Patents

Literature

302 results about "Spin speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

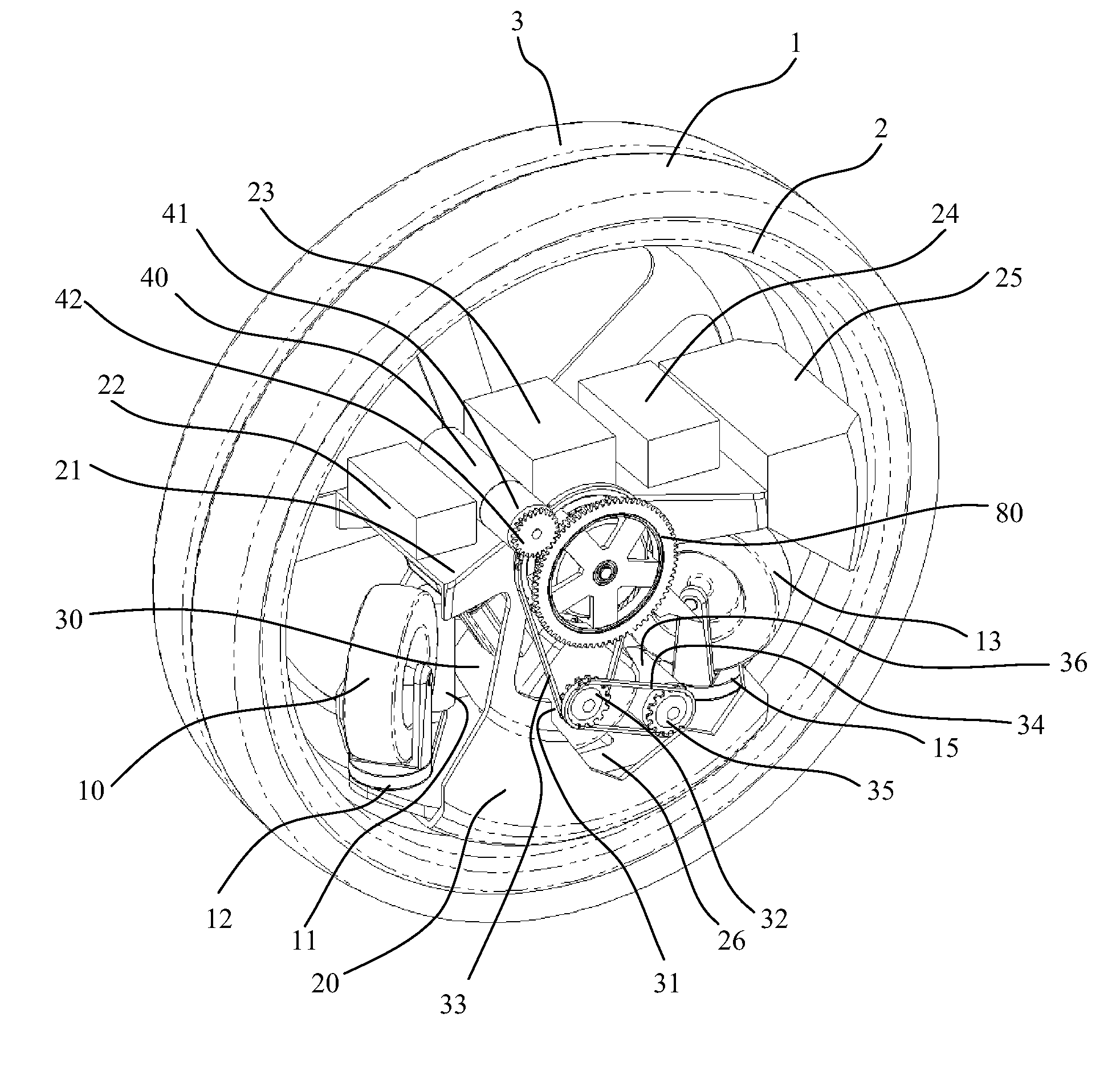

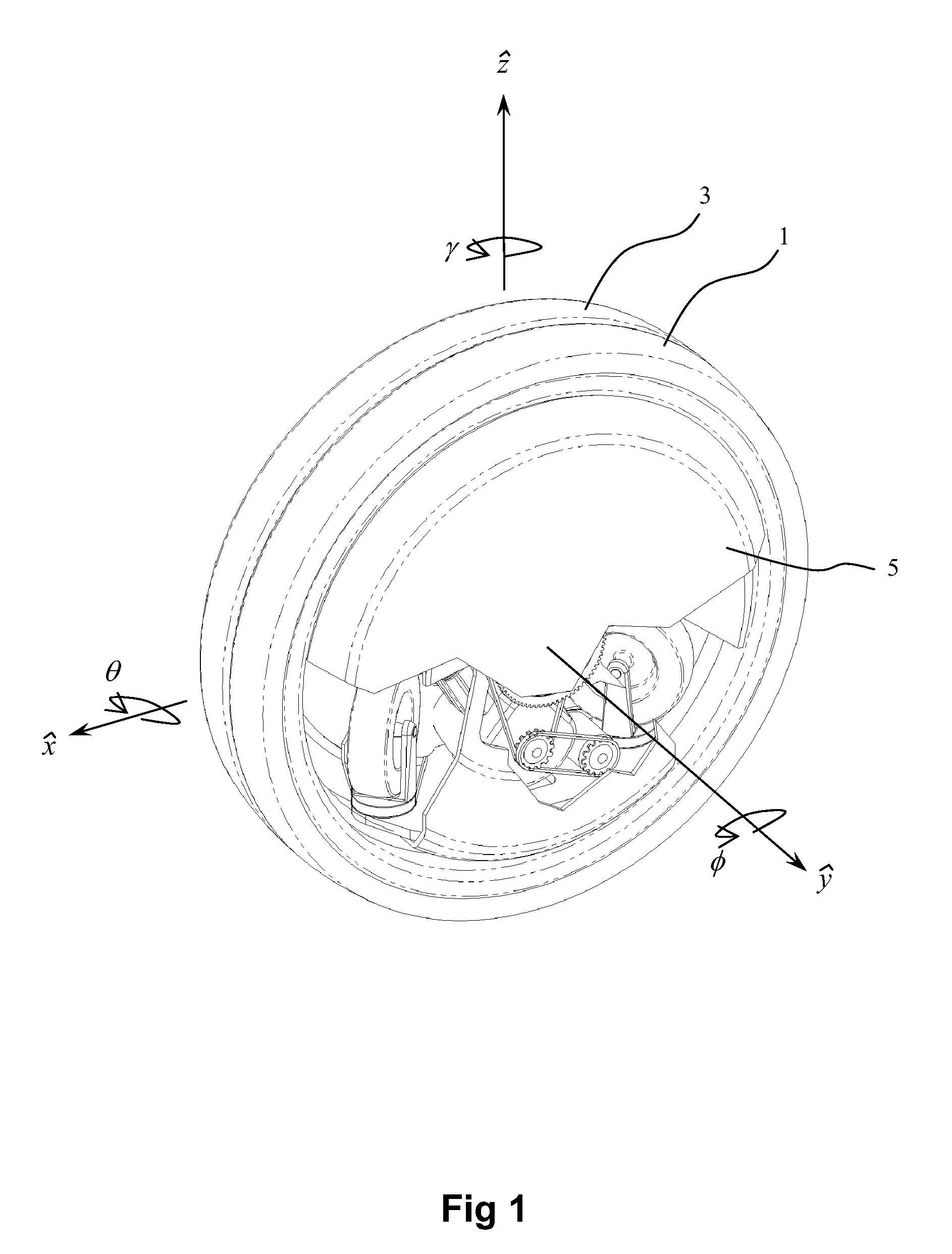

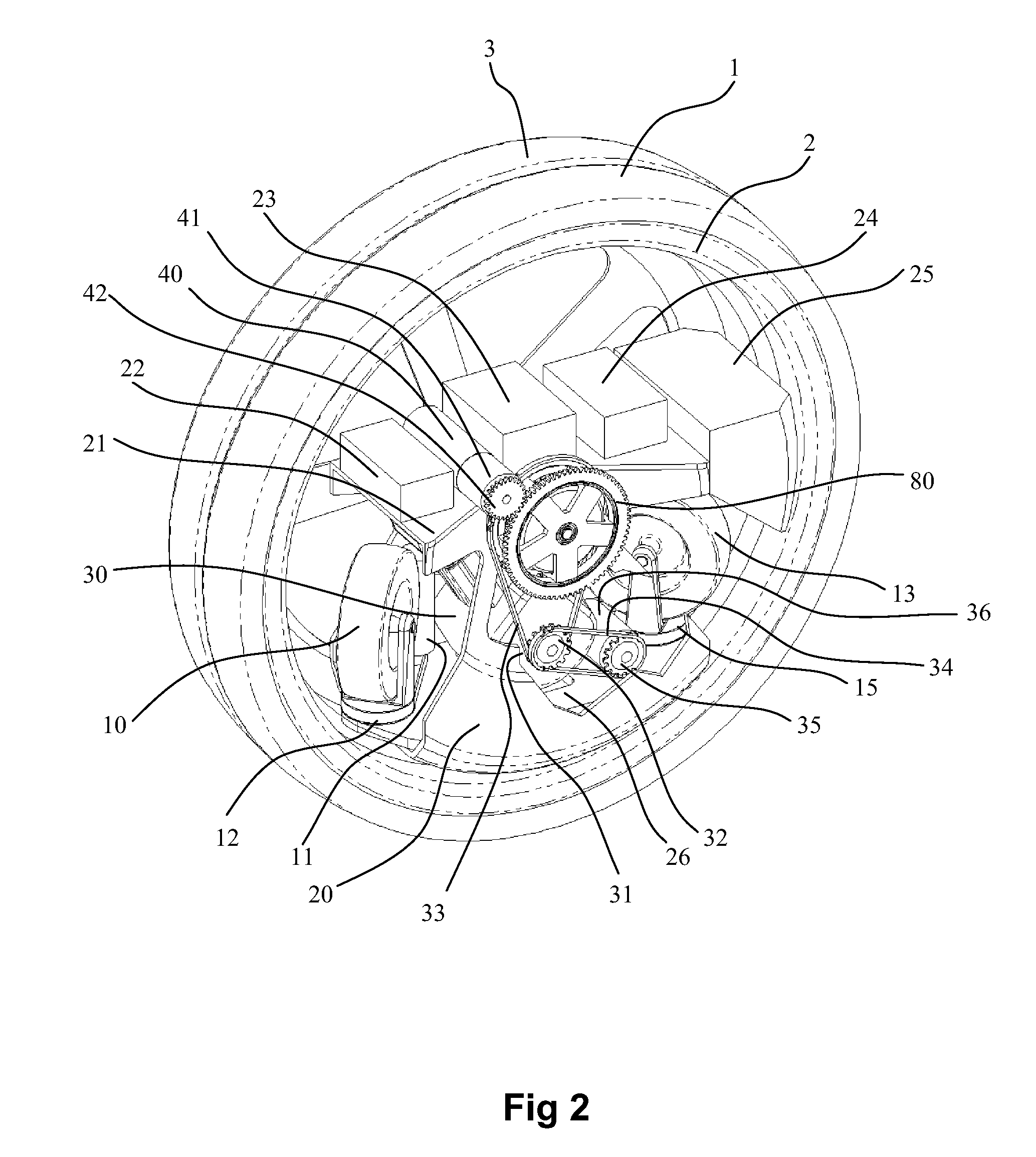

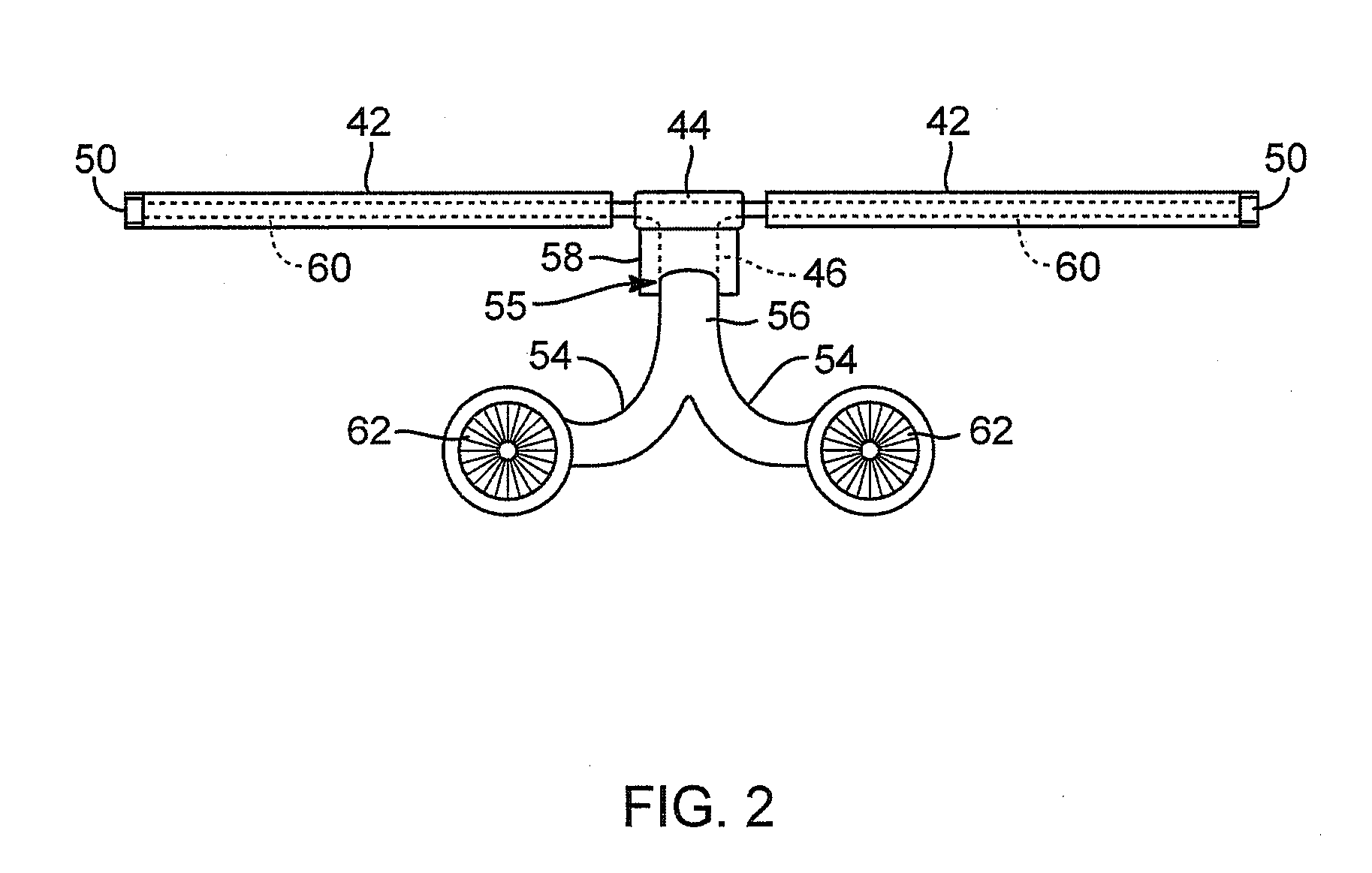

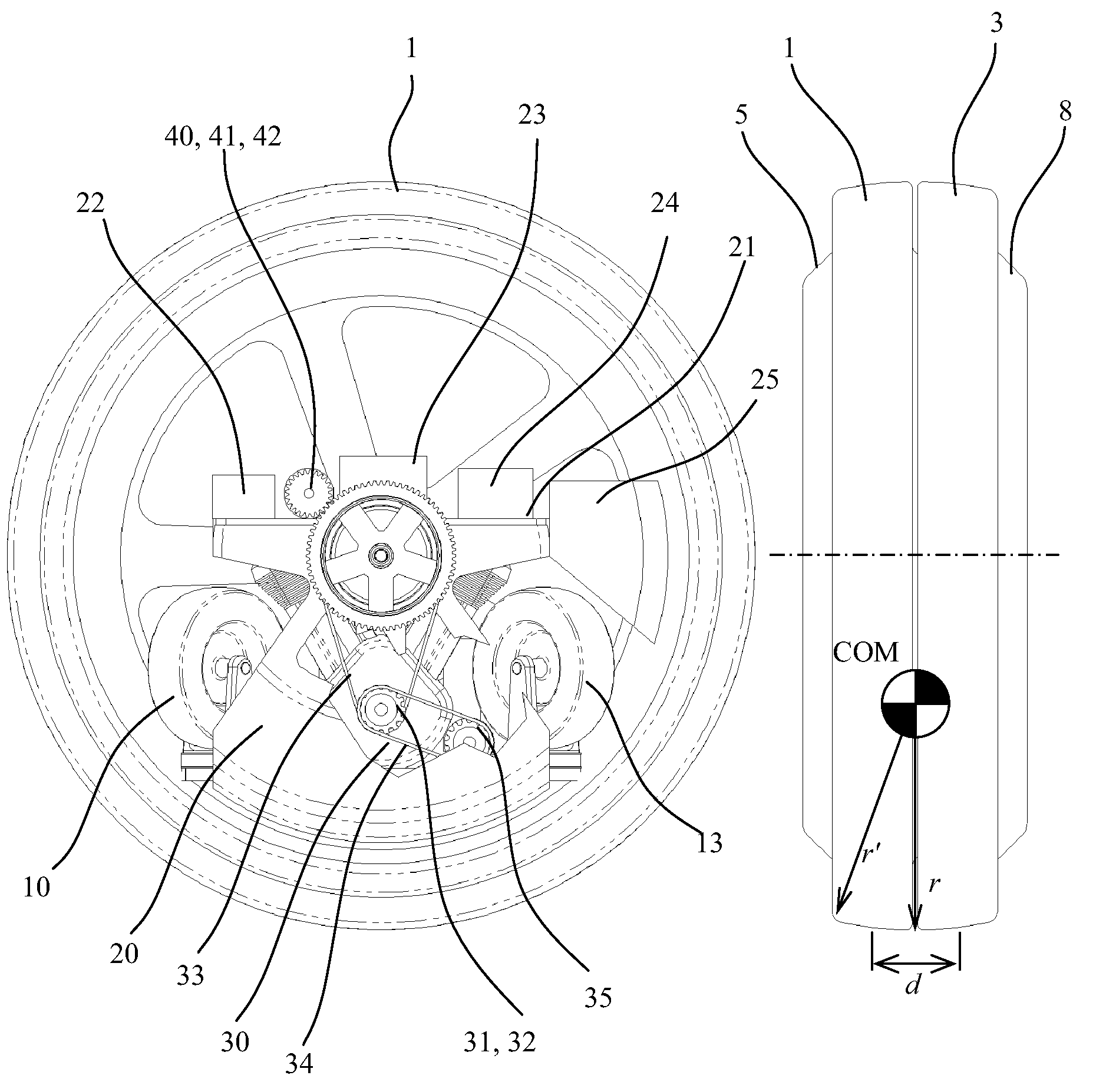

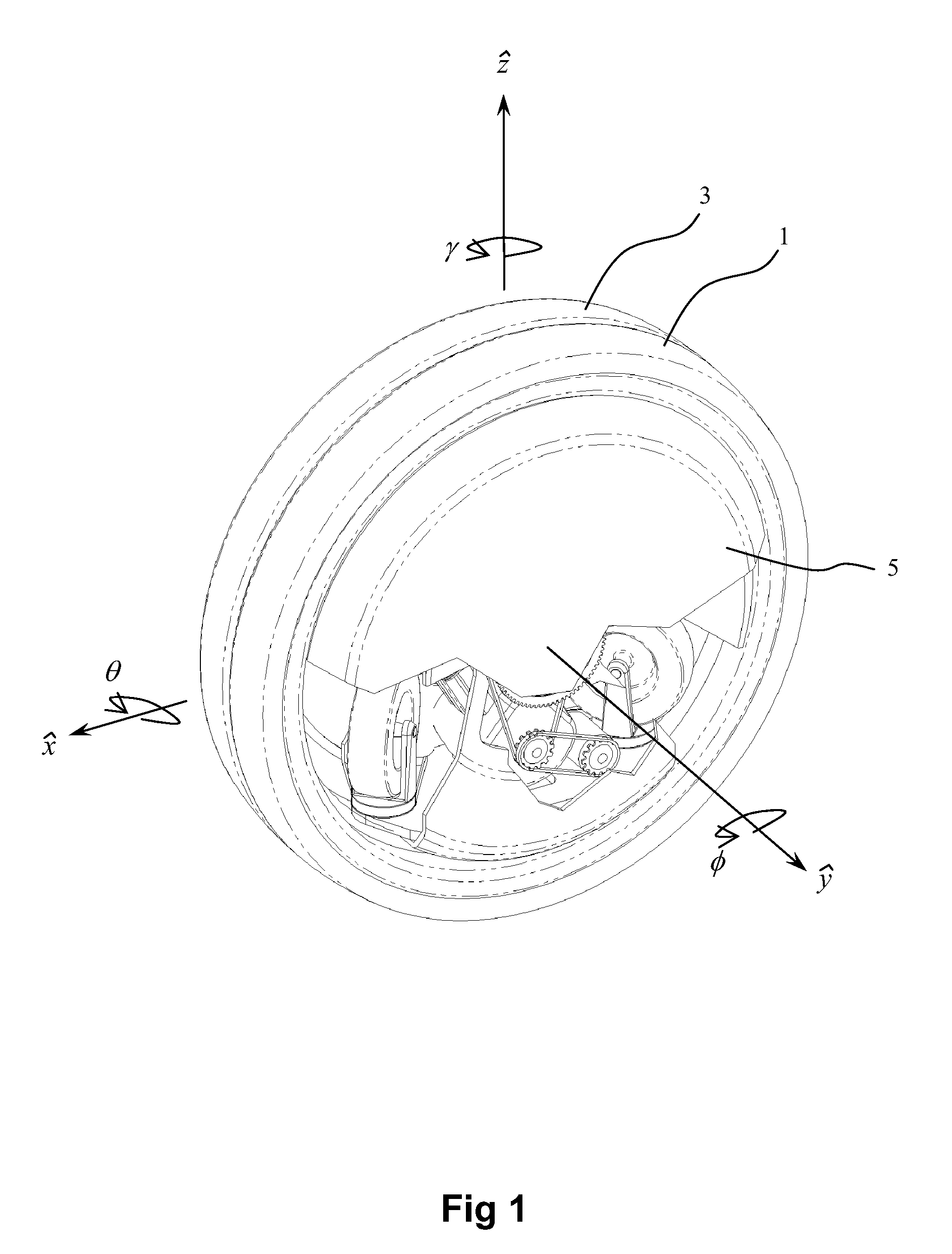

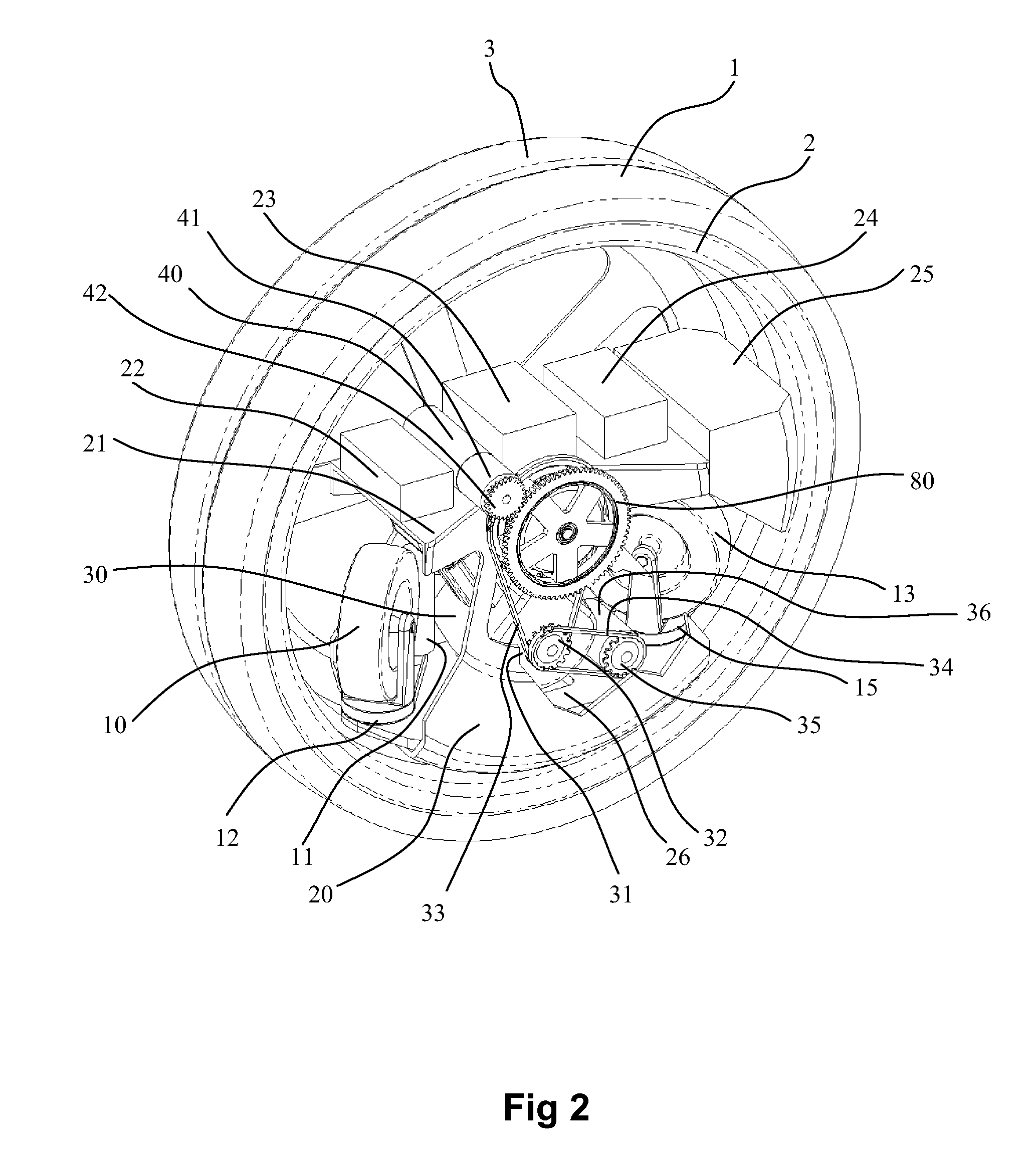

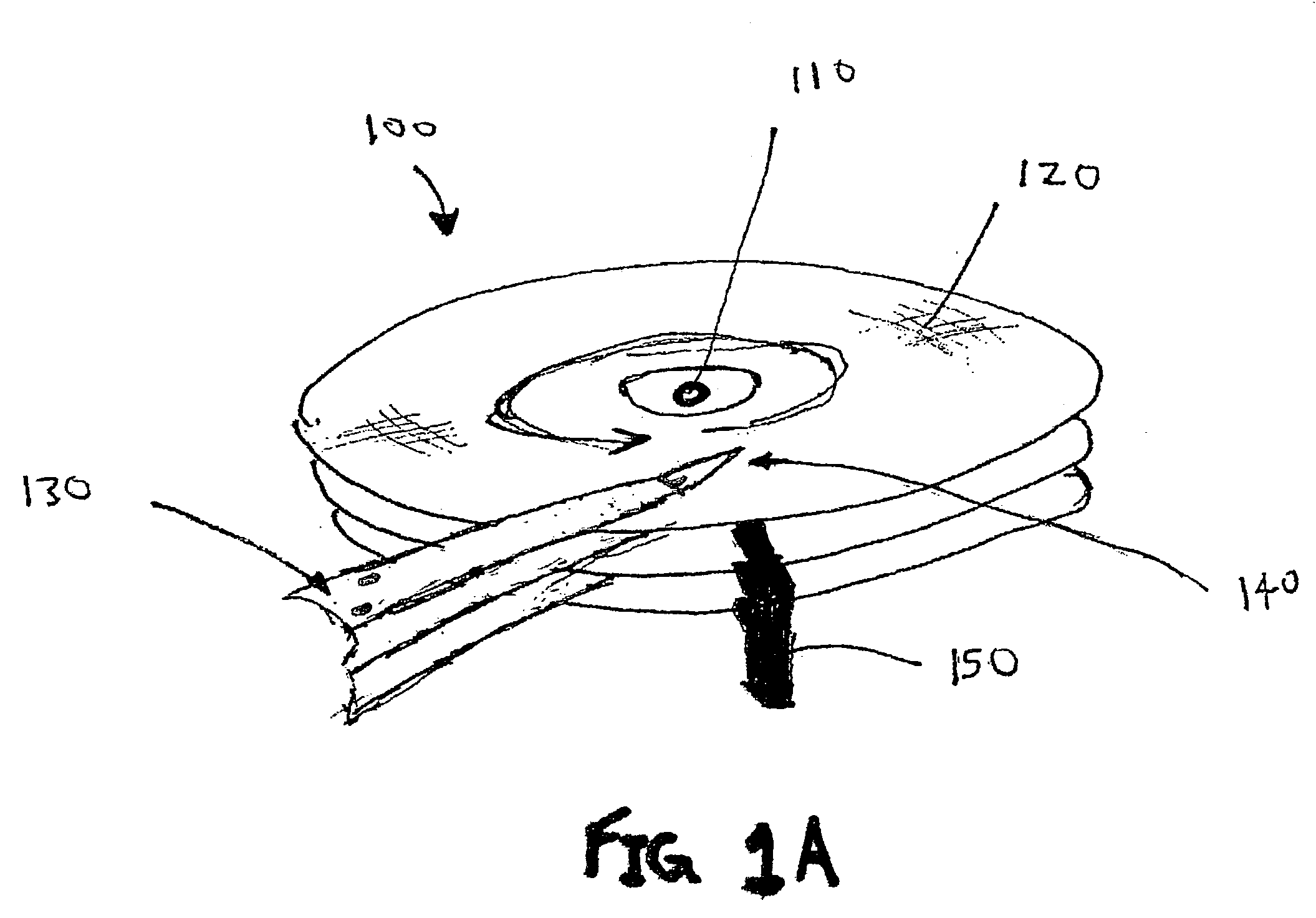

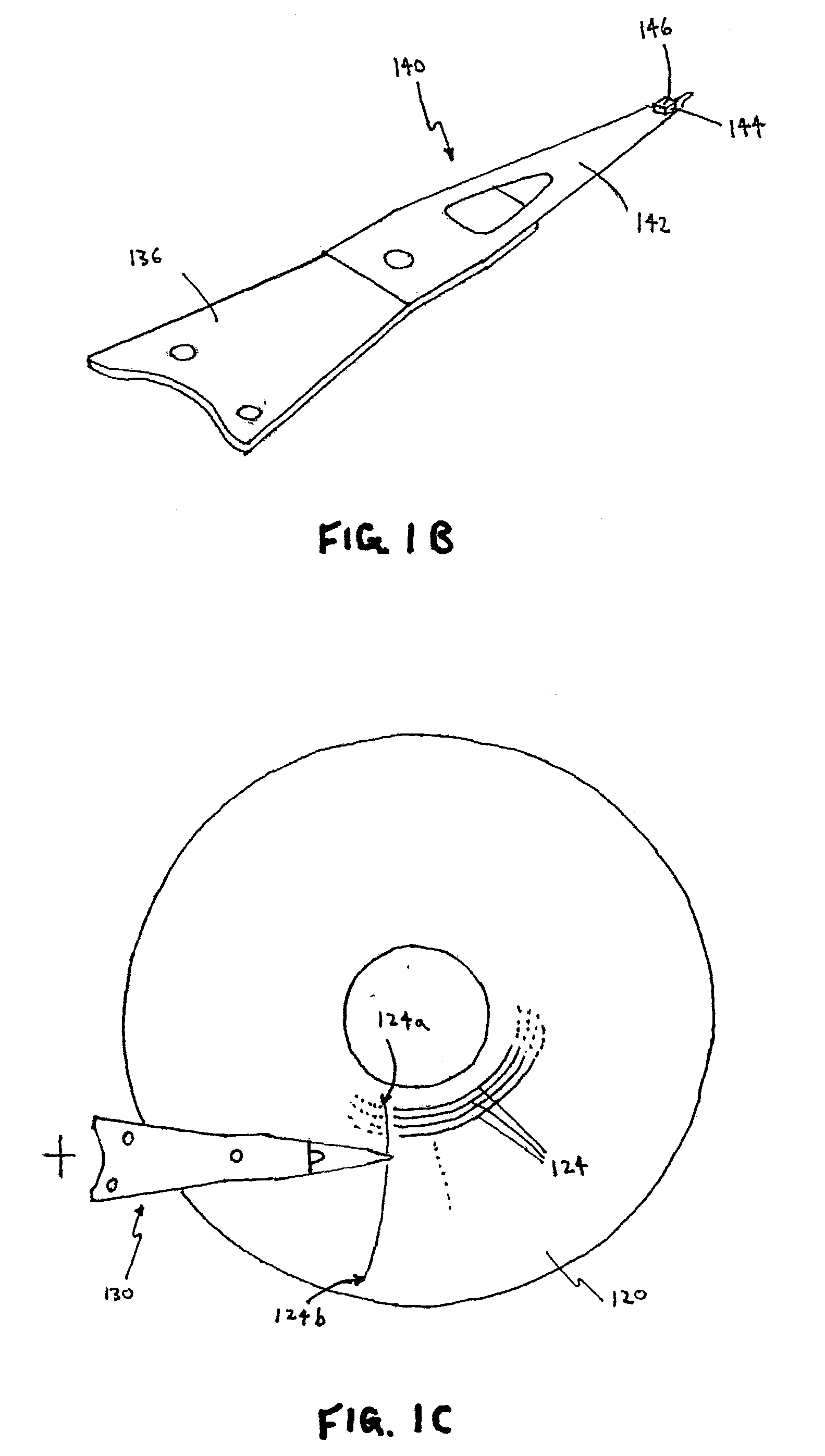

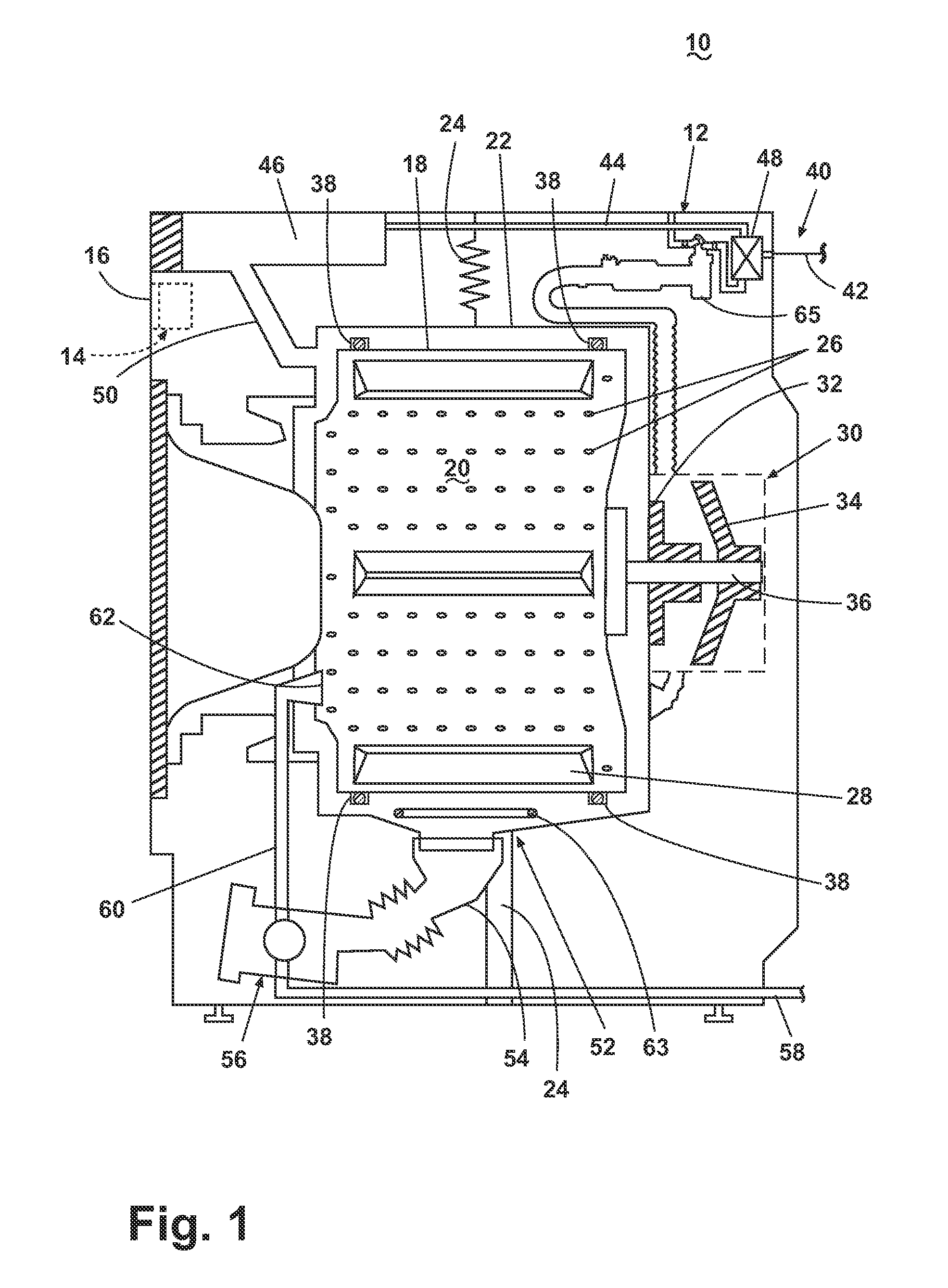

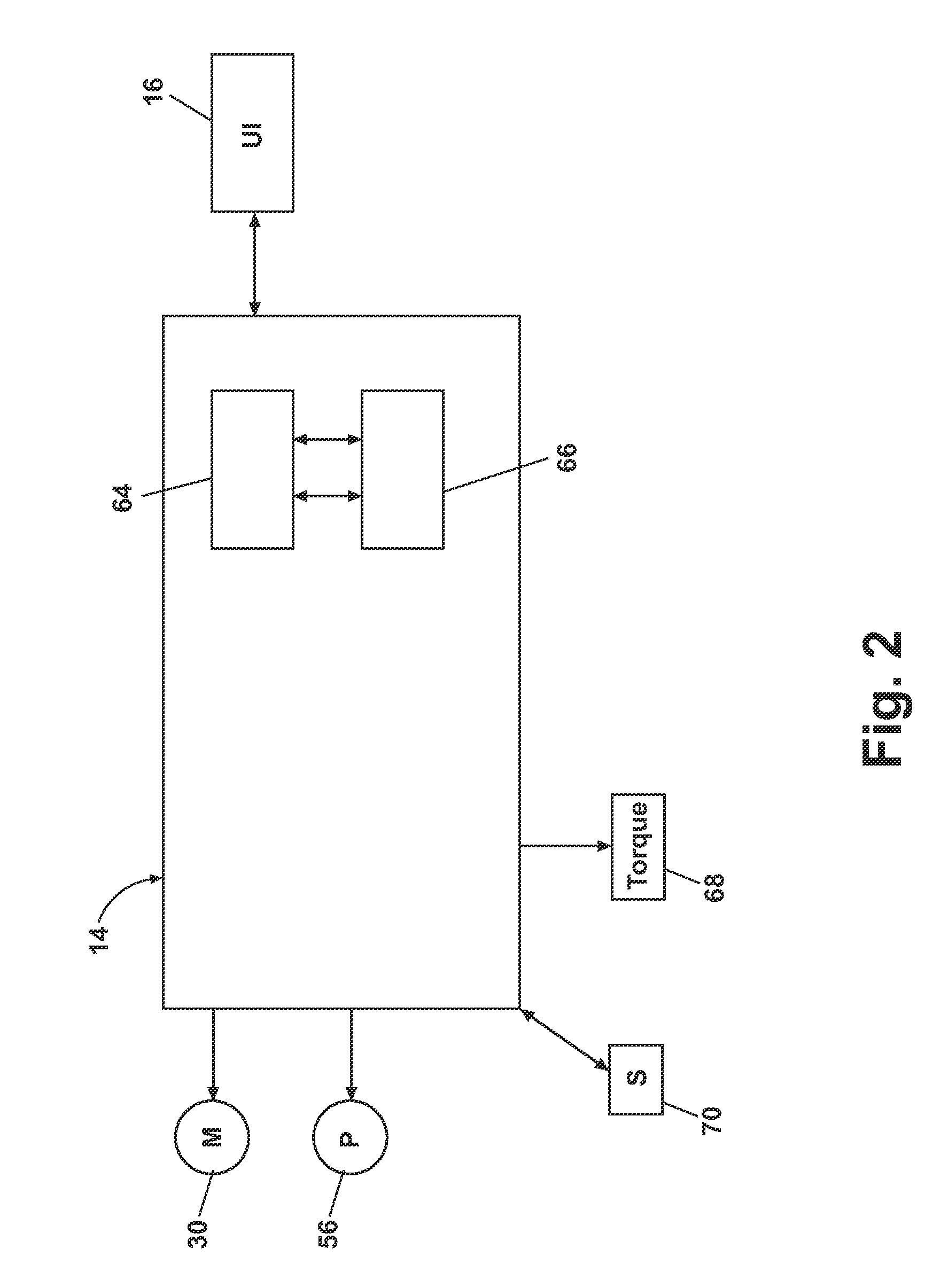

Monowheel Type Vehicle

An engine-propelled monowheel vehicle comprises two wheels, close together, that circumscribe the remainder of the vehicle. When the vehicle is moving forward, the closely spaced wheels act as a single wheel, and the vehicle turns by leaning the wheels. A single propulsion system provides a drive torque that is shared by the two wheels. A separate steering torque, provided by a steering motor, is added to one wheel while being subtracted from the other wheel, enabling the wheels to rotate in opposite directions for turning the vehicle at zero forward velocity. The vehicle employs attitude sensors, for sensing roll, pitch, and yaw, and an automatic balancing system. A flywheel in the vehicle spins at a high rate around a spin axis, wherein the spin axis is rotatable with respect to the vehicle's frame. The axis angle and flywheel spin speed are continually adjustable to generate torques for automatic balancing.

Owner:LEESER KARL F

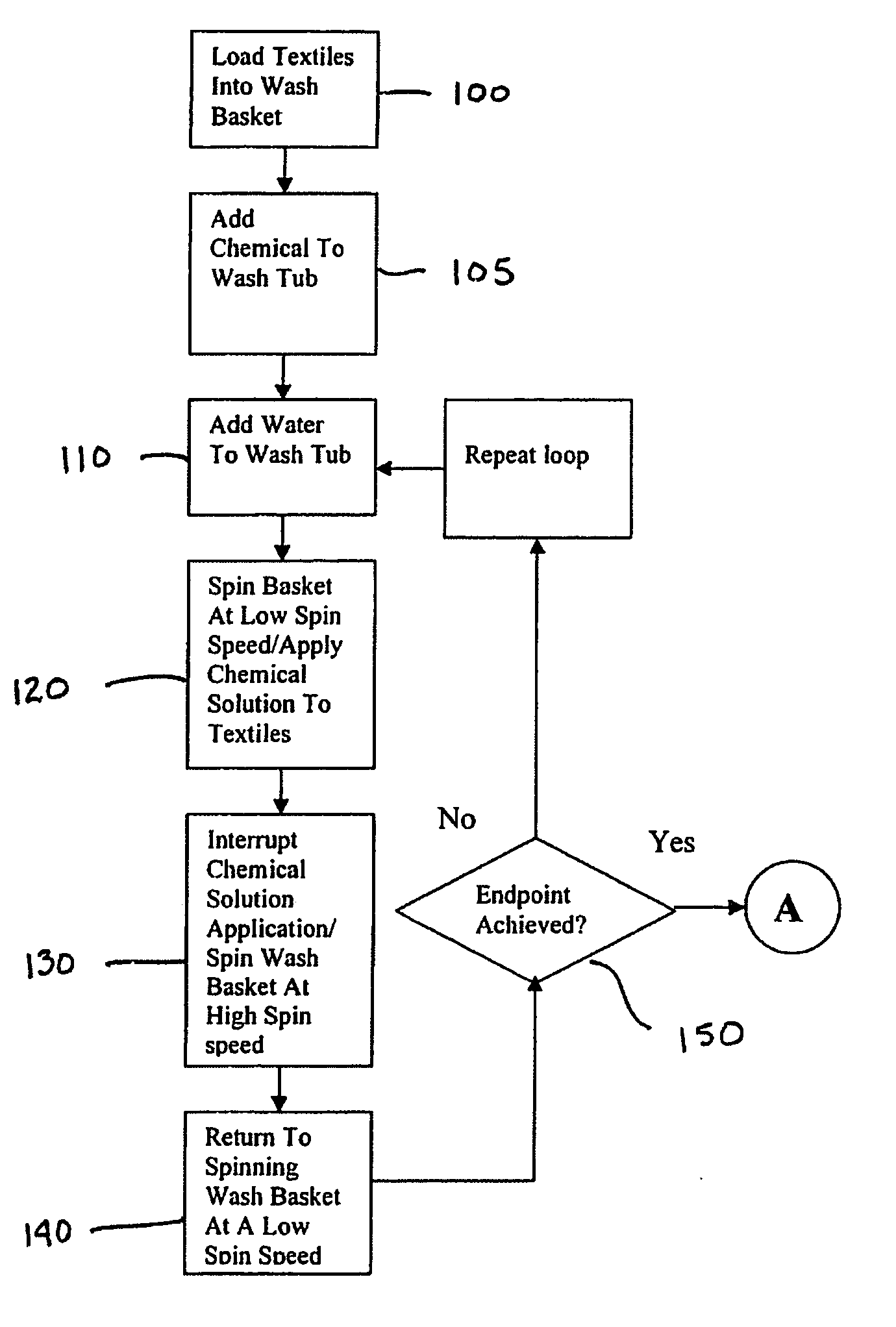

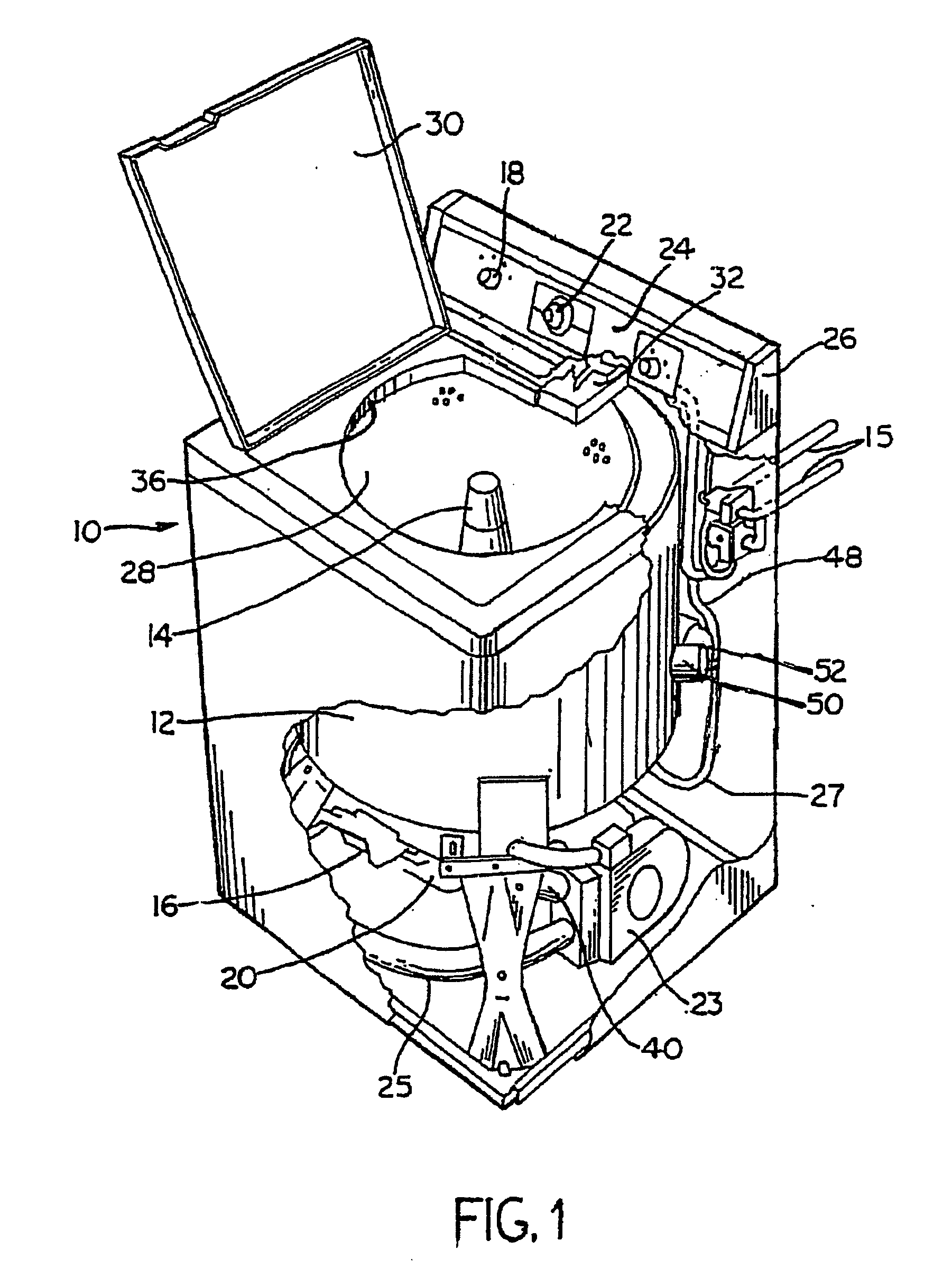

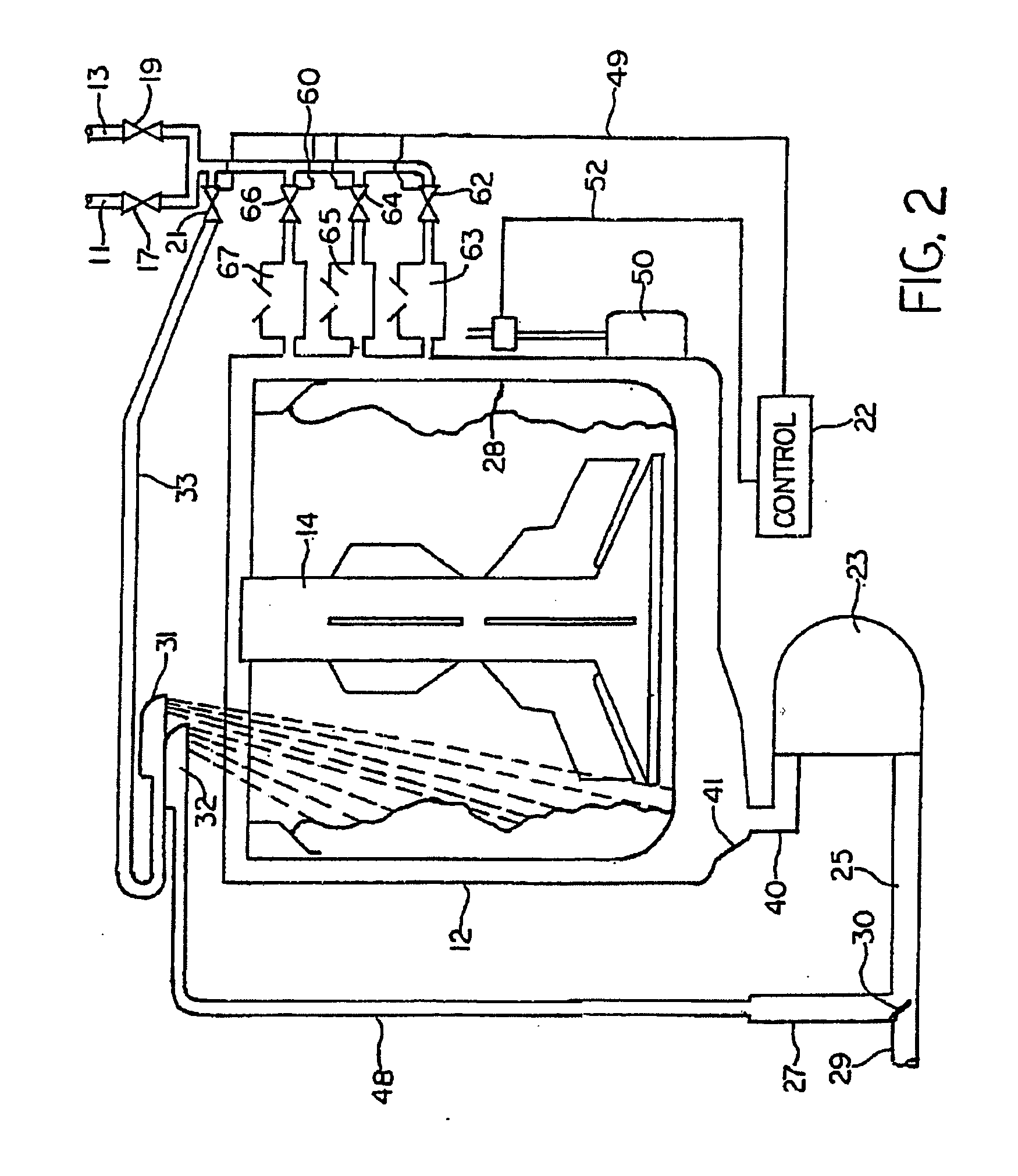

Stain removal process using combination of low and high speed spin

An improved method for treating textiles such as clothing with a concentrated solutions in an automatic washer by alternating the speed of rotation of the automatic washer wash basket from a low spin speed to a high spin speed and applying the concentrated solution to the textiles when the wash basket is spinning at the low spin speed.

Owner:WHIRLPOOL CORP

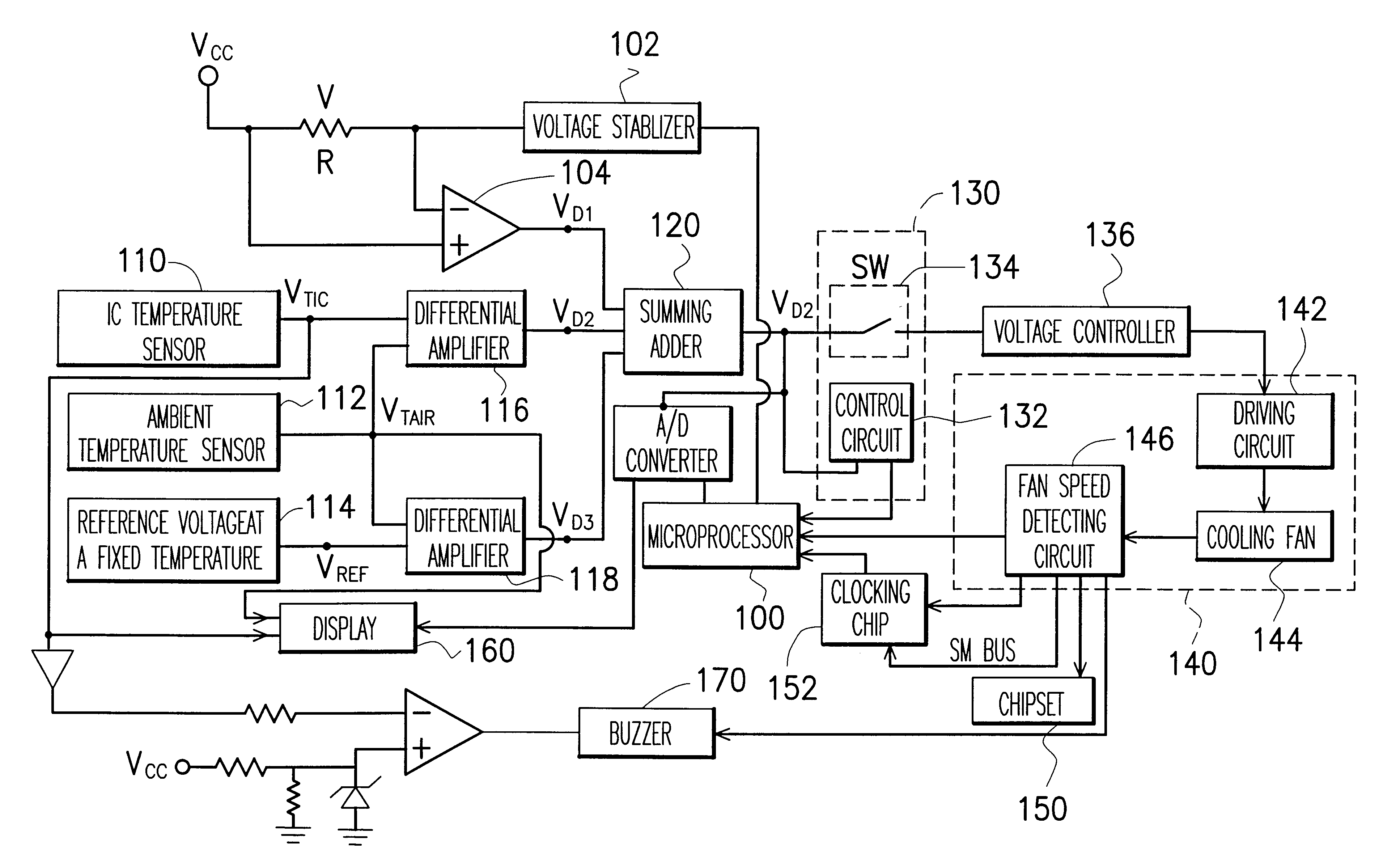

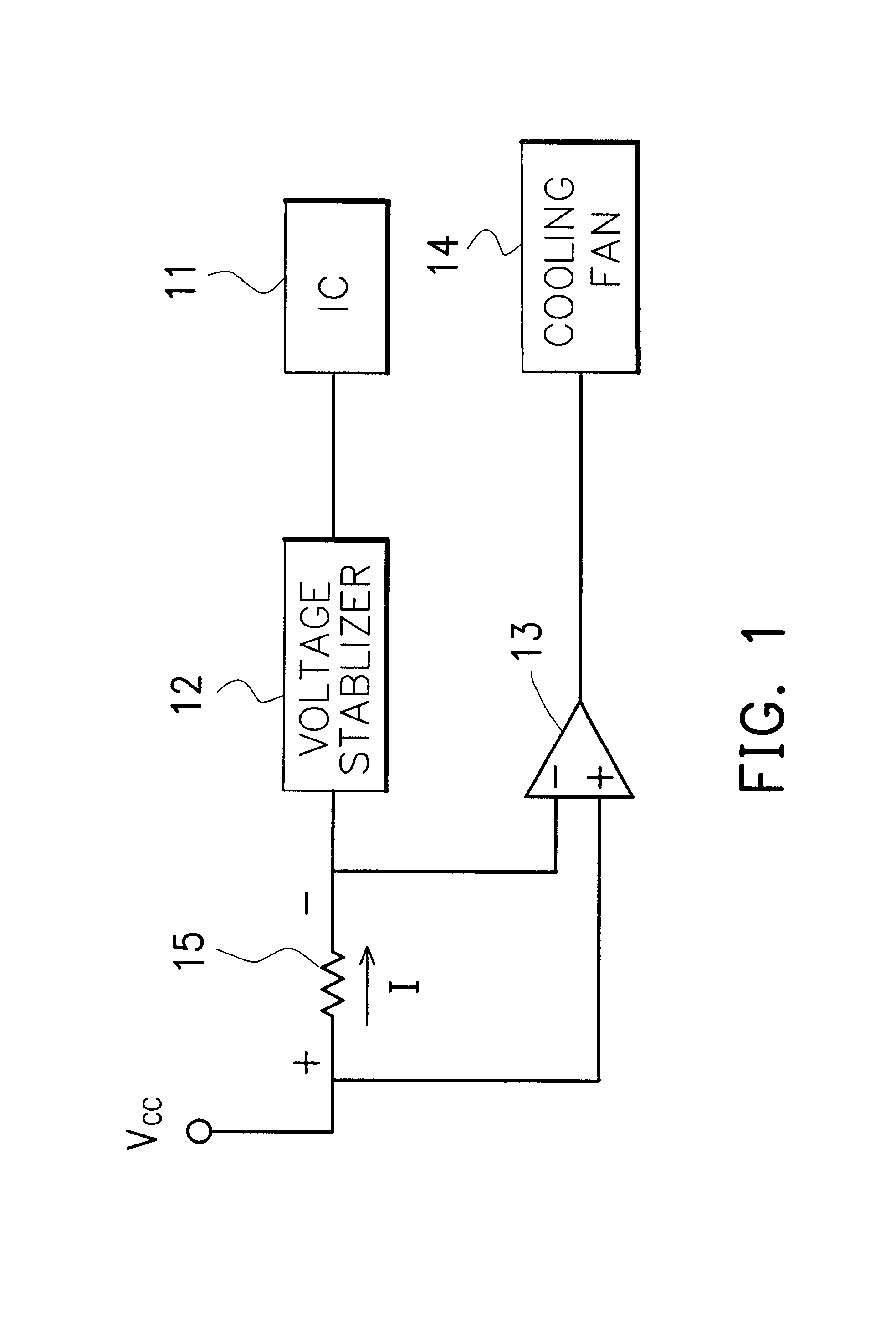

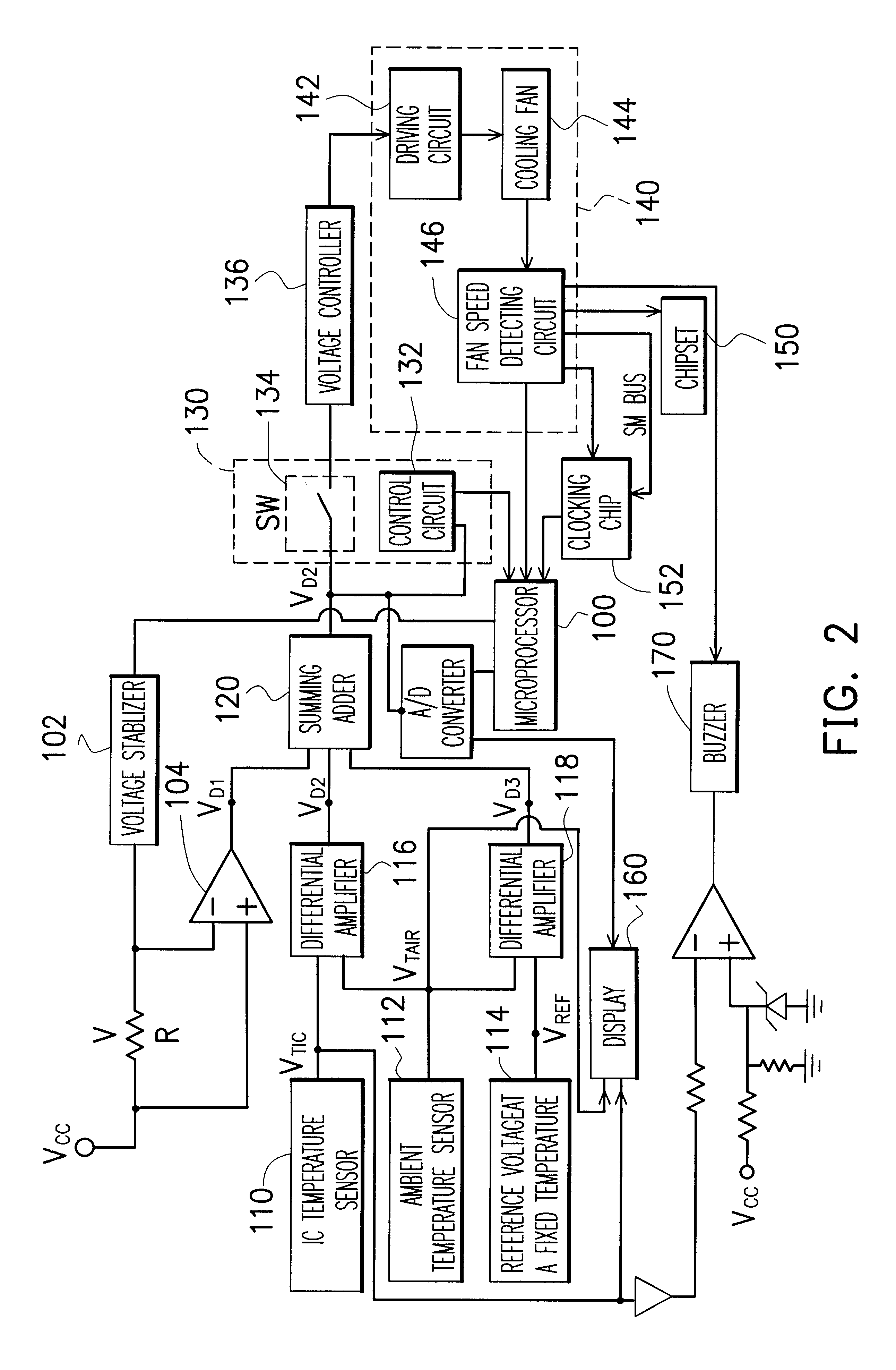

Cooling apparatus for integrated circuit

InactiveUS6906901B1Improve cooling effectDigital data processing detailsSemiconductor/solid-state device detailsControl circuitSpin speed

A cooling apparatus for an integrated circuit. The cooling apparatus comprises cooling fan means, a control circuit and heat pipe means. The control circuit determines a spinning speed of the cooling fan and an operation performance mode of the integrated circuit according to the load and the temperature of the integrated circuit, the ambient temperature and a reference temperature. Within a tolerable range of the output of adder means, the heating pipe means continues dispelling heat of the integrated circuit without turning on the cooling fan. While the output of the adder means exceed the tolerable range, the fan is turned on to enforce the heat dissipation.

