A water holdup measurement method for near-horizontal oil-water two-phase flow

A measurement method and technology of water holdup, which is applied in the field of oil field dynamic monitoring, and can solve the problems of water holdup measurement error and low accuracy of water holdup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Considering that the conductivity difference between the oil and water phases is obvious, and the double parallel line conductance sensor is sensitive to the change of the water film thickness, the present invention combines the fast closing valve method with the double parallel line conductance method to solve the problem of water holdup measurement of near horizontal oil and water two-phase flow .

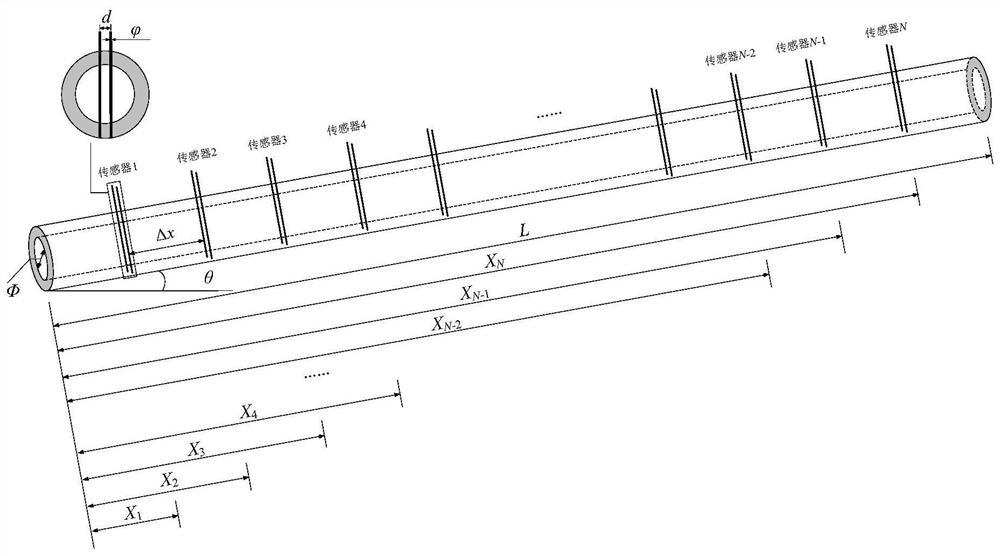

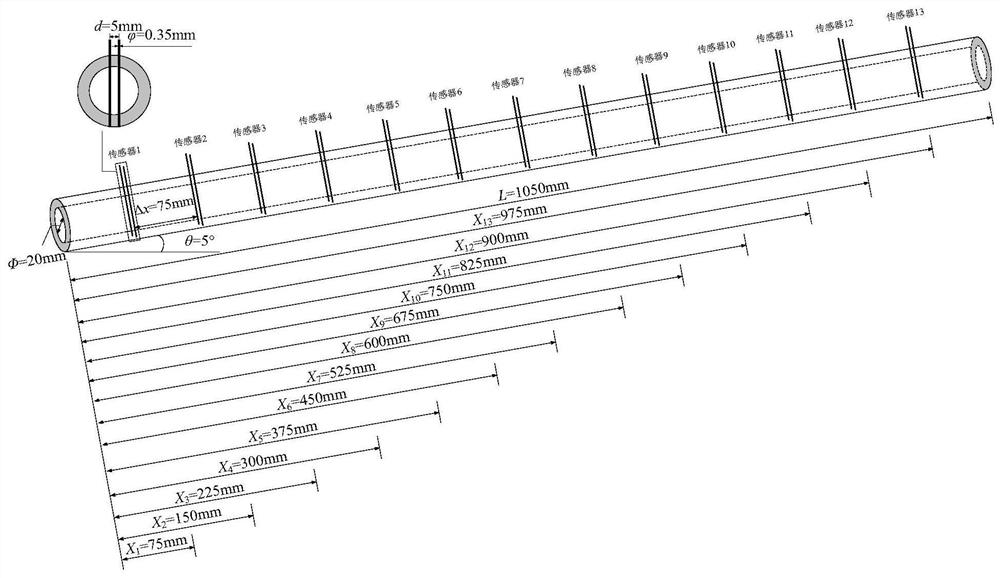

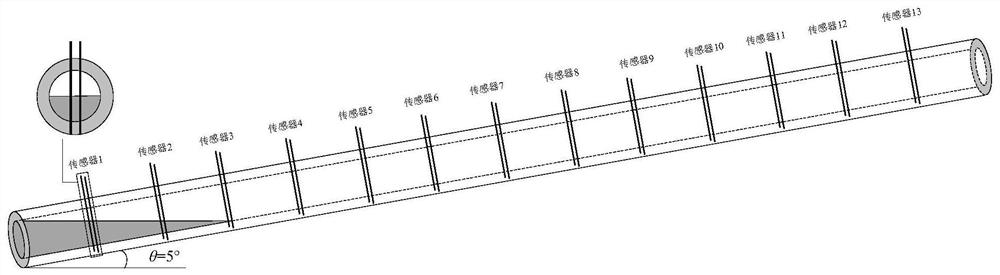

[0036] The layered interface of oil-water two-phase flow in a near-horizontal well has a certain angle with the axis of the wellbore. The height of the water layer measured by the dual-parallel-line conductivity sensor is closely related to the location of the sensor. Therefore, the distribution position of the dual-parallel-line conductivity sensor array must be determined To optimize the design. On this basis, through the signal analysis of the dual-parallel-line conductivity sensor, the accurate measurement of the water holdup of the near-horizontal oil-water two-phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com