Patents

Literature

39 results about "Differences size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

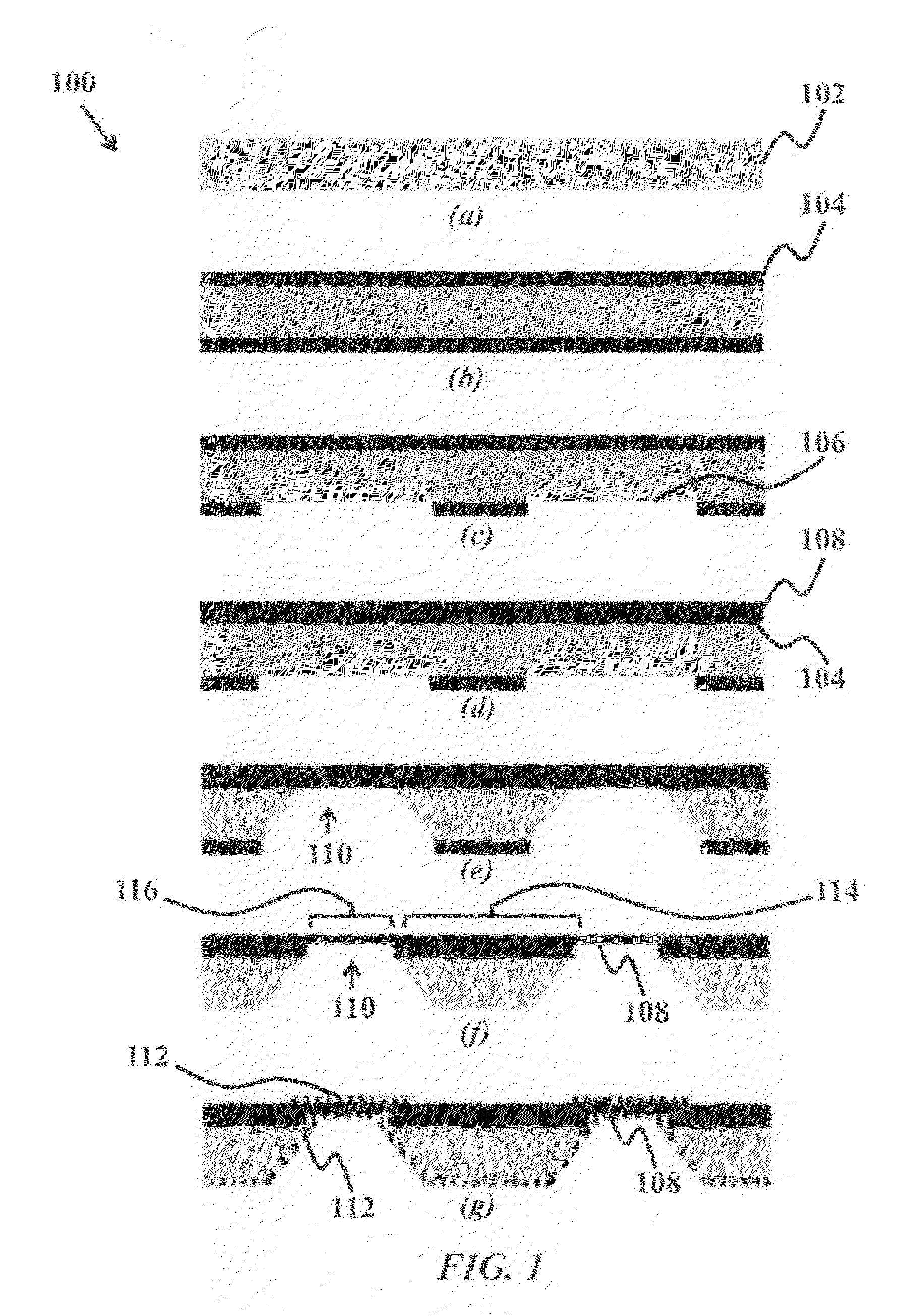

Method for integrated circuit fabrication using pitch multiplication

InactiveUS7115525B2Electric discharge tubesSemiconductor/solid-state device manufacturingResistEngineering

