Patents

Literature

2241 results about "Single step" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

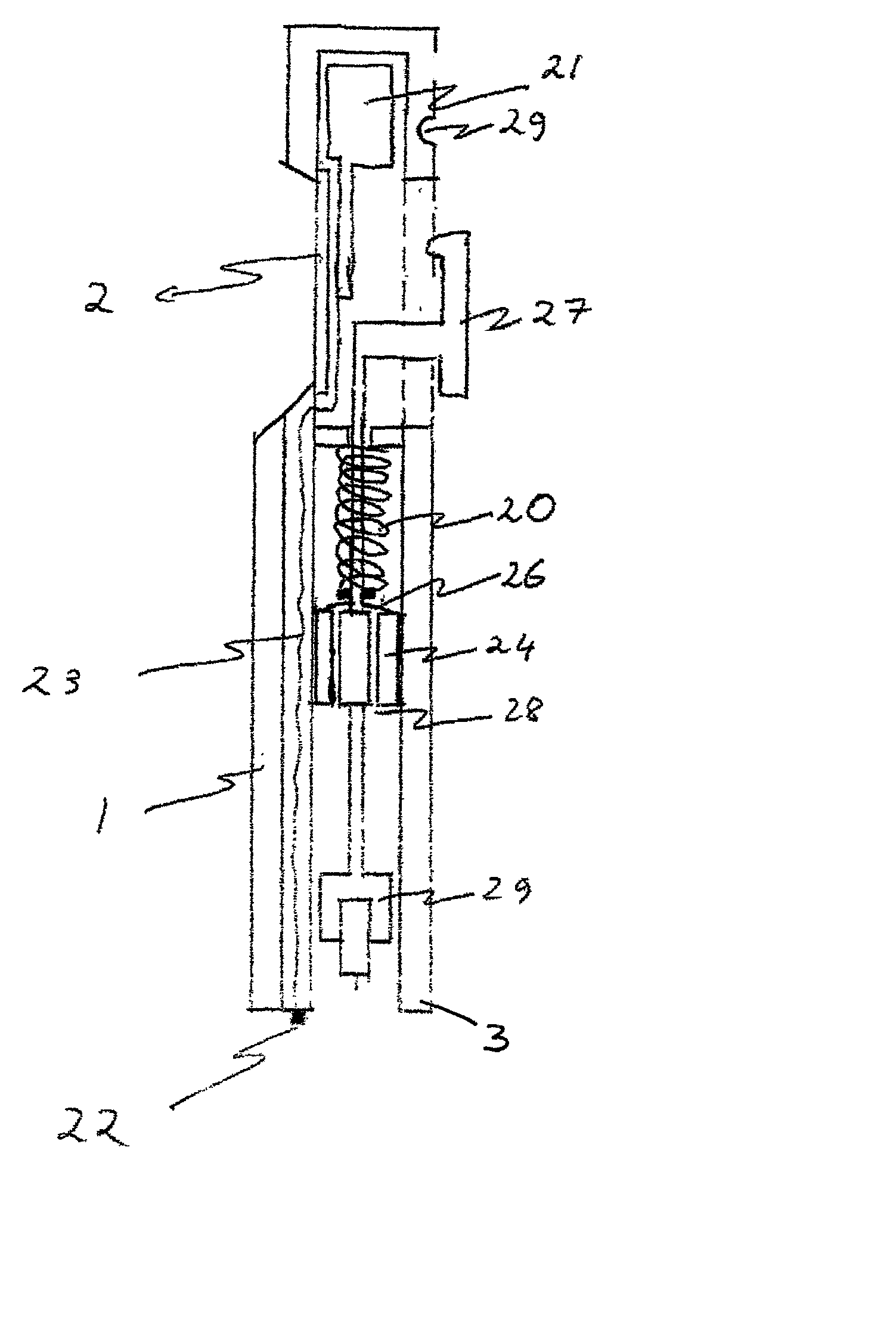

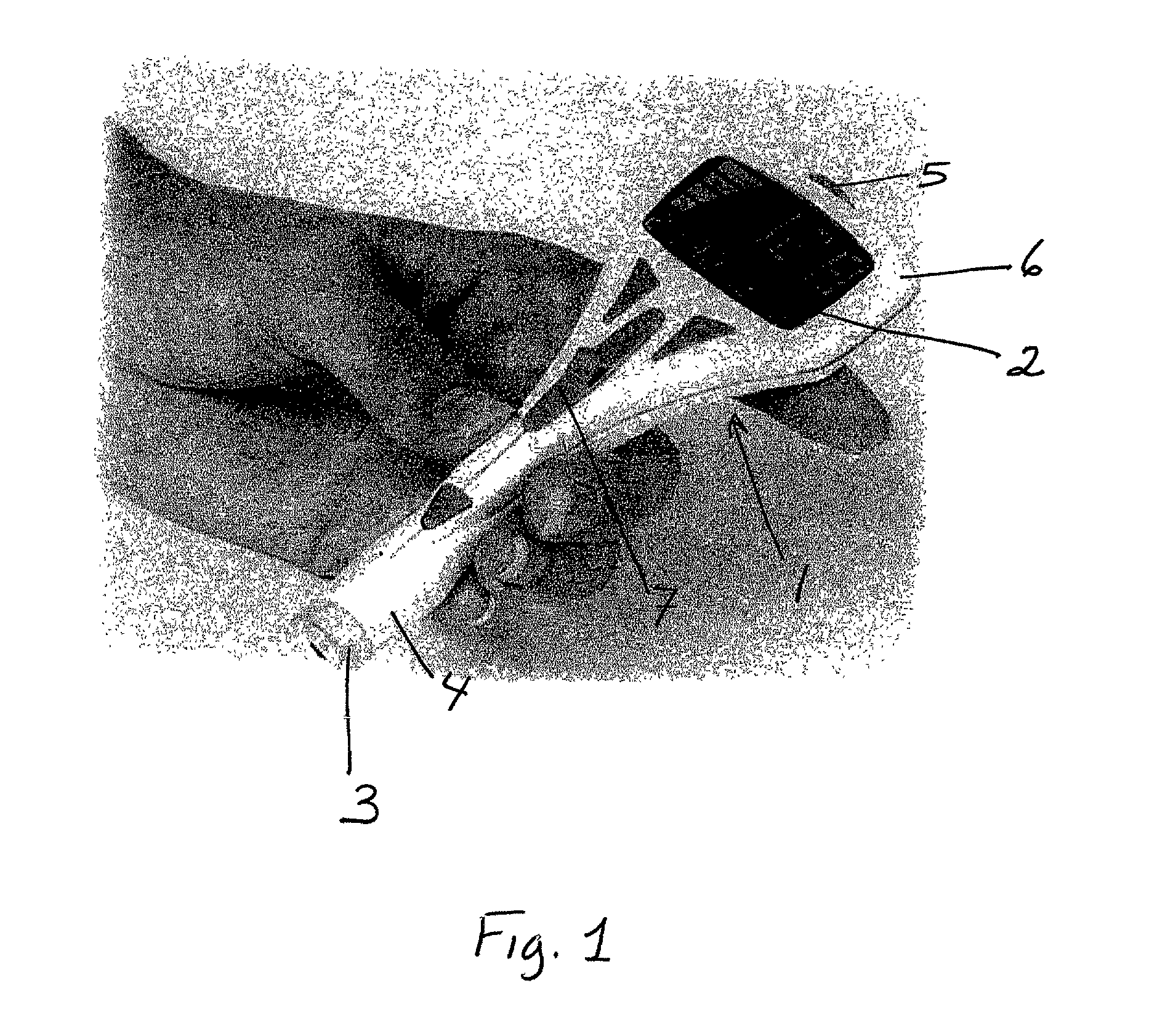

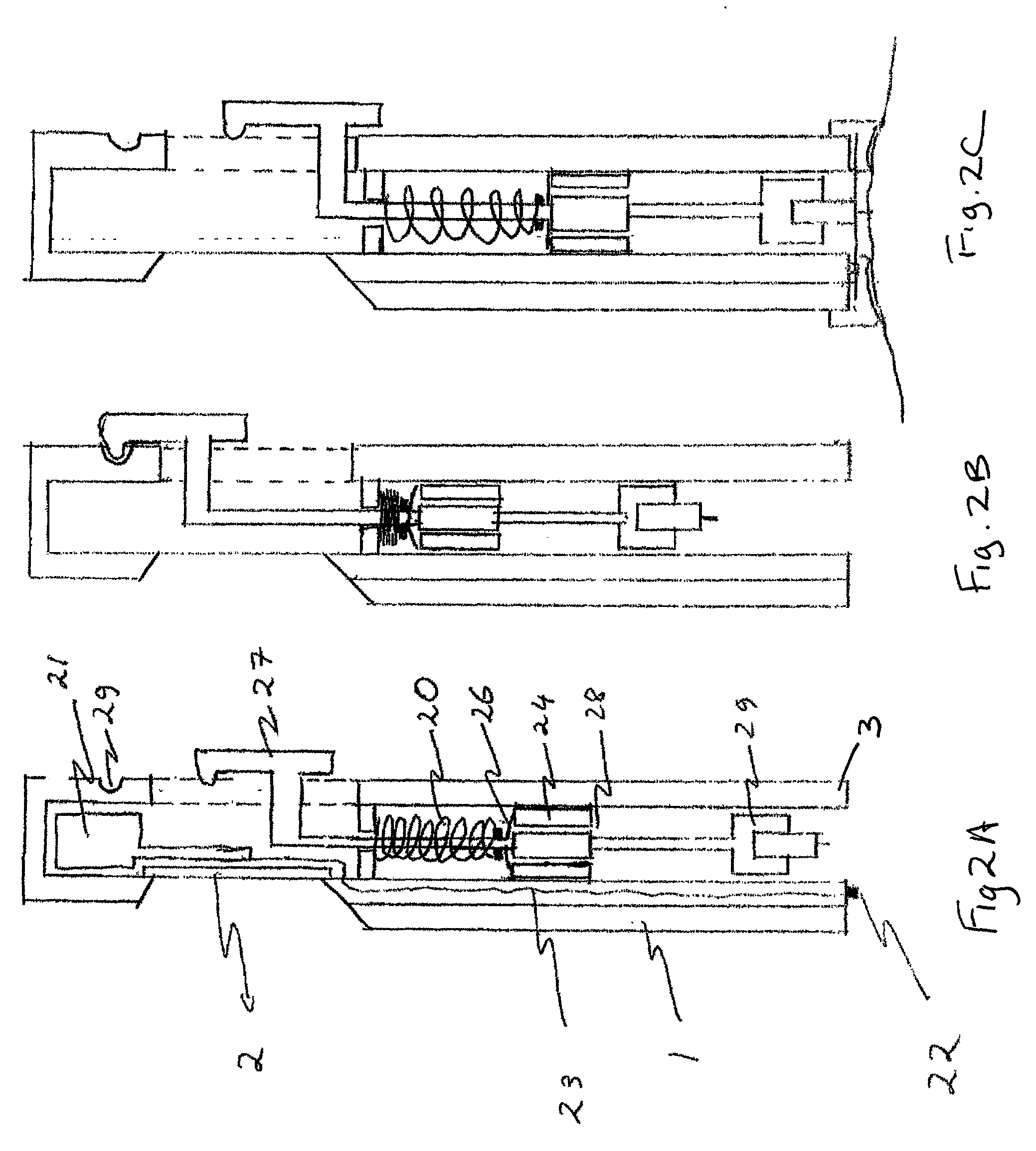

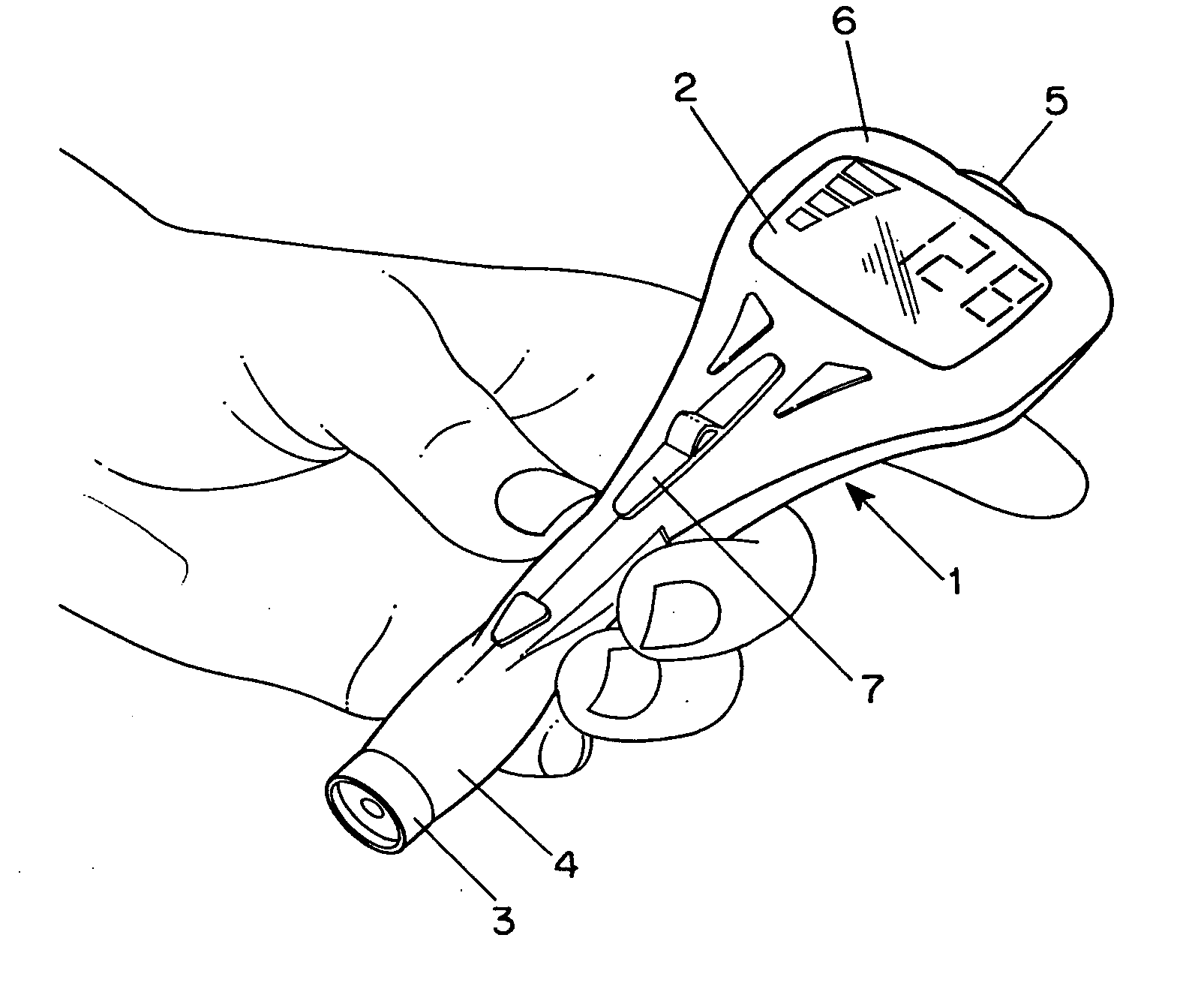

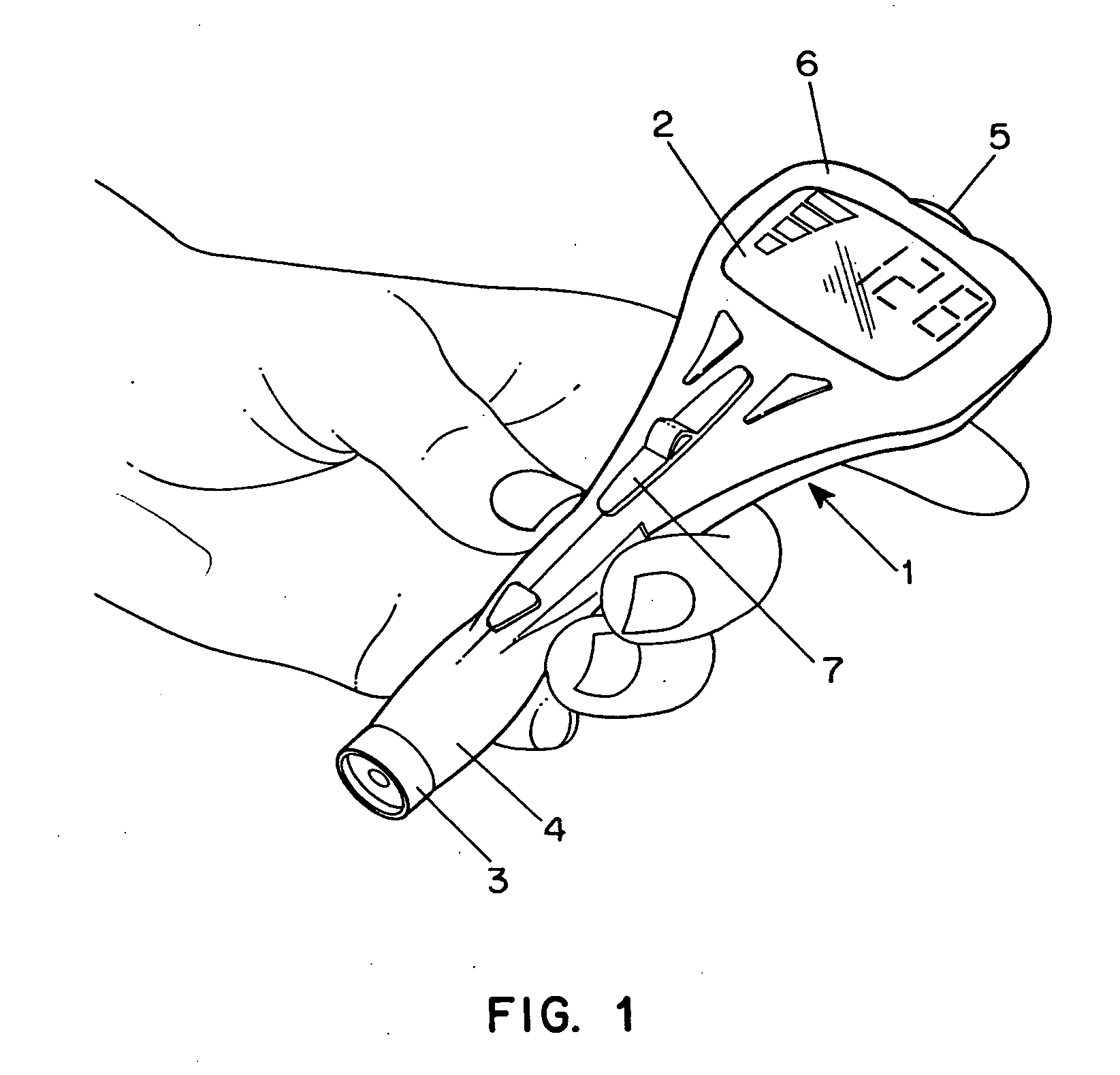

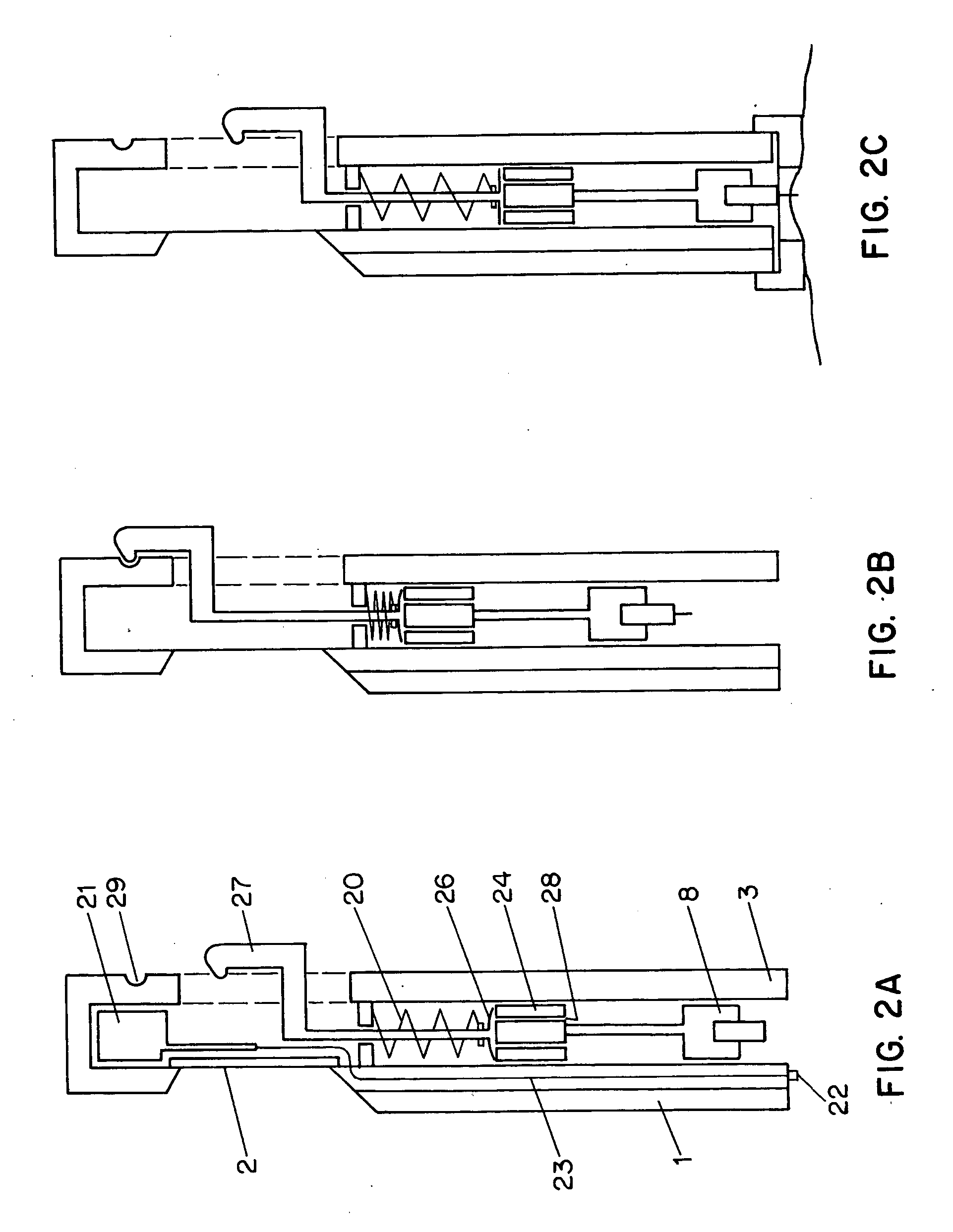

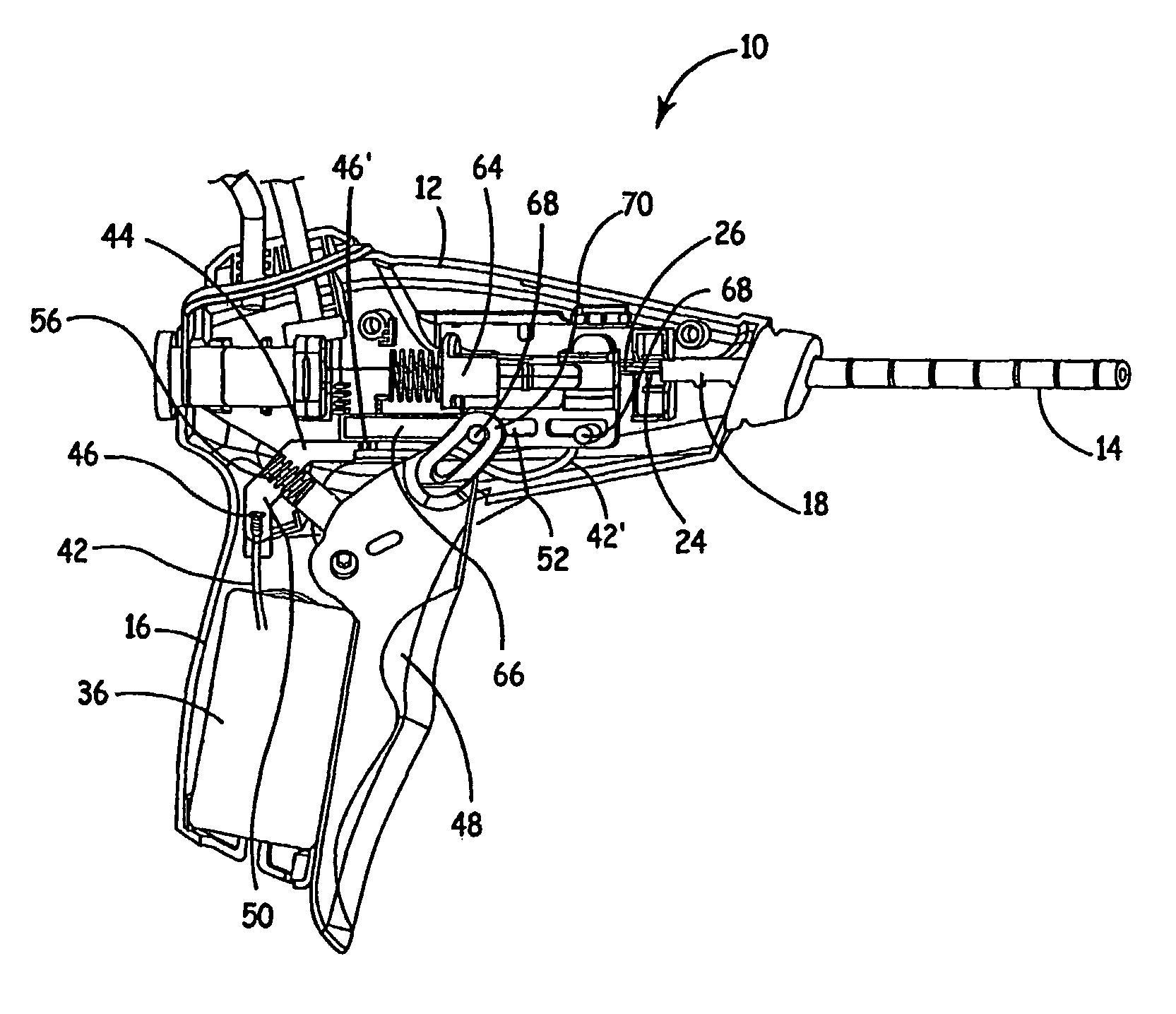

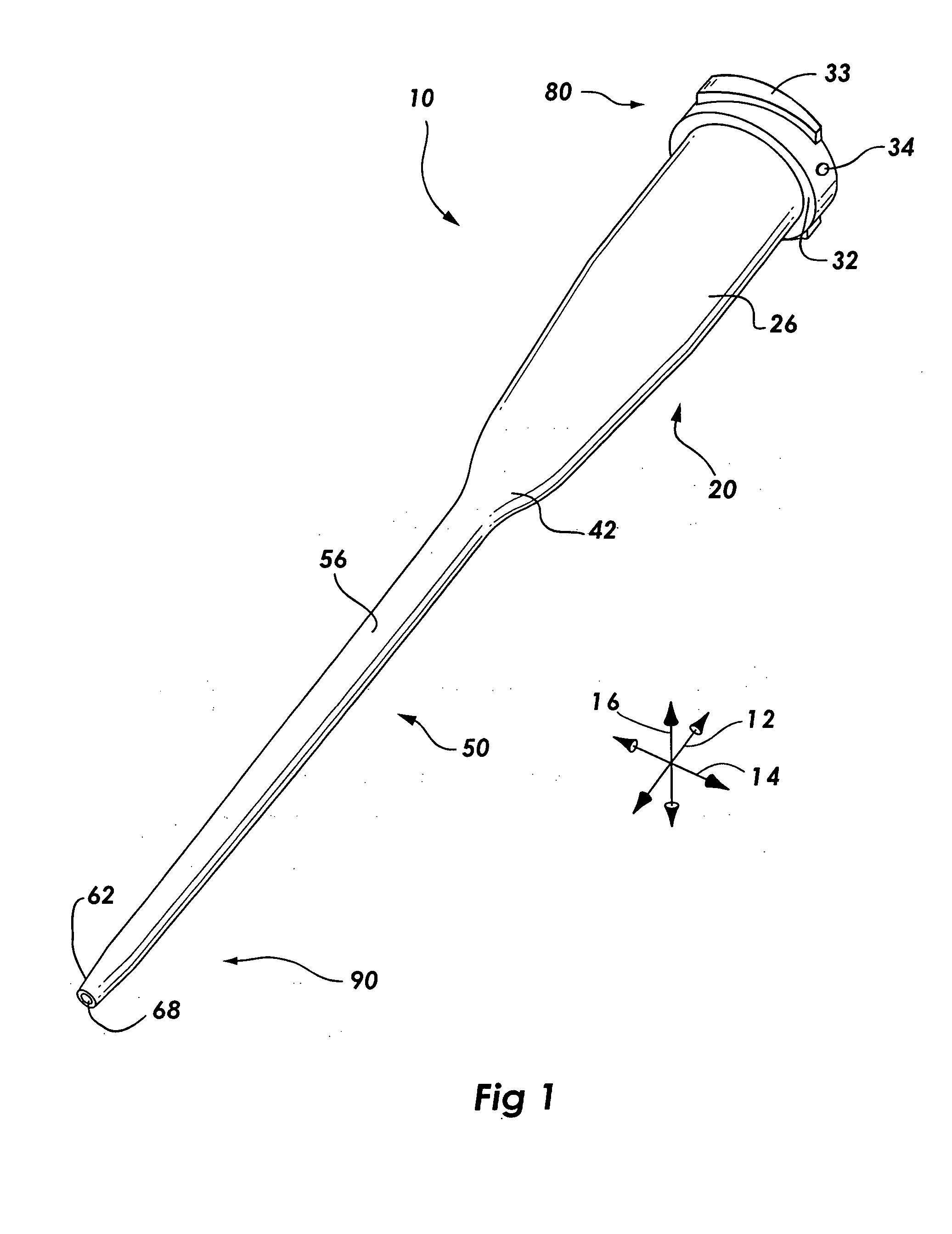

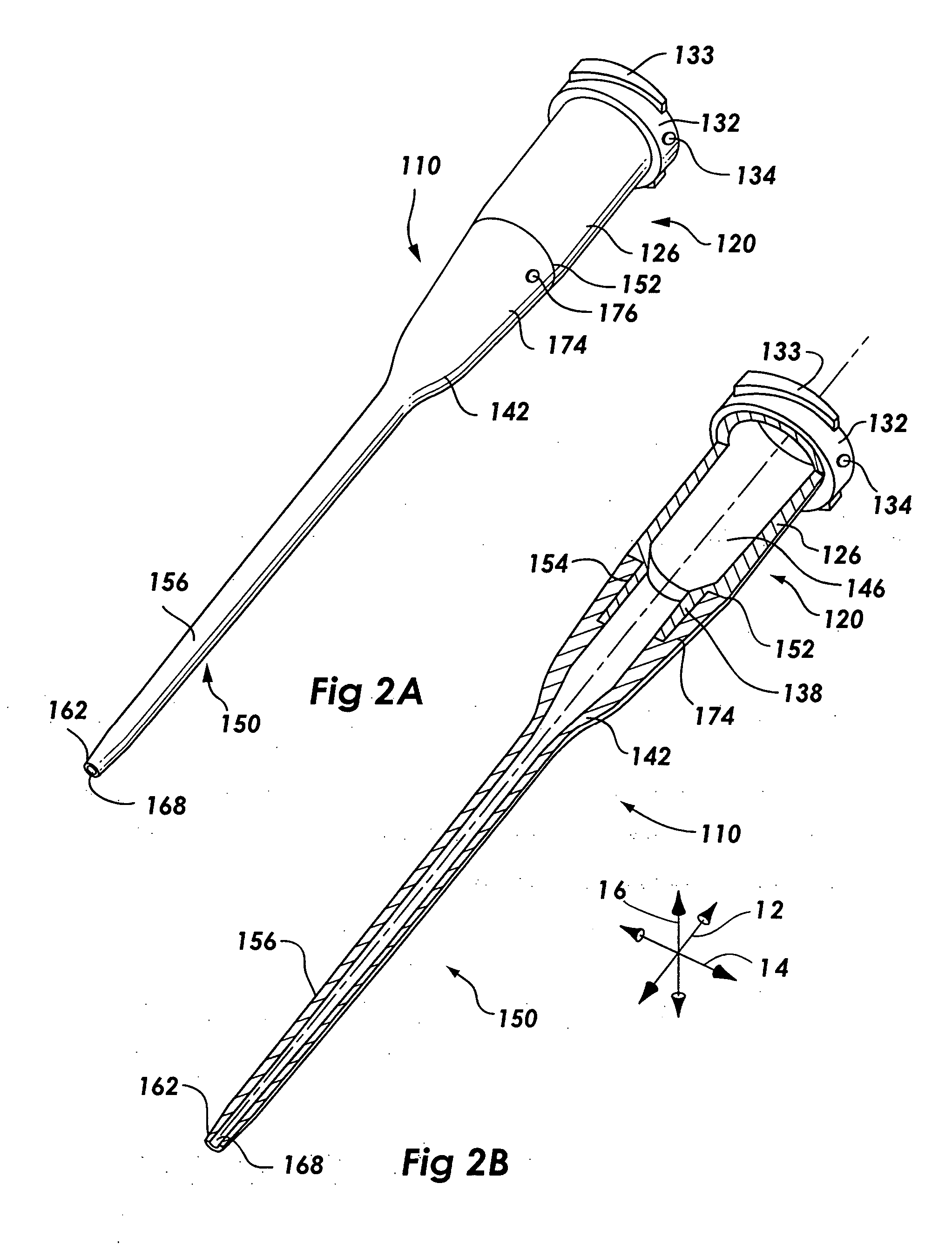

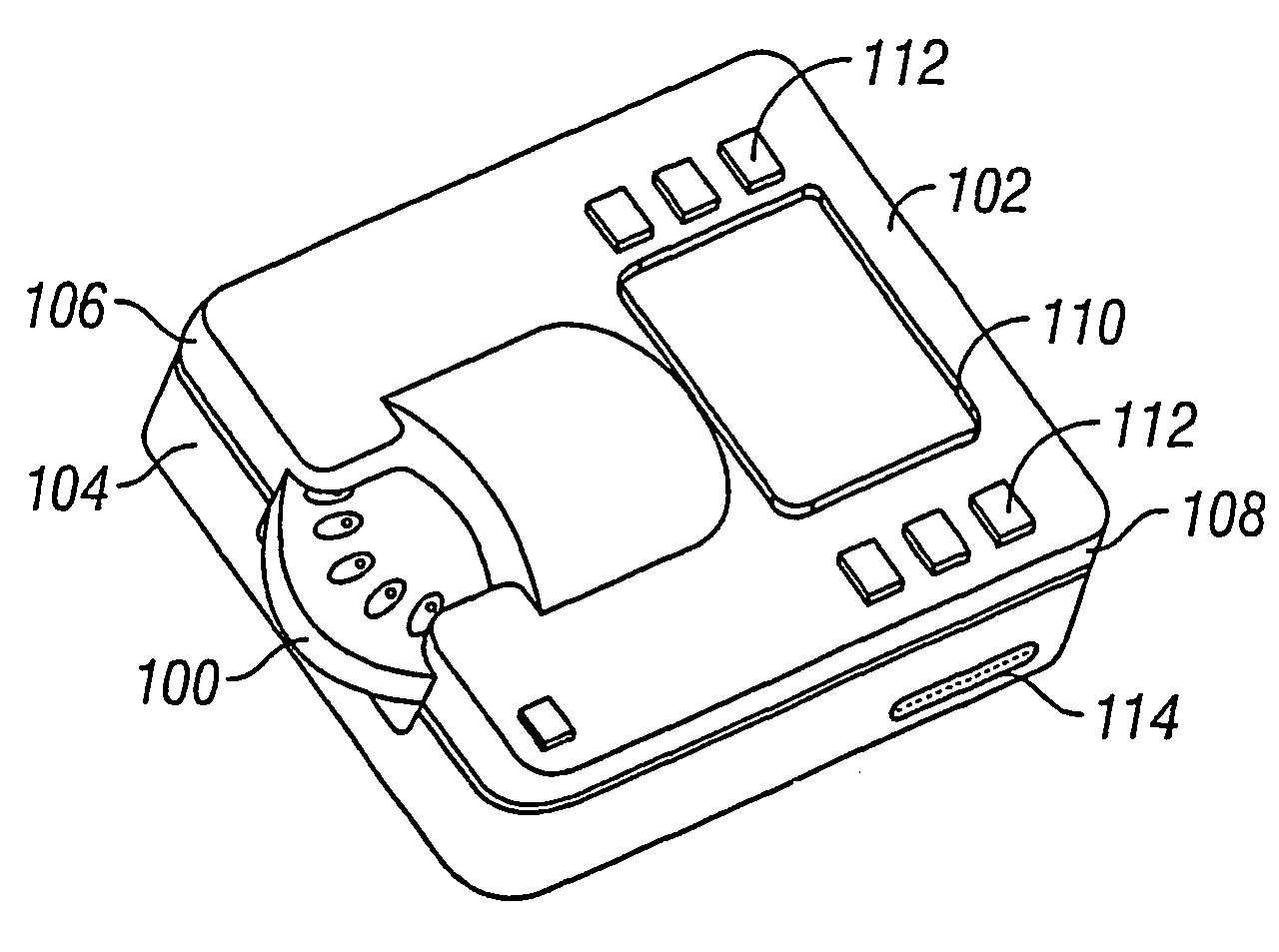

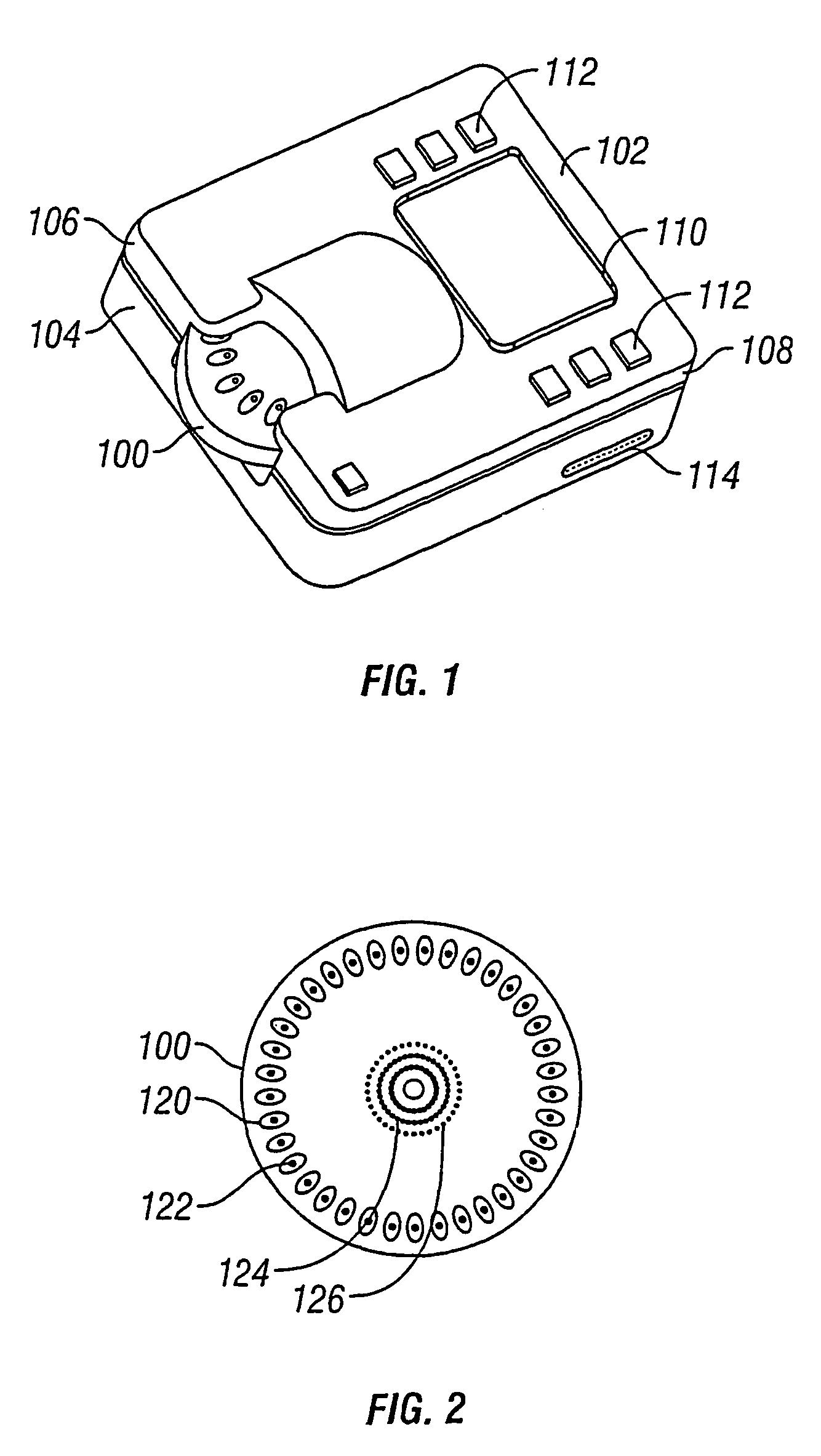

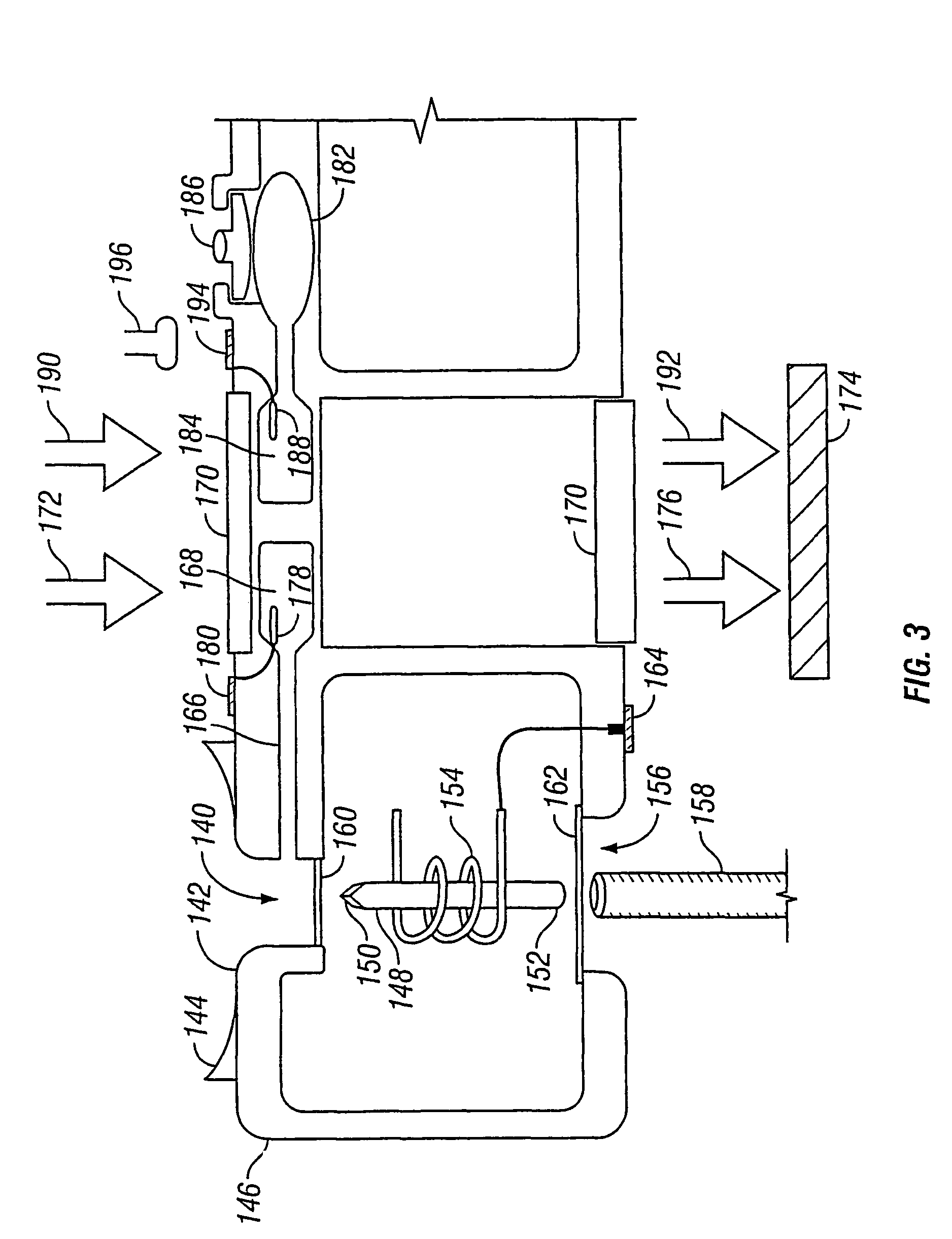

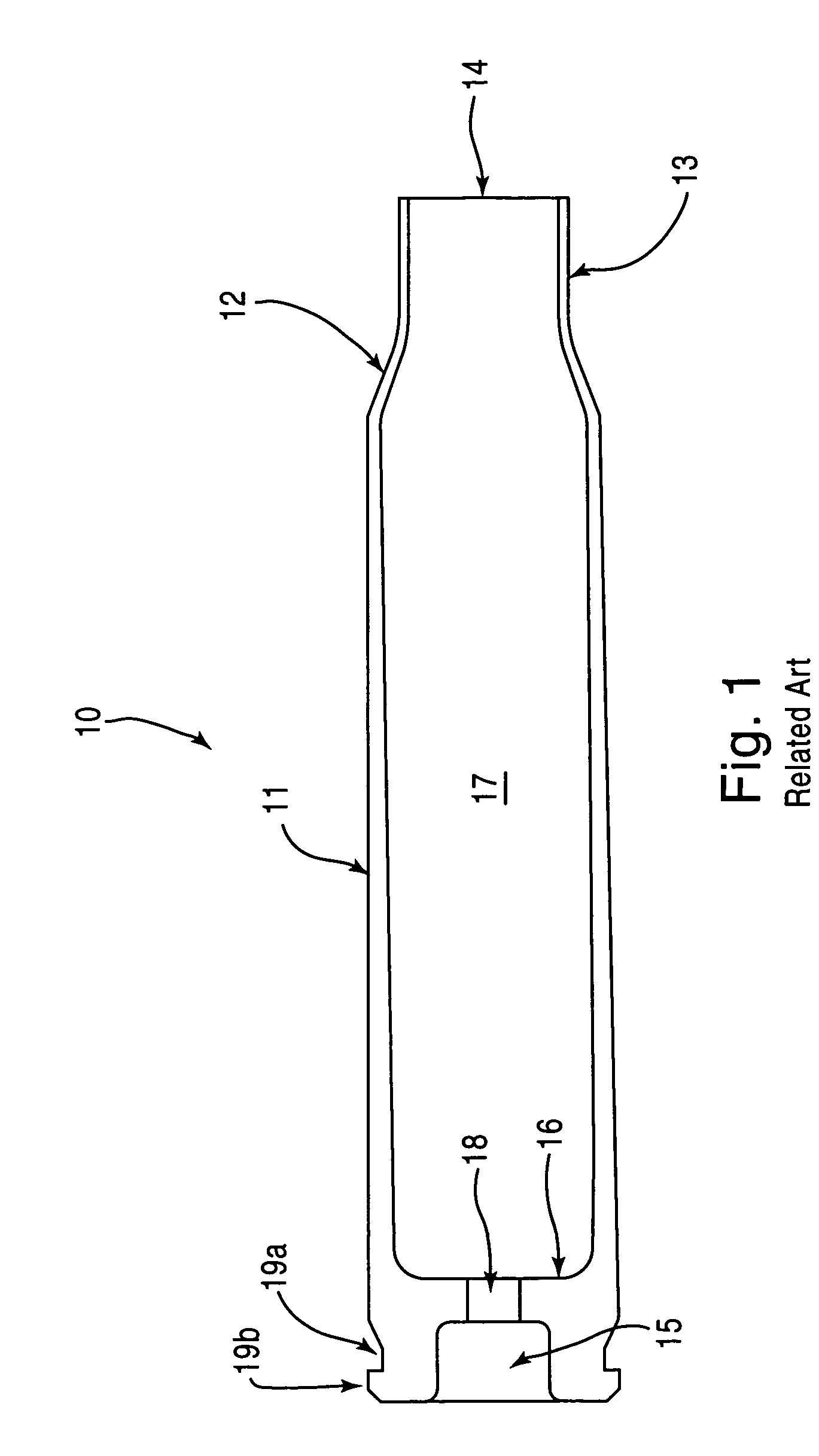

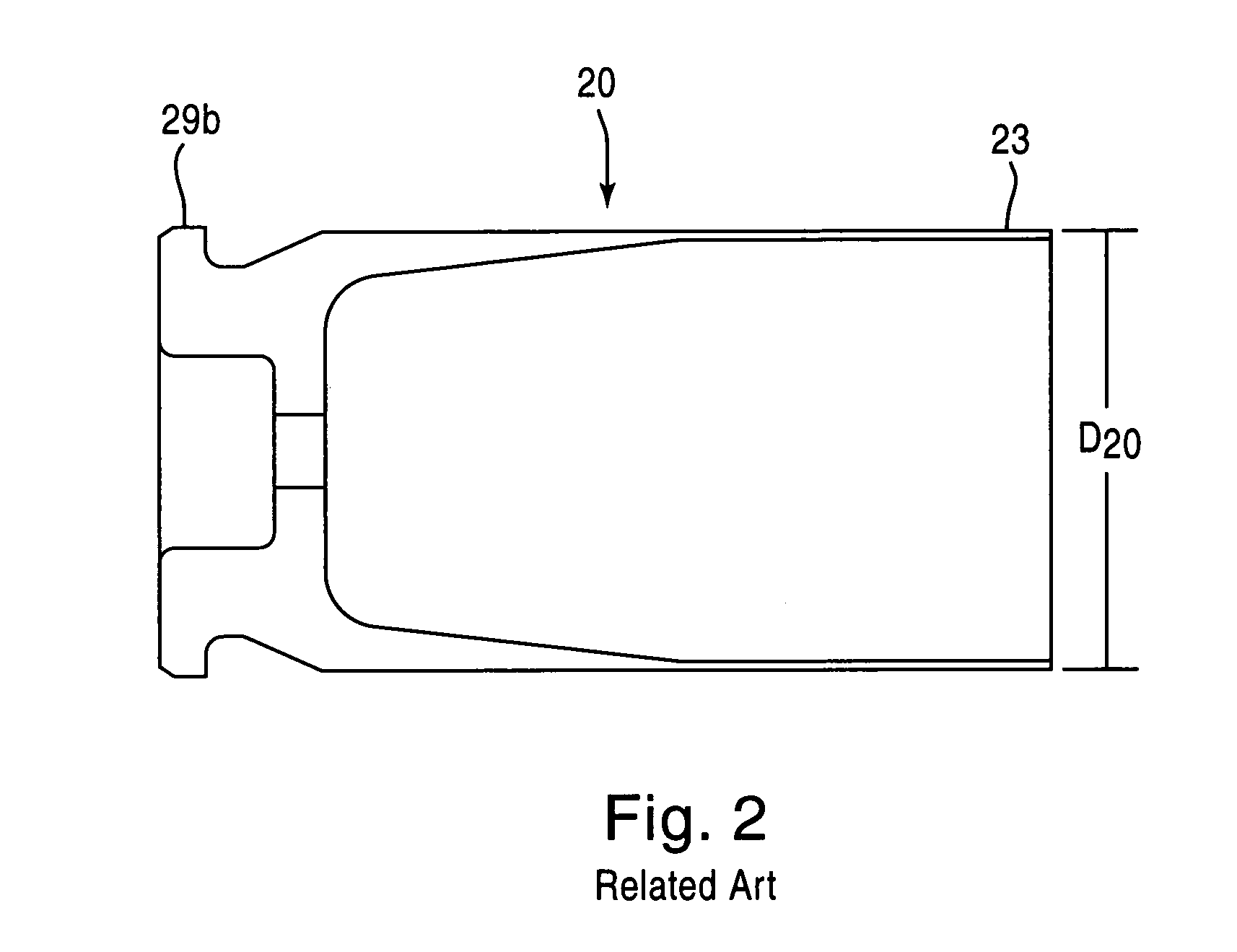

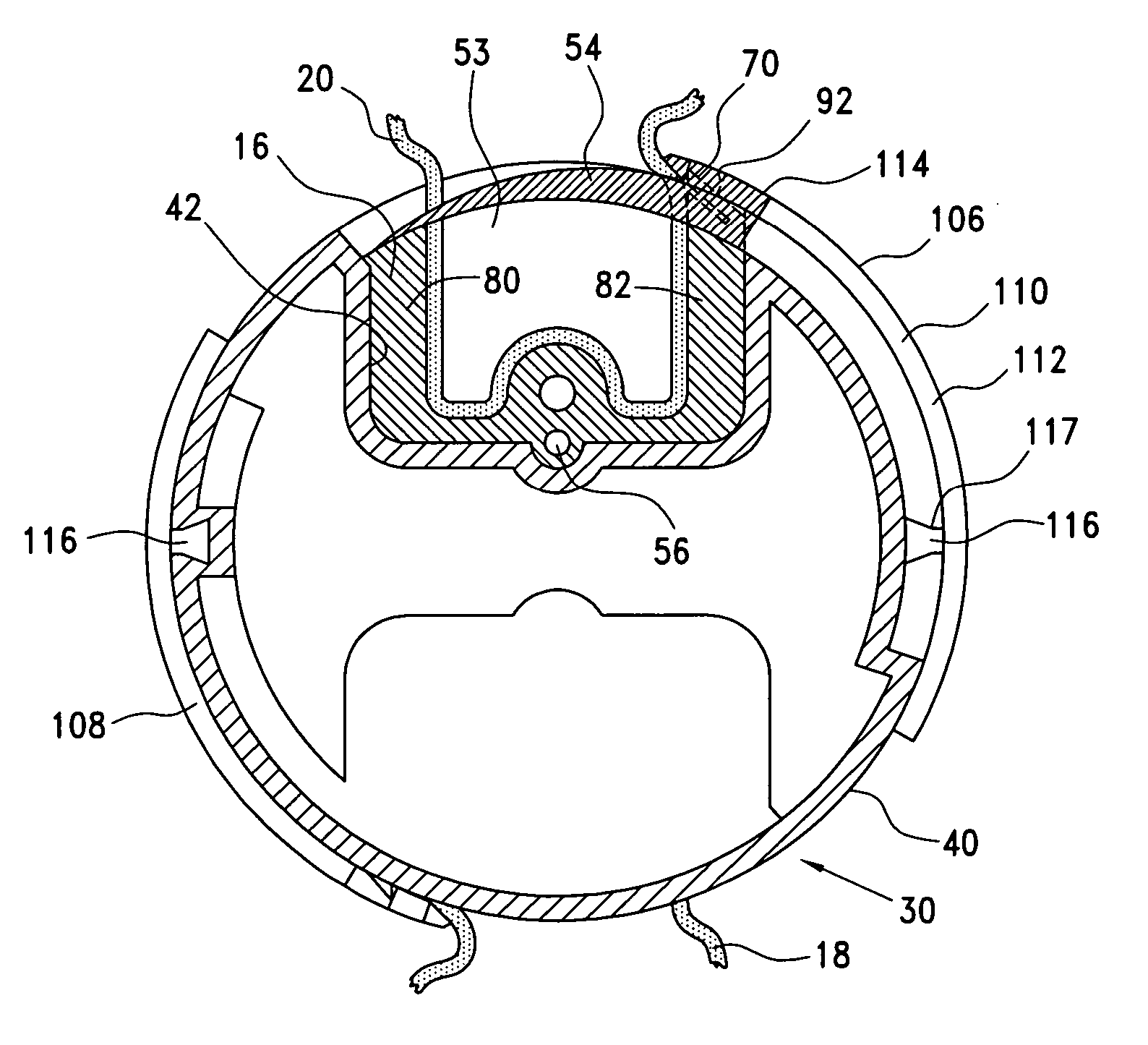

Combined lancet and electrochemical analyte-testing apparatus

InactiveUS20020130042A1Easy to takeReduces and eliminates disposal issueImmobilised enzymesBioreactor/fermenter combinationsAnalyteDisplay device

An apparatus for detection and quantitation of an electrochemically-detect- able analyte, such as glucose, in blood or interstitial fluid includes a meter unit, a lancet and an electrochemical sensor. Of these components, the meter is preferably reusable, while the lancet and the electrochemical sensor are preferably incorporated in assemblies intended for single-use. The meter unit has a housing, within which a lancet is engaged with a mechanism for moving then lancet; a connector disposed within the housing for engaging an electrochemical sensor specific for the analyte and transmitting a signal indicative of the amount of analyte, and a display operatively-associated with a connector for displaying the amount of the analyte to user. The electrochemical sensor is adapted for detection of a particular analyte. In addition, the electrochemical sensor has an absorptive member for uptake of a sample of blood or interstitial fluid. In one version, the lancet moves from a initial position to a piercing position in which skin of the user is pierced and optionally back to a retracted position. The electrochemical sensor is disposed such that the absorptive member takes up a sample from the pierced skin of the user when it is pierced by the lancet without movement of the apparatus. In an alternative version, the lancet is a hollow cannula through which blood or interstitial fluid is transported from the puncture site to an absorbent portion of the electrochemical sensor. In either version, the apparatus provides single-step operation in which sample acquisition and analysis occur as a result of the single action of pressing the apparatus against the users skin.

