Patents

Literature

695results about How to "Shorten the diffusion path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

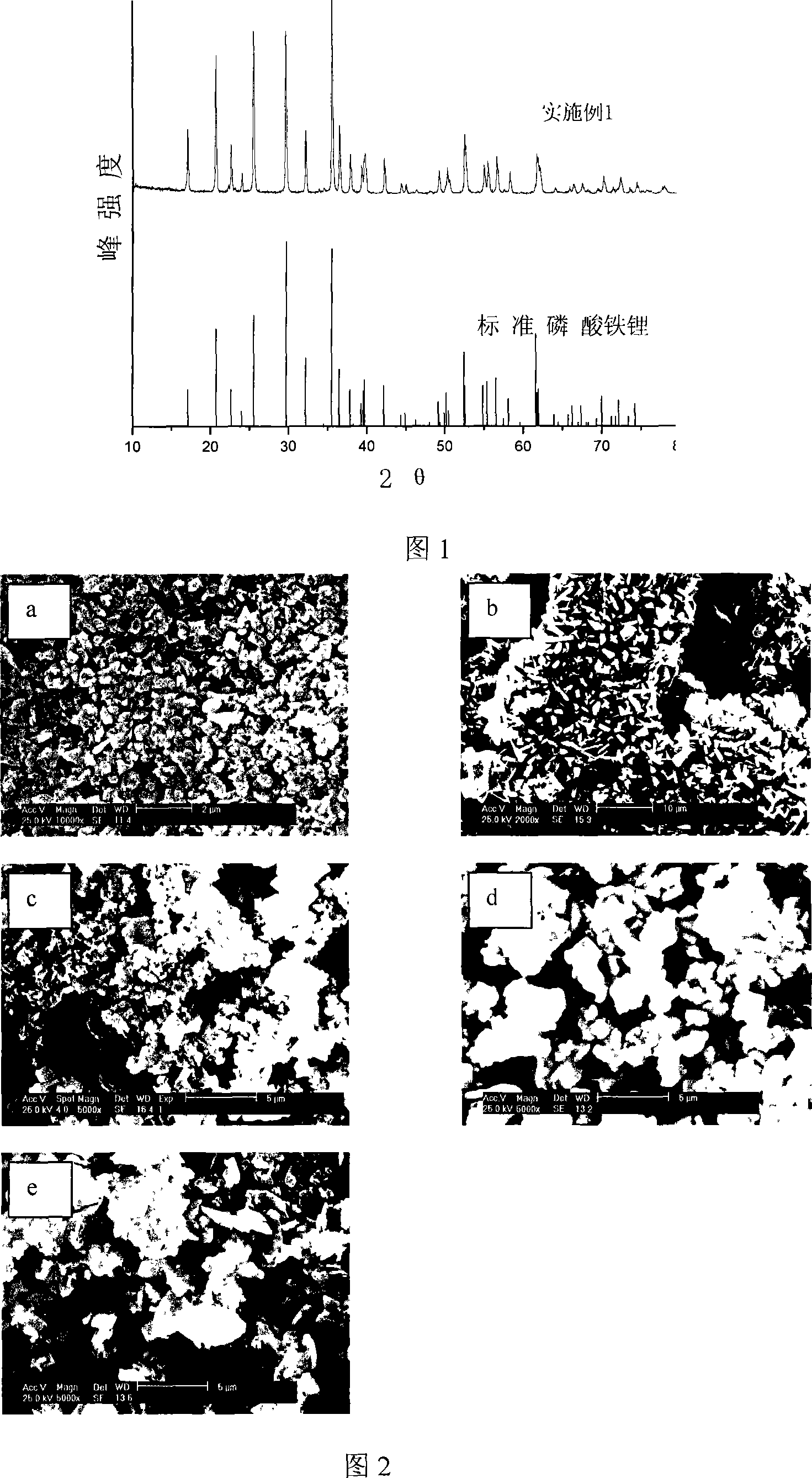

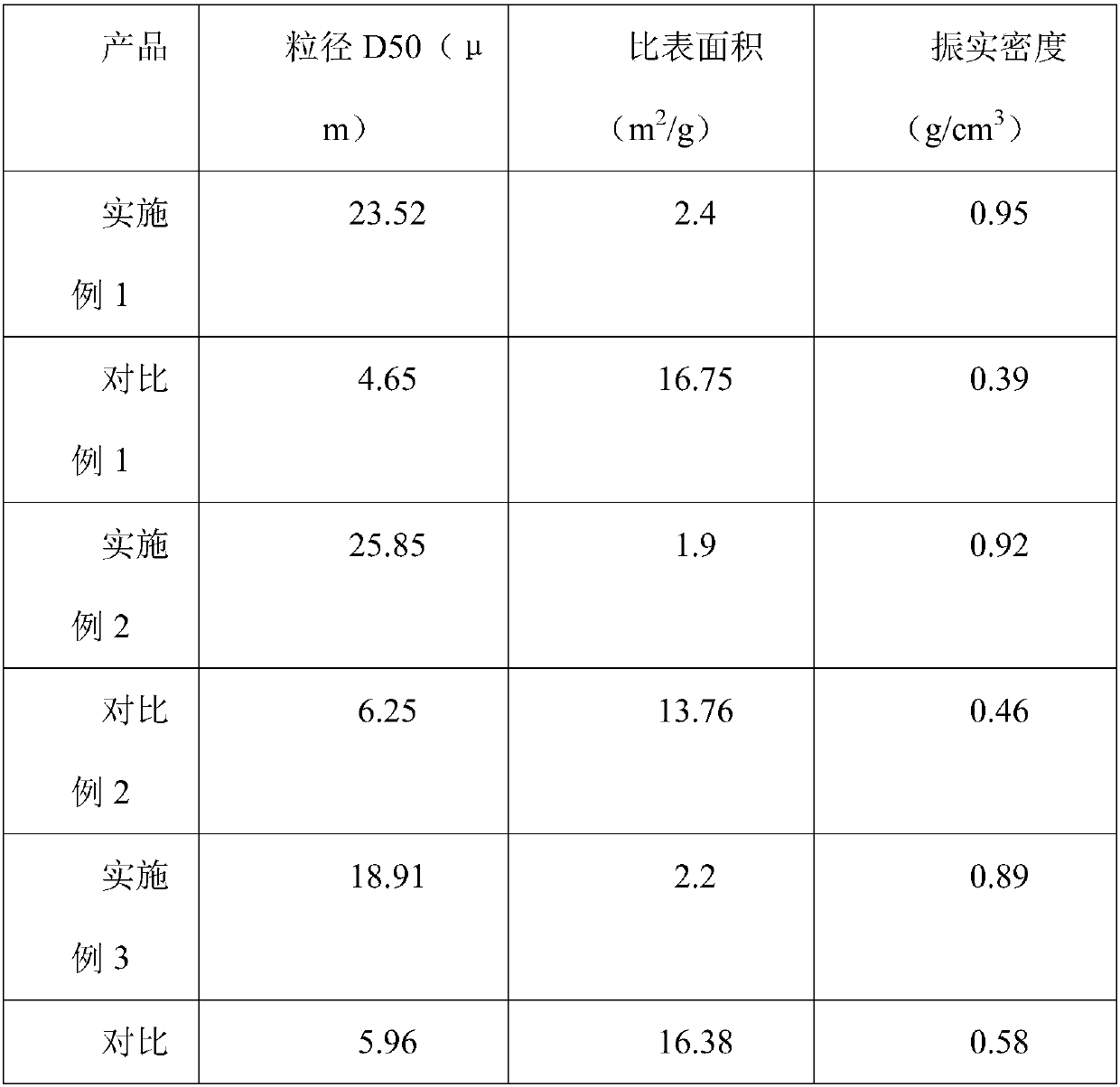

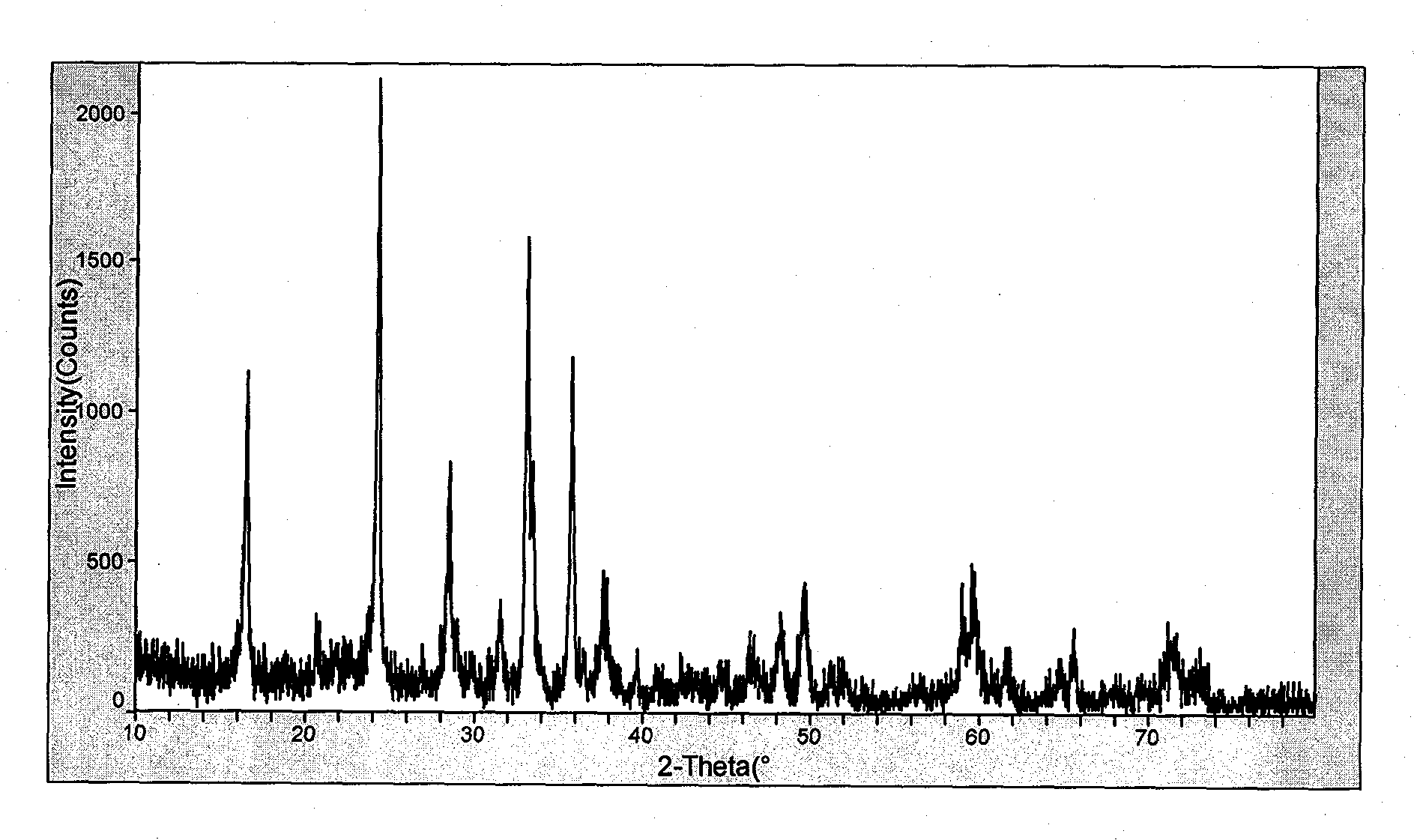

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

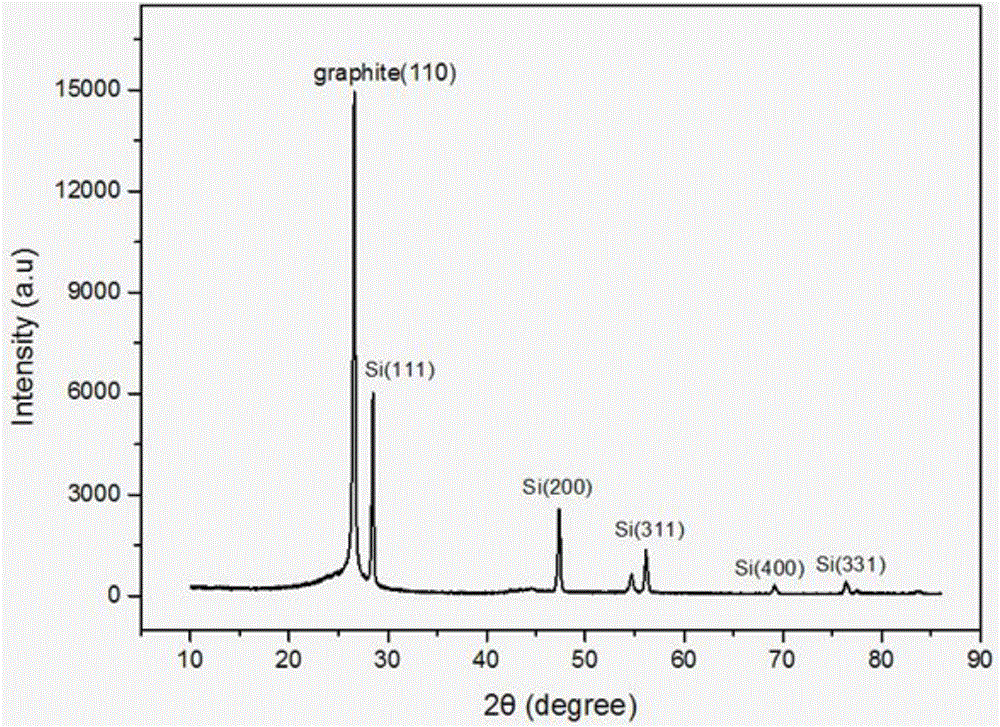

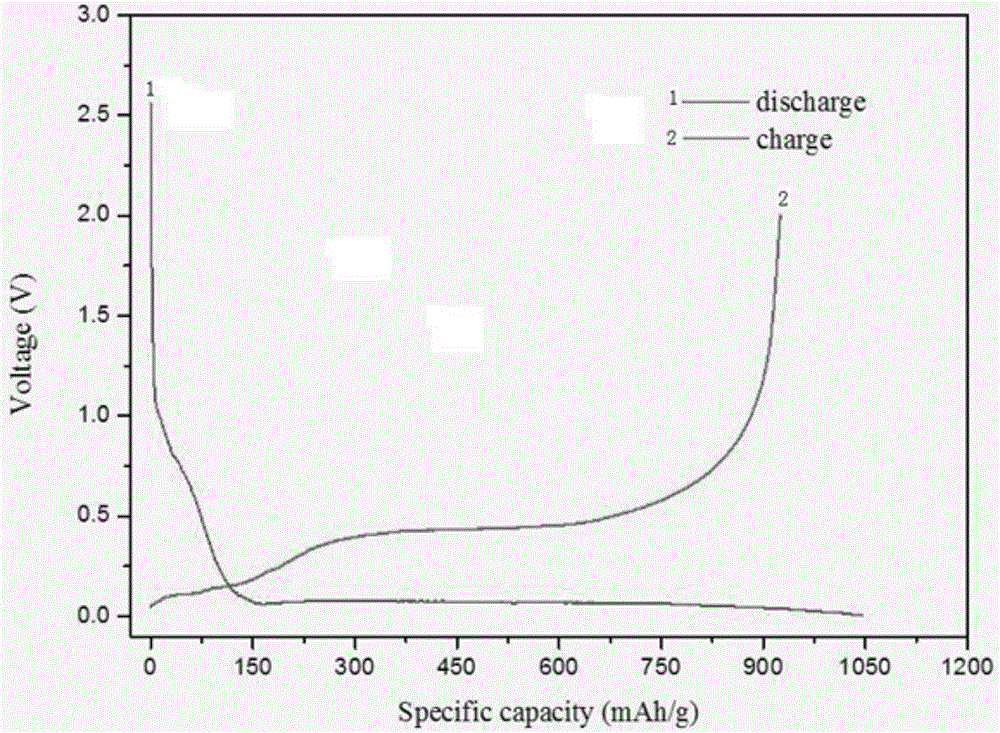

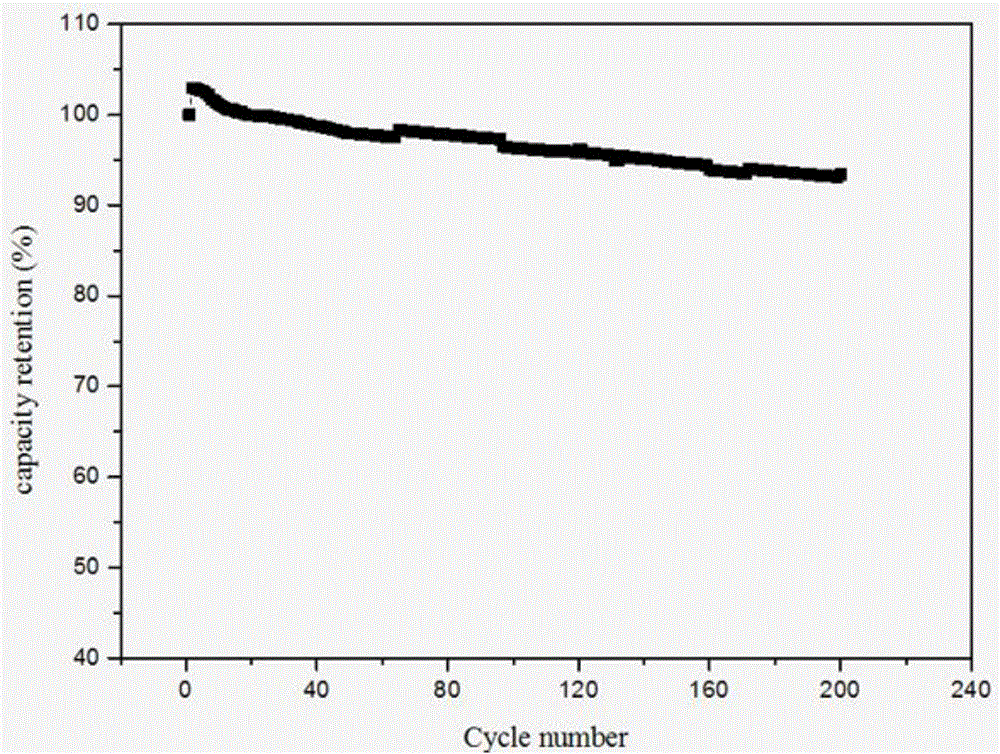

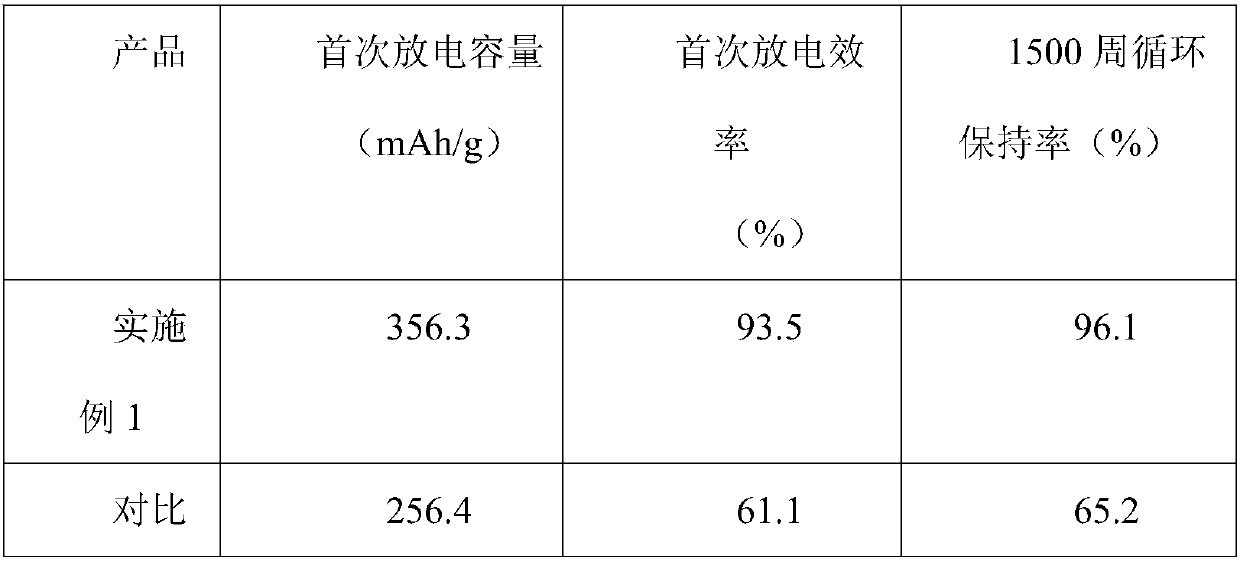

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

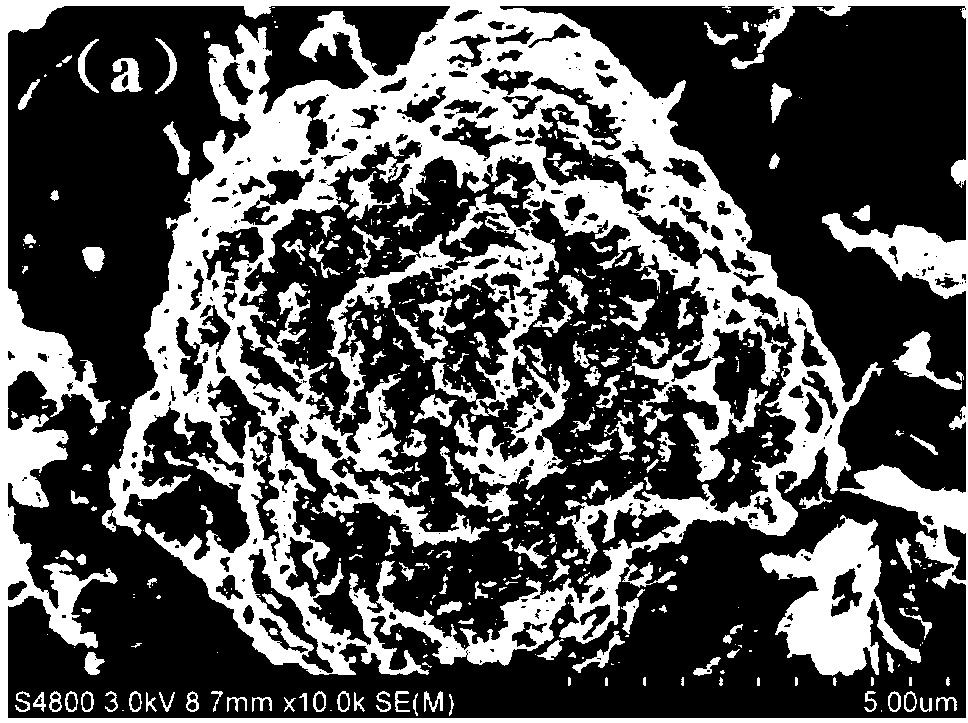

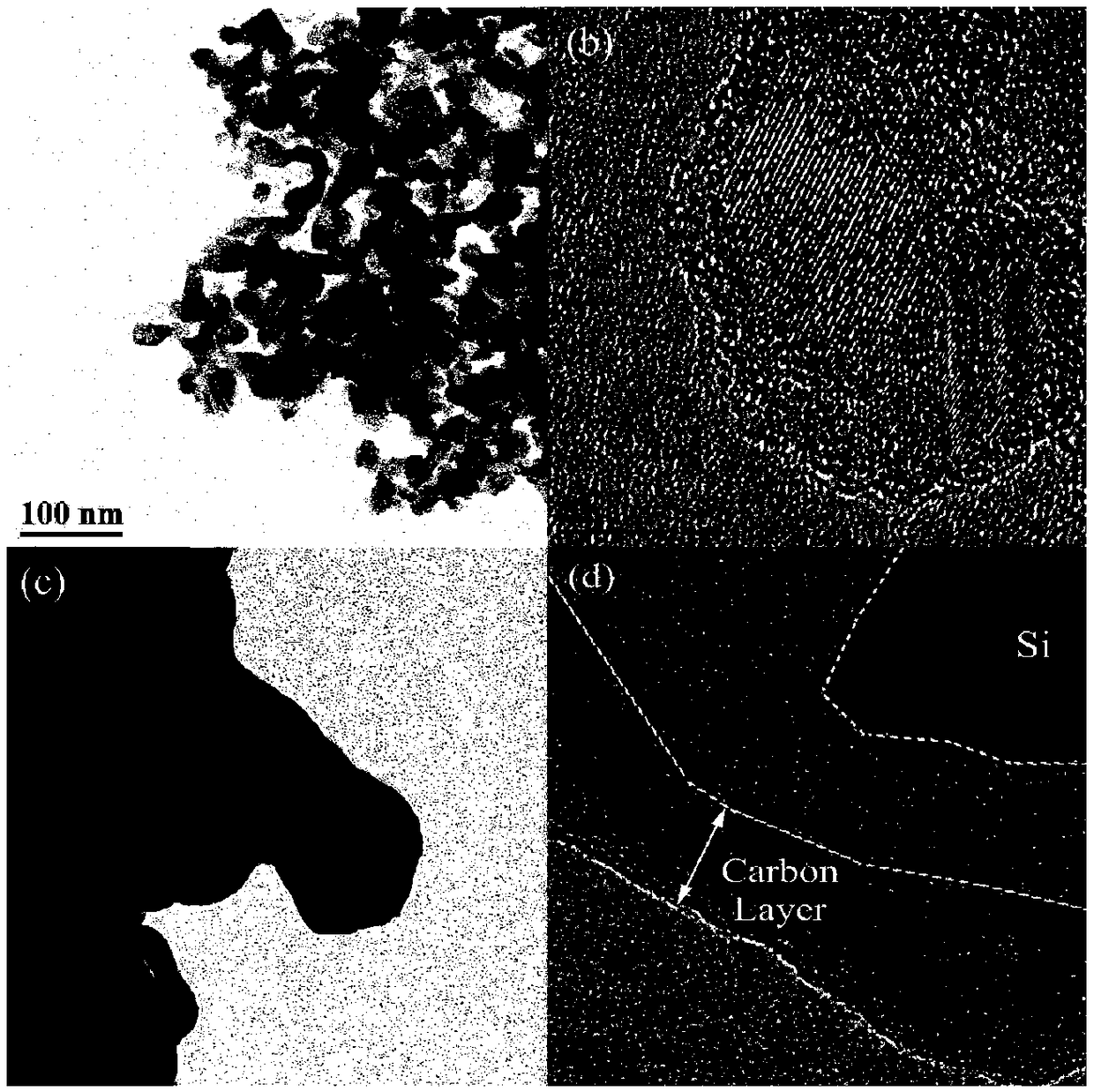

SiOx-based composite material, preparation method and lithium ion battery

ActiveCN103855364AStable structureImprove electronic conductivityMaterial nanotechnologyCell electrodesCarbon layerSpherical shaped

