Patents

Literature

217results about How to "Simple measurement process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for measuring 3d shape using irregular pattern and method for the same

InactiveUS20070165243A1Easy to performEasy to makeFoot measurement devicesCharacter and pattern recognitionMeasurement deviceThree dimensional shape

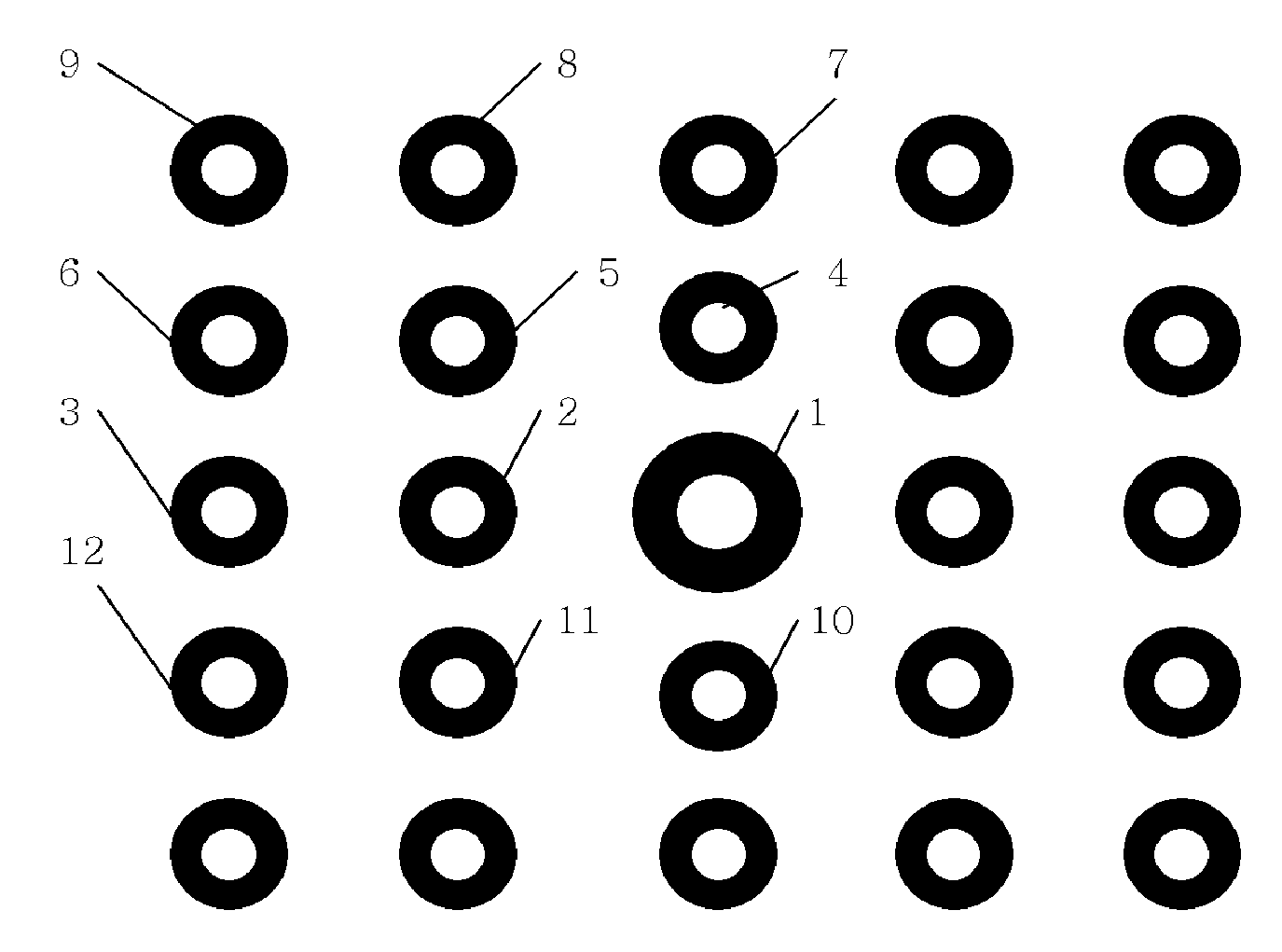

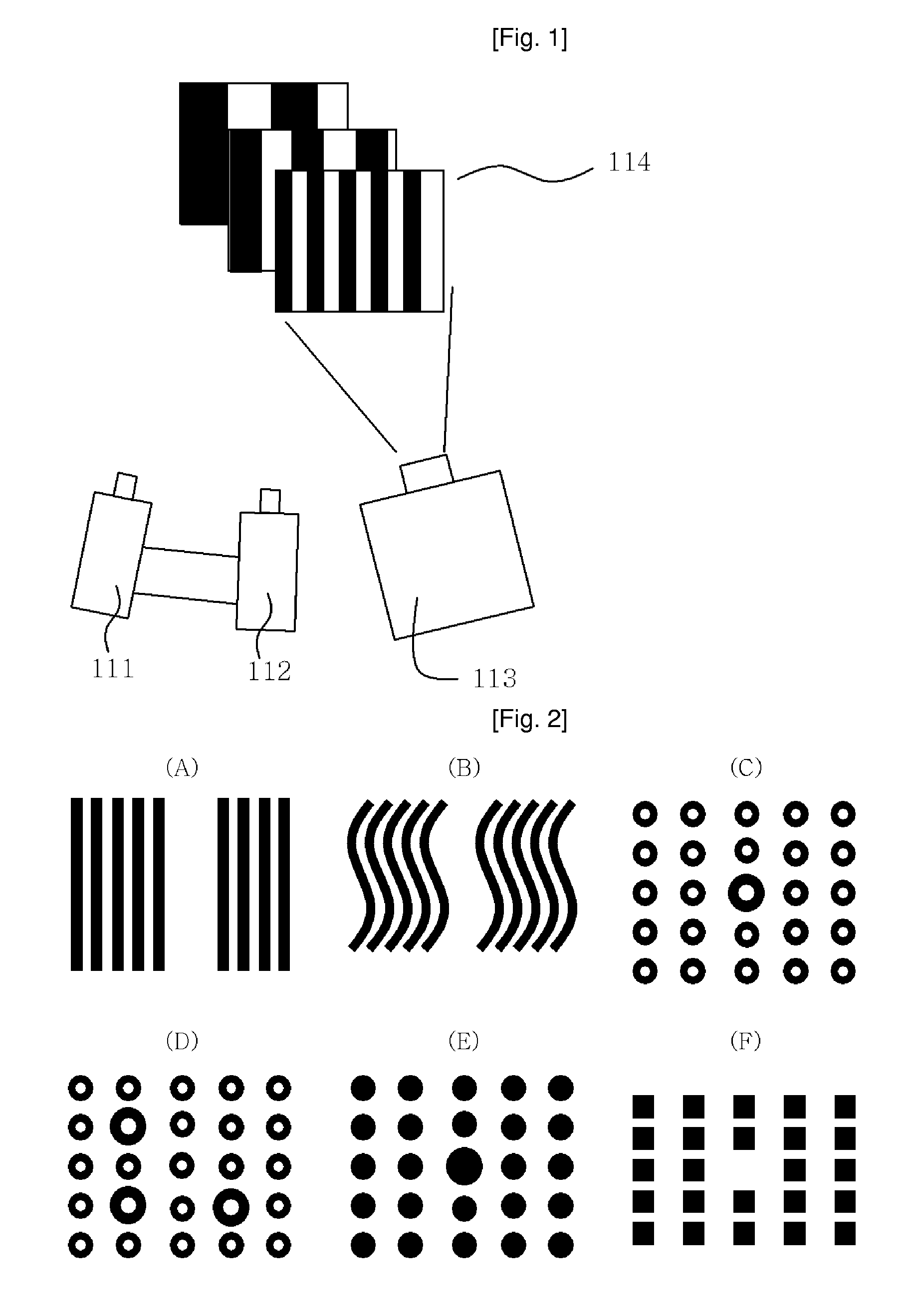

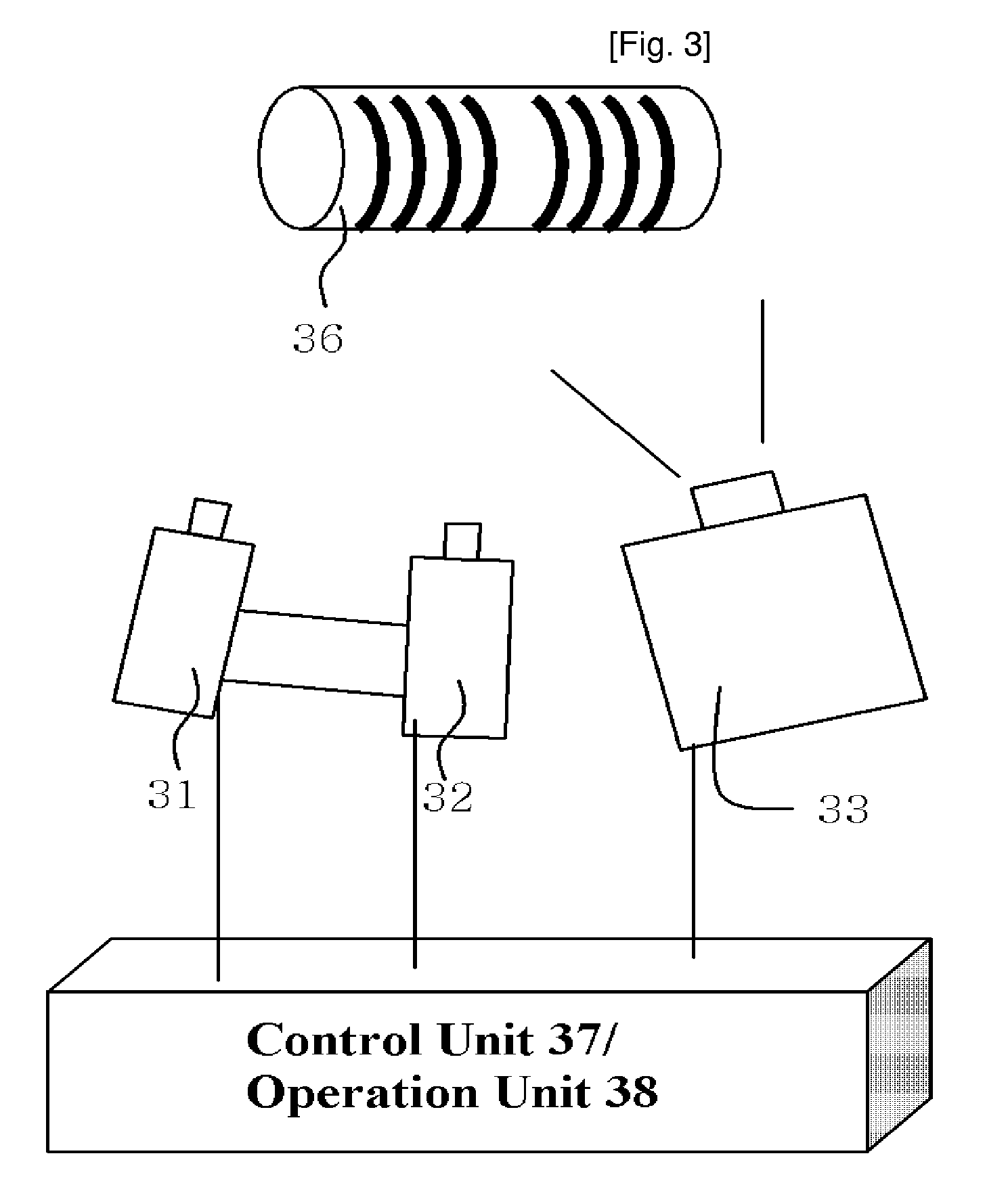

The present invention relates to a device and method for measuring a three-dimensional shape and, more particularly, to a measurement device and method in which a specific pattern is generated on the surface of an object to be measured, the object is photographed using a camera, and data on the 3-D shape are acquired from a photographed image, wherein an irregular pattern is employed, thus simplifying a process of measuring the 3-D shape. The present invention is suitable for the measurement of a moving object, the fabrication of the device can be easily performed, various pattern generation means can be utilized, and an inexpensive and popularized image camera can be used instead of an expensive industrial camera. The present invention can be applied to the fabrication of custom-made shoe soles and custom-made shoes and a medical field.

Owner:KANG CHEOL GWON +1

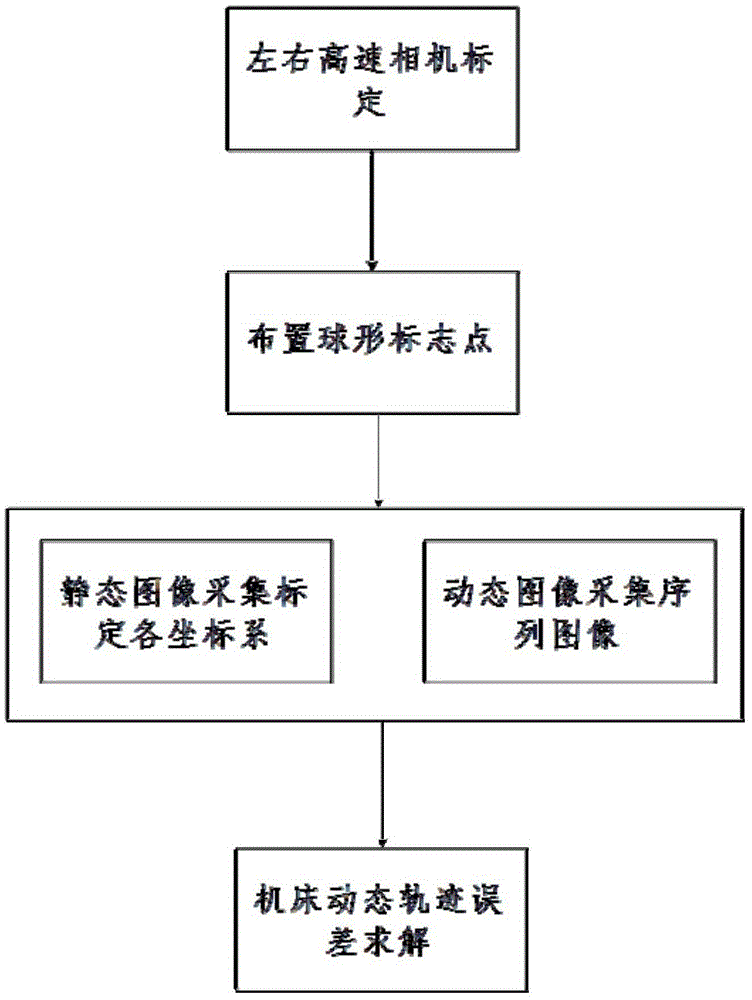

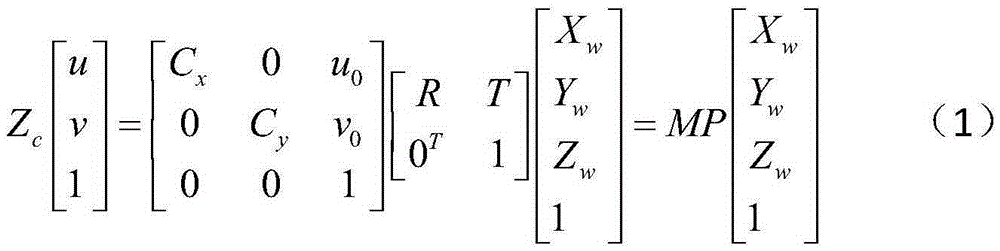

Dynamic error vision measurement method for five-axis numerical control machine tool

ActiveCN105252341ASolve the problem of space trajectory error measurementImprove error measurement accuracyMeasurement/indication equipmentsGeometric errorNumerical control

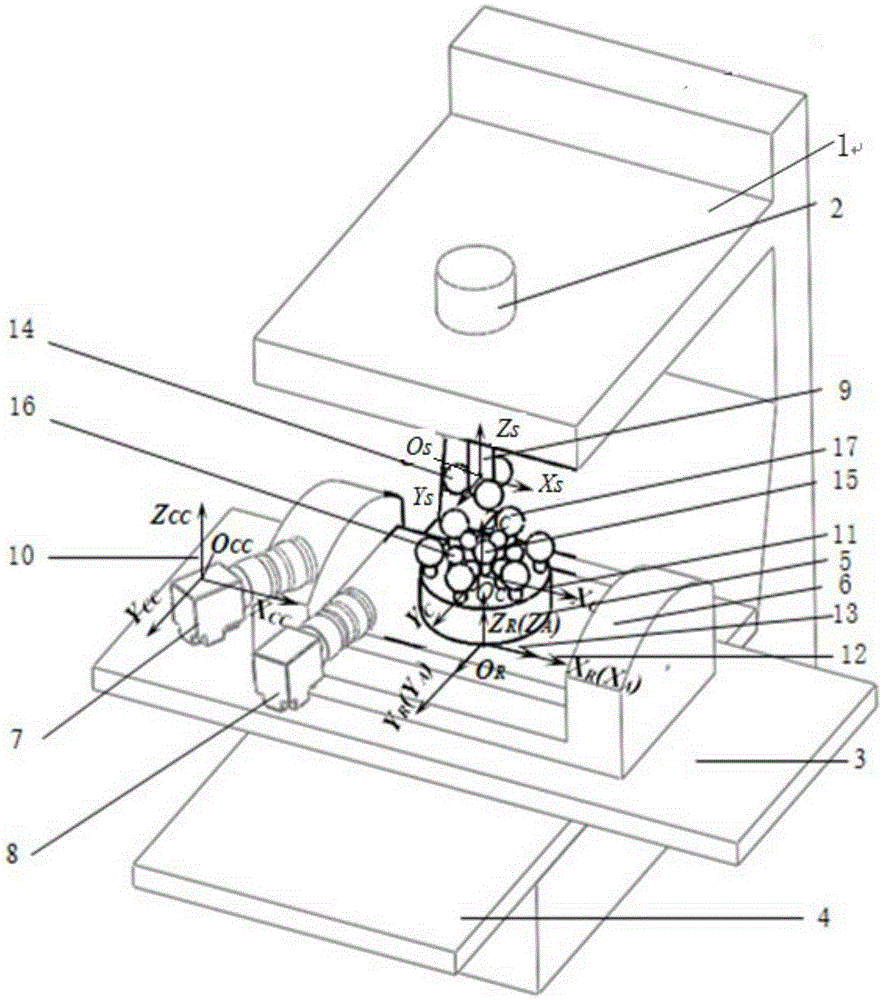

The invention belongs to the field of geometric error measurement for machine tools and relates to a method for measuring dynamic space track errors of the machine tools by means of binocular vision, in particular to a dynamic error vision measurement method for a five-axis numerical control machine tool. The measurement method includes the steps that according to a three-dimension perceptive function of binocular vision measurement, multiple errors are measured and separated at a single time; and four types of spherical mark points are reasonably distributed at a machine tool cutter end and on the surface of a working table, and the position relation among a vision coordinate system, a machine tool reference coordinate system and a machine tool cutter principal axis coordinate system is calibrated by means of feature information of the spherical mark points. During measurement, a vision measurement system continuously, statically and dynamically collects images of the spherical mark points, then moving errors of all machine tool axes are solved, and the obtained theoretical value and actual machine tool moving amount are combined, so that the moving errors of each axis are solved. According to the dynamic error vision measurement method for the five-axis numerical control machine tool, the machine tool space track errors are measured by means of a binocular high-speed camera, so that the error measurement accuracy is improved, the measurement range of the machine tool moving track is widened, the measurement method is simple and reliable, and the measurement process is simplified.

