Hard carbon/graphite composite negative electrode material and lithium ion battery as well as preparation method and application thereof

A negative electrode material, hard carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor high-current charge and discharge performance, poor compatibility with electrolyte, poor stability, etc., to improve transmission, increase voltage The effect of solid density and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

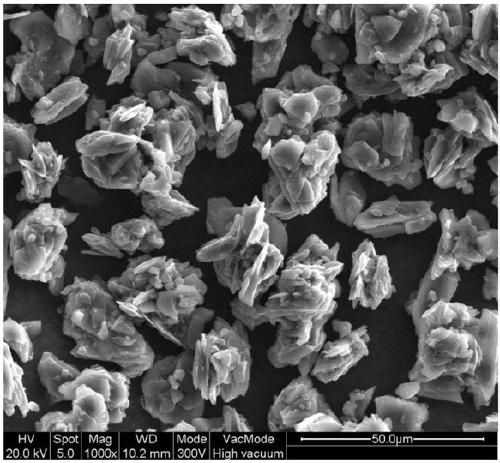

Image

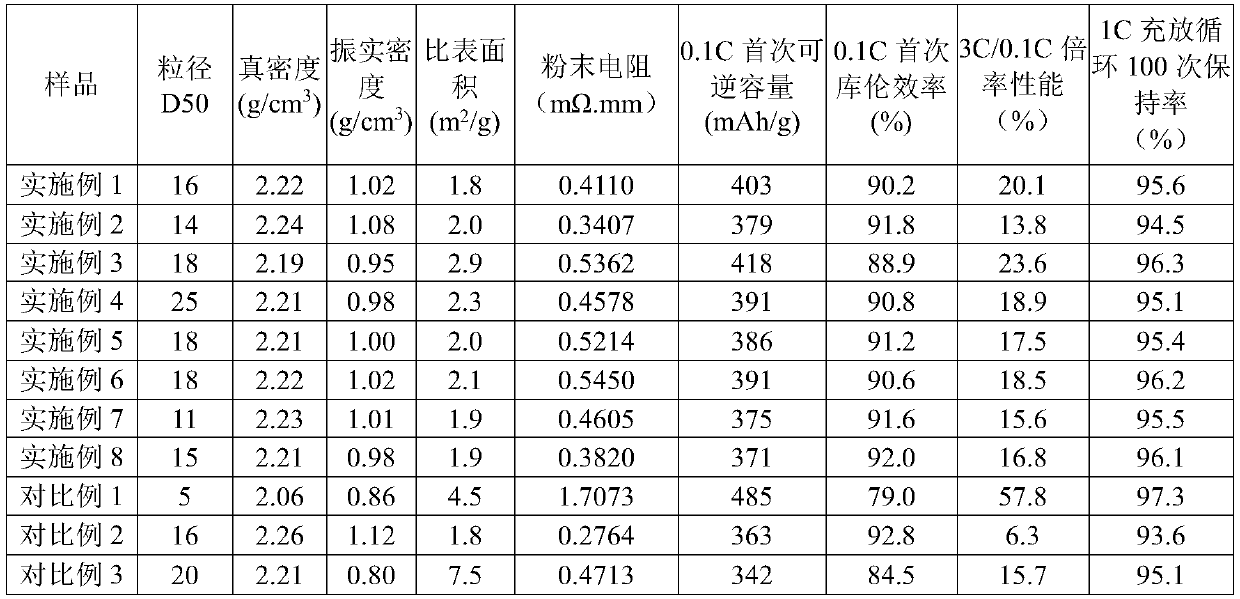

Examples

Embodiment 1

[0048] The high-temperature petroleum asphalt (softening point is about 280°C) is pulverized by a jet mill classifier to make a powder with a volume median particle size D50 of 4 μm, and then put it into a rotary kiln, and feed air at a rate of 5 L / min. Then heat up to 260°C at a heating rate of 2°C / min and keep the temperature constant for 4 hours, then cool down to room temperature to obtain a pitch-based hard carbon precursor; the composite particle artificial graphite (D50=12 μm), the obtained hard carbon precursor, and Tween 20 are mixed according to the mass Mix at a ratio of 100:15:3, use water as a solvent and stir in a high-speed mixer to form a suspension with a solid content of 60%, then put it in a blast drying oven at 100°C for drying, and cool to room temperature to obtain hard carbon / Graphite composite material precursor; put the obtained hard carbon / graphite composite material precursor into a well-type furnace and raise the temperature to 600°C for 2 hours und...

Embodiment 2

[0050] The high-temperature petroleum asphalt (softening point is about 280°C) is pulverized by a jet mill classifier to make a powder with a volume median particle size D50 of 4 μm, and then put it into a rotary kiln, and feed air at a rate of 5 L / min. Then heat up to 260°C at a heating rate of 2°C / min and keep the temperature constant for 4 hours, then cool down to room temperature to obtain a pitch-based hard carbon precursor; the composite particle artificial graphite (D50=12 μm), the obtained hard carbon precursor, and Tween 20 are mixed according to the mass Mix at a ratio of 100:5:3, use water as a solvent and stir in a high-speed mixer to form a suspension with a solid content of 60%, then put it in a blast drying oven at 100°C for drying, and cool to room temperature to obtain hard carbon / Graphite composite material precursor; put the obtained hard carbon / graphite composite material precursor into a well-type furnace and raise the temperature to 600°C for 2 hours unde...

Embodiment 3

[0052] The high-temperature petroleum asphalt (softening point is about 280°C) is pulverized by a jet mill classifier to make a powder with a volume median particle size D50 of 4 μm, and then put it into a rotary kiln, and feed air at a rate of 5 L / min. Then heat up to 260°C at a heating rate of 2°C / min and keep the temperature constant for 4 hours, then cool down to room temperature to obtain a pitch-based hard carbon precursor; the composite particle artificial graphite (D50=12 μm), the obtained hard carbon precursor, and Tween 20 are mixed according to the mass Mix at a ratio of 100:30:3, use water as a solvent and stir in a high-speed mixer to form a suspension with a solid content of 60%, then put it in a blast drying oven at 100°C for drying, and cool to room temperature to obtain hard carbon / Graphite composite material precursor; put the obtained hard carbon / graphite composite material precursor into a well-type furnace and raise the temperature to 600°C for 2 hours und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com