Patents

Literature

110results about How to "Wide viscosity range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

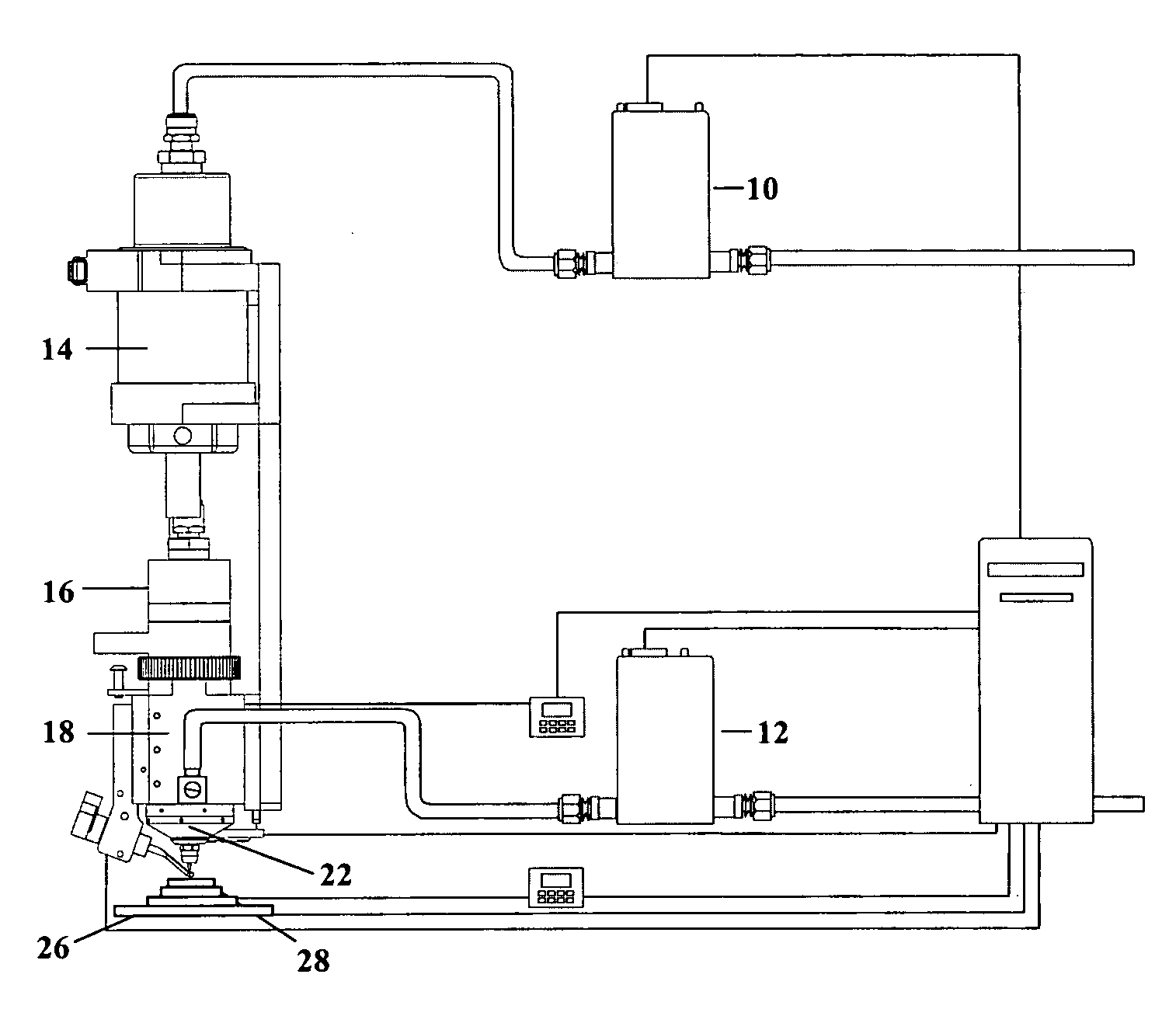

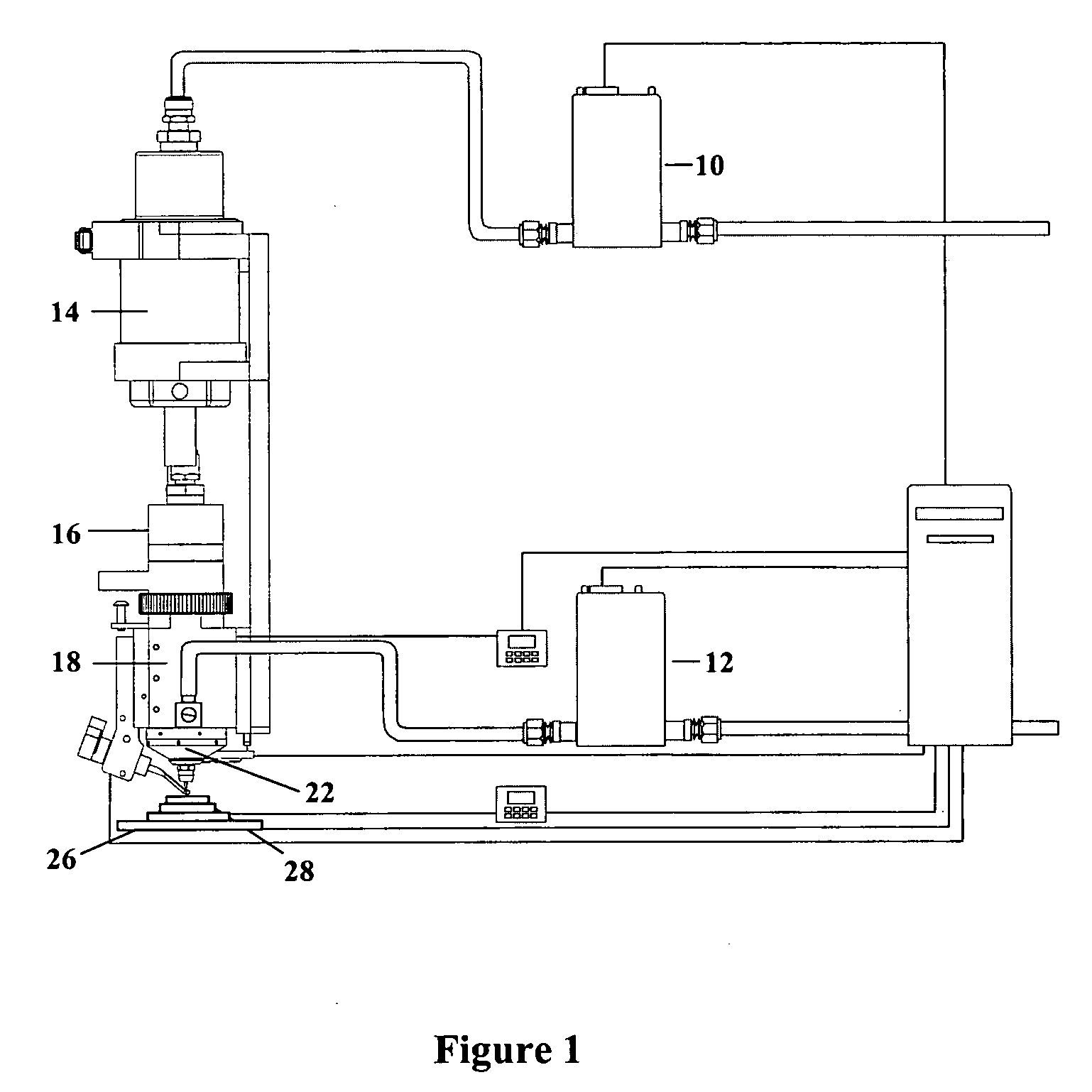

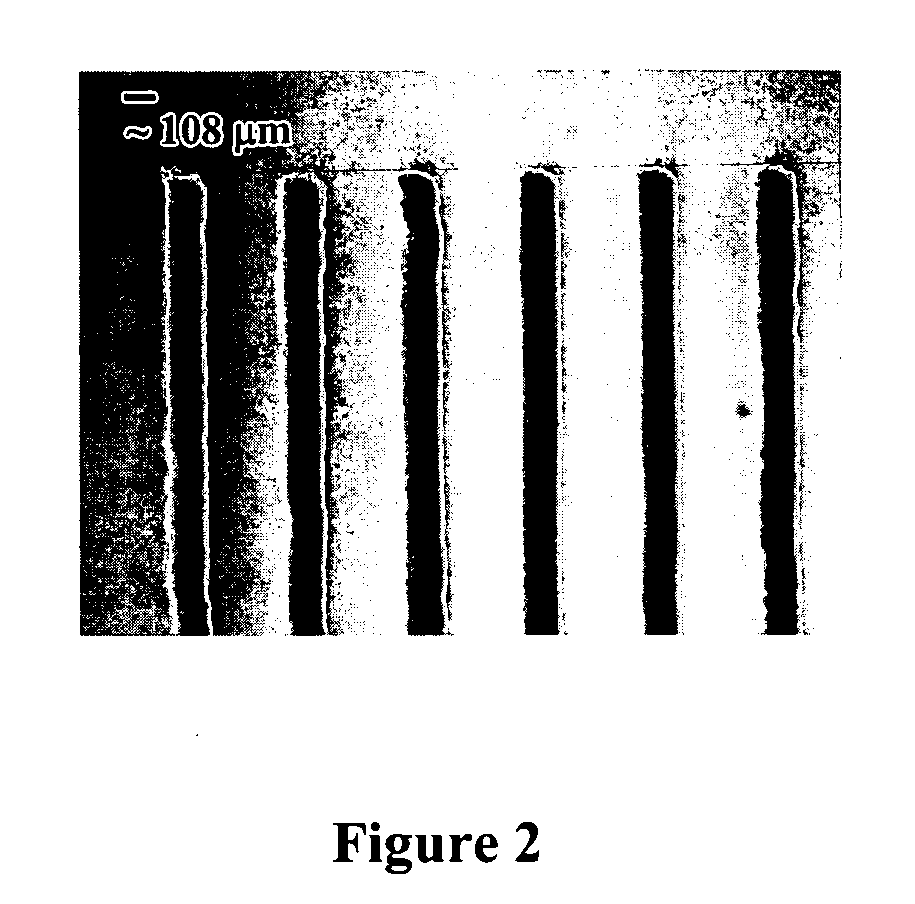

Method and apparatus for mesoscale deposition of biological materials and biomaterials

InactiveUS20060280866A1Wide viscosity rangeMicrobiological testing/measurementPharmaceutical containersDielectricEngineering

Methods and apparatus for the direct deposition or patterning of biological materials and compatible biomaterials. The method is capable of depositing biological materials and biomaterials in a computer defined pattern, and uses aerodynamic focusing of an aerosol stream to deposit mesoscale patterns onto planar or non-planar targets without the use of masks or modified environments. The aerosolized compositions may be processed before deposition (pre-processing) or after deposition on the target (post-processing). Depositable materials include, not are not limited to conductive metal precursors, nanoparticle metal inks, dielectric and resistor pastes, biocompatible polymers, and a range of biomolecules including peptides, viruses, proteinaceous enzymes, extra-cellular matrix biomolecules, as well as whole bacterial, yeast, and mammalian cell suspensions. The targets may be planar or non-planar, and are optionally biocompatible. Applications include biosensor rapid prototyping and microfabrication, lab-on-chip manufacturing, biocompatible electroactive polymer development (ambient temperature bio-production of electronic circuitry), and various additive biomaterial processes for hybrid BioMEMS, Bio-Optics, and microfabrication of biomedical devices.

Owner:OPTOMEC DESIGN CO

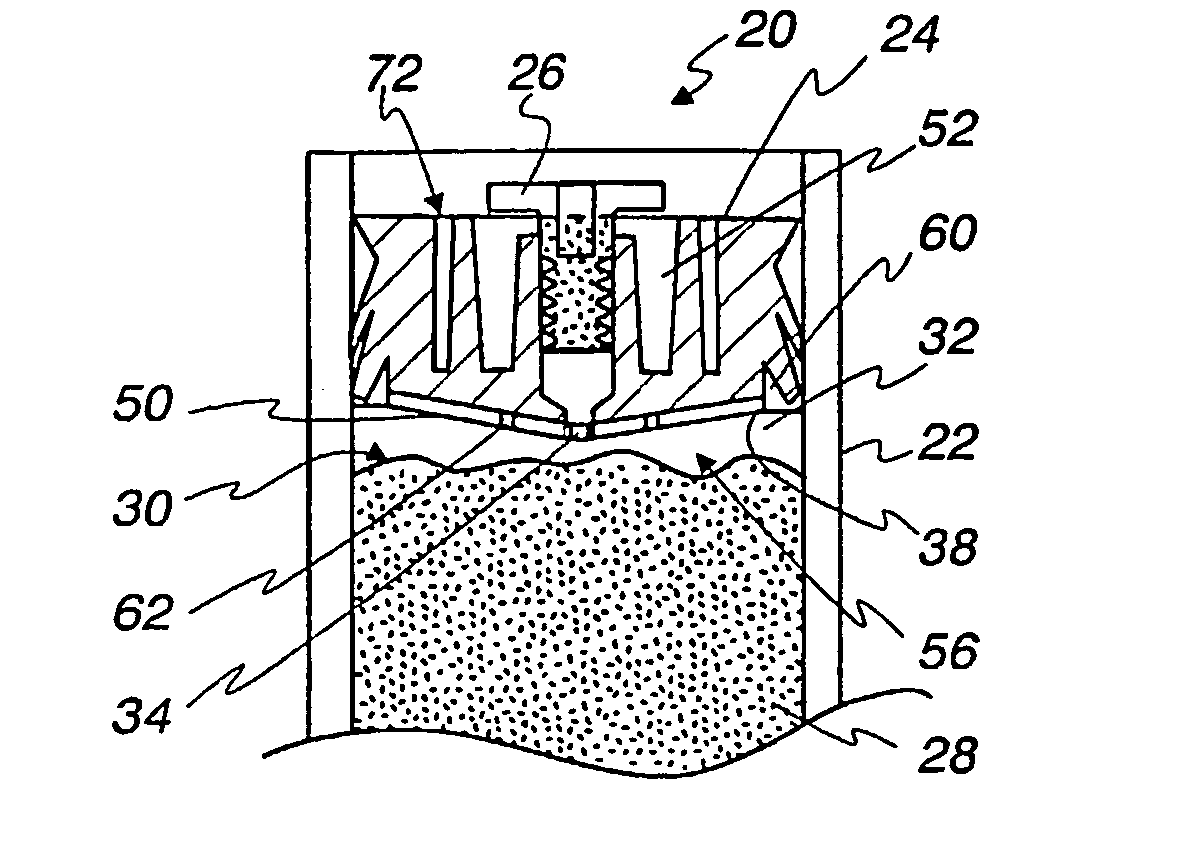

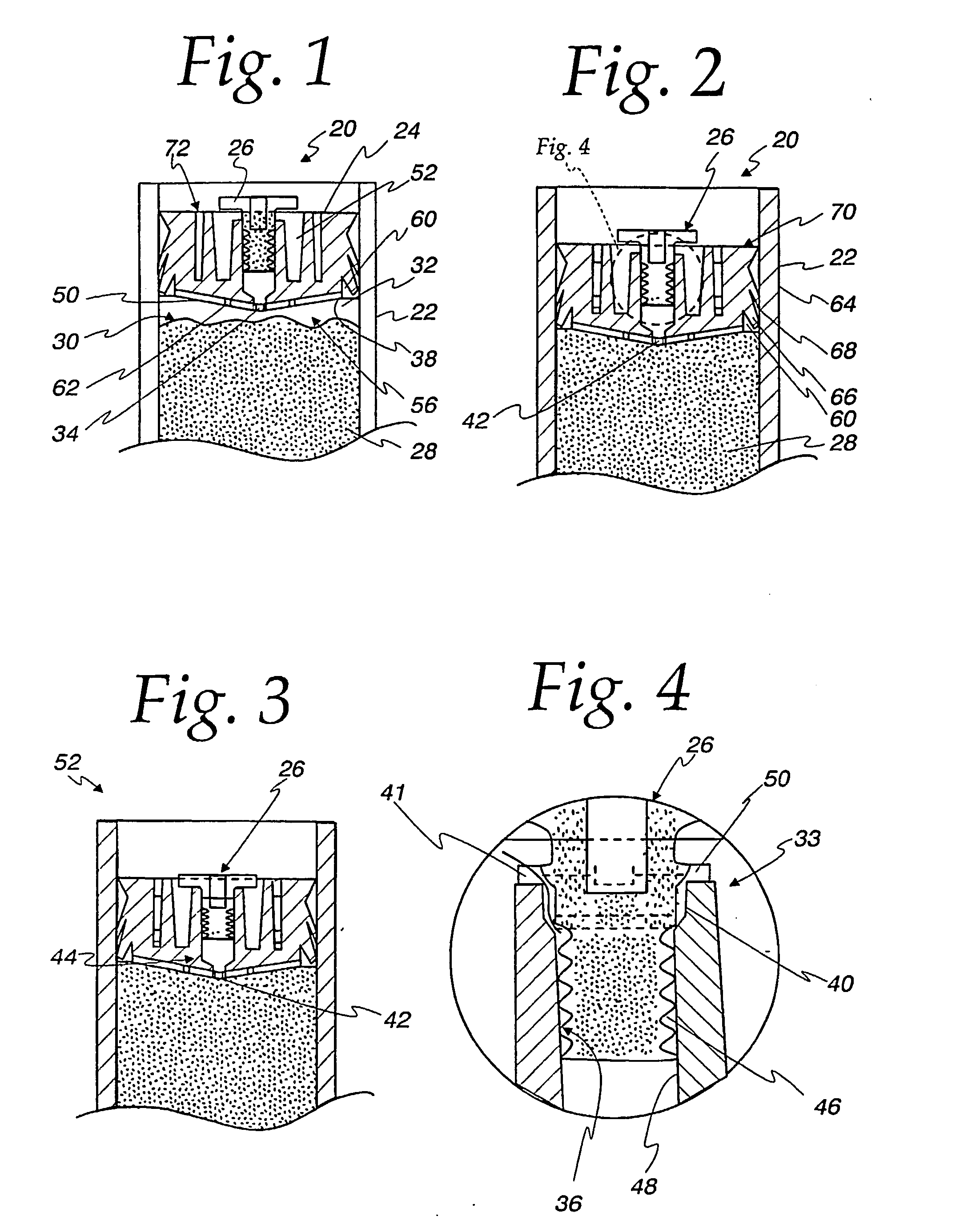

Dispensing cartridge with tortuous vent path

InactiveUS20050029306A1Wide viscosity rangeSimple configurationLiquid surface applicatorsContracting/expanding measuring chambersCombined useEngineering

A dispensing cartridge for a relatively precise dispensing of various fluids having a relatively wide range of viscosities is disclosed. The dispensing cartridge in accordance with the present invention is relatively simpler in configuration than known dispensing cartridges while minimizing leakage of the fluid and eliminating problems associated with chemical attack of the O-ring by the fluid in the dispensing cylinder. In particular, the dispensing cartridge in accordance with the present invention includes a cylinder; a piston with a central bore and a bleed plug. In order to simplify the design, the air vent is configured as a tortuous path, for example, a spiral path, defined by a spiral bleed plug, which in a pre-staged position, allows air to freely escape along the spiral path along the circumference of the plug. As the piston contacts the fluid, the forward motion of piston is resisted by the high back pressure created by the small effective diameter and relatively long length of the spiral path. Once the piston contacts the fluid, the spiral plug is pushed into the piston closing the spiral path. By controlling the fluid flow by way of a tortuous path, the amount of fluid backflow through the piston is minimized if not eliminated, thus eliminating the need for an annular overflow chamber, thereby simplifying the design of the piston. In order to minimize problems related to the sealing of the piston within the dispensing cartridge, the piston may be provided with one or more radially extending sealing lips. These sealing lips are used in lieu of or in conjunction with an O-ring. The sealing lips further simplify the design by eliminating the O-ring as well as the need for an annular chamber adjacent thereto as well as problems relating to chemical attack of the O-ring by the fluid within the dispensing cylinder. In an alternative embodiment for use that is particularly adapted with non-aggressive fluids, the piston is provided with a single sealing lip and an O-ring.

