Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

A technology of lithium-ion batteries and hydrothermal synthesis, which is applied to battery electrodes, phosphorus compounds, structural parts, etc., can solve the problems of poor product rate performance, difficult wastewater treatment, difficult to control particle size, etc., to prolong cycle life and reduce equipment investment The effect of small size and increased compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step, hydrothermal synthesis reaction (Li:Fe:P=3:1:1.03)

[0030] Will contain 223.4g Fe 2+ (that is, 4mol) of pure ferrous sulfate solution that is nearly saturated is diluted to 3.5L (the pH value of this solution is about 0.5); 475.0g of 85% phosphoric acid containing 4.12mol of pure phosphoric acid is diluted to 1L; 503.3g of 12mol of LiOH·H 2 O was dissolved in water and diluted to 3L.

[0031] Add above-mentioned phosphoric acid solution and lithium hydroxide solution in the autoclave of 10L band sealing feeding pipe and cooling coil, after purging the air in the dead volume in the still with inert gas (nitrogen), seal autoclave, under the stirring of rotating speed 200rpm from Heat at room temperature to 40°C, open the feed valve and exhaust valve, and add the ferrous sulfate solution prepared above under stirring at a feed rate of 300ml / min for 11.6 minutes. Seal the autoclave, after stirring for 20 minutes, open the feed valve and exhaust valve, th...

Embodiment 2

[0056] Change the amount of lithium hydroxide as the pH regulator in Example 1 to 8g, and the initial pH of the reaction system is 6.5, and the others are the same as in Example 1.

[0057] After the synthesis is completed, filter and wash to obtain 1080 g of filter cake and 7.4 L of mother liquor. The filter cake was vacuum-dried at 120°C for 12 hours to obtain 617g LiFePO 4 Off-white powder.

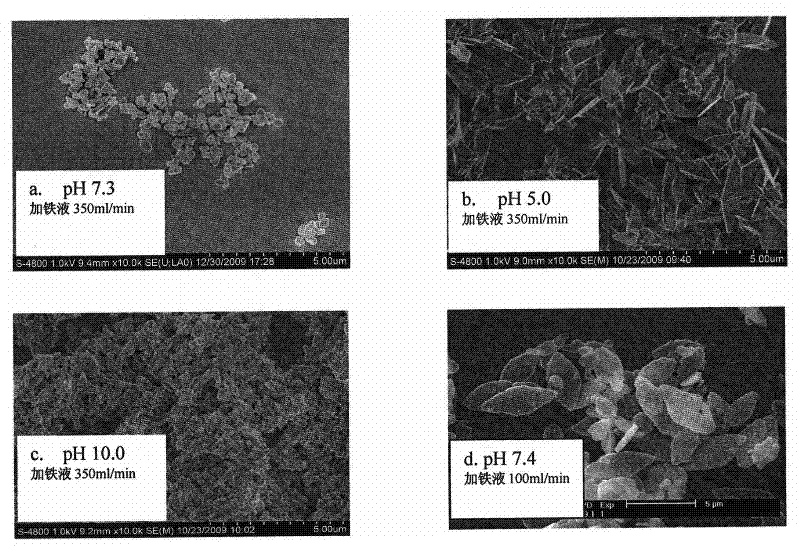

[0058] The particle shape of the product is a hexagonal sheet with indistinct edges and corners, the thickness of the sheet is about 100 nanometers, and there is basically no agglomeration between the particles. The electrochemical performance test results and particle size analysis results are shown in Table 1.

Embodiment 3

[0060] Change the amount of lithium hydroxide as the pH regulator in Example 1 to 22g, and the initial pH of the reaction system is 8.0, and the others are the same as in Example 1.

[0061] After the synthesis is completed, filter and wash to obtain 1091g filter cake and 7.4L mother liquor. The filter cake was vacuum-dried at 120°C for 12 hours to obtain 619g LiFePO 4Off-white powder.

[0062] The particle morphology of the product is a hexagonal sheet with indistinct edges and corners, the thickness of the sheet is about 90 nanometers, and there is a small degree of agglomeration between the particles. The electrochemical performance test results and particle size analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com