Patents

Literature

372 results about "Carbon graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite is one of two naturally occurring crystalline forms of the sixth element, carbon, the other being diamond. It is a soft greyish black mineral with a metallic lustre. A graphite crystal is made up of loosely stacked one atom thick graphene layers much like a deck of cards. These layers can slide around giving graphite its lubricity.

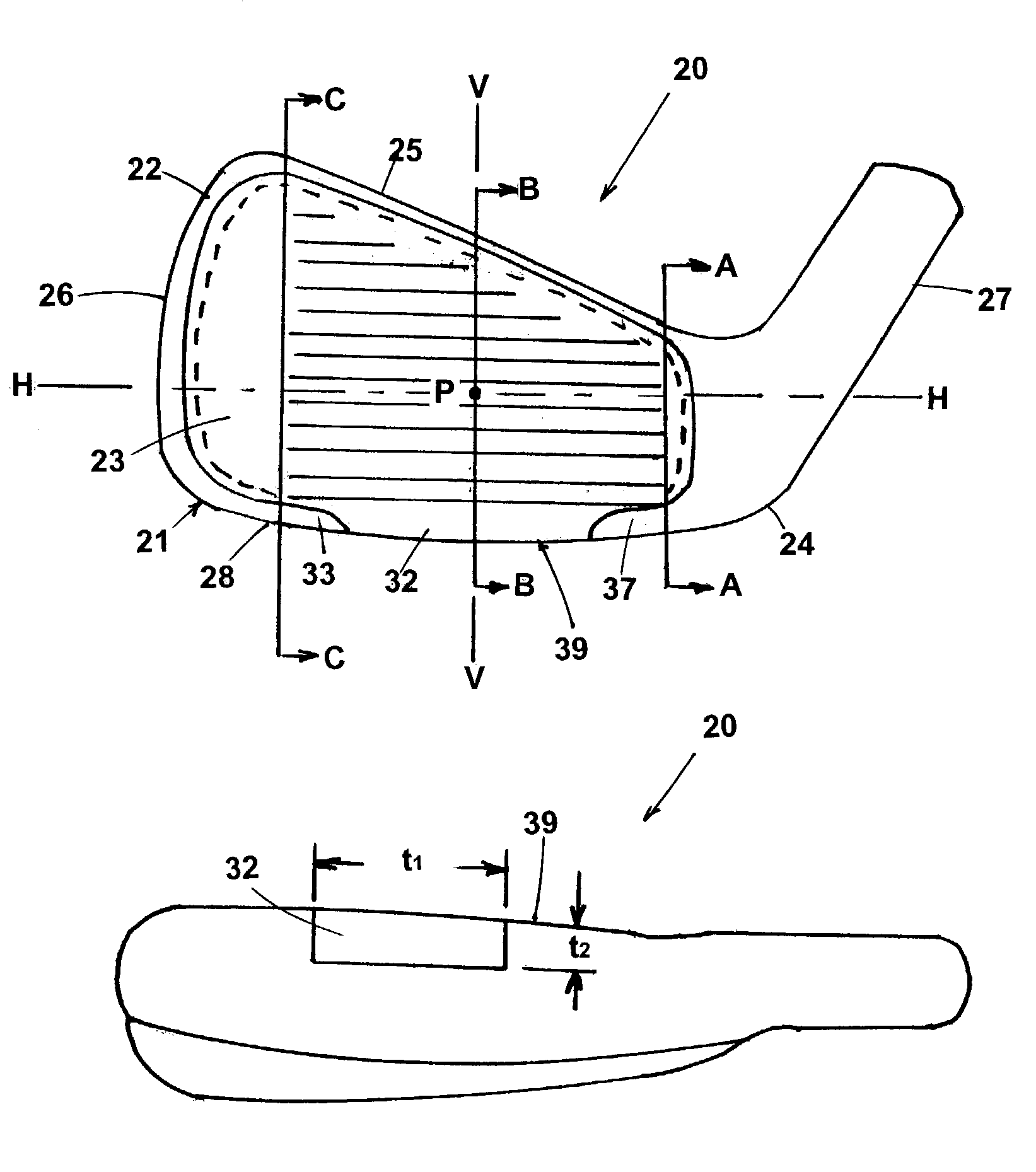

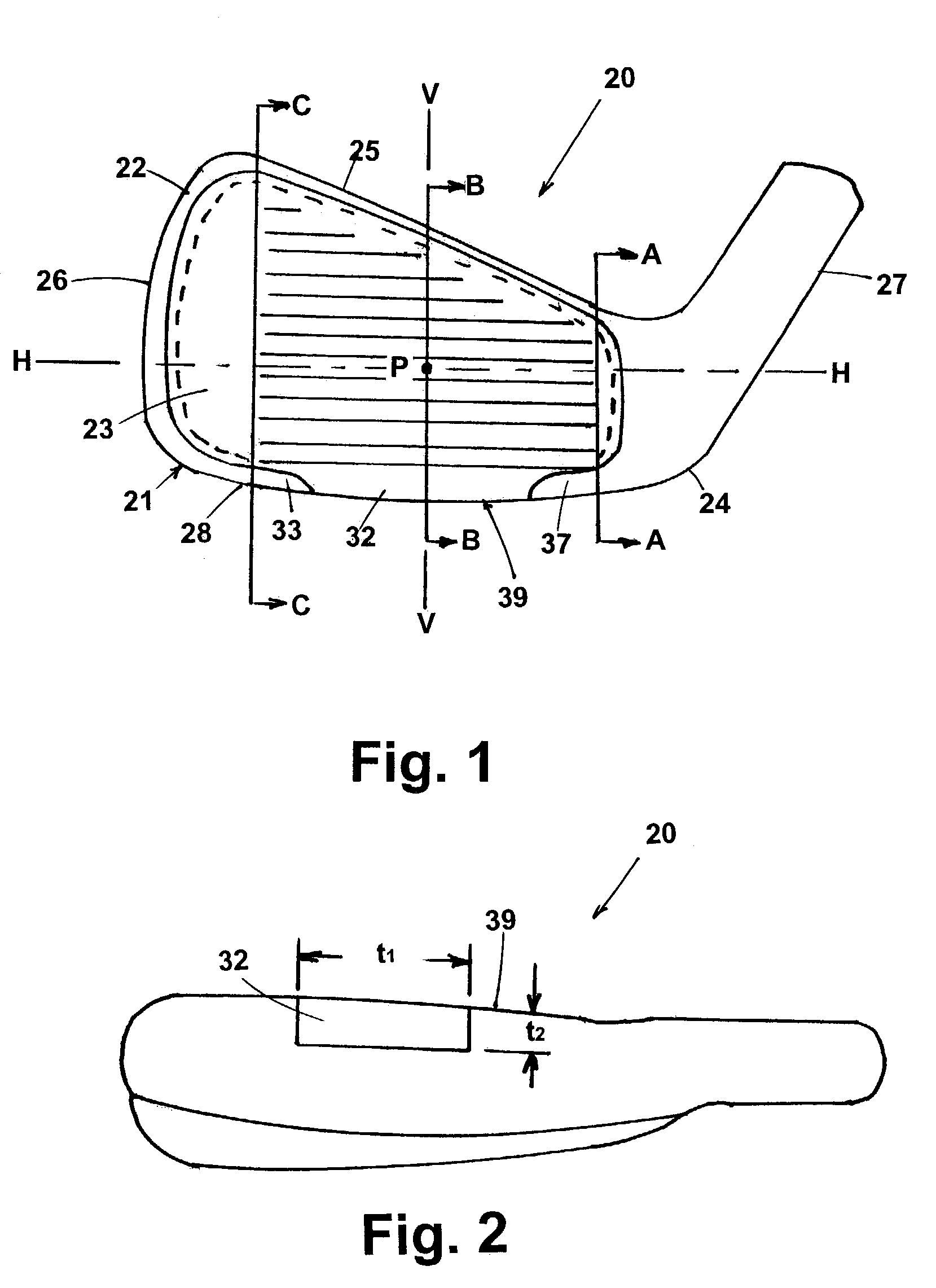

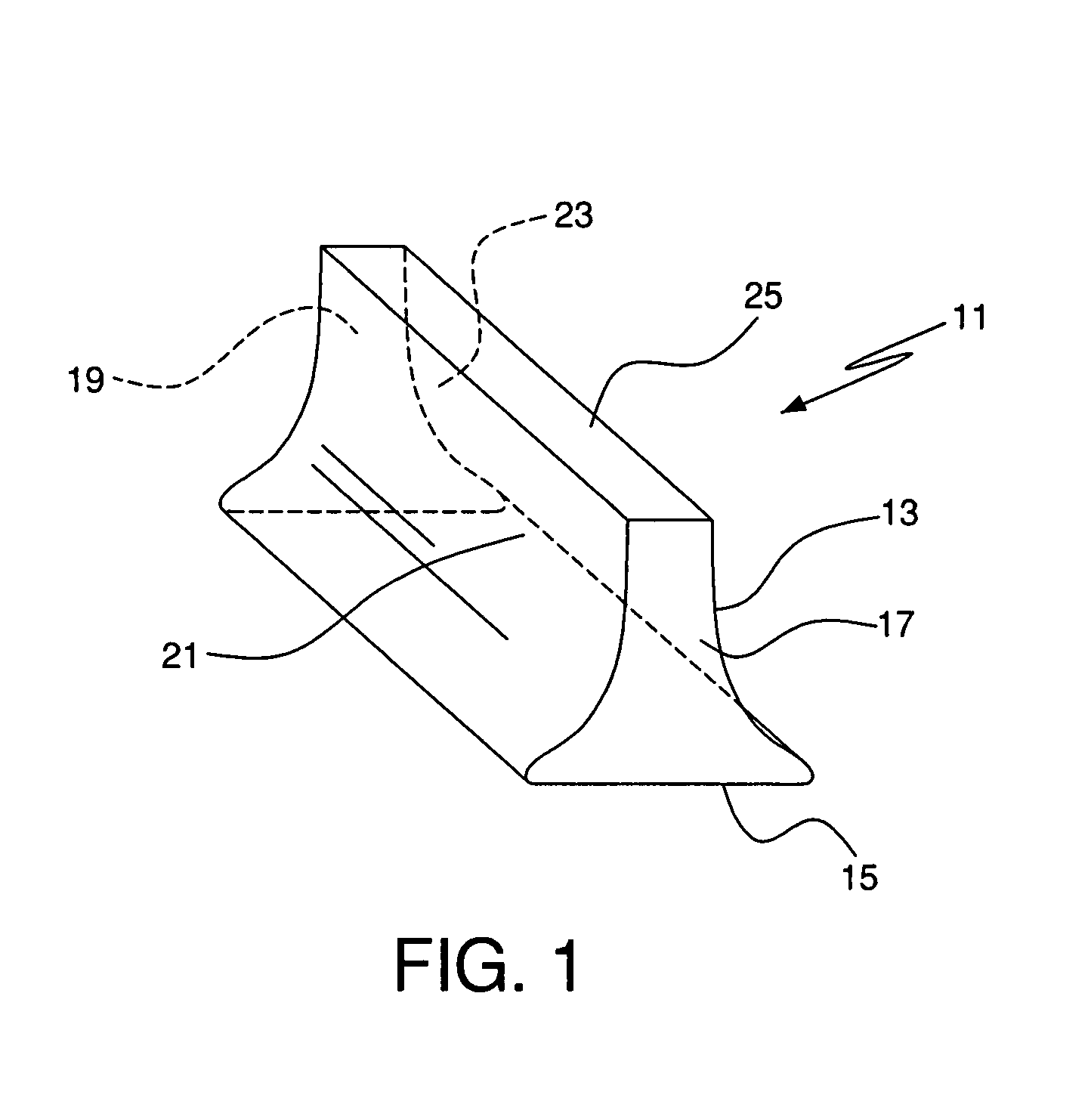

Golf club iron

An iron golf club head having a thin (less than 0.12 inches) first section that has an expanded unsupported front face region. The first section including a central portion forming part of a leading edge and wrapping around a sole section of the club, to create an increase the coefficient of restitution of the club head to greater than 0.8. The club head utilizes a rear insert that in addition to providing support for the front face, also allows for the fine tuning of swing weights with no change in geometry or size of the club head. This is accomplished this by the utilization of weight adjustment inserts that impregnate tungsten loaded plastic into sheets of carbon graphite and epoxy. The percentage of tungsten creating a weight range without any size change in the sheets.

Owner:ACUSHNET CO

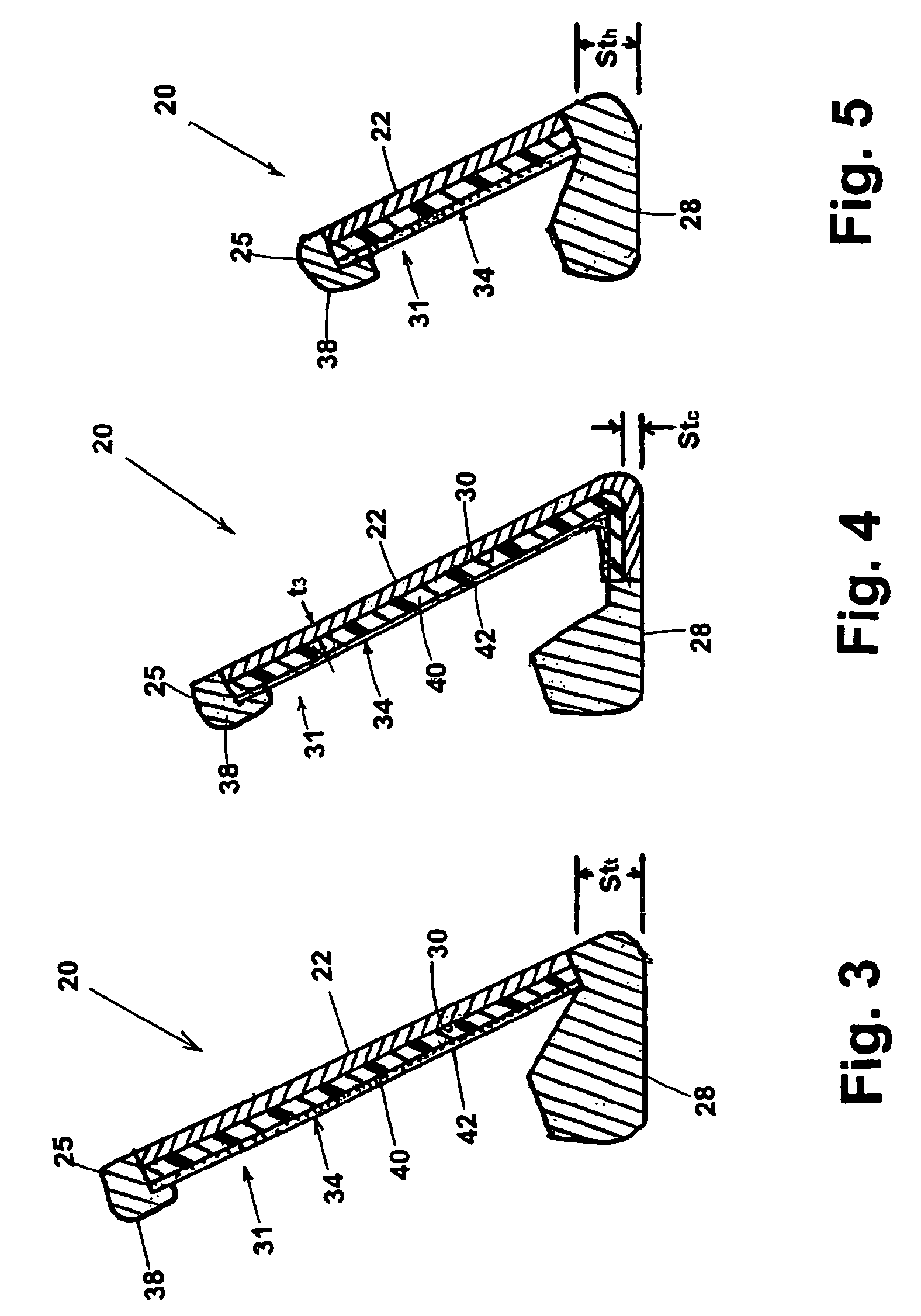

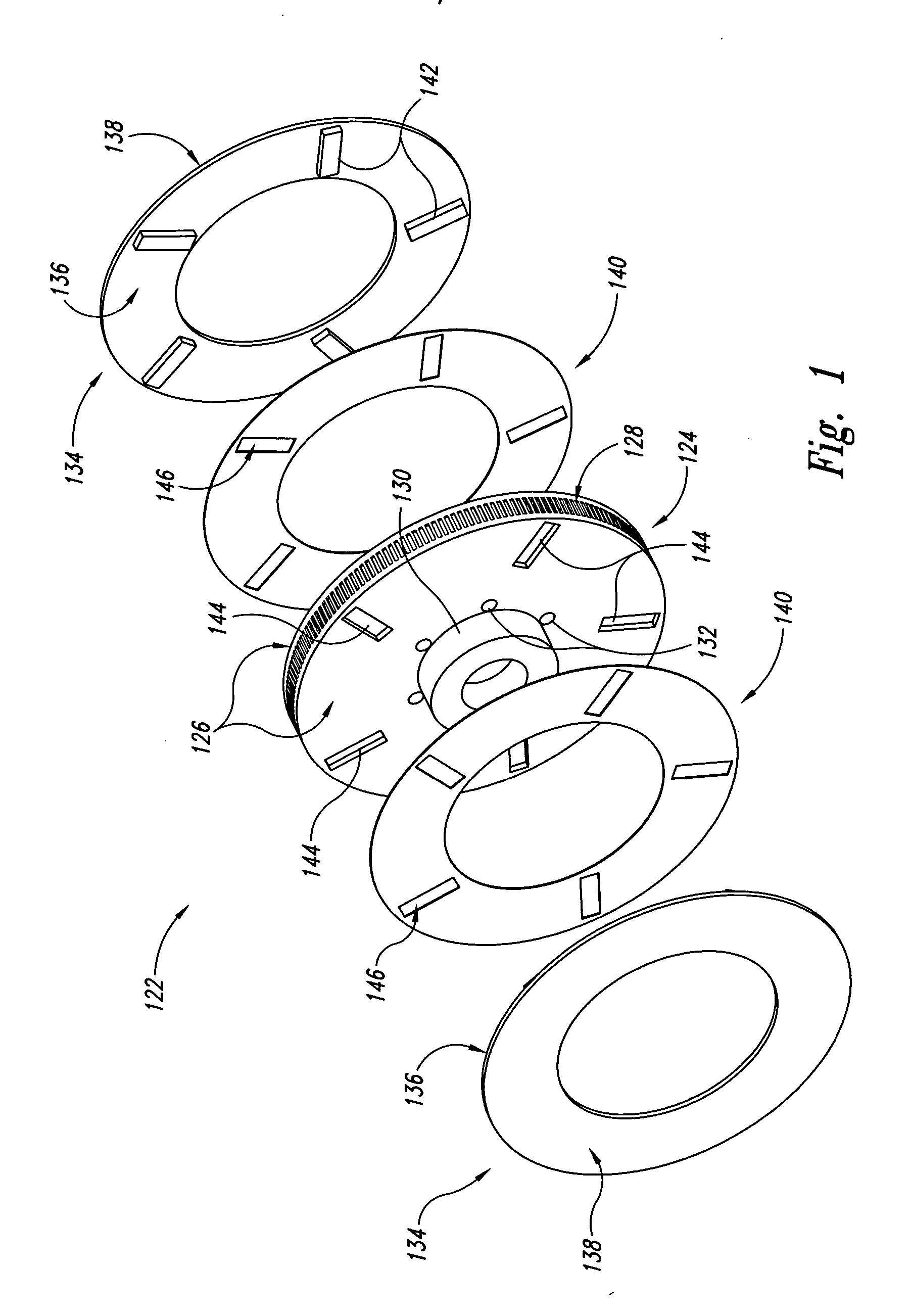

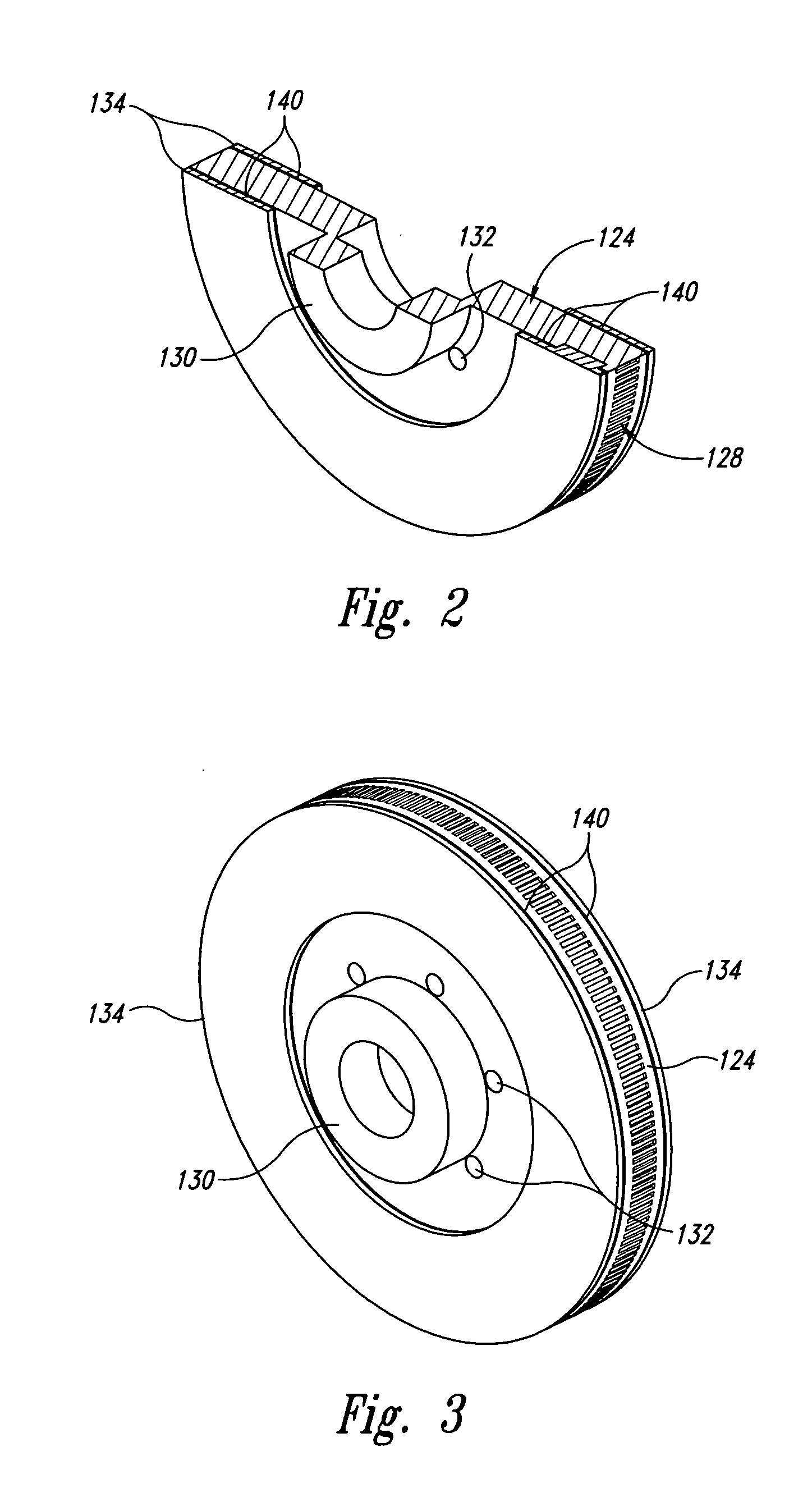

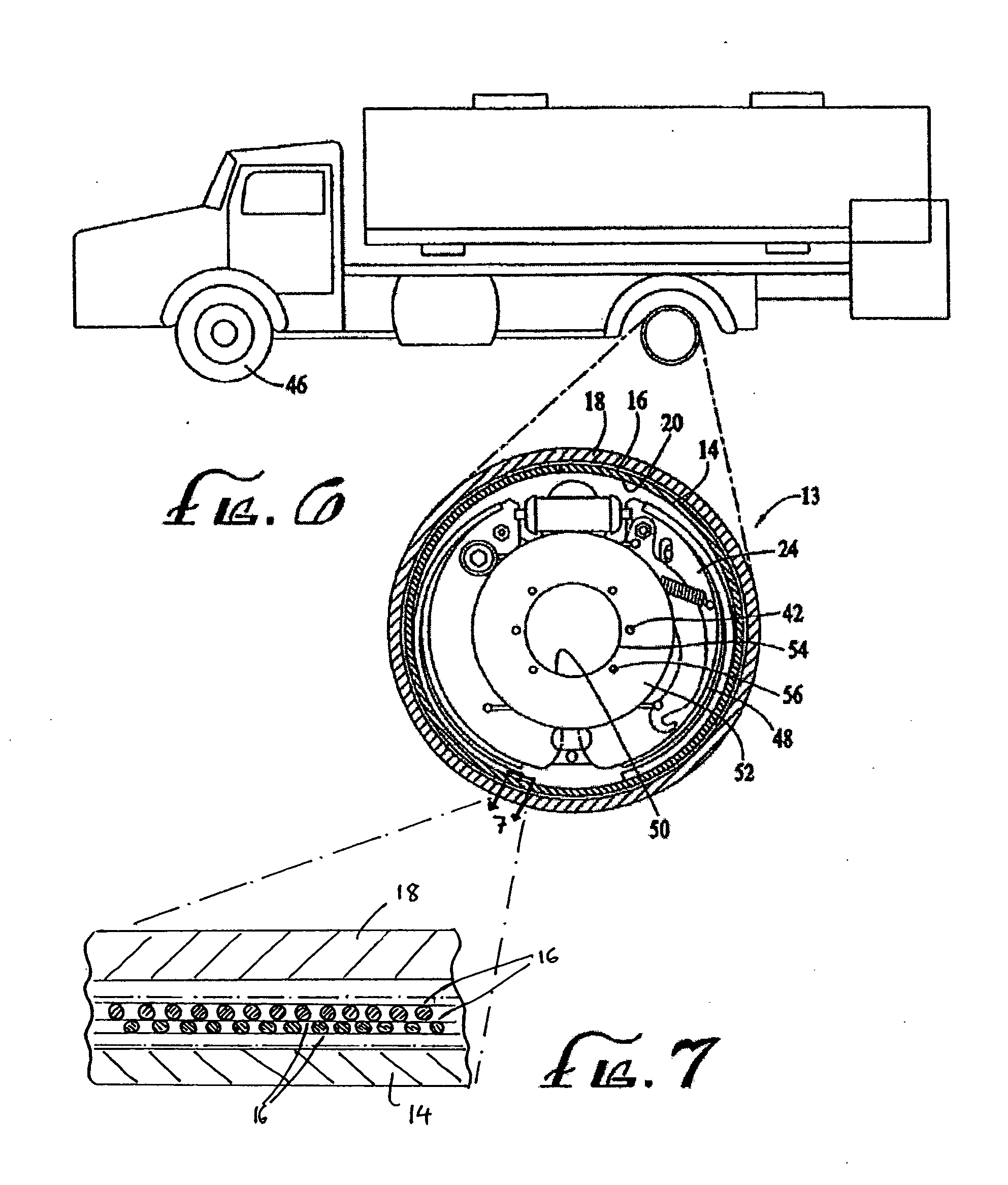

Disc brake rotor assembly and method for producing same

InactiveUS20050183909A1Improve thermal conductivityOptimize acoustic frequency transferBraking element arrangementsNoise/vibration controlAdhesiveMetal alloy

Novel composite disc brake rotor assemblies are provided, along with novel and efficient methods for manufacturing them. Preferably, the rotor assemblies comprise annular wear plates formed of particle reinforced aluminum-based metal matrix composite (MMC), ceramic matrix composite (CMC), or of ‘carbon graphite foam.’ The wear plates, made of a first material, are attached to annular surfaces of a central rotor, made of a second material, by fusing bonding layers between the wear plates and the rotor surfaces. The bonding layers are comprised of at least one of a metal alloy having a melting temperature lower than that of either the first or second materials, and a high-temperature adhesive. Preferably, the wear plates comprise projections that are positioned within adjacent receiving recesses in the center rotor. The bonding layers and projections enhance thermal and acoustical transference between the wear plates and the center rotor section. Carbon graphite foam provides for substantially enhanced heat transference. Use of the fusable binding layer, or adhesive provides for an efficient, low cost method of manufacturing for composite disc brake rotor assemblies.

