Polyester elastomer/PET composite elastic fiber and preparation method thereof

A technology of composite elastic fibers and polyester elastomers, applied in fiber processing, conjugated synthetic polymer rayon, melt spinning, etc., can solve the problems of insufficient elasticity, short production process efficiency, insufficient elasticity of composite elastic fibers, etc. , to achieve the effect of excellent elasticity, saving raw materials and high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029](1) First add 80kg of terephthalic acid, 39kg of 1,4-butanediol, 80kg of double-ended hydroxypolyoxypropylene ether with a molecular weight of 1080 and 40kg of double-ended hydroxypolytetramethylene ether with a molecular weight of 500 into the reactor Stir evenly, then add 0.1kg potassium titanium oxalate, depressurize at 220°C to -10Kpa for 1.5 hours for direct esterification, then raise the temperature to 265°C, gradually depressurize to 60pa for 3 hours, melt and polycondense for 3 hours, and pelletize by casting belt to obtain characteristic viscosity Polyester elastomer chips with a density of 0.9dl / g, wherein the molar ratio of 1,4-butanediol: double-terminated hydroxyl polyether: terephthalic acid is 0.9:0.32:1;

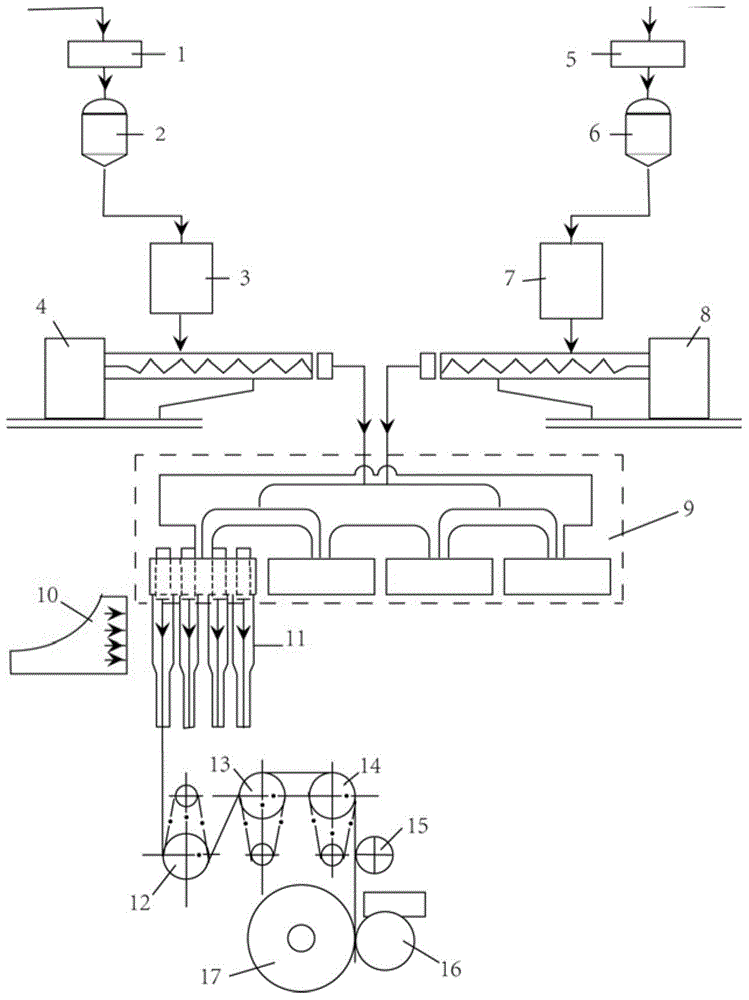

[0030] (2) The resulting polyester elastomer chips and PET chips are in a mass ratio of 50:50 or less figure 1 The process steps shown are for the preparation:

[0031] Pre-crystallize PET chips 1 and polyester elastomer chips 5 in pre-crystallization ...

Embodiment 2

[0034] (1) 80kg terephthalic acid, 40kg 1,4-butanediol, 50kg molecular weight polyoxyethylene glycol of 1280 and 80kg molecular weight of 600 double-ended hydroxyl polytetramethylene ether are added to the reactor and stirred evenly, Then add 0.1kg potassium titanium oxalate, depressurize at 200°C to -20Kpa for 5 hours for direct esterification, then raise the temperature to 265°C, gradually depressurize to 40Pa for 2 hours for melt polycondensation, and the intrinsic viscosity is 1.50 by casting belt cutting dl / g of polyester elastomer chips, where the molar ratio of 1,4-butanediol: double-terminated hydroxyl polyether: terephthalic acid is 0.922:0.358:1;

[0035] (2) The resulting polyester elastomer chips and PET chips are in a mass ratio of 40:60 figure 1 The process steps shown are prepared, because the present embodiment is different except that the following process conditions are different, all the other are the same as embodiment 1:

[0036] PET chips were pre-crysta...

Embodiment 3

[0039] (1) 100kg terephthalic acid, 60kg 1,4-butanediol, 10kg molecular weight are 250 double-ended hydroxyl polyoxypropylene ethers and 80kg molecular weight are 400 polyoxyethylene glycols added to the reactor and stirred evenly, then Add 0.1kg of butyl titanate, depressurize at 215°C to -20Kpa for 2 hours for direct esterification, then raise the temperature to 260°C, gradually depressurize to 60Pa for 4 hours to melt and polycondense, the intrinsic viscosity is 1.18 after casting belt cutting dl / g of polyester elastomer chips, in which the molar ratio of 1,4-butanediol: double-terminated hydroxyl polyether: terephthalic acid is 1.006:0.399:1;

[0040] (2) The resulting polyester elastomer chips and PET chips are in a mass ratio of 30:70 figure 1 The process steps shown are prepared, because the present embodiment is different except that the following process conditions are different, all the other are the same as embodiment 1:

[0041] PET chips were pre-crystallized at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com