Patents

Literature

5151results about "Differential gearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

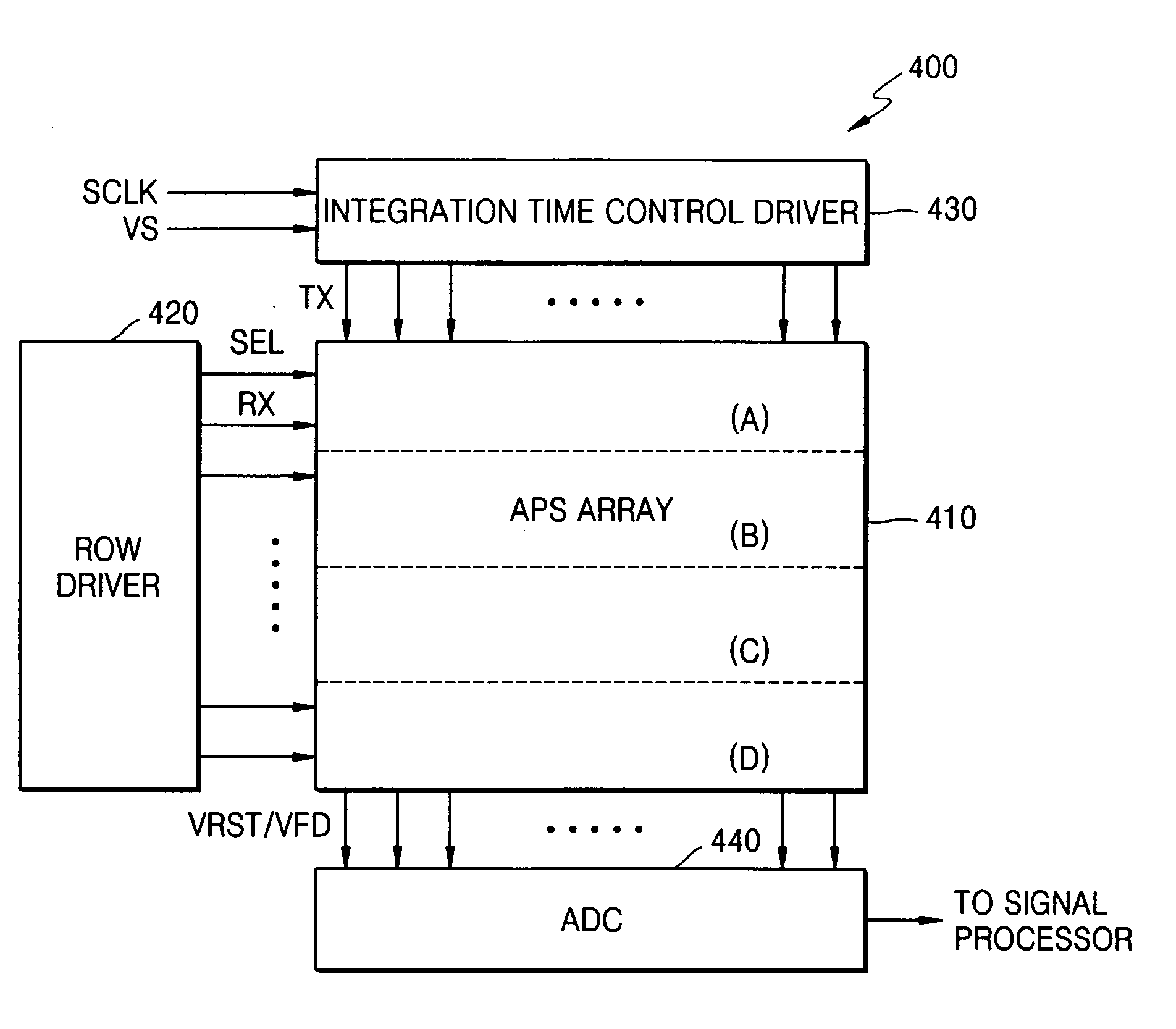

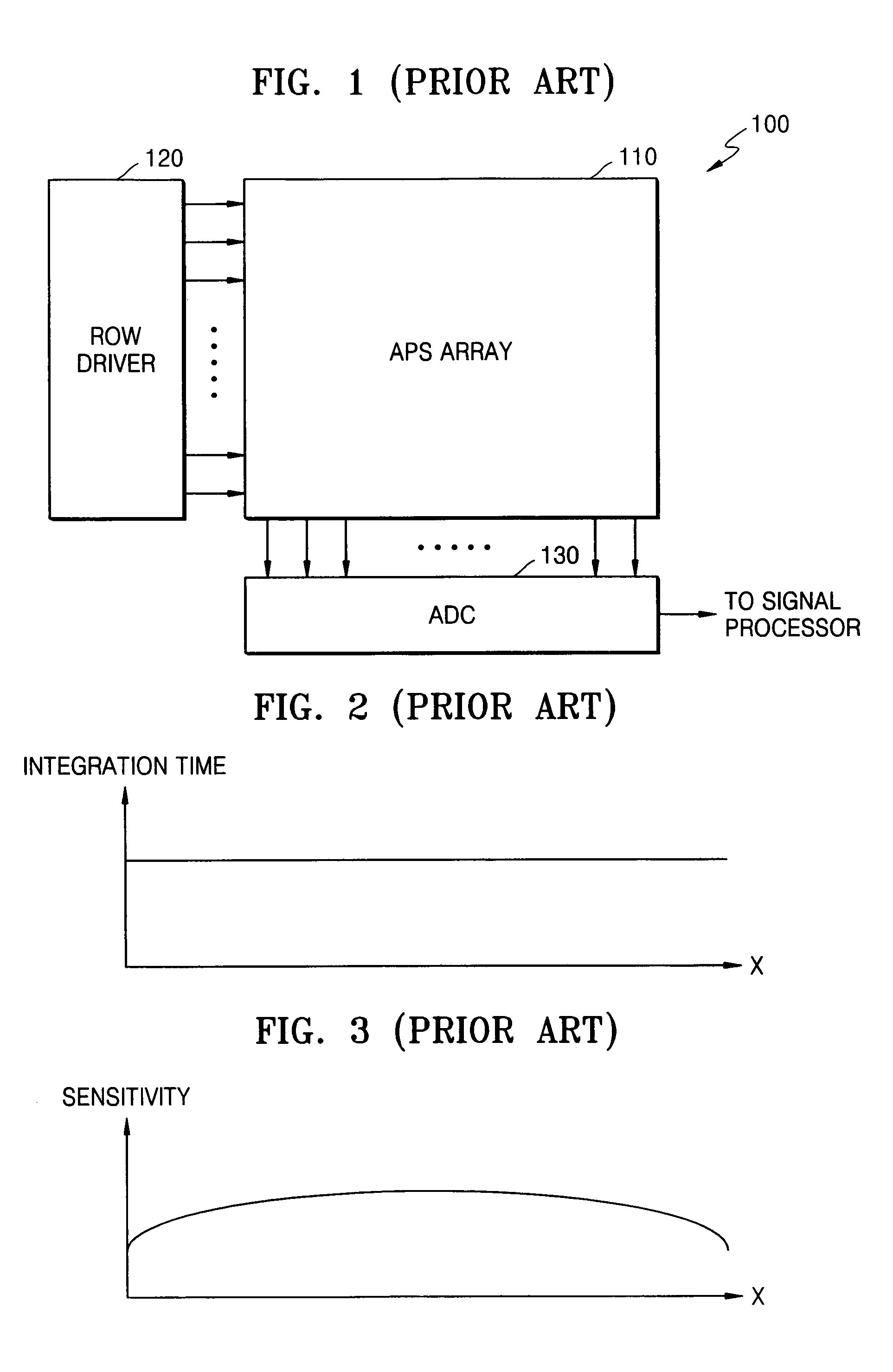

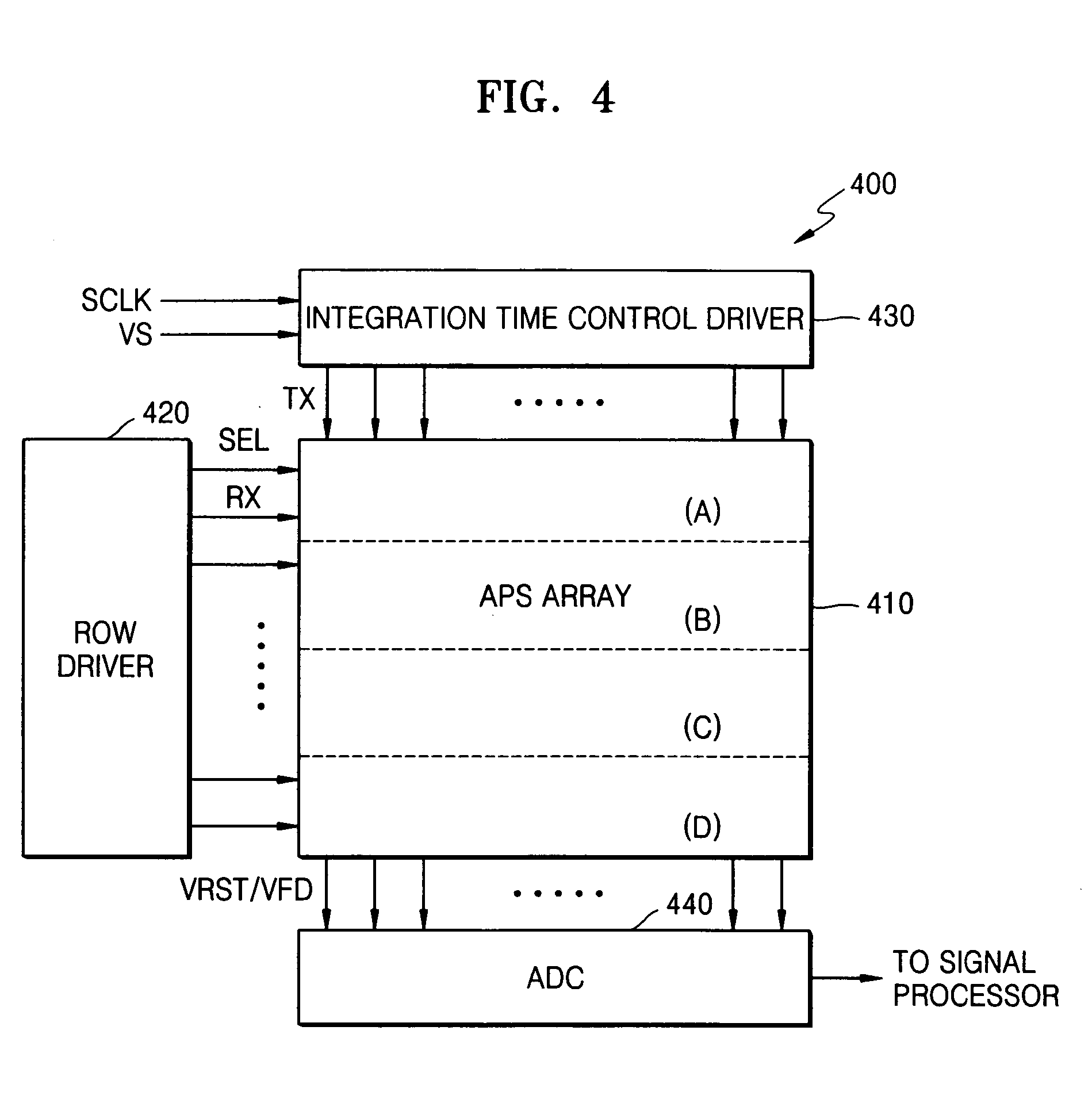

Solid-state image-sensing device that compensates for brightness at edges of a display area and a driving method thereof

ActiveUS7193199B2Lower ratioImprove noiseTelevision system detailsTelevision system scanning detailsCMOS sensorControl signal

A solid-state image-sensing device that compensates for brightness at edges of a screen and a method of driving the device are provided. The solid-state image-sensing device comprises: an active pixel sensor (APS) array including pixels disposed in a two-dimensional matrix, each pixel for outputting a photoelectrically converted image signal generated by a photodiode in response to one of a plurality of transmission control signals transmitted to a selected row of the APS array, and for generating and outputting a reset signal in response to a reset control signal; a row driver for selecting a row of the APS array by generating row selection signals and for generating the reset control signal; an integration time control driver for generating the transmission control signals for setting non-uniform integration times of the photodiodes in each pixel; and an analog-digital converter for converting an analog signal corresponding to a difference between the image signal and the reset signal into a digital signal.

Owner:SAMSUNG ELECTRONICS CO LTD

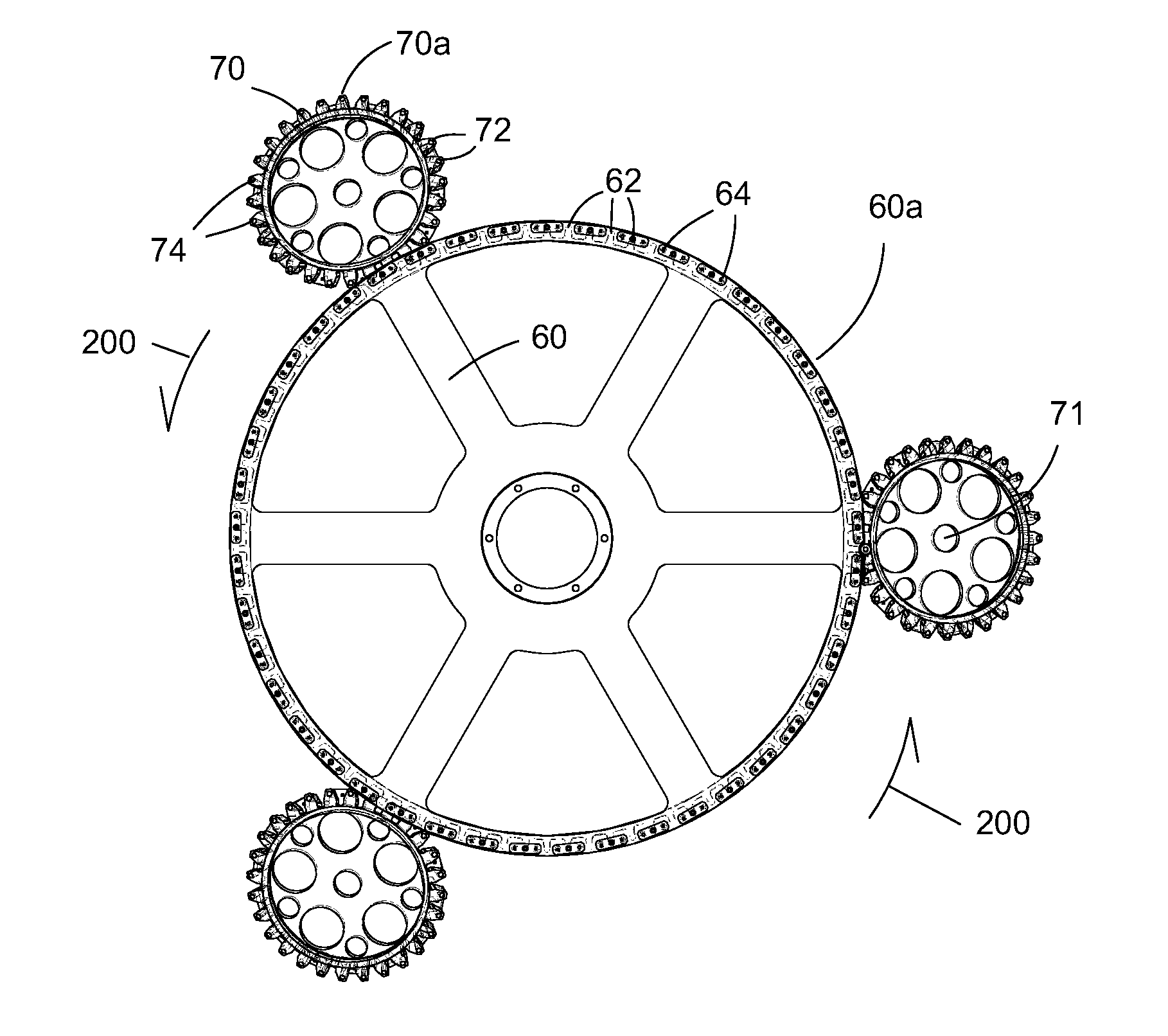

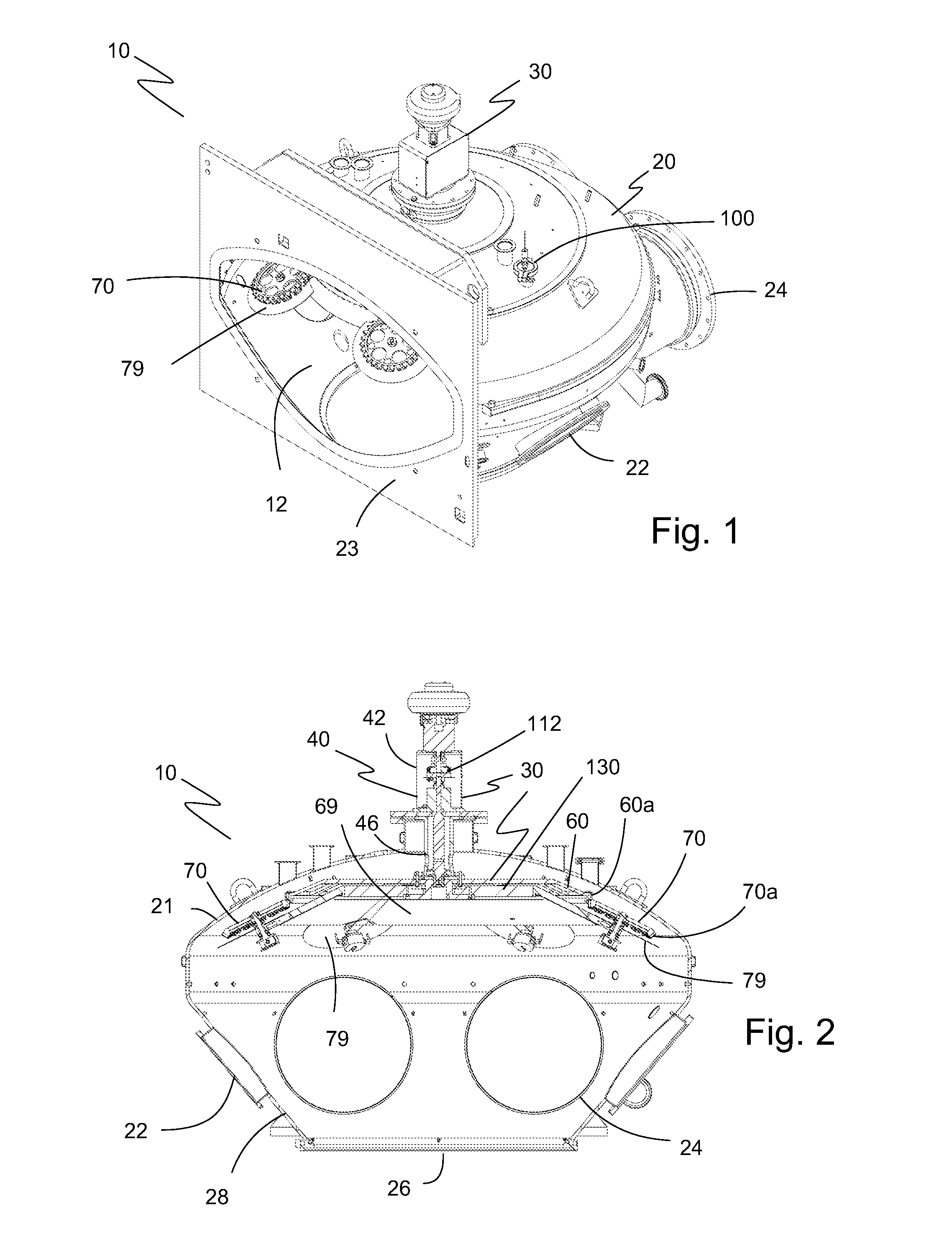

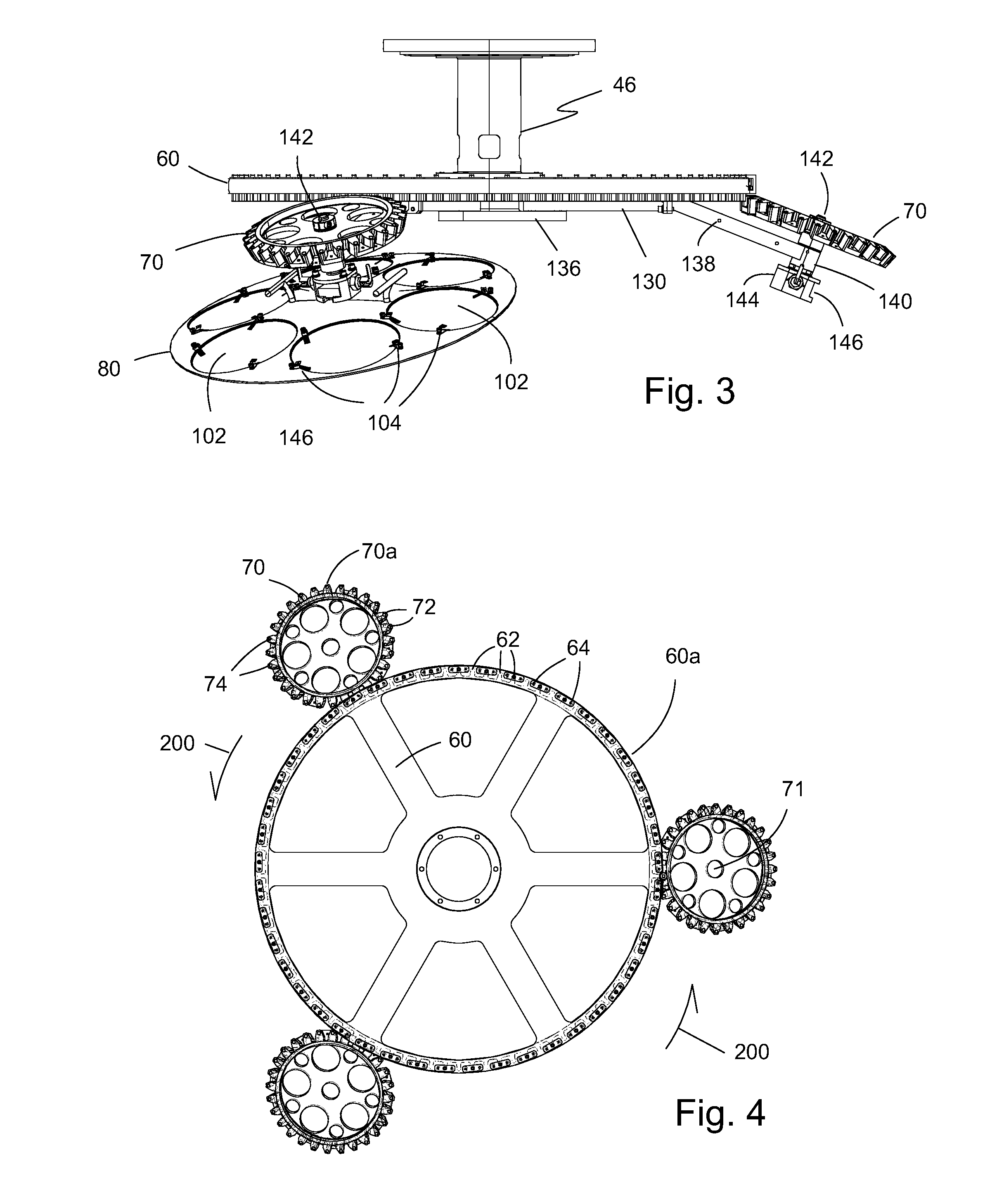

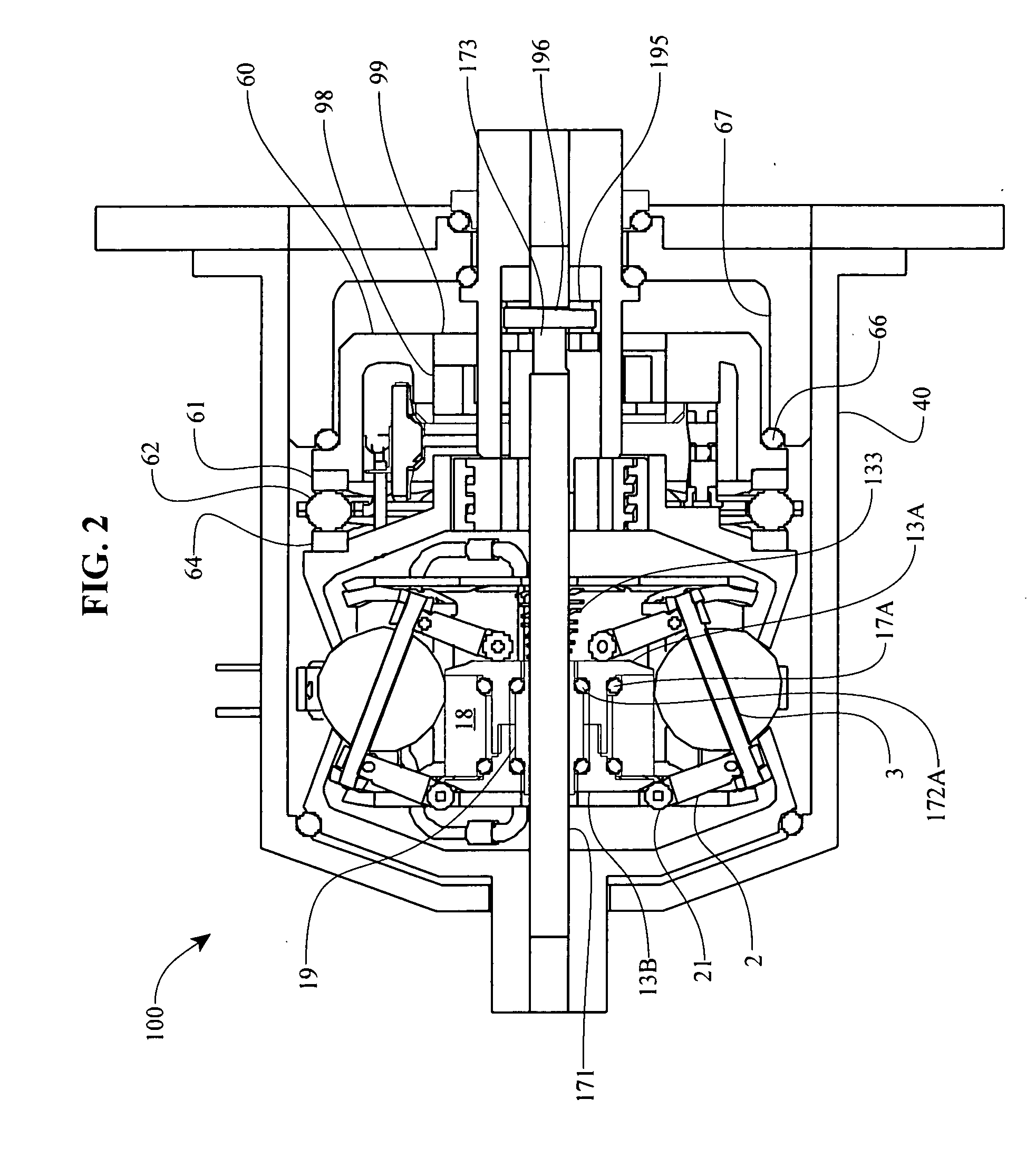

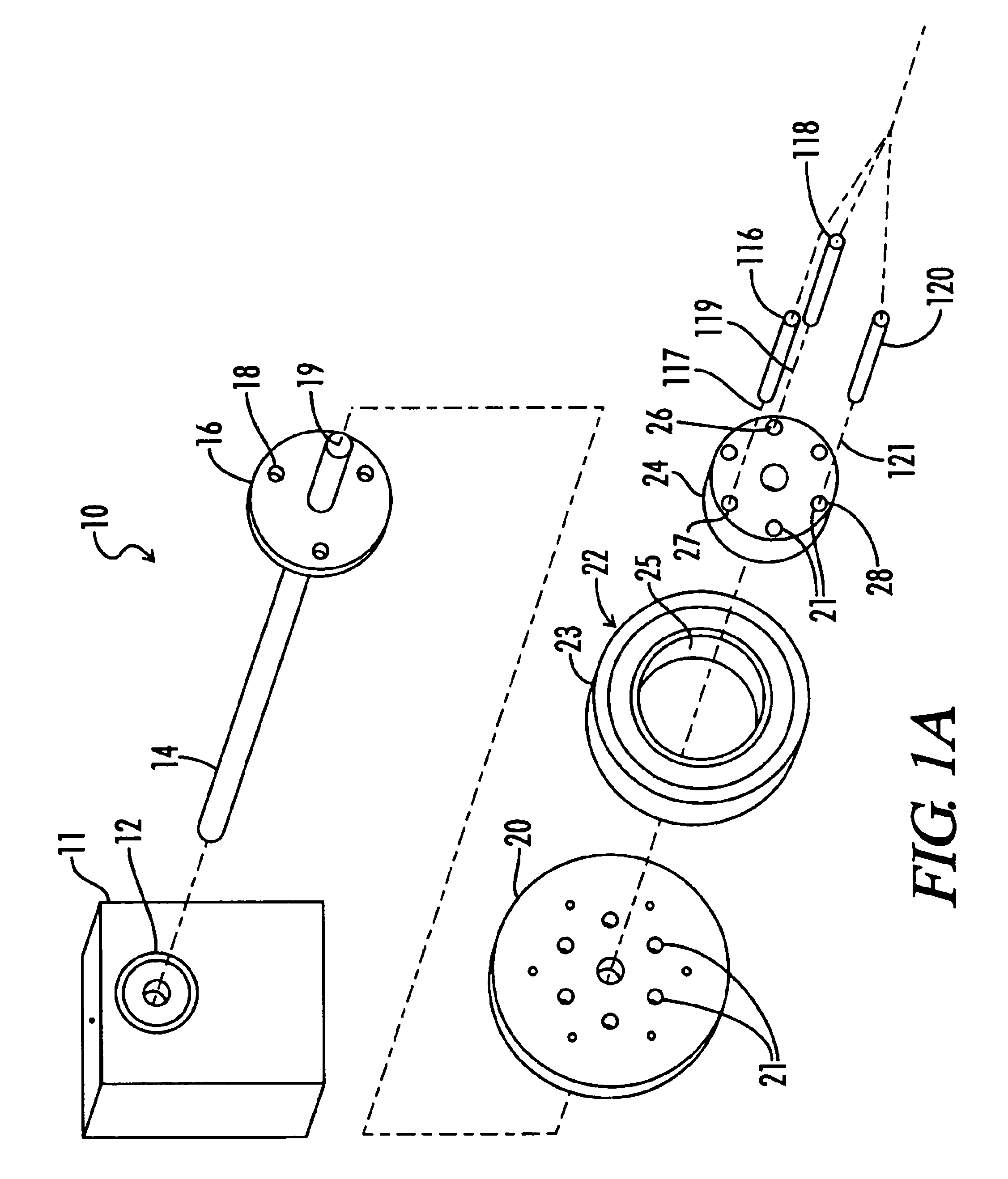

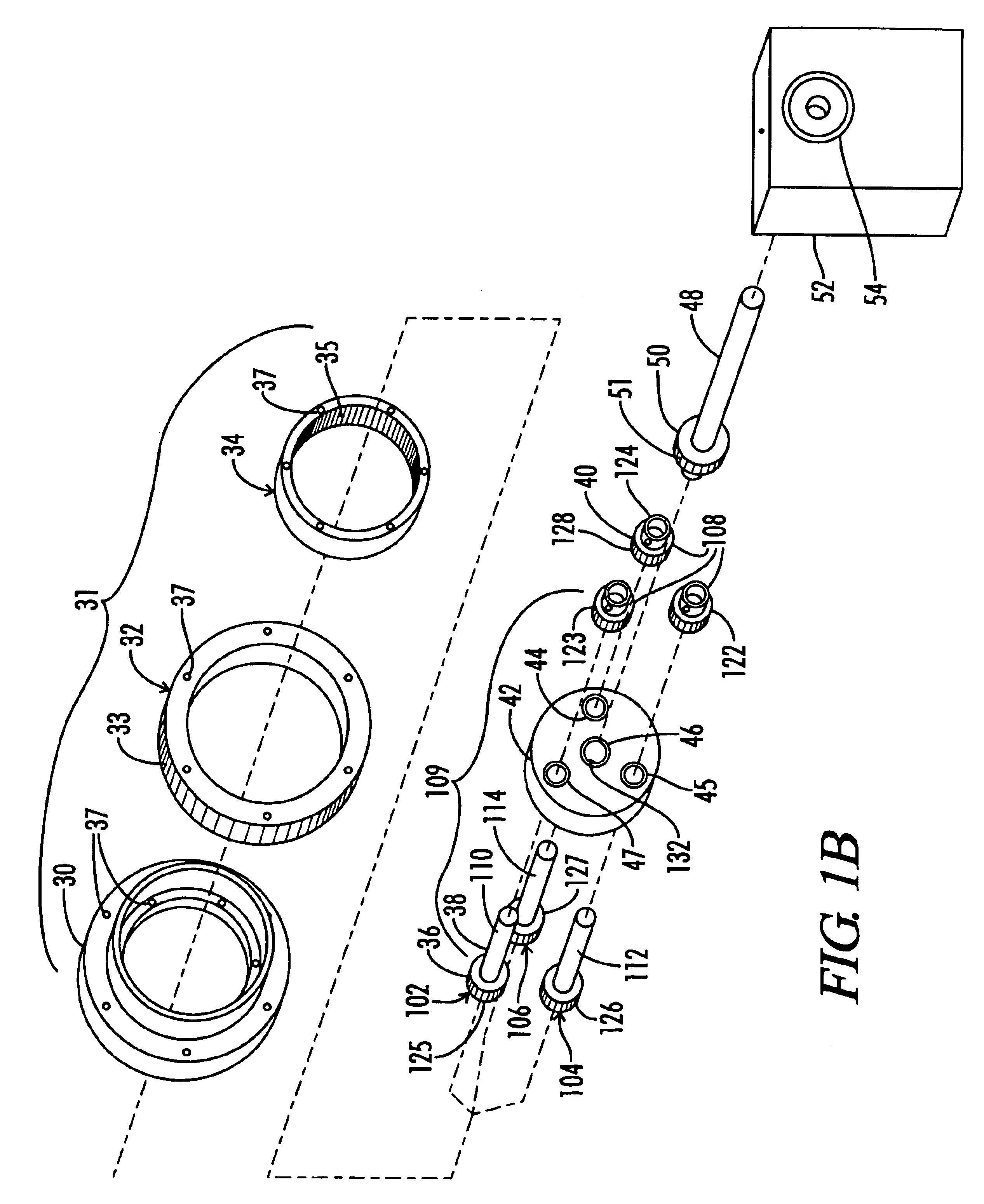

Non-contact magnetic drive assembly with mechanical stop elements

ActiveUS20130095973A1Improve throughputMinimizing particulate contaminationVacuum evaporation coatingSemiconductor/solid-state device manufacturingMechanical driveVacuum deposition

A non-contact magnetic drive assembly with mechanical stop elements for a vacuum deposition system employing a lift-off process having a HULA configuration featuring a plurality of magnets coupled in an annular orientation to a central ring and an orbital ring, each magnet of the orbital ring becomes superposed with a magnet of the central ring as the orbital ring rotates, and a central drive component driving either the central ring, the orbital ring around the central ring or both simultaneously, the central drive component provides a rotational speed allowing non-contact, magnetic drive rotation of the orbital ring around the central ring until a difference between a magnetic drive torque of the superposed magnets and the rotational speed of the central drive component causes the superposed magnets to decouple enabling mechanical drive rotation by interactive contact between a plurality of central ring teeth and a plurality of orbital ring.