Owner:BENMAXX

Light-emitting diode reflector assembly having a heat pipe

InactiveUS6976769B2Point-like light sourcePortable electric lightingConductive polymerCarbon graphite

A light-emitting diode reflector assembly having a heat pipe and a reflector body is provided. The assembly further includes a mounting member for mounting a circuit board having an array of light-emitting diodes. The mounting member and reflector body are made from a thermally-conductive polymer composition comprising: i) about 20% to about 80% by weight of a base polymer matrix such as polycarbonate; and ii) about 20% to about 80% by weight of a thermally-conductive material such as carbon graphite.

Owner:TICONA POLYMERS INC

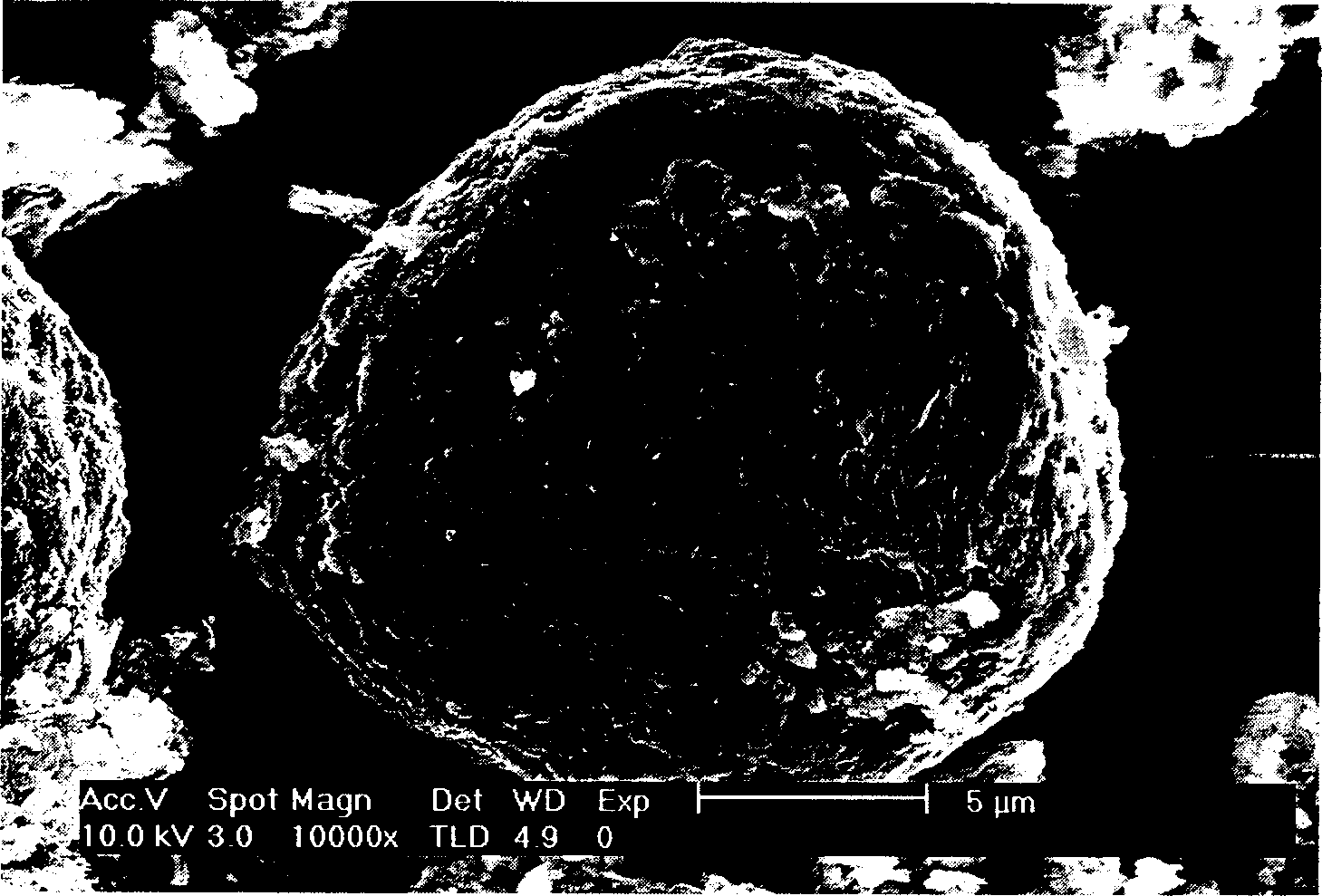

Carbon-silicon composite material with spherical nucleocapsid, and its preparing method and use

This invention relates to a kind of silicon&carbon composite material with a spherical appearance and core-shell structure in spherical particles with a mean diameter of 1.2~53 micron and a 'core-shell' structure, there are silicon particles 5~50wt% and carbon particles 50~95wt%, the core of which is spherical carbon particles with a mean diameter of 1~45 micron. The carbon particles are the mixture of one, two or three kinds of mesophase carbon graphite balls, hard carbon balls and spherical graphite ball. The thickness of the shell is 0.1~4 microns composed of carbon and silicon grains with the average size of 10 nm~4 micron. The carbon&silicon composite materials are achieved through thermal decomposition and chemical vapor deposition after the spherical carbon particles are coated with silicon and carbon composite ultrafine silica slurry.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

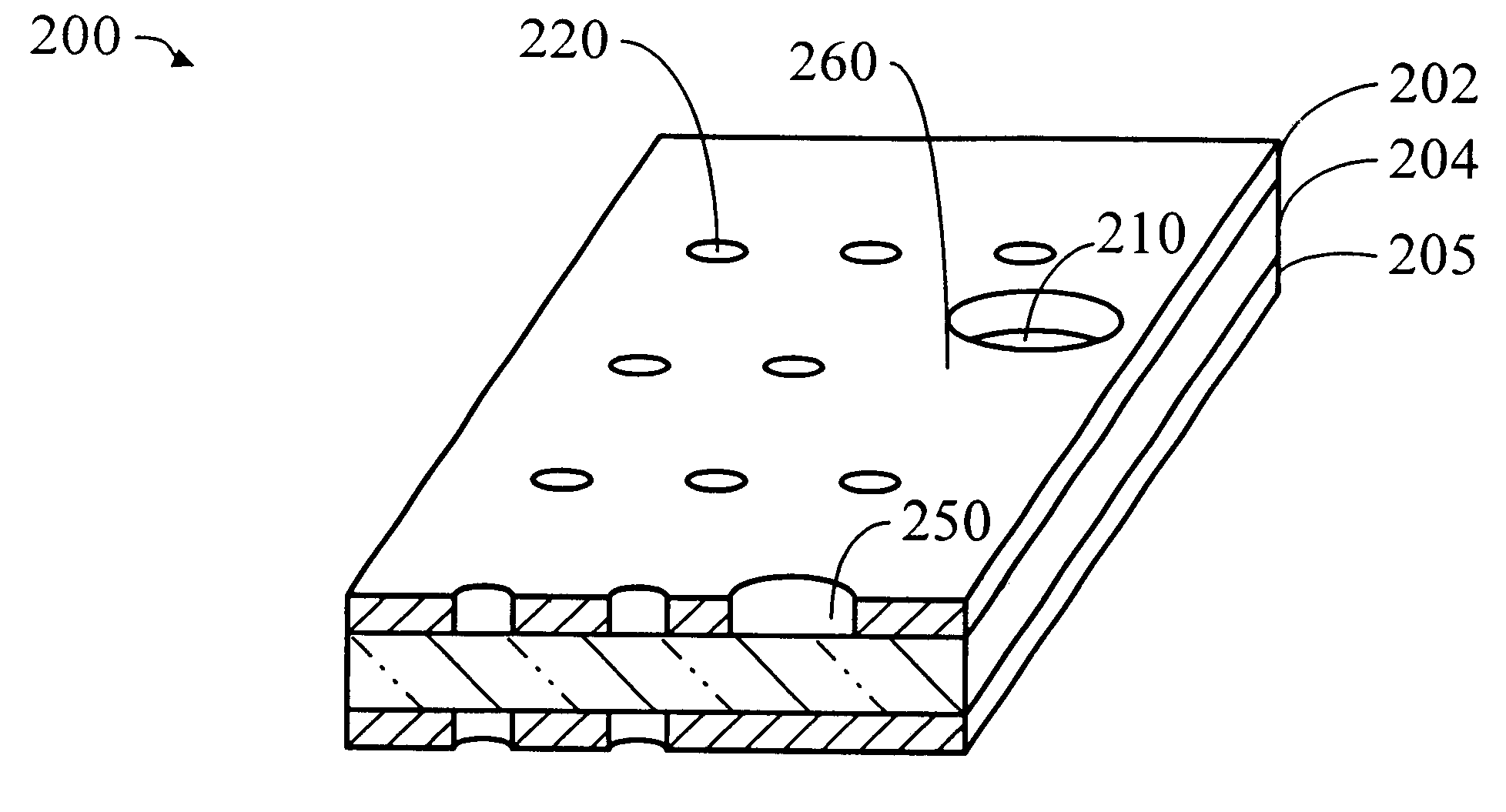

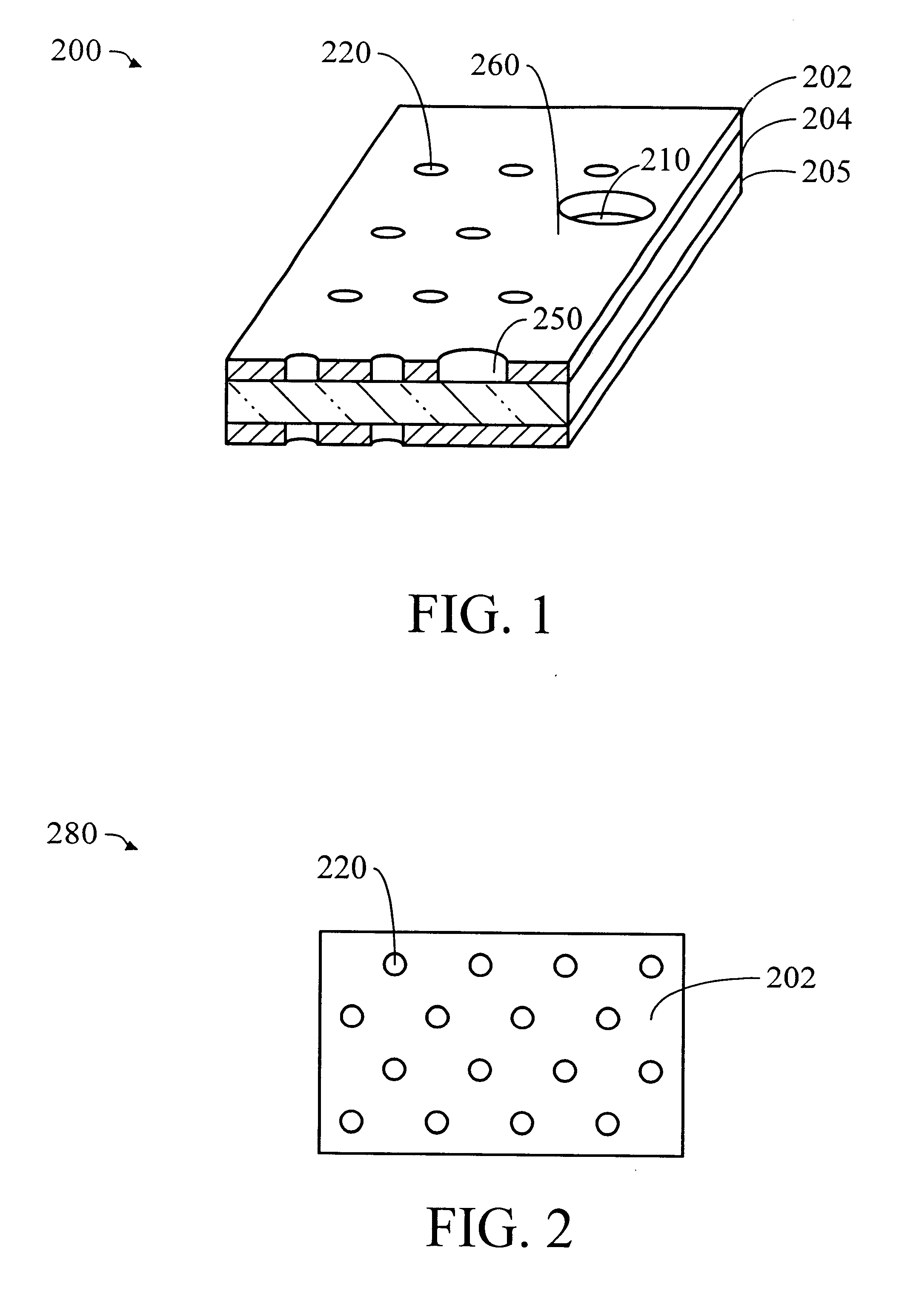

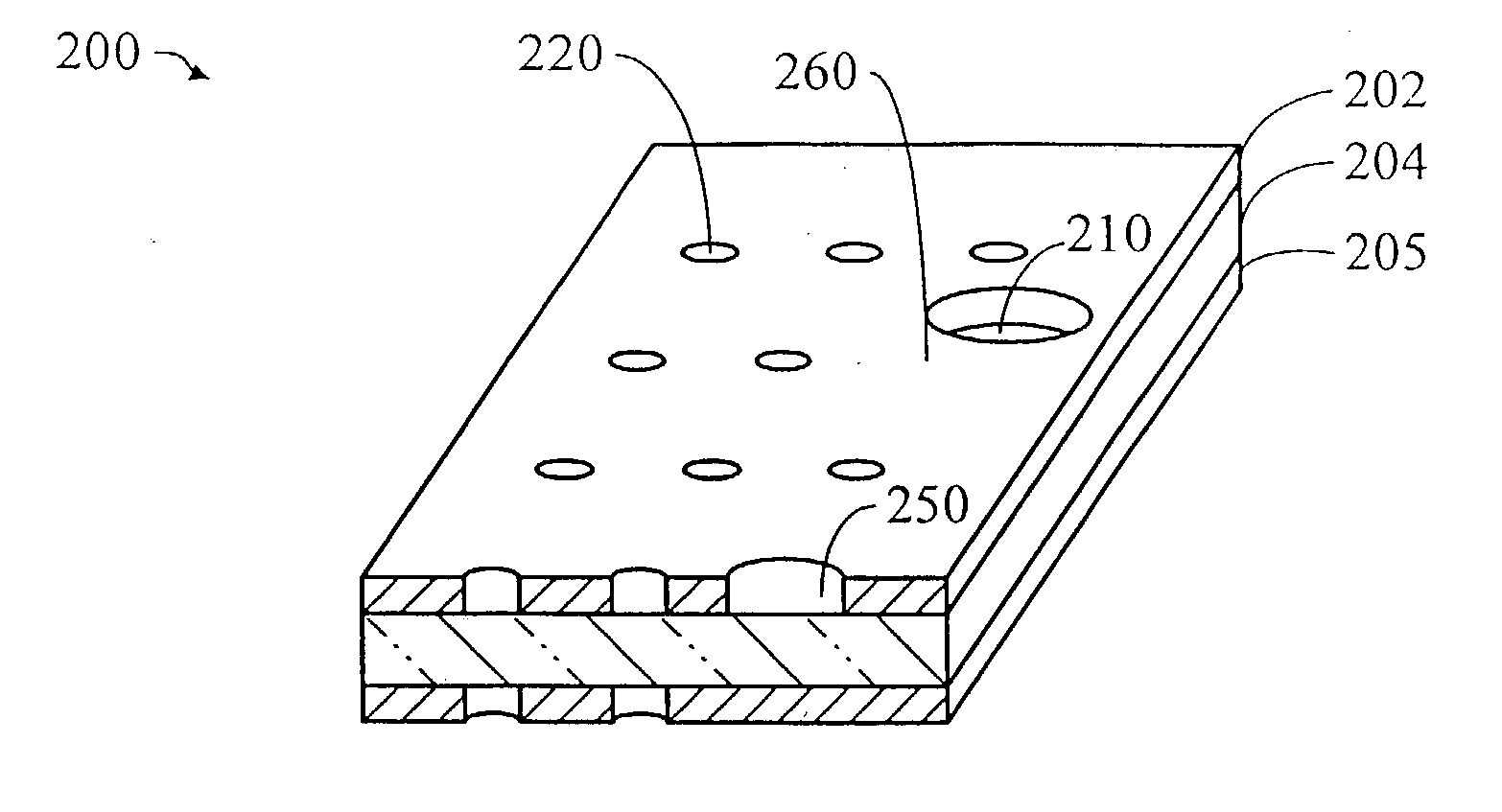

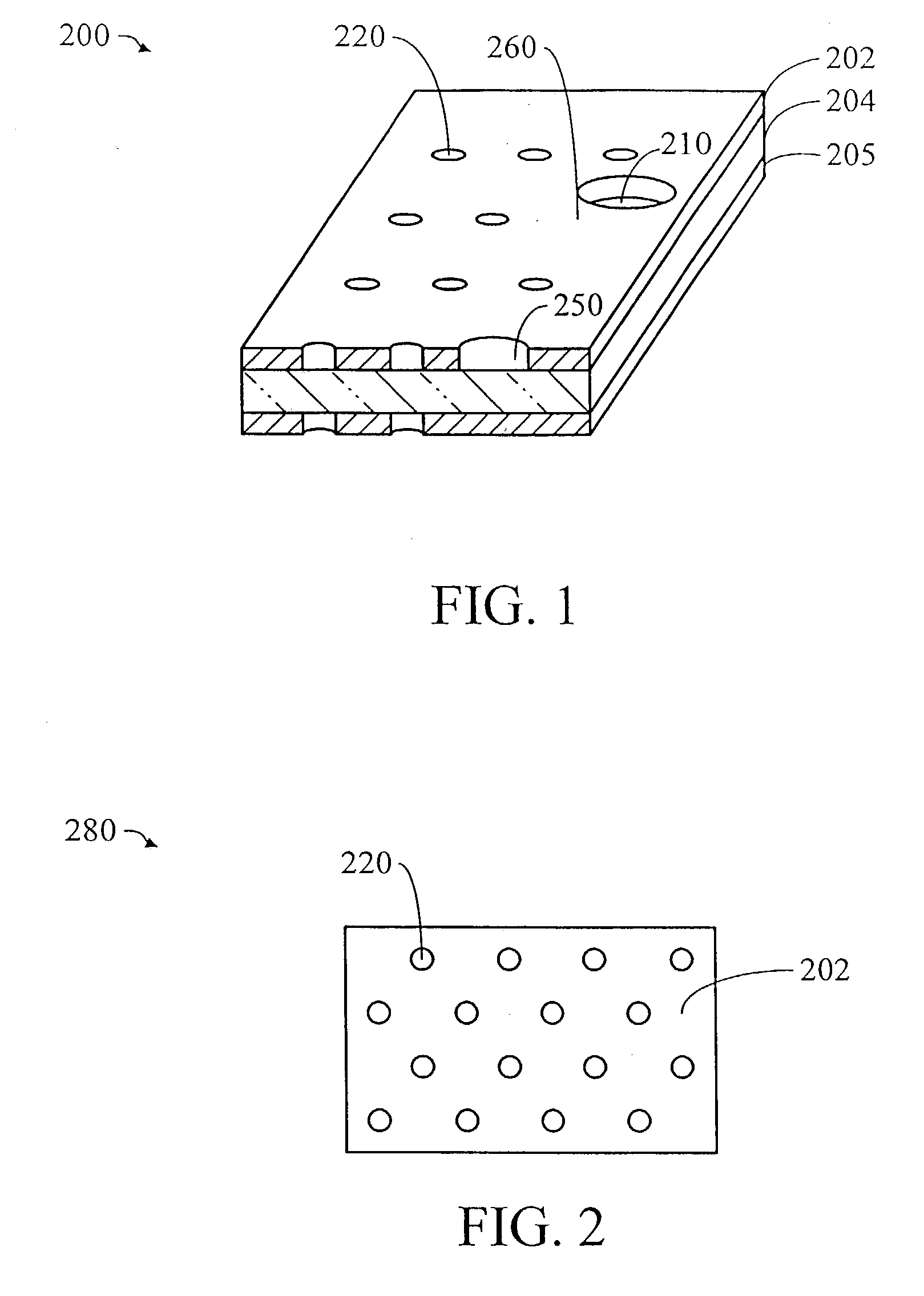

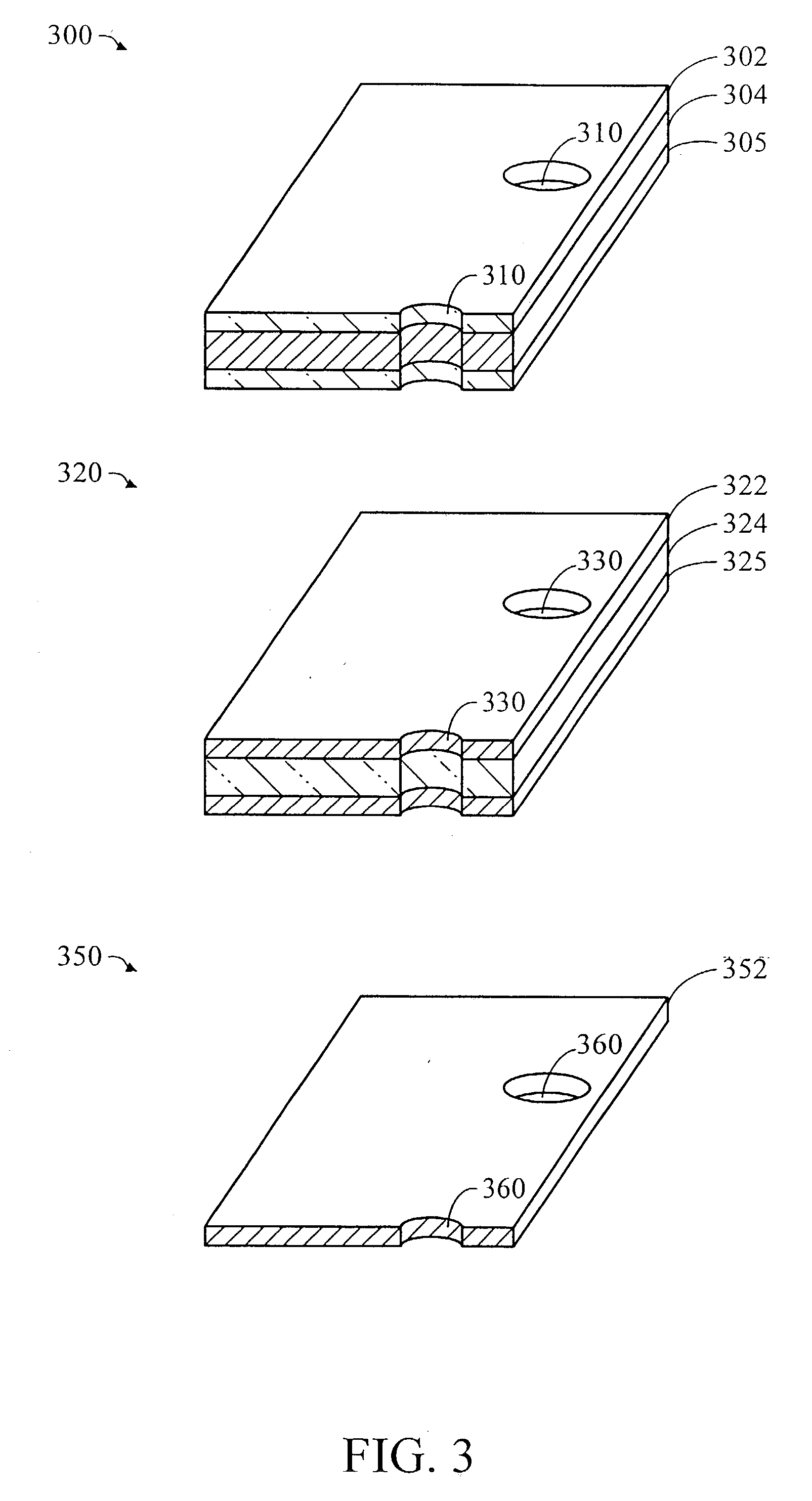

Porous power and ground planes for reduced PCB delamination and better reliability

InactiveUS6613413B1Decrease failureReduce failurePorous dielectricsPrinted circuit secondary treatmentSolventGround plane

Power and ground planes used in Printed Circuit Boards (PCBs) having porous, conductive materials allow liquids (e.g., water and / or other solvents) to pass through the power and ground planes, thus decreasing failures in PCBs (or PCBs used as laminate chip carriers) caused by cathodic / anodic filament growth and delamination of insulators. Porous conductive materials suitable for use in PCBs may be formed by using metal-coated organic cloths (such as polyester or liquid crystal polymers) or fabrics (such as those made from carbon / graphite or glass fibers), using metal wire mesh instead of metal sheets, using sintered metal, or making metal sheets porous by forming an array of holes in the metal sheets. Fabrics and mesh may be woven or random. If an array of holes is formed in a metal sheet, such an array may be formed with no additional processing steps than are performed using conventional PCB assembly methods.

