Patents

Literature

40results about How to "Reduce measurement blind spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distributed optical fiber sensing device based on chaotic laser coherence method, and measurement method of distributed optical fiber sensing device

ActiveCN103123285AAchieve strainEasy to detectThermometers using physical/chemical changesUsing optical meansData acquisitionDisplay device

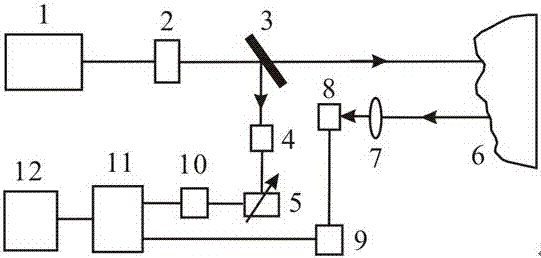

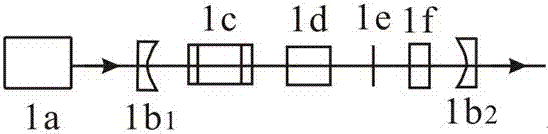

The invention discloses a distributed optical fiber sensing device based on a chaotic laser coherence method, and a measurement method of the distributed optical fiber sensing device. Chaotic laser light which is emitted from a chaotic laser is divided into detection light and reference light; the detection light is amplified by a light amplifier and then emitted into a sending optical fiber through an optical circulator, and a backward Brillouin scattering light signal is generated in the optical fiber; the Brillouin scattering light signal is amplified by the light amplifier, de-noised by a tunable light filter and then emitted into an optical fiber coupler; the optical length of the reference light is regulated by a variable light delay line, and interferes with the backward Brillouin scattering light signal which is generated by the detection light at different positions in the sensing optical fiber in the optical fiber coupler; an interference beat frequency signal is detected by a photoelectrical detector; and Brillouin gain spectra at different lengths are obtained through a data acquisition device and a signal processing device and then output to a display device, so strain or temperature sensing detection is realized.

Owner:TAIYUAN UNIV OF TECH

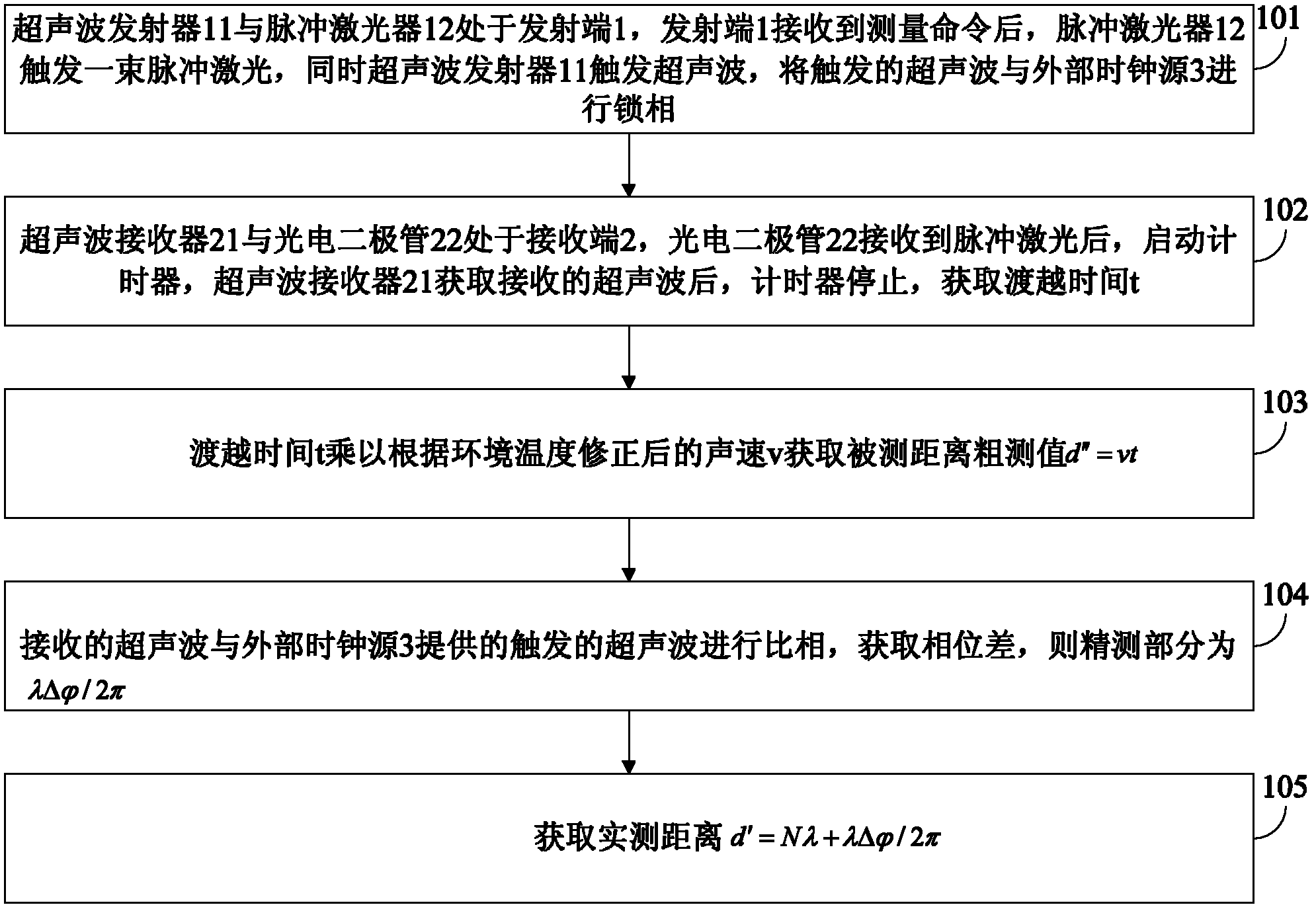

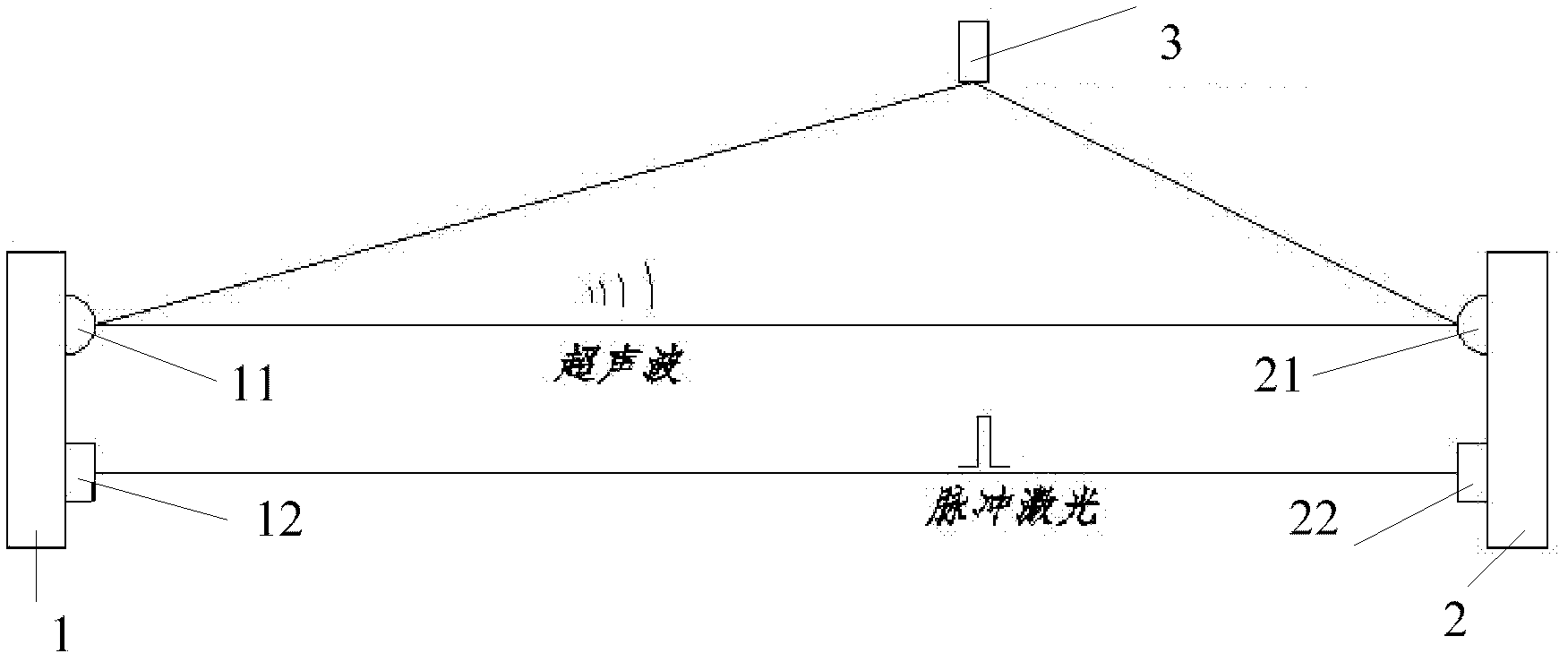

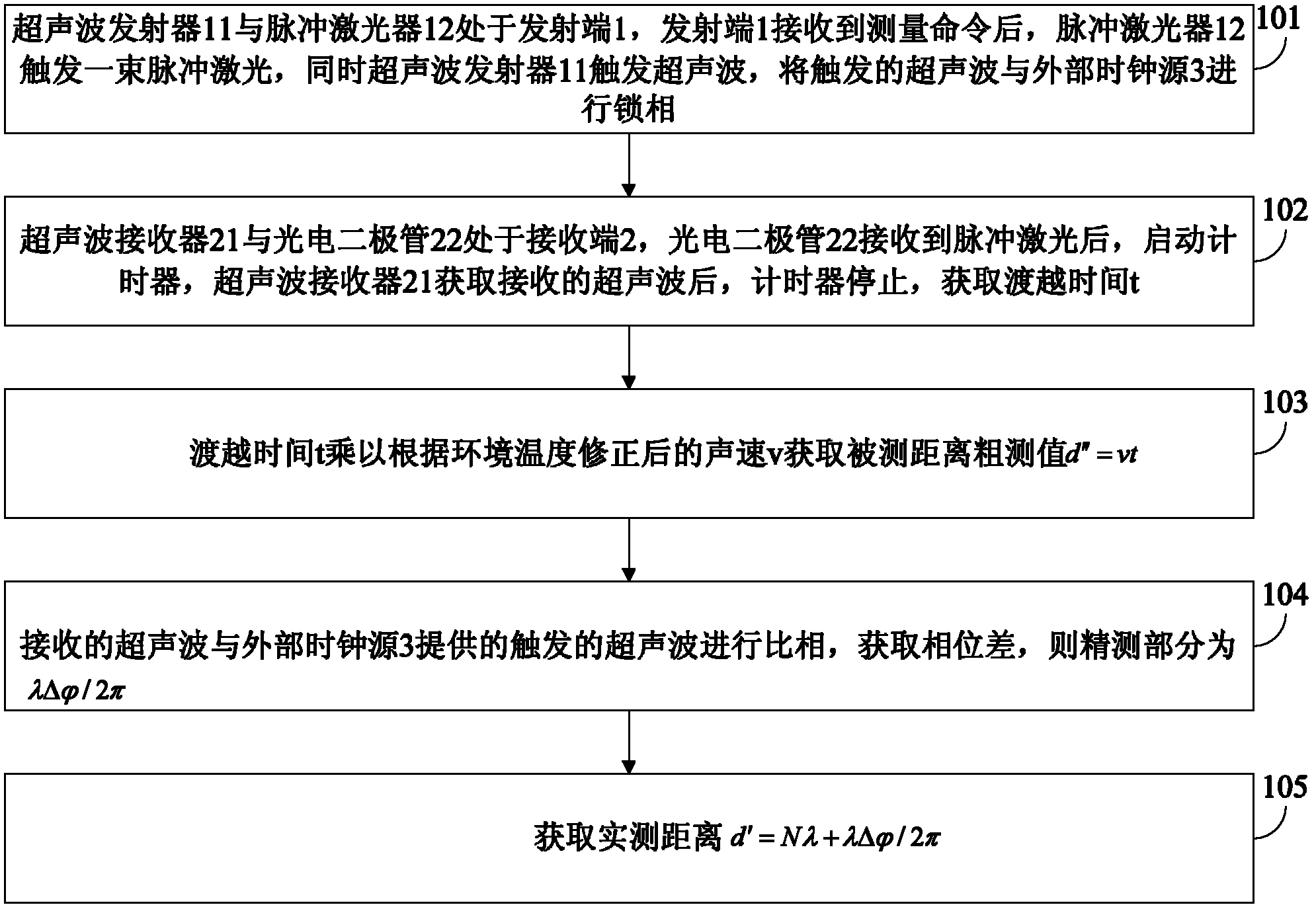

Ultrasonic ranging method

InactiveCN102636780ANot easy to interfereLess susceptible to interferenceUsing reradiationSonificationUltrasonic sensor

The invention discloses an ultrasonic ranging method, belonging to the technical field of electronic measurements. The ultrasonic ranging method comprises the following steps that: an ultrasonic transmitter and a pulse laser are located at a transmitting end, the transmitting end receives a measuring command, subsequently, the pulse laser triggers a beam of pulse laser and the ultrasonic transmitter triggers an ultrasonic wave at the same time, and phase locking is carried out on the triggered ultrasonic wave and an external clock source; an ultrasonic receiver and a photodiode are located at a receiving end, after the photodiode receives the pulse laser, a timer is started, after the ultrasonic receiver acquires the received ultrasonic wave, the timer is stopped to acquire transition time; the transition time multiplies by a revised sound velocity to acquire a rough measurement value of a measured distance; and a phase difference is obtained, a fine measurement part is lambda delta omega / 2phi, and an actually measured distance d' is acquired, wherein d'=Nlambda+lambda delta omega / 2phi. The ultrasonic ranging method has the advantages that the receiver is easily interfered by the transmitter, a measurement blind zone is greatly reduced, the ultrasonic distance measuring directivity is improved, the distance measuring precision is improved within one ultrasonic wavelength; and the ultrasonic ranging method is particularly suitable for distance measurement in a single station type space orientation and measurement system.

