Patents

Literature

160 results about "Characteristic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Viscosity is characteristic property of liquid, viscosity describes the flow of a liquid. Definition: Viscosity is defined as the resistance in the flow of a liquid Or. which resists the flow of liquid is commonly known as Viscosity. A liquid with high viscosity is thick and flows slowly. A liquid with low viscosity is thin and flows quickly.

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

Fluid loss concentrate for hydraulic cement

InactiveUS20060041060A1Reduced fluid lossImprove rheologyTransportation and packagingMixingPolyvinyl alcoholCement slurry

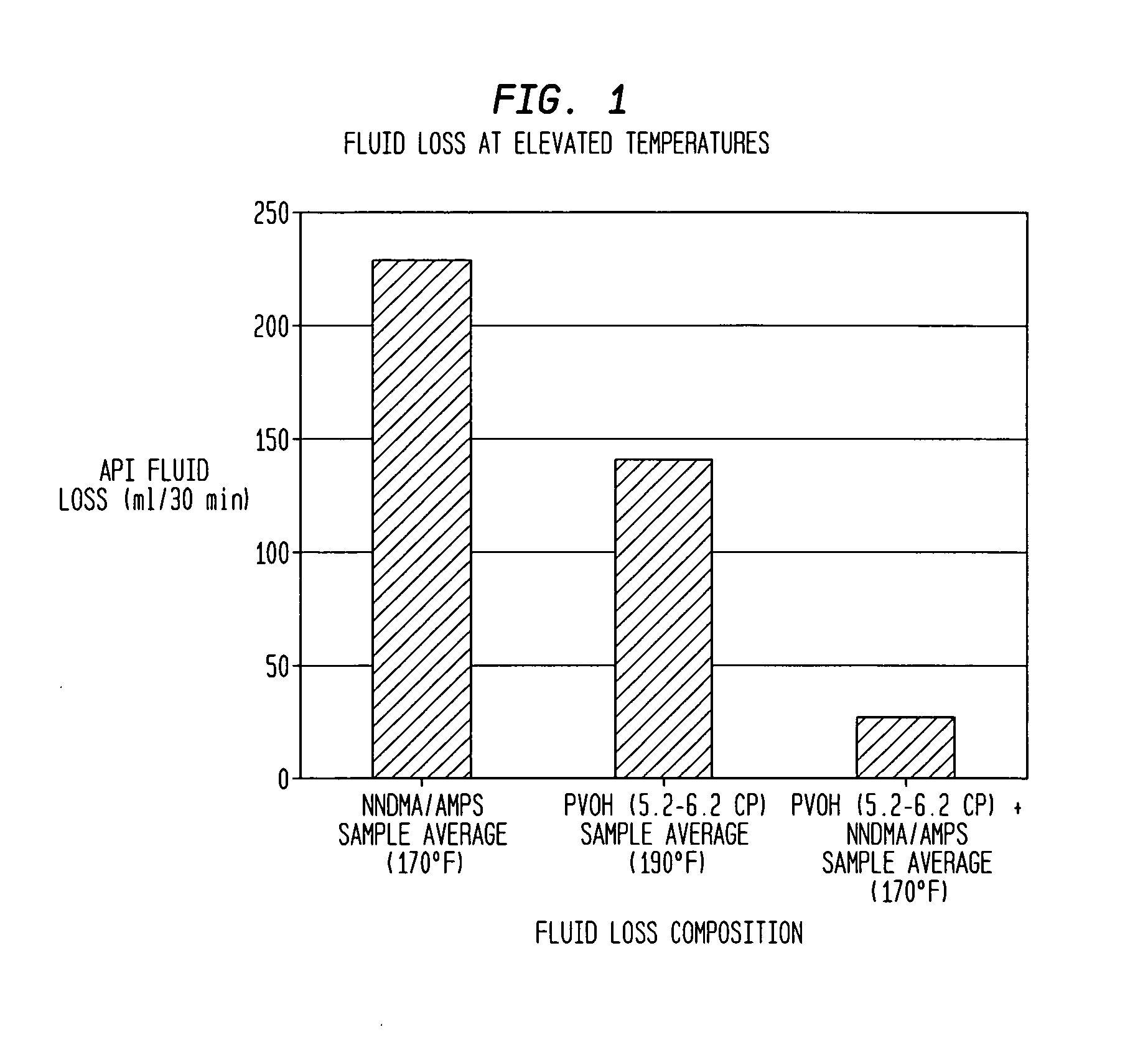

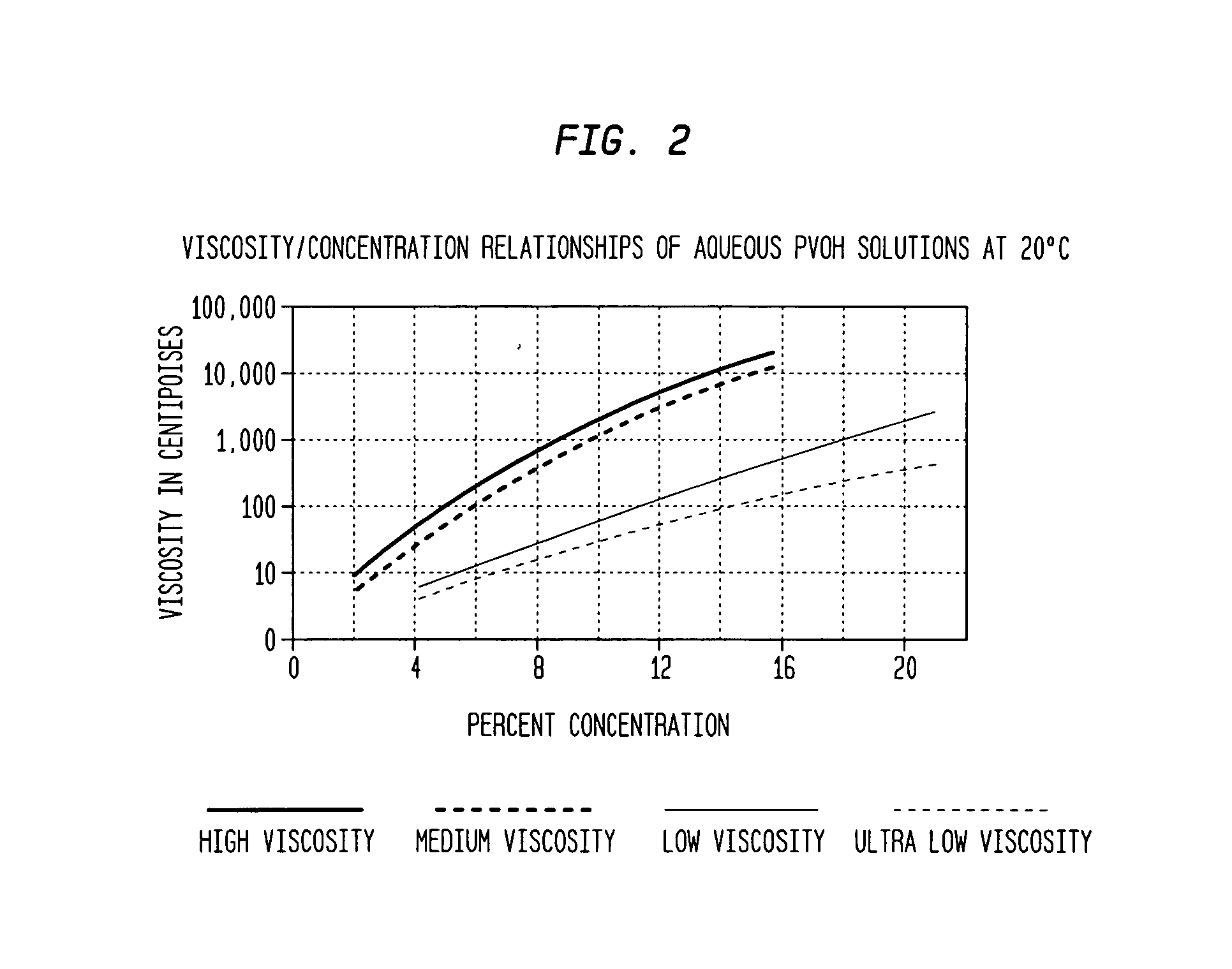

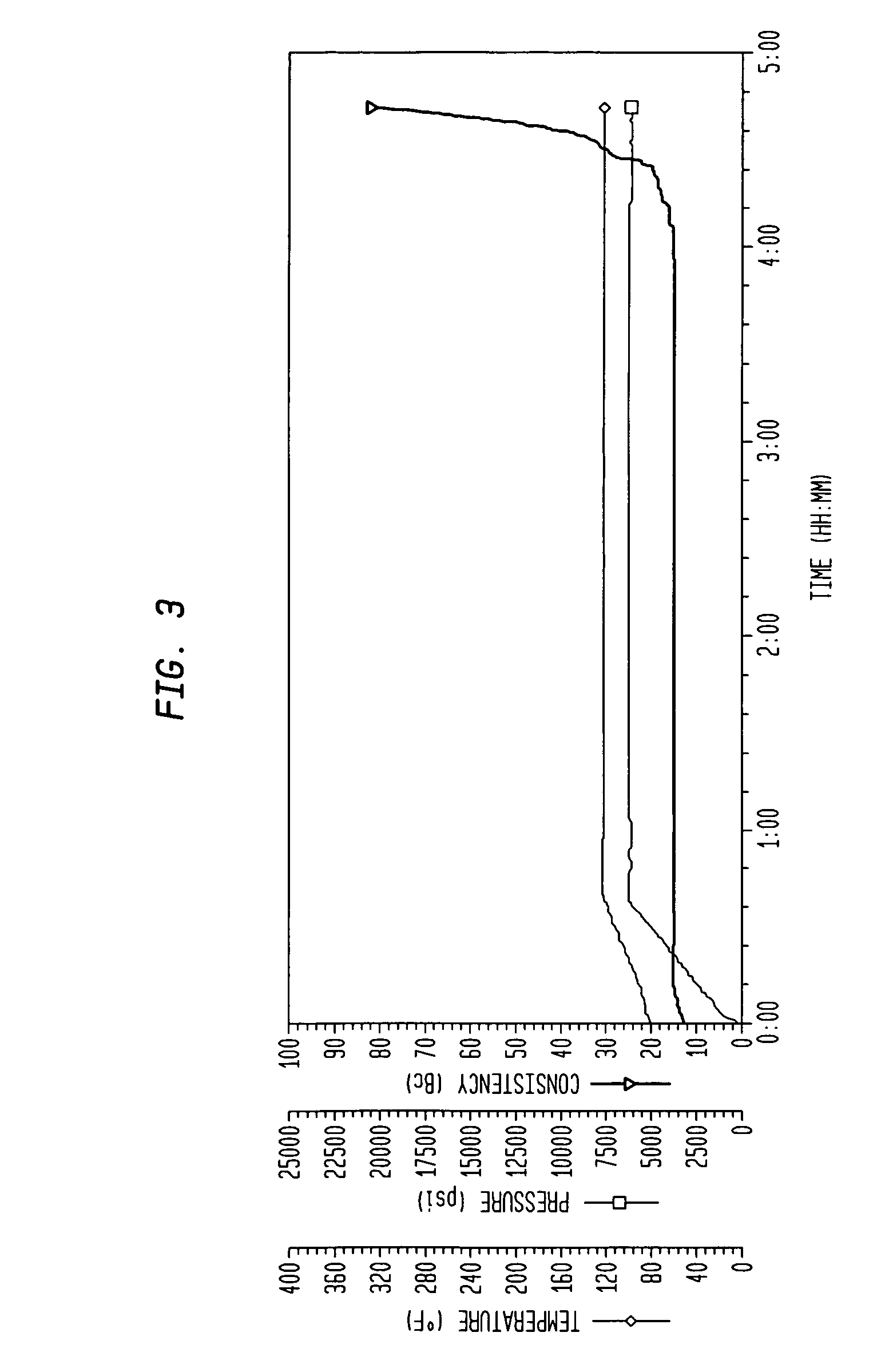

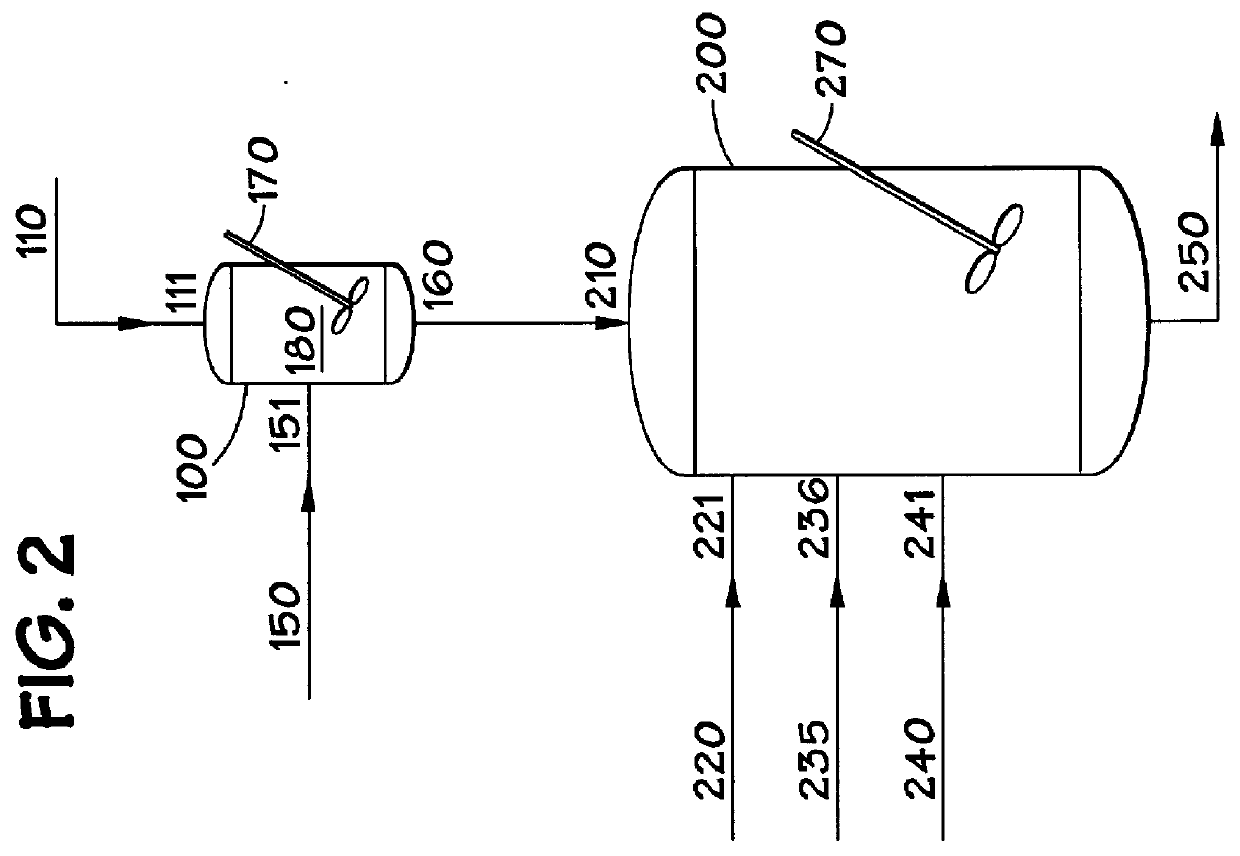

A fluid loss additive for hydraulic cement, comprising a polyvinyl alcohol resin and a fluid loss ameliorating sulfonic acid-functionalized co-resin, where the polyvinyl alcohol has a characteristic viscosity in the range of about 1 to about 25 cps. The invention includes, in some embodiments, an aqueous concentrate of the PVOH resin and the sulfonic acid-functionalized co-resin, where the total resin content is in the range of about 10% to about 40% and the viscosity is less than 15,000 cps. By way of the invention it is possible to adjust hydraulic cement slurry characteristics in real time upon demand and reduce inventory by providing a concentrated aqueous fluid loss additive.