Owner:DALIAN UNIV OF TECH

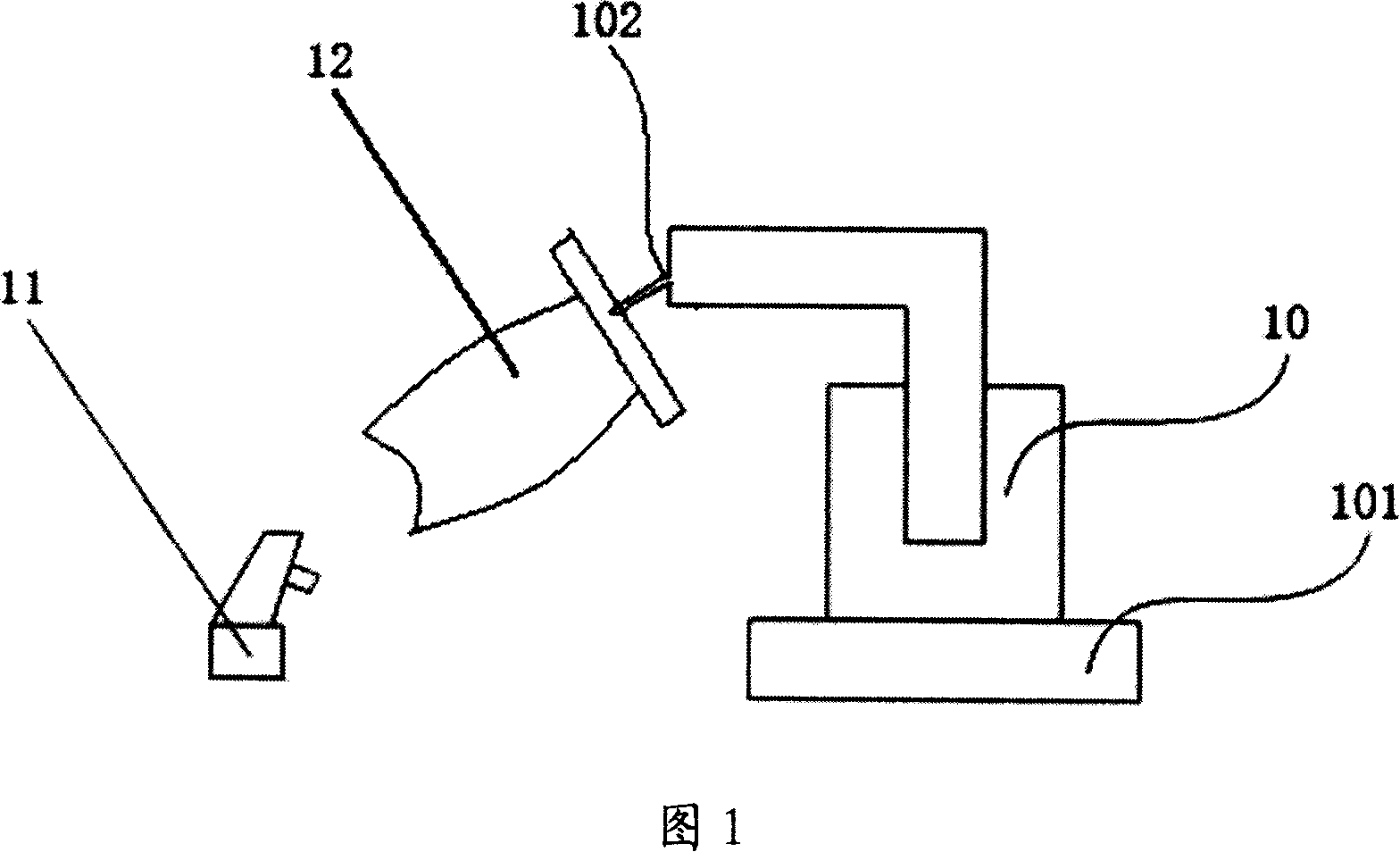

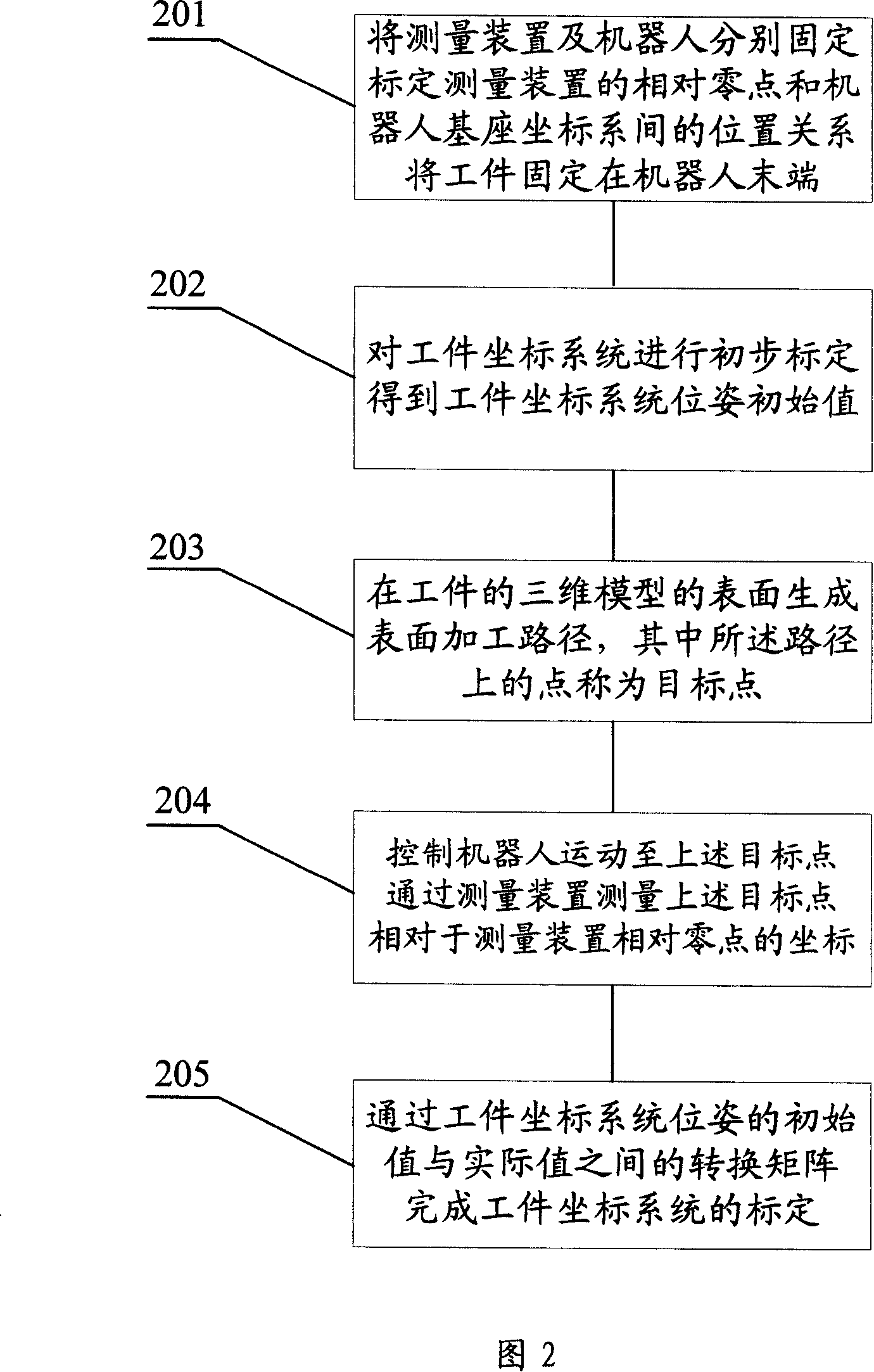

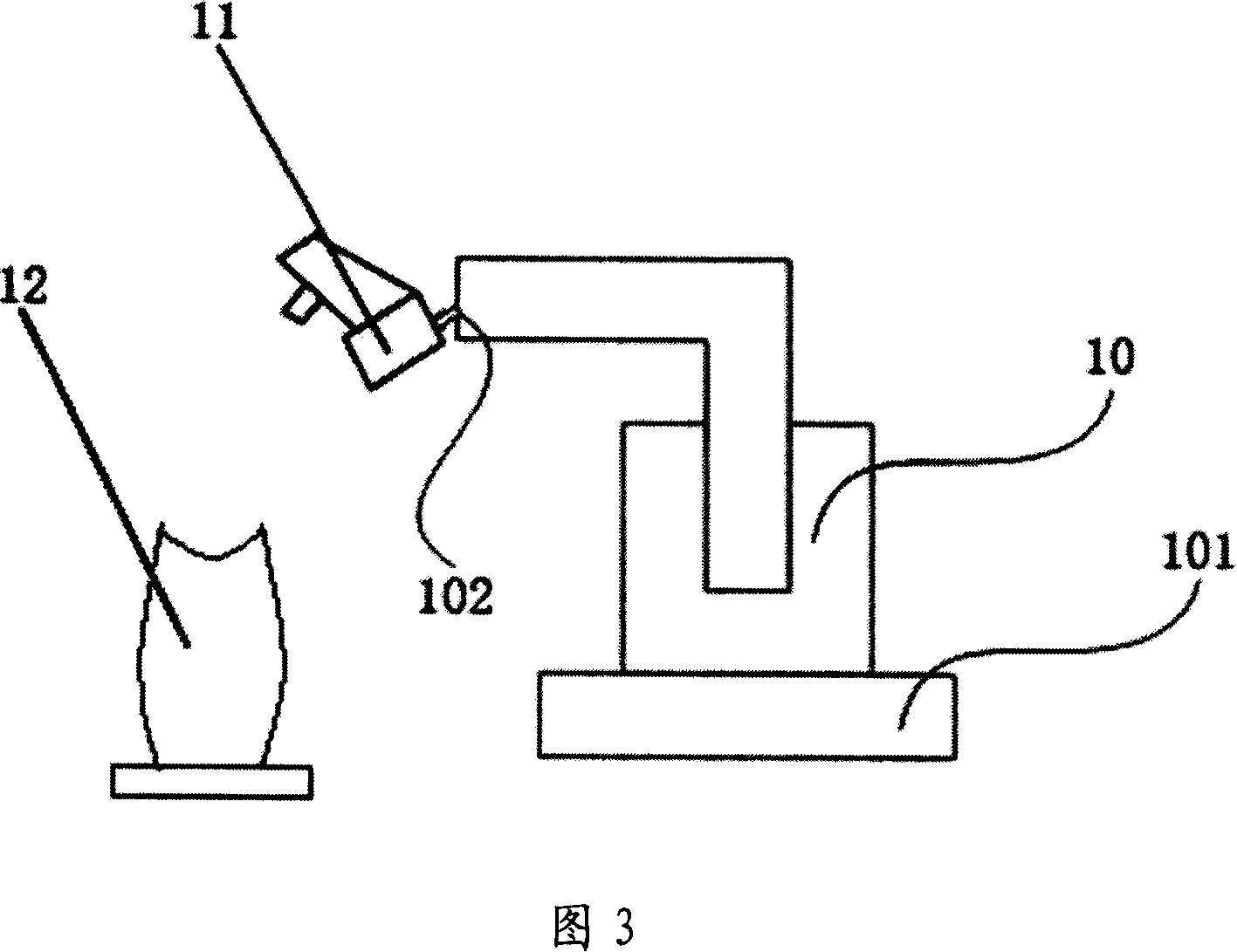

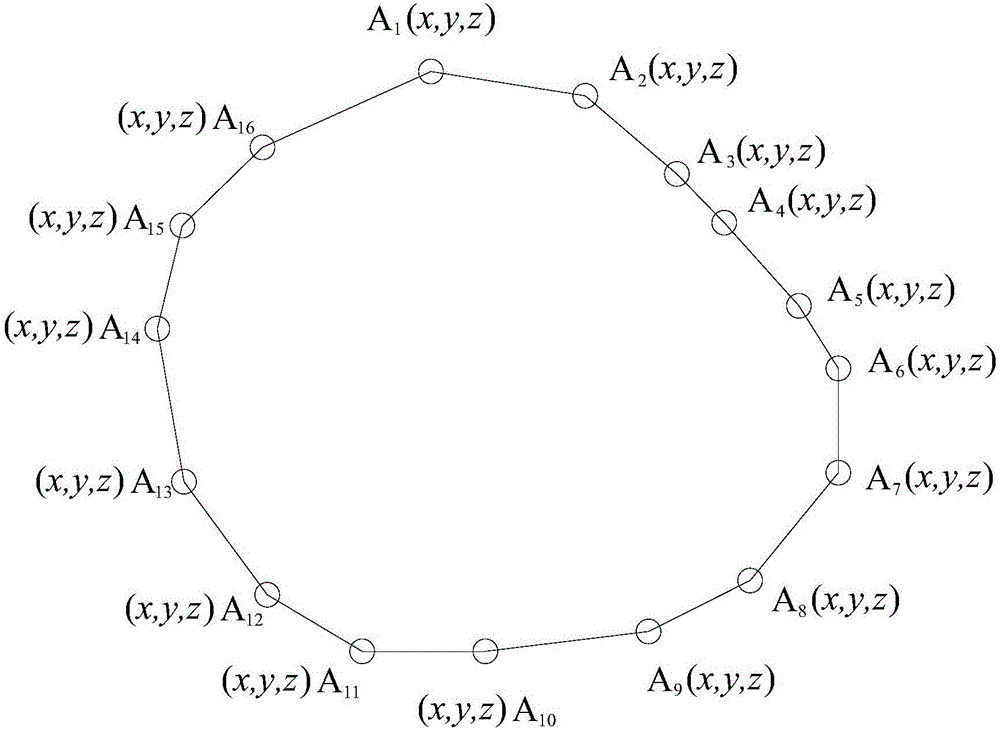

Workpieces reference frame marking method based on relative measurement

ActiveCN101097132ASimple measurement processThe operation process is simple and convenientMeasurement devicesSystem errorRobotic systems

The invention discloses a workpiece reference frame marking method which is based on relative measurement which is used to mark workpiece reference frame whose precision and work precision are higher; the method controls movement of robot by marking position of measuring device and original value of workpiece reference frame, and generating surface process path on surface of dummy surface, records offset of said object point by measuring coordinate of said object point, by resolving conversion matrix between original value and real value of said workpiece reference frame to accomplish marking of said workpiece reference frame; by the method, measurement can be simplified, system error of robot can be compensated, marking precision of robot reference frame and working precision can be increased.

Owner:天津智通信息系统集成有限公司

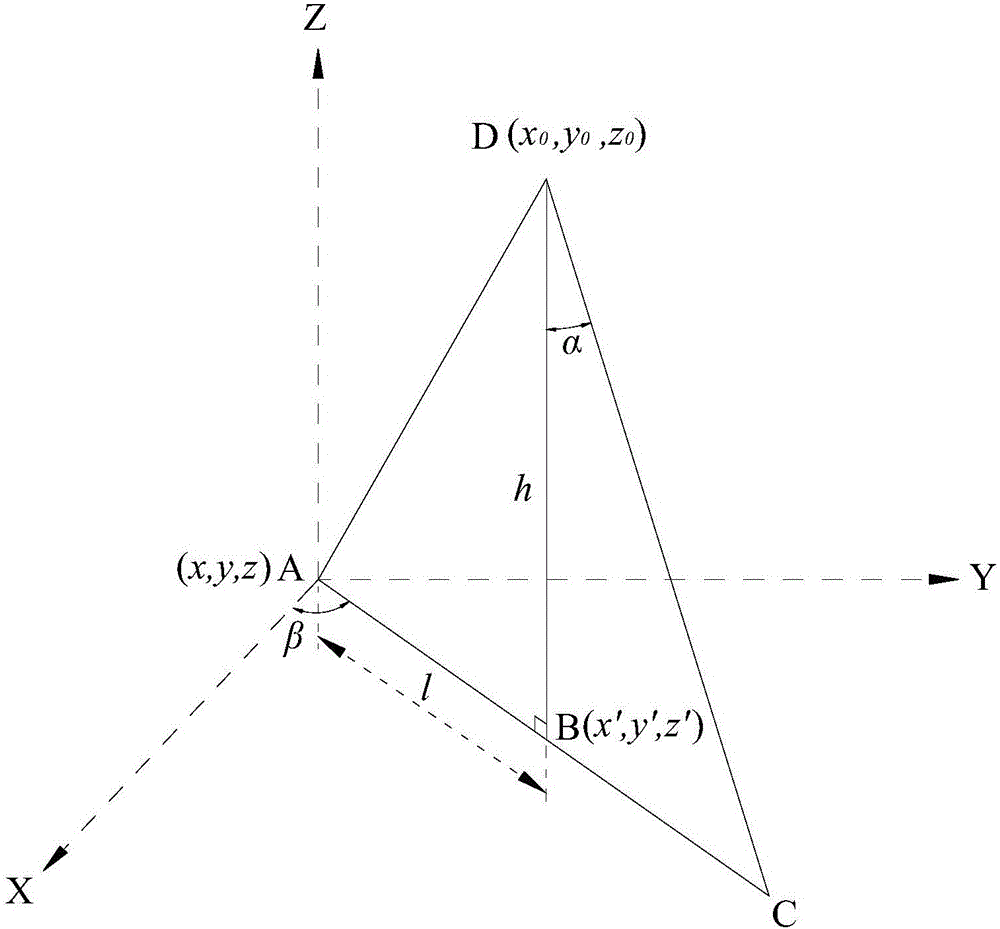

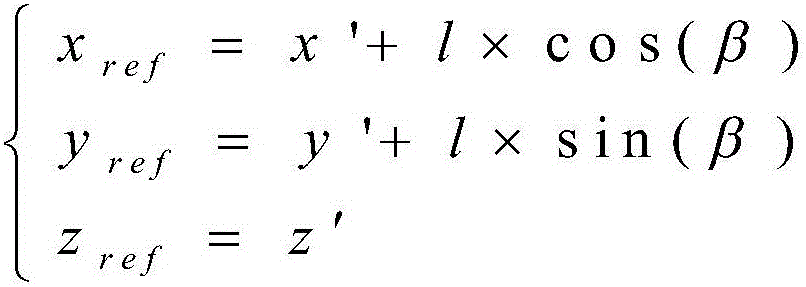

Quick land area measurement device based on unmanned aerial vehicle and measurement method thereof

ActiveCN105698742AMeasurement SimplificationHigh measurement accuracySatellite radio beaconingSoil surveyMeasurement device

The invention discloses a quick land area measurement device based on an unmanned aerial vehicle and a measurement method thereof, wherein the measurement device comprises the components of the unmanned aerial vehicle, wherein the unmanned aerial vehicle is provided with a positioning module for obtaining three-dimensional position information of the unmanned aerial vehicle, a camera which is used for acquiring an image, a height sensor which is used for measuring the height of the unmanned aerial vehicle relative to ground, and a visible light emission module which is used for emitting a vertical light beam and an oblique light beam relative to the unmanned aerial vehicle; and an application terminal which comprises a control system for controlling flight of the unmanned aerial vehicle and an image display module that is used for displaying a measured land image and the three-dimensional position information of the unmanned aerial vehicle. The quick land area measurement device has advantages of simple structure, convenient operation, effective cost reduction and effective measurement efficiency increase. Furthermore the measurement method has functions of simplifying measurement process, greatly reducing workload of measurement personnel in a complicated region and large-area land, improving measurement precision and measurement efficiency and greatly facilitating use of actual engineering personnel.

Owner:SHANGHAI NORMAL UNIVERSITY

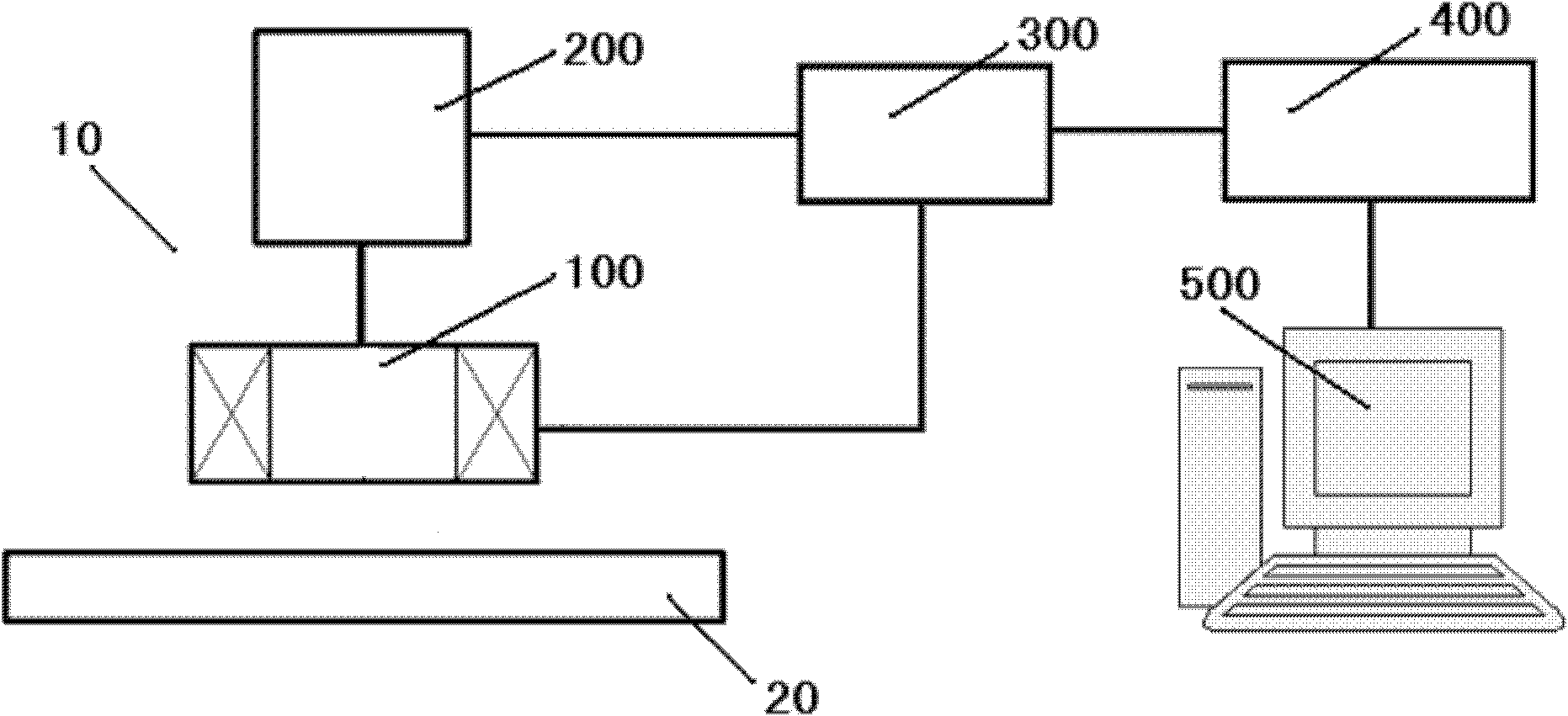

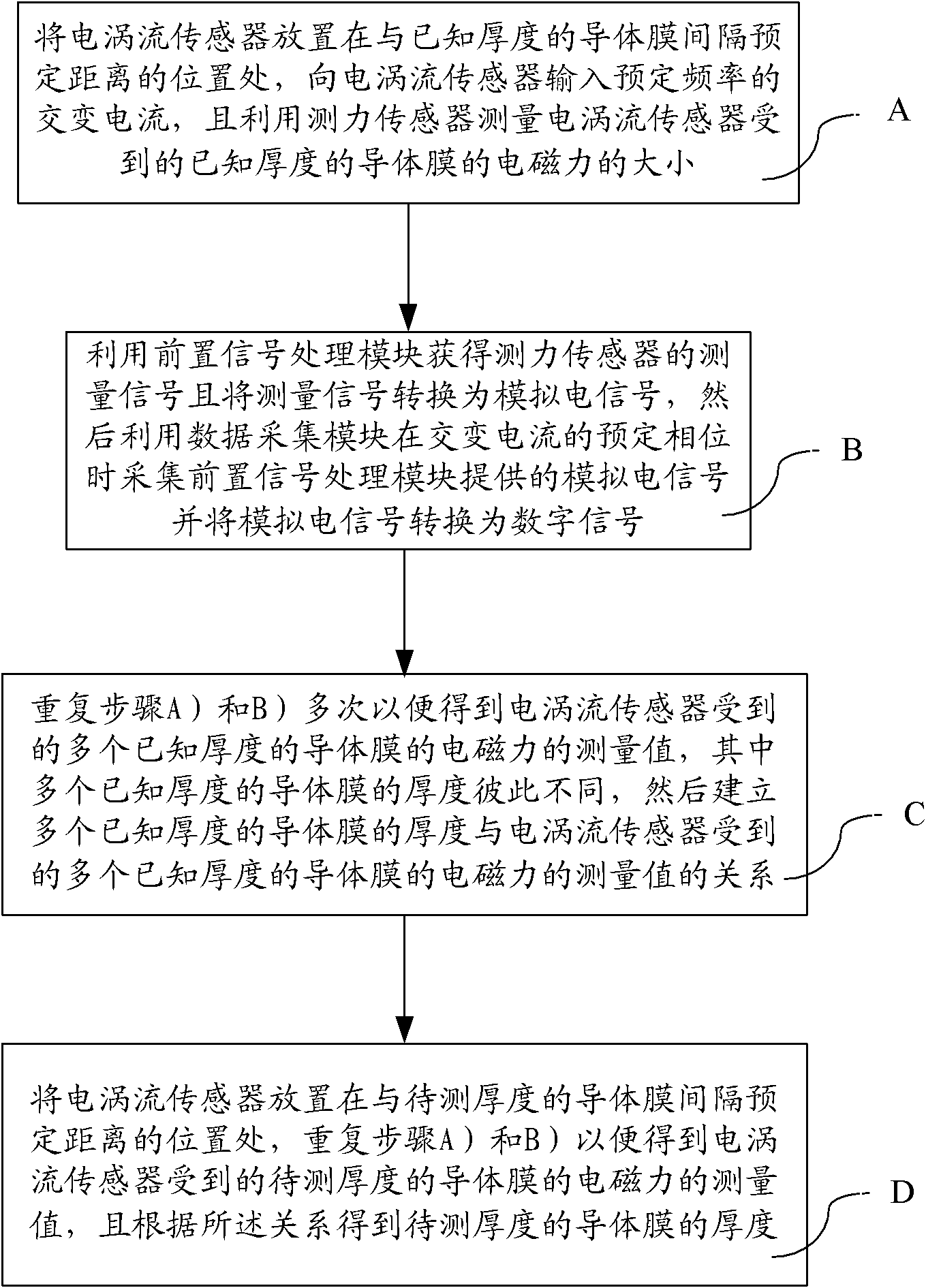

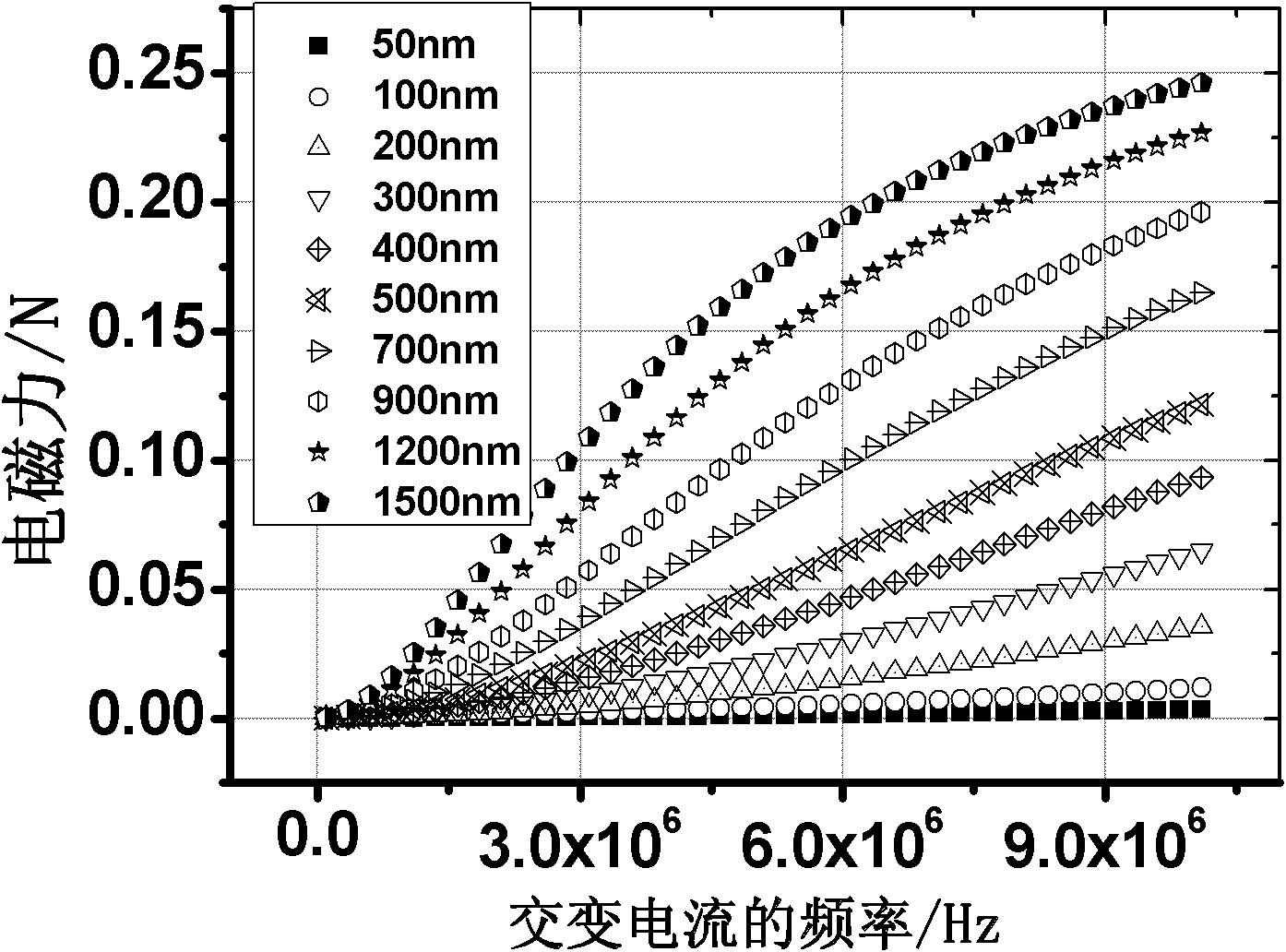

Device and method for measuring thickness of conductor membrane

ActiveCN102538655ASimple measurement processSimple signal processingElectrical/magnetic thickness measurementsPhysicsVIT signals

The invention discloses a device and method for measuring the thickness of a conductor membrane. The device for measuring the thickness of the conductor membrane comprises an eddy current sensor, a force transducer, a front signal processing module and a data acquisition module, wherein the force transducer is connected with the eddy current sensor, and is used for measuring the magnitude of the electromagnetic force of the conductor membrane on the eddy current sensor; the front signal processing module is connected with the eddy current sensor, and is used for inputting alternating current with a preset frequency to the eddy current sensor; the front signal processing module is connected with the force transducer, and is used for acquiring a measuring signal of the force transducer and converting the measuring signal into an analog electric signal; and the data acquisition module is connected with the front signal processing module, and is used for acquiring the analog electric signal provided by the front signal processing module when the alternating current is on a preset phase and converting the analog electric signal into a digital signal. According to the measuring device disclosed by the embodiment of the invention, the thickness of the conductor membrane can be measured easily, conveniently and quickly.

Owner:TSINGHUA UNIV

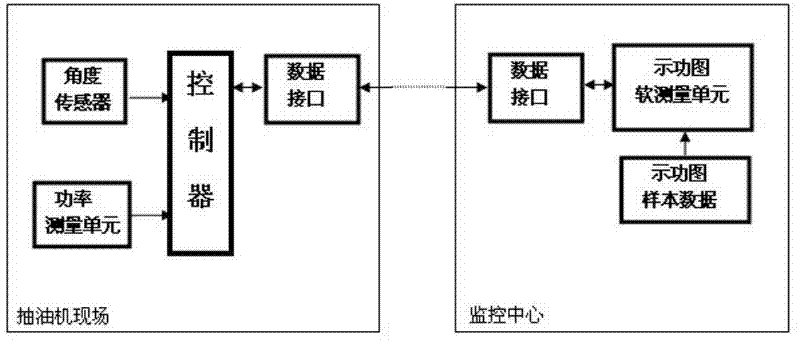

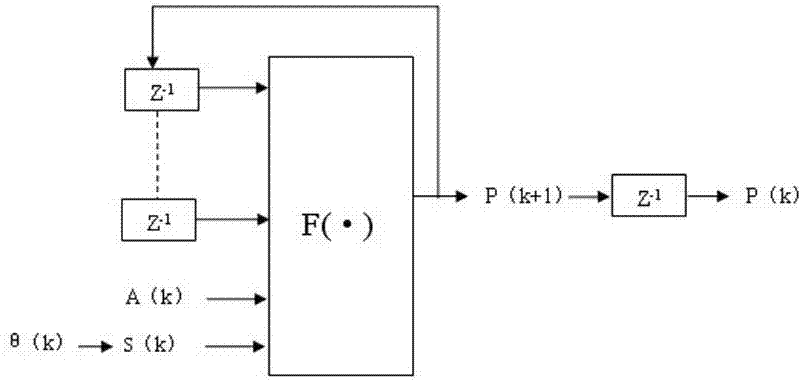

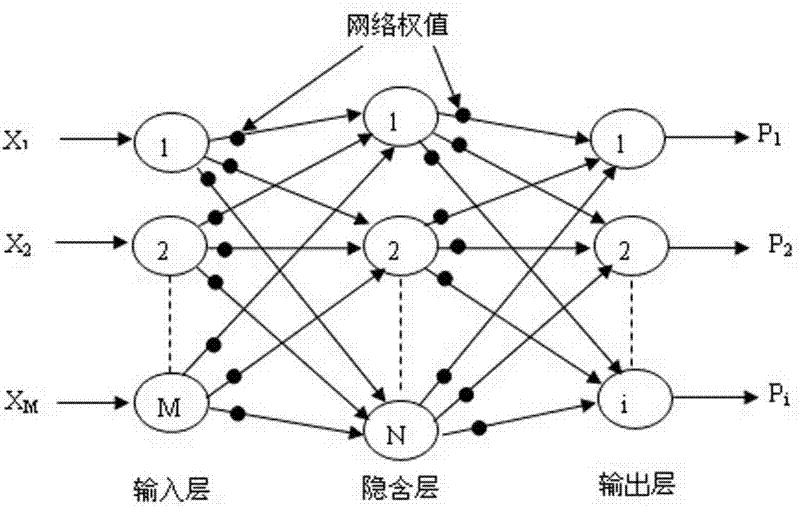

Beam pumping unit indicator diagram soft measurement method based on neural network

InactiveCN102331320ASimple measurement processEasy to measureWork measurementTorque measurementPhysicsMotor power

The invention relates to a soft measurement method of a beam pumping unit based on a neural network, which aims to provide a beam pumping unit indicator diagram measurement method. The method comprises an angle sensor, a power measuring unit, a controller, an element, a data interface, indicator diagram sample data and an indicator diagram soft measurement unit, wherein the angle sensor is used for measuring the swinging angle of a beam; the power measuring unit is used for measuring motor power; the controller completes data acquisition and data calculation; and the indicator diagram soft measurement unit completes neural network training and indicator diagram measurement and display. The method disclosed by the invention has the advantages of simple measurement process, accurate measurement, reliability and the like.

Owner:SHENYANG LIGONG UNIV

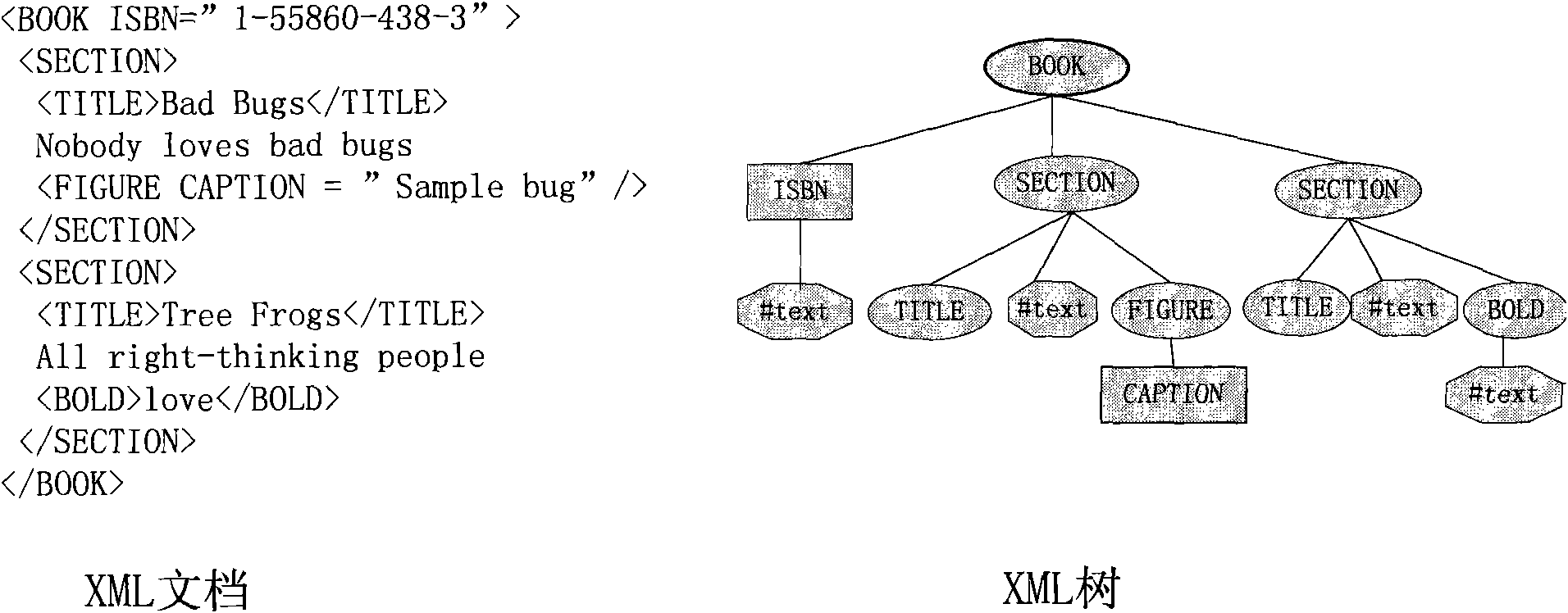

Method for calculating similarity of XML documents

InactiveCN101876995AExtract comprehensiveSimple measurement processSpecial data processing applicationsTheoretical computer scienceDegree of similarity

The invention belongs to the technical field of databases and aims to establish an XML document constraint model known as a bidirectional path constraint model. Based on the model, the invention discloses a new method for calculating the similarity of XML documents. The structural information of the XML documents is extracted more completely through the bidirectional path constraint of a node, so that the similarity of the XML documents is balanced more accurately. A very mature N-Gram thought in the field of natural languages is introduced and an N-Gram-based partition mode is applied in the similarity calculation of path constraint. The extraction and operation of N-Gram information are simplified by making skillful use of positive integers and weight numbers. The method can be used in the fields of XML document classification, clustering, mode extraction and the like.

