Patents

Literature

995results about How to "Increase compaction density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

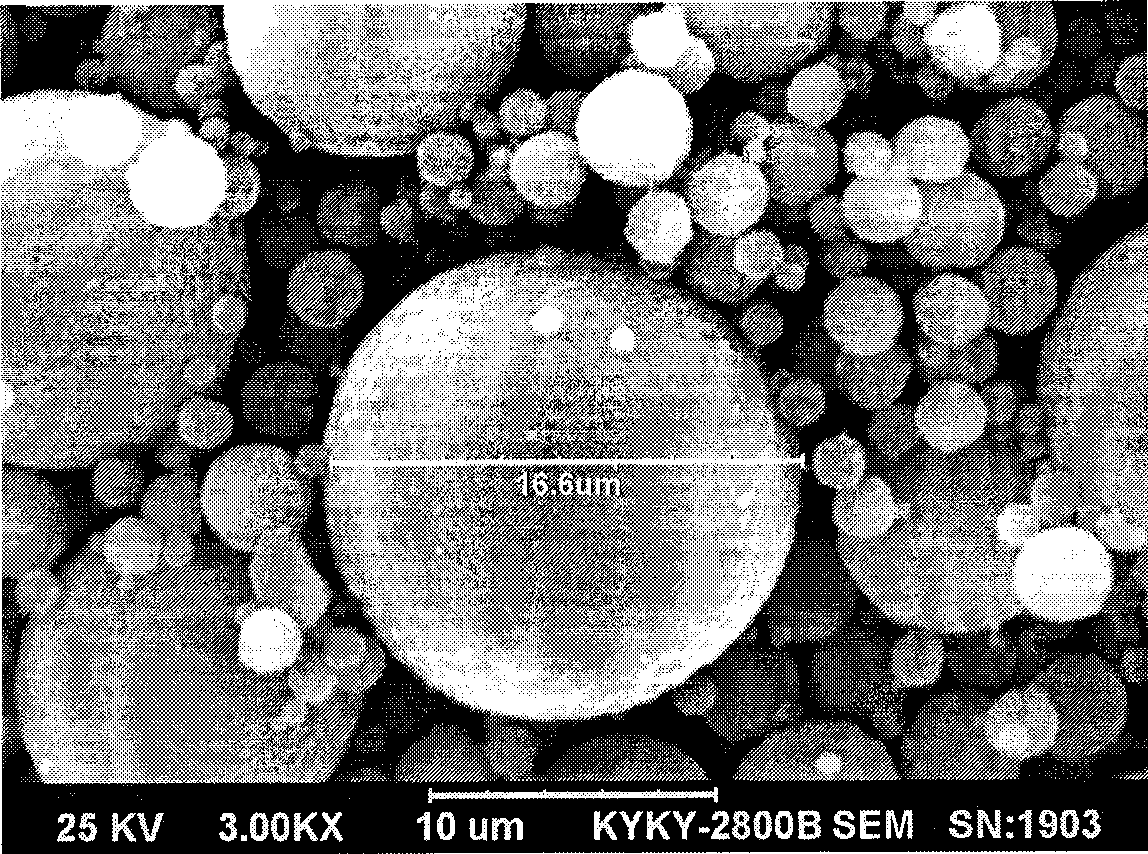

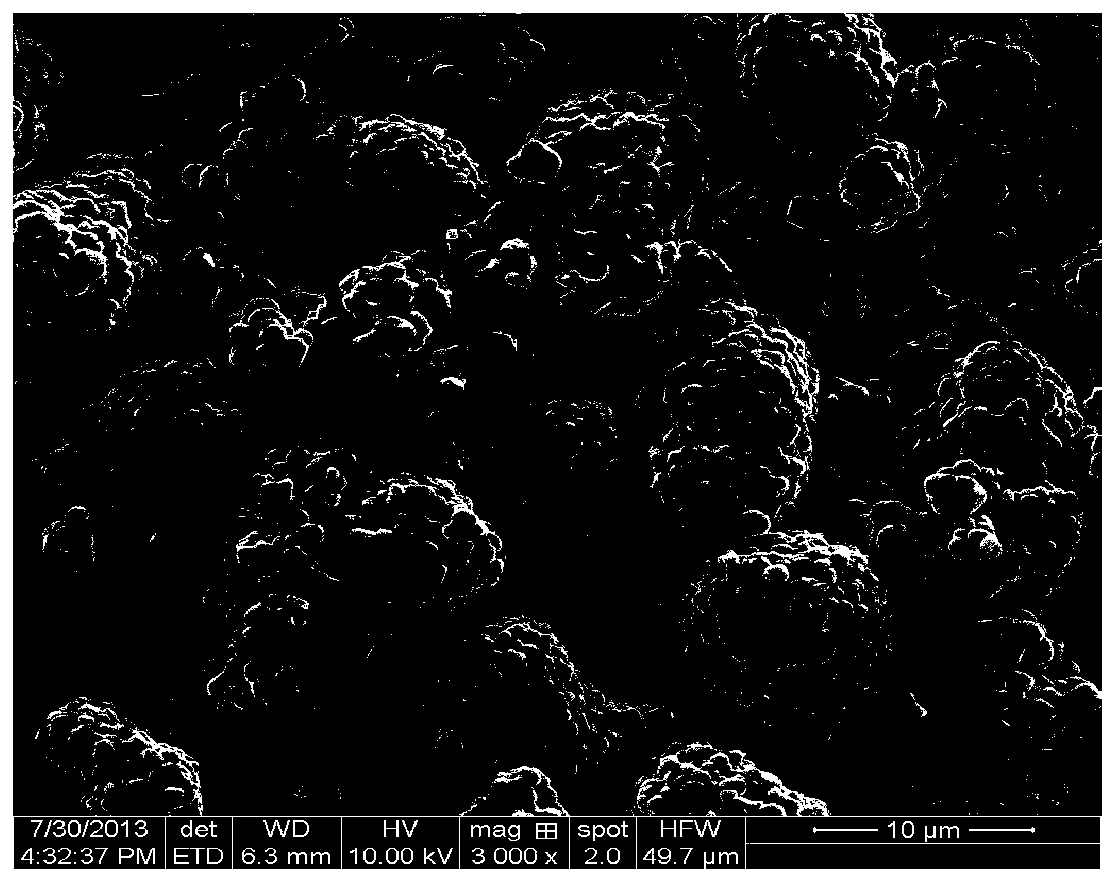

Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

ActiveCN101373829AIncrease capacityHigh bulk densityElectrode manufacturing processesLi-accumulatorsHigh rateLithium titanate

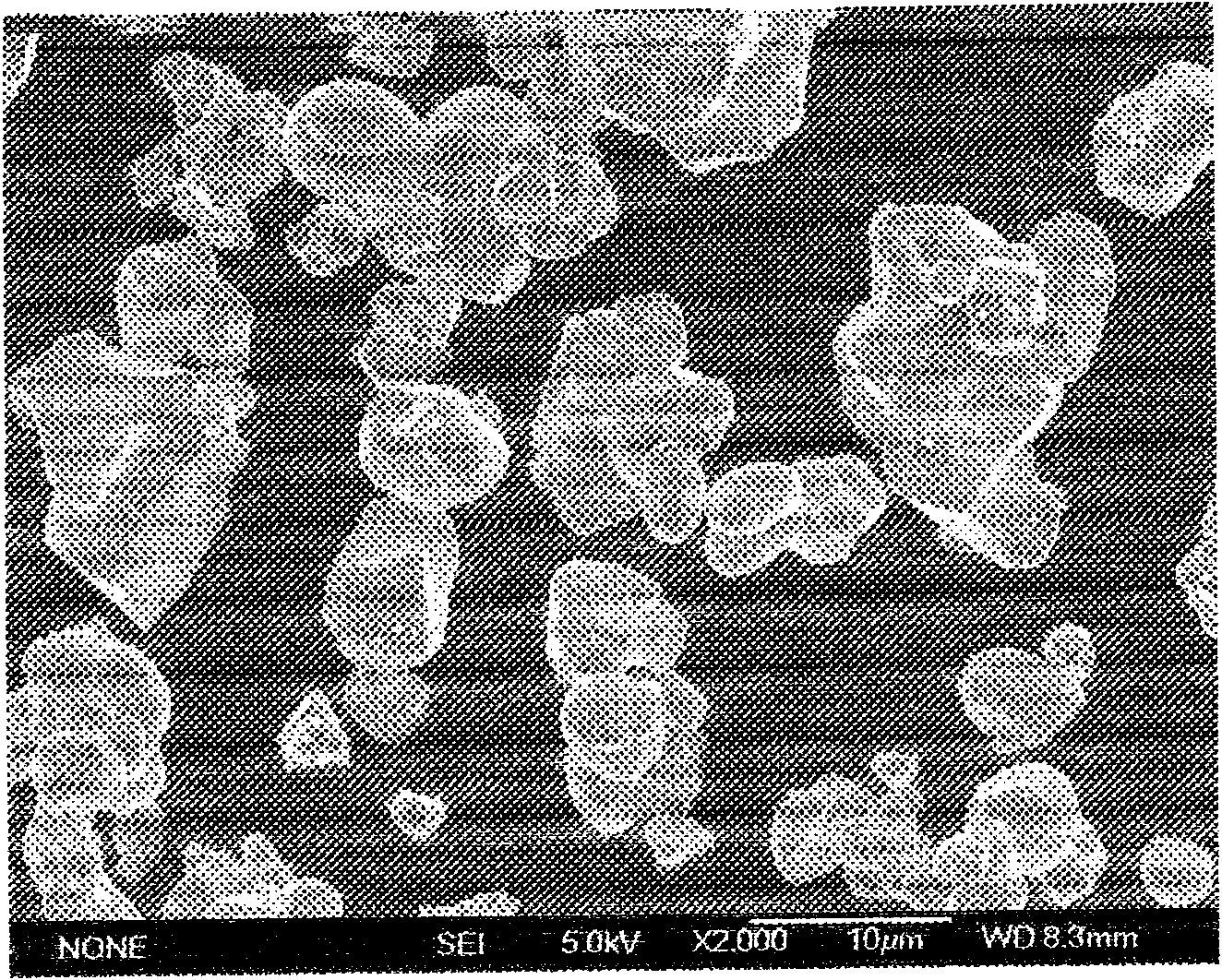

The invention discloses a titanium cathode active substance, a preparation method thereof and a titanium lithium ion power battery, and aims to solve the technical problem of enhancing the rate performance of a lithium ion power battery. The formula of the titanium cathode active substance is Li4Ti5O12 / Mx, wherein Li4Ti5O12 is spinel lithium titanate, M is a dopant such as a metal simple substance, a metal compound, a nonmetallic simple substance or a nonmetallic compound; the elements or the ions contained in the dopant enter the Li4Ti5O12 crystal lattice or are compounded with the Li4Ti5O12 crystal lattice; and the preparation method comprises the following steps: the precursor mixture of compound lithium titanate is prepared, and spray drying and heat treatment are performed. The cathode of the titanium lithium ion power battery adopts Li4Ti5O12 / Mx. Compared with the prior art, the titanium cathode active substance has the advantages of high capacity, high bulk density, high volume specific capacity, good high-rate performance, good product uniformity, good battery processability, low possibility of air bulking of the battery, and low cost.