Owner:GLOBALFOUNDRIES INC

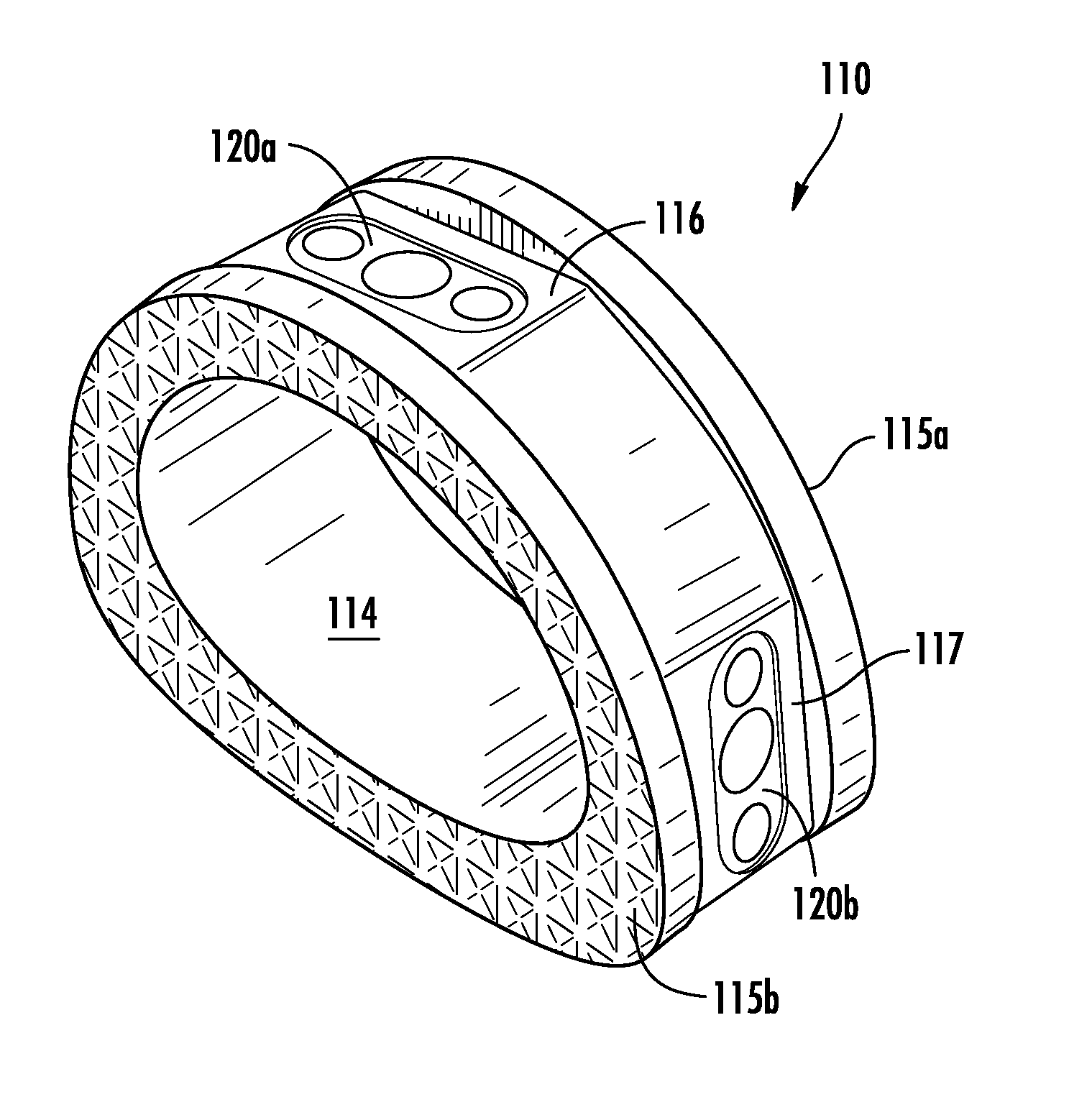

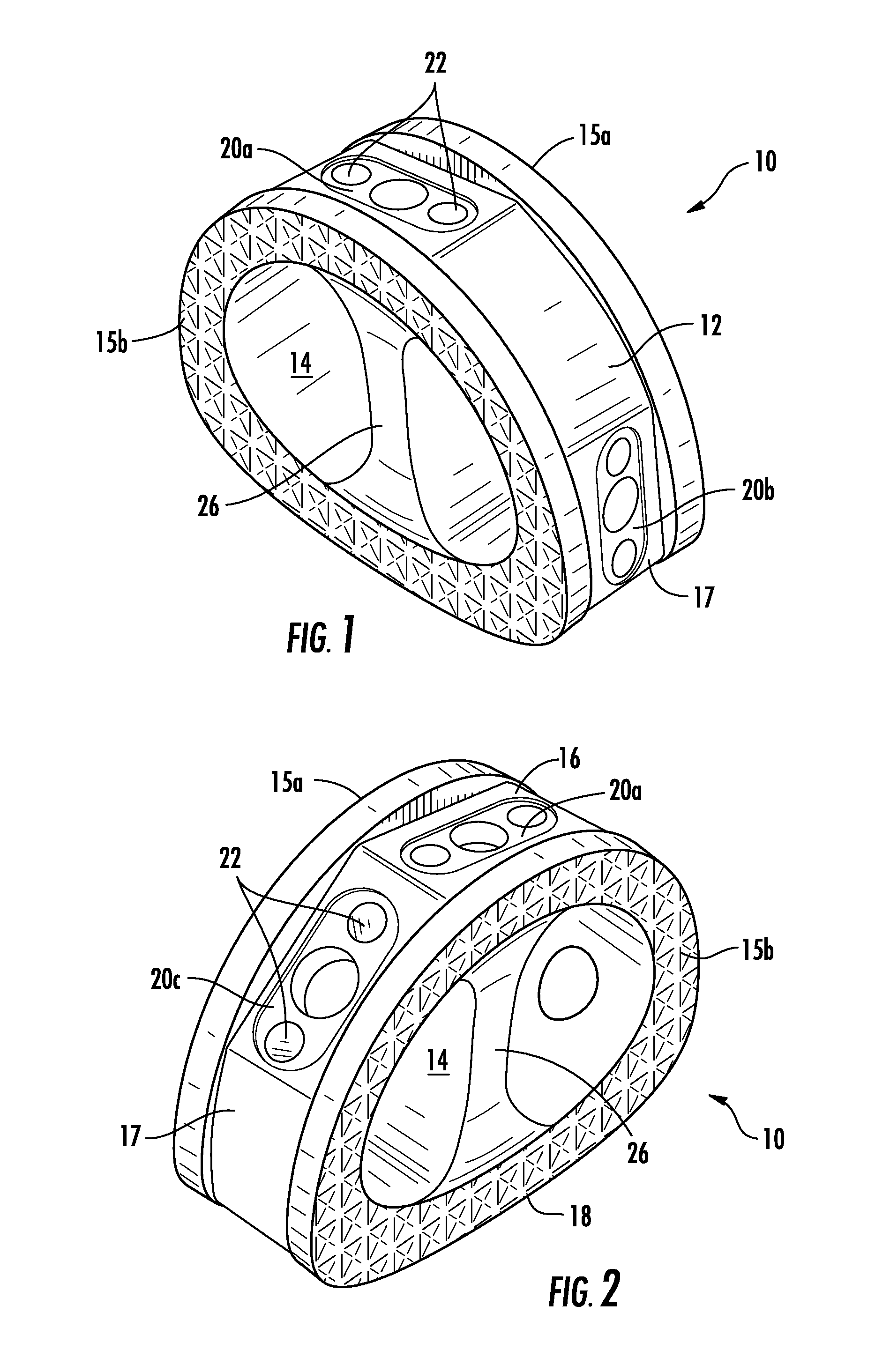

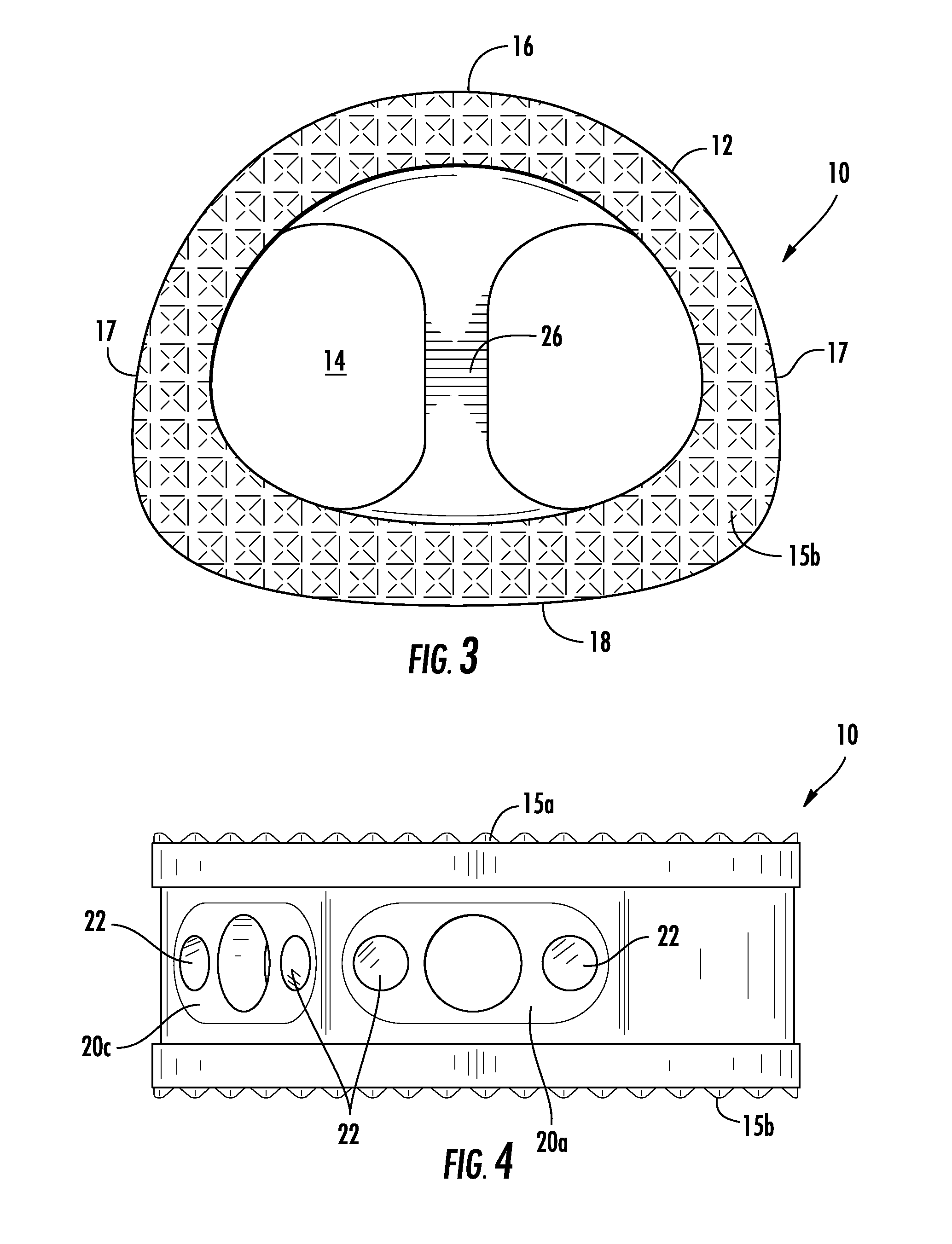

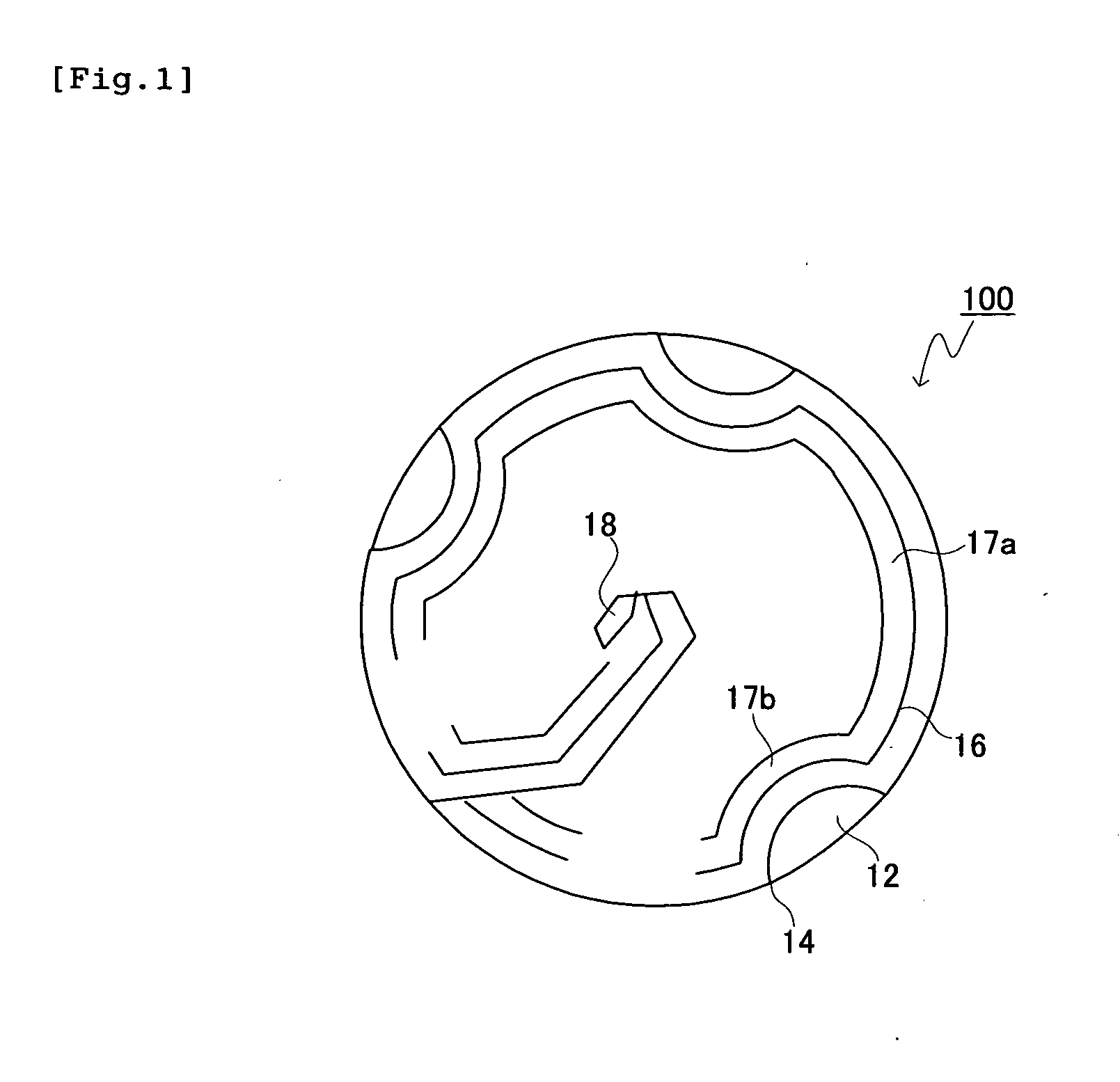

ALIF Spinal Cage

A fusion cage having a substantially continuous sidewall made from any of various materials including titanium, PEEK, a carbon graphite fiber, or even a combination of these materials. A hollow core defined by the sidewall is typically filled with bone graft in order to form a solid fusion with vertebrae. The sidewall of the cage has upper and lower surfaces, an anterior section, at least two lateral sections each connected to the anterior section, and a posterior section connected to the lateral sections. The sidewall is preferably tapered at one of either a four or eight degree incline from the posterior to the anterior section so as to maintain backbone curvature. A plurality of distinct tool ports provide for anterior, lateral and / or anterolateral insertion of the device. Each tool port is provided with screw insertion orifices.

Owner:SHAPIRO GARY S

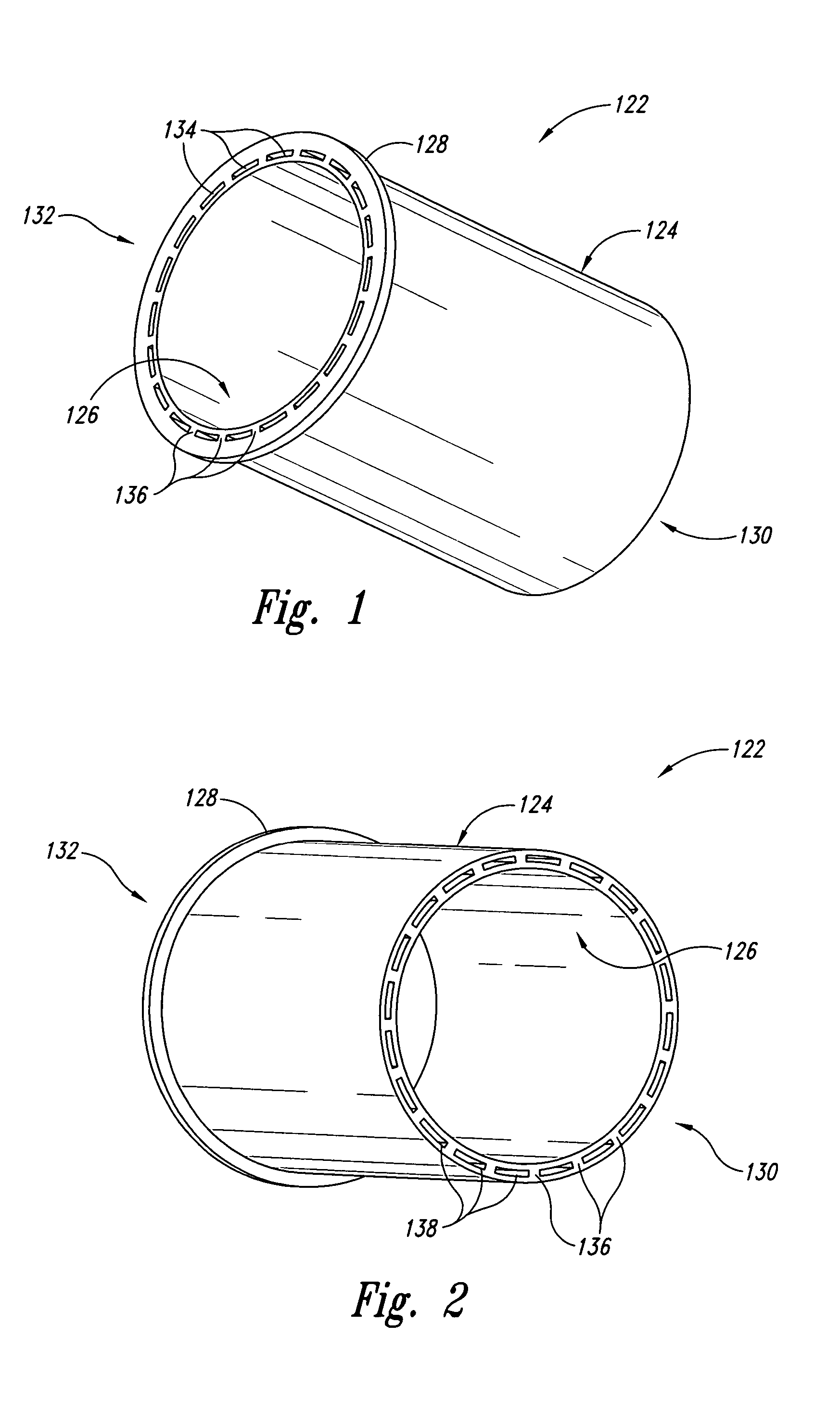

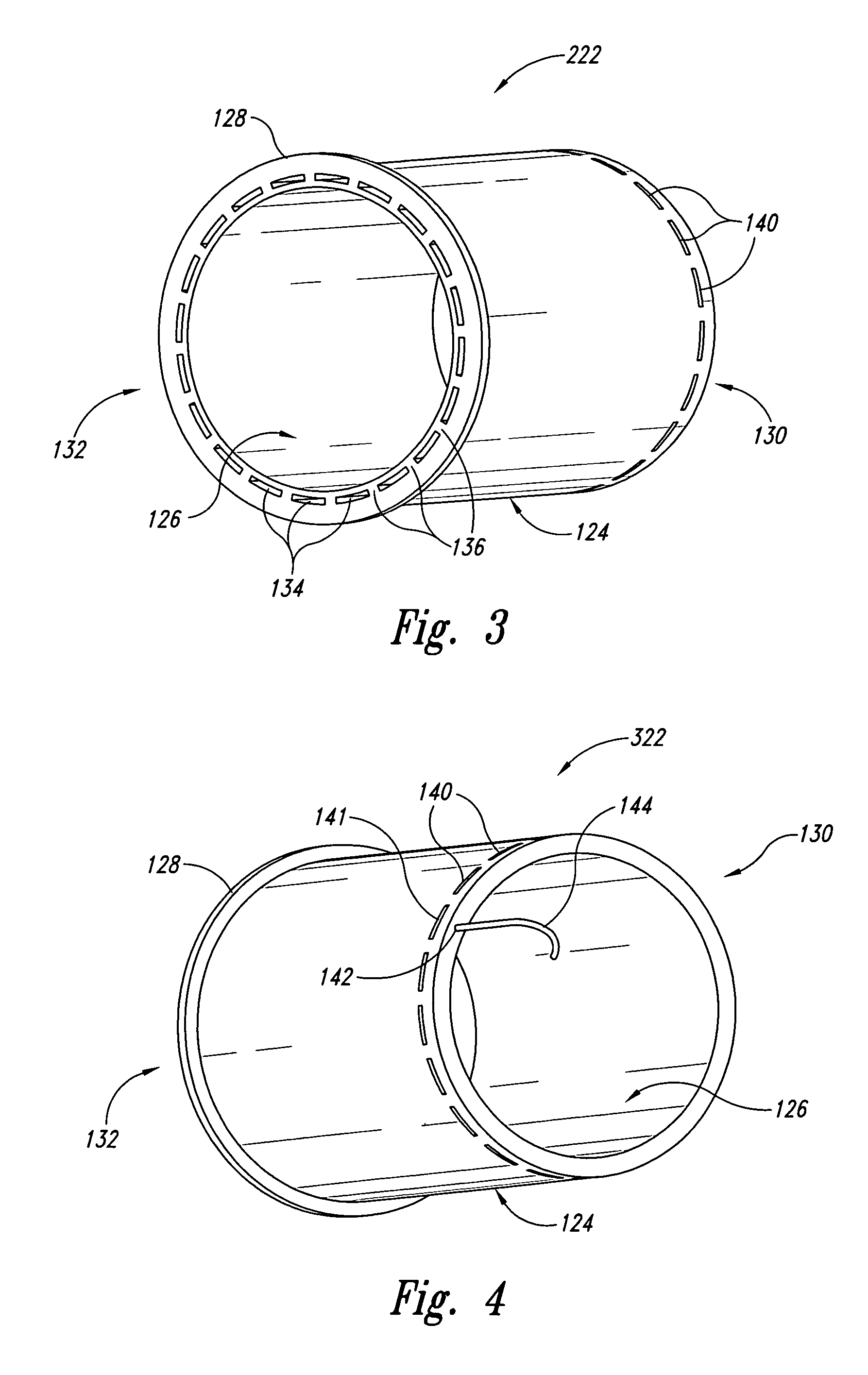

Shutdown seal for reactor coolant pump

InactiveUS20070140877A1Big impactMinimal effectSpecific fluid pumpsEngine sealsCoolant flowProcess failure

A thermally actuated shutdown seal provides a shutdown seal usable in a pump having a primary seal assembly positioned circumferentially about a rotating shaft for separating a region of high pressure coolant fluid from the shaft. The shutdown seal includes a two-piece interlocked housing which encompasses carbon graphite ring segments positioned circumferentially about the shaft, a garter spring and a series of compression springs. The replaceable insert with machined recess contains the shutdown seal assembly and is biased axially with a wave spring and held with the annular recess by a closure ring. The seal is designed with coolant fluid flow directly in contact with such ring segments and specially designed paths around the ring segments during normal pump operation. The seal requires a thermally actuated means for moving the two-piece interlocked housing axially into a blocking position within the coolant flow path to shutdown and minimize fluid flow bypassing the ring segments and between the ring segments and the pump shaft, upon occurrence of a process failure in the facility served by the pump and consequent temperature rise of the fluid being pumped.