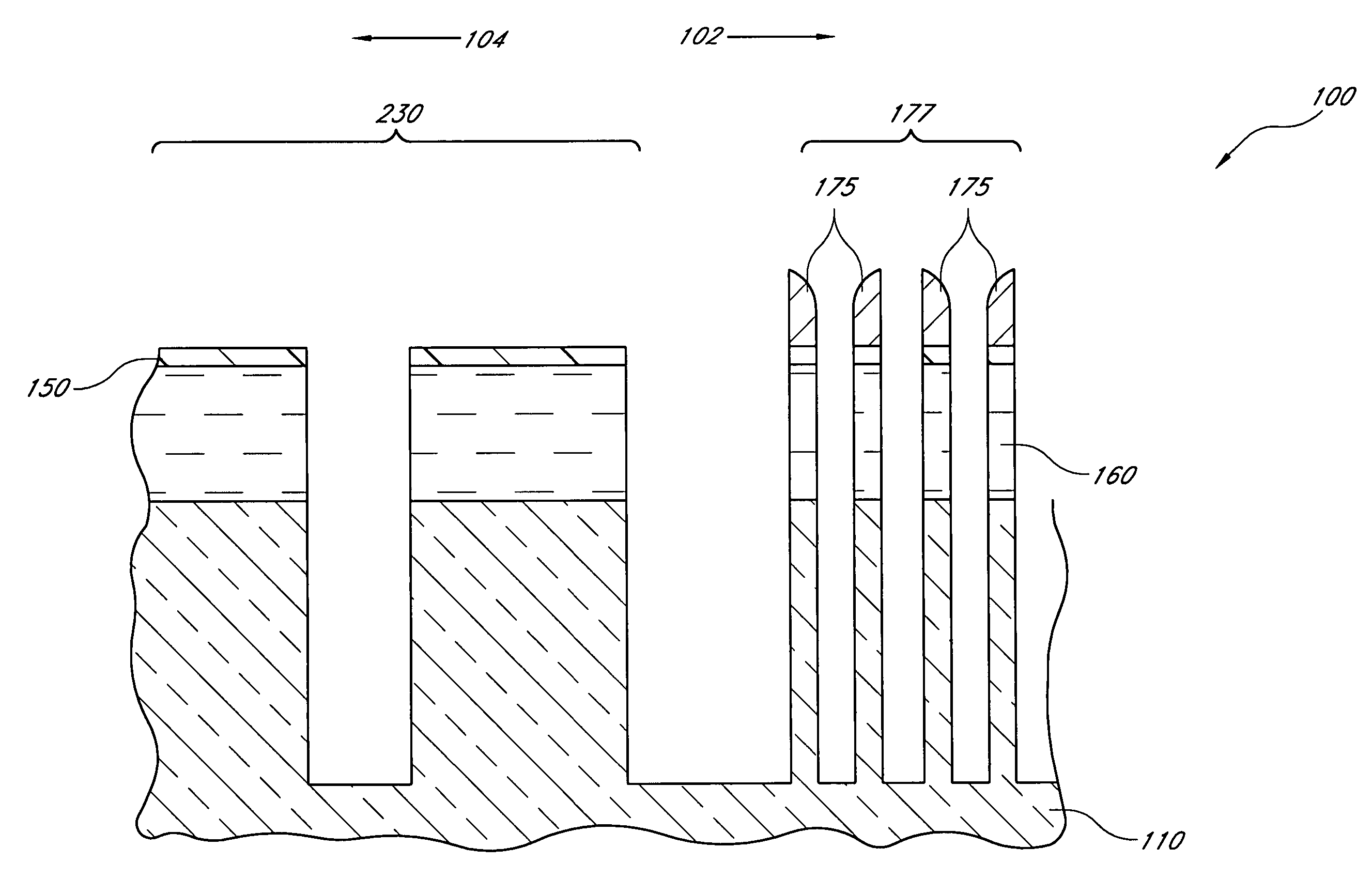

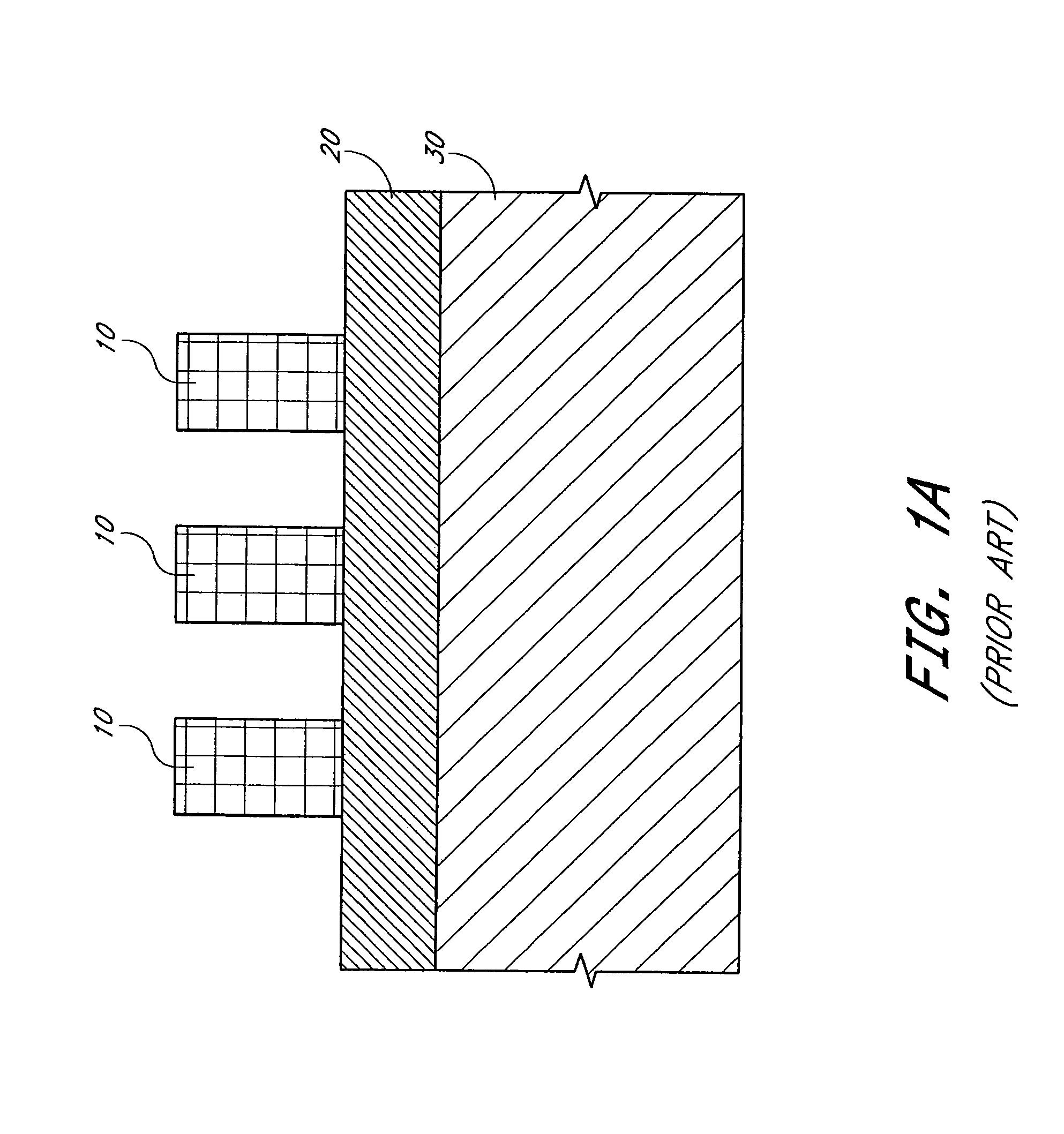

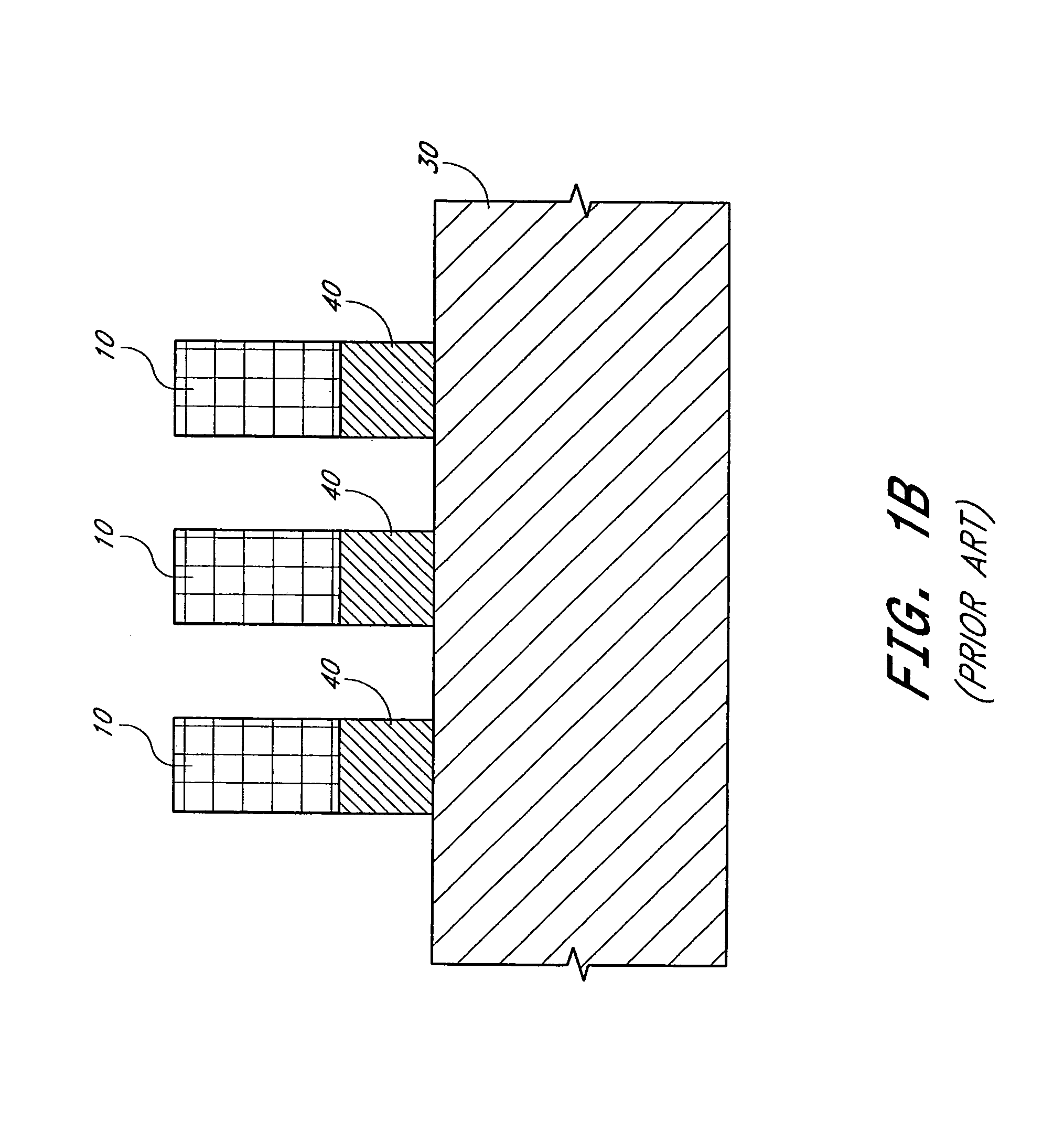

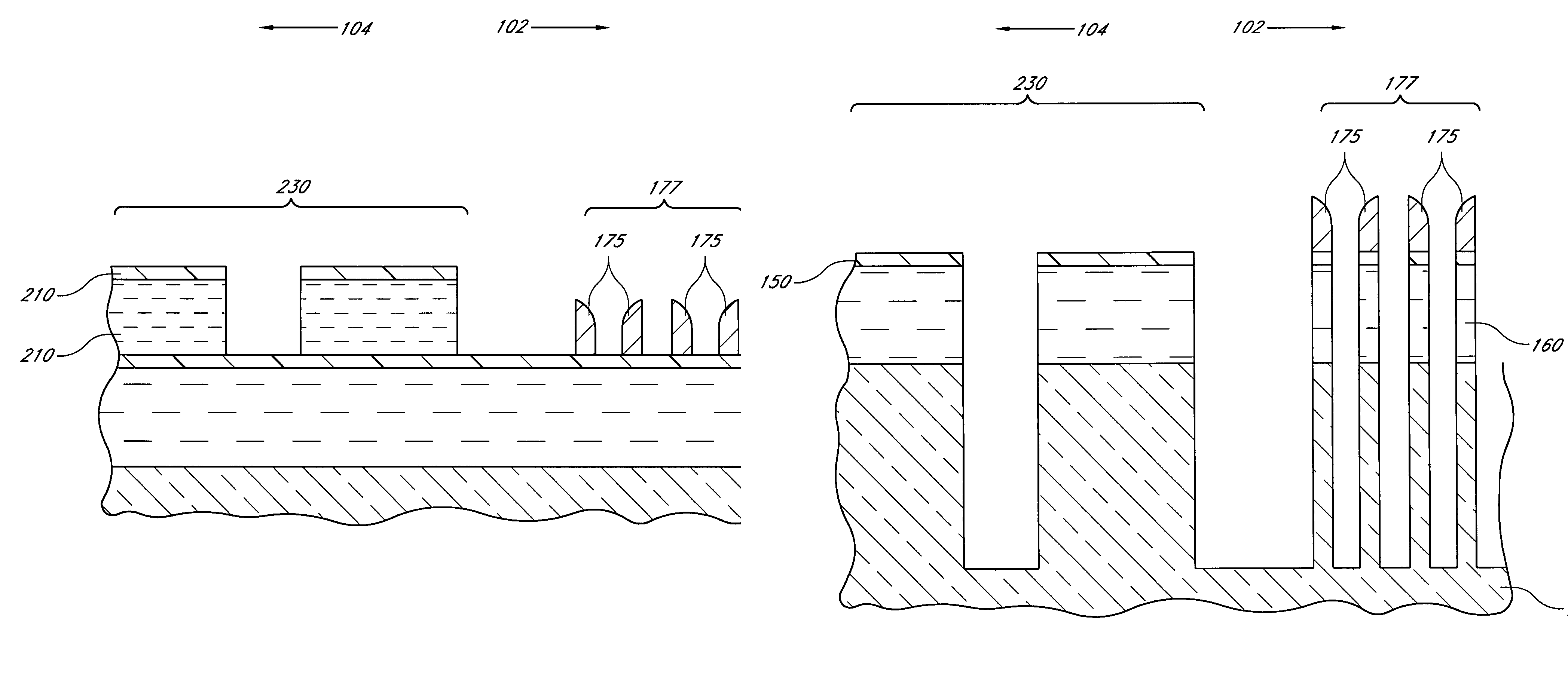

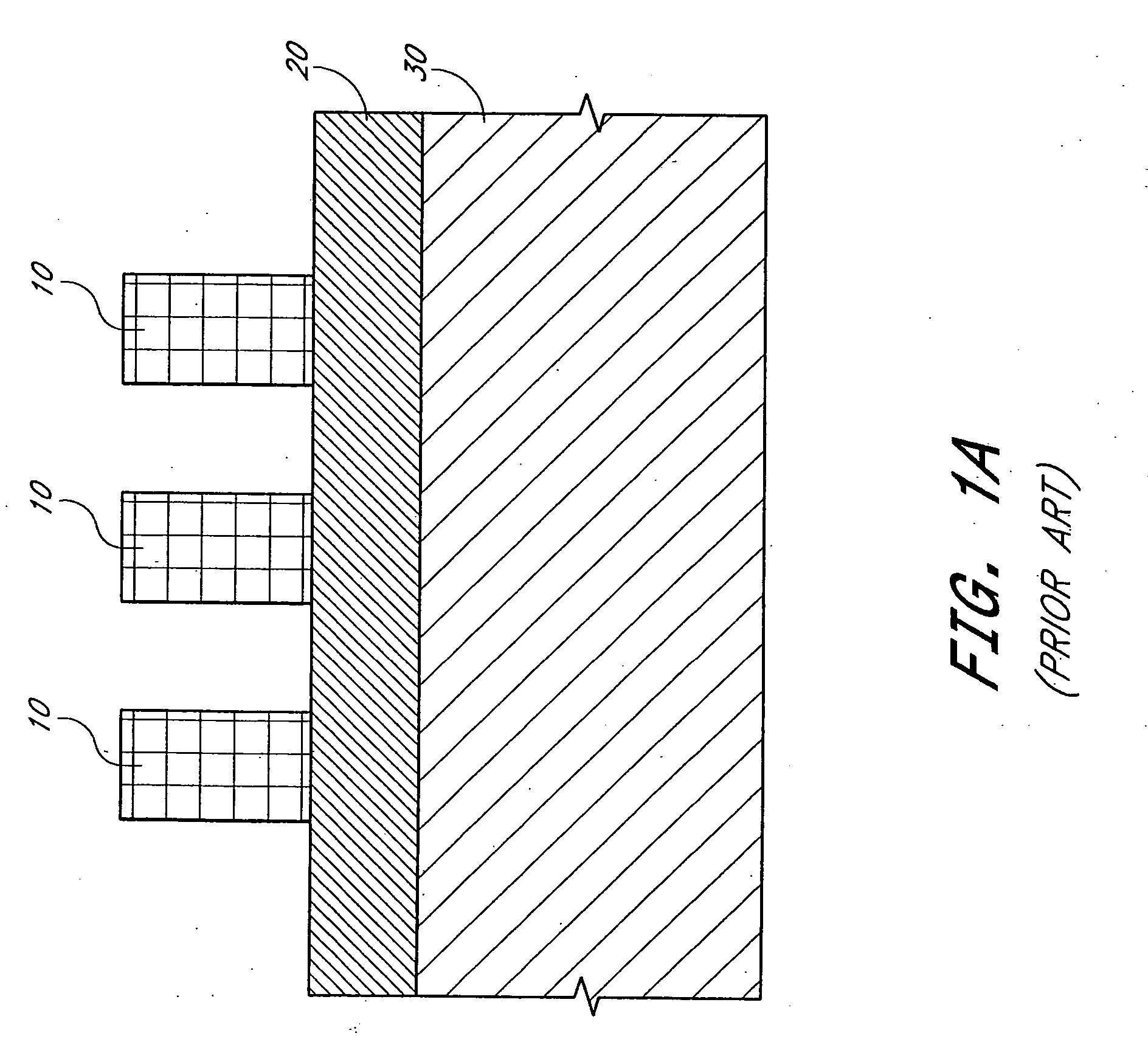

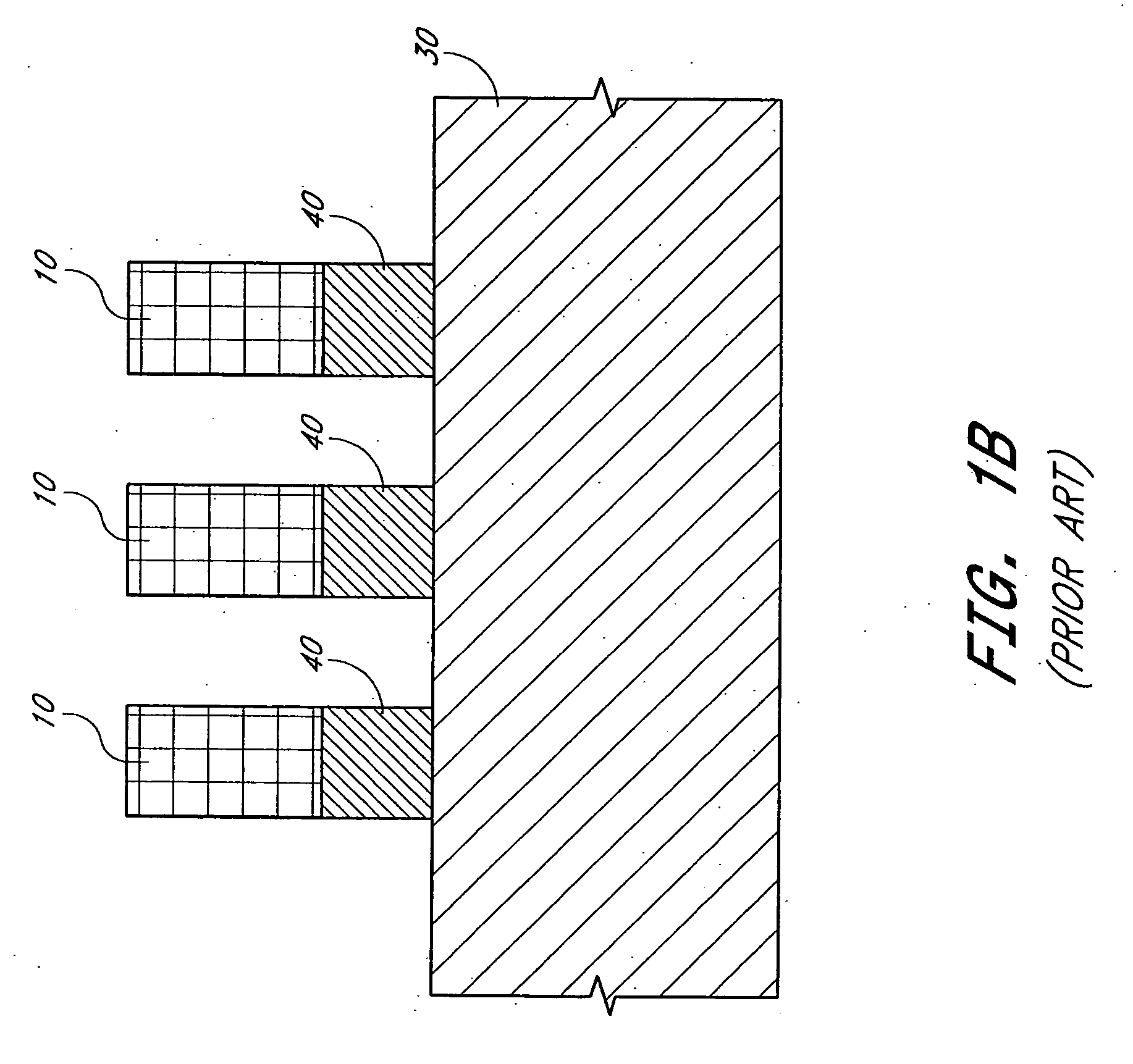

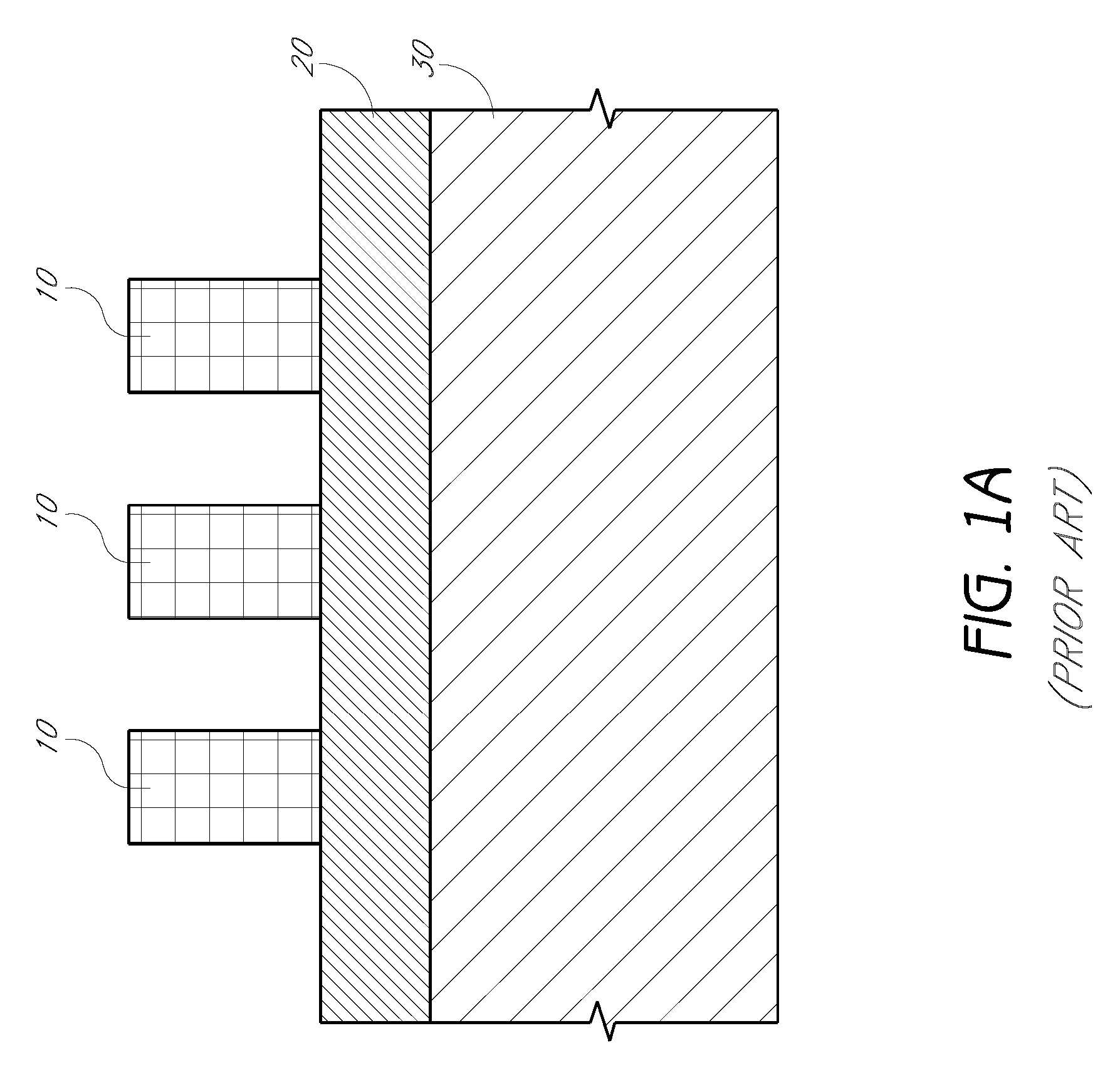

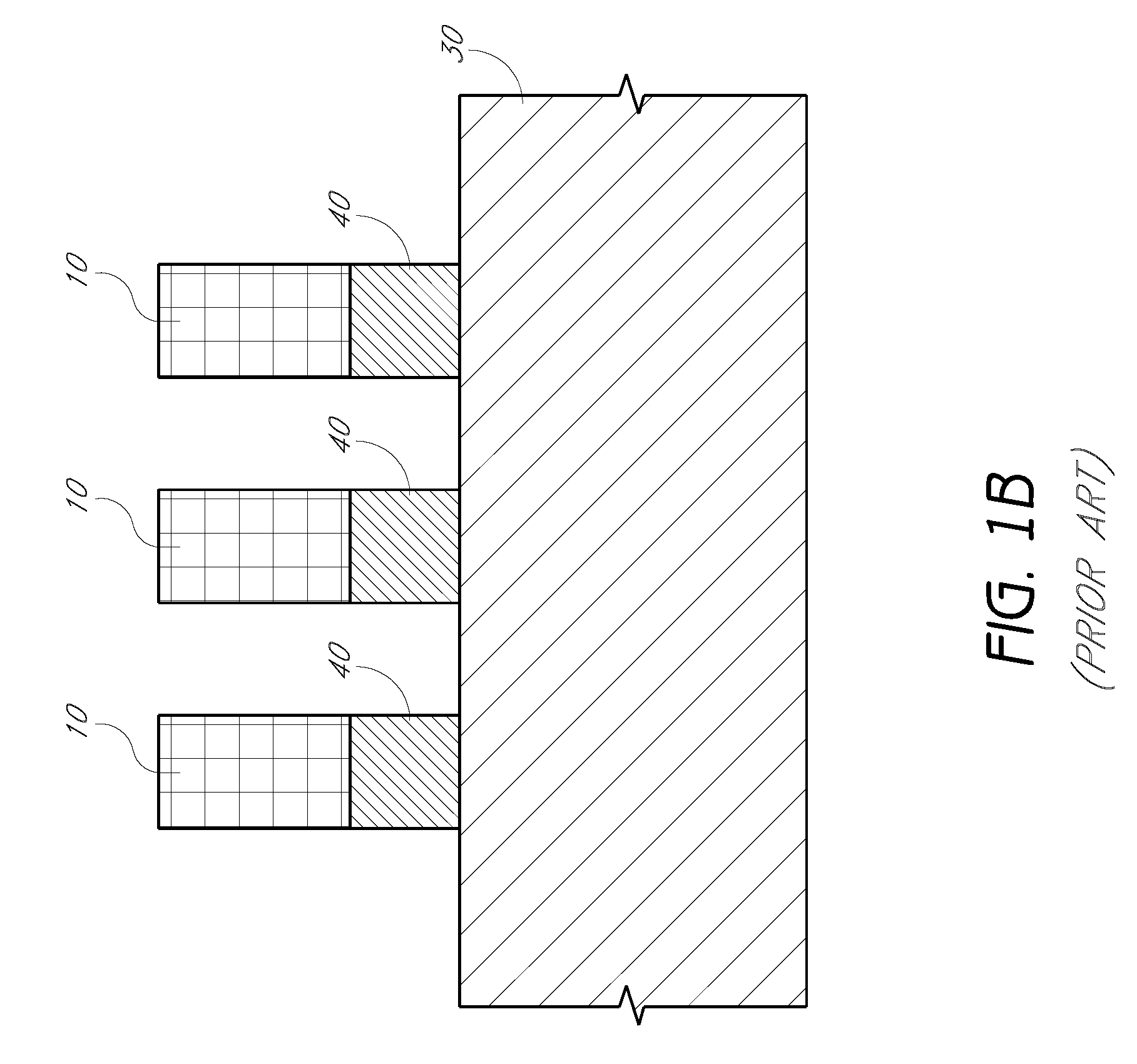

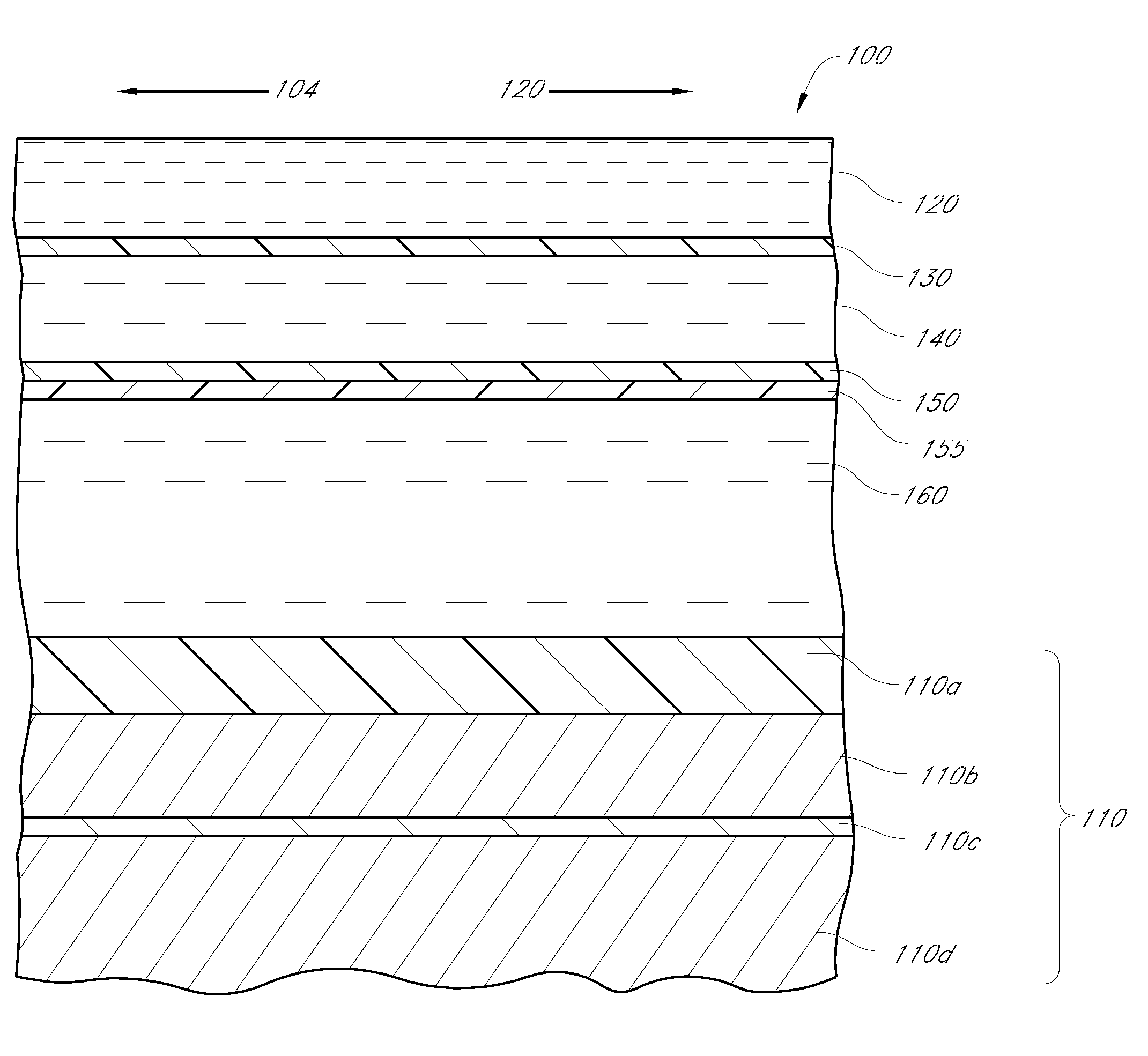

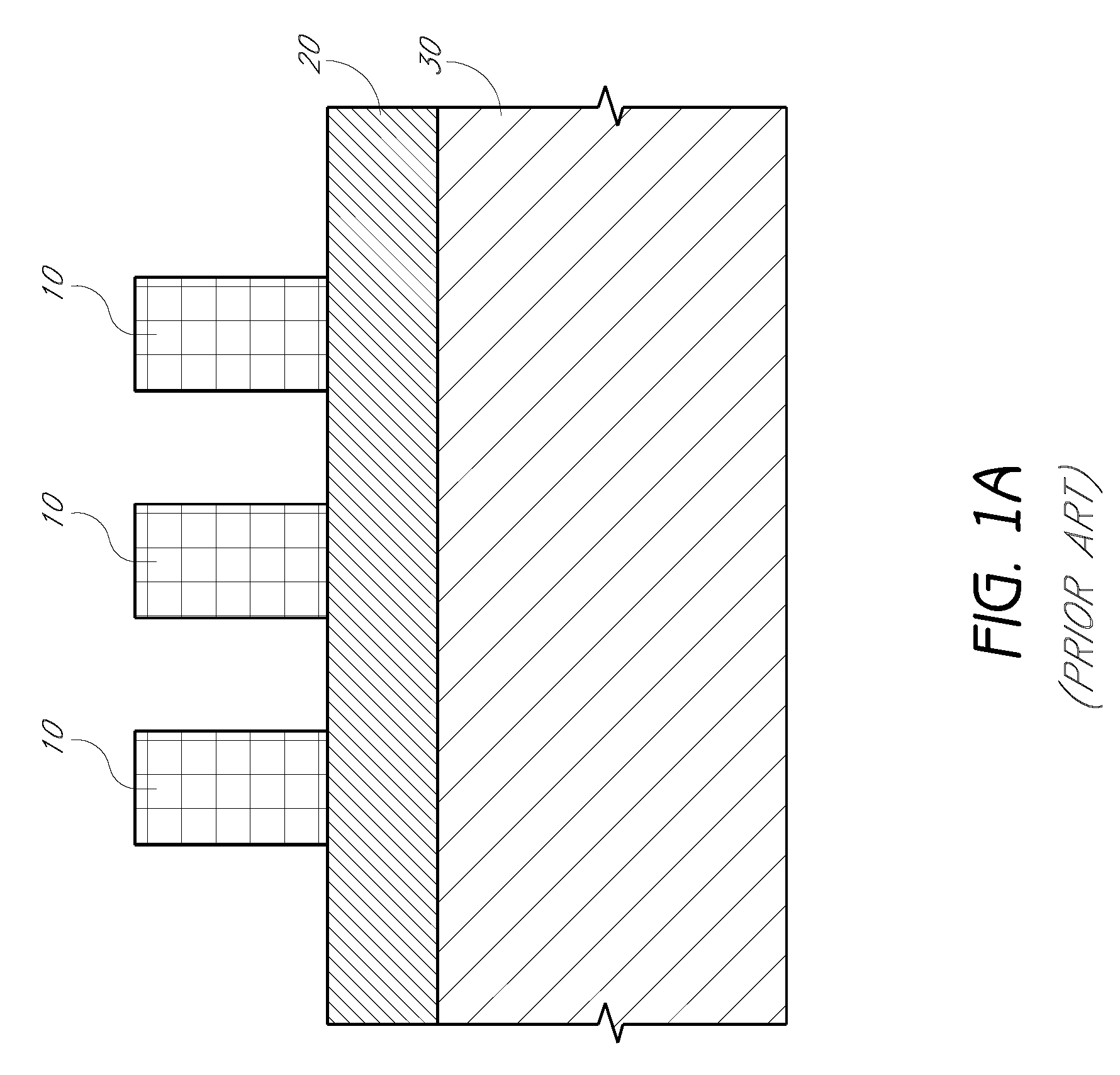

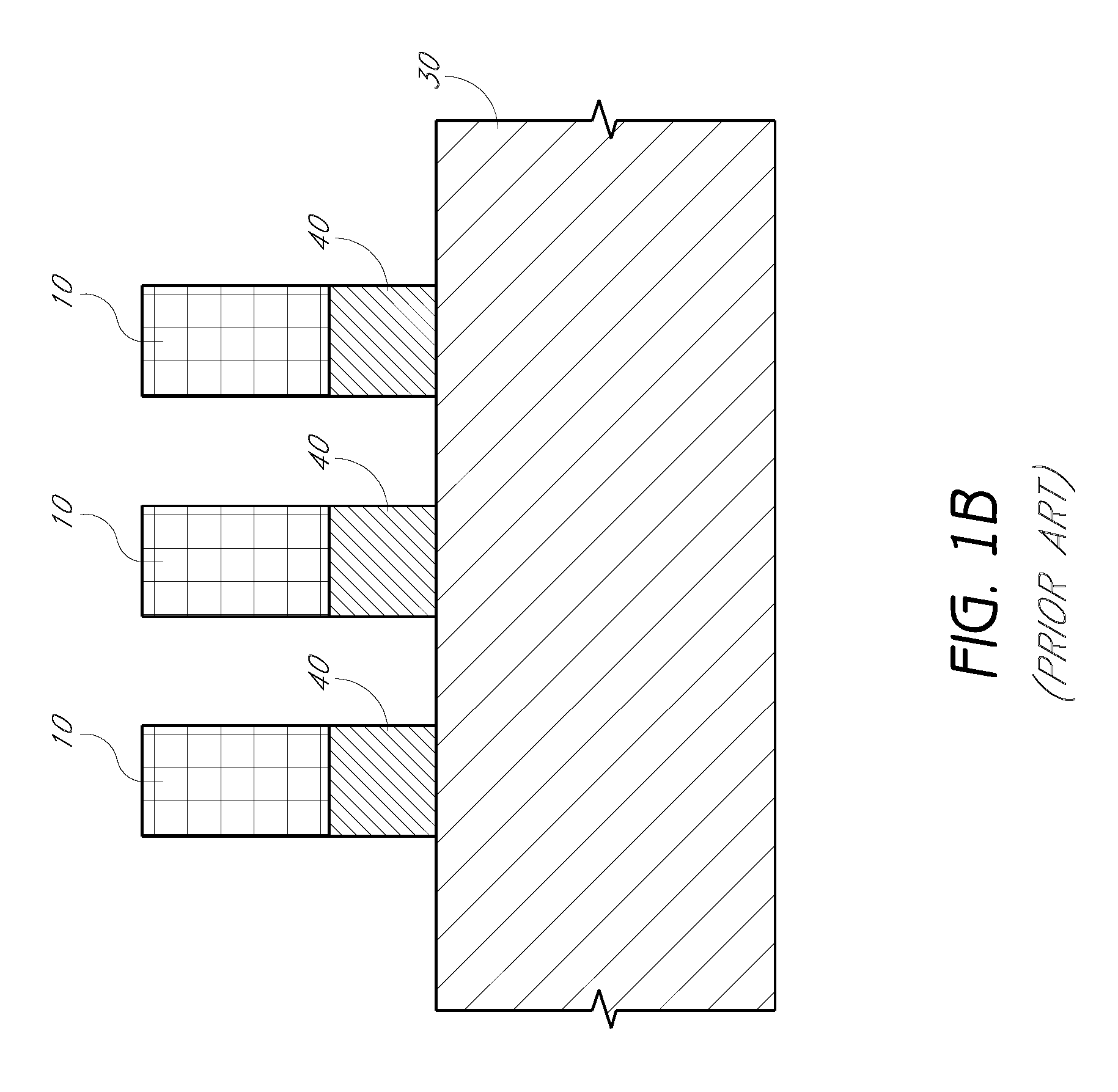

Different sized features in the array and in the periphery of an integrated circuit are patterned on a substrate in a single step. In particular, a mixed pattern, combining two separately formed patterns, is formed on a single mask layer and then transferred to the underlying substrate. The first of the separately formed patterns is formed by pitch multiplication and the second of the separately formed patterns is formed by conventional photolithography. The first of the separately formed patterns includes lines that are below the resolution of the photolithographic process used to form the second of the separately formed patterns. These lines are made by forming a pattern on photoresist and then etching that pattern into an amorphous carbon layer. Sidewall pacers having widths less than the widths of the un-etched parts of the amorphous carbon are formed on the sidewalls of the amorphous carbon. The amorphous carbon is then removed, leaving behind the sidewall spacers as a mask pattern. Thus, the spacers form a mask having feature sizes less than the resolution of the photolithography process used to form the pattern on the photoresist. A protective material is deposited around the spacers. The spacers are further protected using a hard mask and then photoresist is formed and patterned over the hard mask. The photoresist pattern is transferred through the hard mask to the protective material. The pattern made out by the spacers and the temporary material is then transferred to an underlying amorphous carbon hard mask layer. The pattern, having features of difference sizes, is then transferred to the underlying substrate.

Owner:ROUND ROCK RES LLC

Method for integrated circuit fabrication using pitch multiplication

InactiveUS20060046484A1Electric discharge tubesSemiconductor/solid-state device manufacturingImage resolutionDifferences size

Different sized features in the array and in the periphery of an integrated circuit are patterned on a substrate in a single step. In particular, a mixed pattern, combining two separately formed patterns, is formed on a single mask layer and then transferred to the underlying substrate. The first of the separately formed patterns is formed by pitch multiplication and the second of the separately formed patterns is formed by conventional photolithography. The first of the separately formed patterns includes lines that are below the resolution of the photolithographic process used to form the second of the separately formed patterns. These lines are made by forming a pattern on photoresist and then etching that pattern into an amorphous carbon layer. Sidewall pacers having widths less than the widths of the un-etched parts of the amorphous carbon are formed on the sidewalls of the amorphous carbon. The amorphous carbon is then removed, leaving behind the sidewall spacers as a mask pattern. Thus, the spacers form a mask having feature sizes less than the resolution of the photolithography process used to form the pattern on the photoresist. A protective material is deposited around the spacers. The spacers are further protected using a hard mask and then photoresist is formed and patterned over the hard mask. The photoresist pattern is transferred through the hard mask to the protective material. The pattern made out by the spacers and the temporary material is then transferred to an underlying amorphous carbon hard mask layer. The pattern, having features of difference sizes, is then transferred to the underlying substrate.

Owner:ROUND ROCK RES LLC

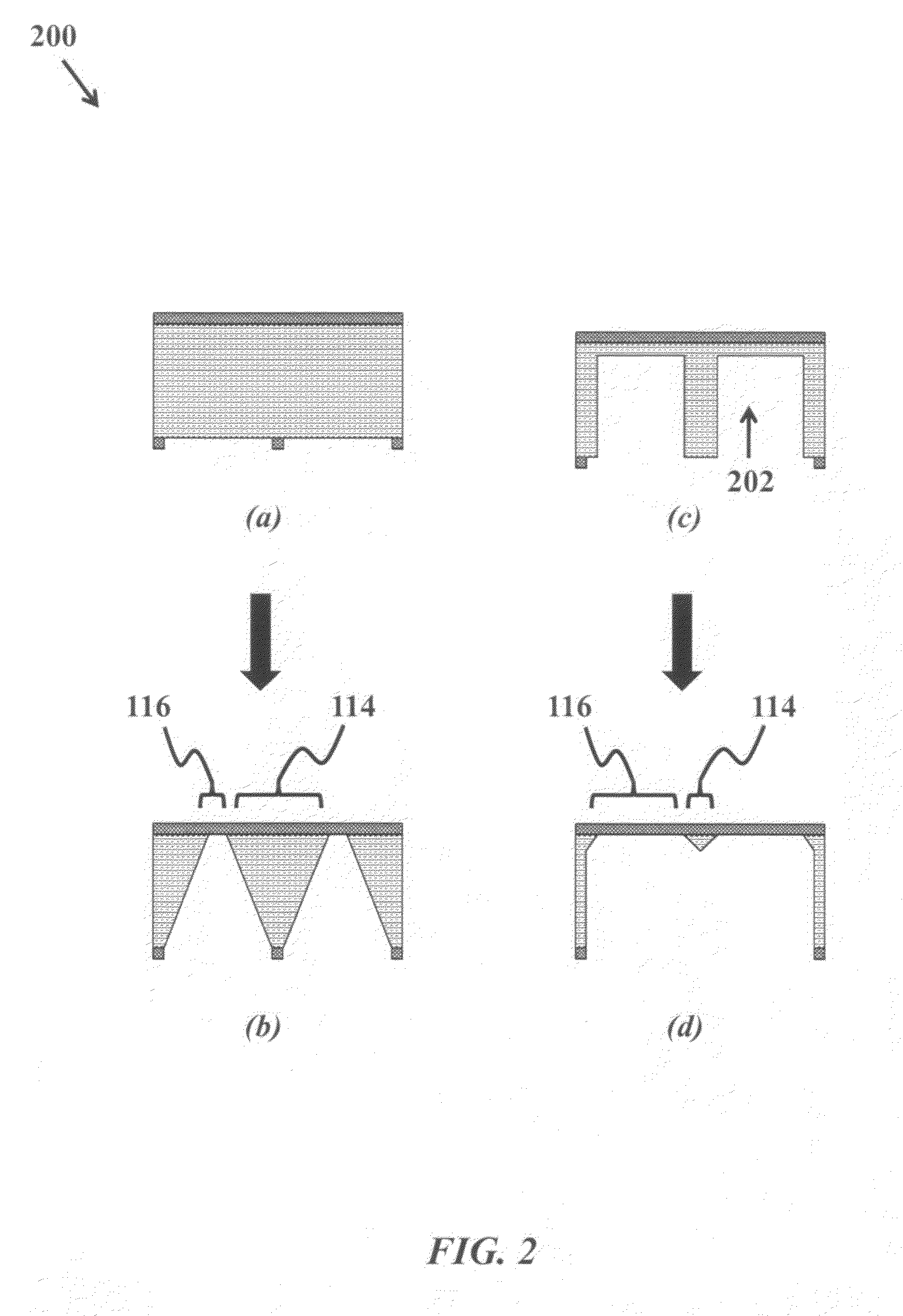

Pitch reduced patterns relative to photolithography features

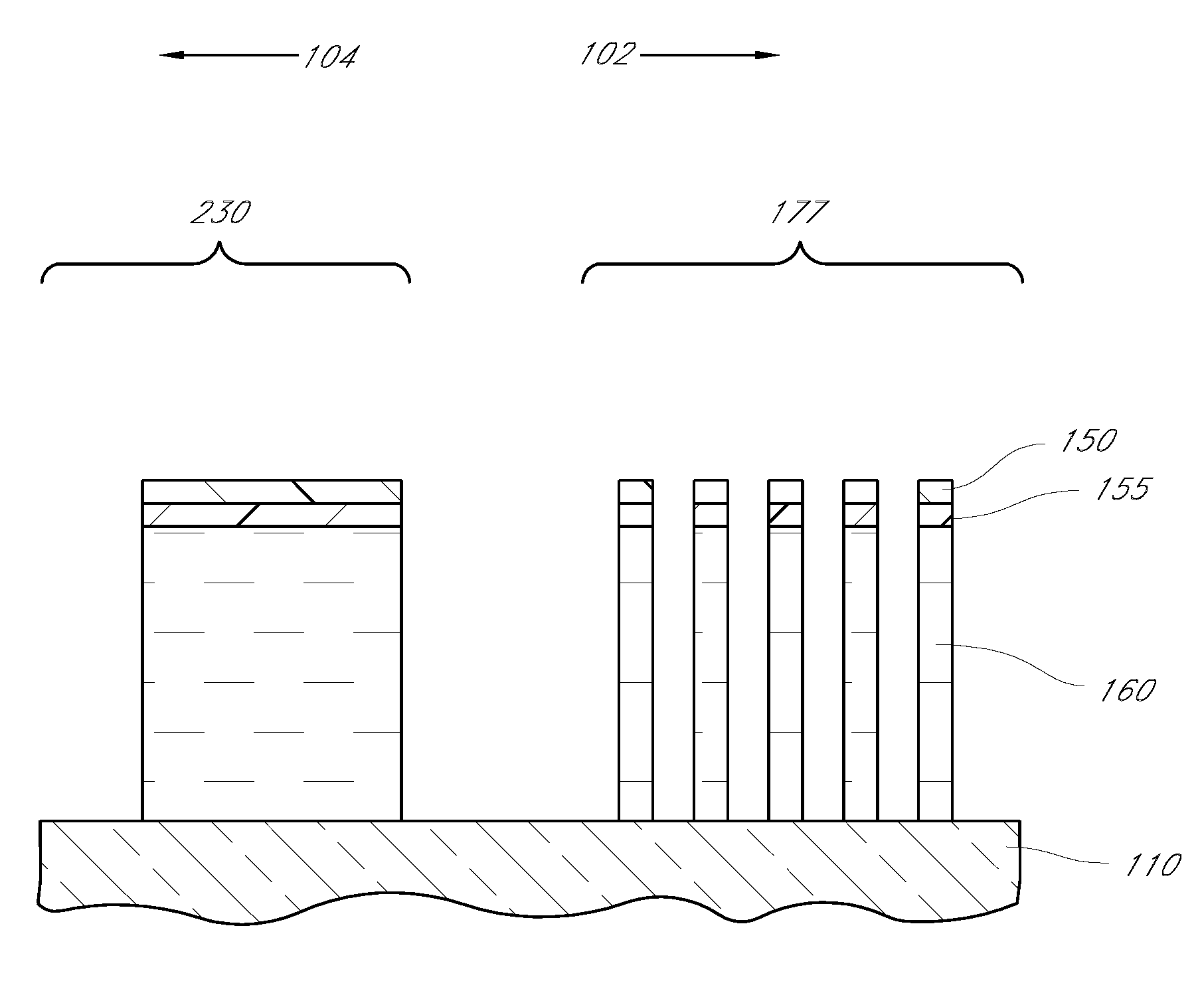

Differently-sized features of an integrated circuit are formed by etching a substrate using a mask which is formed by combining two separately formed patterns. Pitch multiplication is used to form the relatively small features of the first pattern and conventional photolithography used to form the relatively large features of the second pattern. Pitch multiplication is accomplished by patterning a photoresist and then etching that pattern into an amorphous carbon layer. Sidewall spacers are then formed on the sidewalls of the amorphous carbon. The amorphous carbon is removed, leaving behind the sidewall spacers, which define the first mask pattern. A bottom anti-reflective coating (BARC) is then deposited around the spacers to form a planar surface and a photoresist layer is formed over the BARC. The photoresist is next patterned by conventional photolithography to form the second pattern, which is then is transferred to the BARC. The combined pattern made out by the first pattern and the second pattern is transferred to an underlying amorphous silicon layer and the pattern is subjected to a carbon strip to remove BARC and photoresist material. The combined pattern is then transferred to the silicon oxide layer and then to an amorphous carbon mask layer. The combined mask pattern, having features of difference sizes, is then etched into the underlying substrate through the amorphous carbon hard mask layer.

Owner:ROUND ROCK RES LLC

Pitch reduced patterns relative to photolithography features

InactiveUS20070128856A1Semiconductor/solid-state device manufacturingAnti-reflective coatingAmorphous silicon

Differently-sized features of an integrated circuit are formed by etching a substrate using a mask which is formed by combining two separately formed patterns. Pitch multiplication is used to form the relatively small features of the first pattern and conventional photolithography used to form the relatively large features of the second pattern. Pitch multiplication is accomplished by patterning a photoresist and then etching that pattern into an amorphous carbon layer. Sidewall spacers are then formed on the sidewalls of the amorphous carbon. The amorphous carbon is removed, leaving behind the sidewall spacers, which define the first mask pattern. A bottom anti-reflective coating (BARC) is then deposited around the spacers to form a planar surface and a photoresist layer is formed over the BARC. The photoresist is next patterned by conventional photolithography to form the second pattern, which is then is transferred to the BARC. The combined pattern made out by the first pattern and the second pattern is transferred to an underlying amorphous silicon layer and the pattern is subjected to a carbon strip to remove BARC and photoresist material. The combined pattern is then transferred to the silicon oxide layer and then to an amorphous carbon mask layer. The combined mask pattern, having features of difference sizes, is then etched into the underlying substrate through the amorphous carbon hard mask layer.