The invention relates to a SiOx-based composite material, a preparation method and a lithium ion battery. The SiOx-based composite material comprises a SiOx / C material, wherein the SiOx / C material comprises SiOx nano particles, organism cracked carbon, nano conductive particles and amorphous conductive carbon layers, the SiOx nano particles, the organism cracked carbon and the nano conductive particles are wrapped in the amorphous conductive carbon layers, the SiOx / C material is in a spherical shape and comprises a porous structure, and x is more than or equal to 0.5 and less than or equal to 1.3. The composite material is used as a negative electrode material of the lithium ion battery, excellent in cycling performance, excellent in rate performance and low in size expansion effect, applicable to the fields such as top-grade digital electrons, electric tools and next-generation vehicle-mounted devices and wide in market prospect.

Owner:BTR NEW MATERIAL GRP CO LTD

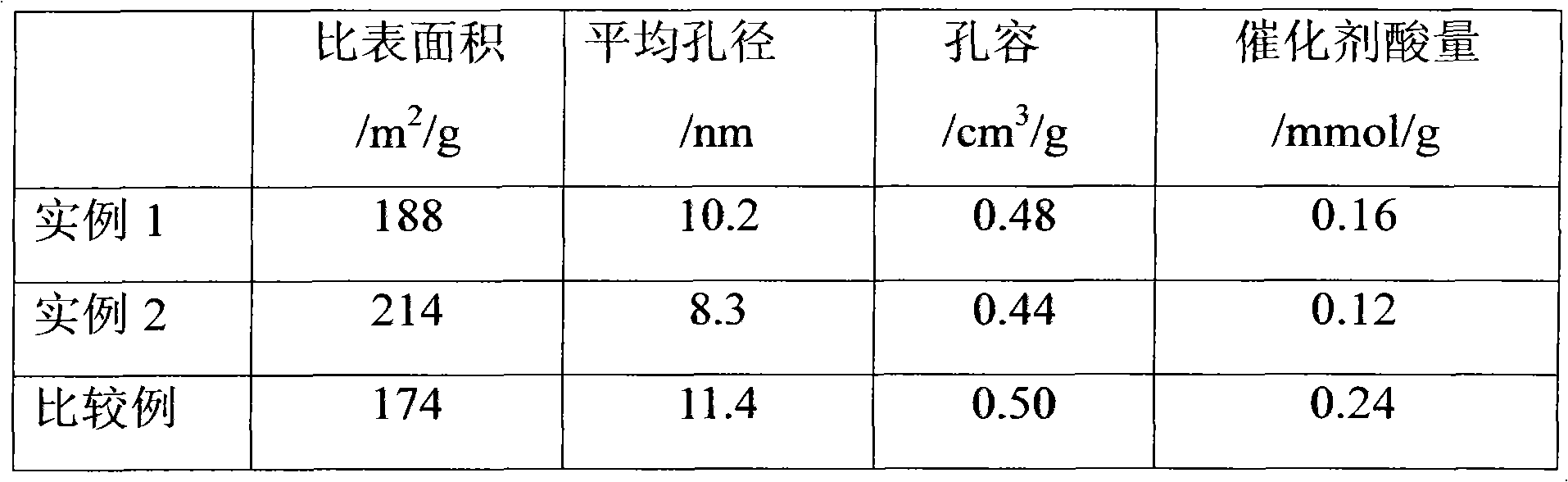

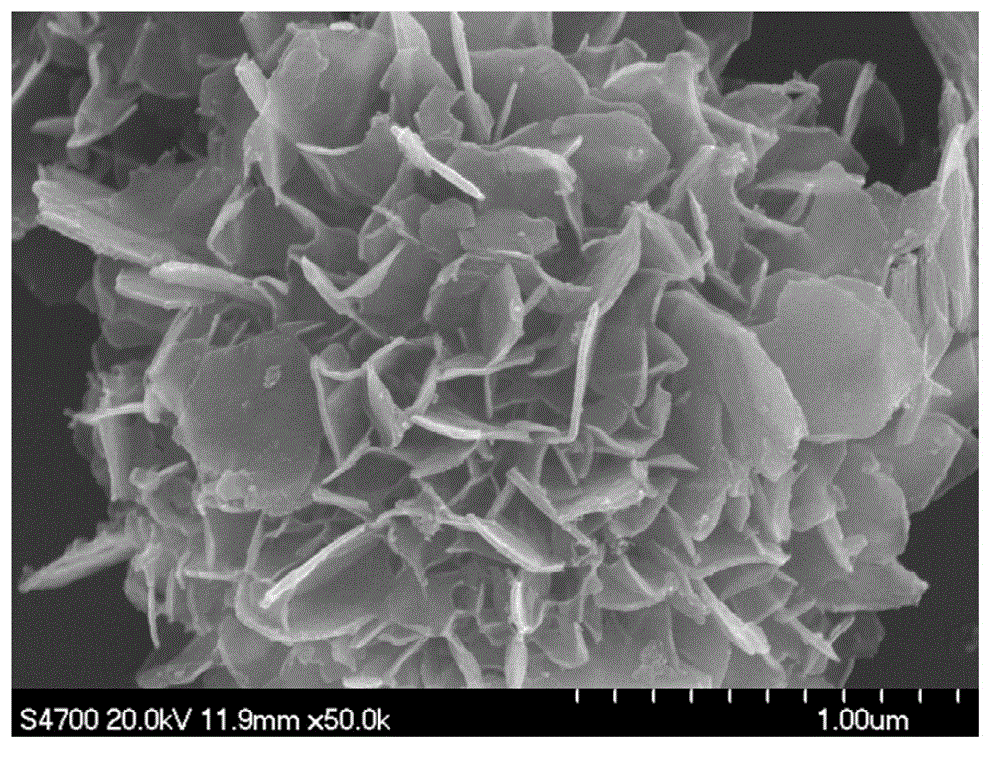

Nano ZSM-5 molecular sieve based catalyst and preparation and use methods

ActiveCN104941695AShorten the diffusion pathEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsStrong acidsZSM-5

The invention discloses a nano ZSM-5 molecular sieve based catalyst and preparation and use methods. The molecular sieve catalyst consists of molecular sieves and metal components, wherein the molecular sieves are nano ZSM-5 molecular sieves with a short b-axis, a medium high silica-alumina ratio, less strong acid, high Lewis acid content, and resistance to hydrothermal deactivation. The preparation method is as follows: mixing a silicon source, an aluminum source, a template agent, a structure promoter, an additive and alkali with water, and stirring to prepare a precursor solution, then crystallizing, separating solid from liquid, and calcinating to obtain molecular sieve raw powder; mixing the molecular sieve raw powder with an ammonium salt solution, stirring, filtering, mixing with the ammonium salt solution for several times, stirring, filtering, and calcinating to obtain hydrogen-type ZSM-5 molecular sieves; mixing with the metal precursor solution, drying and calcinating to obtain the aromatization catalyst. The use method is as follows: transforming oxy-compound raw materials to aromatic hydrocarbon through the catalyst under the reaction conditions. The nano ZSM-5 molecular sieve based catalyst has the characteristics of being high in aromatics yield (reaching up to 99%) and long in service life (the catalyst is alive after 300 hours, and the aromatics selectivity reaches up to 70% after the catalyst is subjected to hydrothermal aging at 760 DEG C for 4 hours).

Owner:TSINGHUA UNIV

Monox/carbon composite material as well as preparation method and use thereof

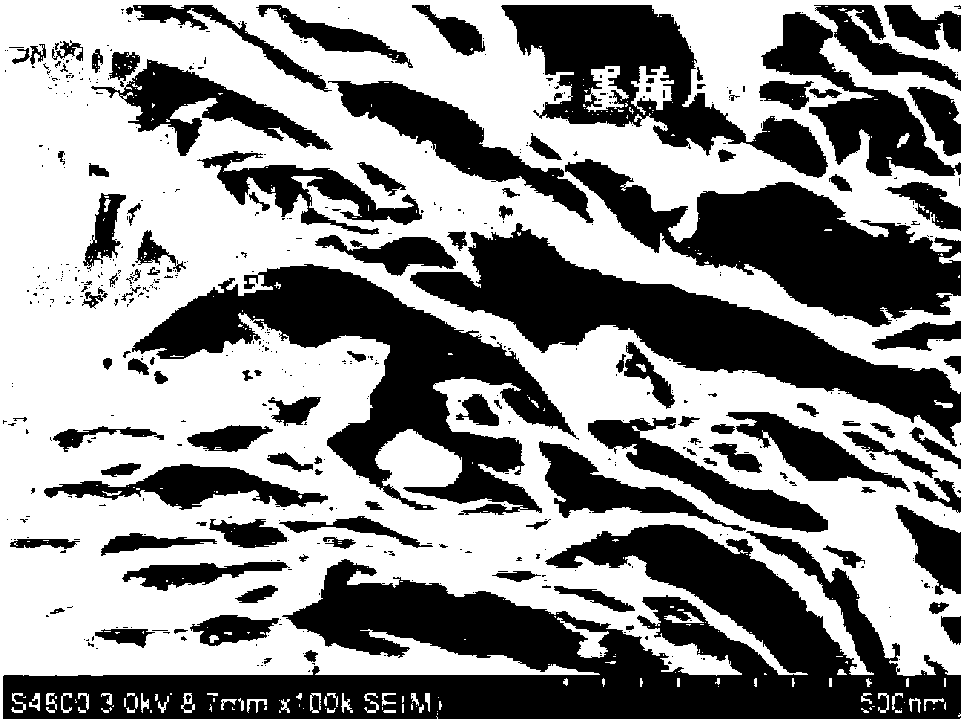

InactiveCN103311526AGood electrical contactShorten the diffusion pathCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a monox / carbon composite material, comprising monox / graphene particles, organic matter pyrolysis carbon and graphite powder, wherein monox particles are adhered to the surface of a grapheme sheet; the organic matter pyrolysis carbon coats the monox / graphene particles, and then is compounded with graphite. The preparation method of the monox / carbon composite material comprises the steps of: mixing monox particles with graphene to obtain the monox / graphene particles; coating organic carbon by obtained monox / graphene particles, thereby obtaining the monox / graphene material coated by the organic matter pyrolysis carbon; and mixing the obtained monox / graphene material coated by the organic matter pyrolysis carbon with the graphite powder, so as to obtain the monox / carbon composite material. The monox / carbon composite material is used as a lithium ion battery cathode material. Thus, the monox / carbon composite material has the characteristics of high first charge and discharge efficiency, excellent cycle performance and power charge and discharge properties, and low volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

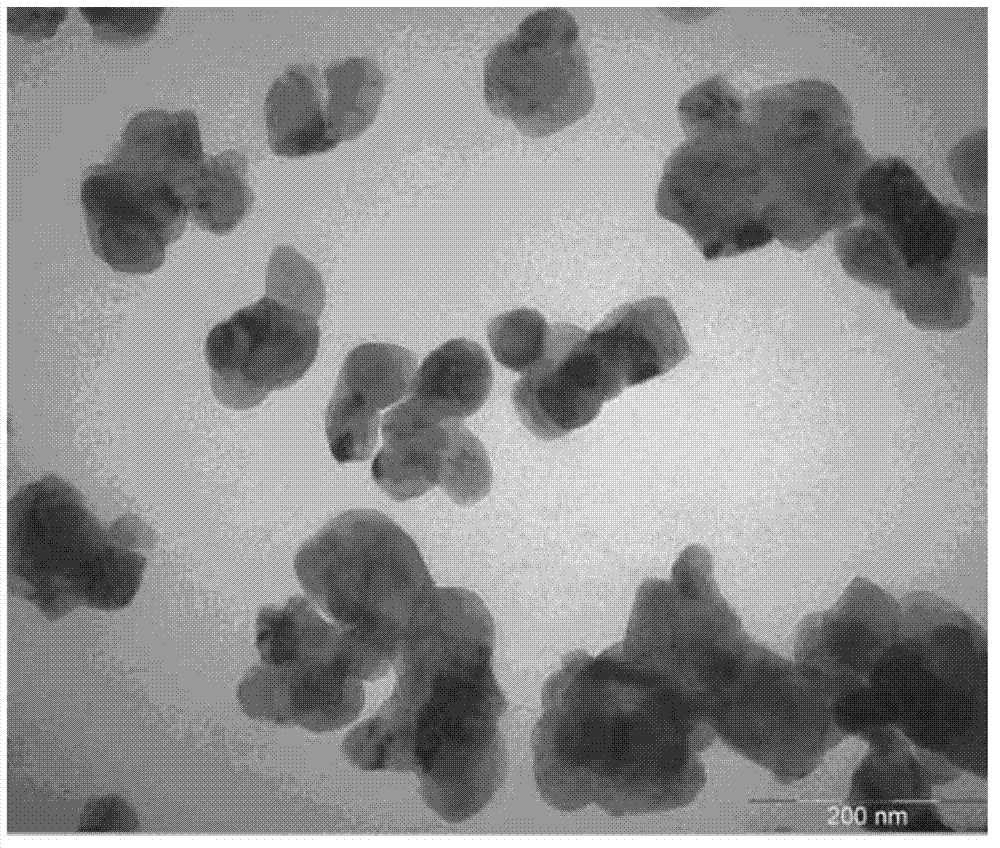

Silicon-carbon composite material, preparation method of silicon-carbon composite material, and lithium ion battery containing silicon-carbon composite material

ActiveCN102969489AImprove conductivityImprove charge and discharge cycle lifeCell electrodesSecondary cellsCarbon compositesCarbon layer

The invention discloses a silicon-carbon composite material, a preparation method of the silicon-carbon composite material, and a lithium ion battery containing the silicon-carbon composite material. The preparation method comprises the following steps of: (1) reducing silicon dioxide by using metal with activity larger than that of silicon, so as to obtain a porous silicon-metal oxide composite; (2) corroding the metal oxide by acid, so as to obtain porous silicon; and (3) coating the surface of the porous silicon by carbon by taking a carbon source as a raw material, so as to obtain the silicon-carbon composite material. The silicon in the silicon-carbon composite material is prepared through using a metallothermic reduction method and porous silicon particles prepared through using the metallothermic reduction method are micron-sized and hardly agglomerate; the pore walls and the pore diameters in the porous silicon particles are nano-sized; compared with imporous micron-sized silicon powder, for the silicon-carbon composite material, the porous silicon particles have the characteristics that a diffusion path of a lithium ion in a silicon substrate is shortened, thus being beneficial to charging and discharging with large current, the pores can hold the volume expansion of silicon during silicon intercalation and the charging and discharging cycle life of the material is prolonged. The surfaces of the porous silicon particles are coated with a carbon layer with the certain pores and the conductivity of the silicon-carbon composite material is enhanced.