Owner:NORDSON CORP

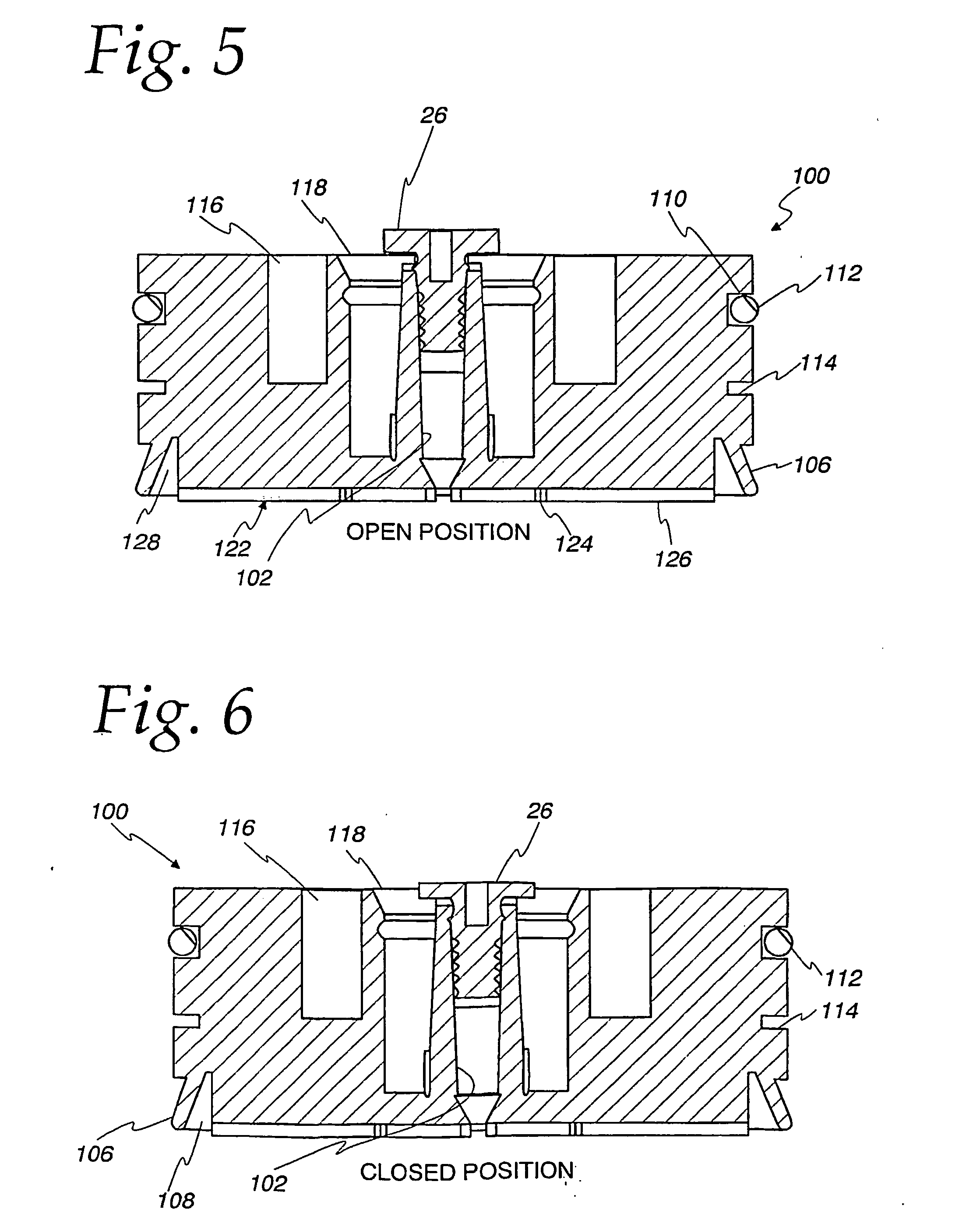

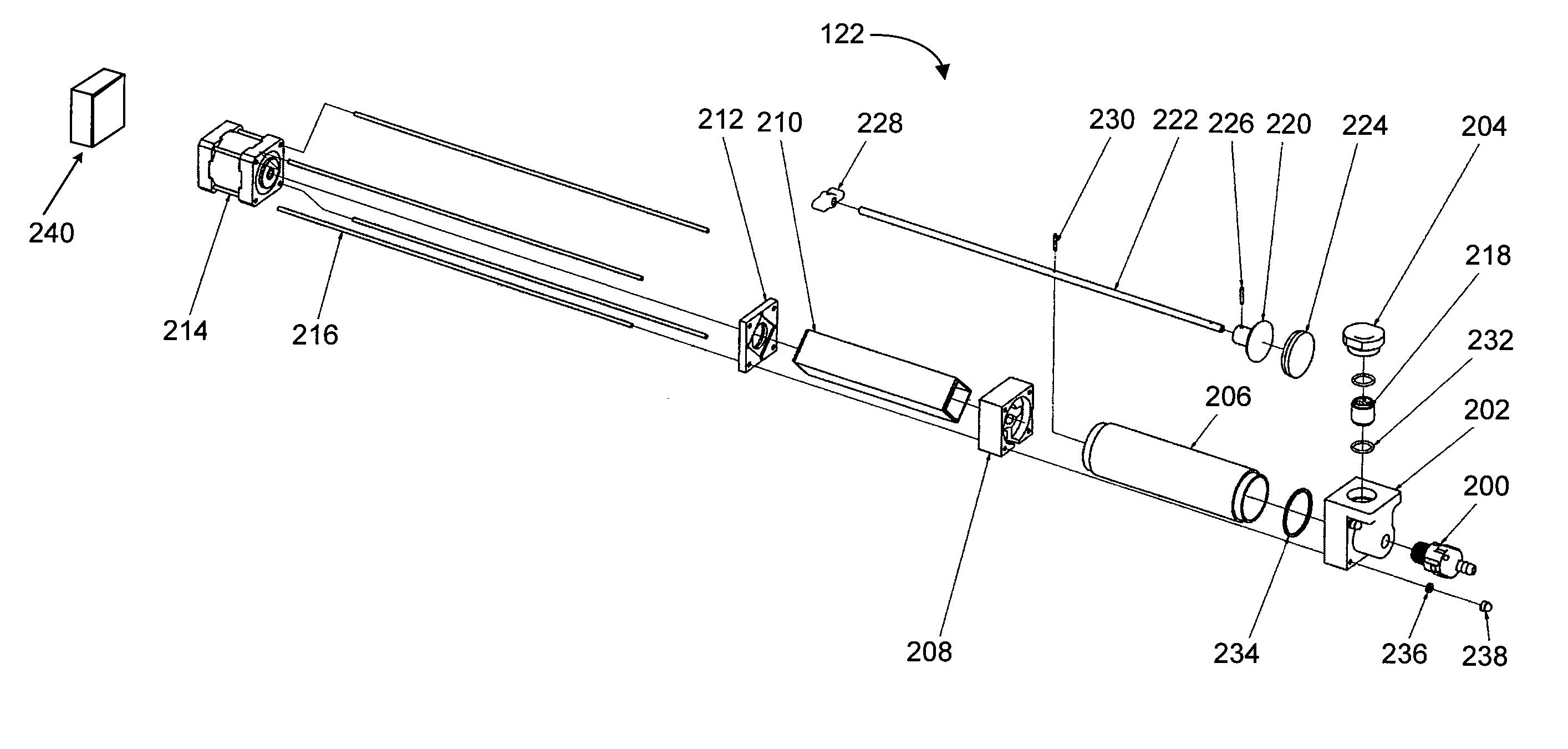

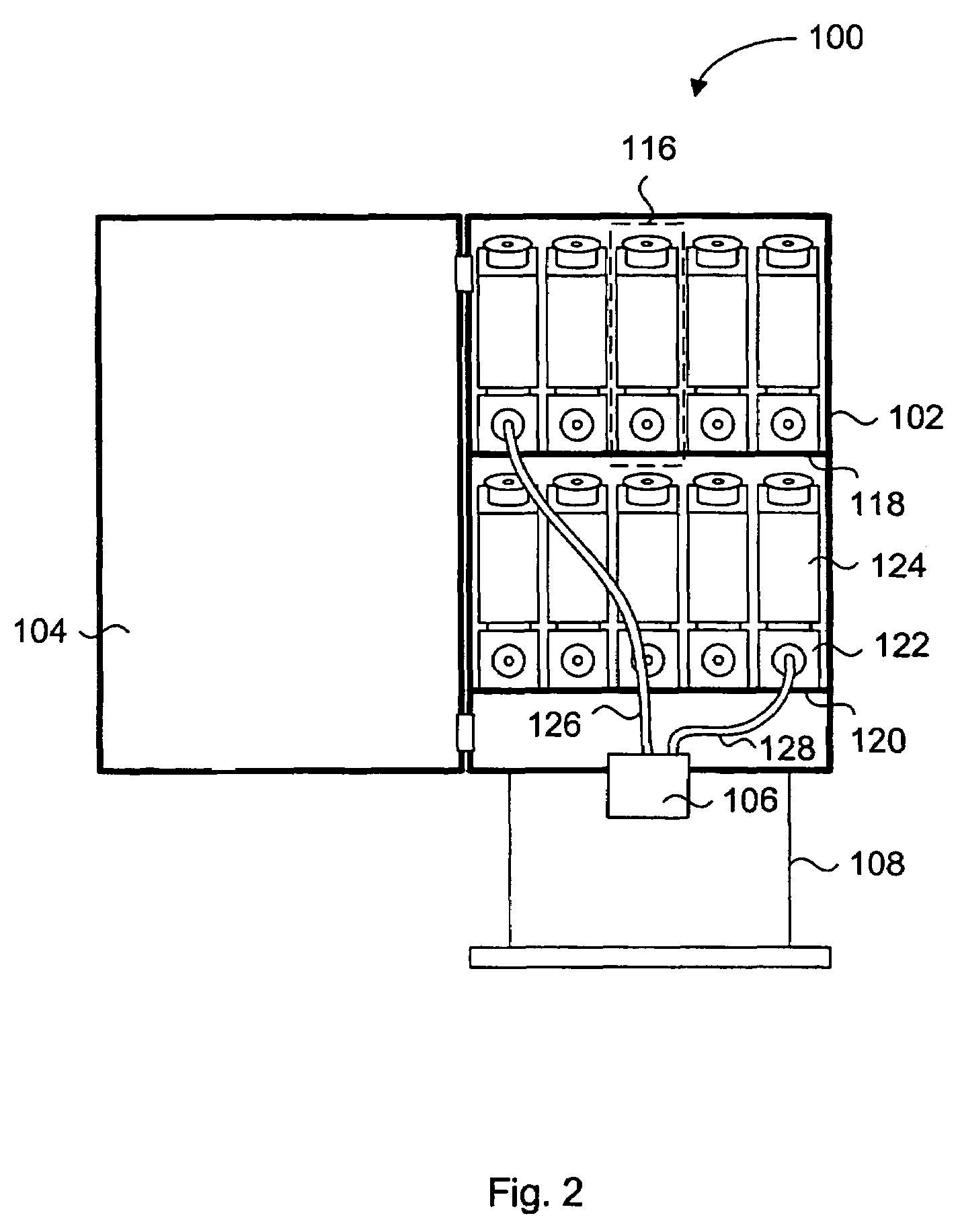

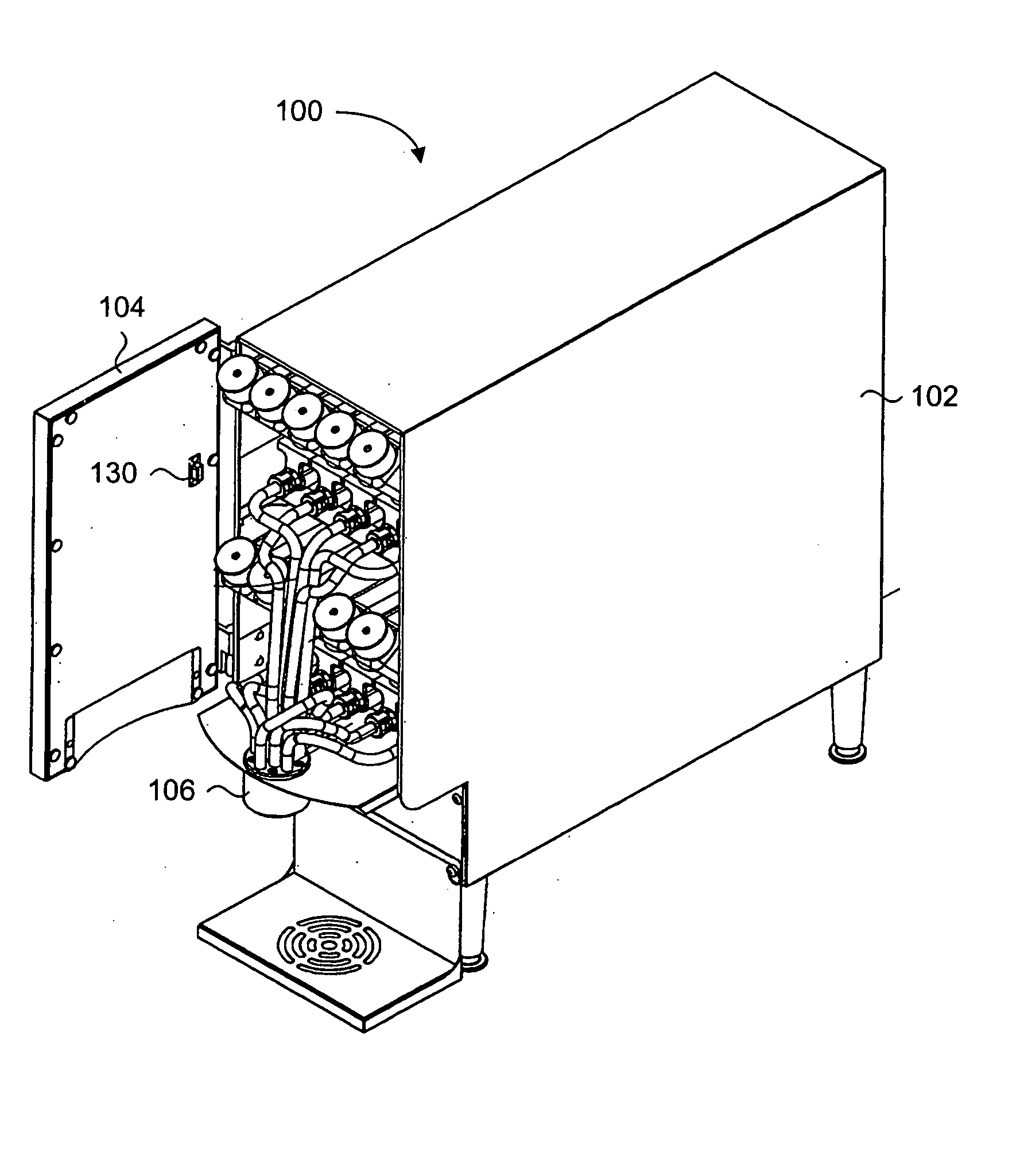

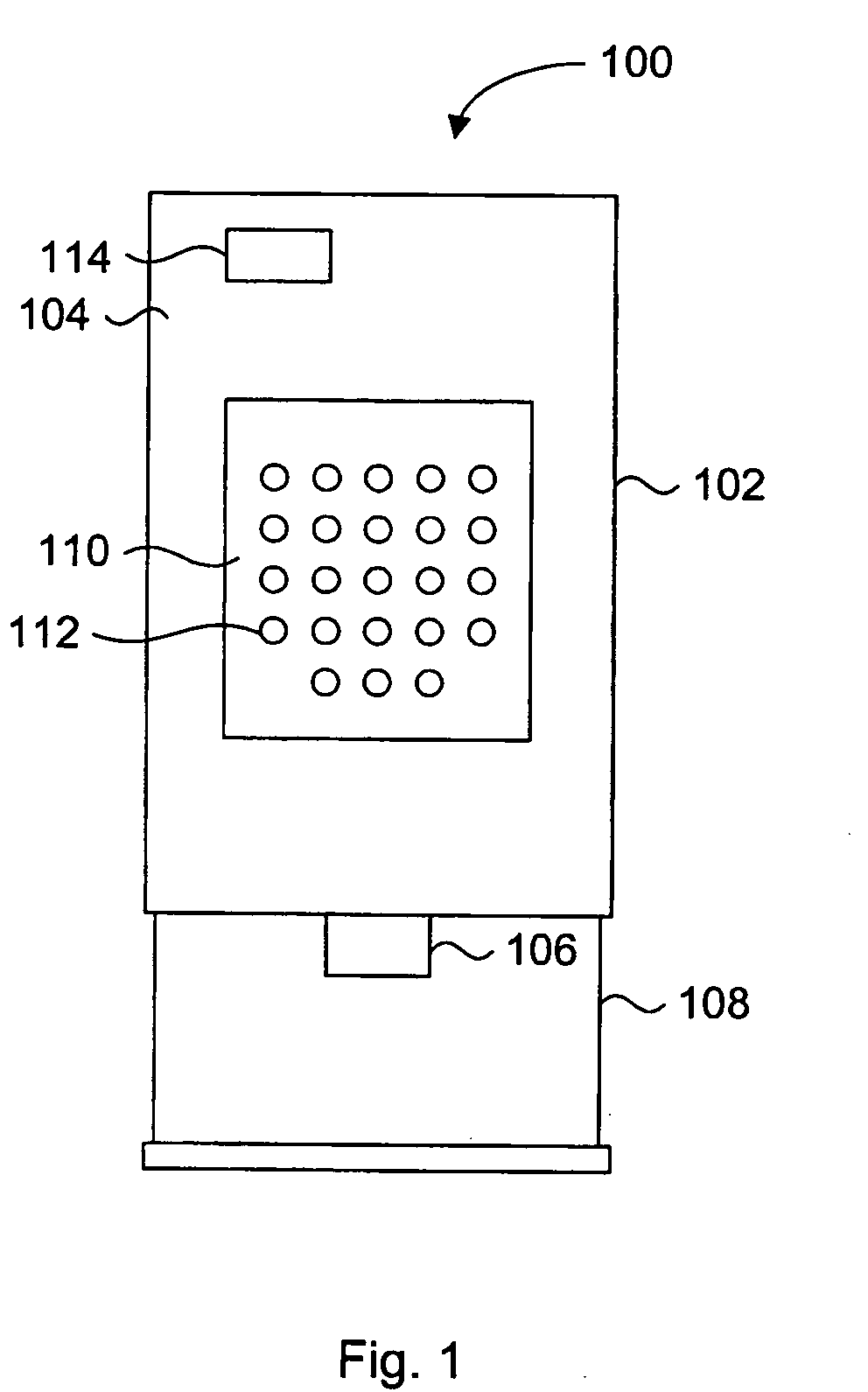

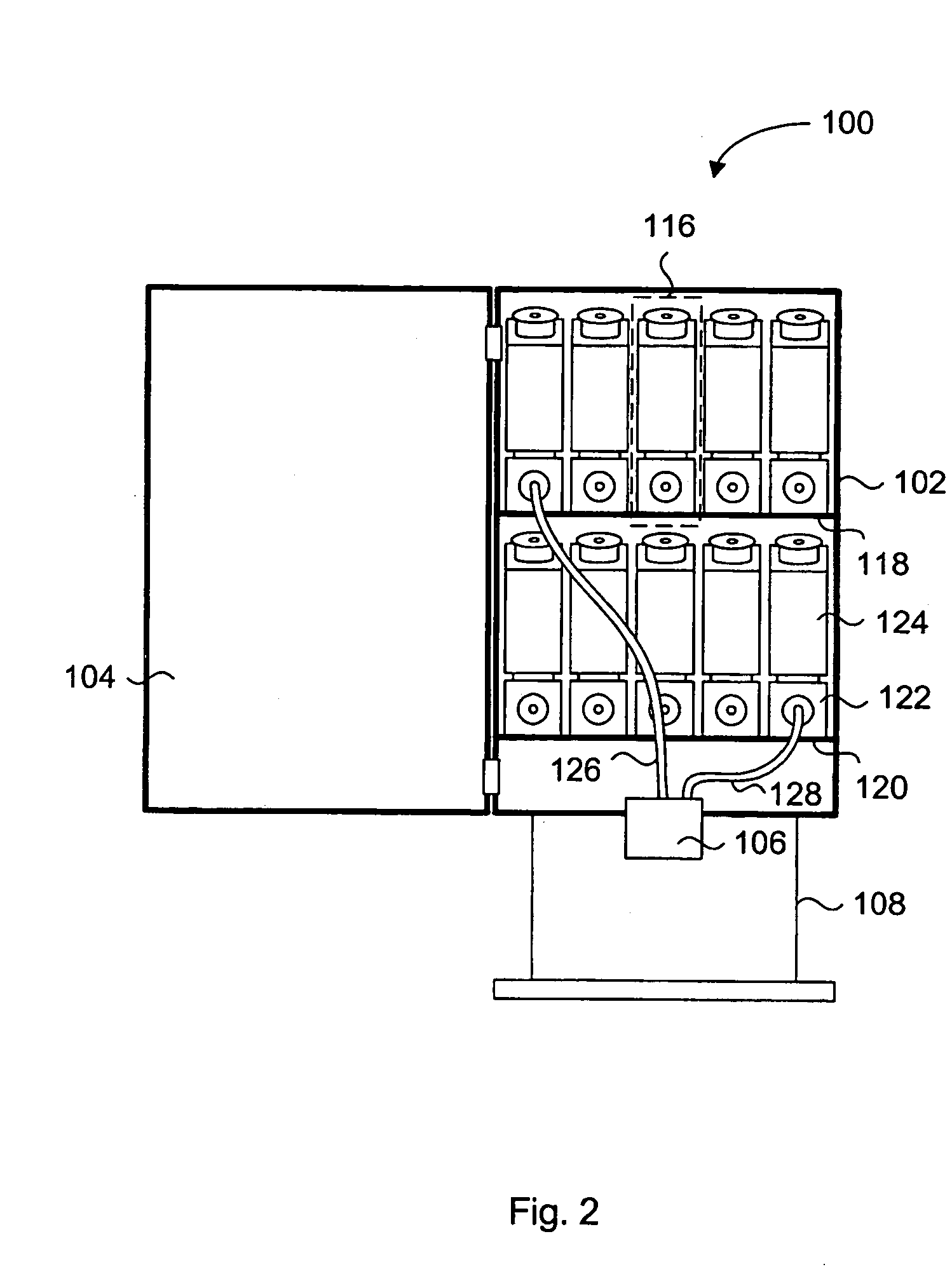

Fluid dispensing apparatus

ActiveUS7337920B2Wide viscosity rangePrevent exitContracting/expanding measuring chambersLiquid flow controllersViscosityMechanical engineering

A concentrated flavour dispensing machine having displacement pumps for delivering between a few millilitres and few ounces of fluids having a viscosity value between 1 to 4000 centepoise is described. The dispensing machine includes a cabinet for containing a multitude of displacement pumps, where each displacement pump is in direct fluid communication with a respective storage tank, and a control panel having a programmable microprocessor mounted to the cabinet for receiving user selections and controlling each individual pump. Each displacement pump includes a stepper motor in engagement with a threaded drive rod for advancing a piston by any one of several predetermined distances to dispense a corresponding volume of fluid. The control panel receives a valid user selection for actuating one or more pumps to dispense the appropriate volume of a concentrated flavouring fluid. The microprocessor tracks the amount of fluid dispensed from each storage tank and alerts users and / or prevents further operation when reservoirs are close to empty to avoid null dispenses to customers. Various maintenance routines can be executed through the user interface, and dispense volumes and combination dispenses can be re-programmed manually or automatically.

Owner:A C DISPENSING EQUIP

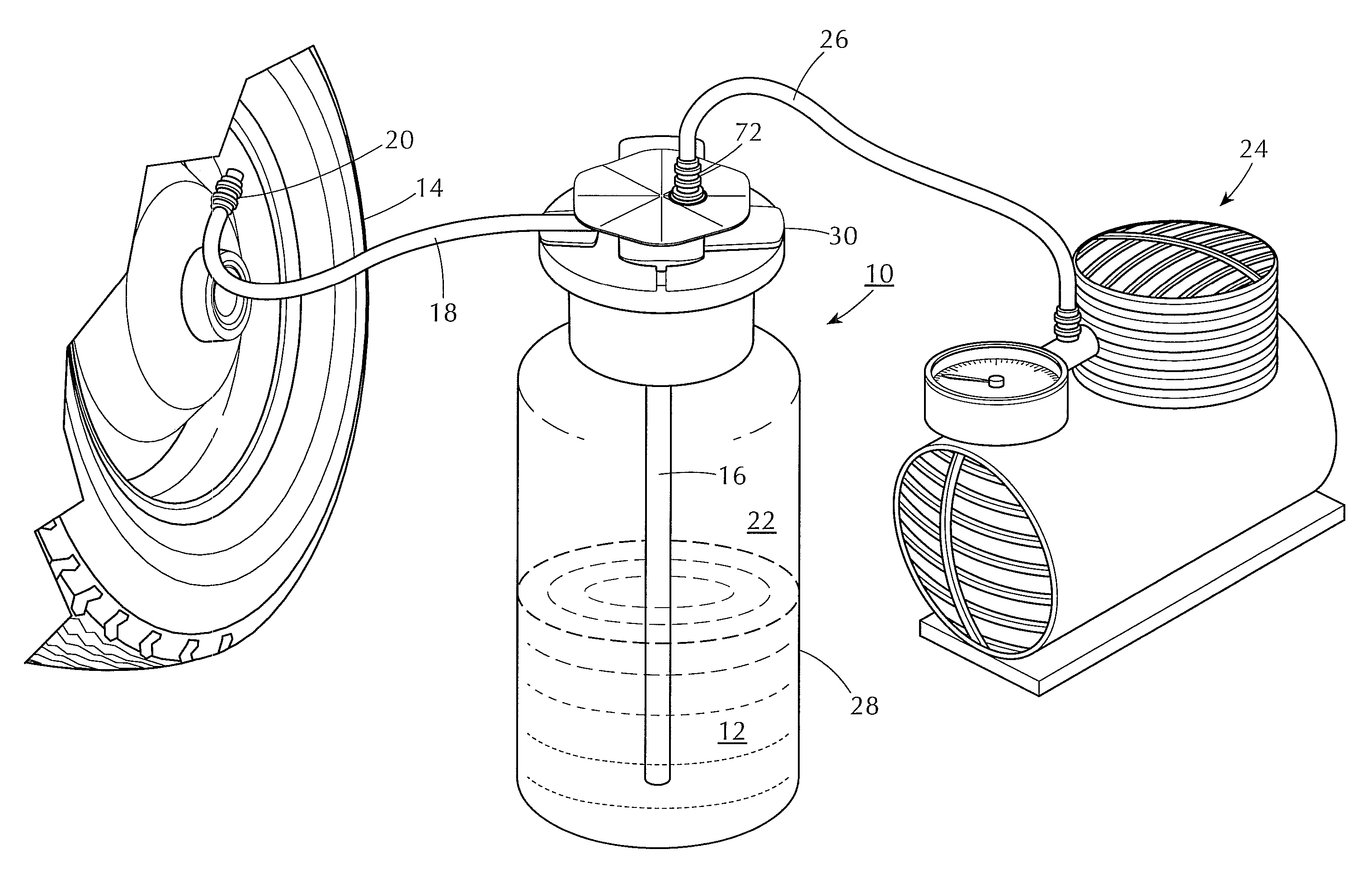

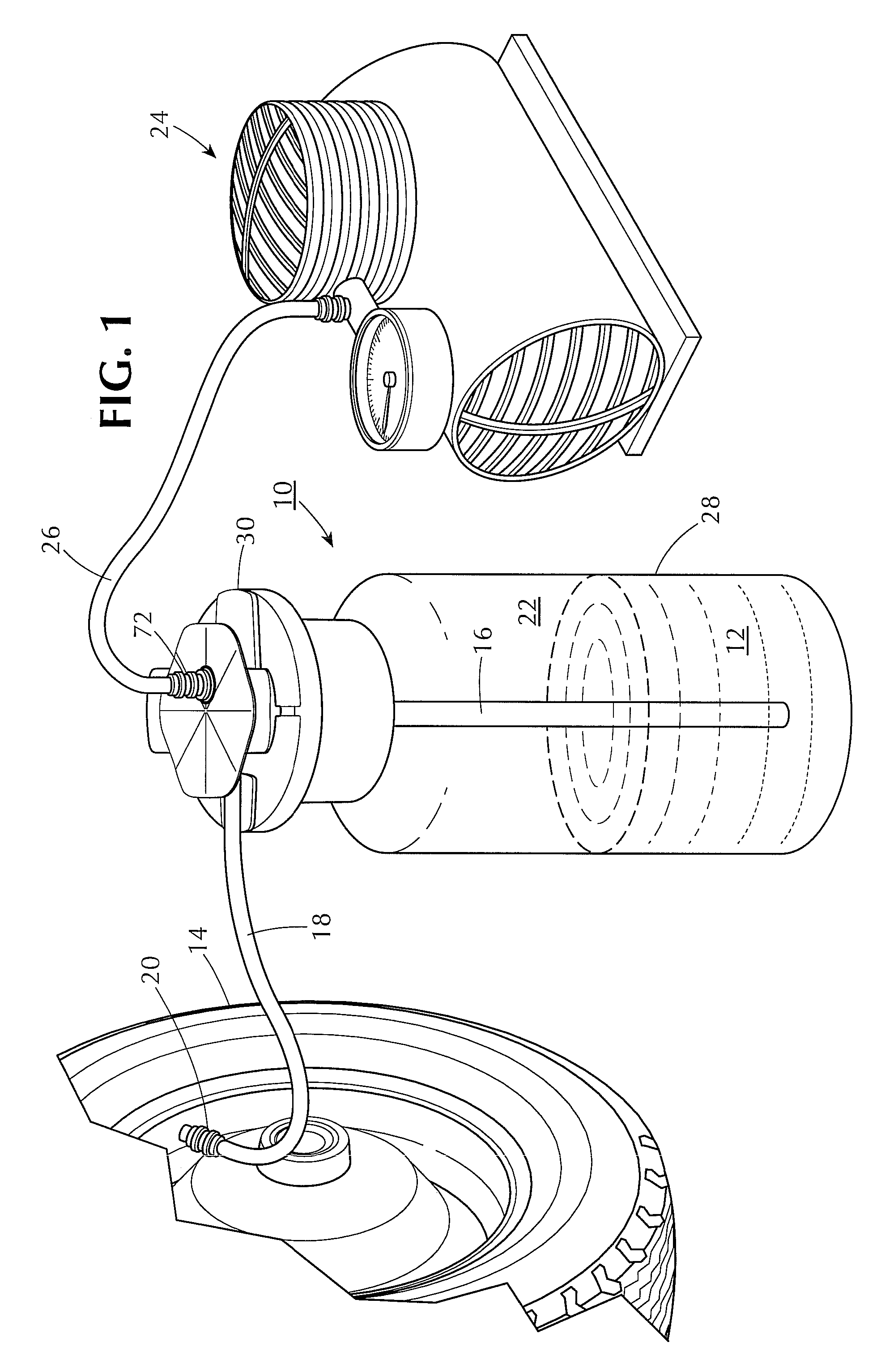

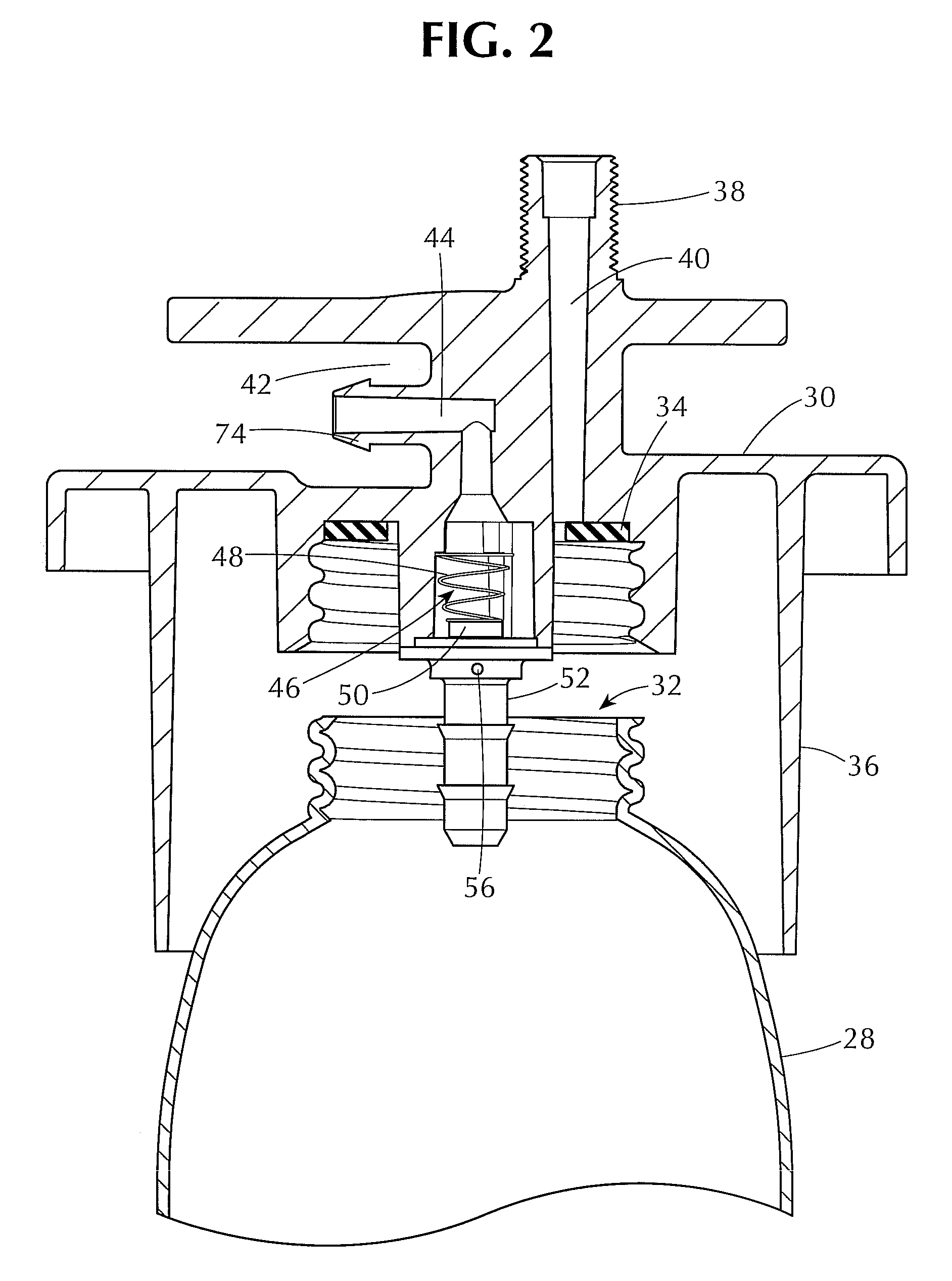

Tire sealant dispensing apparatus

InactiveUS20090107578A1Prevent backflowWide viscosity rangeLiquid fillingLiquid flow controllersLine tubingProduct gas

A tire-sealing apparatus for injecting a sealing composition into a vehicle tire either as a prophylactic or for sealing an existing leak is in the form of a pressurizeable container for a flowable sealant compound. An inlet is provided for introducing compressed gas into the container to pressurize its contents. An outlet line is also provided to deliver the sealant into a tire, the pressurized gas acting on contents of the container and providing the motive force for the delivery. A dip tube extends into the compound and is coupled to a one-way valve to provide a controlled flow of the compound from the container into the tire while preventing back pressure of the tire from either delivering air or compound back into the container. A passageway between the outlet tube and an interior of the container is provided to allow a flow of compressed gas within the container into the outlet tube along with the sealant.