Owner:TWINHEAD INT

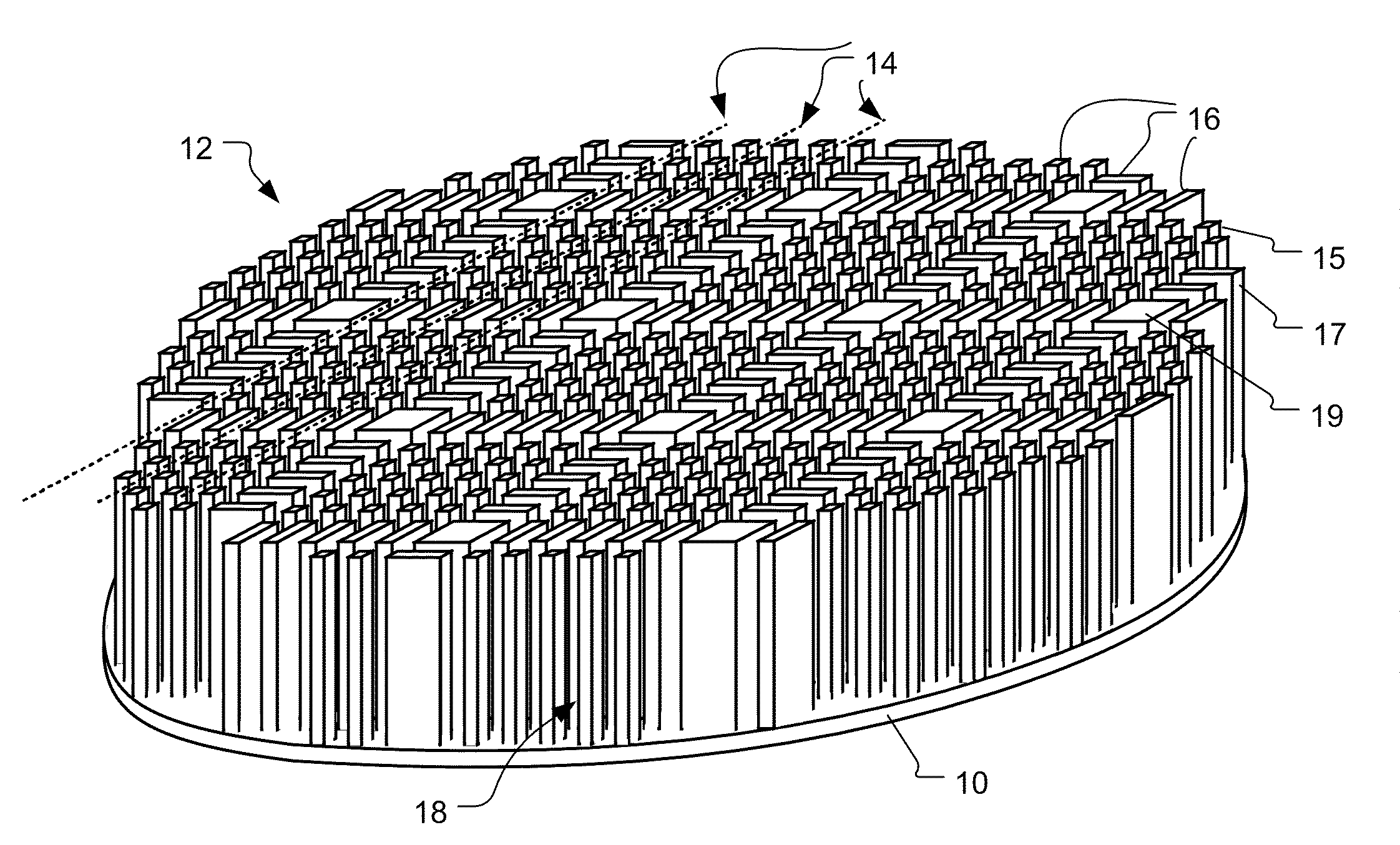

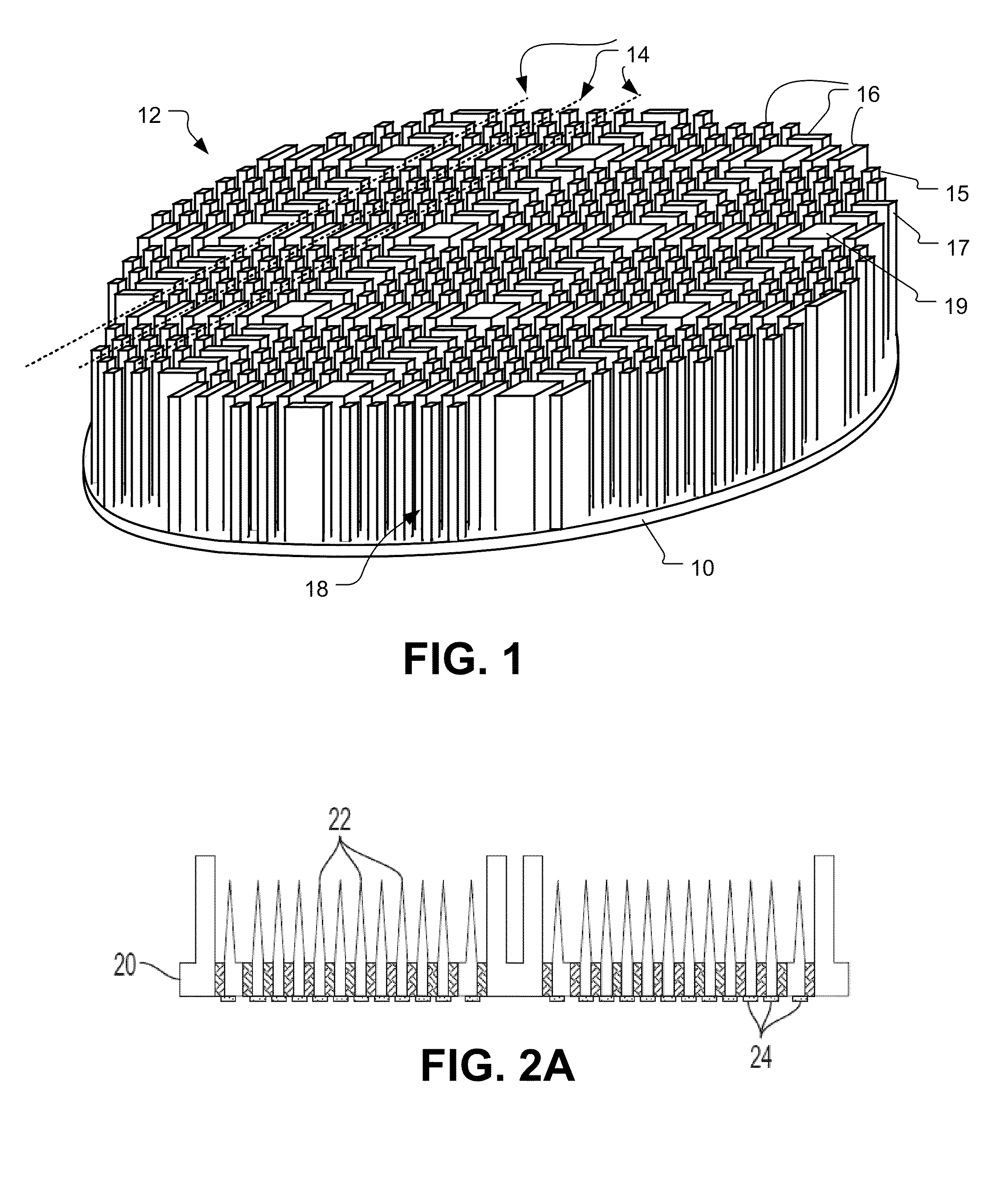

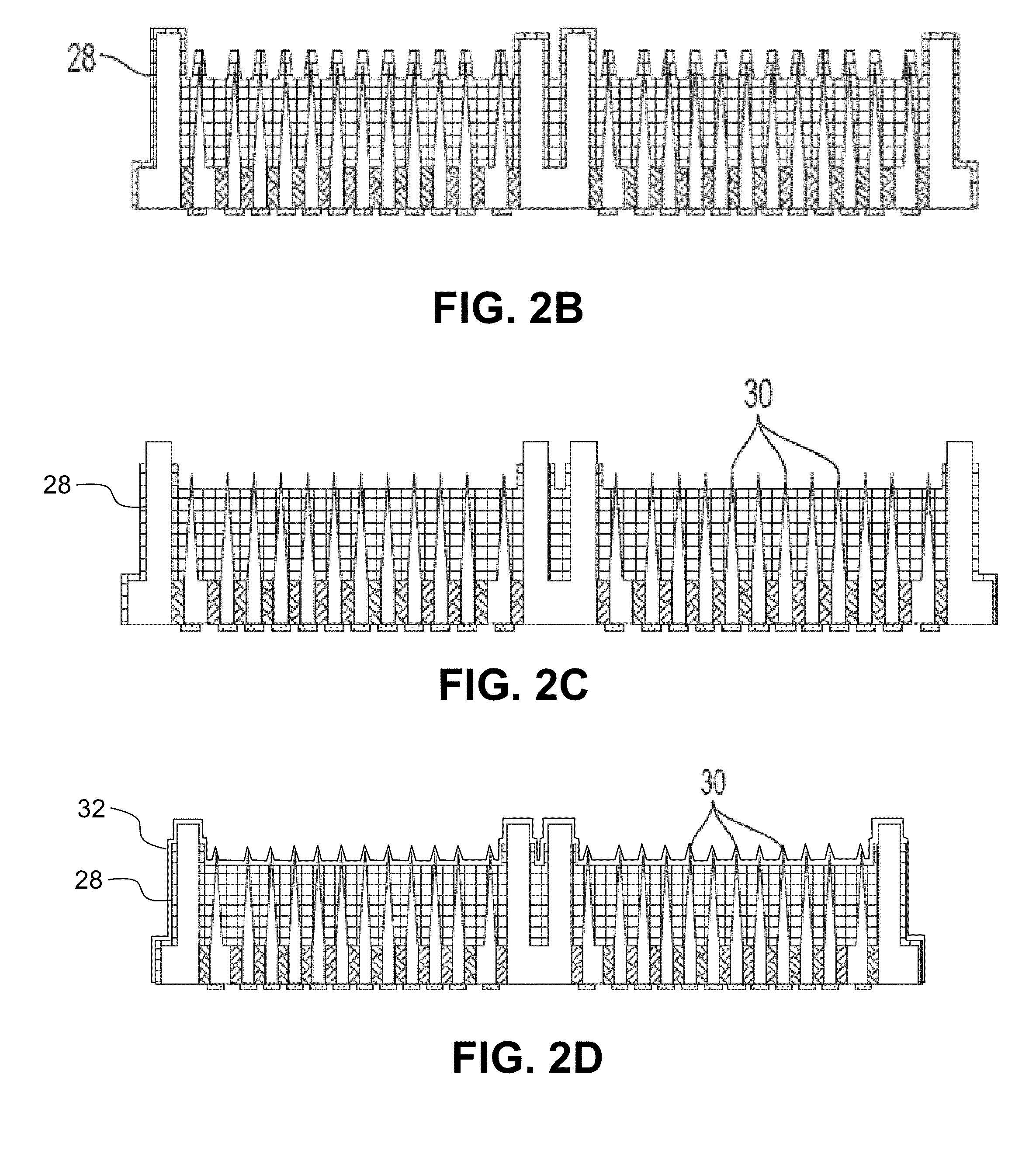

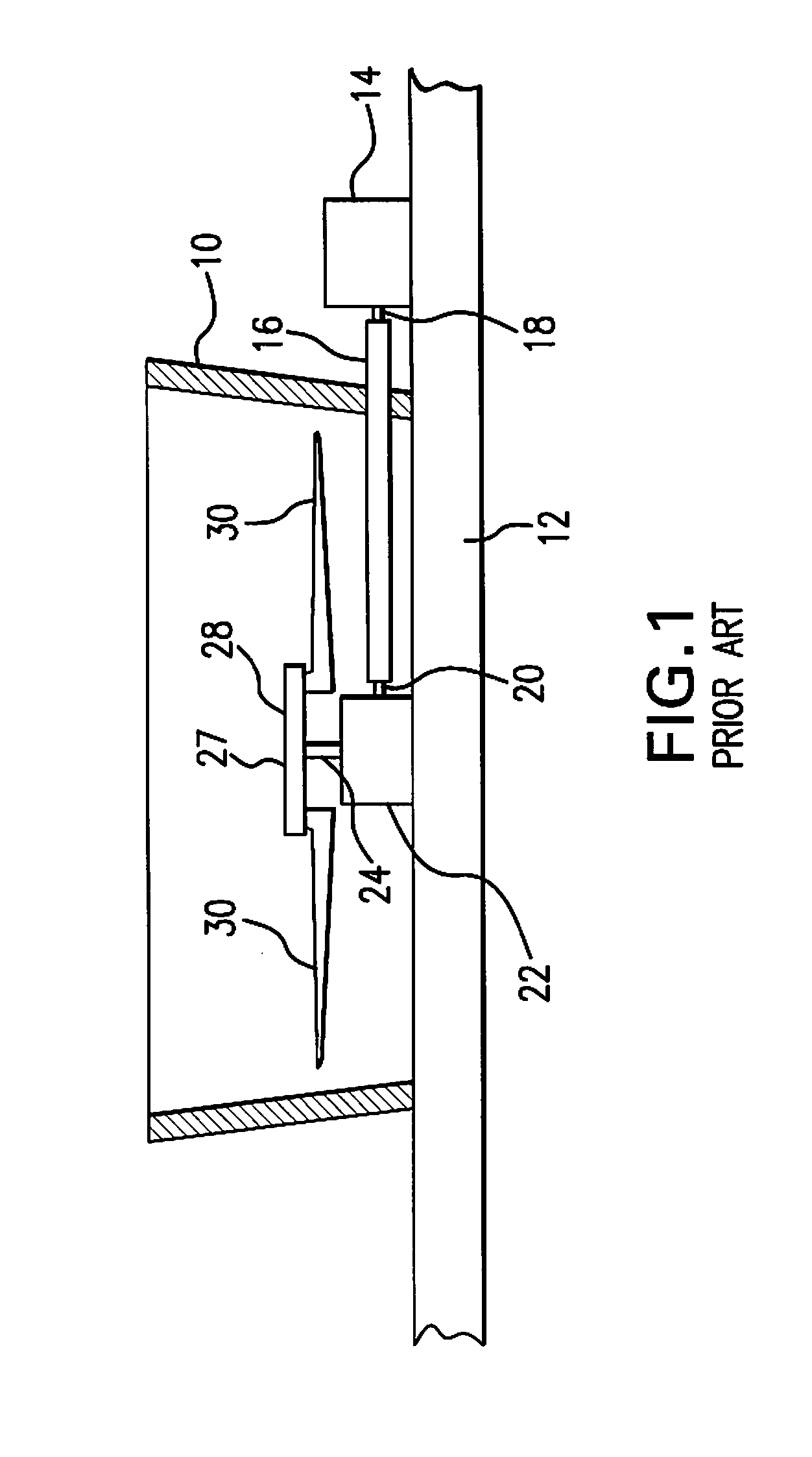

Methods for Wafer Scale Processing of Needle Array Devices

InactiveUS20090301994A1Avoid lack of depthHead electrodesDecorative surface effectsResistHigh volume manufacturing

Methods of fabricating needle arrays on a wafer scale include etching a wafer of columns and needles and coating the same with an electrically insulating material and exposing electrically conductive tips. This process can benefit from using a slow spin speed to distribute resist material across the wafer before etching and using a carrier wafer to support singulated arrays to allow full coverage of upper array surfaces with electrically insulating materials. These processes allow for efficient high volume production of high count microelectrode arrays with a high repeatability and accuracy.

Owner:UNIV OF UTAH RES FOUND

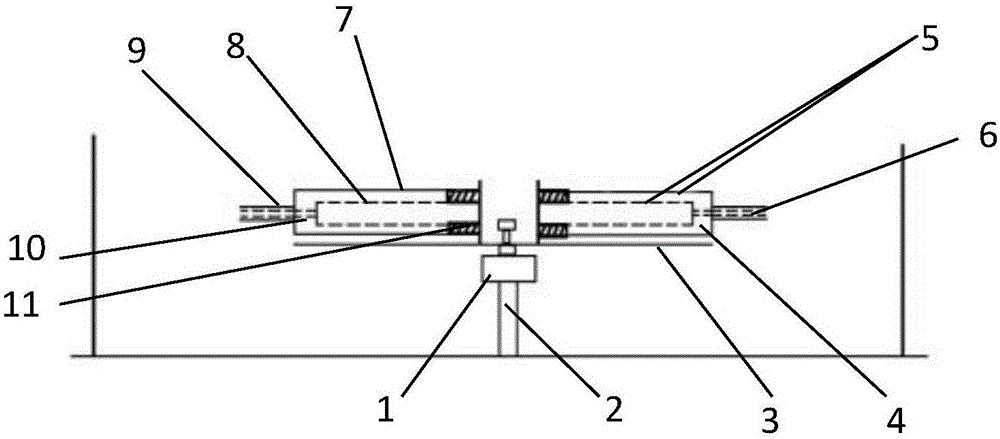

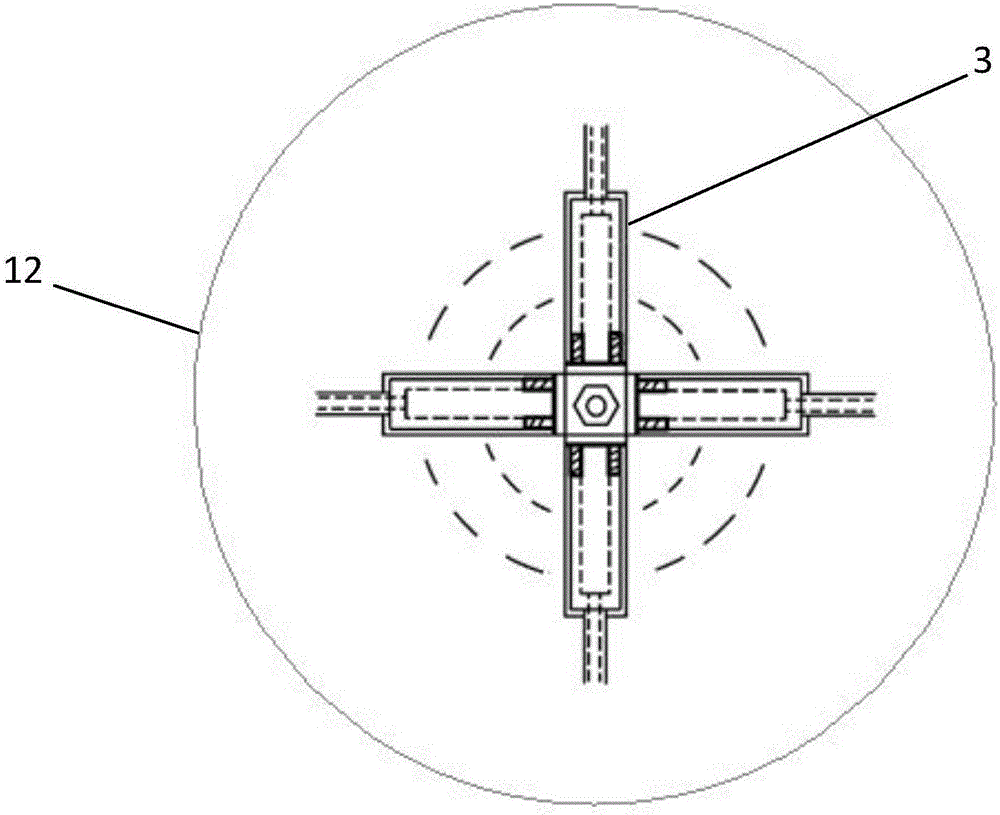

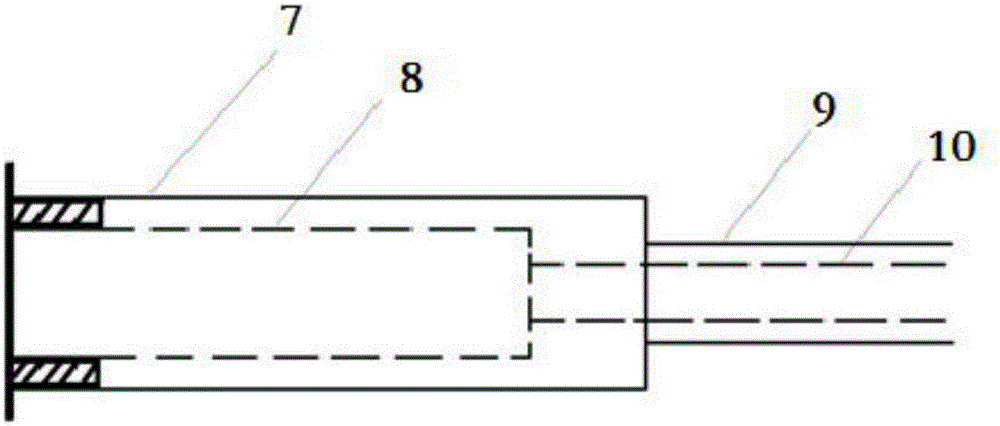

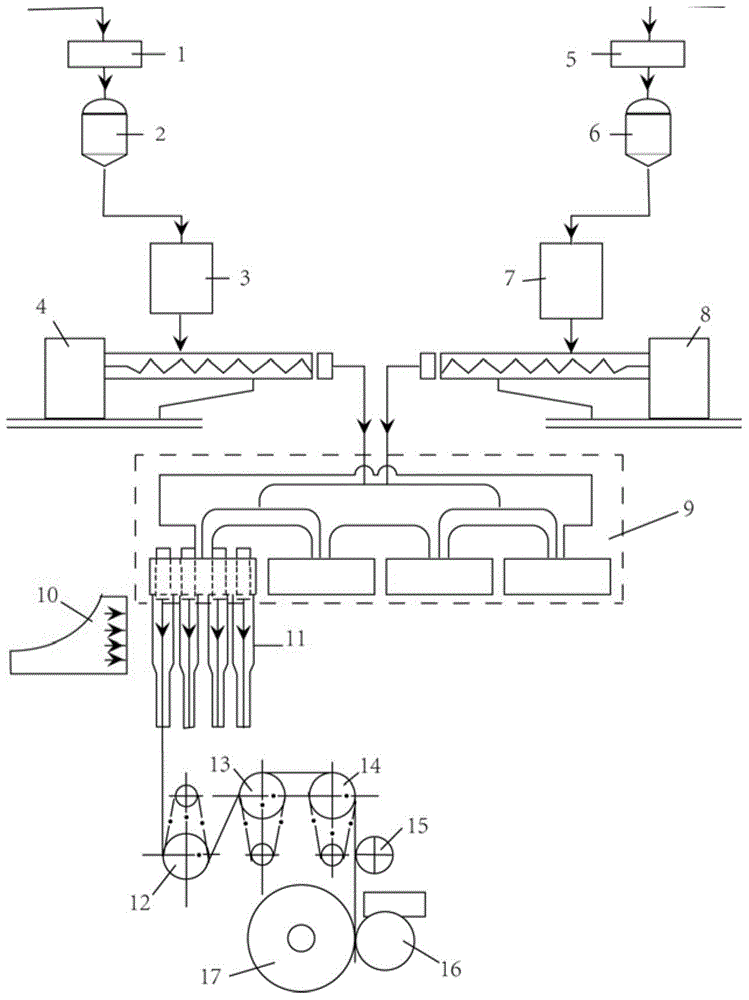

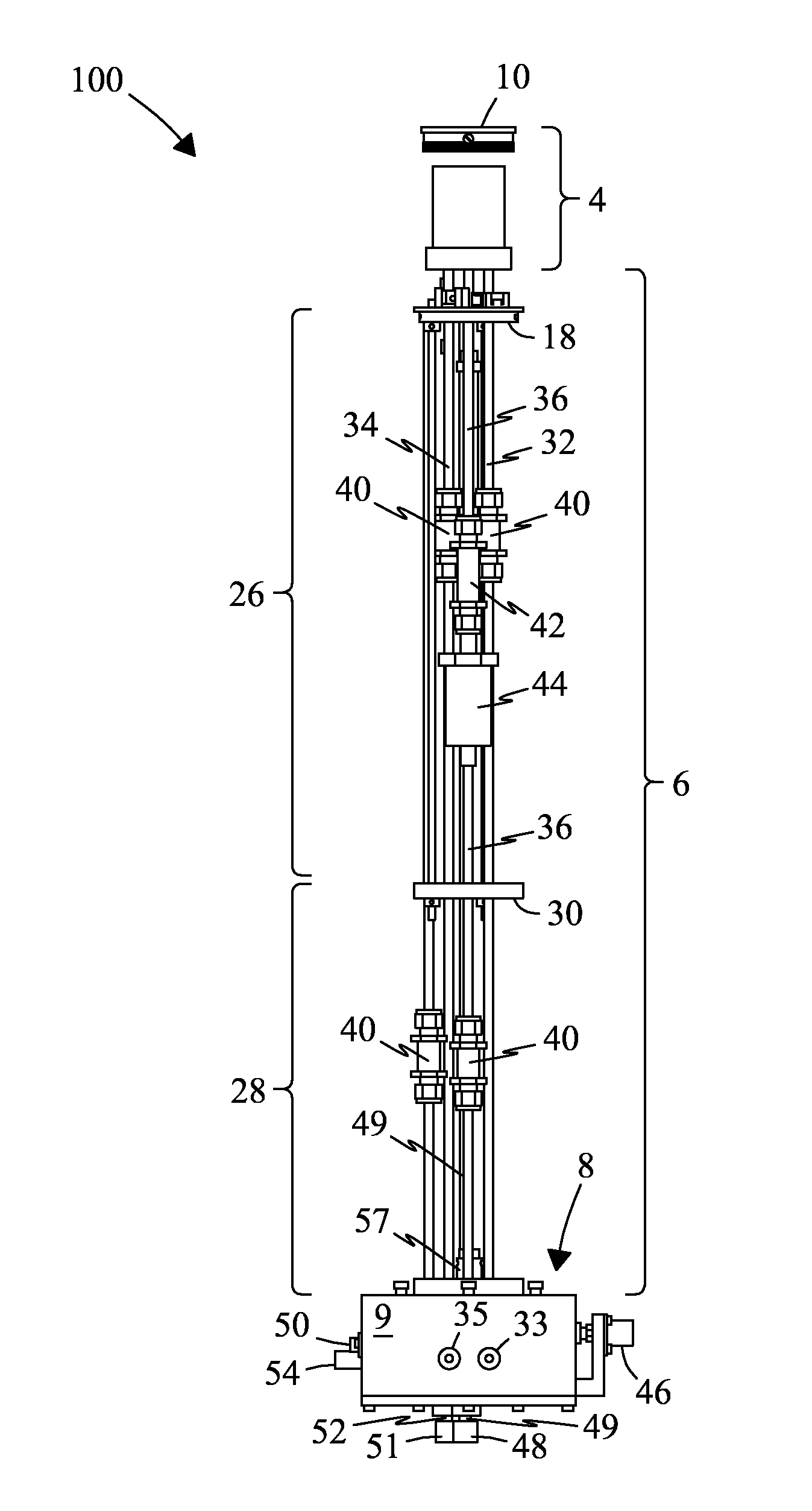

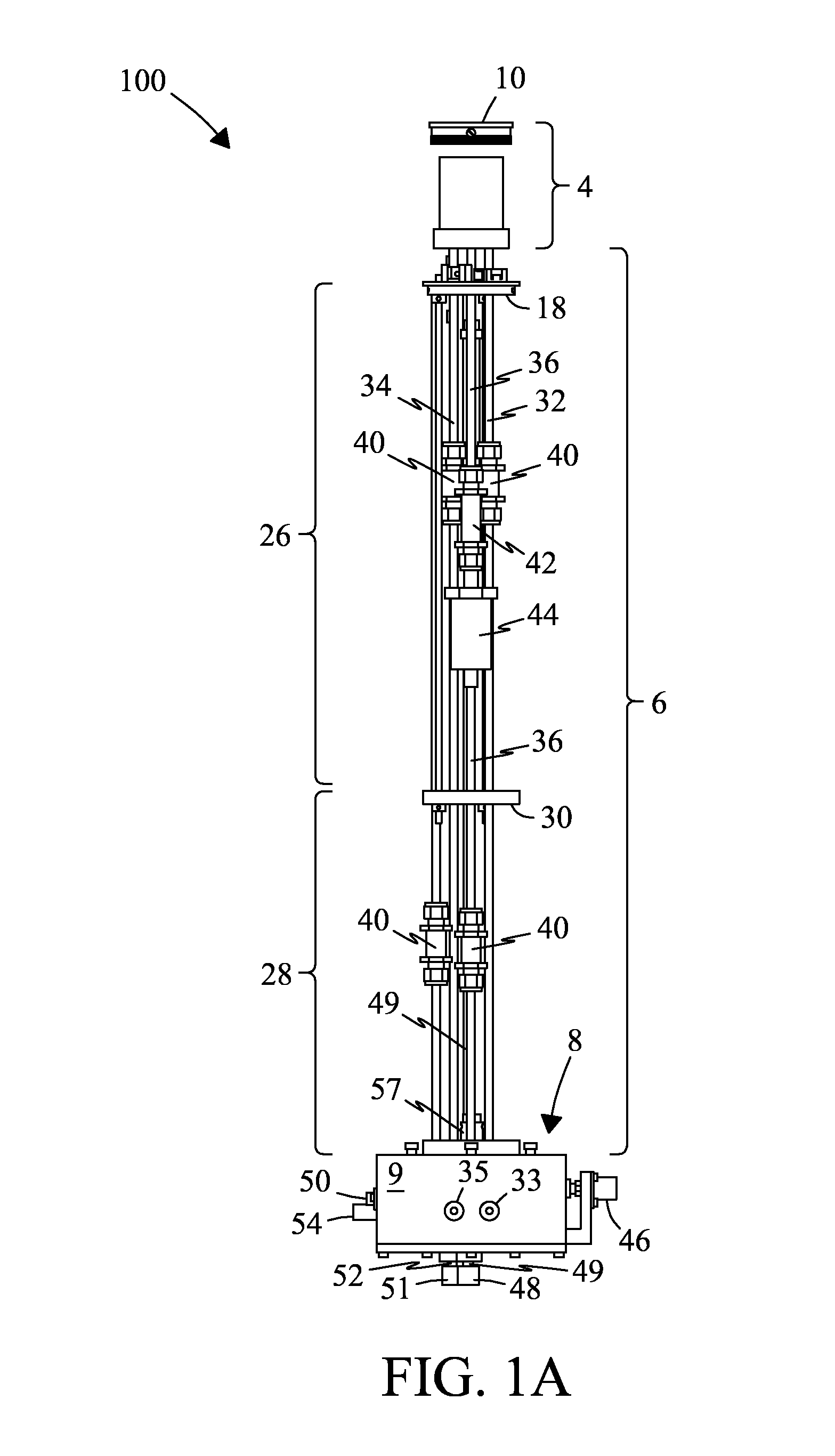

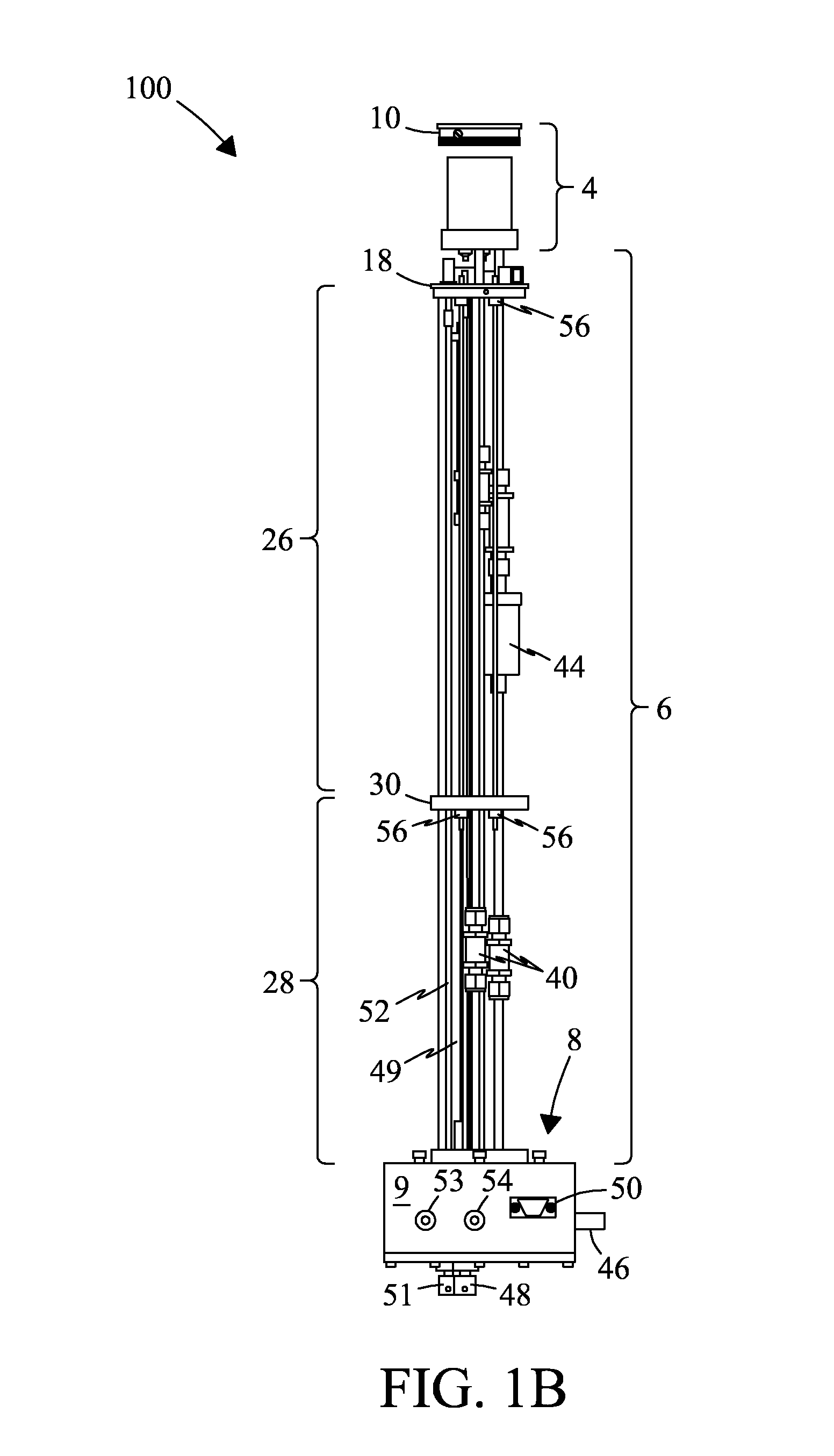

Coaxial centrifugal spinning device and method

InactiveCN106222767AStable productionGuaranteed suitabilityArtificial thread manufacturing machinesFilament/thread formingEngineeringSpin speed

The invention discloses a coaxial centrifugal spinning device and method. The device comprises a direct-current motor, a supporting device, a spinning support, coaxial centrifuge tubes, spinning needle heads and a receiving device, wherein the direct-current motor is fixed to the supporting device, the spinning support is directly and fixedly connected with an output shaft of the direct-current motor, the coaxial centrifuge tubes are fixed to the spinning support, and under the action of the direct-current motor, the spinning support drives the coaxial centrifuge tubes to rotate at high speed; each coaxial centrifuge tube comprises an outer layer centrifuge tube and an inner layer centrifuge tube, each spinning needle head comprises an outer layer needle head and an inner layer needle head, during spinning, a spinning solution or melt in the outer layer centrifuge tubes and the inner layer centrifuge tubes is tossed out under the action of centrifuge force, an outer layer solution wraps an inner layer solution, and superfine fiber of a skin-core structure is formed due to centrifuge force drafting, solvent volatilization and phase separation. The coaxial centrifugal spinning device is simple, high in spinning speed and production efficiency and capable of producing coaxial superfine fiber on a large scale.

Owner:TIANJIN POLYTECHNIC UNIV

Elastomeric fibers comprising controlled distribution block copolymers

InactiveUS20070055015A1High melt flowIncrease chanceWoven fabricsConjugated synthetic polymer artificial filamentsProduction rateYarn

Bicomponent fibers comprising a thermoplastic polymer and an elastomeric compound are made which can be continuously extruded from the melt at high production rates. The elastomeric compound comprises a selectively hydrogenated block copolymer having a controlled distribution elastomeric block which has a mono alkenyl arene blockiness index of less than 40 mol % and high flow. Elastomeric fibers are also provided which comprise a controlled distribution block copolymer and a slip agent. The fibers are useful for the manufacture of articles such as woven fabrics, spunbond non-woven fabrics or filters, staple fibers, yarns and bonded, carded webs. The bicomponent fibers can be made using a process comprising coextrusion of the thermoplastic polymer and elastomeric compound to produce fibers at spinning speeds of at least 1000 mpm and having a denier from 0.1 to 50 g / 9000 m.