Owner:CHERY AUTOMOBILE CO LTD

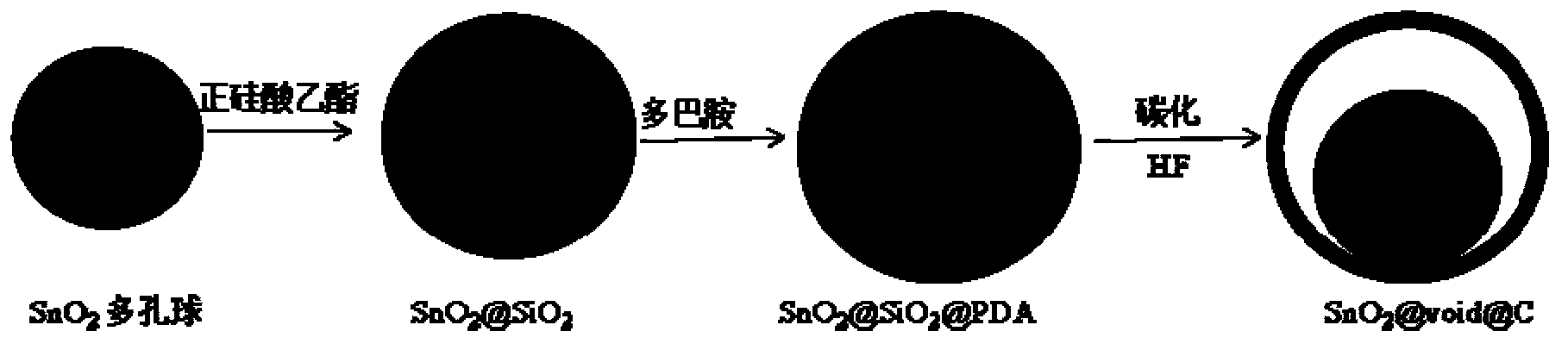

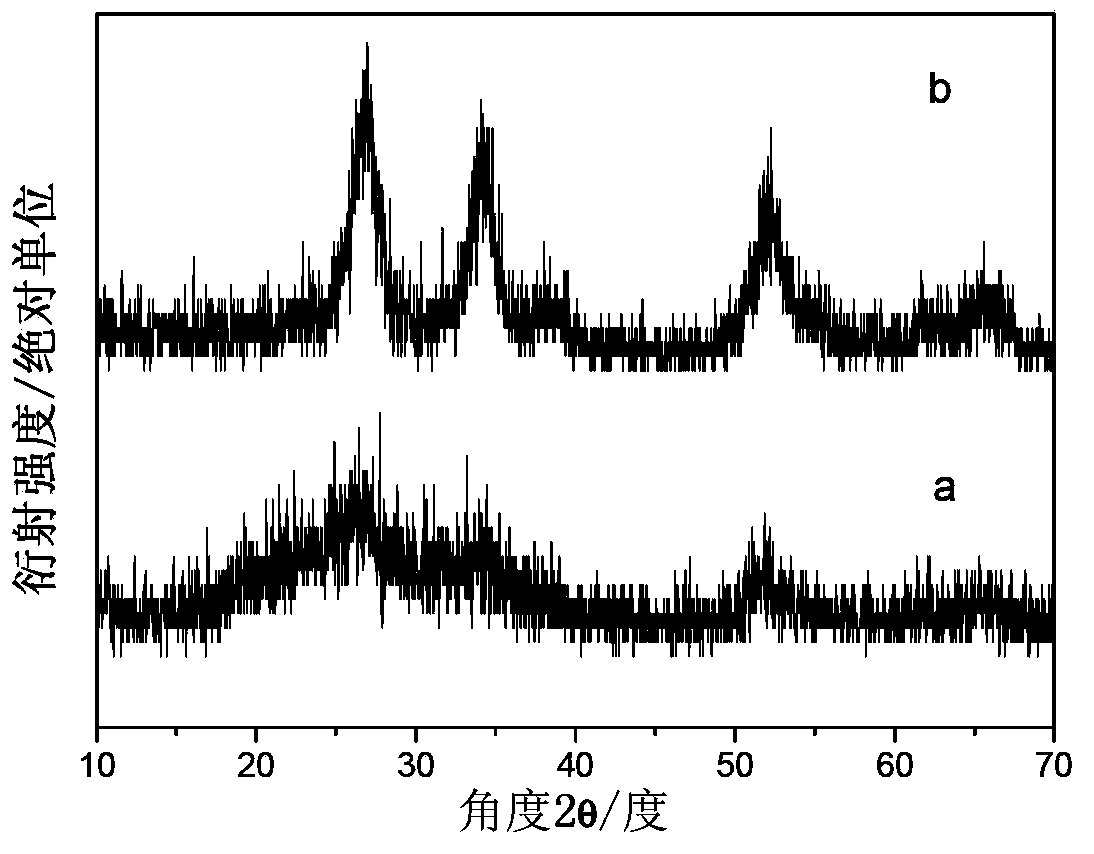

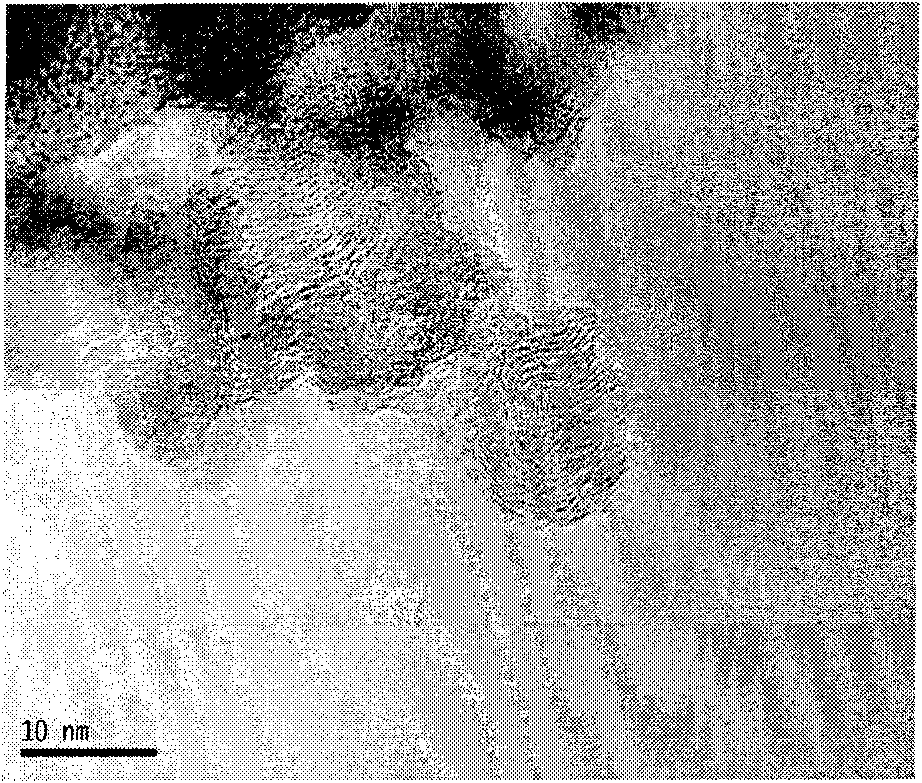

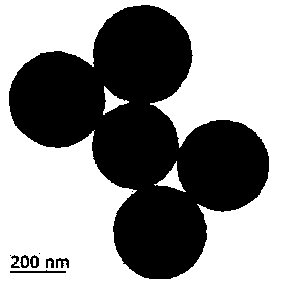

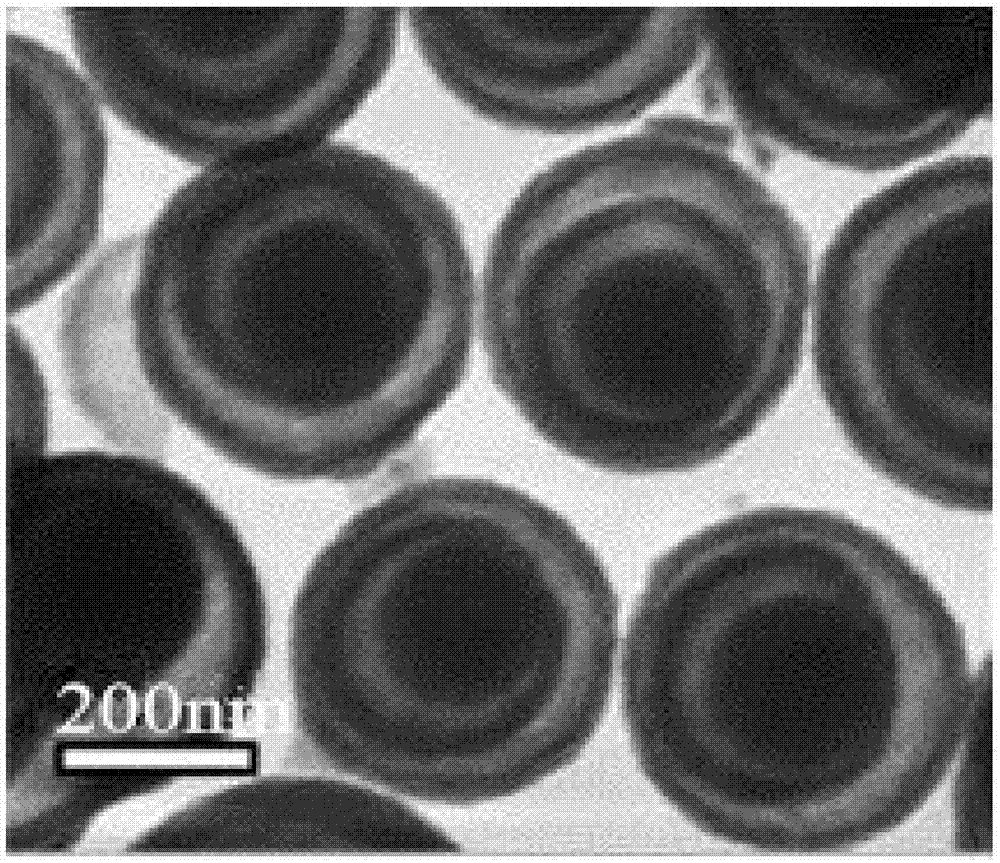

Yolk-shell structure tin dioxide-nitrogen-doped carbon material and preparation method thereof

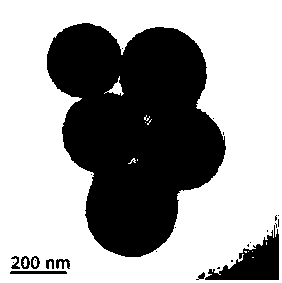

ActiveCN103367719AImprove conductivityImprove electrochemical cycle stabilityMaterial nanotechnologyCell electrodesTin dioxideYolk

The invention relates to a yolk-shell structure tin dioxide-nitrogen-doped carbon material and a preparation method thereof, belonging to the technical field of lithium ion battery electrode material. The yolk-shell structure SnO2@void@N-C material takes porous submicron tin dioxide SnO2 as a core and has the diameter of 200-400 nanometers; nitrogen-doped carbon (N-C) is taken as a shell, and the thickness of the shell is 15-20 nanometers; a cavity has the inner diameter of 300-500 nanometers; in the N-C shell, the mass percent of N element is 8-12%. The porous SnO2 core shortens the lithium ion diffusion path; the volume change of SnO2 can be effectively buffered by a gap between the SnO2 core and a carbon layer in the charge-discharge process, and the N-C can effectively improve the electrical conductivity of the material, so that the yolk-shell structure tin dioxide-nitrogen-doped carbon material has excellent electrochemical cycle stability. The thickness of the carbon layer can be regulated and controlled by controlling the concentration of dopamine or the auto-agglutination time, and the size of the gap can be regulated and controlled by controlling the quantity of tetraethoxysilane; the preparation method can well control the structure of the material, and is simple in technology and convenient to operate.

Owner:BEIJING UNIV OF CHEM TECH

Dehydrogenation catalyst taking Sn-containing alumina as carrier and preparation method thereof

ActiveCN101898131ALarge specific surface areaHigh selectivityCatalyst activation/preparationHydrocarbonsFiberAdditive ingredient

The invention discloses a dehydrogenation catalyst taking Sn-containing alumina as a carrier and a preparation method thereof. The dehydrogenation catalyst takes the Sn-containing alumina as the carrier, nano fibers are carried on the pore surface of the carrier, and dehydrogenation active metal ingredients are carried by an immersion method. The preparation method for the catalyst comprises the following steps of: introducing the carrier to Sn when the alumina is gelled, carrying the carbon nano fibers to the Sn-containing alumina carrier in situ by ethylene cracking, then immersing the dehydrogenation active ingredients, and performing thermal treatment and water vapor treatment to obtain the final dehydrogenation catalyst. When the catalyst is used for a hydrocarbon dehydrogenation reaction process, in particular a propane dehydrogenation process, the catalyst has the advantages of high activity, high selectivity and the like, and particularly greatly improves the stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

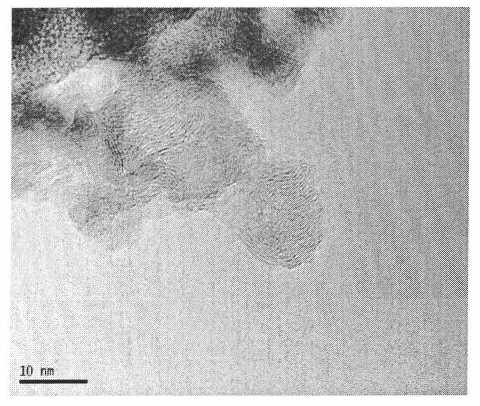

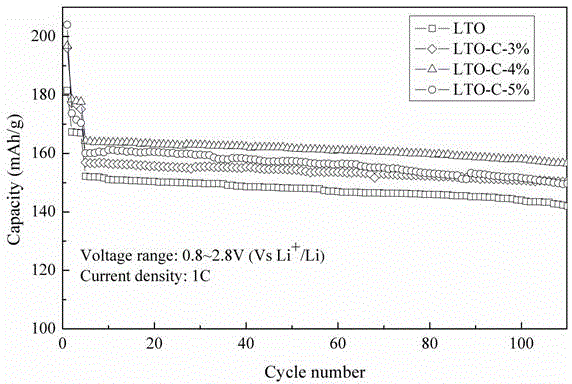

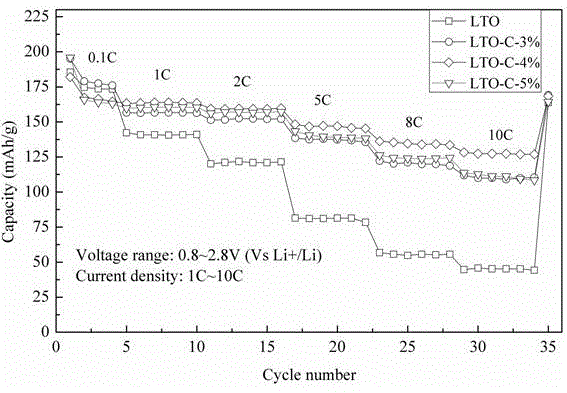

Preparation method of carbon-coated sodium-micron-scale lithium titanate composite anode material

ActiveCN105591079AGuaranteed stabilityLoose particle structureMaterial nanotechnologyCell electrodesMicron scaleOrganotitanium compound

The invention relates to a preparation method of a carbon-coated sodium-micron-scale lithium titanate composite anode material. The method comprises steps as follows: lithium salt is dissolved in an aqueous solution of absolute ethyl alcohol, and the solution is marked a solution a; an organic titanium compound and a carbon source are dissolved in absolute ethyl alcohol, and the solution is marked a solution b; a chelating agent M is dissolved in absolute ethyl alcohol, ultrasonic dispersion is performed, and the solution is marked a solution c; the solution c is slowly dropwise added to the solution b while stirring, and white sol is obtained; then the solution a is slowly dropwise added to the white sol; after the sol is aged, heating, stirring, drying, grinding, sieving and calcination are performed, and the carbon-coated lithium titanate composite anode material is obtained. Lithium titanate has narrower particle size distribution and more uniform particle distribution, and sodium-micron-scale particles are uniformly inlaid to form particles with high tap density; the particle structure is loose and porous, the specific surface area of a formed electrode is larger, getting off of lithium ions in the lithium titanate material is facilitated, and the stability of the crystal structure of the lithium ions in the charge and discharge process is guaranteed.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

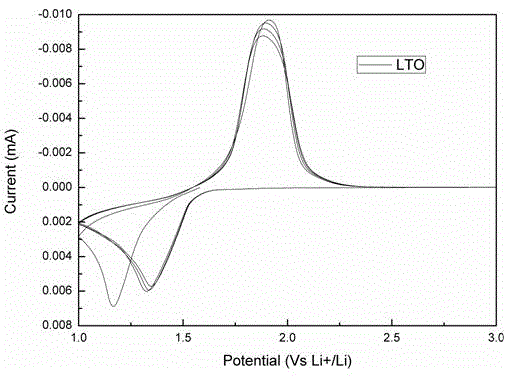

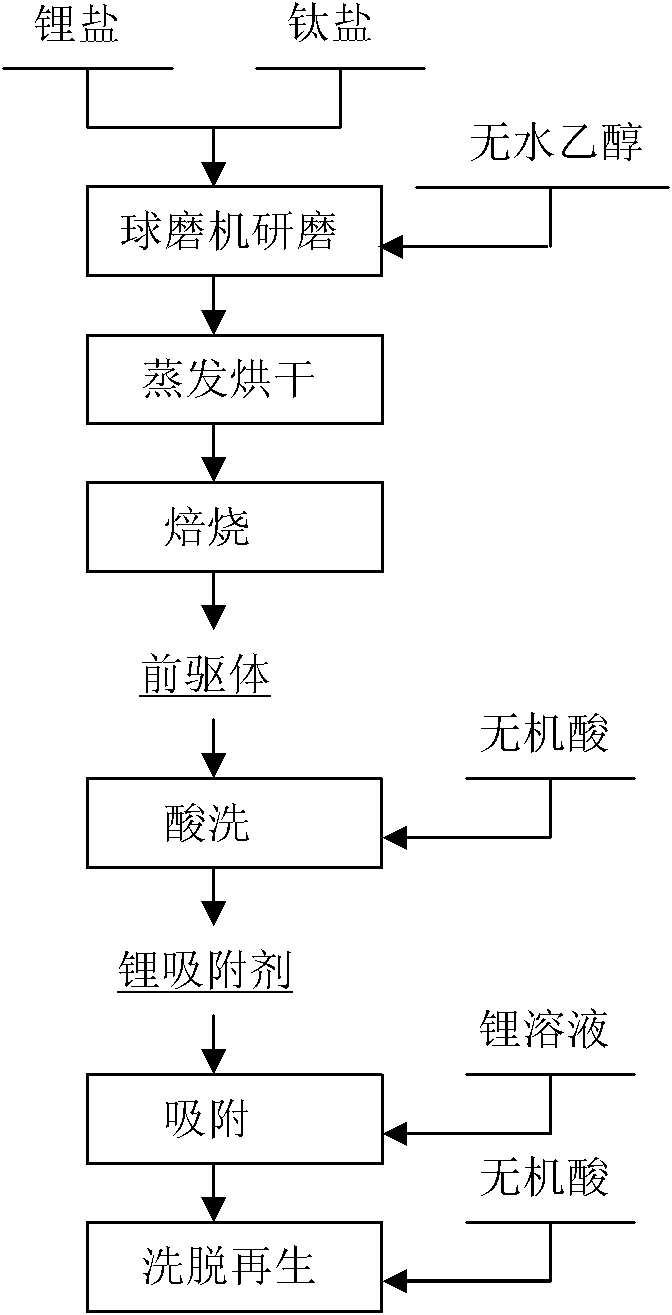

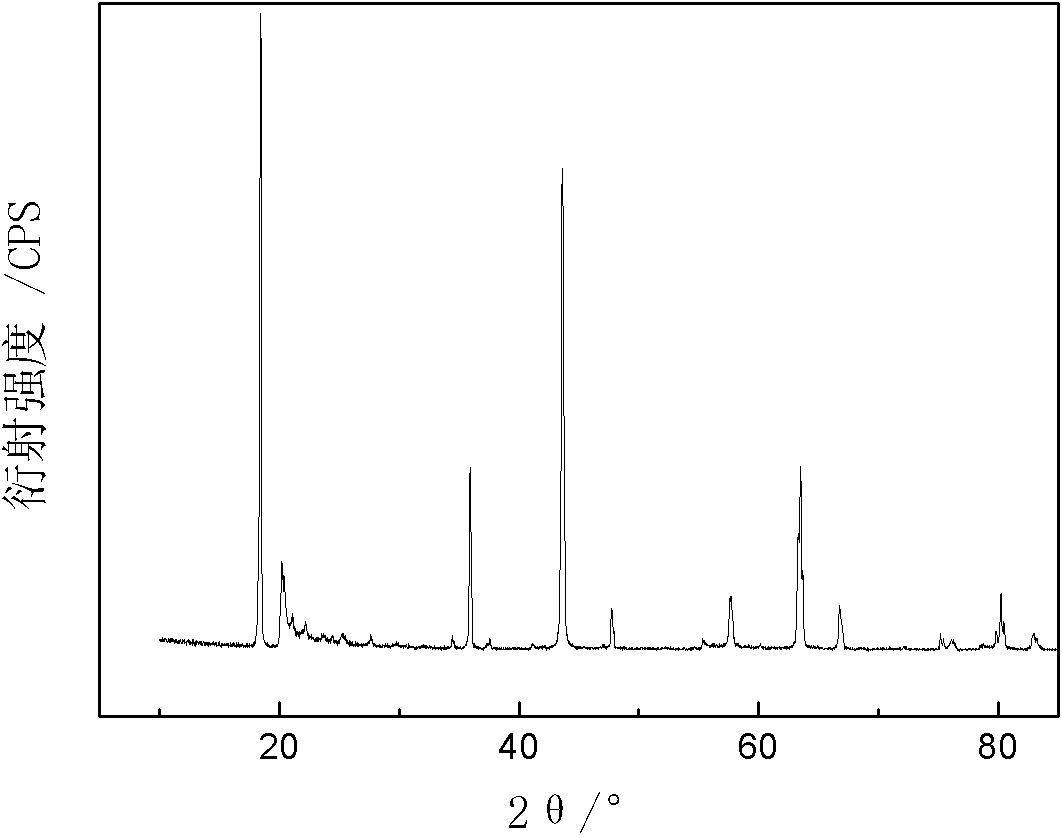

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

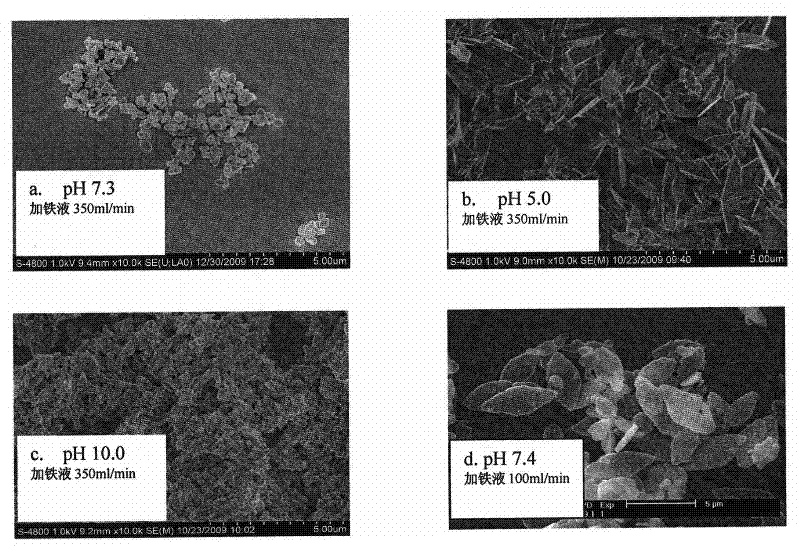

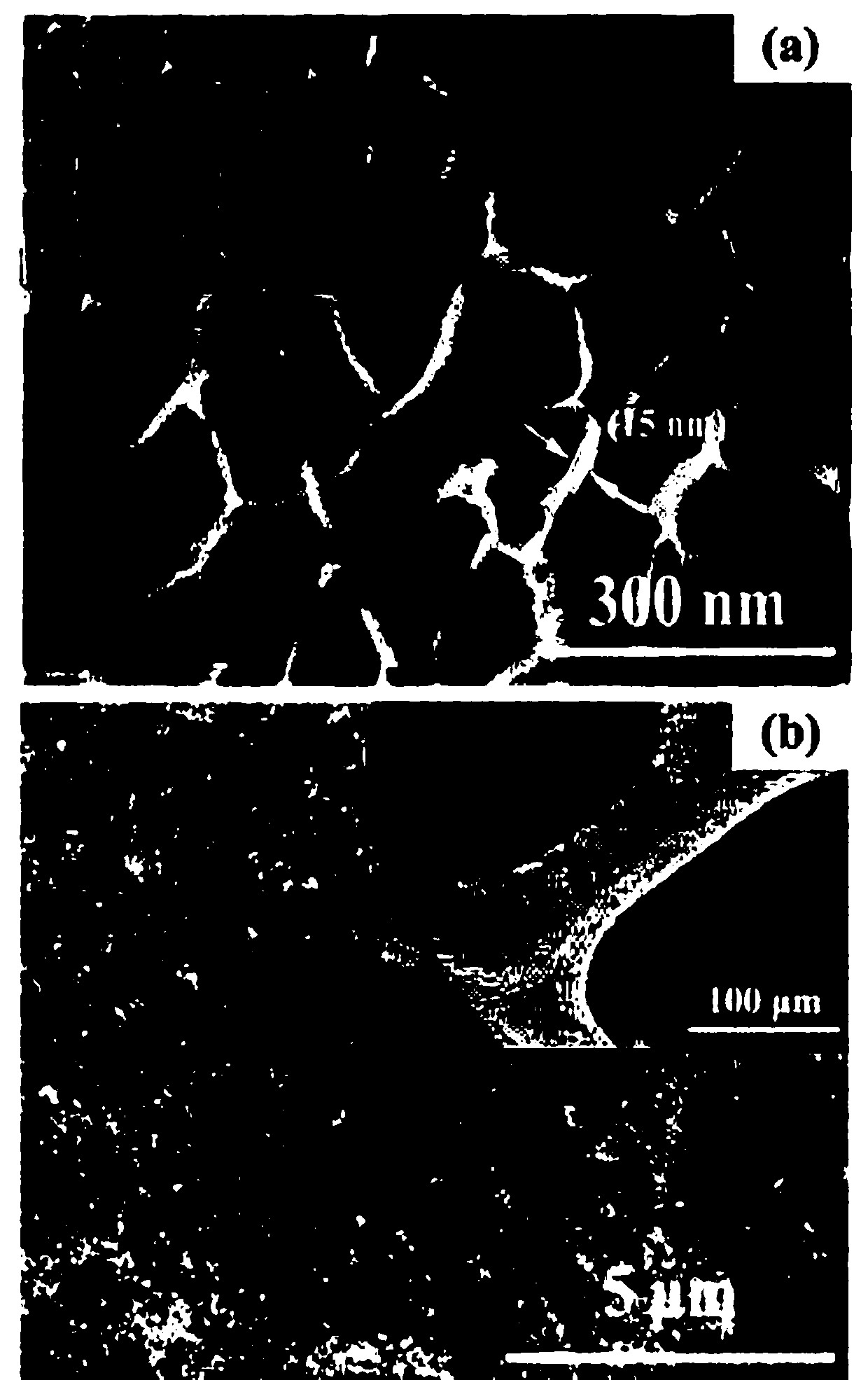

Hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure

InactiveCN101752564AImprove rate discharge performancePromote environmental protectionCell electrodesPhosphorus compoundsLithium hydroxidePhosphoric acid

The invention discloses a hydrothermal synthesis method of LiFePO4 of anode material of lithium ion battery with one-dimensional nanometer structure, which comprises the steps of: 1. respectively adding lithium hydroxide solution and phosphoric acid, evenly adding iron source solution with a certain speed, wherein the molar ratio of the proportion of the added materials Li: Fe: P is 3.0:1.0:1.0-1.15, stirring 10-30 for minutes, adding pH value adjusting agent, leading the initial pH value of a reaction system to be 6.5-8.0, and reacting for 60-480 minutes at 40-180 DEG C; 2. filtering, washing and drying resultant; and 3. packing carbon. The hydrothermal synthesis method can take raw material solution for generating ferrous sulfate as iron source, produces a product with good performance by adjusting the pH value of the reaction system and controlling the feeding speed, eliminates working procedures for crystallizing and drying the ferrous sulfate and the like, is good for reducing water electricity consumption, and has less equipment investment, simple and controllable technology and good batch stability of the product.

Owner:HEBEI UNIV OF TECH

Preparation method of soft/hard carbon modified anode material for lithium ion batteries

InactiveCN107845810ALow tap densityHigh tap densityCell electrodesSecondary cellsCarbon compositesDischarge efficiency

The invention discloses a preparation method of a soft / hard carbon modified anode material for lithium ion batteries. The method comprises the following steps: (1) carrying out mixed granulation; (2)screening and crushing; (3) mixing; (4) treating at high temperature; (5) screening; (6) modifying; (7) carrying out secondary carbonization. The method is characterized in that a soft carbon precursor and a hard carbon precursor are both used as binding agents, kneading and granulating are carried out at a certain temperature and under other conditions, small graphite particles are polymerized soas to enable the internal structure to be further densified and increase the volume density, high-temperature graphitization is then performed, and asphalt and resin are converted to pyrolytic carbon, so that a soft / hard carbon graphite composite systems is formed; the surface of the modified soft / hard carbon composite anode material is evenly coated with a layer of Ti3SiC2, having good electrical conductivity and stable chemical properties, and a conductive network, so that the improvement of the discharge capacity, discharge efficiency and cycling stability of the graphite anode material isbetter promoted.