Owner:TRANS TECH PRODS

Rock bit grease composition

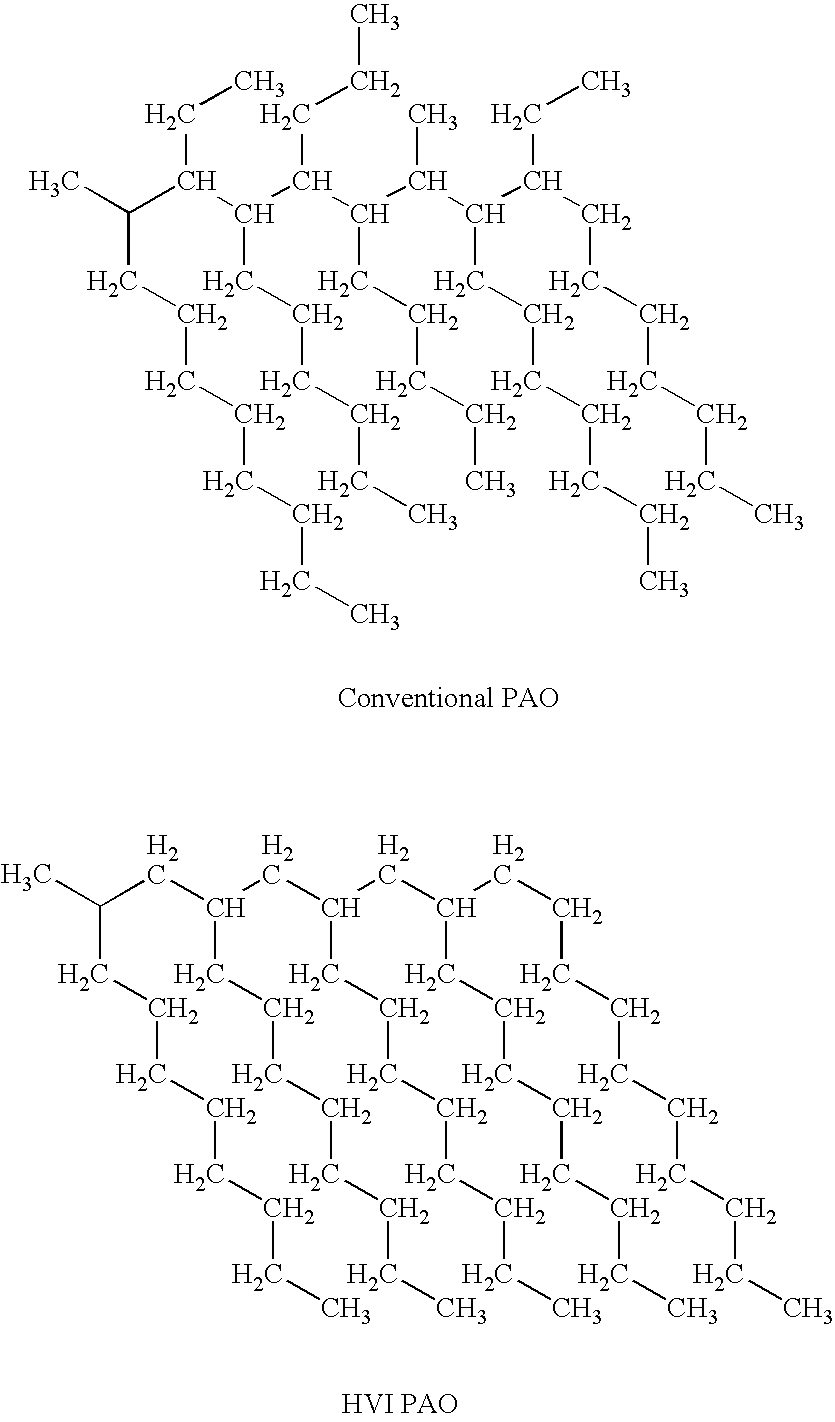

InactiveUS7312185B2Minimizes scoring and galling and wearGood thermal and oxidative stabilityTransportation and packagingHydrocarbon purification/separationViscosity indexLubrication

A grease for rock bit lubrication and other high temperature bearing applications is provided comprising a high viscosity index polyalphaolefin synthetic base fluid in combination with an alkylated naphthalene base fluid.

Owner:TOMLIN SCI

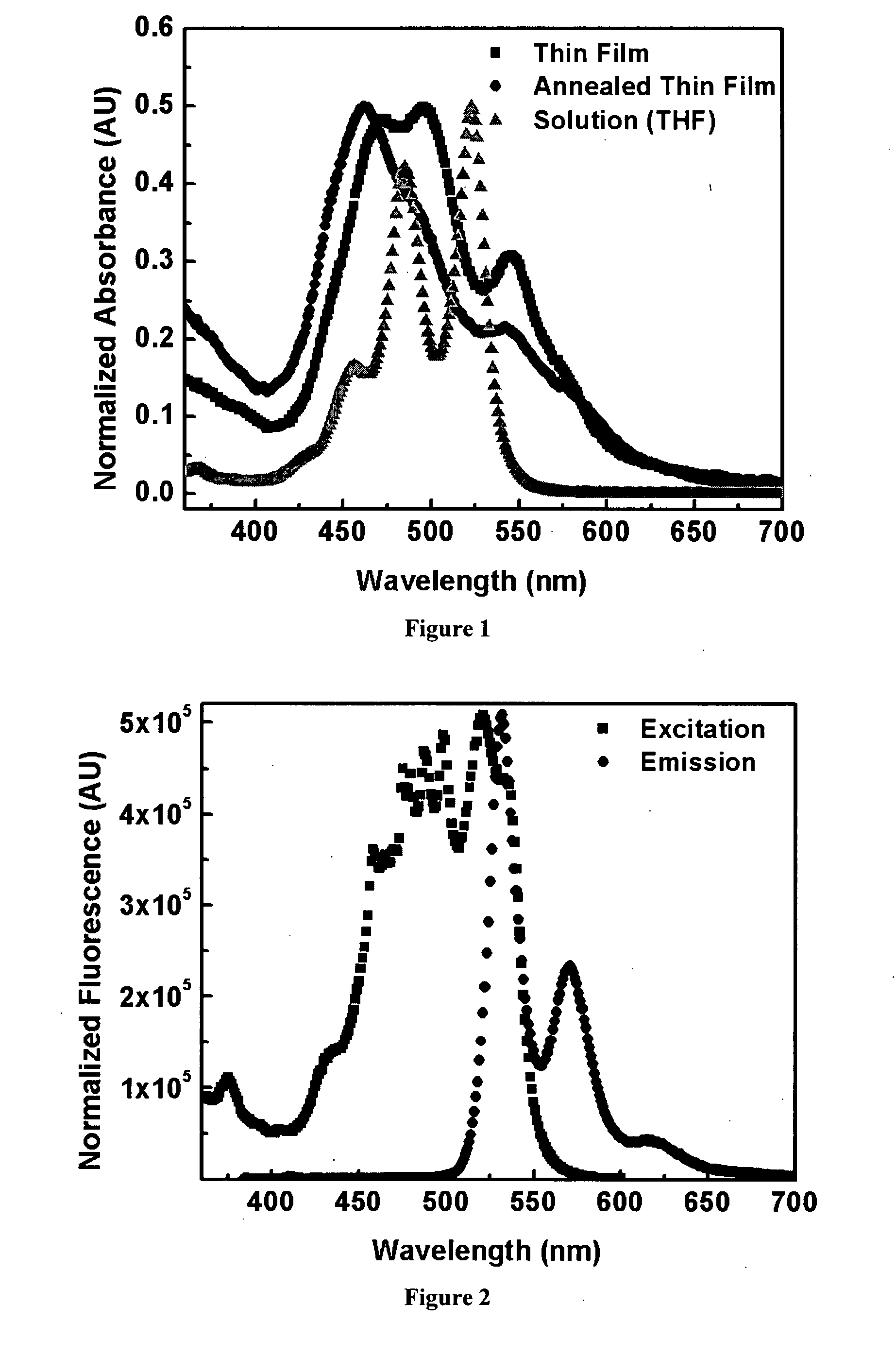

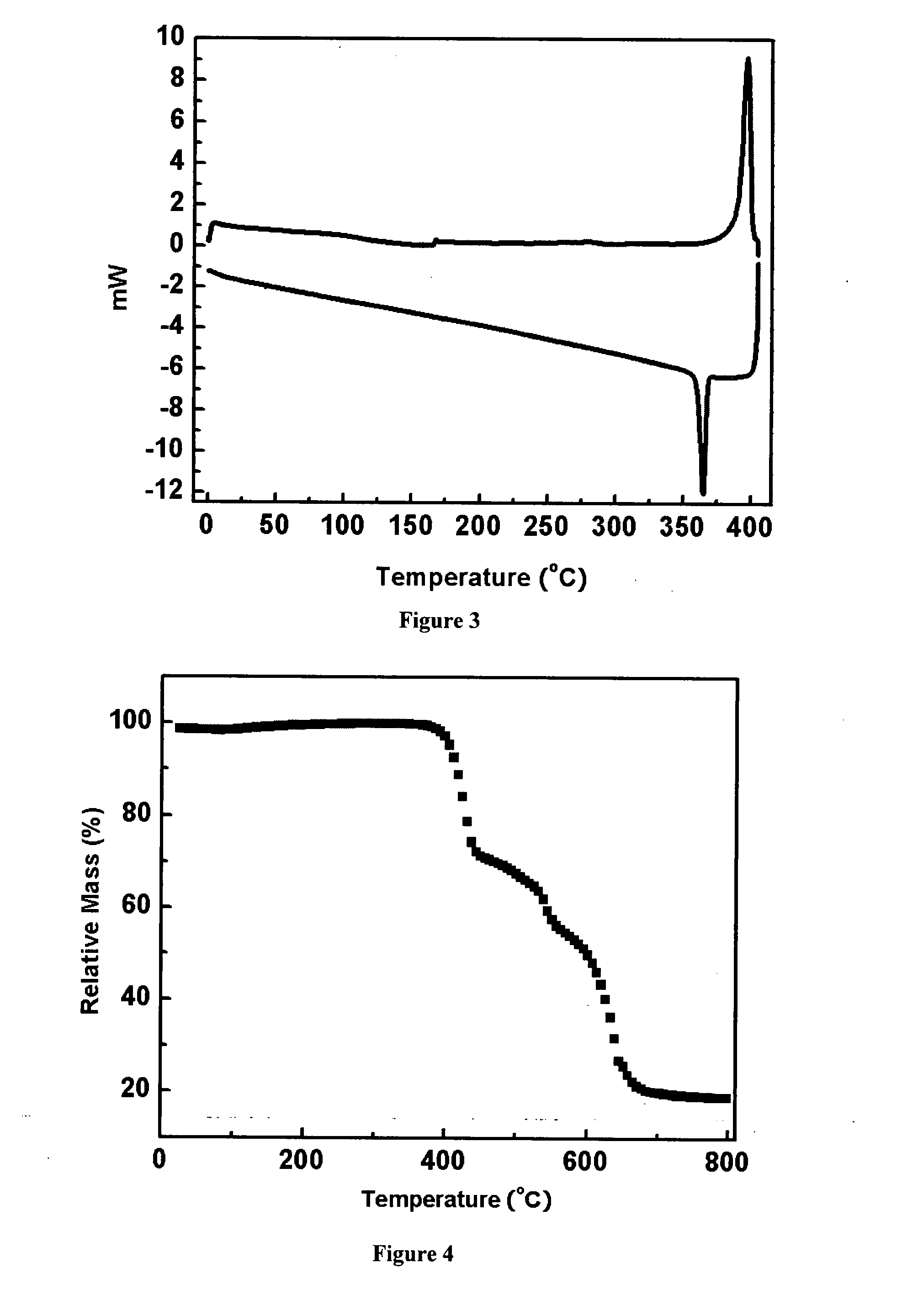

Organic semiconductor materials and methods of preparing and use thereof

ActiveUS20080167435A1Useful electrical propertyWide viscosity rangeOrganic chemistrySolid-state devicesOrganic semiconductorSemiconductor materials

Solution-processable organic n-type semiconductor materials are provided with processes for preparing the same. Composites and electronic devices including the organic n-type semiconductor materials also are provided.

Owner:FLEXTERRA INC

Fluid dispensing apparatus

ActiveUS20050236429A1Wide viscosity rangePrevent exitContracting/expanding measuring chambersLiquid flow controllersFluid controlViscosity

A concentrated flavour dispensing machine having displacement pumps for delivering between a few millilitres and few ounces of fluids having a viscosity value between 1 to 4000 centepoise is described. The dispensing machine includes a cabinet for containing a multitude of displacement pumps, where each displacement pump is in direct fluid communication with a respective storage tank, and a control panel having a programmable microprocessor mounted to the cabinet for receiving user selections and controlling each individual pump. Each displacement pump includes a stepper motor in engagement with a threaded drive rod for advancing a piston by any one of several predetermined distances to dispense a corresponding volume of fluid. The control panel receives a valid user selection for actuating one or more pumps to dispense the appropriate volume of a concentrated flavouring fluid. The microprocessor tracks the amount of fluid dispensed from each storage tank and alerts users and / or prevents further operation when reservoirs are close to empty to avoid null dispenses to customers. Various maintenance routines can be executed through the user interface, and dispense volumes and combination dispenses can be re-programmed manually or automatically.

Owner:A C DISPENSING EQUIP

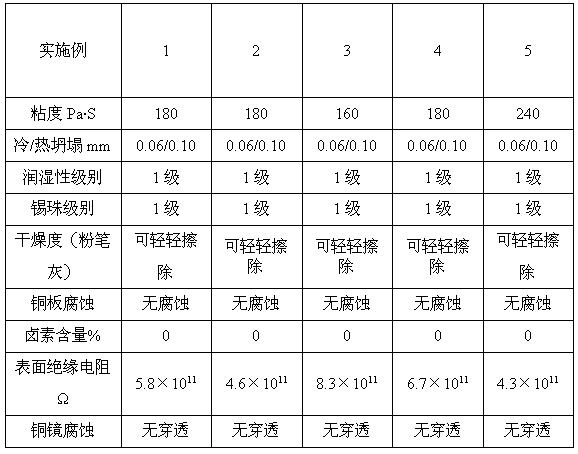

Halogen-free soldering flux for lead-free solder paste

InactiveCN104175023AImprove adhesionWide viscosity rangeWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention relates to the technical field of welding materials, in particular to a halogen-free soldering flux for lead-free solder paste. The halogen-free soldering flux for the lead-free solder paste comprises the following components in percentage by mass: 20 to 35 percent of solvent, 30 to 45 percent of rosin, 5 to 10 percent of surfactant, 10 to 20 percent of organic acid, 3 to 10 percent of antioxidant and 2 to 8 percent of thixotropic agent. According to the halogen-free soldering flux, a rosin mixture consisting of hydrogenated rosin and polymerized rosin at a weight ratio of 1:(1-3) is adopted, so that higher adhesive force of the solder paste is ensured; the proportion of the solvent and the rosin in the soldering flux is regulated, so that the viscosity range of the solder paste is wider; by the compounding of multiple organic acids, the prepared soldering flux is free of halogen, and has higher activity; the antioxidant for preparing the soldering flux is one or a combination of more than two of methylbenzotriazole, an antioxidant BHT, CHIMASSORB3030, benzimidazole and methylimidazole; the solder paste prepared from the soldering flux is long in service life, and has good de-molding effects.

Owner:JIANGSU BOQIAN NEW MATERIALS

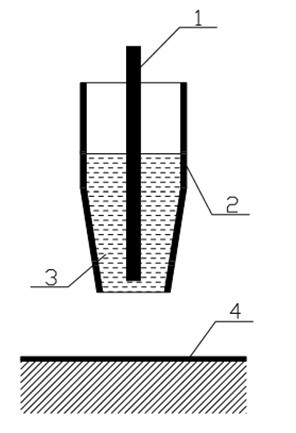

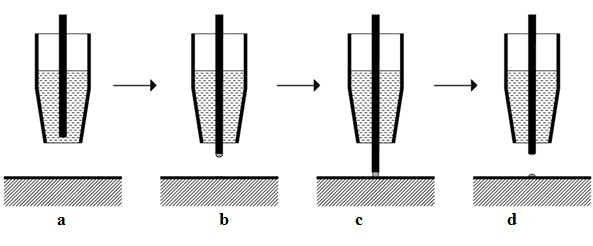

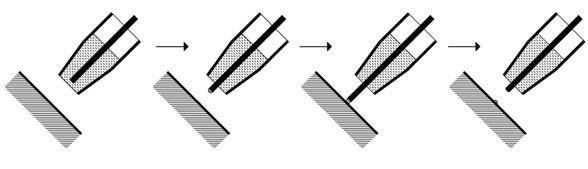

Ultra-micro glue dispensing device and method

InactiveCN102101097ARealize non-contact ultra-micro dispensingAchieve ultra-micro-volume dispensingLiquid surface applicatorsCoatingsTurn angleContact type

The invention provides an ultra-micro glue dispensing device and a method. The device comprises a glass micro tube, a glue solution and a solution moving needle which is arranged in the glass micro tube and can move to pass through the glue solution, wherein the glass micro tube is internally provided with the glue solution. The method comprises the step of realizing the ultra-micro glue dispensing by the micro liquid drop which is absorbed at the front end of the solution moving needle when the solution moving needle is penetrated through the glass micro tube. The invention is simple and easy to run, and can be used for not only the contact type ultra-micro glue dispensing but also the non-contact type ultra-micro glue dispensing, thereby being wide in an applicable viscosity range; the size of a glue spot can be easily changed by adjusting the diameter size of the front end of the solution moving needle, so that the control of glue dispensing quantity can be controlled; the micro adjustment of the size of the glue spot can be realized by controlling the micro distance between the front end of the solution moving needle and a glue dispensing surface; and the glue dispensing can not be limited within the vertical direction, and the micro glue dispensing can be realized at the any directions of the space by changing the turning angle of a turning pair.