Owner:ROUND ROCK RES LLC

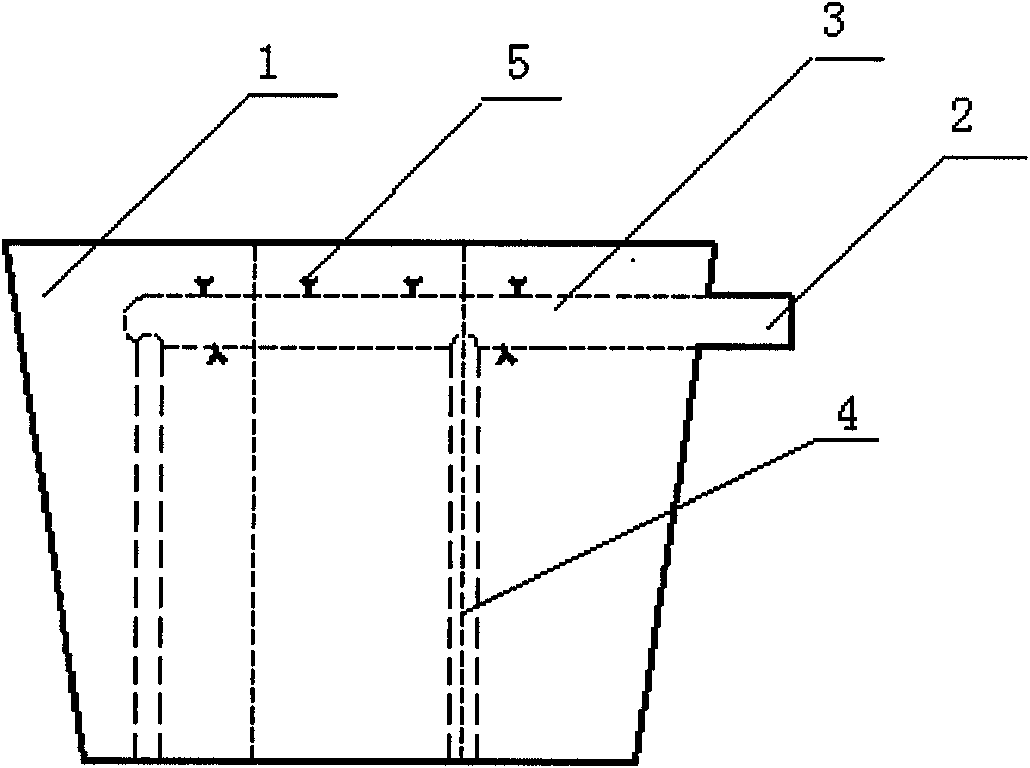

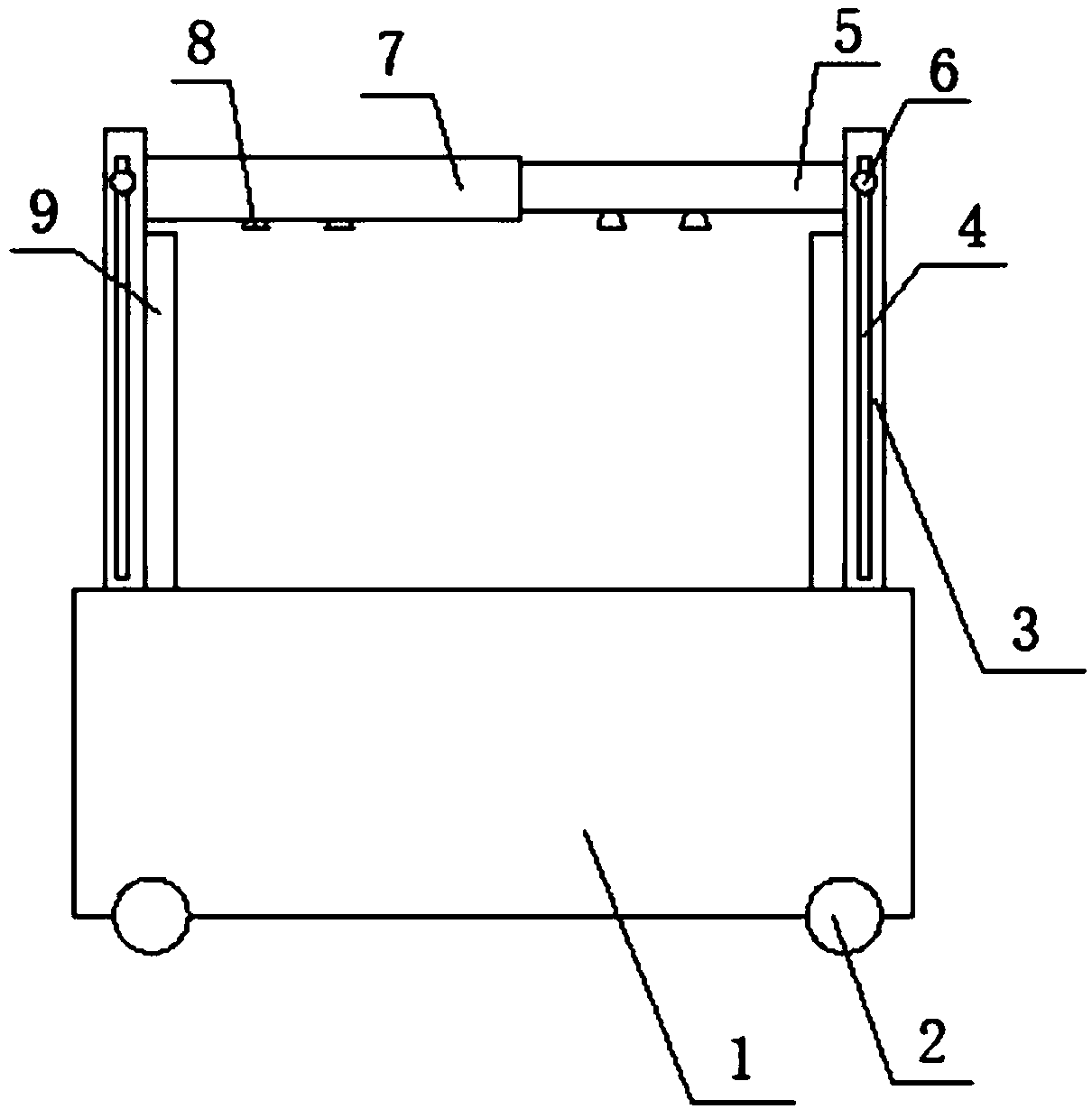

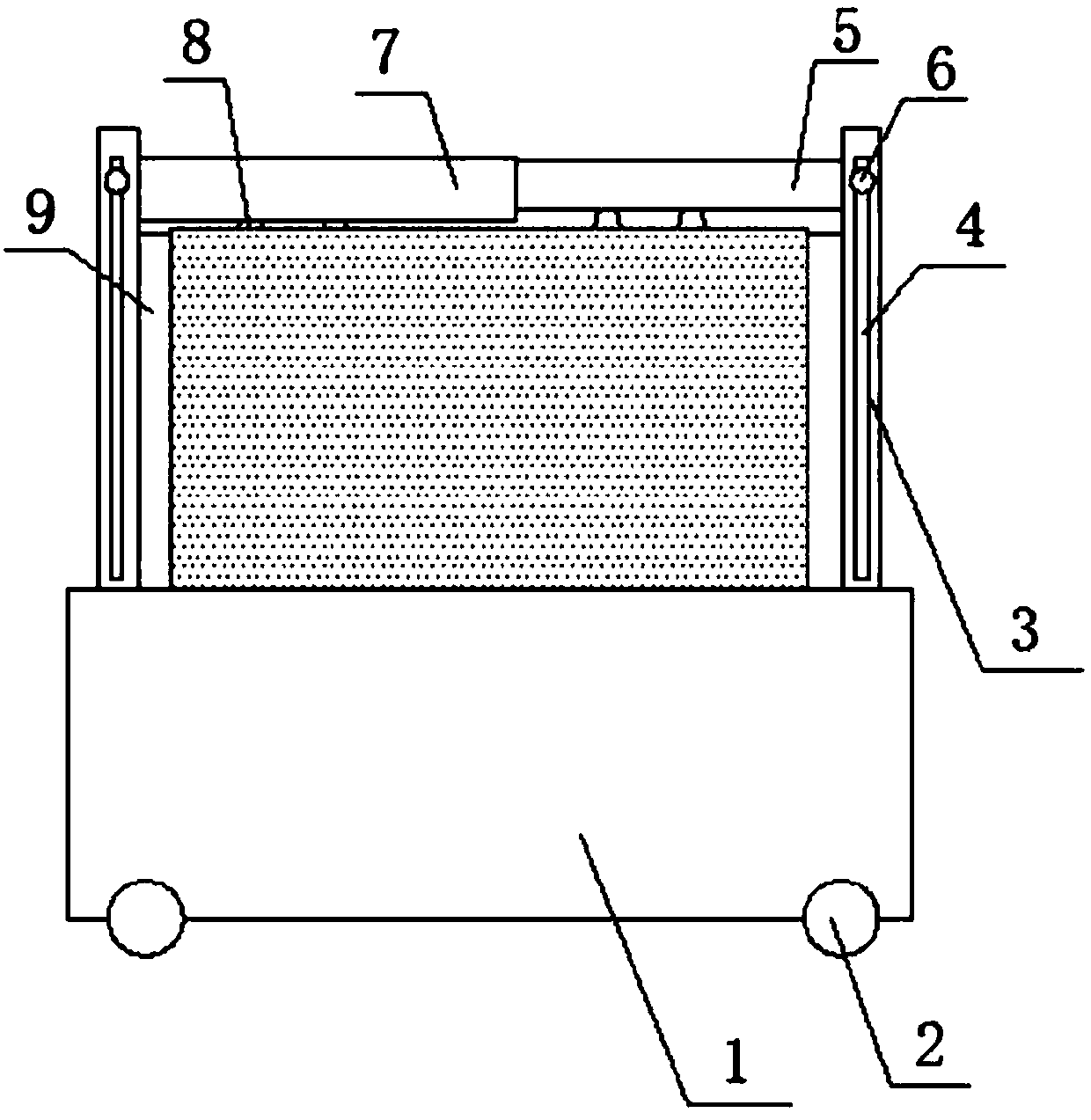

Steel structural overhead ceiling construction platform

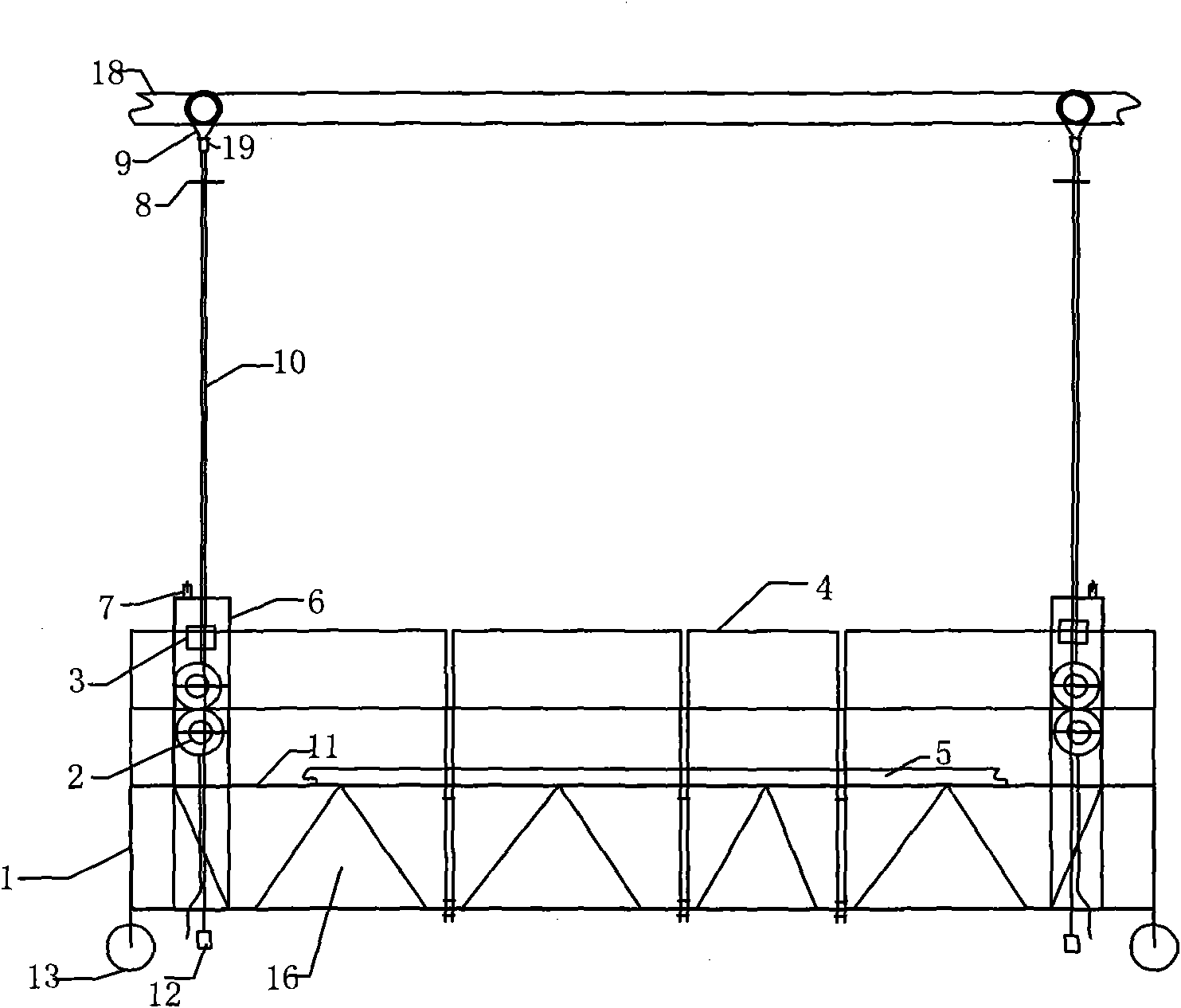

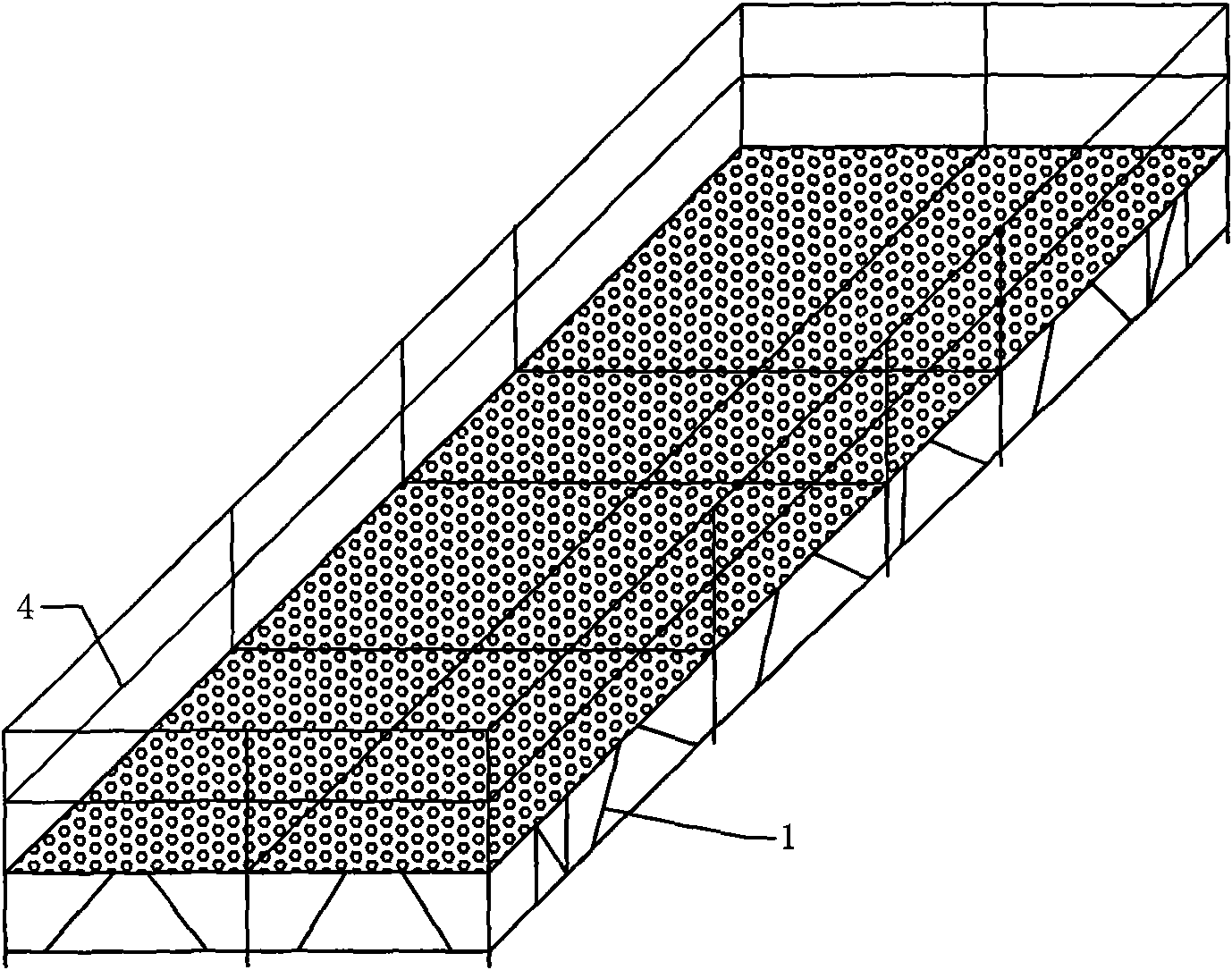

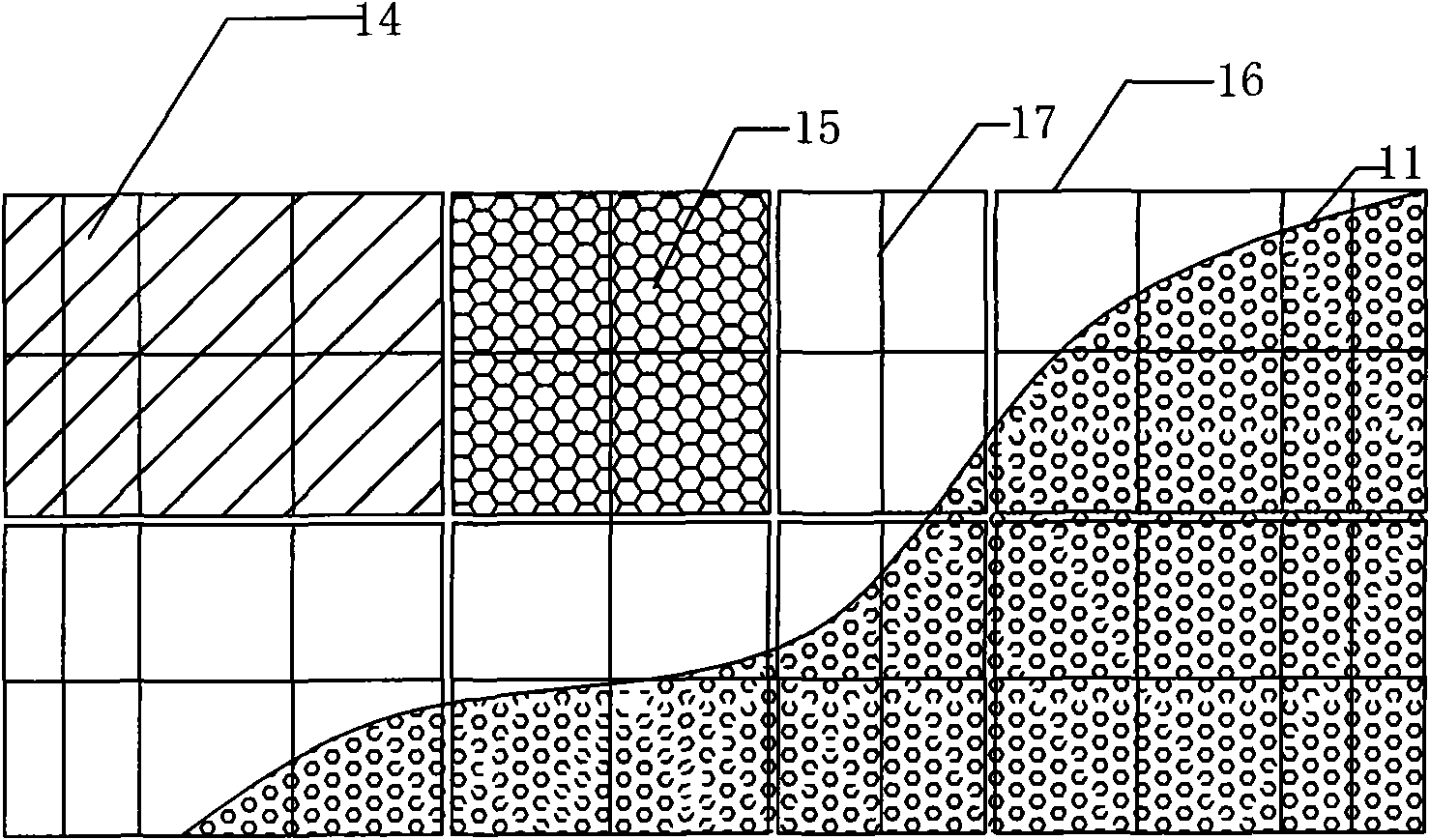

ActiveCN101672102ASimple structureReduce steel consumptionBuilding support scaffoldsReinforced concreteSynchronous control

The invention relates to a steel structural overhead ceiling construction platform comprising a platform body, a synchronous lifting device and lifting point suspension devices. The platform body is of composite steel truss structure. Guardrails and baffle footplates are arranged around the platform body. Four lifting device installing supports are arranged on the platform body. A bottom plate islaid on the platform body and nylon universal wheels are arranged on the lower part of the platform body. The synchronous lifting device is provided with a master control box which is connected with alifter motor by a synchronous control circuit. Four lifters can act singly. The lifting point suspension devices are fixed with a roof truss and each lifting point suspension device comprises a U-shaped clamp ring and a wire rope suspended in the U-shaped clamp ring. Counter weights are arranged on the lower parts of the wire ropes. The platform has the beneficial effects as follows: the platformhas simple structure and consumes little steel. With size being adjustable, the composite platform can be suitable for the steel structural roof trusses in difference size scales and can be even suspended on a top plate of reinforced concrete structure.

Owner:CHINA RAILWAY CONSTR GROUP +1

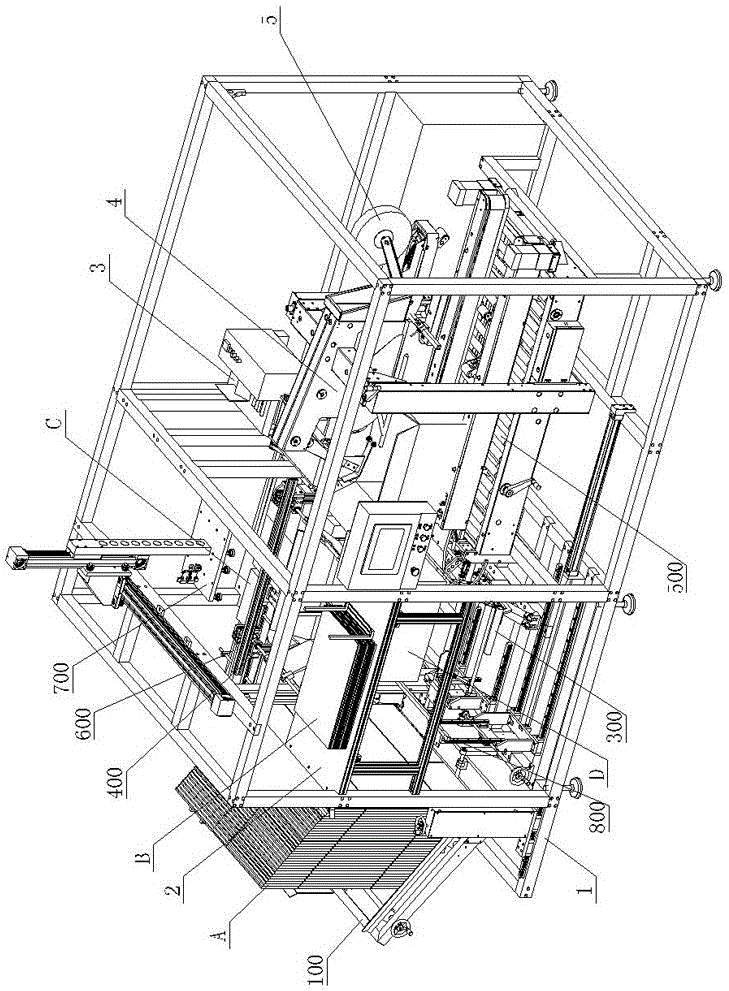

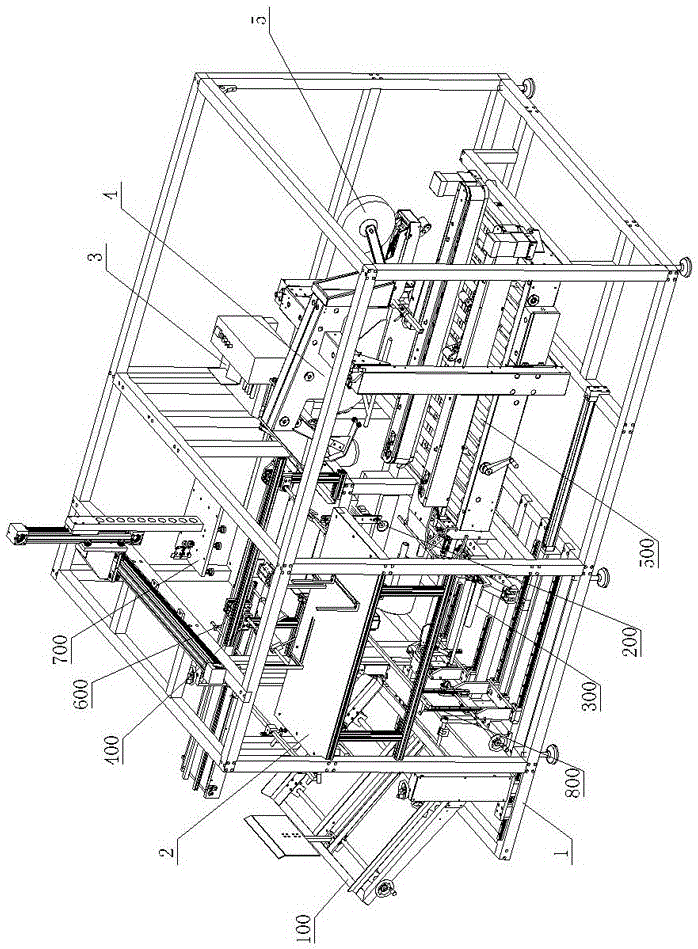

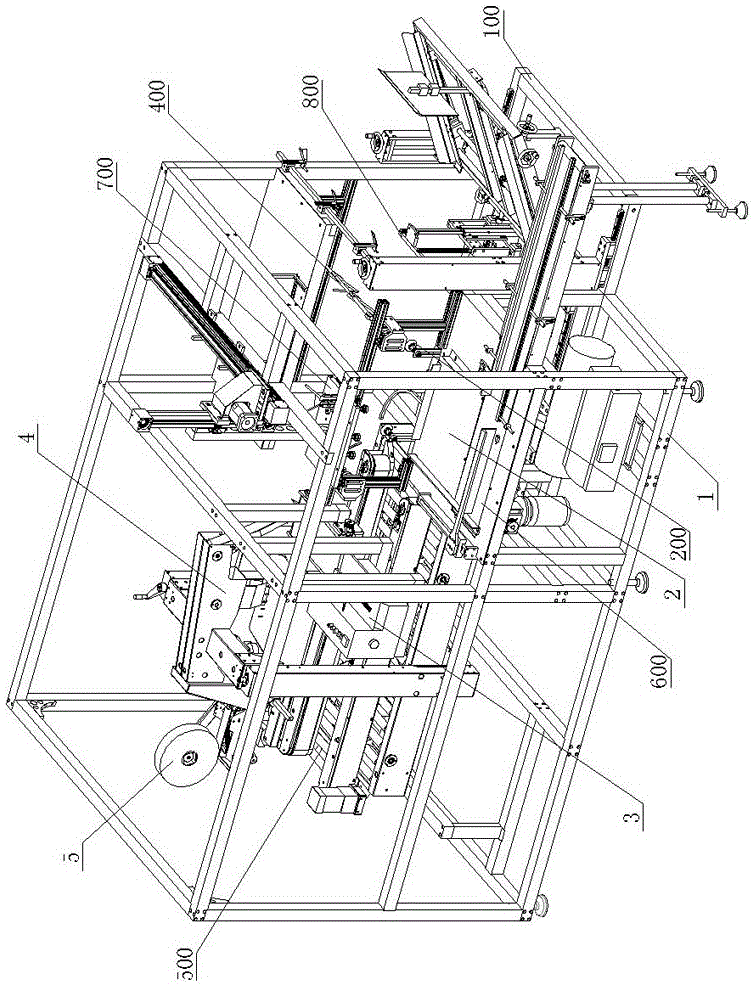

Full-automatic case packing machine

InactiveCN106672327ASimple structureFast packingWrapper twisting/gatheringDifferences sizeMechanical engineering

The invention discloses a full-automatic case packing machine which is characterized in that the full-automatic case packing machine is provided with a case packing station arranged in the center; a storage bin component, a case suction component, a tongue closing component, a tongue opening component and a case sealing platform are arranged around the case packing station; the storage bin component is located on the rear side of the case packing station; the case suction component is located on the right side of the case packing station; the tongue closing component is located at the bottom of the case packing station; the tongue opening component is located at the top of the case packing station; the case sealing platform is located on the front side of the case packing station; a partition plate stacking table and a stacking component are arranged on the left side and the right side of a place above the tongue opening component respectively; a material suction component is arranged above the partition plate stacking table and the stacking component; when the material suction component acts, a to-be-packed product and a partition plate are put in a packing case; and the case packing station is further provided with a case pushing component for pushing the packing case supported by the tongue closing component onto the case sealing platform. The full-automatic case packing machine is simple and compact in structure and wide in case packing range, full-automatic case packing is realized, the case packing speed is high, and the full-automatic case packing machine can be applied to the packing cases in difference sizes conveniently.

Owner:浙江春余机械有限公司

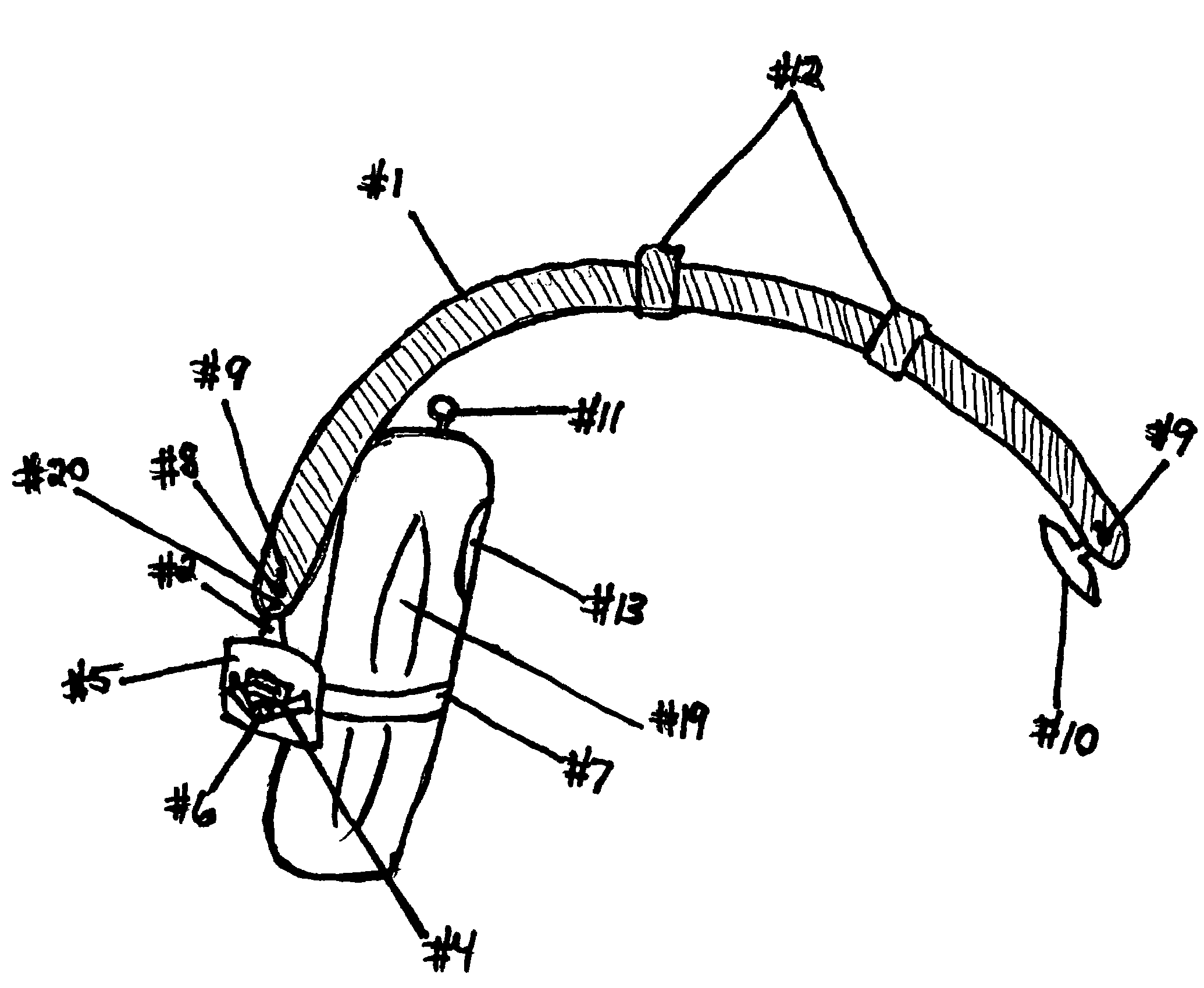

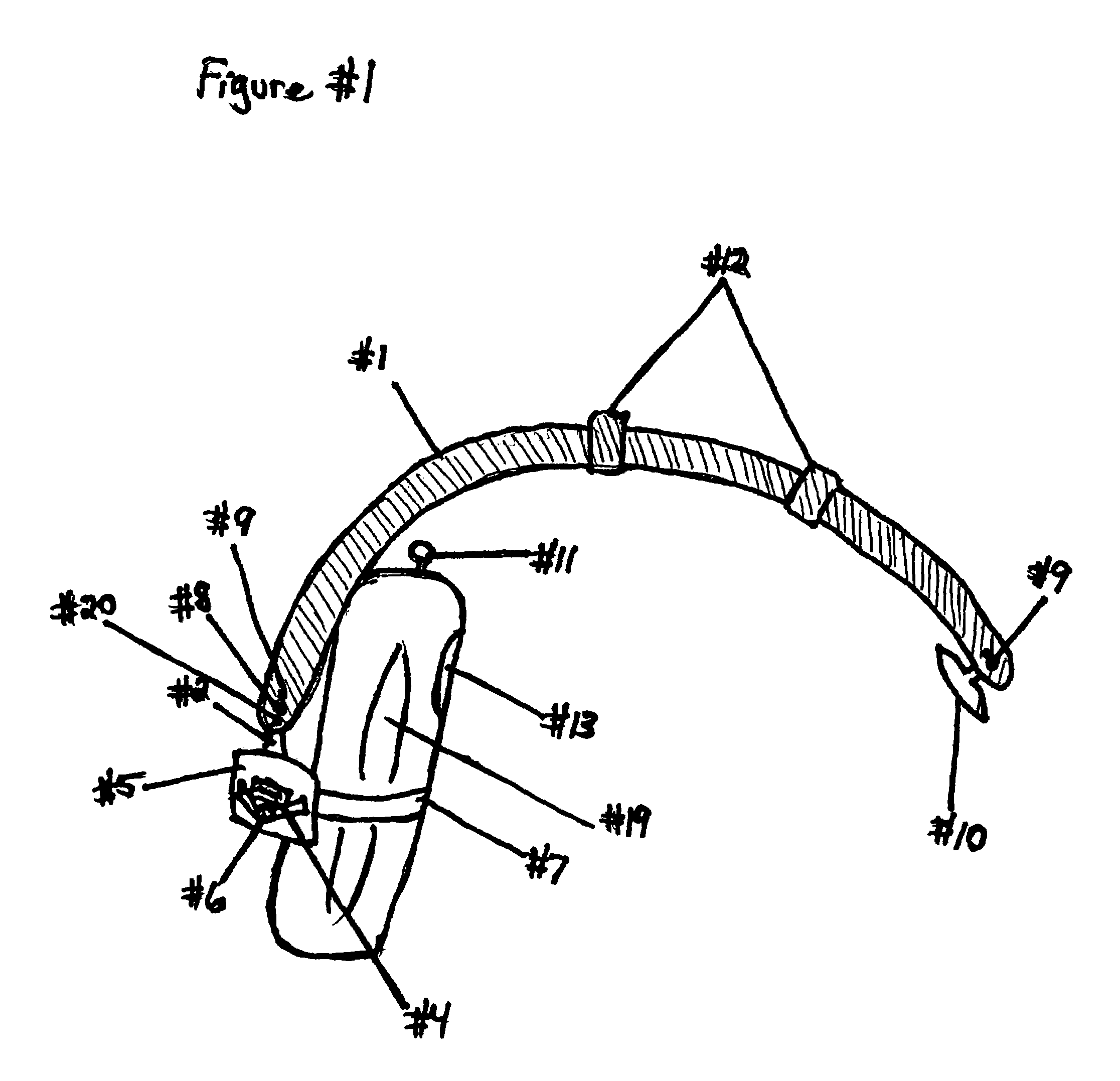

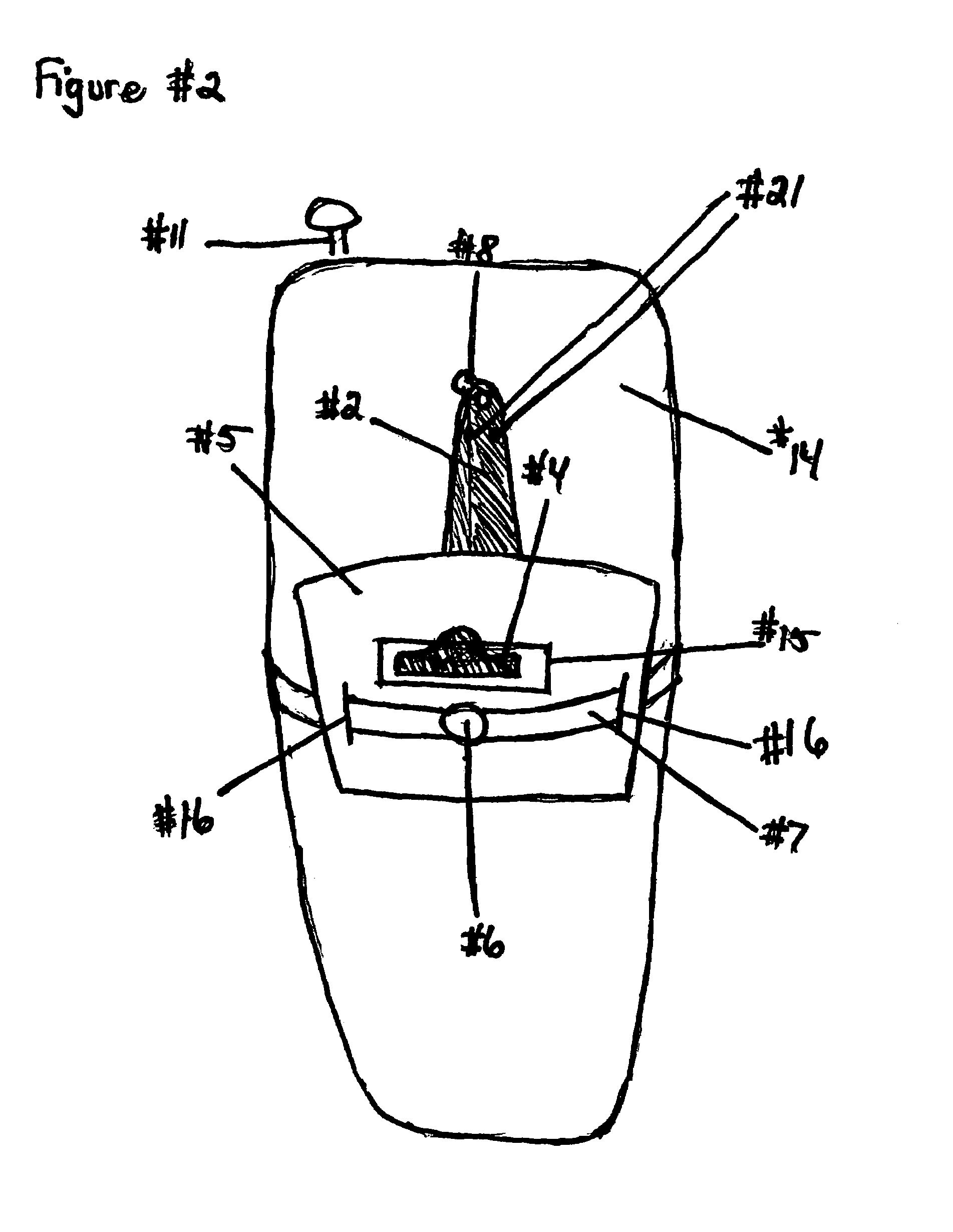

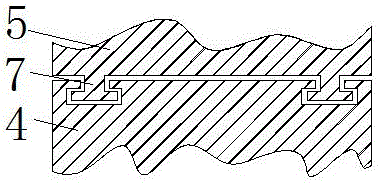

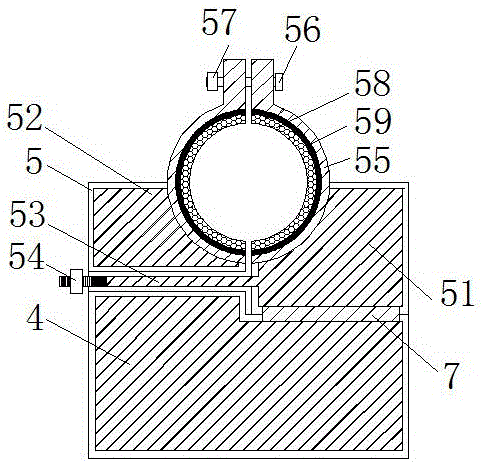

Cell phone holder headband

A cell phone holder headband (1), when placed on the users had, enables the phone to stay in a normal talking position without having to hold it there with one hand. The cell phone is fit into an elastic band (7) that is looped through a plastic plate (5). An elastic strap was chosen to accept difference size ‘Bar’ and ‘Flip’ style cell phones. The plate is fitted to a swivel joint (2), that is connected to one end of the headband. The light weight acrylic band is adjustable (12) for a better fit to the users head and coils up (3) so the user can choose to use the phone still attached to the device, without Wearing the headband. This makes the device easy to store either on or off the phone. This swivel joint feature (2) locks into two positions (21), not only to allow the user to adjust the phone for a more comfortable talking position to the face, but also allows the phone to be worn and adjusted to accommodate either the left or right ear of the user. The cell phone holder headband (1) is relatively easy to construct and equally inexpensive to manufacture and produce.

Owner:BERGH RICHARD ALAN

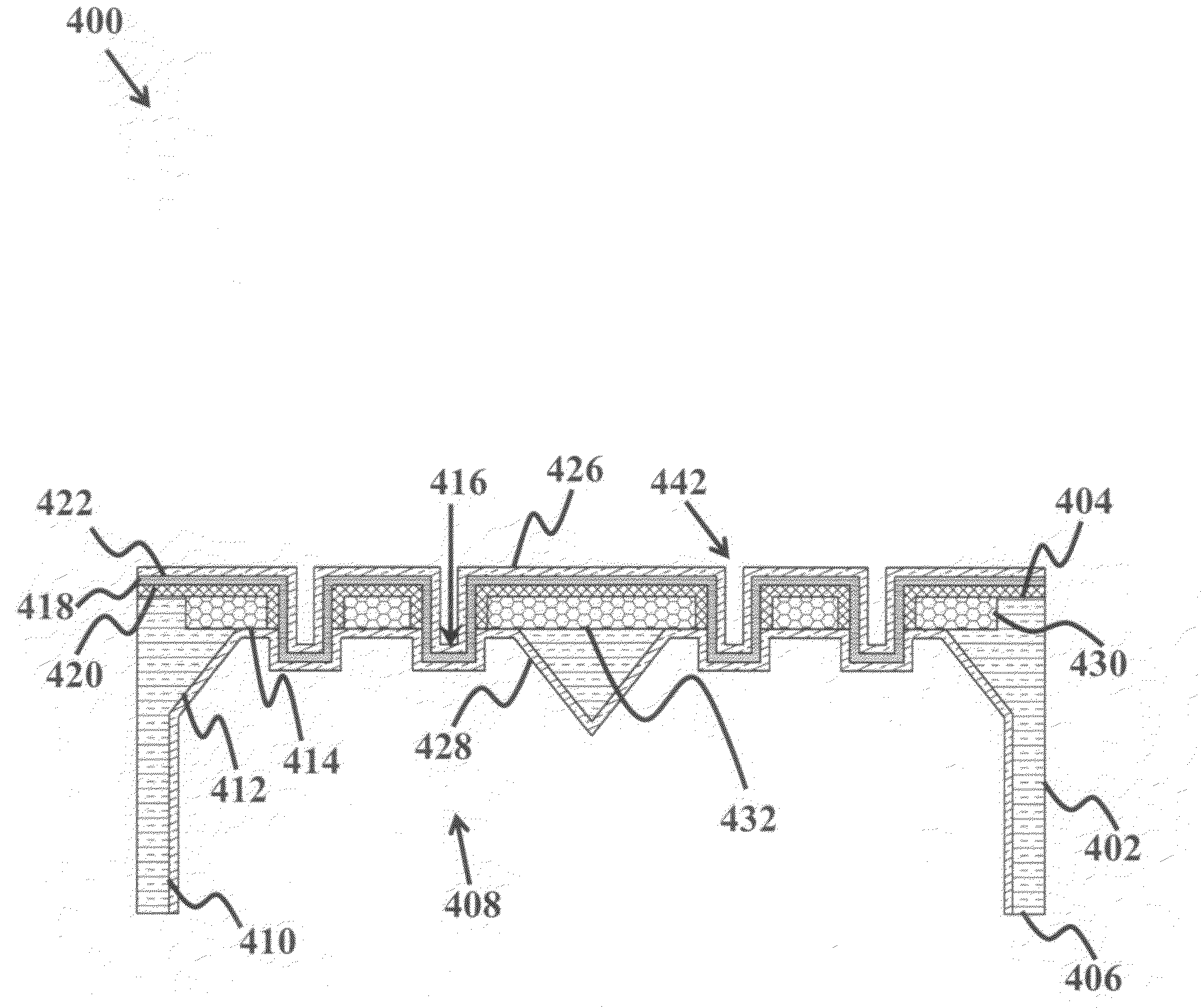

Fabrication method of thin film solid oxide fuel cells

InactiveUS20090087712A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusDifferences sizeReactive-ion etching

A silicon-based solid oxide fuel cell (SOFC) with high surface area density in a limited volume is provided. The structure consists of a corrugated nano-thin film electrolyte and a silicon supportive layer on a two-stage silicon wafer through-hole to maximize the electrochemically active surface area within a given volume. The silicon supportive layer is done by boron-etch stop technique with diffusion doping. The fabrication of two-stage wafer through hole combines deep reactive ionic etching (DRIE) and KOH wet etching of silicon for a wafer through hole containing two difference sizes. By these design and fabrication methods, the absolute electrochemically active area can be as high as five times of that of the projected area.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

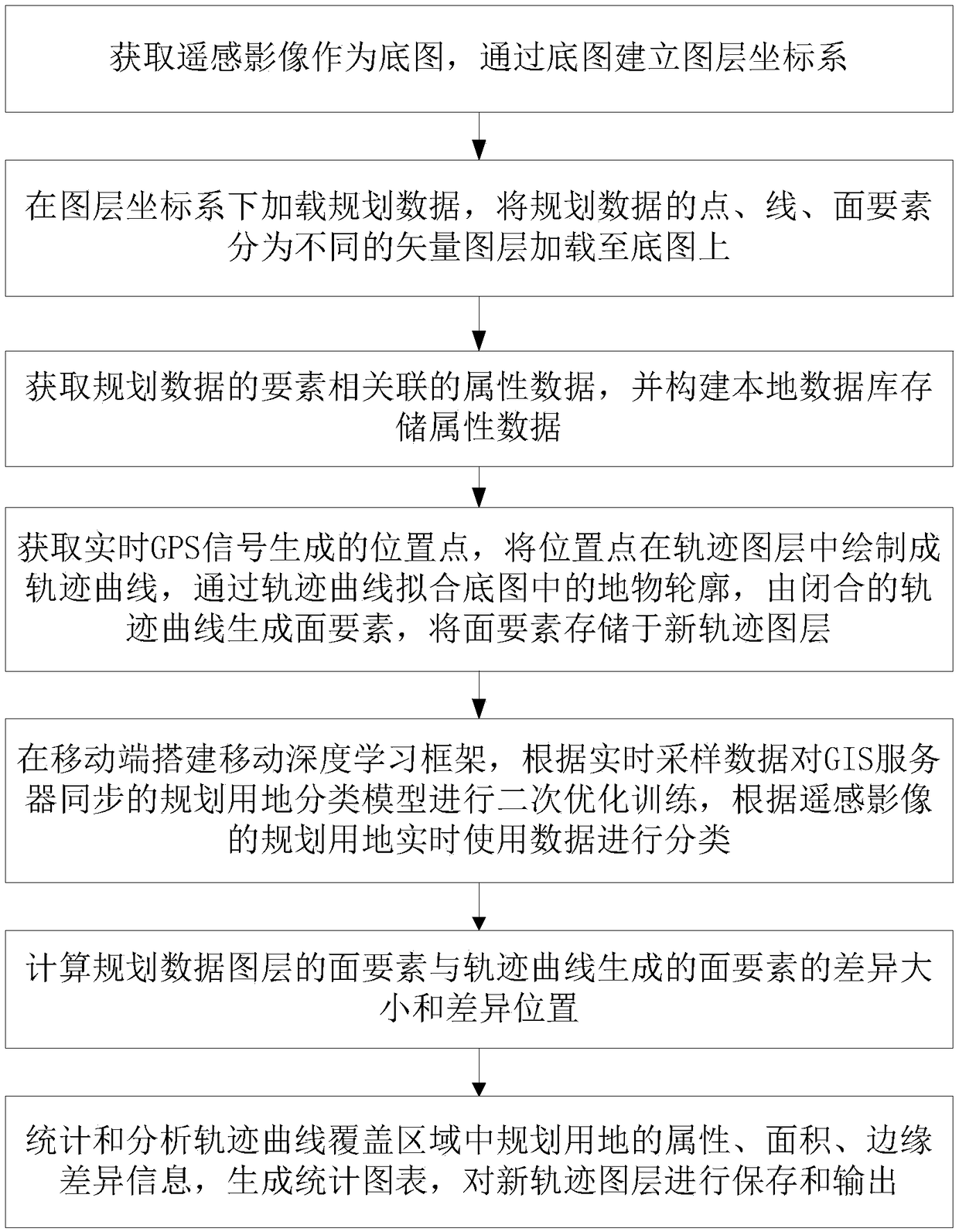

Automatic planning land checking method, electronic device, storage medium and system

ActiveCN108874919ARealize the loadRealize the use effectData processing applicationsCharacter and pattern recognitionTerrainComputer graphics (images)

The invention provides an automatic planning land checking method. The automatic planning land checking method comprises the steps of: performing graphic layer management, obtaining a remote sensing image as the underlying graph, and establishing a graphic layer coordinate system through the underlying graph; performing planning data loading, loading planning data in the graphic layer coordinate system, separating point, line and surface elements of the planning data into different vector graphic layers, and loading to the underlying graph; performing track management, obtaining the position point generated by a real-time GPS signal, drawing a track curve in a track graphic layer according to the position point, fitting the terrain contour in the underlying graph through the track curve, generating the surface element from the closed track curve, and storing the surface element in a new track graphic layer; and performing automatic checking, and calculating the difference size and thedifference position of the surface element of the planning data graphic layer and the surface element generated by the track curve. By means of the automatic planning land checking method, the electronic device, the storage medium and the system provided by the invention, the planning land checking efficiency can be effectively increased; the checking cost can be reduced; and thus, effective technical support is provided for checking the planning land in our country.