Owner:STEIN SEAL +1

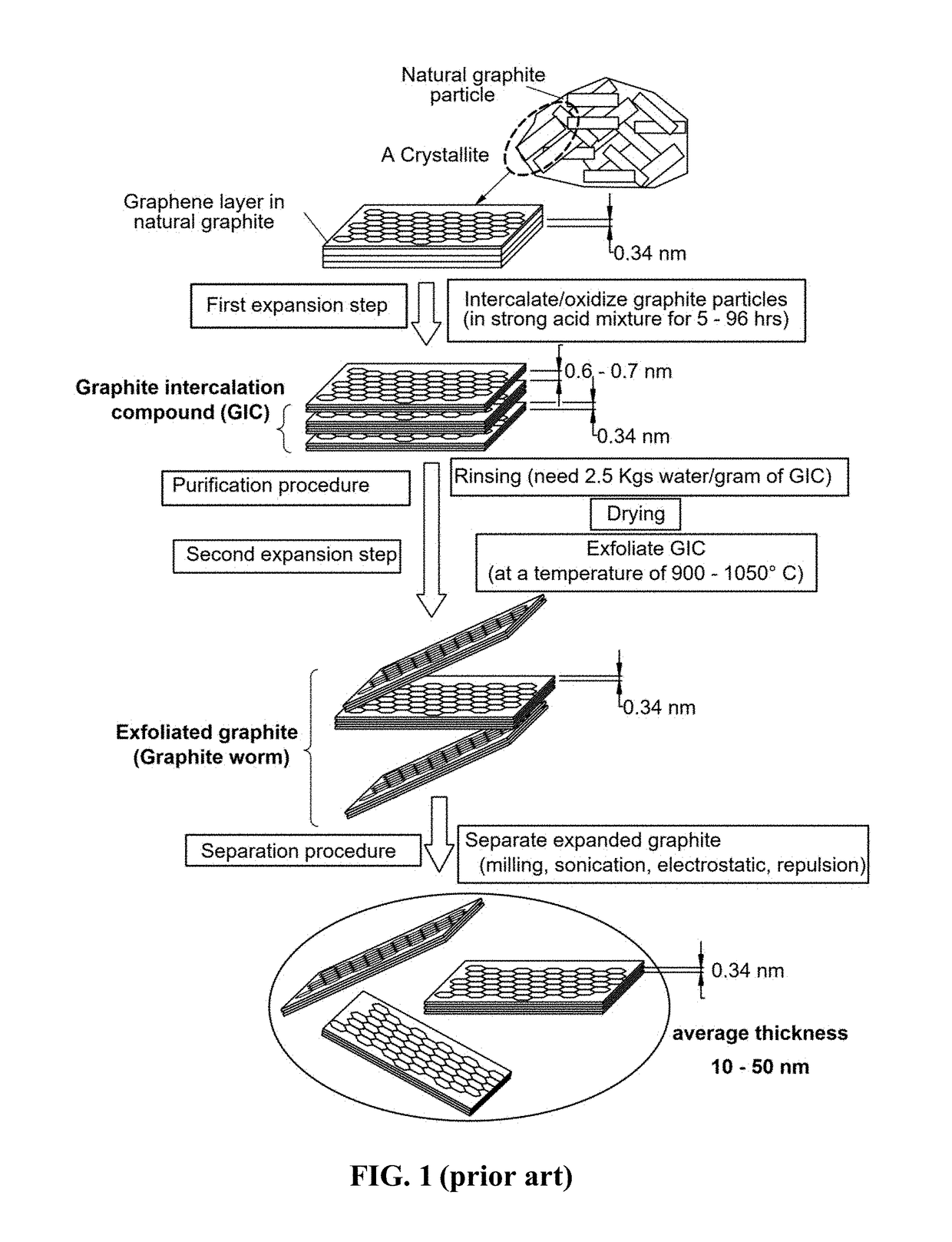

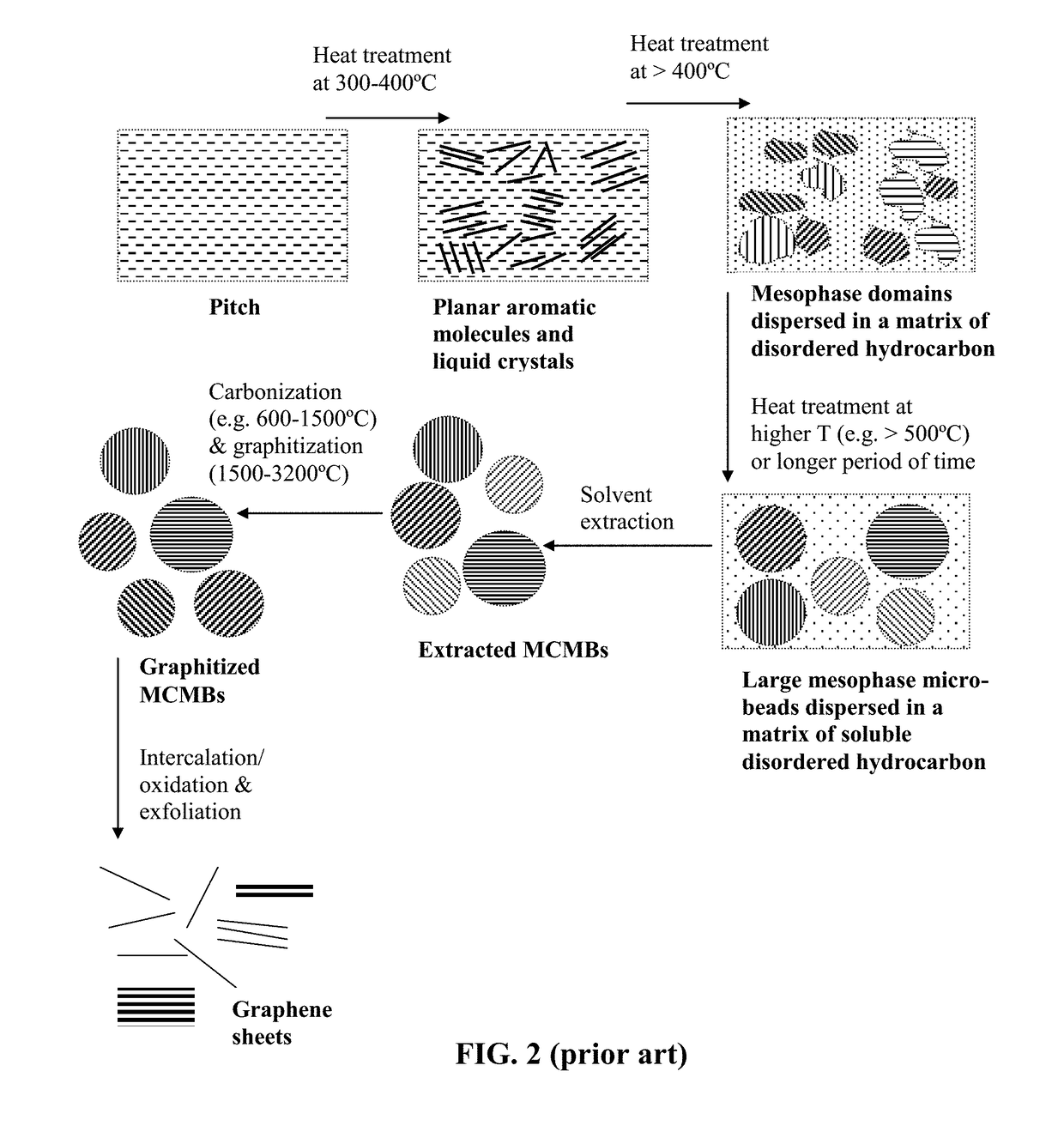

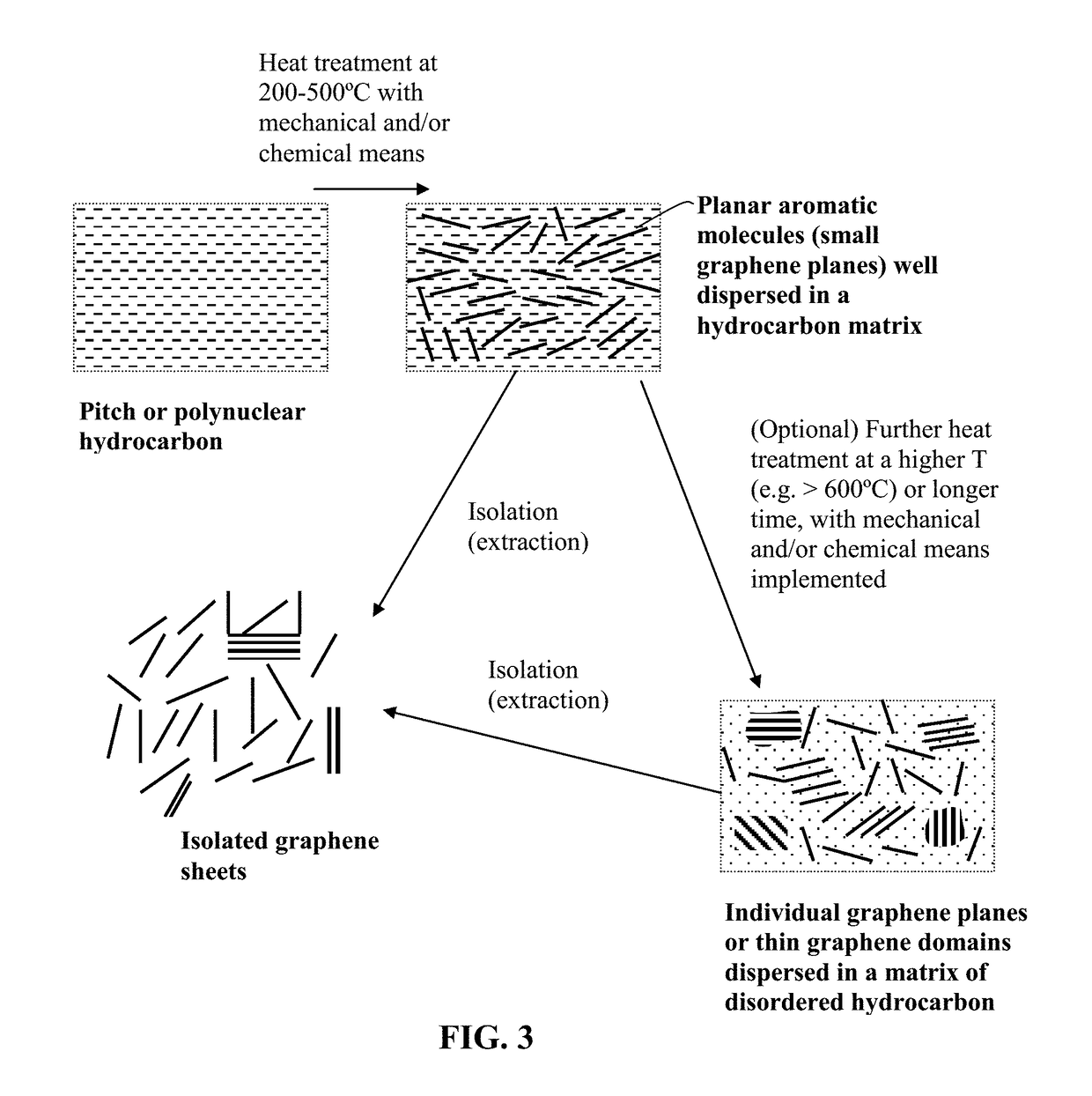

Production of graphene materials directly from carbon/graphite precursor

Provided is a method of producing isolated graphene sheets directly from a carbon / graphite precursor. The method comprises: (a) providing a mass of aromatic molecules wherein the aromatic molecules are selected from petroleum heavy oil or pitch, coal tar pitch, a polynuclear hydrocarbon, or a combination thereof; (b) heat treating this mass and using chemical or mechanical means to form graphene domains dispersed in a disordered matrix of carbon or hydrocarbon molecules, wherein the graphene domains are each composed of from 1 to 30 planes of hexagonal carbon atoms or fused aromatic rings having a length or width from 5 nm to 20 μm and an inter-graphene space between two planes of hexagonal carbon atoms or fused aromatic rings no less than 0.4 nm; and (c) separating and isolating the planes of hexagonal carbon atoms or fused aromatic rings to recover graphene sheets from the disordered matrix.

