Patents

Literature

504results about How to "Promote prolapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

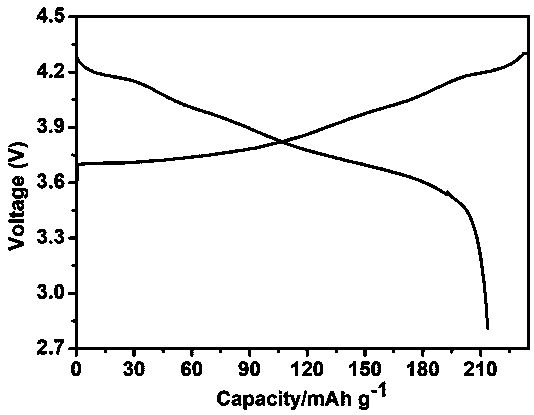

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

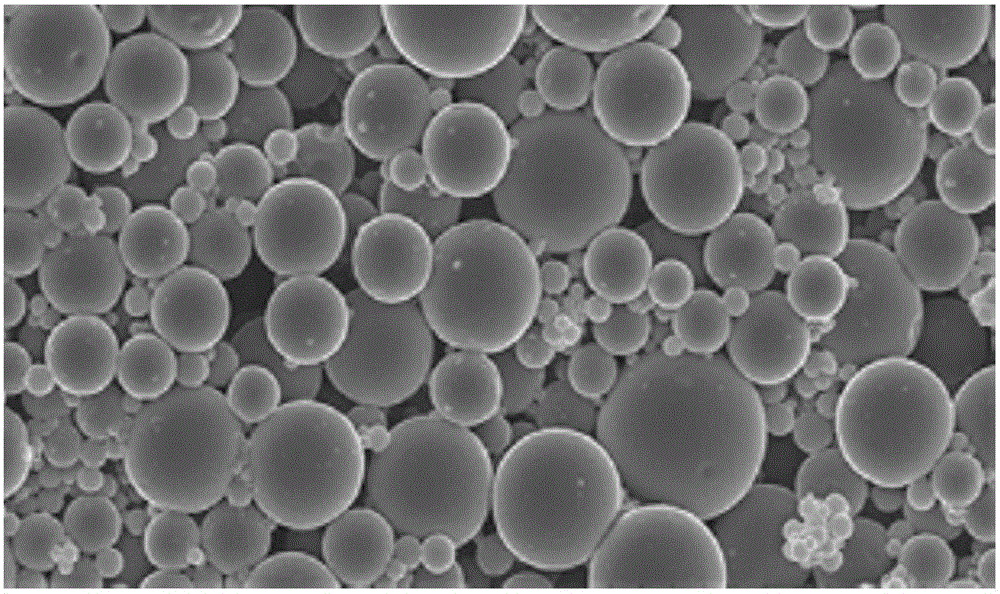

Phenolic resin-based hard carbon microspheres, preparation method thereof, negative electrode material and secondary battery

ActiveCN105914371AReduce areaLow structural stabilityCell electrodesLi-accumulatorsMicrosphereSodium-ion battery

The invention relates to the field of secondary batteries, in particular to phenolic resin-based hard carbon microspheres, a preparation method thereof, and a negative electrode material containing the microspheres. The phenolic resin-based hard carbon microspheres provided by the invention are spherical; d002 is 0.375 to 0.380 nm; the specific surface area is 70 to 350 m<2> / g; the pore volume is 0.08 to 0.18 cm<3> / g. The phenolic resin-based hard carbon microspheres provided by the invention have a small specific surface area, structural stability, large interlayer spacing and rich pore structures, and can be applied to the negative electrode material of a lithium-ion battery or a sodium-ion battery, so that the battery has high capacity and stable cycle performance.

Owner:NINGDE AMPEREX TECH

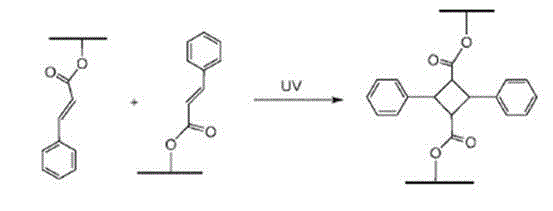

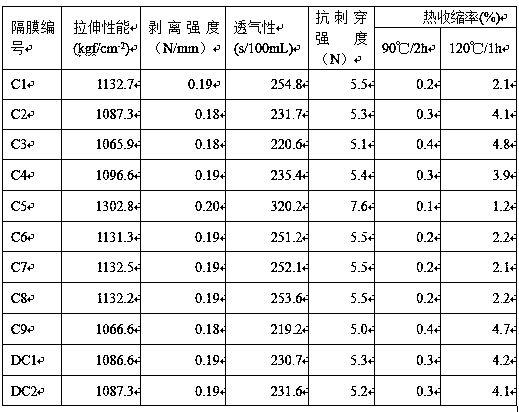

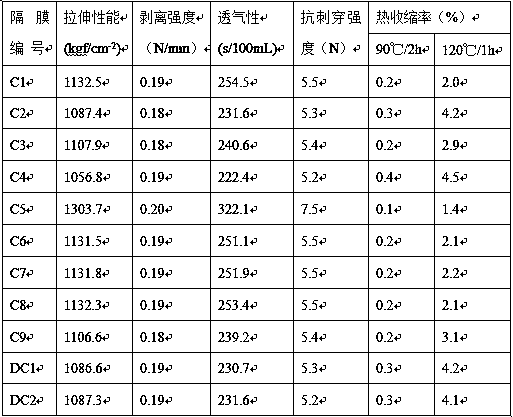

Diaphragm, preparation method of diaphragm and lithium ion battery

ActiveCN104157810AImprove heat resistanceNot easy to fall offSecondary cellsCell component detailsPolymer sciencePolymer substrate

A separator and a method for preparing the separator are provided. The separator includes a polymer substrate,a ceramic layer provided on the polymer substrate and an infiltration part formed between the polymer substrate and the ceramic layer. The polymer substrate contains a base polymer and a first curing resin. The infiltration part has at least a portion infiltrated into the polymer substrate. Each of the infiltration part and the ceramic layer independently contains ceramic particles and a second curing resin.A battery including the separator is also provided.

