Patents

Literature

9124 results about "Hollow cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

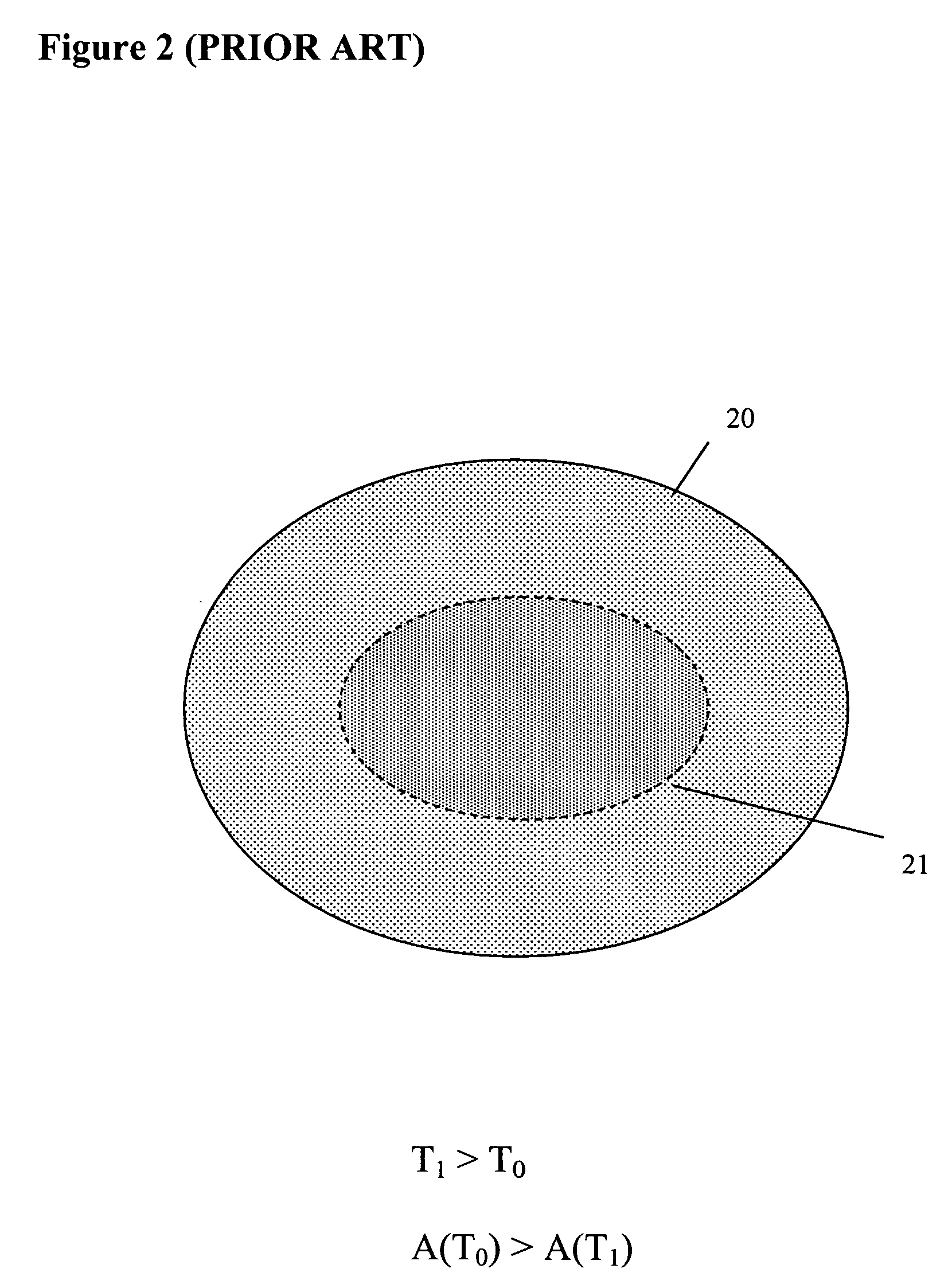

A hollow cylinder is one type of cylinder which is hollow.It has two radius,R is exradius,r is Inside circle radius.

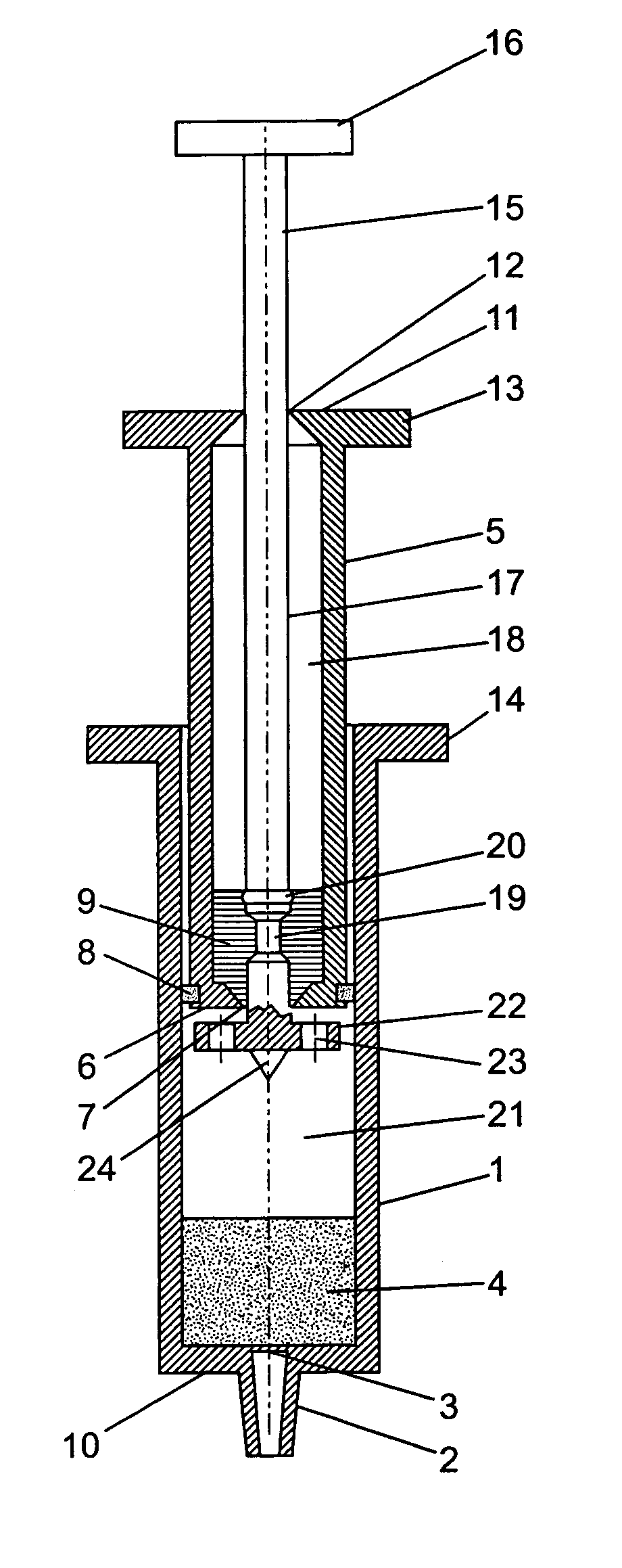

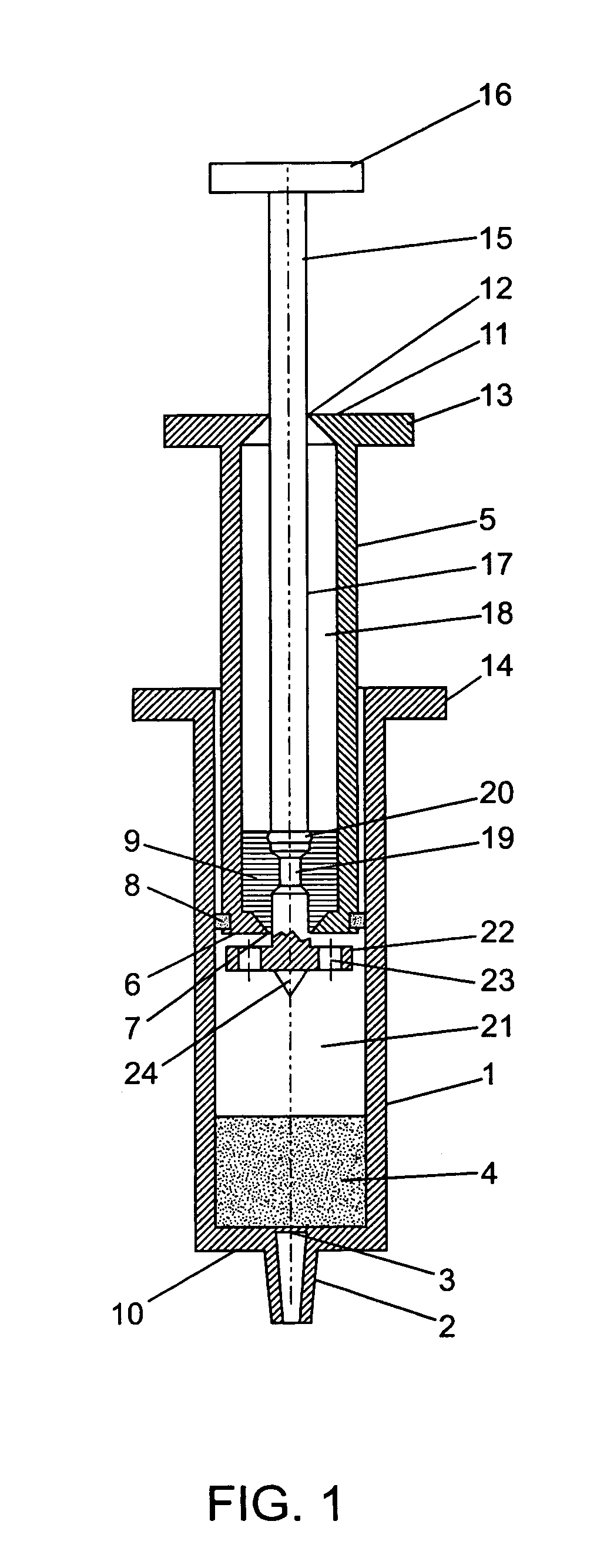

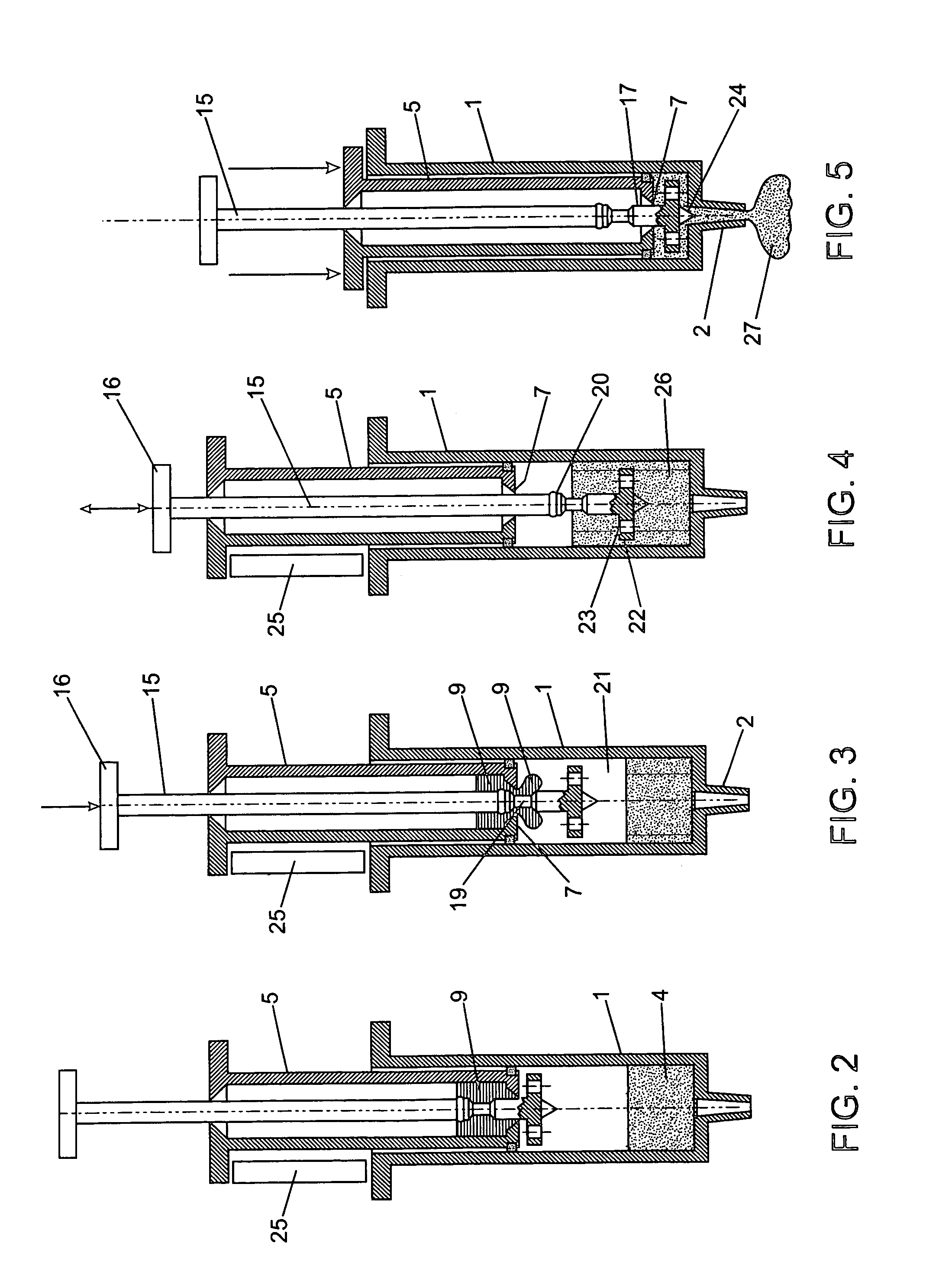

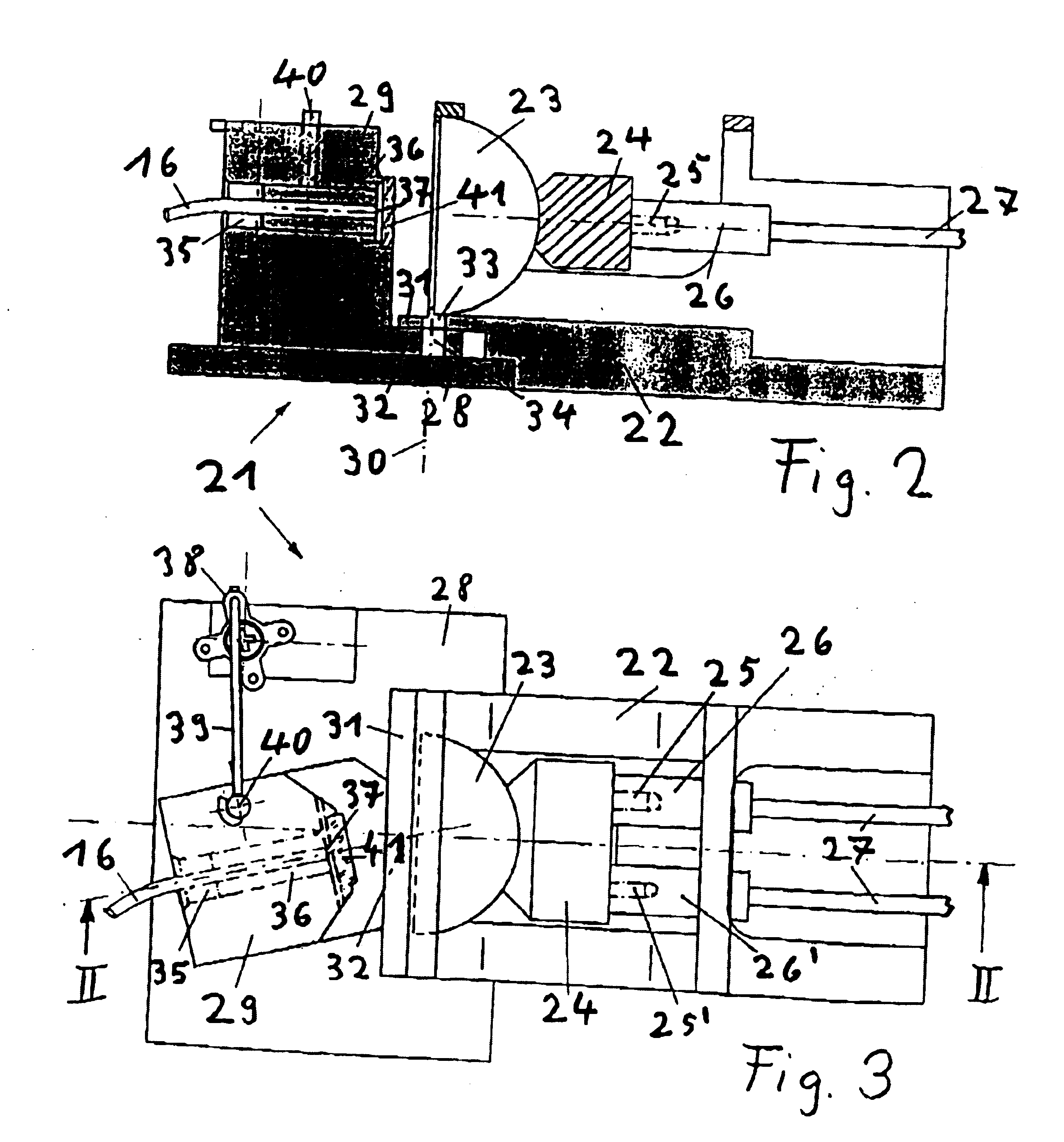

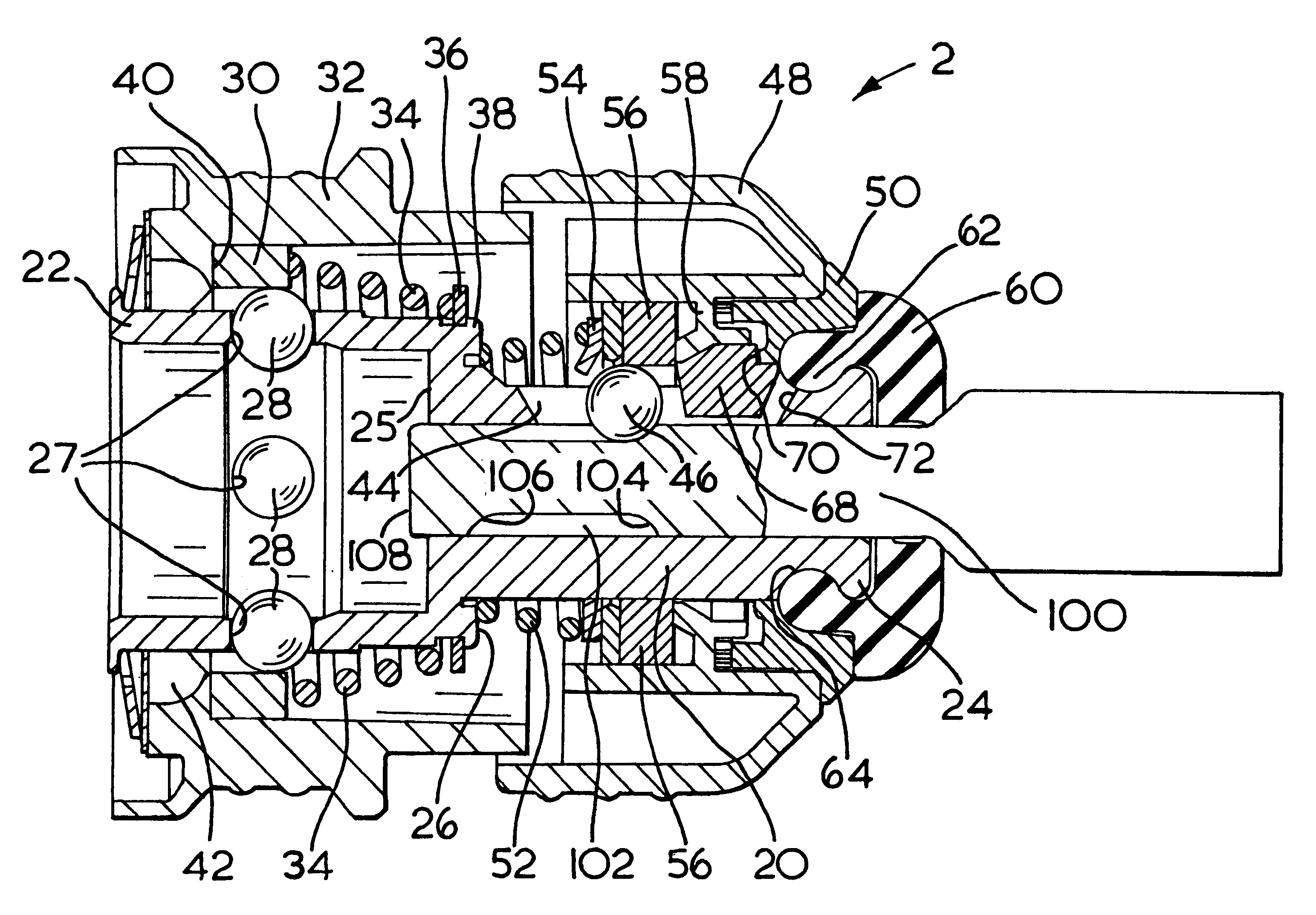

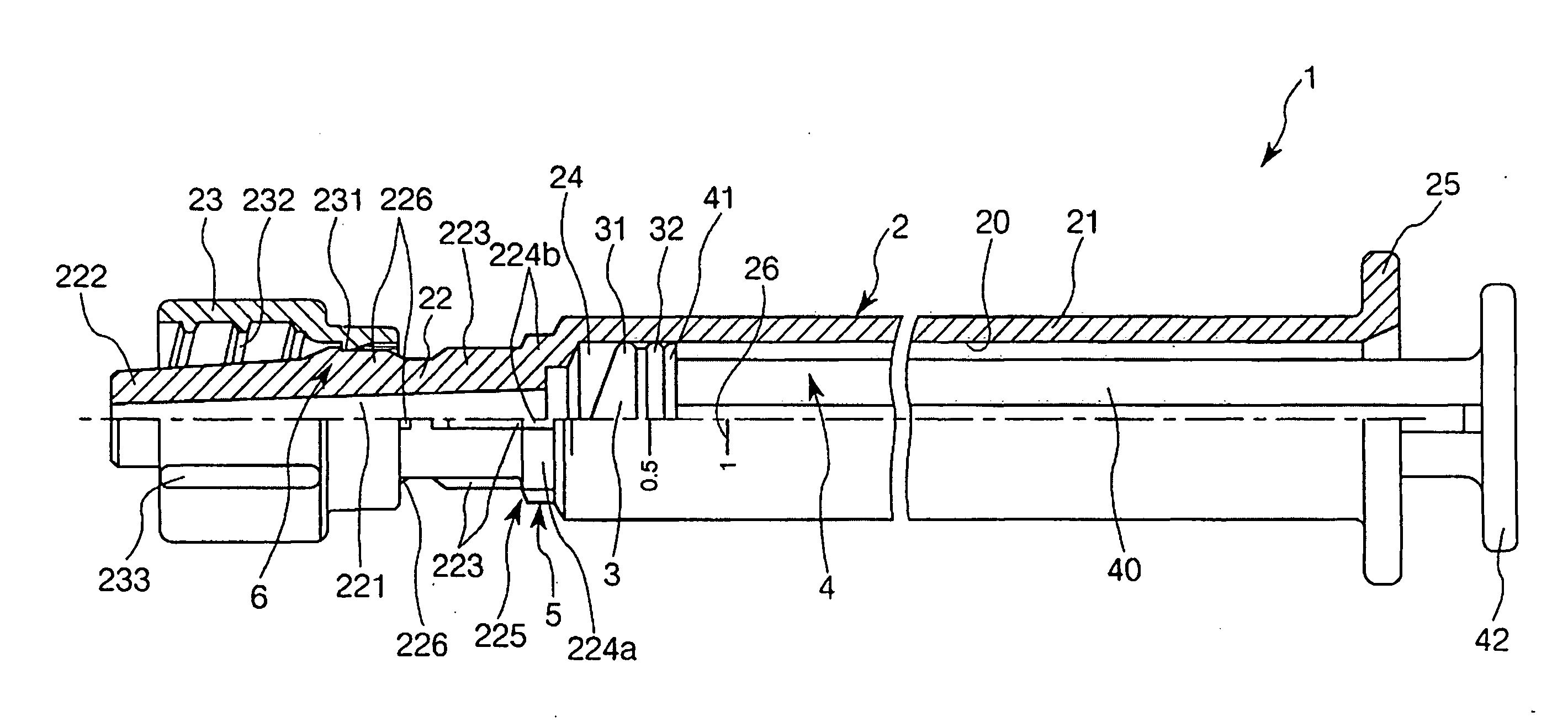

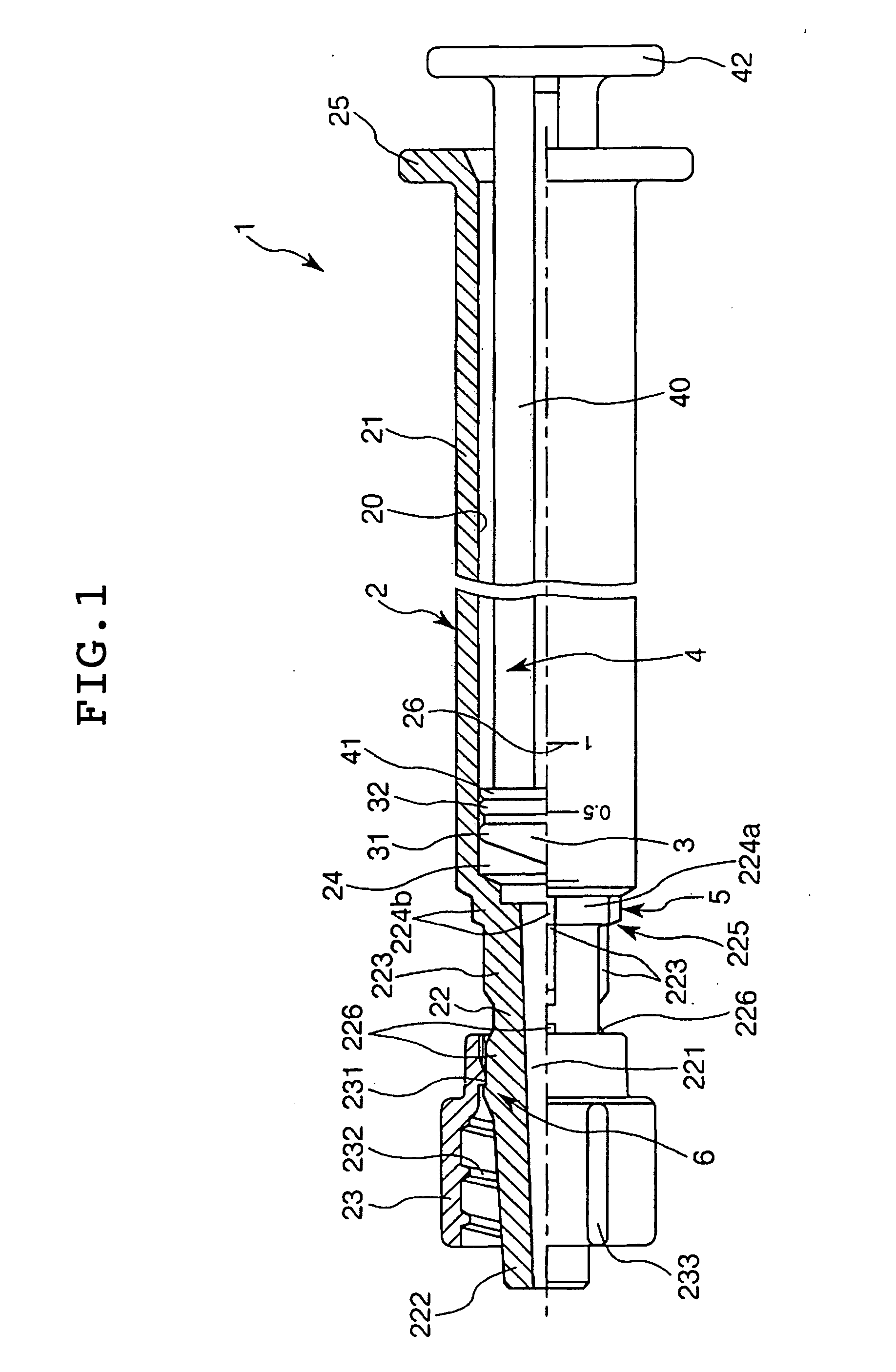

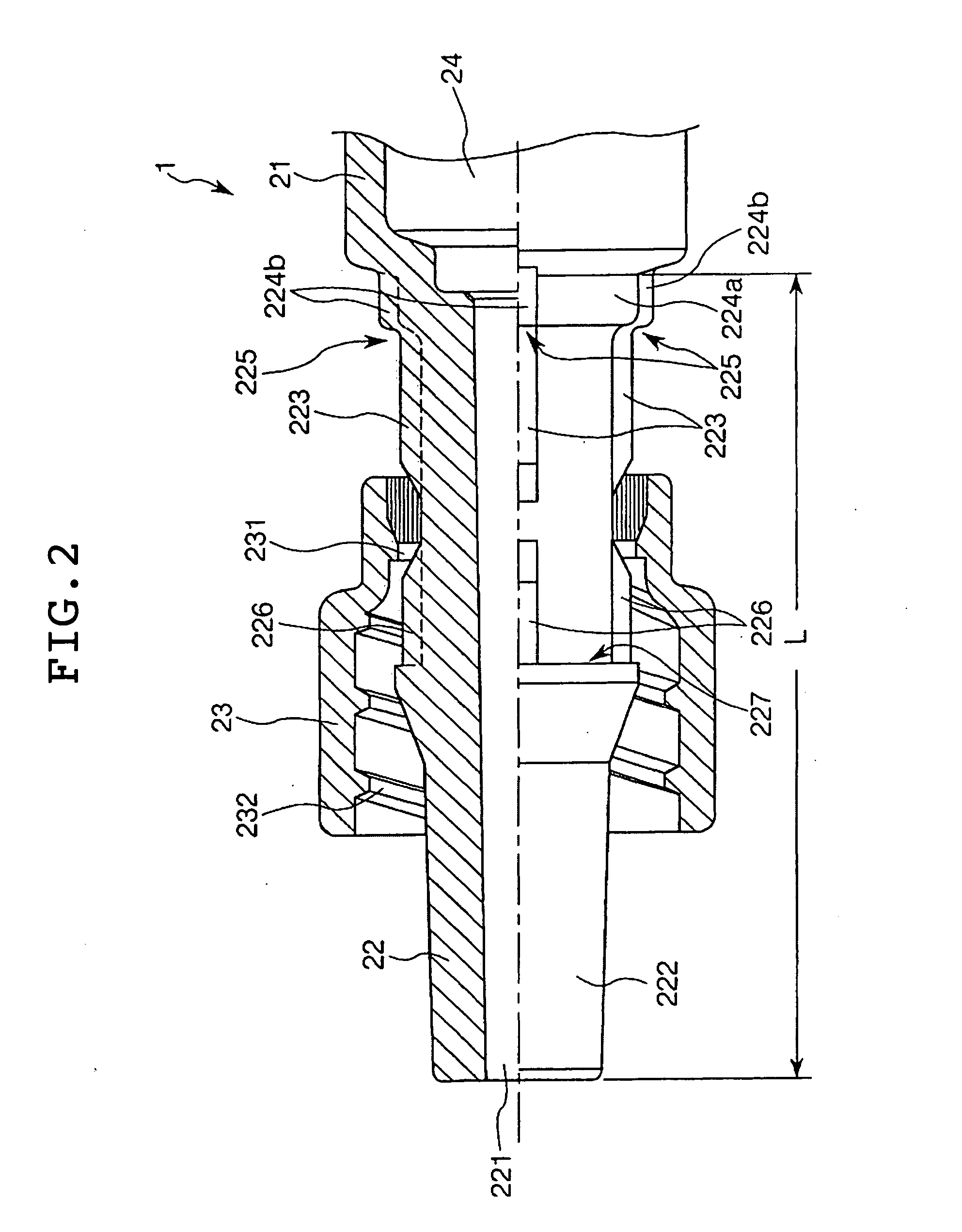

Apparatus and methods for mixing two components

ActiveUS7018089B2Solve the lack of spaceShaking/oscillating/vibrating mixersInfusion syringesEngineeringExtrusion

