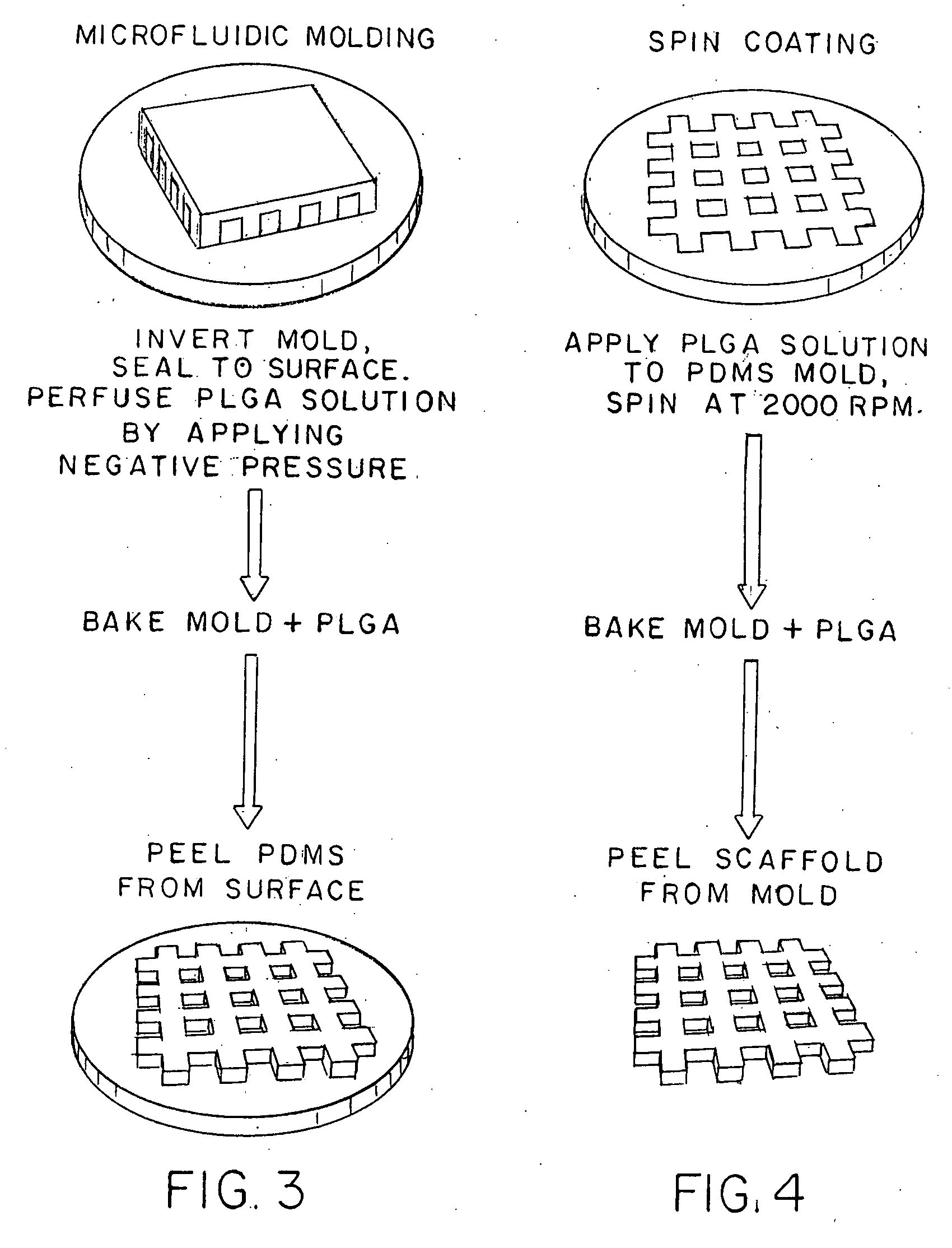

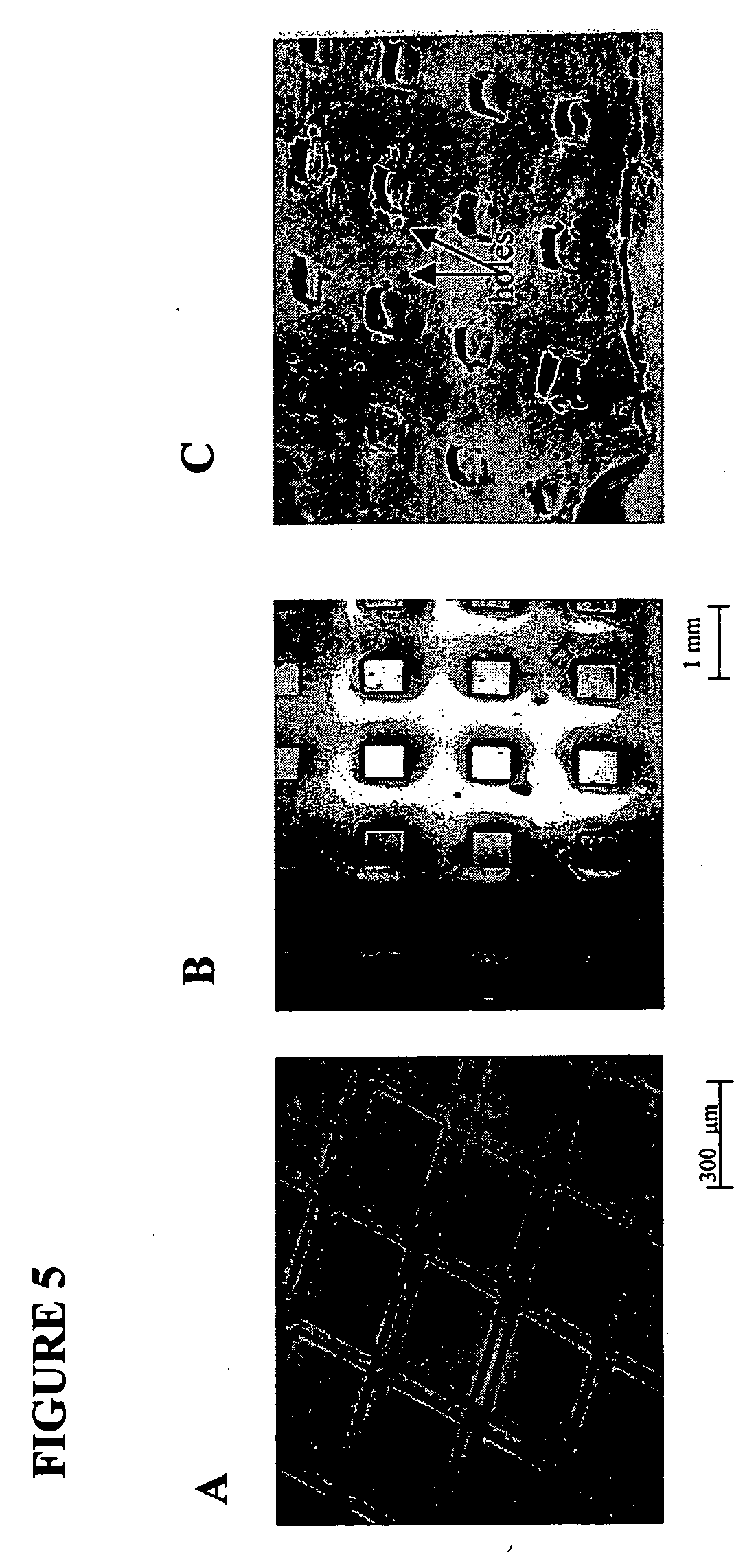

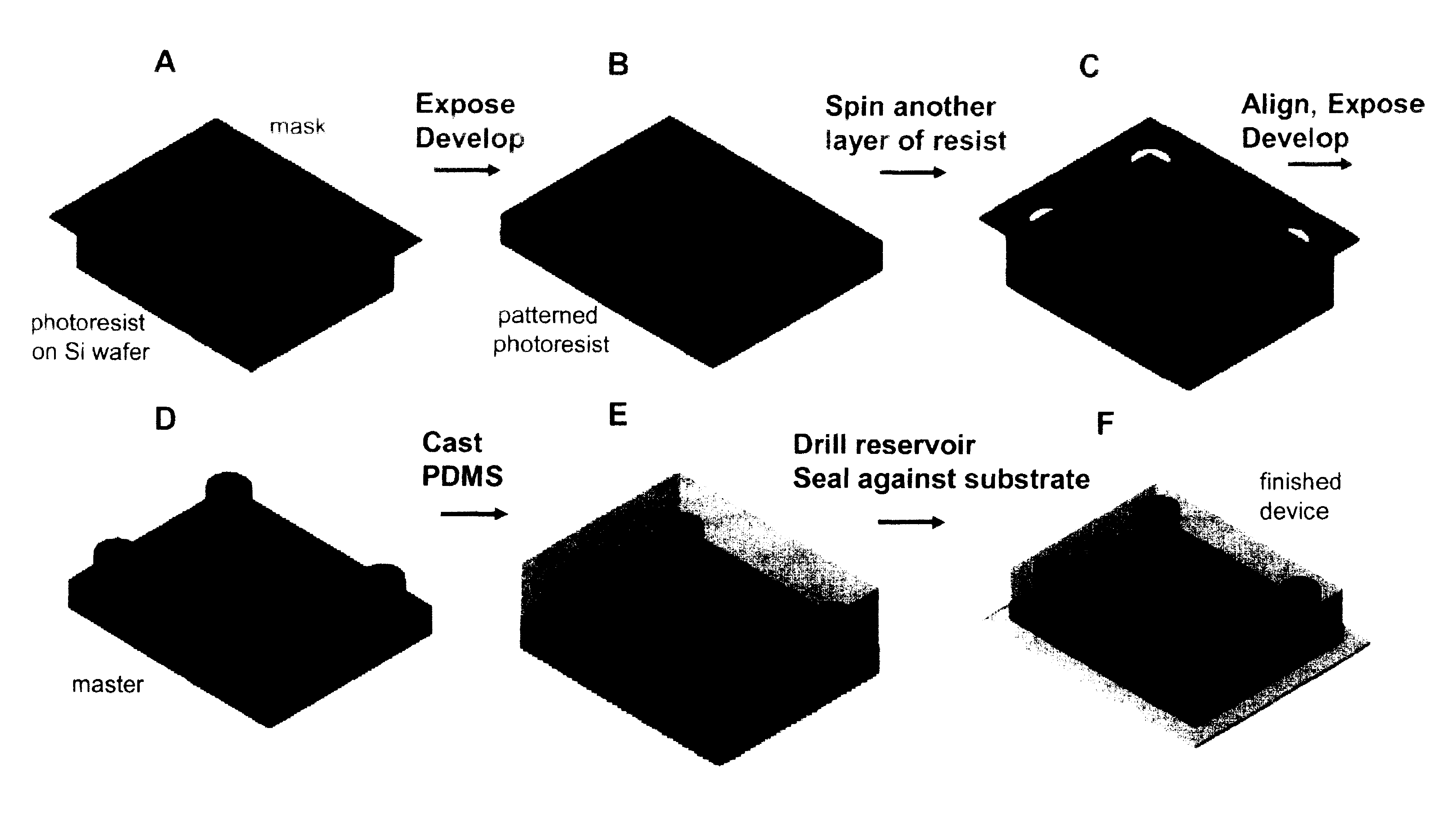

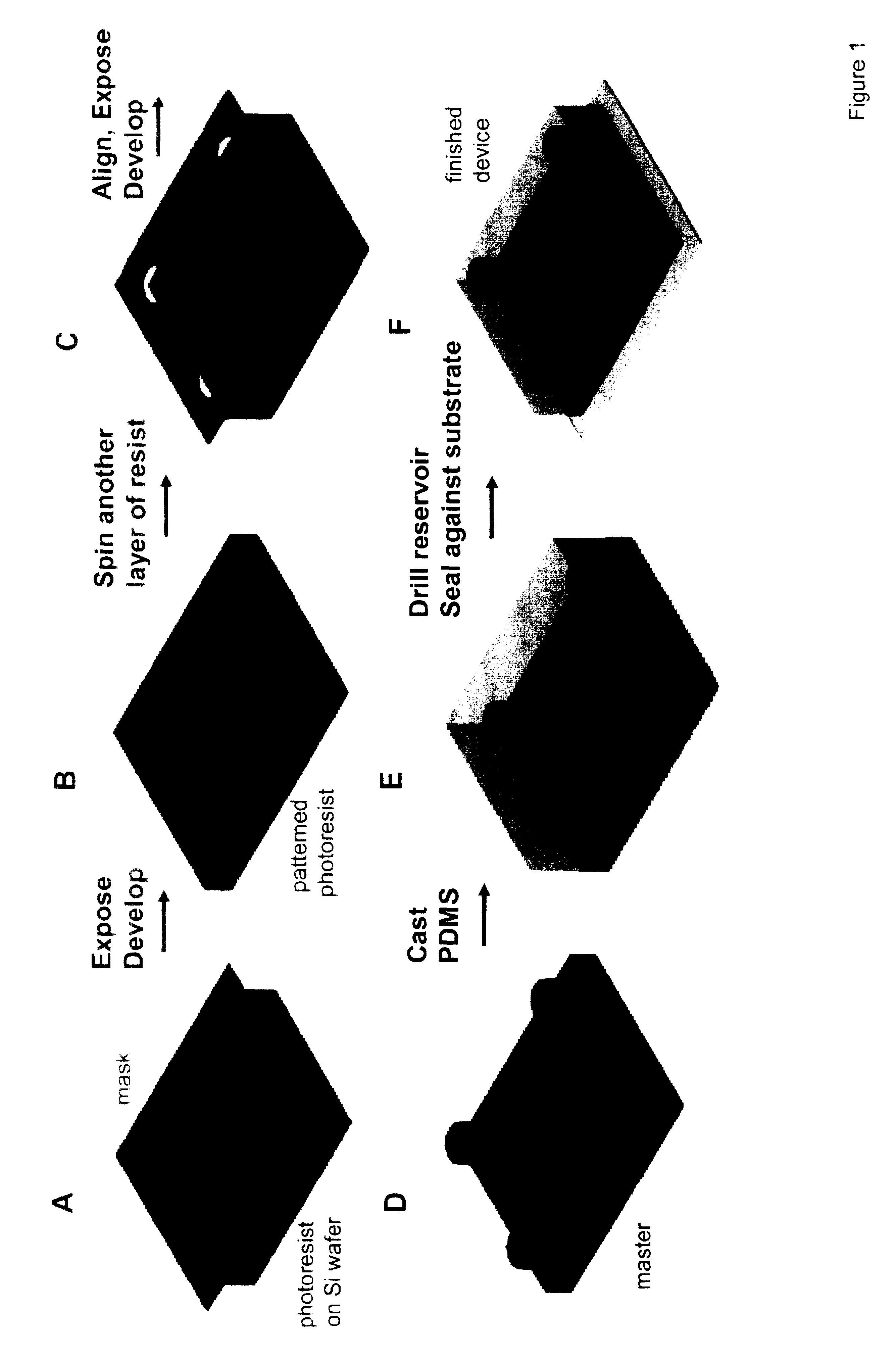

Microfabricated biopolymer scaffolds and method of making same

ActiveUS20050008675A1Rapid microfabricationRapid and iterative experimentationCeramic shaping apparatusCoatingsElastomerMicrofabrication

The invention is a series of soft lithographic methods for the microfabrication of biopoilymer scaffolds for use in tissue engineering and the development of artificial organs. The methods present a wide range of possibilities to construct two- and three-dimensional scaffolds with desired characteristics according to the final application. The methods utilize an elastomer mold which the biopolymer scaffold is cast. The methods allow for the rapid and inexpensive production of biopolymer scaffolds with limited specialized equipment and user expertise.