Owner:LIFESCAN IP HLDG LLC

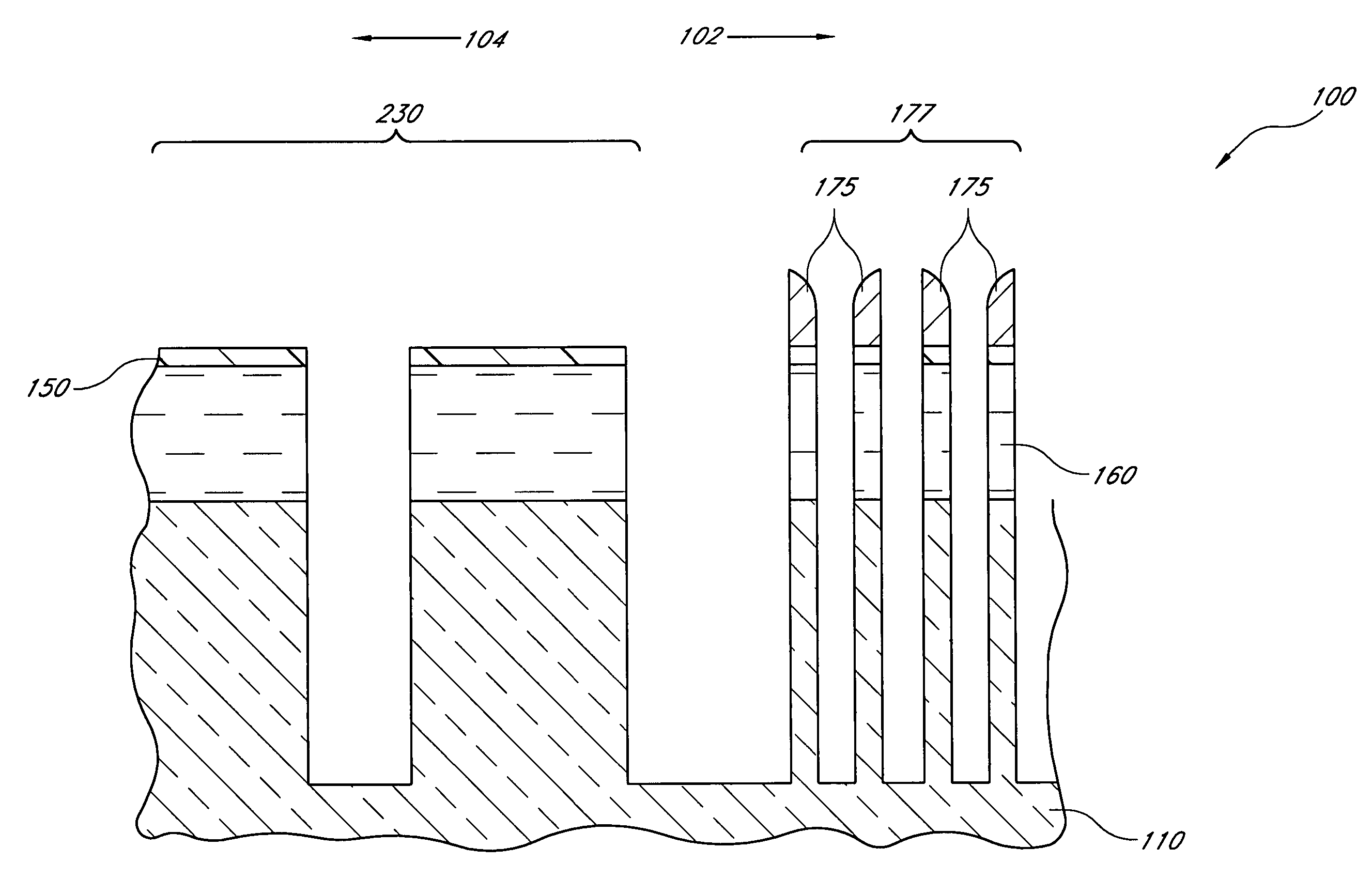

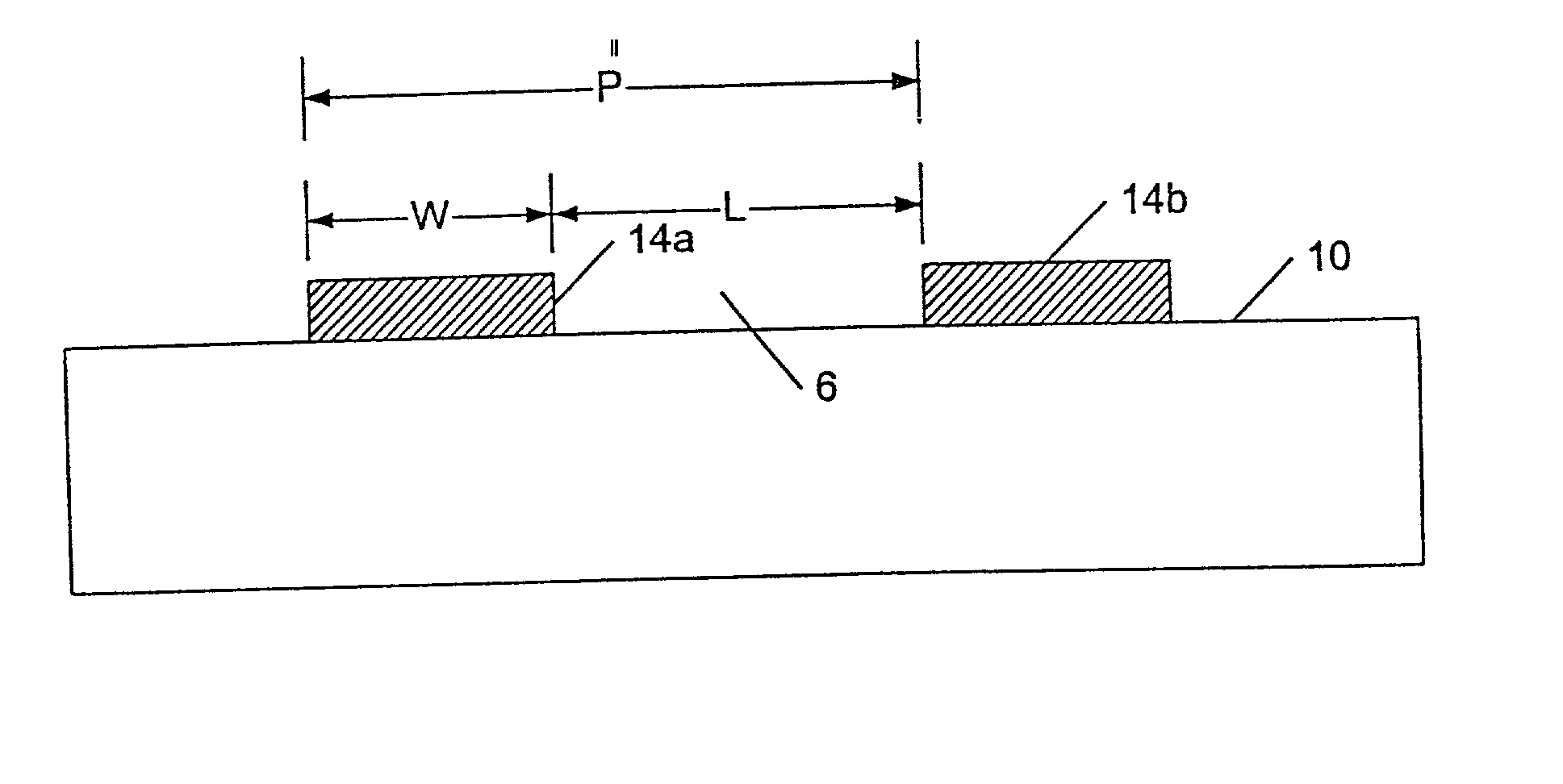

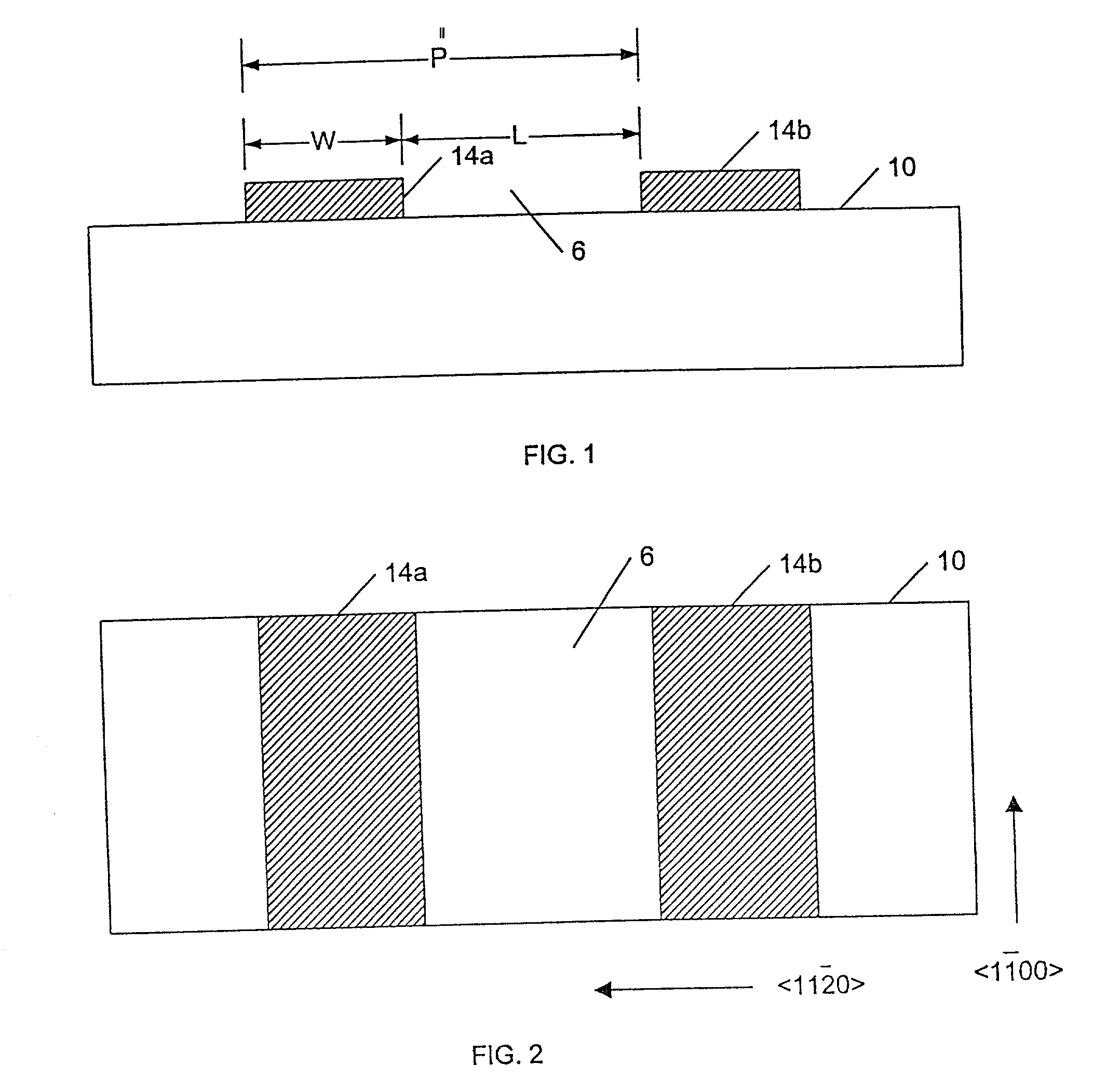

Method for integrated circuit fabrication using pitch multiplication

InactiveUS7115525B2Electric discharge tubesSemiconductor/solid-state device manufacturingResistEngineering

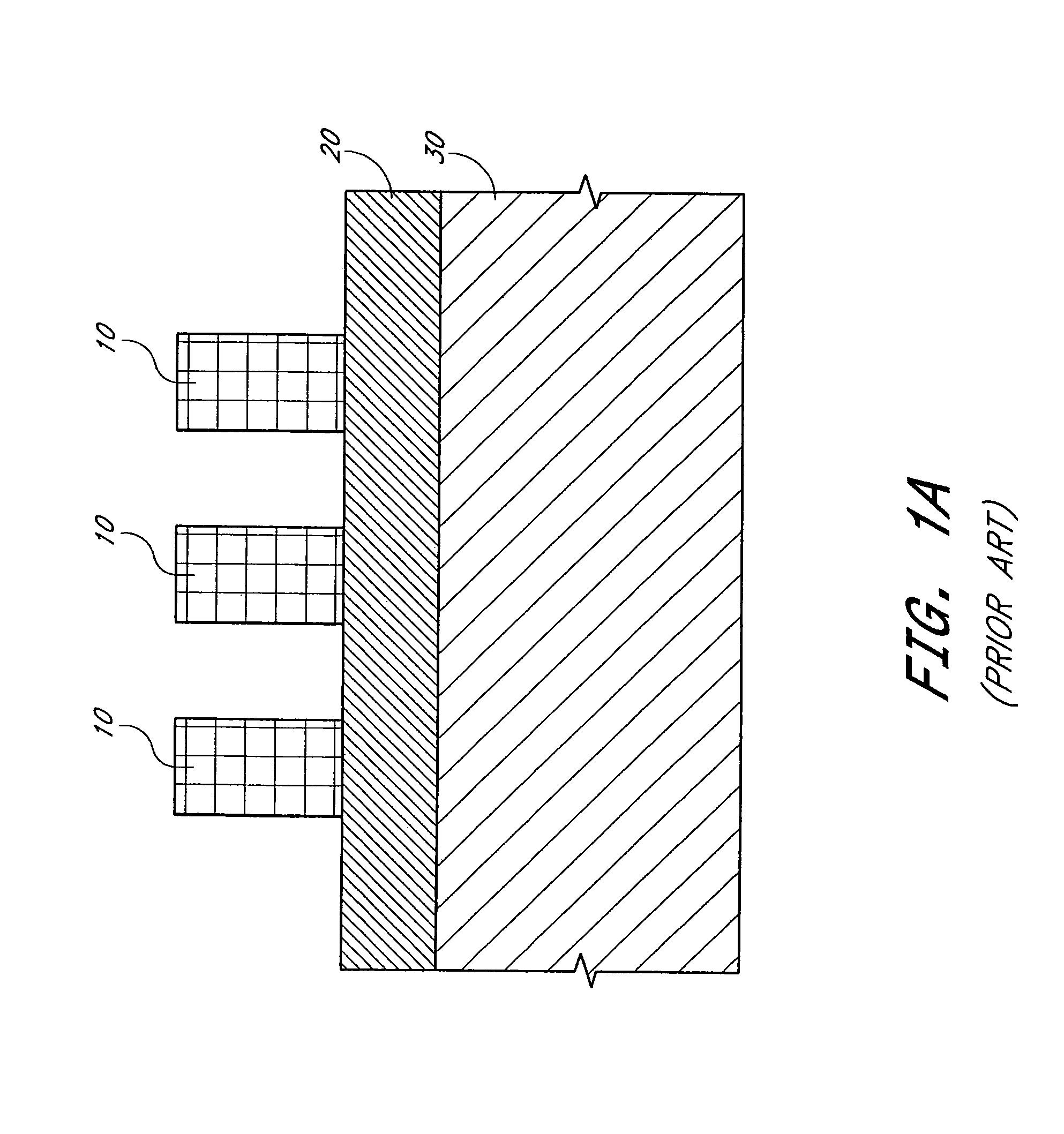

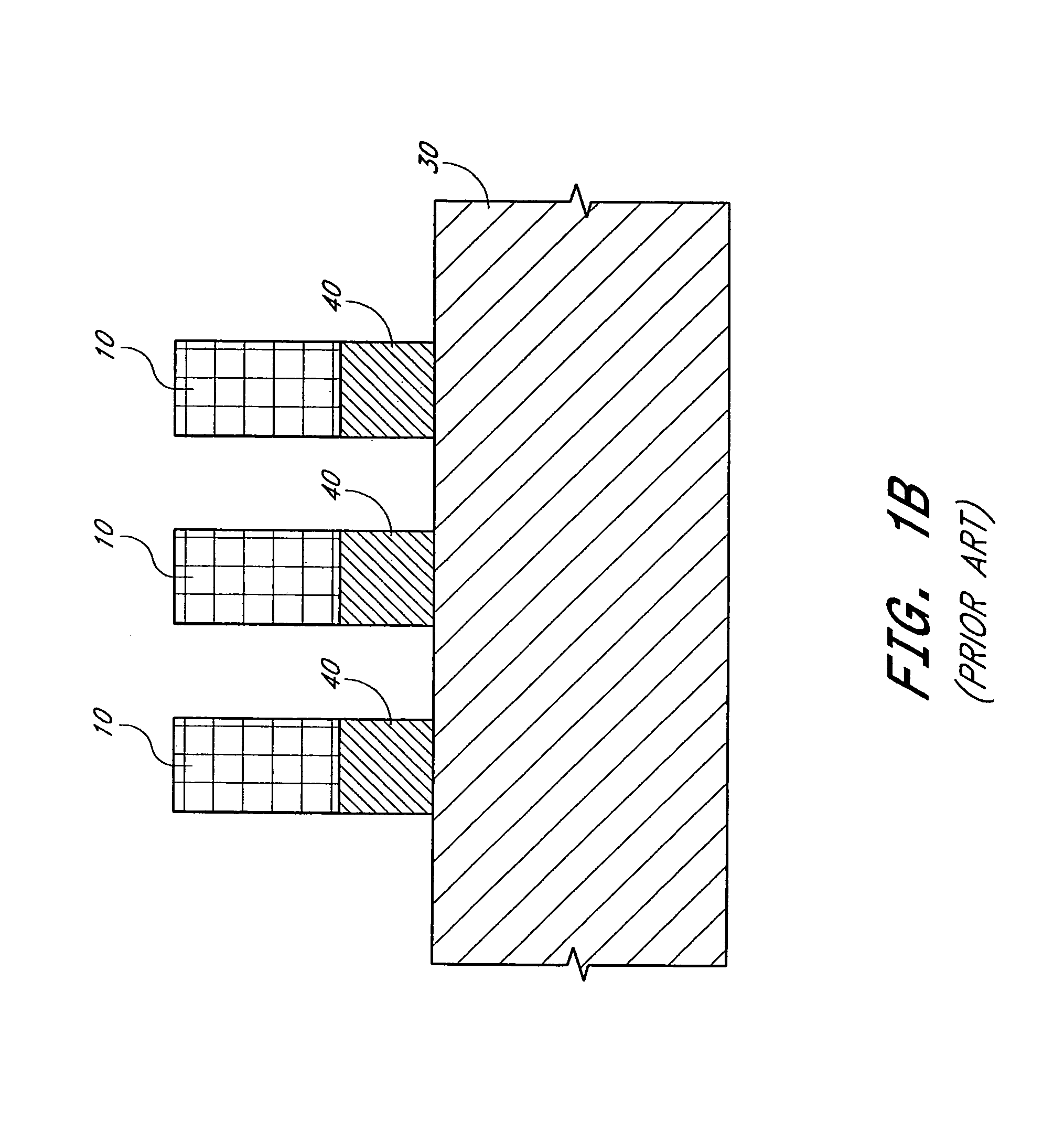

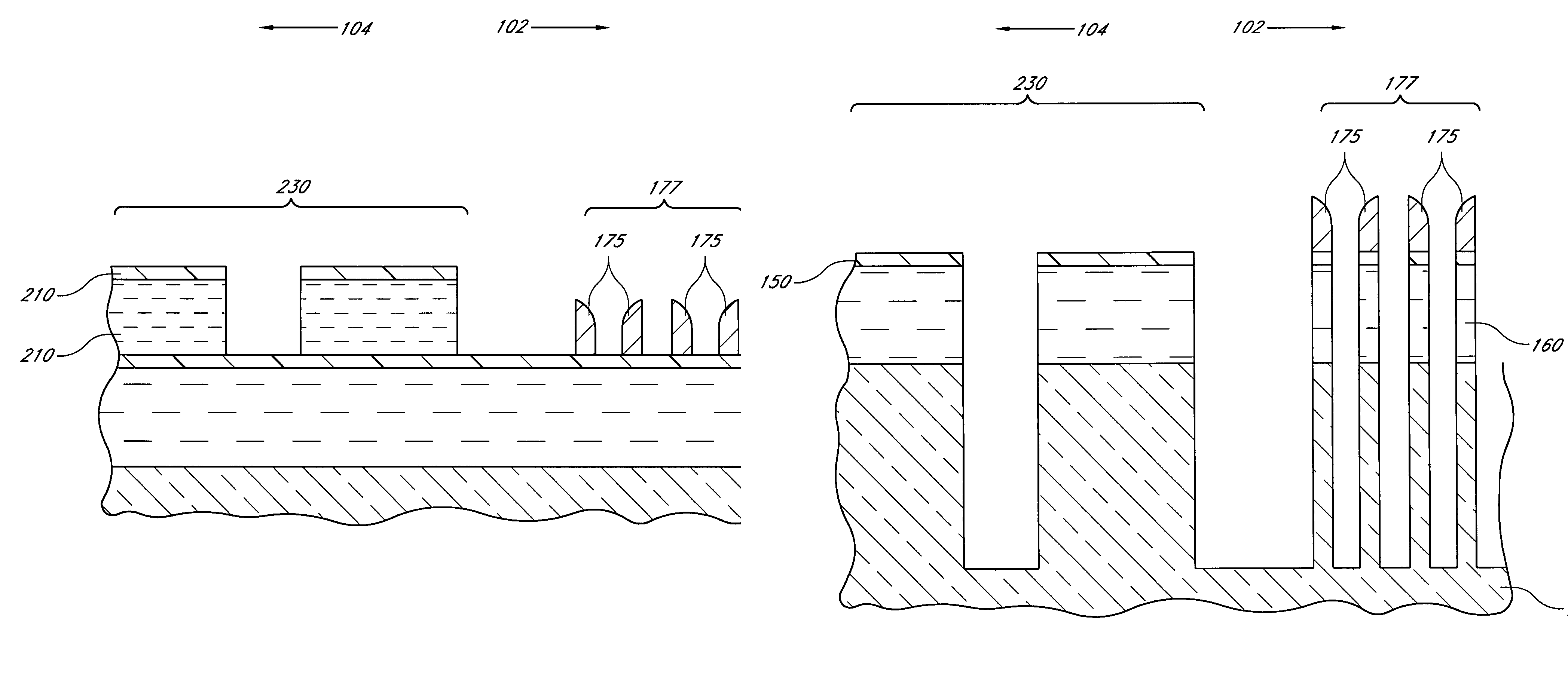

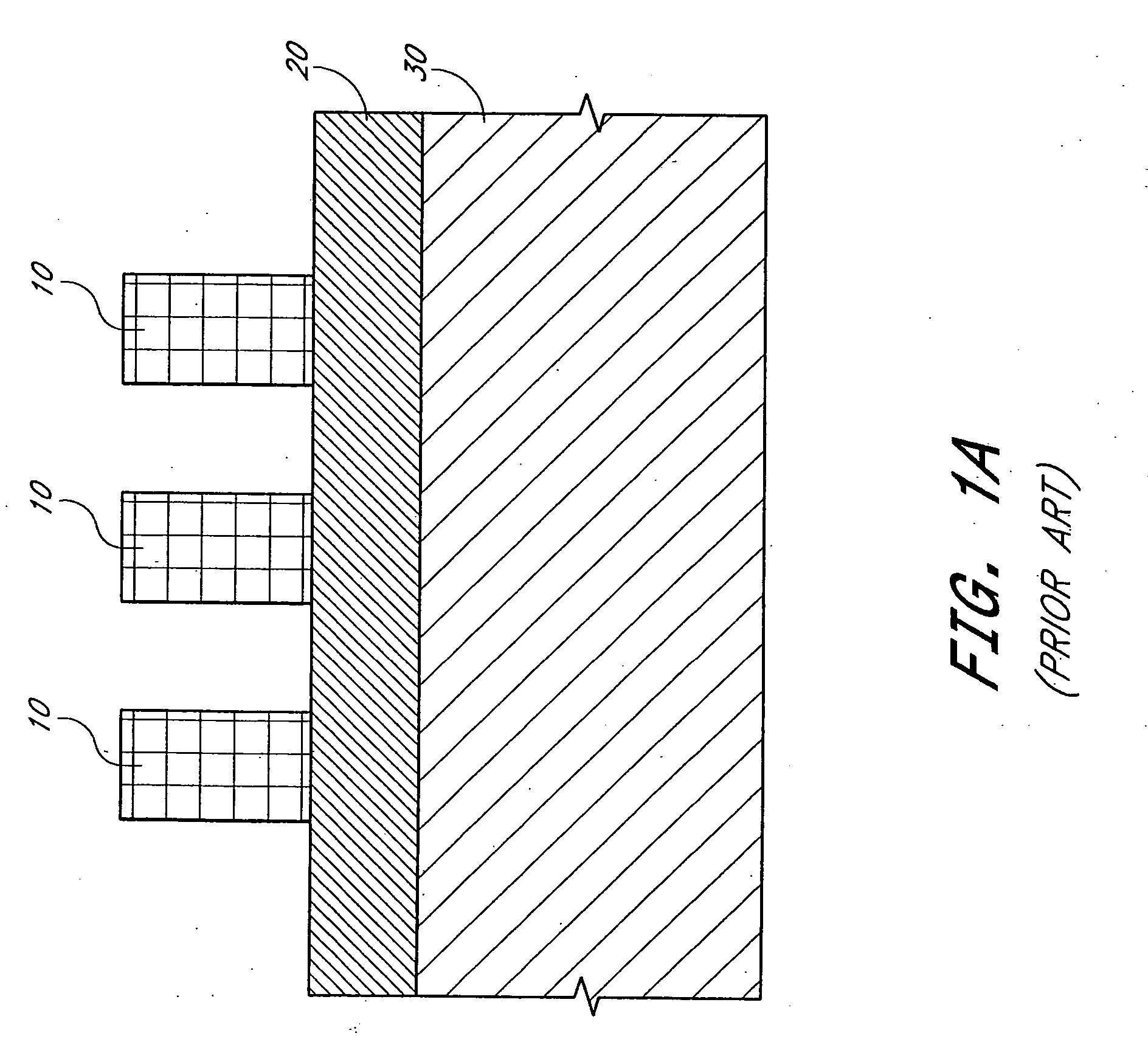

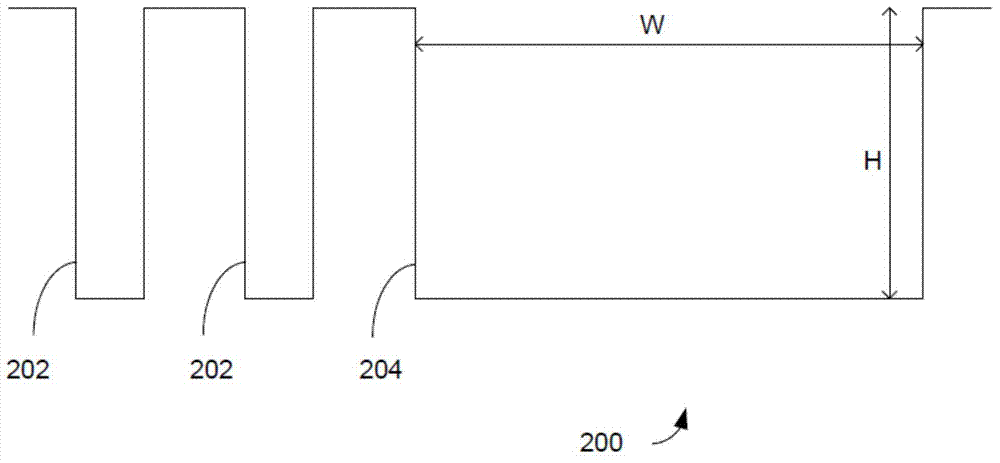

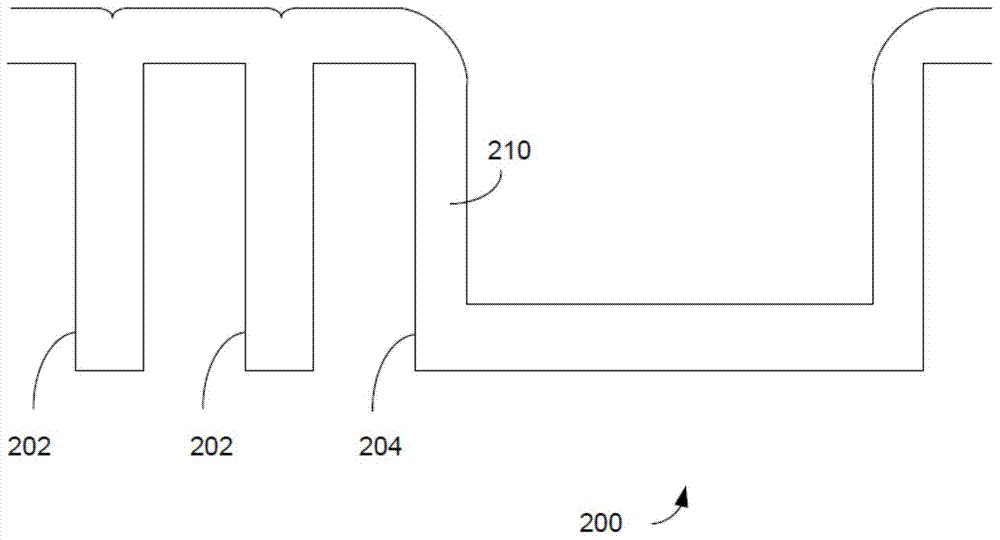

Different sized features in the array and in the periphery of an integrated circuit are patterned on a substrate in a single step. In particular, a mixed pattern, combining two separately formed patterns, is formed on a single mask layer and then transferred to the underlying substrate. The first of the separately formed patterns is formed by pitch multiplication and the second of the separately formed patterns is formed by conventional photolithography. The first of the separately formed patterns includes lines that are below the resolution of the photolithographic process used to form the second of the separately formed patterns. These lines are made by forming a pattern on photoresist and then etching that pattern into an amorphous carbon layer. Sidewall pacers having widths less than the widths of the un-etched parts of the amorphous carbon are formed on the sidewalls of the amorphous carbon. The amorphous carbon is then removed, leaving behind the sidewall spacers as a mask pattern. Thus, the spacers form a mask having feature sizes less than the resolution of the photolithography process used to form the pattern on the photoresist. A protective material is deposited around the spacers. The spacers are further protected using a hard mask and then photoresist is formed and patterned over the hard mask. The photoresist pattern is transferred through the hard mask to the protective material. The pattern made out by the spacers and the temporary material is then transferred to an underlying amorphous carbon hard mask layer. The pattern, having features of difference sizes, is then transferred to the underlying substrate.

