Patents

Literature

3332results about "Electromagnets with armatures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

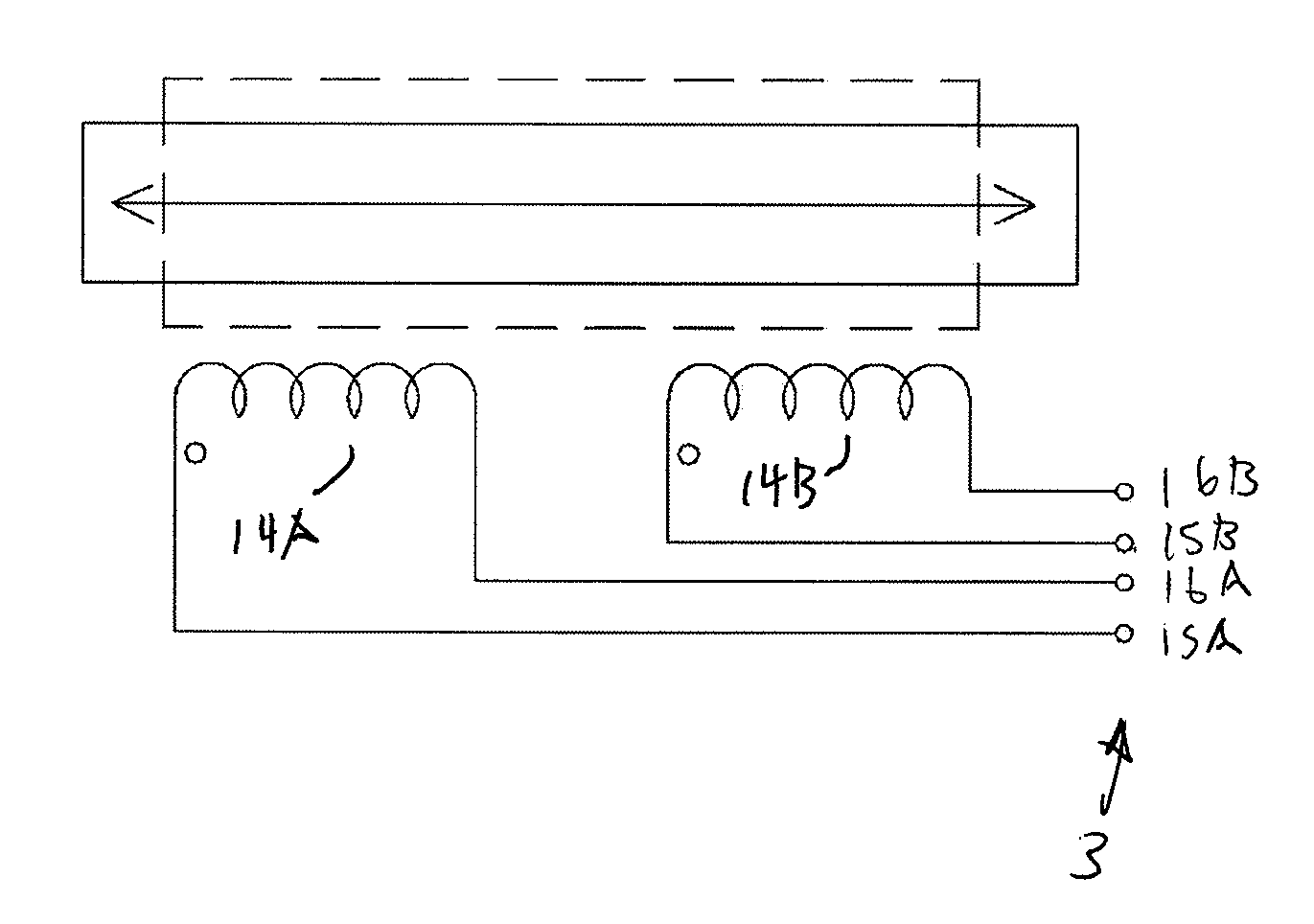

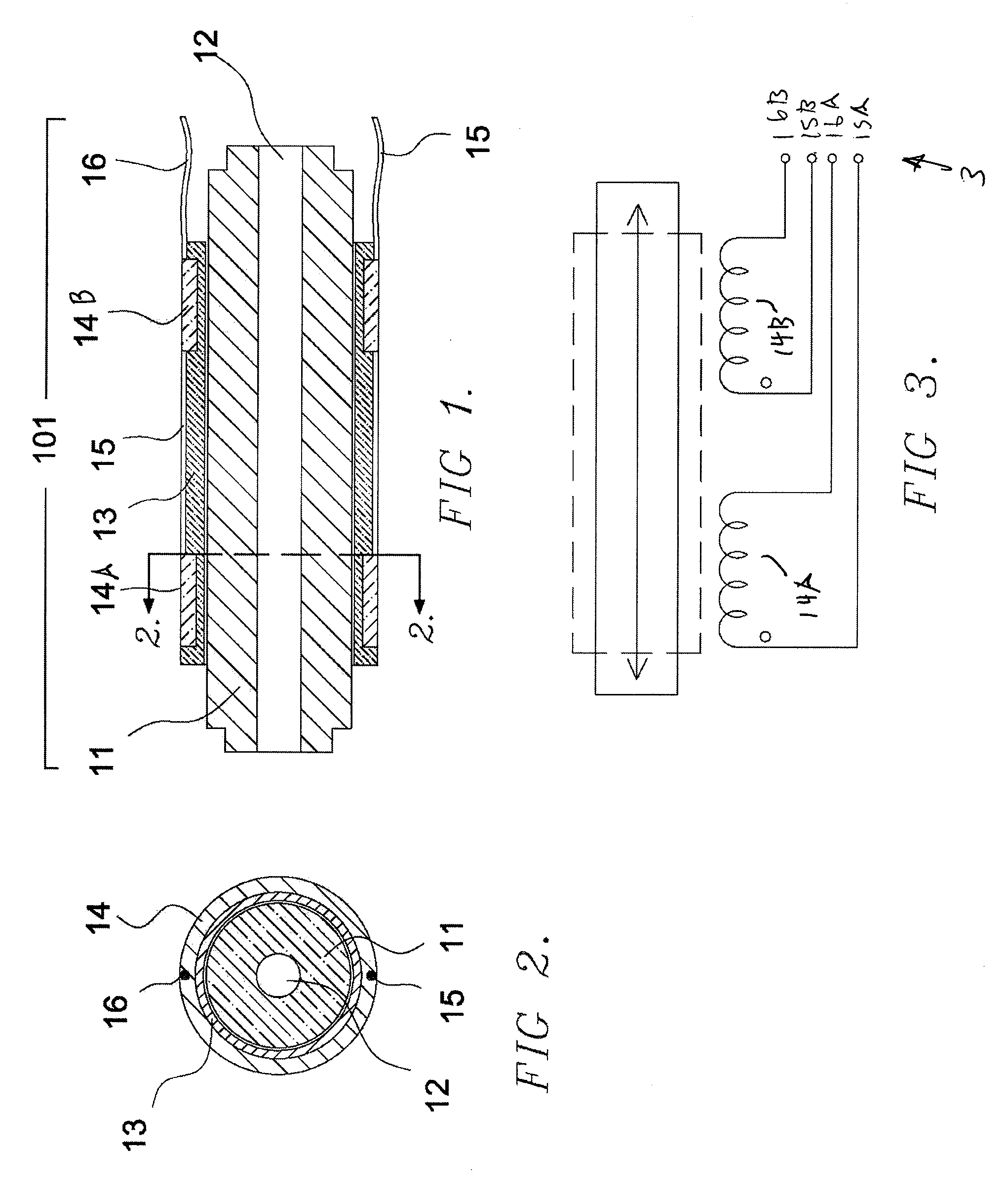

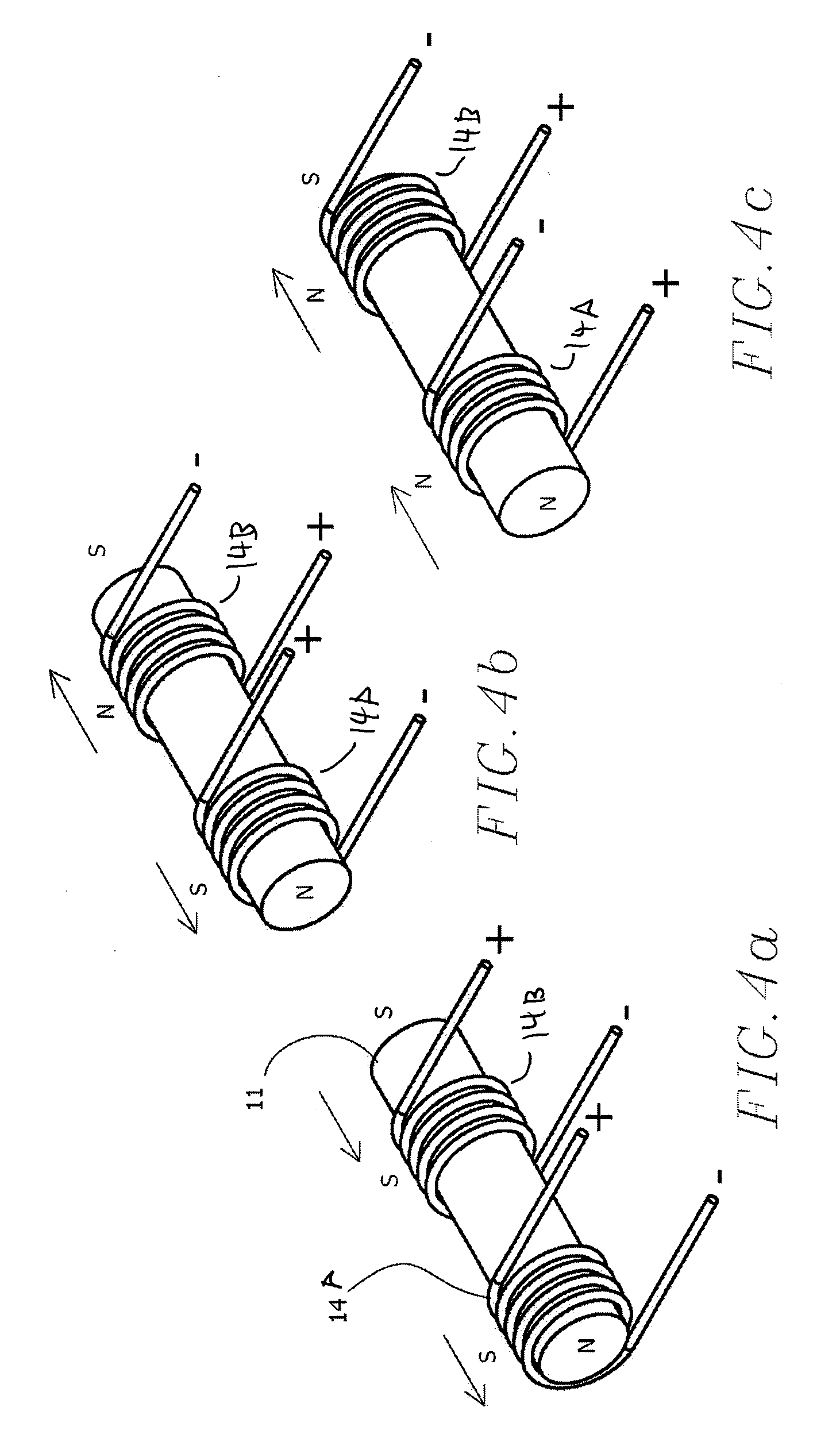

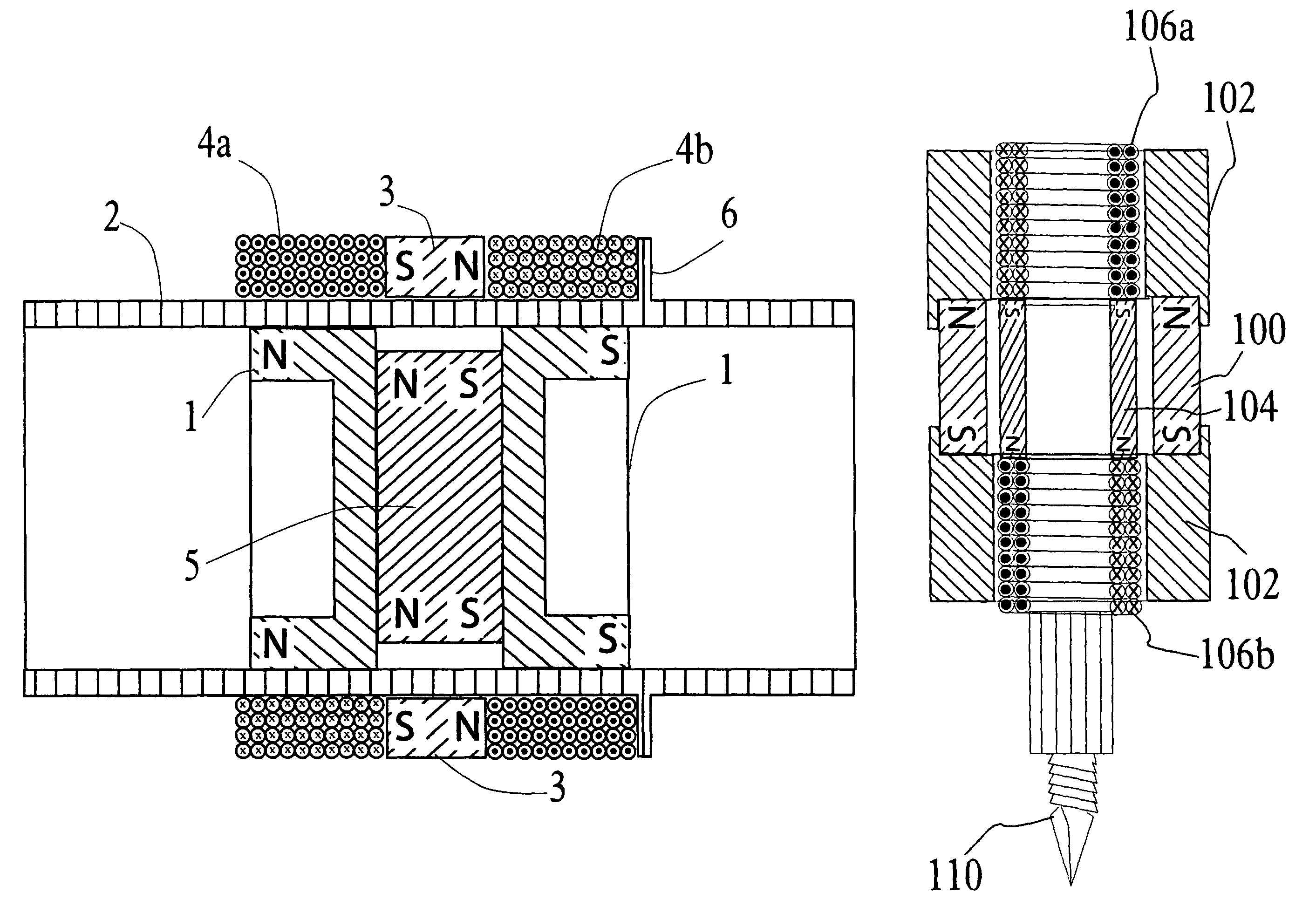

Magnetic linear actuator for deployable catheter tools

InactiveUS20080297287A1Easy to controlGood precisionDiagnostic recording/measuringSensorsDiagnostic Radiology ModalityLinear motion

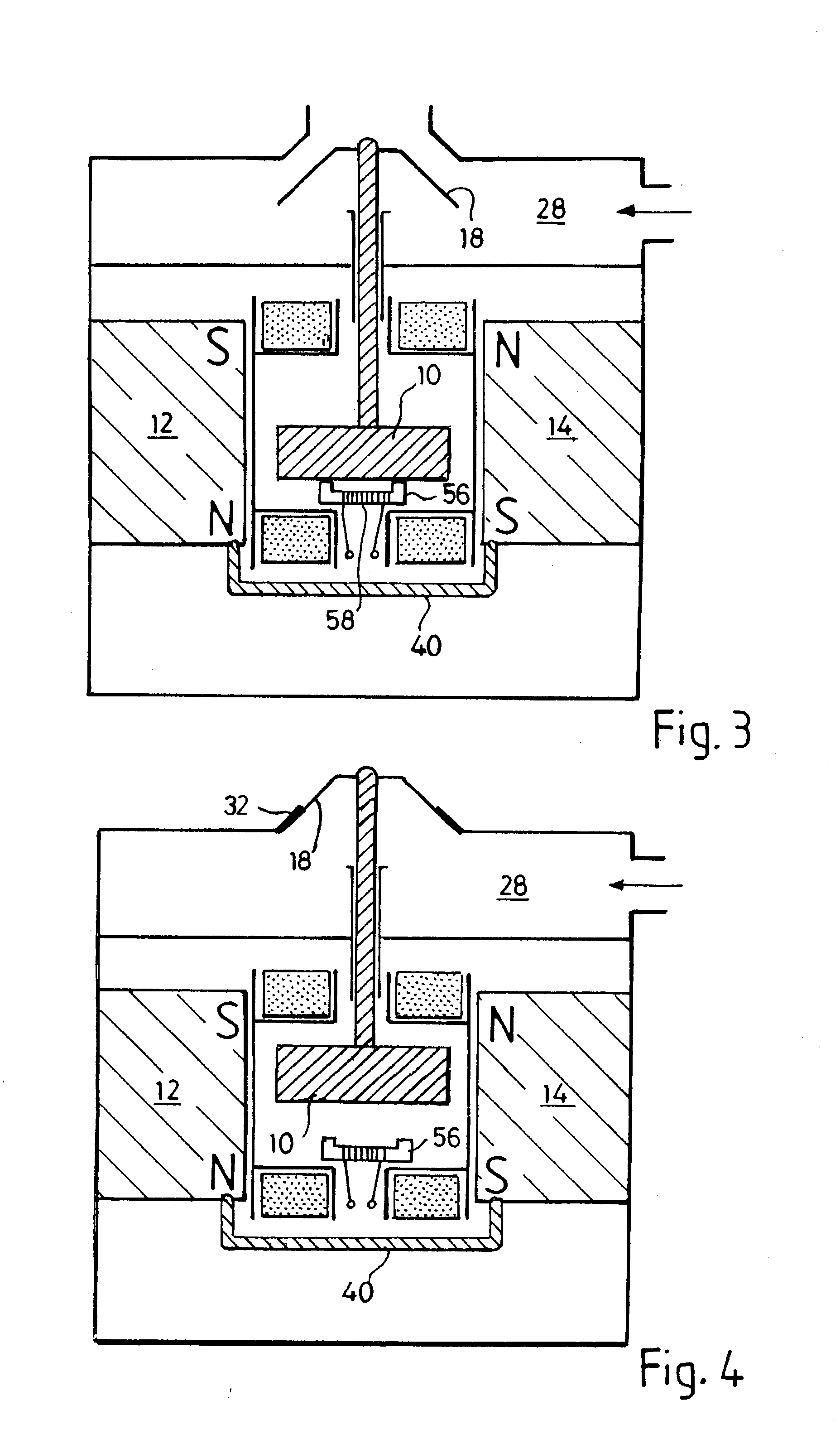

Using the linear forces that are provided by an electromagnetic solenoid applied near the distal end of a medical catheter, various surgical instruments can be actuated or deployed for use in interventional medicine. The linear actuator uses the principles of magnetic repulsion and attraction as a means for moving a bobbin that can be attached to various types of moving components that translate linear movements into the actuation of a tool that is attached to the linear actuator. Using independent solenoid coils, movement modality is increased from two possible positions to three.

Owner:NEURO KINESIS CORP

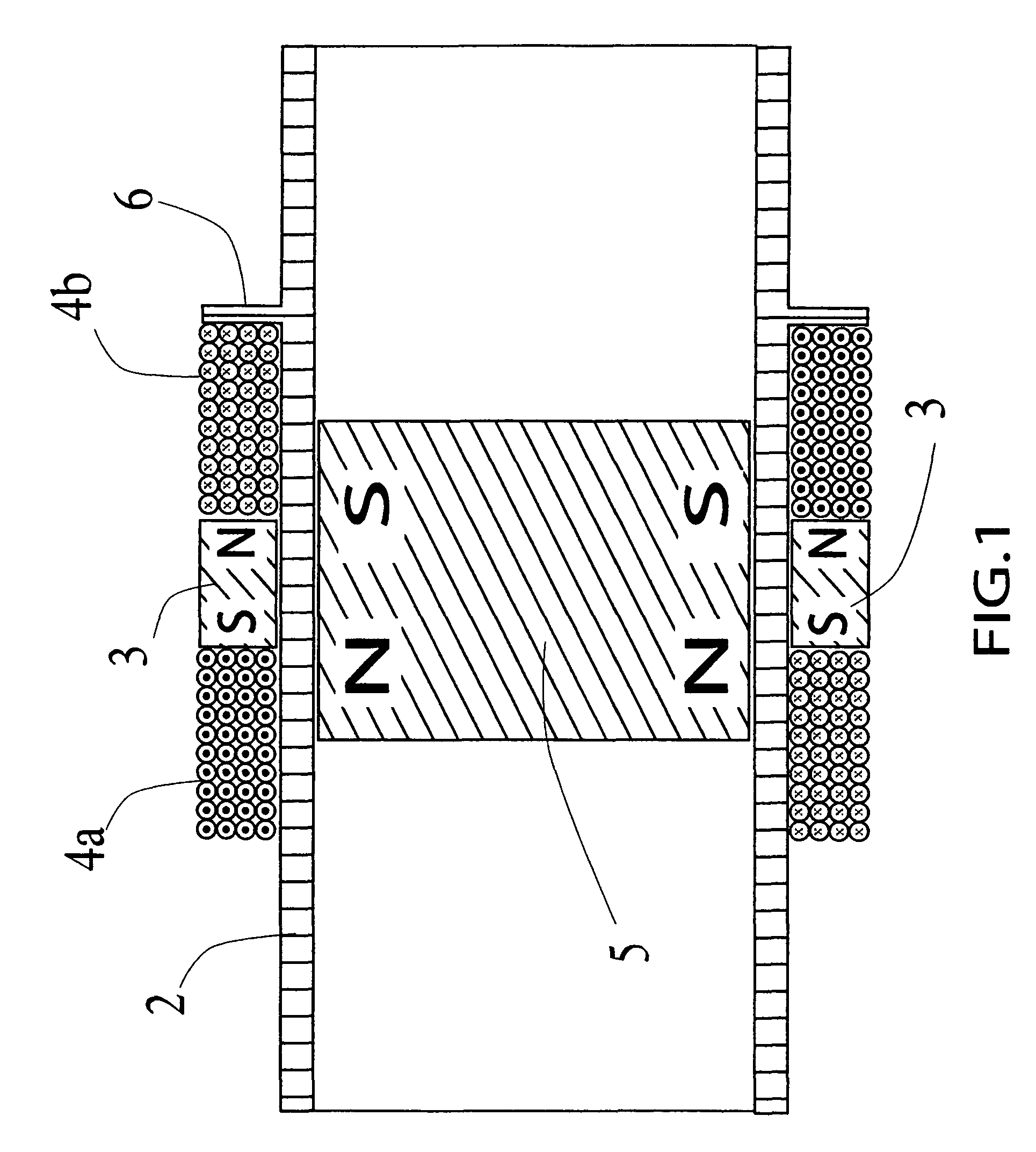

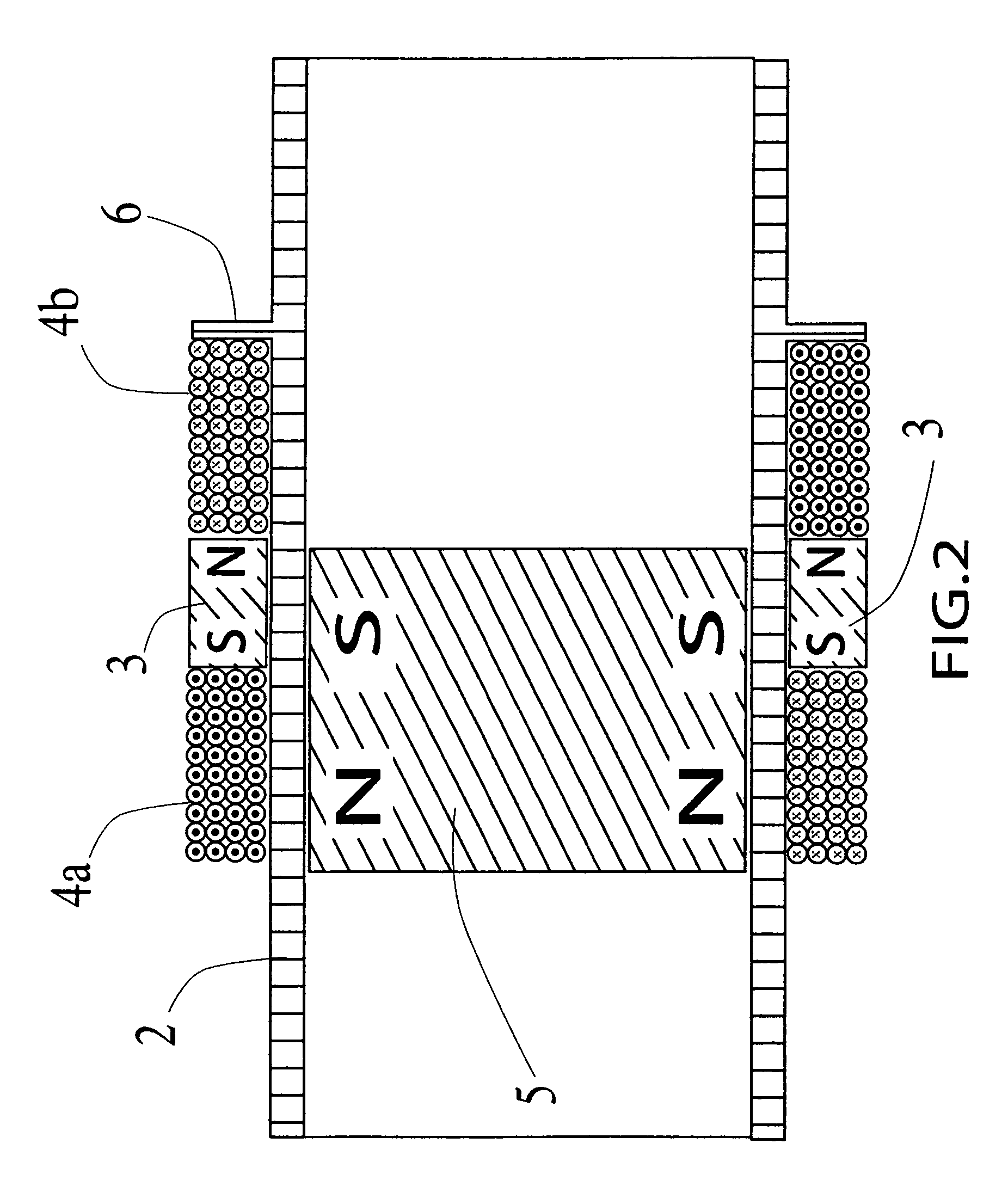

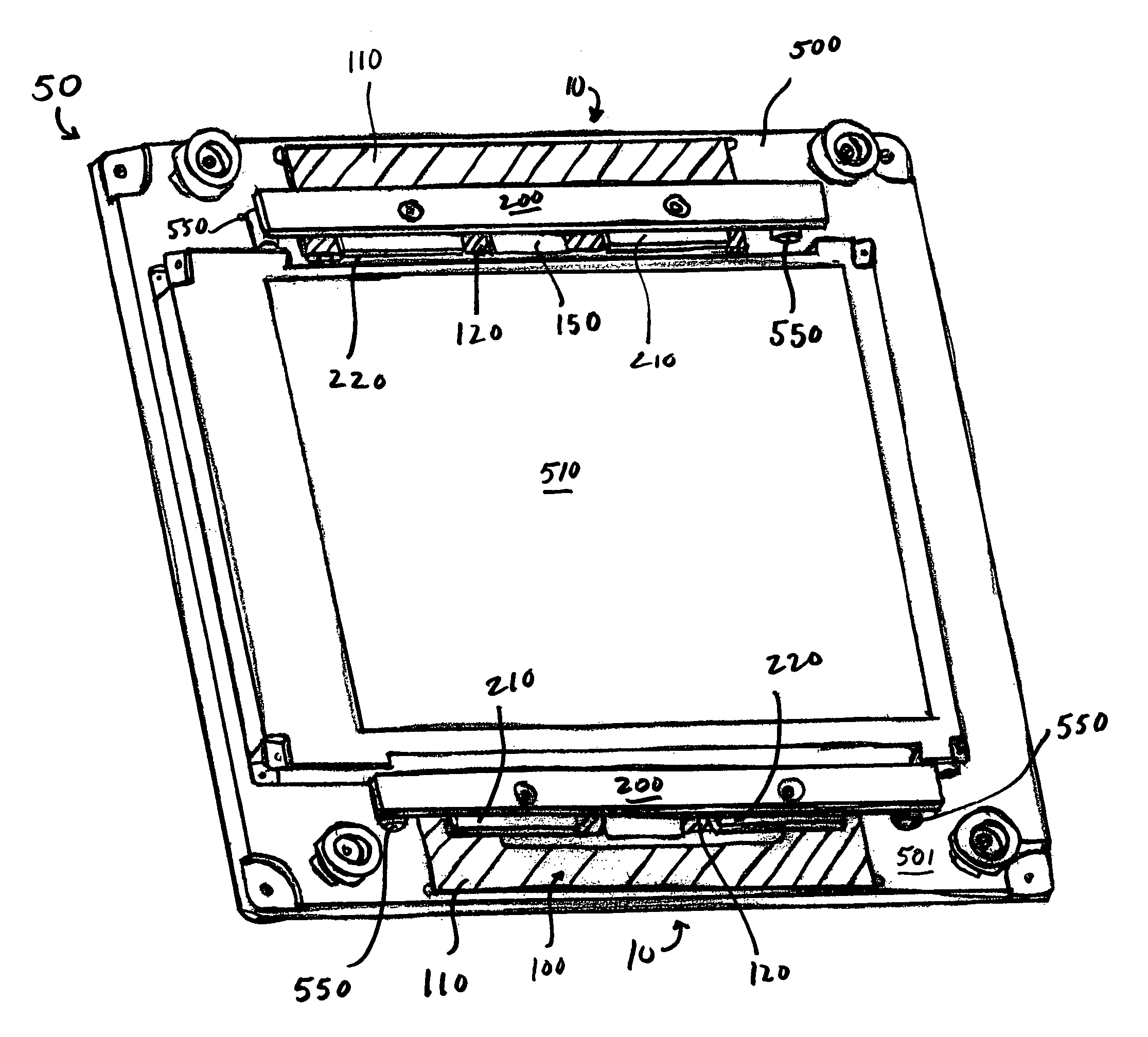

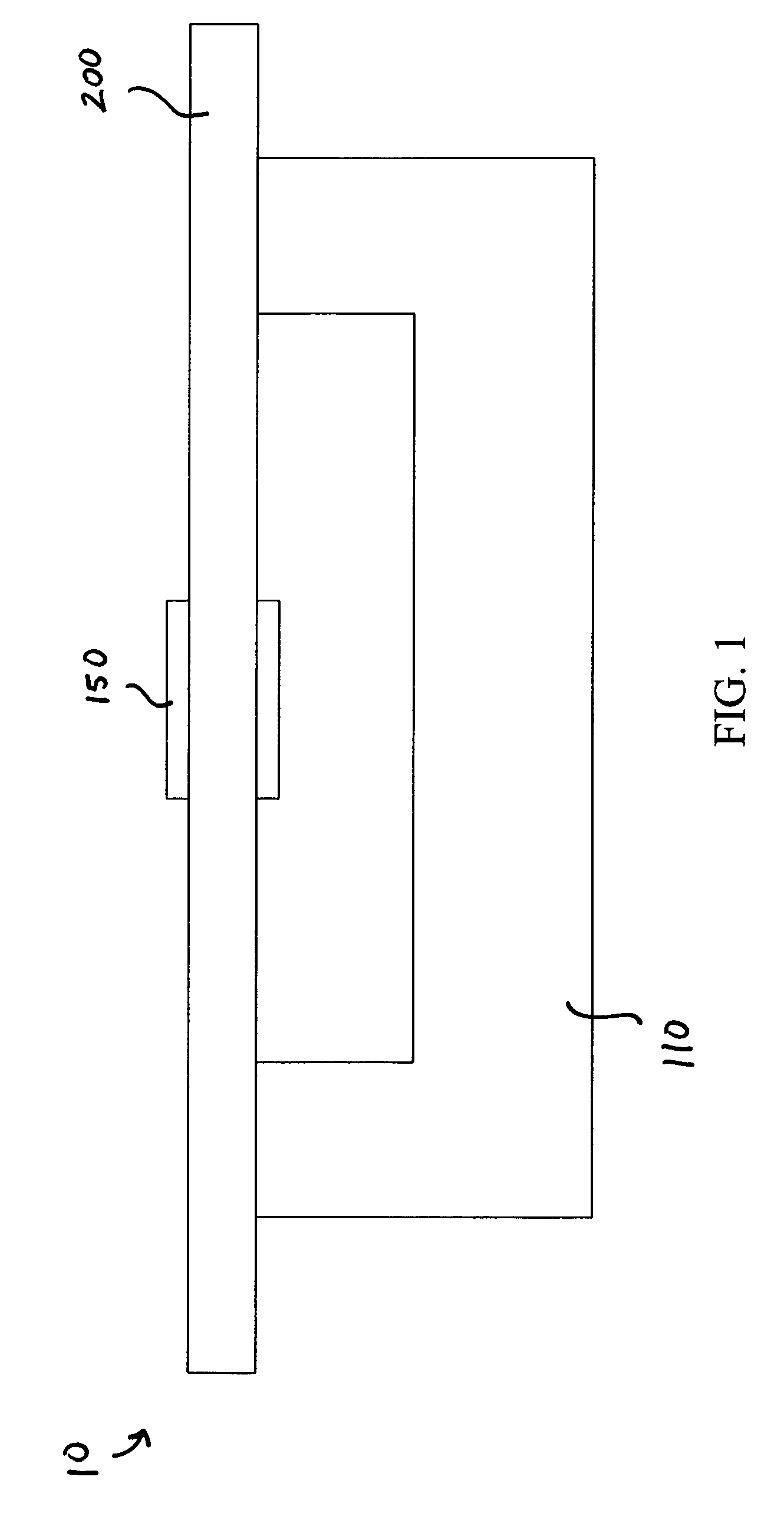

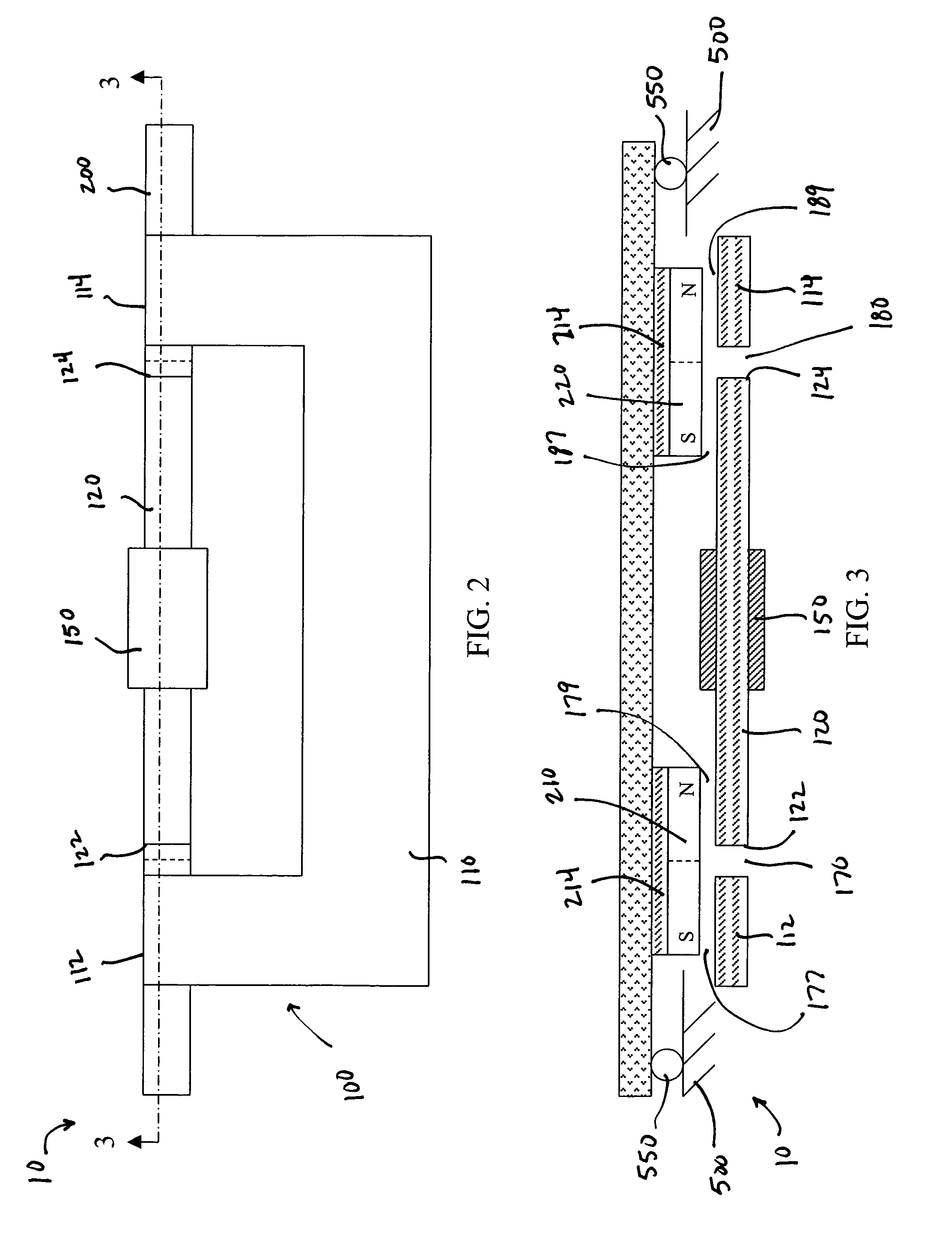

Low energy magnetic actuator

InactiveUS20060066428A1Effectively blocksWeaken energyMagnetic field change switchesNon-mechanical controlsEngineeringActuator

A low energy magnet actuator allows magnetic fields to be turned on and off using a small amount of energy. The magnetic actuator according to the invention generally includes a base suitable for the support of a plurality of magnets. An actuatable shield is positioned in relation to the plurality of magnets so that it effectively blocks the magnetic field when it is positioned over at least one of the magnets. The magnetic fields of the plurality of magnets interact in a manner that allows low energy actuation of the shield.