Owner:RGT UNIV OF CALIFORNIA

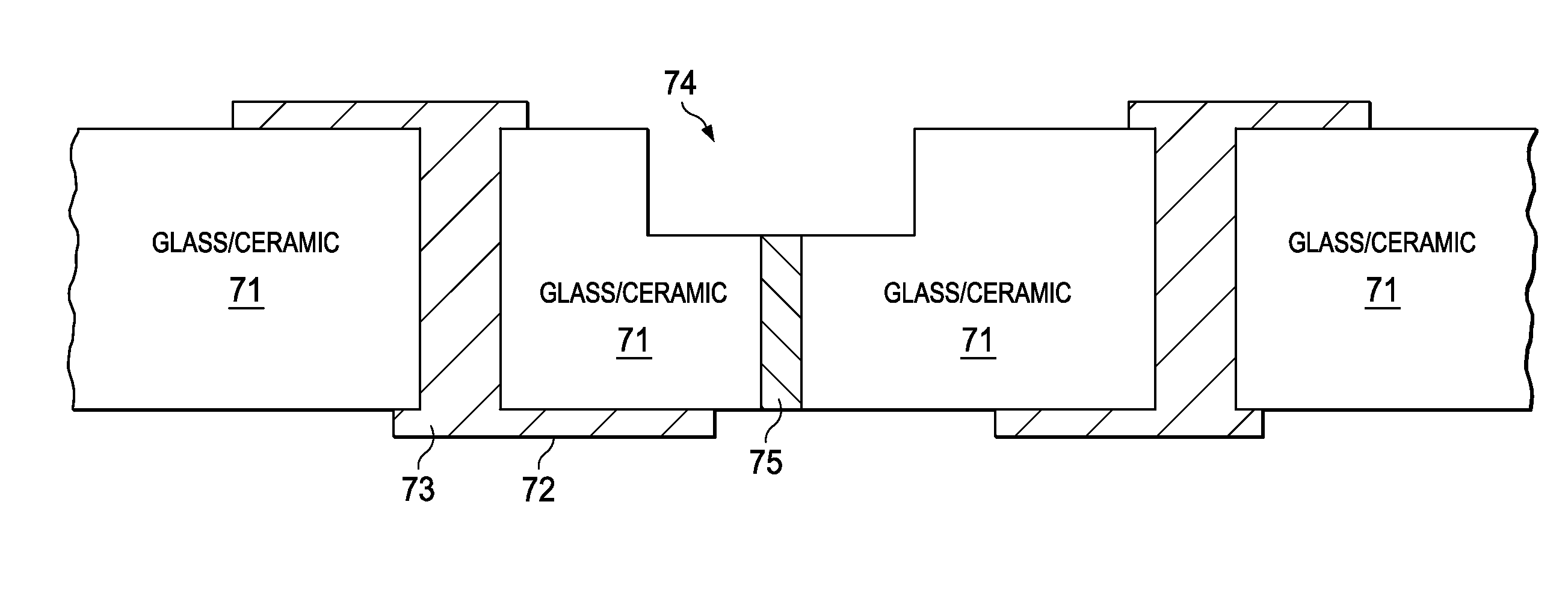

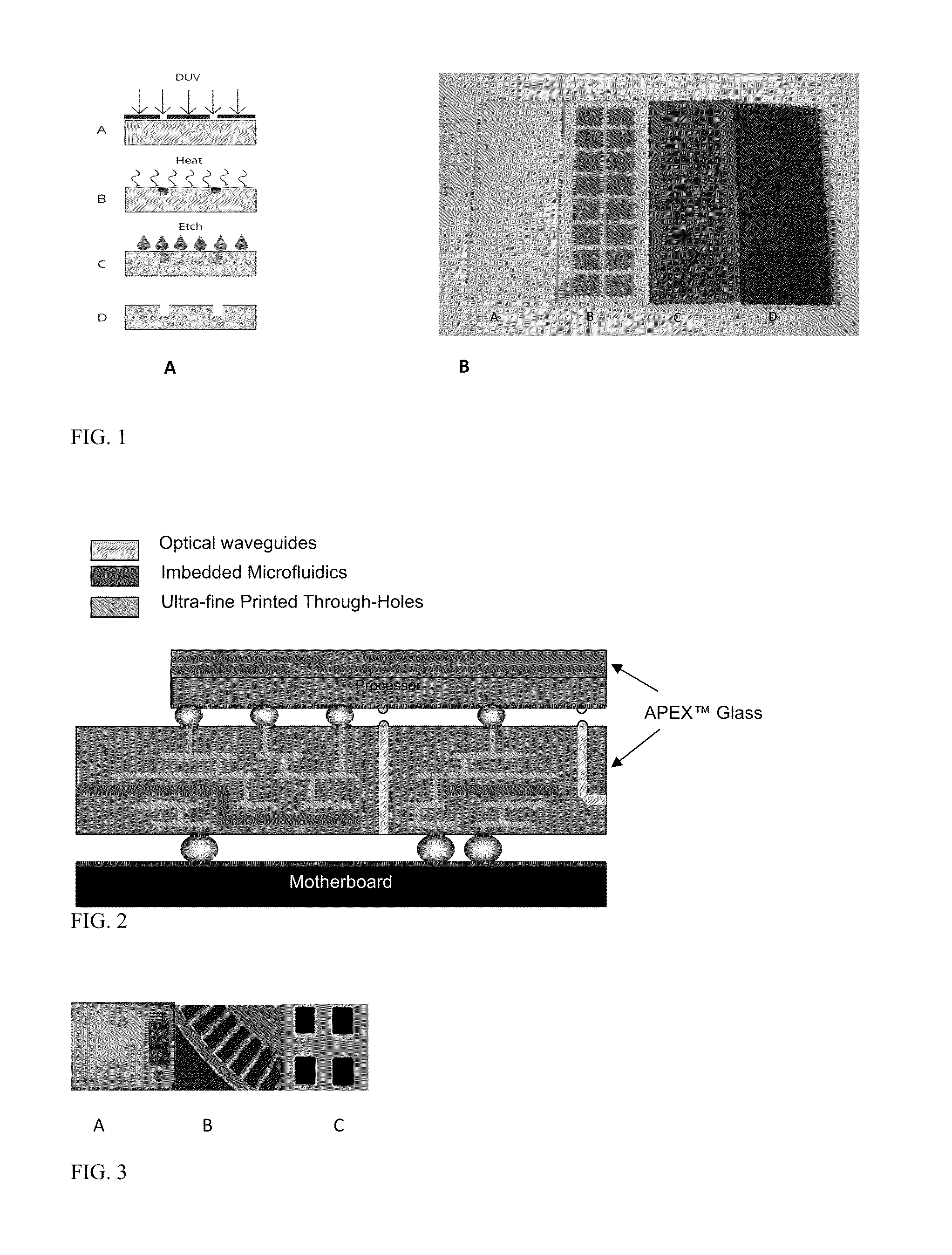

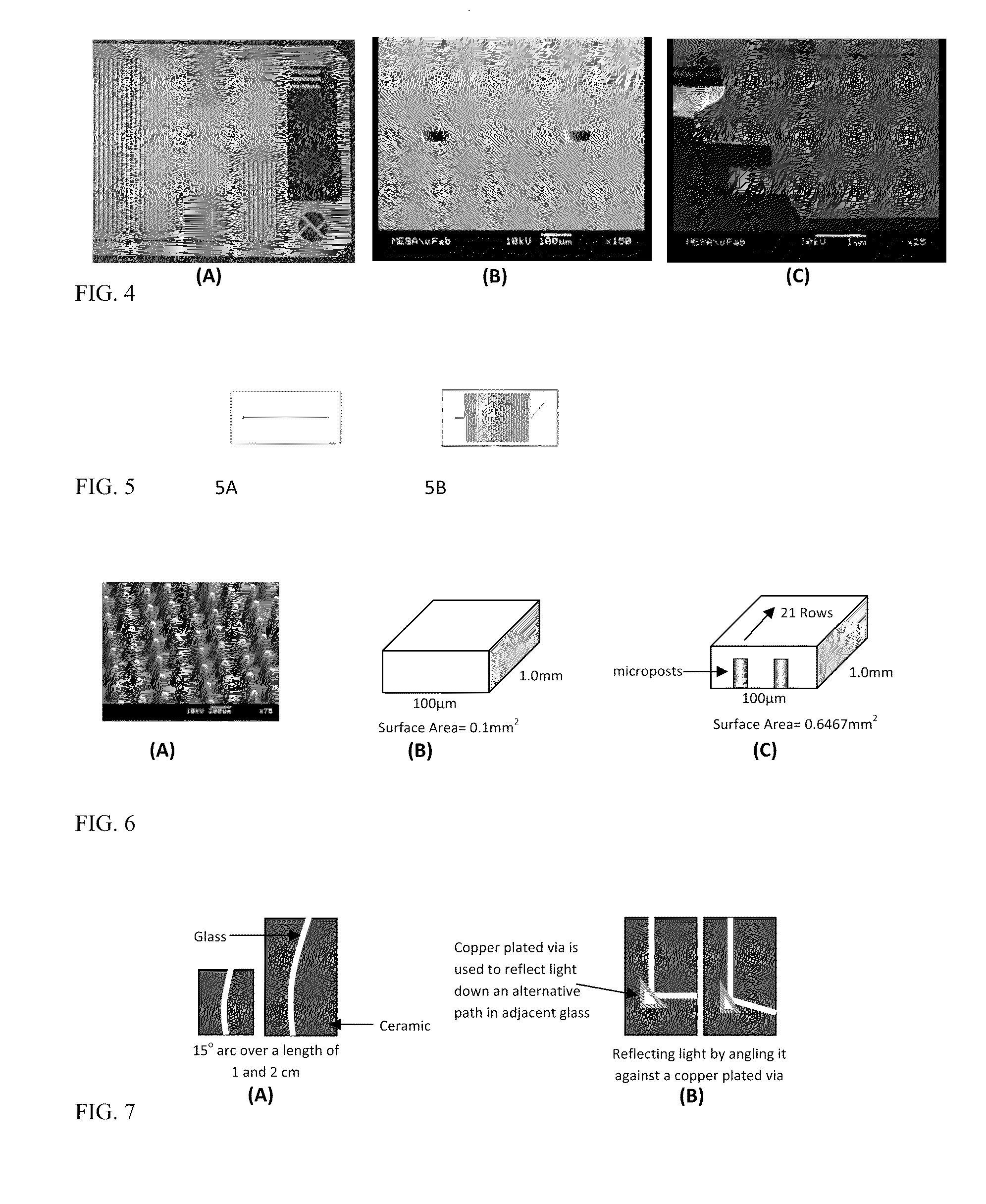

Methods to fabricate a photoactive substrate suitable for microfabrication

InactiveUS20110217657A1Improve performanceSmall layer thicknessContact member manufacturingPhotosensitive materialsLithium oxideSilicon dioxide

A method of fabrication and device with holes for electrical conduction made by preparing a photosensitive glass substrate comprising at least silica, lithium oxide, aluminum oxide, and cerium oxide, masking a design layout comprising one or more holes to form one or more electrical conduction paths on the photosensitive glass substrate, exposing at least one portion of the photosensitive glass substrate to an activating energy source, exposing the photosensitive glass substrate to a heating phase of at least ten minutes above its glass transition temperature, cooling the photosensitive glass substrate to transform at least part of the exposed glass to a crystalline material to form a glass-crystalline substrate and etching the glass-crystalline substrate with an etchant solution to form the one or more depressions or through holes for electrical conduction in the device.