Owner:KRATON POLYMERS US LLC

Self-enhanced polylactic acid fiber and preparation method thereof

ActiveCN102634866AHigh normal temperature mechanical strengthLow boiling water shrinkageArtificial filament heat treatmentMelt spinning methodsFiberSpin speed

The invention relates to a self-enhanced polylactic acid fiber and a preparation method thereof. The self-enhanced polylactic acid fiber provided by the invention is a uniform mixture of a vertical compound crystal polylactic acid micro-fiber and a polylactic acid substrate. In 100 weight parts of self-enhanced polylactic acid fiber, 1-30 parts of vertical compound crystal polylactic acid micro-fiber and 70-99 parts of polylactic acid substrate are contained. The preparation method of the fiber comprises the following steps: firstly, respectively carrying out vacuum drying on PLLA (poly L lactic acid) and PDLA (poly D lactic acid); physically mixing PLLA with PDLA after being dried; fusing the mixture; collecting primary fibers under the conditions that a spinning temperature is 225-245 DEG C and a spinning speed is 500-2500 meters per minute; and thermally drafting and thermally shaping the primary fibers. Compared with the common polylactic acid fiber, the self-enhanced polylactic acid fiber disclosed by the invention has the advantages of higher constant temperature mechanical strength, higher high temperature mechanical strength and lower boiling water shrinkage, so that the use demand is met and the application field is expanded.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