Owner:STEORN

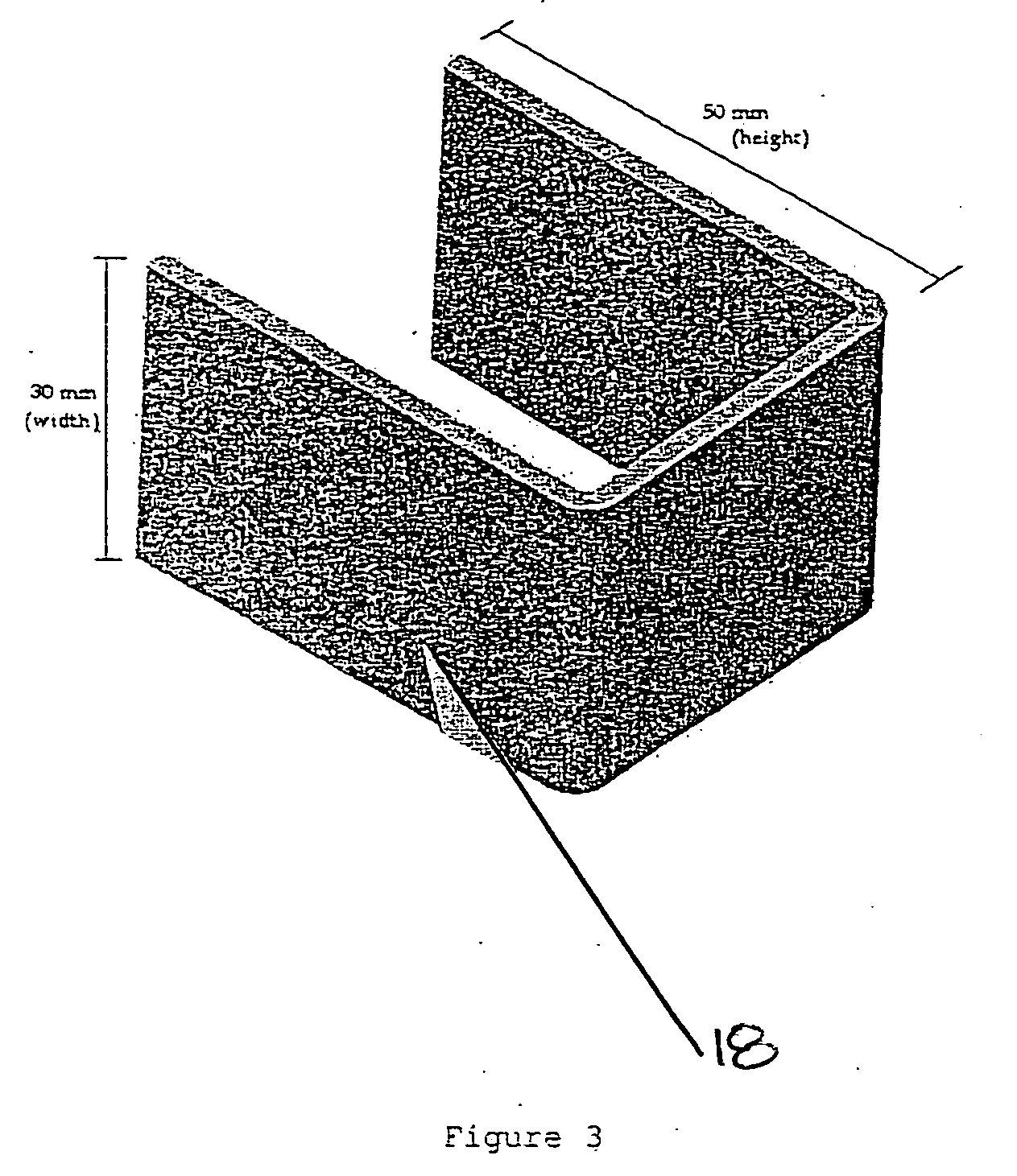

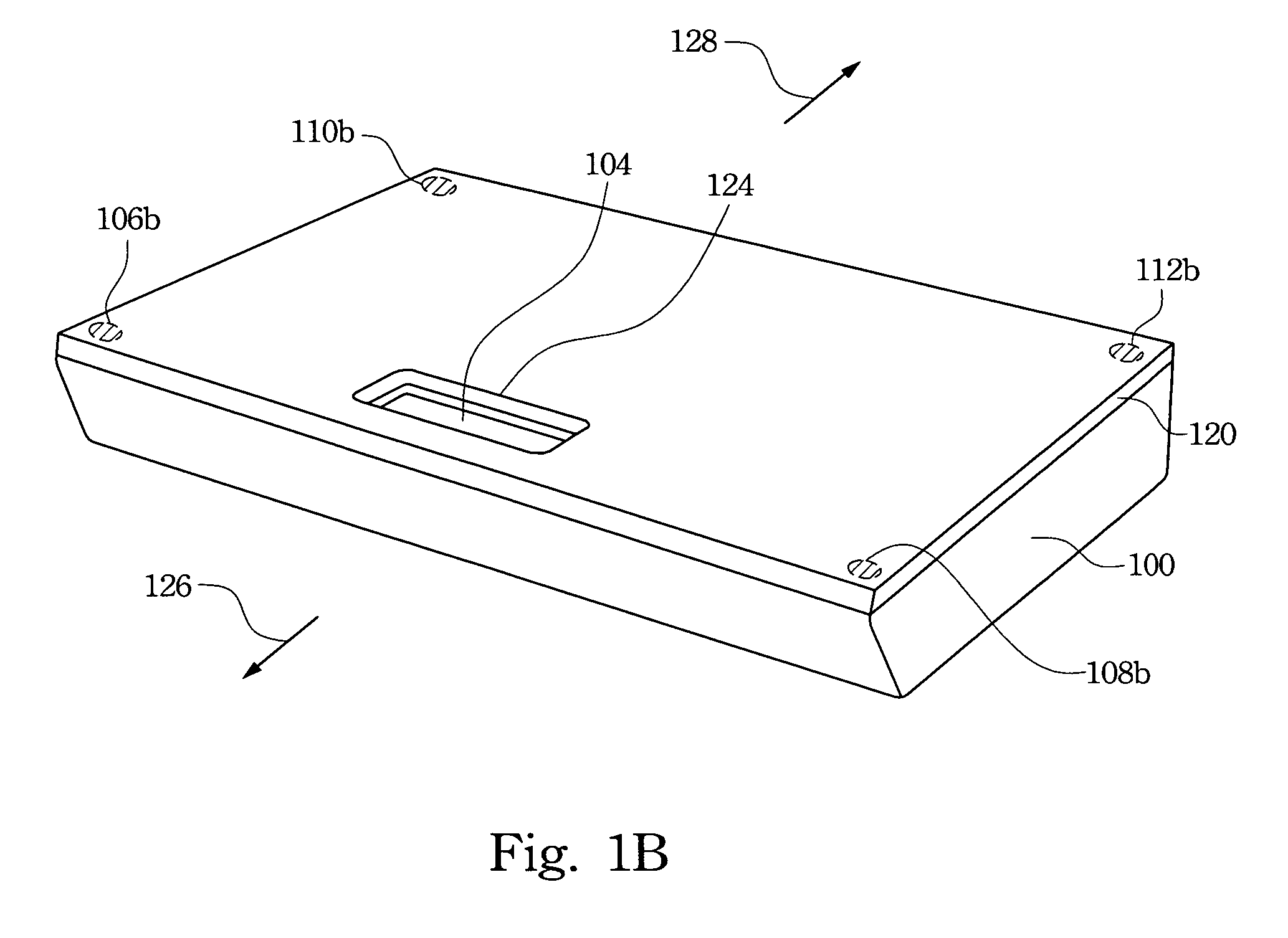

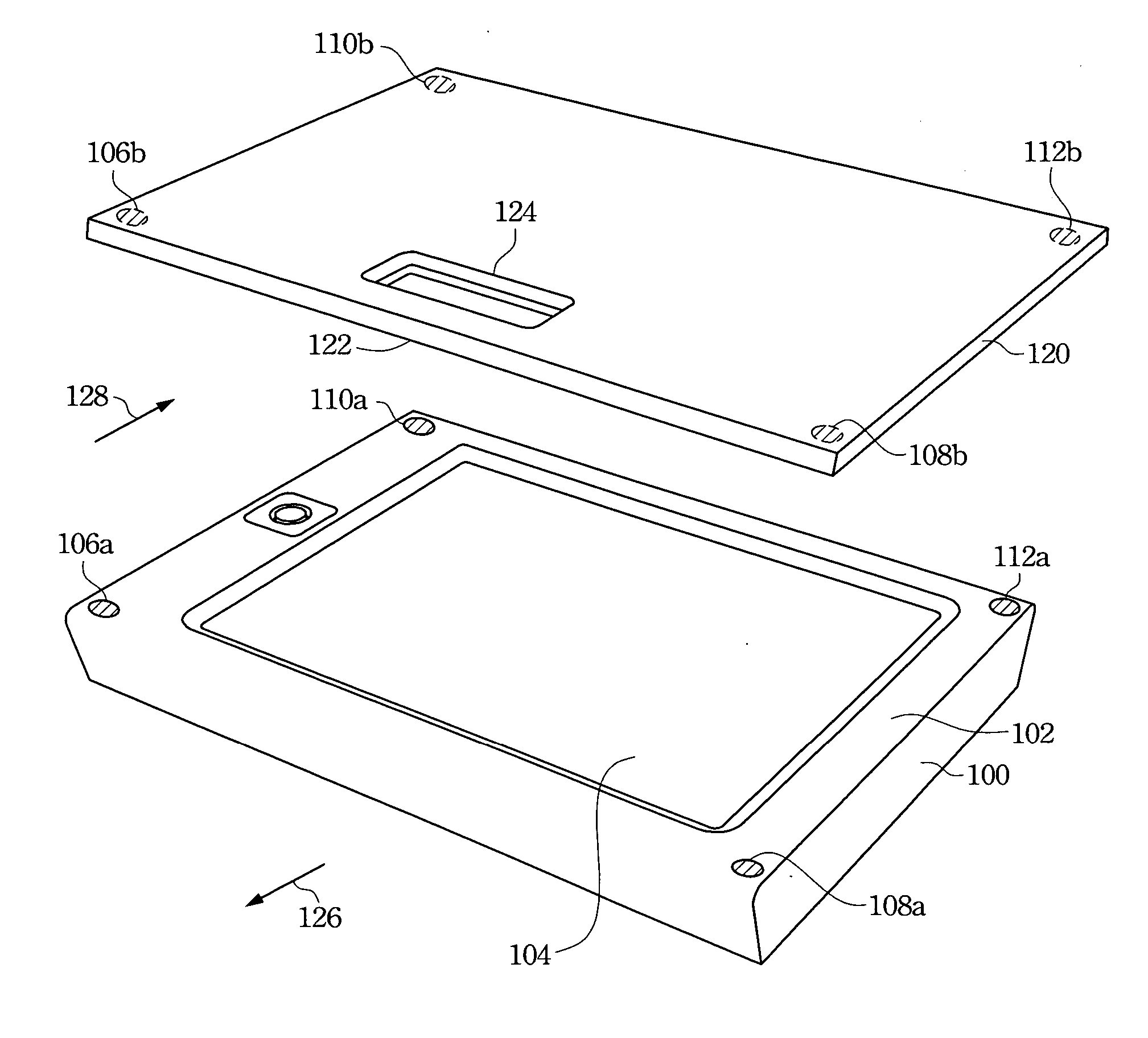

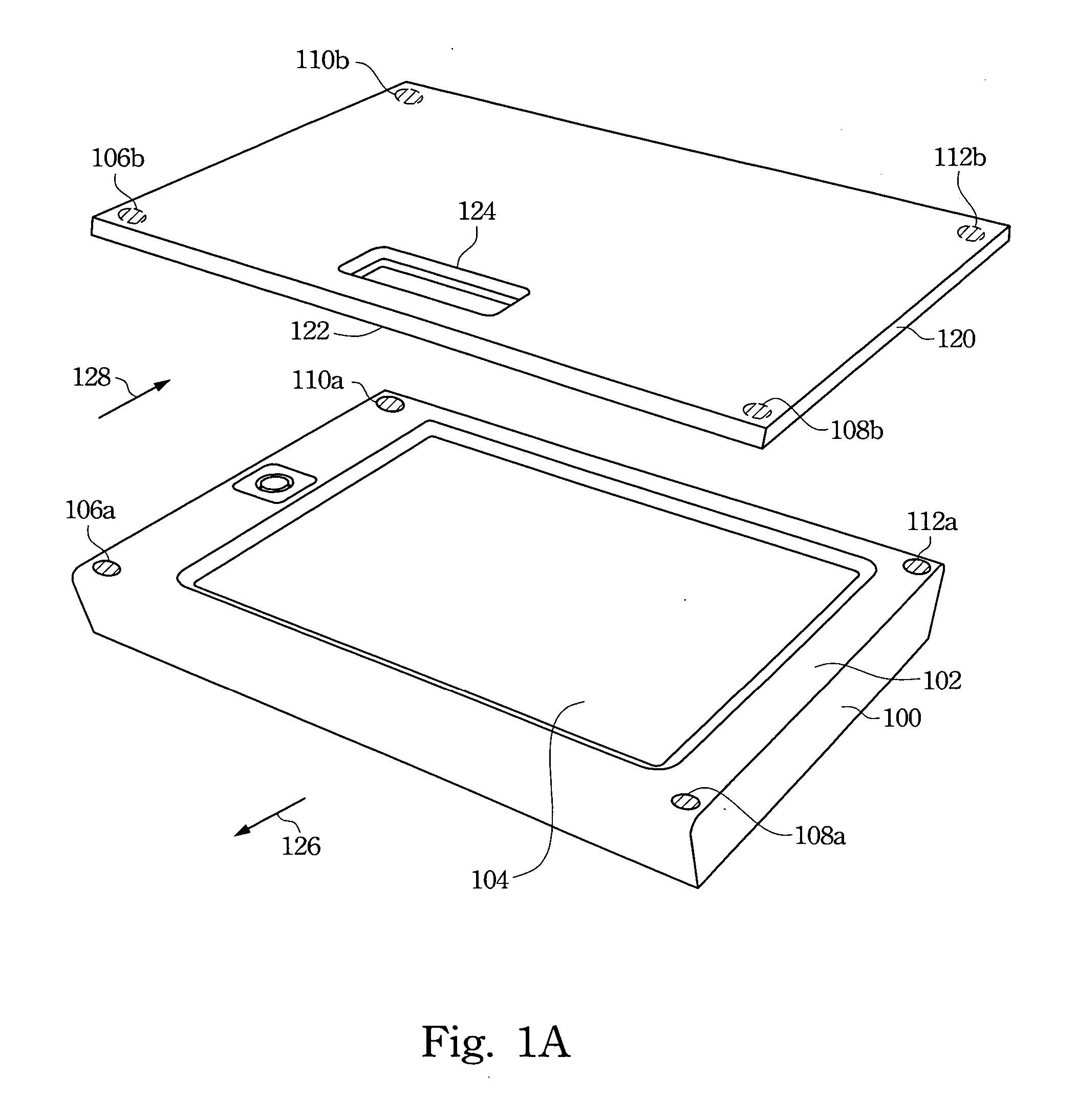

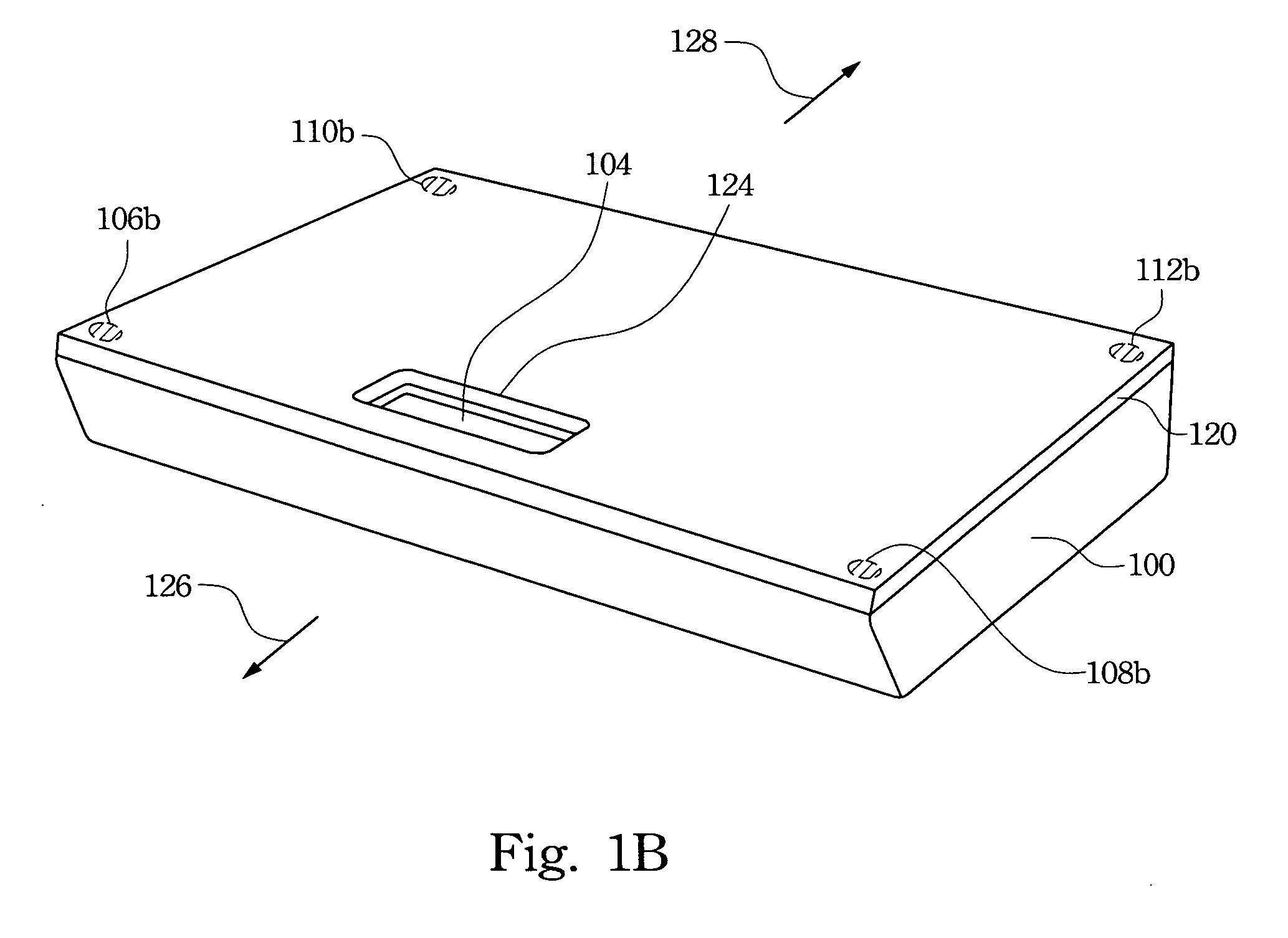

Auto-aligning and connecting structure between electronic device and accessory

ActiveUS7541907B2Increase contactEasy to makeElectromagnets without armaturesDigital data processing detailsMagnetic polesEngineering

Owner:HTC CORP

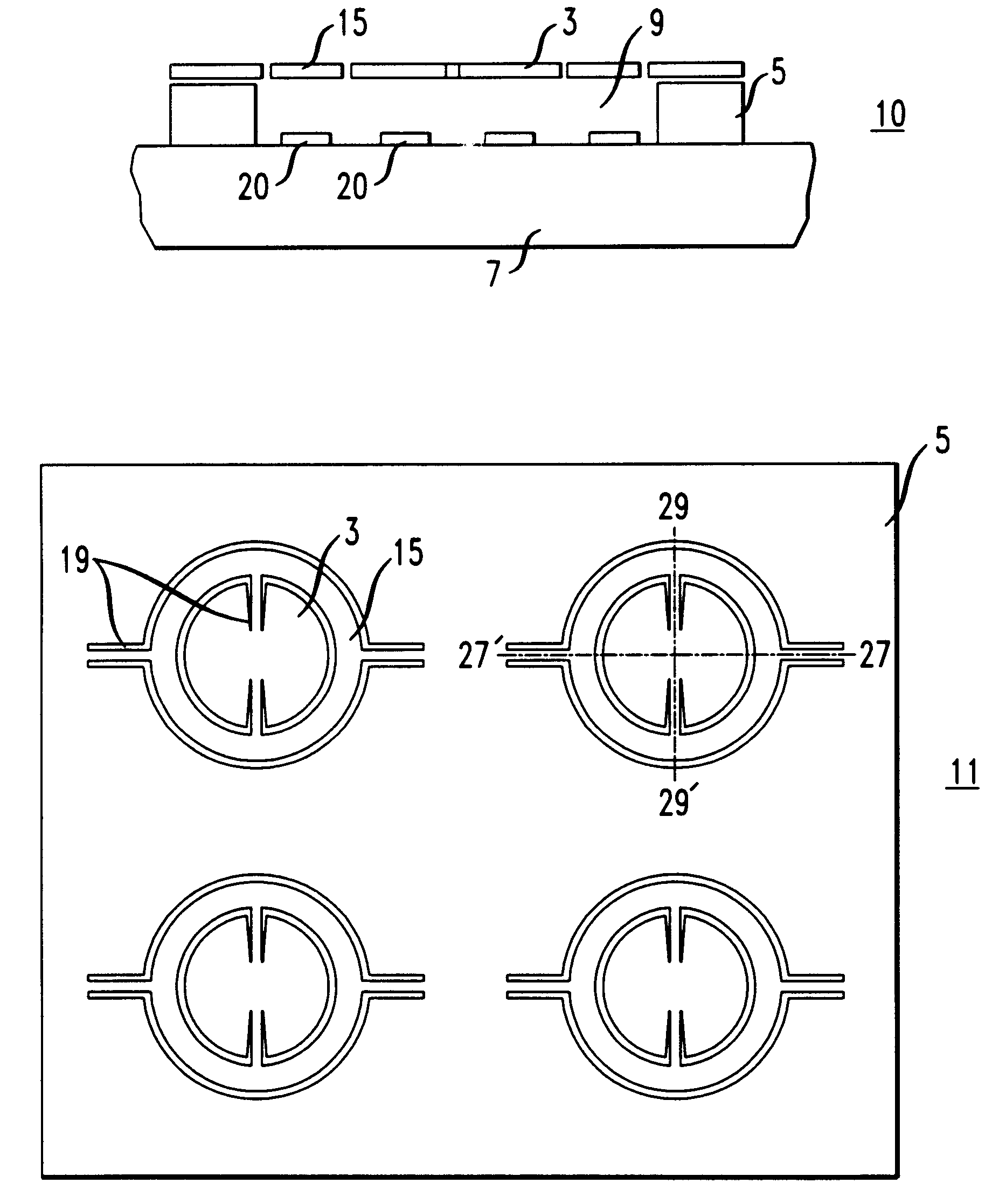

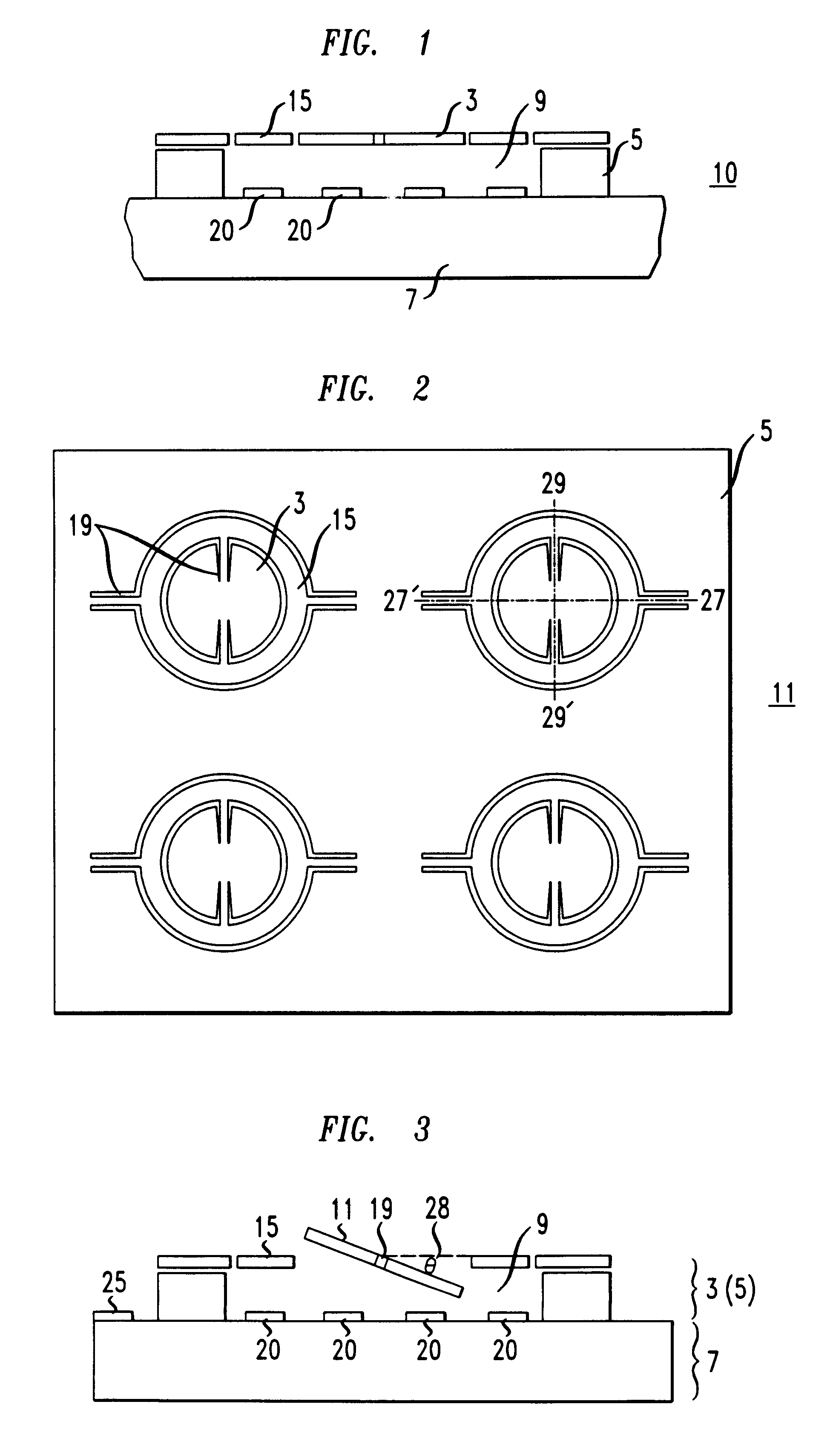

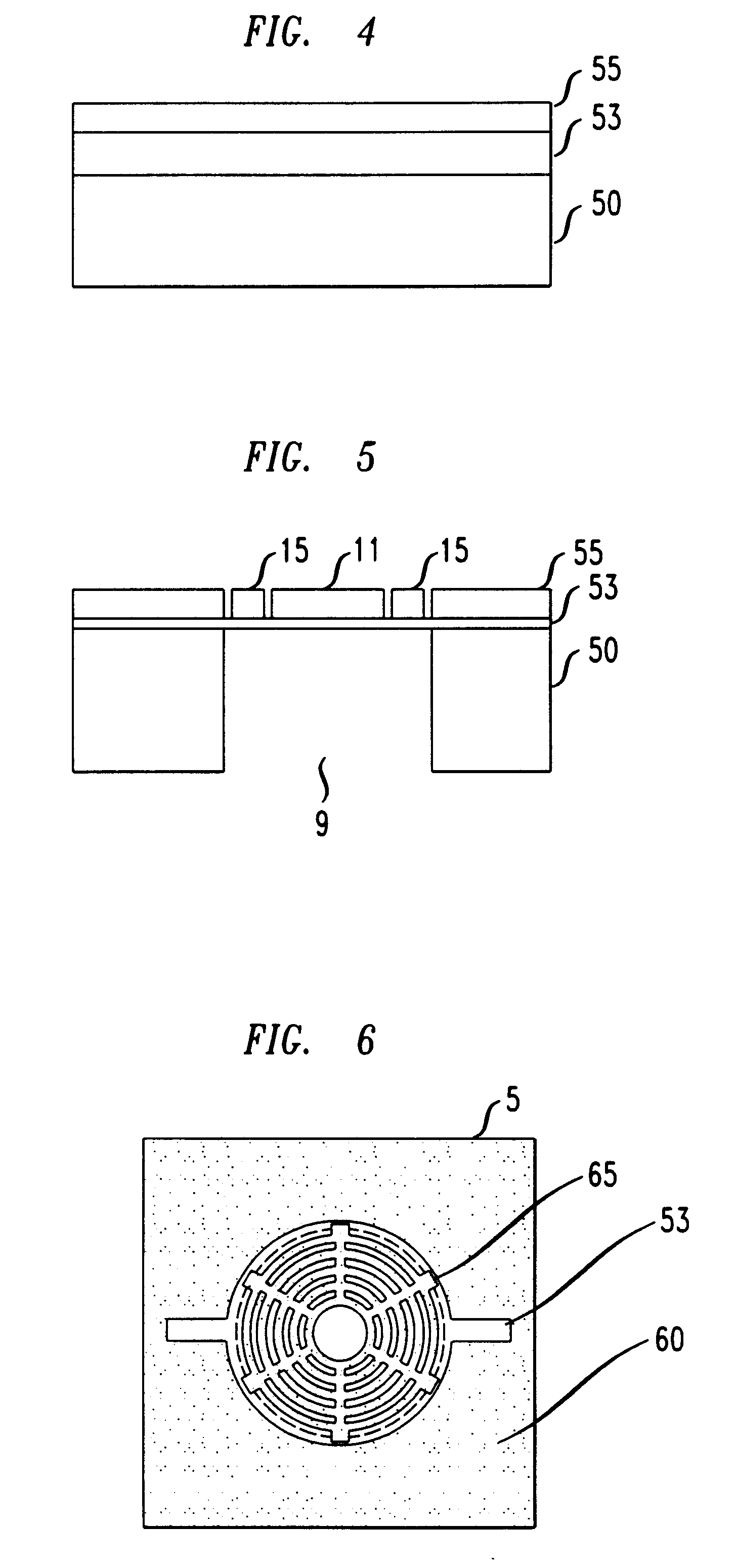

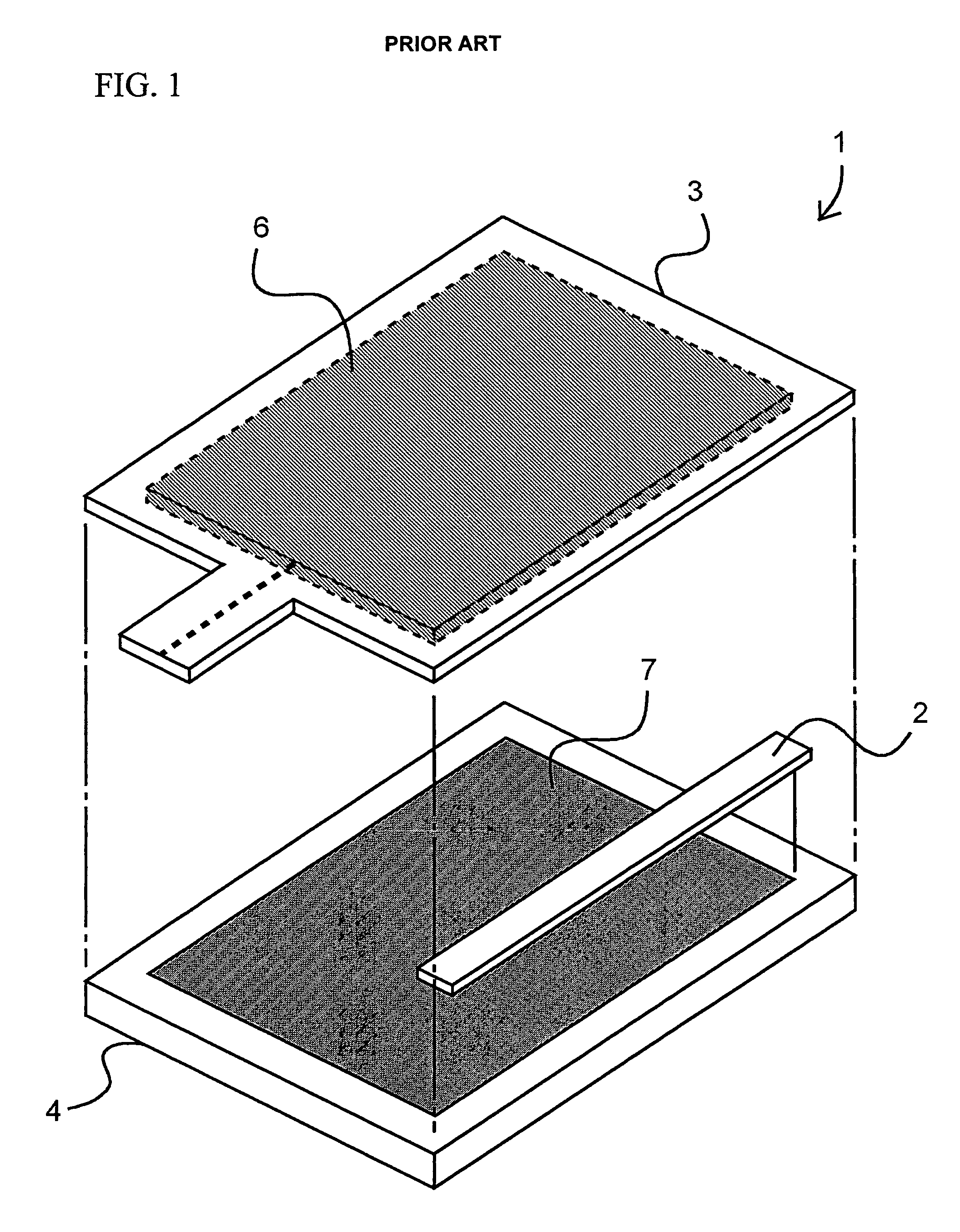

Process for fabricating an optical mirror array

InactiveUS6201631B1Static indicating devicesSemiconductor/solid-state device manufacturingElectricityInterconnection

An electro-optic device which includes a mirror array attached to a base substrate is disclosed. The mirror array comprises a substrate having a plurality of spaced-apart mirrors with underlying cavities (each having a diameter at least about the same size as that of the overlying mirror) formed therein. The base substrate includes a plurality of electrodes as well as a plurality of electrical interconnections. The mirror array is attached to the base substrate so that each mirror of the array as well as a cavity are supported above a set of electrodes. Each mirror of the mirror array rotates relative to the major plane of the substrate in response to an electrical signal. The application of an electrical potential to each mirror relative to at least one electrode of the set of electrodes causes the desired rotation (depending on the magnitude of the electrical potential) up to an angle of about 20 degrees.

Owner:LUCENT TECH INC

Auto-aligning and connecting structure between electronic device and accessory

ActiveUS20070103266A1Increase contactEasy to makeElectromagnets without armaturesDigital data processing detailsMagnetic polesEngineering

Owner:HTC CORP

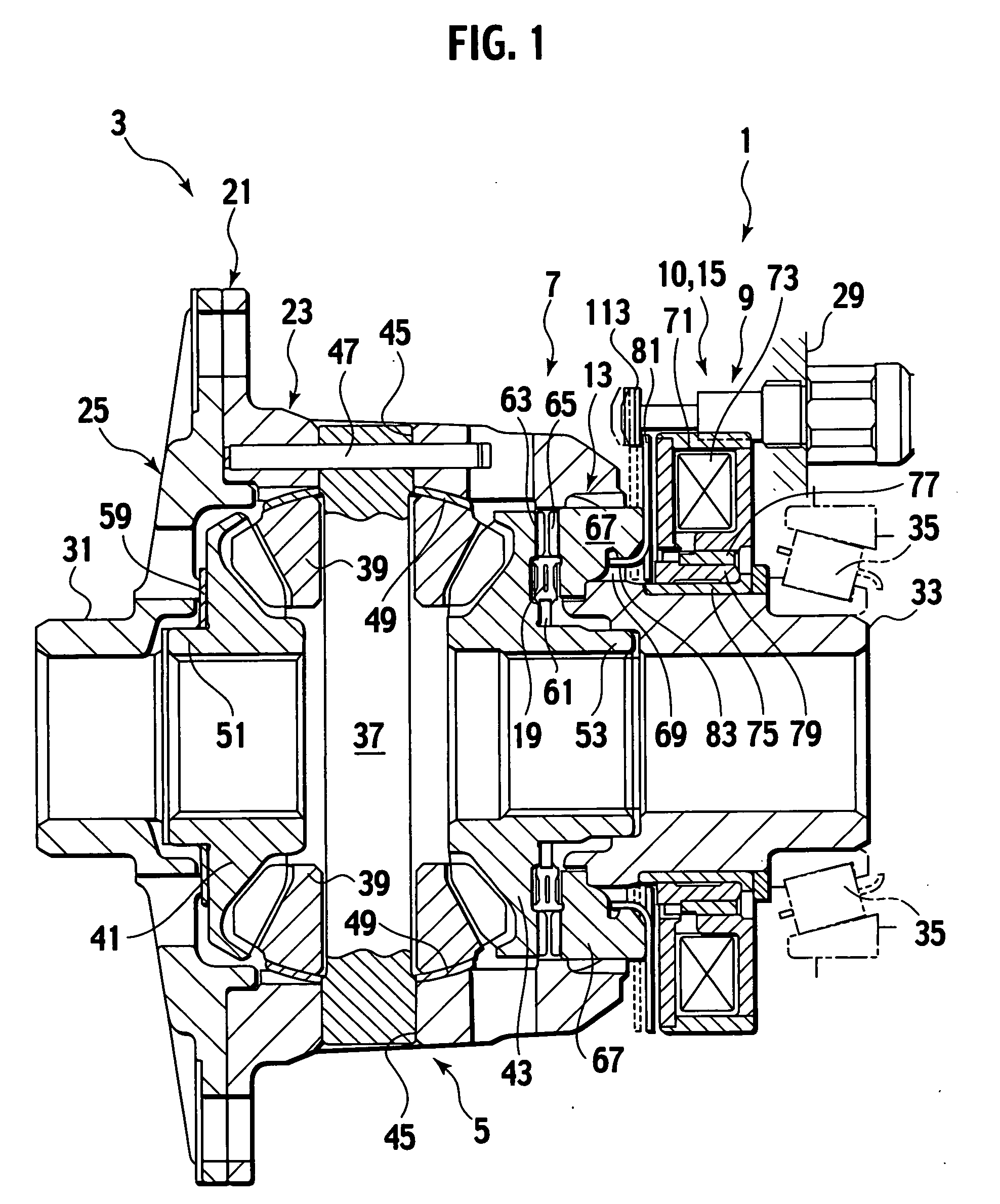

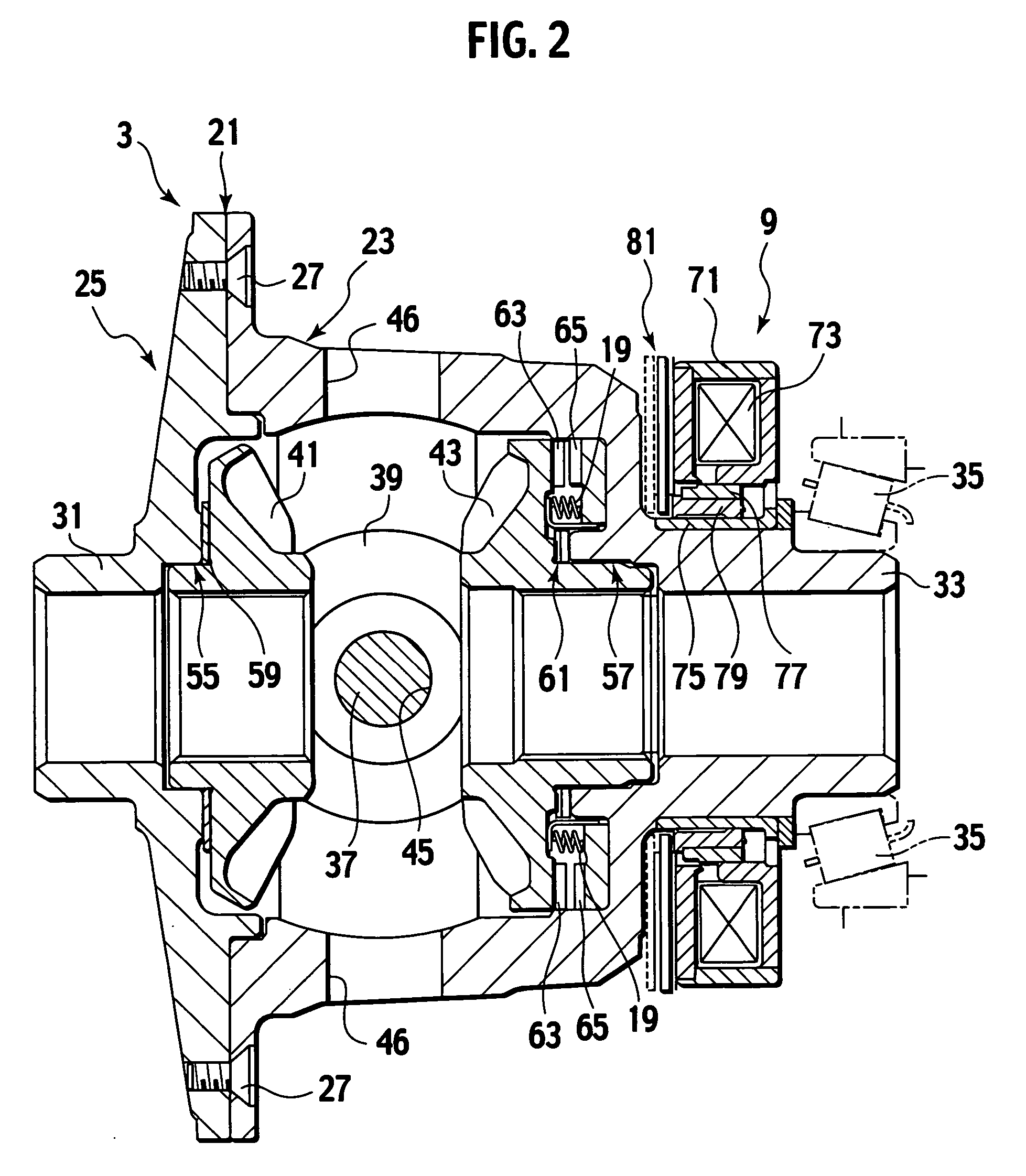

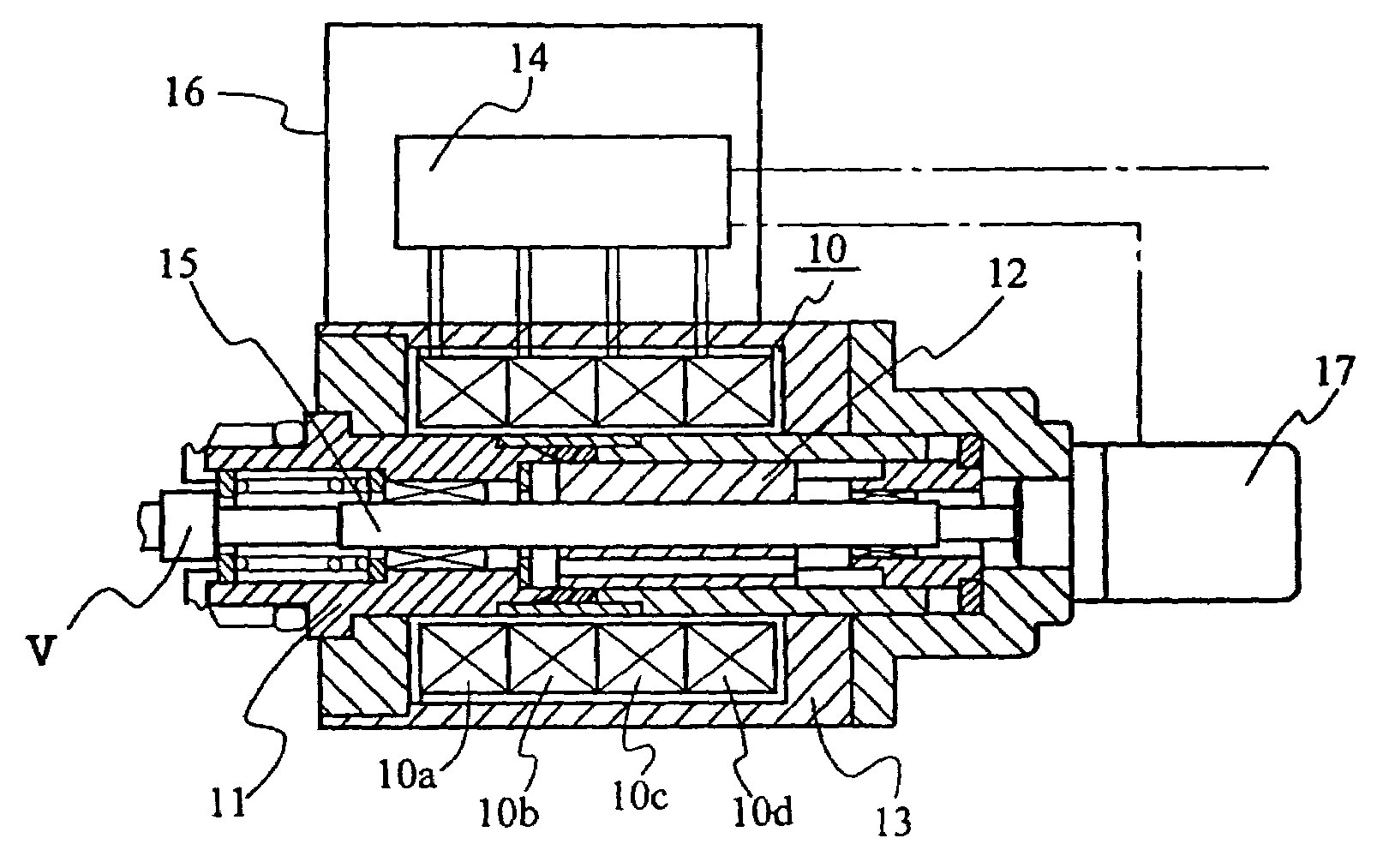

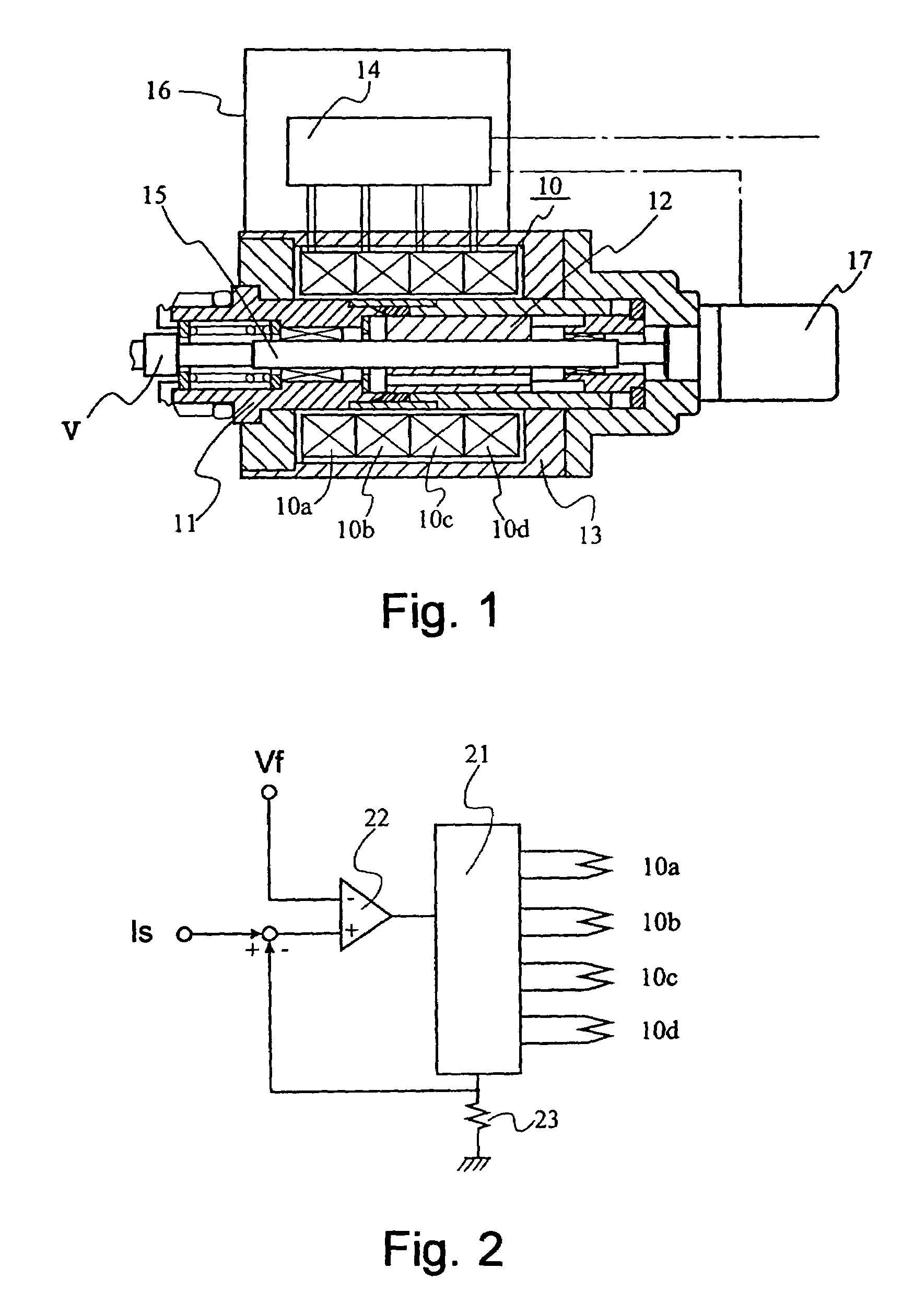

Electromagnetic actuator, and electromagnetic clutch and differential using the same

ActiveUS20050279607A1Inhibit heat generationSuppress power consumptionMechanical actuated clutchesFluid actuated clutchesElectromagnetic clutchEngineering

The electromagnetic actuator includes an electromagnetic coil configured to provide actuation force in accordance with a solenoid current to be supplied, to a clutch and configured to actuate the clutch to control relative rotation between first and second members. The electromagnetic actuator includes a detector configured to detect the clutch actuated to produce a detection signal. The electromagnetic actuator includes a controller configured to respond to the detection signal from the detector to control the solenoid current.