Owner:GLOBAL GRAPHENE GRP INC

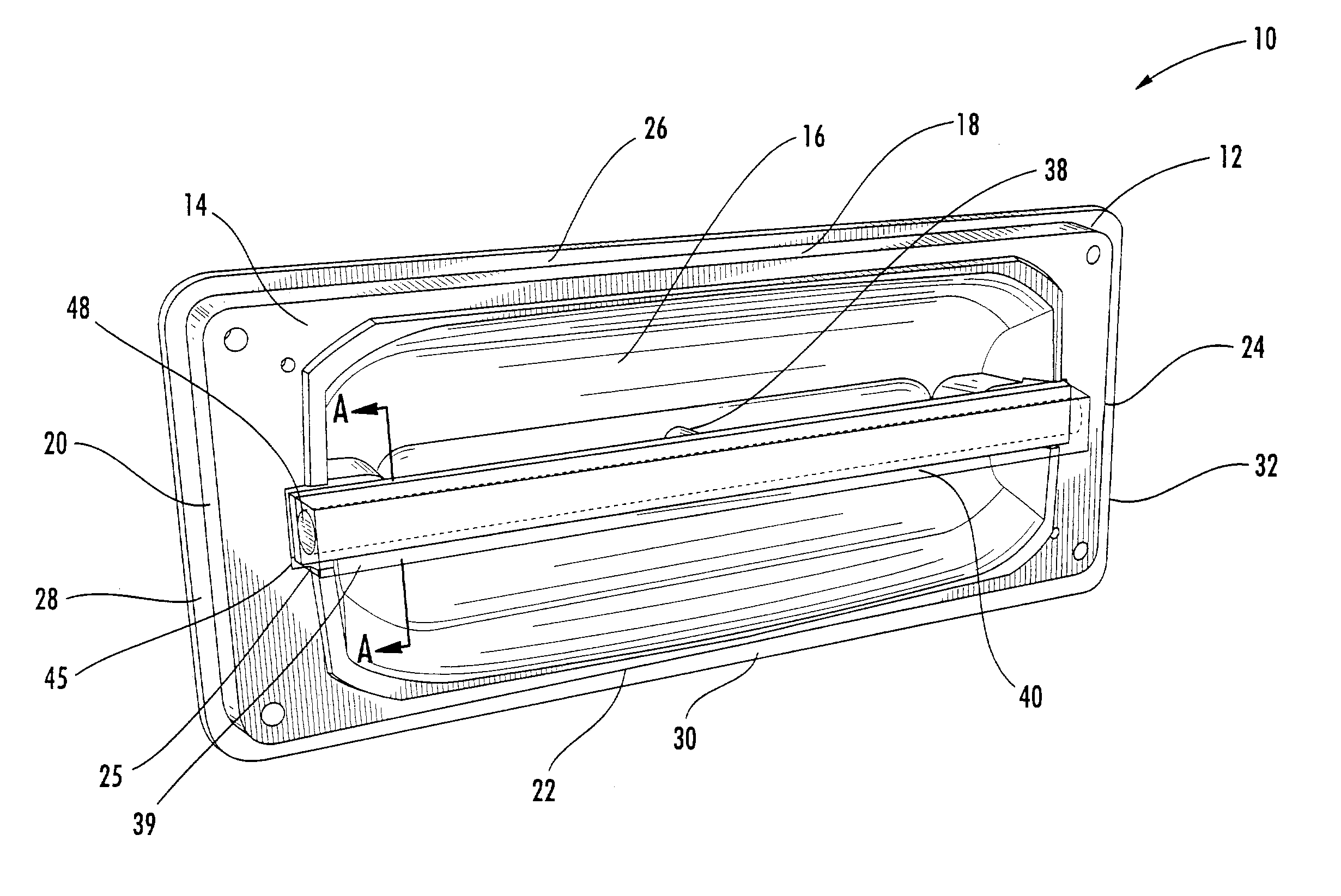

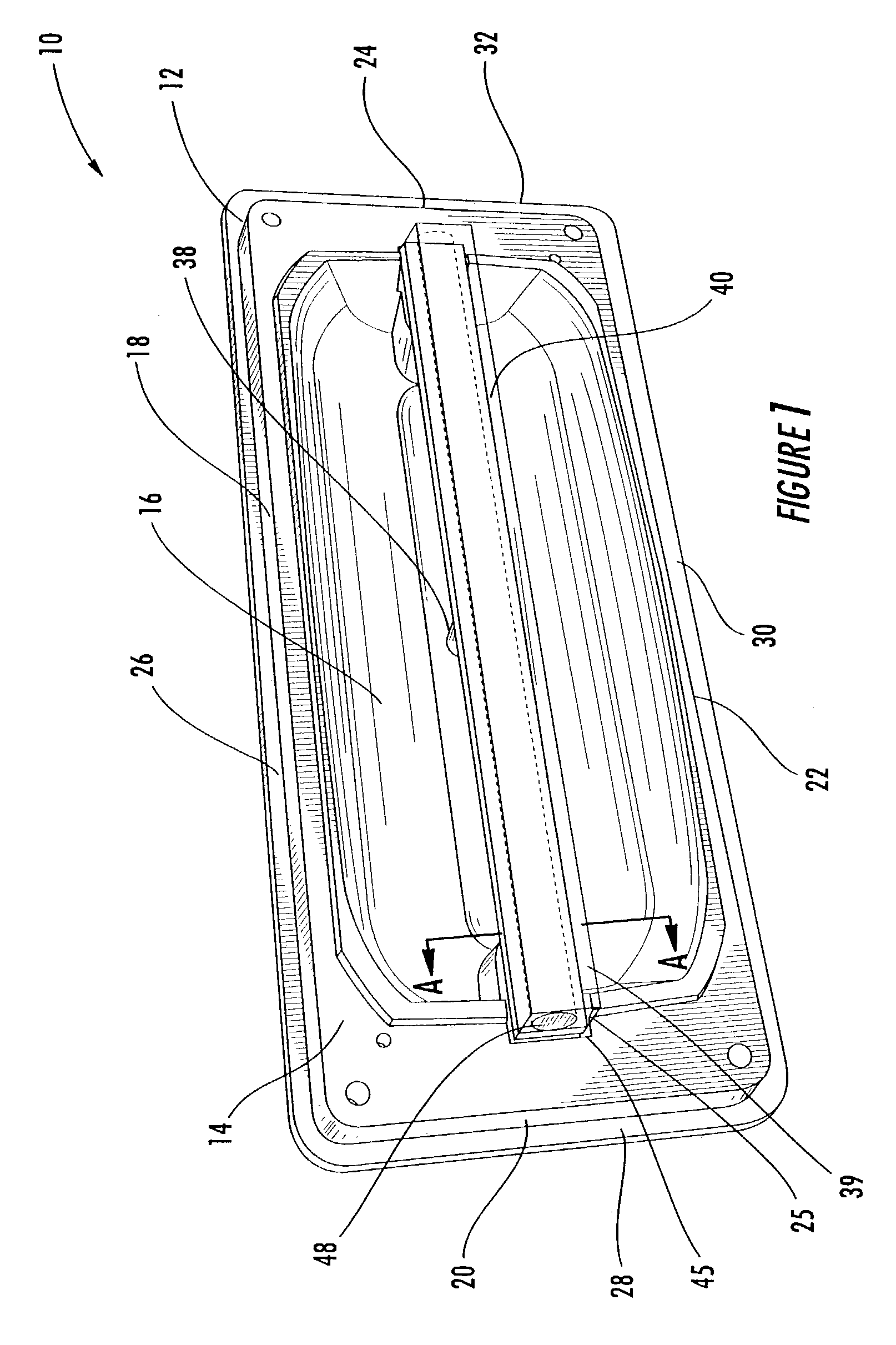

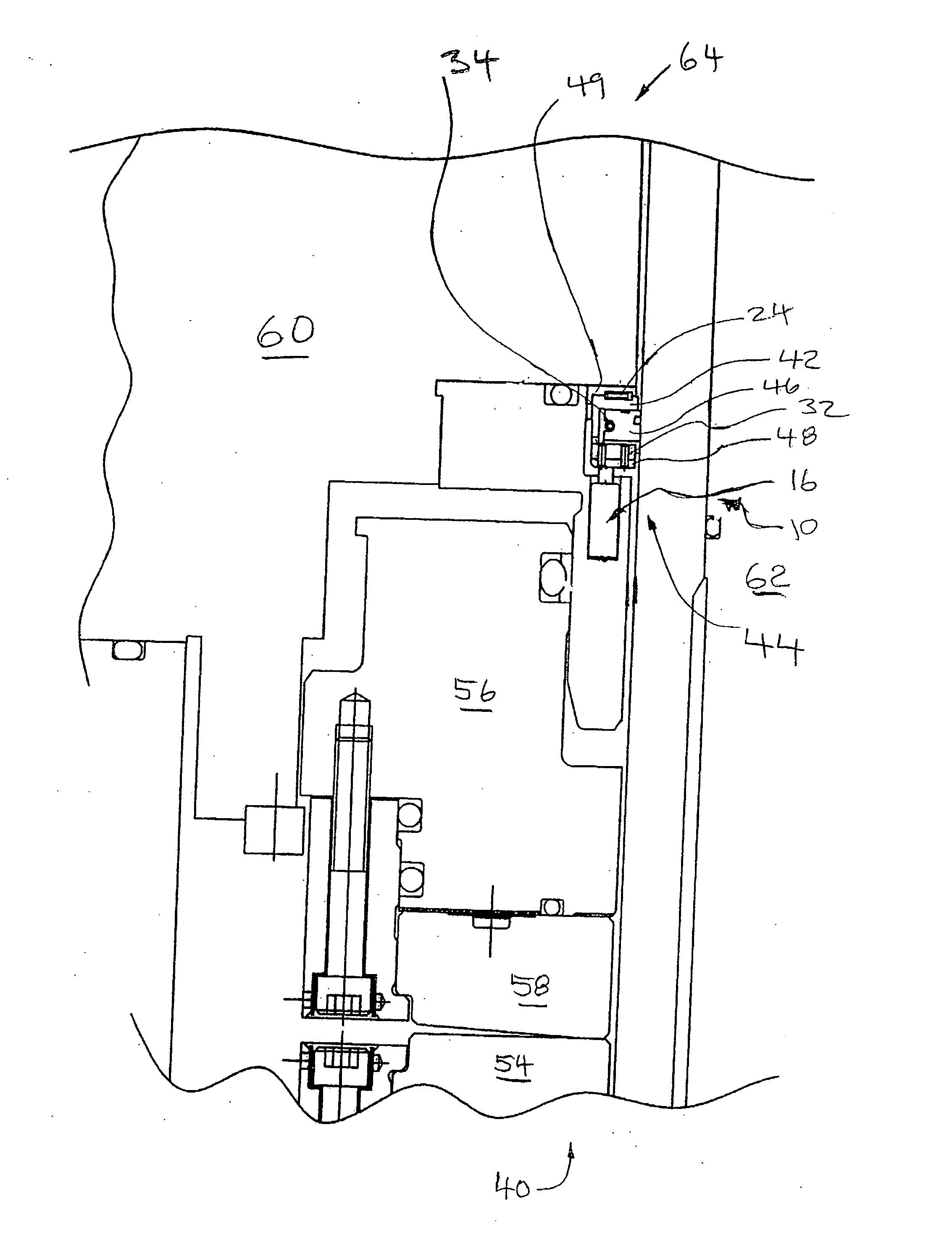

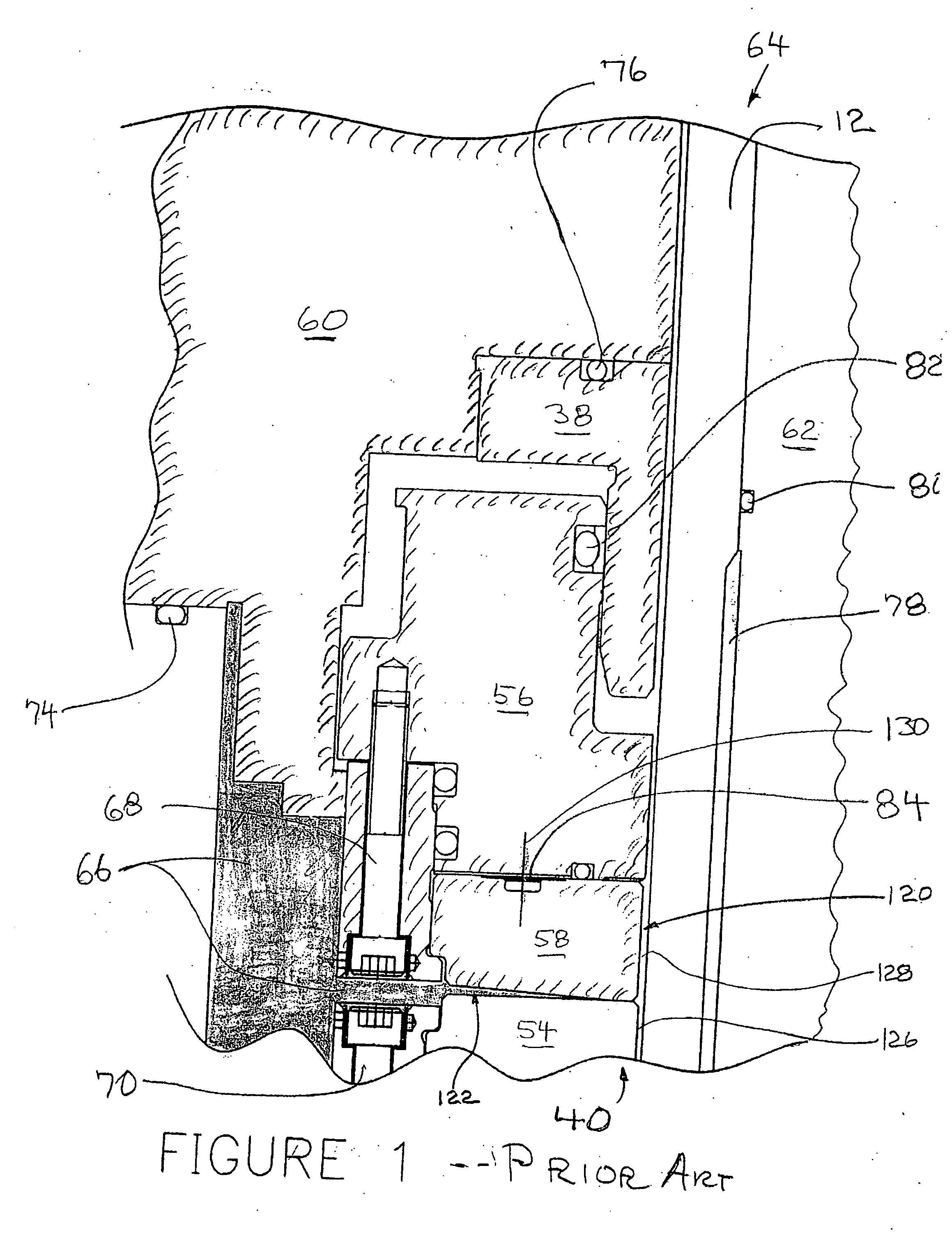

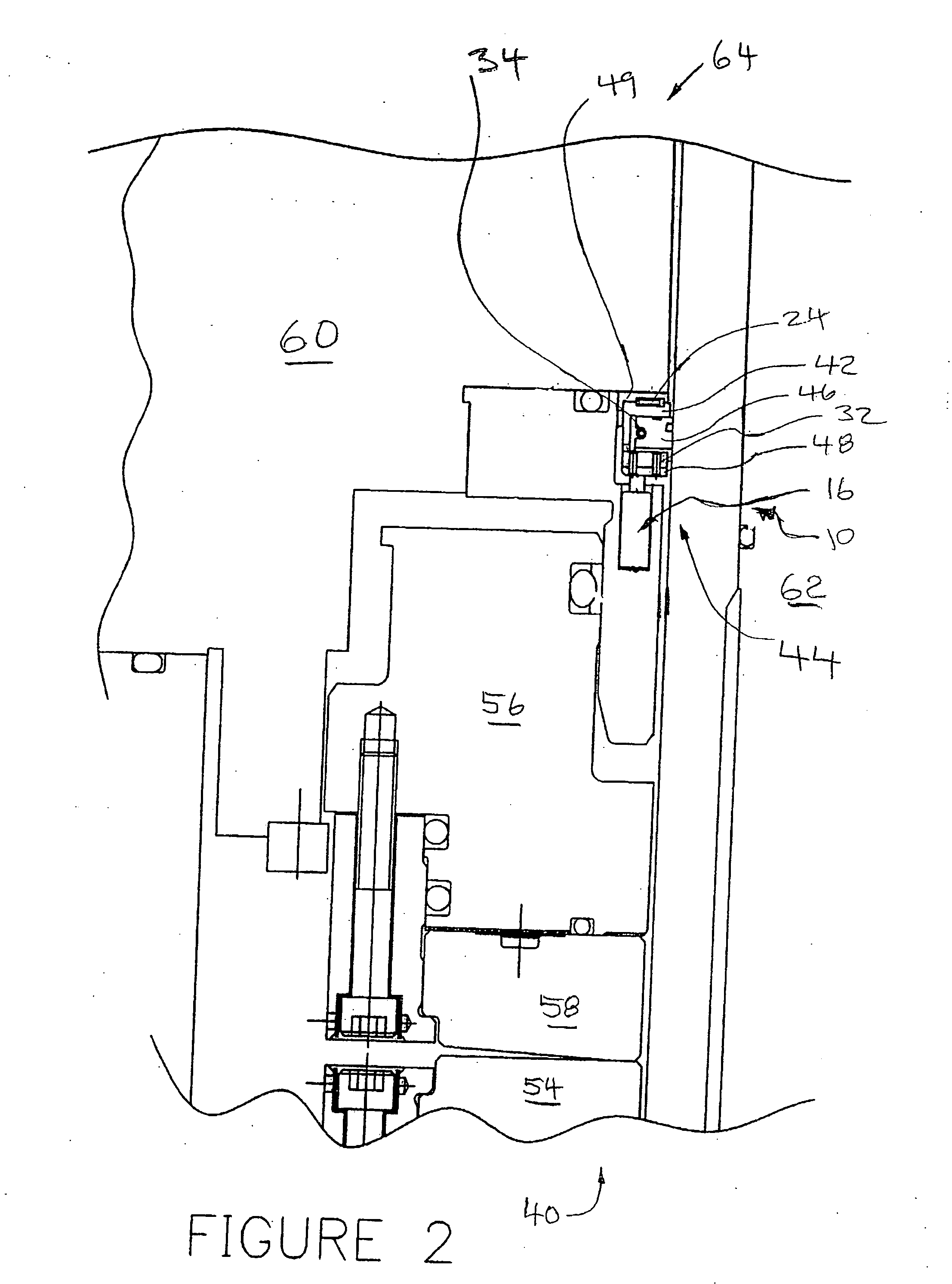

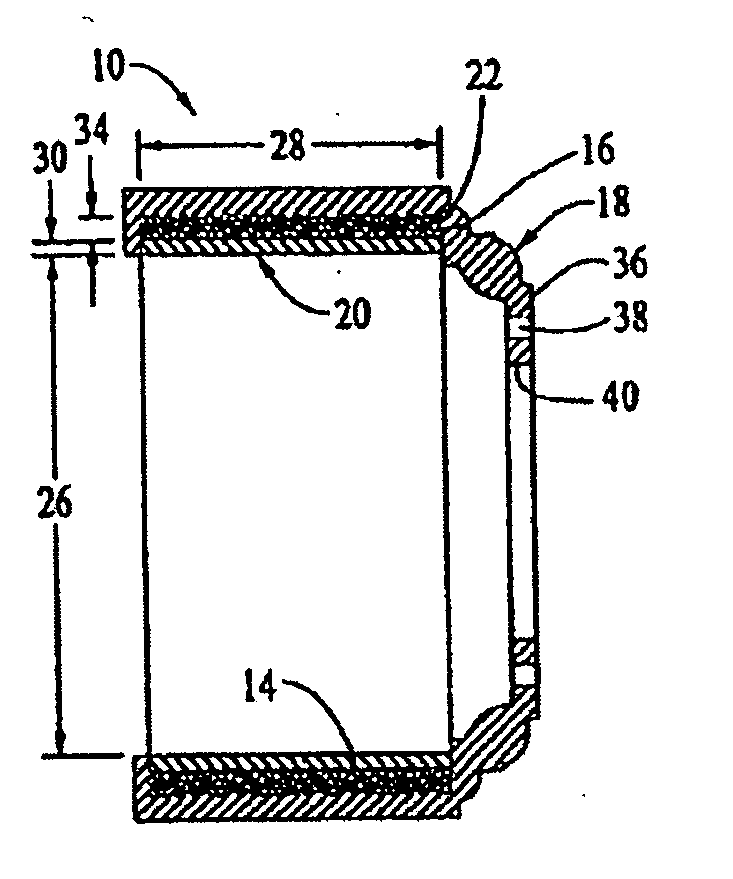

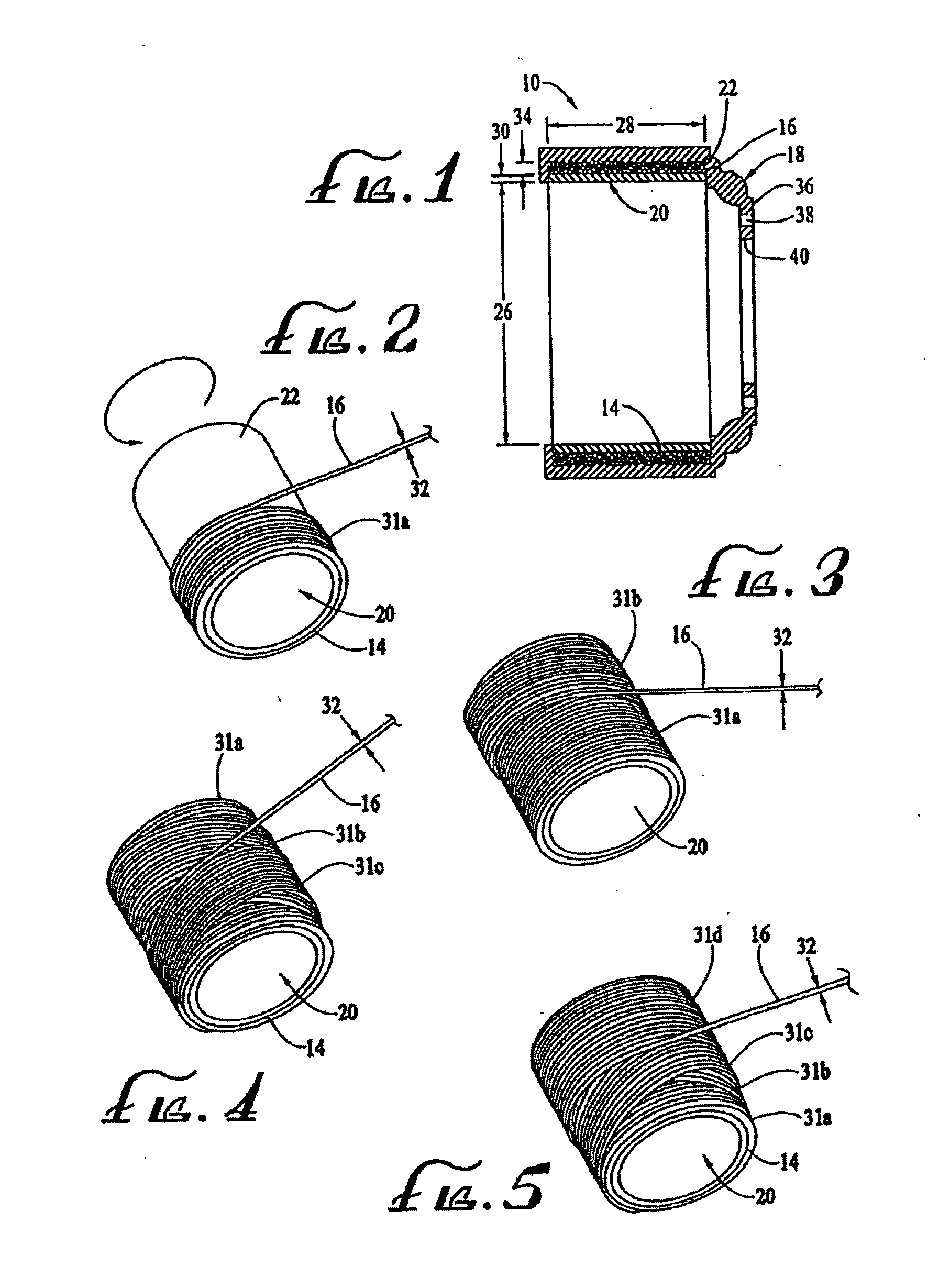

Lightweight reinforced brake drum and method for making same

InactiveUS20050217950A1Reduce manufacturing costAdd supportBraking drumsCoatingsCarbon graphiteEngineering

The invention provides a lightweight brake drum (10) comprising a lightweight, tubular inner member (14) having a reinforcement wrapping retention pattern (e.g., groove) cast in the exterior surface thereof, a length of reinforcement material (e.g., wrapped wire, cable, mesh, fibers, etc.) (16) in communication with a reinforcement retention pattern (e.g., a groove around the inner member) (14), the drum including an outer shell (18). The inner member (14) and the outer shell (18) are made of lightweight materials. Single, or multiple layers of reinforcement material (e.g. wrapping) are applied (e.g., wrapped) around the inner member (14) to support and inhibit expansion of the inner member (14). Because the reinforcement material (16) provides support against expansion, the inner member (14) and the outer shell (18) can be made of lightweight materials. In preferred embodiments, a bonding layer (66) is applied to the exterior surface of the inner member prior to application of the reinforcement material thereon. In preferred embodiments the reinforcement material comprises a low-impedance material such as copper along with another material that has good tensile strength characteristics (e.g., steel, composite fibers, Basalt-fibers, etc.). Preferably, the inner member comprises at least one material selected from the group consisting of a aluminum-based metal matrix composite (MMC) with a particulate reinforcement, ceramic matrix composite (CMC), and carbon graphite foam.

Owner:BENMAXX

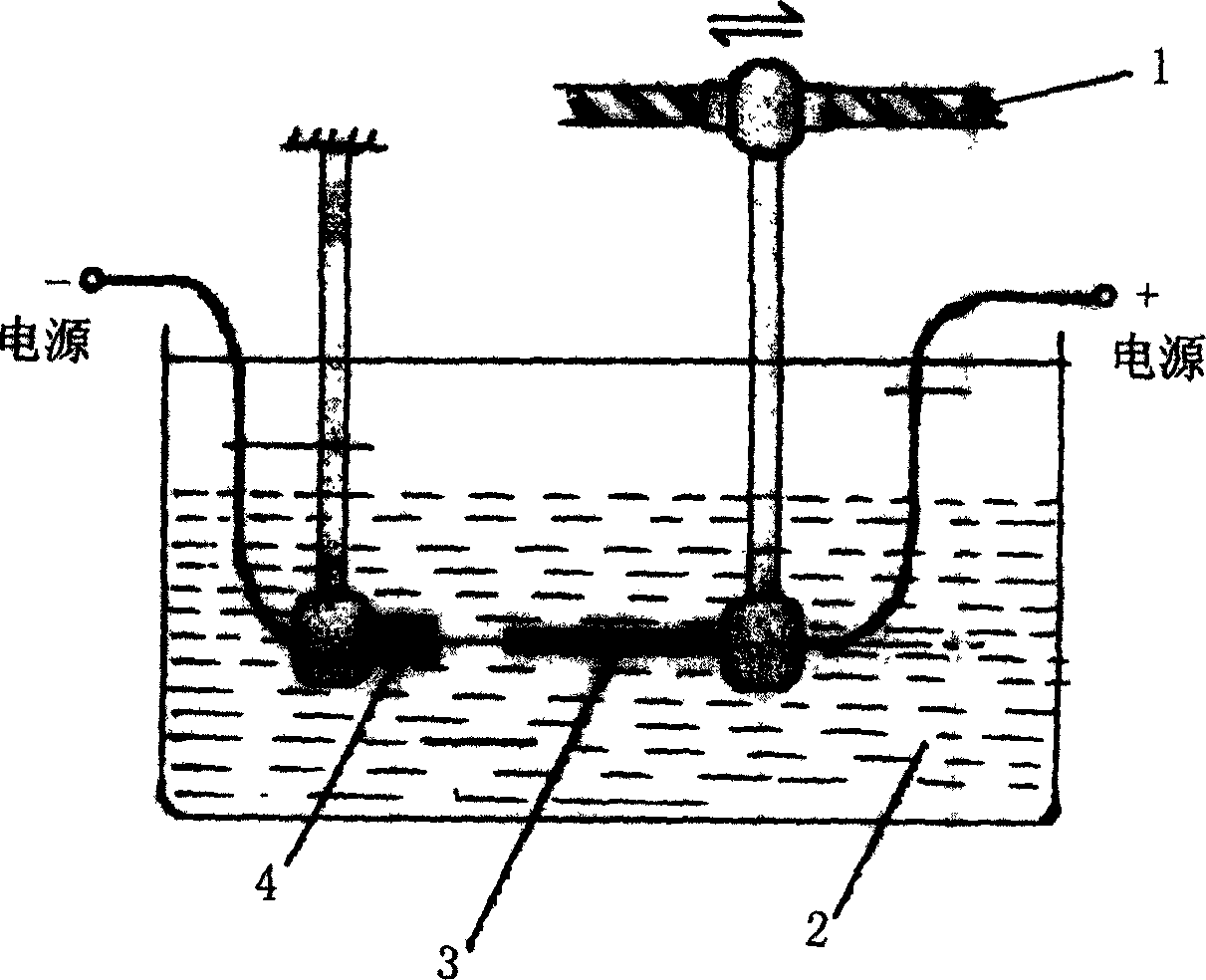

Preparation of aluminium titanium carbide intermediate alloy grain refiner in the ultrasonic field

The invention relates to the composition, structure characteristics and preparation method of a new type of aluminum-titanium-carbon master alloy grain refiner and its application to aluminum and aluminum alloy grain refinement methods and effects. The present invention proposes a composition of an aluminum-titanium-carbon master alloy refiner prepared under the action of an ultrasonic field, which is characterized in that the main component of this type of refiner only needs to include aluminum (Al) , Titanium (Ti), carbon (C) without the need for other additional components. The method for preparing an aluminum-titanium-carbon master alloy under the action of an ultrasonic field proposed by the present invention is characterized in that raw materials such as pure aluminum ingot, potassium fluorotitanate, and graphite carbon are prepared according to the pre-designed master alloy composition; The aluminum ingot is melted by internal heating, and then various raw materials are added; ultrasonic waves are added to the melt that starts to react; after the reaction is completed, the temperature is raised, kept warm, left still, and slag is removed, and then cast into ingots or continuously cast and rolled into wire rods, thereby Get the required master alloy refiner with various components and shapes.

Owner:TSINGHUA UNIV

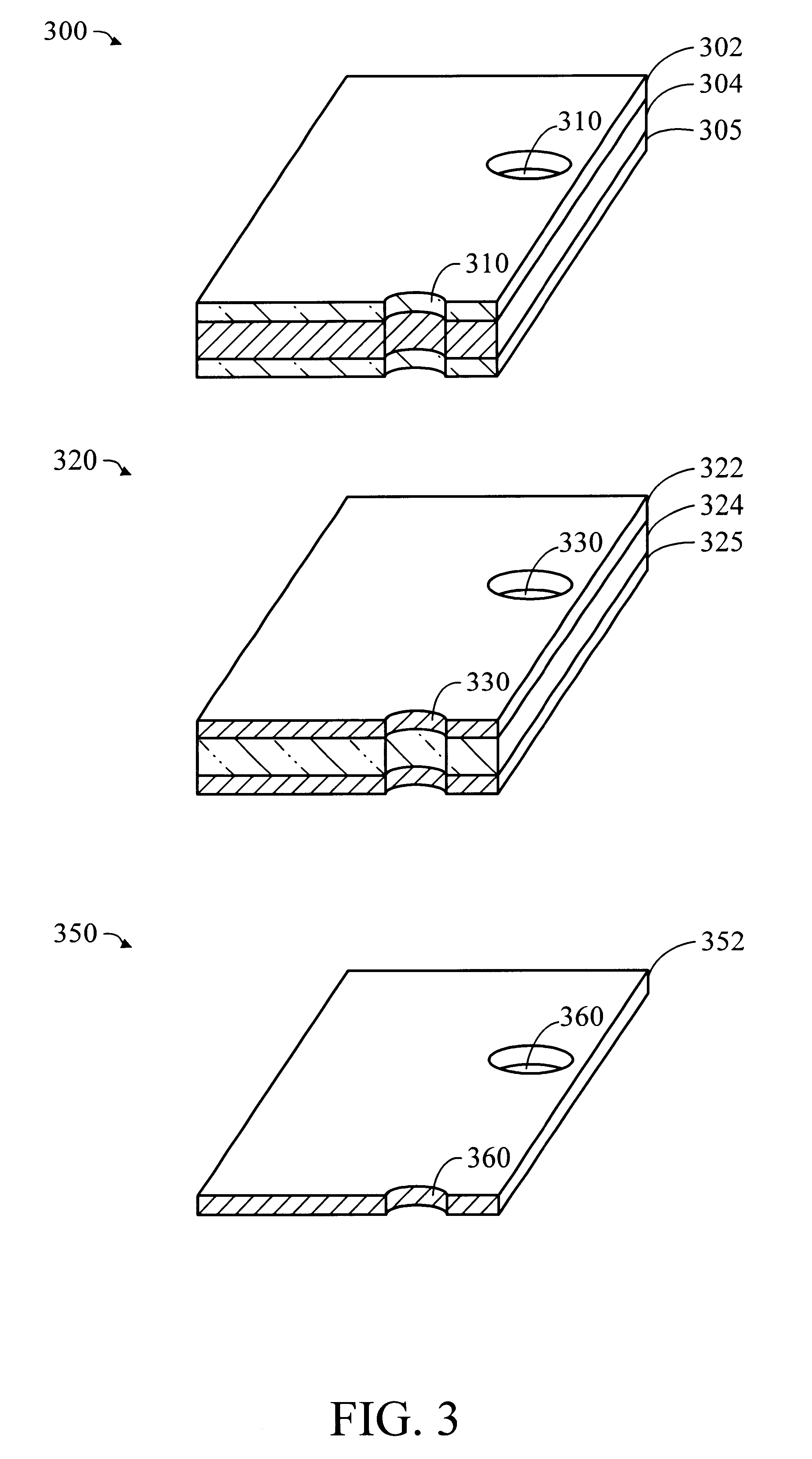

Low CTE power and ground planes

InactiveUS20020050402A1Improve solderabilitySufficient currentPrinted circuit assemblingPrinted circuit aspectsFiberCarbon graphite

Conductive materials that have low coefficients of thermal expansion (CTEs) and that are used for power and ground planes are disclosed. Fibrous materials (such as carbon, graphite, glass, quartz, polyethylene, and liquid crystal polymer fibers) with low CTEs are metallized to provide a resultant conductive material with a low CTE. Such fibers may be metallized in their individual state and then formed into a fabric, or these materials may be formed into a fabric and then metallized or a combination of both metallizations may be used. In addition, a graphite or carbon sheet may be metallized on one or both sides to provide a material that has a low CTE and high conductivity. These metallized, low CTE power and ground planes may be laminated with other planes / cores into a composite, or laminated into a core which is then laminated with other planes / cores into a composite. The resultant composite may be used for printed circuit boards (PCBs) or PCBs used as laminate chip carriers.