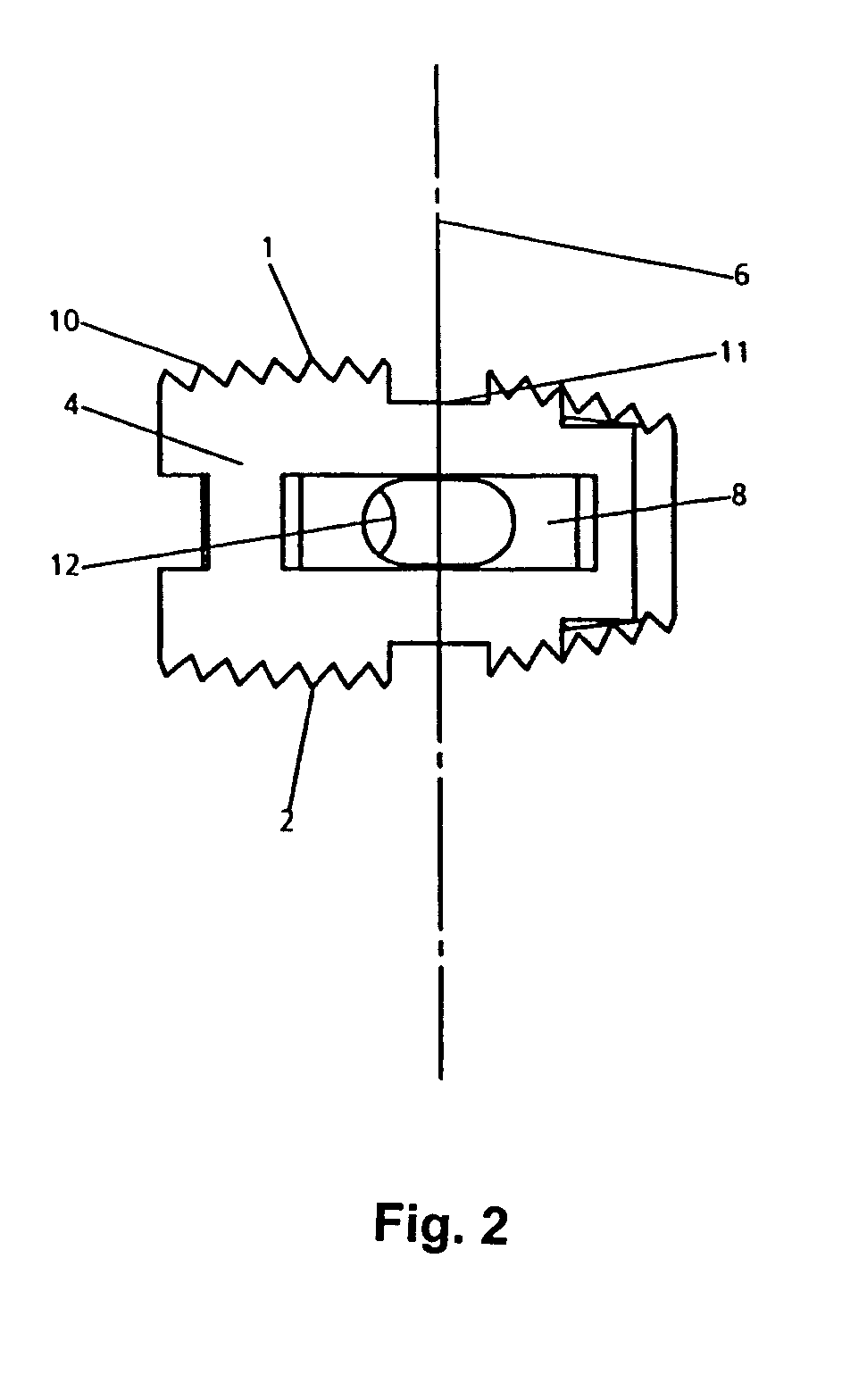

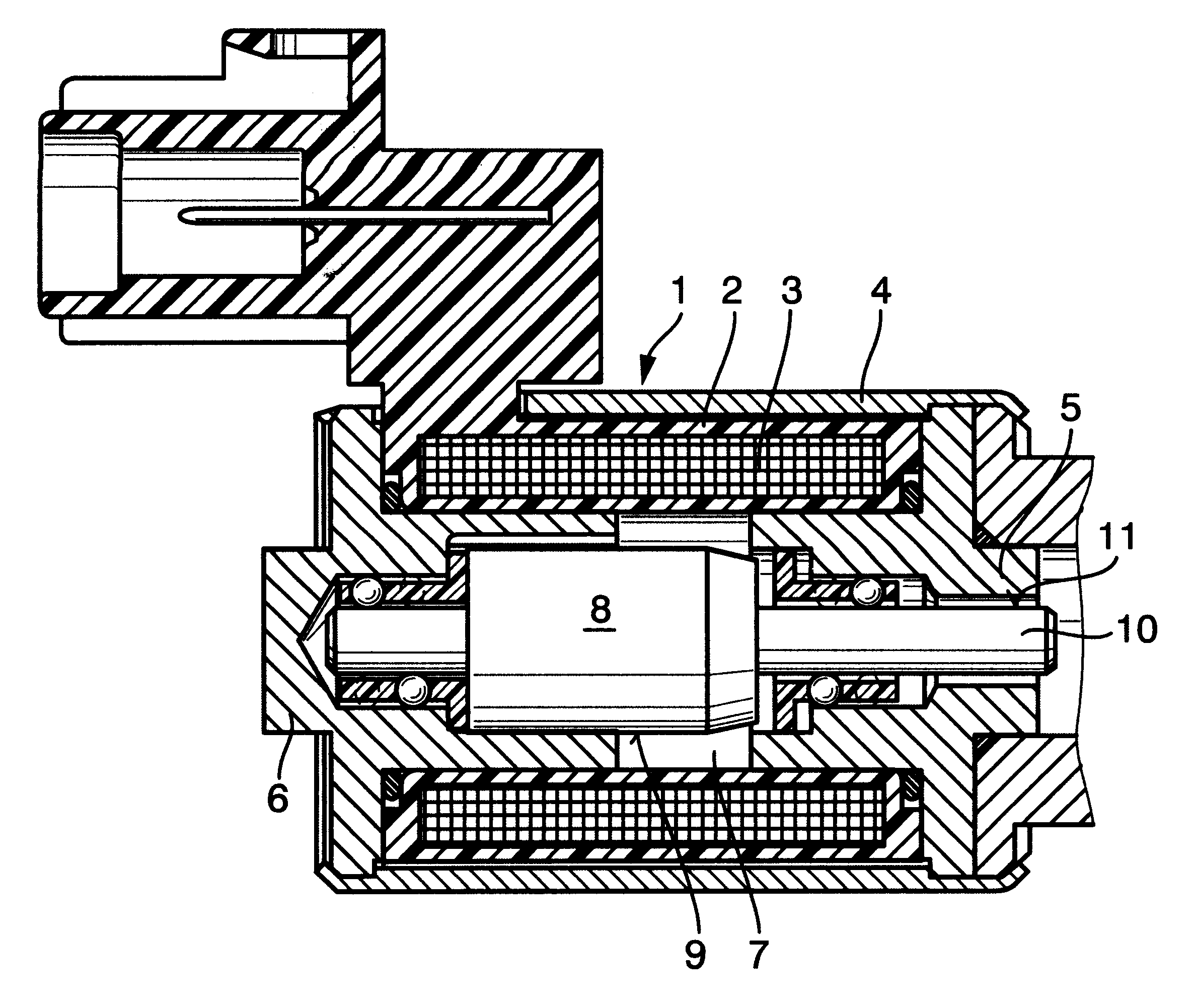

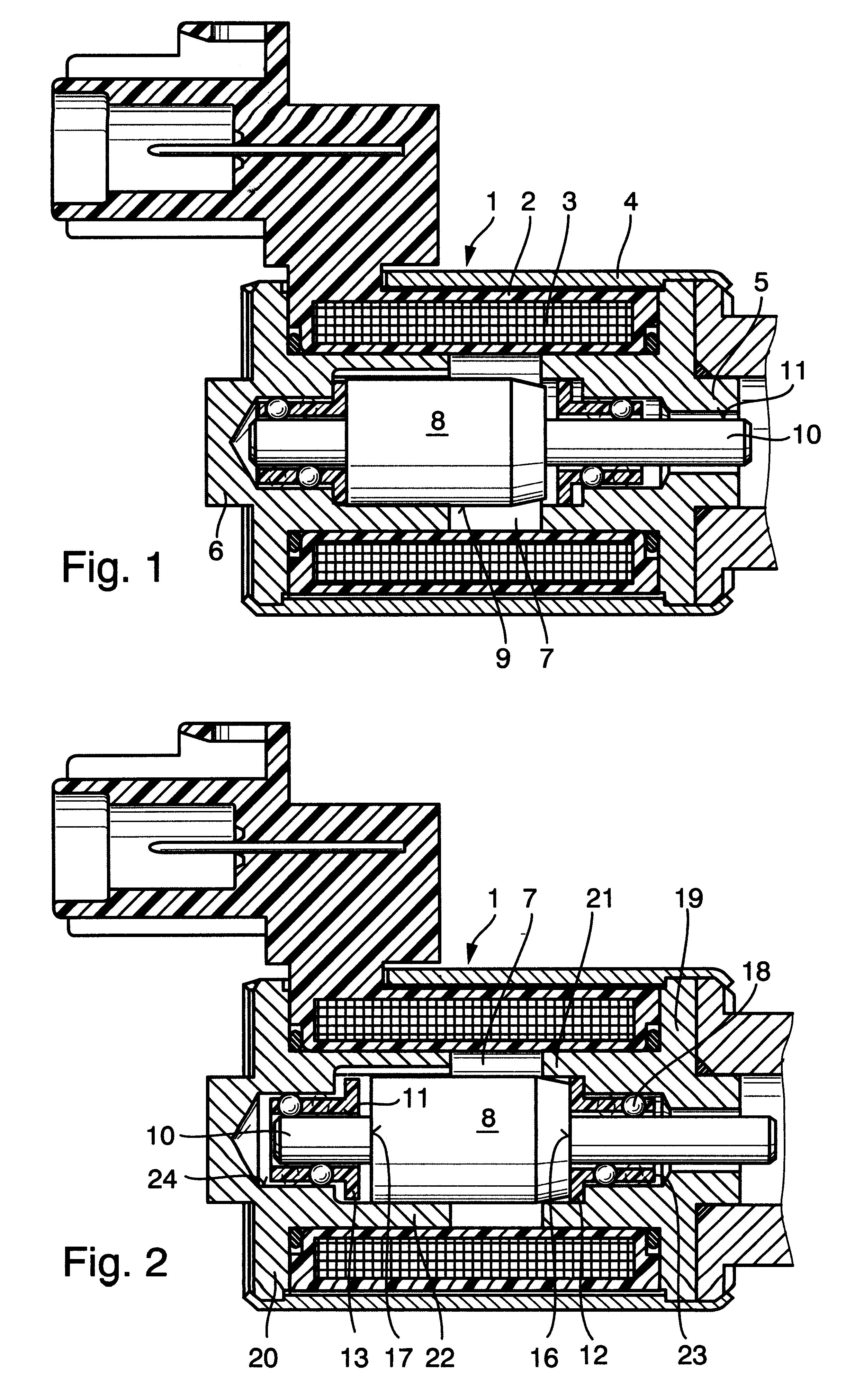

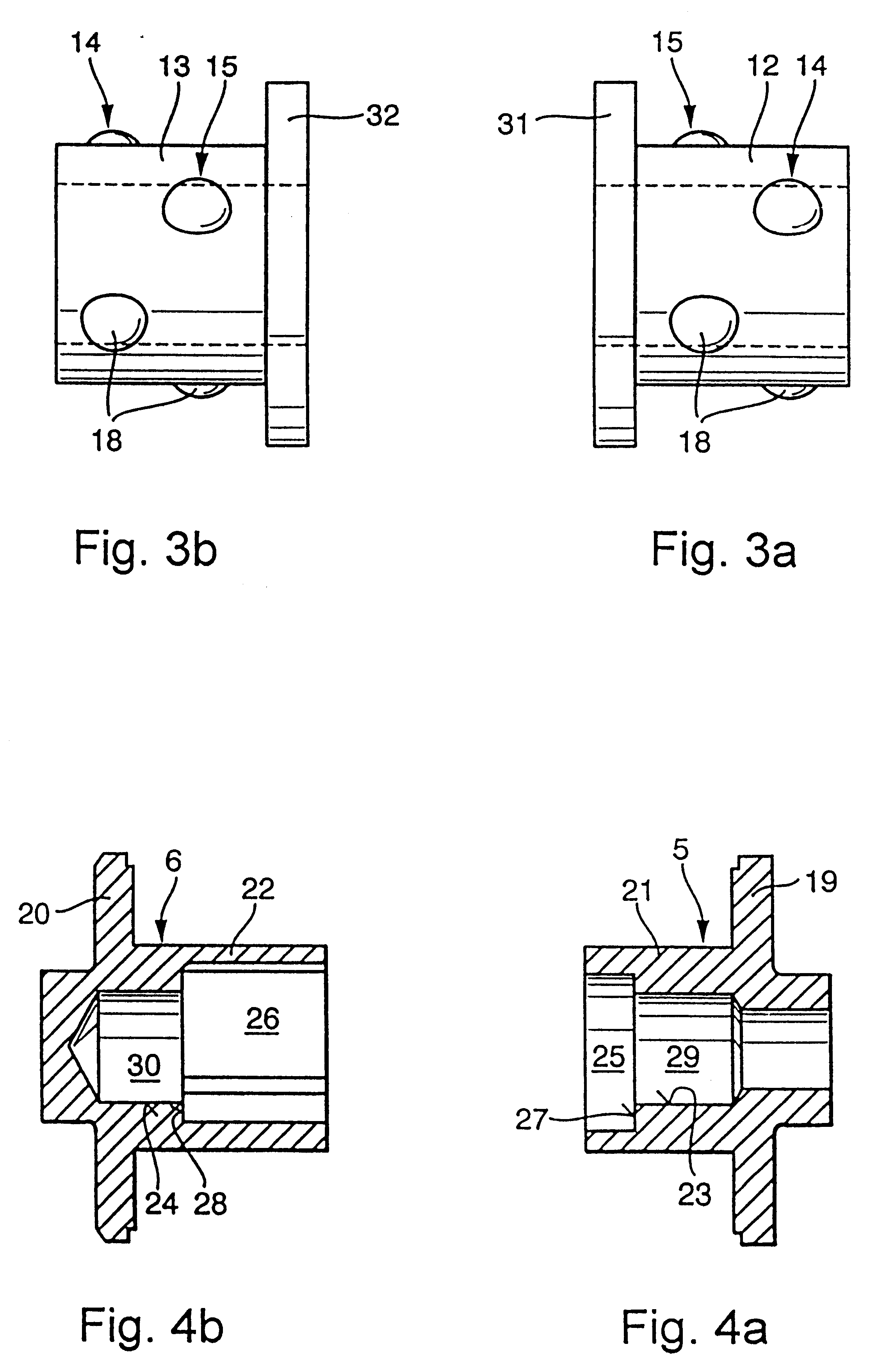

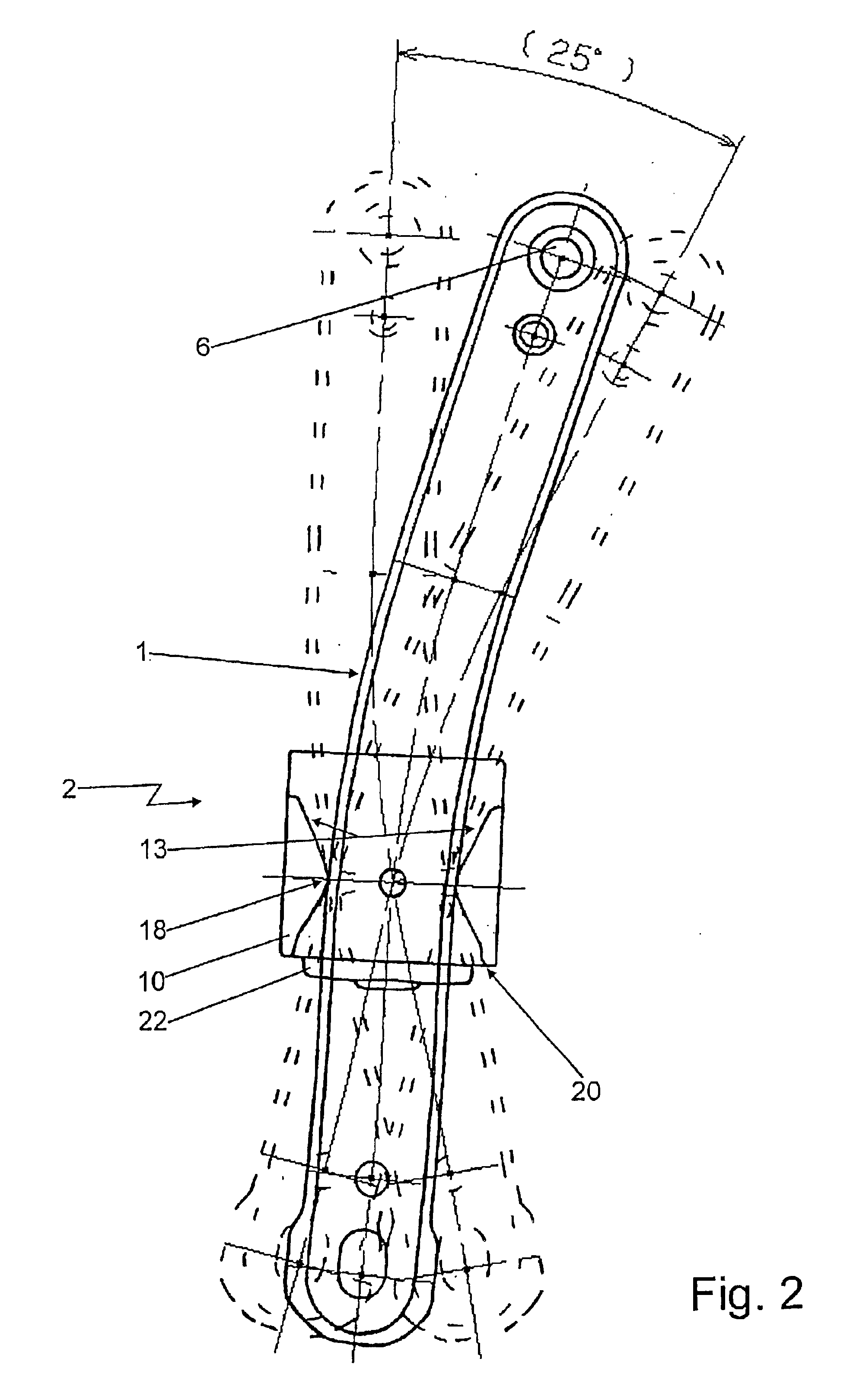

The apparatus for production of mixtures from two components has a container for each and devices to combine the components in the mixing space and for extrusion of the mixture. The powdered component (4) is situated in the lower part of the inner space (21), which is sealed by a bottom (10). This carries a nozzle (2) with closure membrane (3). The inner space (21) is closed on the top by the lower wall (6) and the sliding seal (8). The liquid component (9) is situated in the inner space (18) of the inner hollow cylinder (5). This is closed on the top by the upper wall (11). The lower and upper wall (6) and (11) each have an opening with sealing lips (7) and (12) that are closed by parts of the mixing rod (15). A torus (20), a section with smaller diameter (19), a mixing disk (22), as well as a mandrel (24), are present on the lower part of the mixing rod (15).

Owner:KYPHON

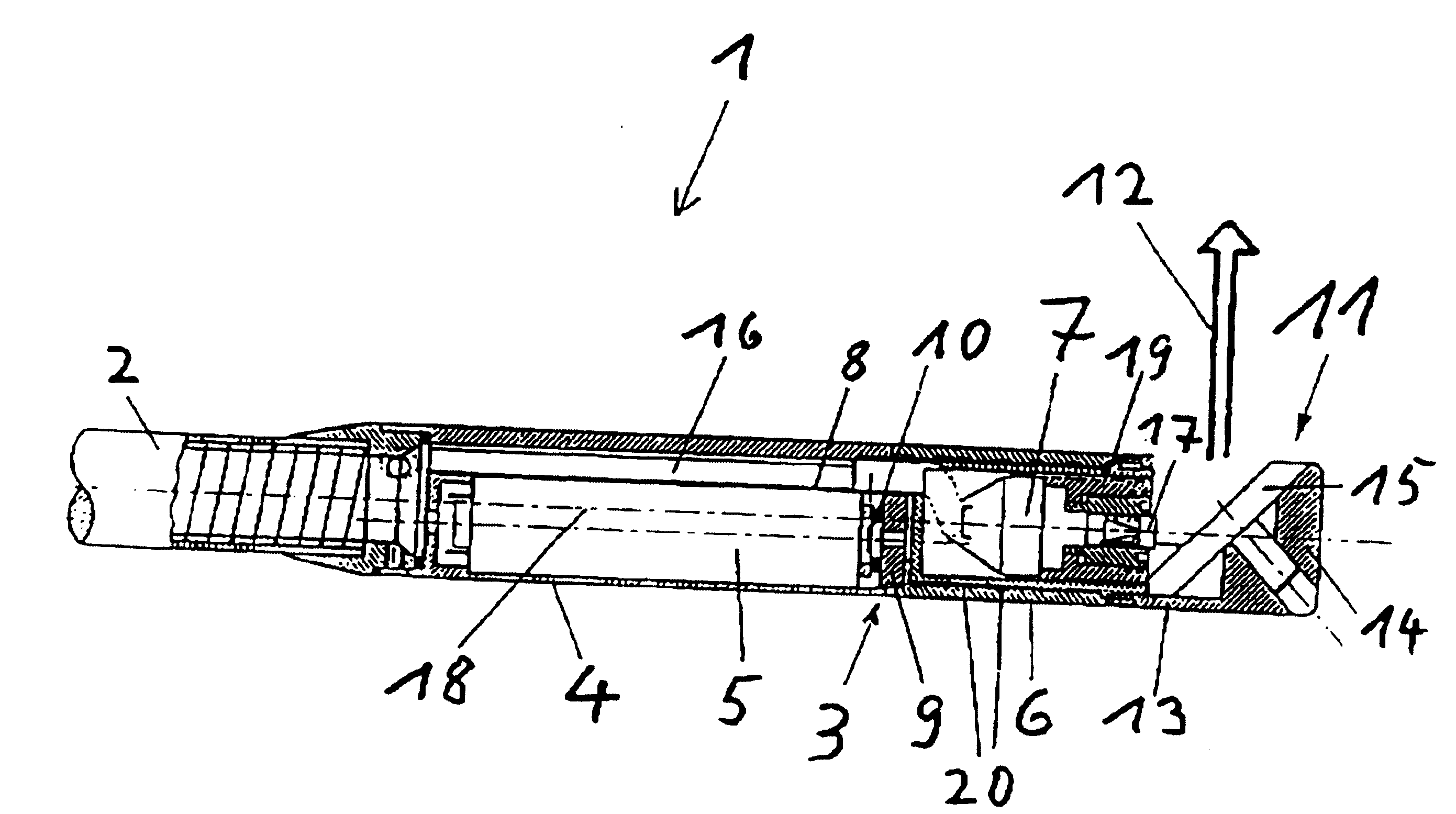

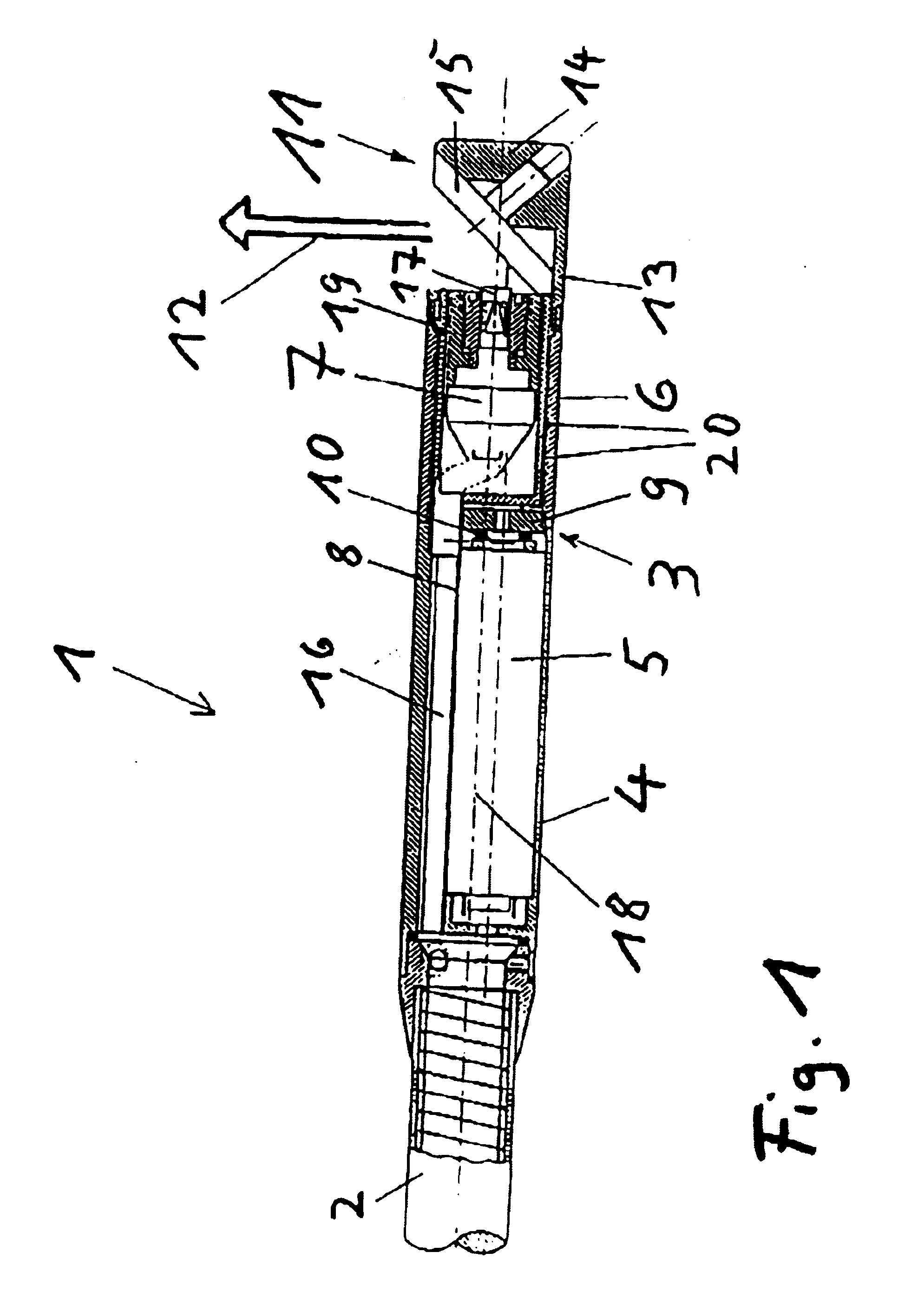

Endoscope with sideview optics

An endoscope (1) is proposed with a rotatable side-viewing optics system (11), which has a mirror (15) for deflecting light onto an object to be examined and for reflecting the image of the object. A video camera (7) is located inside a hollow cylinder (6) that can be moved in rotation and the side-viewing optics system (11) is mechanically connected to the hollow cylinder (6) on the side that faces away from the viewing direction (12) of the video camera (7).

Owner:ZAAR KERSTEN

Intervertebral implant

InactiveUS7303583B1High degreePrevent implantationSurgeryDomestic plumbingLateral regionBiocompatibility Testing

Owner:SYNTHES USA

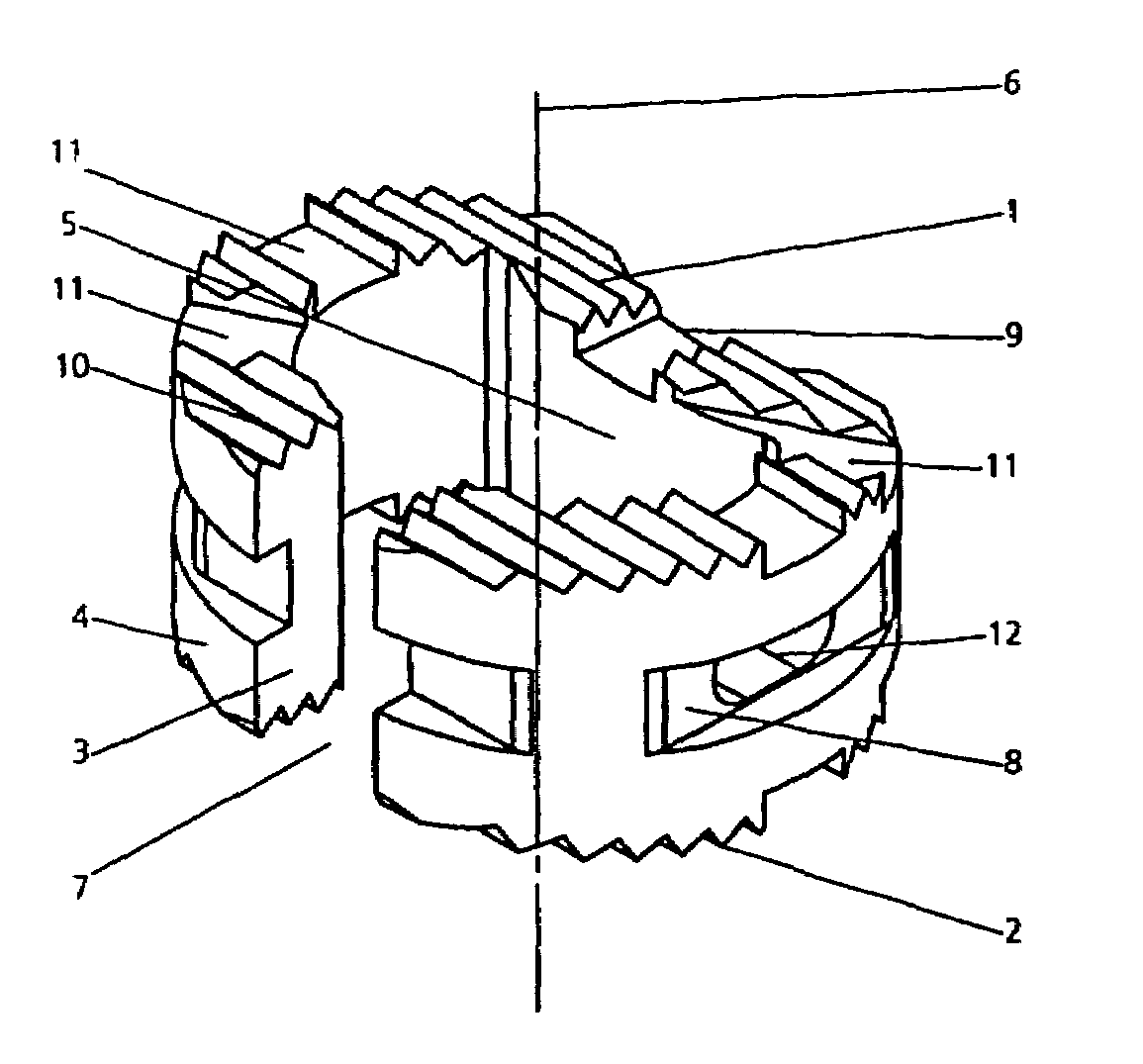

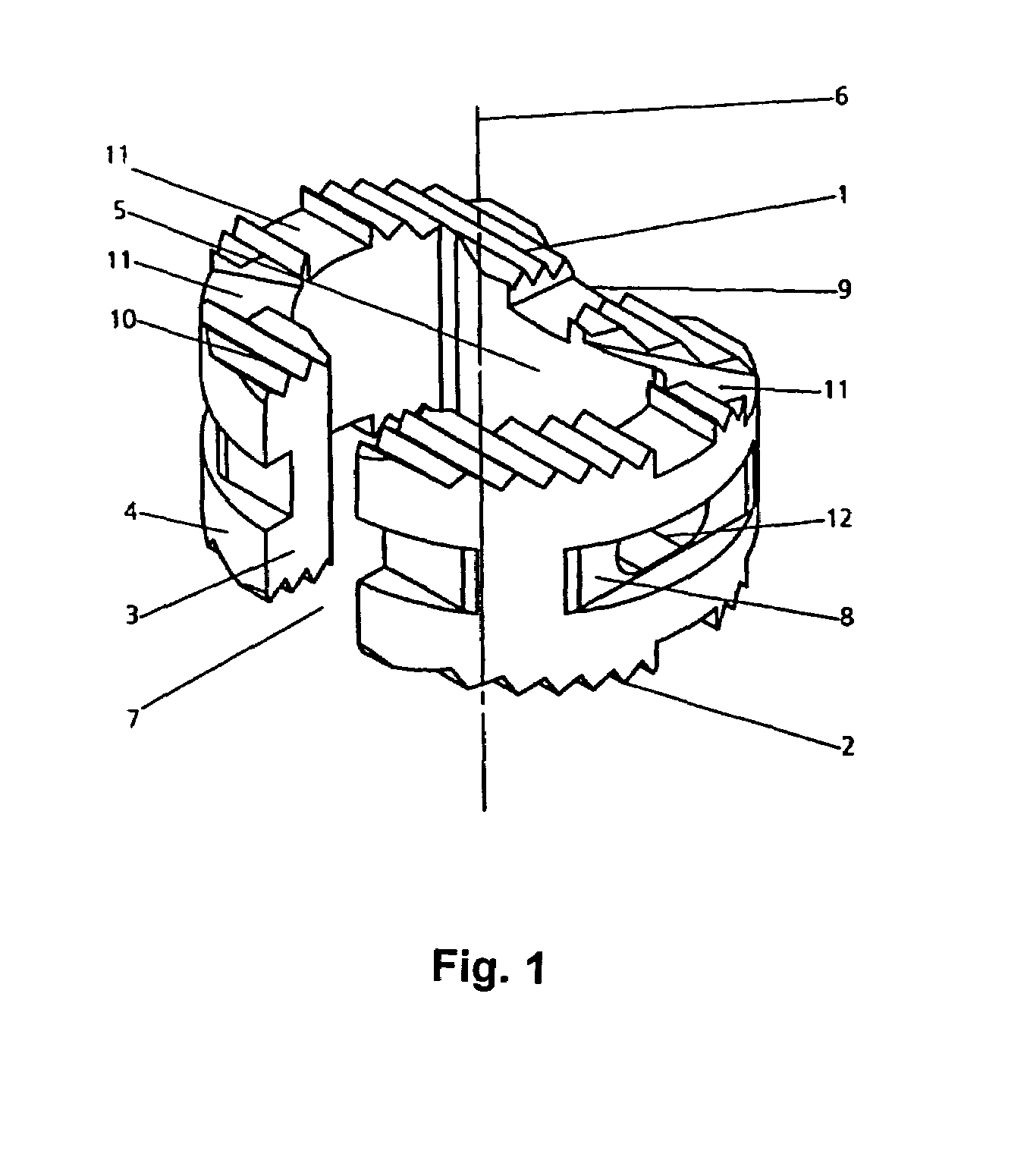

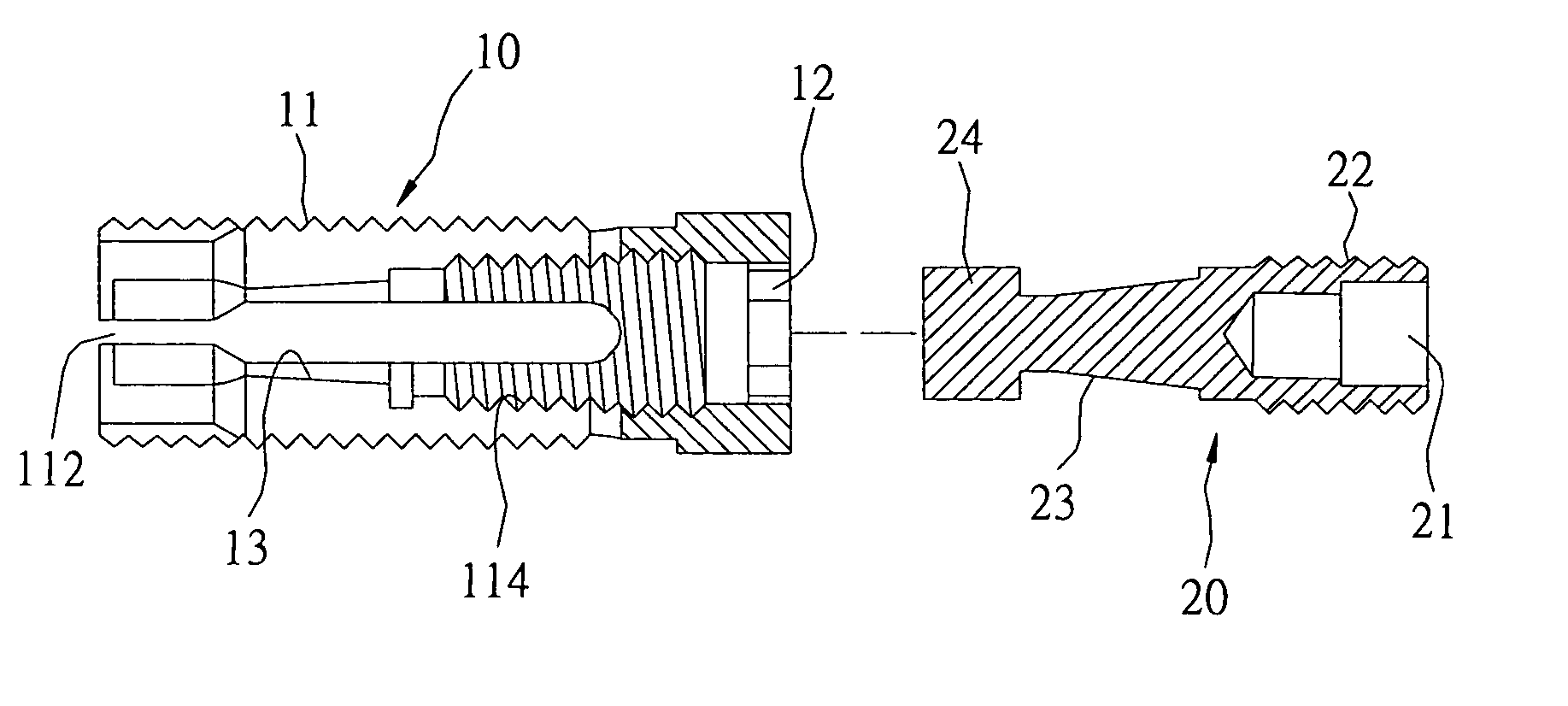

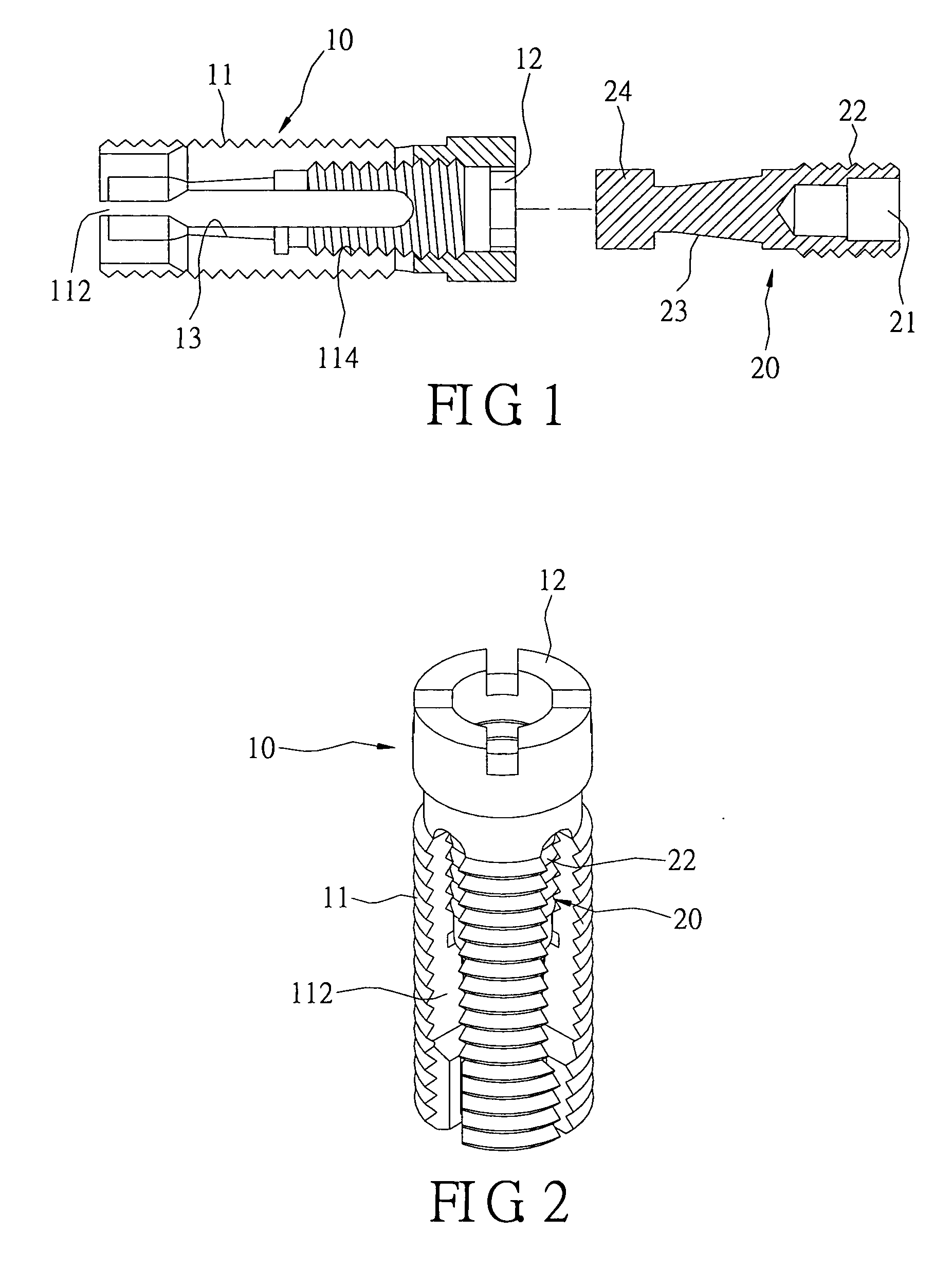

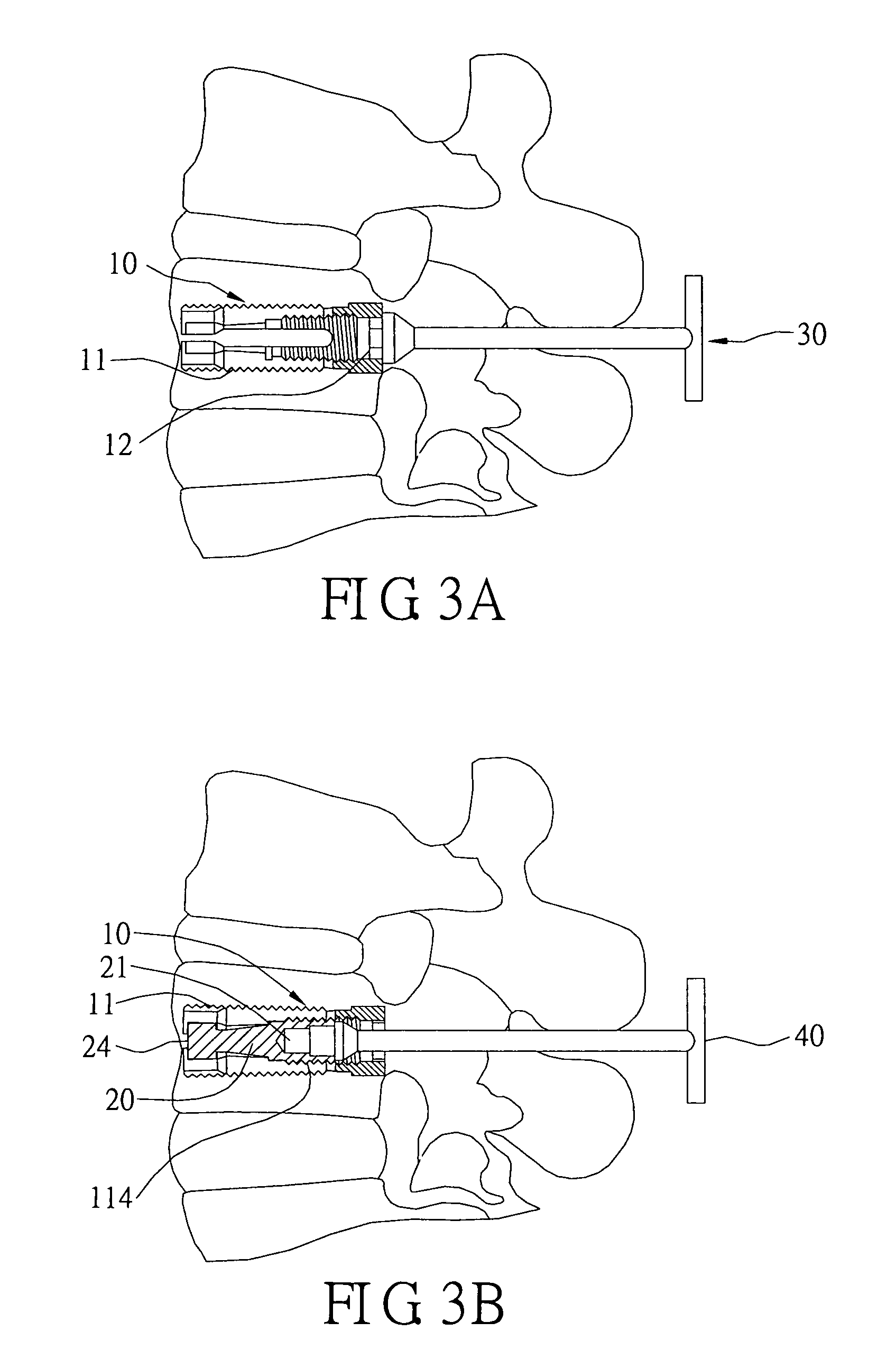

Human bone substitutional implant

A human bone substitutional implant comprises a main body and a push body. The main body is a hollow cylinder with a thread portion or a ratchet portion disposed on its outer wall. The thread portion or the ratchet portion has at least a slit dividing it into four equal parts. An inner thread is disposed on the inner wall of the thread portion or the ratchet portion. An outer thread is disposed on the outer surface of the push body and corresponds to the inner thread. The push body and the main body are joined together via screw connection of the outer thread and the inner thread. Because the main body has a conical passage therein, the main body will be held open a certain angle to support and enhance a fractured bone of the human body when the push body is axially pushed into the main body.