Owner:TIANJIN UNIV

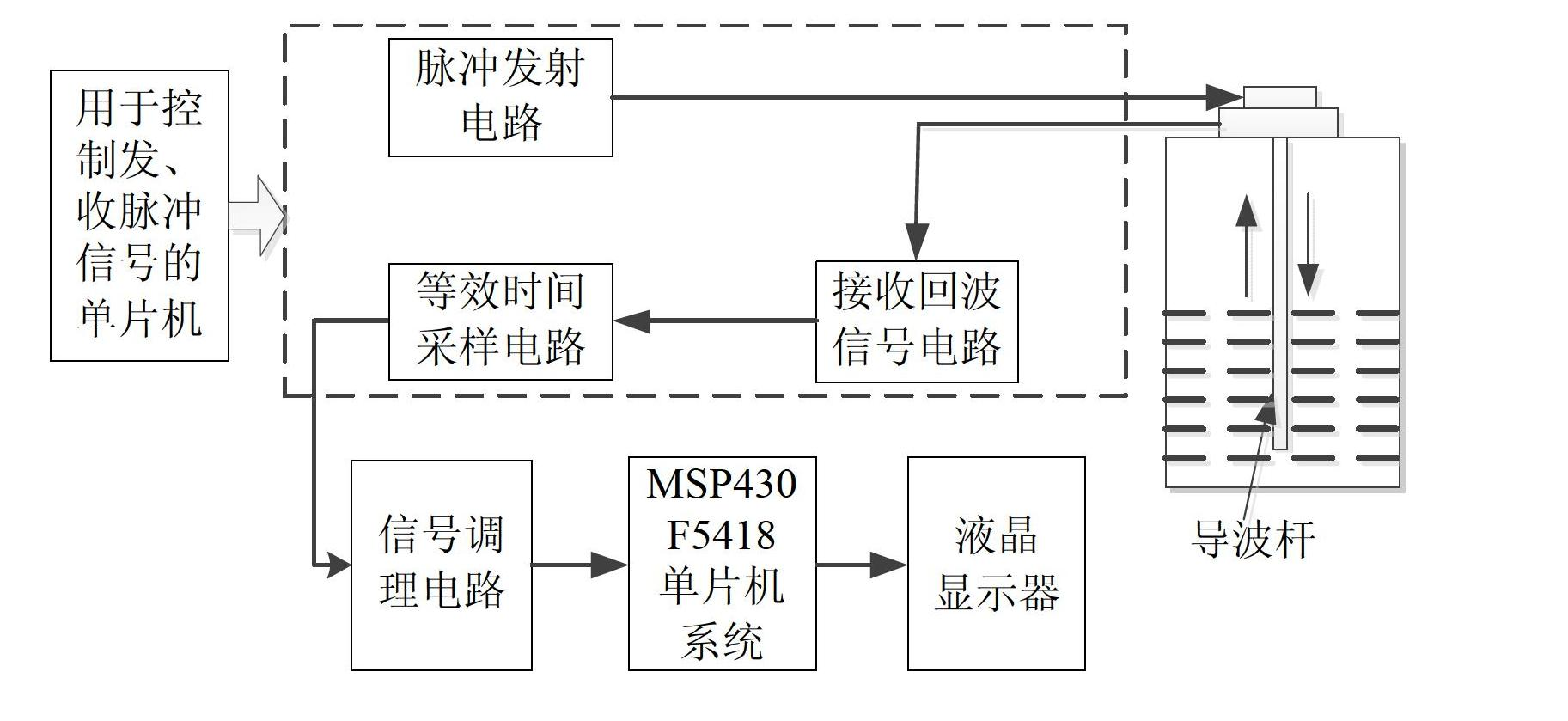

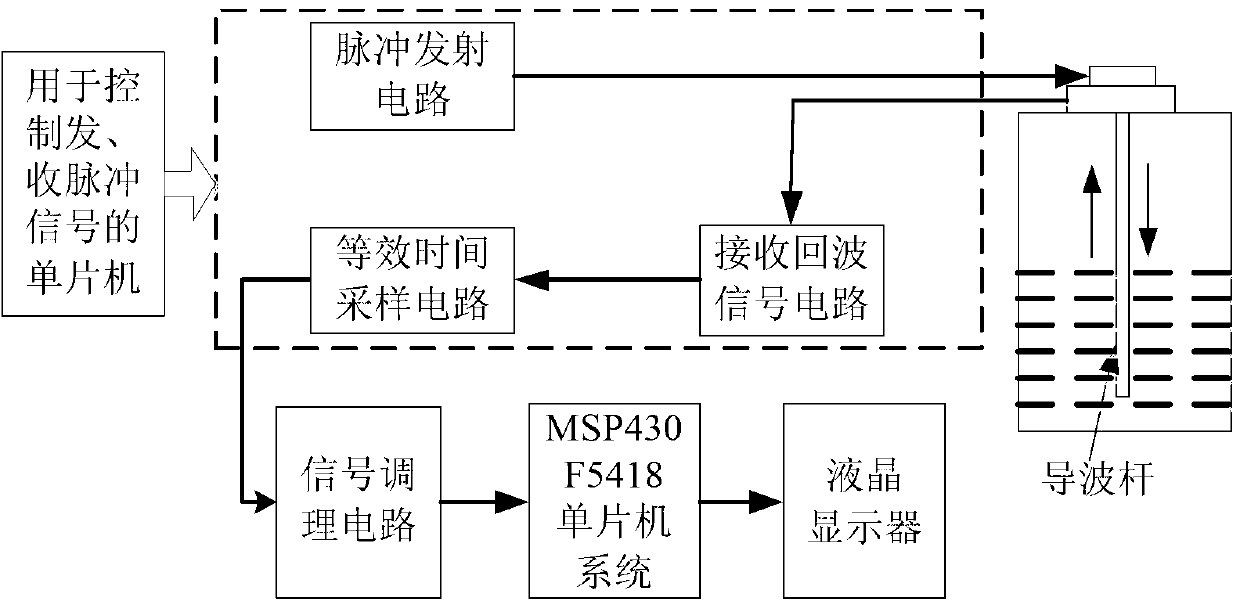

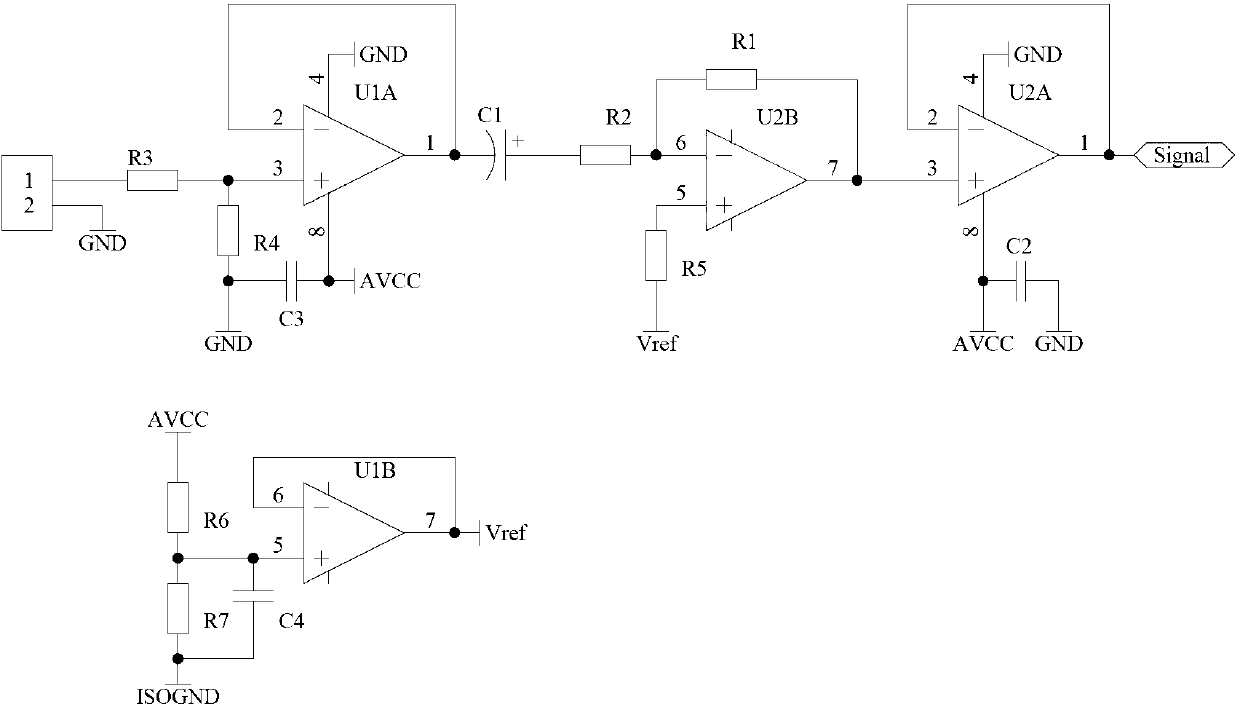

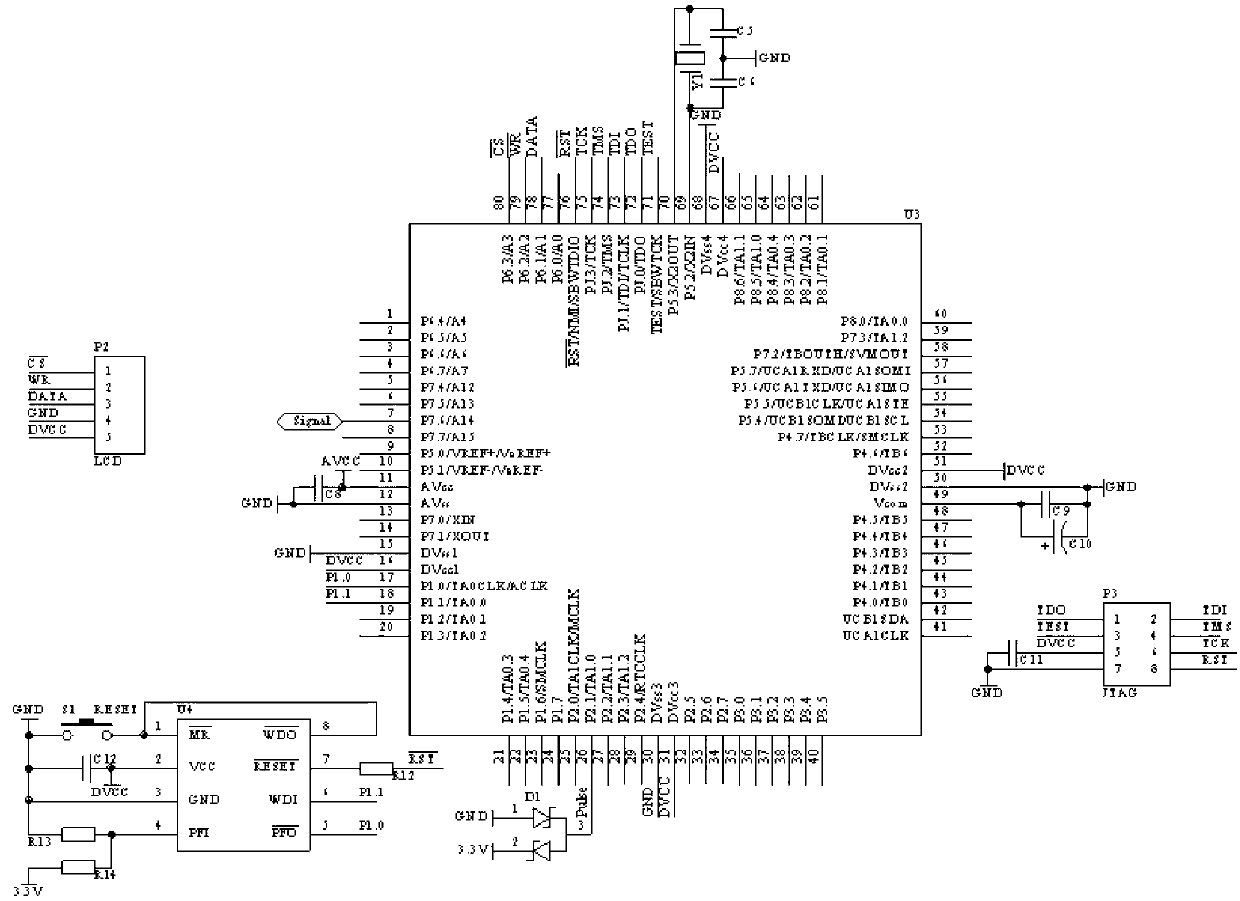

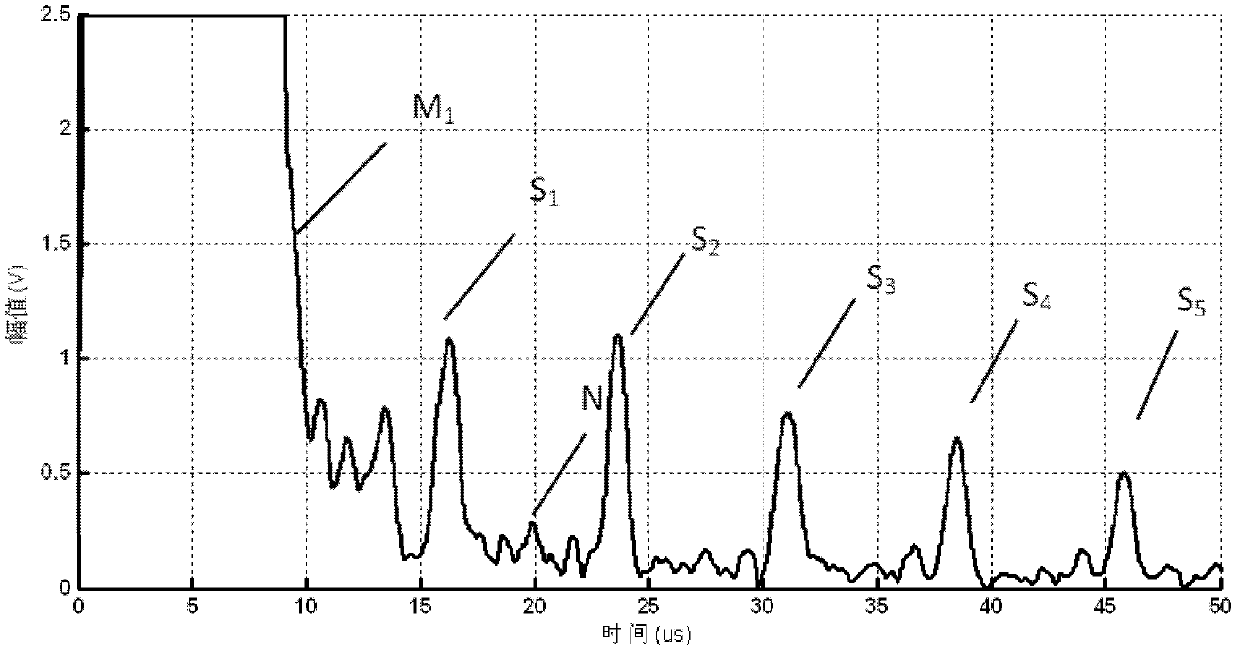

System and method for processing echo signal of guided wave type radar level meter

ActiveCN102661773AHigh measurement accuracyReduce measurement blind spotsMachines/enginesLevel indicatorsPhysicsVIT signals

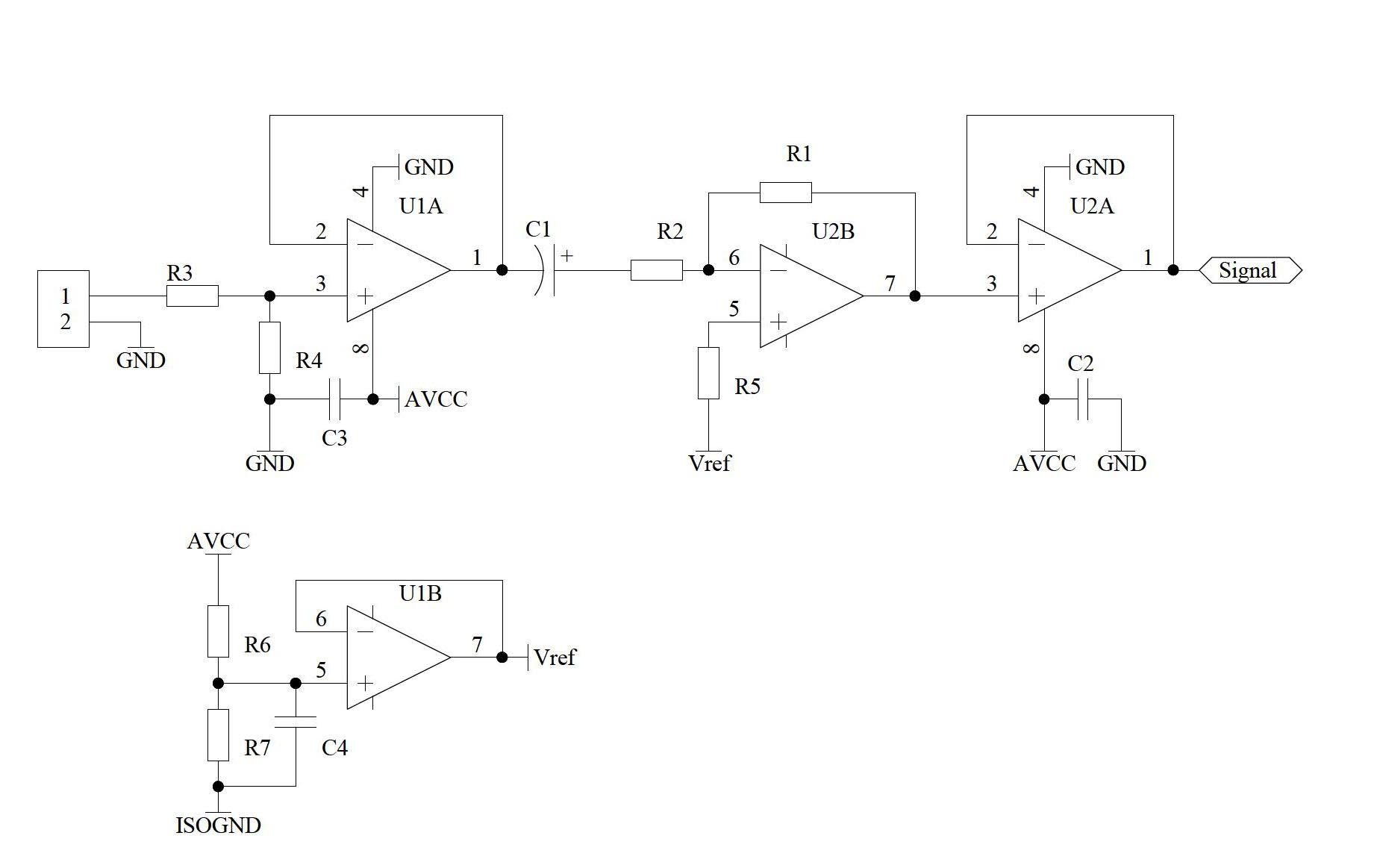

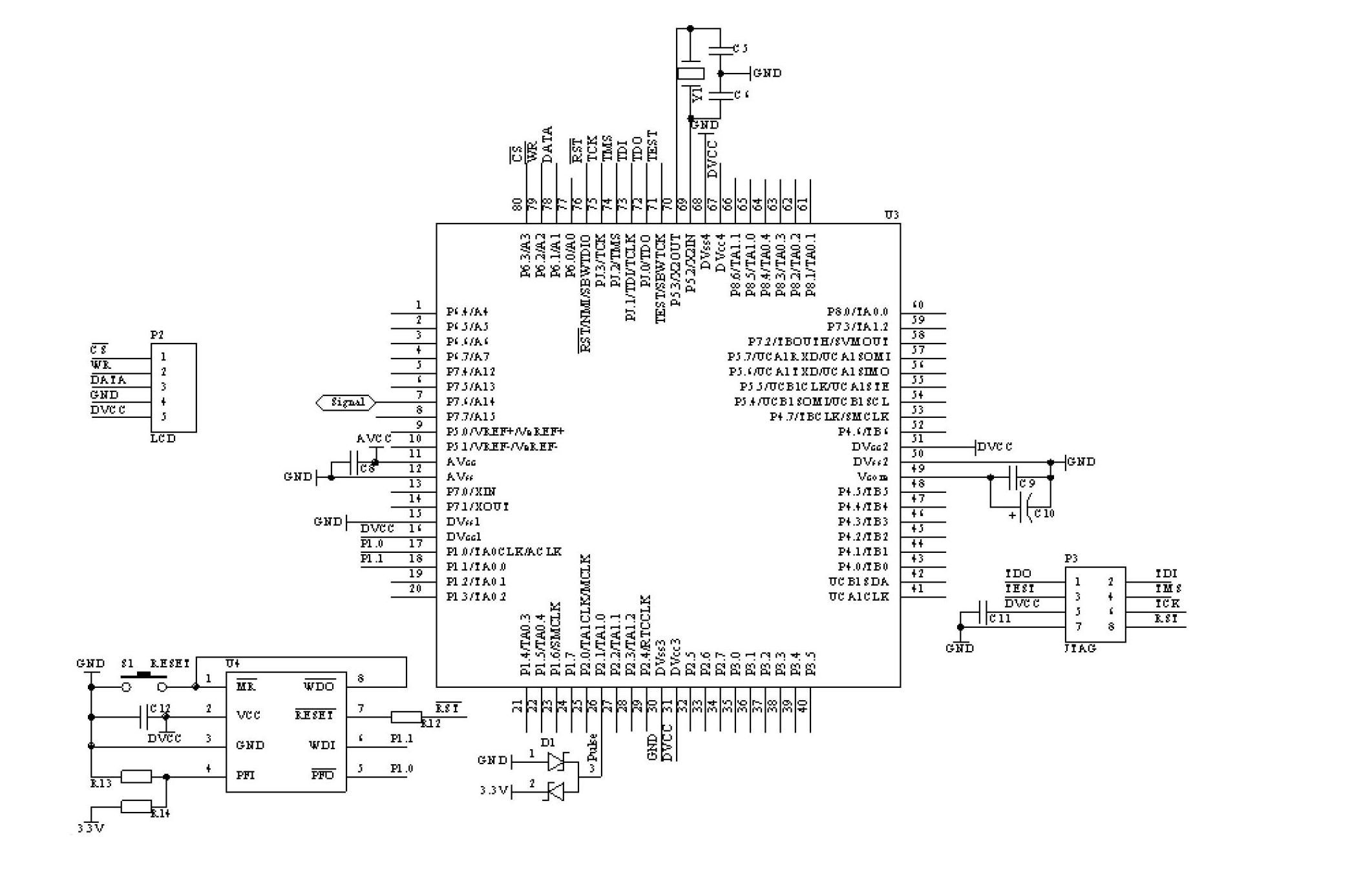

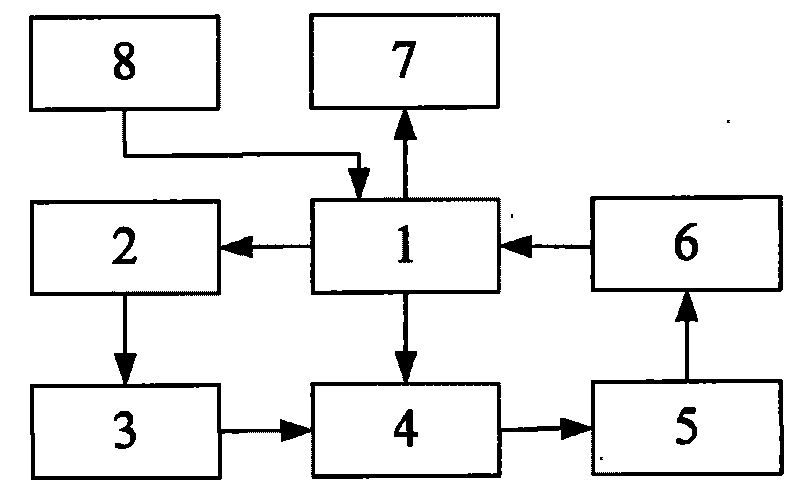

The invention relates to the field of level measurement and provides a system for processing an echo signal of a guided wave type radar level meter taking a single chip as the core. The system is composed of the single chip for controlling the sending and receiving of a pulse signal, a pulse emission circuit, a guided wave rod, an echo signal receiving circuit, an equivalent time sampling circuit, a signal adjusting circuit, a MSP430F5418 single chip system, a liquid crystal display and software. Specific to the material with big relative dielectric constant and the material with small relative dielectric constant, different methods for processing the echo signal are respectively adopted for restraining false echo interference, confirming and correcting a peak value of a real echo, and then fitting or interpolating nominal data, thereby realizing the level measurement.

Owner:HEFEI UNIV OF TECH

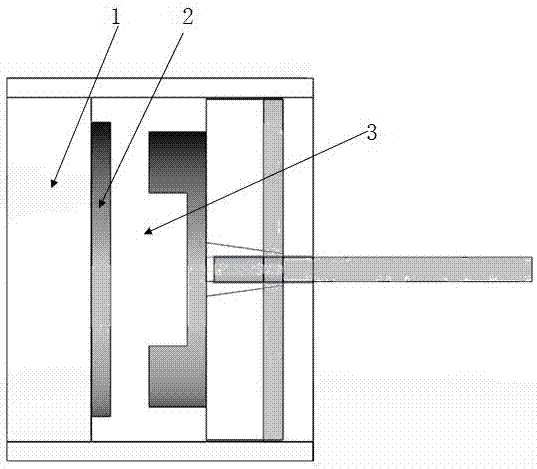

Electromagnetic ultrasonic thickness gauge and measurement method thereof

ActiveCN101701809AAdaptableImprove detection efficiencyUsing subsonic/sonic/ultrasonic vibration meansMicrocontrollerHandling system

The invention provides an electromagnetic ultrasonic thickness gauge for measuring the thickness of a specimen in a variety of abominable environments and a measurement method thereof. The electromagnetic ultrasonic thickness gauge is composed of a microcontroller, a transmitting circuit, an electromagnetic ultrasonic probe, a receiving switch, a conditioning circuit, an echo processing system, a display system and a keyboard, wherein the microcontroller is connected with the transmitting circuit which is connected with the electromagnetic ultrasonic probe, the electromagnetic ultrasonic probe is connected with the receiving switch which is connected with the microcontroller and the conditioning circuit, the conditioning circuit is connected with the echo processing system, and the display system is connected with the microcontroller which is connected with the keyboard. The electromagnetic ultrasonic thickness gauge uses a normal-incidence body wave to measure the thickness and achieves the measurement accuracy which is twice as high as that of piezoelectric ultrasonic thickness gauge at the same frequency. The electromagnetic ultrasonic probe which adopts a pulse electromagnet to offer magnetic field can effectively detect various metallic specimens; as a transceiving separated coil is used for exciting and detecting ultrasonic waves, the blind area for the measurement is small and the measurement thickness can be in a range from 3mm to 200mm.

Owner:零声科技(苏州)有限公司

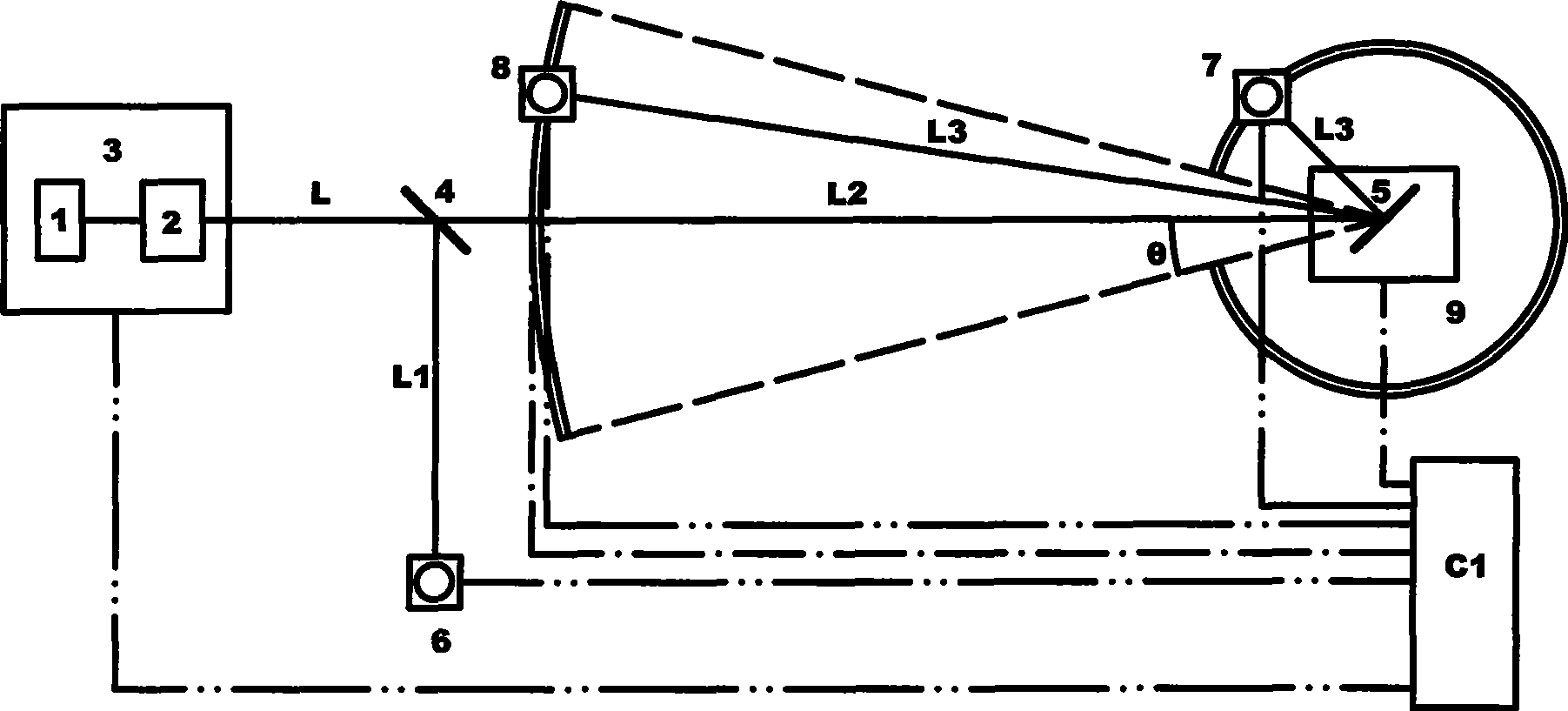

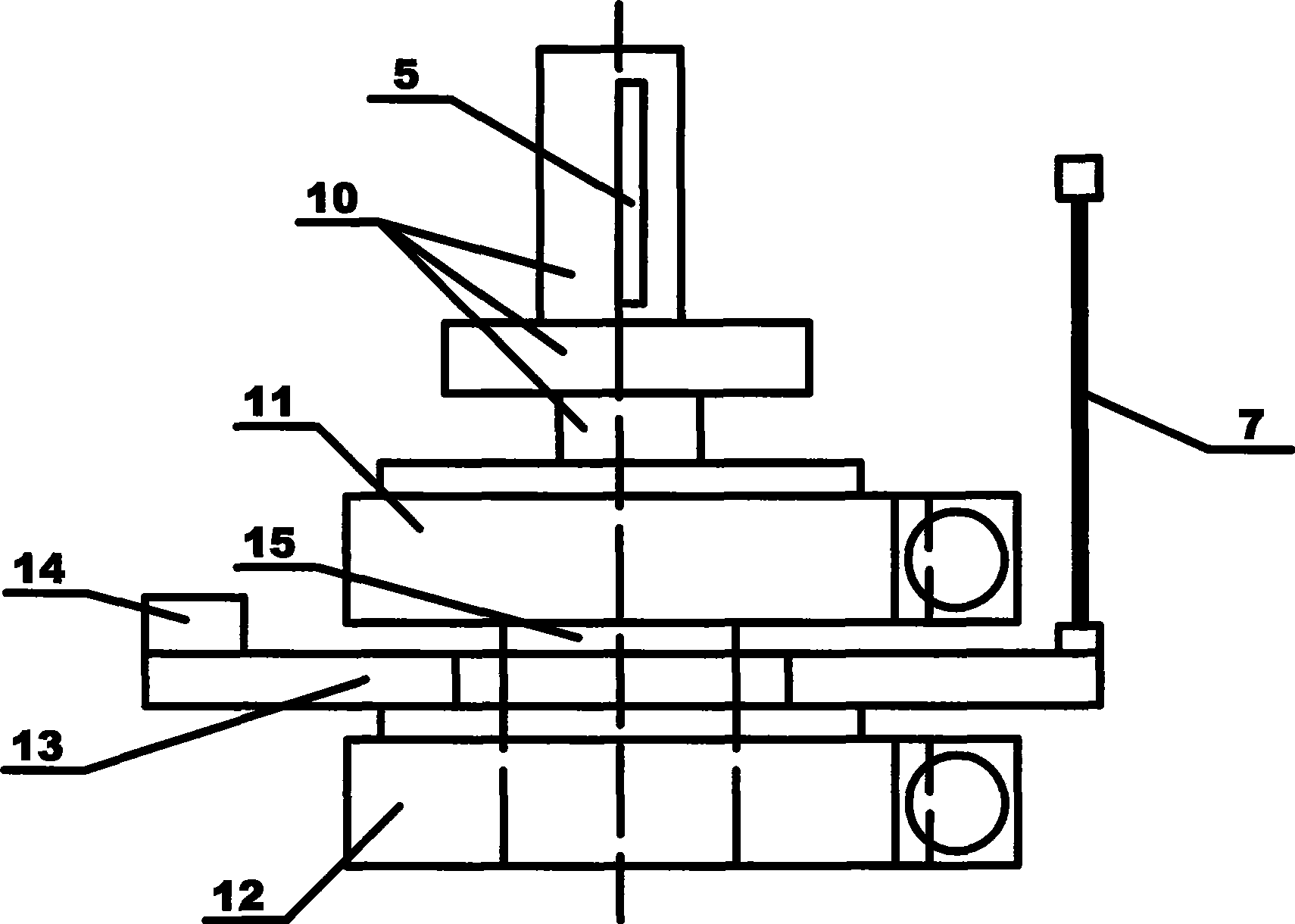

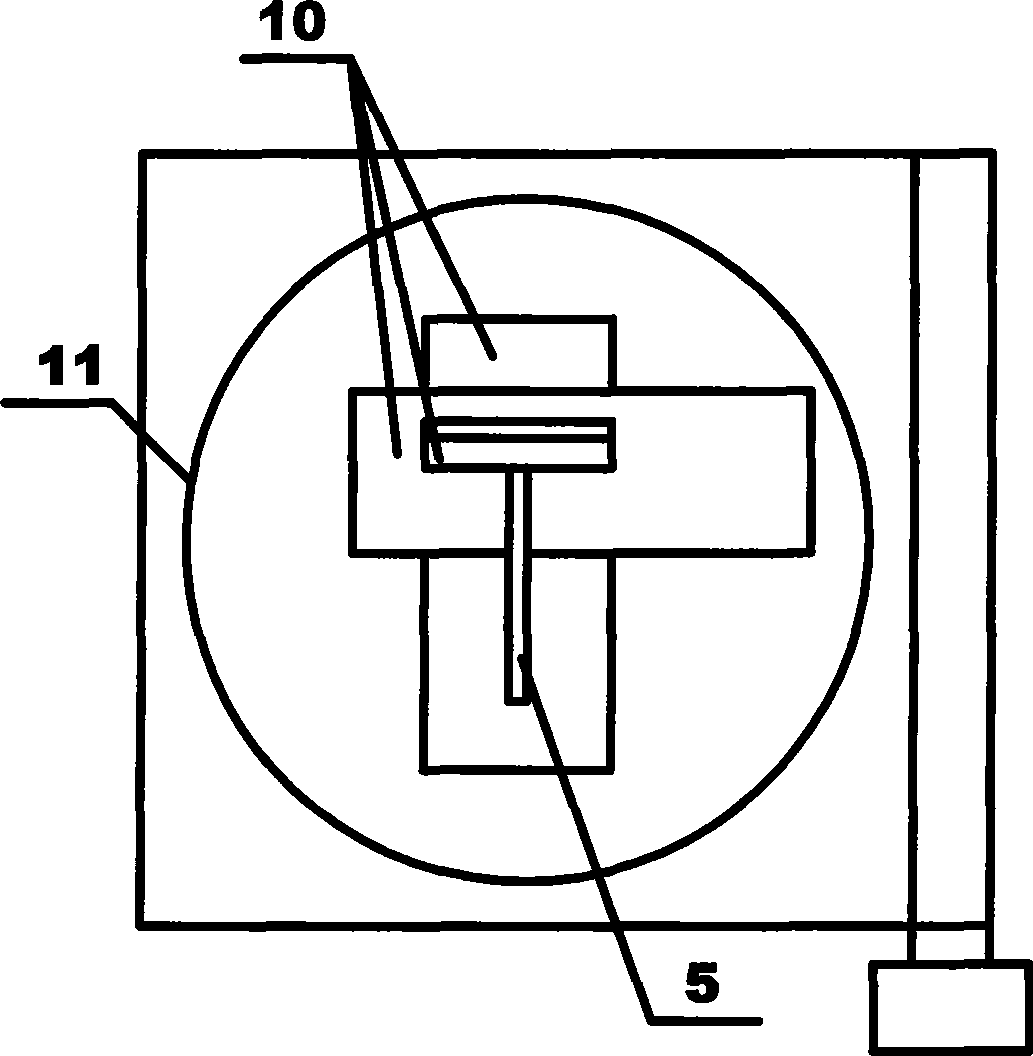

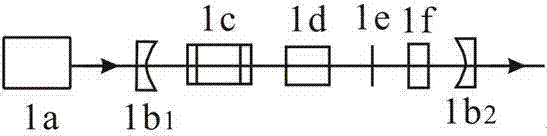

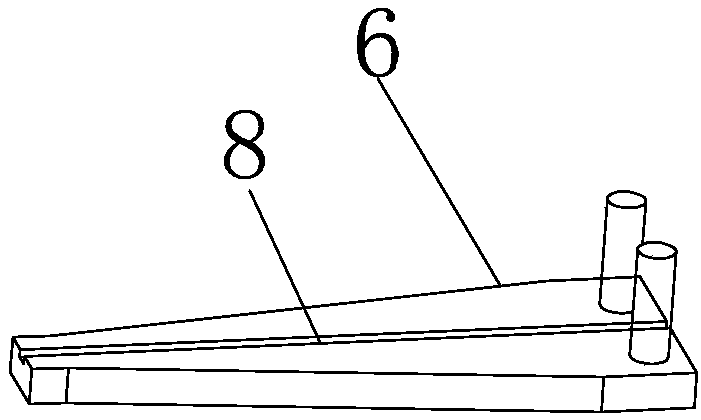

Measuring device and measuring method for diffraction efficiency of grating

InactiveCN101545826AReduce measurement blind spotsEqual propagation distanceTesting optical propertiesObservational errorBlind zone