Owner:SEKISUI SPECIALTY CHEM AMERICA

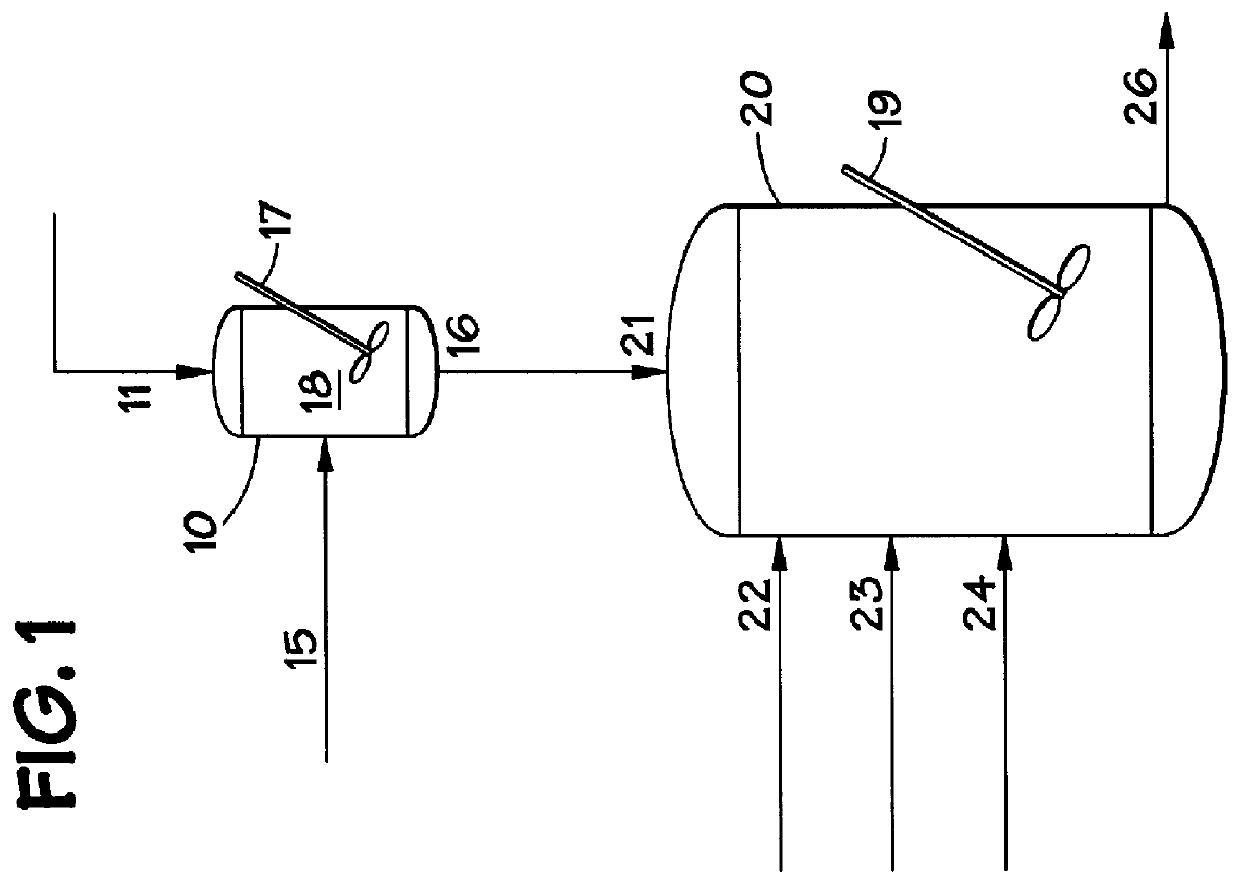

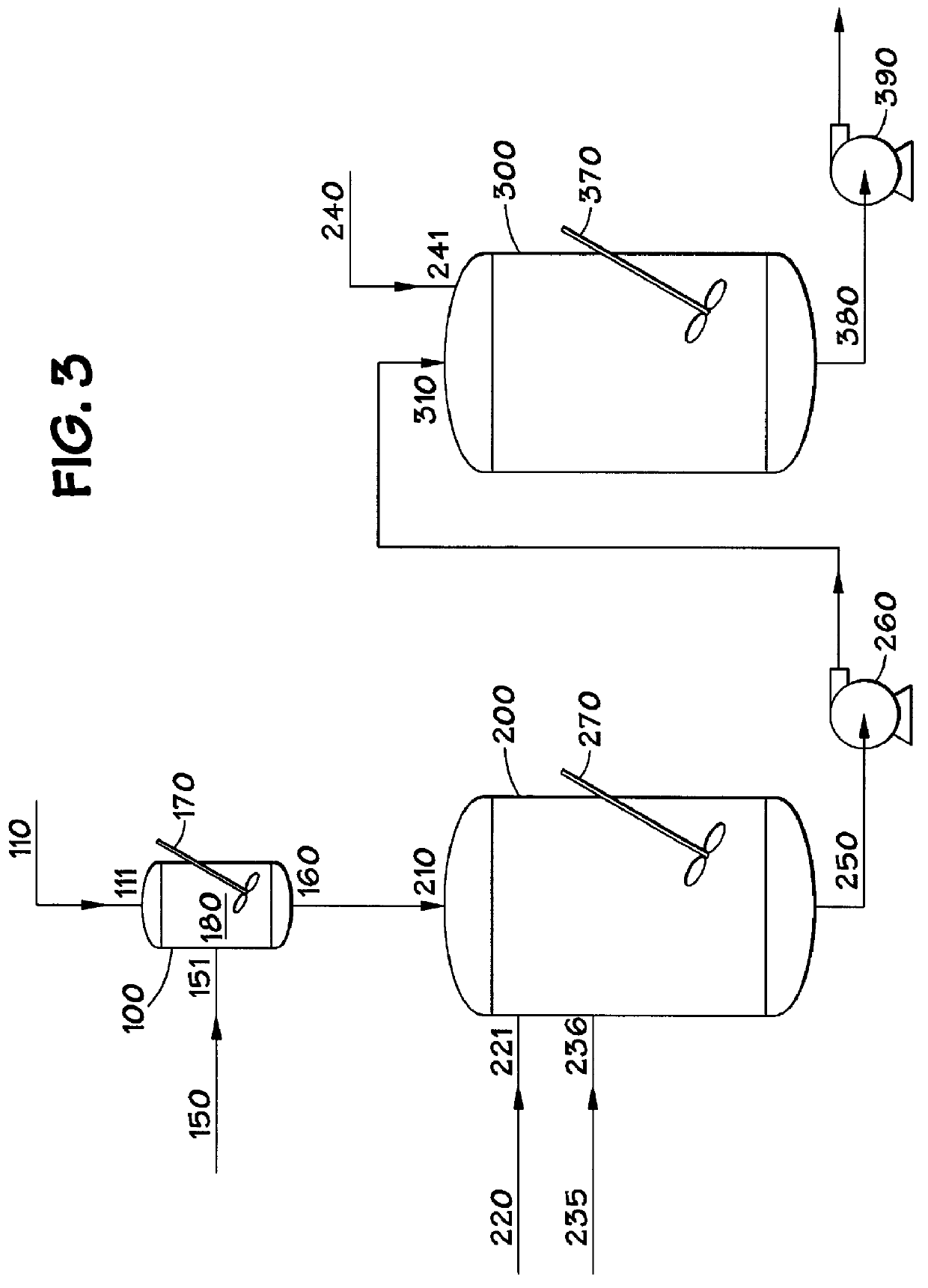

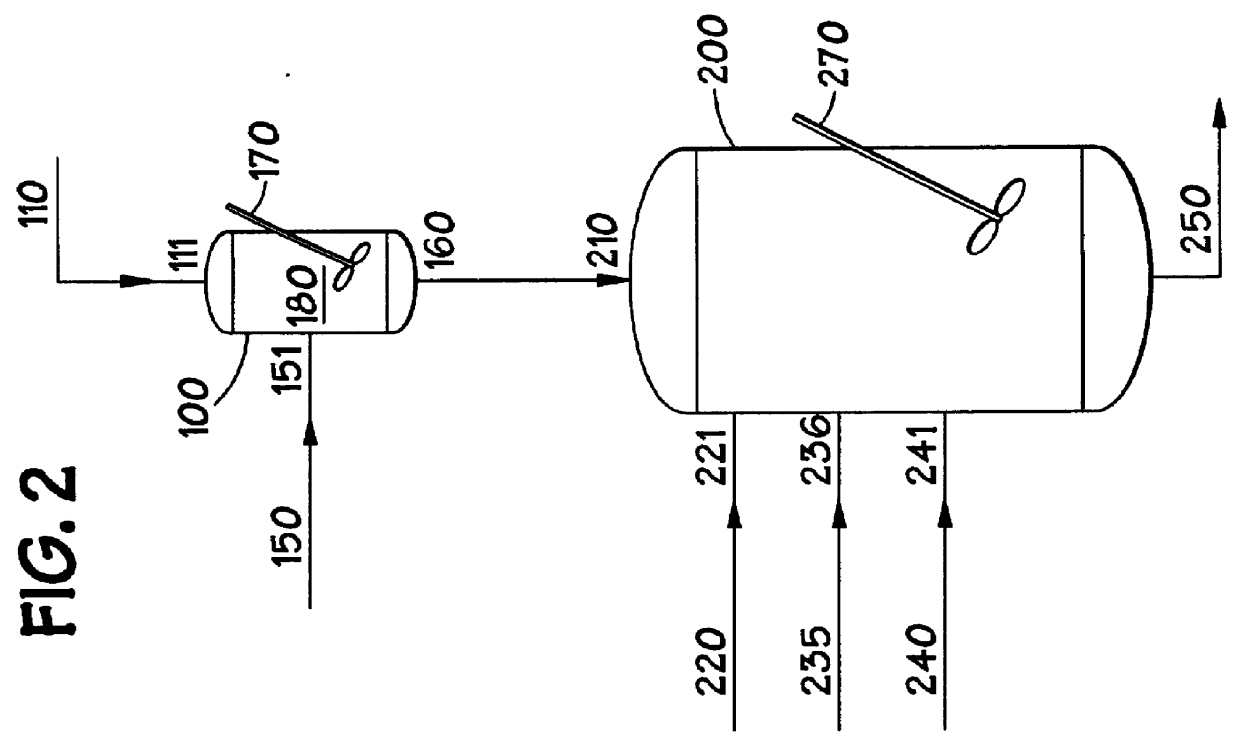

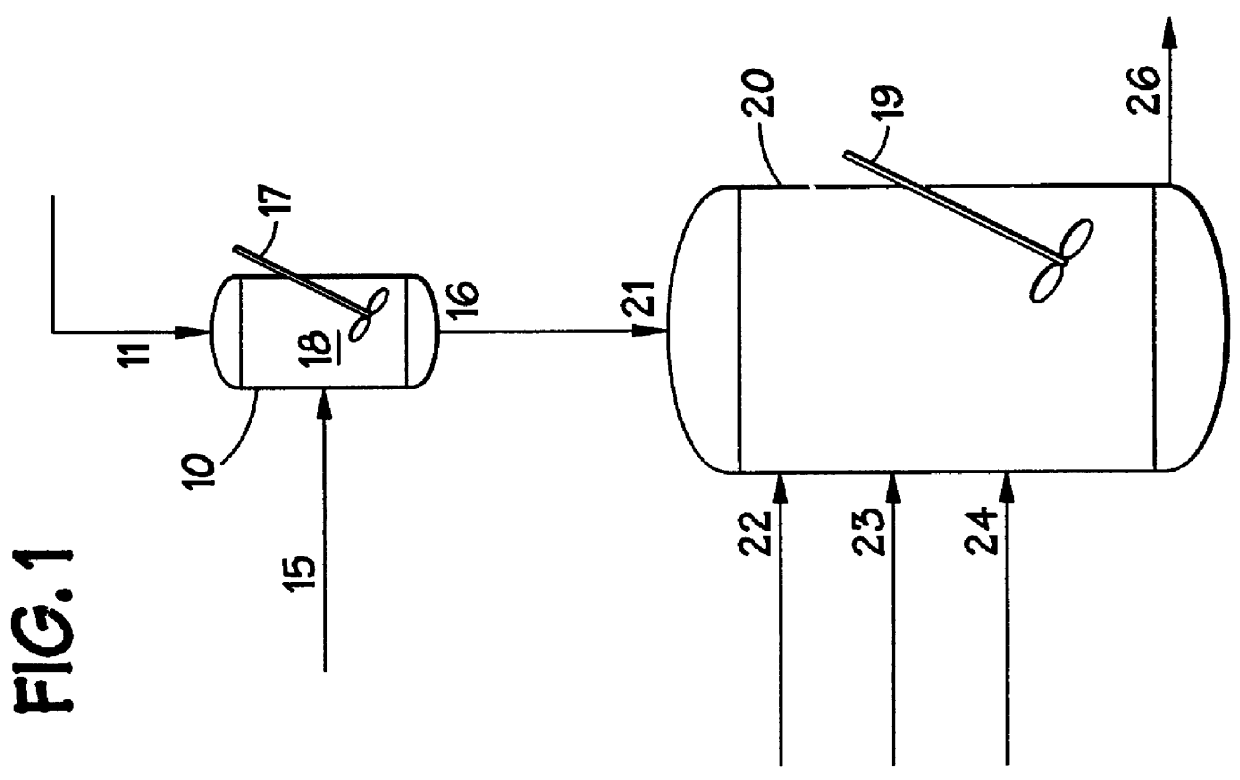

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

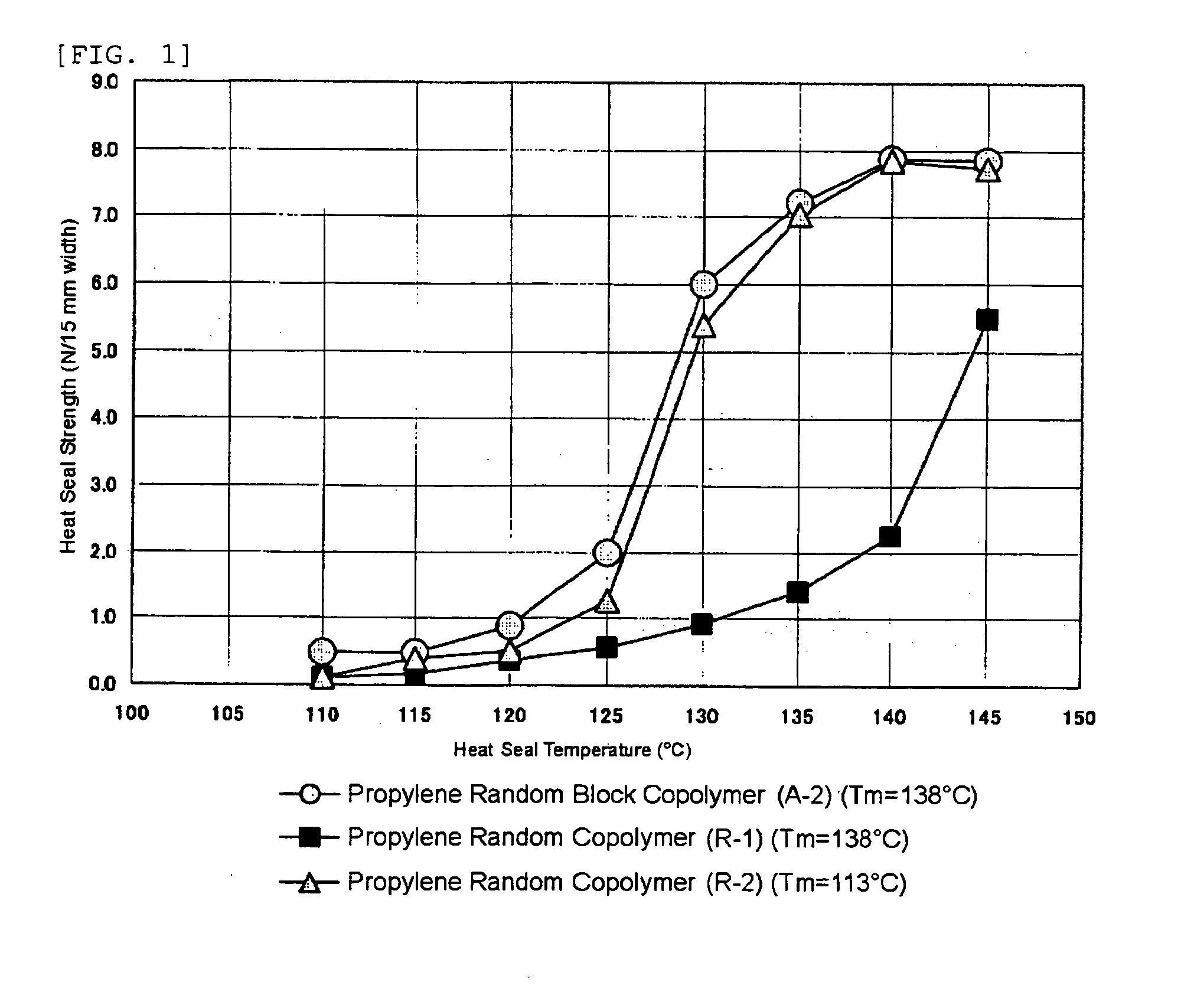

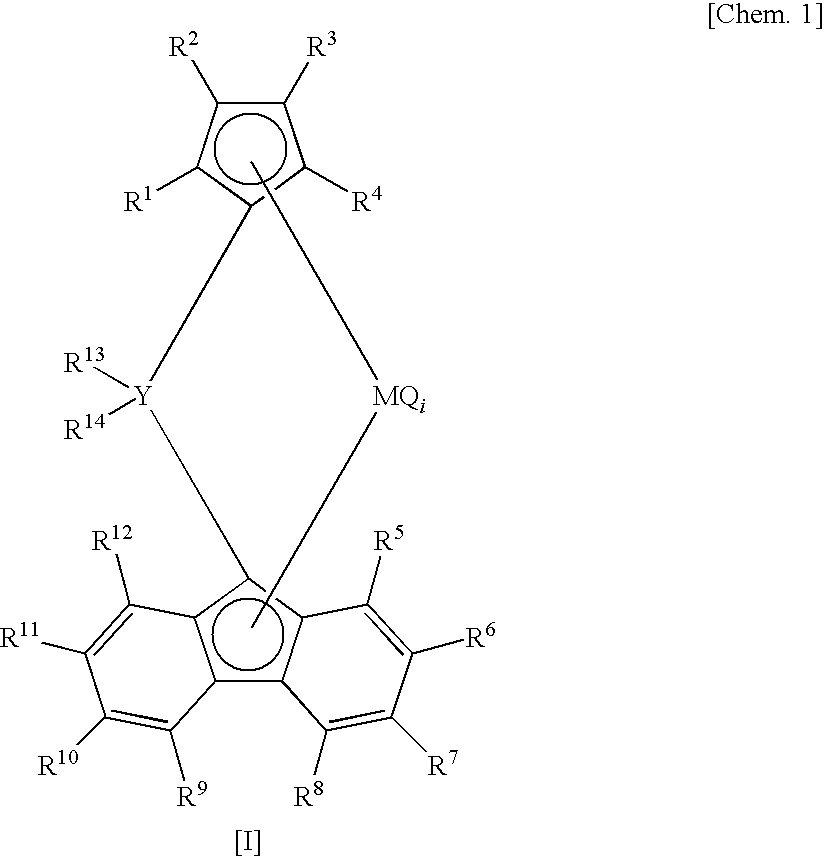

Propylene Random Block Copolymer, Resin Composition Containing the Copolymer and Molded Article Made Thereof

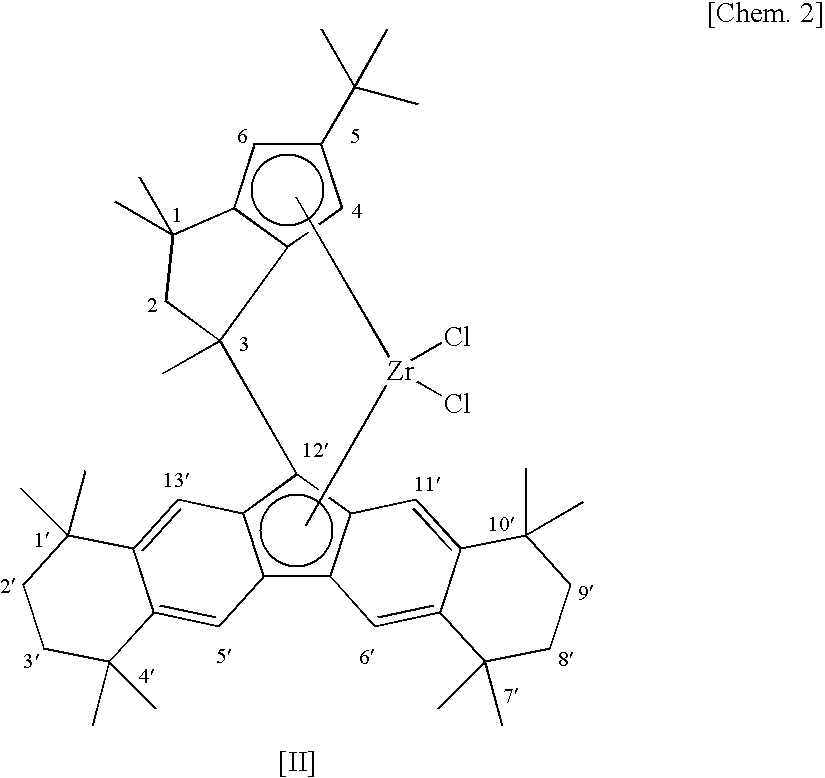

The invention provides a propylene random block copolymer (A) that has a melt flow rate from 0.1 to 100 g / 10 min and a melting point from 100 to 155° C. and includes 90 to 60% by weight of a portion insoluble (Dinsol) in n-decane at room temperature and 10 to 40% by weight of a portion soluble (Dsol) in n-decane at room temperature, wherein the Dinsol satisfies the following requirements (1) through (3) and the Dsol satisfies the following requirements (4) through (6). The invention further provides molded articles such as sheets, films, injection molded articles, hollow molded articles, injection blow molded articles and fibers, which are formed of the propylene random block copolymer (A) or a propylene resin composition containing the propylene random block copolymer (A). (1) The molecular weight distribution (Mw / Mn) obtained by GPC of the Dinsol is from 1.0 to 3.5, (2) the content of skeletons derived from ethylene in the Dinsol is from 0.5 to 13% by mole, (3) the total amount of 2,1- and 1,3-propylene units in the Dinsol is 0.2% by mole or less, (4) the molecular weight distribution (Mw / Mn) obtained by GPC of the Dsol is from 1.0 to 3.5, (5) the intrinsic viscosity [η] in decalin at 135° C. of the Dsol is from 1.5 to 4 dl / g and (6) the content of skeletons derived from ethylene in the Dsol is from 15 to 35% by mole.