Owner:LIFE BIOSCI

Microfluidic device for enabling fluidic isolation among interconnected compartments within the apparatus and methods relating to same

ActiveUS7419822B2Maintaining fluidic isolationArea is exposedBioreactor/fermenter combinationsBiological substance pretreatmentsFluid transportHigh resistance

Embodiments of the invention are directed to a device that combines microfabrication, microfluidic, and surface micropatterning techniques to create a multi-compartment neuronal culturing device that has application across a number of different neuroscience uses. Devices configured in accordance with the invention allow directed growth of neurites and isolation of neurites from their cell bodies. The device can use hydrostatic pressure to isolate insults to one compartment and, thus, expose localized areas of neurons to insults. Due to the high resistance of the microgrooves for fluid transport, insults are contained in the neuritic compartment without appreciable leakage into the somal compartment for a certain period of time (e.g., over 15 h).

Owner:RGT UNIV OF CALIFORNIA

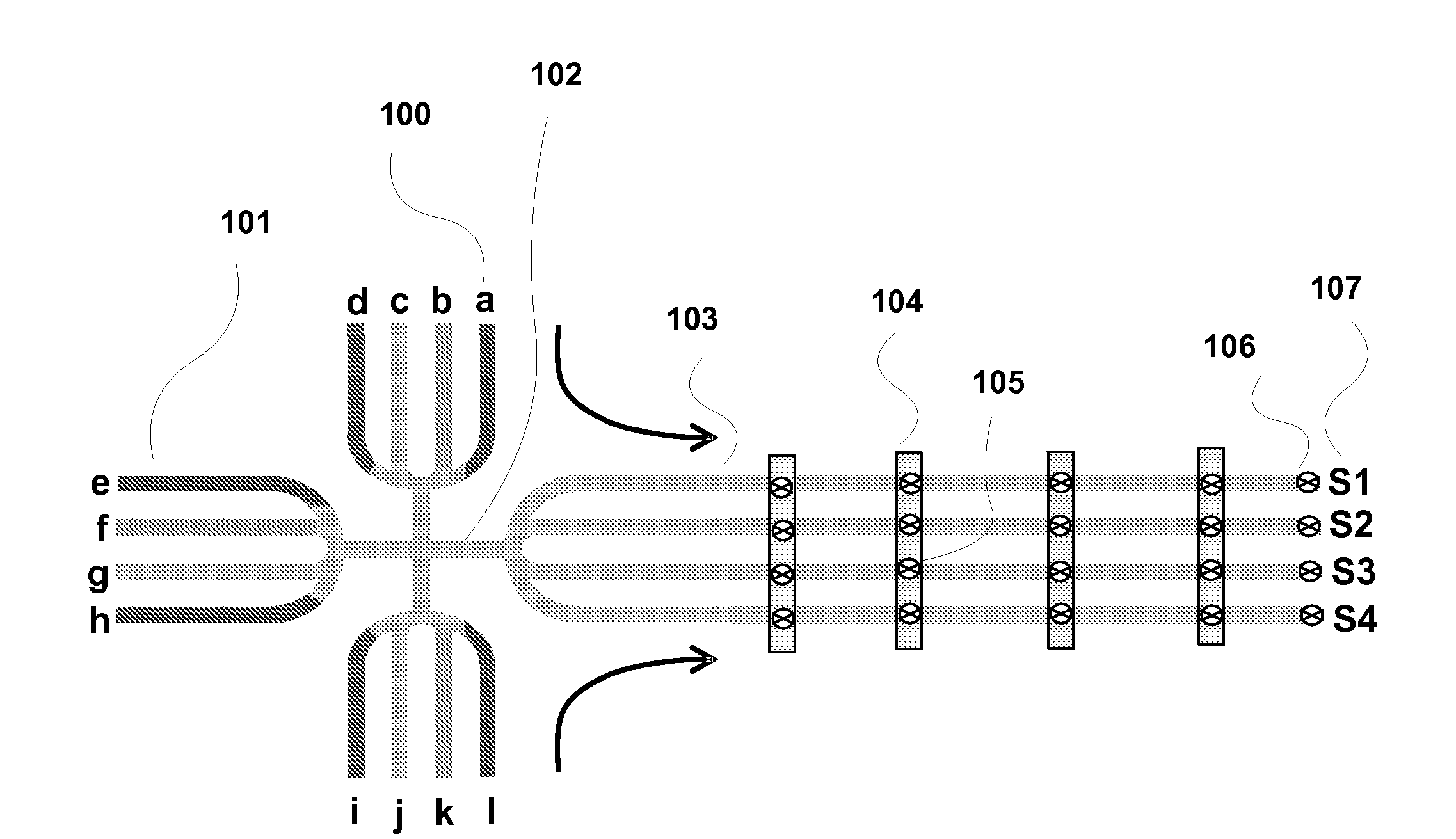

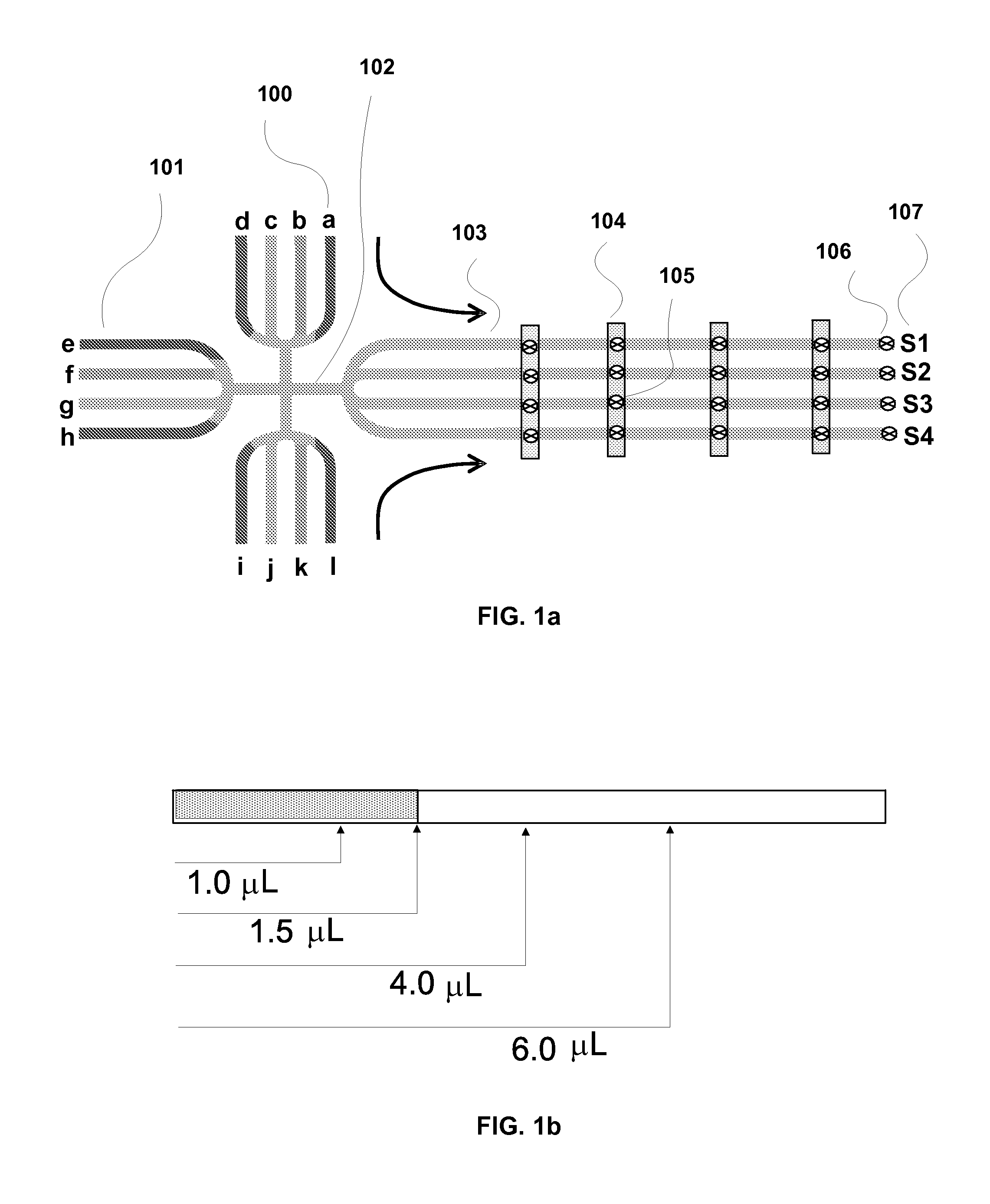

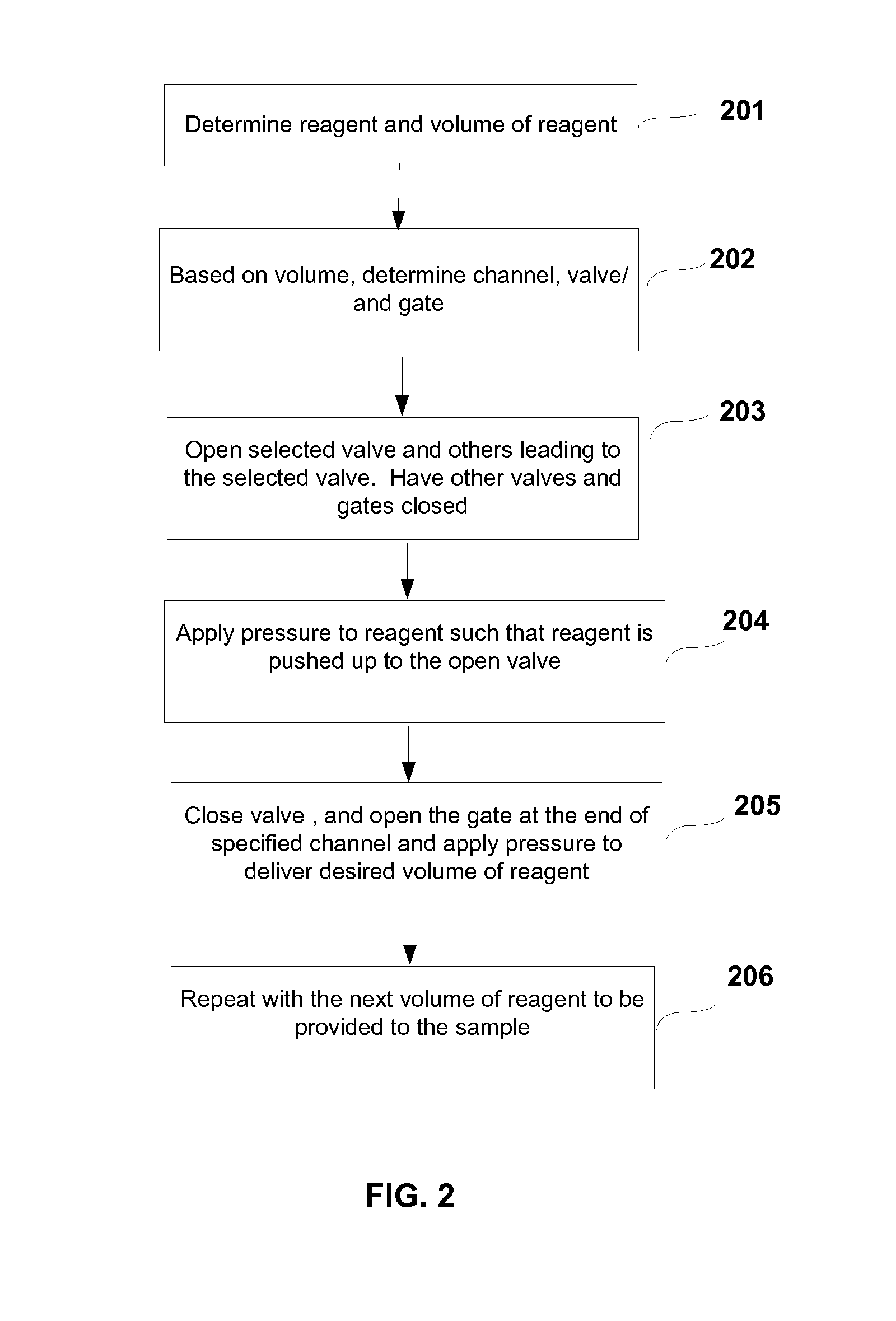

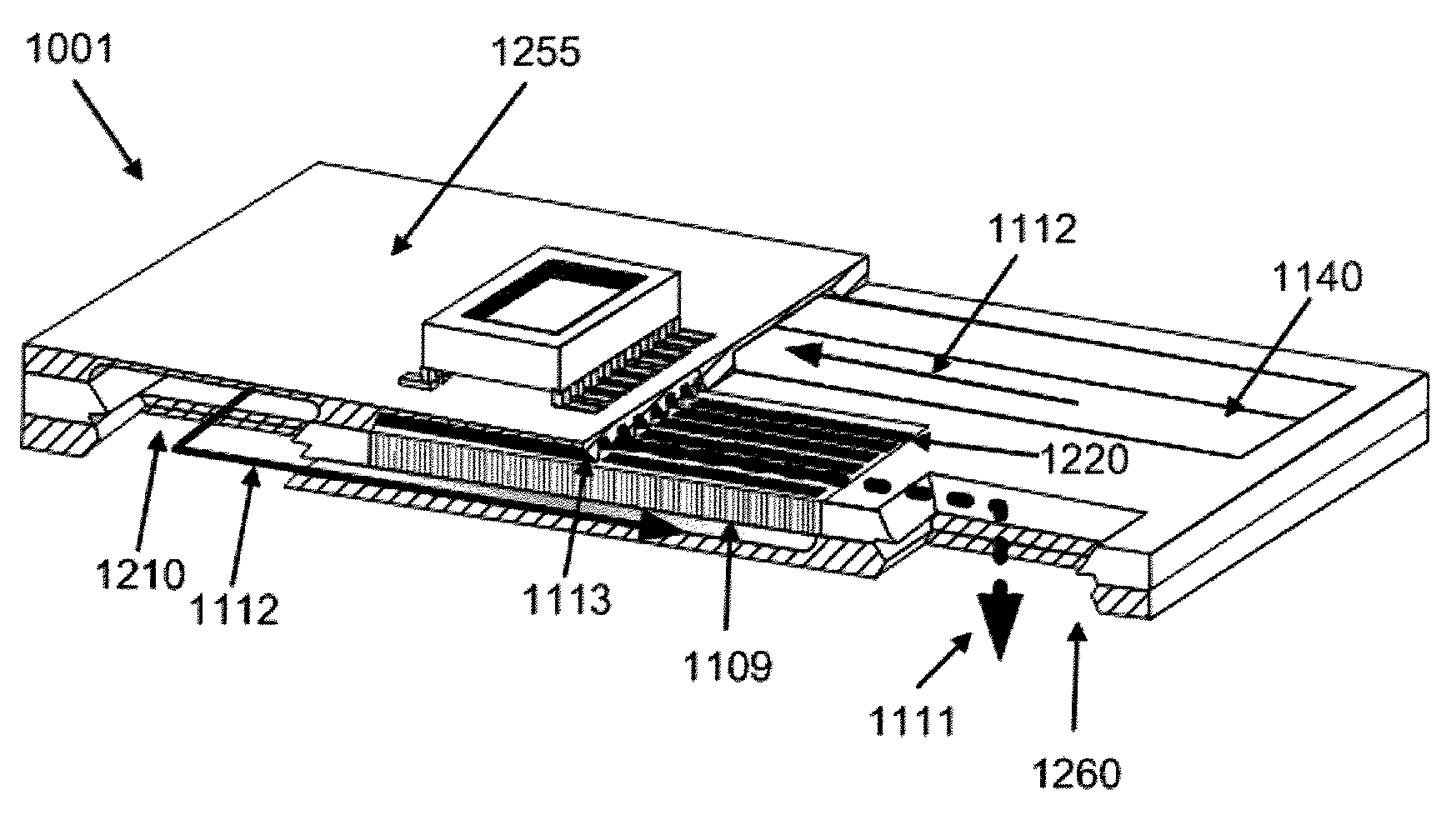

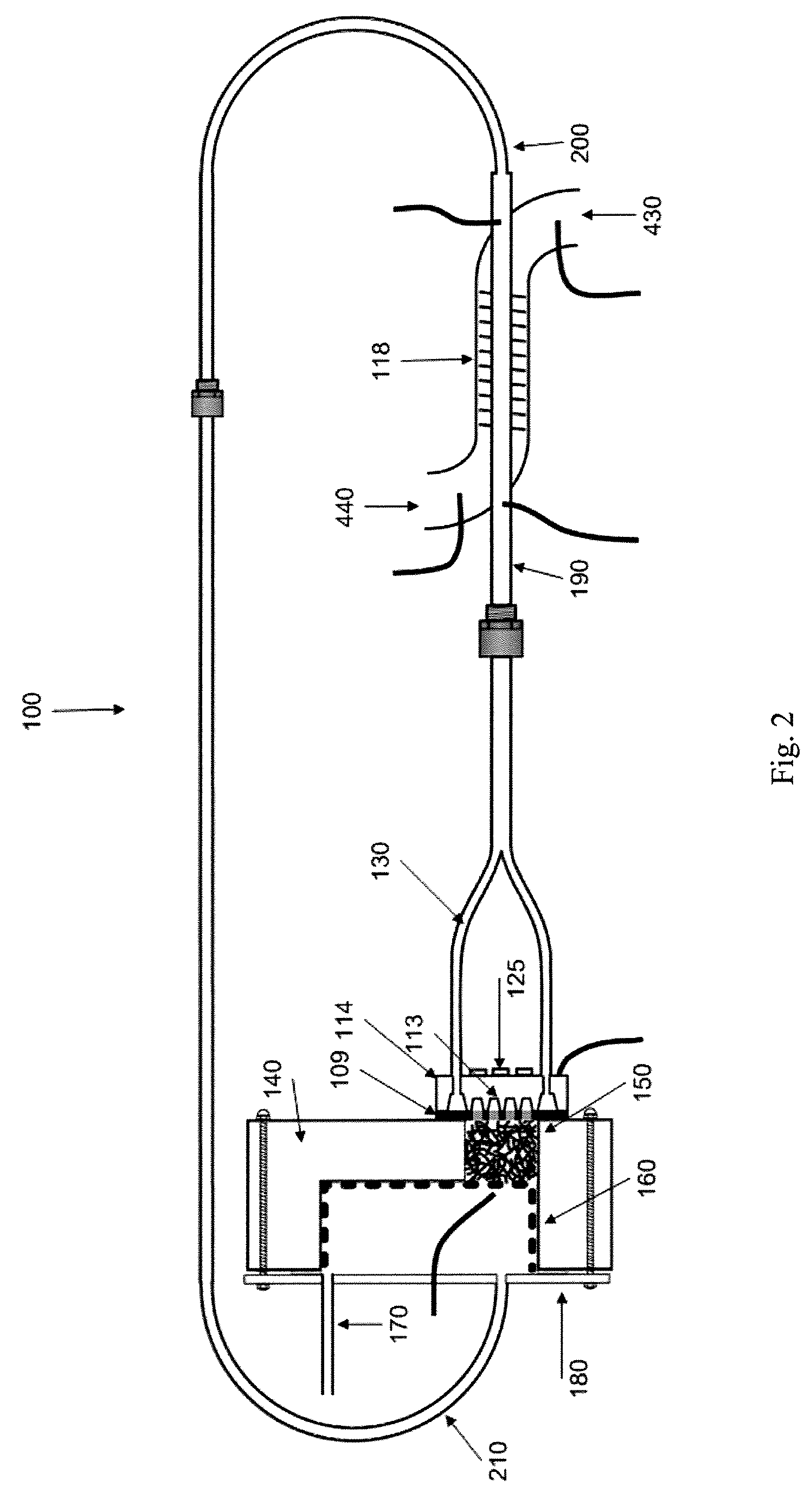

System and method for multiplex liquid handling

InactiveUS20080311585A1Bioreactor/fermenter combinationsHeating or cooling apparatusChemical reactionEngineering

The present invention generally relates to microfabricated devices for carrying out and controlling chemical reactions and analysis. In particular, the present invention provides systems, methods, devices and computer software products related to multiplex liquid handling systems utilizing lab cards related to biological assays.