Owner:SOUTH CHINA UNIV OF TECH

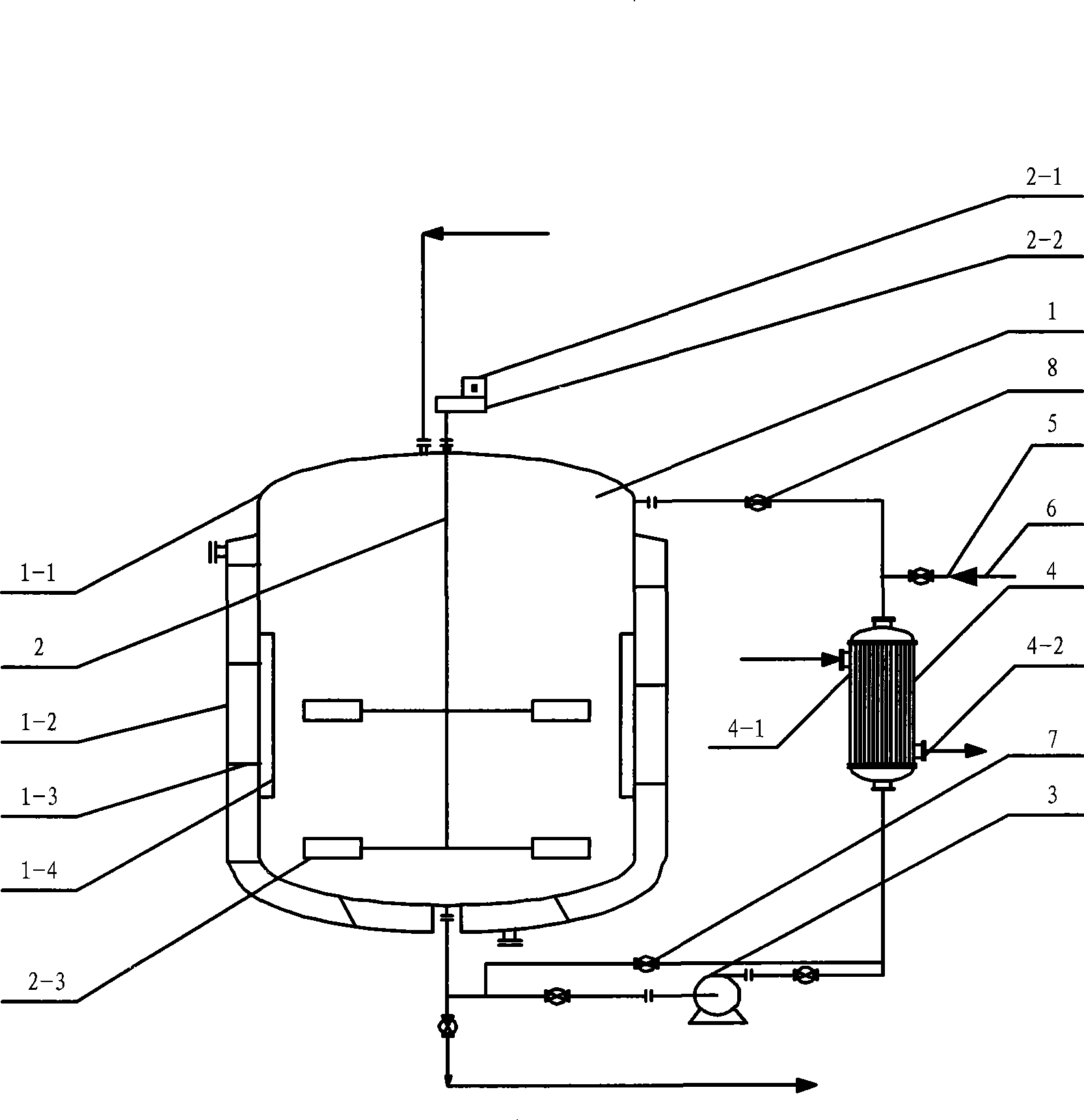

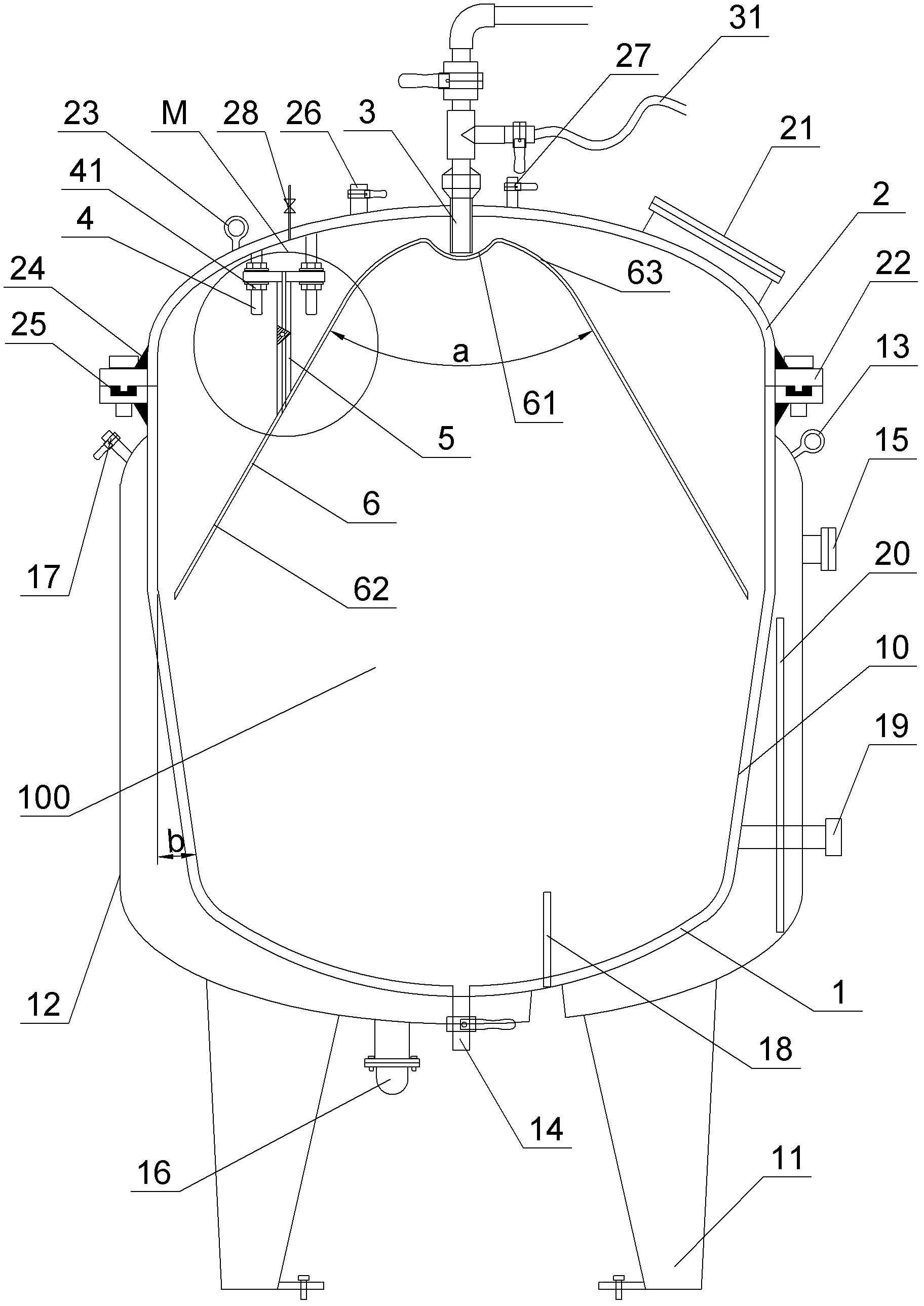

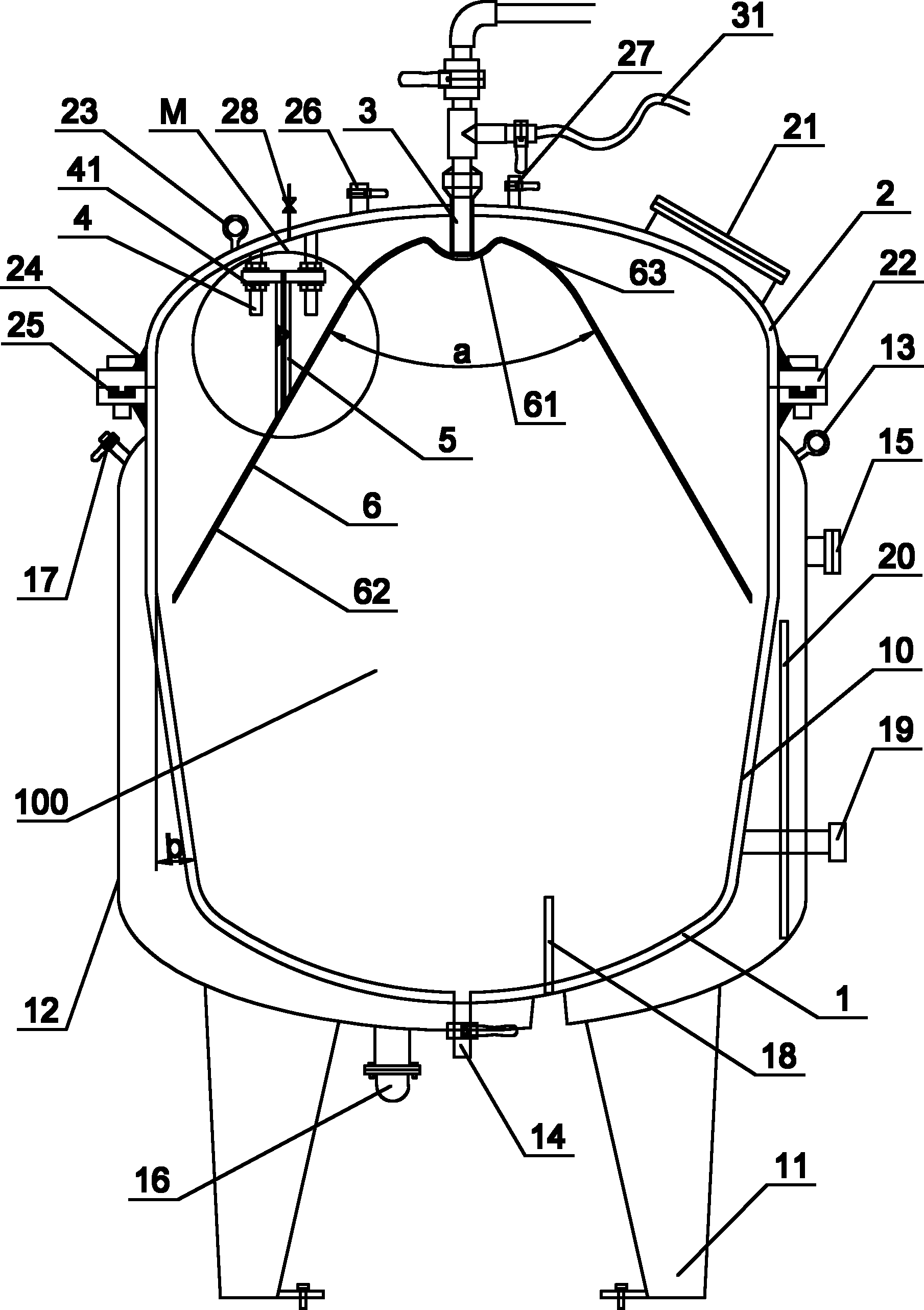

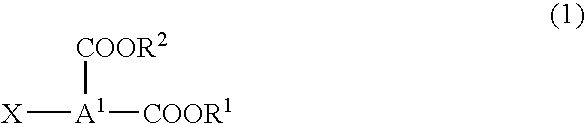

Reaction device with outer circulation device and method for controlling the reaction process

InactiveCN101362070AWide viscosity rangeImprove heat transfer rateChemical/physical/physico-chemical stationary reactorsLiquid-liquid reaction processesOperational costsProcess engineering

The invention discloses a reaction apparatus with external circulation equipment and a method for the reaction apparatus to control reaction process. The reaction apparatus comprises a reaction kettle as well as a fluid conveyer and a heat exchanger. One end of the fluid conveyer is connected to the lower part of the reaction kettle by a pipeline, while the other end is connected with the intake of heat exchanger by the pipeline, and the outlet of the heat exchanger is connected with the upper part of the reaction kettle by the pipeline, thereby constructing an external circulation passage for reactants. Stir and heat exchange are carried out to the reactants by the external circulation passage. The control carried out to the liquid-phase reaction by adopting the reaction apparatus with external circulation equipment and the method for the reaction apparatus to control reaction process is characterized by high heat exchange rate in the reaction process and suitability to a reactant system with a wide viscosity range, meanwhile, the construction cost and operational cost are both relatively low.

Owner:北京德润盛欣科技有限公司

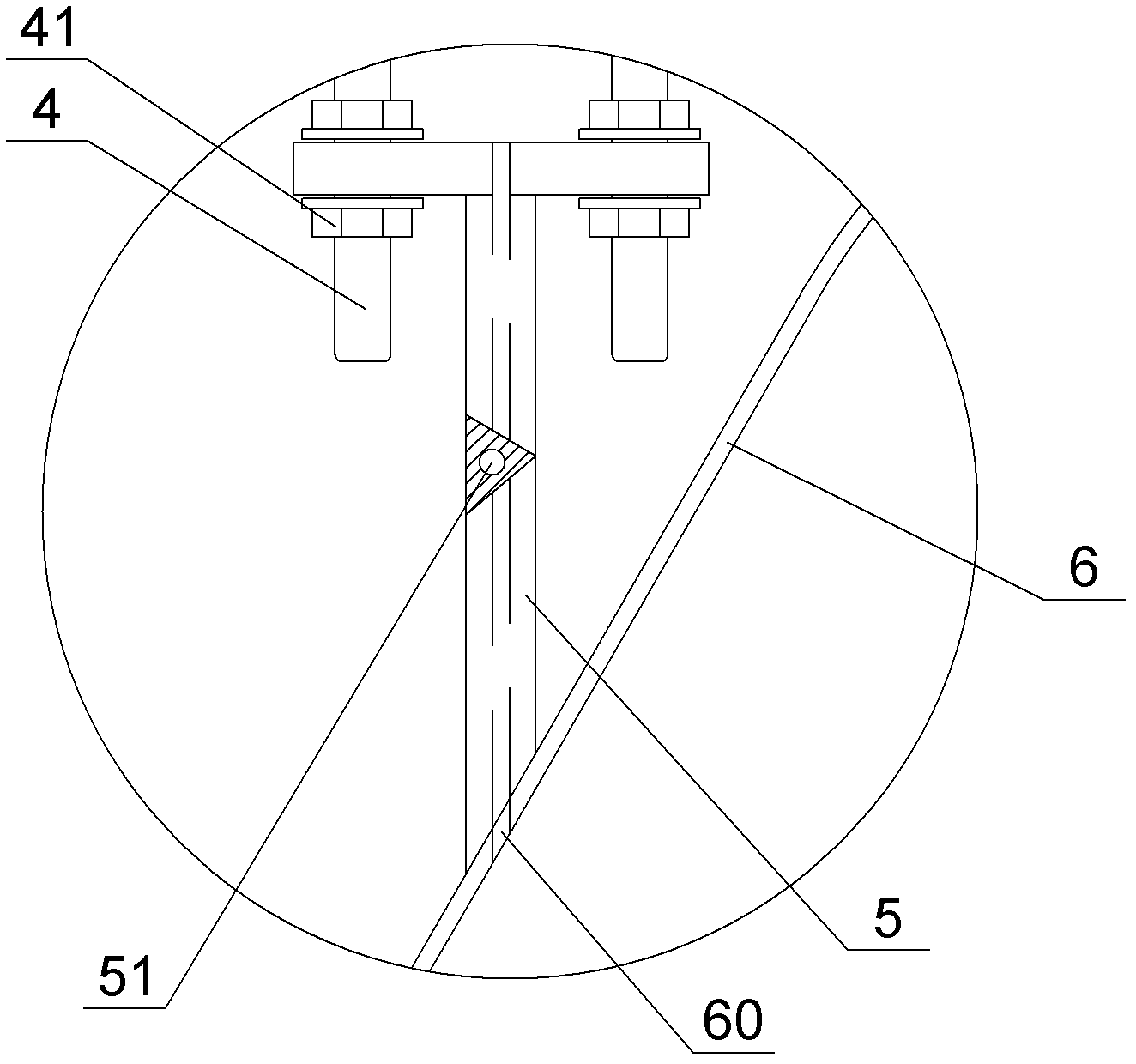

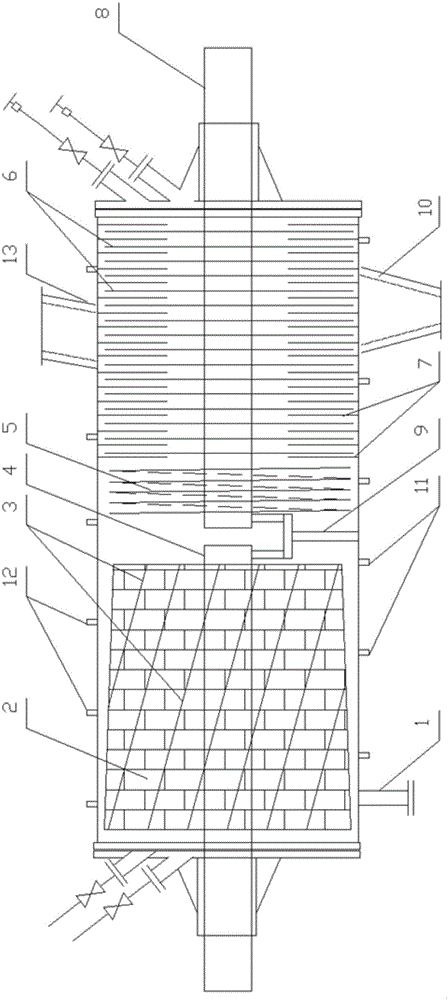

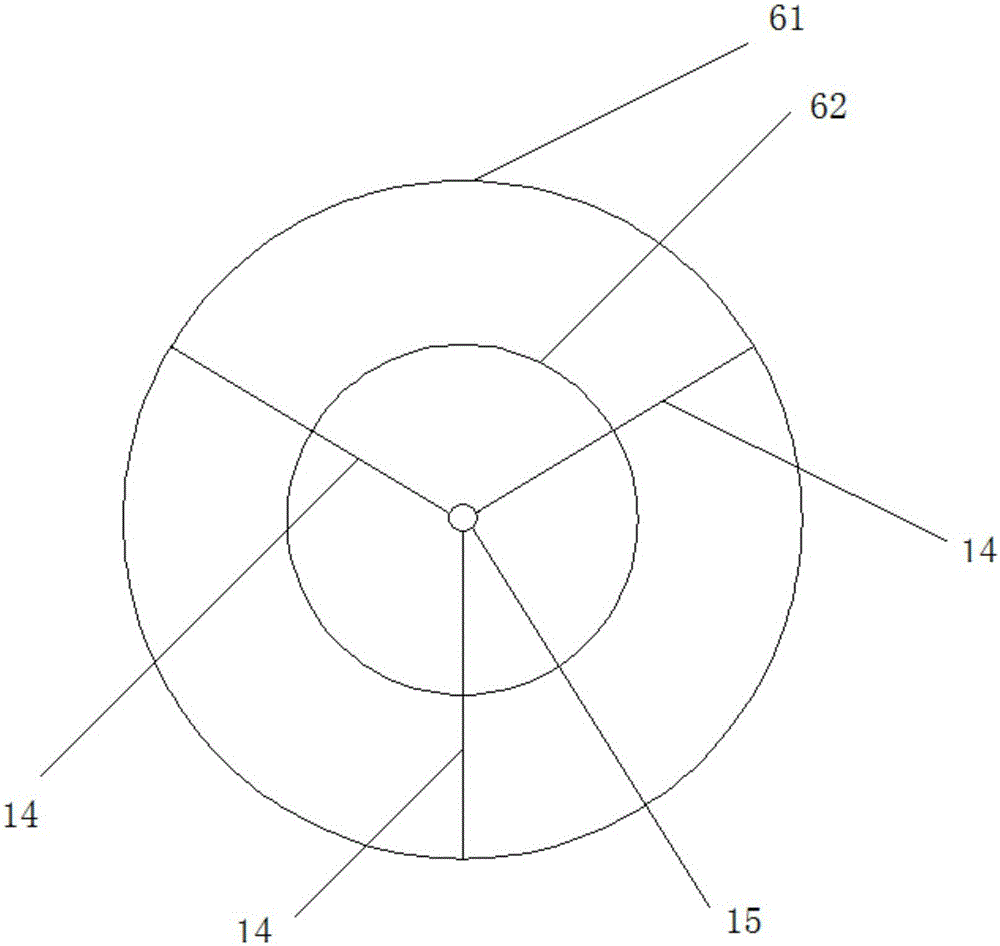

Ultrafiltration membrane deaerating unit

ActiveCN102657958ASolve the accuracy problemGood filtration accuracyLiquid degasificationUltrafiltrationUltrafiltrationDeaerator

The invention discloses an ultrafiltration membrane deaerating unit which is high in deaerating efficiency and effective in deaerating and enables ultrafiltration membrane filtrating precision to be improved and blow holes in spinning to be avoided. The ultrafiltration membrane deaerating unit is capable of removing bubbles once and is widely applicable to feed liquid in wide viscosity range. The ultrafiltration membrane deaerating unit comprises a tank (1) and an upper cover (2). The tank (1) and the upper cover (2) are connected to form a closed space (100). A feed pipe component (3) is connected to the center of the top of the upper cover (2). A liquid outlet (14) is reserved at the center of the bottom of the tank (1). An umbrella-shaped deaerator (6) is arranged on the inner upper portion of the closed space (100) and comprises an overflow groove (61) at the center of the top and a deaeration leveling umbrella-shaped face (62) around the overflow groove (61), and the overflow groove (61) corresponds to a feed inlet of the feed pipe component (3). A slanting deaeration membrane-drawing slope is reserved on the lower middle of the inner wall of the tank (1). The ultrafiltration membrane deaerating unit is widely applicable to the field of ultrafiltration membrane preparation.

Owner:怀集汇清环保设备工程有限公司

Bacterial cellulose/chitosan composite gel and preparation thereof, and application of composite gel in body surface wound surface healing

ActiveCN103463124AGood compatibilityWide viscosity rangeAntibacterial agentsOrganic active ingredientsWound surfaceBody surface

The invention relates to a bacterial cellulose / chitosan composite gel and preparation thereof, and application of the composite gel in body surface wound surface healing. The composite gel is composed of a chitosan solution, bacterial cellulose, an antimicrobial agent, a thickener solution and a neutralization agent. The invention also relates to application of the bacterial cellulose / chitosan composite gel in preparing body surface wound surface healing medicines. The preparation method comprises the following steps: uniformly mixing the chitosan solution, thickener solution, bacterial cellulose and antimicrobial agent, adding the neutralization agent to regulate the pH value to 6.0-9.0, and standing for deforming. The composite gel provided by the invention has favorable film-forming action, and performs the functions of isolating the wound surface and protecting the wound; and the bacterial cellulose / chitosan has the advantages of simple preparation process and easy technical control, and is convenient for industrial production.

Owner:江西佑创销售有限公司

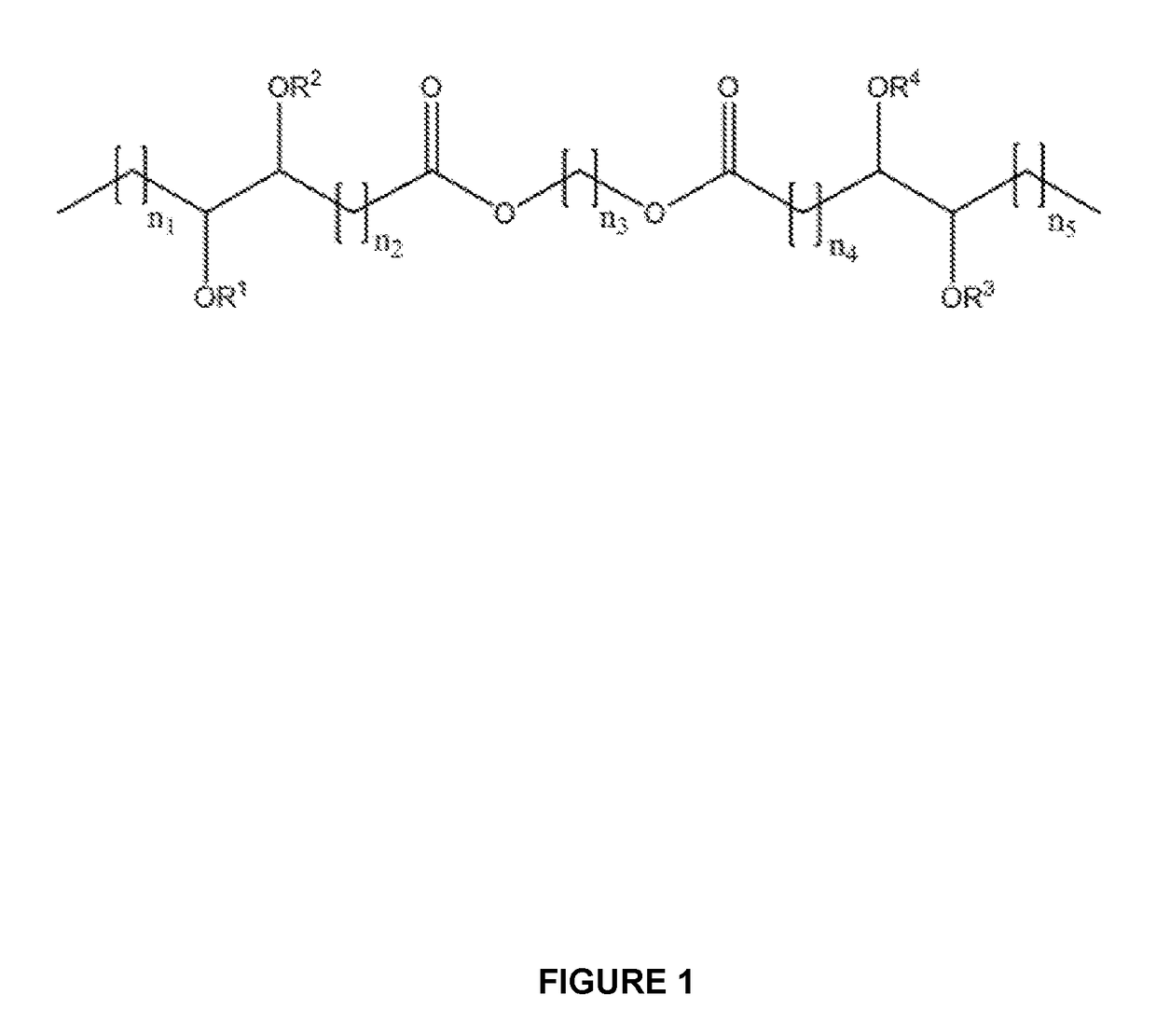

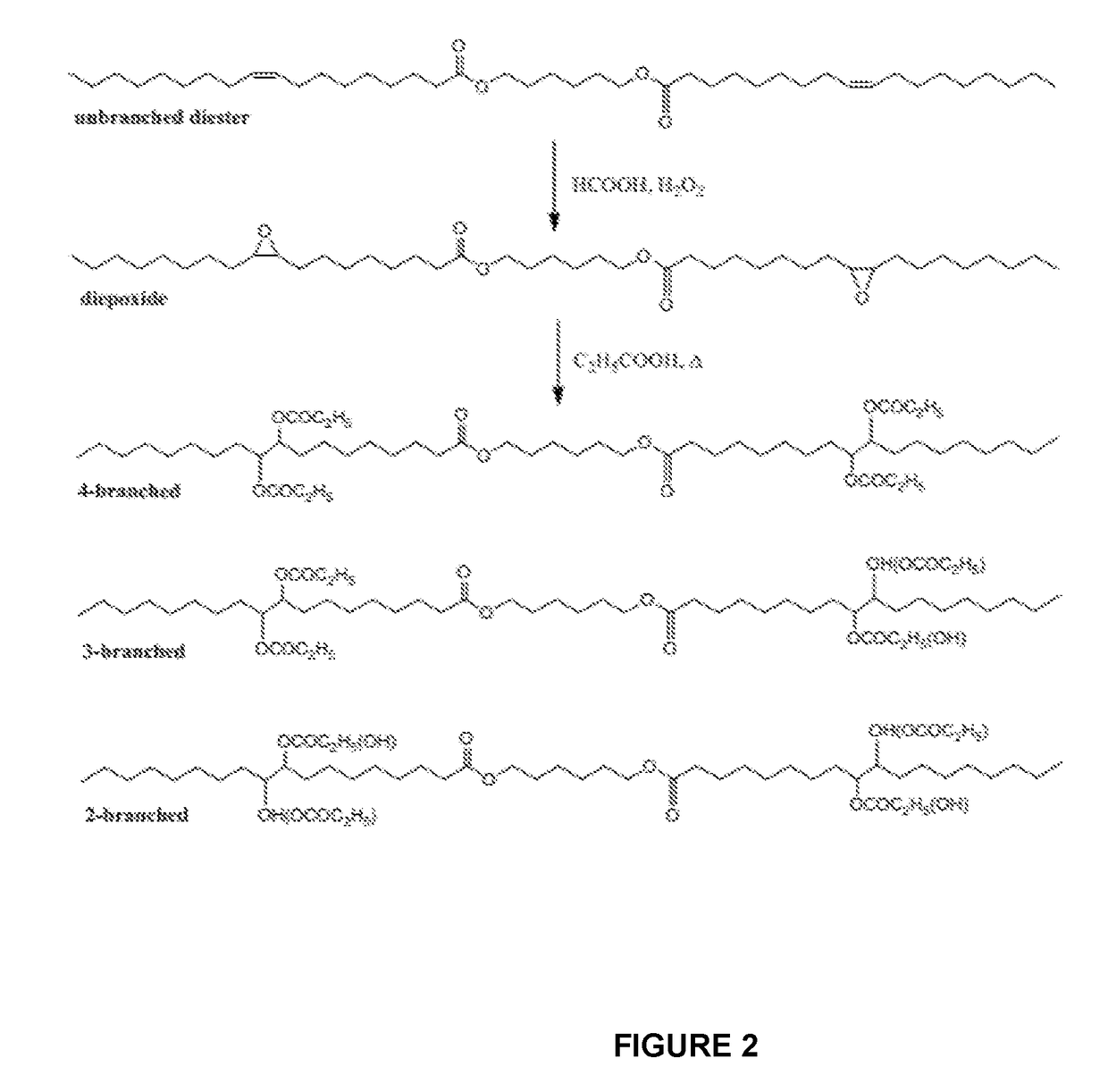

Branched diesters and methods of making and using the same

ActiveUS20170137739A1High viscosityImprove low temperature performanceOrganic chemistryLiquid carbonaceous fuelsVegetable oilSolvent free

The disclosure generally provides branched diester compounds having exceptional low-temperature and flow properties. The disclosure also provides uses of the branched diester compounds in lubricant compositions, for example, as a base oil, and in other applications where their low-temperature and flow properties can be employed beneficially. The disclosure also provides efficient and green methods for making the branched diester compounds.In certain embodiments, a vegetable oil-based diester (1,6-hexyldioleate) was branched with propanoic acid (C3) using a green synthetic approach involving solvent-free and catalyst-free epoxide ring opening followed by in situ normal esterification. A total of three branched ester derivatives possessing varied numbers of internal protruding branched ester groups and hydroxyl groups were obtained. All of the pure branched derivatives were comprised of mixtures of positional isomers and / or stereoisomers. Differential scanning calorimetry (DSC) showed that regardless of the composition inhomogeneity of each branched derivative, crystallization was suppressed completely in all of the branched compounds, and they all demonstrated glass transitions below −65° C.Without being bound by any theory, it is believed that this unique thermal behavior is attributed to the internal protruding branched moieties and hydroxyl groups, which dramatically slowed down mass transfer starting with the least branched compound (2-branched derivative). The viscosity of the branched compounds was one order of magnitude larger than that of the starting di ester due to the increased branching and increased resistance to flow associated with hydrogen bonding introduced by the OH groups. Overall, these branched diesters demonstrated superior low temperature and flow properties comparable to existing non-sustainable commercial lubricants and analogous biobased materials which makes them suitable alternatives for use in lubricant formulations particularly in high performance industrial gear and bearing lubricants.