The invention relates to a measuring device and a measuring method for the diffraction efficiency of a grating. The device comprises a monochromatic source, a beam splitter, a grating rotary table, detectors, a two-dimensional translation platform and a computer. The method is characterized in that: the second detector and the third detector are adopted to move on a small arc and a big arc respectively to detect the energy of a diffracted beam L3 of the grating to be tested; and the method realizes the aims of diminishing a measurement blind zone and reducing the requirement on the size of an optical platform. The double light path synchronous measurement is adopted to remove measurement errors caused by the instability of the light source.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

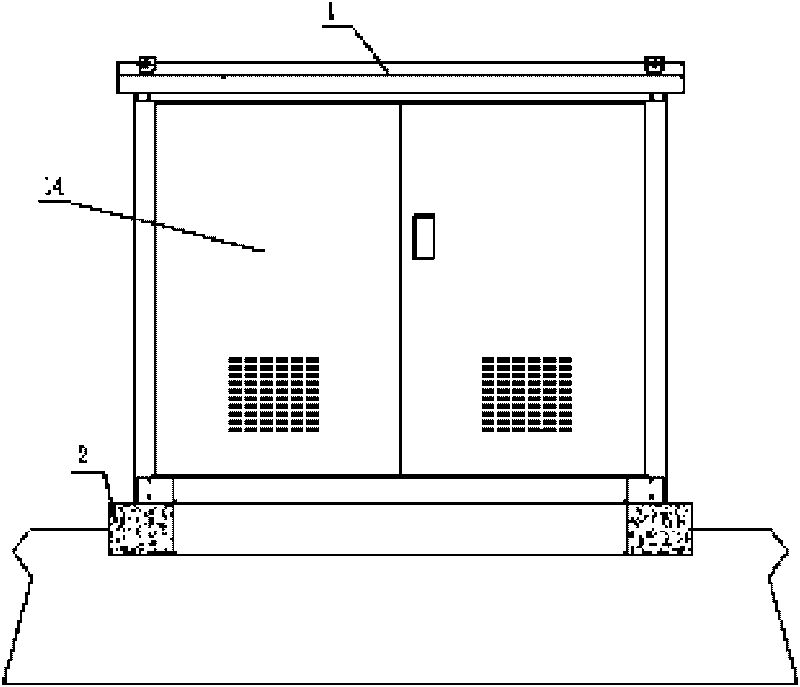

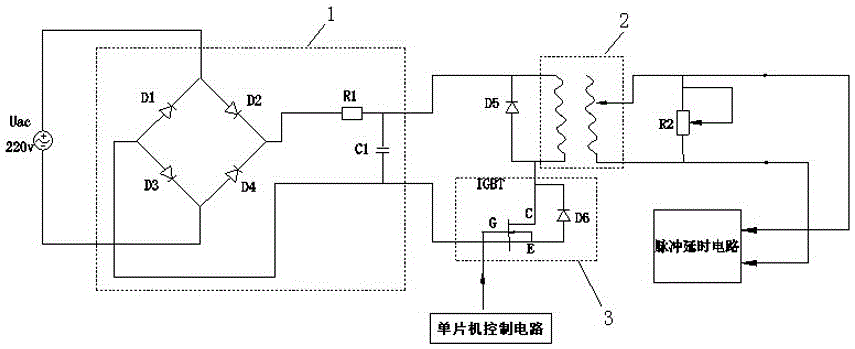

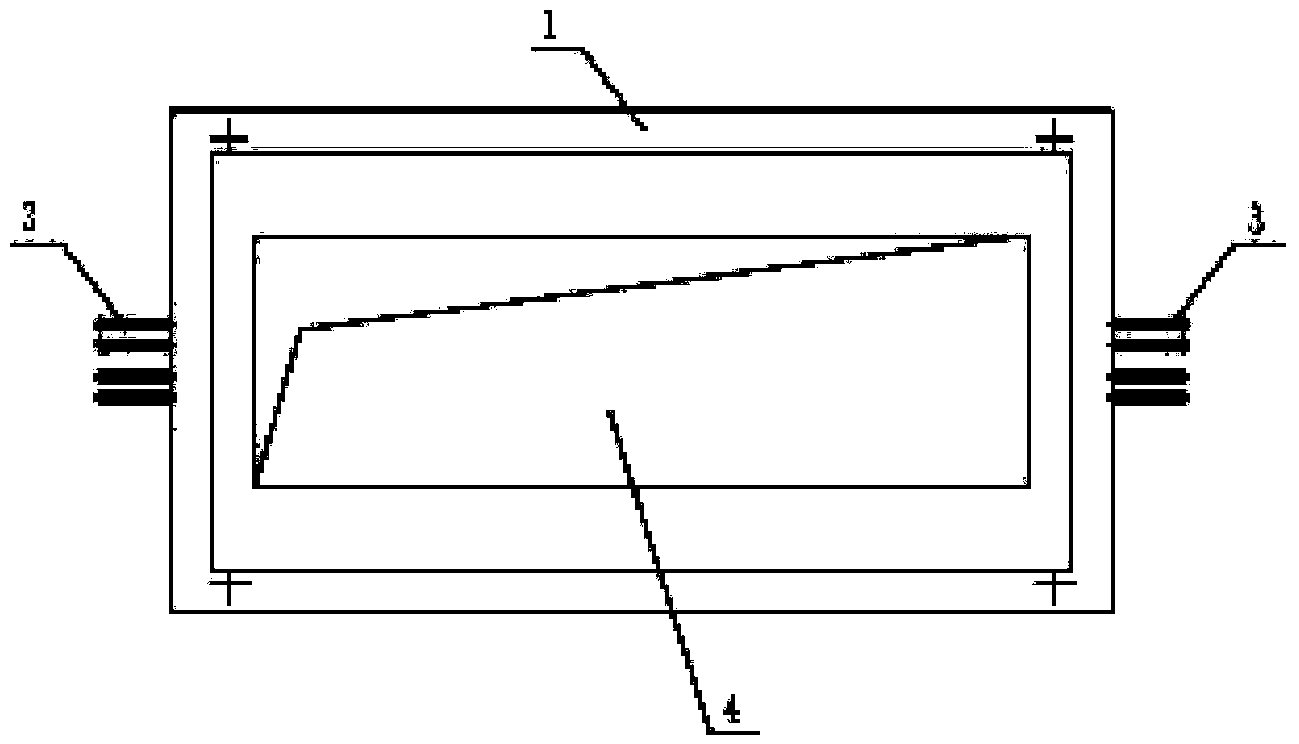

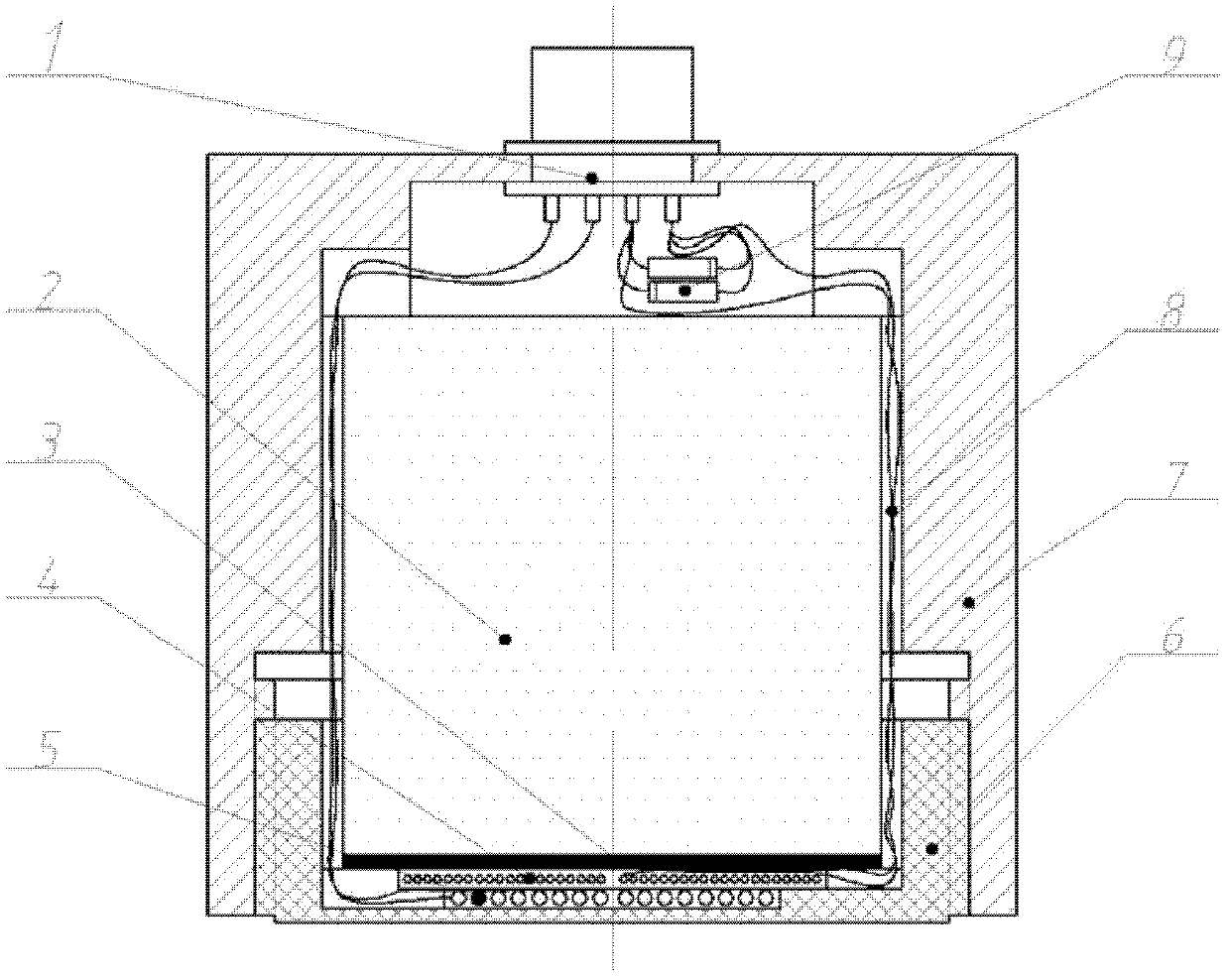

Cable fault simulation and location system

ActiveCN101699540AEasy to debugSimple structureEducational modelsFault location by pulse reflection methodsHigh-voltage cableEngineering

The invention relates to a cable fault simulation and location system, which comprises a cable fault simulation case, an electrode mounting plate arranged in the cable fault simulation case, three incoming line electrodes and three outgoing line electrodes, wherein the three incoming line electrodes are connected with a three-phase wire core in an incoming line cable respectively; the three outgoing line electrodes are connected with a three-phase wire core in an outgoing line cable respectively; a resistance box for simulating disconnection faults, low-resistance faults, high-resistance faults and flashover faults between the incoming line electrodes and the outgoing line electrodes is arranged in the cable fault simulation case; the tail end of the outgoing line cable connected with the outgoing line electrodes is provided with a high-voltage cable terminal; and the high-voltage cable terminal is used for connecting a cable fault location detector. The cable fault location detector comprises a central control unit, an impulse transmission circuit for transmitting impulse signals to a tested cable, a reflection receiving circuit for receiving reflected signals from the tested cable and a high-speed data acquisition circuit, wherein an output end of the reflection receiving circuit is connected with an input end of the high-speed data acquisition circuit.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +1

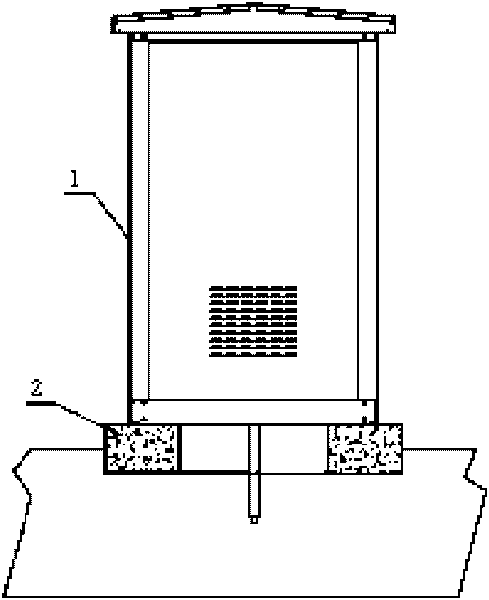

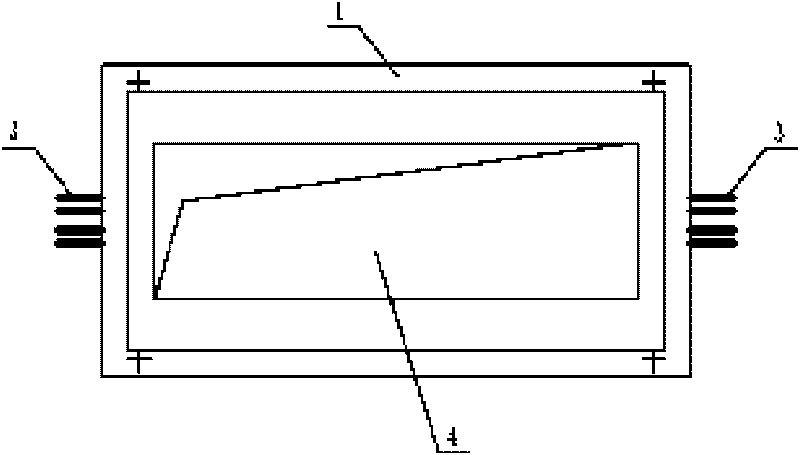

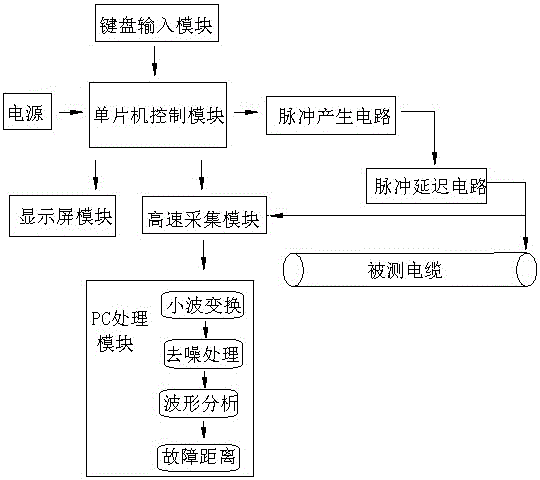

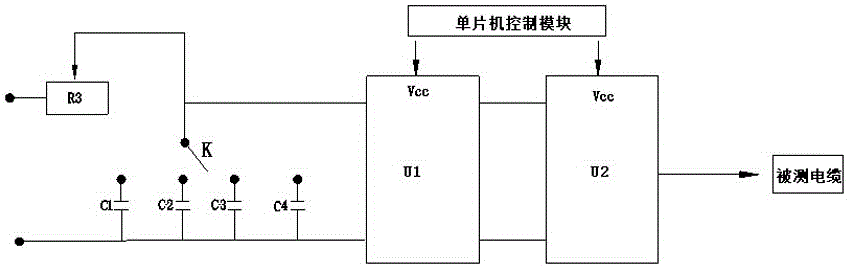

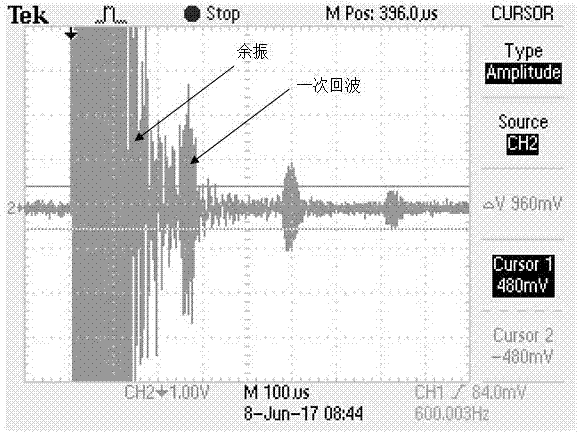

Short-distance cable fault ranging system and ranging method with low-voltage pulse method

ActiveCN106443359ARound waveSmooth waveFault location by conductor typesMicrocontrollerShortest distance

The invention discloses a short-distance cable fault ranging system and a ranging method with a low-voltage pulse method. The short-distance cable fault ranging system comprises a single chip microcomputer control module, a keyboard input module, a display screen module, a pulse generation circuit, a pulse delay circuit, a high-speed acquisition module, a PC processing module, a power supply and a tested cable, wherein the single chip microcomputer control module, the keyboard input module, the display screen module, the pulse generation circuit, the pulse delay circuit, the high-speed acquisition module and the PC processing module are respectively connected with the power supply; the single chip microcomputer control module is connected with the keyboard input module, the display screen module, the high-speed acquisition module and the pulse generation circuit respectively; the pulse generation circuit is connected with the pulse delay circuit; the output end of the pulse delay circuit is connected with the high-speed acquisition module and the tested cable respectively; the high-speed acquisition module is connected with the PC processing module. By adopting the short-distance cable fault ranging system, blind test areas can be effectively reduced, and thus the cable fault ranging accuracy degree can be relatively high.

Owner:NANJING INST OF TECH

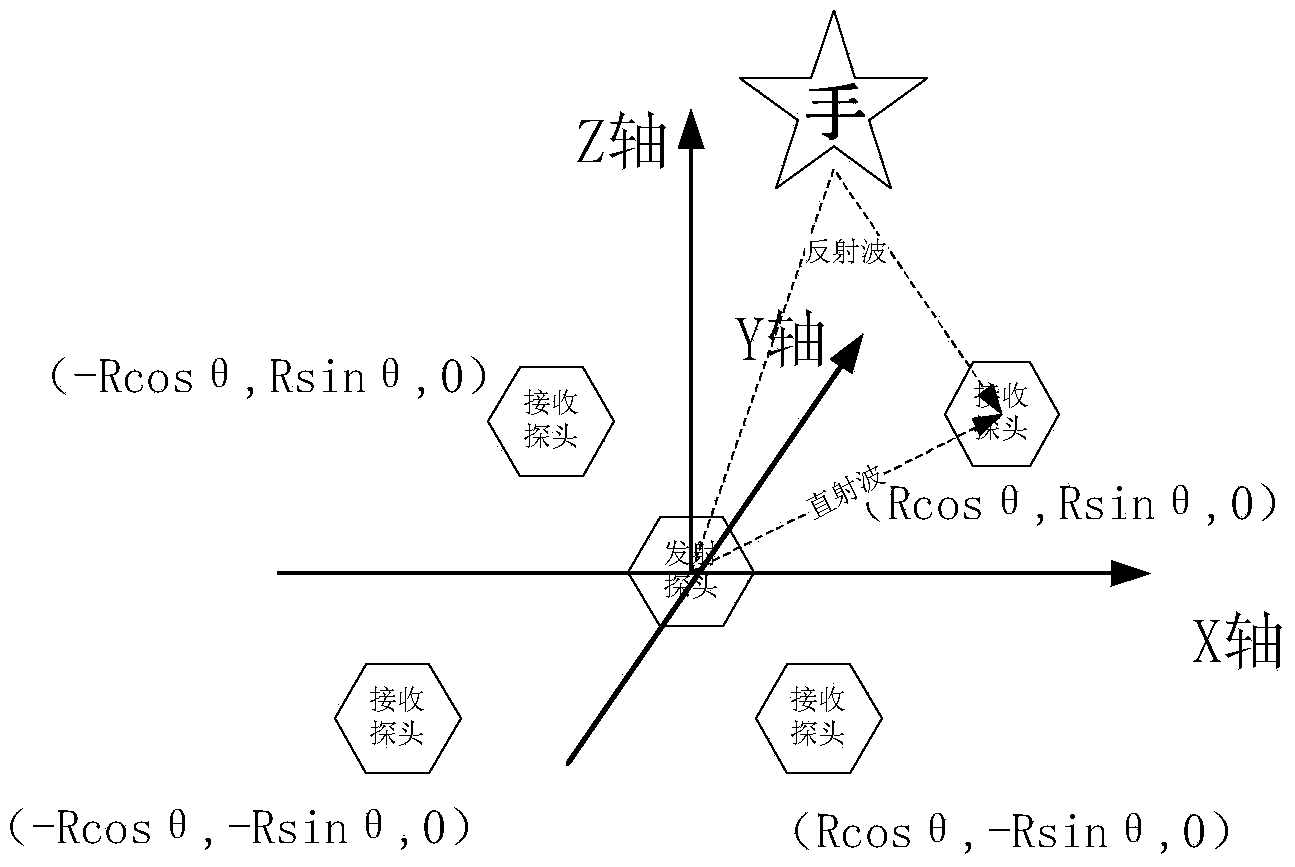

3D gesture recognition controller and method based on ultrasonic locating

ActiveCN103713536AImprove driving abilityReduce the blind area of ultrasonic measurementInput/output for user-computer interactionGraph readingAnalysis dataSonification

The invention discloses a 3D gesture recognition controller and method based on ultrasonic locating. The controller comprises a signal acquisition circuit and a locating and recognition unit. The method includes the steps that a background signal is collected and filtered; an ultrasonic wave transmission signal is colleted, collected data are filtered, and data obtained after the background signal is filtered are subtracted from filtered data; a direct signal and a reflected signal are intercepted, and maximum likelihood estimation is carried out on time delay between the direct signal and the reflected signal; ultrasonic wave signal propagation time is obtained through perpendicular incidence time and the delay time, the propagation distance of ultrasonic waves transmitted by a transmitting probe, reflected through a hand and received by a receiving probe is obtained according to the ultrasonic wave signal propagation time so as to obtain the position coordinates of gestures accordingly, and position coordinate data of standard gestures are collected and stored; the distances between samples in a table and the coordinates of all the standard gestures are calculated; whether the minimum distance between the samples in the table and the coordinates of the standard gestures is smaller than a set value or not is analyzed, if yes, a corresponding labeled gesture is output, and otherwise judgment is not made.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

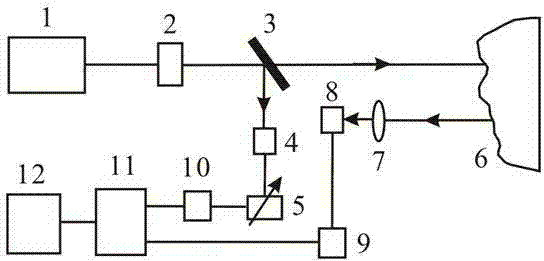

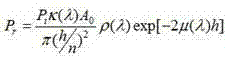

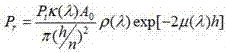

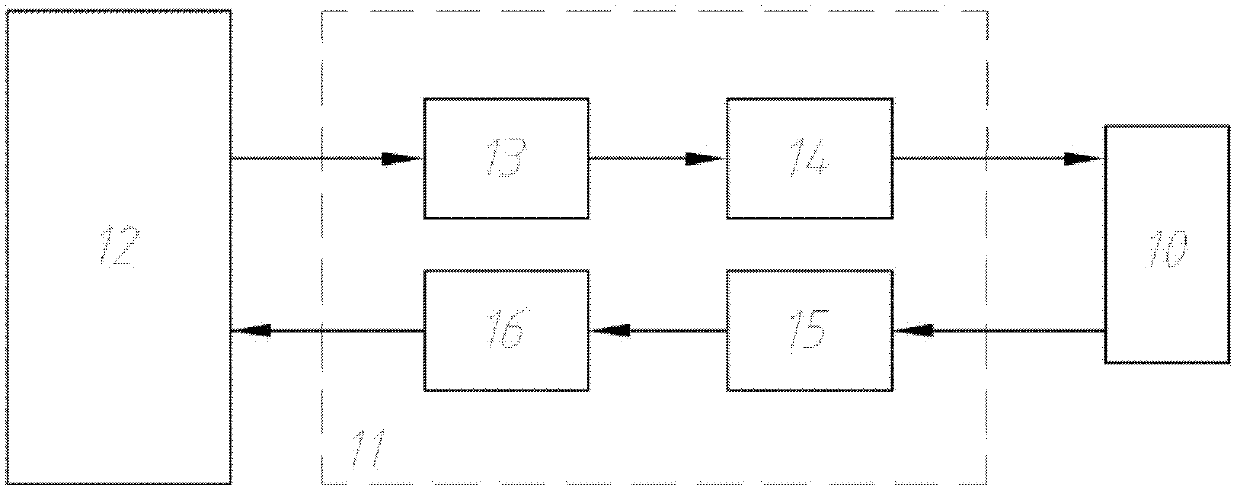

Channel depth measuring method based on chaotic laser device and correlative method thereof

ActiveCN104749579ASolve for distance resolutionSolution depthElectromagnetic wave reradiationPhotovoltaic detectorsInterference resistance

Disclosed is a channel depth measuring method based on a chaotic laser device and a correlative method thereof. The depth of a channel in a shoal water area can be measured on the basis of the chaotic laser device. The method includes on a channel water surface carrier, allowing the chaotic laser device to emit probing light and reference light, allowing the probing light to emit to the water bottom of the channel perpendicularly, collecting reflected probing light signals through a telescope, and converting the probing light signals into electrical signals; converting the reference light into electrical signals through a photoelectric detector, after storing two paths of electrical signals, performing correlation calculation, acquiring the time for light signals flying for a round trip in the channel water, and acquiring the channel depth accordingly. By the aid of the method, the conflict between the distance resolution and measuring depth according to the existing laser radar technology for measuring the channel depth is solved, the distance resolution unit can be centimeter, and the advantage of interference resistance is provided.