Owner:NANKAI UNIV

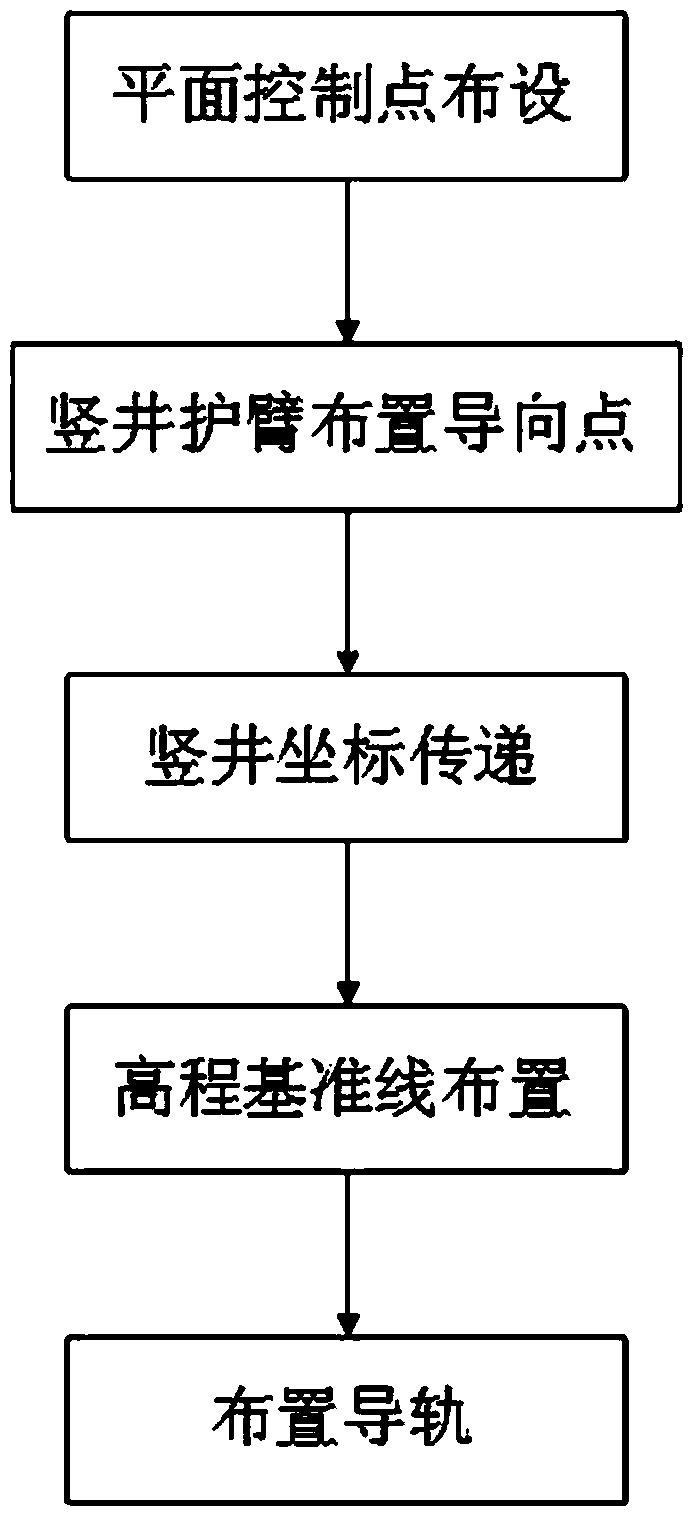

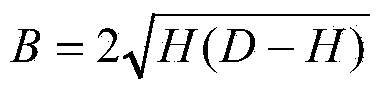

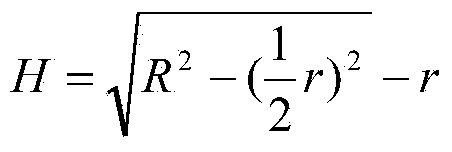

Method for linear directional measurement by utilizing laser in pipe jacking engineering

ActiveCN104251688AIntuitively determinedVery high construction accuracyAngle measurementSurveying instrumentsEngineeringPlane orientation

The invention discloses a method for linear directional measurement by utilizing laser in pipe jacking engineering. The method is characterized by comprising the following steps of plane control point layout, guide point layout on a vertical shaft guard wall, vertical shaft coordinate transmitting, elevation base line layout, guide rail arrangement and detection. The method has the benefits that conventional laser beam single-point orientation is changed into laser cross plane orientation, guide reference is uninterruptedly provided for pipe jacking construction, the deviation of the center of a jacking pipeline from the design axis can be timely discovered, and the construction precision is improved; the method is simple and easy to learn, the measuring speed is high, complicated measurements are reduced, the problem of difficulty in repeated measurement in the directional measurement process of conventional jacking pipes is eliminated, and surveyors are liberated from severe measurement environments; the measurement accuracy is high; a geoplane not only can accurately and rapidly measure whether a machine head is lifted or lowered, but also can set a flow slope, so as to perform sloping rapid induction measurement on the jacking pipe.

Owner:SHAANXI HUASHAN ROAD & BRIDGE ENG

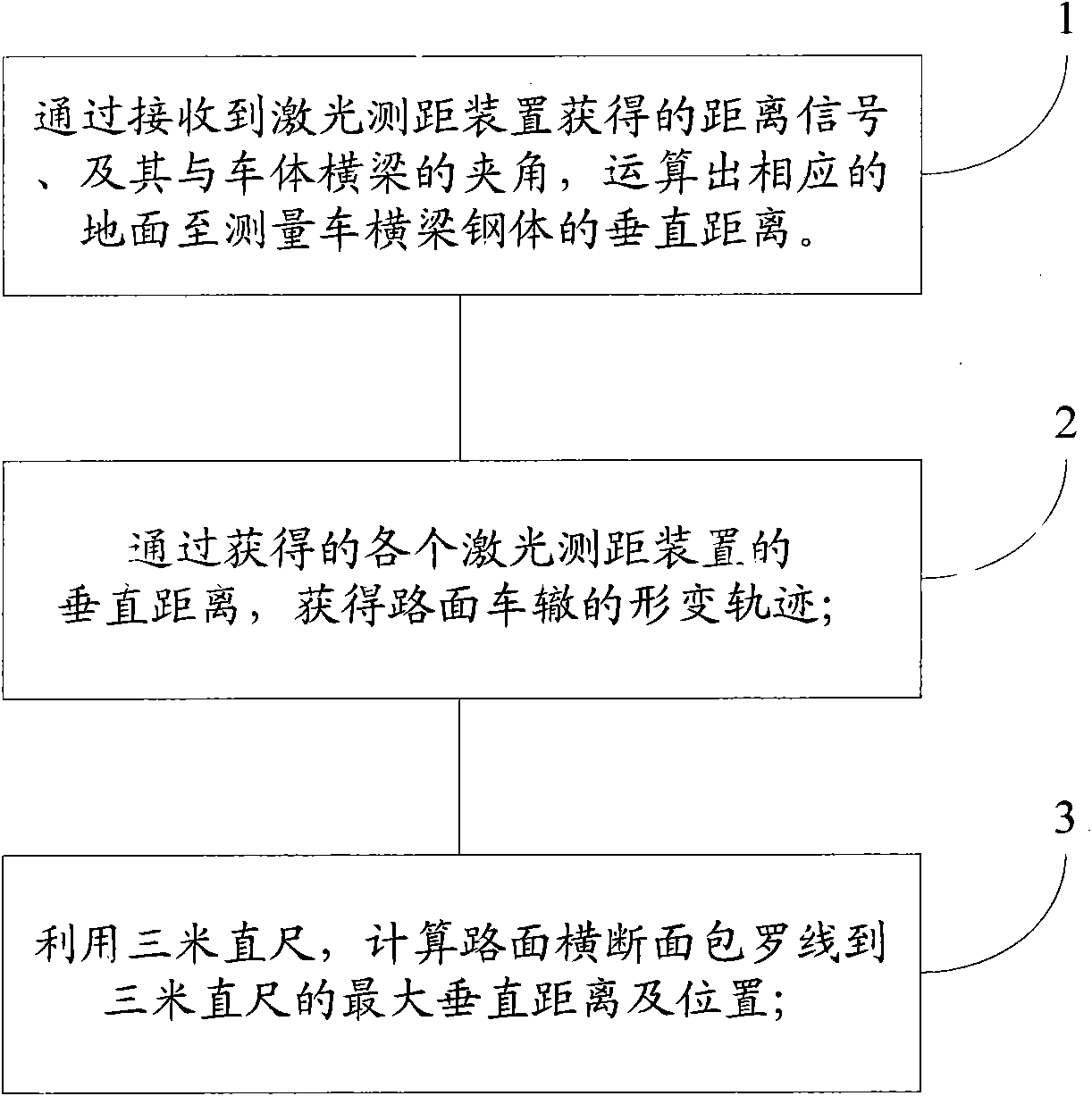

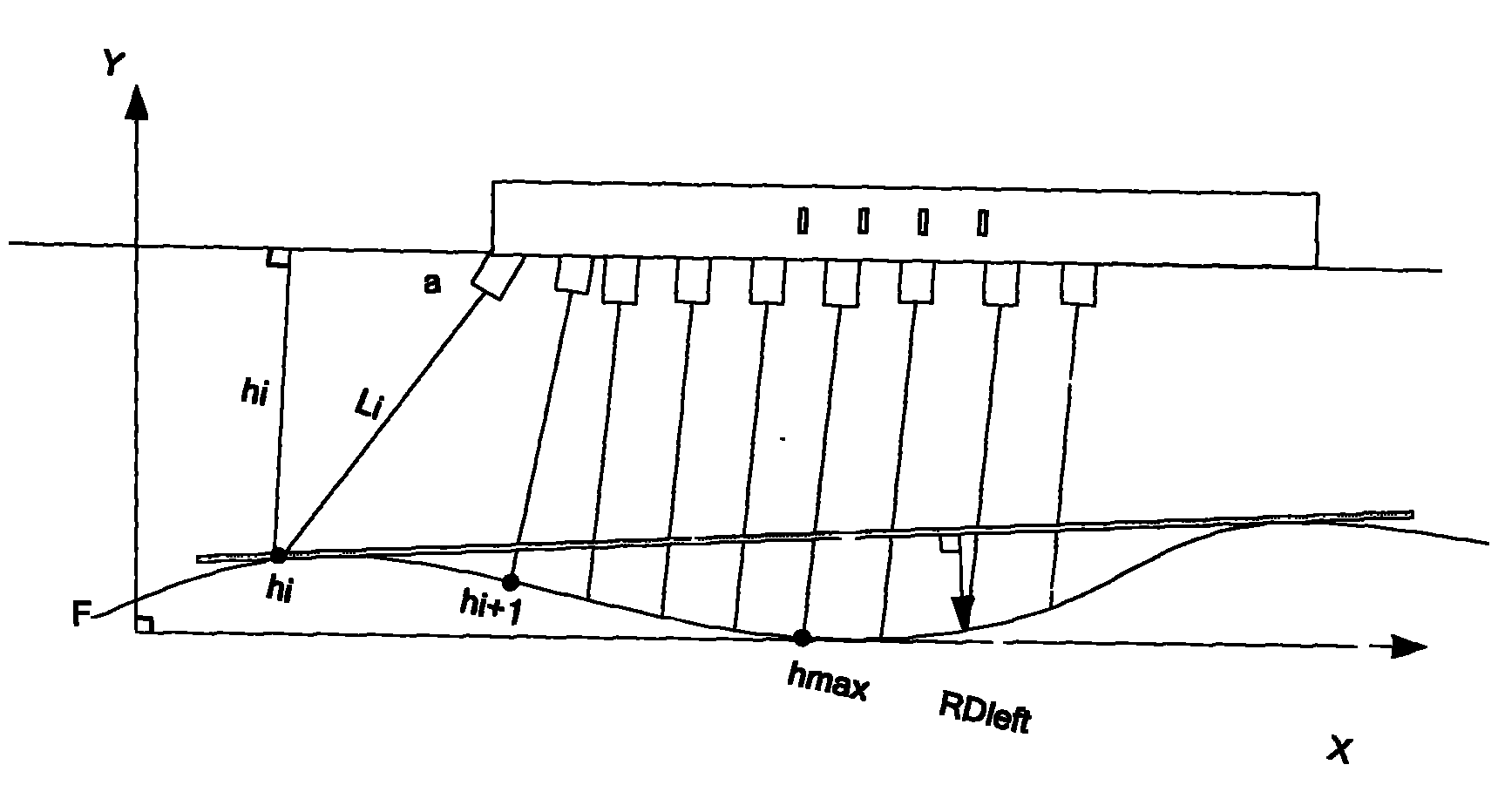

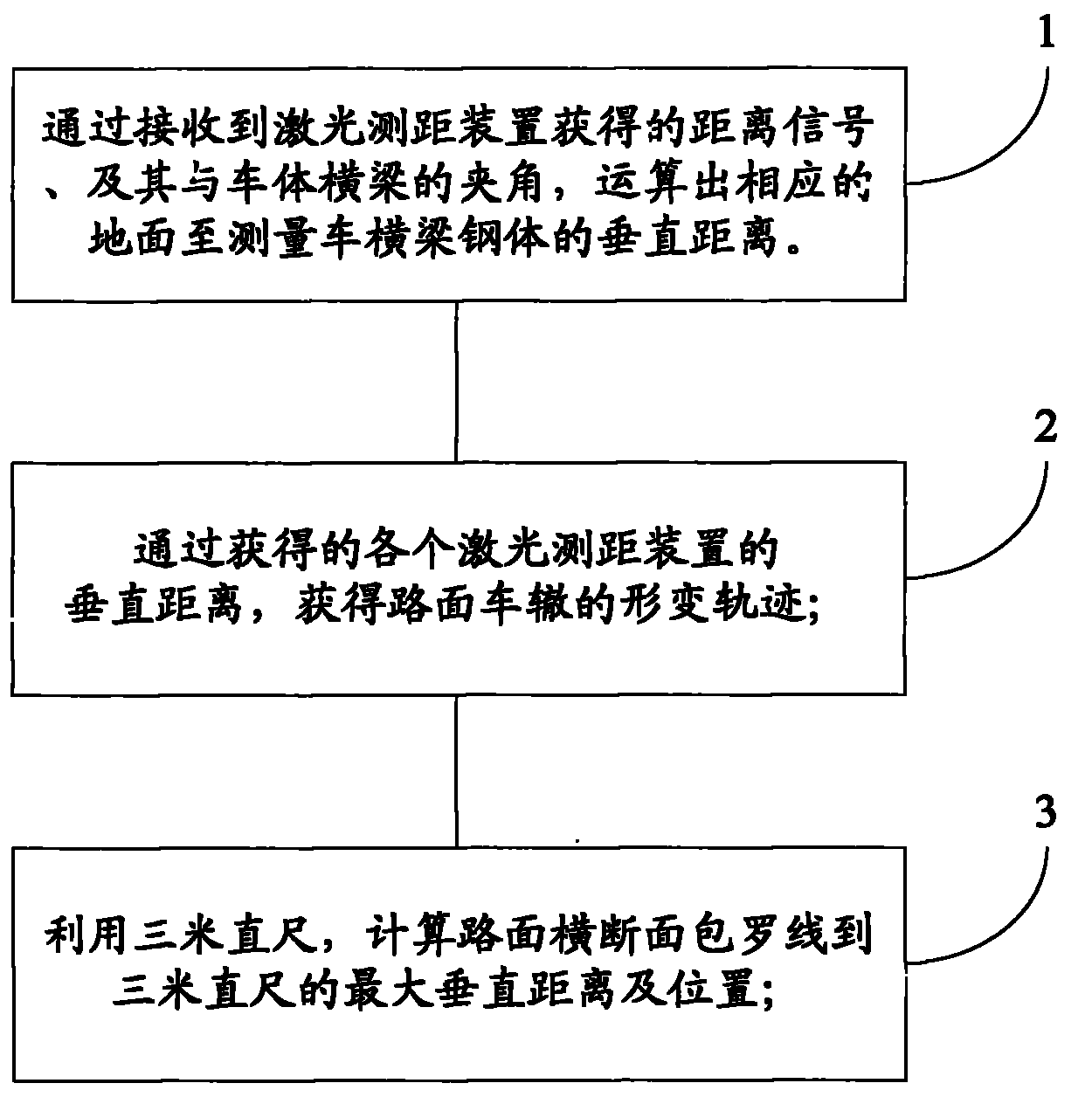

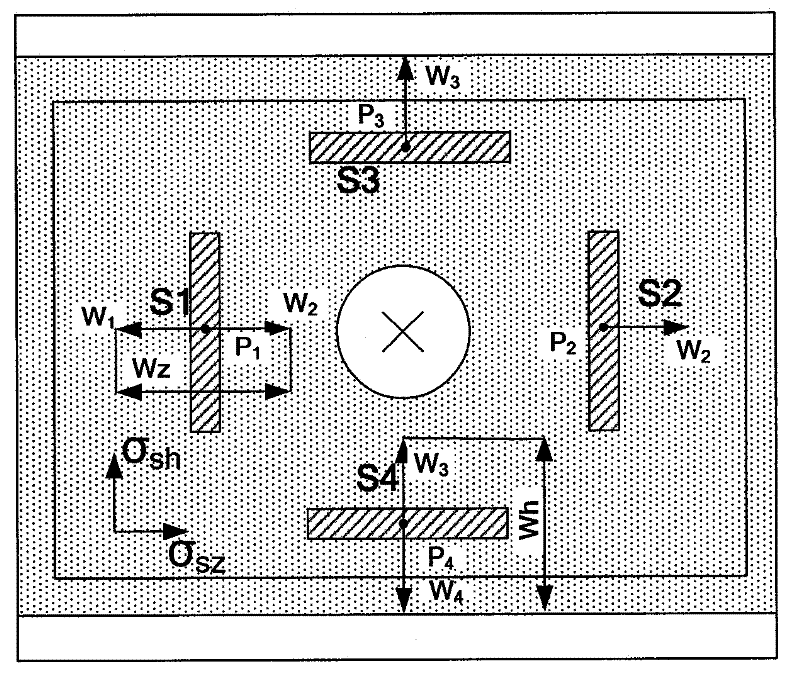

Road rut detection method

ActiveCN101929125ASimple measurement processReduce the cost of rut detectionUsing optical meansRoads maintainencePhysicsLaser ranging

The invention discloses a road rut detection method. In the method, 13 to 25 laser ranging devices are arranged on a cross beam steel body of a measurement vehicle. The method comprises: the laser ranging devices detect the distance to a road according to a preset distance and time interval; a processor works out the corresponding vertical distance from the ground to the cross beam steel body of the measurement vehicle according to the received distance signals which are acquired by the laser ranging devices and the included angle between the processor and the cross beam of the vehicle body; the deformation track curve of a road rut can be acquired according to the obtained vertical distances of the laser ranging devices; the road rut depth can be obtained by using the deformation track curve of the road rut; and road rut data on all sections can be detected quickly by the method. The method of the invention thus is described in detail. In the invention, the measurement process is simple and accurate, devices such as an accelerometer and a gyroscope are not mounted, the rut detection cost is reduced, the detection speed and the accuracy and reliability of the detection result are improved, and the speed of road maintenance is improved.

Owner:ROADMAINT CO LTD

Method and system for measuring residual stresses

InactiveCN102183458ASimple measurement processImprove measurement efficiencyUsing mechanical meansMaterial analysisSpeckle correlationEnvironmental geology

The invention provides a method and system for measuring residual stresses, which are used for solving the problems of fussy and complexed measuring process and lower measuring efficiency in the traditional measuring method. The method comprises the following steps of: acquiring a first speckle image of a region to be measured after the surface of the region to be measured is sprayed with speckles; acquiring a second speckle image of the region to be measured after the surface of the region to be measured is drilled; determining an axial displacement difference between a first axial point anda second axial point and an annular displacement difference between a first annular point and a second annular point according to the first speckle image, the second speckle image and a digital speckle correlation method; and determining the axial residual stress and the annular residual stress of a position where a hole is in according to the axial displacement difference and the annular displacement difference. By means of the technical scheme, fussy pasting and wiring processes are not required in the measurement process so that the measurement process is simplified, therefore the measurement efficiency of the residual stresses is greatly improved, and the whole deformation field before and after the residual stress of the position, where the hole is in, is released can be acquired.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

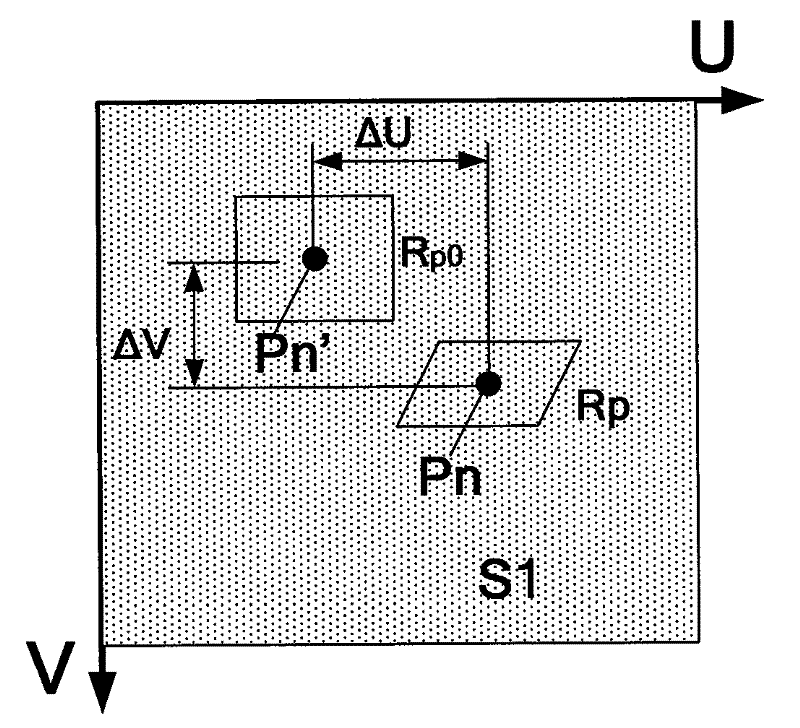

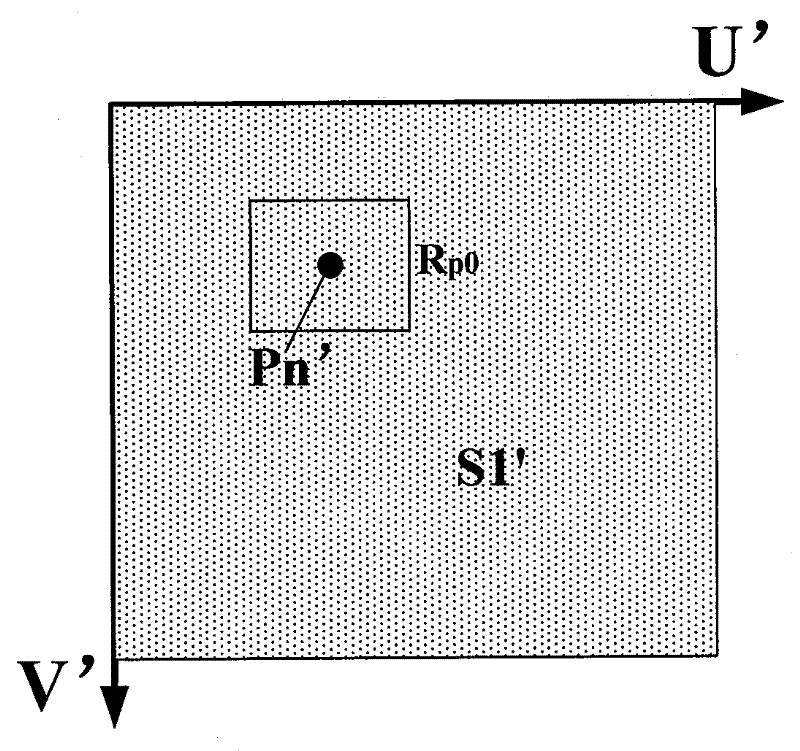

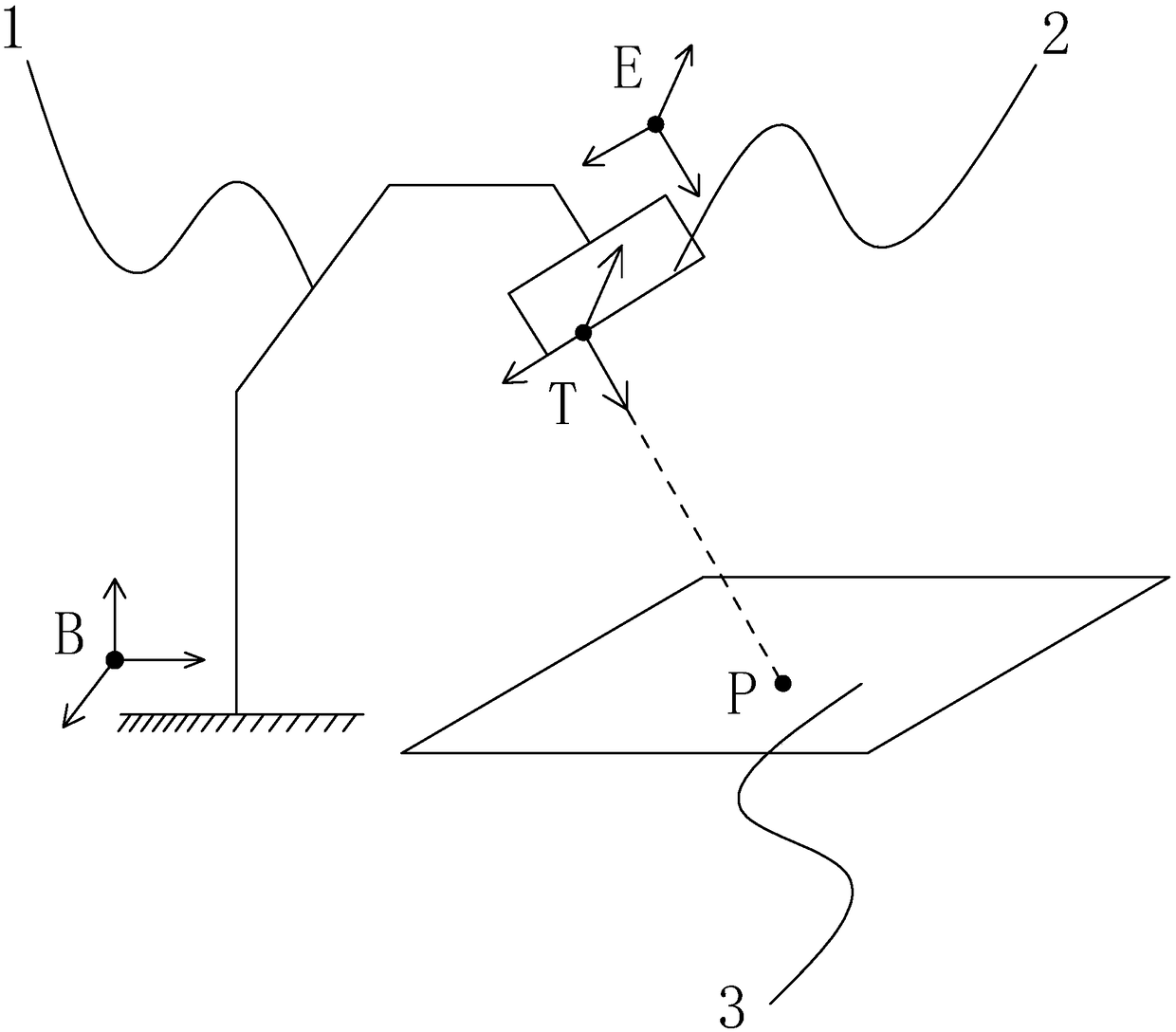

Robot tool coordinate system calibration method based on planar constraints

ActiveCN108731591ASimple measurement processImprove calibration efficiencyUsing optical meansDistance detectionLaser

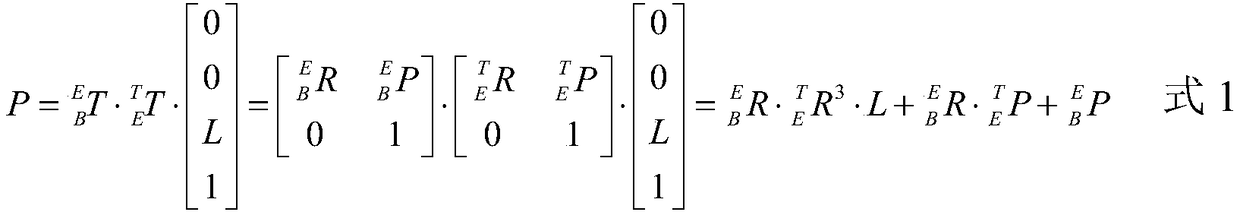

The invention discloses a robot tool coordinate system calibration method based on planar constraints. The robot tool coordinate system calibration method comprises the steps of: setting a motion modeof a robot; establishing a base coordinate system B, an end coordinate system E and a tool coordinate system T; establishing a planar constraint condition; ensuring that an irradiation point is always on a marble platform, keeping the attitude of the end coordinate system E unchanged, and controlling the position of the end coordinate system E to change for six times; ensuring that the irradiation point is always on a marble platform, keeping the position of the end coordinate system E unchanged, and controlling the attitude of the end coordinate system E to change for three times; and solving an irradiation point coordinate equation. During the tool coordinate system calibration process, the calibration of the tool coordinate system can be completed by solving the irradiation point coordinate equation of a laser displacement sensor, the solving of the irradiation point coordinate equation only needs to complete the measurement of 9 sets of data, the calibration efficiency is high, and the laser displacement sensor is utilized for distance detection to ensure sufficient calibration precision of the tool coordinate system.