Owner:BTR NEW MATERIAL GRP CO LTD

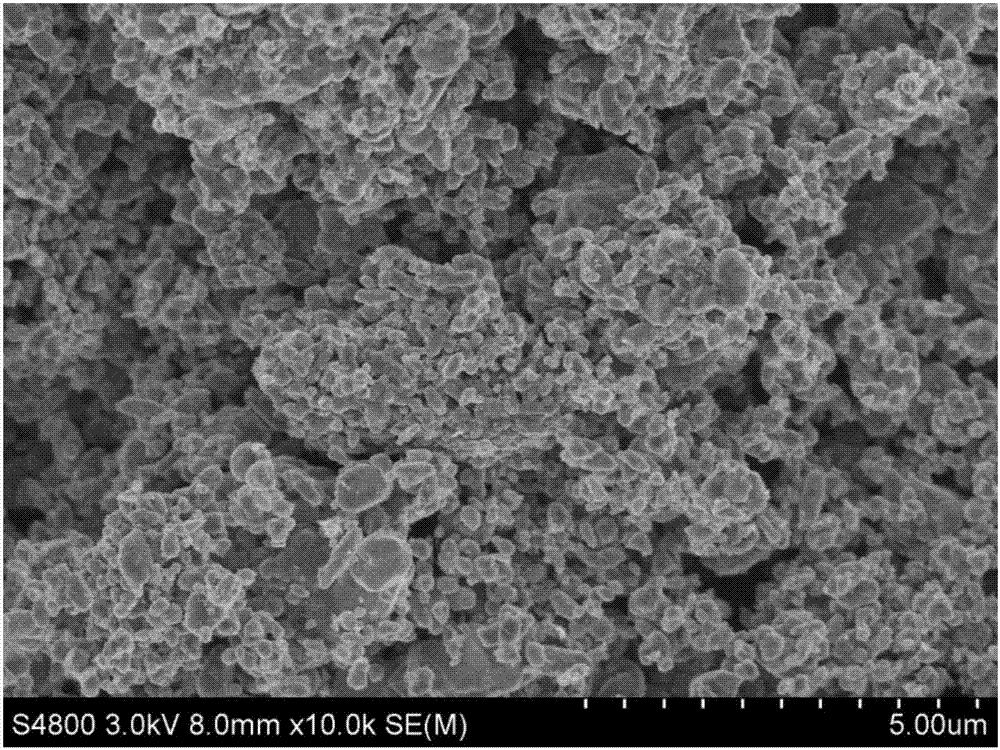

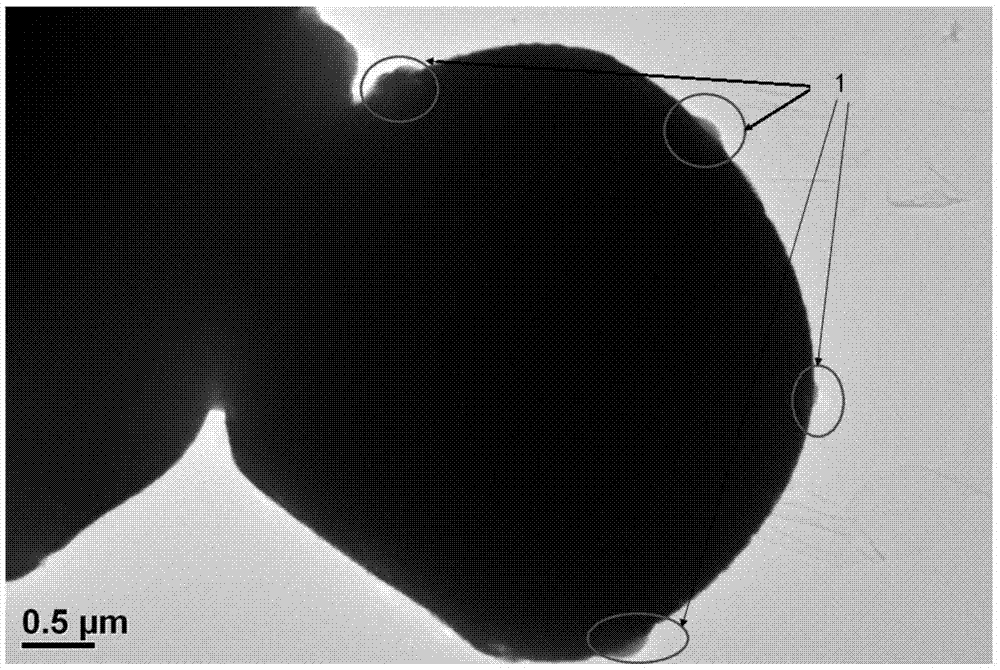

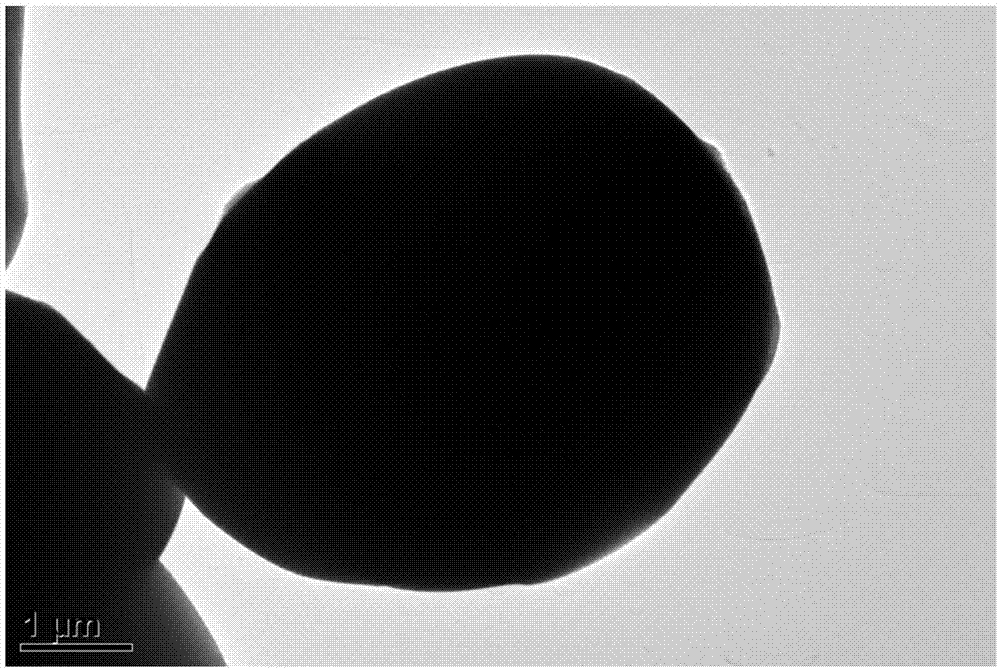

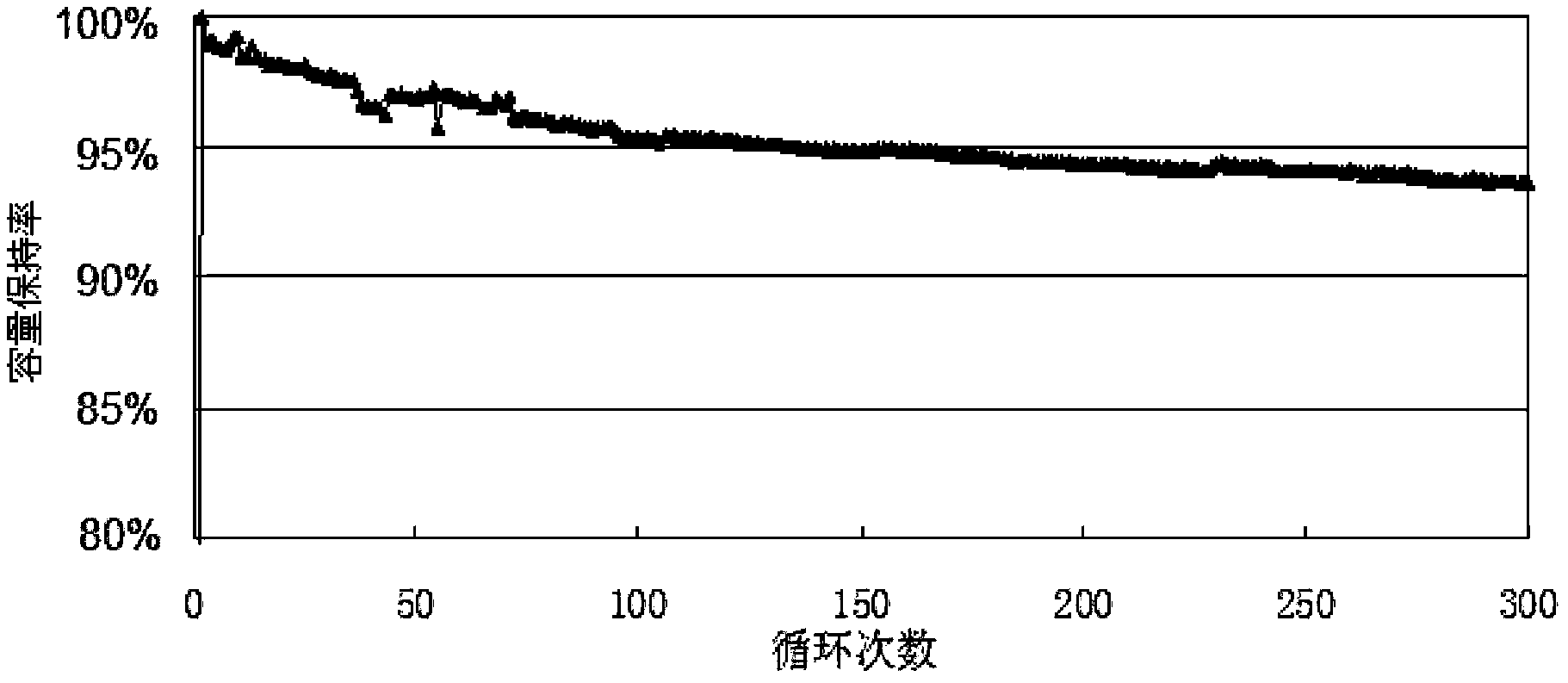

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

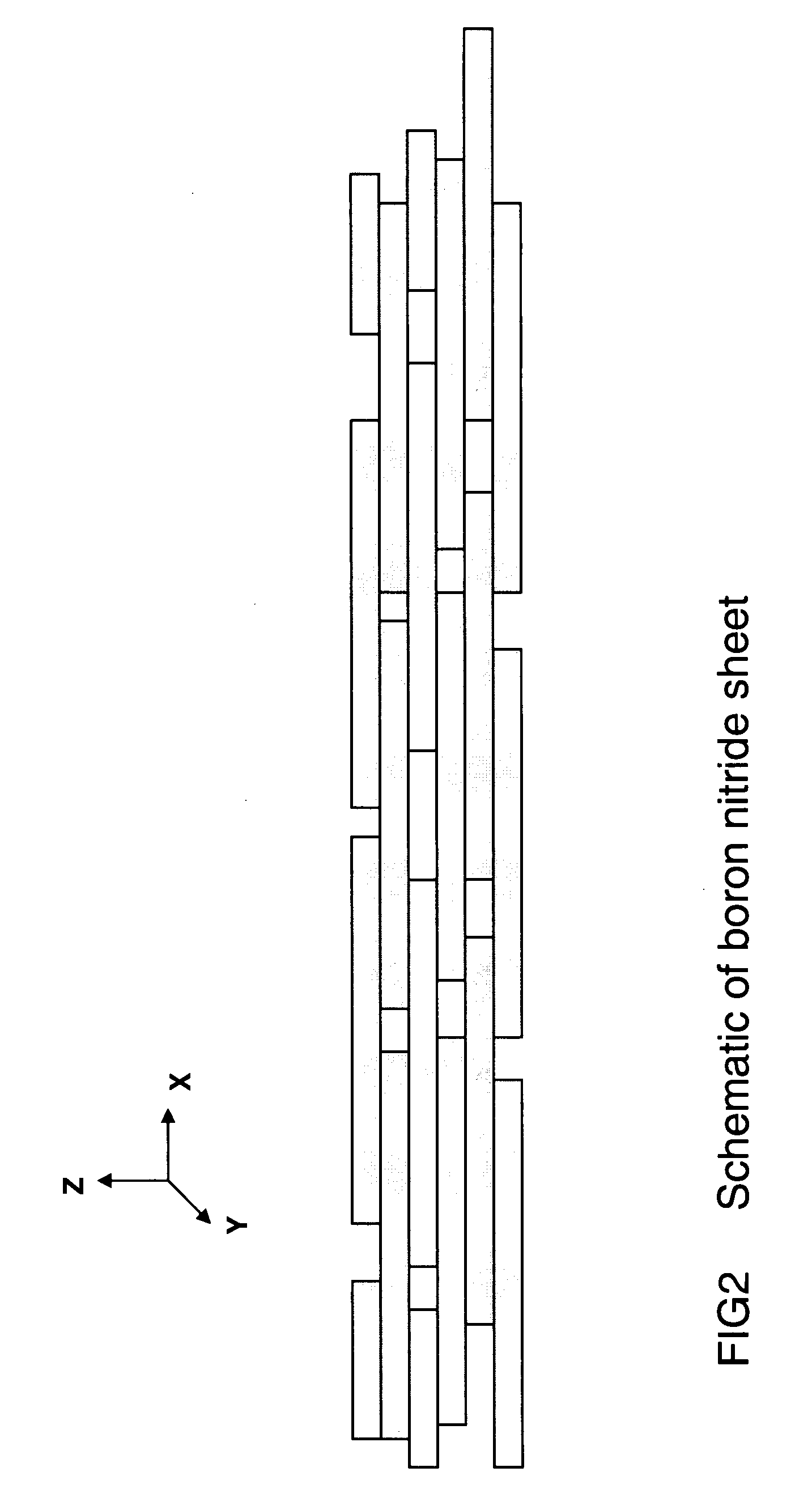

Heat spread sheet with anisotropic thermal conductivity

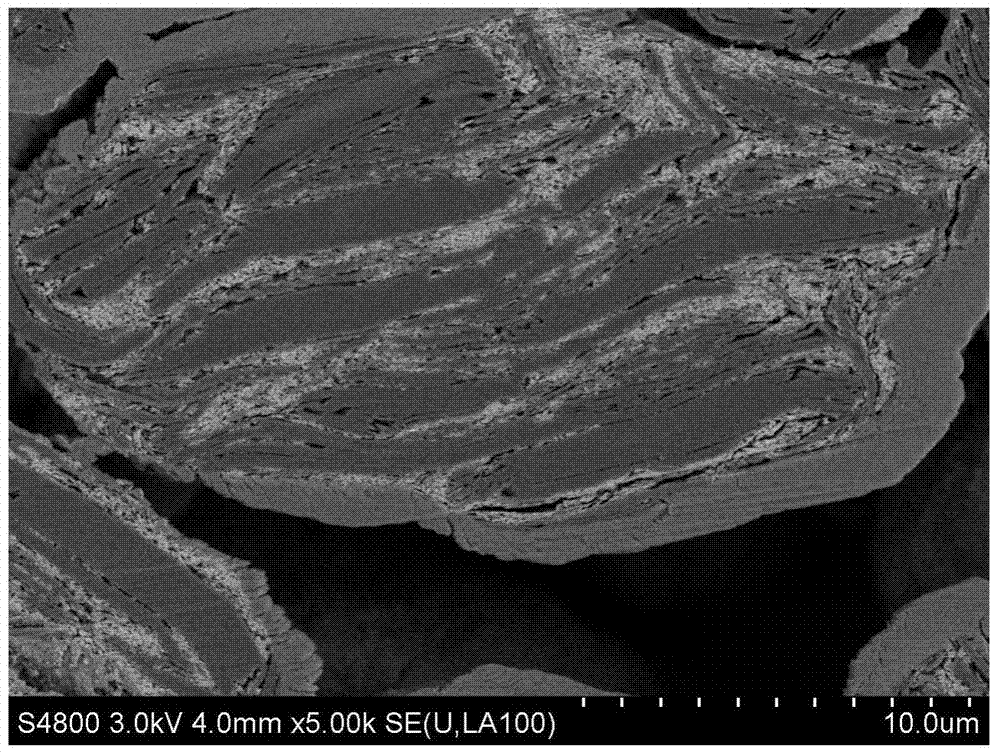

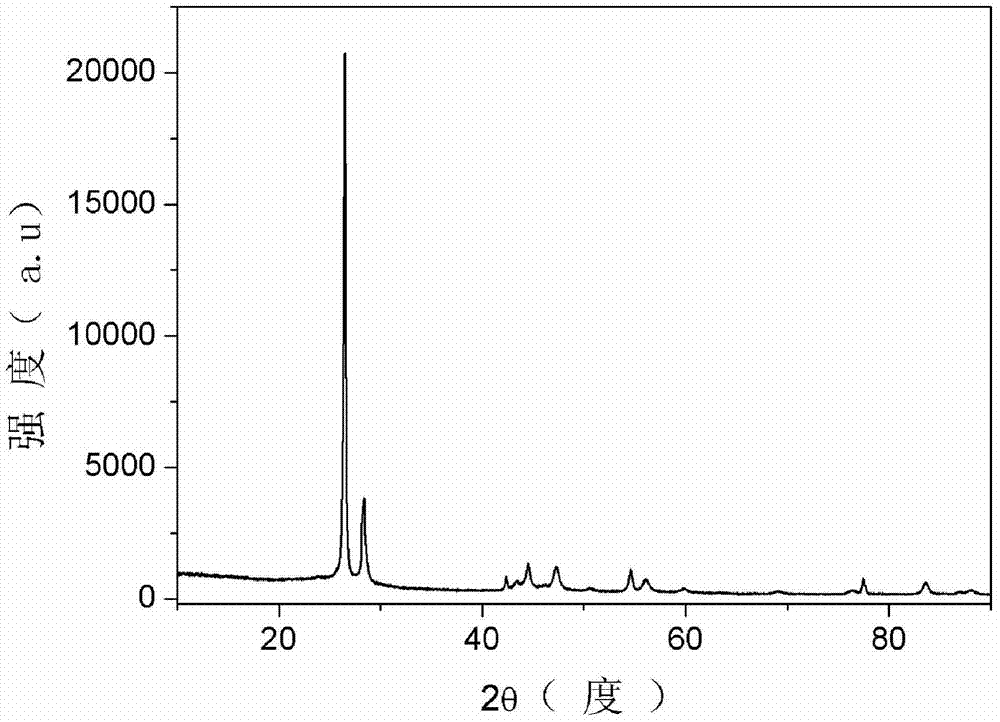

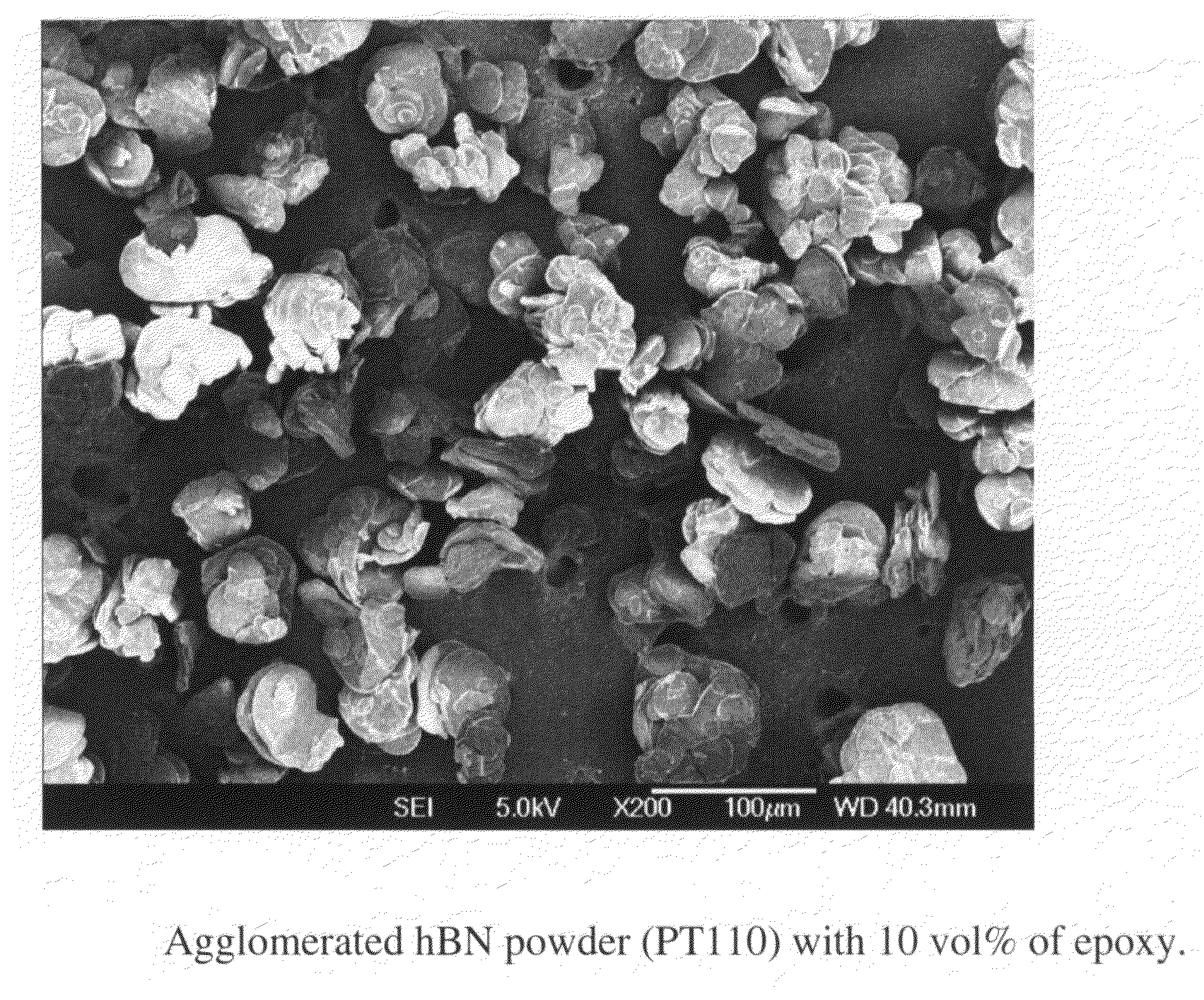

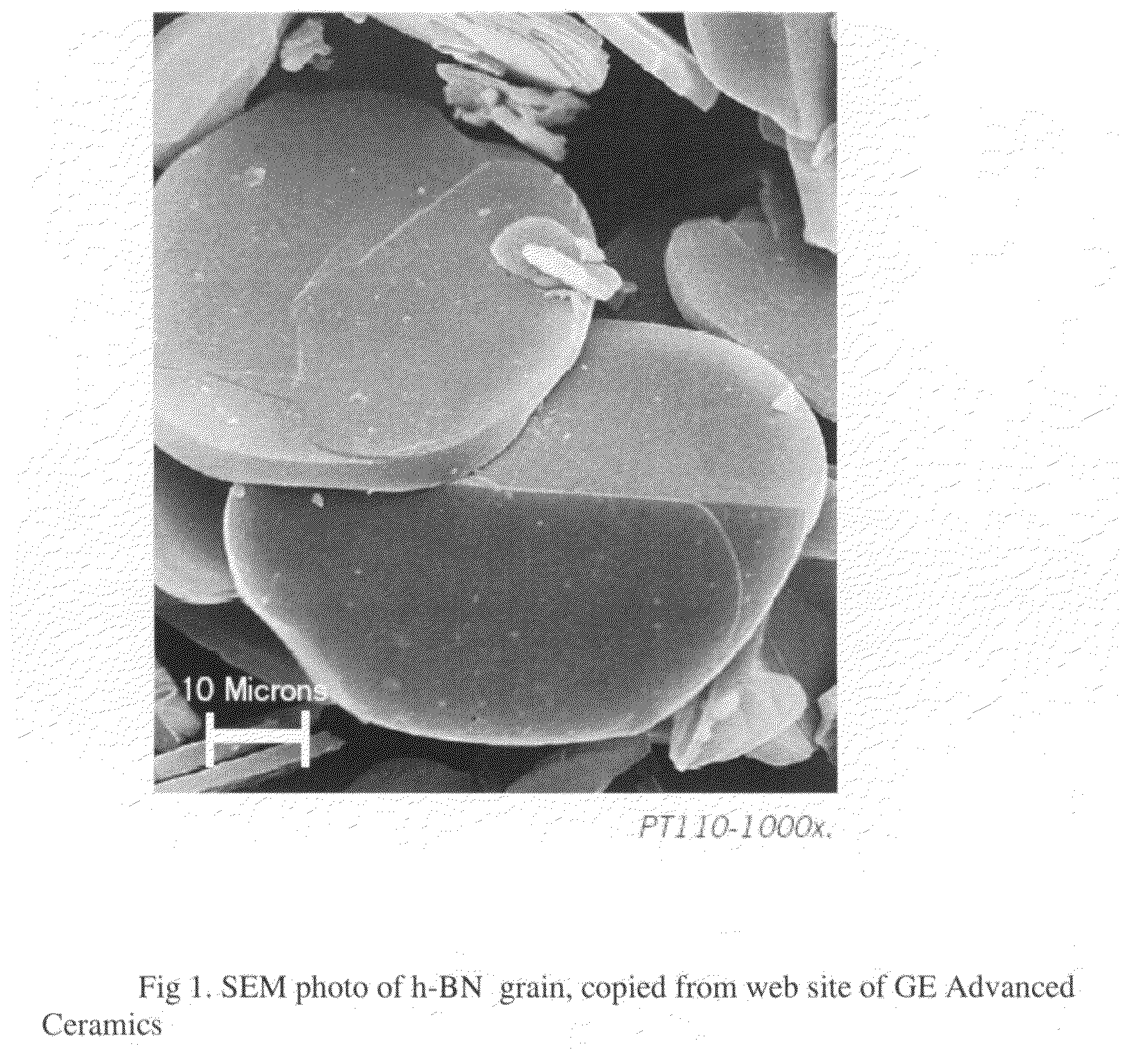

InactiveUS20070259211A1Increase compaction densityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesEpoxySpread sheet

This invention relates to a heat spread sheet material comprised of hexagonal boron nitride with adhesives. Extraction process for adhesive coating greatly decreases the adhesive fraction and provides an evenly distributed thin adhesive film on the surface of hexagonal boron nitride powders. This sheet material shows a layer structure and anisotropic properties. With 10 vol % (5.5 wt %) of phenolic epoxy, thermal conductivity along the base plane of the sheet reaches 48 W / m·K, and CTE reaches 3.5 ppm / K.

Owner:WANG NING

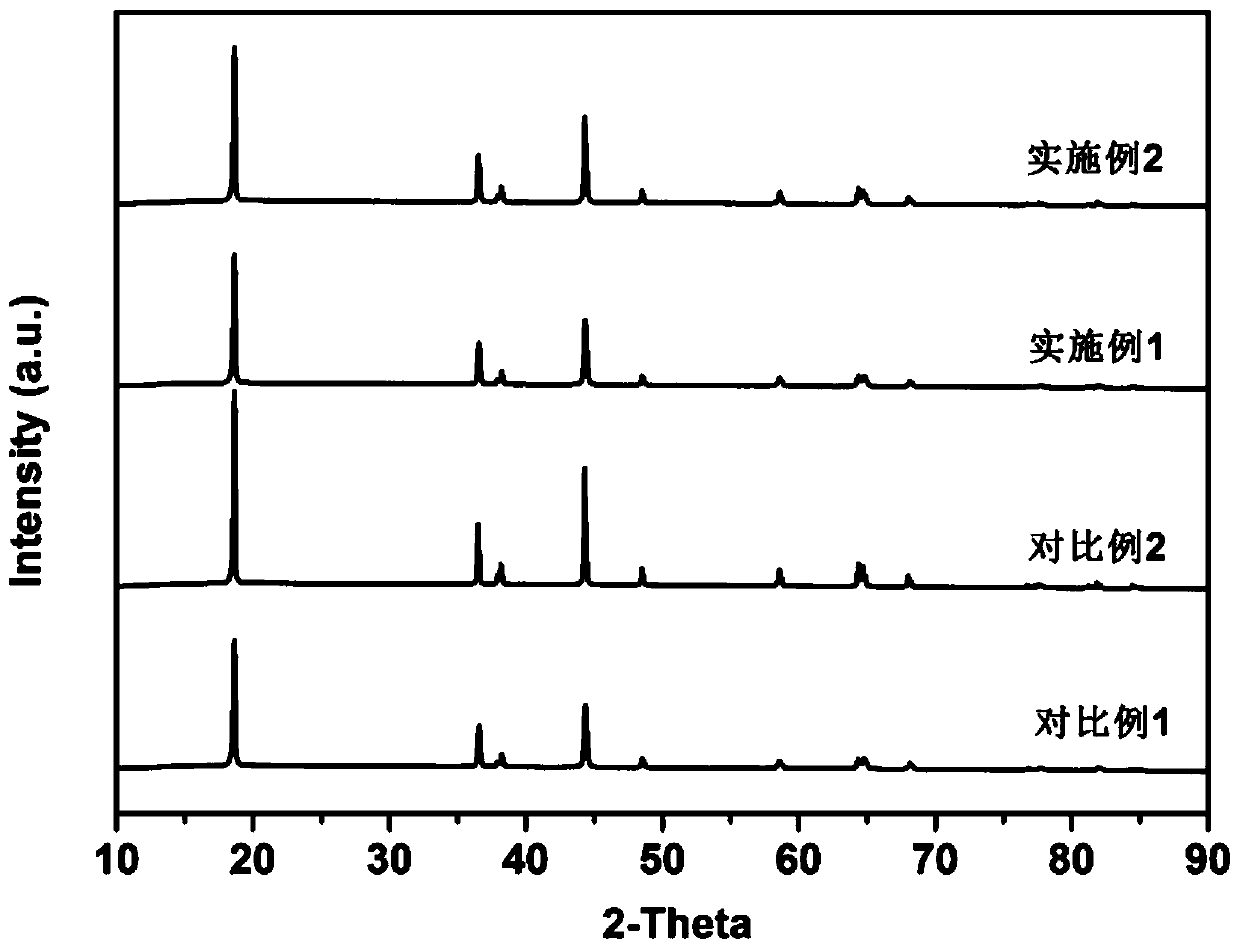

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

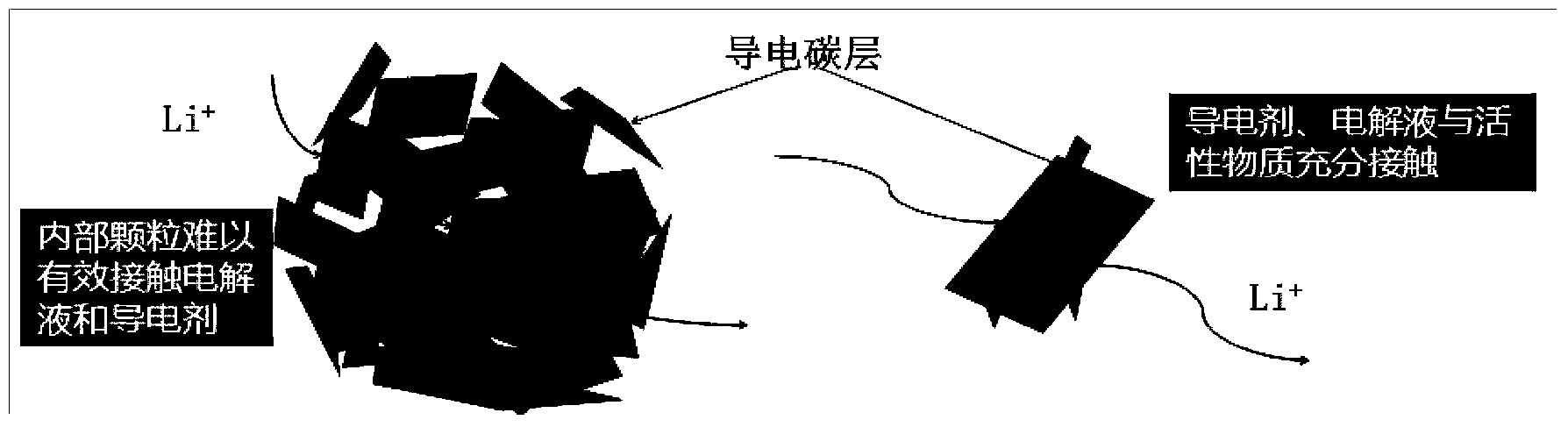

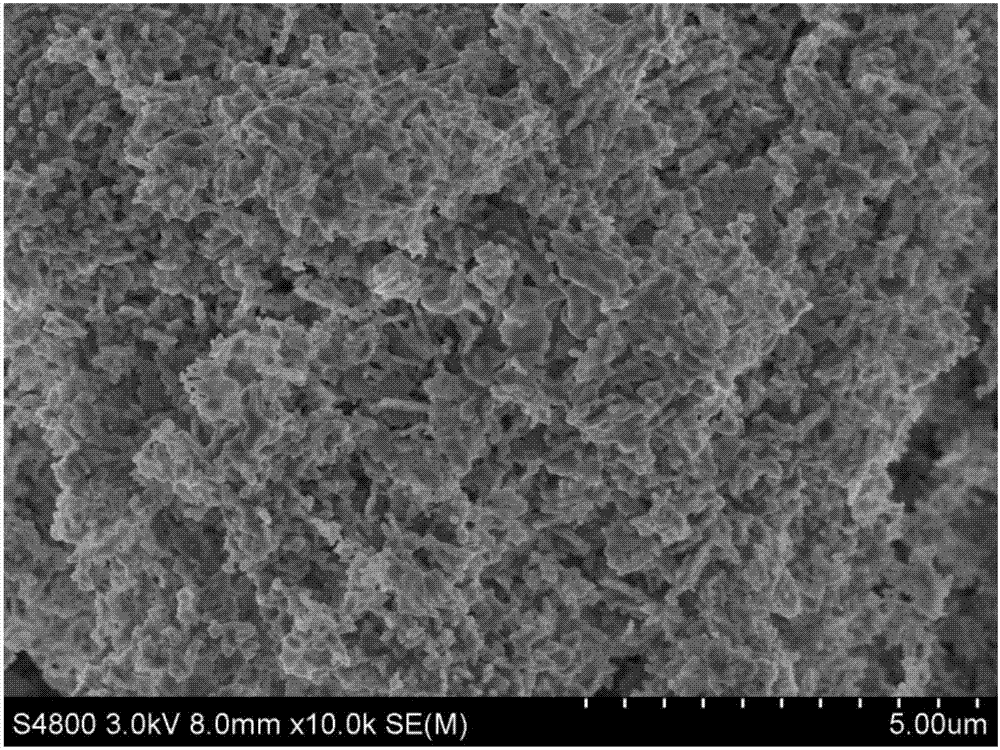

Carbon-coated nano silicon/graphene/cracked carbon layer composition material, preparation method, and lithium ion battery including the composition material

InactiveCN106067547AAchieve perfect compoundSimple processMaterial nanotechnologyCell electrodesNano siliconCarbon layer

The invention relates to a carbon-coated nano silicon / graphene / cracked carbon layer composition material, a preparation method thereof, and a lithium ion battery including the composition material. The composite material comprises spherical particles formed by uniformly dispersing carbon-coated nano silicon in graphene sheets, and a cracked carbon layer which coats the surfaces of the spherical particles. The carbon-coated nano silicon comprises nano silicon and carbon coating layer which coats the surface of the nano silicon. The method is simple, has excellent process performance and is environment-friendly. The carbon-coated nano silicon / graphene / cracked carbon layer composition material has stable structure and high compact density, has excellent performance when being used as an anode material of the lithium ion battery, has high anode capacity, excellent rate capability and cyclic performance, is more than 1500 mAh / g in first-time reversible capacity, is more than 90% in first-time coulomb efficiency and is more than 90% in 500-time cyclic capacity retention ratio and has low expansion.