Owner:SHENZHEN SINUO INDAL DEV

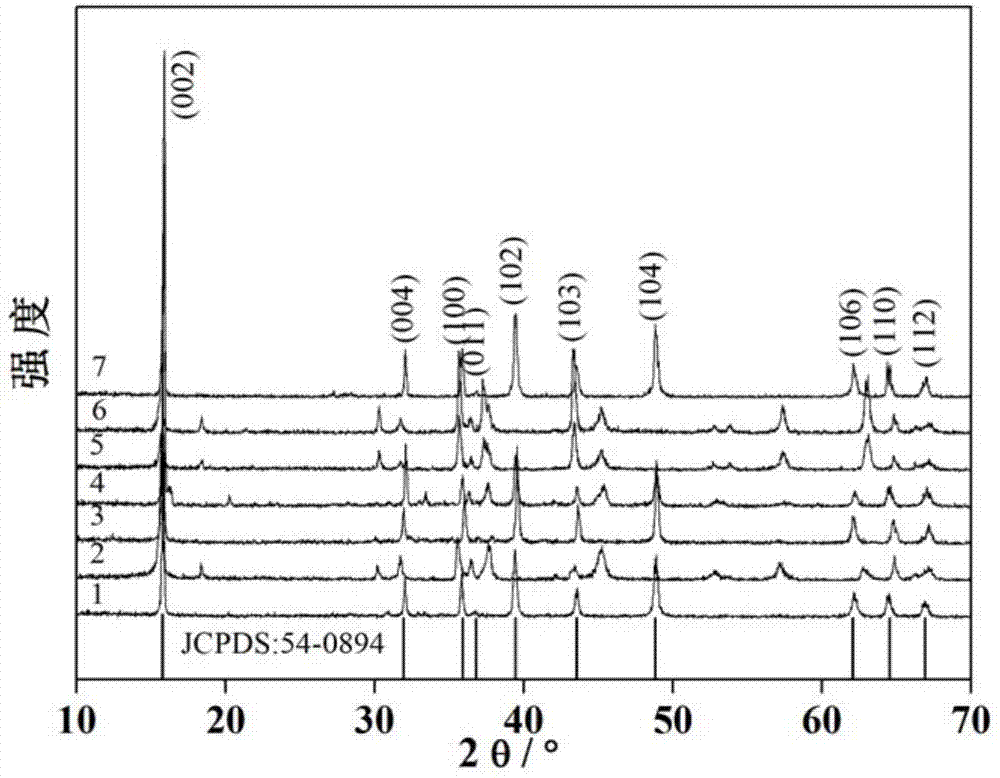

Ternary cathode material, precursor thereof, and preparation method of ternary cathode material and precursor

ActiveCN107585794AHigh activityShorten the diffusion pathCell electrodesSecondary cellsLayered structureSeed crystal

The invention provides a ternary precursor with a composite hetero-structure. The molecular formula of the ternary precursor is Ni<1-a-b>CoM(OH)2@Ni<1-x-y>Co<x>M<y>O<z>, wherein 0<a<1, 0<b<1, 0<a+b<1, 0<x<1, ,0<y<1, 0<x+y<1, 1<z<1.5, and M represents Mn or Al. The ternary precursor comprises a ternary oxide precursor and a ternary hydroxide precursor. The ternary hydroxide precursor is coated on the surface of the ternary oxide precursor. The molecular formula of the ternary oxide precursor is Ni<1-x-y>Co<x>M<y>O<z>, and the molecular formula of the ternary hydroxide precursor is Ni<1-a-b>CoM(OH)2. The invention further provides a preparation method of the ternary precursor. According to the preparation method, a spray pyrolysis method and a co-precipitation method are combined, the ternary oxide precursor obtained by spray pyrolysis is taken as the seed crystal, then a layer of ternary hydroxide precursor is coated on the surface of the ternary oxide precursor through theco-precipitation method to obtain the ternary precursor, and the ternary precursor and lithium salts are mixed and sintered to prepare the ternary cathode material. The ternary cathode material has the advantages of good layered structure, high initial efficiency, high specific capacity, and excellent circulating ratio performance.

Owner:CENT SOUTH UNIV

Method for preparing nano sillicalite-1 type total-silicalite molecular sieve

InactiveCN102774851ASuitable for industrial applicationsShorten the diffusion pathMaterial nanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveMuffle furnace

The invention relates to a method for preparing a nano sillicalite-1 type total-silicalite molecular sieve, belonging to the method for preparing the molecular sieve, and aiming to solve the technical problem that the nano-silicalite-1 type total-silicalite molecular sieve prepared by adopting the existing method has low yield. The method comprises the following steps: preparing the mixed solution of a templating agent and an alkali source, adding a silicon source into the mixed solution, stirring in a sealing form to obtain a mixture gel system, crystallizing the mixture gel system, washing the production of crystallization, centrifuging, drying, putting in a muffle furnace, and calcinating to obtain the nano sillicalite-1 type total-silicalite molecular sieve. The nano sillicalite-1 type total-silicalite molecular sieve prepared by adopting the method has the grain size of less than 20nm and the yield of 42-50%, can be used as the inert carrier of the shape selectivity catalyst and the gas separation membrane material and can be also in the field of gas separation and purification.

Owner:HEILONGJIANG HEIKE TECH CO LTD

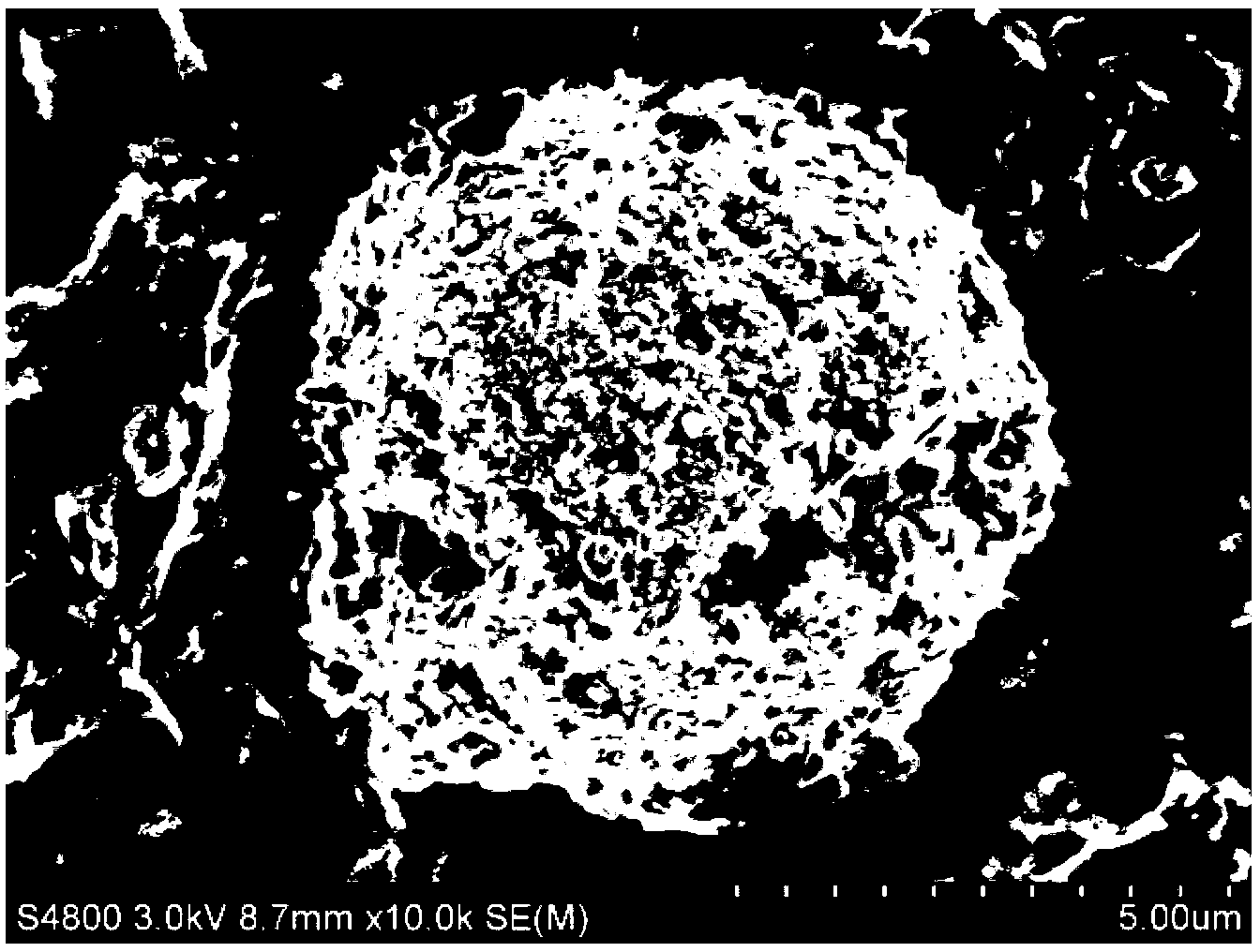

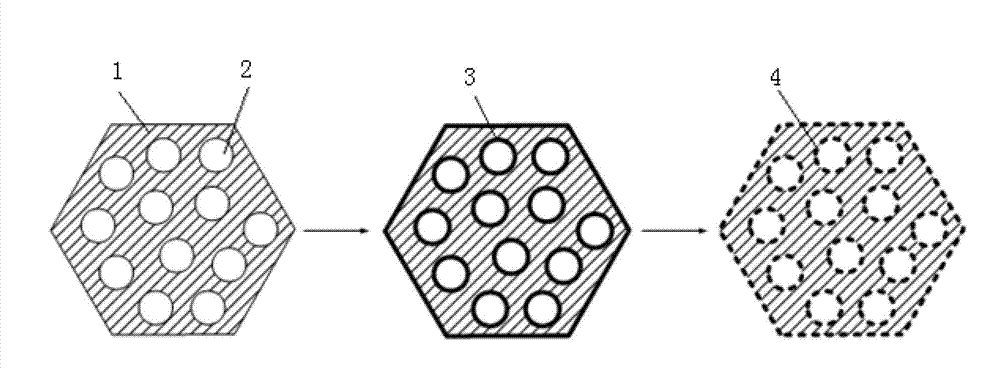

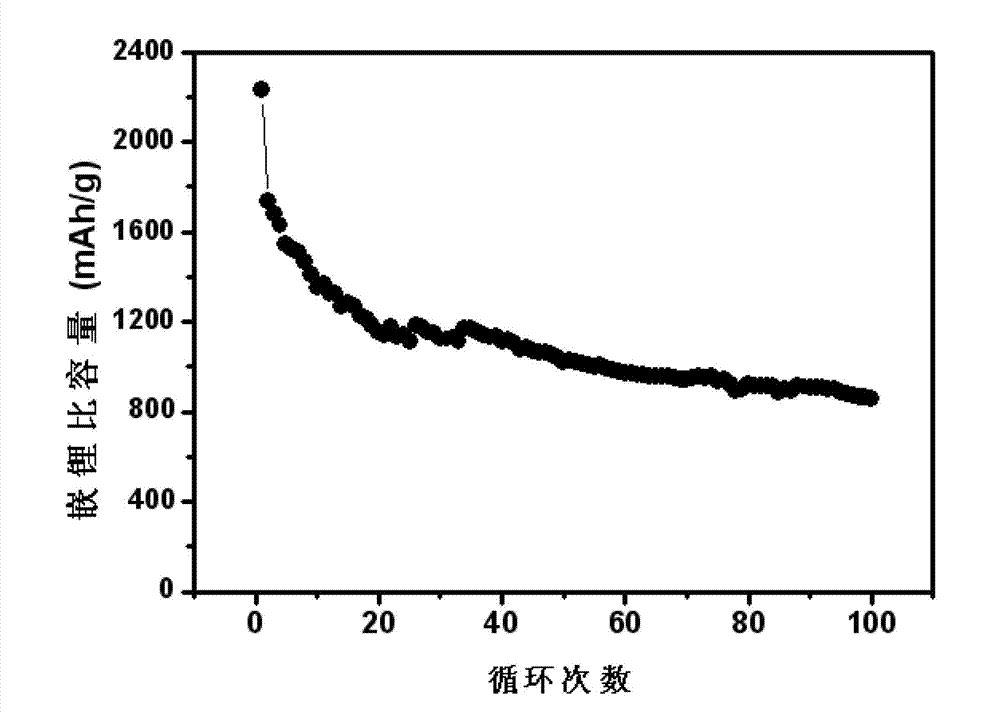

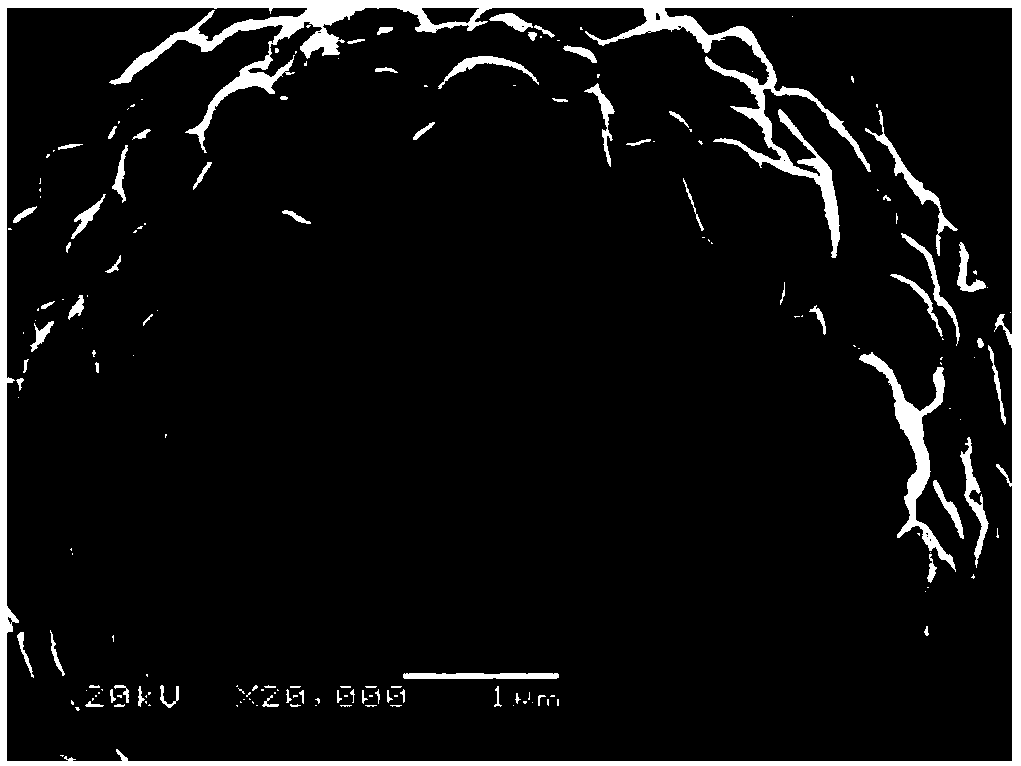

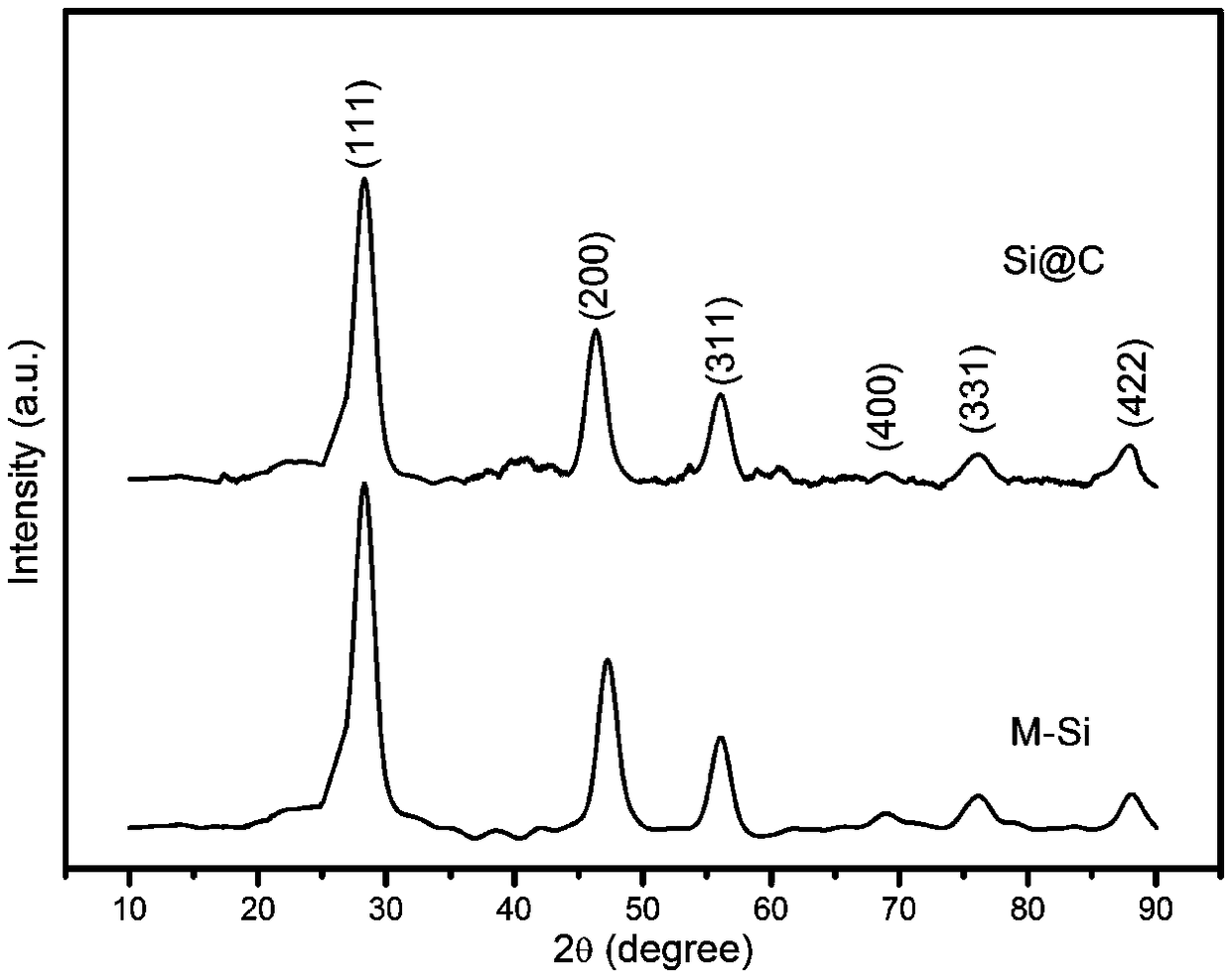

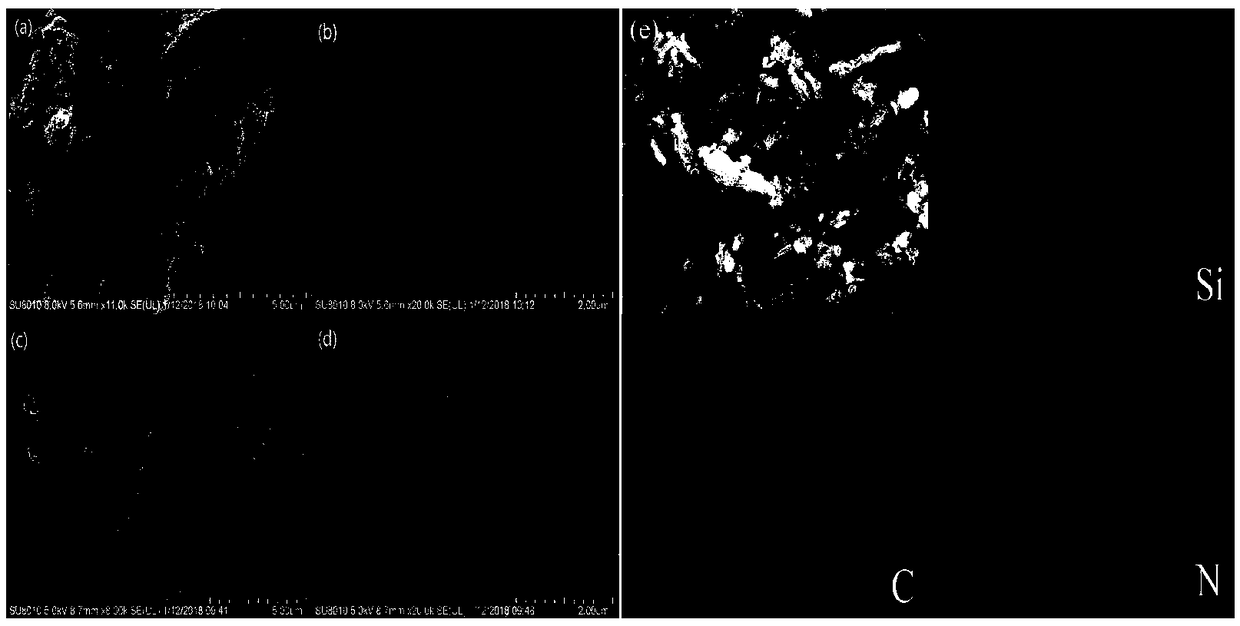

Silicon @ carbon composite material with egg yolk shell structure and preparation and application thereof

ActiveCN109256535AAvoid direct contactShorten the diffusion pathMaterial nanotechnologyCell electrodesCarbon compositesAluminium hydroxide

The invention belongs to the field of battery negative electrode materials, and particularly discloses a preparation method of silicon @ carbon composite material with egg yolk shell structure, whichis characterized in that the preparation method comprises the following steps: step 1) mesoporous nano SiOX, molten salt and magnesium powder are mixed and calcined to obtain mesoporous nano silicon;2) mesoporous nano-silicon powder, the surfactant and the aluminum salt prepared in the step 1) are added into a solution at a pH value of 2, and the mesoporous nano-silicon powder, the surfactant andthe aluminum salt are added into the solution at a pH value of 2; 7, coat aluminum hydroxide colloid on that surface of nano silicon to obtain silicon / aluminum hydroxide colloid composite material; 3) silicon / aluminum hydroxide colloidal composite material is mixed with an organic carbon source, carbon is coated on the surface of the silicon / aluminum hydroxide colloidal composite material, and then the silicon / aluminum hydroxide colloidal / carbon composite material is acuquried by carbonizing operation; 4) aluminum hydroxide colloid of the material obtained in the step 3) is removed by using an acid solution and / or an alkali solution to prepare the silicon @ carbon composite material with the egg yolk shell structure. The invention can stably prepare the silicon @ carbon composite materialwith the egg yolk shell structure, and the material has excellent electrical performance.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material and preparation method

InactiveCN105958038AImprove structural stabilityImprove securityCell electrodesSecondary cellsLithiumHigh voltage

The invention relates to a preparation method of a quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material. The preparation method comprises the following steps: preparing Li<2>CO<3> and Co<3>O<4> as raw materials, adding a doping element M, adding a grain refiner and a cosolvent, and performing first sintering; and adding a grain refiner and a coating compound into a firstly-sintered material serving as a raw material, and performing surface coating and second sintering, wherein the doping element M is one or more of Ti<4+>, Zr<4+>, Mn<4+>, Sn<4+>, Ce<4+>, Ir<3+>, Mg<2+>, Al<3+>, V<5+>, Nb<3+> and Co<2+>, a molecular formula of doped lithium cobaltate is LiCo<1-x>M<y>O<2-y>; and the grain refiner is one or more of oxides of Ti, Nb, V, Al and Zr. The prepared lithium cobaltate positive electrode material has the characteristics of rapid charging, high capacity, high voltage, high cycle and low cost, can be applied under a rapid-charging high-voltage condition, and has superior electrochemical performance.