Owner:TRENT UNIVERSITY

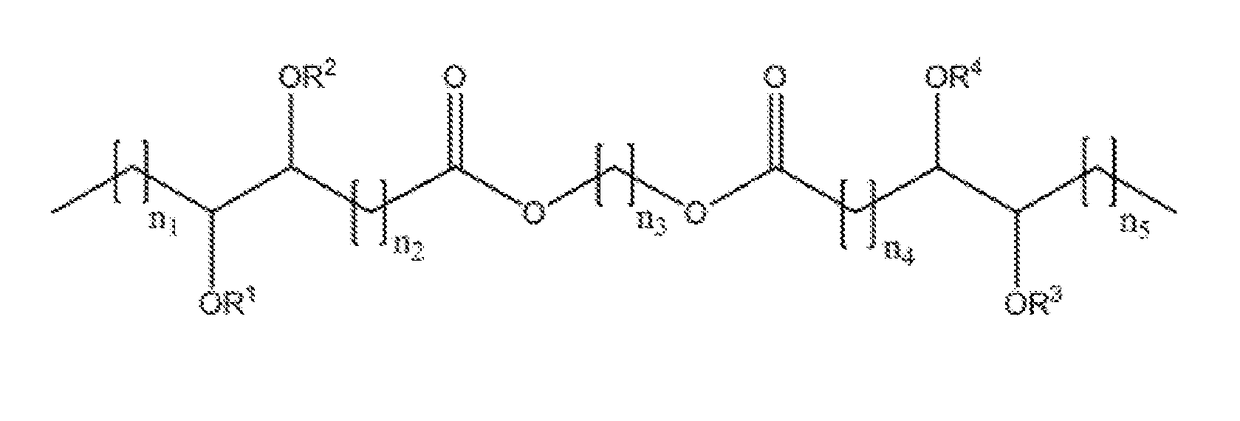

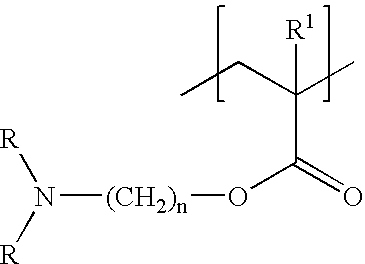

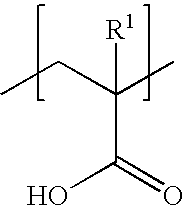

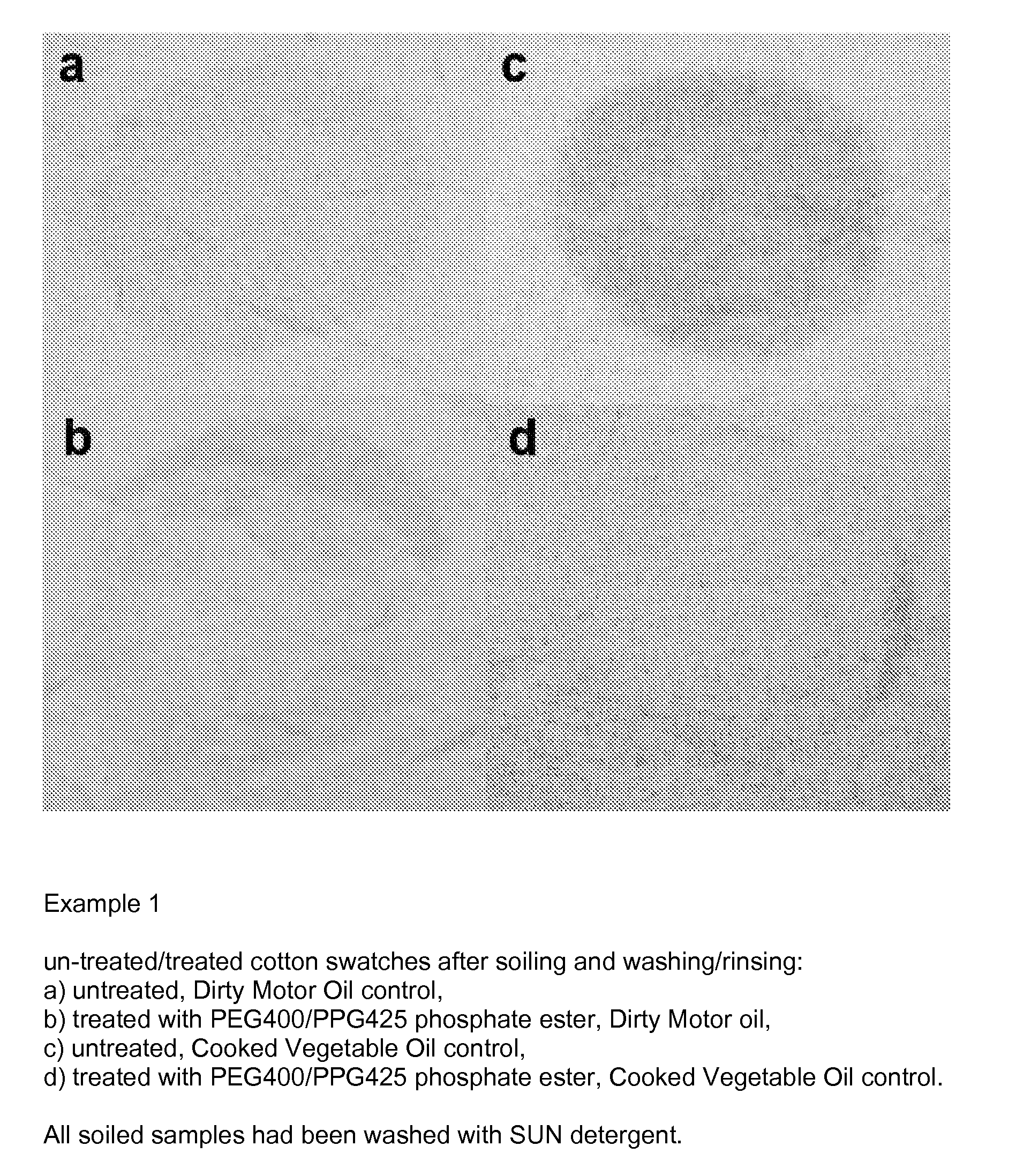

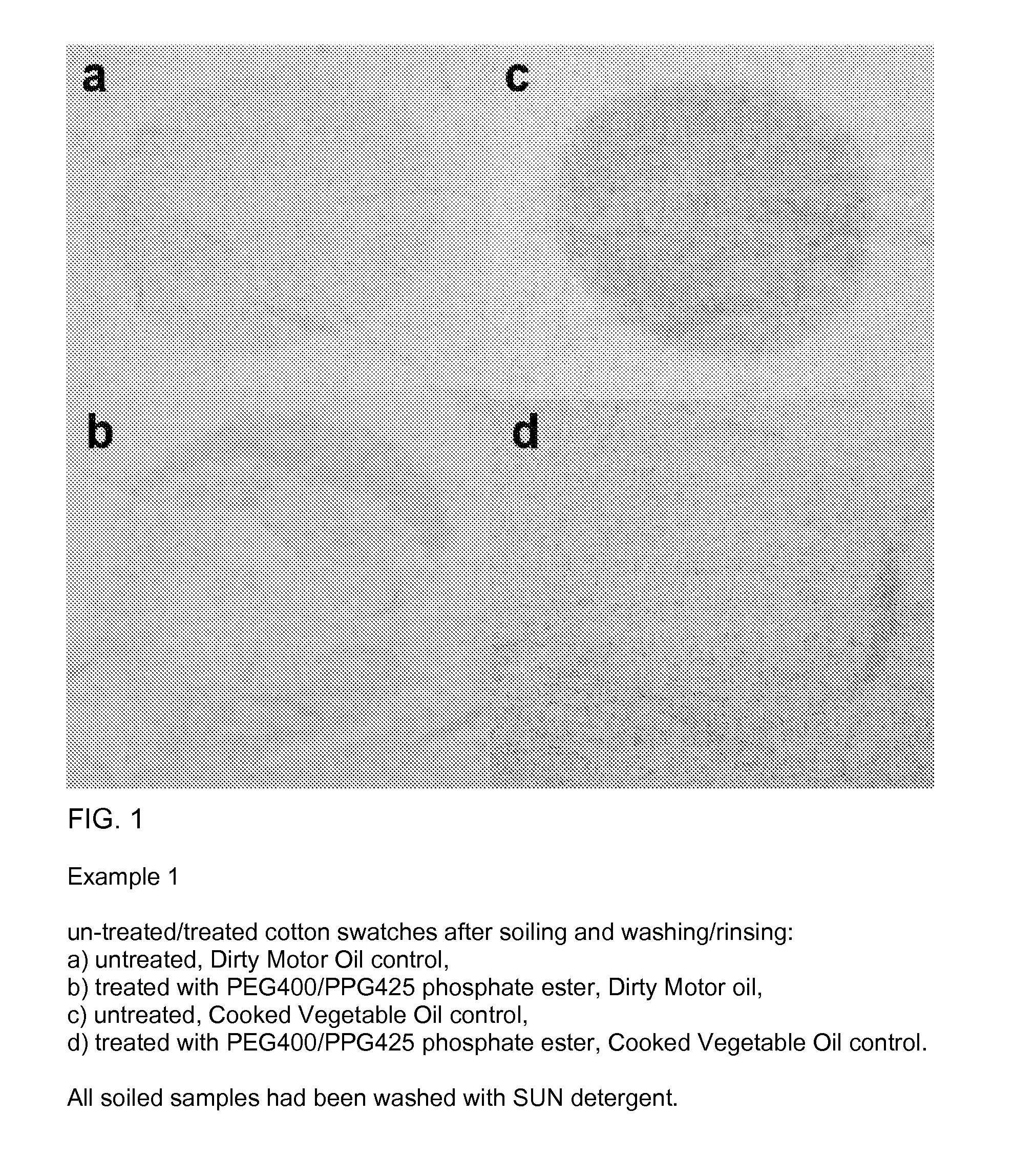

Detergent composition with hydrophilizing soil-release agent and methods for using same

InactiveUS7557072B2Wide viscosity rangeCosmetic preparationsOrganic detergent compounding agentsSoil scienceEnvironmental engineering

Owner:RHODIA OPERATIONS SAS

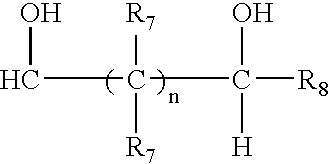

Diols and polymeric glycols for improved dishwashing detergent compositions

InactiveUS6894013B2Superior cleaning and grease cutting and physical stability and dissolution and rheological behaviorImprove physical and enzymatic stabilityOrganic detergent compounding agentsNon-ionic surface-active compoundsDiolOrganic solvent

Disclosed are detergent compositions for hand dishwashing which, by incorporating certain organic solvents, results in a liquid dishwashing detergent composition that is not only a more effective cleaning agent, but also offers improved physical and enzymatic stability and more convenient rheology and handling characteristics than typical liquid dishwashing compositions.

Owner:THE PROCTER & GAMBLE COMPANY

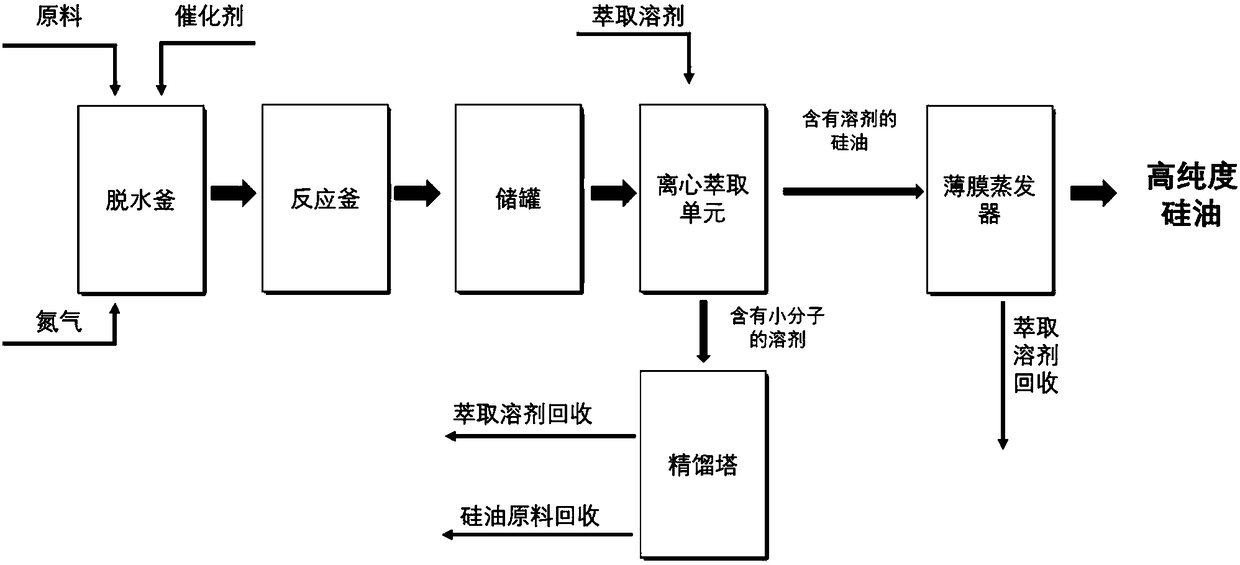

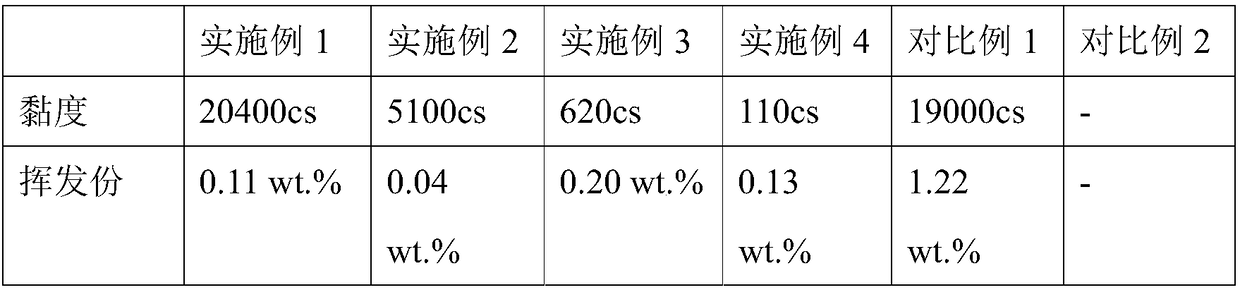

Production method and production system of low-volatile vinyl silicone oil

The invention discloses a production method and a production system of low-volatile vinyl silicone oil. A centrifugal extraction technology is introduced into a synthesis process of vinyl silicone oil, and the vinyl silicone oil is centrifugally extracted to reduce the content of a siloxane ring body. The vinyl silicone oil obtained by centrifugal extraction is taken into a thin film evaporator toremove a solvent to obtain the low-volatile vinyl silicone oil; the solvent obtained by centrifugal extraction is recovered by using a rectifying tower. According to the production method and the production system of the low-volatile vinyl silicone oil, the volatile of vinyl silicone oil is reduced from 0.8wt. % and higher to within 0.1wt. %, equipment costs and production energy consumption arereduced, a production cycle is shortened, and materials can be recycled. At the same time, by changing extraction conditions, solvent types and ratios, the volatile content of products can be easily and accurately controlled and the low-volatile vinyl silicone oils with different quality requirements is produced.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

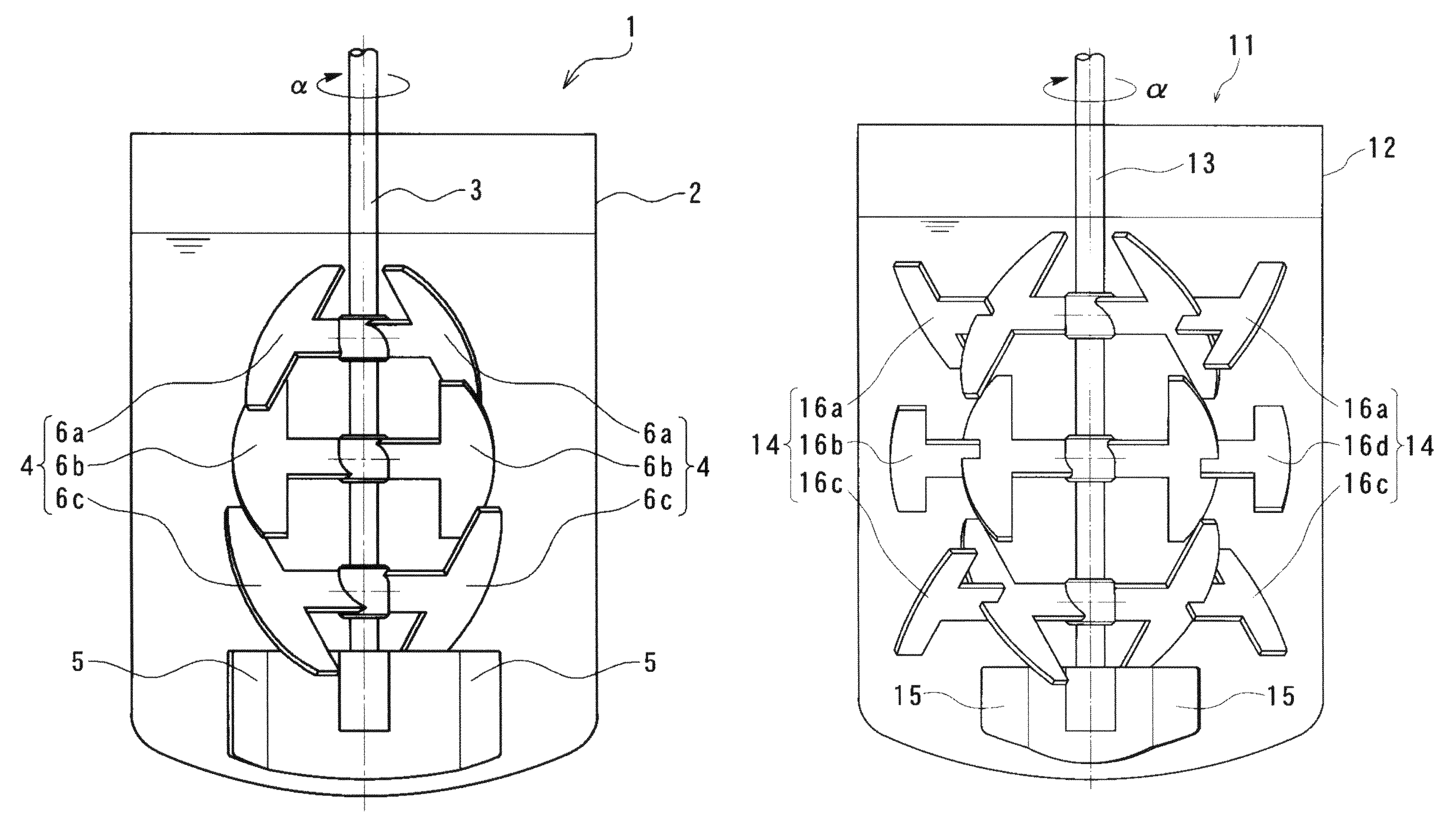

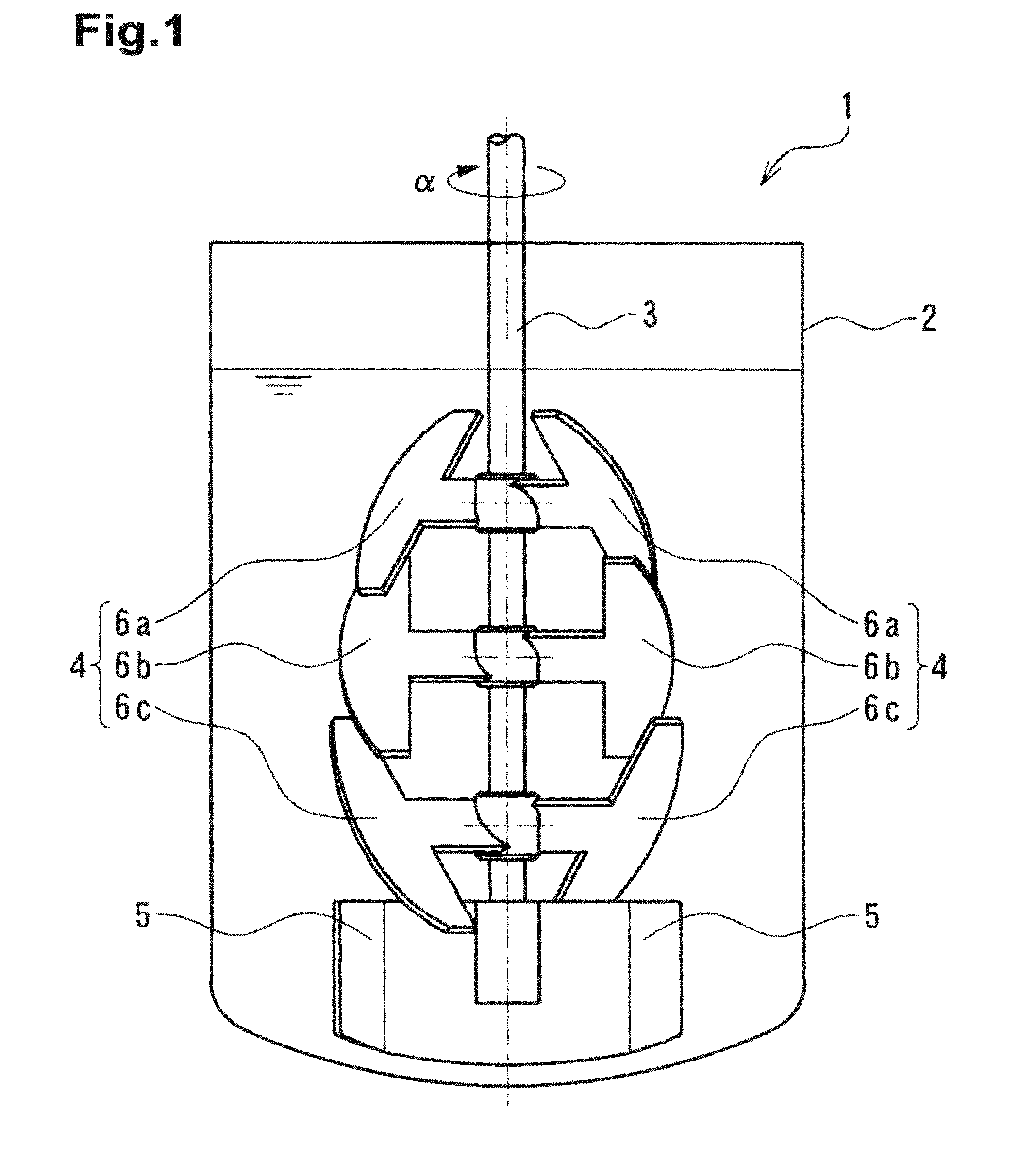

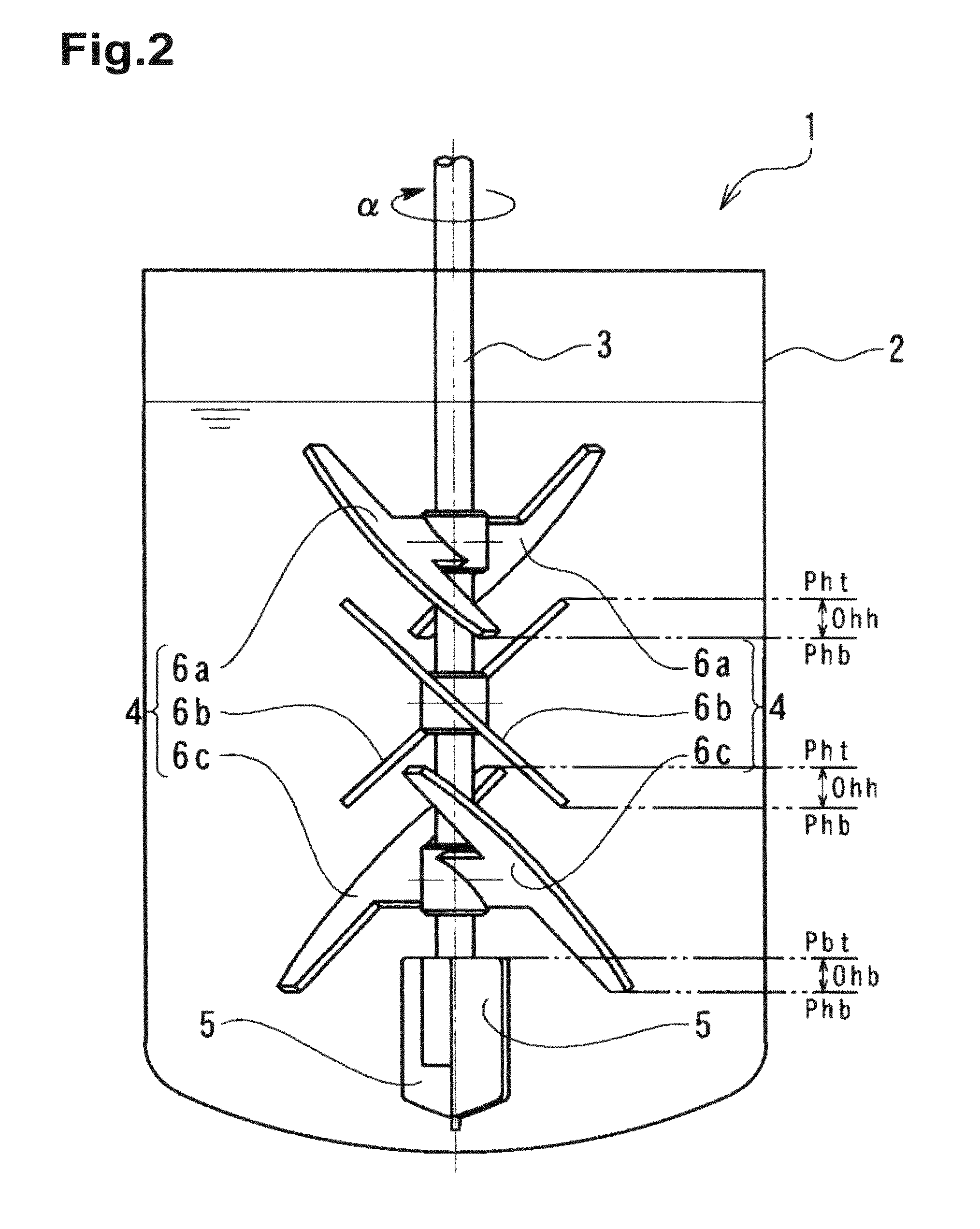

Agitation apparatus and agitation method

ActiveUS8485716B2Rapid and efficientReduce riskFlow mixersRotary stirring mixersEngineeringThixotropy

Owner:DAINIPPON INK & CHEM INC

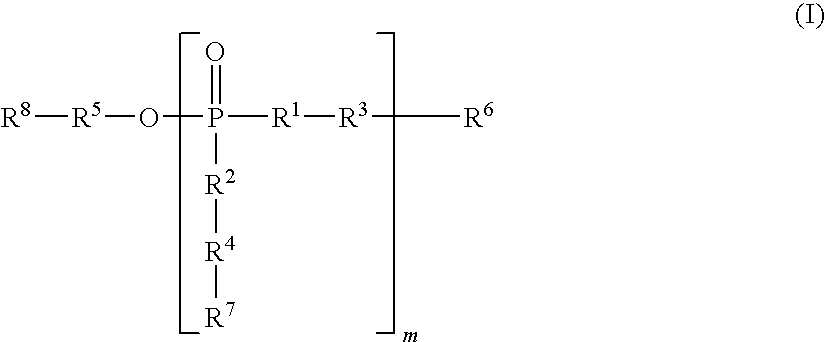

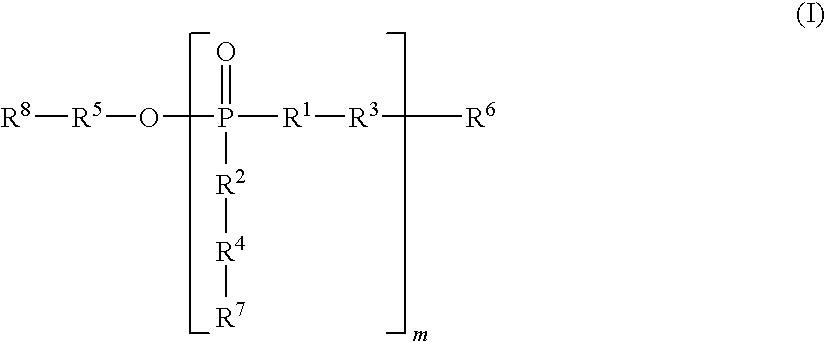

Detergent composition with hydrophilizing soil-release agent and methods for using same

InactiveUS20090233837A1Wide viscosity rangeSurface-active detergent compositionsDetergent mixture composition preparationBleachWater soluble

Laundry detergent compositions that provide soil release benefits to all fabric comprising an organophosphorus soil release agents and optional non-cotton secondary soil release agents. The present invention further relates to a method for providing soil release benefits to cotton fabric by contacting cotton articles with a water soluble and / or dispersible organophosphorus material. The contacting can be during washing or by pretreating by applying the composition directly to stains or by presoaking the clothing in the composition prior to washing. The present invention further relates to providing soil release benefits to all fabric in the laundry wash load in the presence of a bleaching agent.

