Electromagnetic ultrasonic thickness gauge and measurement method thereof

An electromagnetic ultrasonic and thickness gauge technology, which is applied to measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of large size and inconvenient use of the transducer, and achieve short magnetic field duration, high detection efficiency, Environmentally adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

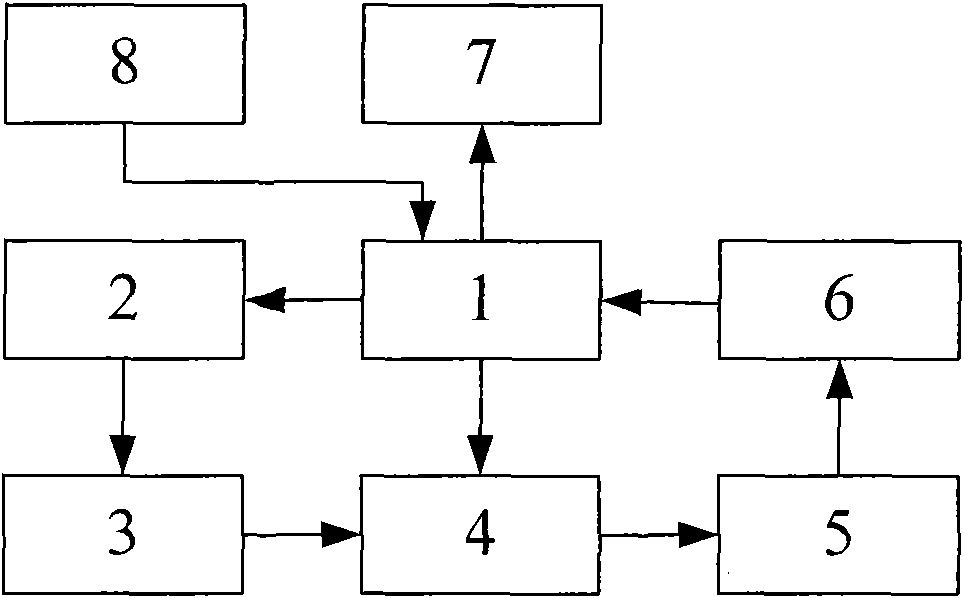

[0028] Embodiment 1, combining figure 1 , an electromagnetic ultrasonic thickness gauge of the present invention, it is by microcontroller (1), transmitting circuit (2), electromagnetic ultrasonic probe (3), receiving switch (4), conditioning circuit (5), echo processing system (6), composed of a display system (7) and a keyboard (8), the microcontroller (1) is connected to the transmitting circuit (2), the transmitting circuit (2) is connected to the electromagnetic ultrasonic probe (3), and the electromagnetic ultrasonic probe (3) is connected to The receiving switch (4), the receiving switch (4) is connected to the microcontroller (1) and the conditioning circuit (5), the conditioning circuit (5) is connected to the echo processing system (6), and the display system (7) is connected to the microcontroller (1 ), the microcontroller (1) is connected to the keyboard (8).

[0029] The present invention also has the following technical characteristics:

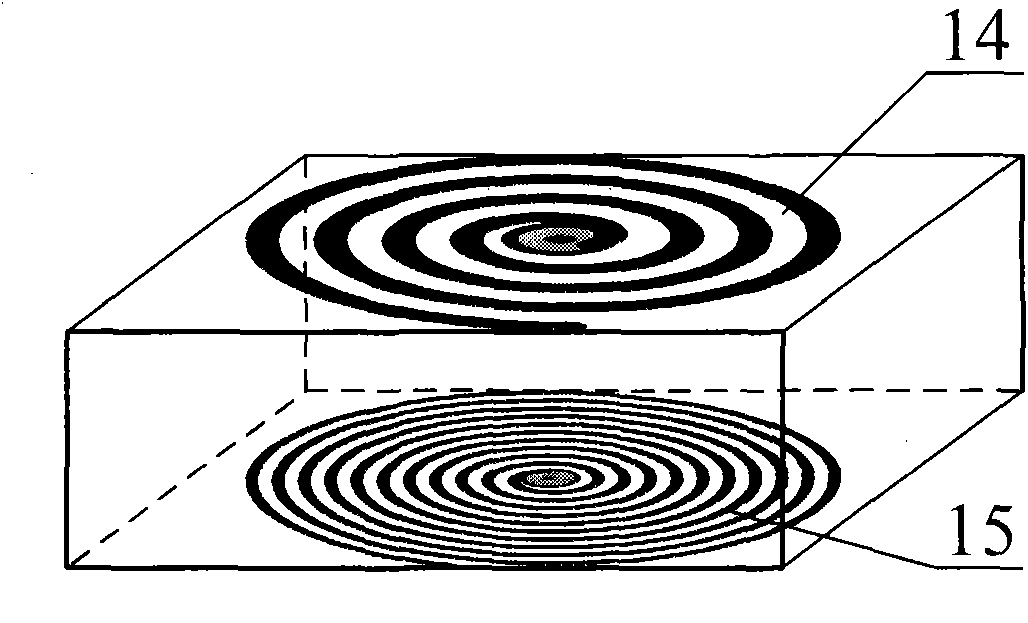

[0030] The electromagn...

Embodiment 2

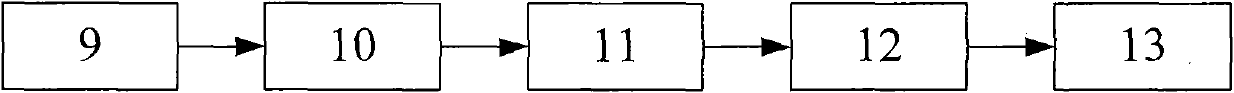

[0043] Example 2, combined with Figure 4 , the echo processing system (6) of the present invention comprises a data acquisition circuit (16), a storage circuit (17), a FIR band-pass filter (18), a correlation detector (19), a FIR low-pass filter (20), Echo position extraction circuit (21), round trip time generator (22); Data acquisition circuit (16) connects storage circuit (17), storage circuit (17) connects FIR band-pass filter (18), FIR band-pass filter (18) connect correlation detector (19), correlation detector (19) connects FIR low-pass filter (20), FIR low-pass filter (20) connects echo position extraction circuit (21), echo position extraction circuit (21) Connect the round trip time generator (22). The data acquisition circuit collects the signal into the memory, the FIR bandpass filter filters the signal to improve the signal-to-noise ratio, the correlation detector further processes the signal, extracts the envelope of the signal through the FIR low-pass filter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com