Owner:FERROTEC USA CORP

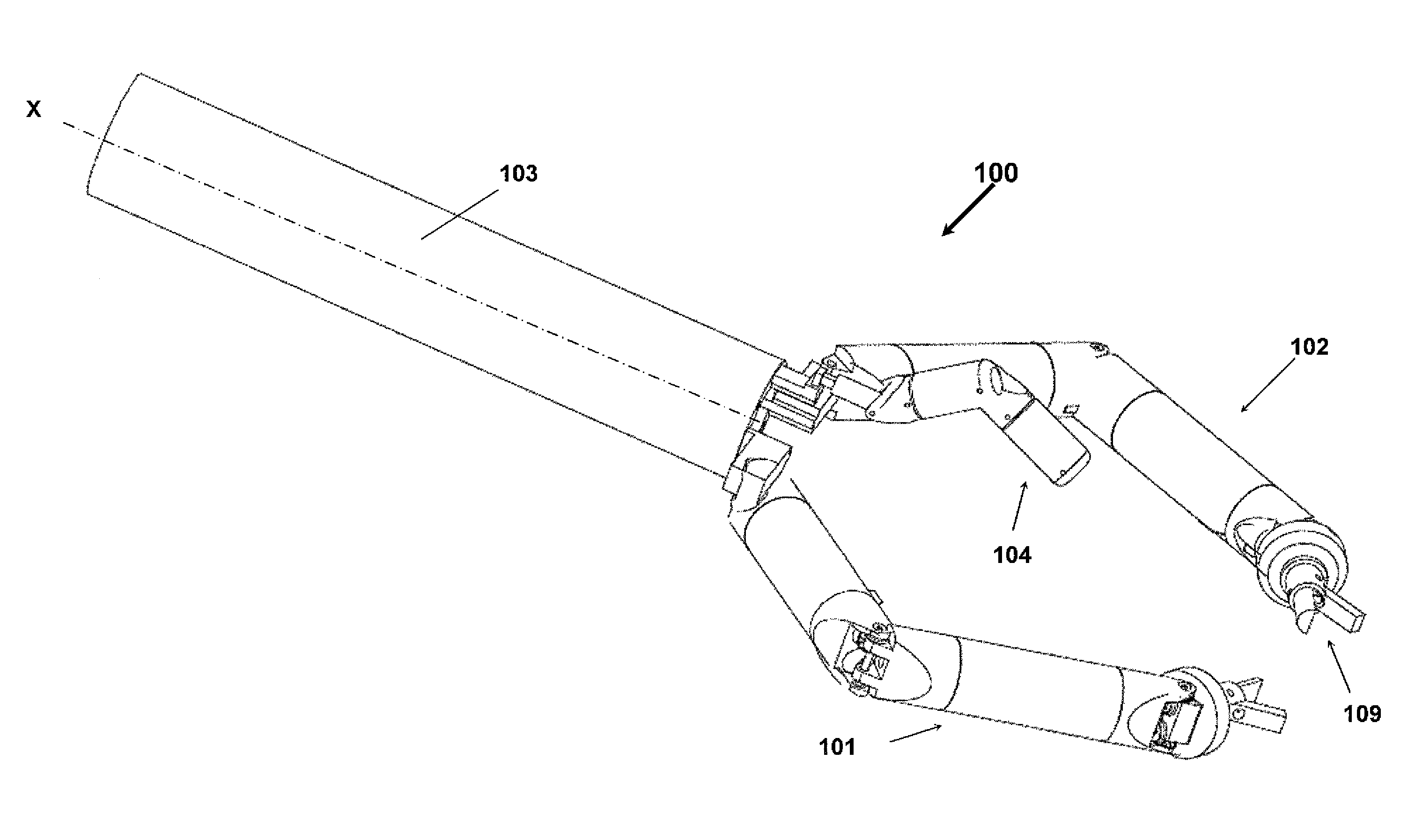

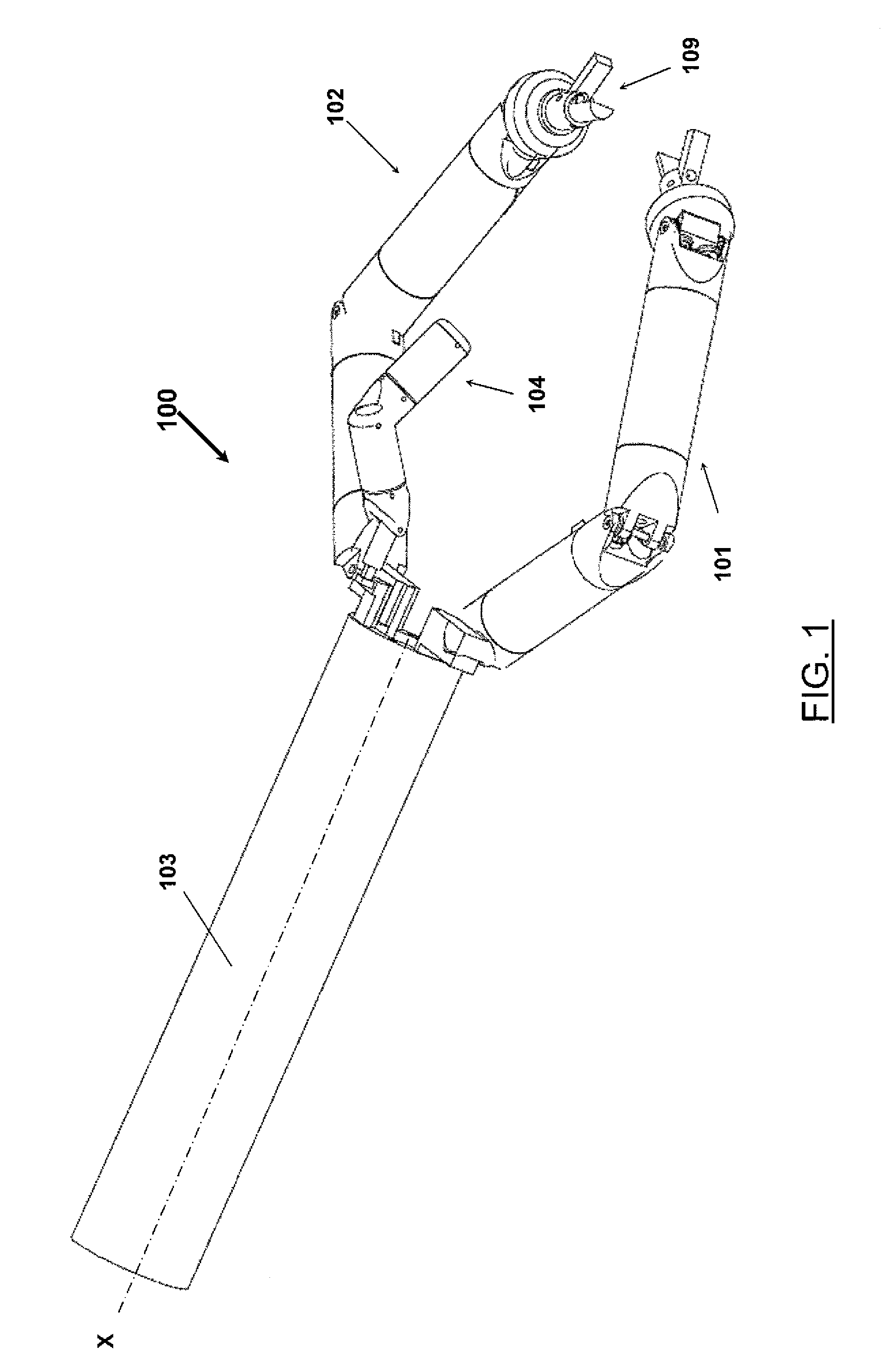

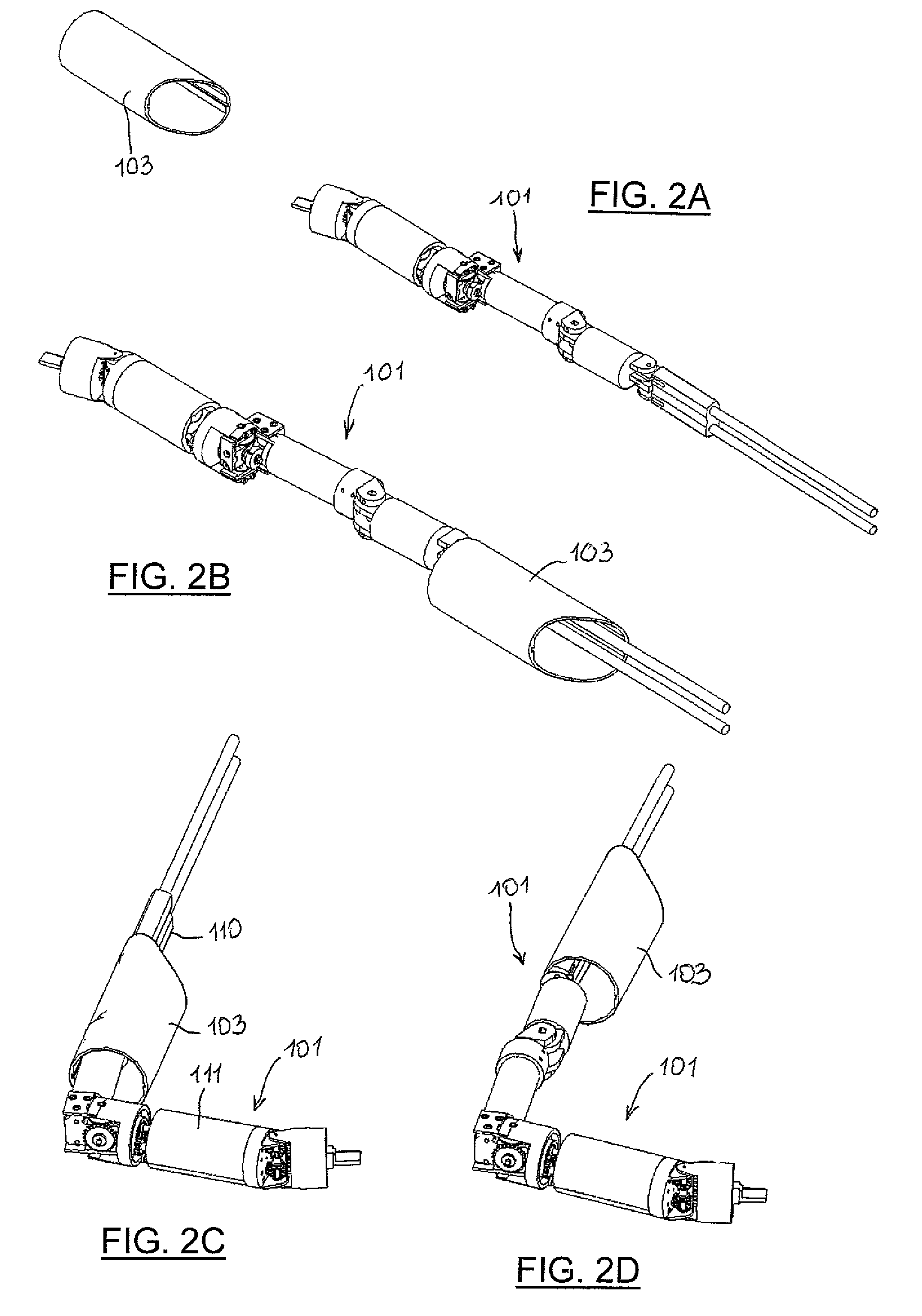

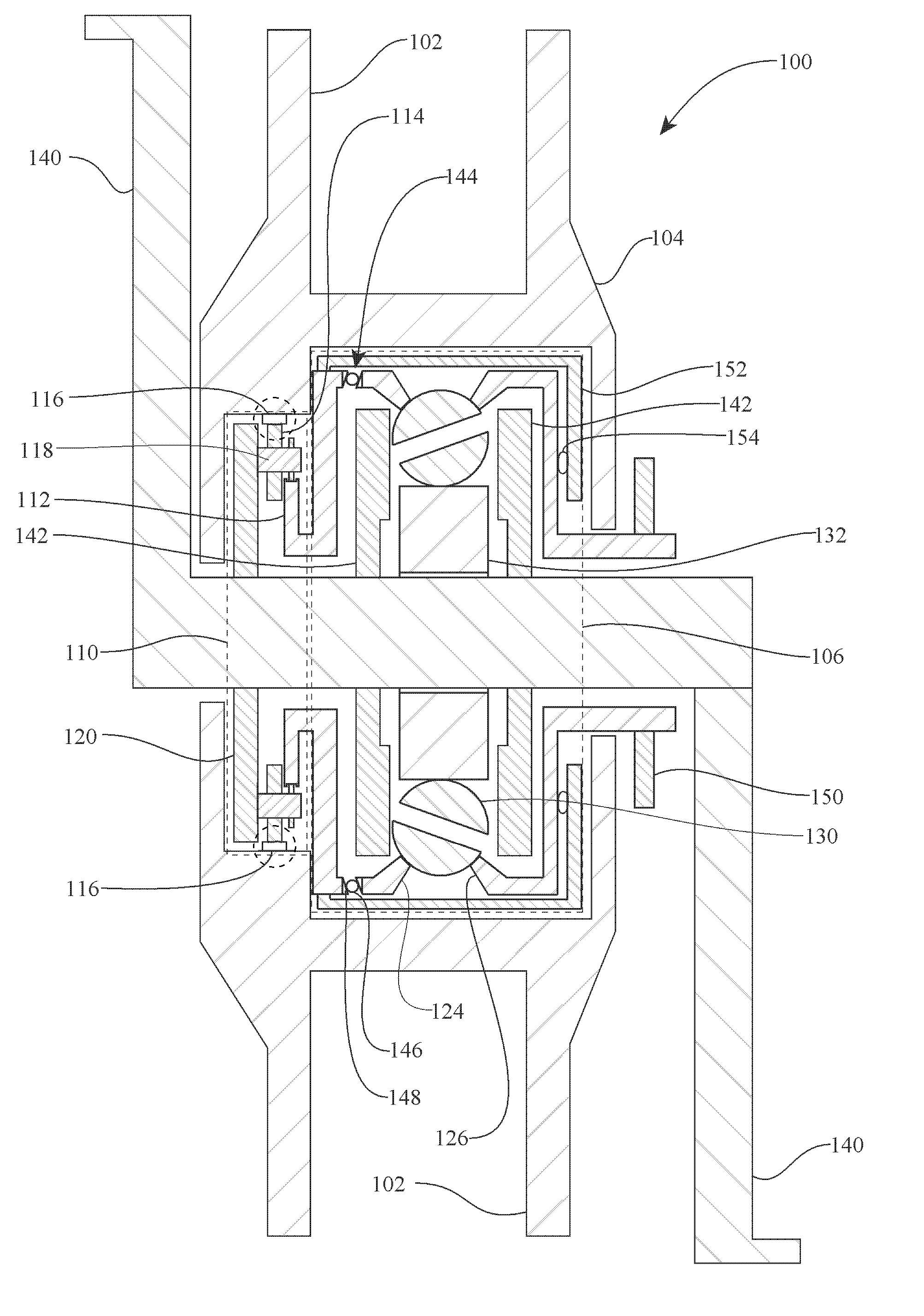

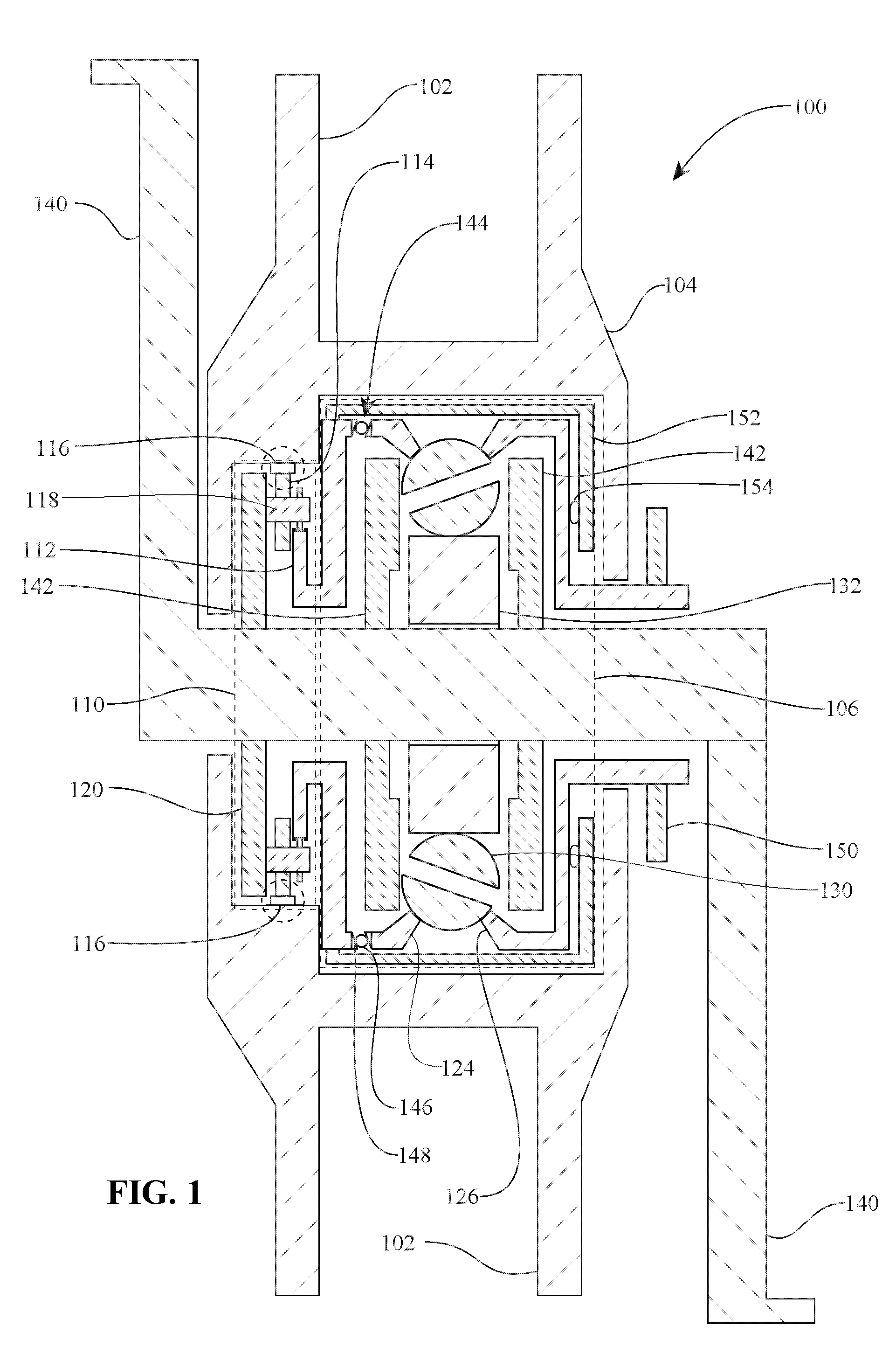

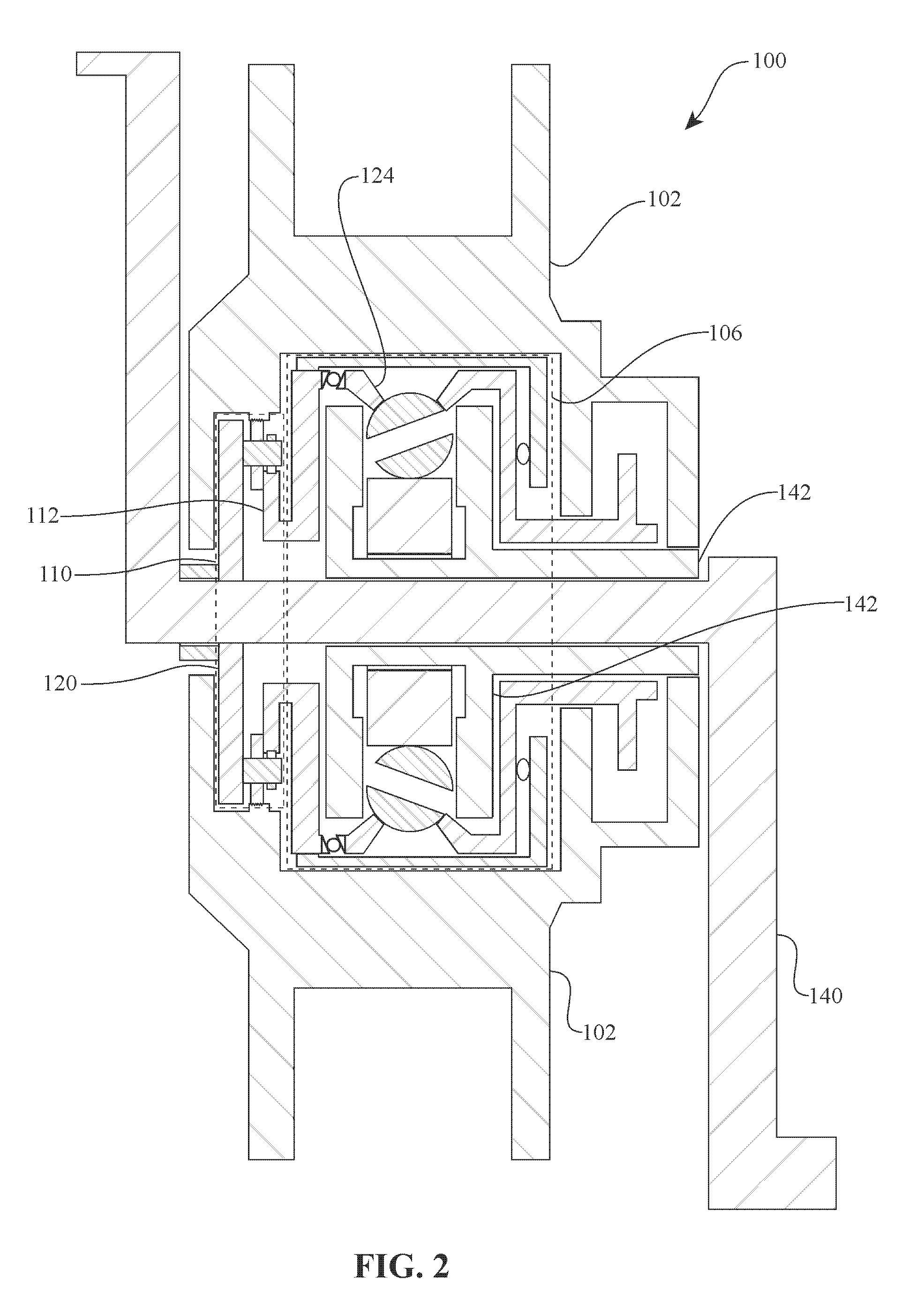

Robotic apparatus for minimally invasive surgery

A robotic arm especially suited for laparoscopic surgery, having a torsional joint and a flexural joint forming serially arranged joints is described. The joints provide respective degrees of freedom for the arm, which further receives drive means for such joints. The robotic arm also has transmission means placed between the drive means have and the joints. The transmission means a first and a second assembly of three gear wheels, preferably conical gear wheels, and a train of three additional gear wheels, preferably straight-cut gear wheels, which couple the first and second assembly to form a differential mechanism.

Owner:SCUOLA SUPERIORE DI STUDI UNIVERSITARI E DI PERFEZIONAMENTO SANTANNA

Continuously variable transmission

InactiveUS20070155567A1Easy to adjustImprove translationWheel based transmissionChain/belt transmissionEngineeringMechanical engineering

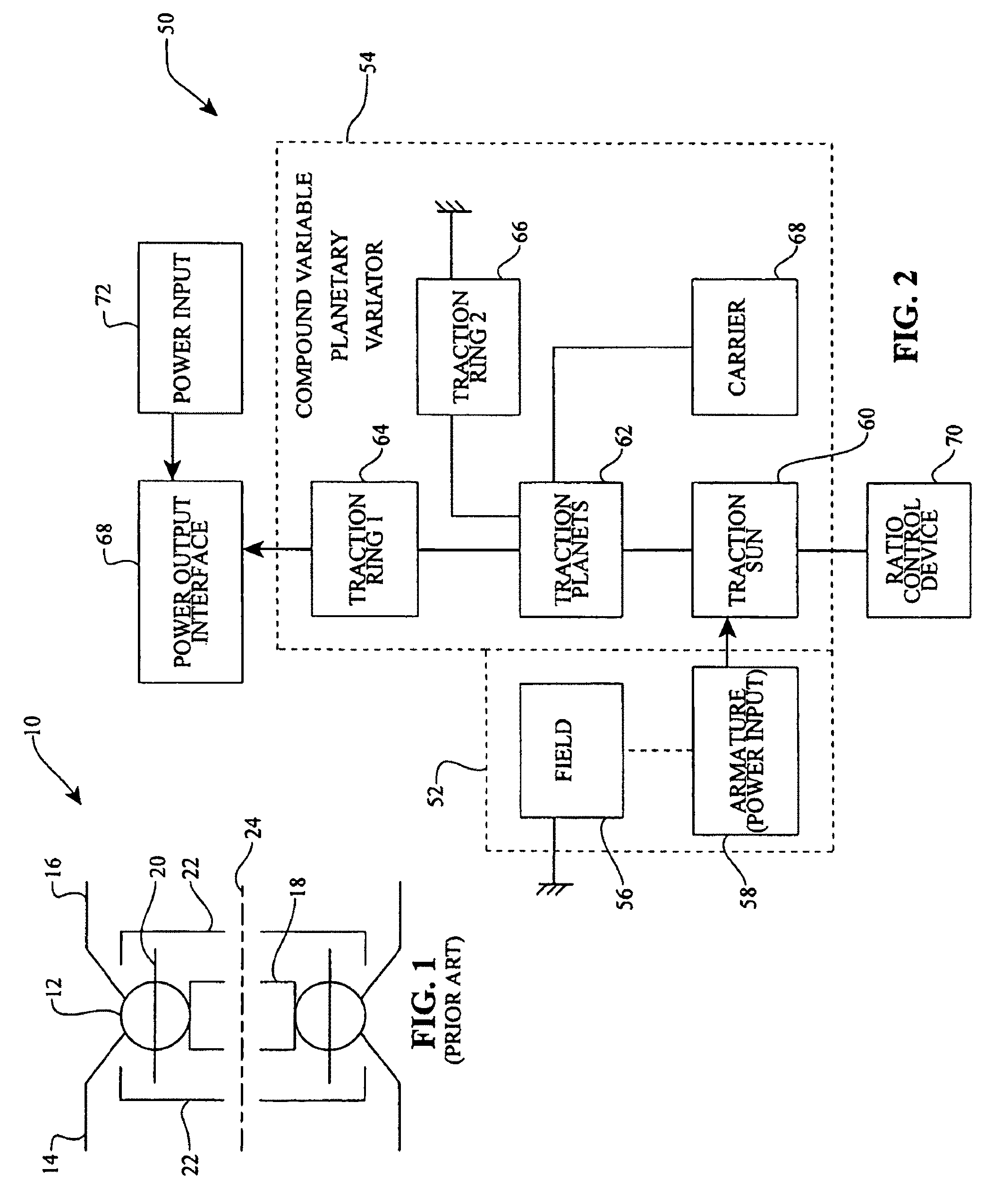

Traction planets and traction rings can be operationally coupled to a planetary gearset to provide a continuously variable transmission (CVT). The CVT can be used in a bicycle. In one embodiment, the CVT is mounted on the frame of the bicycle at a location forward of the rear wheel hub of the bicycle. In one embodiment, the CVT is mounted on and supported by members of the bicycle frame such that the CVT is coaxial with the crankshaft of the bicycle. The crankshaft is configured to drive elements of the planetary gearset, which are configured to operationally drive the traction rings and the traction planets. Inventive component and subassemblies for such a CVT are disclosed. A shifting mechanism includes a plurality of pivot arms arranged to pivot about the centers of the traction planets as a shift pin hub moves axially.

Owner:FALLBROOK INTPROP COMPANY

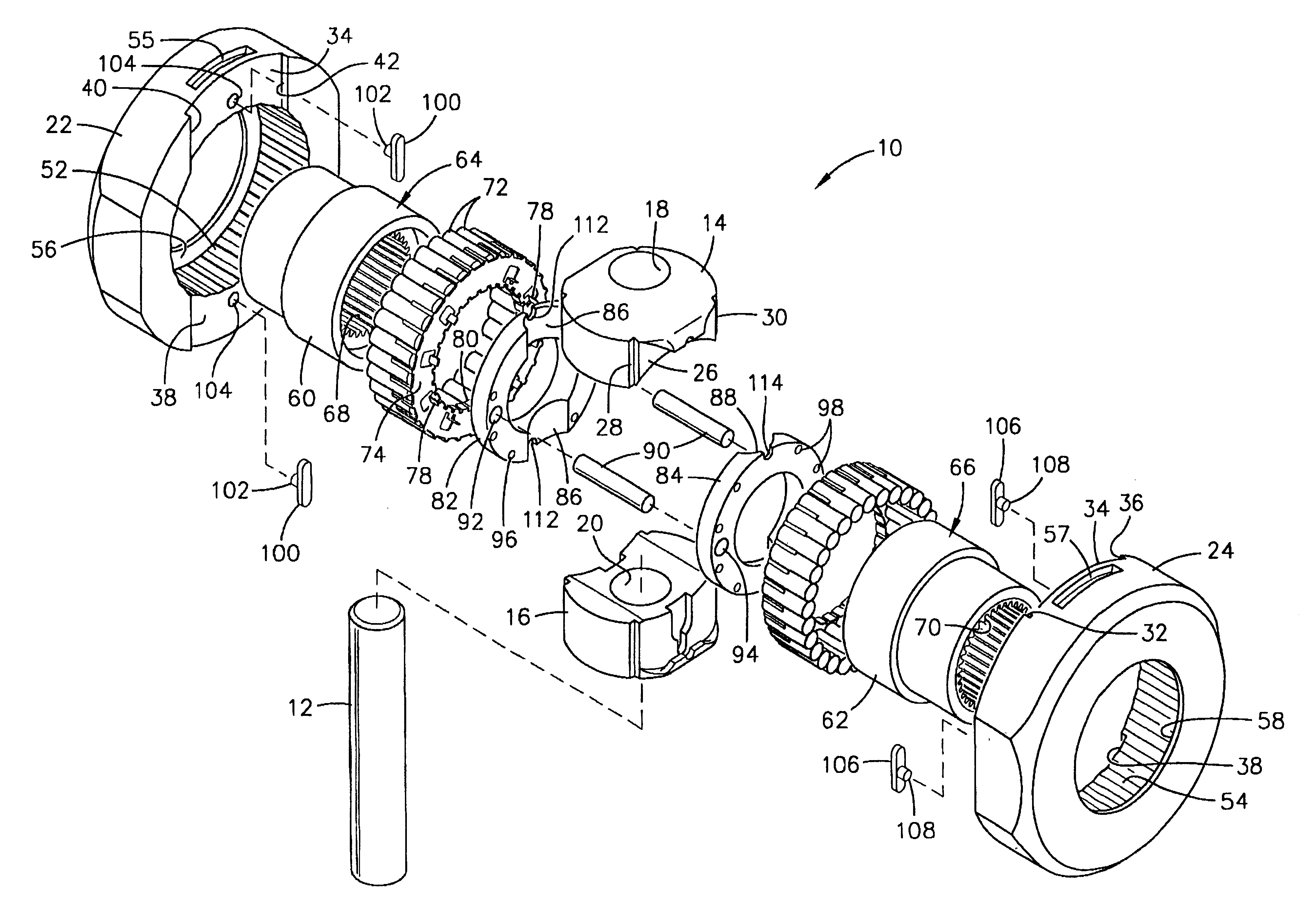

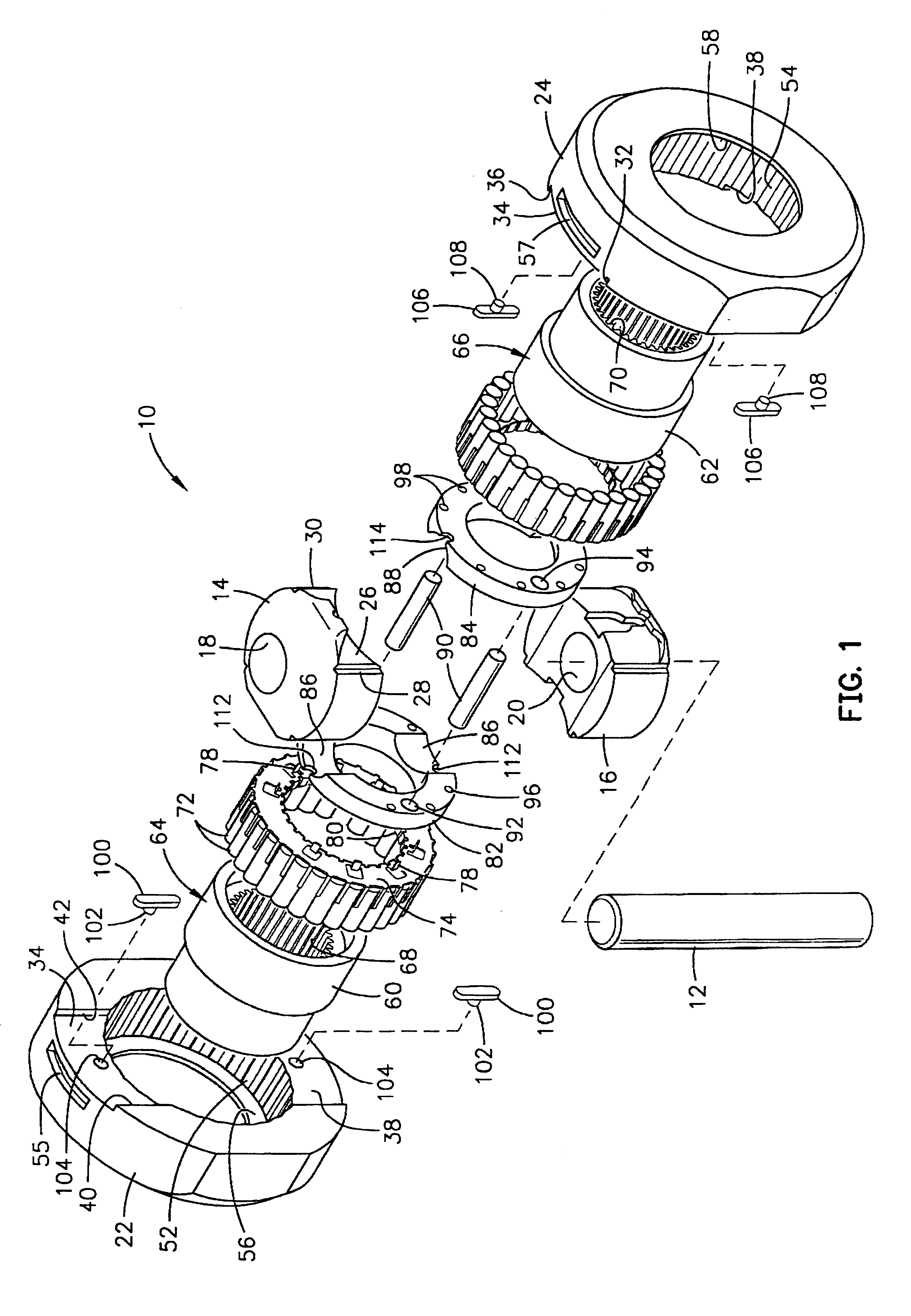

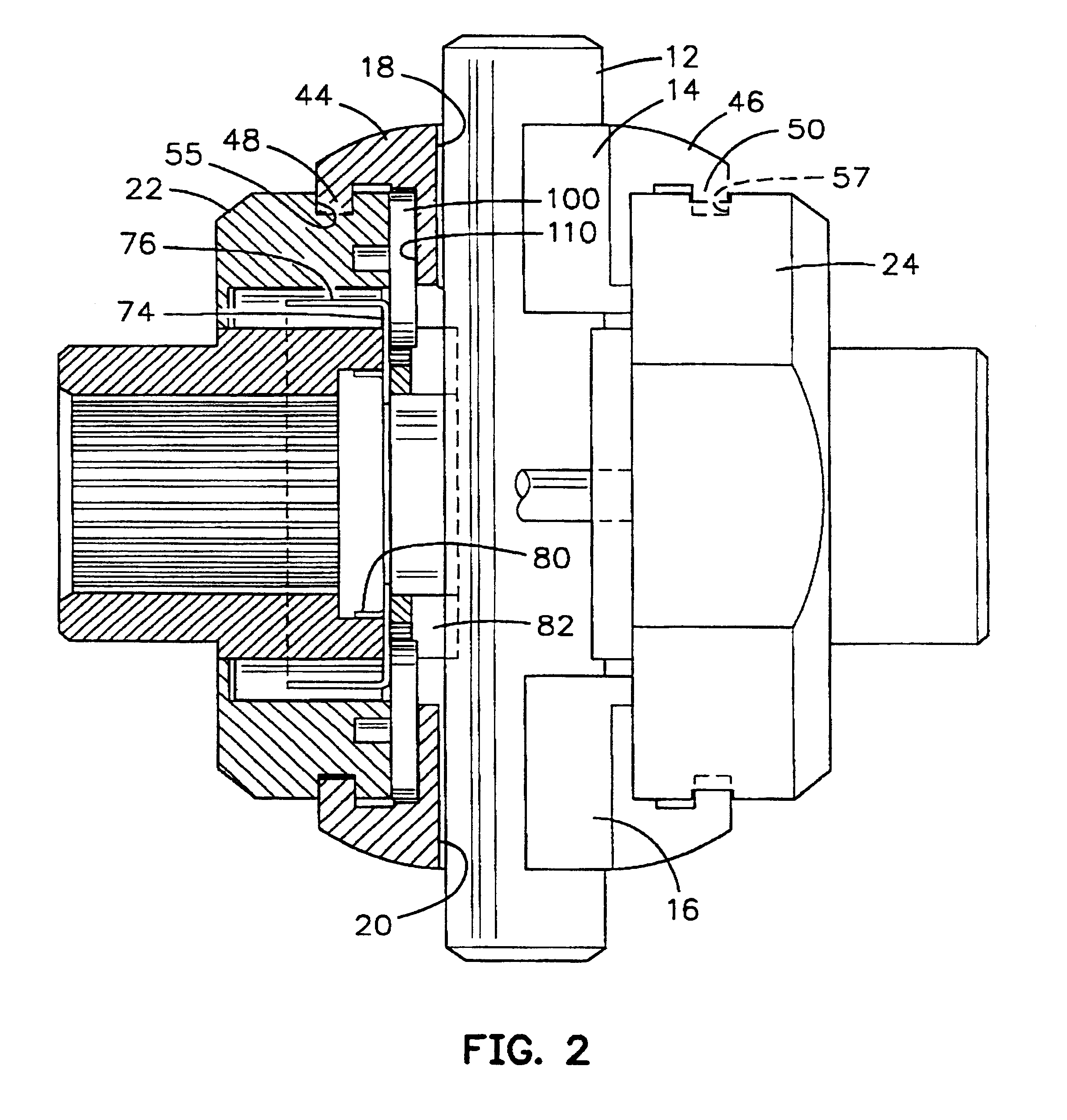

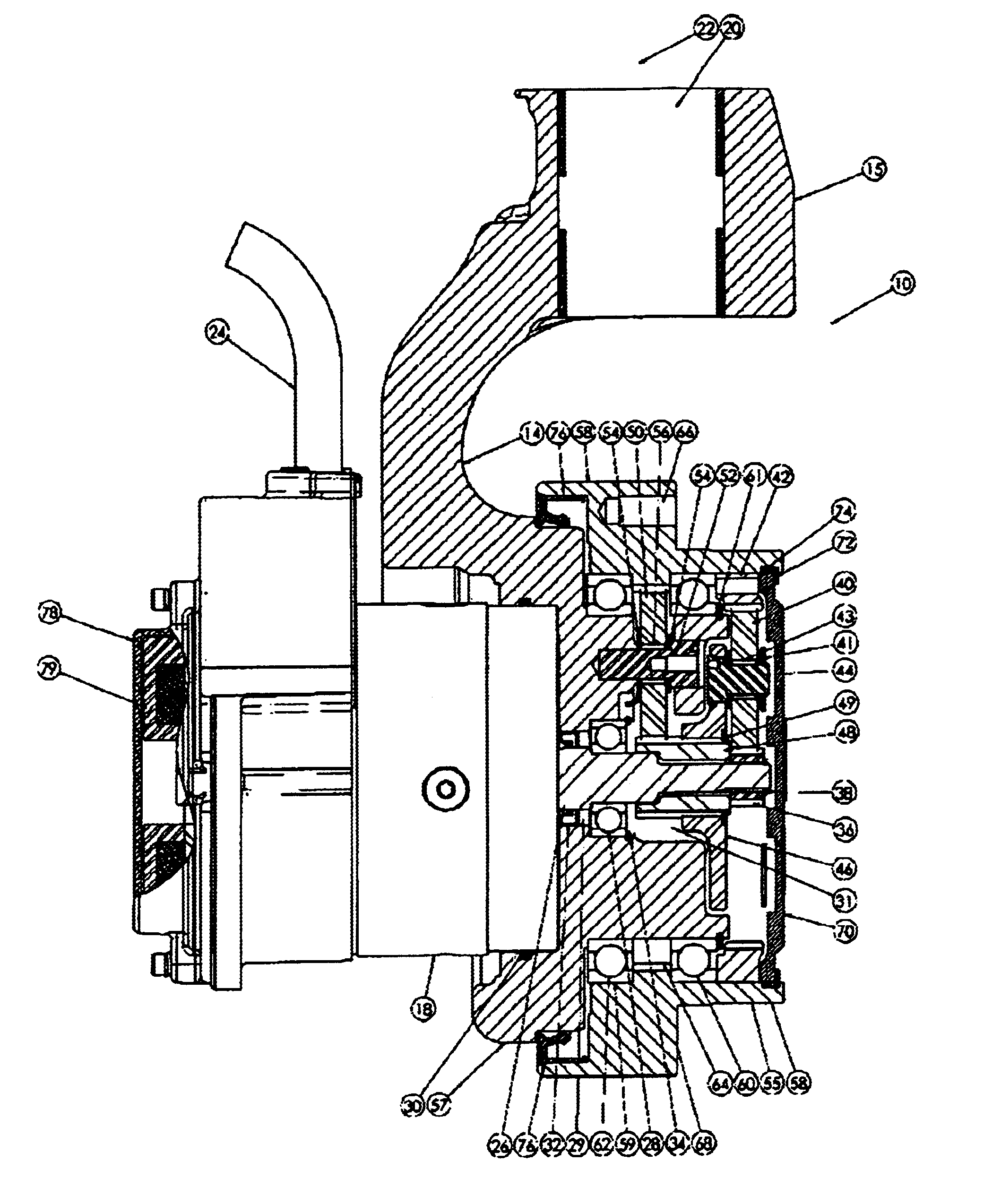

Automotive full locking differential

InactiveUS6269712B1Simple and effective and smooth in its operationMagnetically actuated clutchesDifferential gearingsCouplingEngineering

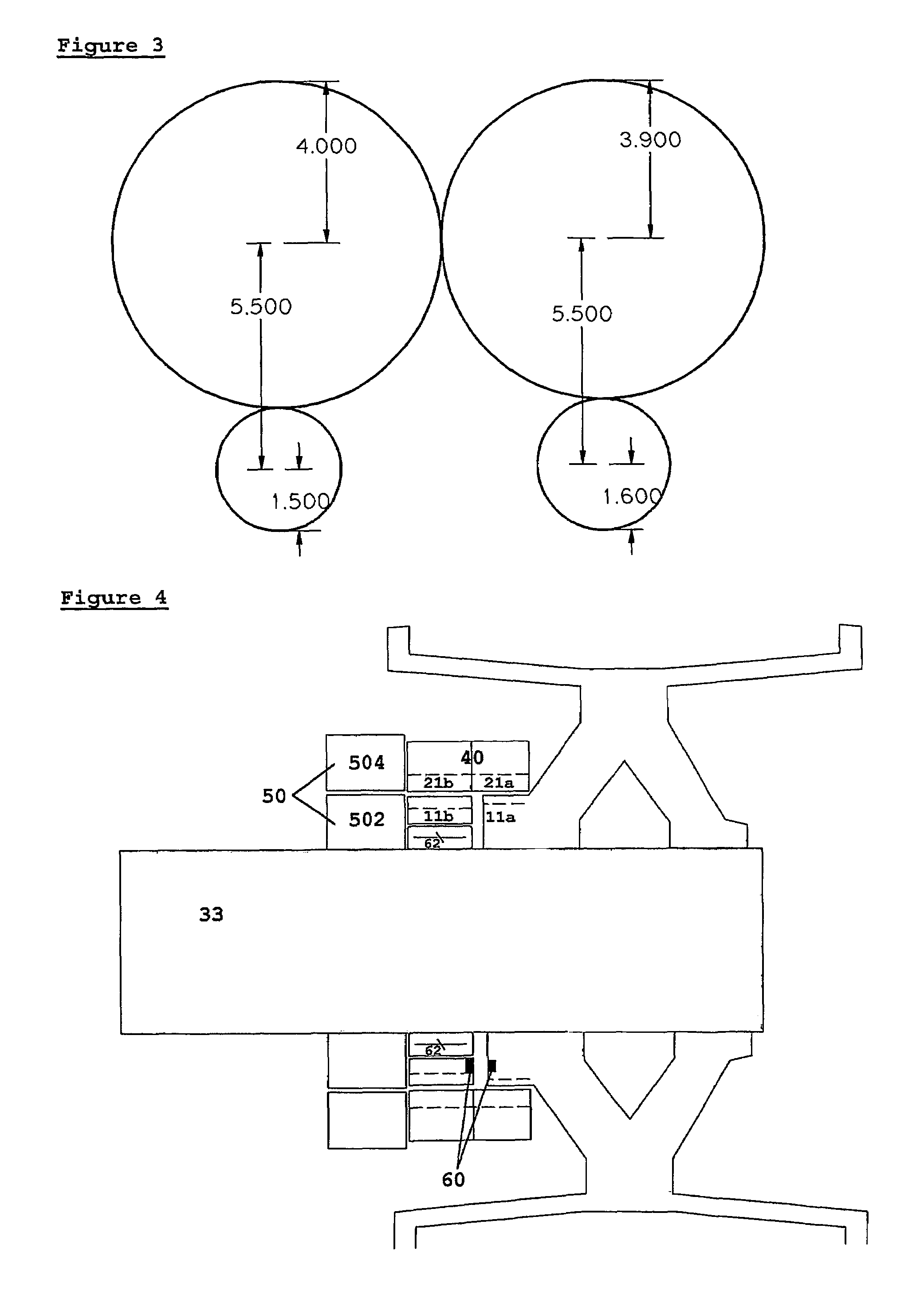

A full-locking differential drive mechanism, comprised of an input drive which is composed of a pair of opposed spaced drive races, each having an inner diameter, a coupling block disposed between the races for coupling them to drive together, output driven means comprising a pair of co-axially disposed coupler members, each having an outer diameter disposed within the drive races inner diameters, which produces a bi-directional roller clutch disposed between the inner diameters and the outer diameters and operative to couple the drive races to the coupler members enabling driving engagement therebetween.