Owner:TAIYUAN UNIV OF TECH

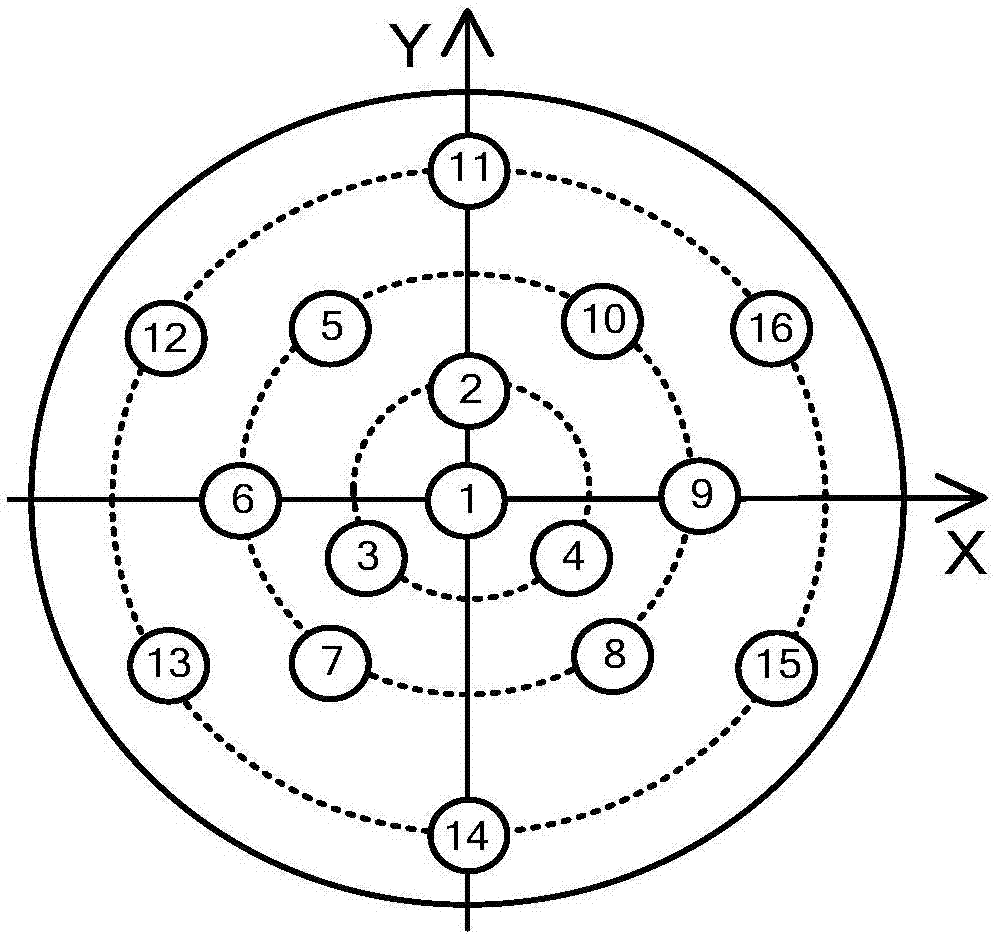

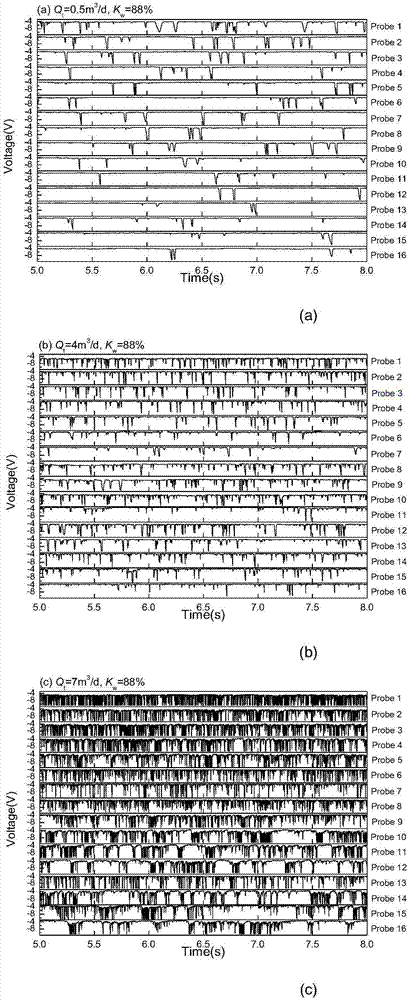

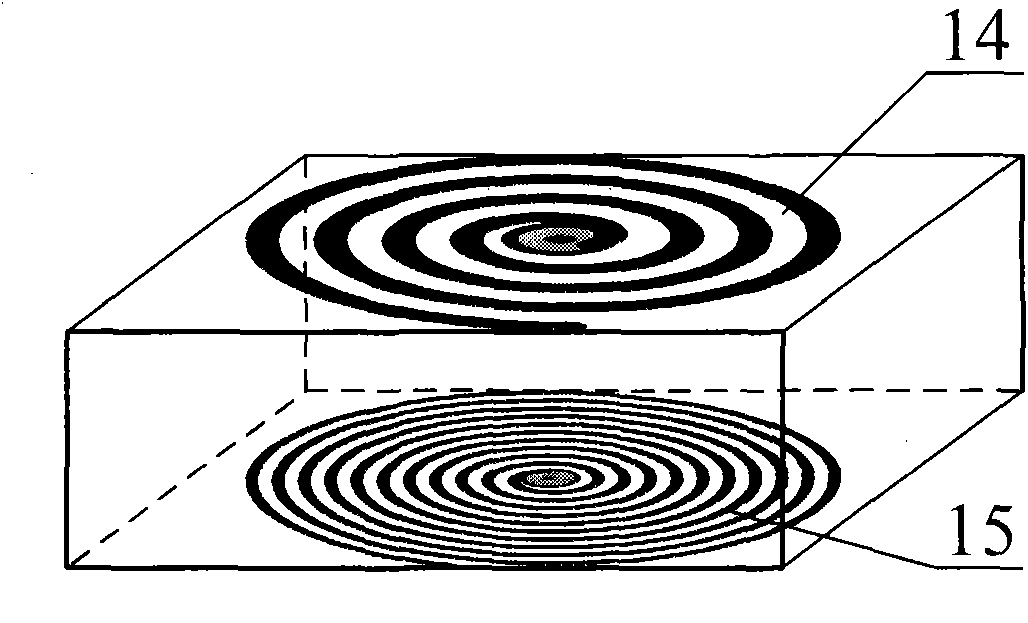

Oil-in-water emulsion oil holdup distribution electrical imaging measurement method

InactiveCN107247075AReduce measurement blind spotsImprove measurement accuracyMaterial analysis by electric/magnetic meansElectrical imagingElectric conductance

The invention relates to an oil-in-water emulsion oil holdup distribution electrical imaging measurement method. A sensor used in the invention comprises multi-path conducting probe sensors placed in the positions of multiple concentric rings in afflux measurement pipes with small pipe diameters in distributed states, and each conducting probe sensor comprises an excitation source probe and a receiving source metal sleeve, wherein the first ring comprises first-path conducting probe sensors, and the conducting probes sensor located on the concentric rings are all uniformly distributed; while measuring, output signals of each path conducting probe sensor are collected, original measurement signals are converted into corresponding square wave signals by using a self-adjustment double-threshold method, the square wave signals are taken as signals to be processed and calculated to obtain the local oil holdup, and later, a cubic spline interpolation algorithm is reused to carry out three-dimensional imaging on pipeline cross-section oil holdup distribution so as to reconstruct distribution behaviors of oil-in-water emulsion oil holdup on a pipeline cross section under the effect of a surfactant.

Owner:TIANJIN UNIV

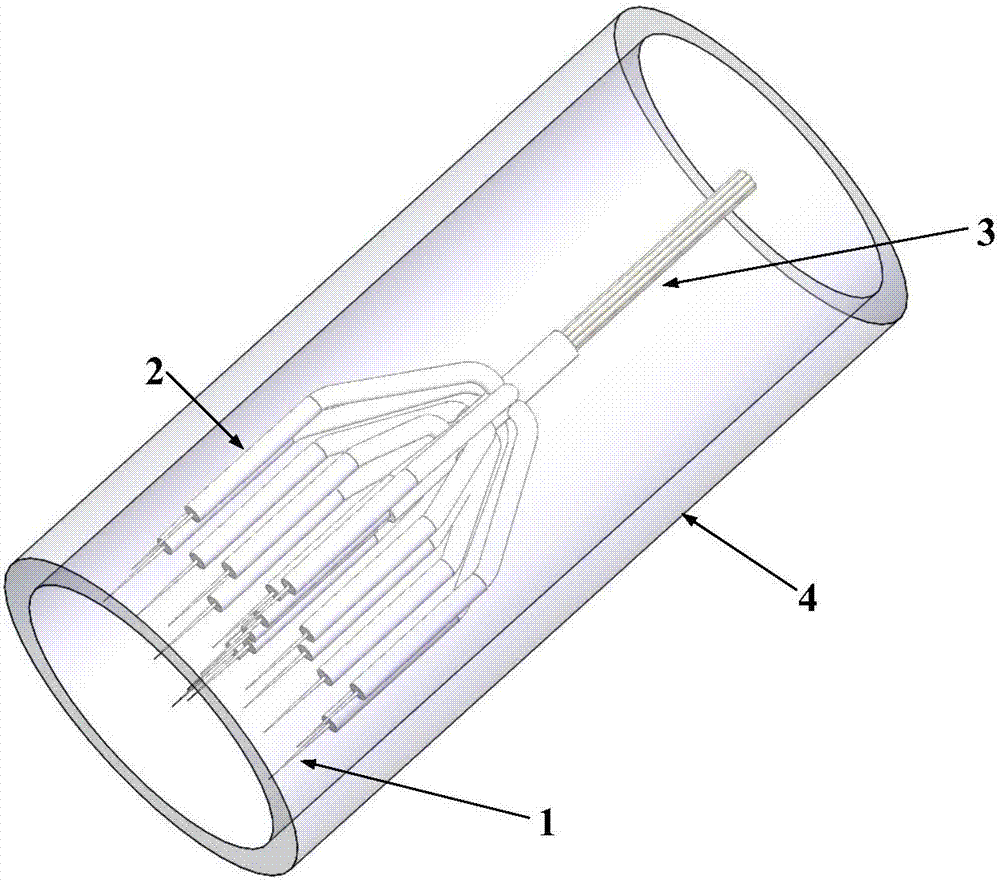

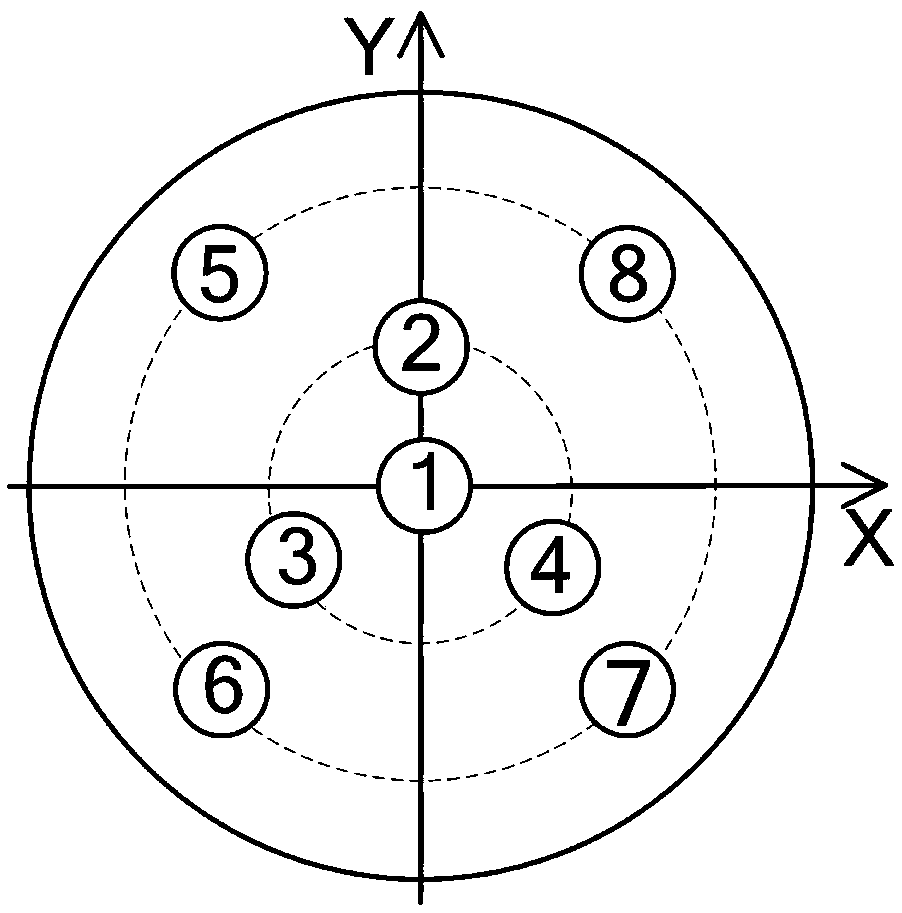

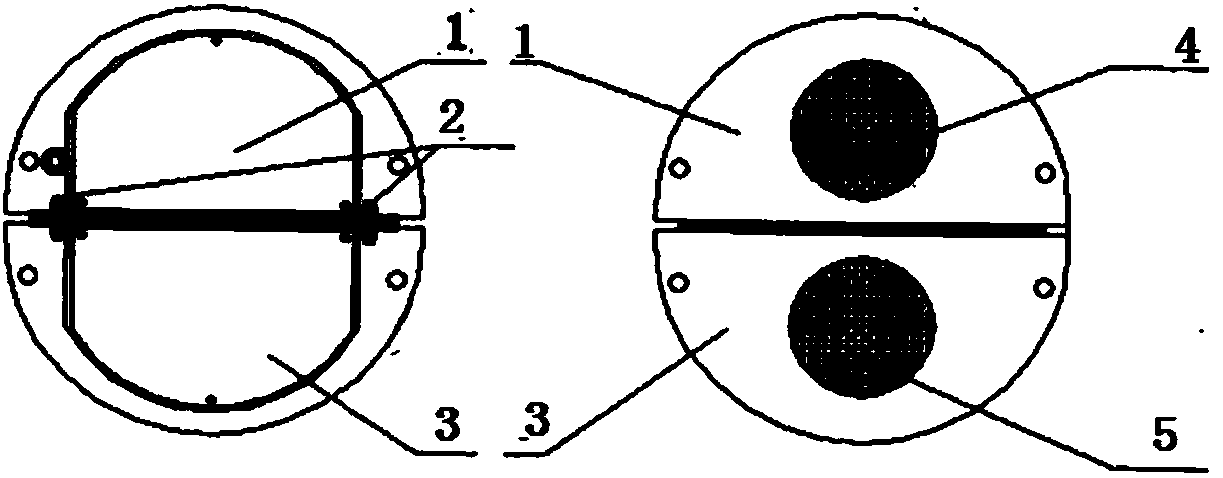

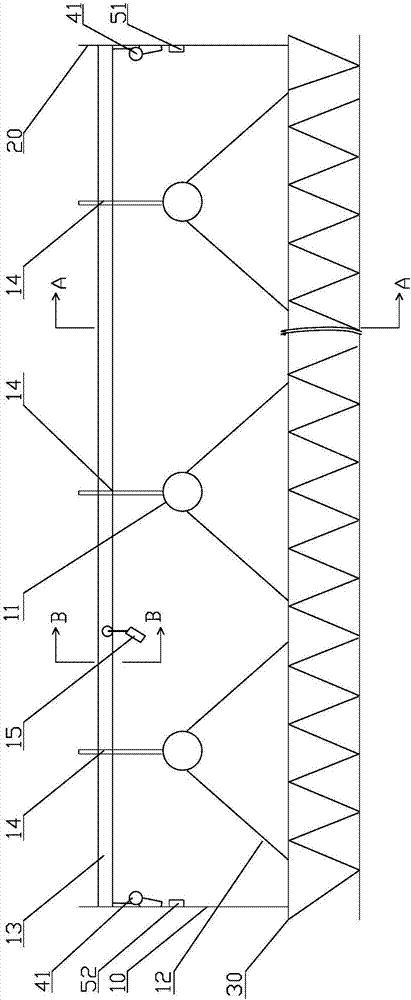

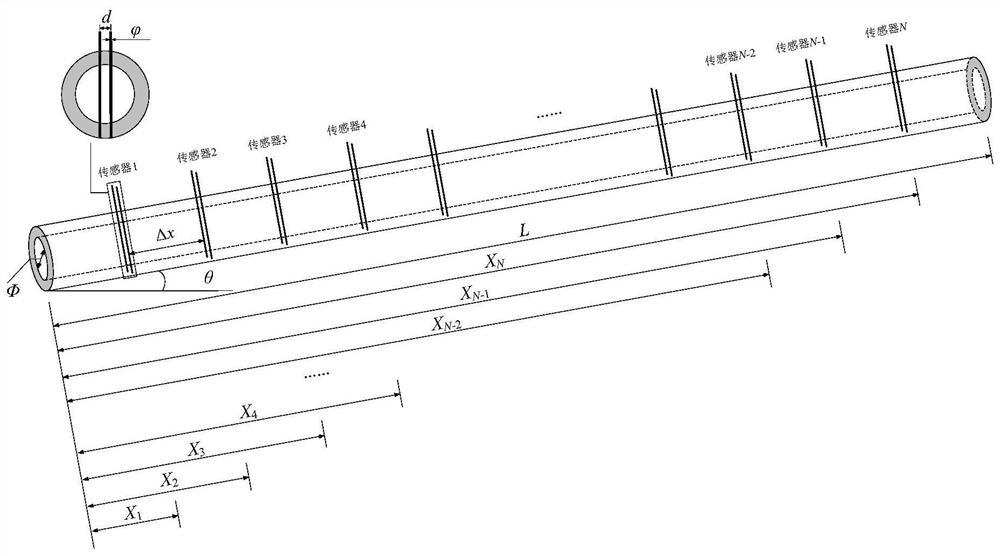

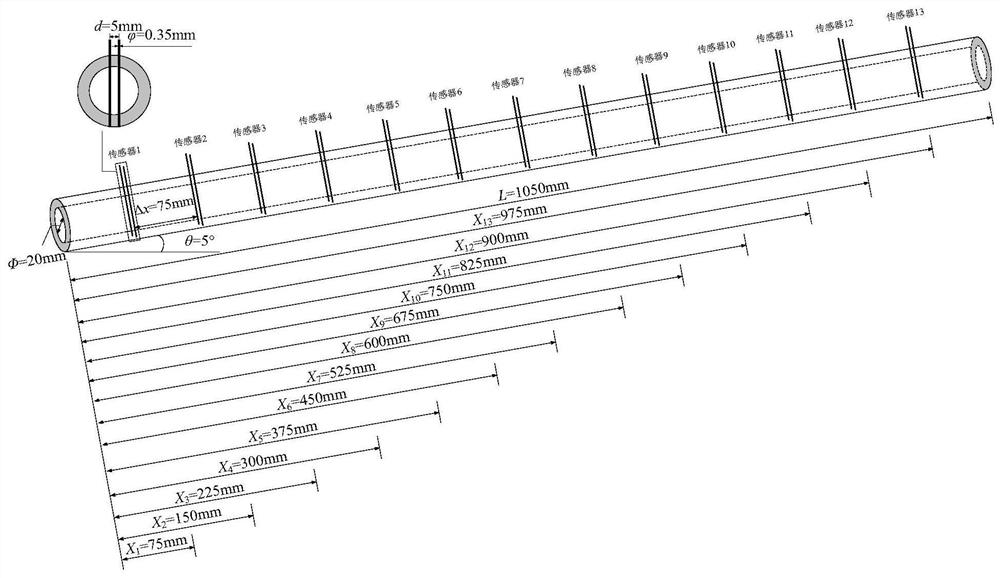

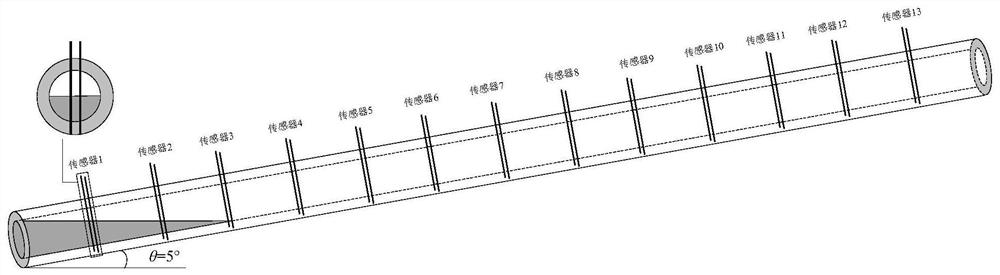

Gas-liquid two-phase flow distribution parameter measurement method for double fiber array sensor

InactiveCN109596526AAchieve concentrationRealize local flow velocity distribution measurementMaterial analysis by optical meansFluid speed measurementGas phaseFiber array

The invention relates to a double fiber array sensor for measuring gas phase distribution parameters of gas-liquid two-phase flow, comprising eight identical dual-fiber probe sensors distributed at three annular locations within the measurement channel. The first ring comprises a 1-way dual-fiber probe sensor and is located in the center of the pipe. The second ring comprises a 3-way dual-fiber probe sensor with an equilateral triangle evenly distributed over a small circumference. The third ring comprises a 4-way dual fiber probe sensor uniformly distributed in a square shape. The radius of the small circle where the second ring sensor is located is equal to half of the radius of the circle in the third ring sensor and one-third of the radius of the measuring pipe. Each of the dual-fiberprobe sensors comprises a metal sleeve and a long and a short and a long identical fiber probes extending from the metal sleeve. The long probe is an upstream fiber probe and the short probe is a downstream fiber probe. The gas-liquid two-phase flow gas distribution parameter measurement method for double fiber array sensor simultaneously provides a gas-liquid two-phase flow distribution parametermeasurement method realized by the array sensor.