Owner:TOCHIGI FUJI IND CO LTD

Plane plate vibration device and switch employing the same

ActiveUS6937124B1Input/output for user-computer interactionRepeater circuitsClassical mechanicsPhysics

Owner:FUJITSU COMPONENENT LTD

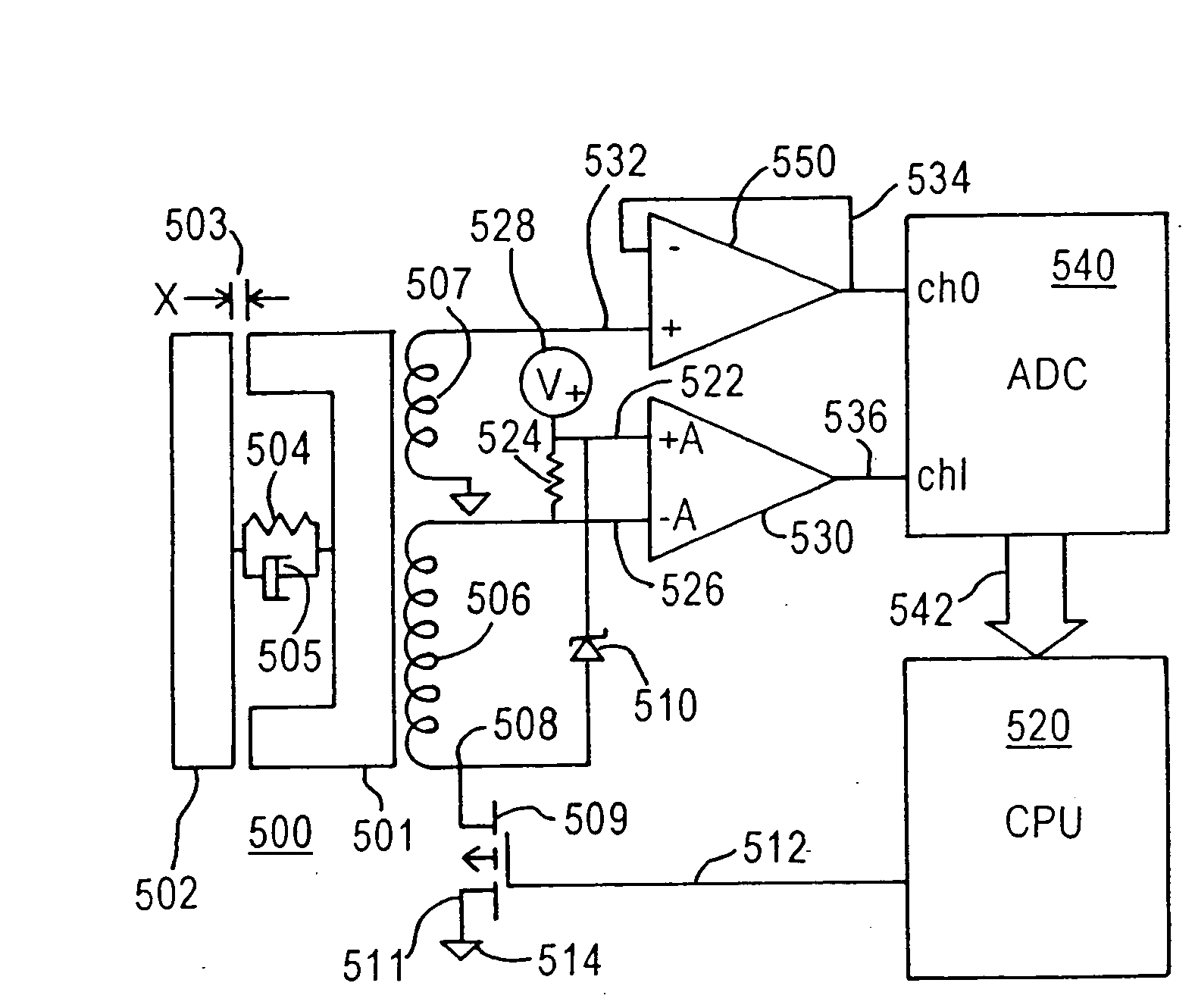

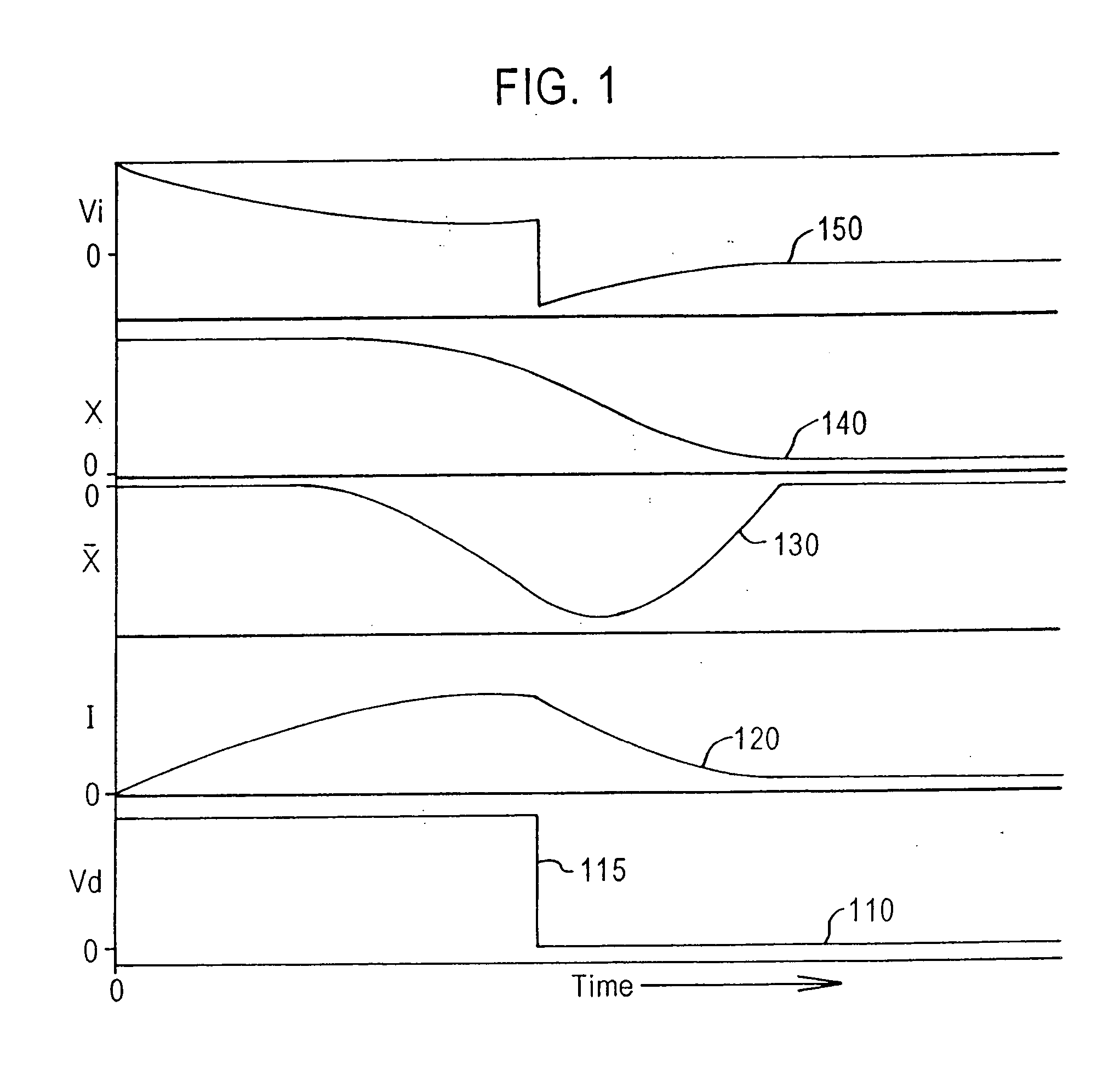

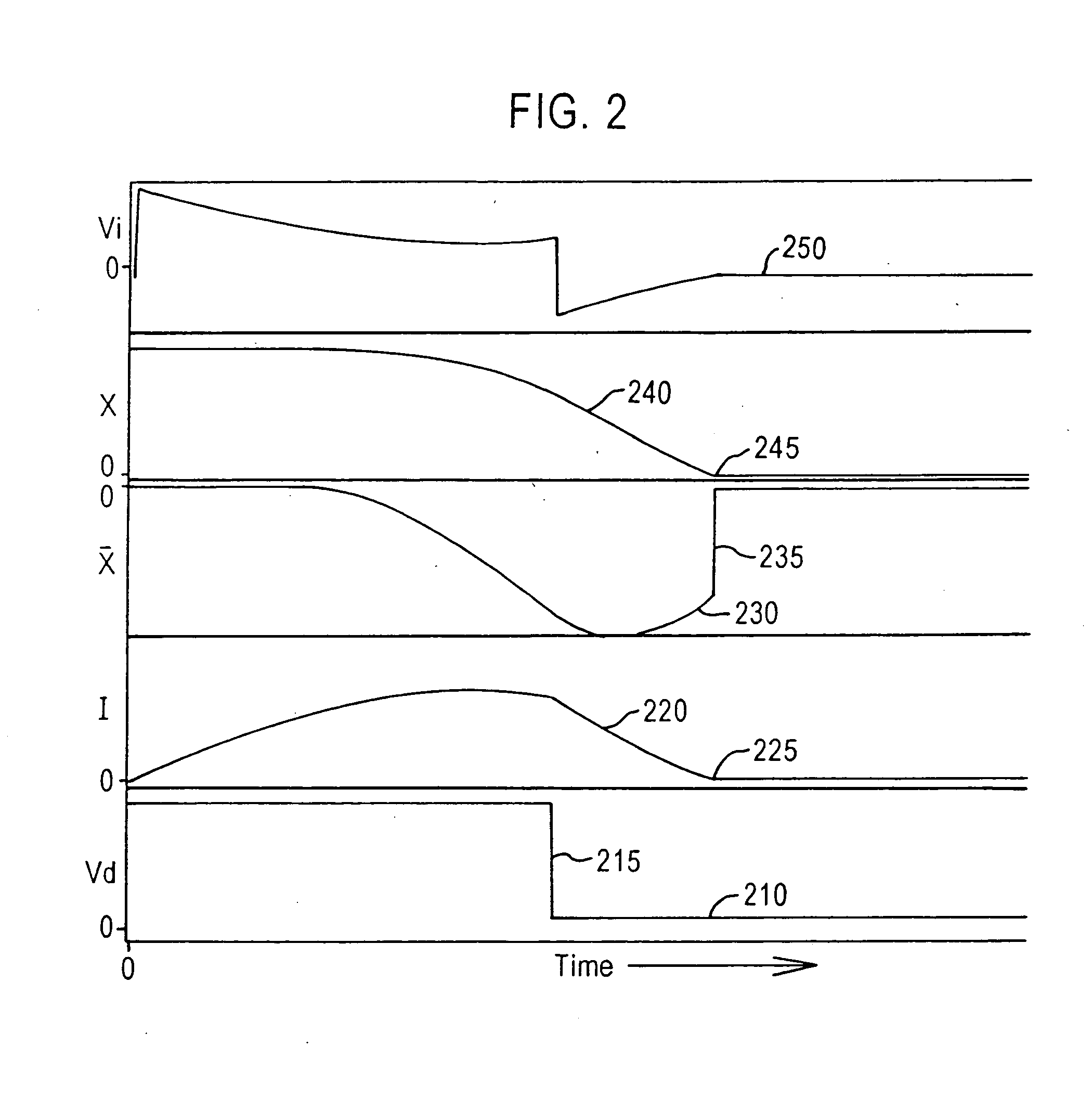

System and method for servo control of nonlinear electromagnetic actuators

InactiveUS20060171091A1Eliminate impactRemove noiseElectrical controlAC motor controlResonance measurementInstability

Servo control using ferromagnetic core material and electrical windings is based on monitoring of winding currents and voltages and inference of magnetic flux, a force indication; and magnetic gap, a position indication. Third order nonlinear servo control is split into nested control loops: a fast nonlinear first-order inner loop causing flux to track a target by varying a voltage output; and a slower almost linear second-order outer loop causing magnetic gap to track a target by controlling the flux target of the inner loop. The inner loop uses efficient switching regulation, preferably based on controlled feedback instabilities, to control voltage output. The outer loop achieves damping and accurate convergence using proportional, time-integral, and time-derivative gain terms. The time-integral feedback may be based on measured and target solenoid drive currents, adjusting the magnetic gap for force balance at the target current. Incorporation of permanent magnet material permits the target current to be zero, achieving levitation with low power, including for a monorail deriving propulsion from the levitation magnets. Linear magnetic approximations lead to the simplest controller, but nonlinear analog computation in the log domain yields a better controller with relatively few parts. When servo-controlled solenoids provide actuation of a pump piston and valves, electronic LC resonance measurements determine liquid volume and gas bubble volume.

Owner:SEALE JOSEPH B +1

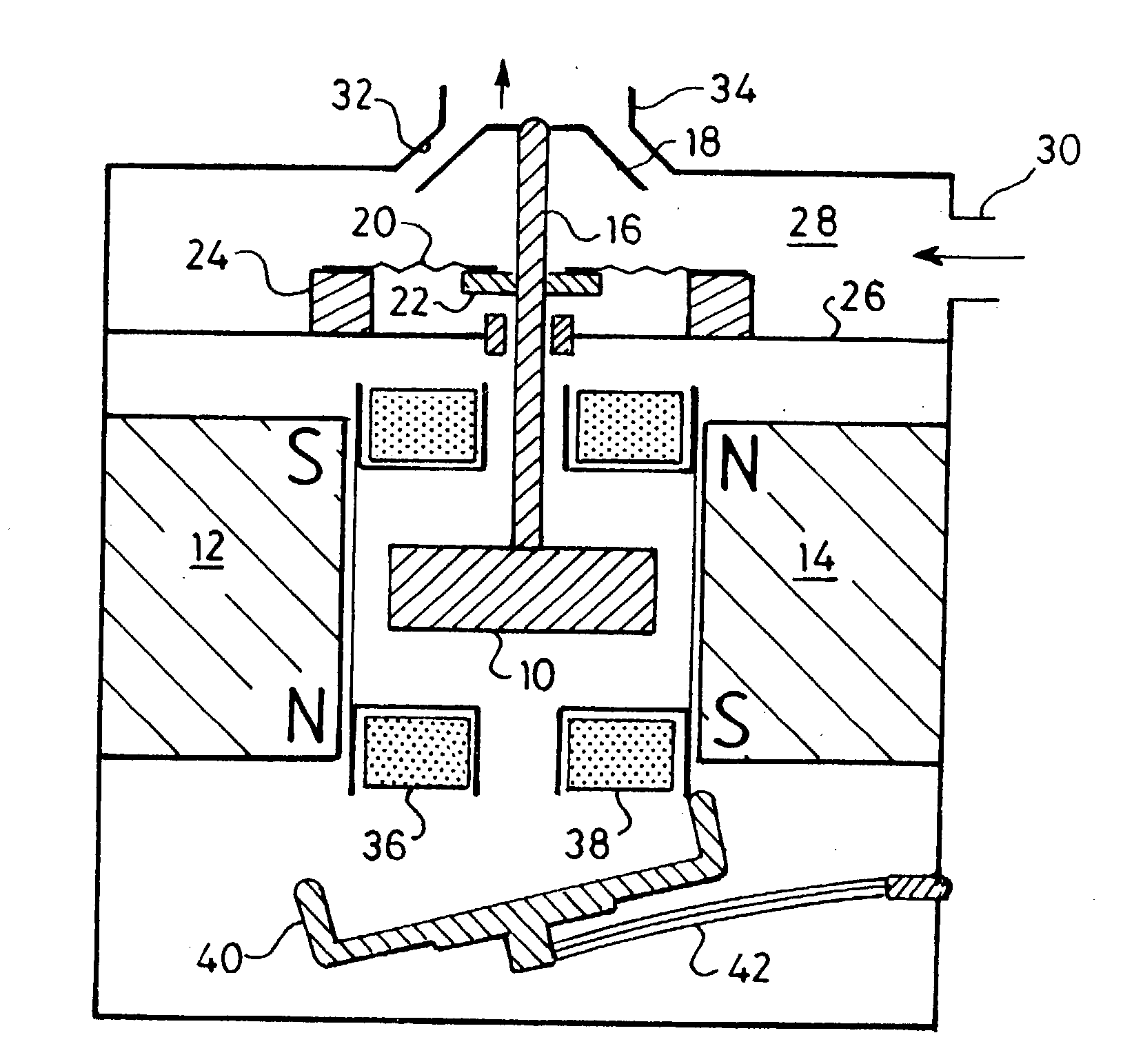

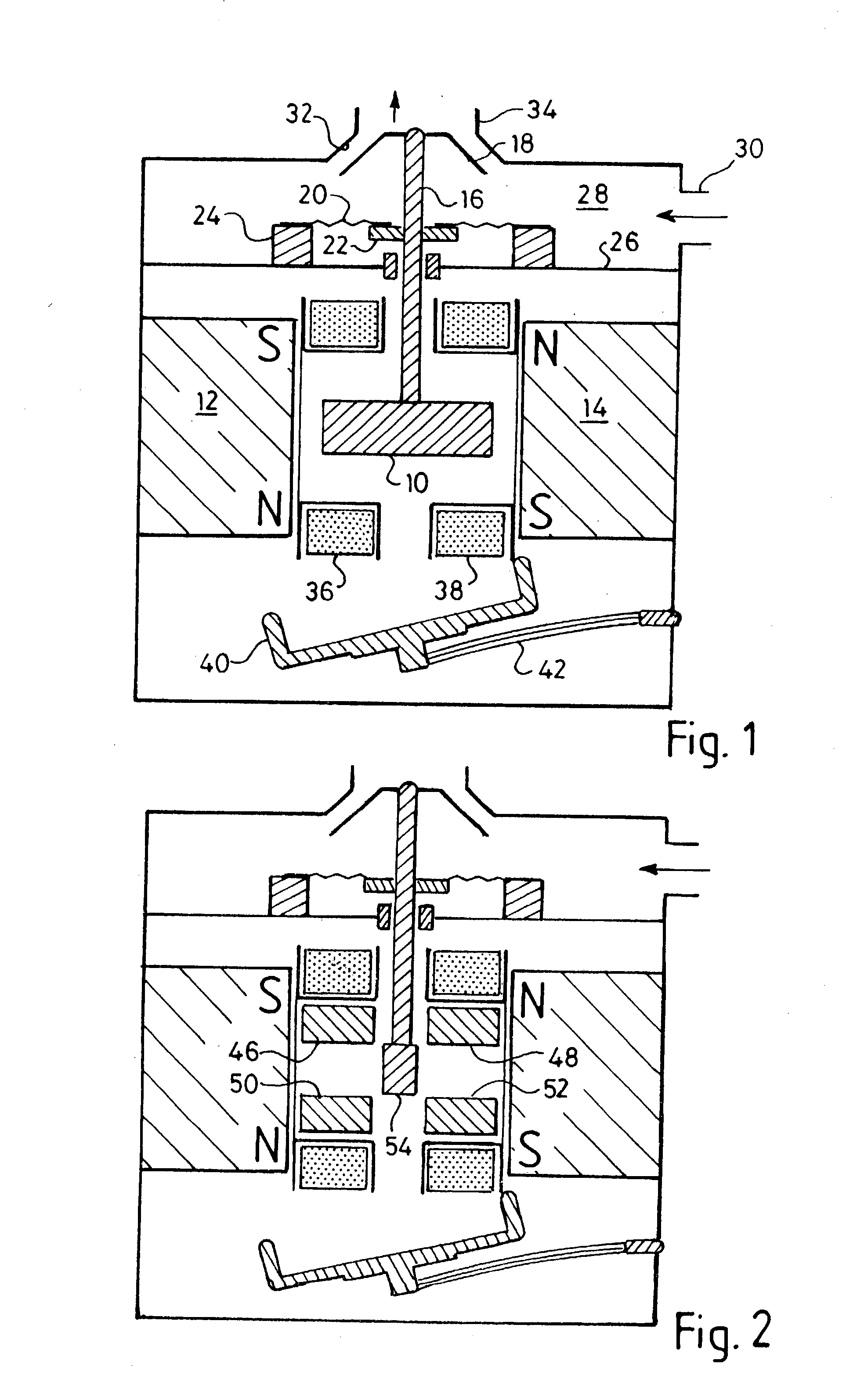

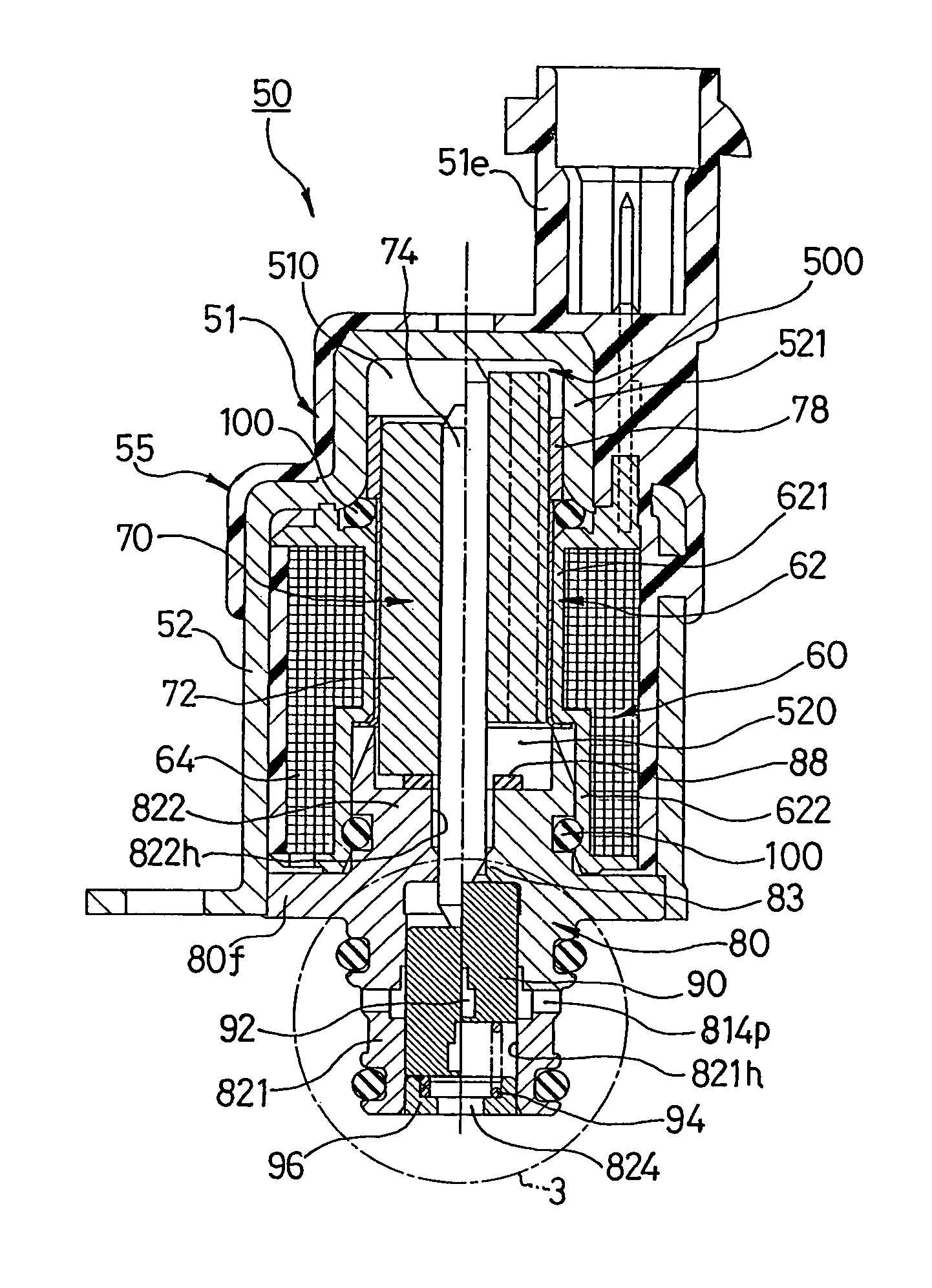

Low frequency electromagnetic motor to create or cancel a low frequency vibration

Electromagnetic motor with a piston that moves linearly with respect to the stator in either direction. Embodiments include a piston internal or external the stator. The piston includes one or more magnetic flux producing elements in all embodiments, with some embodiments having a ferro-magnetic plate on either side of the flux producing element. Further, in all embodiments the stator includes three magnetic flux producing elements with either two coils with one or more magnets therebetween or with the two coils and a coil magnet substitute therebetween. All embodiments provide positive piston return to a center at rest position. In all embodiments the piston is centered with respect to the stator resulting from either magnetic interaction between the piston and stator magnets, or between the piston magnet and the stator magnet substitute coil.

