Flow rate measuring device based on ultrasonic reflecting signal and measuring device

A technology of flow velocity measurement and reflected signal, which is applied in the direction of measuring device, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of large flow state interference, cumbersome layout, large measurement error, etc., and achieve small measurement blind area, measurement The effect of high precision and simple circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

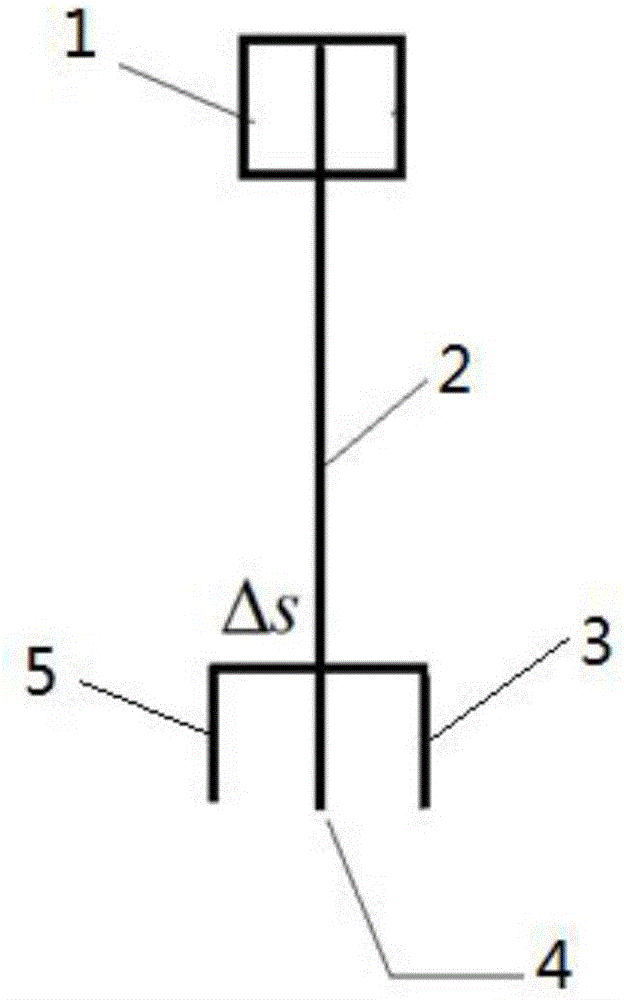

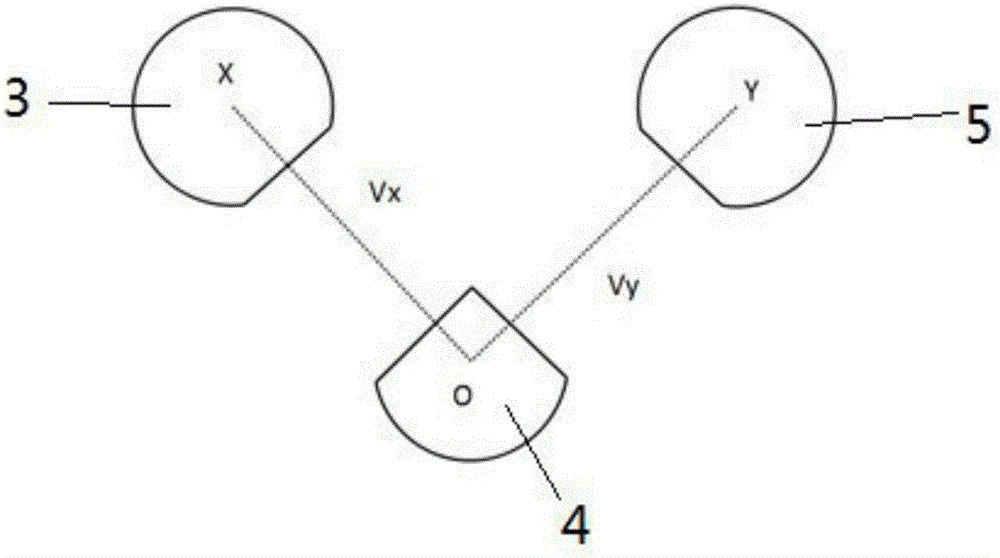

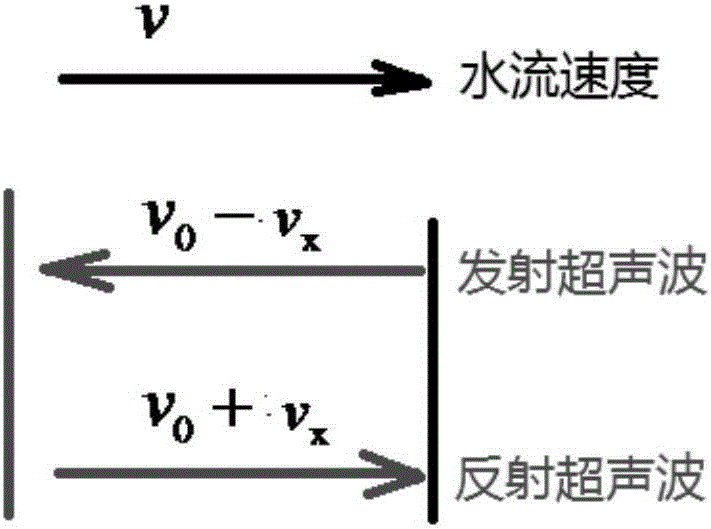

[0022] like figure 1 As shown, a flow velocity measurement device based on ultrasonic reflection signals of the present invention includes a measuring rod 2, which is a hollow cylinder with a diameter of 6-8 mm and made of stainless steel. The bottom end of the measuring rod 2 is installed There is a first probe 4 with ultrasonic transmitting and receiving functions, and a first reflection probe 3 and a second reflection probe 5 are arranged around the first probe 4, and the first reflection probe 3 and the second reflection probe 5 pass through the connecting rod and the measuring rod 2 connection, the first probe 4 is connected with the signal processing unit 1, the signal processing unit 1 includes an ultrasonic signal conditioning unit and a signal detection and transmission unit, the signal detection and transmission unit is used to control the first probe 4 to generate ultrasonic waves and start timing and first The probe 4 receives the reflected ultrasonic wave and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com