Owner:BTR NEW MATERIAL GRP CO LTD

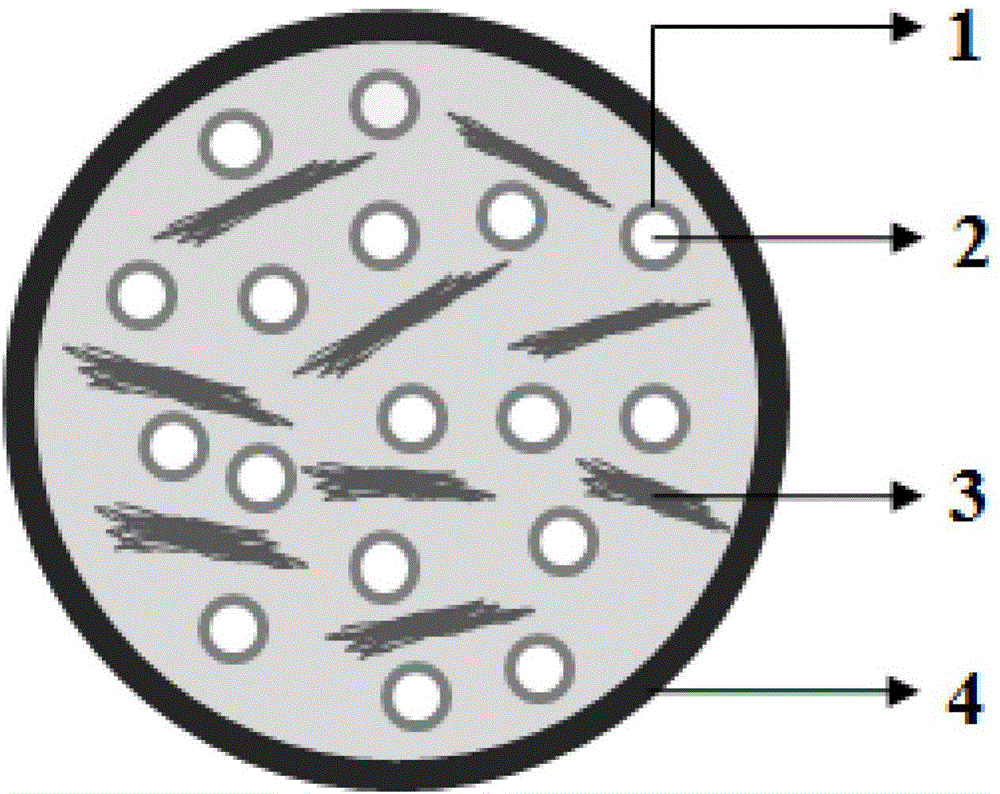

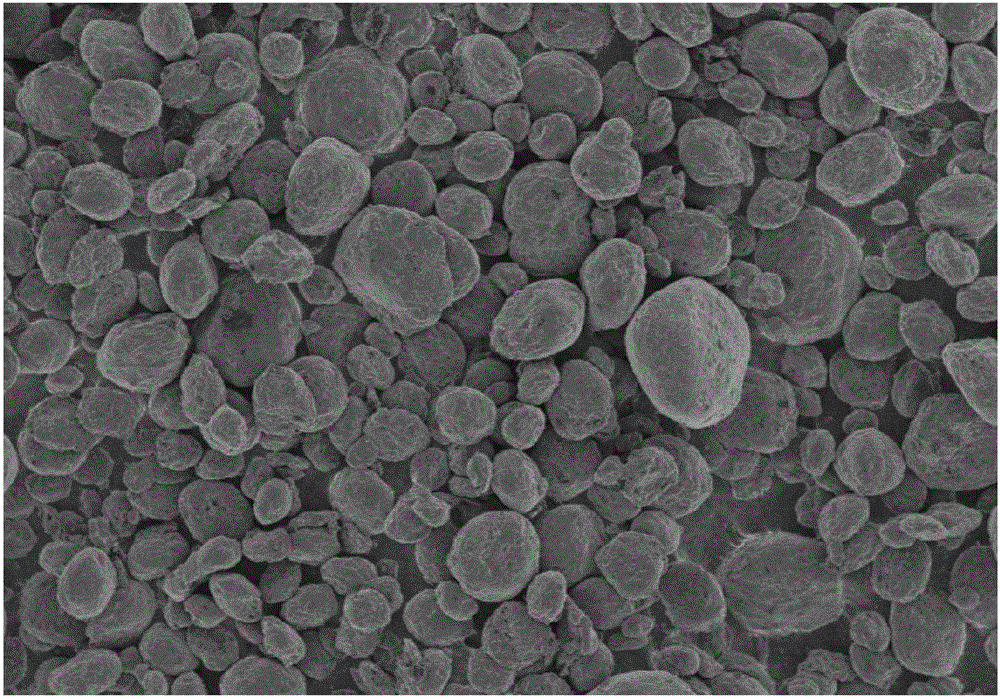

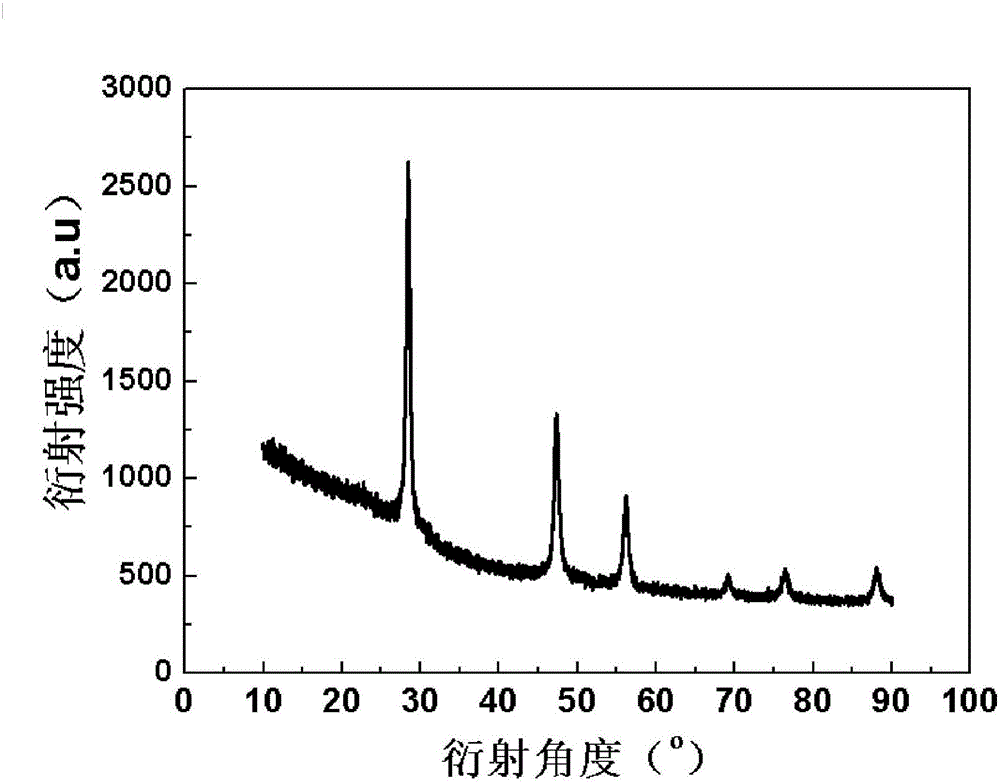

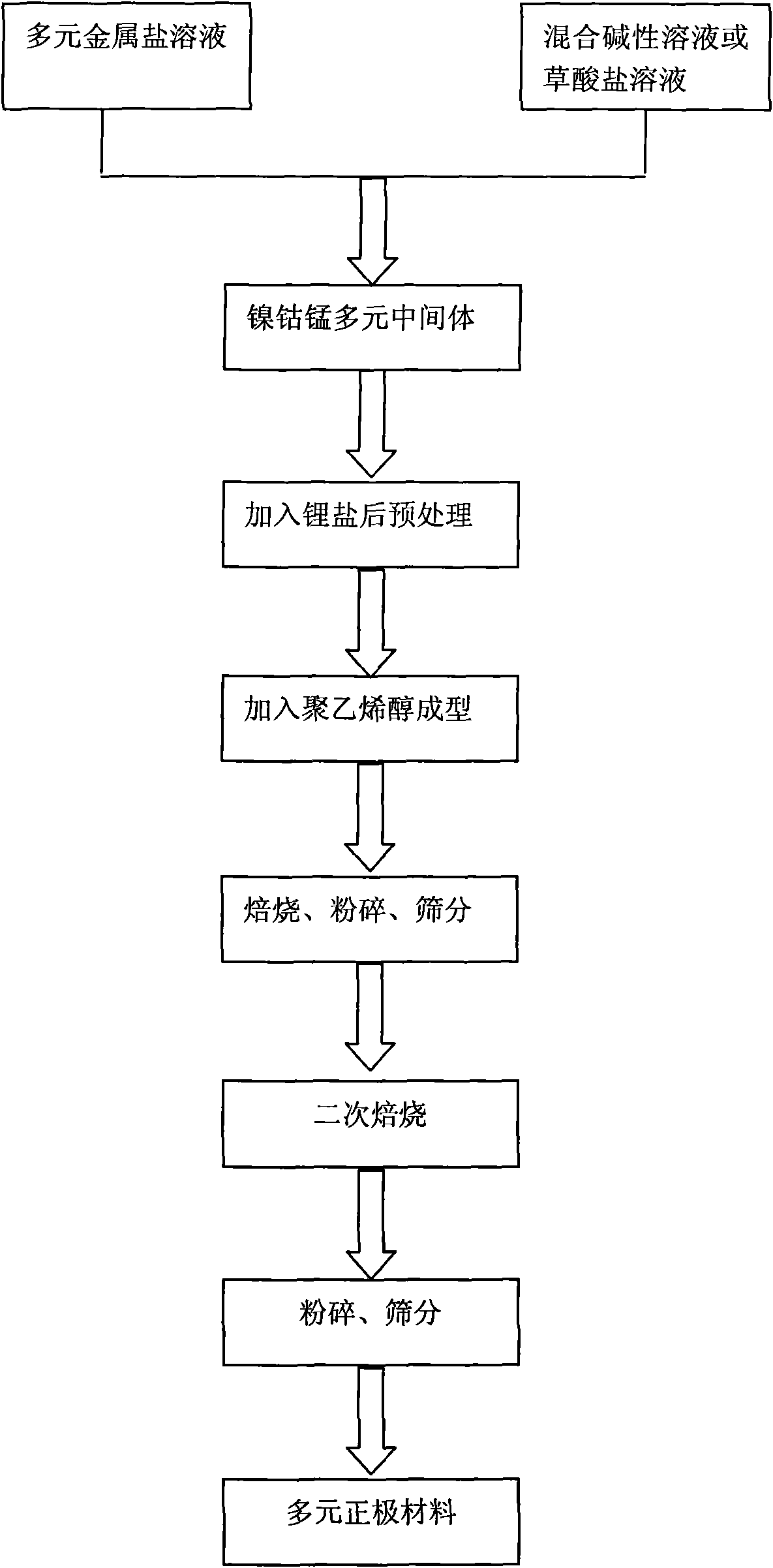

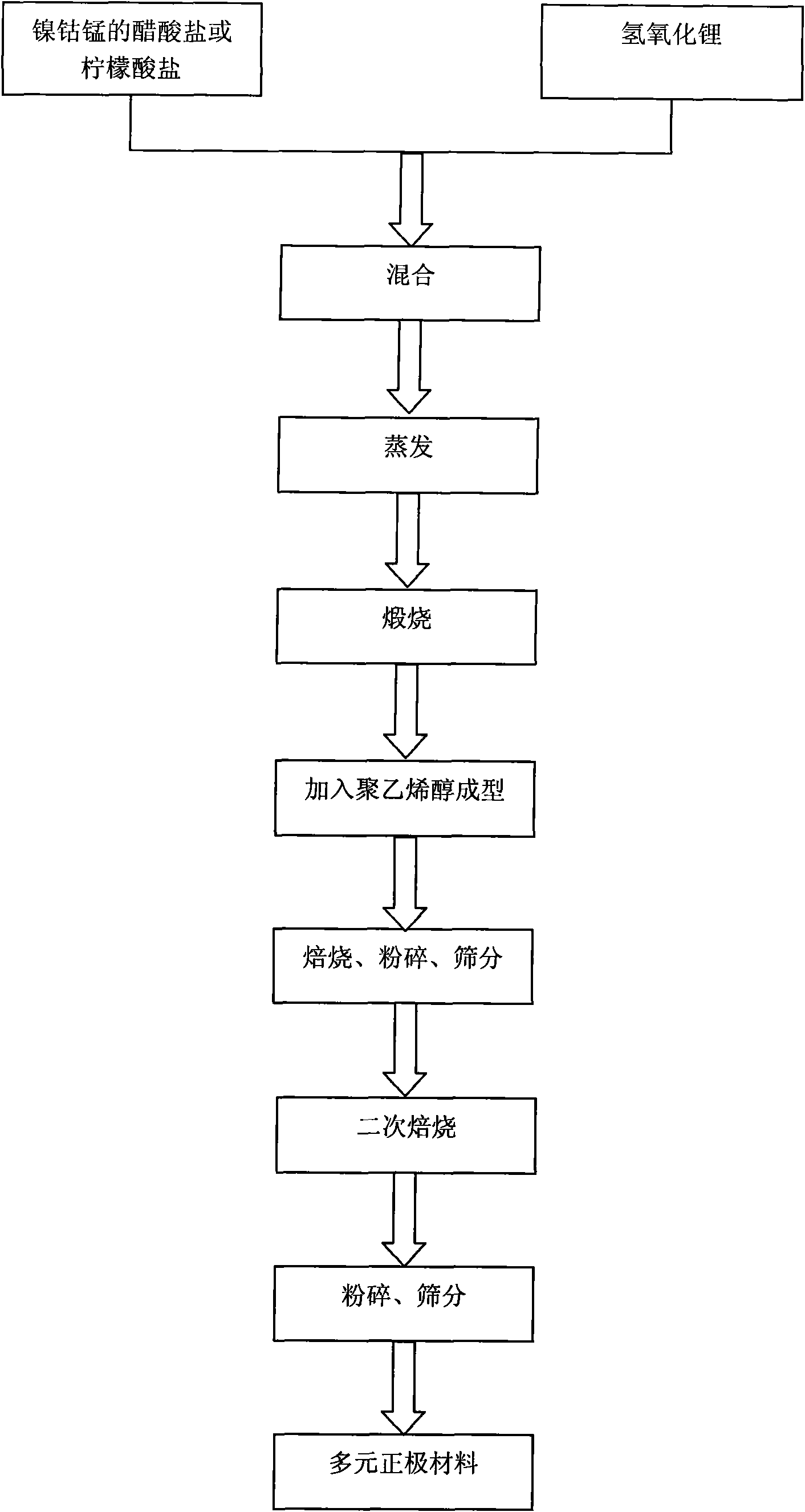

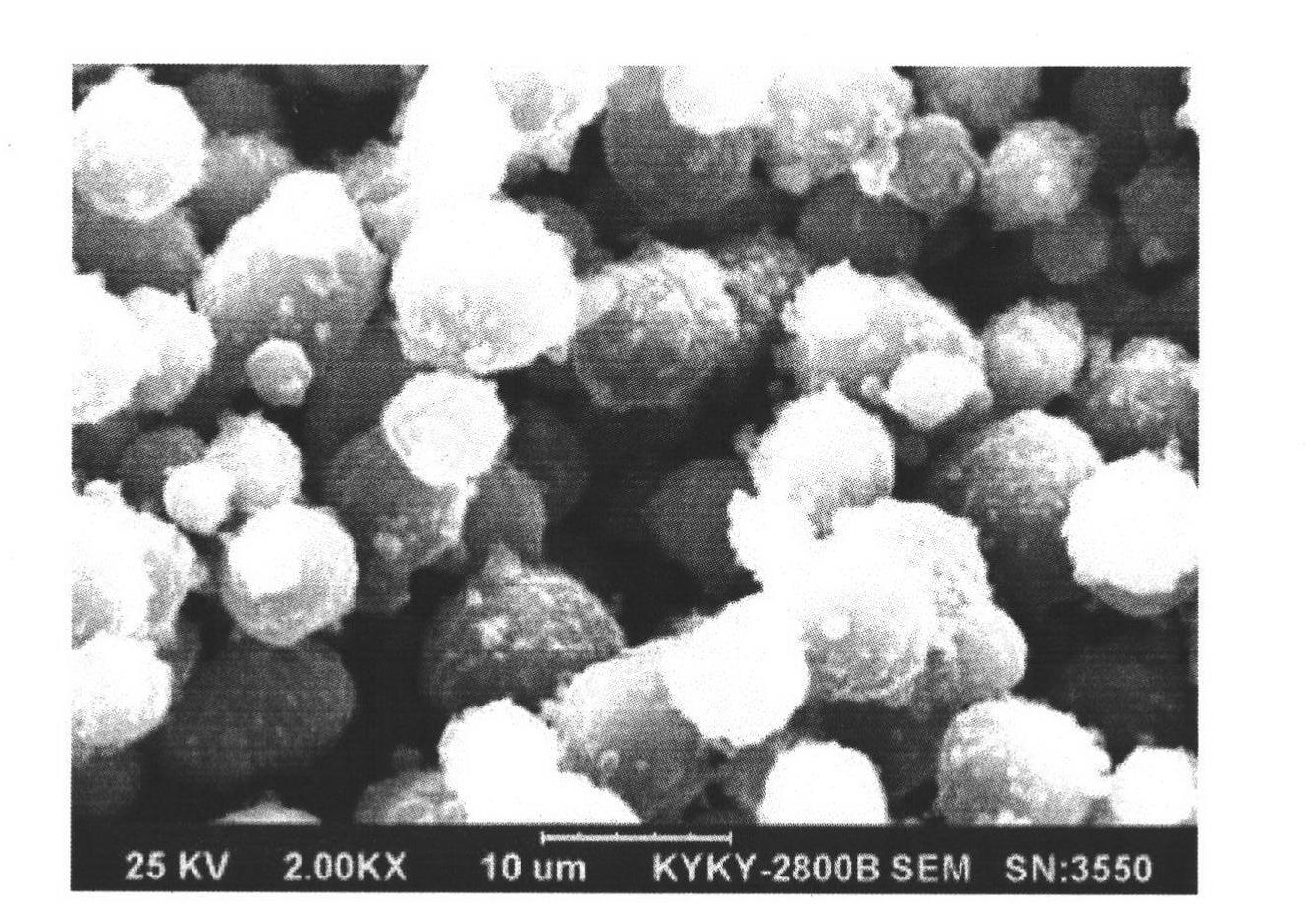

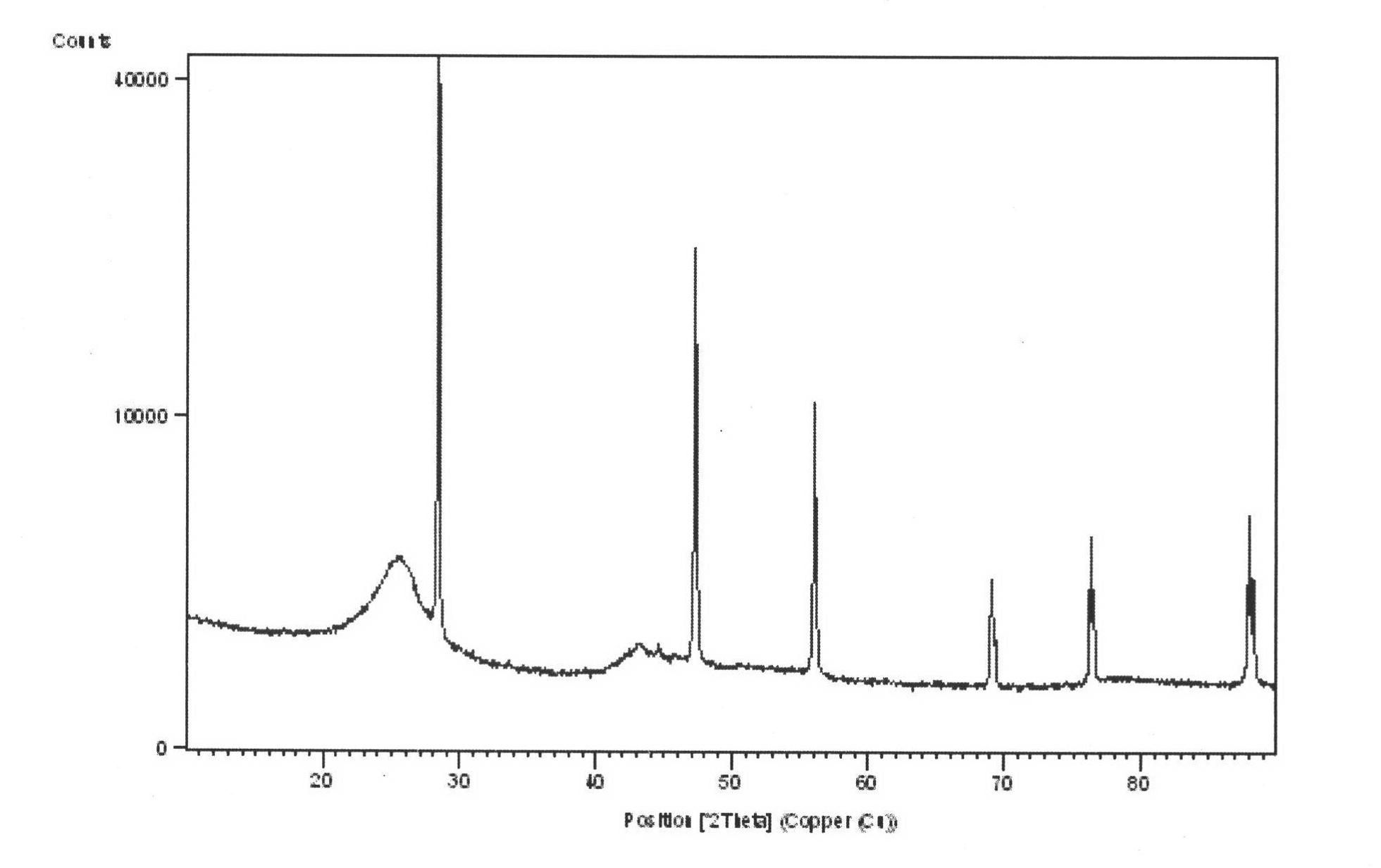

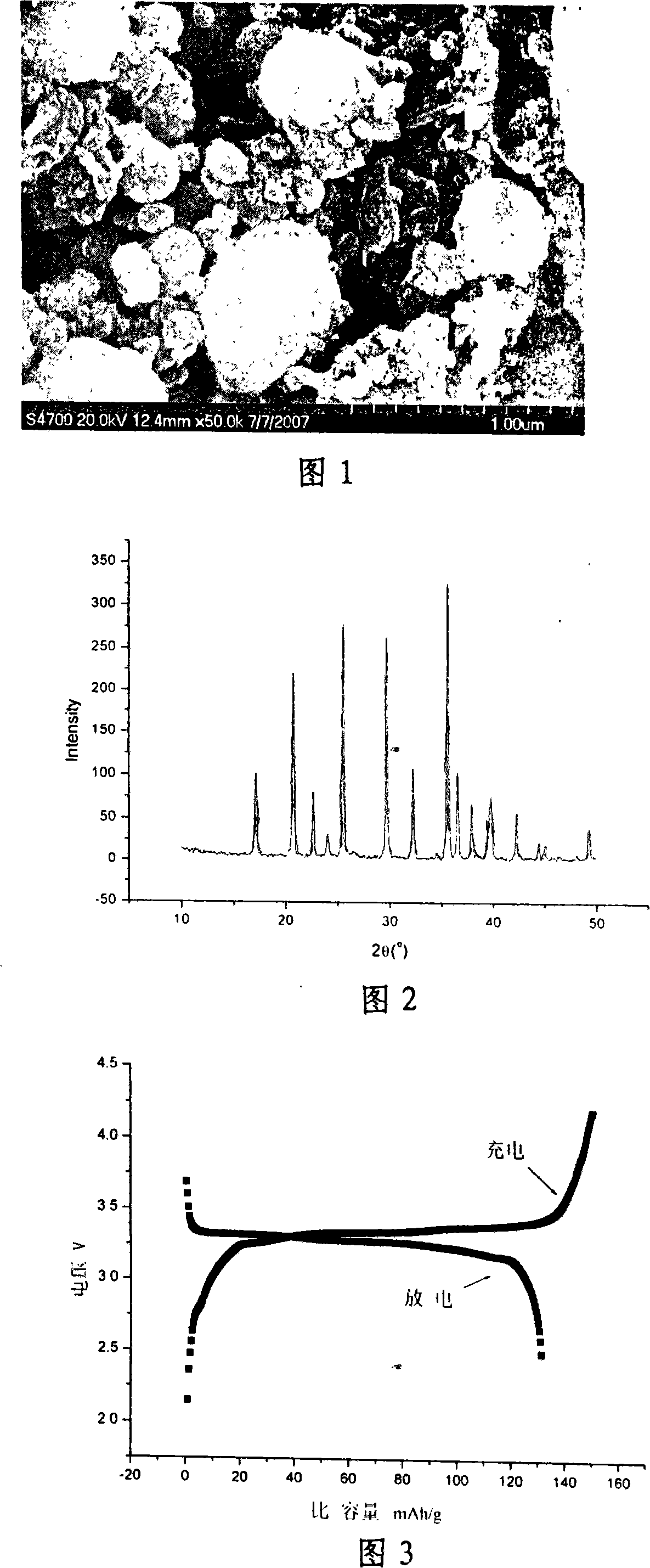

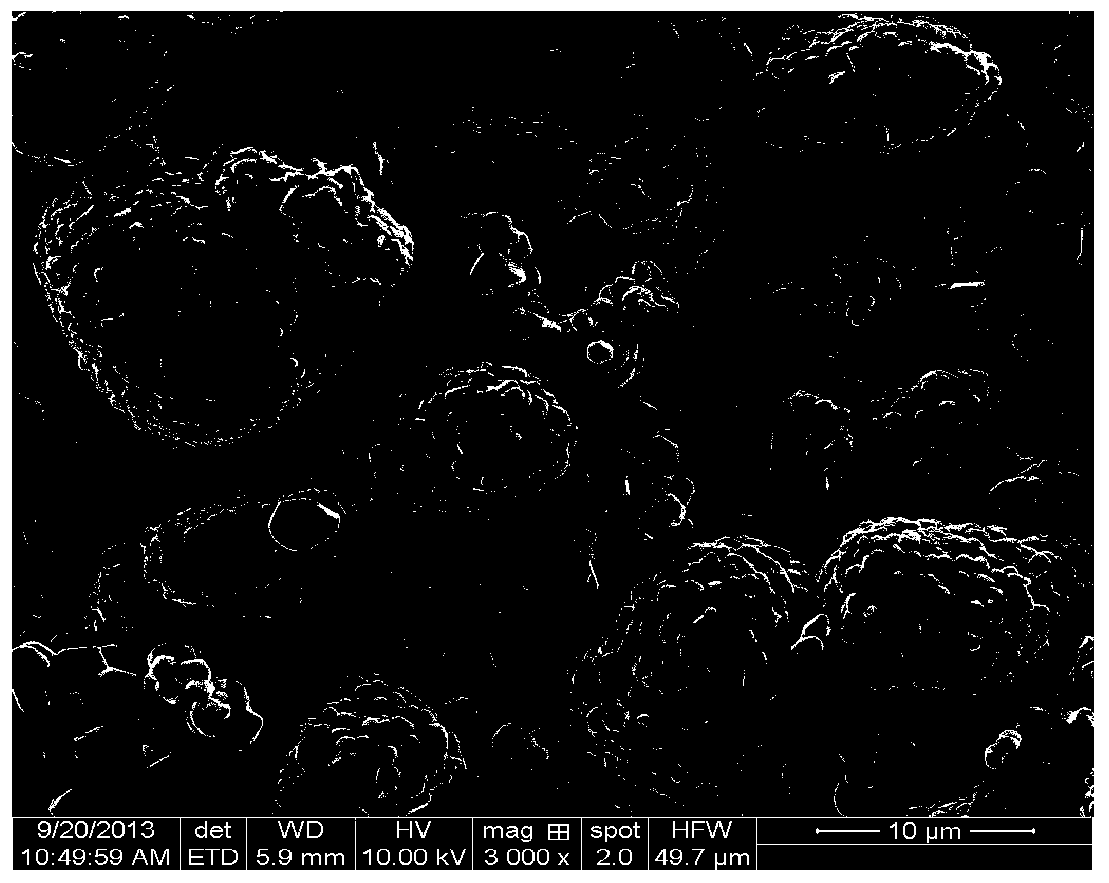

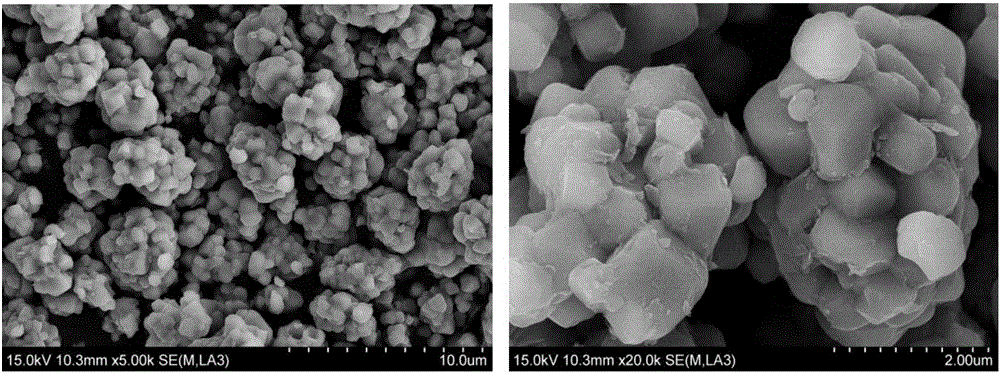

Nickel-cobalt-manganese multi-doped lithium ion battery cathode material and preparation method thereof

InactiveCN101621125AIncrease compaction densityLow hygroscopicityElectrode manufacturing processesSecondary cellsChemical synthesisPolyvinyl alcohol

The invention discloses a nickel-cobalt-manganese multi-doped lithium ion battery cathode material with high compacted density and a preparation method thereof, belonging to the technical field of energy materials. The preparation method of the battery cathode material comprises the following steps: preparing a nickel-cobalt-manganese multi-doped intermediate by a coprecipitation method or a chemical synthesis method; mixing the multi-doped intermediate with lithium salts; after pretreatment, adding polyvinyl alcohol to the obtained mixture; uniformly mixing the polyvinyl alcohol and the mixture and then pressing the mixture into a cake; roasting the cake at 800-950 DEG C; taking the roasted cake out and carrying out cooling, pulverization and 400 meshes of sieving on the cake; then roasting obtained powder at 700-800 DEG C, taking the powder out and carrying out cooling, pulverization and sieving on the powder to obtain the battery cathode material. Granules of the battery cathode material are non-agglomerated single-crystal grains with a grain diameter of 0.6-30 microns, a chemical formula of LiNixCoyMnzM[(1-x-y-z)]O2, a degree of compaction of 3.5-3.7g / cm<3> and a primary discharge capacity of 150-165mAh / g, thus the battery cathode material has good cycle performance and higher safety performance.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

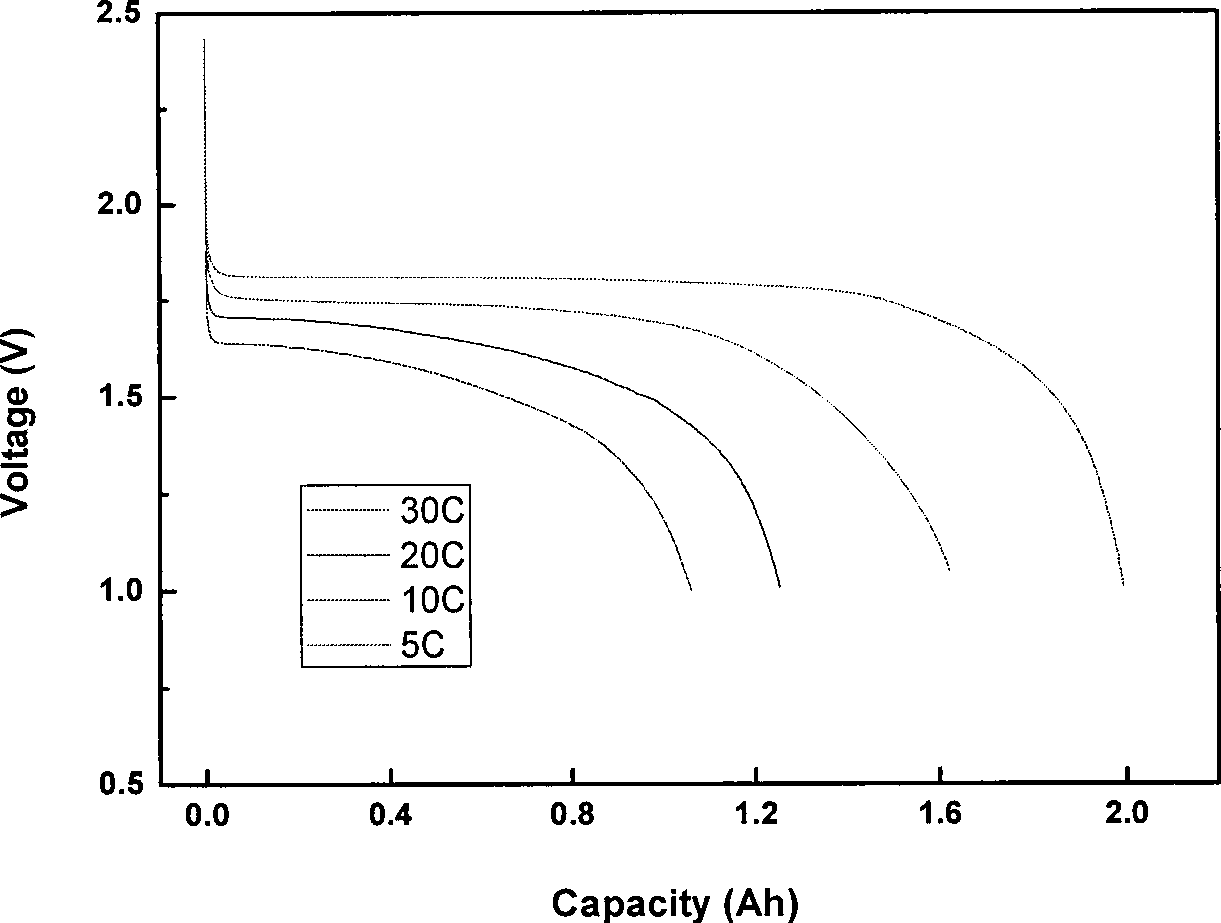

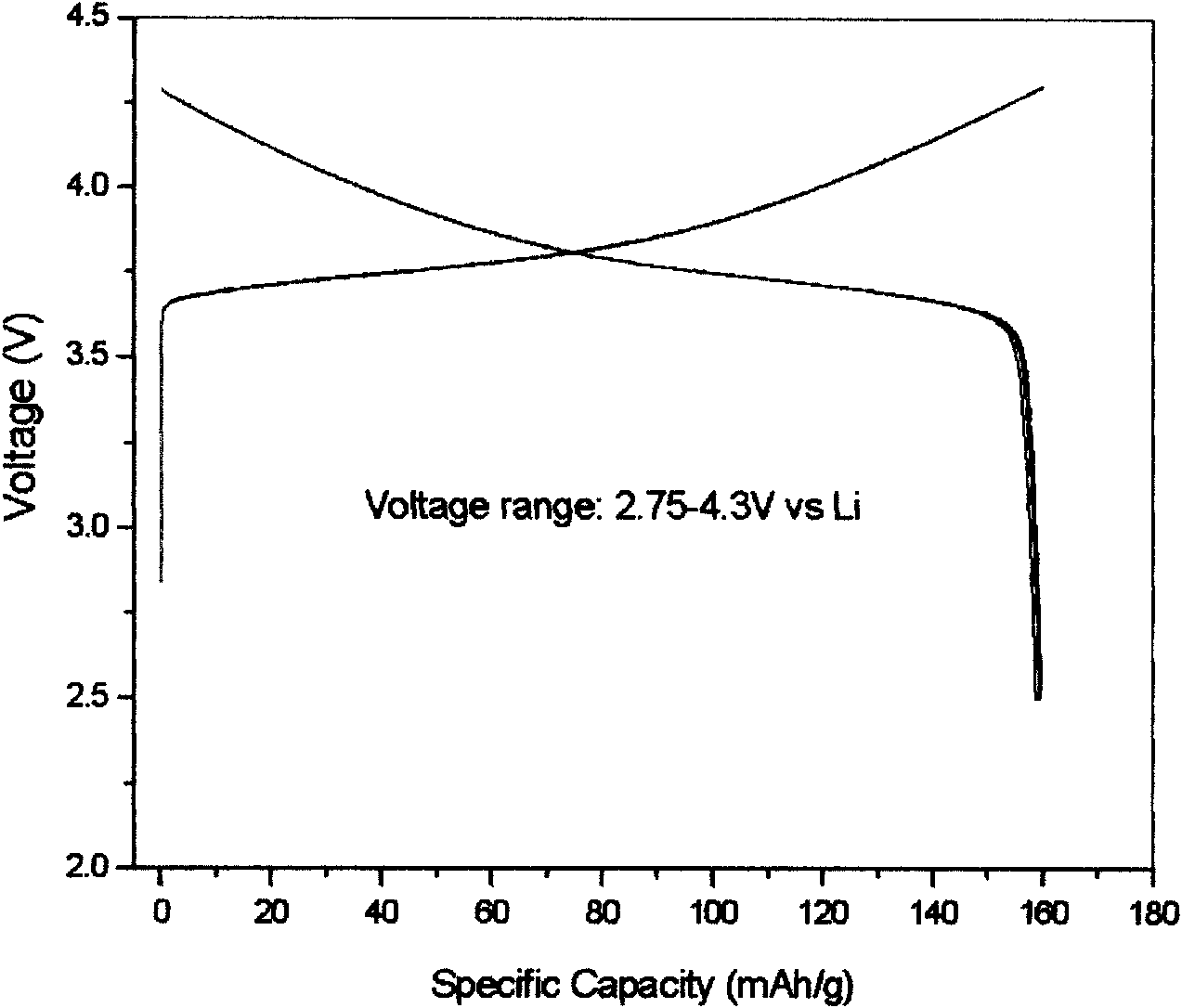

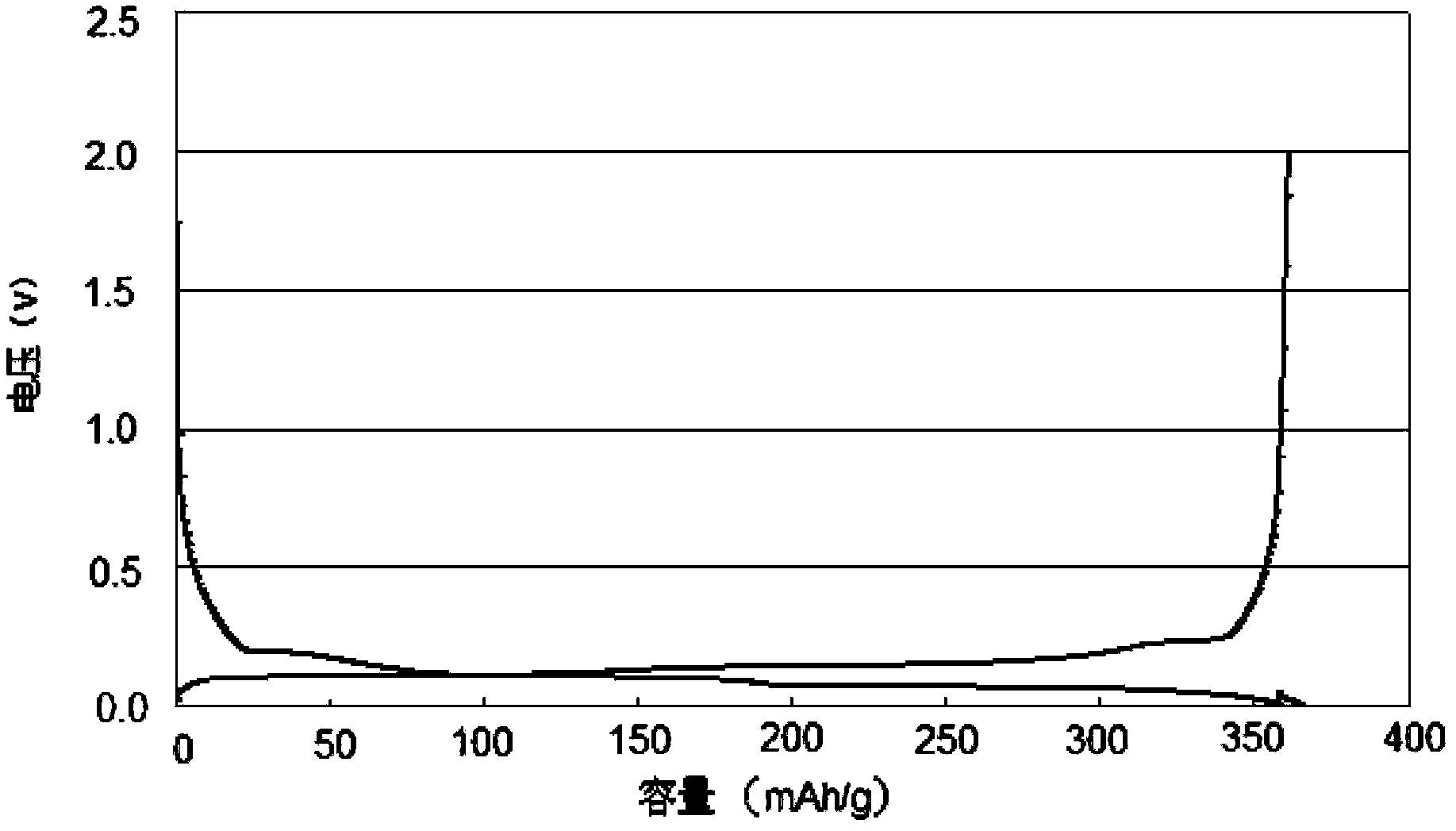

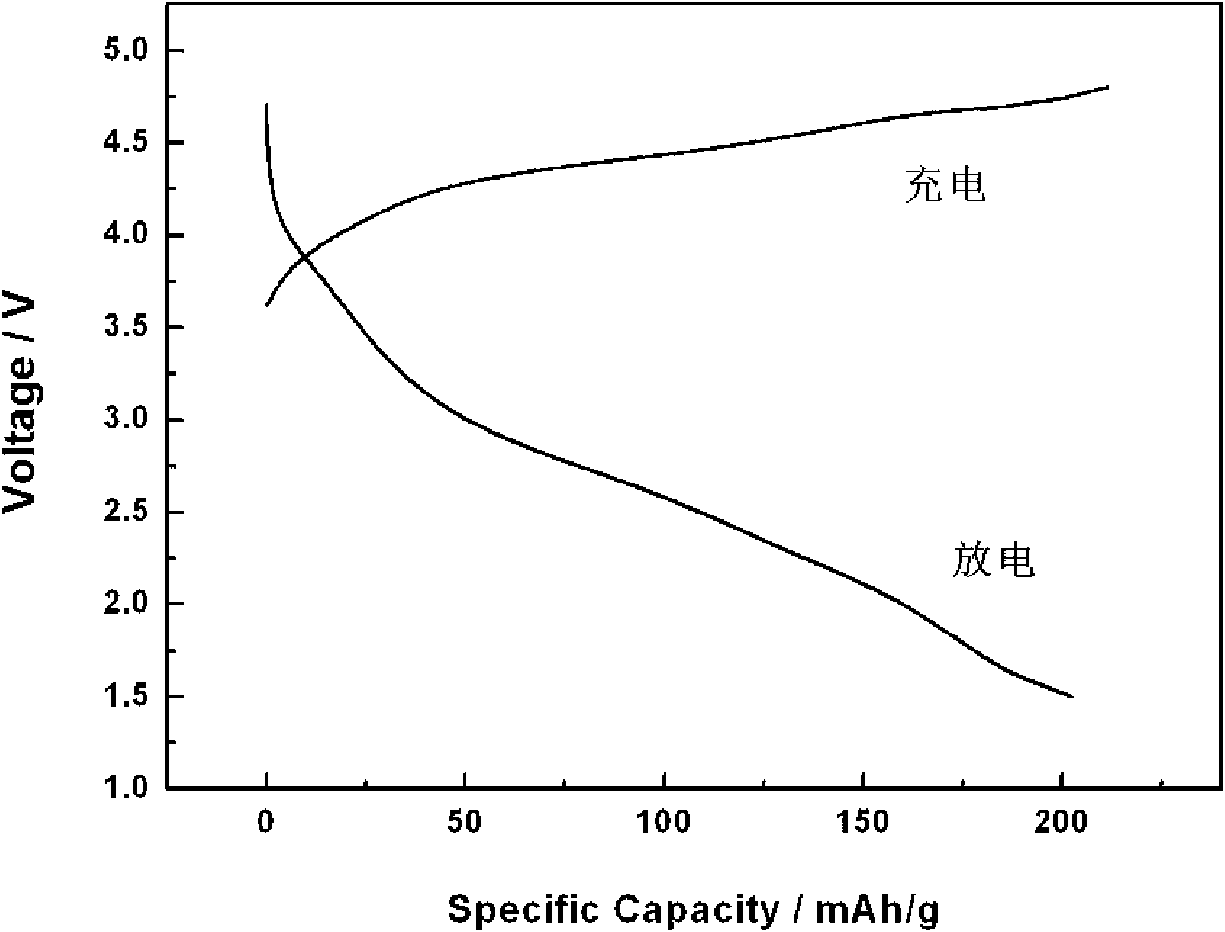

Cathode material for lithium-ion power and energy storage battery and preparation method thereof