Owner:EARTHQUAKE SOUND

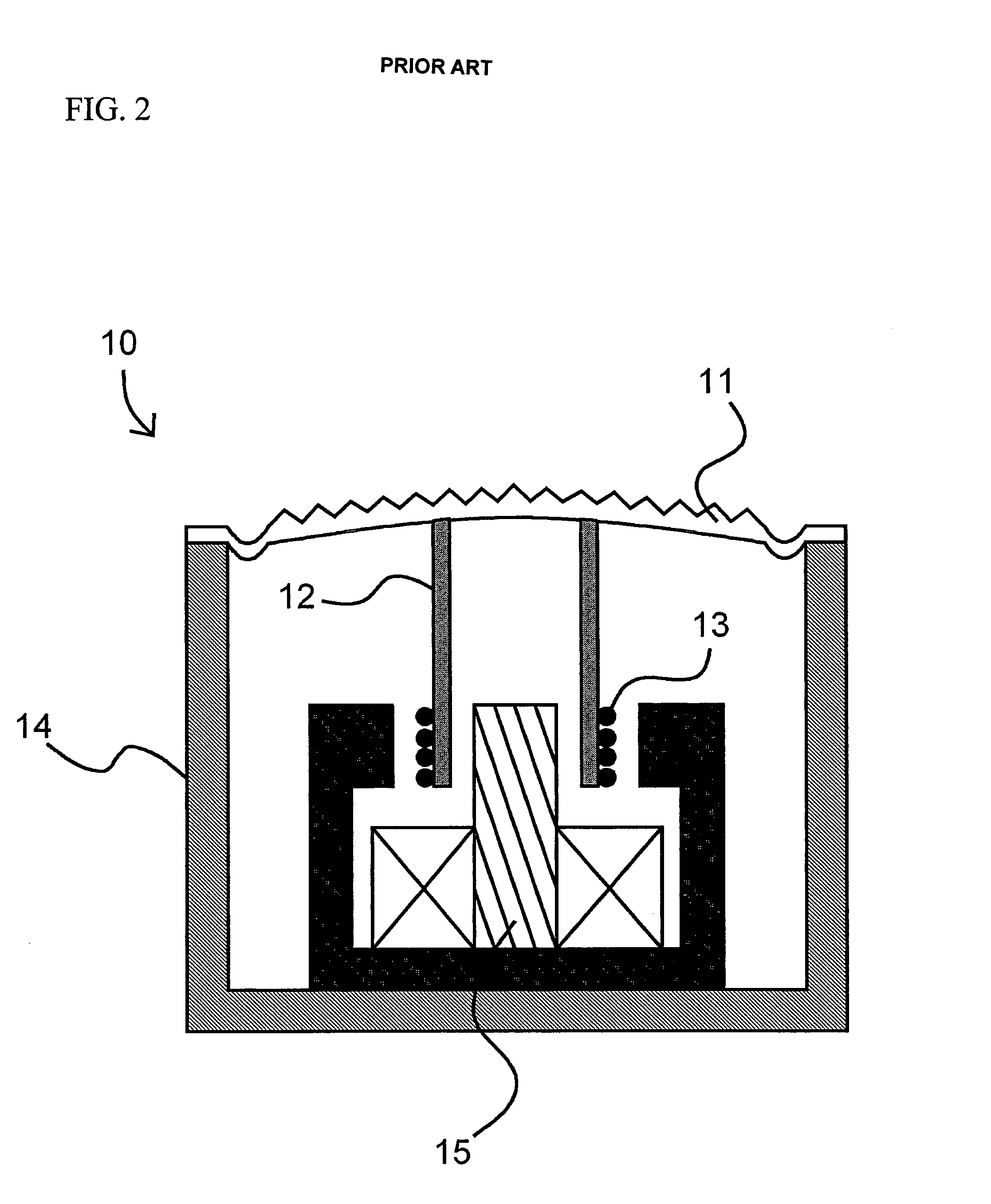

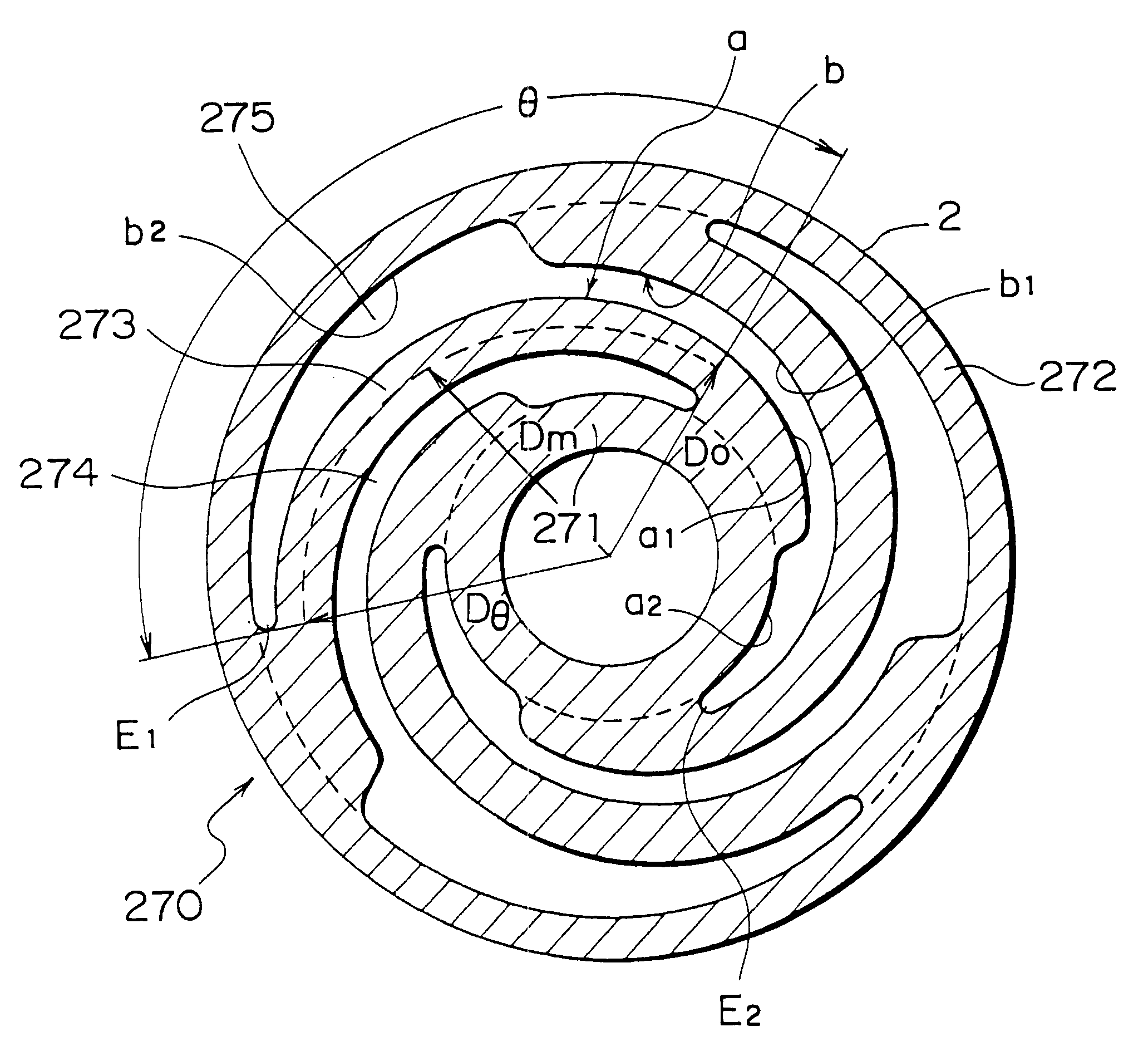

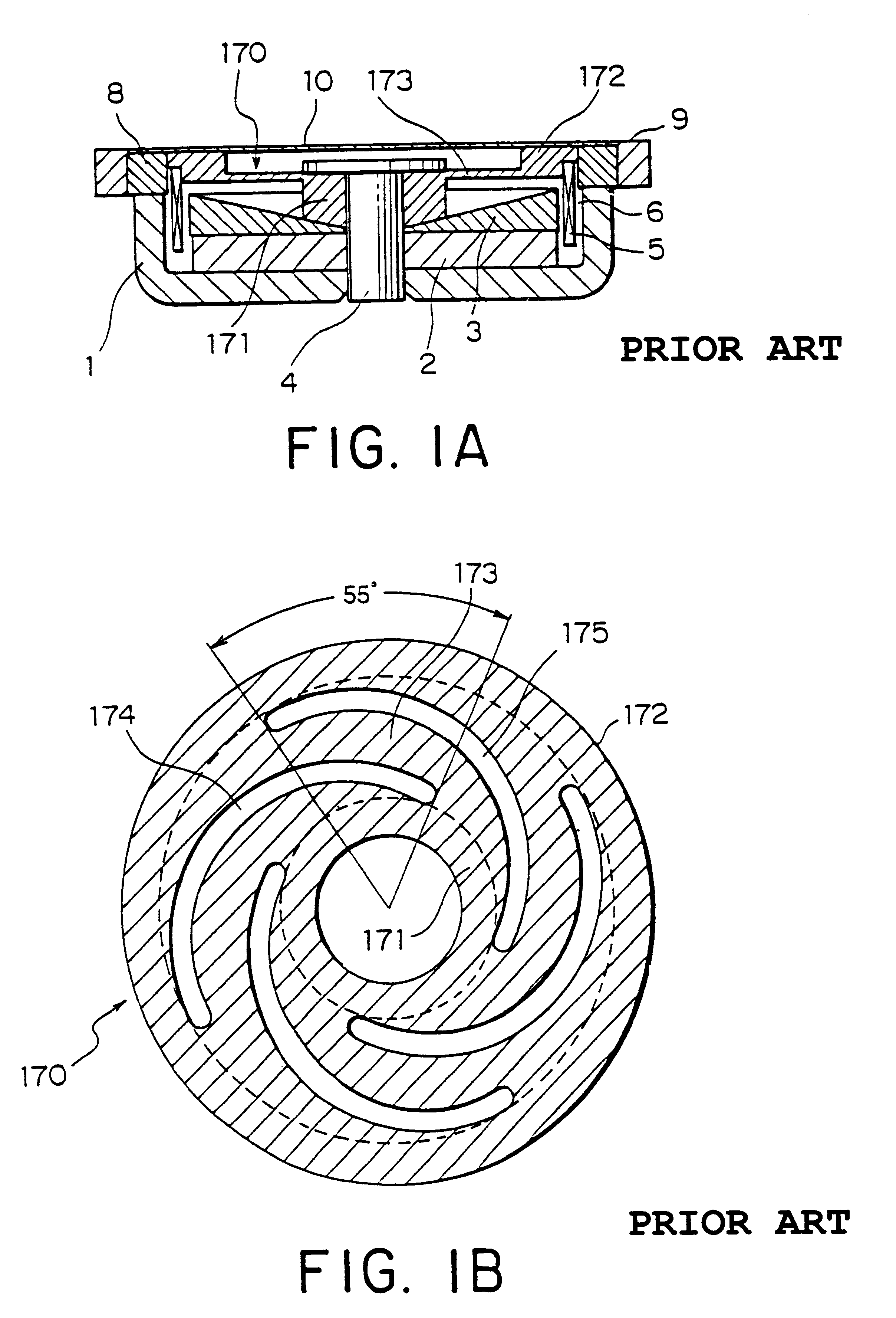

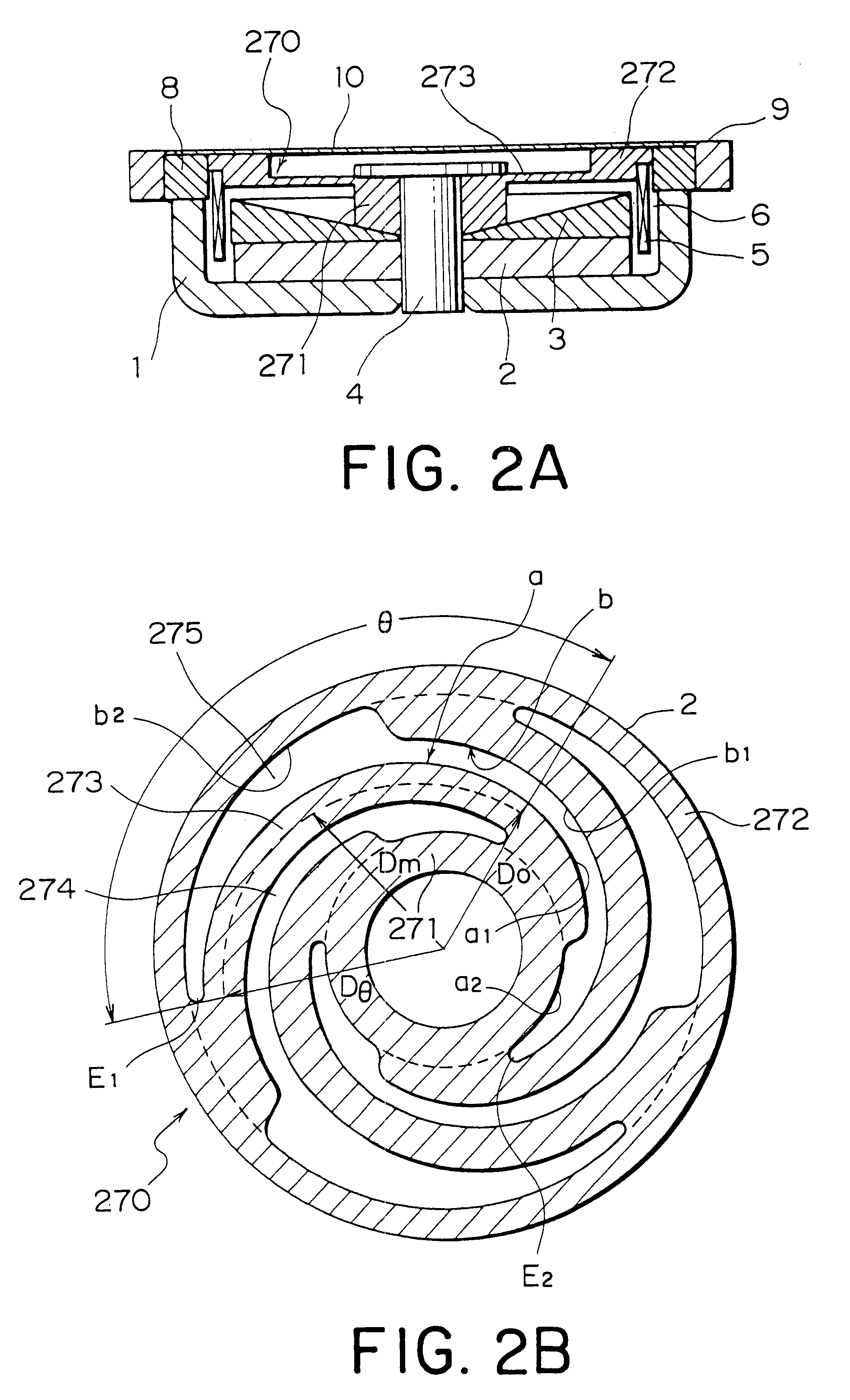

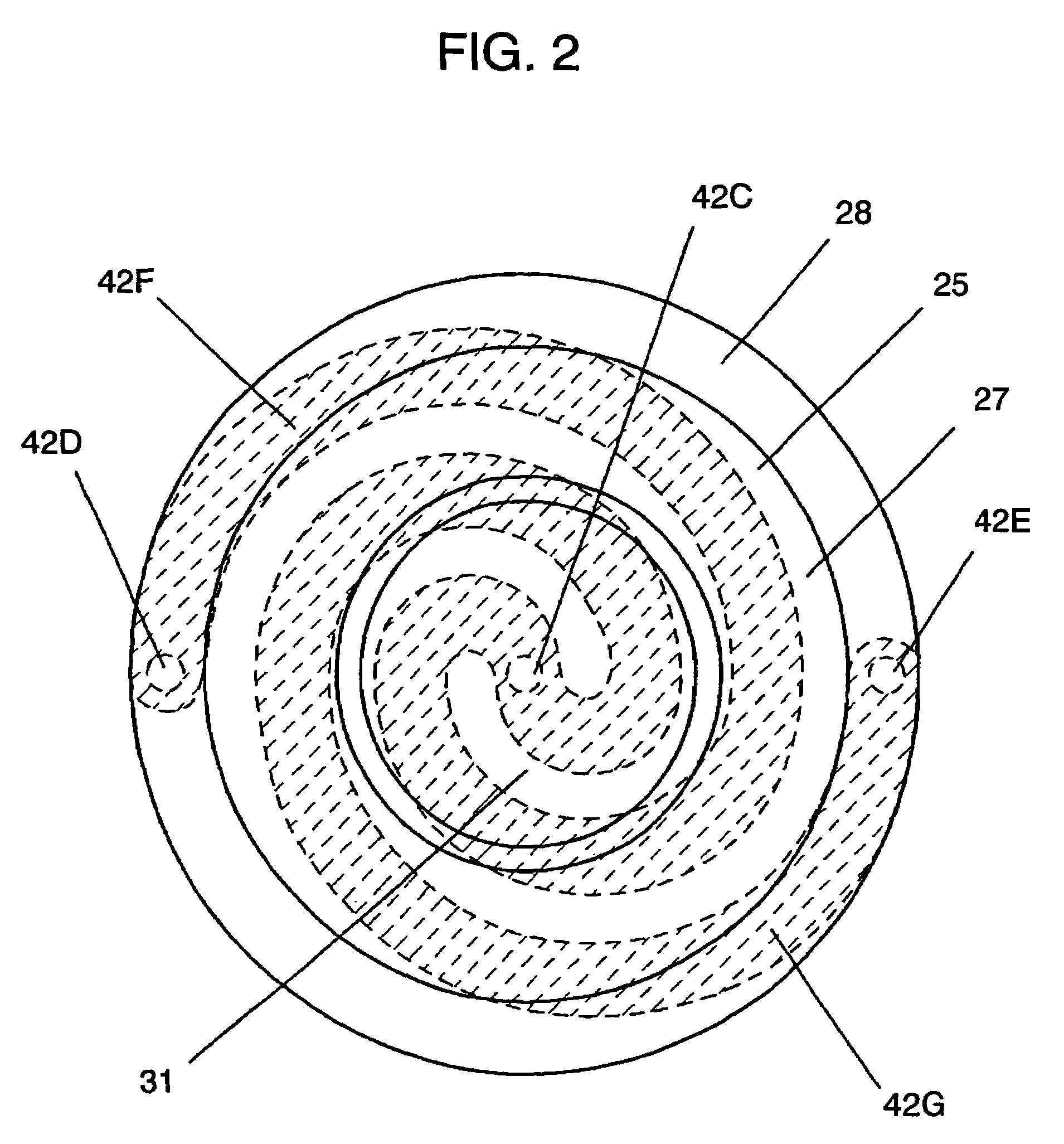

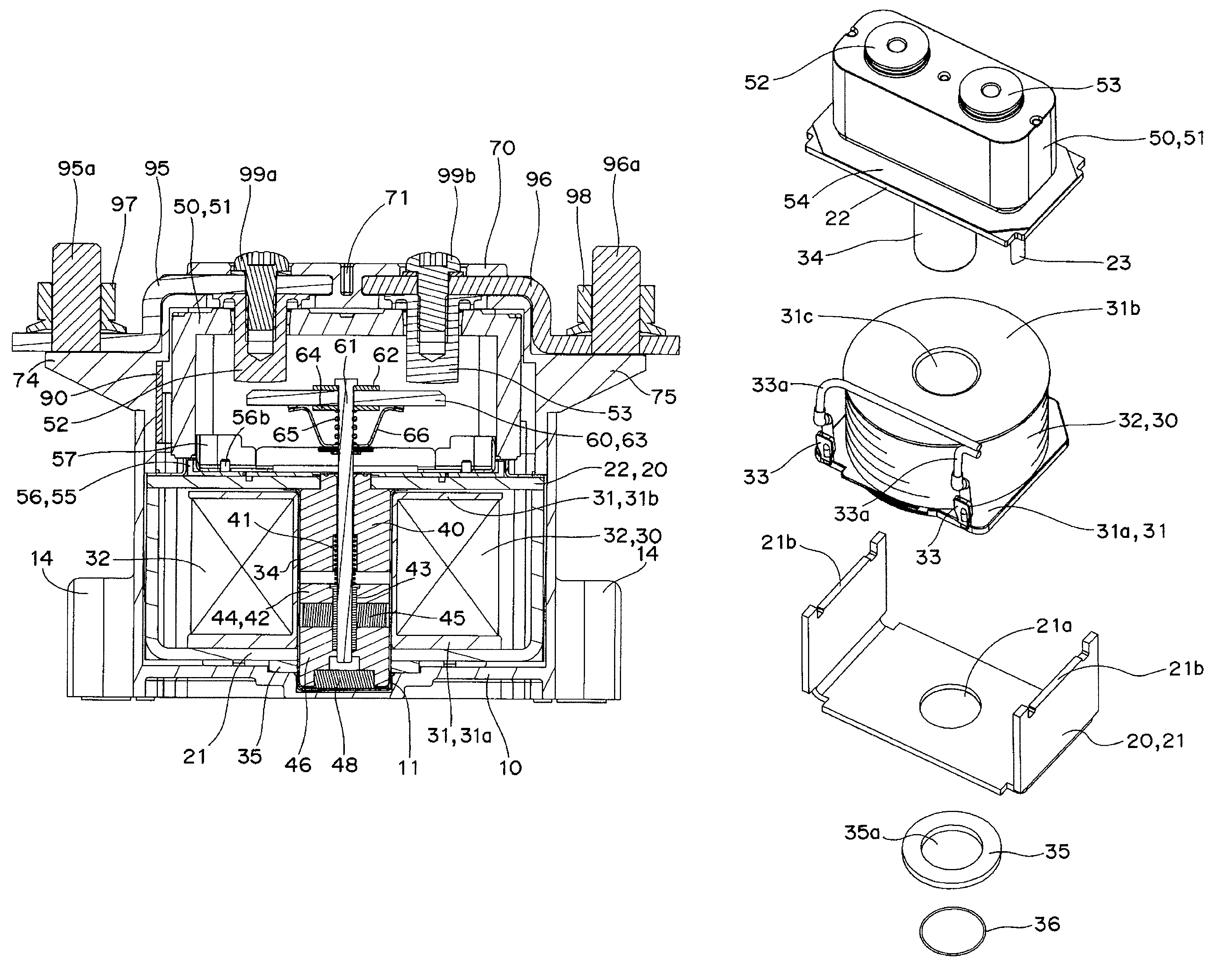

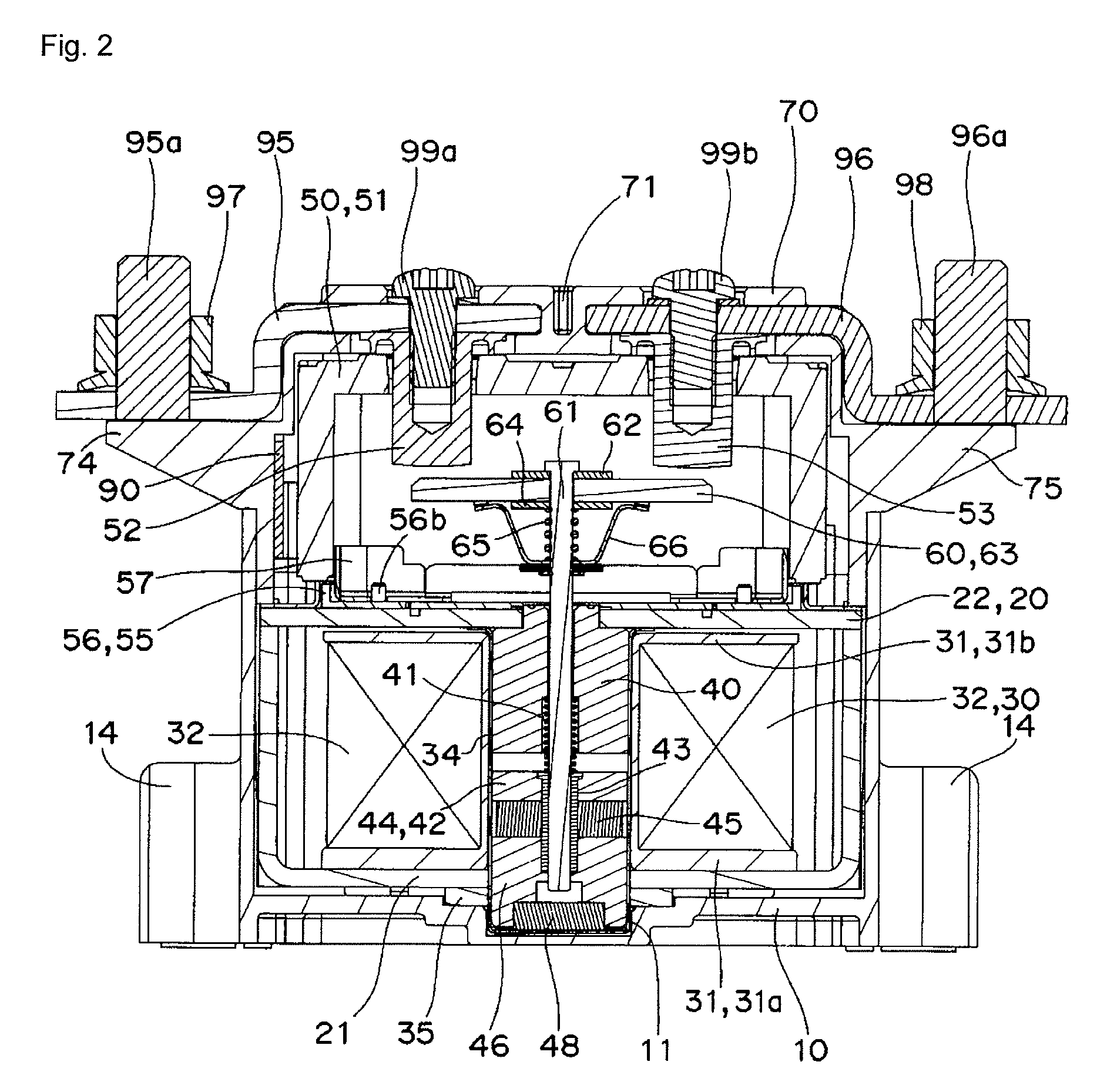

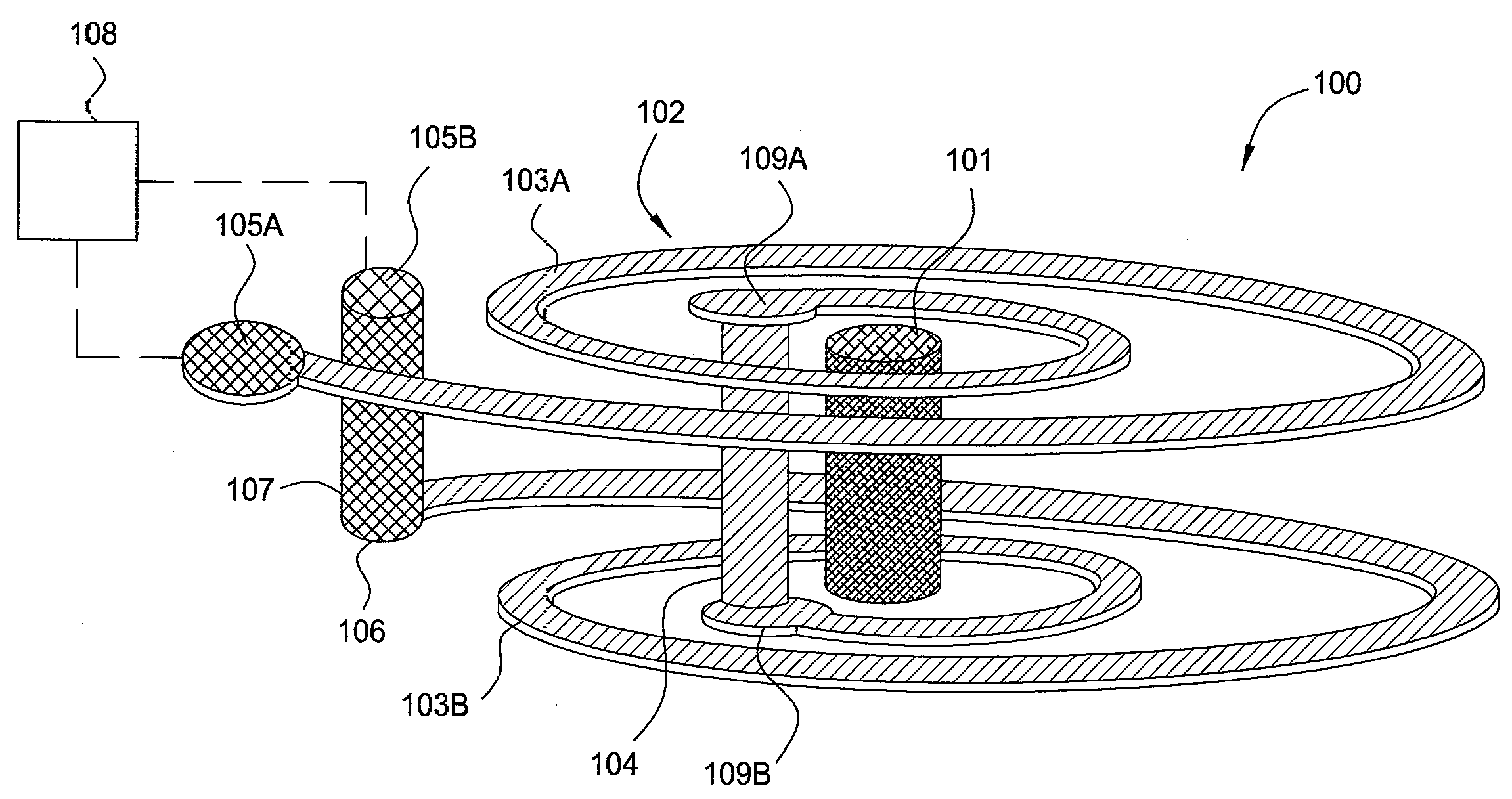

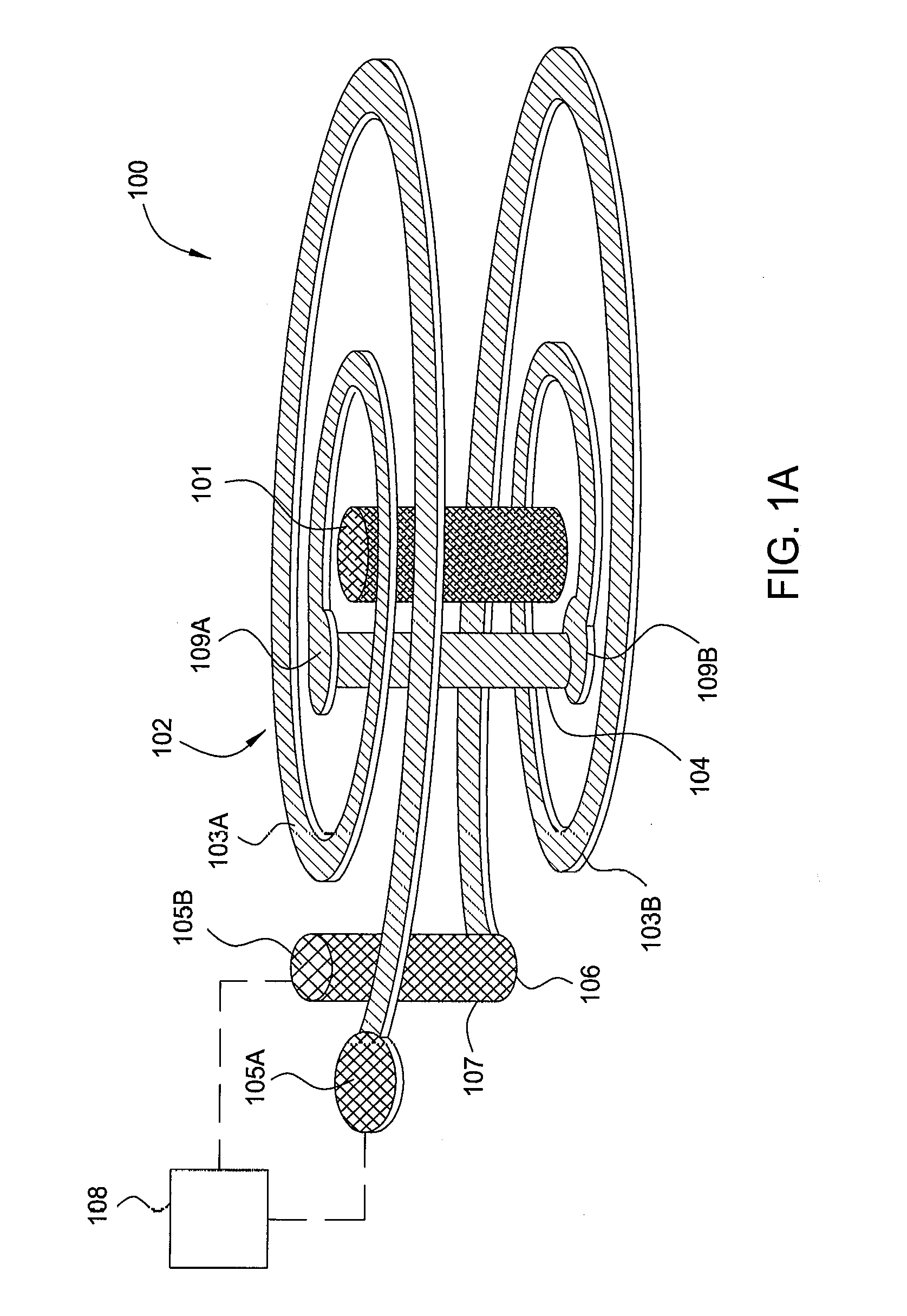

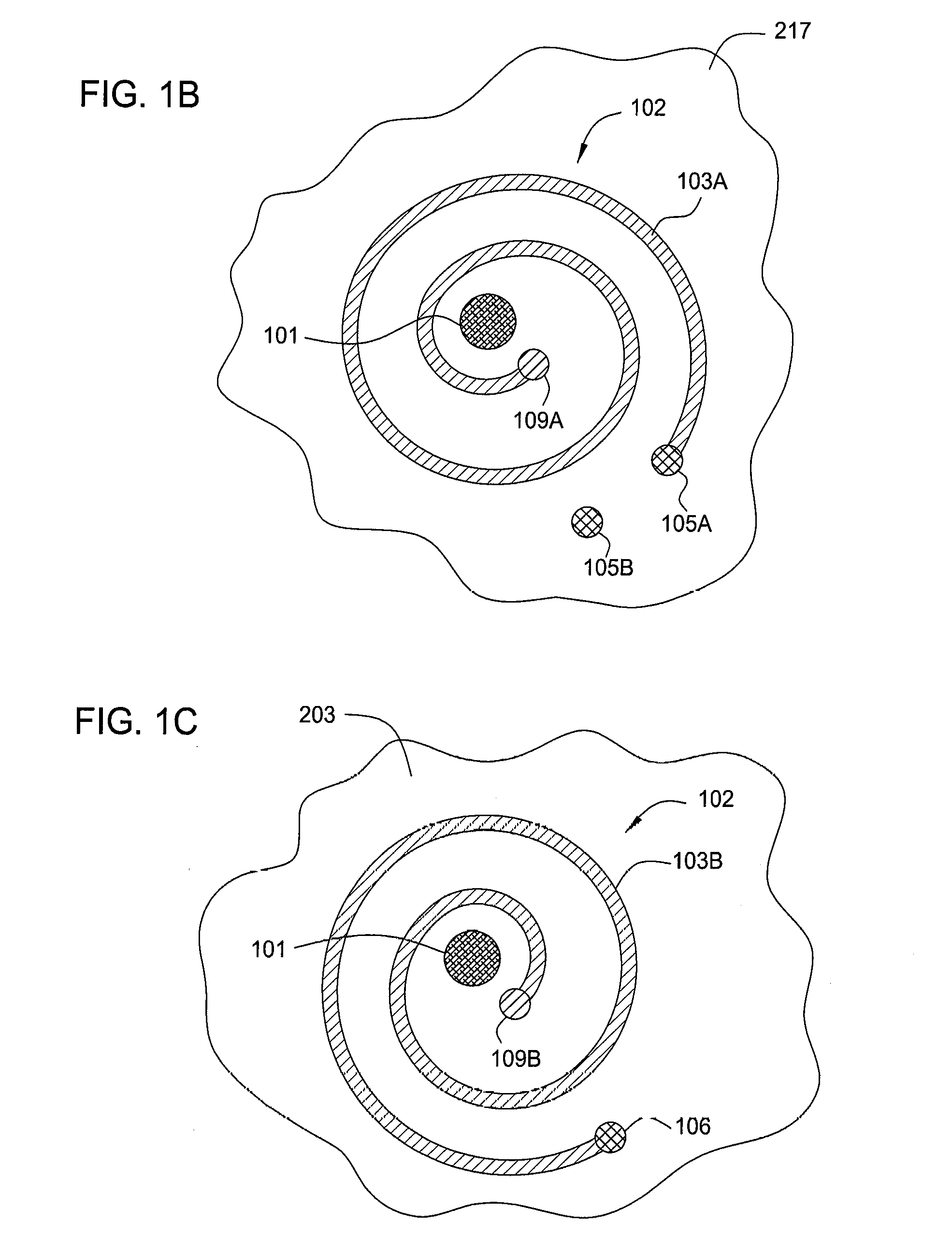

Vibration actuator having magnetic circuit elastically supported by a spiral damper with increased compliance

InactiveUS6377145B1Improve seismic performanceStable characteristicsTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesAngular degreesCoil spring

A vibration actuator includes an electromechanical transducer having a magnetic circuit (1-4) and a driving coil (5), a support frame (9), and a damper (270) elastically supporting the magnetic circuit onto the support frame to flexibly damp the vibration of the magnetic circuit when a driving AC current is supplied to the coil (5). The damper (270) comprises inner and outer ring portions (271, 272) and a plurality of spiral spring portions (273) determined by a plurality of spiral slits (274, 275) formed in the damper. In order to reduce the spiral spring portion determined by the adjacent two spiral slits in its compliance, each of the spiral spring portions has an effective spring length determined by an effective angle (theta) which is determined as an angle (by angular degree) from an inner end of the inner spiral slit to an outer end of the outer spiral slit defining each respective spiral spring portion around a center of the damper. The effective angle is 55 angular degree or more. In a preferable example, the effective spring length is determined by a product (r.theta) of an average radius (r) value by the unit of "mm" and the effective angle (theta) value by unit of the angular degree. The effective spring length is selected to 320 or more, and preferably 400 or more.

Owner:TOKIN CORP

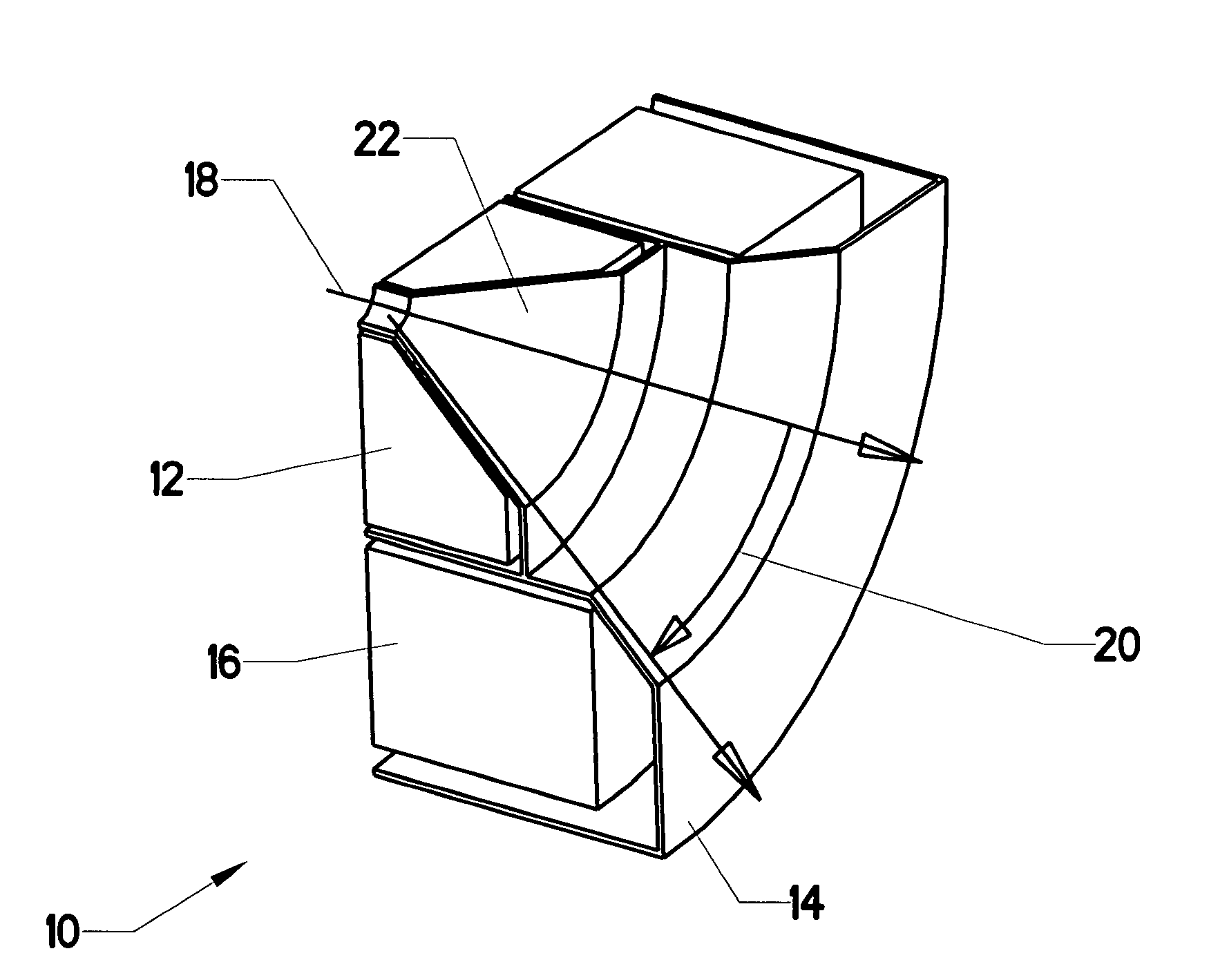

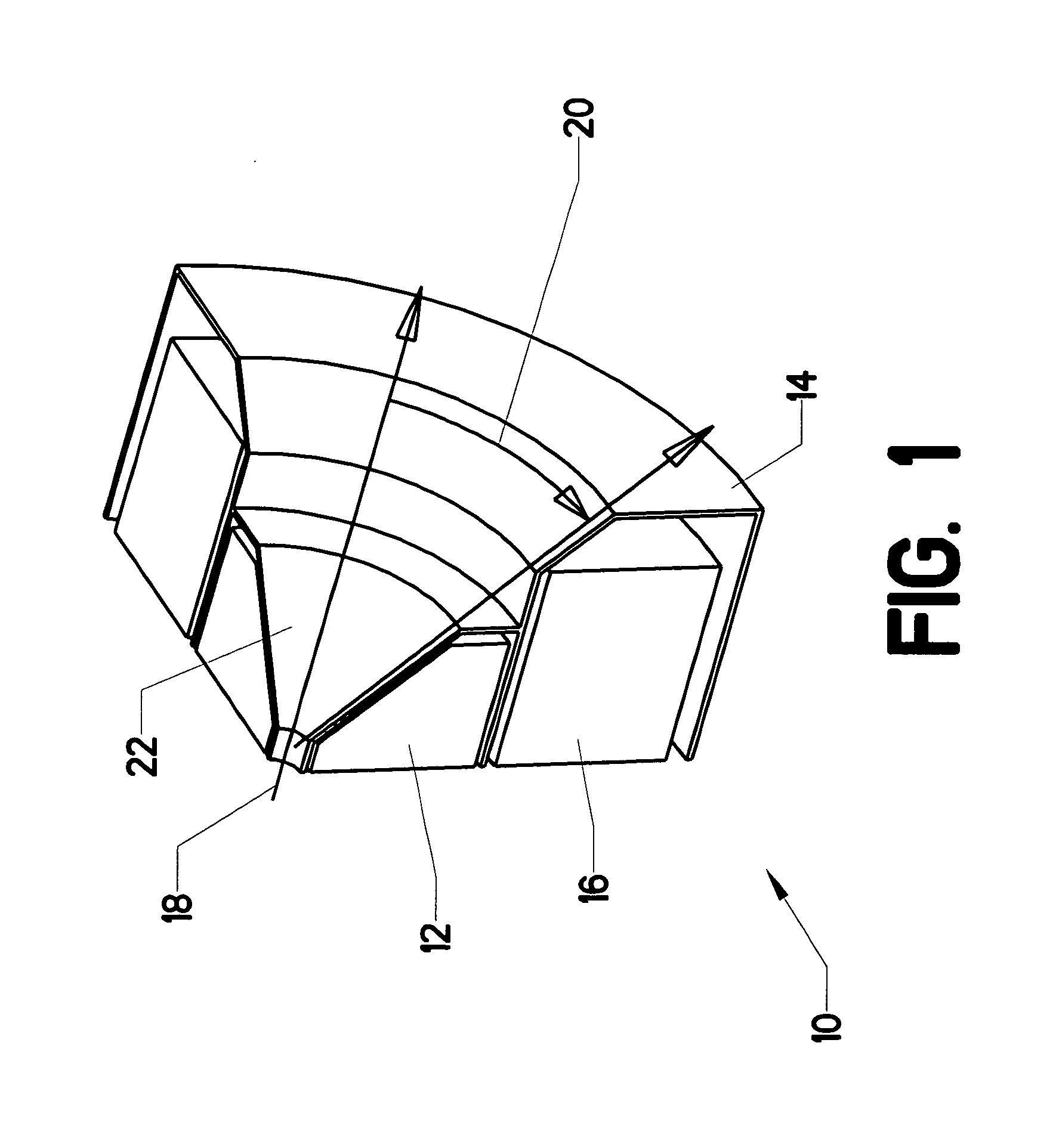

Electromagnetic actuator and integrated actuator and fluid flow control valve

InactiveUS20040025949A1Rapid responseLow driving energyOperating means/releasing devices for valvesPipeline systemsMagnetic polesEngineering

A magnetic device is formed from a permanent magnet generating magnetic flux, an armature which can occupy two positions between four poles and an electromagnet winding to which current can be supplied to produce a magnetic flux in one direction or the other, the flux from the winding causing the armature to move into one position and continue to remain in that position after the current flow ceases. The device can be incorporated into a fluid valve to act as a drive for opening and closing the valve. It may also serve as the drive for opening and closing electrical contacts. Monostable operation can be achieved by locating a magnetic flux shunt at one end of the armature travel. A holding solenoid may be incorporated. A pivoting armature in a fluid tight chamber comprises a fluid flow controlling device. It can adopt either of two home positions in contact with two magnetic poles and is retained by magnetic flux from a permanent magnet. Fluid can flow into and out of the chamber via a first passage. A second passage extends through one of the poles to an opening in the pole face which is covered by the armature when the latter occupies one home position but is uncovered when the armature occupies its other home position. A third fluid passage extends through and leads to a second opening in another pole, which is covered when the armature occupies its said other home position. Passages in the poles house energy storing springs each of which is compressed as the armature approaches the pole. A push rod can extend through a passage in one of the poles for conveying armature movement externally of the device.

Owner:CAMCOM

Solenoid valve

ActiveUS7347221B2Easy to moveMinimal gap widthFuel supply regulationGaseous fuel feeder/distributionPower flowSolenoid valve

A valve assembly comprises two valves and a single solenoid actuator with only one magnetizing coil that controls both valves. The corresponding magnetic circuit comprises a yoke with only two pole pieces. The valves are arranged concentric to one another. The valve closing element of the outer valve is connected to an armature by means of a sleeve. The cup thus formed receives the armature that is connected to the valve closing element of the inner valve. The pole piece and the armature form a transmission air gap through which the sleeve extends. A coupling air gap is formed between the armatures. The armature and the pole piece form a working air gap. The valves are opened collectively and are able to close independently of one another when the coil is rendered currentless.

Owner:KARL DUNGS

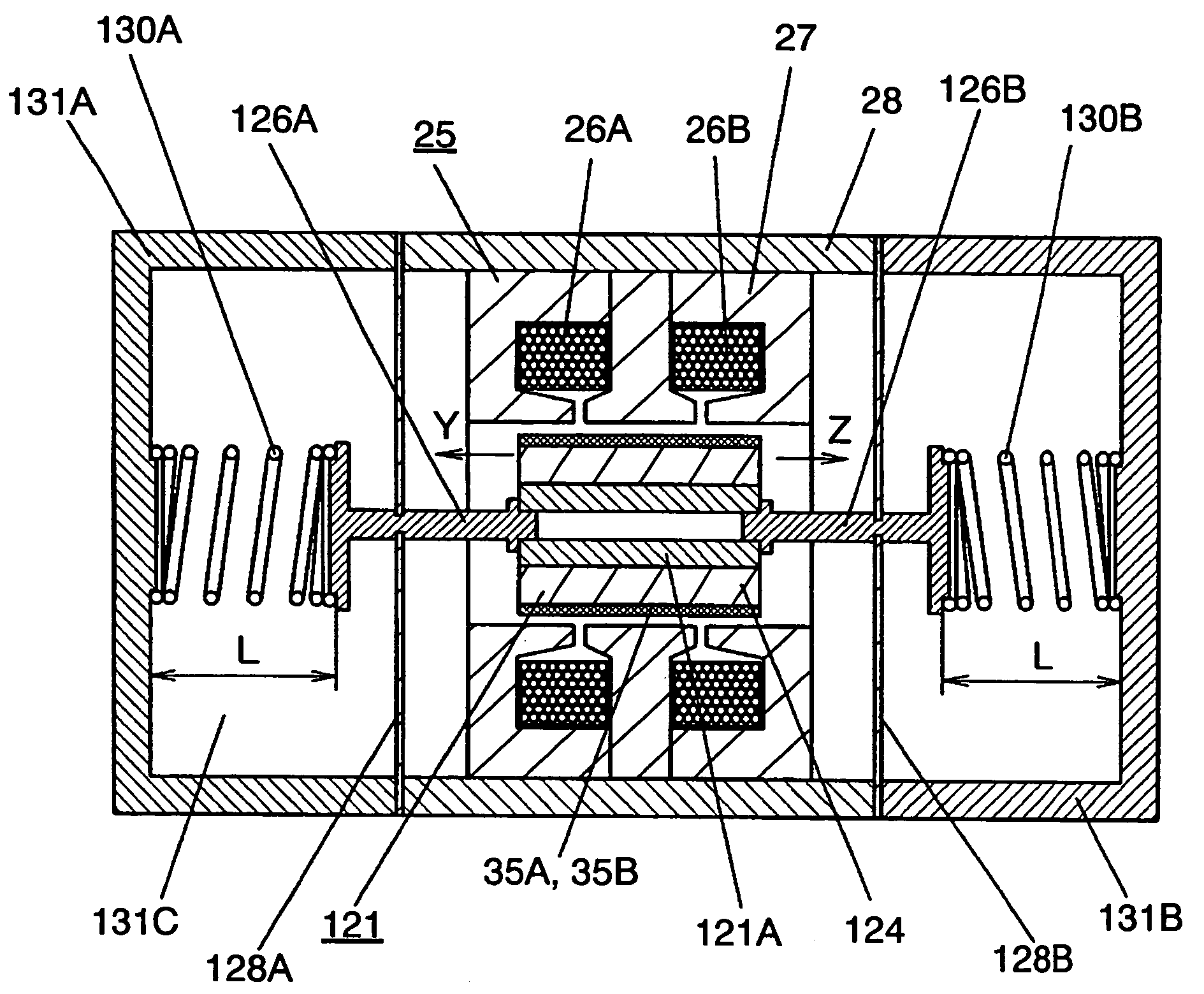

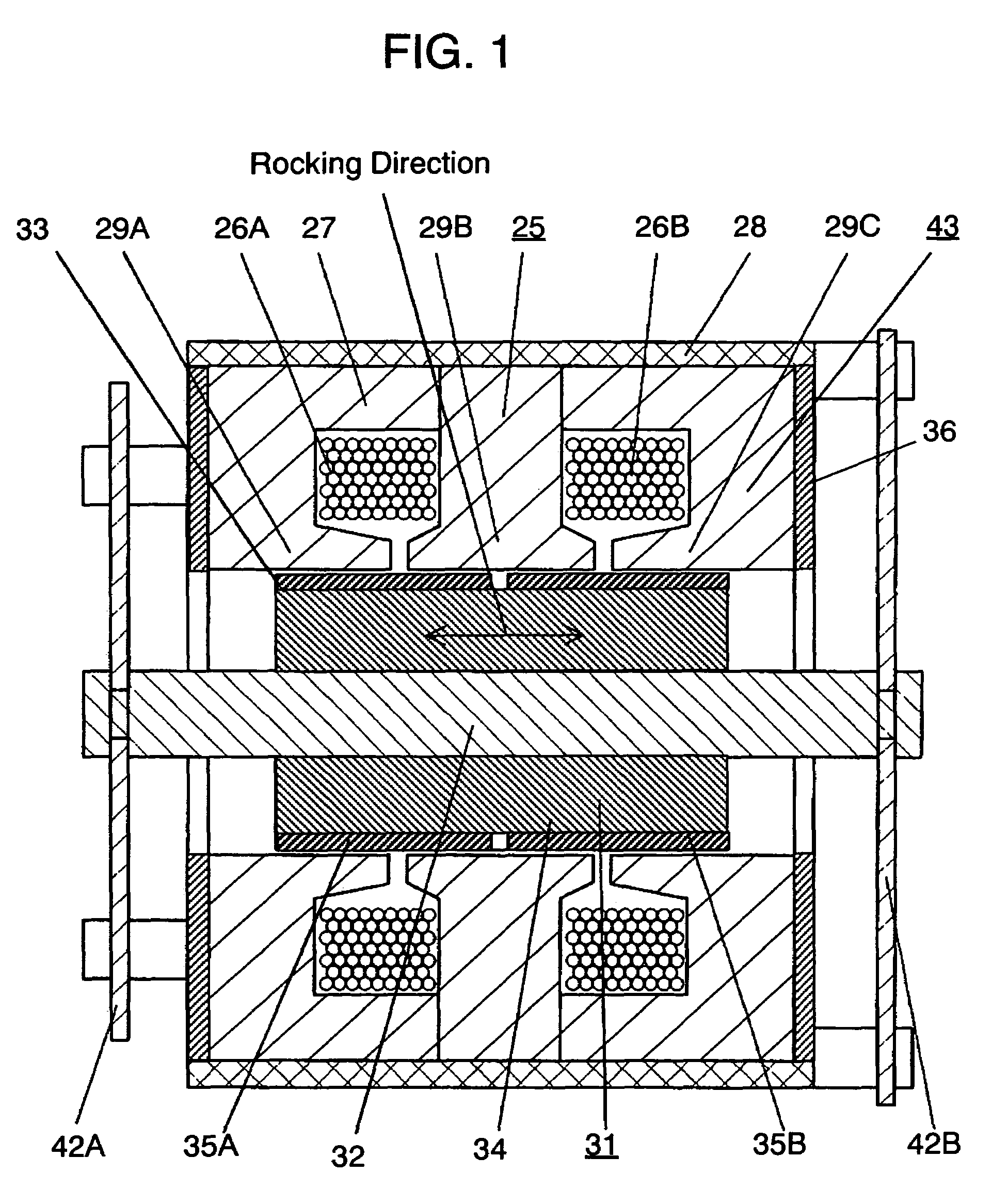

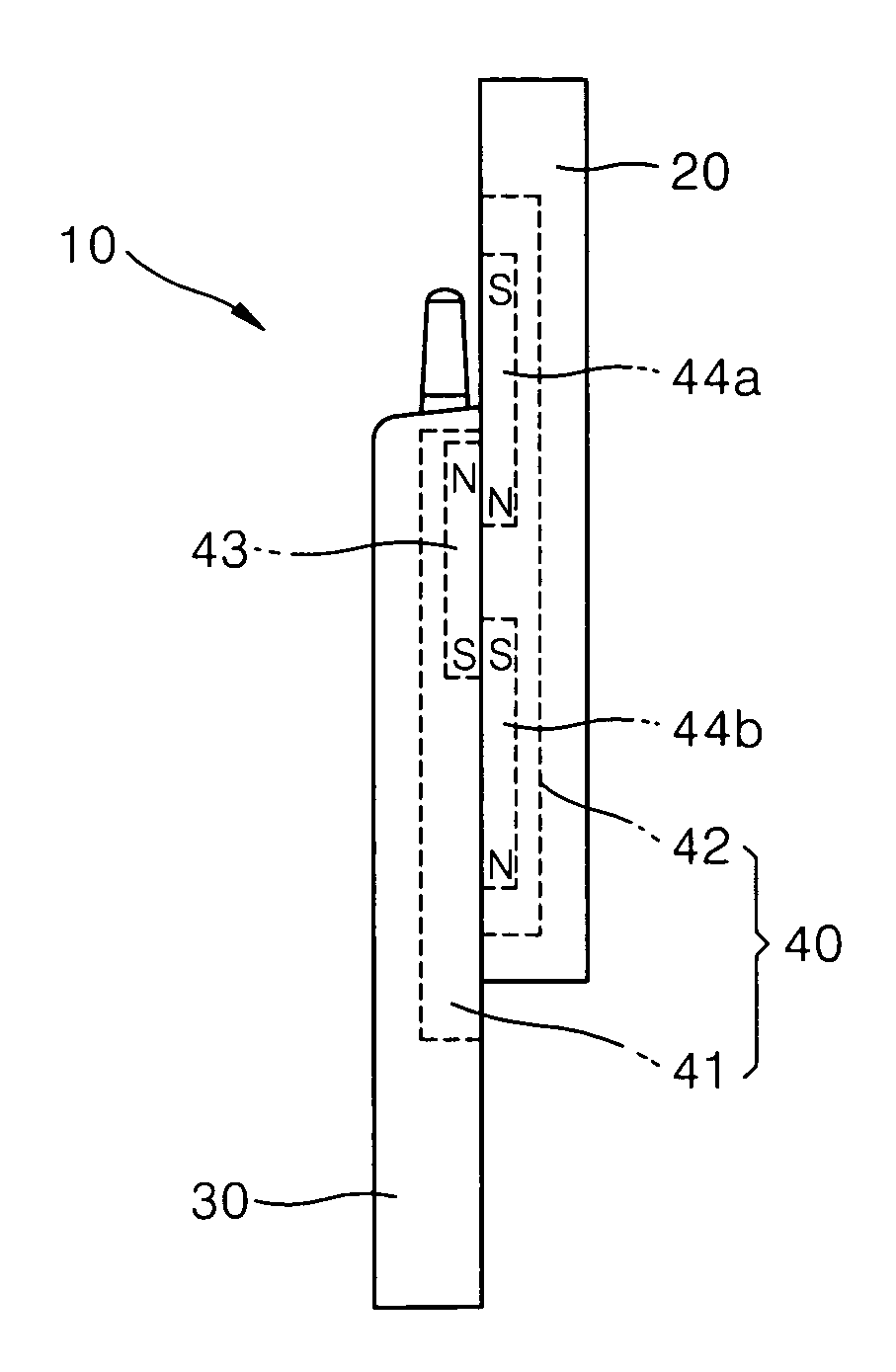

Linear motor, and linear compressor using the same

A linear motor of the present invention has: a stator having a stationary iron core and a magnet wire; a mover having a moving iron core and a magnet; and a plate-shaped elastic member for supporting the mover in a manner to rock in the rocking directions. This construction eliminates a sliding portion for supporting the mover so that it can reduce the loss, which might otherwise accompany the reciprocation of the mover. Moreover, a linear compressor using this linear motor is high in efficiency and reliability.

Owner:PANASONIC CORP

Electromagnetic valve

ActiveUS7273206B2Simple structureReduce manufacturing costOperating means/releasing devices for valvesMultiple way valvesBobbinNuclear engineering

An electromagnetic manipulating portion of an electromagnetic valve includes a fixed iron core fixedly disposed in the inside hole of a bobbin and a movable iron core movably disposed in the inside hole and attracted to the fixed iron core by a magnetic attraction force. The fixed iron core and the movable iron core are composed of the same normally magnetic material in the same shape and in the same size and have compatibility each other.