Owner:WU SHING SHENG

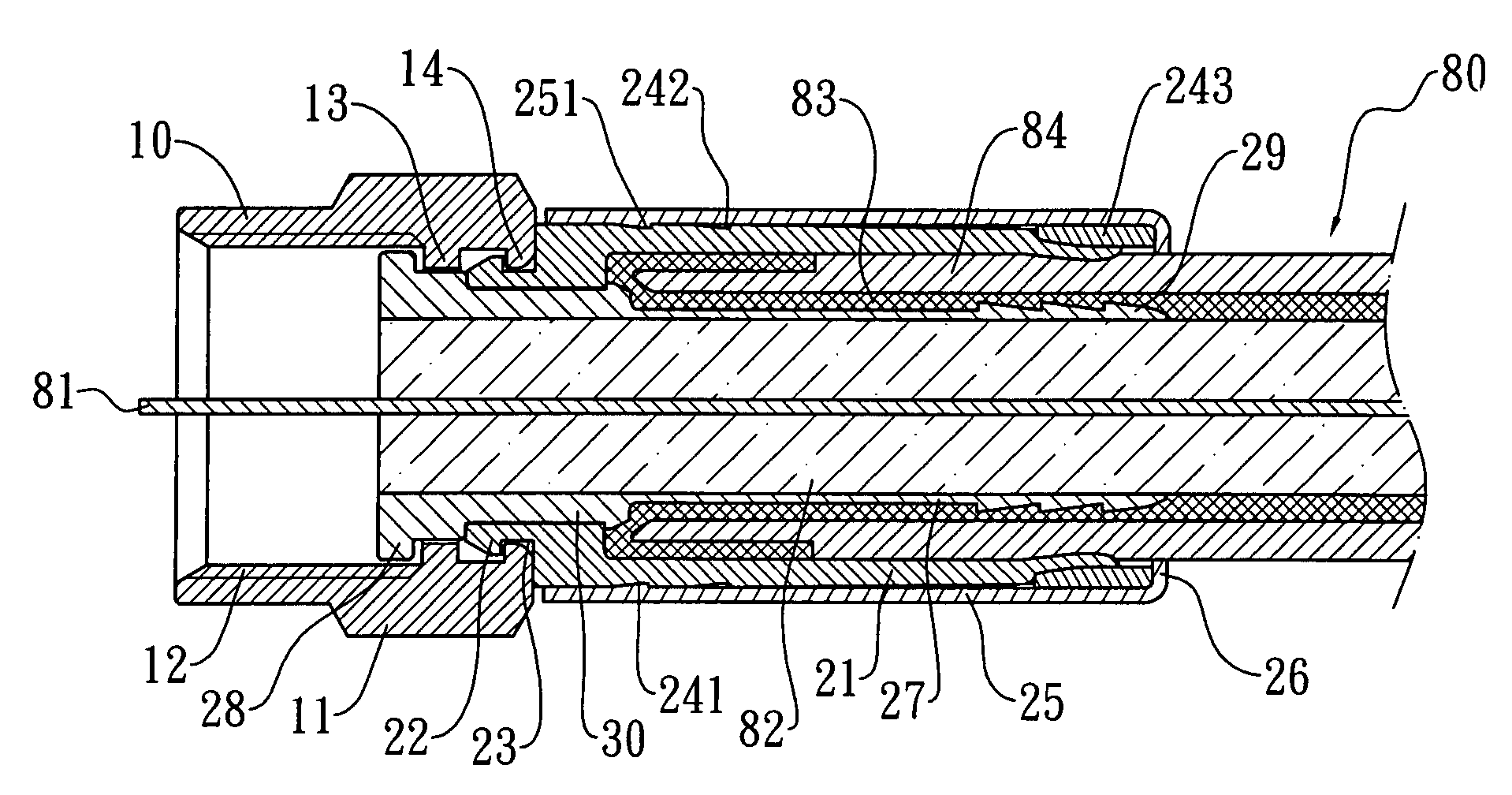

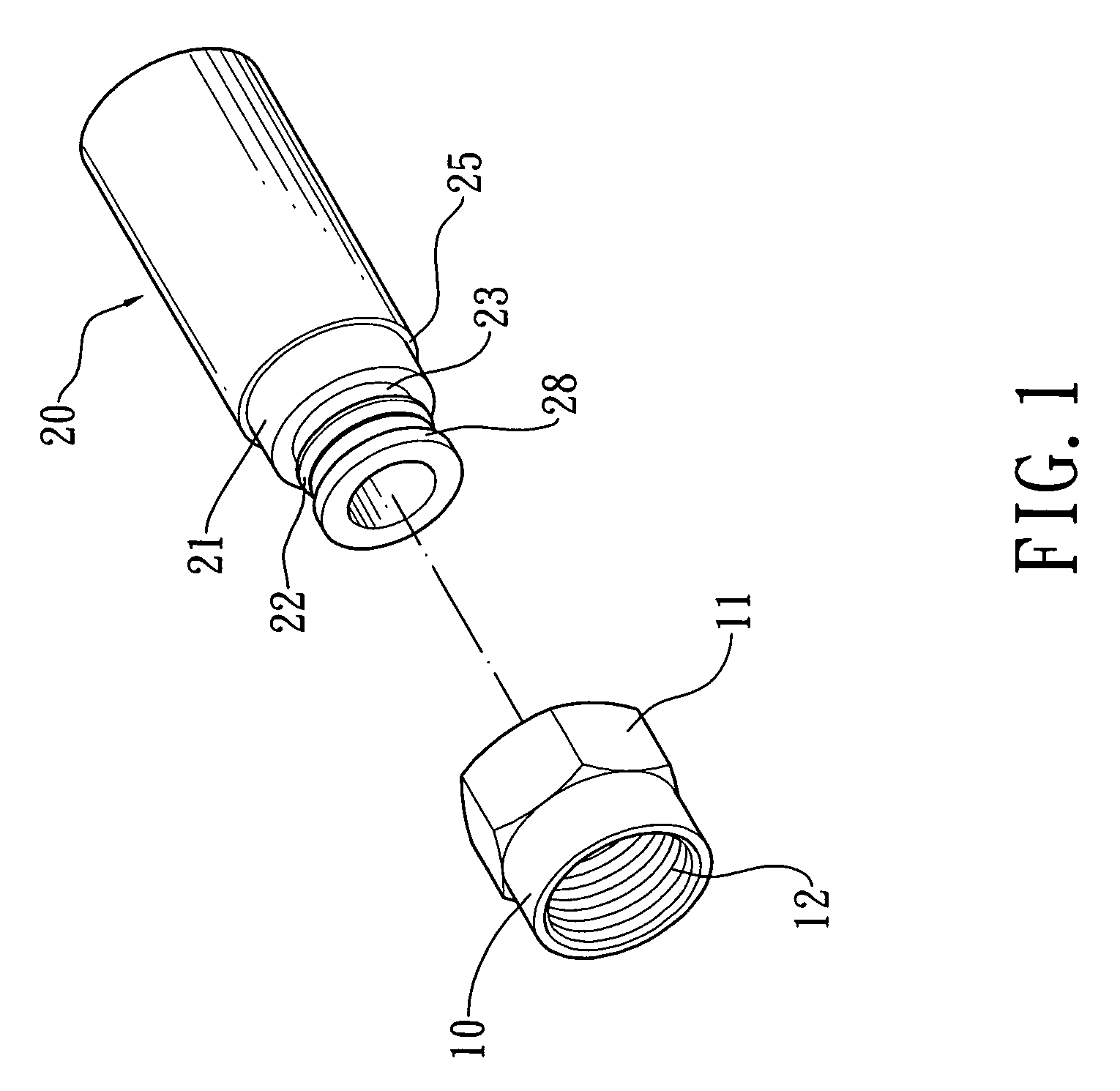

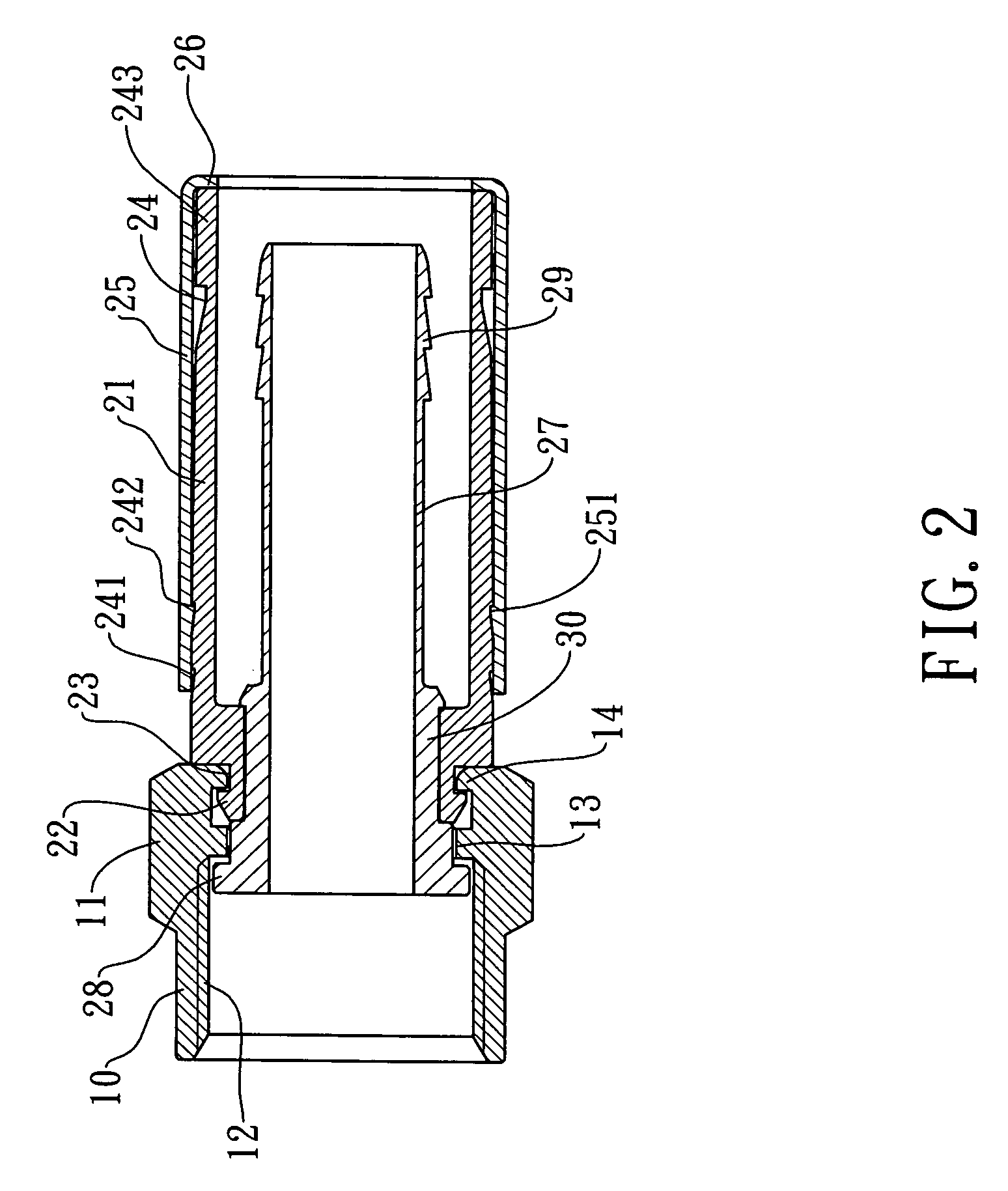

Coaxial cable connector

ActiveUS7125283B1Simple structureEasy to assembleElectrically conductive connectionsCoaxial cableCoupling

A coaxial cable connector comprises a head and a hollow cylinder. The hollow cylinder comprises a protective cylinder, a tubular shaft, and an elastic cylinder. The tubular shaft comprises a guide hole, a plurality of ladders, a locking flange, and a plurality of hooks. The elastic cylinder comprises a trench and a hook at one end and a locking ring defined by a notch near the other end. A bended metal tube having a stopper is mounted on the protective cylinder. In the coupling process, the coaxial cable inserts into the hollow cylinder. By using a pressure from a tool to break the notch of the elastic cylinder, the locking ring is separable from the elastic ring, and the locking ring shifts forward continuously along an inclined surface of the notch. Since the protective cylinder restrains the locking ring, the connector can couple with the coaxial cable tightly by pressing down the locking ring.

Owner:EZCONN

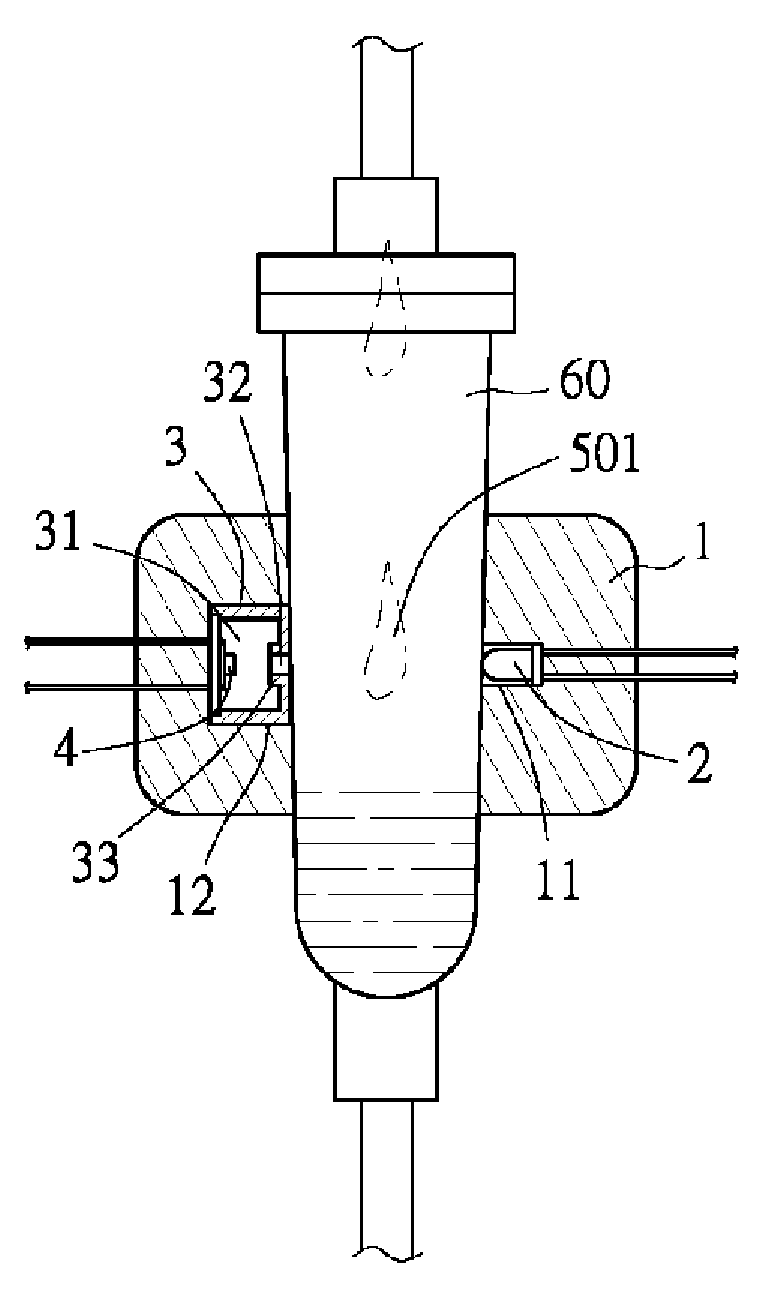

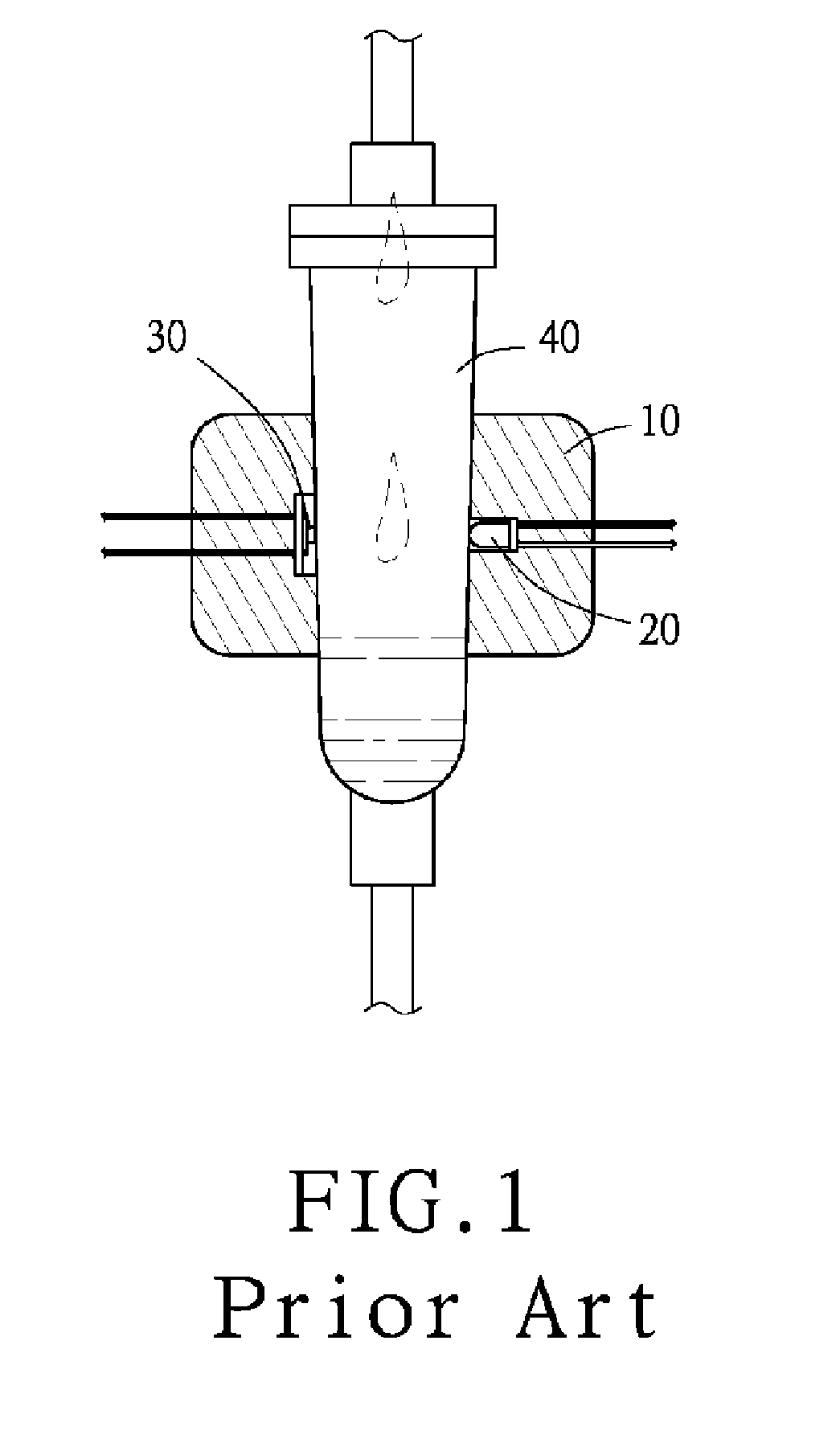

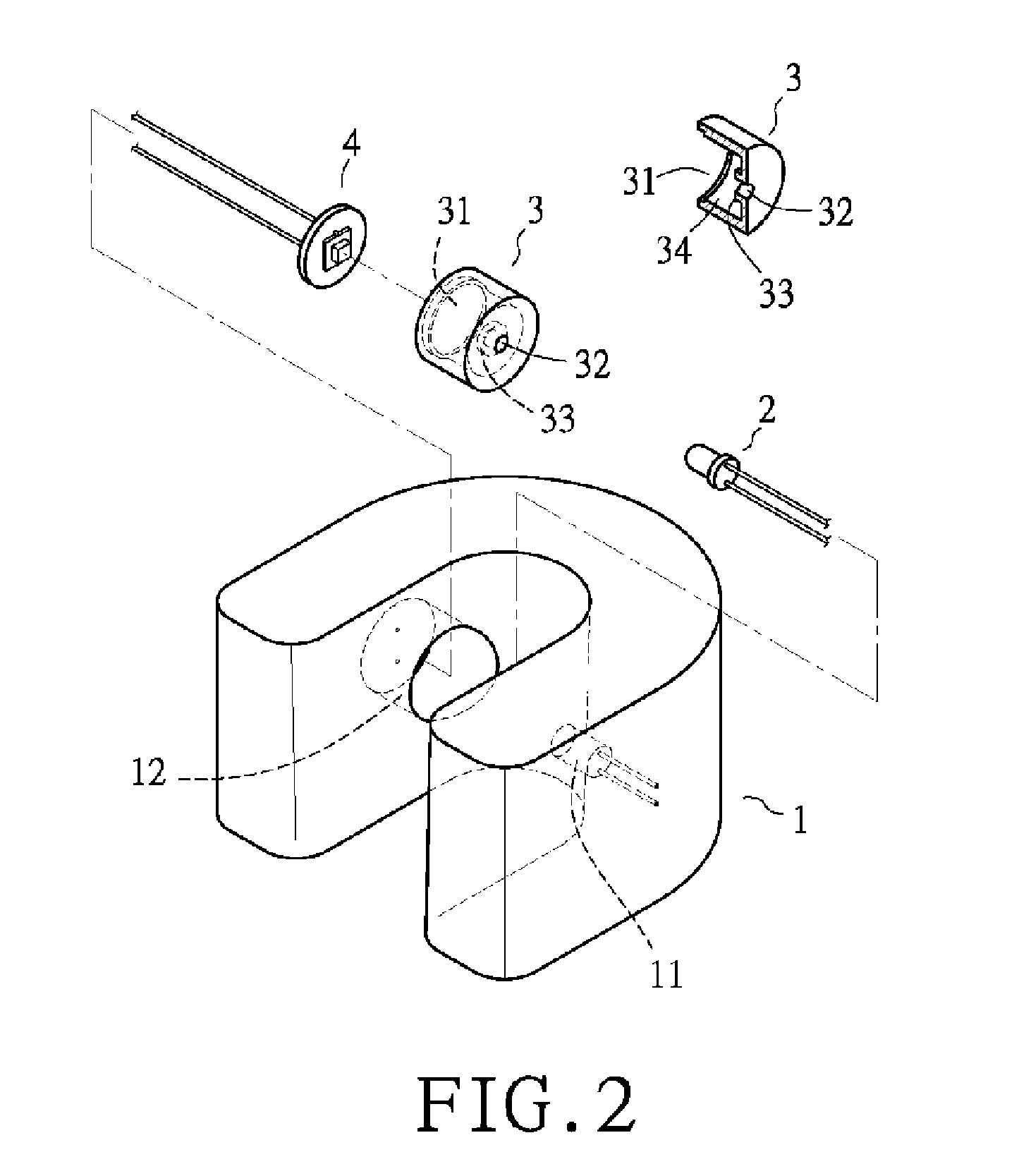

Drop sensing device for monitoring intravenous fluid flow

InactiveUS20080051732A1Reception sensitivity is degradedImprove receiver sensitivityMedical devicesFlow monitorsIV InfusionBiomedical engineering

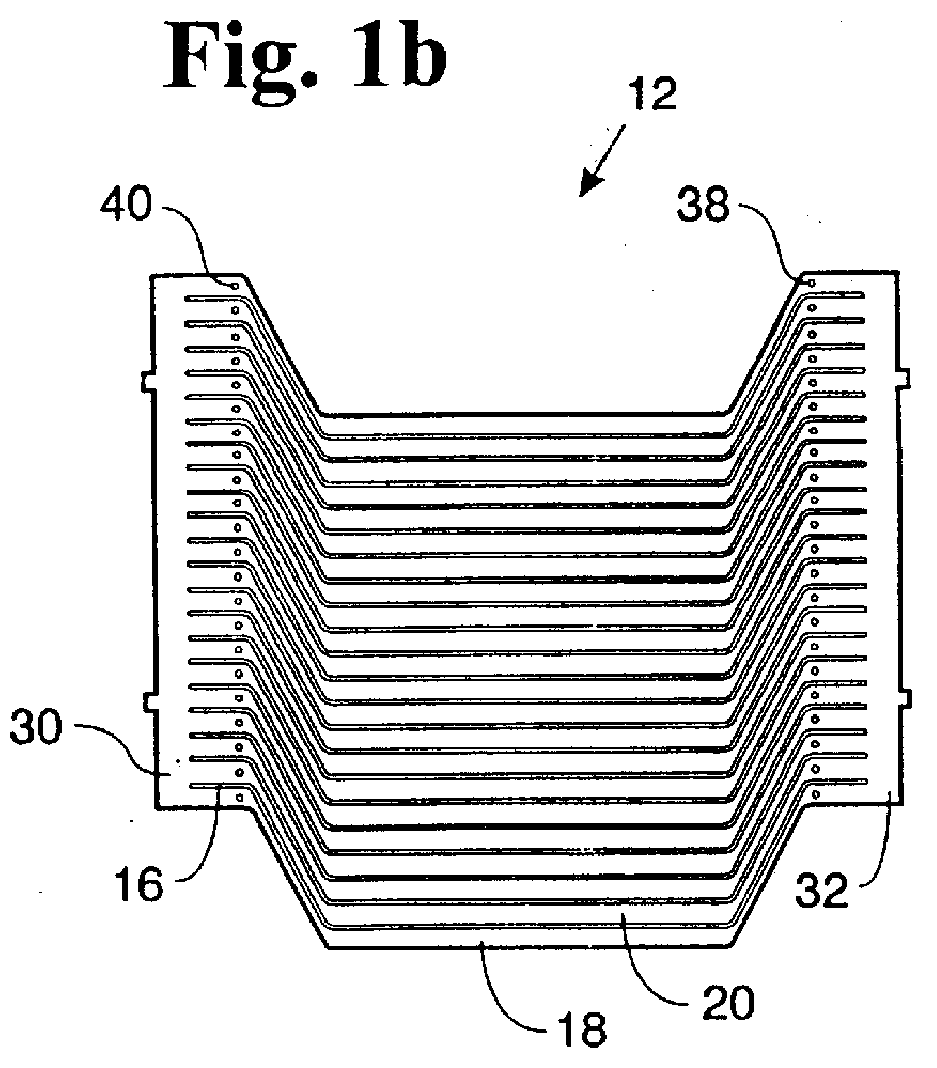

A drop sensing device for monitoring intravenous (IV) fluid flow is provided. The device comprises a U-shaped clip mountable on a drip chamber of an IV infusion set. The clip has a light source provided at one side for emitting radiation and a hollow cylinder provided in a through hole on the side opposite the light source. The cylinder includes an aperture of a diameter smaller than an average diameter of fluid drops passing the drip chamber, and an optical sensor mounted on a rear end of the cylinder opposite the aperture, so as to substantially enhance sensitivity of light ray receiving.

Owner:LEE JU LIN +1

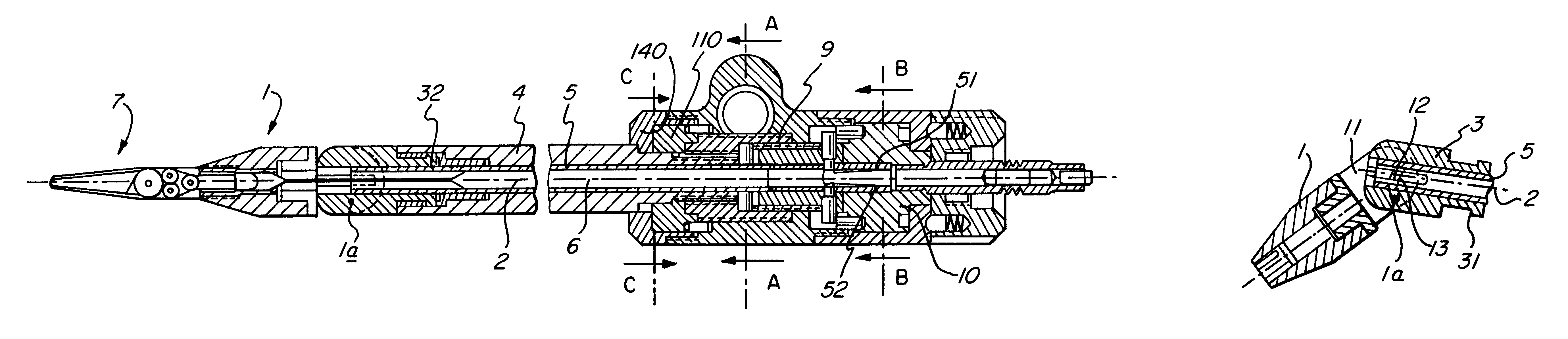

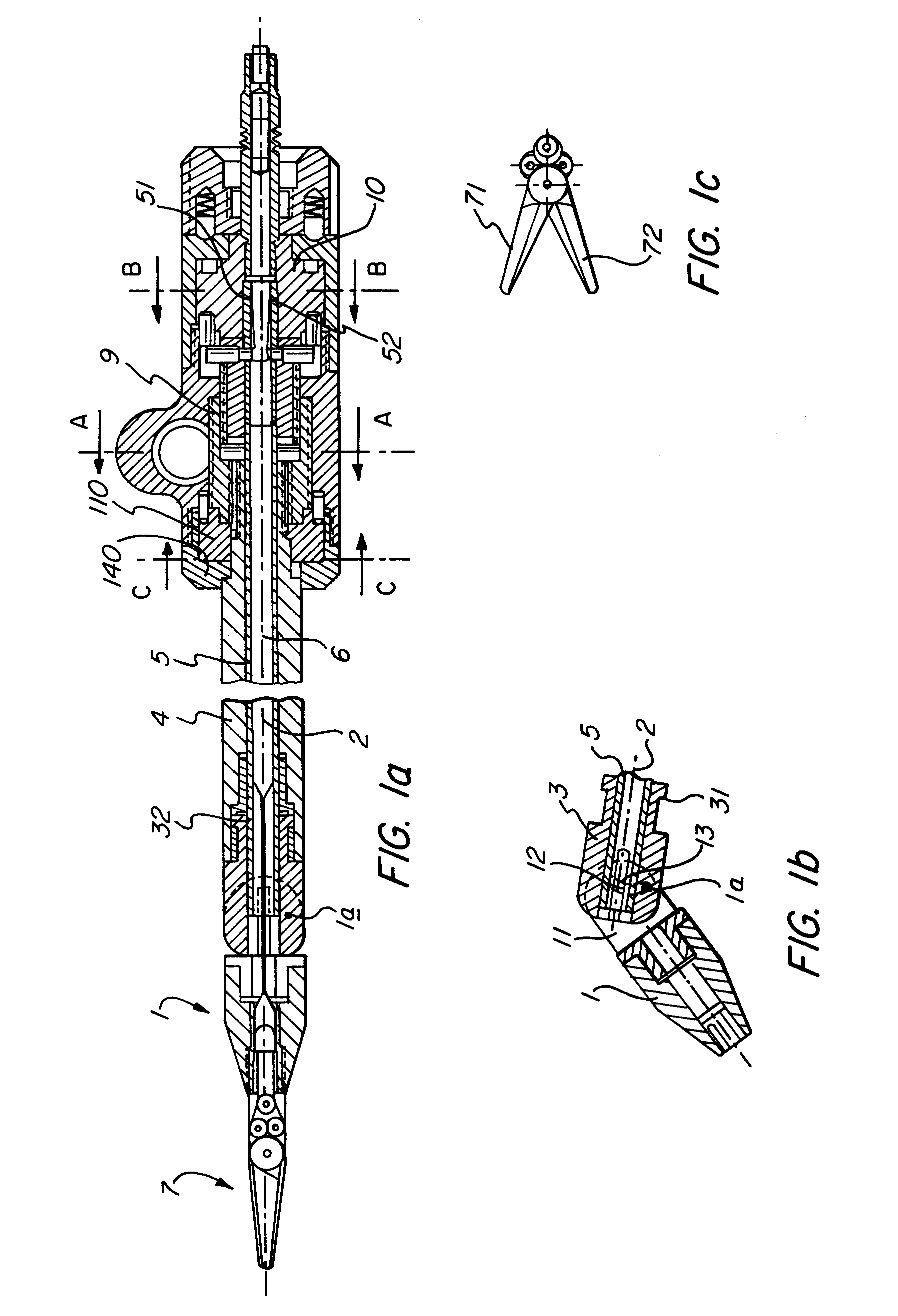

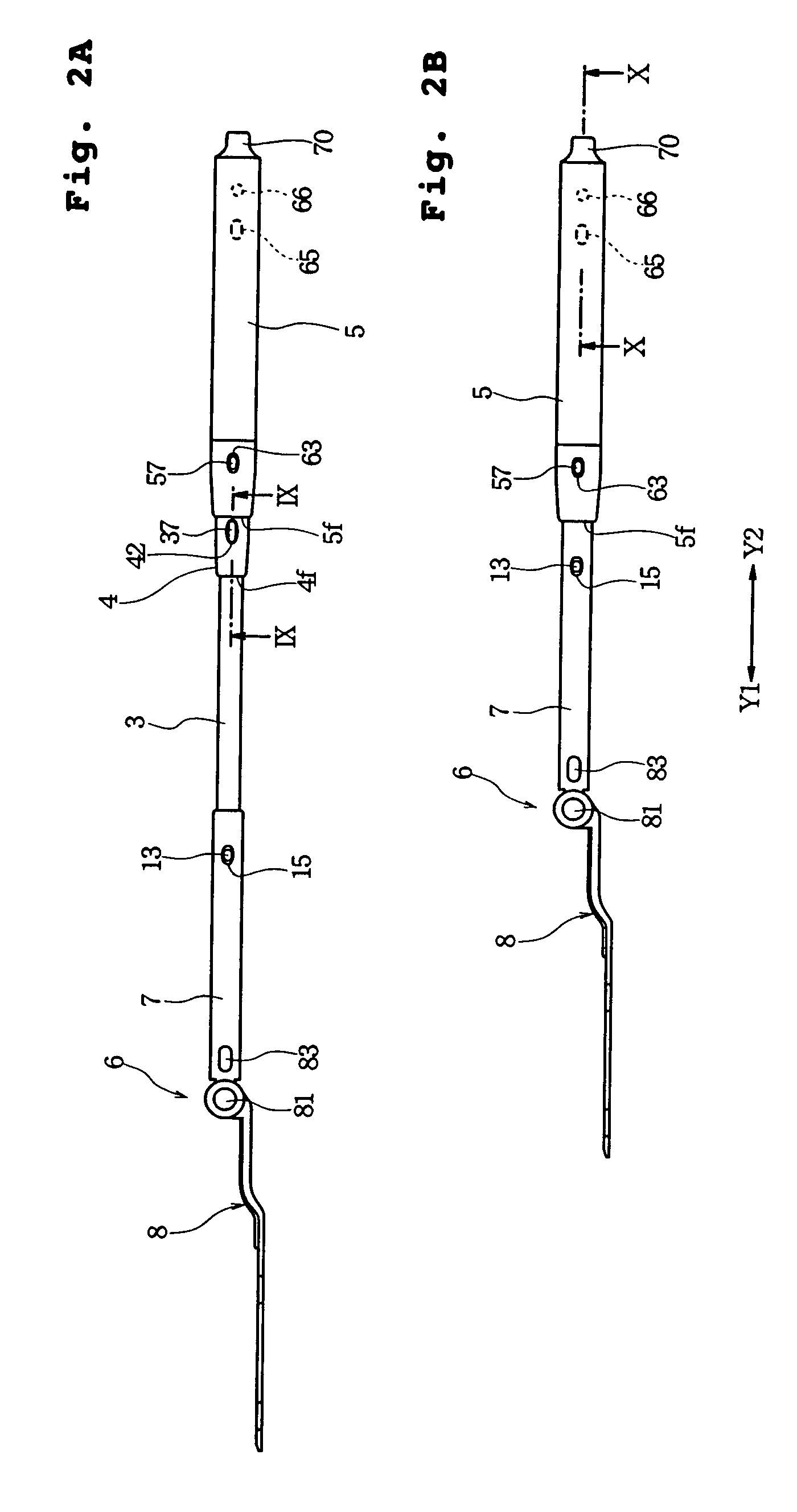

Endoscopic instrument which can be bent

An endoscopic instrument has an external tube and a hollow cylinder coaxially extending along a longitudinal axis and actuatable to move axially in opposite directions to rotate a distal end of the instrument provided with an engaging element between angular positions. The distal end actuated by the outer tube is rotatable about a pin having an axis of rotation which is spaced radially from the longitudinal axis as another pin formed on and extending radially from the cylinder is guided along an arcuate groove provided on the distal end of the instrument.