Owner:FOSHAN INST OF INTELLIGENT EQUIP TECH +1

System and method for in-situ measurement of wall thickness of large thin-walled component

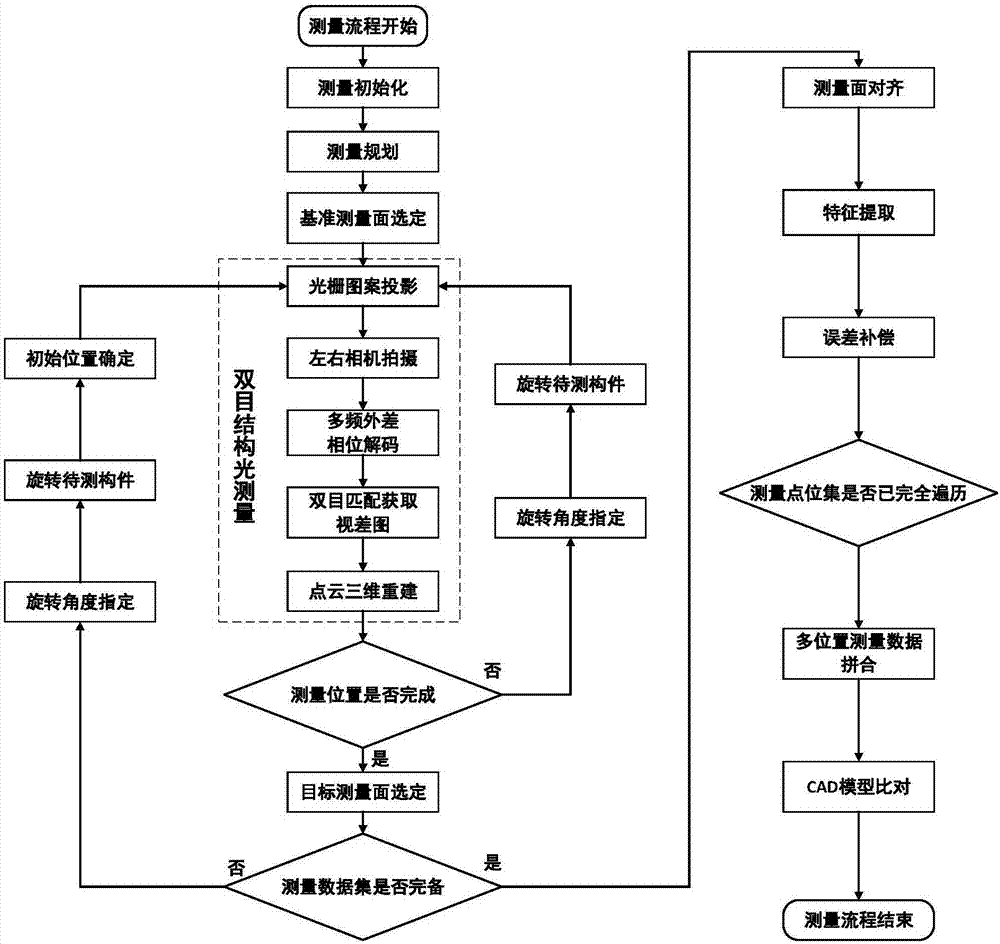

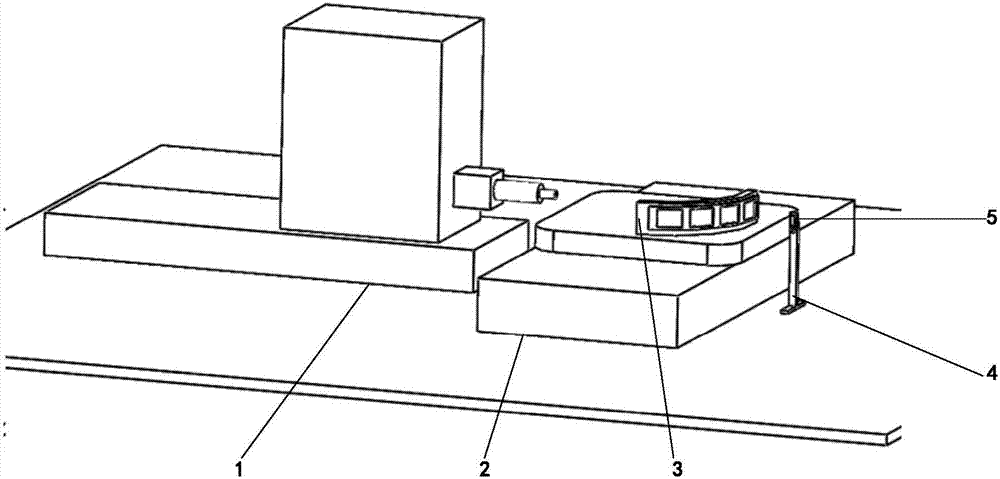

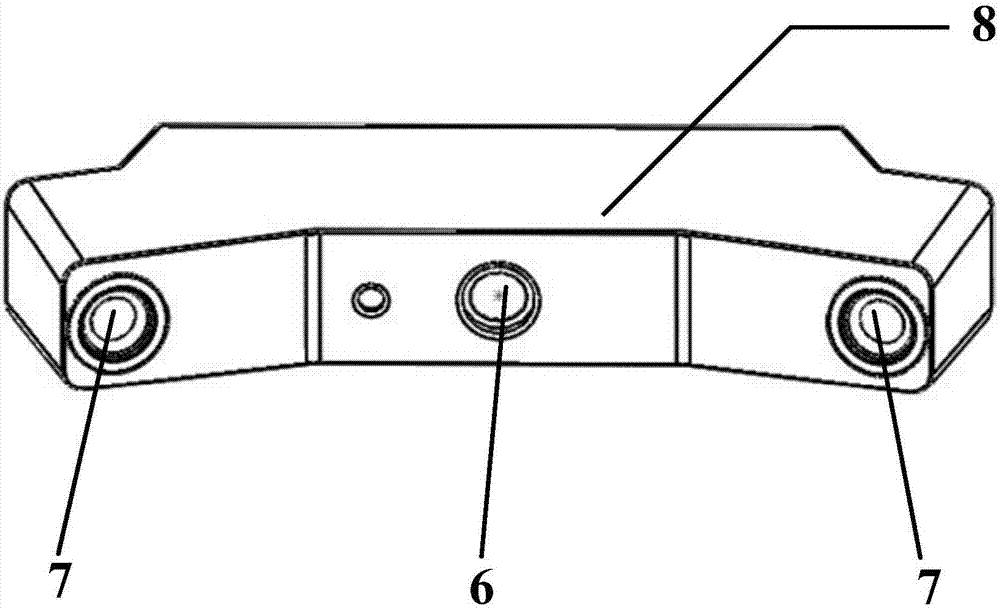

ActiveCN107270820AIntegrity guaranteedImprove measurement efficiencyUsing optical means3d shapesNumerical control

The invention discloses a system and a method for in-situ measurement of the wall thickness of a large thin-walled component. The system includes a numerical control machine tool, a tracer fixture, a measuring head bracket, a binocular structured light measurement device, an industrial computer, and a high-speed communication unit. The method is based on a binocular structured light measurement technology. Point cloud information is acquired according to the requirement on in-site detection of the overall 3D shape and wall thickness distribution of a thin-walled component in the machining process and based on a structured light precision measurement technology. The wall thickness at a corresponding position is acquired by selecting a measurement datum plane and performing differential operation gradually. Finally, the point cloud data measured at multiple positions is compared with a CAD model of the component and merged, and thus, in-situ detection of the large thin-walled component is completed, and accurate wall thickness data at each position is acquired. Precision measurement of a large thin-wall component is realized without contact. The system and the method can provide shape data for machining quality evaluation, and also can guide the machining process.

Owner:SHANGHAI JIAO TONG UNIV +1

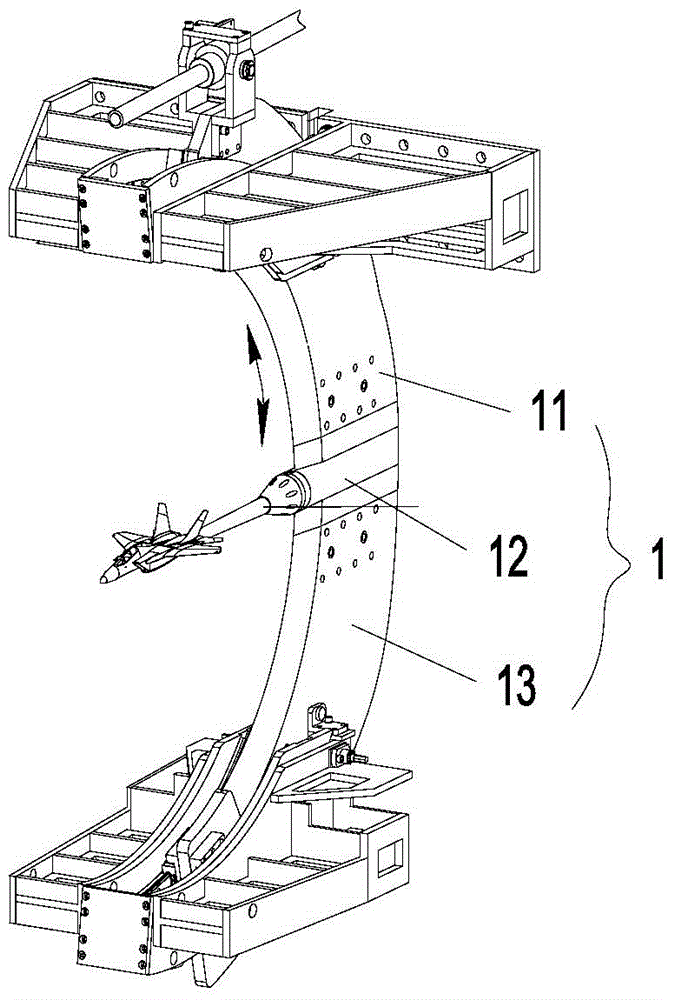

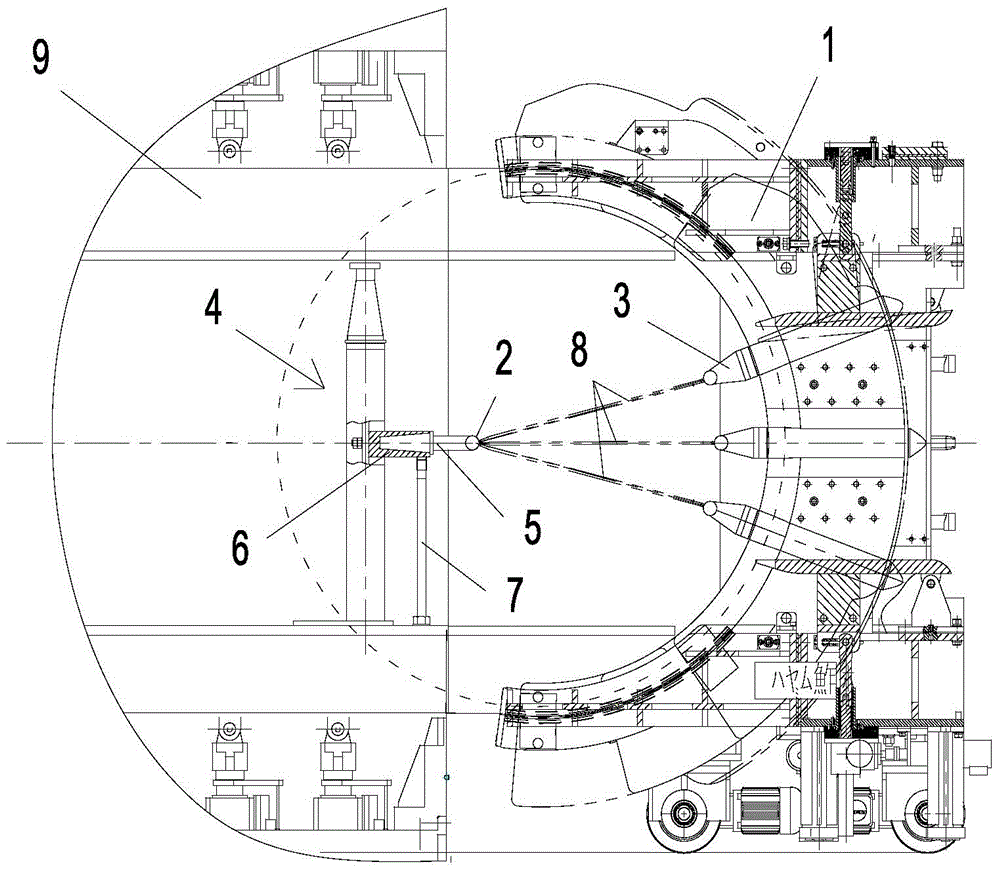

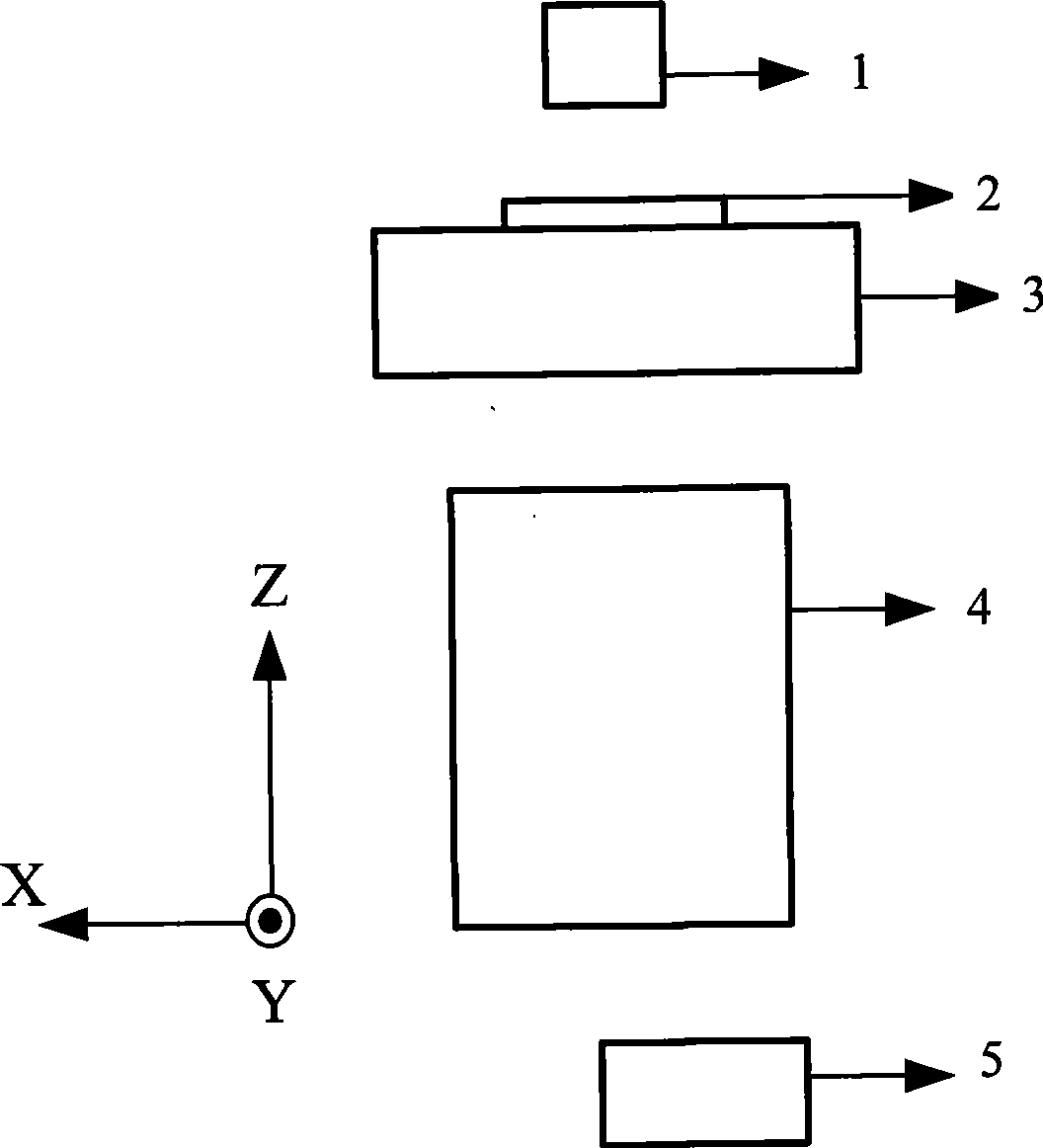

Detecting device and detecting method for rotation center of angle-of-attack mechanism of wind tunnel test section

The invention relates to a detecting device and a detecting method for a rotation center of an angle-of-attack mechanism of a wind tunnel test section. The detecting device comprises a supporting positioning structure with a horizontal extending structure. The supporting positioning structure is provided with a guiding structure which can make the horizontal extending structure move vertically. The extending end of the horizontal extending structure is provided with a detecting positioning structure, and a measuring device which is arranged on the bent cutter supporting plate of the angle-of-attack mechanism of the wind tunnel test section correspondingly with the detecting positioning structure and can perform positive and negative angle-of-attack arc movement of the bent cutter supporting plate. The detecting device and detecting method for the rotation center of the angle-of-attack mechanism of the wind tunnel test section realize more visual and quick measurement process and furthermore establish a standard with small error and high stability. Furthermore the detecting device and the detecting method have advantages of remarkably shortening an application period, reducing number of operators, reducing labor intensity, and greatly reducing cost at each aspect.

Owner:四川省工业设备安装集团有限公司

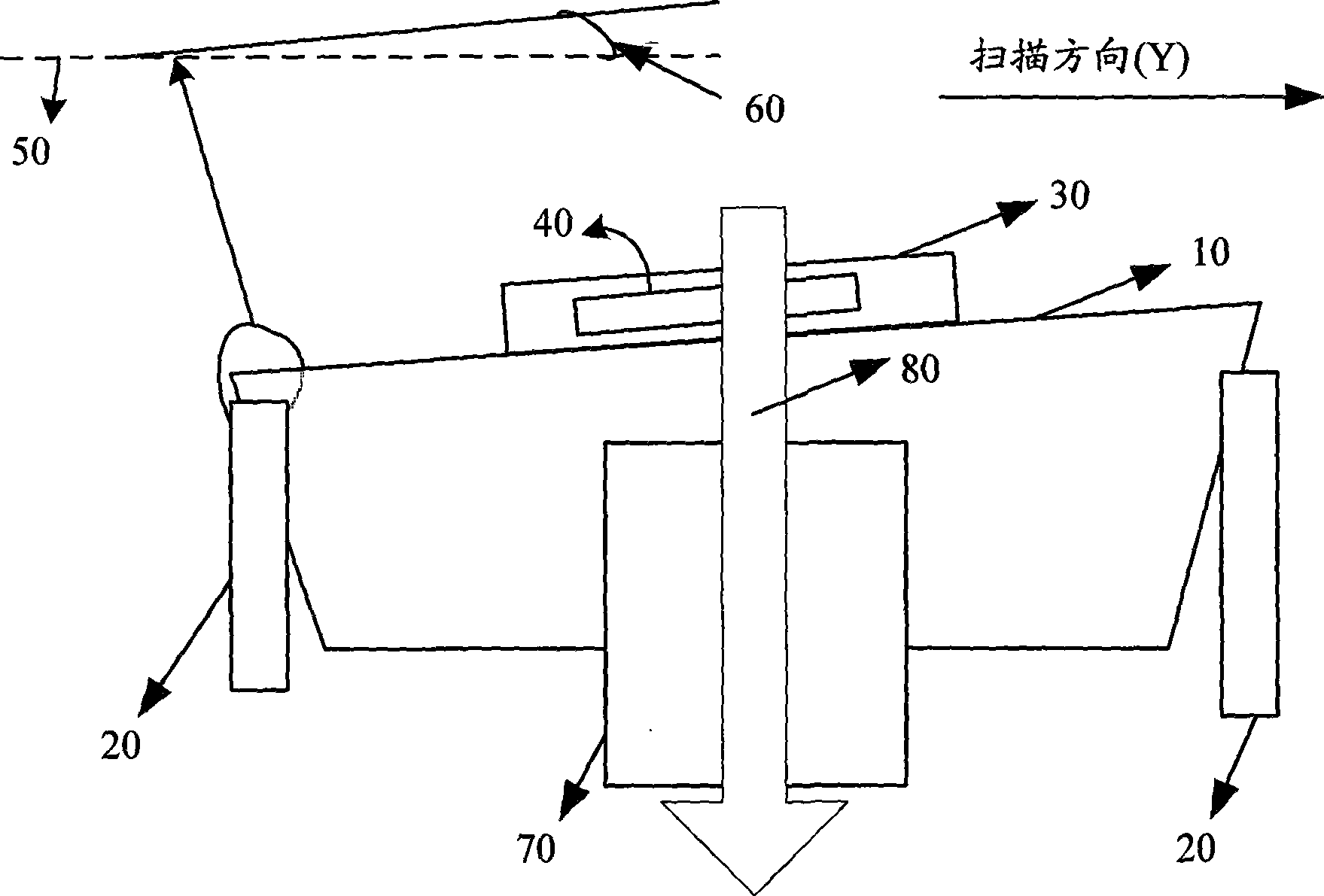

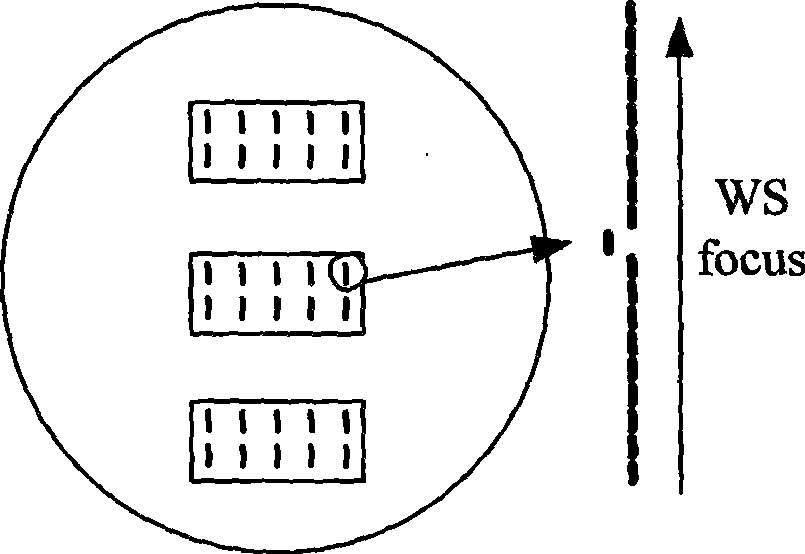

Measuring method and apparatus for mask bench scanning inclination

ActiveCN101477315ASimple measurement processShort timePhotomechanical exposure apparatusMicrolithography exposure apparatusVisual field lossHeight difference

The invention provides a method and a device for measuring oblique scan of a mask platform. The method comprises: firstly, laying a test mask on the mask platform, wherein a plurality of rows of aligning marks are arranged on the test mask; secondly, moving the mask platform, and making a row of aligning marks on the test mask positioned in the center of a visual field of an exposed light source system; thirdly, opening exposed light sources, and making a plurality of aligning marks imaged below a projection objective; fourthly, horizontally and vertically moving an image sensor system, and scanning space images of the row of aligning marks so as to acquire the height difference Zf of vertical positions of the space images of the aligning marks opposite to a focal plane of an image space of the projection objective; fifthly, converting the Zf into the height difference Zi of the vertical positions of the aligning marks opposite to a focal plane of an object space of the projection objective; sixthly, repeatedly executing the second step, the third step, the fourth step and the fifth step so as to acquire the Zi of different rows of aligning marks, and establishing a plurality of corresponding oblique scan deviation models according to the relations between the oblique scan deviation of the mask platform and the Zi; and seventhly, calculating the oblique scan deviation of the mask platform according to the plurality of the models.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

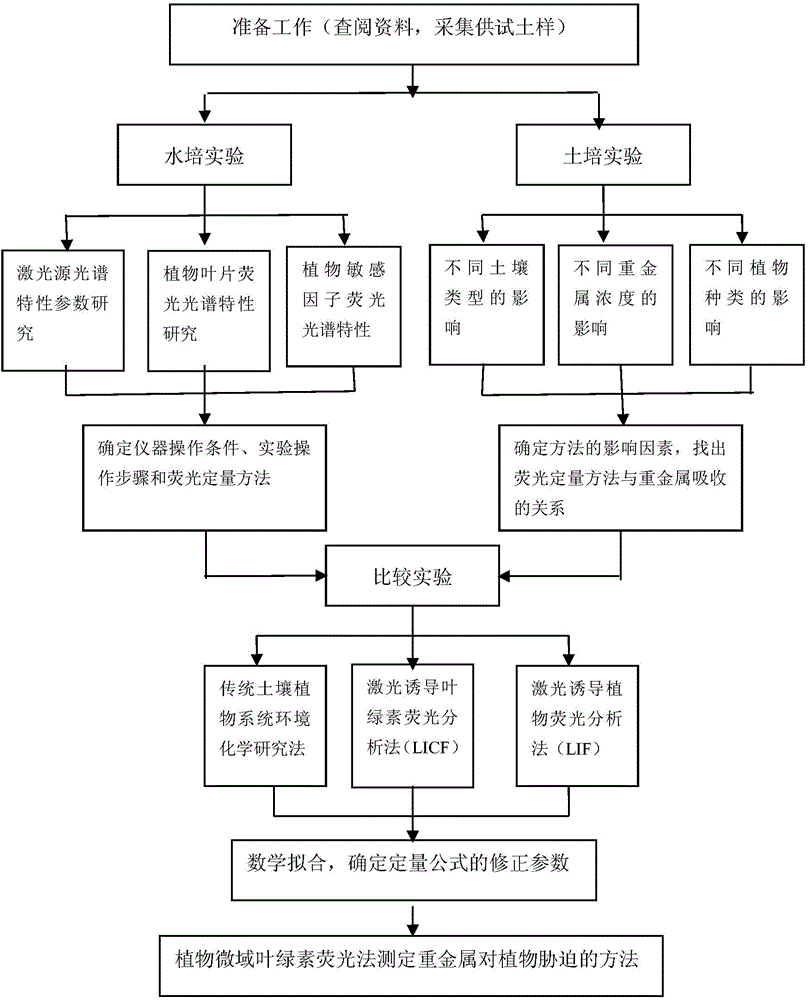

Method or measuring stress of heavy metals on plants by using plant micro-domain chlorophyll fluorescence method

InactiveCN104568887AGood consistency of photoelectric parametersLittle outside influenceFluorescence/phosphorescenceLuminous intensityPhotoluminescence

The invention belongs to the technical field of heavy metal pollution analysis and relates to a method or measuring stress of heavy metals on plants by using a plant micro-domain chlorophyll fluorescence method. The method comprises the following steps: putting plant leaves and quartz glass sheets in a shading box together, taking the representative part of to-be-measured plant leaves, regulating the temperature of a measuring environment to be 20 DEG C, selecting an xenon lamp as a plant fluorescence direct excitation source under shading or infrared conditions, adopting a parallel light source, and recording the photoluminescence intensity; and finally, determining the expression amount of plant leaves stressed or damaged by heavy metals. The method is simple in measurement process, reliable in design principle, convenient to use and operate, high in measurement accuracy, wide in application range and friendly in measurement environment.