Owner:MITSUI CHEM INC +1

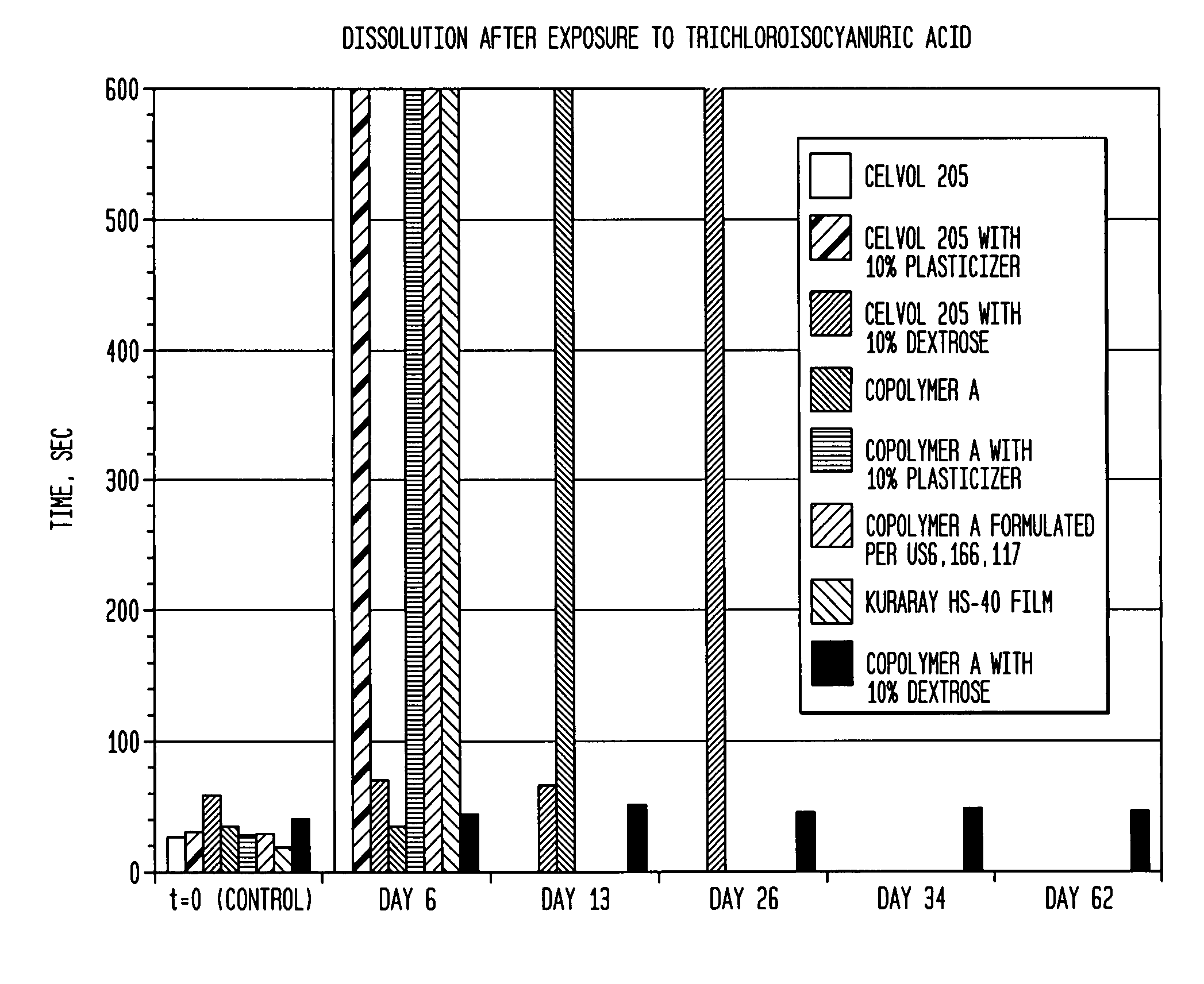

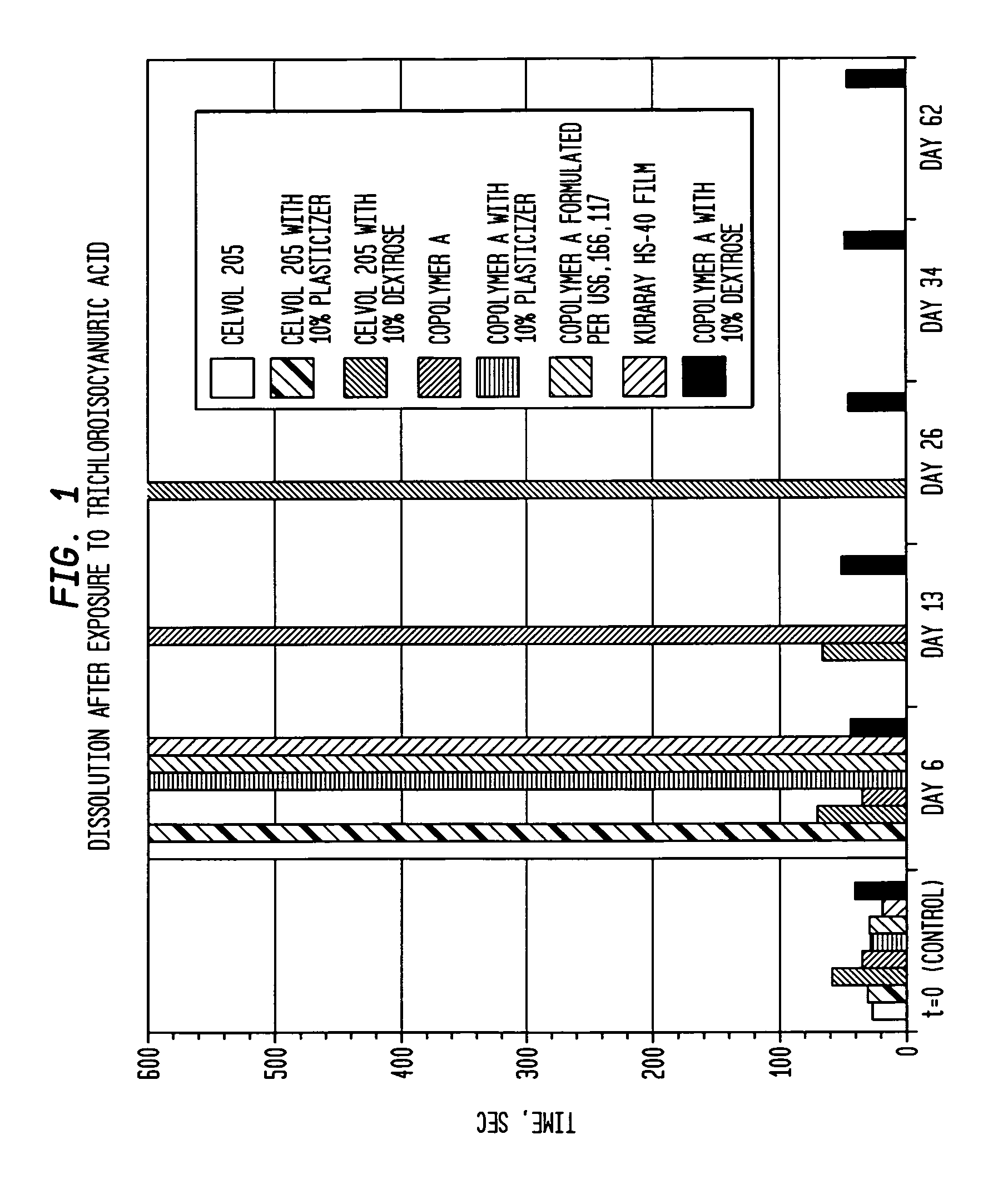

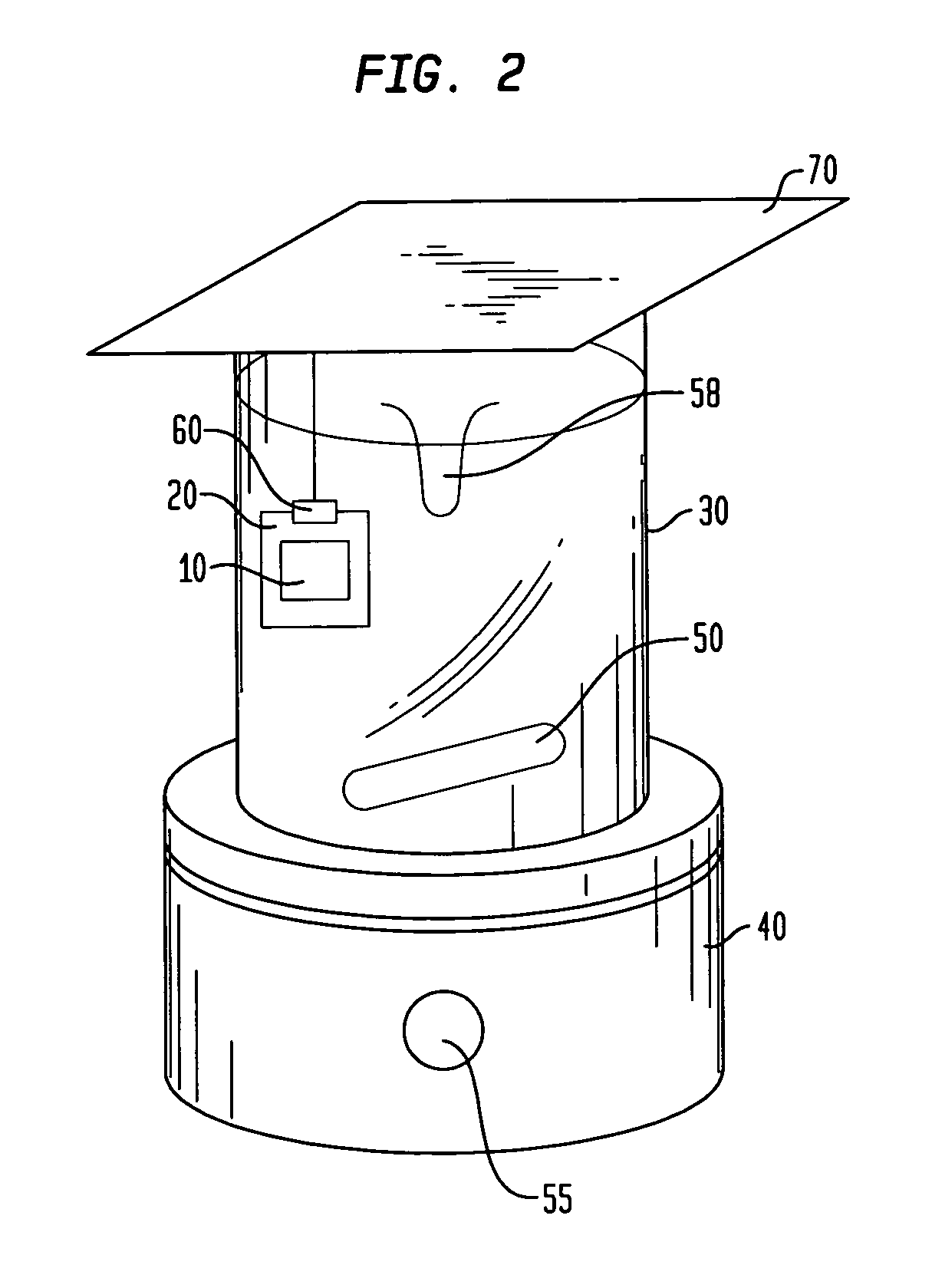

Polyvinyl alcohol films with improved resistance to oxidizing chemicals

ActiveUS7745517B2Good water solubilityExtended shelf lifeOrganic detergent compounding agentsSpecific water treatment objectivesVinyl alcoholCharacteristic viscosity

Owner:SEKISUI SPECIALTY CHEM AMERICA

Method for preparing high molecular weight polyacrylamide dried powder

The preparation of high molecular weight polyacrylamide powder is one low temperature aqua polymerization process, and compared with available technology, the present invention is different in that it adopts the mixture of sodium bicarbonate and sodium carbonate as hydrolyzing agent, the added foaming agent, and trinary initiator system comprising high temperature initiator added before reaction and oxidation-reduction initiator added after the system temperature is controlled in 10-40 deg.c. The polyacrylamide product of the present invention has the advantages of high molecular sieve of 18-23 million, solid content of about 90 %, characteristic viscosity not lower than 23 dl / g, high water solubility, free monomer less than 0.03 % and hydrolysis degree of 20-30 %.

Owner:许振举

Method for preparing high temperature nylon

The present invention provides a preparation method of high-temperature nylon, including the following steps: (a) dicarboxylic acid and diamine are used to prepare 6T salt or 6I salt under the temperature of 80 to 110 DEG C and the carbon atomicity n of the obtained paraphthaloyl acidhexamethylene diamine salt or m-phthalic acryl acidhexamethylene diamine salt is 4 to 16; (b) 6T salt or 6I salt obtained in step (a) and 66 salt or hexanolactam are polymerized to obtain primary condensation compound and the characteristic viscosity of the primary condensation compound in dense sulfuric acid is 0.09 to 0.25dl / g under the temperature of 30 DEG C; (c) the primary condensation compound obtained in step (b) is under solid phase condensation and polymerization to obtain the high-temperature nylon under the temperature of not more than 250 DEG C. The method provided by the present invention can increase the polyamide size stability, mechanic performance and heat resistance, reduce the molecular weight distribution of the high-temperature nylon, and prevent the occurrence of amine exchange, thermal degradation, gelation and other side reactions.

Owner:北京瑞宝知春时代印刷技术开发有限公司

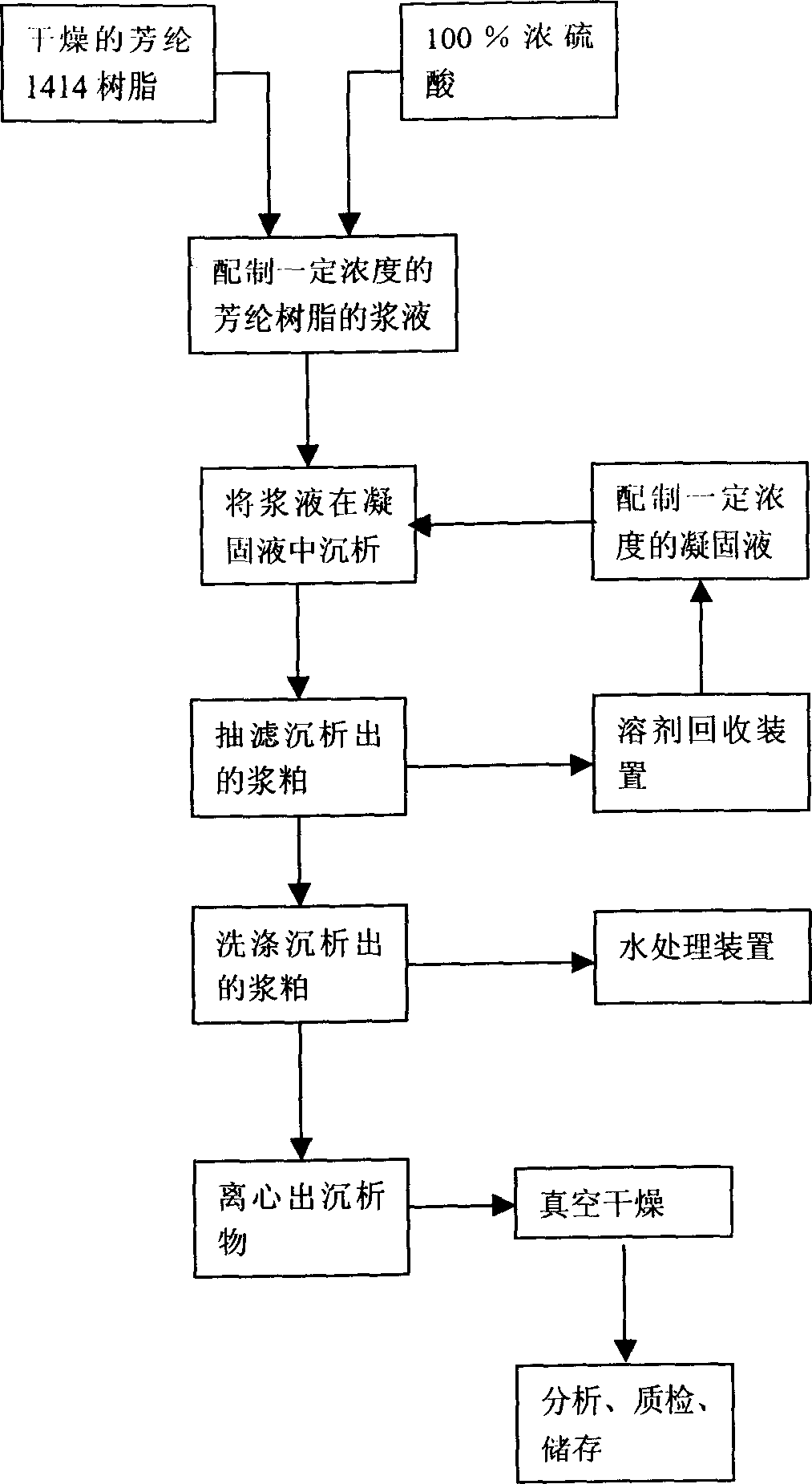

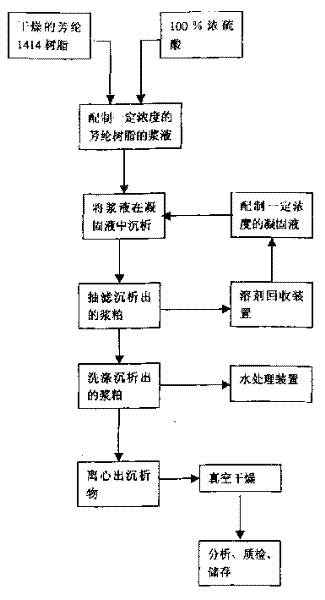

Preparation method of para fanglun slurry cake

A p-aramid fibre pulp is prepared through dissolving the resin "1414" of aramid fibre with a certain characteristic viscosity in concentrated sulfuric acid and high-speed stirring to deposit it. Differential p-aramid fibre pulp can be obtained according to differential use.

Owner:DONGHUA UNIV

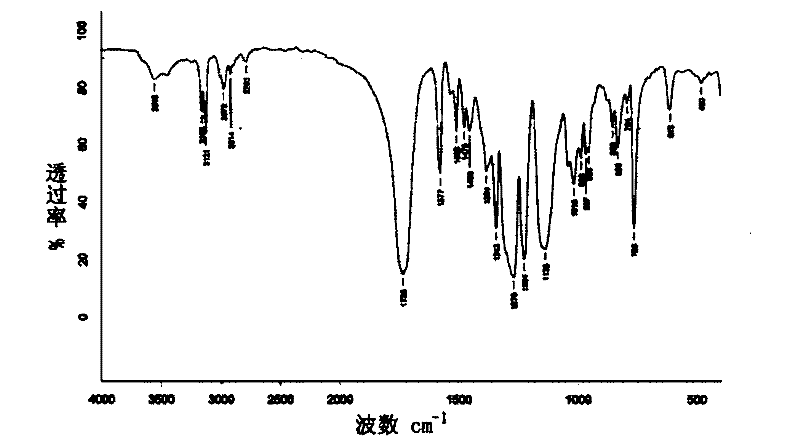

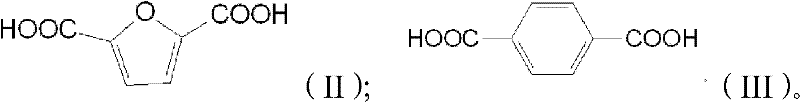

Poly(ethylene 2,5-furandicarboxylate), and preparation method thereof

InactiveCN102190785AImprove performanceWide variety of sourcesEsterification reactionGlass transition

The invention provides poly(ethylene 2,5-furandicarboxylate), which contains the repeating units shown in formula (I) and has a characteristic viscosity not smaller than 0.2 dL / g. The invention also provides a preparation method for poly(ethylene 2,5-furandicarboxylate) provided by the technical scheme, which comprises the following steps of: carrying out esterification reaction on 2,5-furandicarboxylic acid and ethylene glycol under the action of a tin catalyst to obtain a first intermediate product, wherein the esterification reaction pressure is 0.1-0.4 MPa; and carrying out condensation polymerization reaction on the first intermediate product under the pressure of 10-70 Pa to obtain poly(ethylene 2,5-furandicarboxylate). Experiments show that poly(ethylene 2,5-furandicarboxylate) provided by the invention is dark brown, and has a characteristic viscosity of not smaller than 0.2 dL / g, a glass transition temperature of 60-63 DEG C and a melting point of 210-215 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

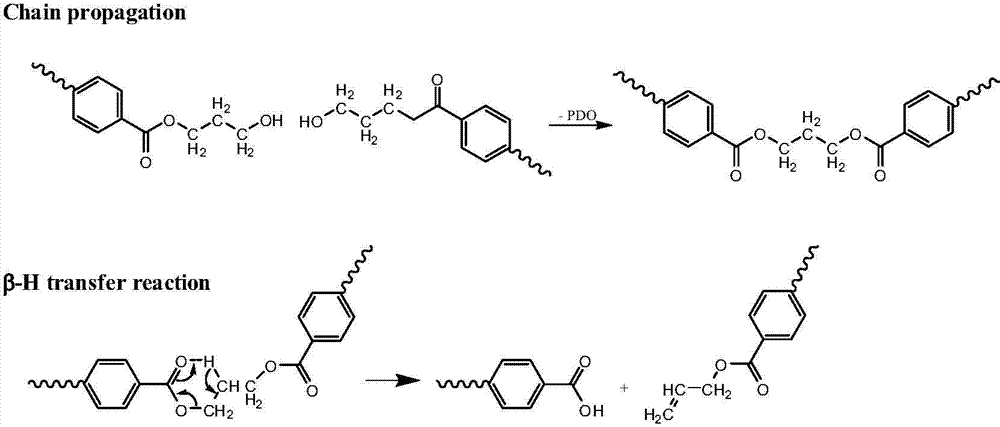

Preparation of biodegradable block copolyester

The invention belongs to the technical field of macromolecular materials, and in particular relates to a preparation method for biodegradable blocked copolyester. The preparation method comprises the following steps: carrying out esterification reaction between adipate and 1,4 butanediol in the presence of catalyst, wherein the reaction time is 3 to 5h, nitrogen is adopted for protection, the reaction pressure is between 0.1 and 0.8MPa and the reaction temperature is between 130 and 180 DEG C during a first stage; and the reaction time is 1.5 to 5h, the reaction pressure is between 0.3 and 0.6MPa and the reaction temperature is between 150 and 200 DEG C during a second stage so as to generate polybutylene adipate; and carrying out ester exchange reaction of dimethyl terephthalate (DMT) and 1,4 butanediol in the presence of catalyst, wherein the nitrogen is adopted for protection, the reaction time is 2 to 5h, the reaction pressure is between 0.1 and 0.7MPa and the reaction temperature is between 150 and 170 DEG C so as to generate polybutylene terephthalate (pbt); and mixing both prepolymers and carrying out melt copolycondensation reaction under negative pressure, wherein the vacuum degree is controlled to be between 0 and 200Pa, the reaction temperature is between 210 and 260 DEG C and the reaction time is 3 to 8h. The preparation method carries out esterification reaction and ester exchange reaction, and the esterification reaction has two stages so as to effectively reduce secondary reaction of 1,4 butanediol. A prepared product has a characteristic viscosity number above 1.2dl / g, a melting point controlled between 100 and 140 DEG C, a tensile strength between 18 and 37MPa and a breaking elongation ratio from 800 to 1,500 percent.