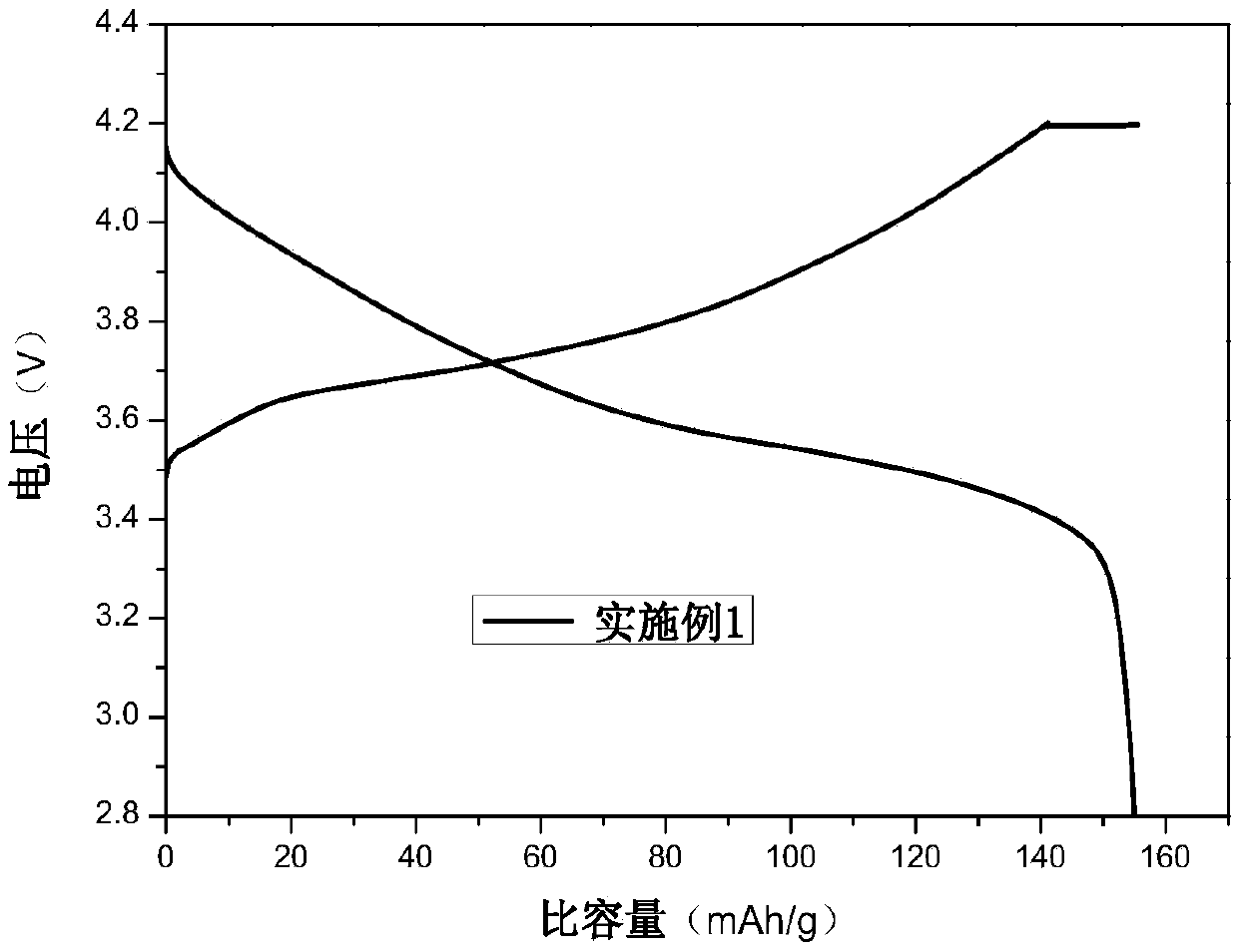

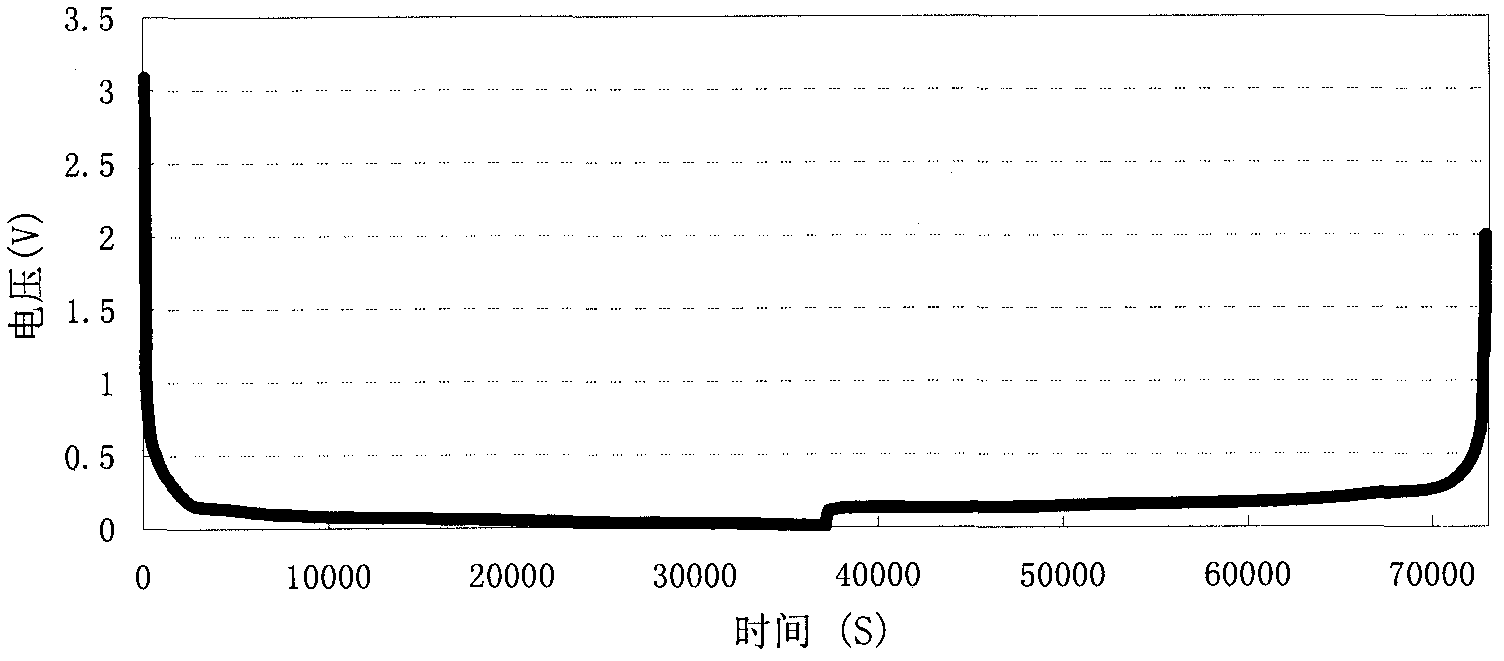

The invention discloses a cathode material for a lithium-ion power and energy storage battery and a preparation method thereof, aiming to solve the problem on how to improve the high-magnification charge-discharge property of the battery and how to enable the battery to have good cycle property. The cathode material is obtained by carbonizing asphalt containing a catalyst at 500-1,300 DEG C. The preparation method comprises the following steps of: raising the temperature and the pressure to have a carbonized thermal polycondensation reaction; washing, extracting and then washing; drying to obtain mesophase microbead precursors; and then carbonizing to obtain the cathode material for the lithium-ion power and energy storage battery. Compared with the prior art, the invention reduces the production cost; because the mesophase soft carbon materials obtained by low-temperature carbonization are adopted, the interior of the cathode material is in a turbostratic structure capable of charging and discharging with high power and high current; and the main raw material of the mesophase soft carbon material is asphalt, so that compared with other hard carbons such as the resin type, the plant, and the like, the cathode material has yield improved by 3-5 times, low cost and higher specific capacity.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +2

Composite conductive agent, lithium ion battery pole pieces and lithium ion battery

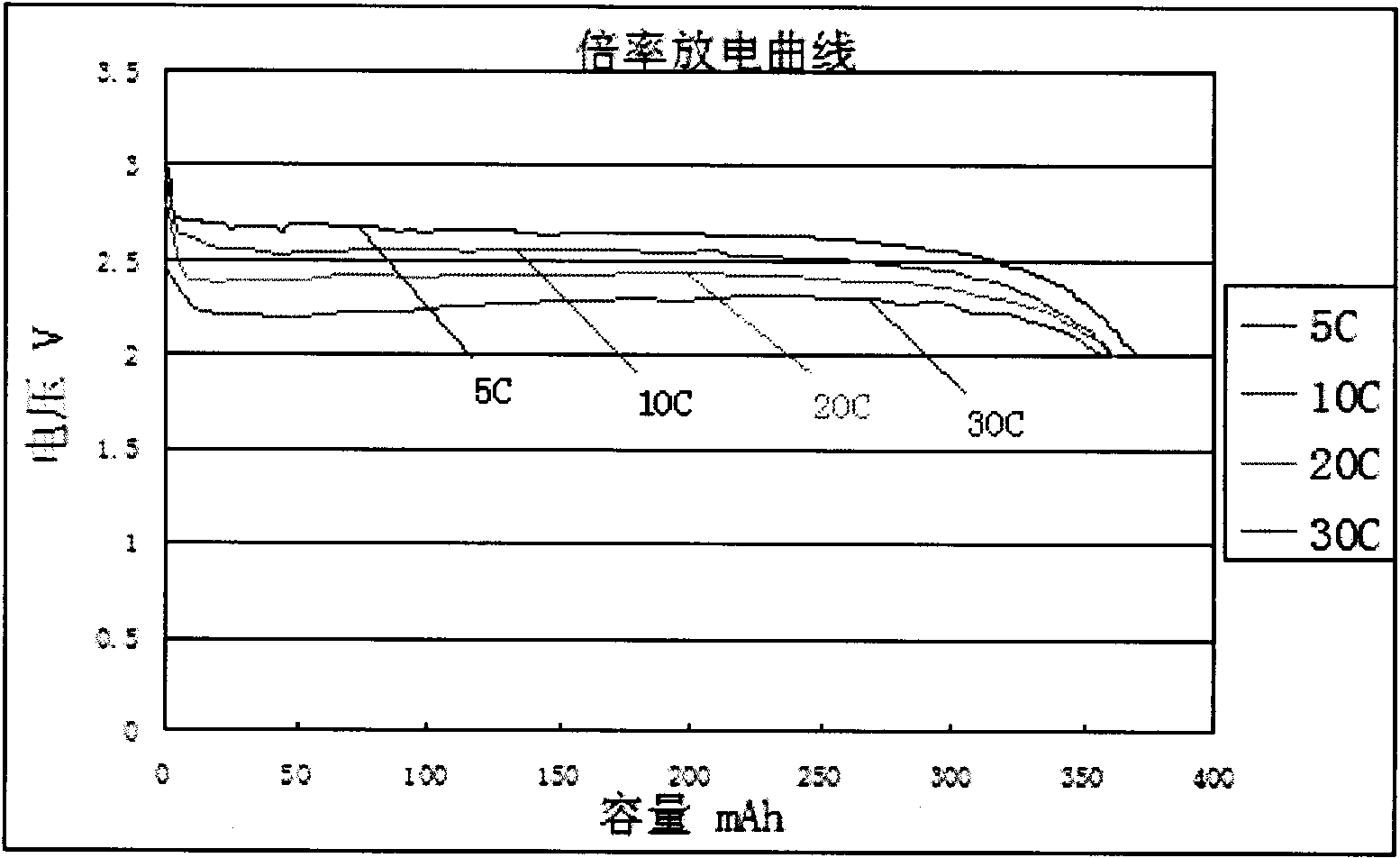

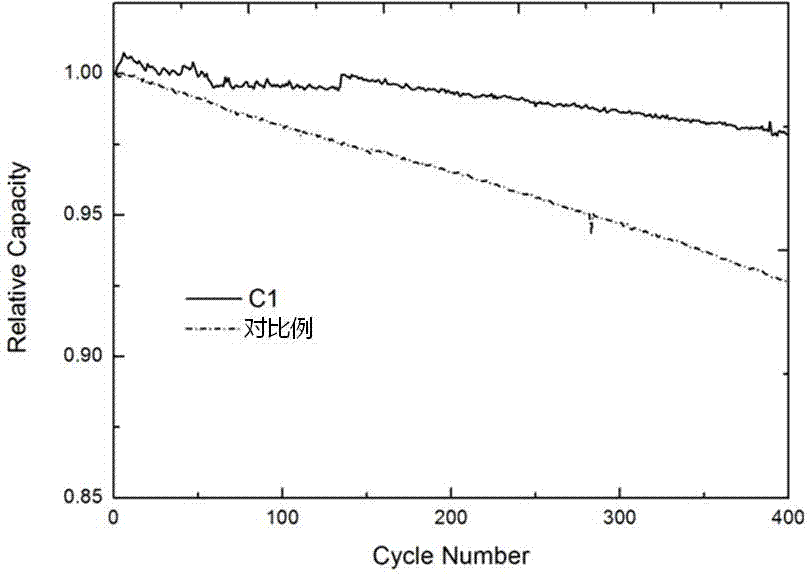

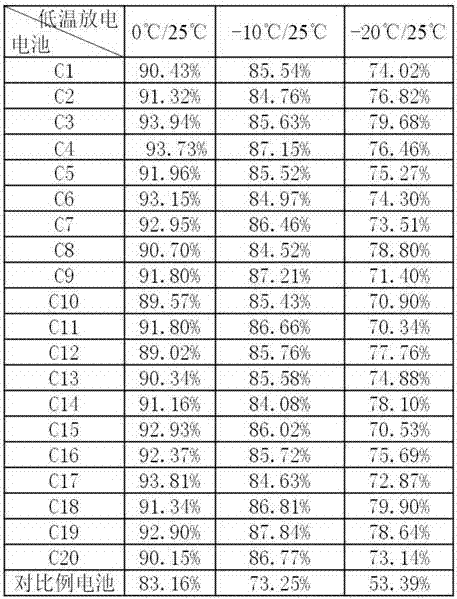

PendingCN107482222AGood rate dischargeExcellent low temperature dischargeSecondary cellsElectrode collector coatingElectrical batteryCarbon nanotube

The invention discloses a novel composite conductive agent, a lithium ion positive pole piece and a lithium ion negative pole piece made of the composite conductive agent, and a lithium ion battery containing the positive pole piece and the negative pole piece. By leading the novel composite conductive agent, the developed pole piece of which the surface has an effective conductive network can be prepared by adding a small amount of conductive agent, so that the prepared lithium ion has excellent rate discharging, low-temperature discharging, high-temperature storage and cyclic properties. The composite conductive agent comprises single-wall or fewer-wall carbon nanotubes and graphene nanosheets, wherein the specific surface area of each single-wall or fewer-wall carbon nanotube is 200 to 1500m<2> / g, the tube diameter is 1 to 10nm, and the tube length is greater than 5mu m; the diameter of each graphene nanosheet is 0.2 to 2mu m, the specific surface area is smaller than 1800m<2> / g, and the thickness is smaller than 2nm.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

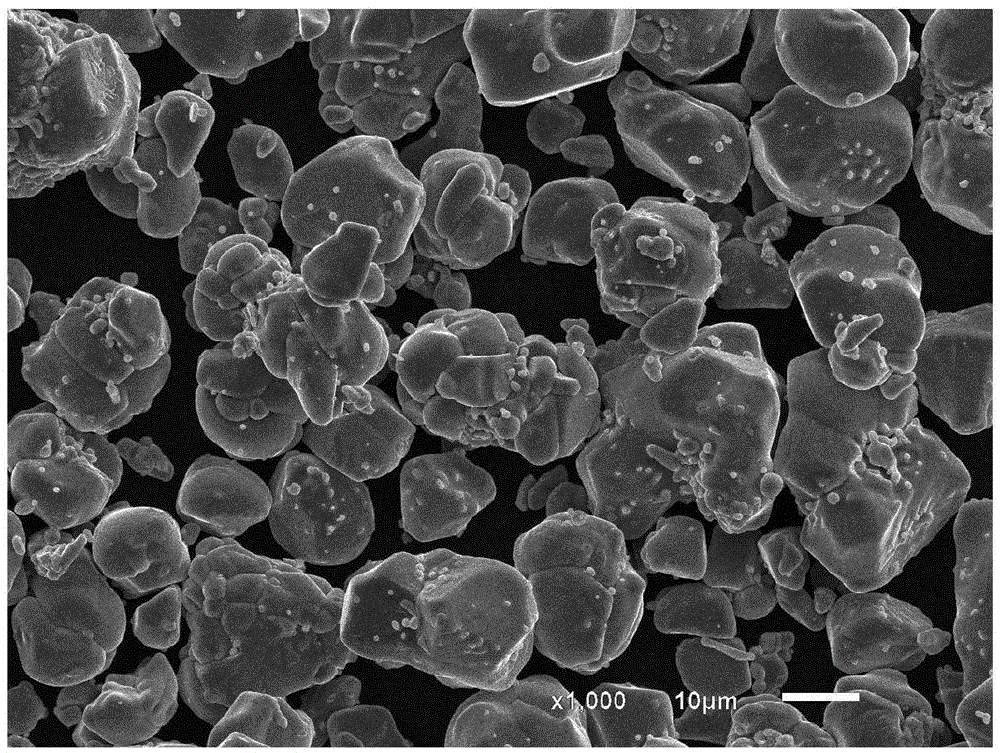

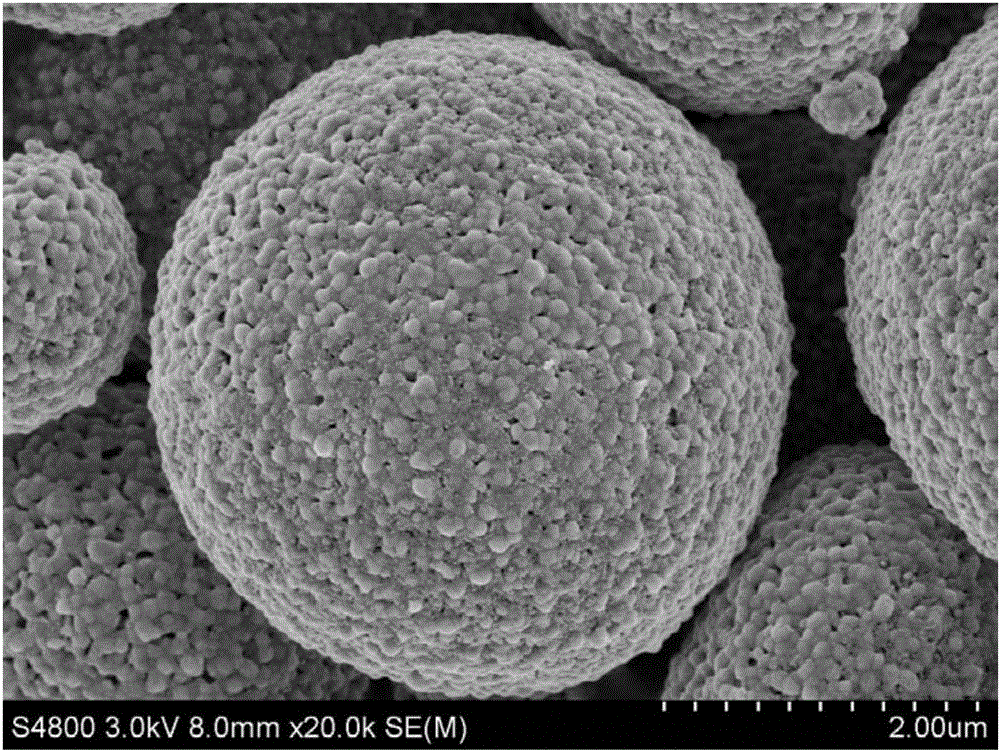

High-performance lithium ion battery cathode material and preparation method thereof

InactiveCN101847722AHigh tap densityImprove electrode processing performanceElectrode manufacturing processesNickel oxides/hydroxidesSingle crystalCobalt

The invention relates to a lithium ion battery cathode material LiNixCoyM1-x-yO2 prepared from micron-sized single crystal particles and a preparation method thereof, wherein x is greater than 0 and is not more than 0.8, y is greater than 0 and is not more than 0.5, and M is one or two of Li, Mn, Al and Mg. The invention is characterized in that (1) composite oxide or hydroxide of transition metal nickel, transition metal cobalt and modified metal M is used as a raw material, the composite oxide or hydroxide is porous aggregate comprising nanocrystals, the average size of the aggregate is 2-50 micrometers, and the specific surface area of the aggregate is greater than 15m<2> / g (measured by BET method); (2) the composite metal oxide or hydroxide and lithium salts are milled in a ball mill, the micron-sized composite metal oxide or hydroxide is converted into nanocrystal particles to obtain a nano-sized mixed precursor of the composite metal oxide or hydroxide and the lithium salts, and the mixed precursor is sintered at uniform temperature to obtain the required lithium ion battery cathode material; and (3) the prepared lithium ion battery cathode material LiNixCoyM1-x-yO2 is basically prepared from micron-sized single crystal particles, and the average size of the single crystal particles is 2-20 micrometers. In addition, the product has excellent physical and electrochemical properties, such as ultra-low specific surface area, reasonable particle size distribution, good electrode processing properties, ultra-long cycle life, excellent rate capability, obvious high and low temperature cycling and storing properties and excellent safety; and the product can be widely used as a high-performance lithium ion battery cathode material. The invention provides the high-performance lithium ion battery cathode material and the preparation method thereof.

Owner:QINGDAO LNCM

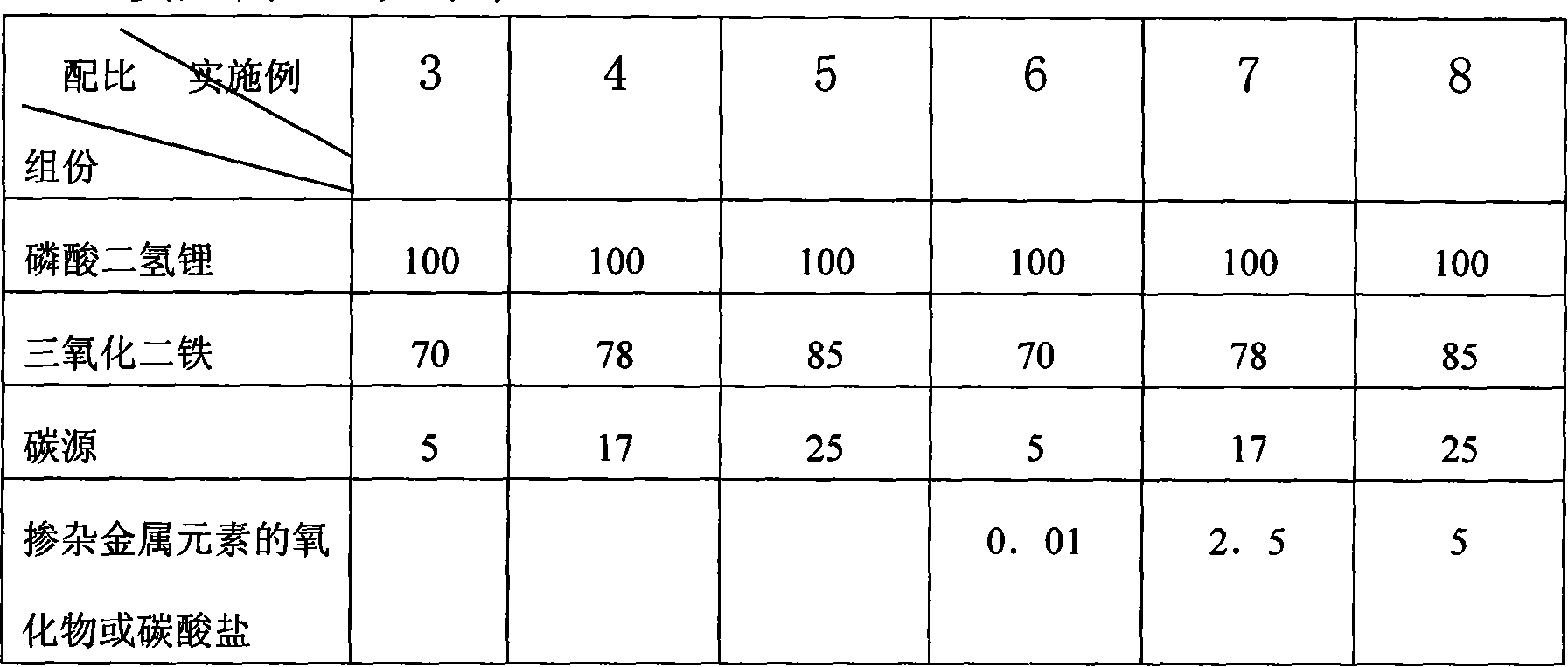

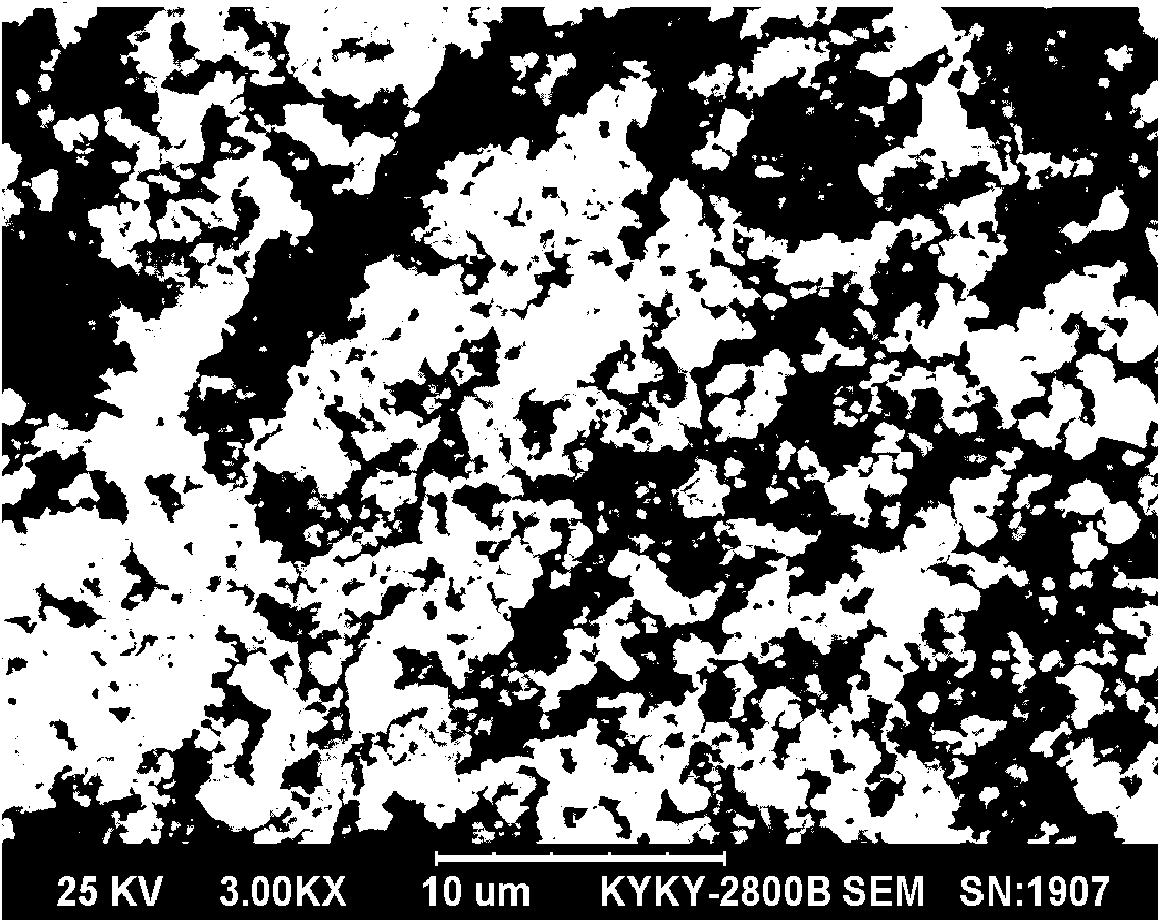

Method of producing lithium iron phosphate with high compacted density and excellent adhesive property

