LiMn1-XFexPO4 positive electrode material having core-shell structure, and preparation method thereof, and lithium ion battery

A core-shell structure and cathode material technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as the influence of material weight ratio to energy, and the unsatisfactory effect of carbon coating on the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of above-mentioned core-shell structure LiMn 1-x Fe x PO 4 A method for preparing a positive electrode material, comprising the following steps: S1) adding a first lithium source compound, a metal source compound, a first phosphorus source compound, LiMn 1-x Fe x PO 4 Mix the nanoparticles, the first complexing agent, and the soluble carbon source with water, and heat until the water evaporates to dryness to obtain an intermediate; 0<x<0.5; S2) Calcining the intermediate to obtain a core-shell structure positive electrode material.

[0031] Wherein, the present invention has no special limitation on the sources of all raw materials, which may be commercially available or self-made.

[0032] In the present invention, the LiMn 1-x Fe x PO 4 The nanoparticles are preferably prepared according to the following method: A) mixing the second lithium source compound, the manganese source compound, the iron source compound, the s...

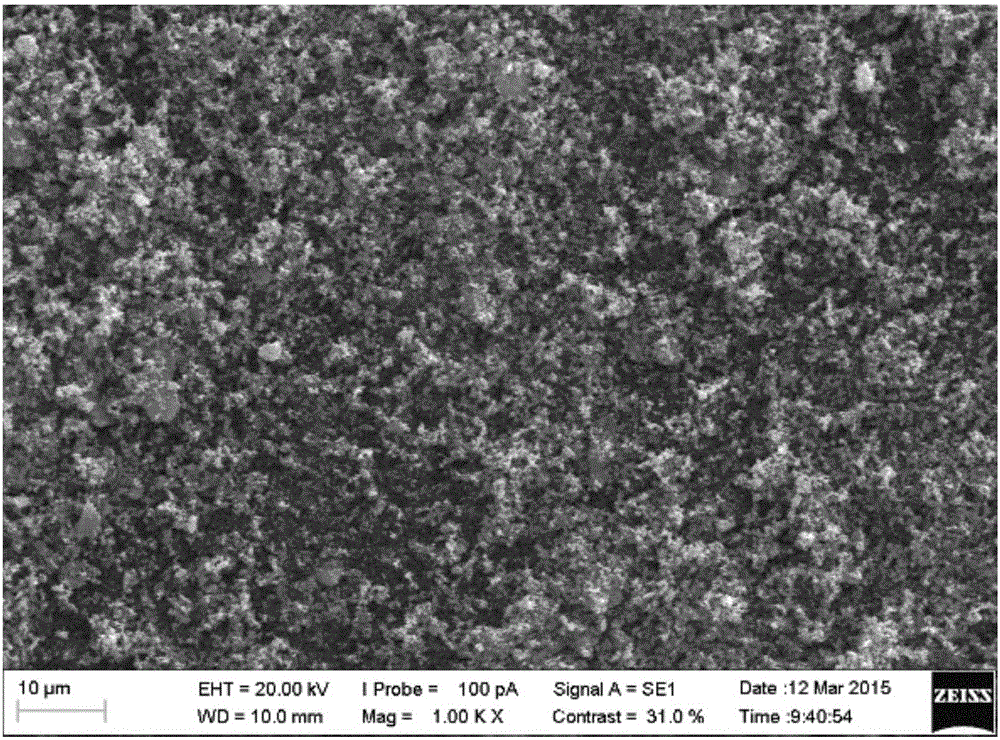

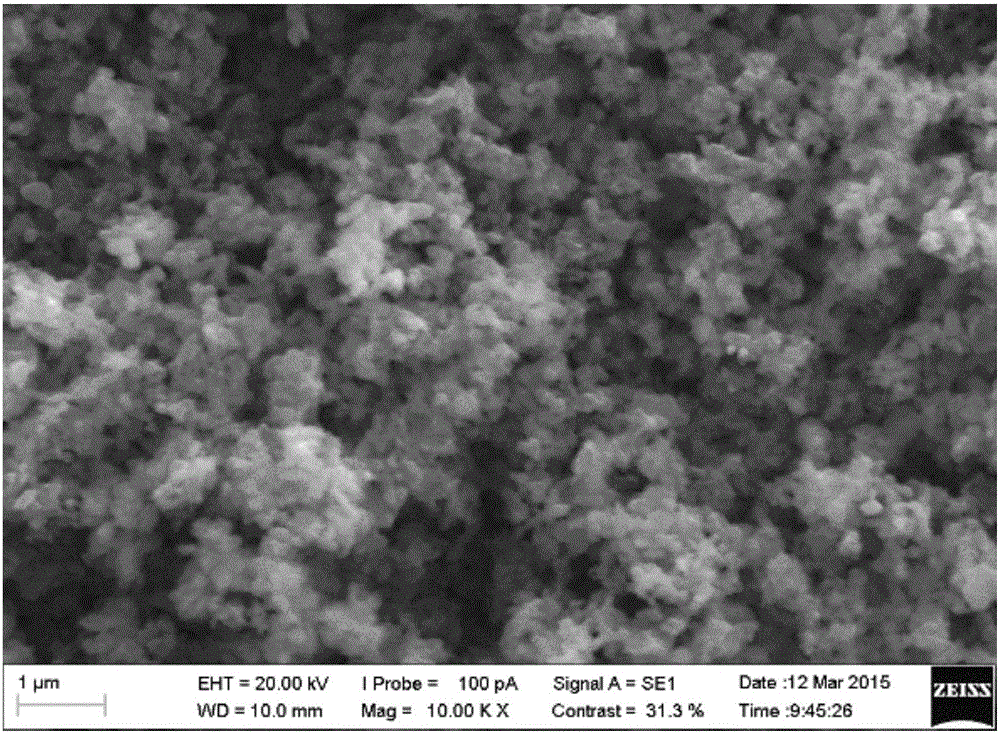

Embodiment 1

[0055] LiMn 0.8 Fe 0.2 PO 4 Synthesis of: Li 2 CO 3 , Mn(Ac) 2 , FeC 2 o 4 , NH 4 h 2 PO 4 According to LiMn 0.8 Fe 0.2 PO 4 The medium stoichiometric ratio is dissolved in deionized water, and the mass added is to obtain the theoretical product LiMn 0.8 Fe 0.2 PO 4 5% citric acid by mass is used as a