Owner:SHANDONG NORMAL UNIV

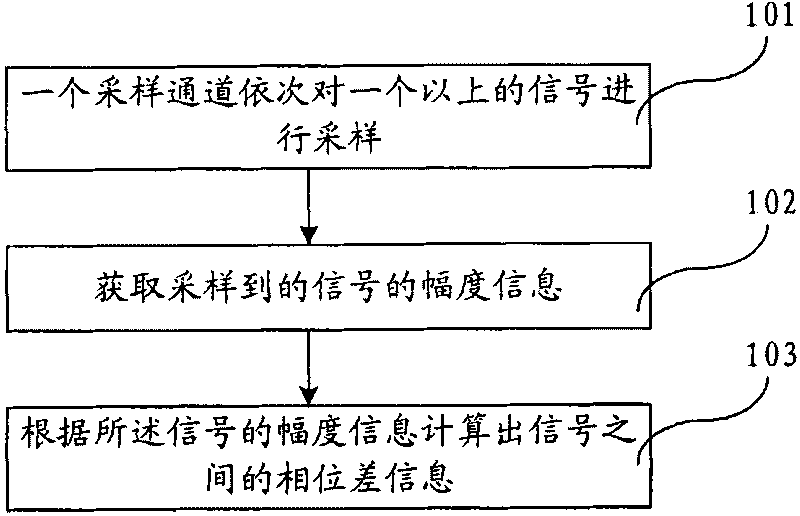

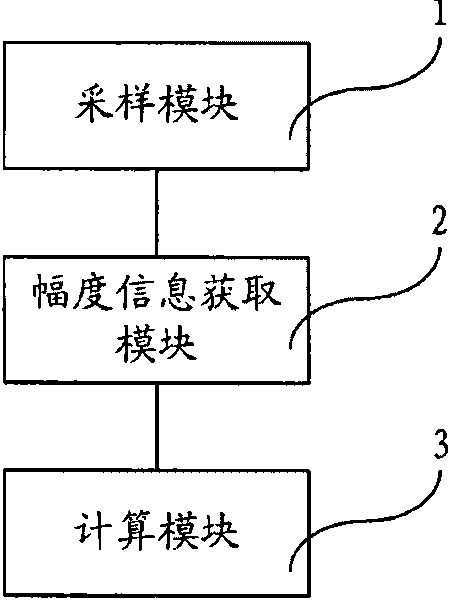

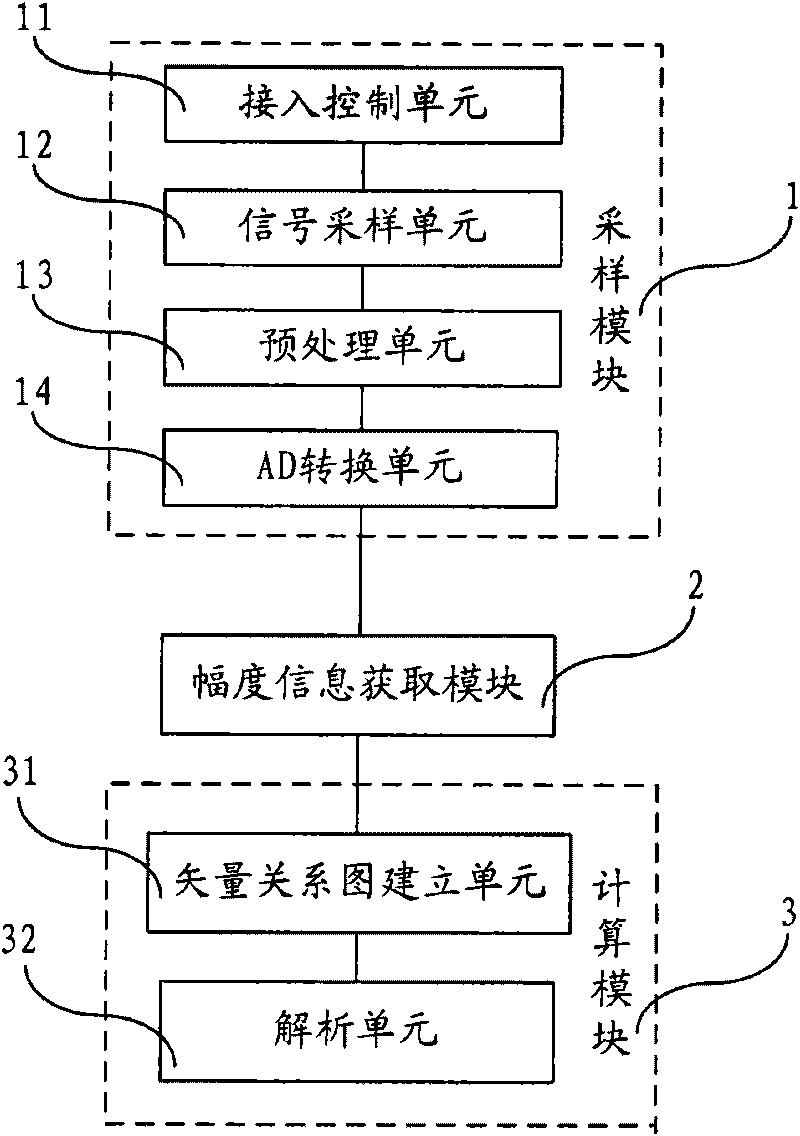

Method, device and system for measuring signal phase difference

ActiveCN101726664AReduce the numberReduce hardware densityResistance/reactance/impedenceVoltage-current phase angleMeasurement devicePhase difference

The embodiment of the invention provides a method, a device, and a system for measuring signal phase difference. The method comprises the following steps: sampling more than two signals and acquiring the amplitude information of the sampled signals by a sampling channel; and calculating phase difference information between the signals according to the amplitude information of the signals. The device comprises a sampling module, an amplitude information acquisition module, and a calculating module, wherein the sampling module comprises at least one sampling channel for sampling more than two signals; the amplitude information acquisition module is used for acquiring the amplitude information of the sampled signals; and the calculating module is used for calculating the phase difference information between the signals according to the amplitude information of the signals. The embodiment of the invention also provides the system for measuring the signal phase difference, which comprises a transmission network and the device for measuring the signal phase difference. The method, the device and the system for measuring the signal phase difference provided by the embodiment of the invention utilize one sampling channel to sample a plurality of signals, which can reduce the hardware density of the device and simplify a measurement flow.

Owner:HENGQIN INT INTPROP EXCHANGE CENT CO LTD

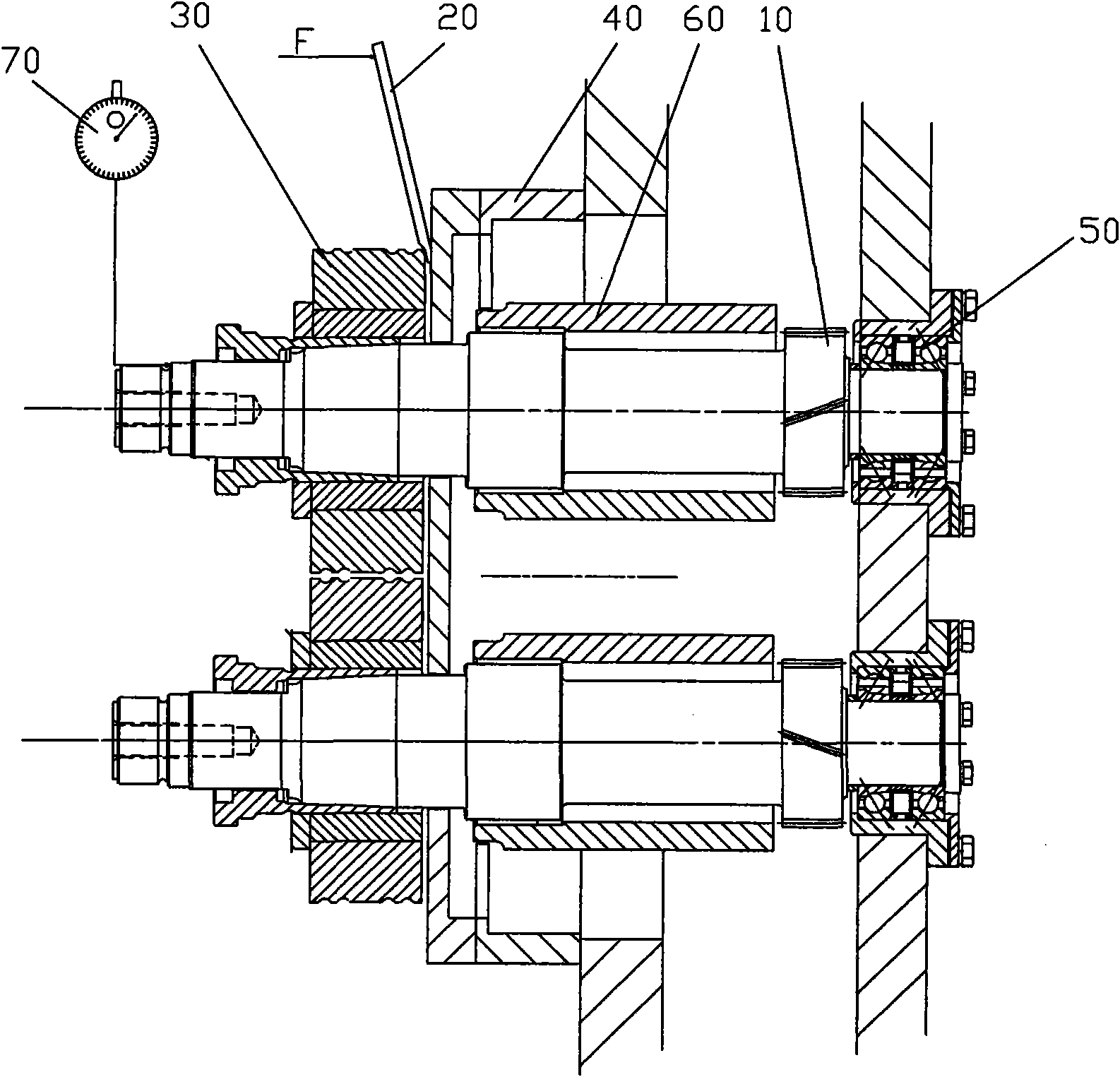

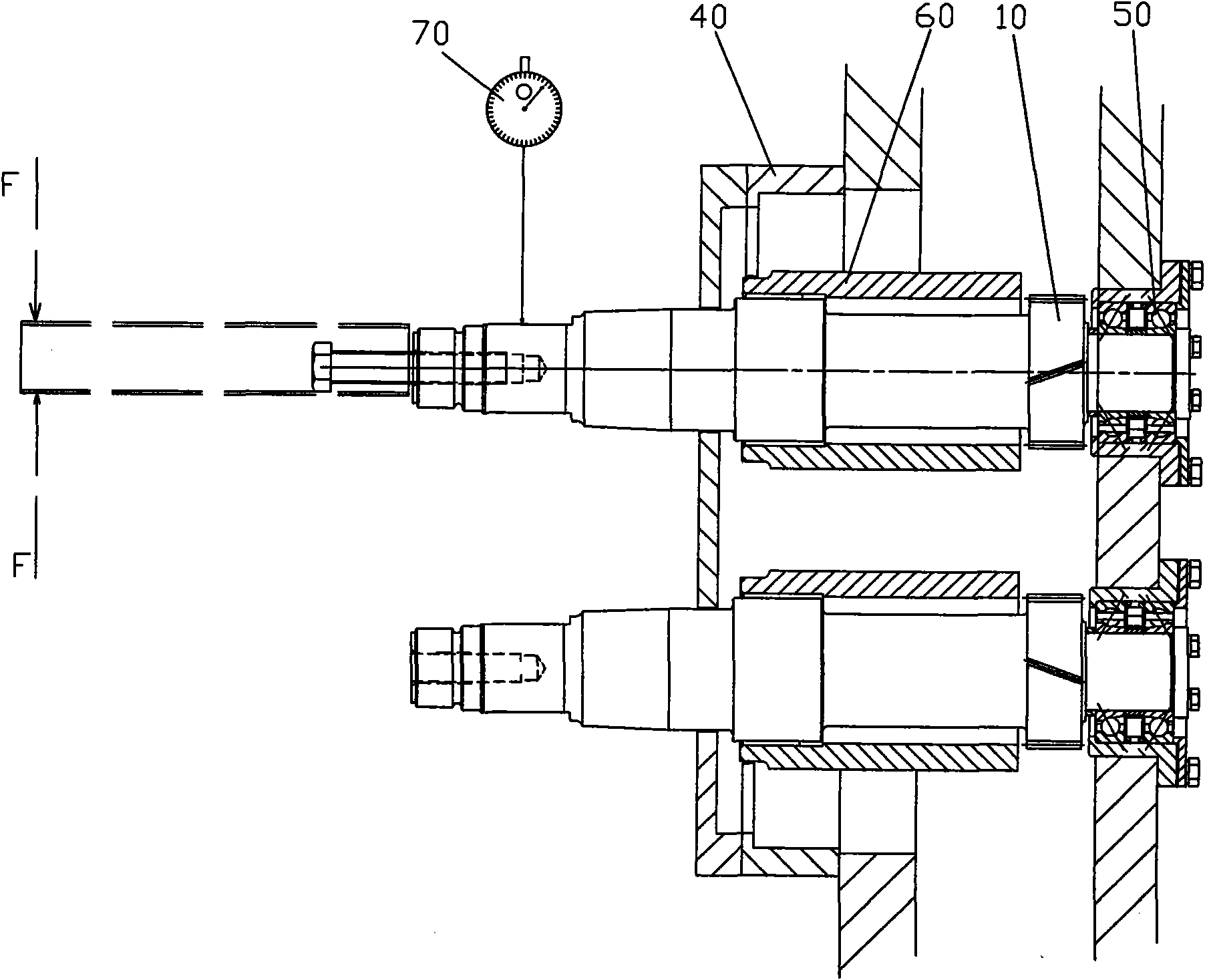

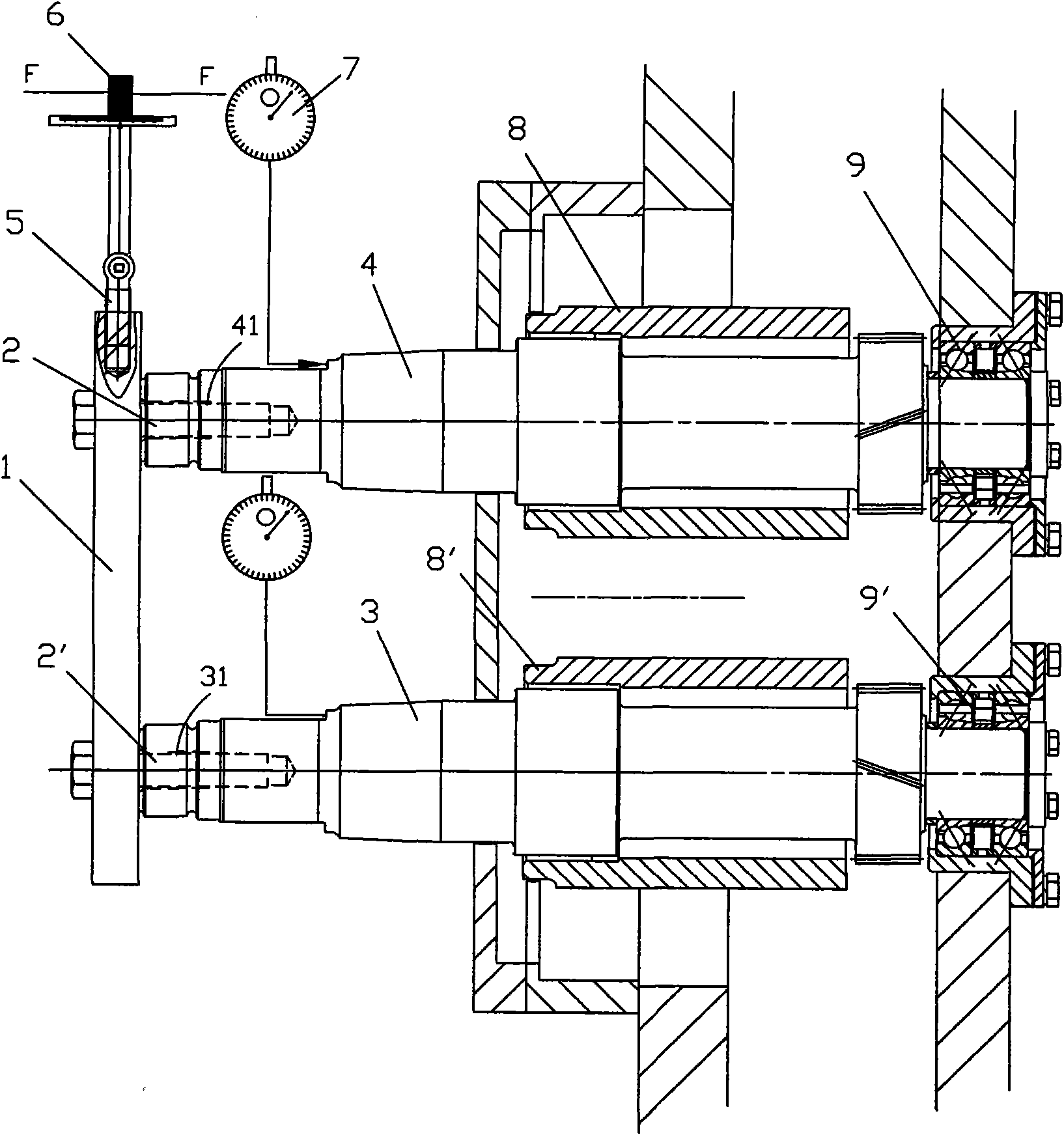

Method for measuring gap between bearings of roll shafts of pinch rolls

ActiveCN101929830AGuaranteed accuracyEasy to operateMechanical clearance measurementsEngineeringTorque wrench

The invention relates to a method for measuring a gap between bearings of roll shafts of punch rolls, which comprises the following steps: 1) vertically taking up a measuring connecting rod, and leading the upper part and the lower part of the measuring connecting rod to be connected with the shaft ends of the upper roll shaft and the lower roll shaft; 2) screwing the top end of the connecting rod into a measuring connecting bolt; 3) inserting one end of a pointer type torque wrench into the measuring connecting bolt; and placing dial indicators on the upper roll shaft and the lower roll shaft; 4) pulling the pointer type torque wrench to the right side by using the hand, and respectively recording values on the dial indicators when the pointer scale value on the pointer type torque wrench achieves the set value, wherein the value measured by the lower roll shaft is the gap between the bearings produced during the action of the left side; 5) pulling the pointer type torque wrench to the left side, and measuring the values of the dial indicators; and 6) adding the values measured by the upper roll shaft and the lower roll shaft during the two actions, and obtaining the accurate actual gap value between the bearings of the upper roll shaft and the lower roll shaft. The method can ensure the precision of the measured value at each time and improve the working efficiency of the measurement by quantifying the control during the measurement process, that is carrying out constant operation on the torque applied during the measurement and carrying out fixed point control on force application points.

Owner:BAOSHAN IRON & STEEL CO LTD

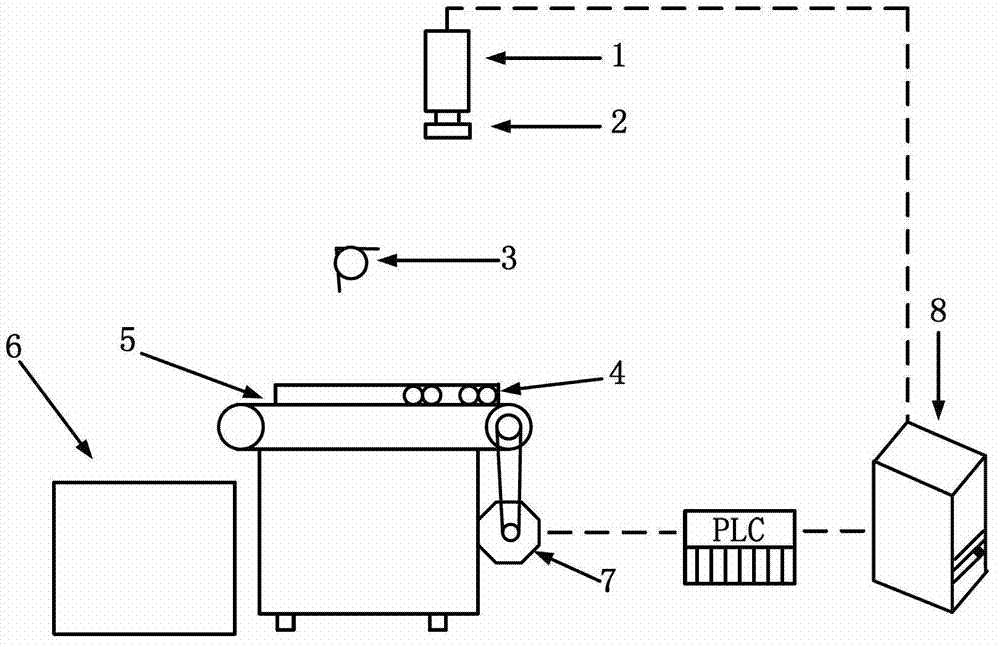

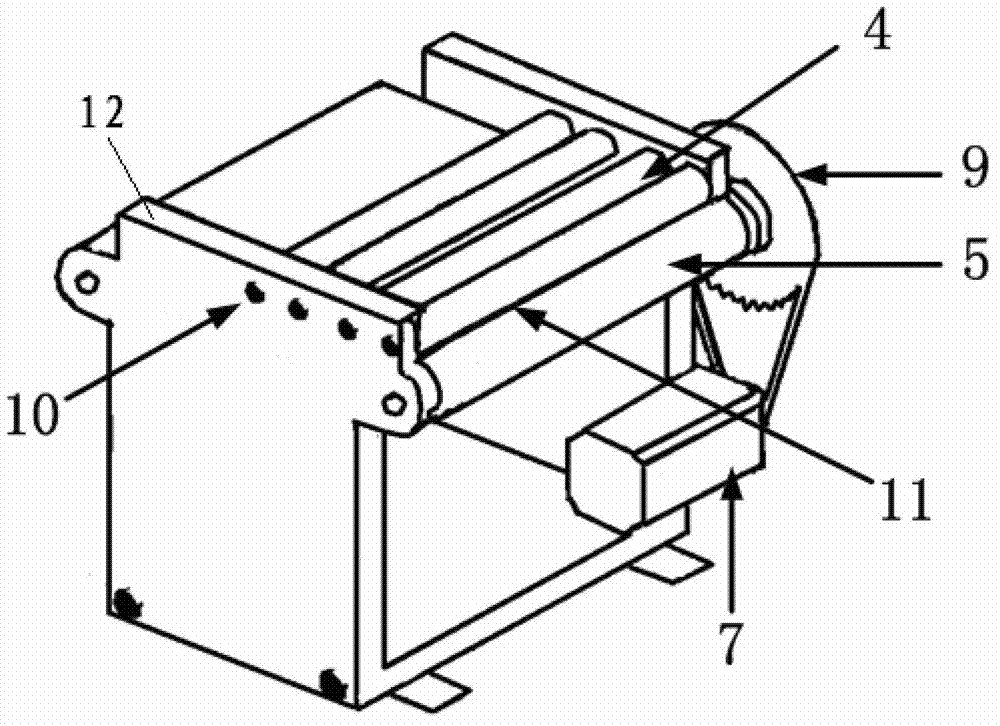

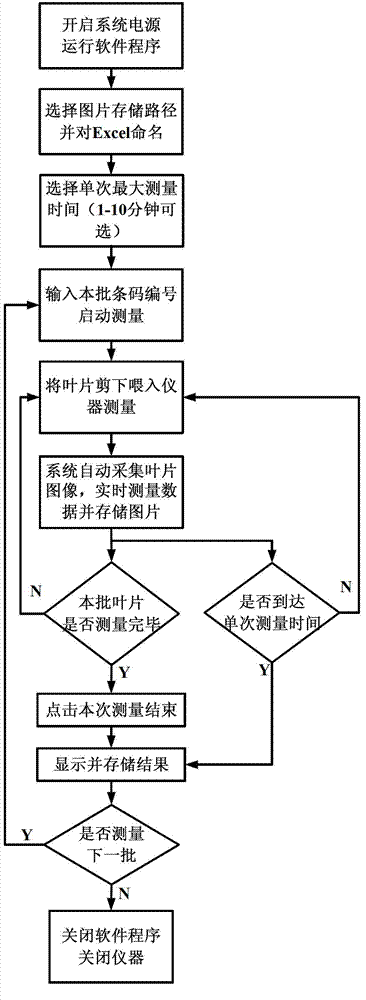

Automatic measuring and analyzing instrument for crop leaf area information

The invention discloses equipment for measuring and analyzing the total leaf area, green leaf area, yellow leaf area and the green leaf index of a crop in a high-precision and high-speed manner. The instrument comprises a leaf transmission device, an image acquisition device, a PLC (Programmable Logic Controller) and a computer system. According to the invention, a machine vision technology is adopted to dynamically acquire the leaf color information of the crop, and the leaves of the crop can be quickly measured at the same time; the defect that a current measuring method can not quickly and efficiently measure the total leaf area, green leaf area and yellow leaf area of the crop is overcome; the measuring process adopts a feeding type flow operation mode, and the operation is convenient; the software compatibility is good; and the foreign part can be automatically removed, and the green leaf part and the yellow leaf part can be recognized. Therefore, the leaf color information can be obtained as long as the leaf is sheared down and directly put into the instrument for measuring and analyzing, without pretreatment for the yellow and green parts of the leaf such as trimming.