Owner:BYD CO LTD

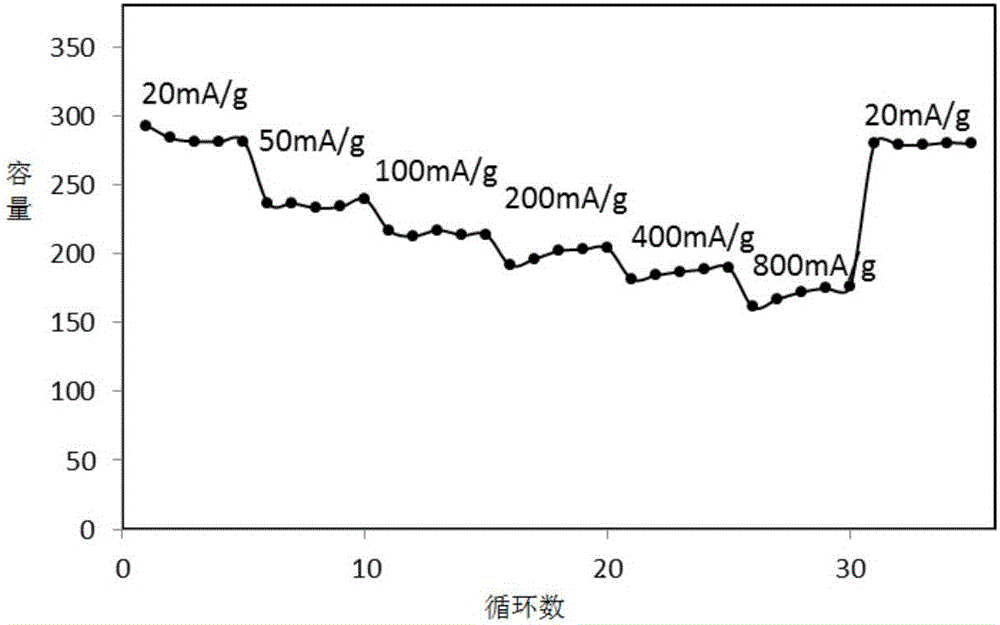

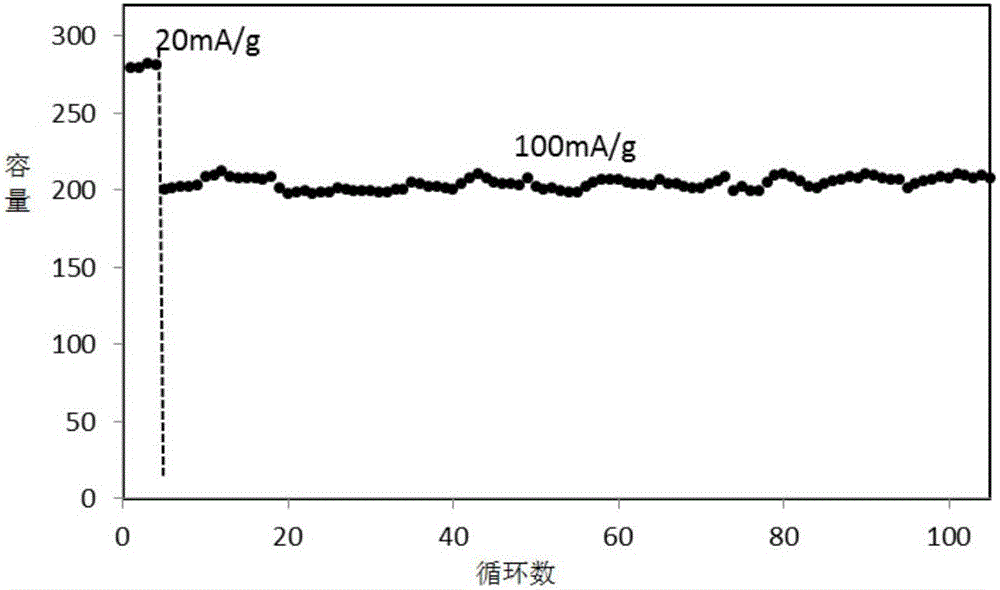

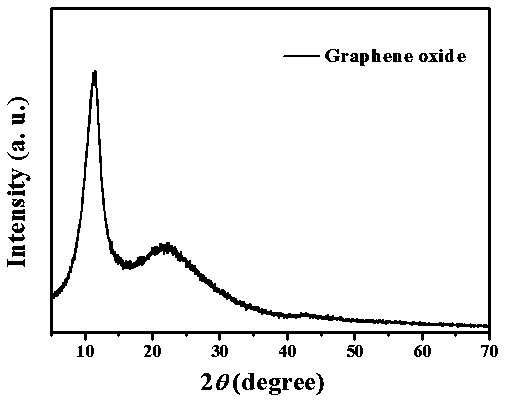

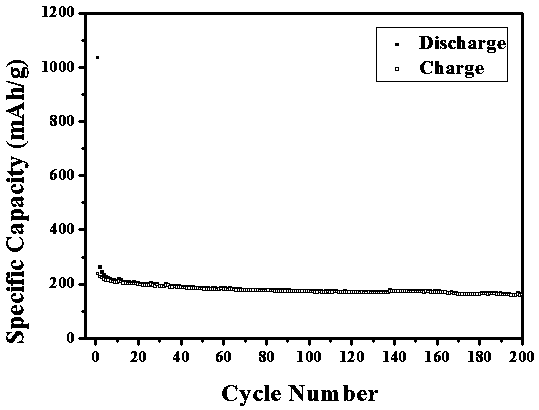

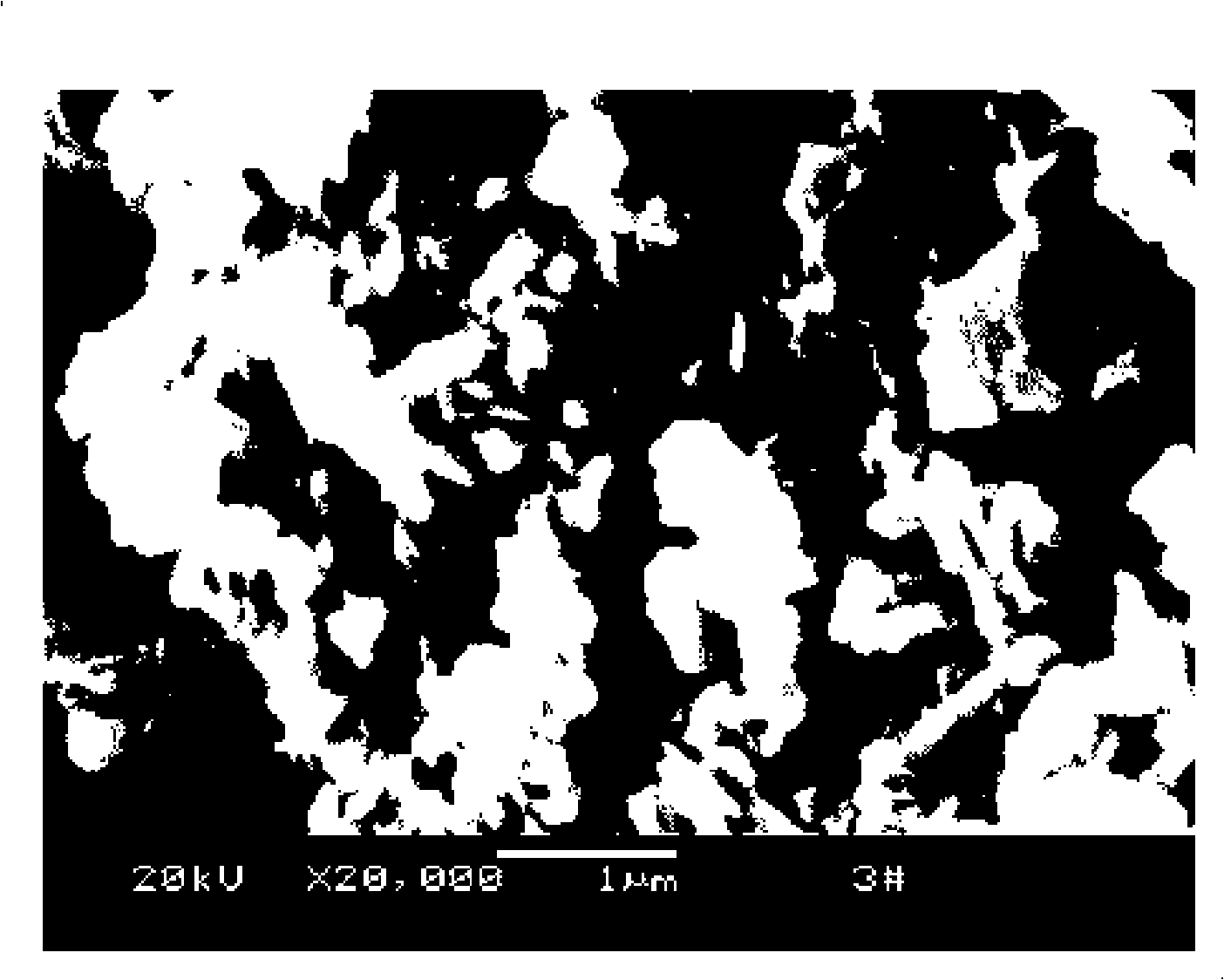

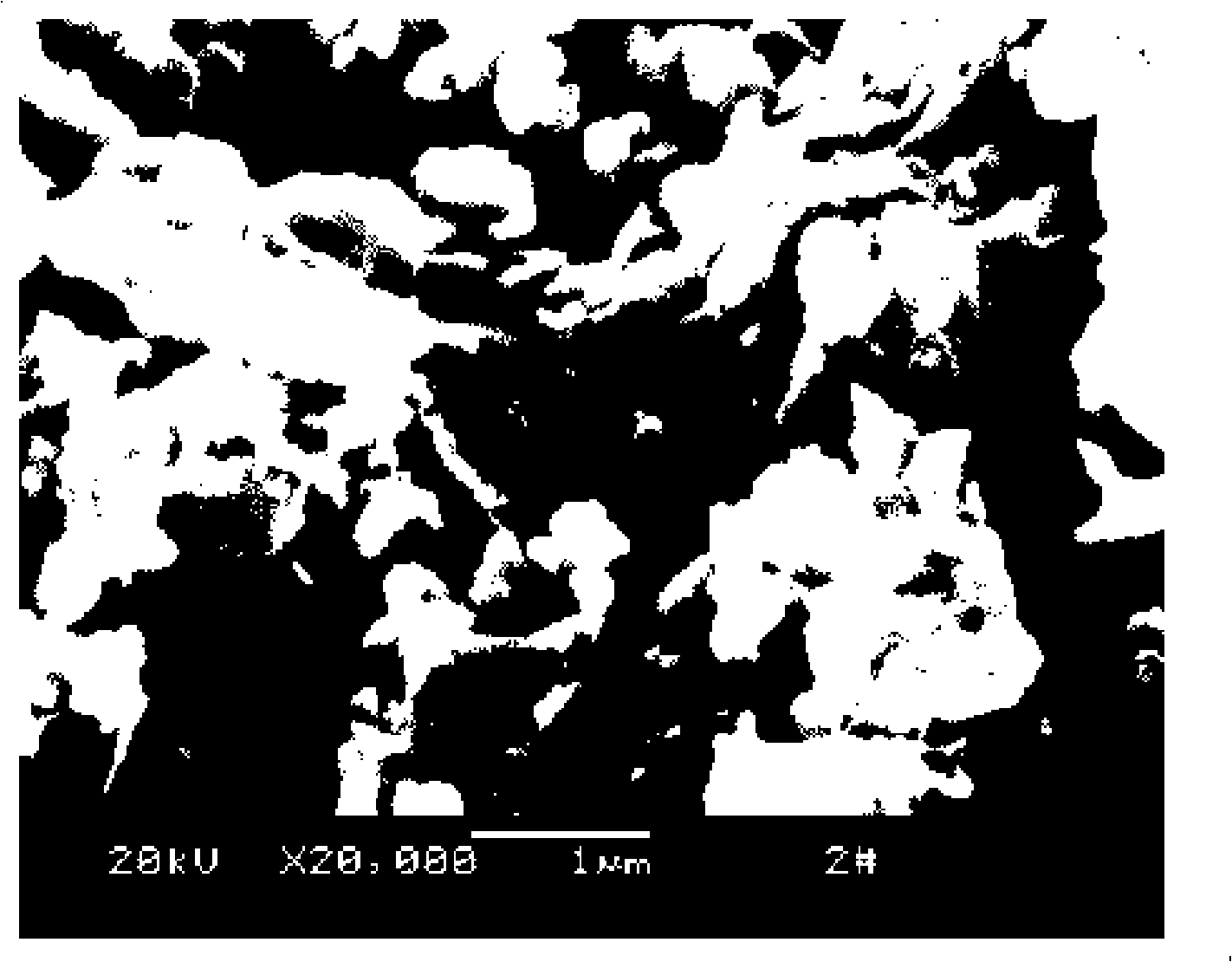

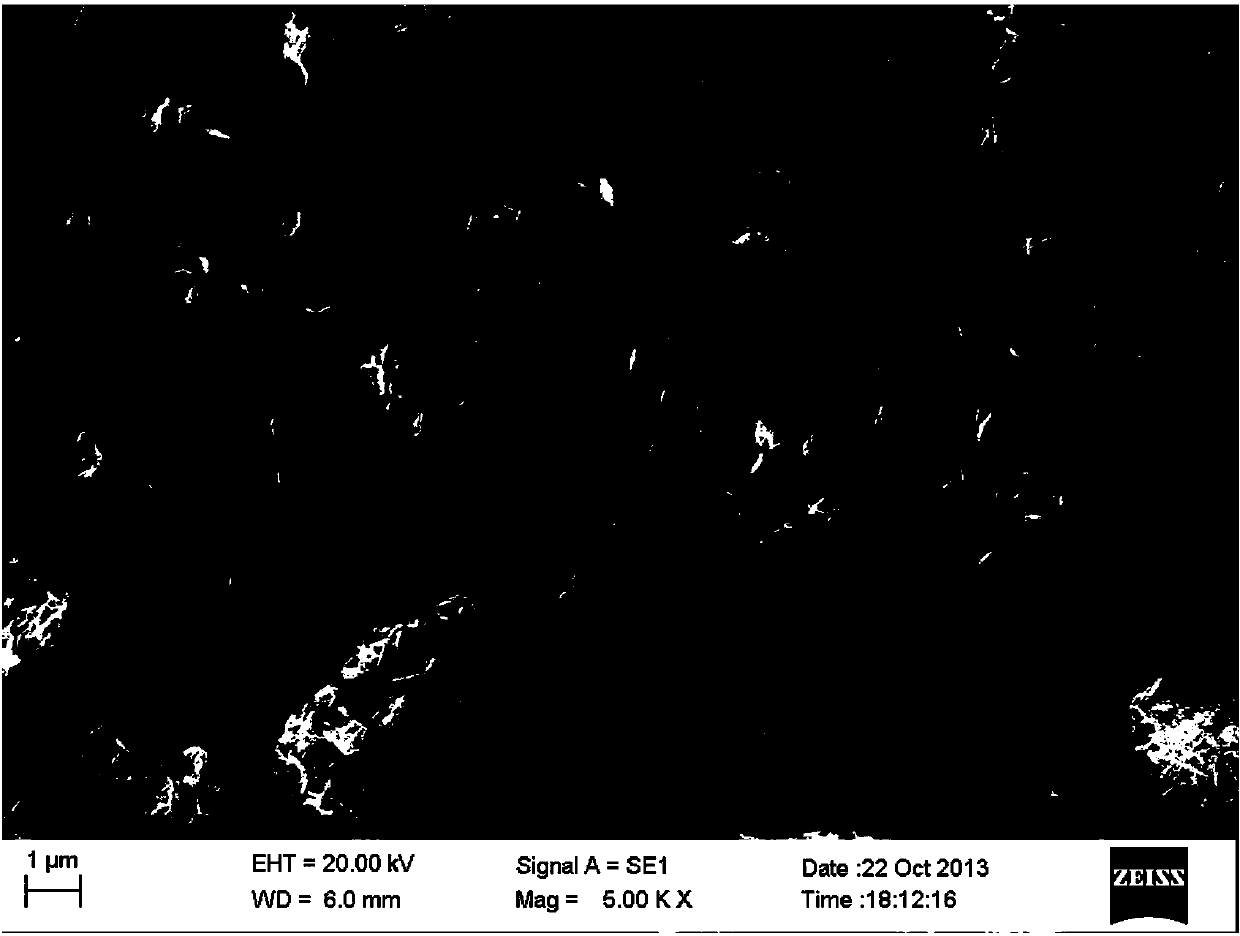

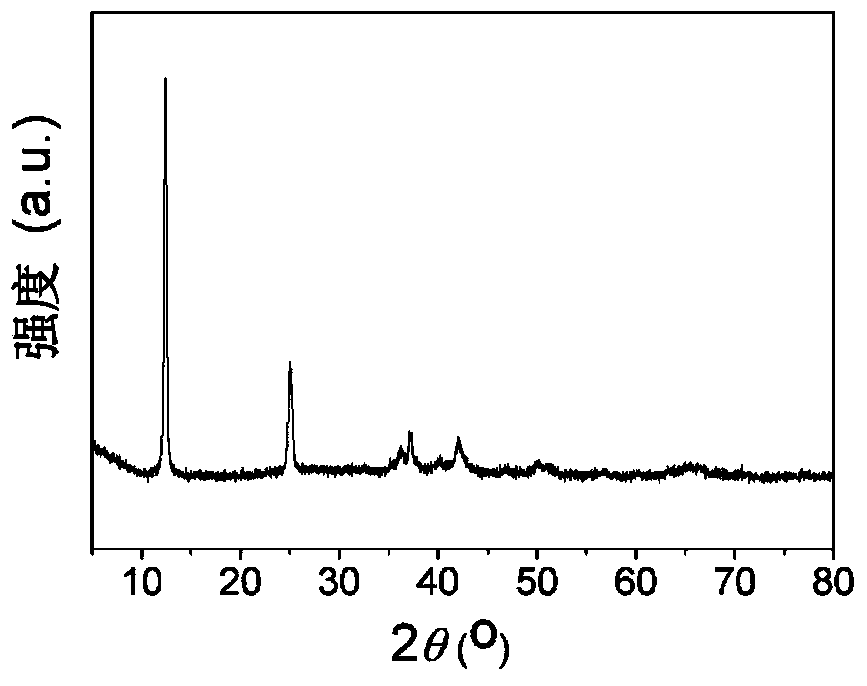

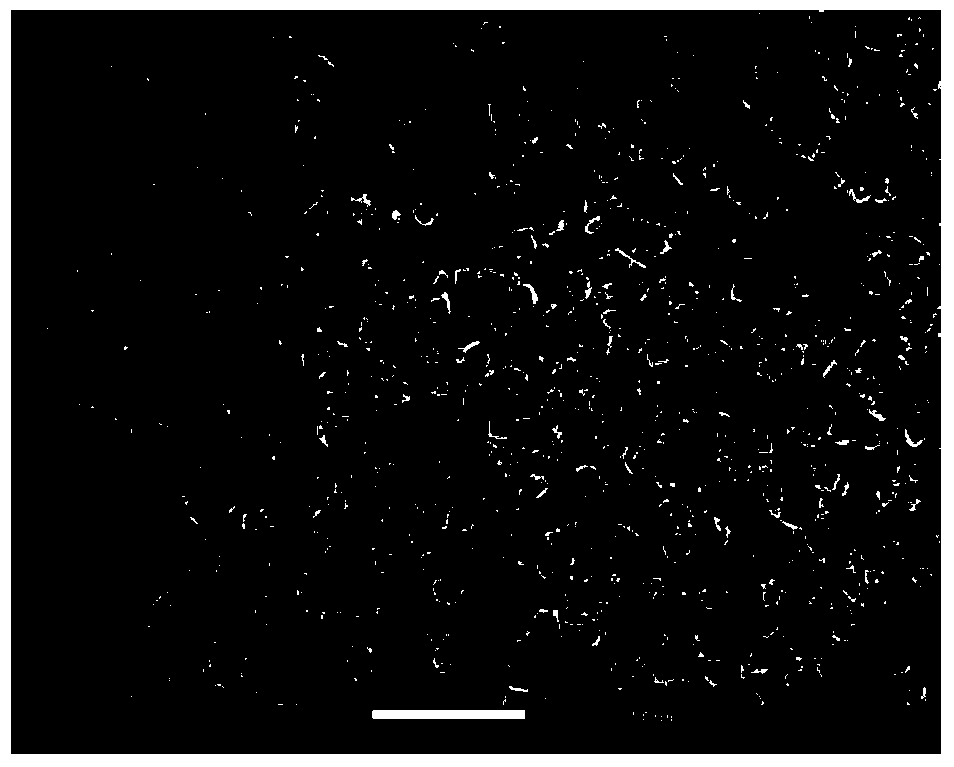

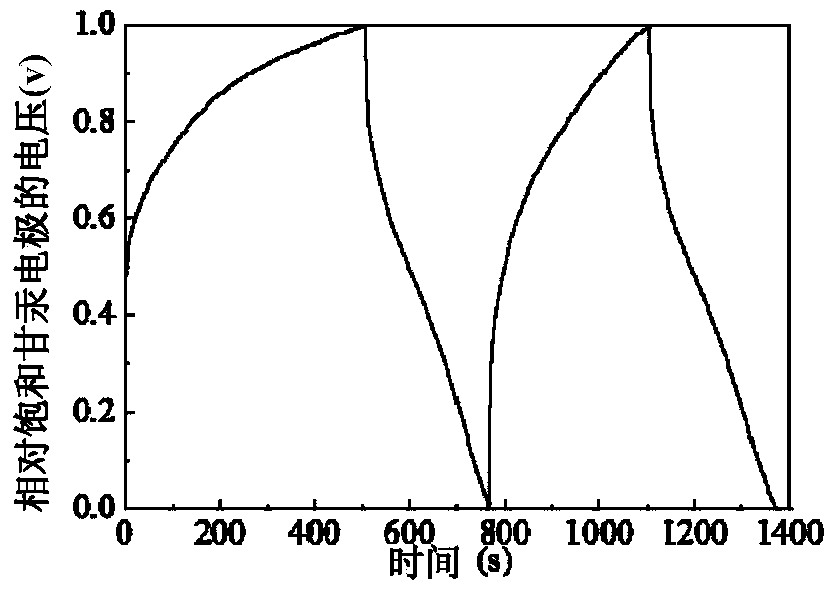

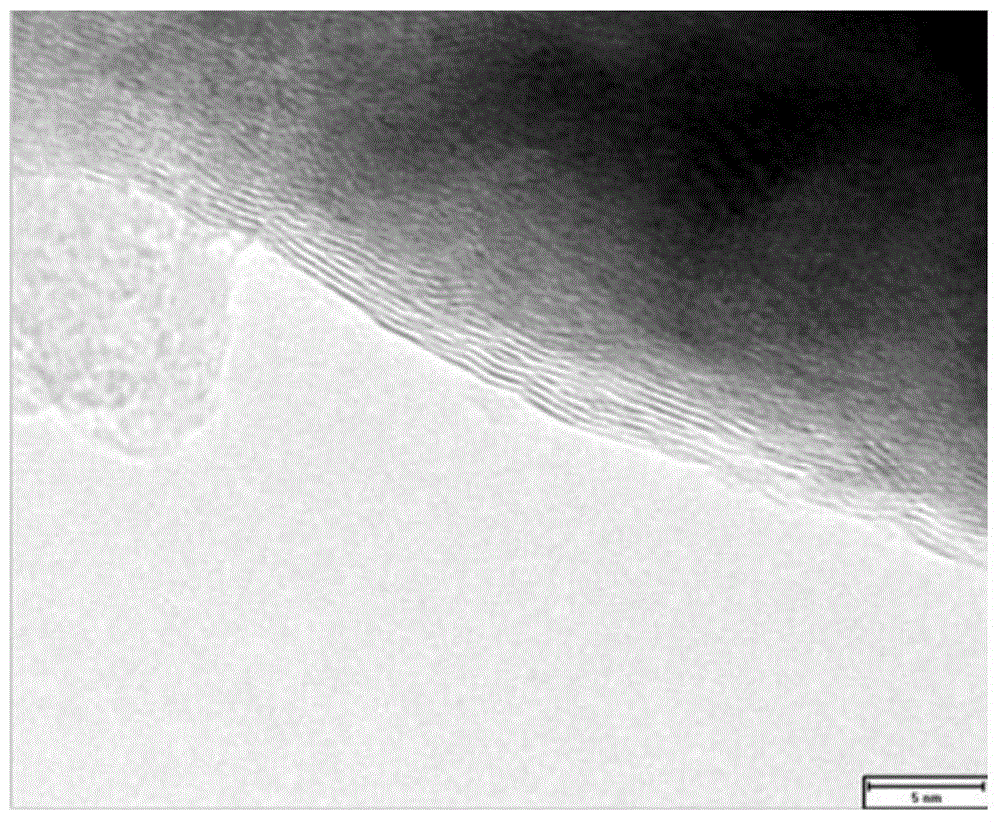

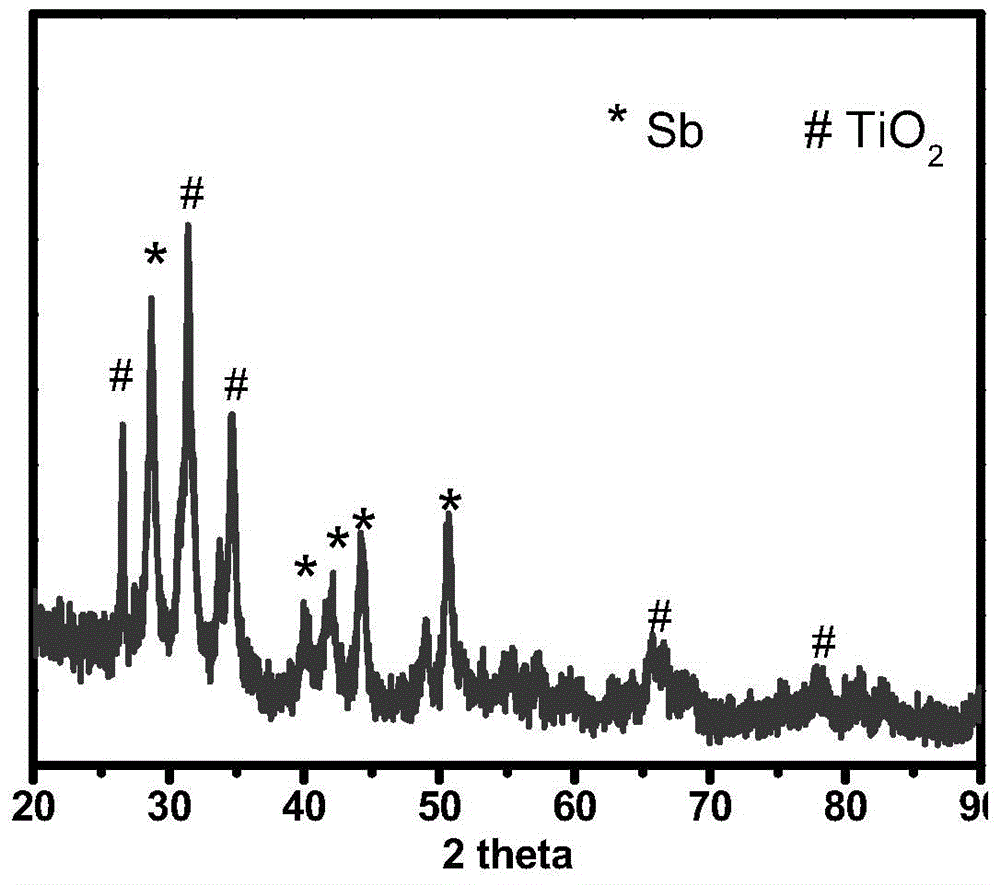

Preparation method of graphene oxide and graphene oxide composite material and use of graphene oxide and graphene oxide composite material in sodium-ion battery

InactiveCN104269534AEasy to embedPromote prolapseSecondary cellsNegative electrodesOxide compositeCopper oxide

The invention discloses a preparation method of graphene oxide and a graphene oxide composite material and a use of the graphene oxide and the graphene oxide composite material in a sodium-ion battery. The graphene oxide and the graphene oxide composite material can be used as sodium-ion battery cathode materials. The graphene oxide composite material is prepared from the graphene oxide and metals or metal oxides by a compounding method, wherein the metals comprise Ag, Au, Cu, Fe, Sn, Si, Ni and Sb, the metal oxides comprise nickel oxide, copper oxide, tin oxide, antimony oxide, cobalt oxide, iron oxide and manganese oxide and a mass percentage of the graphene oxide is in a range of 10-80%. The graphene oxide and the graphene oxide composite material prepared by a plurality of effective processes can be used as sodium-ion battery cathode materials, have the advantages of high specific capacity and good cycling stability, have a low manufacturing cost and are suitable for sodium-ion battery large-scale exploitation and application.

Owner:ZHEJIANG UNIV

Composite cathode material for lithium ion cell and preparing method thereof

ActiveCN101286560AEvenly dispersedWell mixedElectrode manufacturing processesChemical/physical/physico-chemical processesComposite cathodeGraphite

The invention relates to a lithium ion battery composite cathode material and a preparation method thereof, which belongs to the technical field of lithium ion battery. The invention aims at improving the cycle performance of silicon cathode material at the same time when keeping the high ratio volume of lithium ion battery silicon cathode material. The proposal of the invention is that silica-based material coated by disordered carbon is treated with surface modification processing by utilizing lithium salt, namely, the lithium salt is coated on the surface of Si / G / DC (silicon / graphite / disordered carbon) to be prepared into the composite cathode material, therefore, the lithium-embedding and removing depth of the silicon can be effectively controlled, and the material is the lithium ion battery composite cathode material which has high specific capacity and good cyclical stability; furthermore, the material is safe and pollution-free, and presents higher thermal stability in various lithium salt electrolytes and solvents.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