Owner:HUBEI UNIV

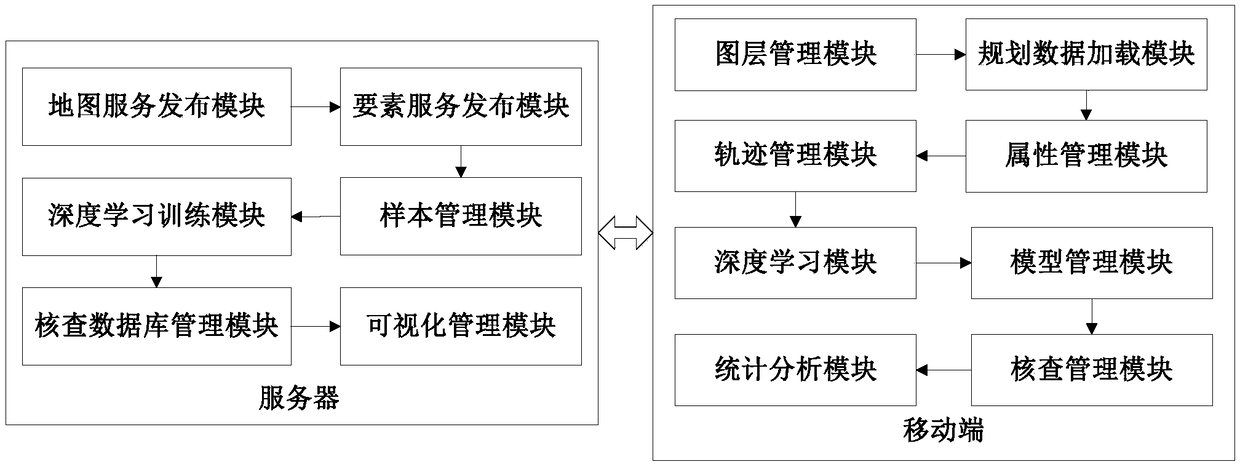

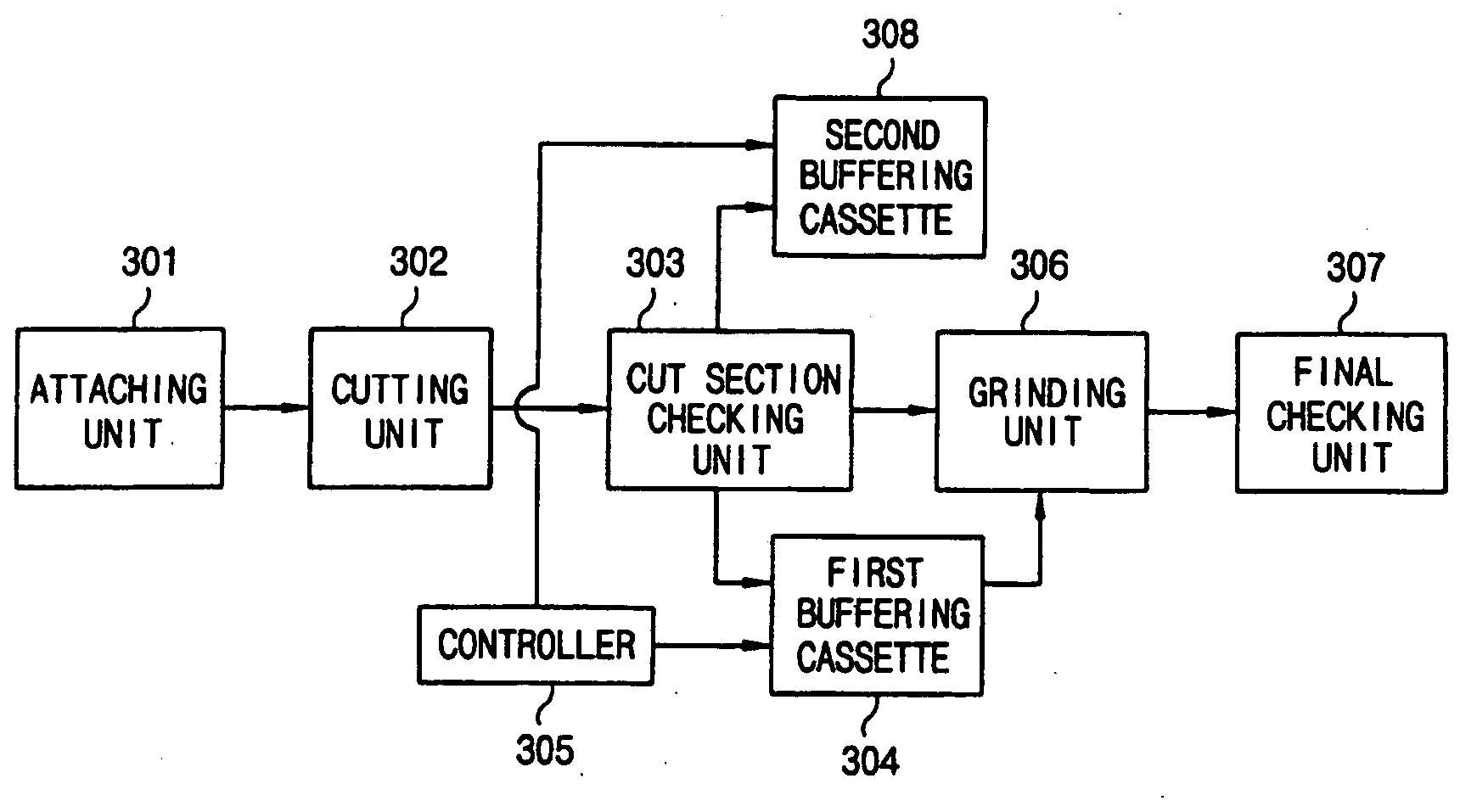

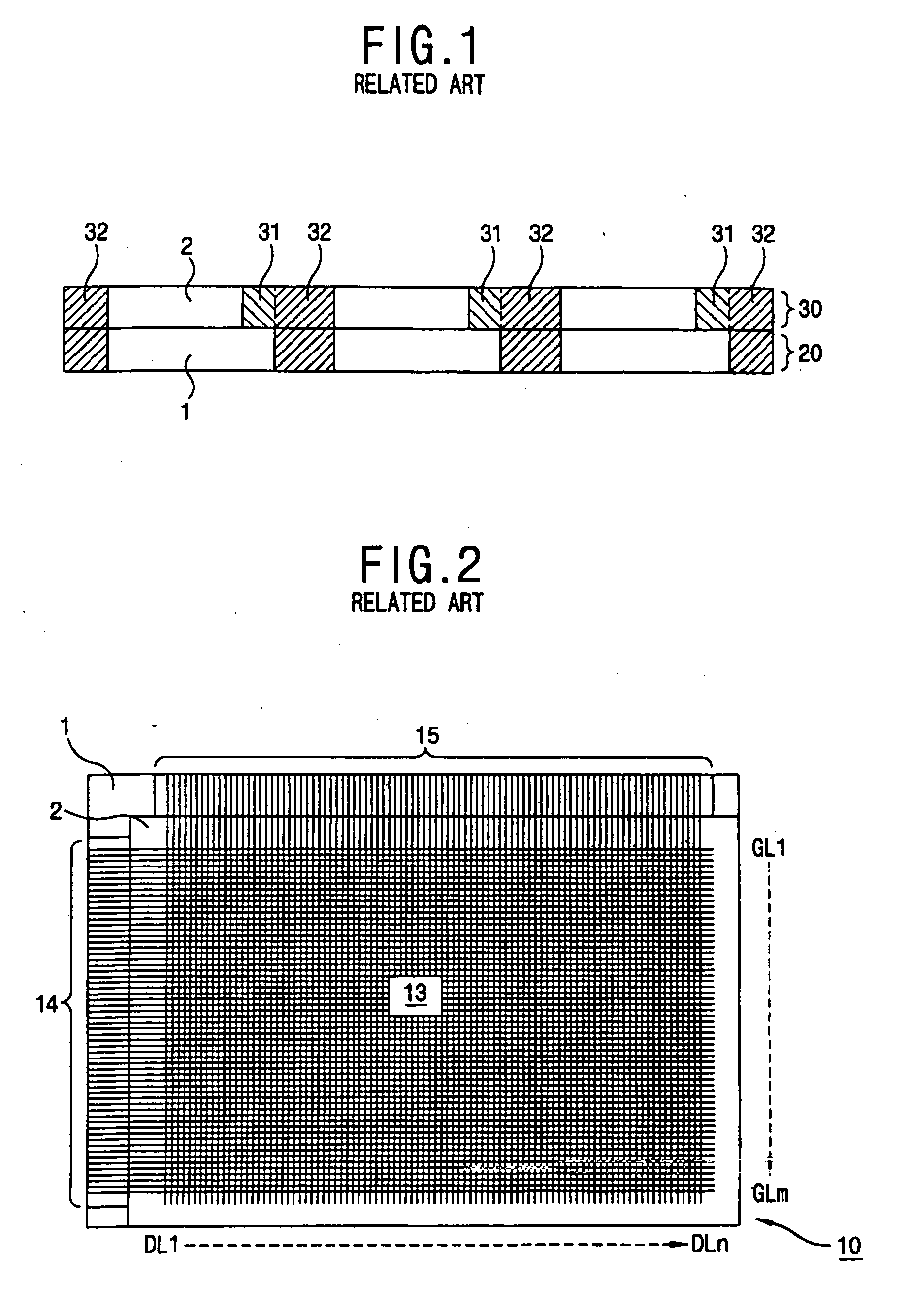

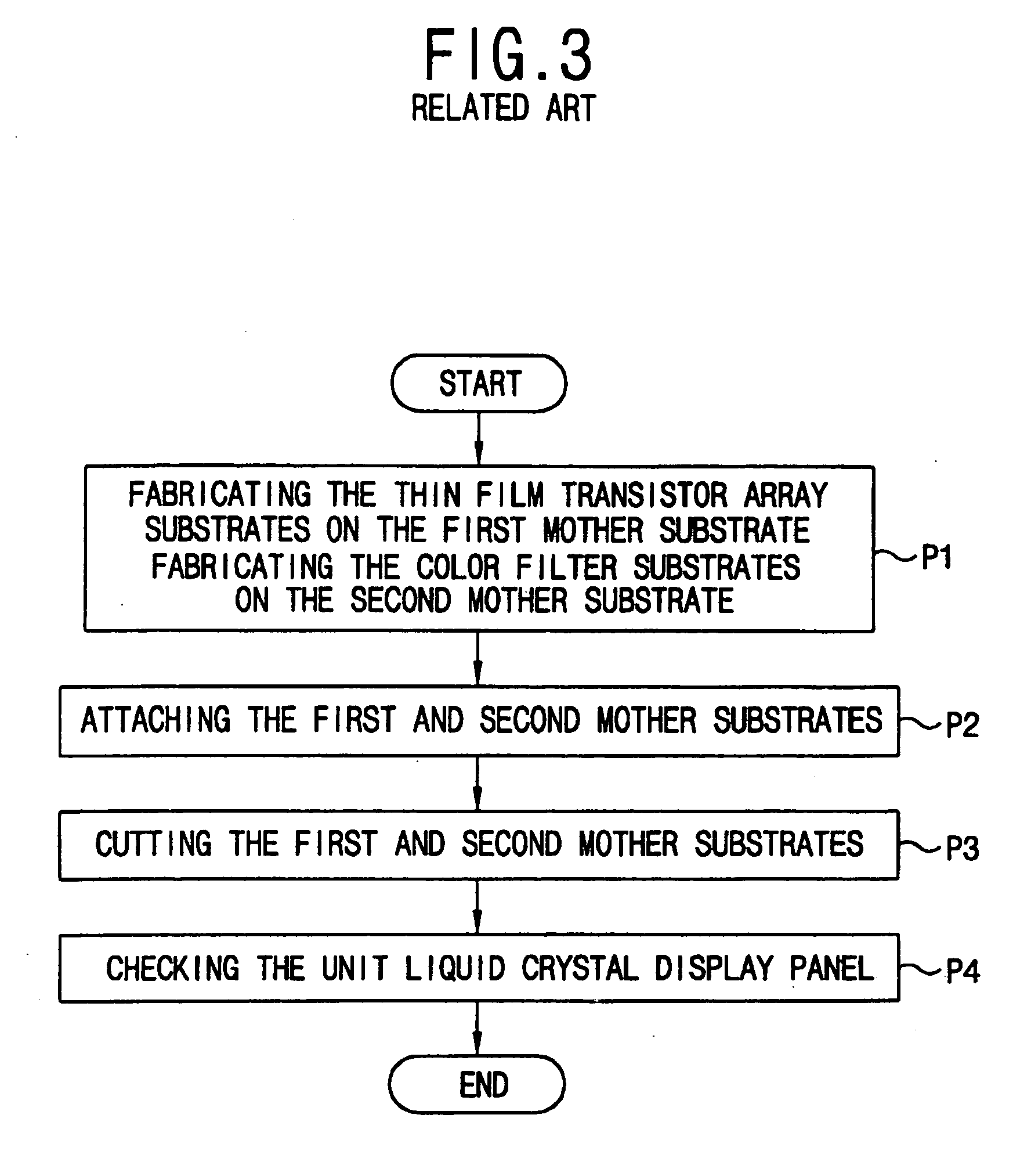

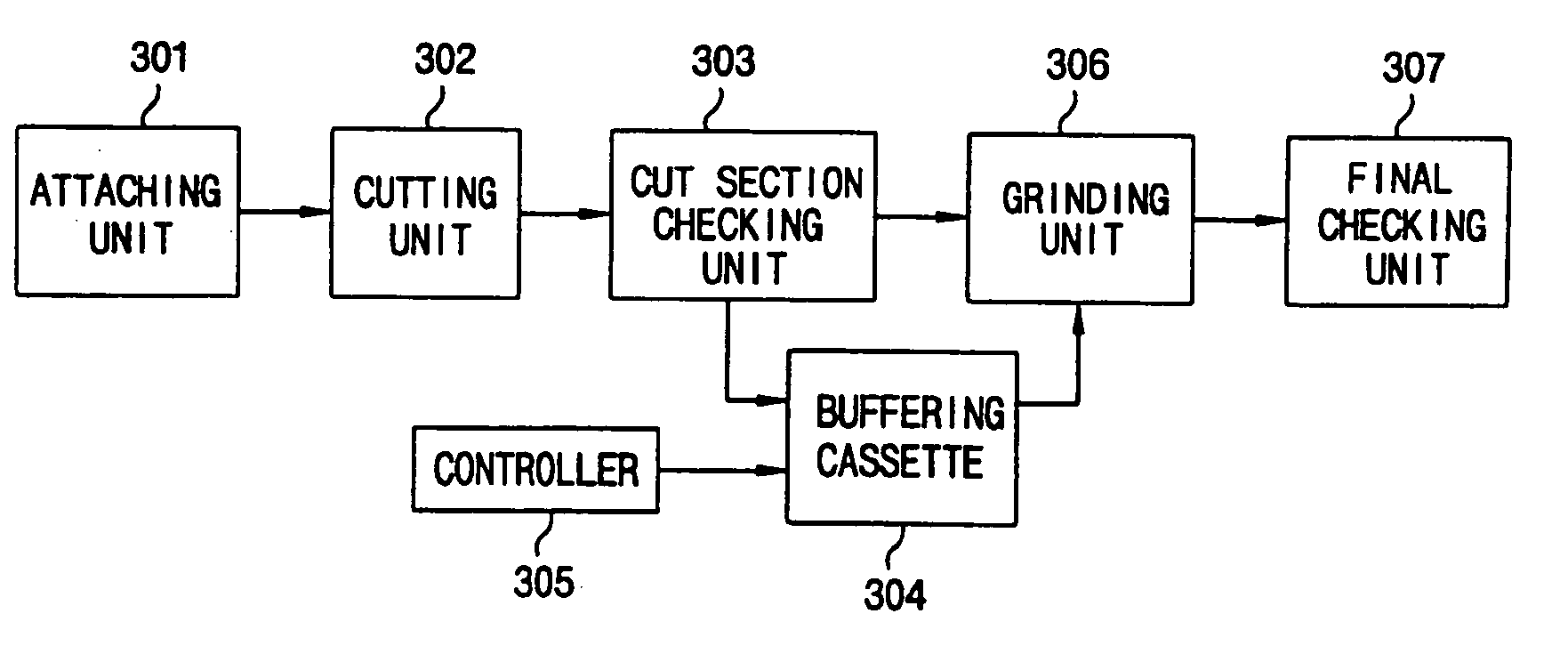

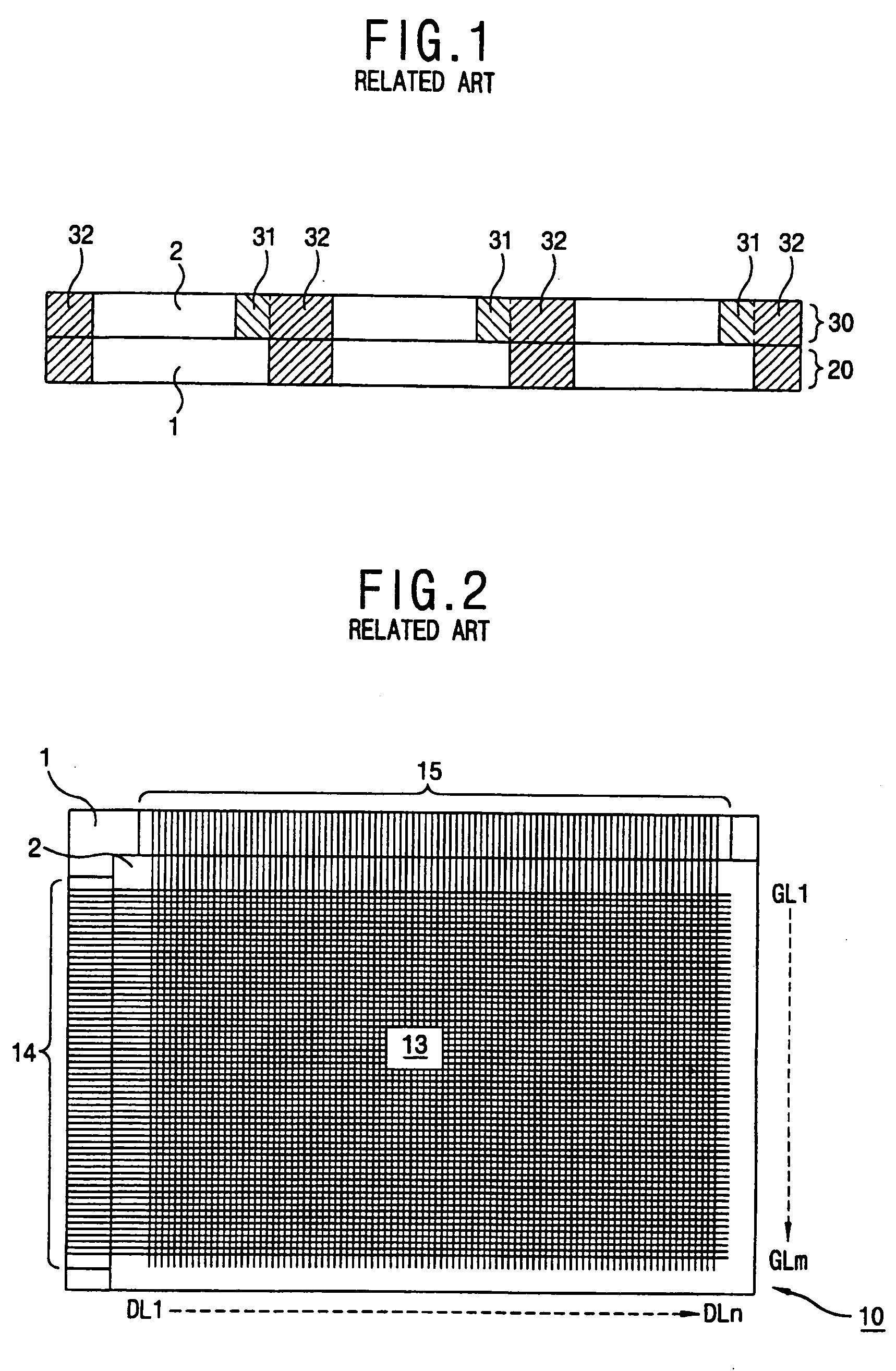

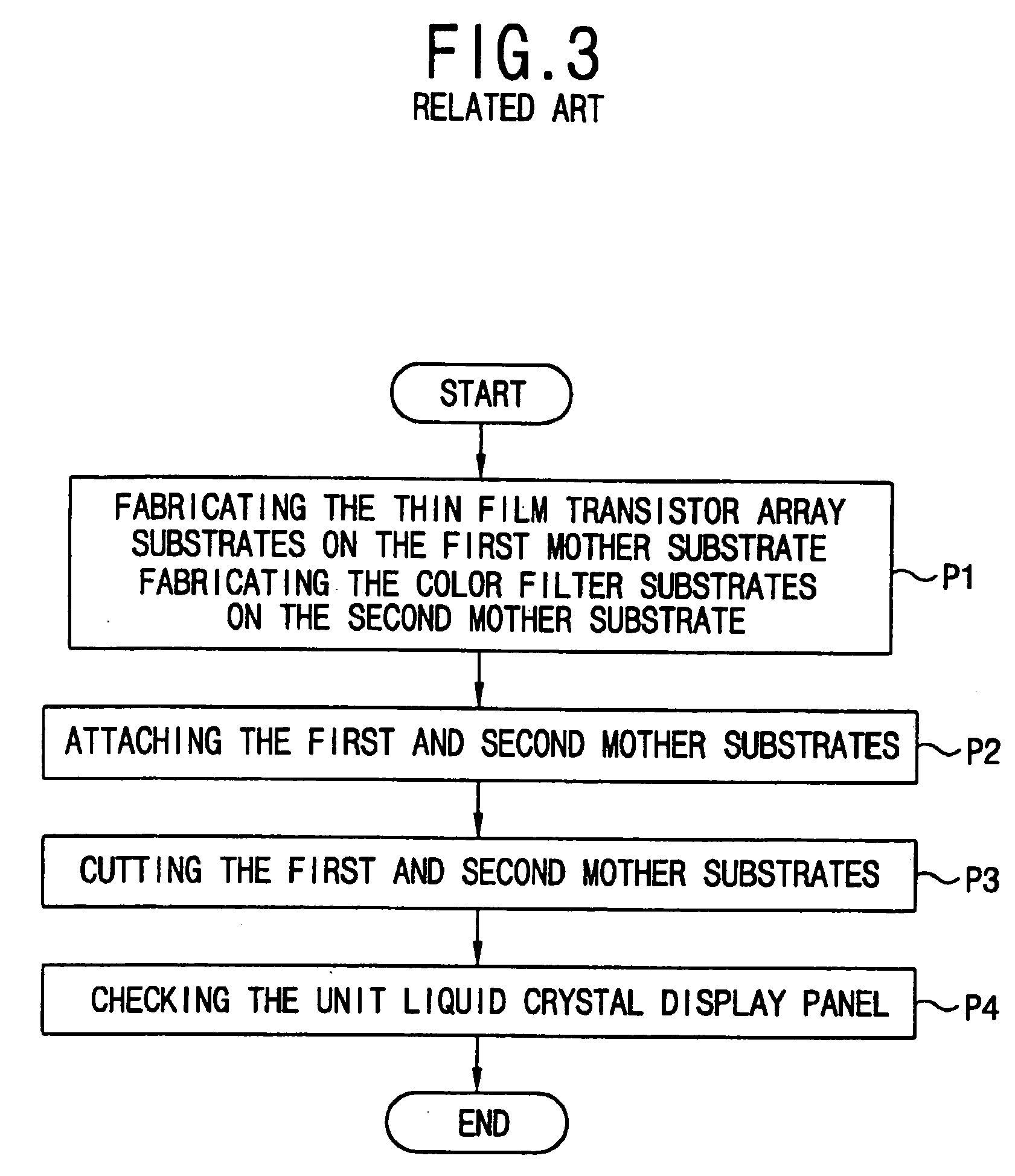

Apparatus and method for fabricating liquid crystal display panel

An apparatus and method for fabricating a liquid crystal display panel are disclosed. In case of the single mode that liquid crystal display panels are fabricated with the same size on a large glass substrate, defective unit liquid crystal display panels are kept and discarded not to proceed with a follow-up process. Thus, a material waste is restrained and a yield can be improved. Meanwhile, in case of the multi-mode that liquid crystal display panels are fabricated with difference sizes on a large glass substrate, sub-models are kept, and then after completing the process for the main models, a follow-up process if performed on the sub-models. Thus use efficiency of the glass substrate can be maximized to improve a productivity and a unit cost of the product can be reduced.

Owner:LG DISPLAY CO LTD

Display screen frame convenient to regulate and applied to computer research and development

ActiveCN108825966AConvenient and effective clamping and fixing effectEasy to adjustDigital data processing detailsStands/trestlesFastenerDifferences size

The invention discloses a display screen frame convenient to regulate and applied to computer research and development. The display screen frame comprises a supporting pedestal; the outer wall of thetop center of the supporting pedestal is connected with a rotating shaft protective housing through a bolt; the outer wall of the top center of the rotating shaft protective housing is provided with an opening I; the inner walls of the centers of the two ends of the rotating shaft protective housing are connected with a horizontally-arranged damping rotating shaft I through a bolt; the outer wallof the top of the circumference of the damping rotating shaft I is connected with a vertically-arranged supporting rod I through a bolt; and the outer wall of the top of the supporting rod I is connected with a rotating circular handle through a bearing. According to the display screen frame convenient to regulate and applied to computer research and development disclosed by the invention, by arranging fixing bolts and a plurality of bolt fasteners, different computer displays can be fixed by regulating the size of a clamping opening according to the difference sizes of the computer display screens; and meanwhile a fixing sucking disc is arranged for adsorbing and fixing the back surface of the computer display screen, so a quite convenient and effective clamping and fixation effect is achieved.

Owner:合肥海诺恒信息科技有限公司

Magnetic levitation pad

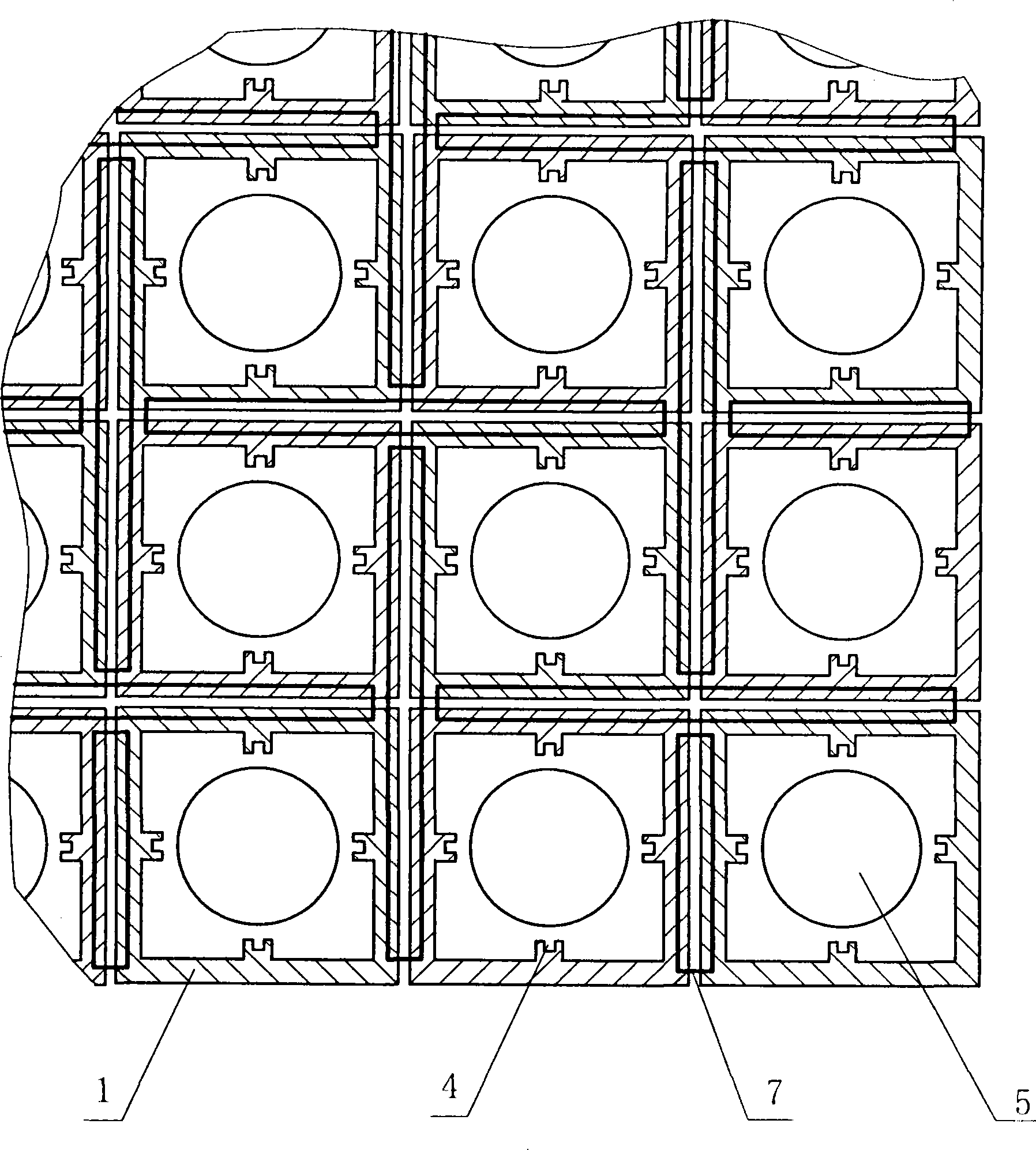

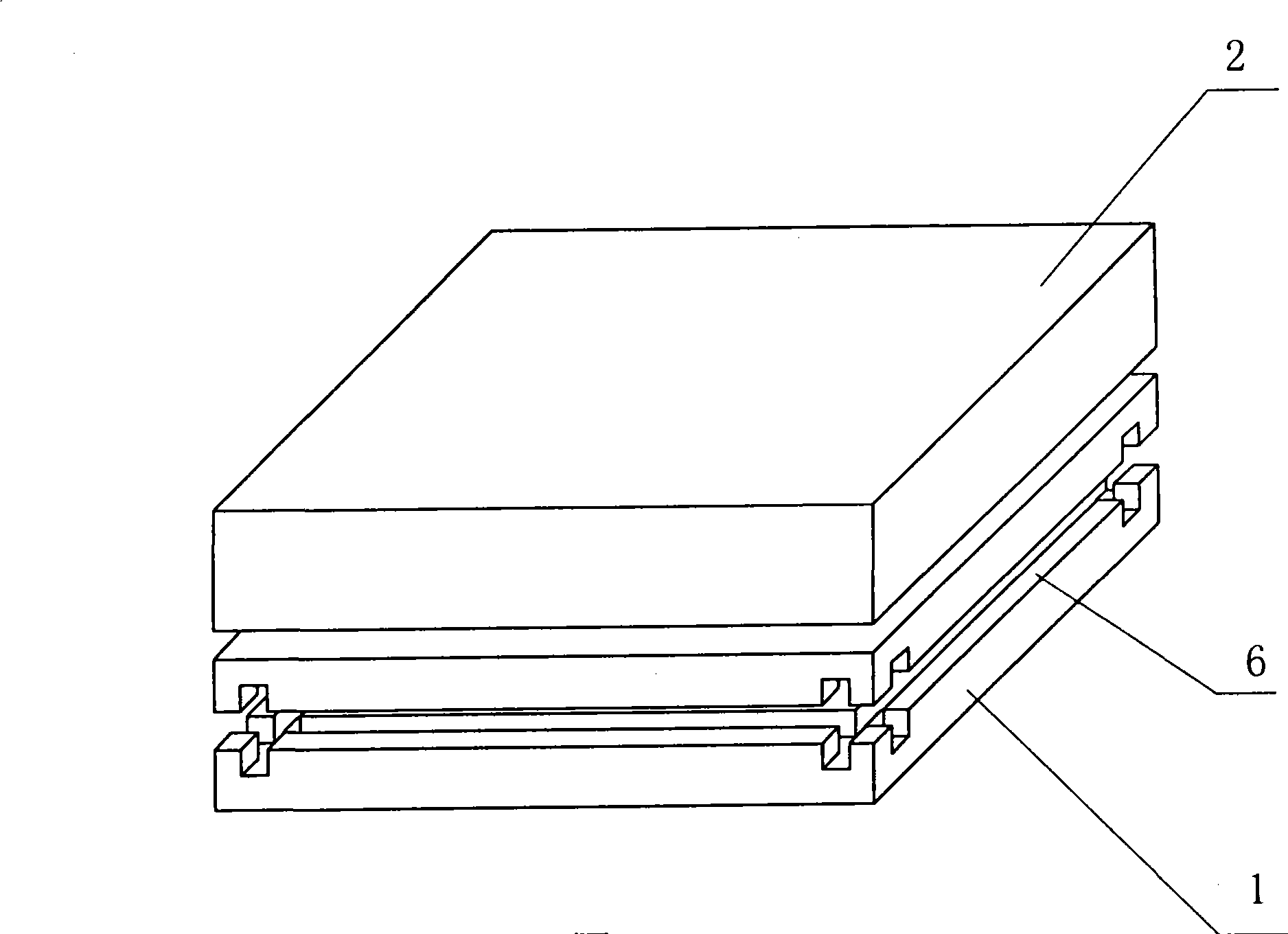

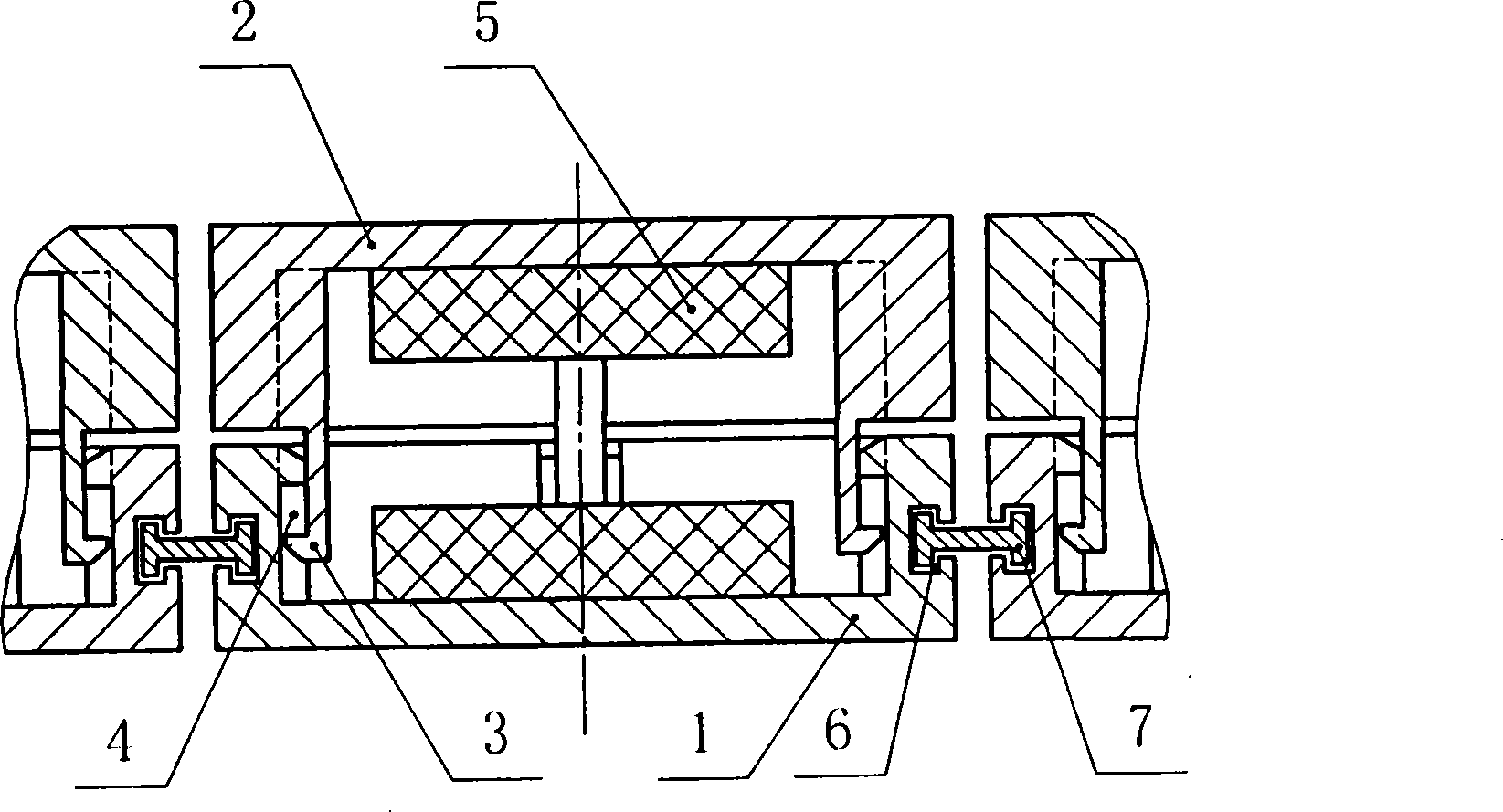

InactiveCN101248935AEasy to useUse without shakingStuffed mattressesSpring mattressesSound generationEngineering