Owner:HUAZHONG AGRI UNIV

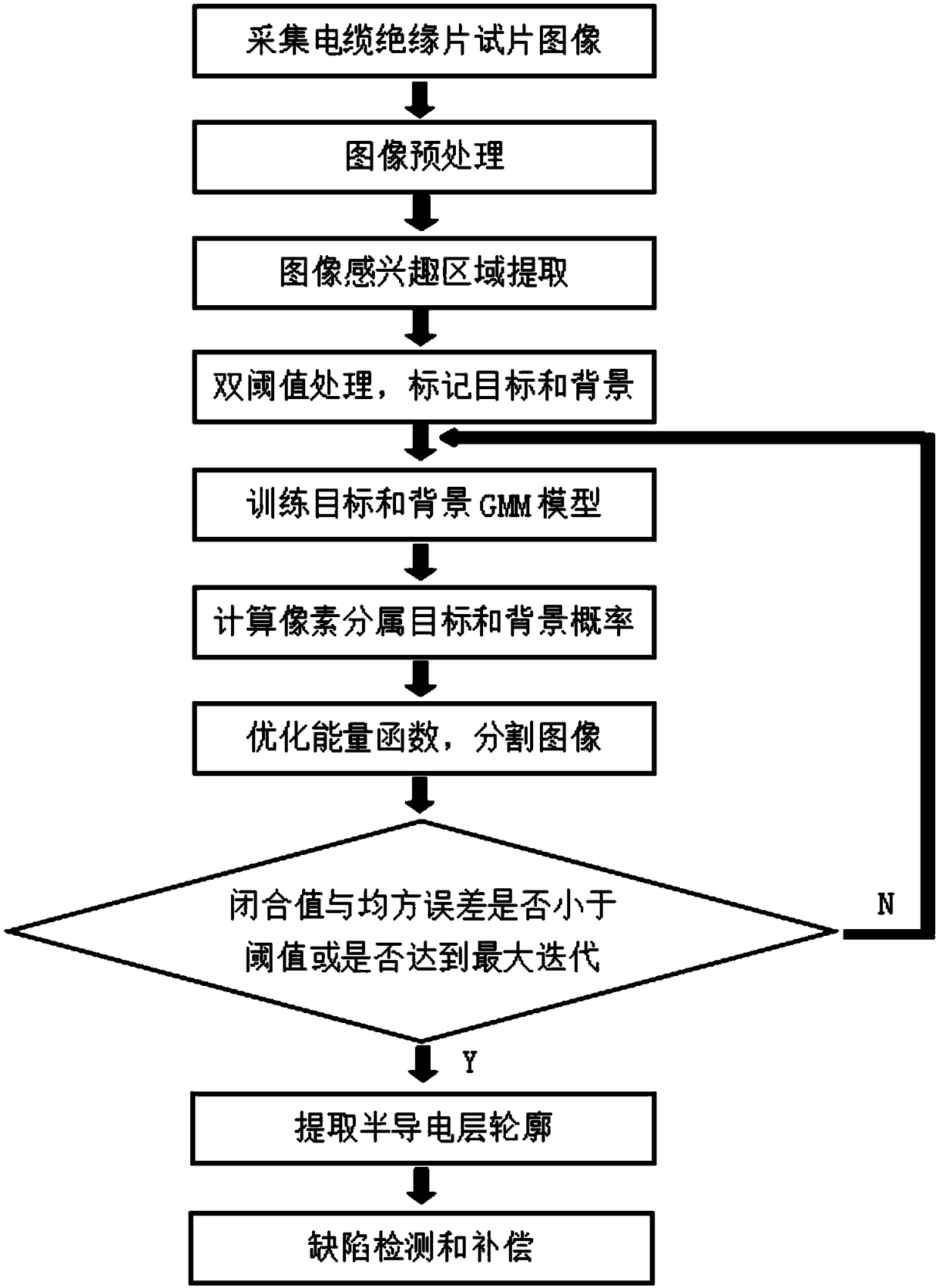

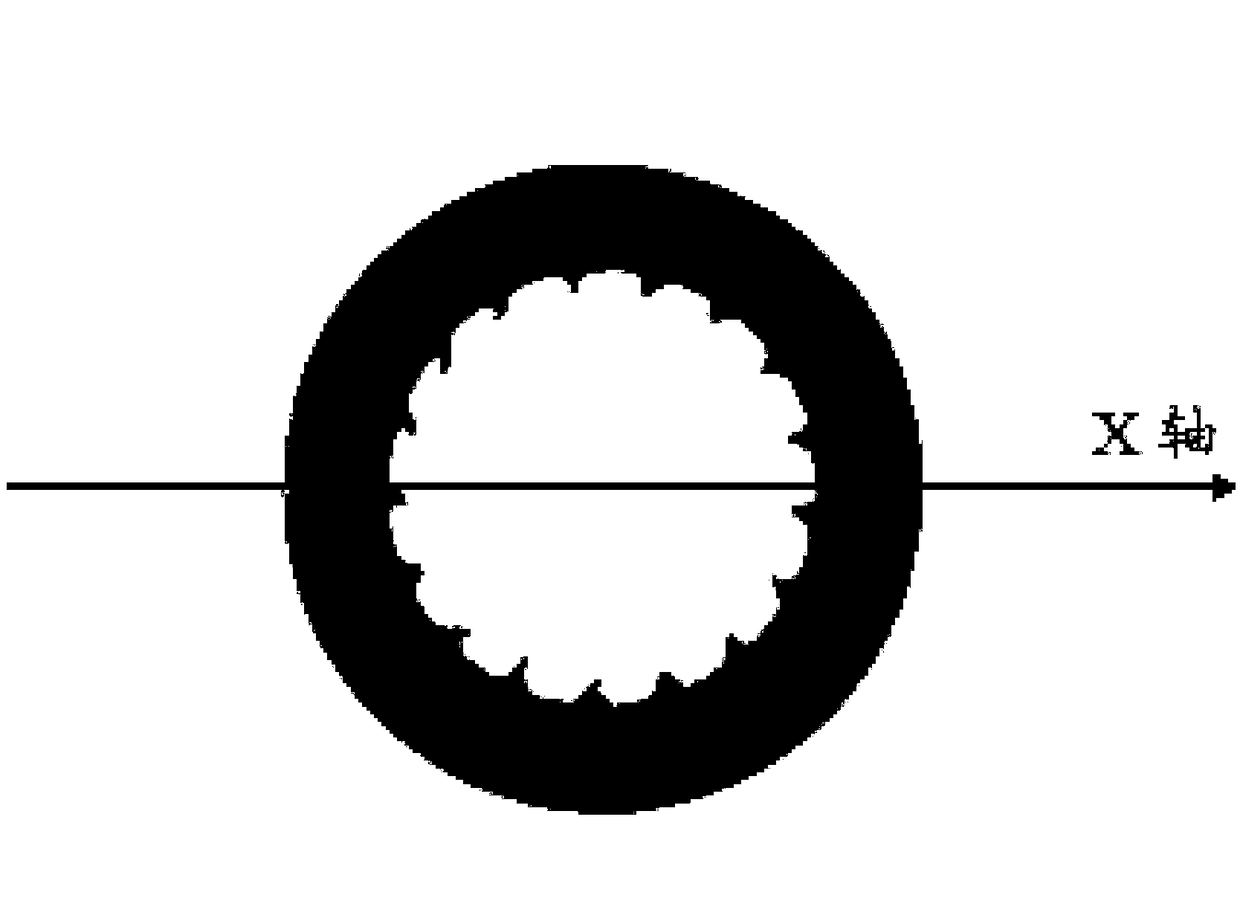

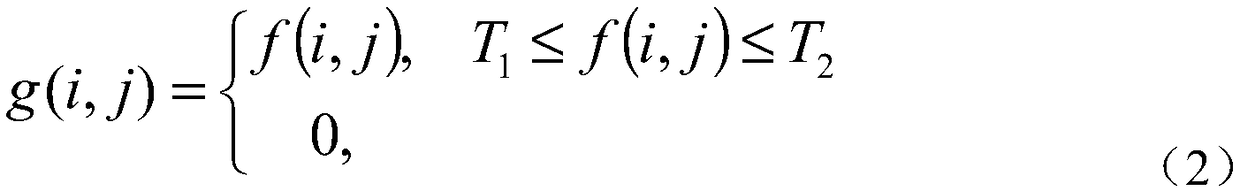

Image processing based cable semi-conductive layer automatic detection method

ActiveCN108846397AImplement automatic detectionSolve problems that cannot be detected automaticallyImage enhancementImage analysisRegion of interestImage pre processing

The invention discloses an image processing based insulating sheet semi-conductive layer automatic detection method, which can achieve automatic detection of an insulating sheet semi-conductive layerof a cable. The method includes: acquiring a cable insulation sheet test piece image; performing image preprocessing; extracting a region of interest; segmenting the region of interest, screening a segmented connected domain set, and generating a semi-conductive layer profile; and performing defect detection and compensation on the generated semi-conductive layer profile. The insulating sheet semi-conductive layer automatic detecting method has high detection efficiency and high precision, fully considers factors such as knife marks and illumination, and greatly reduces the working load of thetesting personnel.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

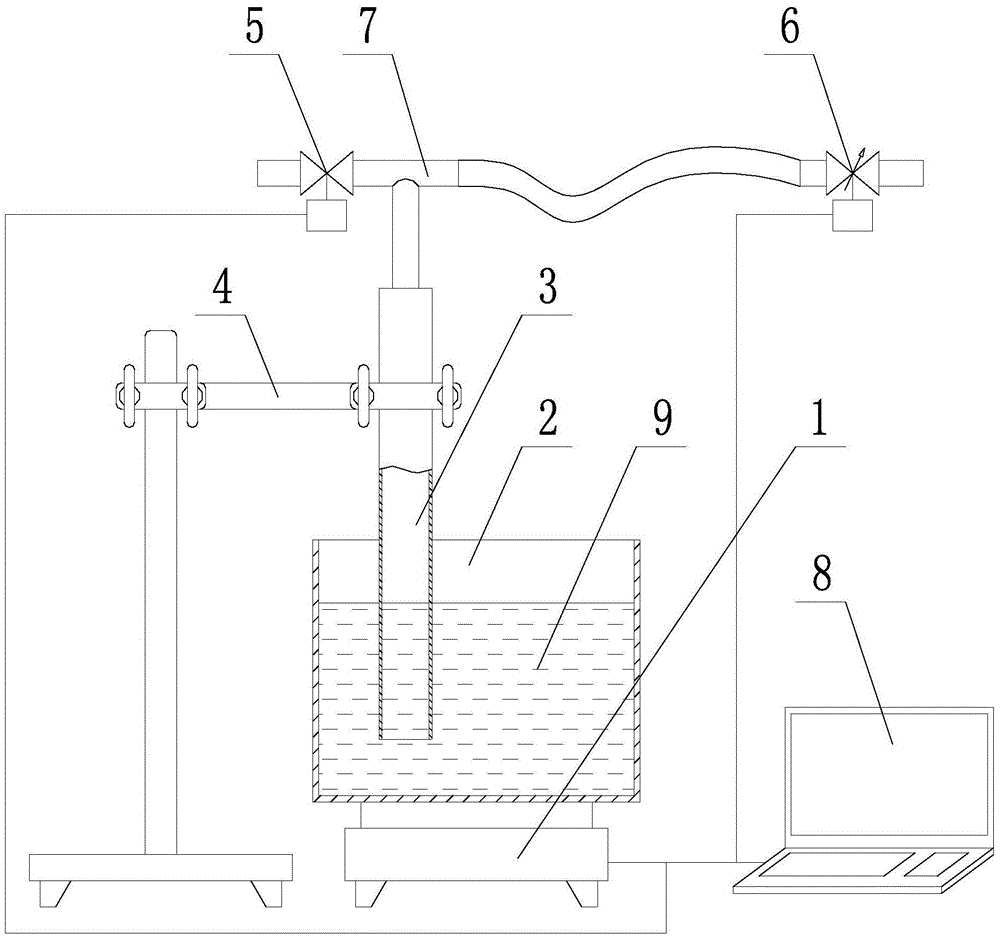

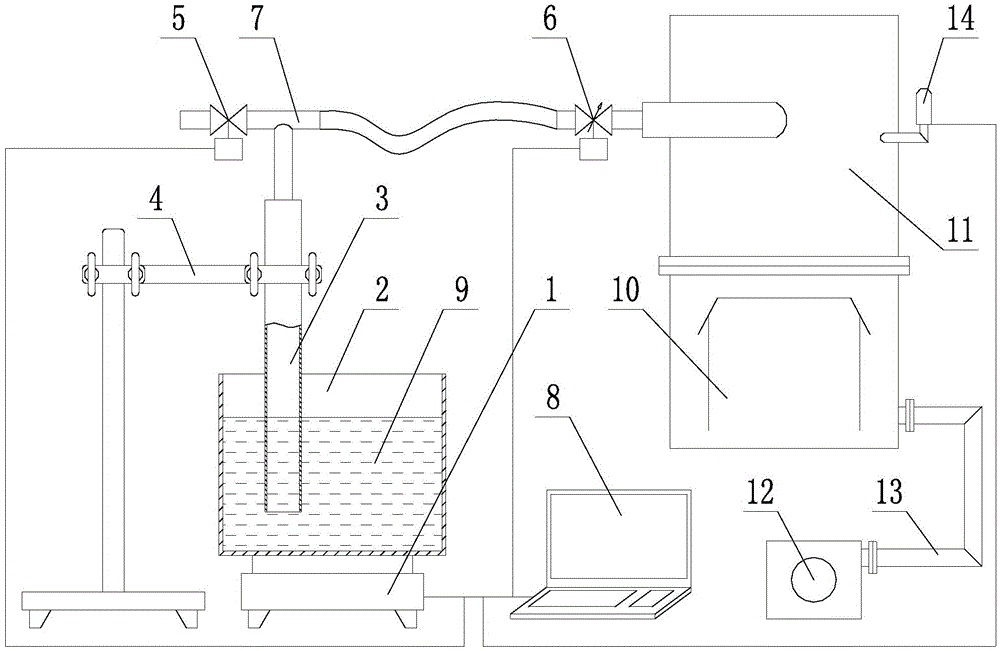

Dropper type gas flow measuring device and method based on weighing principle

InactiveCN105651351ACapable of automated measurementAvoid measurement errorsPump testingVolume/mass flow measurementInlet valveProcess engineering

The invention provides a dropper type gas flow measuring device and method based on a weighing principle. The dropper type gas flow measuring device comprises an electronic scale, an oil storage tank, a dropper, a dropper support, a gas inlet valve, a fine adjustment valve, a three-way tube and a computer, wherein the oil storage tank storing oil is arranged on the electronic scale, a lower-end dropper orifice of the dropper installed on the dropper support is located under the oil liquid level, an upper-end dropper orifice of the dropper is communicated with the gas inlet valve and the fine adjustment valve through the three-way tube, and the fine adjustment valve is communicated with a measured object. The electronic scale is connected with the computer, and weigh data and the time for the measuring process are recorded and stored through the computer. The dropper type gas flow measuring method comprises the steps that the gas inlet valve is turned on; the fine adjustment valve is adjusted to enable gas flow passing through the fine adjustment valve to meet the gas inlet requirements of the measured object; an initial weigh reading is recorded; the gas inlet valve is turned off; gas flow measurement continues, a plurality of continuous time points are recorded in real time, meanwhile weigh readings corresponding to the time points are recorded; when the computer judges that measurement is needed to stop, the gas inlet valve is turned on, and the measurement process is finished; outflow gas flow is calculated.

Owner:NORTHEASTERN UNIV

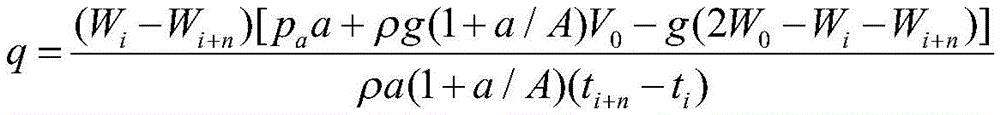

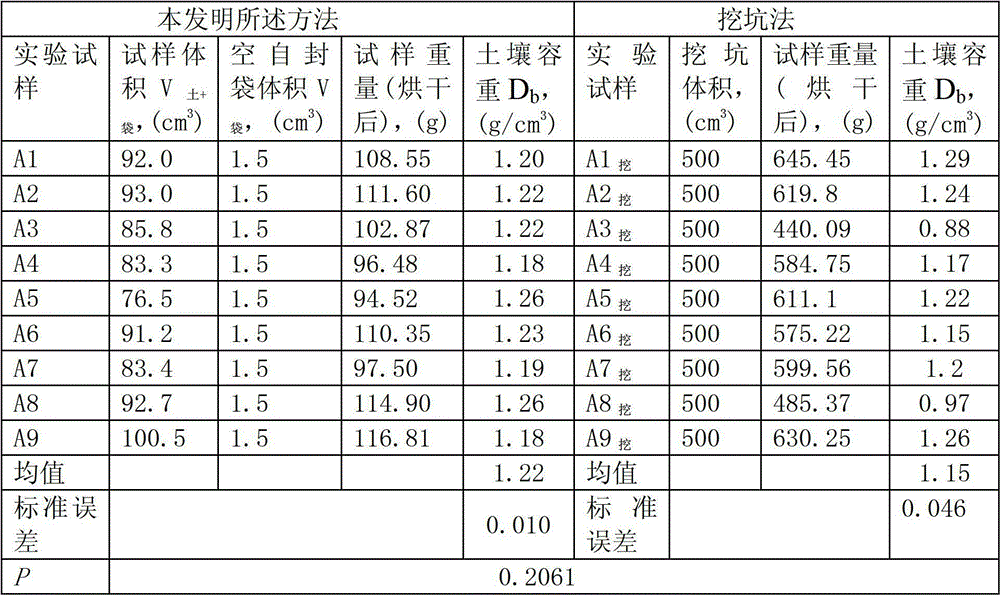

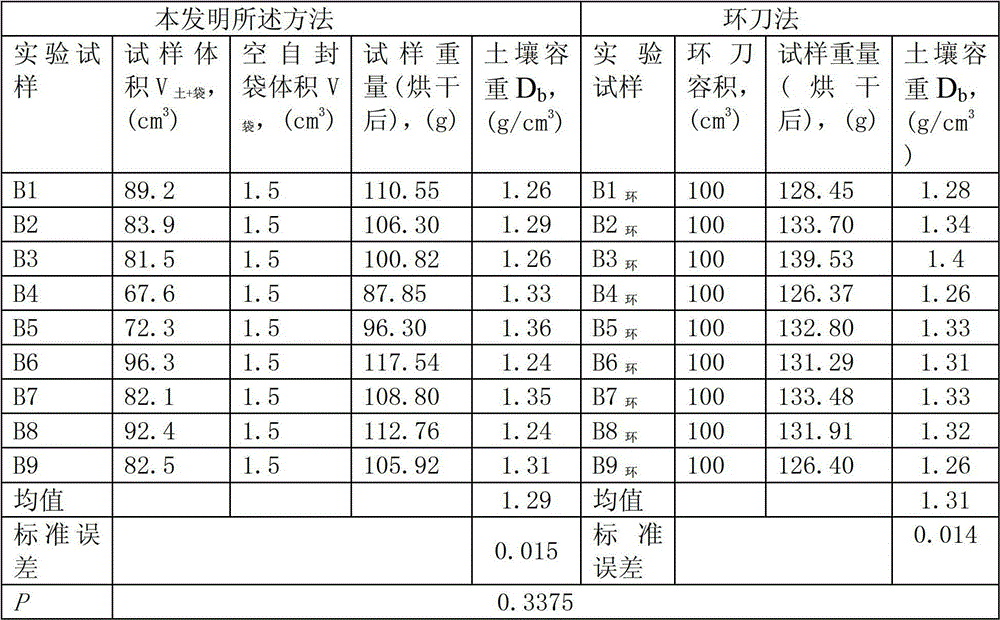

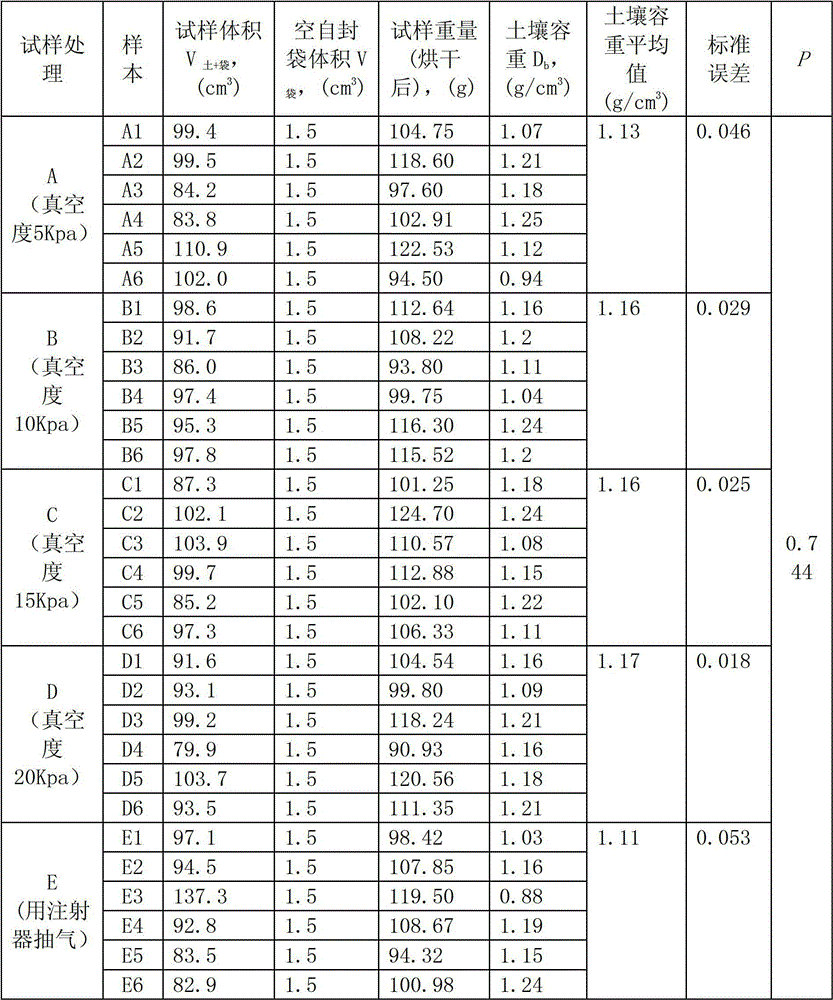

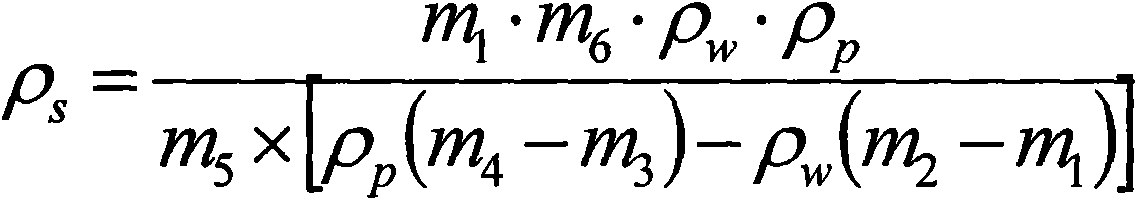

Method for measuring soil bulk density

InactiveCN102721628AReduce mistakesImprove test accuracySpecific gravity measurementSoil horizonEngineering

The invention discloses a method for measuring the soil bulk density. The method comprises the following steps: collecting soil, placing the collected soil into a self-packaging bag and removing air in the self-packaging bag; when the inside of the sealing bag is in a negative pressure state, sealing the self-packaging bag; measuring the volumes of the sealed self-packaging bag and the soil in the sealed self-packaging bag; taking another empty self-packaging bag of which the size is identical with that of the self-packaging bag for accommodating the soil; removing the air in the empty self-sealing bag and measuring the volume of the empty self-packaging bag; sealing the soil in the bag and drying the soil to constant weight to obtain the weight of the soil; and then calculating the bulk density of the soil according to a formula. According to the method disclosed by the invention, the error of the volume of the soil with an irregular shape can be effectively reduced, and thus the test precision of the soil bulk density is improved. In addition, the method is suitable for measuring the bulk density of the soil under special environments (environmental complexity and soil body crushing) and is especially suitable for measuring the bulk density of the soil on discontinuous soil bodies and soil bodies in which more stones and plant root systems exist in the soil, the soil layer thickness is thinner or the soil structure is loose.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

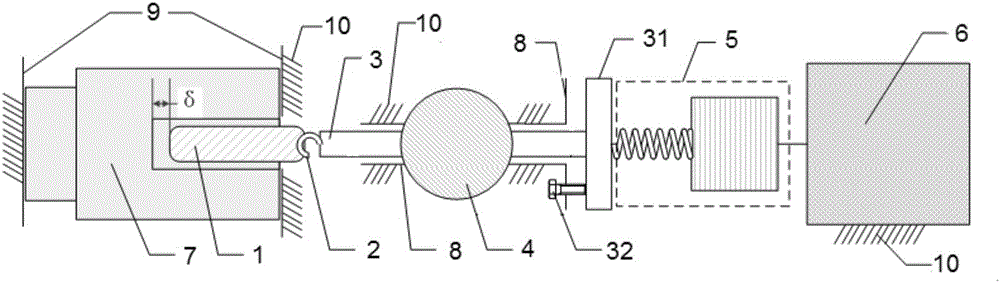

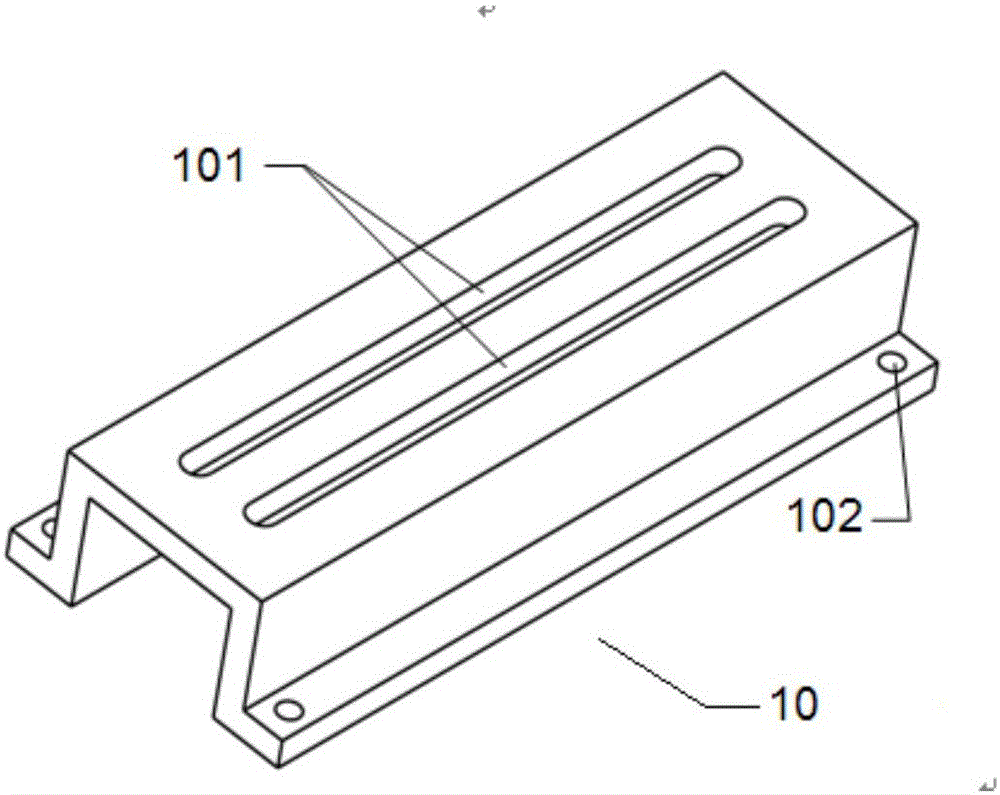

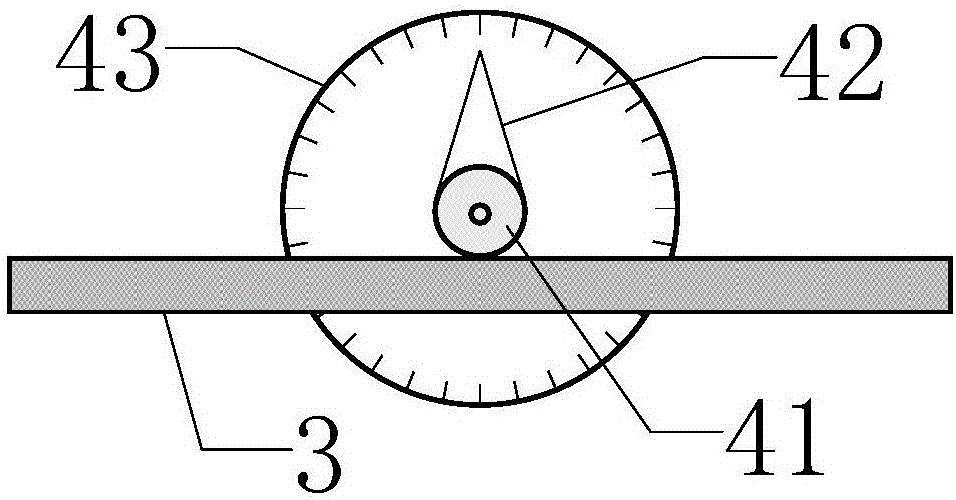

Electromagnet suction measuring device

ActiveCN106568537AHigh measurement accuracySimple measurement processForce measurement by elastic gauge deformationRelative displacementMeasurement device

The present invention discloses an electromagnet suction measuring device. The device comprises an armature, a matched tool, a guide rod, a displacement measurement unit, a spring dynamometer and a traction mechanism. The guide rod is connected with the armature through the matched tool and is capable of sliding along the axial direction of a to-be-measured electromagnet. The displacement measurement unit is used for measuring the displacement of the guide rod. The spring dynamometer is used for measuring the suction of the guide rod along the axial direction of the to-be-measured electromagnet. The traction mechanism is used for pulling the spring dynamometer to move along the axial direction of the to-be-measured electromagnet. According to the technical scheme of the invention, the displacement measurement unit directly measures the relative displacement between the guide rod and a guide groove. The spring dynamometer directly measures the value of the tensile force of the guide rod and the measurement accuracy is high. The value of the tensile force of the guide rod can be read at any displacement. Therefore, the suction measurement at any desired displacement can be realized, and the measurement process is simple.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Novel method for measuring area of rock point load test fracture surface

InactiveCN102721396ASimple measurement processShorten the timeMeasurement devicesGeomorphologyEconomic shortage