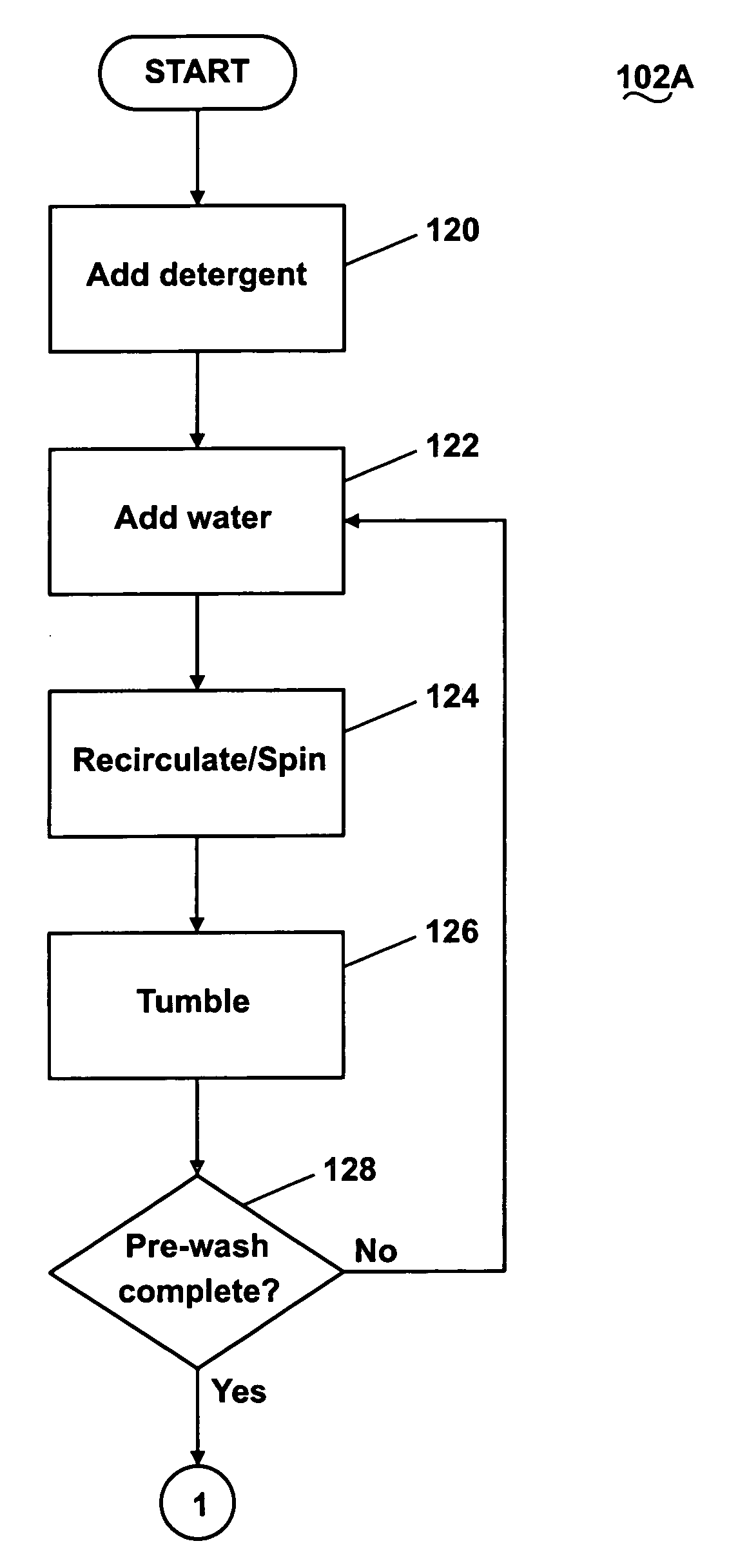

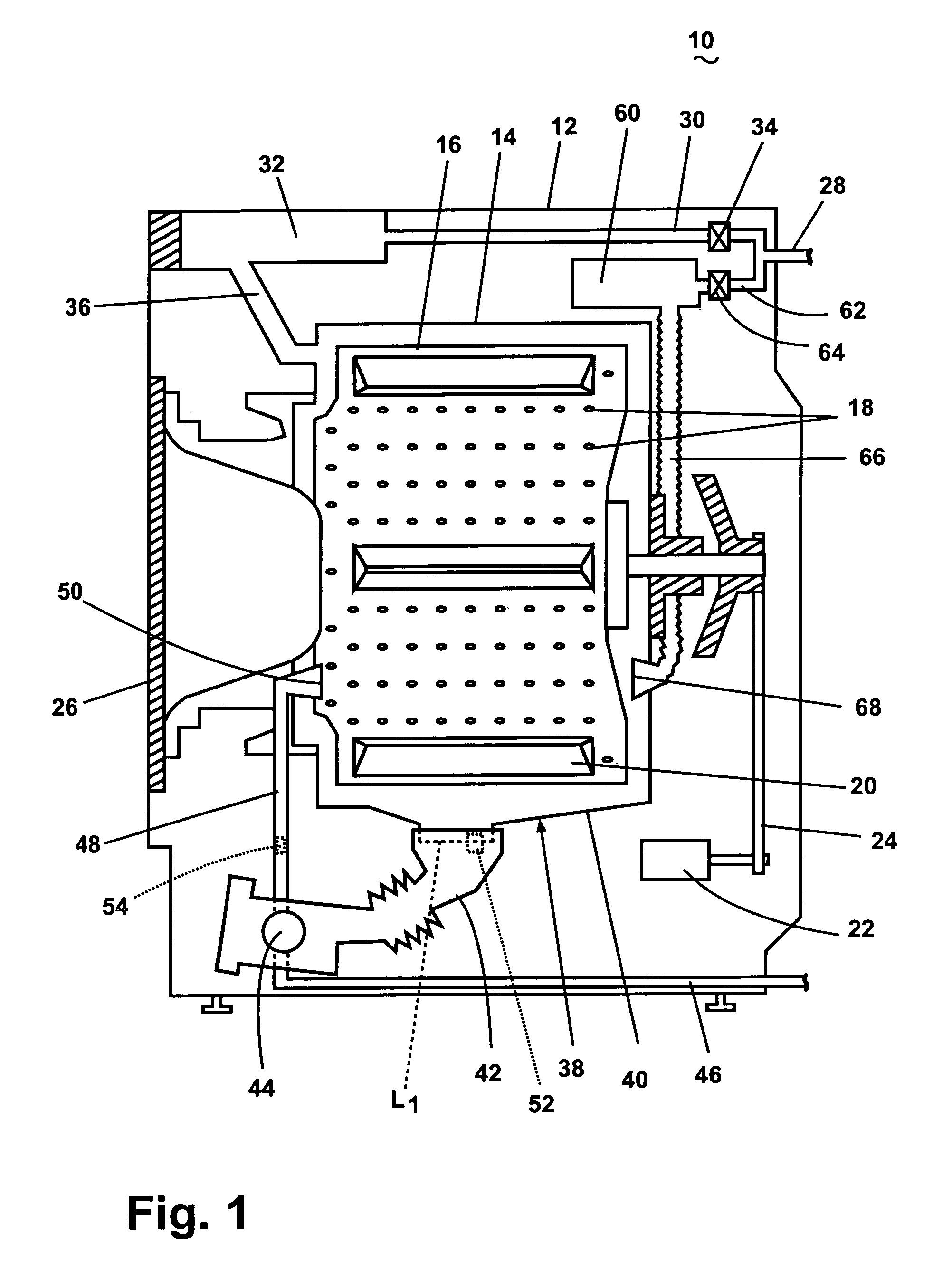

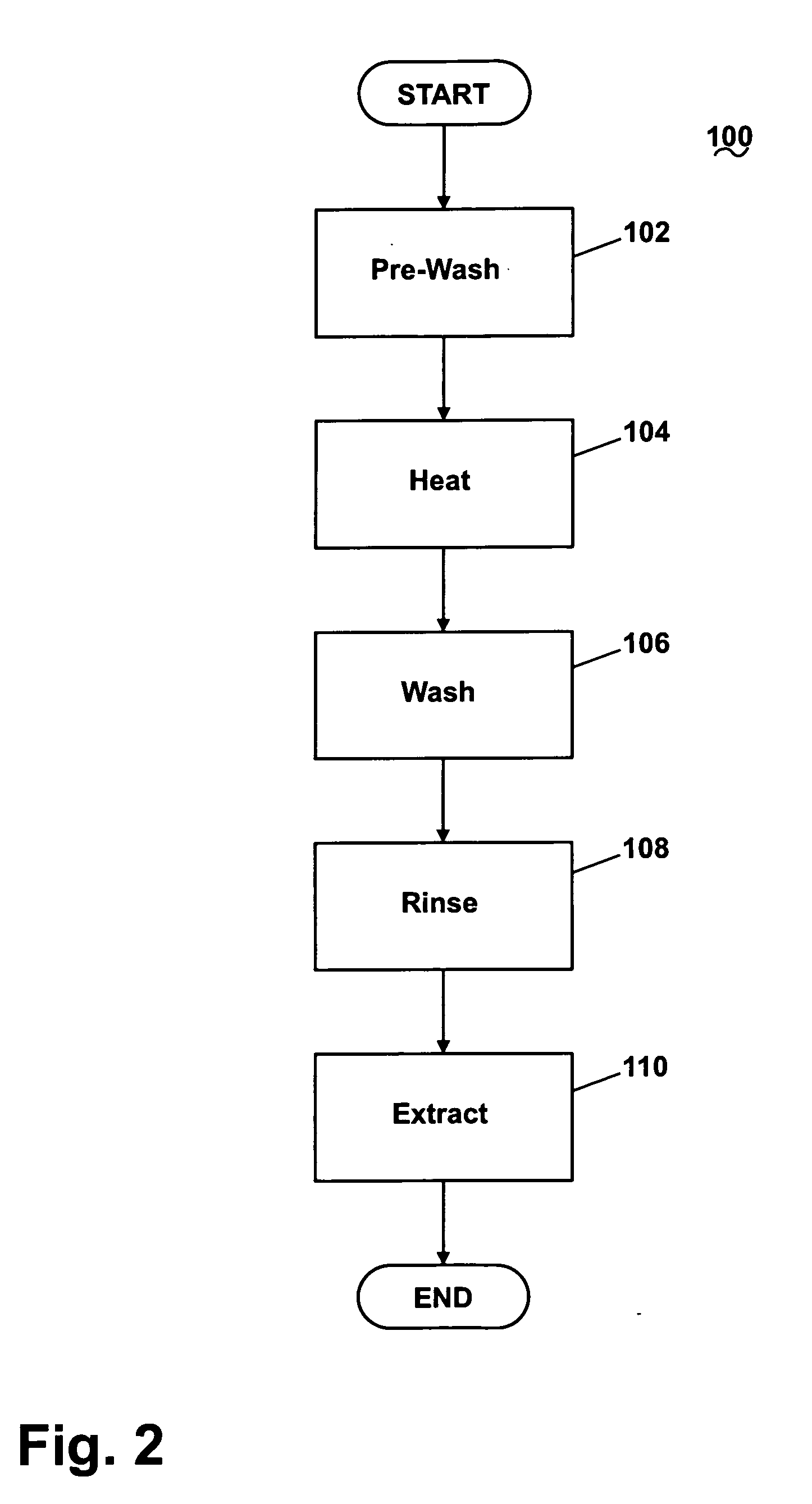

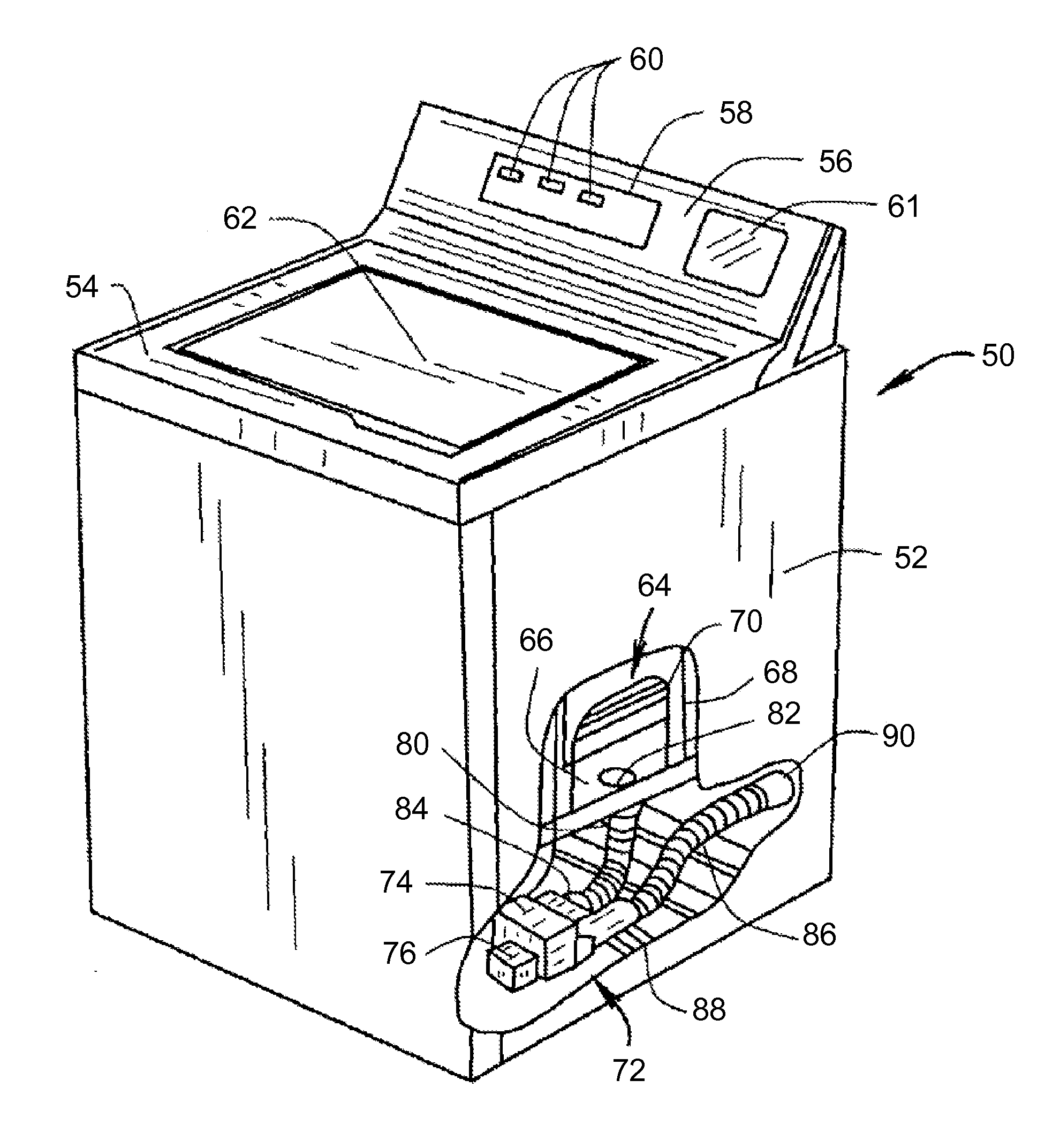

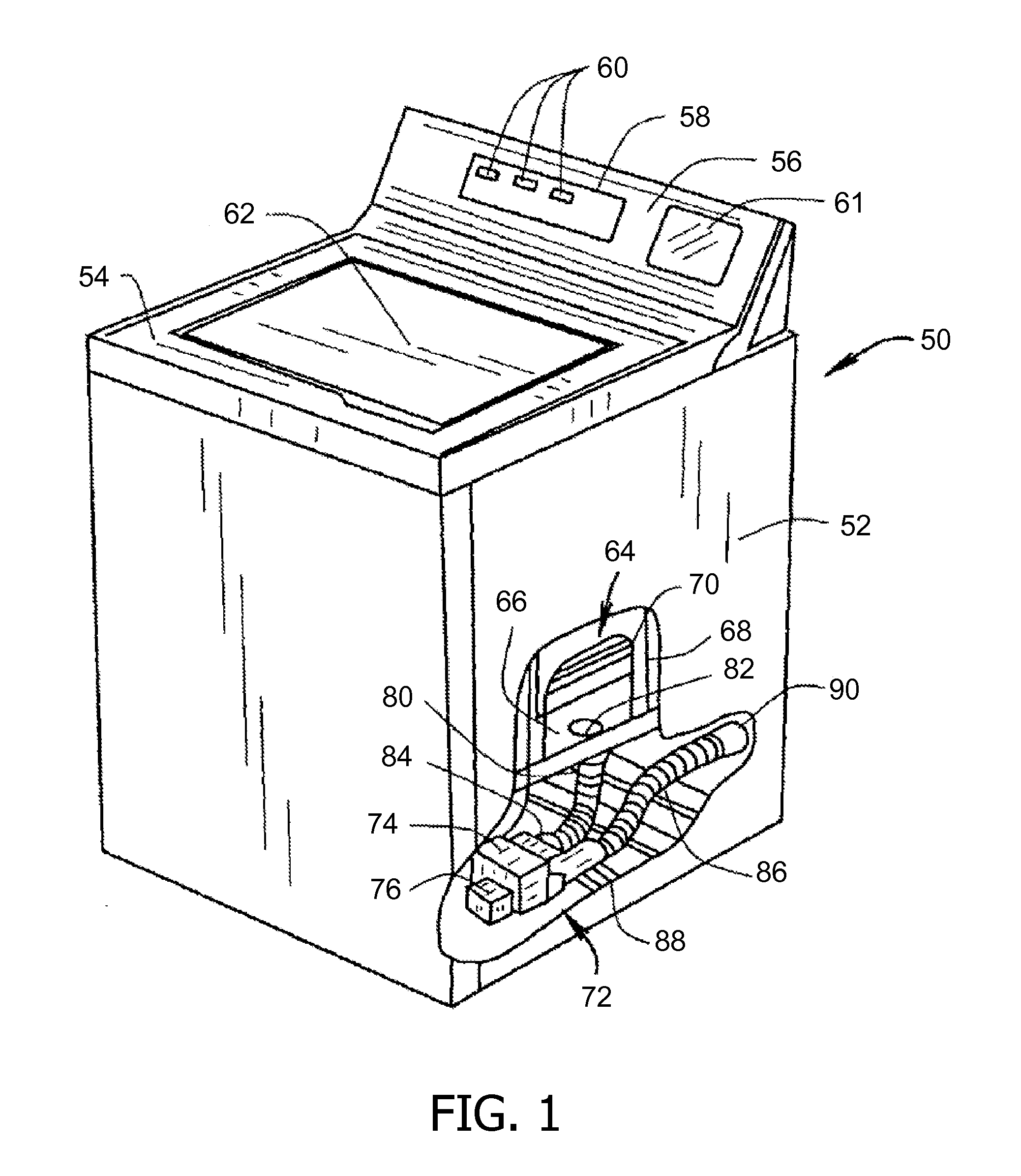

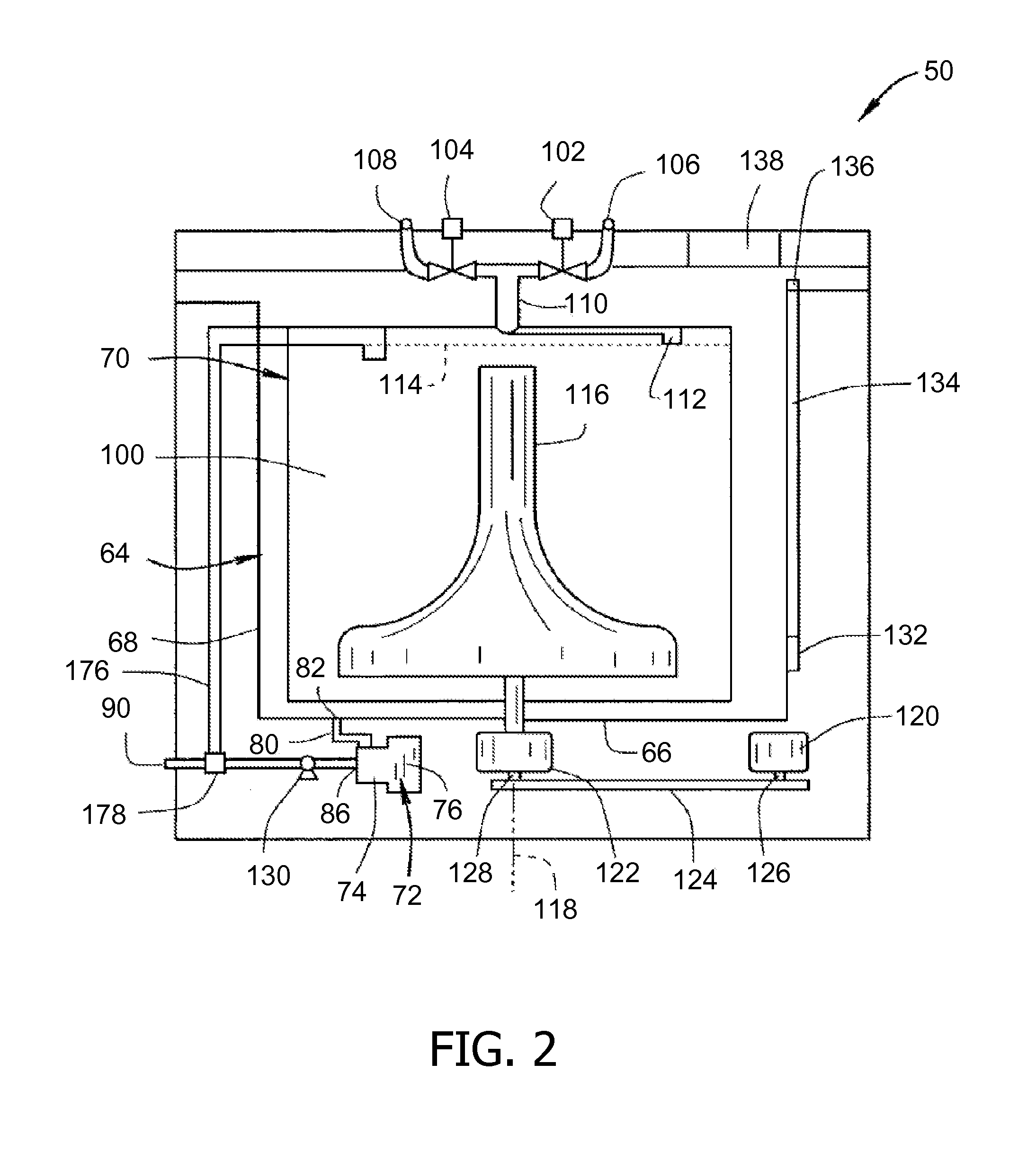

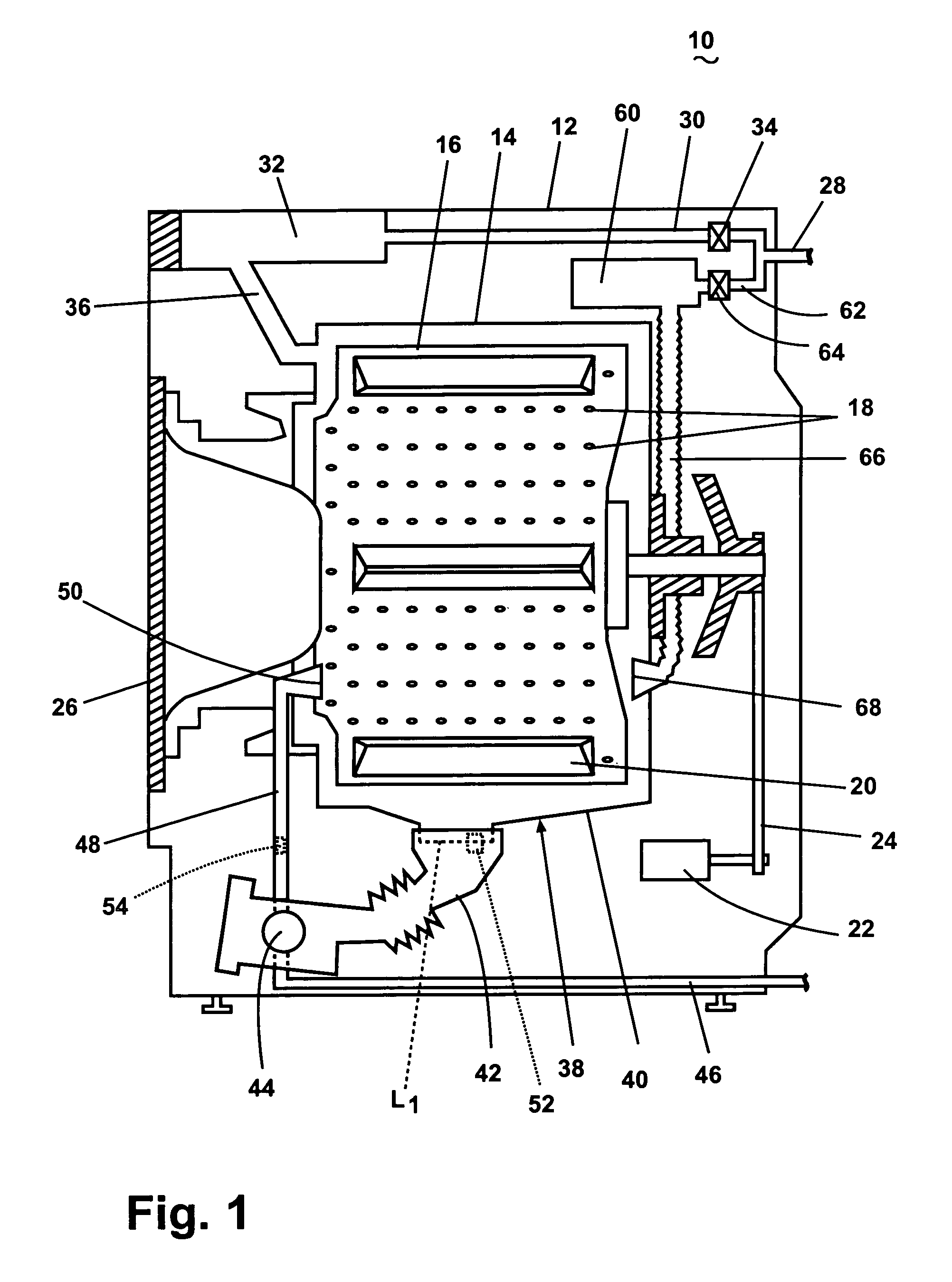

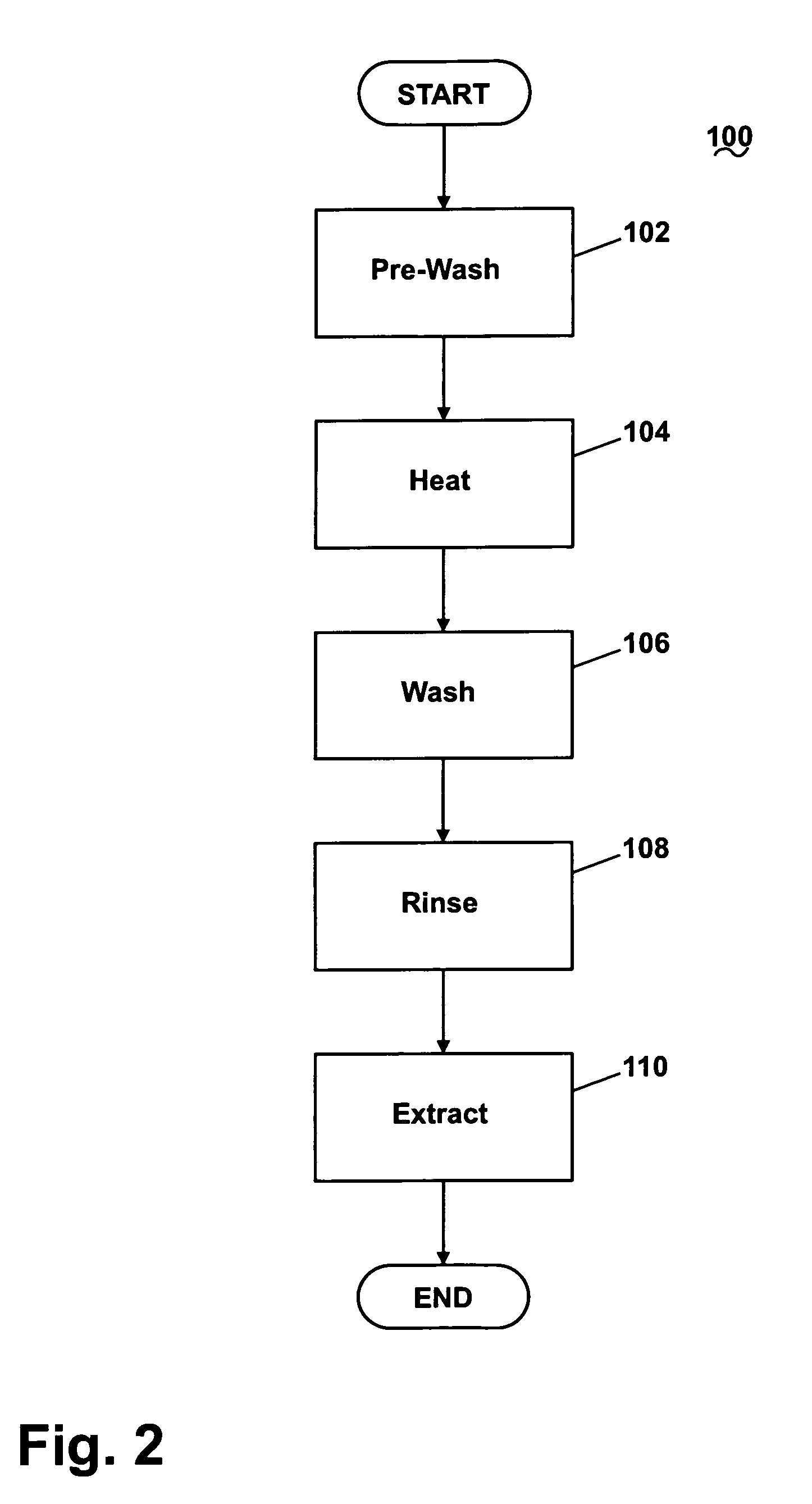

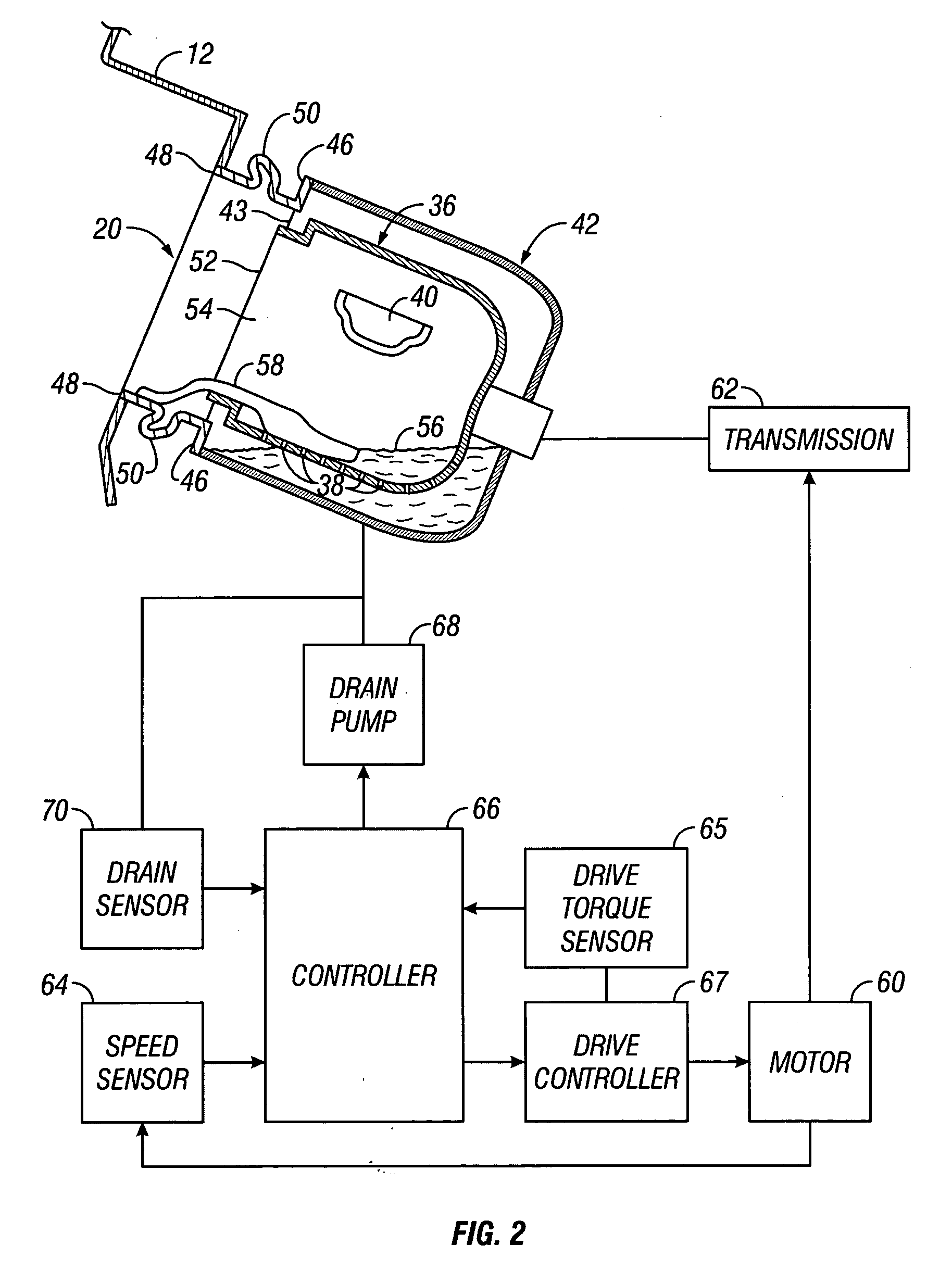

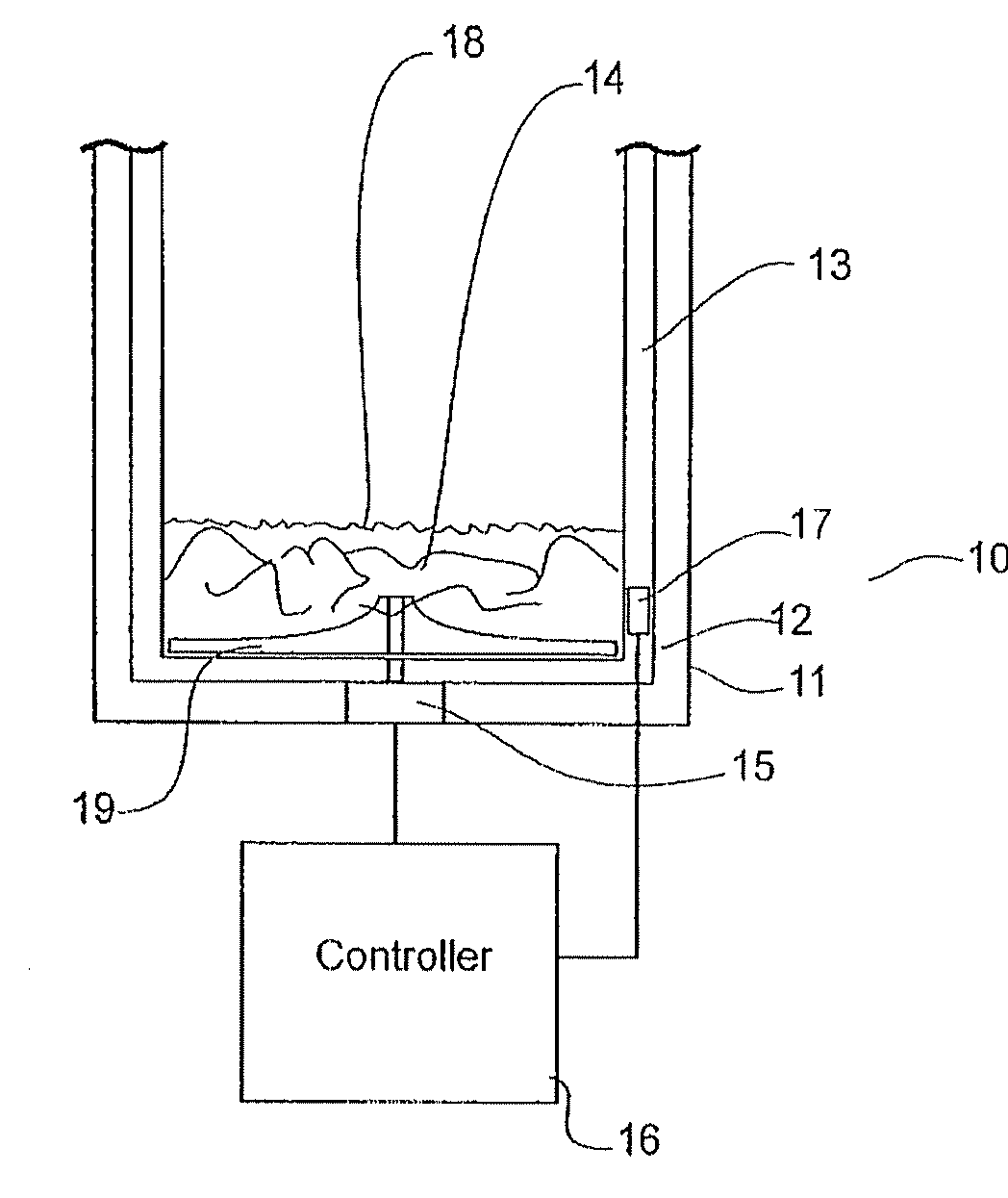

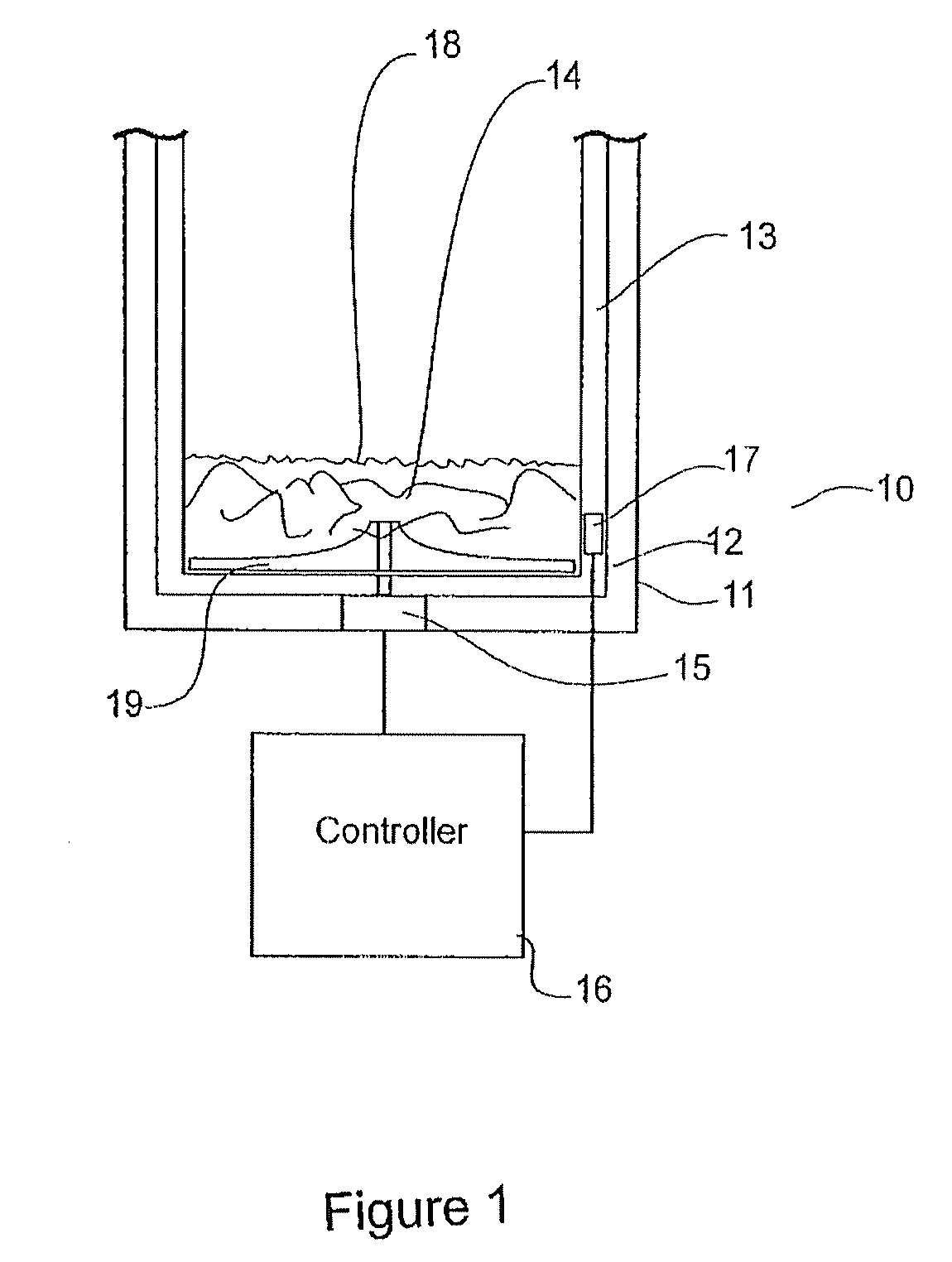

Steam washing machine operation method having dual speed spin pre-wash

InactiveUS20070283506A1Other washing machinesControl devices for washing apparatusProcess engineeringSpin speed

A method for operating a washing machine having a tub with a drum rotatably mounted in the tub and configured to hold a fabric load comprises a pre-wash step; a heating step comprising introducing steam into at least one of the tub and the drum; and a washing step. The pre-wash step comprises recirculating liquid between the tub and the drum; rotating the drum at a first spin speed to distribute the clothing within the drum; and rotating the drum at a second spin speed greater than the first spin speed to draw the liquid through the fabric load.

Owner:WHIRLPOOL CORP

Method and apparatus for balancing an unbalanced load in a washing machine

ActiveUS20120024016A1Increase spinning speedLimitation in spinning speedOther washing machinesControl devices for washing apparatusSpinsControl theory

A washing machine including a suspension system is provided. The suspension system includes a wash tub, a basket rotatably coupled within the wash tub, and a drive and motor assembly. The washing machine further includes a controller configured initiate a spin cycle by increasing a spin speed of the basket to a target spin speed, identify an out-of-balance load prior to reaching the target spin speed, and limit the spin speed of the basket to a spin speed lower than a natural frequency of the suspension system for a predefined period of time.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Steam washing machine operation method having a dual speed spin pre-wash

InactiveUS7765628B2Other washing machinesControl devices for washing apparatusProcess engineeringSpin speed

Owner:WHIRLPOOL CORP

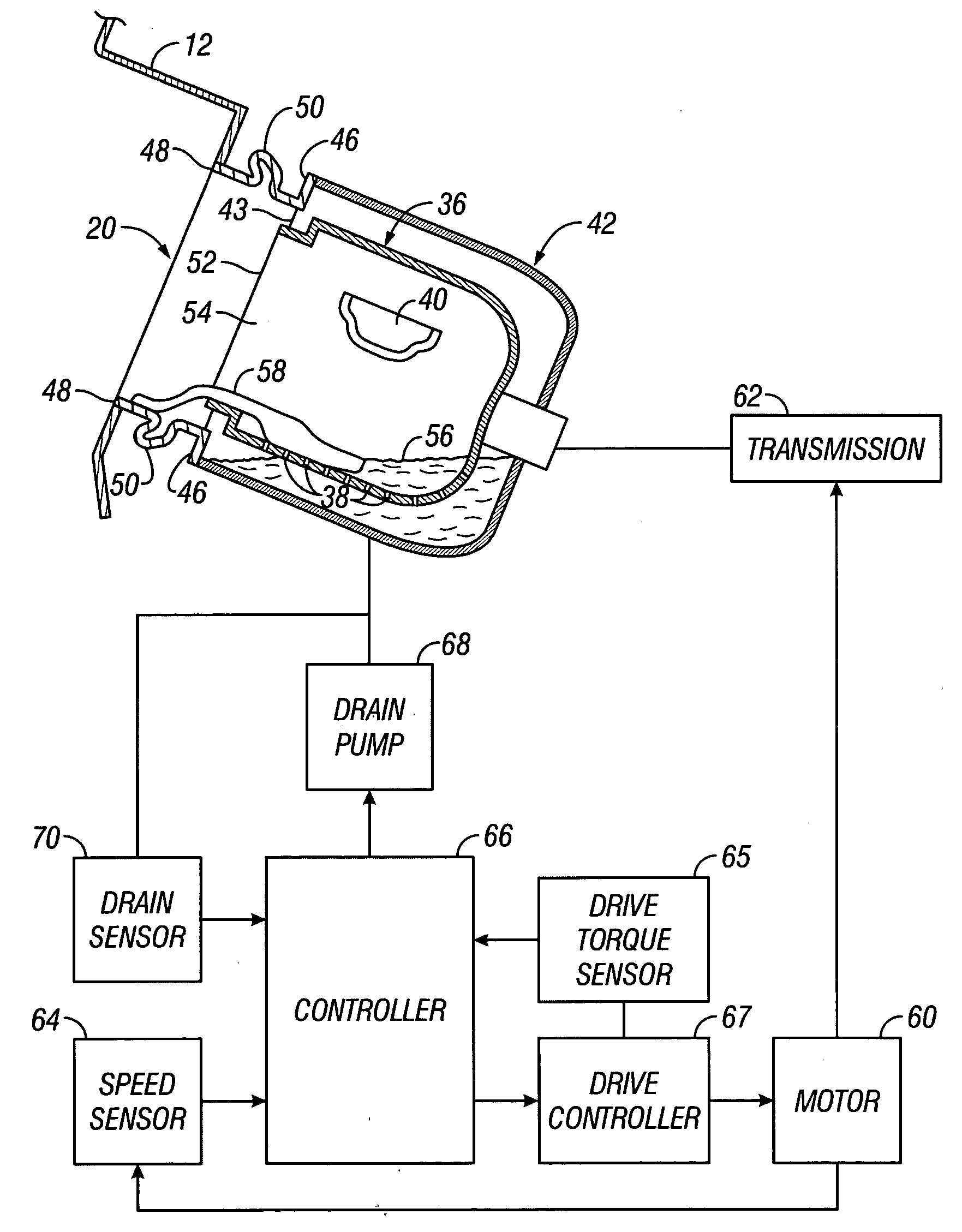

Method and apparatus for spinning fabrics

InactiveUS20050102766A1Reduce rotation speedOther washing machinesControl devices for washing apparatusControl theorySpin speed

The method of the present invention includes rotating the washing basket at a tumble speed insufficient to plaster the fabrics against the basket wall. The rotational speed is increased to a first plaster speed which causes the fabrics to be plastered against the basket wall. The plaster speed is increased to a second plaster speed higher than the first. Then the rotational speed of the washing basket is returned to the first plaster speed and the washing fluid is drained from the washing basket. The spin cycle is then begun. During the spin cycle a torque or speed sensor senses increased torque or reduced rotational speed of the washing basket caused by fabrics frictionally engaging the flexible boot during rotation of the washing basket at the spin speed. If such conditions are sensed, the spin cycle is terminated.

Owner:MAYTAG

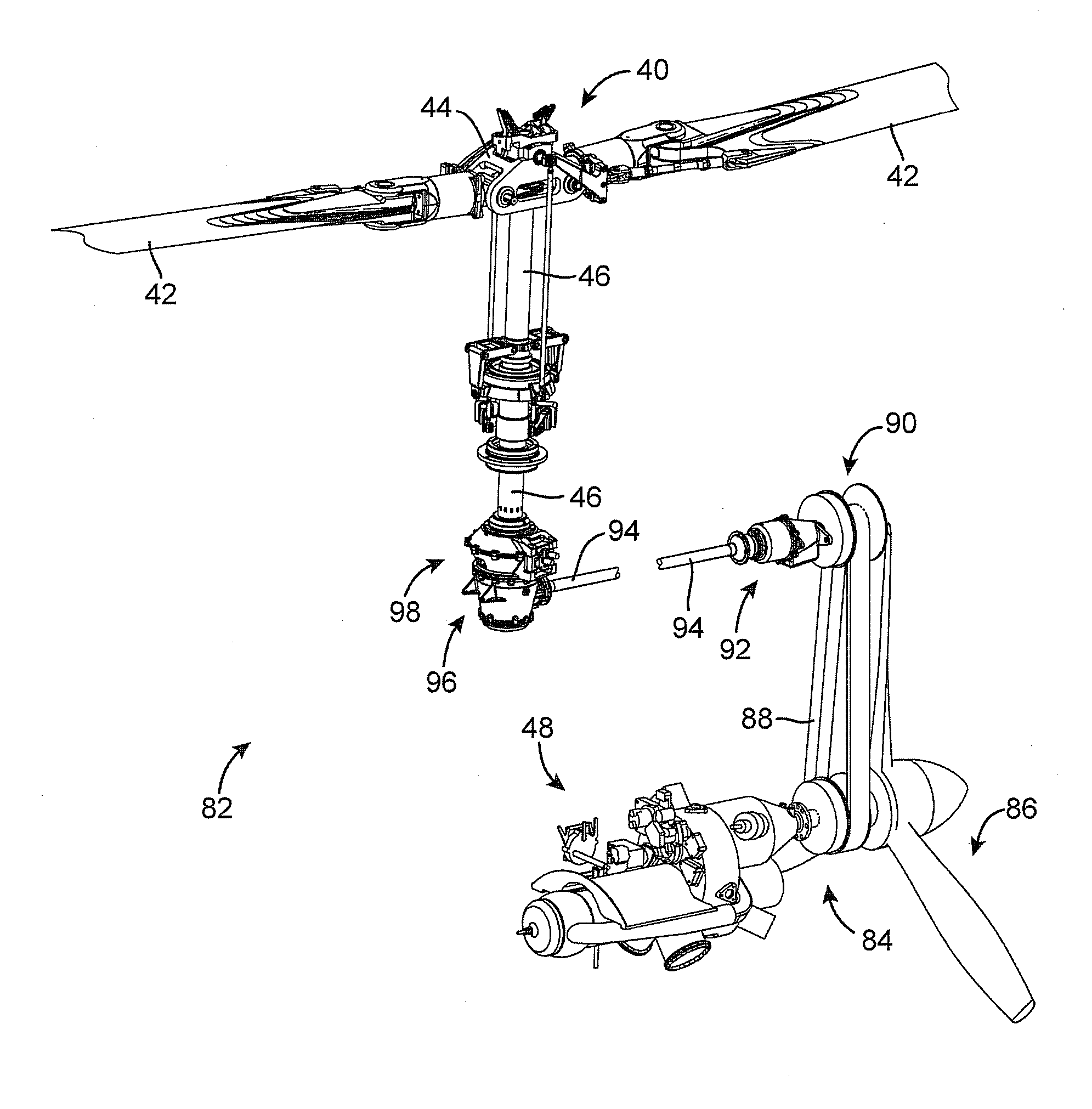

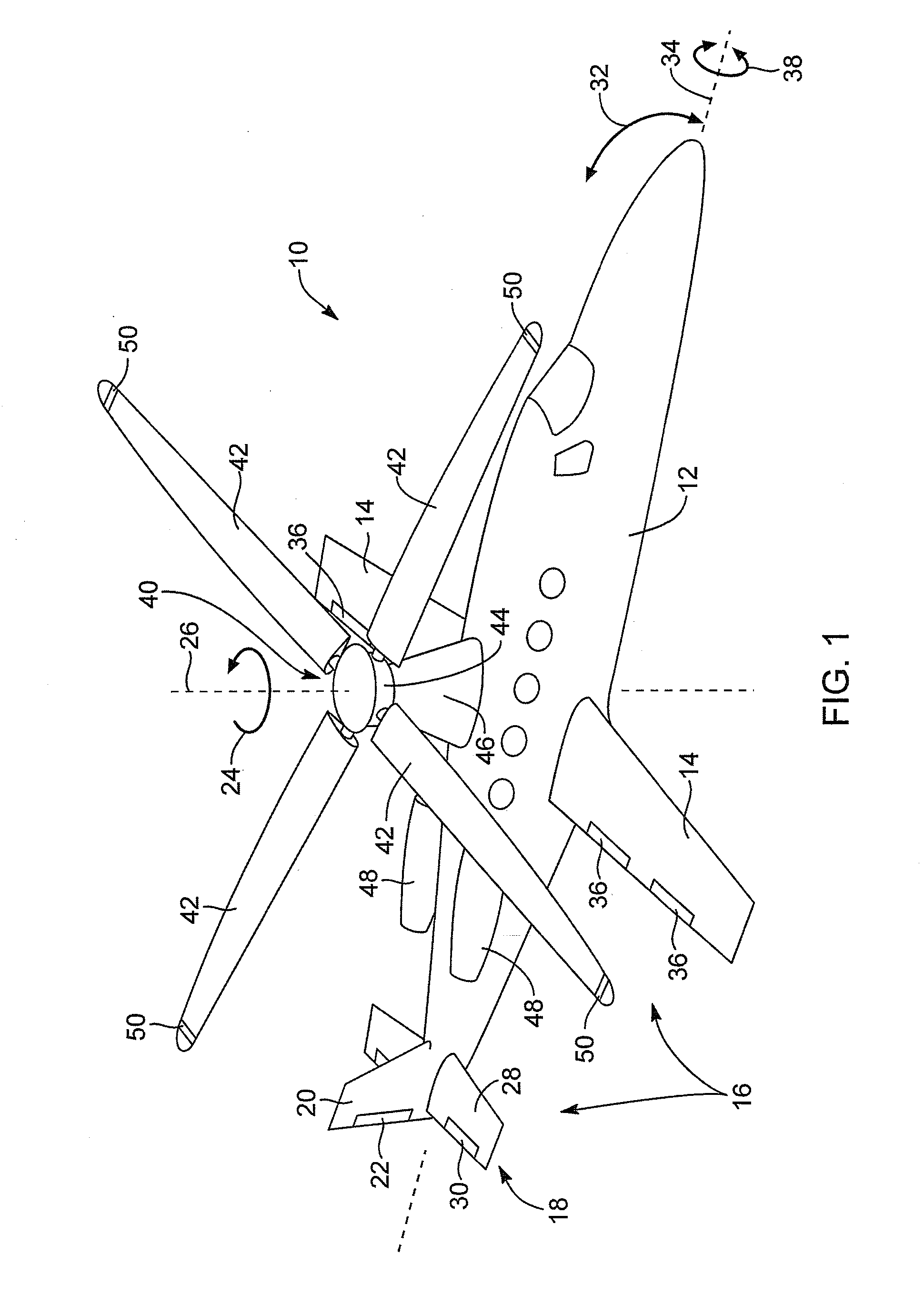

Pre-landing, rotor-spin-up apparatus and method

A method and apparatus for reducing roll of rotorcraft landing in autorotation may include executing a flight with a rotorcraft. The flight may include first, second, and third portions ordered sequentially. During the first portion, the rotorcraft may be flown with the rotor exclusively in autorotation. During the second portion, the rotorcraft may be flown with the rotor powered at least partially by an engine of the rotorcraft, which may increase the rotational speed of the rotor. During the third portion, the rotorcraft may be flown with the rotor exclusively in autorotation. The flight and the third portion may terminate simultaneously with a touch down of the rotorcraft. Kinetic energy stored in the rotor during the second portion, during the third portion, bring the ground speed of the rotorcraft to substantially zero before touching down.

Owner:SKYWORKS GLOBAL INC

Monowheel type vehicle

An engine-propelled monowheel vehicle comprises two wheels, close together, that circumscribe the remainder of the vehicle. When the vehicle is moving forward, the closely spaced wheels act as a single wheel, and the vehicle turns by leaning the wheels. A single propulsion system provides a drive torque that is shared by the two wheels. A separate steering torque, provided by a steering motor, is added to one wheel while being subtracted from the other wheel, enabling the wheels to rotate in opposite directions for turning the vehicle at zero forward velocity. The vehicle employs attitude sensors, for sensing roll, pitch, and yaw, and an automatic balancing system. A flywheel in the vehicle spins at a high rate around a spin axis, wherein the spin axis is rotatable with respect to the vehicle's frame. The axis angle and flywheel spin speed are continually adjustable to generate torques for automatic balancing.

Owner:LEESER KARL F

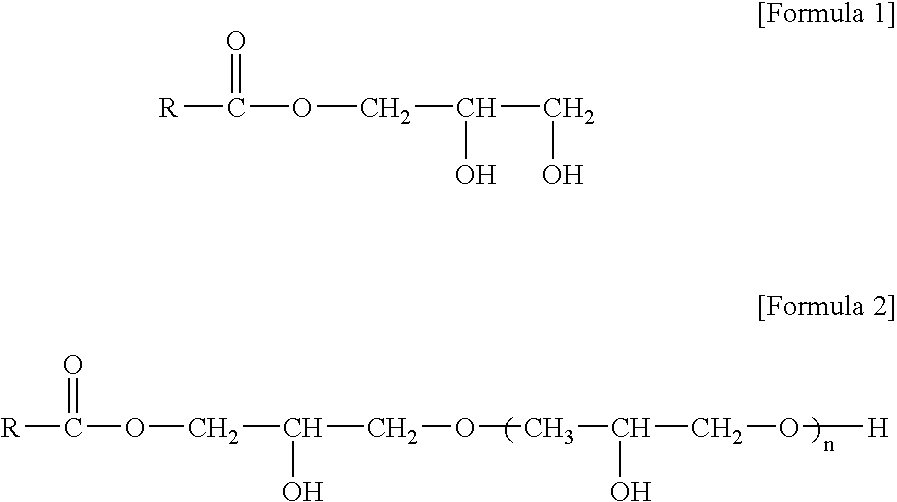

Polyester elastomer/PET composite elastic fiber and preparation method thereof

ActiveCN104831417AIncrease elasticityImprove performanceMelt spinning methodsConjugated synthetic polymer artificial filaments1,4-ButanediolElastomer

The invention discloses a polyester elastomer / PET composite elastic fiber and a preparation method thereof. The preparation method comprises the steps of firstly carrying out reduced-pressure direct esterification on terephthalic acid, 1,4-butanediol and double-ended hydroxyl polyether in a certain proportion in the presence of catalysts, carrying out melt polycondensation to obtain a polyester elastomer, and carrying out a spin-draw-winding one-step process on the prepared polyester elastomer and PET, so as to obtain the polyester elastomer / PET composite elastic fiber, wherein the breaking strength of the polyester elastomer / PET composite elastic fiber is 2.8cN / dtex-3.56cN / dtex, the elongation at break is 16.9%-30.4%, the curling degree is 60%-75%, the curling elasticity rate is 97%-99%, the capillary water absorption height is 9.7cm / 30min-14.1cm / 30min. Compared with normal composite elastic fibers, the polyester elastomer / PET composite elastic fiber has relatively excellent elasticity and relatively soft hand feeling, and the fabric capillary suction effect of the polyester elastomer / PET composite elastic fiber is even higher than those of cotton fabrics; the preparation method is short in production process, high in spinning speed and low in cost, and the prepared composite elastic fiber can be directly used in subsequent weaving without being processed into interlaced yarns.