Owner:KARL STORZ GMBH & CO KG

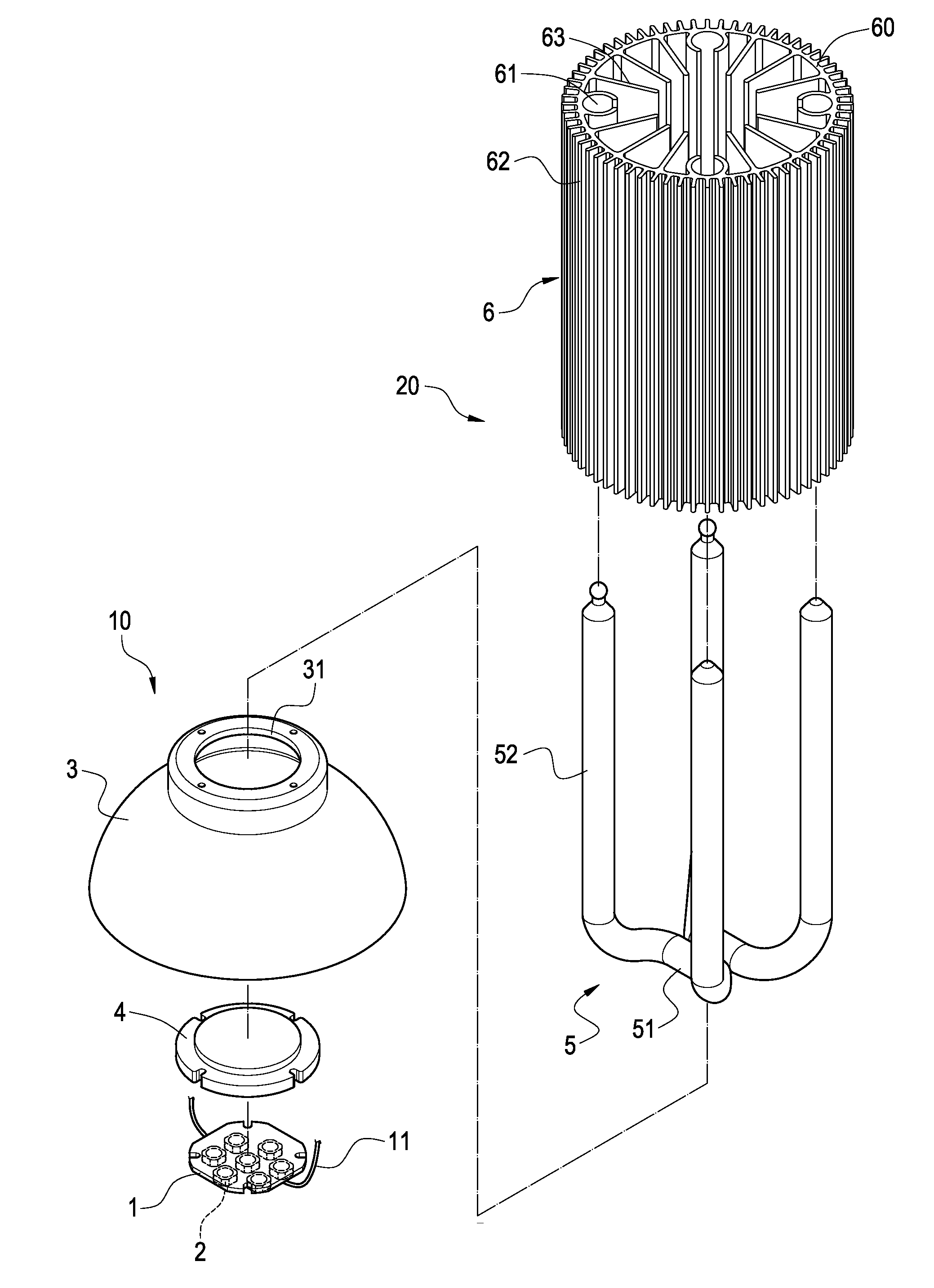

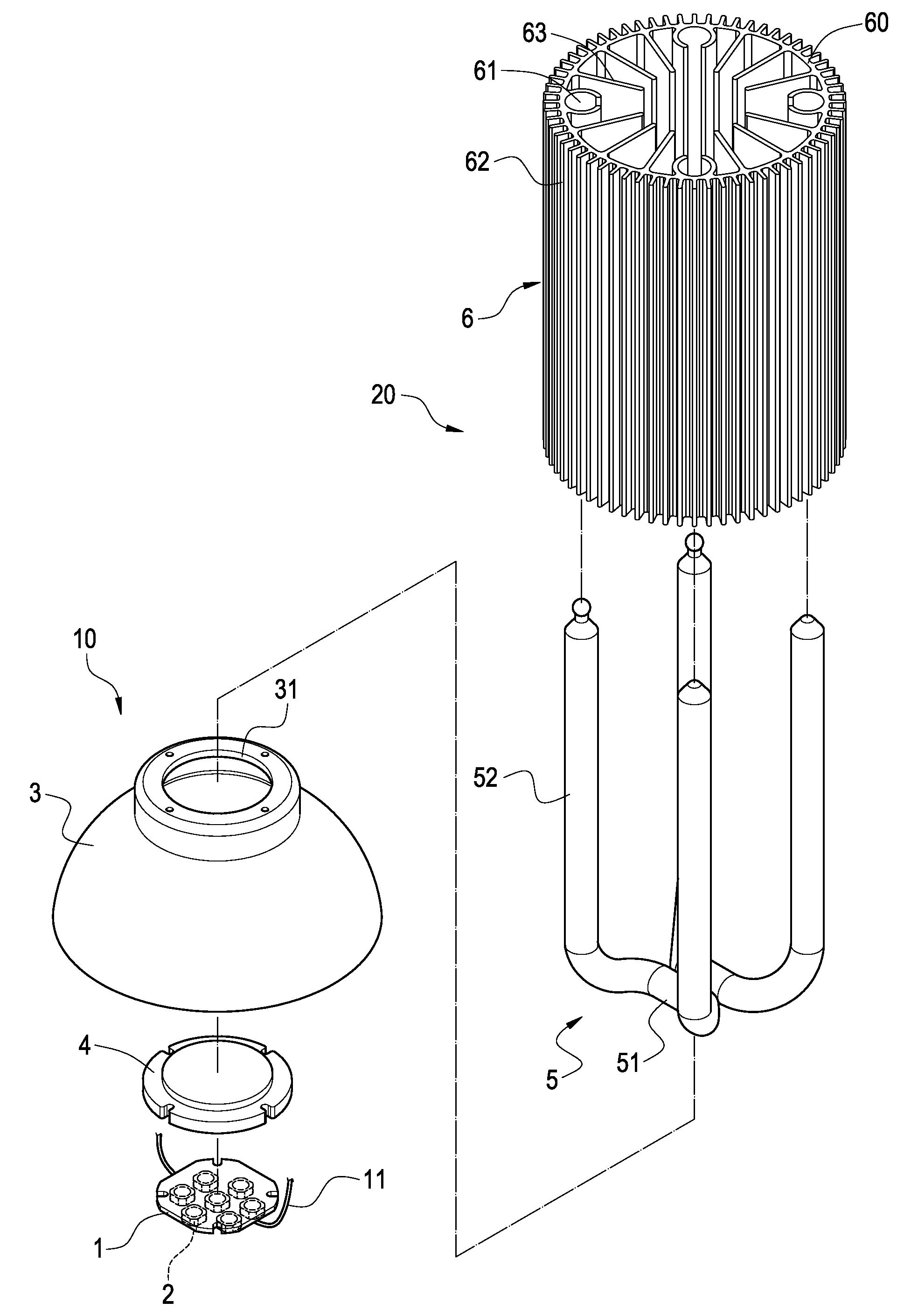

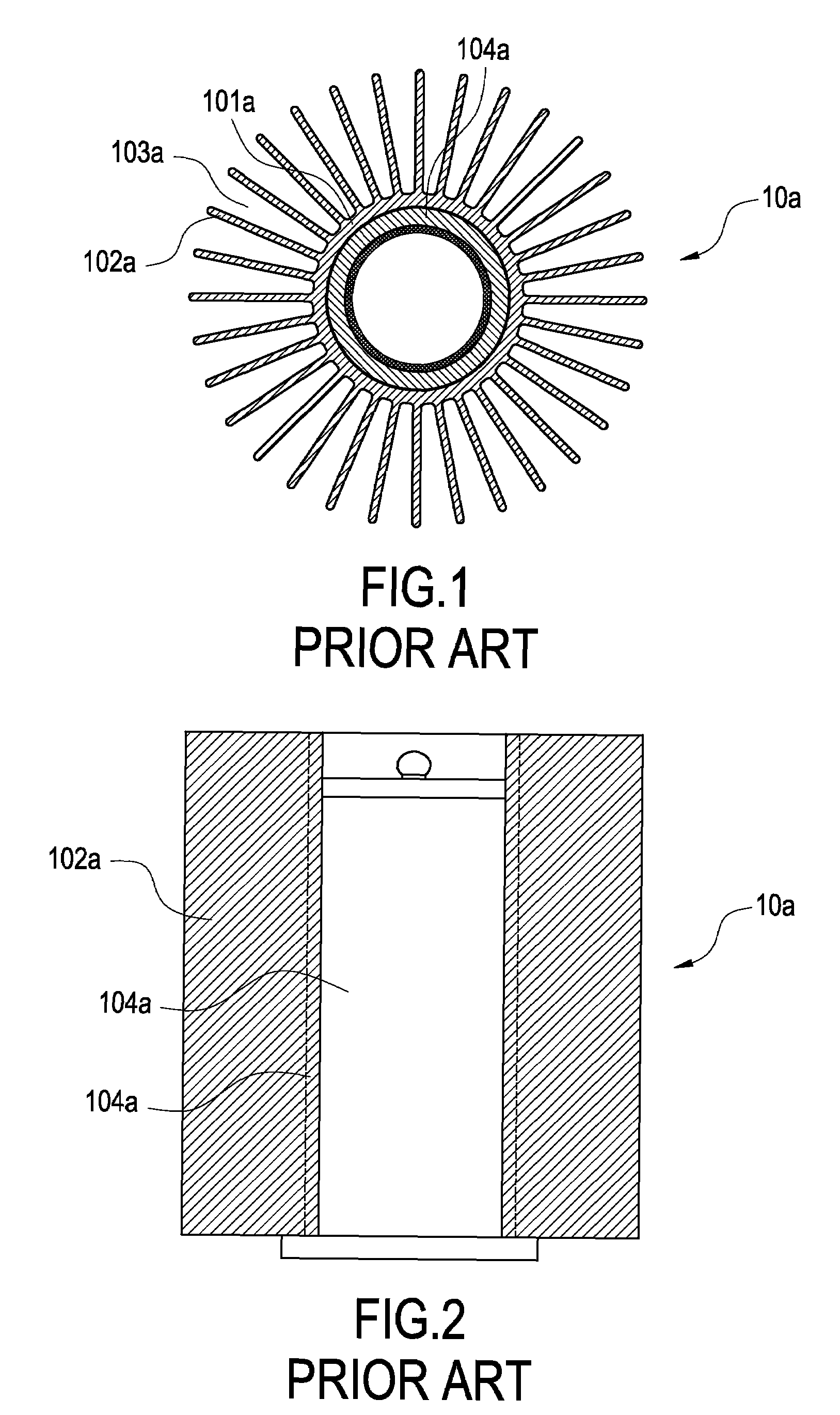

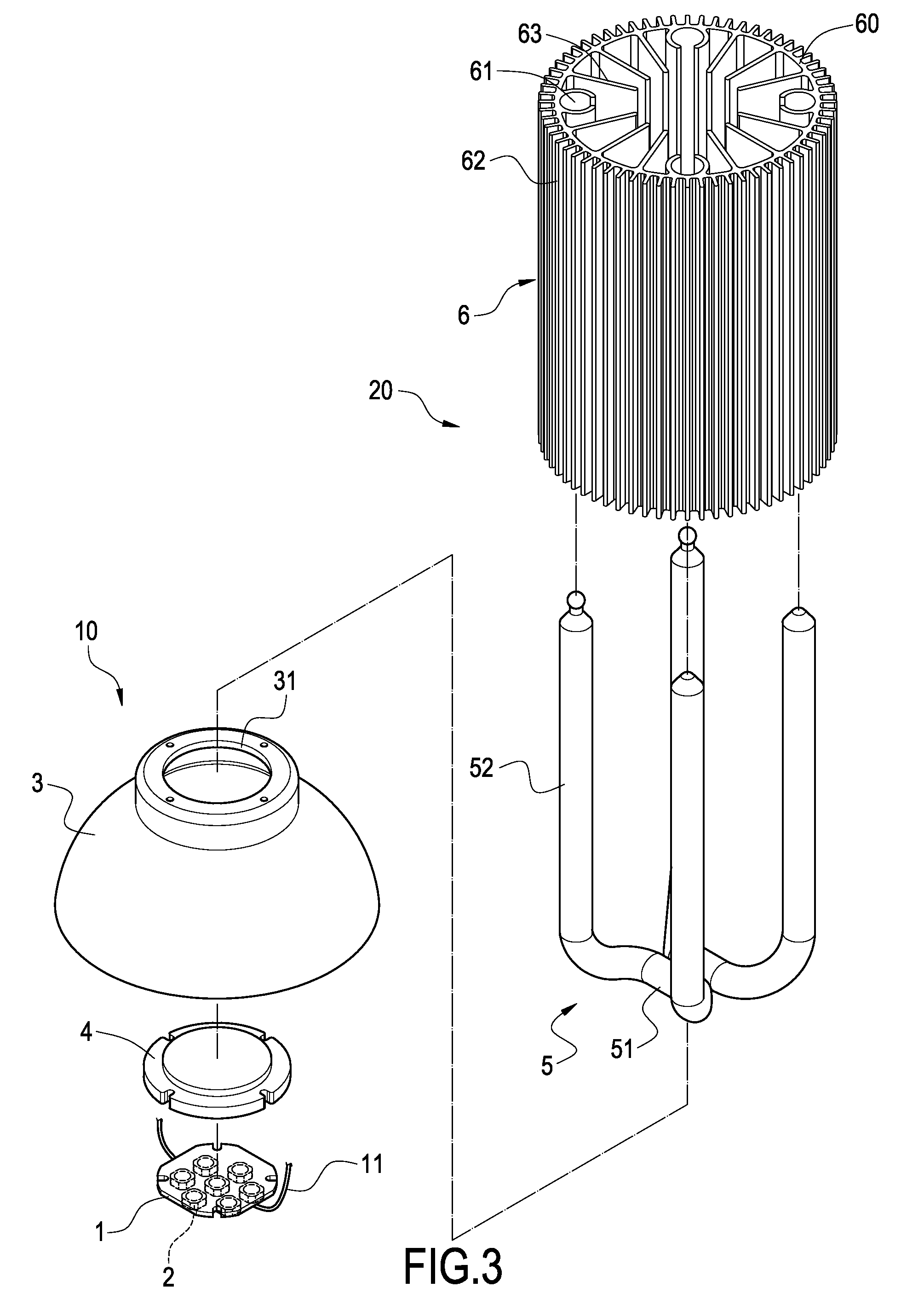

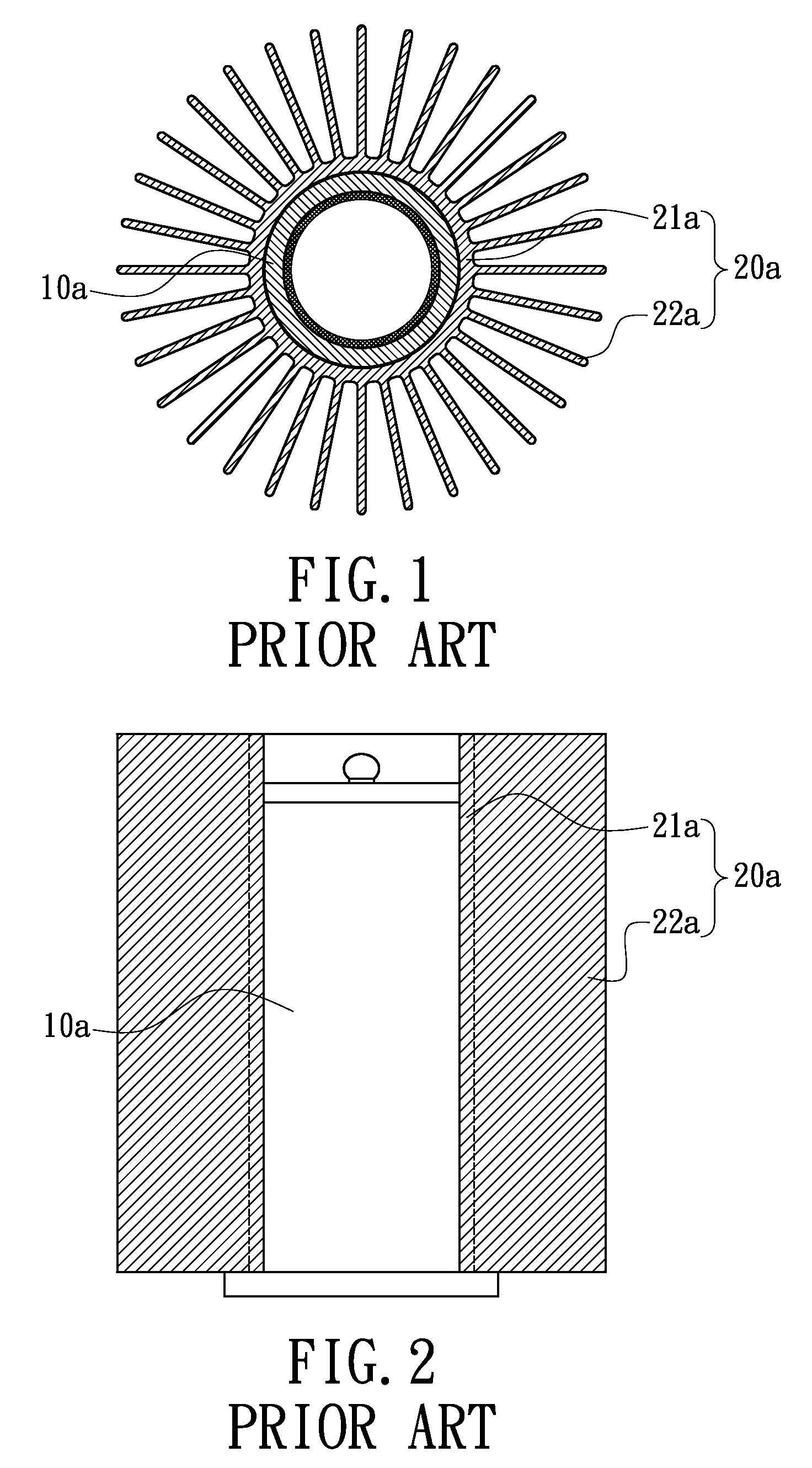

Heat-Dissipating Structure For LED Lamp

InactiveUS20080007954A1Increase contact areaFast conductionPoint-like light sourceLighting heating/cooling arrangementsHeat sinkAluminum extrusion

A heat-dissipating structure for a LED lamp includes a heat-dissipating base, a heat-dissipating body and a plurality of heat pipes. The heat-dissipating body has an outer cylinder formed into a hollow cylinder. The inside surface of the outer cylinder is provided with a plurality of accommodating grooves. The condensed ends of the plurality of heat pipes are inserted into the accommodating grooves. The end to be heated of the heat pipe is adhered to the heat-dissipating base. Further, the inside surface and the outside surface of the outer cylinder are formed with a plurality of heat-dissipating fins made by aluminum extrusion, so that the heat pipes are encircled by the heat-dissipating fins. In this way, the heat can be conducted by the plurality of heat pipes so as to increase the total contacting area. Thus, the heat can be rapidly conducted to the outer cylinder. Further, the heat can be rapidly dissipated to the outside by the heat-dissipating fins, thereby to substantially increase the efficiency in the heat dissipation.

Owner:JAFFE

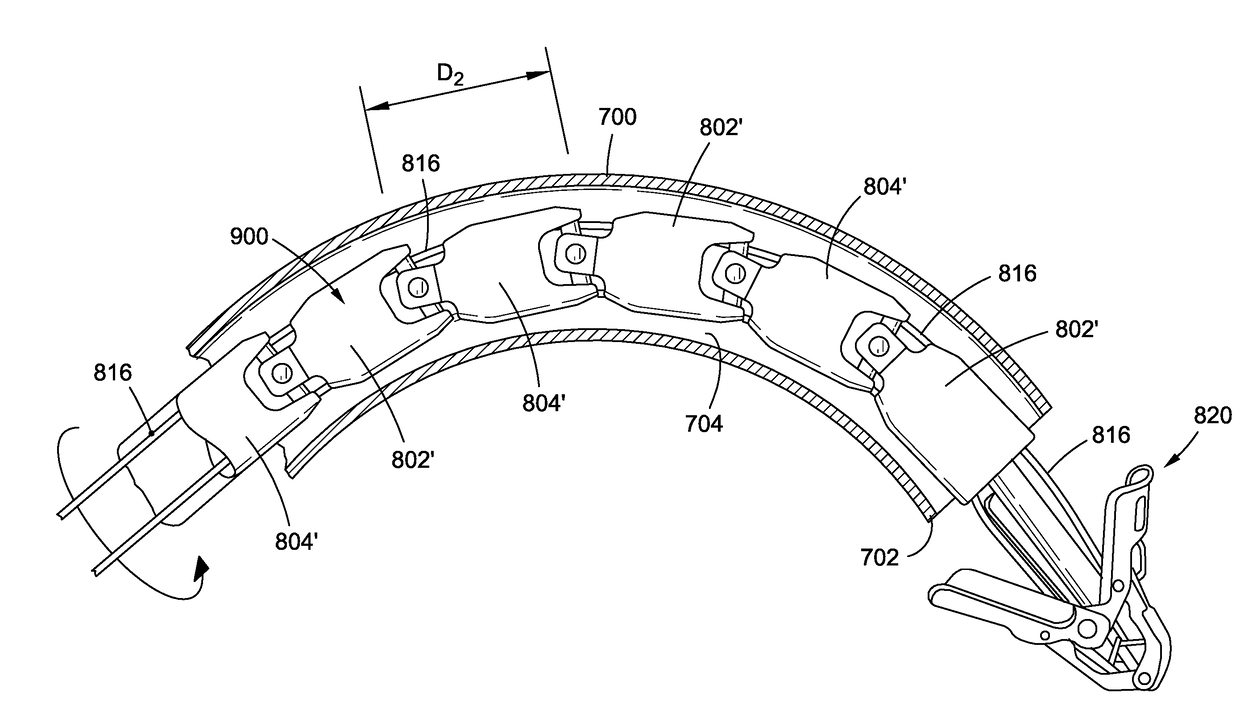

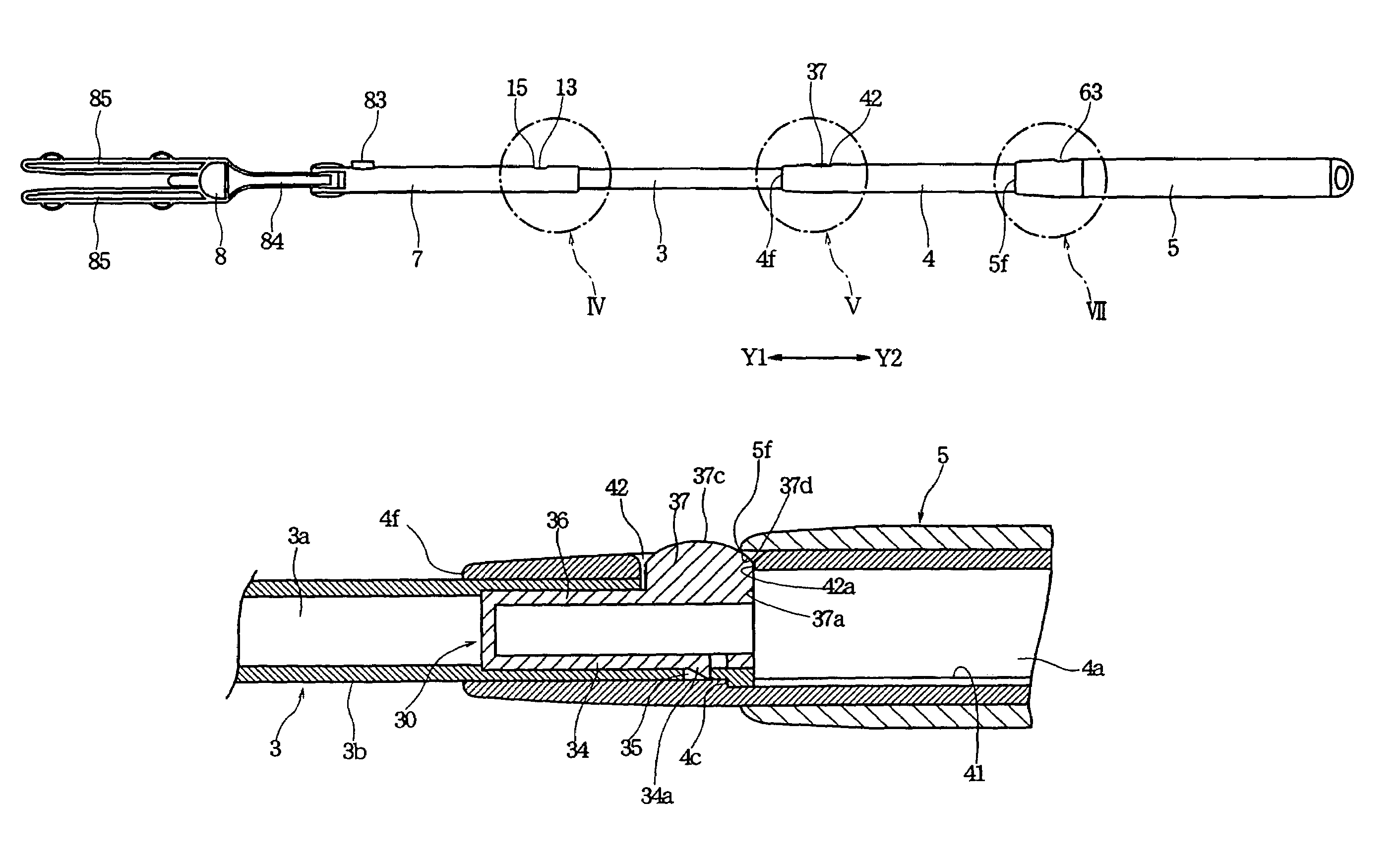

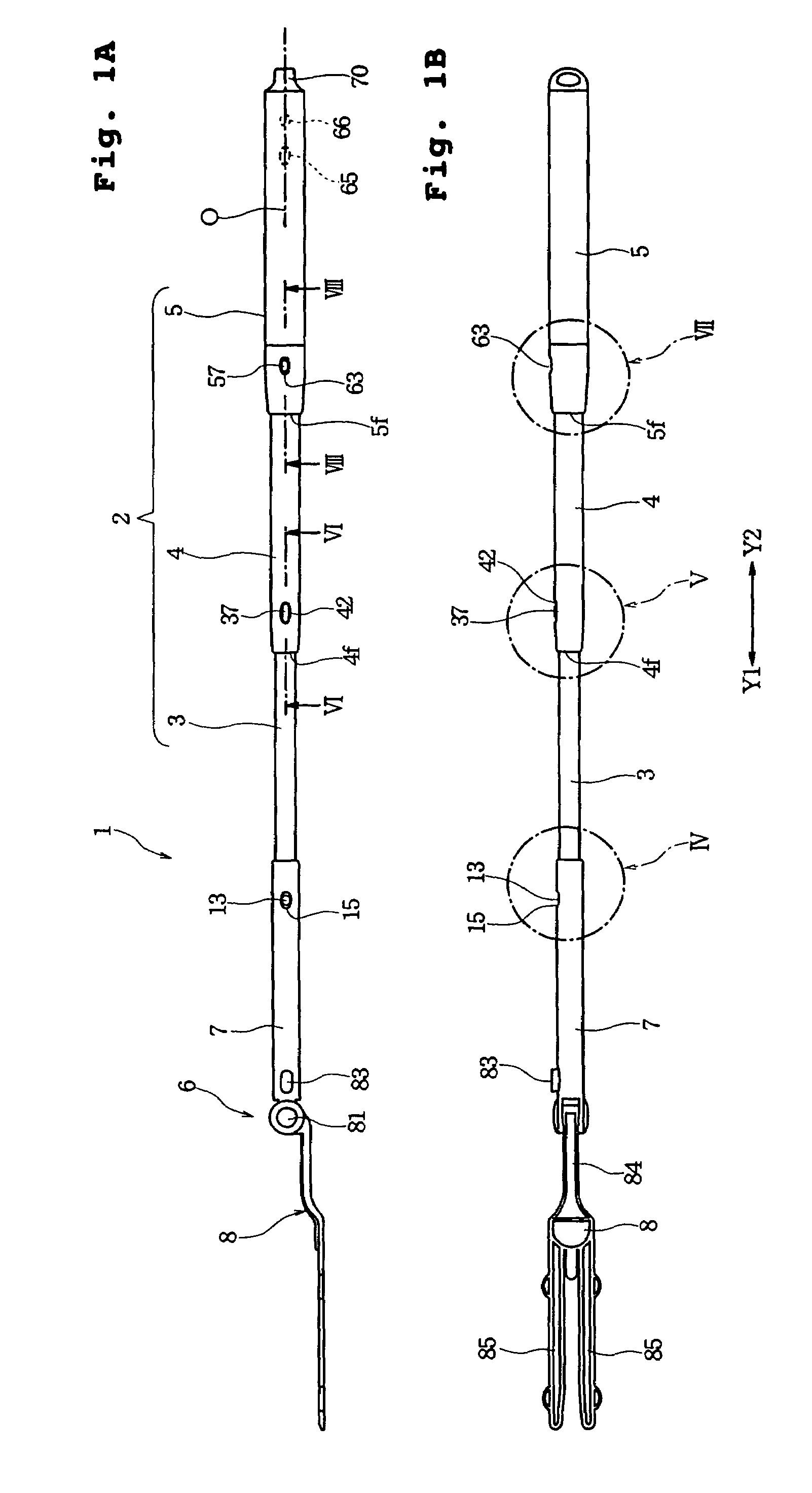

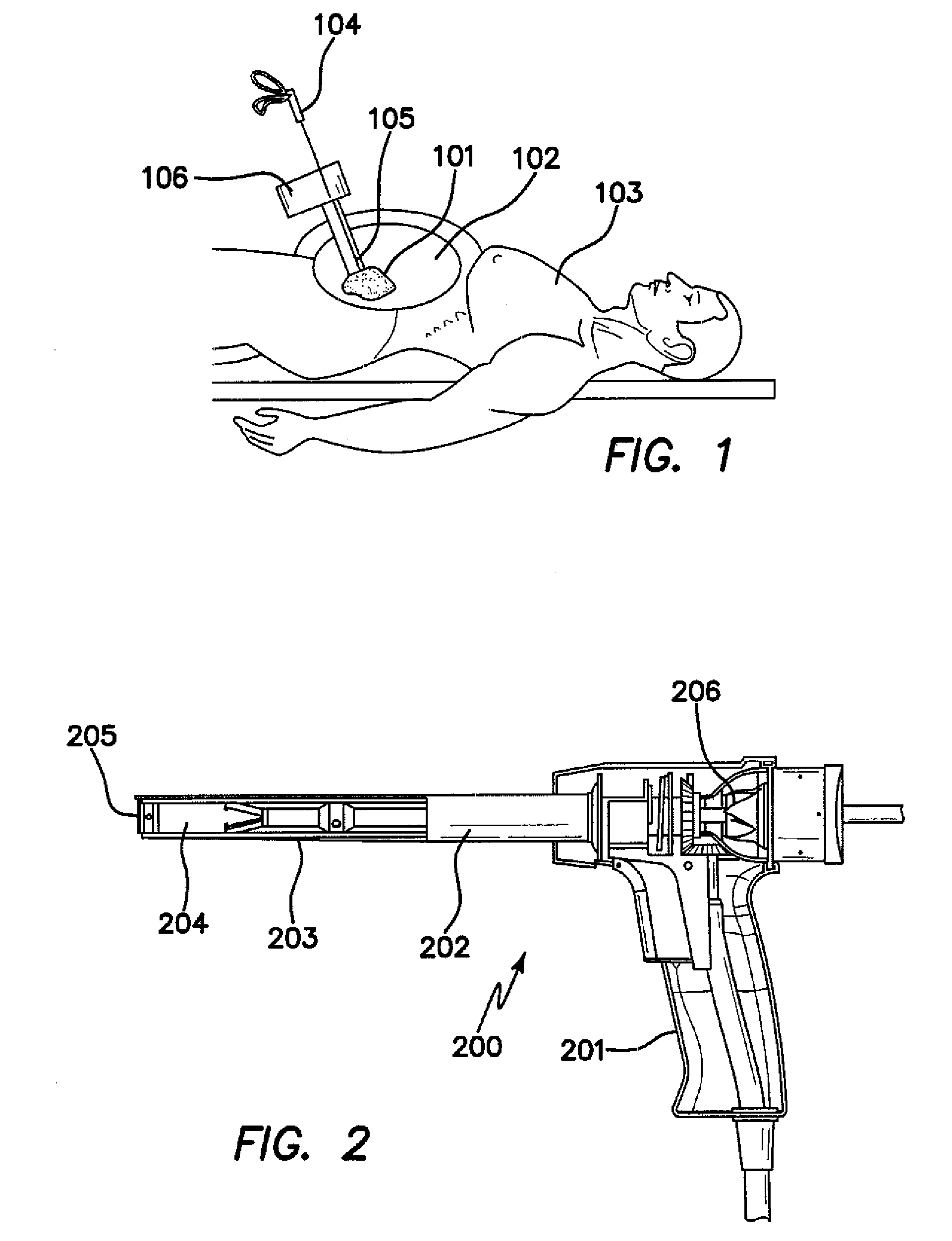

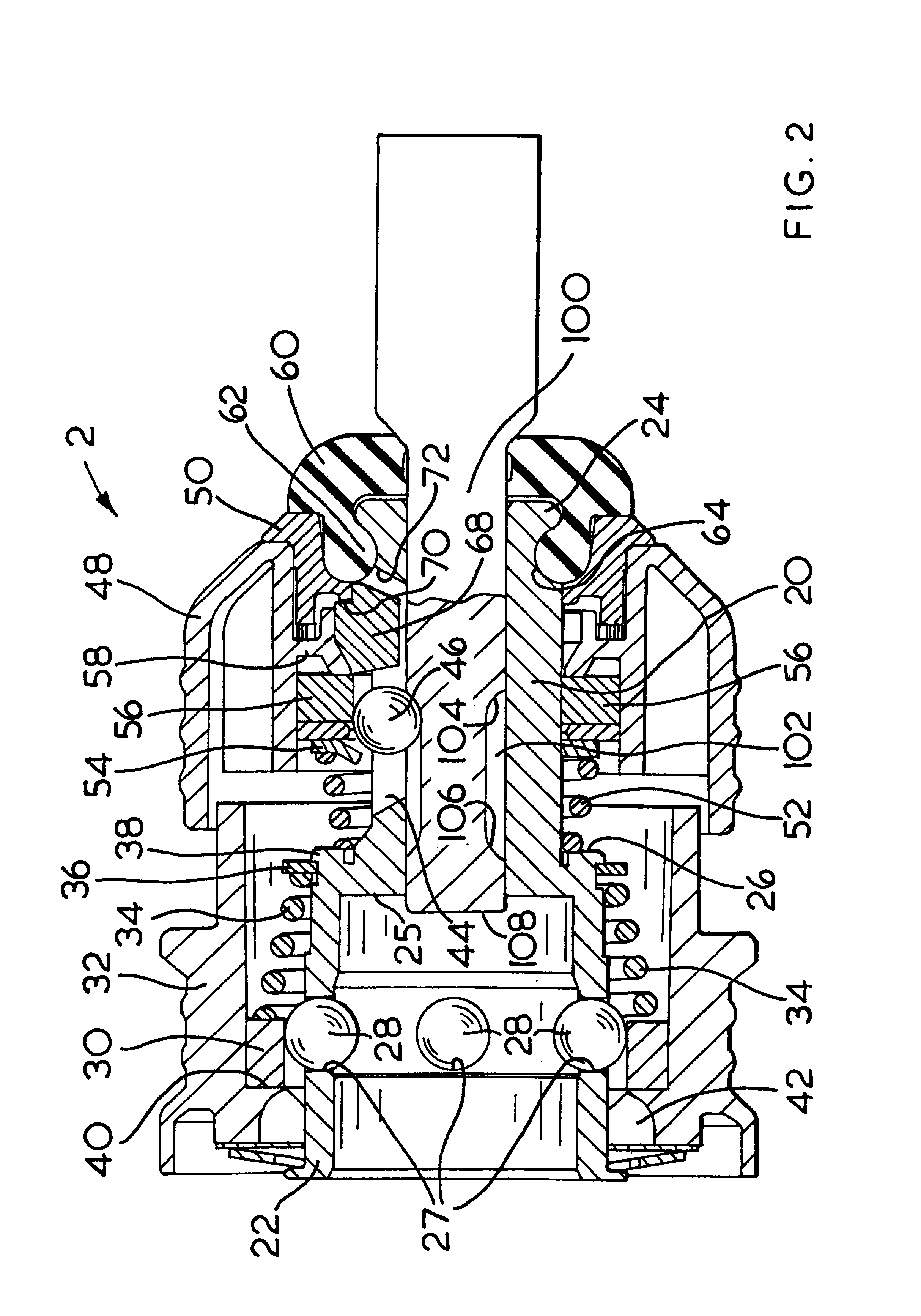

High torsion delivery catheter element

A jointed system for delivering a medical device to a target location within a human anatomy, comprising: a first segment that is a hollow cylinder, wherein a first flange and a second flange are attached to the distal end and extend distally away from the first segment; a second segment that is a hollow cylinder and has a proximal end and a distal end, wherein a third flange and a fourth flange are attached to the proximal end and extend proximally away from the second segment; a connector element having four cylindrical lugs extending radially away from a central point, wherein each lug passes, respectively, through a circular hole, and further wherein the connector element defines at least two separate openings extending in a direction from the distal end of the first segment to the proximal end of the second segment.

Owner:ABBOTT CARDIOVASCULAR

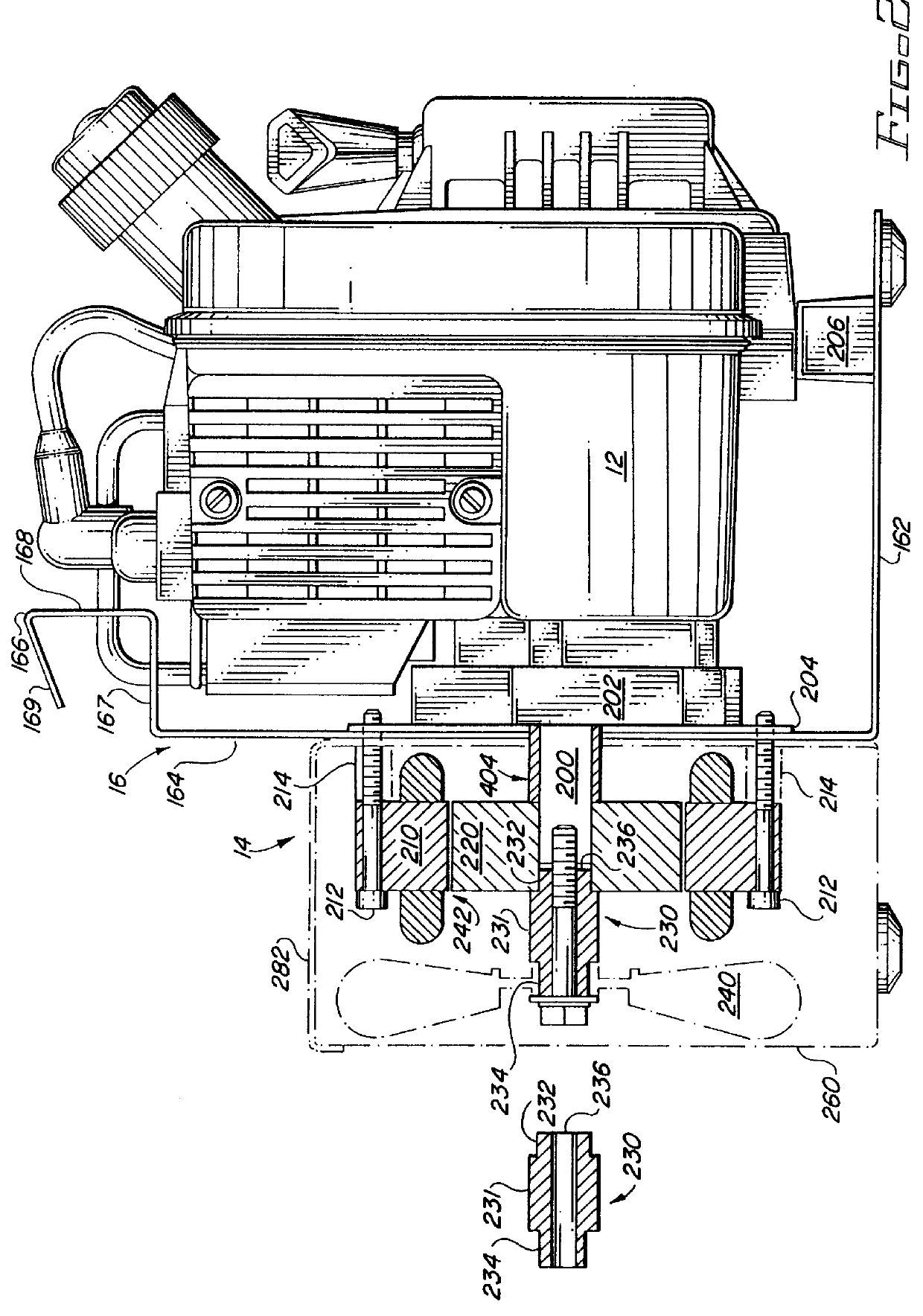

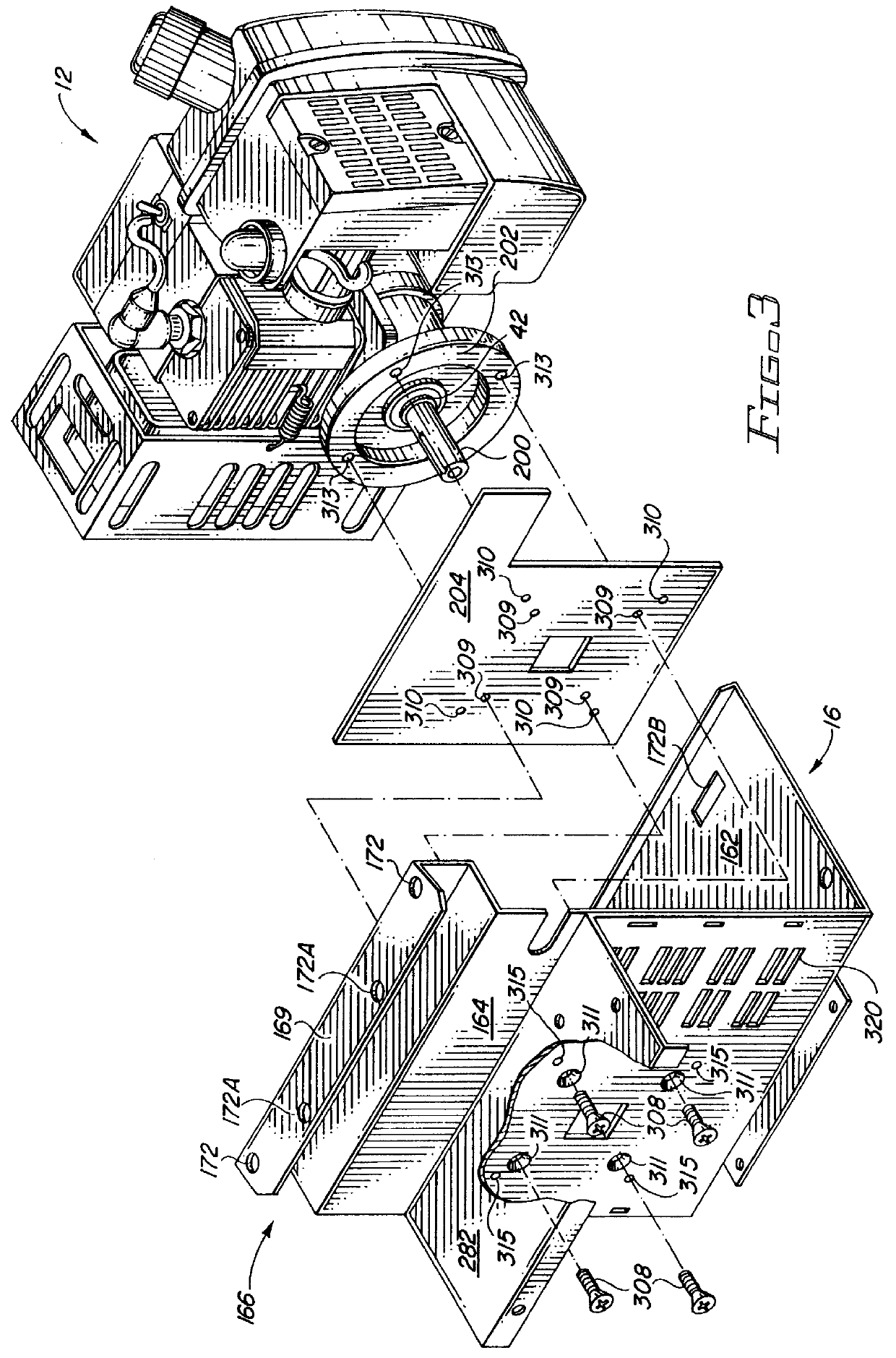

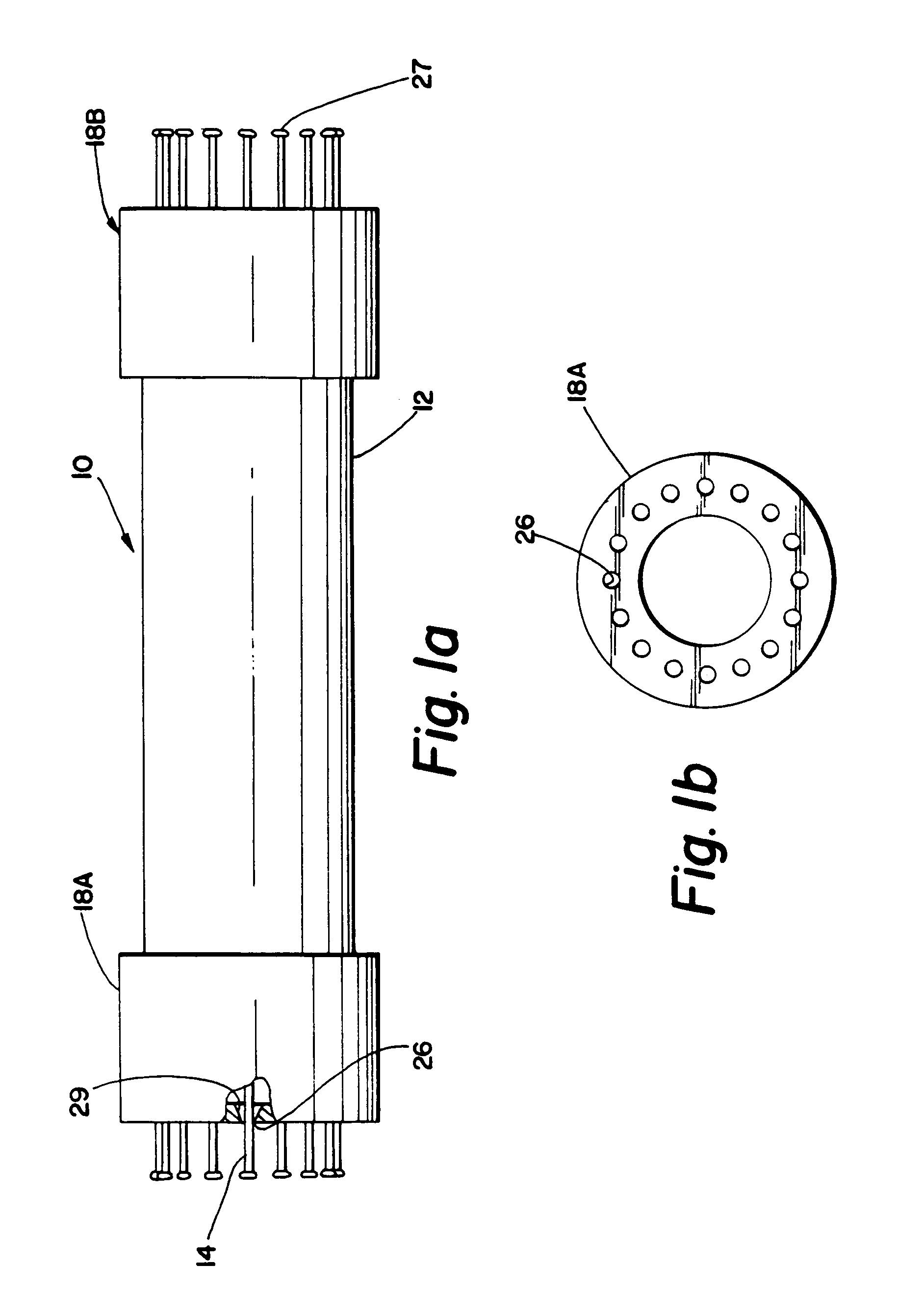

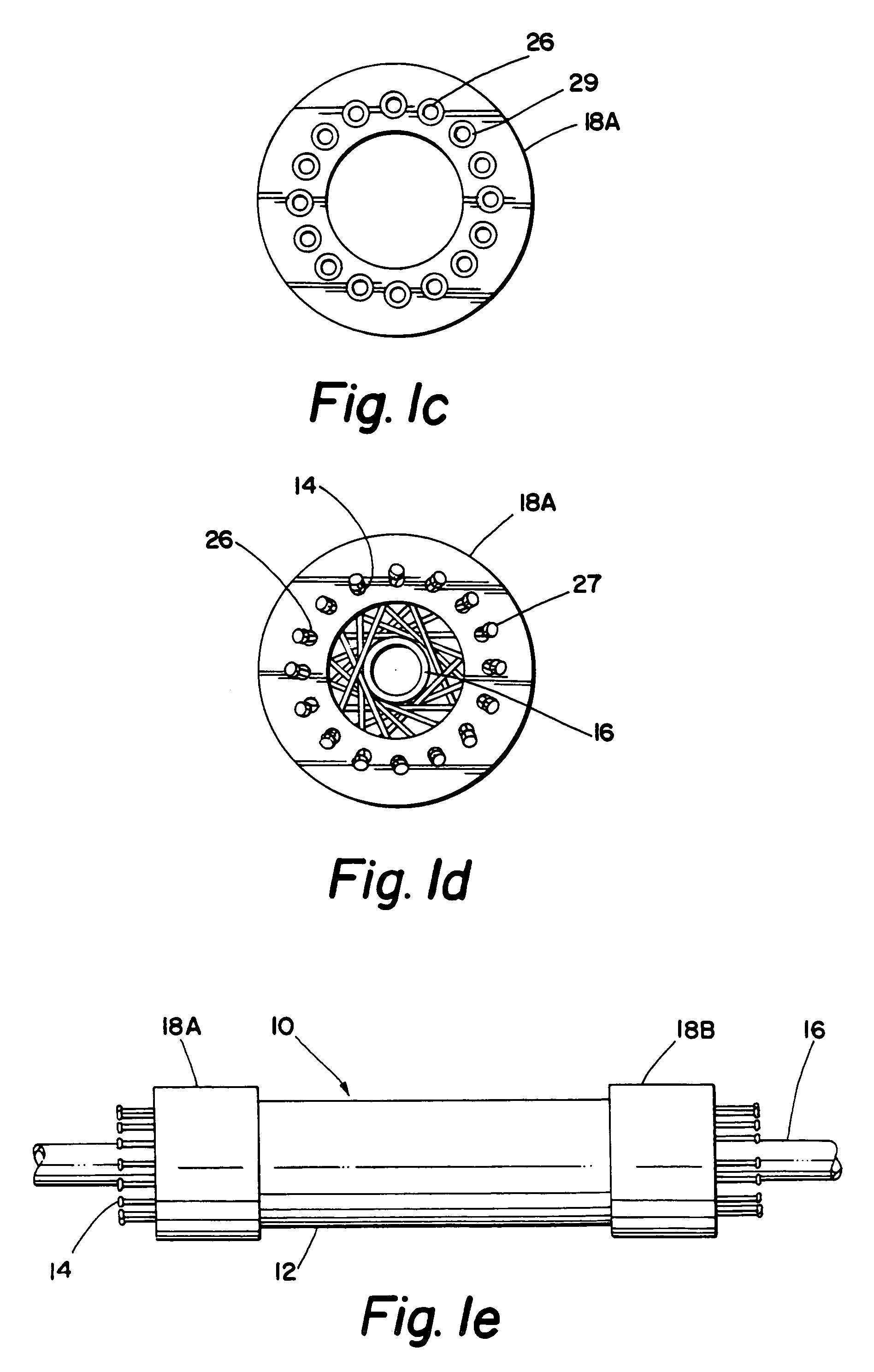

Light weight rotor and stator with multiple coil windings in thermal contact

A lightweight engine-driven generator set including a stator having at least first and second windings (preferably three-phase) and a rotor having a soft magnetic core and a plurality of high energy product permanent magnets, separated by consequence poles, disposed proximate the stator such that relative motion of the rotor and stator causes magnetic flux from the rotor to interact with and induce current in the stator windings. The first winding includes a predetermined number of turns corresponding to a first predetermined voltage output; and the second winding includes a predetermined number of turns corresponding to a second predetermined voltage output, the respective windings being grouped together as a unit and wound about the core such that the respective winding coils are wound in continuous close thermal contact with each other. The first winding generates a relatively high voltage, low amperage signal, and the second winding generates a relatively low voltage, high amperage signal; and a switch provides for selection of the desired output. Preferably the rotor is a hollow cylinder mounted on the engine shaft for rotation about the stator and such that the proper gap distance between rotor and stator is maintained during rotation of the rotor without bearings external to the engine. The low voltage, high amperage winding (or winding group) may be tapped to provide a selectable voltage output. Suitable rectifiers and inverters may be provided to effect selective DC and AC output signals.