The invention relates to a magnetic suspension cushion for a bed or a chair. A cushion body is lined inside an outer cover and consists of supporting boxes that are vertically and horizontally arranged and interconnected, the supporting box comprises a bottom box and an upper cover, a downwardly protruding buckling arm is connected inside the upper cover, a buckle tenon is arranged at the end of the buckling arm, an sliding chute capable of embedding the buckling arm is manufactured inside the bottom box, and two magnets with same polarity are respectively arranged inside the bottom box and the upper cover. The inventive magnetic suspension cushion has the advantages of moderate elasticity, stable service, no sound generation during service, no influence on sleeping of the user and people around the user, and convenience for assembly / disassembly and transportation; and has magnetic therapeutic effect, and can relieve fatigue, tranquilize mind and help sleep. The inventive magnetic suspension cushion is suitable for mattress, foot pad and other cushions with difference sizes.

Owner:连建永

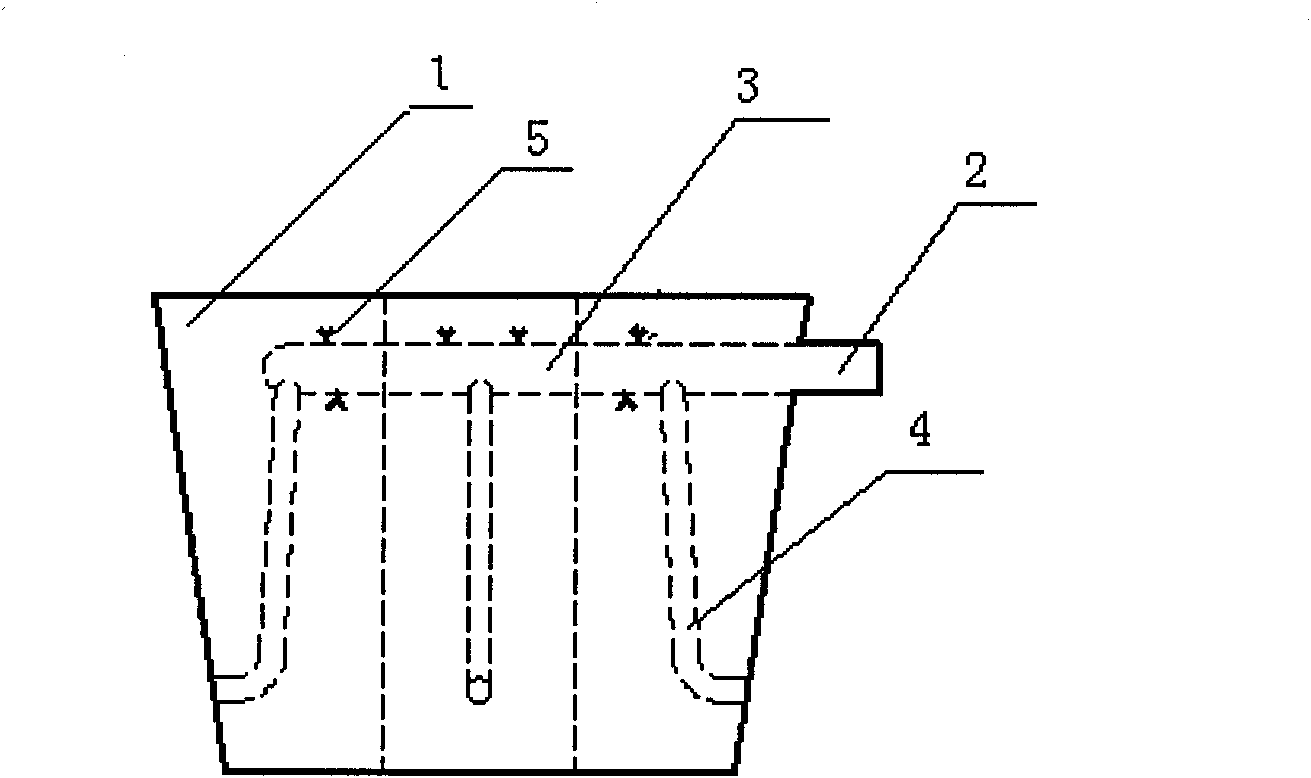

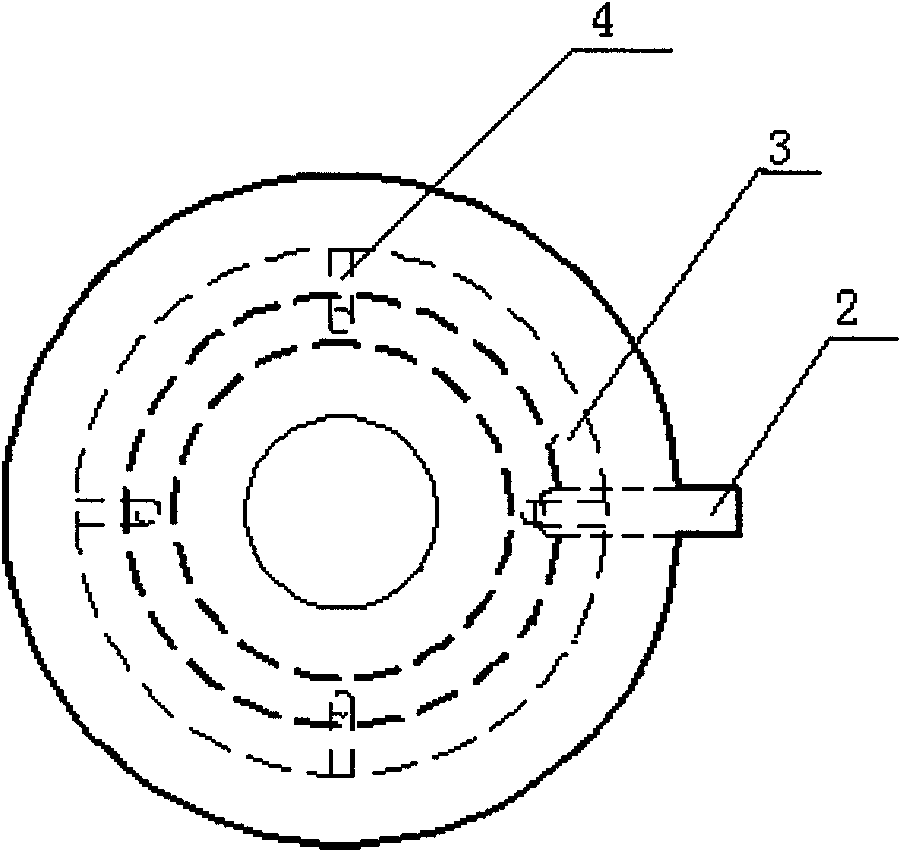

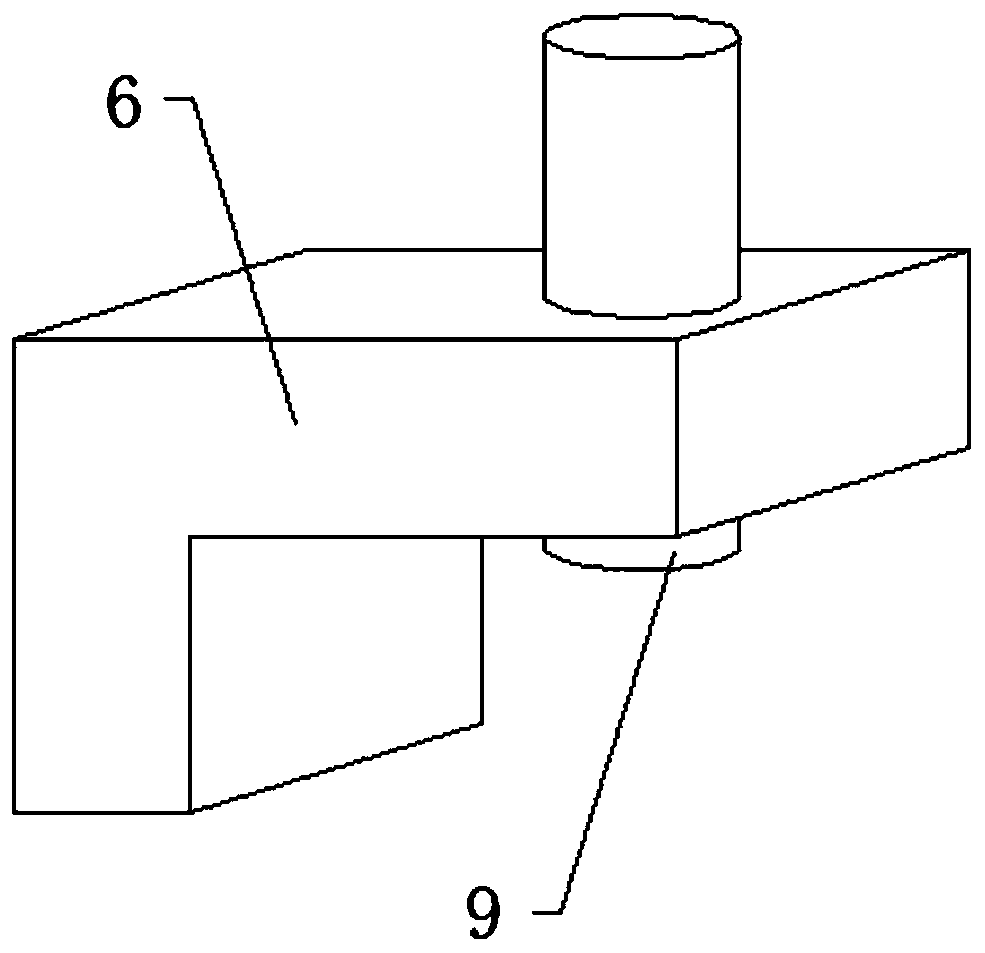

Argon-blowing prefabricated member for continuous casting tundish cover

InactiveCN102179491AImprove sealingGuaranteed metallurgical effectMelt-holding vesselsCooking & bakingMolten steel

The invention relates to an argon-blowing prefabricated member for a continuous casting tundish cover and belongs to the technical field of ferrous metallurgical equipment. Argon-blowing prefabricated members with difference sizes can be designed according to the size of a baking hole, a charging hole, a plug hole and the like of the tundish cover. The argon-blowing prefabricated member comprisesa prefabricated member body; the argon-blowing prefabricated member body has a shape of a cone of which the radius of the upper bottom is greater than that of the lower bottom, or the longitudinal section structure of the prefabricated member body is T-shaped. The prefabricated member body is hollow, an aeration pipeline is arranged in the prefabricated member body, and the prefabricated member body is provided with an aeration hole communicated with the aeration pipeline. The argon-blowing prefabricated member solves the problems that the peripheries of the baking hole and the plug hole are deformed and refractory materials fall off, and guarantee the cast-on can be performed smoothly; and the tightness of the tundish cover is improved, the reduction of the molten steel temperature is inhibited, the molten steel is prevented from being oxidized for secondary time, and meanwhile, the service life of the tundish cover can be prolonged.

Owner:LAIWU IRON & STEEL GRP

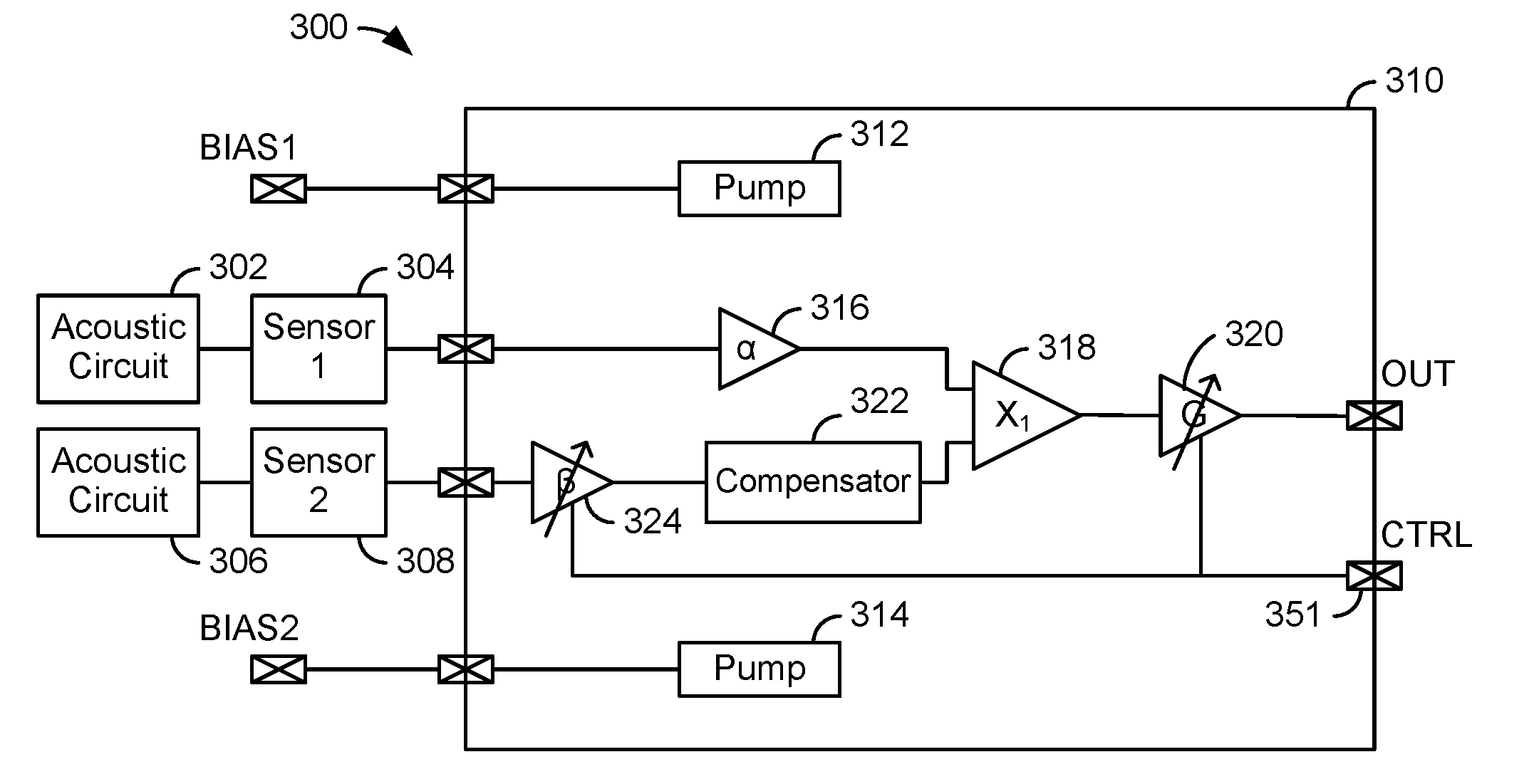

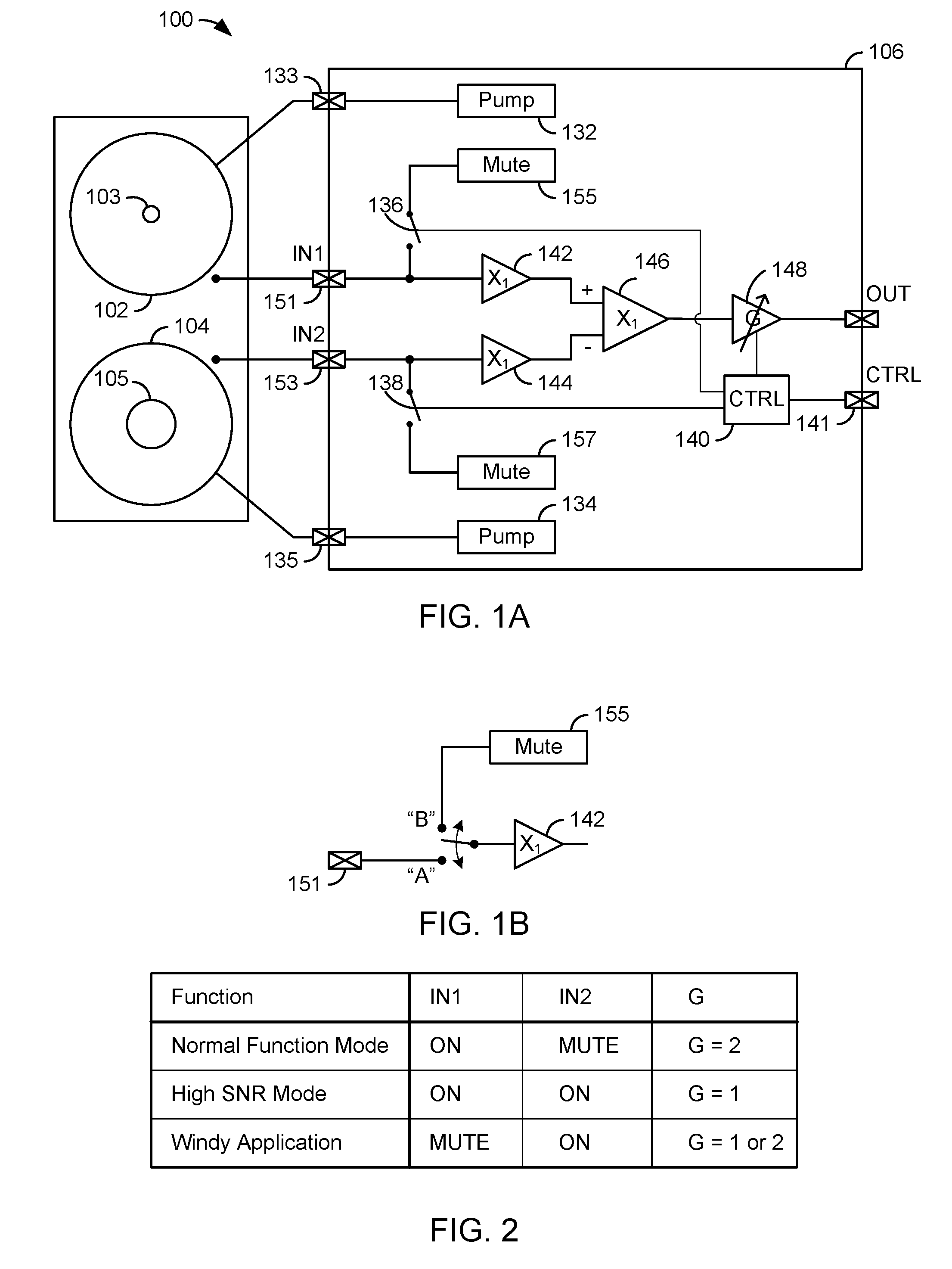

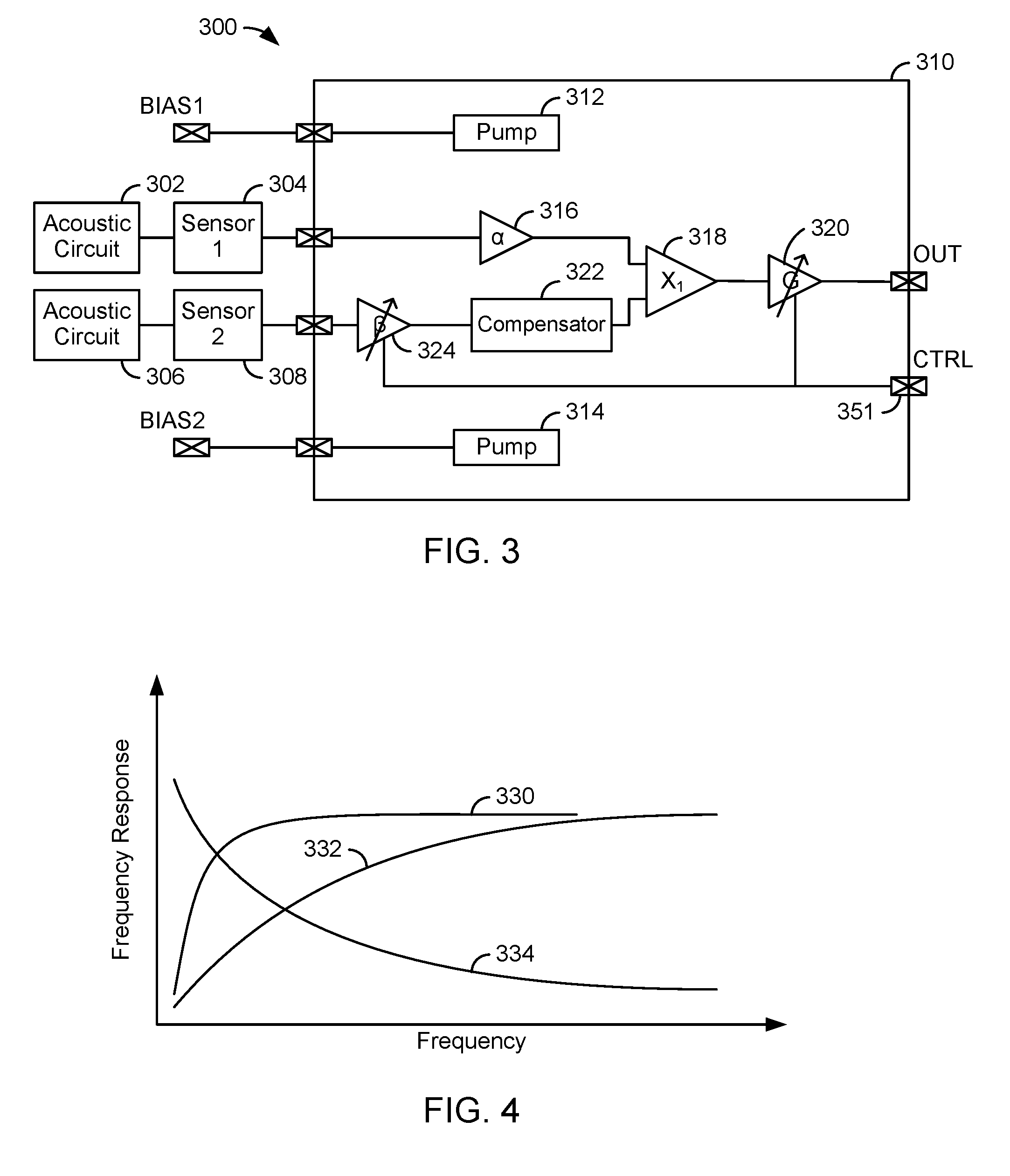

Microphone with wind noise resistance

InactiveUS20170026759A1High frequencyPiezoelectric/electrostrictive microphonesMicrophonesEngineeringDifferences size

A microphone device is comprises a first micro electro mechanical system (MEMS) device and a second MEMS device with difference size of pierce holes in the diaphragms. Signal outputs from the first and second MEMS devices are selectively used to provide wind noise resistance.

Owner:KNOWLES ELECTRONICS INC

Apparatus and method for fabricating liquid crystal display panel

An apparatus and method for fabricating a liquid crystal display panel are disclosed. In case of the single mode that liquid crystal display panels are fabricated with the same size on a large glass substrate, defective unit liquid crystal display panels are kept and discarded not to proceed with a follow-up process. Thus, a material waste is restrained and a yield can be improved. Meanwhile, in case of the multi-mode that liquid crystal display panels are fabricated with difference sizes on a large glass substrate, sub-models are kept, and then after completing the process for the main models, a follow-up process if performed on the sub-models. Thus, use efficiency of the glass substrate can be maximized to improve a productivity and a unit cost of the product can be reduced.