Owner:SMC CORP

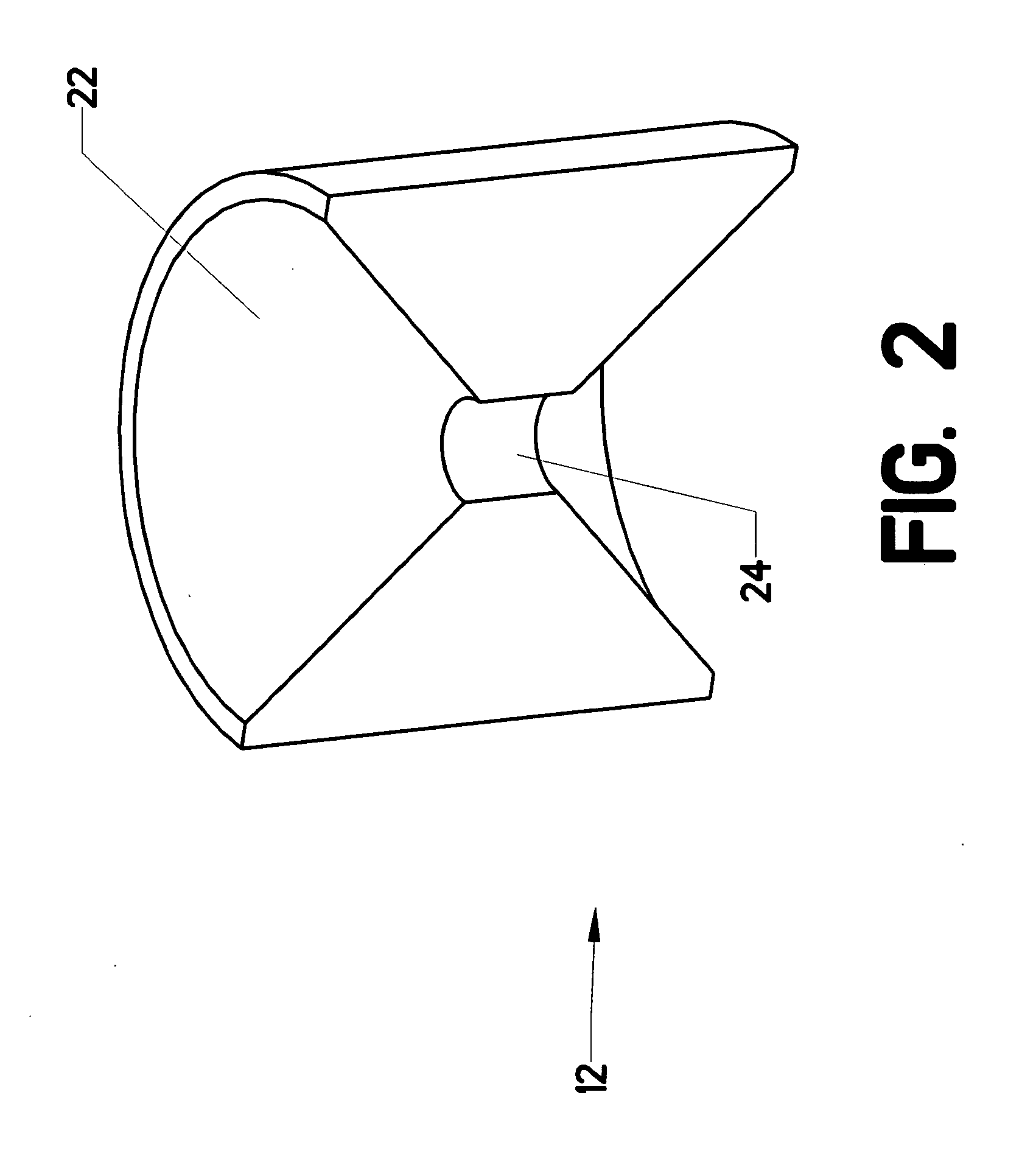

Conical magnet

ActiveUS20100033280A1Simplified representationTransformers/inductances coils/windings/connectionsMagnetic materialsState of artElectrical conductor

An electromagnet having a conical bore. The conical bore is created by wrapping a conductor around a conically-offset helix. The cross sectional area of the conductor can be varied in order to maintain a desired current carrying capacity along the helix. A single element can be used as the conductor. The conductor can also be created by stacking a series of specially-shaped plates analogous to prior art Bitter-disks.

Owner:FLORIDA STATE UNIV RES FOUND INC

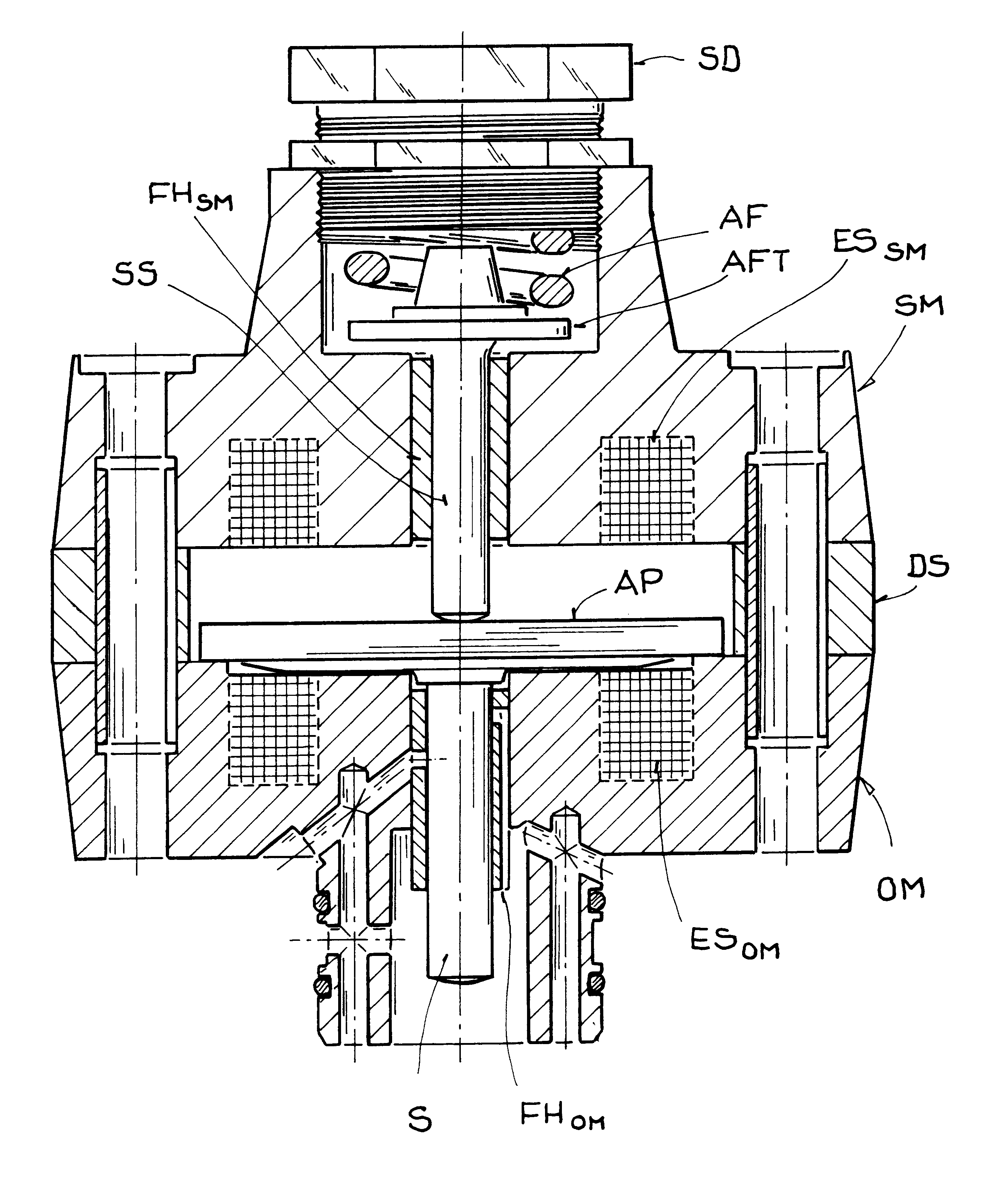

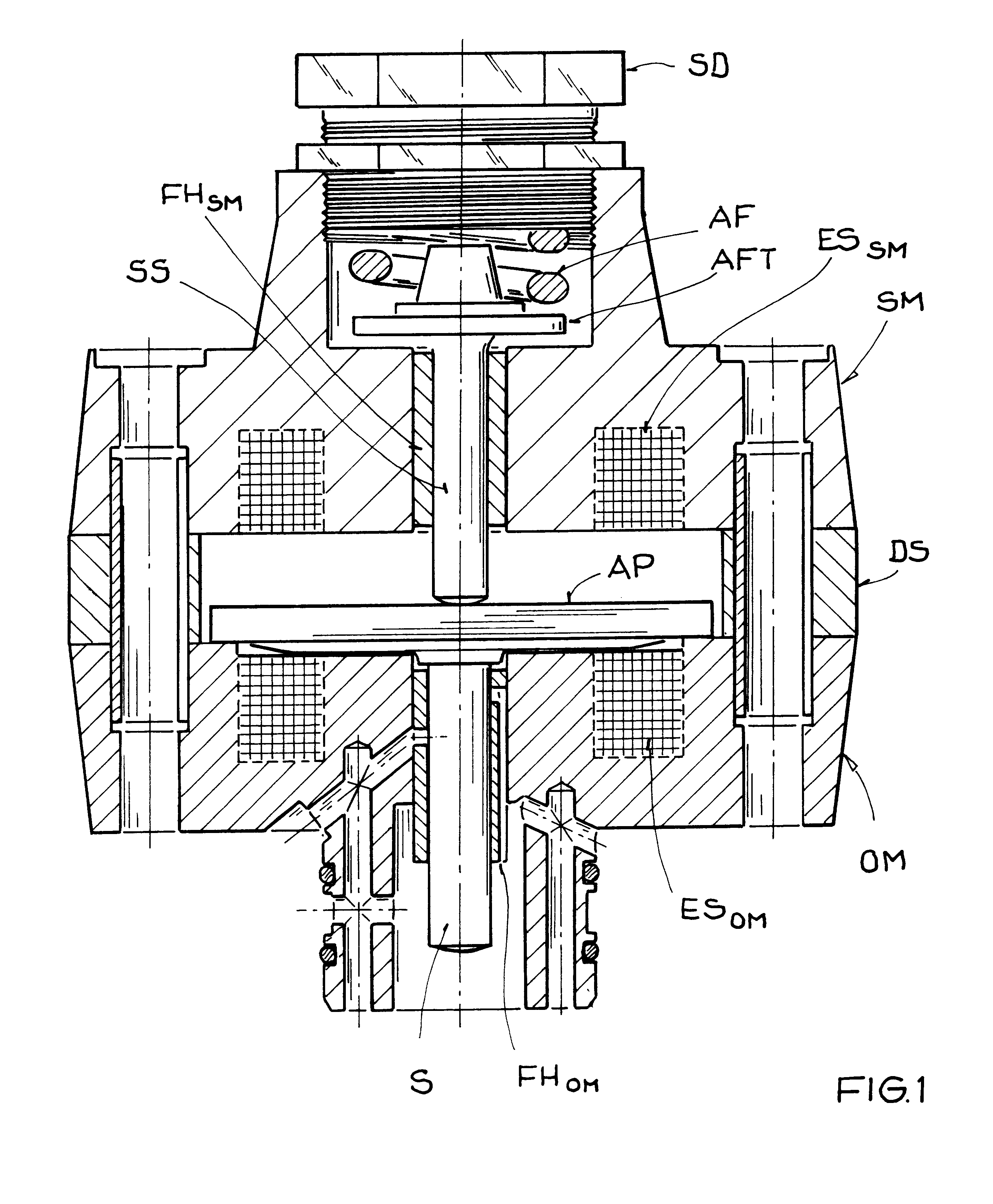

Method for operating actuators for electromagnetically controlling a valve

InactiveUS6216652B1Operating means/releasing devices for valvesMachines/enginesInternal combustion engineActuator

A method of operating an actuator for electromagnetically controlling a valve in an internal combustion engine involves supplying a heating current to the operating coils of the actuator before starting the internal combustion engine from a cold start condition. Thereby, the operating coils, the components surrounding them, and the lubricant are heated to ensure proper viscosity of the lubricant and thus proper operation of the actuator.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

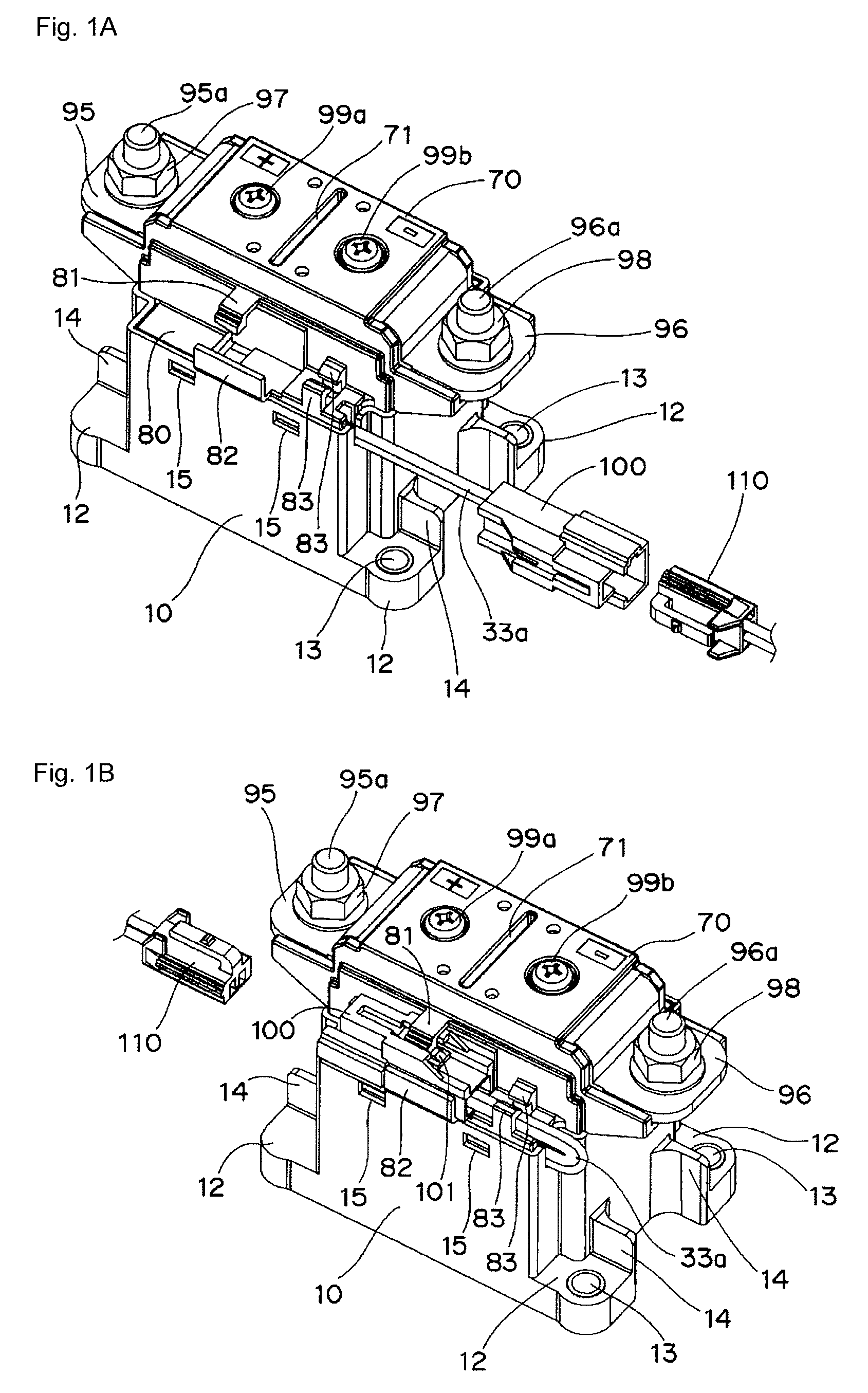

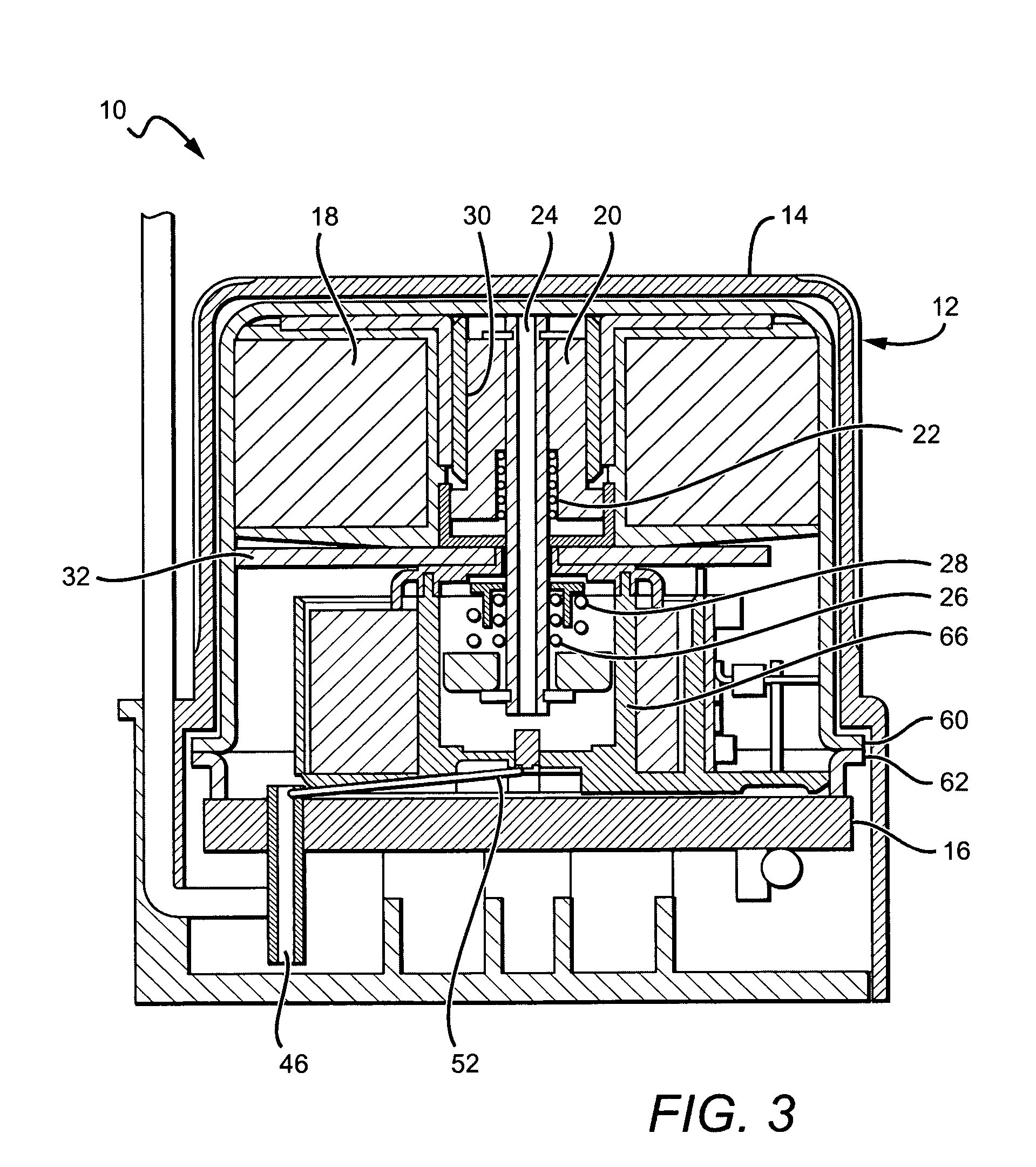

Contact device

ActiveUS8138872B2Large resistanceMagnetic saturation easilyContact mechanismsElectromagnetic relay detailsReciprocating motionDrive shaft

A contact device has a first yoke having a substantially U-shape, a second yoke bridged over both ends of the first yoke, a spool wound with a coil disposed between the first yoke and the second yoke, a movable iron core inserted into a center hole of the spool in a reciprocating mariner, and a contact mechanism unit formed above the second yoke driven with a drive shaft having a lower end fixed to the movable iron core, which reciprocates based on excitation and demagnetization of the coil, and an upper end projecting out from an upper surface of the second yoke. An insertion hole communicating to the center hole of the spool and through which the movable iron core reciprocates is formed in the first yoke. An annular auxiliary yoke including an insertion hole communicating to the insertion hole of the first yoke and through which the movable iron core reciprocates is provided at a lower surface of the first yoke.

Owner:ORMON CORP

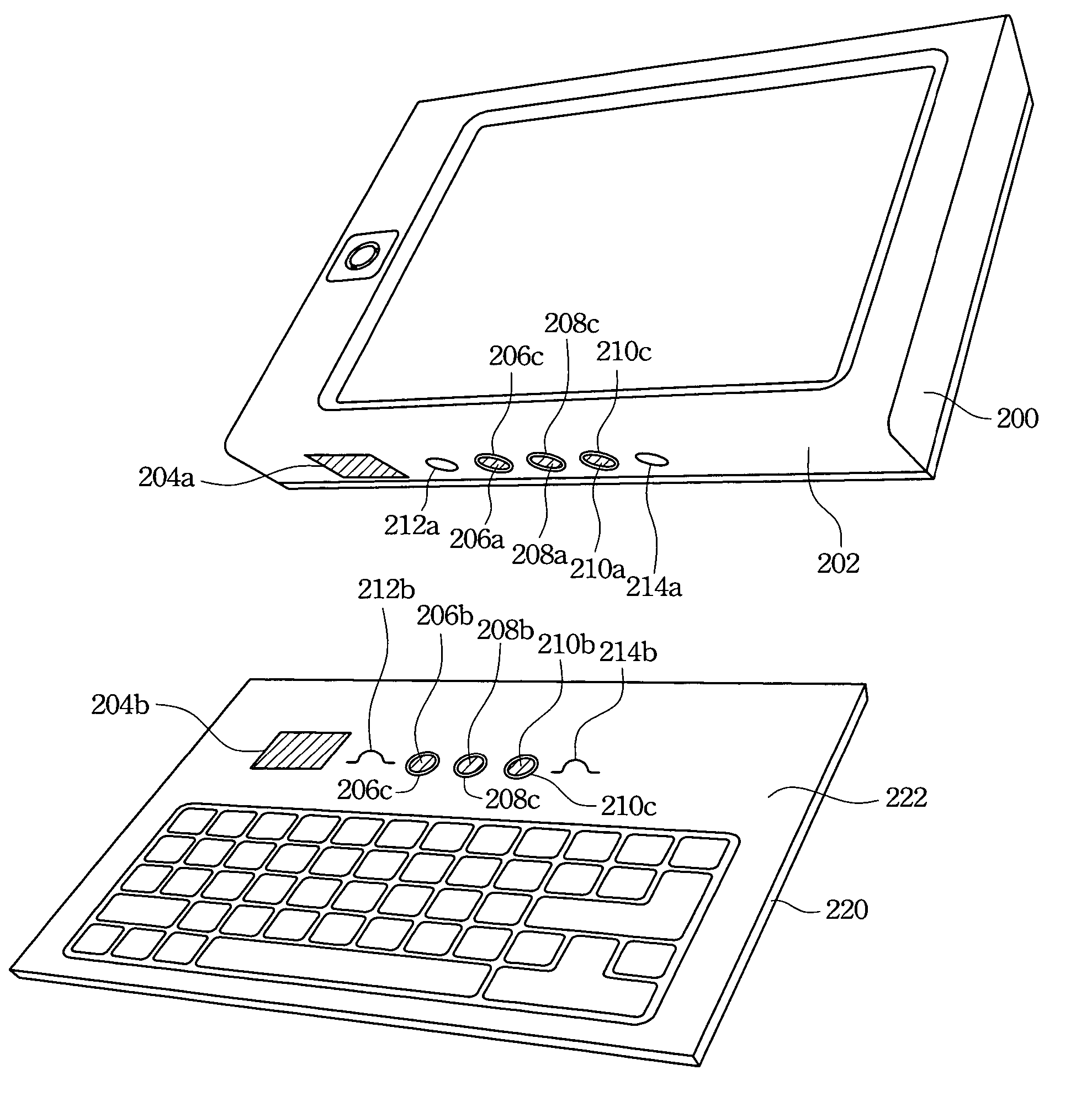

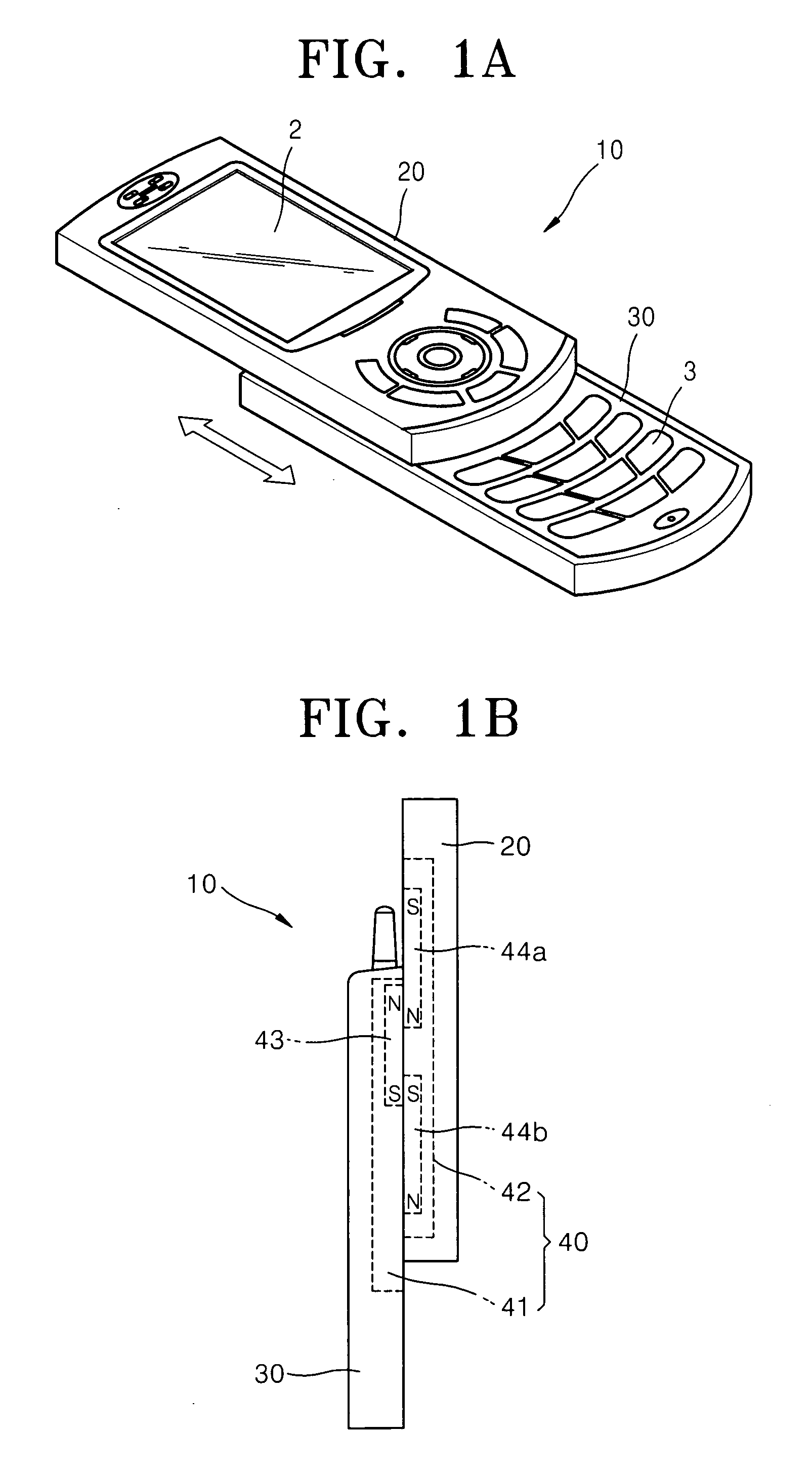

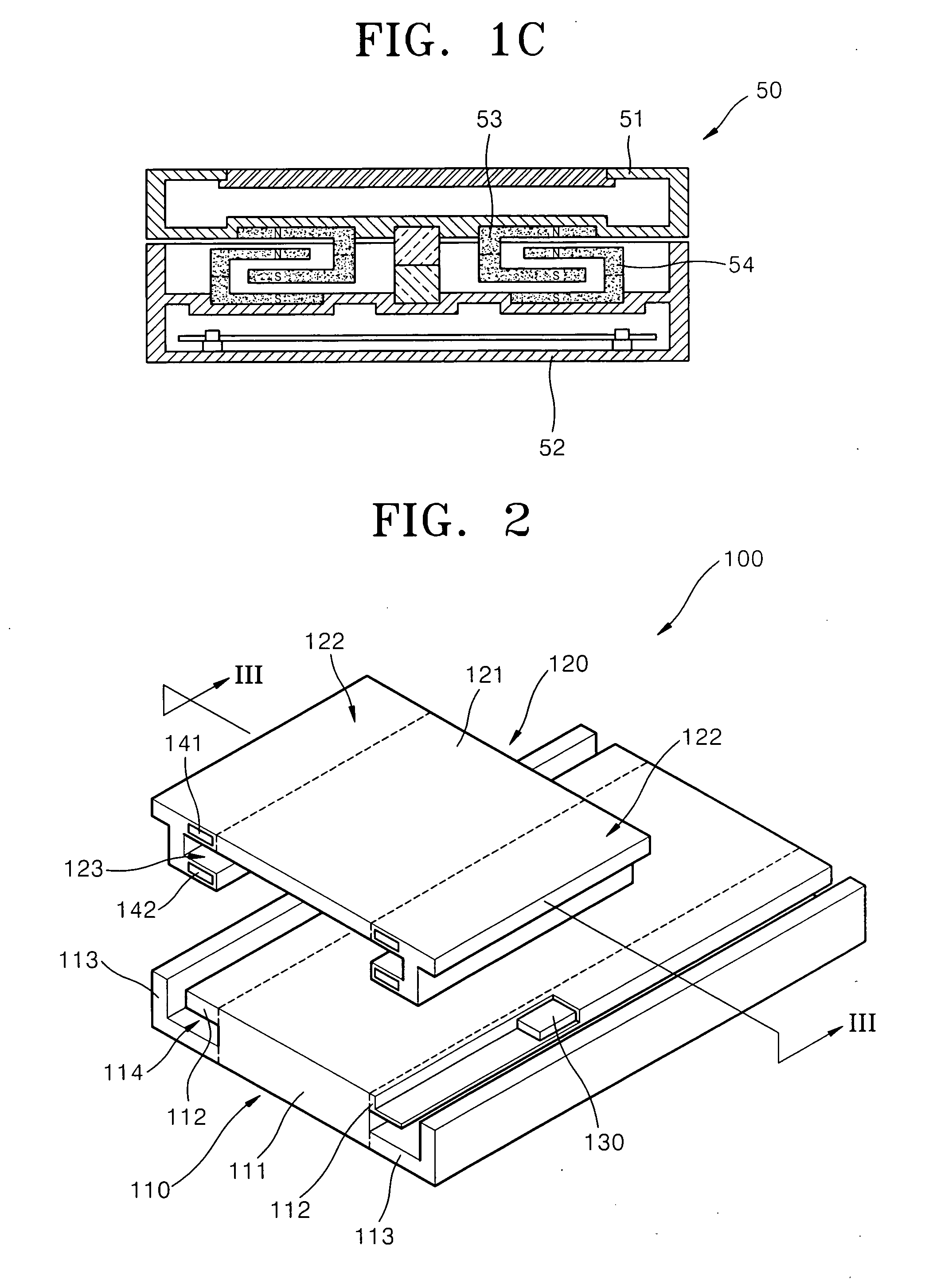

Magnetic levitation sliding structure

InactiveUS20080174392A1Reduce frictionSliding structure is stableElectromagnets without armaturesPermanent magnetsMagnetic polesEngineering

A low friction and stable sliding structure for an electronic device. The sliding structure includes a first sliding member comprising at least one guide portion, a second sliding member including a receiving portion receiving the guide portion so as to slide along the first sliding member, a first magnet portion disposed in the guide portion, such that magnetic poles of the first magnet portion are arranged across a sliding direction, and a second magnet portion disposed in the receiving portion so that a repulsive force can act between the first magnet portion and the second magnet portion.

Owner:HANWHA TECHWIN CO LTD

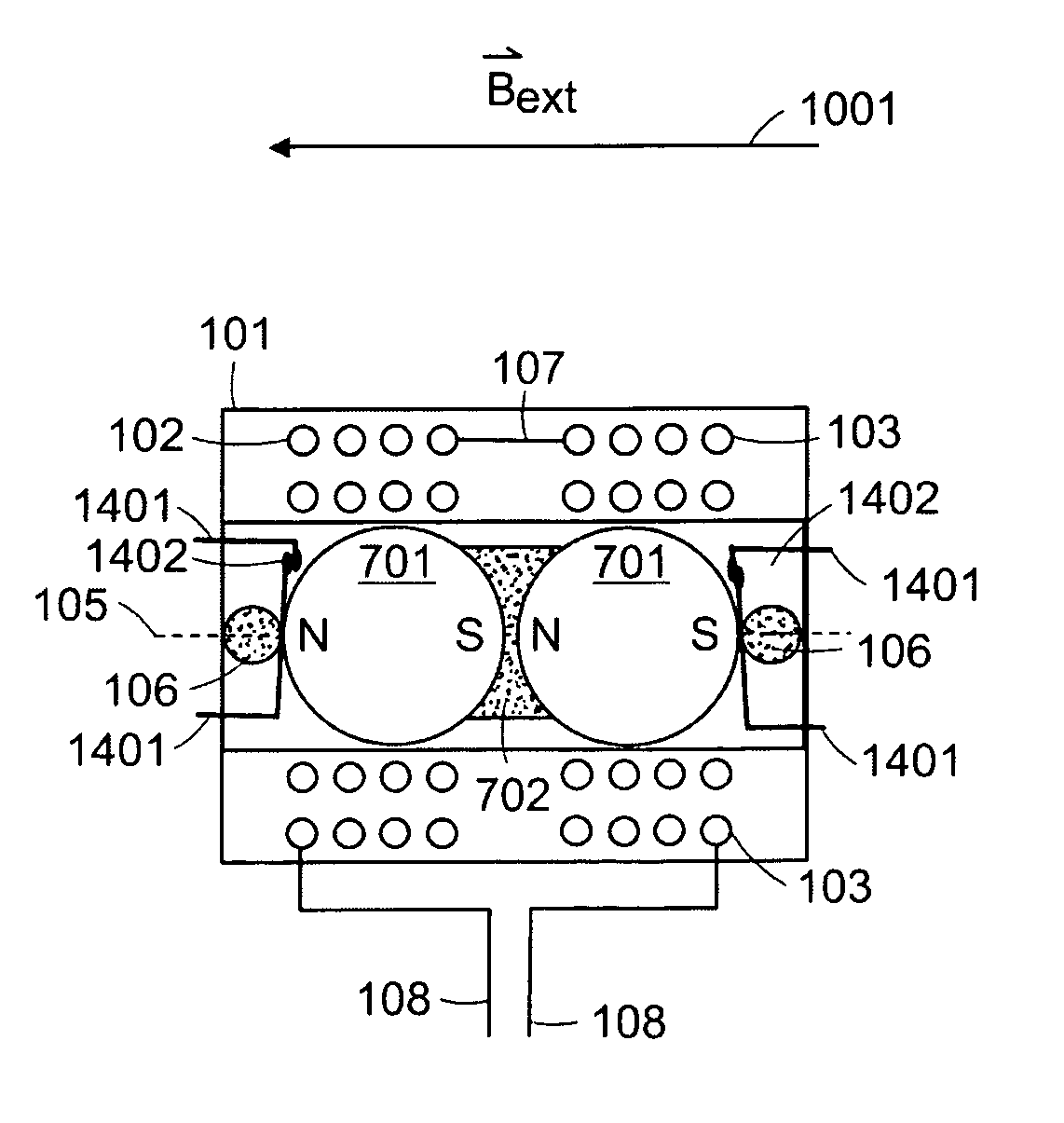

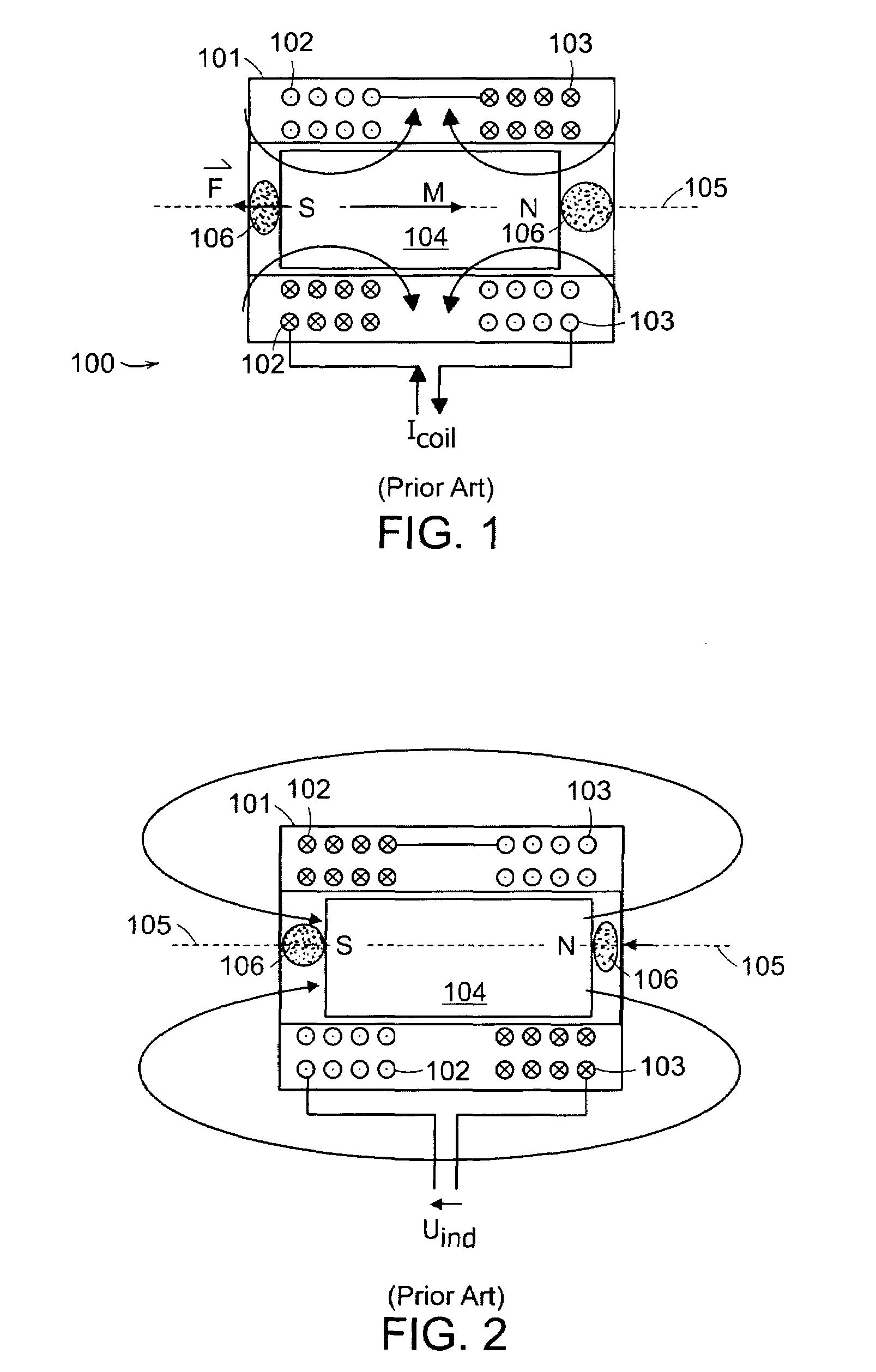

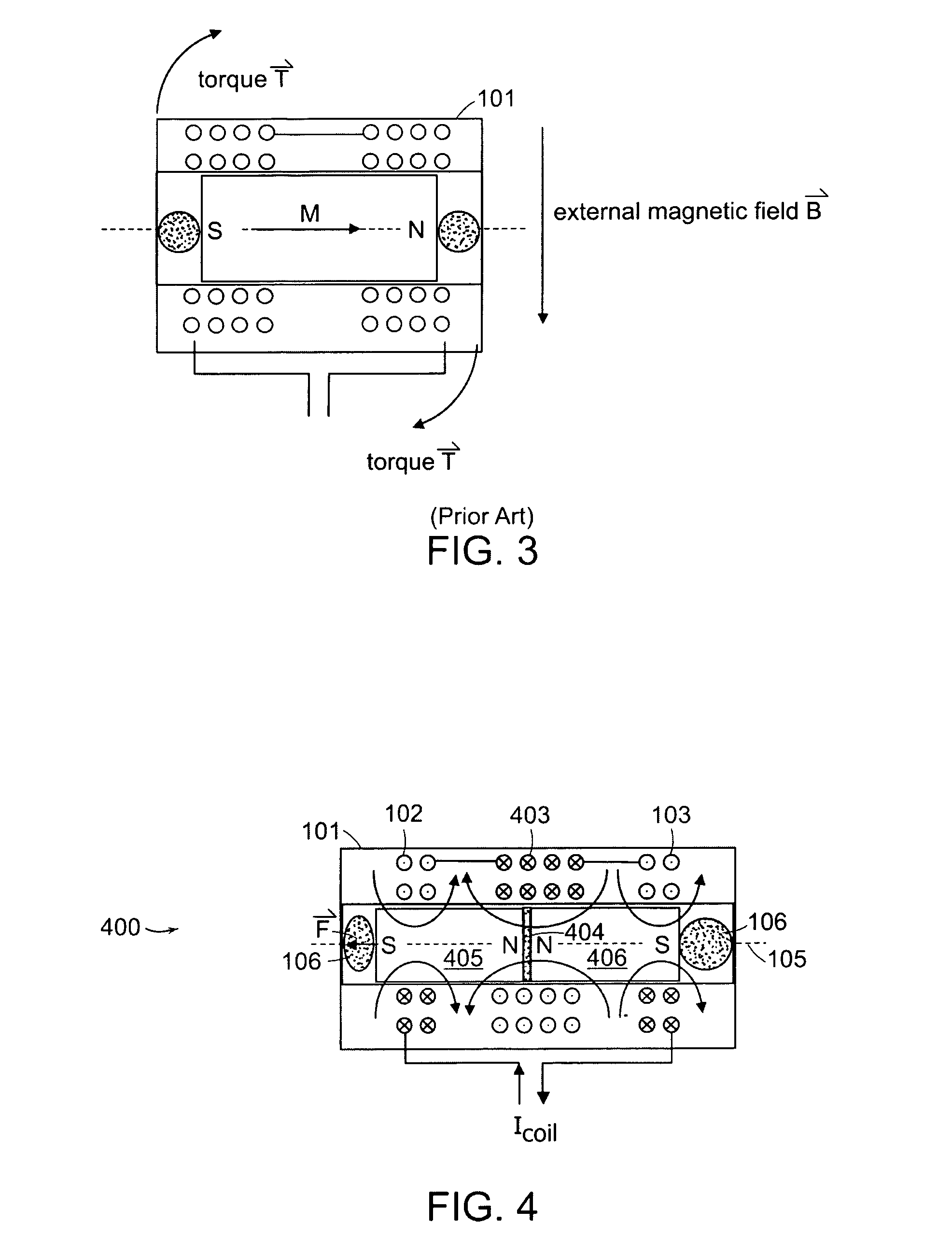

System and method for reducing effect of magnetic fields on a magnetic transducer

InactiveUS7190247B2Process safetyVibration measurement in solidsMagnetic movement switchesMagnetic transducersElectromagnetic drive

An electromagnetic driver transducer free of torque in the presence of an external magnetic field, of any direction and orientation (such as in a Magnetic Resonance Imaging environment). The transducer includes a housing. At least one coil is associated with the housing. A plurality of magnets within the housing are aligned along an axis in an anti-parallel orientation. The magnets are free to move along an axis, wherein vibration of the magnets causes vibration of the housing. The transducer may be, for example, fixed to an ossicle.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