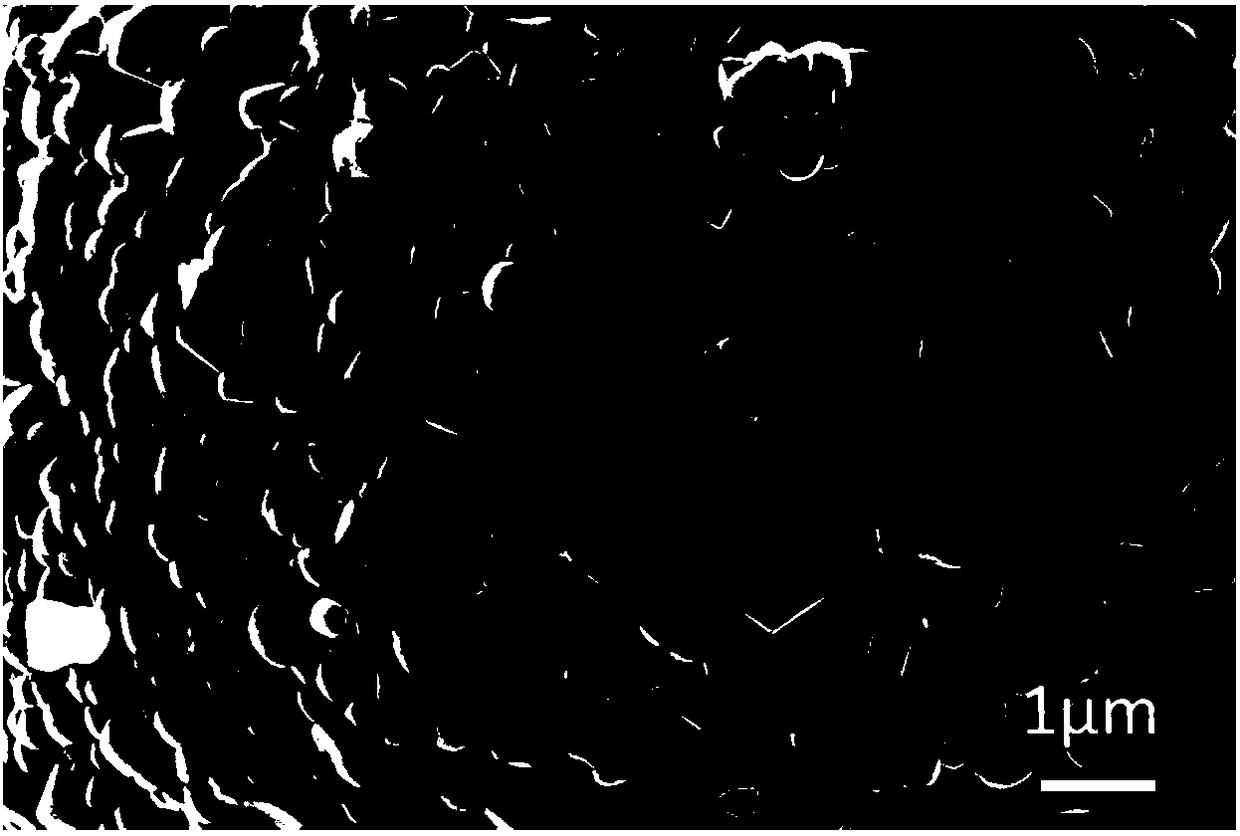

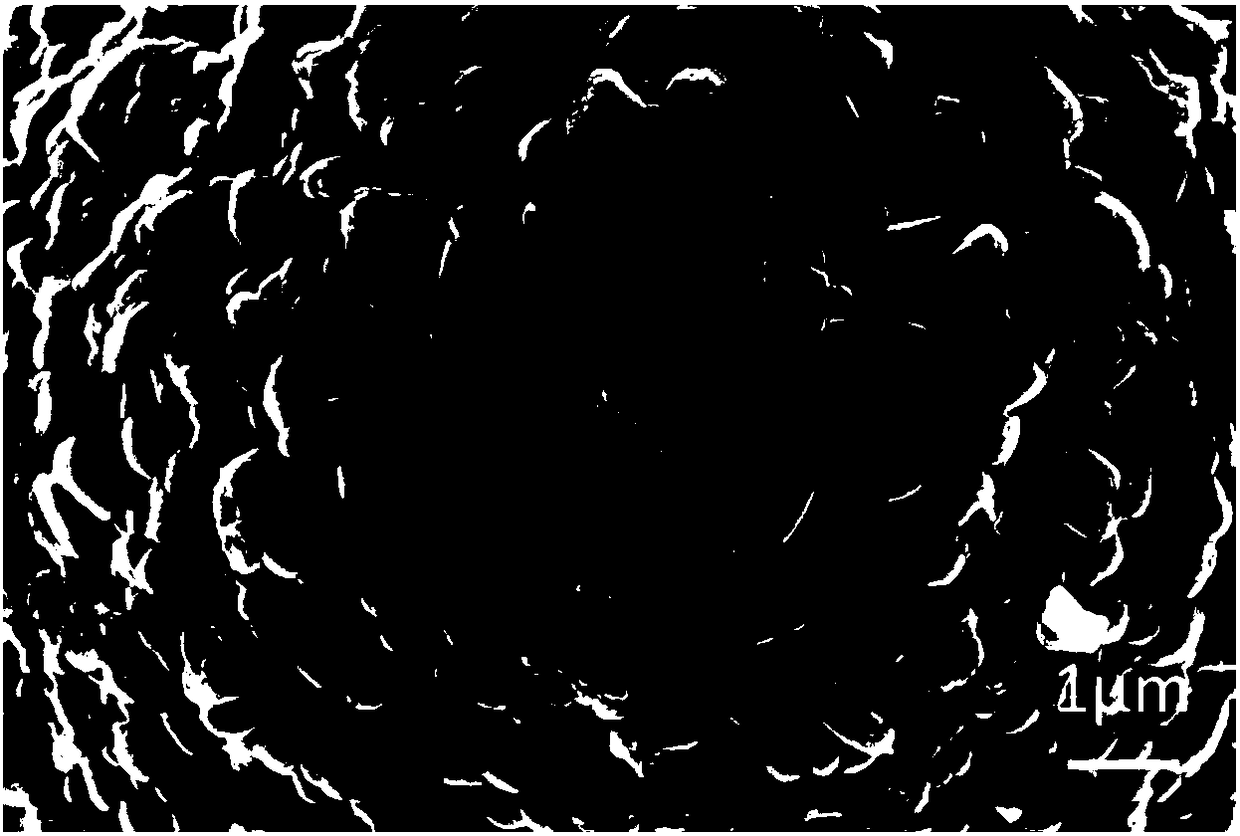

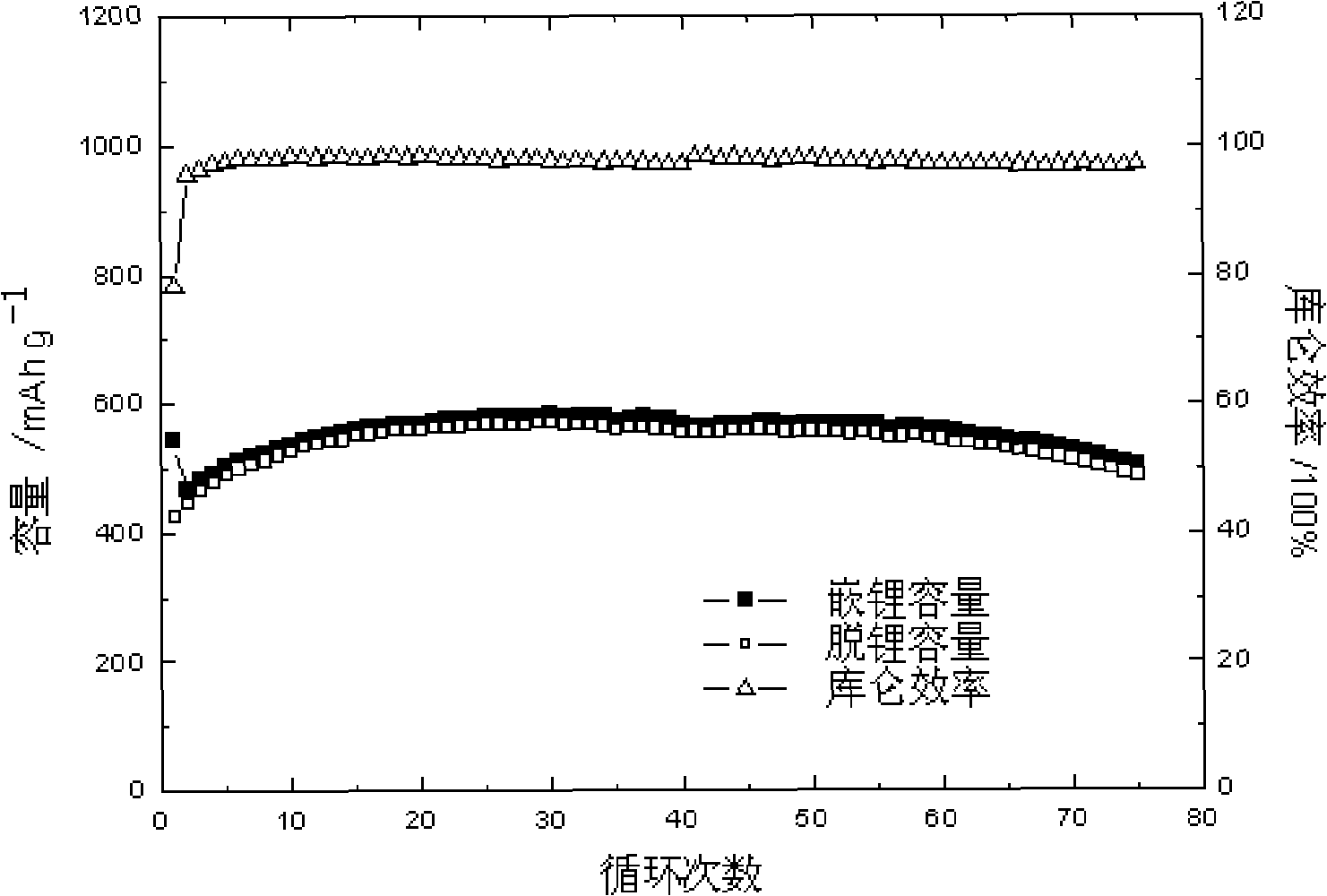

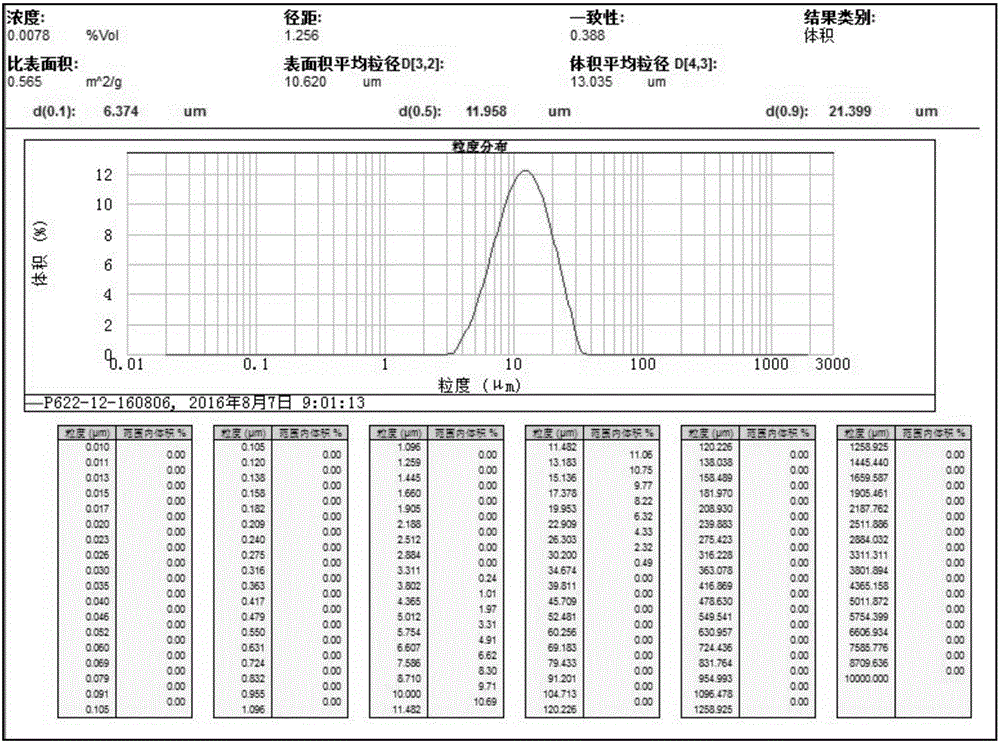

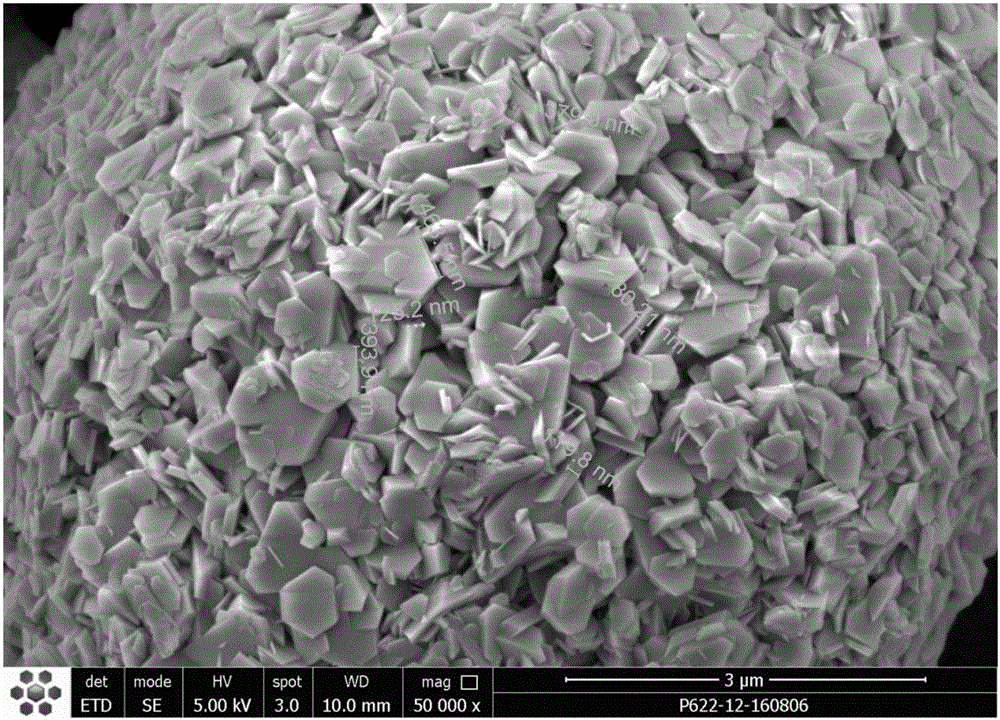

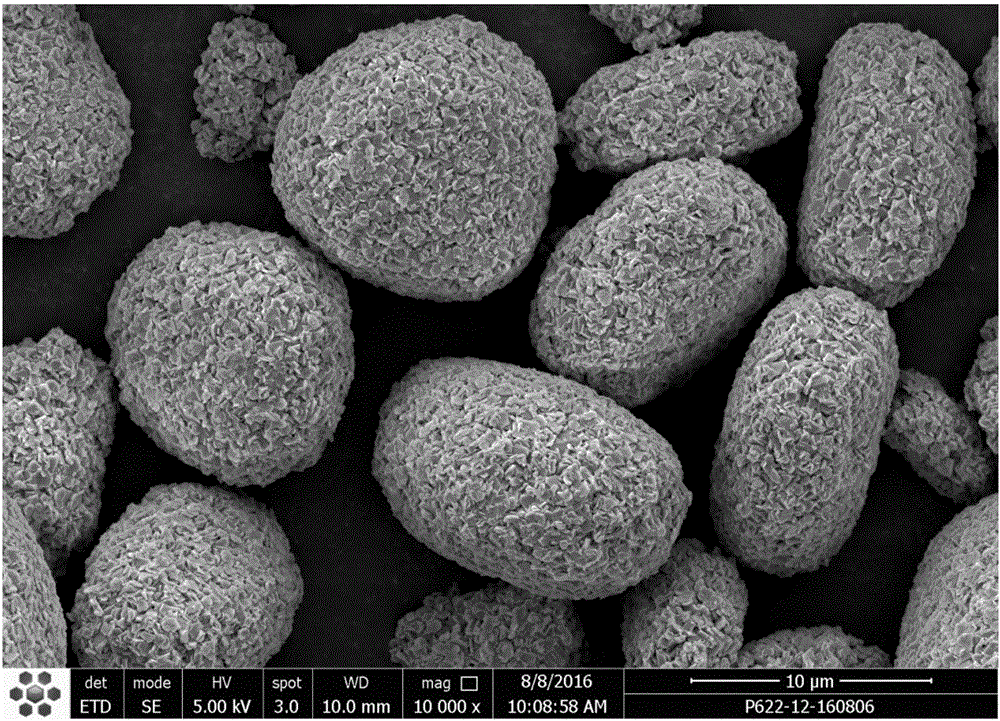

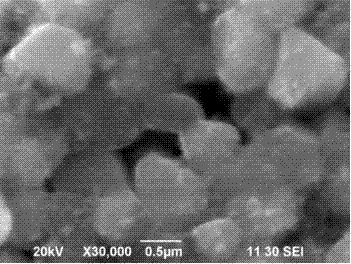

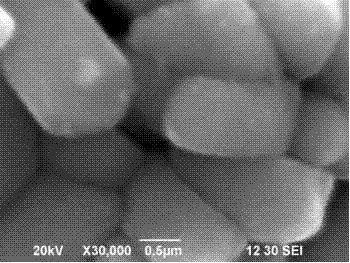

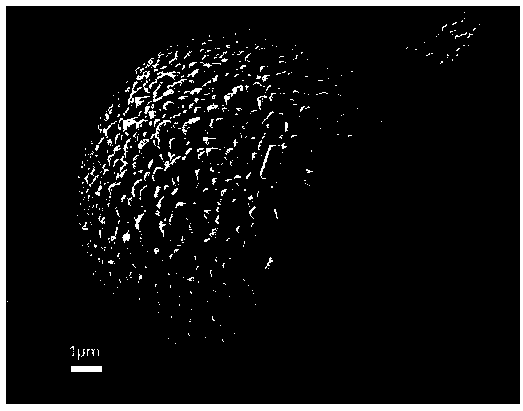

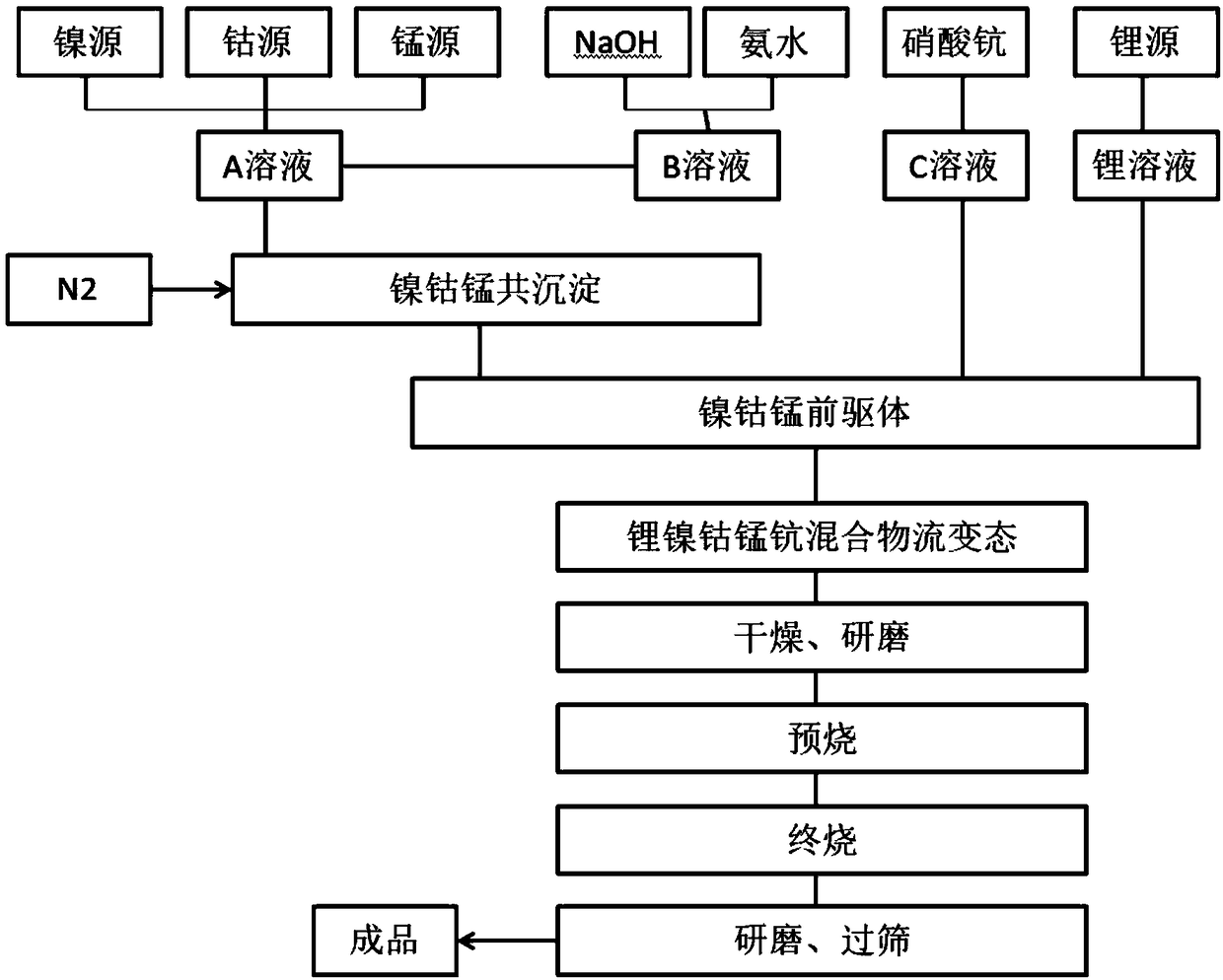

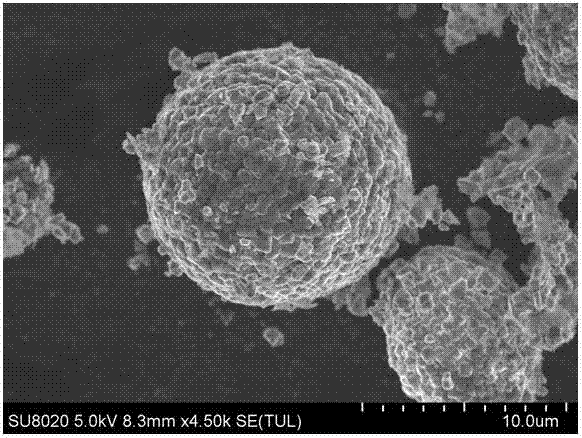

Nickel cobalt lithium manganite precursor of nanosheet agglomeration secondary particle and preparing method thereof

ActiveCN106745336ALarge granularityPromote prolapseMaterial nanotechnologyCell electrodesLithiumMicrometer

The invention provides a nickel cobalt lithium manganite precursor of a nanosheet agglomeration secondary particle. The growth mode inside the precursor is hexagonal nanosheets which are stacked, the side length of the hexagonal nanosheet is 200-500 nanometers, and the thickness is 70-200 nanometers; the particle size of the agglomeration secondary particle D10 is bigger than or equal to 6 micrometers, D50 is equal to 9-15 micrometers, and D90 is smaller than or equal to 30 nanometers. The preparing method of the nickel cobalt lithium manganite precursor of the nanosheet agglomeration secondary particle comprises the steps of firstly preparing a soluble mixed brine solution, adding ammonium hydroxide as a base solution of a reaction kettle, and adjusting the pH of the base solution to be 11-12; inflating nitrogen into the reaction kettle and starting stirring; adding the soluble mixed brine solution, a strong alkaline solution and ammonium hydroxide into the reaction kettle for a stirring reaction, after the reaction for some time, making unqualified feed circularly pumped into the reaction kettle, and aging, compressing and washing an overflowed feed; after washing, drying, screening and storing the material. The nickel cobalt lithium manganite precursor of the nanosheet agglomeration secondary particle is better in uniformity and electrochemical performance; moreover, the product stability is good.