Owner:RHODIA OPERATIONS SAS

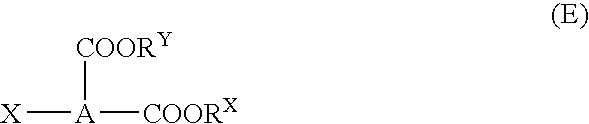

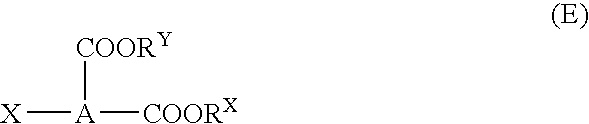

Dicarboxylic diester, process for producing the same, and refrigerating machine lubricating oil comprising the ester

InactiveUS7282601B2Improve hydrolytic stabilityWide viscosity rangeOrganic chemistryOrganic compound preparationMethyl groupRefrigerated temperature

A diester represented by the formulawherein A represents a cyclohexane ring, cyclohexene ring or benzene ring, X is H or methyl group, RX and RY are the same or different and each is C3-C18 branched-chain alkyl group, C1-C18 straight-chain alkyl group, C2-C18 straight-chain alkenyl or C3-C18 cycloalkyl, provided that when A is a benzene ring, RX and RY are different from each other and —COORX and —COORY are attached to two adjacent carbon atoms of the benzene ring, and having the following properties:1) a total acid number of 0.05 mgKOH / g or less,2) a sulfated ash content of 10 ppm or less,3) a sulfur content of 20 ppm or less,4) a phosphorus content of 20 ppm or less,5) a peroxide value of 1.0 meq / kg or less,6) a carbonyl value of 10 or less;7) a volume resistivity of 1×1011 Ω·cm or more,8) a hydroxyl value of 3 mgKOH / g or less, and9) a water content of 100 ppm or less,a process for preparing the same and a refrigerator lubricating oil comprising the diester.

Owner:NEW JAPAN CHEM CO

Polymeric reactor and polyester production method

ActiveCN106268591AHigh viscosityIncrease the devolatilization areaChemical/physical/physico-chemical stationary reactorsCircular discPolyester

The invention discloses a polymeric reactor and a polyester production method. The polymeric reactor comprises a closed horizontal cylinder. A front end rotating shaft is arranged at the portion, close to a material inlet, inside the cylinder. One end of the front end rotating shaft stretches out from the cylinder and is connected with a first power device. A rear end rotating shaft is arranged at the portion, close to a material outlet, of the cylinder, and one end of the rear end rotating shaft stretches out from the cylinder and is connected with a second power device. A supporting structure for supporting the front end rotating shaft and the rear end rotating shaft is arranged inside the cylinder. A cage frame type stirrer is arranged on the front end rotating shaft. A section of screw-type disc is arranged at the portion, close to the front end rotating shaft, of the rear end rotating shaft. A plurality of sets of coaxial circular rings are arranged at the other parts of the rear end rotating shaft. A plurality of scrapers parallel to the faces of the circular rings are arranged among the circular rings. According to the method, the polymeric reactor is used for performing polyester production to obtain a high-viscosity polyester melt. The cage frame type stirrer is arranged at the front end, the multiple circular rings are arranged at the rear end, and the devolatilization efficiency of equipment can be effectively improved.

Owner:SHANGHAI JUYOU CHEM ENG

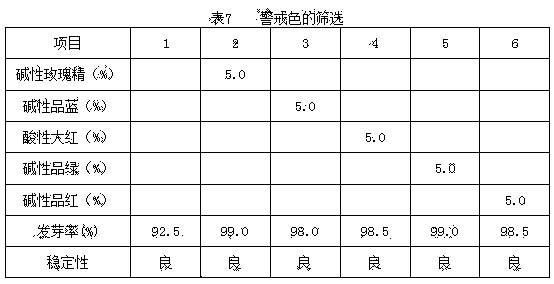

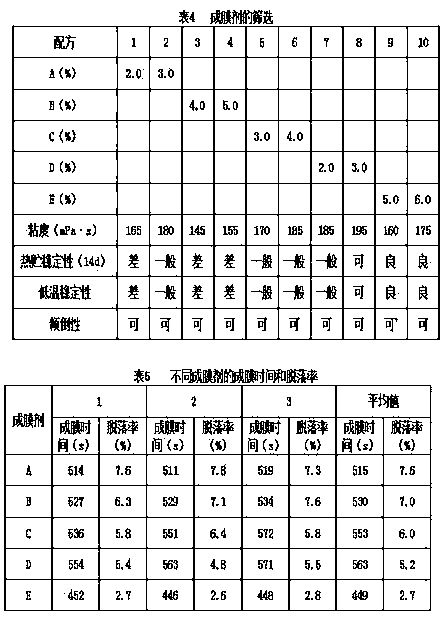

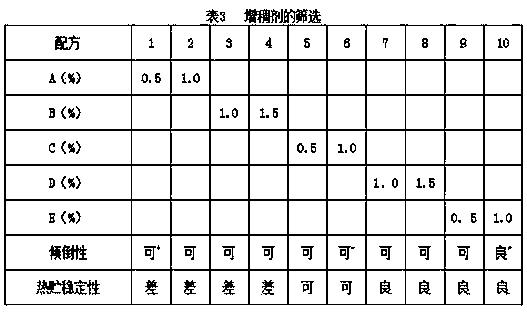

Suspended seed coating for preventing and curing corn smut and preparation method thereof

ActiveCN104255774AGood control effectNot easy to develop resistanceBiocideFungicidesBiotechnologySmut

The invention discloses a suspended seed coating for preventing and curing corn smut and a preparation method thereof. The suspended seed coating for preventing and curing corn smut is characterized by being prepared from the following raw materials in percentage by weight: 3.0-7.0% of imidacloprid, 7.0-12.0% of thiram, 0.2-0.6% of diniconazole, 1.5-2.5% of wetting dispersant, 0.5-1.5% of thickening agent, 2.0-6.0% of antifreezing agent, 0.1-0.3% of preservative, 2.0-6.0% of film-forming agent, 3.0-7.0% of warning colouration, 1.0-5.0% of microelements and the balance of water. The suspended seed coating disclosed by the invention is free of harmful effect on the emergence of seedlings and growth of corn, medicine is wrapped around seeds in a concentrated manner, and the medicine is slowly released. The average control effect for corn underground insects is 77.5%-83.5%, the control effect for head smut is 81.7%-88.4%, and the average growth rate is 16.4%-22.6%.

Owner:WUWEI CHUNFEI CROP SCI & TECH

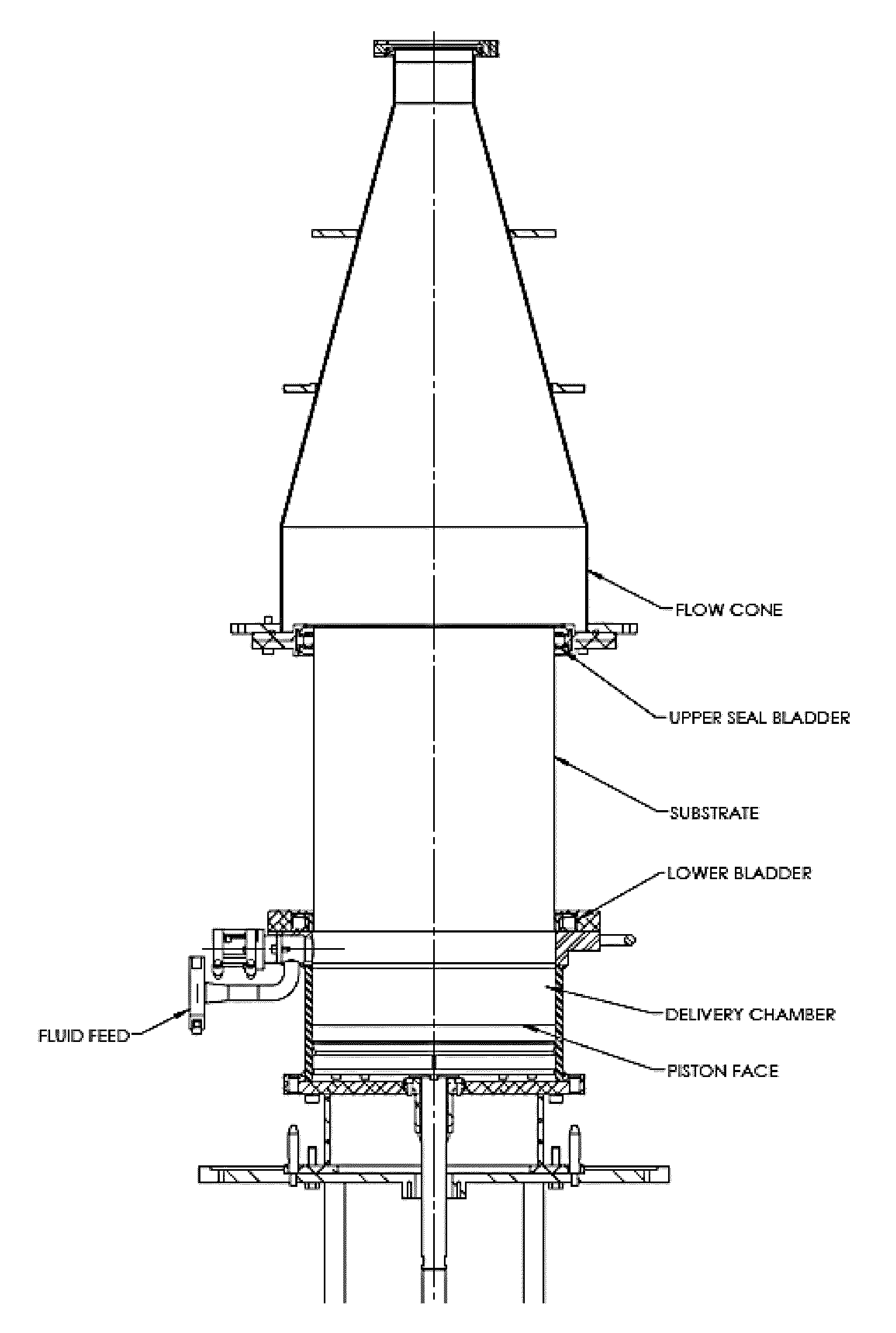

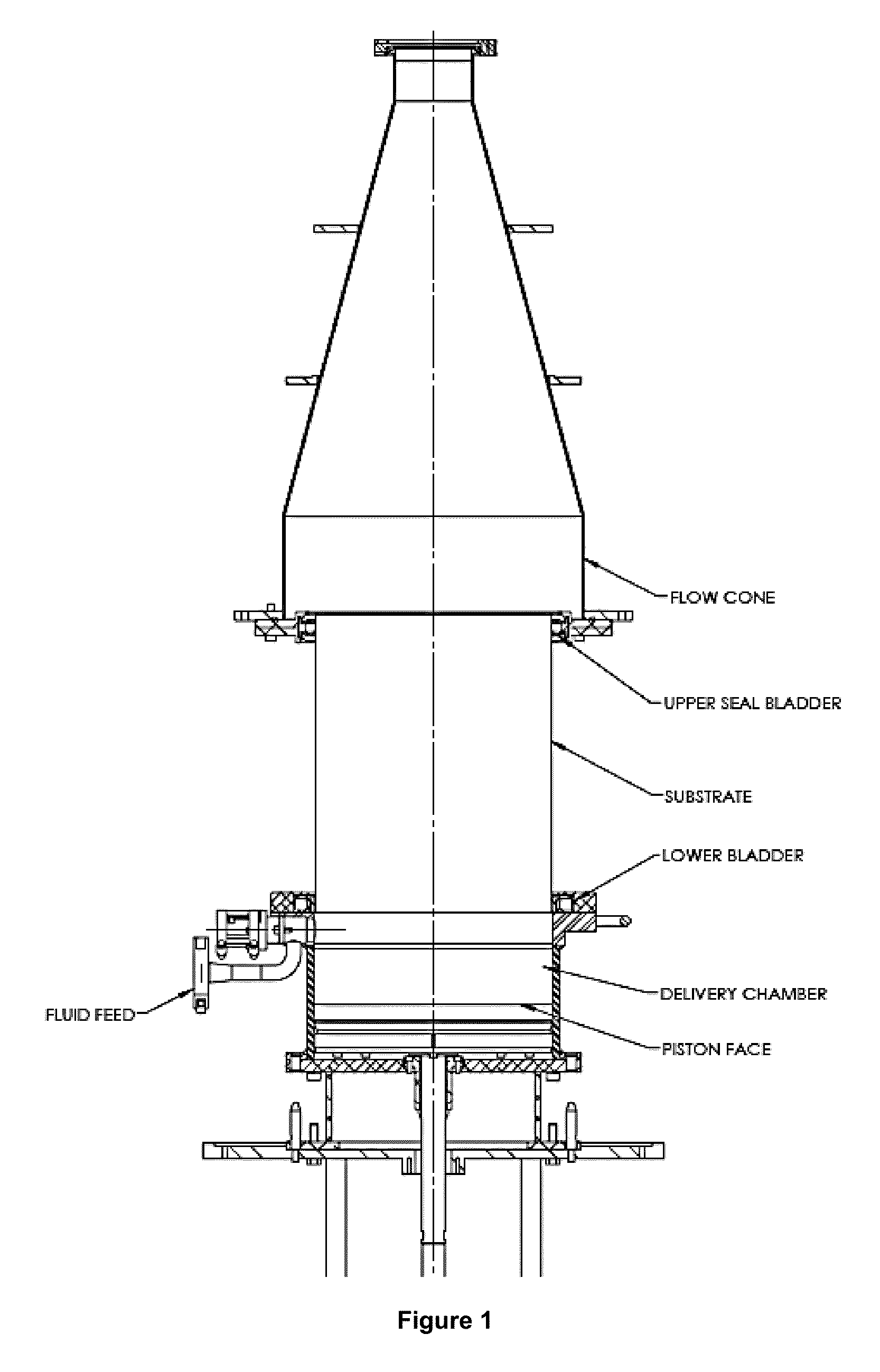

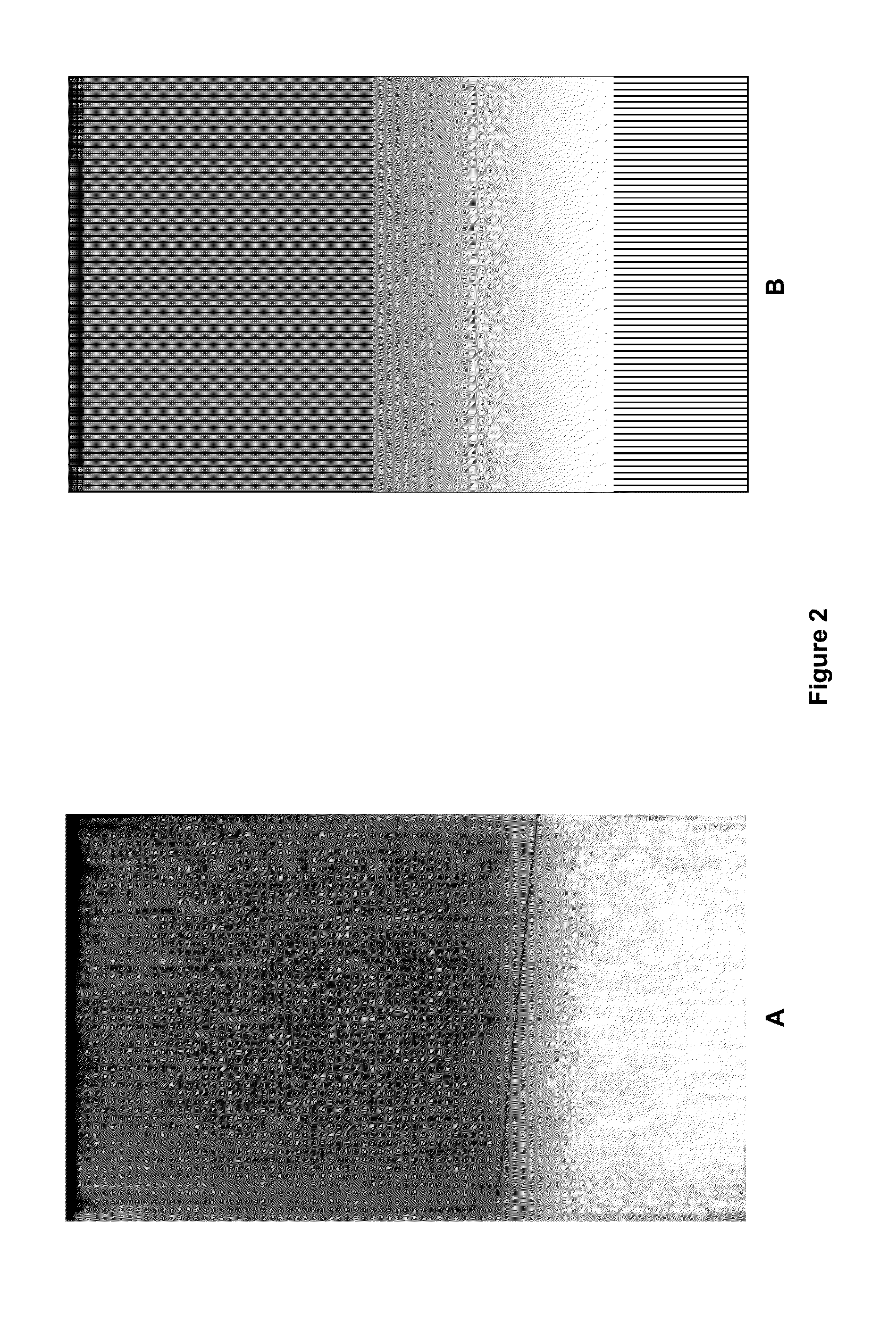

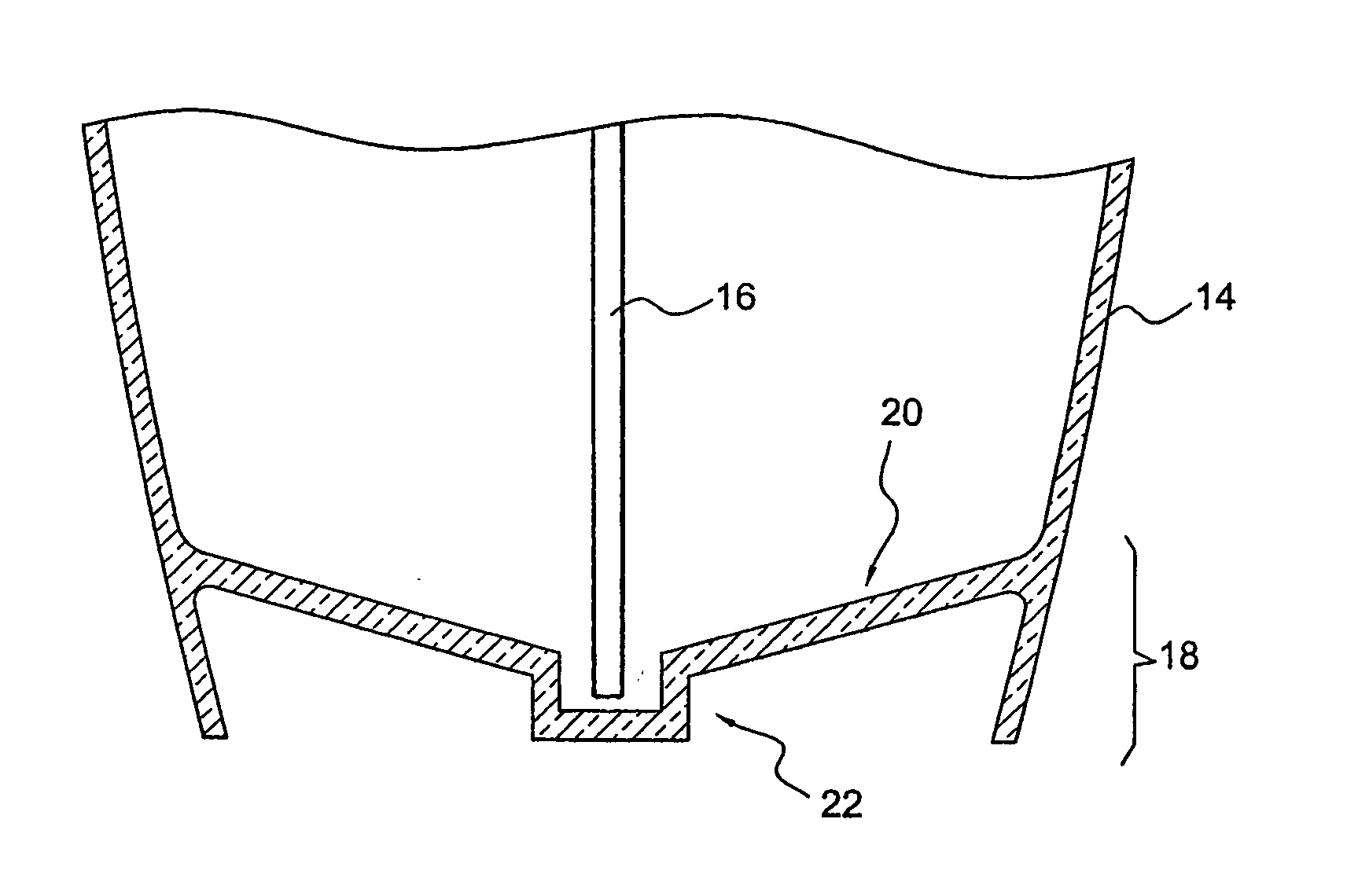

Method of coating a substrate with a catalyst component

ActiveUS9138735B2Accurate coatingEasy to controlExhaust apparatusDispersed particle separationEngineeringPartial filling

A method of coating a substrate with a liquid comprising a catalyst component, the method comprising:(a) holding the substrate vertically, thereby defining upper and lower ends thereof, wherein the vertical substrate comprises a plurality of channels that are open at said upper and lower ends;(b) continuously introducing the liquid into the substrate by pushing or injecting the liquid through the open ends of the channels at the lower end of the substrate with a piston; and(c) after the lower end of the substrate has been partly filled with the liquid in step (b), applying a vacuum to the open ends of the channels at the upper end of the substrate while continuing to introduce the liquid into the substrate.