Owner:TIANJIN UNIV

Floating tray liquid level calculation and measurement method for floating roof storage tank, system and application

InactiveCN110274663AReduce measurement blind spotsHigh precisionMachines/enginesLevel indicatorsGratingEngineering

The invention discloses a floating tray liquid level calculation and measurement method for a floating roof storage tank, a system and an application. The method includes the following steps: in a normal working range of an optical fiber liquid level sensor, an upper optical fiber grating located at the corresponding upper part of a cantilever beam is always subjected to tensile stress in the normal working range, a lower optical fiber grating located at the corresponding lower part of the cantilever beam is always subjected to compressive stress, and the stress of the upper optical fiber grating the stress of the lower optical fiber grating are the largest when the optical fiber liquid level sensor is not loaded; when a liquid level rises and is in contact with a floating drum, the buoyancy of the floating drum changes, the stress of a cantilever beam accordingly changes, the deflection strain of the upper optical fiber grating and the lower optical fiber grating accordingly changes, and a floating tray surface liquid level is obtained according to the changes of the upper optical fiber grating and the lower optical fiber grating; and if the floating tray surface liquid level exceeds a preset value, the optical fiber liquid level sensor is combined with external equipment to perform an alarm. The floating tray liquid level calculation and measurement method for a floating roof storage tank, the system and the application monitor water accumulation on the surface of the floating tray and improve the precision of the monitoring of the water accumulation on the surface of the floating tray.

Owner:CHINA PETROLEUM & CHEM CORP +1

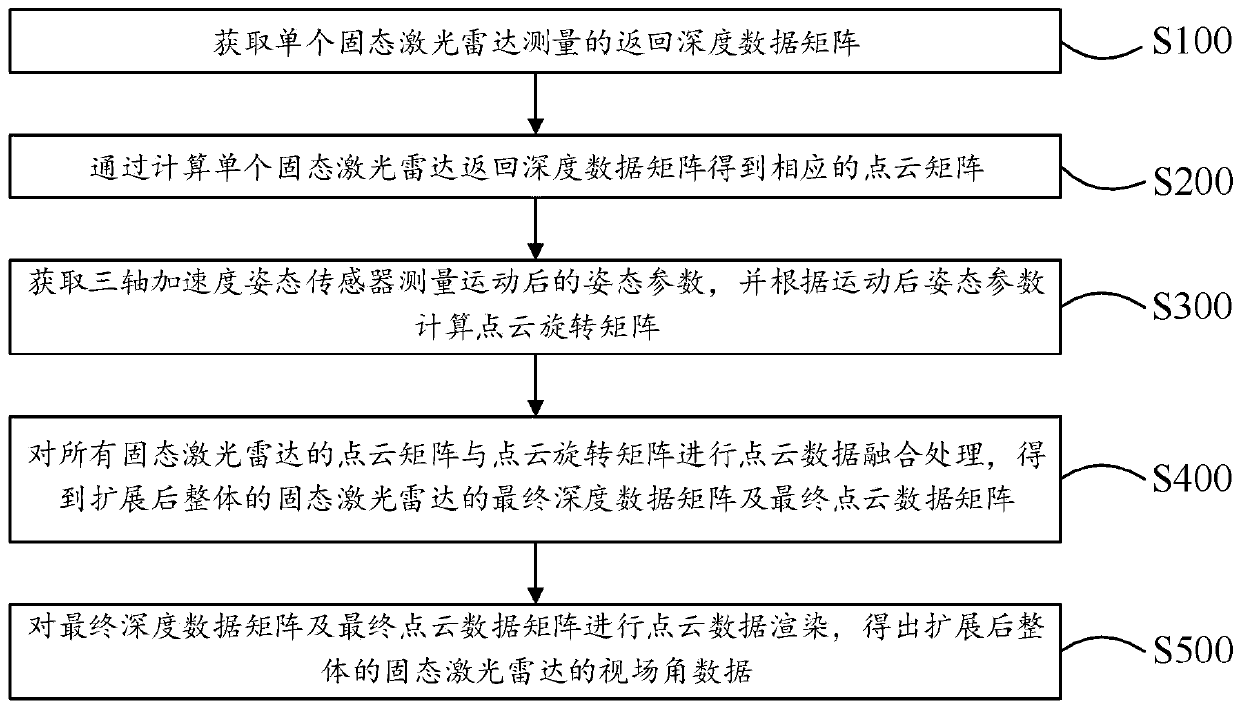

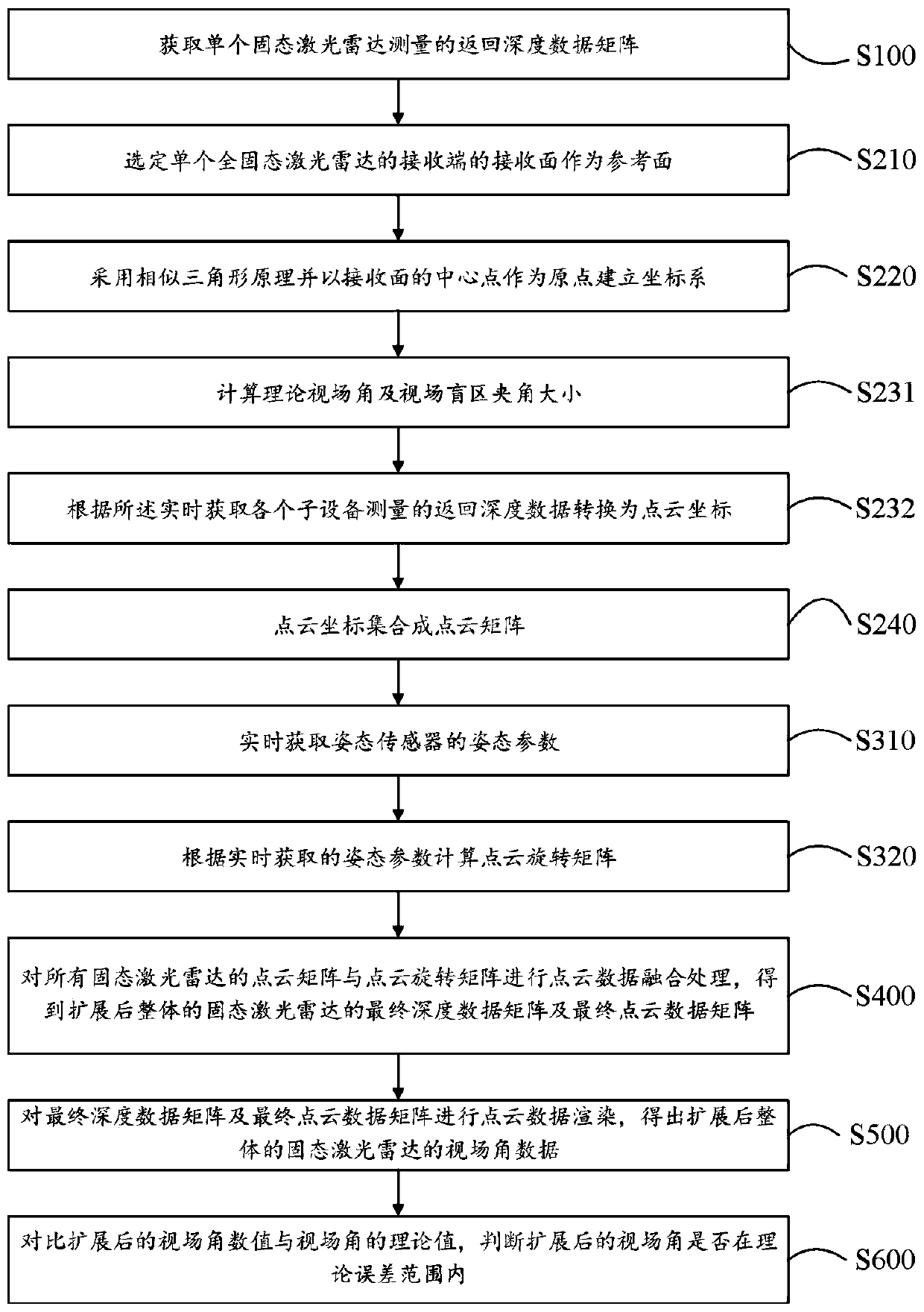

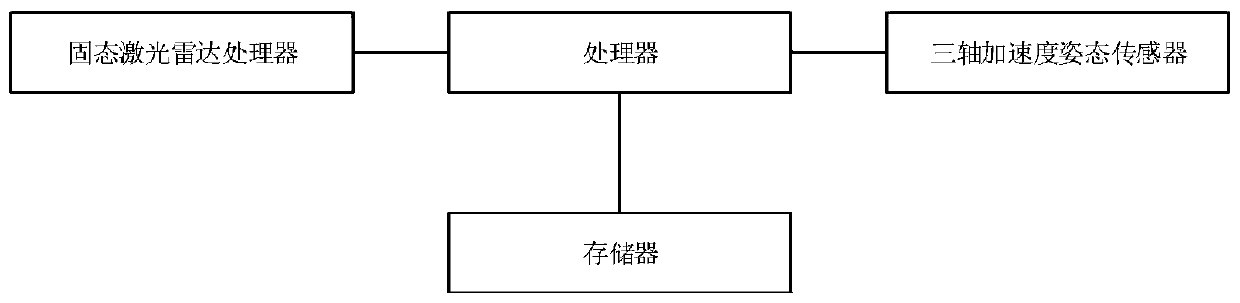

Dynamic expansion method and system for angle of view of all-solid-state laser radars, and storage medium

ActiveCN110398747AReduce measurement blind spotsNavigation by speed/acceleration measurementsElectromagnetic wave reradiationAll solid stateBlind zone

The invention discloses a dynamic expansion method and system for angle of view of all-solid-state laser radars, and a storage medium, and the method comprises the following steps of obtaining a return depth data matrix measured by a single solid-state laser radar; obtaining a corresponding point cloud matrix by calculating the return depth data matrix of the single solid-state laser radar; obtaining an attitude parameter of a three-axis acceleration attitude sensor after measurement motion, and calculating a point cloud rotation matrix according to the post-motion attitude parameter; performing point cloud data fusion on the point cloud matrixes and the point cloud rotation matrixes of all the solid-state laser radars to obtain a final depth data matrix and a final point cloud data matrixof the extended integrated solid-state laser radar; and performing point cloud data rendering on the final depth data matrix and the final point cloud data matrix to obtain the field-of-sight data ofthe extended integrated solid-state laser radar. The all-solid-state laser radar field-of-view angular dynamic expansion method provided by the invention realizes the expansion of the angle of view of the all-solid-state laser radar and reduces measurement blind zones caused by the angle of view.

Owner:HEBERSON TECH (SHENZHEN) CO LTD

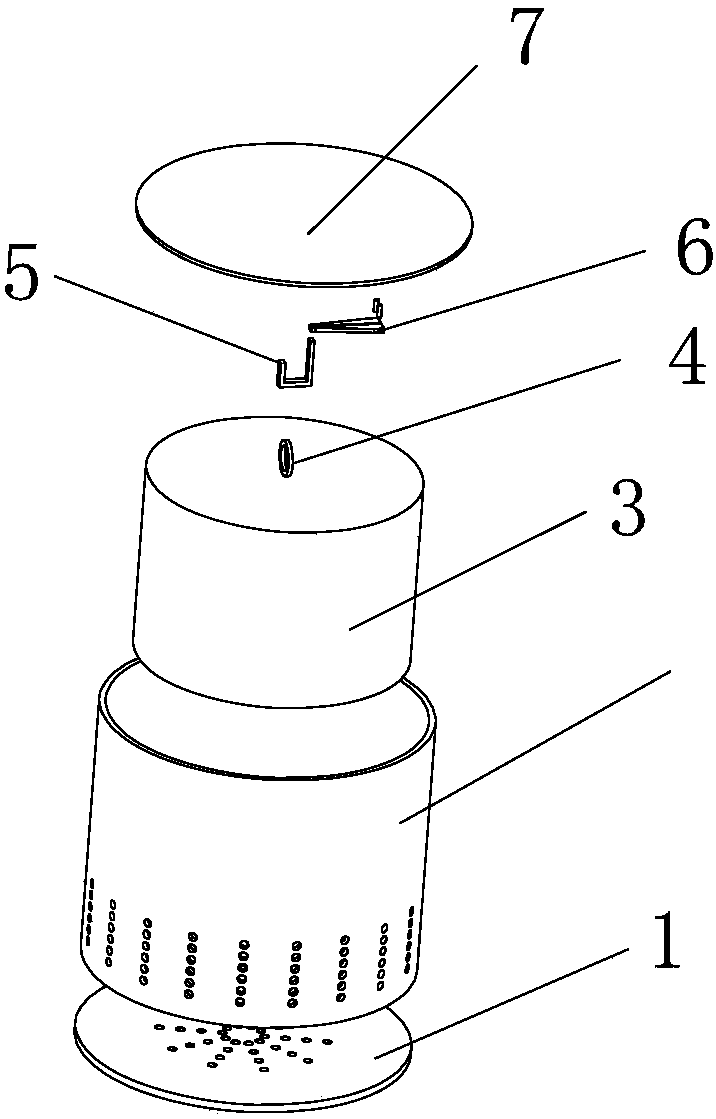

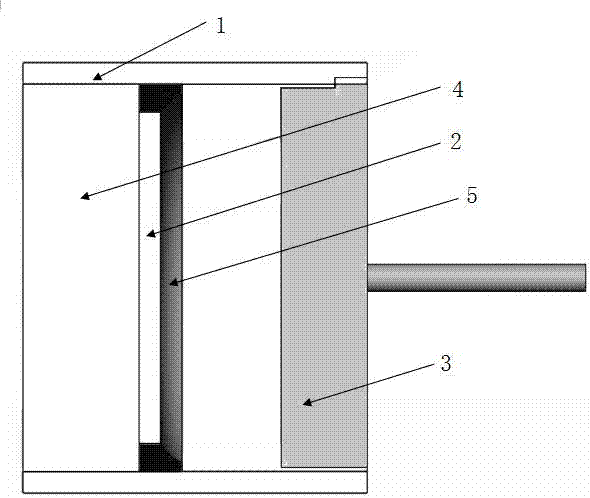

Ultrasonic sensor

InactiveCN107449455ASignificantly reduced aftershockReduce measurement blind spotsConverting sensor ouput using wave/particle radiationShape matchingEngineering

The invention discloses an ultrasonic sensor including a housing and a piezoelectric crystal plate disposed in the housing. A pedestal is mounted on one end of the housing. One side of the piezoelectric crystal plate facing towards the pedestal is provided with flexible adhesive fixedly while the other side is provided with a matching layer fixedly. The paste-shaped matching layer subjected to stirring is fixed on the piezoelectric crystal plate through adhesive dispensing or adhesive brush coating and the matching layer is in clearance-free bonding with the surface of the piezoelectric crystal plate. Then through heating, the material of the matching layer is cured fully, so that the matching layer and the piezoelectric crystal plate are integrated together. According to the invention, residual oscillation is reduced substantially and measurement dead zone is reduced. Through the method of bonding the material of the matching layer and the crystal plate integrally, the echo flexibility is improved. The ultrasonic sensor is simple in structure, low in cost increase and substantially improved in performance.

Owner:SUZHOU YIDELONG ELECTRONICS COMPONENTS CO LTD

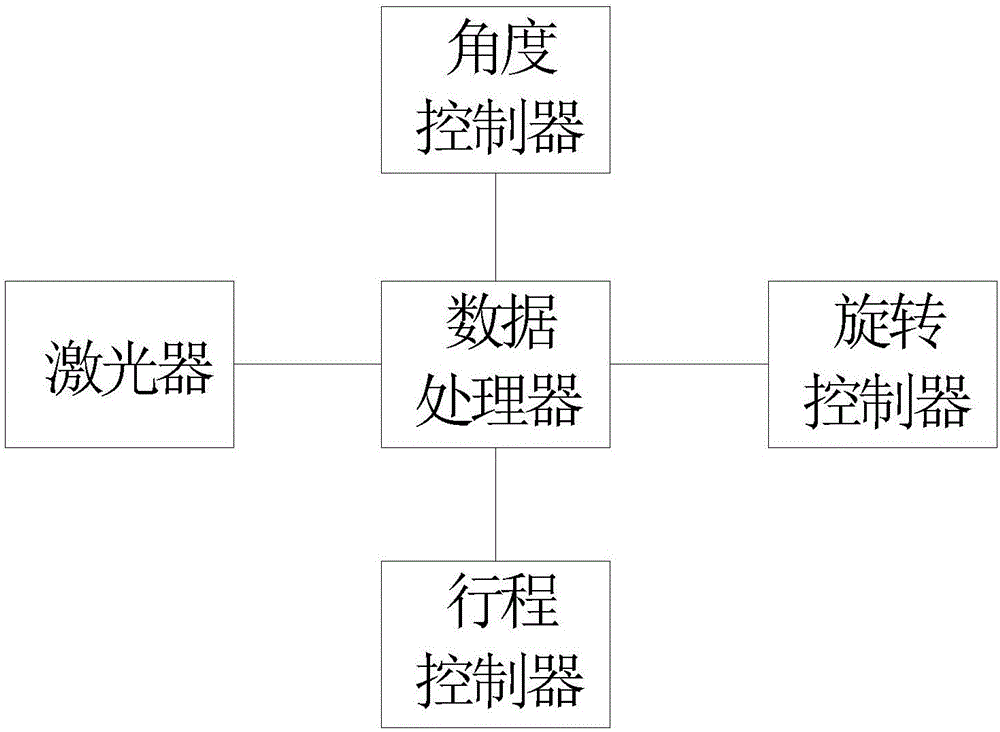

Laser coal measurer

InactiveCN106524911ARealize full range coal yard measurementHigh degree of automationUsing optical meansVertical planeEngineering

The invention discloses a laser coal measurer comprising a laser mounted on the frame of a stacker-reclaimer, a data processor in signal connection with the laser, and a stroke controller in signal connection with the signal processor. An angle controller is fixedly connected with the laser and is used for controlling an intersection angle between the scanning plane and the vertical plane of the laser, and is in signal connection with the data processor. The data processor is used for calculating measurement data, automatically and rationally compensating a shaded part at the front end of a coal yard, generating a three-dimensional solid figure of the coal yard pile shape, and querying the volume and weight of a coal pile in segments.

Owner:JIANGSU ZHONGHAN COMM TECH

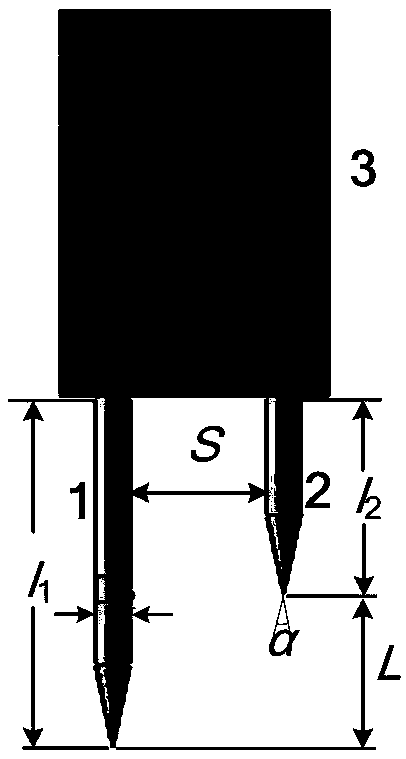

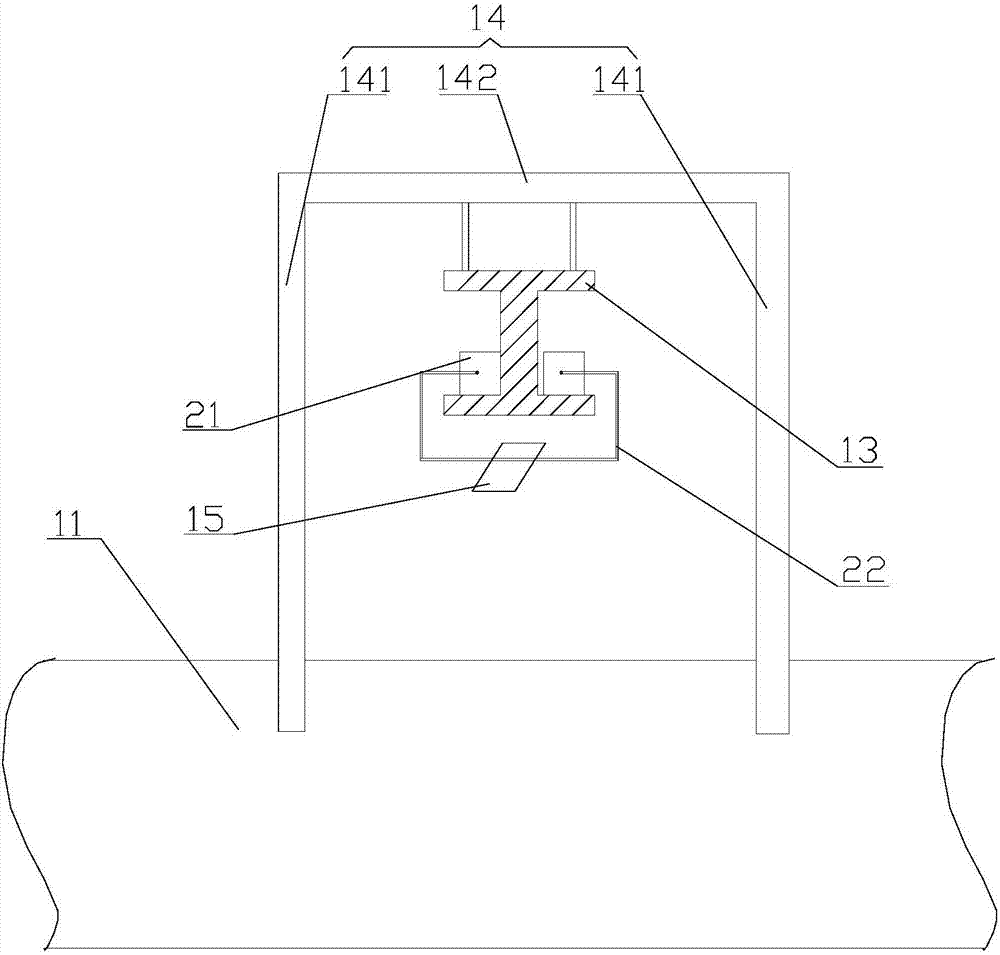

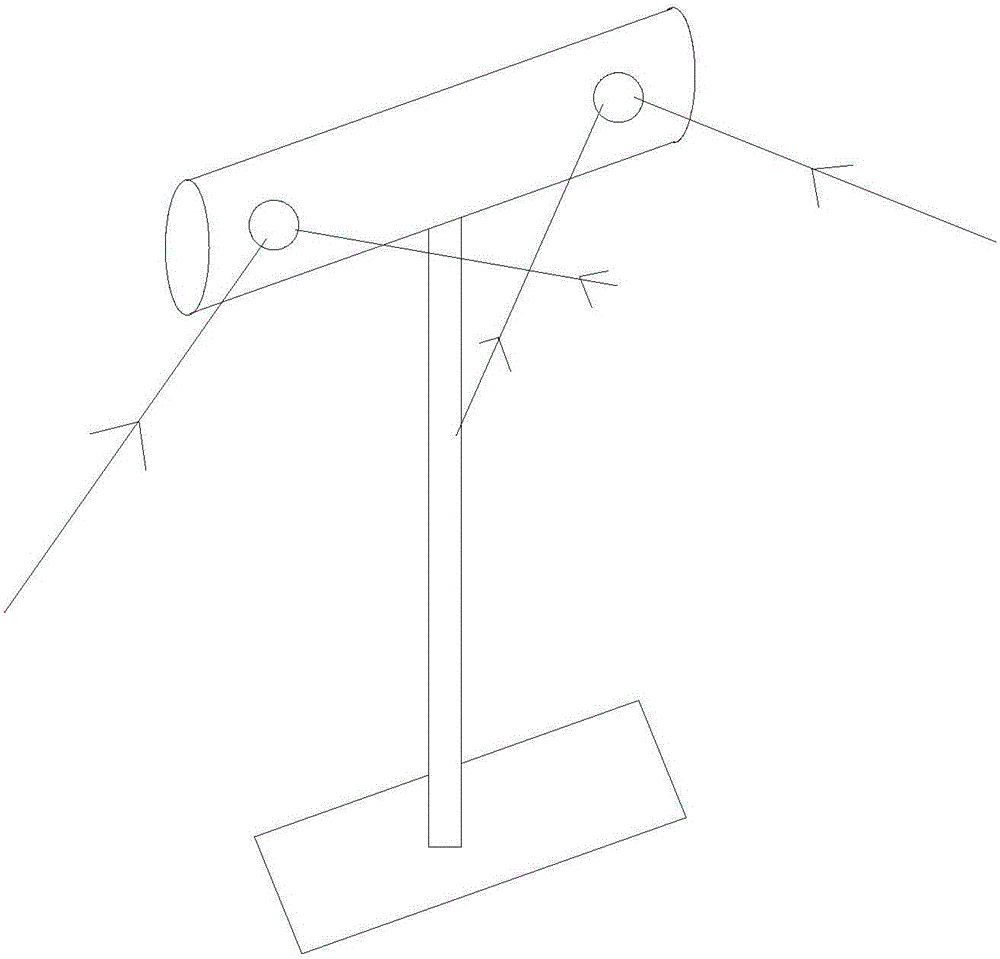

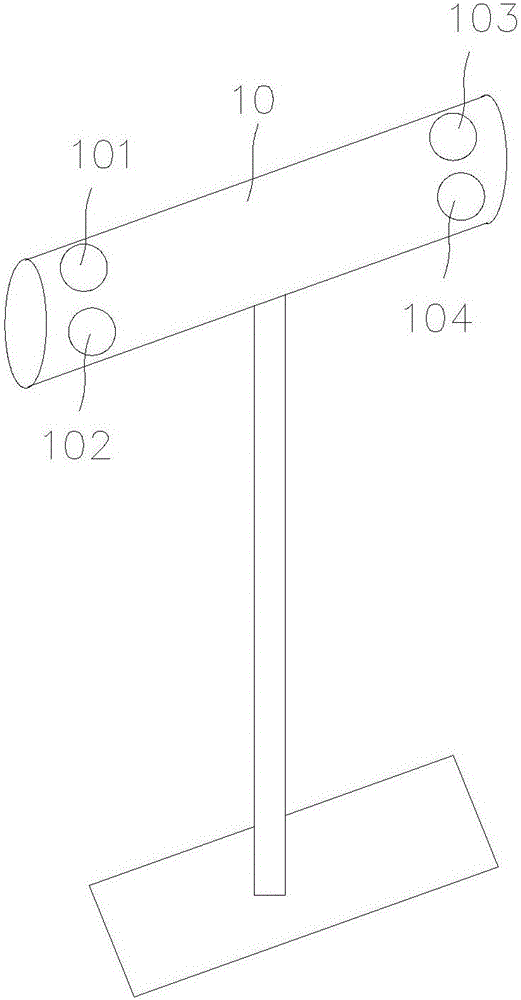

Flow rate measuring device based on ultrasonic reflecting signal and measuring device