Owner:ZENTMYER JOHN

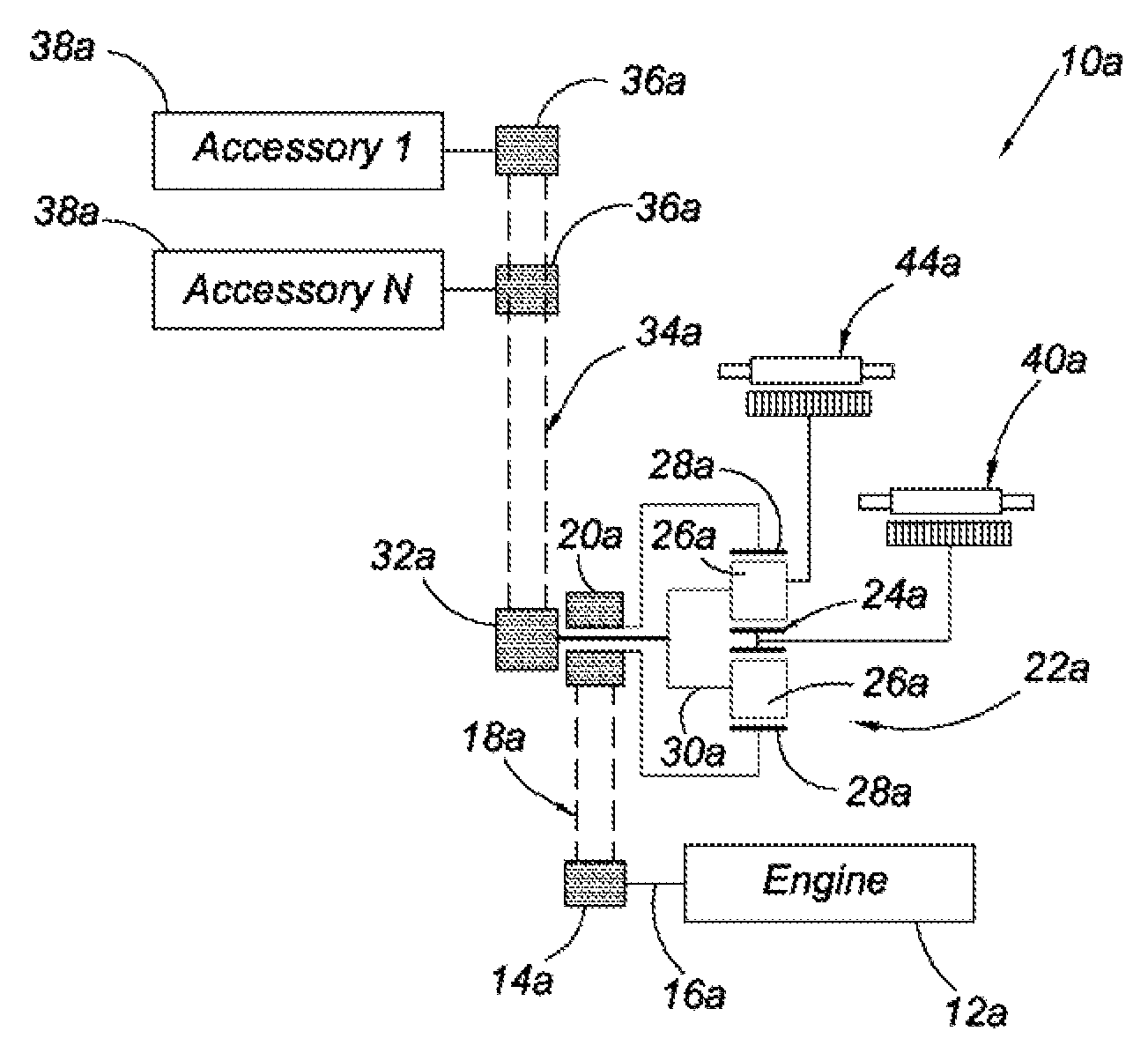

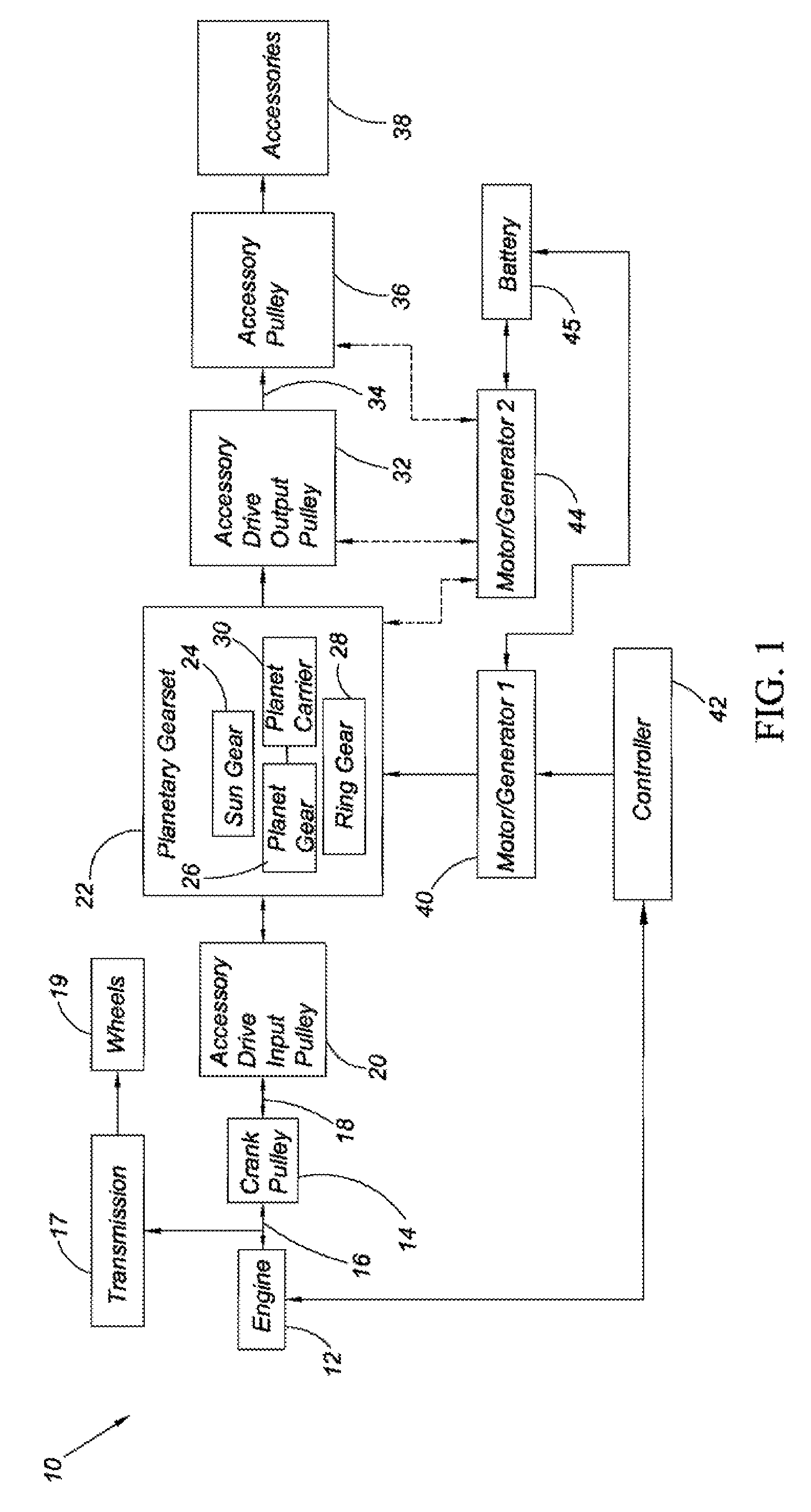

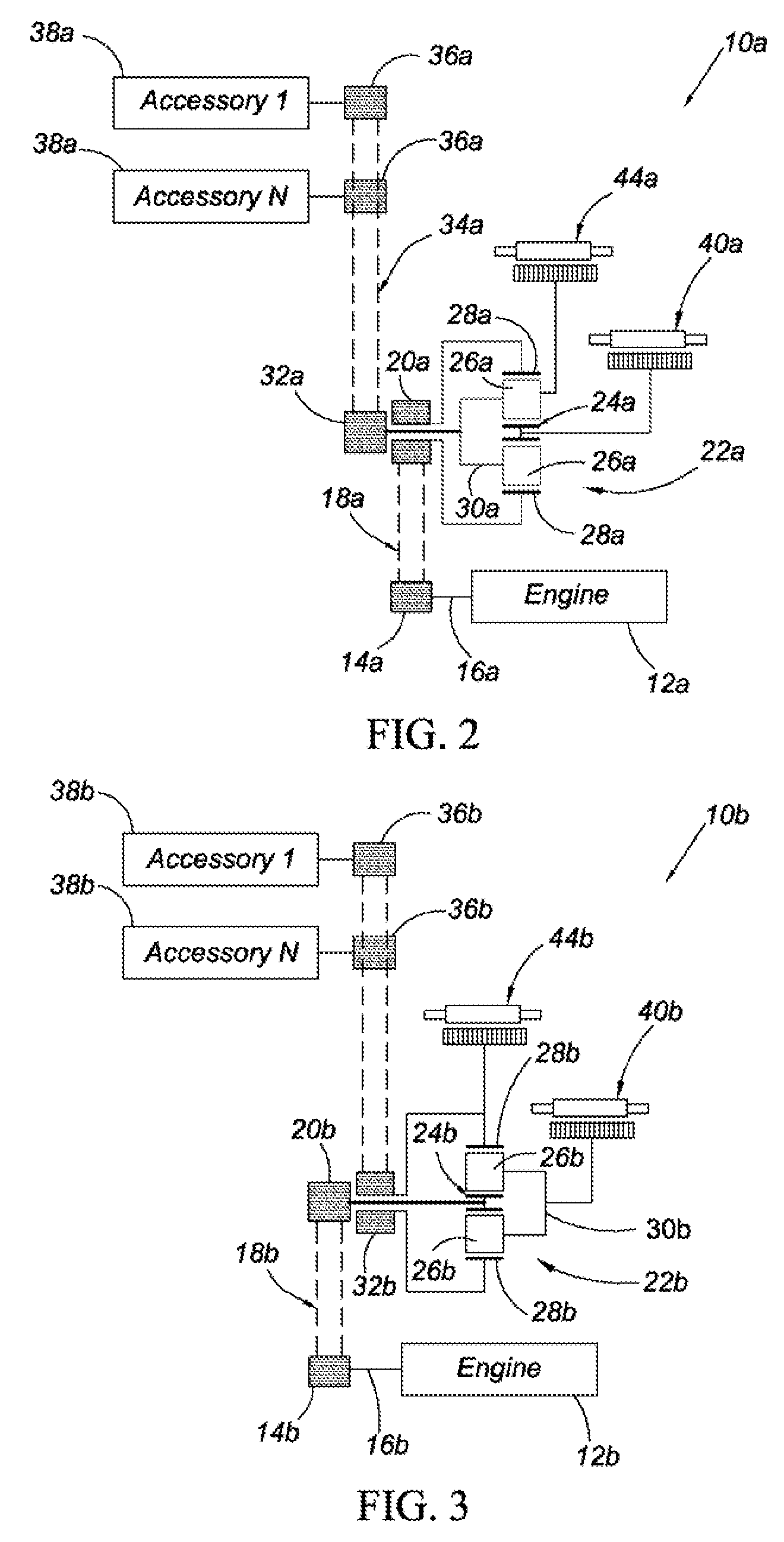

Starter alternator accessory drive system for a hybrid vehicle

The present invention provides an alternator starter accessory drive system for a hybrid vehicle. The starter alternator accessory drive system includes a planetary gear set having a first, second, and third planetary member. An engine is operatively connected to the first planetary member, and a first motor / generator is operatively connected to the second planetary member. A torque transfer device operatively connects a plurality of accessories to the third planetary member. A second motor / generator is operatively connected to either the third planetary member or the torque transfer device. Engine output is transferable through the planetary gear set to drive the accessories at a selectable rate, and the first and second motor / generators are controllable to run the accessories while the engine is off and to re-start the engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

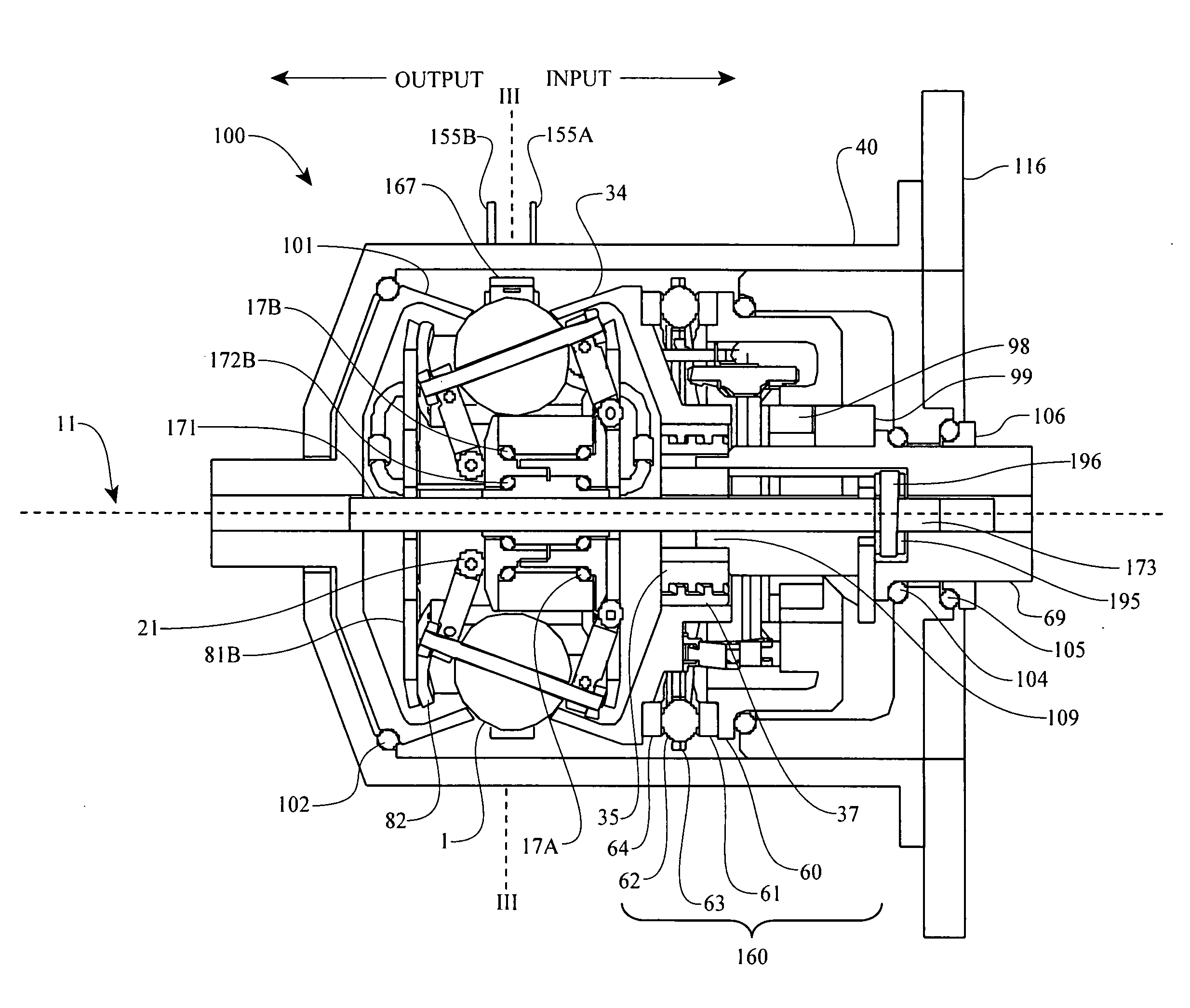

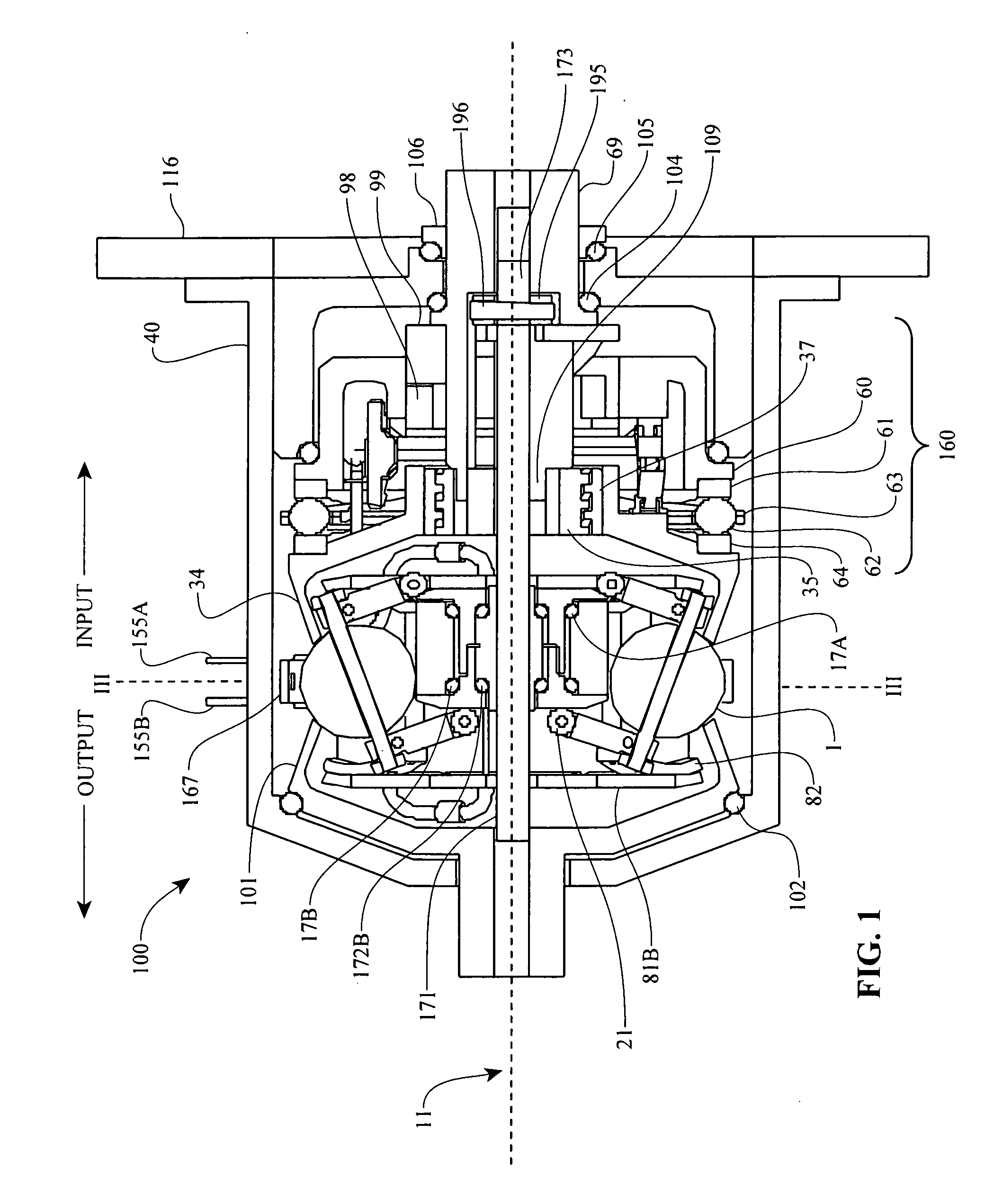

Electromotive drives

A transmission having a plurality of tilting balls and opposing input and output discs provides an infinite number of speed combinations over its transmission ratio range. The transmission provides multiple powerpaths and can be combined with electrical components to provide motor / generator functionality, which reduces the overall size and complexity of the motor and transmission compared to when they are constructed separately. In one embodiment, rotatable components of a continuously variable transmission are coupled separately to an electrical rotor and to an electrical stator so that the rotor and stator rotate simultaneously in opposite directions relative to one another. In other embodiments, an electrical rotor is configured to transfer torque to or from a disc that is in contact with a plurality of speed adjusters, while an electrical stator is configured to transfer torque to a shaft that is operationally coupled to the speed adjusters via an idler.

Owner:FALLBROOK INTPROP COMPANY

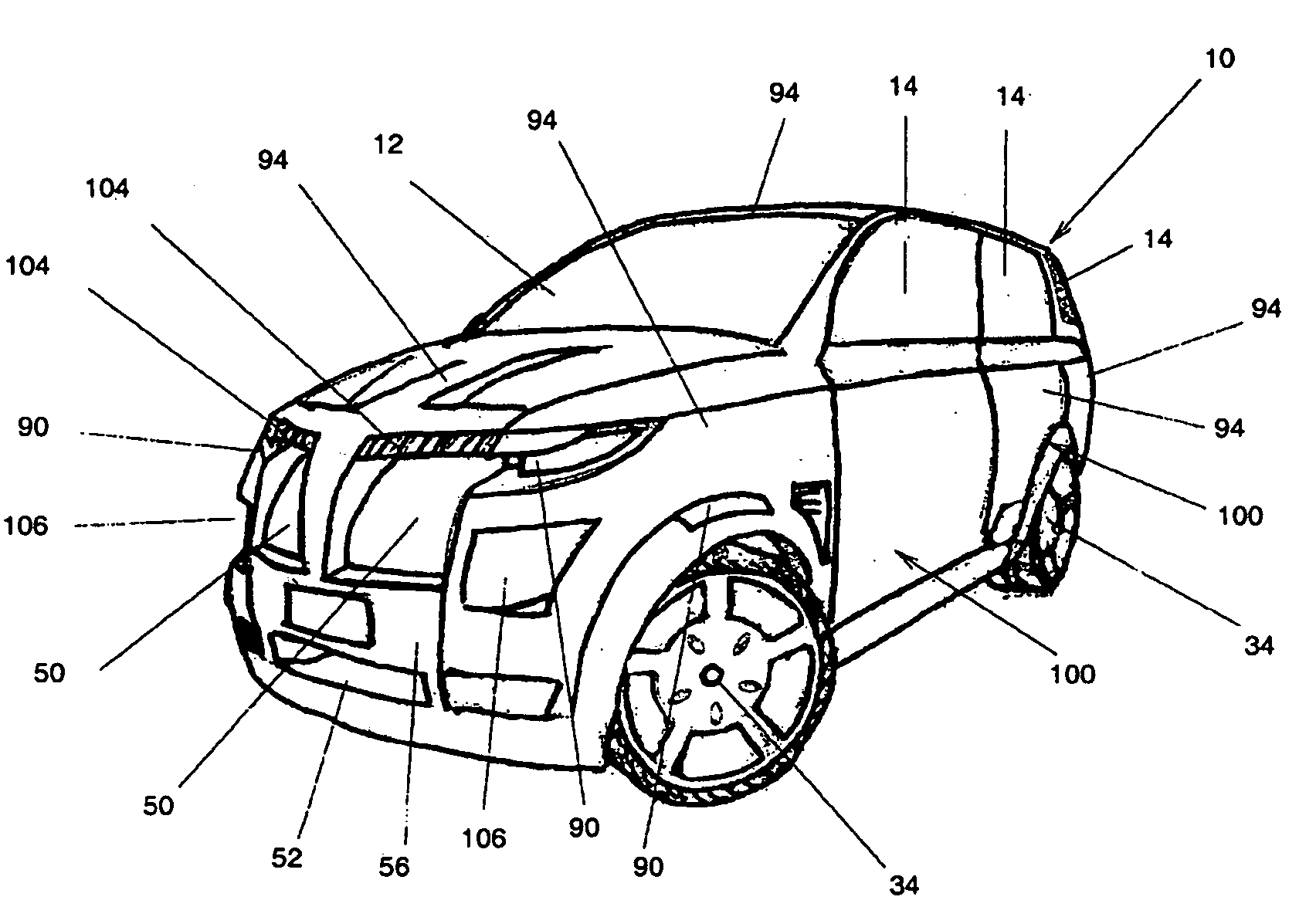

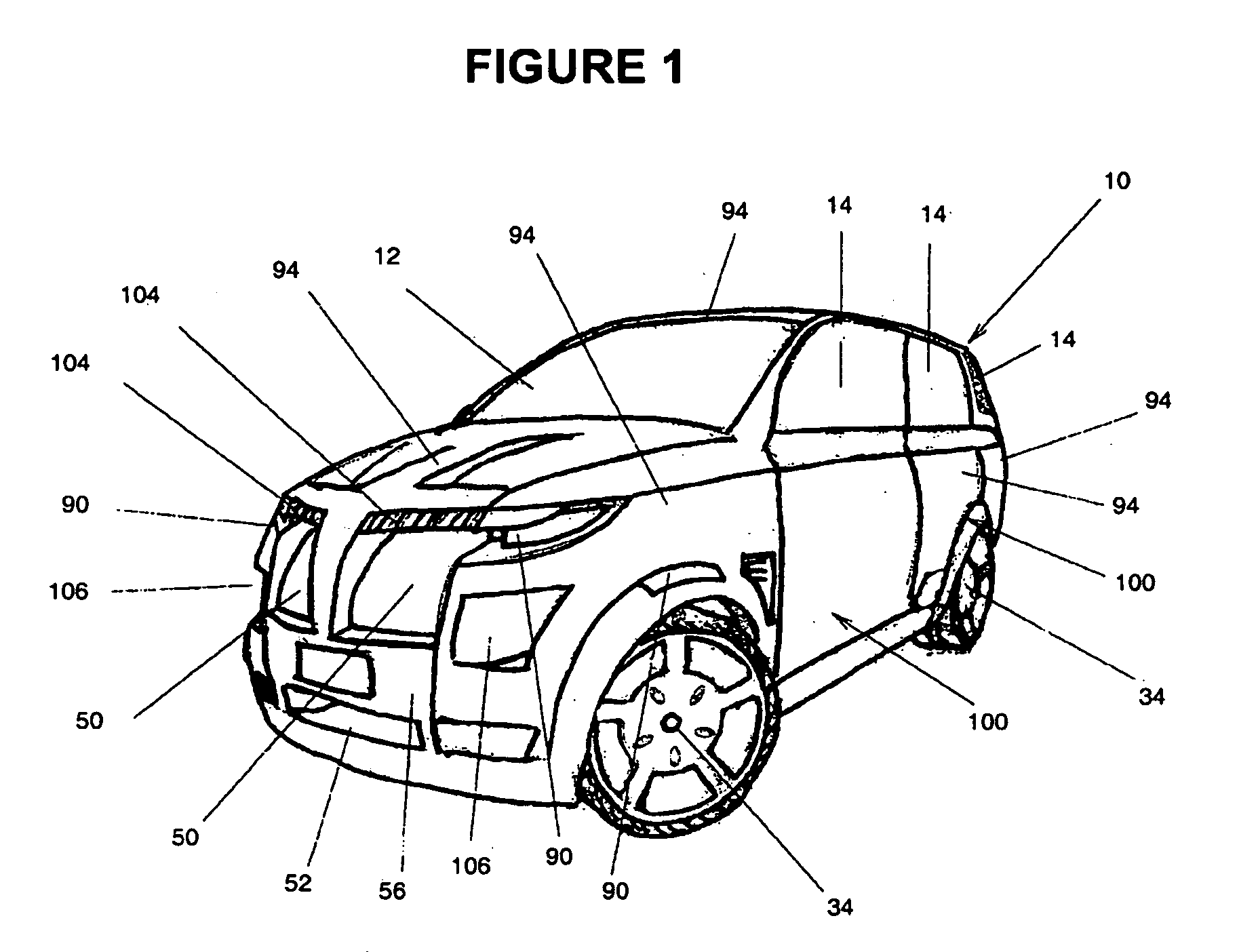

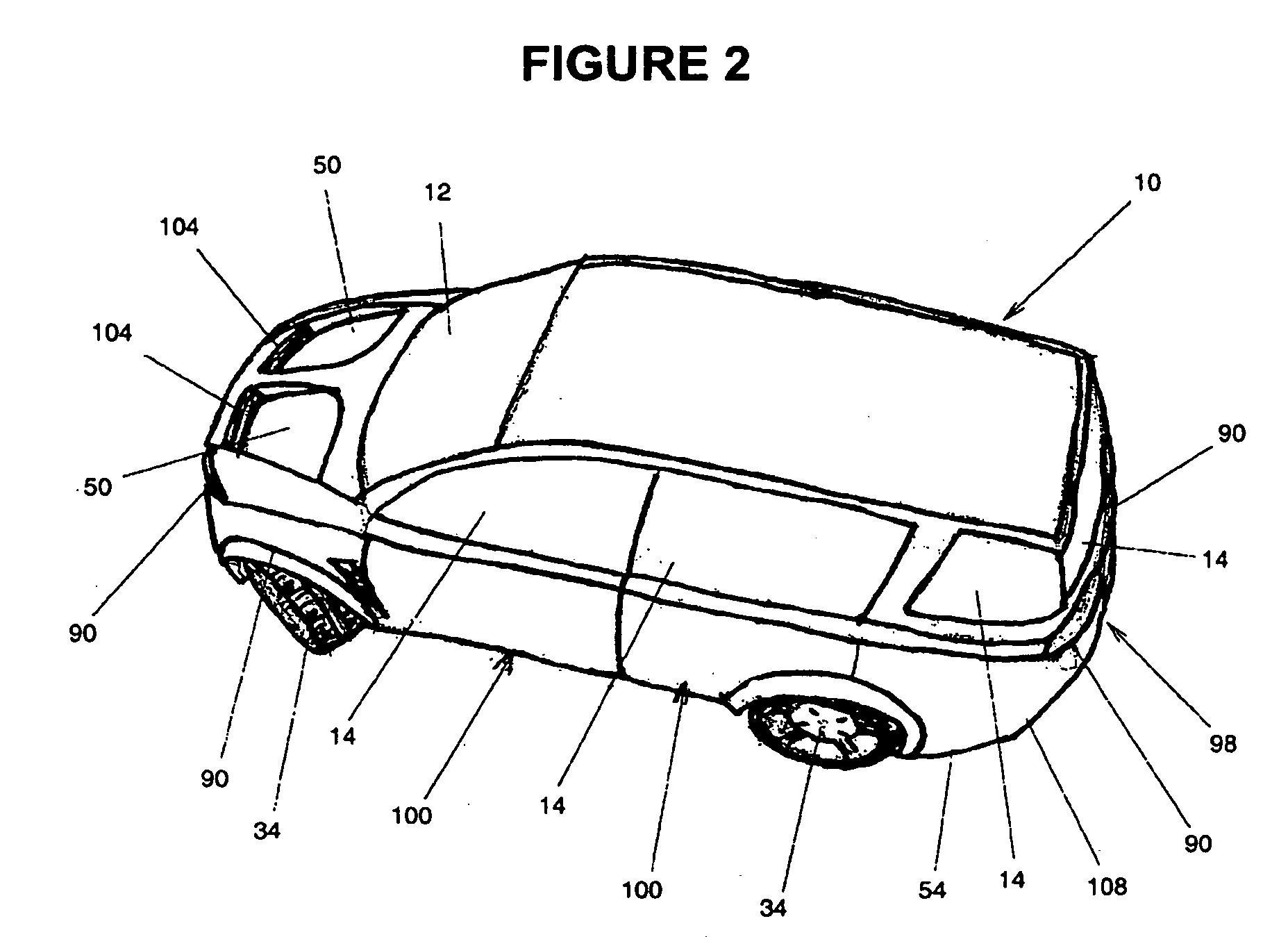

Hybrid electric vehicle

InactiveUS20090145674A1Improve energy efficiencyEasy to operateVehicle seatsDigital data processing detailsRolling resistanceAerodynamic drag

A highly energy efficient automobile that provides payload, safety and performance capacities similar to a comparable vehicle of a given vehicle class. The current invention is ideal for short to medium range urban and suburban driving. The current invention incorporates components in a unique and novel way, in which these components combine to form a system that produces an automobile that reduces overall air pollution while encouraging the commercialization of alternative energy sources. The current invention features an lightweight, low rolling resistance, digitally controlled and direct-drive electric propulsion system. A lightweight spaceframe with a suspension system provides a structure for mounting a low-aerodynamic-drag body system and other components. An intelligent power and thermal management system coupled with a removable auxiliary power module supplies the electrical energy required. While the preferred embodiment is substantially a passenger vehicle, the current invention may be scaled to other land vehicles.

Owner:INT HUMANITIES CENT

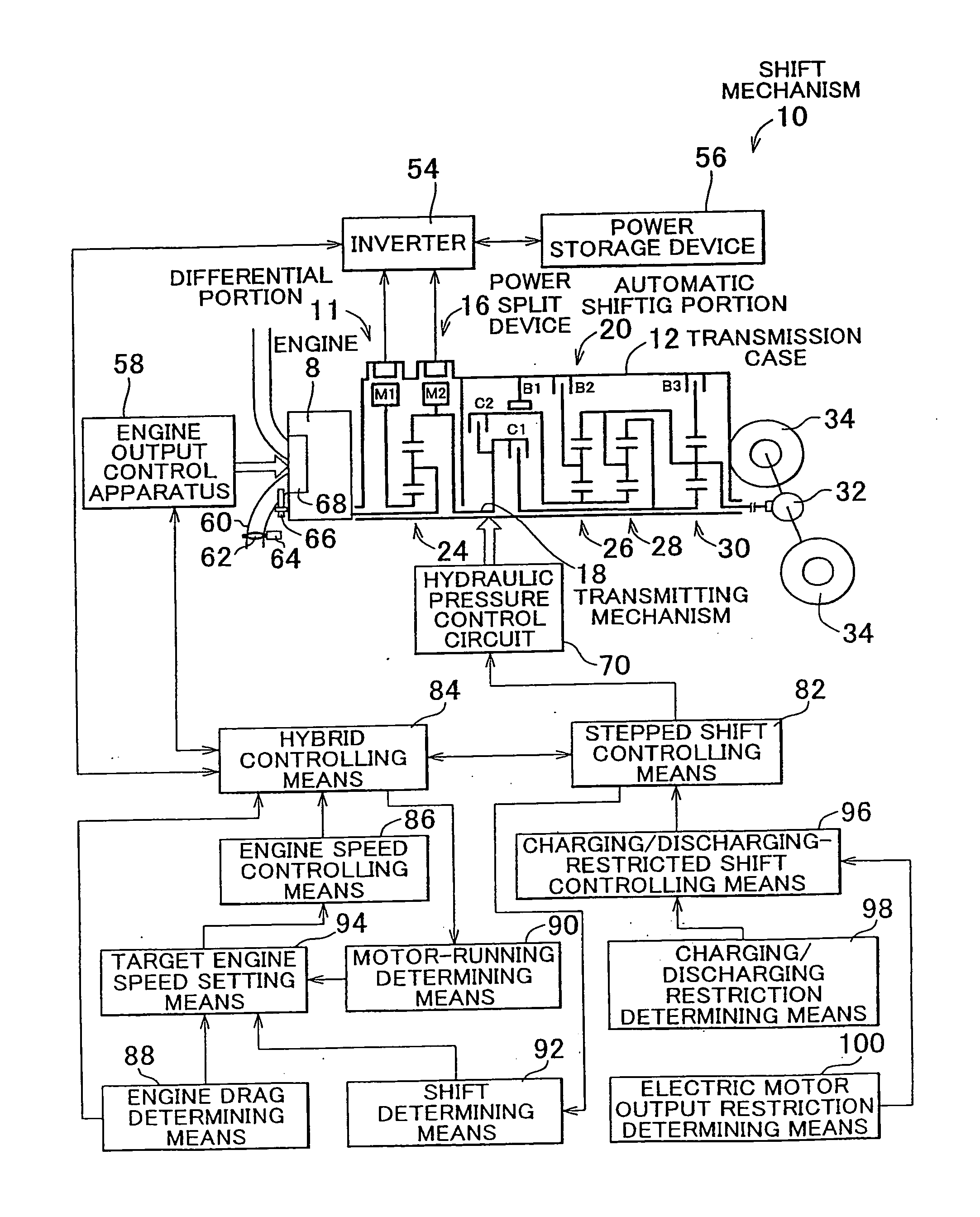

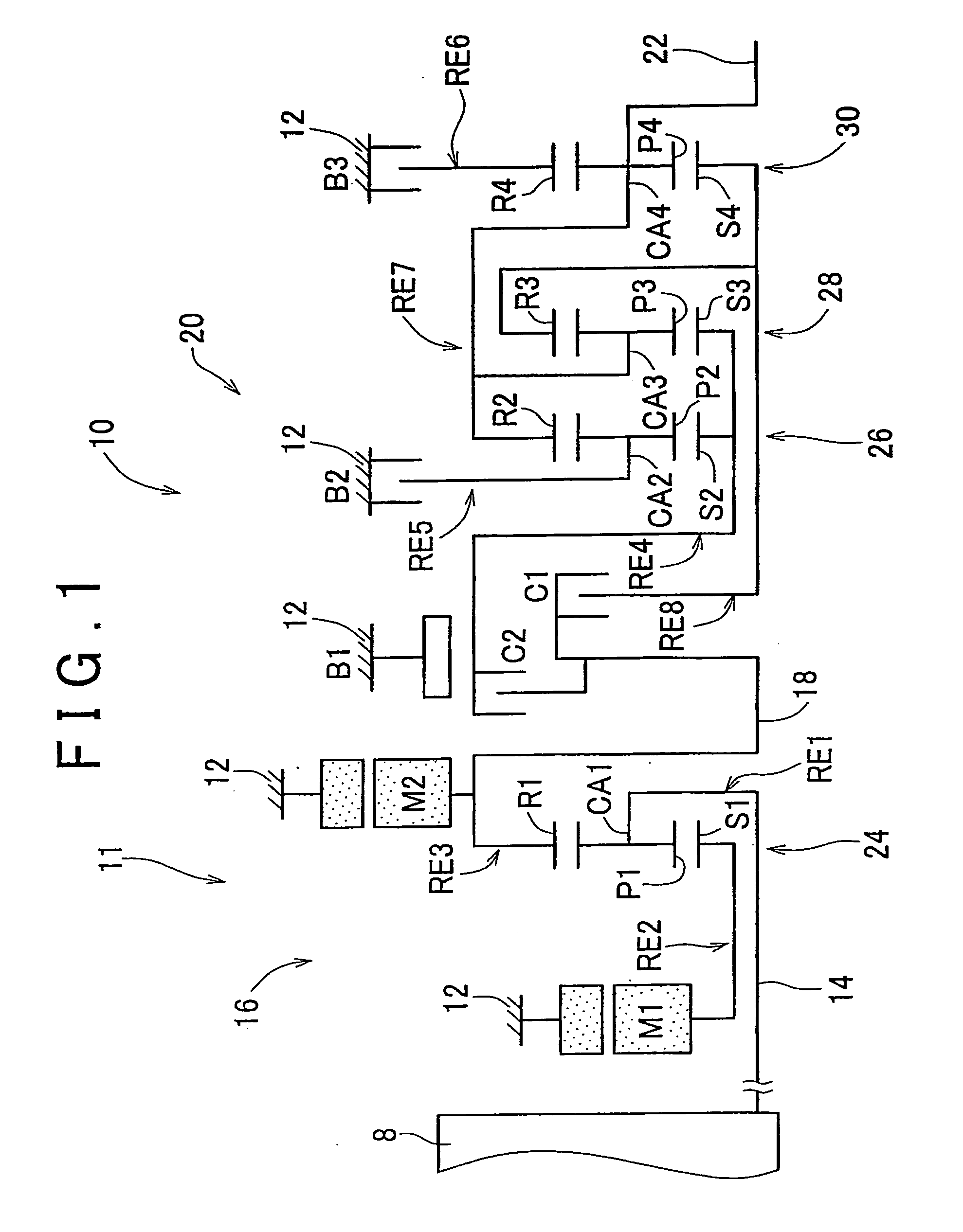

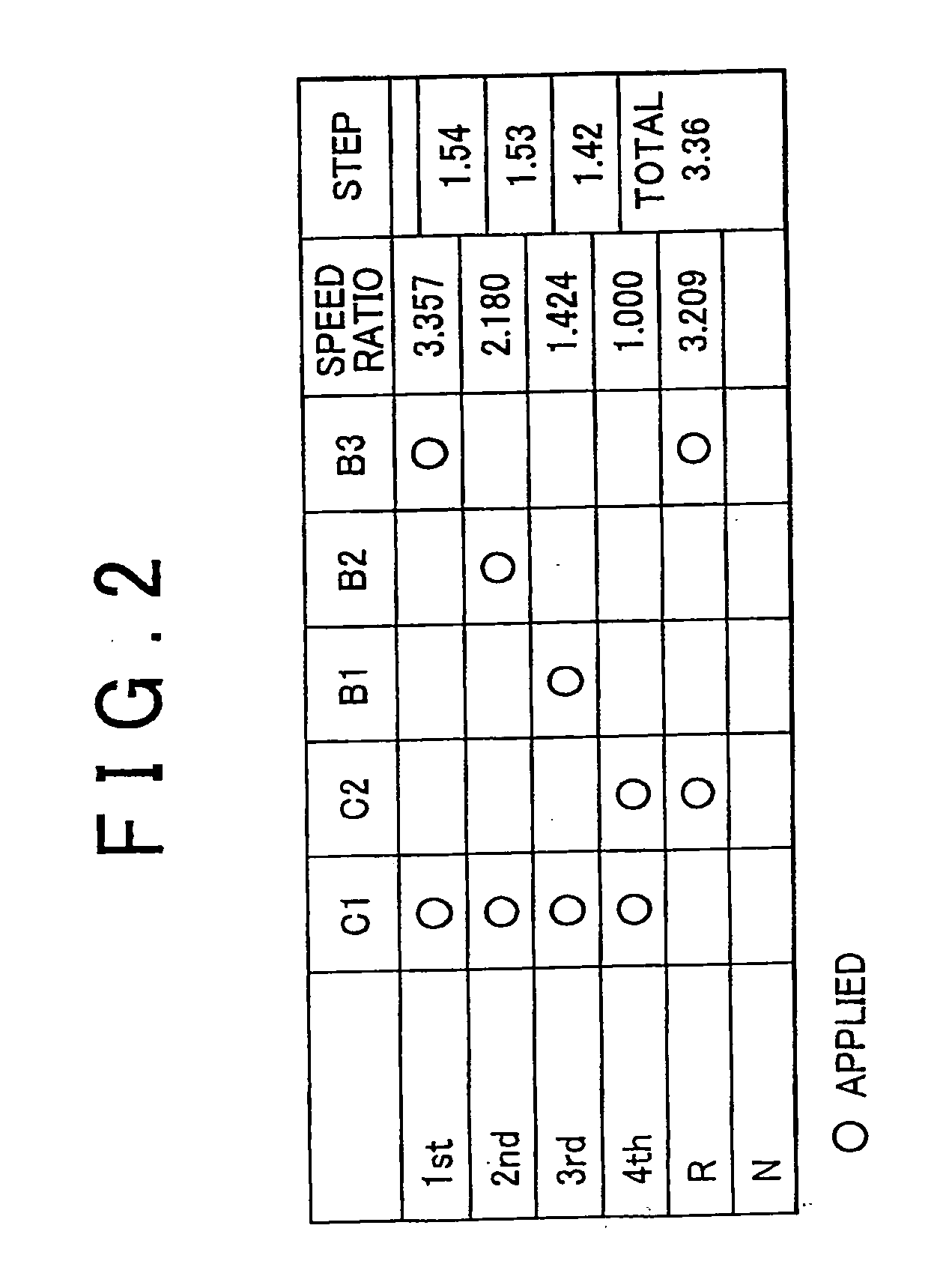

Control apparatus and control method for vehicular drive system

InactiveUS20080149407A1Easy to controlBatteries circuit arrangementsDigital data processing detailsEngineeringElectric power

In a control apparatus of a vehicular drive system, a charging / discharging-restricted shift control apparatus makes a determination to perform a shift in a shifting portion such that less power is charged to a power storage device or discharged from a power storage device when charging or discharging of the power storage device is restricted than when charging or discharging of the power storage device is not restricted.

Owner:TOYOTA JIDOSHA KK

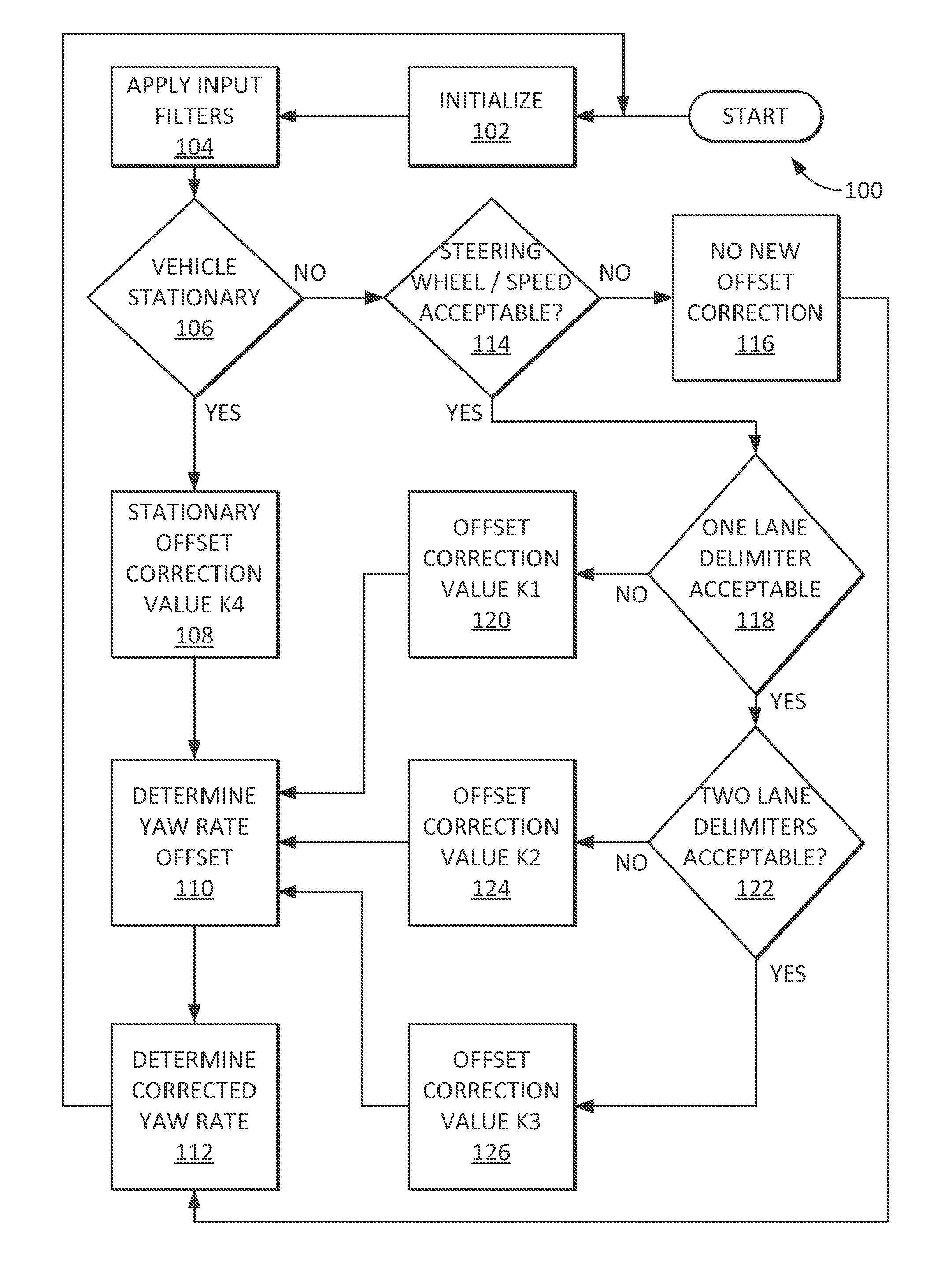

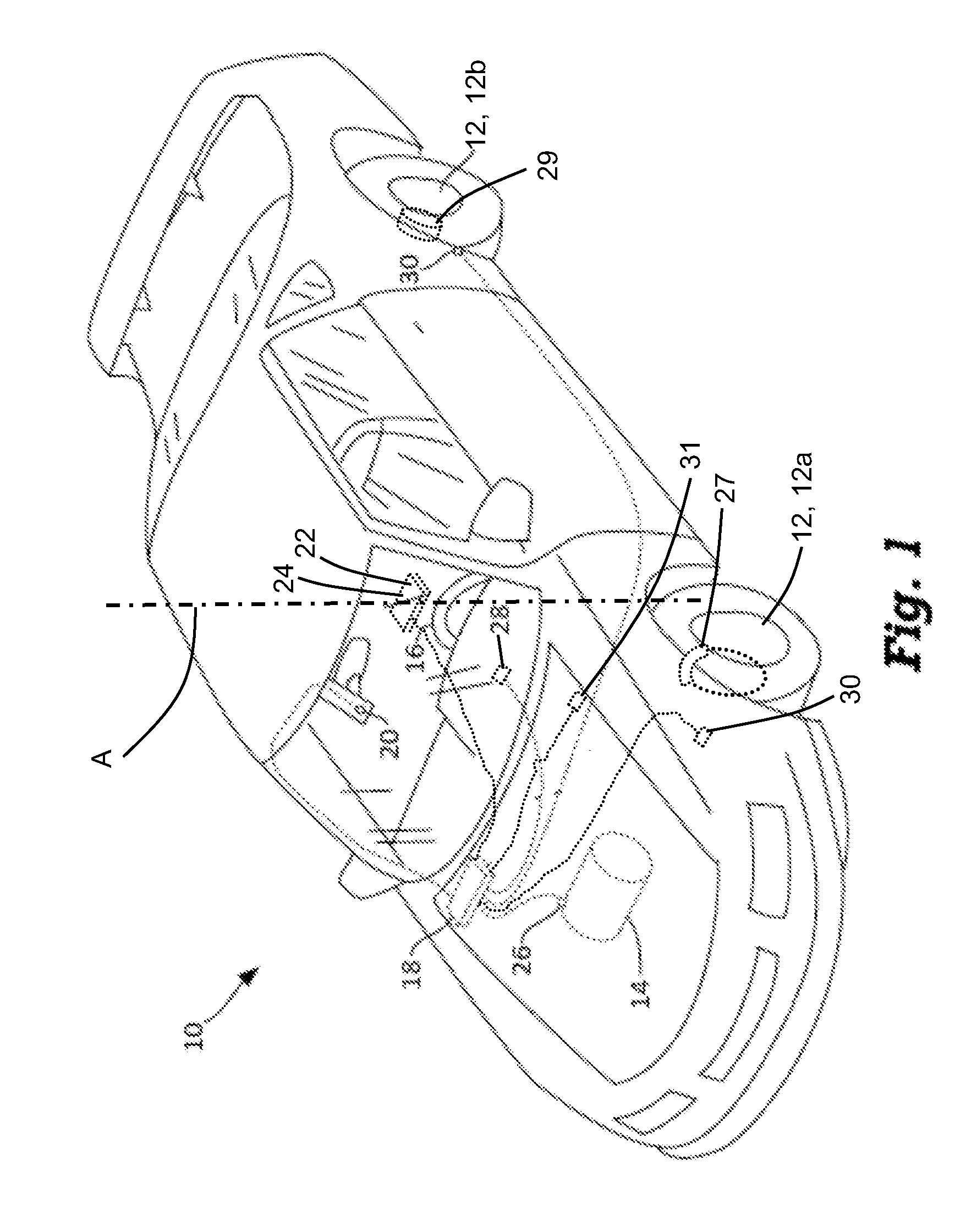

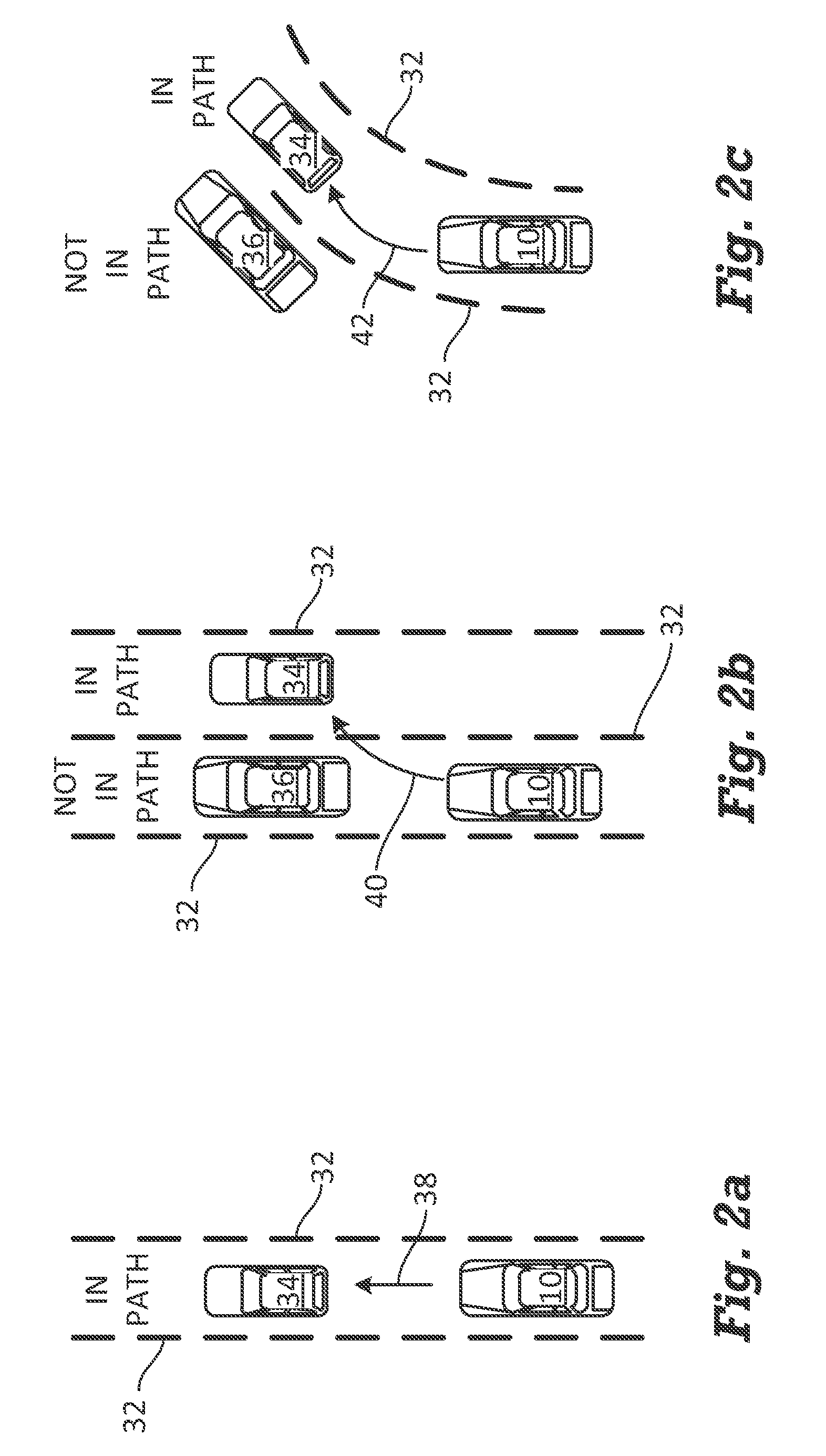

Vehicle yaw rate correction

A control system or method for a vehicle references a camera and sensors to determine when an offset of a yaw rate sensor may be updated. The sensors may include a longitudinal accelerometer, a transmission sensor, a vehicle speed sensor, and a steering angle sensor. The offset of the yaw rate sensor may be updated when the vehicle is determined to be stationary by referencing at least a derivative of an acceleration from the longitudinal accelerometer. The offset of the yaw rate sensor may be updated when the vehicle is determined to be moving straight by referencing at least image data captured by the camera. Lane delimiters may be detected in the captured image data and evaluated to determine a level of confidence in the straight movement. When the offset of the yaw rate sensor is to be updated, a ratio of new offset to old offset may be used.