Owner:GLOBALFOUNDRIES INC

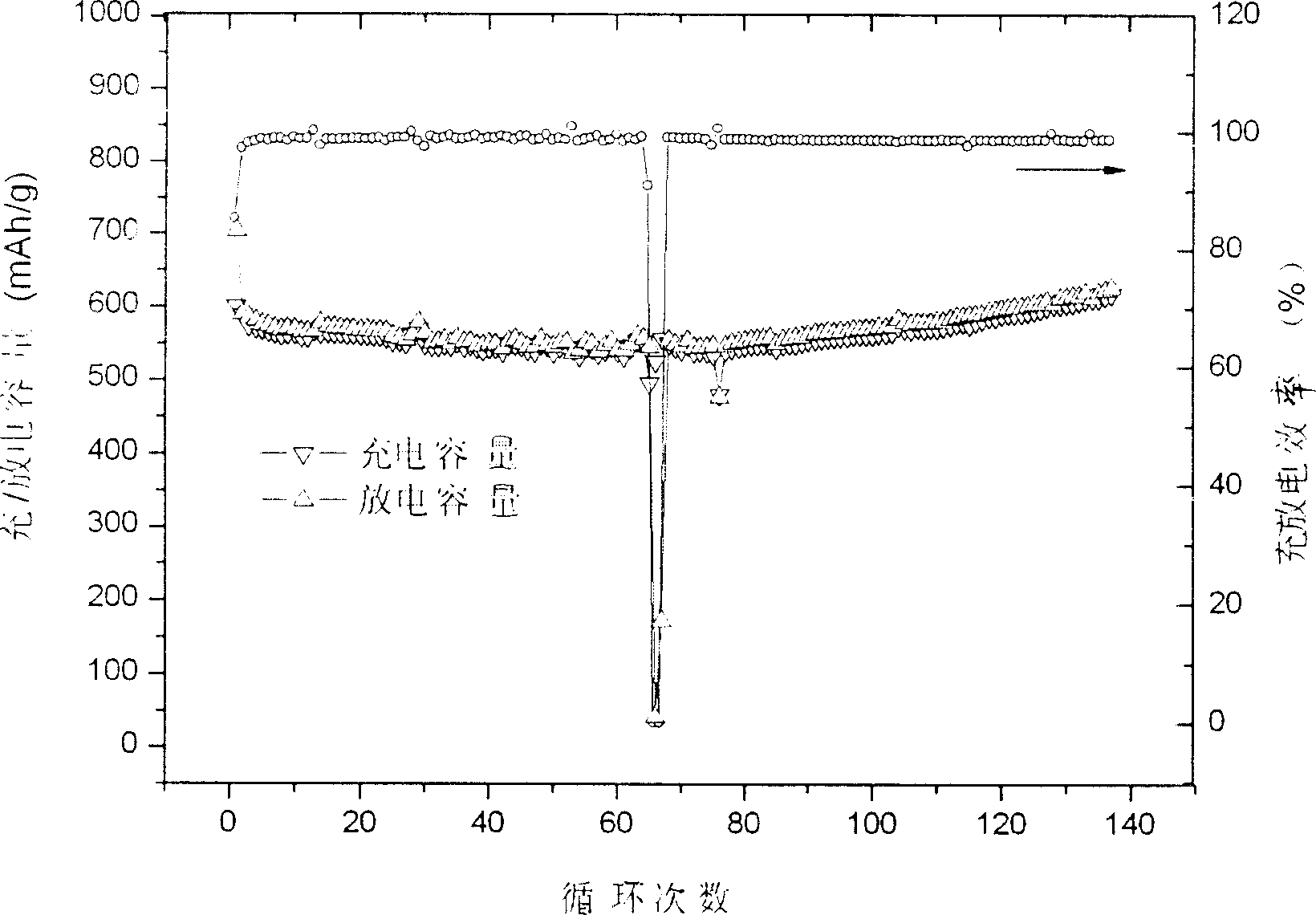

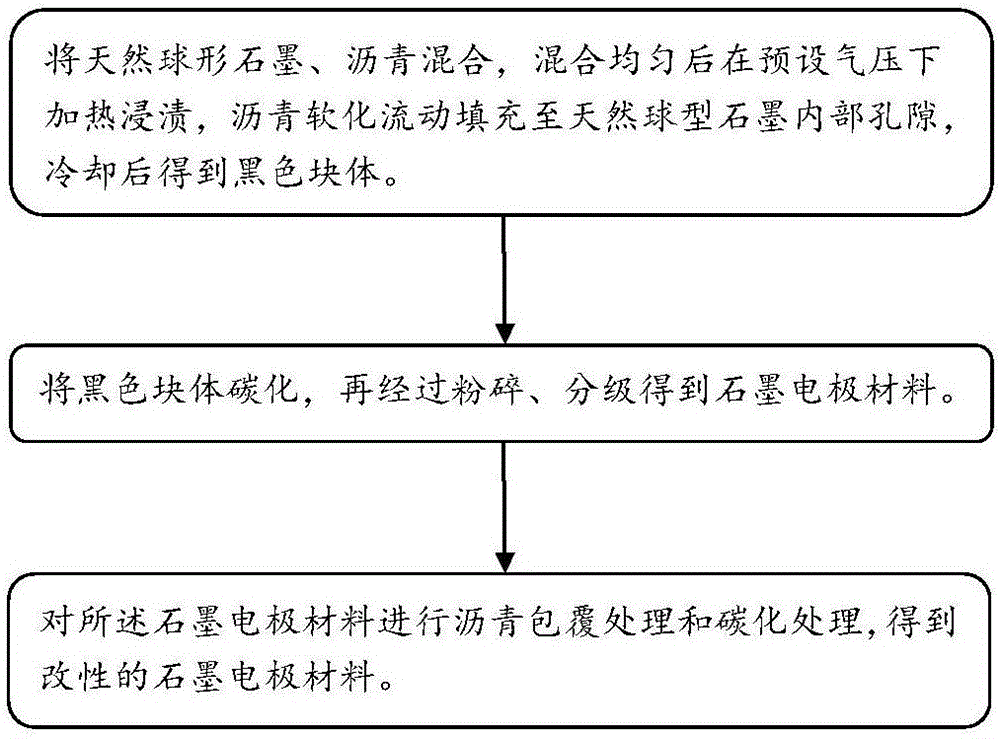

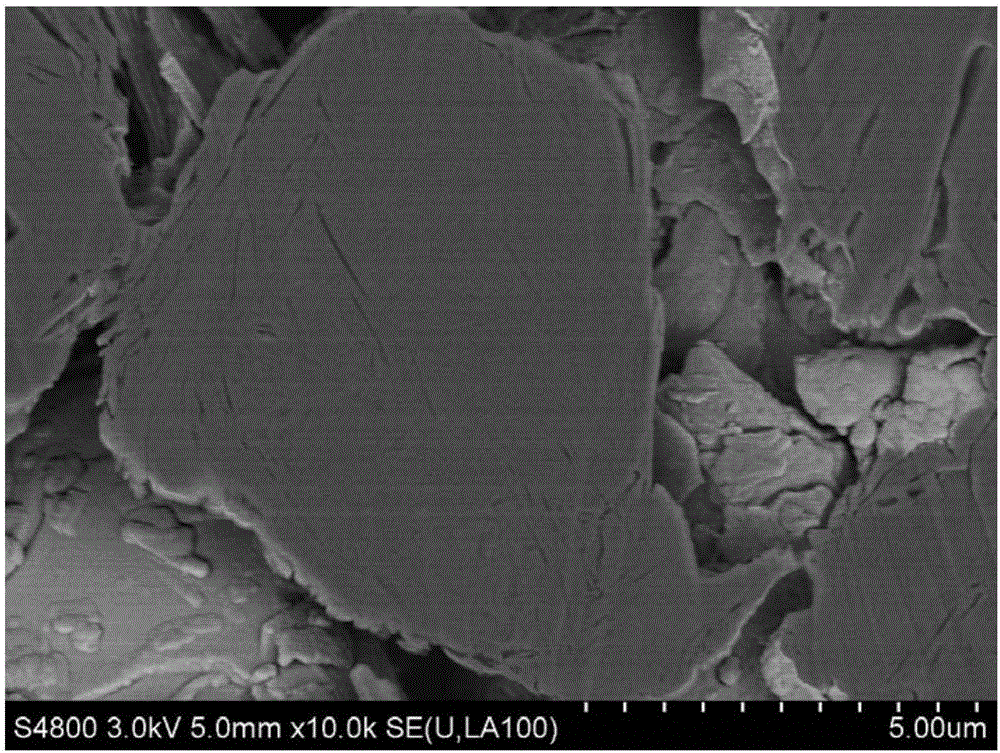

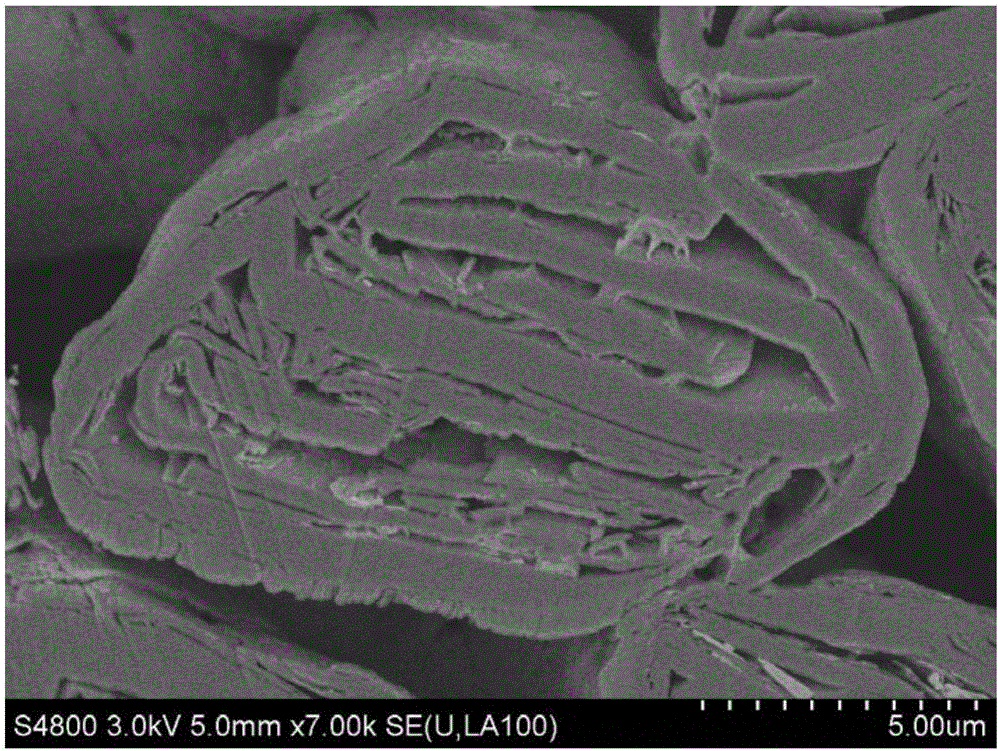

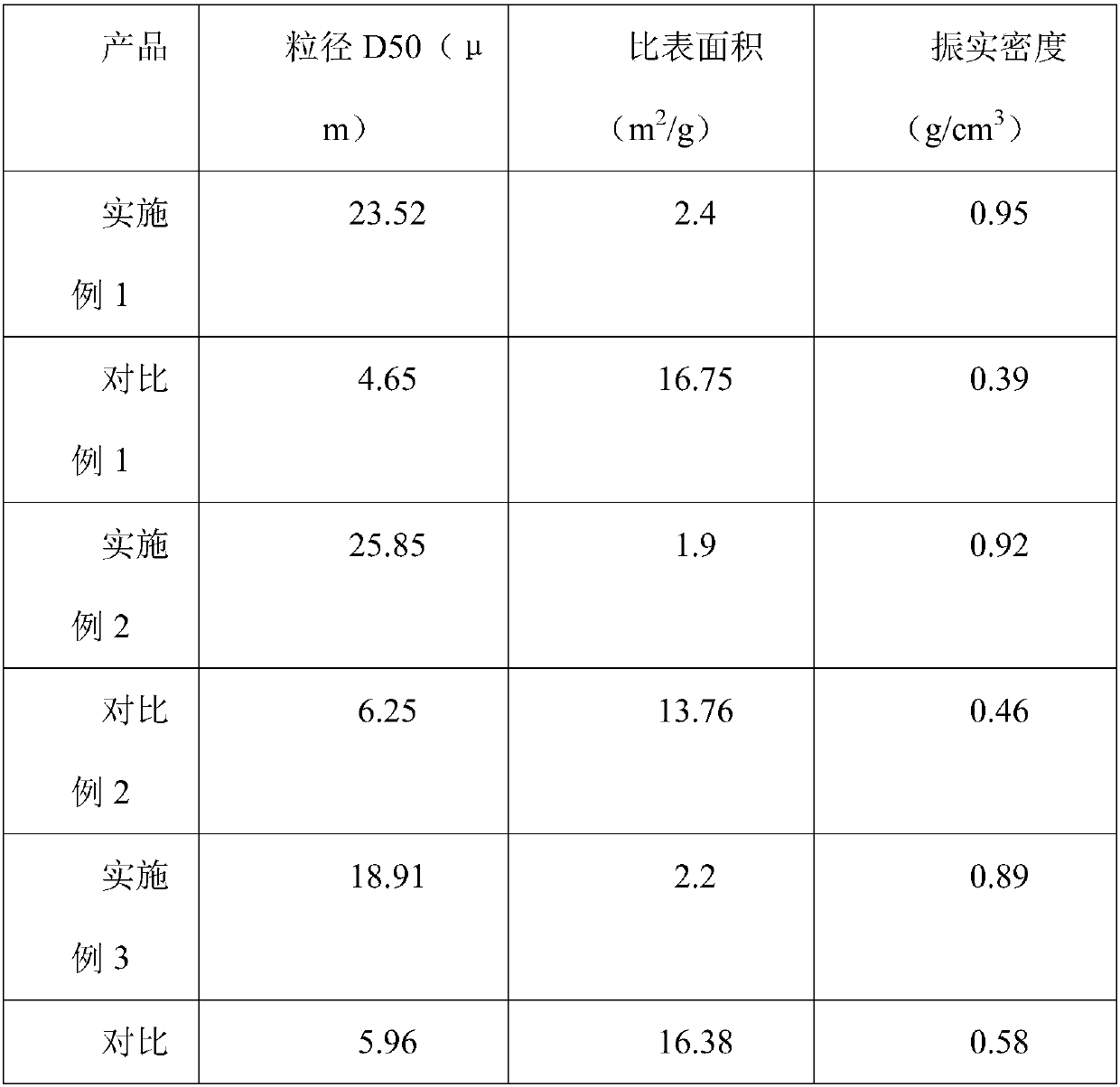

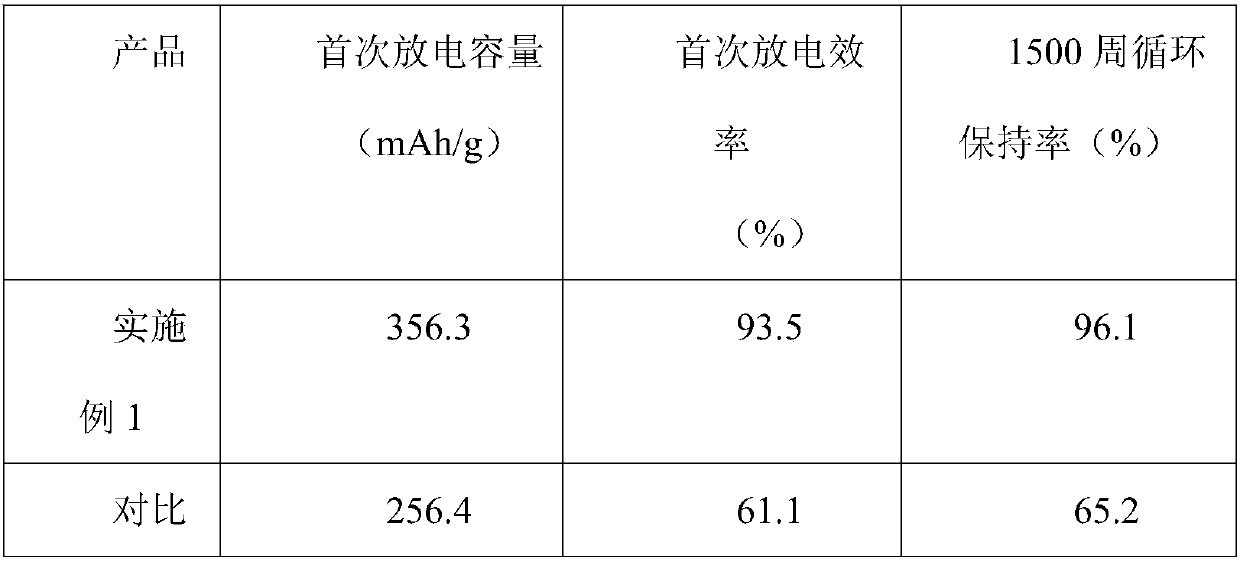

A soft carbon graphite composite anode material, a preparing method and a lithium ion battery

ActiveCN106252596APromote circulationSufficient liquidityCell electrodesSecondary cellsCarbonizationCarbon graphite

A preparing method of a soft carbon graphite composite anode material is provided. The method includes S1) a step of mixing natural spherical graphite and asphalt, heating and dipping under a preset pressure after fully mixing to allow the asphalt to be softened and to flow into and fill inner pores of the natural spherical graphite, and cooling to obtain an intermediate, and S2) a step of carbonizing the intermediate, crushing and grading to obtain the composite anode material. According to the method, the asphalt is softened at a high temperature, flows into and fills the inner pores of the graphite particles and then carbonization is performed to obtain the composite anode material with excellent cyclic performance. The method is simple in process, low in cost and high in practicality. The soft carbon graphite composite anode material prepared by the method and a lithium ion battery applying the soft carbon graphite composite anode material are also provided.

Owner:BTR NEW MATERIAL GRP CO LTD

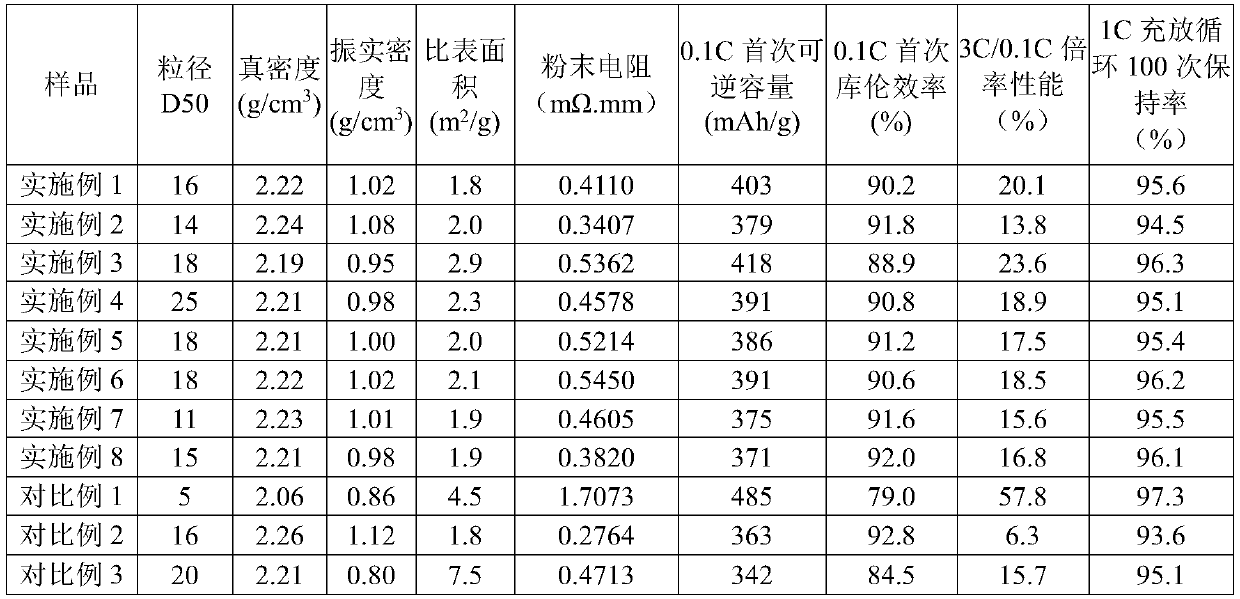

Preparation method of soft/hard carbon modified anode material for lithium ion batteries

InactiveCN107845810ALow tap densityHigh tap densityCell electrodesSecondary cellsCarbon compositesDischarge efficiency

The invention discloses a preparation method of a soft / hard carbon modified anode material for lithium ion batteries. The method comprises the following steps: (1) carrying out mixed granulation; (2)screening and crushing; (3) mixing; (4) treating at high temperature; (5) screening; (6) modifying; (7) carrying out secondary carbonization. The method is characterized in that a soft carbon precursor and a hard carbon precursor are both used as binding agents, kneading and granulating are carried out at a certain temperature and under other conditions, small graphite particles are polymerized soas to enable the internal structure to be further densified and increase the volume density, high-temperature graphitization is then performed, and asphalt and resin are converted to pyrolytic carbon, so that a soft / hard carbon graphite composite systems is formed; the surface of the modified soft / hard carbon composite anode material is evenly coated with a layer of Ti3SiC2, having good electrical conductivity and stable chemical properties, and a conductive network, so that the improvement of the discharge capacity, discharge efficiency and cycling stability of the graphite anode material isbetter promoted.

Owner:SHENZHEN SINUO INDAL DEV

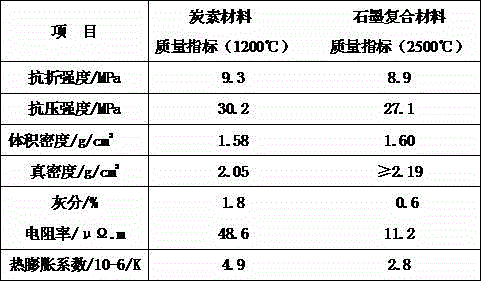

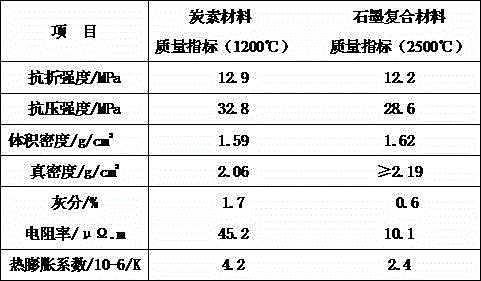

Preparation method of carbon-graphite composite material

The invention relates to a preparation method of a carbon-graphite composite material. The preparation method is characterized in that the carbon-graphite composite material is prepared from the following raw materials in percentage by weight: 1.5-2.5% of carbon black, 5%-8% of graphite with the particle size smaller than or equal to 1mm, 25%-30% of calcined petroleum coke powder with the particle size smaller than or equal to 0.075mm, 15%-20% of calcined petroleum coke with the particle size of 1mm-4mm, 10%-15% of electric calcined anthracite with the particle size of 4mm-10mm, 5%-10% of electric calcined anthracite with the particle size of 10mm-16mm, 5%-15% of calcined pitch coke with the particle size of 10mm-16mm, 18%-20% of coal pitch and short carbon fiber, wherein short carbon fiber is equal to 1%-3% of total weight of the raw materials. The carbon-graphite composite material is prepared by the steps of material preparation, mixed kneading, forming, roasting and graphitization and is excellent in performance, high in breaking strength, relatively good in thermal shock resistance and relatively low in expansion factor; the carbon-graphite composite material does not crack and break and has good stability.

Owner:SHANXI LIANGYU CARBON CO LTD

Nano carbon lubricating additive

InactiveCN1632081AImprove performanceImprove anti-friction and anti-wear effectInorganic pigment treatmentAdditivesMedical equipmentCarbon graphite

Disclosed is a nm carbon lubricity additive belongs to preparing technique of lubricant material, which is made by the following steps: make use of the effect high temperature electric arc of graphite (nm carbon ball ) pole in the discharge course of the graphite (nm carbon ball ) electric arc discharge method to generate carbon graphite (nm carbon ball ), then assemble them to do surface procession and supersonic dispersion, getting the carbon nm ball with diameter of 5-30 nm. Proved by experiment that after adding into carbon nm lubricity additive, its wear resistance is advanced remarkably, the friction coefficient is decreased by more than 60% and the friction coefficient of surface is notably advanced. Besides, with outstanding biological compatibility, it can be used as lubricity additive of elements of machine, biological and medical equipment. Therefore, the invention has significant practical value and potential application in biological and medical equipment field.

Owner:TSINGHUA UNIV

Hard carbon/graphite composite negative electrode material and lithium ion battery as well as preparation method and application thereof

ActiveCN111244407AHigh electron mobilityImprove conductivityCell electrodesSecondary cellsElectrolytic agentCarbon graphite

The invention discloses a preparation method of a hard carbon / graphite composite negative electrode material. The preparation method comprises: S1, carrying out a cross-linking reaction on a hard carbon source to obtain a hard carbon precursor, the hard carbon source being a thermoplastic polymer compound or a non-thermoplastic polymer compound; S2, mixing graphite, a hard carbon precursor and anadditive liquid phase, and drying; S3, carrying out pre-carbonization treatment and carbonization treatment; and S4, performing surface coating treatment. The hard carbon / graphite composite negative electrode material prepared by the preparation method is good in adaptability to electrolyte and other additives, the lithium ion battery prepared from the hard carbon / graphite composite negative electrode material is high in capacity and good in rate capability and cycle performance, and the preparation method is simple and feasible in process, wide in raw material source and low in cost and has awide application prospect.