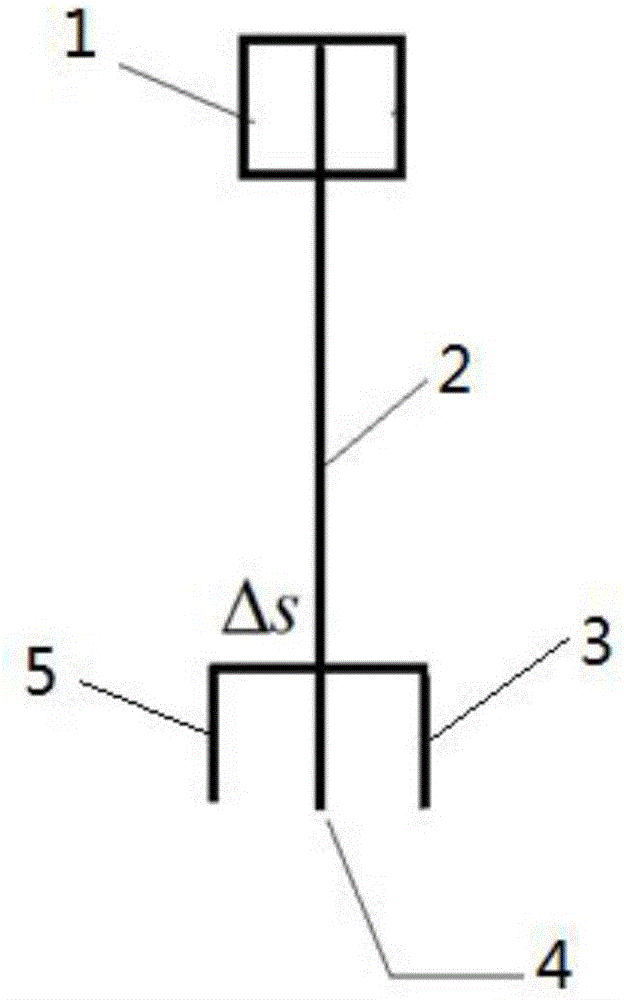

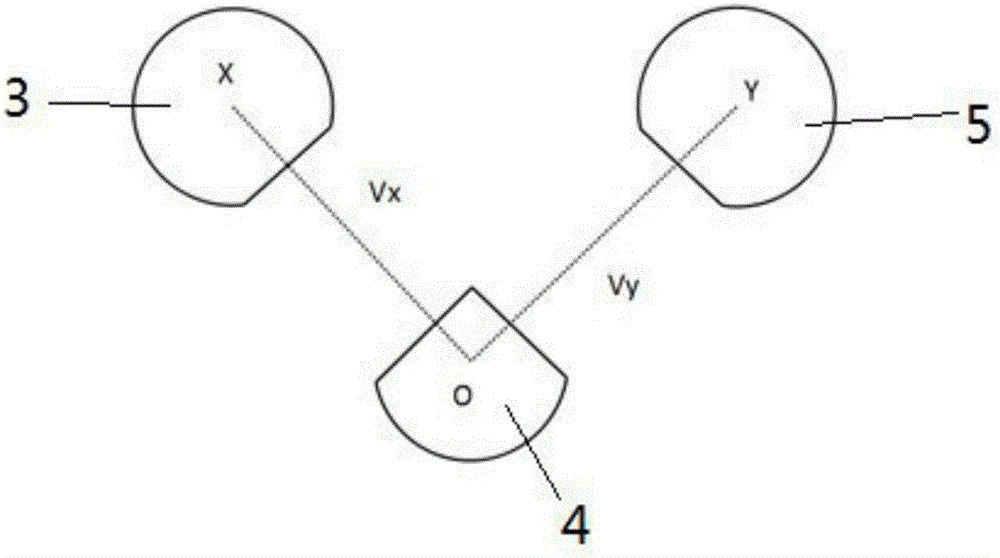

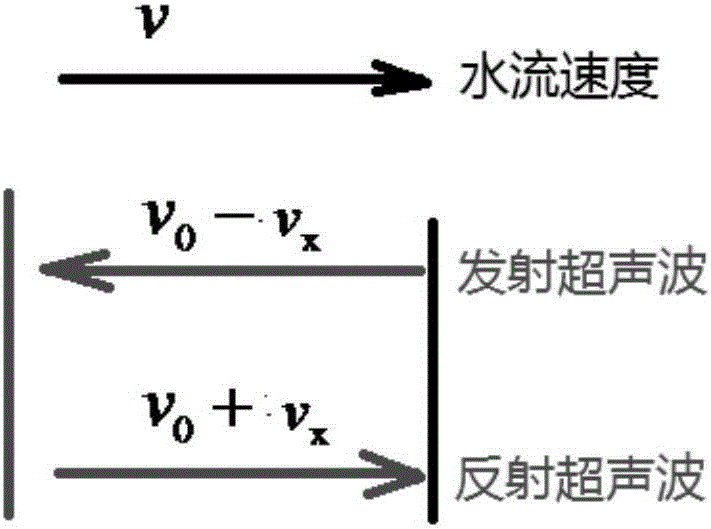

PendingCN106841674AIngenious designWith planar two-dimensional velocityFluid speed measurementSignal processing circuitsUltrasonic doppler

The invention discloses a flow rate measuring device based on an ultrasonic reflecting signal. The flow rate measuring device comprises a measuring rod, wherein a first probe with ultrasonic transmitting and receiving functions is arranged at the bottom end of the measuring rod; a first reflecting probe and a second reflecting probe are arranged around the first probe, and are connected with the measuring rod through connecting rods; the first probe, the first reflecting probe and the second reflecting probe are respectively connected with a signal processing unit. The flow rate measuring device based on the ultrasonic reflecting signal has the advantages that the plane two-dimensional flow rate is realized, the measuring blind area is small, and the like; a signal detection circuit only needs to detect the pulse reflecting time, a signal processing circuit is simple, and the instrument cost is greatly reduced in comparison with that of the ultrasonic Doppler measuring instrument.

Owner:HOHAI UNIV

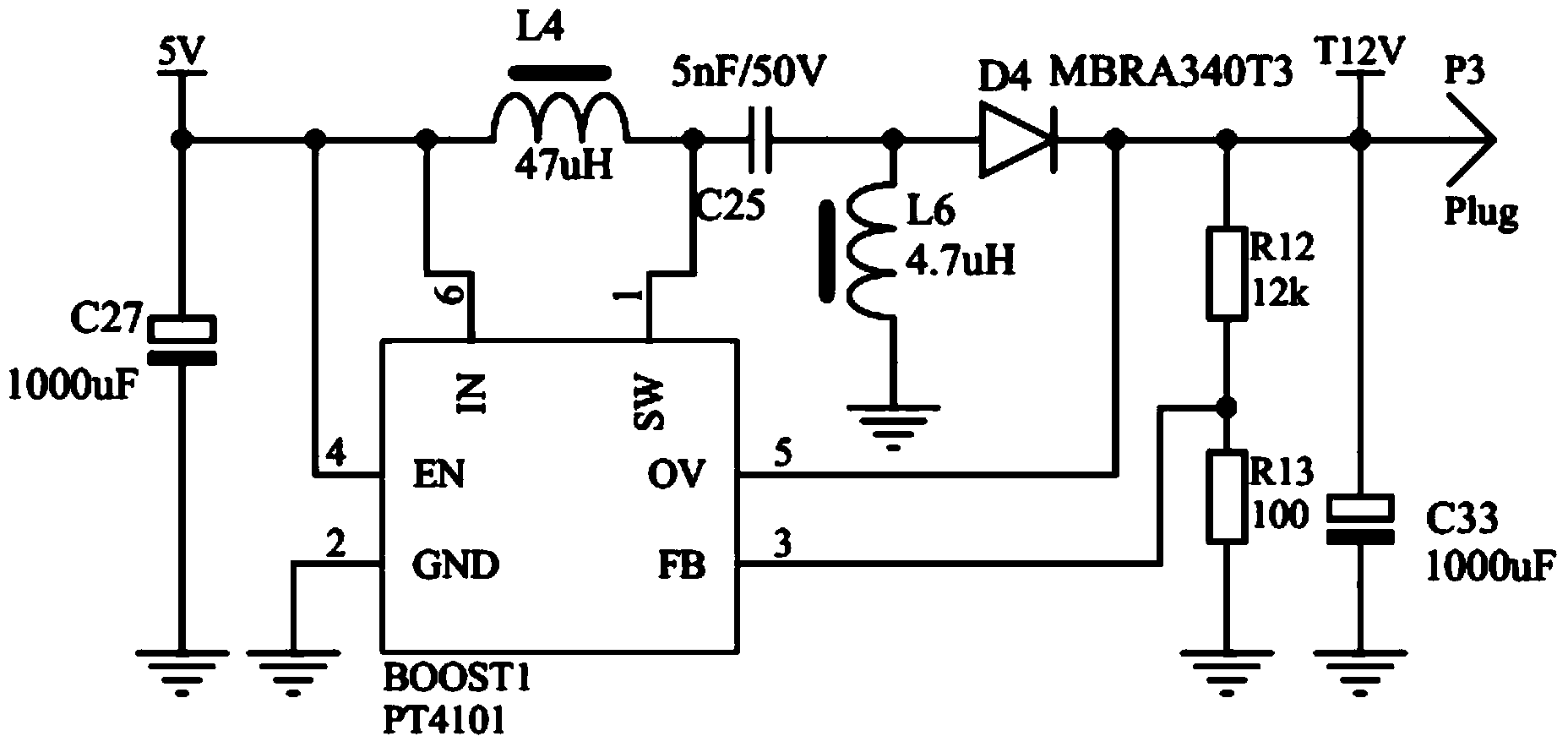

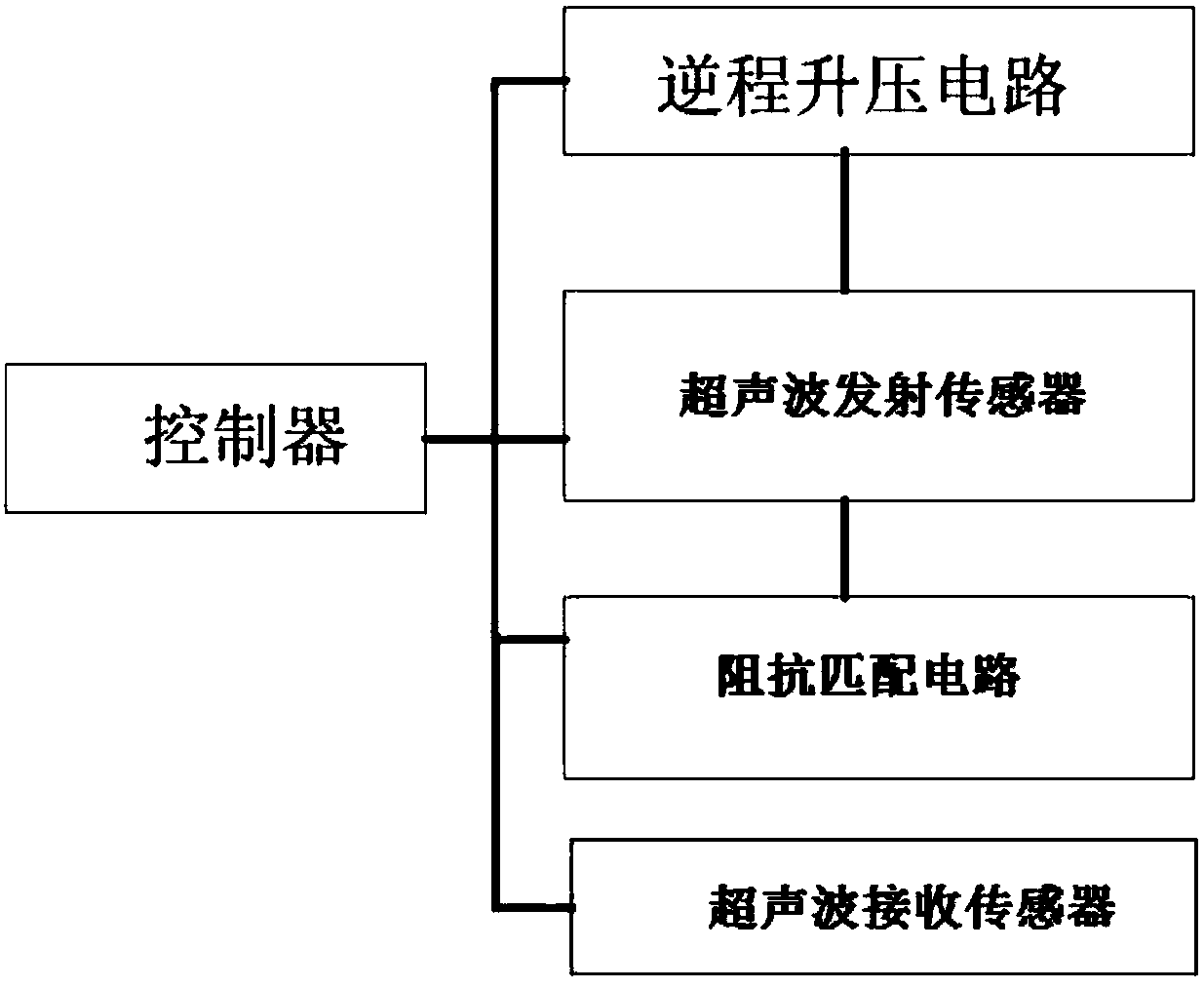

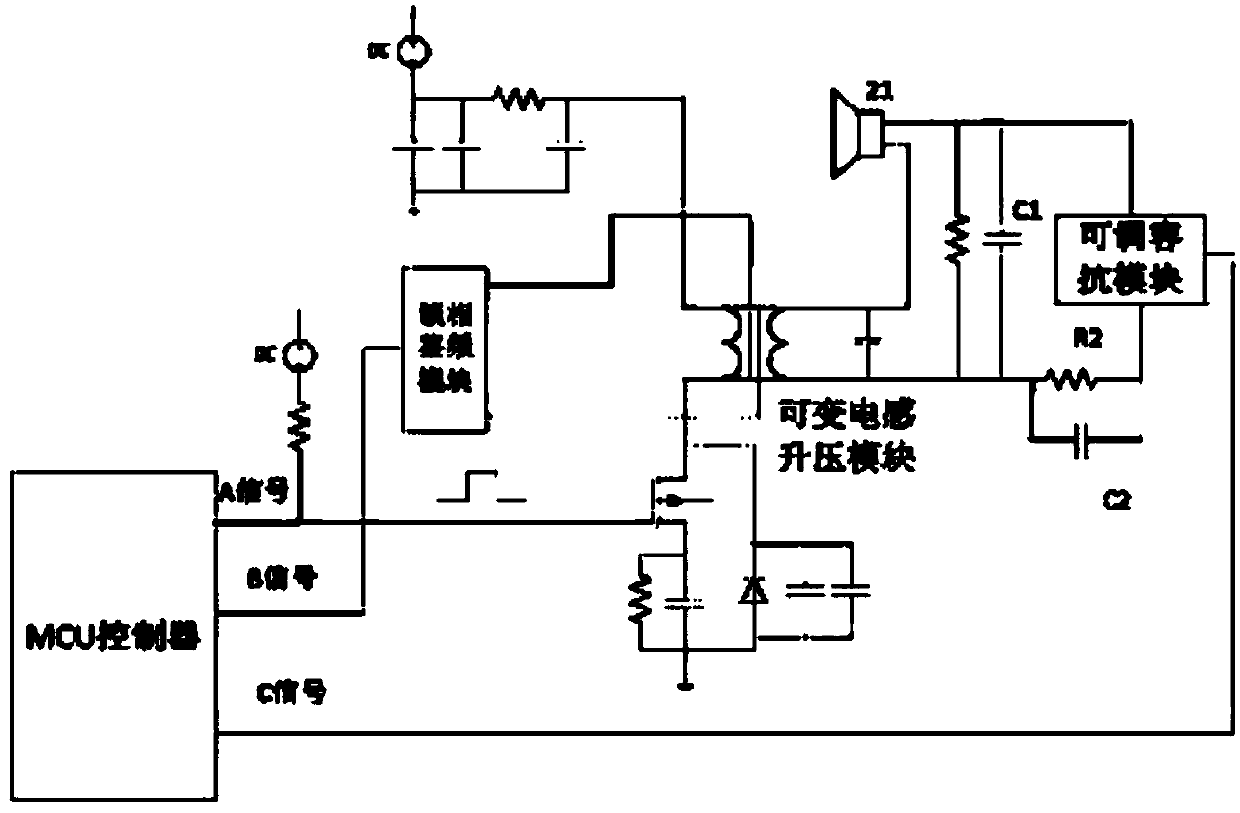

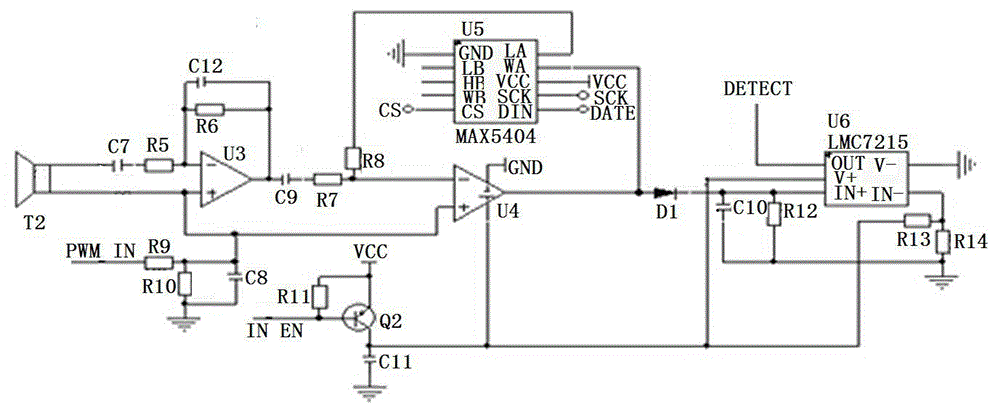

Control system for ultrasonic transducer dead zone

InactiveCN107843306AReduce the driving voltageWeak driving voltageVolume/mass flow measurementUsing subsonic/sonic/ultrasonic vibration meansControl systemControl signal

The invention discloses a control system for the blind area of an ultrasonic transducer, which includes a double-sensor ultrasonic transducer, a controller and a reverse boost circuit; the double-sensor ultrasonic ring energy device includes an ultrasonic transmitting sensor, an ultrasonic receiving sensor, and an ultrasonic transmitting sensor Placed in the shell of the transmitting sensor, the ultrasonic receiving sensor is placed in the shell of the receiving sensor, and the shell of the transmitting sensor and the shell of the receiving sensor are connected together with a connecting piece; The boost circuit adjusts the driving voltage output to the ultrasonic transmitting sensor according to the reverse boost amplitude control signal; the reverse boost amplitude control signal is used to control the driving voltage of the ultrasonic transmitting sensor to change in the same direction as the distance to be measured. The invention has the advantages of small measurement blind area, wide measurement range and high detection precision.