Owner:ROUND ROCK RES LLC

Method for integrated circuit fabrication using pitch multiplication

InactiveUS20060046484A1Electric discharge tubesSemiconductor/solid-state device manufacturingImage resolutionDifferences size

Different sized features in the array and in the periphery of an integrated circuit are patterned on a substrate in a single step. In particular, a mixed pattern, combining two separately formed patterns, is formed on a single mask layer and then transferred to the underlying substrate. The first of the separately formed patterns is formed by pitch multiplication and the second of the separately formed patterns is formed by conventional photolithography. The first of the separately formed patterns includes lines that are below the resolution of the photolithographic process used to form the second of the separately formed patterns. These lines are made by forming a pattern on photoresist and then etching that pattern into an amorphous carbon layer. Sidewall pacers having widths less than the widths of the un-etched parts of the amorphous carbon are formed on the sidewalls of the amorphous carbon. The amorphous carbon is then removed, leaving behind the sidewall spacers as a mask pattern. Thus, the spacers form a mask having feature sizes less than the resolution of the photolithography process used to form the pattern on the photoresist. A protective material is deposited around the spacers. The spacers are further protected using a hard mask and then photoresist is formed and patterned over the hard mask. The photoresist pattern is transferred through the hard mask to the protective material. The pattern made out by the spacers and the temporary material is then transferred to an underlying amorphous carbon hard mask layer. The pattern, having features of difference sizes, is then transferred to the underlying substrate.

Owner:ROUND ROCK RES LLC

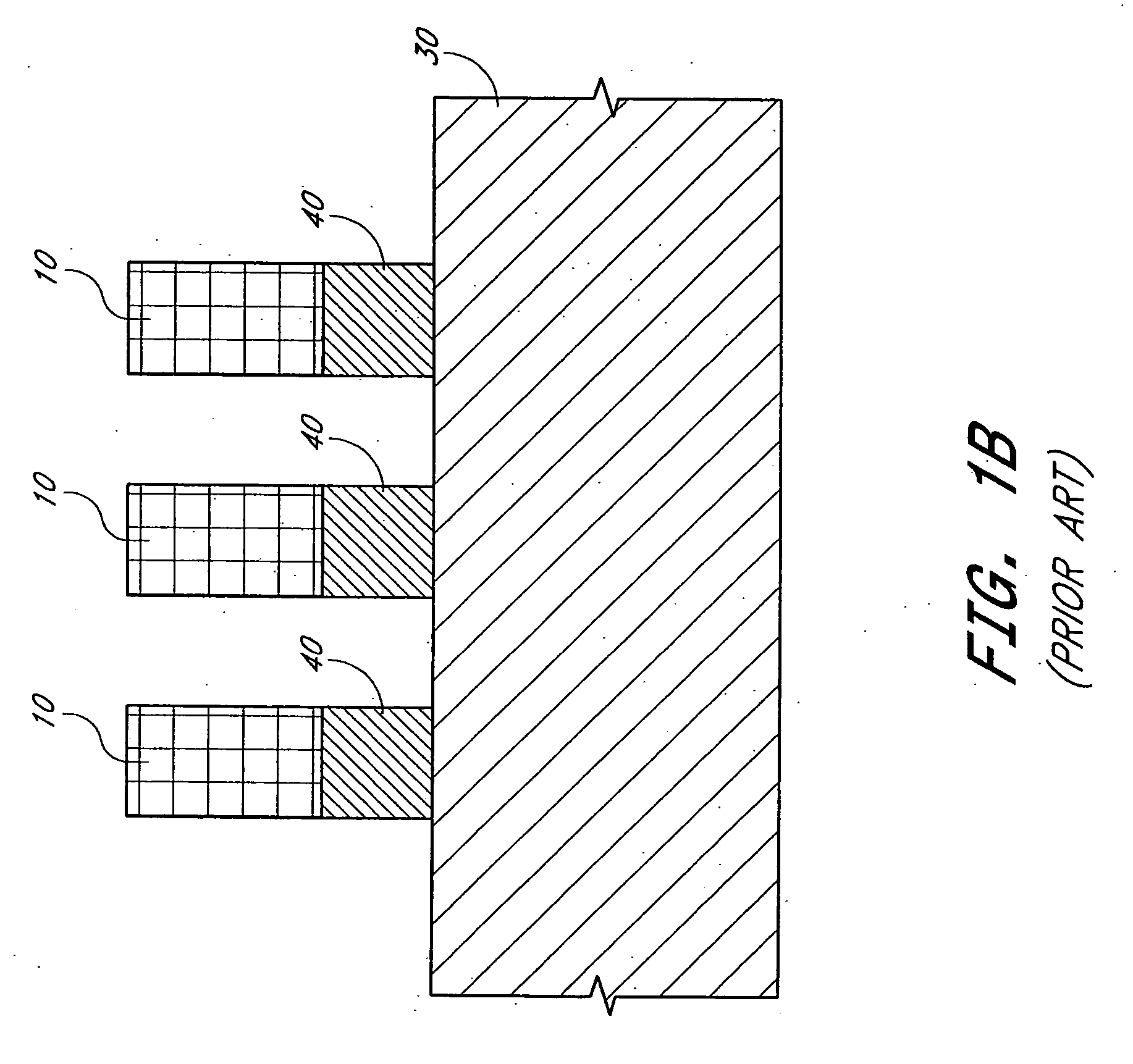

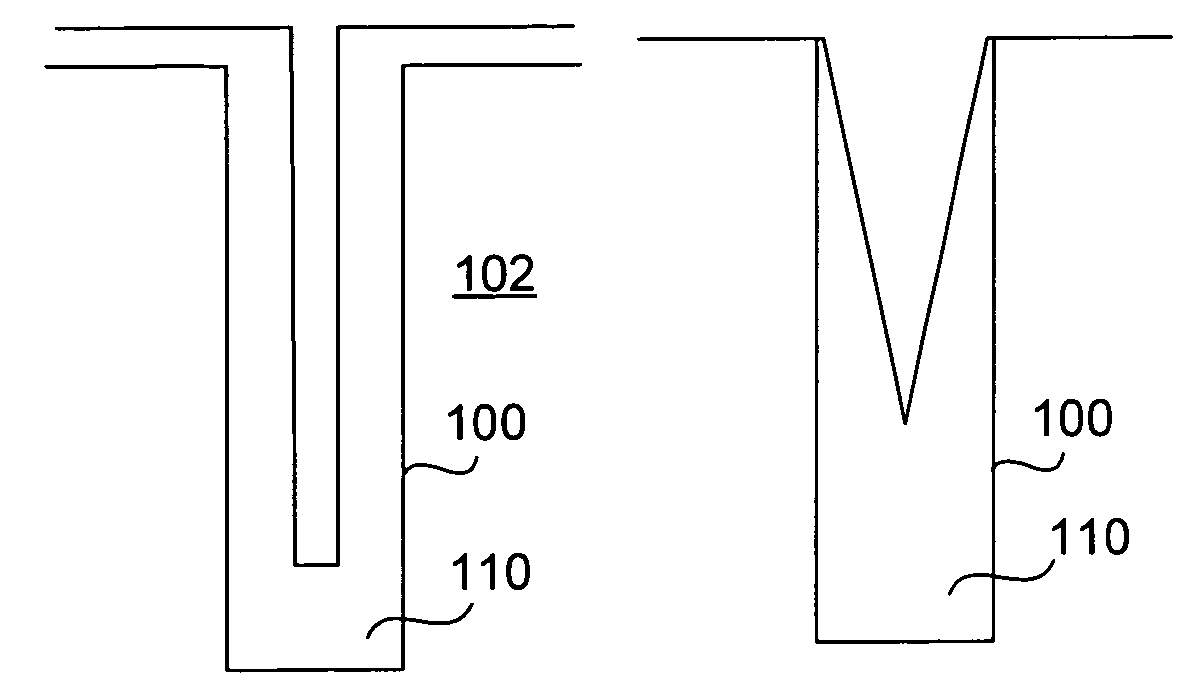

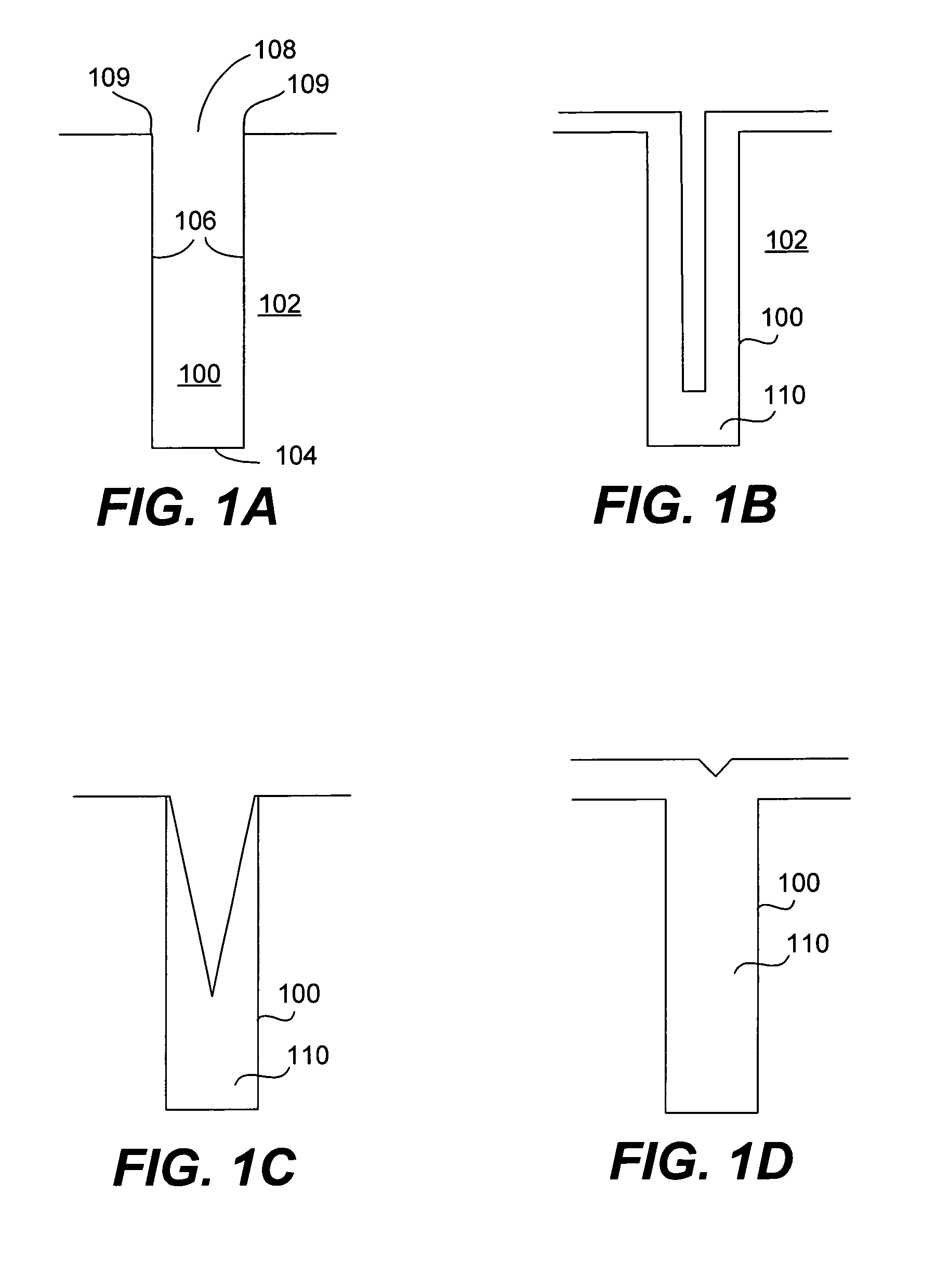

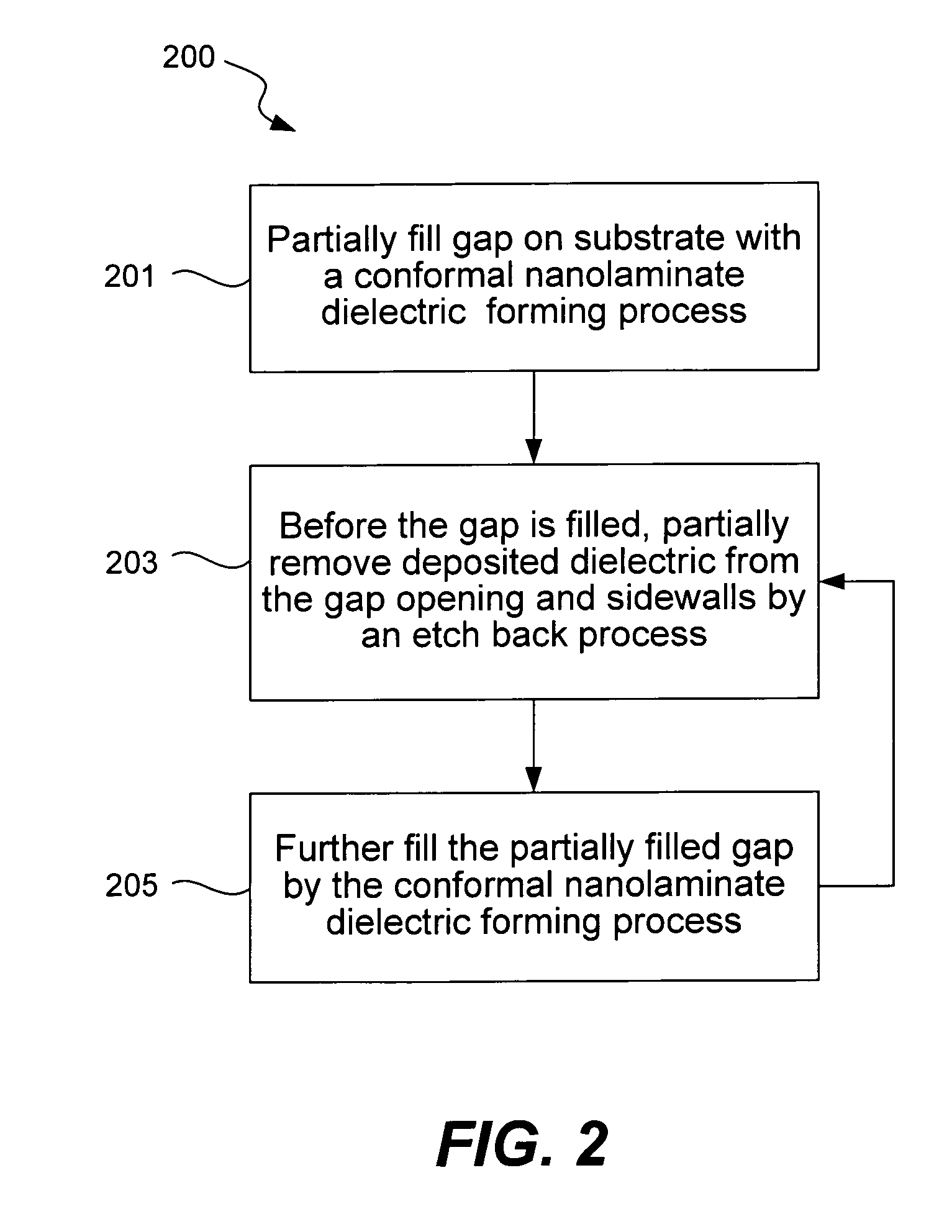

Conformal nanolaminate dielectric deposition and etch back gap fill process

InactiveUS7482247B1Reduce morbidityHigh aspect ratioSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricEngineering

Conformal nanolaminate dielectric deposition and etch back processes that can fill high aspect ratio (typically at least 5:1, for example 6:1), narrow width (typically sub 0.13 micron, for example 0.1 micron or less) gaps with significantly reduced incidence of voids or weak spots involve the use of any suitable confirmal dielectric deposition technique and a dry etch back. The etch back part of the process involves a single step or an integrated multi-step (for example, two-step) procedure including an anisotropic dry etch followed by an isotropic dry etch. The all dry deposition and etch back process in a single tool increases throughput and reduces handling of wafers resulting in more efficient and higher quality nanolaminate dielectric gap fill operations.

Owner:NOVELLUS SYSTEMS

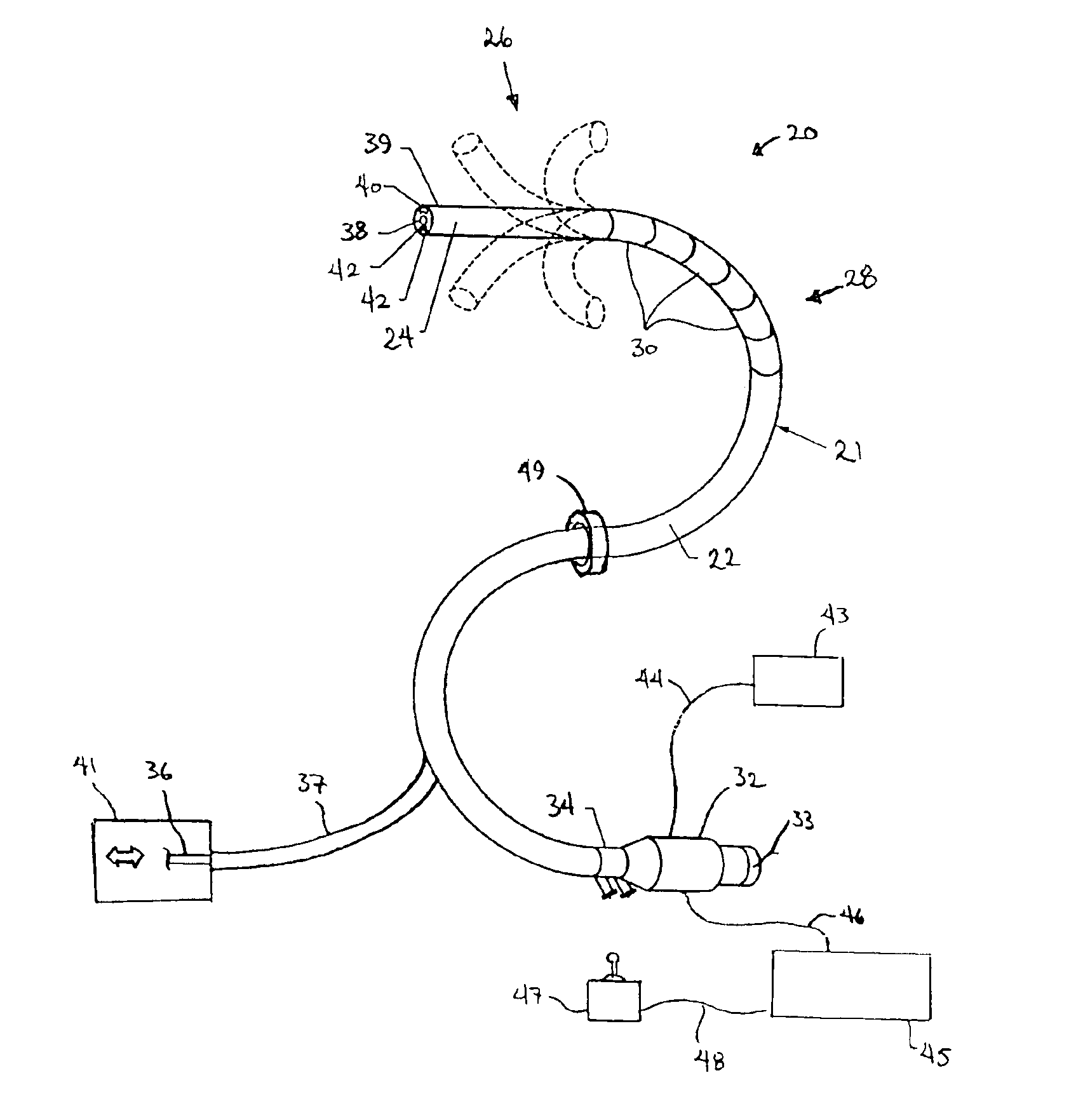

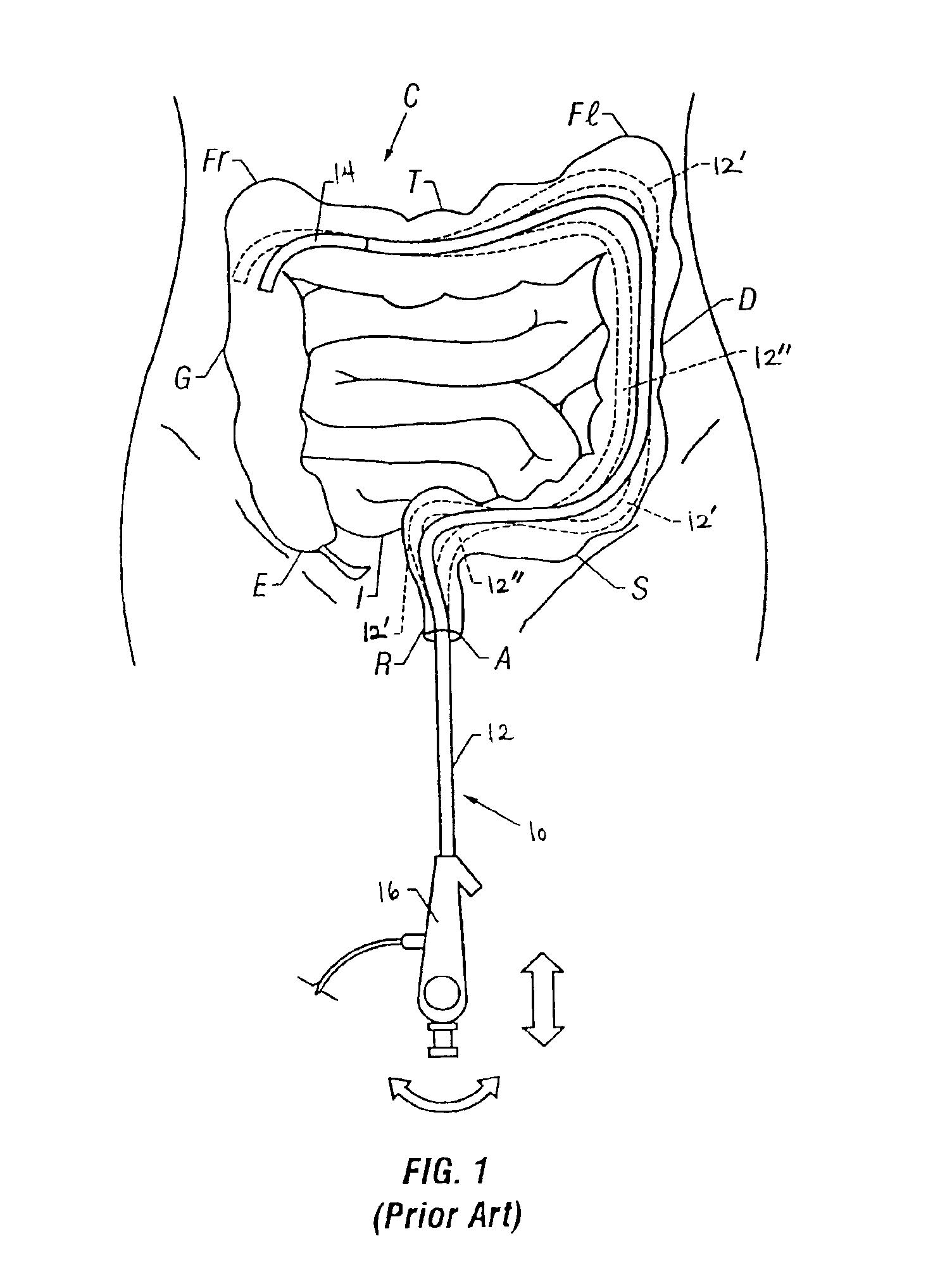

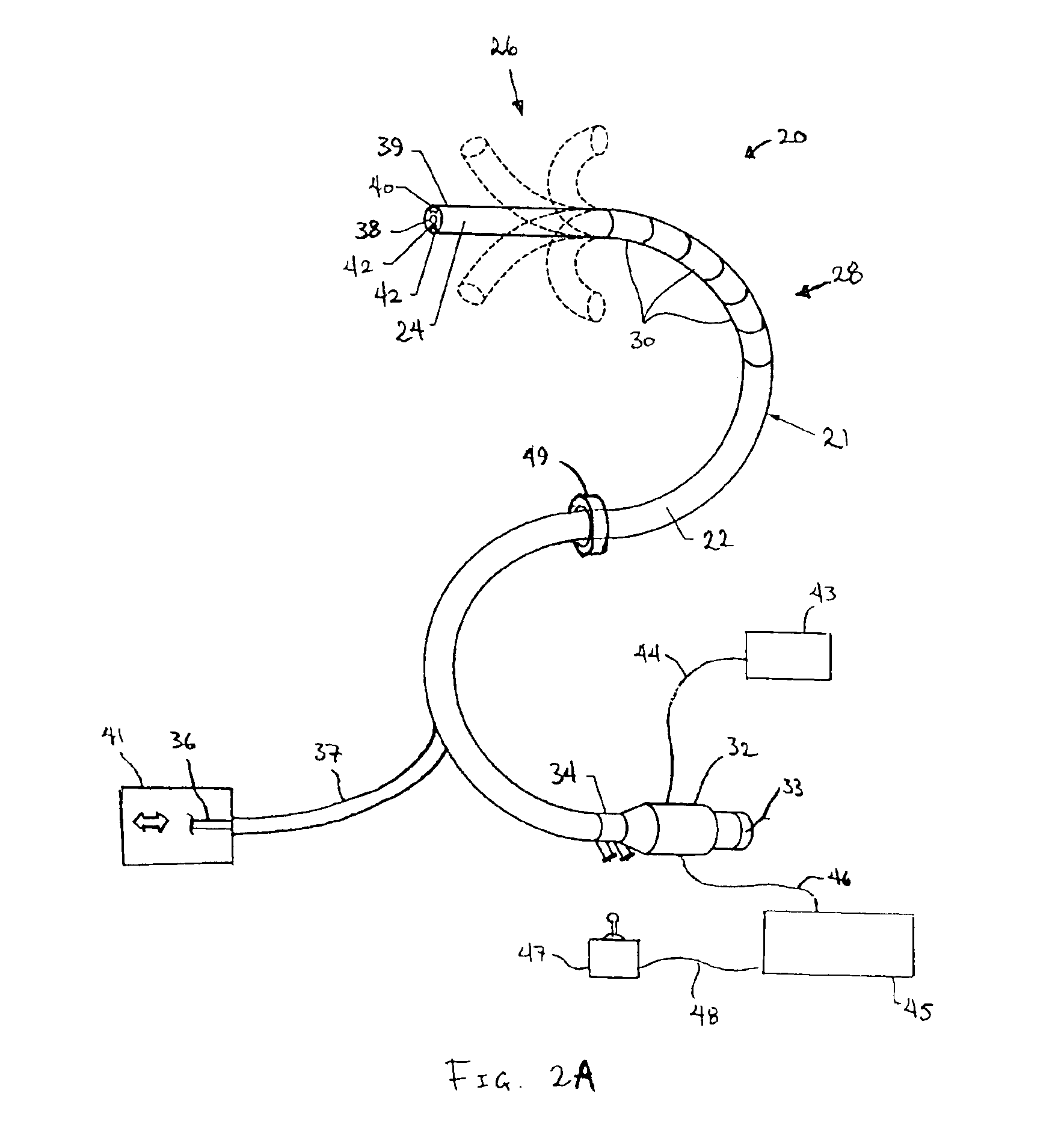

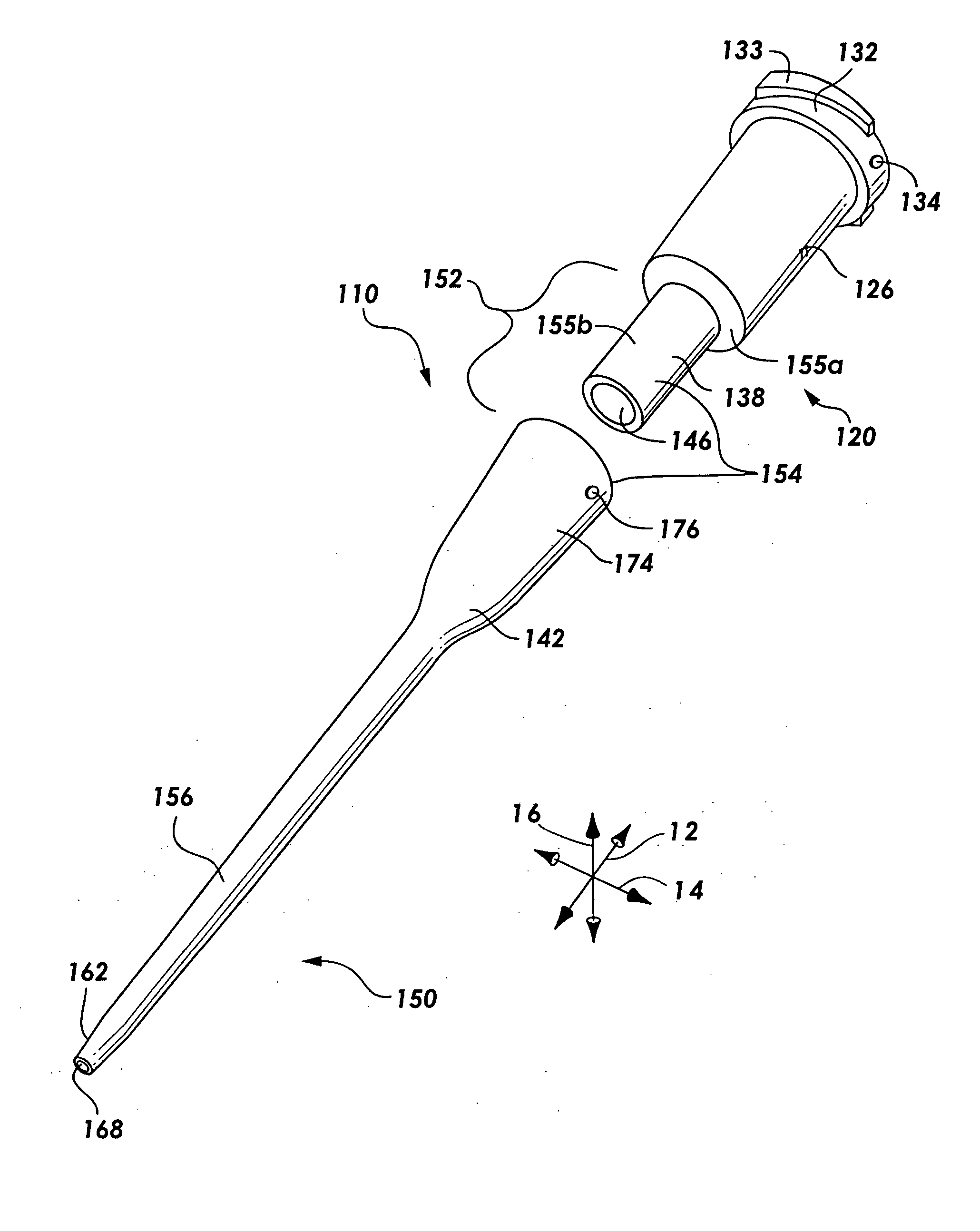

Endoscope with single step guiding apparatus

InactiveUS6974411B2Easy to repositionDesirable column strengthEndoscopesCatheterAutomatic controlDistal portion

An endoscope with guiding apparatus is described herein. A steerable endoscope is described having an elongate body with a manually or selectively steerable distal portion, an automatically controlled portion, a flexible and passively manipulated proximal portion, and an externally controlled and manipulatable tracking rod or guide. The tracking rod or guide is positioned within a guide channel within the endoscope and slides relative to the endoscope. When the guide is in a flexible state, it can conform to a curve or path defined by the steerable distal portion and the automatically controlled portion. The guide can then be selectively rigidized to assume that curve or path. Once set, the endoscope can be advanced over the rigidized guide in a monorail or “piggy-back” fashion so that the flexible proximal portion follows the curve held by the guide until the endoscope reaches a next point of curvature within a body lumen.