The invention discloses a novel method for measuring the area of a rock point load test fracture surface. The technical scheme is that the novel method comprises the steps of (1) preparing transparent area paper formed by small squares according to the area of 1mm*1mm and forming large squares according to the area of 10mm*10mm, (2) placing the transparent area paper on the rock point load test fracture surface, (3) drawing a fracture surface outline on the transparent area paper, and (4) counting the number of complete large area squares in the fracture surface outline and the number of small area squares in incomplete large area squares and calculating the area of the fracture surface. The novel method for measuring the area of the rock point load test fracture surface is simple and effective and makes up the shortages including time wasting and large error by means of a traditional measuring method, and the measuring accuracy of the point load test fracture surface and work efficiency are improved greatly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

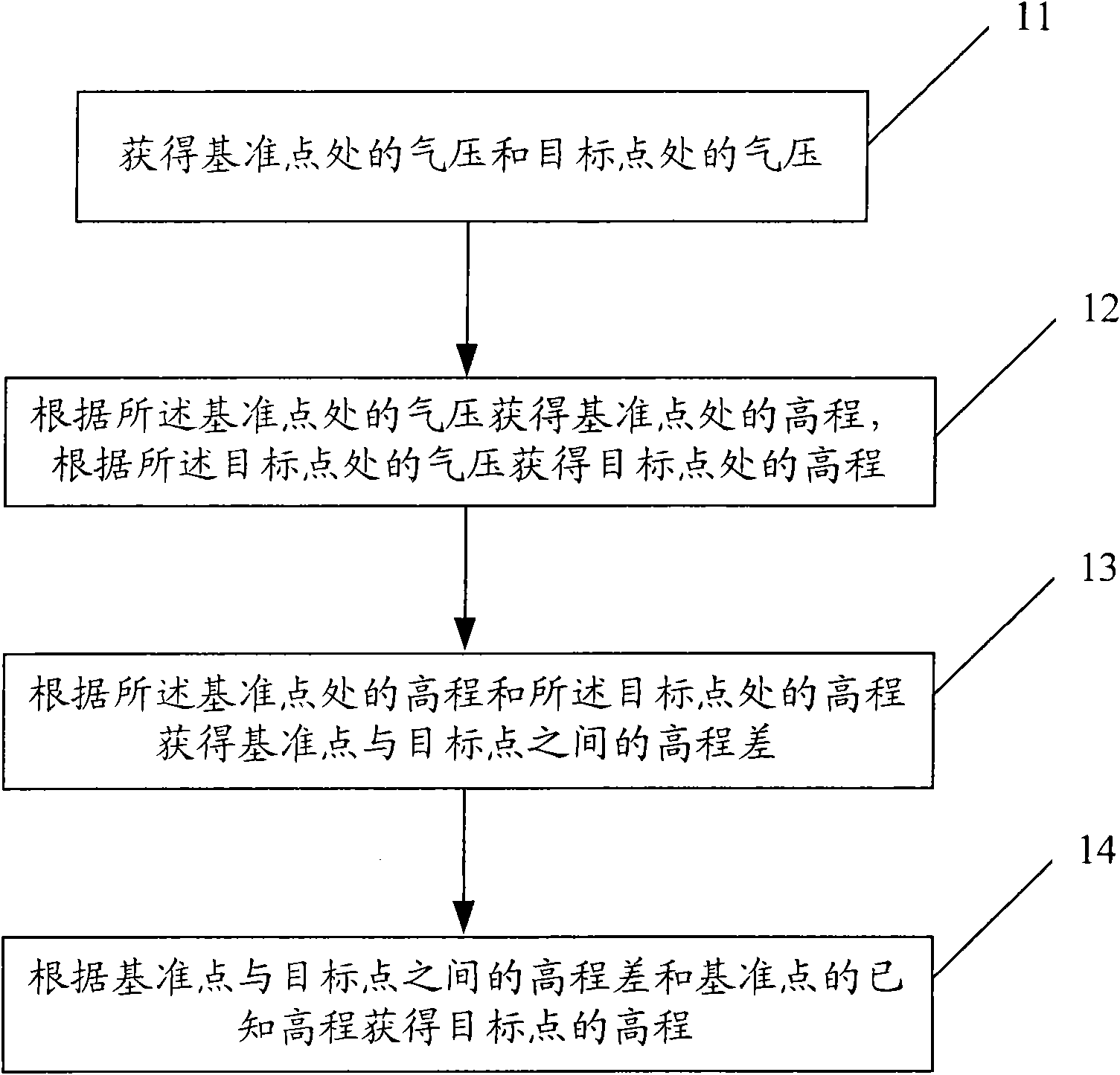

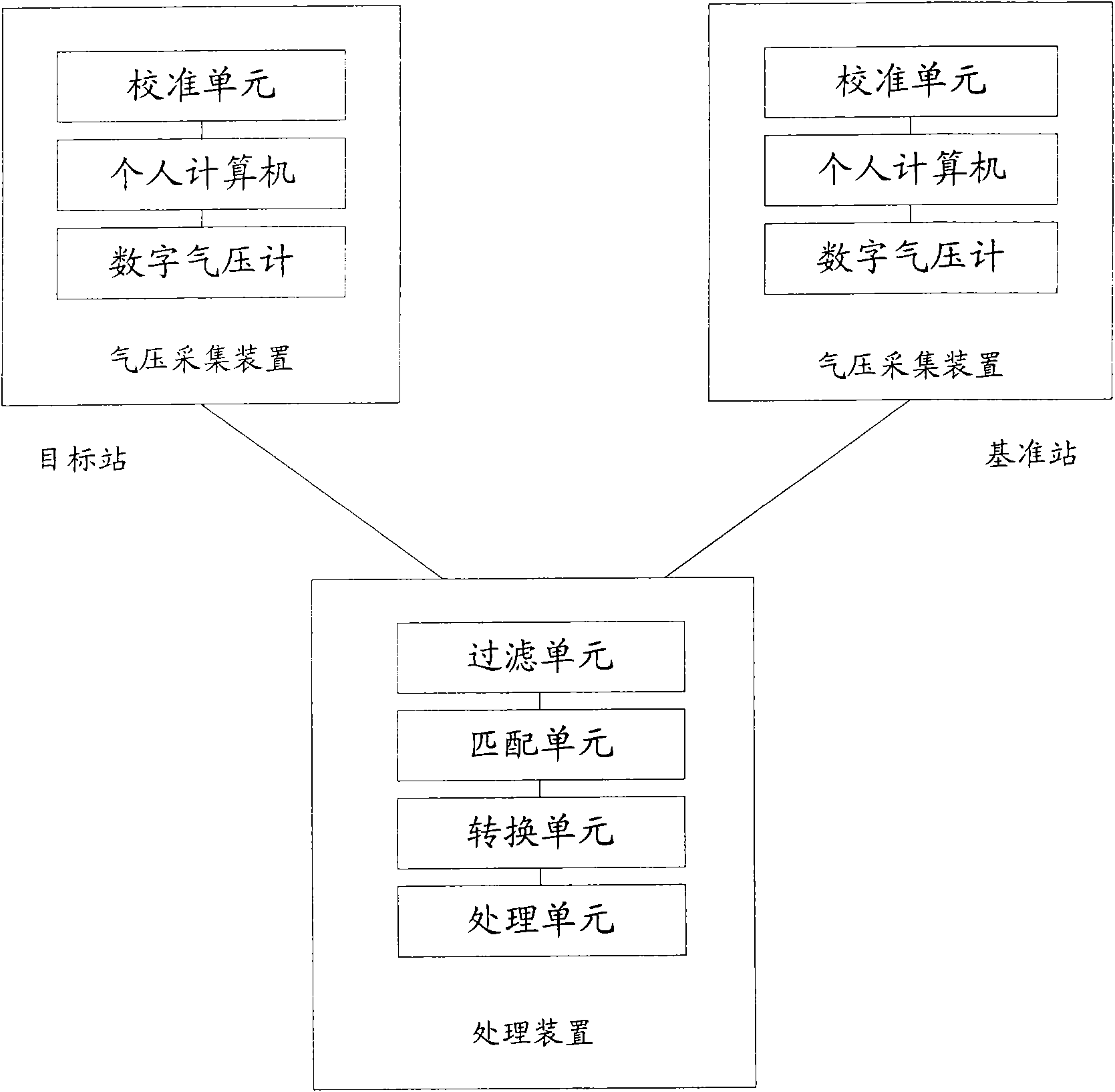

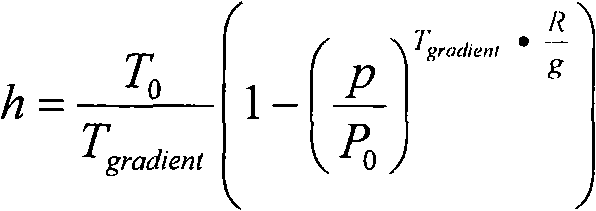

Altitude measurement method and altitude measurement system

InactiveCN101655366ASimple measurement processEasy to measureHeight/levelling measurementPneumatic pressureAmbient occlusion

The embodiment of the invention provides an altitude measurement method and an altitude measurement system and solves the problem that in the prior art measurement under a specific condition is susceptible to ambient occlusion and is slow. The method comprises: acquiring the air pressure at the position of a reference station and the air pressure at the position of a target station; acquiring thealtitude of the position of the reference station according to the air pressure at the position of the reference station and acquiring the altitude of the position of the target station according to the air pressure at the position of the target station; acquiring the altitude difference between the reference station and the target station according to the altitudes of the reference station and the target station; and acquiring the altitude of the target station according to the altitude difference between the reference station and the target station and the known altitude of the target station. The system comprises a processor and two sets of air pressure acquisition devices. According to the method and the system, an air pressure gauge is adopted to measure the altitudes, so the measurement of the altitudes can be measured even when the distance between the reference station and the target station is big. And the reference station and the target station are free from limitation of ambient occlusion and the measurement process is quick and simple.

Owner:ALIBABA (CHINA) CO LTD

Determination method for dispersibility of carbon nano-tubes in resin

ActiveCN103257094AEasy to operateSimple measurement processNanotechnologyParticle size analysisCarbon nanotubeMaterials science

The invention relates to a determination method for dispersibility of carbon nano-tubes in resin. The determination method adopts a scraper fineness meter for determining the fineness of the resin to obtain the dispersibility of the carbon nano-tubes in the resin. Specifically, a series of relationship curves are found by determining the fineness and dispersibility numerical values under the condition of different types of resin and different contents of the carbon nano-tubes, thus establishing the corresponding relationship between the scraper fineness and the dispersibility of each carbon nano-tube. In actual tests, the corresponding dispersibility can be found only by determining the fineness of resin to be tested with reference to the relationship curves. The determination method overcomes the disadvantages of tedious steps, long cycle, incapability of quantification and poor accuracy in a conventional dispersibility determination method, so that the determination process is easy, convenient and feasible, the testing cycle is shortened, the testing cost is reduced, and the determination method has the advantages of rapidness, directness, accuracy and the like and has strong practicability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

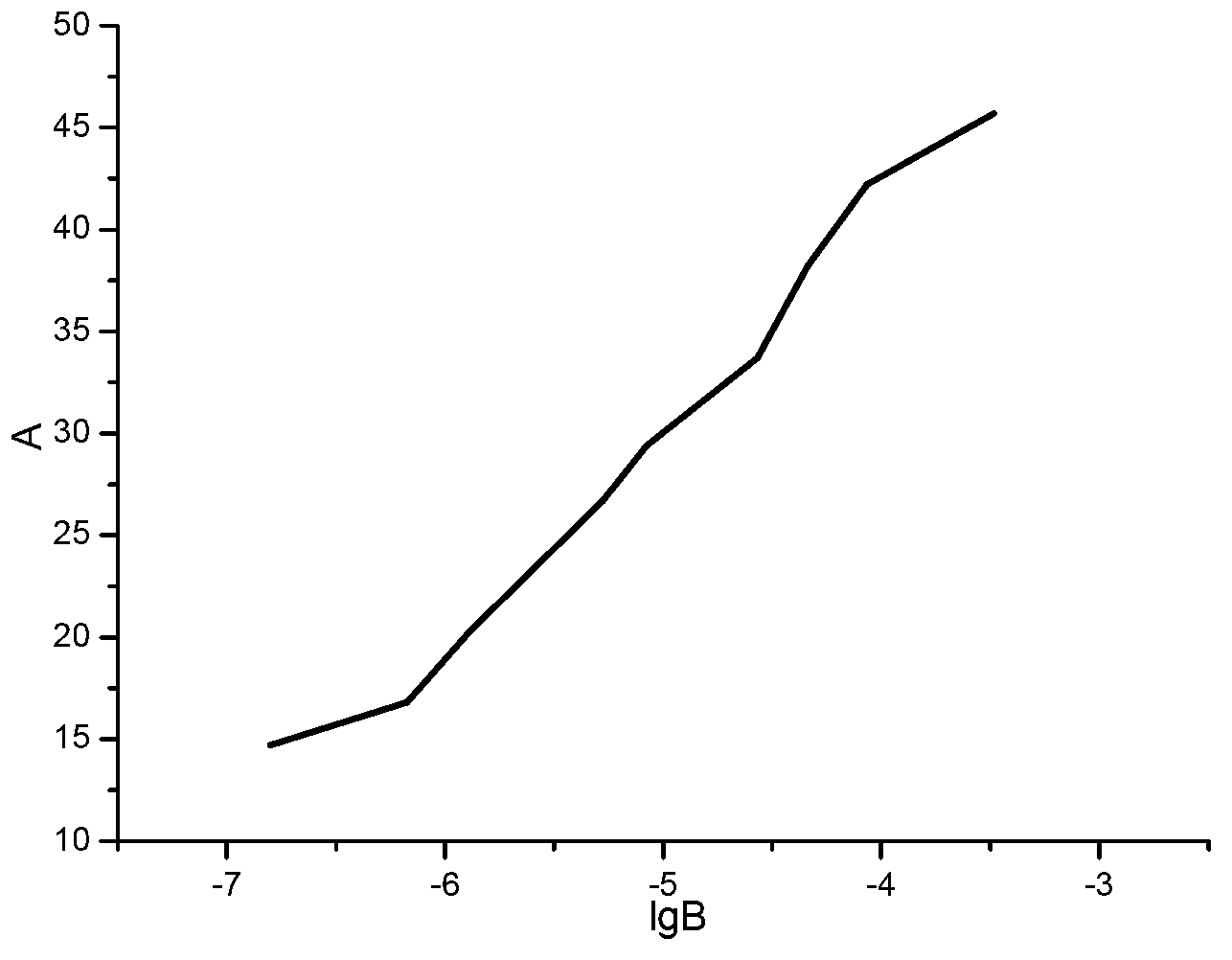

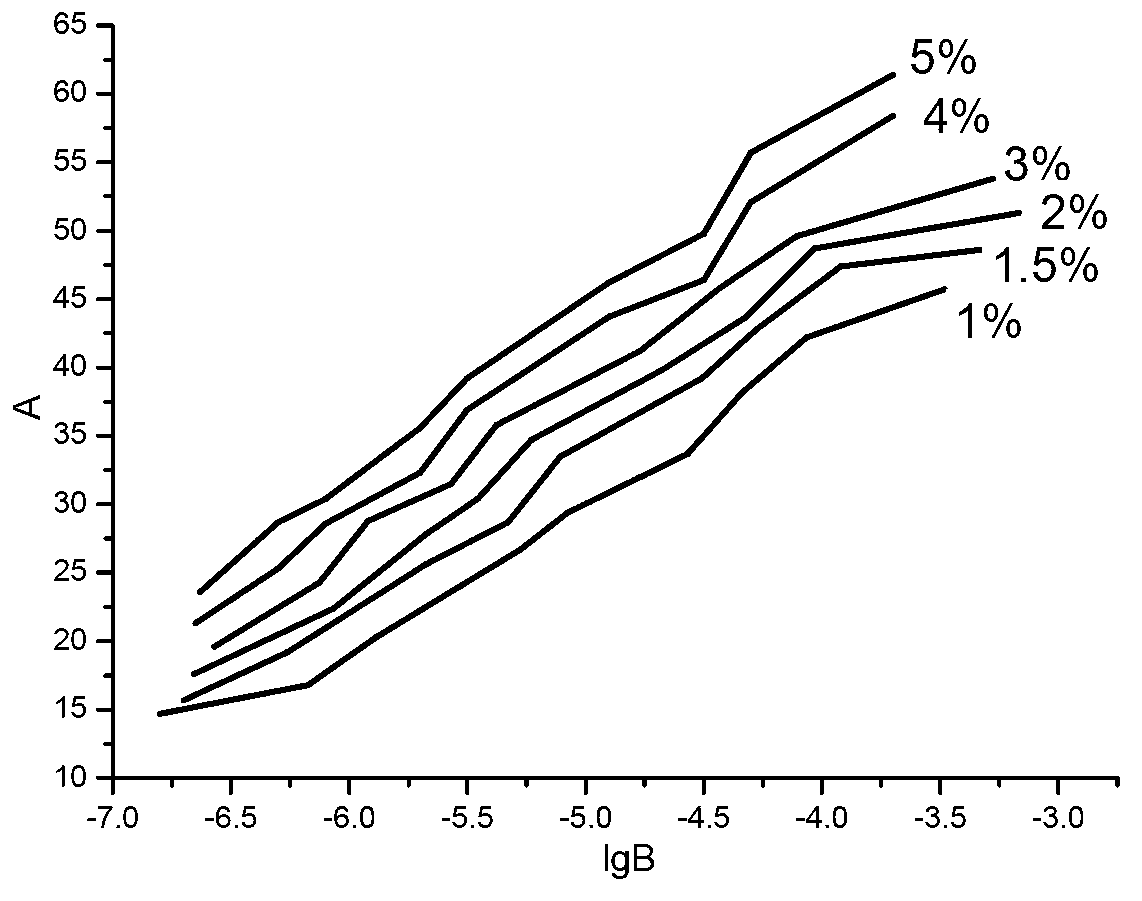

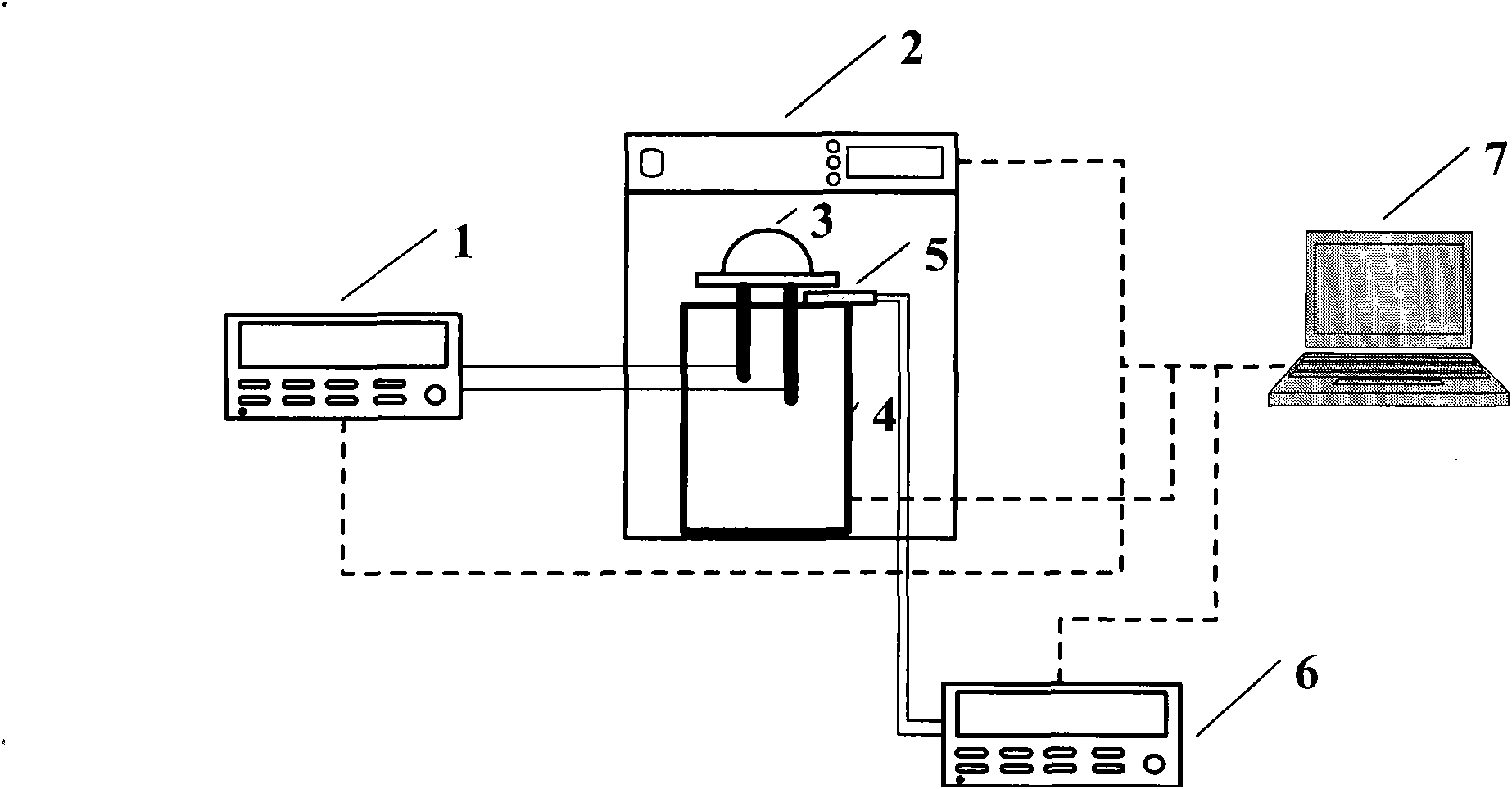

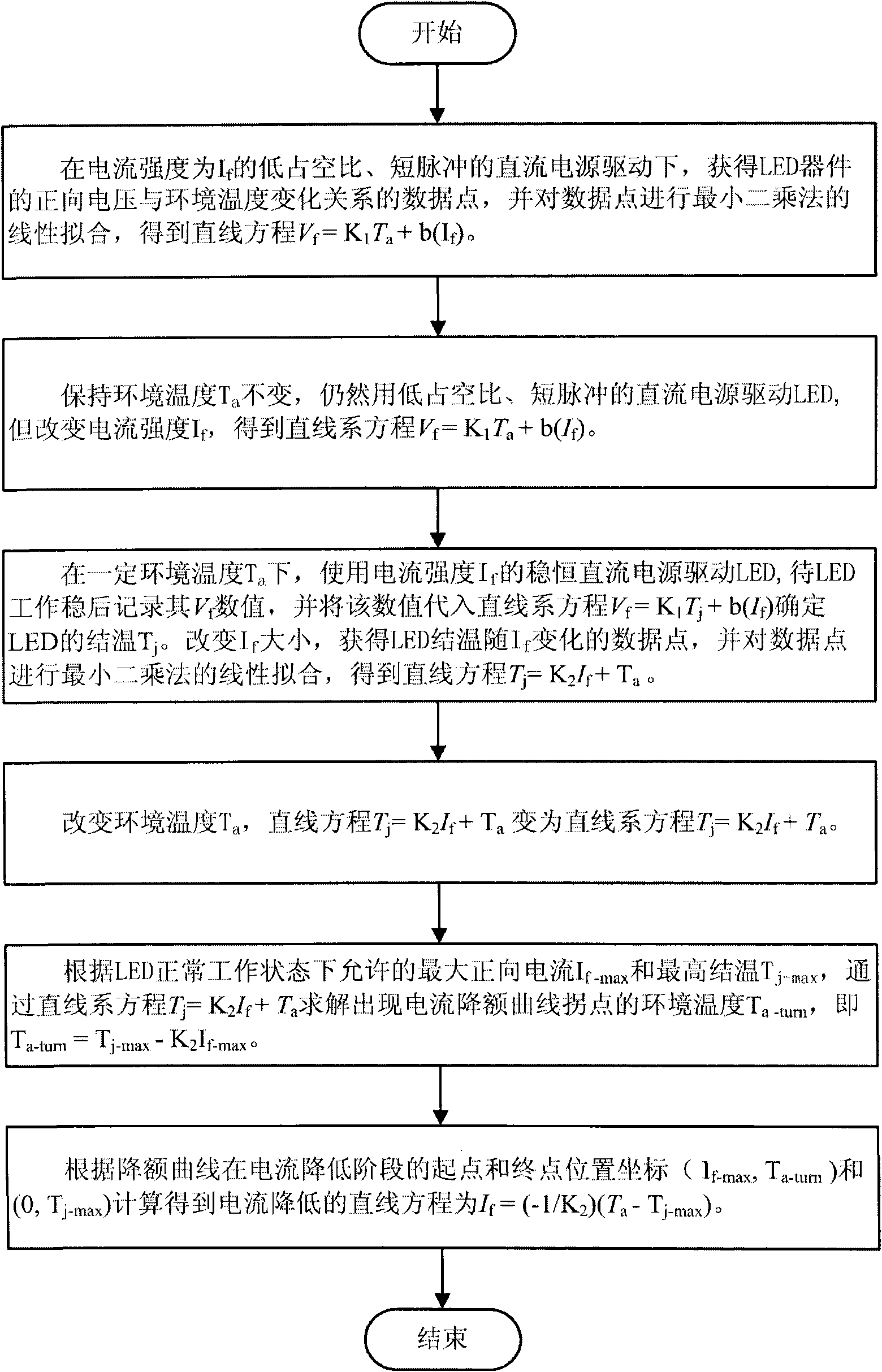

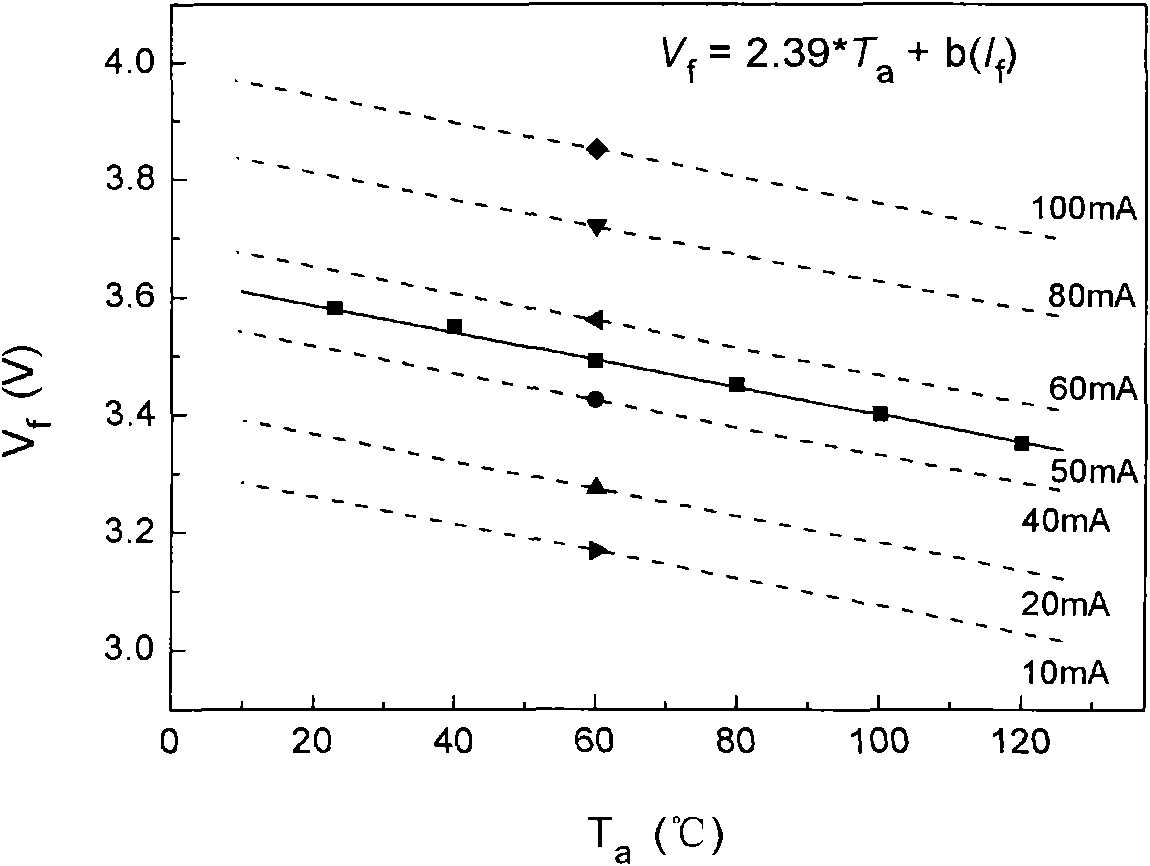

Measurement system and measuring method for derating curve of LED (light-emitting diode)

InactiveCN102565654ASimple measurement processTaking into account the accuracyThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermocouple

The invention relates to a measurement system and a measurement method for a derating curve of an LED (light-emitting diode), belonging to the technical field of detection on thermal properties of semiconductor optoelectronic devices. According to the measurement system disclosed by the invention, the LED to be tested, a thermocouple and a clamp are arranged in a constant-temperature oven, and the LED to be tested and the thermocouple are arranged in the same position on the clamp. A digital source meter is connected with the LED to be tested, and a digital universal meter is connected with the thermocouple. The digital source meter, the digital universal meter, the clamp and the constant-temperature oven are respectively connected with a computer. The digital source meter is used for providing forward current for driving the LED to be tested; the constant-temperature oven is used for providing a stable environmental temperature; the thermocouple is used for detecting the actual environmental temperature in the vicinity of the LED to the tested; the digital universal meter is used for patrol inspection on the resistance of the thermocouple; and the computer is responsible for collecting and processing related data and outputting the graphical derating curve to a user. Compared with the prior art, the measurement system and method disclosed by the invention have the advantages of high efficiency, accuracy and a wide range of applications.

