Absorbable copolymers with improved thermal stability

a technology of copolymer and thermal stability, which is applied in the field of absorbable copolymers, can solve the problems of lack of thermal stability, molecular weight consistency, and inherent viscosity retention of polymers resulting from this disclosure, and achieves the effects of improving thermal stability, reducing the number of polymers, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]With reference to the drawings, the invention will now be described in more detail. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood to one of ordinary skill in the art to which the presently disclosed subject matter belongs. Although any methods, devices, and materials similar or equivalent to those described herein can be used in the practice or testing of the presently disclosed subject matter, representative methods, devices, and materials are herein described.

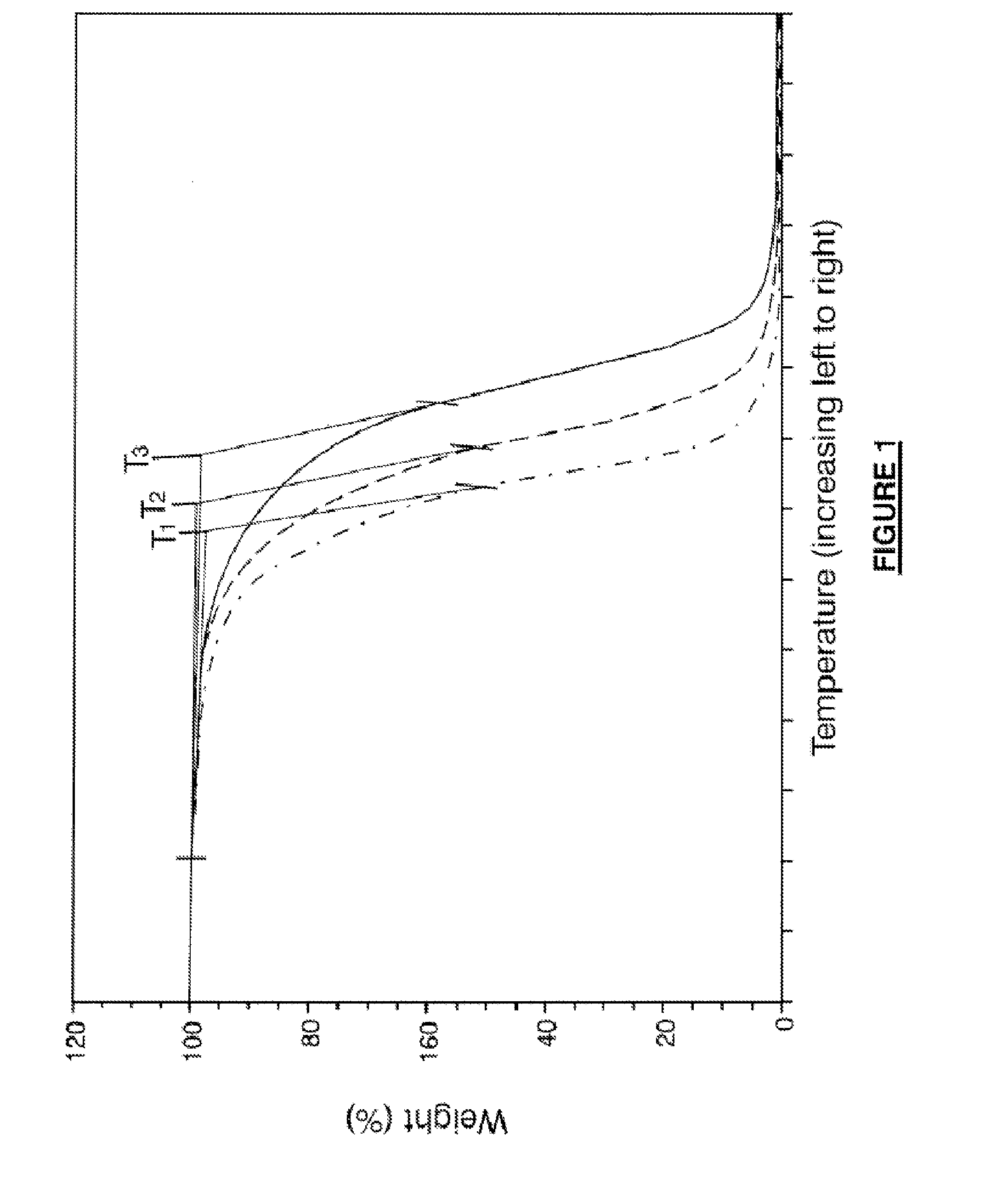

[0037]The present disclosure is directed to absorbable aliphatic polyesters with improved characteristics including thermal stability, molecular weight consistency, and inherent viscosity retention following melt extrusion. Further, fibers made from the polymers may exhibit increased strength. In one embodiment, the aliphatic polyesters of the present disclosure may include linear, crystalline block copolymers, such as di-block, tri-block and penta-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com