Owner:COLEMAN POWERMATE

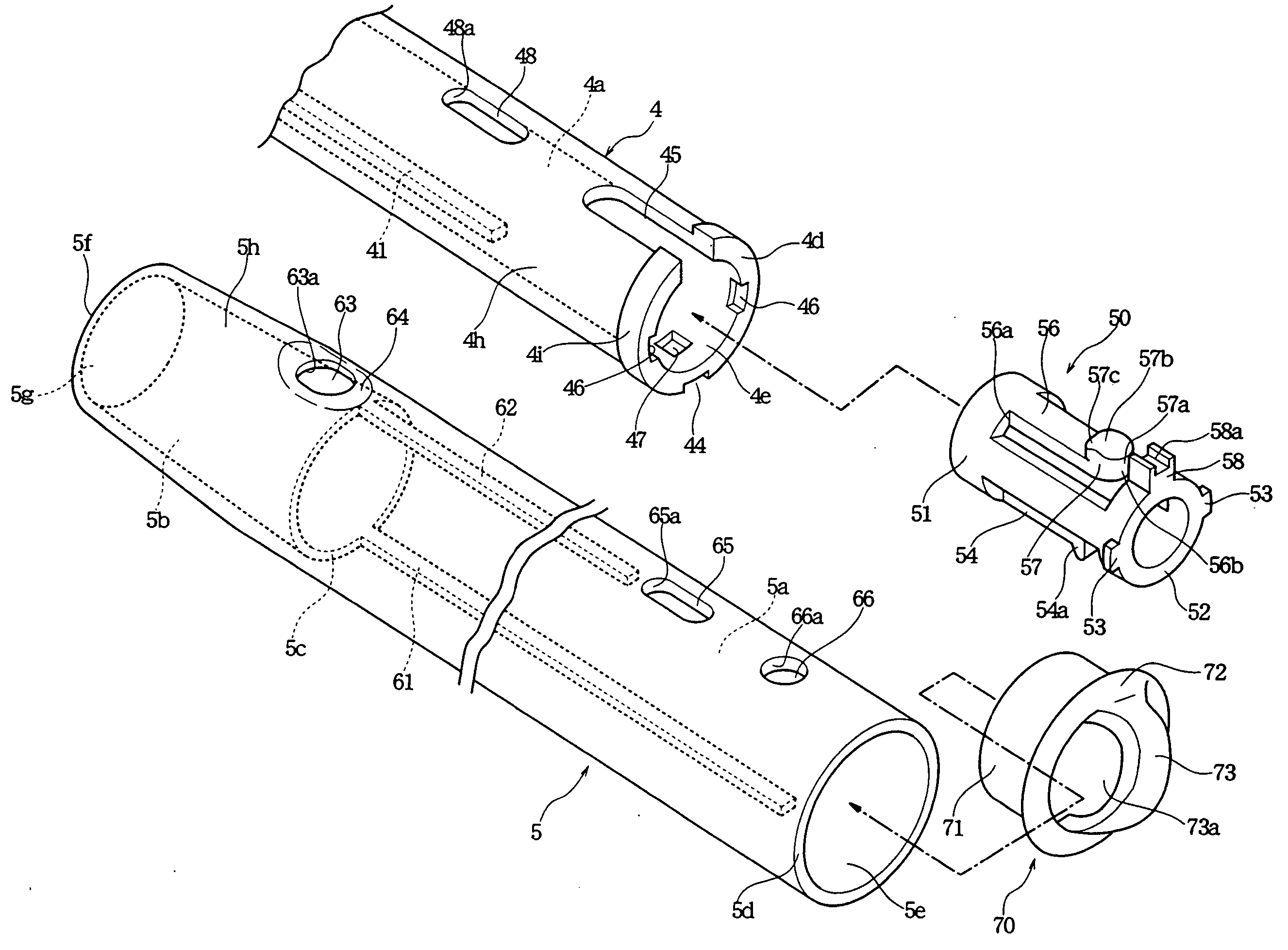

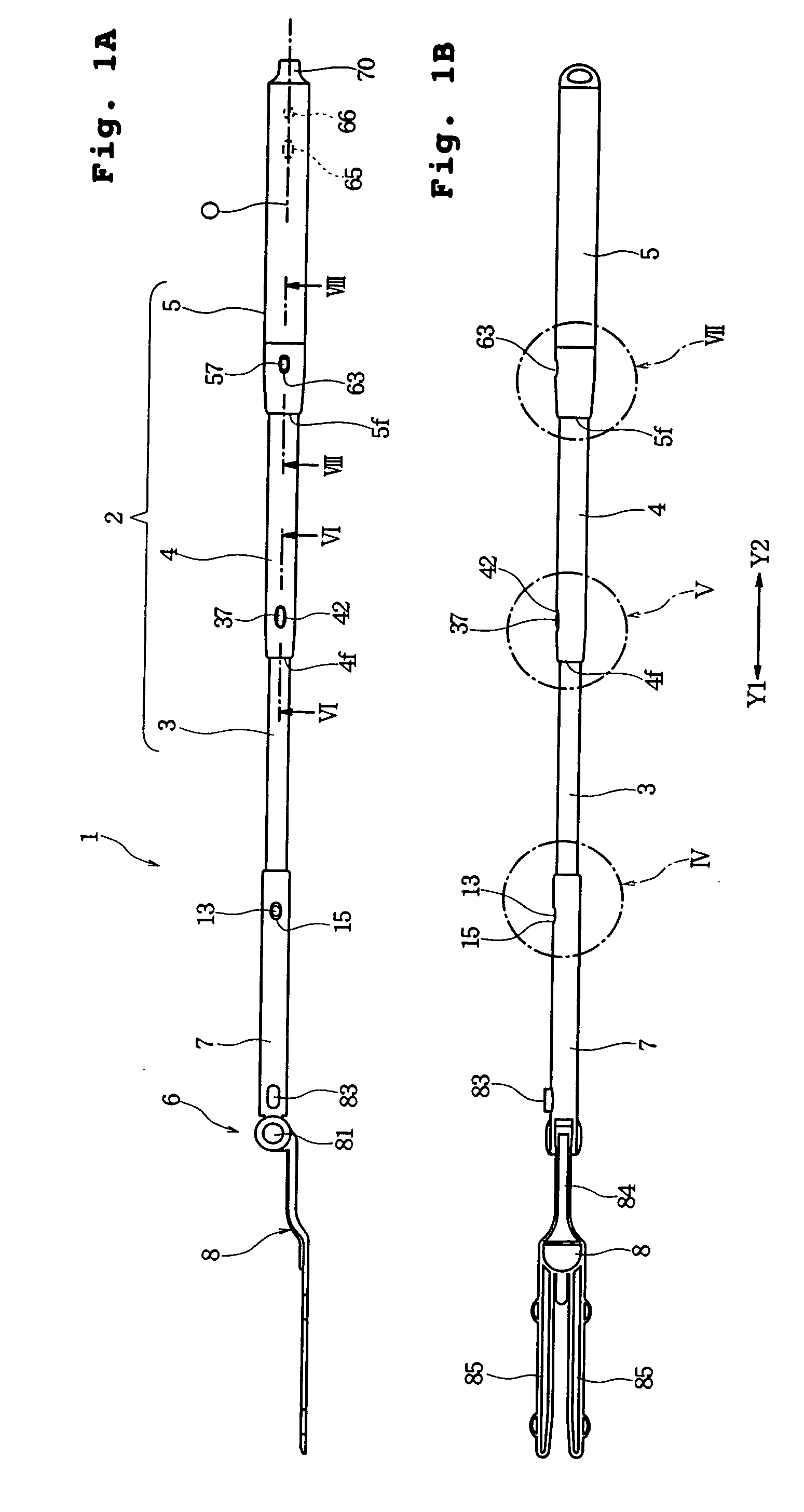

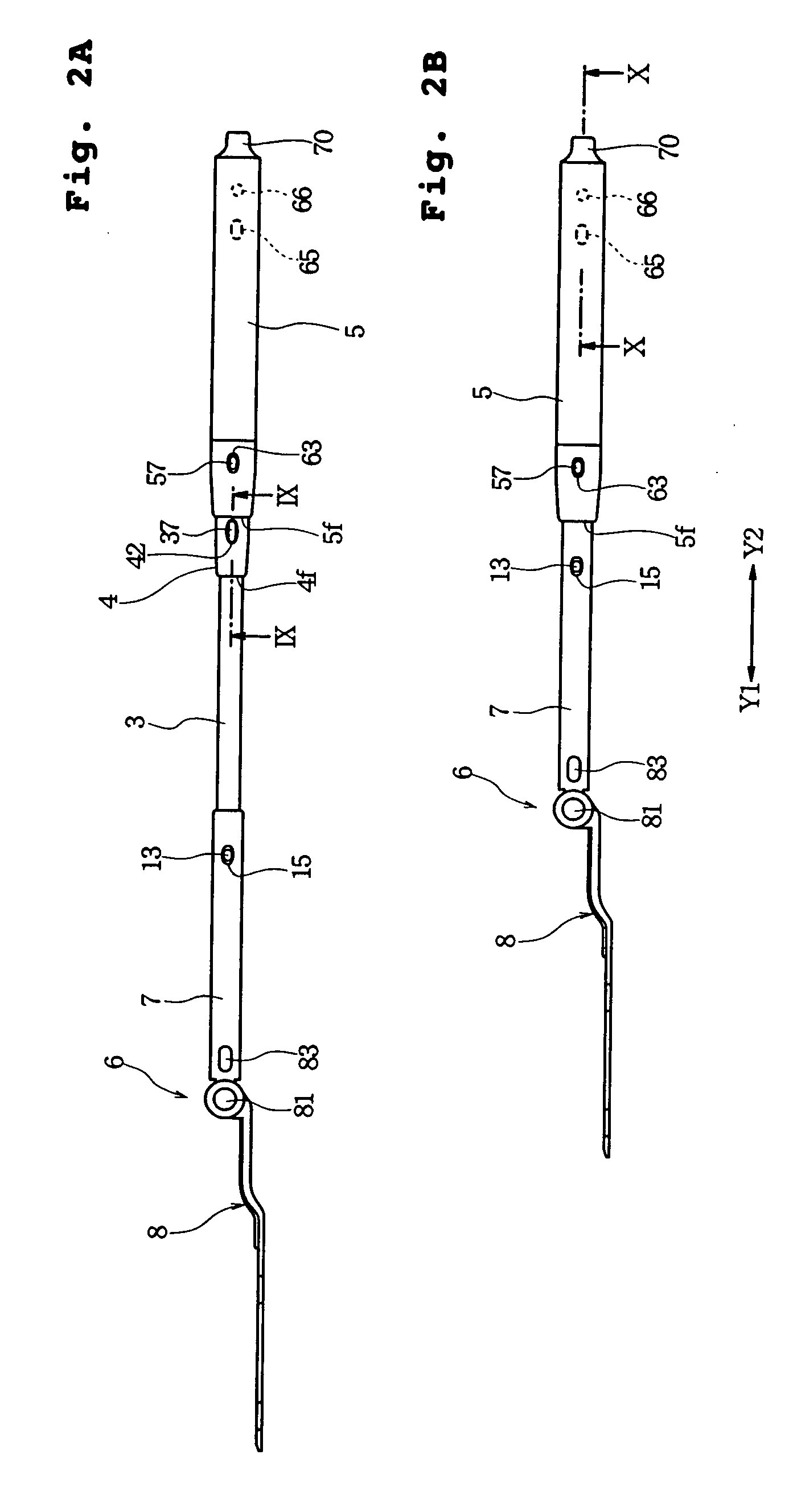

Holding device and cleaning tool with the holding device

InactiveUS7219386B2Easily be extended and retractedStable maintenanceTravelling carriersHoldersEngineeringFront and back ends

Disclosed is a holding device including: a telescopic handle having axially opposed front and rear ends and constructed of at least two separate shafts, of which a front-side separate shaft axially fits within a rear-side separate shaft being a hollow cylinder; and a support member provided at the front end of the telescopic handle for attachment of a cleaning wiper. The front-side separate shaft has an axially extending elastic arm and an engaging projection provided at a leading end of the elastic arm, while the rear-side separate shaft has a through-hole passing through a cylinder wall thereof, in which the engaging projection engages when the front-side separate shaft projects from the rear-side separate shaft by a predetermined length. Pressing the engaging projection, which engages in the through-hole, from outside the rear-side separate shaft permits release of the engaging projection from the through-hole.

Owner:UNI CHARM CORP

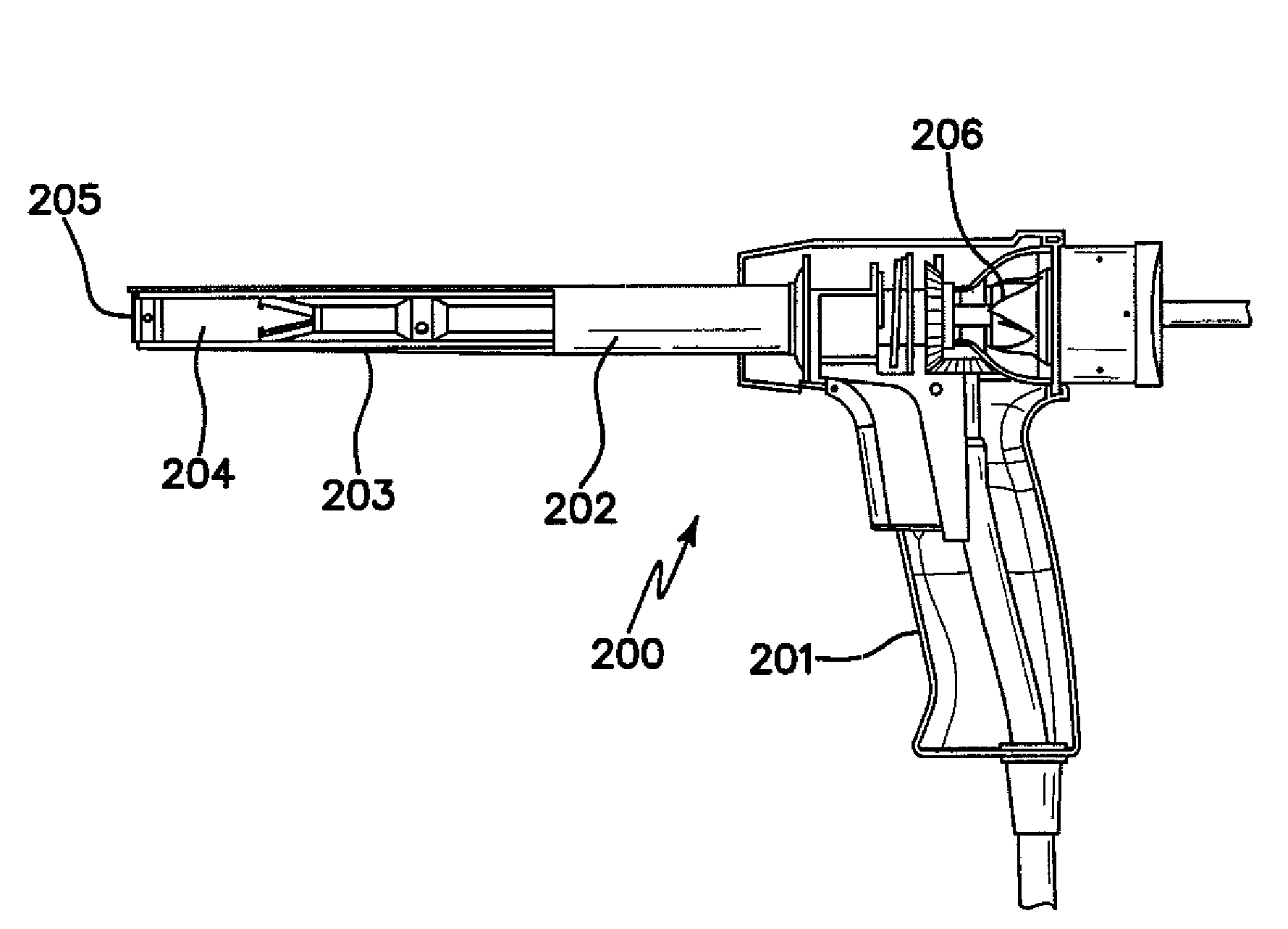

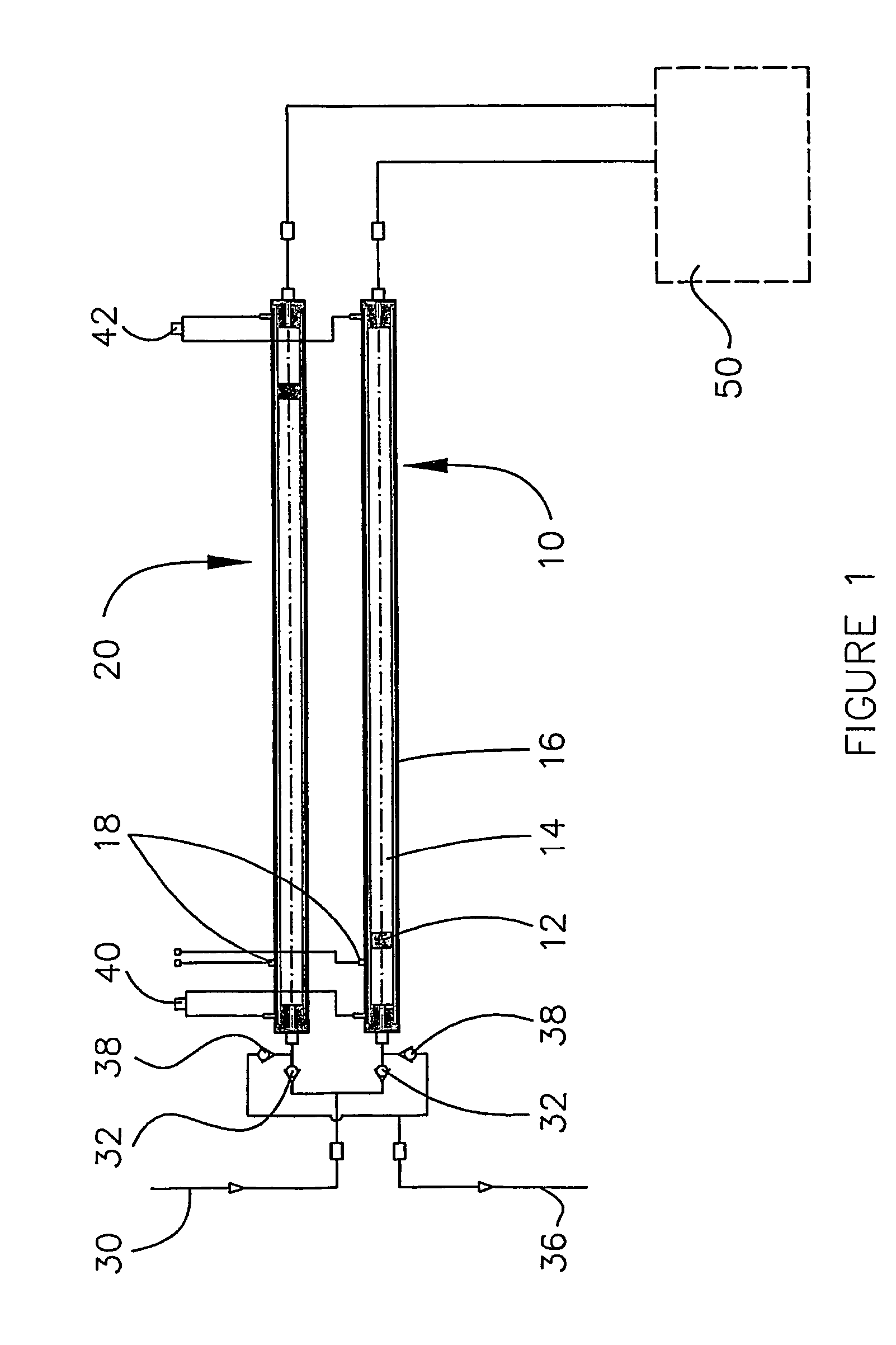

Method and apparatus for tissue morcellation

InactiveUS20080255597A1Easy rotary cuttingFacilitate tissue cuttingDiagnosticsExcision instrumentsCoringSurgical department

The invention relates to a tissue morcellator for minimally invasive surgery. The morcellator has a metallic cutting ring mounted on a visually transparent hollow cylinder, which in combination with a visually transparent outer morcellator tube enables a surgeon to visualize the inside of the morcellator shaft for detection of loose tissue fragments in the device. A tenaculum used with the morcellation device has a spacer for preventing contact with the blade. The cutting tube can oscillate, rather than rotate, along the longitudinal axis of the cutting tube. The morcellator utilizes an extendable tissue guide on the outer tube of the morcellator shaft for preventing the tissue from rotating along the longitudinal axis of the morcellator tube. This allows the tissue to be continuously rotated into the morcellator device for continuous peel. The tissue guide can also be fully retracted to allow for coring of the bulk tissue.

Owner:APPL MEDICAL RESOURCES CORP

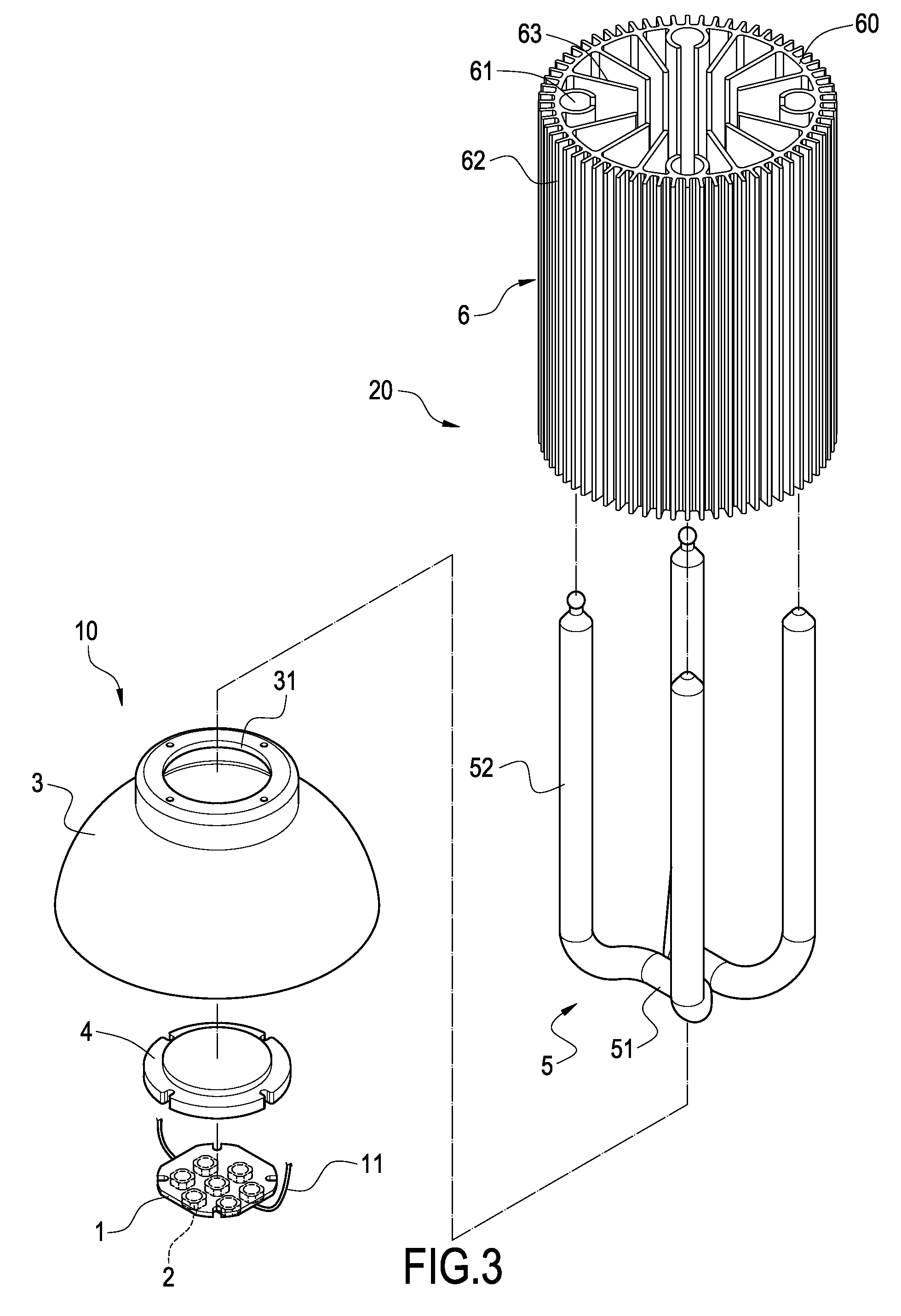

Heat-dissipating structure for LED lamp

InactiveUS7494248B2Increase contact areaFast conductionPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

A heat-dissipating structure for a LED lamp includes a heat-dissipating base, a heat-dissipating body and a plurality of heat pipes. The heat-dissipating body has an outer cylinder formed into a hollow cylinder. The inside surface of the outer cylinder is provided with a plurality of accommodating grooves. The condensed ends of the plurality of heat pipes are inserted into the accommodating grooves. The end to be heated of the heat pipe is adhered to the heat-dissipating base. Further, the inside surface and the outside surface of the outer cylinder are formed with a plurality of heat-dissipating fins made by aluminum extrusion, so that the heat pipes are encircled by the heat-dissipating fins. In this way, the heat can be conducted by the plurality of heat pipes so as to increase the total contacting area. Thus, the heat can be rapidly conducted to the outer cylinder. Further, the heat can be rapidly dissipated to the outside by the heat-dissipating fins, thereby to substantially increase the efficiency in the heat dissipation.

Owner:JAFFE

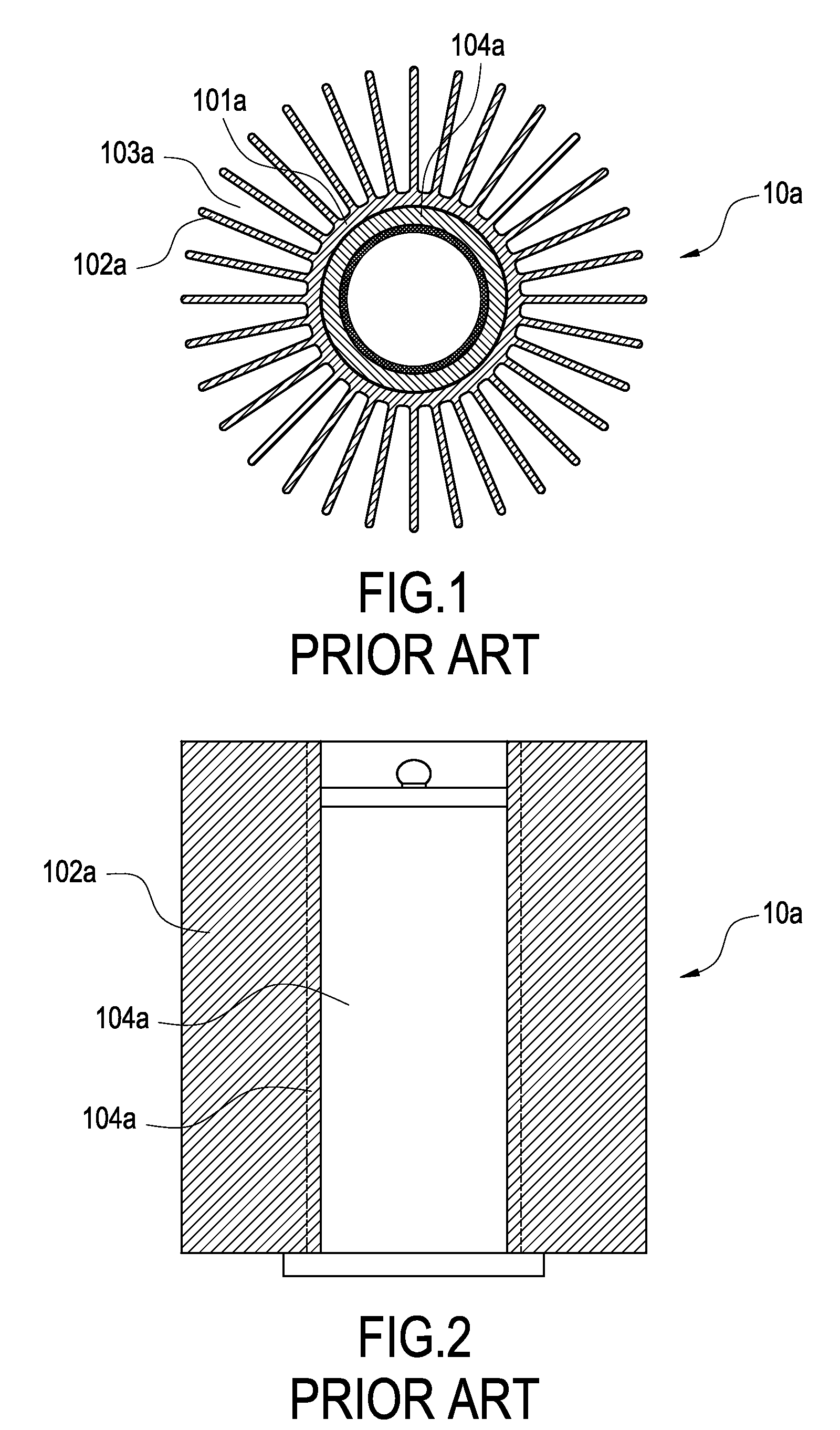

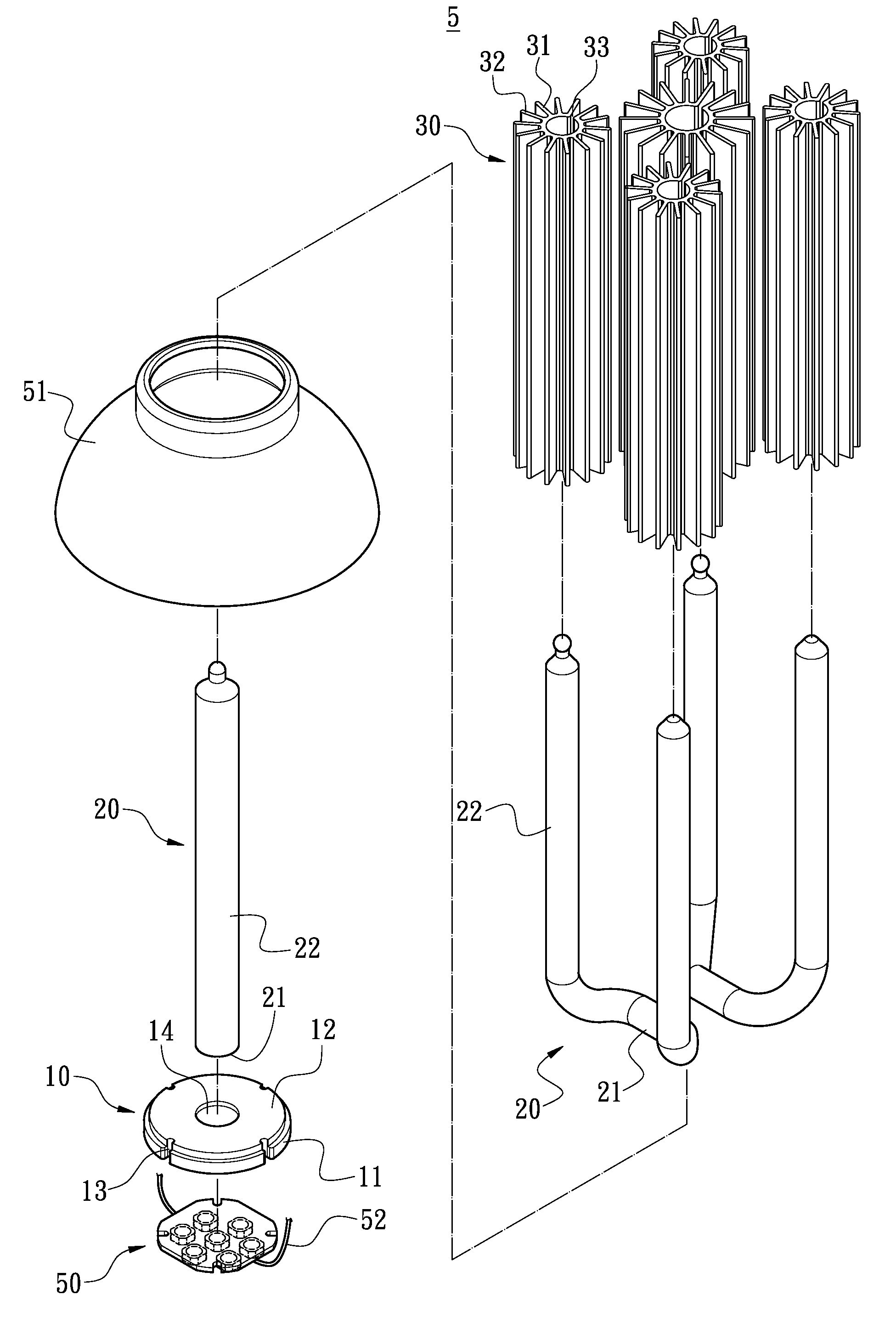

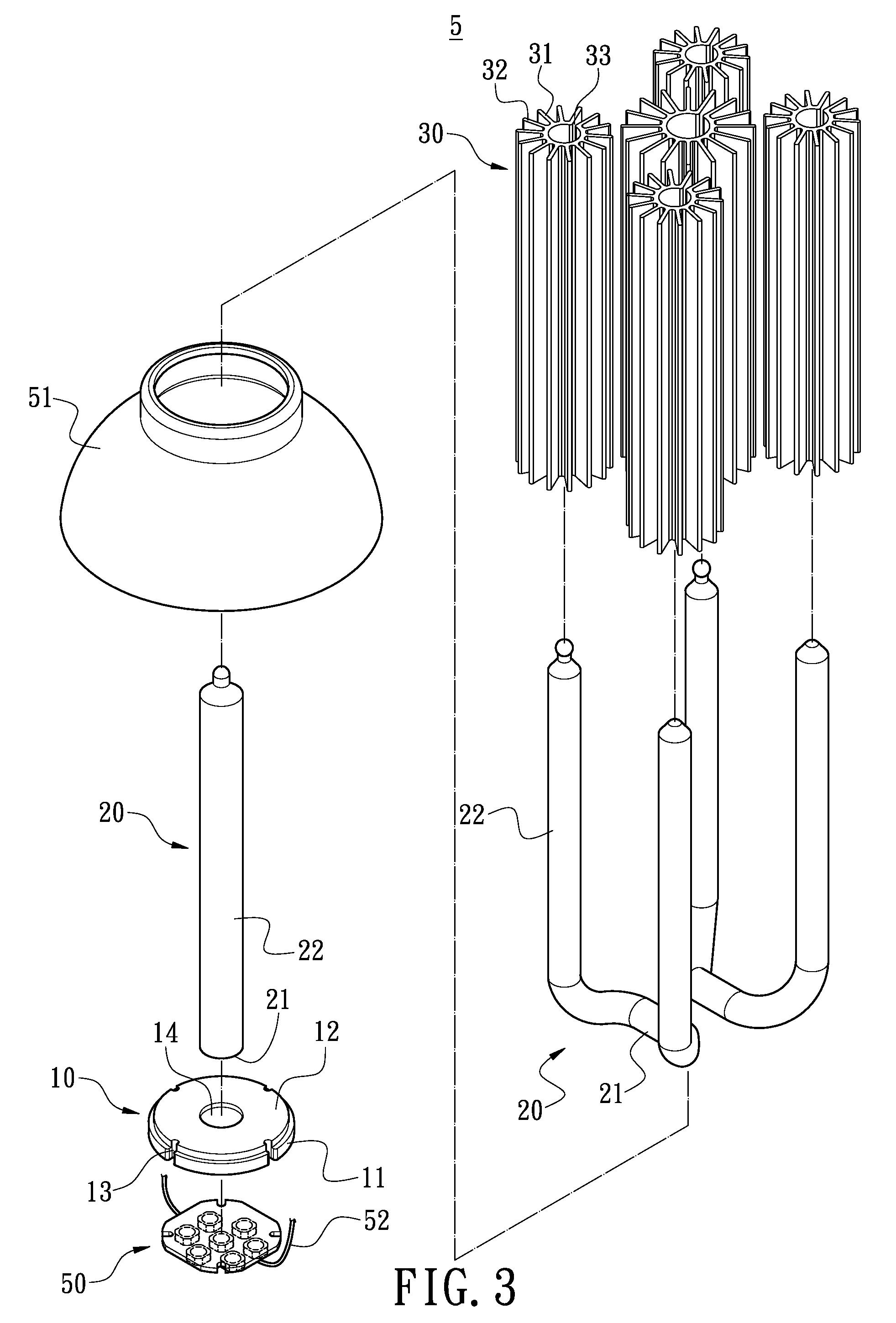

Multiple-Set Heat-Dissipating Structure For LED Lamp

InactiveUS20080007955A1Extend your lifePoint-like light sourceLighting heating/cooling arrangementsHeat conductingWorking temperature

A multiple-set heat-dissipating structure for a LED lamp for performing the heat dissipation of the LED set includes a heat-conducting base, a plurality of heat pipes and a plurality of heat-dissipating bodies. On end face of the heat-conducting base is used for adhering to and contacting with the LED set. Each heat pipe has a heat-absorbing end and a heat-releasing end, respectively. The heat-absorbing end is connected to the other end face of the heat-conducting base. Each heat-dissipating body has a hollow cylinder. The outer periphery of the cylinder is formed with a plurality of radial heat-dissipating pieces and is connected on the heat-releasing end of each heat pipe. By dispersing each heat pipe and heat-dissipating body, the heat generated by the operation of the LED set can be conducted and dissipated by each heat pipe and heat-dissipating body at multiple points. In this way, the LED set can be continuously operated under a suitable working temperature and thus its life can be elongated.