Owner:GUANGHAN SIKE XINDA TECH CO LTD

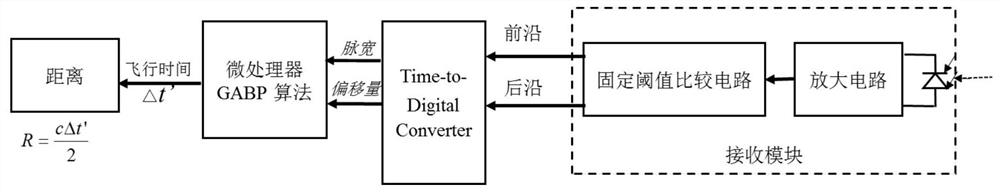

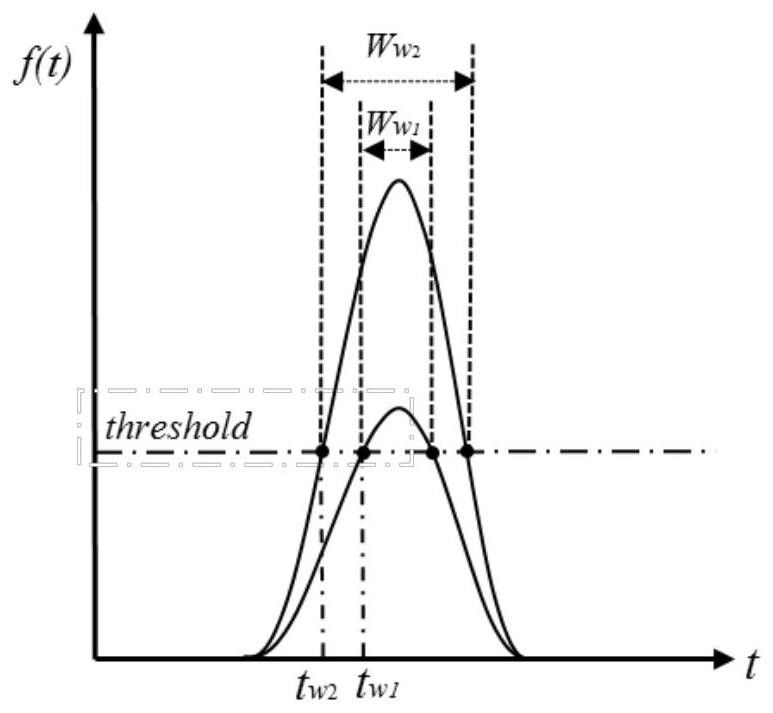

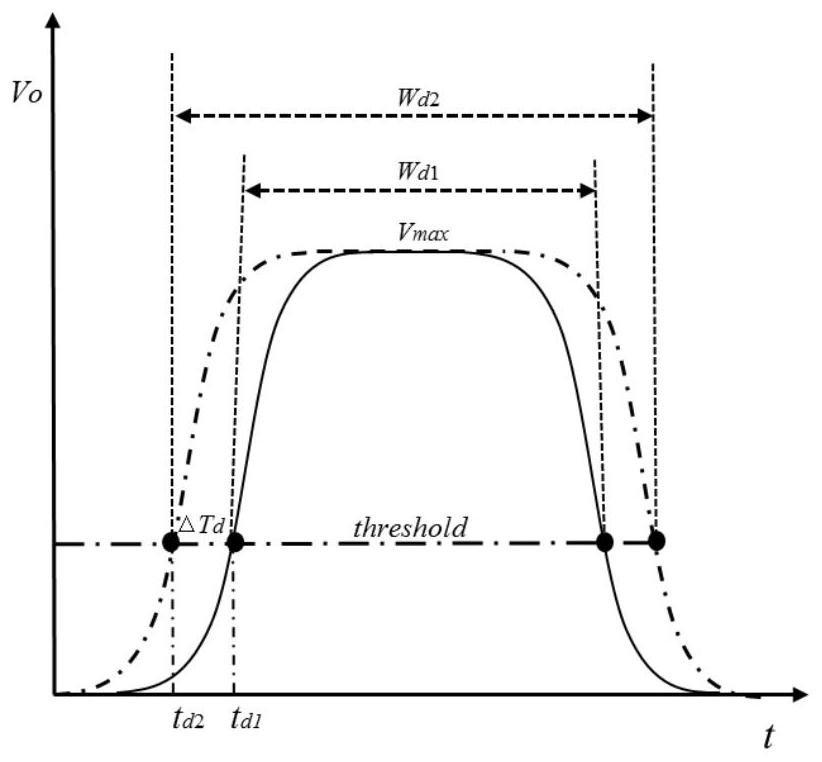

Pulse laser ranging error compensation method based on GABP

ActiveCN111983625AAvoid enteringSimple structureNeural architecturesElectromagnetic wave reradiationHemt circuitsEngineering

The invention requests to protect a pulse laser ranging error compensation method based on GABP, and the method comprises the following steps: 1, designing a hardware circuit which is used for detecting an optical signal, converting the optical signal into an analog electric signal, and converting the analog signal into a digital signal through employing a fixed threshold value; inputting the digital signal into a time measurement unit, and measuring the pulse width of the echo signal and an original flight time parameter value; 2, setting different target objects, and obtaining the parametervalues of the pulse width and flight time error of the echo signal in the data obtaining mode in the step 1; the data analysis software obtains correction curve network parameters by using a GABP regression analysis method; 3, writing the optimized neural network parameters obtained in the step 2 into a microprocessor; and carrying out an actual ranging test in a range of 60-600cm, and verifying the ranging precision of the range finder based on the GABP compensation algorithm.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Cable fault simulating and positioning system

ActiveCN103985300AMeet training requirementsEasy to debugEducational modelsFault location by pulse reflection methodsControl theoryElectric cables

The invention relates to a cable fault simulating and positioning system. The cable fault simulating and positioning system comprises a cable fault simulation box, an electrode installing plate, three wire inlet electrodes and three wire outlet electrodes, wherein the electrode installing plate is installed in the cable fault simulation box. The three wire inlet electrodes are connected with three-phase cable cores in a wire inlet cable respectively, and the three wire outlet electrodes are connected with three-phase cable cores in a first wire outlet cable respectively. The cable fault simulation box is internally provided with a resistance box for simulating the break line, low resistance, high resistance and flashover fault between the wire inlet electrodes and the wire outlet electrodes, and the tail end of a second wire outlet cable connected with the wire outlet electrodes is provided with a high-voltage cable terminal. The high-voltage cable terminal is used for connecting a cable fault positioning detecting instrument. The cable fault positioning detecting instrument comprises a central control unit, an impulse transmission circuit, a reflecting receiving circuit and a high speed data collecting circuit, wherein the impulse transmission circuit is used for sending a pulse signal to a tested cable, the reflecting receiving circuit is used for receiving a reflecting signal of the tested signal, and the output end of the reflecting receiving circuit is connected with the input end of the high speed data collecting circuit.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +2

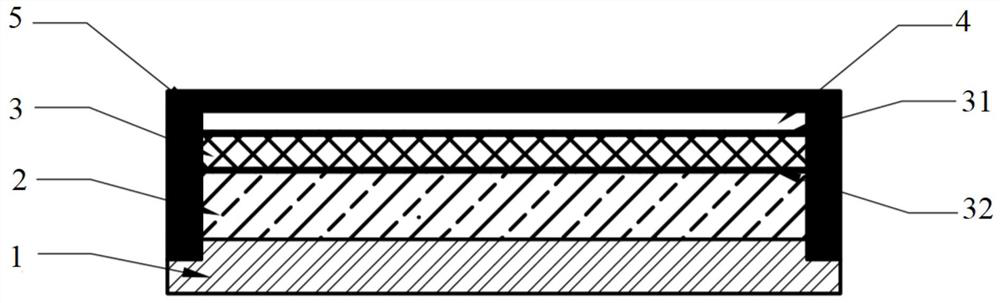

An eight-beam broadband phased array transducer and its preparation method

ActiveCN112495744BIncrease signal strengthHigh precisionMechanical vibrations separationPhased arrayMeasurement precision

The invention discloses an eight-beam broadband phased array transducer and a preparation method thereof, comprising: a metal base, a backing foam, a composite material piezoelectric sheet and a matching layer arranged in sequence; the composite material piezoelectric sheet comprises a plurality of Piezoelectric elements and decoupling materials filled between the elements, wherein the piezoelectric elements are arranged in a sparse phased array, and the positive and negative electrodes of the piezoelectric elements are respectively provided with electrode sheets for applying different phases of electricity. signal to form four beams in two mutually perpendicular directions; the matching layer includes a plurality of matching elements and a decoupling material filled between the elements, wherein the matching element gap is aligned with the piezoelectric element gap and the spacing is consistent . The present invention can realize eight-beam DVL with four beams in two vertical directions, and realize broadband, which is not only more conducive to the calculation of Doppler frequency shift, but also improves the signal strength of the received echo signal, Improve measurement accuracy and reduce measurement blind spots.

Owner:SHANGHAI ACOUSTICS LAB CHINESE ACADEMY OF SCI

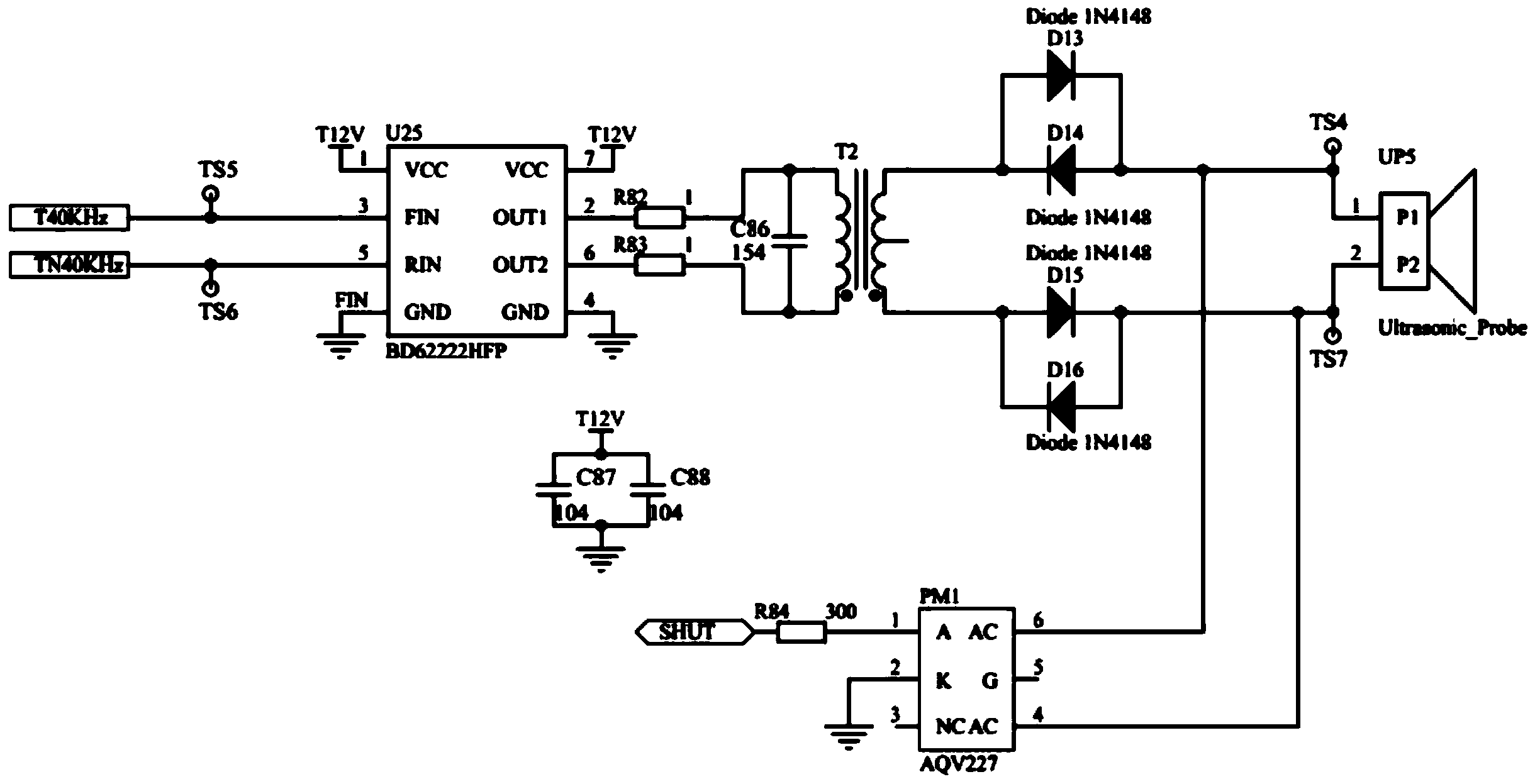

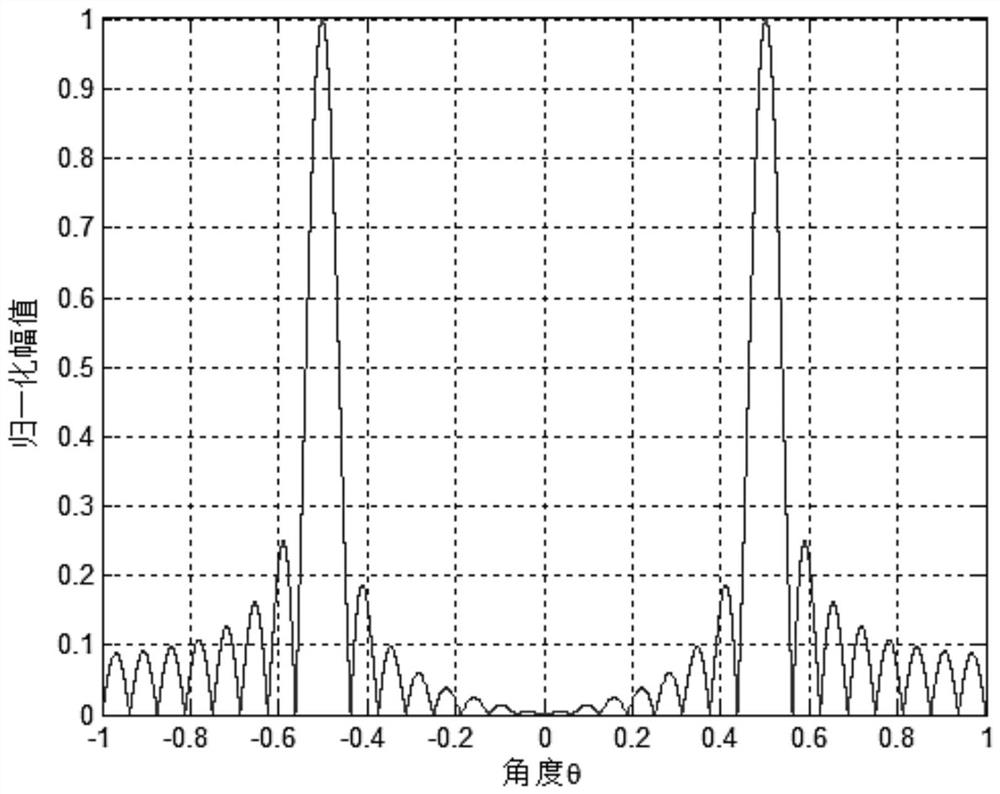

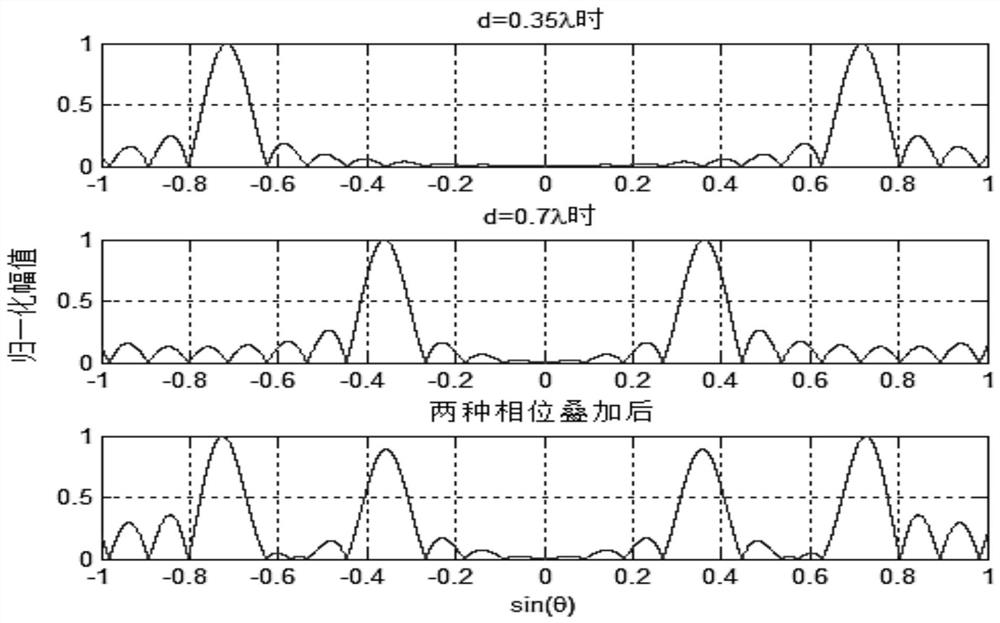

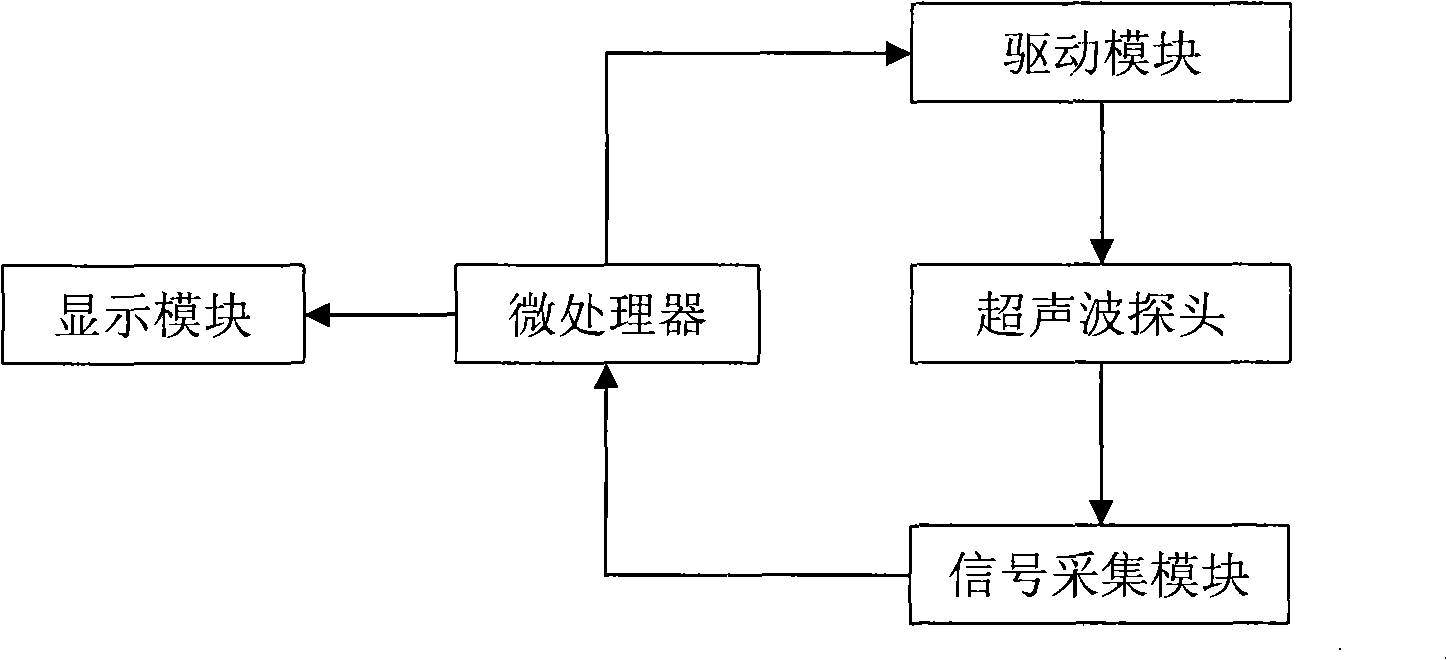

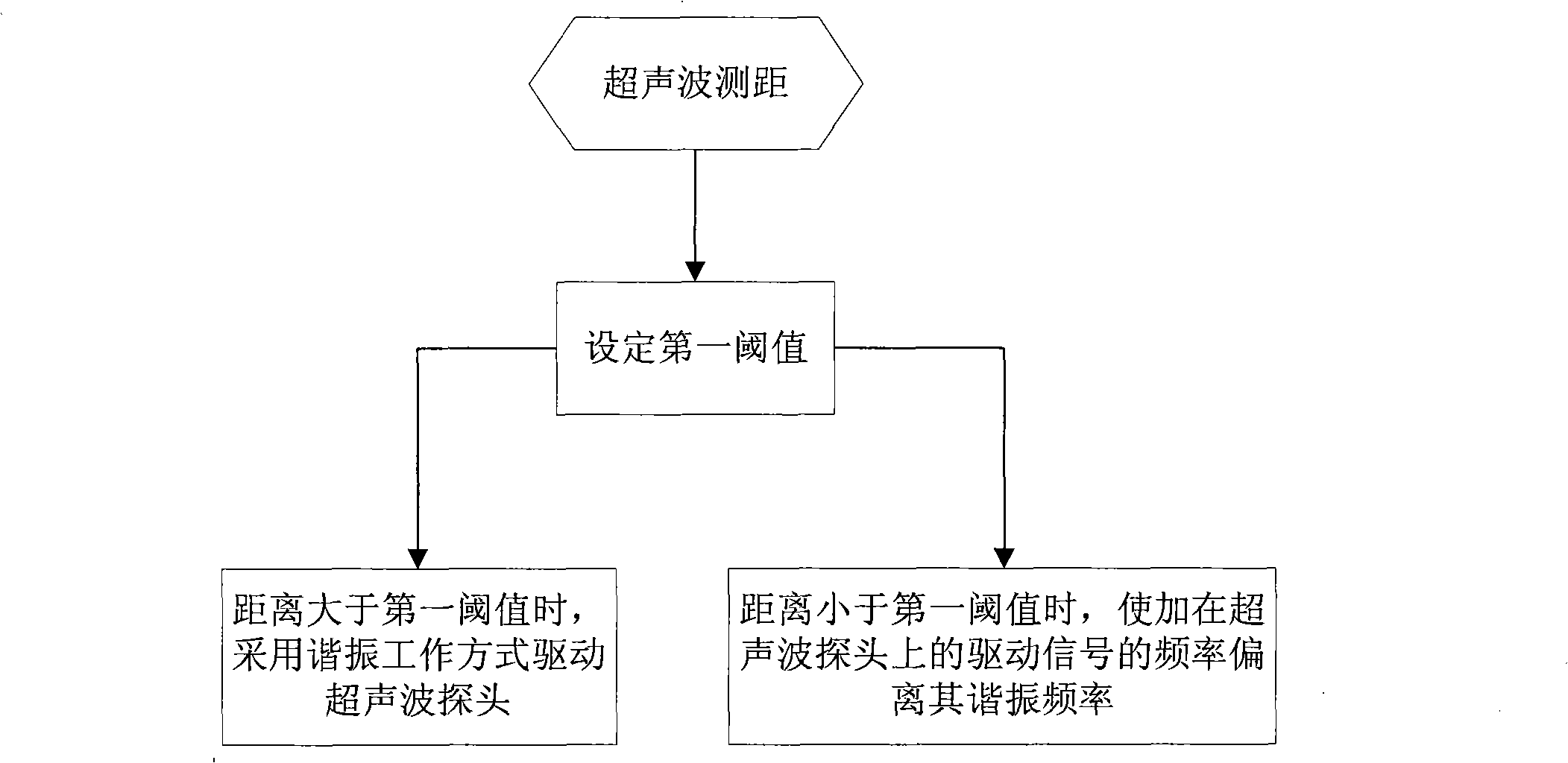

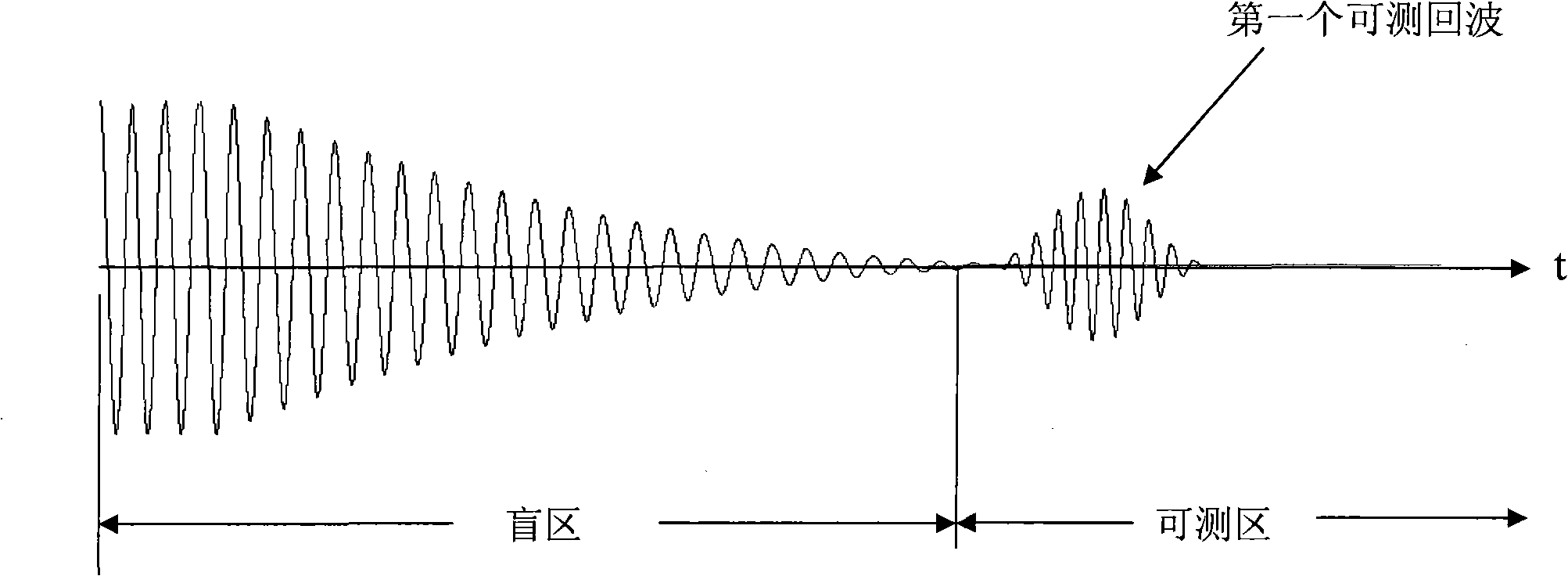

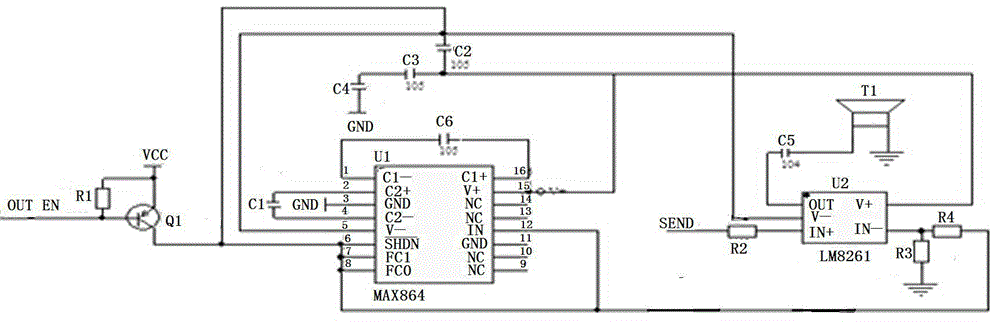

Ultrasonic ranging method and system thereof

The invention belongs to the technical field of electronic measurement and discloses a method for ultrasonic ranging and a system thereof. The ultrasonic ranging method comprises the following steps: a first threshold value is set; when the distance of the measured object is larger than the threshold value, a resonance operation mode is adopted to drive an ultrasonic probe; when the distance of the measured object is smaller than the threshold value, the driving signal frequency which is applied on the ultrasonic probe deviate from the resonance frequency of the signal. The invention also discloses an ultrasonic ranging system which adopts the method, comprising an ultrasonic probe, a microprocessor, a driver module, a signal acquisition module and a signal display module. Compared with the prior art, the invention can greatly reduce a measurement blind area from the known 40cm to below 10cm.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Small dead zone ultrasonic wave sensor

InactiveCN104569995ALong measuring distanceReduce measurement blind spotsAcoustic wave reradiationObservational errorElectron

The invention relates to the field of electronic sensors, in particular to a small dead zone ultrasonic wave sensor. The small dead zone ultrasonic wave sensor comprises a main control chip, a temperature measuring element, an emission circuit and a receiving circuit, wherein the temperature measuring element, the emission circuit and the receiving circuit are each connected with the main control chip; the small dead zone ultrasonic wave sensor is simple in structure; the range of a dead zone of a system is 5 cm; when the dead zone of the system ranges from 10 cm to 60 cm, an error is smaller and the measuring error is 0; when the dead zone of the system ranges from 60 cm to 500 cm, the error is larger and the error is 1-3 cm; due to the influence of the mass of the ultrasonic wave sensor, the system can only measure distance within 5 cm; meanwhile with the increasing of measuring distance, the error is increased gradually, the error can be basically controlled less than 2%, and the precision is higher.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

System and method for processing echo signal of guided wave type radar level meter

ActiveCN102661773BOvercome the problem of true echo maximum peak point offsetHigh measurement accuracyMachines/enginesLevel indicatorsDielectricMicrocontroller

The invention relates to the field of level measurement and provides a system for processing an echo signal of a guided wave type radar level meter taking a single chip as the core. The system is composed of the single chip for controlling the sending and receiving of a pulse signal, a pulse emission circuit, a guided wave rod, an echo signal receiving circuit, an equivalent time sampling circuit, a signal adjusting circuit, a MSP430F5418 single chip system, a liquid crystal display and software. Specific to the material with big relative dielectric constant and the material with small relative dielectric constant, different methods for processing the echo signal are respectively adopted for restraining false echo interference, confirming and correcting a peak value of a real echo, and then fitting or interpolating nominal data, thereby realizing the level measurement.