Owner:LG DISPLAY CO LTD

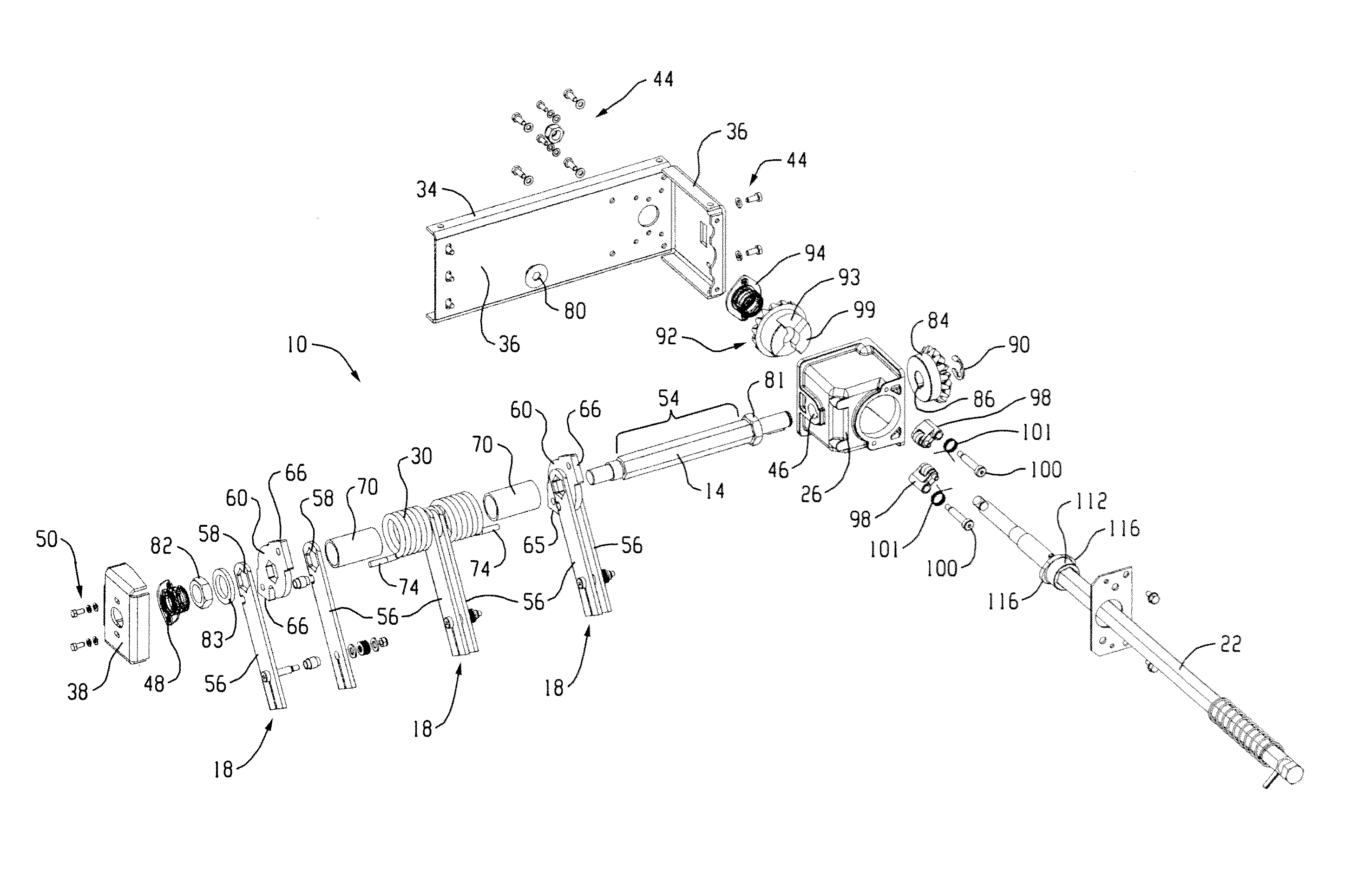

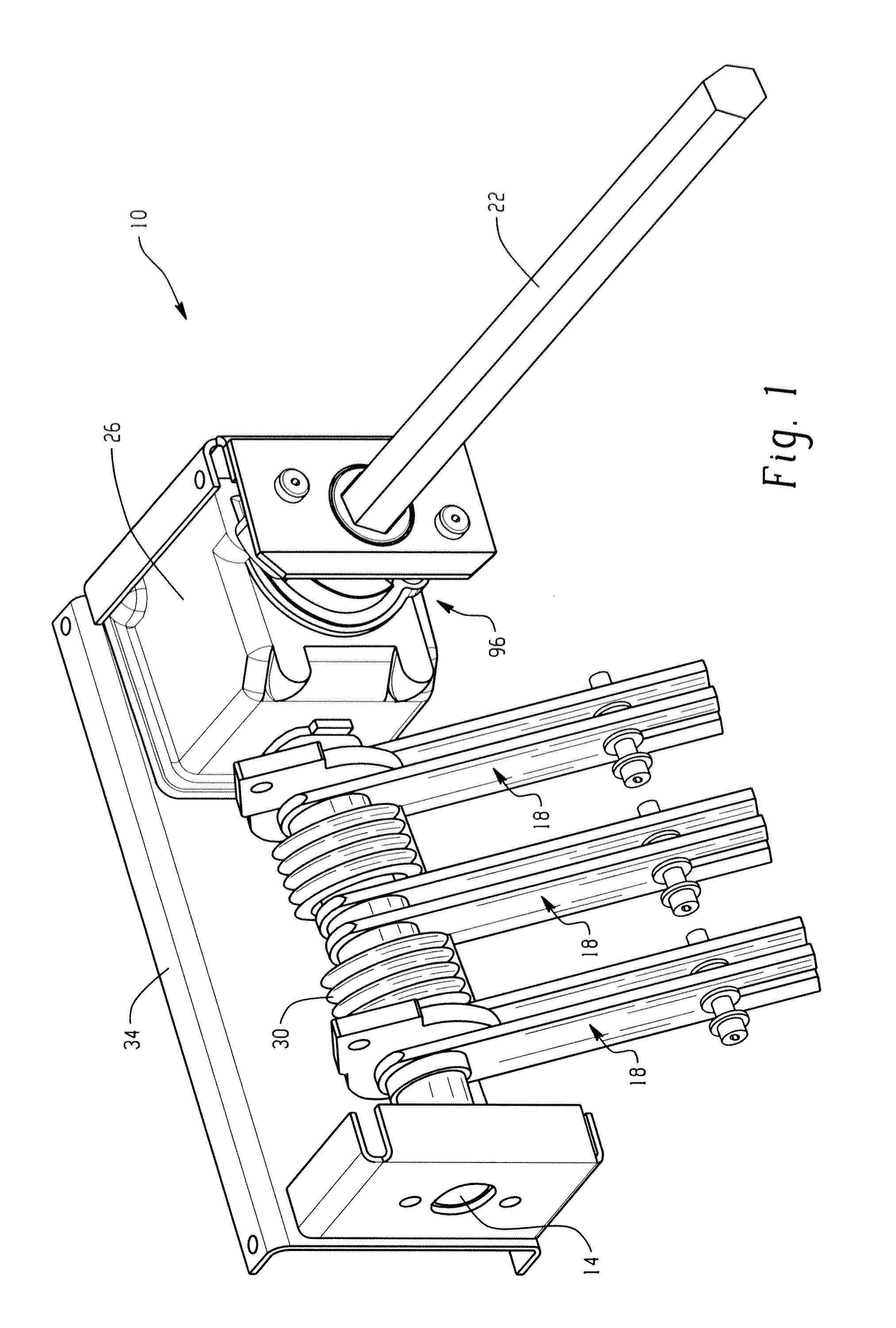

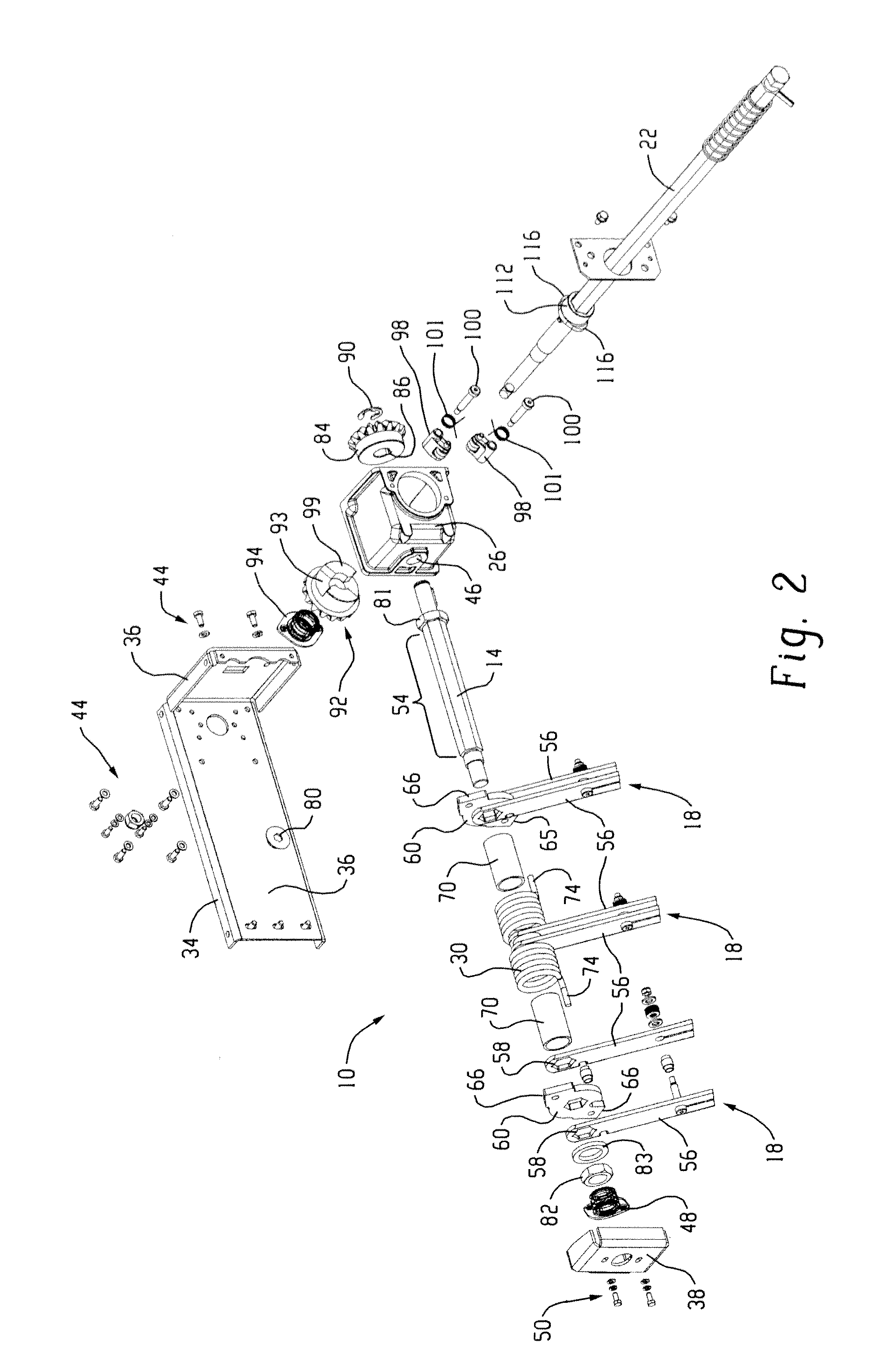

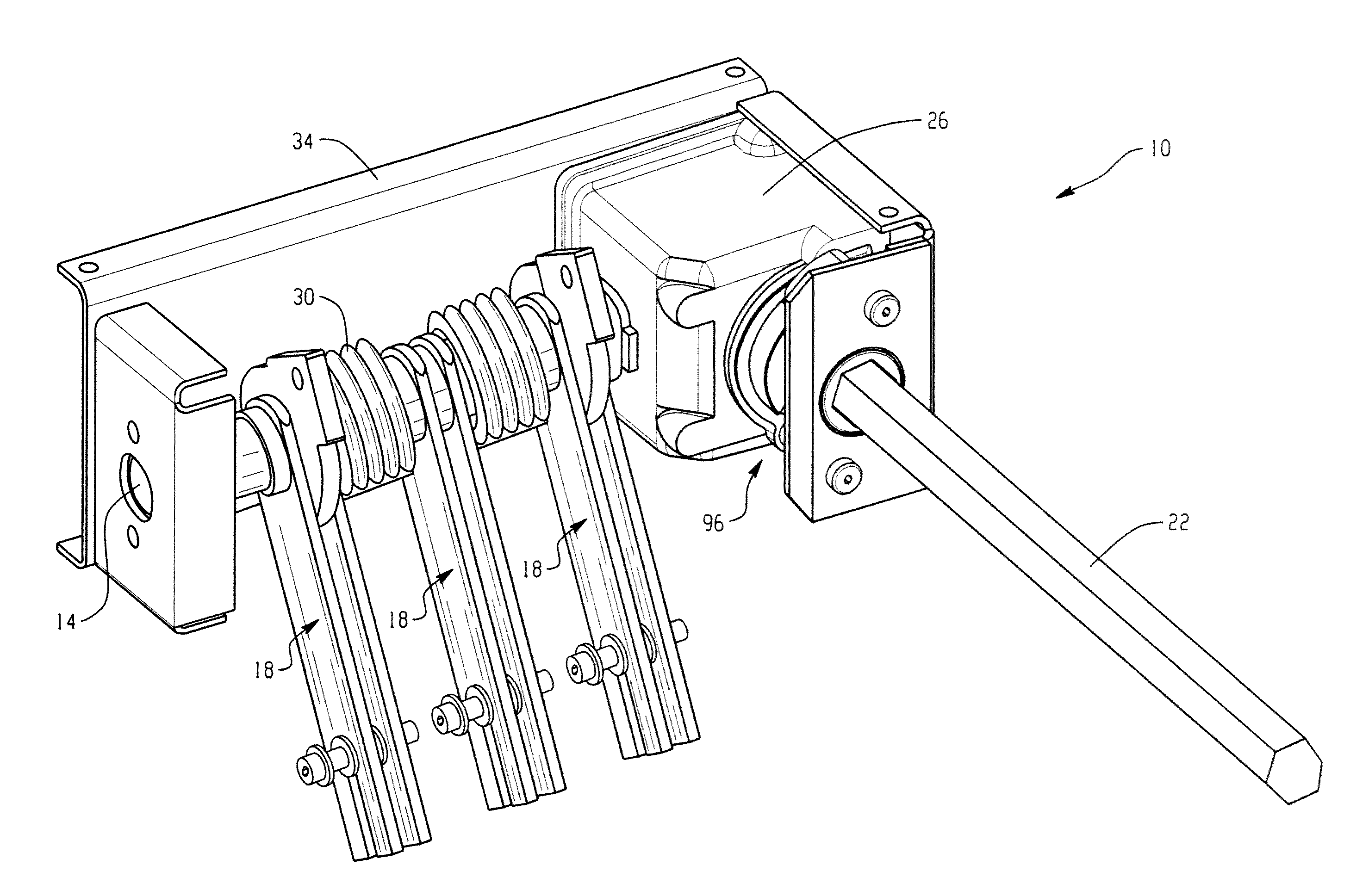

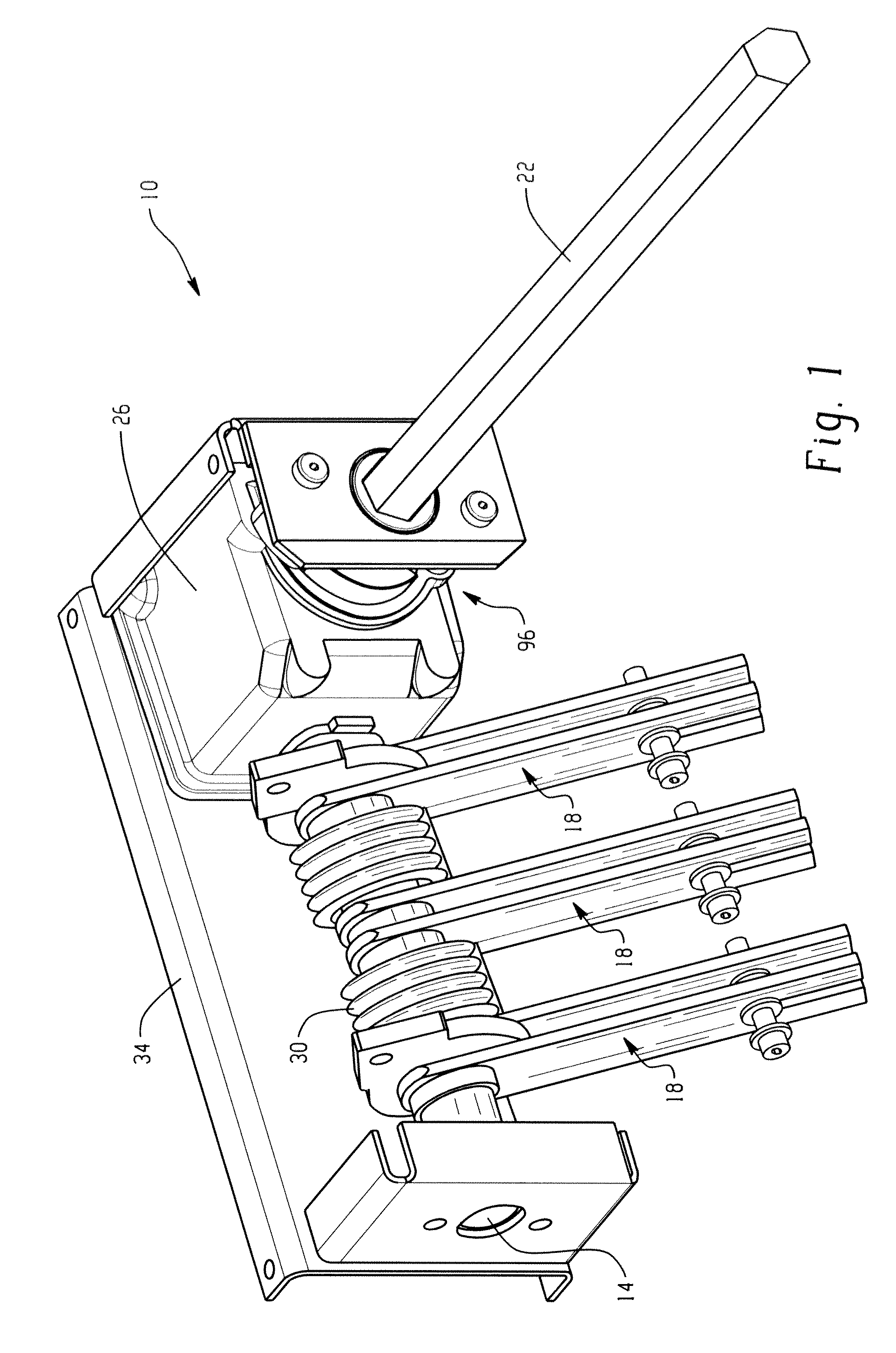

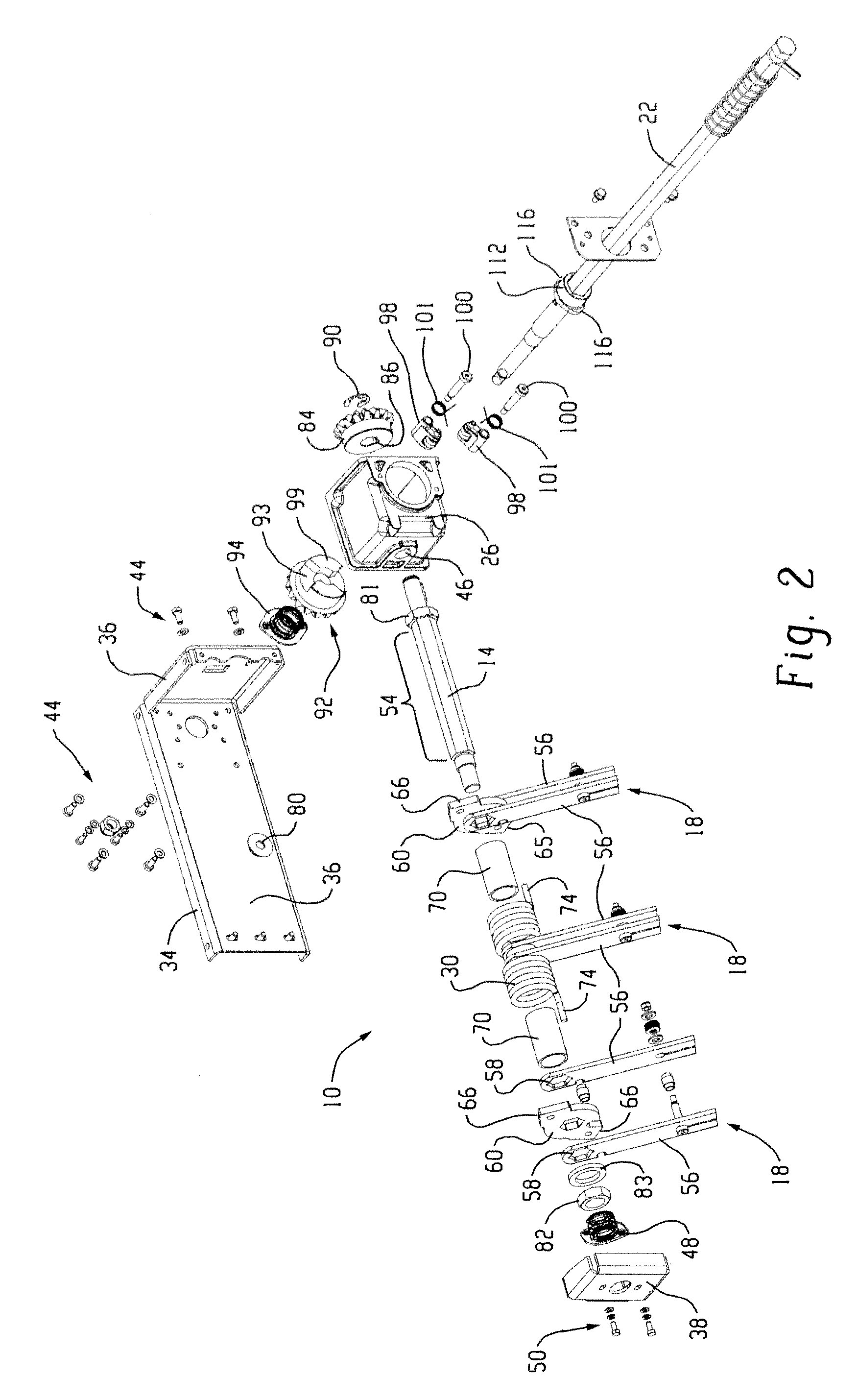

Scalable medium voltage latching earthing switch

ActiveUS20120273333A1Quick closeCompact designSnap-action arrangementsSwitches with movable electrical contactsDetentEngineering

A scalable earthing switch that incorporates a torsion spring to effect rapid closure of the switch. The torsion spring is supported coaxially about a rotatable shaft on which contact blades are mounted resulting in compact design. The blade contacts are separated axially along the length of the shaft by one or more spacers. By using difference size spacers the distance between adjacent blade contacts can be changed and, thus, the earthing switch can be easily scaled for different applications. A latching (detent) mechanism is provided for latching the switch in an open position.

Owner:ROCKWELL AUTOMATION TECH

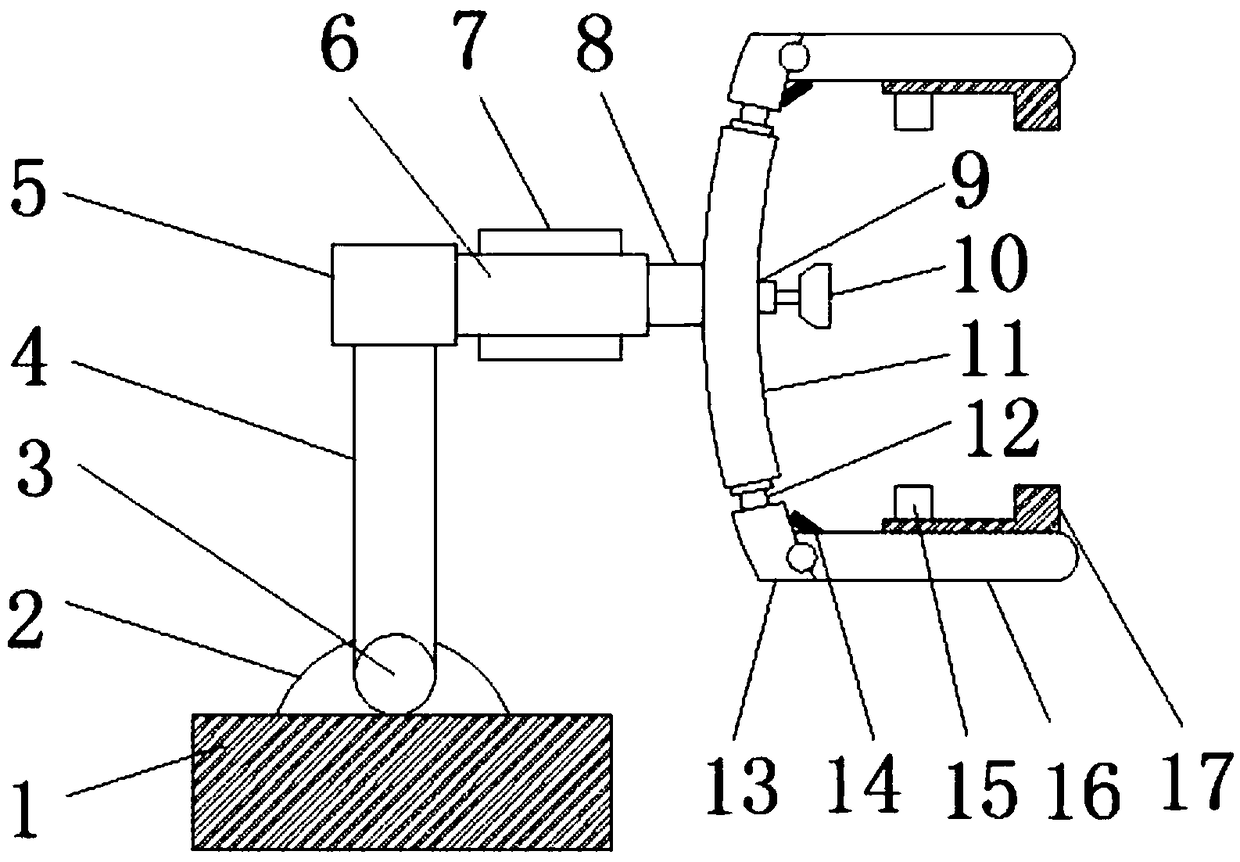

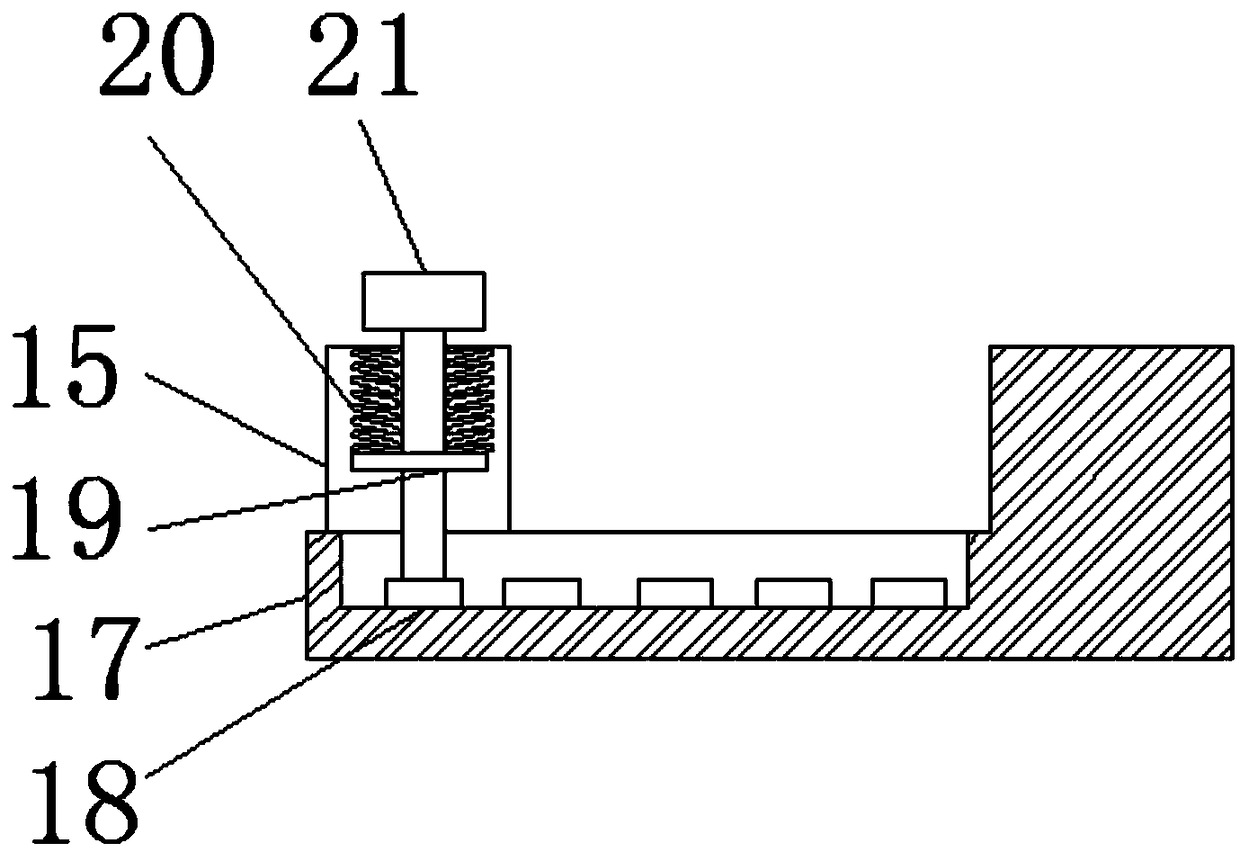

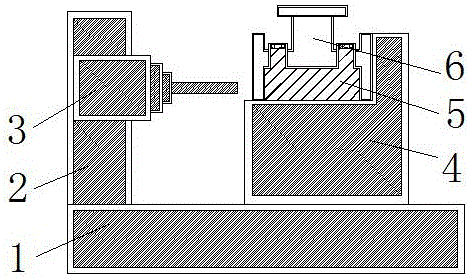

Fixing device of perforating machine for drilling valve

InactiveCN106002373AImprove practicalityEasy to fixPositioning apparatusMetal-working holdersFixed frameEngineering

The invention discloses a fixing device of a perforating machine for drilling a valve. The fixing device comprises a base. A fixing frame is fixedly installed on the upper surface of the base. A perforating device is fixedly installed in the middle of the fixing frame in a sleeved mode. One end of the perforating device penetrates through and extends to the outside of the right side of the fixing frame. The upper surface of the base is fixedly connected with a fixing platform on the right side of the fixing frame. A fixing device body is installed at the top end of the fixing platform in a sliding mode, and a valve device is fixedly installed in an inner cavity of the fixing device body in a sleeved mode. According to the fixing device of the perforating machine for drilling the valve, the bottom end of a first fixing plate is in sliding connection with the top end of the fixing platform, so that the valve devices in difference sizes are fixed, and the practicability of the fixing device is improved. The valve device is fixed with a fixing screw and a nut. The outer wall of the valve device is effectively extruded through a locking sleeve, so that the fixing effect is improved. Moreover, an anti-sliding sleeve is adopted for sliding prevention, sliding caused by vibration generated when the perforating machine is used for perforating the valve device is prevented, and therefore the fixing accuracy is improved.

Owner:JIANGSU WUXI HUISHAN PUMP IND

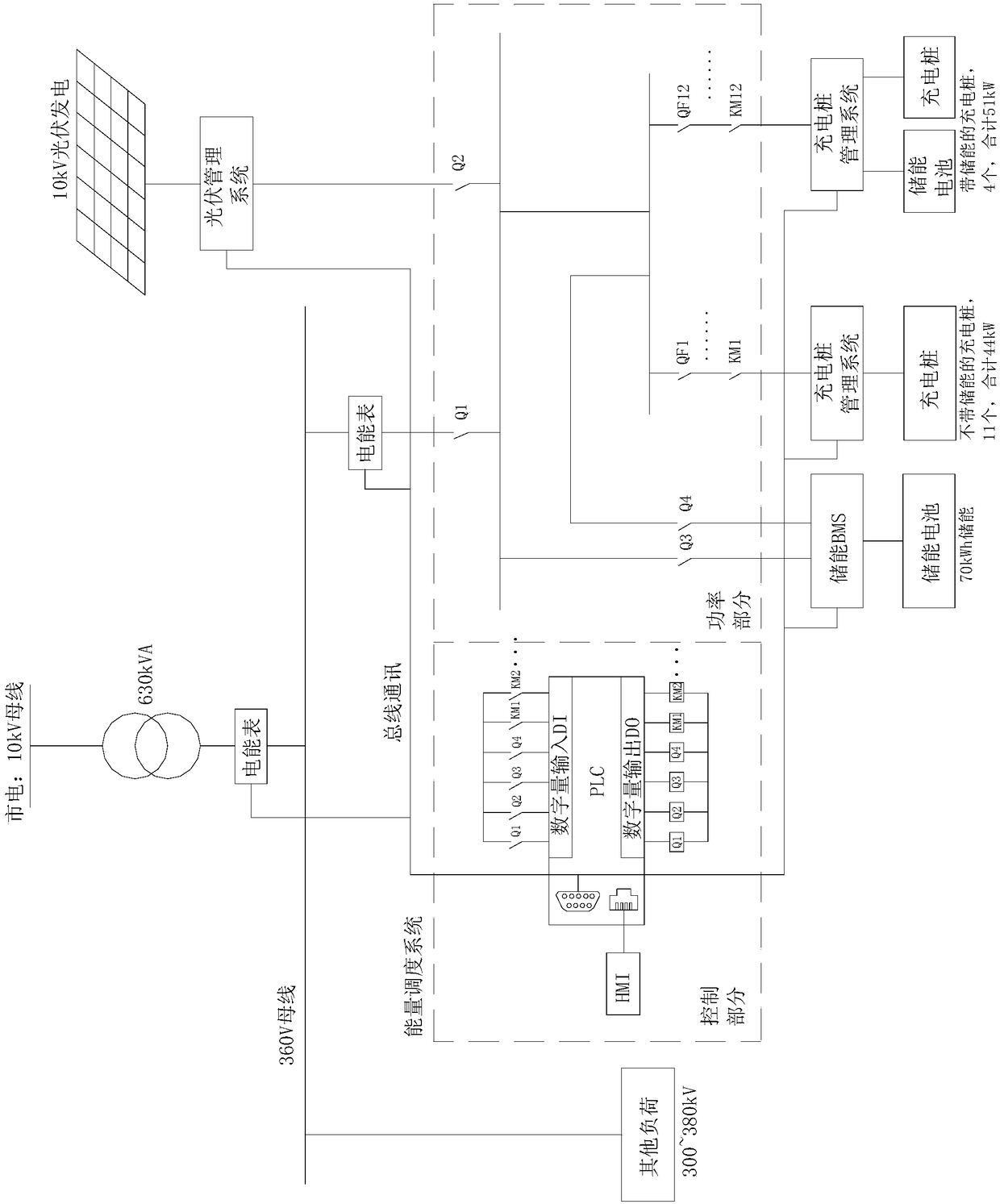

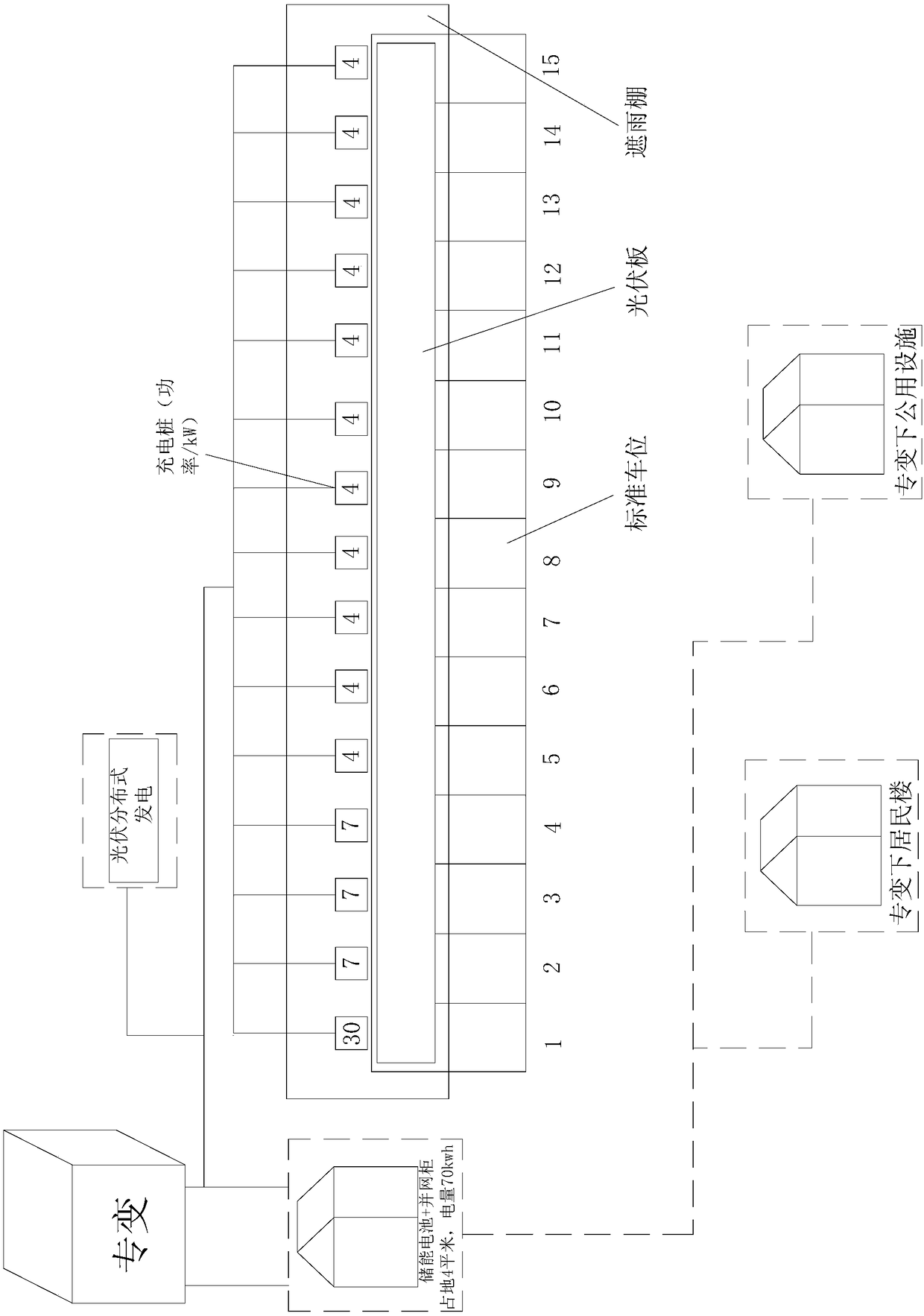

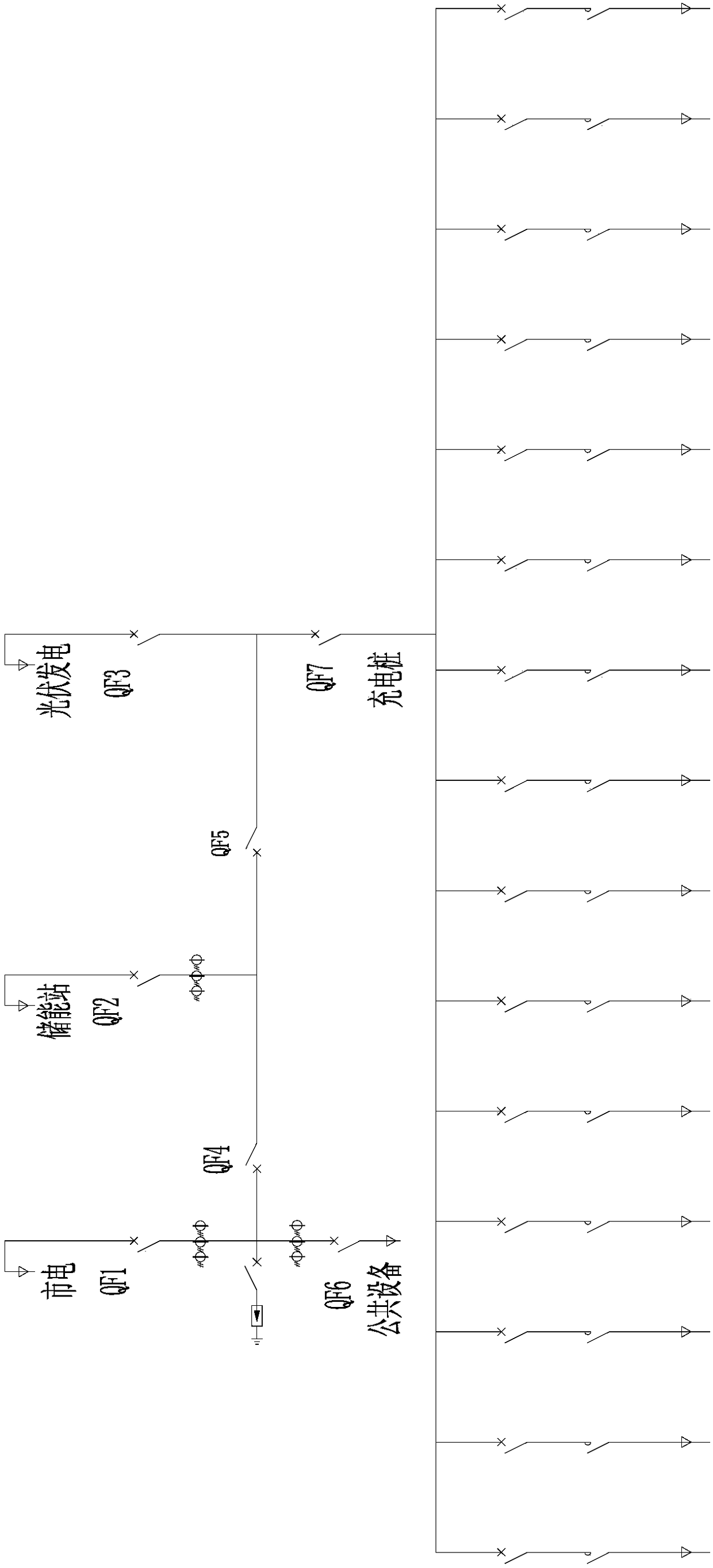

Charging system for electric vehicle, and charging method thereof

InactiveCN108206562AHigh adjustment accuracyMeet the needs of different charging loadsCharging stationsMobile unit charging stationsElectricityComputer module

The invention discloses a charging system for an electric vehicle. The charging system for the electric vehicle comprises a control unit, a clean energy unit, an energy storage unit and a charging unit; the charging unit is separately connected with the commercial power, the clean energy unit and the energy storage unit, and used for receiving electric energy and charging the electric vehicle; theenergy storage unit is separately connected with the commercial power and the clean energy unit, and used for receiving and storing electric energy; the control unit is connected with the clean energy unit, the energy storage unit and the charging unit, and used for controlling electric energy flow of each unit; the charging unit comprises more than one charging assemblies and energy storage modules; the various charging assemblies are in communication connection; and the various energy storage modules are mutually connected. The invention further discloses a charging method; the charging method comprises an independent charging mode and a networking charging mode; in the independent charging mode, the single charging assembly charges a single load; and, in the networking charging mode, the multiple charging assemblies charge the single load together. Both the charging system and method disclosed by the invention have the advantages of being suitable for loads of difference sizes, improving the charging precision and the like.