Owner:JAFFE

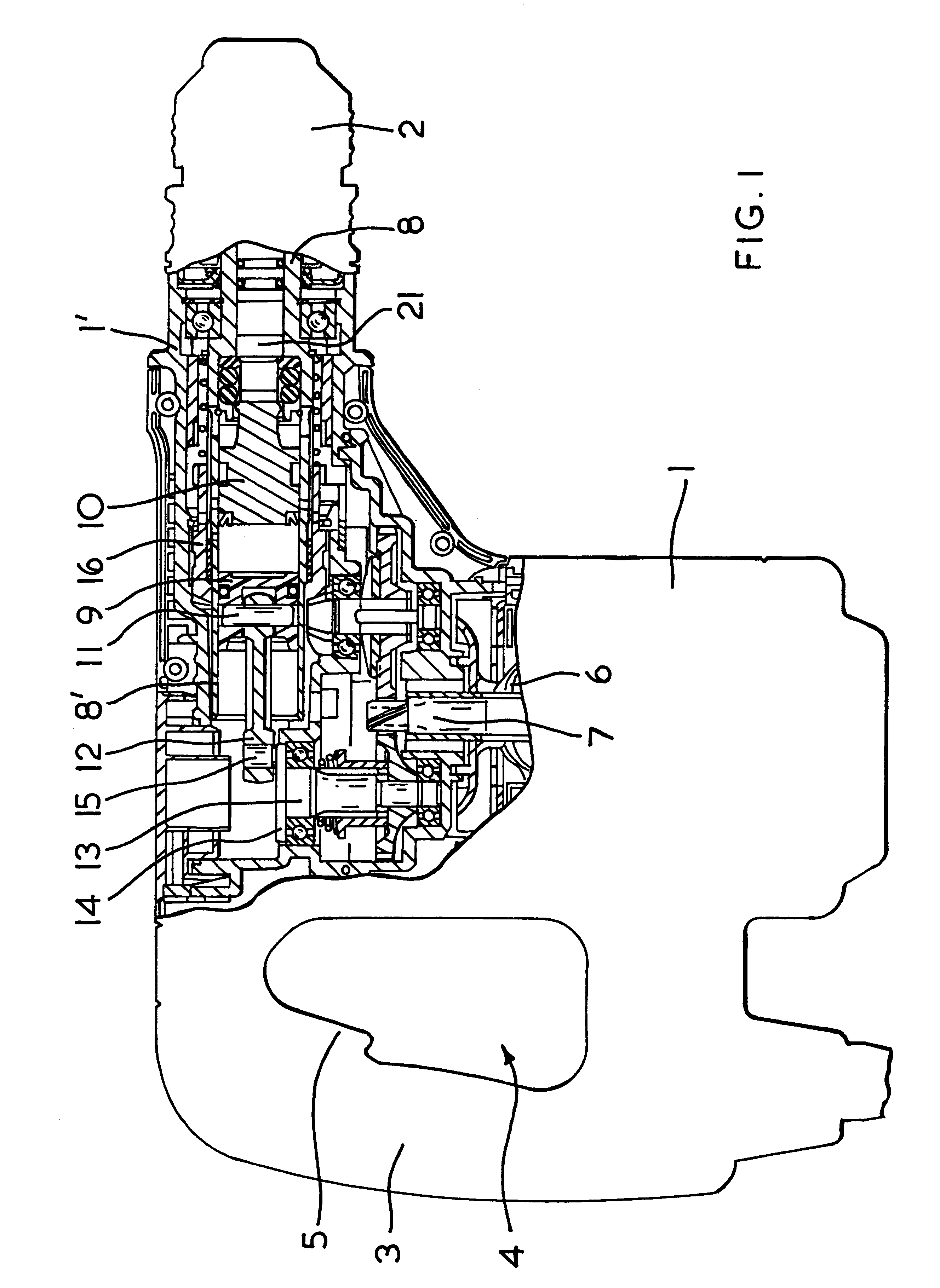

Rotary hammer

InactiveUS6241026B1Weakening rangeReduce risk of damageConstructionsChucksEngineeringFront and back ends

A tool holder attachable to a spindle of a hammer and which can receive a bit, the bit having a shank with at least one retaining groove extending along part of the shank, the retaining groove having a defined length, a front end and a rear end that limit axial movement of the bit in the tool holder, which tool holder comprises a hollow cylinder having an axis, an axial bore, a rear end that can be attached to the spindle of the hammer, and a front end that can receive the shank of the bit so that the bit is slidable within the cylinder in an axial direction, at least one retaining element that is located so that it can extend radially into the bore of the cylinder and into the at least one retaining groove of the bit so that the retaining element can be hit by the rear end of the retaining groove during the transition to idling and limit the extent of axial movement of the bit within the cylinder, at least one radial restraining element limiting movement of the retaining element in the radial direction, at least one axial restraining block limiting movement of the retaining element in the axial direction, when hit by the retaining element the axial restraining block movable to a limited extent in the axial direction with respect to the radial restraining element, and a resilient element located forward of the axial restraining block and arranged so as to attenuate the impact transmitted through the axial restraining block from the retaining element.

Owner:BLACK & DECKER INC

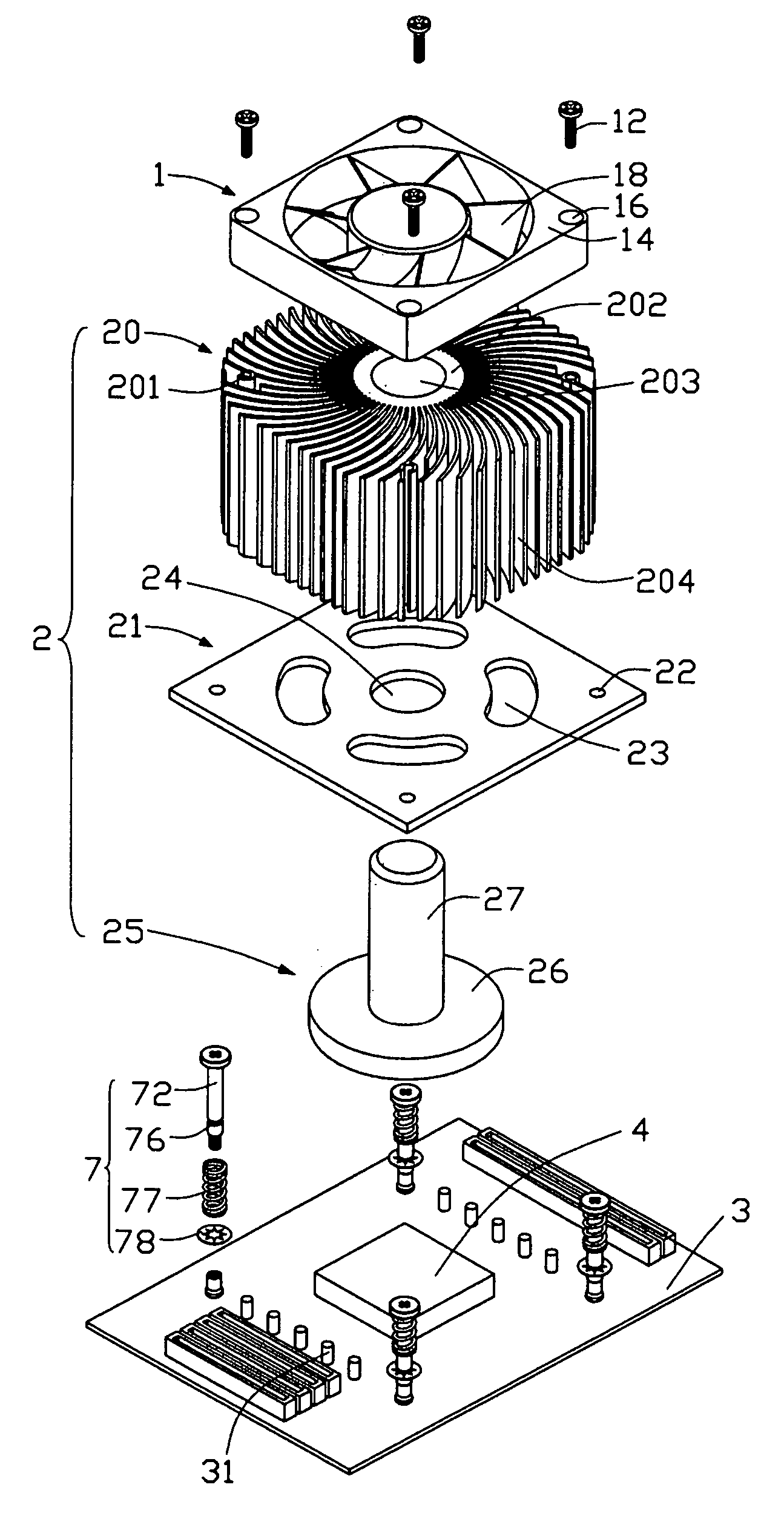

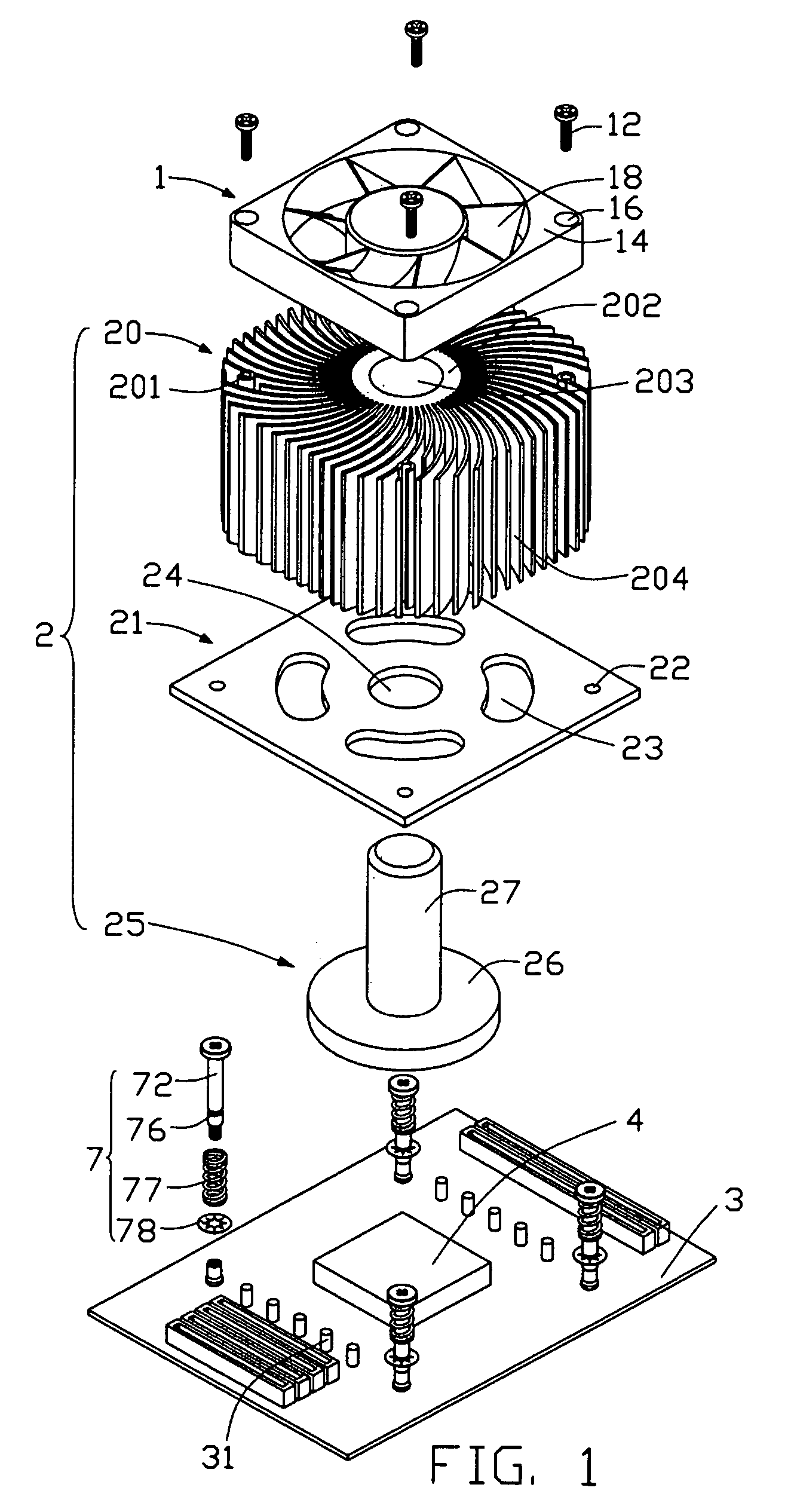

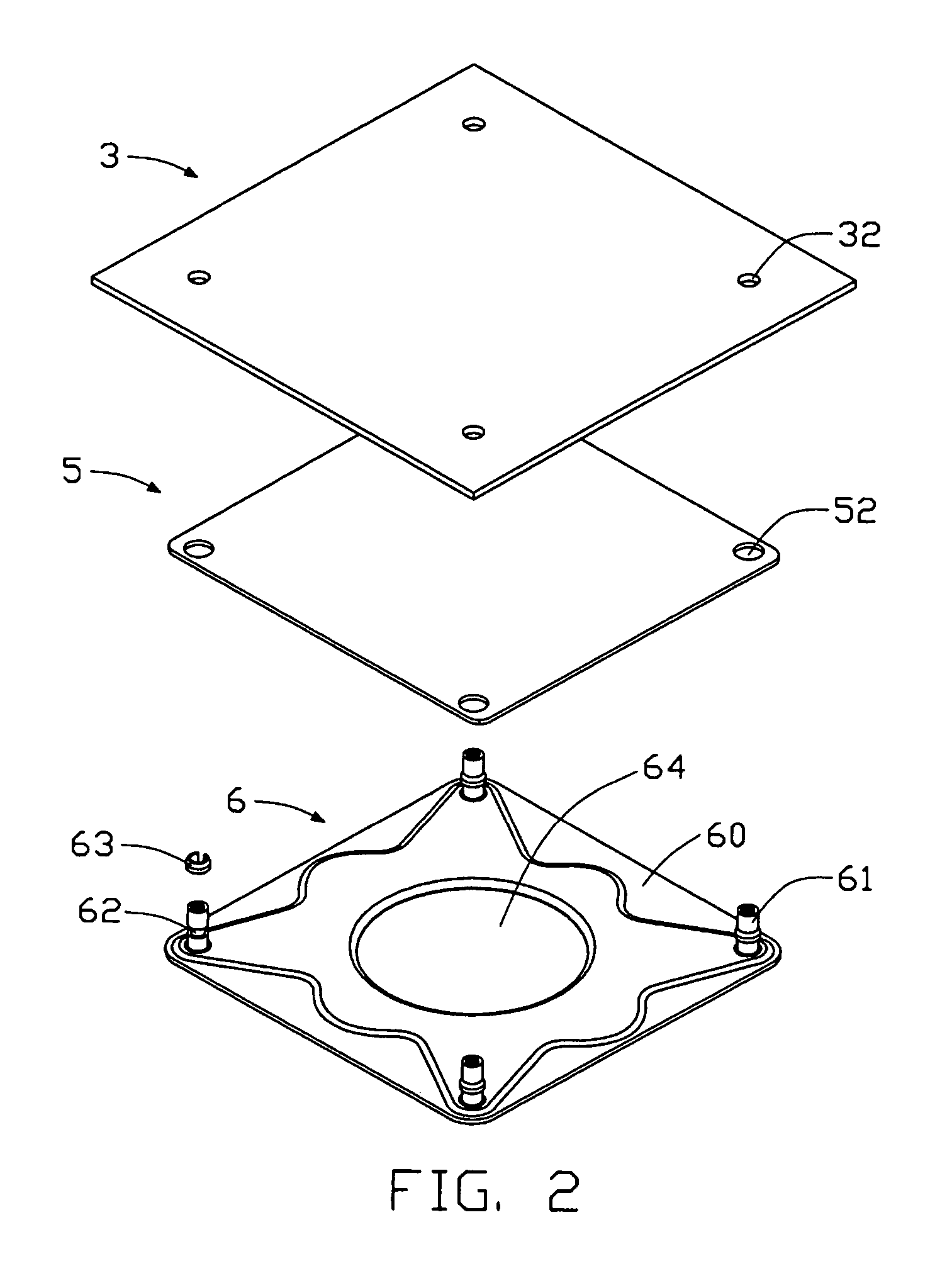

Heat dissipation device

InactiveUS7142422B2Effective coolingDigital data processing detailsSemiconductor/solid-state device detailsEngineeringCapacitor

A heat dissipation device includes a mounting plate (21) for mounting the heat dissipation device to a circuit board (3) on which a CPU (4) and a plurality of capacitors (31) are mounted, a heat sink (20), a core (25), and a fan (1) mounted on the heat sink. The heat sink locates above the mounting plate and includes a hollow cylinder (202) and a plurality of curved fins (204) extending outwardly from the cylinder. The core includes a base (26) for contacting the CPU and a post (27) extending from the base through the mounting plate to be received in the cylinder. The mounting plate is spaced from the circuit board to allow the capacitors to locate between the mounting plate and the circuit board. The mounting plate defines a plurality of openings (23) for providing access for cooled air from the fan to the CPU and the capacitors.

Owner:HON HAI PRECISION IND CO LTD +1

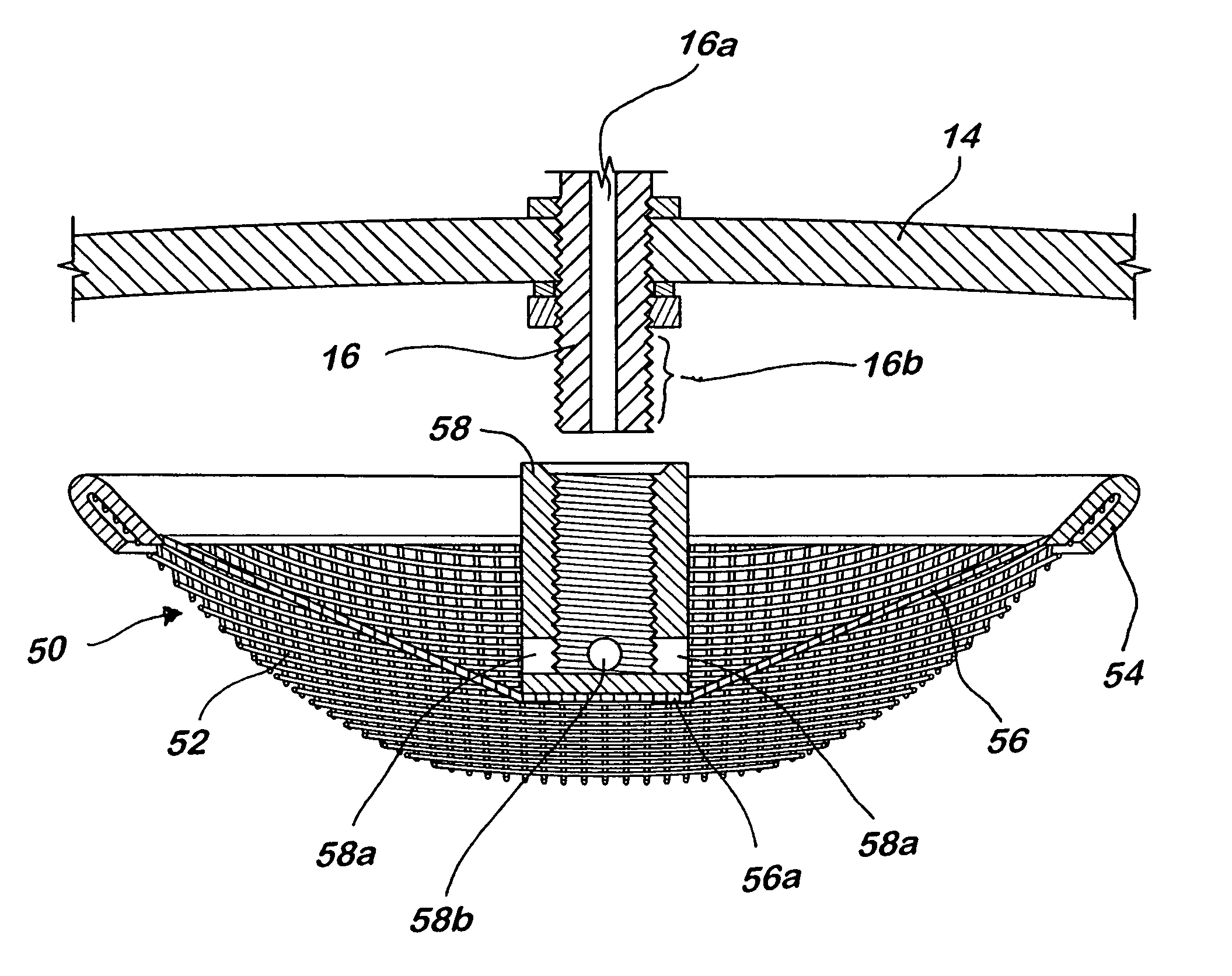

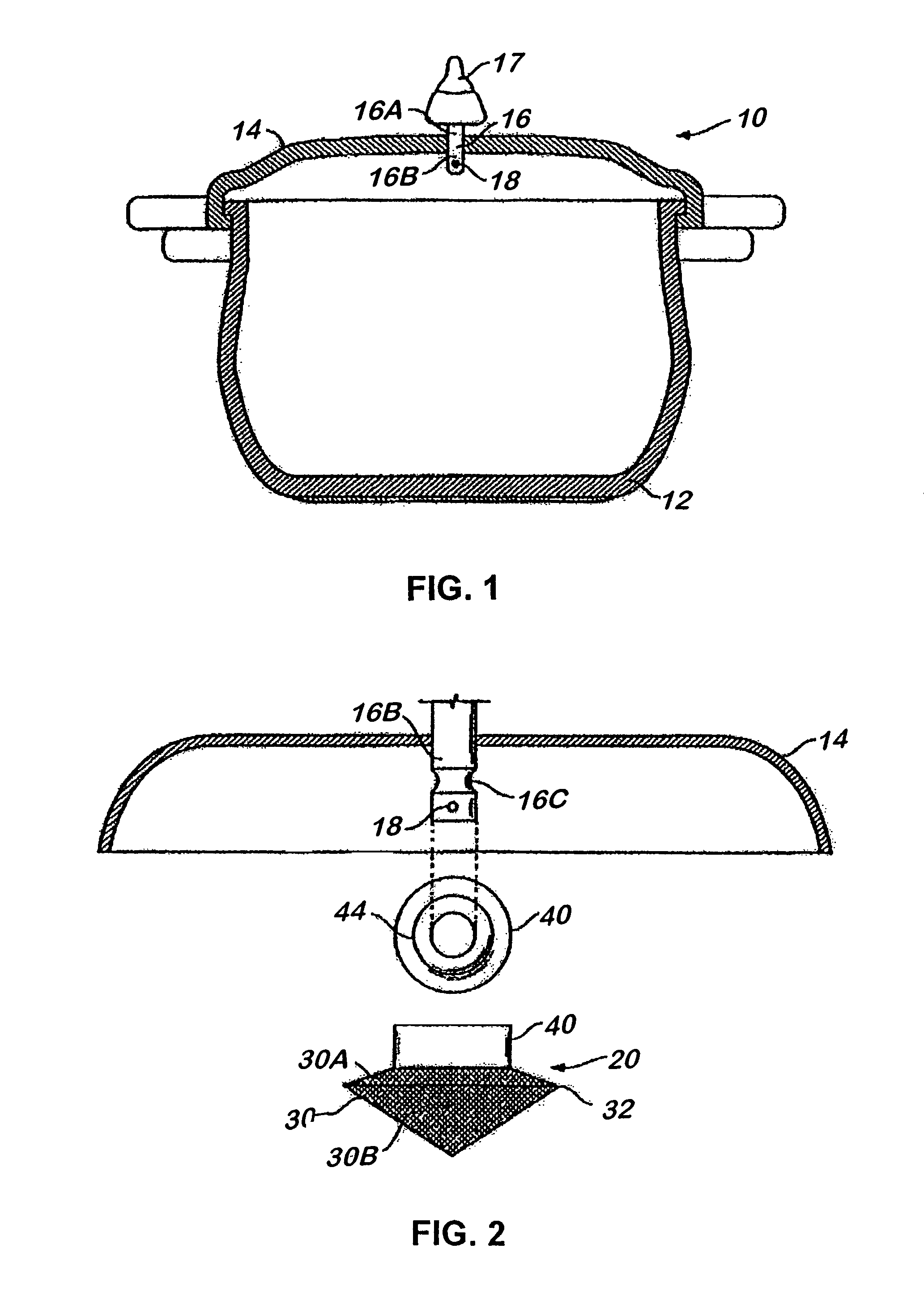

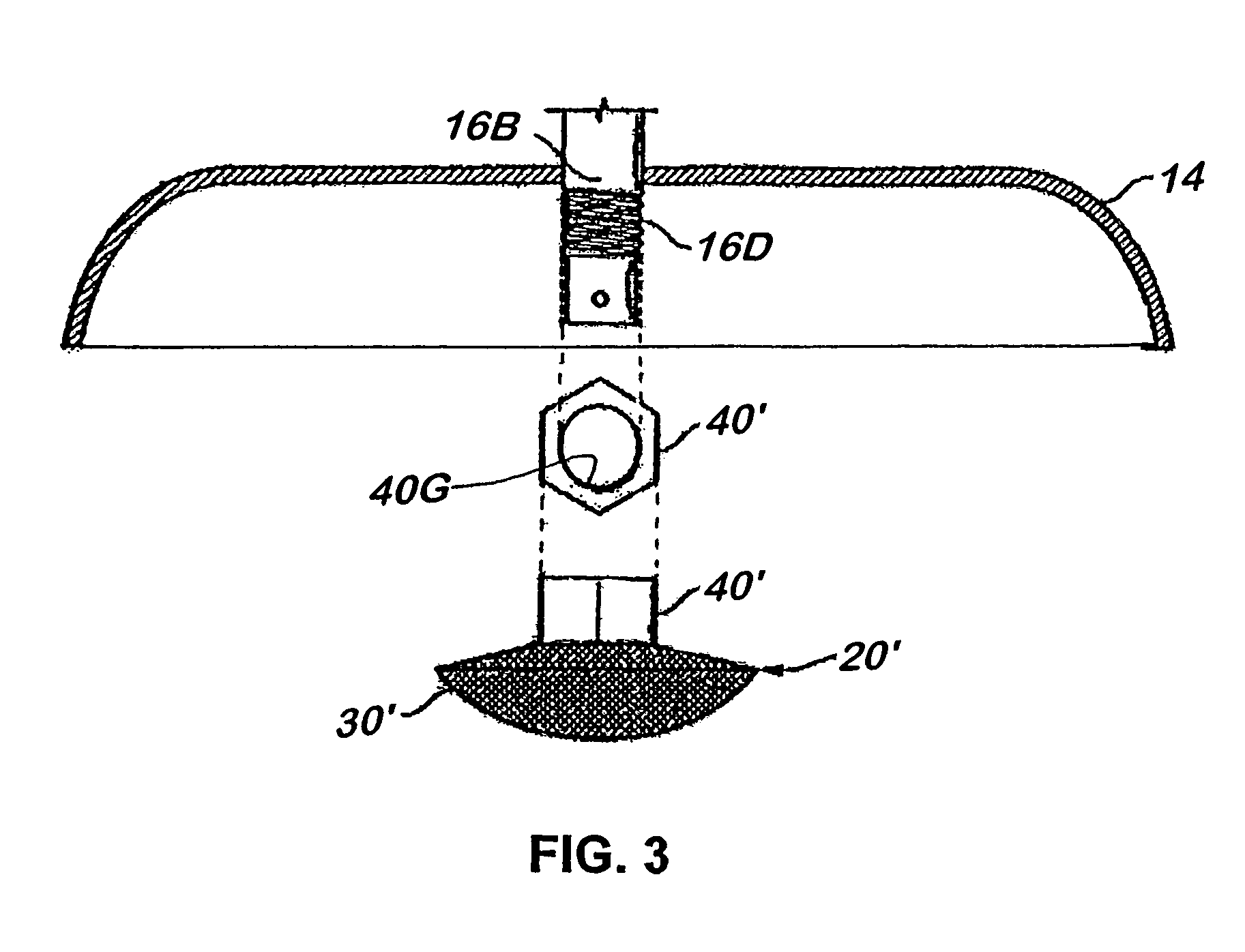

Protective device for a pressure cooker and pressure cooker with a protective device

InactiveUS8302800B2Reduce insecuritySecurity pressureContainer/bottle contructionPressure-cookersEngineeringDome shape

A protective device attached to a pressure release valve of a lid of a pressure cooker, including a dome-shaped mesh casing body, a ring-shaped reinforcing frame fixed to the upper edge of the mesh casing body, a bridge plate provided on the reinforcing frame with both ends thereof fixed to the reinforcing frame so that the bridge plate diametrically crosses the ring-shaped reinforcing frame keeping distance from the bottom of the mesh casing body, and an attachment member of substantially a hollow cylinder provided at the center of the bridge plate.

Owner:HASEGAWA TOM HIROSHI

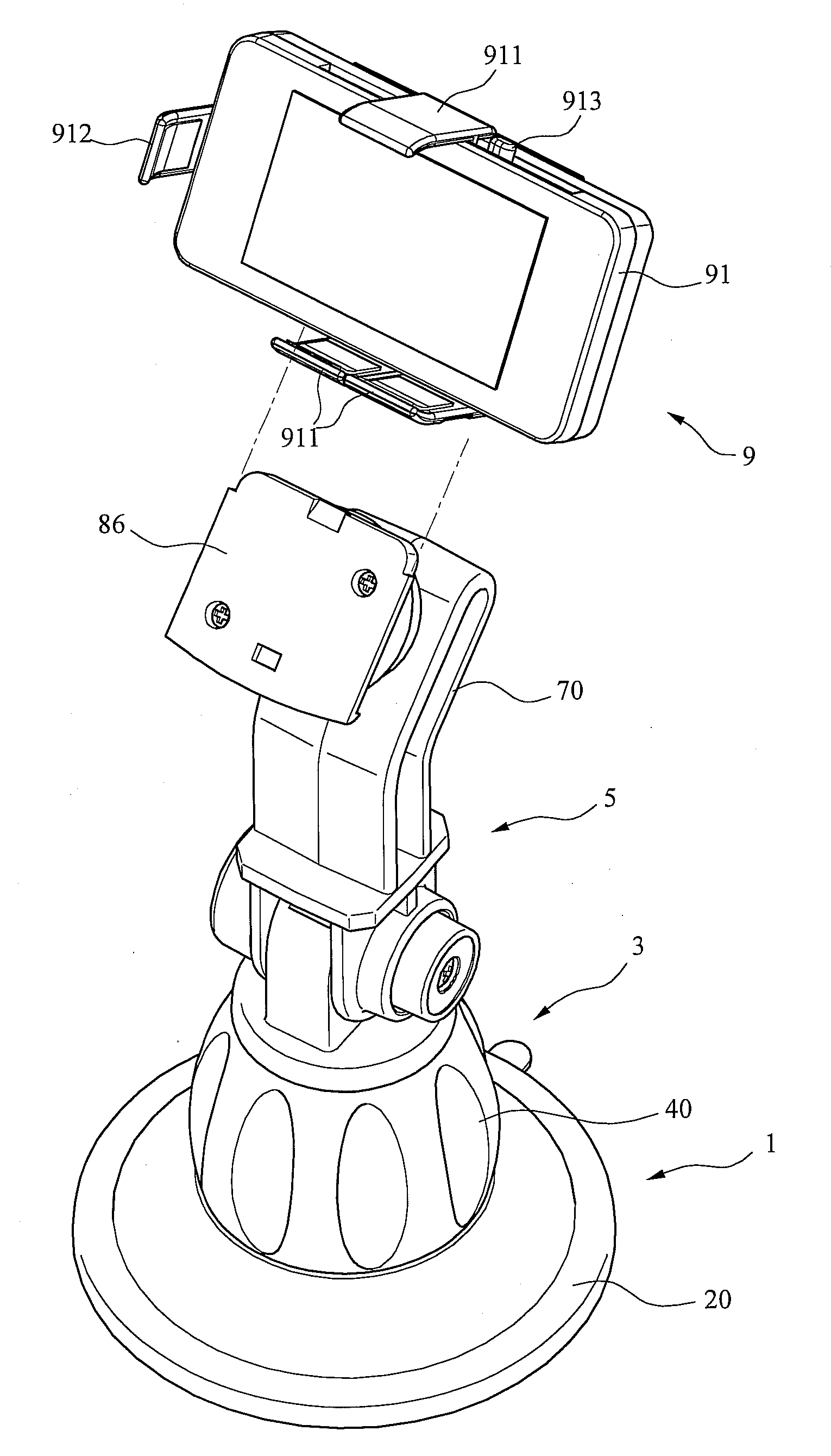

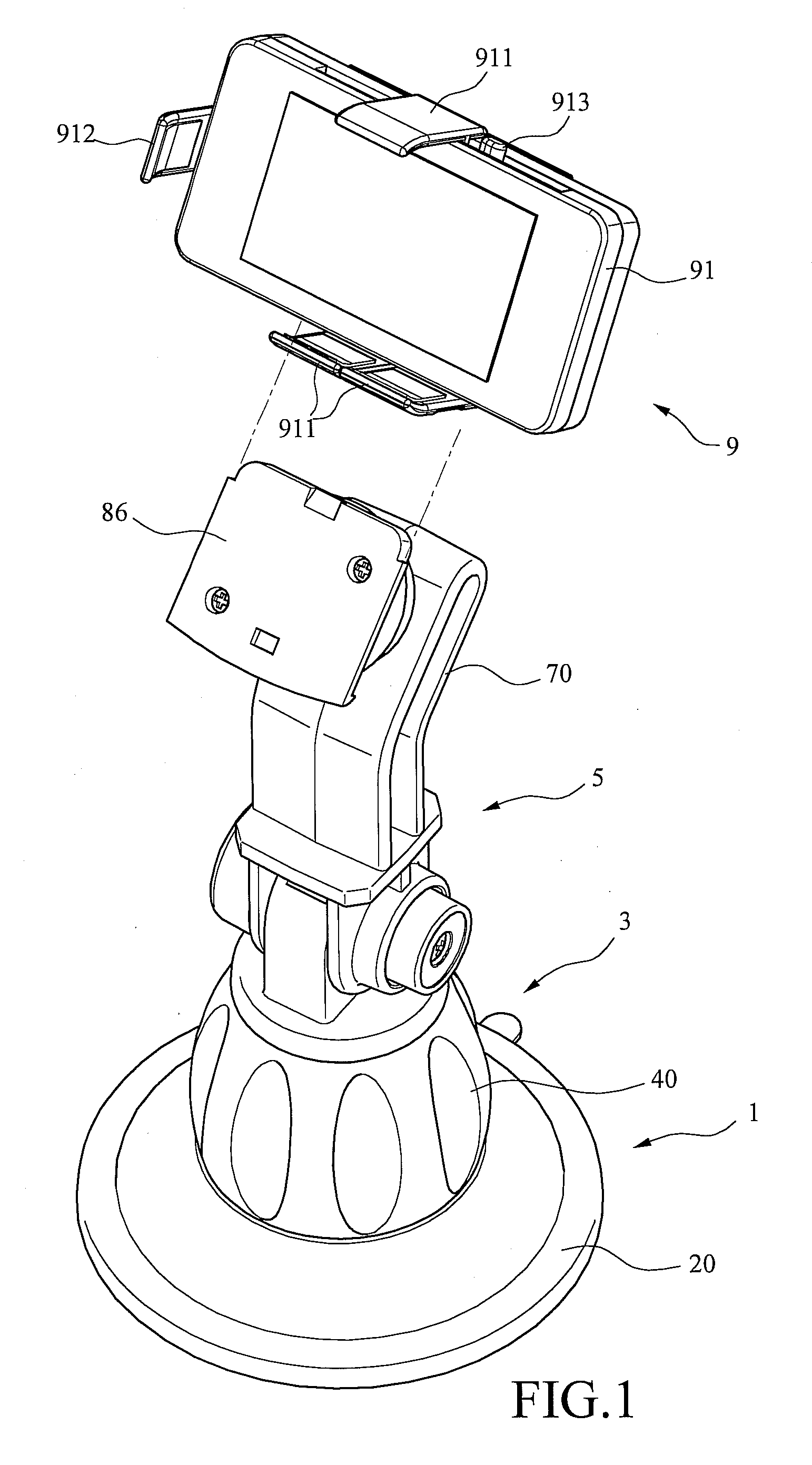

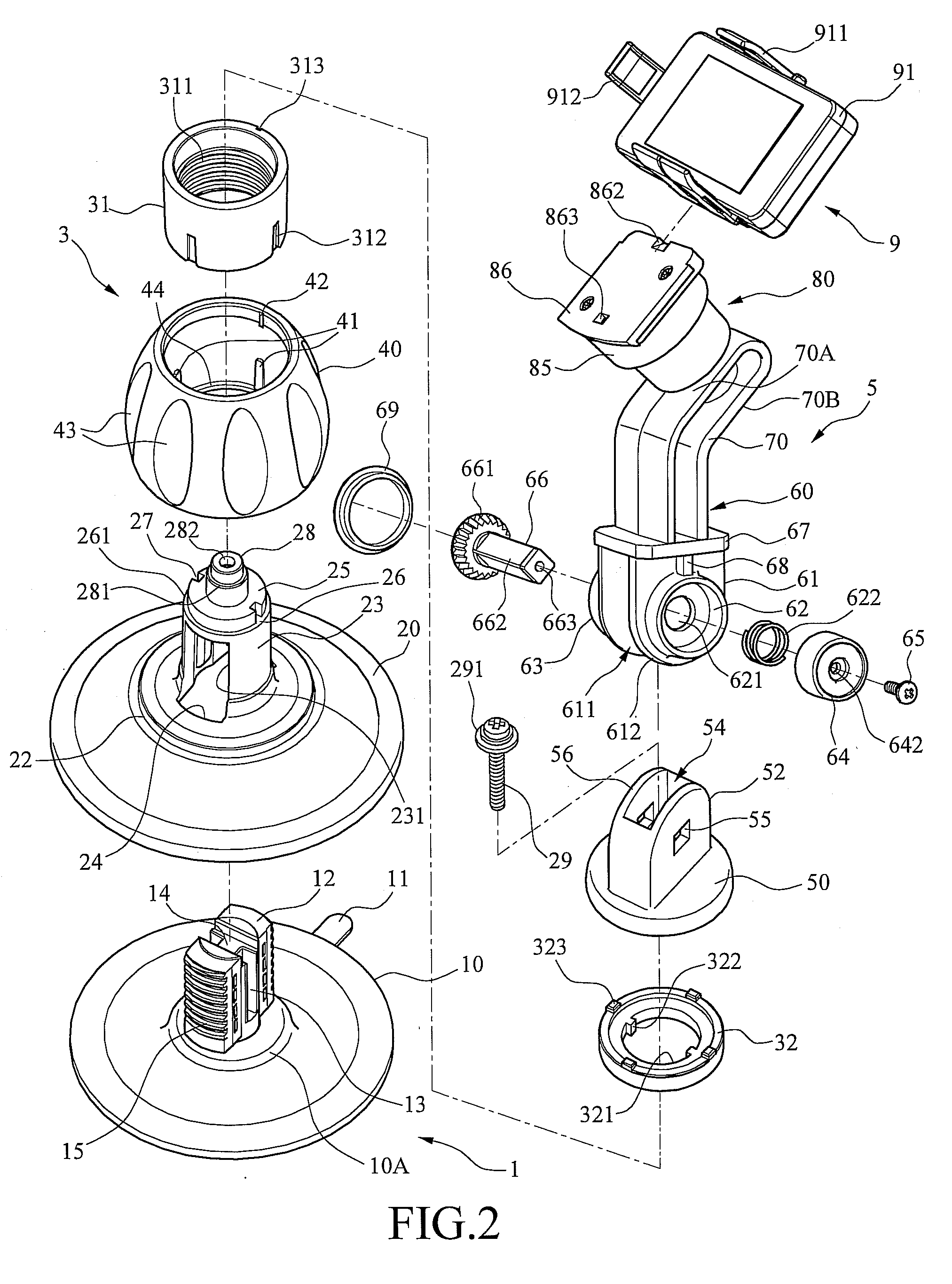

Article holder with suction cup

InactiveUS20090308993A1Robust and durable and easily operatedStands/trestlesKitchen equipmentDashboardCoupling

A holder includes a suction cup comprising a circular plate formed of resilient material and a rigid bell wherein the plate includes a central coupling member including outer threads, and the bell includes a hollow cylinder including two opposite openings with the outer threads disposed thereat; a manipulation assembly comprising a tube including an internal threaded section threadedly secured to the outer threads, a sleeve securely put on the tube, and a coupling mechanism seated upon the sleeve; and a pivot assembly comprising a pivot mechanism pivotably secured to the coupling mechanism, an arm extended upward from the pivot mechanism, and a seat assembly rotatably, pivotably secured to the arm. Preferably, the holder is adapted to hold an article (e.g., mobile phone) when it is immovably and captively retained on a dashboard of a motor vehicle.