Owner:湖南美特新材料科技有限公司 +1

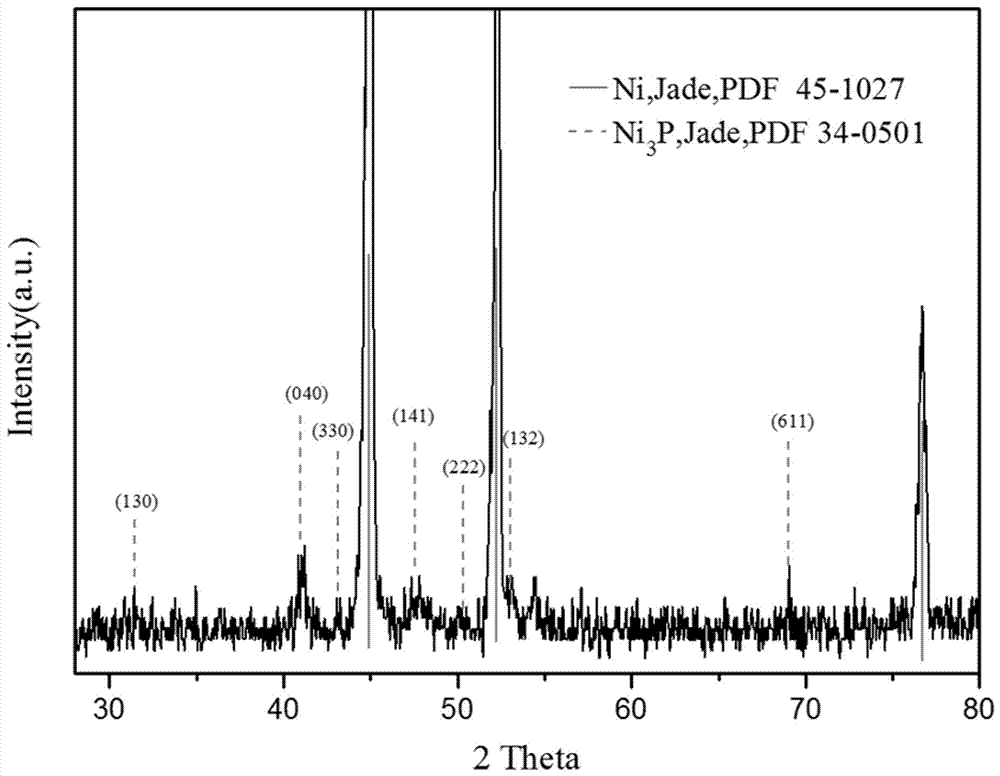

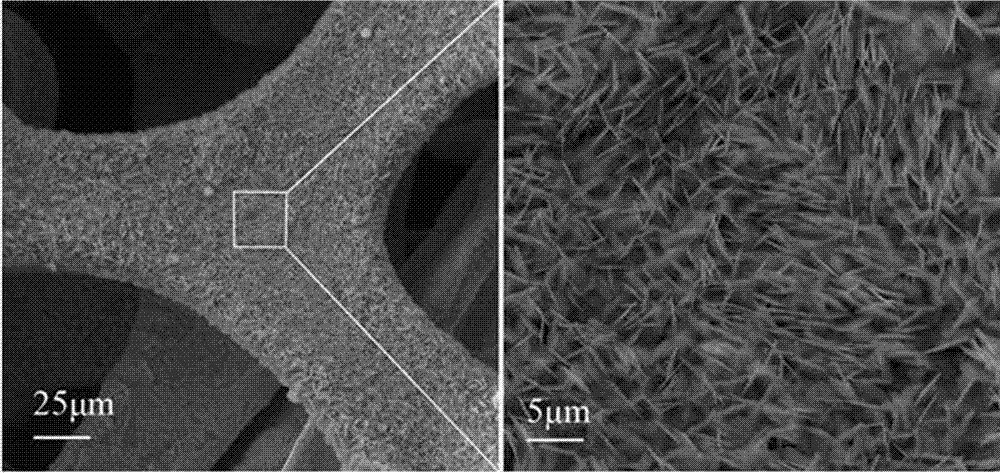

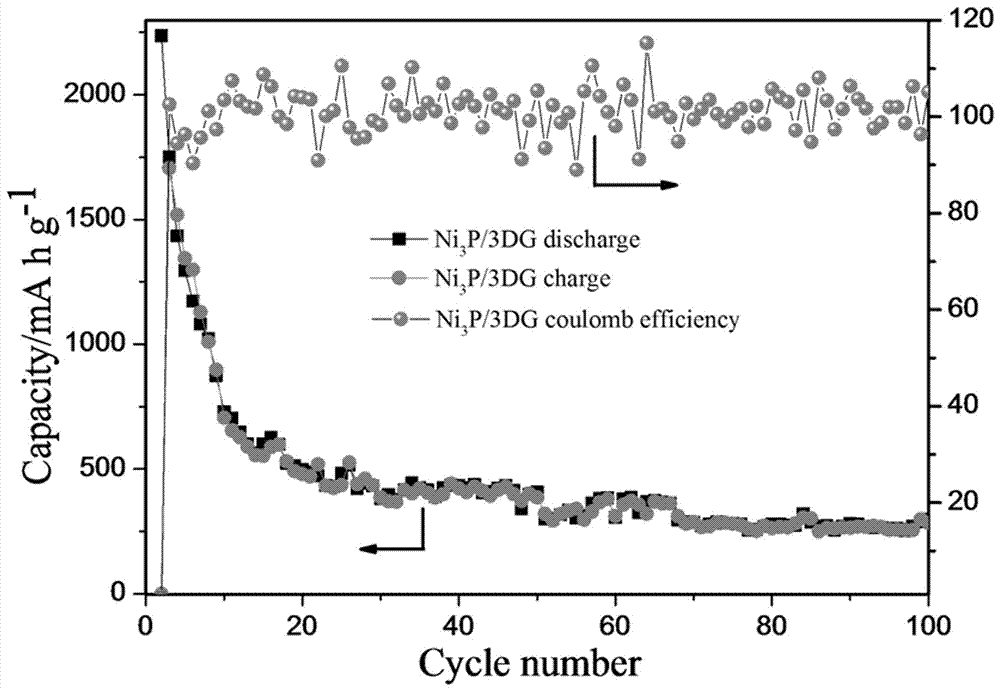

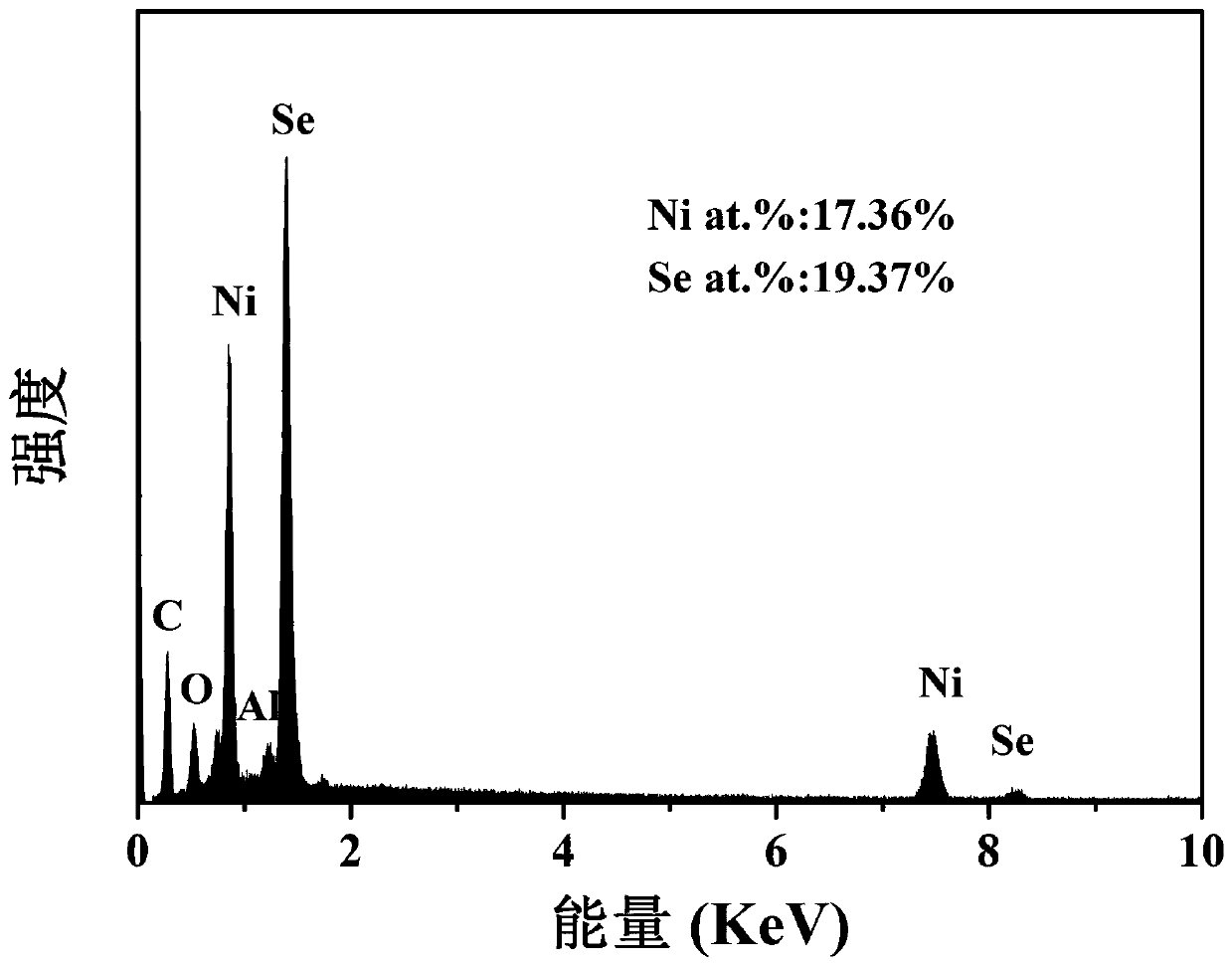

Sodium ion battery nanosheet array nickel phosphide/three-dimensional (3D) graphene composite material and preparation method thereof

ActiveCN107331851AImprove cycle stabilityImproved magnification performanceMaterial nanotechnologyCell electrodesSodium-ion batteryInorganic phosphorus

The invention discloses a sodium ion battery nanosheet array nickel phosphide / three-dimensional (3D) graphene composite material and a preparation method thereof. The preparation method comprises the steps of preparing 3D graphene by using foam nickel and a chemical vapor deposition (CVD) method, enabling the 3D graphene and deionized water having a pH value of 3 to be subjected to a hydrothermal reaction, and generating an Ni(OH)2 nanosheet array structure on a foam nickel substrate loaded with the 3D graphene; respectively placing nanosheet array Ni(OH)2 / 3D graphene composite material and a phosphorus source at the two ends of a tube furnace, heating the tube furnace, replenishing one end of the tube furnace, where the inorganic phosphorus source is placed, with flowing inert gas, and carrying out heat treatment; cooling the product of the reaction to room temperature to obtain the nanosheet array nickel phosphide / 3D graphene composite material. The whole preparation method provided by the invention is simple and environmentally-friendly; nickel phosphide is compounded with the 3D graphene, so that the material performance is improved; when the composite material is used as a self-supported sodium ion battery anode material, a conductive additive is not needed; the sodium ion battery nanosheet array nickel phosphide / 3D graphene composite material has high specific capacity and good rate performance, thus having a wide industrial application prospect.

Owner:TAIYUAN UNIV OF TECH

Preparation method for petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth

InactiveCN107591527AUniform particle sizeStable structureMaterial nanotechnologyCell electrodesTetraethyl orthosilicateEnvironmental resistance

The invention relates to a preparation method for a petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth, and belongs to the technical field of nanometer material production. The preparation method comprises the steps of mixing ethanol, deionized water, ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde for reaction; drying a solid phase and performing calcination in argon; etching the solid phase with a sodium hydroxide solution to obtain the solid phase, and drying the solid phase to obtain the hollow mesoporous carbon nanometer sphere; mixingsodium molybdate dihydrate, thiourea and the hollow mesoporous carbon nanometer sphere for hydrothermal reaction, performing centrifugal washing after hydrothermal reaction, drying the solid phase, and performing high-temperature calcination under protection of argon atmosphere to obtain the petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth. The preparation method has the advantages that the raw material is low in cost, the process is environmental-friendly, high yield is achieved, and the prepared petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth can be used as a lithium ion battery electrode material, a photocatalytic material or an electrocatalytic material.

Owner:YANGZHOU UNIV

Zeolites, the production thereof, and their uses for upgrading heavy oils

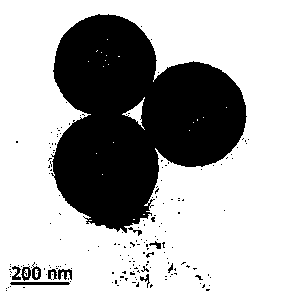

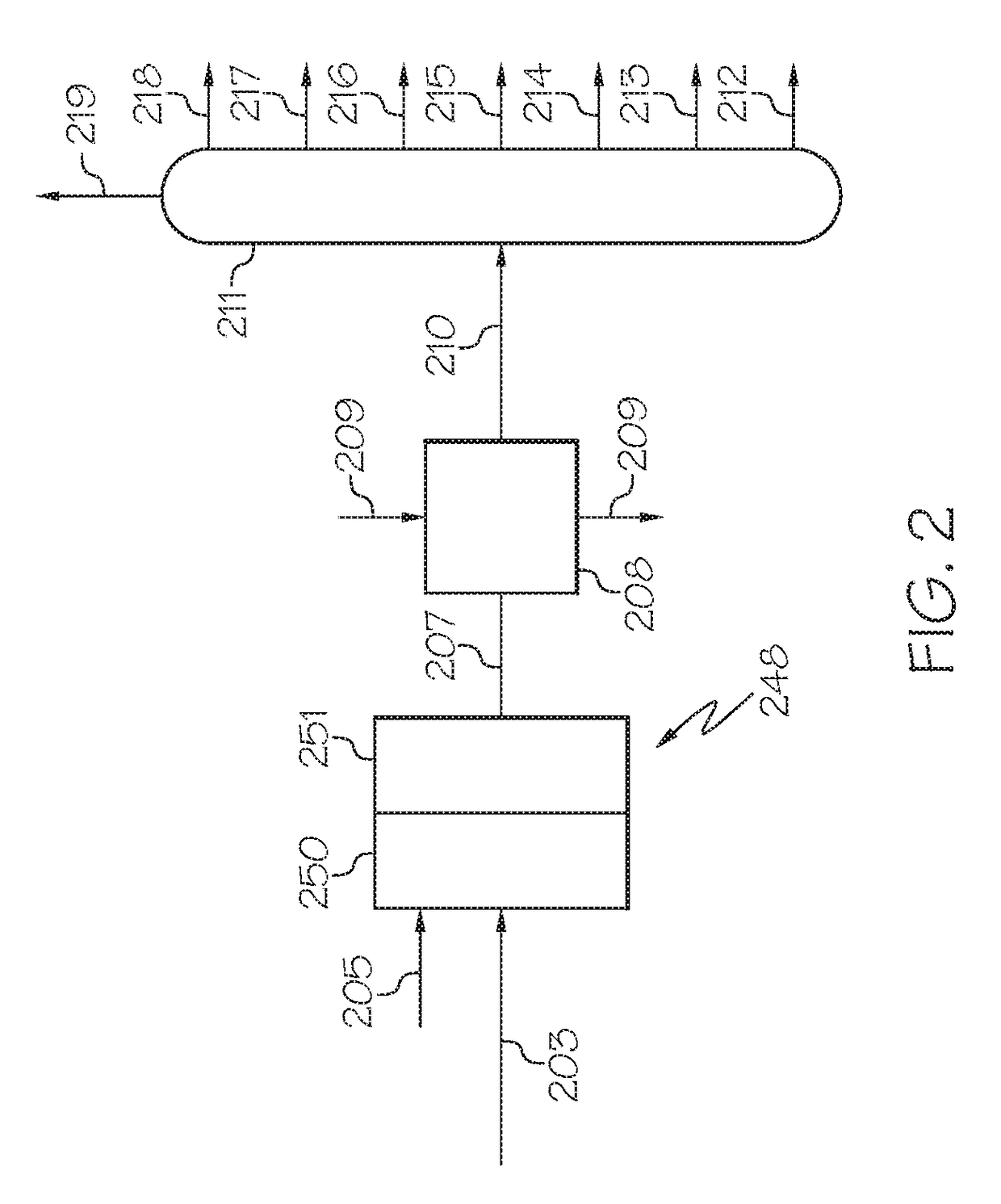

ActiveUS20180333708A1Low costLess expensiveCatalytic crackingMolecular sieve catalystsFuel oilChemistry

According to one or more embodiments, a nano-sized, mesoporous zeolite particle may include a microporous framework comprising a plurality of micropores having diameters of less than or equal to 2 nm and a BEA framework type. The nano-sized, mesoporous zeolite particle may also include a plurality of mesopores having diameters of greater than 2 nm and less than or equal to 50 nm. The zeolite particles may be integrated into hydrocracking catalysts and utilized for the cracking of heavy oils in a pretreatment process.

Owner:SAUDI ARABIAN OIL CO

Egg-shaped dual-carbon shell layer tin-based negative electrode material of lithium ion battery and preparation method for negative electrode material

InactiveCN107369819AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesTin dioxideCarbonization

The invention provides an egg-shaped dual-carbon shell layer tin-based negative electrode material of a lithium ion battery and a preparation method for the negative electrode material. The egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite comprises a porous stannic oxide sphere kernel and a dual-layer carbon shell for coating the surface of the porous stannic oxide sphere kernel, and a hollow layer exists between the two parts; the preparation method comprises the steps of preparing the egg-shell-shaped silicon dioxide-coated porous stannic oxide sphere nanocomposite by adopting a surfactant soft template method, and then attaching an organic pyrolytic carbon raw material on the surface of the nanocomposite, and performing a hydrothermal reaction and then carrying out condensation polymerization and carbonization to obtain the egg-shell-shaped carbon-silicon dioxide-carbon-coated stannic oxide sphere nanocomposite, and finally, performing etching by adopting a sodium hydroxide alkali solution to obtain the egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite. Finally, the invention provides the tin-based negative electrode material of the lithium ion battery with nanometer scale, high conductivity and capability of effectively suppressing the volume effect of stannic oxide, and a preparation method for the negative electrode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