Owner:HEFEI UNIV OF TECH

A channel water depth measurement method based on chaotic laser device and its correlation method

ActiveCN104749579BReduce measurement blind spotsImproved shallowest sounding capabilityElectromagnetic wave reradiationElectricityPhotovoltaic detectors

Owner:TAIYUAN UNIV OF TECH

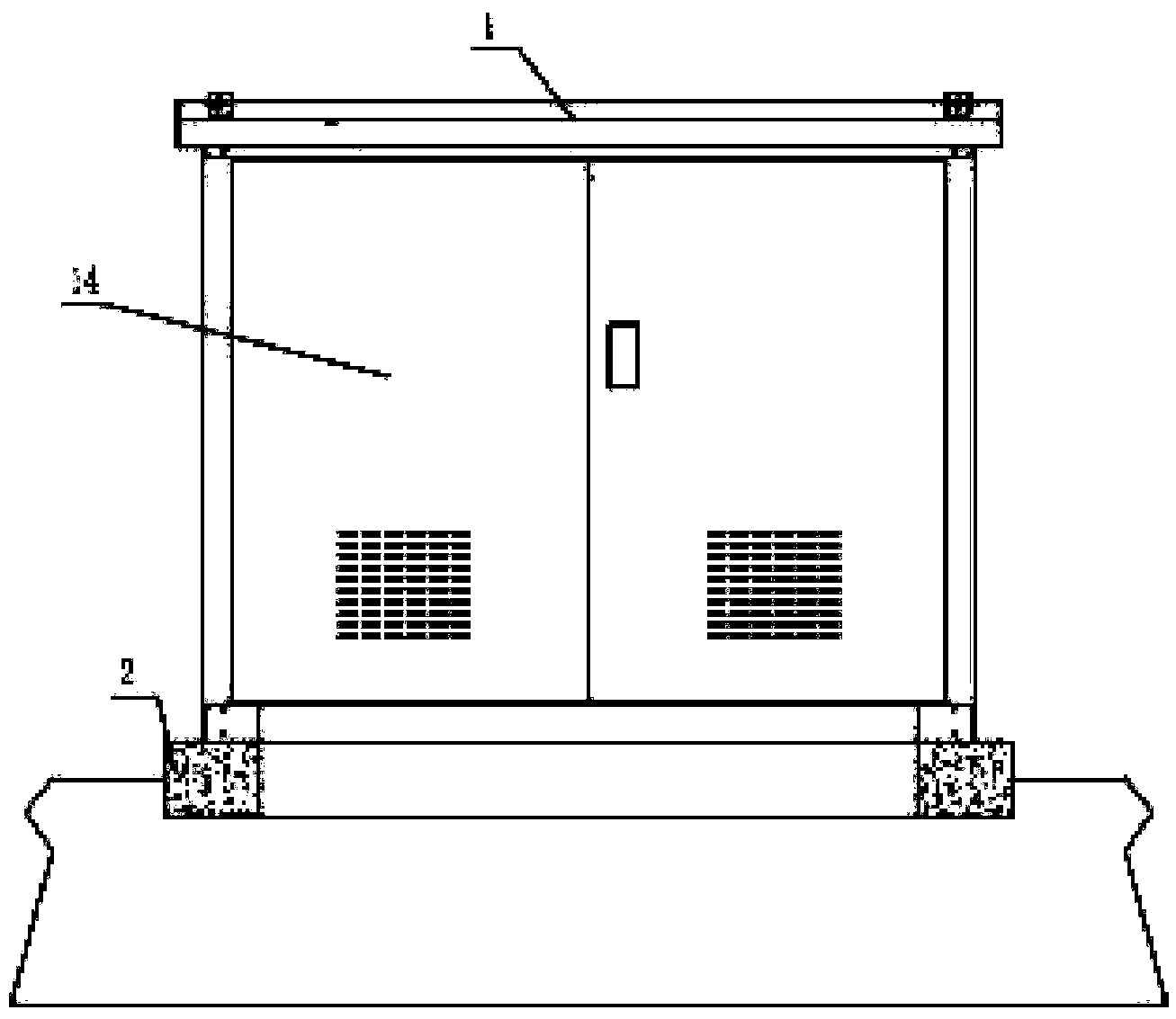

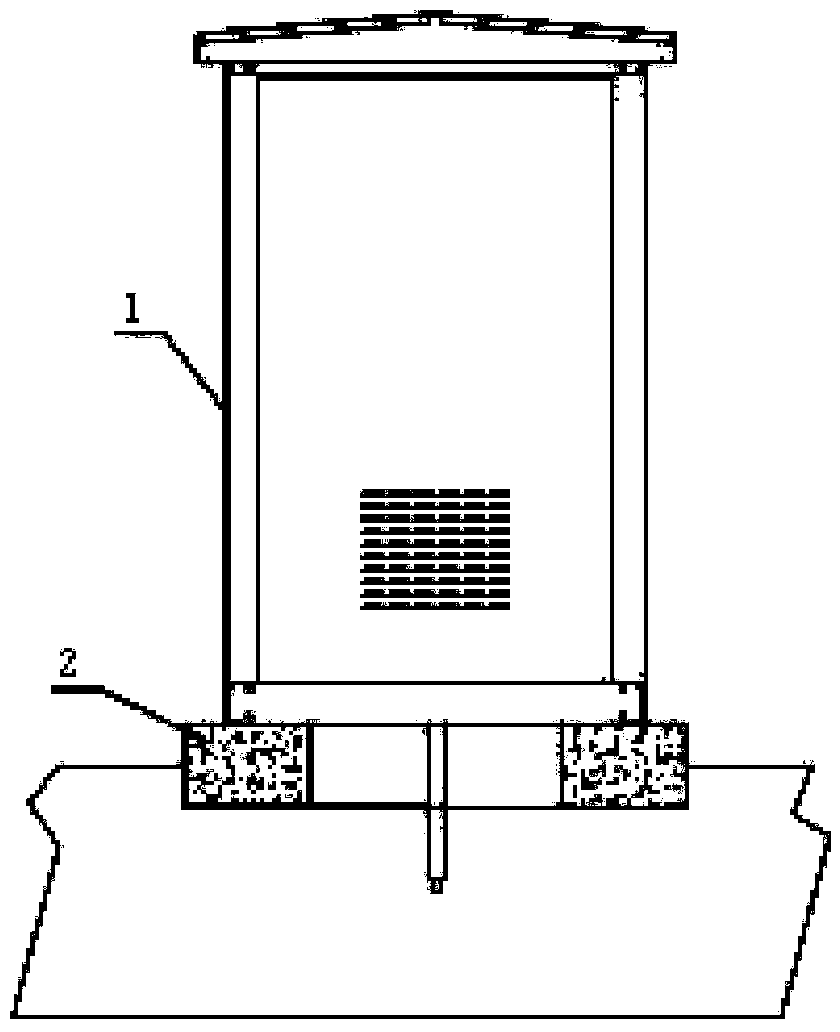

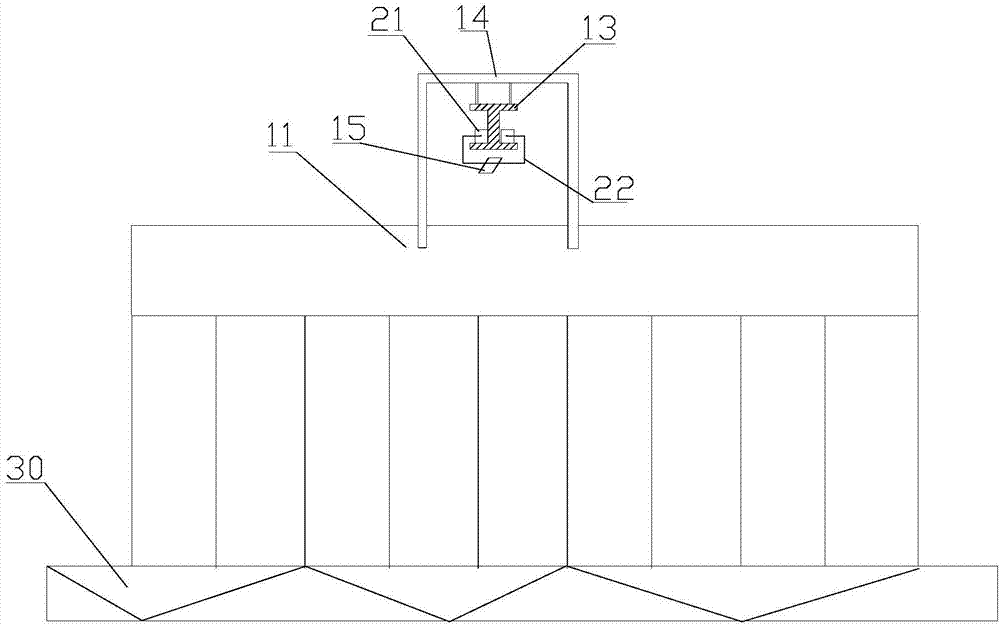

A real-time monitoring device for temperature field of air-cooled condenser

ActiveCN104697352BAccurately judge the work situationImprove monitoring accuracySteam/vapor condensersStaff timeDisplay device

Owner:HUADIAN HEAVY IND CO LTD

Tetra-nocular camera positioning device and method

PendingCN106780606AExpand the camera rangeCases to prevent duplicate identificationImage enhancementImage analysisBlind zoneComputer science

The invention provides a tetra-nocular camera positioning device. The device comprises a left upper camera, a left lower camera, a right upper camera and a right lower camera, wherein an upper binocular camera is formed by the left upper camera and the right upper camera, and a lower binocular camera is formed by the left lower camera and the right lower camera; and the upper binocular camera faces upwards, while the lower binocular camera faces downwards. Compared with the prior art, the tetra-nocular camera positioning device has the advantages that the tetra-nocular camera is formed by four cameras, and the pitching angle and camera interval are accurately designed, so that the measurement blind zone is as small as possible while the longitudinal vision of the tetra-nocular camera is enlarged, the shooting range of the tetra-nocular camera is greatly increased, and the experience effect is optimized.

Owner:VR TECH HLDG LTD

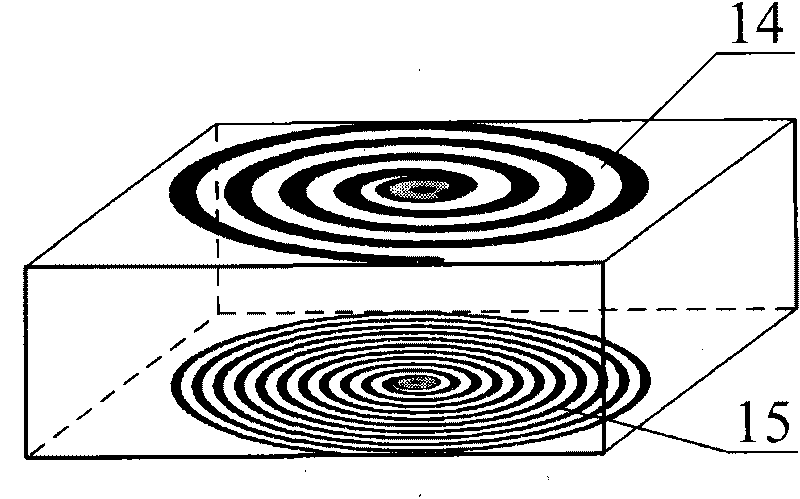

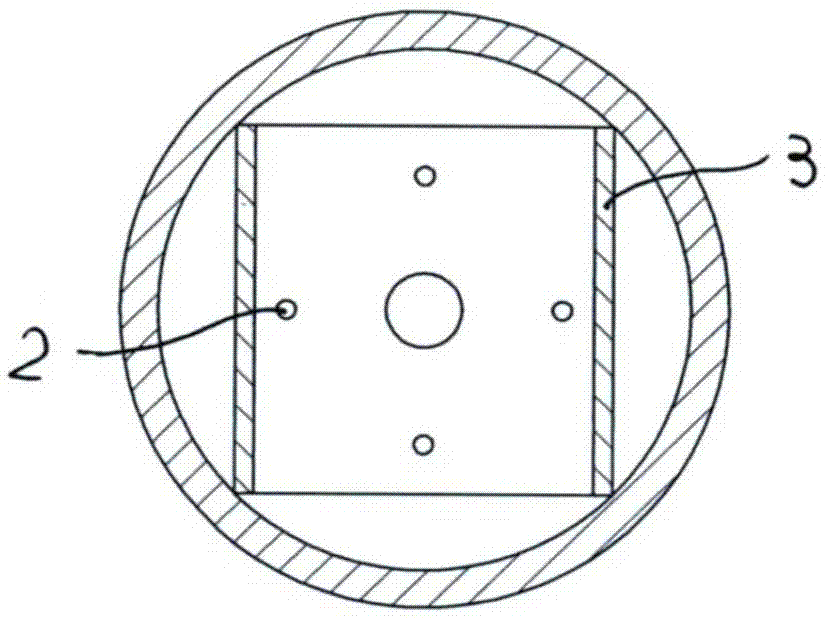

Electromagnetic ultrasonic transducer for measuring wall thickness of test piece and method for measuring wall thickness of test piece

ActiveCN102564364BImprove incentive efficiencyImprove receiver sensitivityUsing subsonic/sonic/ultrasonic vibration meansUltrasonic sensorBlind zone

The invention discloses an electromagnetic ultrasonic transducer for measuring wall thickness of a test piece and a method for measuring the wall thickness of the test piece. The transducer comprises an upper shell, a lower shell which is abutted with the upper shell and comprises a secondary stepped hole at the bottom, an exciting plane coil which is arranged inside the deepest stepped hole at the bottom of the lower shell, a receiving plane coil which is arranged inside the deeper stepped hole at the bottom of the lower shell and coaxially laminated with the exciting plane coil, a shielding layer and a magnet element, which are sequentially arranged on the receiving plane coil, and a joint, which is arranged on the upper shell, respectively connected with the two plane coils through an insulated wire and used for being connected with a thickness meter so as to measure the wall thickness of the test piece. The two plane coils do not interfere with each other in a space so that the transducer has high exciting efficiency, high receiving sensitivity and high signal-to-noise ratio, and simultaneously, reduces a measuring blind zone by arrangement of the designed dual coils and other elements.

Owner:HUAZHONG UNIV OF SCI & TECH

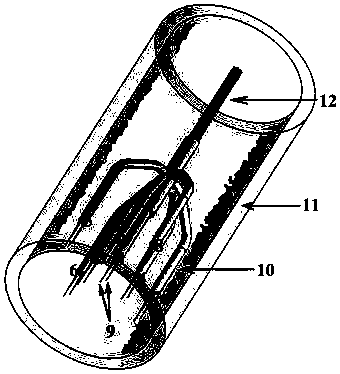

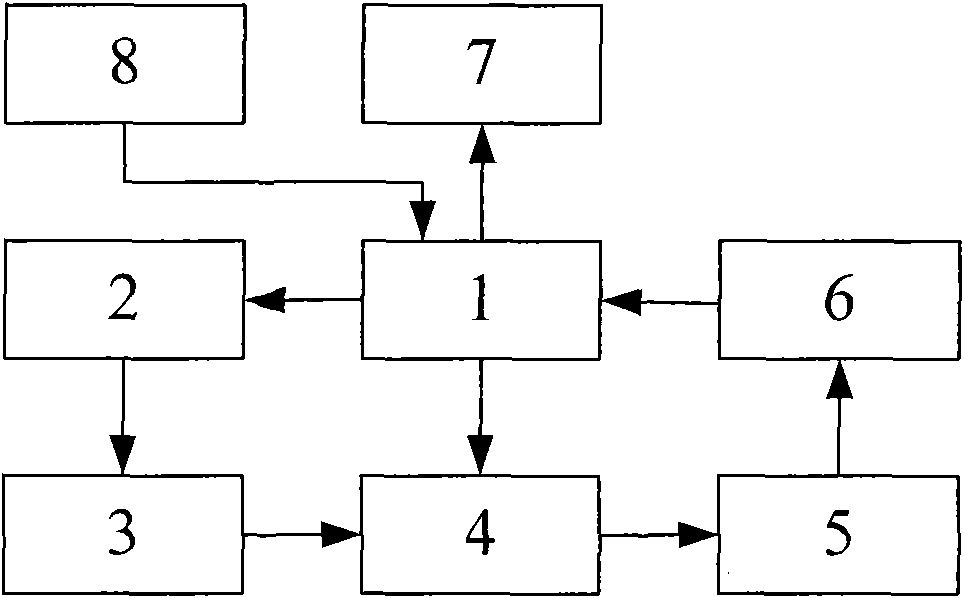

A water holdup measurement method for near-horizontal oil-water two-phase flow

ActiveCN107677705BReduce measurement blind spotsAccurate measurementMaterial resistanceSensor arrayMeasurement device

The invention relates to a method for measuring a water holding rate of a near-horizontal oil-water two-phase flow. A measuring device used by the method comprises a test pipe, an upstream fast-closing valve, a downstream fast-closing valve and an array of double-parallel line conductivity sensors. The two fast-closing valves are respectively arranged at two ends of the test pipe. The double-parallel line conductivity sensors are distributedly inserted into different cross sections of the test pipe. The test pipe is fixed in an experimental pipe. When a flow can stably flow, the upstream and downstream fast-closing valves are fast closed, after the oil-water two-phase flow in the pipe to be detected is layered through standing, the double-parallel line conductivity sensors in the oil-waterinterface carry out acquisition and processing of signals so that height hw of water layers at the double-parallel line conductivity sensor positions and sensor position parameters n are obtained, and a water holding rate is calculated through the hw and n.

Owner:TIANJIN UNIV

Electromagnetic ultrasonic thickness gauge and measurement method thereof

ActiveCN101701809BAdaptableImprove detection efficiencyUsing subsonic/sonic/ultrasonic vibration meansMicrocontrollerHandling system

The invention provides an electromagnetic ultrasonic thickness gauge for measuring the thickness of a specimen in a variety of abominable environments and a measurement method thereof. The electromagnetic ultrasonic thickness gauge is composed of a microcontroller, a transmitting circuit, an electromagnetic ultrasonic probe, a receiving switch, a conditioning circuit, an echo processing system, adisplay system and a keyboard, wherein the microcontroller is connected with the transmitting circuit which is connected with the electromagnetic ultrasonic probe, the electromagnetic ultrasonic probe is connected with the receiving switch which is connected with the microcontroller and the conditioning circuit, the conditioning circuit is connected with the echo processing system, and the display system is connected with the microcontroller which is connected with the keyboard. The electromagnetic ultrasonic thickness gauge uses a normal-incidence body wave to measure the thickness and achieves the measurement accuracy which is twice as high as that of piezoelectric ultrasonic thickness gauge at the same frequency. The electromagnetic ultrasonic probe which adopts a pulse electromagnet to offer magnetic field can effectively detect various metallic specimens; as a transceiving separated coil is used for exciting and detecting ultrasonic waves, the blind area for the measurement is small and the measurement thickness can be in a range from 3mm to 200mm.

Owner:零声科技(苏州)有限公司

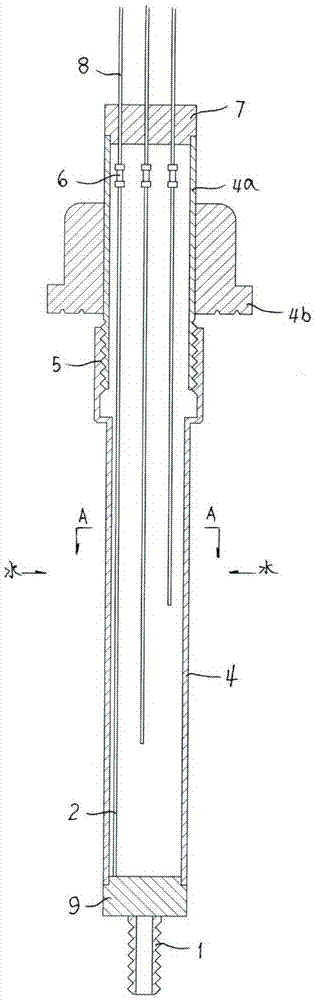

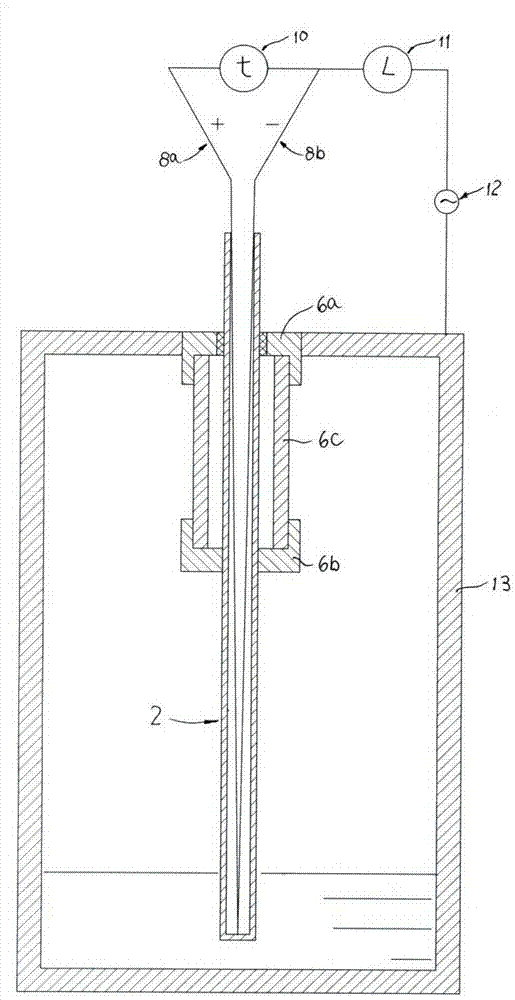

Integrated electric contact liquid level liquid temperature measurement sensor

ActiveCN102661772BRealize the measurement functionRealize the temperature dual parameter measurement functionThermometers using electric/magnetic elementsUsing electrical meansLiquid temperatureMetal framework

The invention discloses an integrated electric contact liquid level and liquid temperature measurement sensor. An electric contact and phi2 armored thermocouple electrodes are adopted in the sensor. A plurality of armored thermocouple electrodes are longitudinally arranged on a metal framework and are arranged in a stainless steel protection sleeve integrally; and an electrode lead is led out from a bundle in an upper sealed end plug of the protection sleeve and connected with secondary meters such as a millivolt thermometer and an electric contact water level meter. The integrated electric contact liquid level and liquid temperature measurement sensor is inserted into a high-temperature and high-pressure container to directly measure a real liquid level and a real liquid temperature, so that the sensor is small in measurement error, high in resolution and assembled and used easily and has a compact structure. The sensor is used for measuring the liquid level and the liquid temperature of relevant high-temperature and high-pressure containers of a nuclear reactor, such as a reactor core, a spent fuel battery, a pressure stabilizer and a steam generator, and also can be used for measuring the liquid level and the liquid temperature of the conventional high-temperature and high-pressure containers.

Owner:成都中核鑫星应用技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com