Owner:INTUITIVE SURGICAL OPERATIONS INC

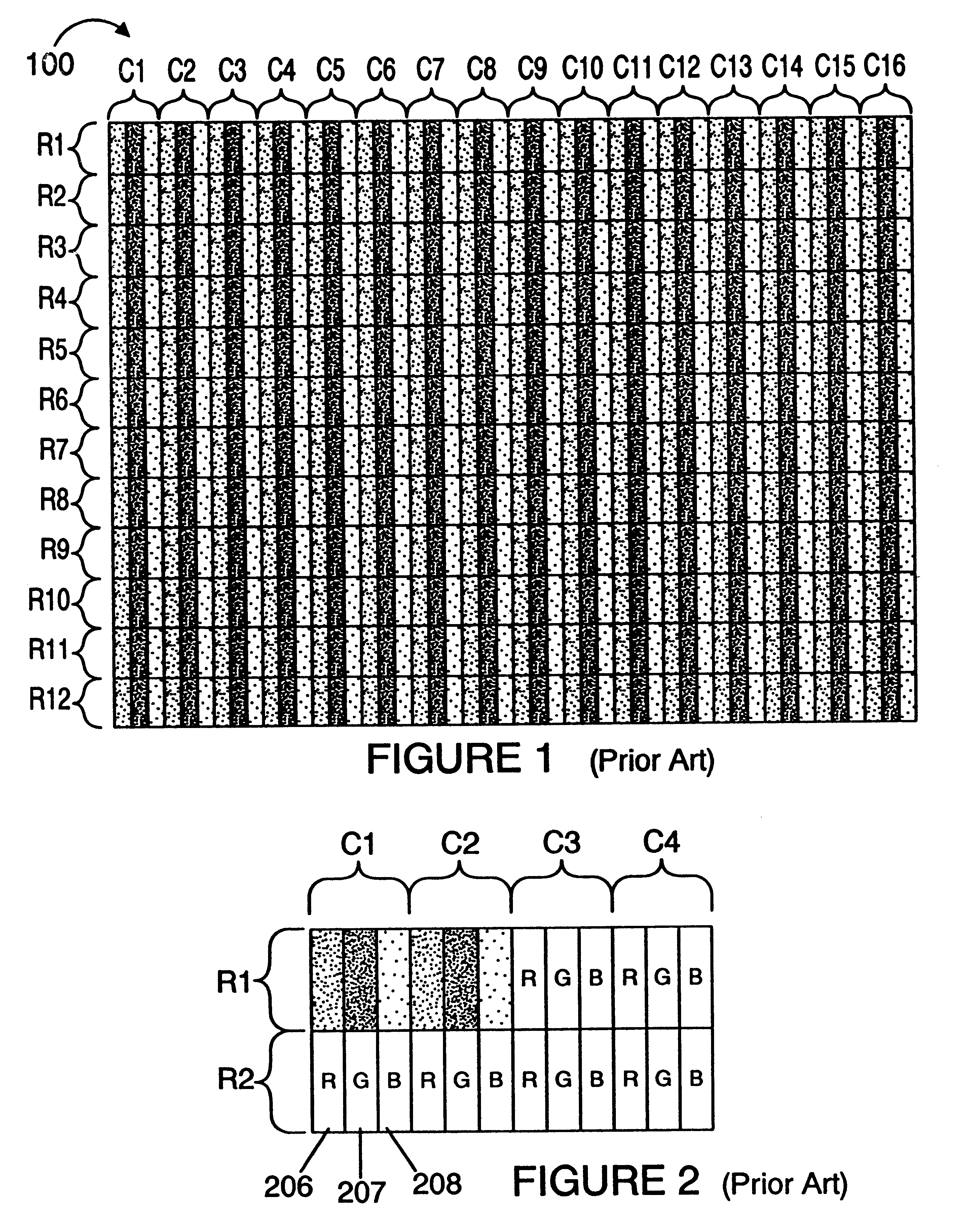

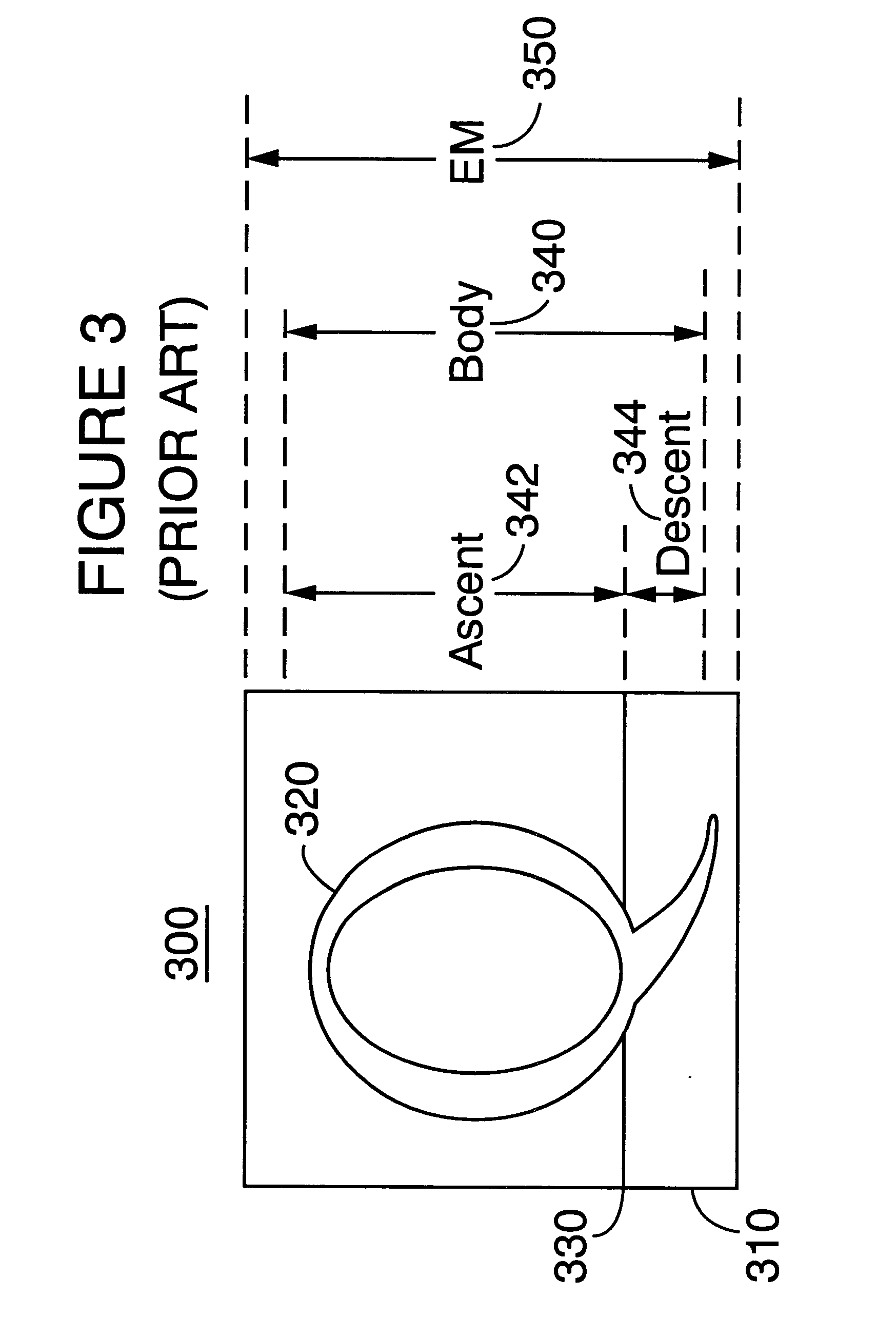

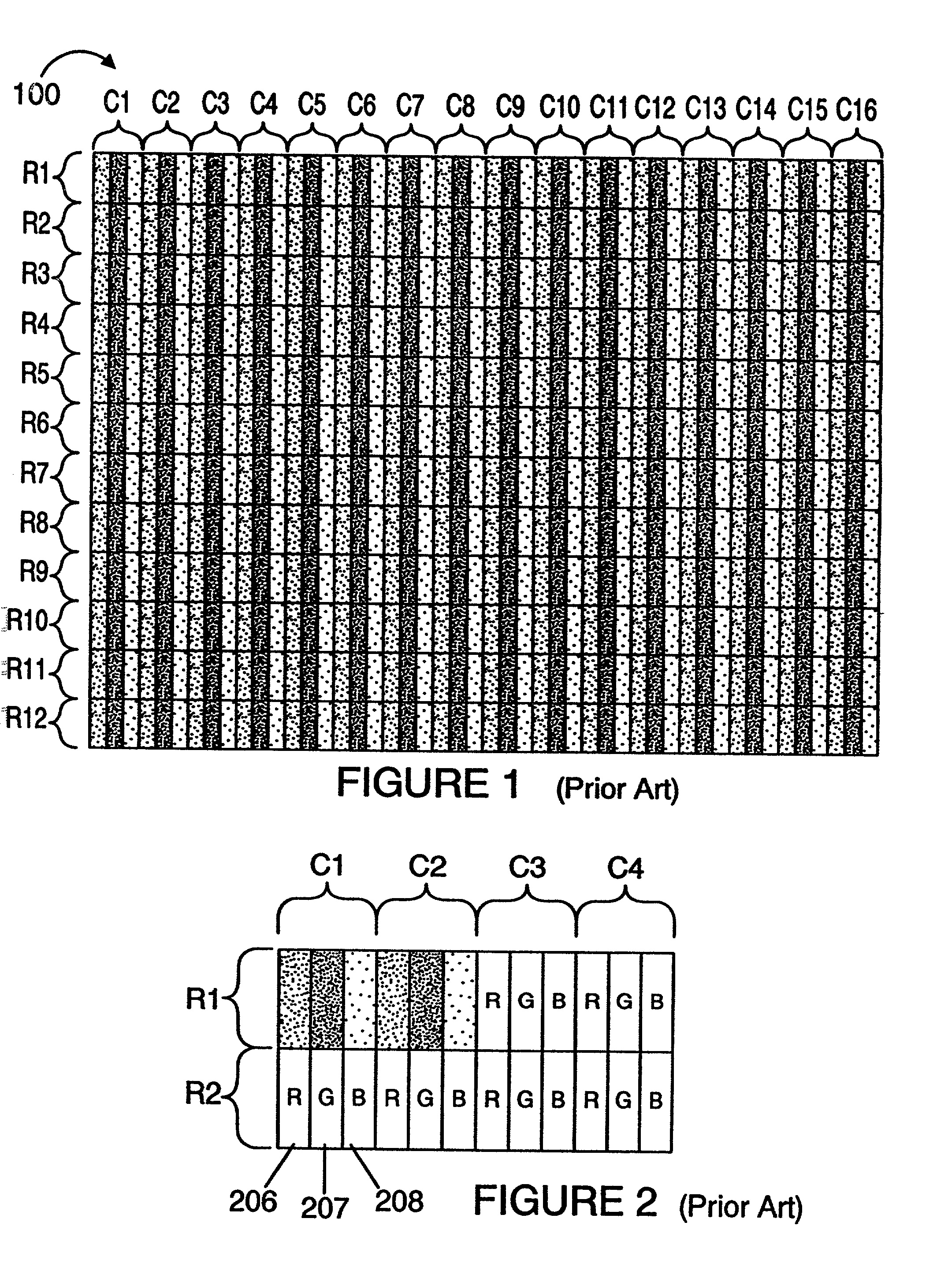

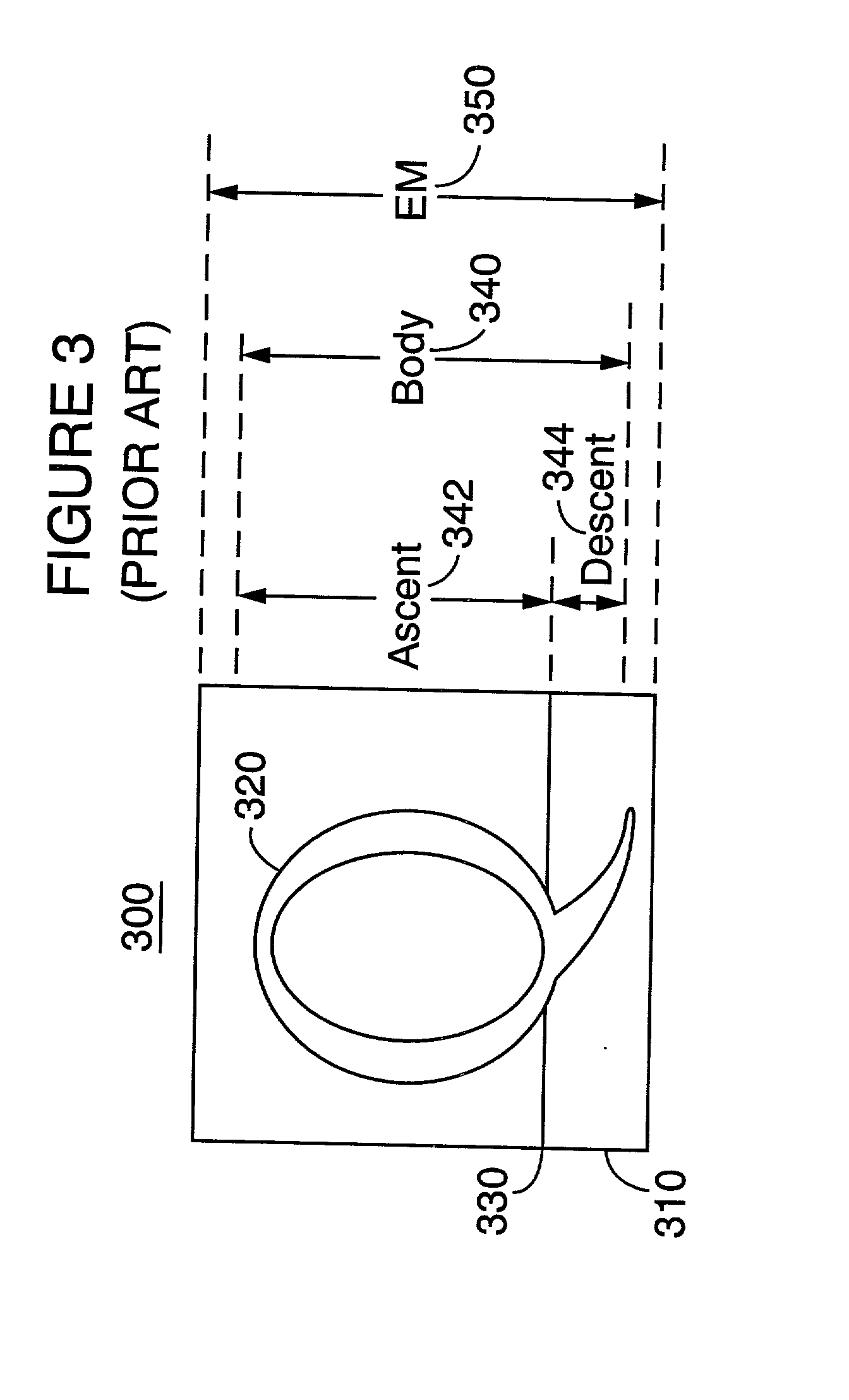

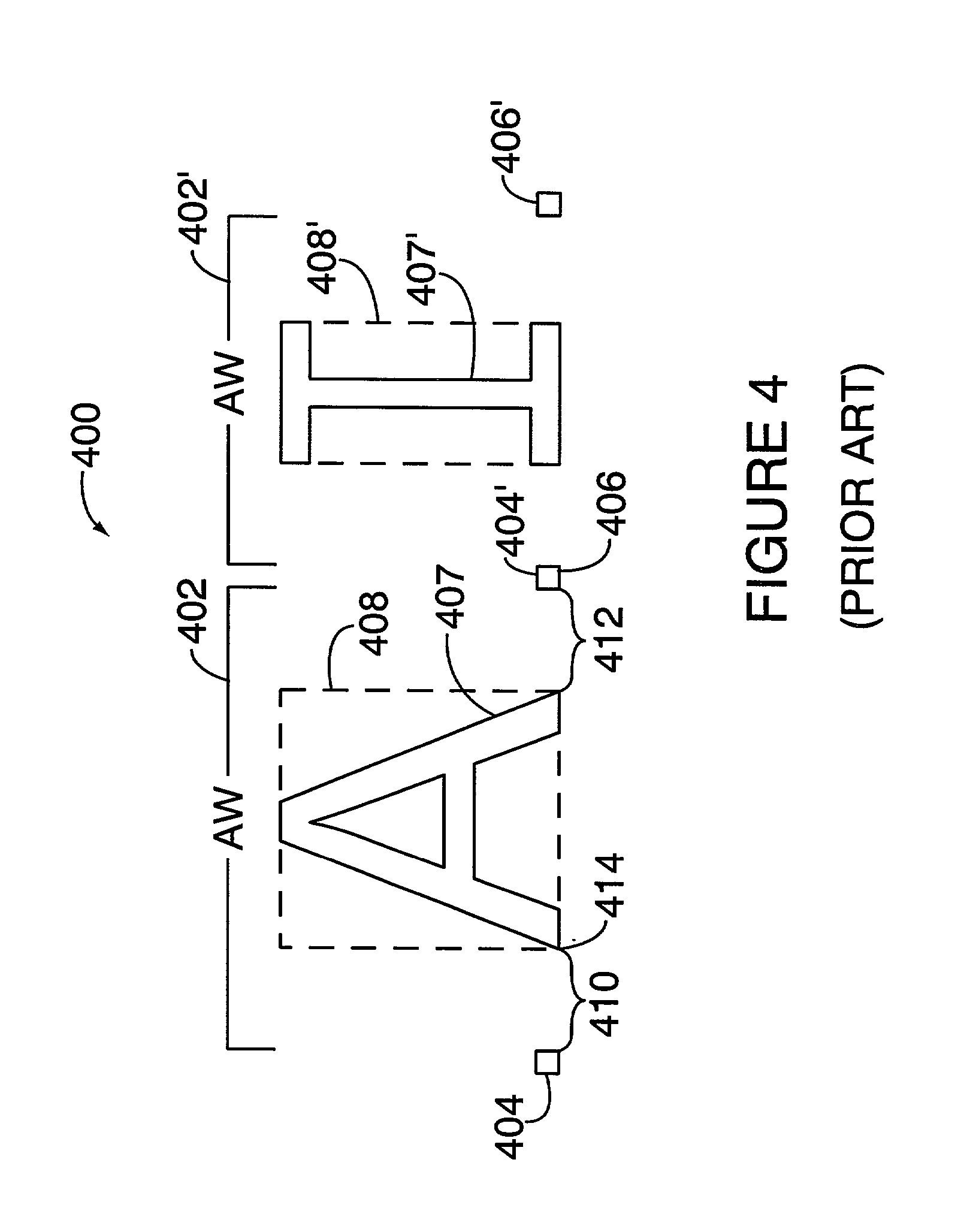

Methods apparatus and data structures for enhancing the resolution of images to be rendered on patterned display devices

InactiveUS6393145B2Improve imaging resolutionHigh resolutionTelevision system detailsImage enhancementSub-pixel resolutionArray data structure

Techniques for improving the resolution of images (either analog images, analytic images, or images having a higher resolution than that of a display device) to be rendered on patterned displays. In one aspect of the present invention, an overscaling or oversampling process may accept analytic character information, such as contours for example, and a scale factor or grid and overscale or oversample the analytic character information to produce an overscaled or oversampled image. The overscaled or oversampled image generated has a higher resolution than the display upon which the character is to be rendered. Displaced samples of the overscaled or oversampled image are then combined (or filtered). An analytic image, such as a line drawing for example, may be applied to the oversampling / overscaling process as was the case with the character analytic image. However, since the analytic image may have different units than that of the character analytic image, the scale factor applied may be different. Since an ultra resolution image is already "digitized", that is, not merely mathematically expressed contours or lines between points, it may be applied directly to a process for combining displaced samples of the ultra-resolution image to generate another ultra-resolution image (or an image with sub-pixel information). The functionality of the overscaling / oversampling process and the processes for combining displaced samples may be combined into a single step analytic to digital sub-pixel resolution conversion process.

Owner:MICROSOFT TECH LICENSING LLC +1

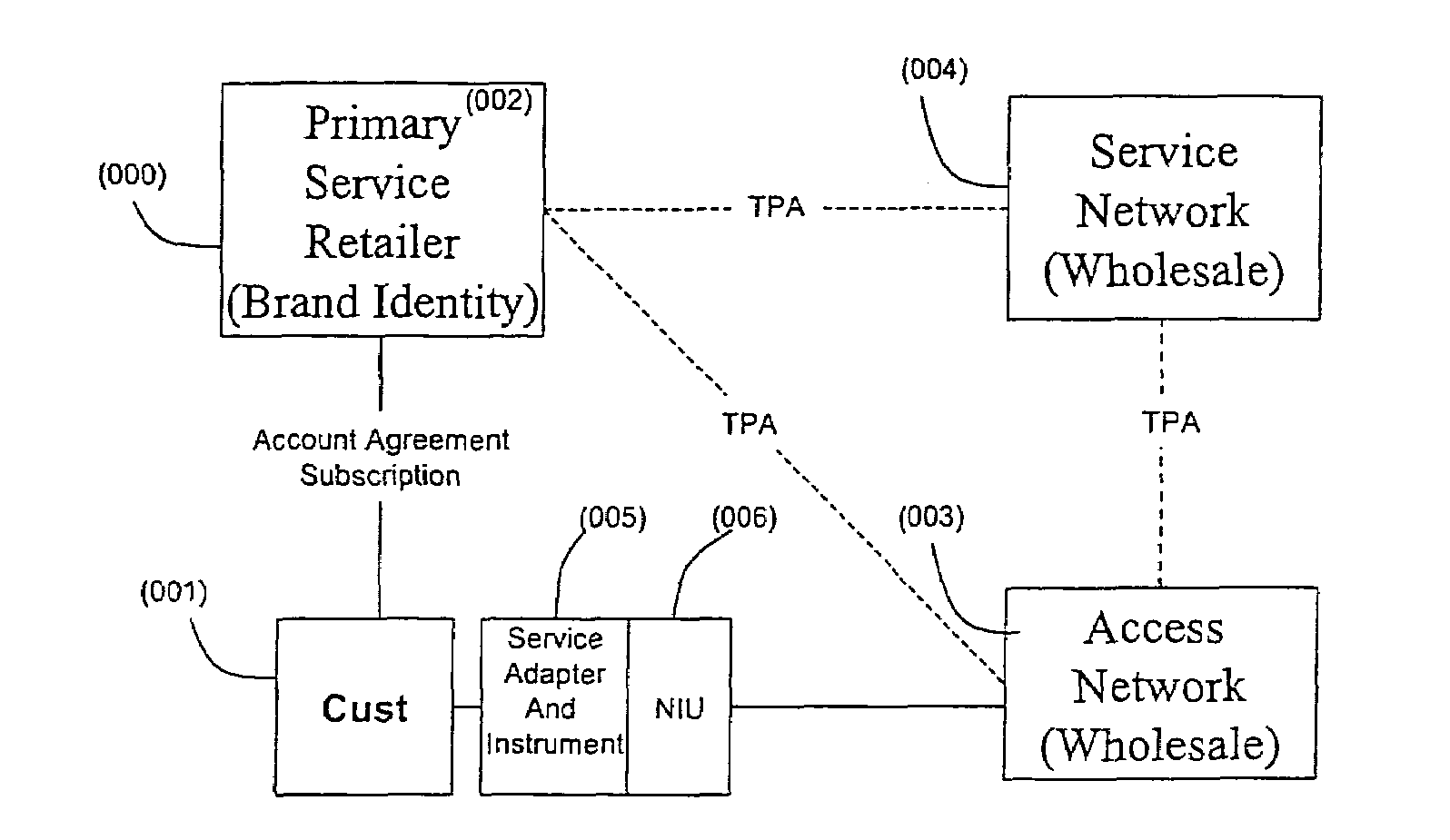

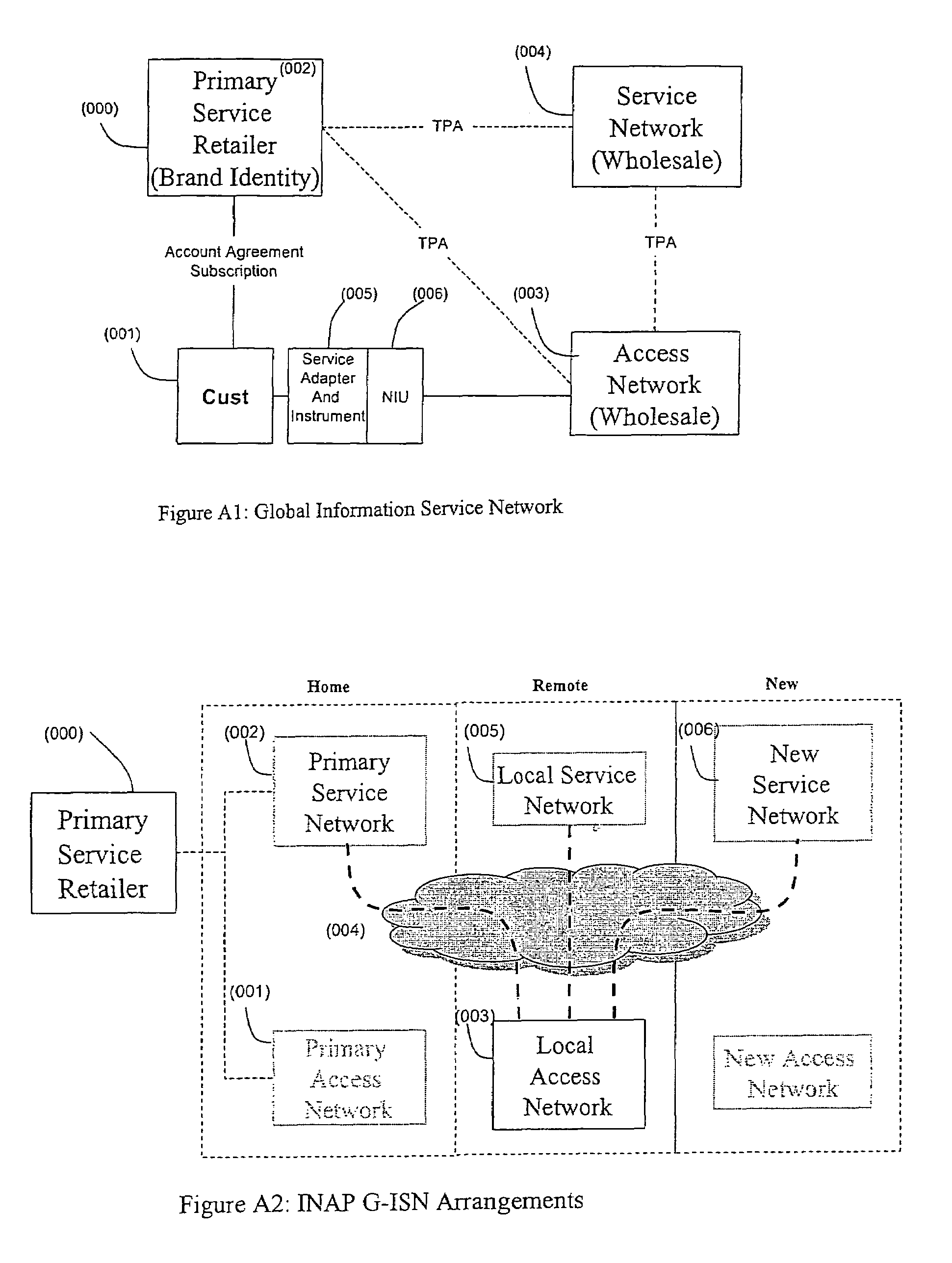

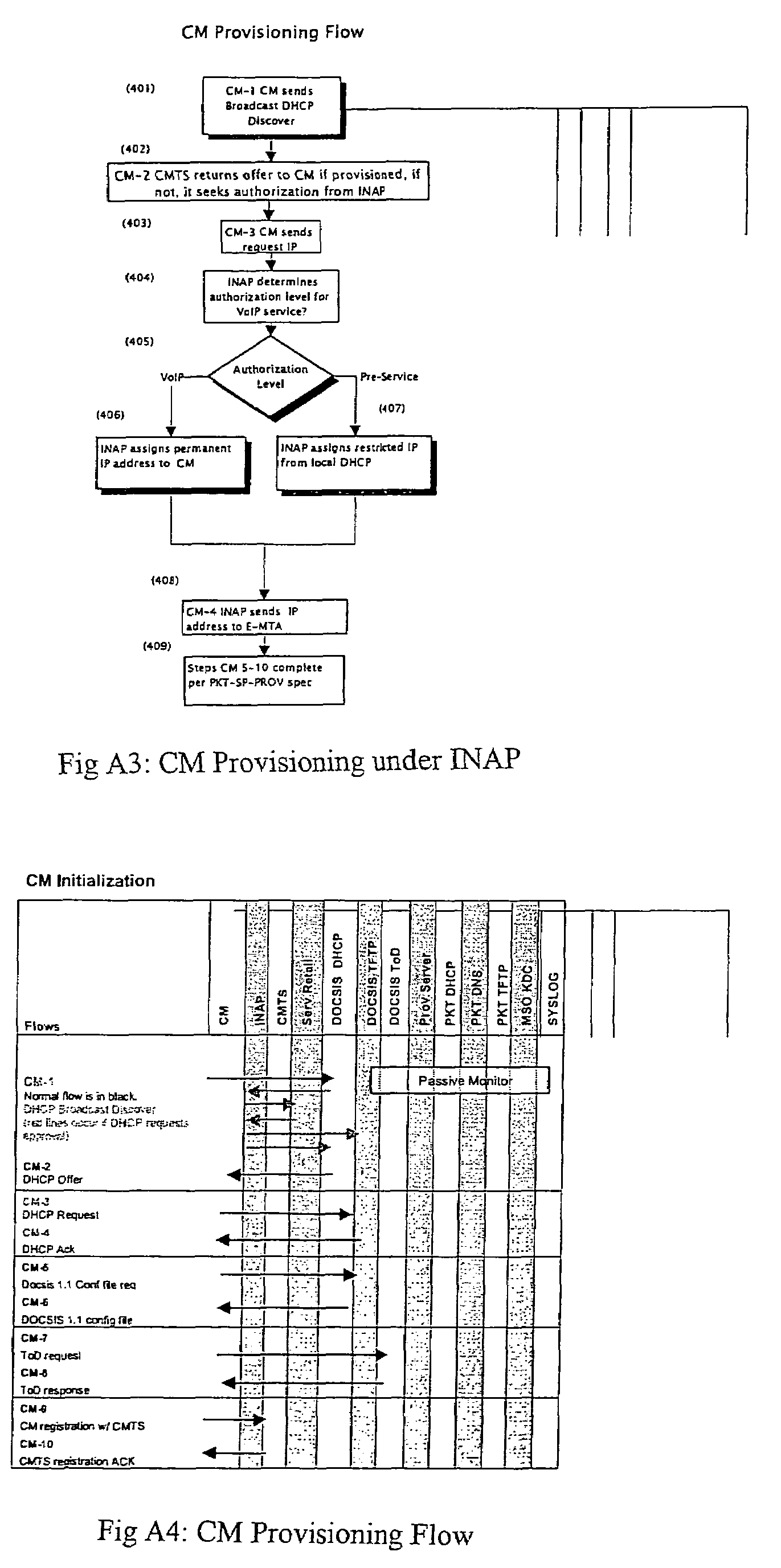

Intelligent network providing network access services (INP-NAS)

InactiveUS7496652B2Efficient use ofConsiderable timeBroadband local area networksMultiple digital computer combinationsIntelligent NetworkSmart network

An open Information Services network architecture is disclosed which enables multiple business entities to assume specialized roles of access provider, service provider, and service retailer. The disclosed technology provides instant plug-and-play service, decouples access and service networks and provides seamless (single step) access enabling customers to maintain a service account regardless of location. The benefits of the disclosed technology, among others, include: Multi-level and multi-service registration; Broker Services providing customers with a choice of provider; Security Services relating to distribution; Revenue Assurance services, Gentle Reminder / Gentle Touch; Revenue Assurance services pertaining to usage integrity verification upon registration; mobile services derived from G-ISN; and claim benefits pertaining to LNP services derived from G-ISN.

Owner:AI-CORE TECH LLC +1

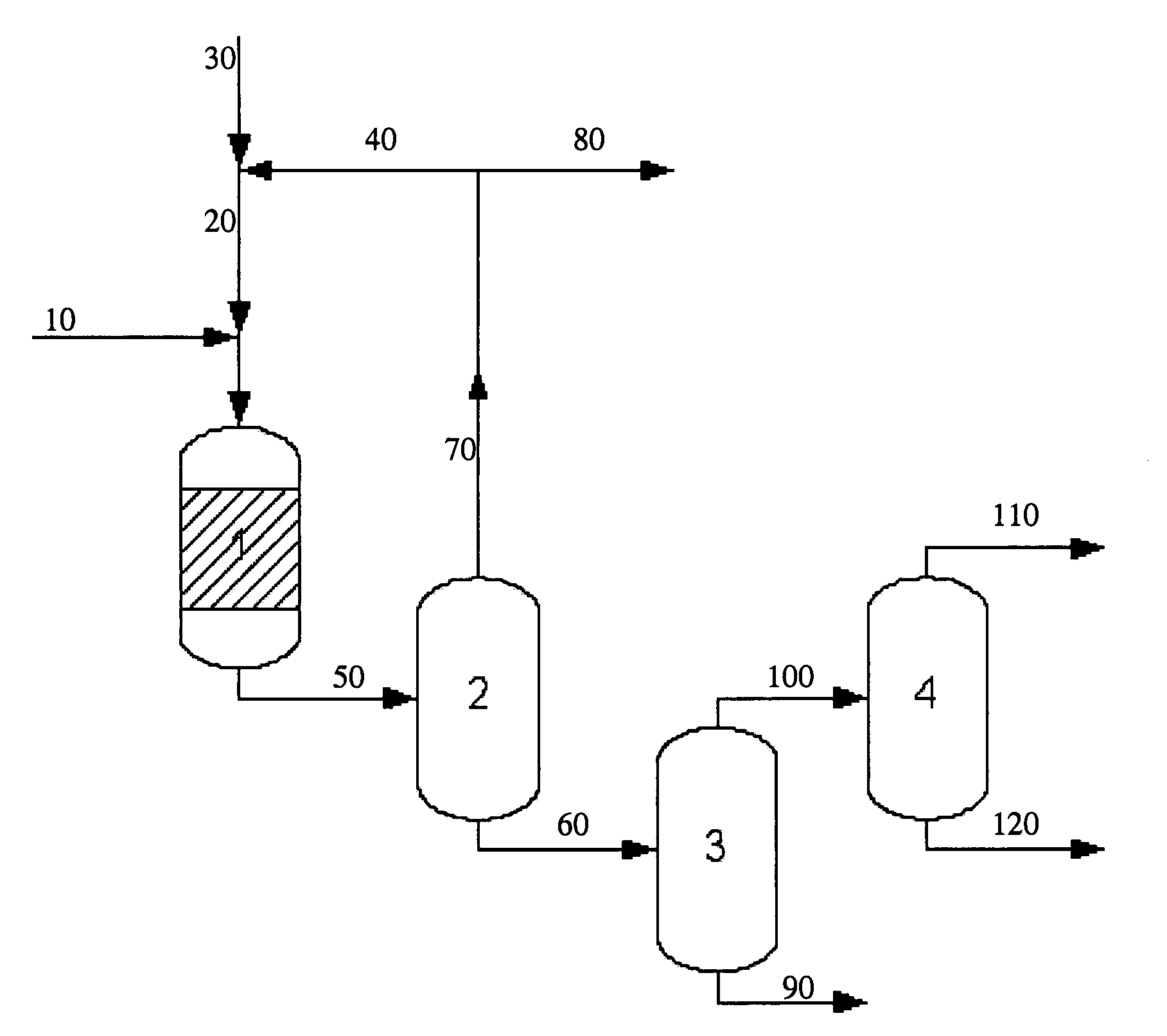

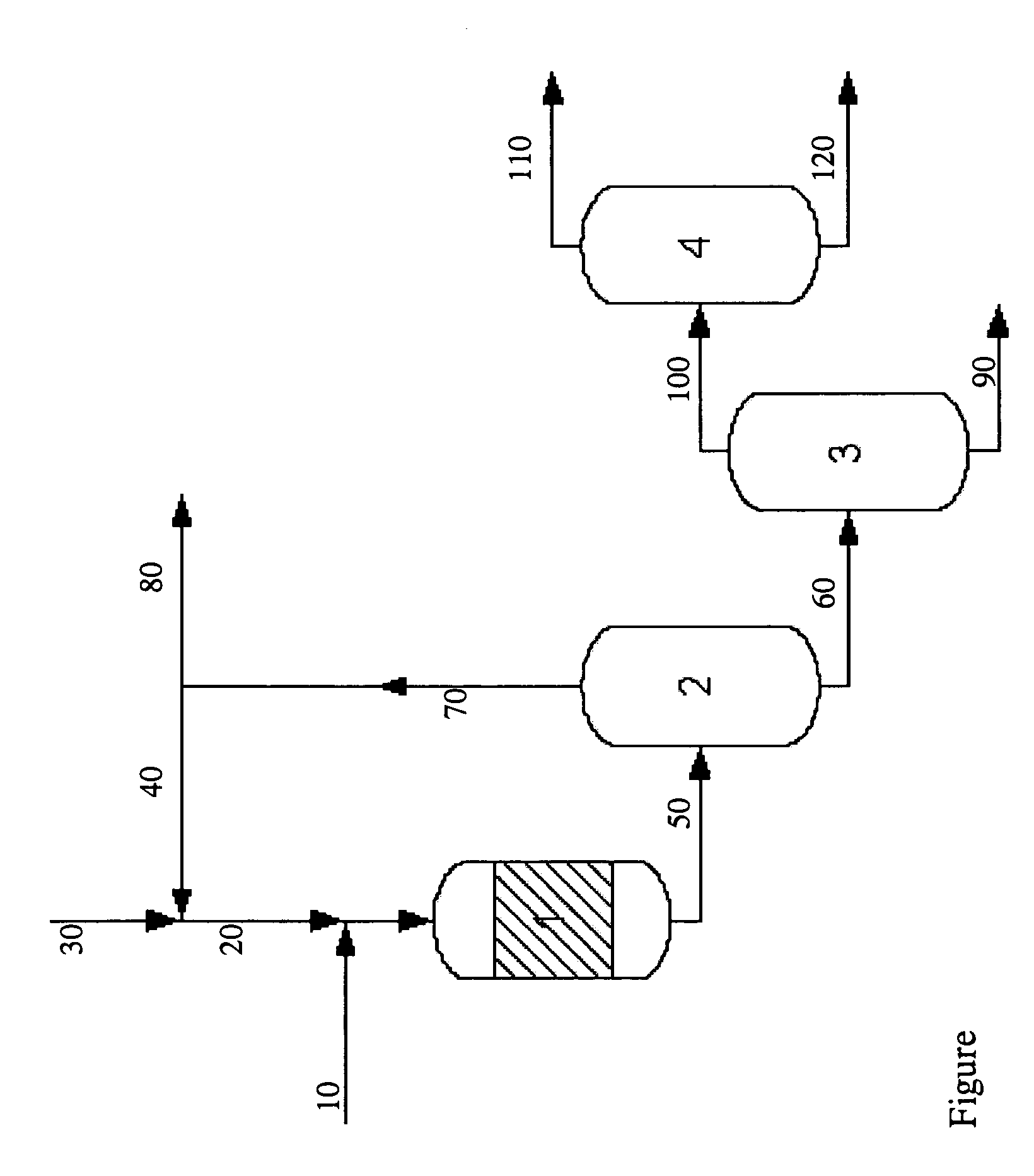

Production of diesel fuel from vegetable and animal oils

A process for producing a fuel composition from vegetable and / or animal oil comprises hydrodeoxygenating and hydroisomerizing the oil in a single step. The fuel composition has acceptable lubricity and comprises a mixture of C14 to C18 paraffins having a ratio of iso to normal paraffins of 2 to 8 and less than 5 ppm sulfur.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

Combined lancet and electrochemical analyte-testing apparatus

InactiveUS20050011759A1Easy to takeReduces and eliminates disposal issueImmobilised enzymesBioreactor/fermenter combinationsTissue fluidDisplay device

An apparatus for detection and quantitation of an electrochemically-detectable analyte, such as glucose, in blood or interstitial fluid includes a meter unit, a lancet and an electrochemical sensor. Of these components, the meter is preferably reusable, while the lancet and the electrochemical sensor are preferably incorporated in assemblies intended for single-use. The meter unit has a housing, within which a lancet is engaged with a mechanism for moving then lancet; a connector disposed within the housing for engaging an electrochemical sensor specific for the analyte and transmitting a signal indicative of the amount of analyte, and a display operatively-associated with a connector for displaying the amount of the analyte to user. The electrochemical sensor is adapted for detection of a particular analyte. In addition, the electrochemical sensor has an absorptive member for uptake of a sample of blood or interstitial fluid. In one version, the lancet moves from a initial position to a piercing position in which skin of the user is pierced and optionally back to a retracted position. The electrochemical sensor is disposed such that the absorptive member takes up a sample from the pierced skin of the user when it is pierced by the lancet without movement of the apparatus. In an alternative version, the lancet is a hollow cannula through which blood or interstitial fluid is transported from the puncture site to an absorbent portion of the electrochemical sensor. In either version, the apparatus provides single-step operation in which sample acquisition and analysis occur as a result of the single action of pressing, the apparatus against the users skin.