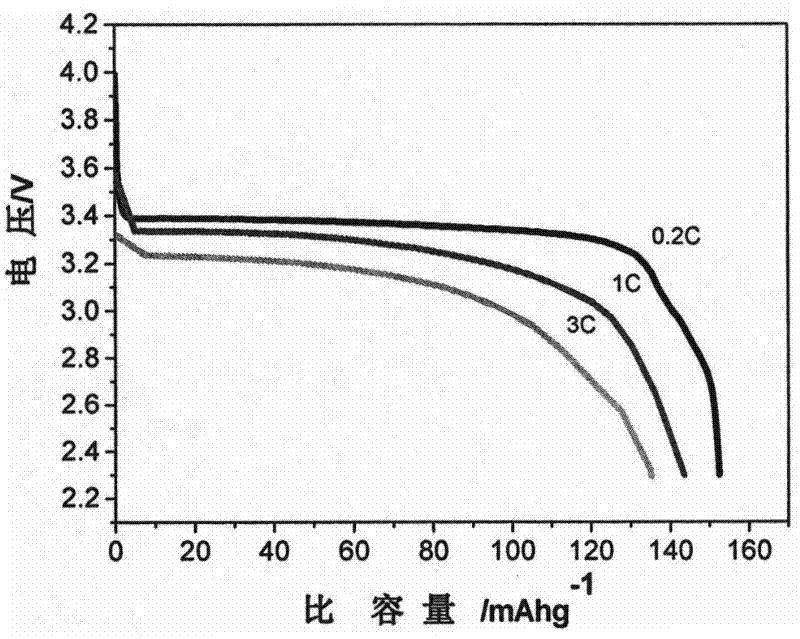

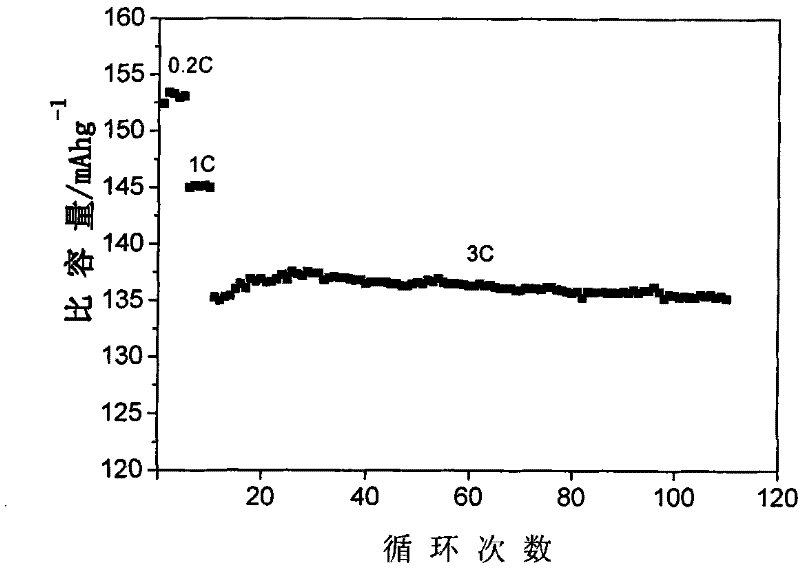

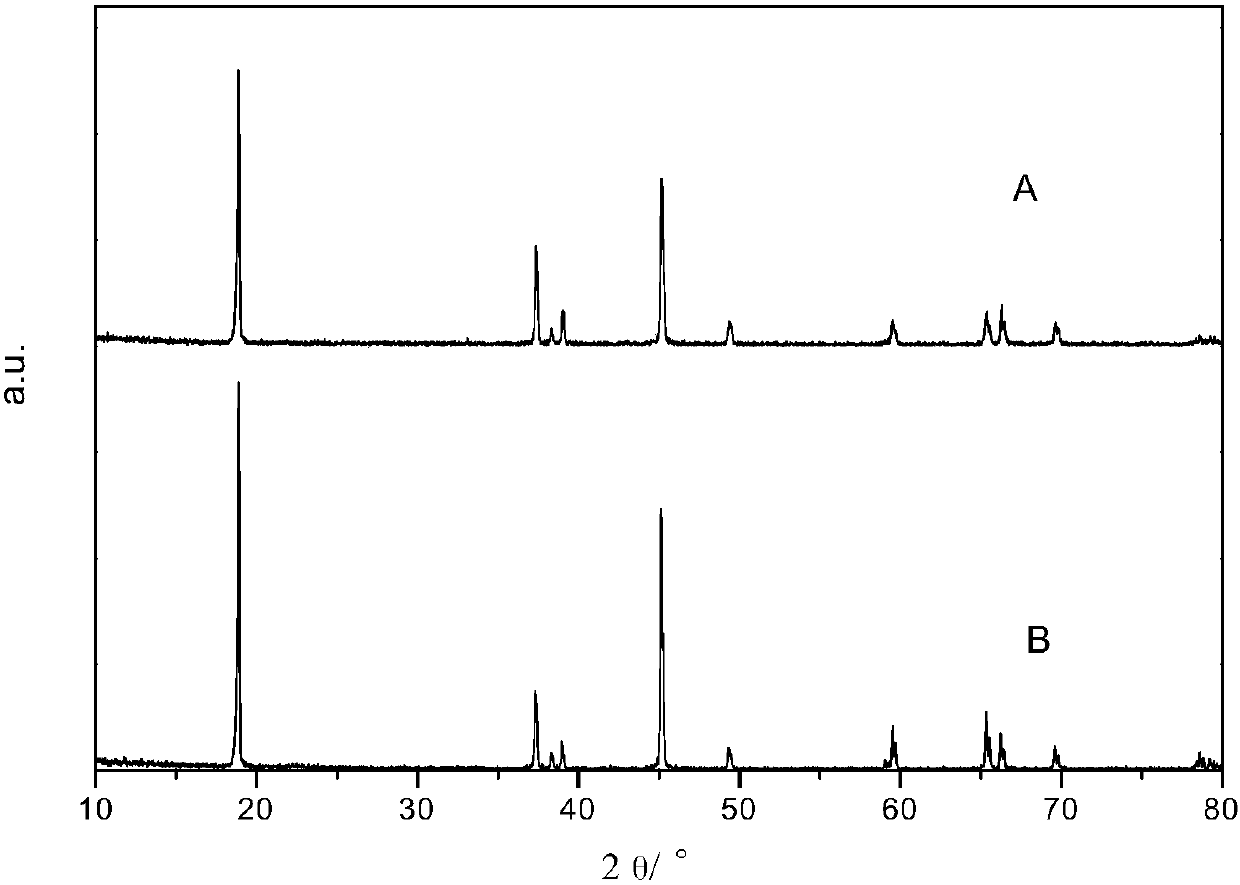

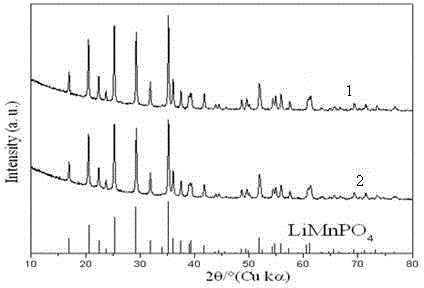

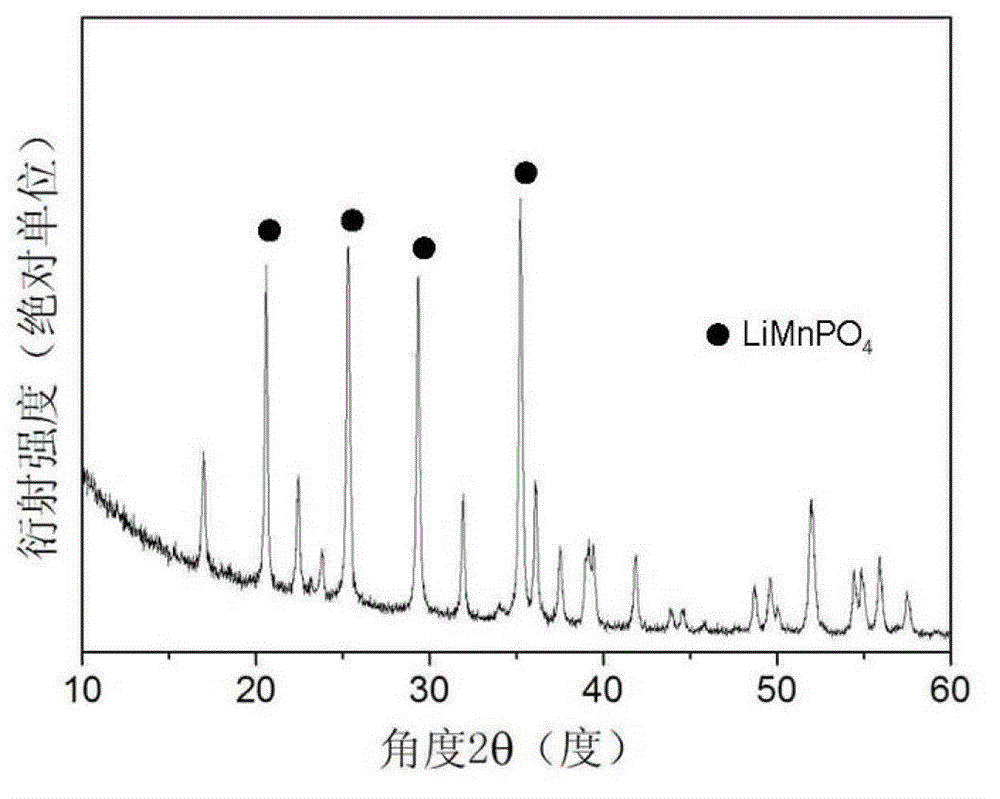

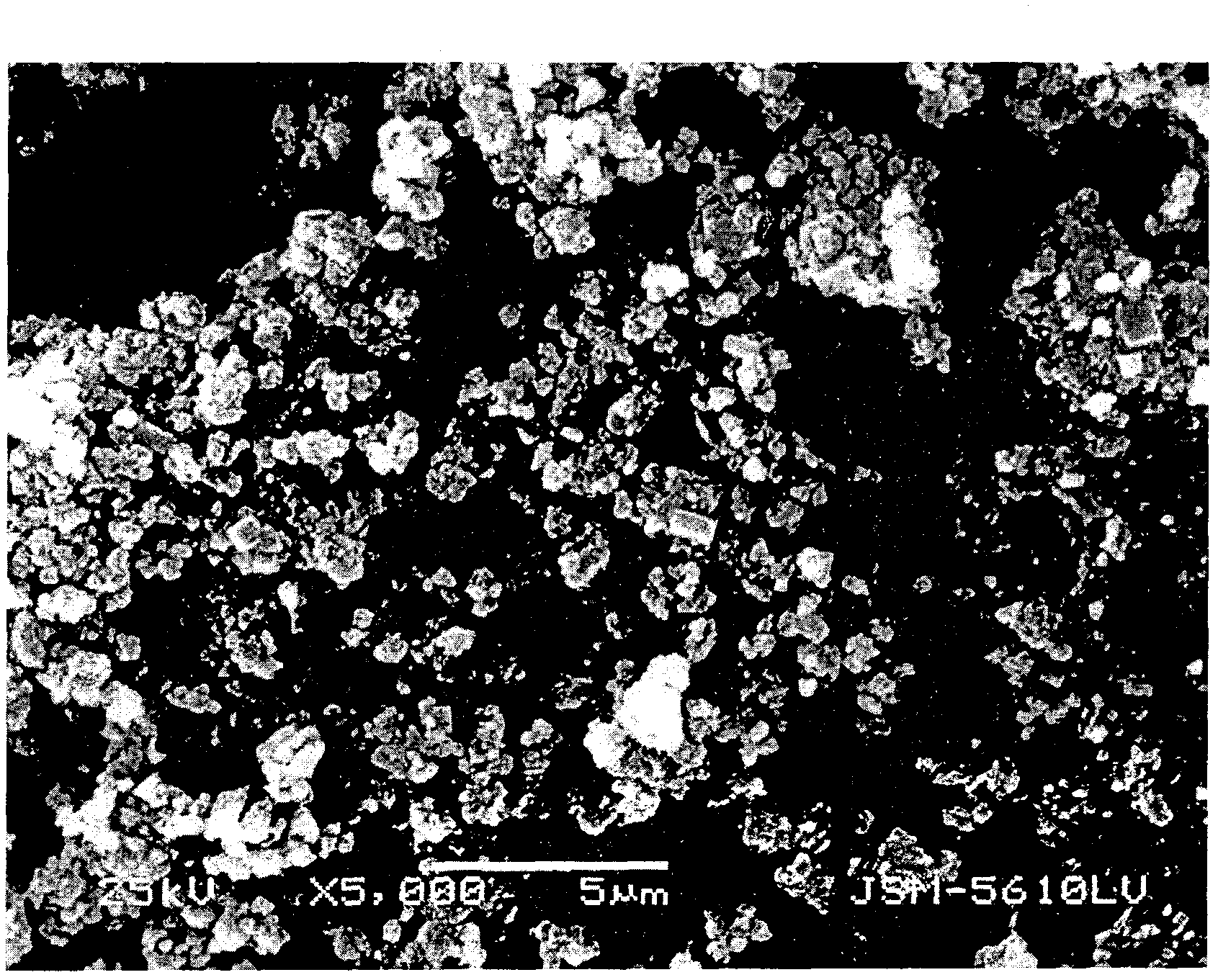

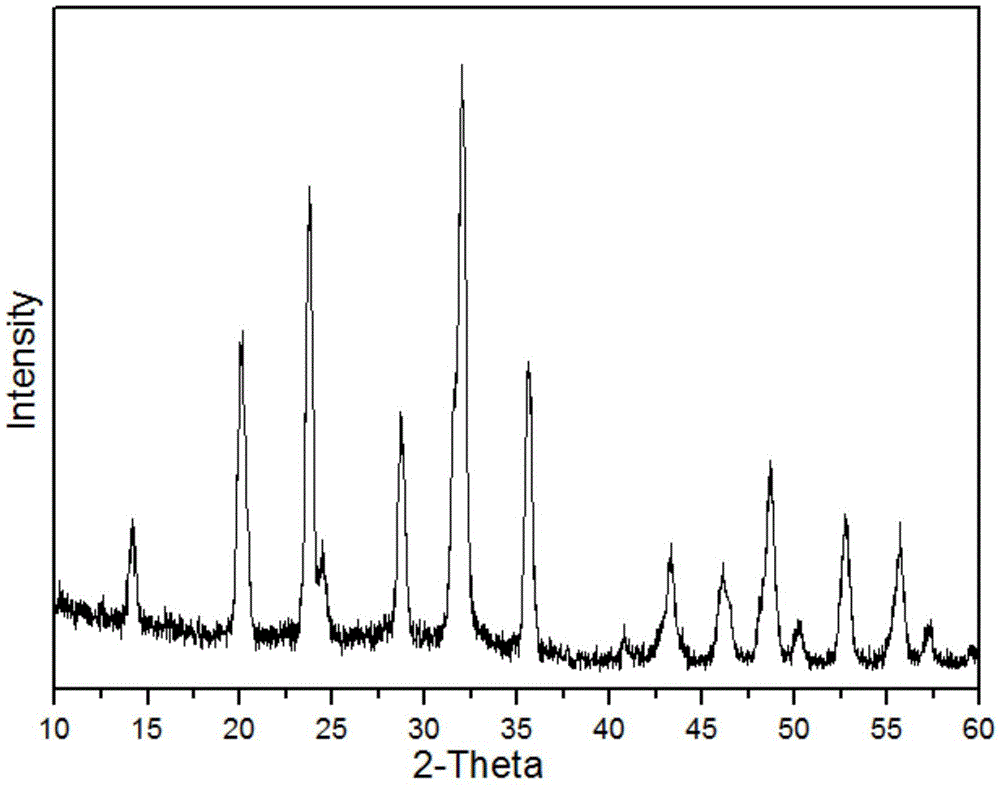

Lithium manganese iron phosphate and preparation method and application therefor

ActiveCN105226273AShorten the diffusion pathImprove electrochemical performanceCell electrodesPhosphorus compoundsPower batteryLithium iron phosphate

The invention provides lithium manganese iron phosphate and a preparation method and an application therefor. The preparation method for the lithium manganese iron phosphate comprises the steps of preparing a lithium iron phosphate solution and a lithium manganese phosphate solution through a sol-gel method separately; and then calcining the lithium iron phosphate solution and the lithium manganese phosphate solution at an inert atmosphere to obtain the lithium manganese iron phosphate. The primary particle of the lithium manganese iron phosphate prepared by the preparation method of the invention is about 100-nanometer; and the lithium manganese iron phosphate is 140-160 mAh / g in specific capacity, higher in the rate capacity, and can be used as positive electrode materials of power batteries.

Owner:BYD CO LTD

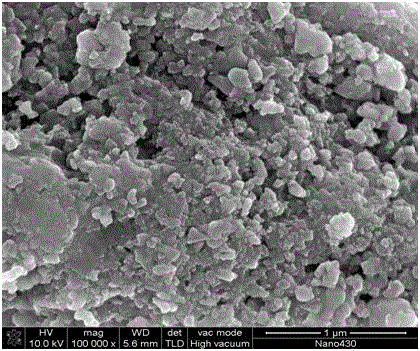

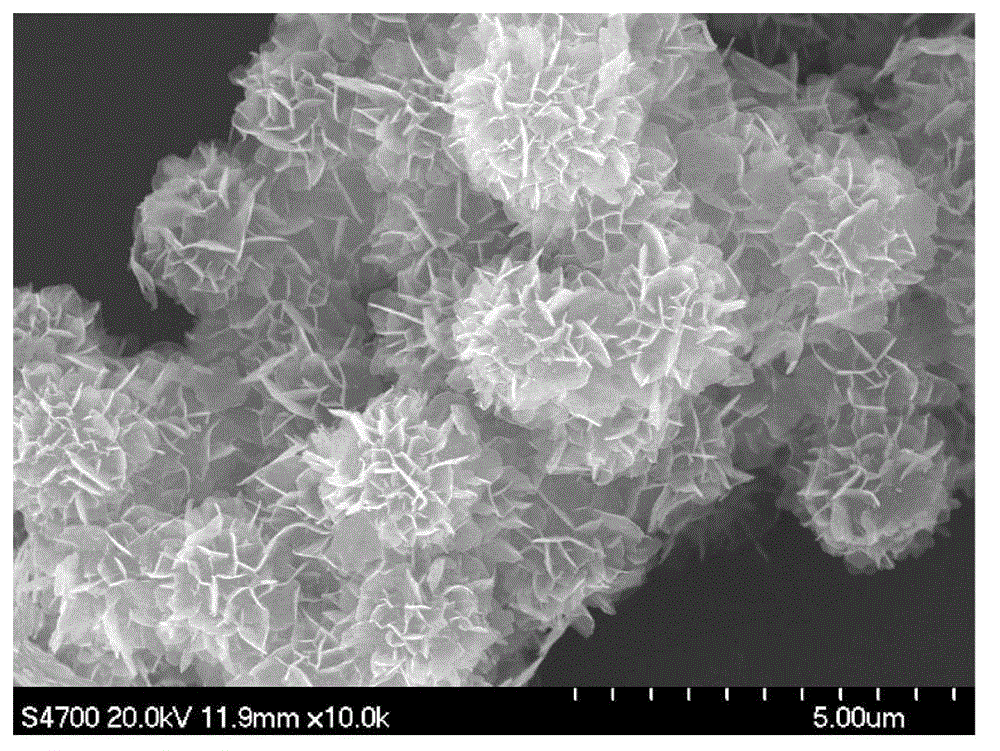

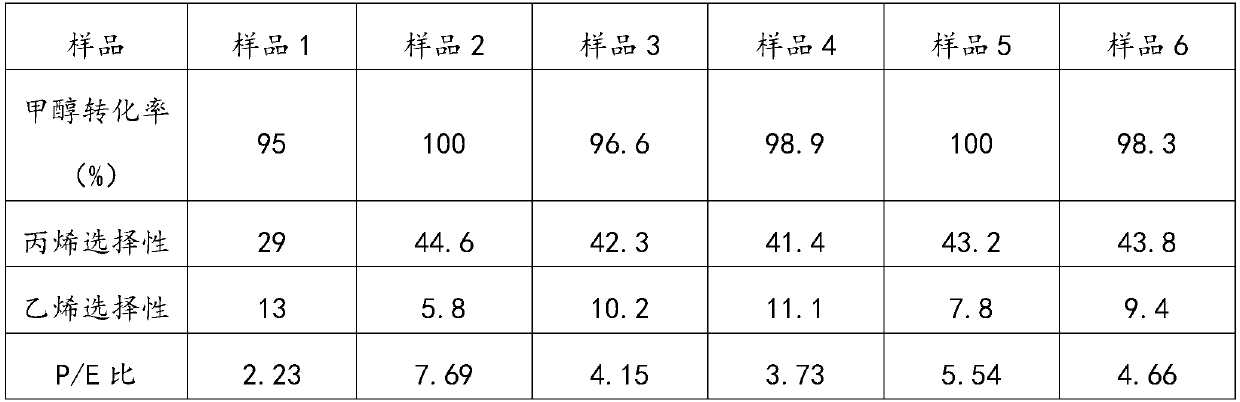

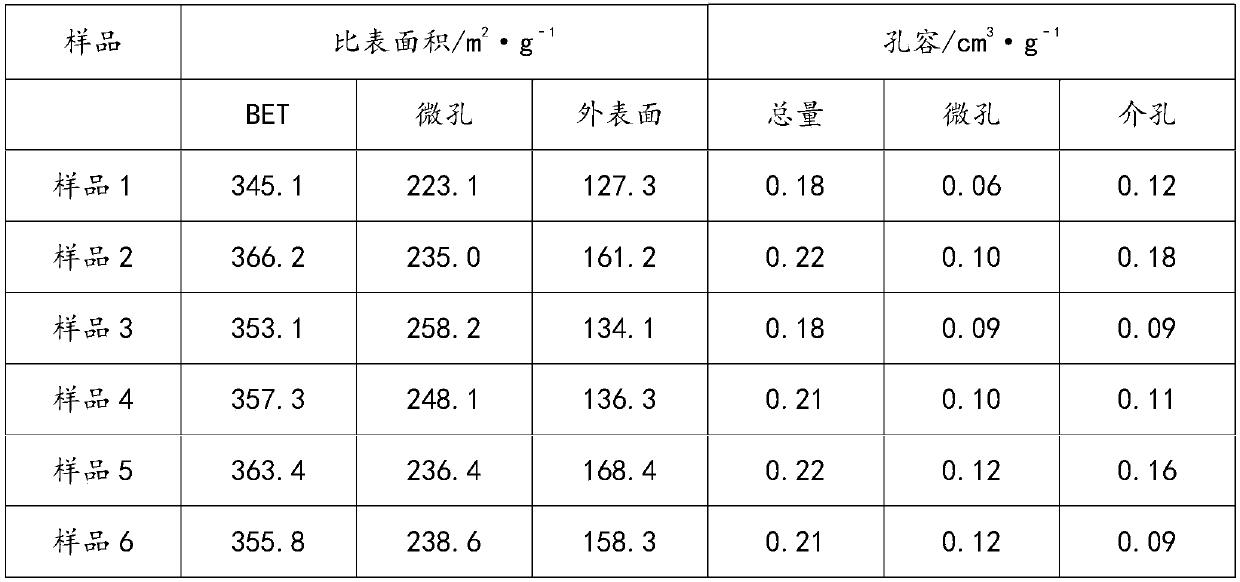

Positive pole material of lithium ion battery and preparation method of material

ActiveCN102983334AImprove conductivityImprove discharge capacityCell electrodesPhosphorus compoundsAluminium-ion batteryLithium electrode

The invention provides a positive pole material of a lithium ion battery. The positive pole material of the lithium ion battery comprises a plurality of sheet-like carbon composite manganese-lithium phosphate material sheets; and the sheet-like carbon composite manganese-lithium phosphate material sheets are arranged in a radial shape. The manganese-lithium phosphate has a chemical formula shown by the formula (1): LiMn1-xMxPO4 (I), wherein x is more than 0 and is less than 0.2; and M is one of Ti, Co, Fe, Mg, Al, Cr and Nb. The positive pole material of the lithium ion battery provided by the invention comprises the sheet-like carbon composite manganese-lithium phosphate material sheets; the sheet-like carbon composite manganese-lithium phosphate material sheets are arranged in the radial shape to form multiple turns, so that the diffusion path of lithium ions in manganese-lithium phosphate grains can be reduced by using the positive pole material with the shape; and meanwhile, the positive pole material with the shape has a specific surface area, so that lithium ions are rapidly deintercalated and transferred. Furthermore, the positive pole material and a battery conduction additive are sufficiently and uniformly mixed, so that the positive pole material of the lithium ion battery provided by the invention has high discharge capability and circulation property.

Owner:宁波富理电池材料科技有限公司

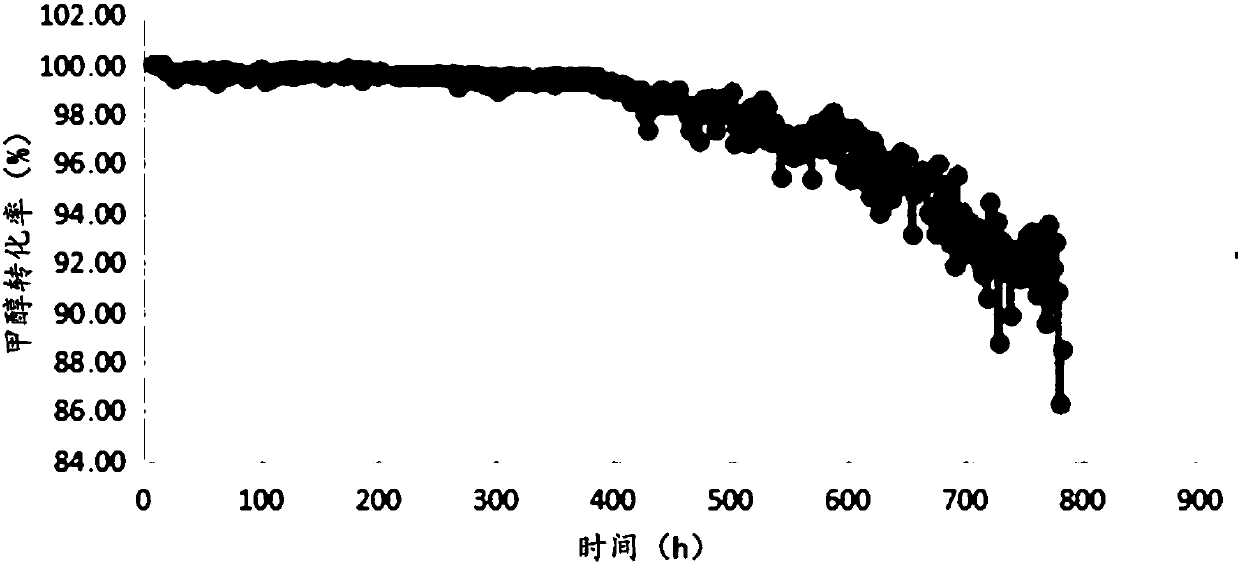

Method for preparing hierarchically porous ZSM-5 molecular sieve for methanol to propylene

ActiveCN108046288AShorten micropore channel lengthImprove diffusivityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPtru catalystIon exchange

The invention discloses a method for preparing a hierarchically pore porous ZSM-5 molecular sieve for methanol to propylene. The method comprises the steps as follows: a, mixing an aluminum source, asilicon source, an alkali source and a ZSM-5 molecular sieve seed crystal with water to form a gel; b, pre-crystallizing the gel in a reactor at 80-140 DEG C for 6-48 h; c, quenching a pre-crystallized product obtained in step b, adding an organic template, heating the pre-crystallized product containing the template to 100-180 DEG C for crystallization reaction, performing solid-liquid separation, washing and drying on a crystallized product after the reaction to obtain molecular sieve original powder; d, placing the molecular sieve original powder obtained in step c in an ammonium salt solution for ion exchange to obtain an ammonia-type ZSM-5 molecular sieve, and then performing calcination to obtain the HZSM-5 molecular sieve. The prepared molecular sieve catalyst has good propylene selectivity and good carbon deposition resistance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