Owner:SHANGHAI SHANSHAN TECH CO LTD

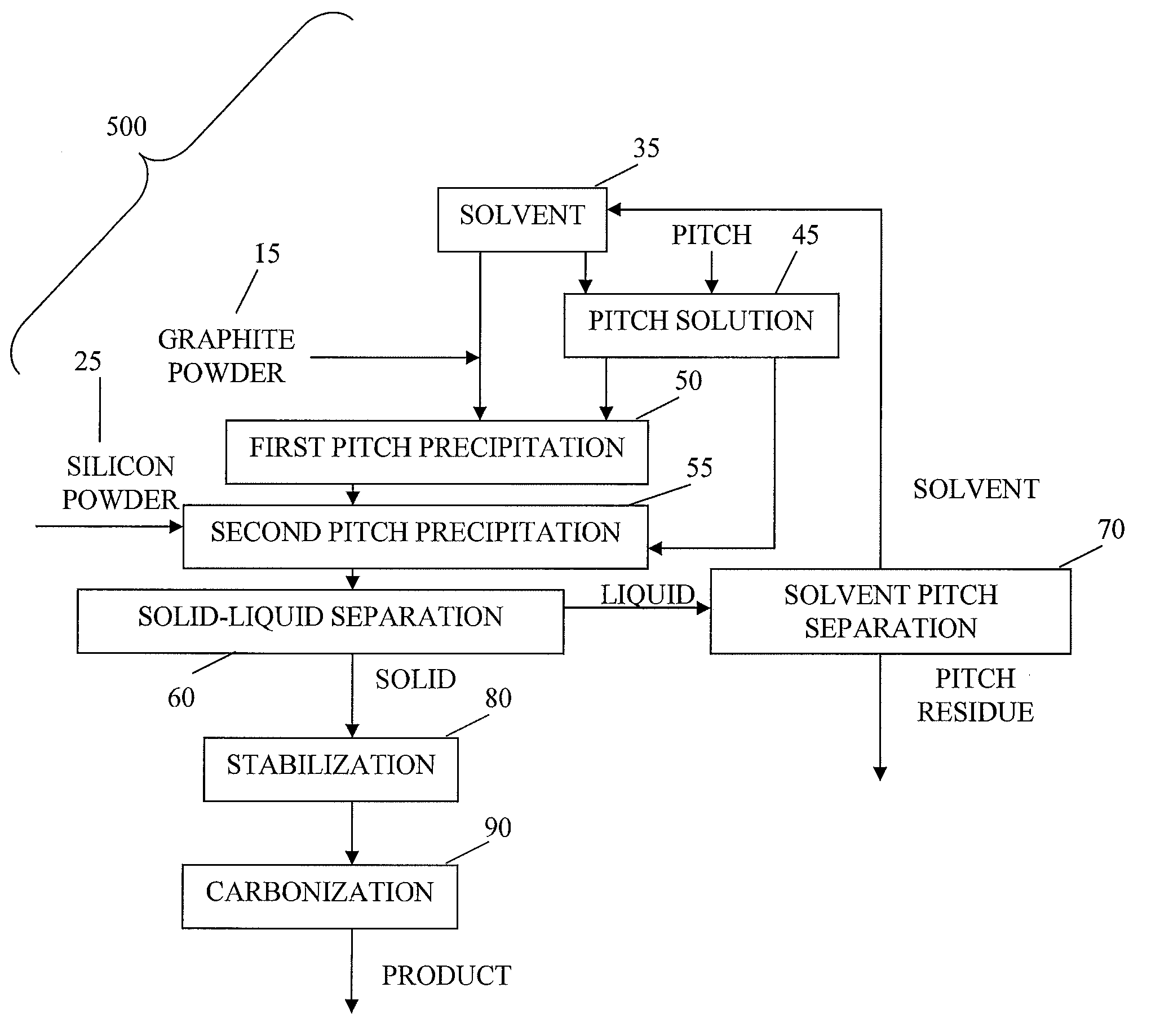

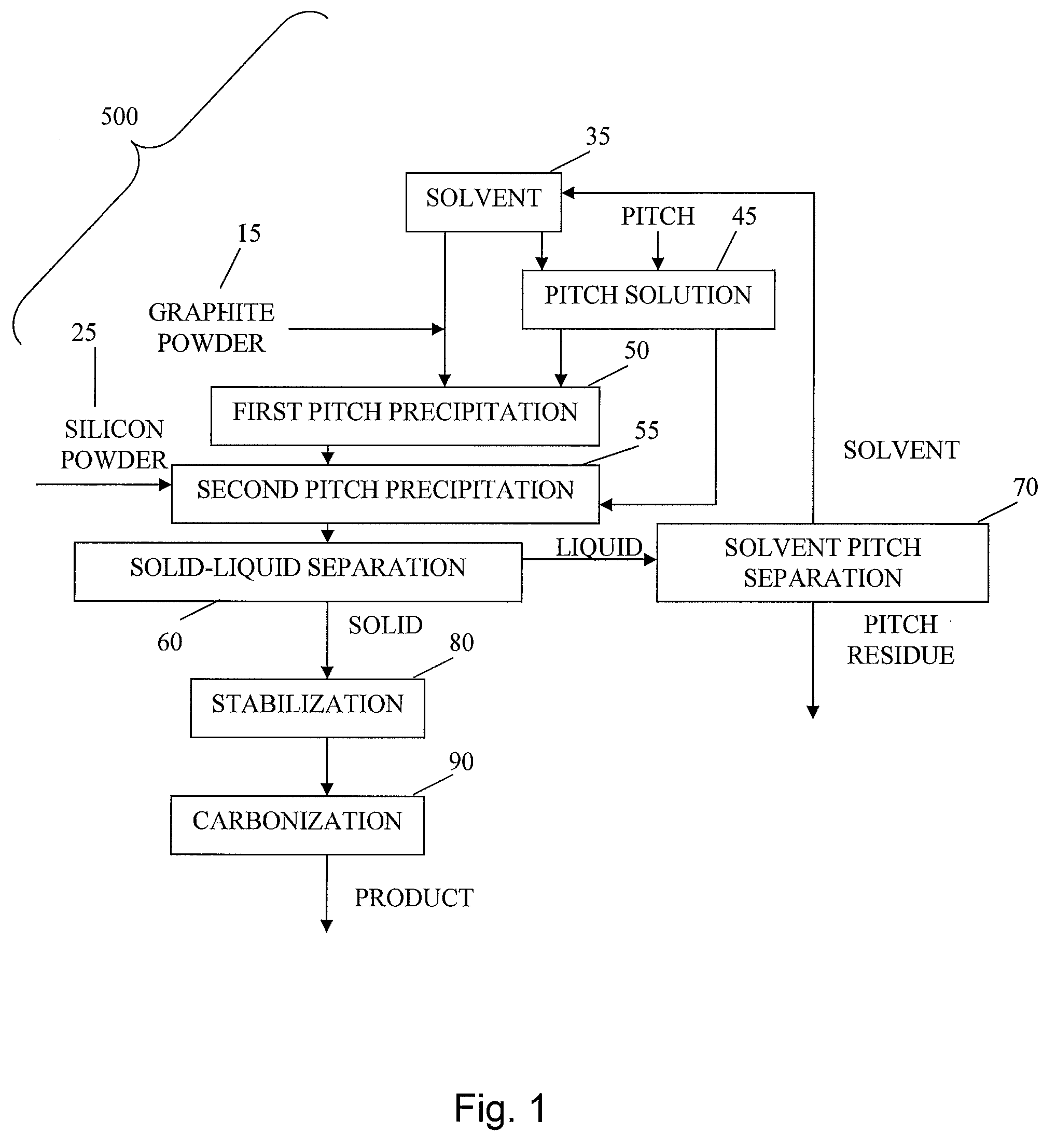

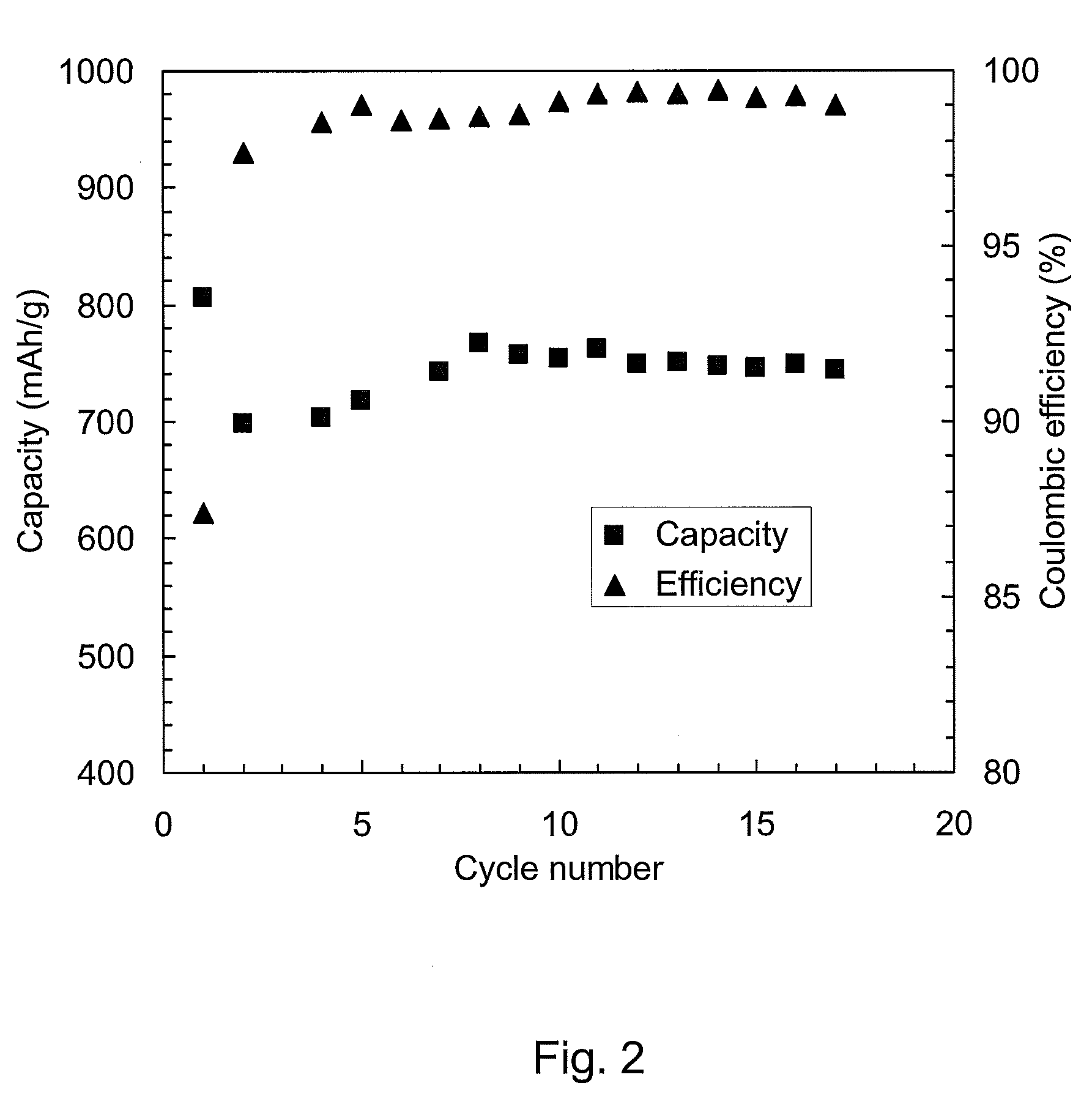

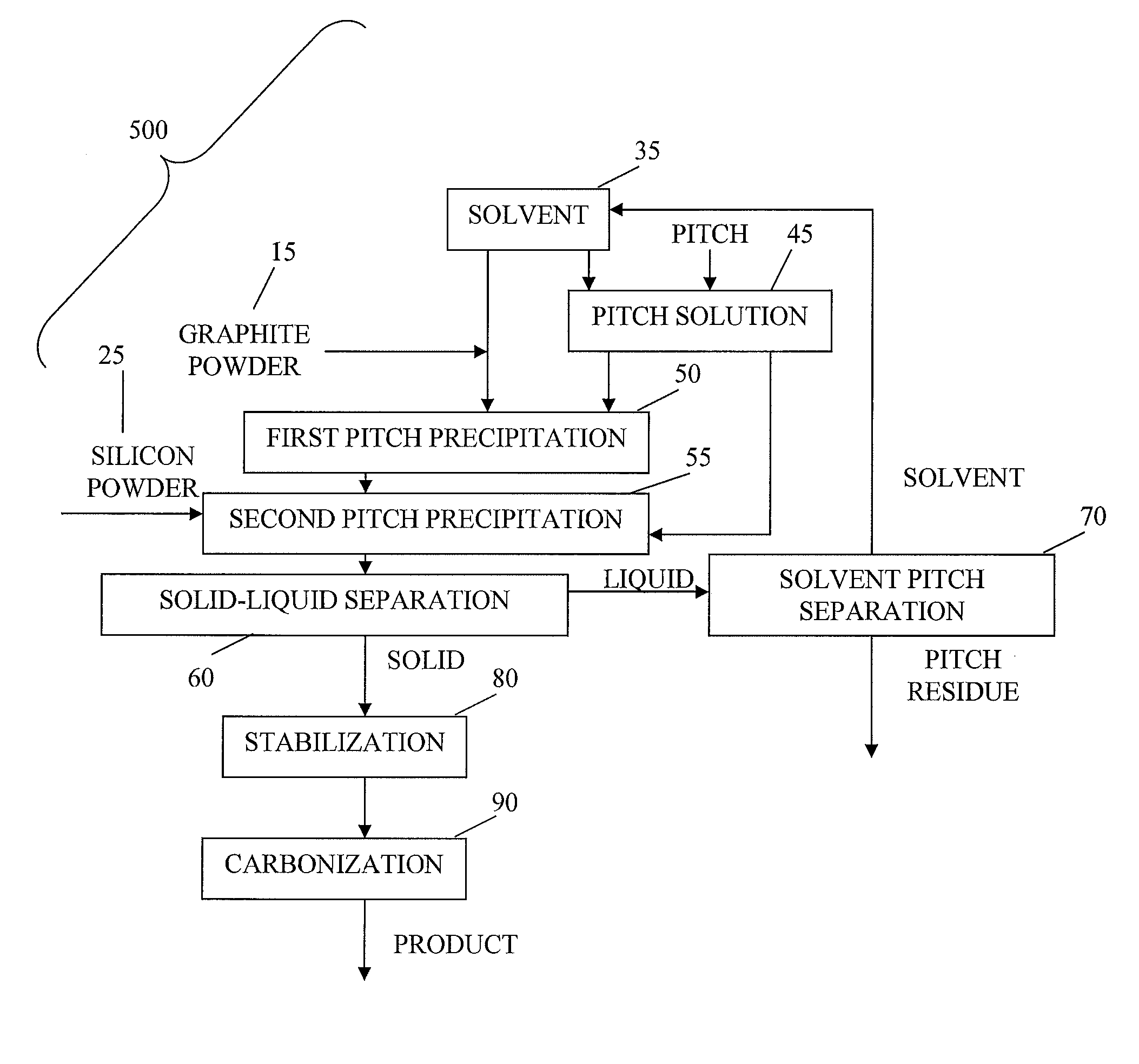

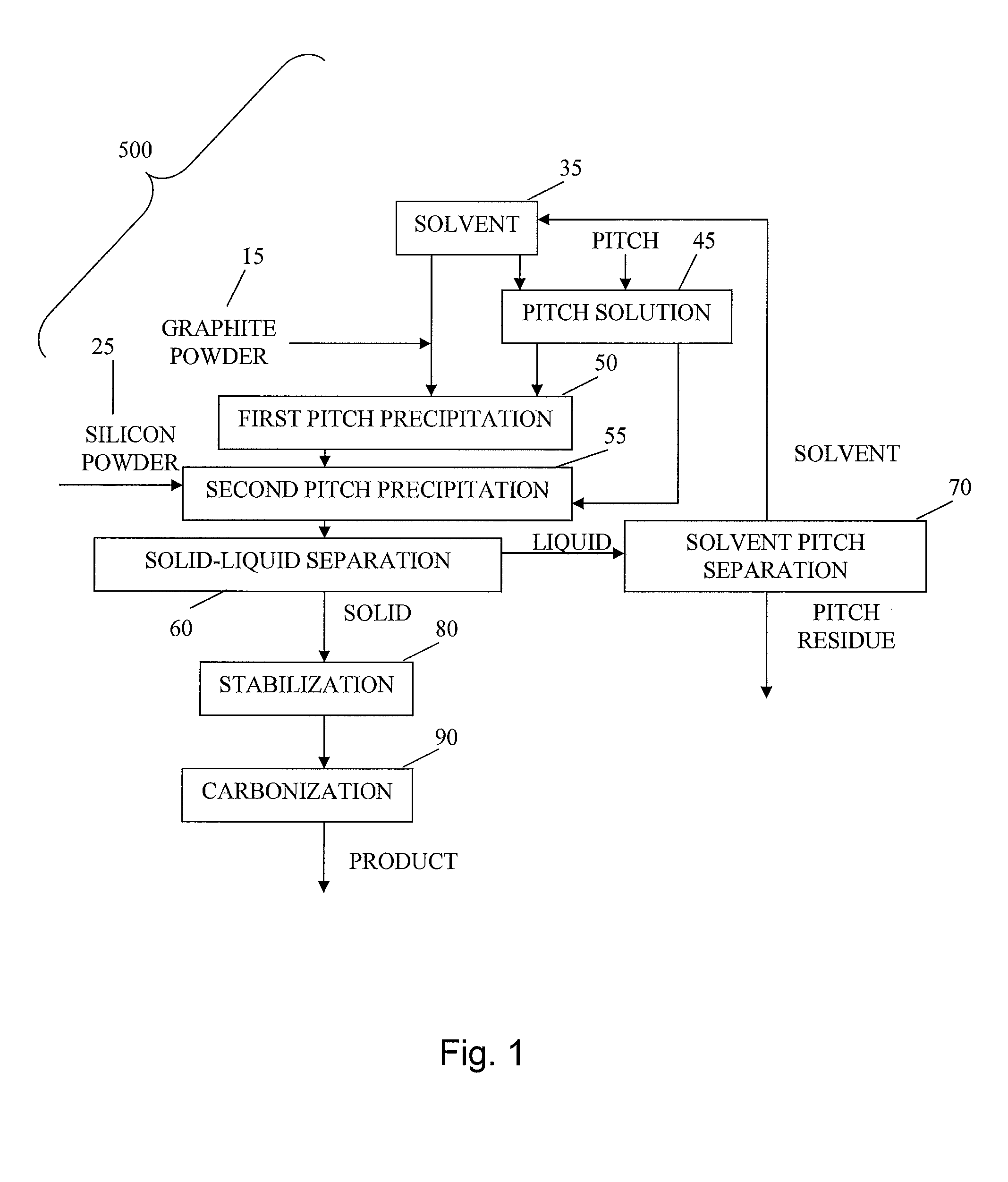

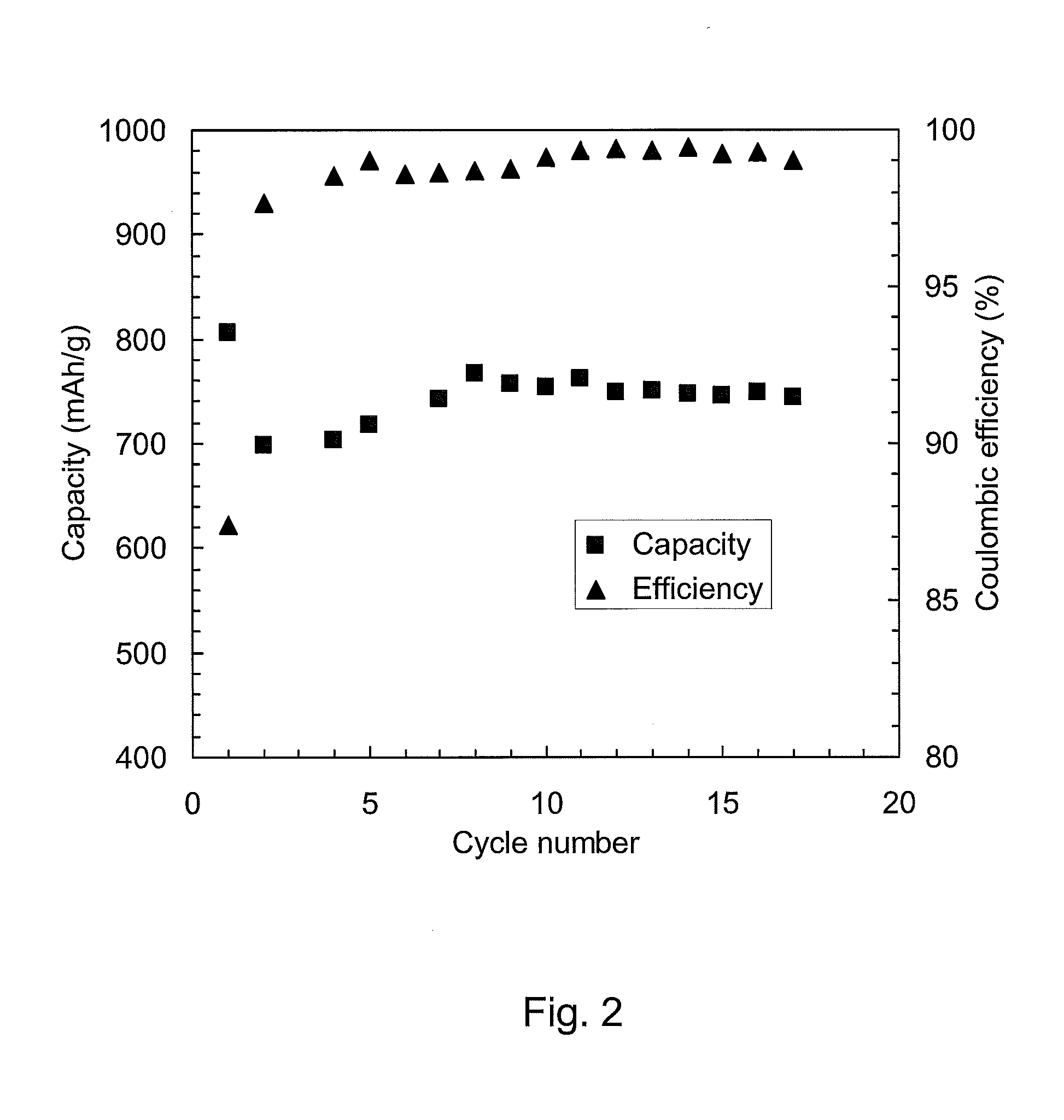

Methods of preparing composite carbon-graphite-silicon particles and using same

A process for production of coated silicon-carbon composite particles includes providing a carbon residue-forming material, providing particles of a carbonaceous material, and coating in a liquid suspension mixture the particles of carbonaceous material with the carbon residue-forming material to form coated carbonaceous particles. Providing silicon particles added to the mixture, coating the silicon particles embedded on the coated carbonaceous particles to form silicon-carbon composite particle. Some embodiments utilize the composite particle in an anode of a battery.

Owner:PYROTECK INC

Porous power and ground planes for reduced PCB delamination and better reliability

InactiveUS20030196749A1Reduce failureImprove solderabilityPorous dielectricsWave amplification devicesPolyesterMetal coating

Power and ground planes that are used in Printed Circuit Boards (PCBs) and that comprise porous, conductive materials are disclosed. Using porous power and ground plane materials in PCBs allows liquids (e.g., water and / or other solvents) to pass through the power and ground planes, thus decreasing failures in PCBs (or PCBs used as laminate chip carriers) caused by cathodic / anodic filament growth and delamination of insulators. Porous conductive materials suitable for use in PCBs may be formed by using metal-coated organic cloths (such as polyester or liquid crystal polymers) or fabrics (such as those made from carbon / graphite or glass fibers), using metal wire mesh instead of metal sheets, using sintered metal, or making metal sheets porous by forming an array of holes in the metal sheets. Fabrics and mesh may be woven or random. If an array of holes is formed in a metal sheet, such an array may be formed with no additional processing steps than are performed using conventional PCB assembly methods.

Owner:GLOBALFOUNDRIES INC

Riser heating and insulating agent

InactiveCN101798233AHas the double effect of heat preservationWith feverFoundry mouldsFoundry coresCarbon graphiteSteel casting

The invention discloses a riser heating and insulating agent, which comprises the following components in percentage by weight: 5 to 35 percent of Al, 10 to 25 percent of AlN, 3 to 20 percent of low-carbon graphite, 5 to 25 percent of magnesia-alumina spinel, 5 to 15 percent of quartz, 10 to 30 percent of ferric oxide powder, 5 to 20 percent of corundum, 5 to 10 percent of organosilicon phlogopite, and 1 to 10 percent of MgO; and the riser heating and insulating agent is prepared by the following processes: crushing, pulverizing, mixing, pelletizing, drying, and the like. The riser heating and insulating agent has double effects of heating and insulating, and has good insulating effect. Because the riser heating and insulating agent has a granular appearance, dust and smoke are not generated in the using process, and the environment is not polluted. Due to the adoption of the low-carbon graphite, castings do not have carburizing phenomenon, and the molten steel is not polluted. The riser heating and insulating agent is particularly applied to open risers of low carbon steel large-scale steel castings and stainless steel castings with the weight of over 80 tons.

Owner:HENAN UNIV OF SCI & TECH

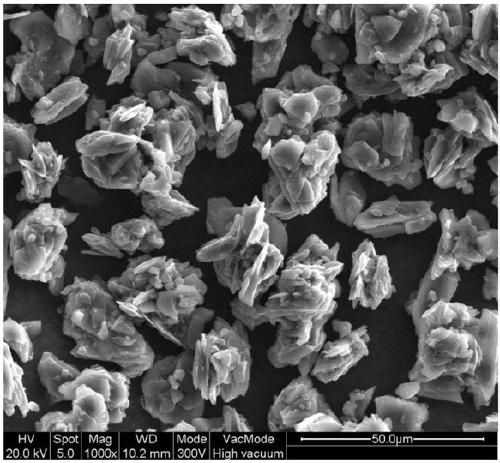

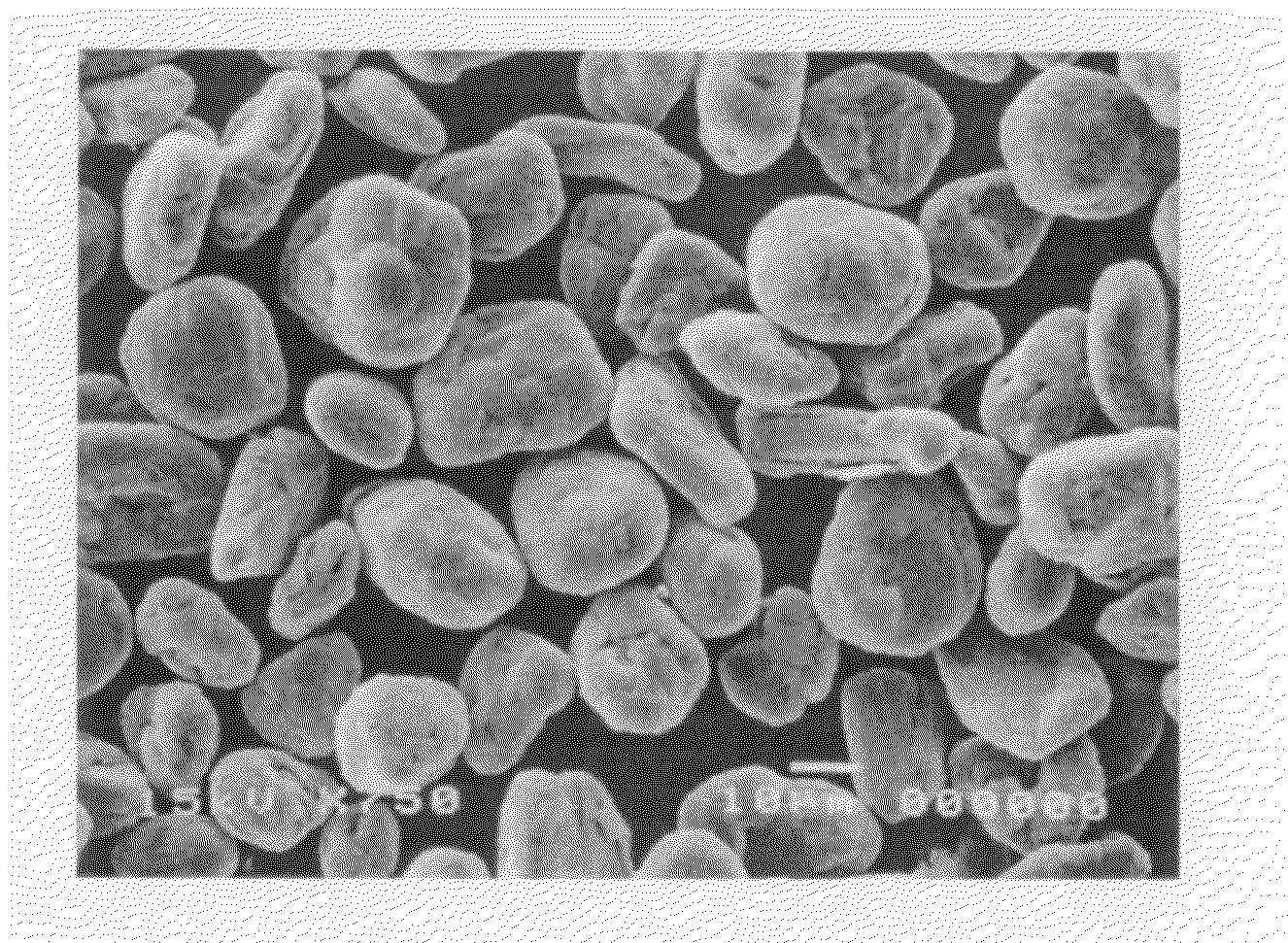

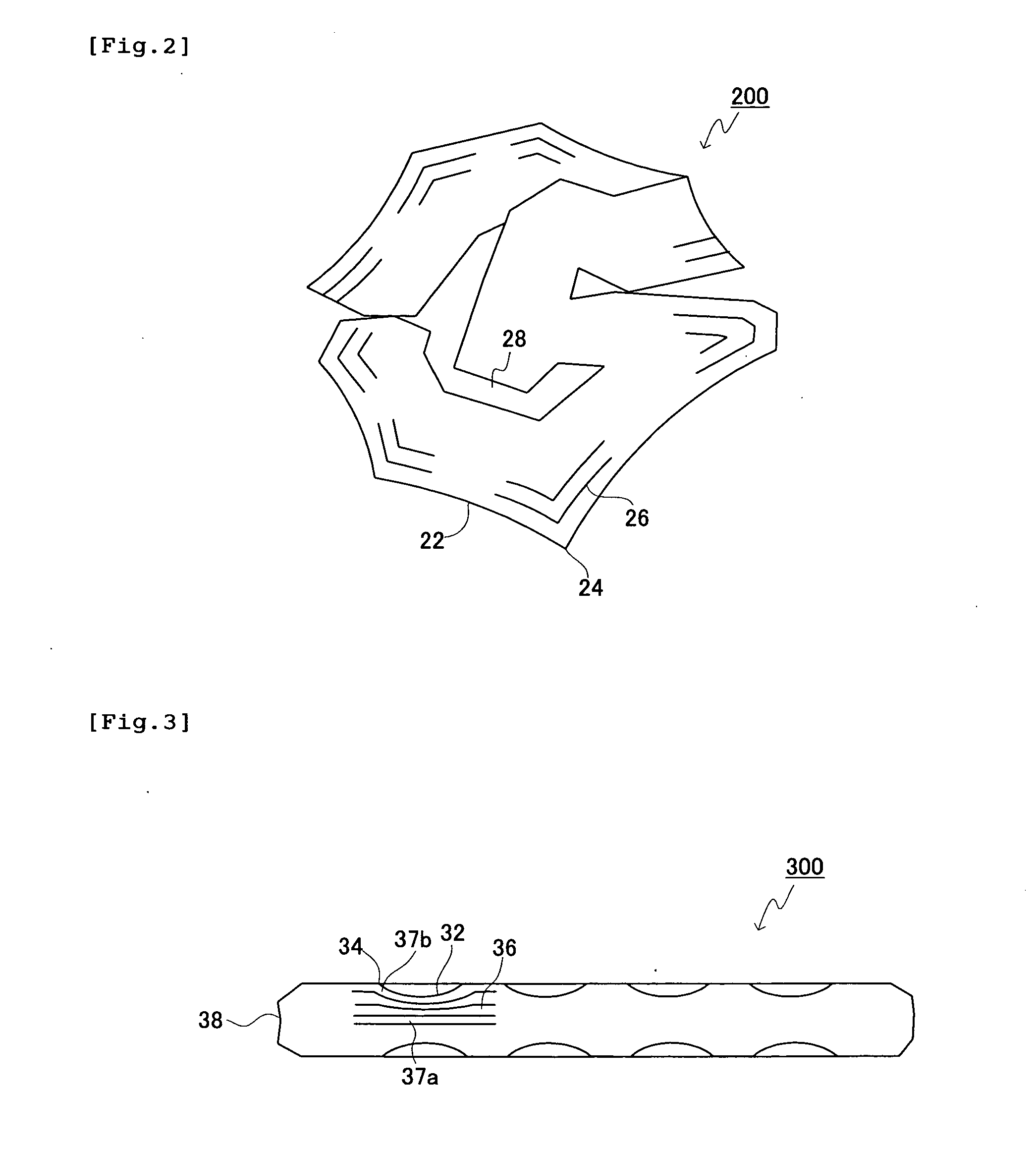

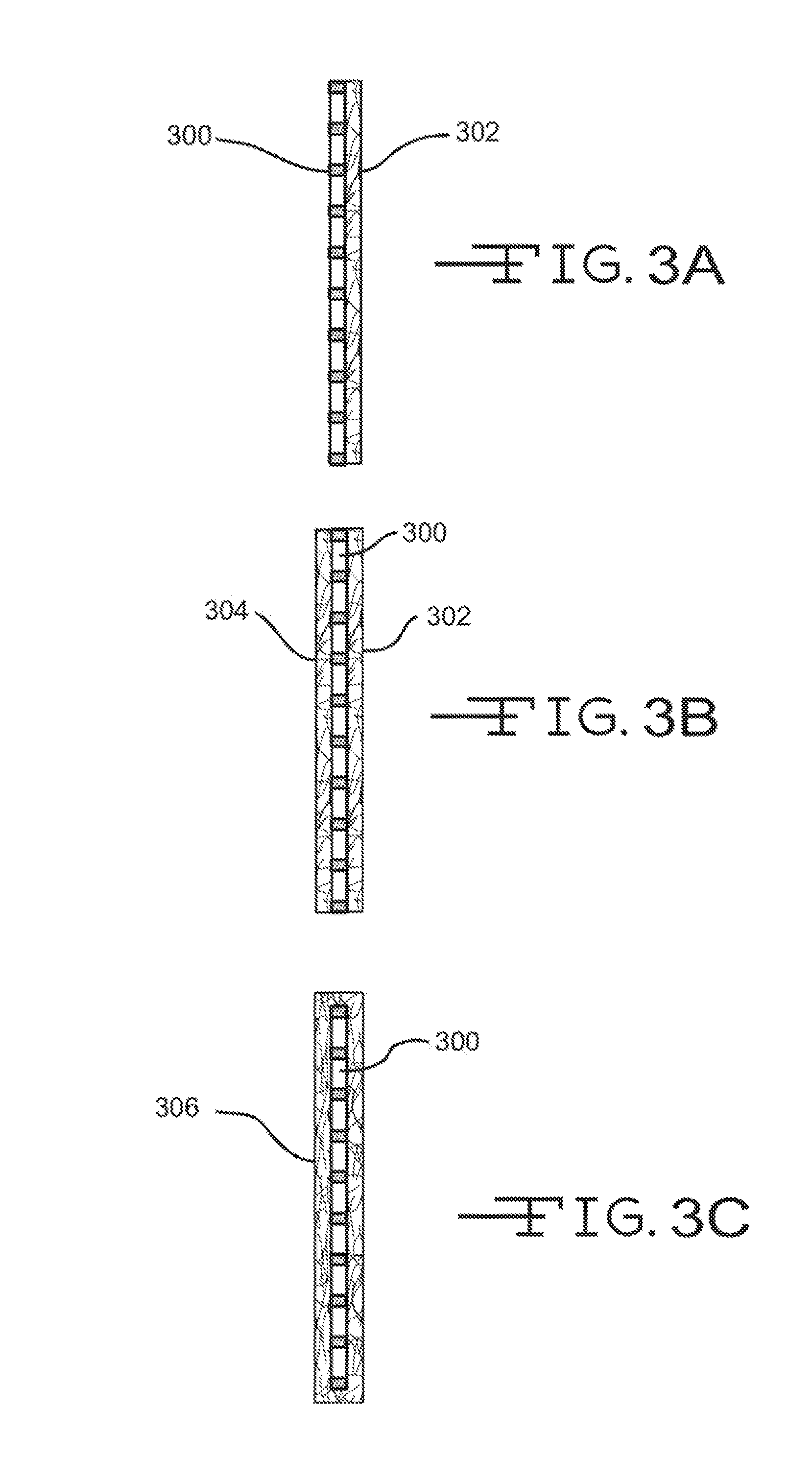

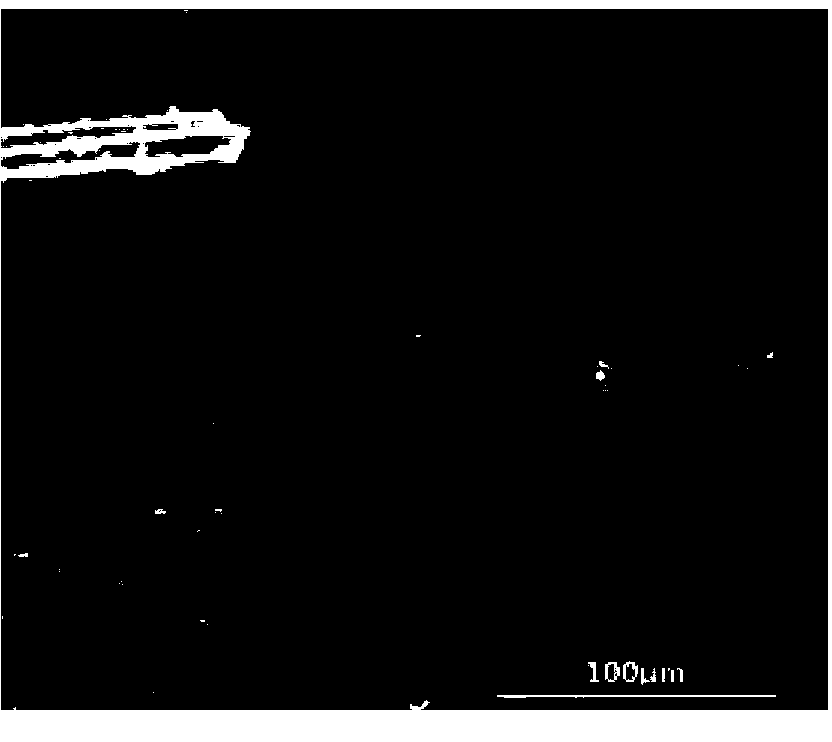

Graphite Particle, Carbon-Graphite Composite Particle and Their Production Processes

ActiveUS20090258298A1Improved cycle life characteristicsLarge capacityGraphiteElectrode carriers/collectorsCarbon layerLithium

The present invention relates to a graphite particle and a carbon-graphite composite particle both suitable for use in electrode for lithium ion secondary battery, as well as to processes for producing these particles.The graphite particle of the present invention has an average particle diameter of 5 to 50 μm, wherein one or more recesses having a depth of 0.1 to 10 μm are formed in the surface. The graphite particle is produced by a mixing step for mixing raw material graphite particles and recess-forming particles, a press molding step for press-molding the mixture composed of the raw material graphite particles and the recess-forming particles to obtain a molded article, a pulverization step for pulverizing the molded article, and a separation step for separating and removing the recess-forming particles from the pulverized molded article. The carbon-graphite composite particle of the present invention is produced by performing a thermal CVD step which comprises covering the surface of the above-mentioned graphite particle with a carbon layer.