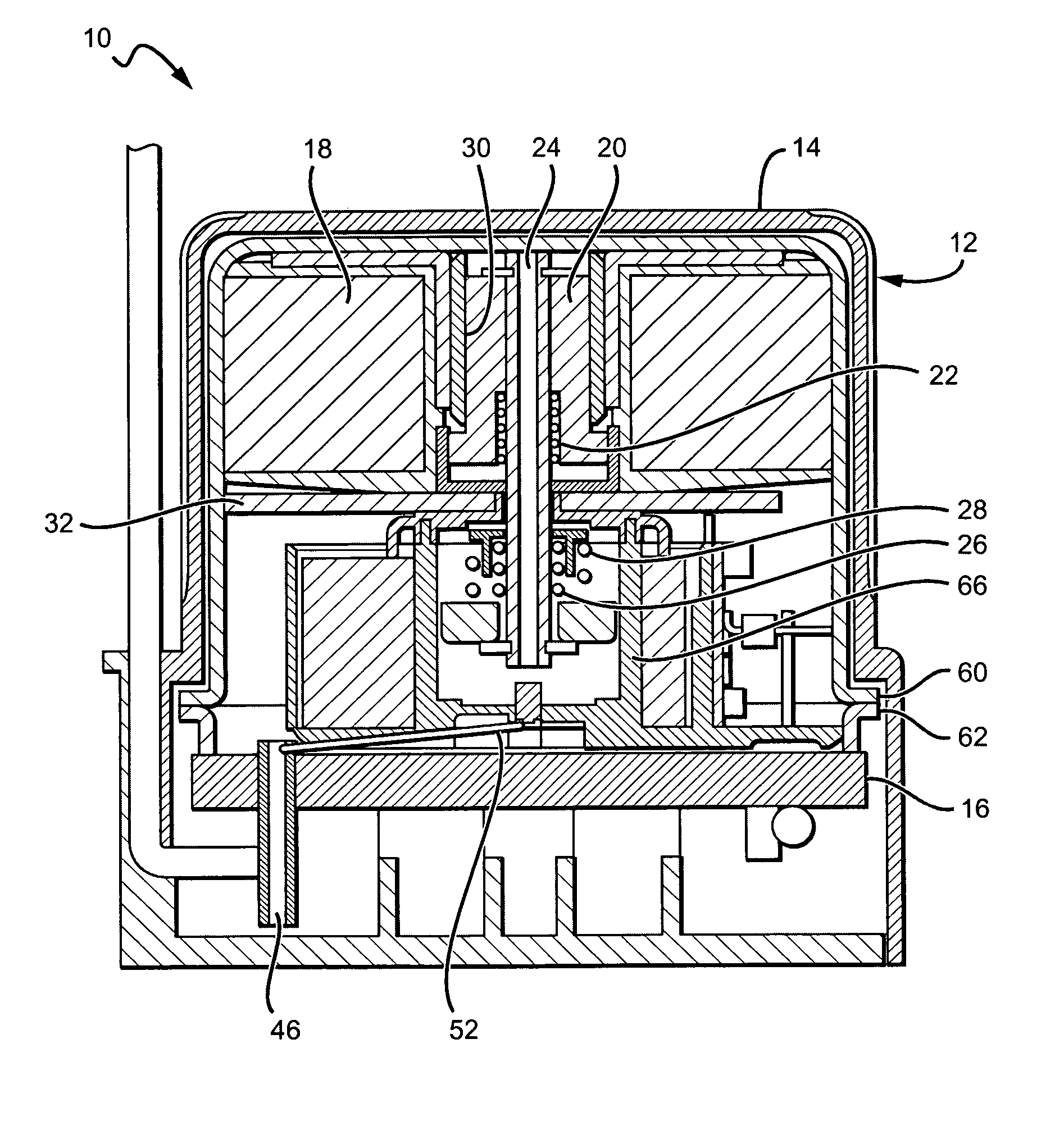

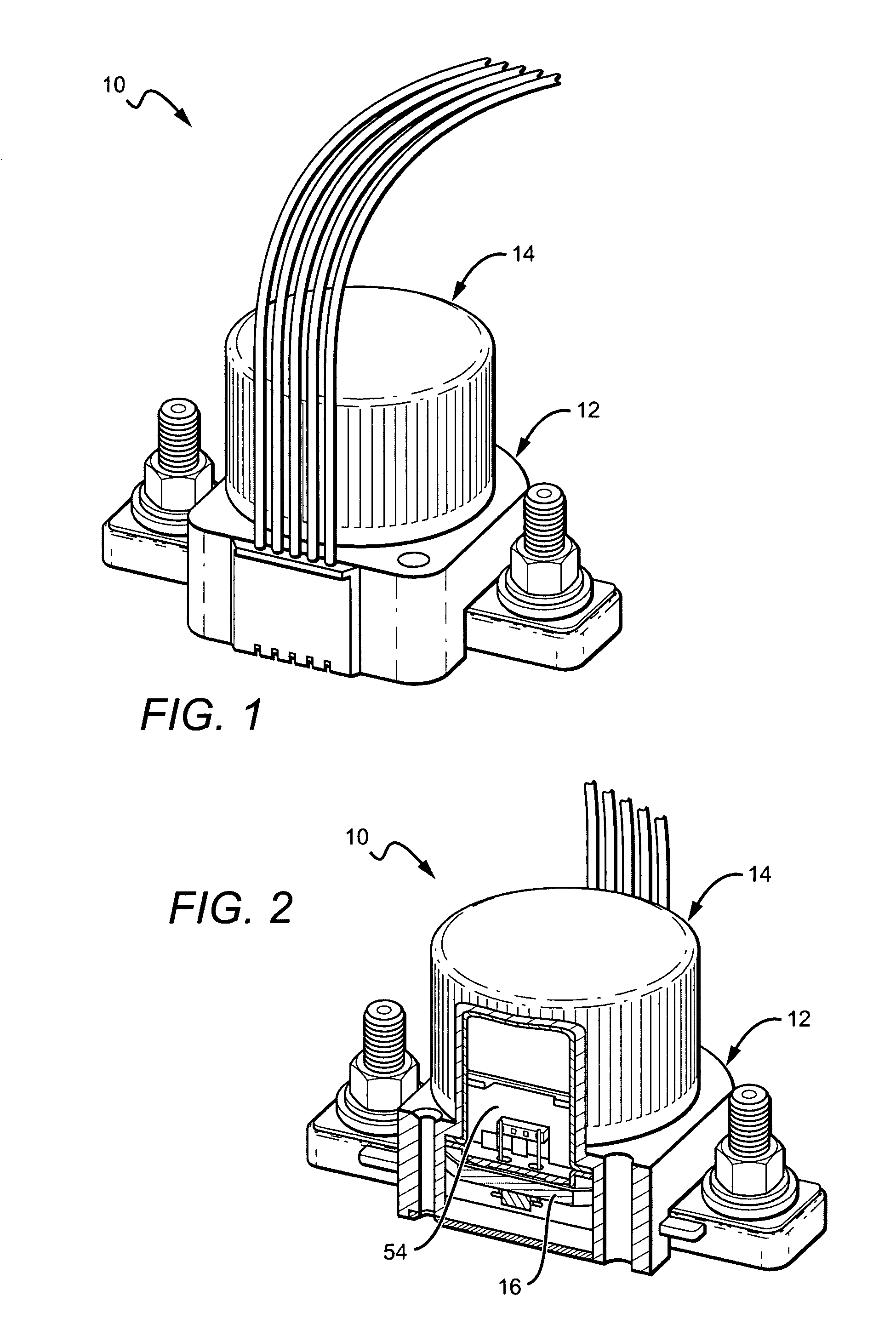

Sealed contactor

ActiveUS7944333B2Less expensiveEasy and flexible to manufactureContacts enclosures/screensElectromagnetic relay detailsHermetic sealElectrical performance

Owner:GIGAVAC INC

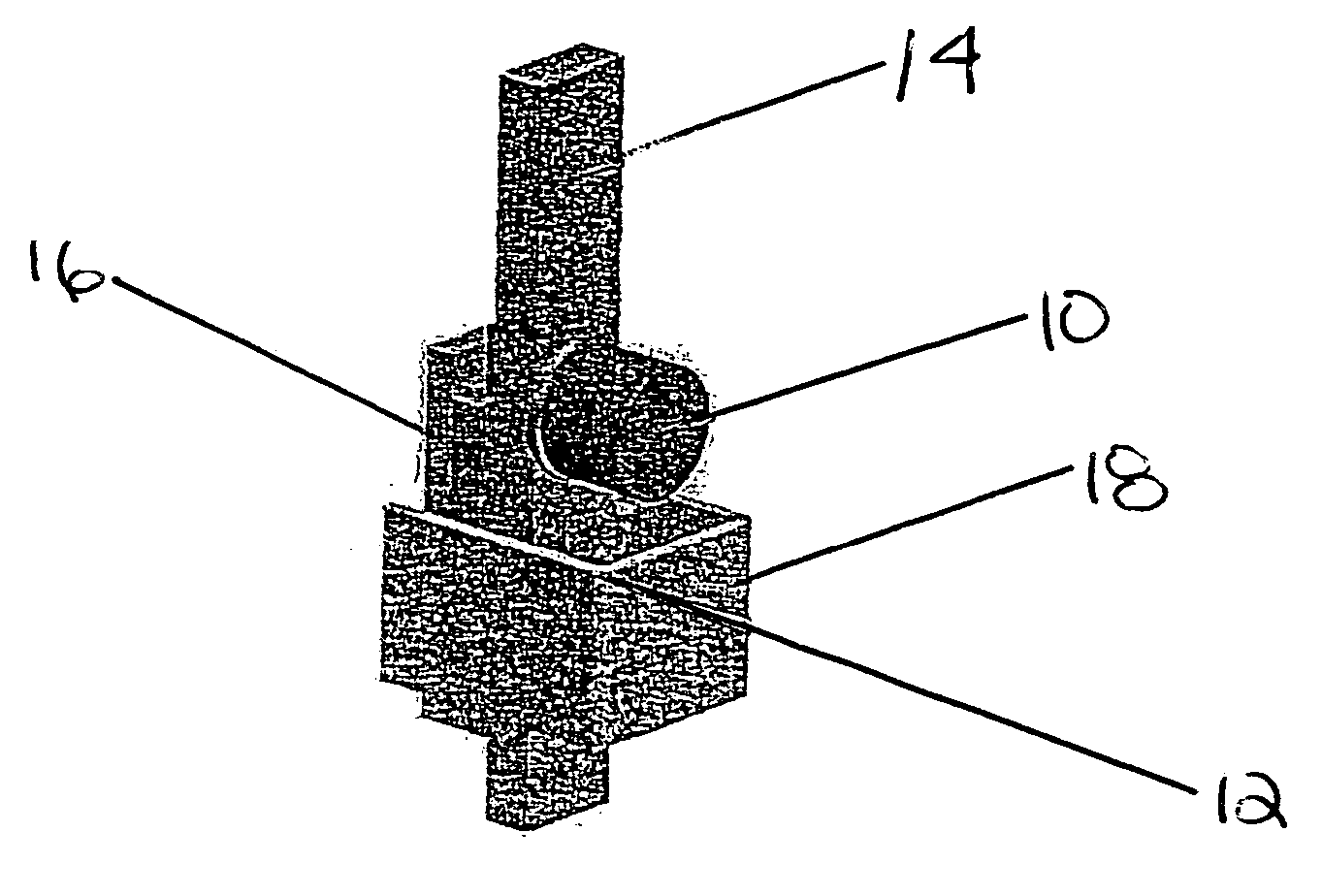

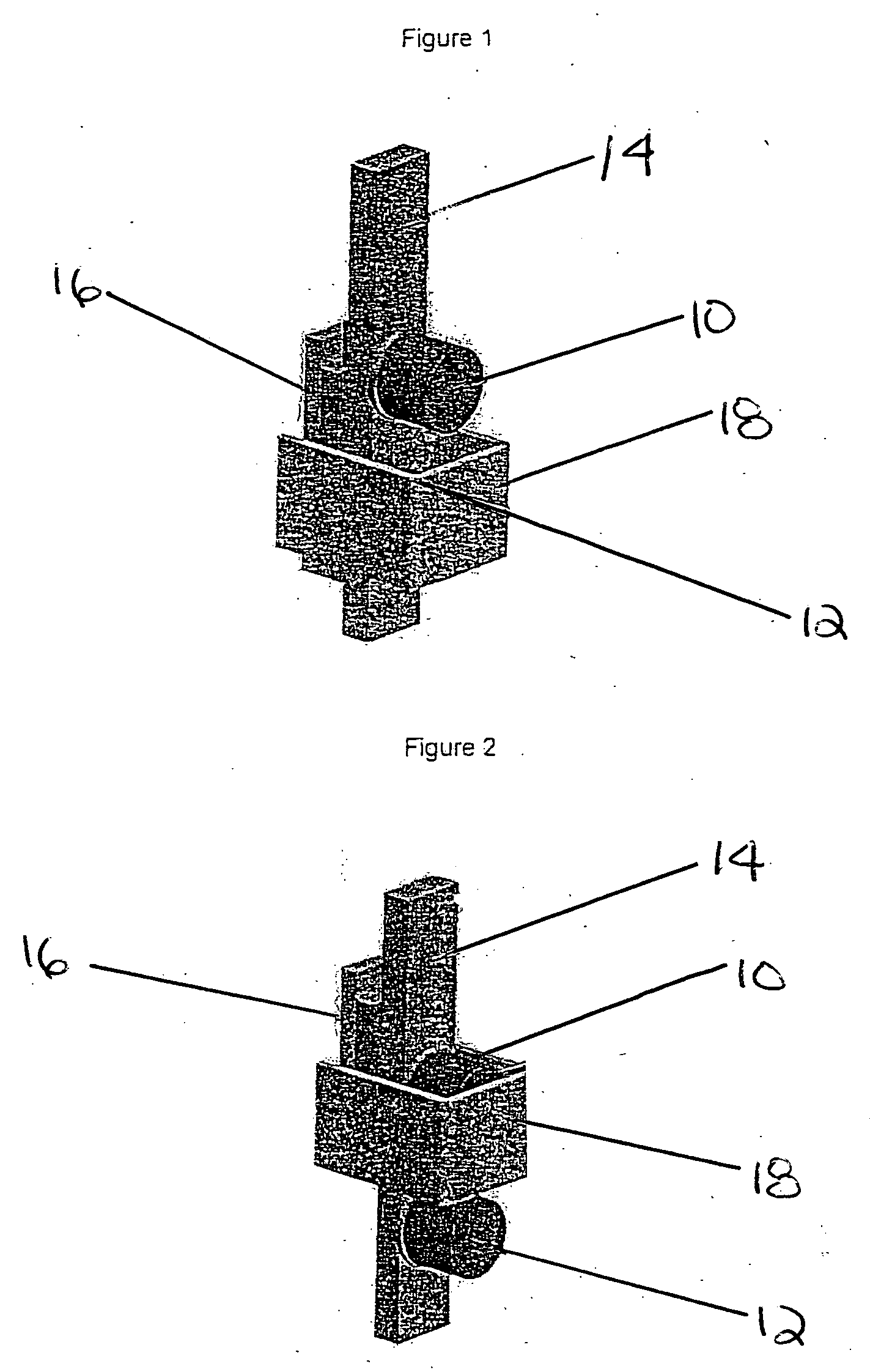

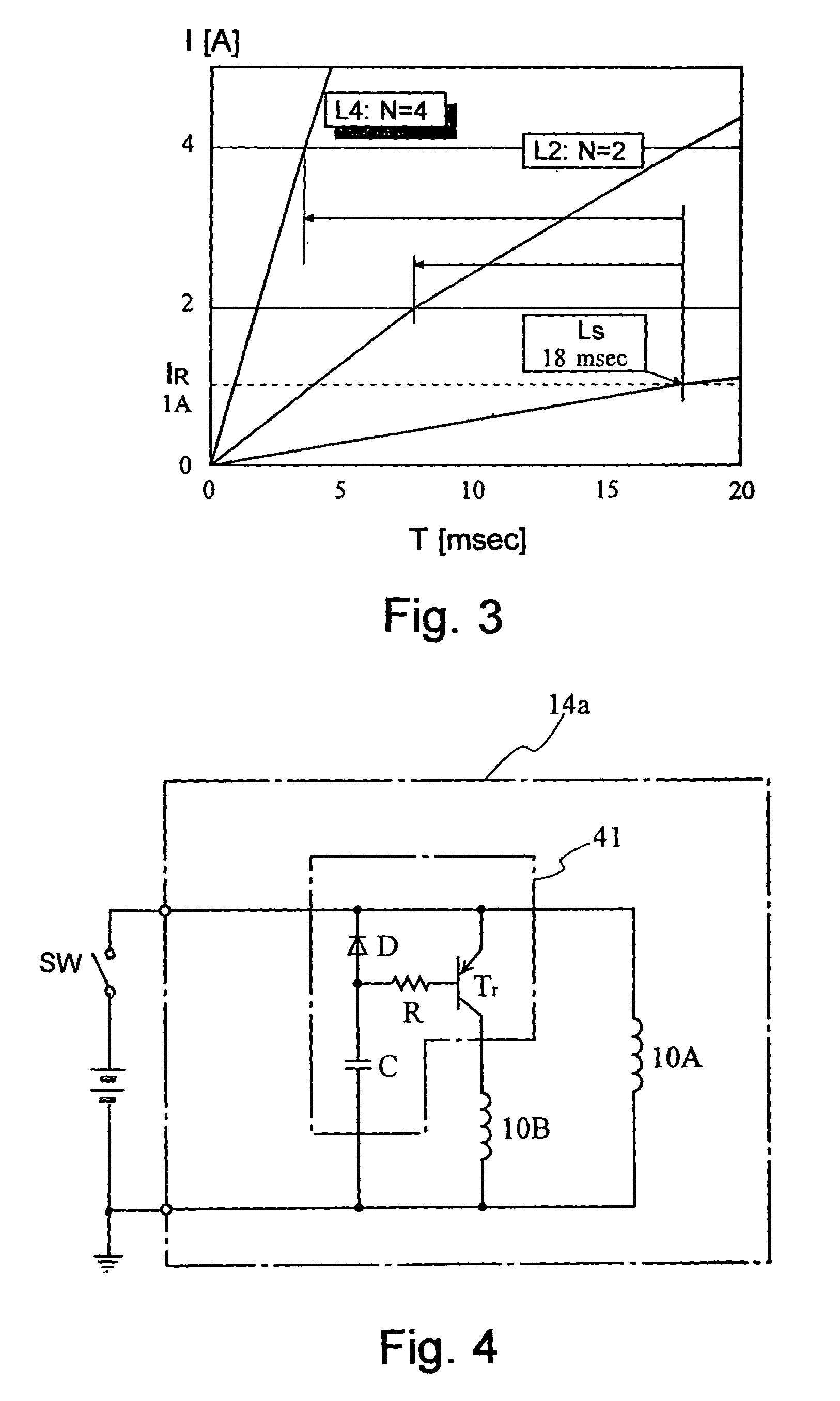

Moving magnet actuator

An apparatus includes an electromagnetically conductive assembly including a first member having a first end and a second end and a second member disposed between the first end and the second end of the first member. The second member and the first end of the first member define a first gap. The second member and the second end of the first member define a second gap. A movable member moves with respect to the conductive member. A first magnet is coupled to the movable member and is disposed a distance from the first gap. A second magnet is coupled to the movable member and is disposed a distance from the second gap.

Owner:IMMERSION CORPORATION

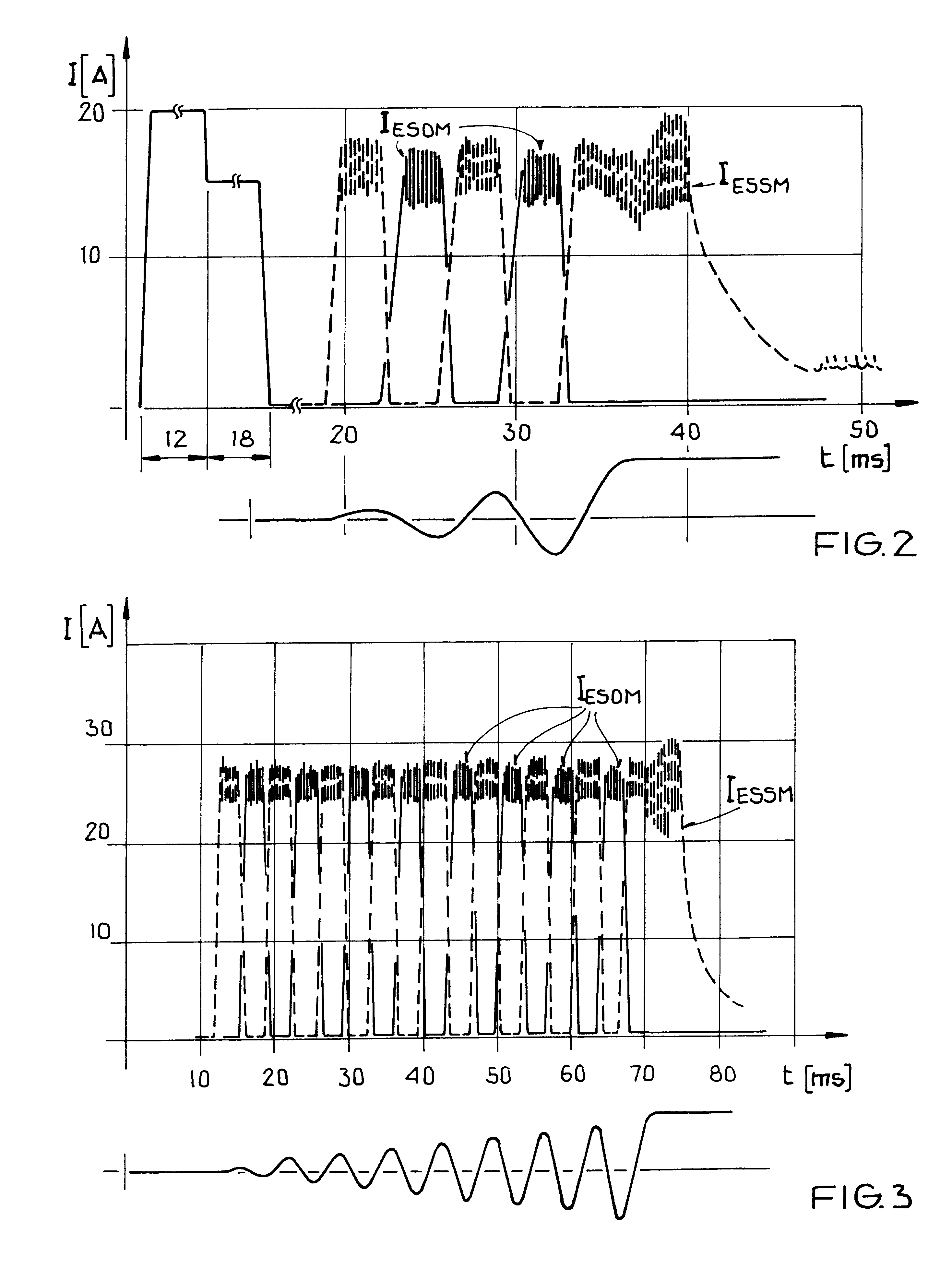

Electromagnetic operating device

InactiveUS6968859B1Increase power loadAdapt effectivelyOperating means/releasing devices for valvesPipeline systemsExcitation currentSpring force

Disclosed is a solenoid type electromagnetic operating device which needs a relatively large current only for a limited short period at an excitation start initial stage and is adapted to achieve the speeding up at an excitation start stage and an improvement in responsiveness as well as power saving without increasing a power load on each of a drive circuit and power supply. The device is used for exerting a mechanical output on a valve element against a spring force, and comprises a solenoid coil composed of a plurality of split coils mutually electrically independent, an iron core structure including a fixed core, a movable core and a yoke and assembled with the solenoid coil so as to form a magnetic path loop through which magnetic fluxes from the split coils pass in common, an excitation controller for selectively switching / controlling the excitation current to each split coil, and a transmission mechanism for transmitting the mechanical output based on the displacement of the movable core magnetically attracted to the fixed core to the valve element when one or more of the split coils are excited.

Owner:YUKEN KOGYO

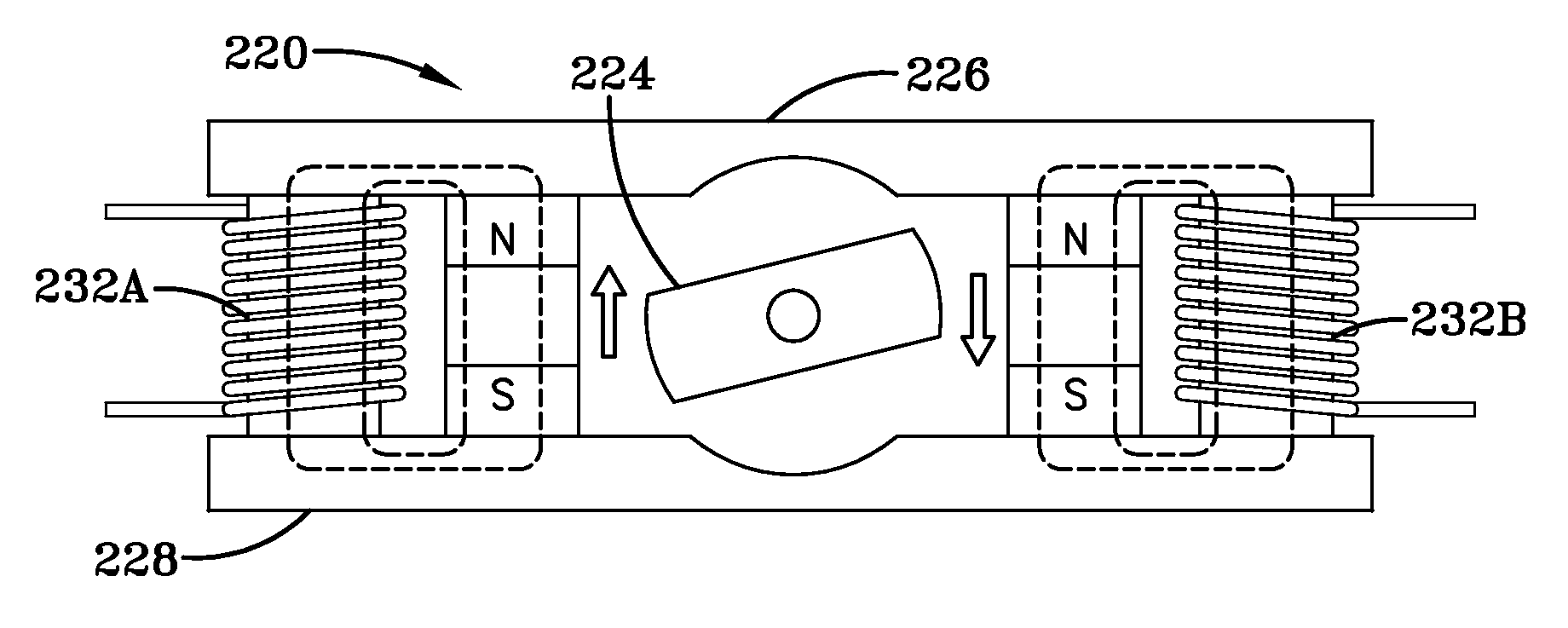

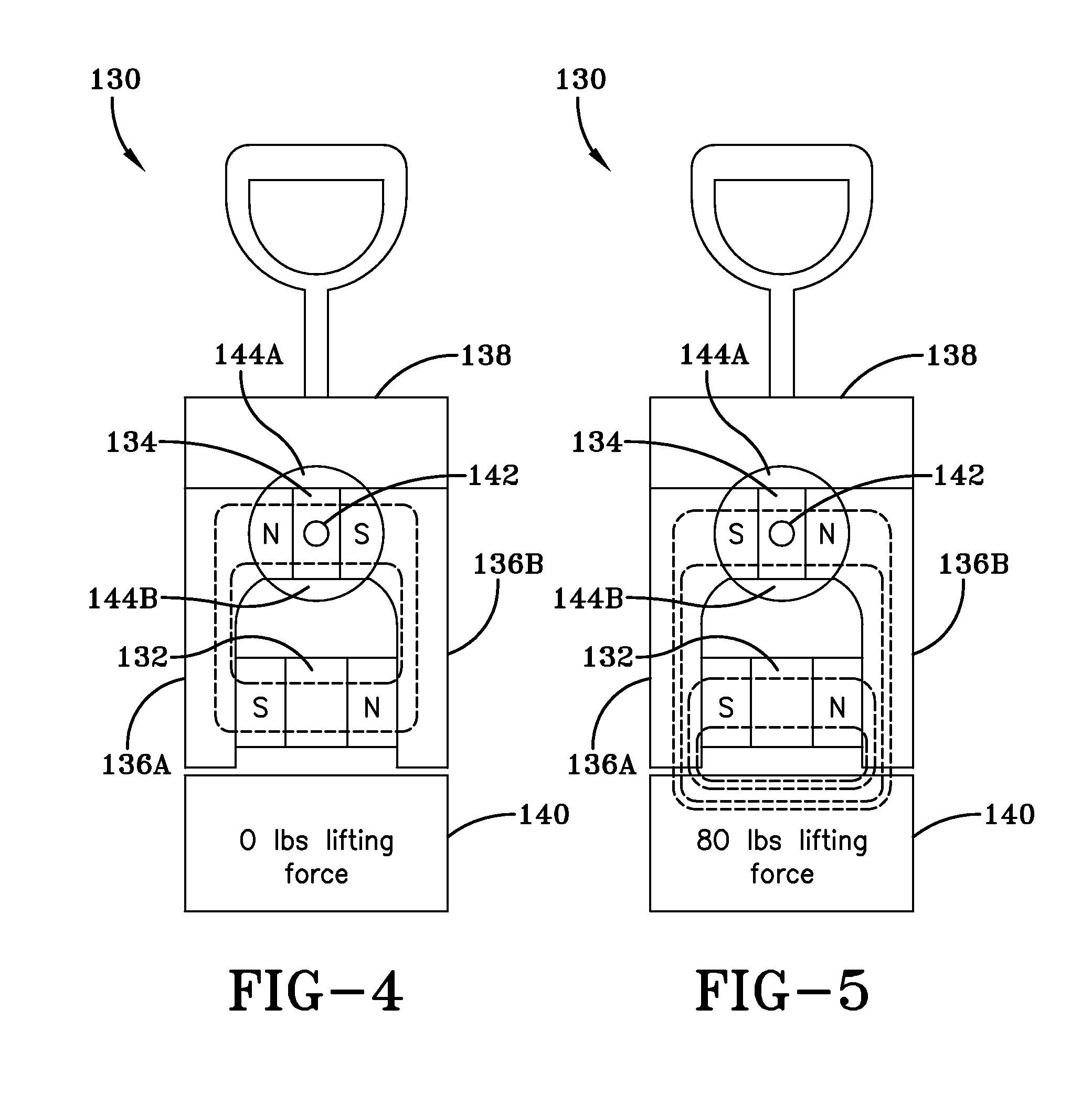

System and method for utilizing magnetic energy

InactiveUS7453341B1Improve energy efficiencyIncrease the magnetic fieldSynchronous generatorsWindingsEngineeringMagnetic energy

The present invention is a system and method for utilizing magnetic energy. The basic principles of the present invention may be implemented in a variety of systems and methods. A magnet may be rotated or an electromagnet may be controlled in order to control a magnetic field generated by a set of magnets. As a result, numerous, substantial benefits may be achieved by providing at least one set of multiple magnets. For example, the present invention may be used in systems and methods to perform a variety of functions including, but not limited to: (1) to control, manipulate, hold, and / or release a load; (2) to open and / or close a pathway; (3) to open and / or close a circuit; (4) to apply a magnetic field to a load and / or to remove a magnetic field from a load; (5) to intermittently apply and remove a magnetic field; (6) to increase the magnetic field that may be applied to a load; (7) to induce a load into motion; (8) to create energy; and (9) to improve the energy efficiency of a device or system.

Owner:HILDENBRAND JACK W

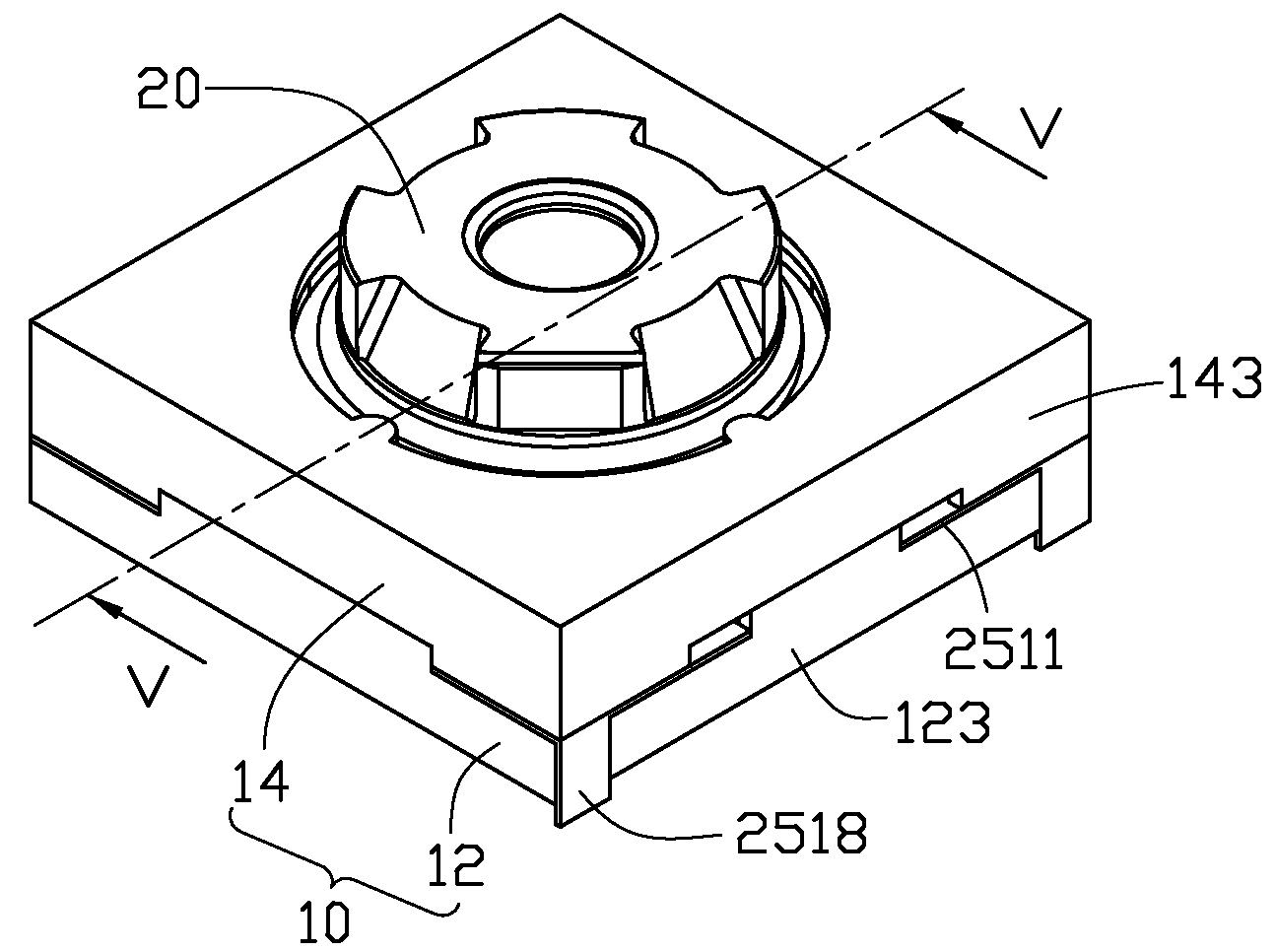

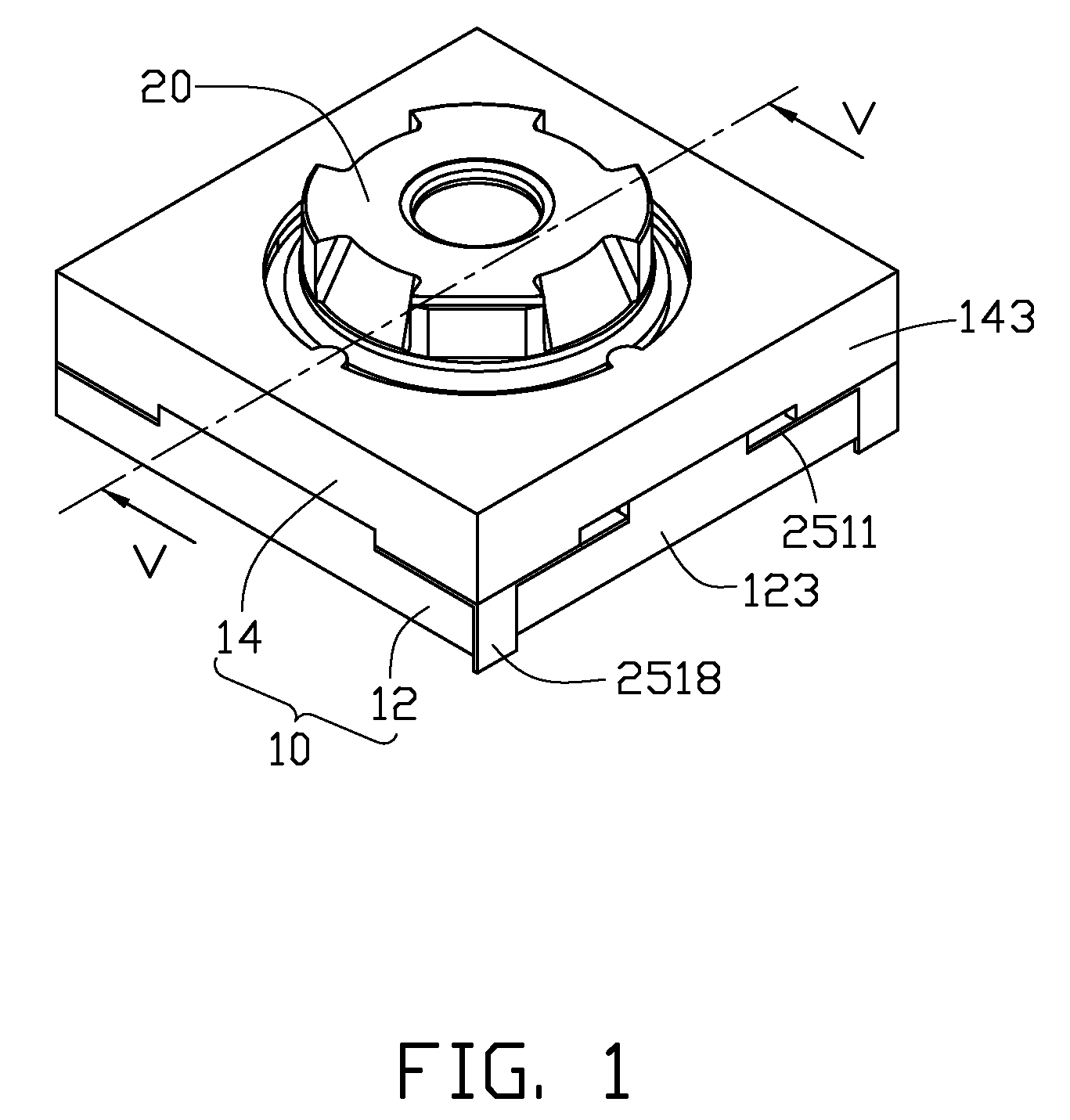

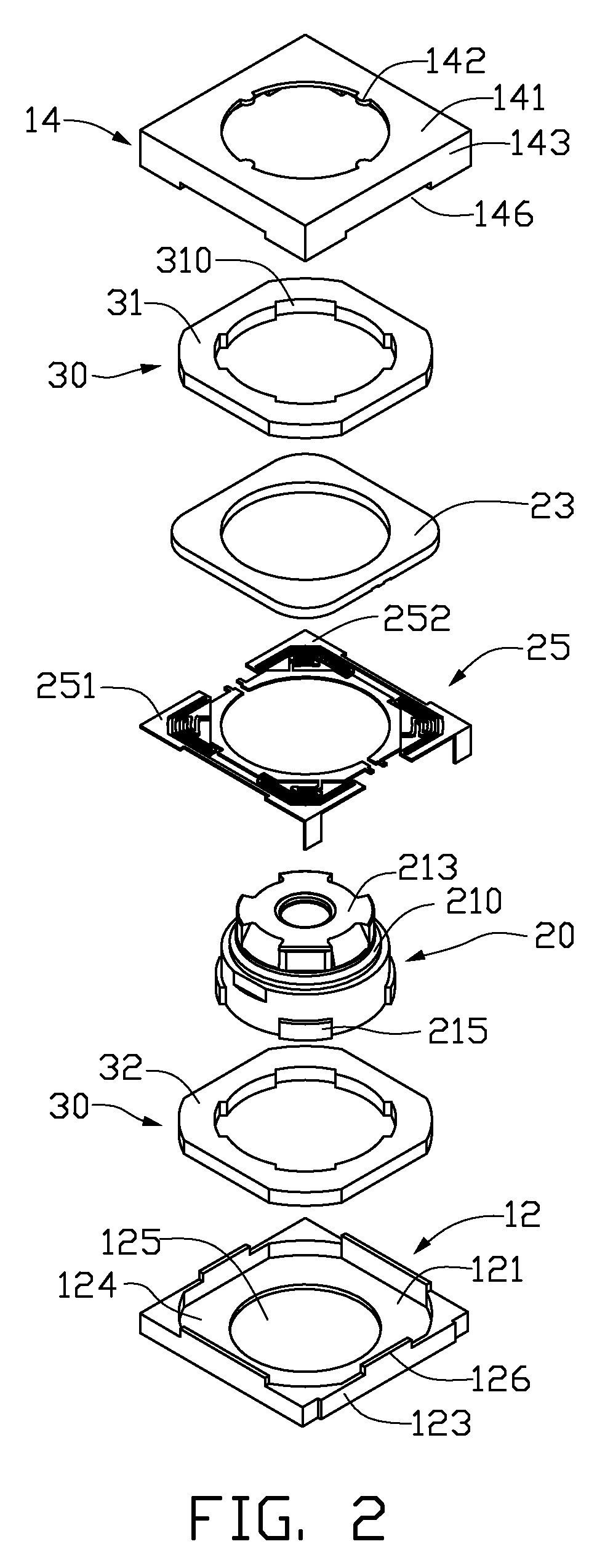

Camera module

InactiveUS20090310959A1Television system detailsProjector focusing arrangementFocal positionCamera module

An exemplary camera module includes a lens mount, a lens unit, a magnet unit, a printed circuit board (PCB)-based Rogowski coil and a blade spring. The PCB-based Rogowski coil is fixed around the lens unit. The PCB-based Rogowski coil establishes an induced magnetic field when an electric current is applied thereto. The induced magnetic field interacts with the magnet unit to generate a magnetic force moving the lens unit telescopically. The blade spring includes a plurality of ribs. Each rib includes a moveable end connected with the lens unit and an opposite fixed end. The moveable end moves together with the lens unit with respect to the fixed end to cause the ribs to distort and generate an elastic force. The lens unit stops at a focal position when the magnetic force and the elastic force come to a balance.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Solenoid valve

ActiveUS20050166979A1Easy to moveMinimal gap widthFuel supply regulationGaseous fuel feeder/distributionSolenoid valveEngineering

A valve assembly comprises two valves and a single solenoid actuator with only one magnetizing coil that controls both valves. The corresponding magnetic circuit comprises a yoke with only two pole pieces. The valves are arranged concentric to one another. The valve closing element of the outer valve is connected to an armature by means of a sleeve. The cup thus formed receives the armature that is connected to the valve closing element of the inner valve. The pole piece and the armature form a transmission air gap through which the sleeve extends. A coupling air gap is formed between the armatures. The armature and the pole piece form a working air gap. The valves are opened collectively and are able to close independently of one another when the coil is rendered currentless.