Owner:TONGJI UNIV

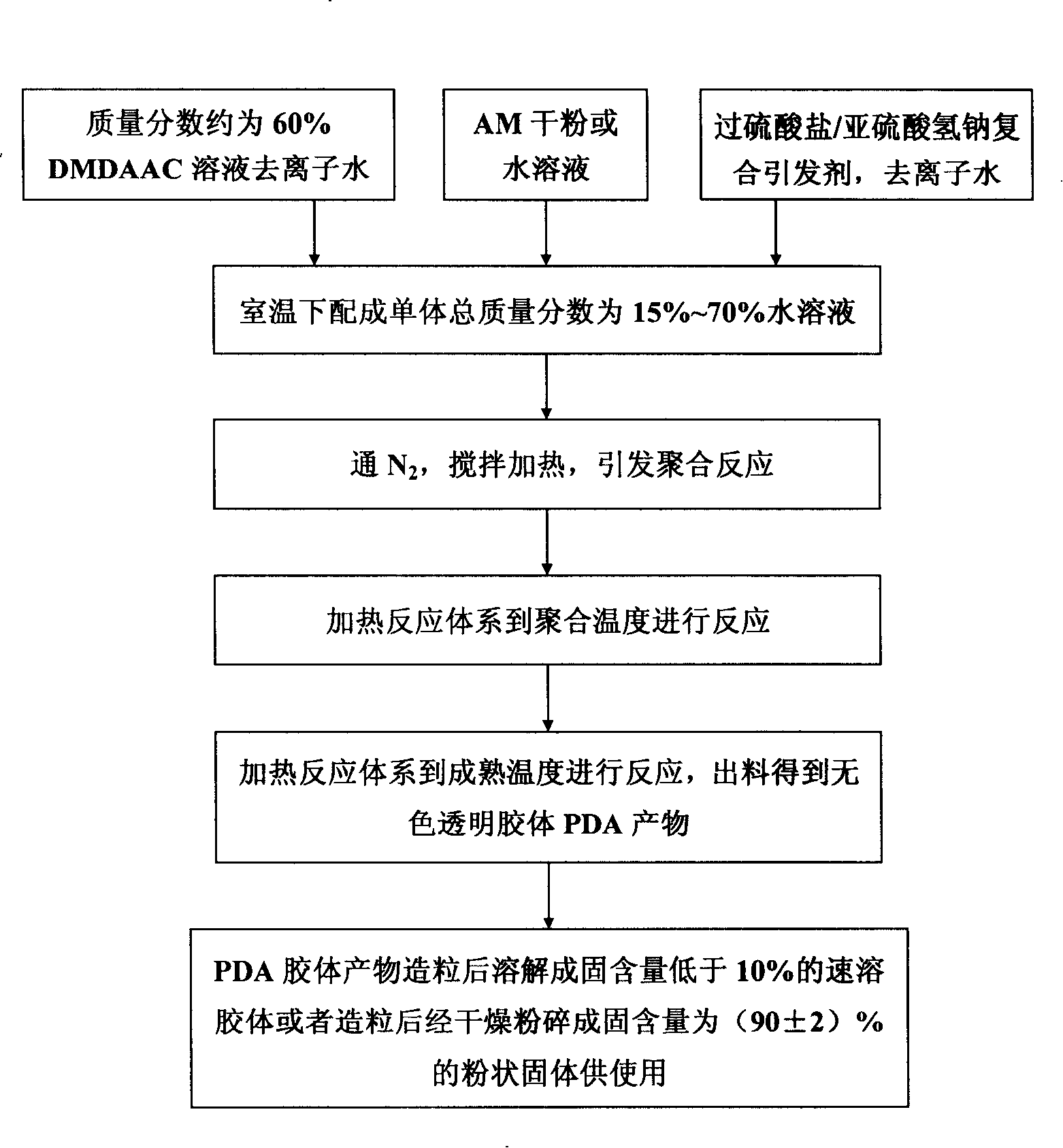

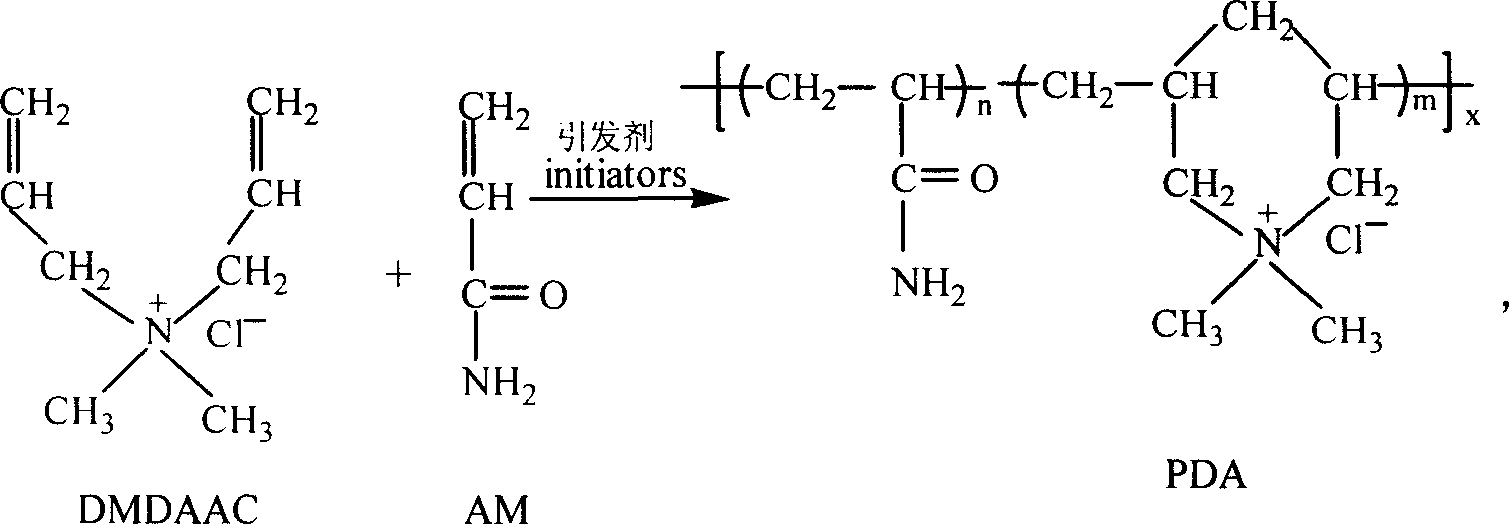

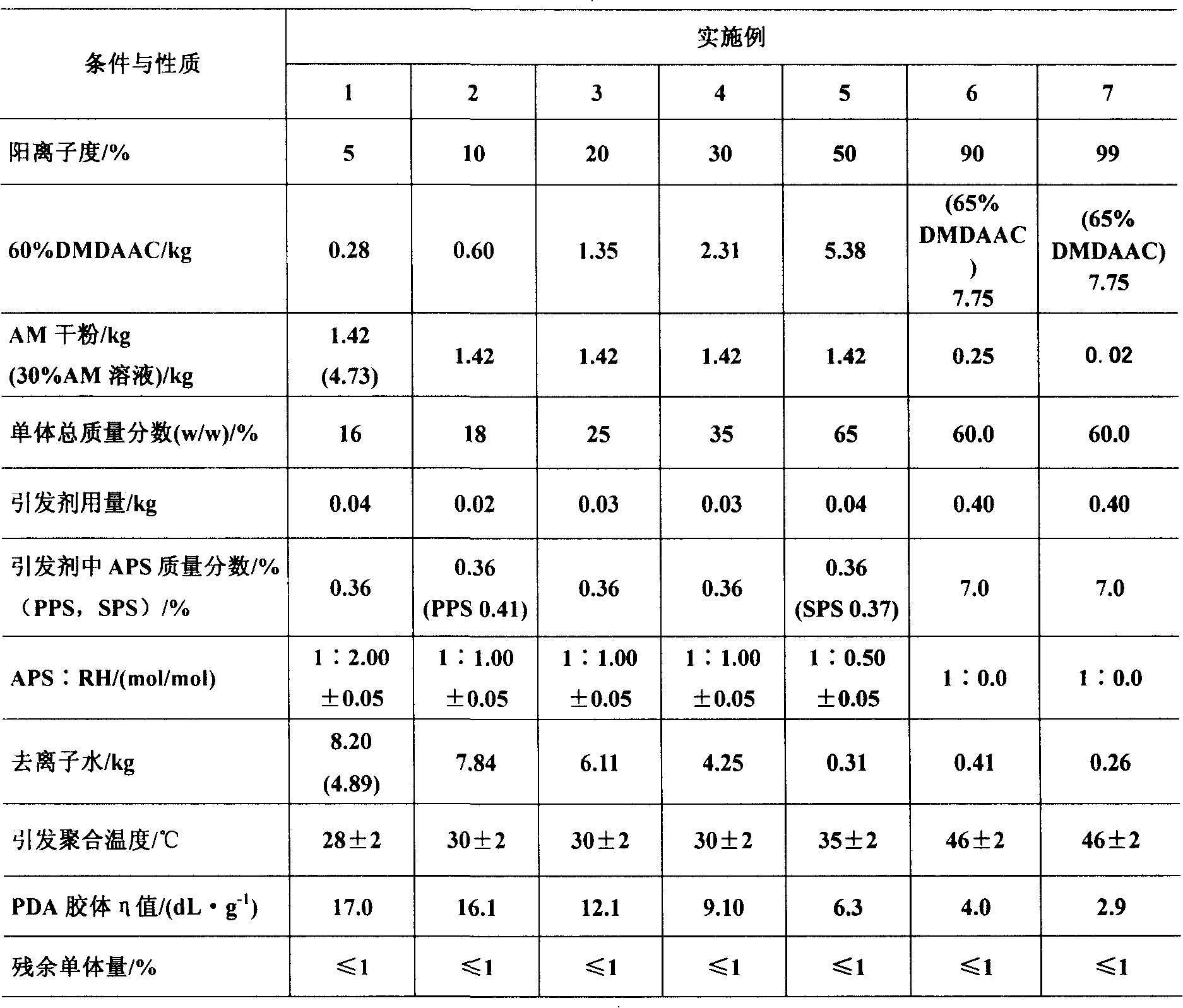

Water solution polymerization preparation method for dimethyl diallyl ammonium chloride and acrylamide copolymers

InactiveCN101186672AReduce material costsSatisfy the initiation temperature requirementPetroleumReducing agent

The invention discloses a water solution polymerization production method of dimethyl diallyl ammonium chloride and acrylamide copolymer, which uses cation industrial monomer DMDAAC and industrial non-ionic monomer AM prepared by industrial one-step method as raw materials, uses initiator via water solution polymerization to prepare dimethyl diallyl ammonium chloride and acrylamide copolymer, with high relative molecular weight and cation degree serialization. The invention uses cheap materials, has wide adjustable proportion between oxidant and reducer in initiator, and the application for initializing polymerization temperature of different cation degree PDA products. The invention has simple and mild reaction condition, while the PDA product cation degree is 5-99%, relative characteristic viscosity is 17.0-2.9dL / g, and residual monomer content is lower than 1%. The product has high cation degree serialization, high relative molecular weight of PDA product in each cation degree, strong adaptability, simple method, easy industrialization, and wide application in oil development, paper making, mining, weaving, dying, water treatment, and daily chemical or the like.

Owner:NANJING UNIV OF SCI & TECH

Biobased polyethylene terephthalate

The invention discloses a biobased polyethylene terephthalate. The melting point of the biobased polyethylene terephthalate is between 255 and 270 DEG C, and the ethylene glycol in the raw materials is a biobased ethylene glycol, namely the carbon element in the ethylene glycol component of the raw materials is sourced from biological materials. The polyethylene terephthalate sourced from biobased materials has excellent performances, and the melting point, the diethylene glycol content, the terminal group content, the characteristic viscosity of the biobased polyethylene terephthalate are the same as those of the polyethylene terephthalate sourced from common petroleum based materials; moreover, the biobased polyethylene terephthalate also meets the requirements on environmental protection.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

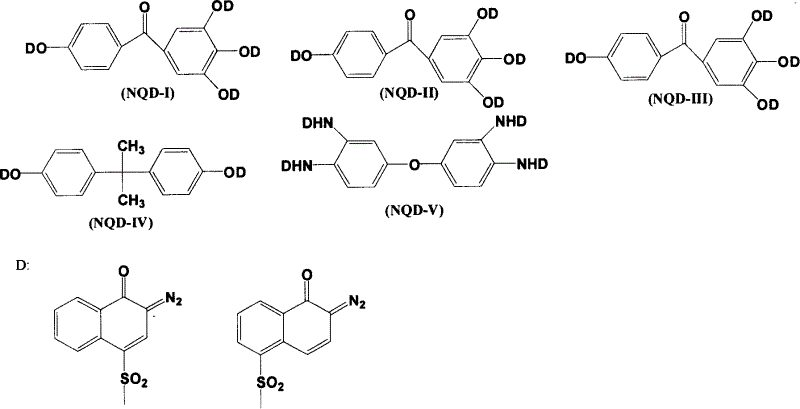

Process for preparing water base developing photosensitive polyimide material

InactiveCN1648154AHigh photosensitivityGood film formingPhotosensitive materials for photomechanical apparatusWater basedBenzoic acid

The present invention belongs to the preparation process of water base developing photosensitive polyimide material. Aromatic dialphanyl diacyl chloride, 3,5-diamino benzoic acid, 4, 4'-diamino-3, 3'-dihydroxy diphenyl methane and 4, 4'-diamino-3, 3'-dihydroxy diphenyl sulfone are polymerized to produce polyamate as one kind of imide prepolymer. The prepolymer has characteristic viscosity of 0.35-0.50, and when 2-diazo naphthoquinone derivative as photosensitizer is added, the prepolymer becomes excellent photosensitive material with high photosensitive performance, good filming performance and high heat resistance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Polyaryl thioether sulfone and its preparation method

A polyaryl thioether sulfone is disclosed, which has the characteristic viscosity for its solution of 0.15-0.54, the vitrification temp higher than 210 deg.C, the thermal deformation temp higher than 180 deg.C and thermal decomposing temp higher than 480 deg.C and thermal decomposing temp higher than 480 deg.C. Its preparing process features that the halogenated aryl compound is added to the reaction system of Na2S.xH2O and bichlorodiphenyl sulfone, and composite catalyste and assistant are used.

Owner:SICHUAN UNIV

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents using a halohydrocarbon

InactiveUS6162773AGood drag reduction effectInherent viscosityOther chemical processesLiquid organic insulatorsHalohydrocarbonAluminoxane