Owner:TONGFANG OPTO ELECTRONICS

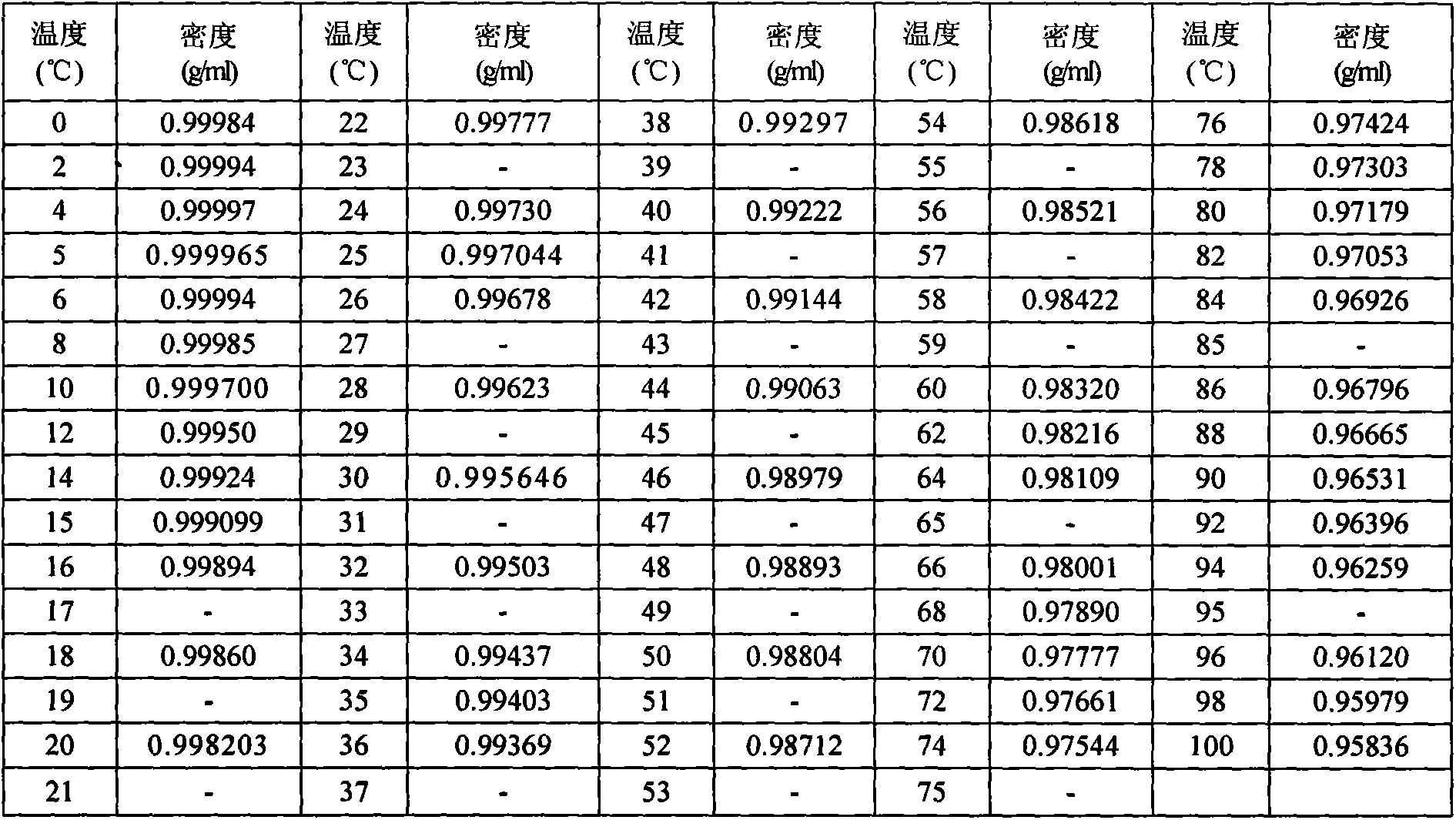

Method for determining volume weight of irregular, hard and dry soil block

InactiveCN103776725AImprove test accuracyWon't breakPermeability/surface area analysisSpecific gravity measurementSoil scienceParaffin oils

The invention relates to a method for determining the volume weight of an irregular, hard and dry soil block. The specific process comprises the following steps: (1) collecting two soil block samples; (2) weighing the mass of one dry soil block; (3) putting the dry soil block into liquid paraffin to carry out covering; (4) cooling the soil block covered with a paraffin film and weighing the mass of a paraffin sealed soil block; (5) weighing the sum of masses of a beaker and water before putting the paraffin sealed soil block into the beaker; (6) weighing the mass of the beaker after the paraffin sealed soil block is put into the beaker; (7) weighing the other soil blocks, crushing and weighing the mass; drying and weighing; (8) transferring the liquid paraffin with a certain volume and weighing; calculating the density of the liquid paraffin; (9) checking a table to obtain the density of the water at a testing temperature; and (10) calculating the volume weight of the sample. The technology provided by the invention is used for determining the irregular and easily-crushed soil blocks and does not damage the structure of the soil body; the liquid paraffin is used for covering so that the soil block and the water are sufficiently separated; the mass is accurately weighed by a balance and the volume of the soil block can be accurately measured; the determination process is convenient and simple and is easy to grasp; needed tools are few and the determination cost is low.

Owner:NORTHWEST A & F UNIV +1

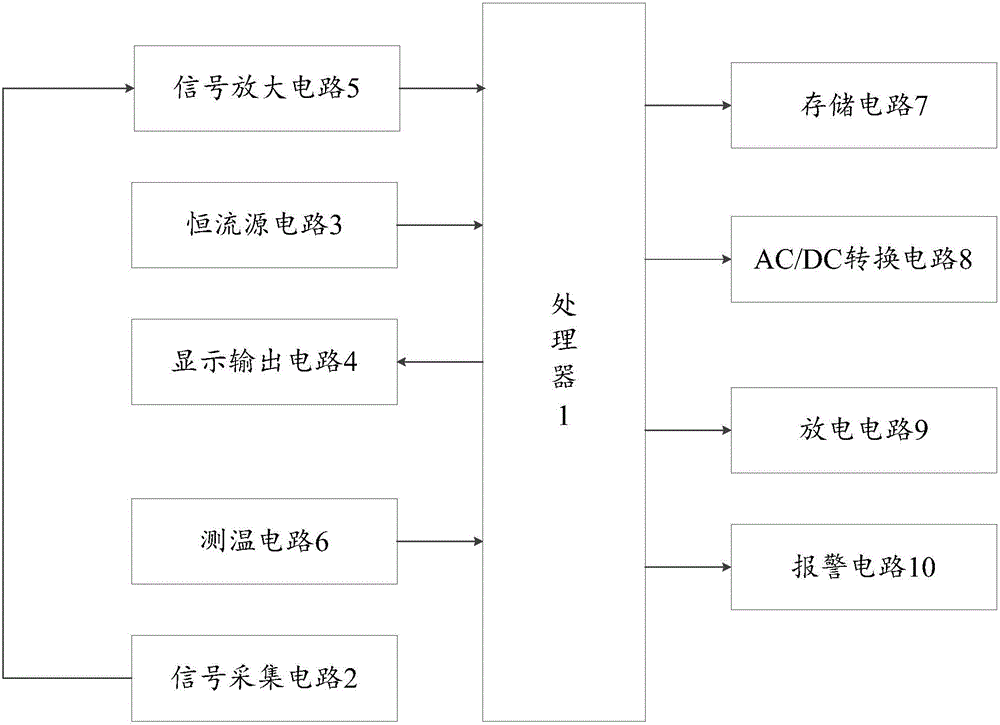

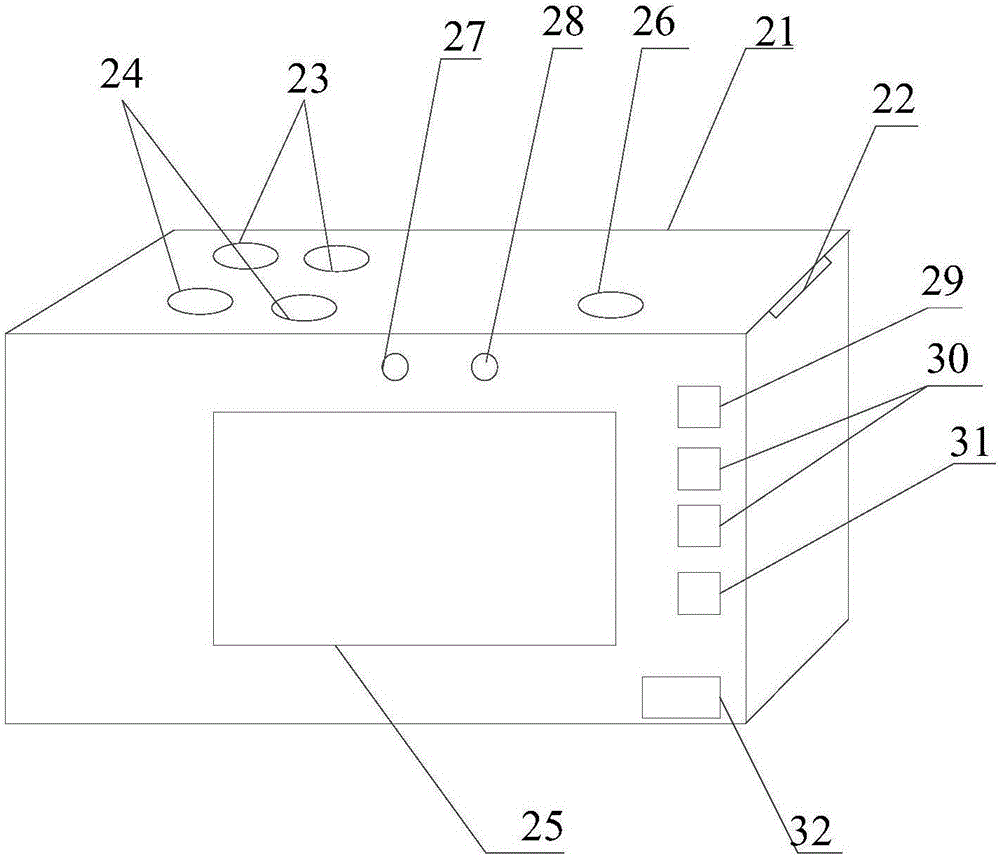

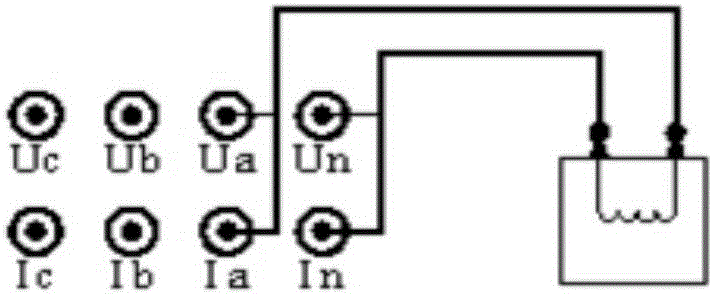

Multichannel direct-current resistor tester

InactiveCN106771632ASimple measurement processReduced measurement timeResistance/reactance/impedenceLow voltageTransformer

The invention provides a multichannel direct-current resistor tester. The multichannel direct-current resistor tester comprises a shell, wherein a processor is arranged in the shell; a signal acquisition circuit is connected with a first port of the processor, and the signal acquisition circuit is sued for acquiring voltage; a constant-current source circuit is connected with a second port of the processor, and the constant-current source current is used for providing constant current; a display output circuit is connected with a third port of the processor and used for displaying a measured resistance value; and a test mode of the direct-current resistor tester comprises a single-circuit resistor or a single-circuit inductance test mode, a single-direction high-low-voltage winding test mode, a single-side Y connection test mode, a single-direction YN connection test mode and a single-side angular connection test mode; therefore, since the direct-current resistor tester has five test modes, transformers of different connection modes can be tested, the measurement procedure is simple, the measurement time is greatly saved, and the working efficiency is increased.

Owner:EWATT TECH CO LTD

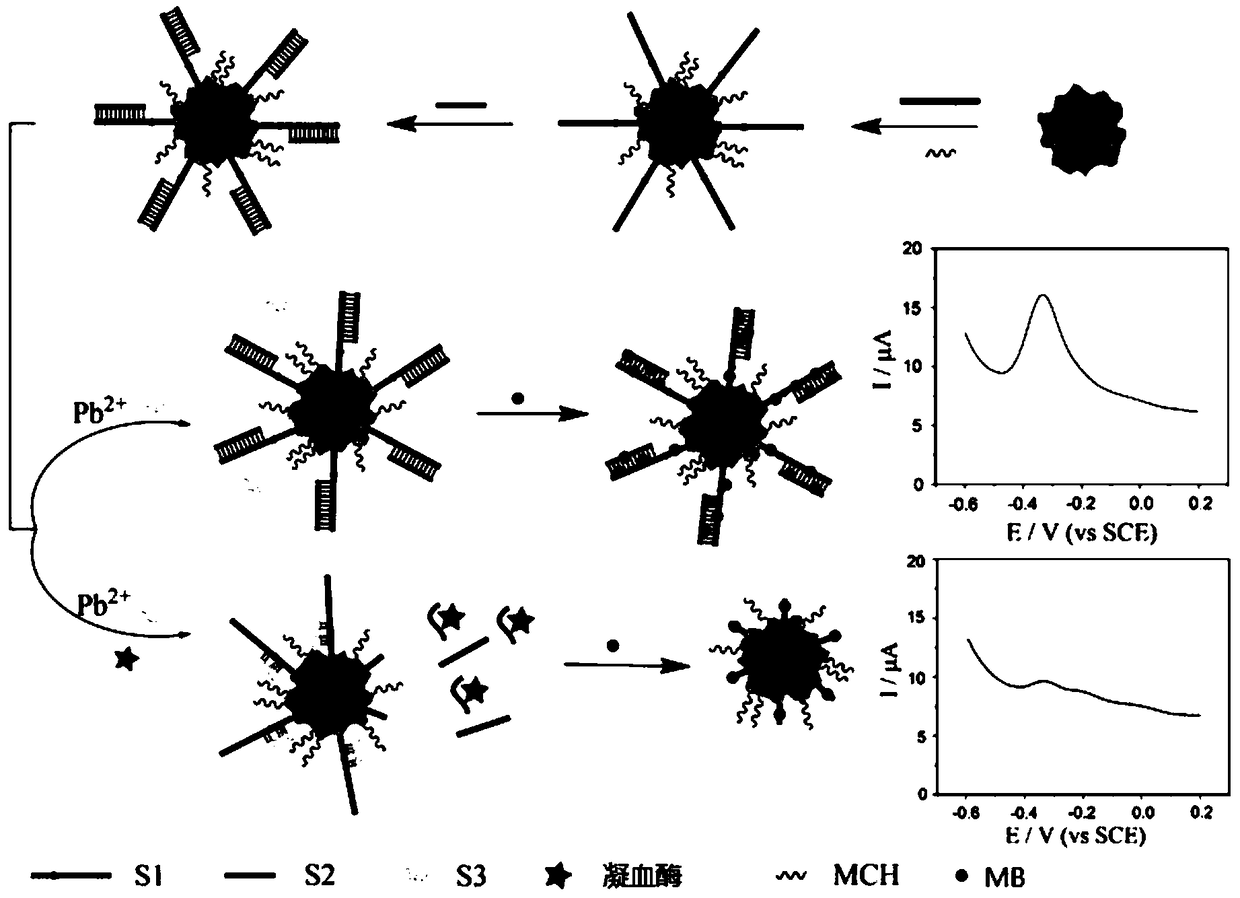

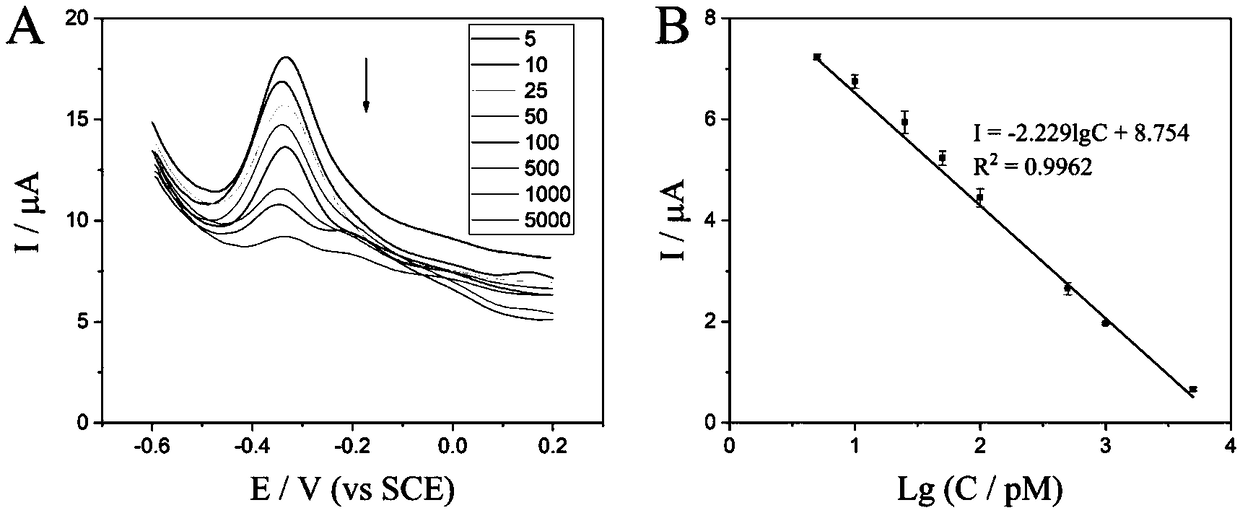

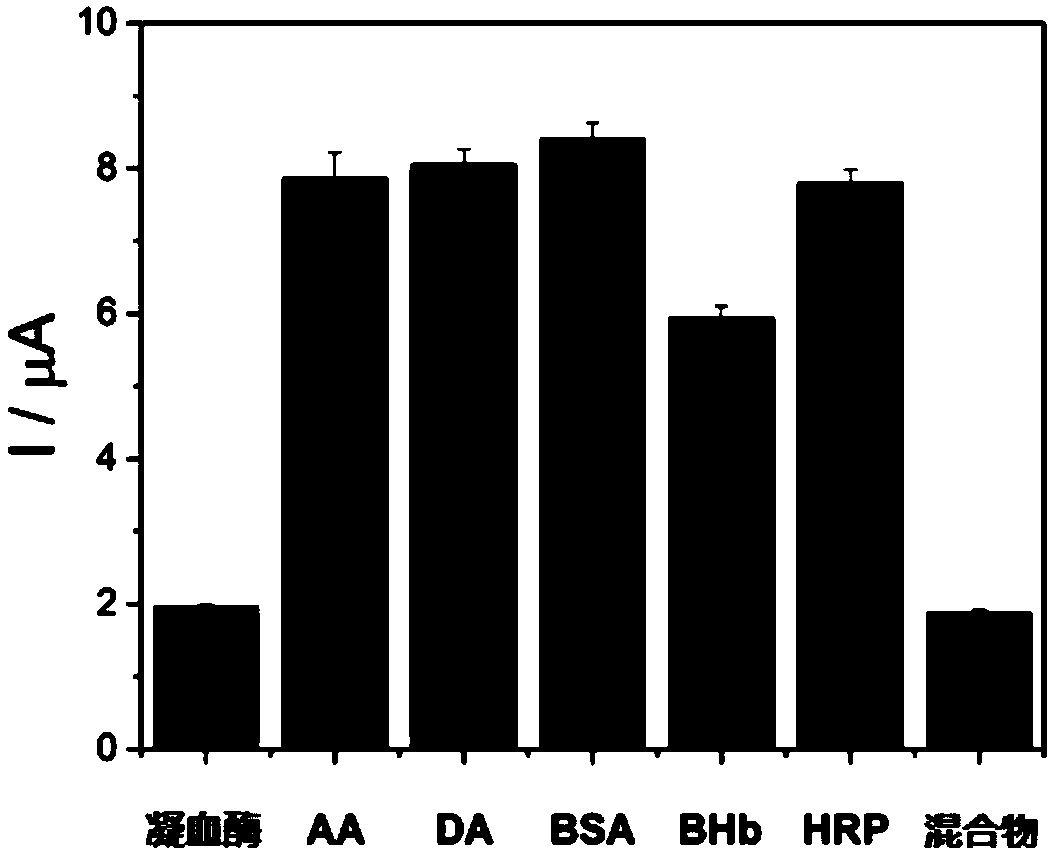

Method for detecting thrombin by electrochemical biosensor on basis of magnetic biocomposite and lead ion-dependent DNase

InactiveCN108802142AThe measurement process is simpleHigh sensitivityMaterial analysis by electric/magnetic meansEnzyme digestionElectrochemical biosensor

The invention belongs to the technical field of analysis and detection and particularly relates to a method for detecting thrombin by an electrochemical biosensor on the basis of a magnetic biocomposite and lead ion-dependent DNase. The method comprises the following steps: a) construction of the magnetic biocomposite Fe3O4@Au-S1 / S2; b) enzyme digestion assistance of lead ion-dependent DNase; c) construction of the electrochemical biosensor: adding MB (methylene blue) to an obtained reactant in step b), performing an incubation reaction to obtain a sample, adsorbing the sample to the surface of a magnetic glassy carbon electrode by magnetic induction, measuring a DPV signal of MB and establishing a standard curve; d) sample detection: detecting a thrombin sample with the method, measuringthe DPV signal, and substituting the signal into the standard curve to obtain thrombin concentration of the sample. With adoption of the method, thrombin can be detected rapidly with high sensitivityand high selectivity, and the defects of low sensitivity, long time consumption for detection, too high cost and troublesome step of the conventional detection method are overcome.

Owner:NANJING MEDICAL UNIV

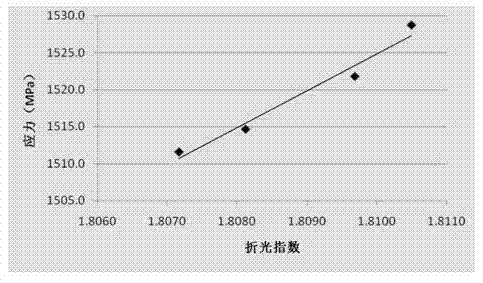

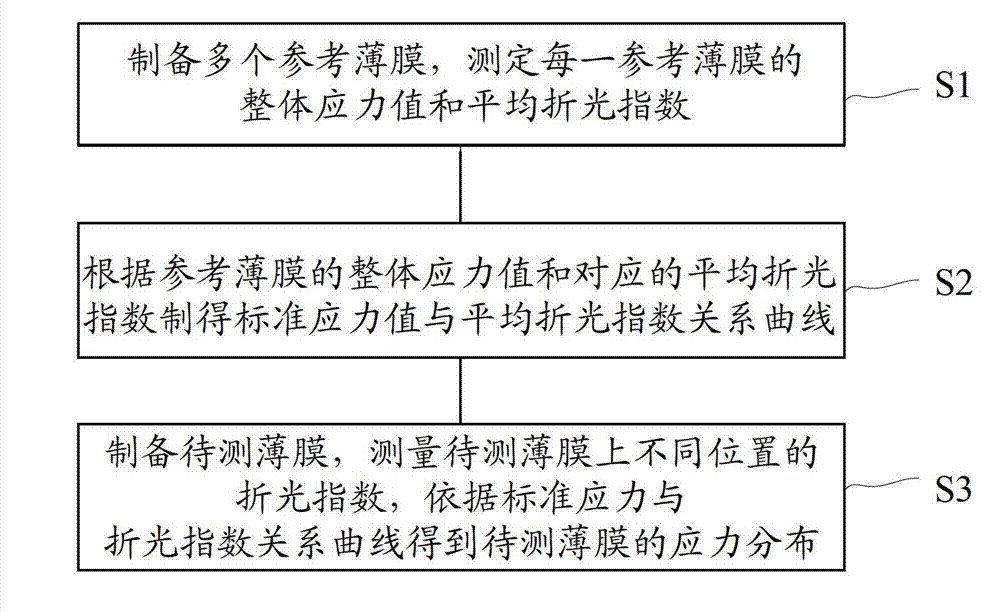

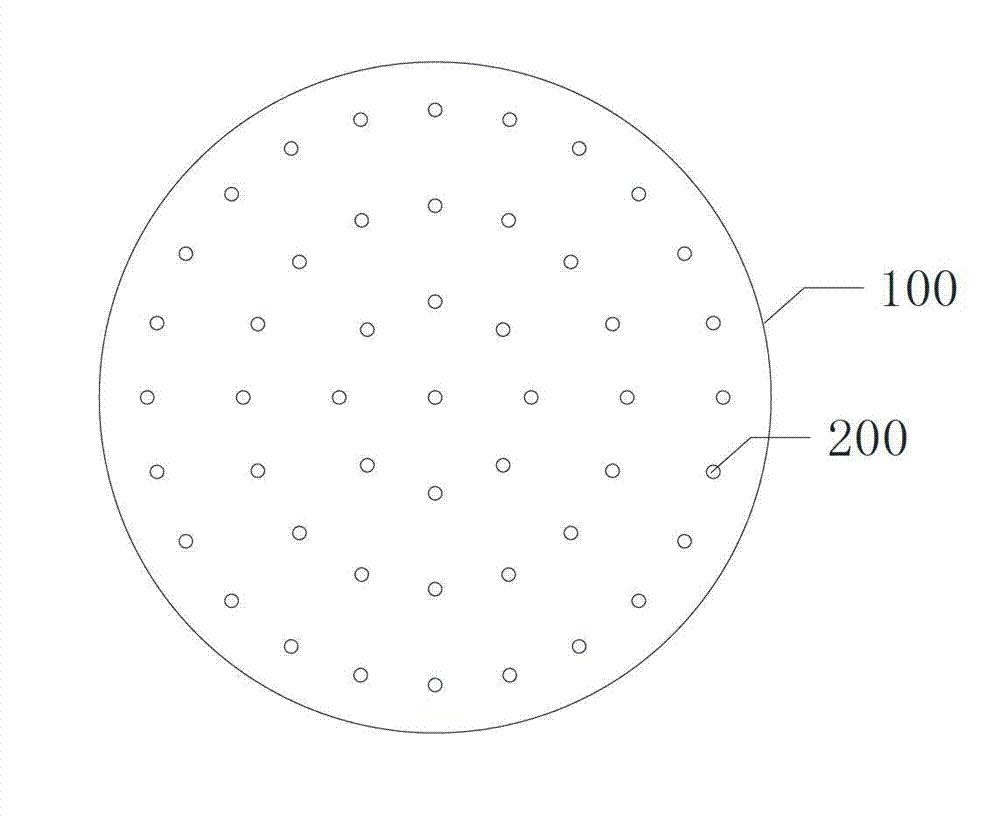

Method for detecting film stress distribution

InactiveCN102818664AQuick checkSimple measurement processForce measurement by measuring optical property variationDeposition processRefractive index

The invention discloses a method for detecting film stress distribution. The method for detecting film stress distribution comprises the following steps: manufacturing a plurality of reference films with different process parameters by using a deposition process; measuring an overall stress value and an average refractive index of each reference film; making a relation curve of a standard stress value and the average refractive index according to the overall stress value and the corresponding average refractive index of the reference film; preparing a film to be measured; measuring the refractive indexes of points to be detected at different positions on the film to be measured; obtaining the stress value of each point to be detected of the film to be measured according to the relation curve of the standard stress value and the average refractive index; and determining the stress distribution of the film to be measured. With the adoption of the method, the stress distribution situation of the film to be measured can be obtained only by measuring the refractive index of the film to be measured for only one time, thereby being beneficial to carrying out detection control over film deposition.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com