Owner:JOHNSON MATTHEY PLC

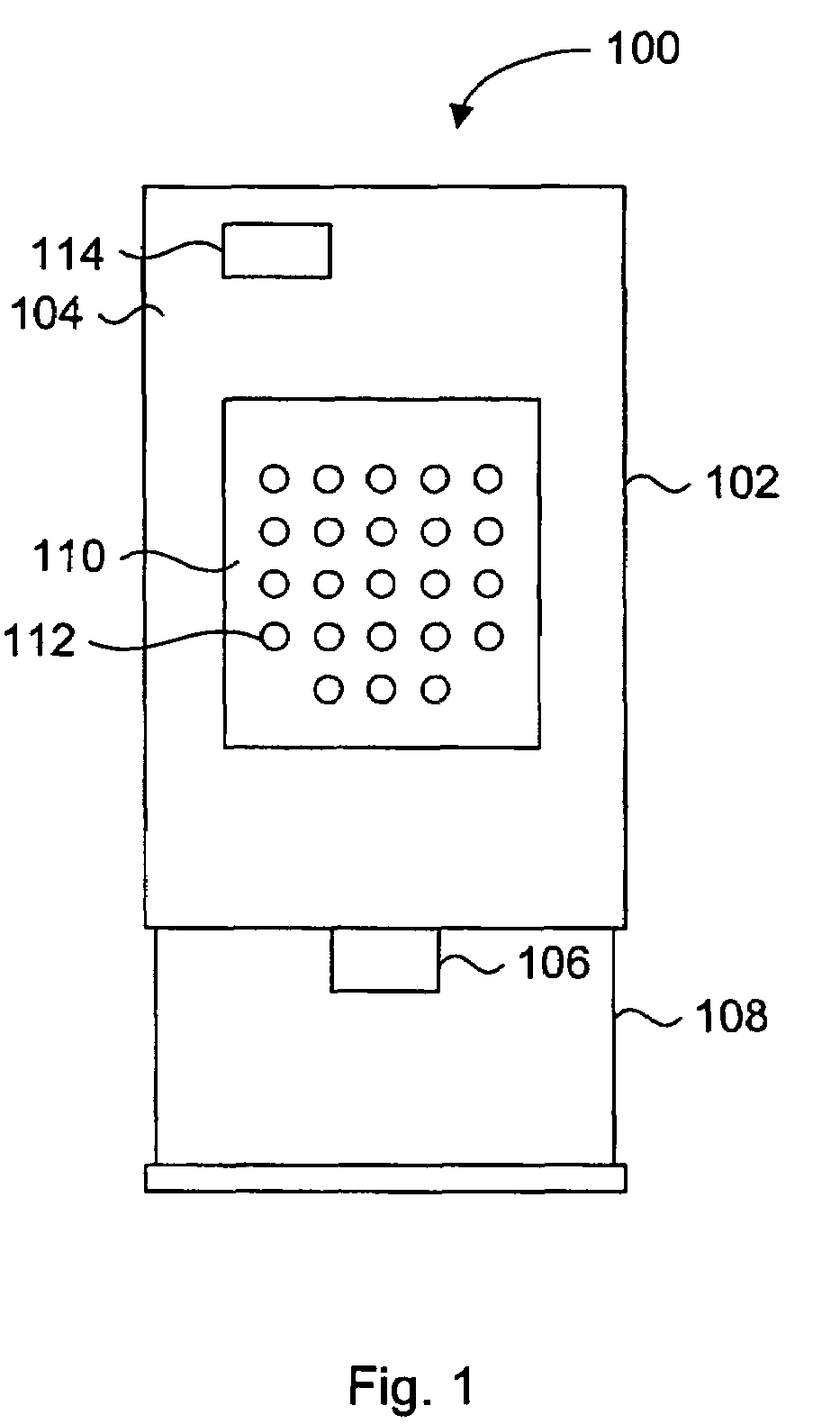

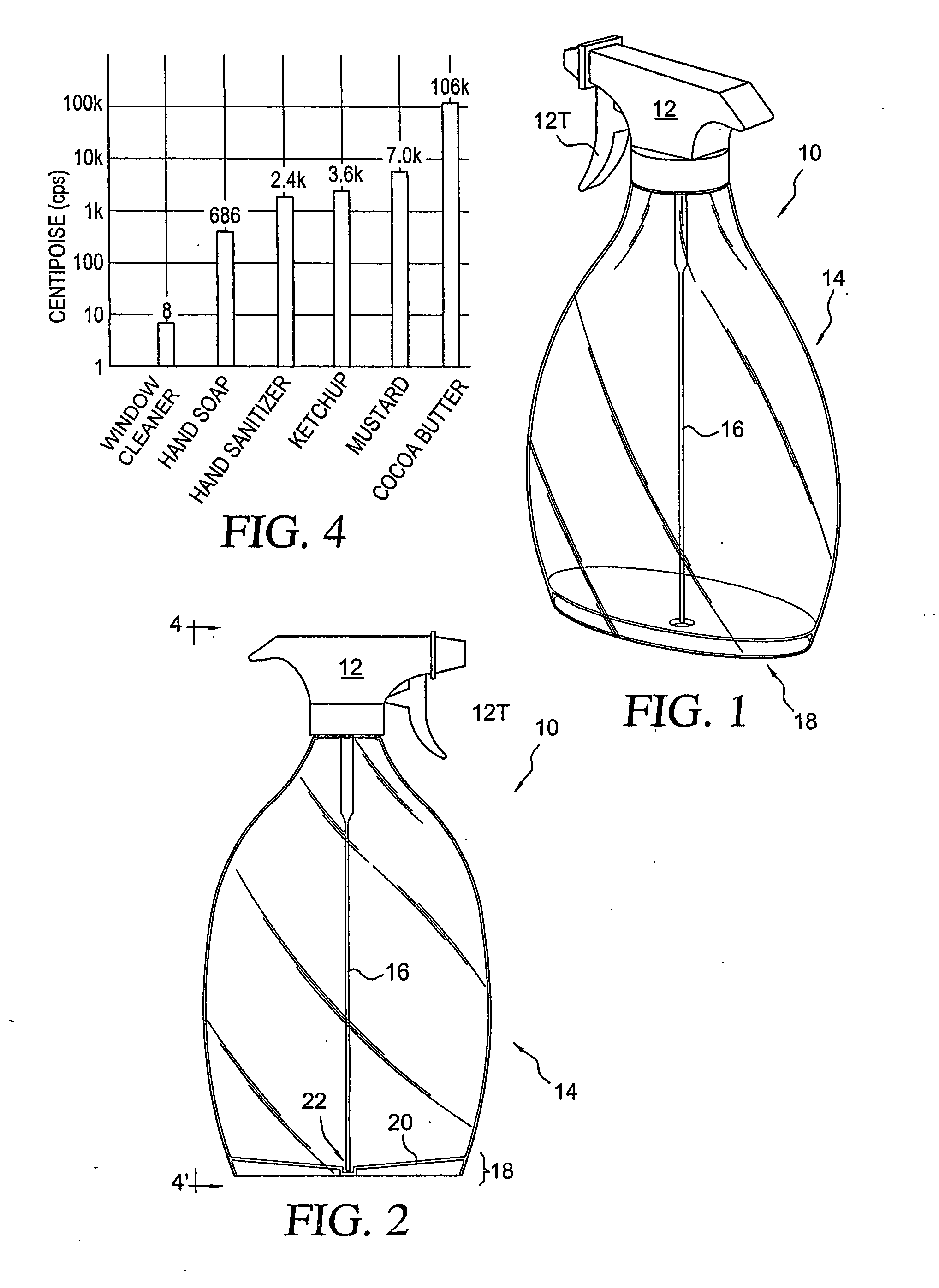

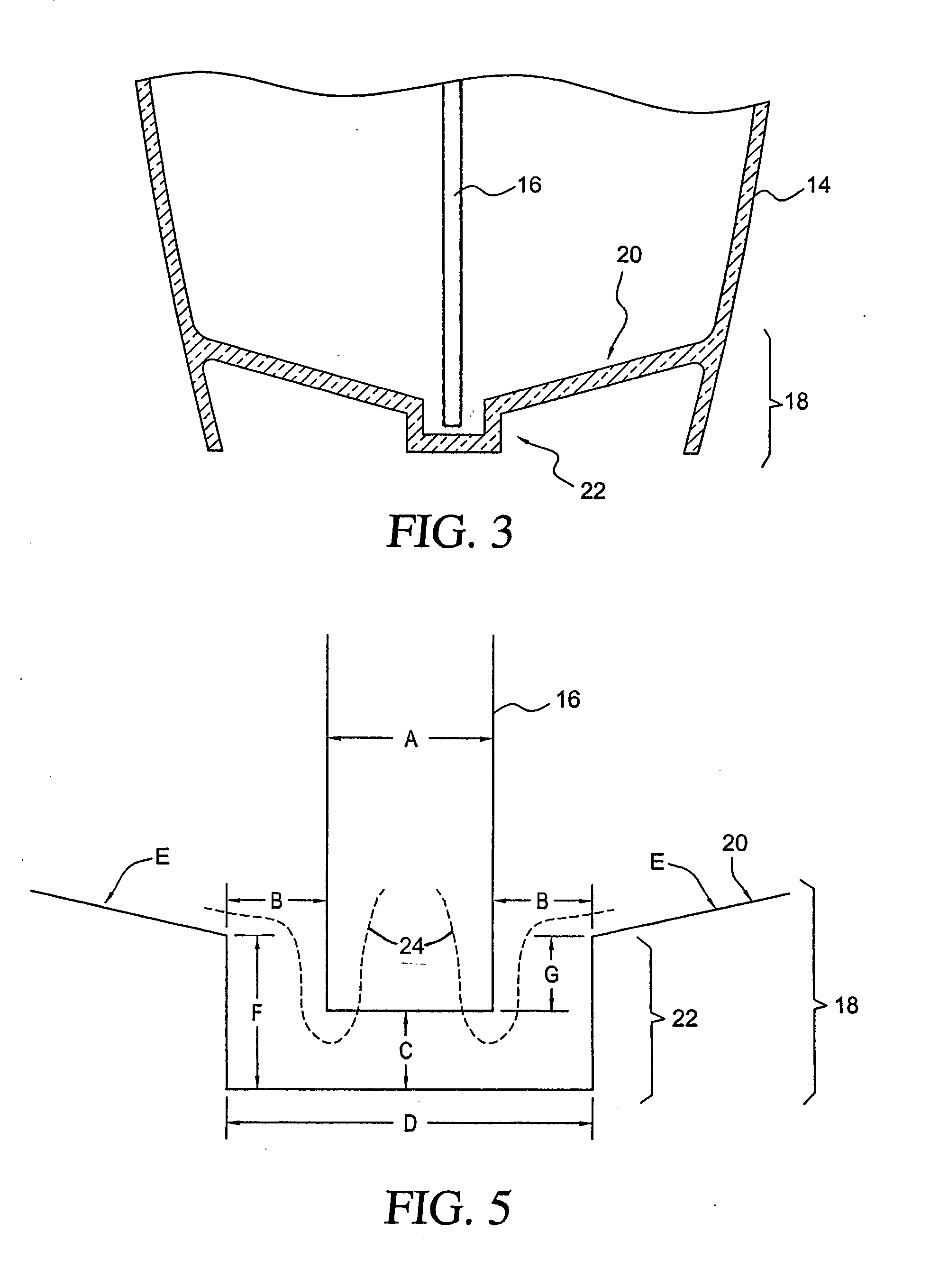

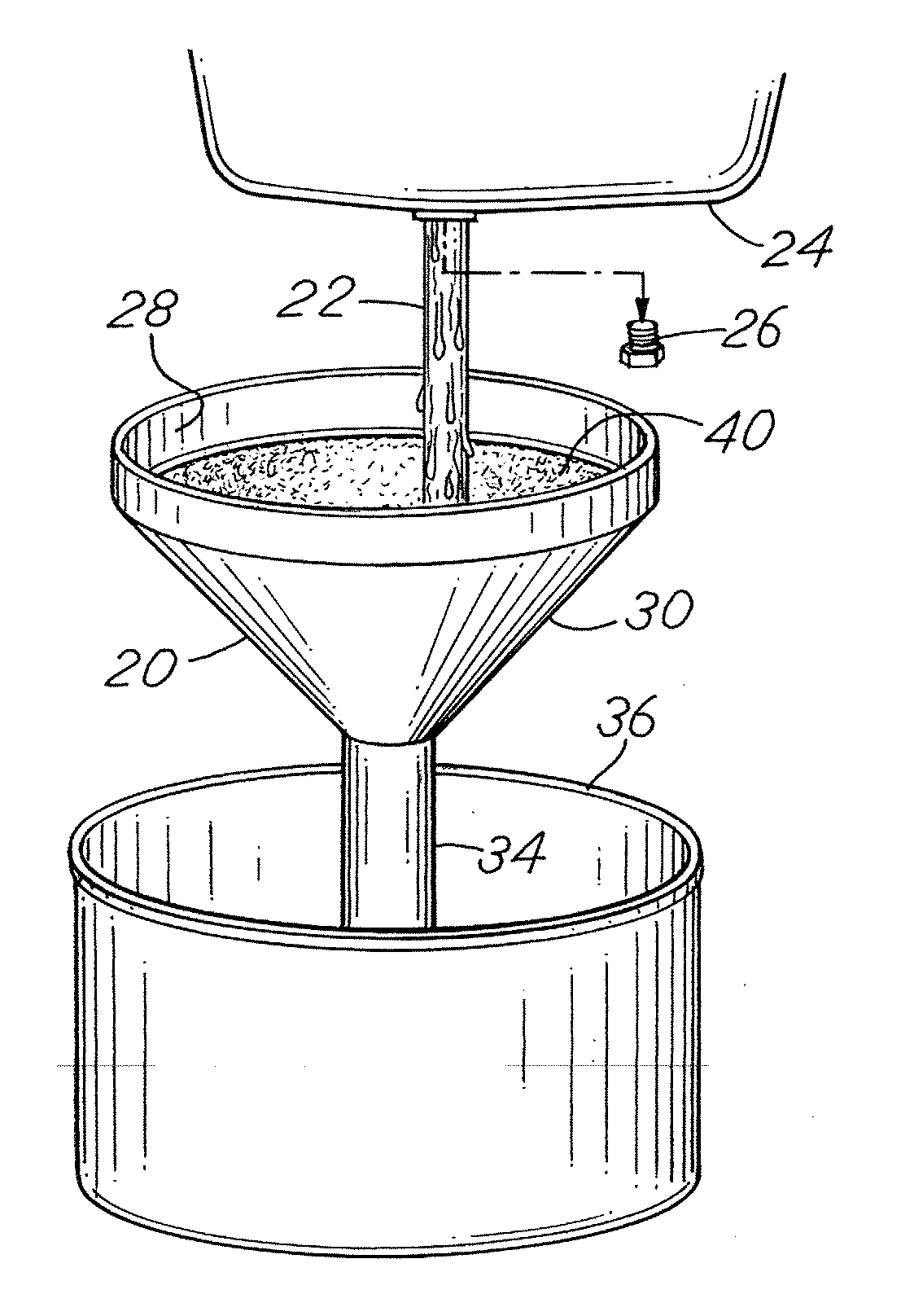

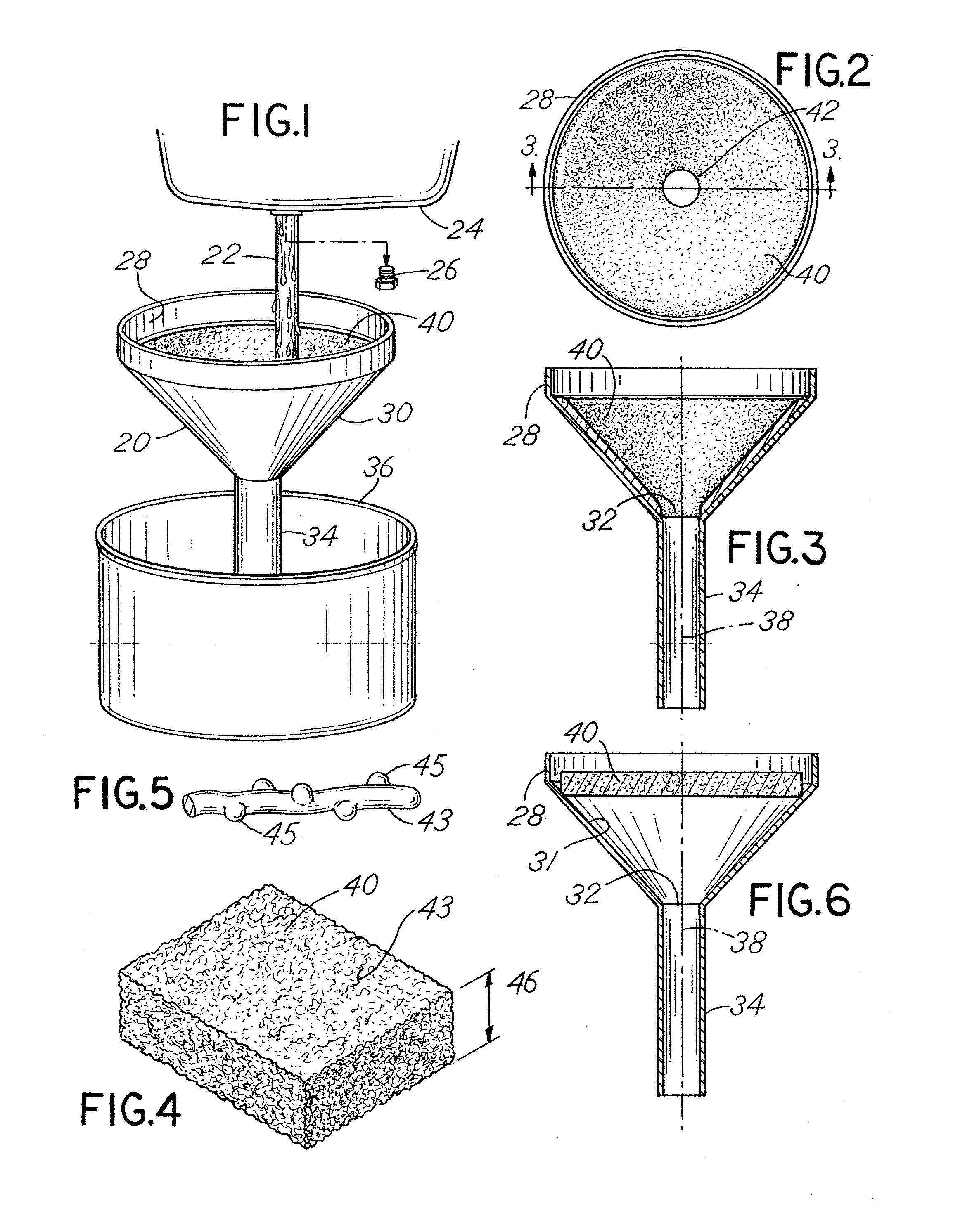

Liquid pump dispensing system for liquids having wide ranges of viscosities with no waste

InactiveUS20120006855A1Wide viscosity rangeNo wasteLiquid transferring devicesSingle-unit apparatusLiquid viscosityRegimen

A liquid pump dispensing system for dispensing liquids having a wide range of viscosities is described as incorporating a unified approach to determining the dimensions of selected elements of a collection area as a function of the viscosity range of the liquid being dispensed. Four illustrative liquid viscosity ranges are described leading to defining specific values for the physical dimensions of several key elements of the dispensing technique. The dispensing rate is thereby optimized for the full range of viscosities contemplated. An additional complementary feature of slope ranges formed into a bottom shelf feeding into the collection area further optimizes the flow rate and assures a virtually waste free liquid dispensing regimen.

Owner:EHRMANN SCOTT J

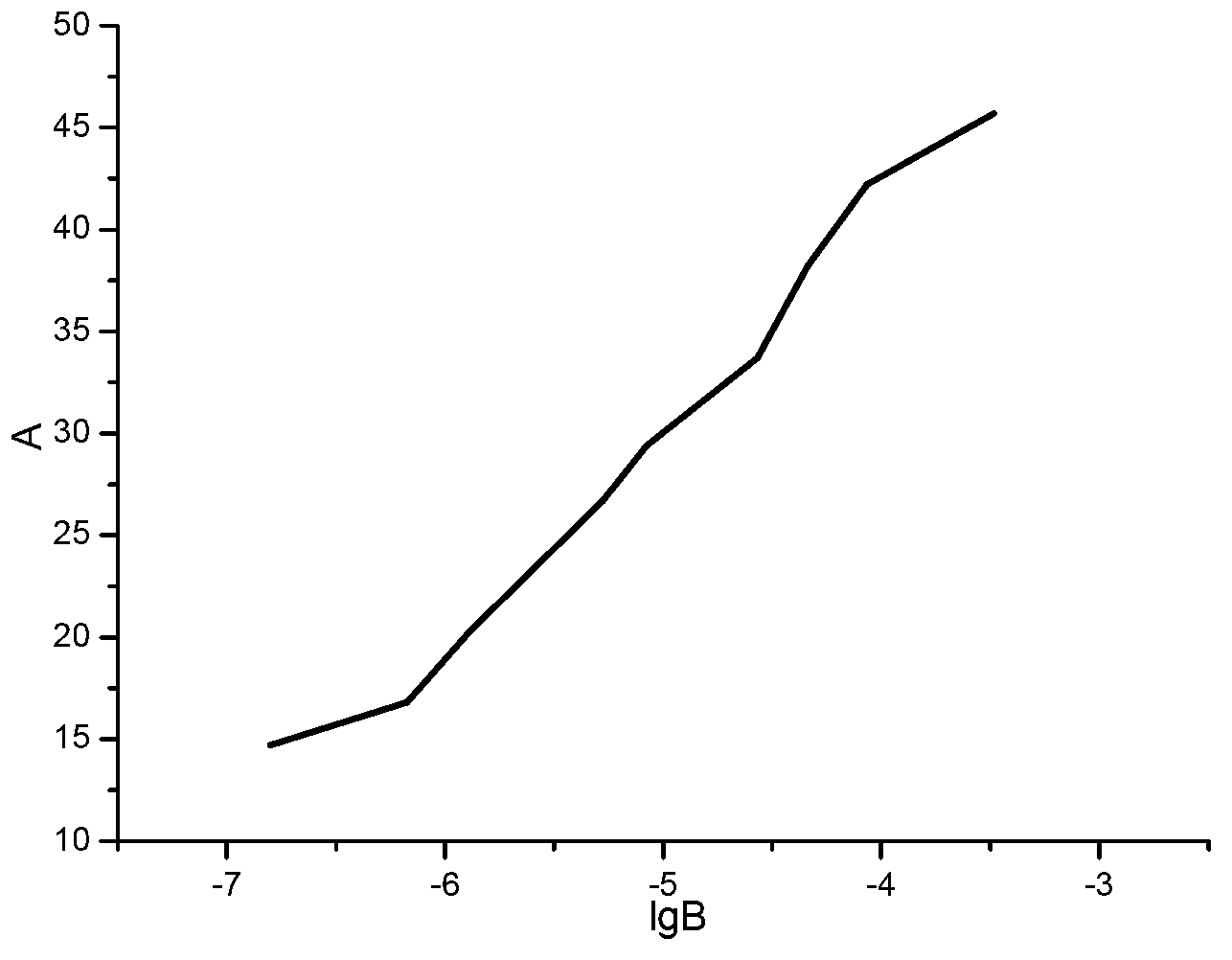

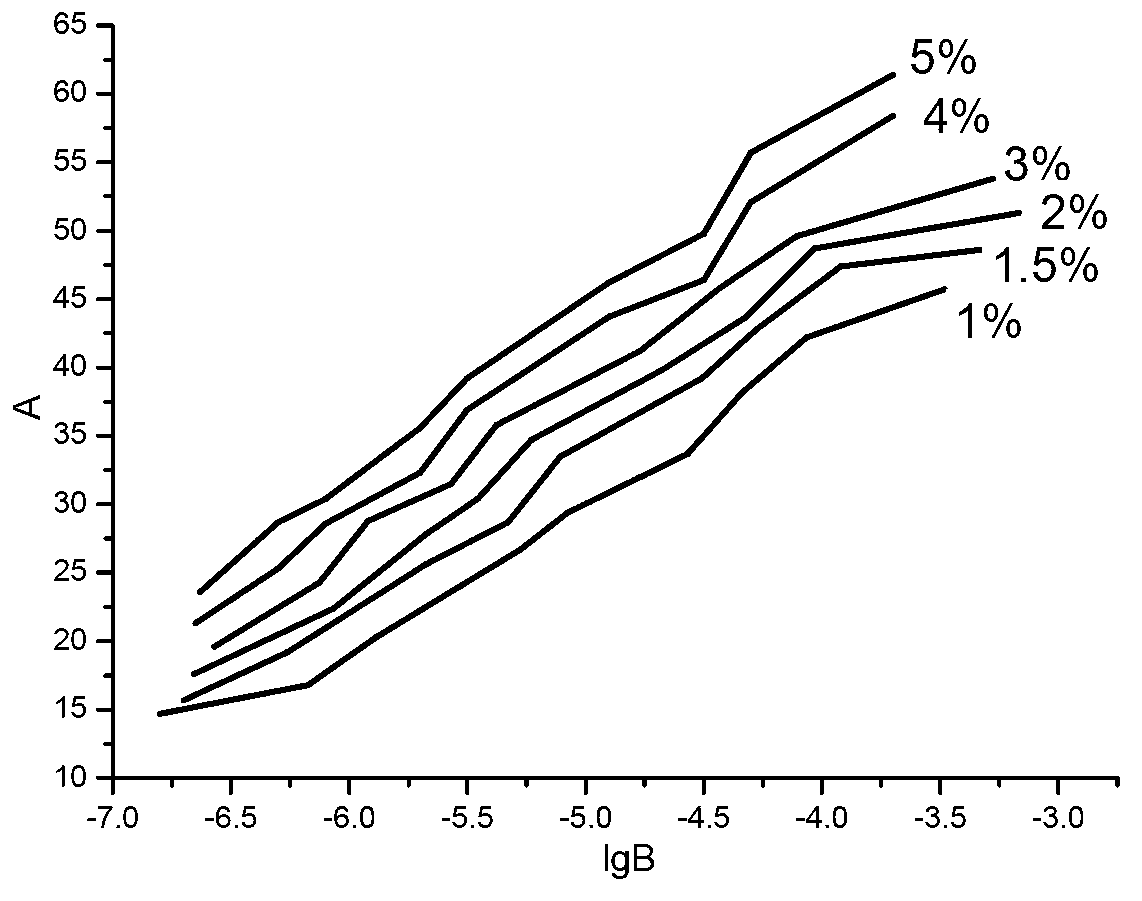

Determination method for dispersibility of carbon nano-tubes in resin

ActiveCN103257094AEasy to operateSimple measurement processNanotechnologyParticle size analysisCarbon nanotubeMaterials science