Owner:CHANG TA SHUO

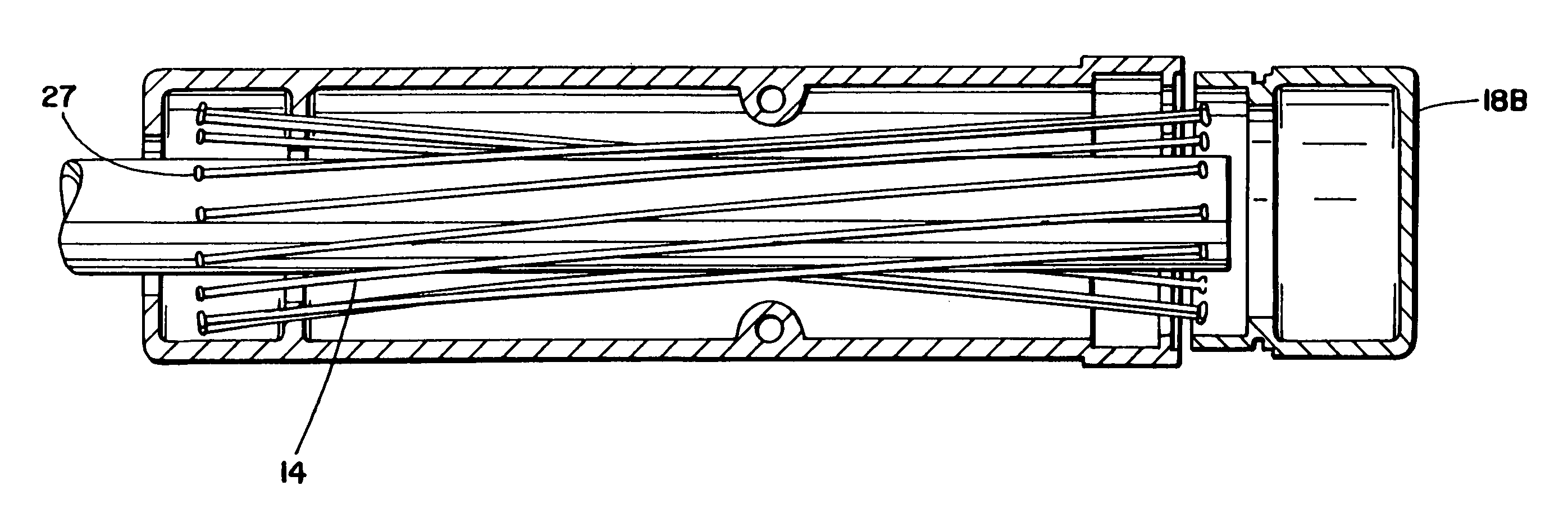

Armature for an electromotive device

InactiveUS6111329AMaximize conductor-packing factorMaximize conductor volume to gap ratioWindings insulation shape/form/constructionMagnetic circuit rotating partsGlass fiberEngineering

An armature for an electric motor is constructed from a pair of precision machined copper plates cut in a pattern to produce a series of axially extending surface conductive bands with each band separated from the other by an insulated cutout. The precision machined plates are rolled to form two telescoping, hollow cylinders with each cylinder having a pattern of conductive bands representing a half-electric circuit. The outer surface of the inner cylinder is wrapped with several layers of fiberglass strands for structural stability and insulation. The fiberglass wrapped inner cylinder is telescoped inside the outer cylinder. The outer surface of the telescoped structure is also wrapped with several layers of fiberglass strands for structural stability. The conductive bands from the outer cylinder being the near mirror image of the conductive bands of the inner cylinder are helically coupled to form a complete electrical circuit. The resulting tubular structure is encapsulated in a potting material for further structural stability and insulation. The result is a freestanding ironless core inductive armature coil for a DC motor with brushes. The armature also has a commutator, which is mounted at one end of the coil and is in electrical contact with the helically coupled conductive bands. An insulated flywheel and shaft assembly is mounted inside the coil with the flywheel behind the commutator for motor mounting and operation.

Owner:THINGAP

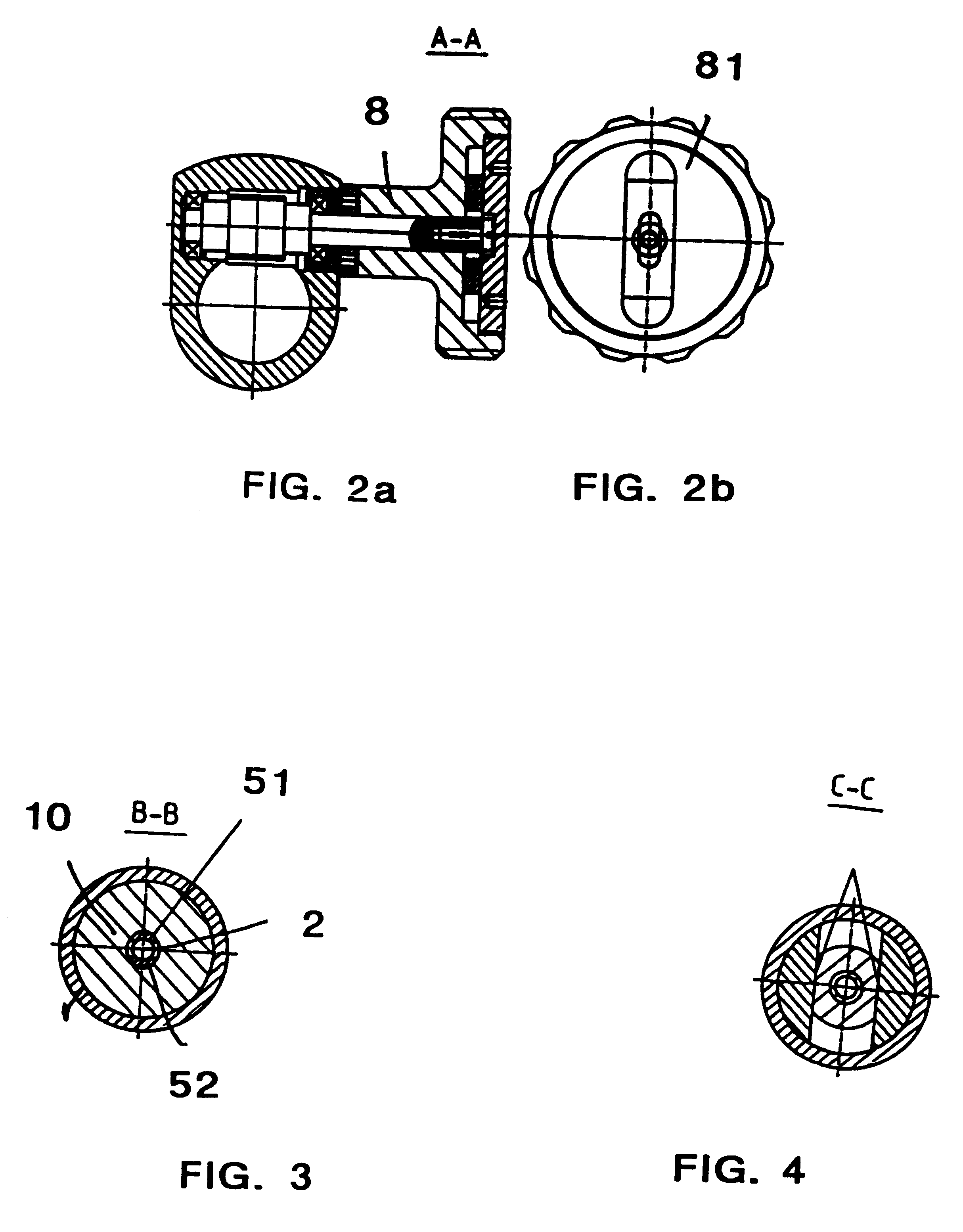

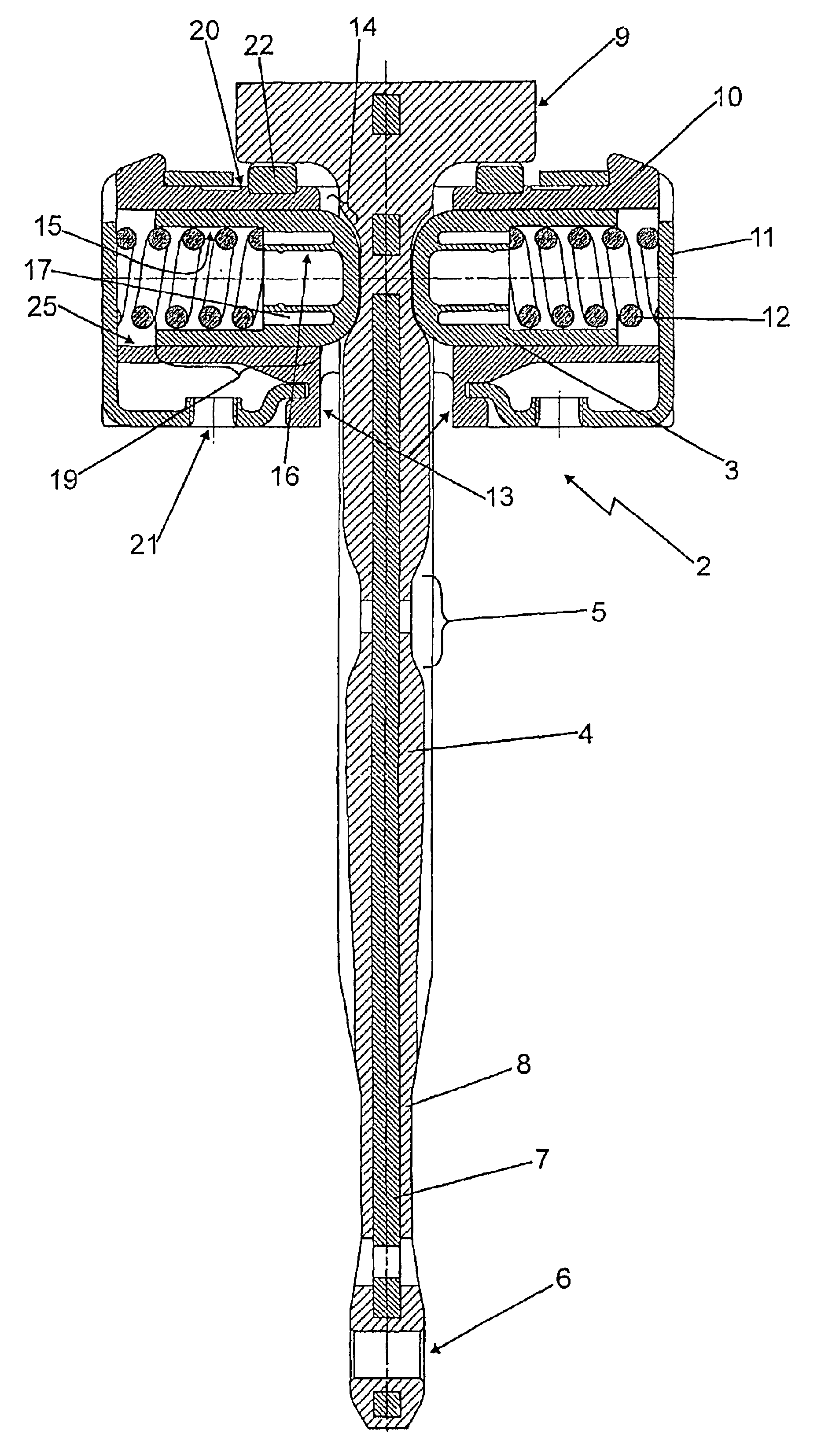

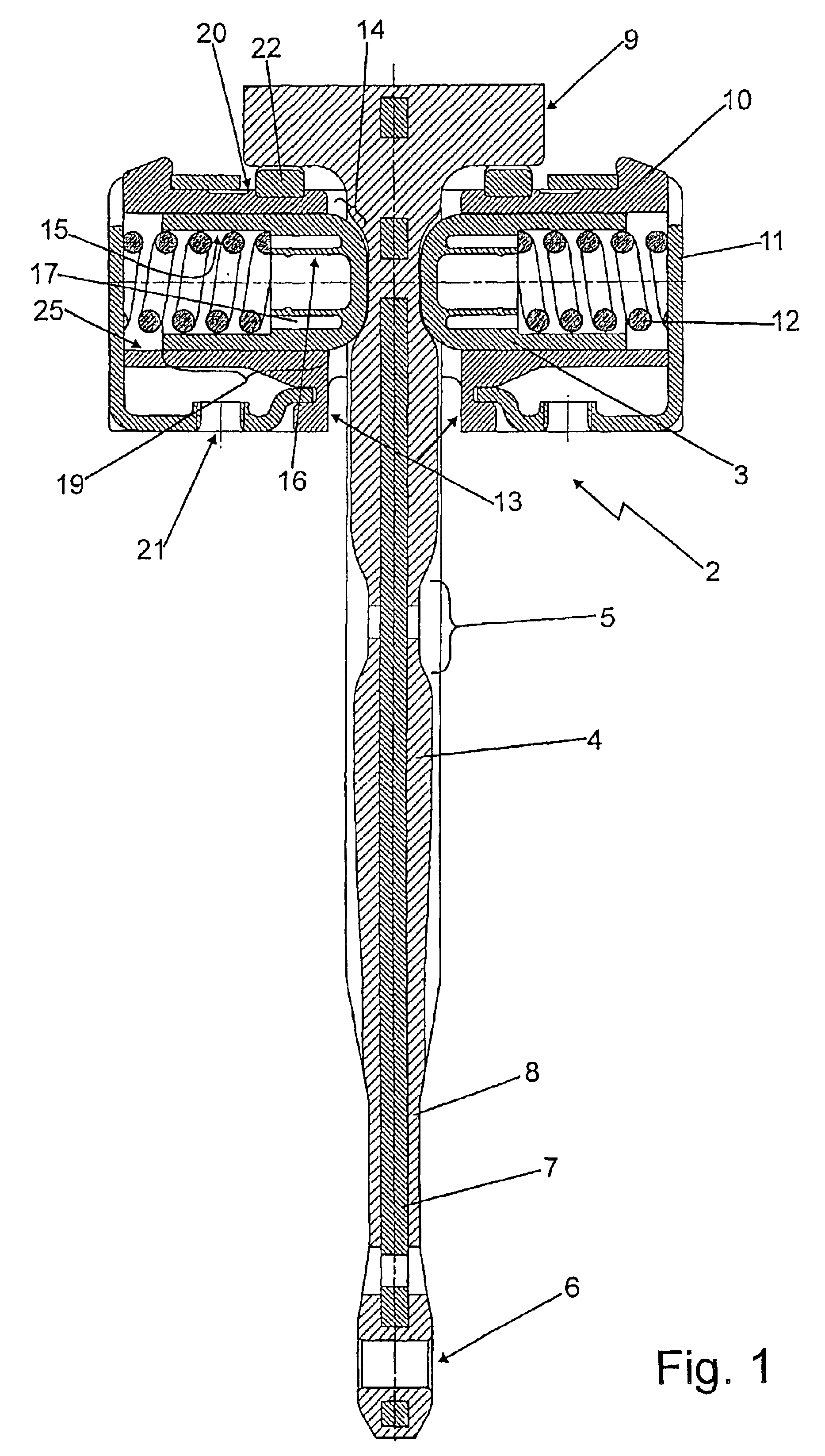

Electromagnet, particularly a proportional magnet for operating a hydraulic valve

InactiveUS6313726B1Inexpensive simple configurationIncrease the lengthOperating means/releasing devices for valvesElectromagnets with armaturesBall bearingEngineering

An electromagnet (1), particularly a proportional magnet for operating a hydraulic valve, said electromagnet (1) comprising at least one coil winding (3) carried by a hollow cylindrical coil spool (2) which is circumferentially surrounded by a hollow cylindrical magnet housing (4) and limited at each end by a pole shoe (5, 6), said electromagnet (1) further comprising an axially moveable cylindrical armature (8) which is arranged in a hollow cylinder of the coil spool (2) that is configured as an armature space (7), the armature (8) being mounted for low friction in rotary, longitudinally moveable axial guides, and electromagnetically produced axial movements of the armature (8) can be transmitted to a hydraulic valve piston via a push rod (10) which is connected to the armature (8) to form an axial extension thereof. According to the invention, the rotary, longitudinally moveable axial guides of the armature (8) comprise at least one bushing-less linear ball bearing having a number of circumferentially spaced balls while being configured at the same time as an anti-stick means of the armature. The outer peripheral surface (9) of the armature (8) and / or the outer peripheral surface (11) of the push rod (10) is configured as an inner running track for the balls, and the inner peripheral surface of one or more components which limit the armature space (7) of the coil spool (2) forms an outer running track for the balls.

Owner:INA WALZLAGER SCHAEFFLER KG

Holding device and cleaning tool with the holding device

InactiveUS20050097691A1Easy to extendEasy to retractCarpet cleanersKitchenware cleanersEngineeringFront and back ends

Disclosed is a holding device including: a telescopic handle having axially opposed front and rear ends and constructed of at least two separate shafts, of which a front-side separate shaft axially fits within a rear-side separate shaft being a hollow cylinder; and a support member provided at the front end of the telescopic handle for attachment of a cleaning wiper. The front-side separate shaft has an axially extending elastic arm and an engaging projection provided at a leading end of the elastic arm, while the rear-side separate shaft has a through-hole passing through a cylinder wall thereof, in which the engaging projection engages when the front-side separate shaft projects from the rear-side separate shaft by a predetermined length. Pressing the engaging projection, which engages in the through-hole, from outside the rear-side separate shaft permits release of the engaging projection from the through-hole.

Owner:UNI CHARM CORP

Syringe, cap and method of producing prefilled syringe

InactiveUS20060106349A1Easy and assured connectionInfusion syringesTube connectorsEngineeringPrefilled Syringe

A first female connector and a second female connector that has on its outer periphery a screw portion engaging a female screw can be alternatively connected to the top of a syringe. A mouth portion with a smaller diameter than a barrel portion of an outer hollow-cylinder main body is provided at the top of an outer hollow-cylinder. A lock adapter is provided on the outer periphery of the mouth portion. The lock adapter is rotatable about the mouth portion and axially movable in an axial direction of the mouth portion. The lock adapter can be moved to a position at the base of the mouth portion where the operation of fitting a male taper portion formed at the top of the mouth portion into a bore portion of the first female connector is not interrupted. The lock adapter can be fixed to the mouth portion at the position to which the adapter is moved.

Owner:TERUMO KK

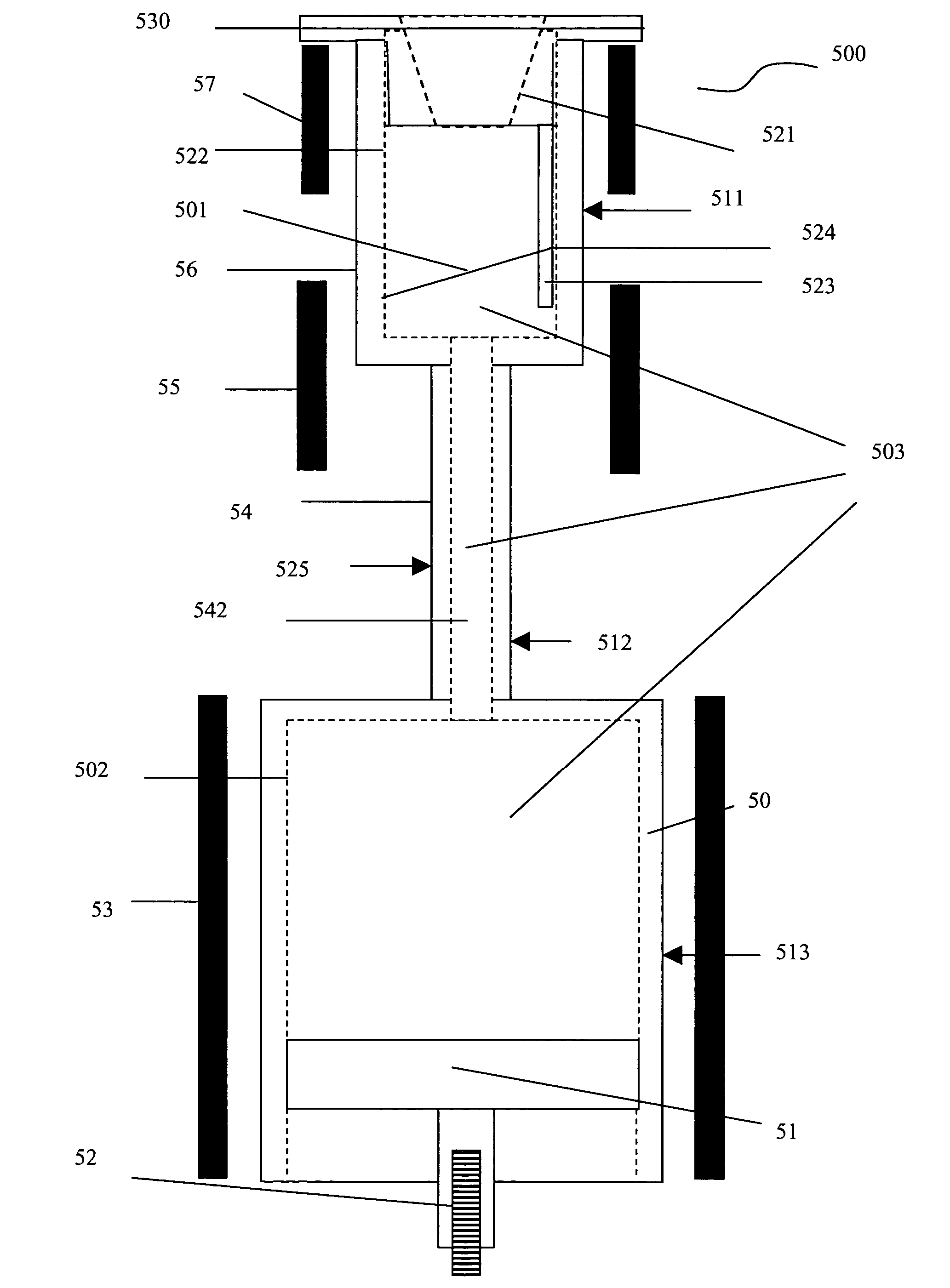

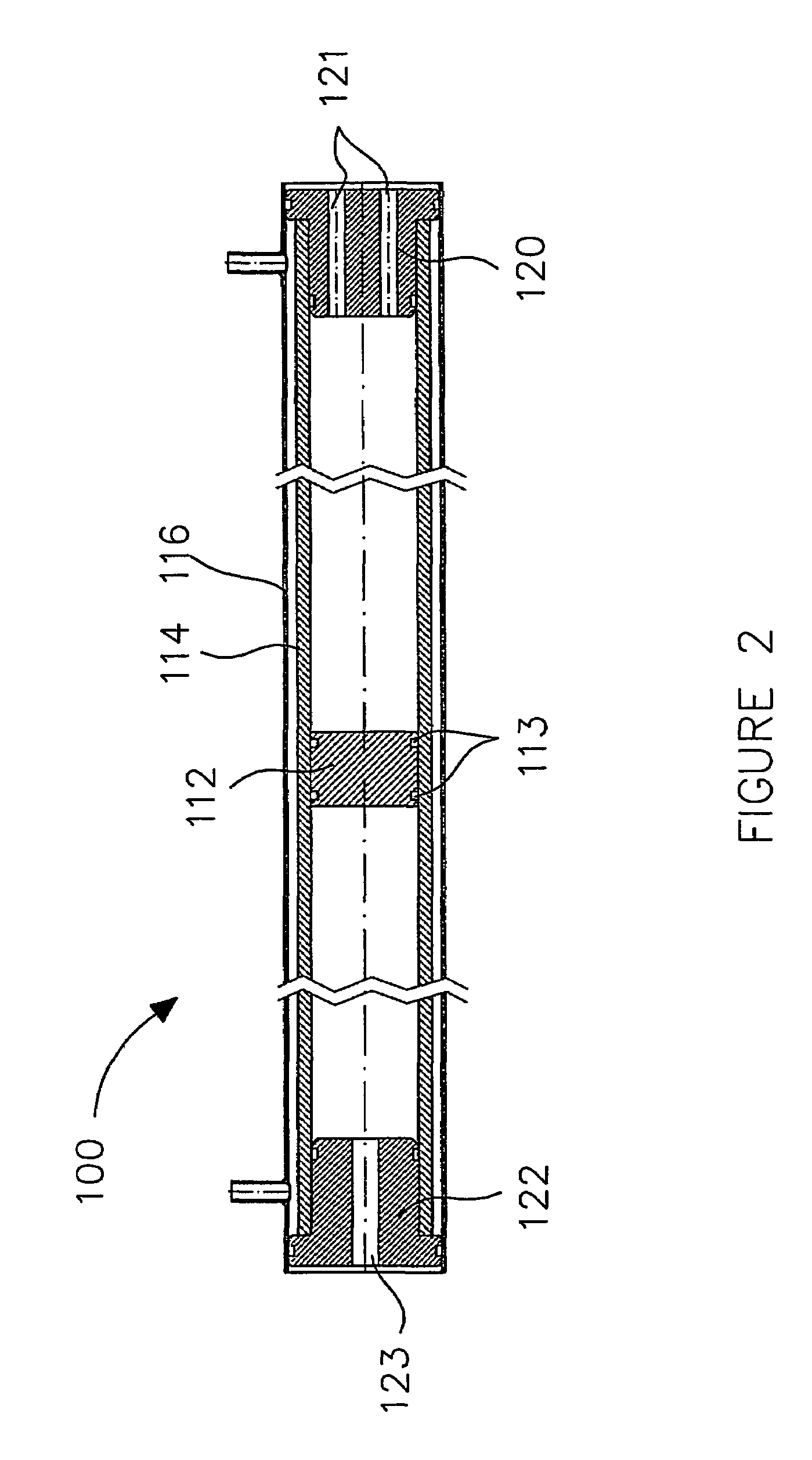

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

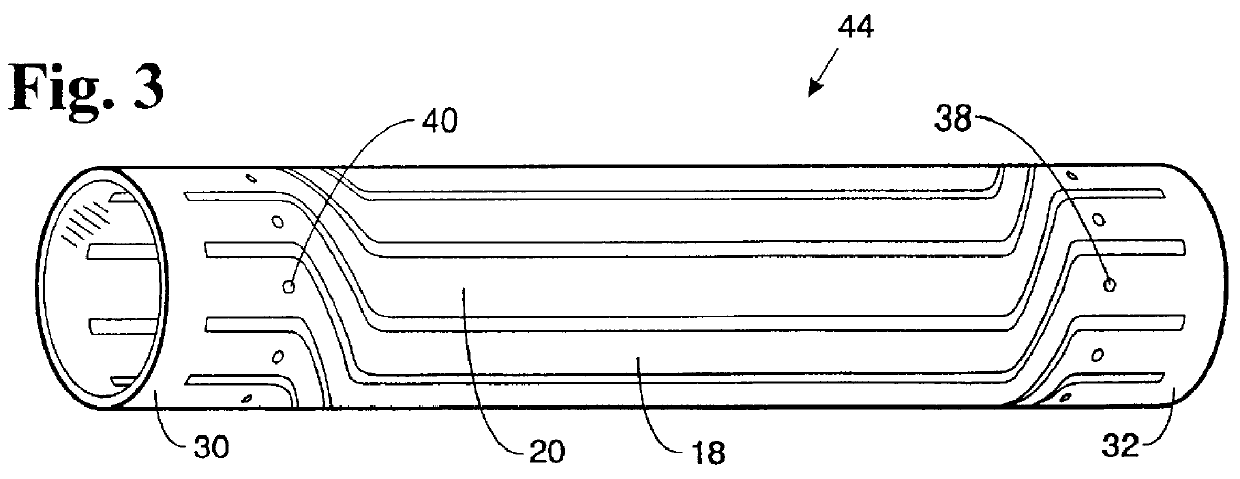

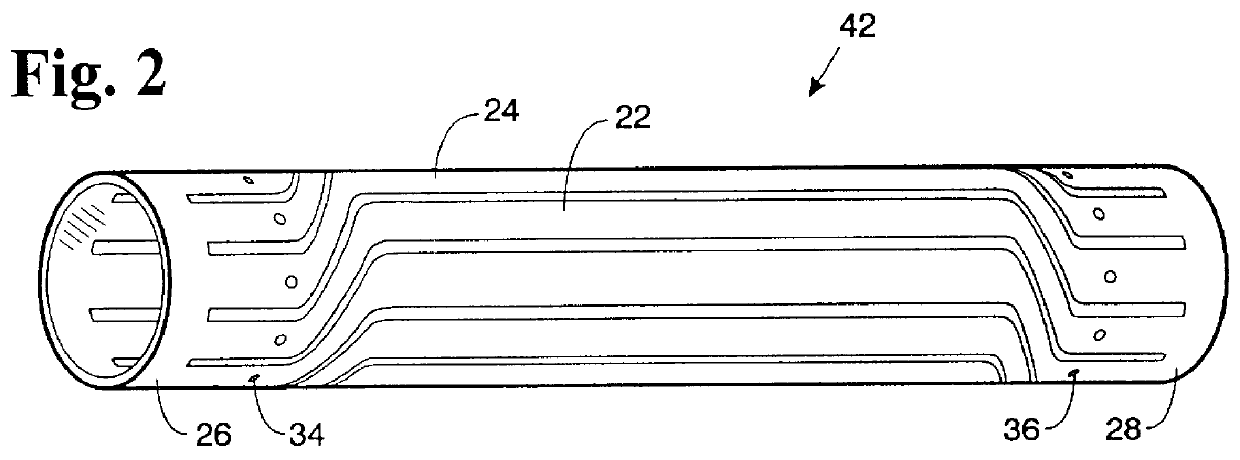

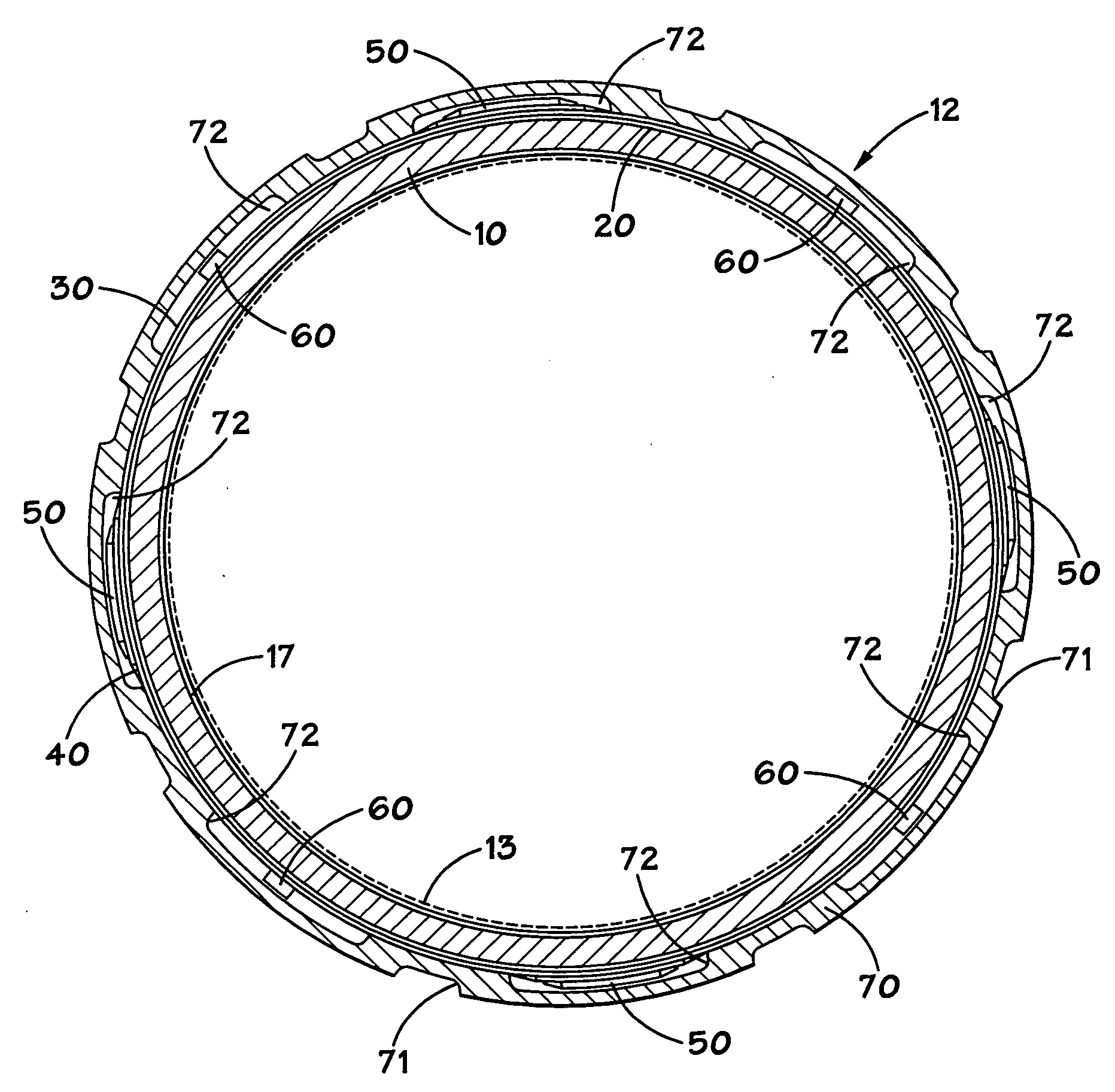

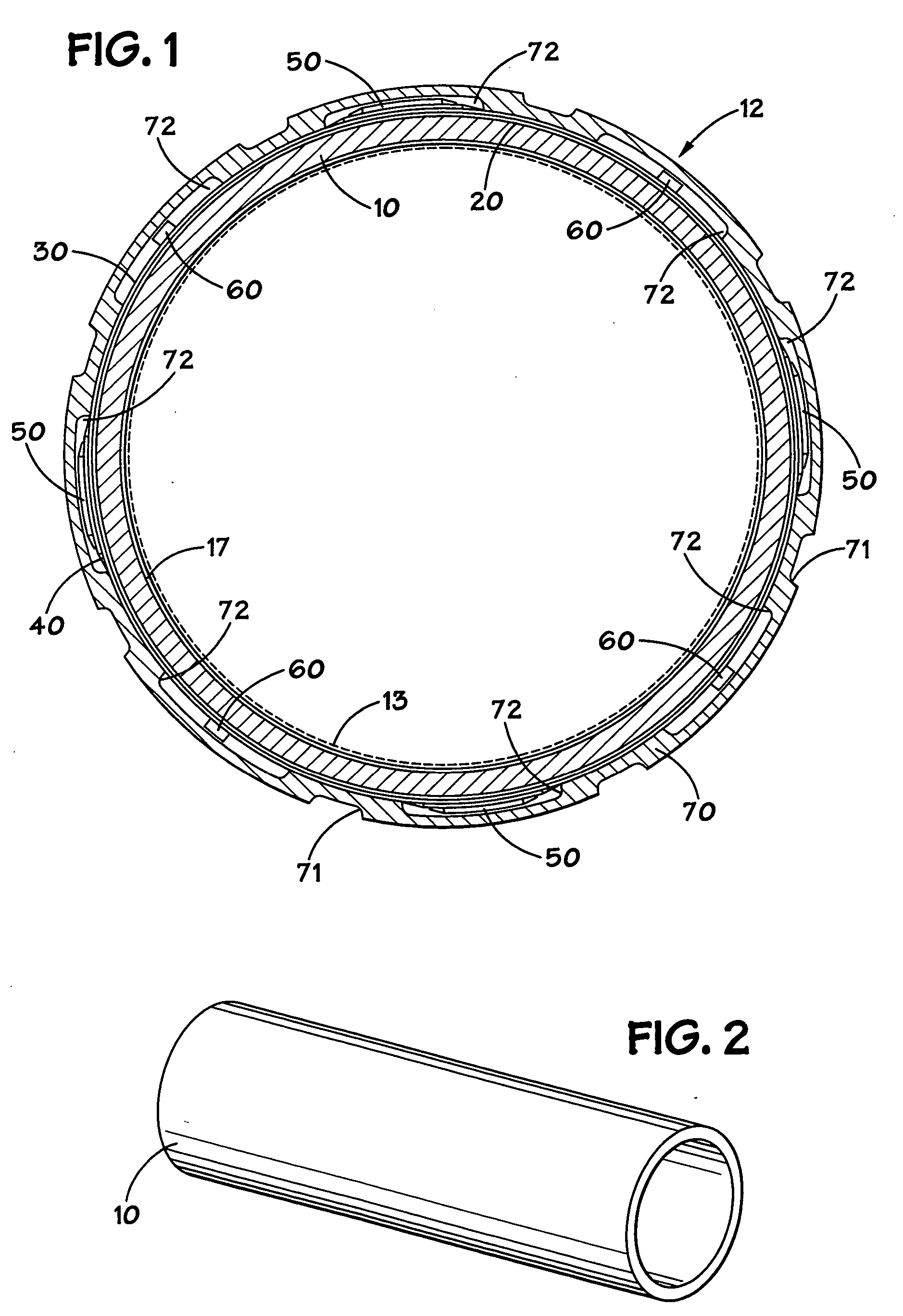

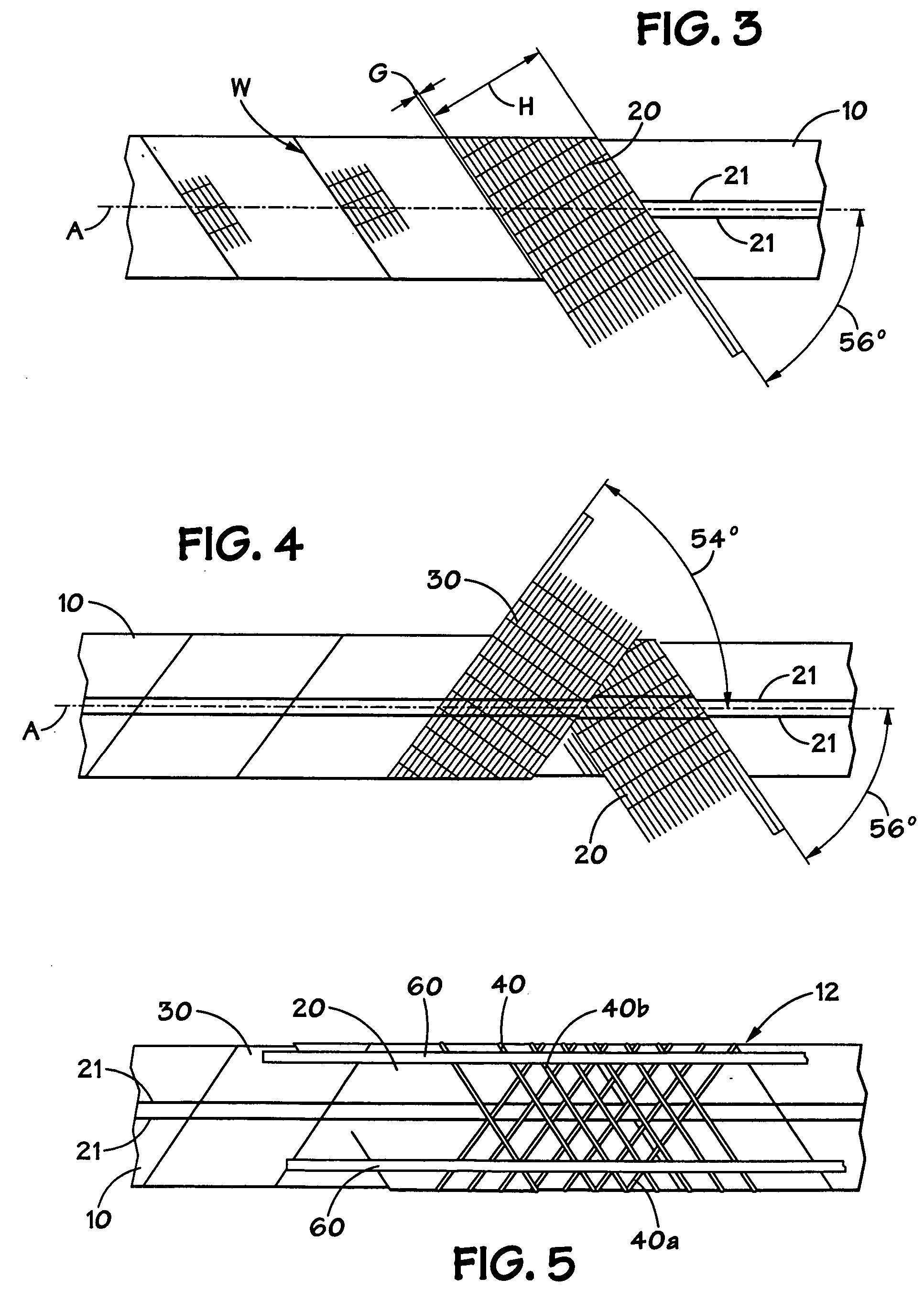

Pipe liner

InactiveUS20060151042A1Improve protectionPipe elementsFlexible pipesEngineeringMechanical engineering

A liner for pipe, methods to make liners, and methods for using them, the liner in one aspect including as a first layer a hollow cylinder of polymeric material, a second layer of wrap material around the first layer, a third layer of wrap material wrapped around the second layer, at least one strengthener member on the liner and extending from a first end thereof to a second thereof, and an exterior cover, the liner being a stand-alone structure.