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

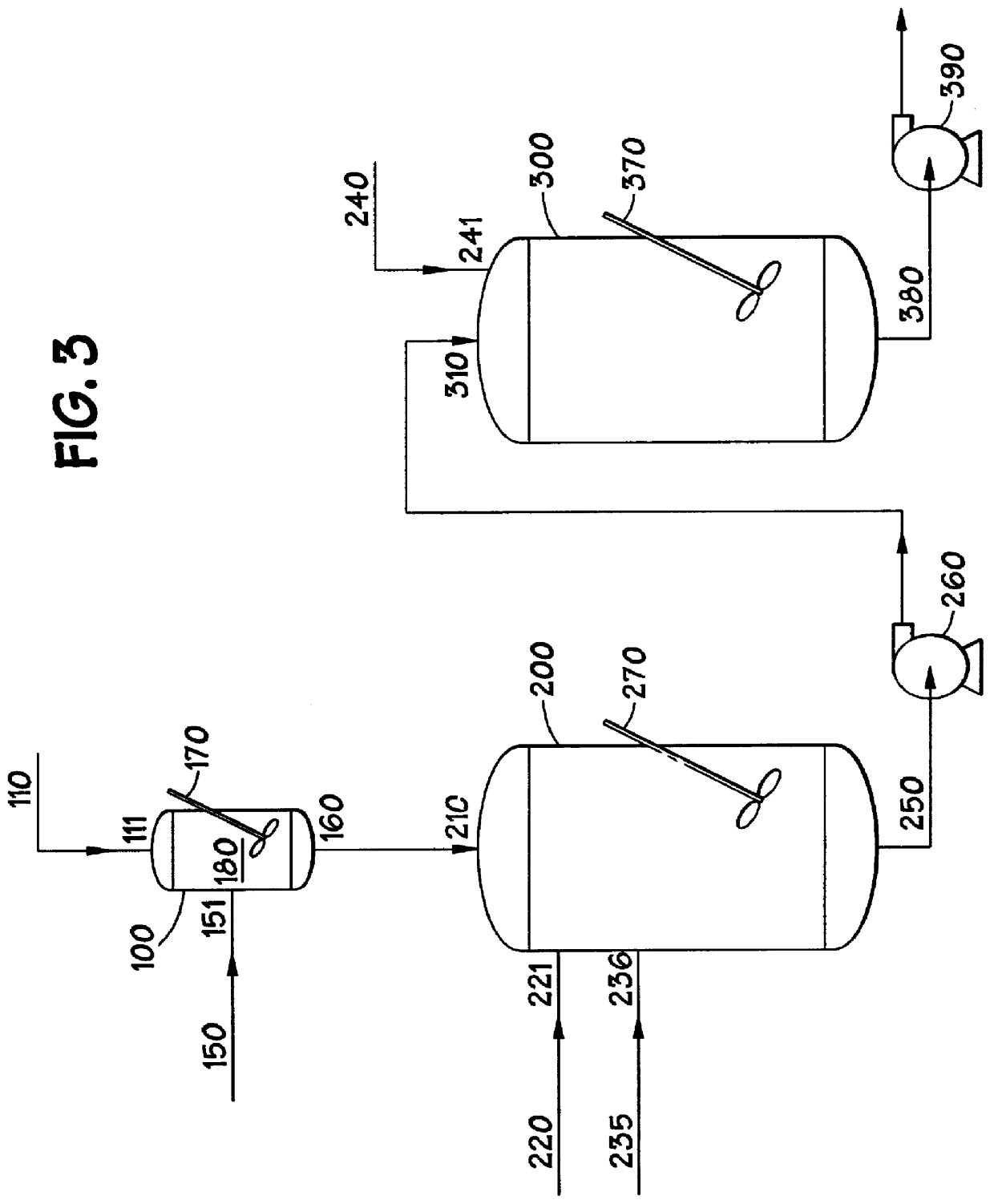

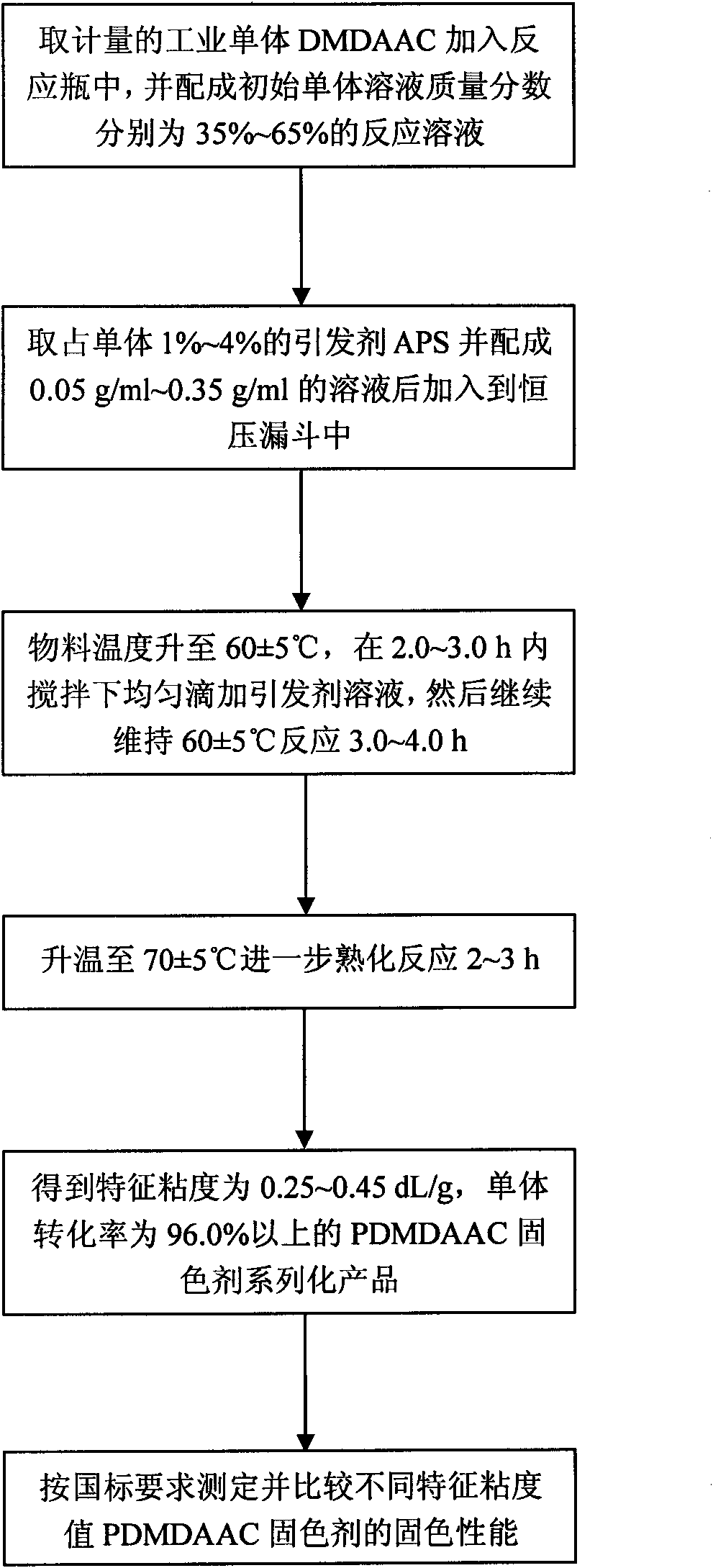

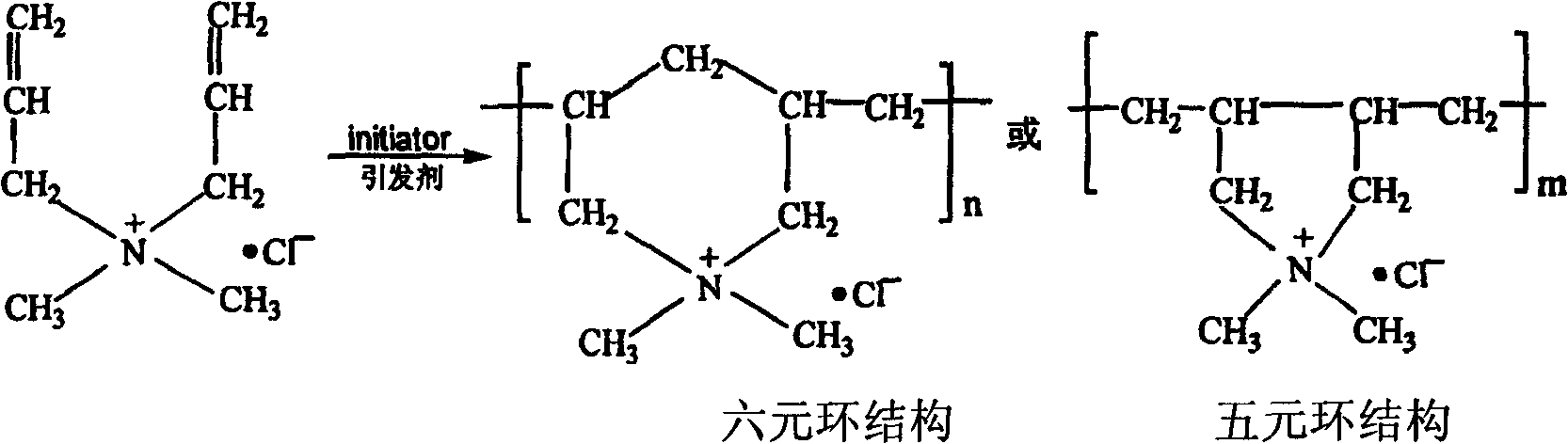

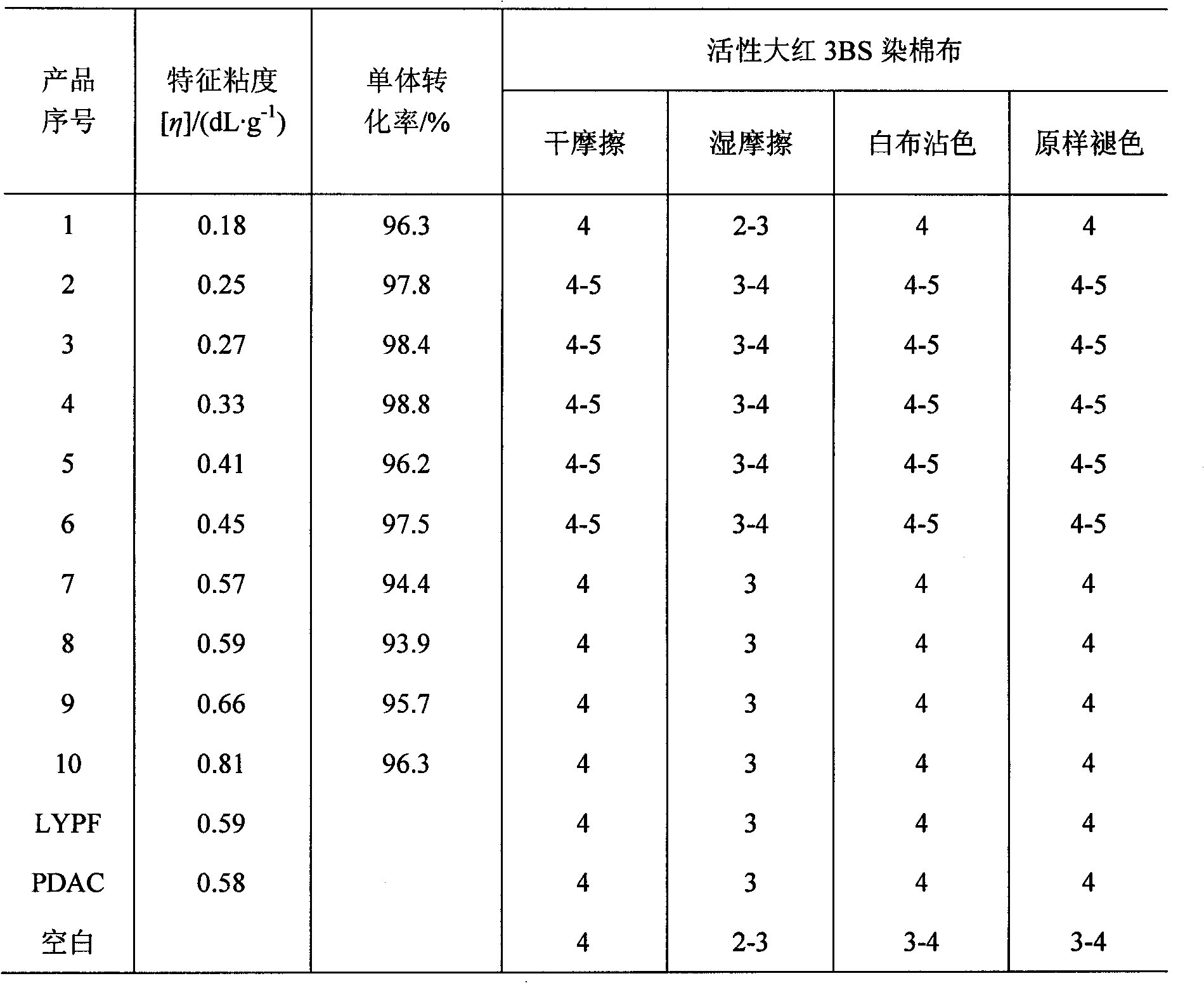

Relative molecular mass controlled polyquaternium color fixing agent and synthesizing method thereof

InactiveCN101891854AExcellent fastness performanceImprove color fixationDyeing processPolyquaterniumChemistry

The invention discloses a relative molecular mass controlled polyquaternium color fixing agent and a synthesizing method thereof. The method comprises the following steps: adding weighed industrial DMDAAC monomer into a reactor to prepare a reacting solution with the initial monomer solution mass fraction of between 35 percent and 65 percent; weighing initiator ammonium persulfate APS to prepare an initiator solution, and adding the mixture into a constant pressure funnel; heating the reacting solution, uniformly dropwise adding the ammonium persulfate initiator solution into the constant pressure funnel in a stirring state, preserving the temperature to keep on reacting after dropwise adding of the initiator is completed; and further heating and curing the reacting solution after temperature preservation so as to further improve the monomer conversion rate to obtain the relative molecular mass controlled polyquaternium color fixing agent PDMDAAC. The product has a specific range of characteristic viscosity values of between 0.25dL / g and 0.45dL / g, and has excellent color fixing performance; and the reacting monomer conversion rate is over 96.0 percent with high yield.

Owner:NANJING UNIV OF SCI & TECH

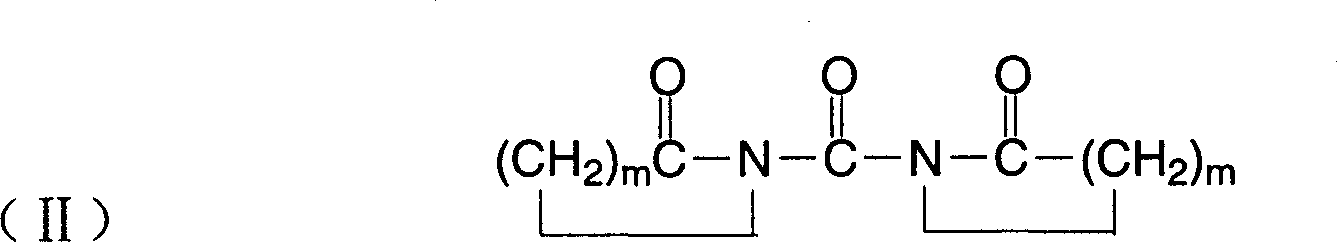

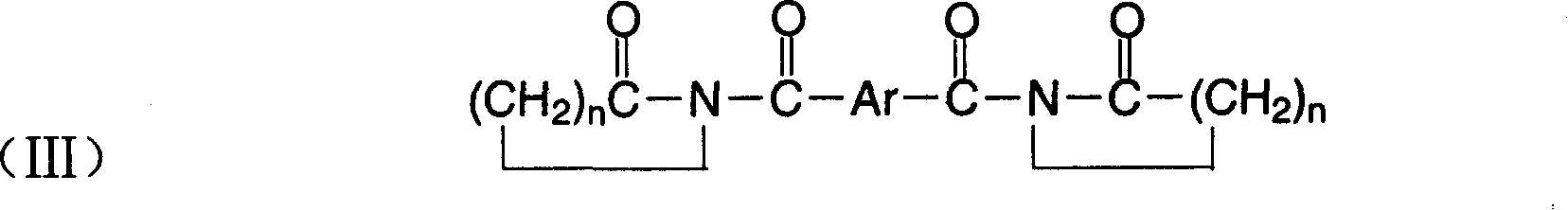

Process for preparing high-molecular aliphatic polyester

the invention discloses a preparing method of macromolecular aliphatic polyester, which is characterized by the following: proceeding melting polycondensation for diatomic alcohol and diacid; obtaining low-molecular hydroxy polyester prepolymer with even molecule at 2000-7000 or characteristic viscosity under 0.5; adopting aliphatic diacyl dilactone amide or aromatic diacyl dilactone amide to melt to expand chain; obtaining the product.