Owner:LIFESCAN IP HLDG LLC

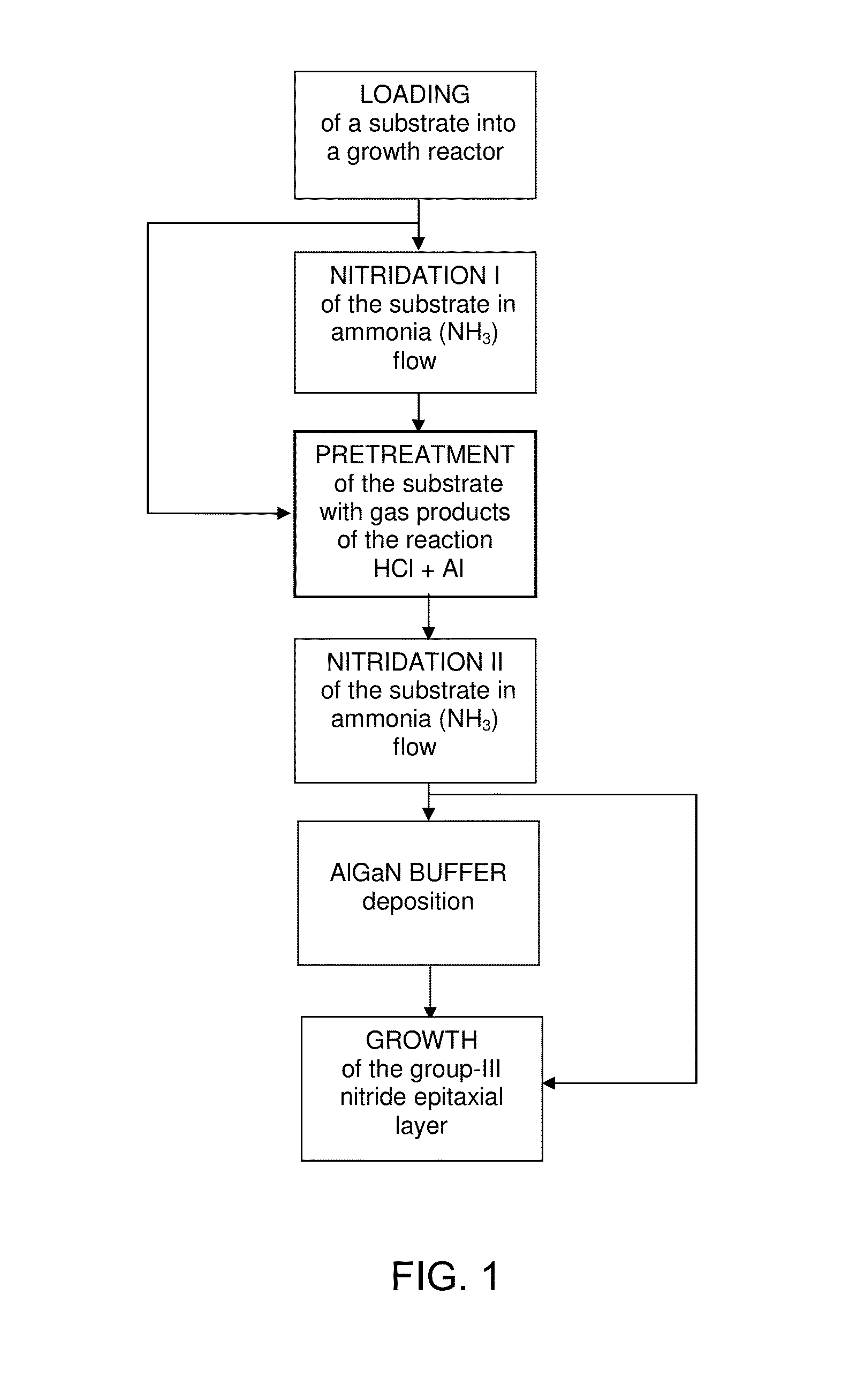

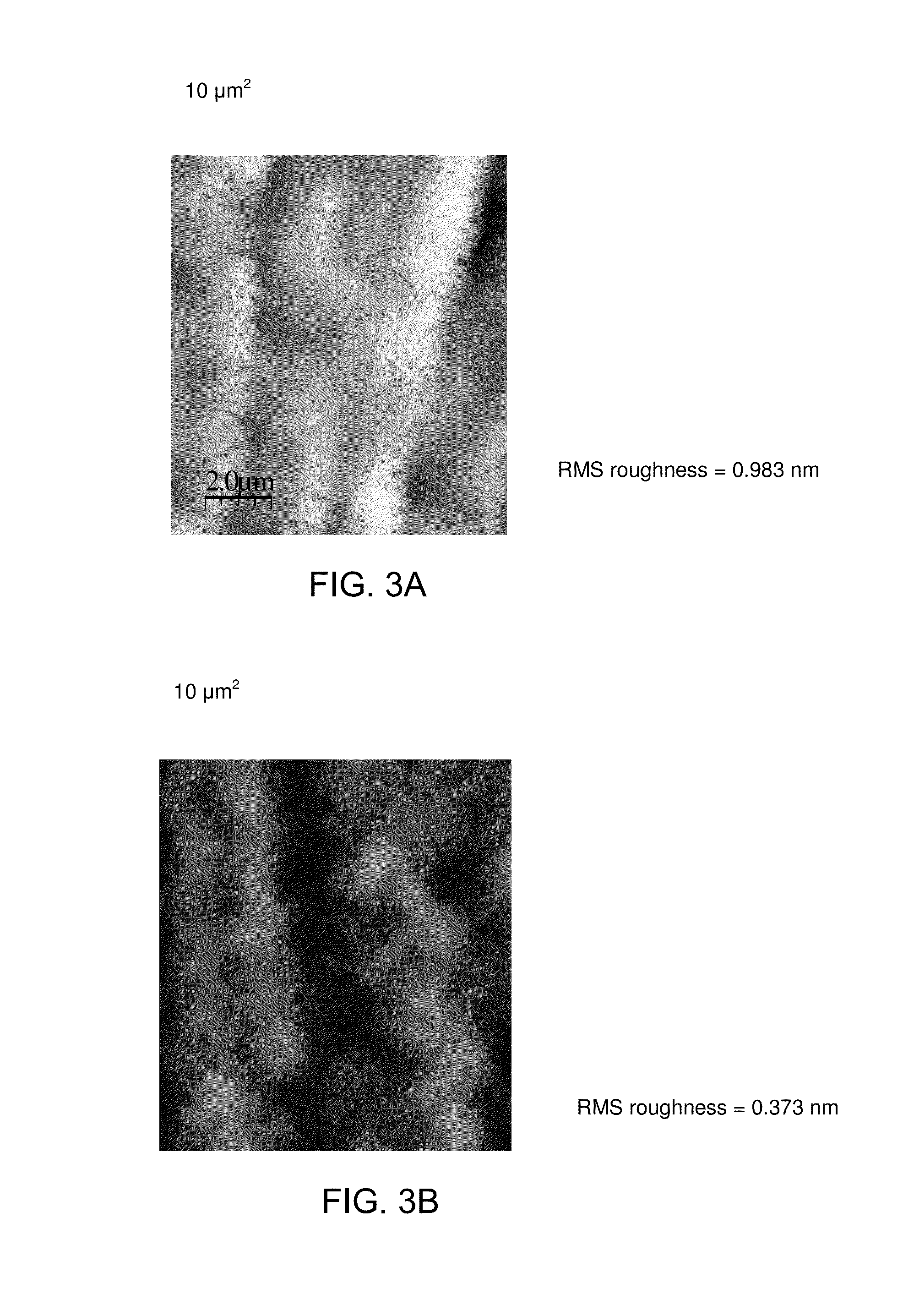

Method for Substrate Pretreatment To Achieve High-Quality III-Nitride Epitaxy

The present invention relates to a method for producing a modified surface of a substrate that stimulates the growth of epitaxial layers of group-III nitride semiconductors with substantially improved structural perfection and surface flatness. The modification is conducted outside or inside a growth reactor by exposing the substrate to a gas-product of the reaction between hydrogen chloride (HCl) and aluminum metal (Al). As a single-step or an essential part of the multi-step pretreatment procedure, the modification gains in coherent coordination between the substrate and group-III nitride epitaxial structure to be deposited. Along with epilayer, total epitaxial structure may include buffer inter-layer to accomplish precise substrate-epilayer coordination. While this modification is a powerful tool to make high-quality group-III nitride epitaxial layers attainable even on foreign substrates having polar, semipolar and nonpolar orientation, it remains gentle enough to keep the surface of the epilayer extremely smooth. Various embodiments are disclosed.

Owner:OSTENDO TECH INC

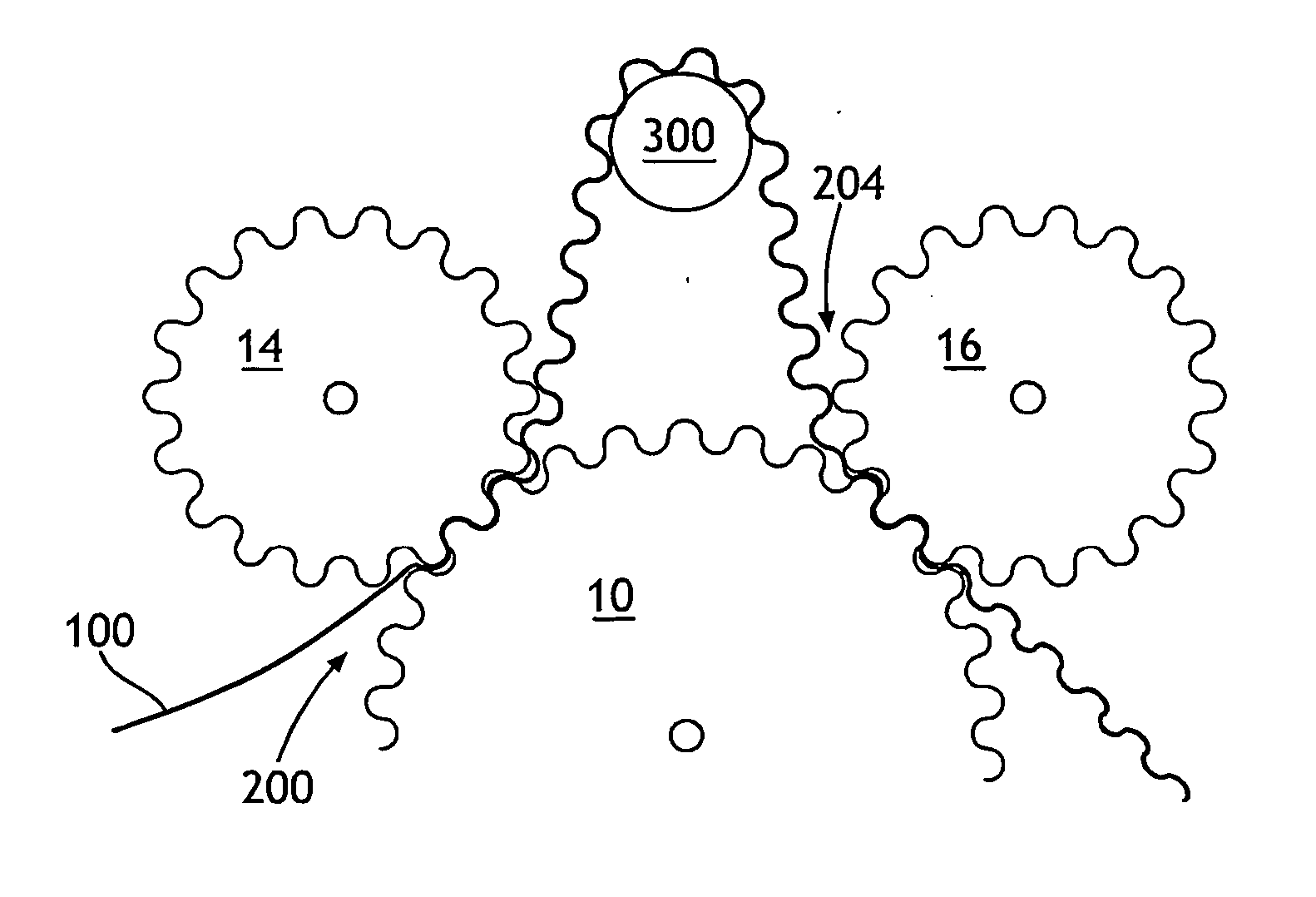

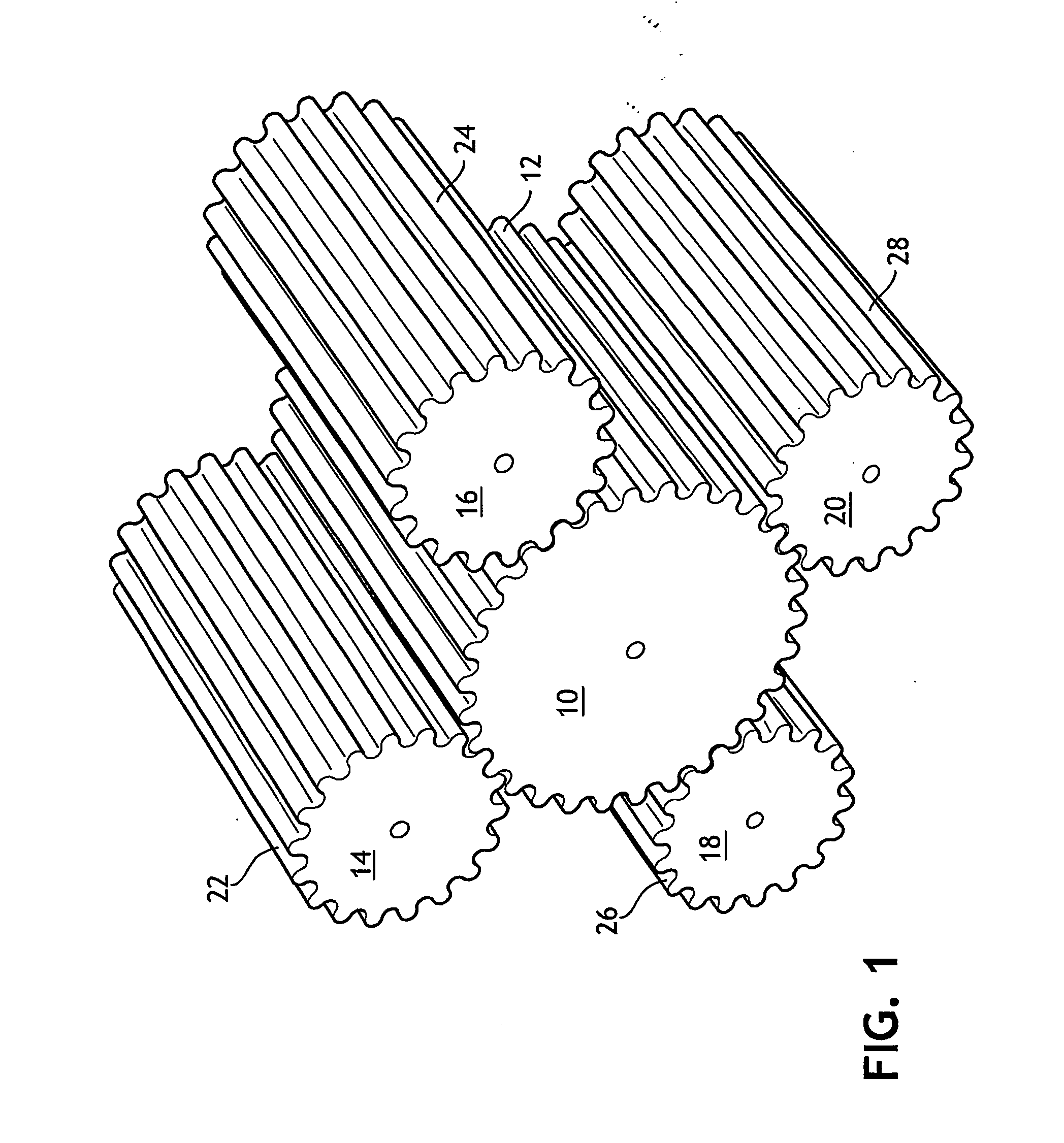

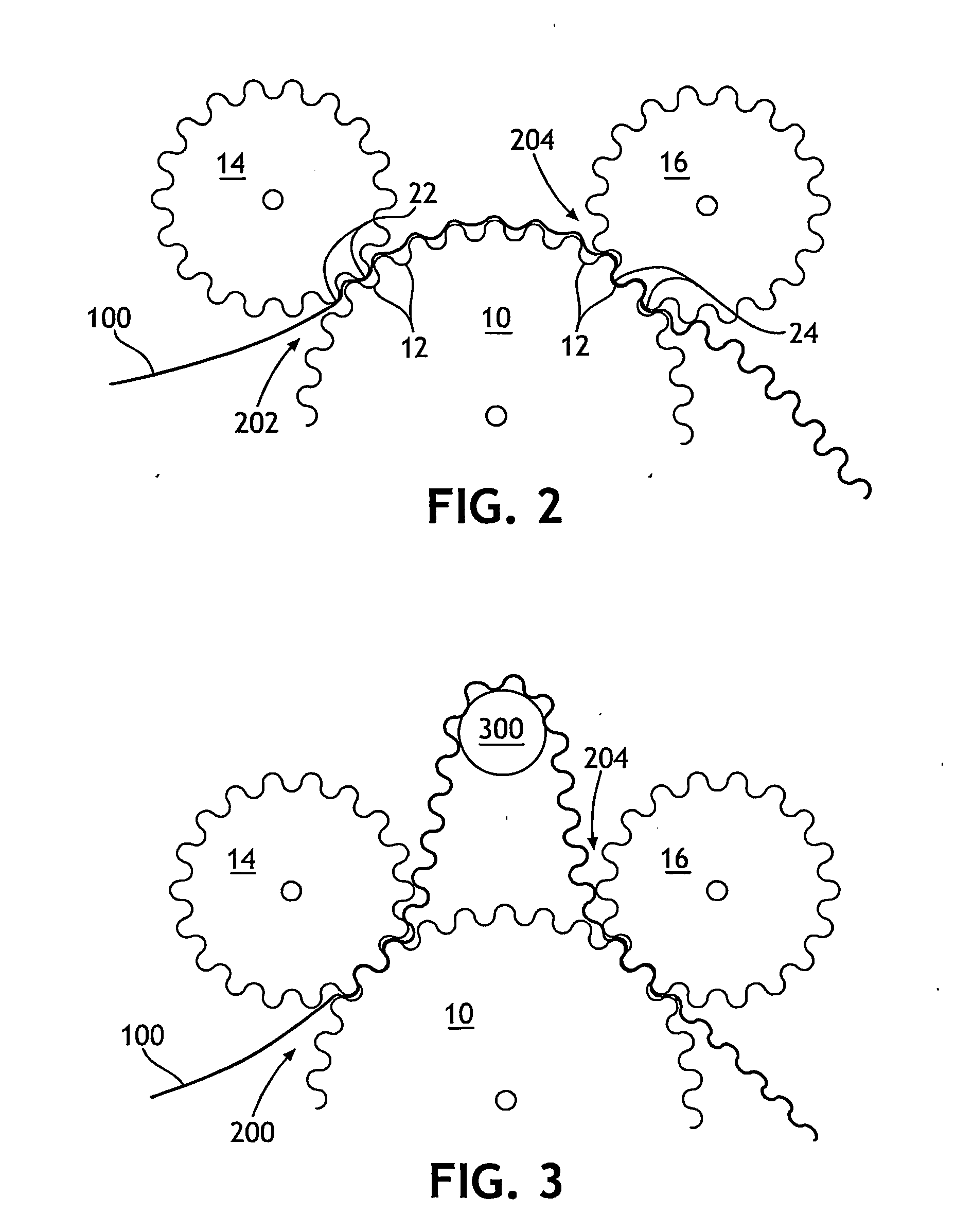

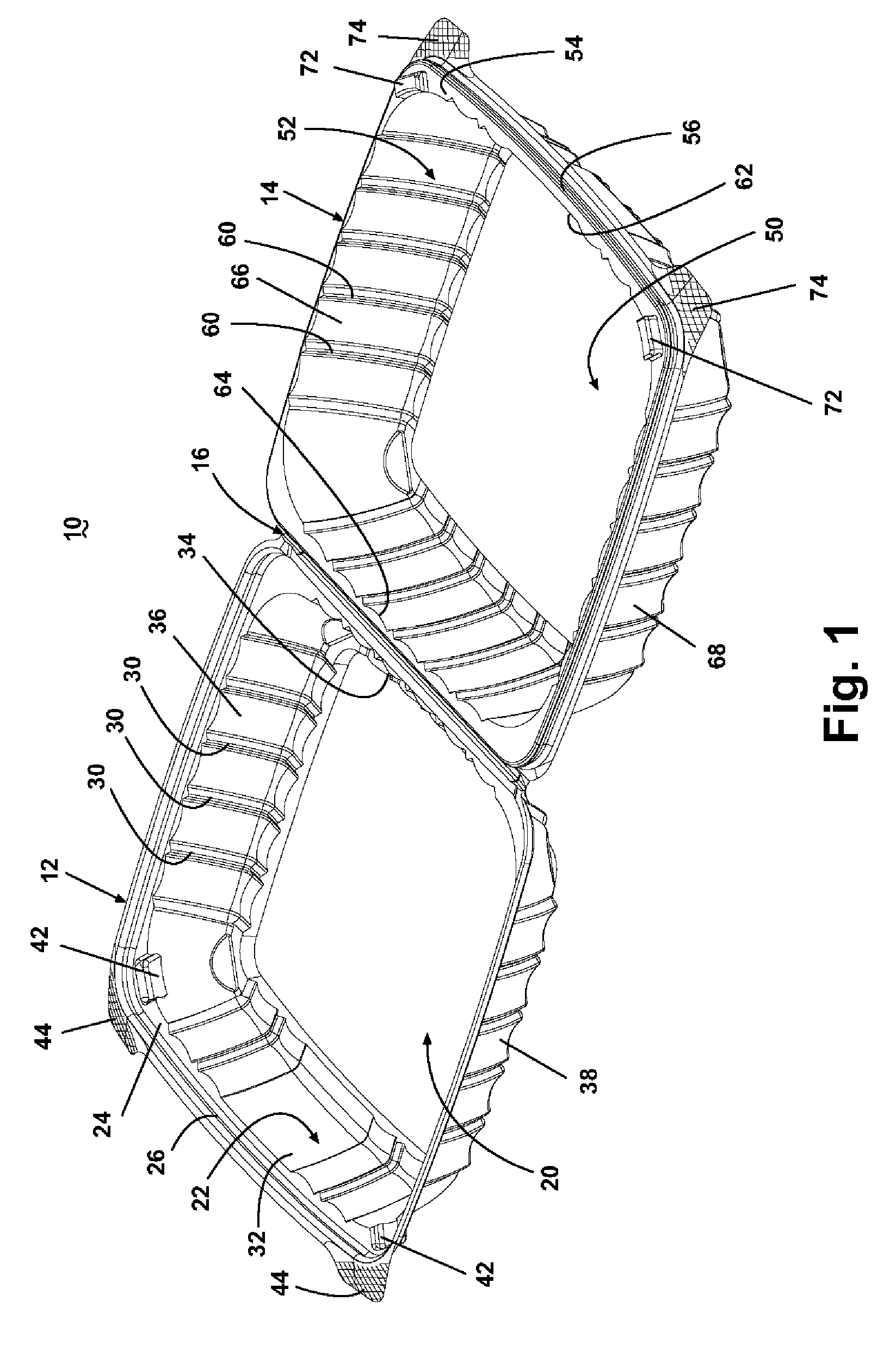

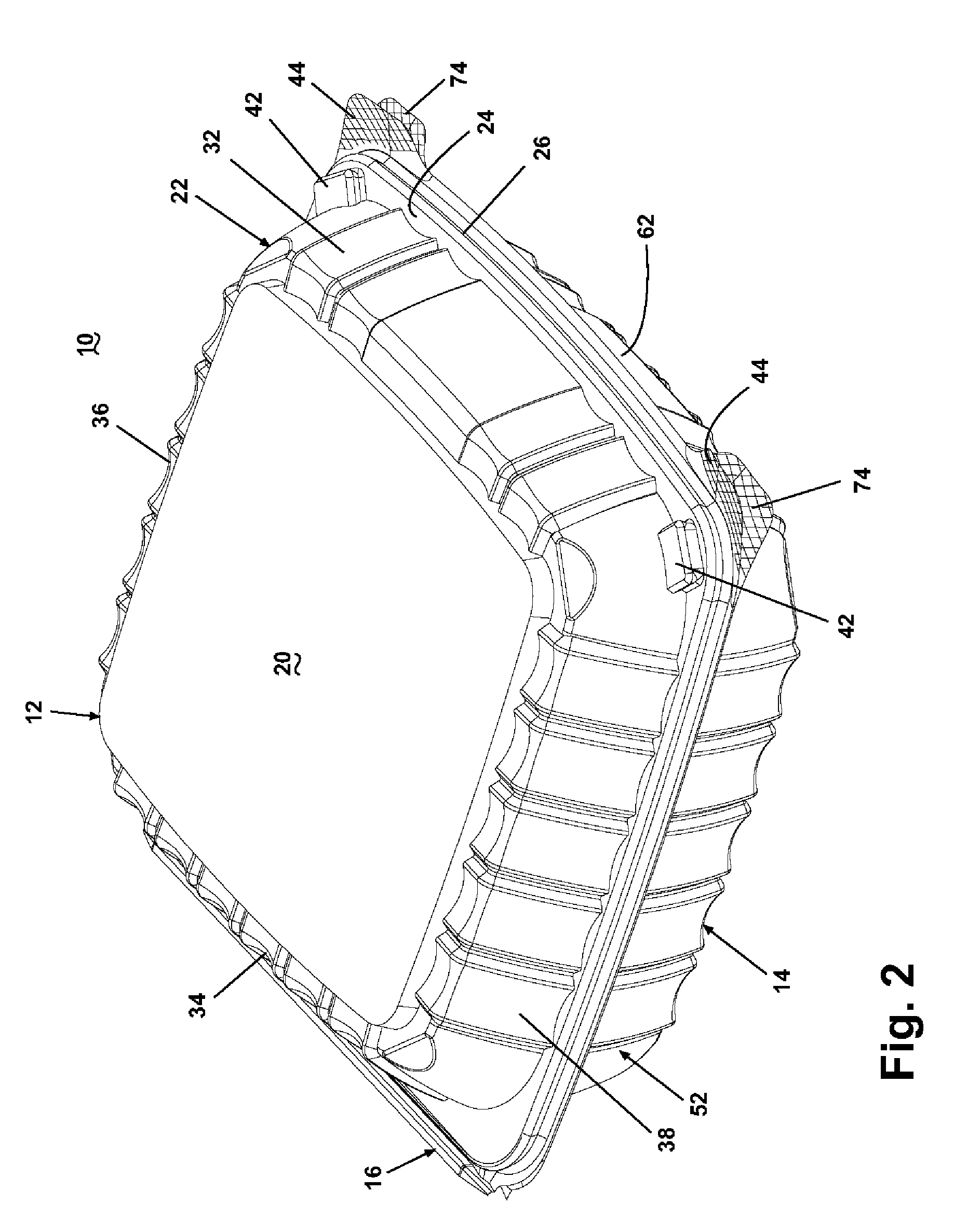

Device and process for treating flexible web by stretching between intermeshing forming surfaces

InactiveUS20060151914A1Increase flexibilityWidely vary degree of stretchDough-sheeters/rolling-machines/rolling-pinsConfectioneryPersonal Care ProductBiomedical engineering

A series of nips (200, 202, 204, 412, 414) formed by intermeshing grooves (22, 24, 26, 28) provides for a higher degree of stretch, particularly for lightweight webs (100) by stretching in stages in multiple grooved nips. The ability to adjust the degree of stretch at each nip can provide a high degree and variability of stretch with reduced web damage compared to a single step application of the same stretch. Improvements to the manufacture of lightweight components of personal care products such as diaper backing components are obtained.

Owner:KIMBERLY-CLARK WORLDWIDE INC

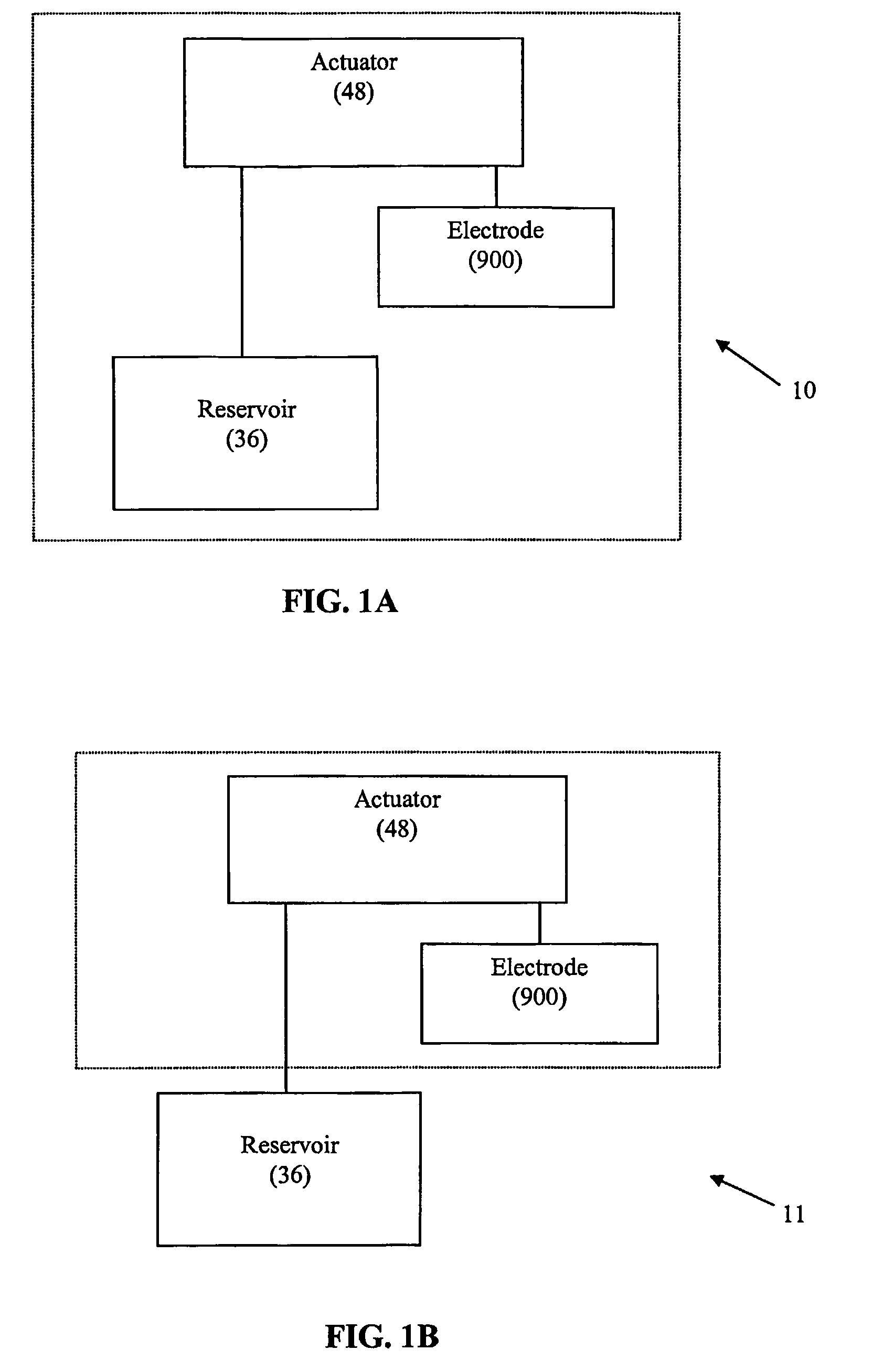

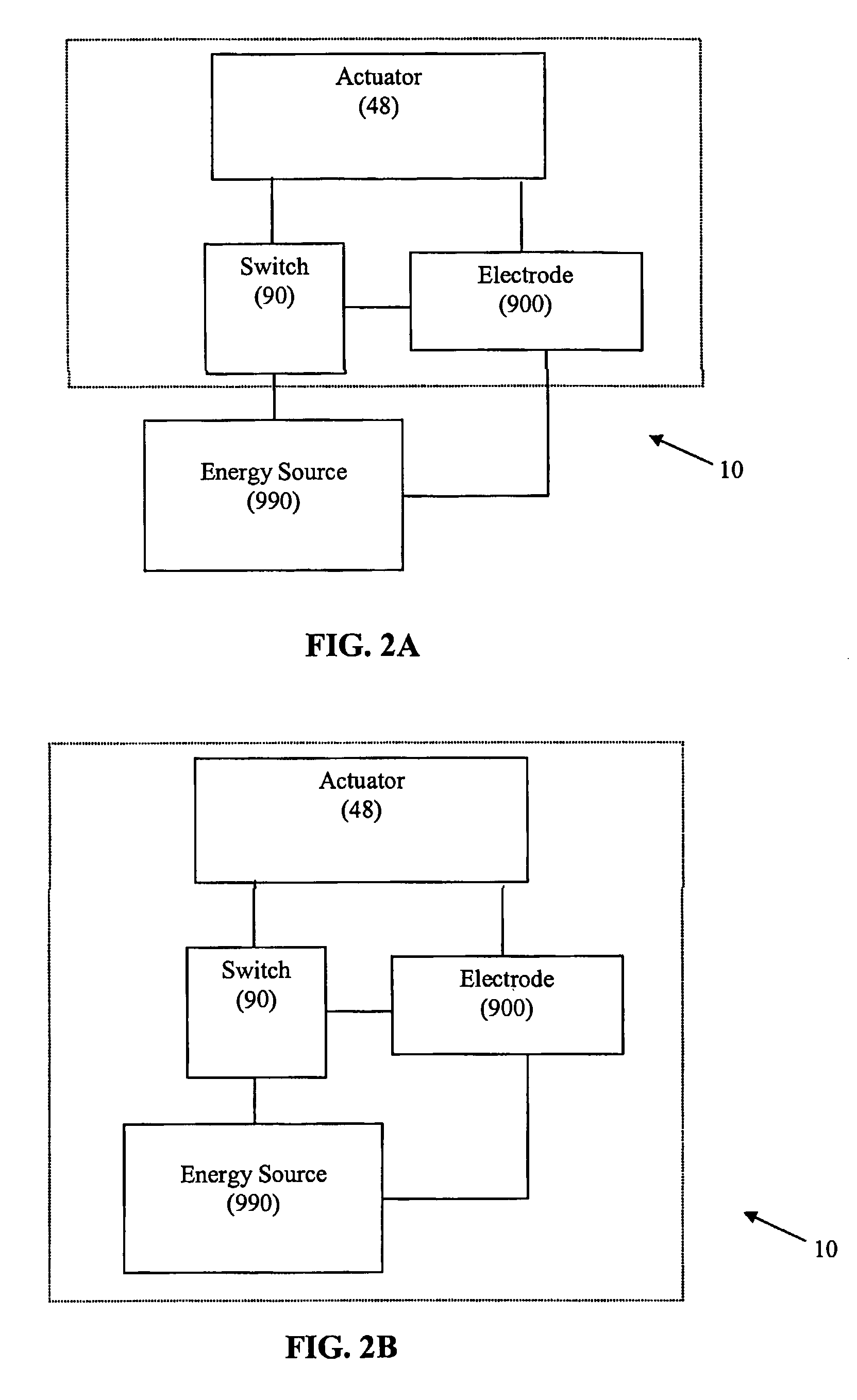

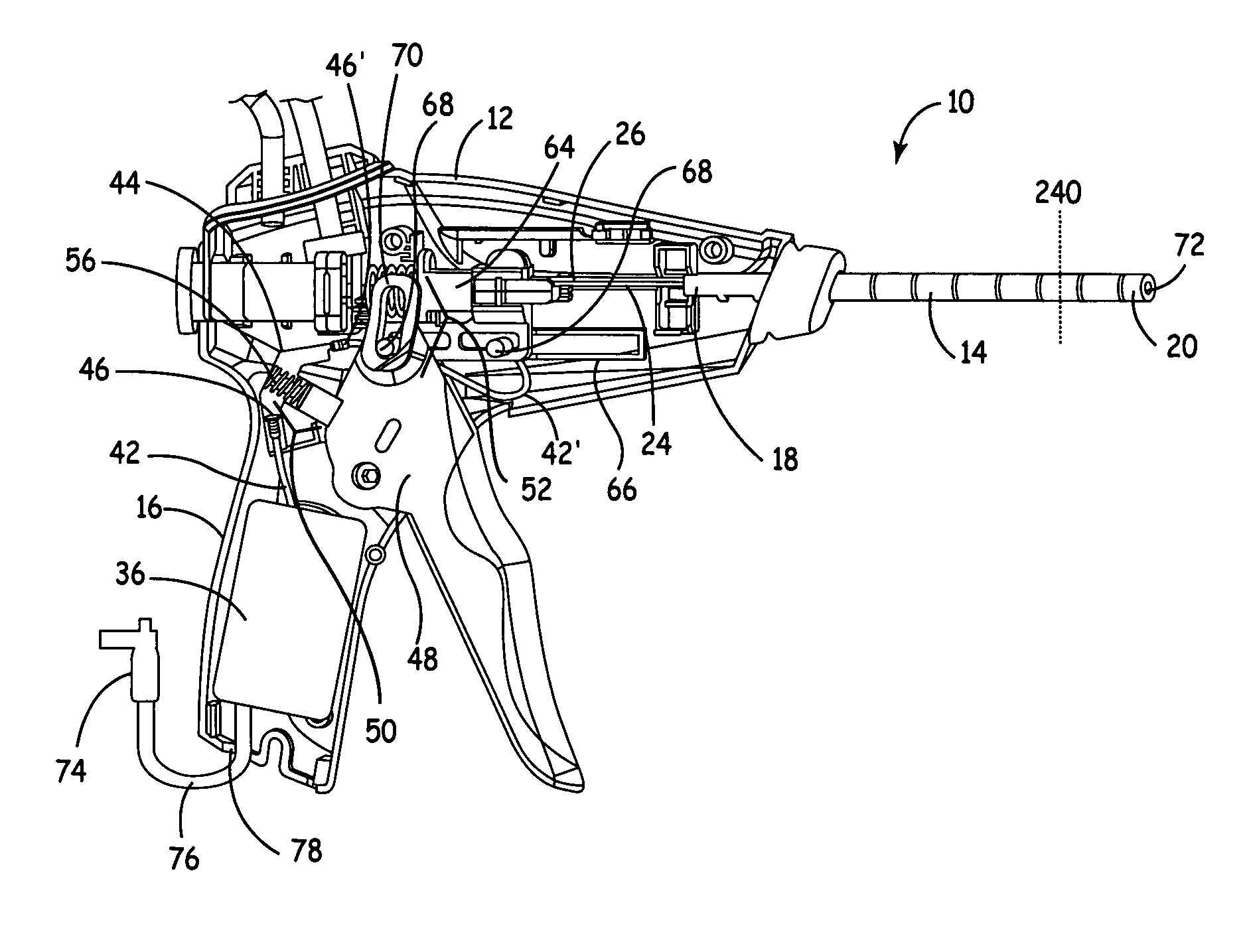

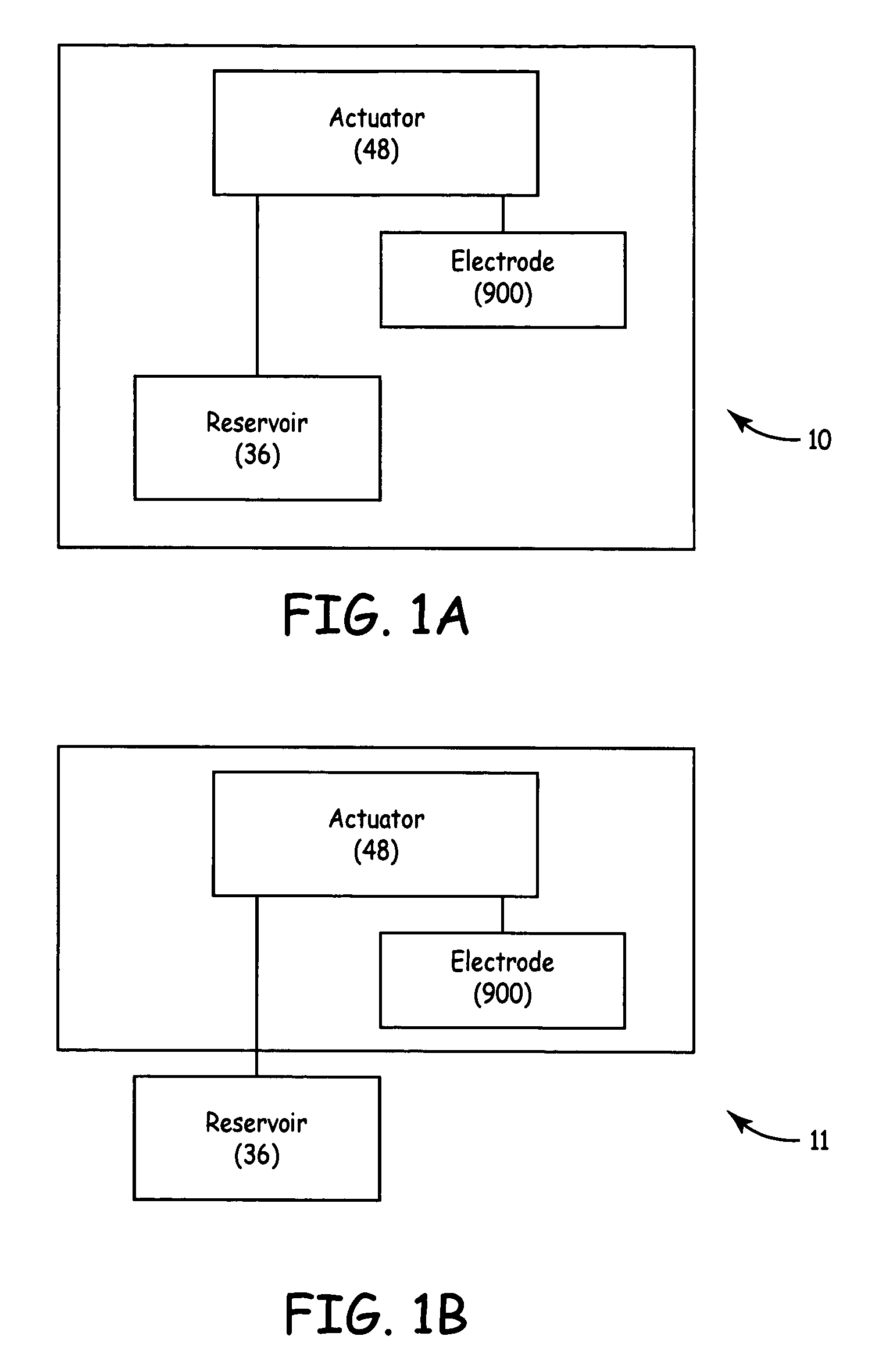

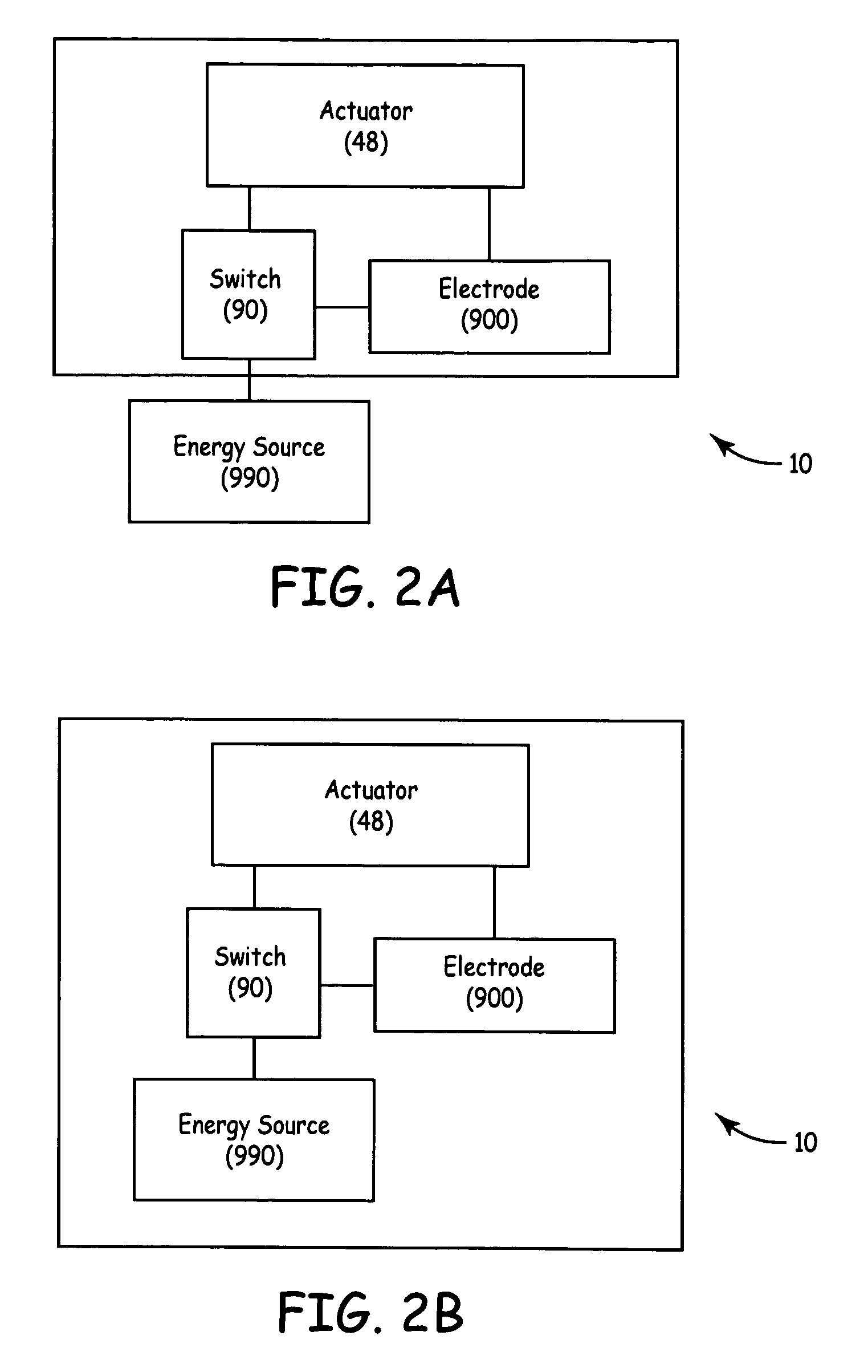

Tuna device with integrated saline reservoir

InactiveUS8911438B2Simplify wet electrode tissue ablation proceduresSimplify dry electrode techniquesSurgical needlesSurgical instruments for heatingActuatorTissue ablation