Owner:KARL DUNGS

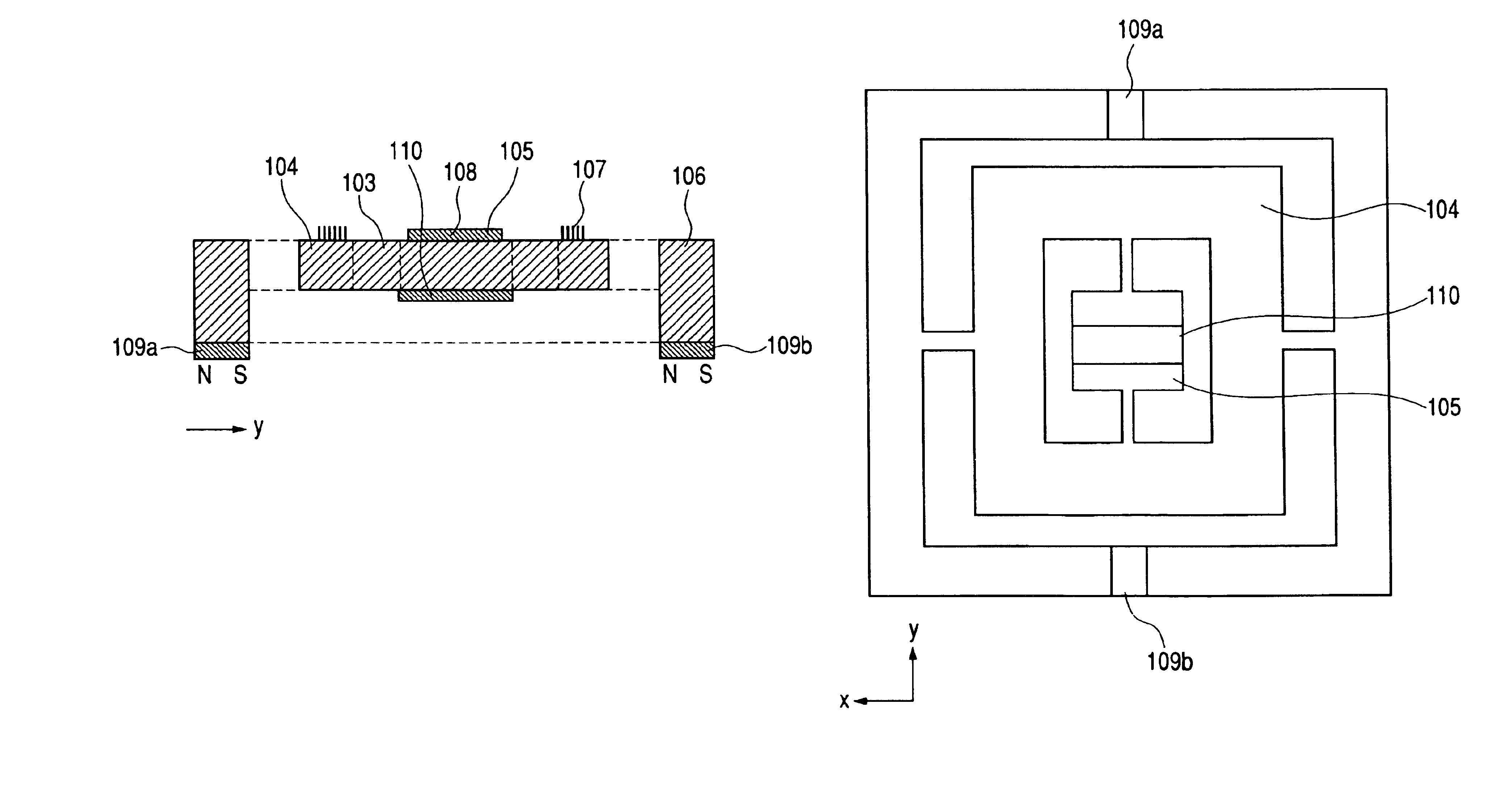

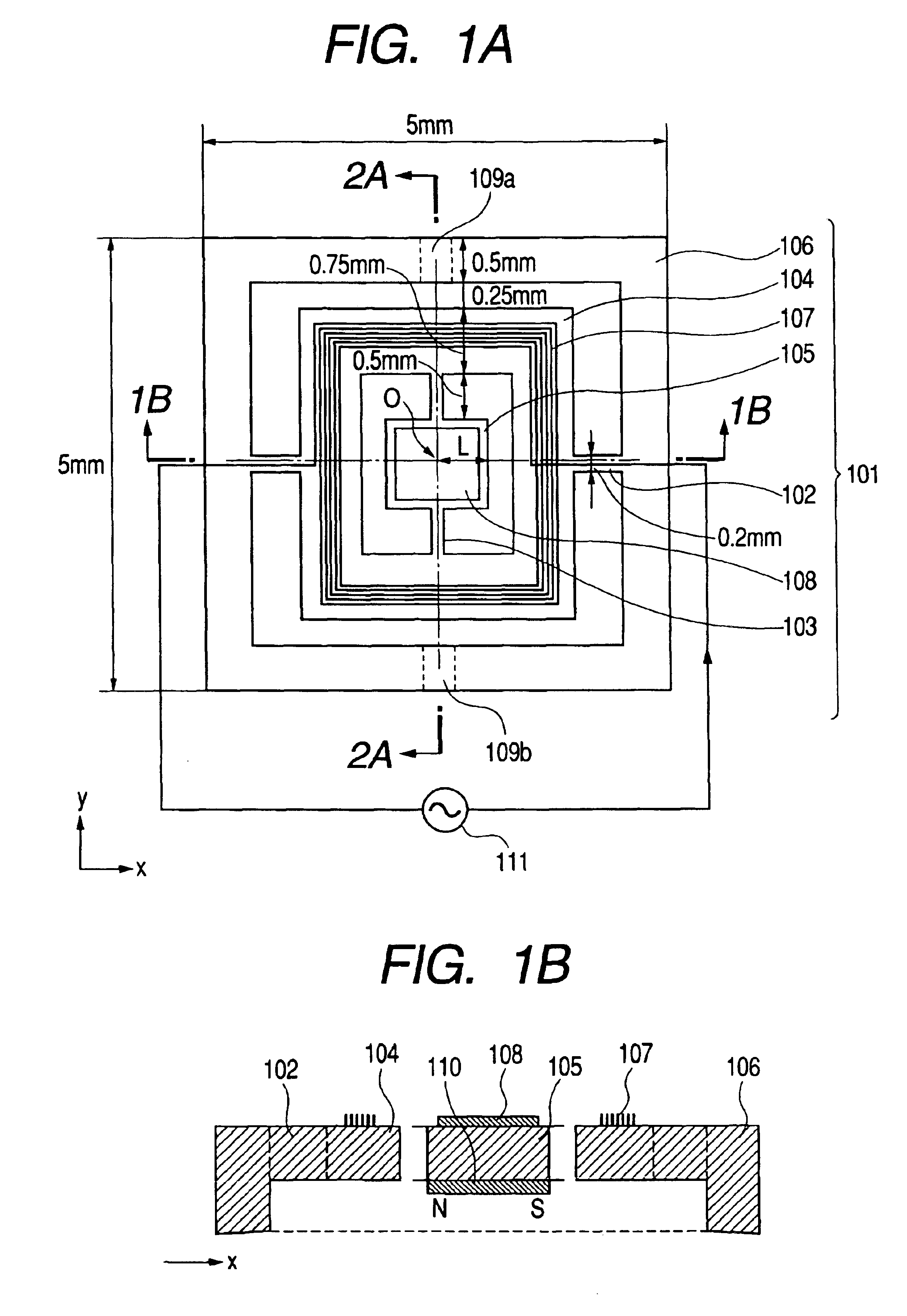

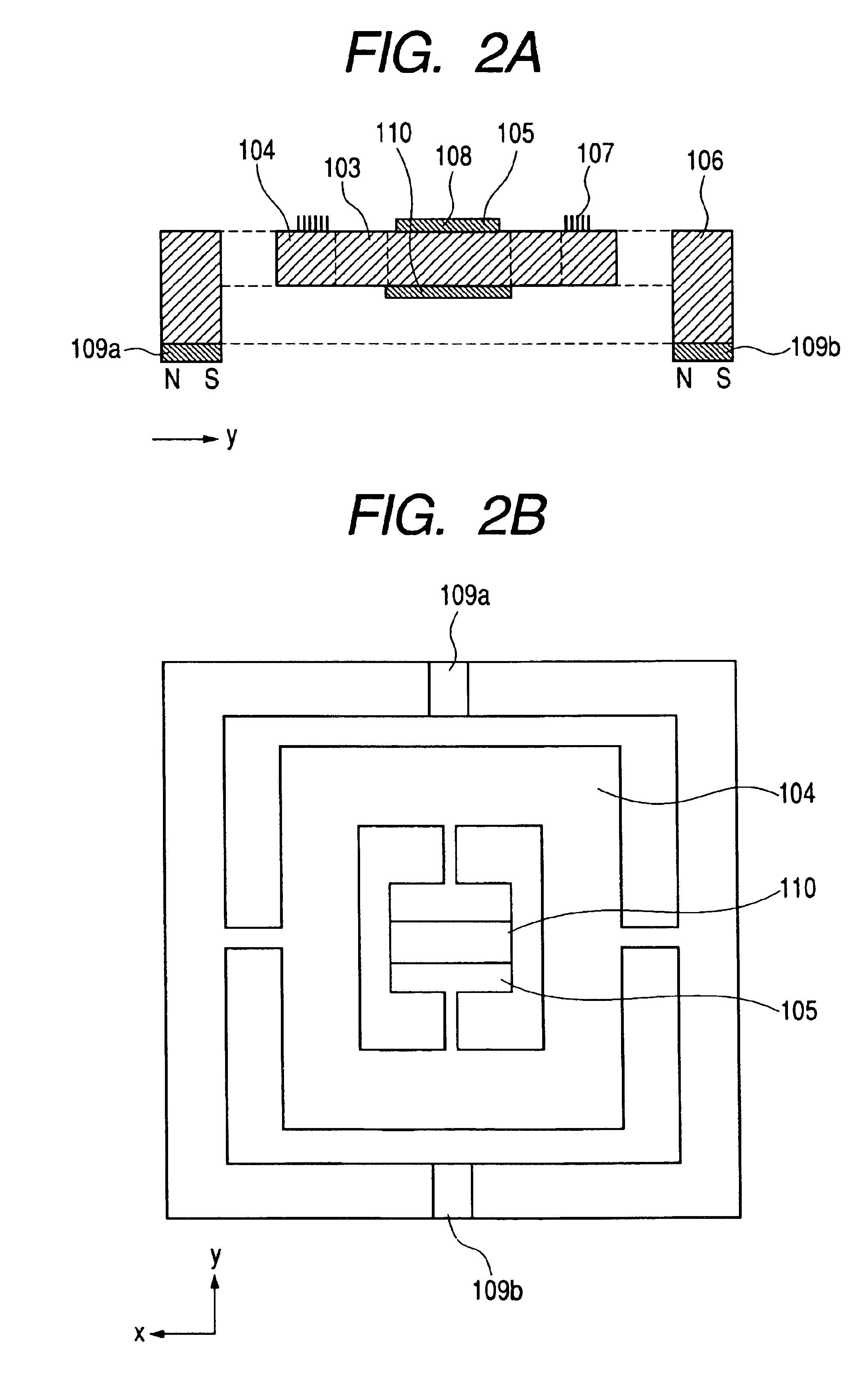

Oscillation device, optical deflector using the oscillation device, and image display device and image forming apparatus using the optical deflector, and method of manufacturing the oscillation device

InactiveUS6924915B2Increase speedLarge displacementDynamo-electric machinesPiezoelectric/electrostrictive devicesDisplay deviceEngineering

Disclosed is an oscillation device comprising: a first movable plate adapted to be oscillated about a first rotation axis; a first elastic supporting portion for oscillatively supporting the first movable plate; a supporting substrate for fixing the first elastic supporting portion; a first magnetic field generating portion arranged in a position remote from the first movable plate; a second movable plate adapted to be oscillated about a second rotation axis; and a second elastic supporting portion fixed to the first movable plate for oscillatively supporting the second movable plate, in which a first coil is provided in the first movable plate to be turned round the second movable plate, and in which a second magnetic field generating portion is provided in the second movable plate. The oscillation device is capable of: operating at a high speed with large displacement; enhancing an energy efficiency; and oscillating about two axes.

Owner:CANON KK

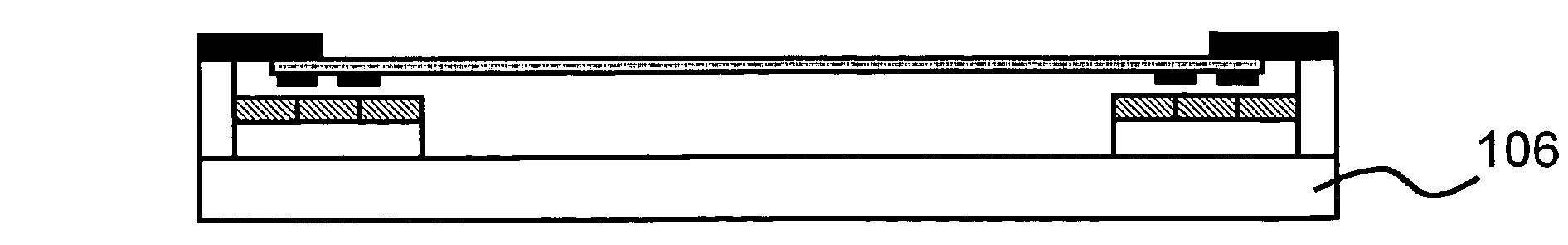

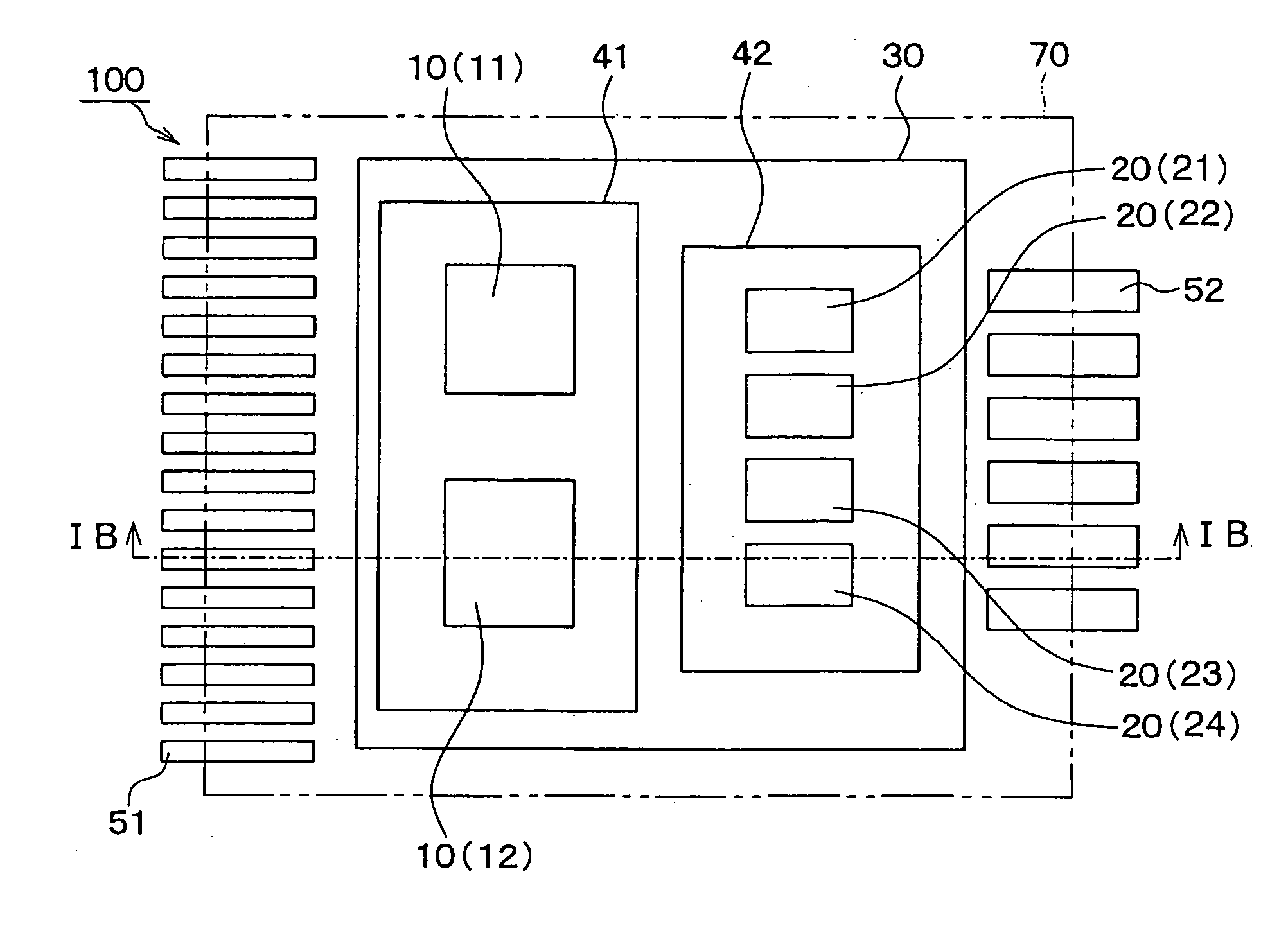

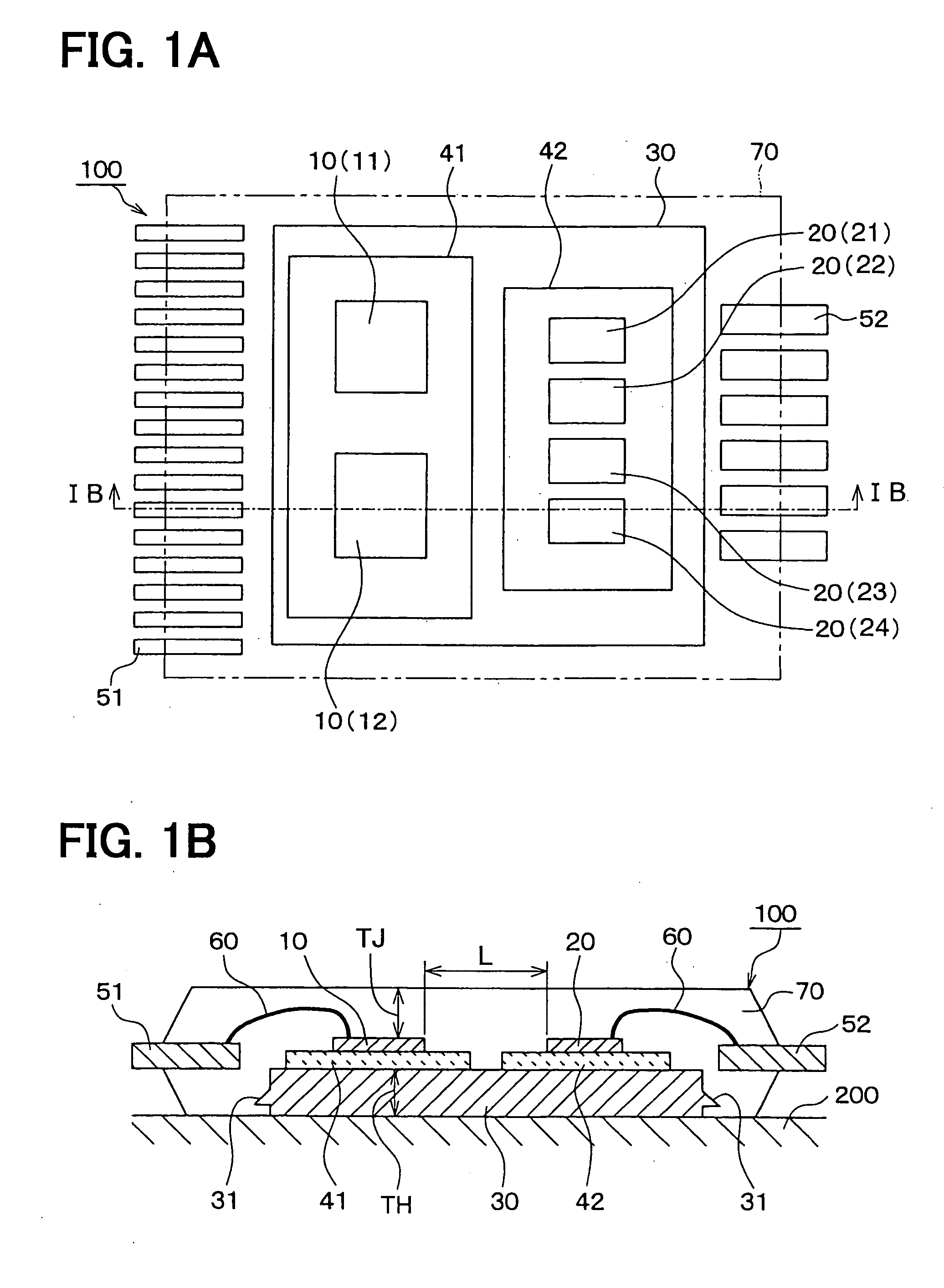

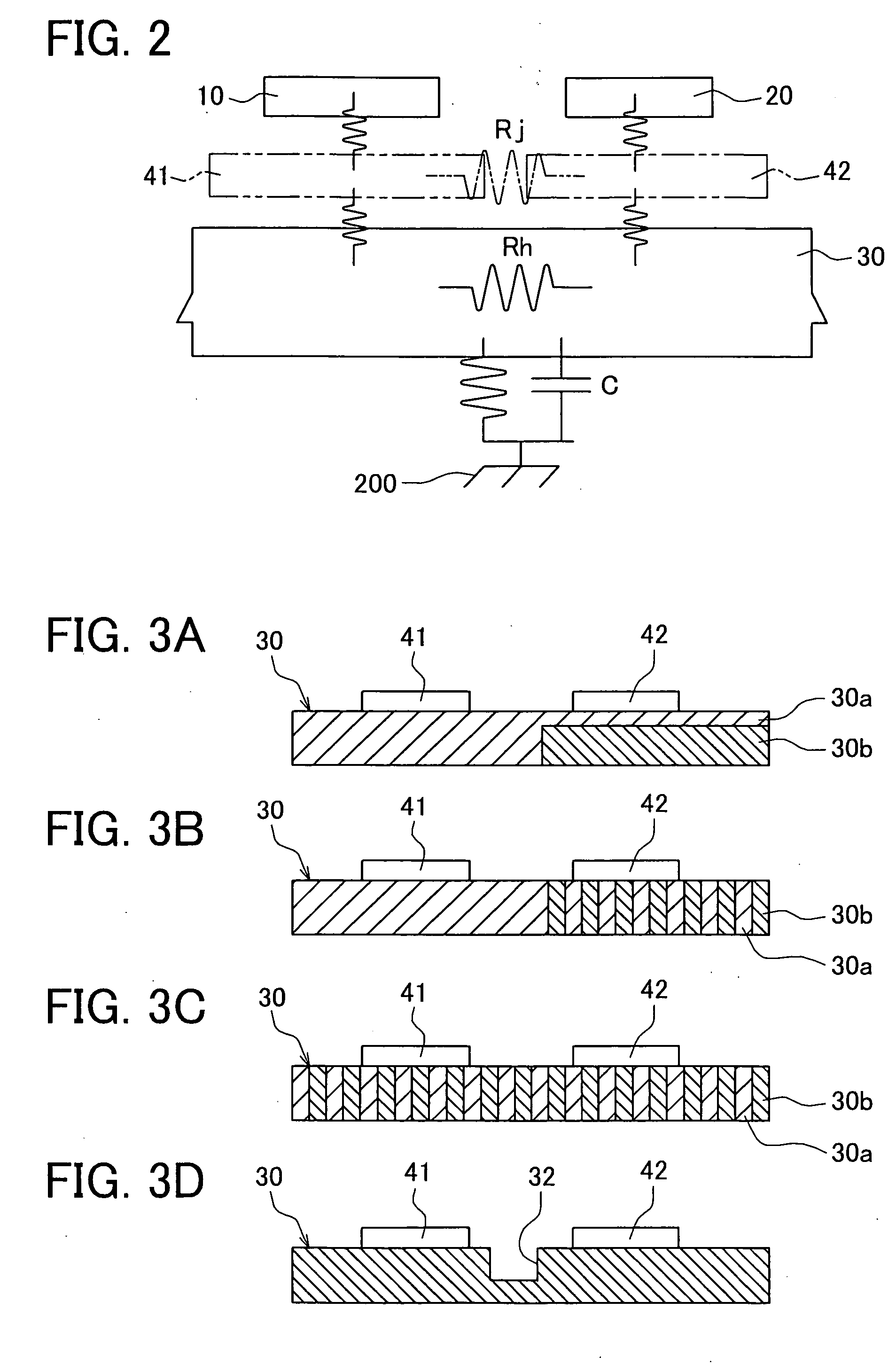

Semiconductor device and method for manufacturing the same

InactiveUS20050231925A1Small sizeReduce dead spaceSemiconductor/solid-state device detailsCircuit arrangements on support structuresEngineeringSemiconductor

An electric device includes: a first electric element; a second electric element capable of flowing large current therethrough so that heat is generated in the second electric element; a heat sink; and a first wiring board and a second wiring board, which are disposed on one side of the heat sink. The large current in the second electric element is larger than that in the first electric element. The first wiring board and the second wiring board are separated each other. The first electric element is disposed on the first wiring board, and the second electric element is disposed on the second wiring board.

Owner:DENSO CORP

Integrated magnetic features

InactiveUS20080079530A1Transformers/inductances coils/windings/connectionsElectromagnets with armaturesDevice formExternal reference

The present invention generally relates to the process of forming a magnetic element or magnetic device that may be used to form a component within an integrated circuit device using a combination of electroless plating and various standard semiconductor processing techniques. In one embodiment, a plurality of magnetic devices are formed on a surface of a substrate so that the orientation of features on the surface of the substrate can be ascertained. In one embodiment, the magnetic devices formed on a surface of a substrate are used to physically align a substrate to an external reference having a similar orientation of magnetic elements.