Owner:SICHUAN UNIV +1

Appliance with user interface having multi-user mode

InactiveUS20080235614A1Programme controlInput/output processes for data processingSoft keyTherapeutic Devices

In accordance with the present disclosure, a system for providing a customizable multi-user interface for a treatment appliance is presented. The system includes a user interface having a display region. The display region may include a user selection menu wherein one of a plurality of stored users may be selected. Once a user is selected, various customized user interface parameters and wash cycles associated with that user will be available for selection. The customized user interface parameters may include brightness, contrast, volume, and the like. Each cycle may include various customized wash cycle parameters, such as wash temperature, spin speed and soil level. The user interface may further include a plurality of soft keys provided for the selection of menu options on the display. In addition, the user interface may include a rotatable knob from which cycle selections may be made.

Owner:ELECTROLUX HOME PROD CORP NV

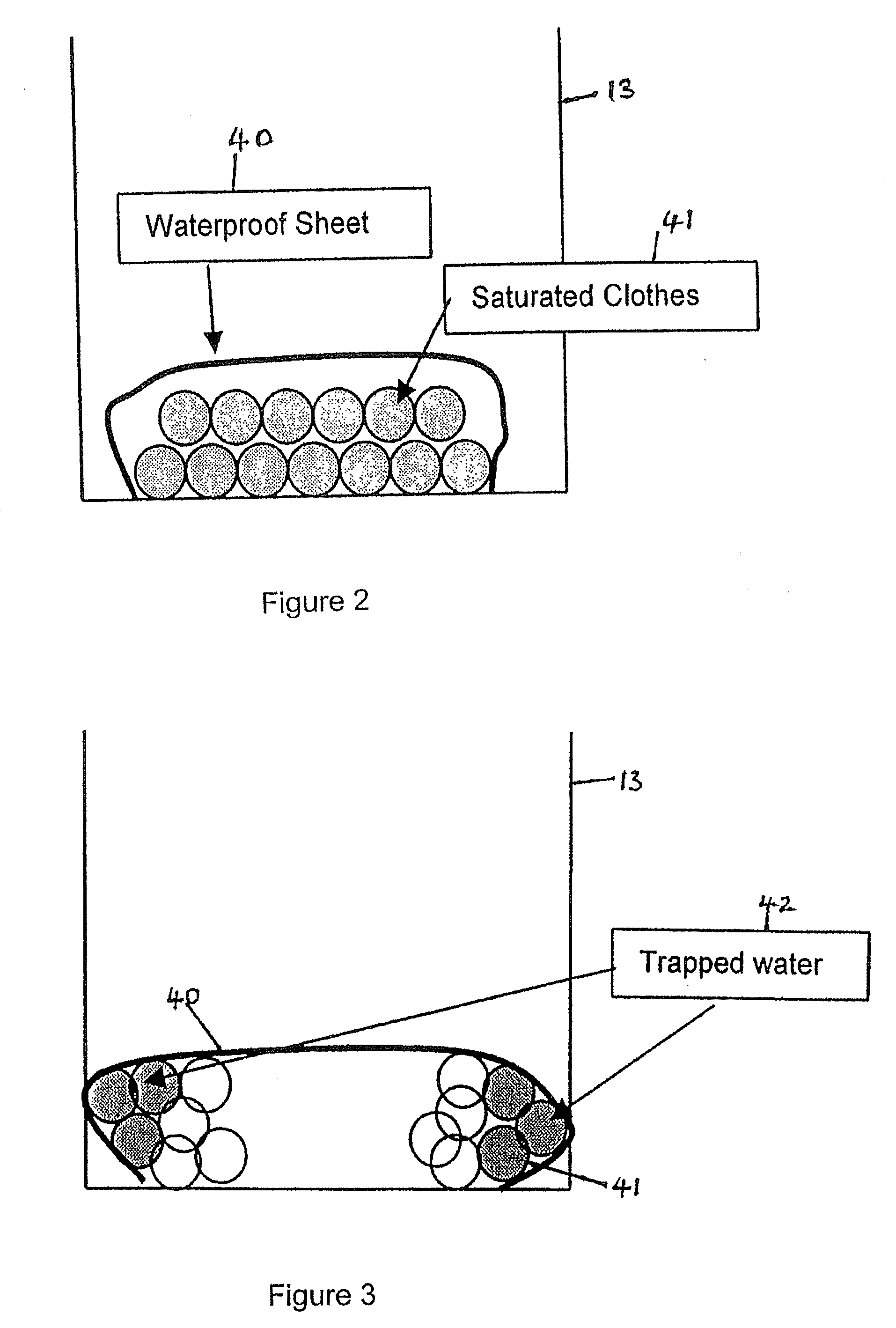

Fluid entrapment detection

InactiveUS20080178398A1Other washing machinesControl devices for washing apparatusEngineeringEntrapment

A washing machine includes a cabinet, a wash tub supported within the cabinet, a spin basket for holding a wash load, the spin basket rotatable in the wash tub by a motor, and a controller for driving the motor to rotate the spin basket. The controller is adapted to detect water entrapment within a wash load in a spin basket of a washing machine by measuring a first parameter indicative of the rotational inertia of the spin basket when accelerated to a first spin speed, controlling the spin basket to dewater a wash load in the spin basket, measuring a second parameter indicative of the rotational inertia of the spin basket at the first speed, comparing the first and second parameters, and detecting whether there is water entrapped in the wash load based on the comparison between the first and second parameters.

Owner:FISHER & PAYKEL APPLIANCES LTD

Intermediate power down mode for a rotatable media data storage device

Owner:PANASONIC CORP

Polyolefin fiber and method of producing the same

ActiveUS20090093180A1Desirable maintenanceDesirable of whitenessFilament/thread formingGlass/slag layered productsYarnPolymer science

A polyolefin fiber includes 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of titanium dioxide (TiO2). The polyolefin fiber may further include 0.2 to 1.0 wt % of spin finish provided on a surface thereof. The polyolefin fiber is spun to have a circular section, a modified cross-section including an X-shaped section, a Y-shaped section, a deltaic section, an oval section, a diamond section, a bladebone-shaped section, and a combined section thereof, or a combined section of the circular section and the modified cross-section. A method of producing a polyolefin fiber includes (a) melt extruding a composition which contains 93 to 99 wt % of polyolefin resin, 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of any one titanium dioxide (TiO2) of rutile titanium dioxide, anatase titanium dioxide, and brookite titanium dioxide at 240 to 300° C. and performing winding at a spin speed of 500 to 2,000 mpm to produce a undrawn yarn, and (b) drawing the undrawn yarn at a draw ratio of 1.0 to 5.0, crimping the drawn yarn to 5.5 to 9.0 ea / cm by using a crimper, attaching 0.2 to 1.0 wt % of spin finish to a surface of the fiber by spraying or dipping, heat setting the spin finish at 100 to 130° C. for 3 to 10 min, and cutting the resulting polyolefin fiber to predetermined lengths. A method of producing a polyolefin fiber includes melt extruding a composition which contains 93 to 99 wt % of polyolefin resin, 0.2 to 5.0 wt % of hydrophilic additive, and 0.05 to 3.00 wt % of any one titanium dioxide (TiO2) of rutile titanium dioxide, anatase titanium dioxide, and brookite titanium dioxide at 230 to 270° C., winding at a spin speed of 40 to 300 mpm to produce a undrawn yarn, drawing the undrawn yarn at a draw ratio of 1.0 to 5.0, crimping the drawn yarn to 5.5 to 9.0 ea / cm by using a crimper, attaching 0.2 to 1.0 wt % of spin finish to a surface of the fiber by spraying or dipping, heat setting the spin finish at 100 to 130° C. for 3 to 10 min, and cutting the resulting spin finish to predetermined lengths. The polyolefin fiber has desirable maintenance of hydrophilicity and whiteness after rinsing is performed by using water and low foaming property and excellent carding workability required to produce non-woven fabrics (particularly, spunlace non-woven fabrics). The polyolefin fiber improves clearness of point and embossing patterns during thermal point bonding and thermal embossing processes.

Owner:KOLON GLOTECH INC

Alginate/polyvinyl alcohol composite fiber and its preparing process

ActiveCN1986920AHigh strengthReduce manufacturing costWet spinning methodsConjugated synthetic polymer artificial filamentsCross-linkFiber

The present invention is alginate / polyvinyl alcohol composite fiber and its preparation process. The production process includes the following steps: mixing 2-8 wt% concentration sodium alginate solution and 5-15 wt% concentration water solution of polyvinyl alcohol in the polymerization degree of 1000-6000 at 30-100 deg.c, filtering and debubbling to form spinning liquor; spinning in a wet spinning machine at spinning speed of 10-80 m / min, solidifying in the first coagulating bath, drafting, cross-linking in the second coagulating bath and re-drafting to form the composite fiber; bundling drafting, steam drying, hot settling and other steps to produce alginate / polyvinyl alcohol composite fiber. The alginate / polyvinyl alcohol composite fiber has high strength, high elasticity and good biocompatibility, and may be applied in fabric, medical bandage, etc.