Owner:MEDTRONIC INC

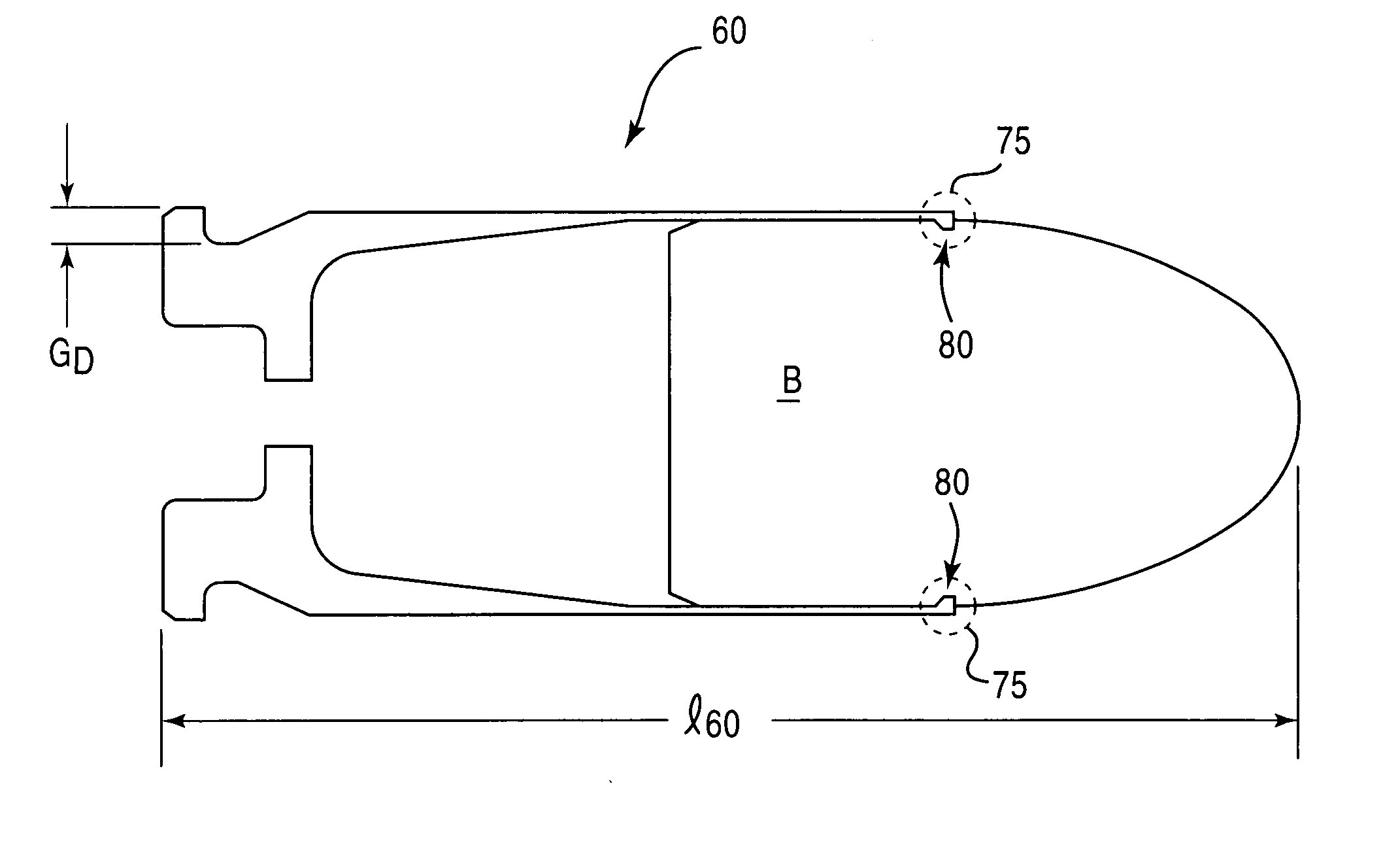

Catheter assemblies and injection molding processes and equipment for making the same

InactiveUS20050033237A1Increased complexityExtension of timeMouldsInfusion syringesMulti materialCatheter hub

Various single-part catheter assemblies, multi-part integrated catheter assemblies, and methods and apparatus for making the same are disclosed. The single-part catheter assemblies include a catheter hub integrally formed with a catheter tube for insertion into the bloodstream of a patient. The multi-part integrated catheter assemblies include a catheter hub integrally formed to a catheter tube for insertion into the bloodstream of a patient. The catheter assemblies of the invention may be injection molded in a single step or in multiple steps by injecting flows of molten plastic into a cavity of molds provided herein such that the flows converge into an even distribution about the circumference of the sleeve. The mold may have a core pin designed to fit into the cavity. Through the use of the even distribution of flows, the core pin may be seated within the cavity in an untensioned manner. The catheter assemblies of the invention may be produced of a single material or of multiple materials.

Owner:BECTON DICKINSON & CO

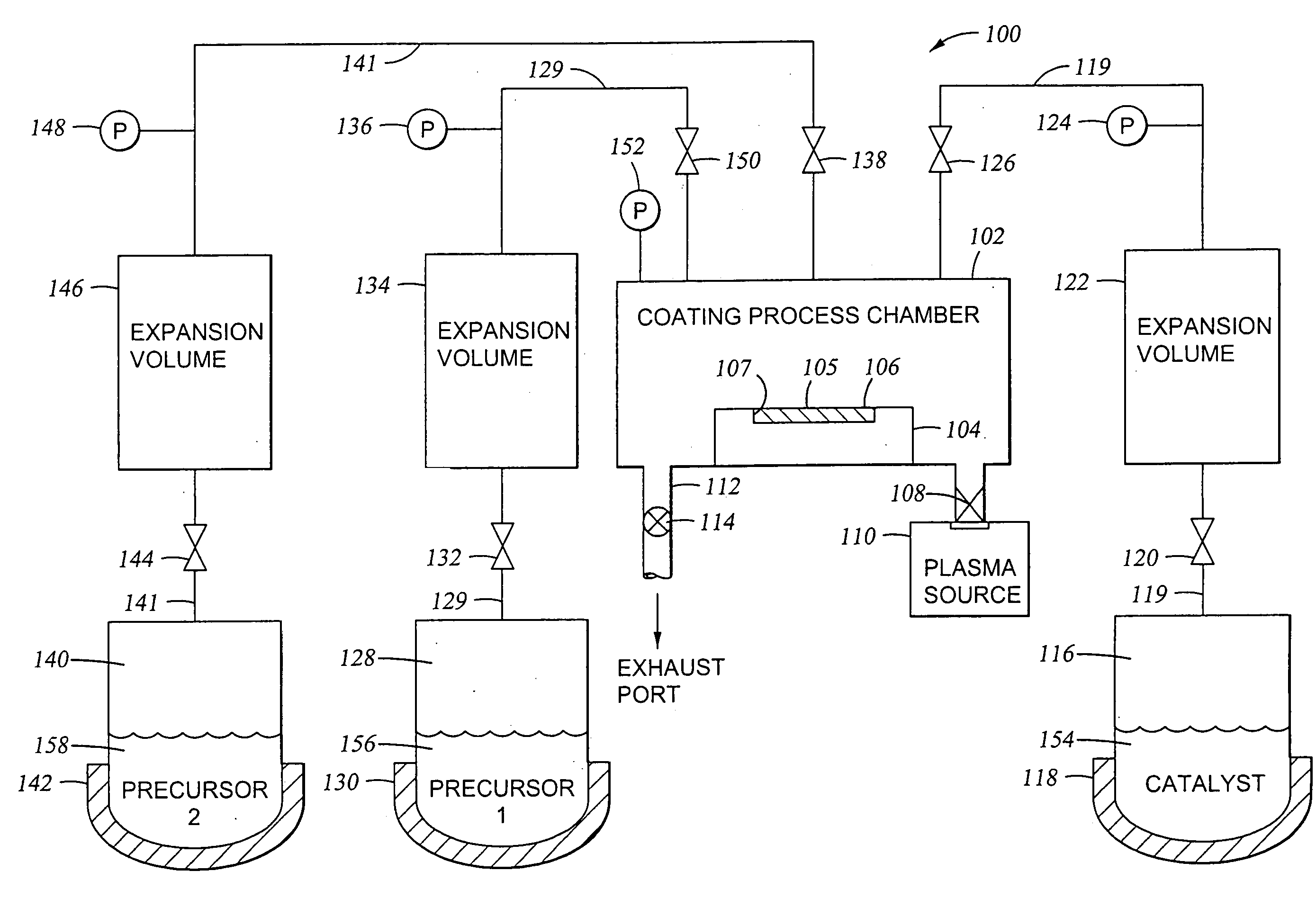

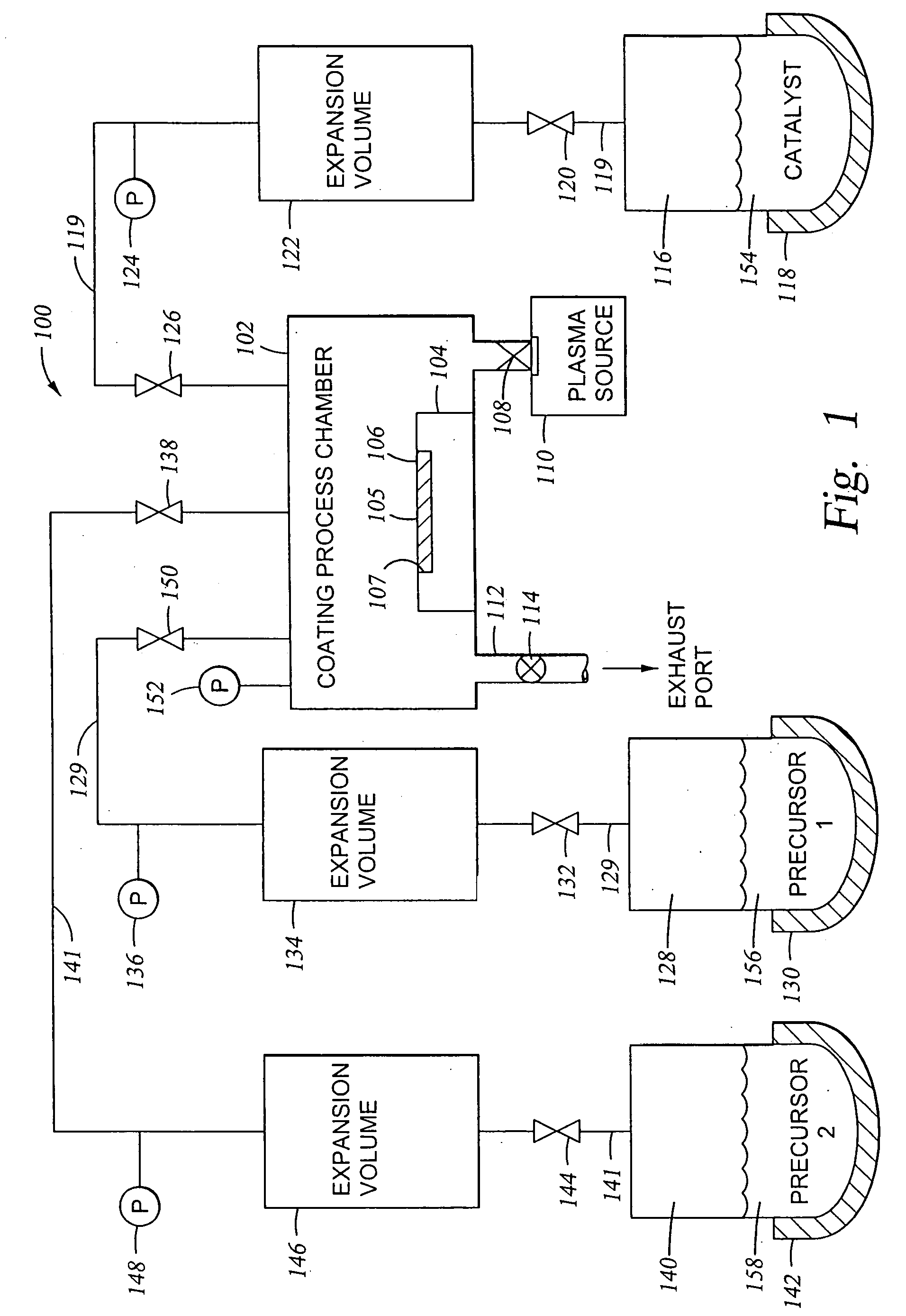

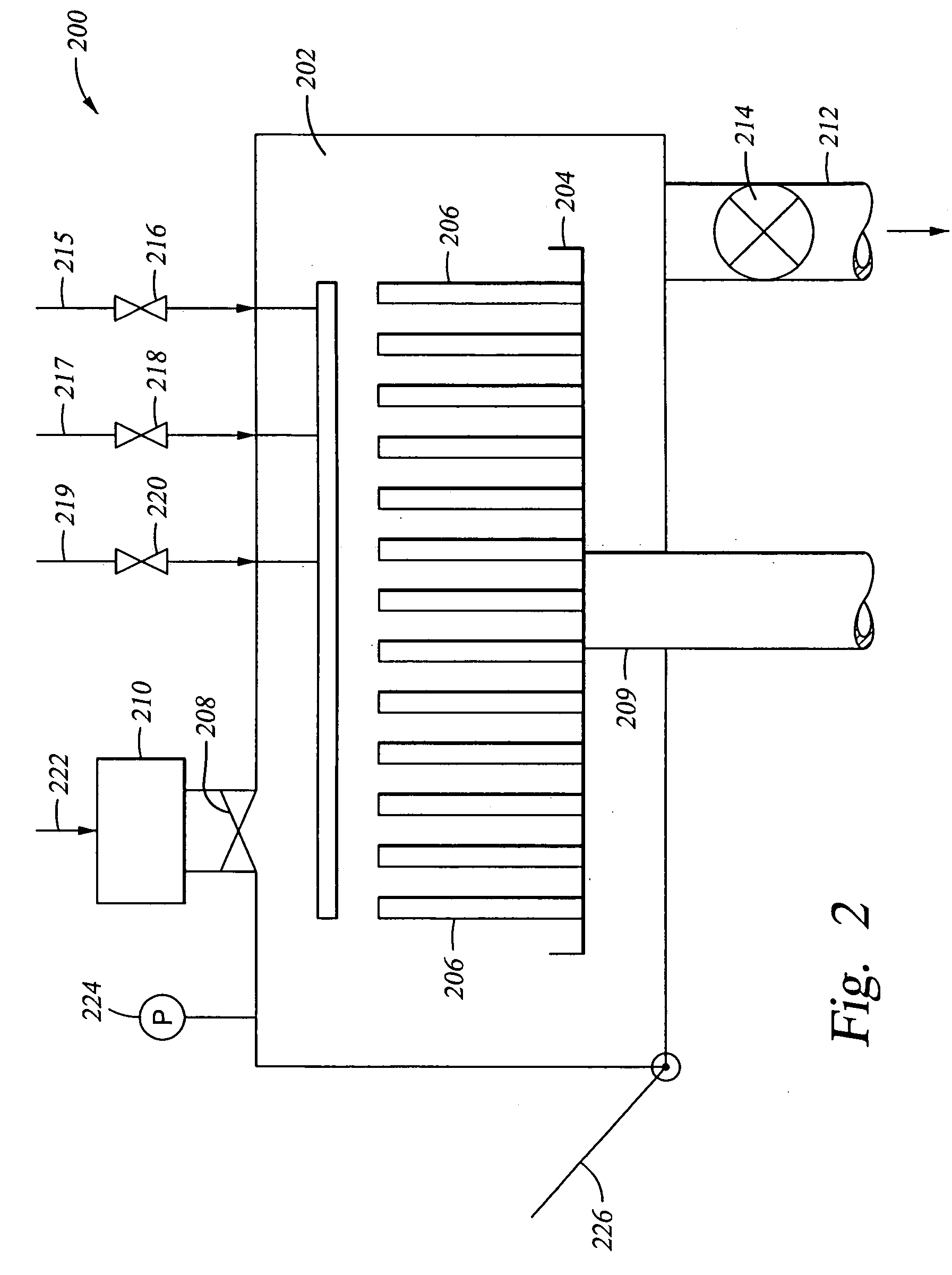

Apparatus and method for controlled application of reactive vapors to produce thin films and coatings

ActiveUS20060213441A1Highly accurate amountSimple methodMaterial nanotechnologyPretreated surfacesGas phaseThin layer

A vapor phase deposition method and apparatus for the application of thin layers and coatings on substrates. The method and apparatus are useful in the fabrication of electronic devices, micro-electromechanical systems (MEMS), Bio-MEMS devices, micro and nano imprinting lithography, and microfluidic devices. The apparatus used to carry out the method provides for the addition of a precise amount of each of the reactants to be consumed in a single reaction step of the coating formation process. The apparatus provides for precise addition of quantities of different combinations of reactants during a single step or when there are a number of different individual steps in the coating formation process. The precise addition of each of the reactants in vapor form is metered into a predetermined set volume at a specified temperature to a specified pressure, to provide a highly accurate amount of reactant.

Owner:JEFFREY D CHINN & ROMUALD NOWAK +1

TUNA device with integrated saline reservoir

ActiveUS7322974B2Simplify wet electrode tissue ablation proceduresSimplify dry electrode techniquesSurgical needlesSurgical instrument detailsSaline waterActuator

Methods and apparatus for ablating a target tissue are discussed. Such methods and apparatus include those that simplify tissue ablation. For example, a tissue ablation device having an actuator, such as a trigger mechanism, coupled to a power source and an electrode is discussed. A single step of engaging the actuator causes the electrode to be introduced into the target tissue and causes energy to be delivered from the power supply to the tissue via the electrode. By way of additional example, a tissue ablation device having an actuator coupled to a fluid source and an electrode is discussed. A single step of engaging the actuator causes conductive fluid to flow from the fluid source to the target tissue location and causes the electrode to be introduced to the target tissue location. The fluid source may be a conductive fluid, such as saline, which may increase the efficiency of ablation. Various other configurations and methods that simplify tissue ablation are also discussed.

Owner:MEDTRONIC INC

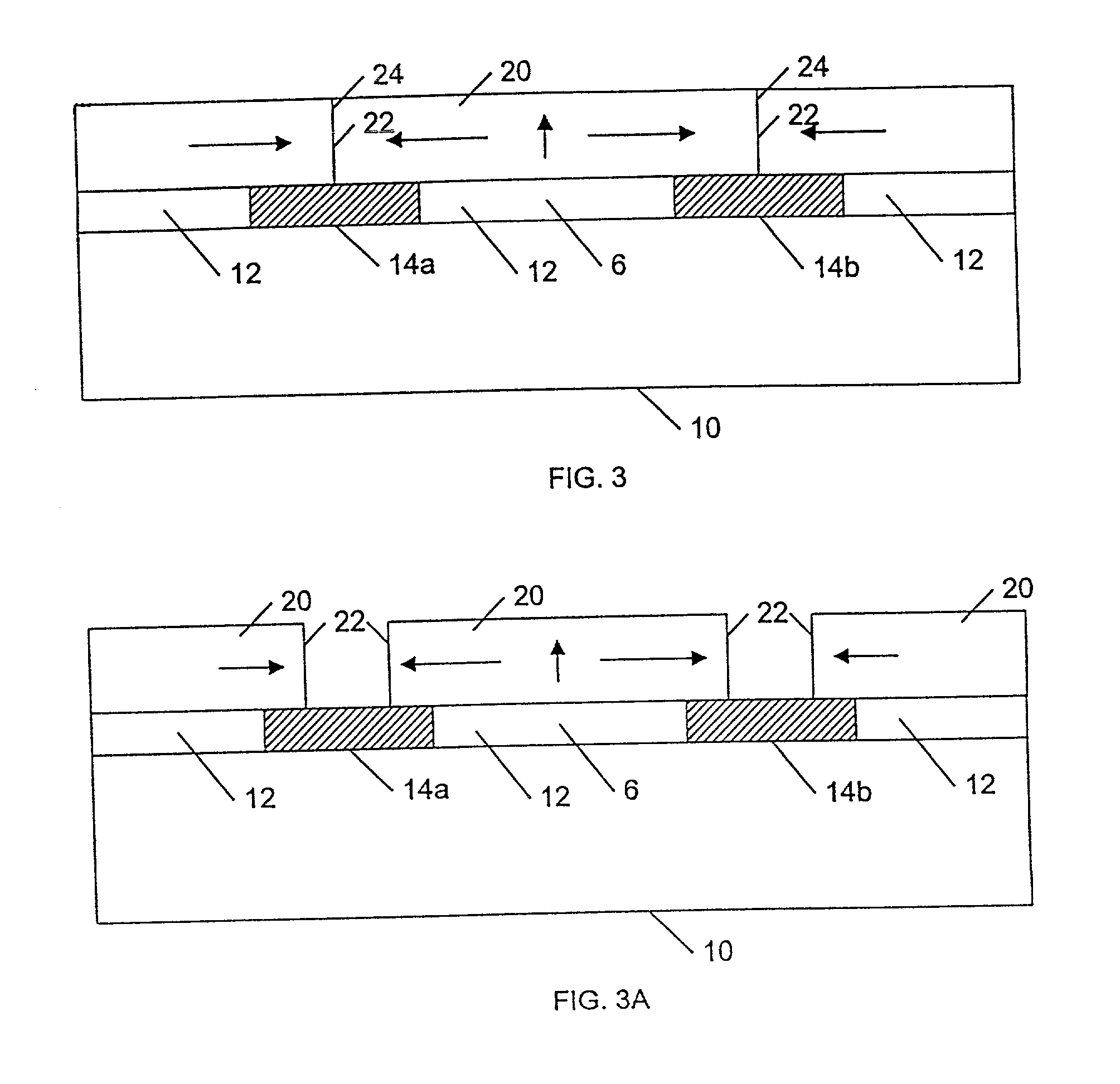

Single step pendeo-and lateral epitaxial overgrowth of group III-nitride epitaxial layers with group III-nitride buffer layer and resulting structures

InactiveUS20020022290A1Semiconductor laser structural detailsSemiconductor/solid-state device manufacturingSemiconductor structureGallium nitride

A method of fabricating a gallium nitride-based semiconductor structure on a substrate includes the steps of forming a mask having at least one opening therein directly on the substrate, growing a buffer layer through the opening, and growing a layer of gallium nitride upwardly from the buffer layer and laterally across the mask. During growth of the gallium nitride from the mask, the vertical and horizontal growth rates of the gallium nitride layer are maintained at rates sufficient to prevent polycrystalline material nucleating on said mask from interrupting the lateral growth of the gallium nitride layer. In an alternative embodiment, the method includes forming at least one raised portion defining adjacent trenches in the substrate and forming a mask on the substrate, the mask having at least one opening over the upper surface of the raised portion. A buffer layer may be grown from the upper surface of the raised portion. The gallium nitride layer is then grown laterally by pendeoepitaxy over the trenches.

Owner:CREE INC

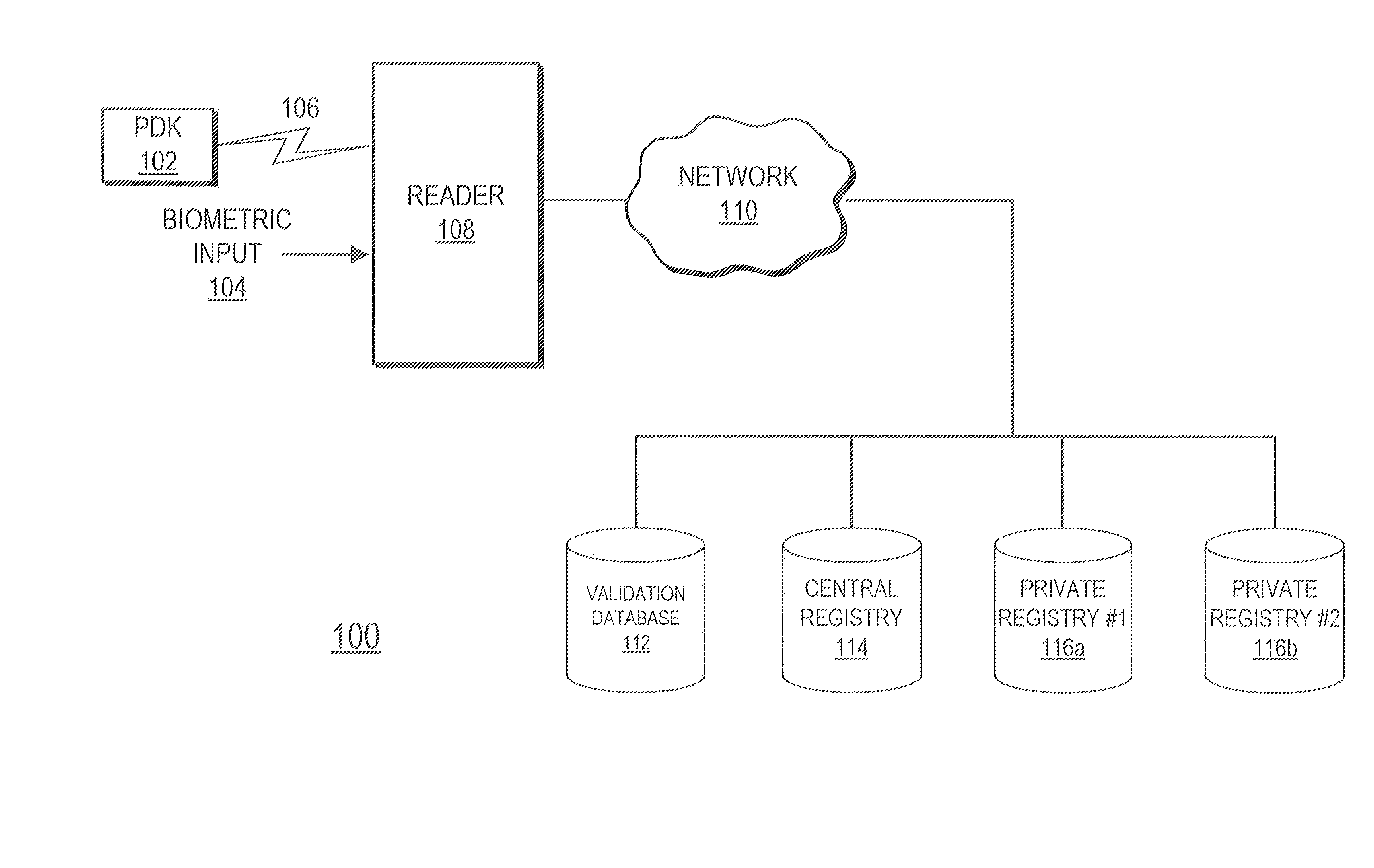

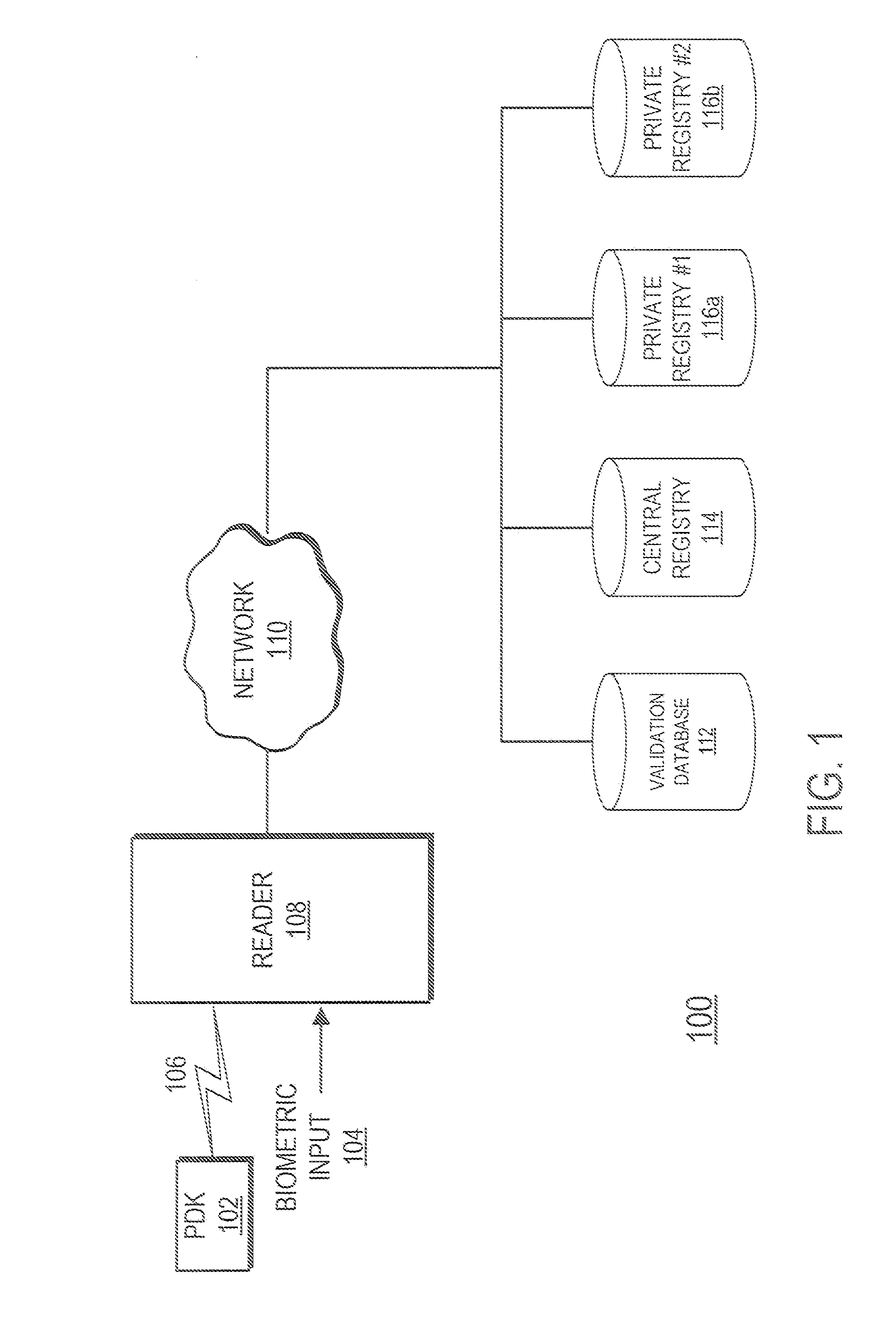

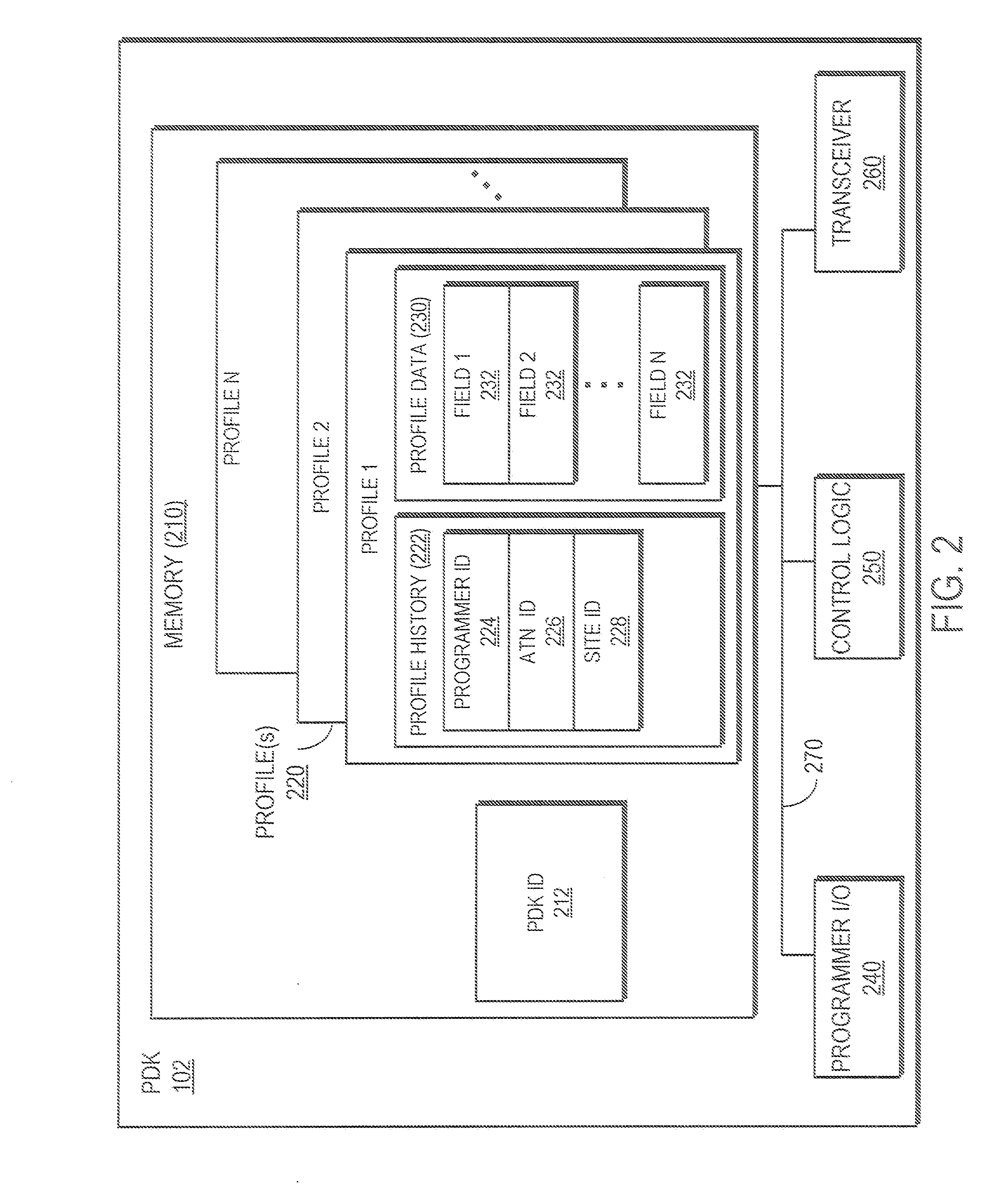

Single step transaction authentication using proximity and biometric input

ActiveUS20070245158A1Efficient and secure and highly reliable authenticationAcutation objectsUser identity/authority verificationWireless transmissionTransaction processing

A system and method provide efficient, secure and highly reliable authentication for transaction processing and / or access control applications in which only biometric input is required from the user. A Personal Digital Key stores a biometric profile that comprises a representation of physical or behavioral characteristics that are uniquely associated with an individual that owns and carries the PDK. The PDK wirelessly transmits the biometric profile over a secure wireless transaction to a Reader for use in a biometric authentication process. The Reader compares the received biometric profile to a biometric input acquired at the point of transaction in order to determine if the transaction should be authorized.