Owner:SHANSHAN ENERGY (NINGXIA) CO LTD

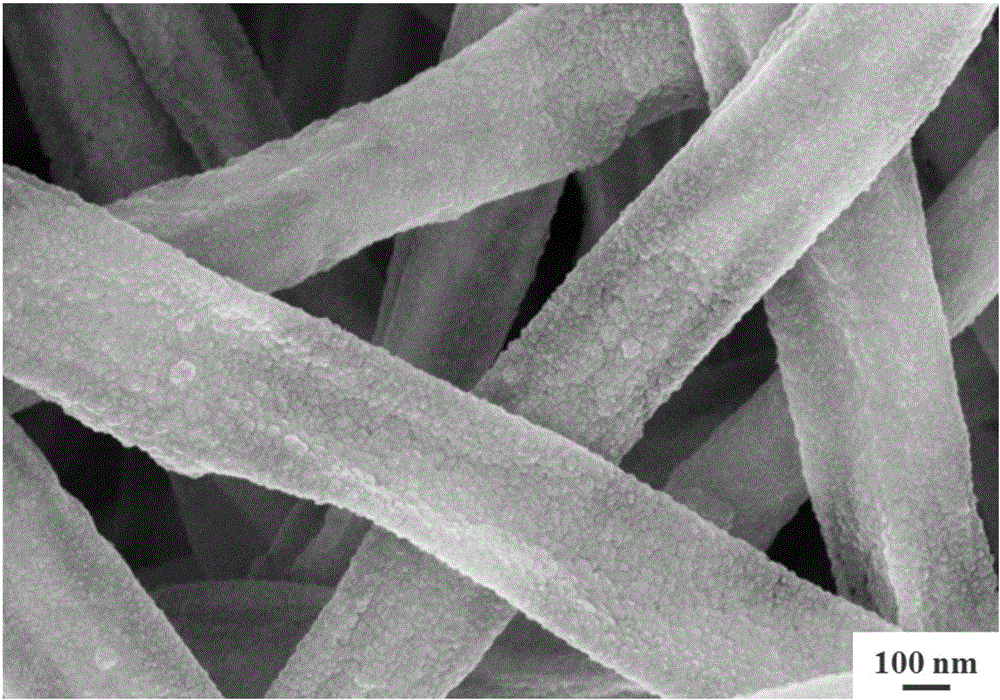

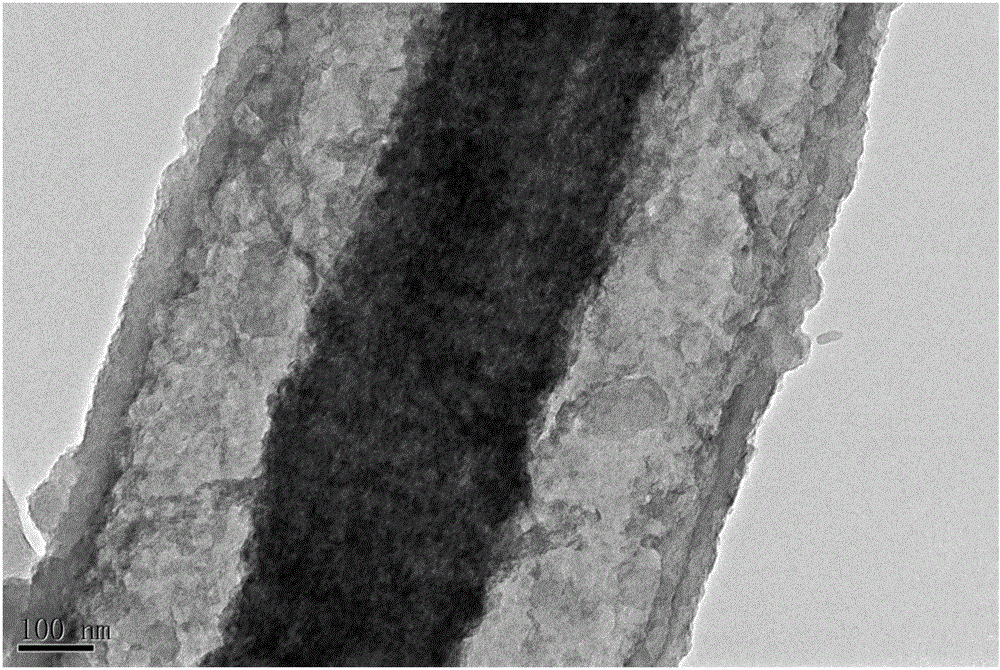

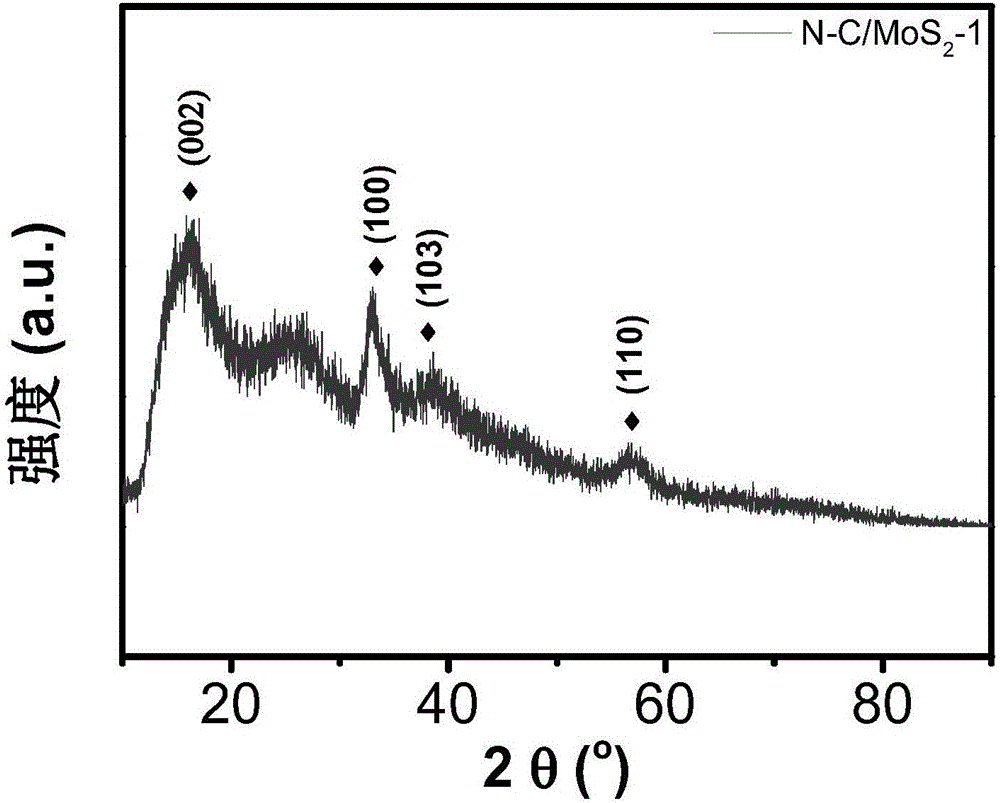

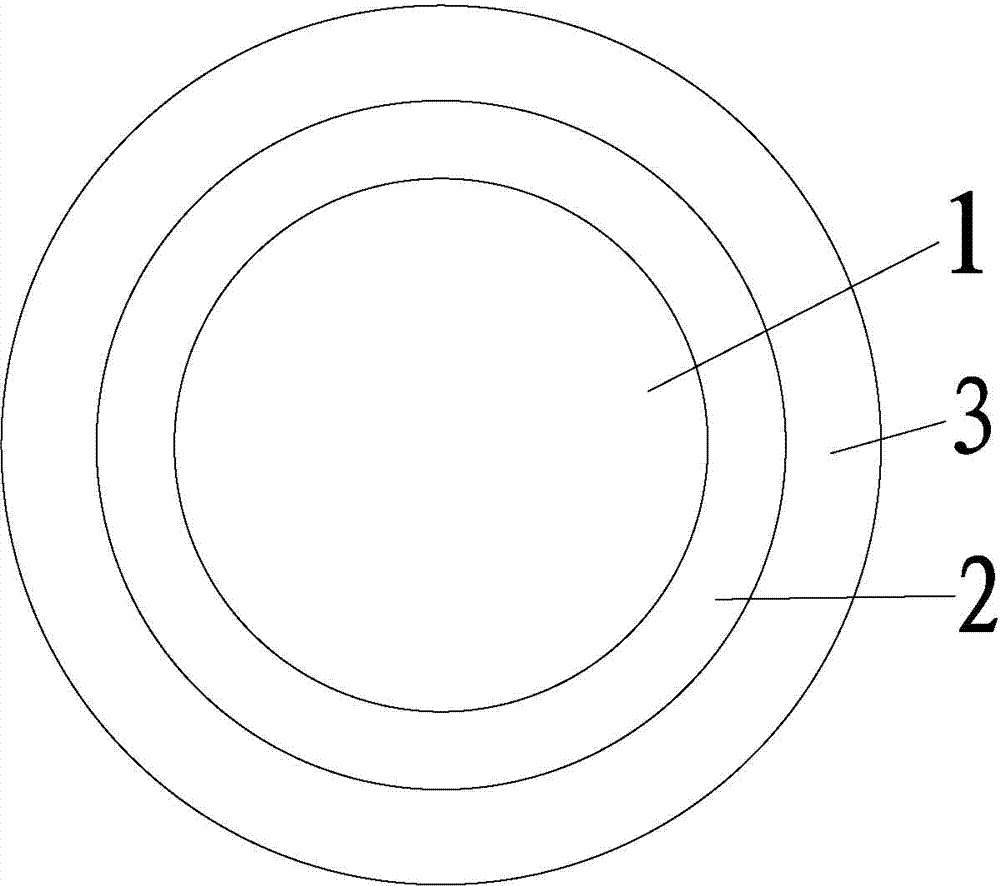

Molybdenum disulfide/nitrogen-doped carbon nanofiber composite material and preparation method and application thereof

ActiveCN106450181AHigh specific capacityImprove cycle stabilityCell electrodesSecondary cellsFiberIn situ polymerization

The invention relates to a molybdenum disulfide / nitrogen-doped carbon nanofiber composite material and a preparation method and an application thereof. The composite material is of a pipe sleeving structure, a molybdenum disulfide fiber core is arranged in the composite material and a nitrogen-doped carbon nanofiber shell is arranged outside the composite material; and a gap is arranged between the molybdenum disulfide fiber core and the nitrogen-doped carbon nanofiber shell. The preparation method comprises the steps of dissolving ammonium thiomolybdate and polymethyl methacrylate into a solvent and carrying out electrostatic spinning to obtain a polymethyl methacrylate / ammonium thiomolybdate nanofiber; carrying out drying and surface treatment, immersing the nanofiber into a pyrrole / hydrochloric acid solution, dropwise adding a ferric chloride / hydrochloric acid solution and carrying out in-situ polymerization to obtain the fiber coated with polypyrrole on the surface; and washing and drying the fiber, carrying out high-temperature reduction under the condition of taking an argon / hydrogen mixed gas as a protective atmosphere and then carrying out high-temperature carbonization under an argon condition. The composite material has high specific capacity and good cycle stability, and can be used as an efficient and safe novel negative electrode material of a lithium-ion battery.

Owner:DONGHUA UNIV

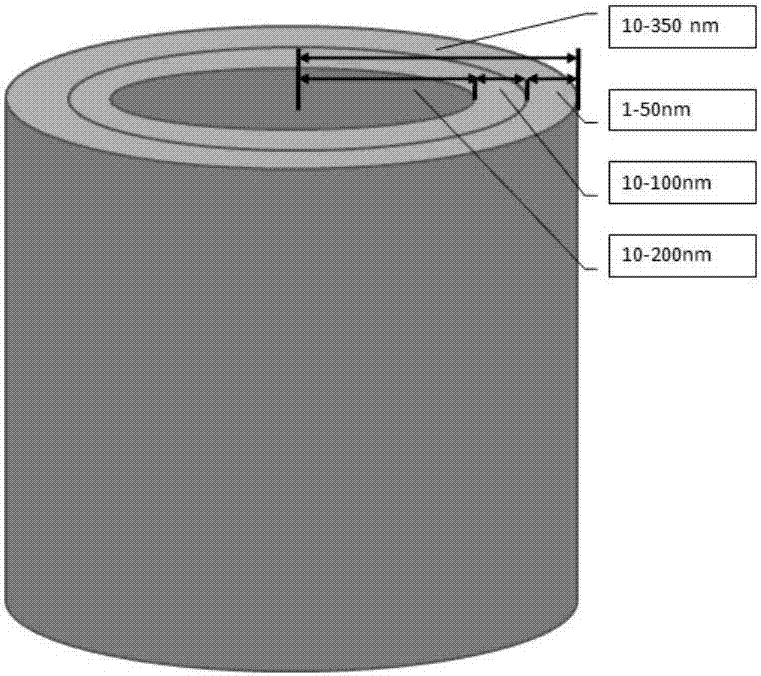

Coating structure applicable to high-voltage charge-discharge and manufacturing method of coating structure

ActiveCN102931384AImprove efficiencyInhibit corrosionCell electrodesElectrical batteryCharge and discharge

The invention relates to the technical field of lithium ion batteries, in particular to a coating structure applicable to high-voltage charge-discharge and a manufacturing method of the coating structure. A first metal oxide layer and a second metal oxide layer coat the surface of a cathode material layer, the first metal oxide layer coats the surface of the cathode material layer, the second metal oxide layer coats the outer surface of the first metal oxide layer, and the weight of the first metal oxide layer occupies 40 to 70 percent of the total weight of the first metal oxide layer and the second metal oxide layer. The coating structure contains active substances, so the first charge-discharge efficiency of a material is improved; by a surface ceramic oxide layer, corrosion of hydrogen fluoride (HF), release of metal ions and extraction of active oxygen are well inhibited; and a lithium ion secondary battery with the structure is applicable to charge-discharge at high voltage of more than 4.30 V, high in energy density, high in cycle performance and high in safety performance, and high-temperature storage performance is greatly improved.