Owner:BEIJING UNIV OF CHEM TECH

Composite catalyst and polytrimethylene terephthalate preparation method

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

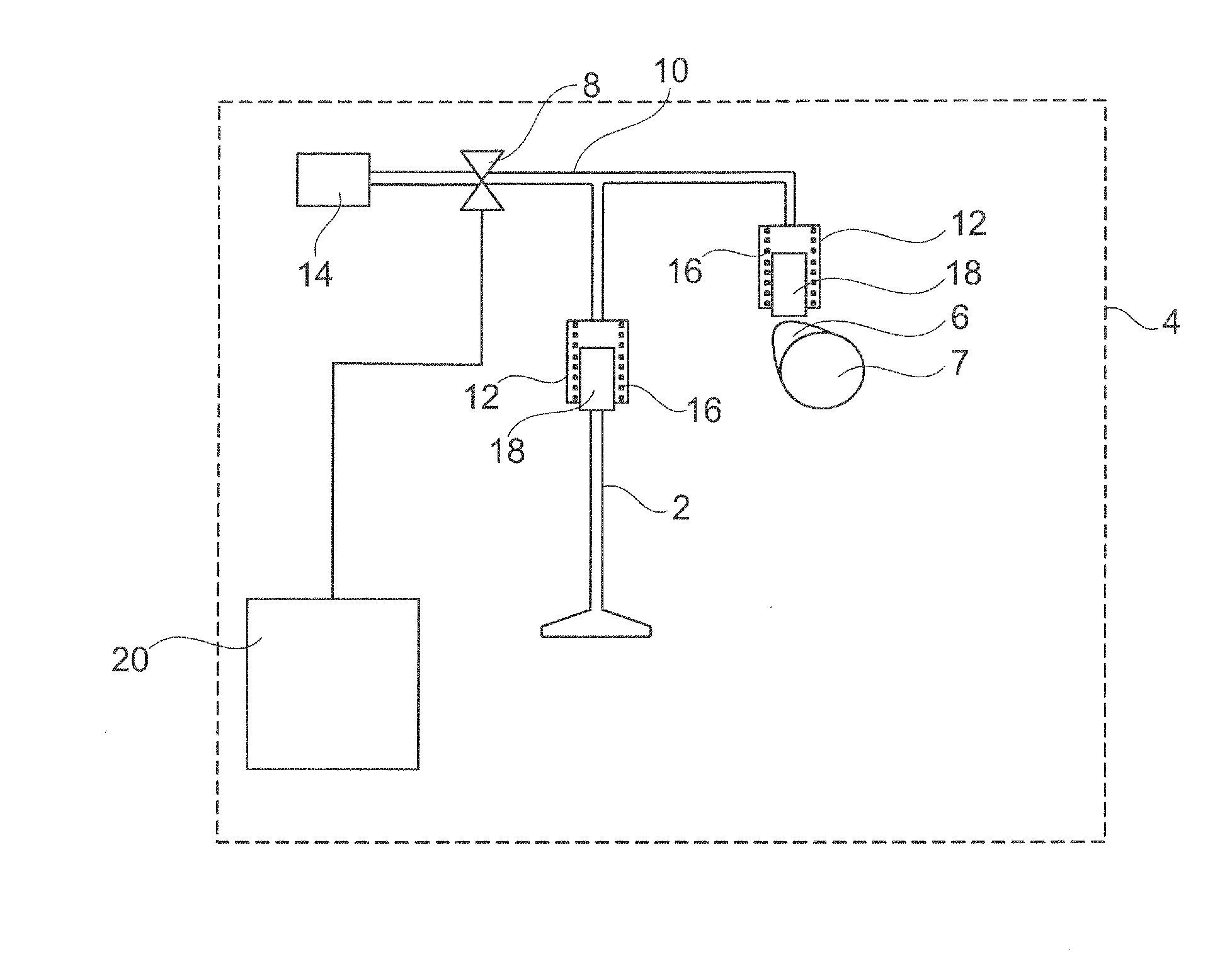

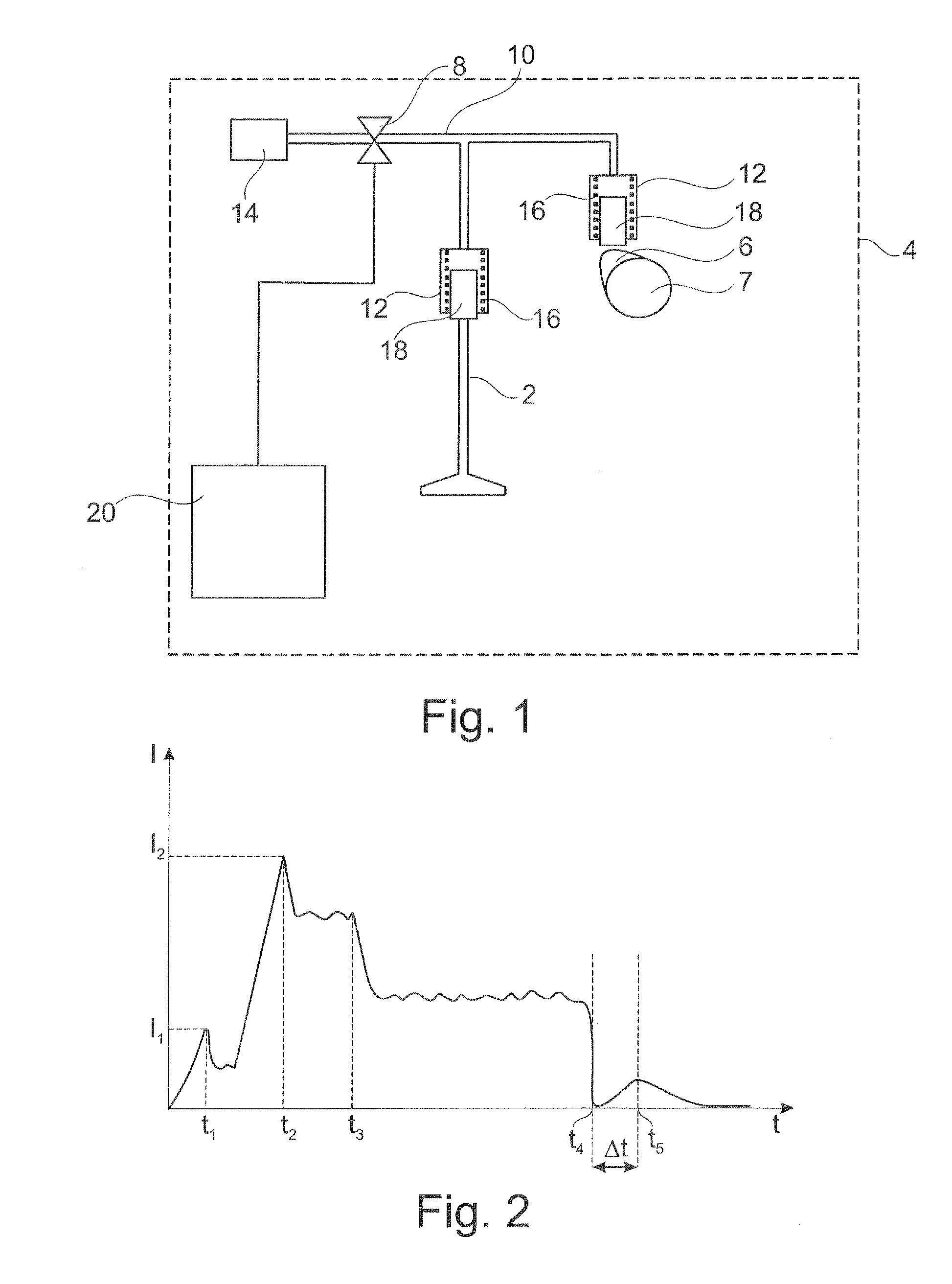

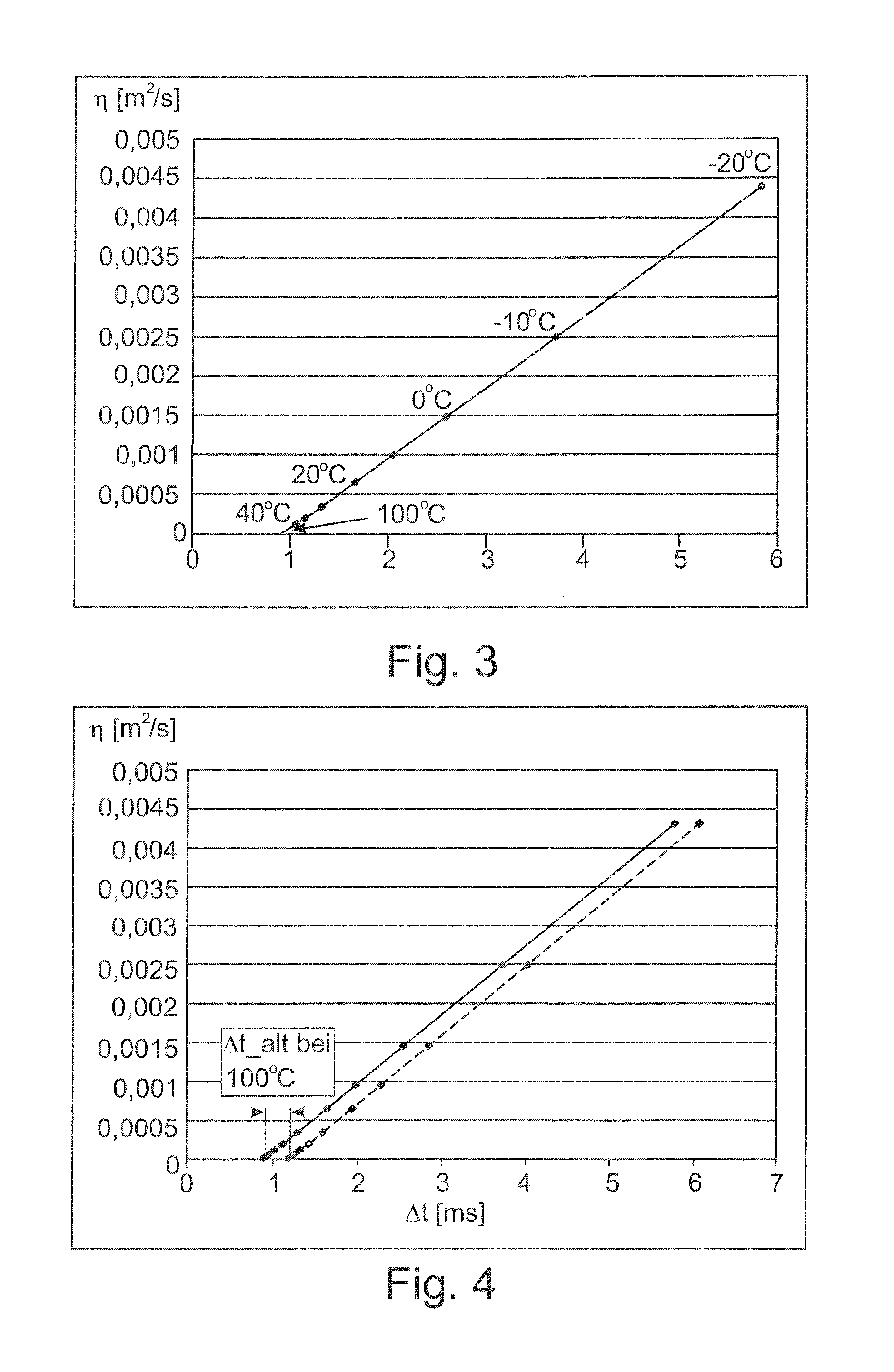

Method and control device for determining a characteristic viscosity variable of an oil

InactiveUS20120006289A1Avoid damageHigh viscosityElectrical controlInternal combustion piston enginesSolenoid valveElectrical control

In order for the viscosity of the engine oil to be determined as directly as possible, particularly in the case of a motor vehicle with hydraulic control of the gas exchange valves, provision is made for a time period which a hydraulic component, in particular a solenoid valve, requires to move from a first position to a second position to be used as a measure of the viscosity. In particular, an electrical control signal for the solenoid valve is evaluated in the process. An additional sensor arrangement is not required. The determined viscosity is preferably actively used for controlling the gas exchange valves.

Owner:SCHAEFFLER TECH AG & CO KG

Polypropylene resin composition and expanded molding

ActiveUS9522984B2Excellent characteristicsLight weightThin material handlingExtensional viscosityPolymer science

A polypropylene-based resin composition is provided that can provide a foam molding that exhibits an excellent closed cell characteristic and excellent extrusion characteristics, that is light weight and has a rigid feel, and that has an excellent recyclability.This polypropylene-based resin composition contains 100 weight % or is less than 100 weight % but at least 70 weight % of component (A) below and contains 0 weight % or is greater than 0 weight % but not more than 30 weight % of component (B) below,component (A):a propylene-based resin composition that comprises at least the following two components: a propylene-α-olefin copolymer (A1) satisfying conditions (A-1) to (A-3) and a propylene homopolymer (A2), (A1) and (A2) being obtained by polymerization by a multistage polymerization method, and this propylene-based resin composition having a content of (A1) of 1 to 20 weight % and a content of (A2) of 99 to 80 weight %, having a melt flow rate in the range from 5 to 20 g / 10 minutes and exhibiting strain hardening in a measurement of extensional viscosity at a temperature of 180° C. and a strain rate of 10 s−1,(A-1) an α-olefin content of 15 to 85 weight %,(A-2) an intrinsic viscosity η of 5 to 20 dL / g,(A-3) a Mw / Mn of 5 to 15;component (B):a propylene-based resin composition comprising at least the following two components: a propylene homopolymer or a propylene-α-olefin copolymer having a content of non-propylene α-olefin of less than 1 weight % (B1), which has an MFR of 10 to 1000 g / 10 minutes, and a propylene-α-olefin copolymer (B2) that has a weight-average molecular weight of 500,000 to 10,000,000 and a content of non-propylene α-olefin of 1 to 15 weight %, (B1) and (B2) being obtained by polymerization by a multistage polymerization method, and this propylene-based resin composition having a content of (B1) of 50 to 90 weight % and a content of (B2) of 50 to 10 weight %, and satisfying prescribed conditions (B-1) to (B-3).

Owner:JAPAN POLYPROPYLENE CORP

Propylene resin composition and interior automotive member comprising the same

InactiveUS6867252B1Improve mechanical propertiesGood lookingPedestrian/occupant safety arrangementSuperstructure subunitsElastomerInjection moulding

Owner:PRIME POLYMER CO LTD +1

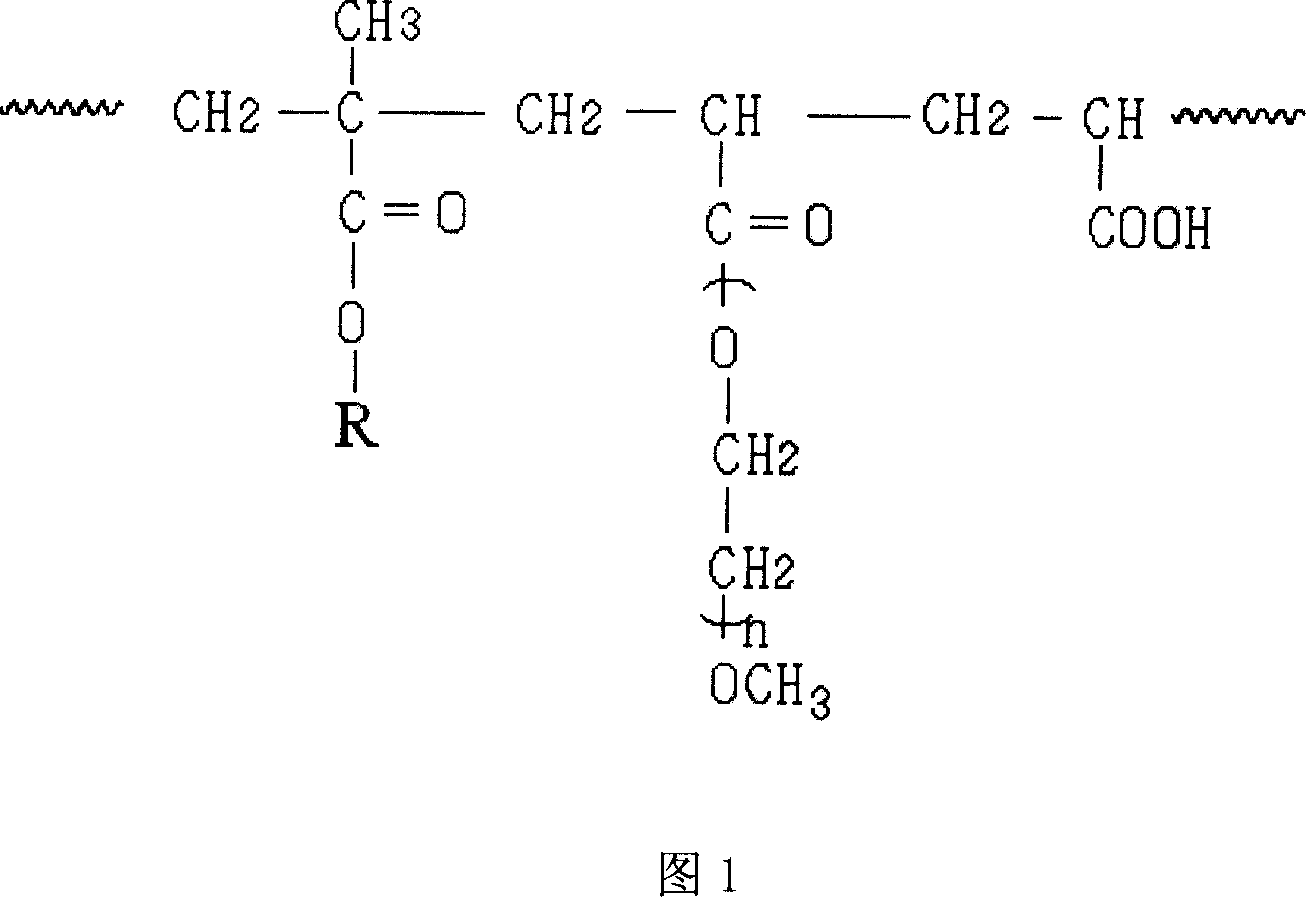

High molecular dispersant agent and its preparing method

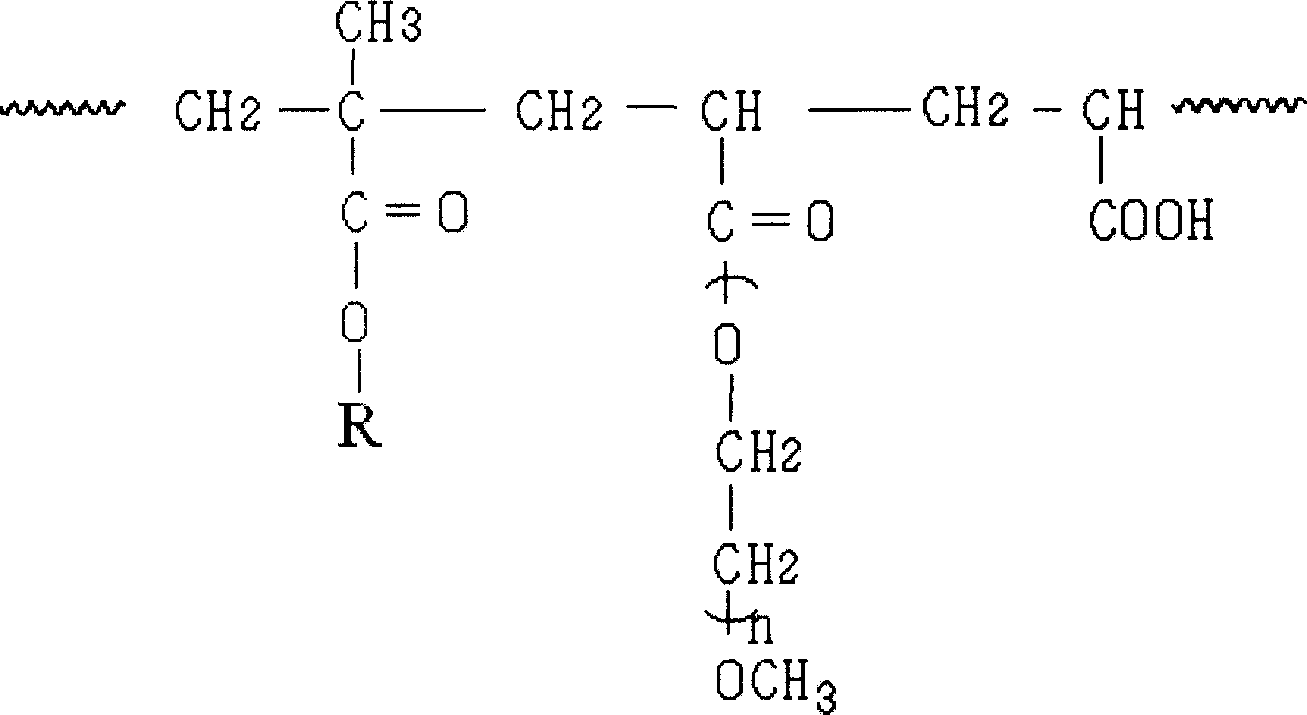

InactiveCN101045199AImprove dispersion efficiencyImprove performanceTransportation and packagingMixingEthylene glycolPigment

A high-molecular disperser with 7.2-7.5 centipoises as characteristic viscosity features that the methoxy ethanediol is used as hydrophilic chain segment playing the space stabilizing role and the ester radical is used as anchor group of pigment. Its preparing process includes such steps as synthesizing coarse product, purifying and preparing final product.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

Moisture-curing polyurethane hot-melt adhesive for manufacturing of composite boards

The invention discloses a moisture-curing polyurethane hot-melt adhesive for manufacturing of composite boards, and belongs to the field of adhesives. The adhesive is prepared from the following raw materials: (a) a polyurethane prepolymer prepared through polymerization of isocyanate and polyhydric alcohols and (b) an acrylate polymer with a characteristic viscosity lower than 0.1. The adhesive has excellent bonding properties, is applicable to bonding of metallic and nonmetallic materials, and can be used for preparing high-performance metallic-nonmetallic composite boards.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

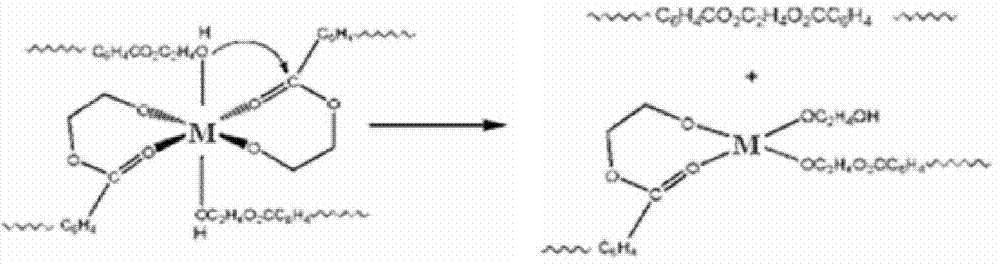

Method for preparing filaments for spinning through recycled PET (polythylene terephthalate) bottle

InactiveCN103911681AHigh crystallinityHigh strengthMonocomponent copolyesters artificial filamentAlcoholPolyethylene terephthalate

The invention discloses a method for preparing filaments for spinning through a recycled PET (polythylene terephthalate) bottle. The method comprises the steps of smashing, washing and drying the recycled PET bottle to obtain PET fragments; adding the PET fragments into a parallel homonymous double-screw extruder, and performing melt blending and filtering to obtain a melt; conveying the melt into a closed reaction container, injecting nitrogen into the closed reaction container, adding dihydric alcohol under the driving of nitrogen flow, then adding an aluminum-based catalyst, and mixing and stirring to perform alcoholysis reaction to obtain a treated melt; conveying the treated melt into a pressure-resistant reaction container through a closed pipeline from the closed reaction container, vacuumizing the closed pressure-resistant reaction container, stirring the melt under negative pressure to perform condensation polymerization, forming silks through a neck mold after the melt characteristic viscosity is 0.65dl / g-0.70dl / g, and performing high spinning to obtain the filaments for spinning. The filaments for spinning prepared by the method disclosed by the invention are high and stable in mechanical property, the operation is simple, the production efficiency is high, and the method is suitable for industrial production.

Owner:HANGZHOU HUAERLI CHEM FIBER CO LTD

Preparing method for PDMC with high monomer conversion rate and serialized relative molecular mass

The invention discloses a preparing method for PDMC with a high monomer conversion rate and serialized relative molecular mass. The amount of adopted monomer initial content coupling initiator is controlled for preparing the PDMC with the high monomer conversion rate and the serialized relative molecular mass, the monomer conversion rate of a serialized PDMC product obtained through preparation is larger than 98%, the characteristic viscosity value is 2.0-14.0 dL / g, a monomer is DMC, the mass fraction of the monomer is 35-70%, the initiator is water-soluble peroxide initiator, and the amount of the adopted initiator accounts for 0.20-2.00% of the mass fraction of the monomer. According to the method, the industrial product DMC concentrated, adsorbed, purified and cleaned is used as a raw material, a metal ion chelating agent and the water-soluble peroxide initiator are added under the nitrogen condition, and two-step temperature rising initiates polymerizing so that a target product can be generated. The obtained product serves as a positive ion water-soluble polymer with the high monomer conversion rate and the serialized relative molecular mass, is stable in quality, and is widely applied to multiple fields of oil exploitation, papermaking, mining, spinning and printing and dyeing, daily-use chemical industry, water treatment and the like.