Owner:青岛源海新材料科技有限公司

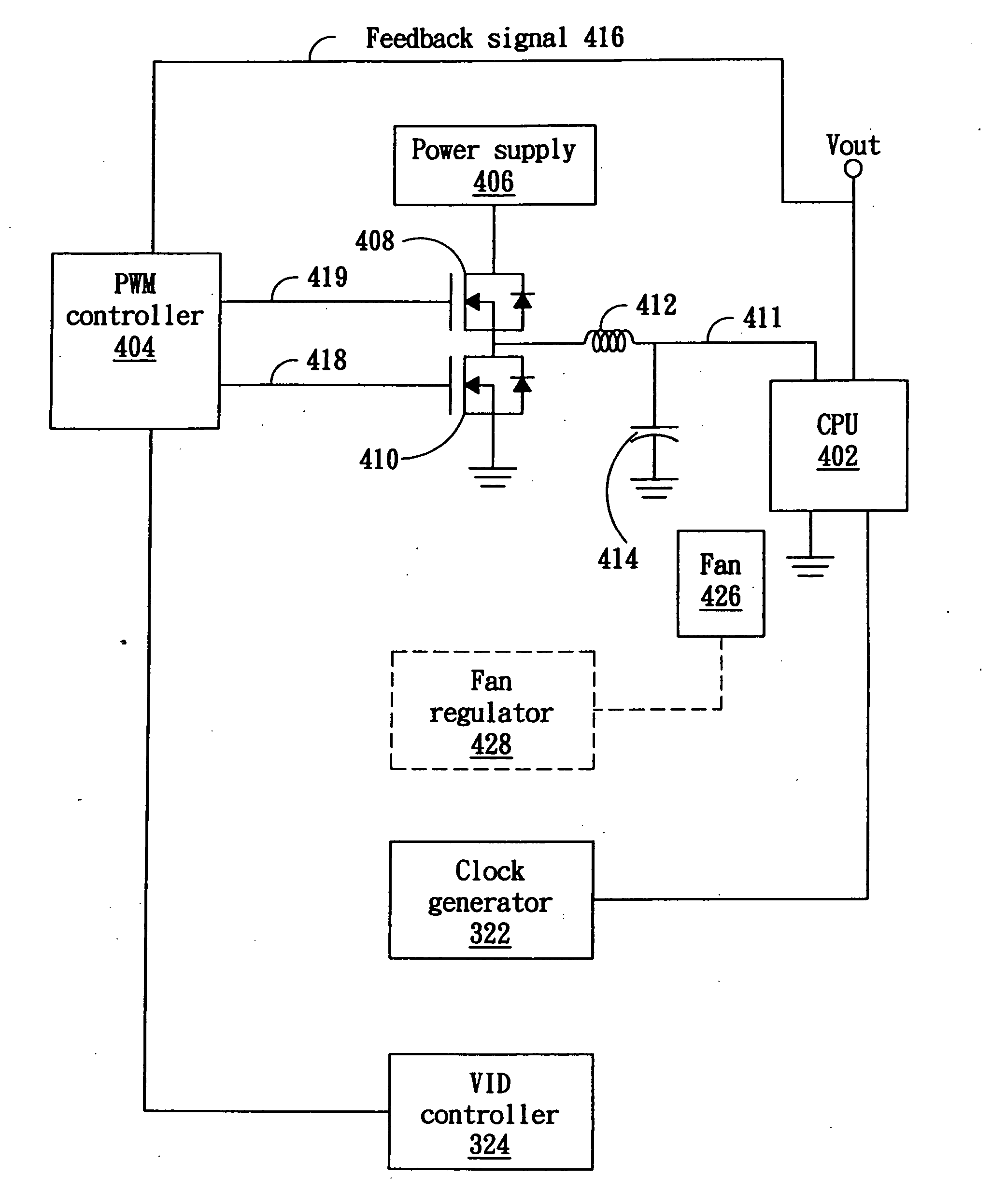

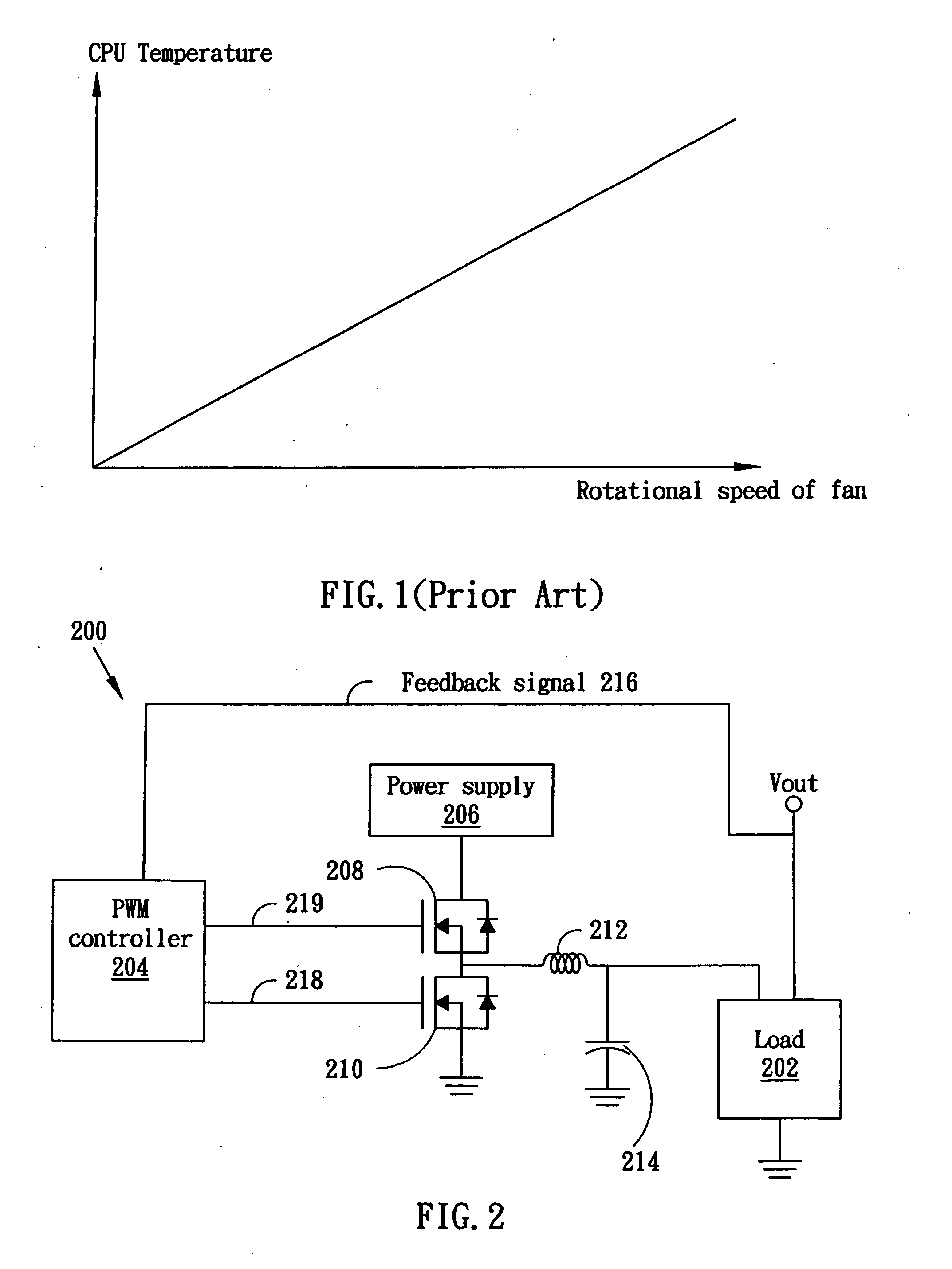

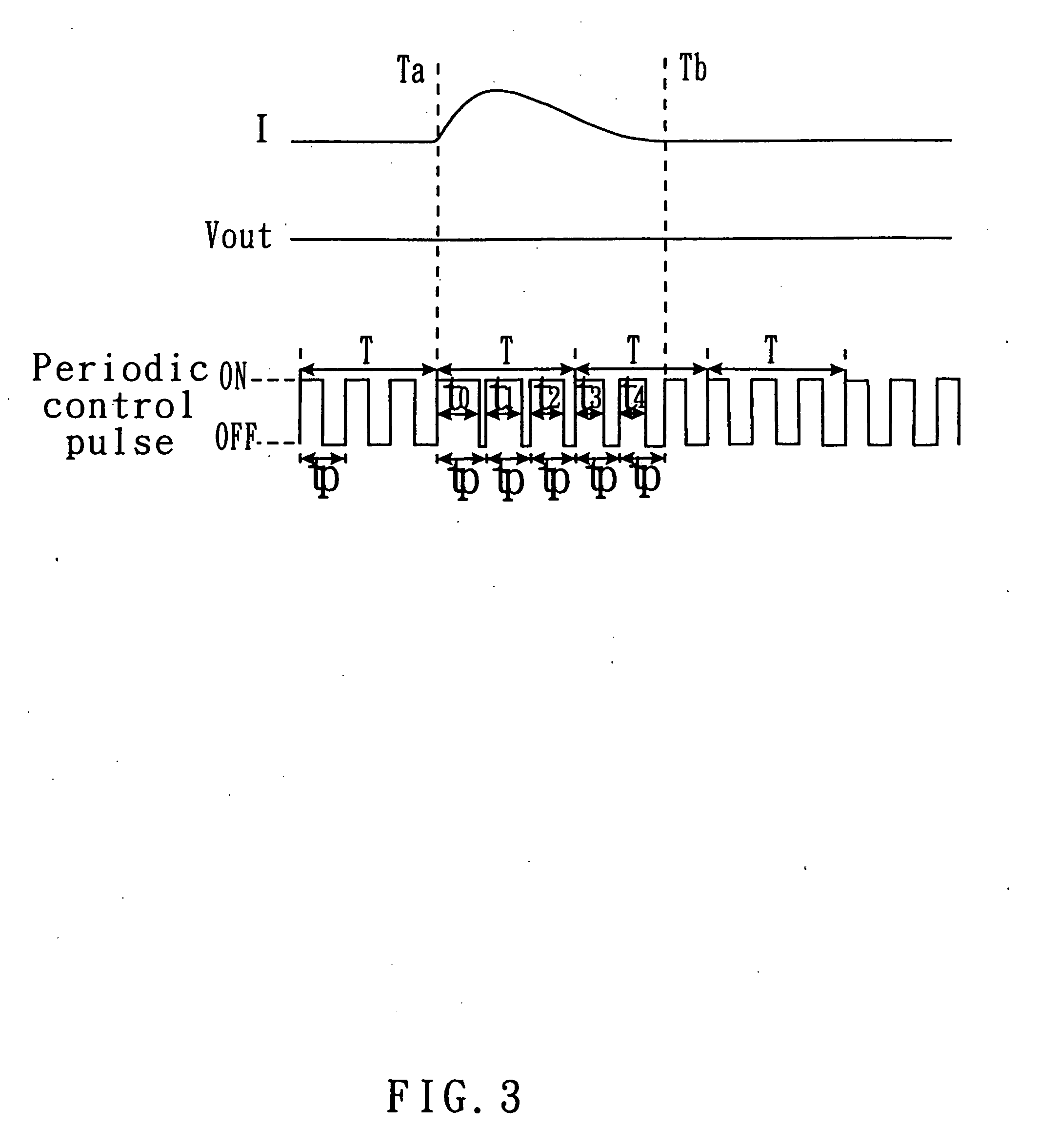

System and method for regulating a load by utilizing pulse width modulation

InactiveUS20060127066A1Avoid instabilityAdjustable frequencyDigital data processing detailsField or armature current controlClock rateEngineering

The invention is directed to a system and method for regulating a load (such as a CPU). A pulse-width-modulation (PWM) regulator calculates the duty cycle of the control pulse from a PWM controller, and then compares the duty cycle to a predetermined threshold. Thereafter, the PWM regulator regulates working conditions, such as clock frequency, supplied voltage, or fan spin speed, based on the above comparison.

Owner:AOPEN

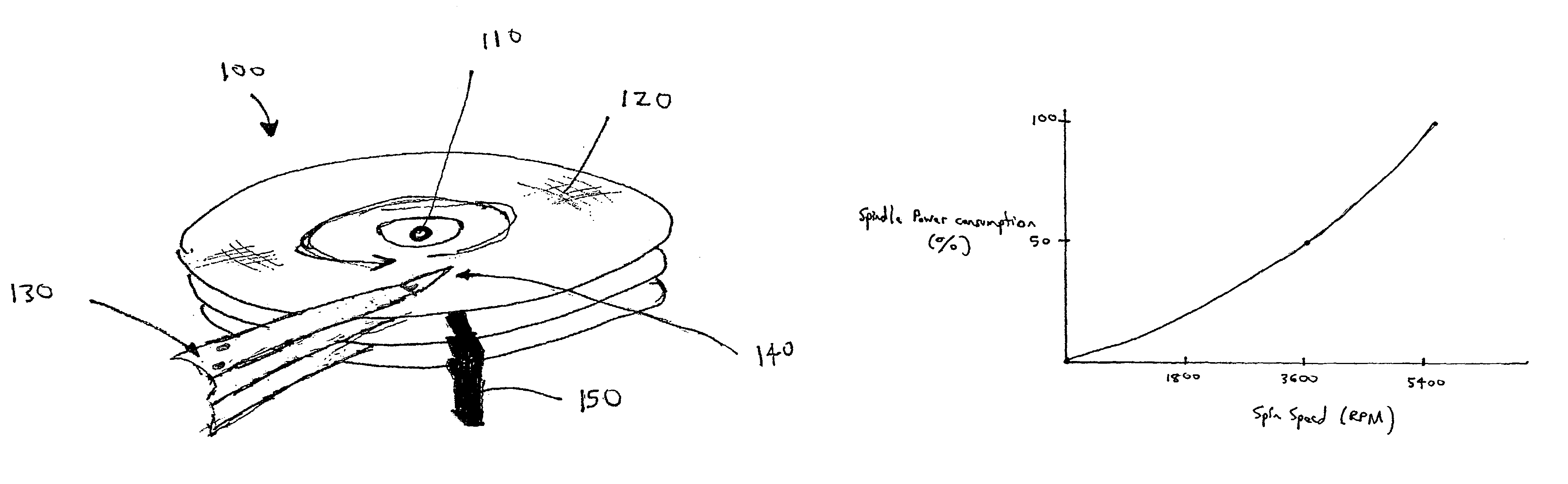

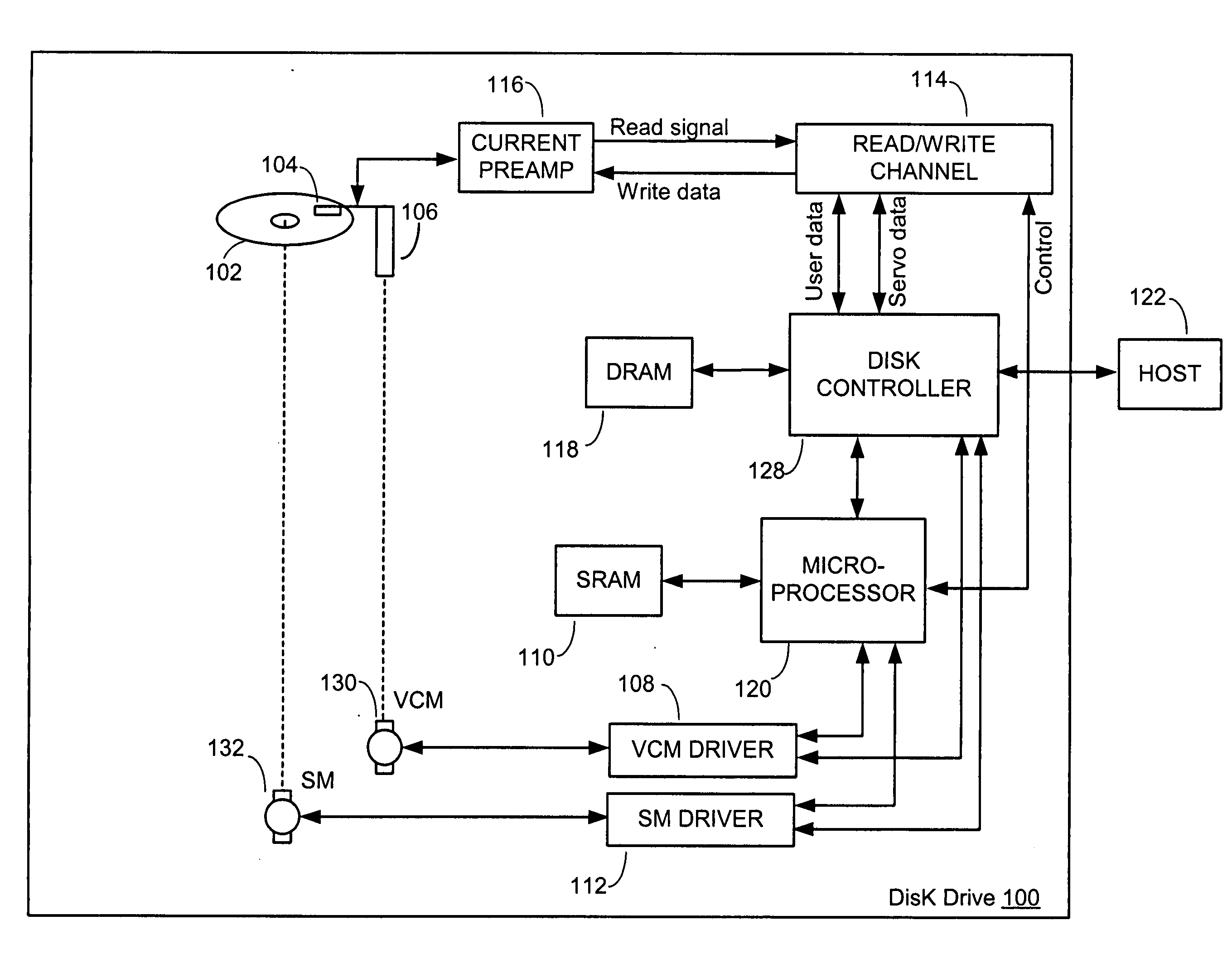

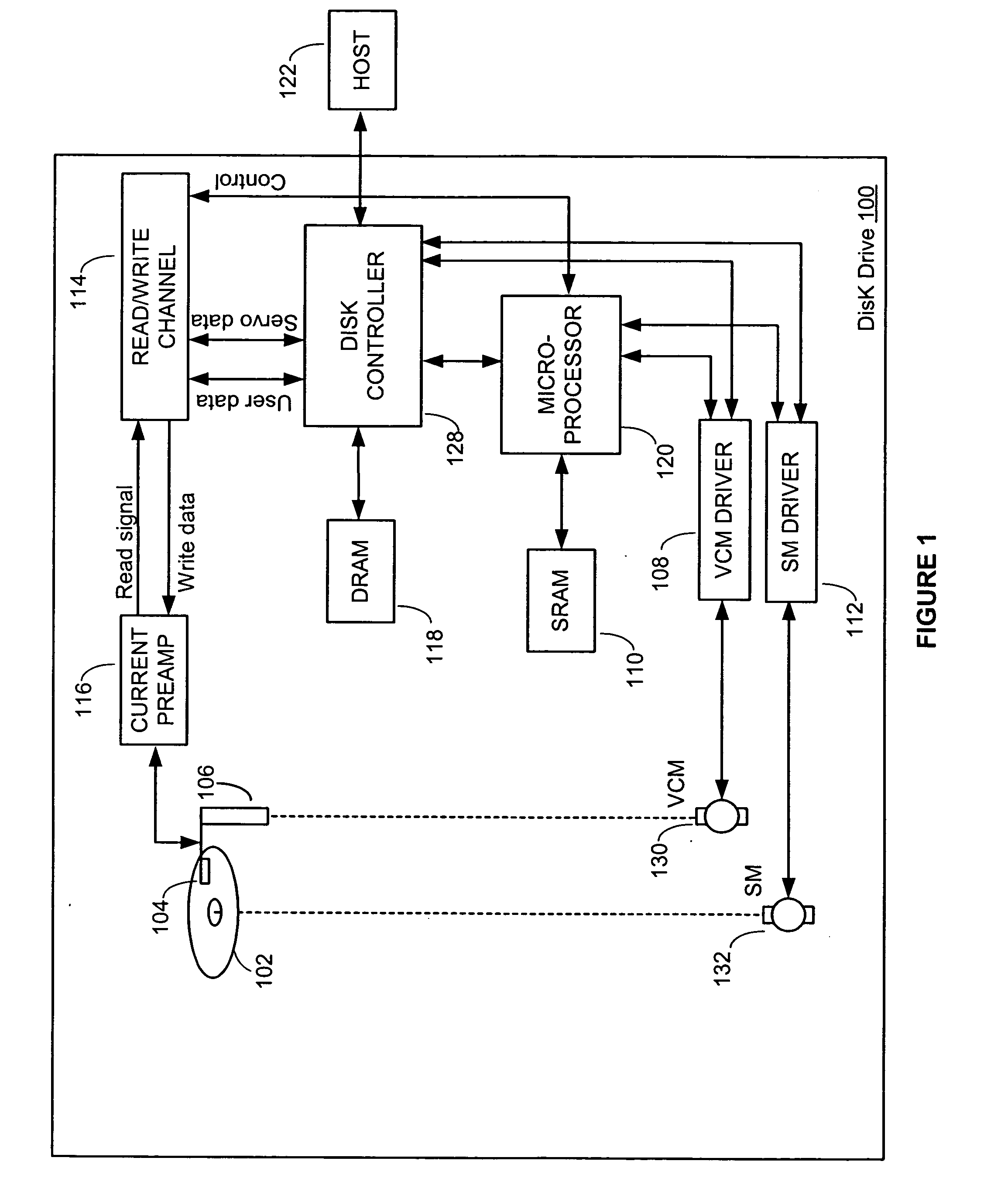

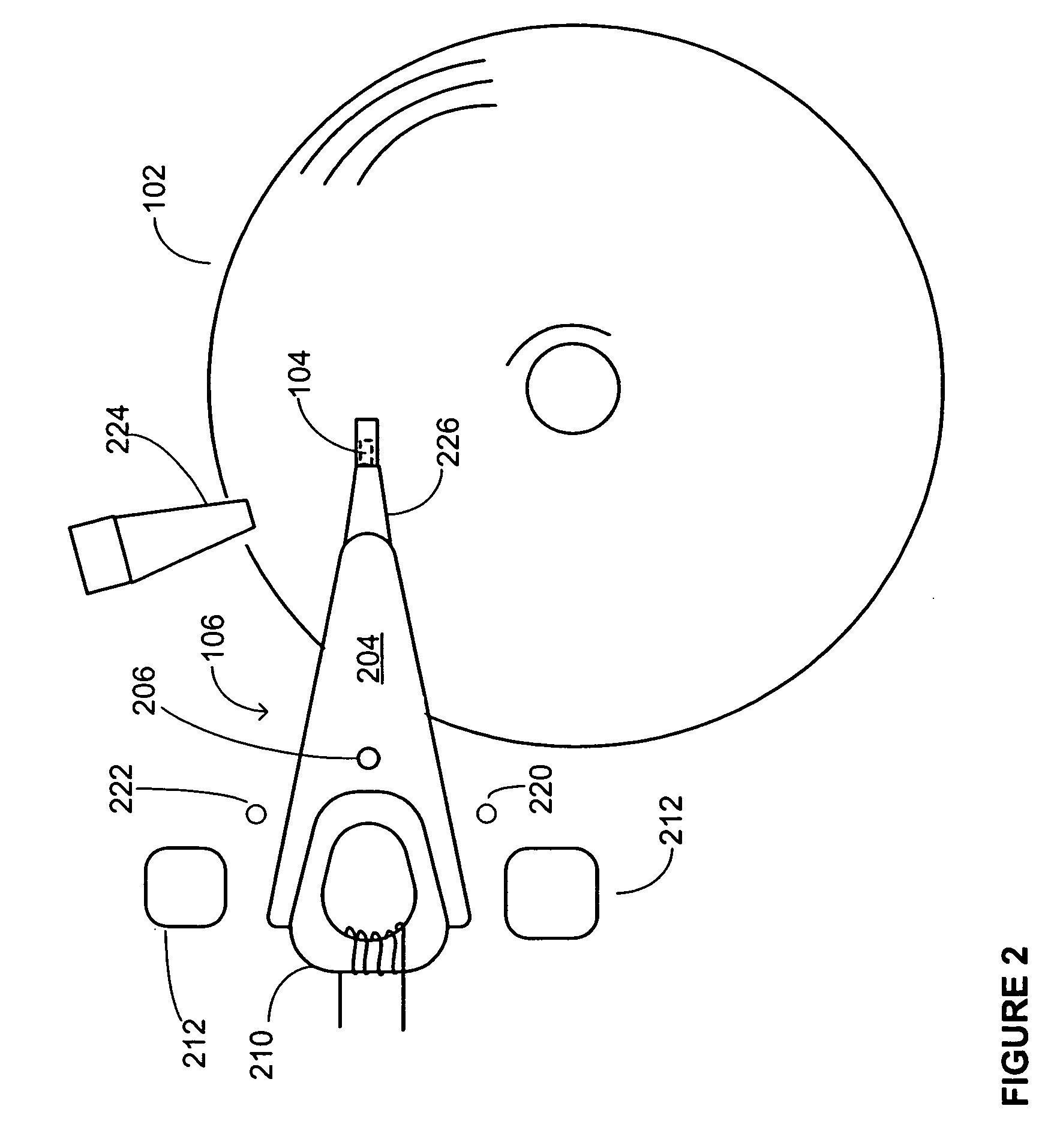

Operating a rotatable media storage device at multiple spin-speeds

InactiveUS20050141375A1Avoid excessive distanceCombination recordingDisposition/mounting of recording headsSpinsWorkload

A rotatable media storage device operates using multiple disk spin-speeds, e.g., a reduced spin-speed and a nominal spin-speed. A disk is spun up to a reduced spin-speed and an initial data transfer is began while the disk spins at the reduced spin-speed, if an amount of work that has been requested is below a threshold. The disk is spun up to a further spin-speed (e.g., a nominal spin-speed), which is greater than the reduced spin-speed, and the initial data transfer is began while the disk spins at the further spin-speed, if the amount of work that has been requested is above the threshold. Alternative embodiments using multiple disk spin-speeds are also provided.