Owner:APPLIED MATERIALS INC

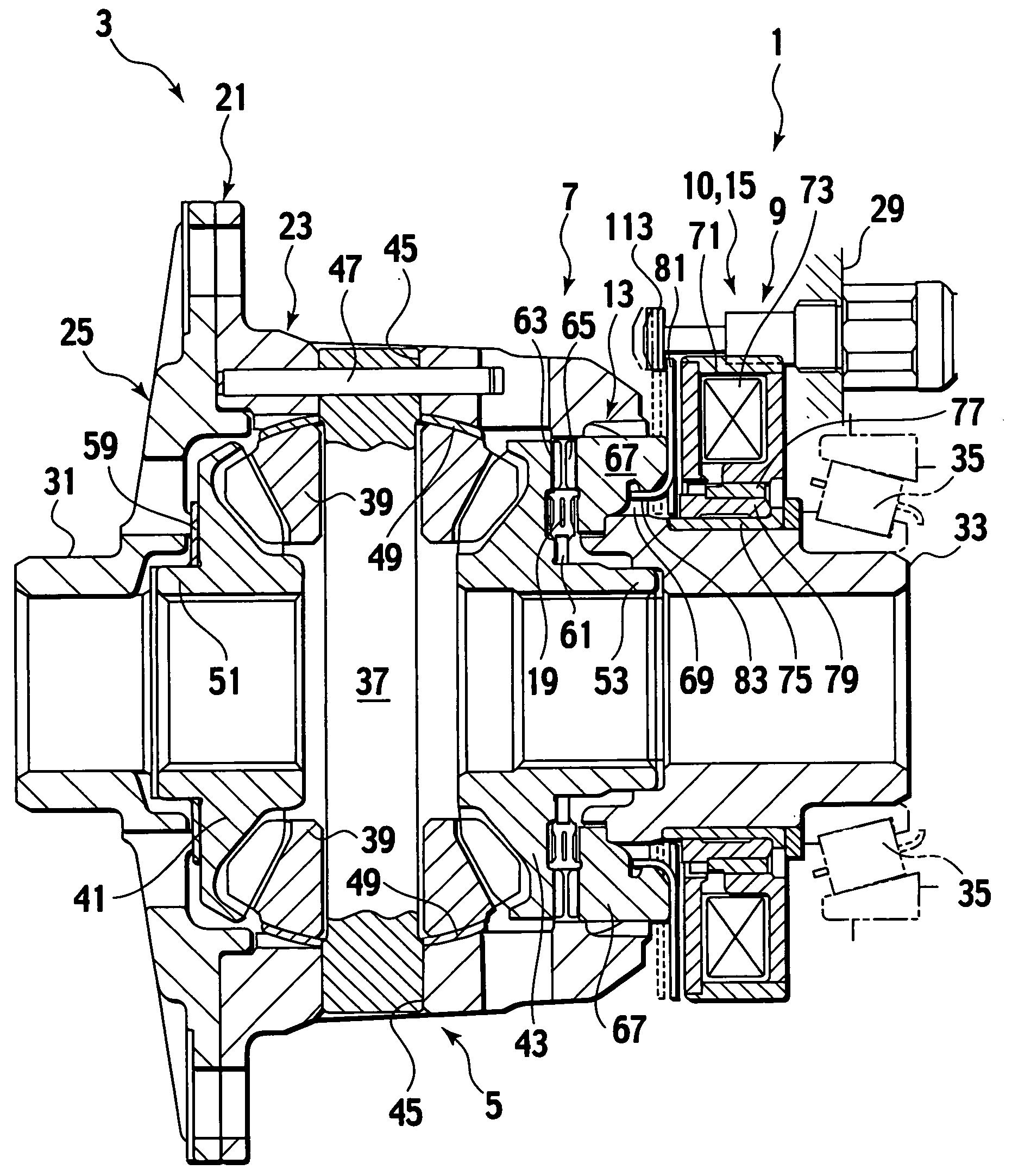

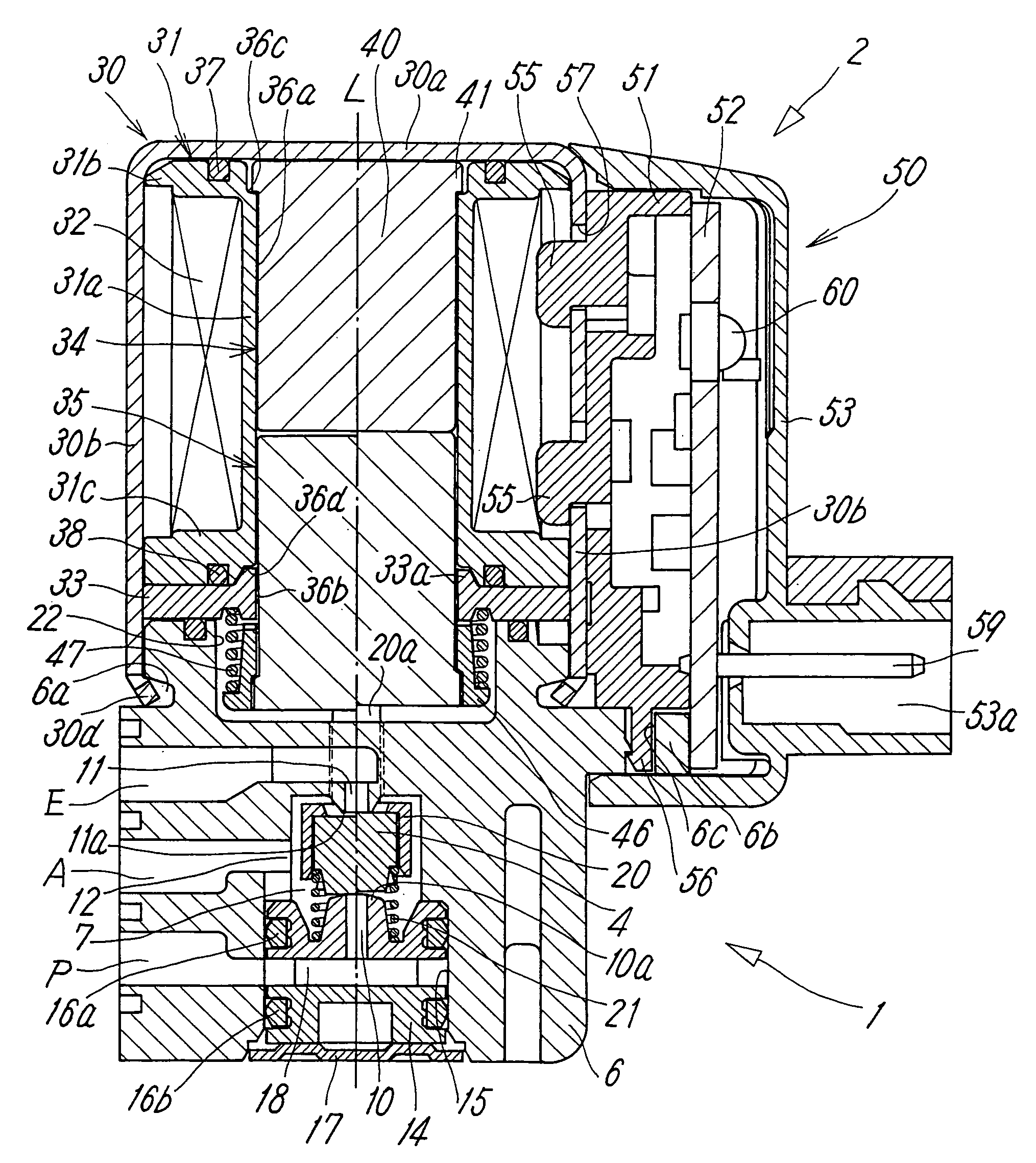

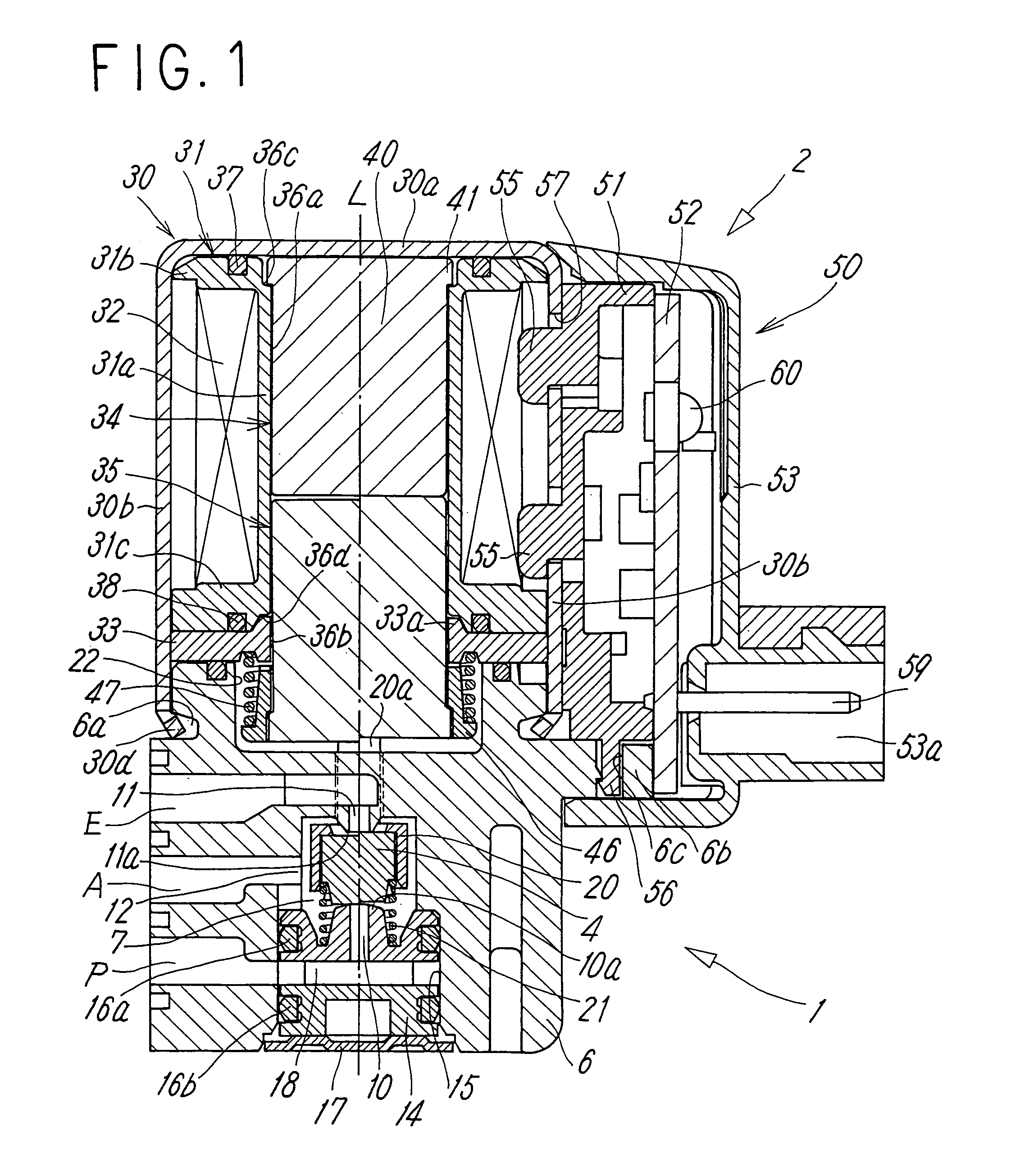

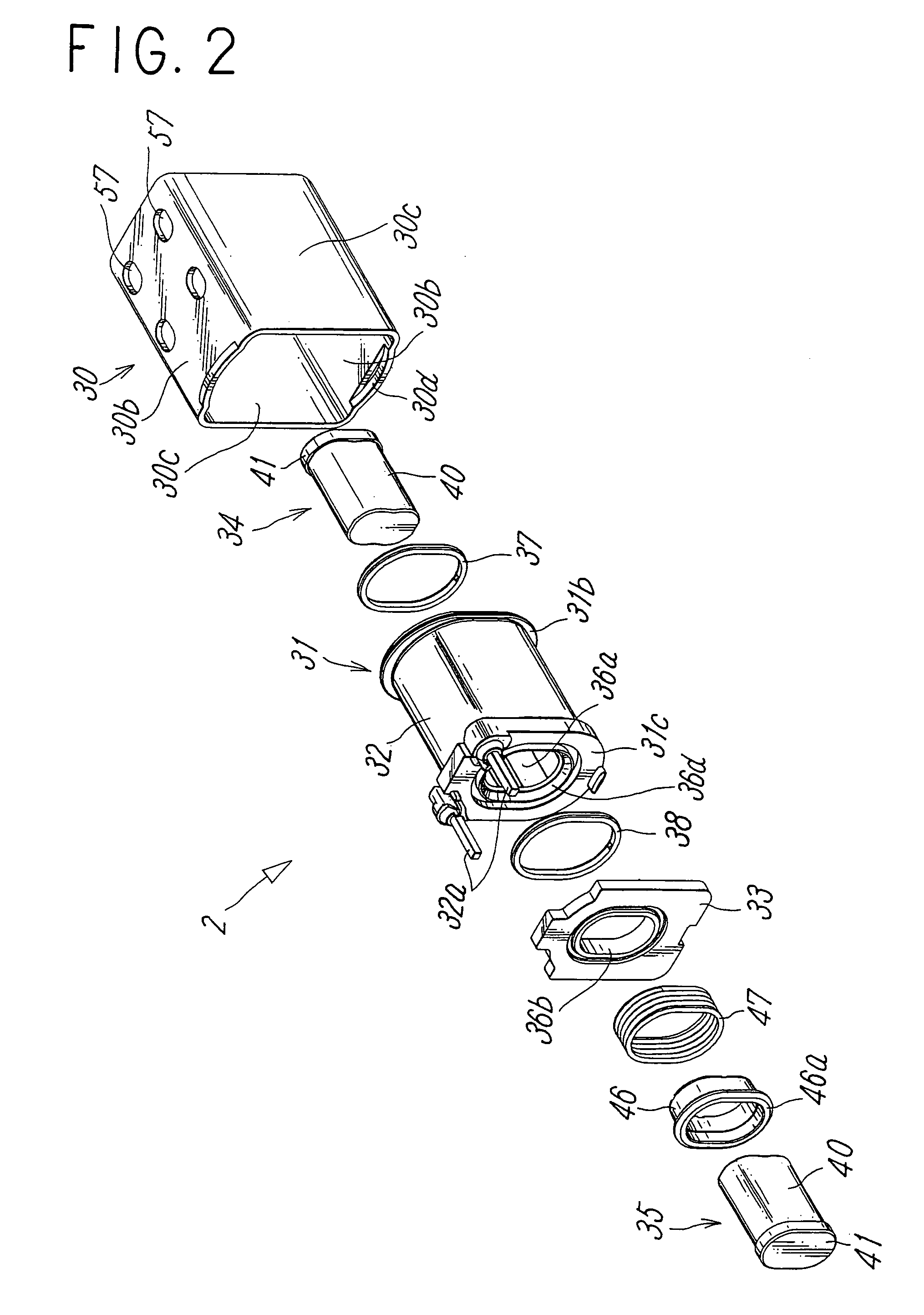

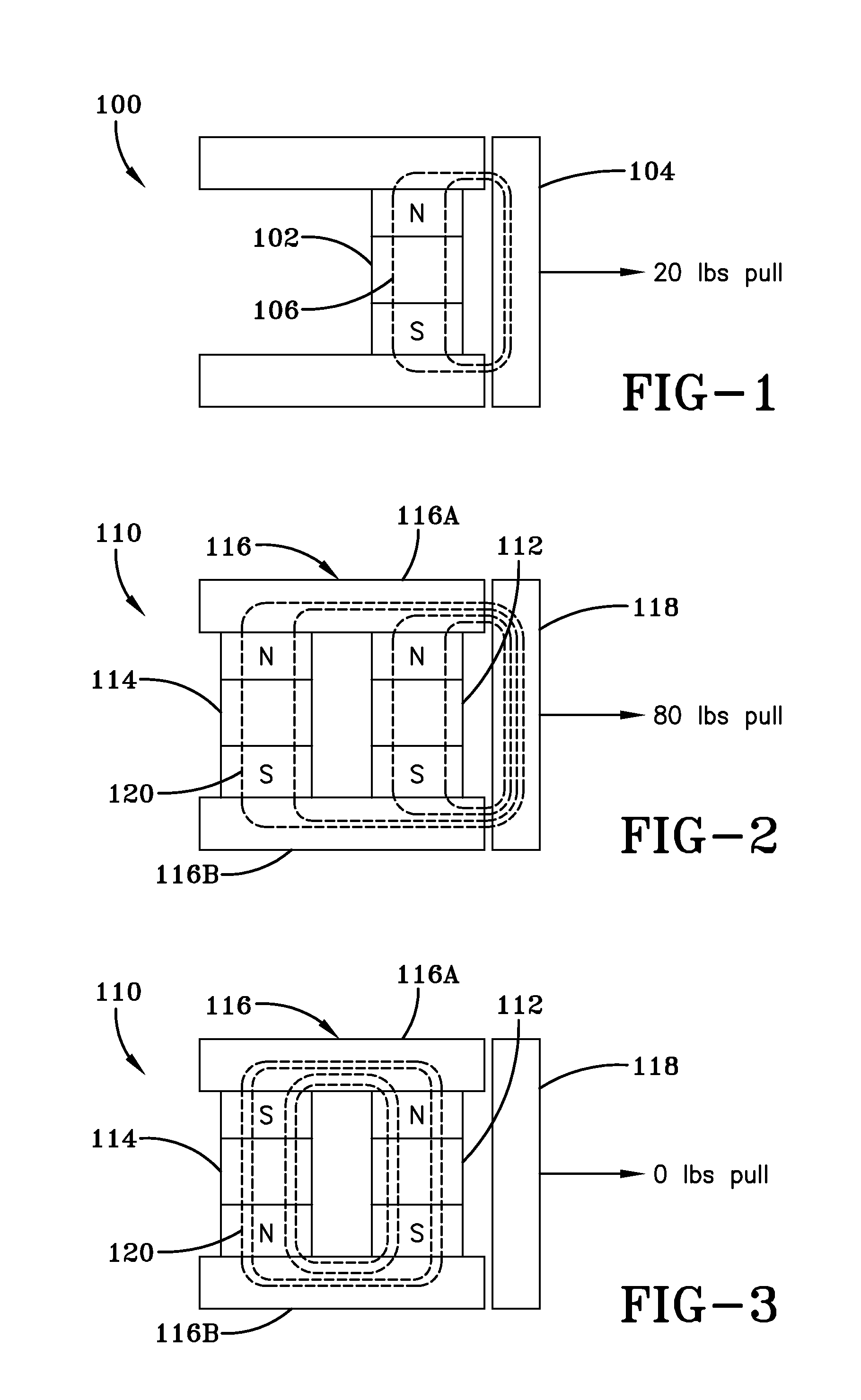

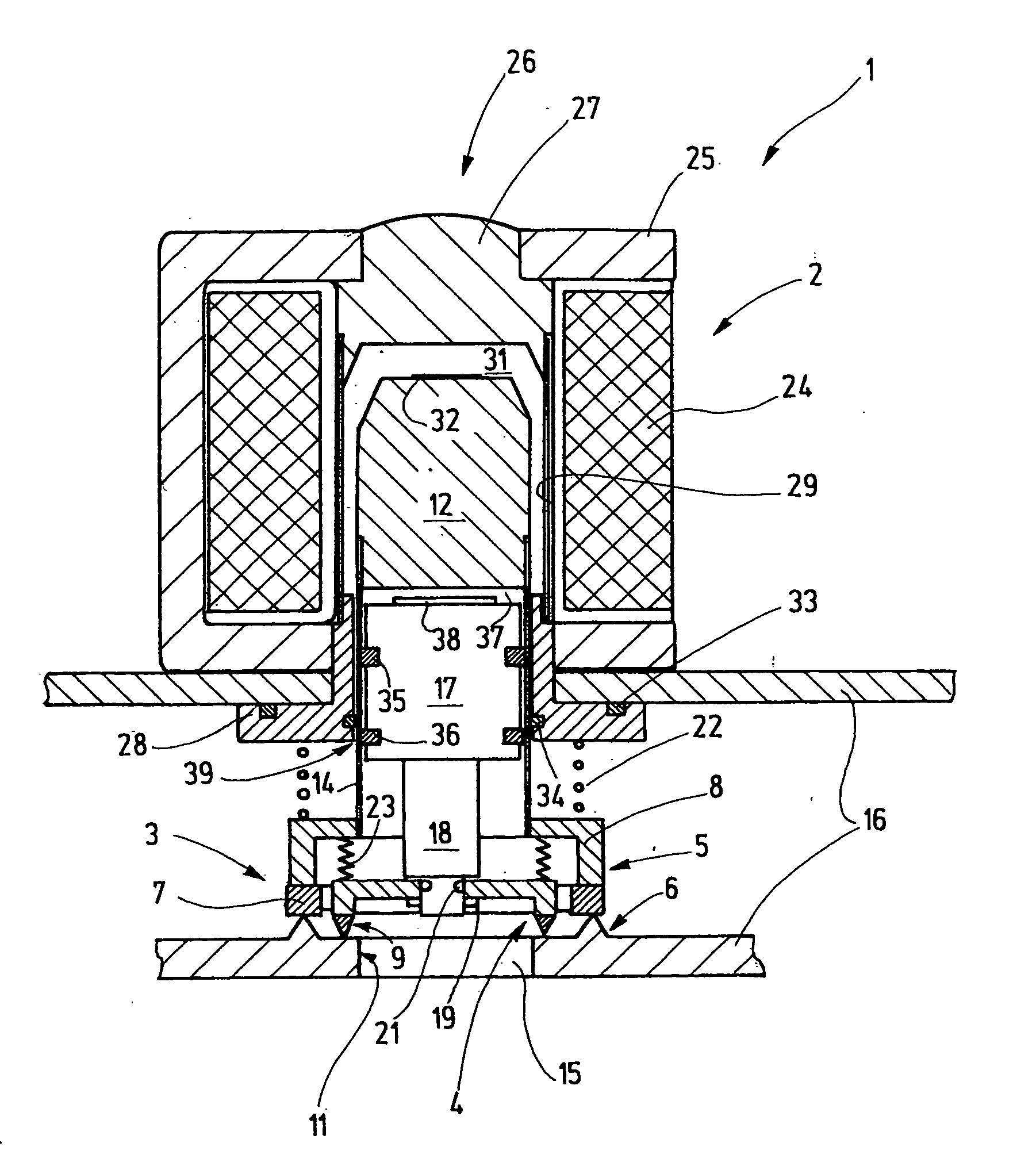

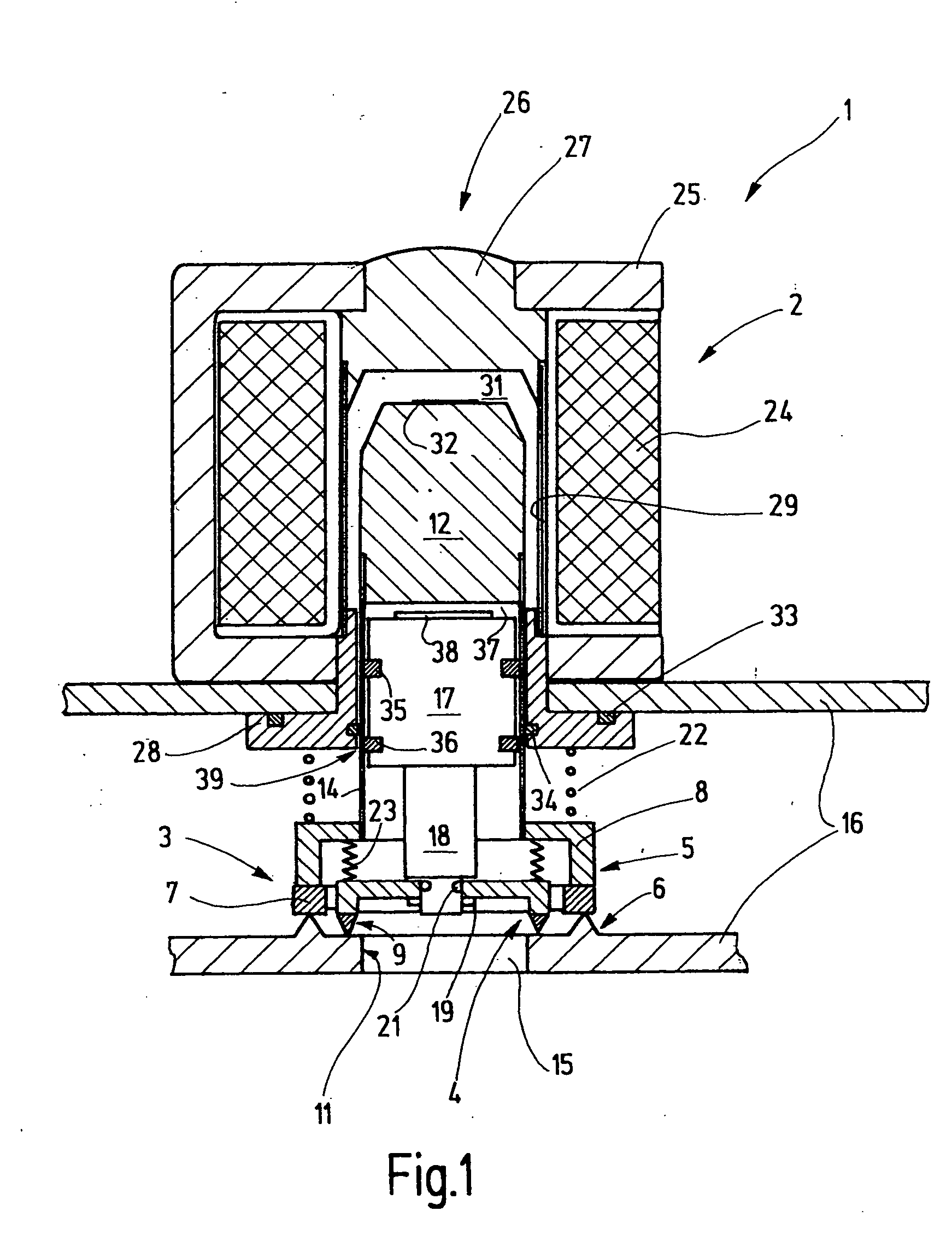

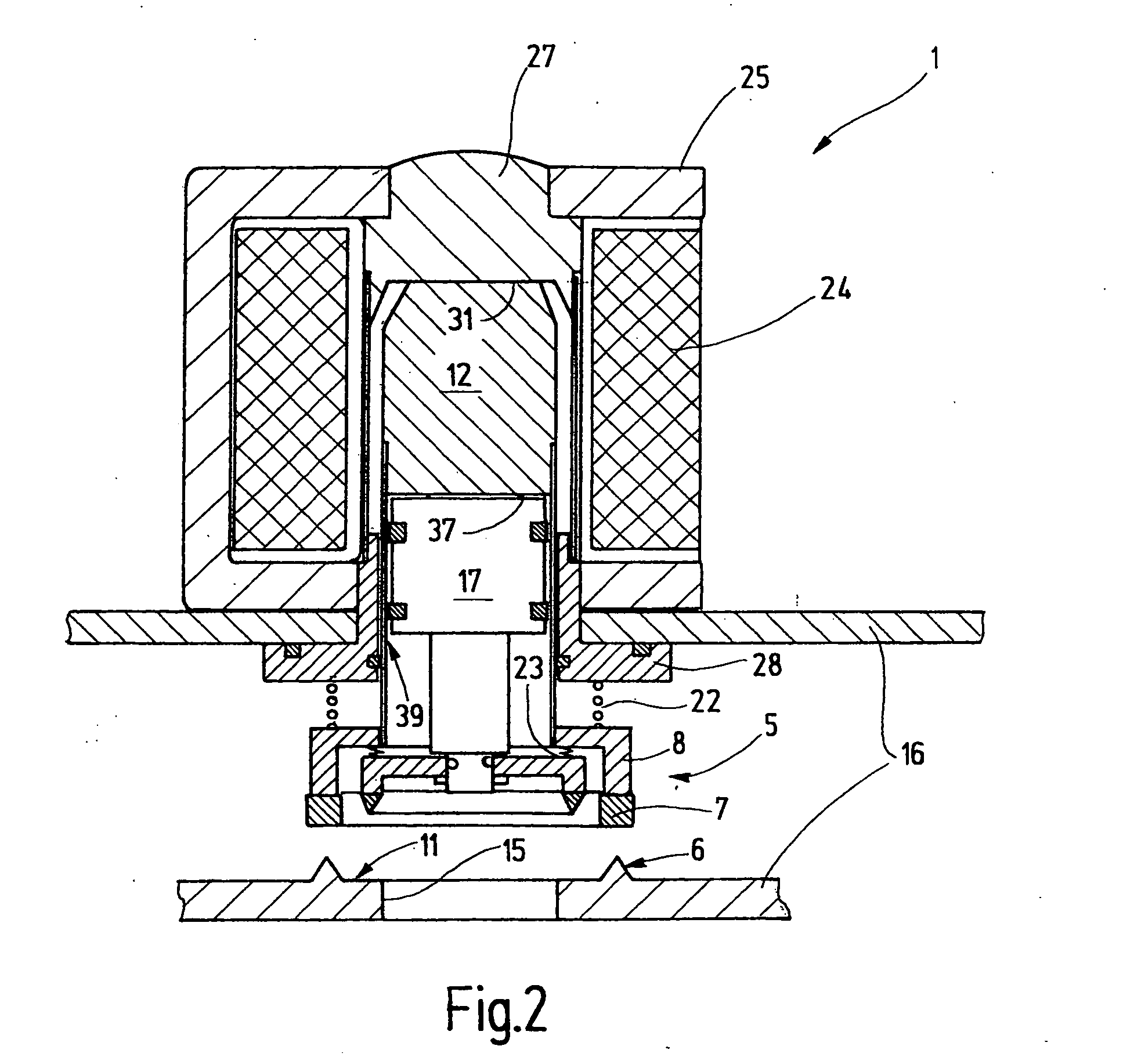

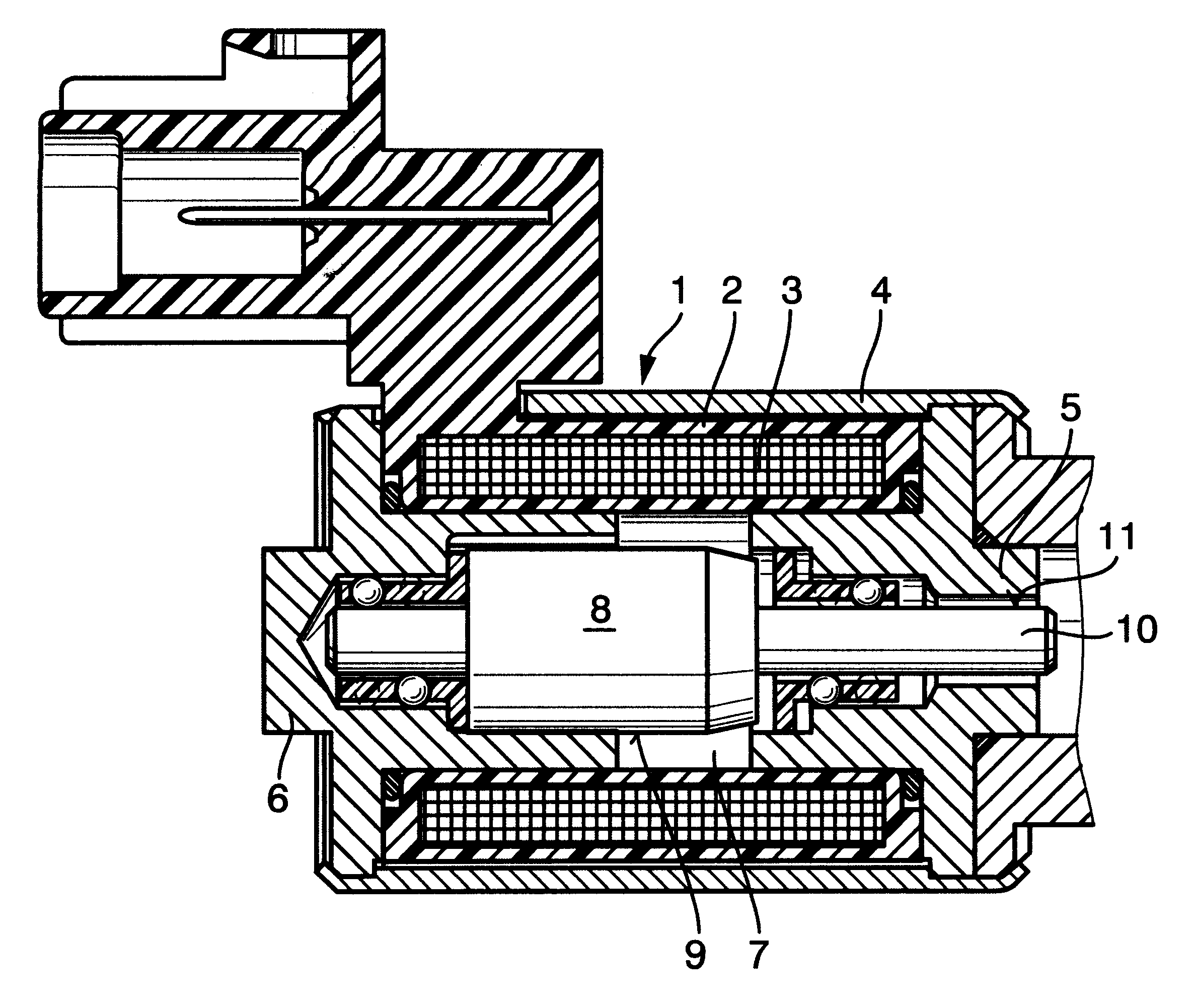

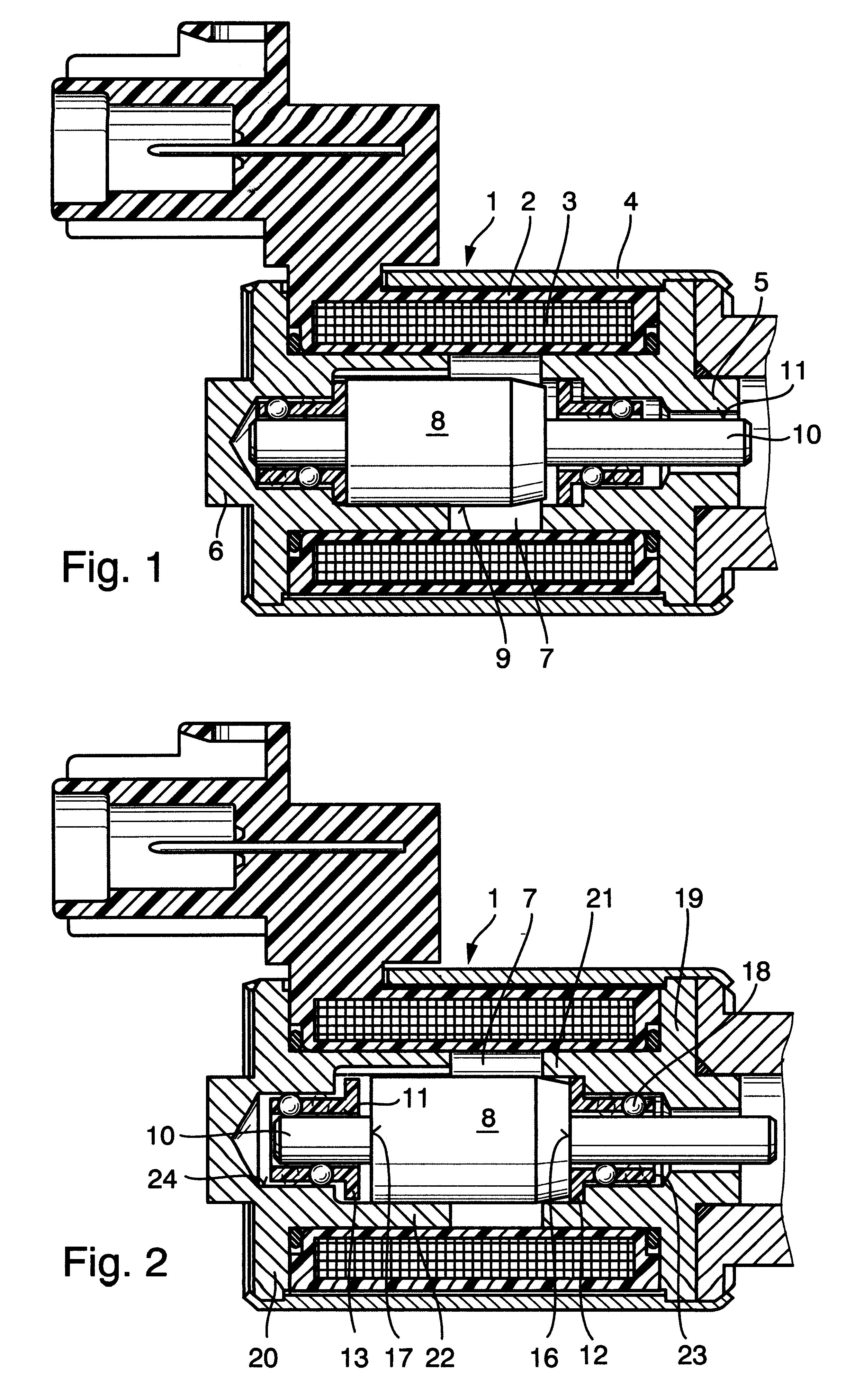

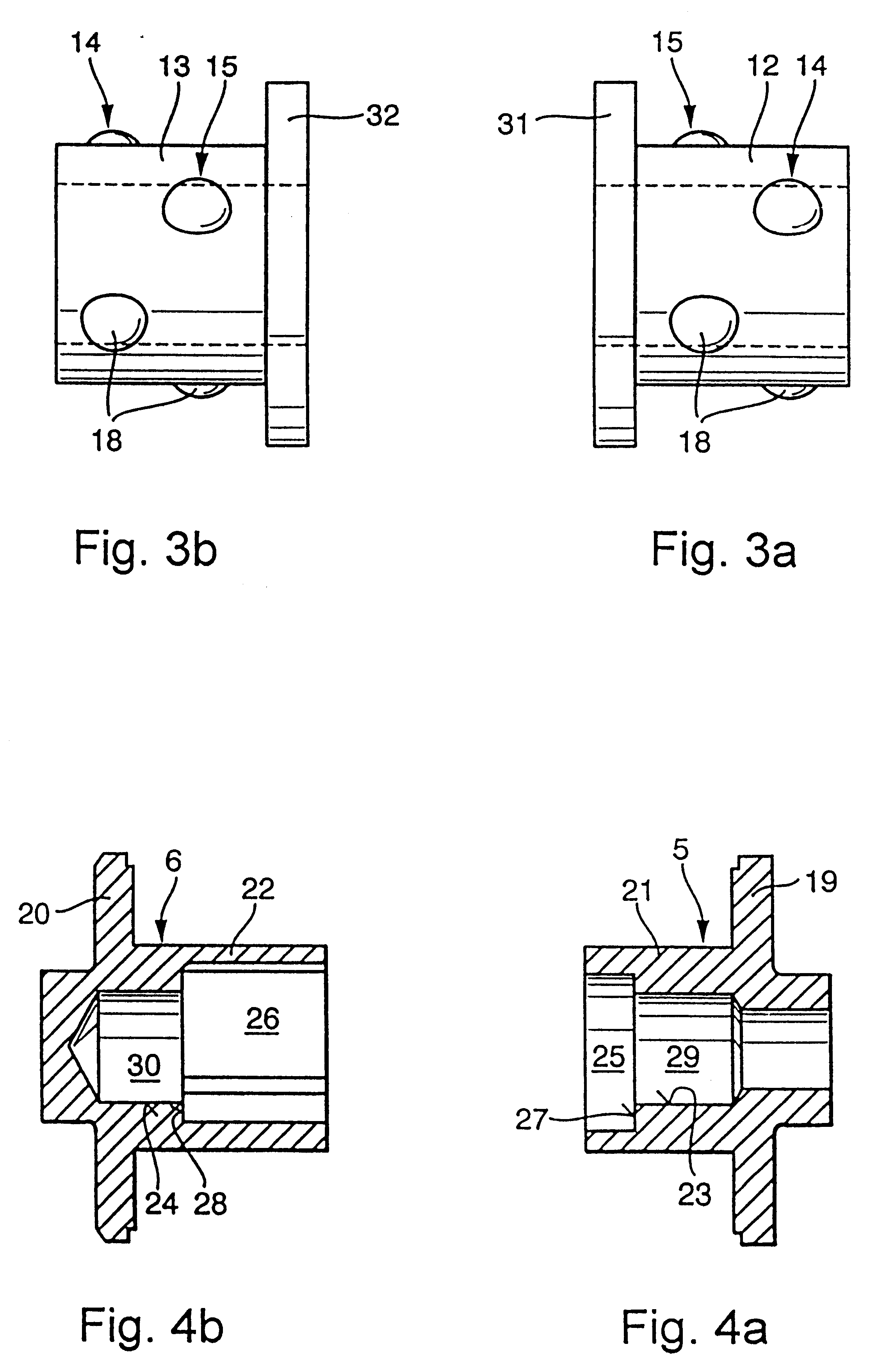

Electromagnet, particularly a proportional magnet for operating a hydraulic valve

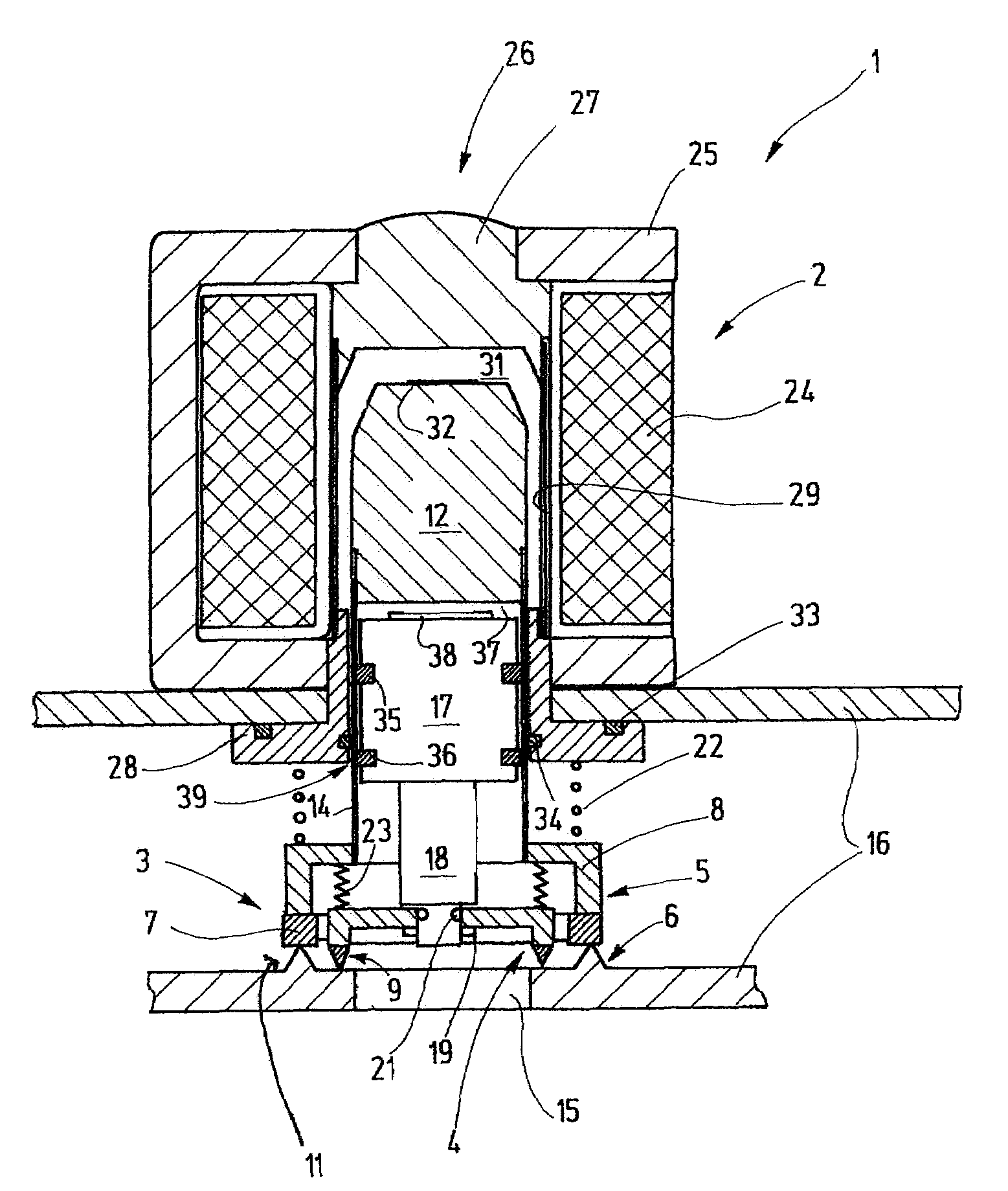

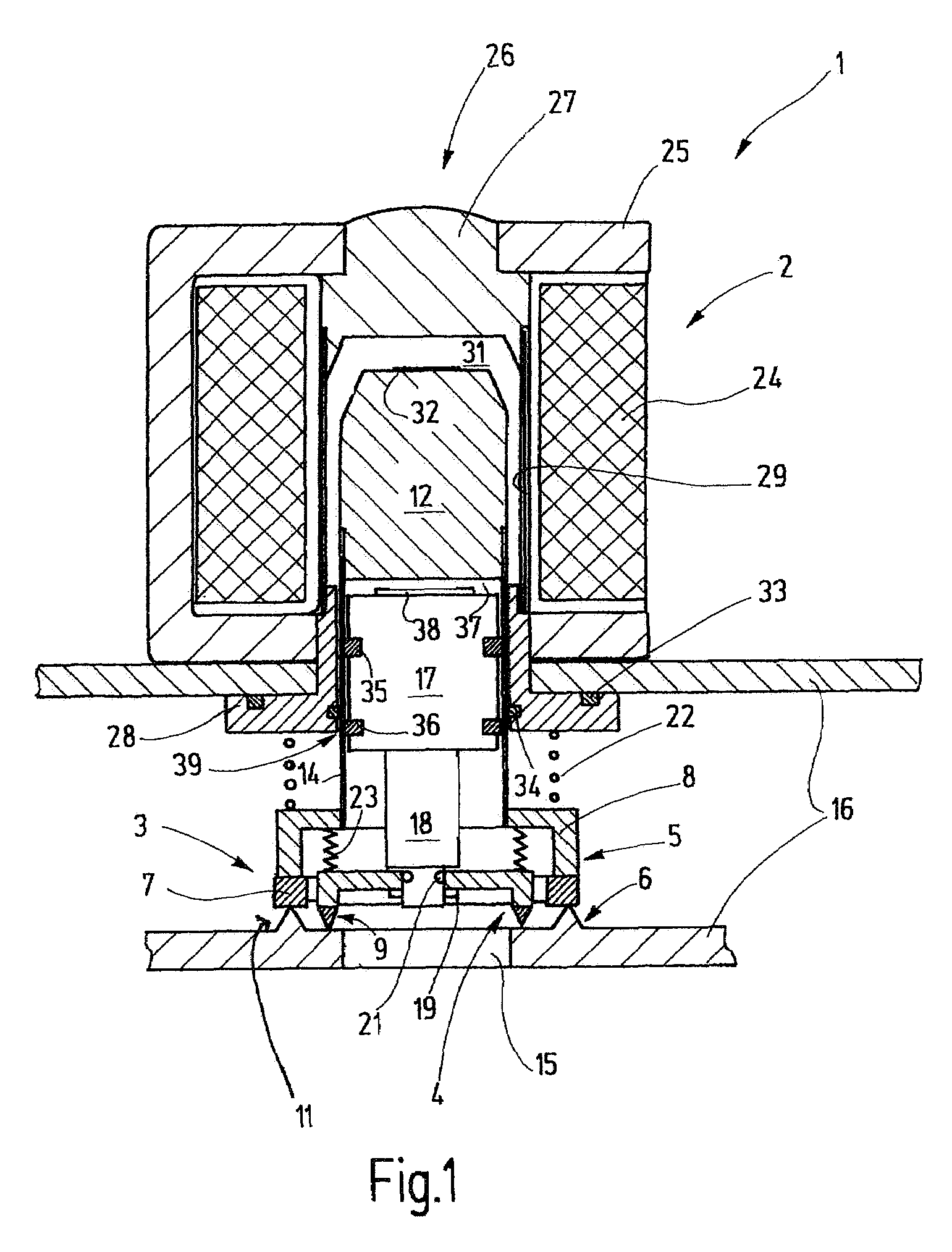

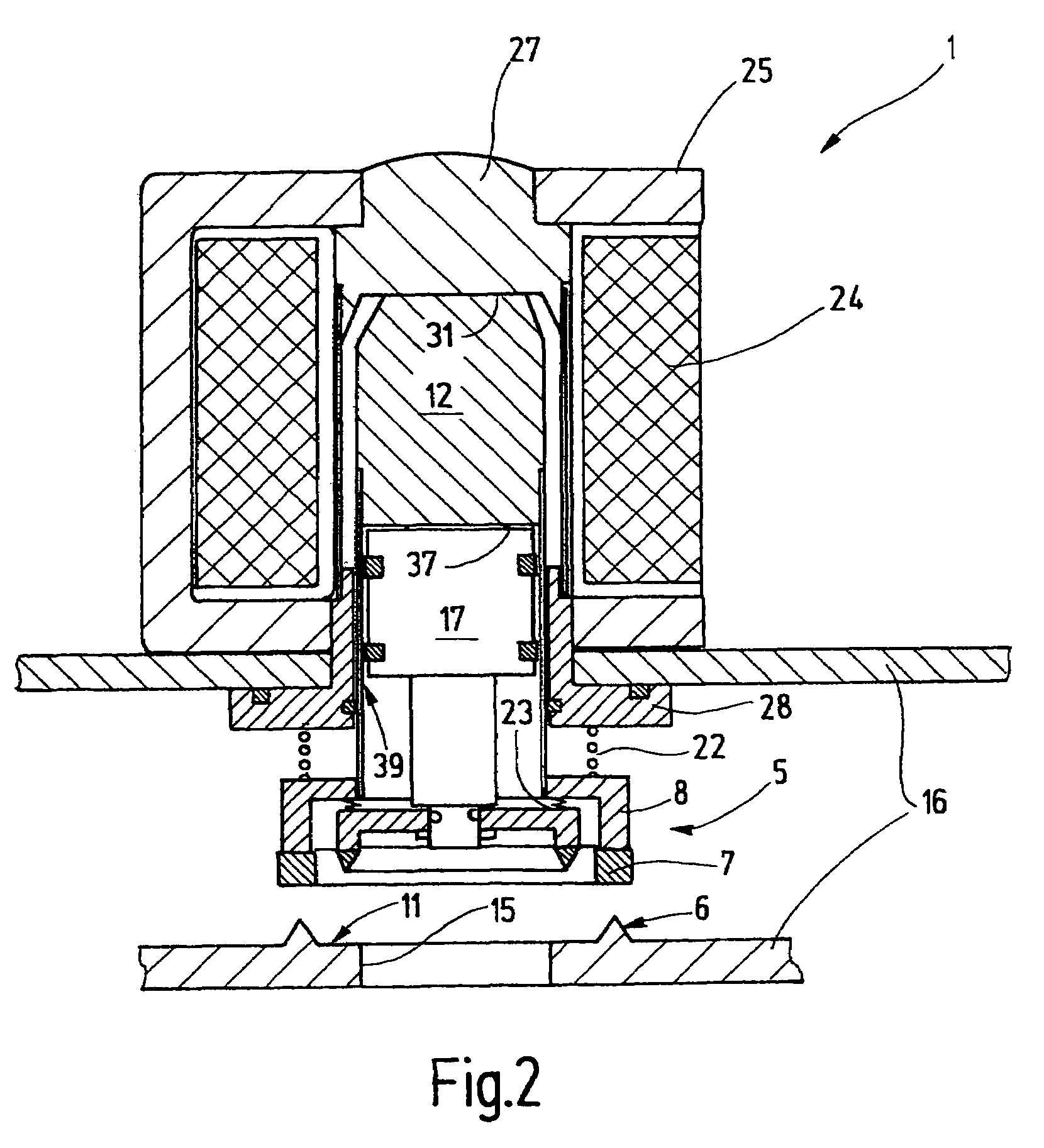

InactiveUS6313726B1Inexpensive simple configurationIncrease the lengthOperating means/releasing devices for valvesElectromagnets with armaturesBall bearingEngineering

An electromagnet (1), particularly a proportional magnet for operating a hydraulic valve, said electromagnet (1) comprising at least one coil winding (3) carried by a hollow cylindrical coil spool (2) which is circumferentially surrounded by a hollow cylindrical magnet housing (4) and limited at each end by a pole shoe (5, 6), said electromagnet (1) further comprising an axially moveable cylindrical armature (8) which is arranged in a hollow cylinder of the coil spool (2) that is configured as an armature space (7), the armature (8) being mounted for low friction in rotary, longitudinally moveable axial guides, and electromagnetically produced axial movements of the armature (8) can be transmitted to a hydraulic valve piston via a push rod (10) which is connected to the armature (8) to form an axial extension thereof. According to the invention, the rotary, longitudinally moveable axial guides of the armature (8) comprise at least one bushing-less linear ball bearing having a number of circumferentially spaced balls while being configured at the same time as an anti-stick means of the armature. The outer peripheral surface (9) of the armature (8) and / or the outer peripheral surface (11) of the push rod (10) is configured as an inner running track for the balls, and the inner peripheral surface of one or more components which limit the armature space (7) of the coil spool (2) forms an outer running track for the balls.

Owner:INA WALZLAGER SCHAEFFLER KG

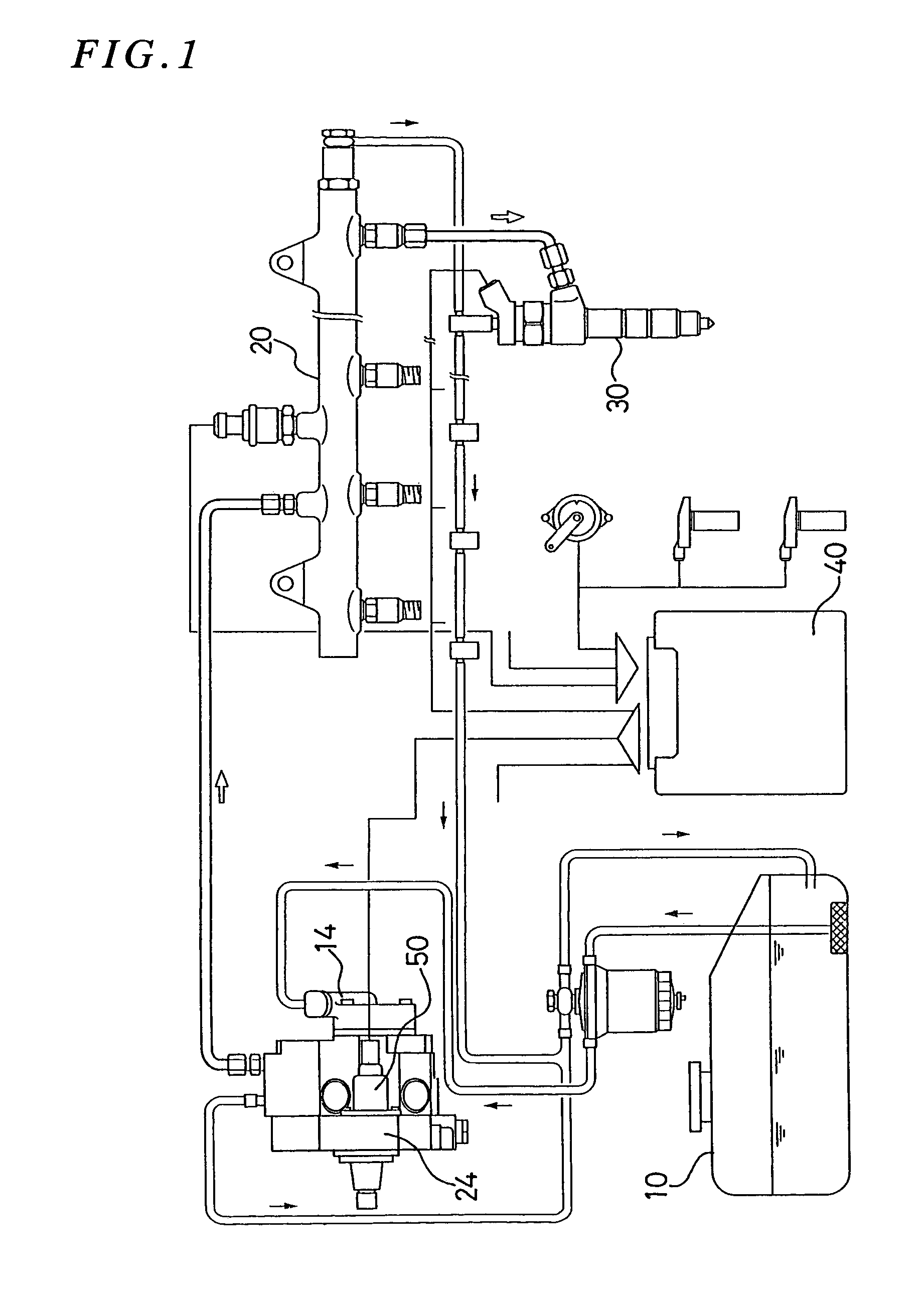

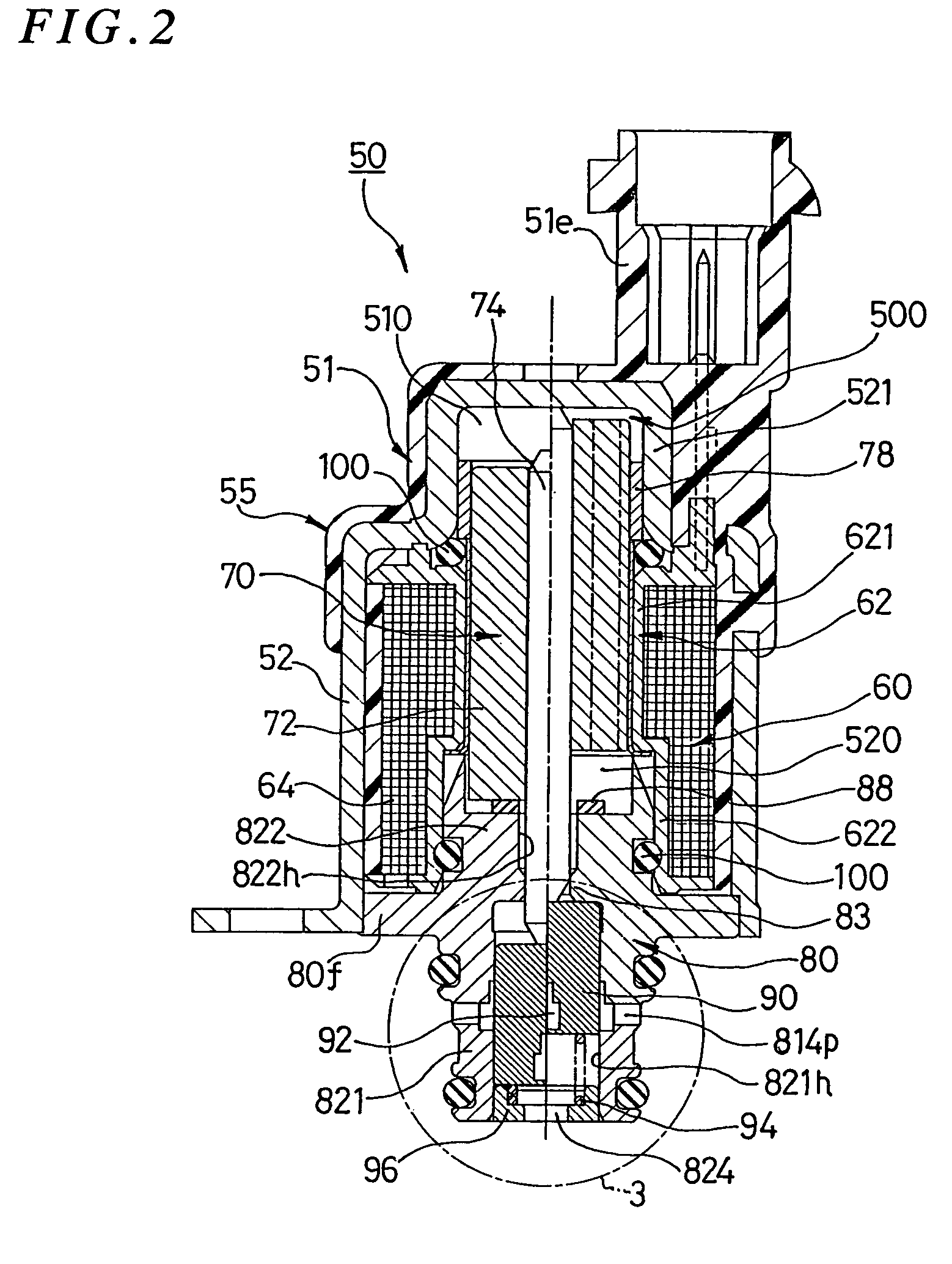

Fluid flow rate control valve, anchor for mover and fuel injection system

InactiveUS7131426B2Large meritOperating means/releasing devices for valvesMachines/enginesEngineeringFuel injection

Owner:BOSCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com