Owner:MAGNA ELECTRONICS INC

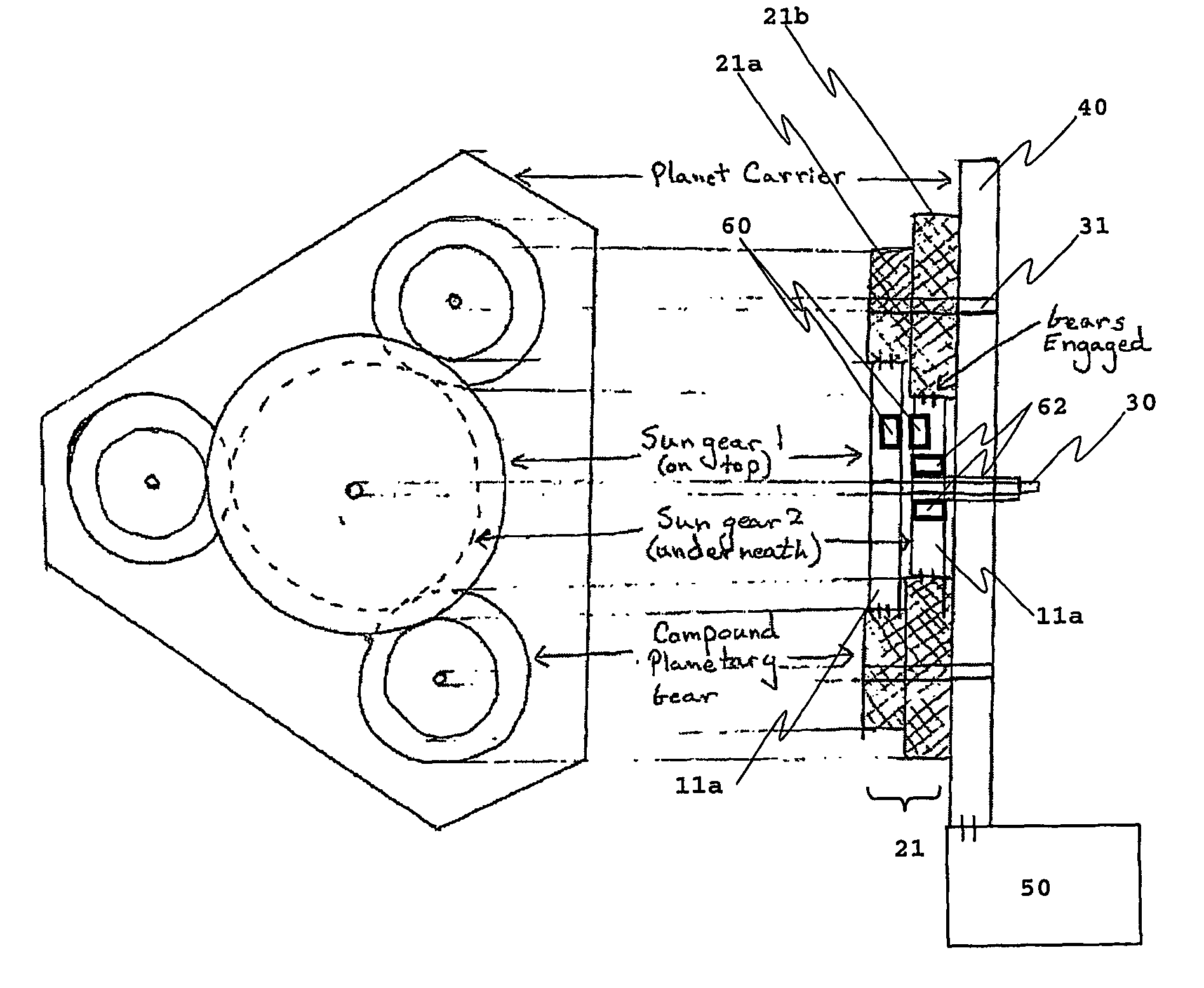

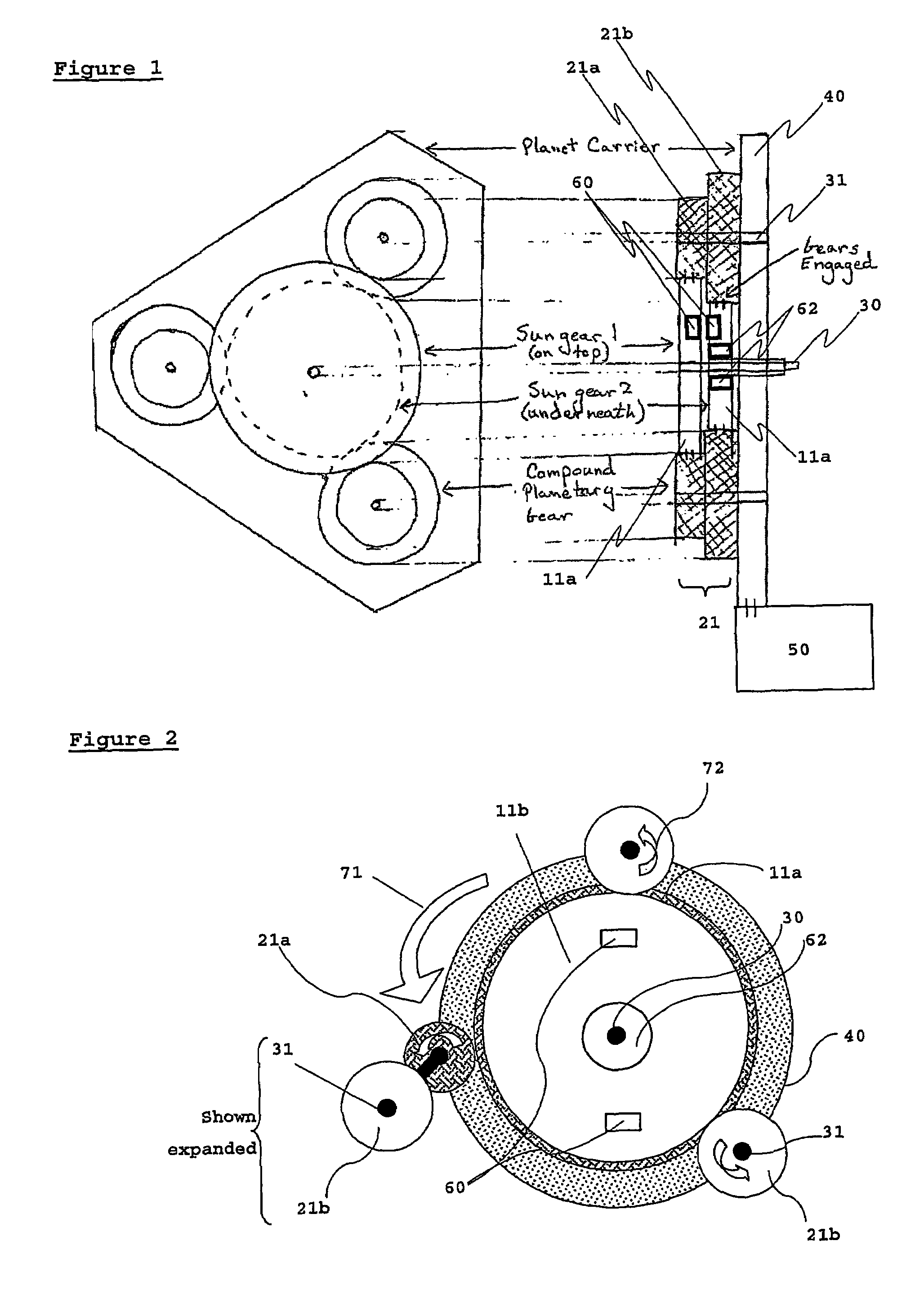

Geared wheel motor design

InactiveUS7469858B2High levelLower levelEnergy efficient operational measuresToothed gearingsGear wheelGear system

The present invention is a compound planetary gear system which has a moveable sun gear and a lockable sun gear to change the gear ratio between a high gear ratio and a pseudo 1:1 slipping ratio. The system makes use of a ratchet and pawl mechanism to provide a safety backup for when the lockable sun gear is locked. The invention may be used to move the aircraft from a stationary position, for taxiing, and for pre-rotating the wheels prior to landing.

Owner:BOREALIS TECH LTD

Electric traction drives

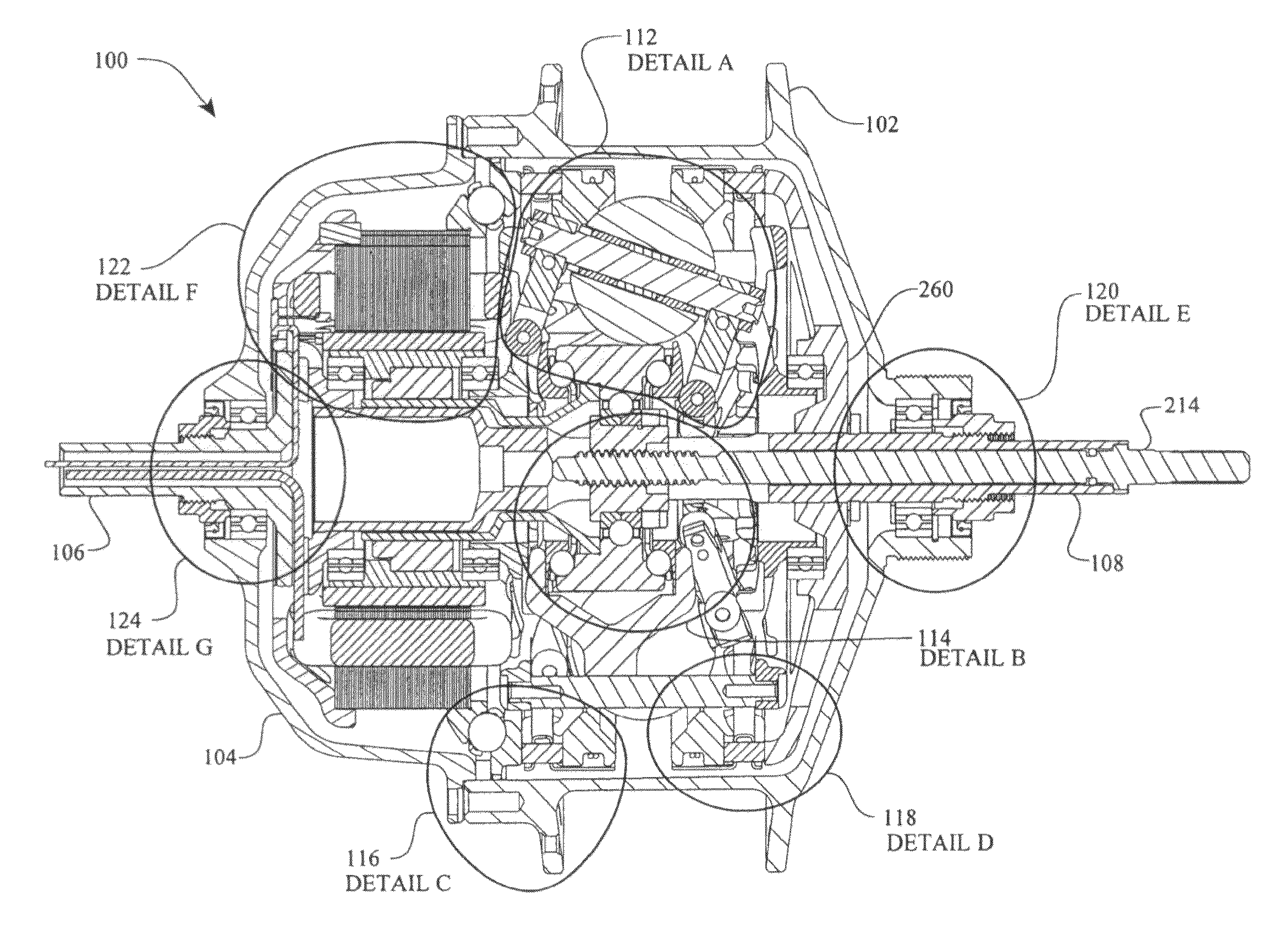

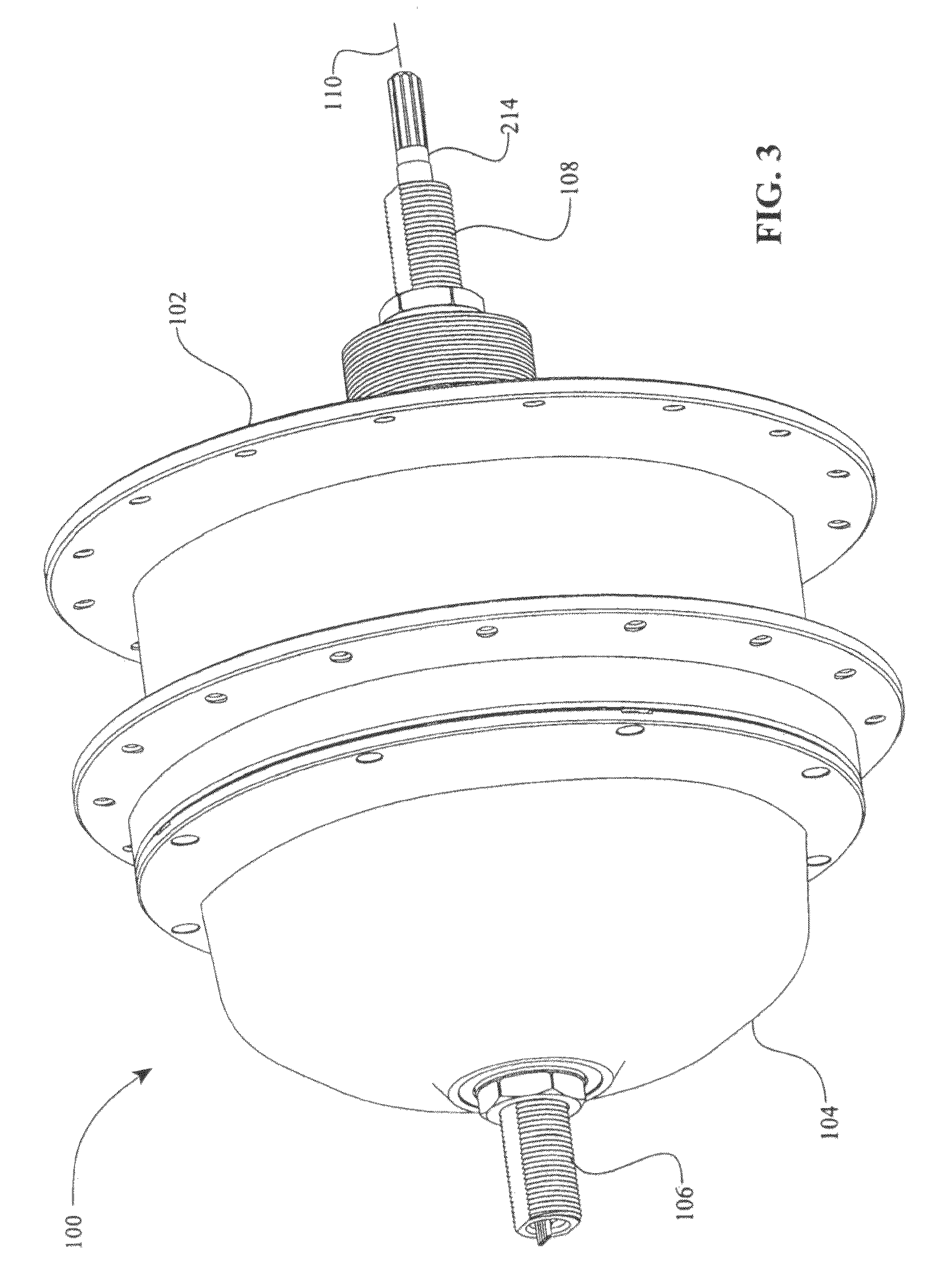

Inventive embodiments are directed to components, subassemblies, systems, and / or methods for electric traction drives employing a continuously variable transmission (CVT) having a variator provided with a plurality of tilting traction planets and opposing traction rings. In one embodiment, an electric traction drive is provided with an electromotive device configured to transfer power to or from a traction sun of a CVT, In other embodiments, an electric traction drive is provided with an electromotive device that couples to certain components of a CVT such as a traction ring, a carrier assembly, and a main axle. Various inventive shifting assemblies having shift cams and shift cam cages can be used to facilitate adjusting the transmission speed ratio of a CVT. Various related devices include embodiments of, for example, a power input apparatus, a speed ratio shifter, a shift cam actuator, a shift nut, and a carrier assembly configured to support the tilting traction planets.

Owner:FALLBROOK INTPROP COMPANY

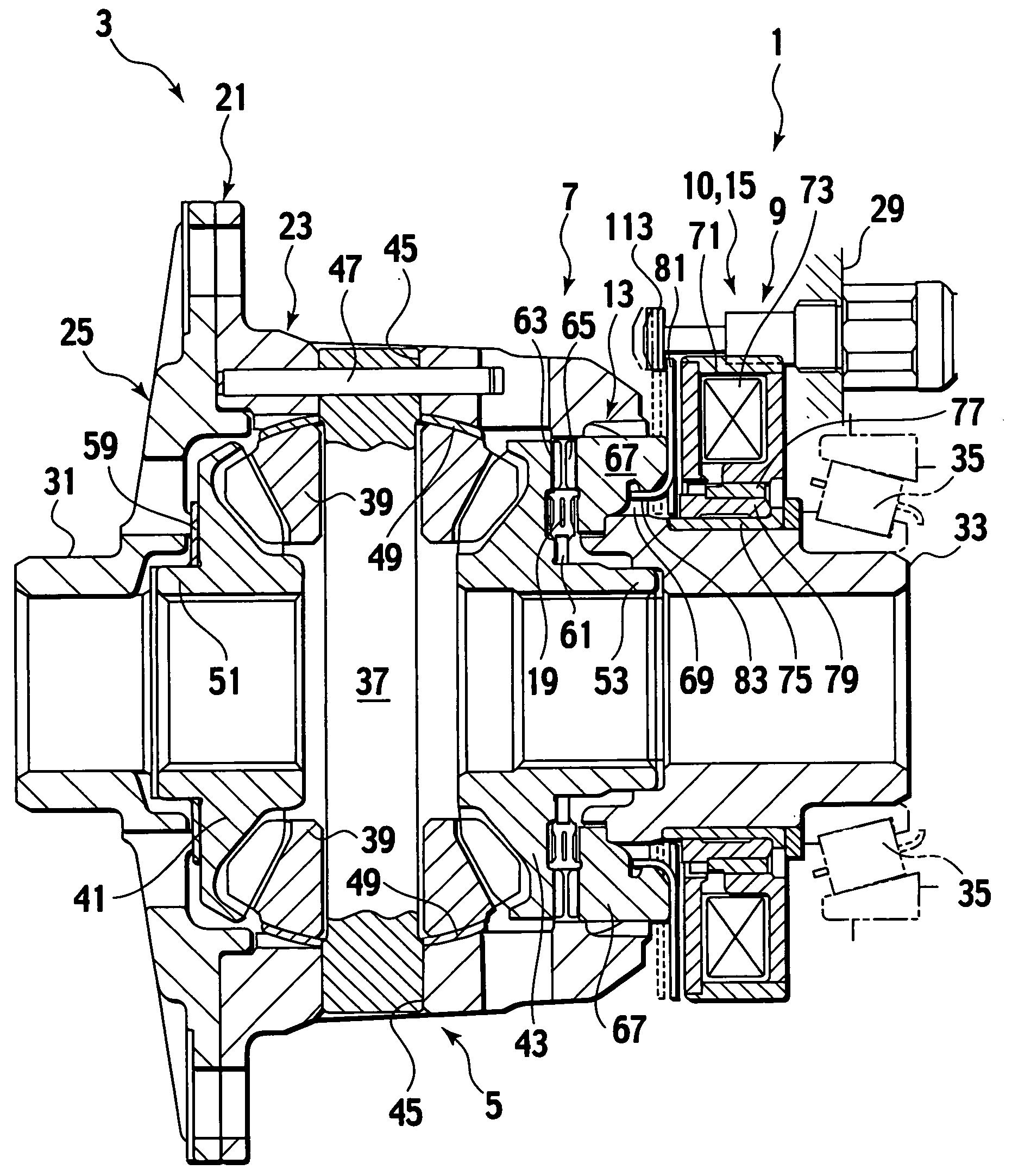

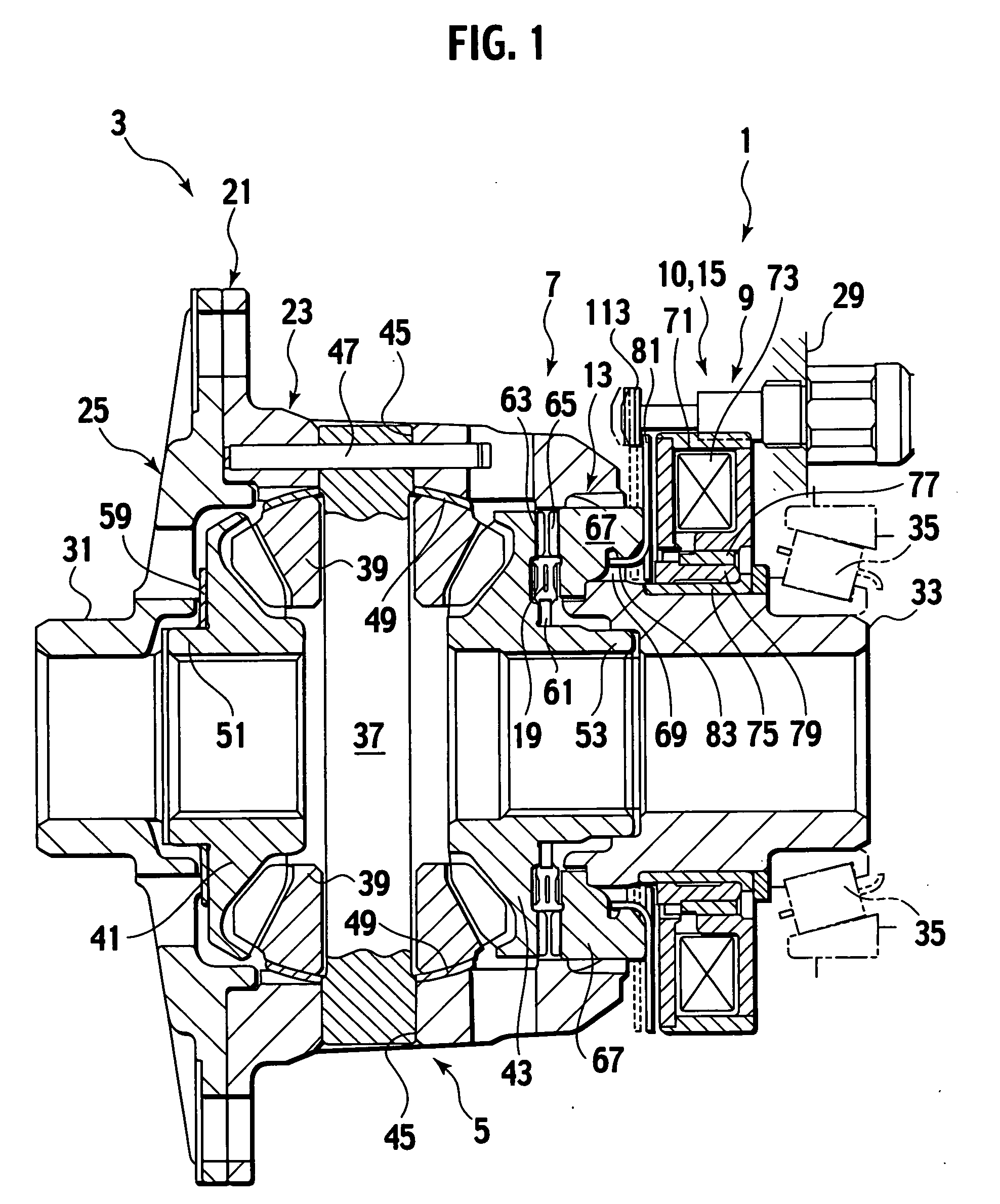

Electromagnetic actuator, and electromagnetic clutch and differential using the same

ActiveUS20050279607A1Inhibit heat generationSuppress power consumptionMechanical actuated clutchesFluid actuated clutchesElectromagnetic clutchEngineering

The electromagnetic actuator includes an electromagnetic coil configured to provide actuation force in accordance with a solenoid current to be supplied, to a clutch and configured to actuate the clutch to control relative rotation between first and second members. The electromagnetic actuator includes a detector configured to detect the clutch actuated to produce a detection signal. The electromagnetic actuator includes a controller configured to respond to the detection signal from the detector to control the solenoid current.