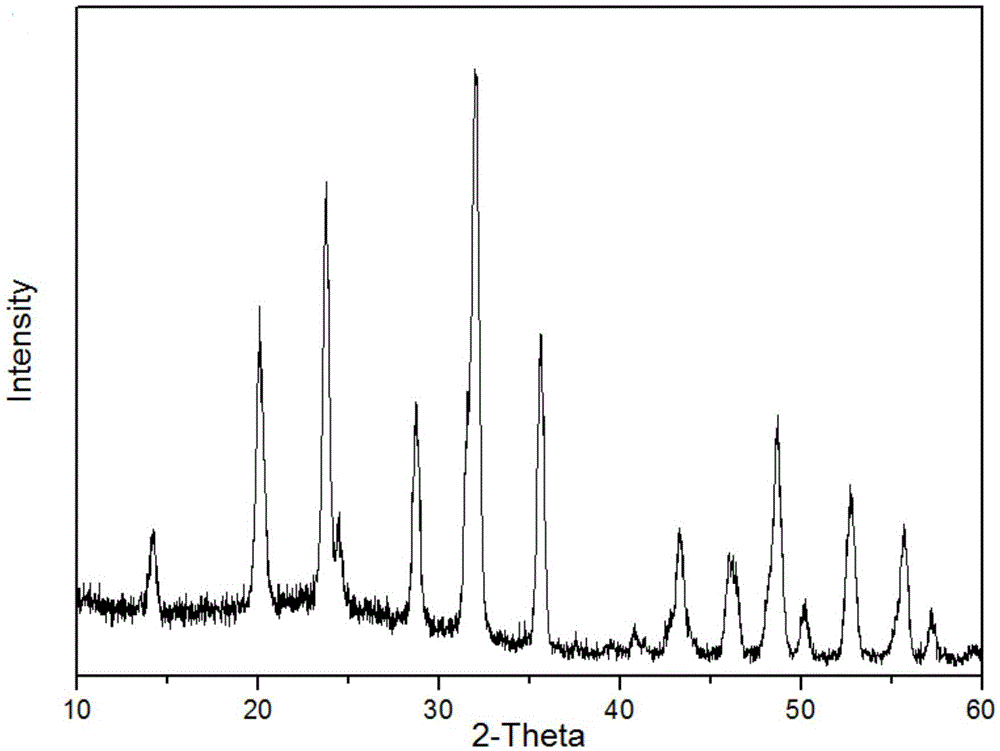

LiMn1-XFexPO4 positive electrode material having core-shell structure, and preparation method thereof, and lithium ion battery

InactiveCN106058225AReduce coating contentShorten the diffusion pathCell electrodesSecondary cellsCarbon coatingTransmission performance

The invention provides a core-shell structure positive electrode material, which comprises an inner core and a shell, wherein the inner core is LiMn1-XFexPO4 nanoparticles, the shell is a mixture of carbon and a lithium-containing metal salt, the lithium-containing metal salt is a lithium-containing metal phosphate and / or lithium-containing metal pyrophosphate, and x is more than 0 and is less than 0.5. According to the present invention, the LiMn1-XFexPO4 nanoparticles are adopted as the inner core, wherein the lithium ion diffusion path can be shortened, the time of the diffusion of the lithium ions among the particles can be reduced, and the material ion transmission performance can be improved with the nano-treatment of the material; and the mixture of the carbon and the lithium-containing metal phosphate and / or lithium-containing metal pyrophosphate is adopted as the coating layer, wherein the conductivity of the material ions can be increased and the carbon coating effect is effectively improved with the addition of the lithium-containing metal phosphate and / or lithium-containing metal pyrophosphate, such that the rate performance and the cycle performance of the core-shell structure positive electrode material are significantly improved, and the high compaction density is provided.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

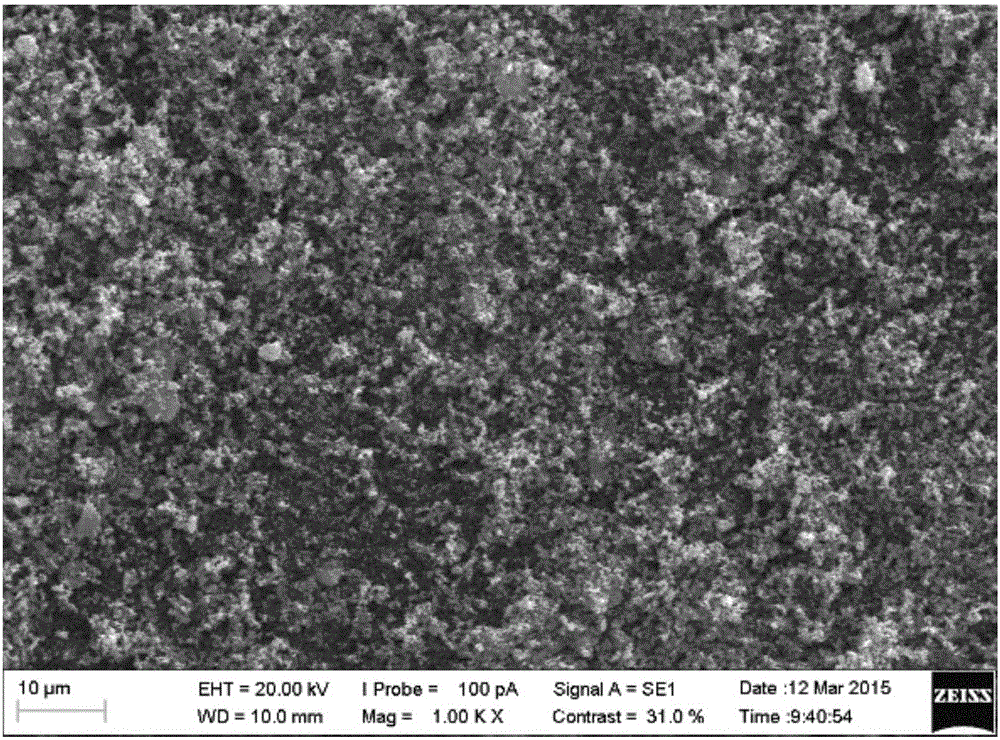

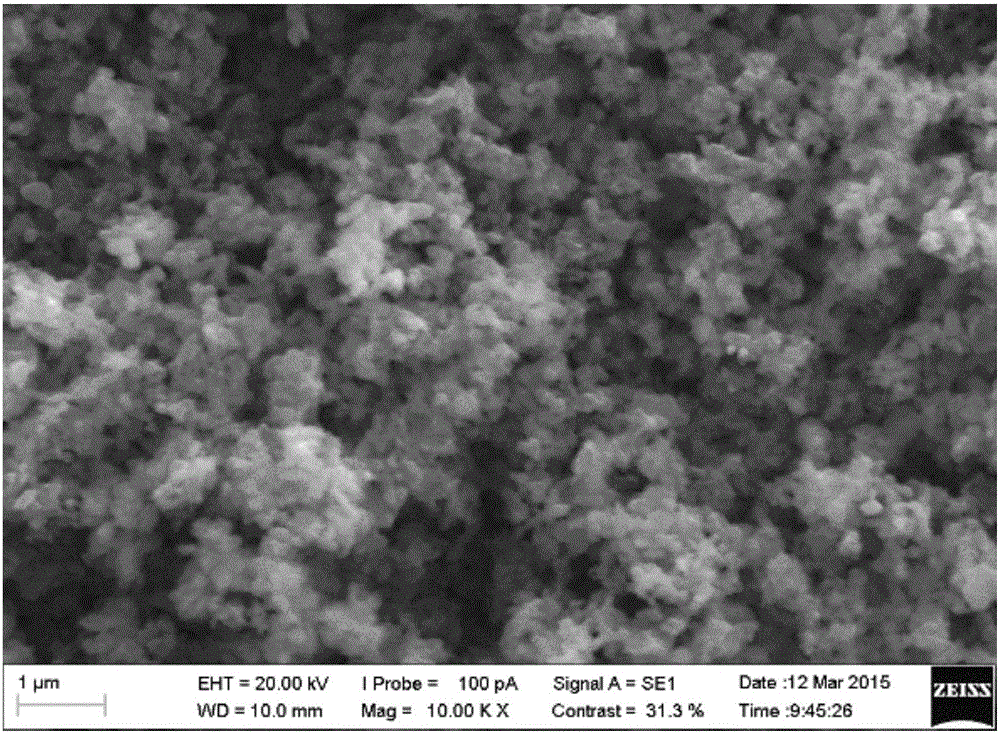

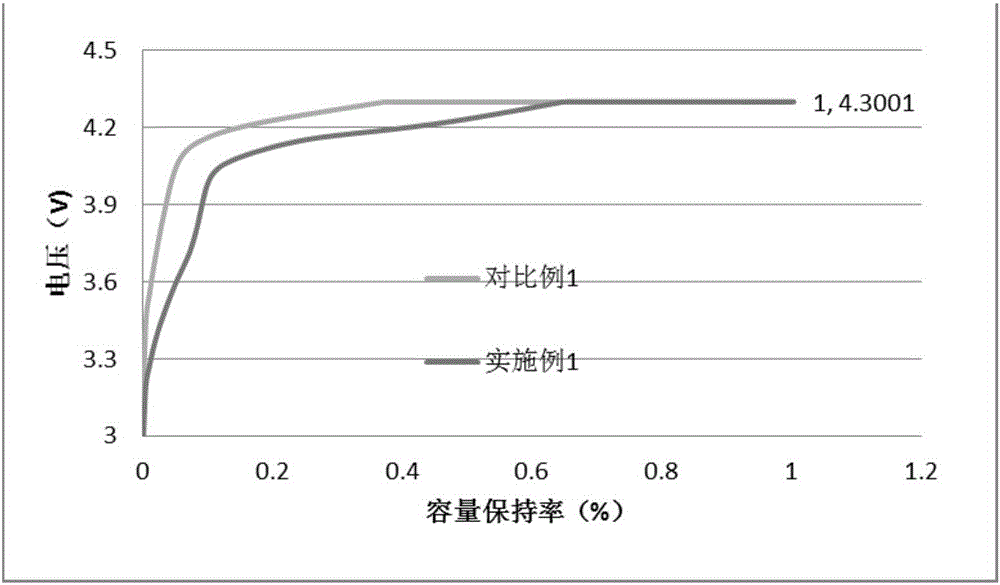

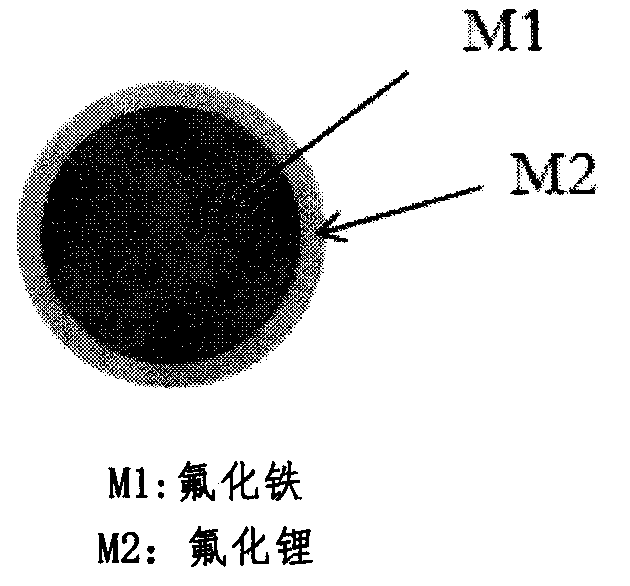

Lithium battery electrode material and preparation method thereof

InactiveCN104143639AShorten the diffusion pathImprove cycle performanceCell electrodesSecondary cellsSlurryIron fluoride

The invention provides a long-life nano-iron fluoride electrode material and a preparation method thereof. The electrode material is characterized in that the nano-iron fluoride particle is coated with a lithium fluoride nano-layer on the surface, thus reducing direct contact of the electrolyte solution and iron fluoride, and enhancing the cycle life. The preparation method comprises the steps of: putting iron fluoride particles into a soluble lithium salt solution, performing stirring constantly to form a uniformly dispersed slurry; and drying the slurry, then placing the dried slurry in a sealed container, and introducing a fluoride gas to carry out reaction under certain temperature and certain time, thus obtaining the lithium fluoride coated iron fluoride anode material.

Owner:周明炯 +1

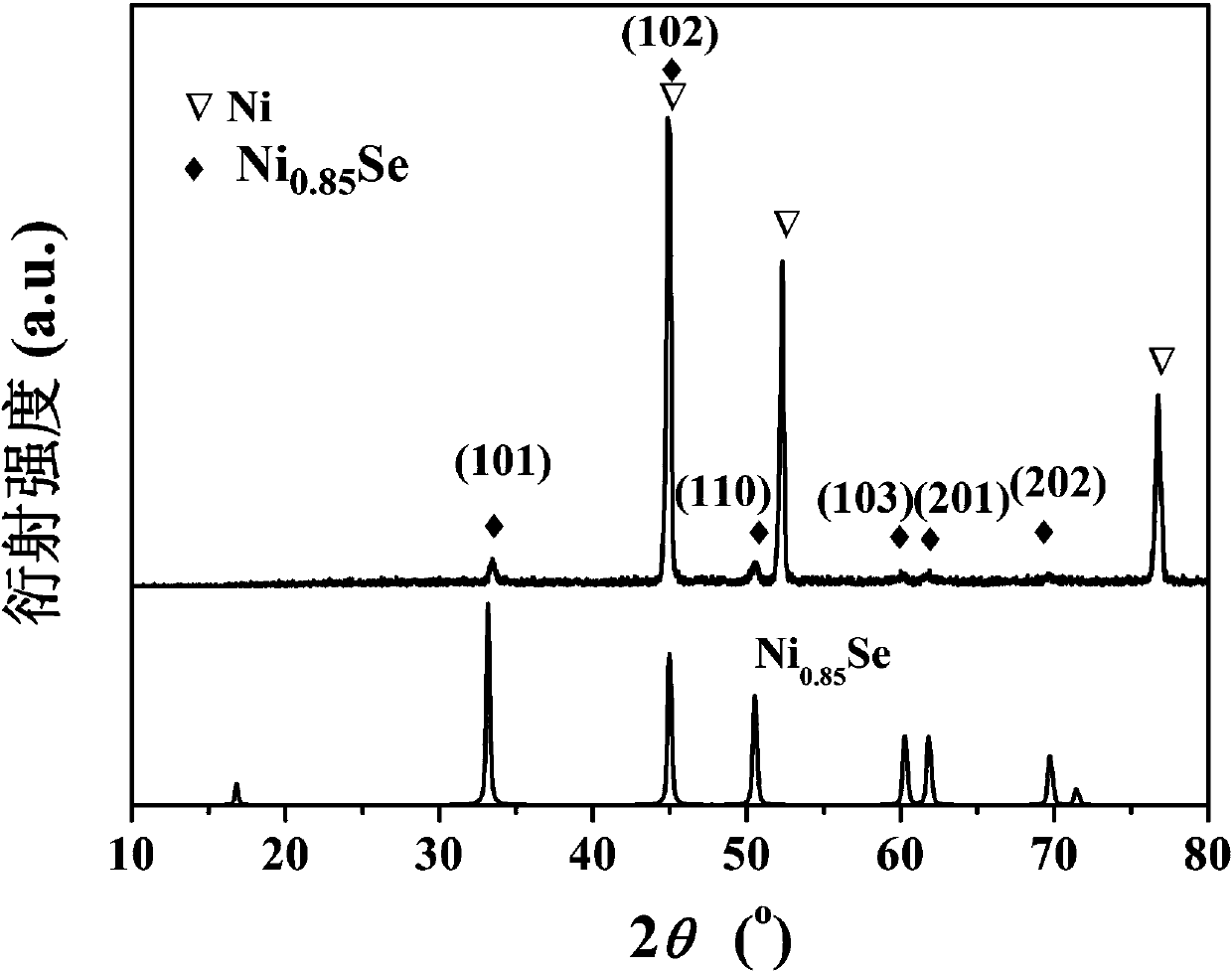

Honeycomb nickel selenide nanosheet array electrode material and preparation method thereof

InactiveCN107818873AEasy accessSave raw materialsHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceReaction temperature

The invention discloses a honeycomb nickel selenide nanosheet array electrode material and a preparation method thereof, and belongs to the technical field of supercapacitor electrode material preparation. The honeycomb nickel selenide nanosheet array electrode material is prepared according the steps of mixing Se powder and an Na2SO3 solution, and preparing an Na2SeSO3 solution with certain concentration through heating and refluxing; adding the prepared Na2SeSO3 solution into a high-pressure reactor, then adding preprocessed foamed nickel into the N2SeSO3 solution, controlling the reaction temperature and time, and acquiring a honeycomb nickel selenide nanosheet array. The acquired electrode material has excellent electrochemical performance, the specific capacitance can reach up to 3105F / g when the current density is 1.0A / g, and the specific capacitance can still reach up to 1460F / g even if the current density reaches up to 10A / g. The honeycomb nickel selenide nanosheet array electrode material is prepared by adopting a one-step hydrothermal method, and is cheap in raw material, simple to operate, low in cost, high in efficiency, free of impurities and high in purity. The honeycomb nickel selenide nanosheet array electrode material is applicable to supercapacitors.

Owner:ANYANG NORMAL UNIV

C/Li2MSiO4-xNy/C (M=Fe, Mn, Co) composite positive electrode material for lithium ion battery and preparation method thereof

InactiveCN102315432AHigh charge and discharge capacityImproved magnification performanceCell electrodesCarbon compositesIon content

The invention relates to a C / Li2MSiO4-xNy / C (M=Fe, Mn, Co) composite positive electrode material with outstanding electrochemical performances for a secondary lithium ion battery and a preparation method thereof. According to the technical scheme of the invention, the nitrogen element is doped to partially replace oxygen in a crystal structure; the charge balance in a material is controlled by the lithium ion content; a solid phase reactor is formed by organic carbon and inorganic porous carbon; and an N-doped silicate carbon composite positive electrode material with outstanding electrochemical performances for the secondary lithium ion battery is synthesized by utilizing a high-temperature carbon thermal reduction method. The material prepared by the method provided by the invention has the advantages of higher charge-discharge specific capacity, preferable multiplying power efficiency and very good use value, and is especially suitable for power batteries.

Owner:JIANGSU ZHENGTONG ELECTRONICS TECH

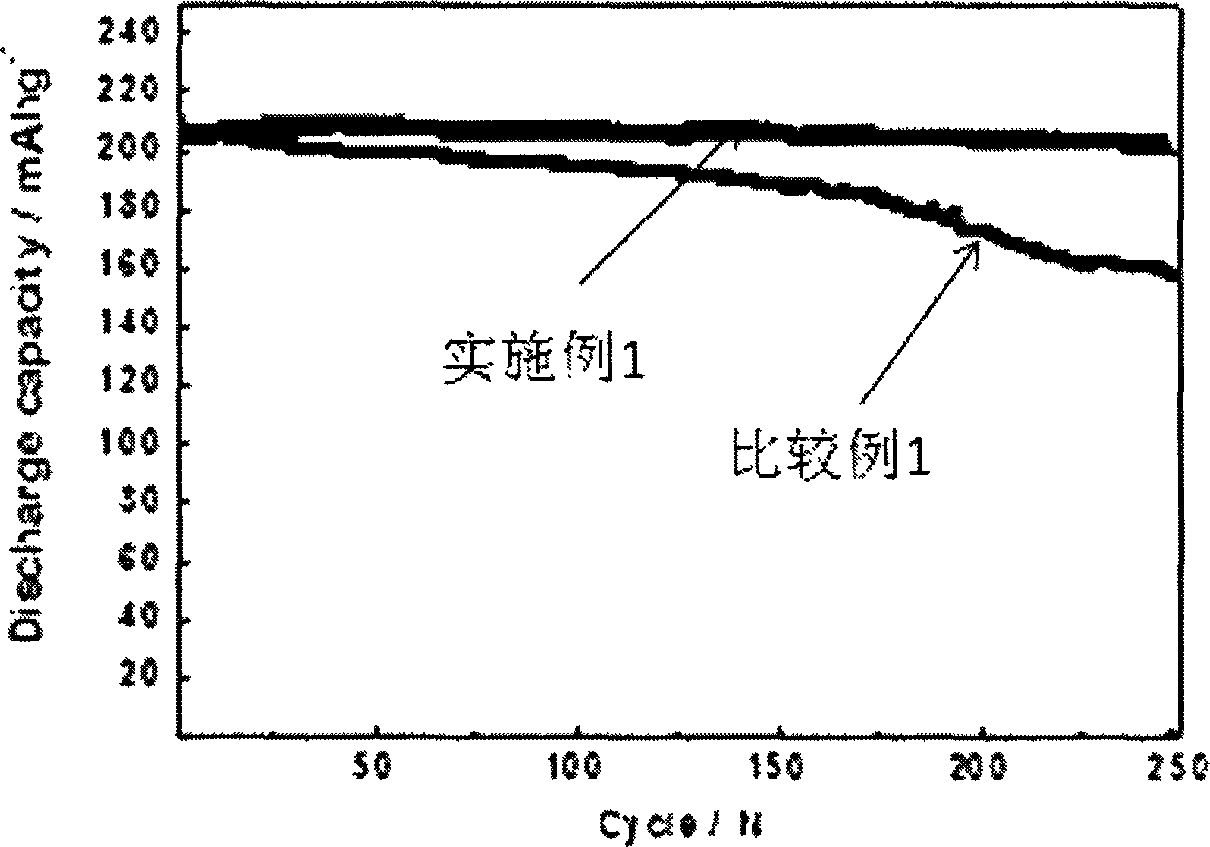

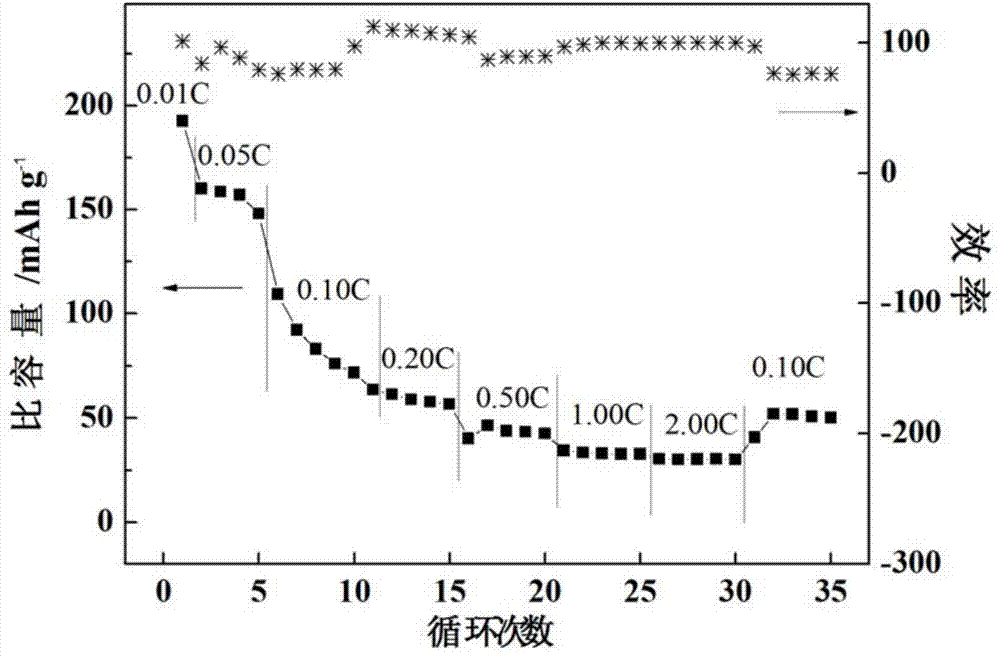

Co-precipitation synthesis method for Na2/3Ni1/3Mn2/3O2 as electrode material and preparation method of Na2/3Ni1/3Mn2/3O2 electrode

InactiveCN103922427ALarge specific heat capacityPrevent battery explosionCell electrodesNickel compoundsIonMuffle furnace

The invention provides a co-precipitation synthesis method for Na2 / 3Ni1 / 3Mn2 / 3O2 as an electrode material and a preparation method of a Na2 / 3Ni1 / 3Mn2 / 3O2 electrode. The co-precipitation synthesis method comprises the steps of (1) mixing a nickel source compound solution and a manganese source compound solution, then, violently stirring to prepare a mixed solution with the nickel-to-manganese molar ratio of (0.8-1.5):1, and meanwhile, adding a complexing agent to complex until the pH value of the solution is up to 7.5-8.5; (2) adding a precipitant for precipitating to obtain a precipitate, carrying out suction filtration on the obtained precipitate, washing and drying; (3) carrying out ball milling on the dried product and a sodium source compound with a stoichiometric ratio, and mixing for 3-10h; (4) placing the ball-milled mixture into a muffle furnace to pretreat and calcine at high temperature to obtain a final product, namely, Na2 / 3Ni1 / 3Mn2 / 3O2. Proved by an electrochemical test, the material provided by the invention has the specific discharge capacities of 195mAh / g (0.01C), 153mAh / g (0.05C), 84mAh / g (0.10C), 53mAh / g (0.20C) and 49mAh / g (0.50C) in a rate performance test. The co-precipitation synthesis method is wide in raw material source, easy to prepare, low in aqueous sodium ion electrolyte cost and friendly to environment.