Owner:AFFYMETRIX INC

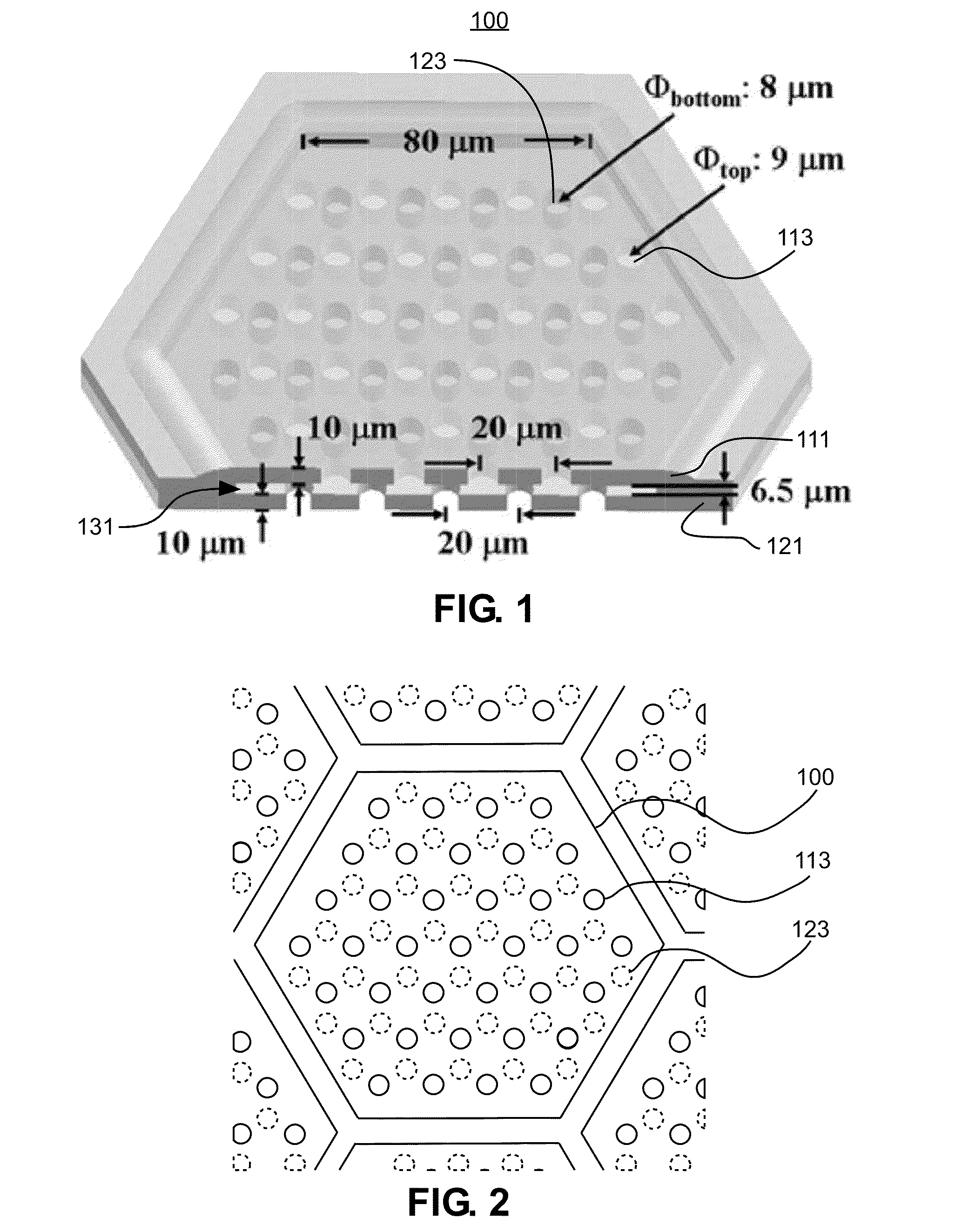

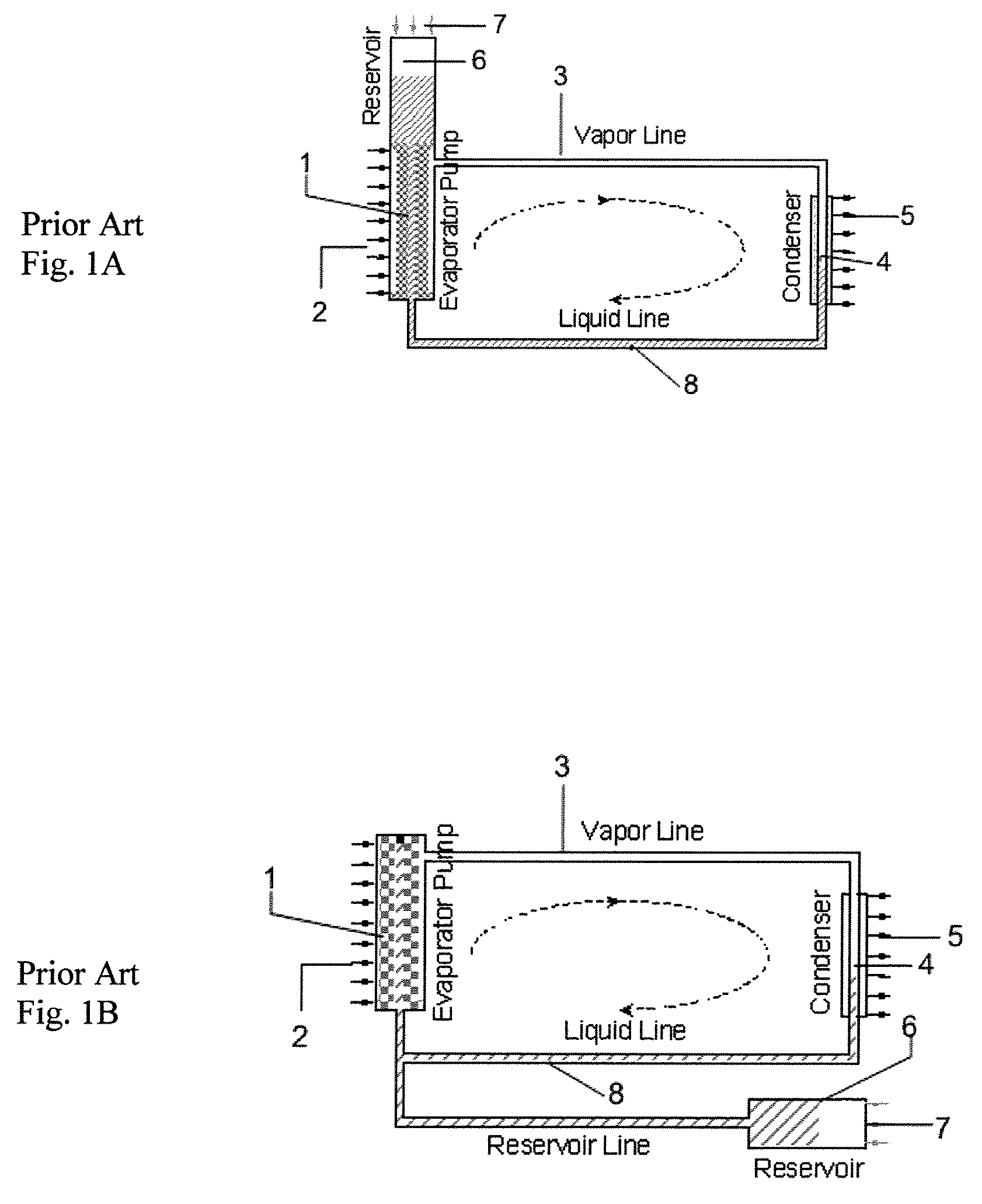

Silicon MEMS based two-phase heat transfer device

InactiveUS20070095507A1Semiconductor/solid-state device detailsSolid-state devicesMicron scaleVolumetric Mass Density

The present invention is a MEMS-based two-phase LHP (loop heat pipe) and CPL (capillary pumped loop) using semiconductor grade silicon and microlithographic / anisotrophic etching techniques to achieve a planar configuration. The principal working material is silicon (and compatible borosilicate glass where necessary), particularly compatible with the cooling needs for electronic and computer chips and package cooling. The microloop heat pipes (μLHP™) utilize cutting edge microfabrication techniques. The device has no pump or moving parts, and is capable of moving heat at high power densities, using revolutionary coherent porous silicon (CPS) wicks. The CPS wicks minimize packaging thermal mismatch stress and improves strength-to-weight ratio. Also burst-through pressures can be controlled as the diameter of the coherent pores can be controlled on a sub-micron scale. The two phase planar operation provides extremely low specific thermal resistance (20-60W / cm2). The operation is dependent upon a unique micropatterened CPS wick which contains up to millions per square centimeter of stacked uniform micro-through-capillaries in semiconductor-grade silicon, which serve as the capillary “engine,” as opposed to the stochastic distribution of pores in the typical heat pipe wick. As with all heat pipes, cooling occurs by virtue of the extraction of heat by the latent heat of phase change of the operating fluid into vapor. In the cooling of a laptop computer processor the device could be attached to the processor during laptop assembly. Consistent with efforts to miniaturize electronics components, the current invention can be directly integrated with a unpackaged chip. For applications requiring larger cooling surface areas, the planar evaporators can be spread out in a matrix and integrally connected through properly sized manifold systems.