Owner:NANJING UNIV OF SCI & TECH

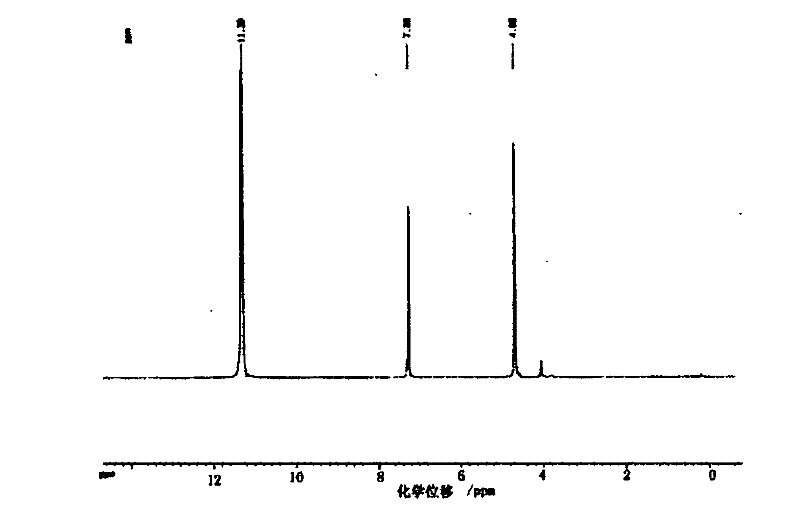

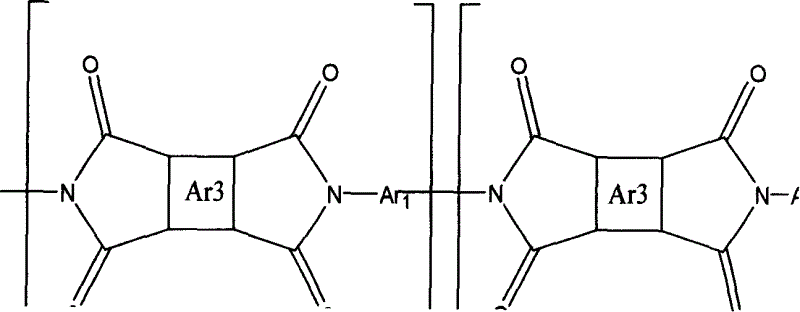

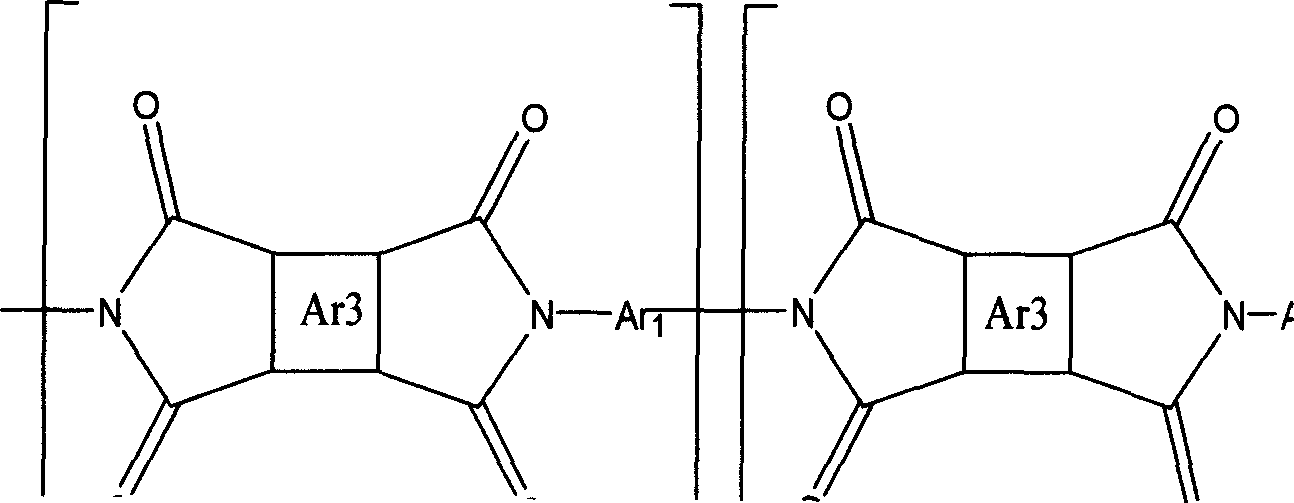

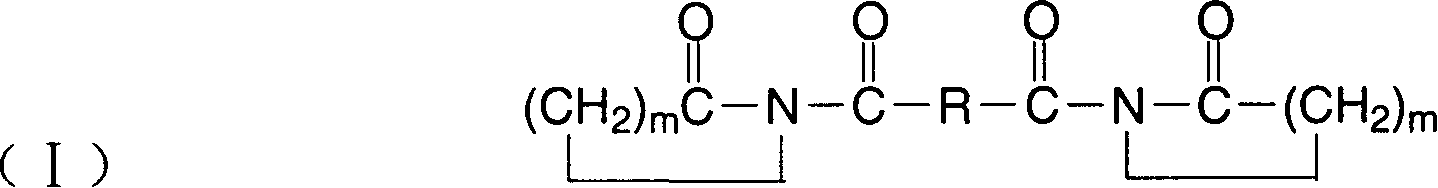

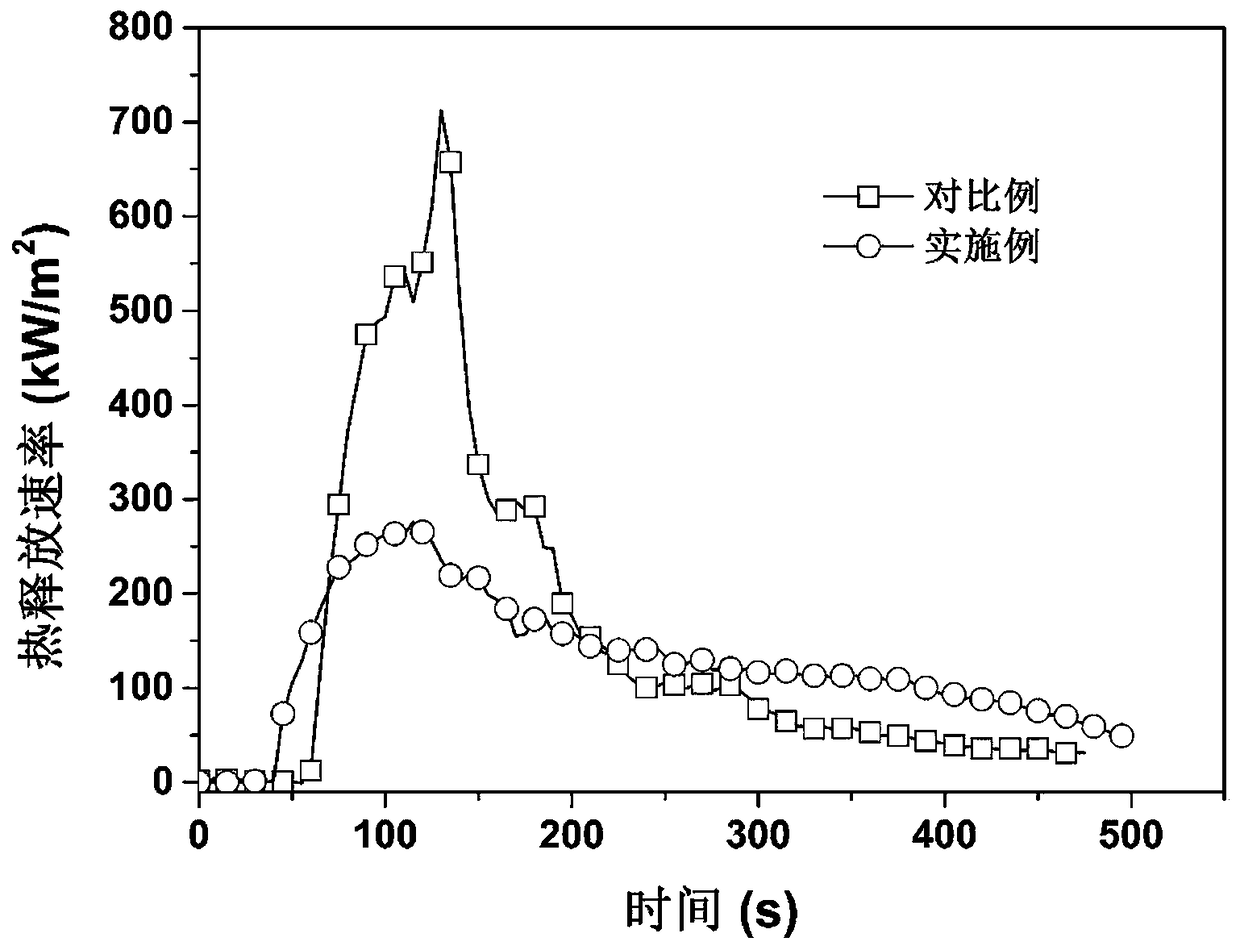

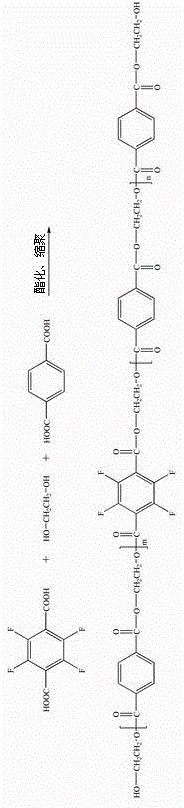

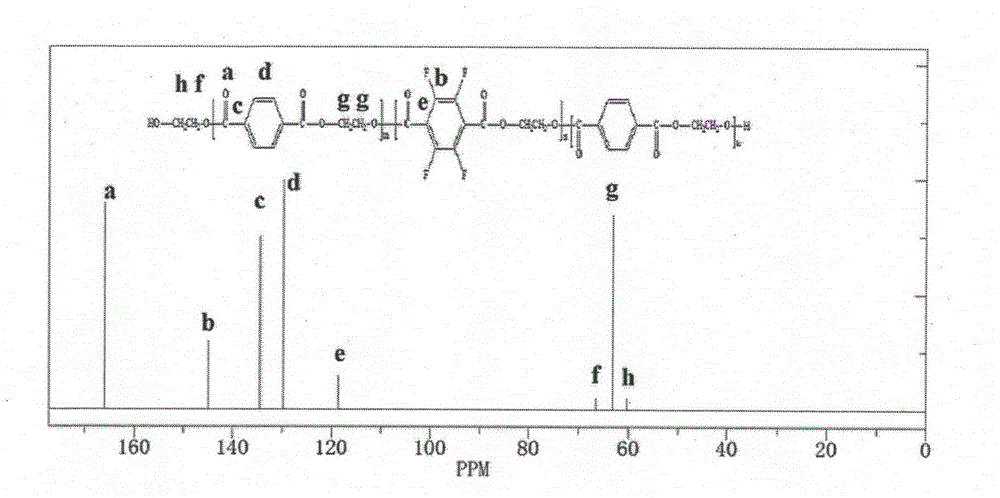

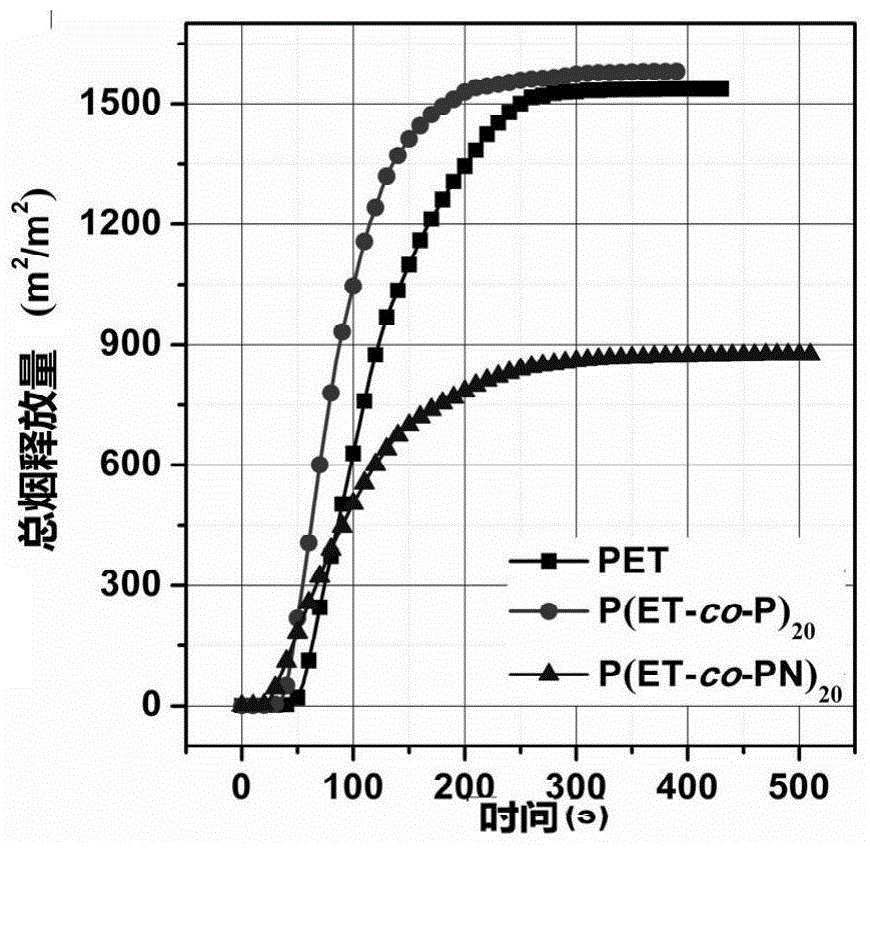

Benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance and preparation method of copolyester

ActiveCN108359084APreserve thermoplastic processabilityIncrease melt viscosityStructural unitStructure based

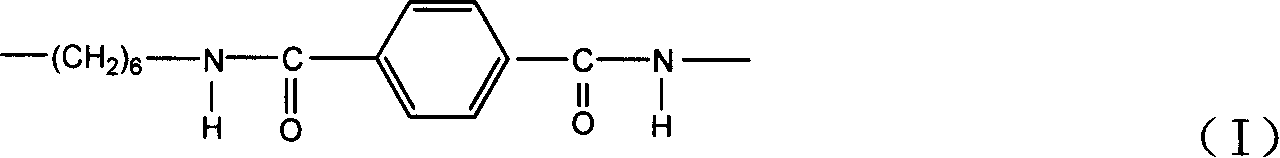

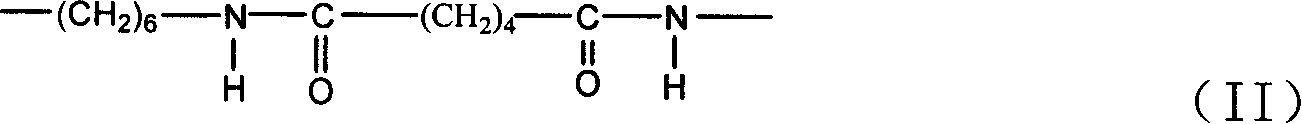

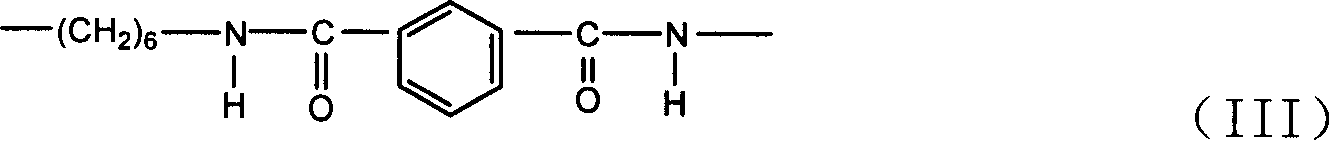

The invention discloses a benzene imide structure based high-temperature self-crosslinking copolyester with effects of flame retardancy, smoke suppression and melt drop resistance. Copolyester is prepared from structural units represented by I, II and III or structural units represented by I, II and IV through random copolymerization, wherein the characteristic viscosity [eta] of copolyester is 0.41-1.12 dL / g, and the limit oxygen index is 24.2%-38.7%; the vertical combustion class is in a range from V-2 to V-0; the p-HRR (peak of heat release rate) in a cone calorimetry test is reduced by 7.1%-72.1% as compared with that of pure PET, and total smoke release is decreased by 2.0%-59.2% as compared with that of pure PET. The invention further discloses a preparation method of copolyester. Ahigh-temperature self-crosslinking group introduced in the preparation process is a benzene imide group, and prepared copolyeste cannot be subjected to crosslinking during processing and polymerization, so that thermoplastic processability of polyester is retained; meanwhile, due to the tackifying effect and high charring property brought by the self-crosslinking action at high temperature or during combustion, prepared copolyester has excellent flame retardancy, smoke suppression and melt drop resistance effects.