Owner:TOCHIGI FUJI IND CO LTD

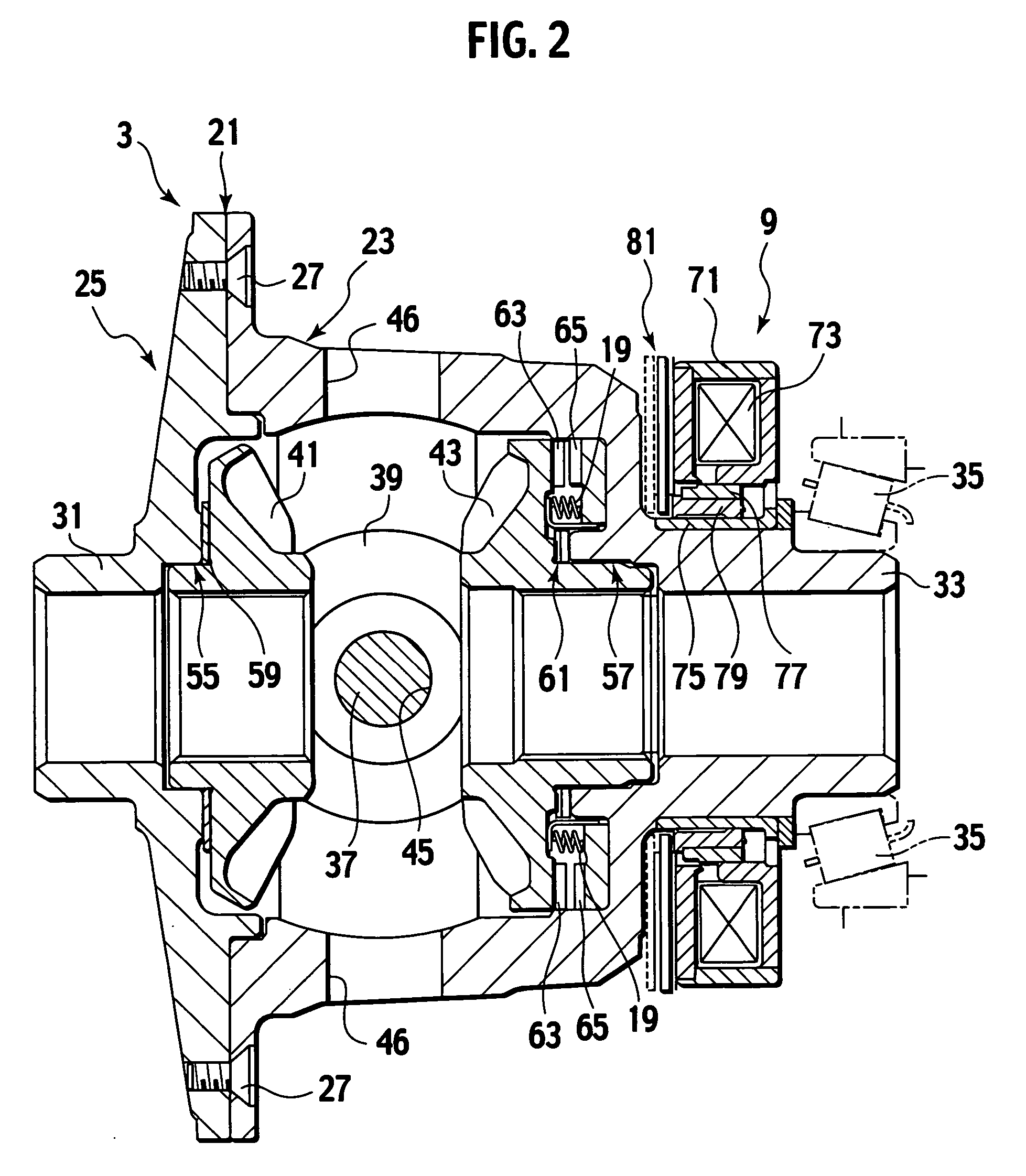

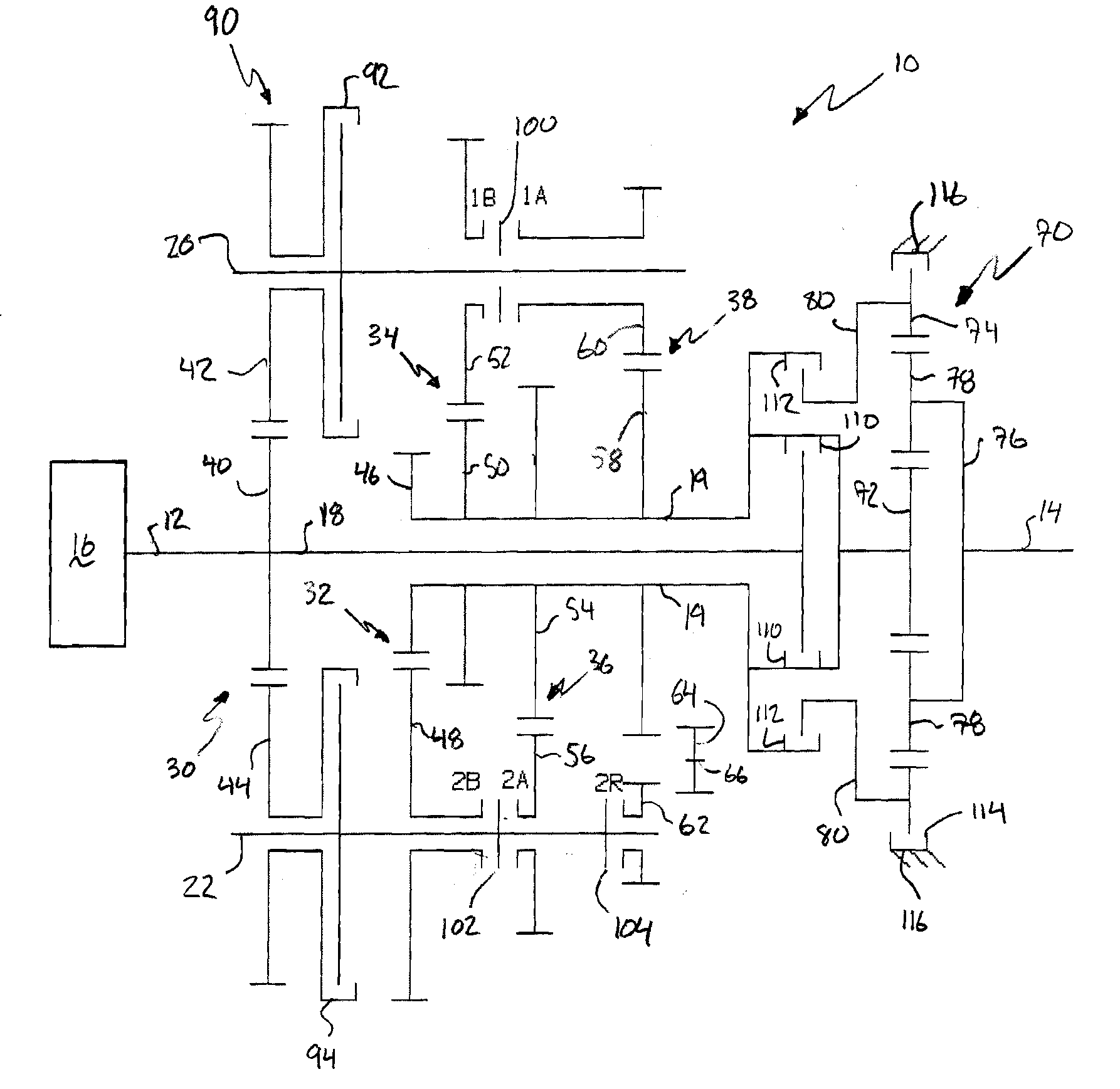

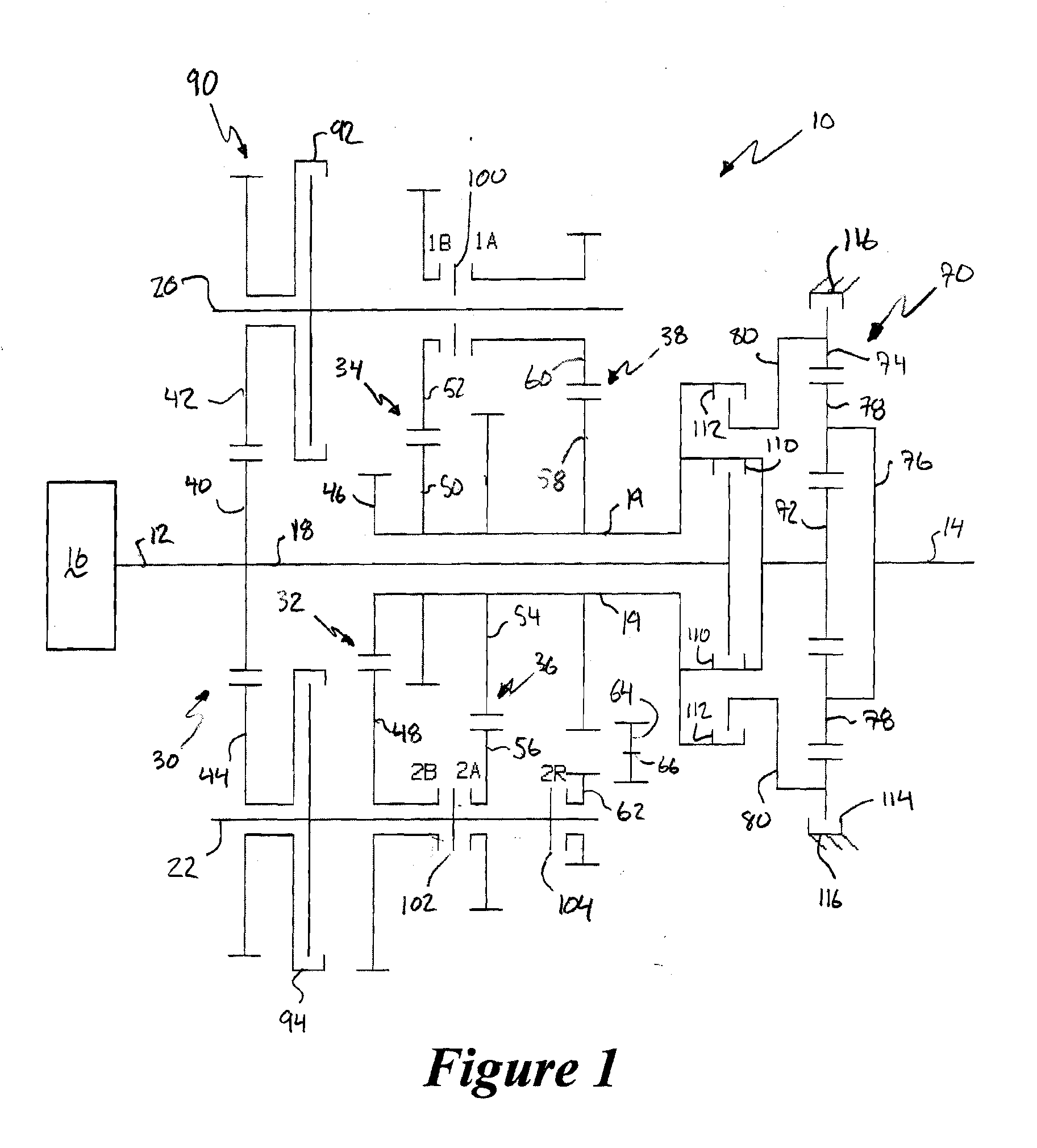

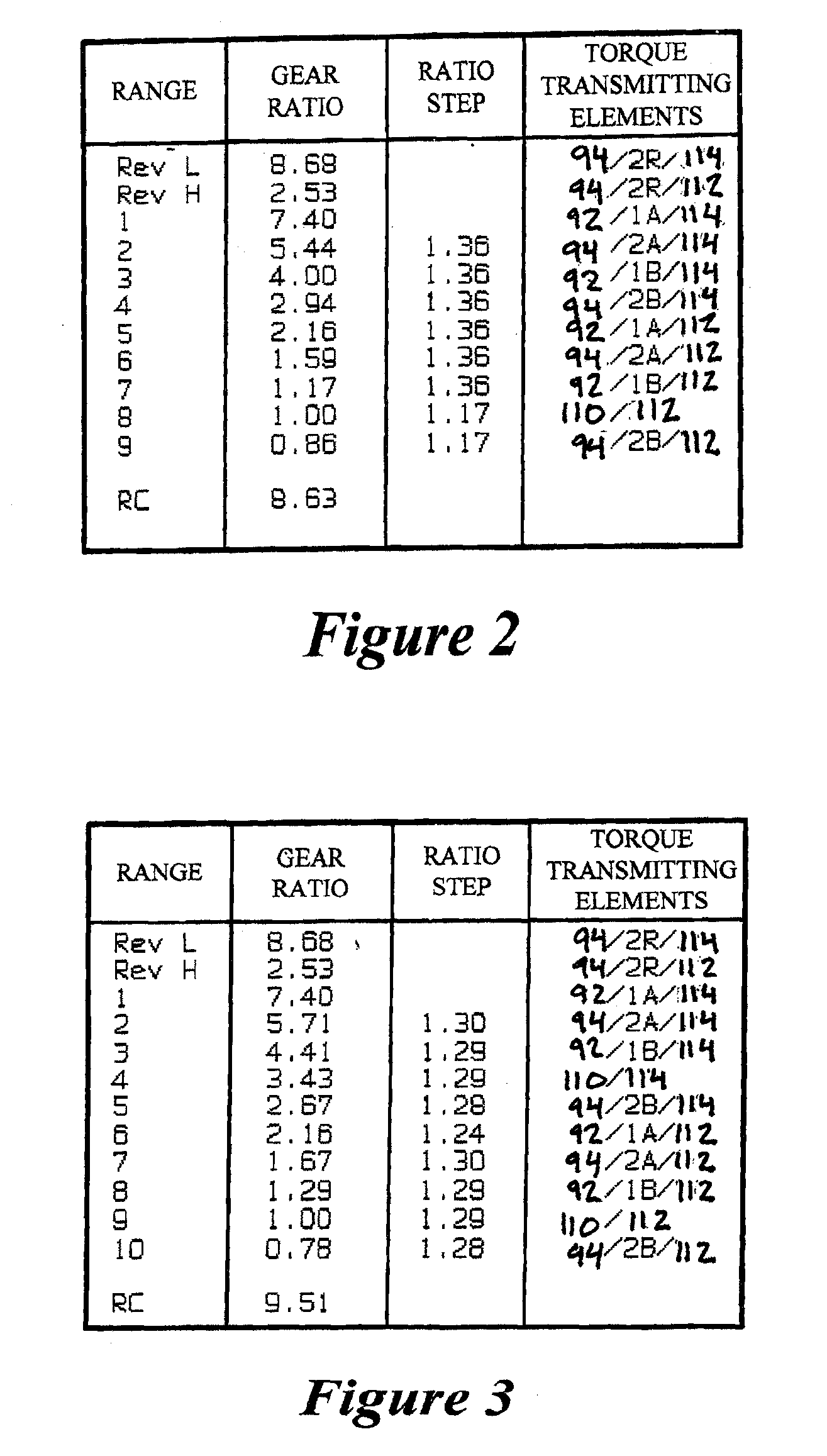

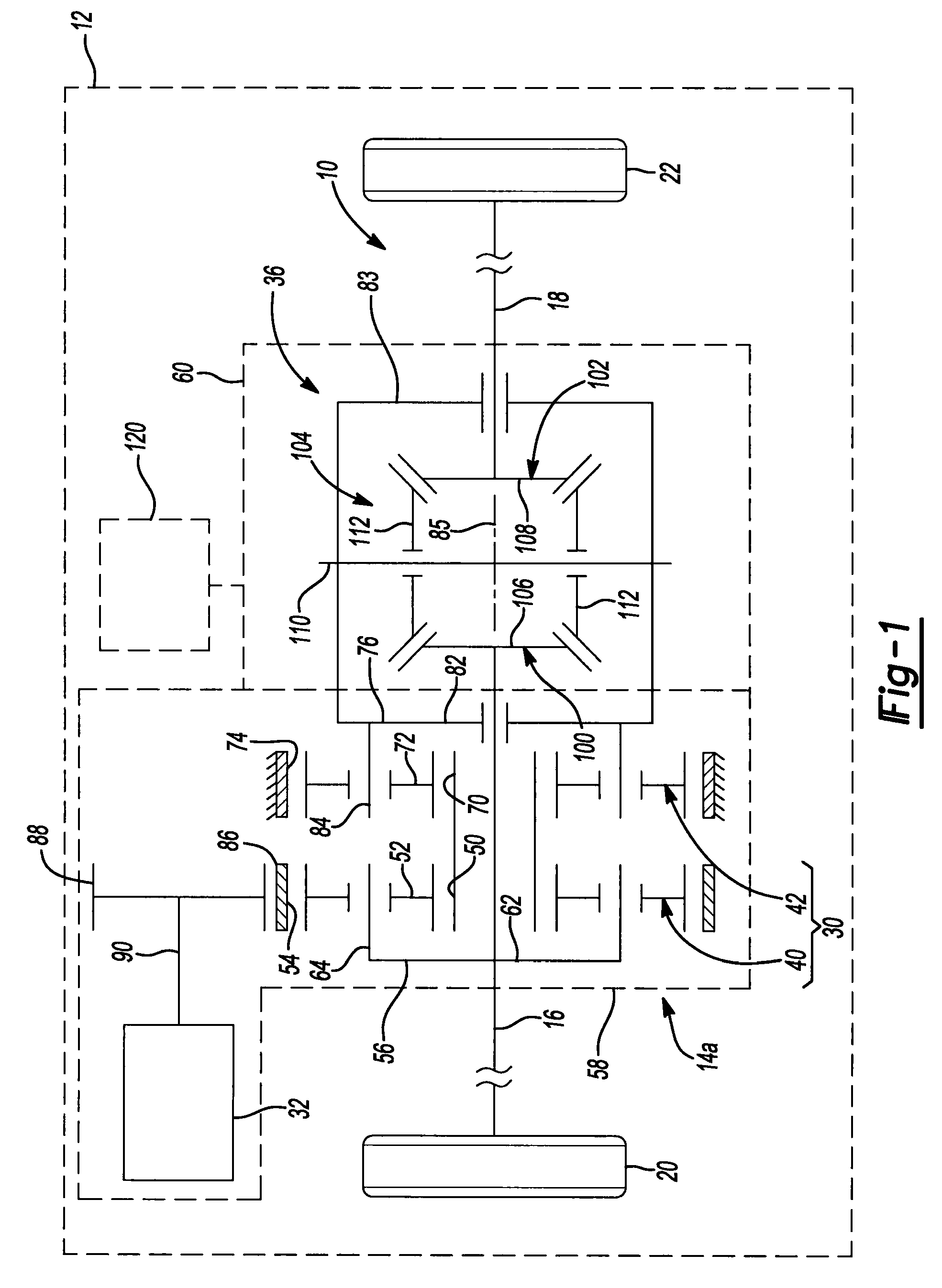

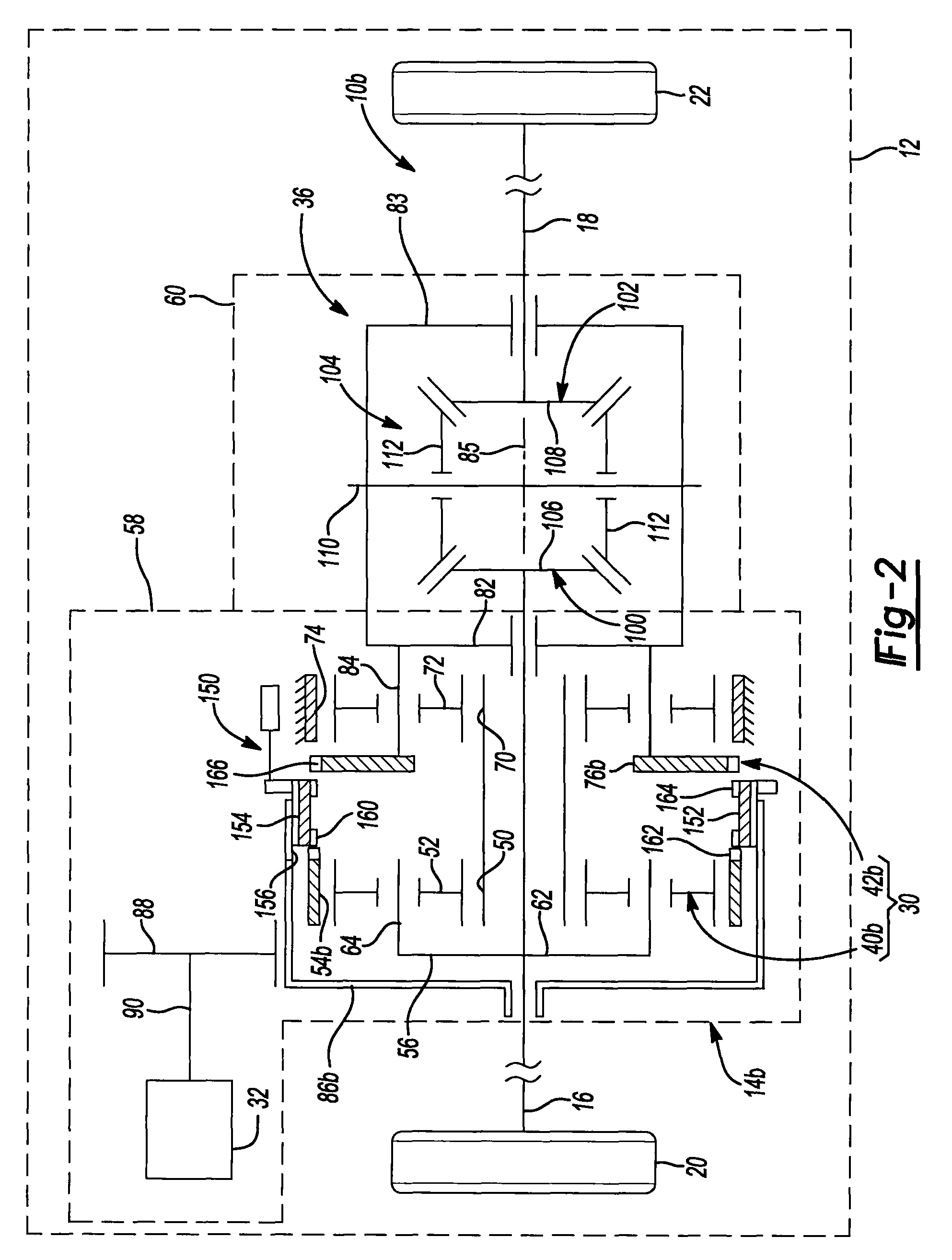

Compound differential dual power path transmission

InactiveUS20050227803A1Wider ratio spreadTransmission relatively inexpensive and efficientHybrid vehiclesElectric propulsion mountingGear wheelTorque transmission

A vehicle transmission includes a differential gearset having five coaxial gear elements and two output members. Two of the gear elements are controllable via torque-transmitting devices such as friction brakes or electric motors to establish a plurality of speed ratios between the input shaft and the two output members. The two output members are selectively operatively connectable to an output shaft via a gear arrangement that allows for a plurality of speed ratios between the output members and the output shaft. If the torque-transmitting devices are electric motors or hydraulic pumps, then a continuously variable speed ratio between the input shaft and the output shaft is achievable. The plurality of speed ratios between the two output members and the output shaft enable a plurality of compound split operating modes, facilitating smaller and less powerful motors or pumps compared to the prior art.

Owner:GM GLOBAL TECH OPERATIONS LLC

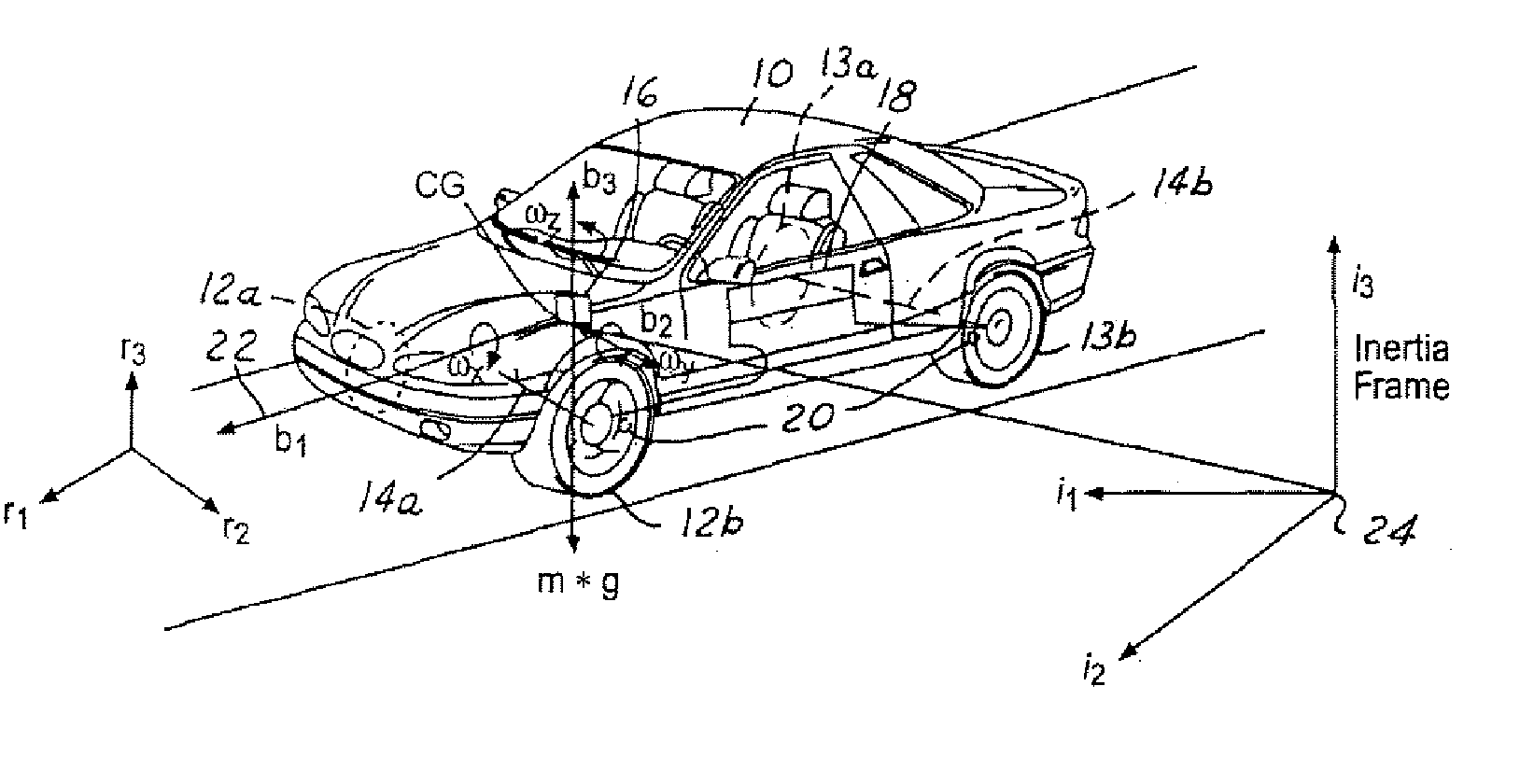

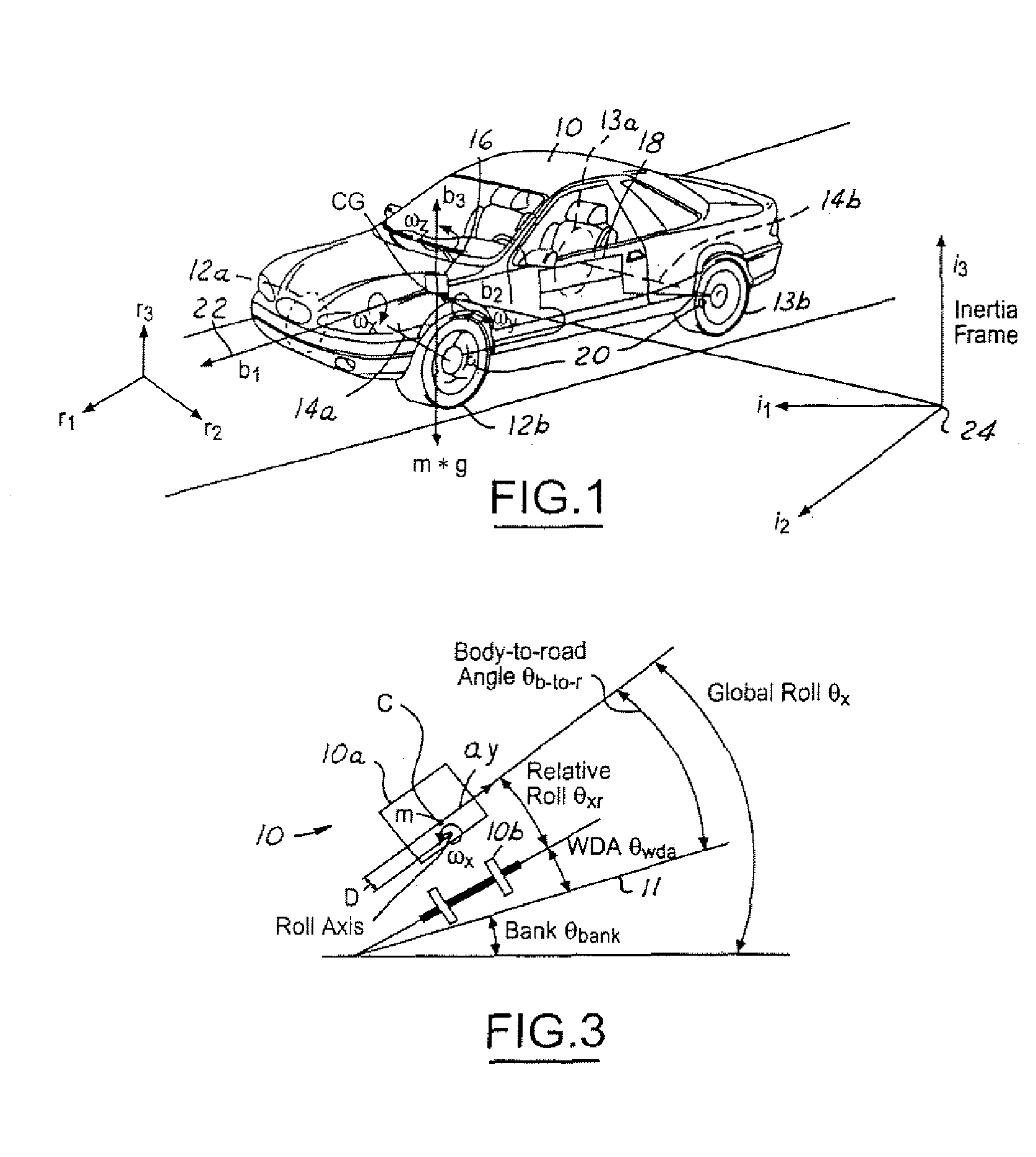

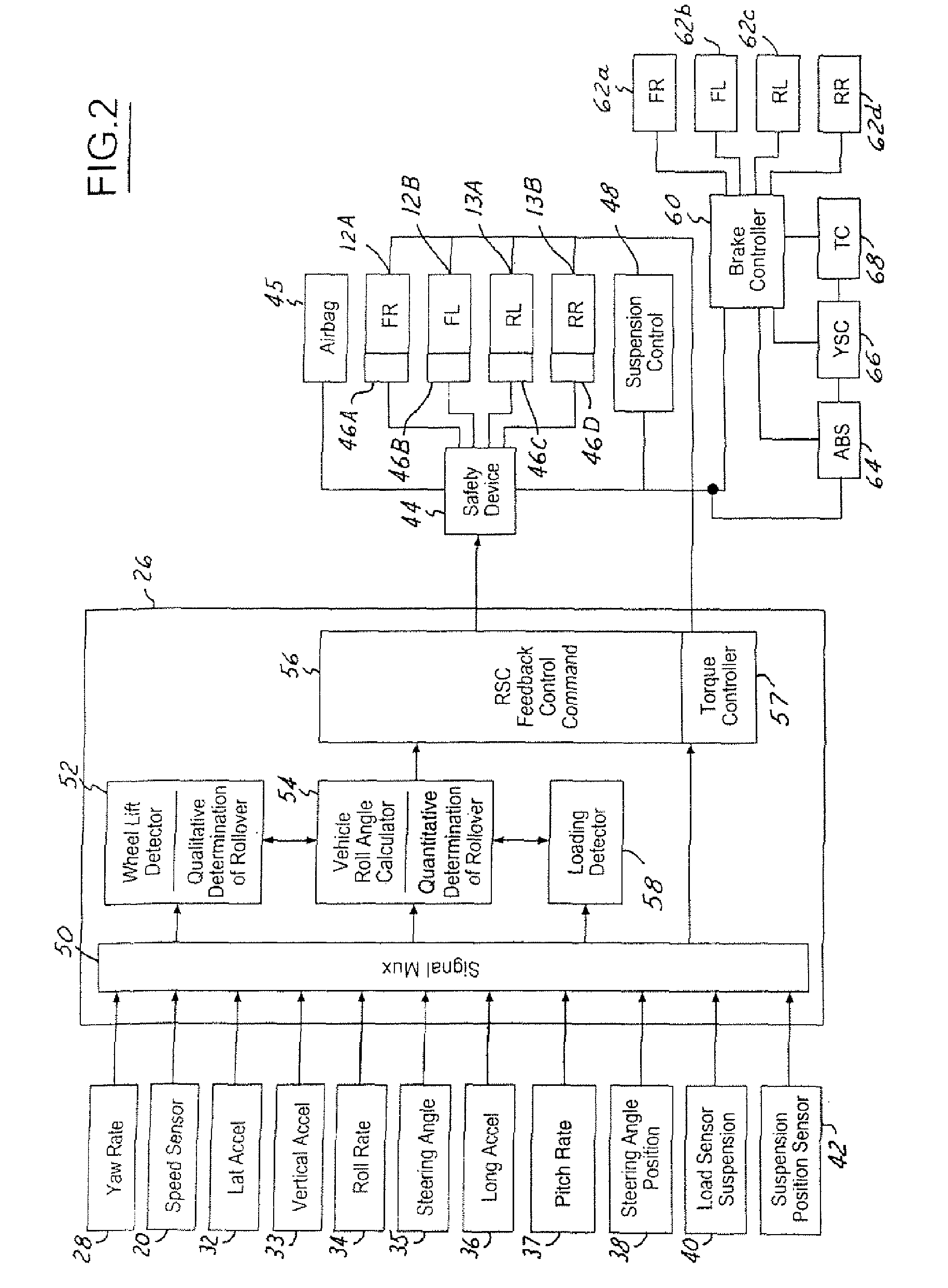

Roll stability control using four-wheel drive

ActiveUS20060074530A1Increase driving torque of drivenSimple torque controlHand manipulated computer devicesDigital data processing detailsRolloverControl system

A control system (18) and method for controlling an automotive vehicle (10) includes a number of sensors that are used to generate a potential rollover signal. In response to the potential rollover, active differentials (112, 114, 116) may be used alone or in addition to braking to prevent the vehicle from rolling over.

Owner:FORD GLOBAL TECH LLC

Gear driven power converter

A differential power coupling for generating forward and reverse motions and allowing stopping of the rotation for a vehicle using a rotational power supply to power a variable speed transmission having first and second outputs. The power coupling uses a rotational outside gear with an outside face coupled to the first power supply, a rotational support body coupled to the second power supply and adapted to rotate axles of differential gears around a central axis, and at least one differential gear rotationally mounted on the axle attached to the rotational support body and coupled to the inside face. The differential gear is further coupled to the output shaft and adapted to create a fully variable rotation of the outputs shaft including forward, reverse and stopped rotation. A method is also described for controlling a rotational speed of an output shaft by converting an input rotation into a first and second rotation, differentiating the first rotation and the second rotation to achieve a third rotation; and transferring the third rotation to the output shaft as a function of the difference.

Owner:LUPER JERRY

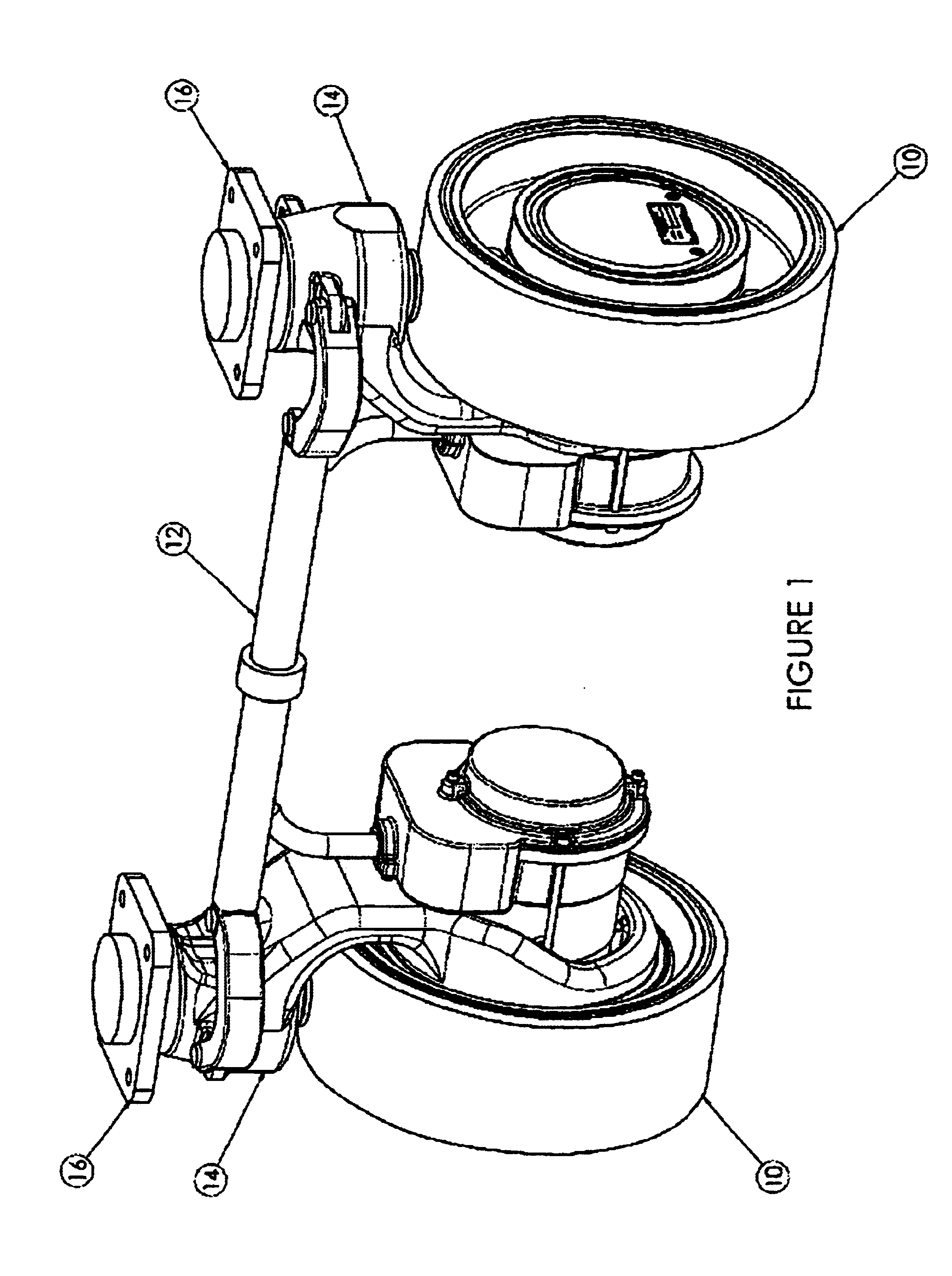

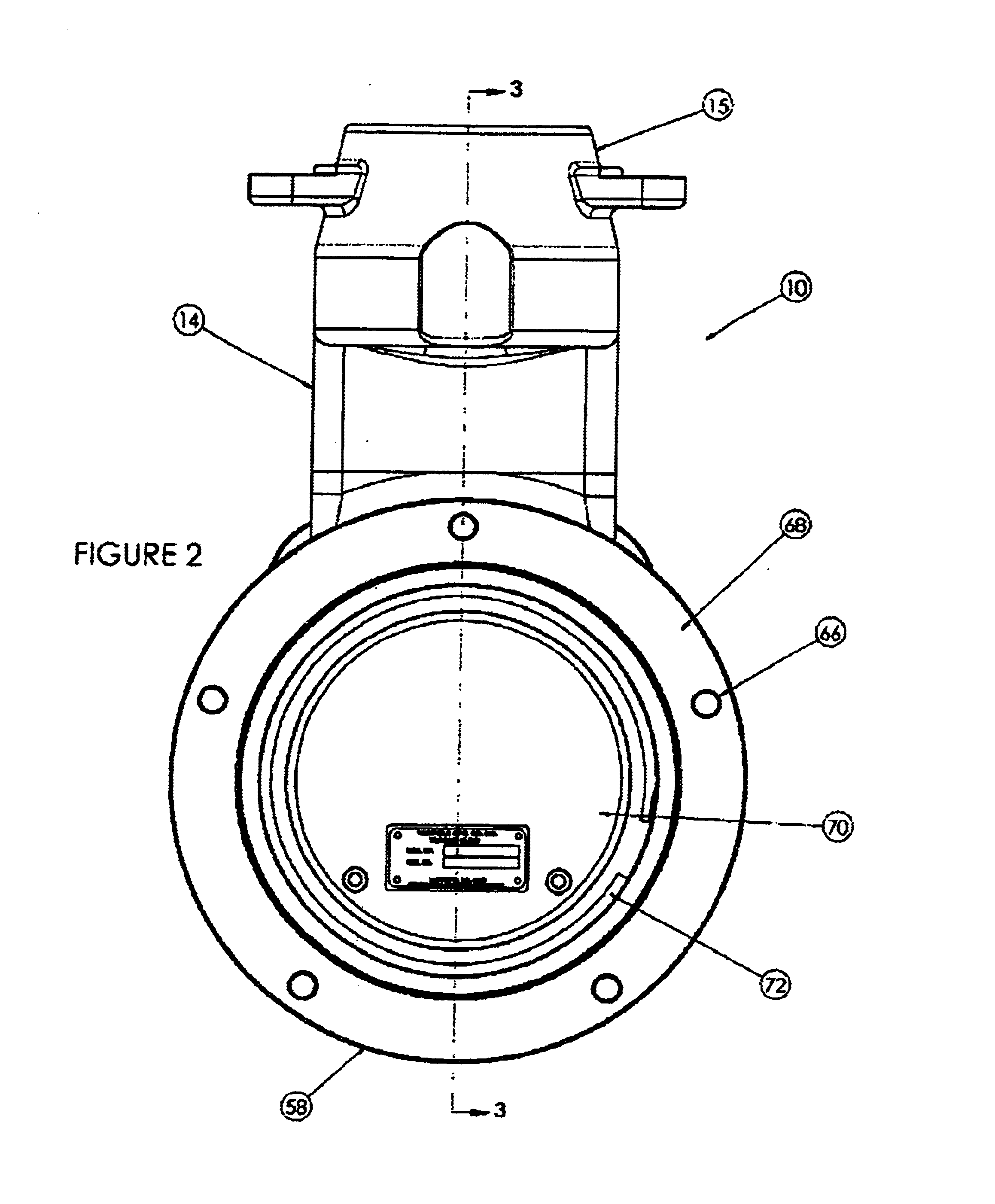

Bi-directional overrunning clutch

InactiveUSRE38012E1Prevent rotationYielding couplingFluid couplingsElectronic control systemDrive shaft

A bi-directional overrunning clutch is disclosed for controlling torque transmission between a secondary drive shaft and secondary driven shafts. The overrunning clutch includes a pinion input shaft in a differential housing that engages with a clutch housing rotatably disposed within the differential housing. At least one race is located adjacent to the clutch housing and is engaged with an output shaft. A cage is located between the race and the clutch housing. The cage is movable with respect to the clutch housing. A <DEL-S DATE="20030304" ID="DEL-S-00001" / >first<DEL-E ID="DEL-S-00001" / > coil is mounted within the differential housing adjacent to the cage and is adapted to produce an electromagnetic field when energized which causes the cage to drag with respect to the clutch housing. The dragging of the cage with respect to the clutch housing positions <INS-S DATE="20030304" ID="INS-S-00001" / >rolls within <INS-E ID="INS-S-00001" / >the cage to engage the clutch housing with the race when wheels on a primary drive shaft lose traction. <DEL-S DATE="20030304" ID="DEL-S-00002" / >A<DEL-E ID="DEL-S-00002" / > <INS-S DATE="20030304" ID="INS-S-00002" / >If desired a <INS-E ID="INS-S-00002" / >second coil <DEL-S DATE="20030304" ID="DEL-S-00003" / >is<DEL-E ID="DEL-S-00003" / > <INS-S DATE="20030304" ID="INS-S-00003" / >may be <INS-E ID="INS-S-00003" / >mounted within the differential housing adjacent <DEL-S DATE="20030304" ID="DEL-S-00004" / >adjacent<DEL-E ID="DEL-S-00004" / > to the cage. The second coil is adapted to produce an electromagnetic field when energized which advances cage with respect to the clutch housing causing the clutch housing to engage with the races. When the second coil is activated, the output shaft drives the pinion input shaft producing engine braking. An electronic control system is utilized to control the energizing of the coils.