Owner:SMART PIPE COMPANY

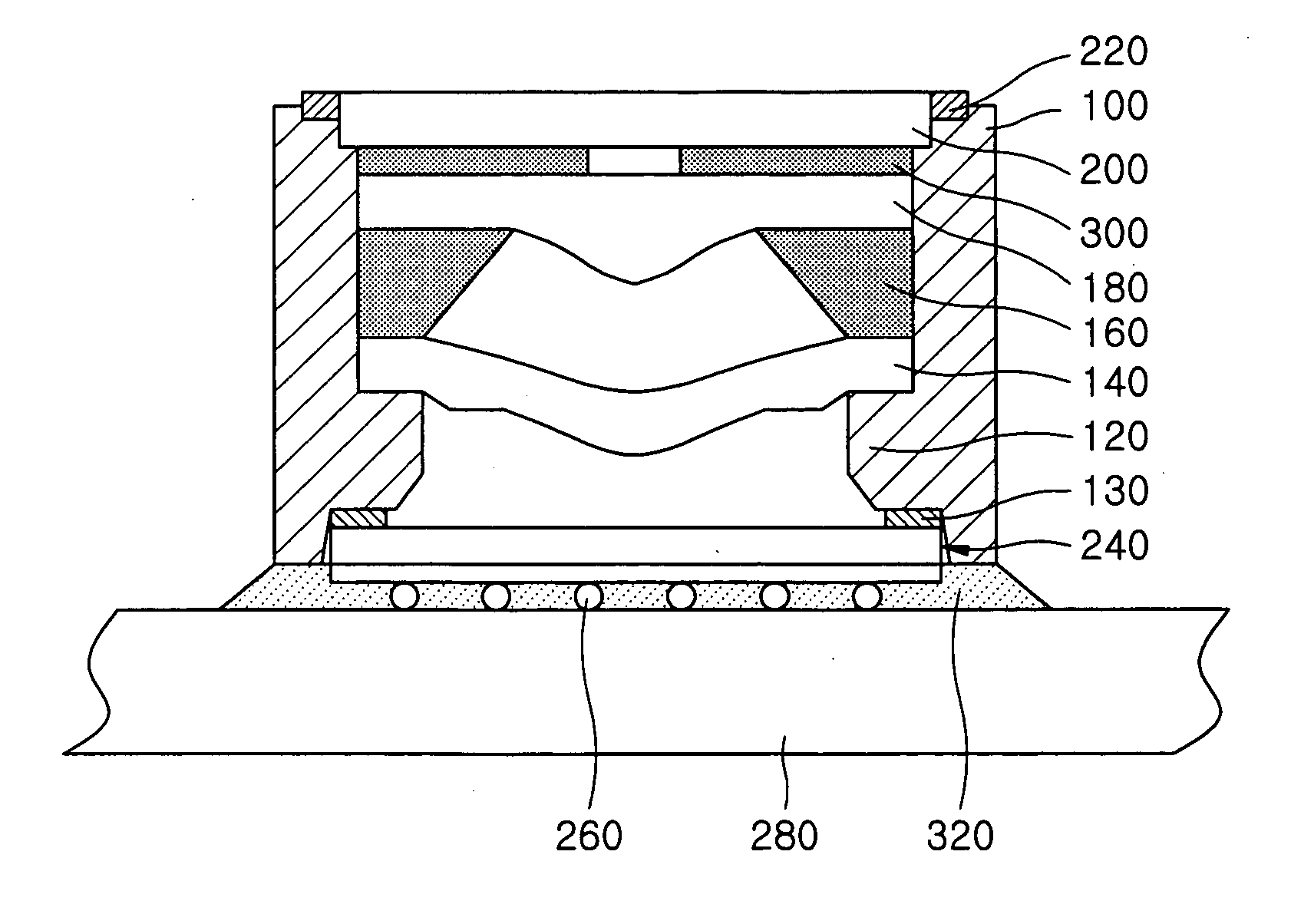

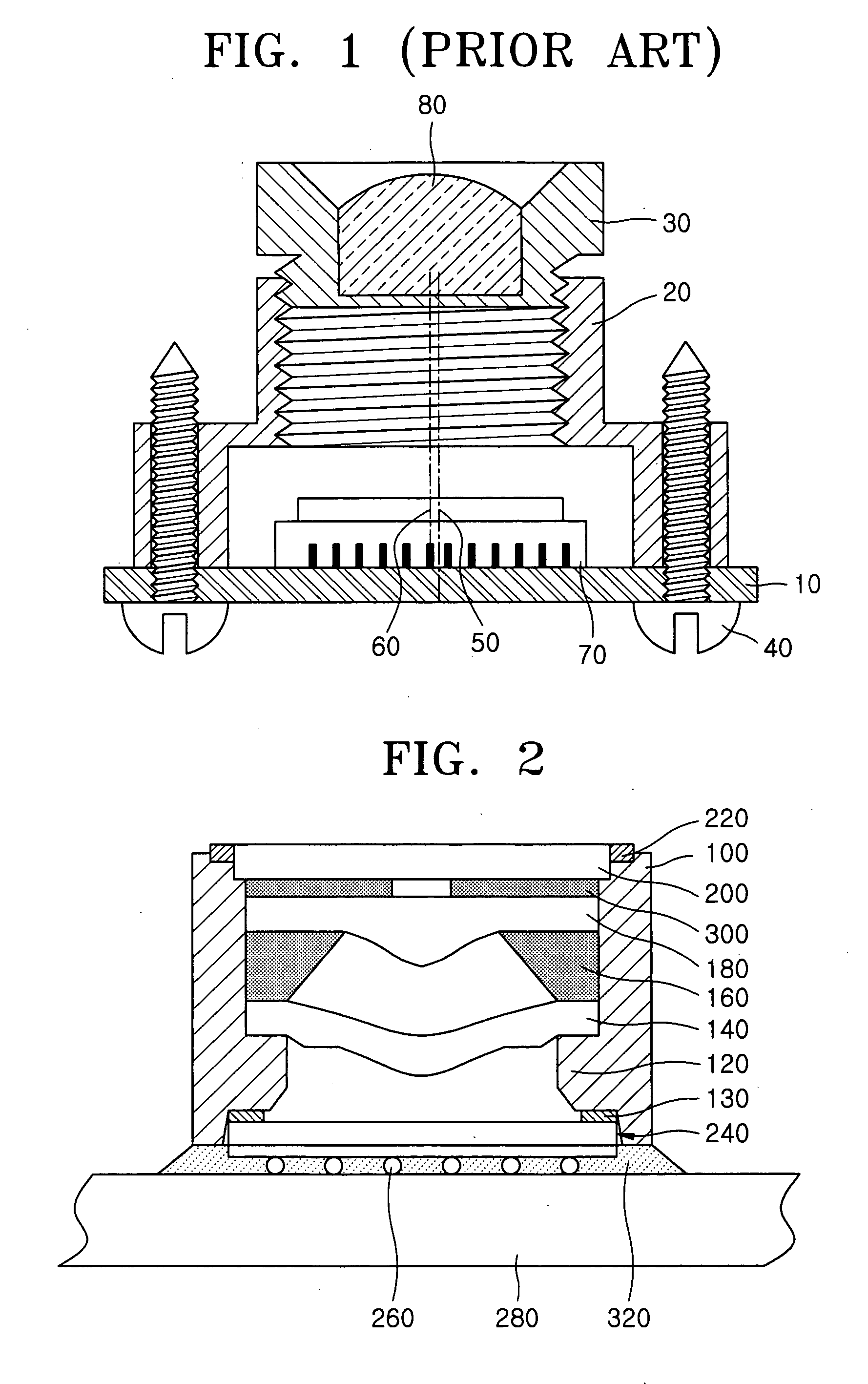

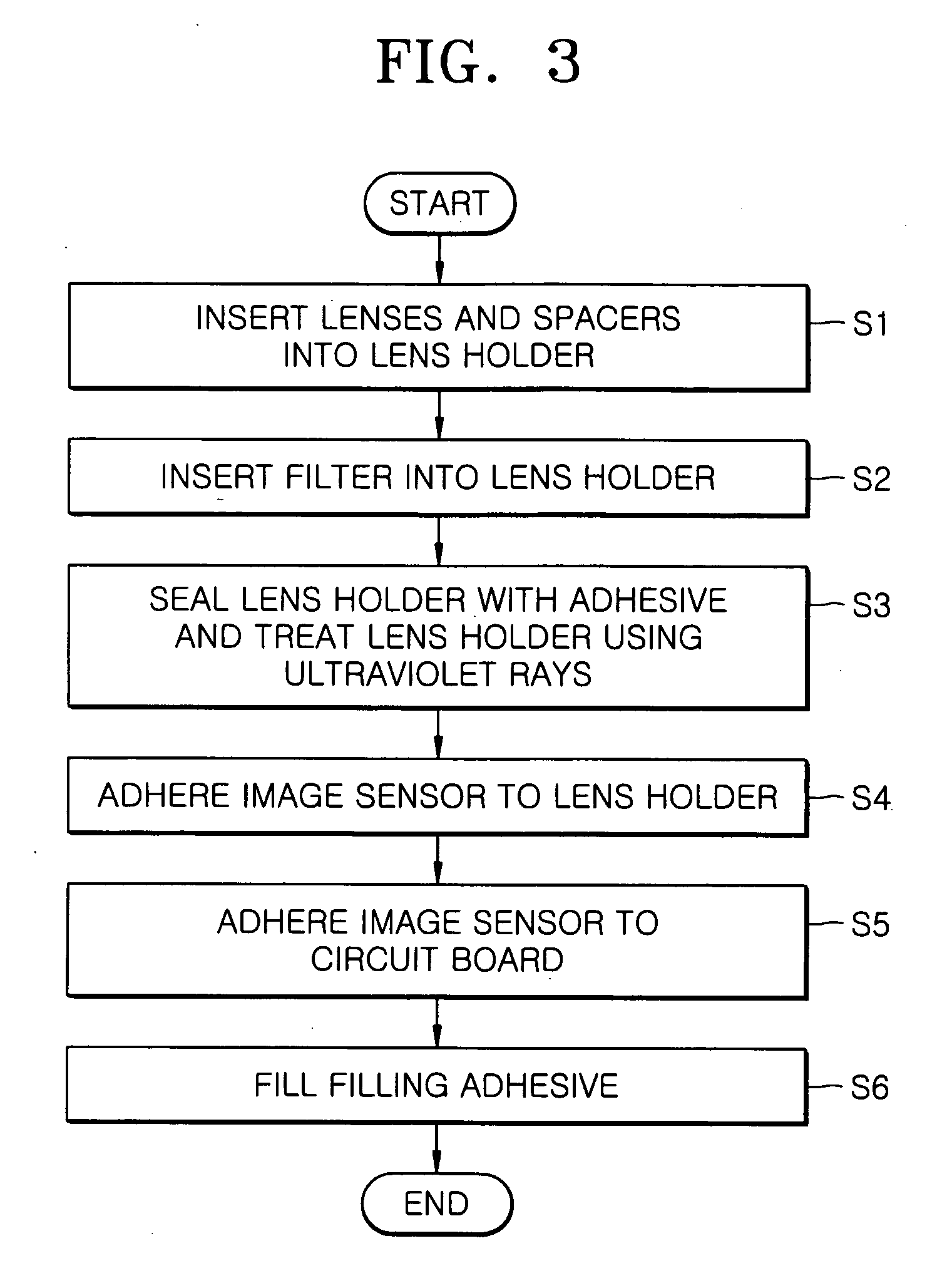

Image sensor camera module and method of fabricating the same

ActiveUS20060028573A1Simplify the assembly processImage can be preventedTelevision system detailsSemiconductor/solid-state device detailsCamera moduleAll optical

The invention involves an image sensor camera module and a method of fabricating the image sensor camera module. The image sensor camera module uses a single-body type lens holder defined by a hollow cylindrical body having a shoulder protruding radially inwardly from an inner surface thereof. First and second lenses therein are spaced apart by a first spacer and a filter therein is spaced from the second lens by a second spacer. An image sensor is adhered to a lower rim of the body, and the filter is adhered to an upper rim thereof. All optical elements within the lens holder thus are affixed in fixed relative position compatible with a predefined focal length and axis. Moreover, the adhesively sealed interior of the body of the image sensor camera module prevents particulate contamination.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus for compressing a gas to a high pressure

ActiveUS7527482B2Increase volumeReduce volumePositive displacement pump componentsFlexible member pumpsElectronic controllerFoot per second

A method is provided for compressing a gas in a single cycle and in a single cylinder to a pressure of at least 17.2 Mpa with a compression ratio of at least about five to one. The method further comprises dissipating heat from the cylinder during the compression stroke whereby the gas is discharged with a temperature significantly less than isentropic. The apparatus comprises a hollow cylinder and a reciprocable free-floating piston disposed therein. The piston divides the cylinder into: (a) a compression chamber within which a gas can be introduced, compressed, and discharged; and, (b) a drive chamber, into which a hydraulic fluid can be introduced and removed for actuating the piston. The apparatus further comprises a piston stroke length to piston diameter ratio of at least seven to one. For operating the apparatus with a compression ratio of at least five to one, an outlet pressure of at least 17.2 Mpa, and a gas discharge temperature significantly less than isentropic, the apparatus can further comprise a variable displacement hydraulic pump for controlling piston velocity, an electronic controller for maintaining an average piston velocity that is less than 0.5 feet per second, and a heat dissipator for dissipating heat from the cylinder.

Owner:WESTPORT FUEL SYST CANADA INC

Pressure-ball sliding doorstop

InactiveUS6842943B2Precise constructionHigh stop forceBuilding braking devicesWing fastenersEngineeringMechanical engineering

A doorstop that includes a retainer piece disposed on one of a door and a door support, the retainer piece including a plastic housing with a main opening and a guide opening arranged perpendicular to the main opening and parallel to a pivot axis of the door. The doorstop also includes a door retaining rod articulated on the other of the door and the door support. The door retaining rod passes through the main opening of the retainer piece housing and includes a brake ramp and a catch depression on a side of the door retaining rod. The doorstop also includes a catch device configured to determine specific door opening positions. The catch device includes a brake body and a spring. The catch device connects the retainer piece and the door retaining rod to each other in a moveable manner. The brake body includes a hollow cylinder having a semi-spherical closed end and an open end and is slidingly disposed in the guide opening of the retainer piece. The open end accommodates the spring so that the closed end is pre-tensioned by the spring relative to the brake ramp and catch depression and is guided in the guide opening free of tilt.

Owner:EDSCHA ENG GMBH

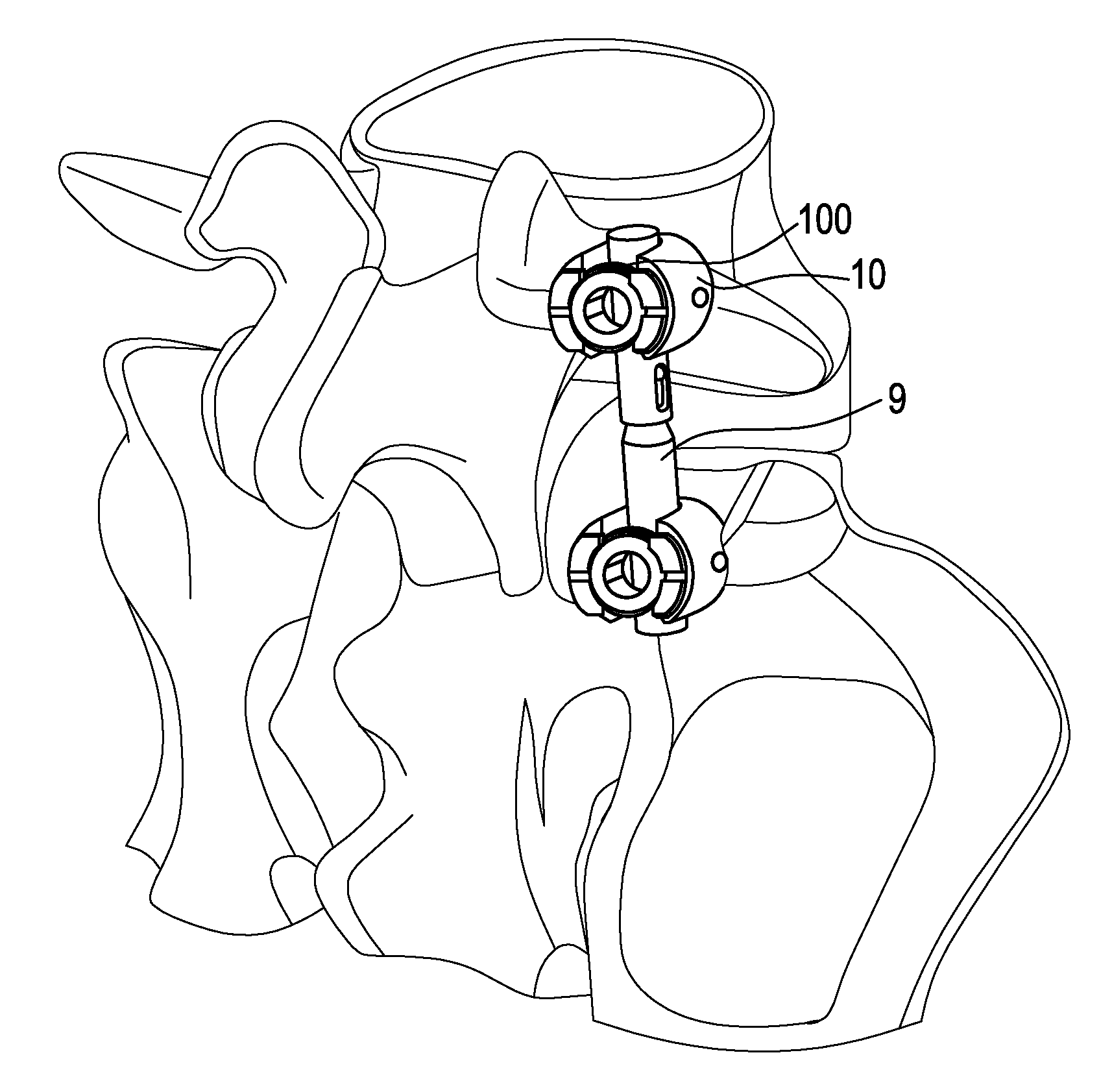

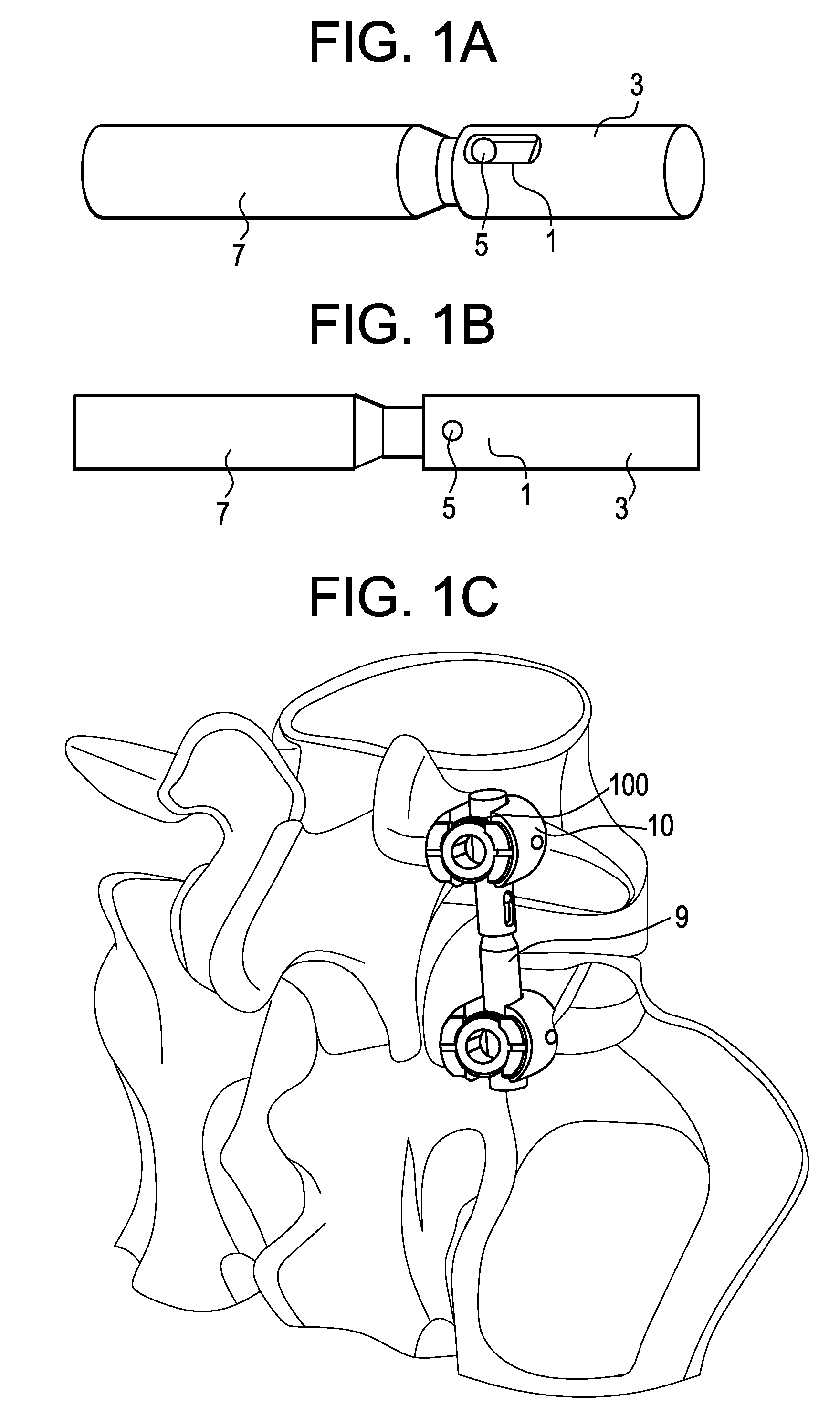

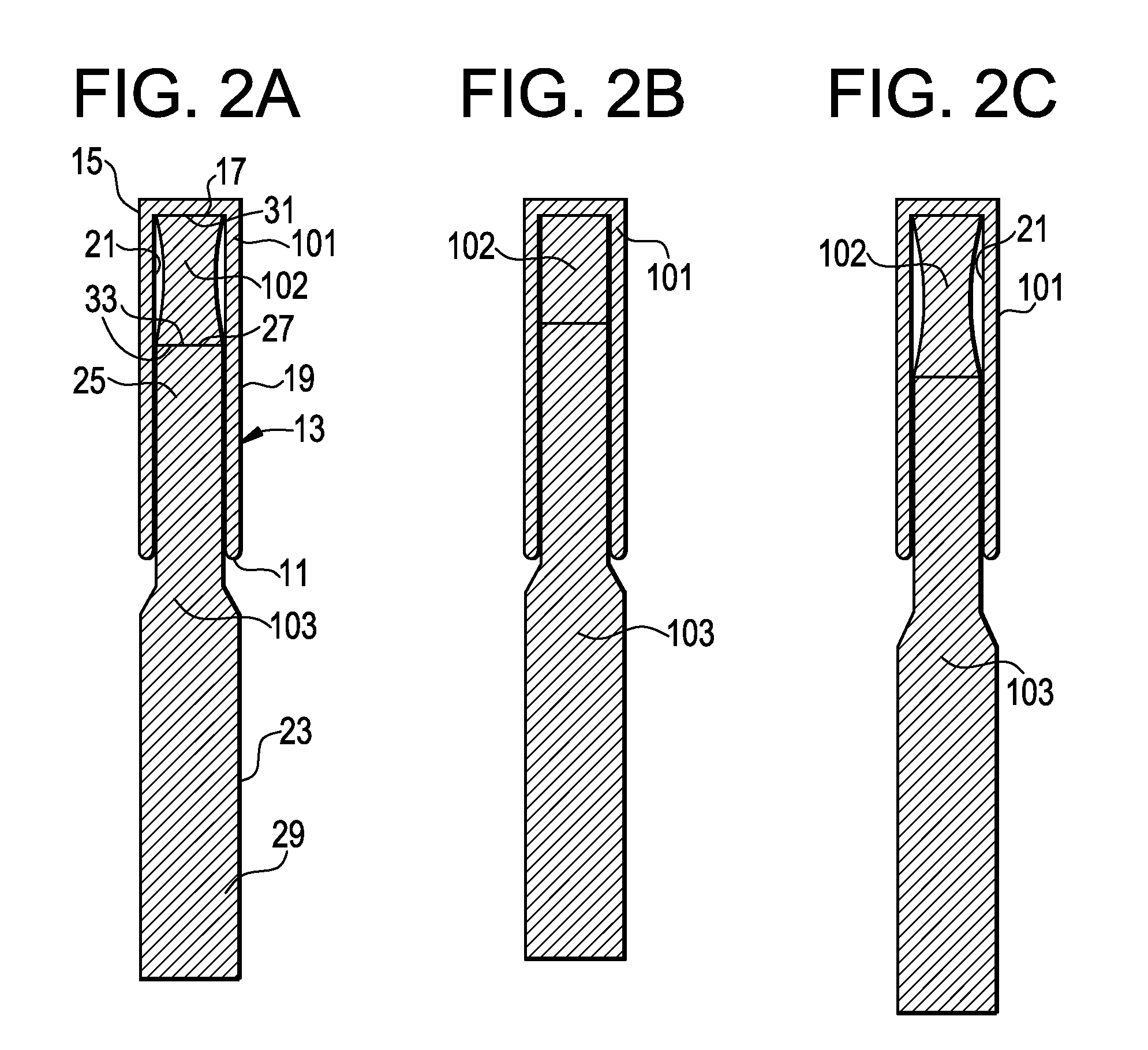

Spinal Dynamic Stabilization Rods Having Interior Bumpers

A dynamic stabilization device for use in the human spine, comprising i) a hollow, closed-end cylinder component that is configured for attachment to a first pedicle screw, ii) a solid rod component that is configured on one end to slide freely within the hollow cylinder component, and configured at the other end for attachment to a second pedicle screw and iii) an elastomer component contained within the hollow cylinder and located between the closed end of the hollow cylinder and the end of the solid rod component.

Owner:DEPUY SYNTHES PROD INC

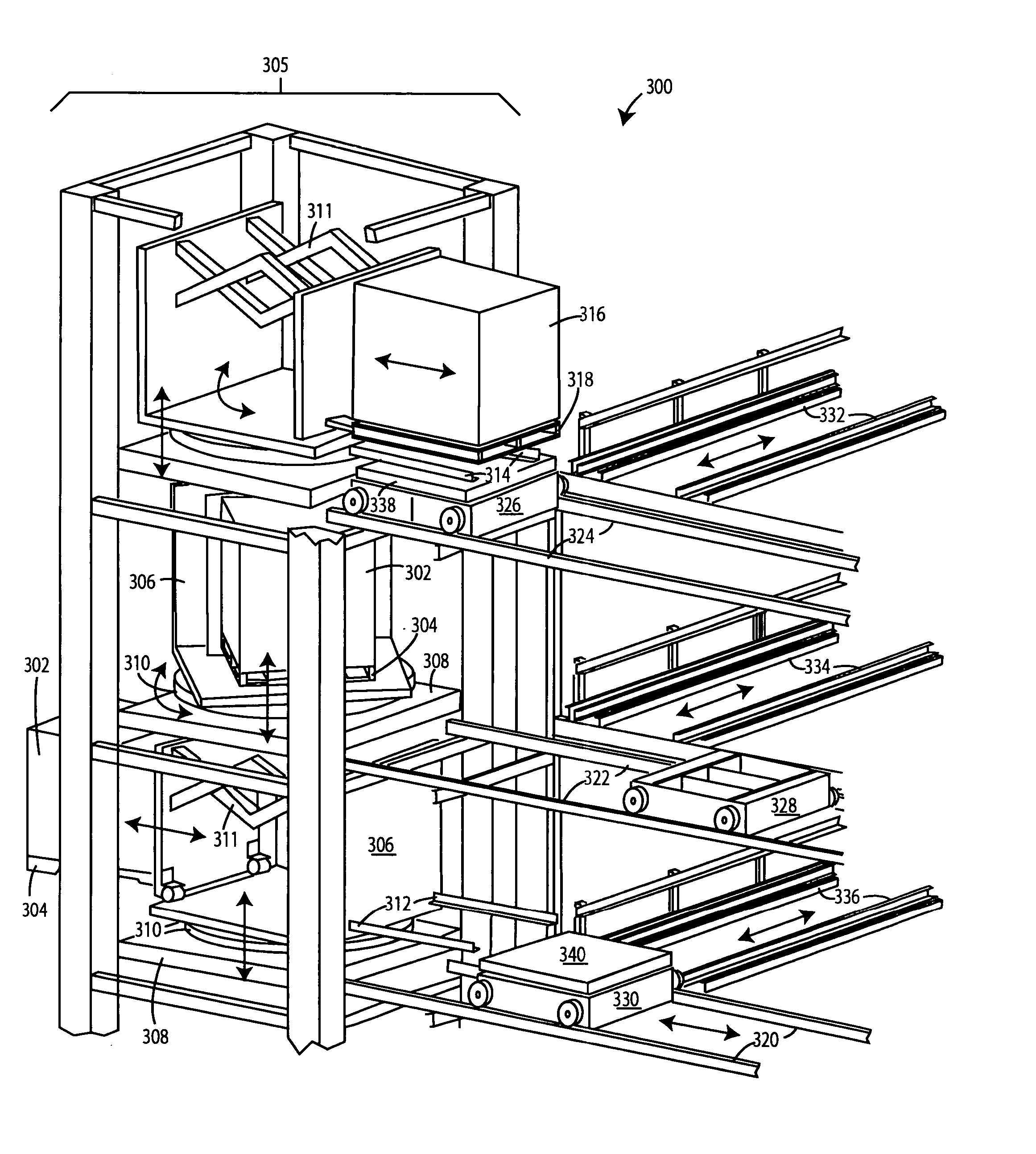

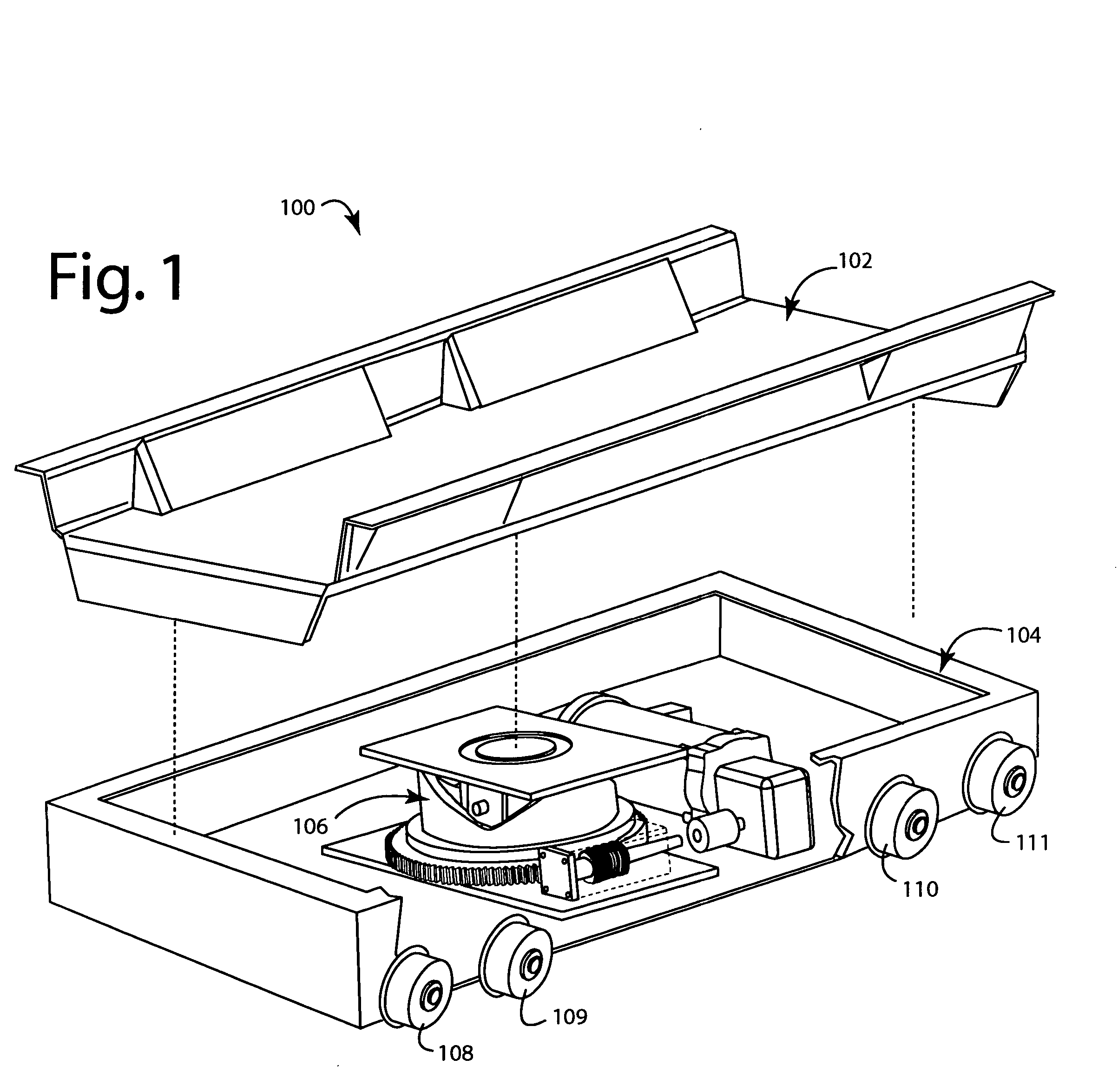

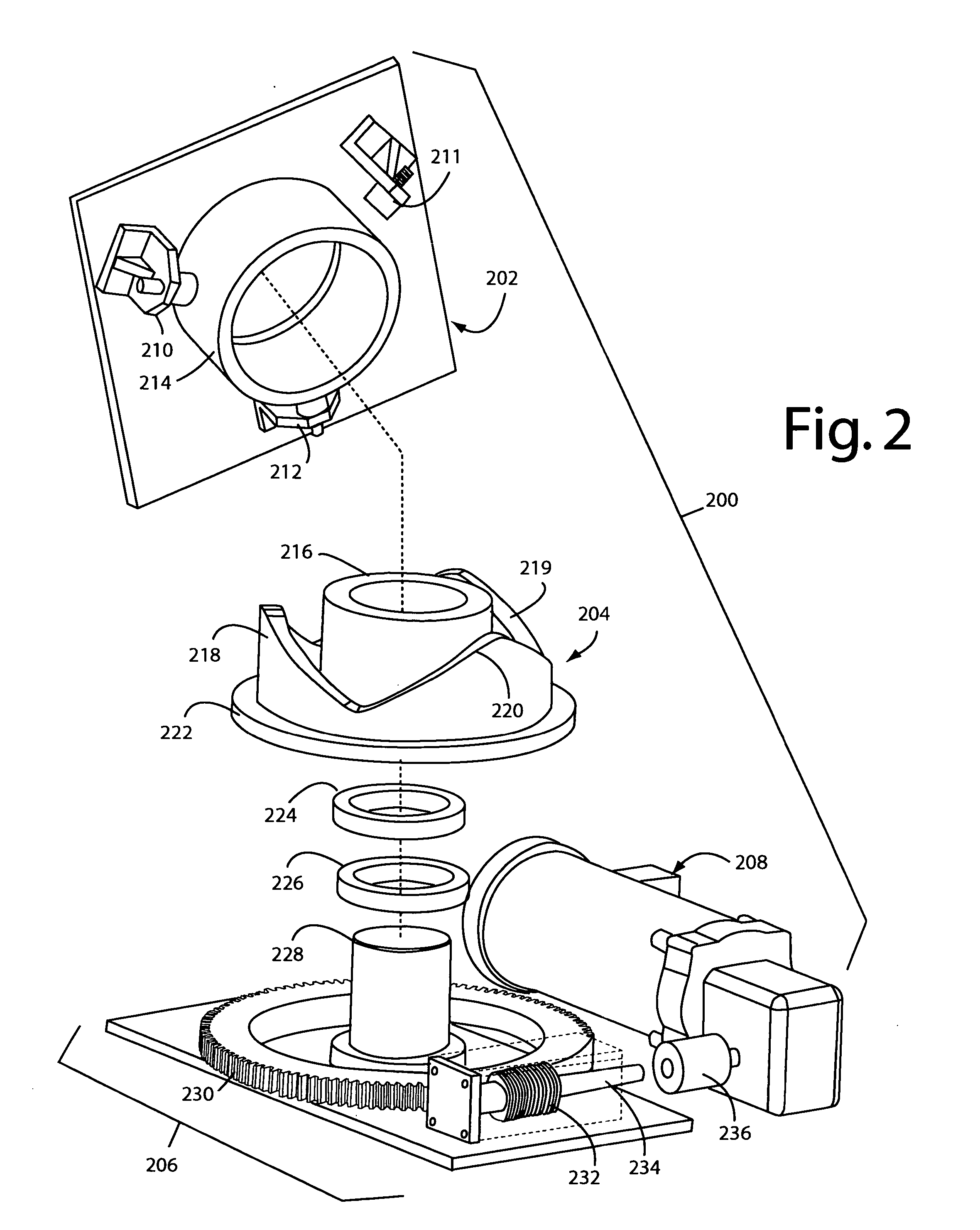

Automated warehouse row cart and lift

ActiveUS20050118003A1Little maintenanceEfficient and robustElevatorsLoading/unloadingEngineeringStepper motor

An automated warehouse system row cart includes a lifter that uses cams to raise and lower pallets. Three symmetrical cam lobes are cut into a hollow cylinder. Three matching cam lifters ride these lobes and are attached to an elevator plate. A stepper motor running in one direction is used to raise and lower the elevator plate by virtue of the action between the cam lobes and lifters.

Owner:SWISSLOG LOGISTICS

Universal support and vibration isolator

InactiveUS7500642B2Decrease stockGood adhesionNon-rotating vibration suppressionPipe elementsEngineeringVibration isolation

A pipe support is provided that includes a frame capable of being placed around an existing pipe and a plurality of support members within the frame. The frame is a hollow cylinder that includes two connectable halves divided along the diameter of the hollow cylinder. The pipe support includes two bearing rings connected to the frame for supporting each of the plurality of members at a minimum of two contact points. Each of the two bearing rings include bearing points for each support member arranged in a cylindrical pattern concentric with the hollow cylinder frame. The pipe support includes means for rotating each of the support members at a first contact point with respect to a second contact point so that the support members engage a pipe placed within the pipe support. The support members are rods that provide vibration isolation to a pipe placed within the pipe support.

Owner:SEICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com