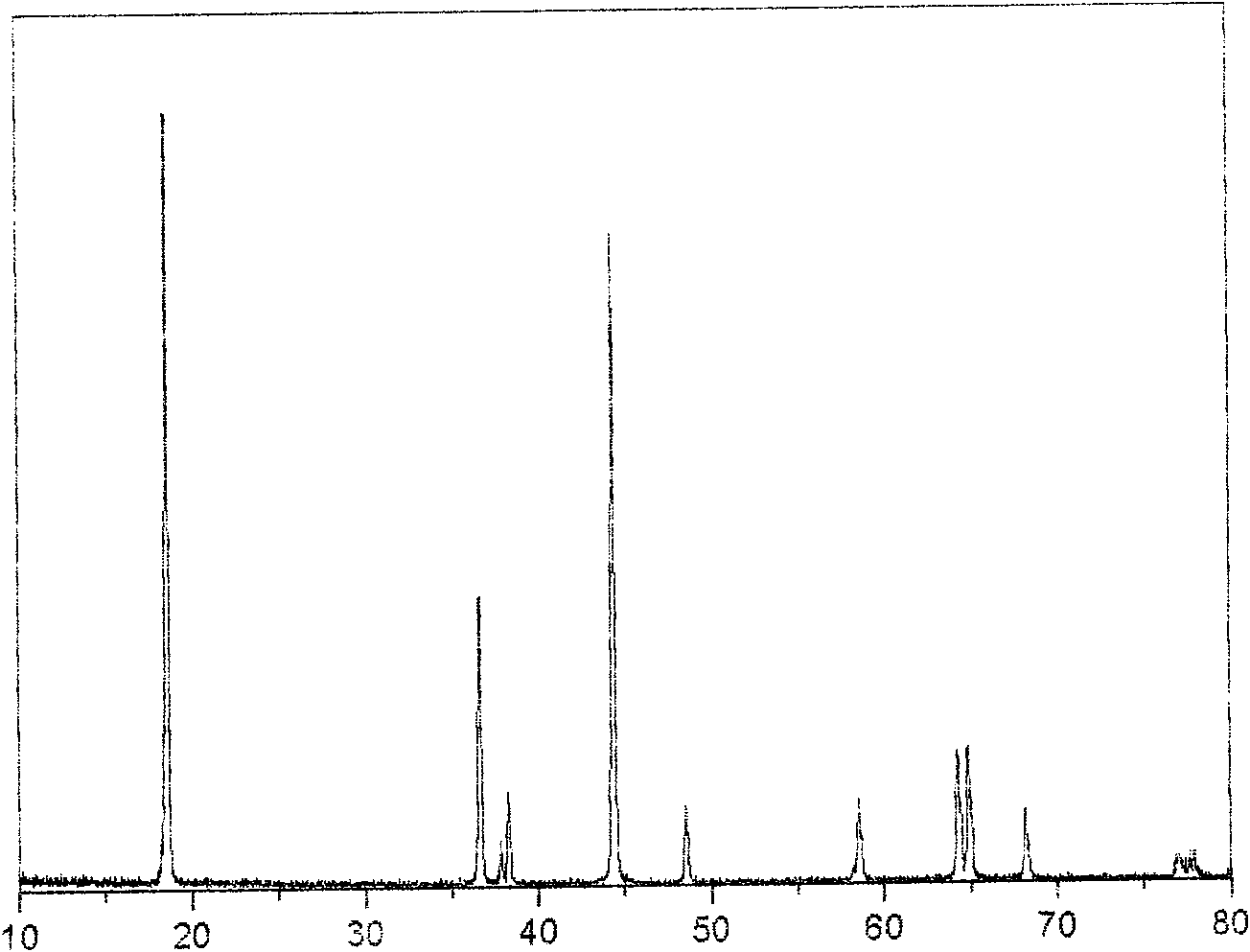

InactiveCN101152961AGood winding performanceGood bonding performanceCell electrodesPhosphorus compoundsNitrogen atmosphereOxide

The present invention relates to a method preparing phosphate iron lithium with high compacted density and good cohesiveness. The technical points are as follows: firstly, ferric oxide, phosphate dihydrogen lithium, oxide or carbonate doping metal elements and carbon source are ball-milled evenly in an aqueous solution and are then sprayed and dried so that a spherical powder is obtained; the spherical powder is secondly mixed with carbon source; after ball-milling and in nitrogen atmosphere protection, the mixture is presintered for 4 hours to 48 hours in 300 DEG C to 400 DEG C; after breaking, the mixture is heat treated for 4 hours to 48 hours in a high temperature of 600 DEG C to 800 DEG C so the phosphate iron lithium with high compacted density and good cohesiveness is obtained. The present invention has the advantages that the phosphate iron lithium prepared by the present invention is good in cohesiveness when used as lithium ion battery anode, an anode plate is high in compacted density, softness and winding performance. The preparing method generates no harmful gas, costs little, is simple in process and especially suitable for large-scale industrial production.

Owner:天津科斯特汽车技术有限责任公司

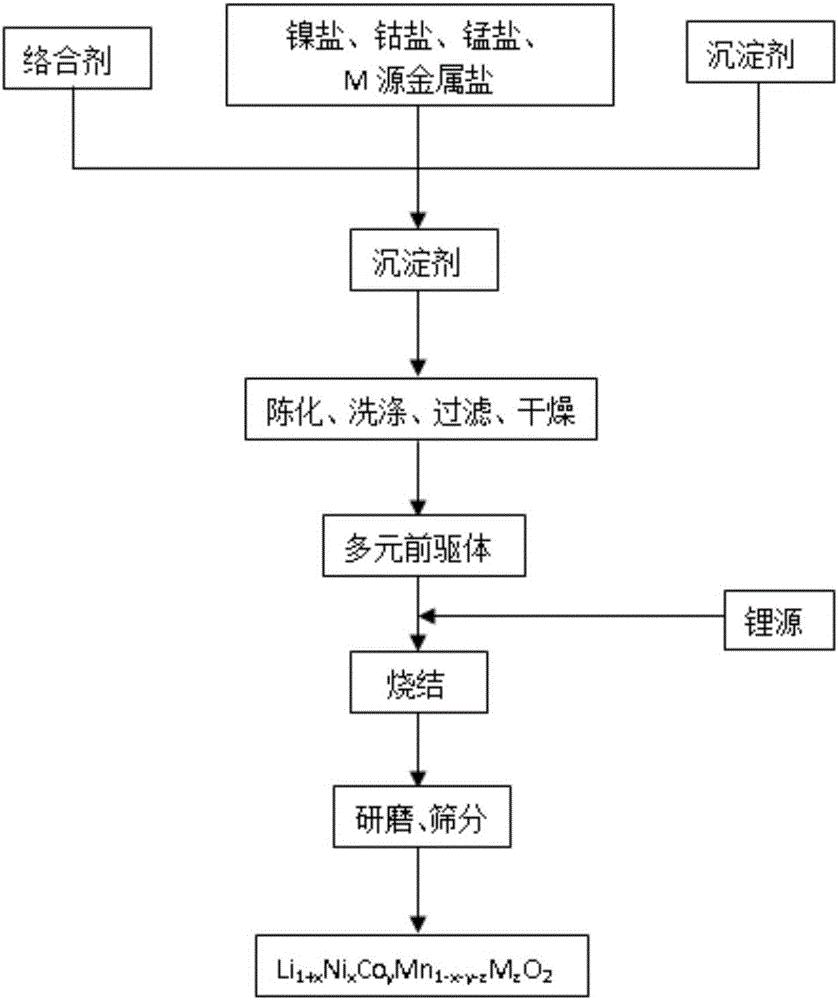

Method for preparing ternary positive electrode material of lithium ion battery

ActiveCN103811744AImprove space utilizationIncrease volumetric energy densityCell electrodesSecondary cellsEnergy densityLithium electrode

The invention relates to a method for preparing a ternary positive electrode material of a lithium ion battery. The method comprises the following steps: preparing an aggregate material A from a lithium source and a precursor, preparing a single-crystal or single crystal-like material B from a lithium source and a precursor, uniformly mixing the aggregate material A and the single-crystal or single crystal-like material B, sintering to form a material C, and coating powder of the material C with a coating, thereby obtaining the lithium-ion ternary positive electrode material. The aggregates with different granularity and shapes and the single-crystal or single crystal-like ternary material are mixed, and single-crystal particles can be effectively arranged among aggregate particles, so that the graded material is in full contact with a conductive agent and an adhesive, the space utilization rate and the compaction density of the material can be improved, the volume energy density of the material is improved, the electrical property of the material is fully exerted, the effect of heat stability of the material is improved, and the safety of the battery is improved.

Owner:QINGHAI TAIFENG XIANXING LITHIUM ENERGY TECH CO LTD

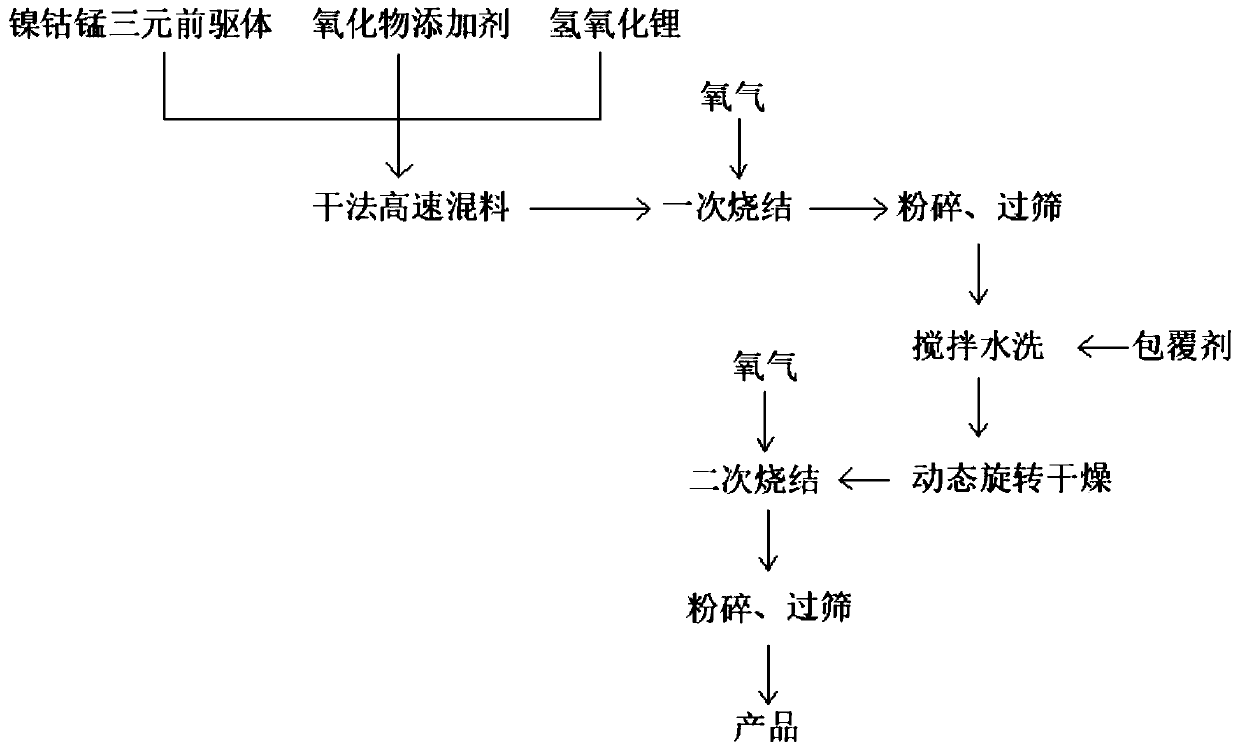

High-nickel single-crystal ternary cathode material with low surface residual alkali content and preparation method thereof

InactiveCN110436531AIn-situ encapsulationUniform coating in situCell electrodesSecondary cellsLithium hydroxideSingle crystal

The invention discloses a high-nickel single-crystal ternary cathode material with low surface residual alkali content and a preparation method thereof. The preparation method comprises the followingsteps: weighing lithium hydroxide, an oxide additive and a nickel-cobalt-manganese ternary precursor, and carrying out uniform mixing through a dry high-speed mixing process so as to prepare a mixed material; subjecting the mixed material to first sintering so as to obtain a first sintered material; crushing the first sintered material, and carrying out sieving so as to obtain a first crushed material; weighing the first crushed material, a coating agent and deionized water, and carrying out water washing under stirring so as to prepare a slurry, wherein the coating agent comprises an elementX which is one or more selected from the group consisting of B, Al, Ba, Zr, Mg, Ca, Ti, Si, V, Sc, Nb, Ta and Z; drying the slurry under a vacuum condition through a dynamic rotary drying process so as to obtain a dry material; subjecting the dry material to secondary sintering so as to obtain a secondary sintered material; and crushing the secondary sintered material, and carrying out sieving soas to obtain a product. The high-nickel single-crystal ternary cathode material and the preparation method thereof provided by the invention has the following advantages: alkali reduction by water washing and in-situ coating by a wet process can be synchronously completed; the process is simple; high compaction density is realized; and the content of residual alkali is low.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

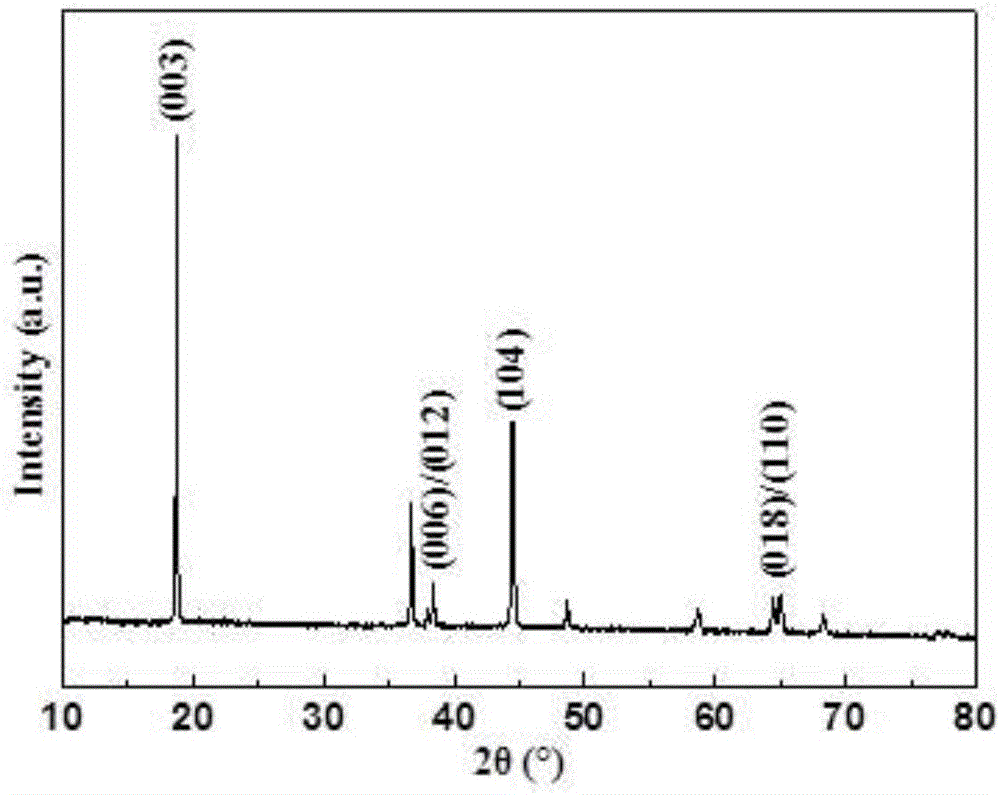

Doped monocrystal multi-component material for lithium ion batteries and preparation method of such doped monocrystal multi-component material

InactiveCN106784686AIncrease energy densityHigh tap densityHybrid capacitor electrodesCell electrodesManganeseCharge discharge

The invention belongs to the technical field of anode materials for lithium ion batteries and particularly discloses a doped monocrystal multi-component material for lithium ion batteries and a preparation method of such doped monocrystal multi-component material. The doped monocrystal multi-component material and the preparation method thereof have the advantages that nickel-cobalt-manganese ternary materials are modified, and M-source metals are doped when a precursor is prepared to decrease the material sintering temperature and improve material tapping density, so that the mixed arrangement degree of Ni<2+> in a Li<+> layer is weakened obviously; through high-temperature sintering and tempering processes, the precursor of the multi-composite material, prepared through a coprecipitation method, is more stable in crystal structure, metal ions in the material are inhibited from dissolving through surface coating, side reaction between the metal ions and electrolyte is inhibited, and stability and electrochemical performance of an active material are further enhanced; a doped monocrystal multi-component material finished product is stable in crystal structure, high in safety and compaction density and excellent in rate capability and cycle performance, so that specific capacity and charge-discharge voltage of the material are further enhanced; the preparation method is small in doping quantity, simple to operate, easy to control, widely applicable and suitable for large-scale production.

Owner:烟台卓能锂电池有限公司

High density lithium ion battery cathode material lithium cobalt oxide and preparation method thereof

InactiveCN102447107AIncrease compaction densityIncrease volumetric energy densityCell electrodesCobalt compoundsManufacturing technologySodium-ion battery

The invention relates to a manufacture technology of a lithium ion battery cathode material and specifically provides a high density lithium ion battery cathode material lithium cobalt oxide and a preparation method thereof. The high density lithium ion battery cathode material lithium cobalt oxide of the invention has a chemical formula of Li1+xCo(1-a-b-c) MgaTibAlcFdO(2-d), wherein a, b, c, d and x satisfy relations of: 0<=a<=0.03, 0.001<=b<=0.02, 0<=c<=0.01, 0<=d<=0.02 and 0<=x<=0.08; and a preferable value of a, a preferable value of b, a preferable value of c and a preferable value of d satisfy relations of: 0.005<=a<=0.01, 0.002<=b<=0.01, 0<=c<=0.005 and 0<=d<=0.005; and a cation M is doped or cladded by one or a composition of several selected from magnesium, titanium and aluminium. The invention can enhance stability of material structure, cycle performance and safety performance of the lithium ion battery as well as effectively increase space utilization rate of the material and compacted density of the cathode material, thereby substantially raising volume energy density of the material.

Owner:JIANGSU KING LITHIUM CELL

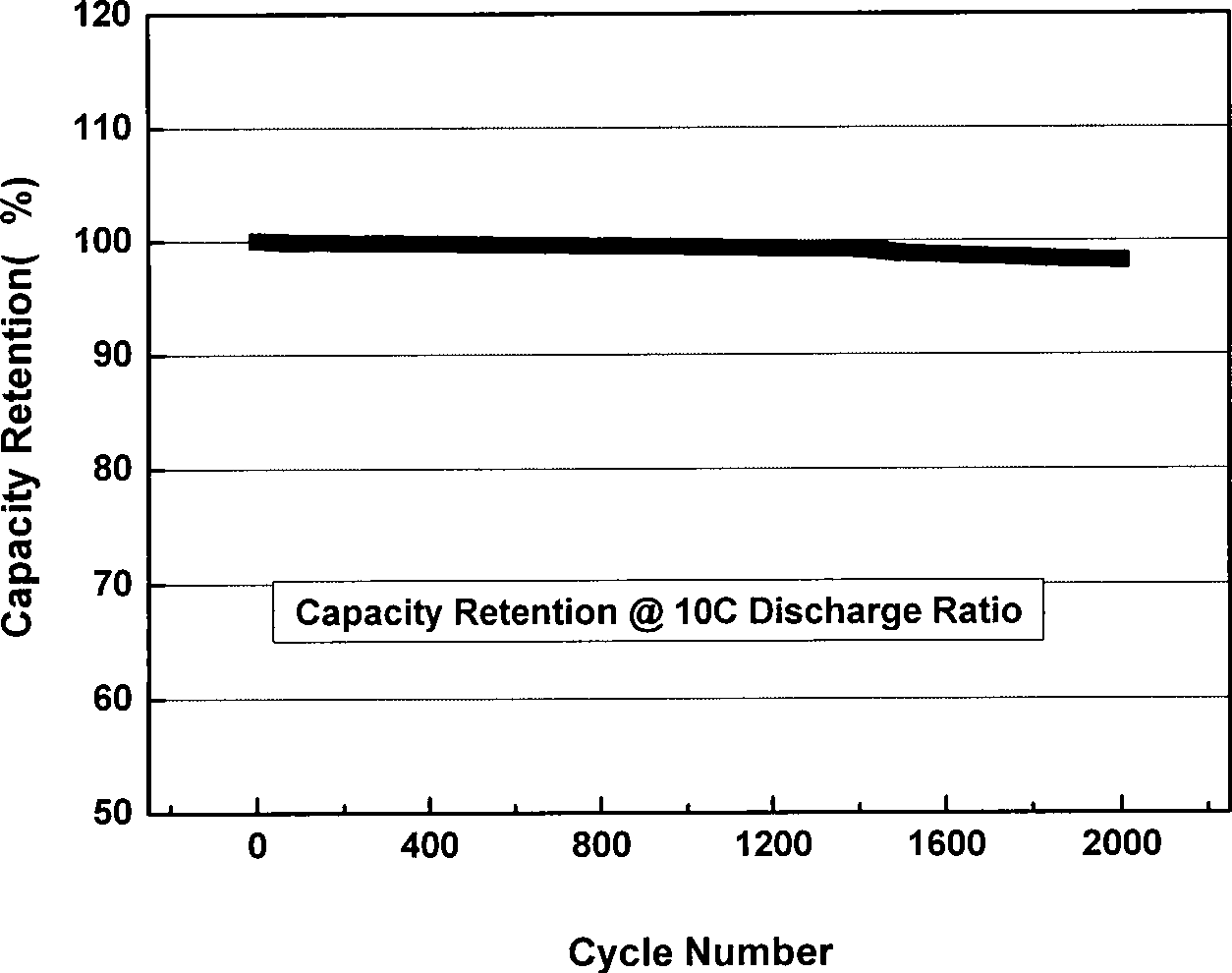

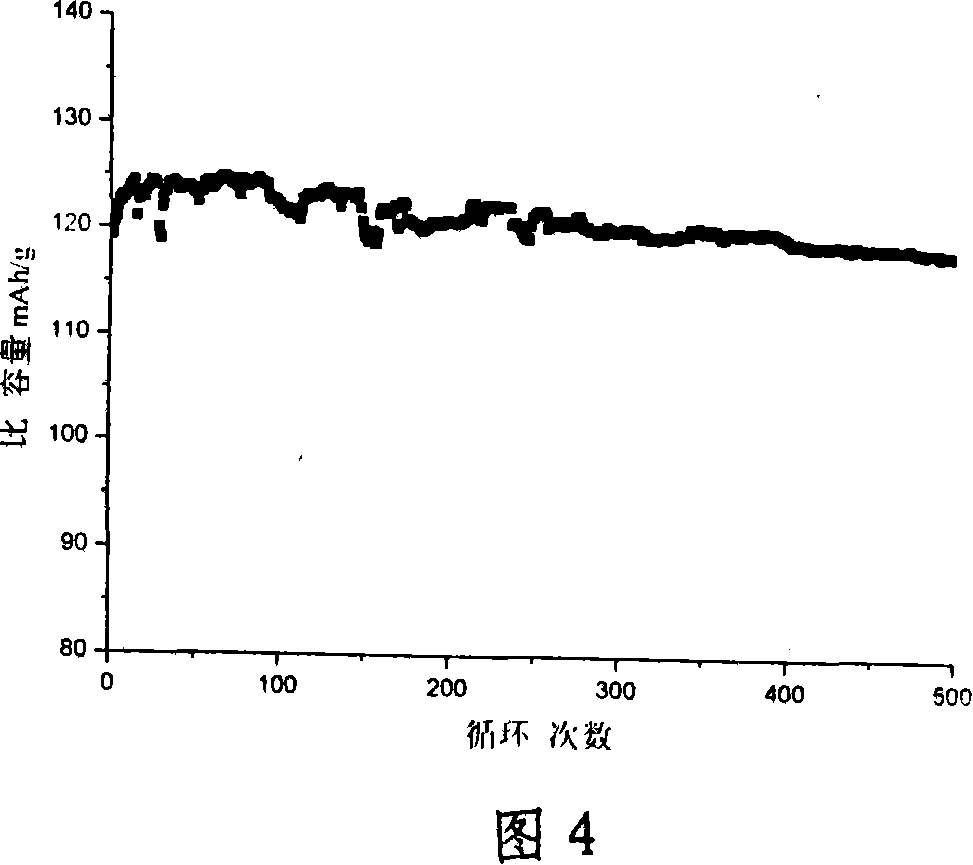

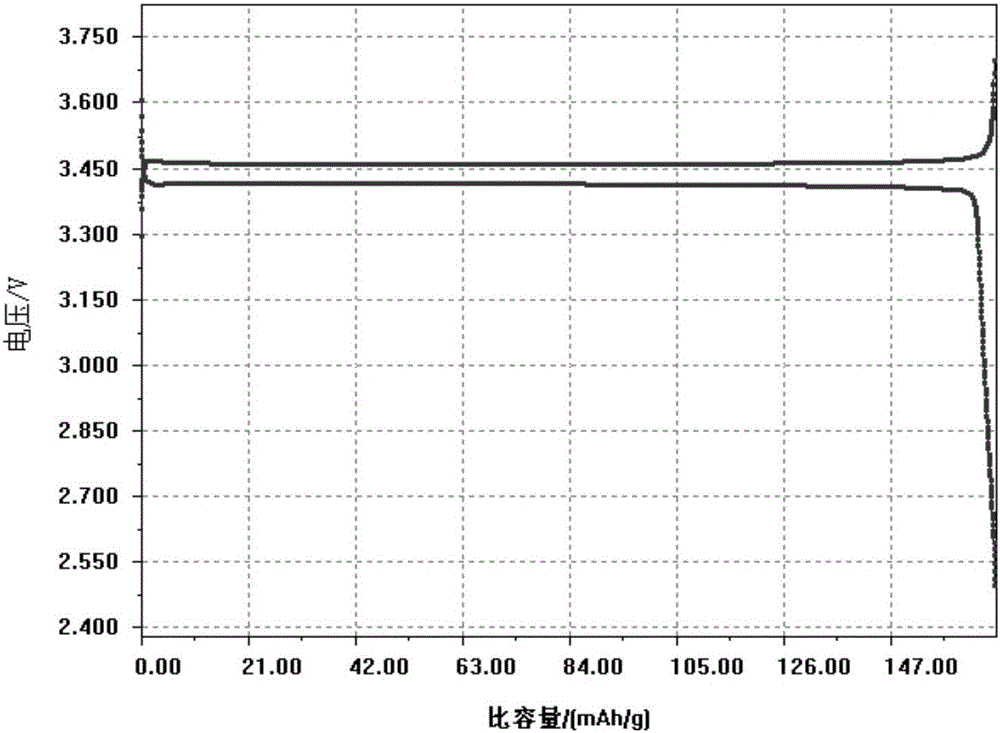

High-compaction-density lithium iron phosphate and preparation method thereof

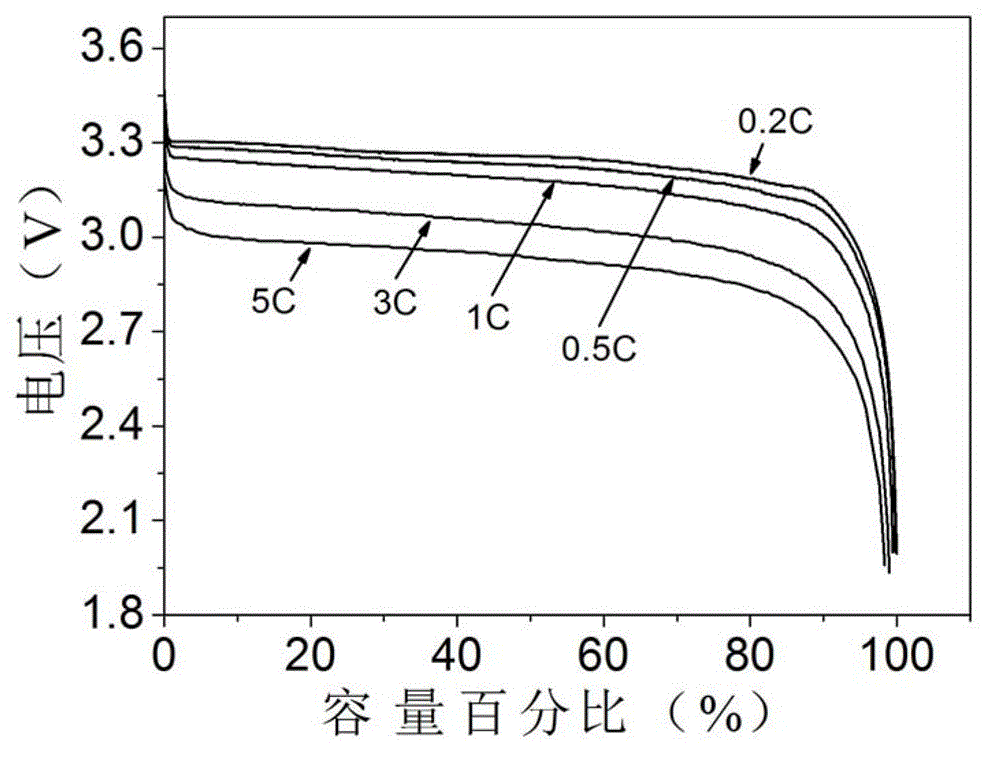

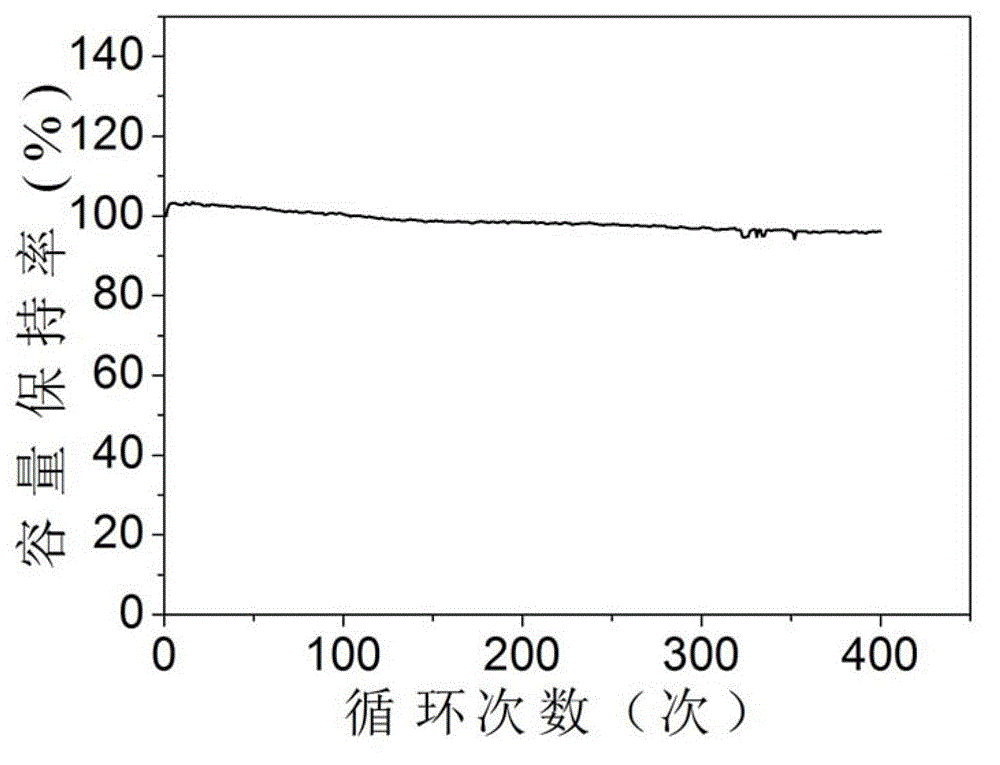

InactiveCN107256968AIncrease compaction densityHigh specific capacityCell electrodesLithium iron phosphatePhosphoric acid