Owner:HILLIARD

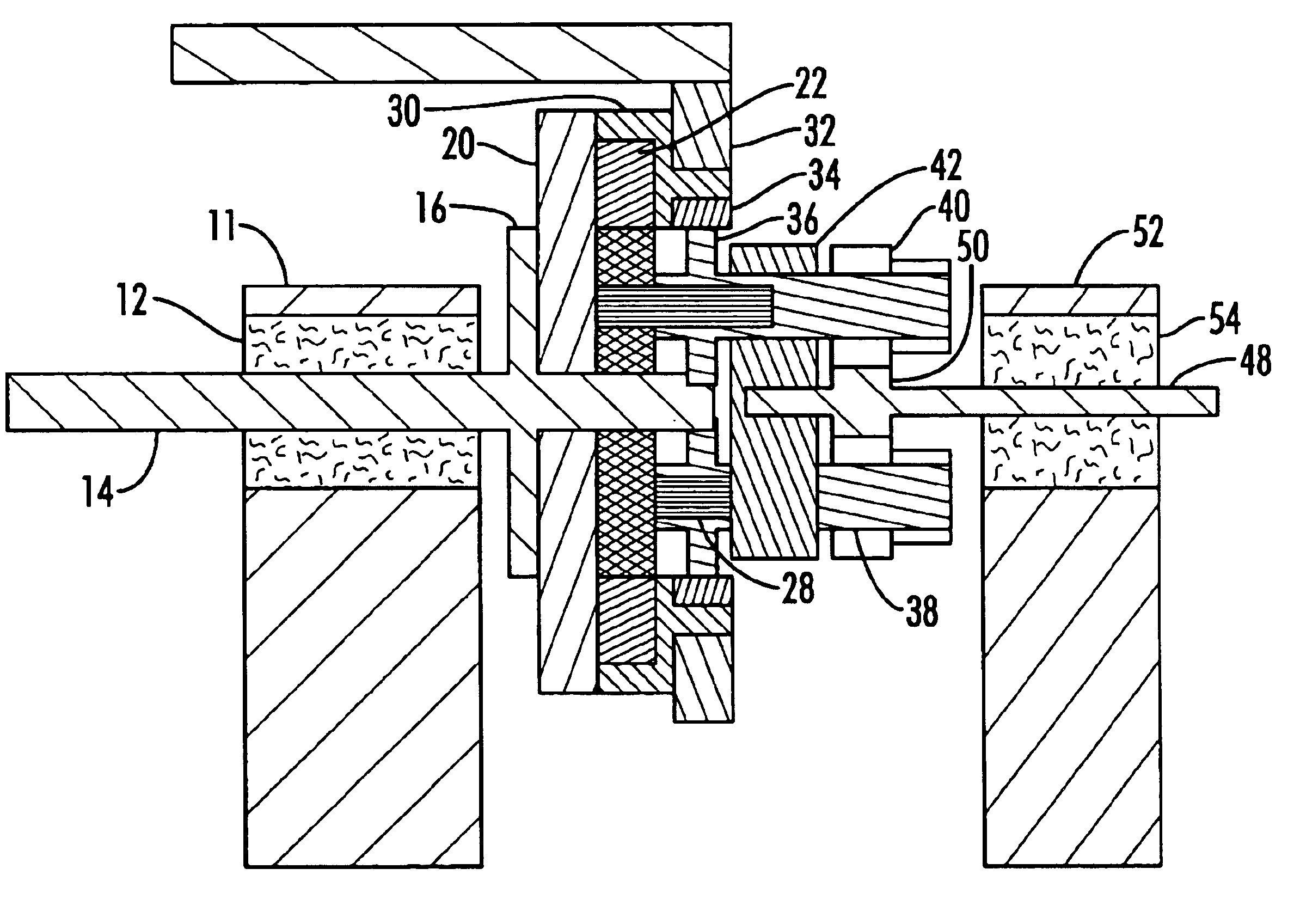

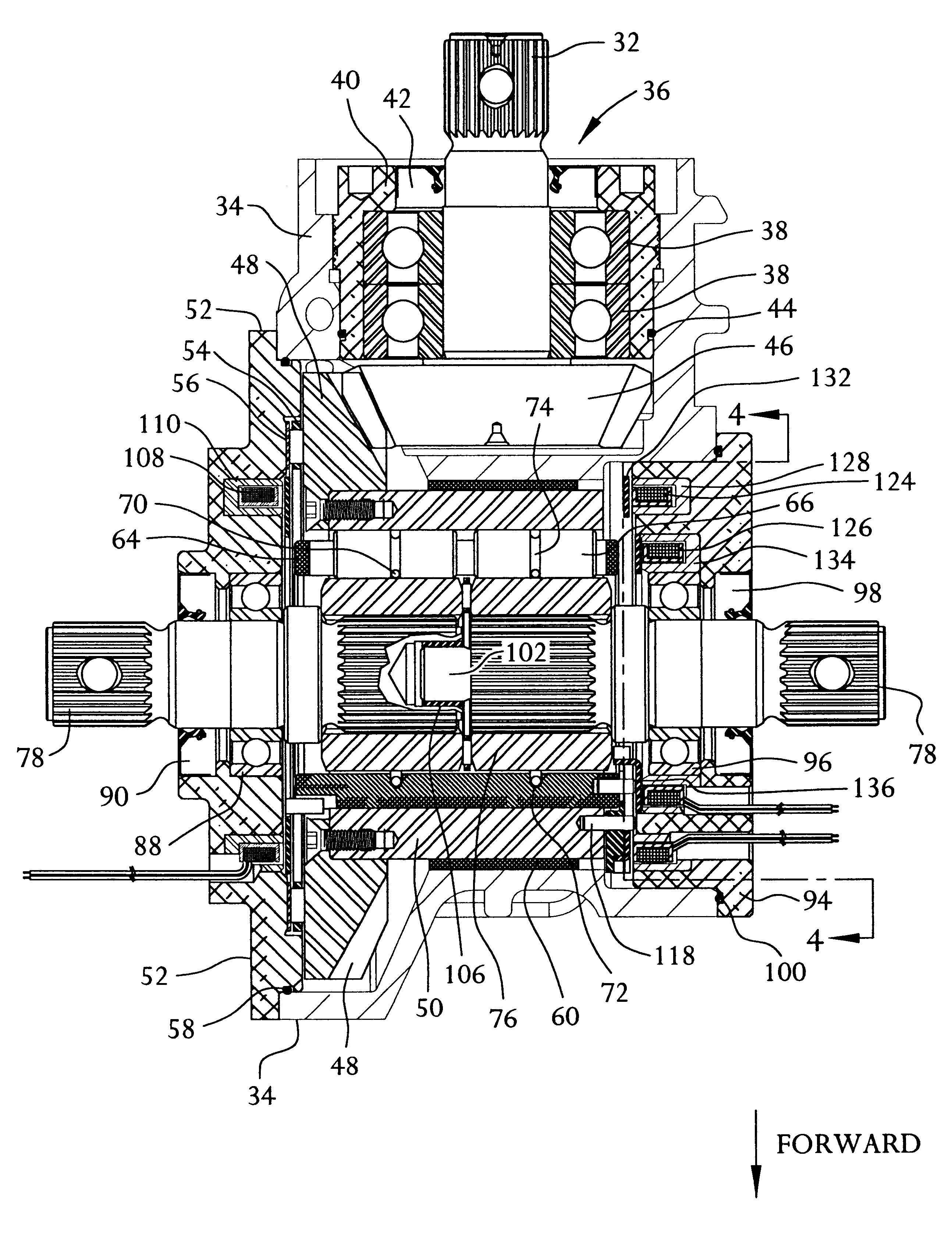

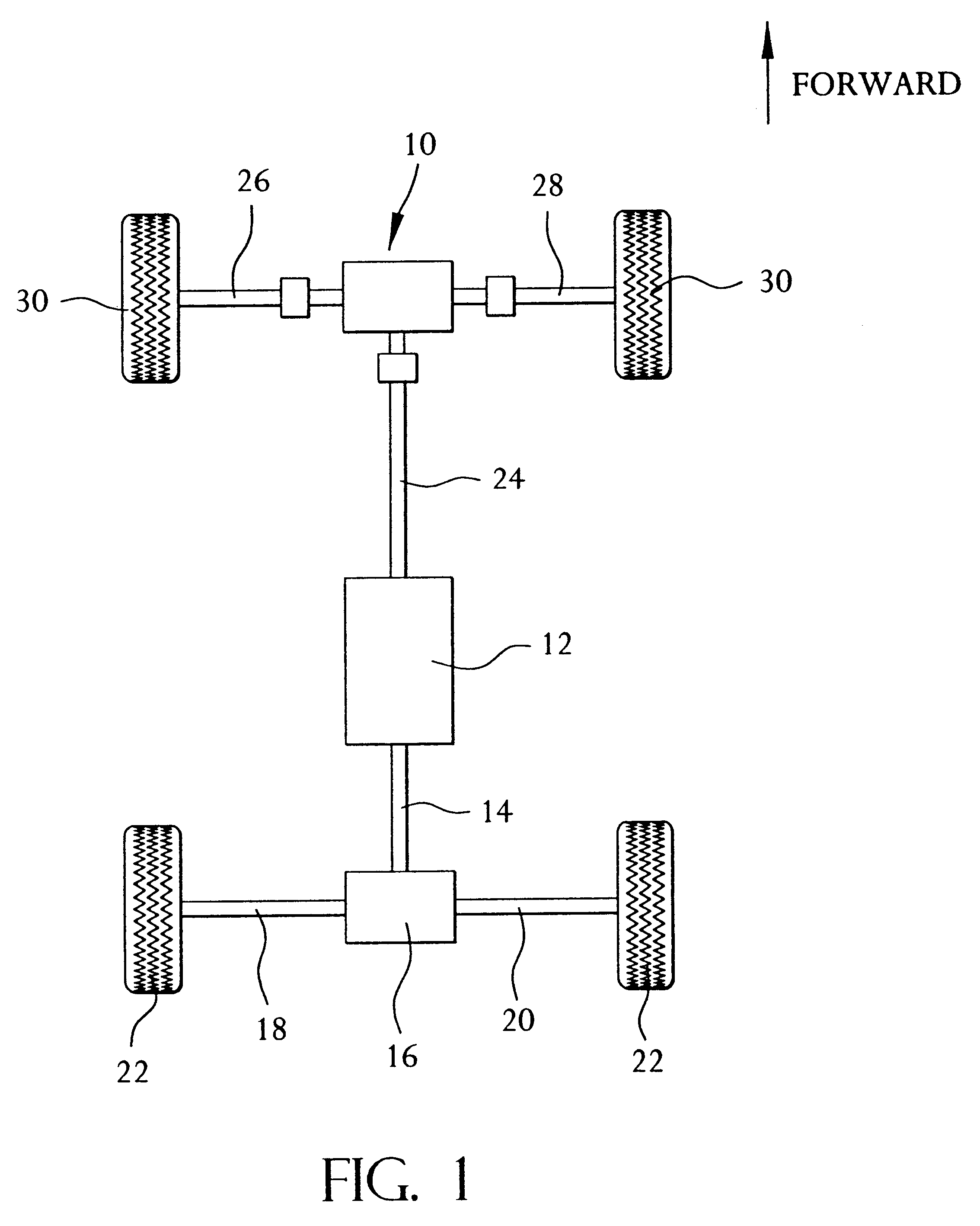

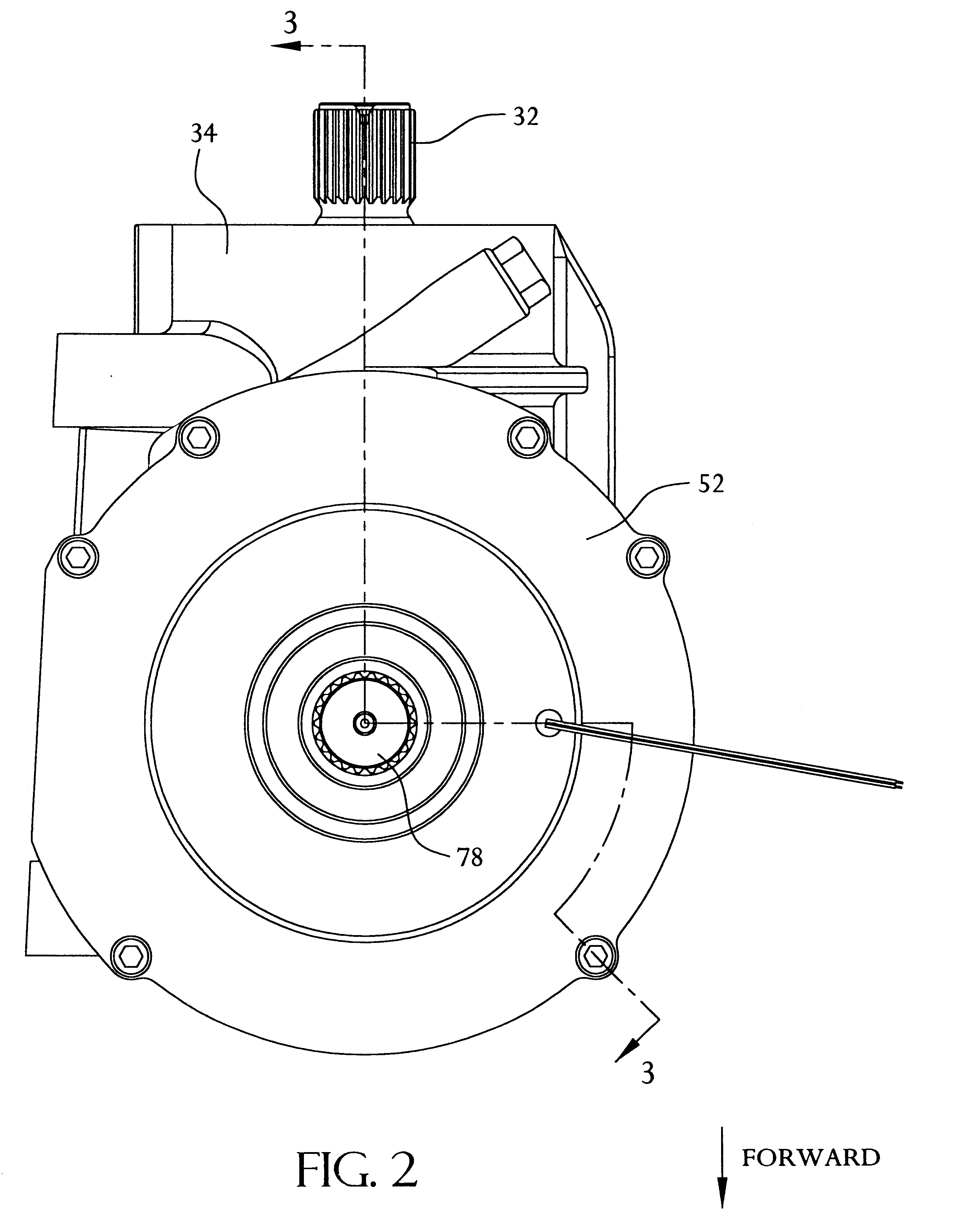

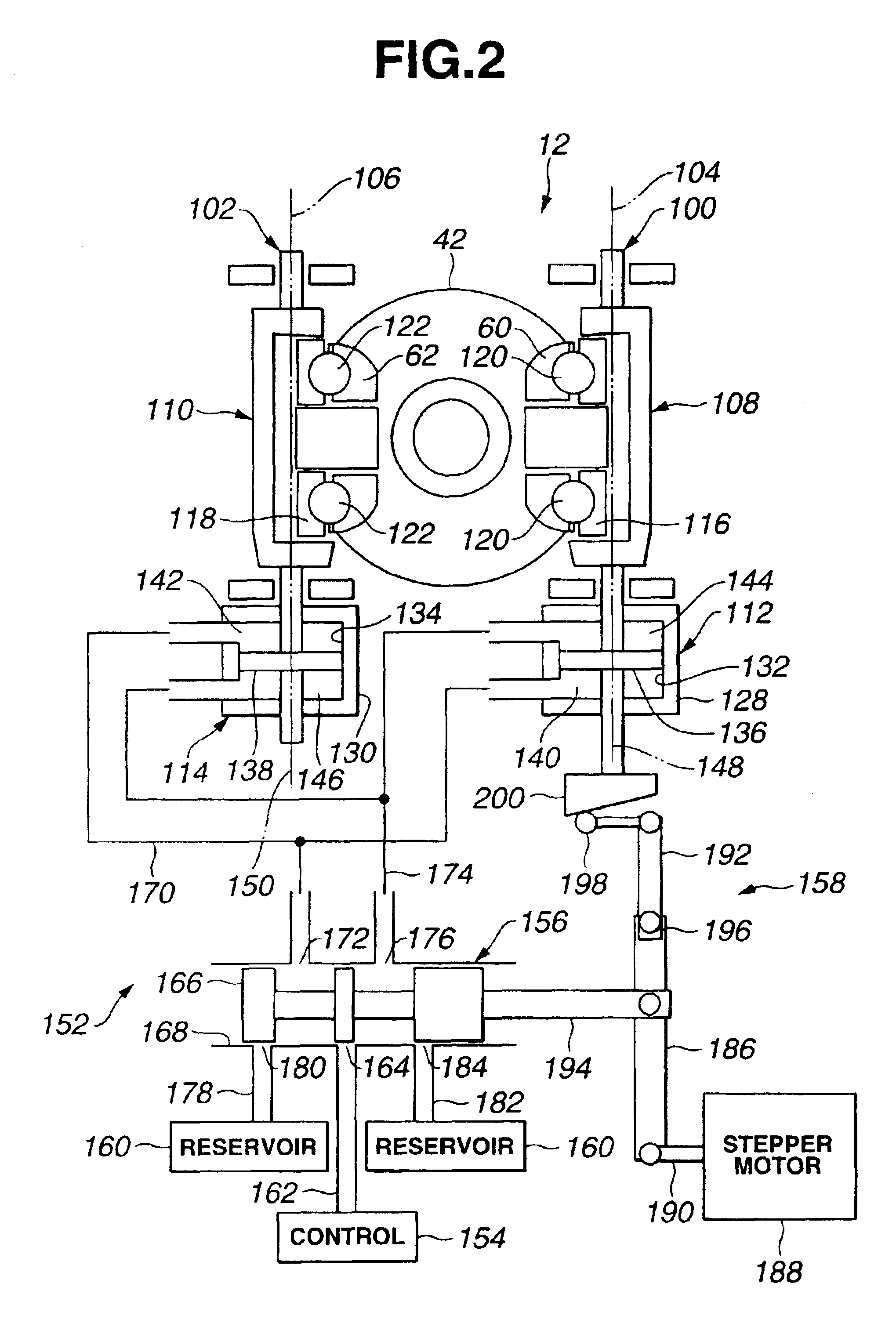

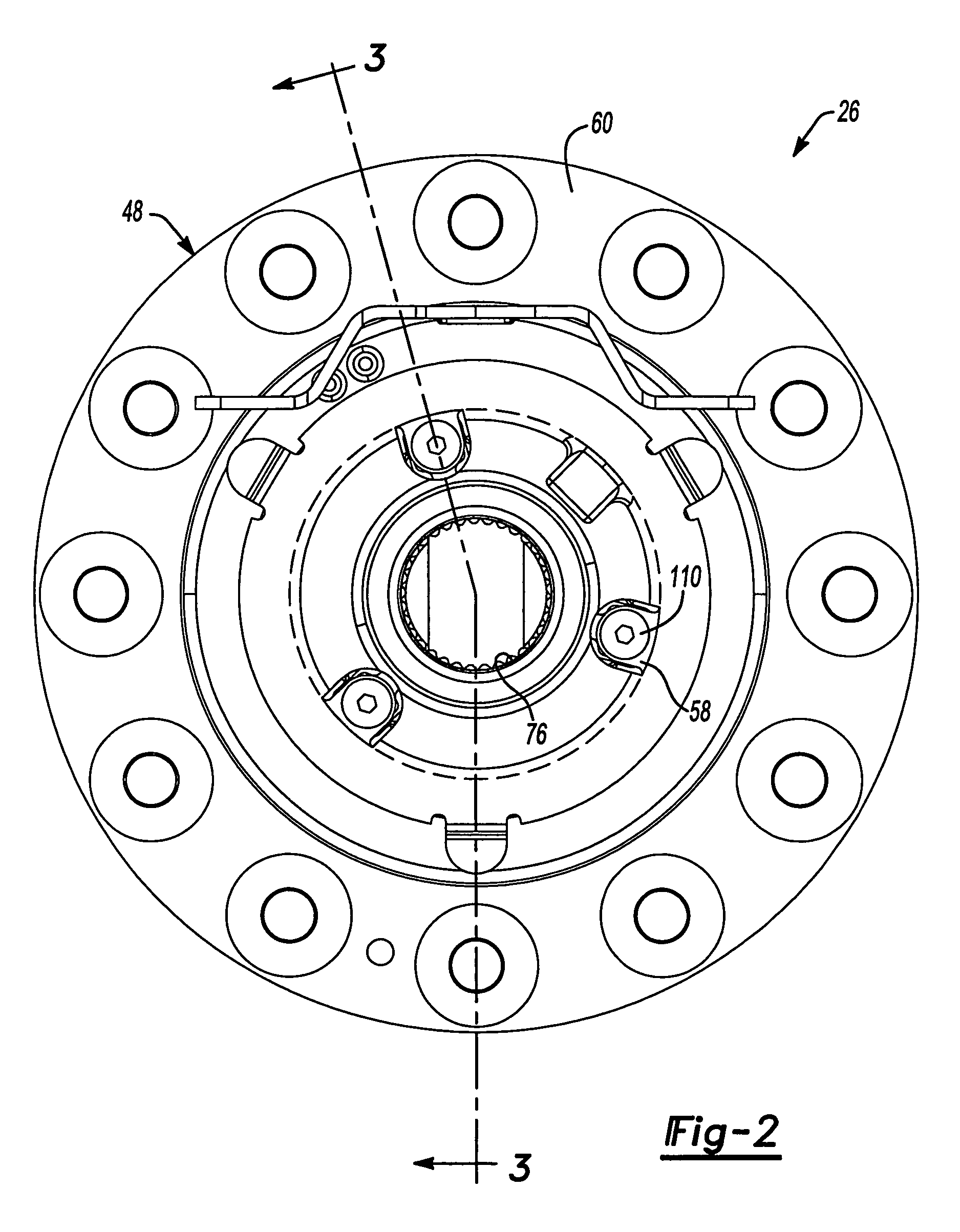

Dual ball ramp actuator for locking differential

A dual ball ramp actuator having a control ring acting with a pressure plates to supply an axial clutch clamping force to a differential clutch assembly where the ball ramp paths follow overlapping eccentric grooves that can be actuated in both the forward and reverse directions. The dual ramp feature doubles the effectiveness and sensitivity when compared to a single ramp system. The overlapping eccentric ball ramps increase (effectively double) the angular travel distance while reducing the ramp angle (in half). The forward and reverse feature provides clutch actuation in both the forward and reverse directions. The dual ramp, 3-piece sandwich construction permits the central control ring to roll up on two sets of balls on each side. This structure doubles the axial travel available to compress a disc pack and lock up the differential with the same ball ramp angle when compared to a single ramp system involving only two ramp plates.

Owner:DANA AUTOMOTIVE SYST GRP LLC

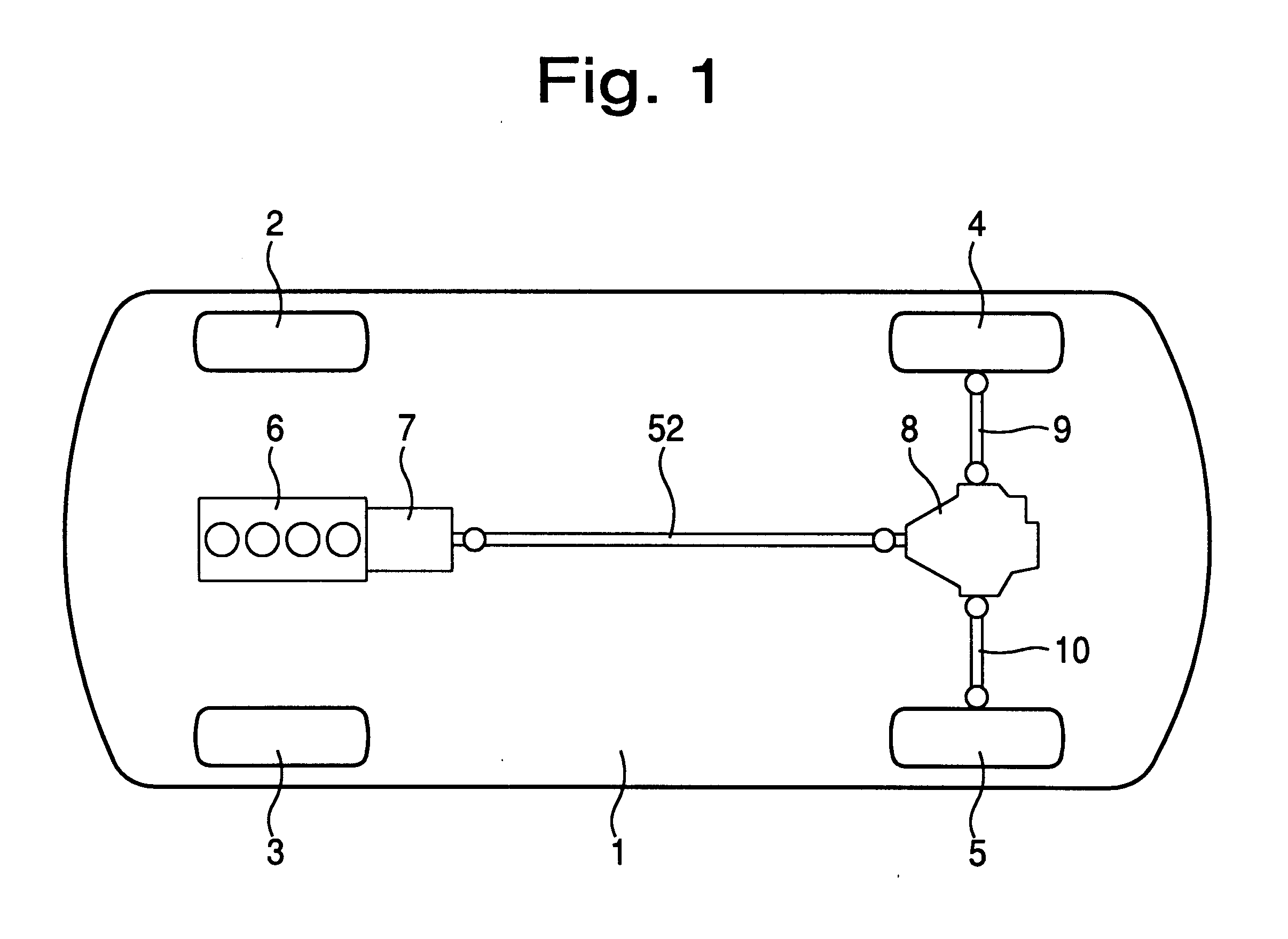

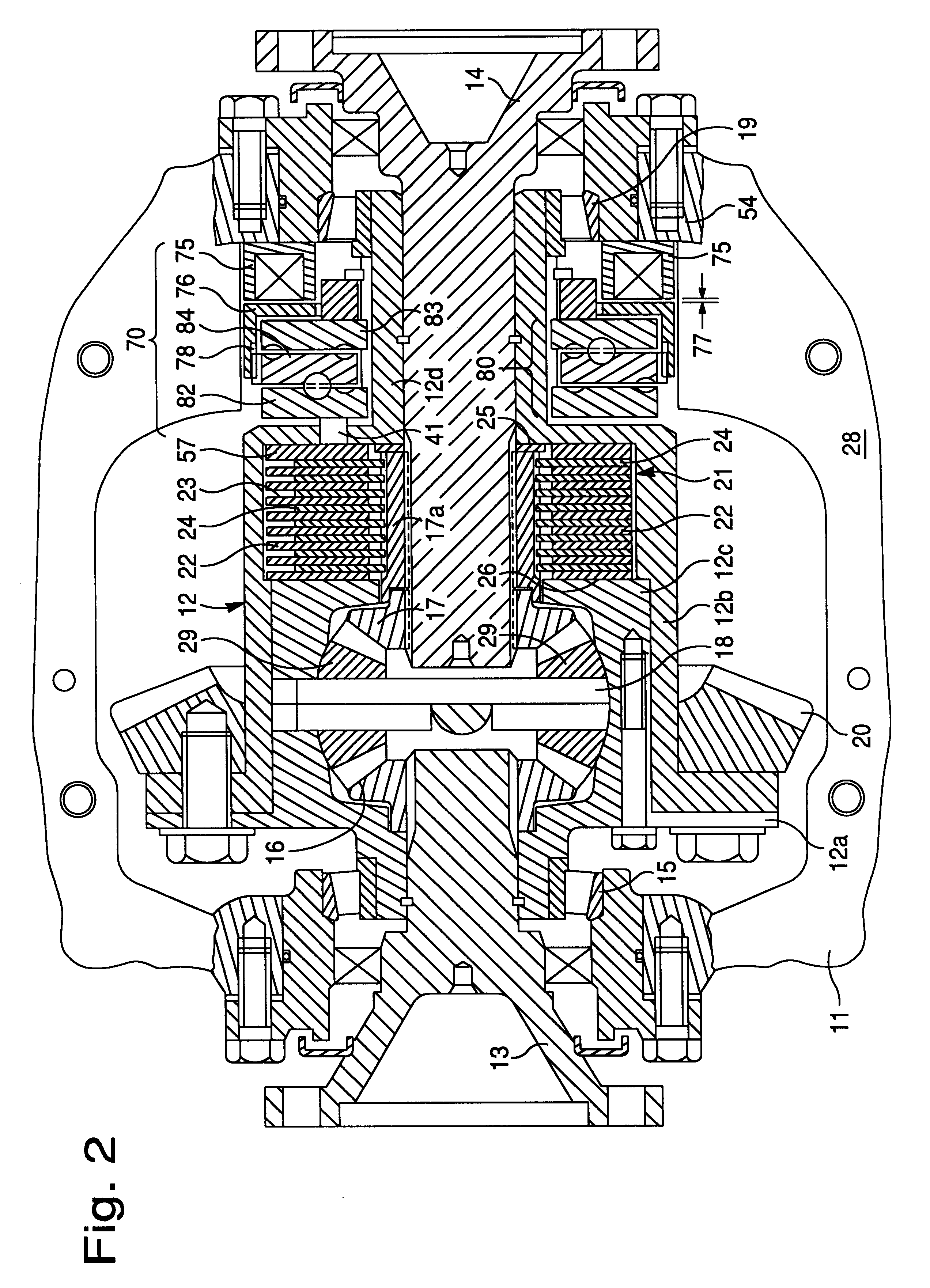

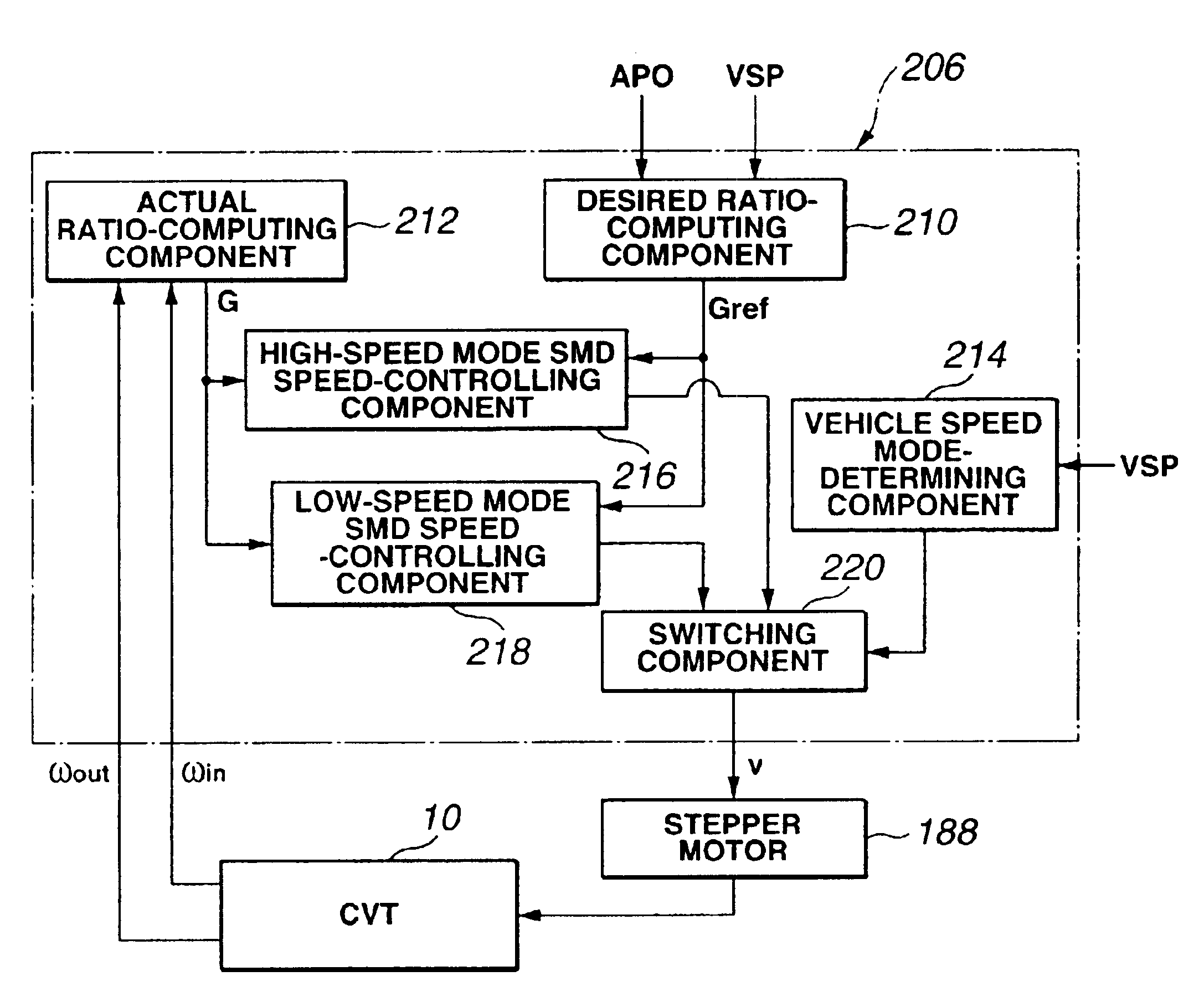

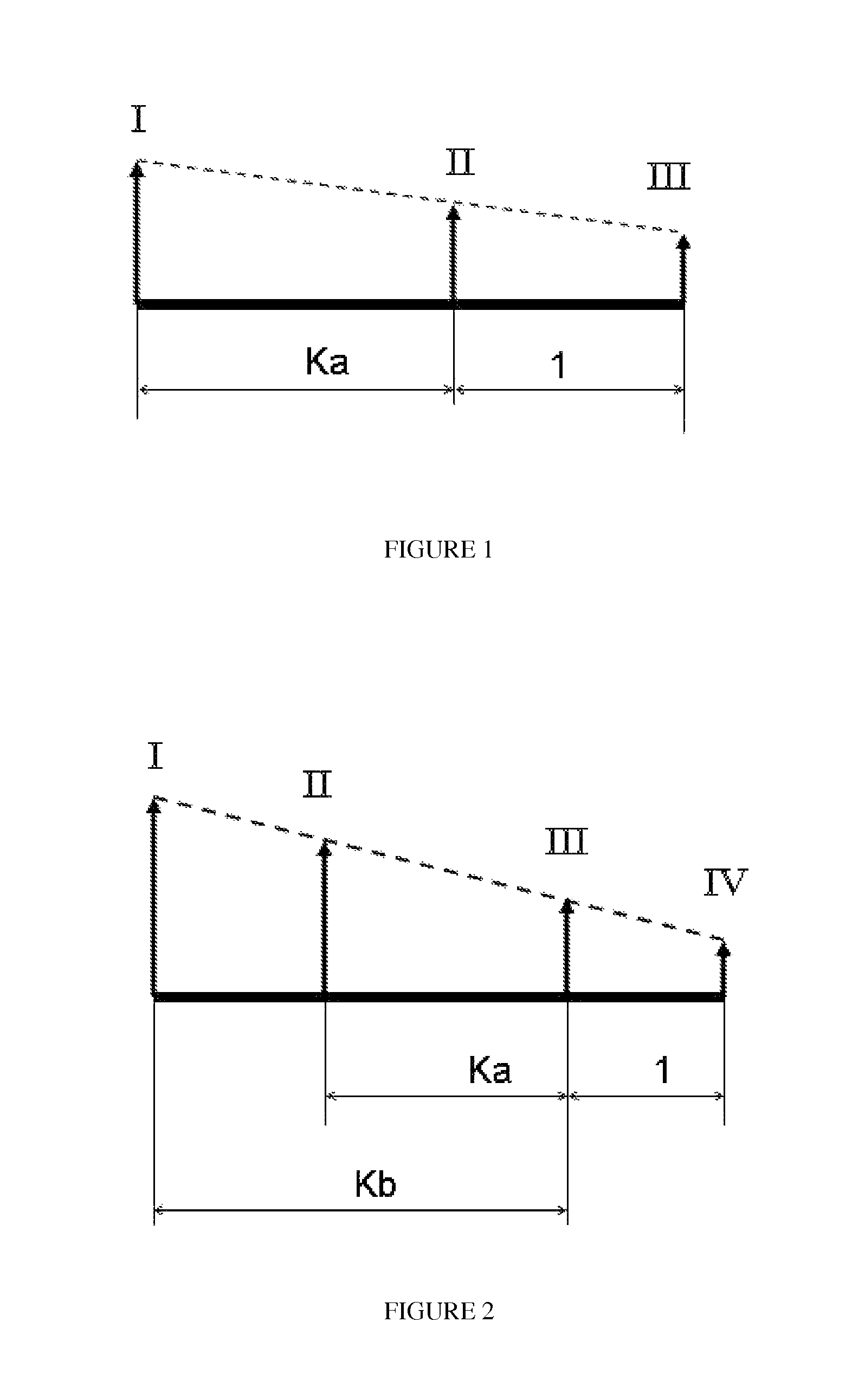

Extension of operating range of feedback in CVT ratio control

InactiveUS6839617B2Easy to operateDigital data processing detailsRate of change measurementRotation velocityPulse sequence

Operating range of feedback in CVT ratio control has been extended by use of stabilized values as an actual value of CVT ratio. The actual value of CVT ratio is derived from first and second pulse train signals provided by input and output speed sensors. Updating of rotational speed of the input member is repeated at intervals governed by the first pulse train. Updating of rotational speed of the output member is repeated at intervals governed by the second pulse train. Updating of an old value of a ratio between the latest value of the rotational speed of the input member and the latest value of the rotational speed of the output member to a new value thereof is repeated each time immediately after the rotational speeds of the input and output members have been updated since the latest updating of an old value of the ratio.

Owner:NISSAN MOTOR CO LTD

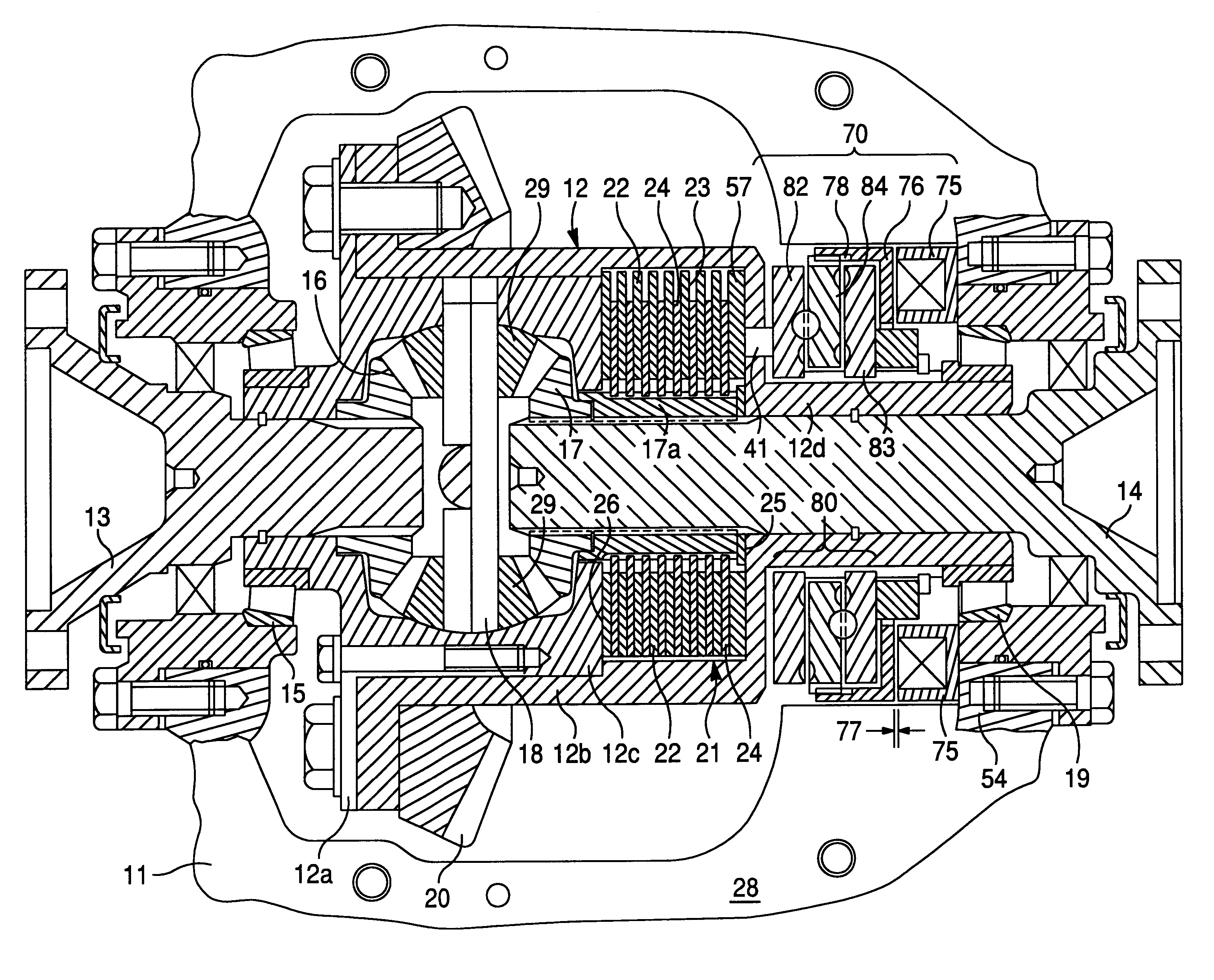

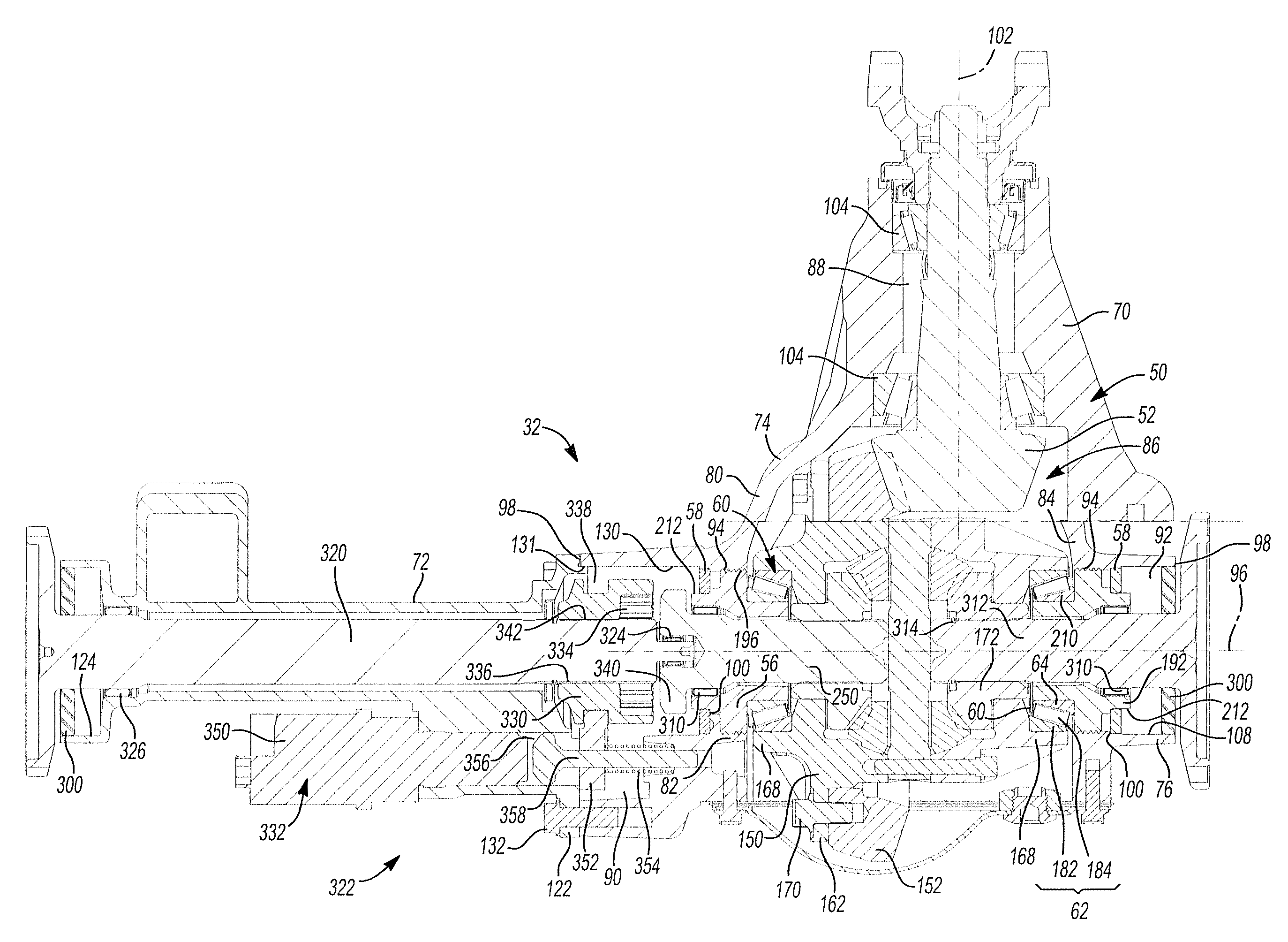

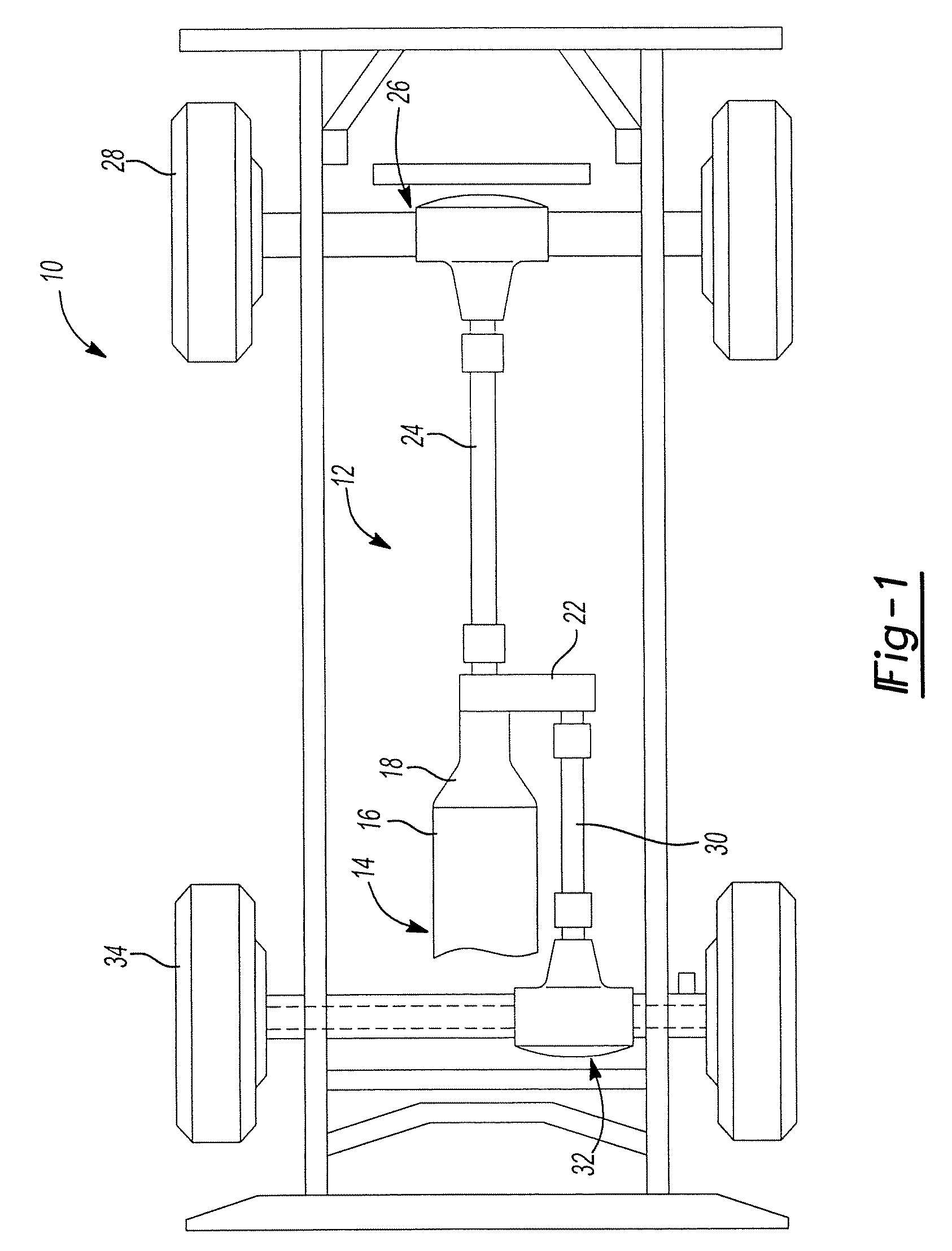

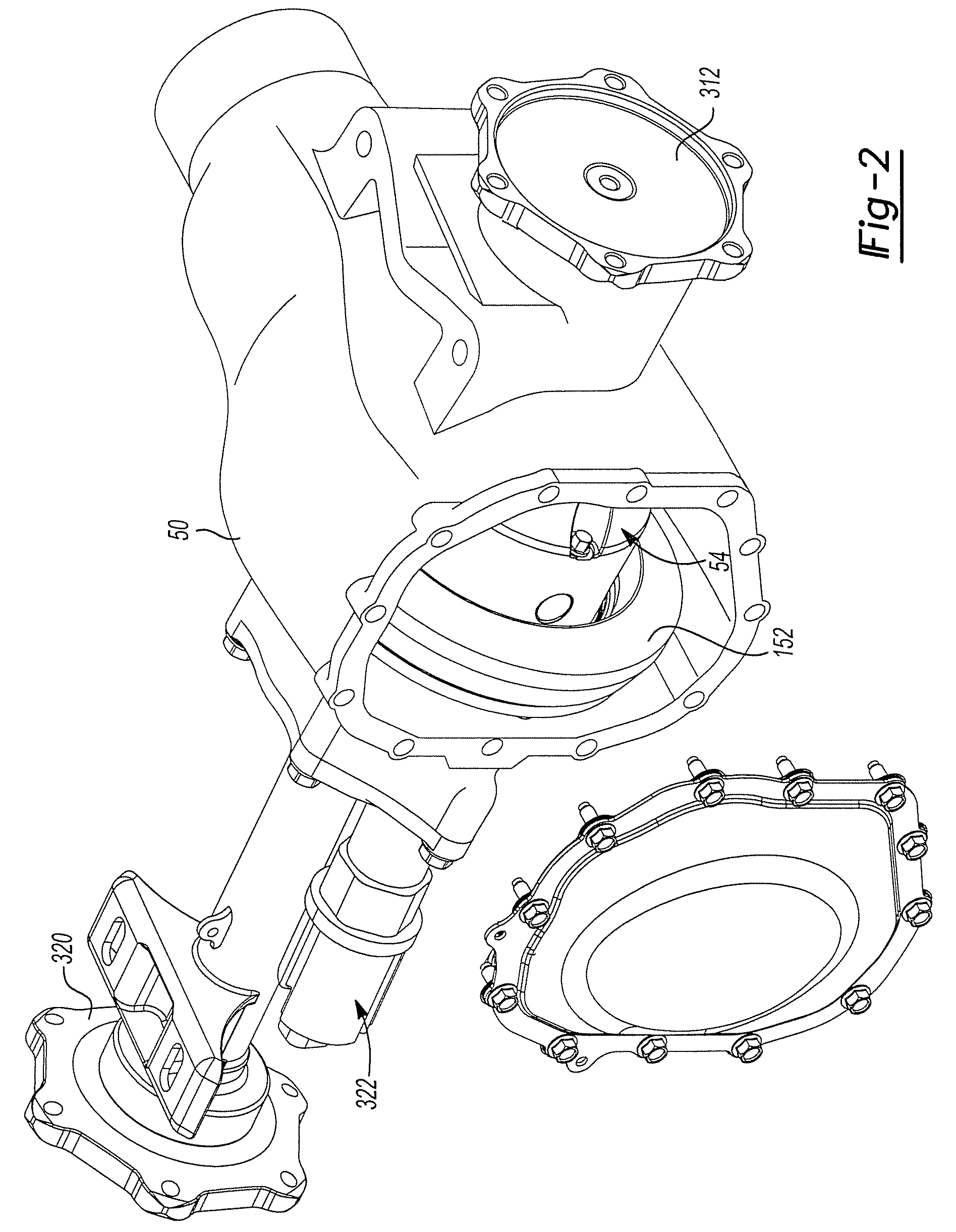

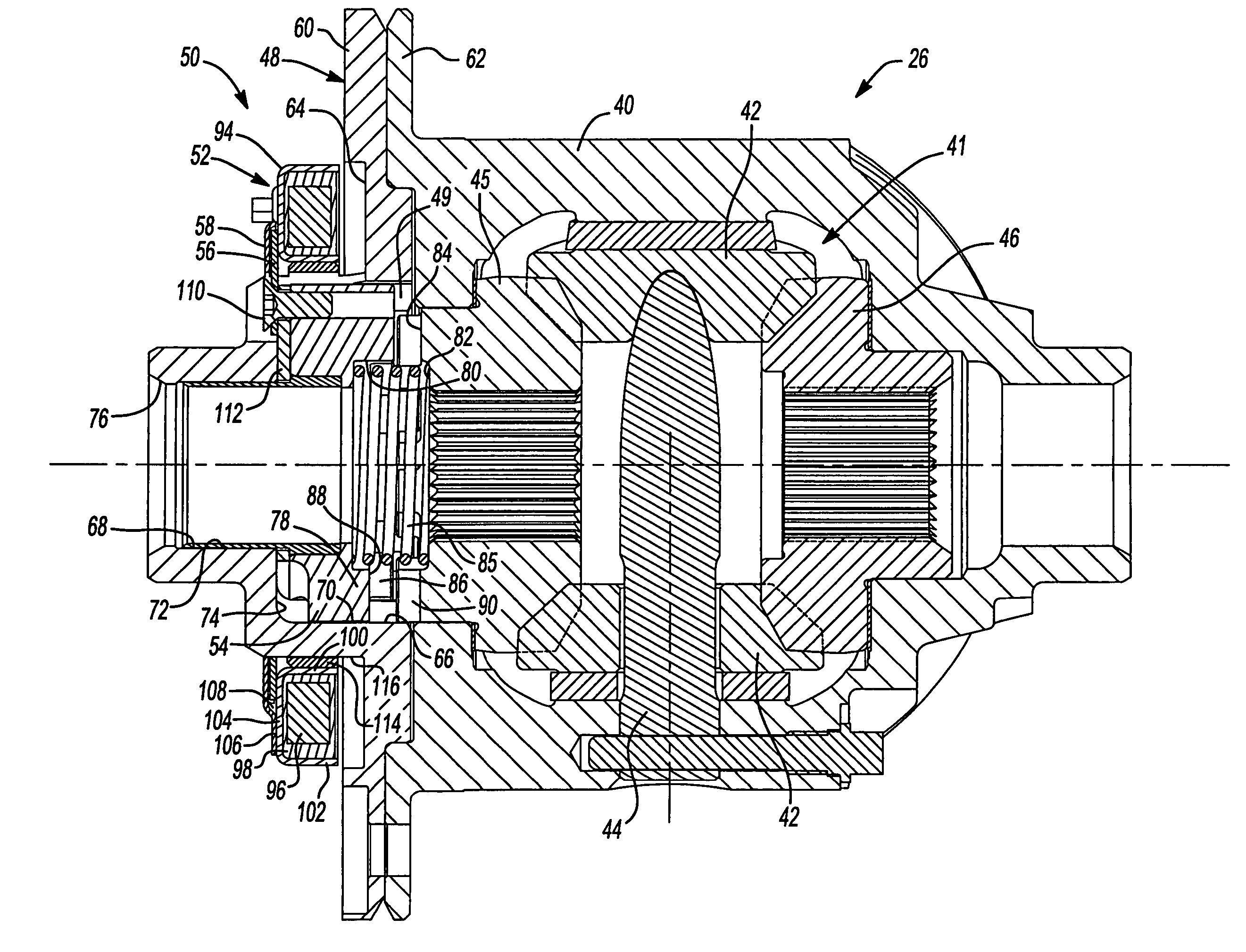

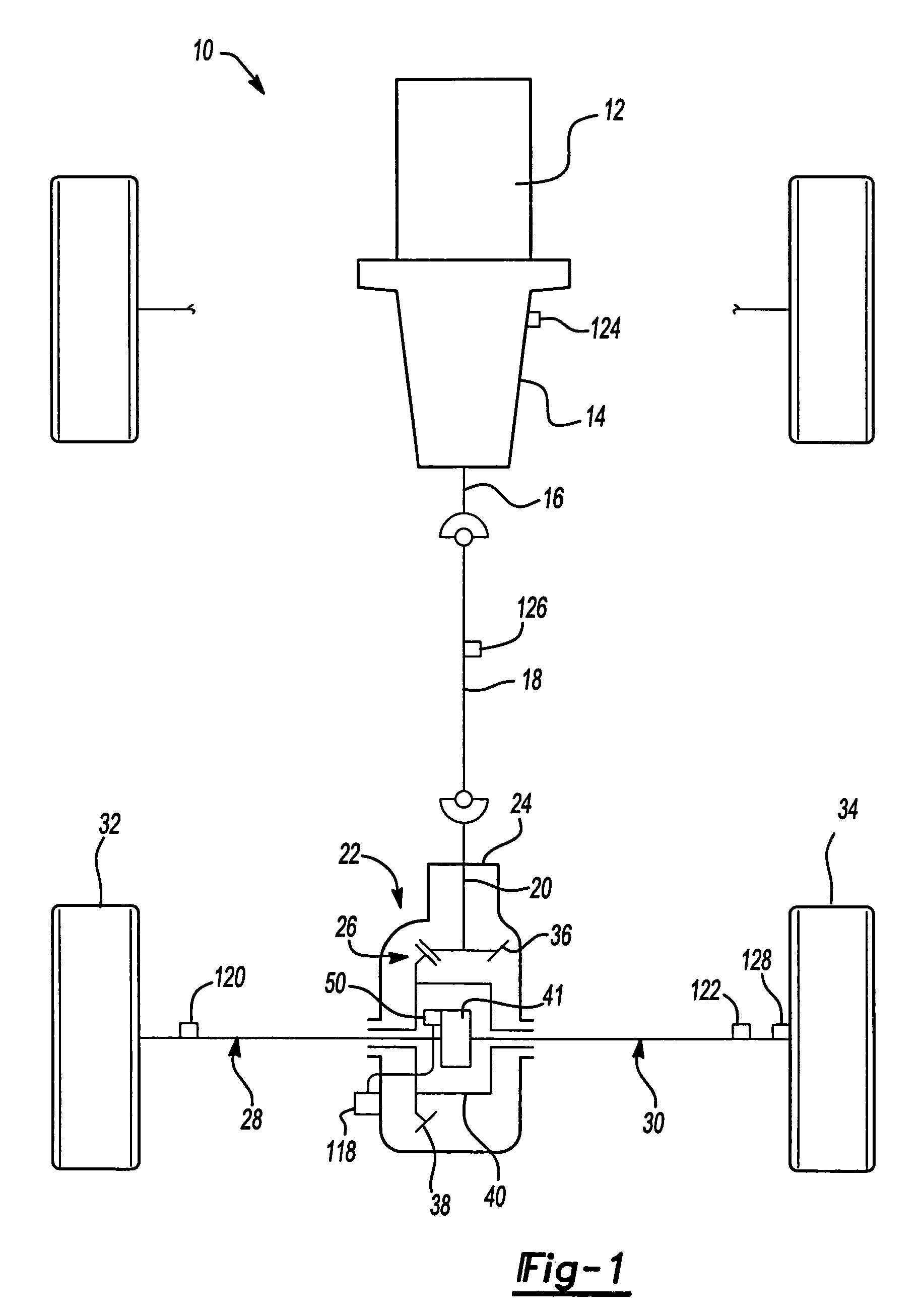

Axle assembly with torque distribution drive mechanism

An axle assembly with an input member, a first planetary gear set, a differential assembly, and a second planetary gear set. The first planetary gear set has a first transmission input that is driven by the input member. The differential assembly has a differential carrier and first and second differential output members received in the differential carrier. The second planetary gear set has a planet carrier coupled to the differential carrier for common rotation. A sun gear of the first planetary gear set is non-rotatably coupled to a sun gear of the second planetary gear set.

