Dropper type gas flow measuring device and method based on weighing principle

A technology based on gas flow and weighing principles, applied in measuring devices, liquid/fluid solid measurement, measurement flow/mass flow, etc., can solve the problems of limited reading accuracy, difficult operation, large measurement error, etc., and shorten the time interval between readings , avoid measurement errors, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

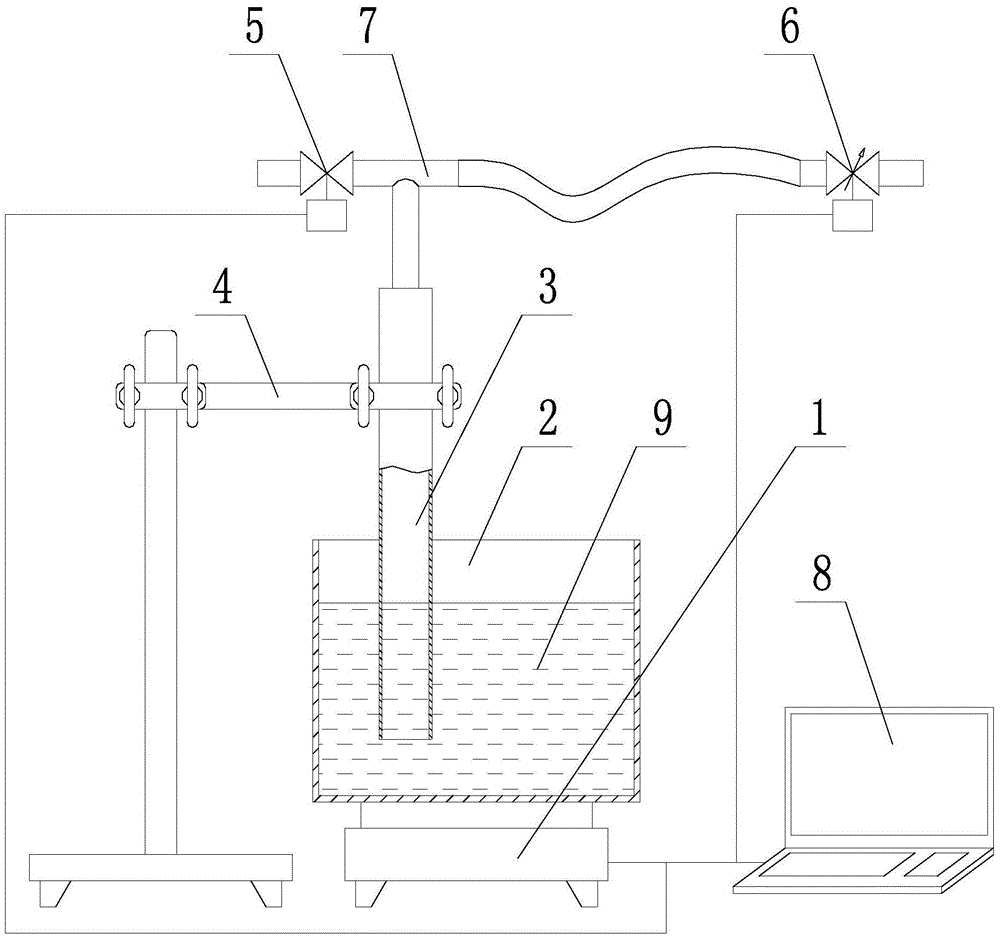

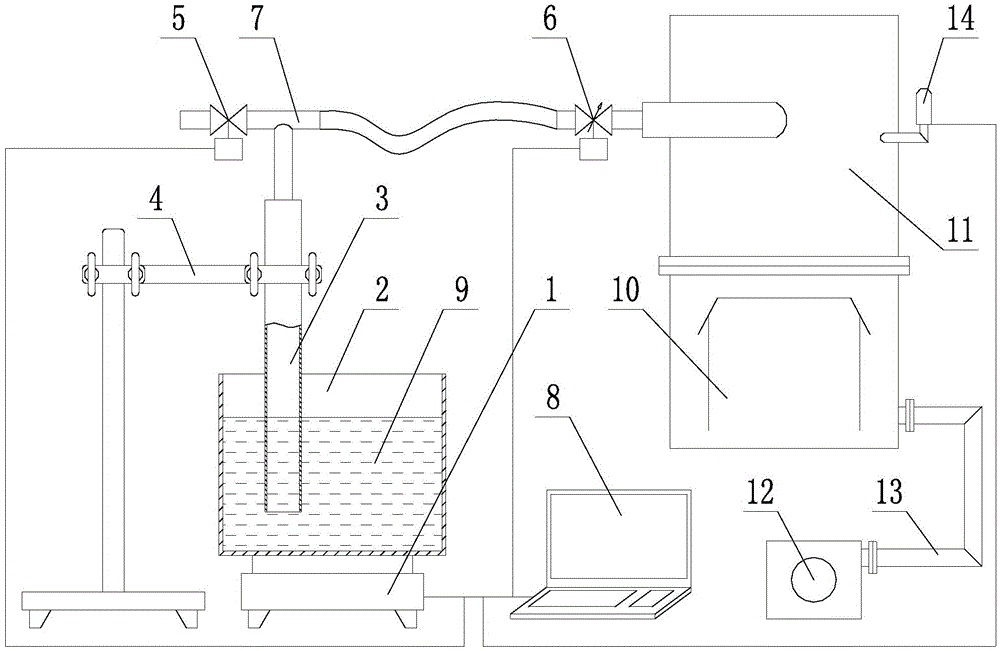

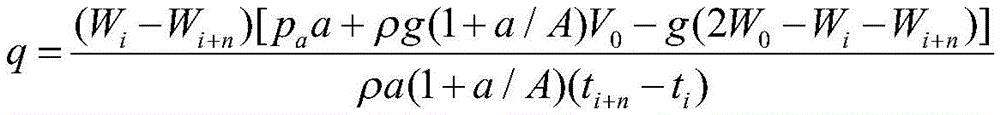

[0050] Such as figure 1 As shown, a dropper-type gas flow measurement device based on the weighing principle includes an electronic scale 1, an oil storage tank 2, a dropper 3, a dropper bracket 4, an intake valve 5, a fine-tuning valve 6, a three-way pipe 7 and Computer 8, the oil storage tank 2 is placed on the electronic scale 1, and oil liquid 9 is stored in the oil storage tank 2; the dropper 3 is vertically installed on the dropper bracket 4, and the lower end nozzle of the dropper 3 is located in the oil storage tank 2, below the liquid level of the oil liquid 9, and the pipe body of the dropper 3 has no contact with the oil storage tank 2; The mouth is connected with the air outlet of the air intake valve 5, and the air inlet of the air intake valve 5 is communicated with the atmosphere; The air outlet is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com