The invention discloses high-compaction-density lithium iron phosphate and a preparation method thereof. The preparation method includes that an iron phosphate material mixed with large particles and small particles is mixed with a lithium source, a lithium iron phosphate precursor with iron phosphate as a skeleton is obtained by further grinding, and the high-compaction-density lithium iron phosphate can be obtained through calcination. The maximum available compaction density of a pole piece produced from the obtained lithium iron phosphate is between 2.3g / cm<3> and 2.45g / cm<3>; a battery prepared by taking the high-compaction-density lithium iron phosphate as a cathode active material is high in specific capacity and good in cycle performance, 1C discharge is above 140mAh / g, and the cycle of the average value of cycling to less than 80% of the capacity of the first three cycles is above 3895; in addition, the preparation method is simple in process and high in operability, requirements of current industry fields on the compaction density of the cathode material can be met, and good cost advantage can be provided.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

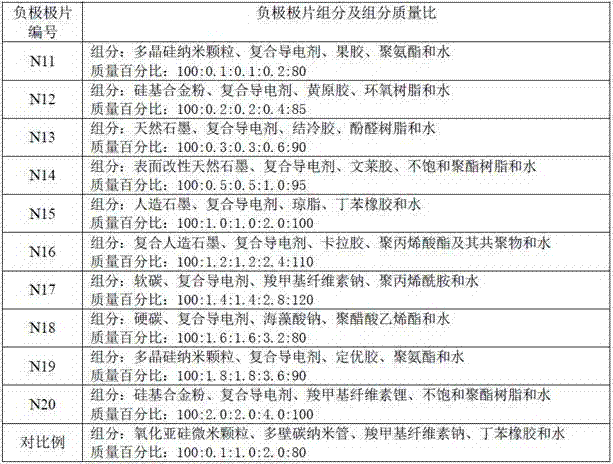

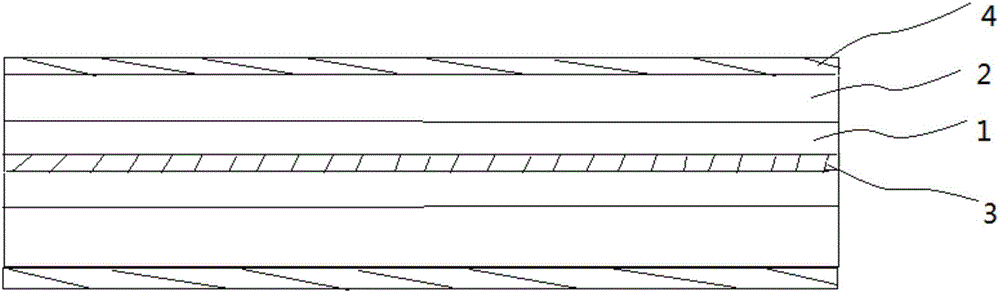

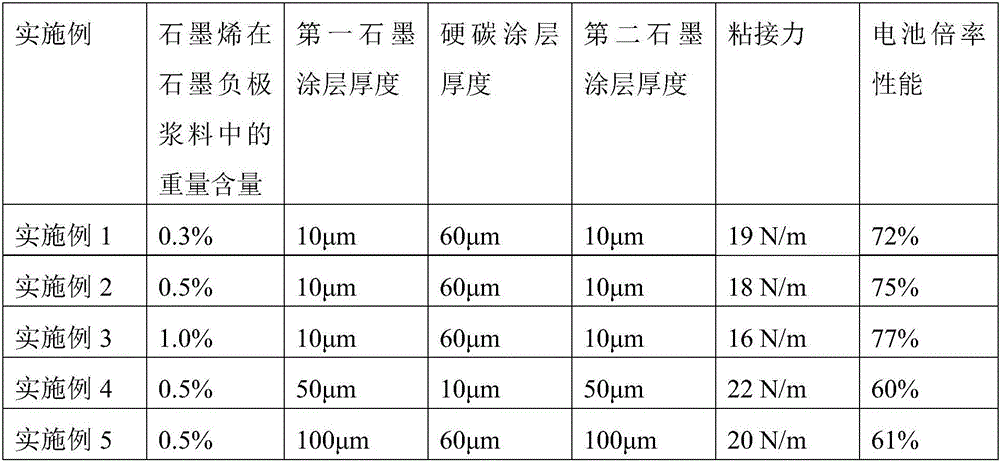

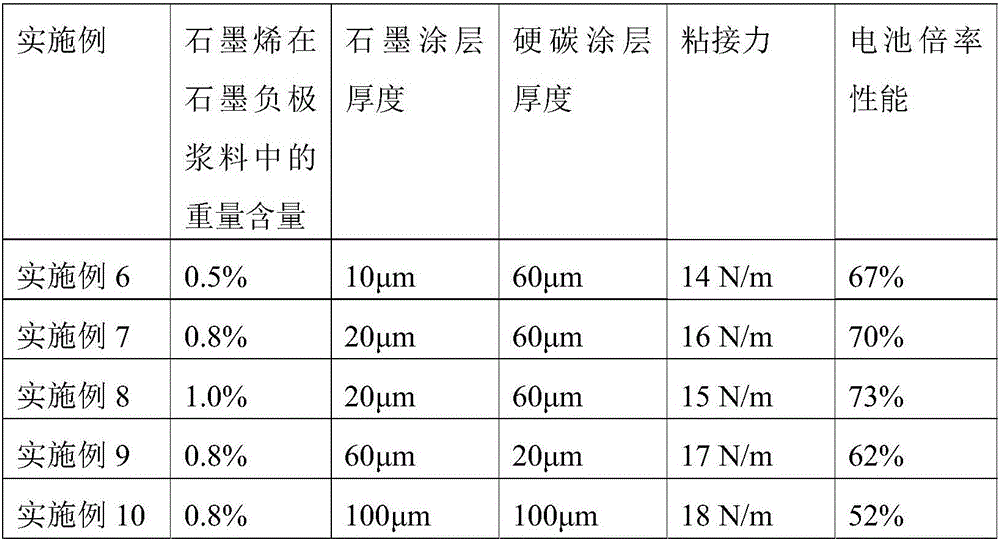

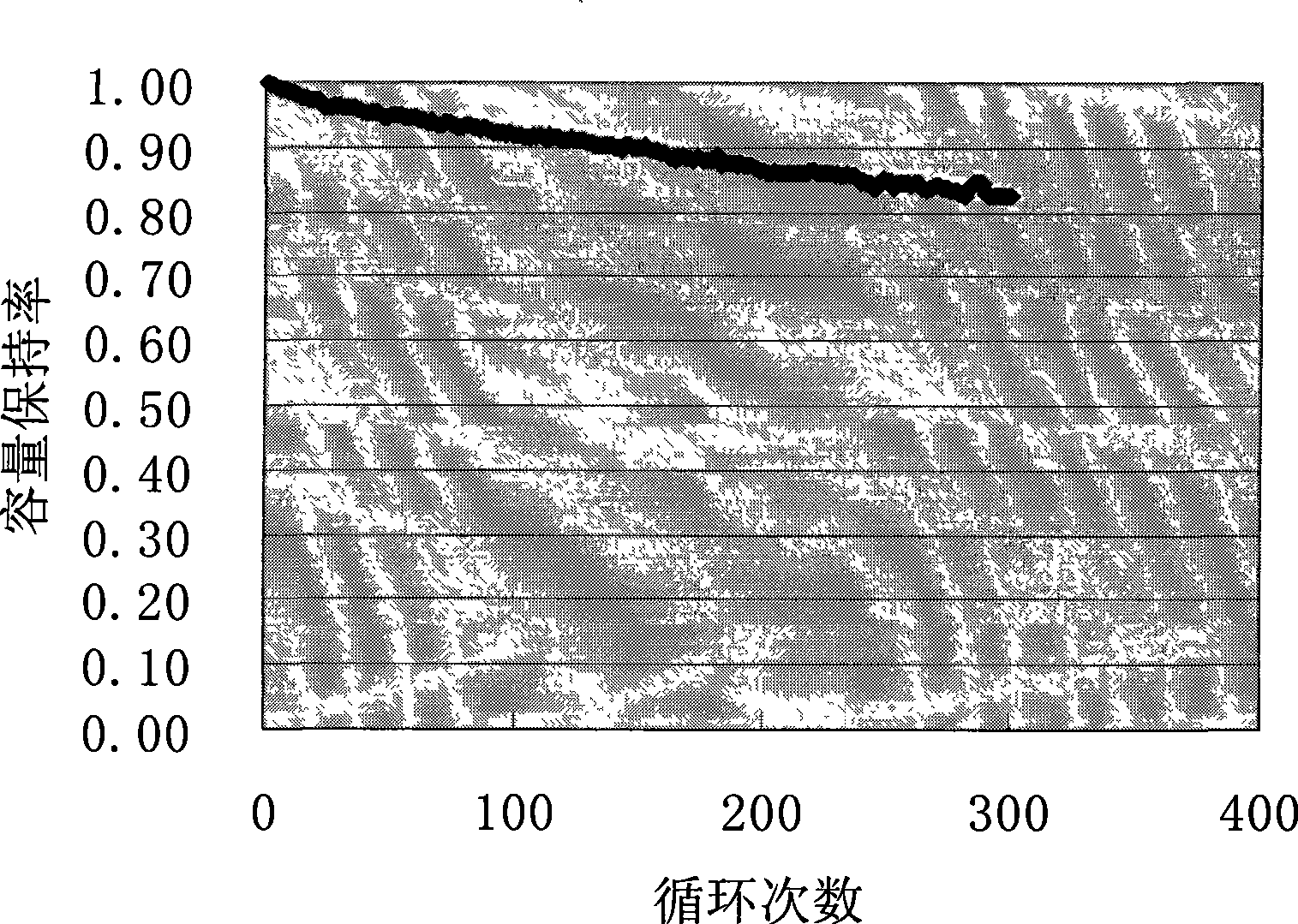

Pole piece of negative electrode and preparation method of pole piece as well as lithium-ion battery using negative electrode

InactiveCN106058154AIncrease compaction densityImprove dynamic performanceCell electrodesSecondary cellsCarbon coatingPole piece

The invention relates to the field of lithium-ion battery materials and in particular relates to a pole piece of a negative electrode and a lithium-ion battery using the negative electrode. The pole piece of the negative electrode, provided by the invention, comprises a negative electrode current collector, a graphite coating and a hard carbon coating; graphene is used as a conductive agent and is added into the graphite coating, so that on one hand, dynamics properties of the graphite coating can be improved; on the other hand, the lubrication effect of the graphene conductive agent is utilized, so that damage to materials by residual stress caused by cold pressing can be reduced, and the compaction density of the negative electrode is improved. A corresponding negative electrode preparation method is simple and feasible, and the materials do not need to be modified, so that the manufacturing cost of battery cells is reduced.

Owner:DONGGUAN AMPEREX TECH

A making method for anode slice of lithium ion battery

InactiveCN101241988AImprove adhesionHigh bonding strengthElectrode manufacturing processesActive material electrodesAdhesivePhysical chemistry

The present invention discloses a method for manufacturing a positive pole piece of the lithium ion battery, and the method comprises coating the positive material adhesive on the collector after mixing, and at the same time substituting the single adhesive in the conventional method with two or more than two adhesives with different magnitude of molecular weight. The method of the invention effectively increases the binding adhesive force of the positive pole piece after coating, further the processing capabilities of coating surface density of the pole piece, compacted density and flexibility can be further increased, and effectively realize the advancing of the battery capability and the optimizing of the capability.

Owner:SHENZHEN BAK BATTERY CO LTD

Negative pole material, preparation for battery and battery manufactured by the negative pole material

ActiveCN101393985AOptimized formulaHigh densityElectrode manufacturing processesSecondary cellsSolventAdhesive

The invention relates to a negative material of a battery, which comprises a carbon negative active material, a conductive agent, a thickening agent, an adhesive and a solvent, and the proportion of the parts by weight among ingredients is 110-140:1-10:1-10:1-10:80-200, wherein the carbon negative active material is a mixture of natural graphite and artificial graphite in proportion of 10: 1-4. The invention further relates to a method for preparing the negative material of the battery and a battery prepared by adopting the negative material. The invention optimizes the formula for the carbon negative material, improves the density of an electrode sheet of the negative electrode, improves the compacted density of the natural graphite used as the negative active material of a lithium battery, and meanwhile improves the volume capacity of the negative electrode, and greatly improves the circulation performance of a prepared finished product battery core.

Owner:ZHENGZHOU BAK BATTERY CO LTD

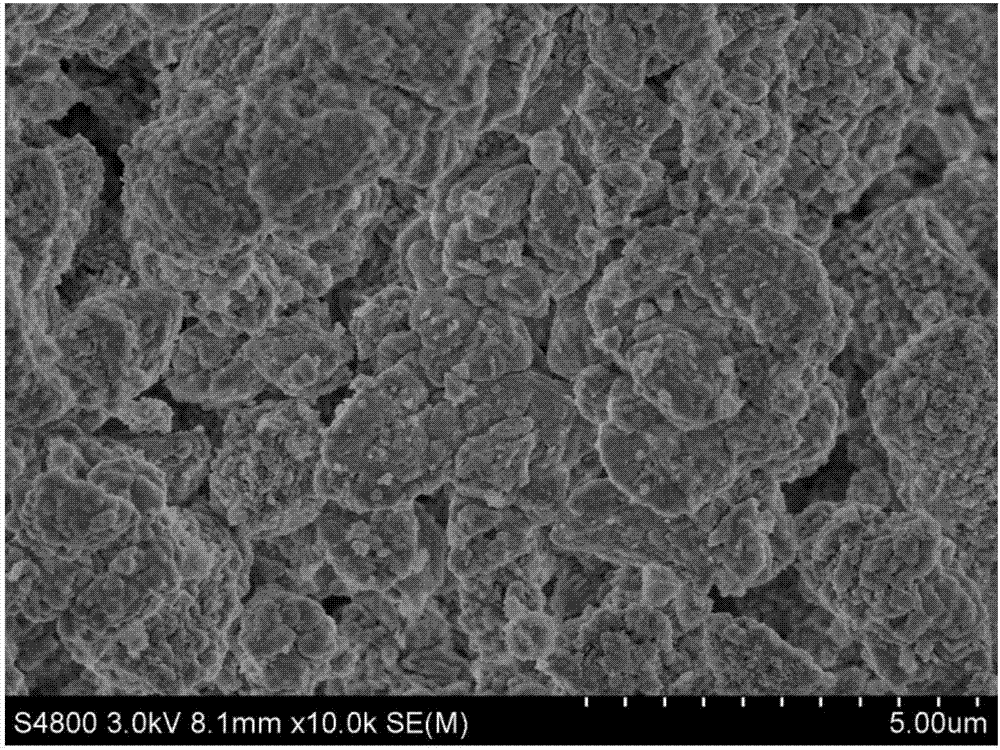

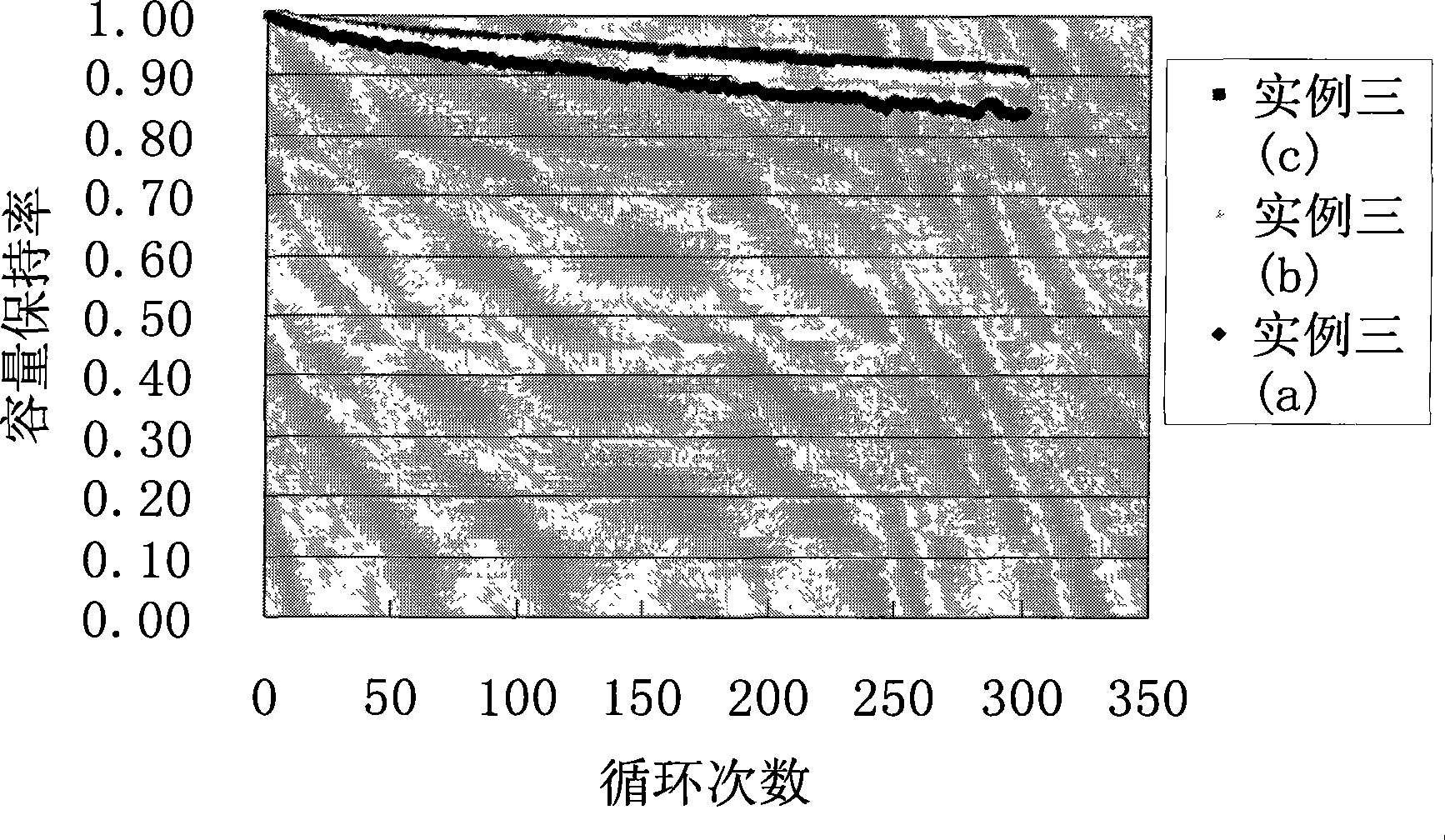

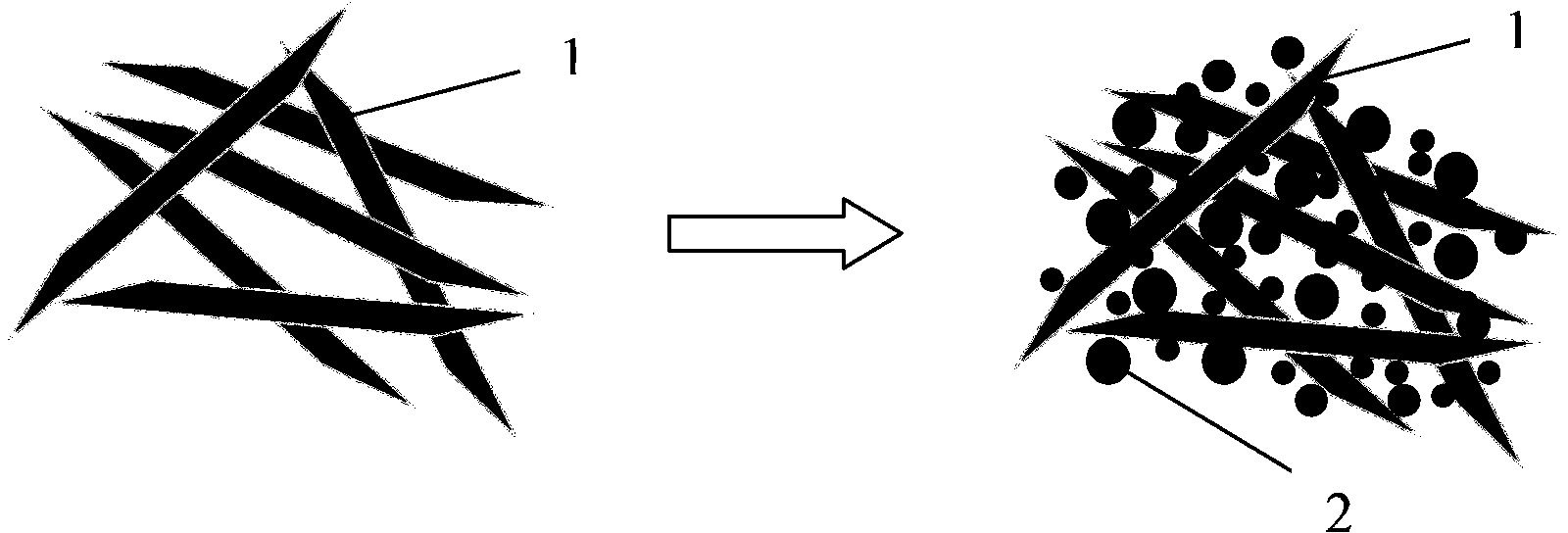

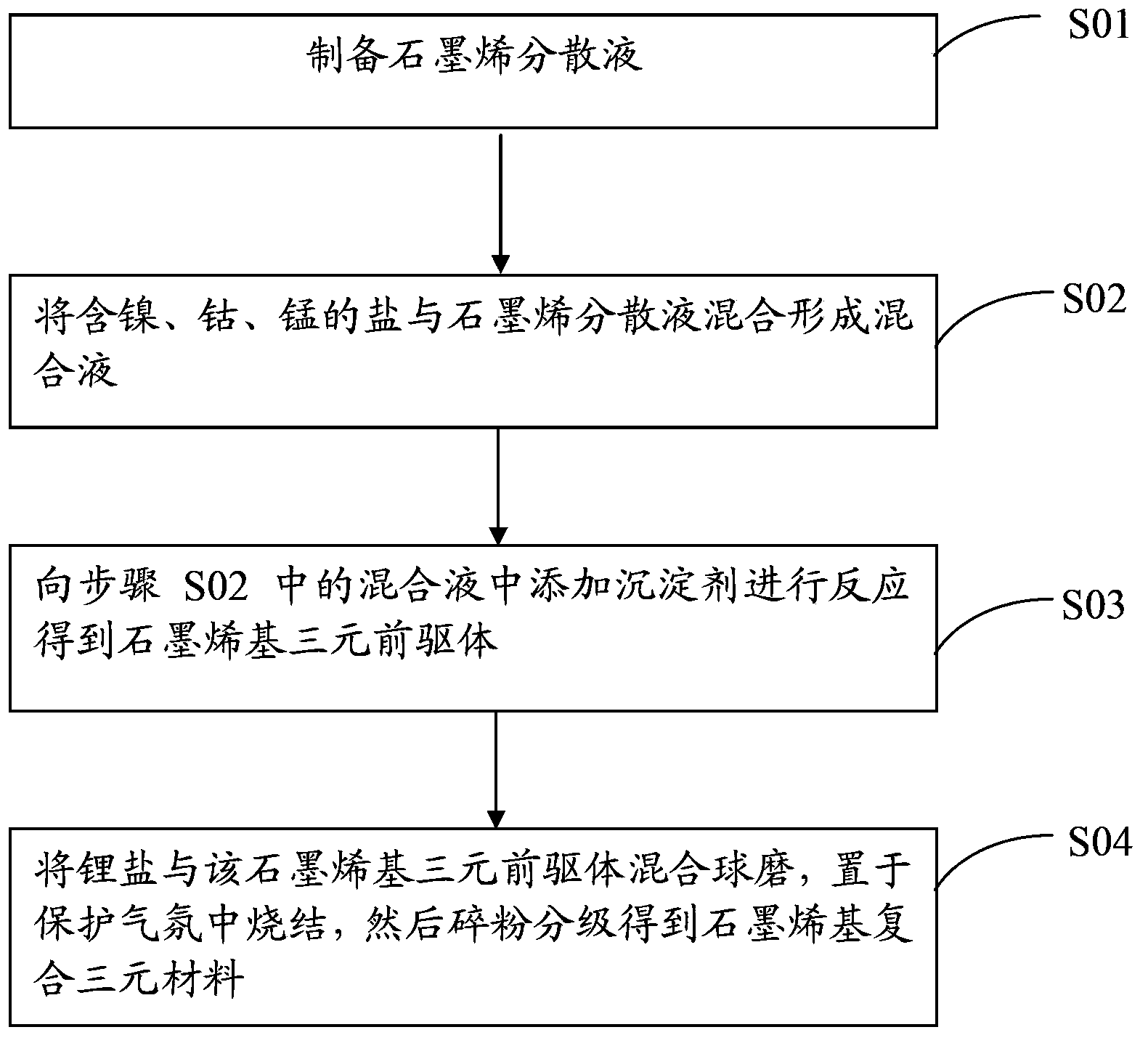

Graphene-based composite ternary material, preparation method thereof, and lithium ion battery

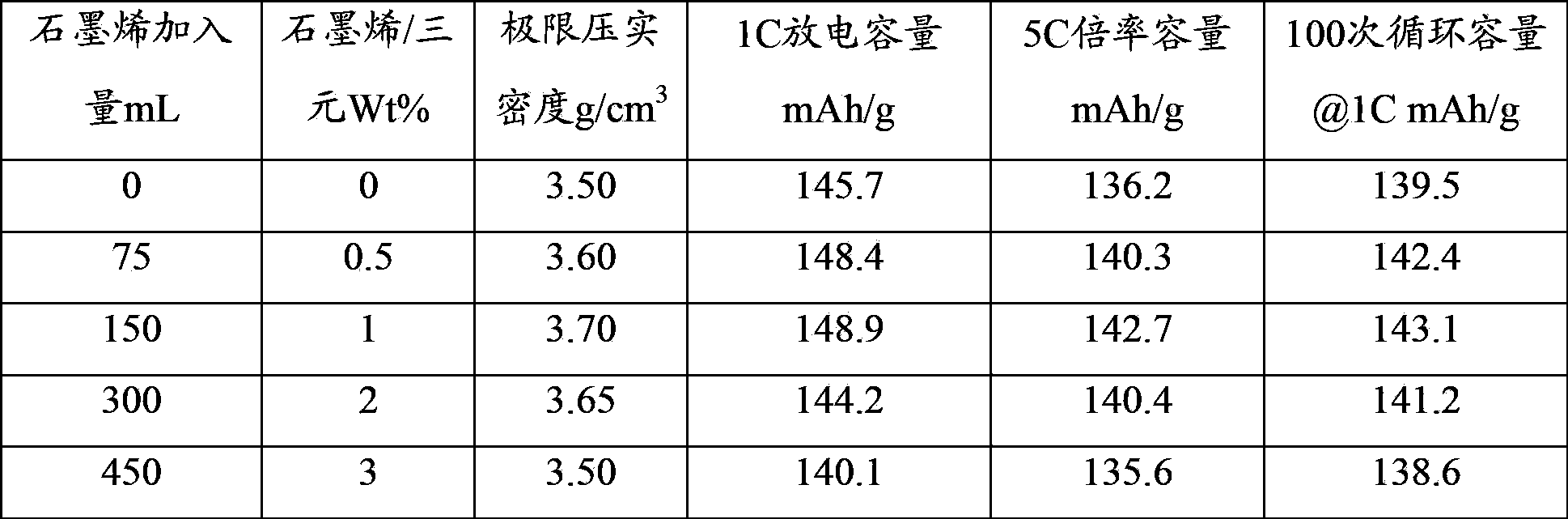

ActiveCN103904330AIncrease compaction densityReduce breakageMaterial nanotechnologyCell electrodesManganeseCobalt

The invention provides a graphene-based composite ternary material. The ternary material comprises graphene and a nickel-cobalt-manganese ternary material, wherein the graphene is prepared by sintering oxidized graphene, is composed of single-layered graphene slices or multi-layered graphene slices whose layer number is less than 10, and accounts for 0.1% to 10.0% of the total weight of the composite ternary material; and the nickel-cobalt-manganese ternary material has a primary particle structure or a secondary particle structure, has a molecular formula of Li(Ni<x>Co<y>Mn<z>)O2, wherein the sum of x, y, and z is equal to 1, and x, y, and z are all in a range of 0 to 1, and accounts for 90.0% to 99.9% of the total weight of the composite ternary material. The graphene slices are freely stacked in the graphene, thus conductive nets and cavities are formed, and the nickel-cobalt-manganese ternary material particles are embedded into the cavities between the nano graphene layers through a chemical precipitation method. The invention also provides a preparation method of the graphene-based composite ternary material.