Owner:HUNAN GUOAO POWER EQUIP

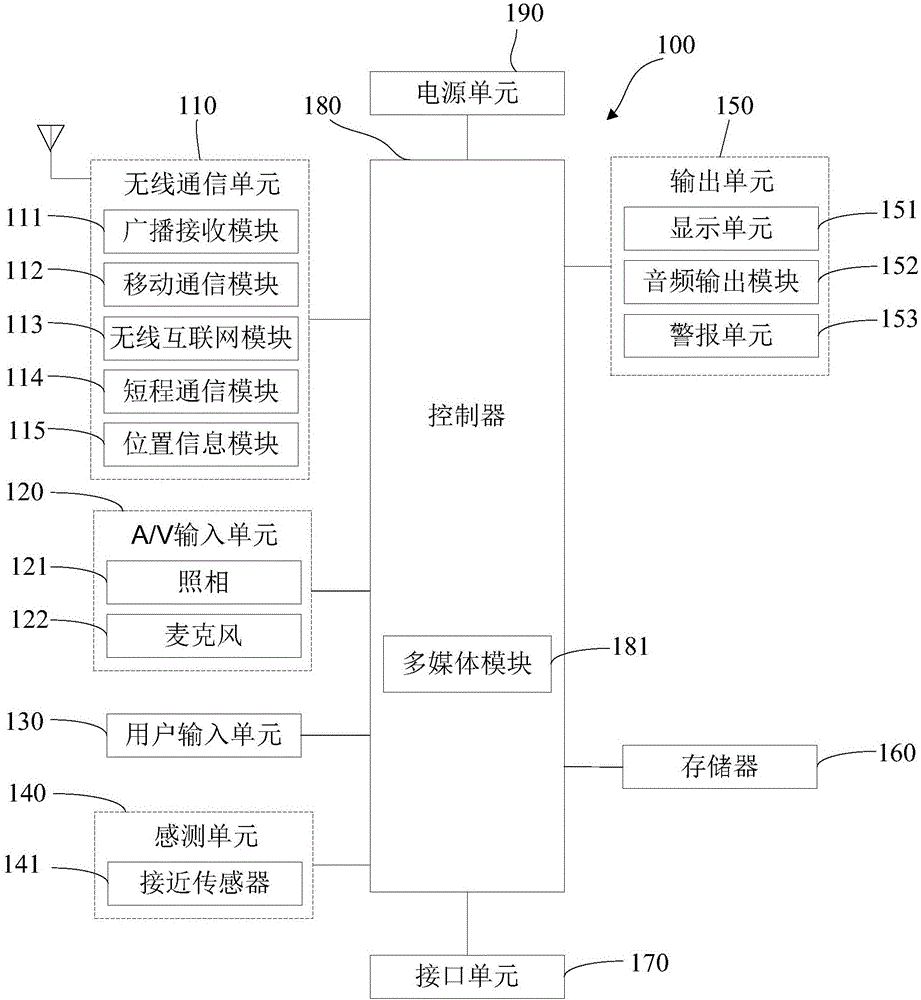

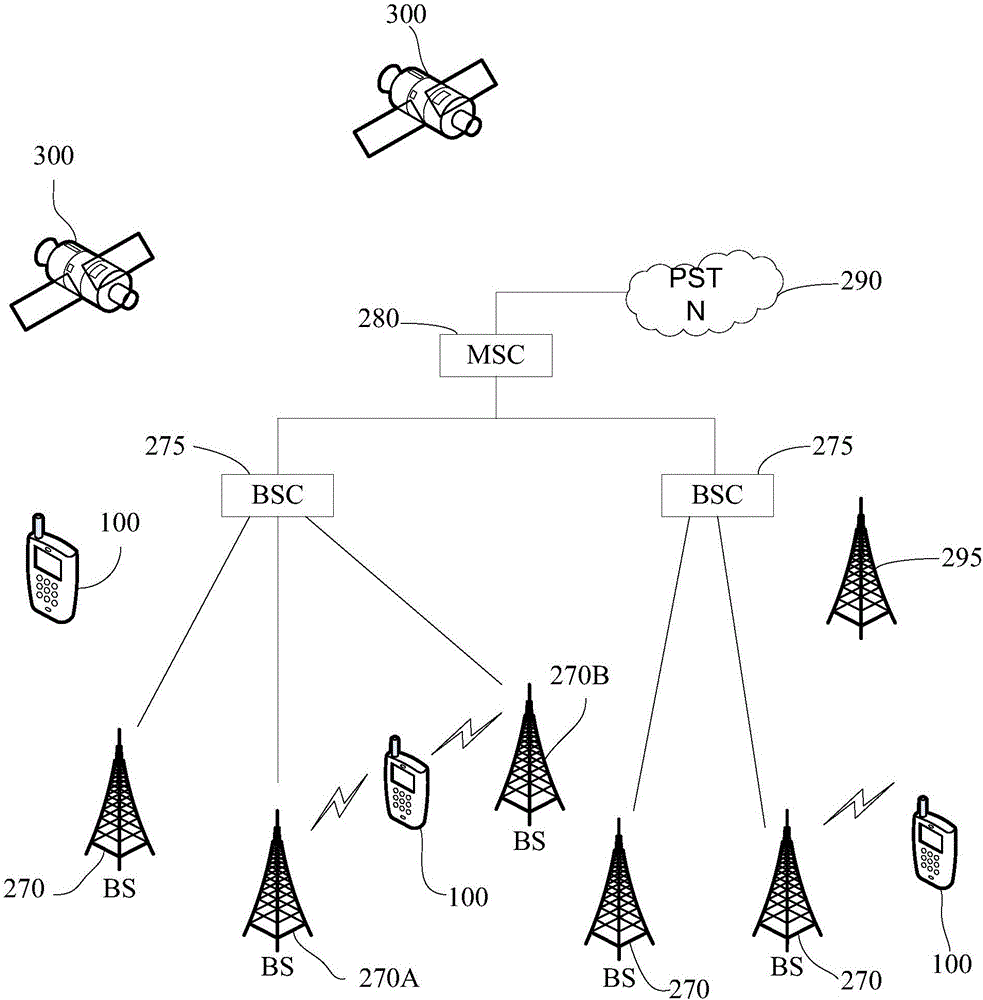

Mobile terminal and waterproof method of the mobile terminal

InactiveCN106452493ARealize the effect of sealing and waterproofingSolve the problem of the appearance step difference sizeTransmissionDifferences sizeSealant

Owner:NUBIA TECHNOLOGY CO LTD

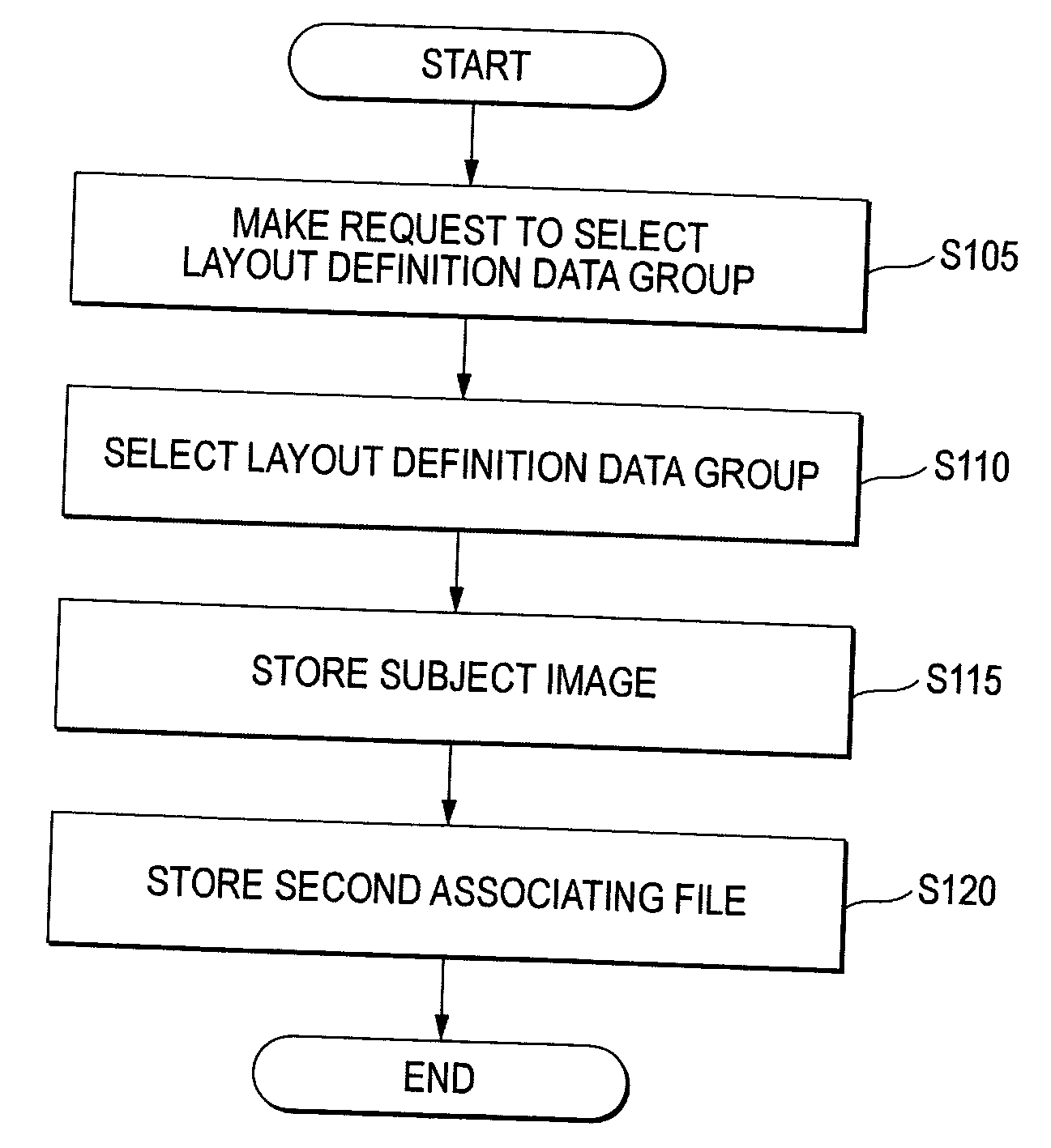

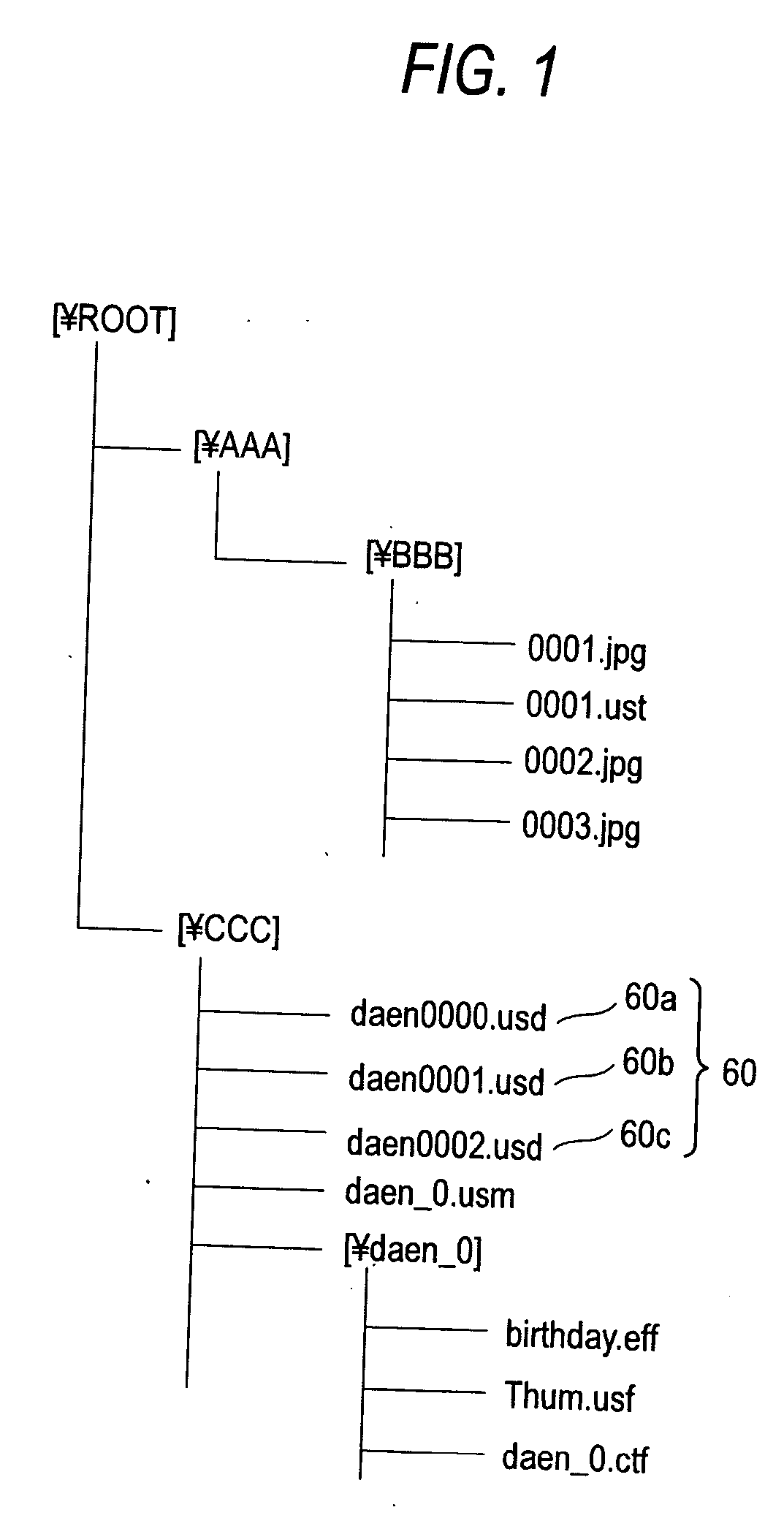

Digital camera, print system, and data structure

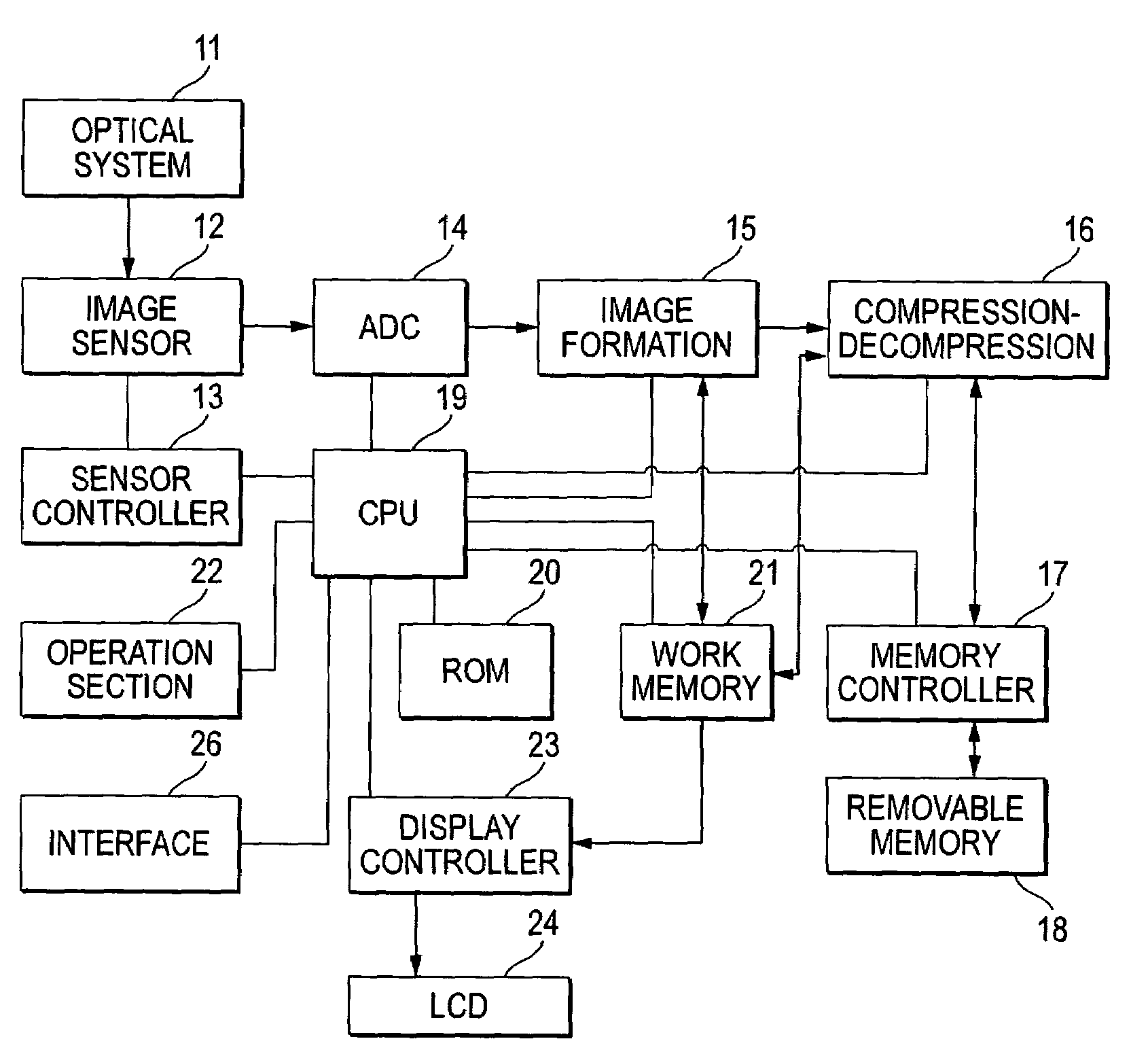

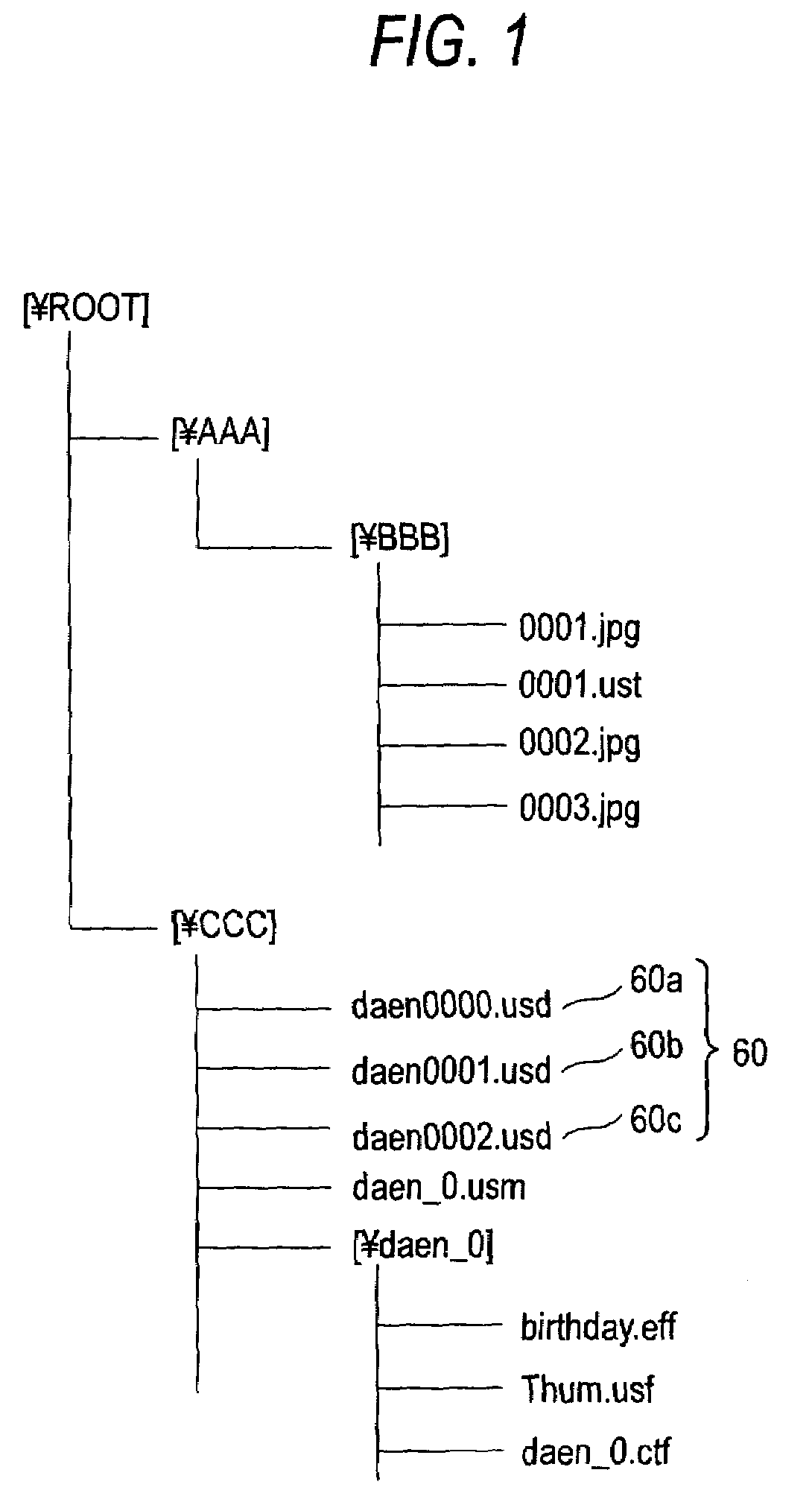

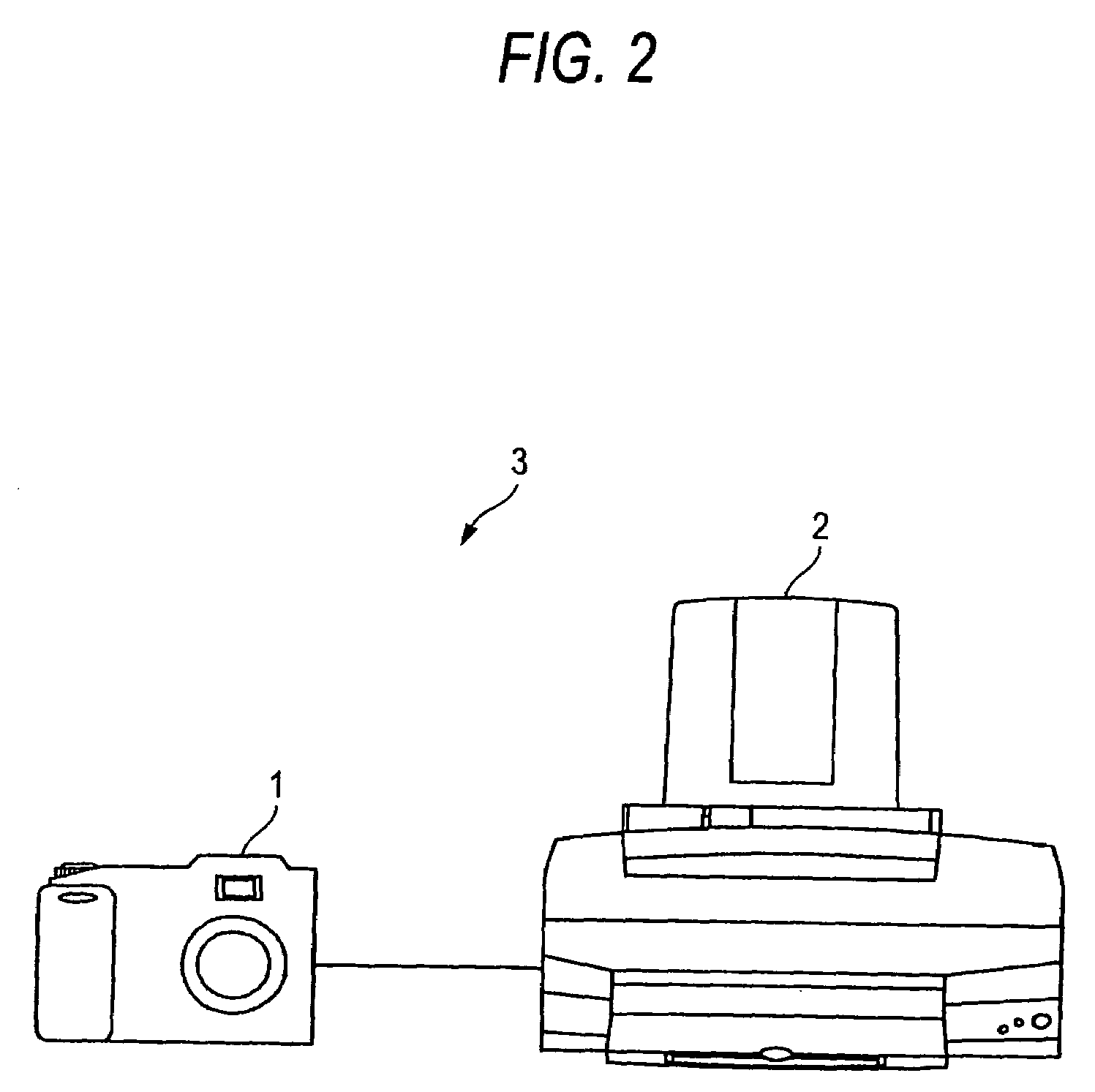

InactiveUS7719570B2Television system detailsColor television detailsComputer graphics (images)Differences size

A digital camera includes: an optical system for forming an optical image of a subject; an image pickup unit that converts the formed optical image of the subject and outputs a subject image; and a recording unit that associates the subject image output by the image pickup unit with a layout definition data group and stores the subject image in a nonvolatile memory. The layout definition data group is stored in the nonvolatile memory and is made up of pieces of layout definition data that define a layout to draw a subject image for a drawing medium of a specific size. The pieces of layout definition data making up the layout definition data group with which the subject image is associated defines similar layouts for drawing media of difference sizes.

Owner:SEIKO EPSON CORP

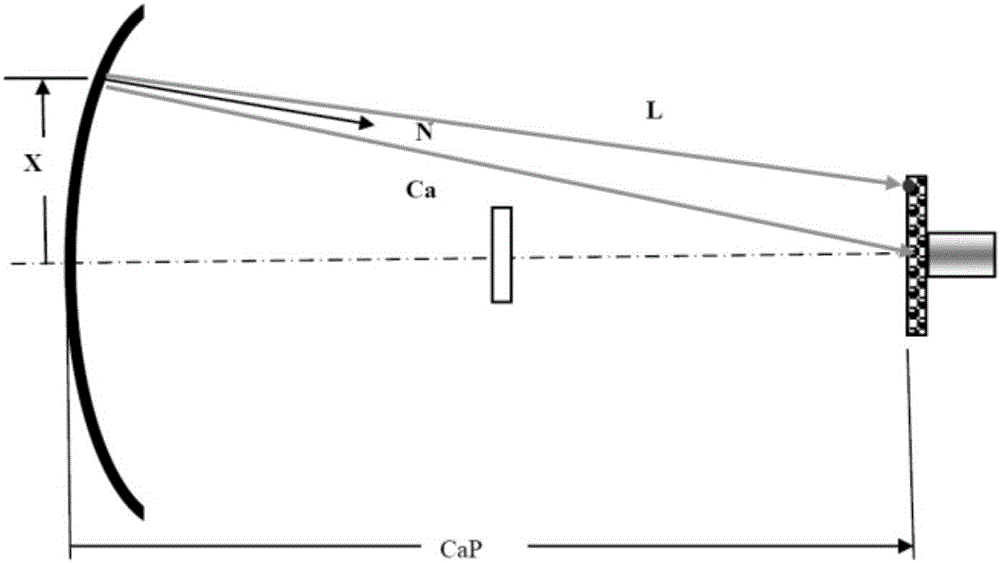

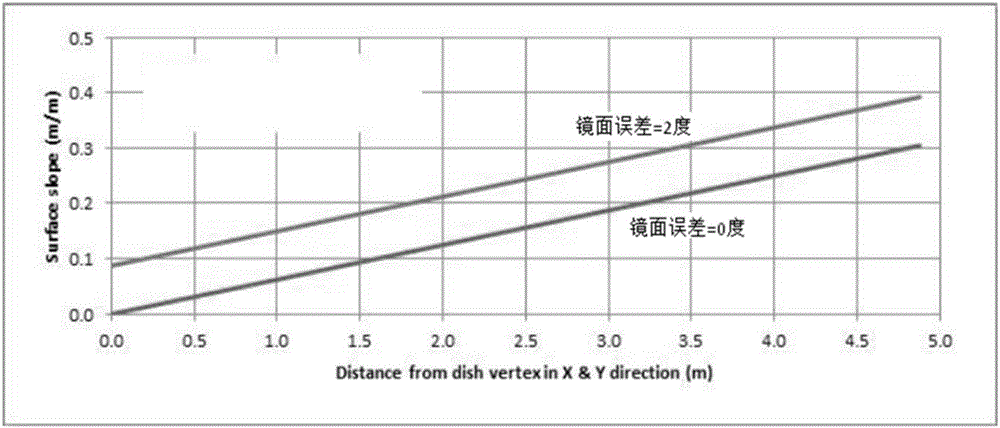

Butterfly tracking system lens focusing method

The application discloses a butterfly tracking system lens focusing method comprising the steps that (1) a light guide plate and a camera are arranged on the center line of a butterfly tracking system, and the light guide plate is composed of spot light sources which can be independently turned on / off; (2) a normal vector corresponding to each pixel point in the camera is calculated according to the determined spot light source coordinates, lens reflection point coordinates and the coordinates of the camera, and the adjusting angle of a lens is obtained according to the inclined angle of the normal vector and the normal vector of a butterfly lens parabolic equation; and (3) a lens surface angle tangent is obtained through fitting by utilizing a least square method according to the relationship between the lens surface slope and the normal vector, the angle is compared with a required lens angle and the difference size is the adjusting quantity of the lens. The method comprises the advantages that the error angle of the lens can be accurately calculated; time for obtaining measurement data required by lens focusing can be reduced; and the method is suitable for batch focusing. Time can be saved and focusing efficiency can be enhanced.

Owner:ORIENTAL GREAT OCEAN NEW ENERGY TECH DEV CO LTD

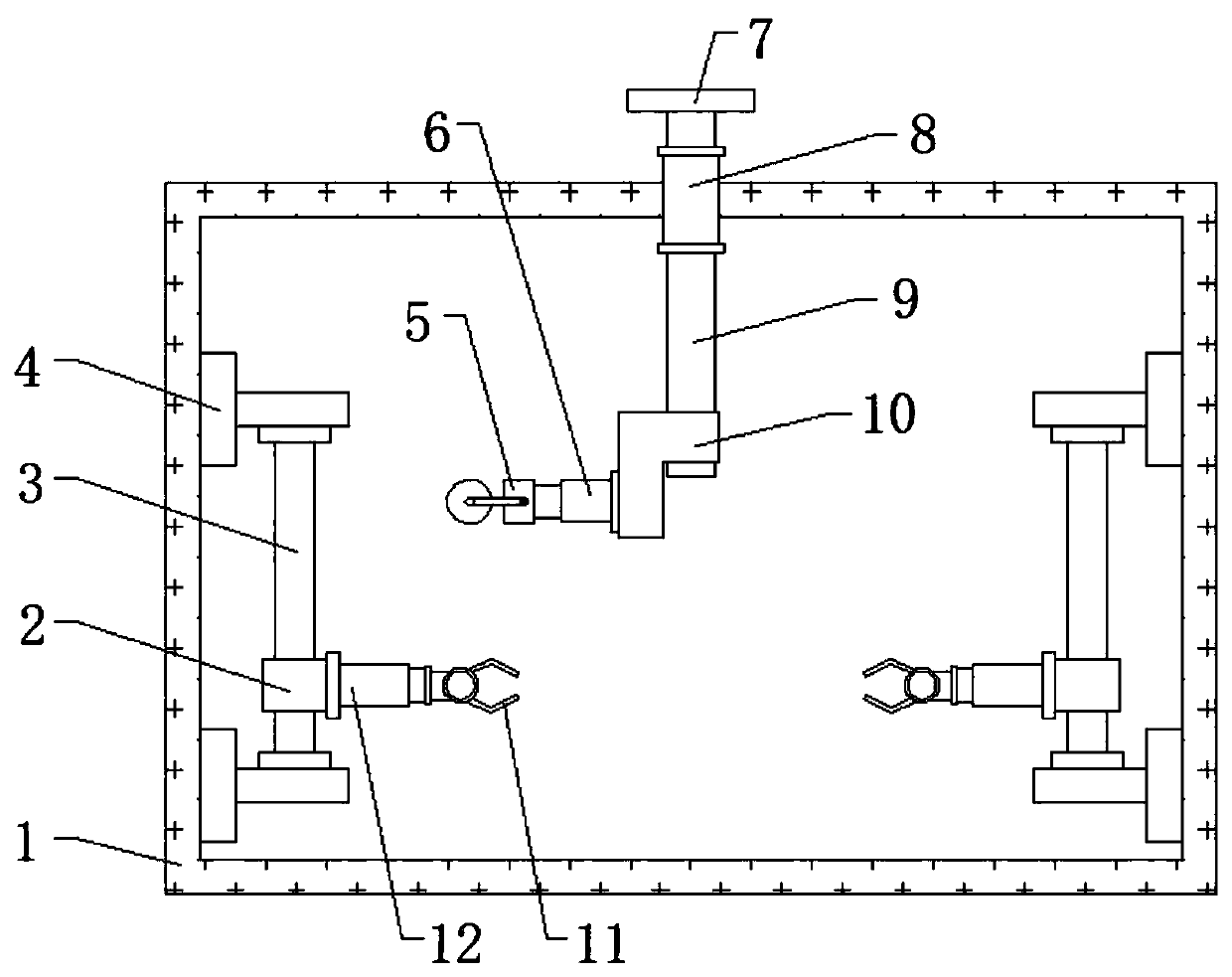

Polishing device for engine piston insert ring machining

InactiveCN110340795AEasy to polishAvoid flyingPolishing machinesGrinding work supportsEngineeringDifferences size

The invention discloses a polishing device used for engine piston insert ring machining. The polishing device comprises a box body and two clamping mechanisms, a mounting hole is formed in the middleof the outer wall of the top of the box body, a casing pipe is inserted into the circumference inner wall of the mounting hole, a connecting rod is inserted into the circumference inner wall of the casing pipe, the circumference outer wall of the connecting rod is sleeved with an L plate, the outer wall of one side of the L plate is fixedly provided with a second electric telescopic rod through abolt, one end of an extension rod of the second electric telescopic rod is fixedly provided with a polishing machine through a bolt, and a polishing sheet is hinged to the outer wall of one side of the polishing machine. The connecting rod is rotated in the casing pipe, the polishing machine is driven to do circumference motion, the piston insert ring inner ring is polished, the polishing sheet ofthe polishing machine moves downwards, the piston insert ring outer ring is polished, and for difference sizes of piston insert rings, corresponding polishing is carried out through adjusting the length of the second electric telescopic rod.

Owner:SHIYAN TONGLU IND

Automobile ceramic brake and preparation method thereof

InactiveCN109723741AIncrease coefficient of frictionImprove toughnessFriction liningHigh resistanceFiber

The invention discloses an automobile ceramic brake and a preparation method thereof. The automobile ceramic brake comprises the following raw materials in parts by weight: 26-28 parts of ceramic fibers, 3-4 parts of high-carbon graphite, 14-20 parts of fluorapatite, 7-9 parts of antimony sulfide, 3-5 parts of chromite, 15-18 parts of an inorganic adhesive, 13-18 parts of copper fibers and 5-8 parts of barite. The preparation method comprises the following steps: accurately and quantitatively weighing ceramic fibers, high-carbon graphite, fluorapatite, antimony sulfide, chromite, copper fibersand barite; respectively crushing the weighed raw materials; and respectively filtering the crushed raw materials with filter sieves of difference sizes. The invention relates to the technical fieldof ceramic brakes and particularly provides the automobile ceramic brake and the preparation method thereof. The adopted inorganic adhesive is a high-temperature-resistant inorganic nano composite adhesive prepared by polycondensation of an inorganic nano-material, and has high heat resistance, and the adhesiveness thereof cannot be adversely affected by the temperature. Besides, since ceramic fibers, high-carbon graphite and fluorapatite are adopted, the friction coefficient and the toughness of the brake can be enhanced, and the wear resistance of the brake is greatly improved.