Owner:E AAM DRIVELINE SYST

Differential and bearing arrangement

Owner:AMERICAN AXLE & MFG

Planetary gearbox with integral electric motor and steering means.

InactiveUS6852061B2Improve efficiencySmall sizeElectric propulsion mountingDifferential gearingsGear wheelEngineering

A new, useful and compact wheel motor drive arrangement for applications on such construction equipment as scissor lifts and other similar scaffolding equipment where hydraulically driven systems have historically been used to provide power to the wheels to move the equipment is disclosed. An electric motor is mounted to a spindle bracket which is pivotably connected to the frame of the equipment to allow the unit to be pivoted around a vertical axis for steering purposes. A gear reducing planetary gear system is mounted around the drive shaft of the motor is positioned totally within the rotating wheel hub. The output ring gear of the planetary gear system is integrally formed to the interior of the wheel hub so that there is a direct application through the planetary gear system to the wheel hub to provide greater efficiency.

Owner:FAIRFIELD MFG CO INC

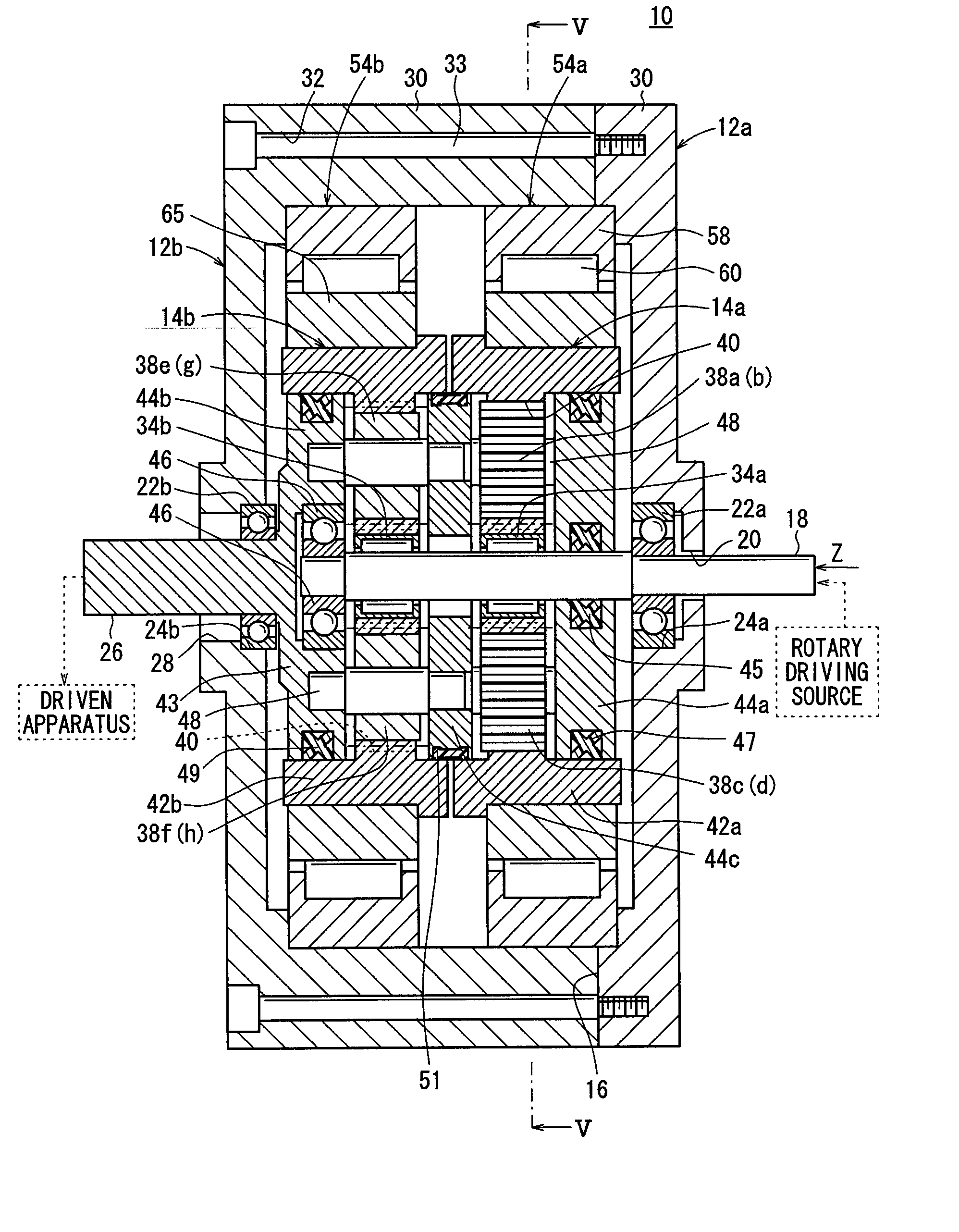

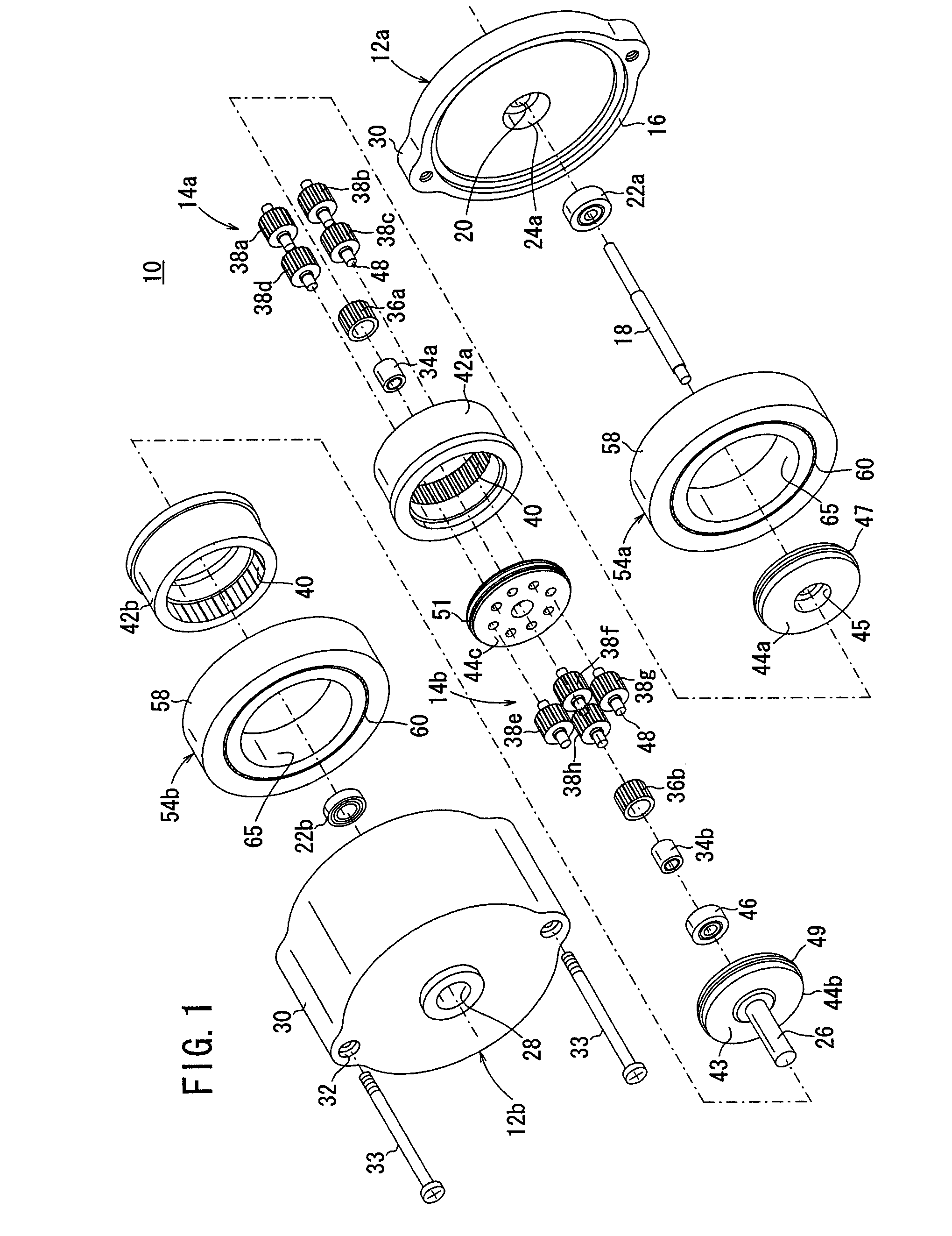

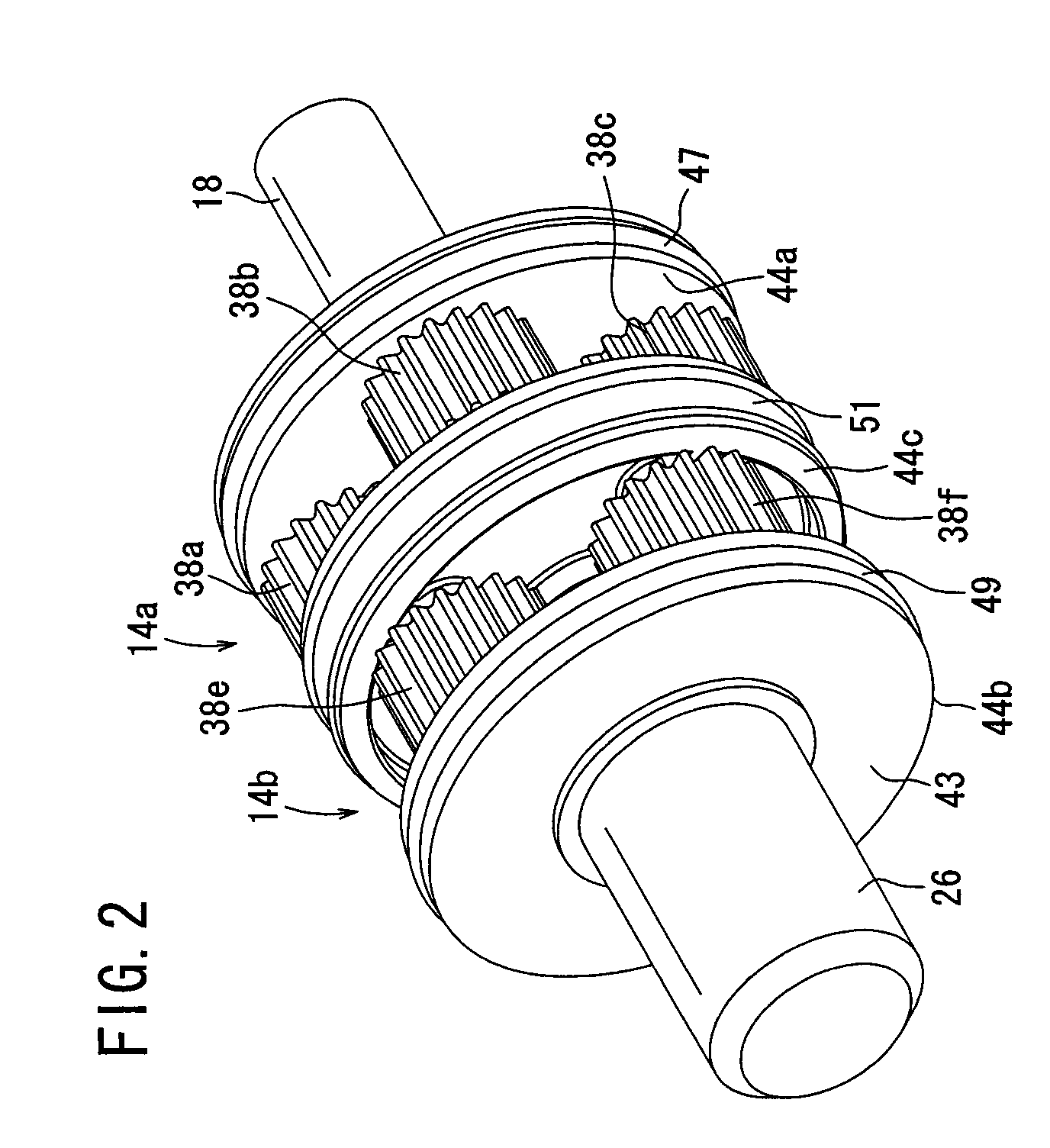

Automatic Speed Reducing Ratio-Switching Apparatus

ActiveUS20070191177A1Smooth transmissionToothed gearingsDifferential gearingsGear wheelStatic friction

An automatic speed reducing ratio-switching apparatus comprising an input side carrier, an output side carrier, and an intermediate carrier includes first and second planetary gear mechanisms juxtaposed in the axial direction of an input shaft, first and second inner clutch members which are rotatable in one direction while locking rotation in the other direction of the input shaft, and have mutually different locking directions, first and second outer clutch members which are rotatable in one direction while locking rotation in the other direction of the input side or output side ring gear, and have mutually different locking directions, and a viscous resistance member functioning under a static frictional force to integrally rotate the input side or output side sun gear, the input side or output side planet gears, and the input side or output side ring gears respectively in an identical direction.

Owner:SMC CORP

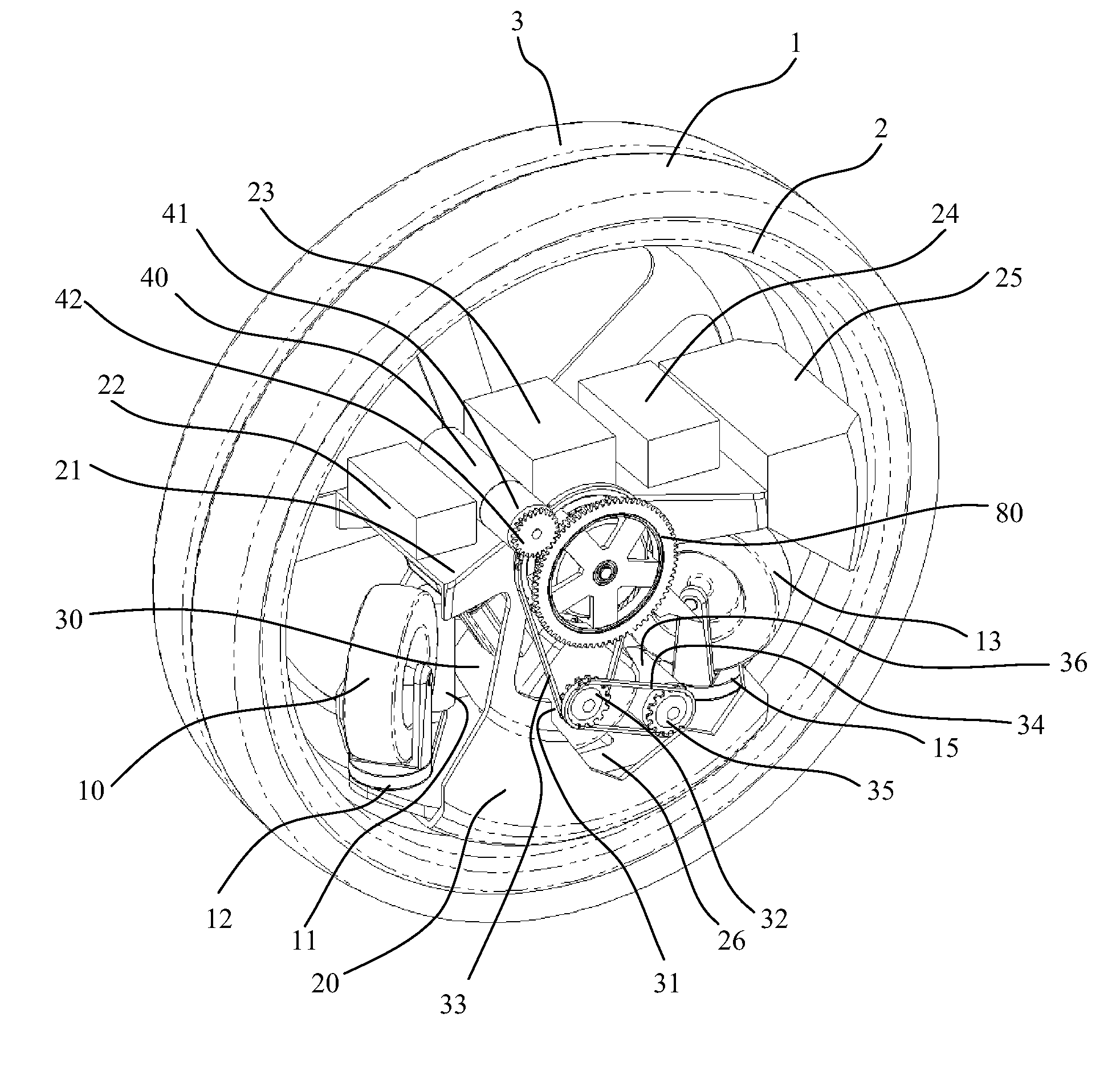

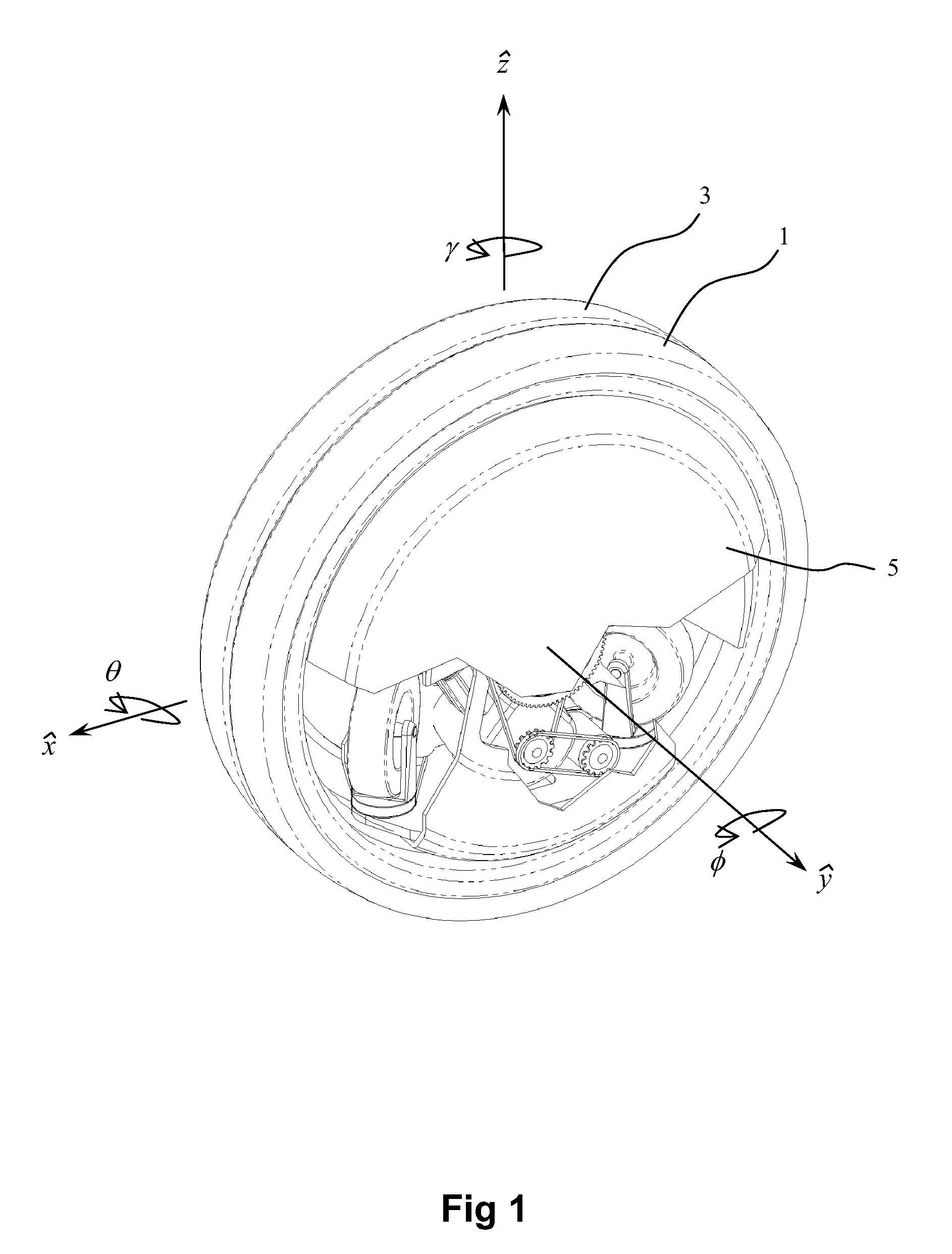

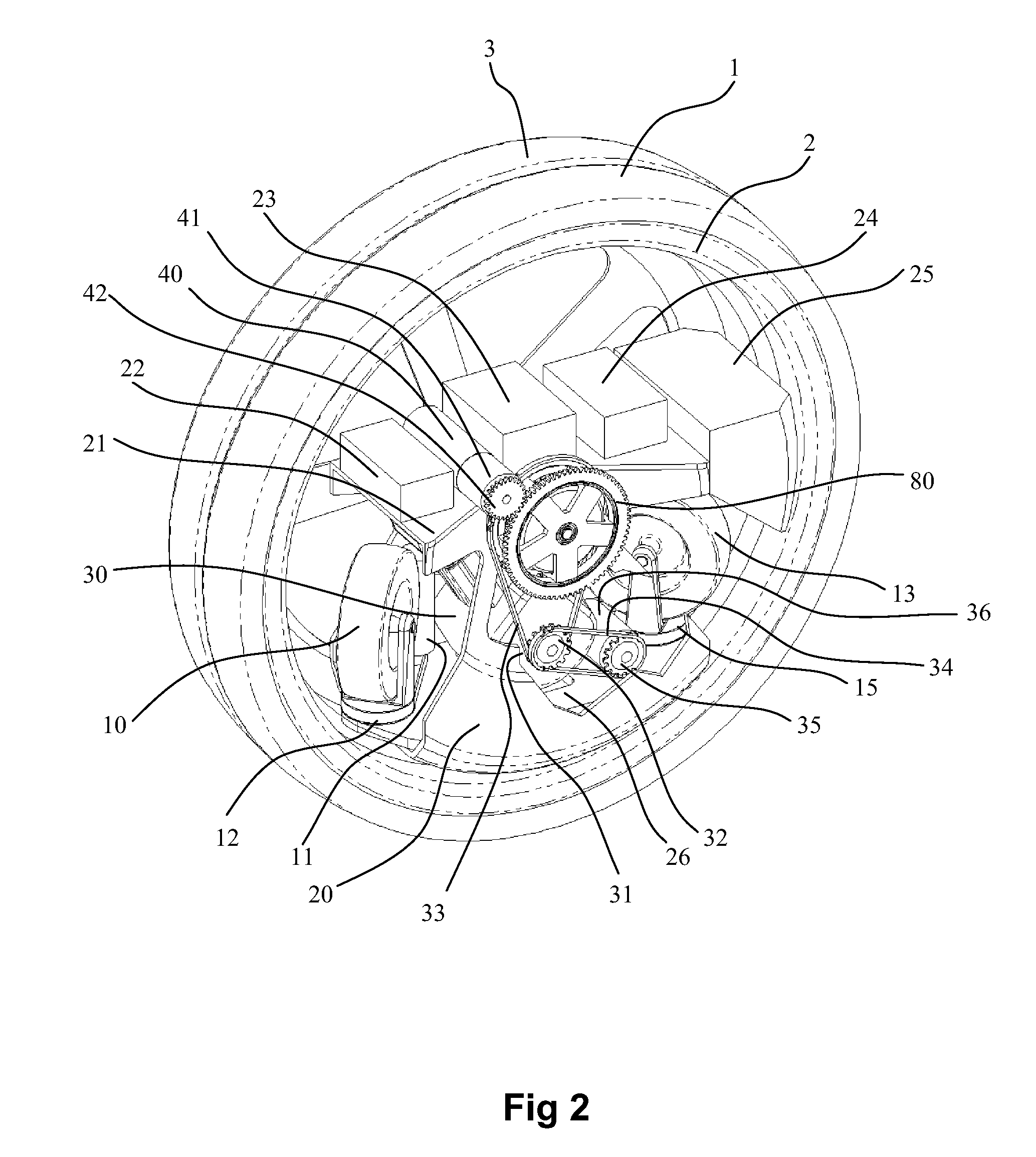

Monowheel Type Vehicle

An engine-propelled monowheel vehicle comprises two wheels, close together, that circumscribe the remainder of the vehicle. When the vehicle is moving forward, the closely spaced wheels act as a single wheel, and the vehicle turns by leaning the wheels. A single propulsion system provides a drive torque that is shared by the two wheels. A separate steering torque, provided by a steering motor, is added to one wheel while being subtracted from the other wheel, enabling the wheels to rotate in opposite directions for turning the vehicle at zero forward velocity. The vehicle employs attitude sensors, for sensing roll, pitch, and yaw, and an automatic balancing system. A flywheel in the vehicle spins at a high rate around a spin axis, wherein the spin axis is rotatable with respect to the vehicle's frame. The axis angle and flywheel spin speed are continually adjustable to generate torques for automatic balancing.