Owner:三亚哈尔滨工程大学南海创新发展基地

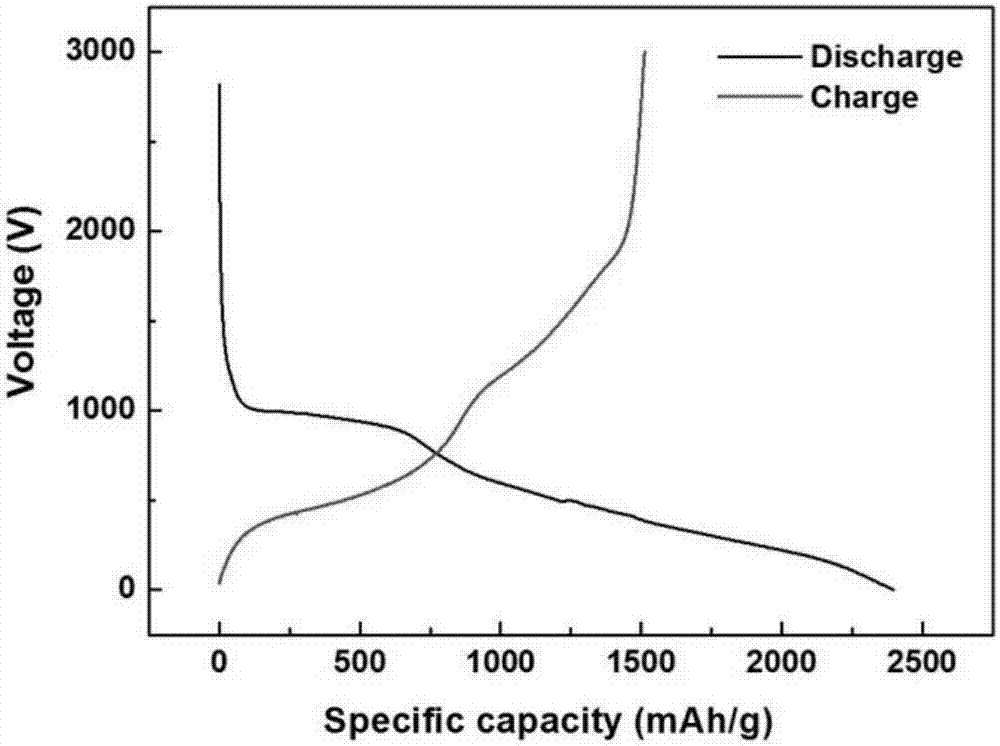

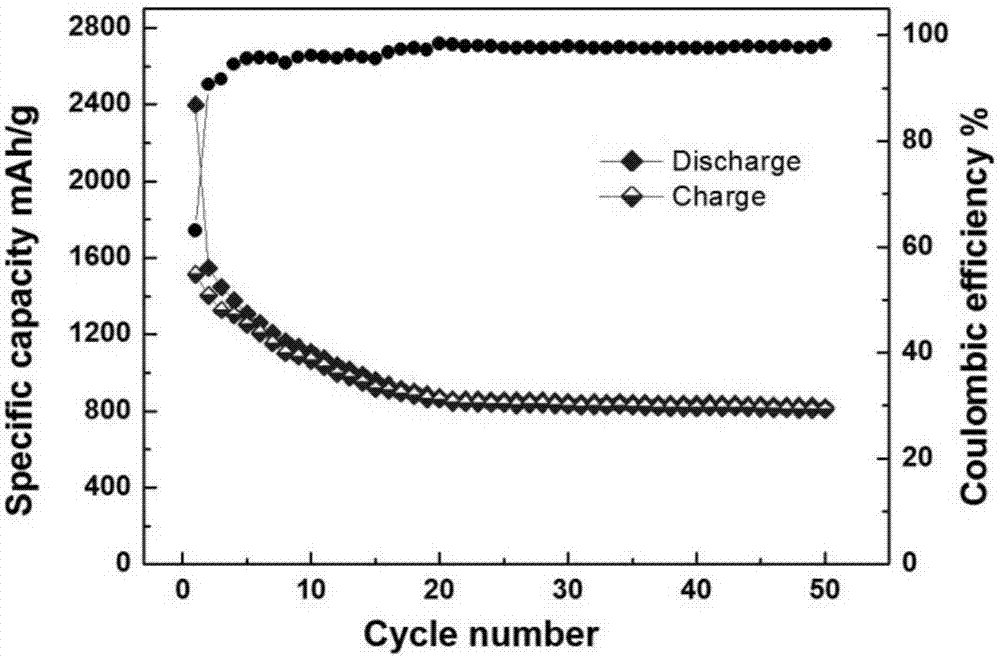

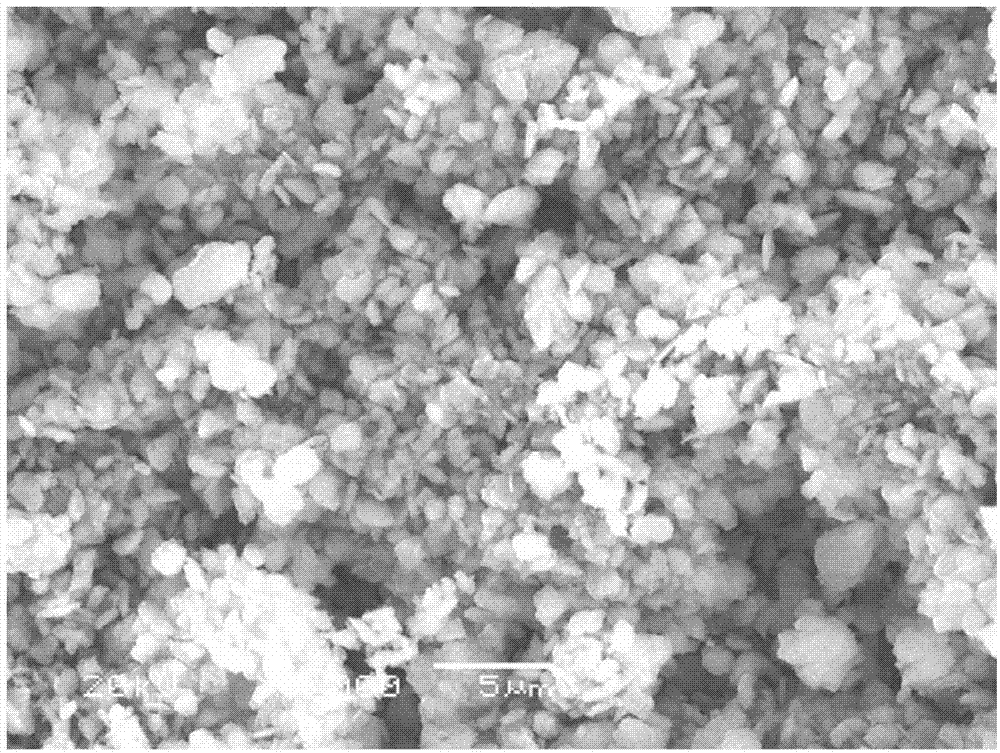

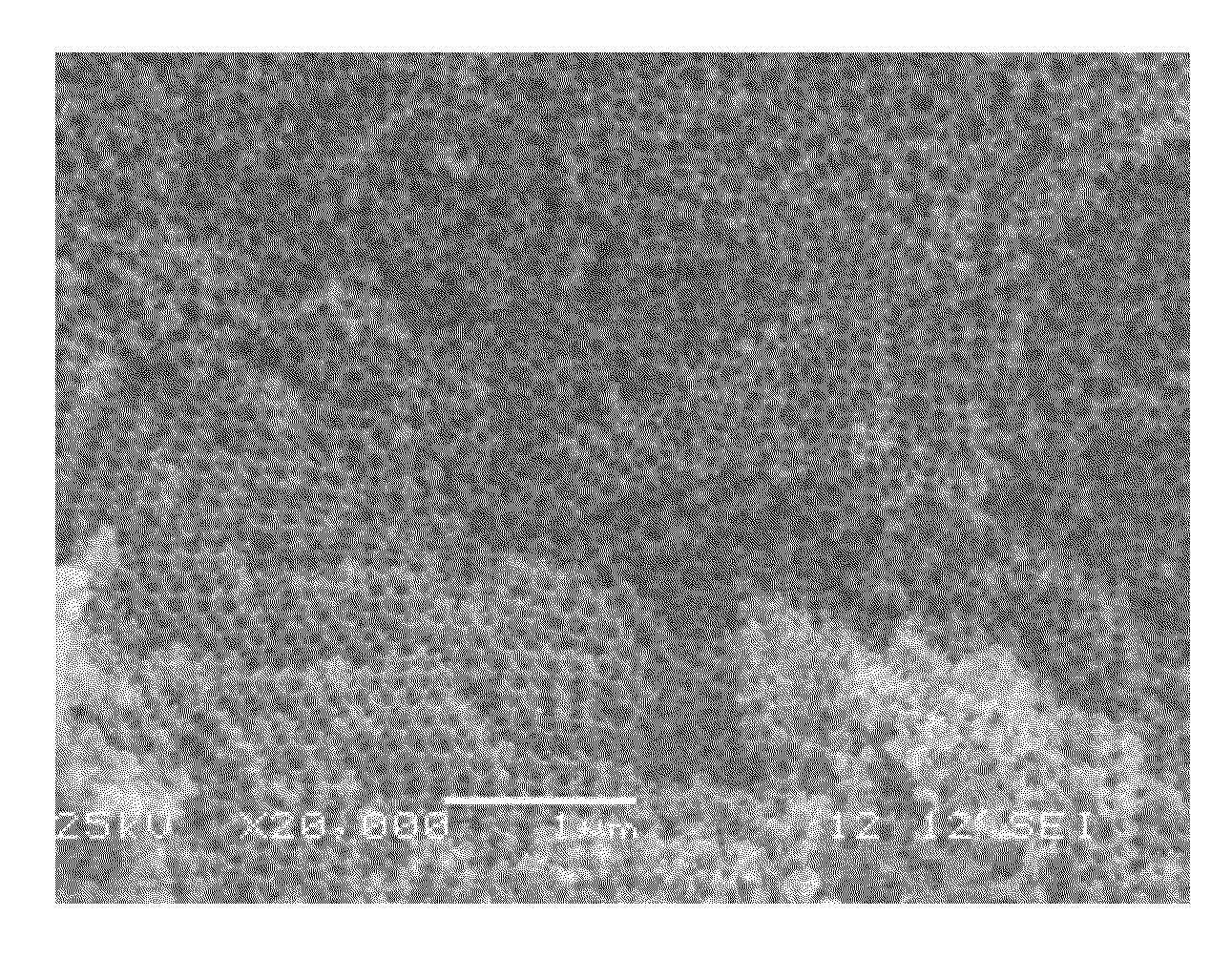

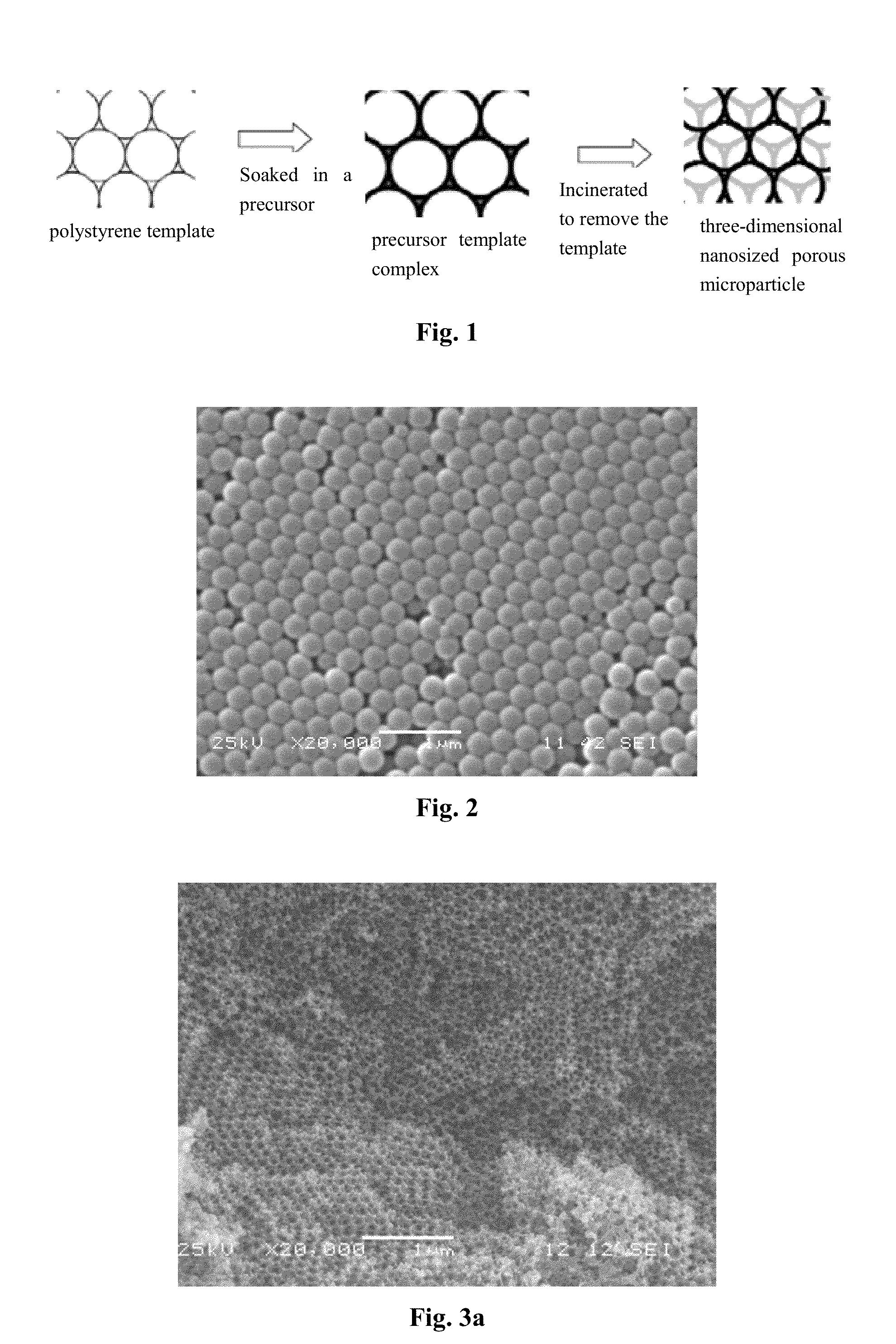

Three-dimensional nanosized porous metal oxide electrode material of lithium ion battery and preparation method thereof

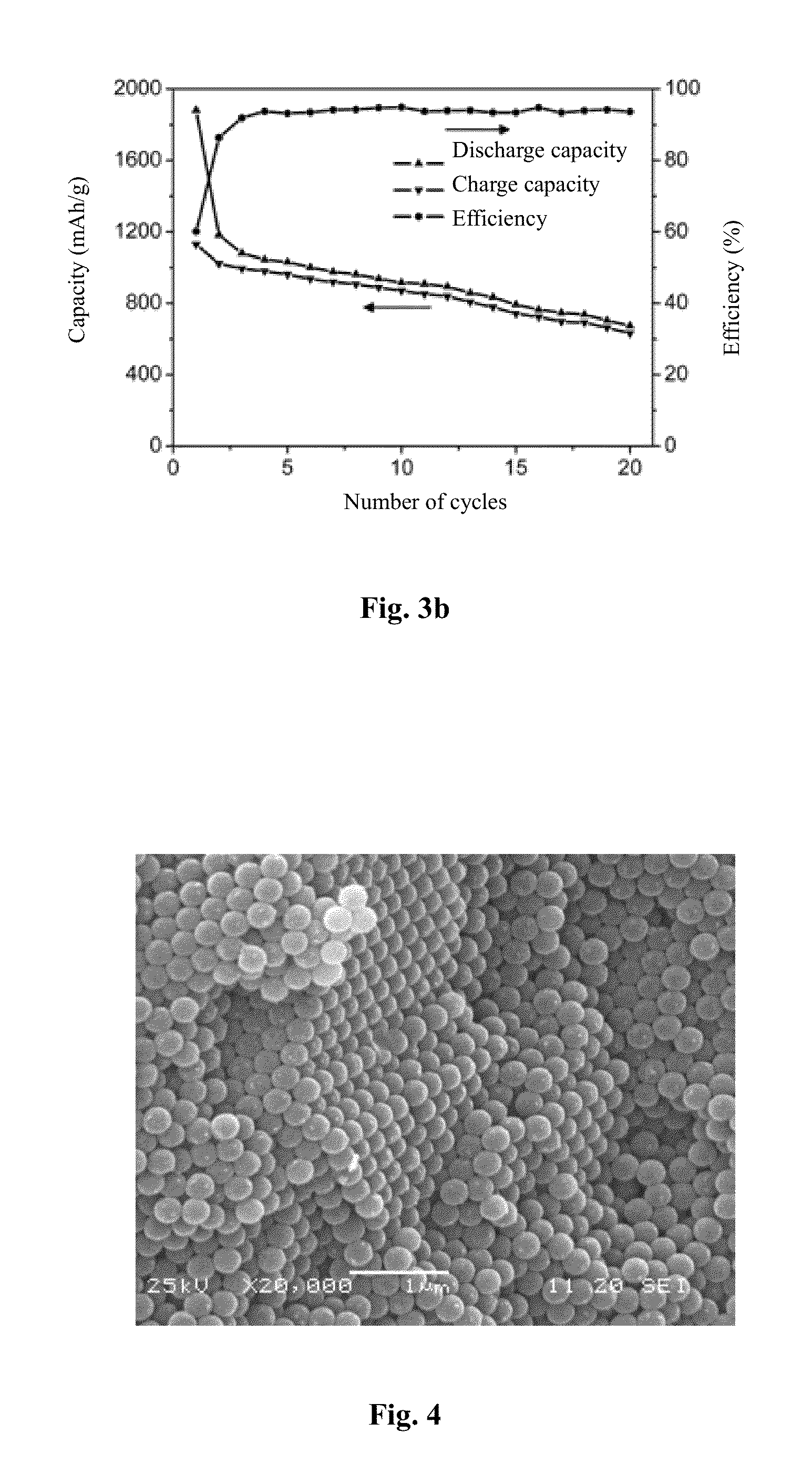

InactiveUS20130143115A1Shorten the diffusion pathIncrease capacityElectrode thermal treatmentActive material electrodesElectrochemical responseLithium electrode

A preparation method of a three-dimensional nanosized porous metal oxide electrode material of lithium ion battery, which soaks a dried polymer colloidal crystal microsphere template in a metal salt solution as a precursor solution for a period of time, and obtains a precursor template complex after filtration and drying; heats the precursor template complex to a certain temperature at a low heating rate and keeps the temperature, and then obtains the three-dimensional nanosized porous metal oxide electrode material of lithium ion battery after cooling to room temperature. A metal oxide electrode material is manufactured, with the three-dimensional nanosized porous metal oxide electrode material thereby improving the ionic conductivity of the negative electrode material of lithium ion battery, and shortens the diffusion path of the lithium ions during an electrochemical reaction process, and improves the rate discharge performance of lithium ion battery greatly.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

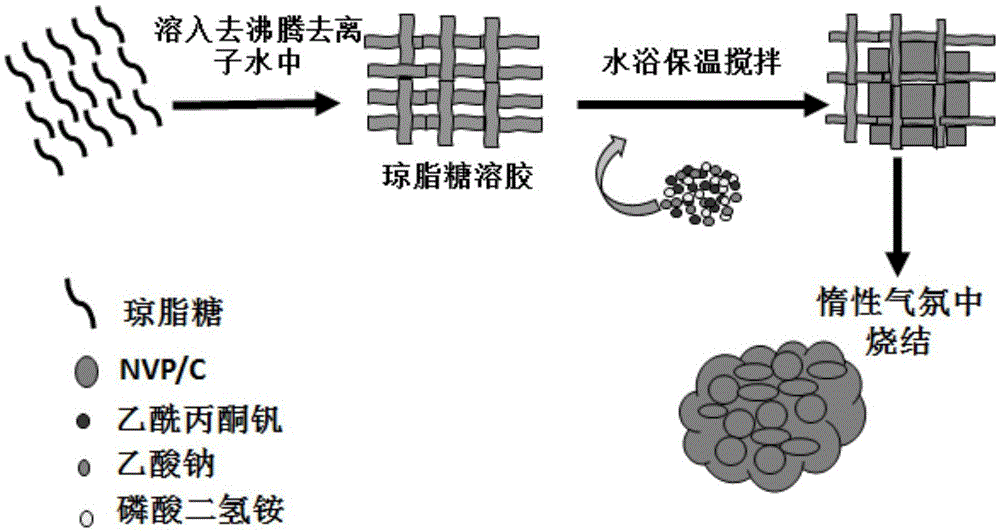

Sodium vanadium phosphate sodium ion battery positive electrode material and preparation method therefor

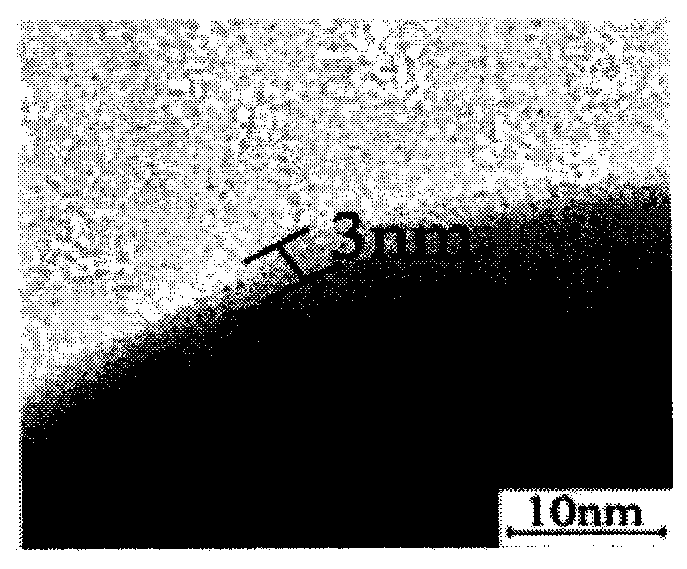

InactiveCN105552328APromote prolapseEasy to embedMaterial nanotechnologyCell electrodesCarbon layerCarton

The invention discloses a sodium vanadium phosphate sodium ion battery positive electrode material and a preparation method therefor, and belongs to the fields of an energy storage material and technology. The positive electrode material comprises a three-dimensional carbon framework and Na3V2(PO4)3 composite granules; the Na3V2(PO4)3 composite granules adopt core-shell structures, wherein Na3V2(PO4)3 is taken as the core part while a carton layer is adopted as the shell part; the thickness of the carbon layer is 1-4nm; the grain diameter of the Na3V2(PO4)3 composite granules is 20-200nm; and the Na3V2(PO4)3 composite granules are positioned in the gaps of the three-dimensional carbon framework. The invention also discloses a method for preparing the sodium vanadium phosphate sodium ion battery positive electrode material by adopting a sol-gel method and a ball-milling method. The preparation method is simple in process; and the finally-synthesized positive electrode material has the characteristics of large specific surface area, small grain diameter dimension and uniform carbon layer coating, so that the positive electrode material is excellent in the electrochemical performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com