Owner:NIPPON POWER GRAPHITE CO LTD

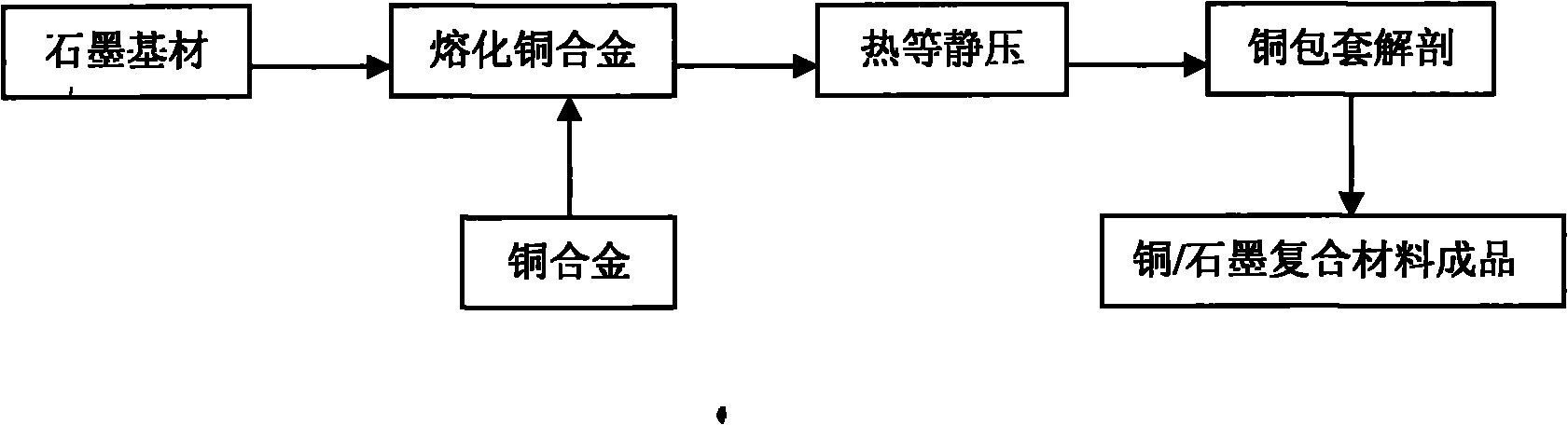

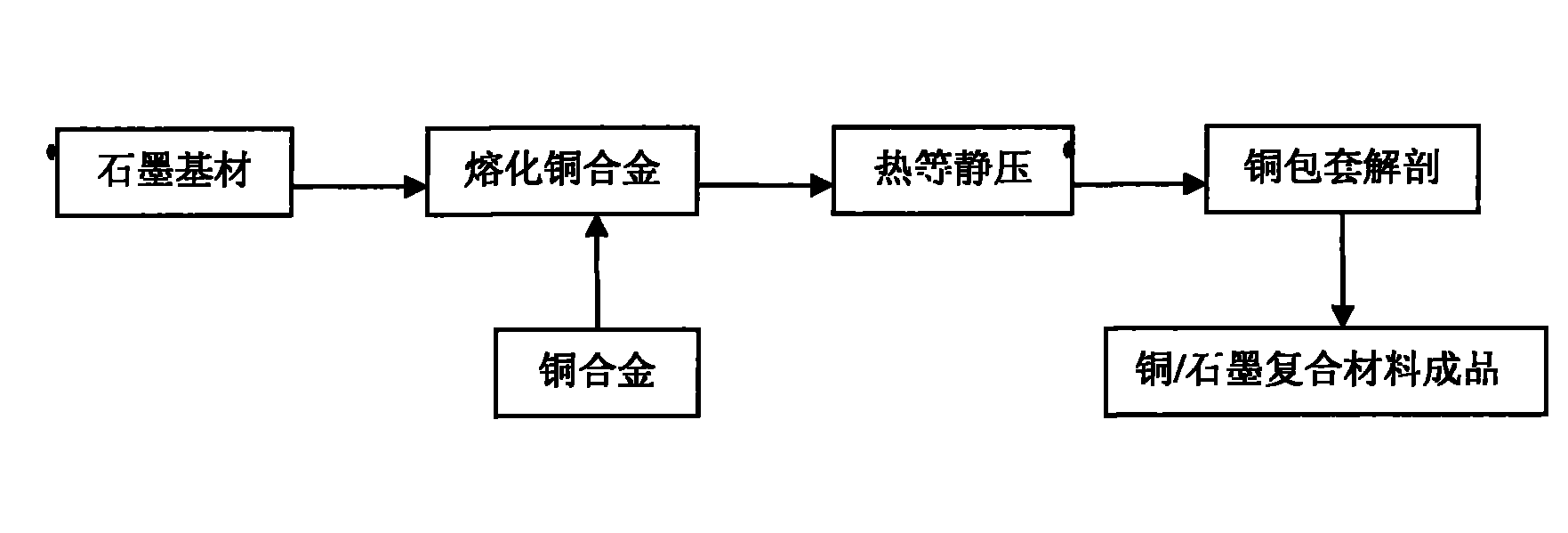

Copper/graphite compound material and preparation method thereof

ActiveCN102146552AHigh mechanical strengthIncreased mechanical toughnessHot-dipping/immersion processesThermal insulationCarbon graphite

The invention relates to a copper / graphite compound material and a preparation method thereof. In the compound material, carbon graphite is used as a substrate material, and a tin bronze alloy is used as a dipping metal. The preparation method comprises the following steps: (1) melting the tin bronze alloy to meltwater in a heat treatment furnace, immersing carbon graphite material blocks, and cooling so as to form a copper clad wrap coated by the graphite material blocks; (2) putting the copper clad wrap obtained in the step (1) in a hot isostatic press for hot isostatic press dipping at the temperature of 1100-1300 DEG C under the pressure of 60-80MPa at the atmosphere of argon, carrying out thermal insulation and pressure preservation for 60-120 minutes, and then carrying out belt pressure cooling; and (3) taking out the copper clad wrap obtained in the step (2) and then dissecting the copper clad wrap by using a machining method. The copper / graphite compound material is applied to machinery motive seal or bearings with high parameters (the temperature changes between minus 253 to 350 DEG C and the rotate speed is over 10000 rpm).

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

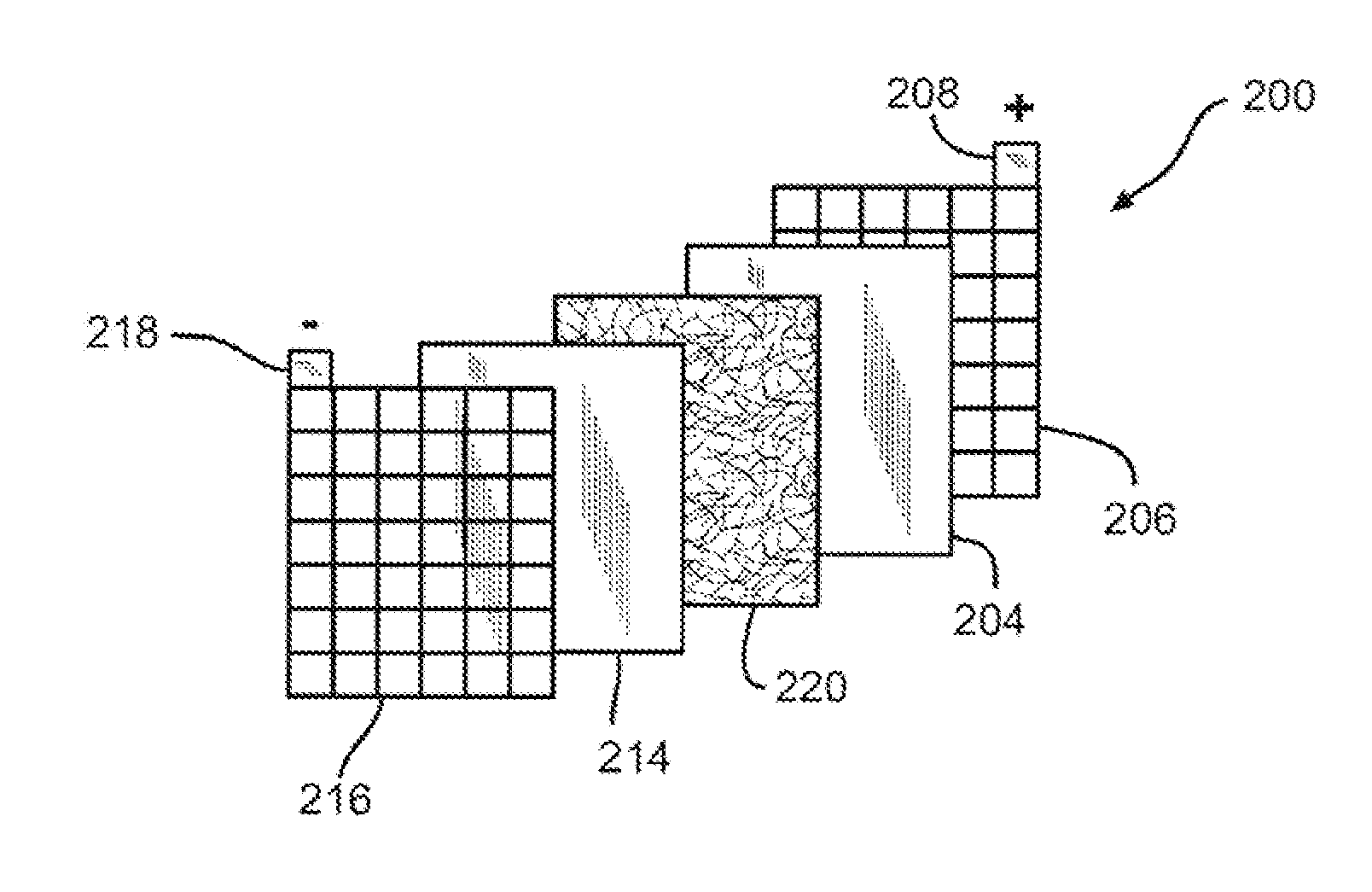

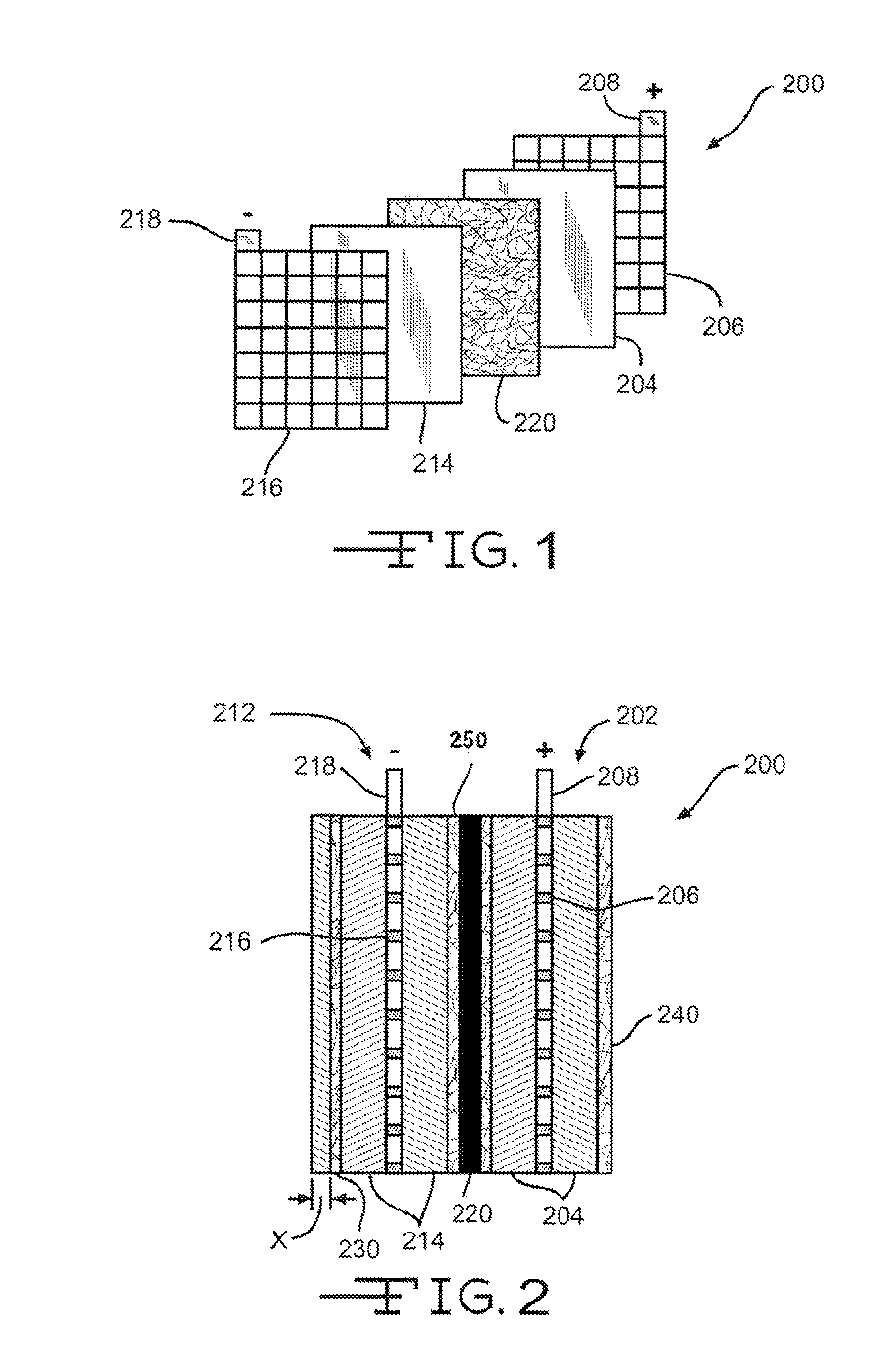

Methods of preparing composite carbon-graphite-silicon particles and using same

InactiveUS20090252864A1Electrode thermal treatmentNegative electrodesCarbon compositesCarbon graphite

A process for production of coated silicon-carbon composite particles includes providing a carbon residue-forming material, providing particles of a carbonaceous material, and coating in a liquid suspension mixture the particles of carbonaceous material with the carbon residue-forming material to form coated carbonaceous particles. Providing silicon particles added to the mixture, coating the silicon particles embedded on the coated carbonaceous particles to form silicon-carbon composite particle. Some embodiments utilize the composite particle in an anode of a battery.

Owner:PYROTECK INC

Pasting paper made of glass fiber nonwoven comprising carbon graphite

ActiveUS20150099189A1Enhance electron flowImprove charge acceptanceElectrode manufacturing processesFinal product manufactureElectron flowCarbon graphite

Embodiments of the invention provide a lead-acid battery having a positive electrode, a negative electrode, and a separator positioned between the electrodes to electrically insulate the electrodes. Battery includes a nonwoven fiber mat positioned adjacent an electrode. Mat includes a mixture of first glass fibers having diameters between 8 μm to 13 μm and second glass fibers having diameters of at least 6 μm and a silane sizing. An acid resistant binder bonds the glass fibers to form mat. A wetting component is applied to increase the wettability such that mat exhibits an average water wick height of at least 1.0 cm after exposure to water for 10 minutes. A conductive material is disposed on a surface of mat such that when mat is adjacent an electrode, the conductive material contacts the electrode. An electrical resistance of less than 100,000 ohms per square enables electron flow about mat.

Owner:JOHNS MANVILLE CORP

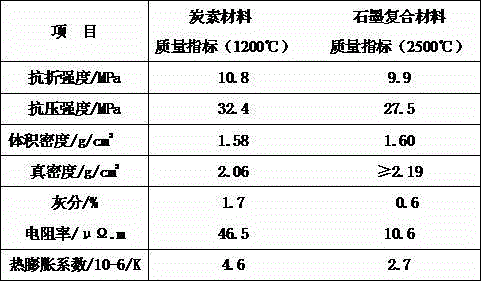

Production method for composite carbon graphite material

The invention relates to a production method for a composite carbon graphite material. The method comprises the following steps: putting pitch coke powder and carbon black in a kneading kettle for mixed kneading, adding melted coal pitch heating and keeping the temperature to obtain carbon powder; putting three carbon fibers in a mixing tank and adding a polyvinyl alcohol aqueous solution to prepare a carbon fiber mixed solution; and adding the carbon powder and the carbon fiber mixed solution to the kneading kettle for mixed kneading, press forming, high-temperature roasting, coal pitch soakage, secondary high-temperature roasting, rough turning, resin soakage, machine processing, secondary resin soakage and grinding into powder. The prepared carbon powder and short fibers are roasted into the composite carbon graphite material which improves the thermal shock resistance, the strength and the impact resistance by 50 percent to 100 percent than a common carbon material and has excellent wearing resistance, thereby being a first-choice carbon graphite material in the aeronautical and astronautic industry and the war industry.

Owner:WUXI ZHONGQIANG ELECTRIC CARBON CO LTD

Preparation method for carbon/carbon-graphite composite material used for pantograph slide plate of high-speed train

The invention relates to a preparation method for a carbon / carbon-graphite composite material, and particularly relates to a preparation method for a carbon / carbon-graphite composite material used for a pantograph slide plate of a high-speed train. The objective of the invention is to solve problems, namely bad mechanical properties and weak conductivity, of carbon / carbon composite materials prepared in the prior art. The method comprises specific operation steps of (1) preparation of a graphite suspending liquid; (2) preparation of a graphite prefab; and (3) dipping-carbonization densification of asphalt. The method is advantaged by (1) improving mechanical properties of carbon slide plates; (2) reducing resistivity of the carbon slide plates and increasing conductivity; and (3) reducing damage to contact nets and reducing arc wear. The carbon / carbon-graphite composite material is mainly used for materials of the pantograph slide plate of the high-speed train.

Owner:HARBIN INST OF TECH

Method for manufacturing large-specification carbon graphite sealing material matrix

A method for manufacturing a large-specification carbon graphite sealing material matrix comprises the following steps that 1, carbon black and modified pitch are subjected to mixing and pinching, lump making and carbonizing treatment, secondary carbon black powder is obtained, a dispersing agent and modified pitch are mixed and stirred, and modified pitch slurry is obtained; 2, coke powder, graphite powder and the secondary carbon black powder are mixed, mixed powder is obtained, then the mixed powder and the modified pitch slurry are subjected to mixing and pinching, flaking and smashing, flakes are obtained, mesocarbon microbeads and the obtained flakes are mixed, and mixed aggregate is obtained; 3, the mixed aggregate is subjected to isostatic compaction treatment, and green blanks are obtained after demolding; 4, the green blanks are calcined and carbonized, and the carbon graphite sealing material matrix is obtained.The method for manufacturing the large-specification carbon graphite sealing material matrix is short in machining period and low in production cost, and the obtained carbon graphite sealing material matrix has the advantages of being large in specification, high in strength and the like.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

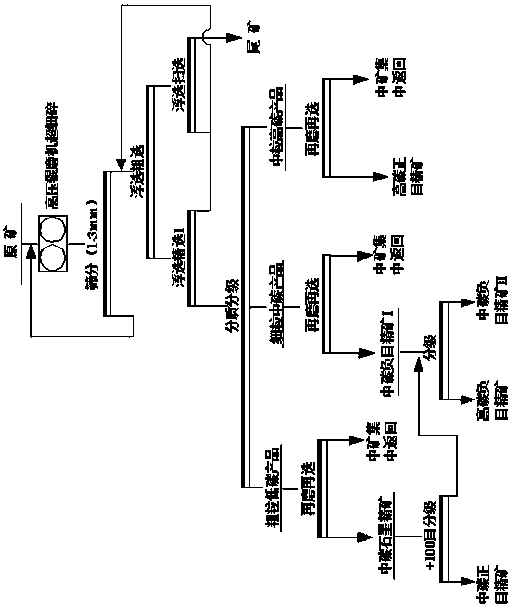

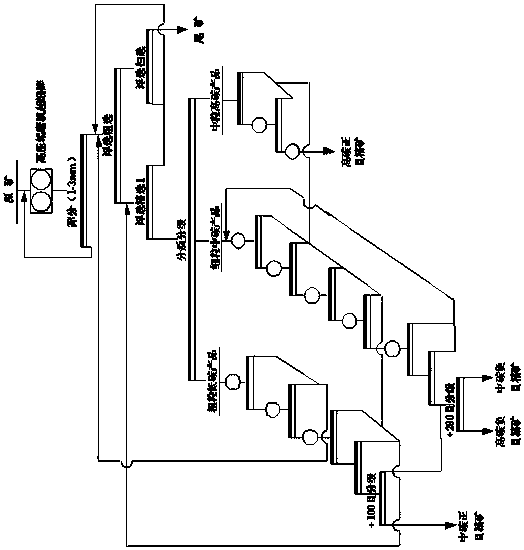

Grading and separating method for protecting crystalline graphite flakes

The invention provides a grading and separating method for protecting crystalline graphite flakes, and aims to solve the problem of high loss rate of the crystalline graphite flakes. The method comprises the following steps: (1) performing closed circuit grinding on raw ore with a high-pressure grinding roller; (2) grading and separating a ground product obtained in step (1) after 'primary rougherflotation, primary concentration and primary scavenging' flotation; (3) re-grinding and re-separating a coarse-grain low-carbon product to obtain medium-carbon graphite concentrate and middling, screening the medium-carbon graphite concentrate to obtain medium-carbon positive-mesh concentrate and medium-carbon negative-mesh concentrate I; re-grinding and re-separating a medium-grain high-carbon product to obtain high-carbon positive-mesh concentrate and middling; re-grinding and re-separating a fine-grain medium-carbon product to obtain medium-carbon negative-mesh concentrate I; grading the medium-carbon negative-mesh concentrate to obtain high-carbon negative-mech concentrate and medium-carbon negative mesh concentrate II. By adopting the method, differential separation of graphite is realized, and the added value of the graphite concentrate is increased.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Fiber reinforced concrete/cement products and method of preparation

InactiveUS7285167B2Improve propertiesHigh strengthSolid waste managementPolymer scienceCarbon fibers

Concrete and / or cement products and mixes with reinforcing carbon graphite fibers having a length of about 2½ inches to about 3½ inches, and / or nano and / or micron sized carbon fibers, and a method of reinforcing concrete.

Owner:OGDEN TECH

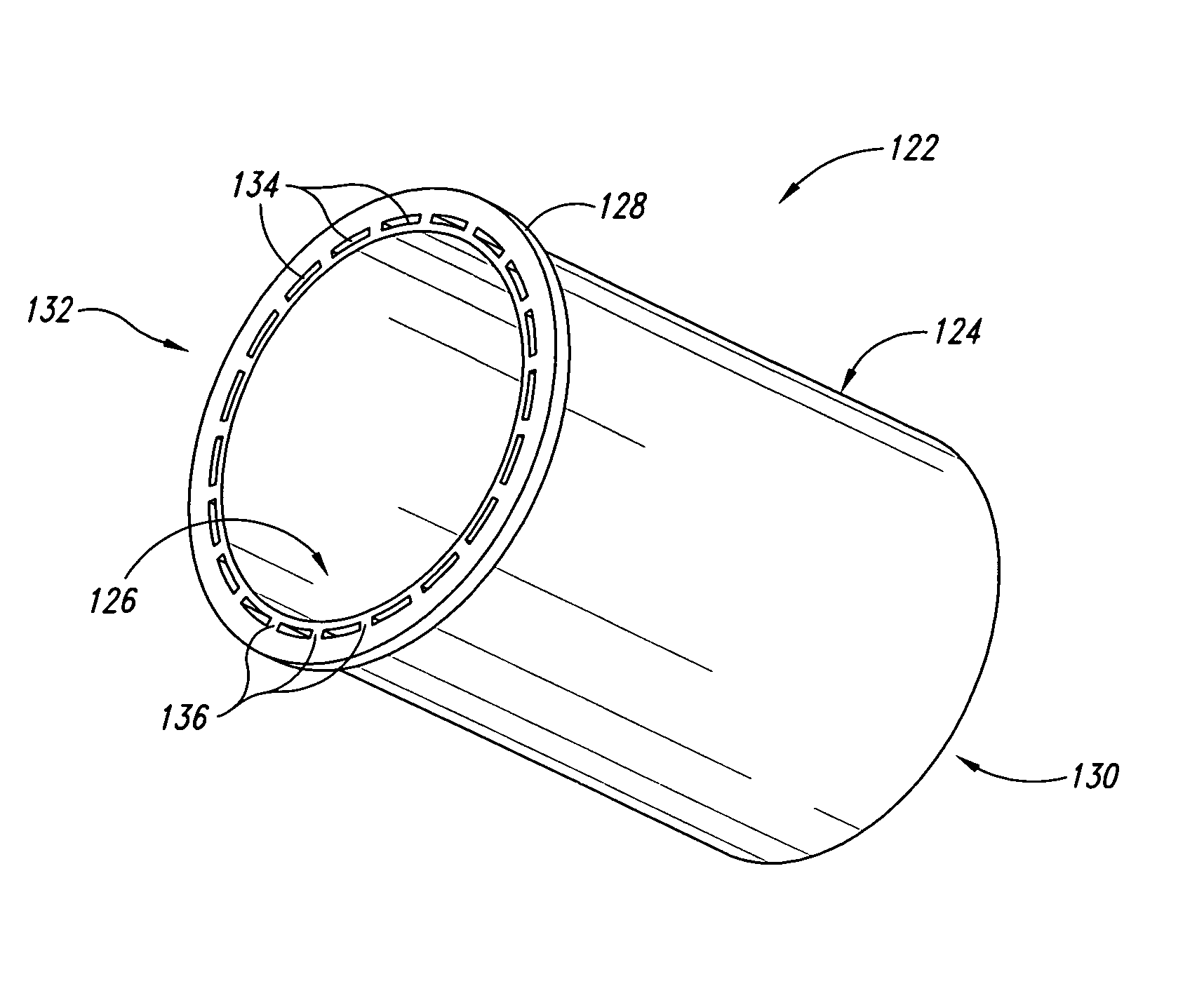

Fluid-cooled cylinder liner

InactiveUS7290506B2Improve thermal conductivityReduce manufacturing costCylinder headsCylindersParticulatesCarbon graphite

Particular embodiments of the present invention provide novel fluid-cooled cylinder liners. Preferred liners are annular cylinders containing a plurality of passages, arranged generally parallel to the axis of the cylinders, and integrated between the inner and outer surfaces of the cylinders. Preferably, the integral passages are arranged so that they are typically closer to the outer surface of the liner than the inner surface. Each passage has at least two openings. A passage with two openings on opposite end of the cylinder runs the entire length of the liner, while a passage with a opening at one end of the liner and a second opening along a surface of the liner runs only for a fraction of the liner length. In preferred embodiments, openings on the outer surface of the liner will be arranged in a circle lying on a plane perpendicular to the axis of the cylinder, and near either end of the cylinder; ensuring that each passage traverses the majority of the length of the liner. Preferably, the cylinder liners comprise at least one material selected from the group consisting of aluminum, a aluminum-based metal matrix composite (MMC) with a particulate reinforcement, superalloys, ceramic matrix composite (CMC), and carbon graphite foam. Preferably, the liners comprise a heating element.

Owner:BENMAXX

Porous carbon-graphene-metal oxide composite material and preparation method and application thereof

ActiveCN105914048AFast transferIncrease the areaHybrid capacitor electrodesHybrid/EDL manufactureInternal resistancePorous carbon

The invention discloses a porous carbon-graphene-metal oxide composite material and a preparation method and an application thereof. By the method, the porous carbon-graphene-metal oxide composite material is obtained by searching a substance with a porous material in the natural world, carrying out high-temperature thermal treatment on the substance and graphene oxide to obtain a porous carbon-graphene composite material and compounding a metal oxide on the composite material. By the porous carbon-graphene-metal oxide composite material, the contradictive problems that the artificially prepared porous material is discontinuous in specific surface area and structure and relatively high in internal resistance can be solved; the specific surface area and the conductivity of the porous material are further improved by a graphene material; and the characteristics of high specific surface area and high conductivity are unified on the same composite material. Meanwhile, the capacitive property of the composite material and the strength of the composite material can be further improved by addition of the metal oxide; the composite material can be applied to the aspects of a super capacitor electrode material and the like; the production process is simple and feasible; and the production cost is low.

Owner:XIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com