Owner:SICHUAN UNIV

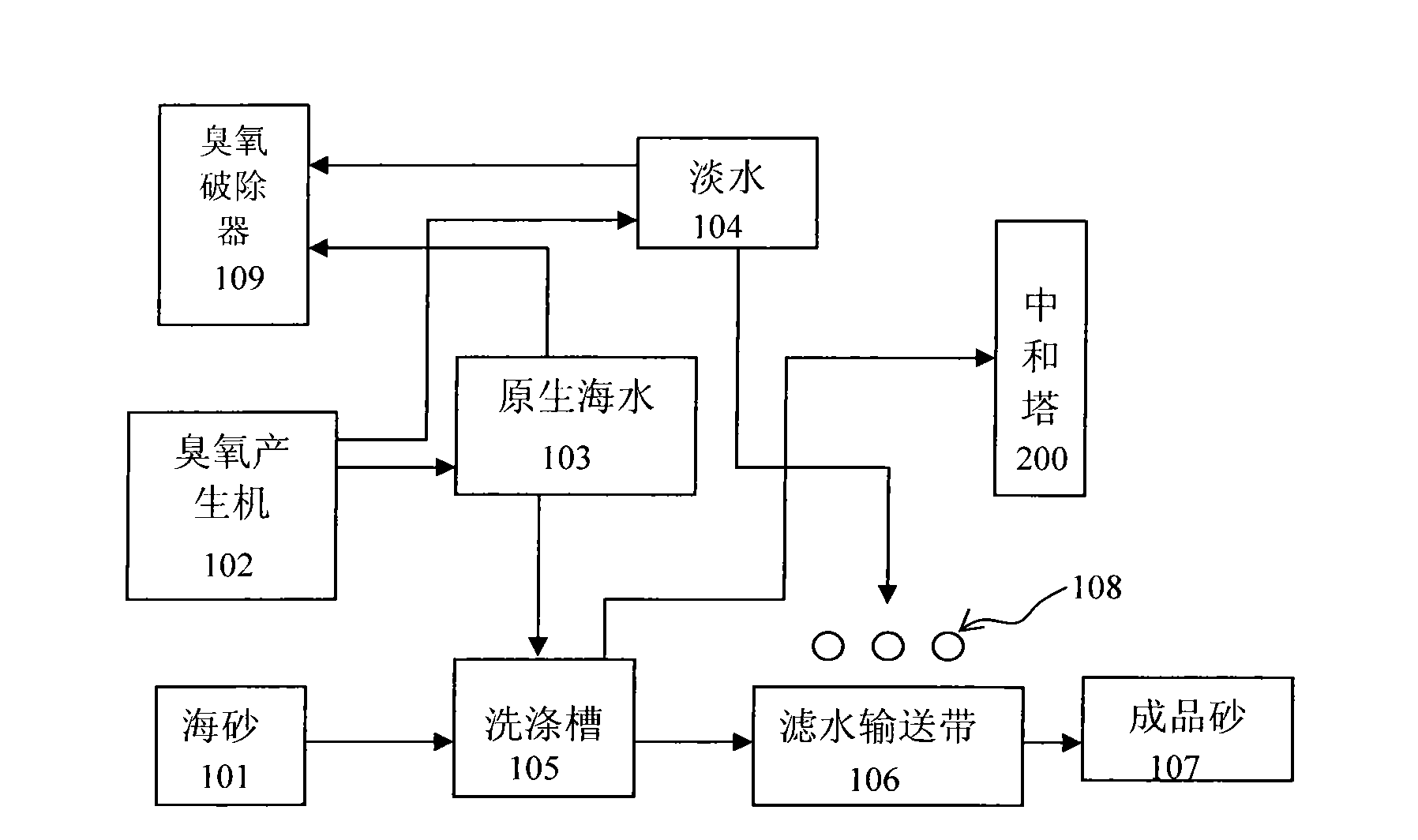

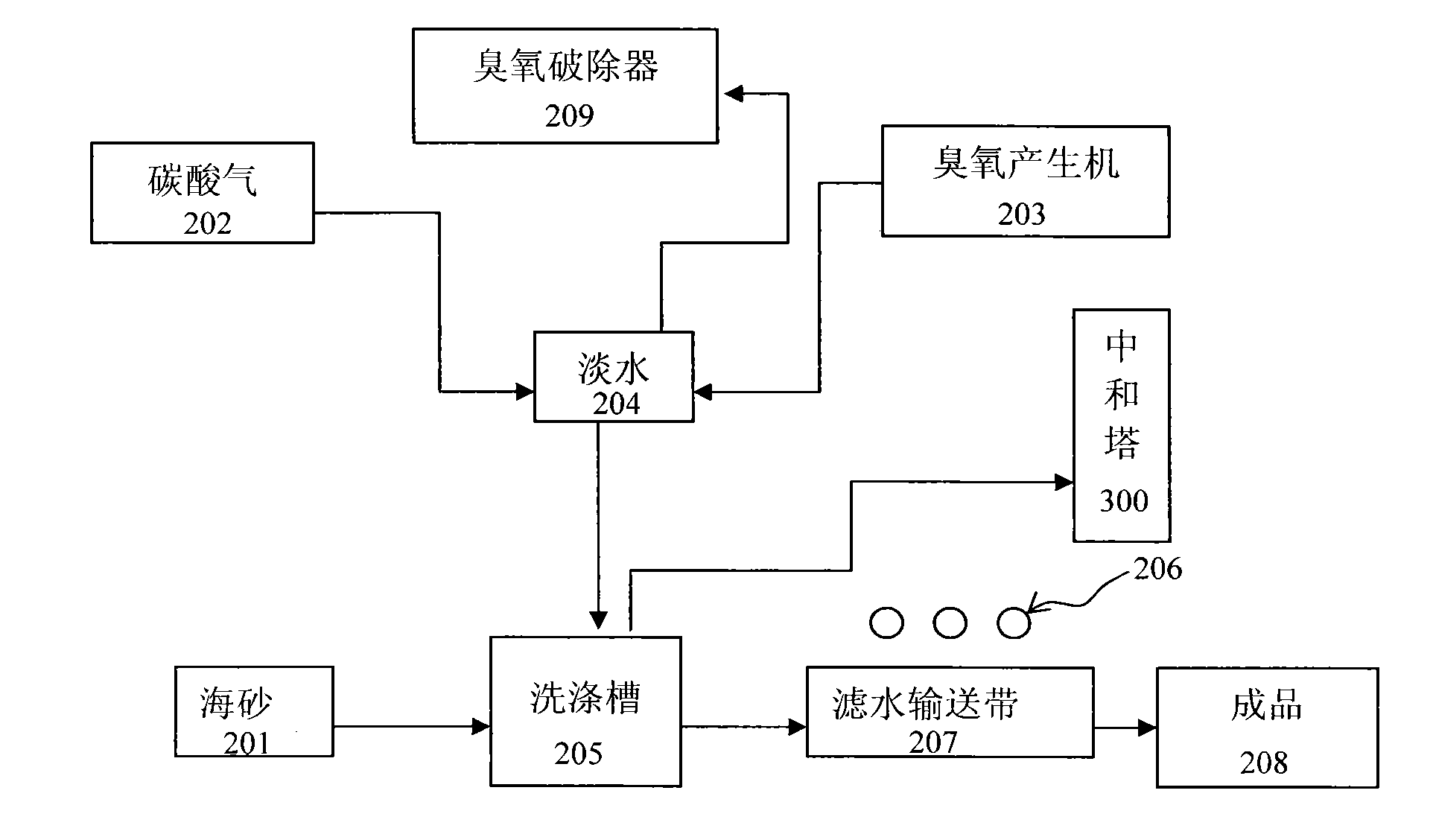

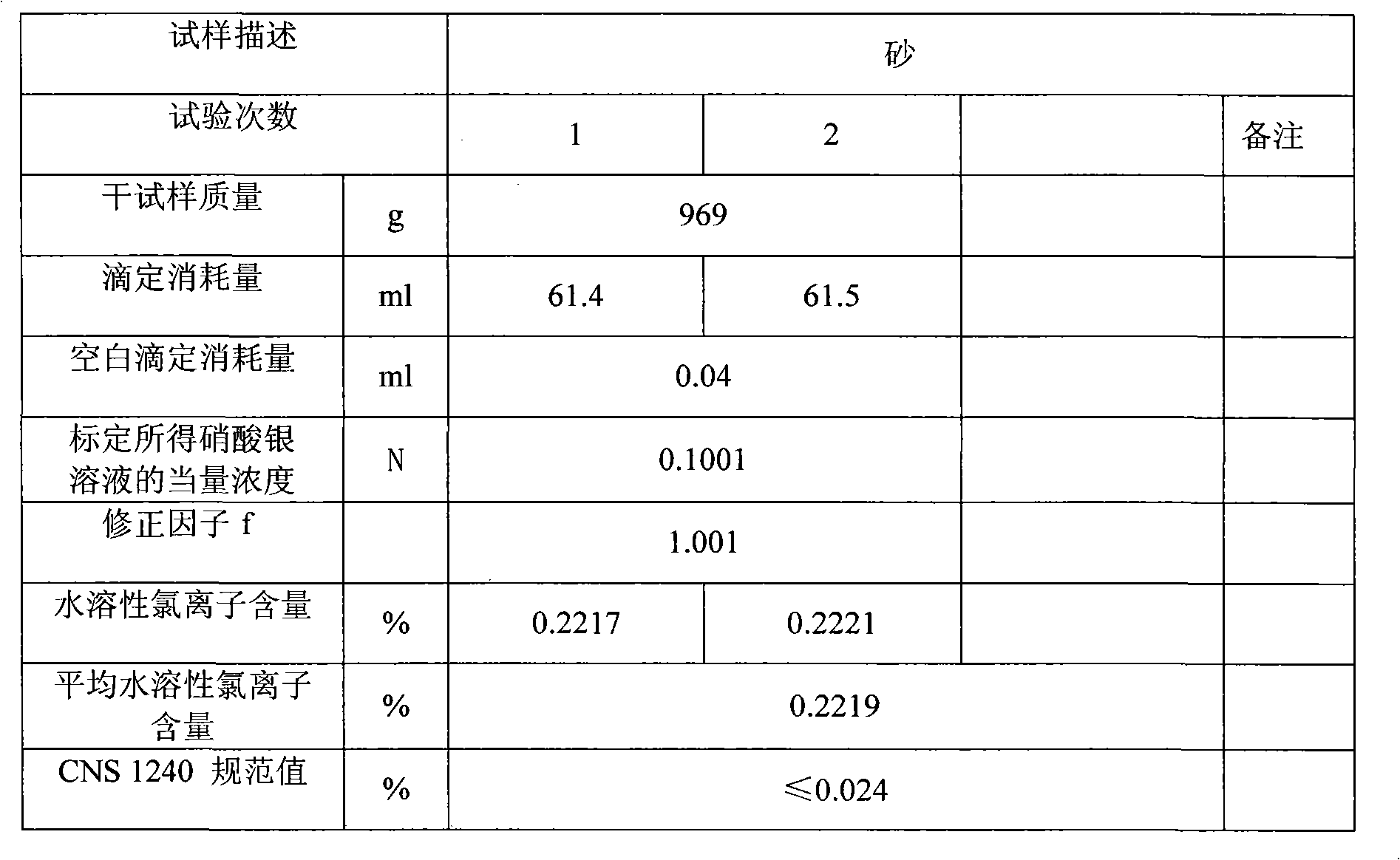

Method for supercritically washing sea sand, river sand and hill sand

InactiveCN101537414AOvercome physical propertiesReduce viscosityCleaning using liquidsHigh concentrationHazardous substance

The invention discloses a method for supercritically washing sea sand, river sand and hill sand, which mainly applies two-phase coexistence washing water formed by mixing gaseous ozone, carbonic acid gas and liquid water, overcomes the capillary phenomenon caused by physical characteristics viscosity and surface tension of water, and generates supercritical washing to remove substances on the surface of the sea sand which are harmful to cement, reinforcing steel bar and the like, such as chloride, sulfate, organic substances, algae and the like. The ozone as a strong oxidizing agent plays a role in decomposing the organic substances, so when high-concentration ozone water is used as washing water, the ozone water has high efficiency and low cost in removing harmful ions of the sea sand or the river sand, and has the characteristic of no harmful substance residue; and the washed sea sand does not have odor, and has low content of ash, and can become high quality sand for construction and engineering.

Owner:汤奇岳

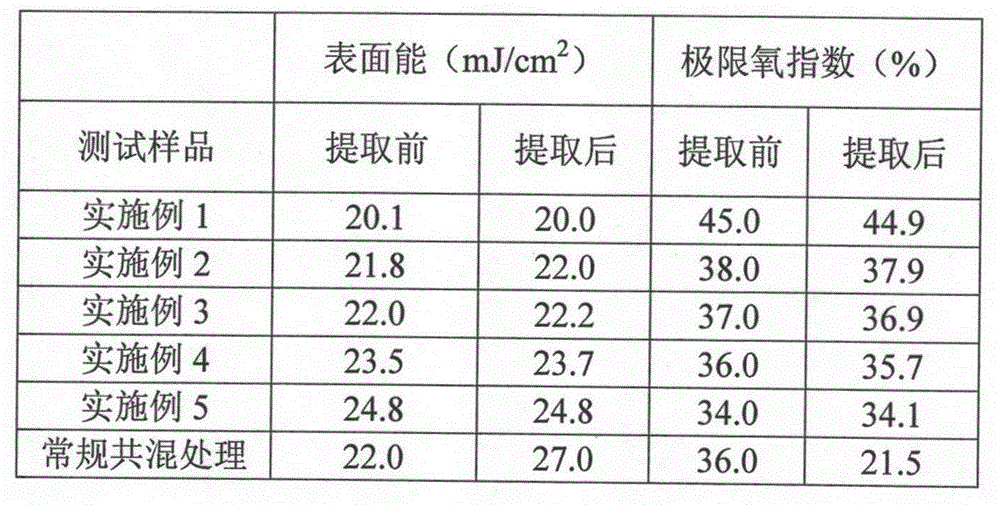

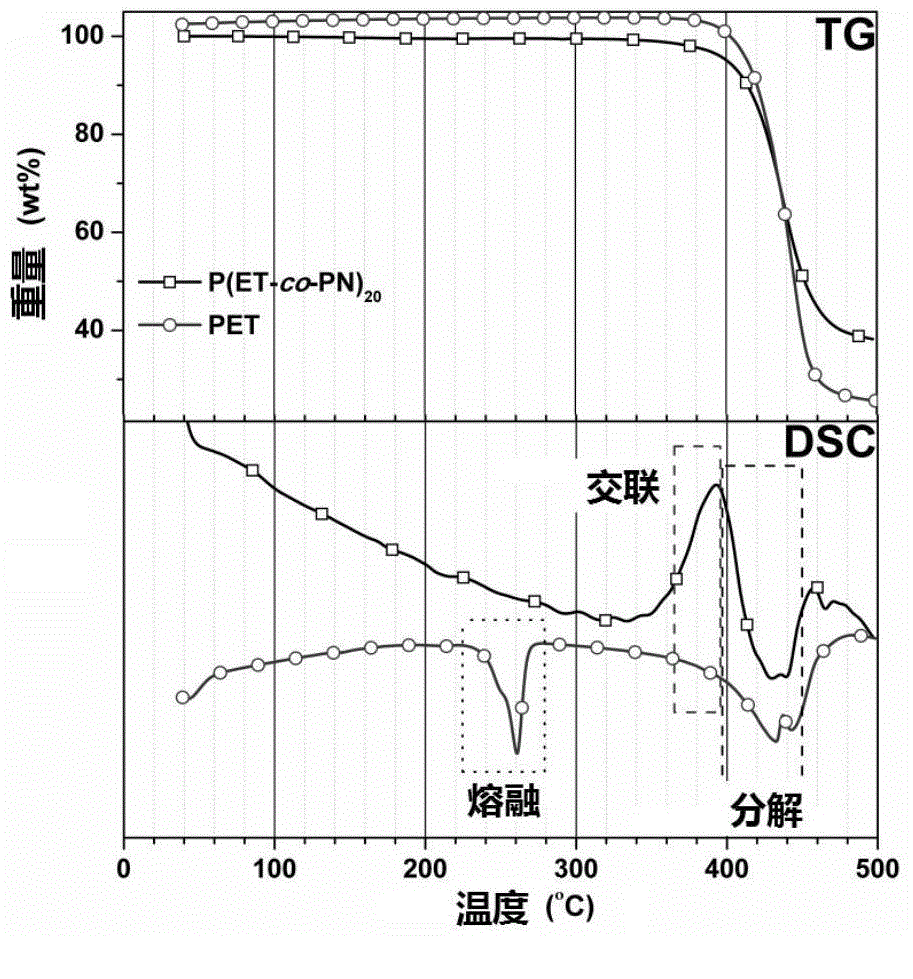

Fluorine-containing anti-fouling fire-resisting polyester and preparation method thereof

The invention discloses fluorine-containing anti-fouling fire-resisting polyester and a preparation method thereof. A PET chain segment of the anti-fouling fire-resisting polyester contains -OCH2CH2OCOC6H4COOCH2CH2O- and -OCH2CH2OCOC6F4COOCH2CH2O-, a molar ratio of the two chain segments is 95:5 to 1:99, the surface energy of the polyester is less than 25mJ / cm<2>, a limit oxygen index is more than 34, and the characteristic viscosity of the polyester is greater than 0.55dL / g. The preparation method comprises the following steps: mixing raw materials such as ethylene glycol, terephthalic acid and 2,3,5,6-tetrafluoroterephthalic acid according to a ratio, and carrying out esterification reaction between the terephthalic acid and ethylene glycol under a pressurizing condition; then carrying out prepolymerization under the high temperature and normal pressure, and carrying out post-polymerization reaction under a high temperature and vacuum condition, thus preparing the anti-fouling fire-resisting polyester. The prepared polyester has hydro-oleophobicity, is excellent in fire resistance and anti-fouling performance and is wide in application prospect in the field of home textiles.

Owner:DONGHUA UNIV

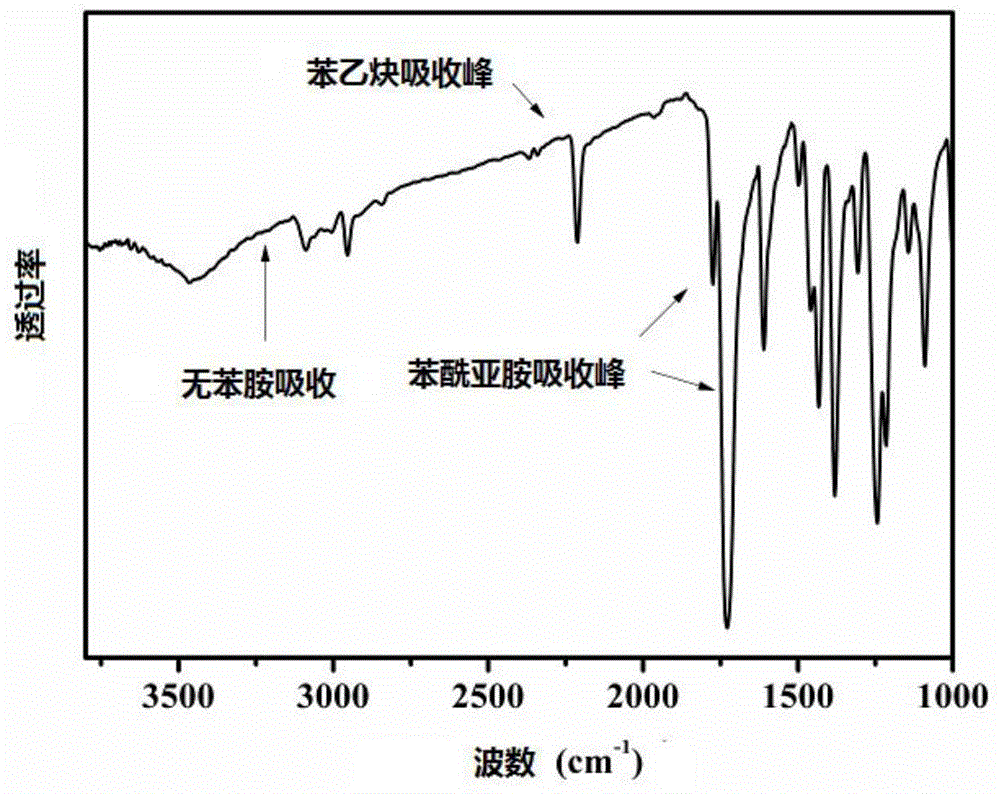

Monomer containing benzimide phenylacetylene structure, high temperature self-crosslinked copolyester and preparation method thereof

ActiveCN104592094AHigh self-crosslinking flame retardant efficiencyGood flame retardantOrganic chemistryPolymer scienceChemical reaction

The invention discloses a monomer containing a benzimide phenylacetylene structure. The monomer can enable self-crosslinking chemical reaction of a synthesized polymer under high temperature. The monomer containing a benzimide phenylacetylene structure and the structural units represented by I and II for synthesis of polyester can undergo random copolymerization to obtain high temperature self-crosslinked copolyester, and when the copolyester contains a PET structural unit, the characteristic viscosity number [eta] is 0.44-1.38dL / g, the vertical combustion UL-94 grade is from V-2 to V-0, the oxygen index LOI is 24.0-35.0%, and the cone calorimeter test peak heat release rate PHRR and the smoke release total amount are both lower than pure polyester. The invention also discloses a preparation method of the copolyester. The benzimide and phenylacetylene in the copolyester involved in the invention can generate synergistic cross-linking effect, so that the copolyester has very high flame-retardant and anti-dripping efficiency, and also the copolyester is endowed with excellent flame retardant, anti-dripping and smoke suppressing performance. The method provided by the invention is basically consistent with the synthesis method of conventional polyester, not only is mature in technology, and easy and convenient to operate, but also is easy to control and convenient for industrial production.

Owner:SICHUAN UNIV

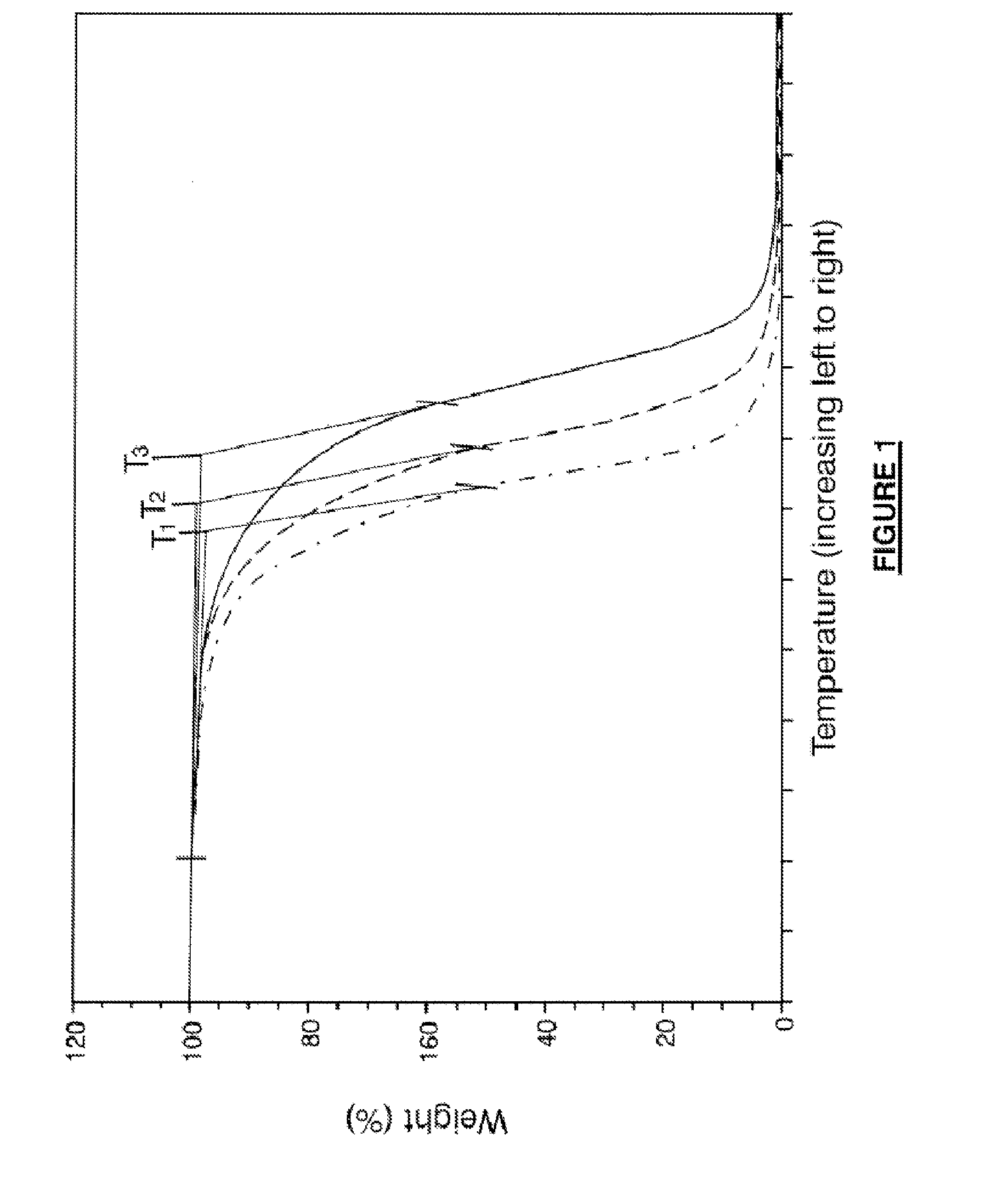

Absorbable copolymers with improved thermal stability

The present invention relates to absorbable block copolymers with improved characteristics including thermal stability, molecular weight consistency, inherent viscosity retention following melt extrusion, and fibers made from the polymers exhibit increased strength.

Owner:POLY MED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com