The invention relates to a determination method for dispersibility of carbon nano-tubes in resin. The determination method adopts a scraper fineness meter for determining the fineness of the resin to obtain the dispersibility of the carbon nano-tubes in the resin. Specifically, a series of relationship curves are found by determining the fineness and dispersibility numerical values under the condition of different types of resin and different contents of the carbon nano-tubes, thus establishing the corresponding relationship between the scraper fineness and the dispersibility of each carbon nano-tube. In actual tests, the corresponding dispersibility can be found only by determining the fineness of resin to be tested with reference to the relationship curves. The determination method overcomes the disadvantages of tedious steps, long cycle, incapability of quantification and poor accuracy in a conventional dispersibility determination method, so that the determination process is easy, convenient and feasible, the testing cycle is shortened, the testing cost is reduced, and the determination method has the advantages of rapidness, directness, accuracy and the like and has strong practicability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

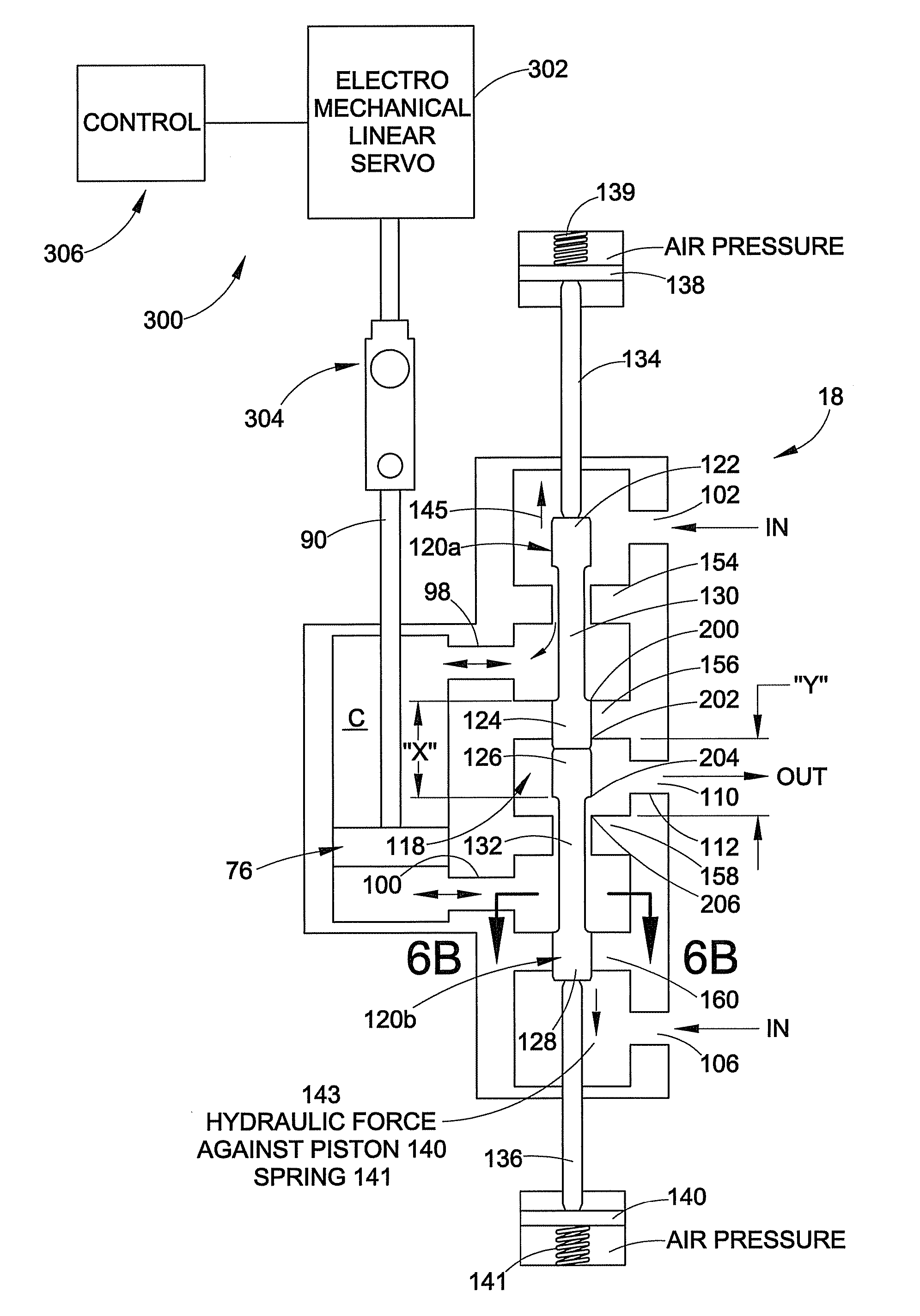

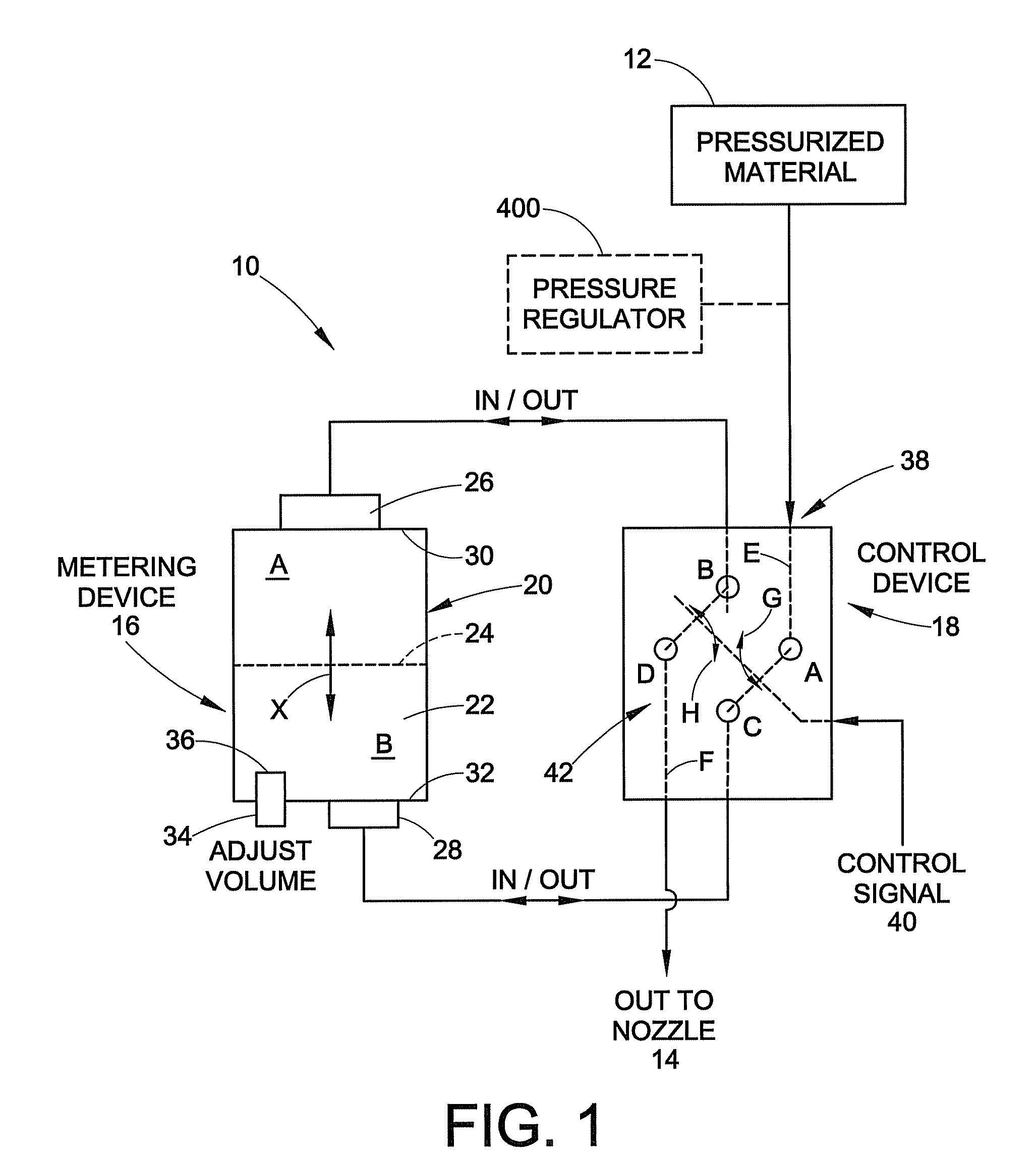

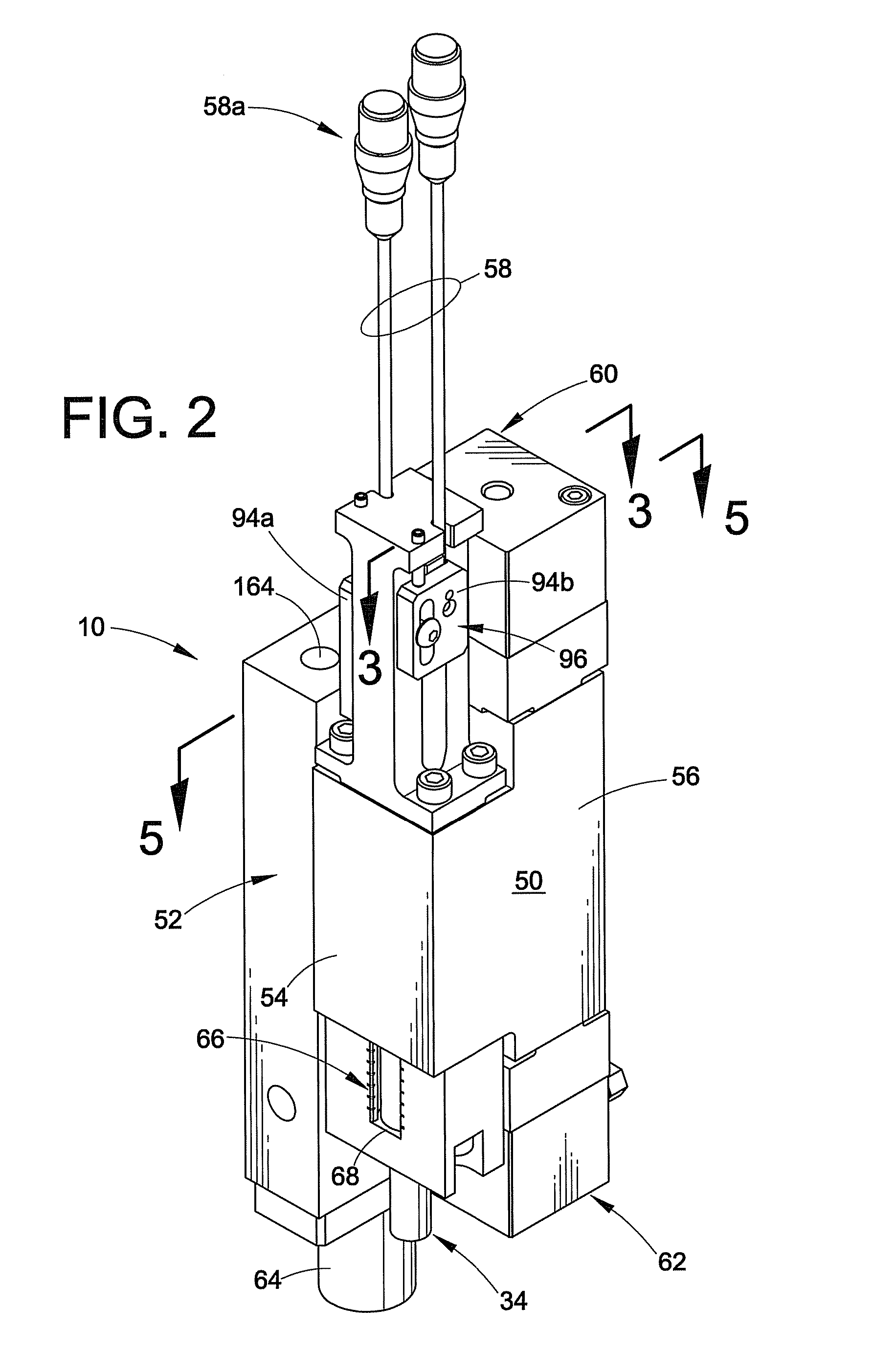

Liquid material dispenser

ActiveUS20100065585A1Eliminate time lagWide viscosity rangeOpening closed containersBottle/container closureSpool valveTime delays

Methods and apparatus for dispensing liquid material provide the option to dispense precise and repeatable quantities or volume of material over a wide range of viscosities. In one embodiment, a metering chamber is provided that can be filled and emptied at the same time so as to eliminate time delays between dispensing operations. The material may be under pressure and that pressure is used to fill and empty a metering chamber. In another embodiment, a control device is provided with a metering chamber wherein the control device operates to switch pressurized fluid between two passages to the metering chamber. In a more specific embodiment, the control device may be, for example, a valve, and more specifically in one embodiment a pneumatically actuated spool valve

Owner:NORDSON CORP

A kind of organosilicon separating gel and its preparation method and application

ActiveCN101570637BWide viscosity rangeHigh flash pointBiological testingBlood Collection TubeSilanes

The invention discloses an organosilicon separating gel, its preparation method and application. The silicone separating gel is made of the following components in parts by weight: 54-82 parts of organopolysiloxane; 4-15 parts of hydroxyl silicone oil; 10- 25 parts; 1-6 parts of silane coupling agent. The preparation method of the organosilicon separating gel is to mix the components uniformly, heat up to 60-116°C, stir and keep warm for 5-12 hours, and then vacuumize at 120-180°C for 1-6 hours to obtain the organosilicon separating gel. glue. The application of the organosilicon separating gel is to prepare a rapid blood collection tube with serum separating gel. The organosilicon separating gel provided by the invention is hygienic, safe, non-toxic, strong in isolation, good in liquid sealing, and has superior thixotropic performance. The invention provides a method for preparing organic silicon separating gel, which has simple process, mild and controllable preparation conditions, and is easy to popularize.

Owner:广州标美药用辅料有限公司

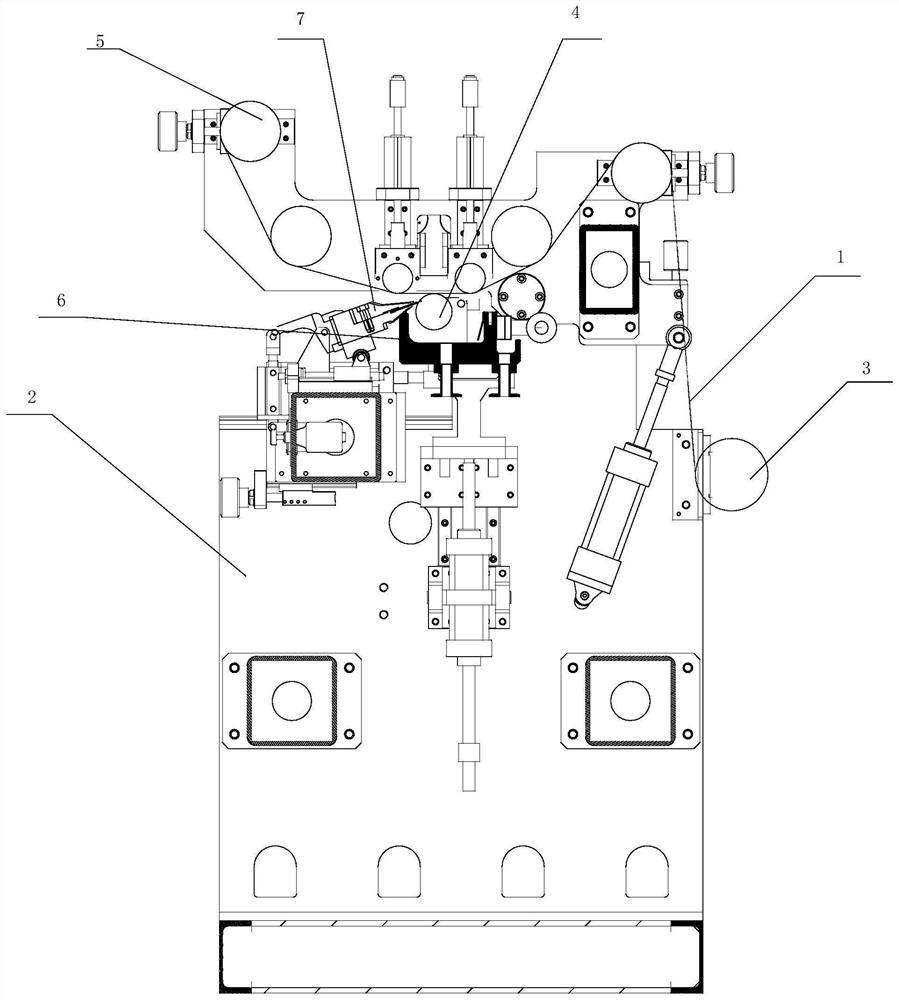

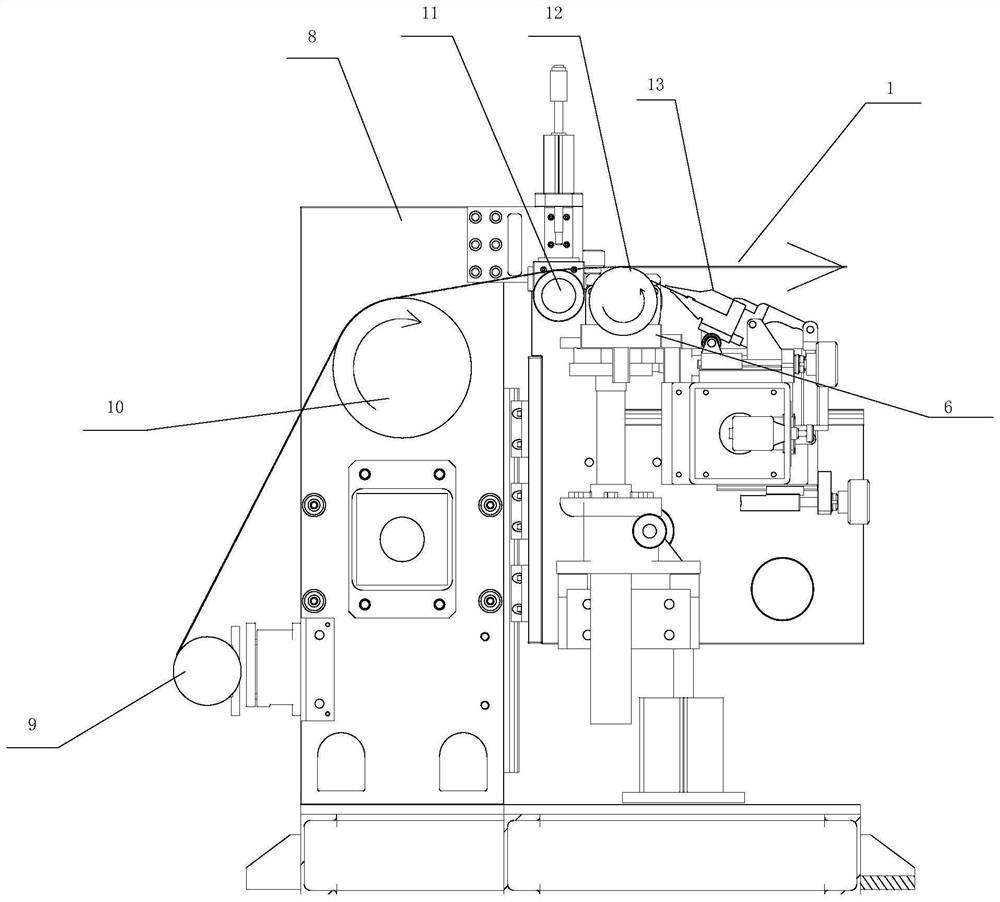

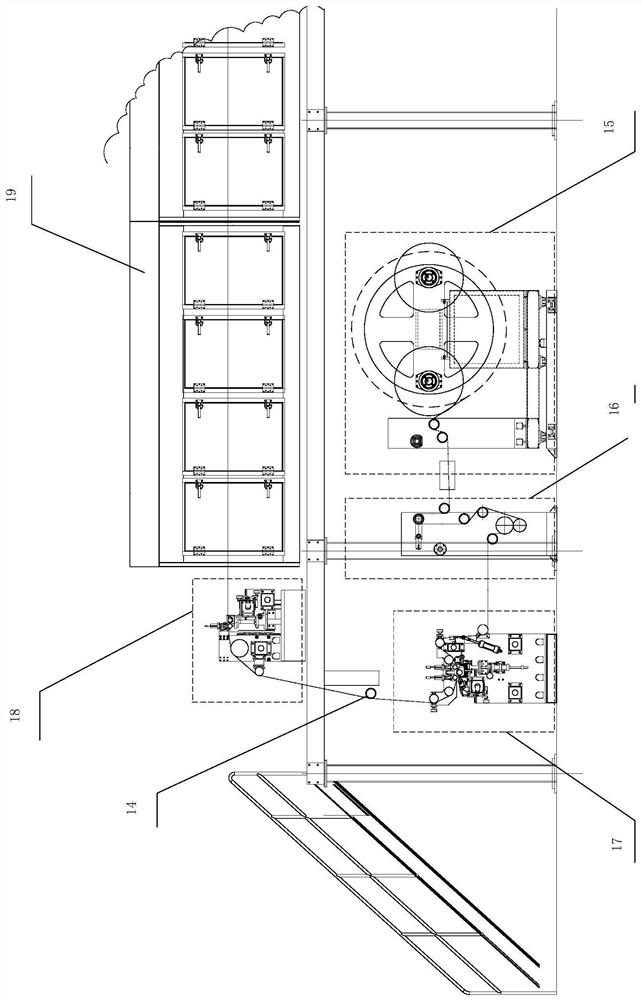

Double-sided coating equipment and processing technology applying double-sided coating equipment

PendingCN112604911ACorrection high efficiencyBroaden applicationPretreated surfacesCoatingsEngineeringMechanical engineering

The invention relates to double-sided coating equipment. The double-sided coating equipment comprises front-side coating equipment and back-side coating equipment, wherein the back-side coating equipment comprises a second rack, and a first guide roller, a traction roller, a second guide roller and a second coating roller which are sequentially distributed below a base material in the back-side coating direction of the base material are erected on the second rack; and a glue tank used for infiltrating part of the second coating roller is arranged under the second coating roller, the second guide roller is arranged on one side of the second coating roller, a second scraper is fixed to the other side of the second coating roller, the blade point of the second scraper is connected with the outer surface of the second coating roller in an abutting mode, the front-side coating equipment is located below the back-side coating equipment, and a middle roller is positioned between the front-side coating equipment and the back-side coating equipment. According to the high-efficiency double-sided coating equipment and a processing technology applying the double-sided coating equipment, double-sided coating can be achieved on one coating line.

Owner:SUZHOU ACME MACHINERY

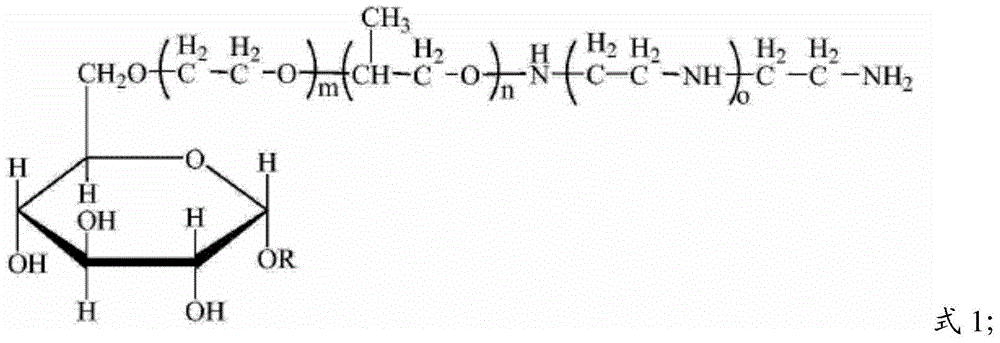

Base fluid for biomass drilling fluid, and preparation method and application thereof

ActiveCN106467725APromote environmental protectionWide viscosity rangeDrilling compositionAlcoholWell drilling

The invention provides a base fluid for a biomass drilling fluid and a preparation method thereof. The base fluid comprises, by weight, 60 to 90 parts of amino acid alcohol ester, 5 to 30 parts of polyetheramine alkyl glucoside and 5 to 10 parts of methylsilicone oil. The above components are mixed so as to obtain the base fluid for the biomass drilling fluid. According to the invention, amino acid alcohol ester has the advantage that the viscosity of amino acid alcohol ester is slightly influenced by temperature changes as the viscosity of ester substances, and has the characteristics of environment friendliness and biodegradability; through addition of polyetheramine alkyl glucoside, the surface activity of the base fluid is substantially improved, so the base fluid has good ecological security and intermiscibility; and as methylsilicone oil is added, the base fluid has good lubricity, physiological inertness and chemical stability. Thus, the base fluid for the biomass drilling fluid in the invention has the advantages of high environment friendliness, a wide viscosity range, a low freezing point, good lubricity, etc. and can meet performance demands for preparation of base oil for the drilling fluid. The invention also provides the biomass drilling fluid.

Owner:CHINA PETROCHEMICAL CORP +2

Dicarboxylic diester, process for producing the same, and refrigerating machine lubricating oil comprising the ester

InactiveUS7271282B1Improve hydrolytic stabilityWide viscosity rangeOrganic chemistryOrganic compound preparationMethyl groupCyclohexanes

A diester represented by the formulawherein A represents a cyclohexane ring, cyclohexene ring or benzene ring, X is H or methyl group, RX and RY are the same or different and each is C3-C18 branched-chain alkyl group, C1-C18 straight-chain alkyl group, C2-C18 straight-chain alkenyl or C3-C10 cycloalkyl, provided that when A is a benzene ring, RX and RY are different from each other and —COORX and —COORY are attached to two adjacent carbon atoms of the benzene ring, and having the following properties:1) a total acid number of 0.05 mgKOH / g or less,2) a sulfated ash content of 10 ppm or less,3) a sulfur content of 20 ppm or less,4) a phosphorus content of 20 ppm or less,5) a peroxide value of 1.0 meq / kg or less,6) a carbonyl value of 10 or less;7) a volume resistivity of 1×1011Ω·cm or more,8) a hydroxyl value of 3 mgKOH / g or less, and9) a water content of 100 ppm or less,a process for preparing the same and a refrigerator lubricating oil comprising the diester.

Owner:NEW JAPAN CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com