Owner:UNIVERSITY OF CINCINNATI

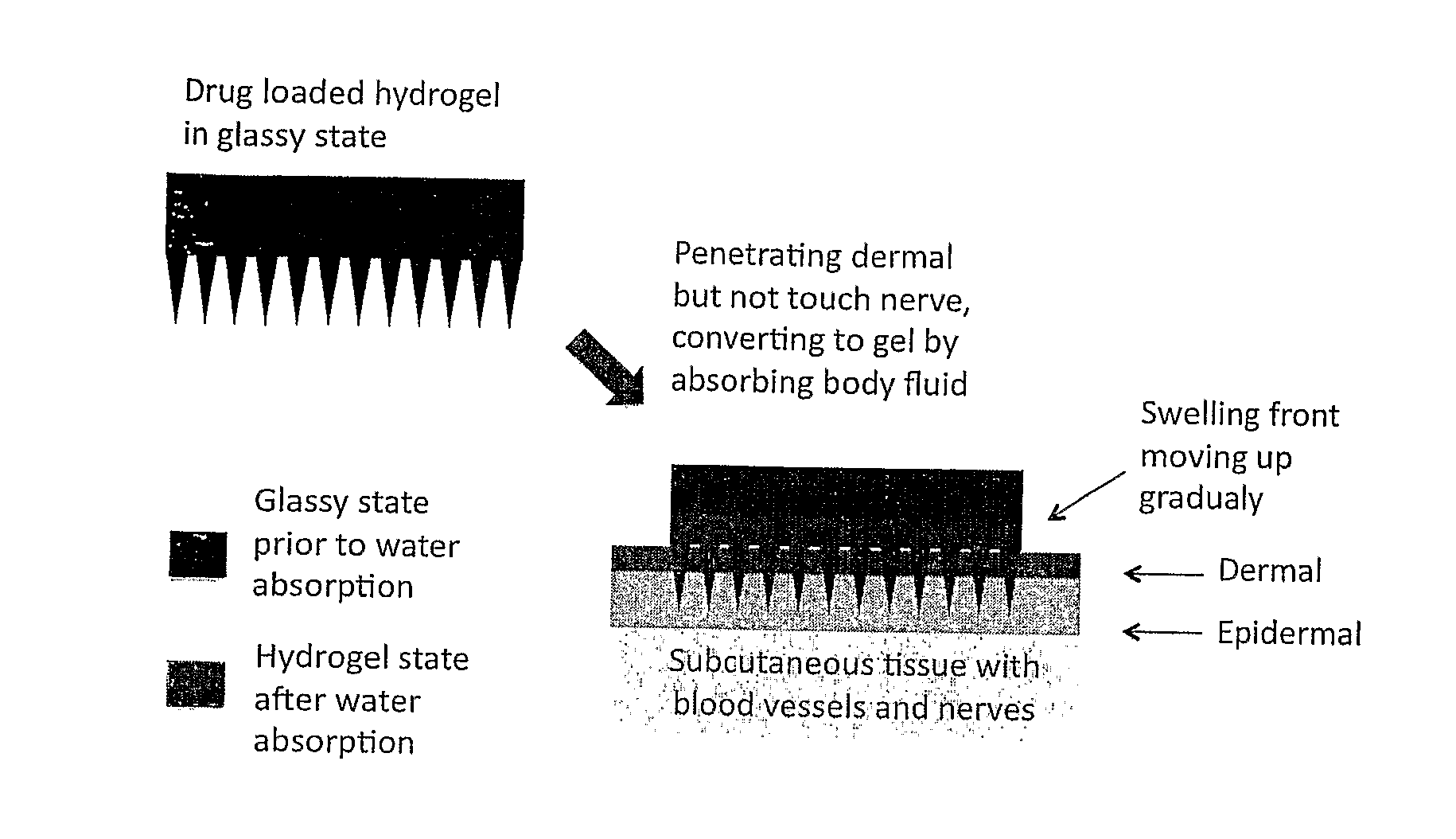

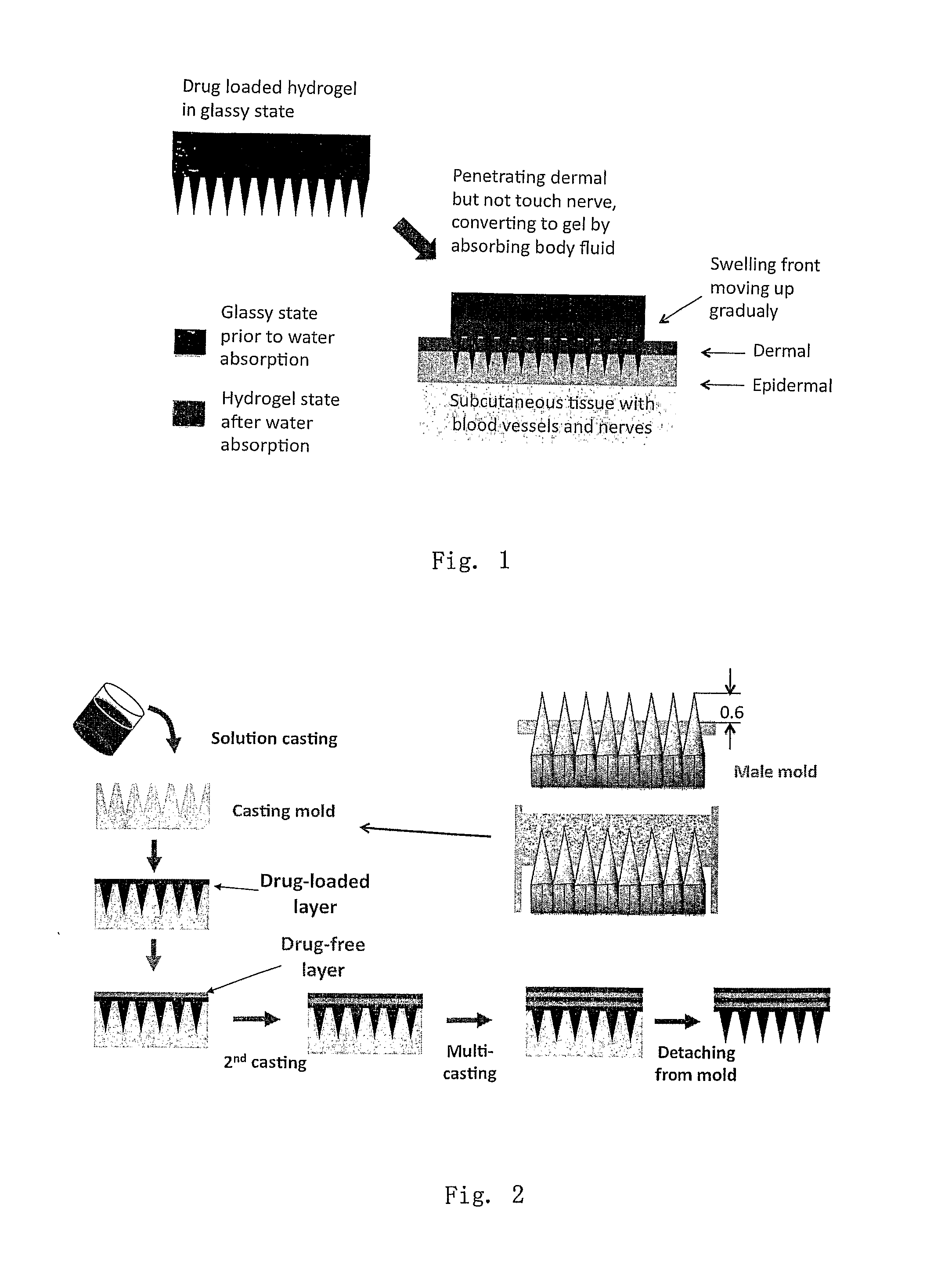

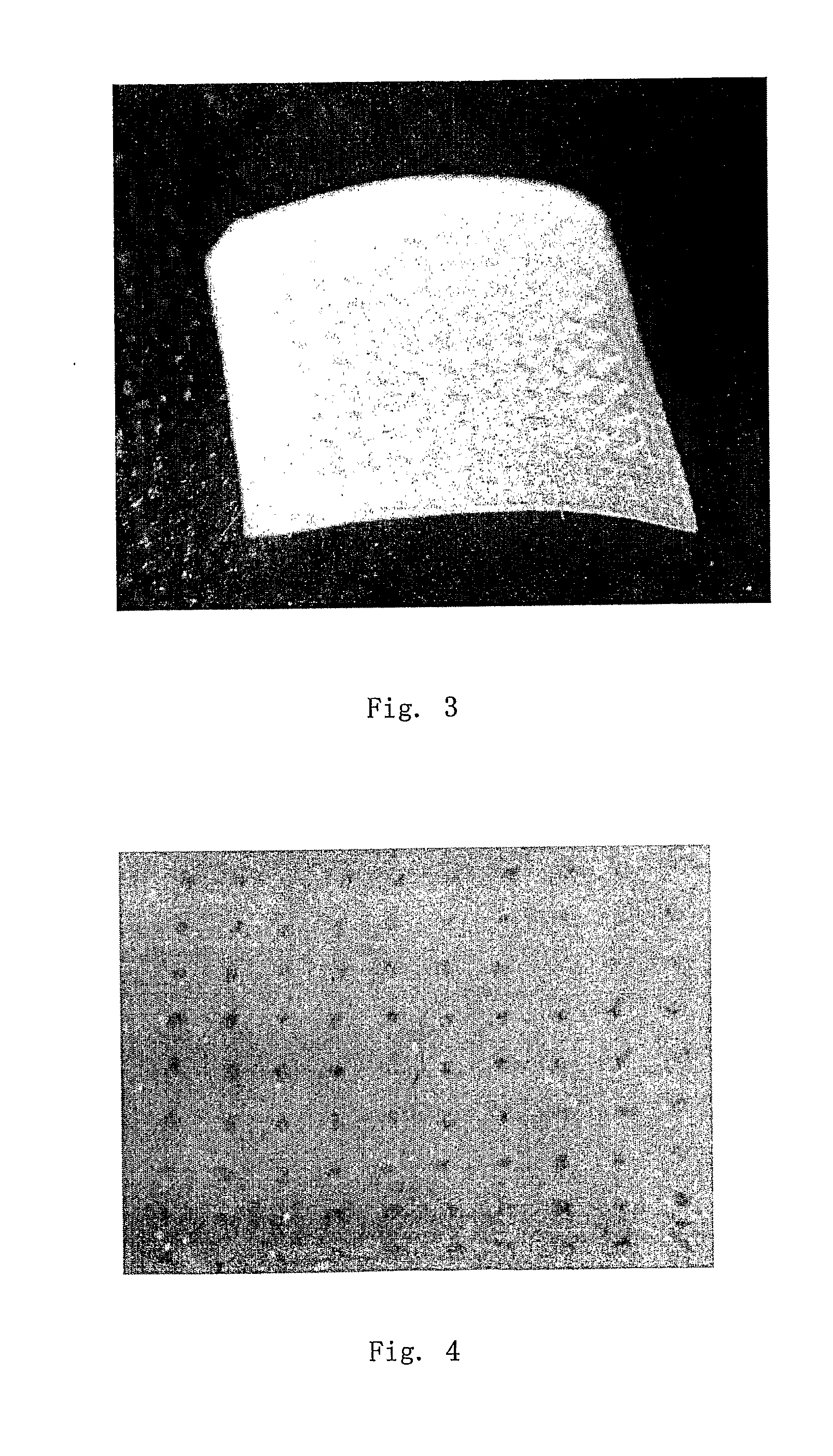

Phase-transition polymeric microneedles

ActiveUS20110195124A1Easy yet multi-functional fabrication processPowder deliveryPeptide/protein ingredientsOrganic solventMicrofabrication

This invention discloses a novel microneedle system, phase-transition microneedle patch, which overcomes all the limitations that existing microneedles encountered. The microneedle patch is formed of an integrated polymeric piece consisting of a microneedle array and a plate (called holding plate) on which the needles stand. The microneedles of the patch are hard and strong enough to penetrate epidermis at dry state but turn to be hydrogel state soft and permeable to hydrophilic agents when absorbing body fluid. The hydrogel state of the patch is a hydrophilic network held by physical or chemical cross-linking junctions. The pores of the network are opened up by body fluid for drugs and macromolecules to diffuse through. The polymeric materials used to form the microneedle patch have been used in the pharmaceutical field for years and have proven compatibility with the skin and with proteins. The drugs may be stored in the matrix of the microneedle array as well as the holding plate so that the requirement for high dose applications may be full filled. In addition, molding (casting) of this type of microneedle patch is simple, easy to achieve and needs no microfabrication systems and organic solvents. By a programmed molding (casting), the patch may be assembled in a layered structure with desired drug concentration in each layer, respectively. Due to this design, a programmed pulse or a zero order release of drugs may easily be achieved. In addition, delicate proteins loaded in the patch are kept in a dry and hydrophilic glassy state before being released, the most favored state for protein storage. Finally, during the swelling-based drug release, the microneedle patch increases their thickness gradually between the skin and the back cover (which holds the needles) lo create a sustained pressure to ensure good contact of the microneedles inside epidermis.

Owner:JIN TUO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com