complexing agent, heated and stirred in a water bath at 80°C for 8-12h, until the water is evaporated to dryness, and the obtained product is vacuum-dried at 80°C and -0.98MPa for 24h. After drying, put the product in a tube furnace, raise the temperature to 450°C at a rate of 5°C / min, keep it for 8 hours, then raise it to 750°C at a rate of 5°C / min, keep it for 12 hours, and get LiMn after cooling. 0.8 Fe 0.2 PO 4 .

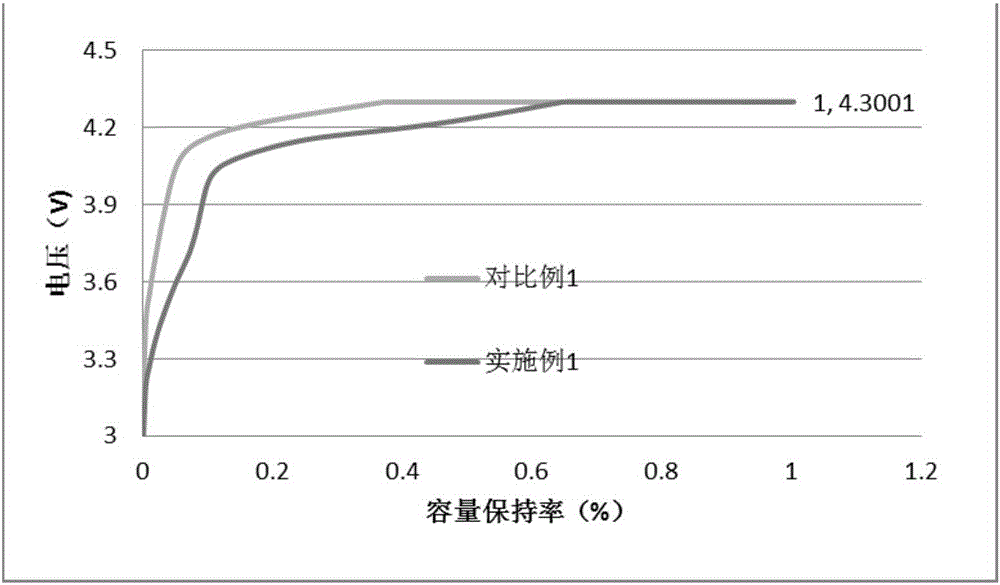

[0056] LiFeP 2 o 7 / C co-coated nano-LiMn 0.8 Fe 0.2 PO 4 Synthesis of : 1mol Li 2 CO 3 , 2mol FeC 2 o 4 , 2mol NH 4 h 2 PO 4 Dissolve in deionized water, add 25mol LiMn 0.8 Fe 0.2 PO 4 , mass are LiMn 0.8 Fe 0.2 PO 4 5% citric a...

Embodiment 2

[0060] LiMn 0.8 Fe 0.2 PO 4 Synthesis of: according to LiMn in Example 1 0.8 Fe 0.2 PO 4 synthetic method for synthesis.

[0061] LiFeP 2 o 7 / C co-coated nano-LiMn 0.8 Fe 0.2 PO 4 Synthesis of : 2mol Li 2 CO 3 , 4mol FeC 2 o 4 , 4mol NH 4 h 2 PO 4 Dissolve in deionized water, add 25mol LiMn 0.8 Fe 0.2 PO 4 , mass are LiMn 0.8 Fe 0.2 PO 4 5% by mass of citric acid complexing agent and 10% of glucose were heated and stirred in a water bath at 80° C. for 8-12 hours until the water was evaporated to dryness. The obtained product was vacuum-dried at 80°C and -0.98MPa. After drying, the product is placed in a tube furnace, and the temperature is raised to 600°C at a heating rate of 5°C / min, kept for 2 to 5 hours, and LiFeP is obtained after cooling. 2 o 7 / C co-modified nano-LiMn 0.8 Fe 0.2 PO 4 .

[0062] With the core-shell structure cathode material prepared in embodiment 2 i.e. LiFeP 2 o 7 / C co-coated nano-LiMn 0.8 Fe 0.2 PO 4 As a positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com