Owner:HUAWEI TECH CO LTD

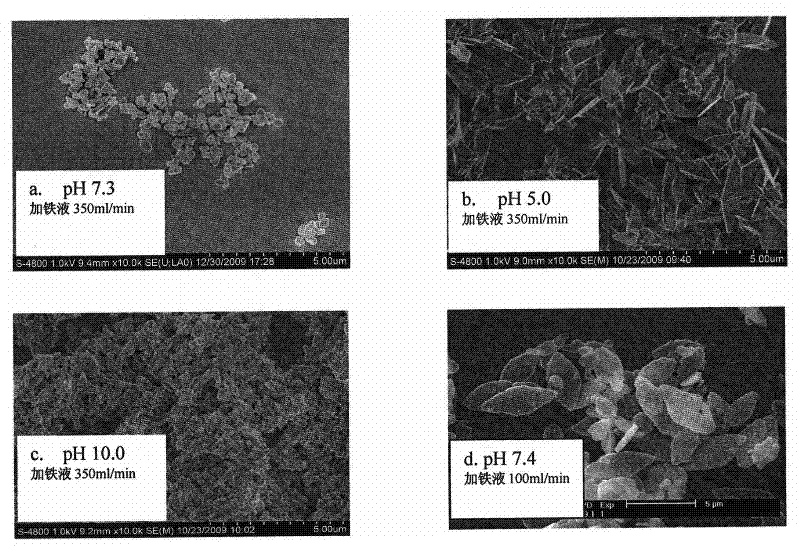

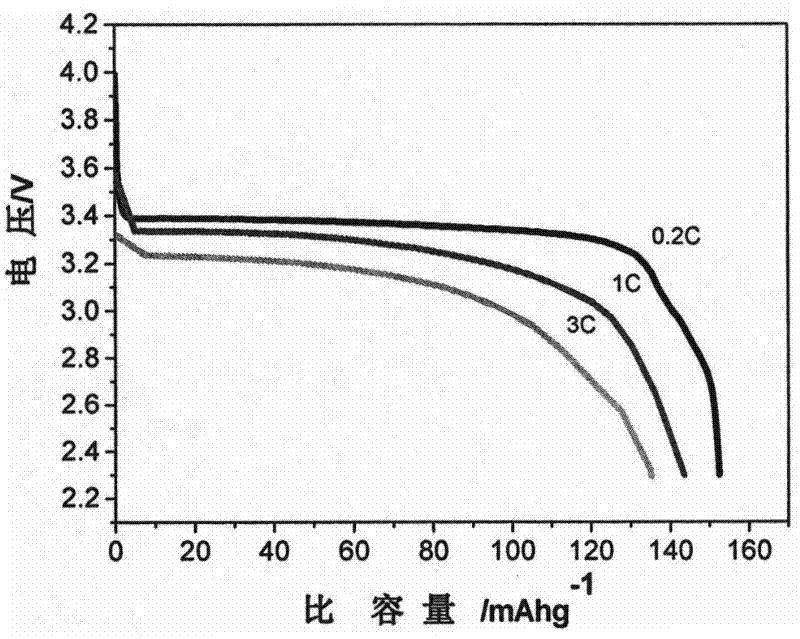

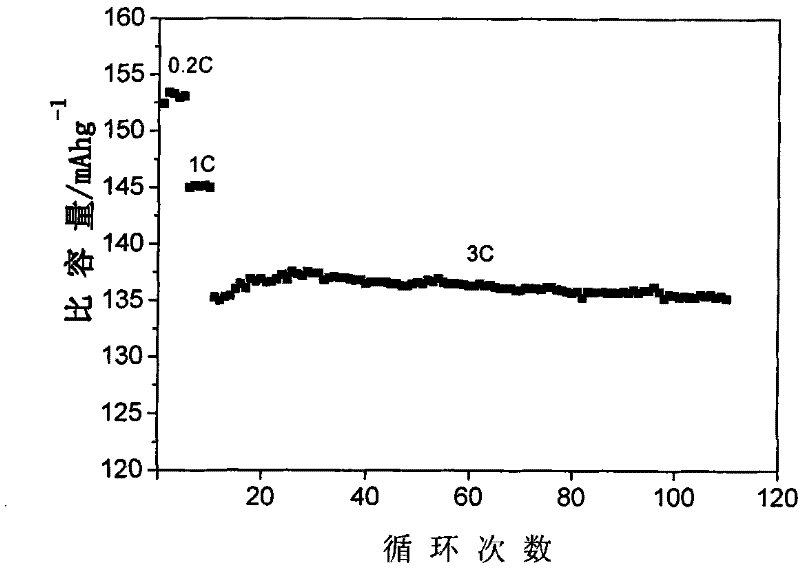

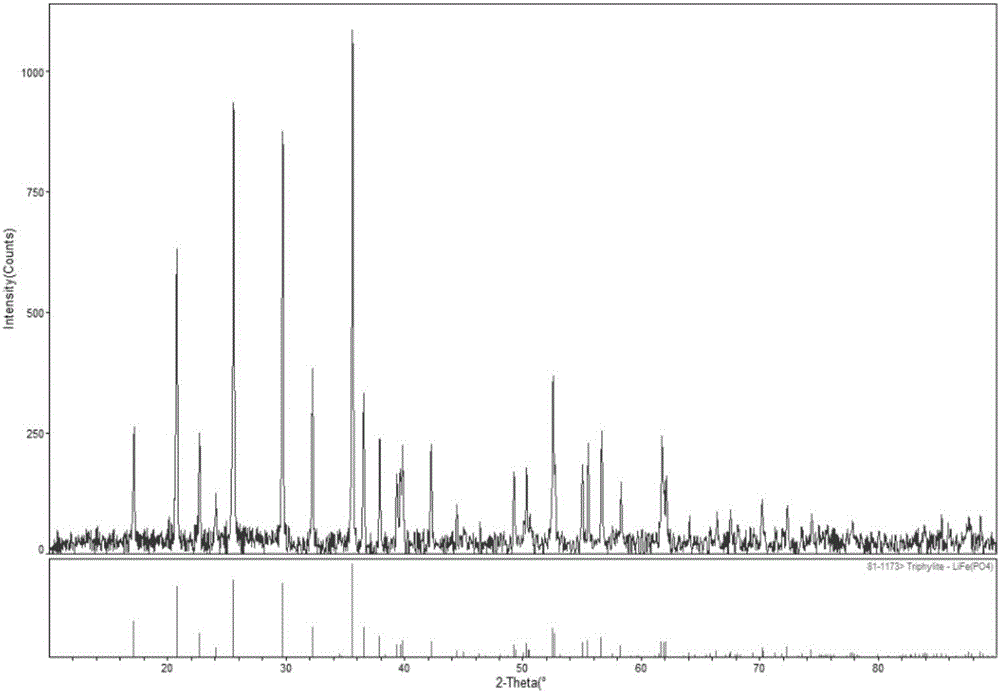

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

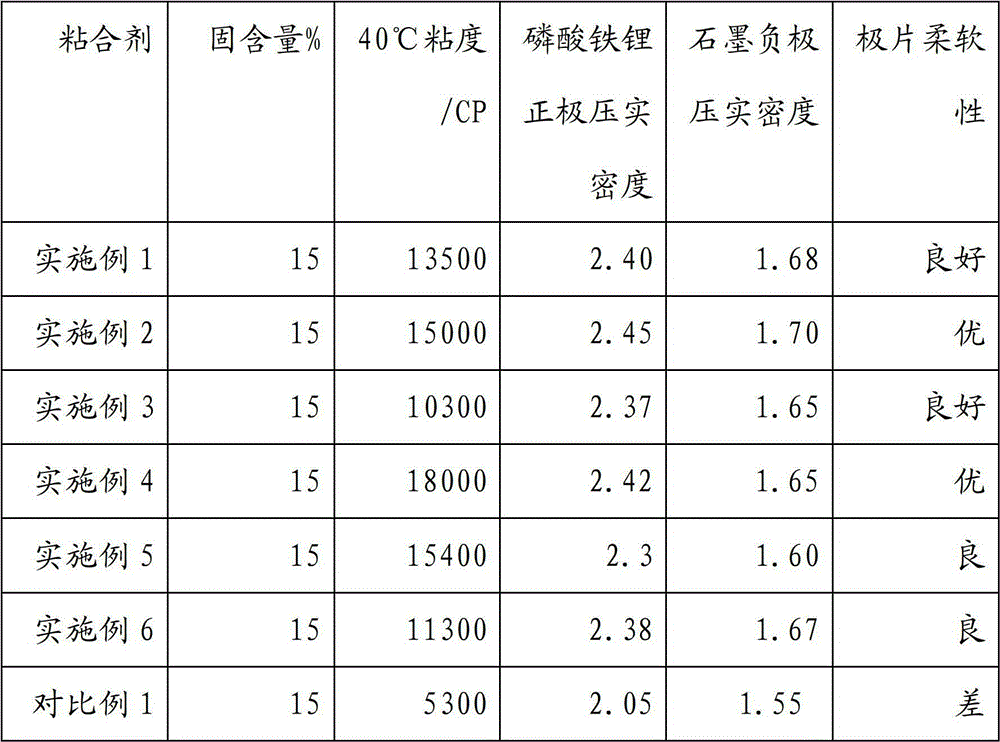

Preparation method for aqueous binder used for lithium ion battery

InactiveCN102746813AImprove cycle performanceImproved magnification performanceCell electrodesAcid polymer adhesivesHydrophilic monomerAluminium-ion battery

The invention provides a preparation method for an aqueous binder used for a lithium ion battery. The method comprises the following steps: weighing unsaturated hydrophilic monomers, unsaturated lipophilic monomers and auxiliary agents; dissolving the weighed unsaturated hydrophilic monomers in distilled water and uniform mixing the dissolved unsaturated hydrophilic monomers with the weighed unsaturated lipophilic monomers and auxiliary agents under stirring; adjusting the pH value of an obtained mixture to be 5 to 13, blowing in high purity nitrogen to remove oxygen and adjusting temperature to a constant temperature; adding an initiator for initiation of polymerization; and extracting residual monomers under vacuum so as to obtain the aqueous binder for a lithium ion battery. The aqueous binder for a lithium ion battery provided in the invention has the advantages of environment friendliness, low production cost and good bonding performance; an electrode slice prepared from the aqueous binder for a lithium ion battery has good flexibility and high compacted density and enables performance of positive and negative electrode materials of a lithium ion battery to be fully played; and a prepared lithium ion battery has good cycle performance and rate capability.

Owner:张倩

Lithium ion battery cathode material and preparation method thereof

ActiveCN105449197AEasy to prepareEasy to operateCell electrodesSecondary cellsThermal expansionCobalt

The invention provides a lithium ion battery cathode material and a preparation method thereof. The method comprises: taking a lithium source, a cobalt source and a compound with doped elements as raw materials, respectively preparing two kinds of bulk phase doped lithium cobalt oxide precursors of median grain diameters (namely D50 grain diameters), carrying out surface doped treatment to the two kinds of lithium cobalt oxide semi-finished products, finally mixing the two kinds of lithium cobalt oxide semi-finished products, carrying out surface coating, and finally preparing the high voltage and high density lithium ion battery cathode material. The prepared lithium ion battery cathode material is featured by good electrical property, specifically high capacity, high cycle retention rate, low thermal expansion coefficient and high compaction density.

Owner:北京盟固利新材料科技有限公司

Synthetic graphite negative electrode material and preparation method thereof

ActiveCN104143635AIncrease compaction densityImprove discharge capacityCell electrodesSecondary cellsAdhesiveRoom temperature

The invention discloses a synthetic graphite negative electrode material and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing spherical natural graphite, needle coke-produced coke powder and a graphitization catalyst so as to obtain a mixture; 2) subjecting the mixture and an adhesive which can be graphitized to heating and kneading for 1 to 2 h; 3) pressing the kneaded object into a block shape so as to obtain a formed body of the kneaded object; 4) charring the formed body at 800 to 1500 DEG C under the protection of inert gas and cooling the charred formed body to room temperature; and 5) carrying out catalytic graphitization high temperature treatment at 2800 to 3200 DEG C. The method provided by the invention overcomes the defects of insufficient compacted density and low discharge capacity of a synthetic graphite negative electrode material prepared by using a conventional negative electrode preparation method, can improve cycle performance of the negative electrode material and enables the synthetic graphite negative electrode material with high charge and discharge capacity and high charge and discharge efficiency to be obtained.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

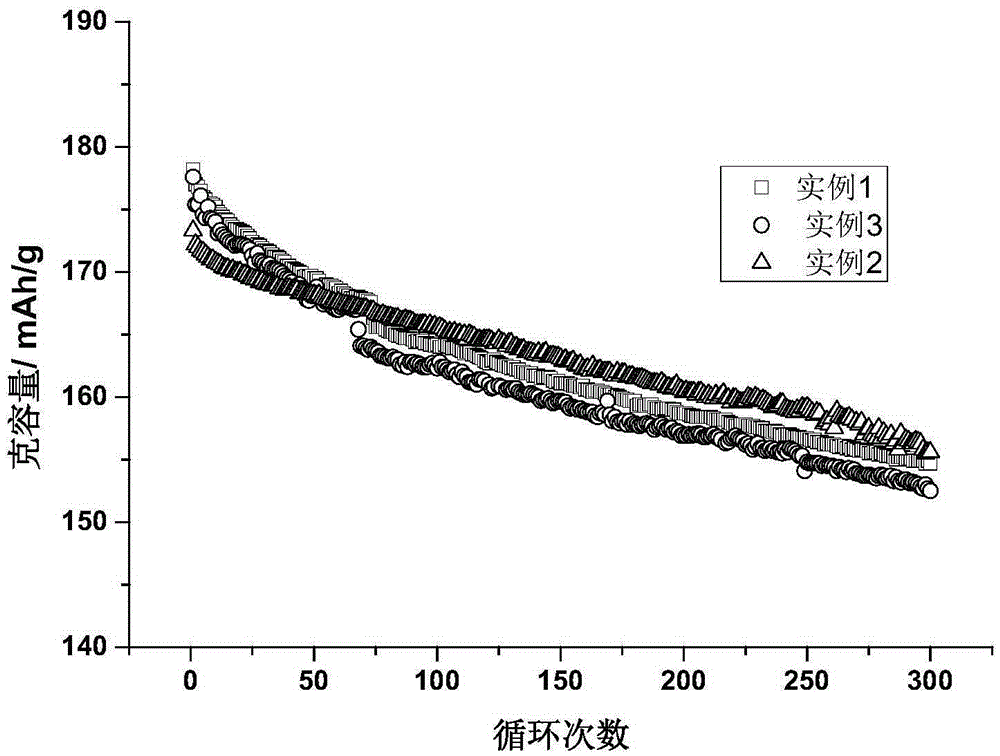

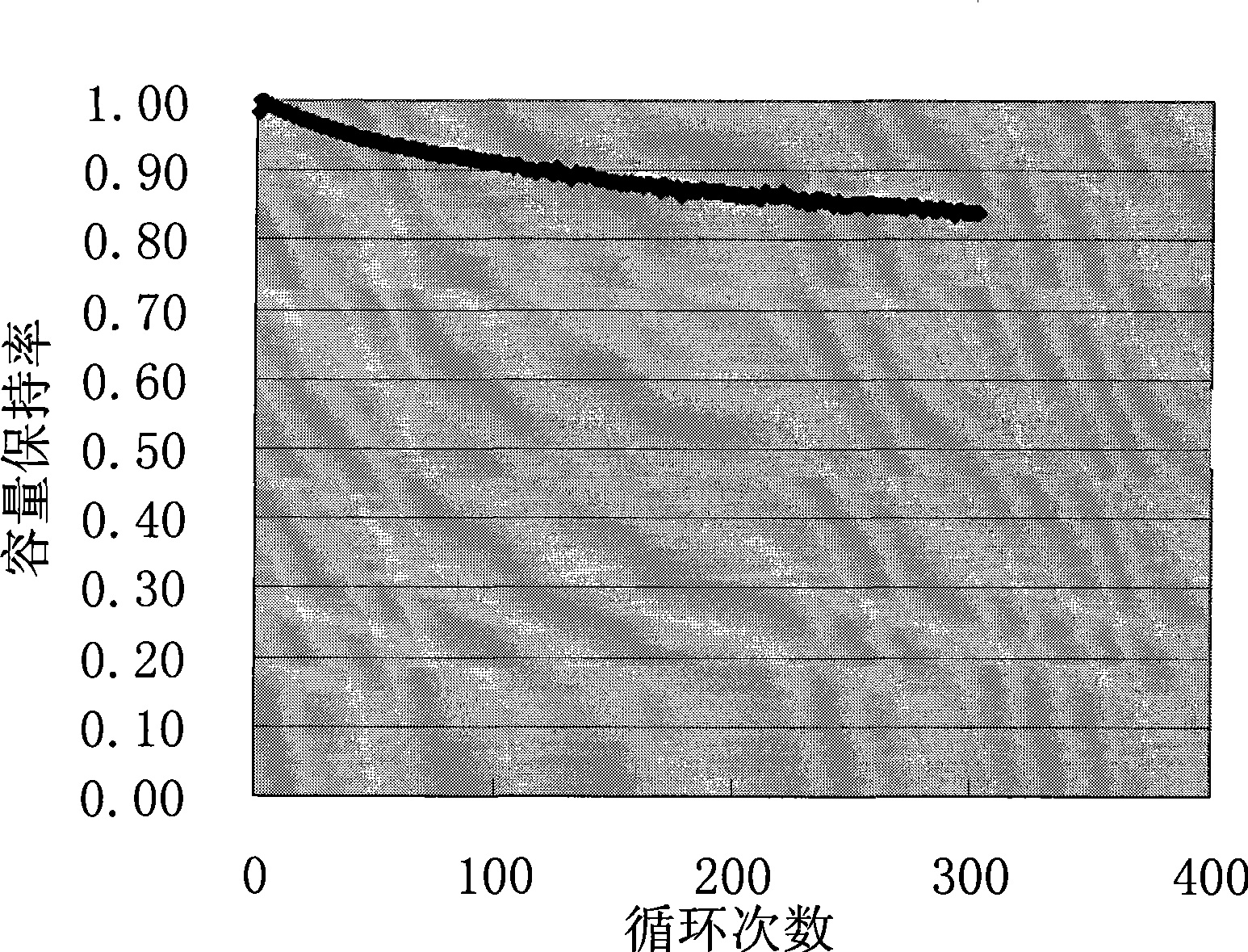

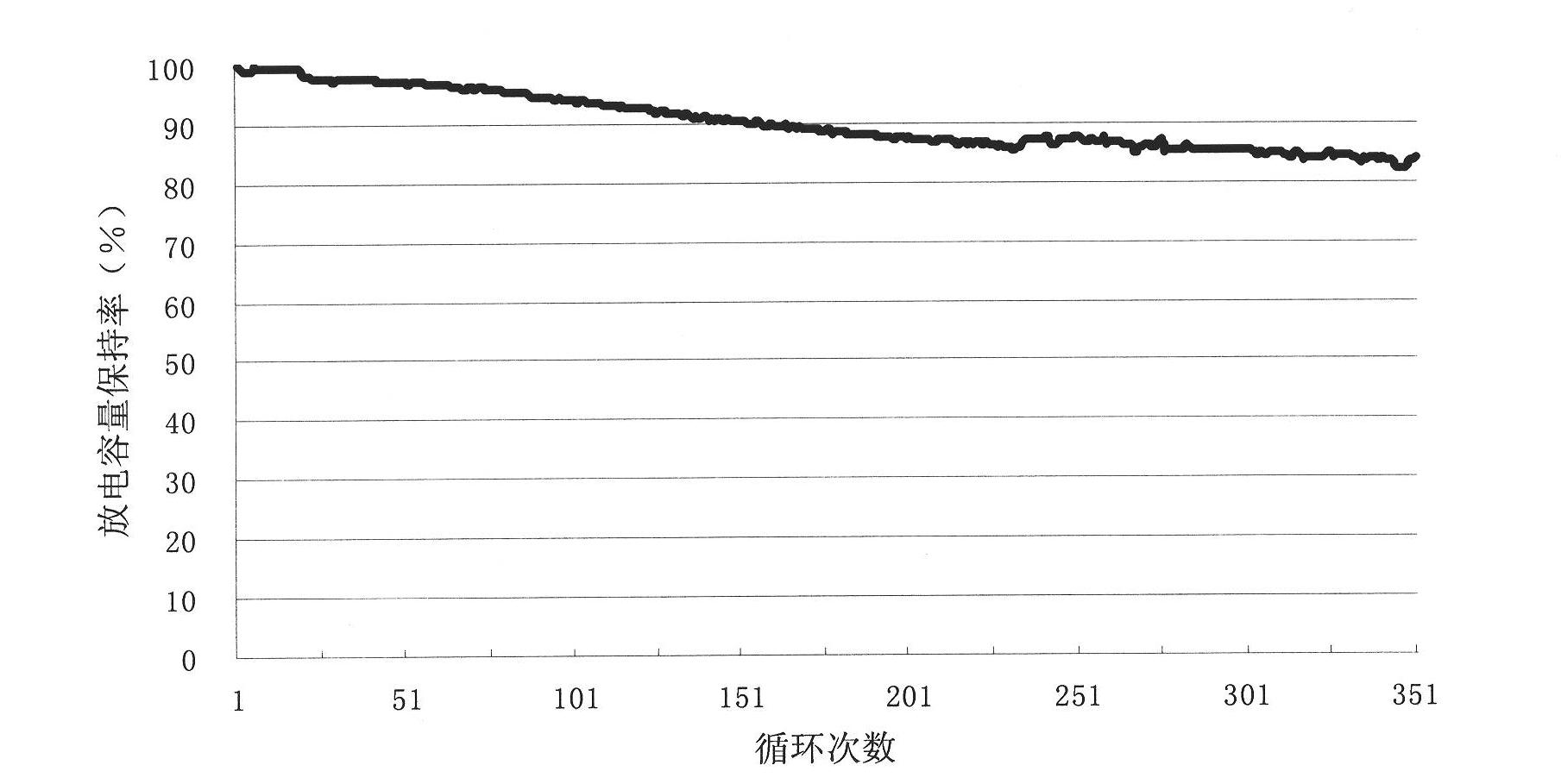

Preparation method of high compaction density lithium ion cathode material

The invention relates to a preparation method of a high compaction density lithium ion cathode material. The preparation method comprises the following steps: (1) uniformly mixing a boron compound with a precursor material to obtain a pretreated precursor material; (2) sufficiently mixing the pretreated precursor material with a lithium salt to obtain a mixture; and (3) carrying out solid phase sintering on the mixture in an oxidizing atmosphere, cooling and crushing to obtain the high compaction density lithium ion cathode material. According to the preparation method, the precursor material is pretreated, the boron compound is firstly uniformly attached to the precursor, and then the pretreated precursor material is mixed with the lithium salt for sintering, so that doped element boron is uniformly distributed in a product phase so as to achieve the purpose of uniform doping. According to the high compaction density lithium ion cathode material prepared by the invention, the tap density is greater than or equal to 2.3 g / cm<3>, the manufacturing compaction density is greater than or equal to 3.70 g / cm<3>, the primary discharge gram capacity can reach more than 153 mAh / g, and the circulating capacity retention rate in 300 circles reaches more than 85%.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Composite graphite particles for lithium secondary battery and preparation method thereof

ActiveCN102593434AIncrease compaction densityImprove discharge capacityCell electrodesLithiumRoom temperature

The invention relates to a preparation method for composite graphite particles for a lithium secondary battery. The method comprises the following steps: 1, heating and kneading spherical natural graphite particles, adhesive capable of being graphitization, and graphitized catalyst to form a kneaded thing; 2, pressing the kneaded thing into block to form a formed kneaded thing; 3, under the protection of an inert gas, carbonizing the formed kneaded thing at the temperature of 800-1,500 DEG C, and cooling the kneaded thing to room temperature; 4, under the protection of the inert gas, allowing the formed kneaded thing to be subjected to catalysis and graphitization high-temperature processing at the temperature of 2,800-3,200 DEG C; and 5, performing classifying or screening after the kneaded thing is smashed. The invention further relates to composite graphite particles for the lithium secondary battery prepared by the method. The composite graphite particles have higher compacted density, large discharge capacity, good circulation performance, good electrochemistry performance, better high-current charge-discharge performance, and better safety, discharge platform availability and higher platform retention rate.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

