Fluorine-containing anti-fouling fire-resisting polyester and preparation method thereof

A flame retardant polyester and antifouling technology, applied in the field of fluorine-containing antifouling flame retardant polyester and its preparation, can solve the problems of poor pollution resistance, poor flame retardancy, etc. Flame retardant properties, effects of improving hydrophobic and oleophobic properties and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

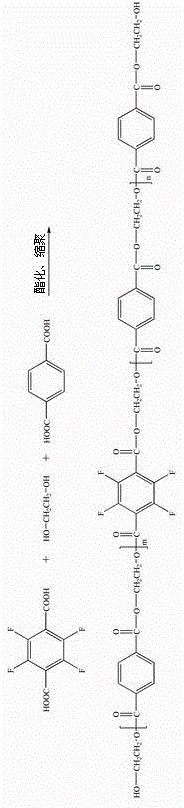

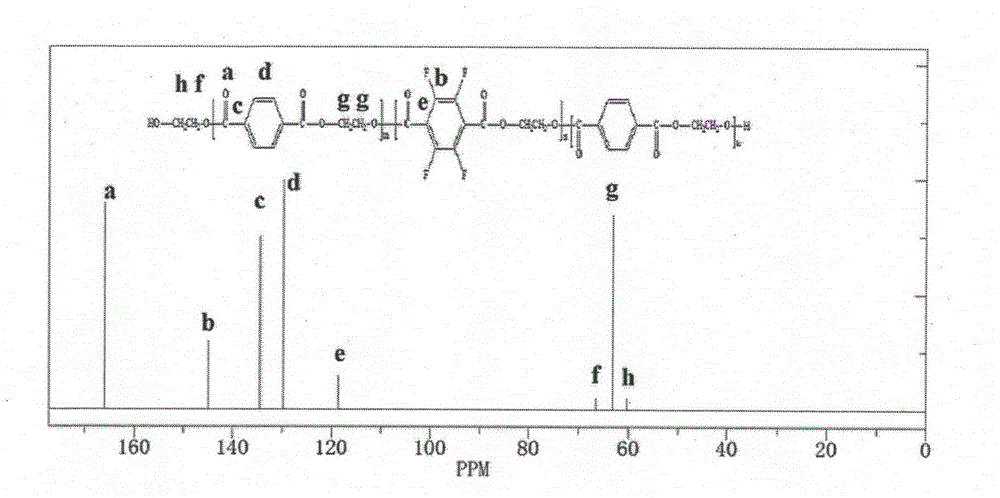

Method used

Image

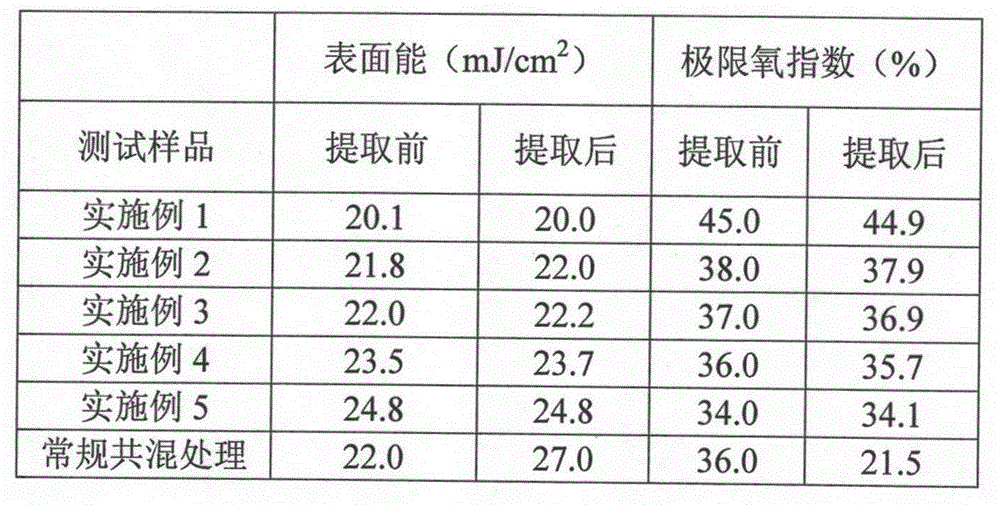

Examples

Embodiment 1

[0022] Ethylene glycol, terephthalic acid, 2,3,5,6-tetrafluoroterephthalic acid are used as raw materials, mixed in proportion, and the molar ratio of terephthalic acid to ethylene glycol is 1:0.95, and The molar ratio of terephthalic acid to 2,3,5,6-tetrafluoroterephthalic acid is 1:99 for feeding. The polymerization reaction is divided into esterification and polycondensation processes. The esterification reaction is under the protection of nitrogen, and the pressure is 0.2 Under the condition of MPa, terephthalic acid and ethylene glycol undergo an esterification reaction to form a prepolymer, and the reaction temperature is 250°C for 4 hours. The polycondensation reaction is carried out pre-condensation at high temperature and normal pressure, the reaction temperature is 280°C, and kept for 3 hours; then the post-condensation is carried out under high temperature and high vacuum conditions, the vacuum degree is lower than 60Pa, the reaction temperature is 290°C, and the rea...

Embodiment 2

[0024] Ethylene glycol, terephthalic acid, and 2,3,5,6-tetrafluoroterephthalic acid are used as raw materials, mixed in proportion, and the molar ratio of terephthalic acid to ethylene glycol is 1:1.35, and The molar ratio of terephthalic acid and 2,3,5,6-tetrafluoroterephthalic acid is 10:90 for feeding, the polymerization reaction is divided into esterification and polycondensation process, the esterification reaction is under the protection of nitrogen, and the pressure is 0.4 Under the condition of MPa, terephthalic acid and ethylene glycol undergo an esterification reaction to form a prepolymer, and the reaction temperature is 245°C for 3 hours. The polycondensation reaction is carried out at high temperature and normal pressure for pre-condensation, the reaction temperature is 270°C, and kept for 3h; then the post-condensation is carried out under high temperature and high vacuum conditions, the vacuum degree is lower than 60Pa, the reaction temperature is 285°C, and the ...

Embodiment 3

[0026] Ethylene glycol, terephthalic acid, 2,3,5,6-tetrafluoroterephthalic acid are used as raw materials, mixed in proportion, and the molar ratio of terephthalic acid to ethylene glycol is 1:1.25, and The molar ratio of terephthalic acid and 2,3,5,6-tetrafluoroterephthalic acid is 50:50 for feeding. The polymerization reaction is divided into esterification and polycondensation processes. The esterification reaction is under the protection of nitrogen, and the pressure is 0.3 Under the condition of MPa, terephthalic acid and ethylene glycol undergo an esterification reaction to form a prepolymer, and the reaction temperature is 250°C for 2 hours. The polycondensation reaction is pre-condensed at high temperature and normal pressure, the reaction temperature is 280°C, and kept for 2h; then the post-condensation is carried out under high temperature and high vacuum conditions, the vacuum degree is lower than 60Pa, the reaction temperature is 290°C, and the reaction time is 3h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com