Owner:PROXENSE

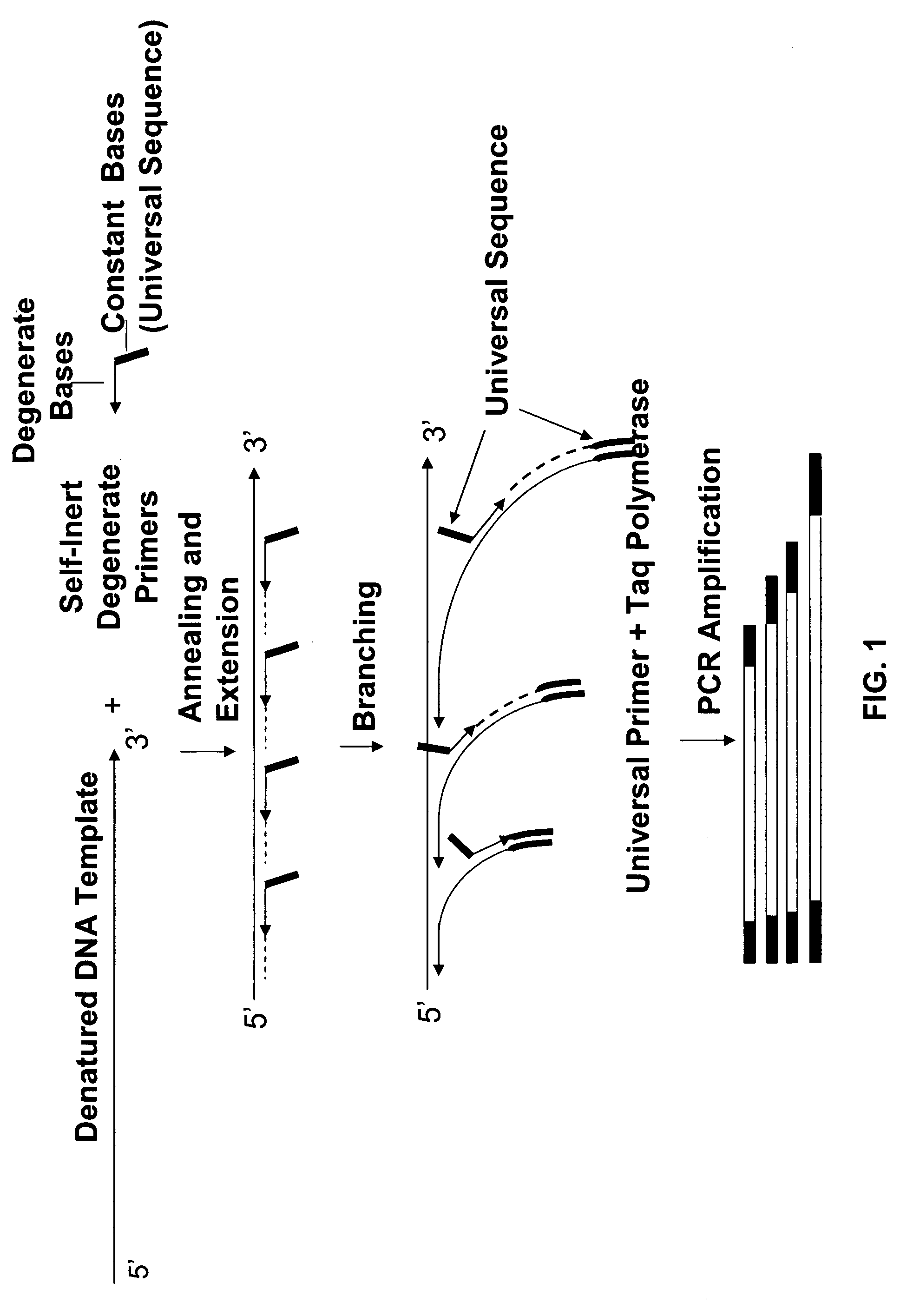

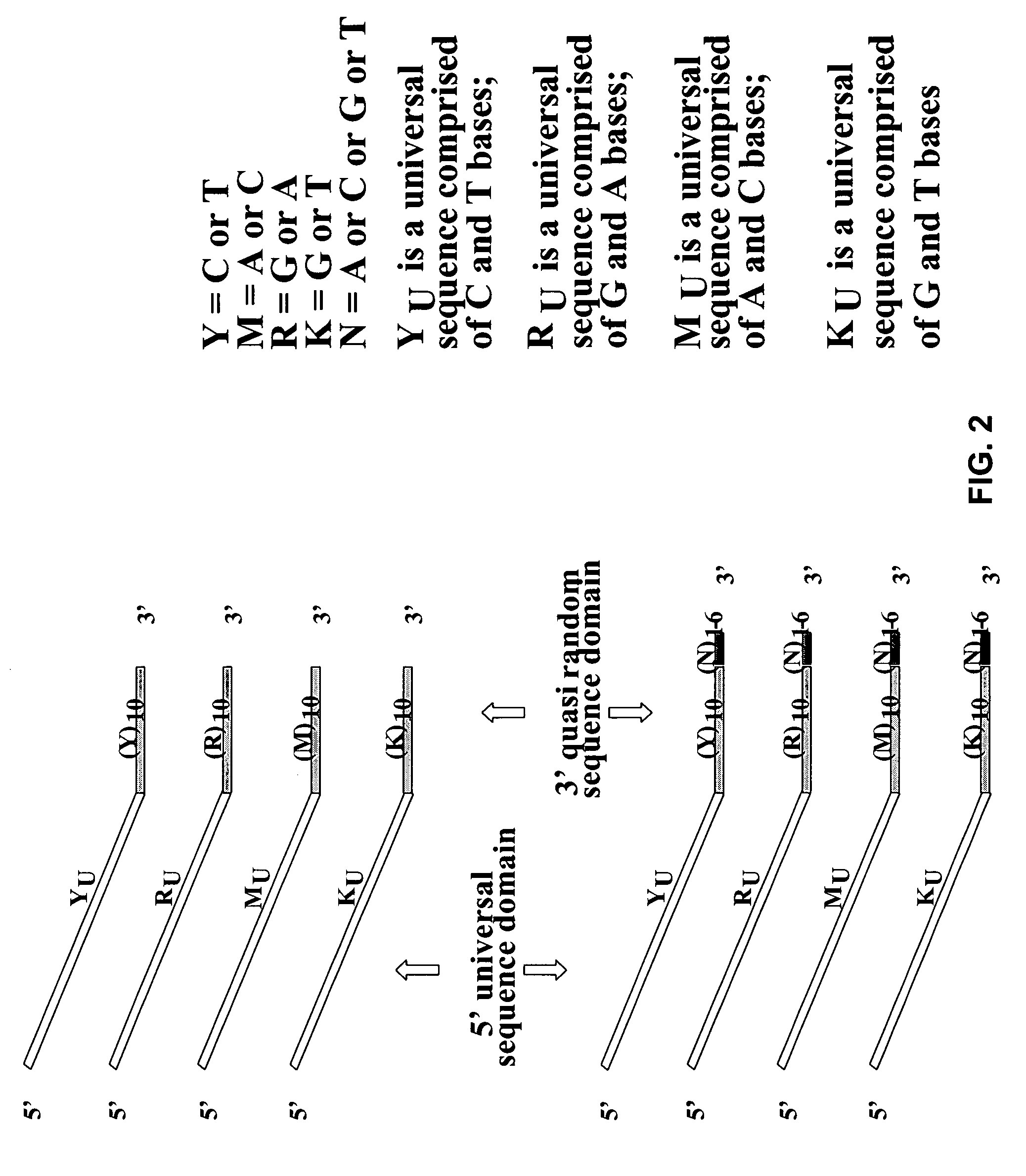

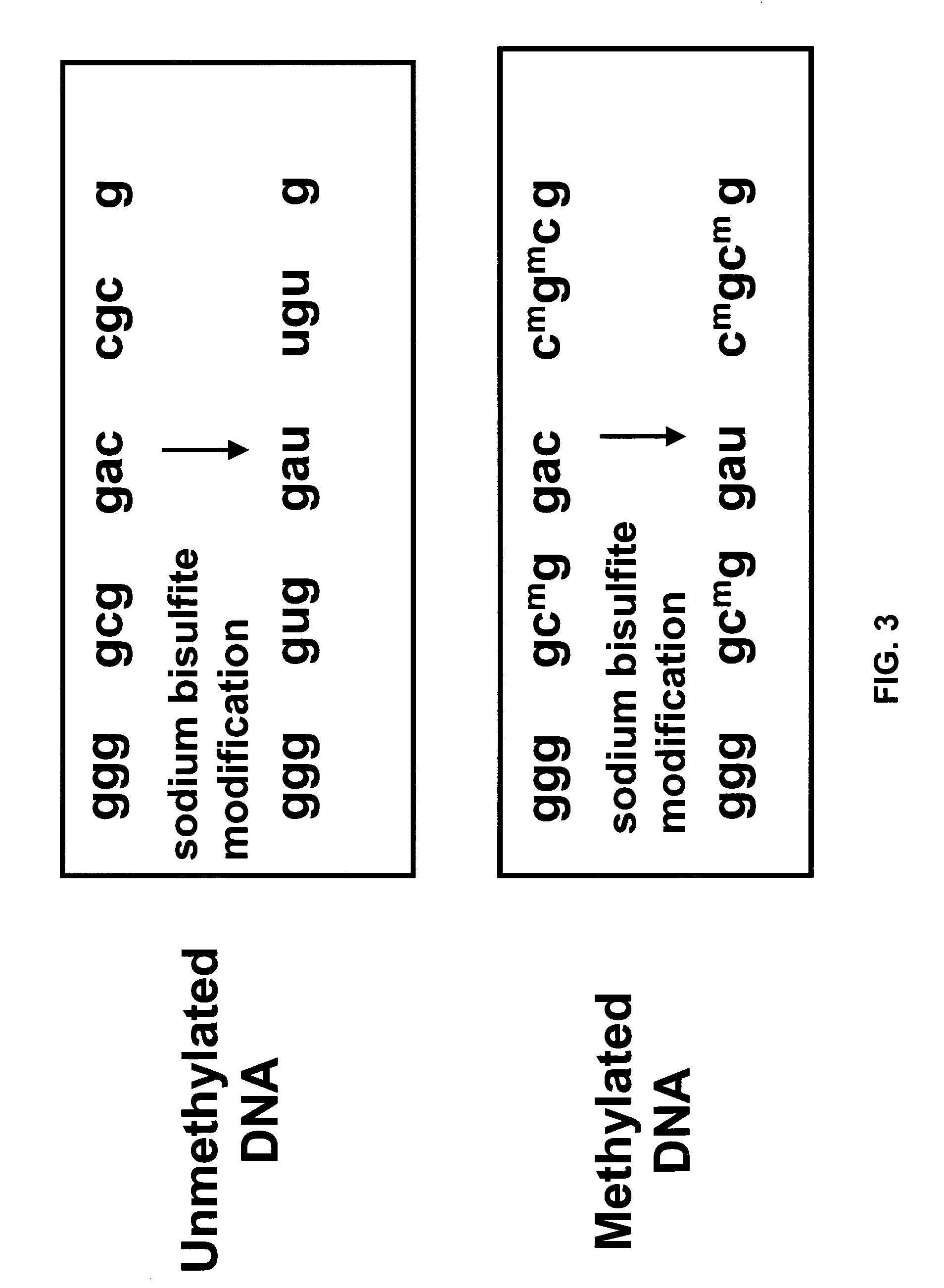

Methods and compositions for generating and amplifying DNA libraries for sensitive detection and analysis of DNA methylation

InactiveUS20050202490A1Reduce stepsReduce stretchMicrobiological testing/measurementFermentationDNA methylationCell free

The present invention regards a variety of methods and compositions for obtaining epigenetic information, such as DNA methylation patterns, through the preparation, amplification and analysis of Methylome libraries. In several aspects of the present invention, there are methods based on methylation-dependent enrichment or depletion of genomic DNA isolated from cellular and cell-free sources. In additional embodiments, there are methods and compositions for single-step high throughput preparations of Methylome libraries.

Owner:TAKARA BIO USA INC

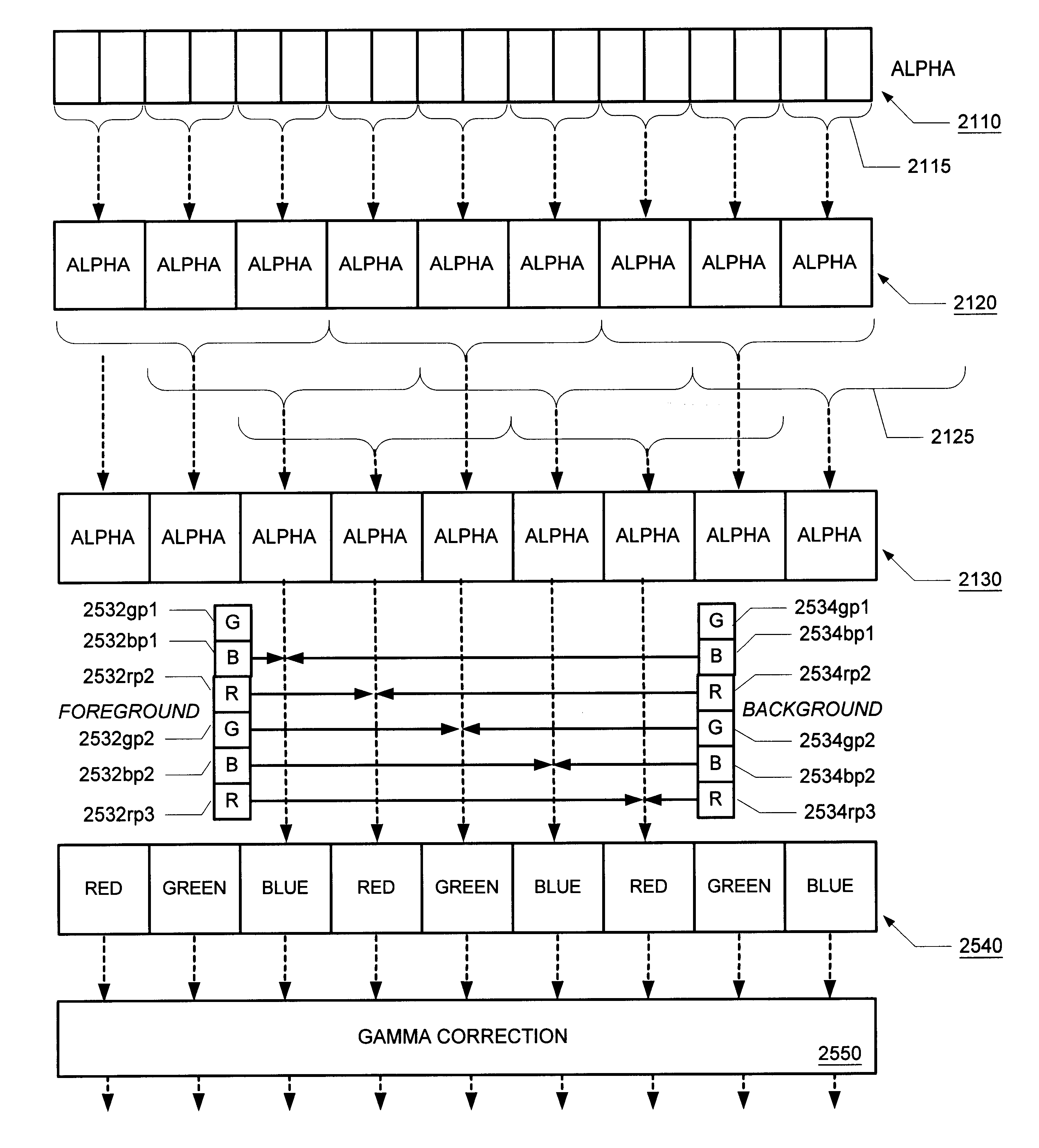

Methods apparatus and data structures for enhancing the resolution of images to be rendered on patterned display devices

InactiveUS20010048764A1Improve imaging resolutionHigh resolutionImage enhancementTelevision system detailsSub-pixel resolutionArray data structure

Techniques for improving the resolution of images (either analog images, analytic images, or images having a higher resolution than that of a display device) to be rendered on patterned displays. In one aspect of the present invention, an overscaling or oversampling process may accept analytic character information, such as contours for example, and a scale factor or grid and overscale or oversample the analytic character information to produce an overscaled or oversampled image. The overscaled or oversampled image generated has a higher resolution than the display upon which the character is to be rendered. Displaced samples of the overscaled or oversampled image are then combined (or filtered). An analytic image, such as a line drawing for example, may be applied to the oversampling / overscaling process as was the case with the character analytic image. However, since the analytic image may have different units than that of the character analytic image, the scale factor applied may be different. Since an ultra resolution image is already "digitized", that is, not merely mathematically expressed contours or lines between points, it may be applied directly to a process for combining displaced samples of the ultra-resolution image to generate another ultra-resolution image (or an image with sub-pixel information). The functionality of the overscaling / oversampling process and the processes for combining displaced samples may be combined into a single step analytic to digital sub-pixel resolution conversion process.

Owner:MICROSOFT TECH LICENSING LLC +1

Integrated blood sampling analysis system with multi-use sampling module

A simple, miniaturized, disposable acquisition and test module for monitoring glucose or other analytes successively for multiple times is described. The apparatus is designed to collect and test small volumes of blood in a single step. Many samples can be acquired and analyzed using a single disposable sampling module, minimizing the number of disposables and improving ease of use of the system.

Owner:SANOFI AVENTIS DEUT GMBH

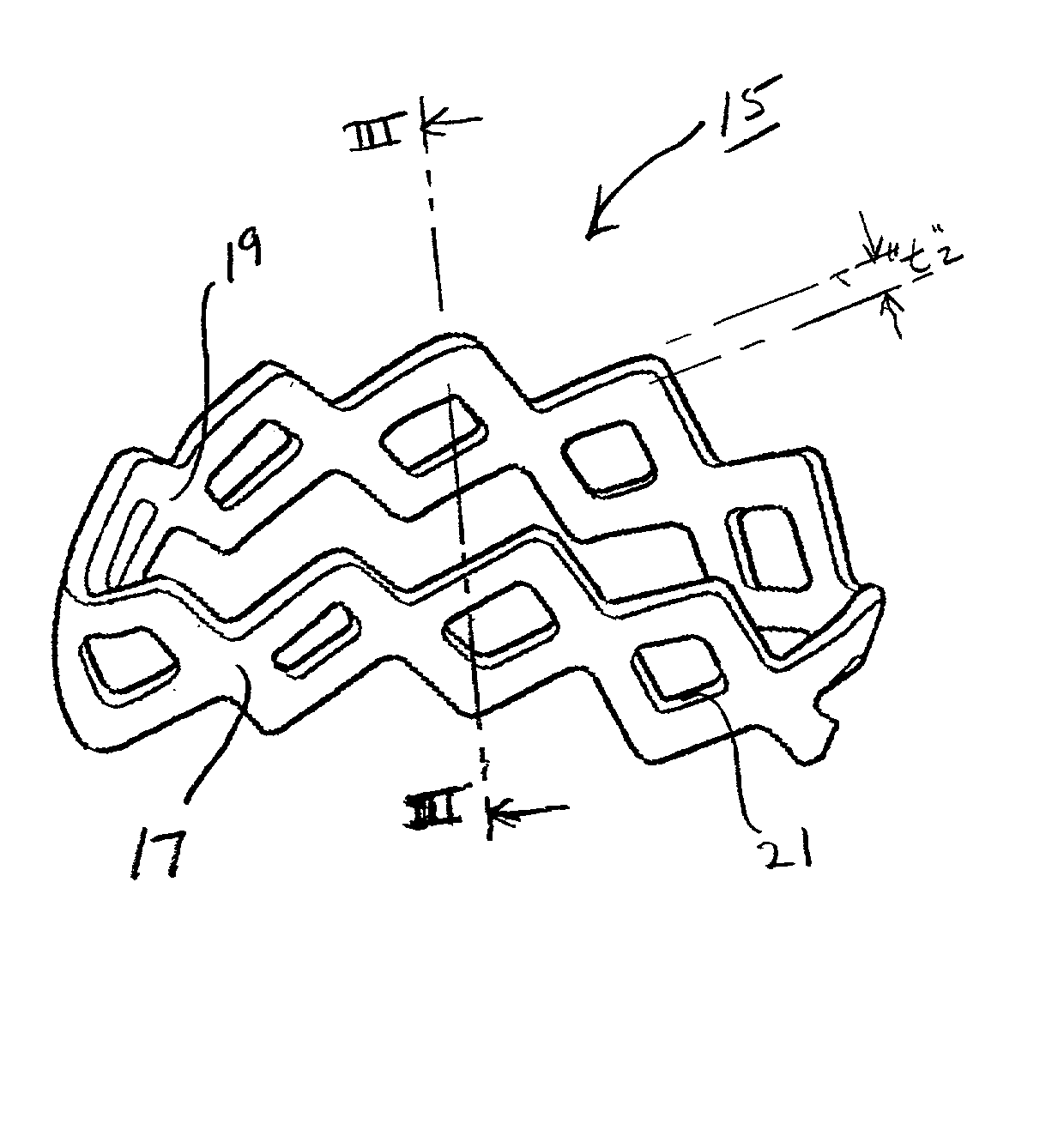

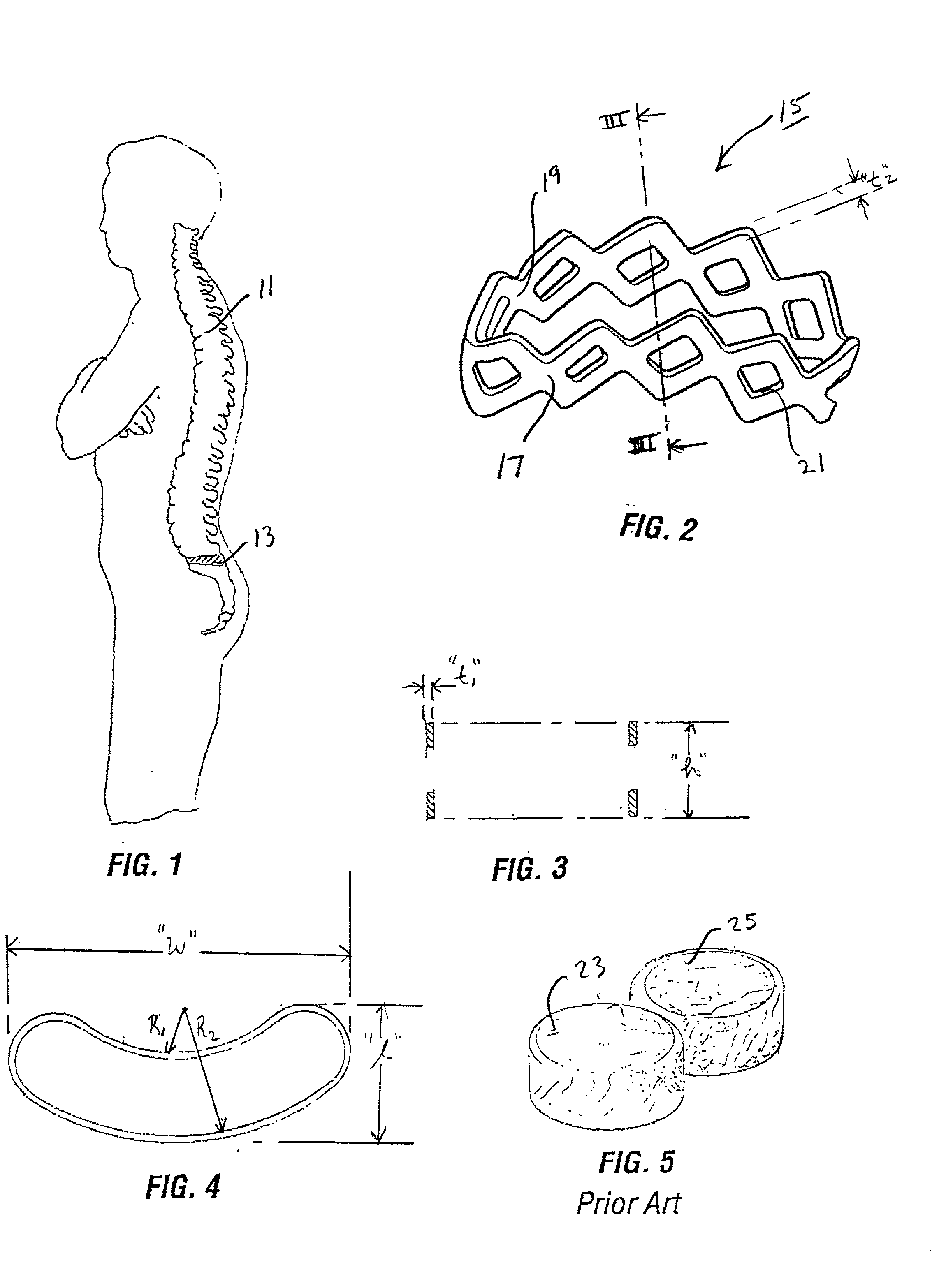

Intervertebral cage and method of use

InactiveUS20020055781A1Facilitates inter-body fusionInternal osteosythesisBone implantProsthesisCancellous bone

An intervertebral prosthesis for implantation between adjacent vertebrae of the human spine is shown. The prosthesis is formed as a unitary cage body configured and sized to be inserted between adjacent vertebrae in a single step implantation procedure. The cage body is banana shaped as viewed from above, the body having an exterior surface and an interior surface, the interior surface defining an internal recess for receiving cancellous bone material during an implantation procedure. The cage body can be formed as an interlinked mesh.

Owner:DEPUY ACROMED INC

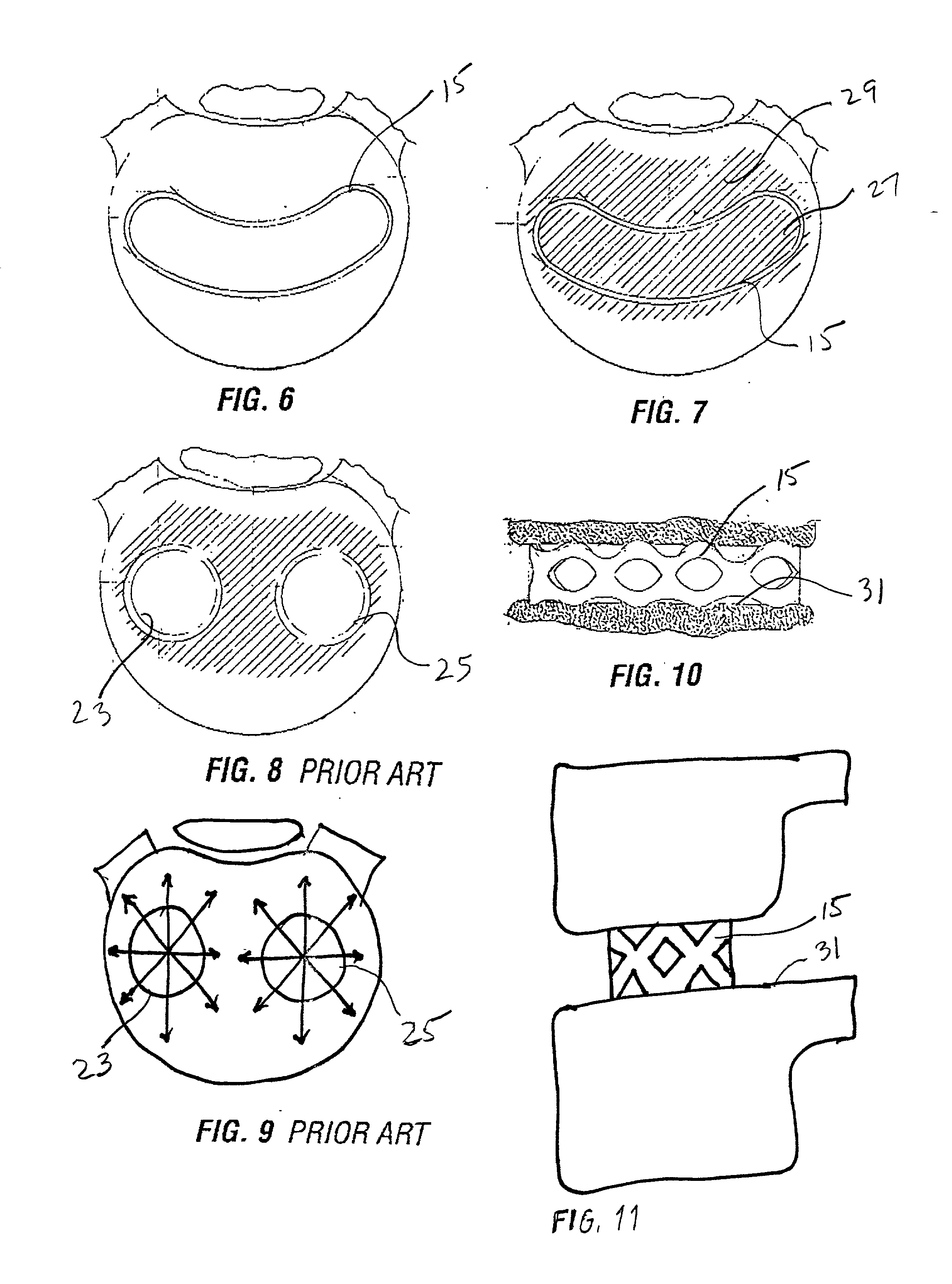

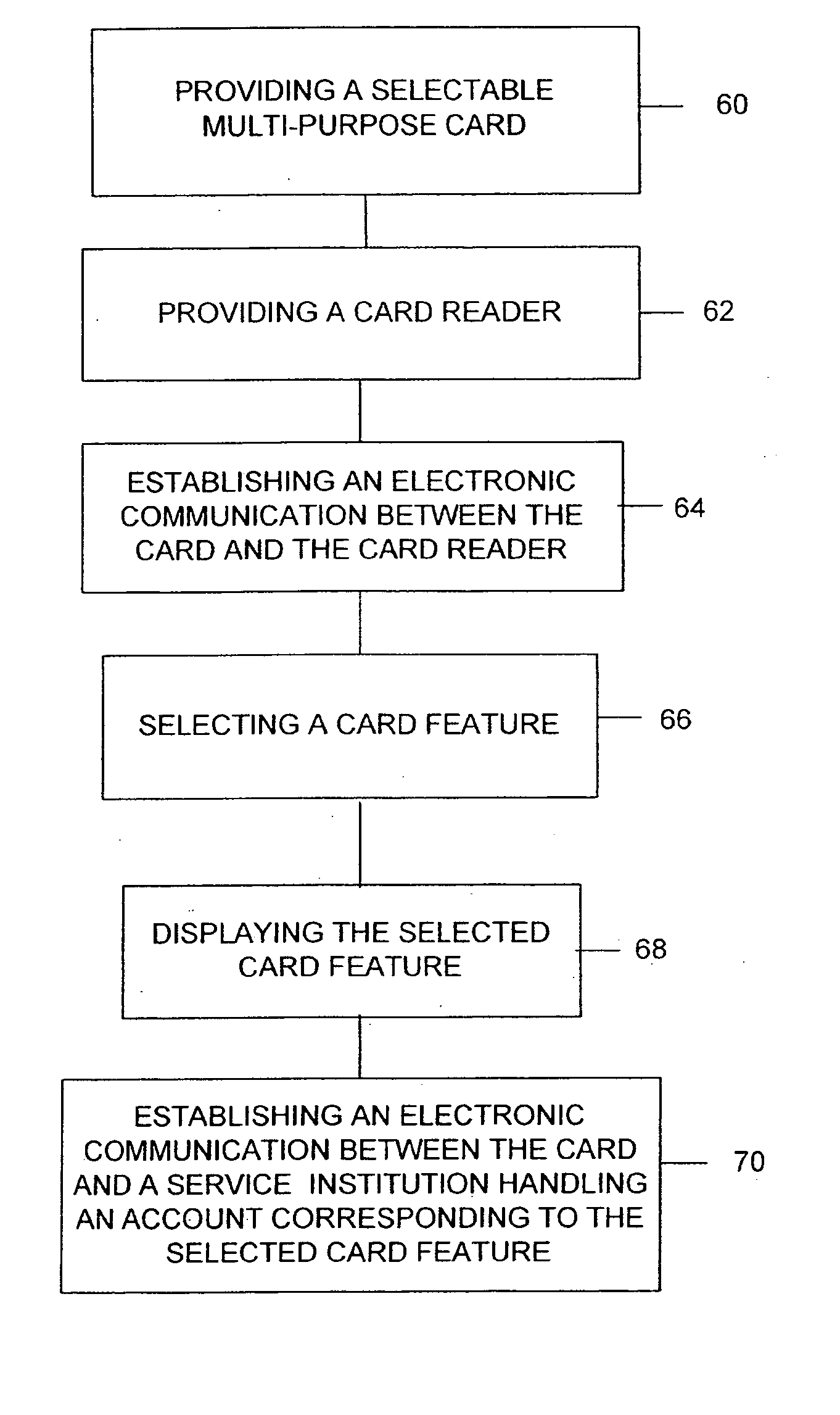

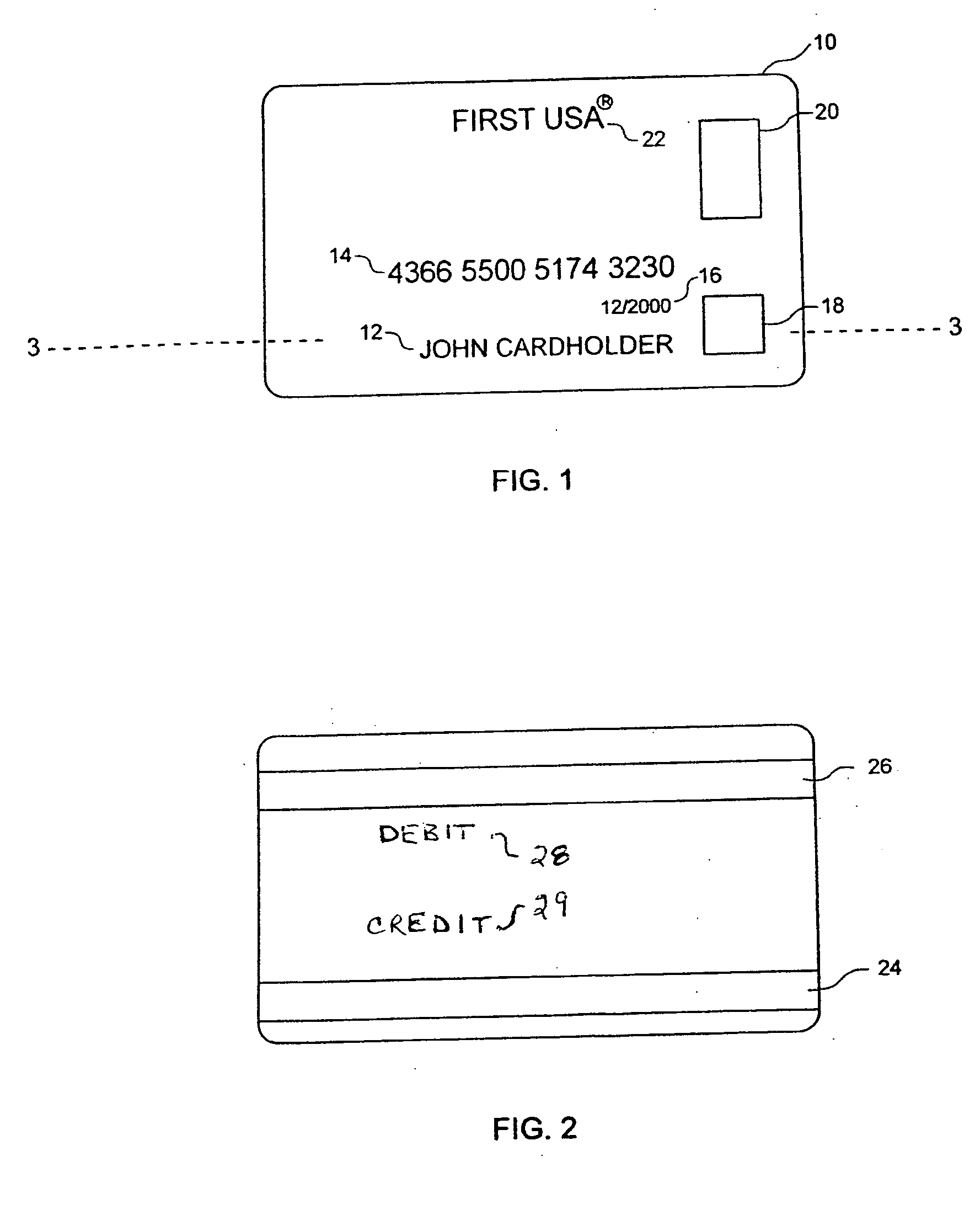

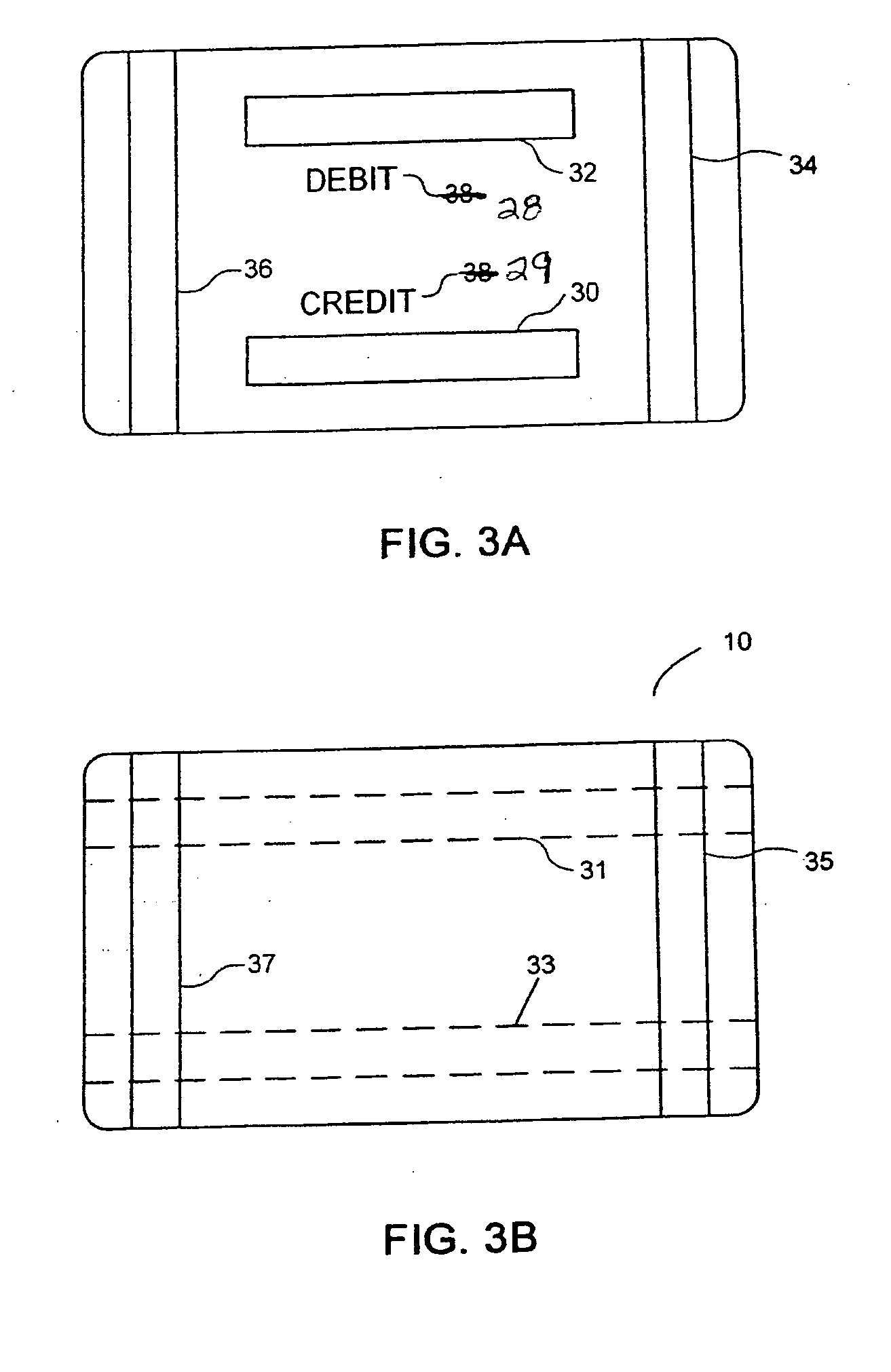

Selectable multi-purpose card

InactiveUS20050092830A1Prevent unauthorized accessPayment architectureRecord carriers used with machinesComputer hardwareFlexible display

A selectable, multi-purpose card comprising a plurality of features stored in memory means operatively mounted on the card and selection means for allowing a user to select a feature in a few simple steps, preferably in a single step. In one embodiment the card includes a plurality of magnetic strips positioned on the card in a manner to allow swiping each magnetic strip separately using conventional reading devices. Each magnetic strip activates a different feature of the card. In another embodiment the card includes a programmable magnetic strip, a plurality of features stored in memory means mounted on the card, a plurality of buttons or contacts, and means for programming the magnetic strip with a different card feature. The card may also include a thin, flexible display.