Owner:DONGGUAN AMPEREX TECH

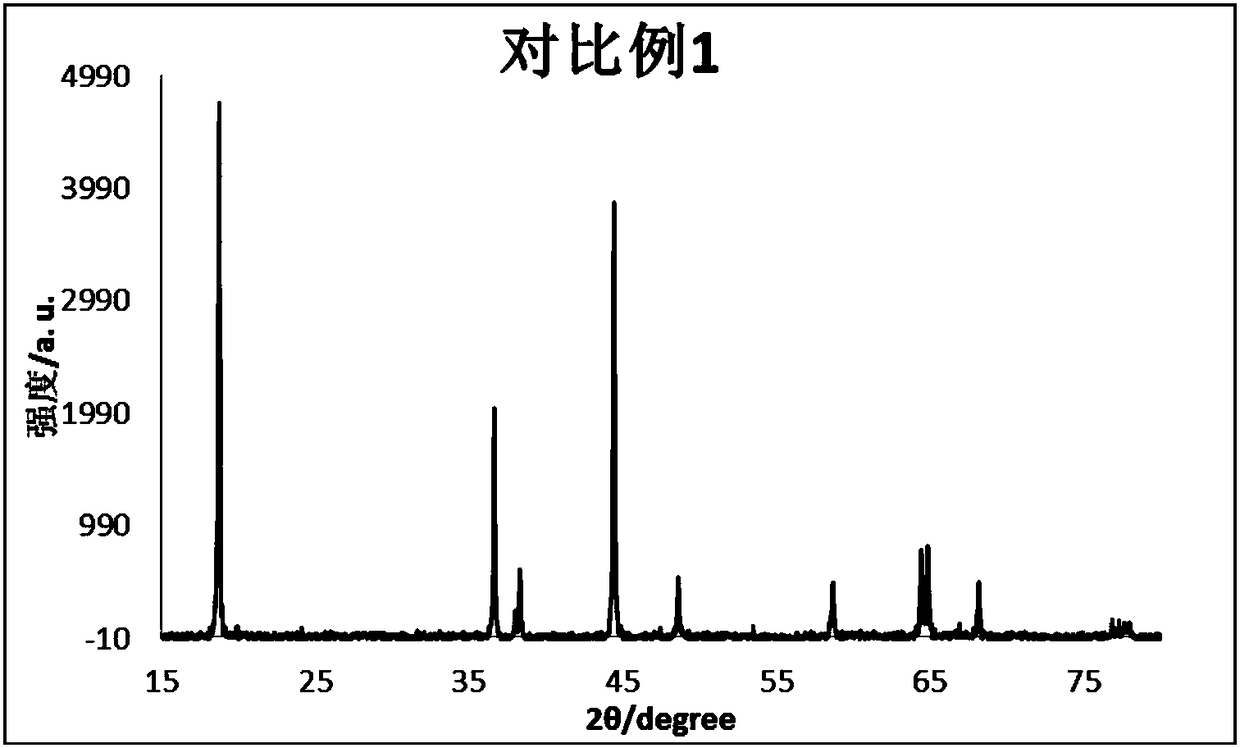

Preparation method of high-nickel ternary cathode material

InactiveCN109461907AReduce mixingReduce residual alkali contentCell electrodesSecondary cellsPower batteryPhysical chemistry

The invention discloses a preparation method of a high-nickel ternary cathode material. The method comprises the steps of 1) pre-oxidizing a high-nickel ternary cathode material precursor with an oxidizing agent to obtain an oxidized high-nickel ternary precursor; 2) uniformly mixing the pre-oxidized high-nickel ternary precursor with a lithium source and a modified assistant, and performing calcining to obtain an oxidized and modified high-nickel ternary cathode material; 3) carrying out coating modification of a lithium-containing compound on the oxidized and modified high-nickel ternary cathode material to obtain a coated and modified high-nickel ternary cathode material for a power battery. According to the method disclosed by the invention, the material precursor is pre-oxidized withthe oxidizing agent, so that Ni<2+> can be fully oxidized into Ni<3+>, the cation mixing degree of the material is reduced, and the capacity of the material is expanded; and through the coating modification of the lithium-containing compound, the content of residual alkali on the surface of the material can be reduced, the generation of side reactions can be effectively inhibited, the embedding and separation of lithium ions are improved, and finally the cycling performance and the rate performance of the material are improved.