Owner:PANASONIC CORP

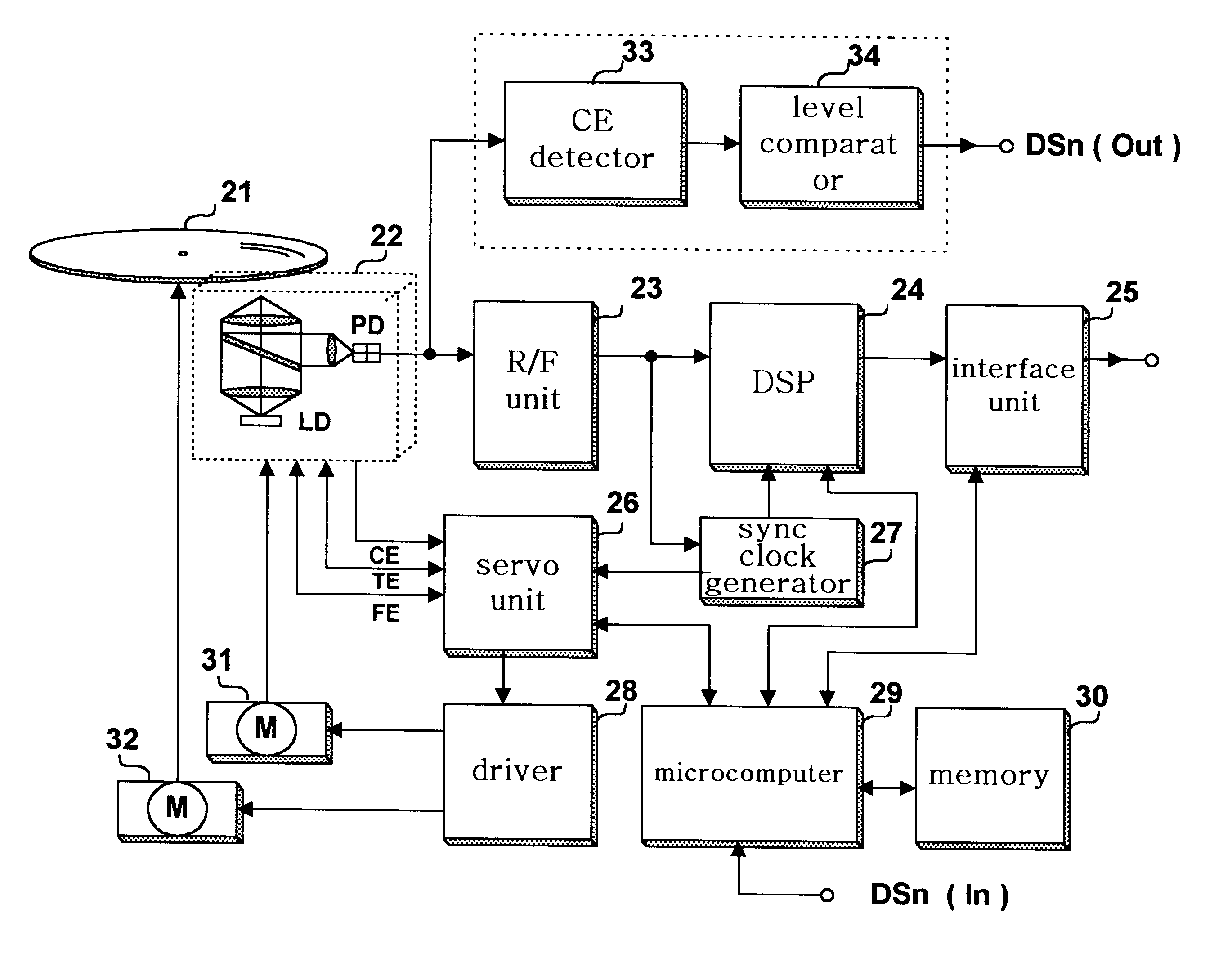

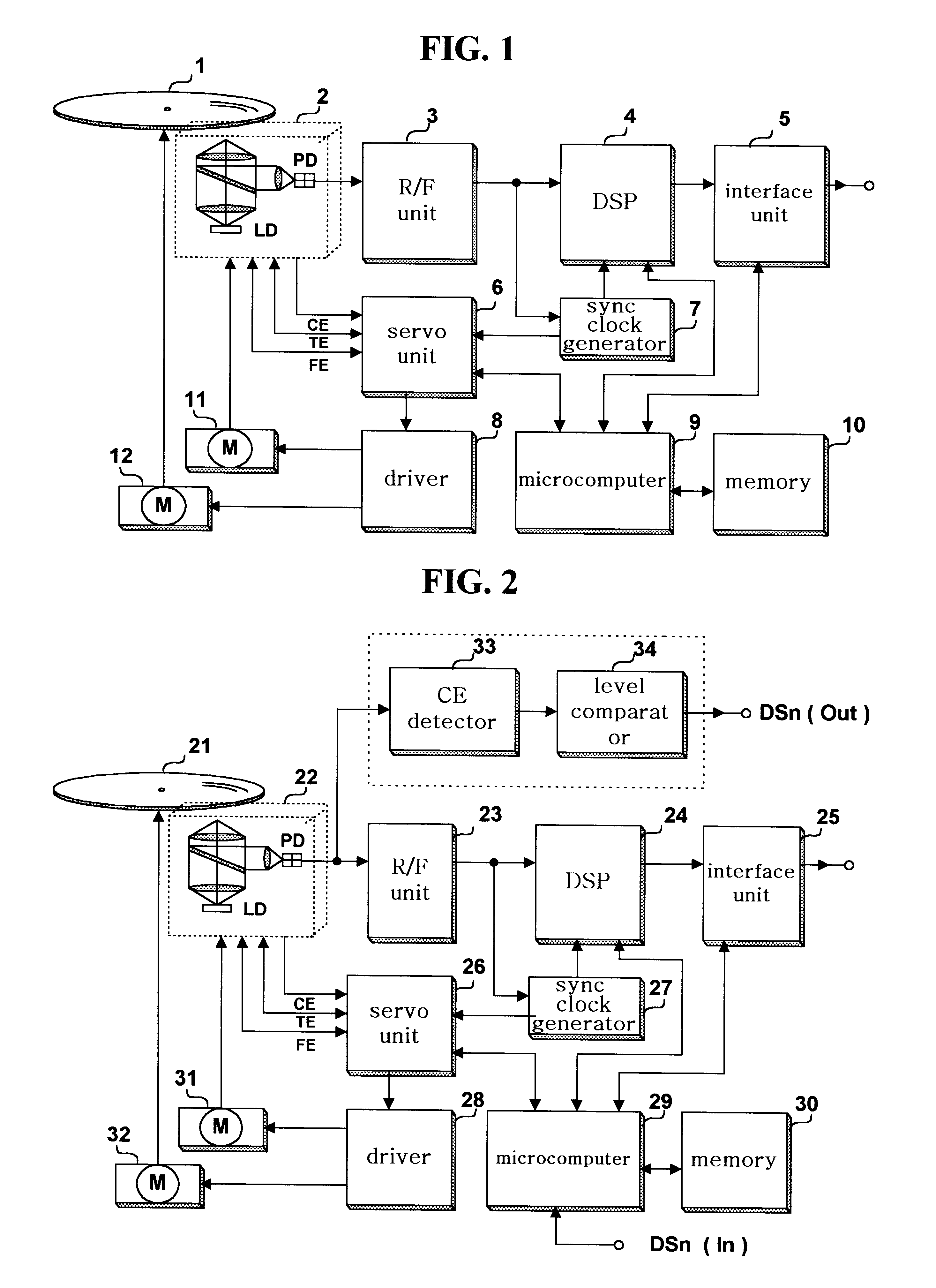

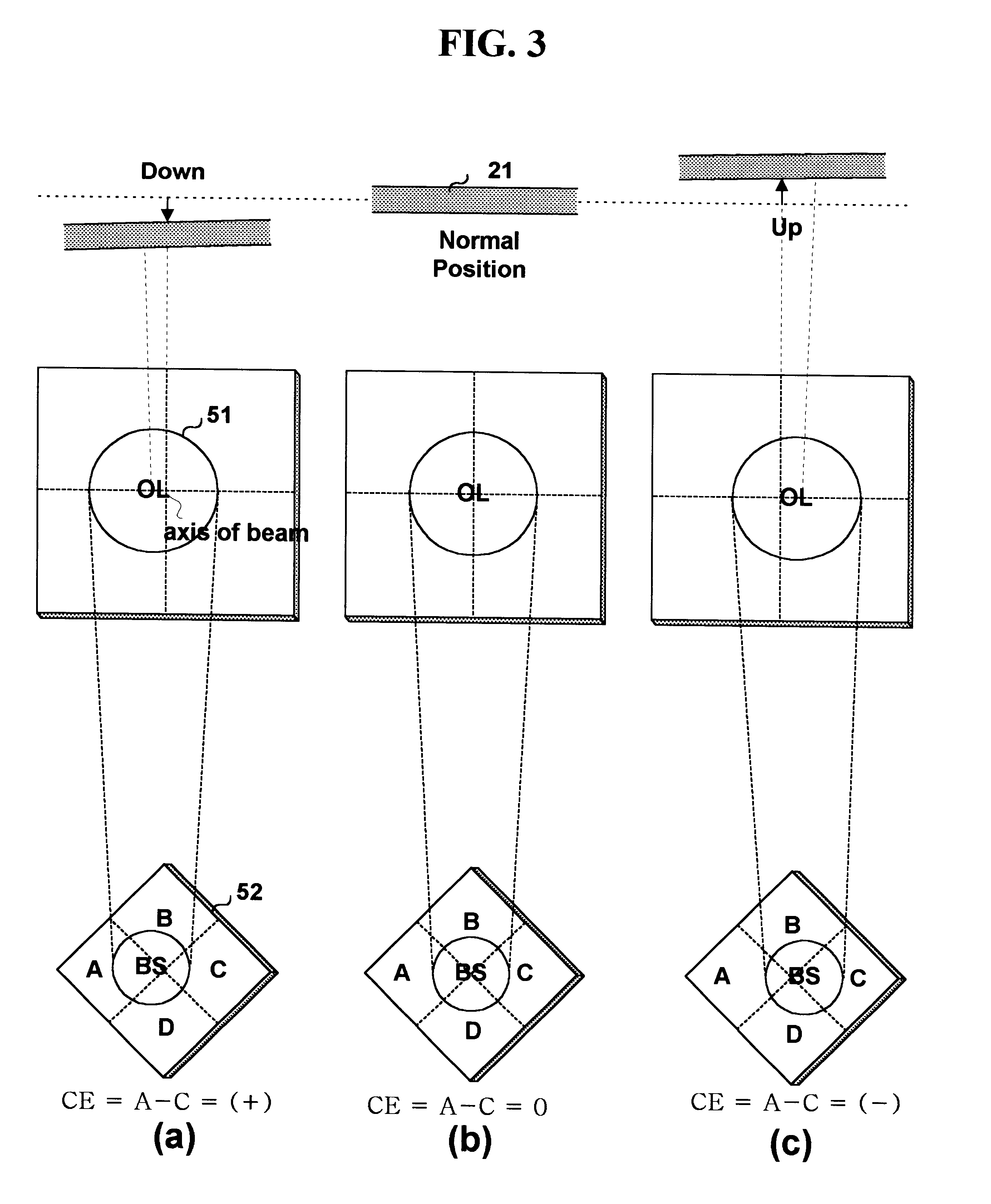

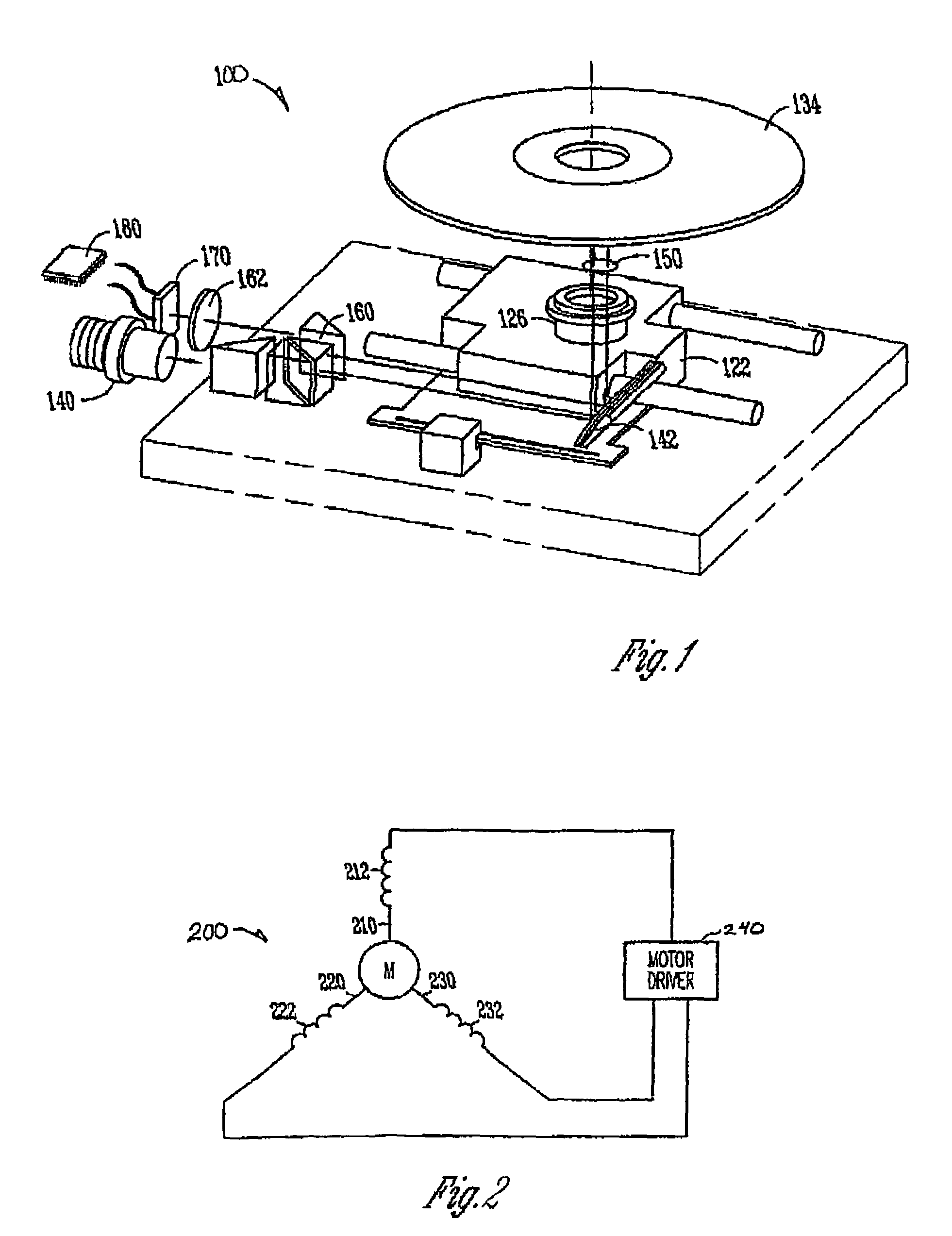

Servo control apparatus and method for compensating for axial vibration of an optical disk

A servo control apparatus and method that adjust the allowable maximum rotation speed of an optical disk based upon the amount of disk axial vibration. The servo control apparatus in accordance with the present invention includes a driver for rotating the optical disk, a detector for detecting the amount of axial vibration of the optical disk, and a controller for controlling the rotation speed of the optical disk based upon the detected amount of disk axial vibration. The servo control apparatus and method in accordance with the present invention prevents data read error due to disk axial vibration by adjusting the allowable maximum disk rotation speed in consideration for the amount of disk axial vibration caused by imperfect disk manufacturing process, disk clamping error, or disk tilt.

Owner:LG ELECTRONICS INC

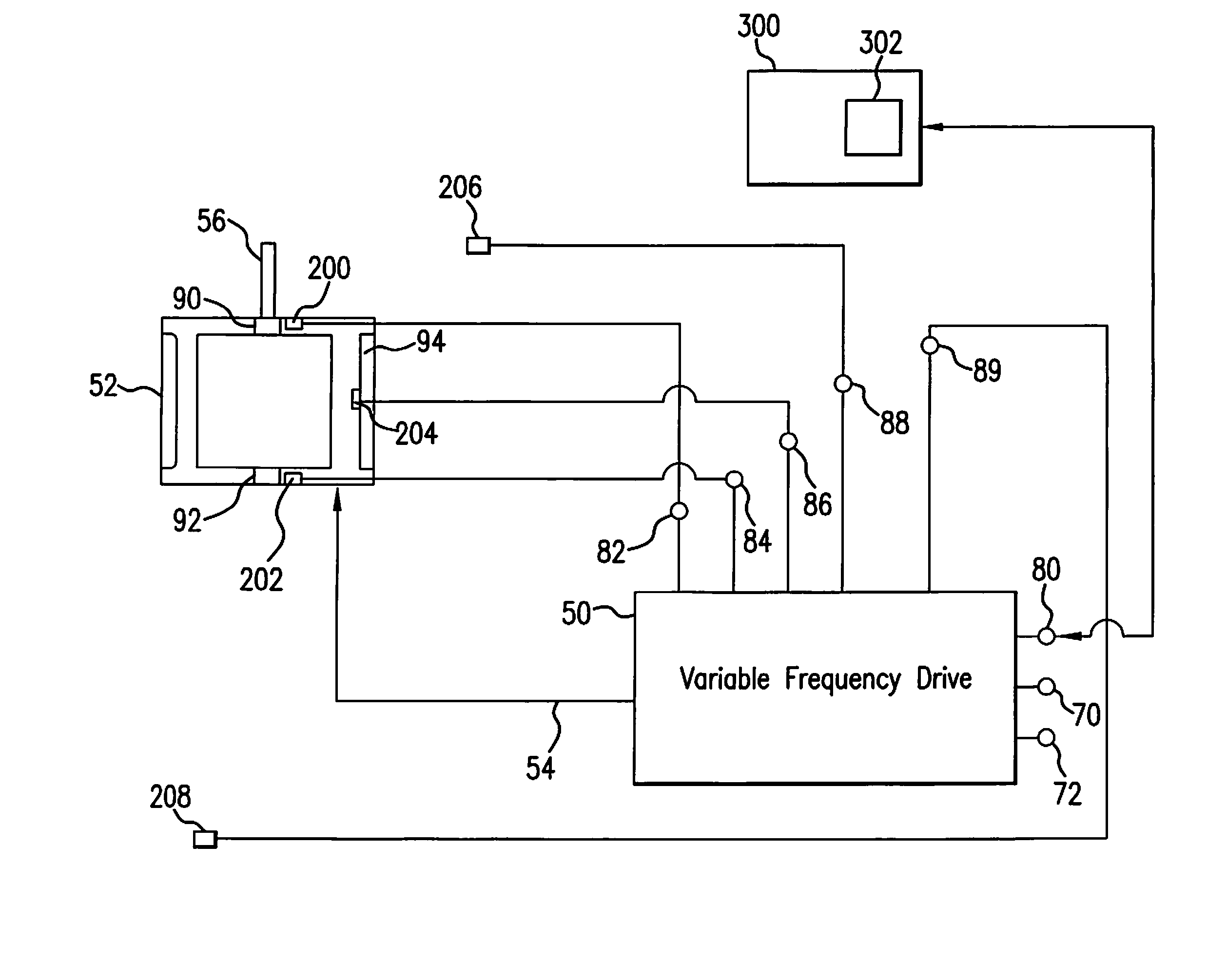

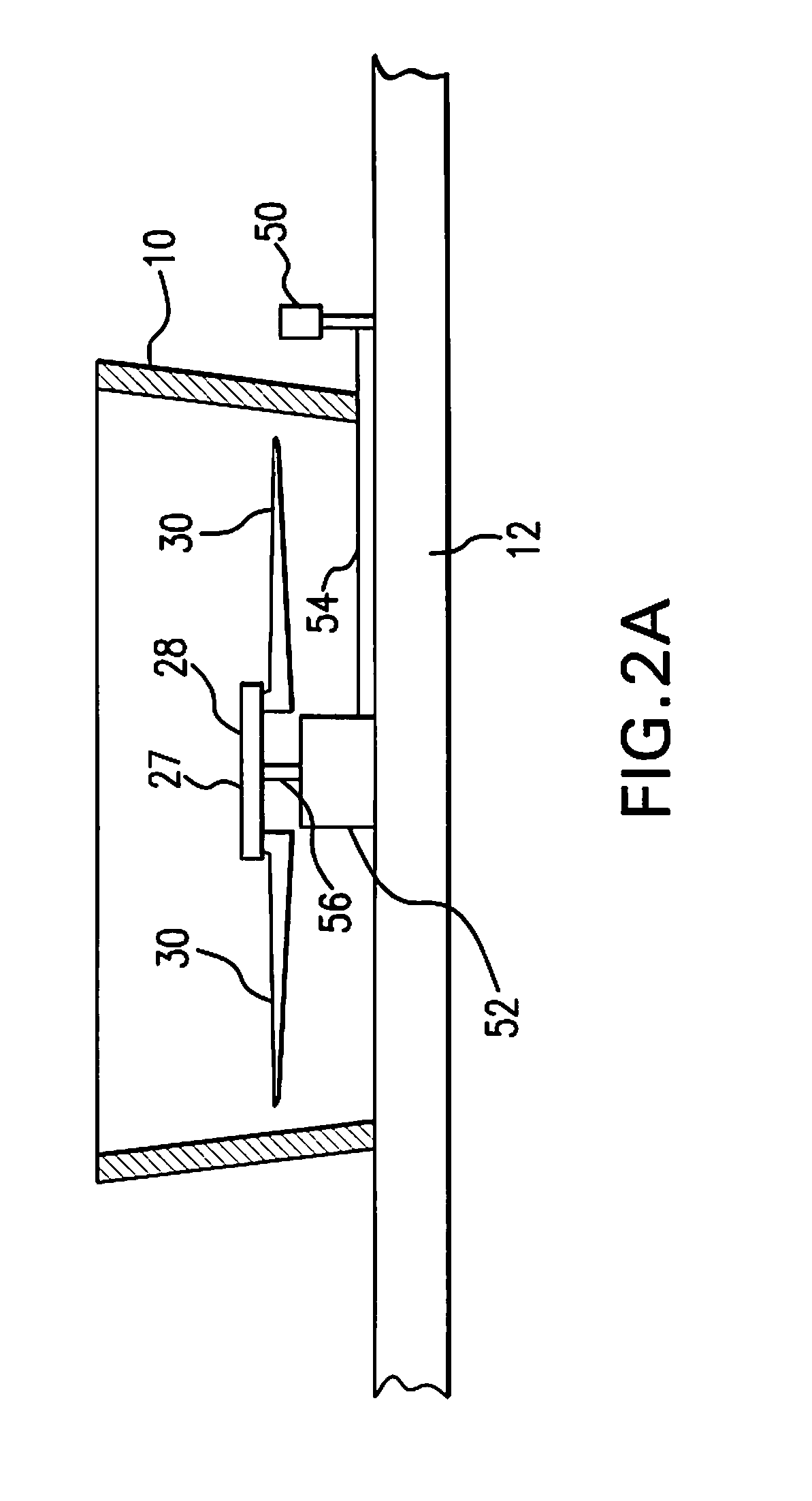

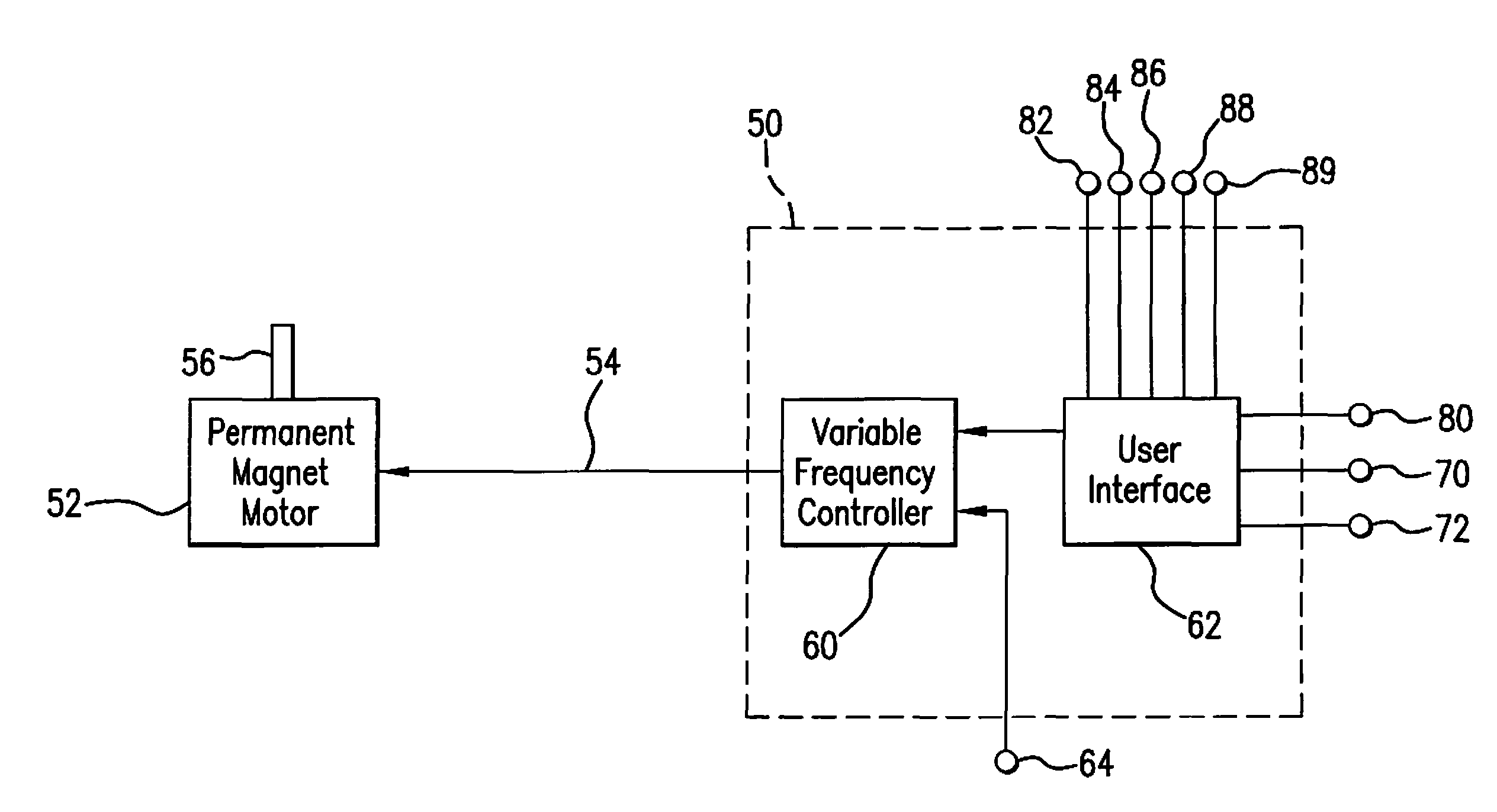

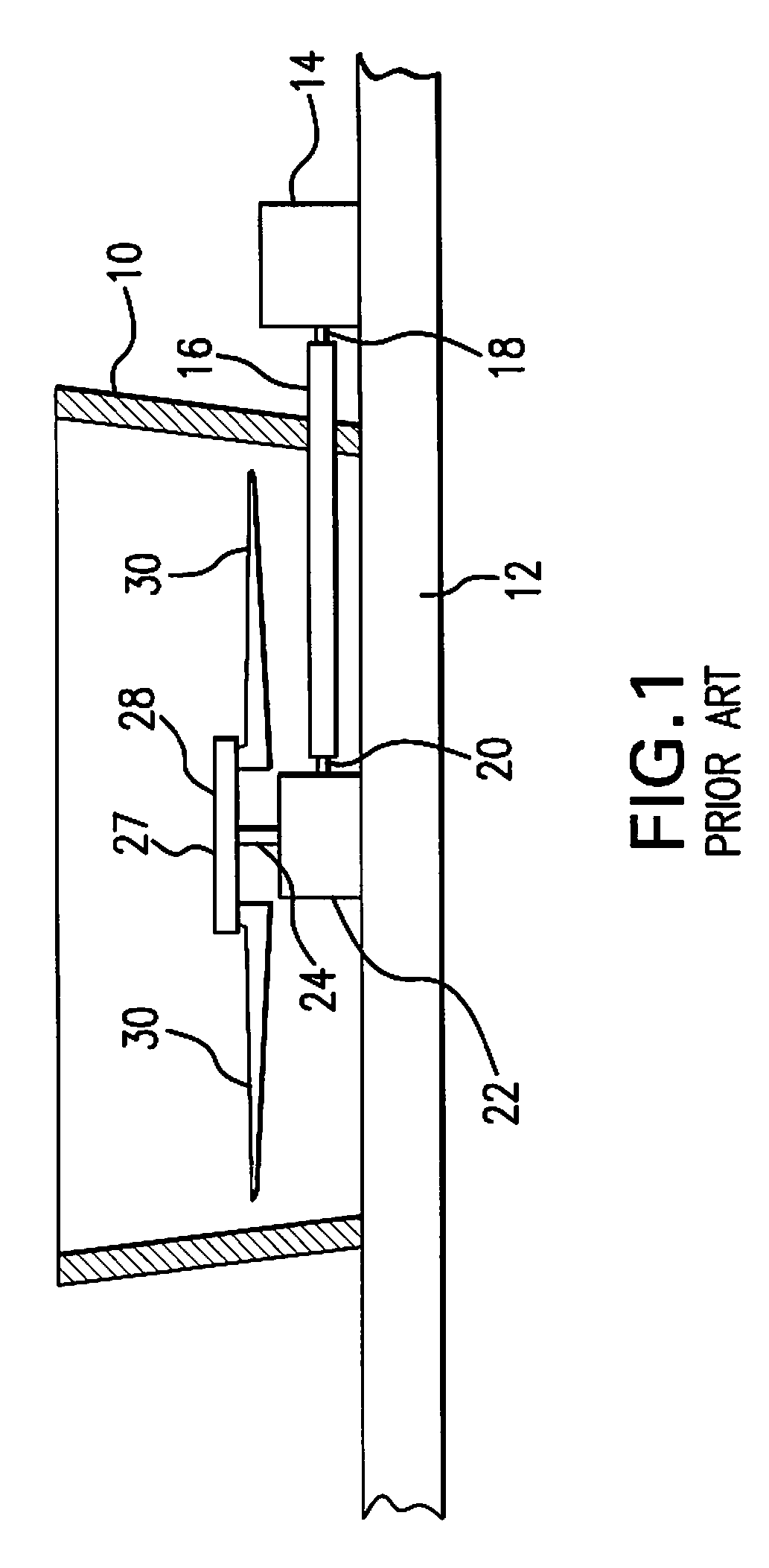

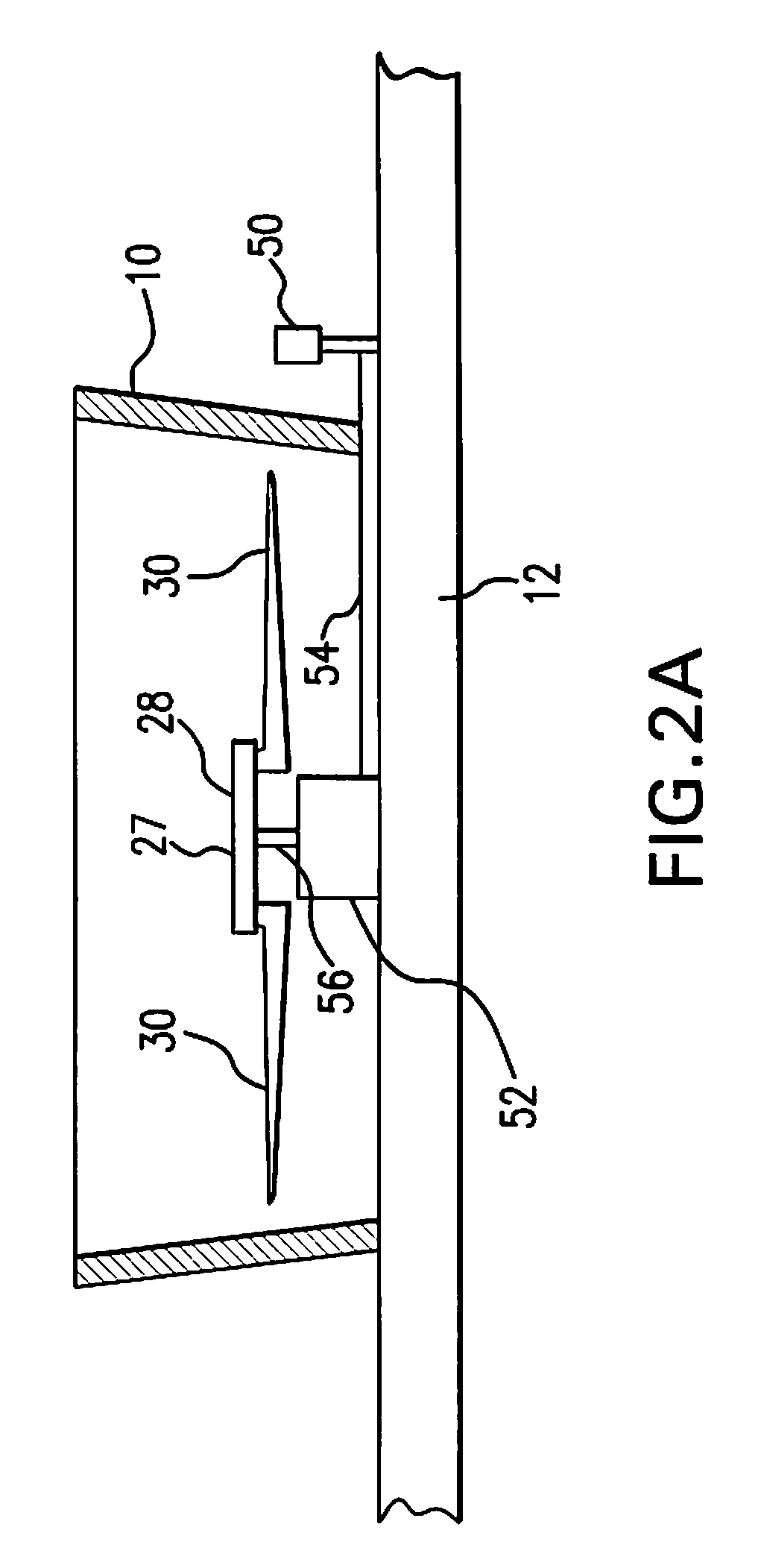

Integrated Fan Drive System For Cooling Tower

An integrated fan drive system for a cooling tower comprising a high-torque, low speed permanent magnet motor having a rotatable shaft, a fan comprising a hub that is directly connected to the rotatable shaft and a plurality of fan blades that are attached to the hub, and a variable frequency drive device in electrical signal communication with the permanent magnet motor to control the rotational speed of the permanent magnet motor. The high-torque, permanent magnet motor comprises no more than two bearings in operative association with the shaft. The variable frequency drive device has a variable frequency controller that has an input for receiving AC power and an output for providing electrical signals that control the operational speed of high-torque, permanent magnet motor. The variable frequency drive device also includes a user interface in electronic data signal communication with the variable frequency controller to allow a user to input motor speed control data.

Owner:PRIME DATUM

Integrated fan drive system for cooling tower

Owner:PRIME DATUM

Sealed magic angle spinning nuclear magnetic resonance probe and process for spectroscopy of hazardous samples

ActiveUS20140167756A1Prevent proliferationEasy to controlAnalysis using nuclear magnetic resonanceElectric/magnetic detectionMagic angle spinningNMR - Nuclear magnetic resonance

A magic-angle-spinning (MAS) nuclear magnetic resonance (NMR) probe is described that includes double containment enclosures configured to seal and contain hazardous samples for analysis. The probe is of a modular design that ensures containment of hazardous samples during sample analysis while preserving spin speeds for superior NMR performance and convenience of operation.

Owner:BATTELLE MEMORIAL INST

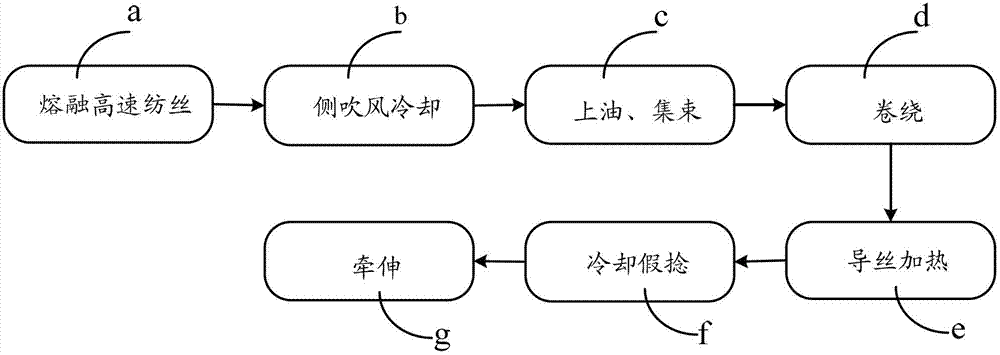

Complete-extinction thin and light meshy polyamide fiber 6 draw textured yarn (DTY) manufacture method

ActiveCN103046147AExtended service lifeTo achieve the requirements of spinning temperatureSpinnerette packsFilament forming substance formingYarnExtinction

An embodiment of the invention discloses a complete-extinction thin and light meshy polyamide fiber 6 draw textured yarn (DTY) manufacture method. The method comprises the following steps of (a) fusion and high-speed spinning, (b) lateral blowing and cooling, (c) oil coating and beam concentration, (d) winding, (e) fiber guiding and heating, (f) cooling and false twisting, (g) drafting, and finally complete-extinction thin and light meshy polyamide fiber 6 DTY is obtained. By adjusting selection of a spinneret plate, the spinning temperature, cooling conditions, spinning speed, oil coating rate, winding speed and the like, the problems including much floating fiber, multiple broken ends and low full barrel rate in the complete extinction thin and light meshy polyamide fiber 6 DTY production process, uneven filling power, poor mesh evenness, much rigor-point broken filament and low in strength of post-processed yarns are solved, the product production quality is stable, and the rate of finished products is high.