Owner:LEESER KARL F

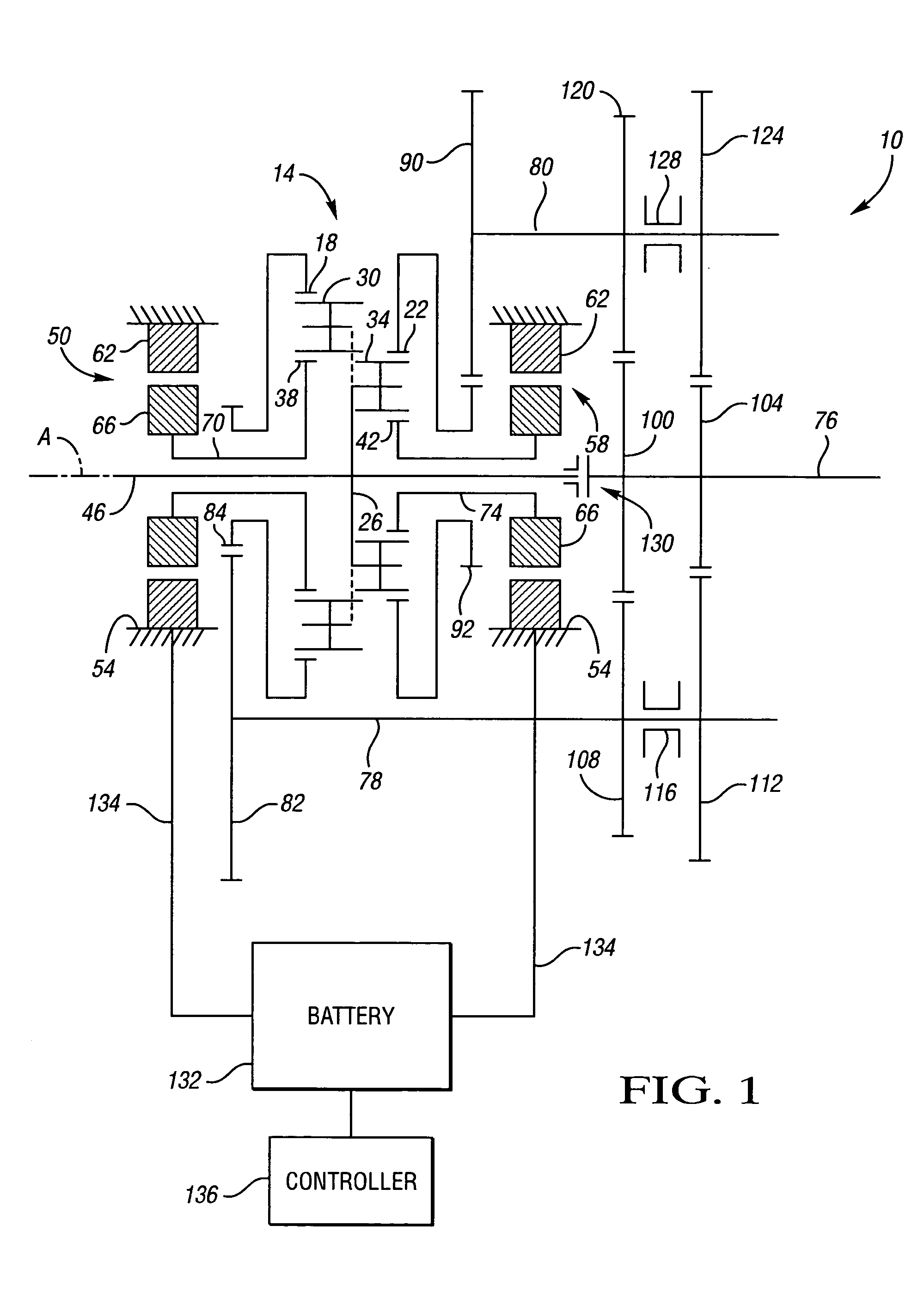

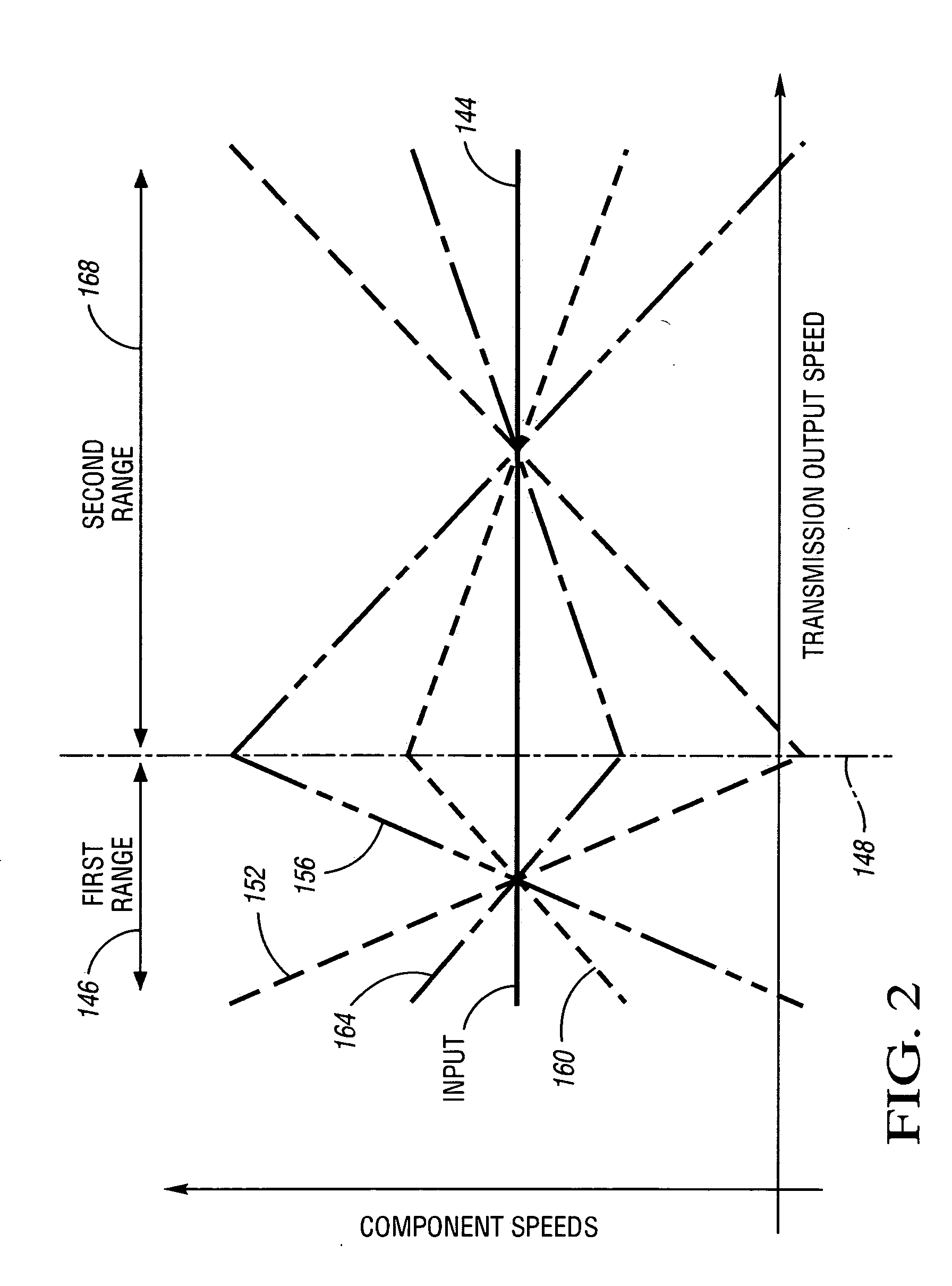

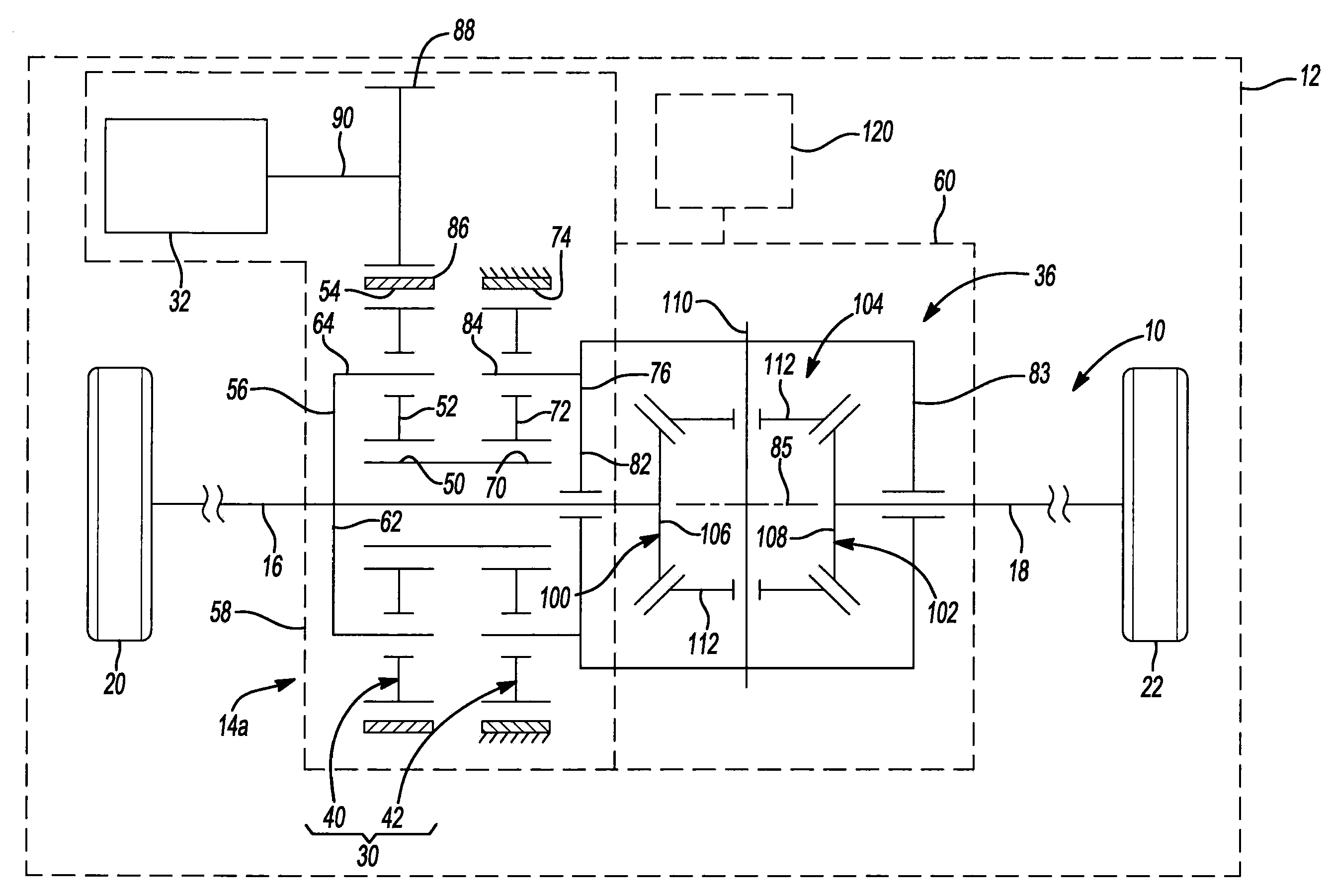

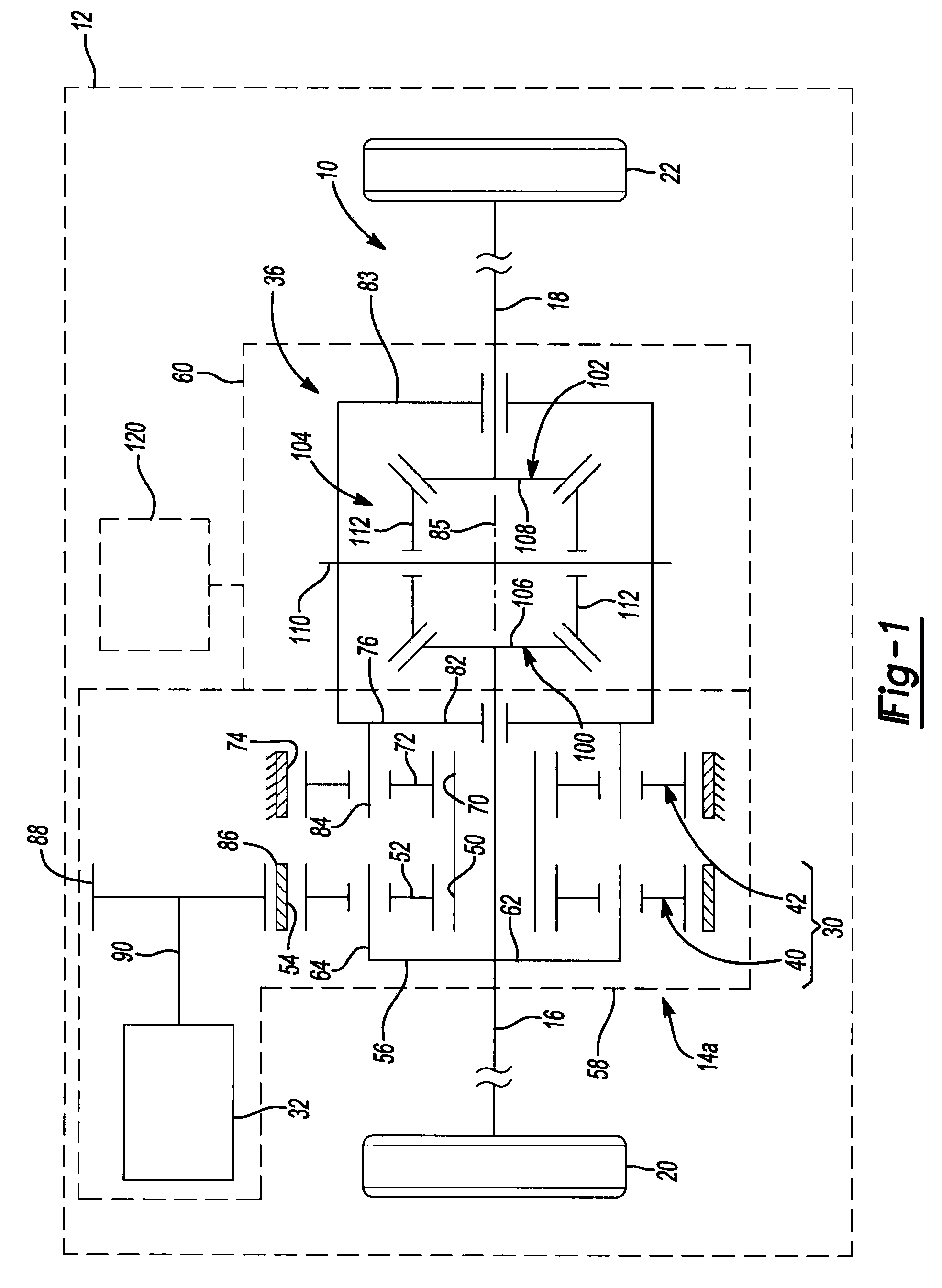

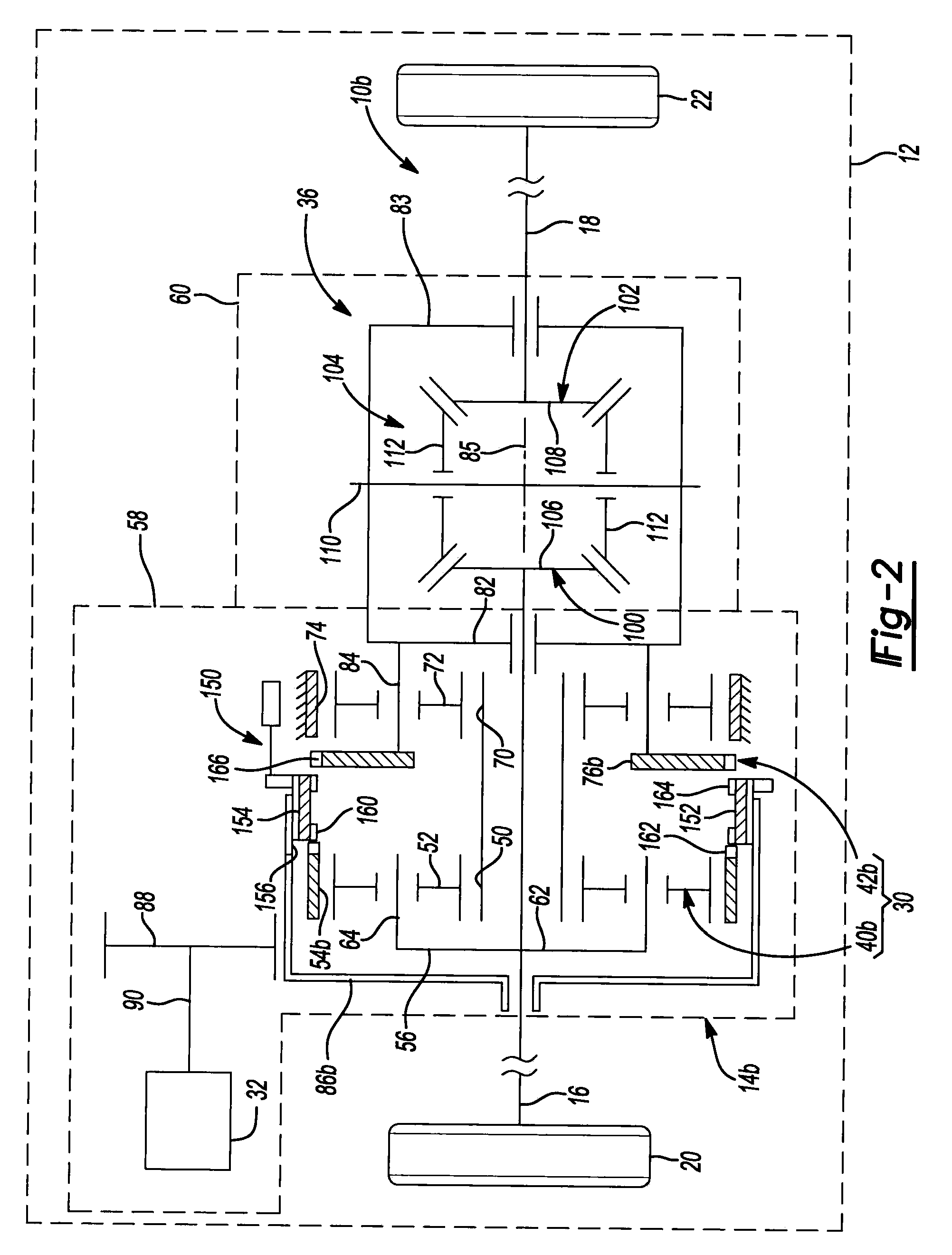

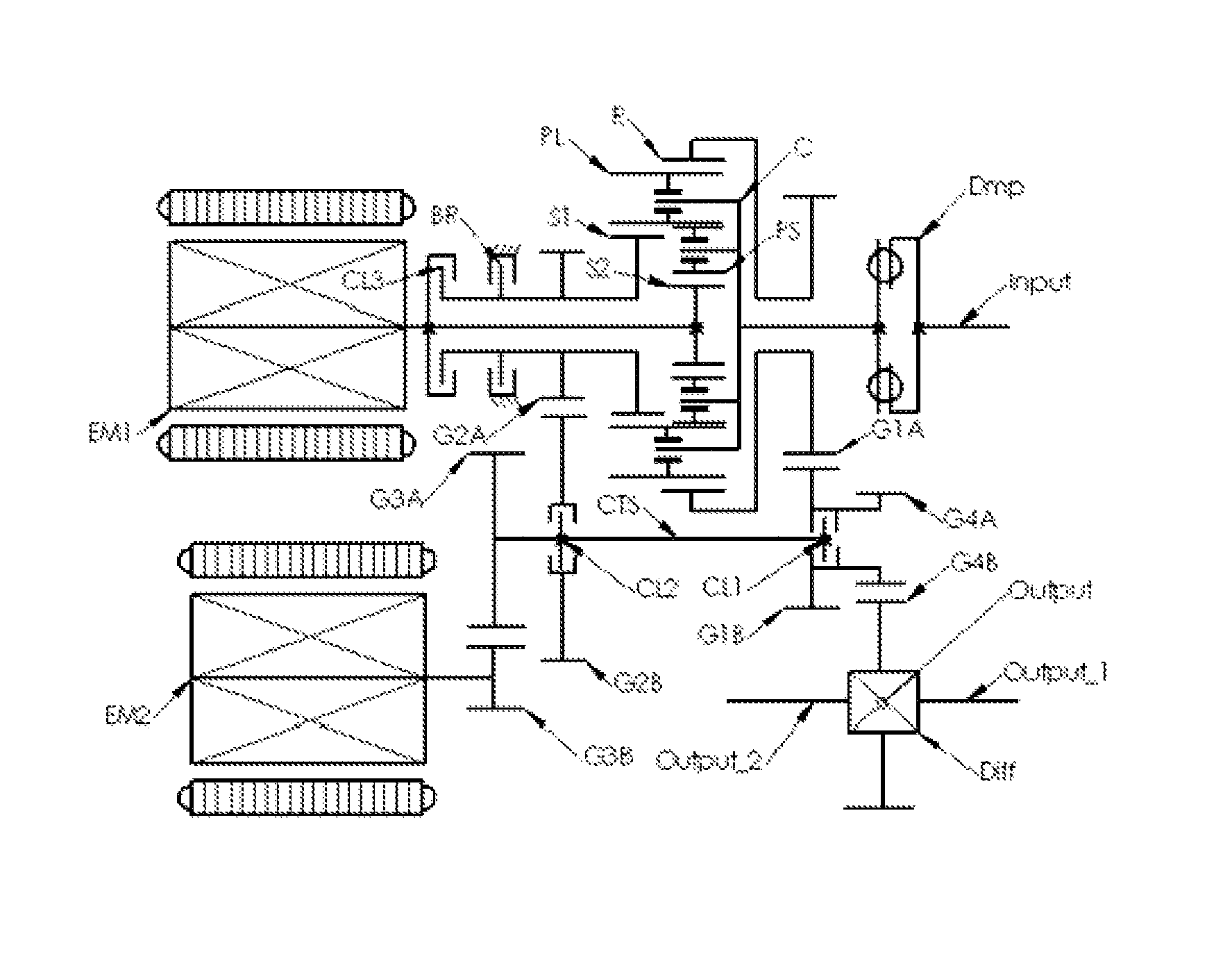

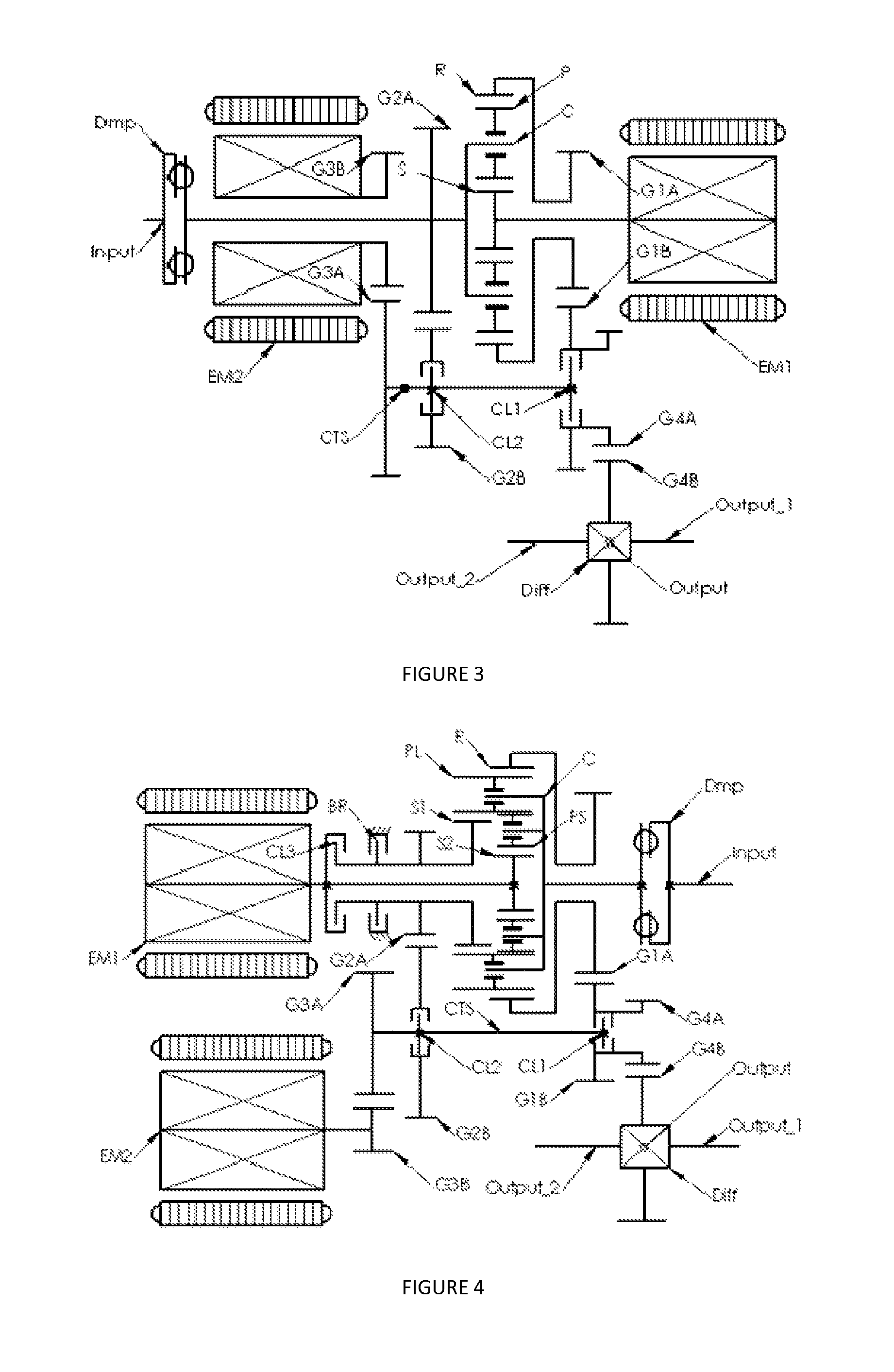

Dual-mode electromechanical variable speed transmission apparatus and method of control

InactiveUS8734281B2Improve transmission efficiencyAvoid powerHybrid vehiclesElectric propulsion mountingElectric machineDual mode

A dual-mode electro-mechanical variable speed transmission includes an input shaft, an output shaft system, a gear system having at least three branches, two electric machines, and at least a clutch. The first electric machine couples to a branch of the gear system, the output shaft system couples to another branch of the gear system, the input shaft couples to the remaining branch or one of the remaining branches of the gear system, and the second electric machine selectively couples either to the same branch that is coupled to the output shaft system with a speed ratio or to one of the remaining branches that that is not coupled to the first electric machine with a different speed ratio. The transmission provides at least two power splitting modes to cover different speed ratio regimes. The transmission can also provide at least a fixed output shaft to input shaft speed ratio.

Owner:SHANDONG LIANCHENG GREENMAX TECH

Electromagnetic locking differential assembly

InactiveUS6958030B2Mechanical actuated clutchesElectrodynamic brake systemsGear wheelElectromagnetic lock

Owner:AMERICAN AXLE & MFG

Multi-speed transmission

A transmission is provided having an input member, an output member, a dual clutch assembly, two countershaft gearing arrangements, one planetary gear set, a plurality of interconnecting members, and a plurality of torque transmitting devices. Each of the countershaft gearing arrangements includes a plurality of co-planar gear sets. The torque transmitting devices include a combination of clutches, brakes, and synchronizers.

Owner:GM GLOBAL TECH OPERATIONS LLC

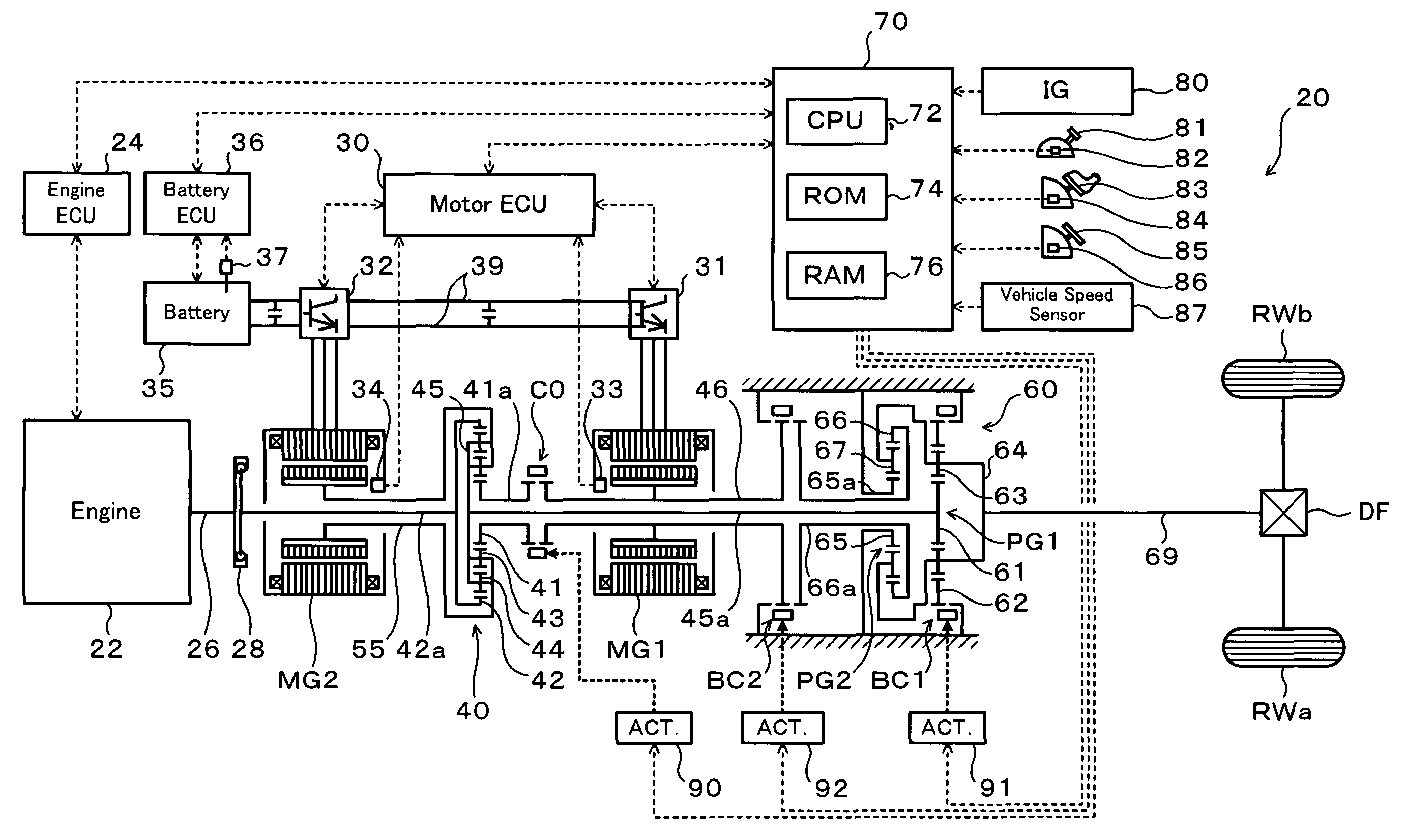

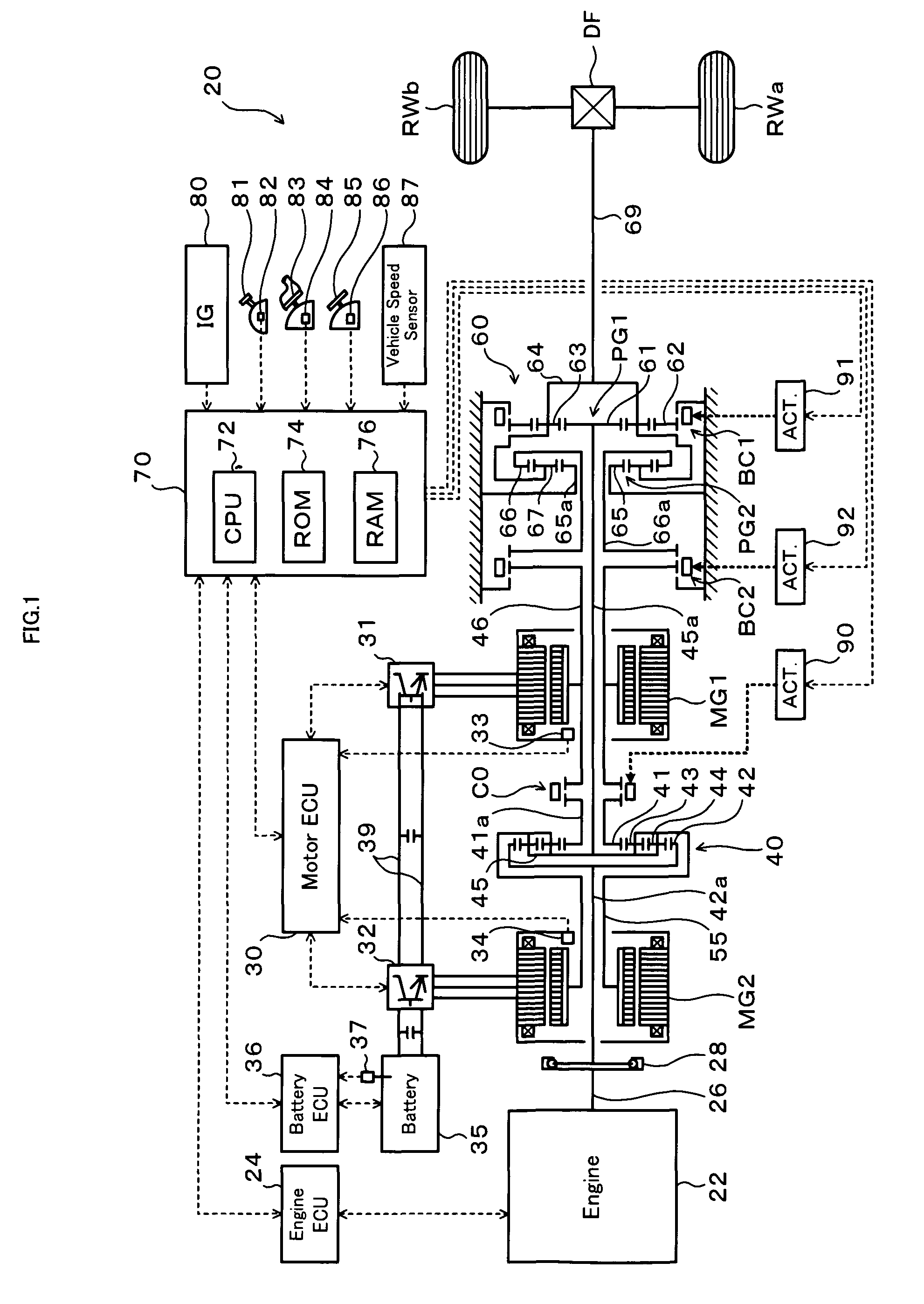

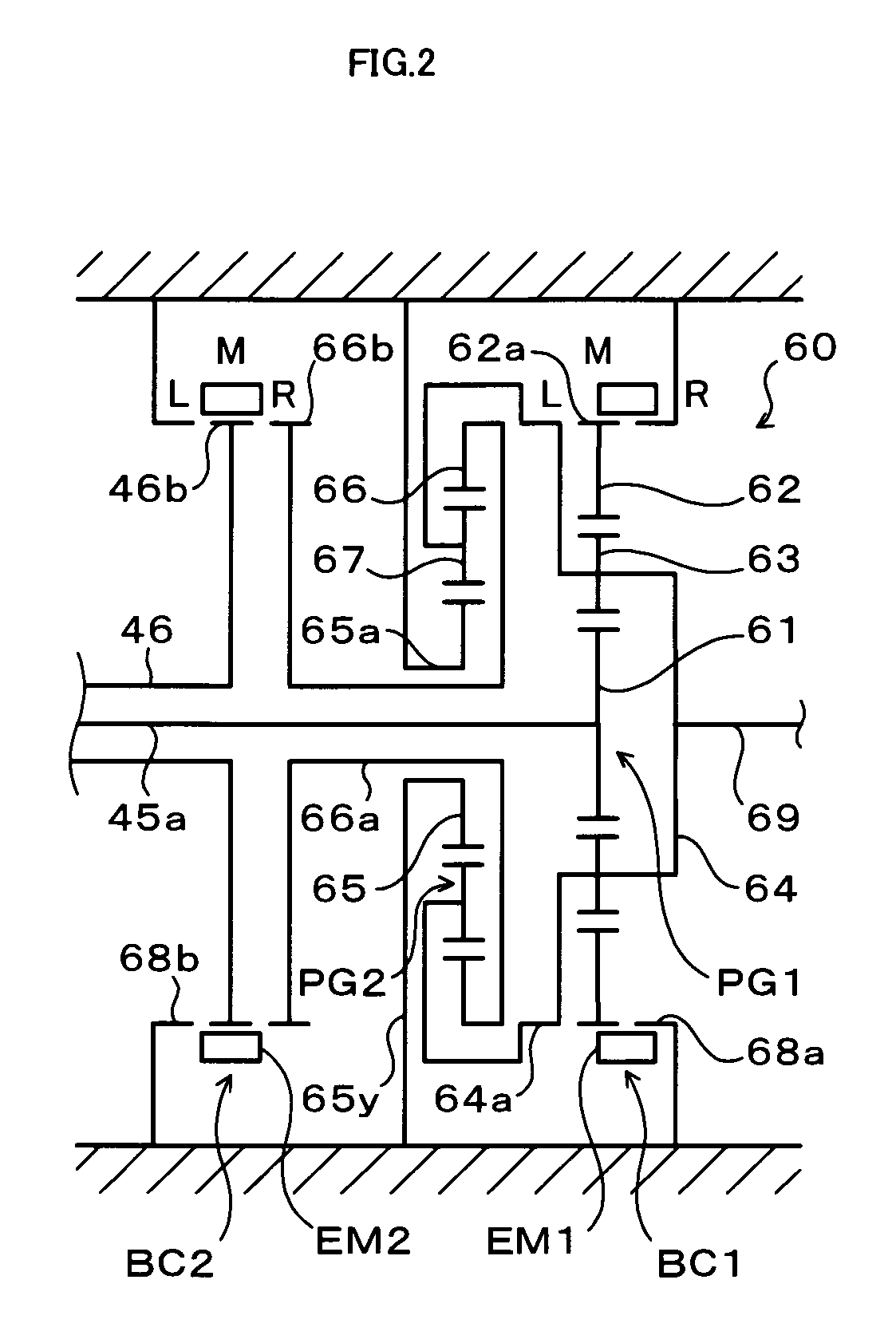

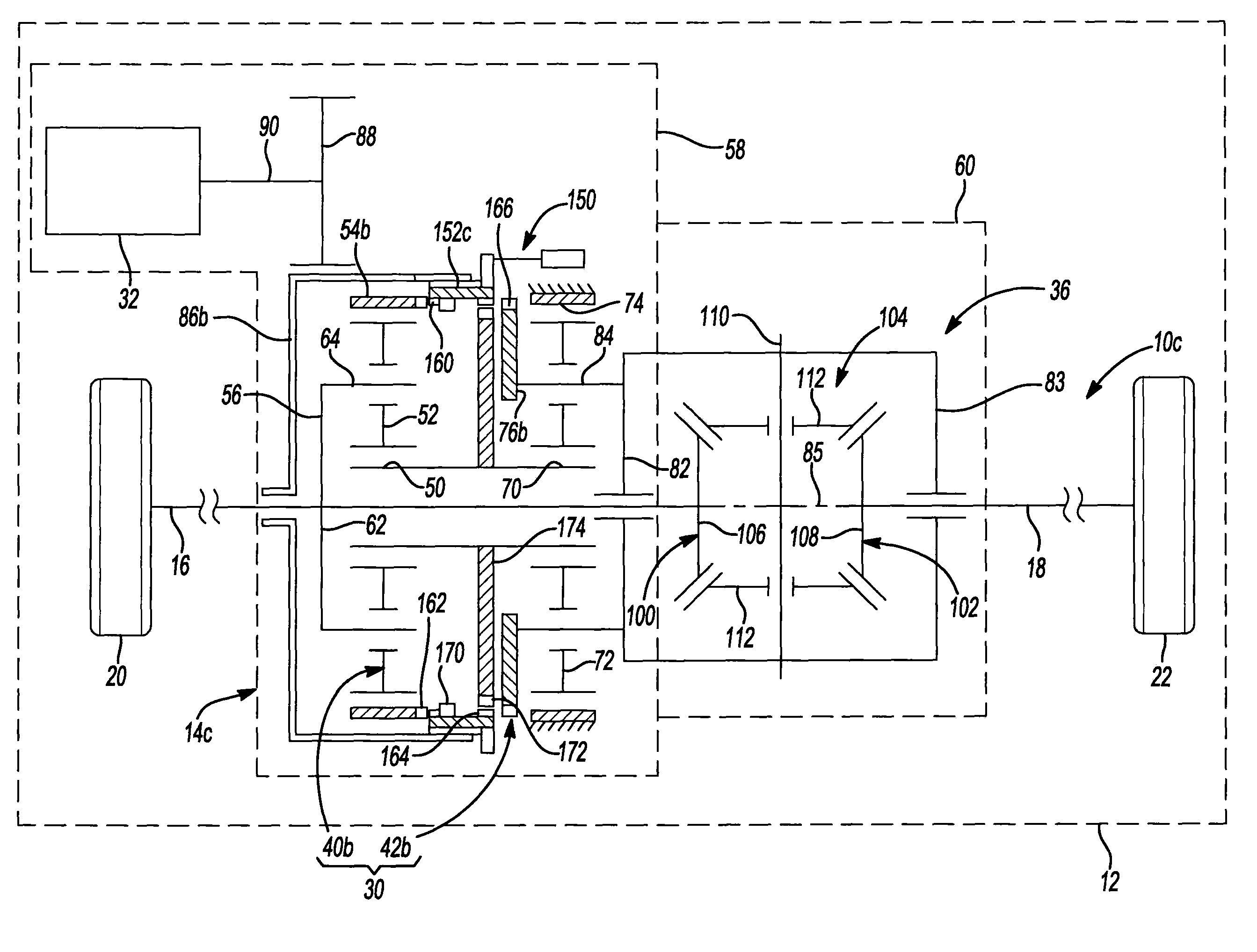

Power output apparatus and hybrid vehicle with power output apparatus

InactiveUS7806795B2Improve transmission efficiencyWide driving rangeHybrid vehiclesElectric propulsion mountingEngineeringPinion

A hybrid vehicle 20 of the invention is equipped with a power distribution integration mechanism 40 and a transmission 60. The power distribution integration mechanism 40 is a double pinion planetary gear mechanism constructed to include a carrier 45 connecting with a motor MG2, a sun gear 41 connecting with a motor MG1, and a ring gear 42 connecting with an engine 22 and to have a gear ratio of approximately 0.5. The transmission 60 includes a three element-type first change speed planetary gear mechanism PG1, a three element-type second change speed planetary gear mechanism PG2, a brake clutch BC1 configured to fix a ring gear 62 of the first change speed planetary gear mechanism PG1 in a non-rotatable manner and release the ring gear 62 in a rotatable manner, and a brake clutch BC2 configured to enable and disable power transmission via the second change speed planetary gear mechanism PG2.

Owner:TOYOTA JIDOSHA KK

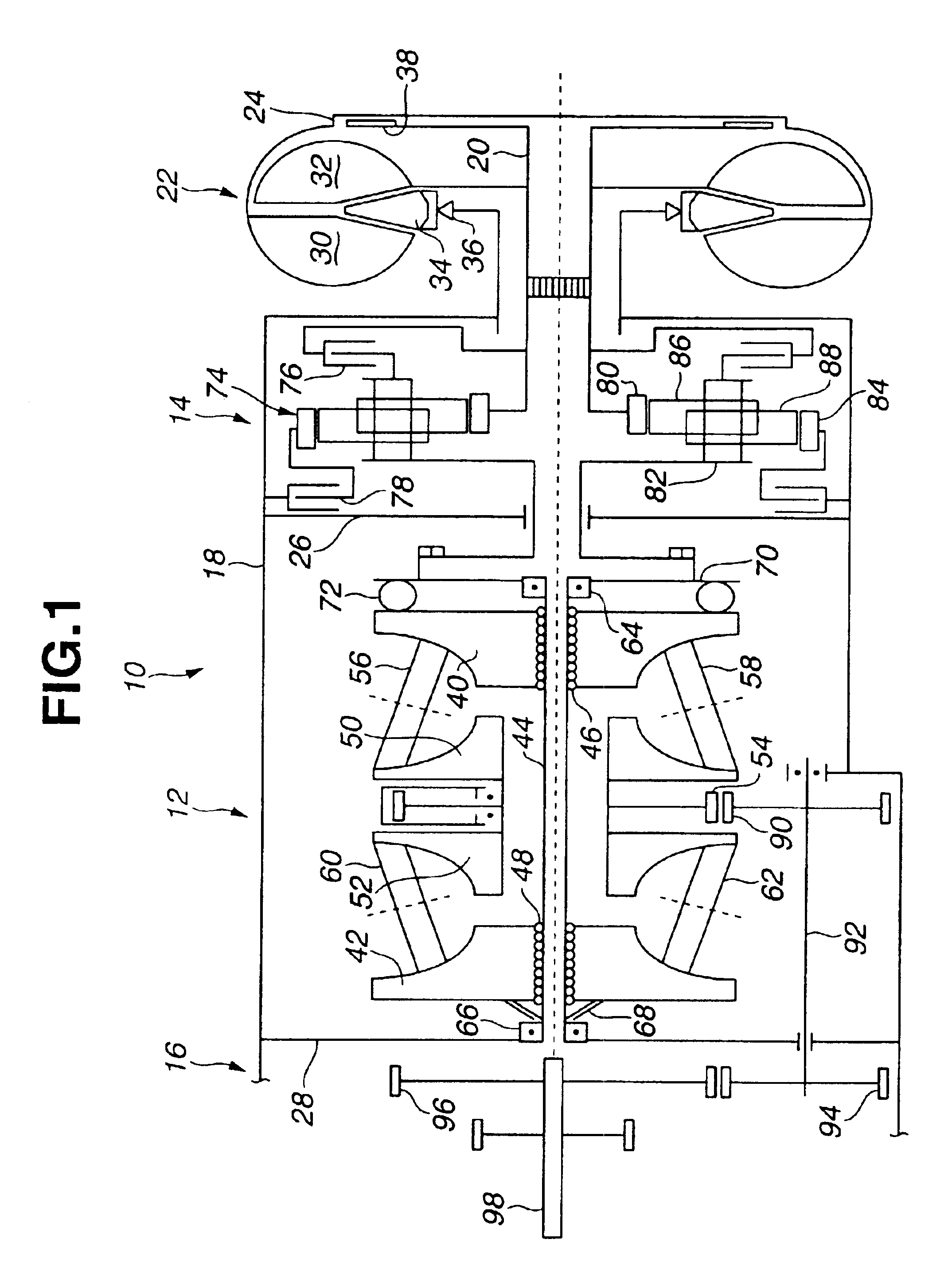

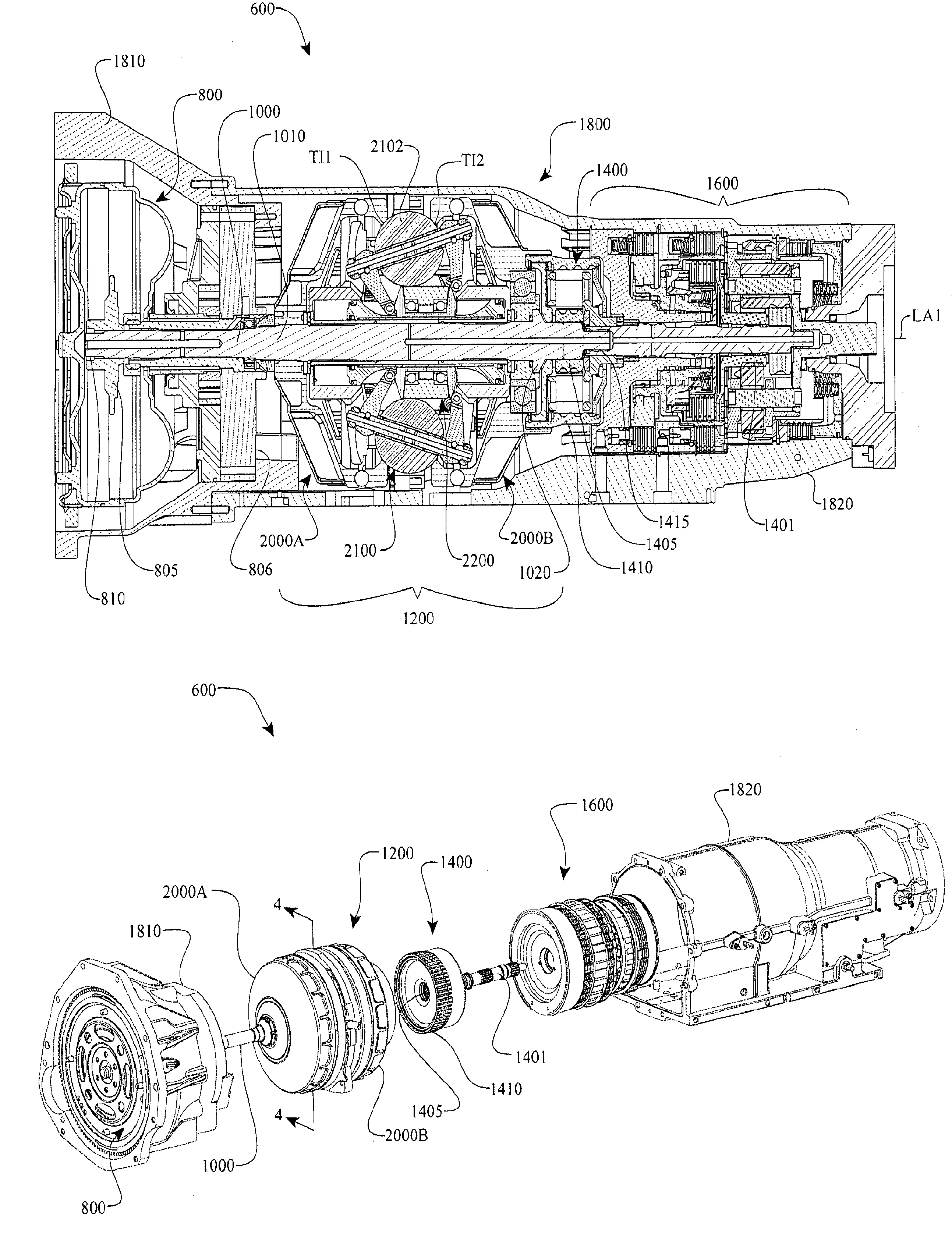

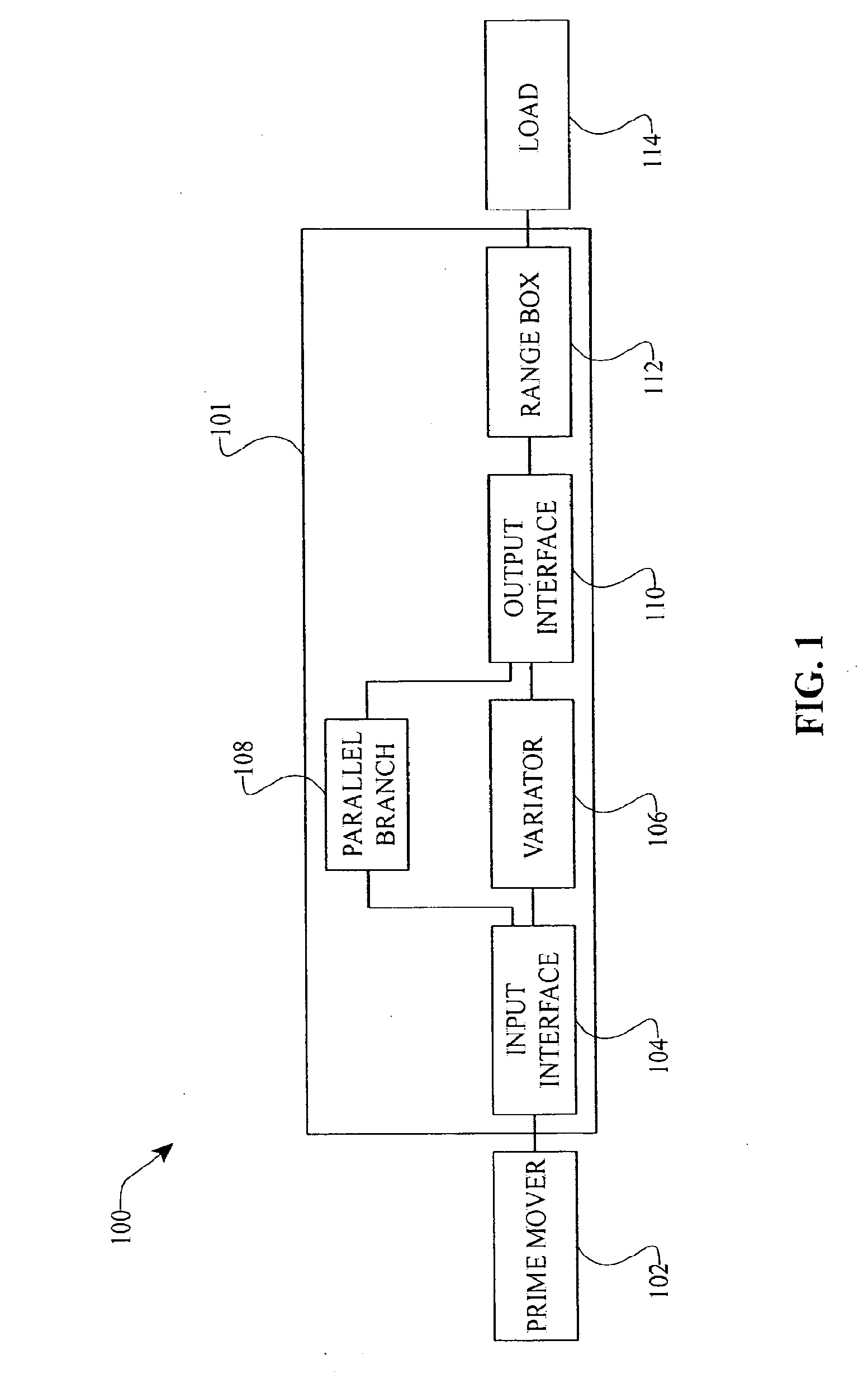

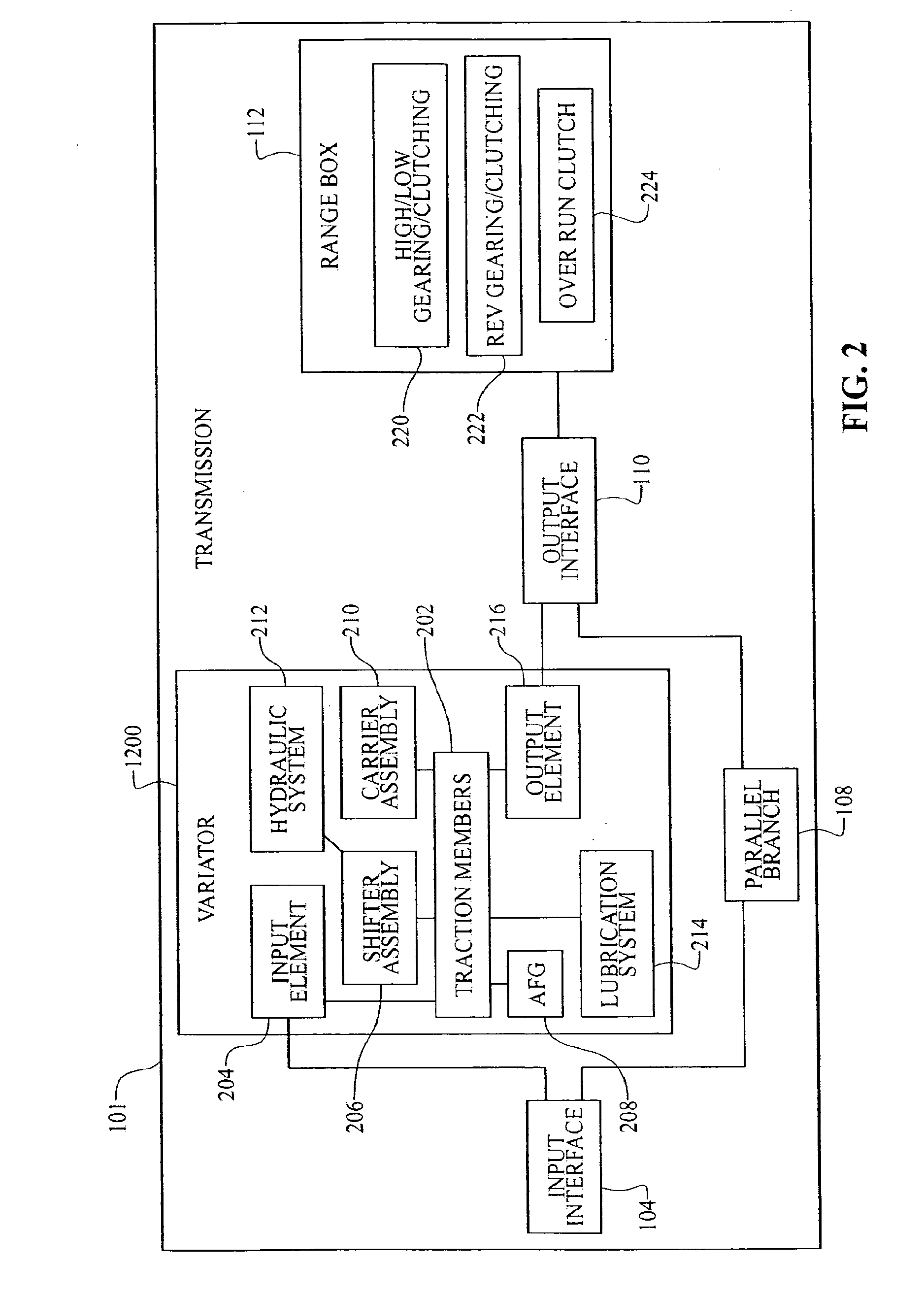

Continuously variable transmissions and methods therefor

Components, subassemblies, systems, and / or methods for continuously variable transmissions (CVT) having a variator provided with a plurality of tilting, traction planets and traction rings are described. In one embodiment, a variator is coupled to a rangebox to provide multiple operating modes. In another embodiment, a hydraulic system is configured to control the transmission ratio of the variator and the rangebox. Shift-cam-and-sun subassemblies can be used to facilitate shifting of the transmission ratio of a CVT. A transmission housing and bell housing can be adapted to house components of a CVT and, in some embodiments, to cooperate with other components of the CVT to support operation and / or functionality of the CVT. Related devices include, for example, a pivot arm, a control feedback mechanism, axial force generation and management mechanisms, a control valve integral with an input shaft, a pivot pin hub, and a rotatable carrier configured to support planet-pivot arm assemblies.

Owner:FALLBROOK INTPROP COMPANY

Axle assembly with torque distribution drive mechanism

An axle assembly with an input member, a first planetary gear set, a differential assembly, and a second planetary gear set. The first planetary gear set has a first transmission input that is driven by the input member. The differential assembly has a differential carrier and first and second differential output members received in the differential carrier. The second planetary gear set has a planet carrier coupled to the differential carrier for common rotation. A sun gear of the first planetary gear set is non-rotatably coupled to a sun gear of the second planetary gear set.

Owner:E AAM DRIVELINE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com