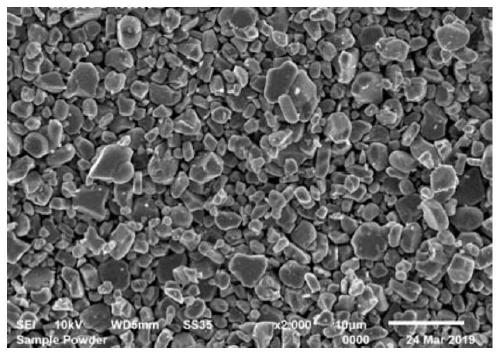

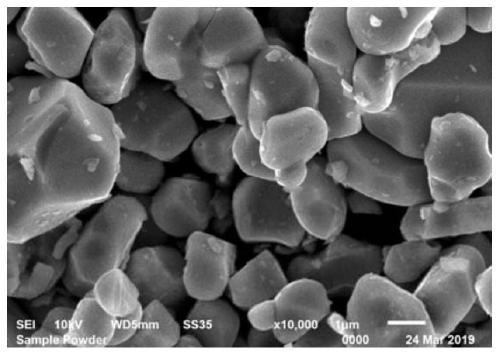

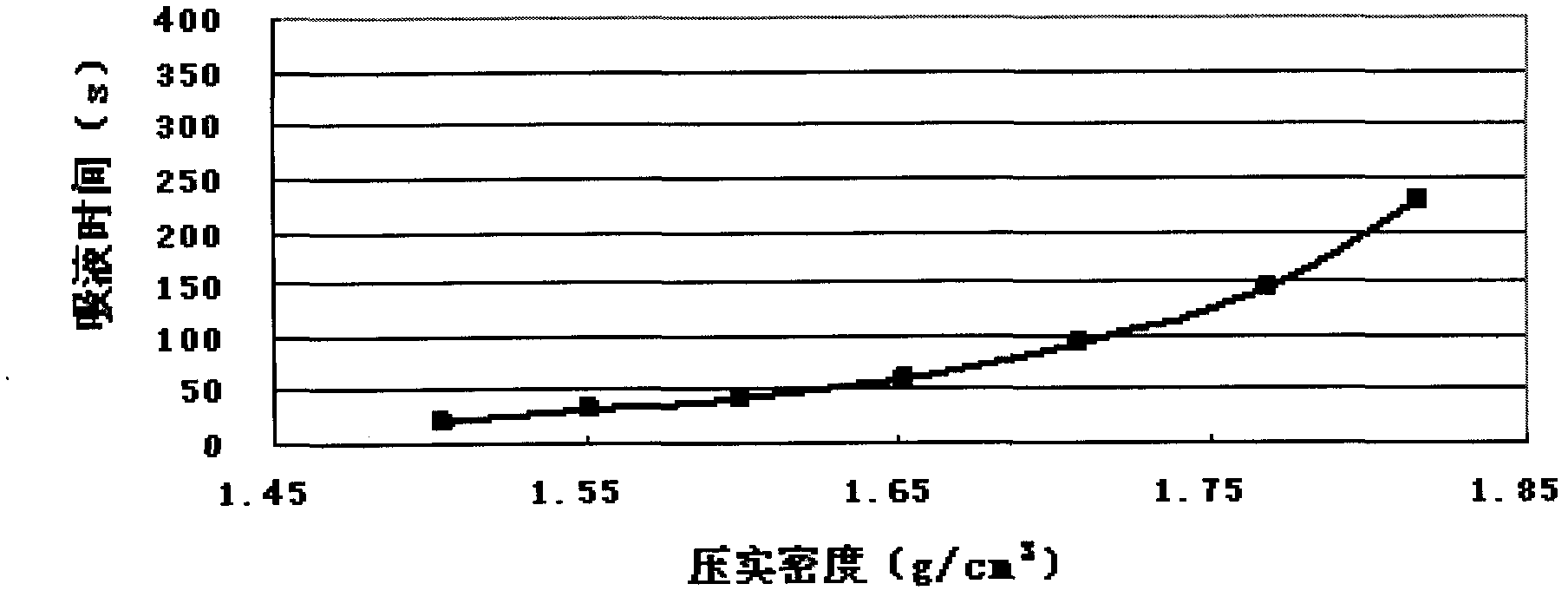

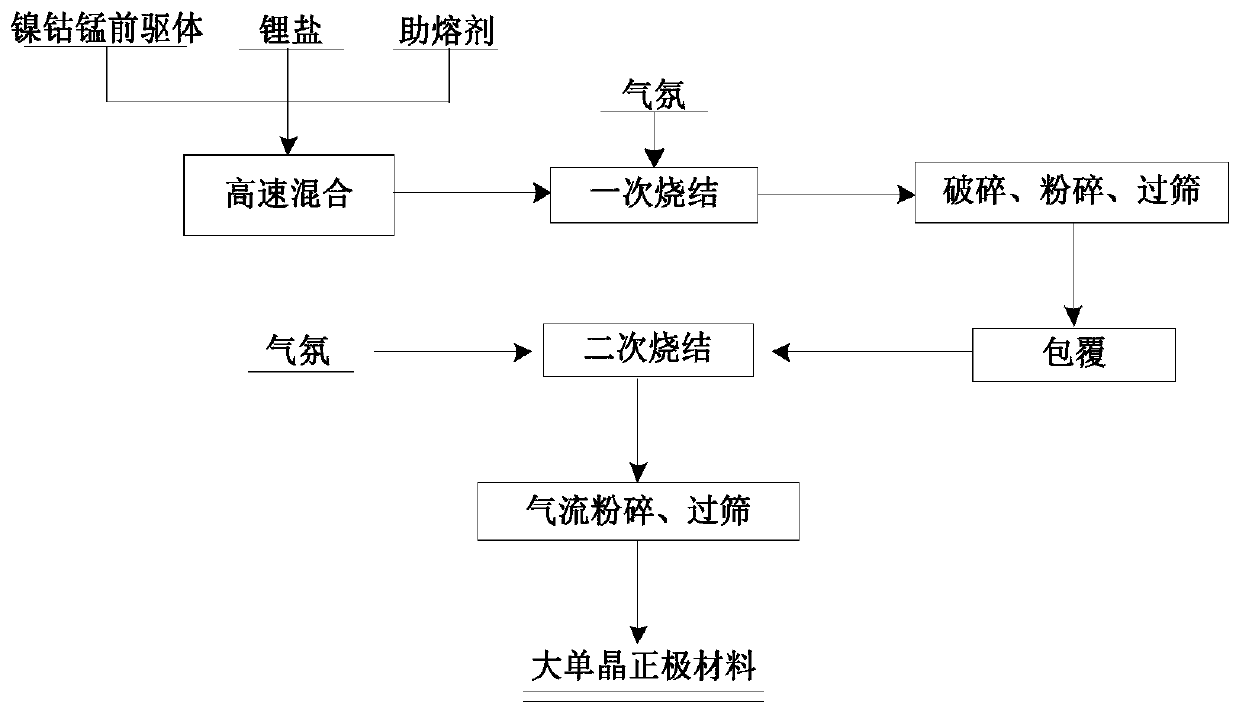

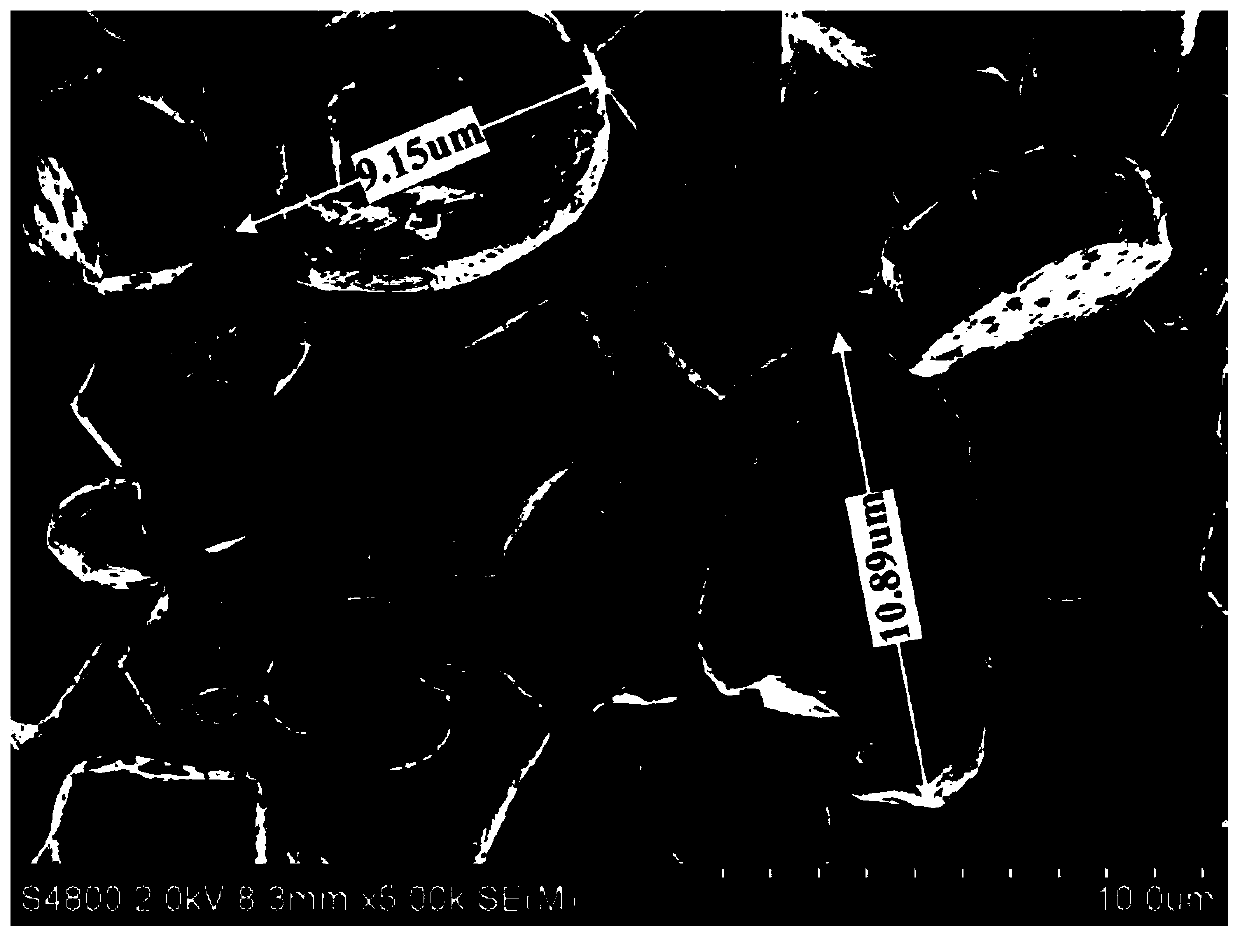

Preparation method of large single crystal lithium ion battery nickel cobalt lithium manganate cathode material

InactiveCN110534733AUniform thicknessHigh crystallinitySecondary cellsPositive electrodesDispersityManganate

The invention relates to a preparation method of a single crystal lithium ion battery nickel cobalt lithium manganate cathode material. The method comprises the following steps of: (1) taking a small-grain crystal spherical NCM ternary precursor, a lithium salt and an A element-containing nano fluxing agent as raw materials, uniformly mixing the raw materials by adopting a dry-method high-speed mixing mode, and performing primary sintering under an oxygen-enriched atmosphere condition; (2) subjecting the sintered material to jaw breaking, roller pairing, crushing and sieving so as to obtain asingle-crystal once-sintered base material; and (3) mixing the primary sintering base material with a B element-containing nano coating agent, sintering again under an oxygen-enriched atmosphere condition, and then performing jaw breaking, roller pairing, crushing and sieving to obtain the large single crystal lithium nickel cobalt manganate cathode material. The cathode material prepared by the invention has the characteristics of the large particle size, the good dispersity, the moderate specific surface area, the high compaction density, the high voltage, the good high-temperature cycle performance and the like.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

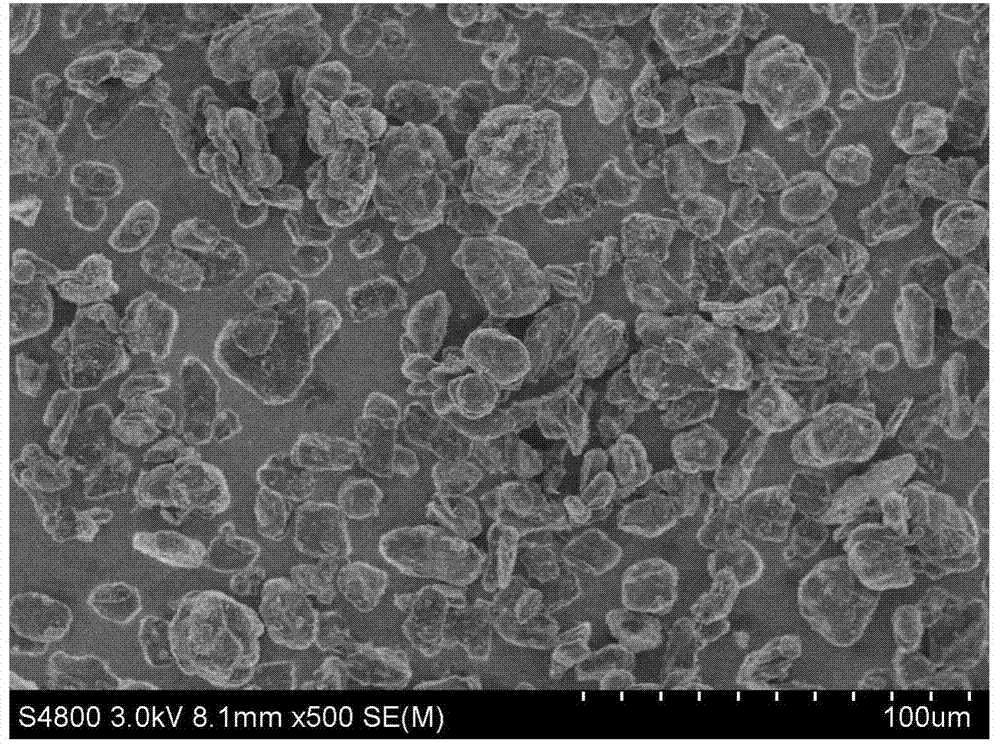

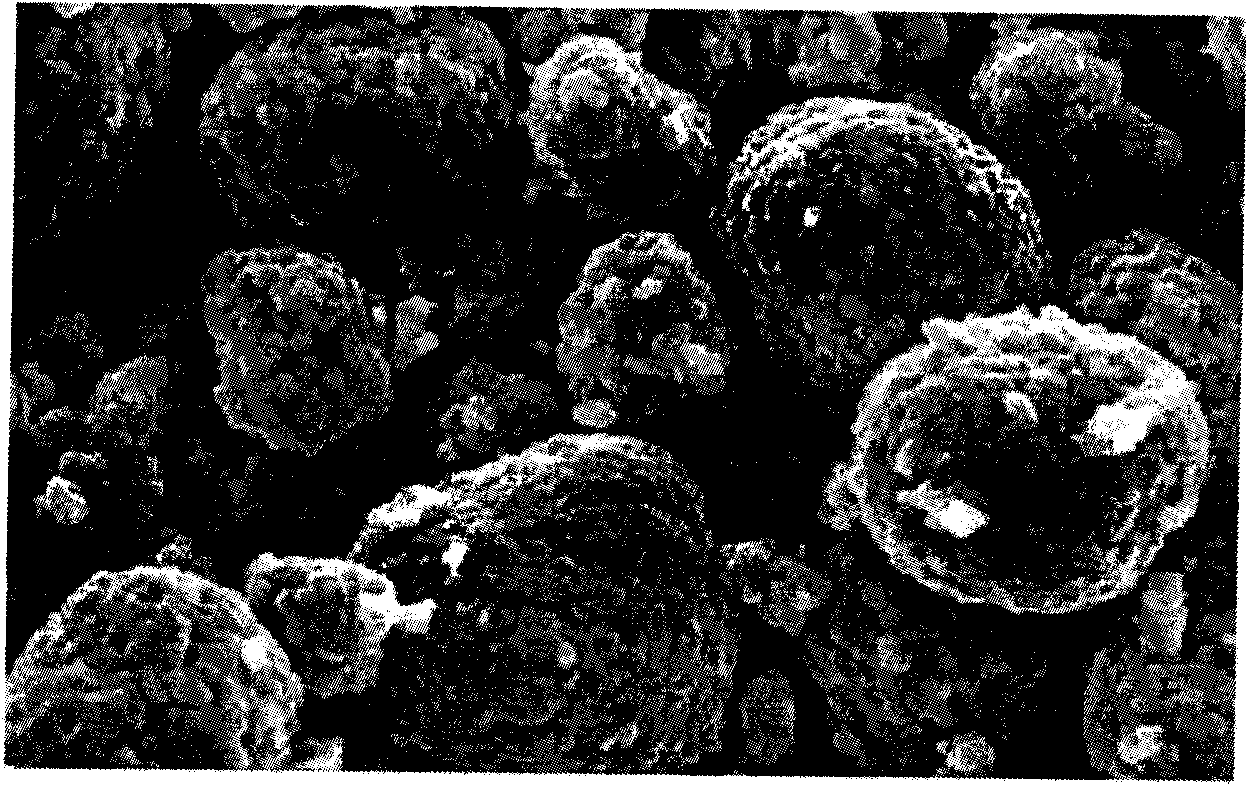

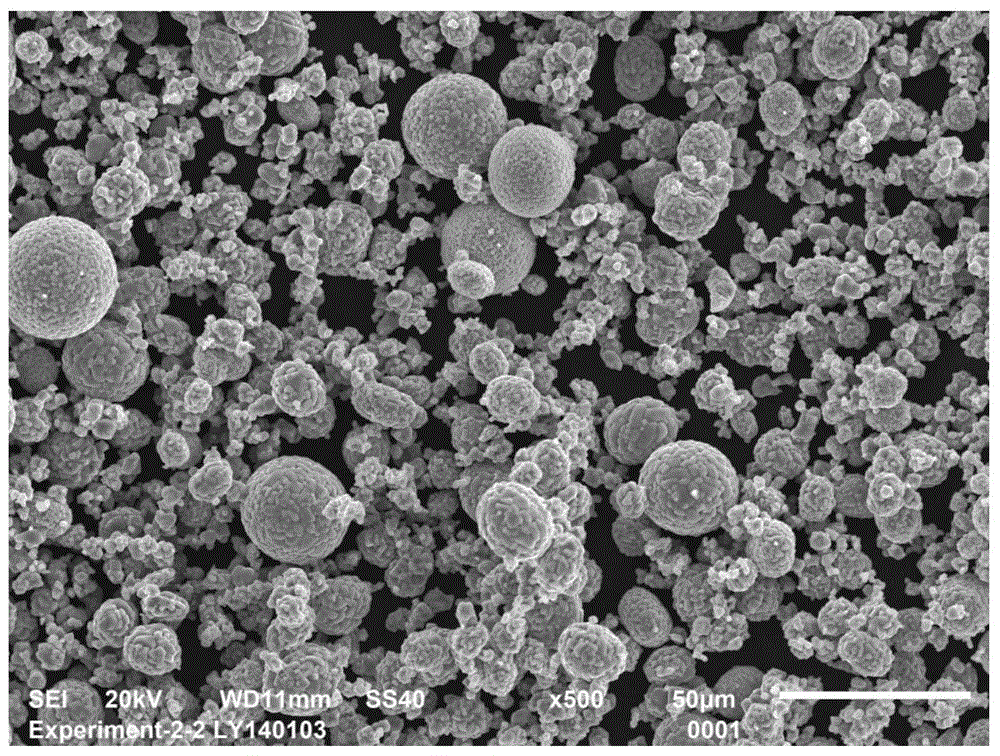

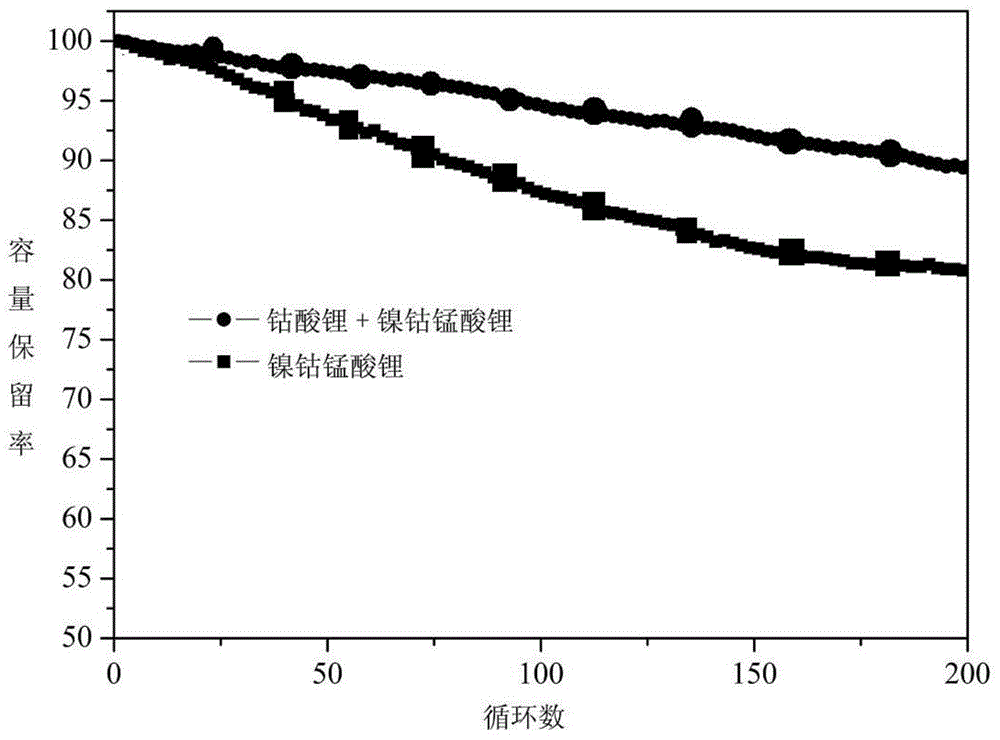

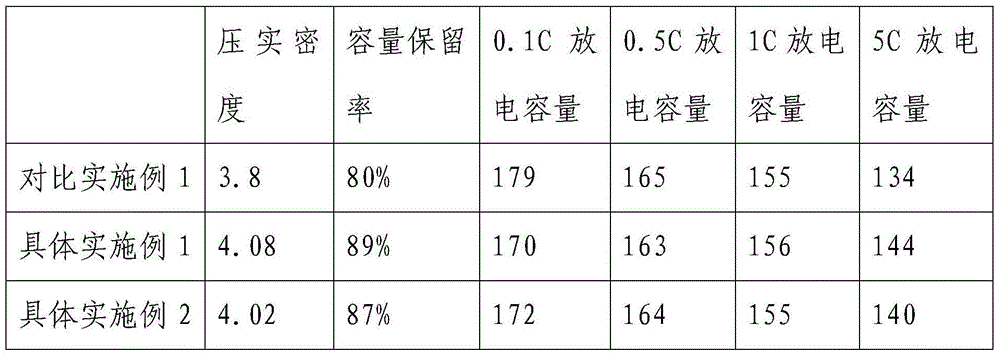

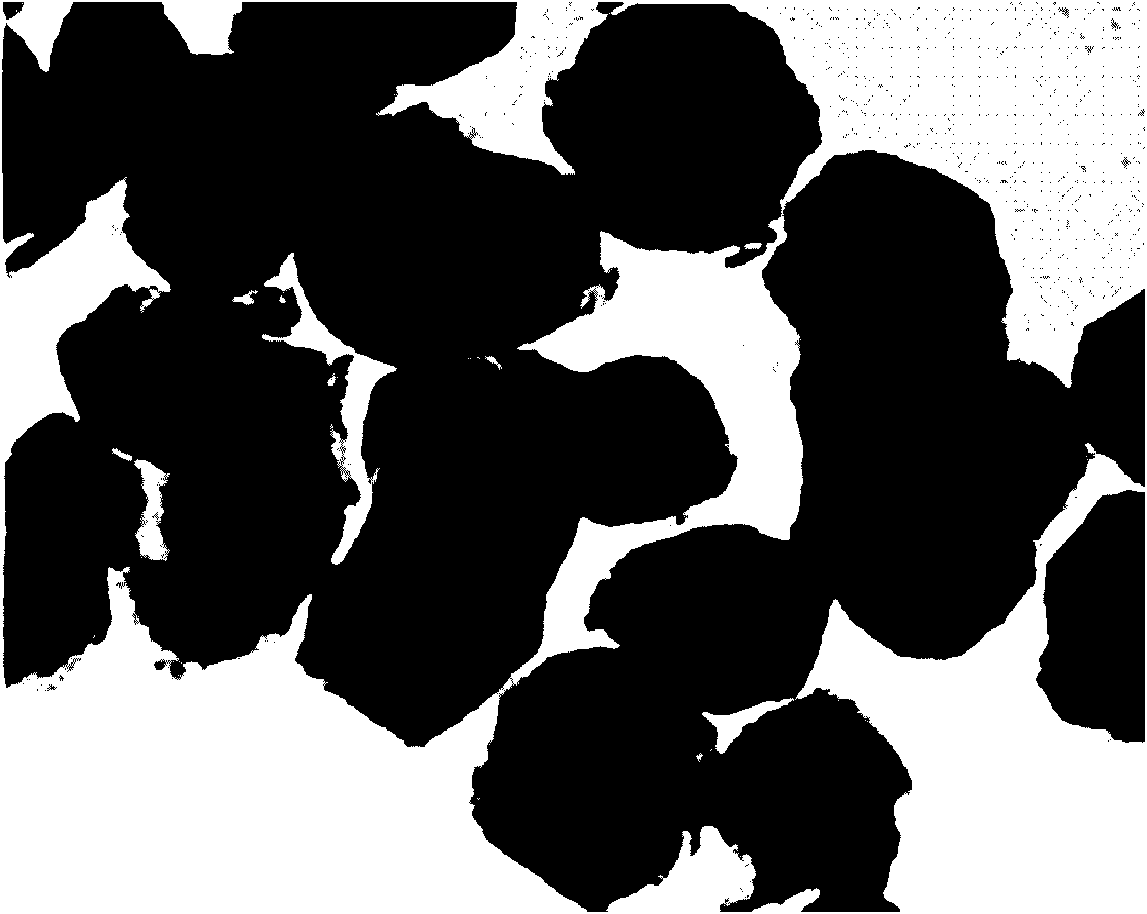

Mixed lithium battery positive material and preparation method thereof

InactiveCN103985857ALarge particlesSmall particlesCell electrodesSecondary cellsDecompositionManganese

The invention belongs to the field of inorganic non-metallic materials and relates to a mixed lithium battery positive material and a preparation method thereof. The preparation method comprises the following steps: mixing cobalt oxide and a nickel-cobalt-manganese ternary material precursor, and performing two-step sintering, thereby directly obtaining a mixed positive material of lithium cobalt oxide and nickel cobalt lithium manganate, wherein a microscopic structure formed by coating nickel cobalt lithium manganate particles with lithium cobalt oxide particles is shown in the figure in the specification, and the diameter of the lithium cobalt oxide particles is less than that of the nickel cobalt lithium manganate particles. According to the structure that large and small spheres of lithium cobalt oxide and nickel cobalt lithium manganate are arranged in a mixed manner, gaps the material can be effectively filled, and the compaction density of the material is improved; the conductivity of the material can be improved after the material is coated with lithium cobalt oxide, dislocation of Li and Ni in a nickel cobalt lithium manganate crystal structure can be effectively alleviated, and decomposition of high-valence nickel ion catalytic electrolyte is inhibited; moreover, the compaction density of nickel cobalt lithium manganate can be improved after being coated with lithium cobalt oxide, so that the capacity, stability, high-current discharge capacity and rate performance of the battery in unit volume can be effectively improved.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

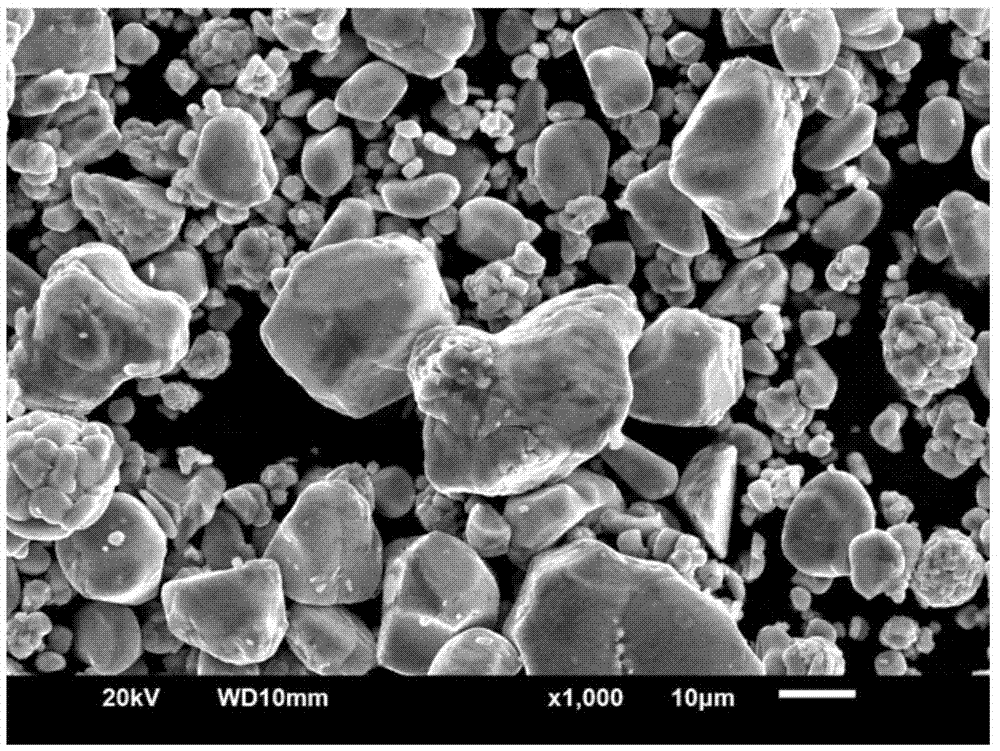

High density spherical nano lithium iron phosphate material, a preparation method thereof, and lithium ion battery containing same

ActiveCN106229505ATightly boundImprove liquidityCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

A high density spherical nano lithium iron phosphate material, a preparation method thereof, and a lithium ion battery containing the same are provided. The preparation method comprises the following steps: (1) pre-sintering a lithium resource, iron phosphides, adulterant, and a carbon source with protective gas after dry mixing; (2) mixing a pre-sintering material, dispersant, and deionized water, and performing ultra fine grinding; (3) performing spray drying on a sizing agent obtained by ultra fine grinding, to obtain a spherical nano lithium iron phosphate precursor; and (4) performing chemical vapor deposition coating on the spherical nano lithium iron phosphate precursor obtained in step (3), to prepare the high density spherical nano lithium iron phosphate material. A primary particle size of the lithium iron phosphate material prepared in the present invention is not large, and a powder conductivity may reach 10.1 S / cm, so that a material capacity, low temperature, rate performance, and fabrication and cycling performance may be well balanced.

Owner:江苏贝特瑞纳米科技有限公司

Silicate anodal material for lithium ion battery and preparation method thereof

ActiveCN101635345AImprove conductivityThe surface of the material is evenly distributedElectrode manufacturing processesActive material electrodesState of artMagnification

The invention discloses a silicate anodal material for lithium ion batteries and a preparation method thereof to solve the technical problem of the enhancement of the material density of the silicate anodal material. The general formula of the anodal material is Li2MSiO4 / D, wherein the Li2MSiO4 is the active substance of the silicate anodal material, D is a modifying agent doped and covered on the surface of the Li2MSiO4. The preparation method comprises the following steps: preparing a modifying agent source solution; putting the Li2MSiO4 into the solution to obtain a mixture; and carrying out spraying, drying, hot processing and fusion processing on the mixture. Compared with the prior art, the invention utilizes a liquid-phase method to cover, modify and fuse the silicate anodal material so as to ensure that the silicate anodal material has the characteristics of high stacking density, high compacted density, high volume specific capacity, favorable processing performance of batteries and low cost. Batteries produced by the silicate anodal material have higher safety performance, magnification performance and cyclic performance.

Owner:BTR NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com