Owner:浙江亚特新材料有限公司

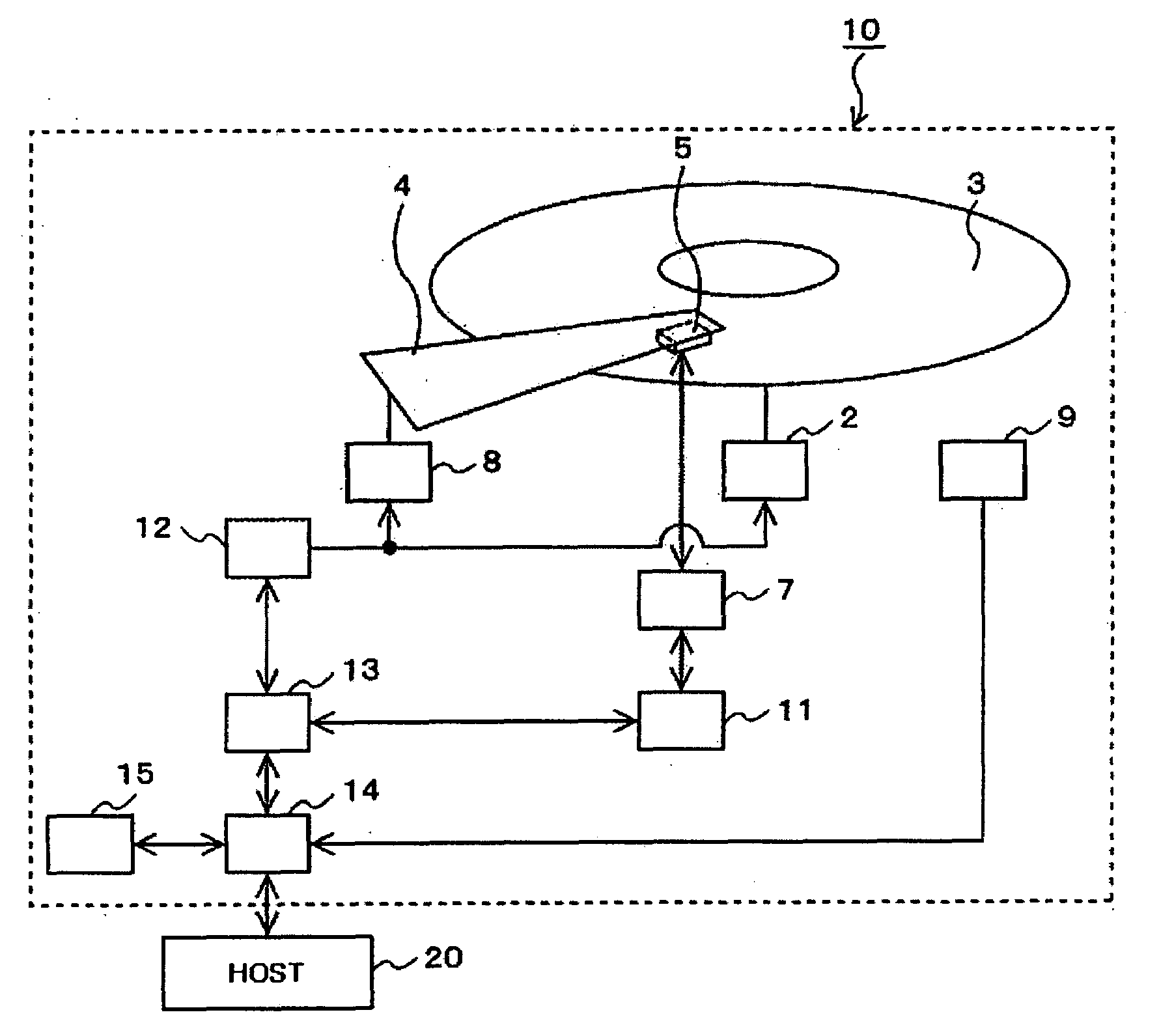

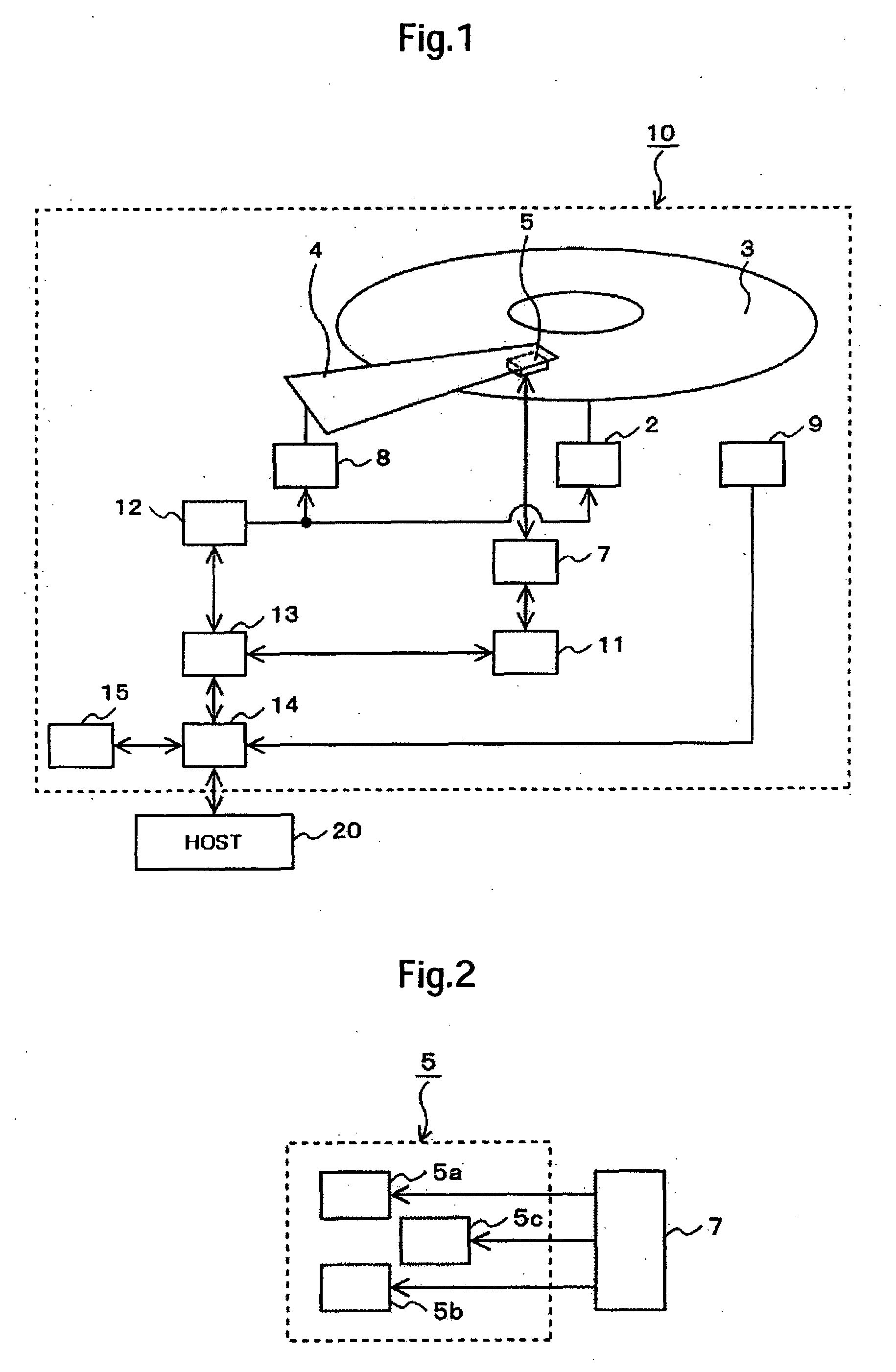

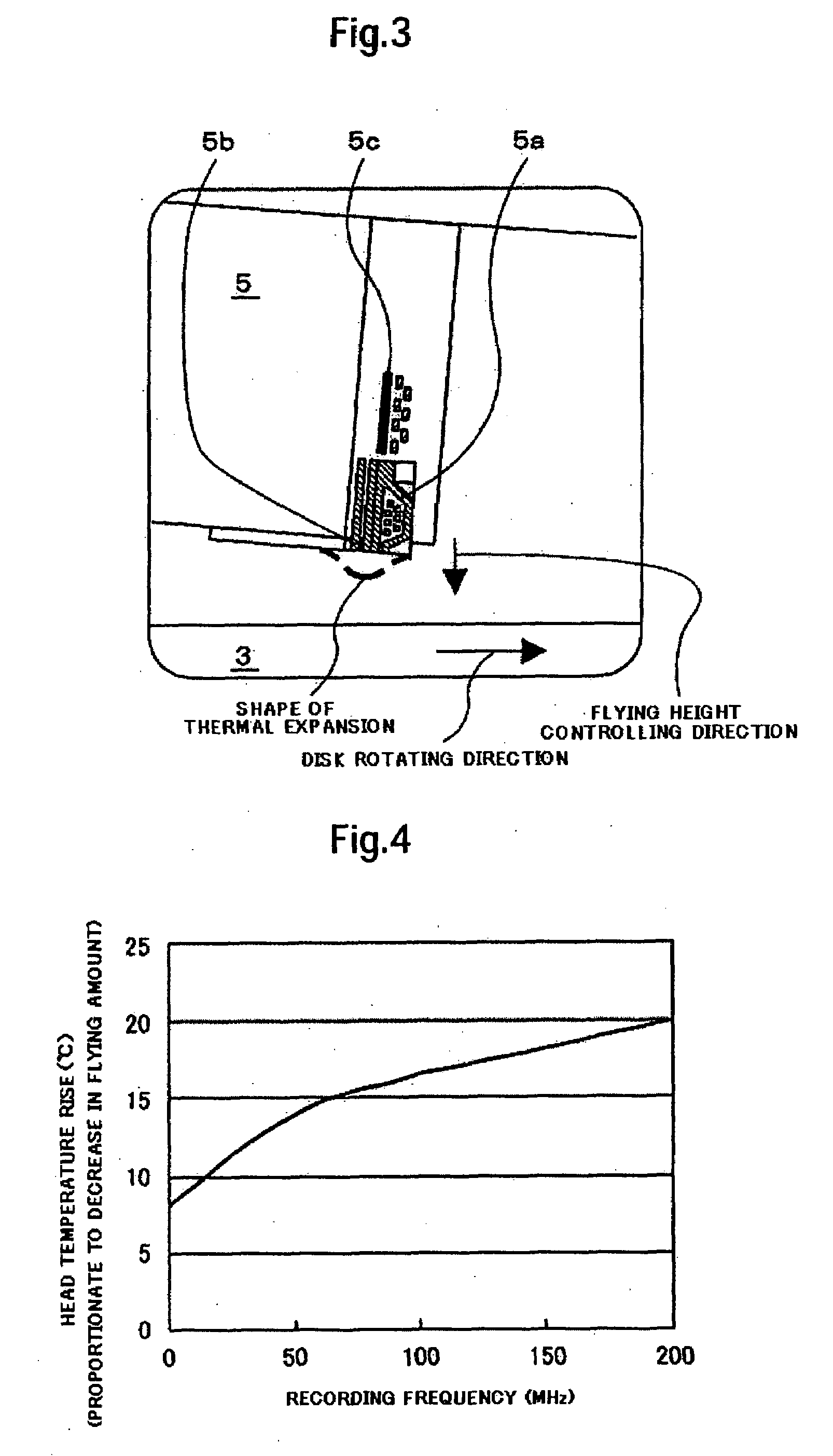

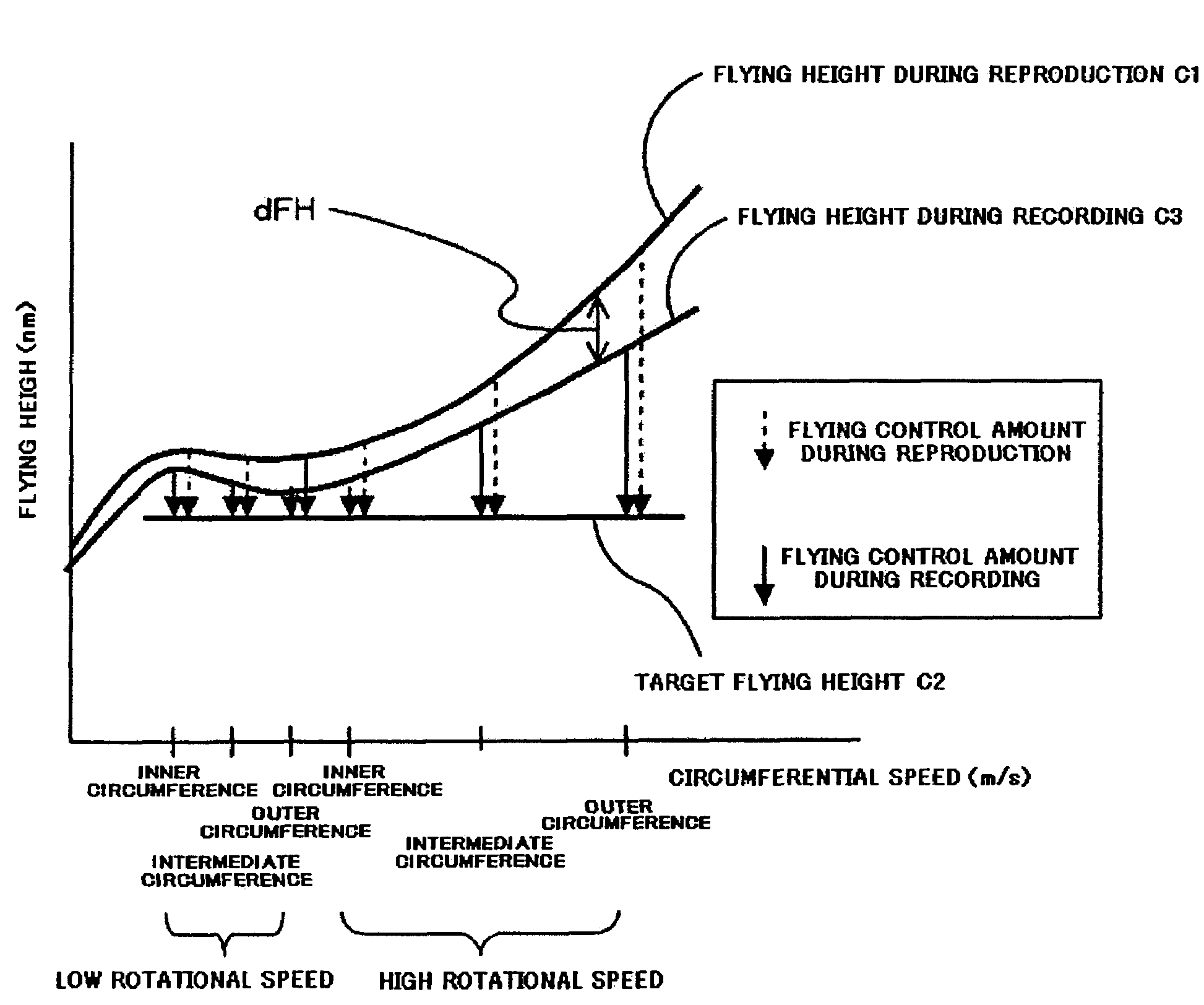

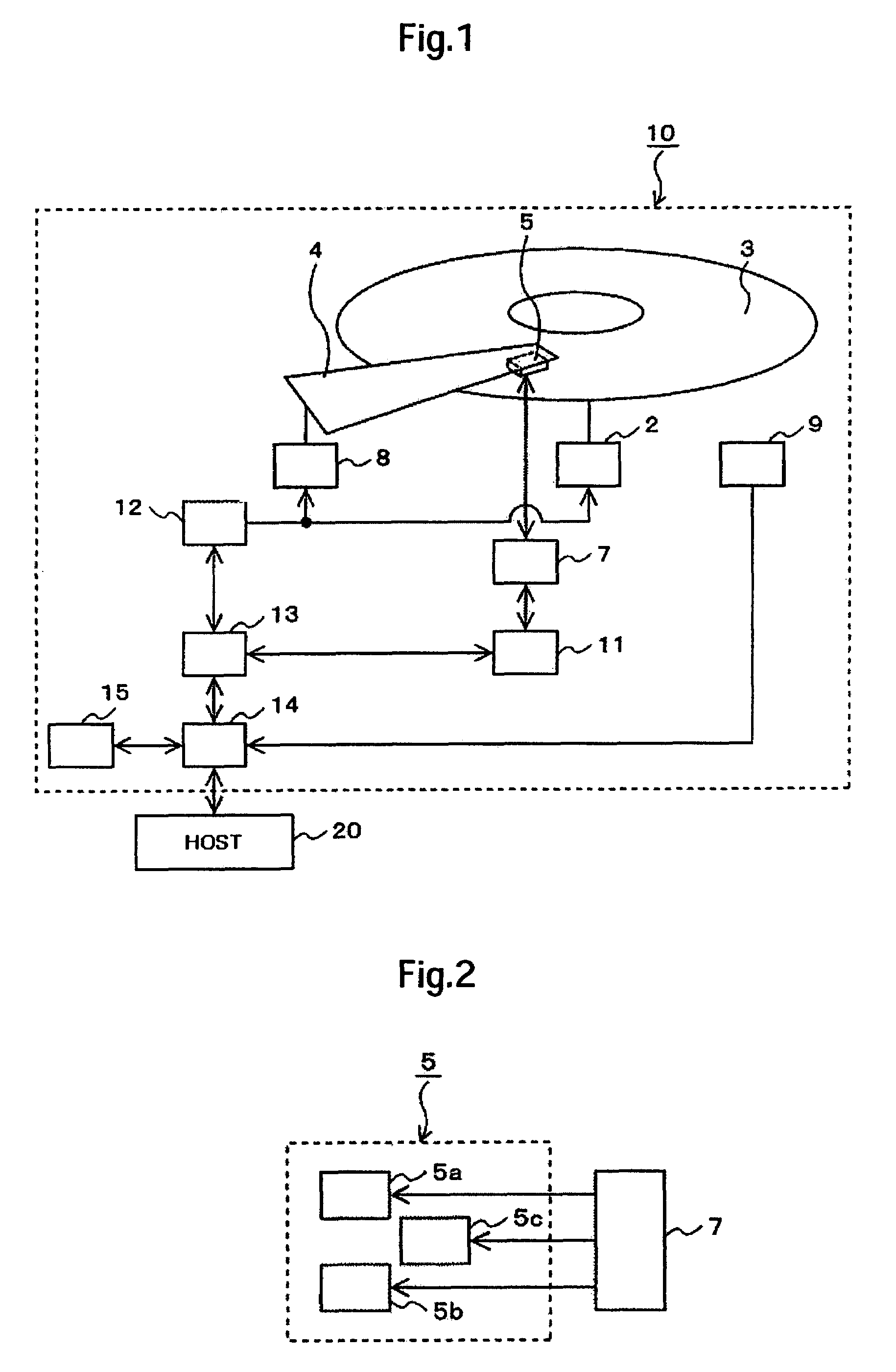

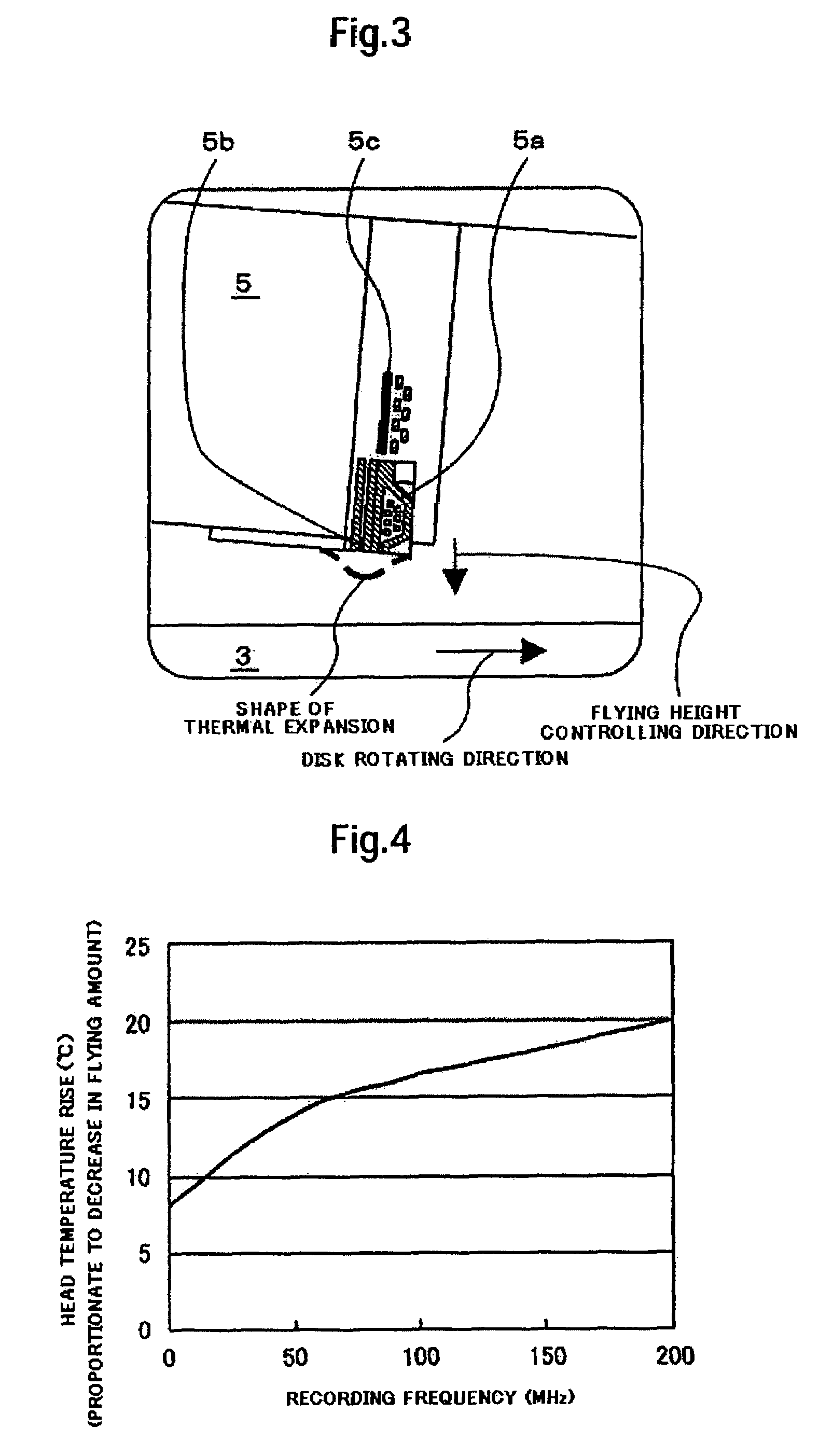

Disk drive

InactiveUS20070188908A1Improve transfer rateReduce noiseDriving/moving recording headsRecord information storageLow speedFlying height

Embodiments in accordance with the present invention allow a magnetic disk drive to achieve noise reduction and low power consumption through rotation at a low speed and a high transfer rate through rotation at a high speed while allowing reliability to be maintained and achieving an improved recording density. An embodiment of a magnetic disk drive in accordance with the present invention includes, a magnetic disk medium driven at a plurality of rotational speeds, a magnetic head for recording and reproducing data in and from the magnetic disk medium, a heater for controlling a flying height of the magnetic head, and a control unit for controlling the current to the heater, and in that the control unit controls the current to the heater. The control unit controls the current to the heater according to the plurality of rotational speeds.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

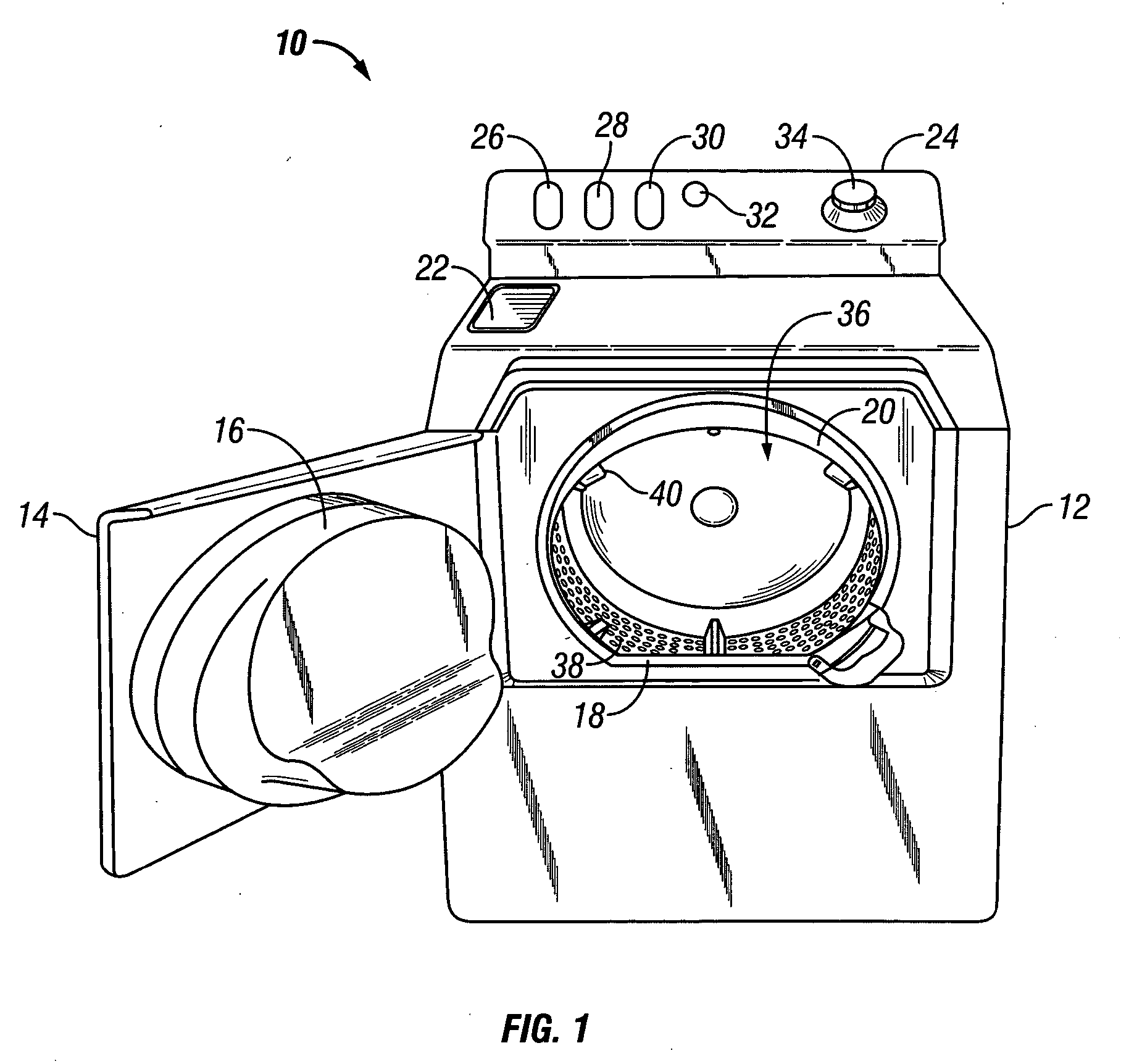

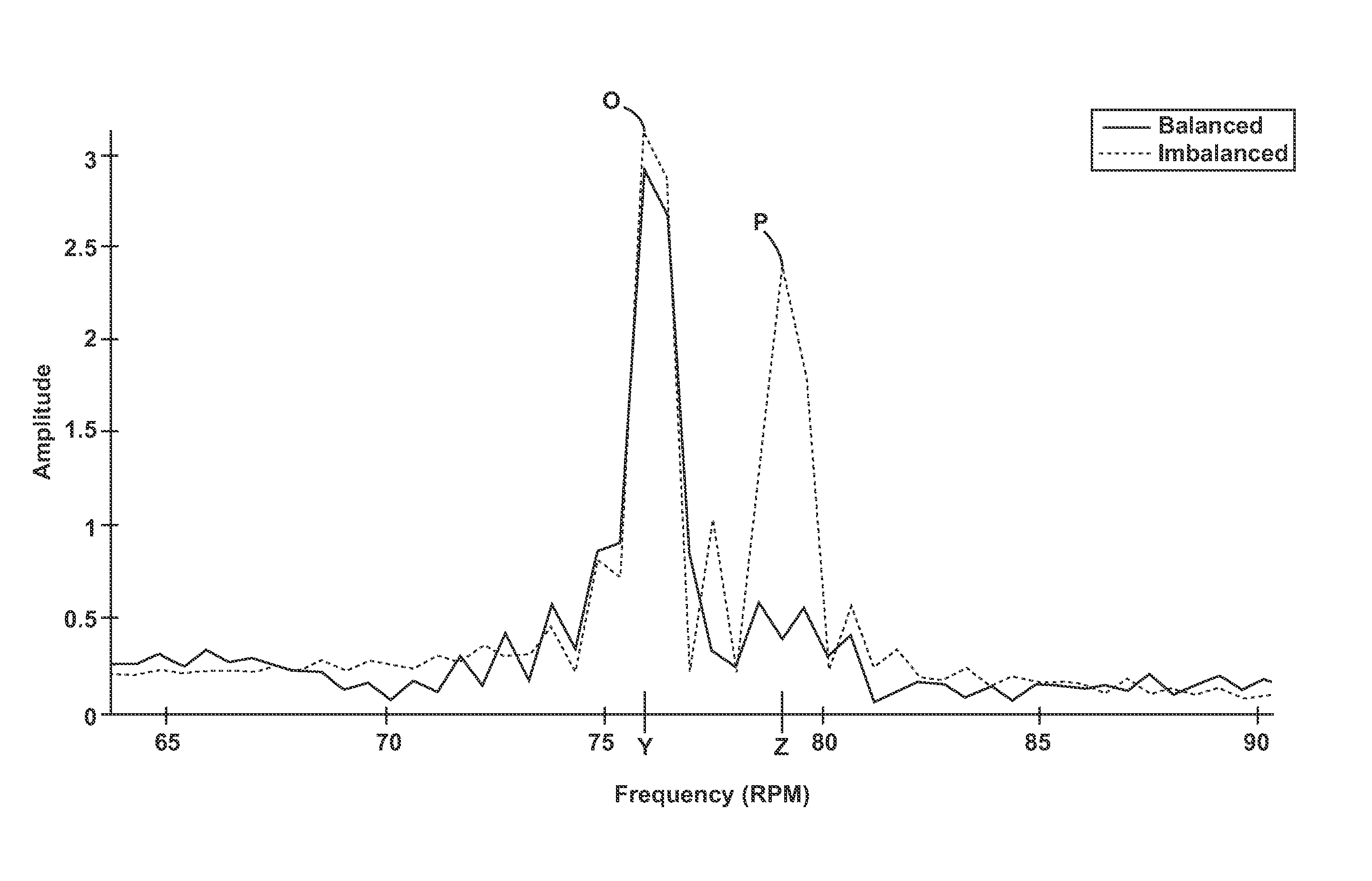

Method and apparatus for redistributing an imbalance in a laundry treating appliance

ActiveUS8984693B2Shorten speedIncrease rotation speedOther washing machinesControl devices for washing apparatusLaundryControl theory

An apparatus and method for detecting an imbalance in the laundry load and effecting a redistribution of the imbalance by reducing the rotational speed of the treating chamber such that part of the load may redistribute while part of the load remains satellized, without ceasing rotation, and increasing the rotational speed back to a spin speed after redistribution.

Owner:WHIRLPOOL CORP

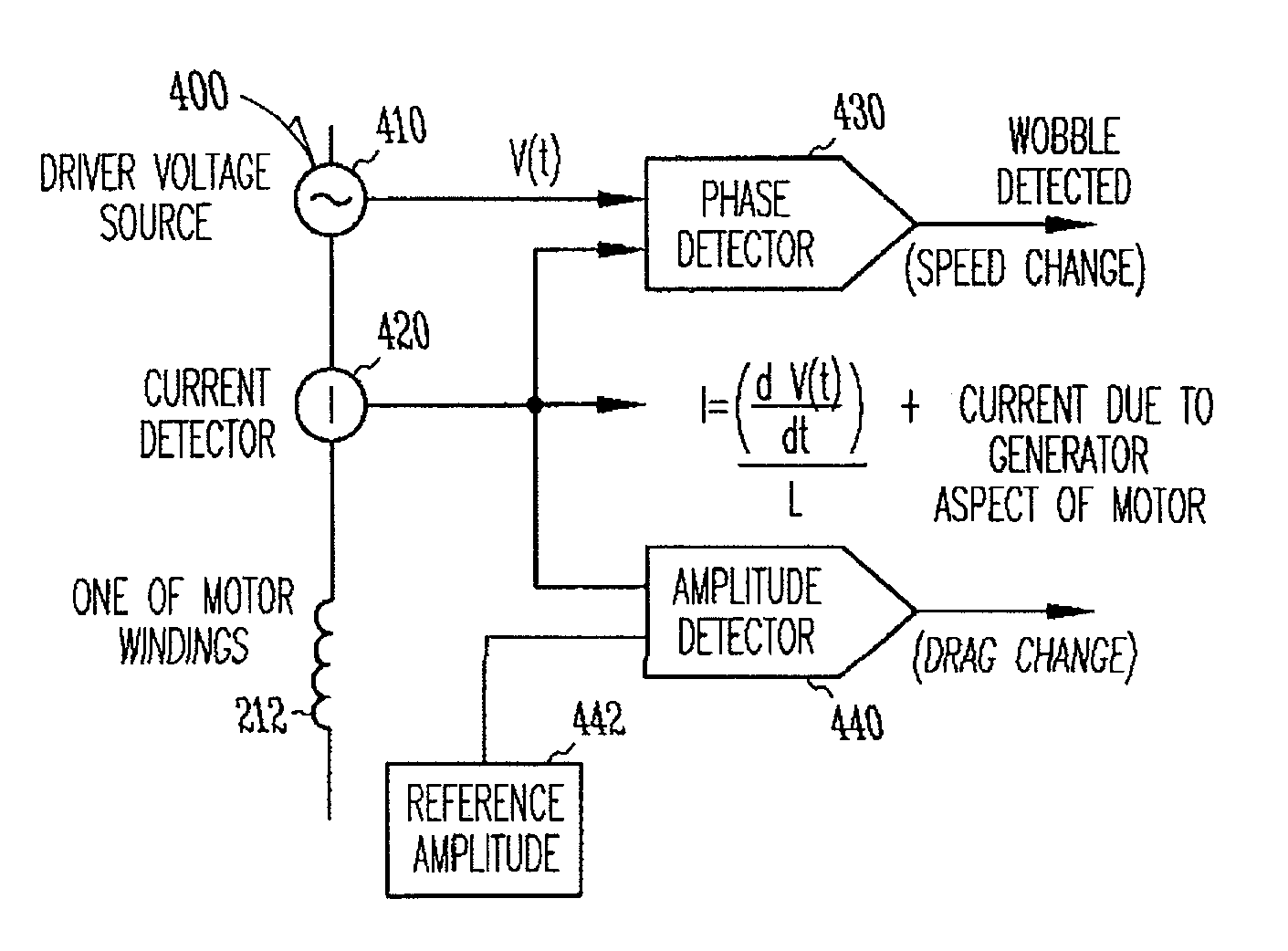

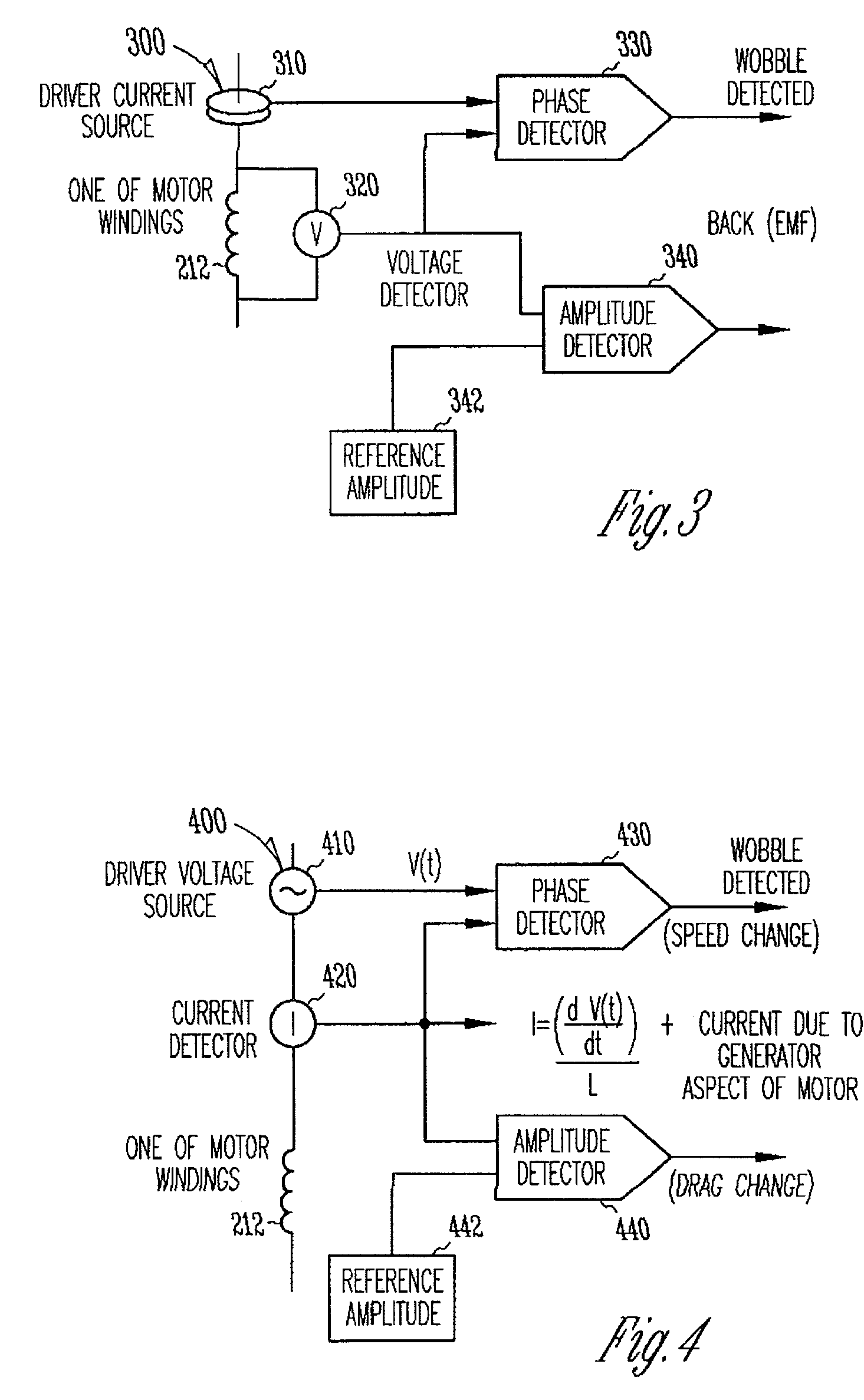

Method of CD/DVD vibration detection by monitoring motor conditions

InactiveUS7130255B2Operational securityAvoid destructionCombination recordingDisposition/mounting of recording headsMotor driveElectric machine

This invention describes a method and apparatus to determine a safe rotational speed for a CD / DVD drive by detecting the amount of vibration of the disk by measuring the operating conditions of the spindle motor. A disk drive includes a motor for rotating the disk and an apparatus for monitoring the current or back emf in the windings of the motor. When the current or the back emf varies from a normal level, the disk is vibrating and a signal indicating a vibration condition is sent to the spindle motor driver. The maximum speed that the disk rotated is slowed until a vibrating condition is no longer detected and the rotational speed associated with a particular disk is based dynamically on the amount of vibration detected. Disks may also be identified that cannot spin a minimum rate of speed.

Owner:GATEWAY

Disk drive that controls heater current according to rotational speed

InactiveUS7457073B2Reduce noiseReduce power consumptionDriving/moving recording headsFluid-dynamic spacing of headsLow speedFlying height

Embodiments in accordance with the present invention allow a magnetic disk drive to achieve noise reduction and low power consumption through rotation at a low speed and a high transfer rate through rotation at a high speed while allowing reliability to be maintained and achieving an improved recording density. An embodiment of a magnetic disk drive in accordance with the present invention includes, a magnetic disk medium driven at a plurality of rotational speeds, a magnetic head for recording and reproducing data in and from the magnetic disk medium, a heater for controlling a flying height of the magnetic head, and a control unit for controlling the current to the heater, and in that the control unit controls the current to the heater. The control unit controls the current to the heater according to the plurality of rotational speeds.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com