System and method for processing echo signal of guided wave type radar level meter

A technology of radar level meter and echo signal, which is applied in the direction of engine lubrication, liquid/fluid solid measurement, instruments, etc. It can solve the problems of large measurement blind area, weak false echo suppression ability, and insufficient measurement accuracy, and achieve improvement The effect of measuring accuracy and reducing the measurement blind area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

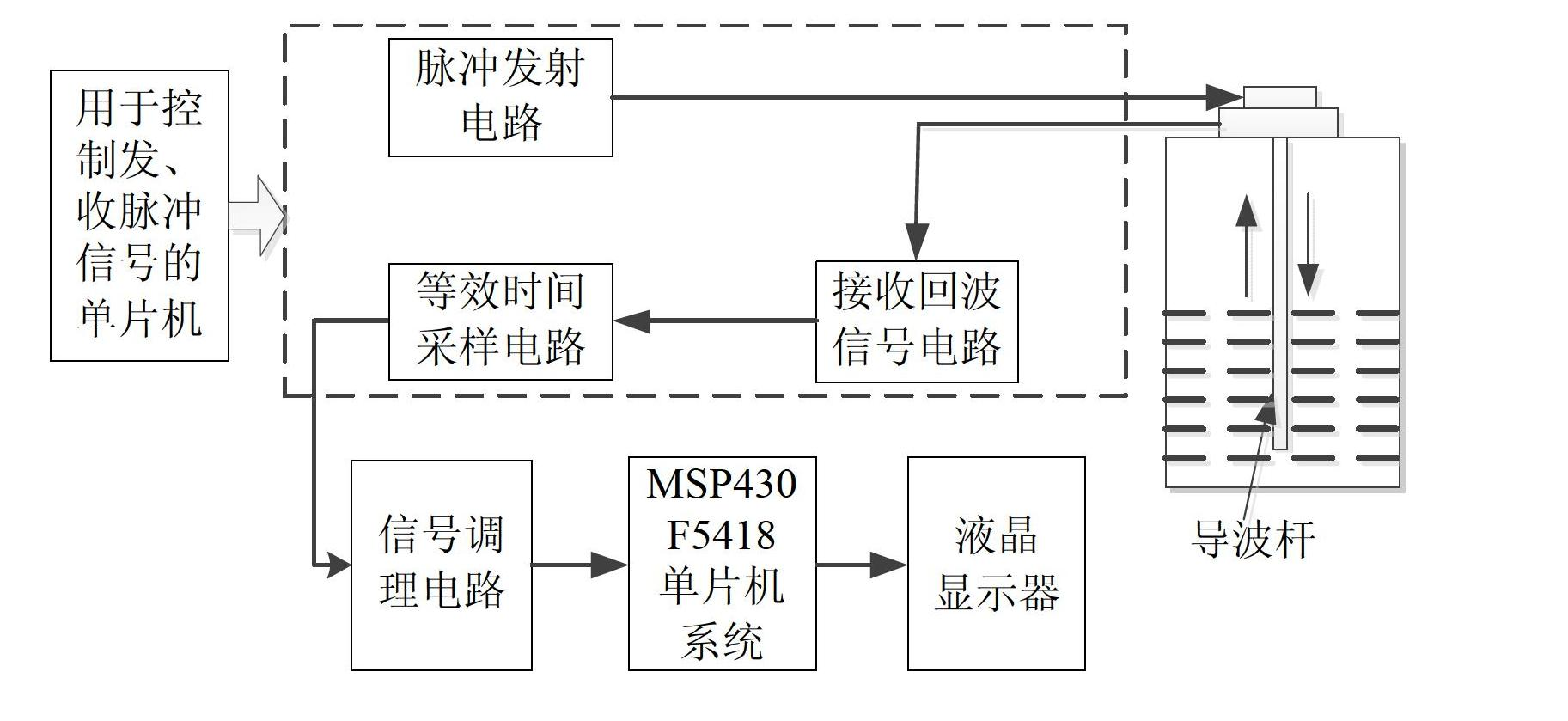

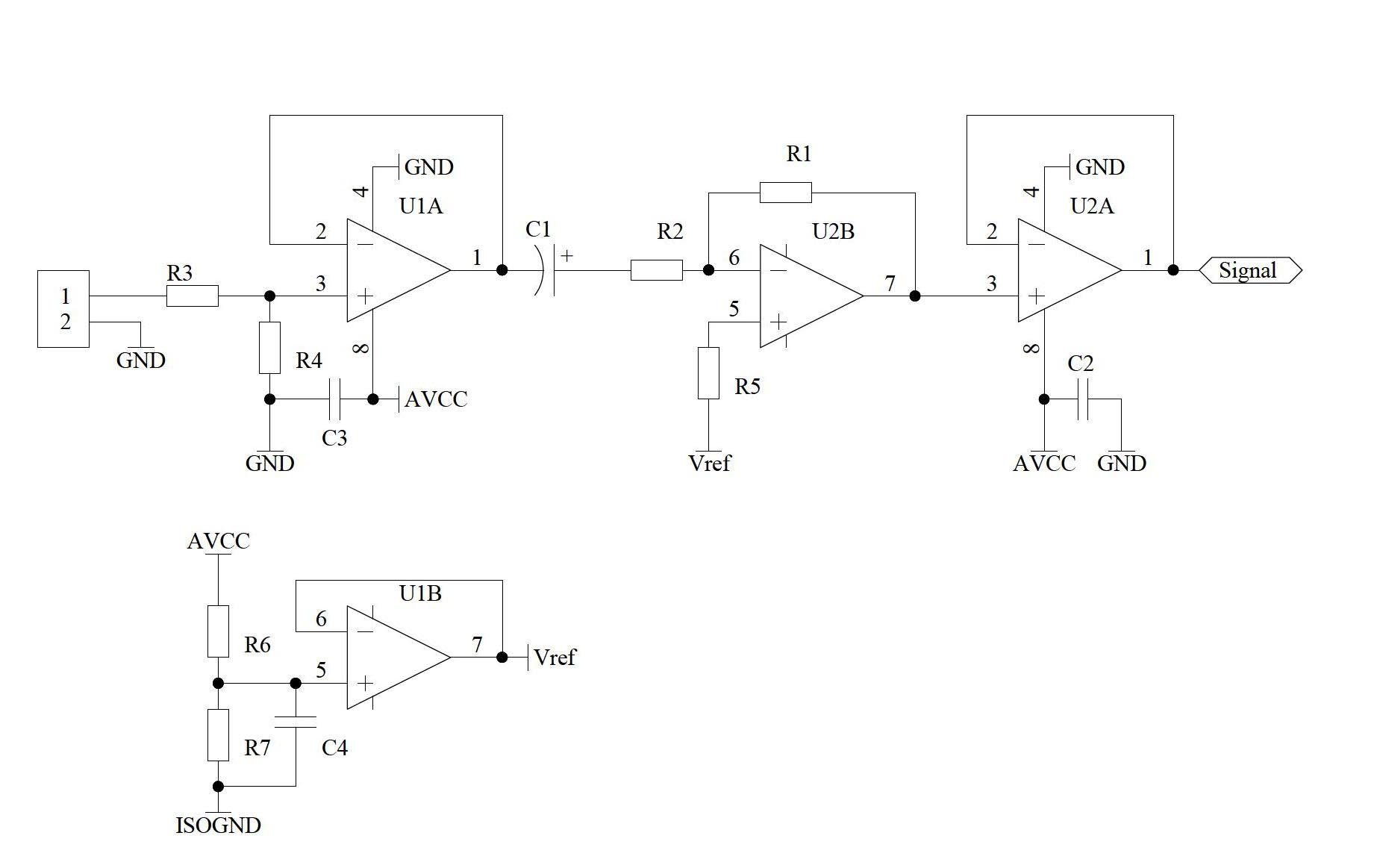

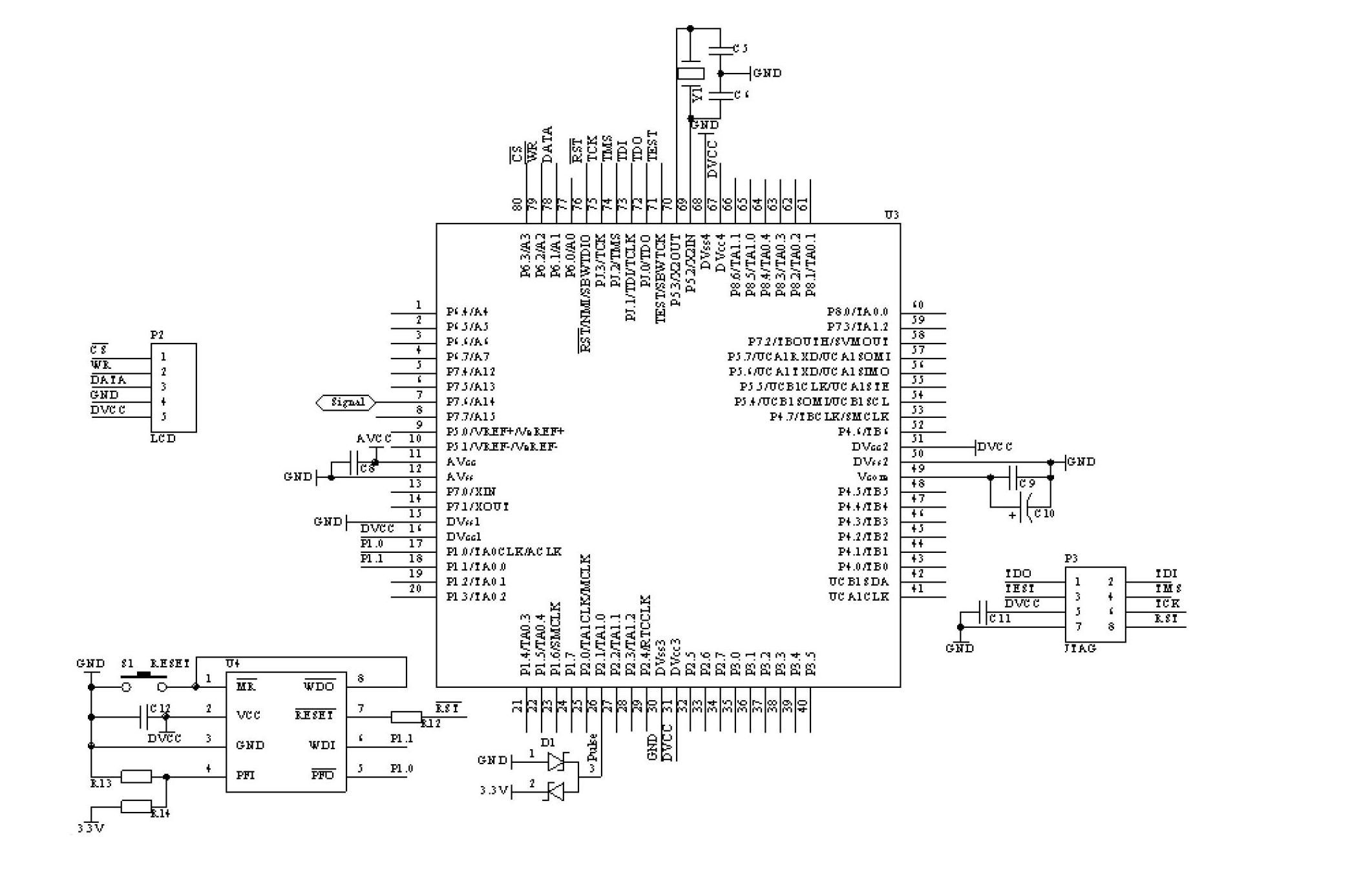

[0034] The block diagram of the guided wave radar level meter system is as follows: figure 1 As shown, it is composed of single-chip microcomputer for controlling sending and receiving pulse signals, pulse transmitting circuit, probe, receiving echo signal circuit, equivalent time sampling circuit, signal conditioning circuit, MSP430F5418 single-chip microcomputer system, liquid crystal display and software. The single-chip microcomputer used to control the sending and receiving of pulse signals controls the transmission and reception of pulses; the transmitting pulse circuit transmits electromagnetic wave pulse signals to the probe, and the pulse signal propagates along the probe until it reaches the place where the relative permittivity of the air and the surface of the material changes suddenly. Reflection occurs; the reflected echo propagates upward along the probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com