Owner:JPMORGAN CHASE BANK NA

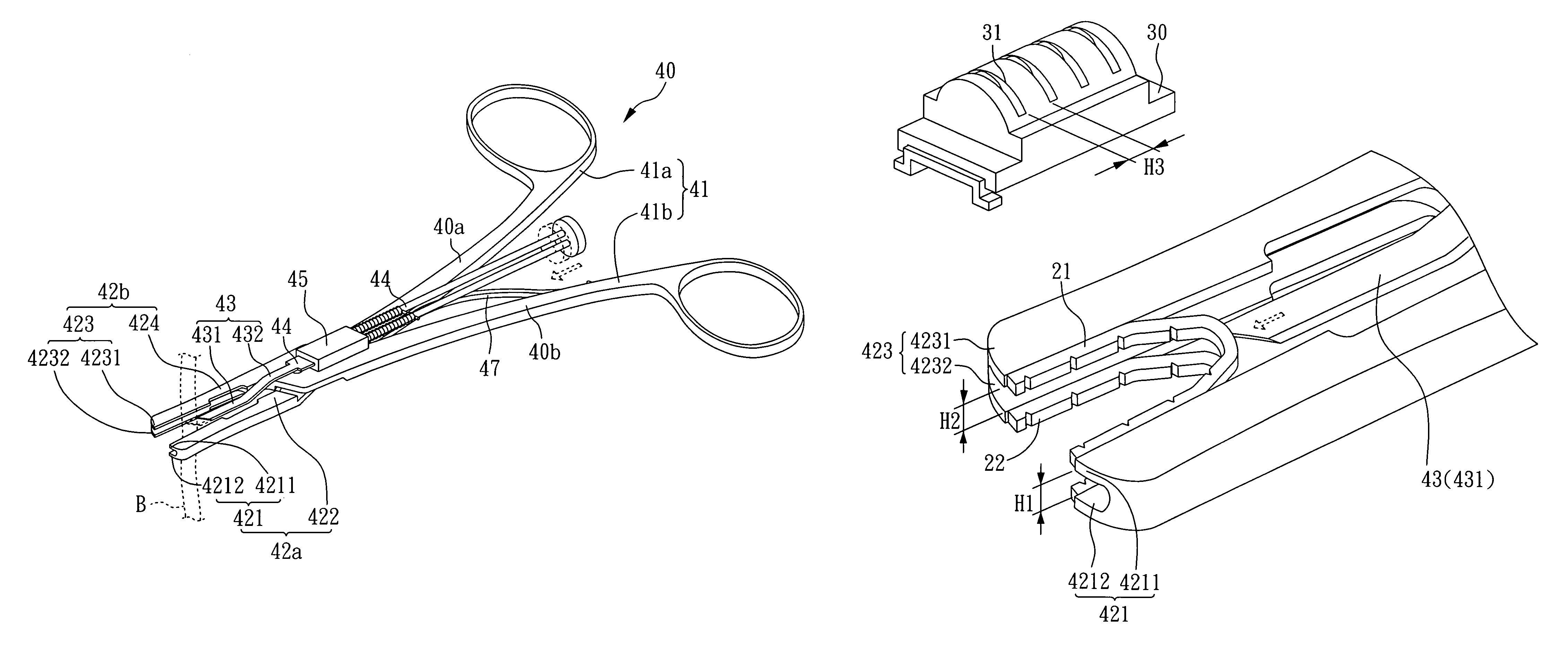

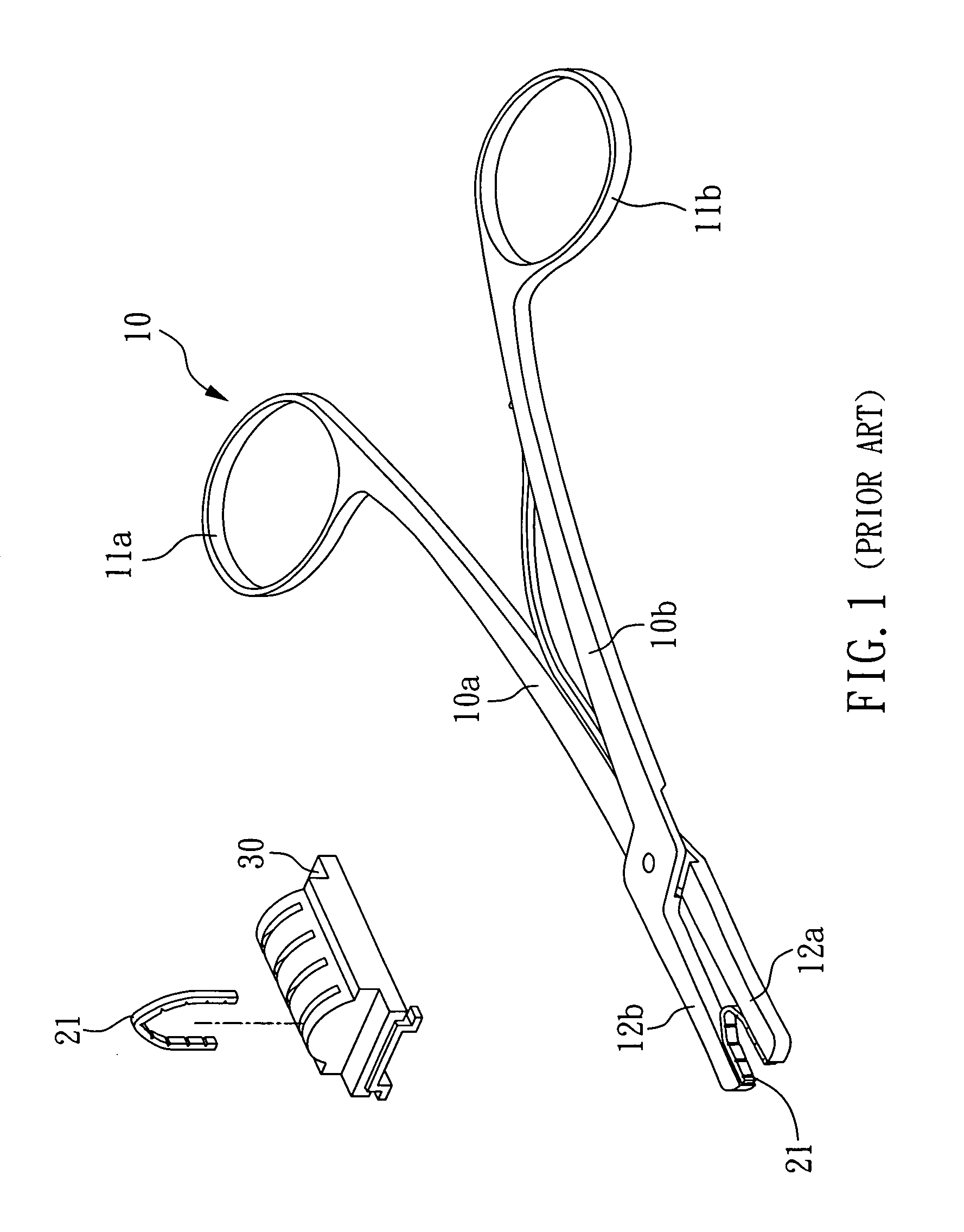

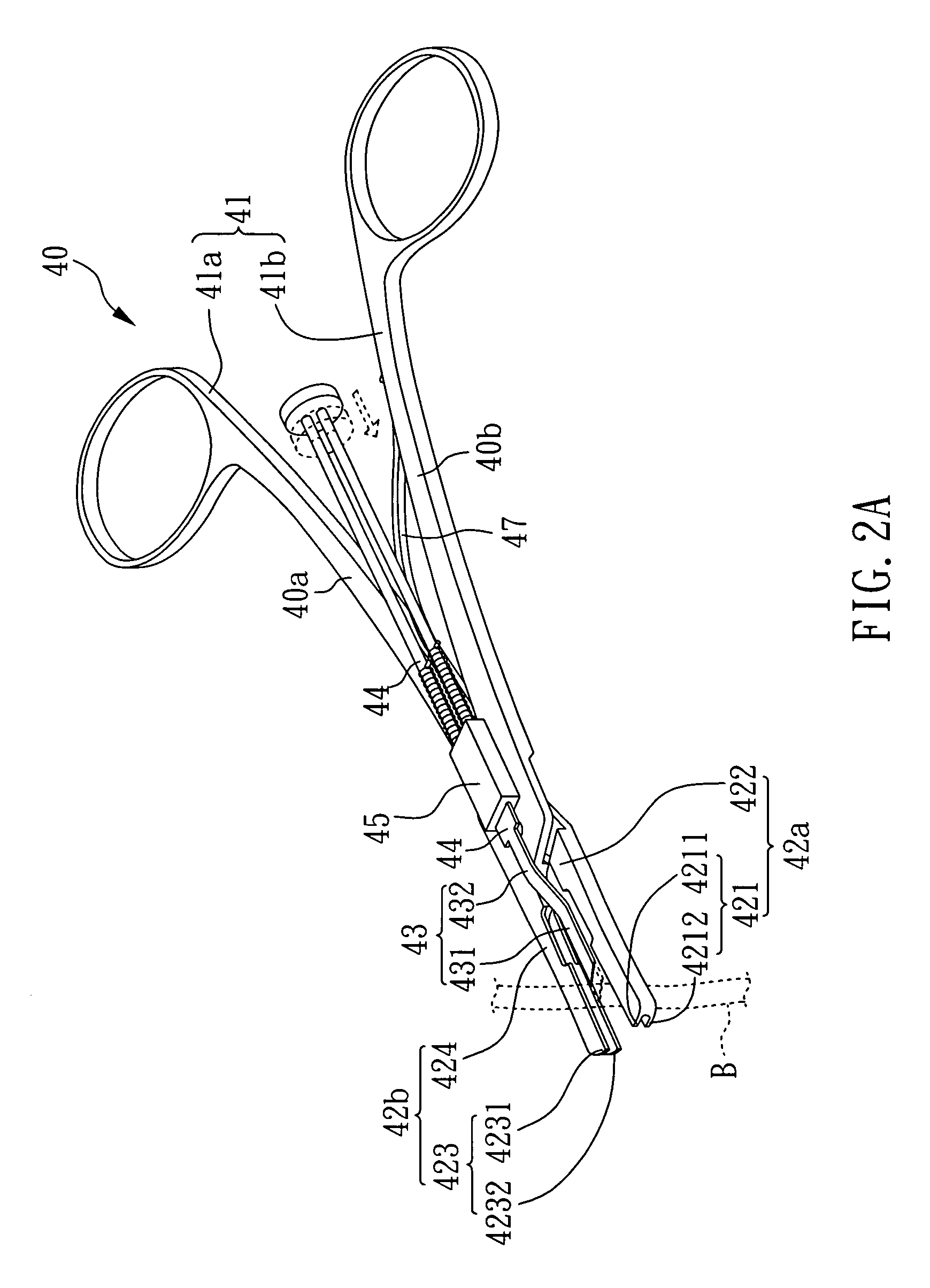

Integrated double clips applier with division device for clamping clips

The present invention relates to a clip applier for clipping and dividing blood vessels, including: a handle; a first jaw unit; and a second jaw unit. The clip applier of the present invention can bring up two ligating clips at the same time with the first jaw unit and the second jaw unit, whereas the two clamping positions of the blood vessel can be clamped with the ligating clips simultaneously by the clip applier of the present invention in a single step, and thus the operating steps can be simplified, and the time involved with the surgical operation can be shortened.

Owner:CHENG MING HUEI +2

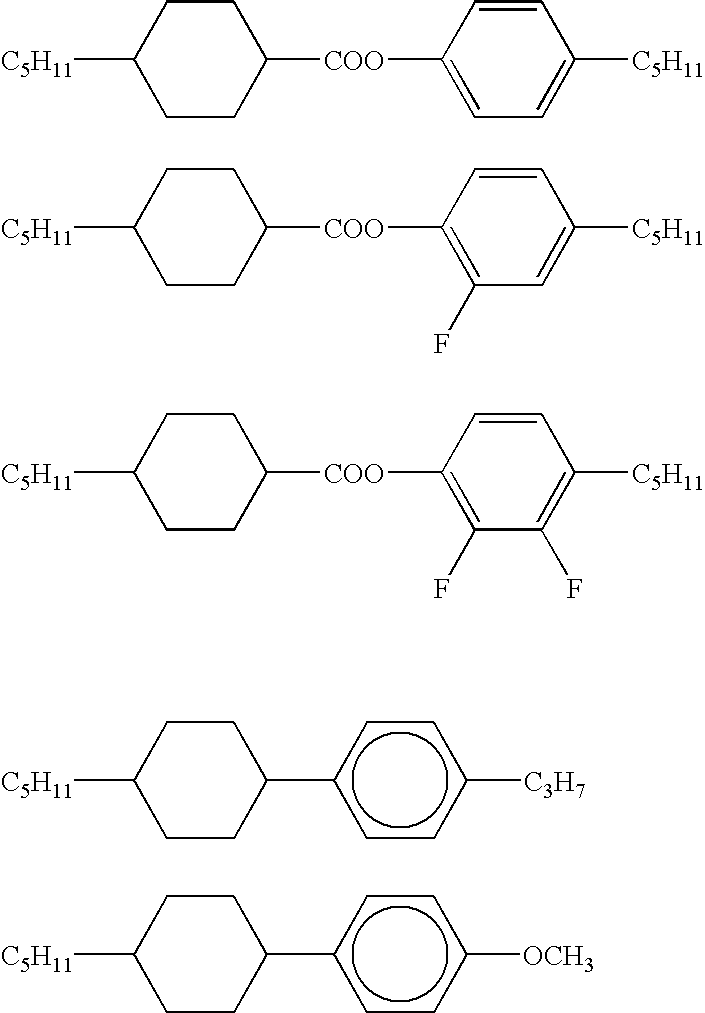

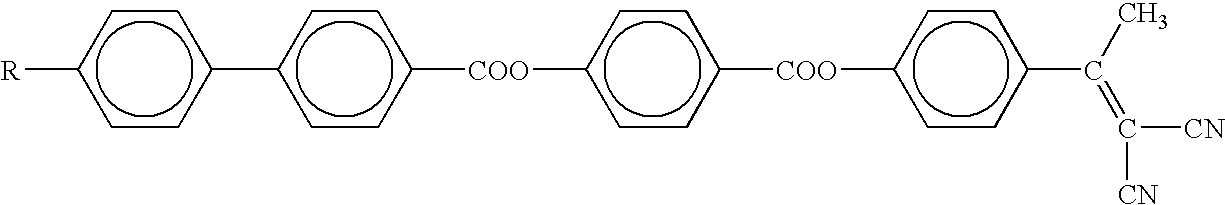

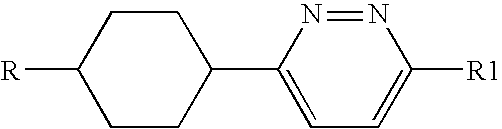

Electrically switchable polymer-dispersed liquid crystal materials including switchable optical couplers and reconfigurable optical interconnects

InactiveUS6821457B1Lower switching voltageDiffusing elementsPhotomechanical apparatusWavelengthOptical coupler

A new photopolymerizable material allows single-step, fast recording of volume holograms with properties that can be electrically controlled. Polymer-dispersed liquid crystals (PDLCs) in accordance with the invention preferably comprise a homogeneous mixture of a nematic liquid crystal and a multifunctional pentaacrylate monomer in combination with photoinitiator, coinitiator and cross-linking agent. Optionally, a surfactant such as octancic acid may also be added. The PDLC material is exposed to coherent light to produce an interference pattern inside the material. Photopolymerization of the new PDLC material produces a hologram of clearly separated liquid crystal domains and cured polymer domains. Volume transmission gratings made with the new PDLC material can be electrically switched between nearly 100% diffraction efficiency and nearly 0% diffraction efficiency. By increasing the frequency of the switching voltage, switching voltages in the range of 50 Vrms can be achieved. The optional use of a surfactant allows low switching voltages at lower frequencies than without a surfactant. In an alternative embodiment, a PDLC material in accordance with the invention can be utilized to form reflection gratings, including switchable reflection gratings. In still further embodiments, a PDLC material in accordance with the invention can be used to form switchable subwavelength gratings. By further processing, static transmission, reflection, and subwavelength PDLC materials can be formed. In addition, PDLC materials in accordance with the present invention can be used to form switchable slanted transmission gratings suitable for switchable optical coupling and reconfigurable optical interconnects.

Owner:LEIDOS

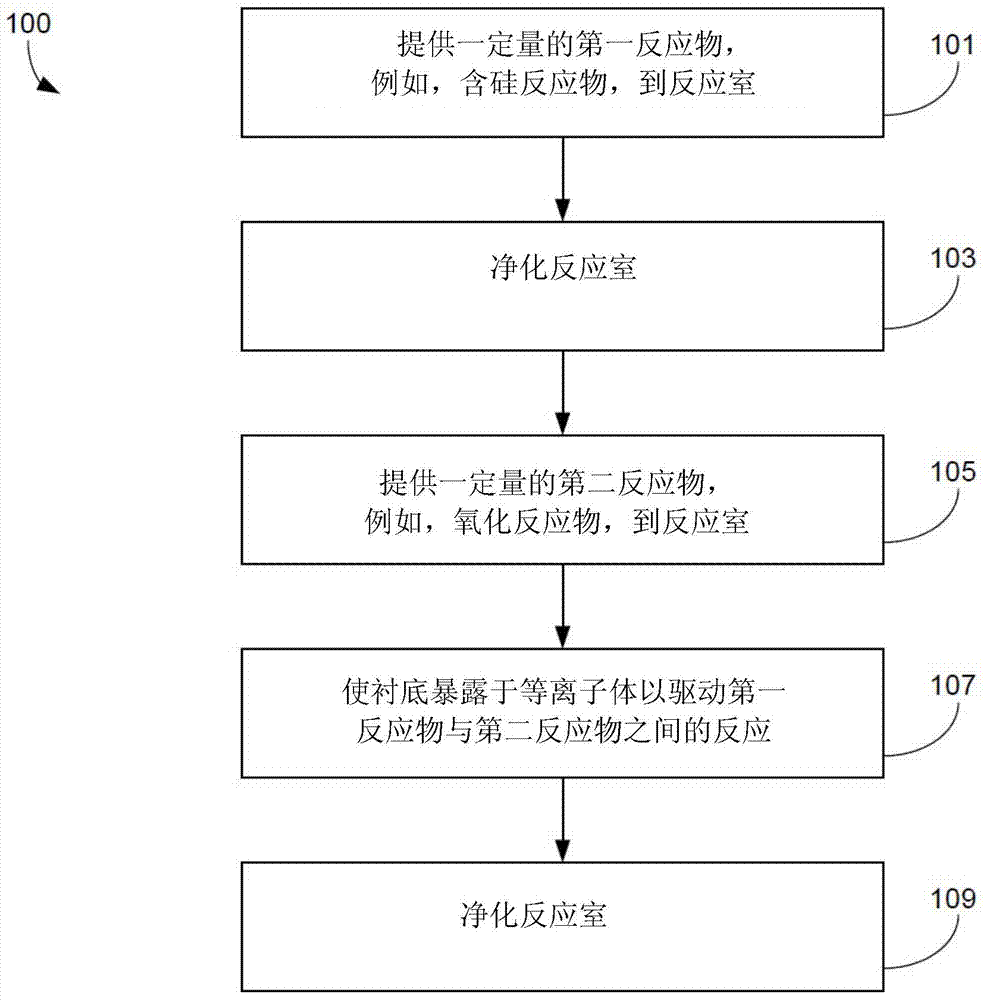

Gapfill of variable aspect ratio features with a composite PEALD and PECVD method

ActiveCN104517892ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringWide gap

The invention relates to gapfill of variable aspect ratio features with a composite PEALD and PECVD method, and specifically provides methods and apparatus for filling one or more gaps on a semiconductor substrate. The disclosed embodiments are especially useful for forming seam-free, void-free fill in both narrow and wide features. The methods may be performed without any intervening etching operations to achieve a single step deposition. In various implementations, a first operation is performed using a novel PEALD fill mechanism to fill narrow gaps and line wide gaps. A second operation may be performed using PECVD methods to continue filling the wide gaps.

Owner:LAM RES CORP

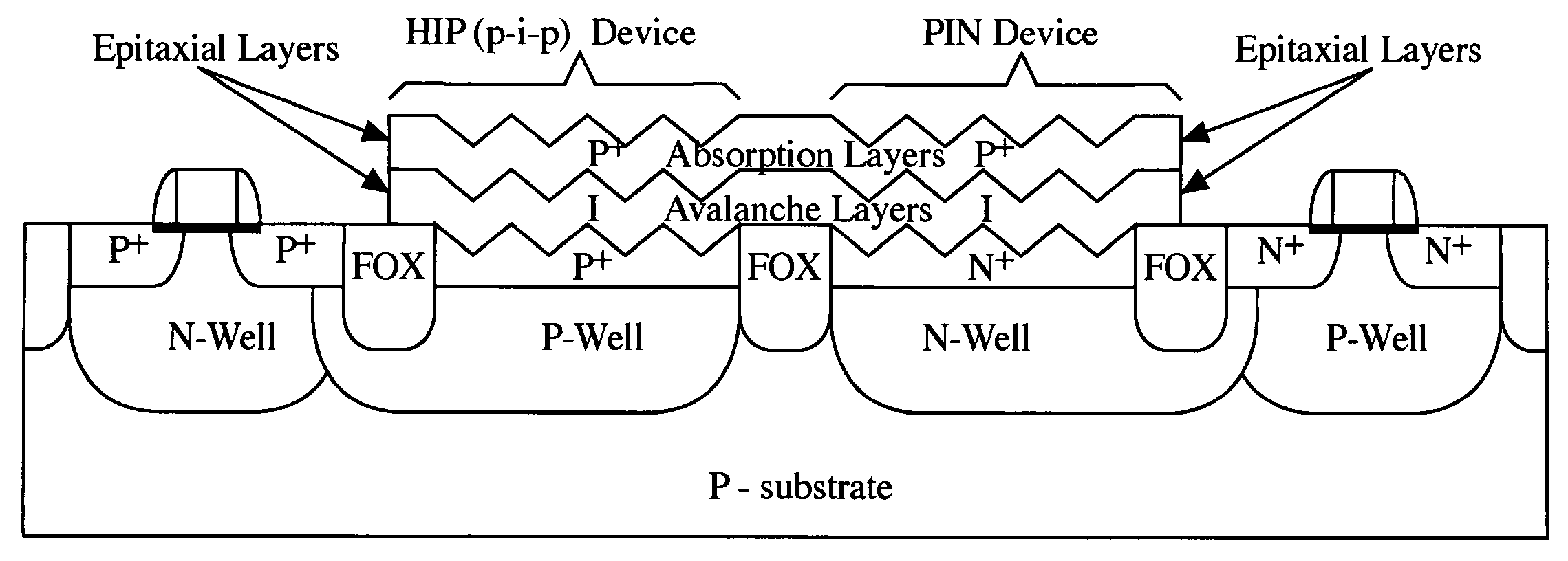

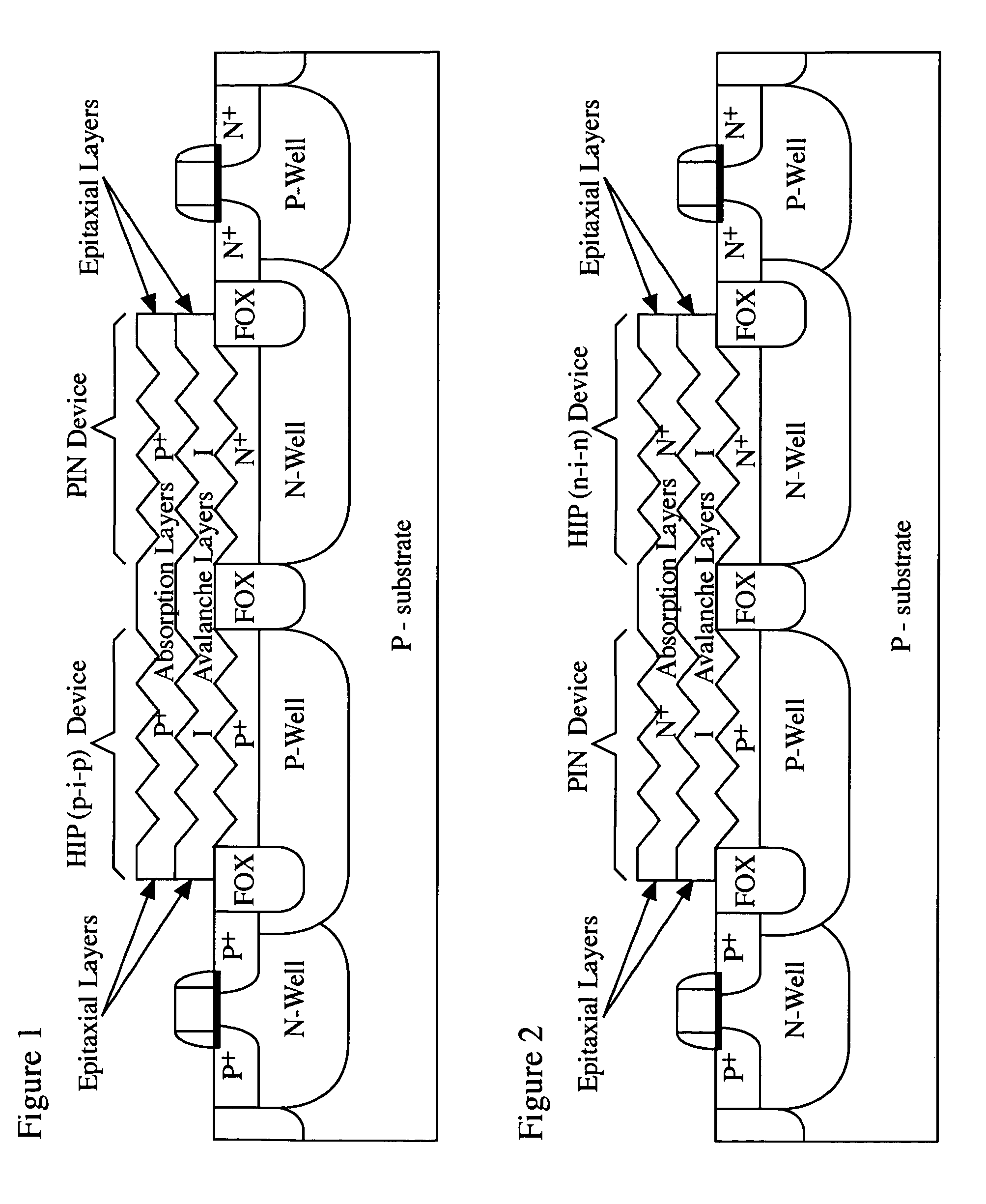

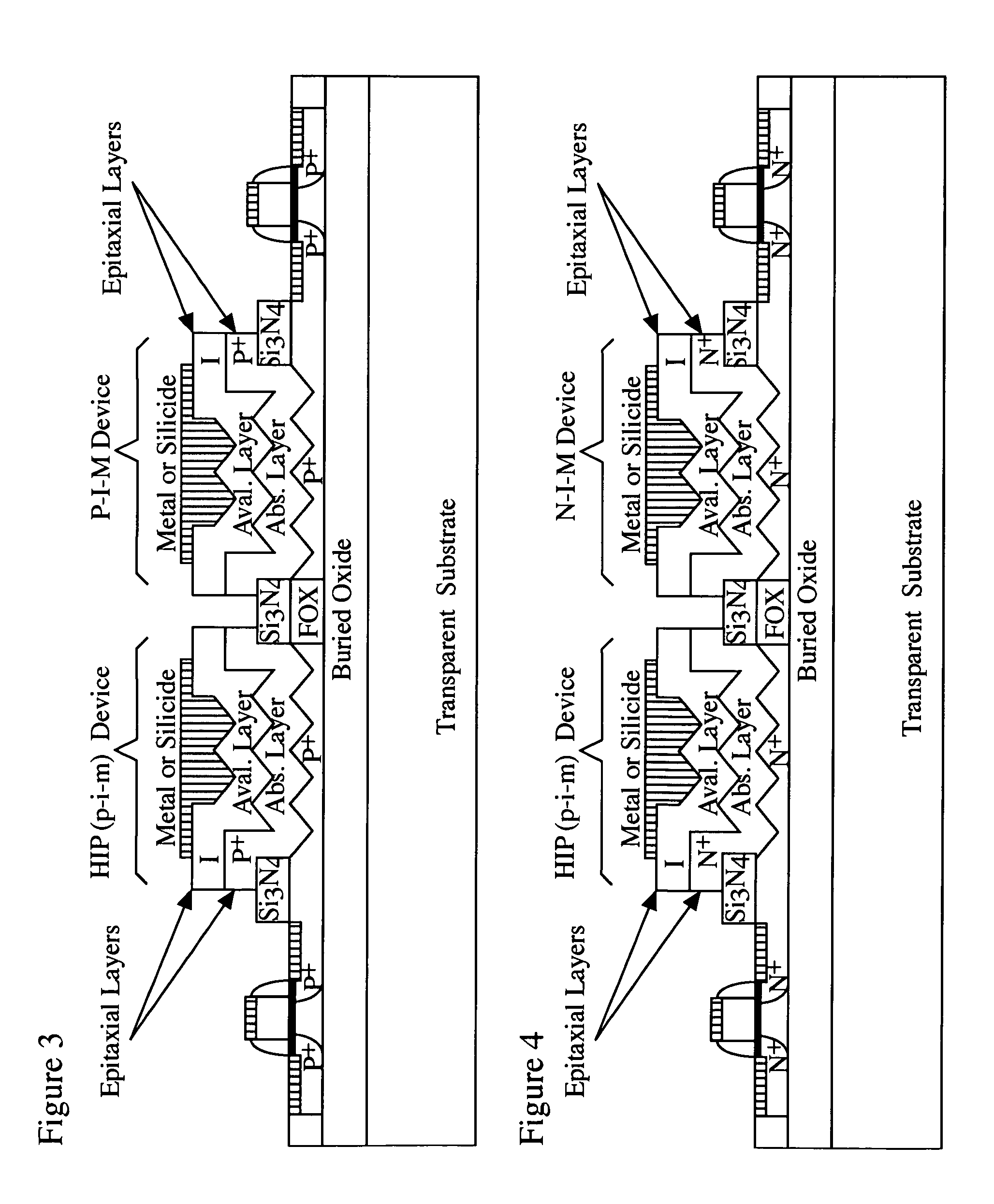

Light-sensing device

ActiveUS7521737B2Solid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionPixel density

A method of fabricating light-sensing devices including photodiodes monolithically integrated with CMOS devices. Several types of photodiode devices (PIN, HIP) are expitaxially grown in one single step on active areas implanted in a common semiconductor substrate, the active areas having defined polarities. The expitaxially grown layers for the photodiode devices may be either undoped or in-situ doped with profiles suitable for their respective operation. With appropriate choice of substrate materials, device layers and heterojunction engineering and process architecture, it is possible to fabricate silicon-based and germanium-based multi-spectral sensors that can deliver pixel density and cost of fabrication comparable to the state of the art CCDs and CMOS image sensors. The method can be implemented with epitaxially deposited films on the following substrates: Silicon Bulk, Thick-Film and Thin-Film Silicon-On-Insulator (SOI), Germanium Bulk, Thick-Film and Thin-Film Geranium-On-Insulator (GeOI).

Owner:QUANTUM SEMICON

Lead free, composite polymer based bullet and cartridge case, and method of manufacturing

A lead-free, composite polymer based bullet and cartridge case and methods of manufacturing the same, wherein the composite polymer material includes a tungsten metal powder, nylon 6 / 6, nylon 6, short glass fibers, as well as additives and stabilizers. The cartridge case includes a lip lock configured to matingly engage a cannelure formed along an outer circumferential surface of the bullet. The cartridge case also includes resilient walls wherein the case may snap fit onto the bullet. The bullet and cartridge case may be formed in a single step process by injection molding or a two step process including injection molding and a welding process.

Owner:POLYTECH AMMUNITION

Catalytic process for converting renewable resources into paraffins for use as diesel blending stocks

A process for converting renewable resources such as vegetable oil and animal fat into paraffins in a single step which comprises contacting a feed which is a renewable resources with hydrogen and a catalyst which comprises a non-precious metal and an oxide to produce a hydrocarbon product having a ratio of odd-numbered hydrocarbons to even-numbered hydrocarbons of at least 2:1.

Owner:REFINING TECH SOLUTIONS LLC

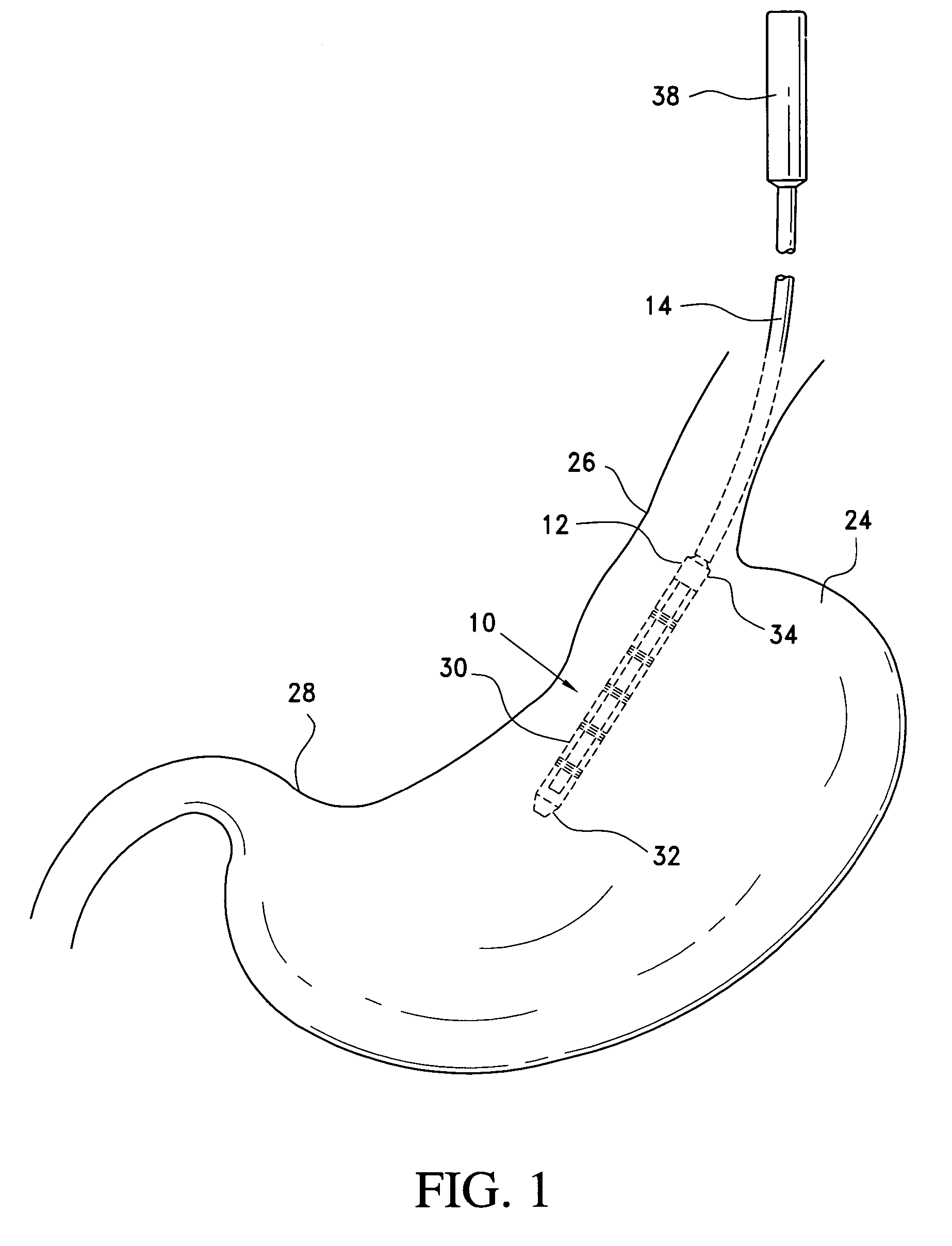

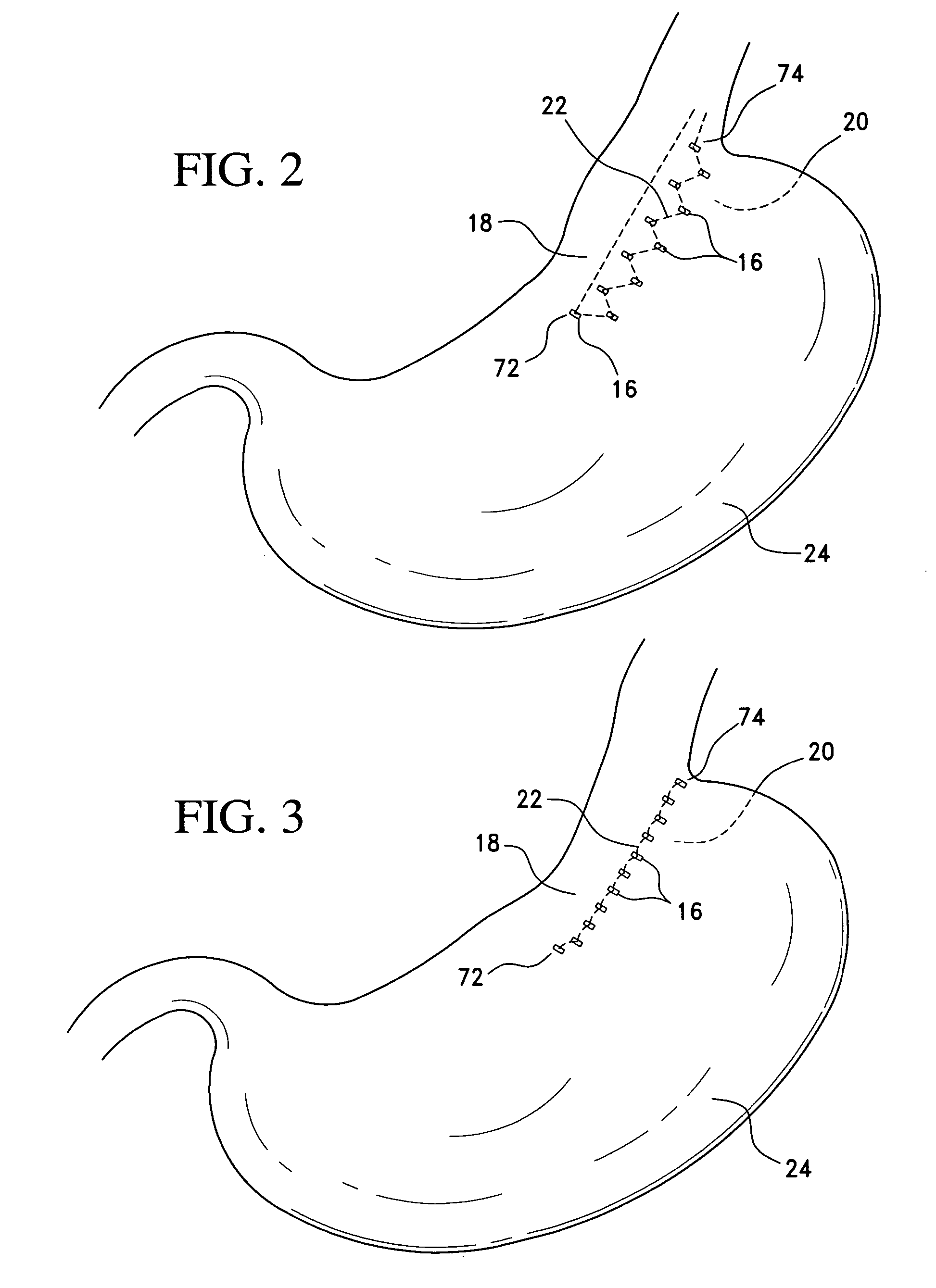

Method and apparatus for endoscopically performing gastric reduction surgery in a single step

An endoscopic gastric reduction apparatus adapted for applying a series of pledgets to anterior and posterior gastric walls for the creation of a mattress stitch suture within the stomach includes an applier having a distal end and a proximal end. The applier is secured at a distal end of a support shaft shaped and dimensioned for passage down the esophagus and into the stomach. The applier includes an applier body having a suction slot shaped and dimensioned for receiving tissue therein for the application of at least one pledget housed within the suction slot for selective coupling with tissue suctioned within the suction slot.

Owner:ETHICON ENDO SURGERY INC

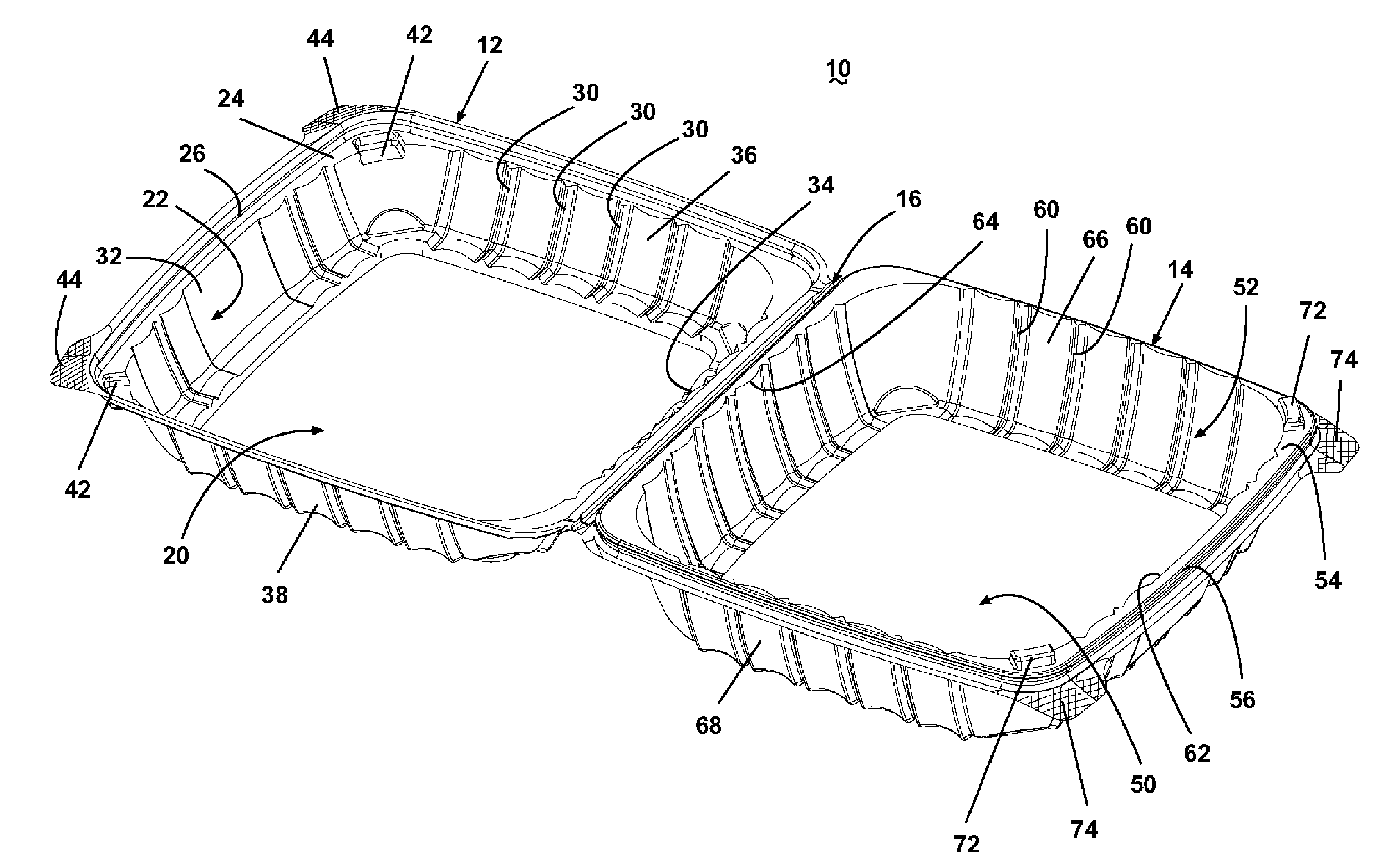

Container with one-step closing

A clam-shell container comprising a cover hingedly connected to a tray, with both the cover and tray having cooperating structures that form a leak-proof seal when the clam-shell container is closed. The container and cooperating structures are formed such that the user can effect the formation of the leak-proof seal in a single step. The creation of the leak-proof seal preferably corresponds to the closing of the clam-shell container.

Owner:DART CONTAINER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com