Owner:枣阳神虎摩擦材料有限责任公司

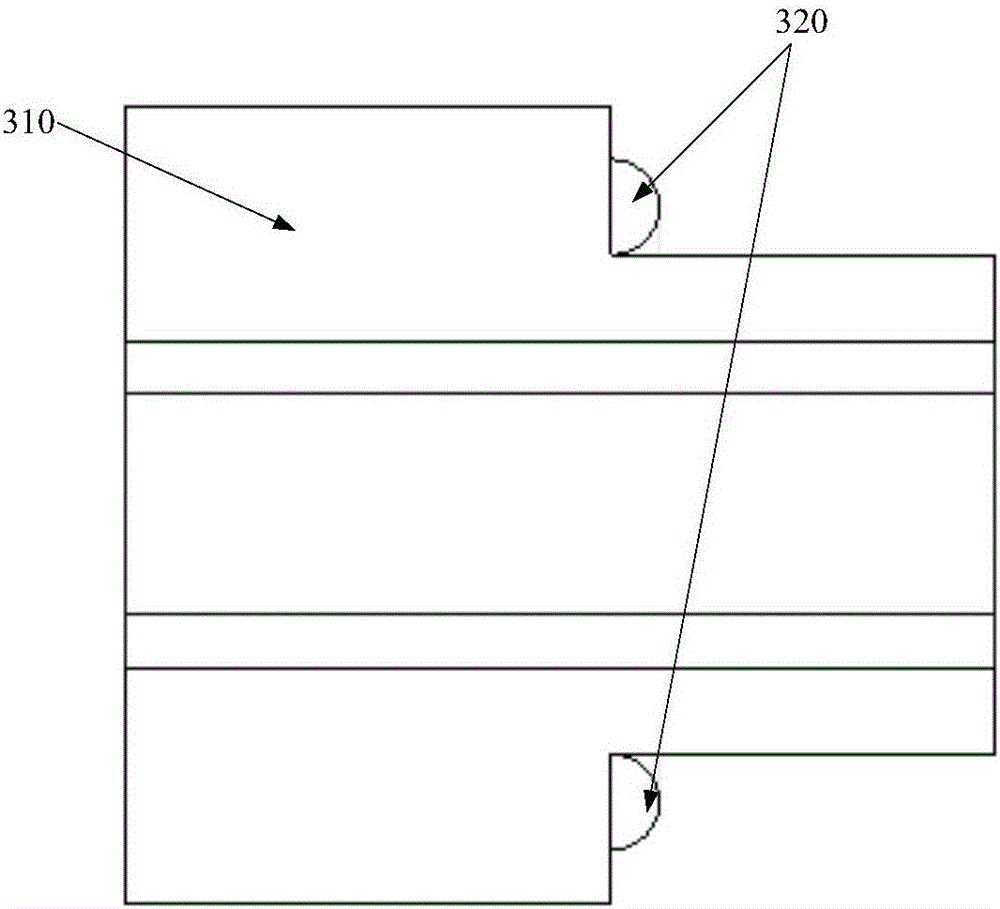

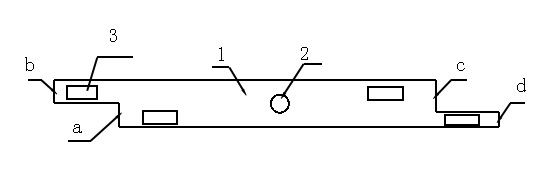

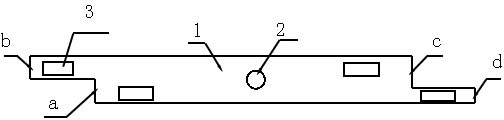

Gap and surface difference combination measuring tool for vehicle body

The invention provides a gap and surface difference combination measuring tool for a vehicle body. The combination measuring tool is made by a GCr15 of which the length is 100 millimeters, the width is 10 millimeters and the thickness is 5 millimeters; the two ends of the measuring tool are respectively provided with two opposite steps; the end heads of the two steps and end head stairs form four sizes, namely a, d, b and c; and a through hole is formed in the middle of the measuring tool; the end head sizes, namely a and d, are used for measuring the size of the gap; the end head stair sizes, namely c and b, are used for measuring the size of the surface difference; and a group of gap and surface difference combination measuring tool consists of seven parts, has seven groups of different gap sizes and surface difference sizes and can be used for measuring 14 kinds of commonly used gap sizes and 14 kinds of commonly used surface difference sizes. The combination measuring tool combines the gap sizes and the surface difference sizes, can be used for measuring two indexes, and is convenient, practical and low in cost.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Digital camera, print system, and data structure

InactiveUS20050273710A1Television system detailsColor television detailsComputer graphics (images)Differences size

A digital camera includes: an optical system for forming an optical image of a subject; an image pickup unit that converts the formed optical image of the subject and outputs a subject image; and a recording unit that associates the subject image output by the image pickup unit with a layout definition data group and stores the subject image in a nonvolatile memory. The layout definition data group is stored in the nonvolatile memory and is made up of pieces of layout definition data that define a layout to draw a subject image for a drawing medium of a specific size. The pieces of layout definition data making up the layout definition data group with which the subject image is associated defines similar layouts for drawing media of difference sizes.

Owner:SEIKO EPSON CORP

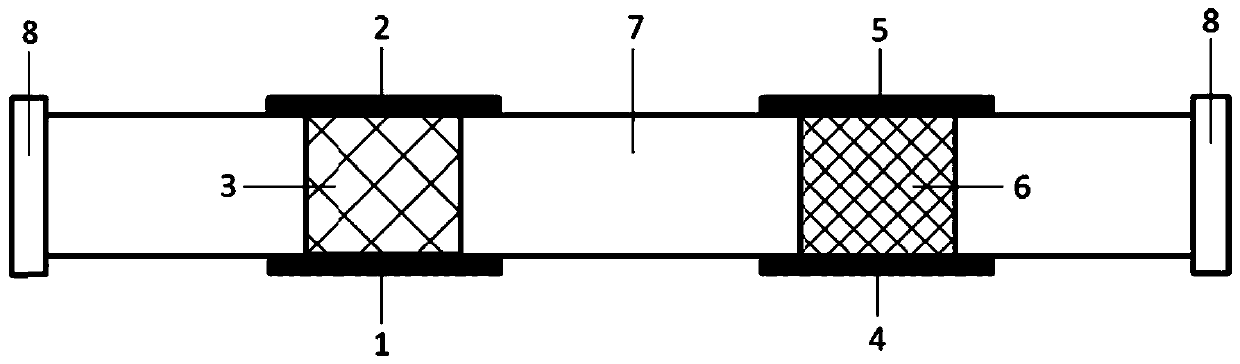

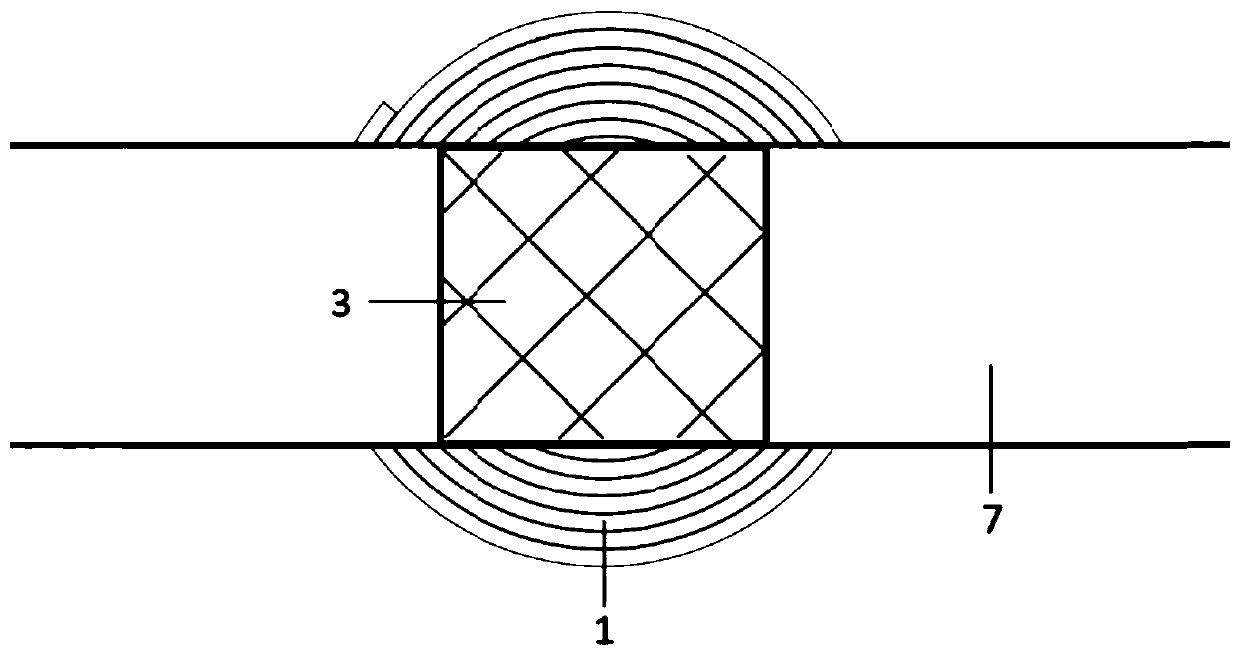

Planar inductance coil type hydraulic oil grain graded monitoring device

InactiveCN110243735AEfficient detectionReduce abrasive contentParticle size analysisParticle suspension analysisComputer moduleEngineering

The invention provides a planar inductance coil type hydraulic oil grain graded monitoring device. The device comprises a detection pipeline, connection structures arranged on the two sides of the detection pipeline and used to connect the monitoring device to bypass pipelines, and a plurality of graded detection modules arranged on the detection pipeline, wherein the graded detection modules comprise a coarse filter element inductance detection area in the direction of a liquid to be detected flowing into the detection pipeline, and a fine filter element inductance detection area in the direction of the liquid to be detected flowing out of the detection pipeline. The device provided by the invention has the advantages that filter elements with different meshes are added into the detection pipeline to effectively absorb metal grains in hydraulic oil, so that the metal grains can be detected, the grains with difference sizes can be effectively separated from the hydraulic oil, grain size information can be acquired, and the grain content in the hydraulic oil can be reduced; and two planar inductance coils which are parallelly connected and oppositely arranged according to the design of the device achieve higher detection sensitivity.

Owner:DALIAN MARITIME UNIVERSITY

Scalable medium voltage latching earthing switch

ActiveUS9177739B2Quick closeEasy to scaleSnap-action arrangementsSwitches with movable electrical contactsEngineeringDifferences size

A scalable earthing switch that incorporates a torsion spring to effect rapid closure of the switch. The torsion spring is supported coaxially about a rotatable shaft on which contact blades are mounted resulting in compact design. The blade contacts are separated axially along the length of the shaft by one or more spacers. By using difference size spacers the distance between adjacent blade contacts can be changed and, thus, the earthing switch can be easily scaled for different applications. A latching (detent) mechanism is provided for latching the switch in an open position.

Owner:ROCKWELL AUTOMATION TECH

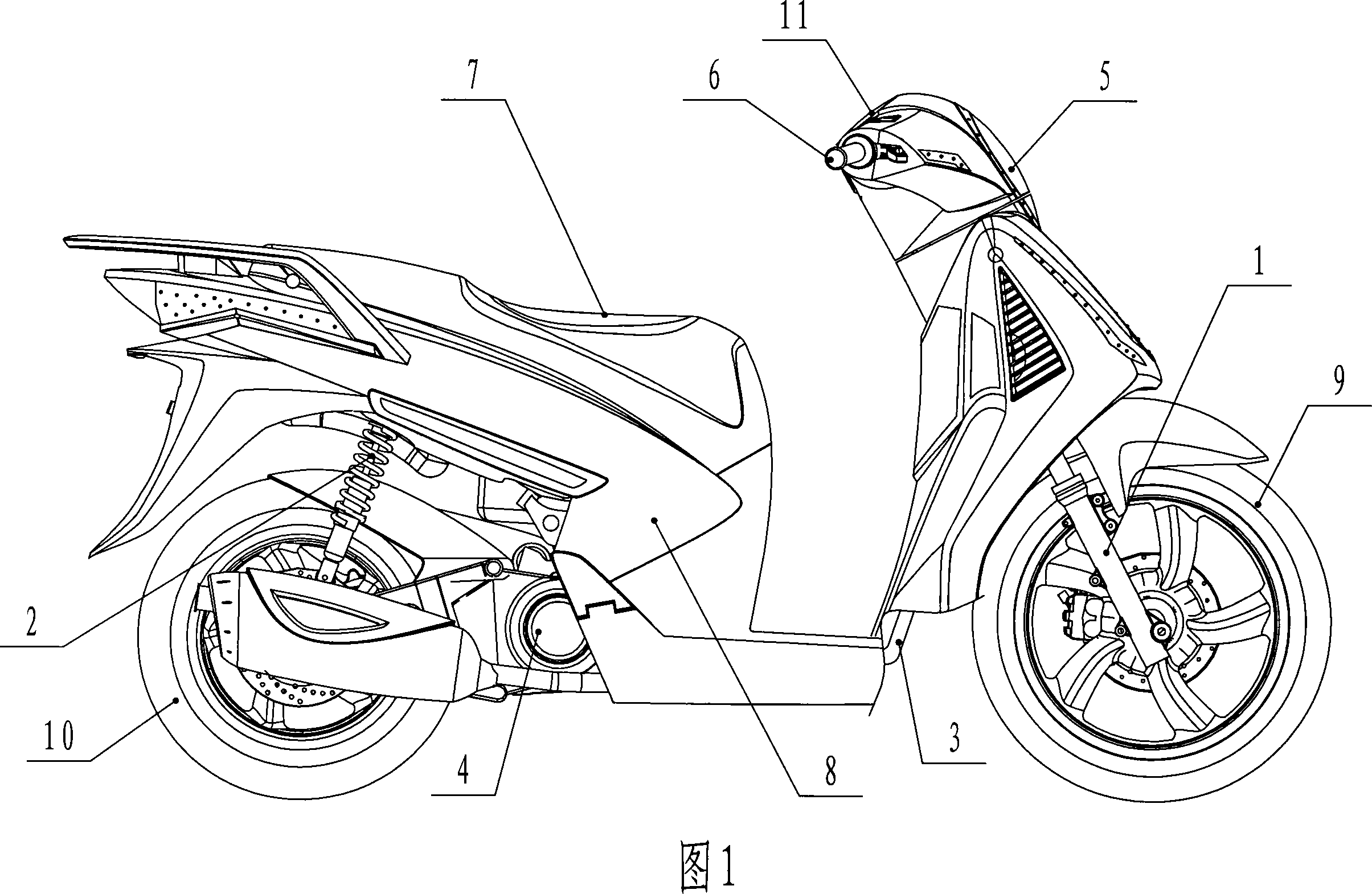

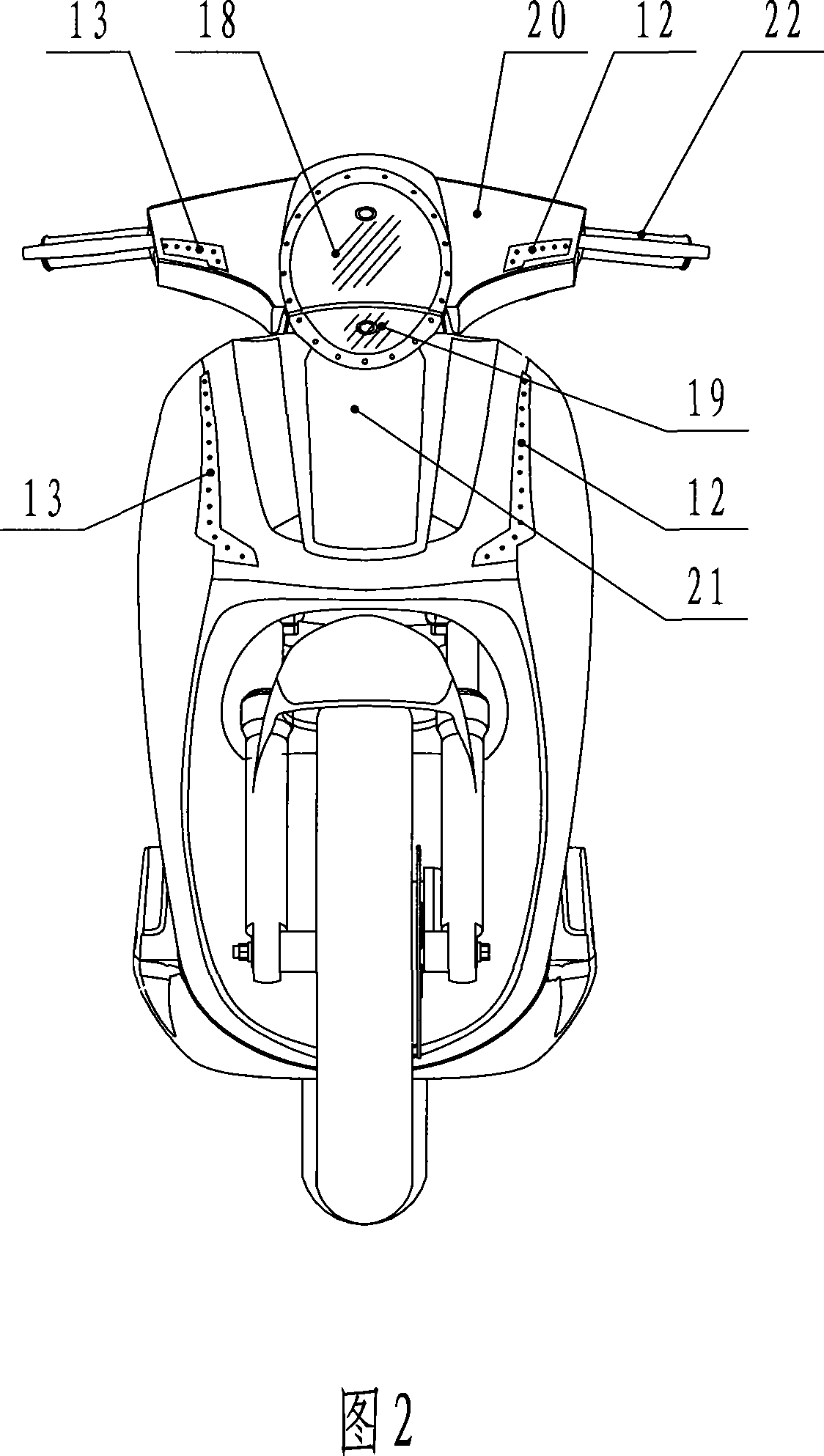

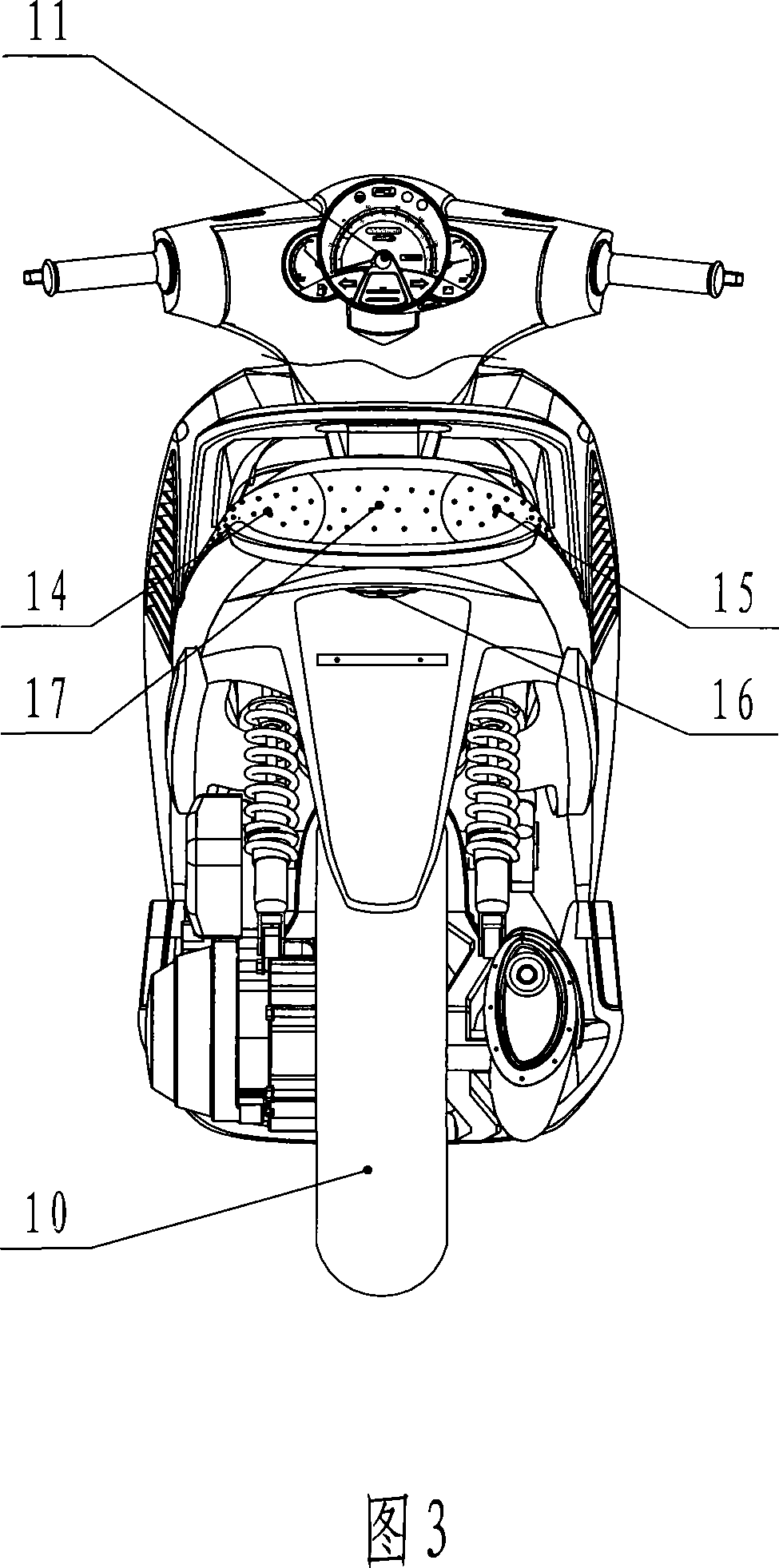

Novel large and small wheels pedal motrocycle

InactiveCN101143609AInsufficient improvement settingsMeet needsOptical signalMotorcyclesEngineeringSignaling system

A novel pedal motorcycle with wheels in difference sizes belongs to the technical field of motorcycles. The technical problem to be solved is to provide a novel pedal motorcycle with wheels in difference sizes. The technical proposal is that: the novel pedal motorcycle with wheels comprises a front decelerator, a rear decelerator, a frame, an engine, an electric lighting signal system, an operation system, a cushion, cover parts, a front wheel, a rear wheel and instruments, etc. The invention is characterized in that the diameter of the front wheel is bigger than that of the rear wheel; signal lamps, a rear number plate lamp, a tail lamp and a stop lamp set in the electric lighting signal system are all LED lamps. The invention has the advantages of application to pedal motorcycles, improvement of deficiencies of current pedal motorcycles and satisfaction of the demand of current customers compared with the prior art.

Owner:广州天马集团天马摩托车有限公司

Displayer supporting device

Owner:HEFEI HUIKE JINYANG TECH

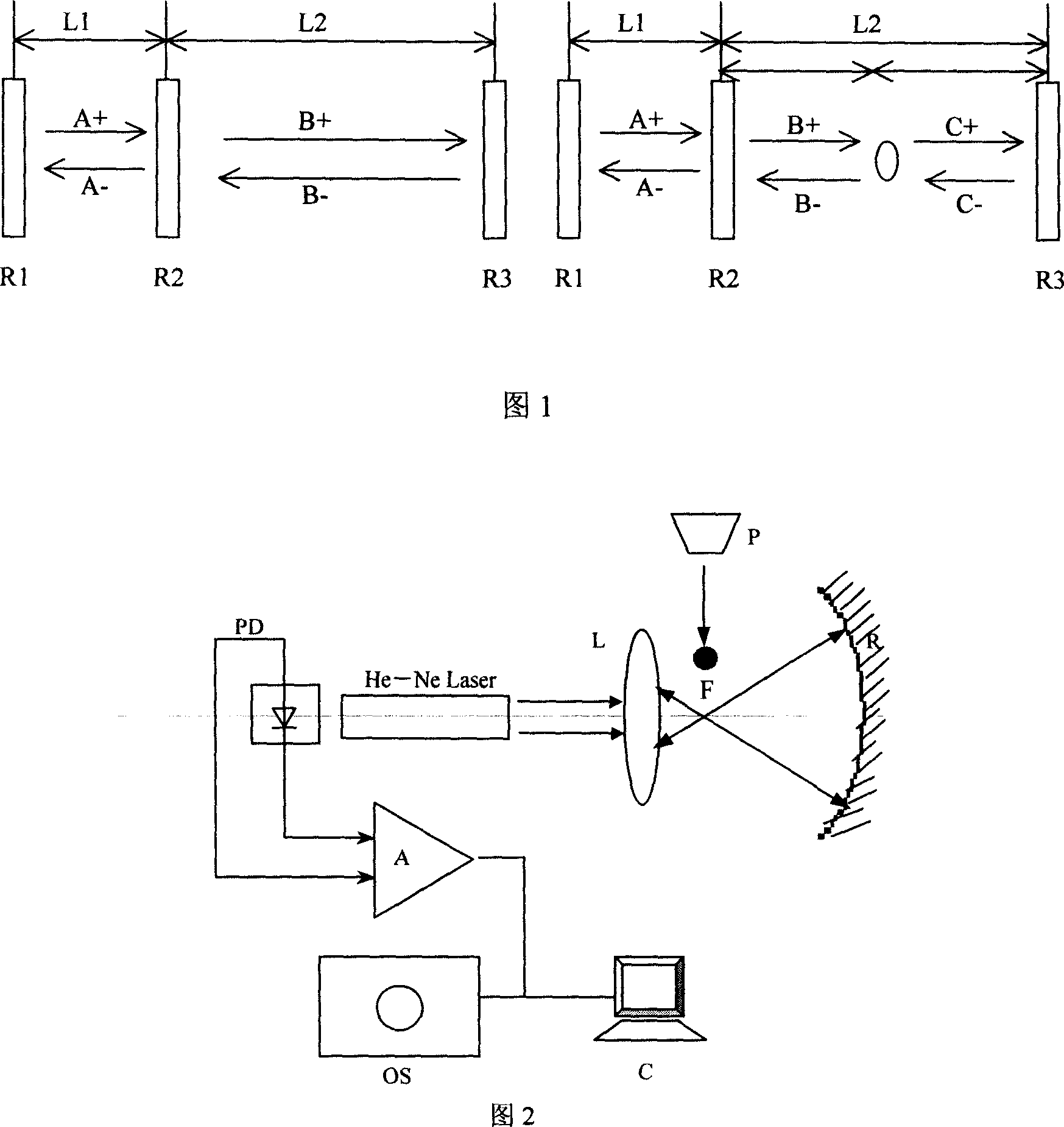

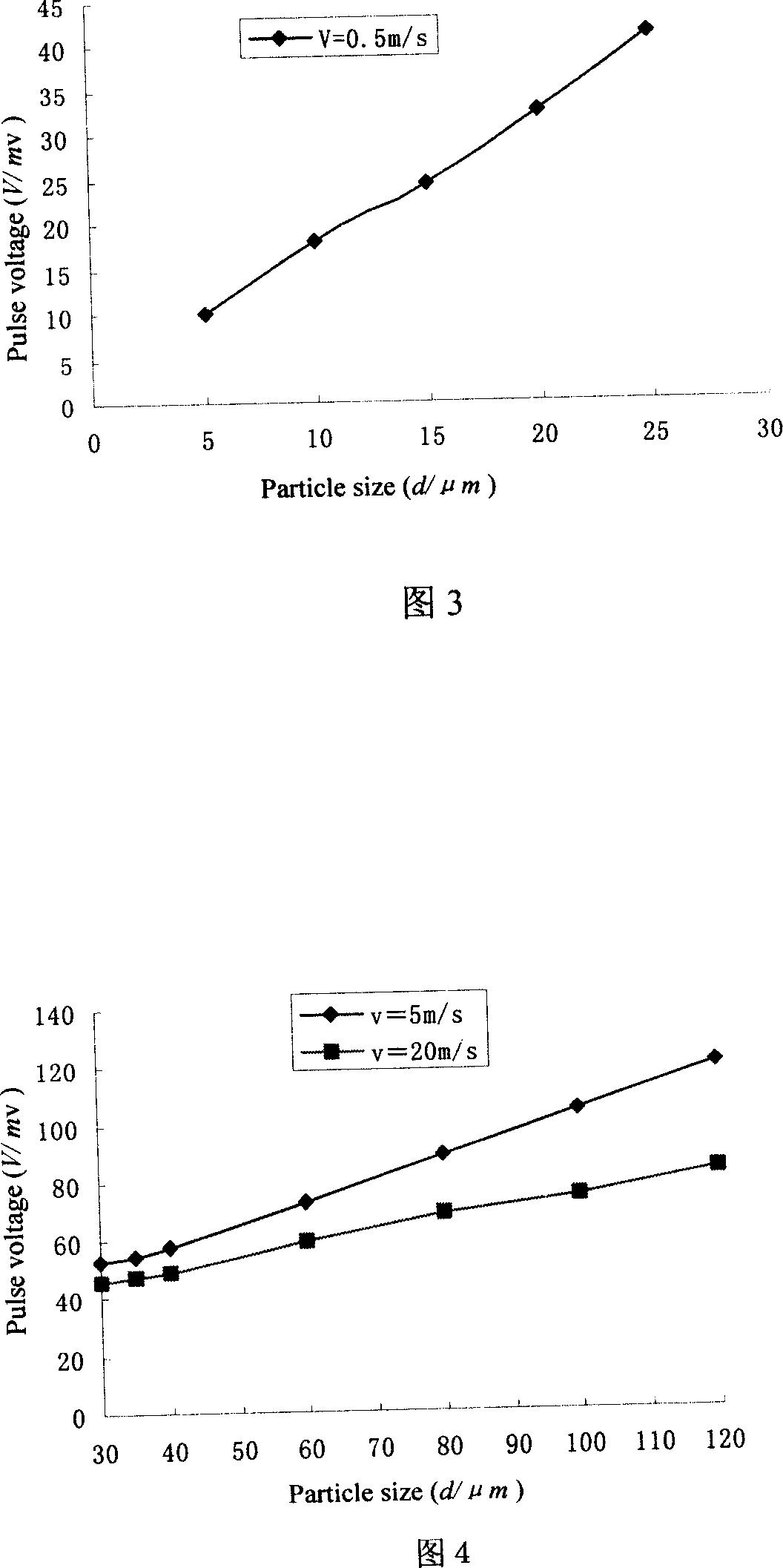

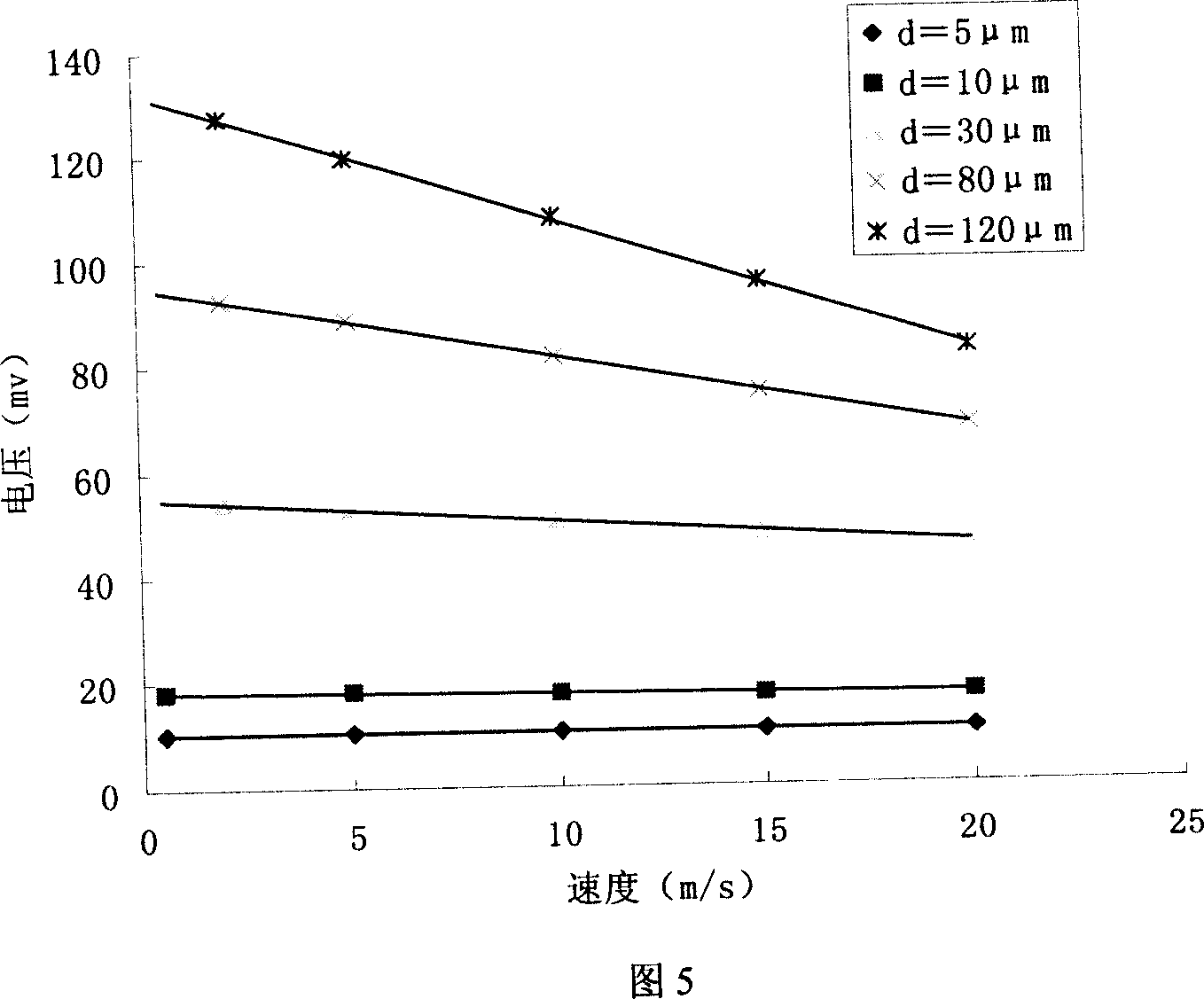

Measuring method of remoteness grain based on laser feedback effect

InactiveCN1963378AEasy to implementGood repeatabilityUsing electrical meansUsing optical meansFeedback effectMeasurement device

This invention discloses one thin particle measurement method based on laser feedback effect, which uses laser added spectrum resonance chamber thin particle diffraction to generate laser feedback effect, wherein, through measuring light energy changes of laser it measures particle size, speed and number parameters; the measurement device adopts heliium neon laser added with concaved total reflection lens and focus co-focus design added resonance chamber relative to difference sizes and speed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com