Owner:郑州中科新兴产业技术研究院 +1

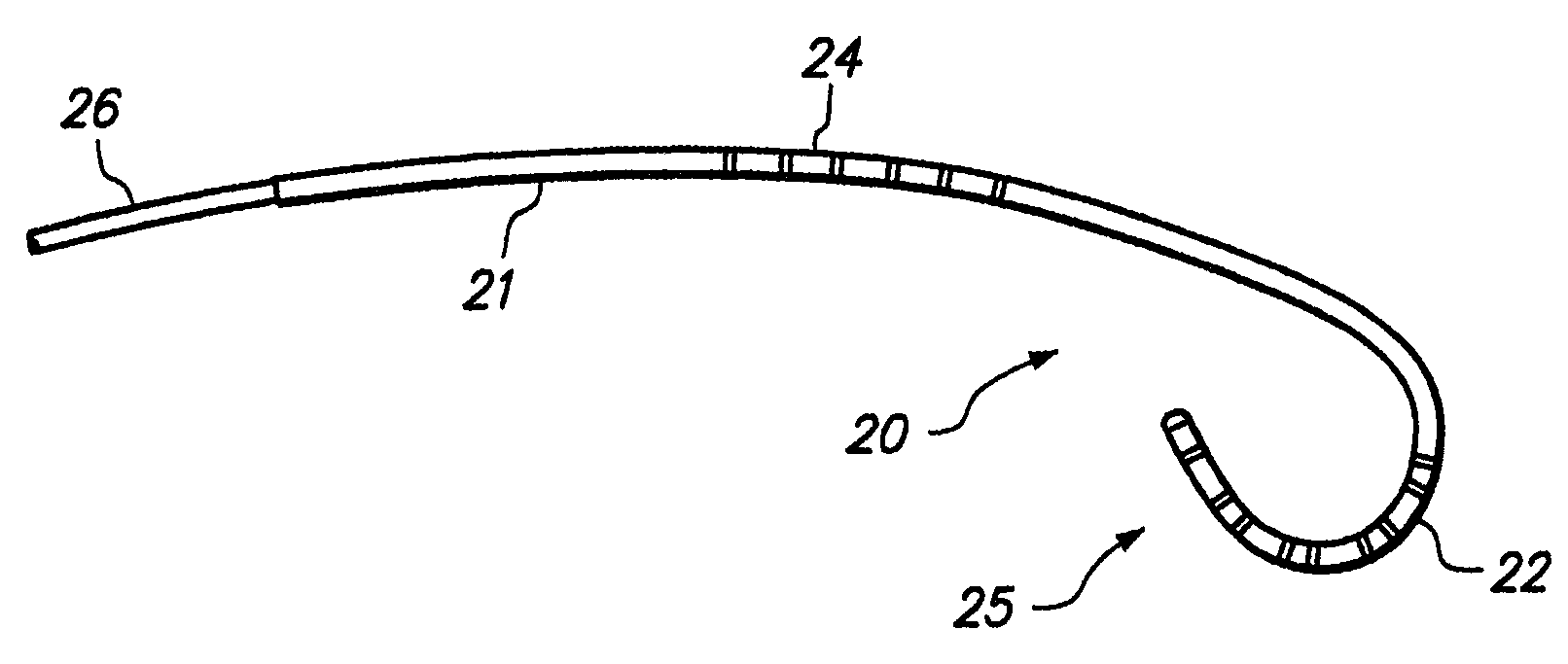

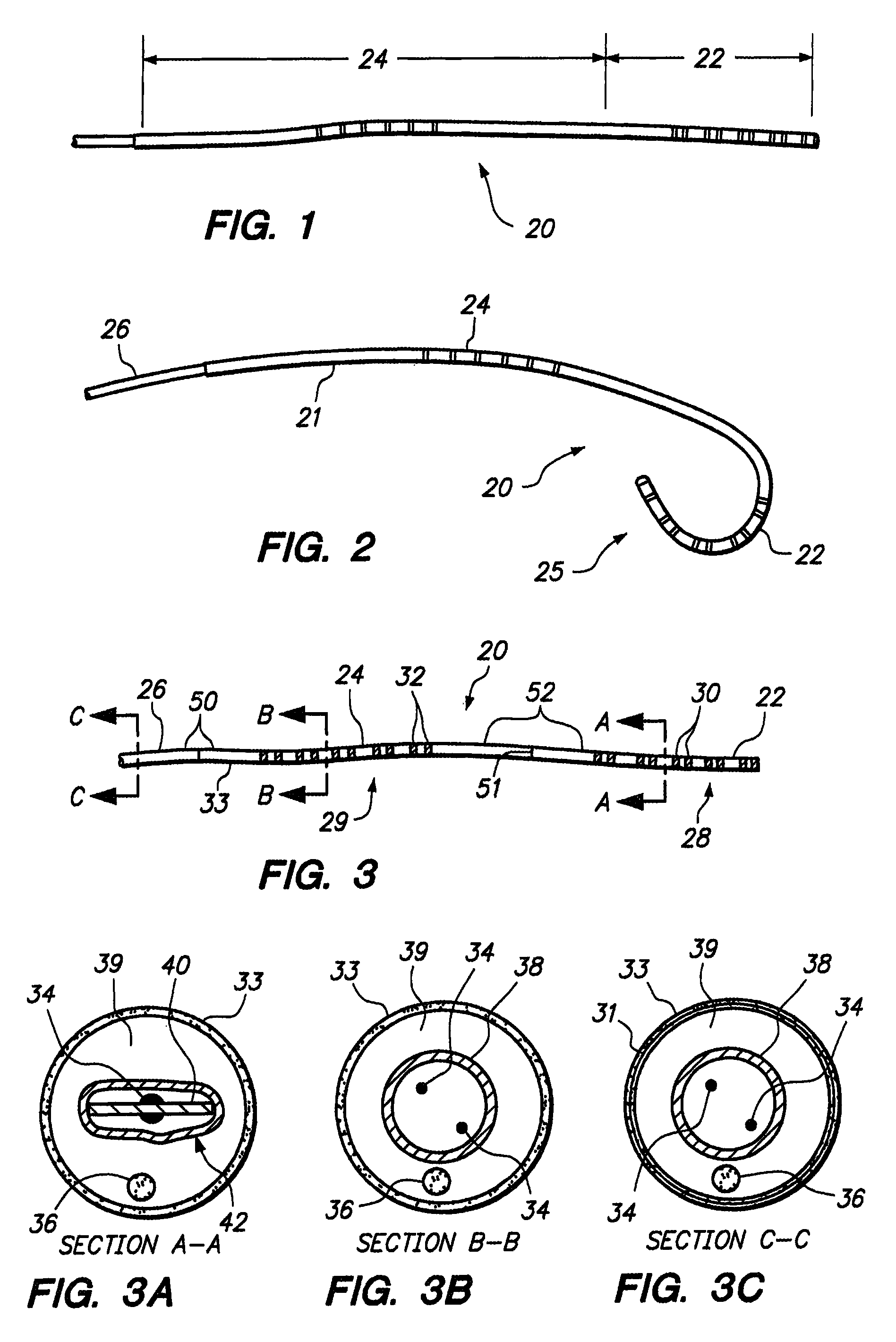

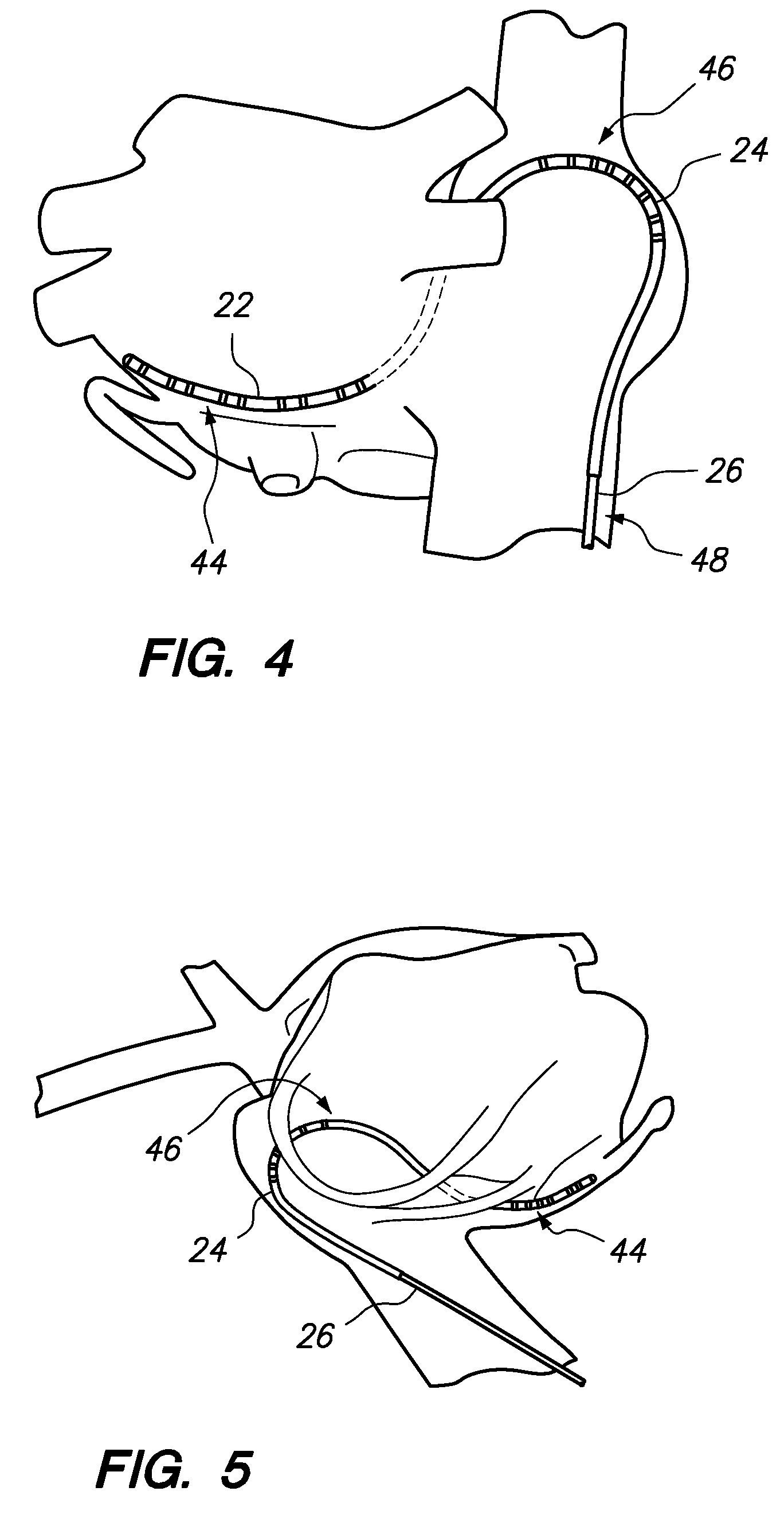

Multi-bend steerable mapping catheter

An electrophysiology catheter introduced through the groin and inferior vena cava into the right side of the heart comprises an elongate flexible shaft having a steerable distal section and a prolapsing section located proximally of the distal section. The distal section is inserted into the coronary sinus and a back-steering force is applied to the catheter to anchor the distal section therein, after which the catheter is further advanced to prolapse the prolapsing section against the high right atrium. Electrical pathways in both the coronary sinus and the high right atrium are mapped using respective electrode pairs carried on the distal and prolapsing sections of the catheter.

Owner:BOSTON SCI SCIMED INC

Artificial graphite lithium ion battery anode material and preparation method thereof

ActiveCN103887502AMaterial rigidity weakenedReduce rigidityCell electrodesSecondary cellsGraphiteSilicon dioxide

The invention discloses an artificial graphite lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1) mixing coal tar maltha with an additive according to a weight ratio of 5:1-50:1, well mixing, performing thermopolymerization reaction; (2) performing reduced pressure treatment of the reaction product; (3) performing carbonizing treatment, crushing, and grading treatment; (4) performing graphitization treatment. The additive is one or more of silicon, silica and silicon carbide. The artificial graphite lithium ion battery anode material has a high compaction density and first discharge capacity, and cells prepared by using the material as a lithium ion battery anode material have excellent comprehensive properties, stable structure, and good safety performance. The preparation method is simple and practical in process, wide in raw material source, and low in cost.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Diaphragm, preparing method of diaphragm and lithium ion battery

ActiveCN104078633AGood heat resistanceImprove heat resistanceCell seperators/membranes/diaphragms/spacersSecondary cellsCeramic particlePolymer substrate

The invention provides a diaphragm, a preparing method of the diaphragm and a lithium ion battery comprising the diaphragm. The diaphragm comprises a polymer substrate and slurry layers positioned at the inside and on the surface of the substrate; each slurry layer comprises ceramic particles and curing resin; the curing resin is obtained through performing cross-linking and curing reaction on curing agents or initiating agents positioned inside the substrate and cross-linking resin positioned in the slurry layers; the high-temperature-resistant performance of the diaphragm is excellent; a heat-resistant layer cannot easily fall; and the winding, the preparation and the practical application are easier.

Owner:BYD CO LTD

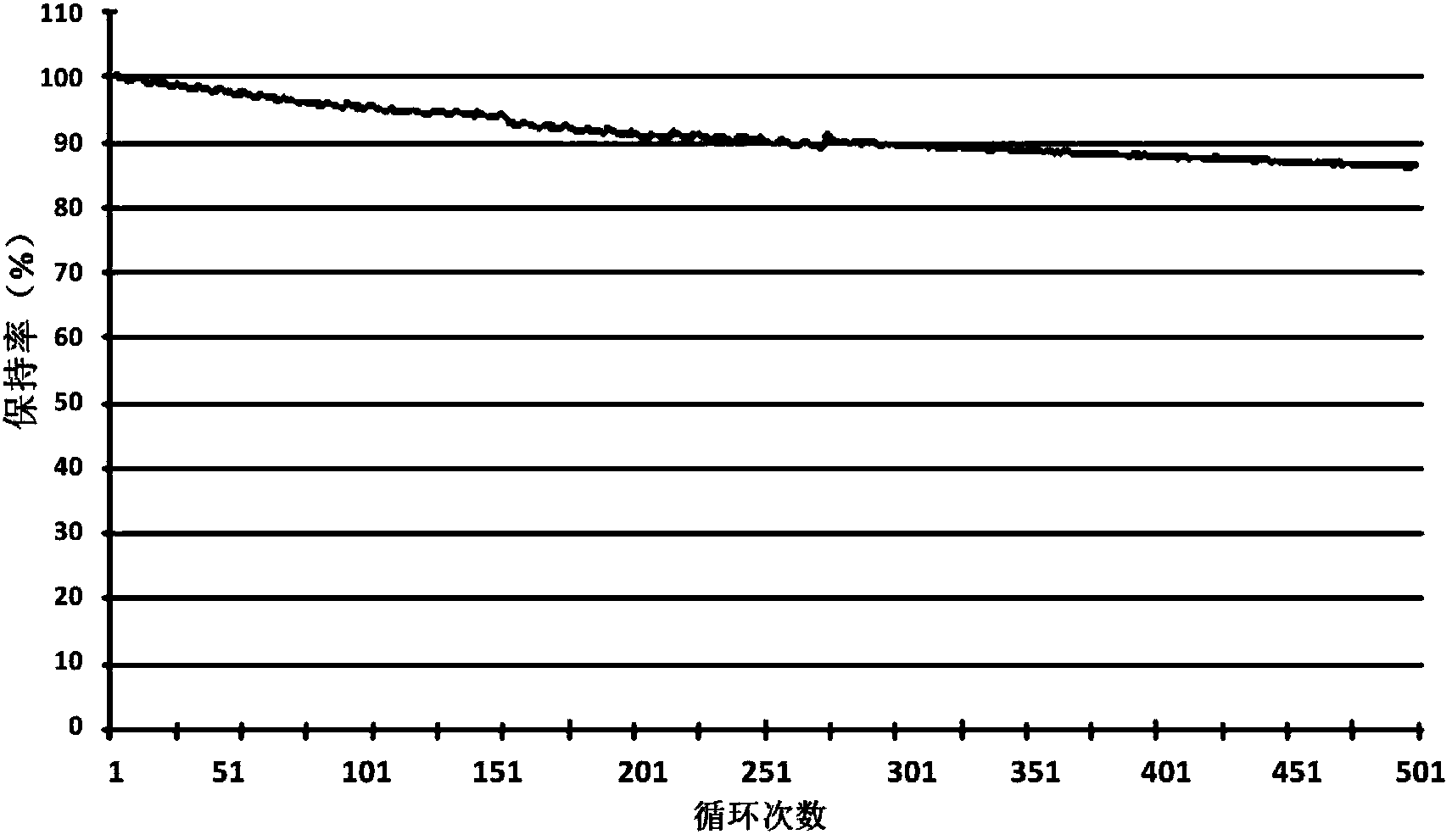

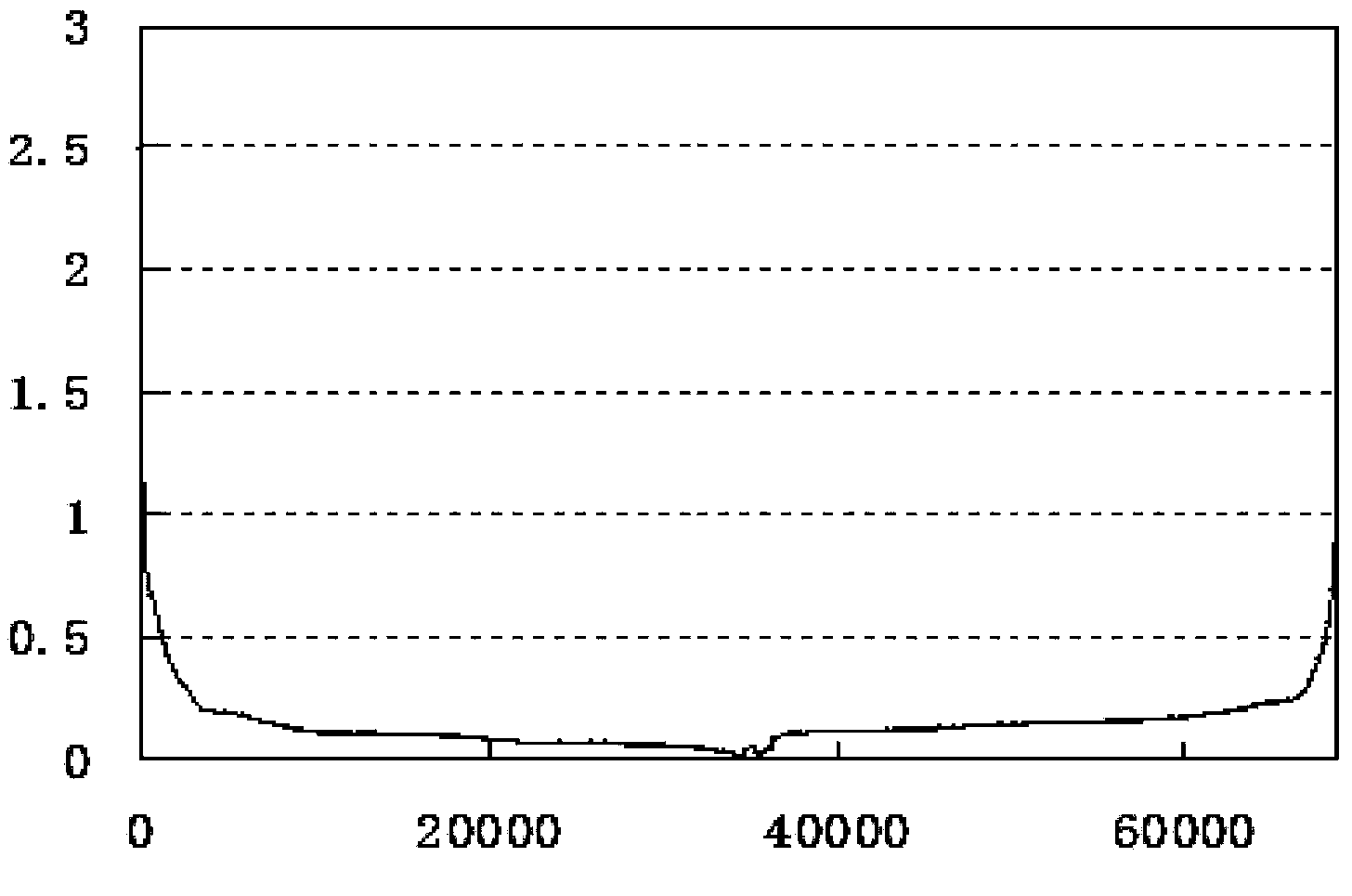

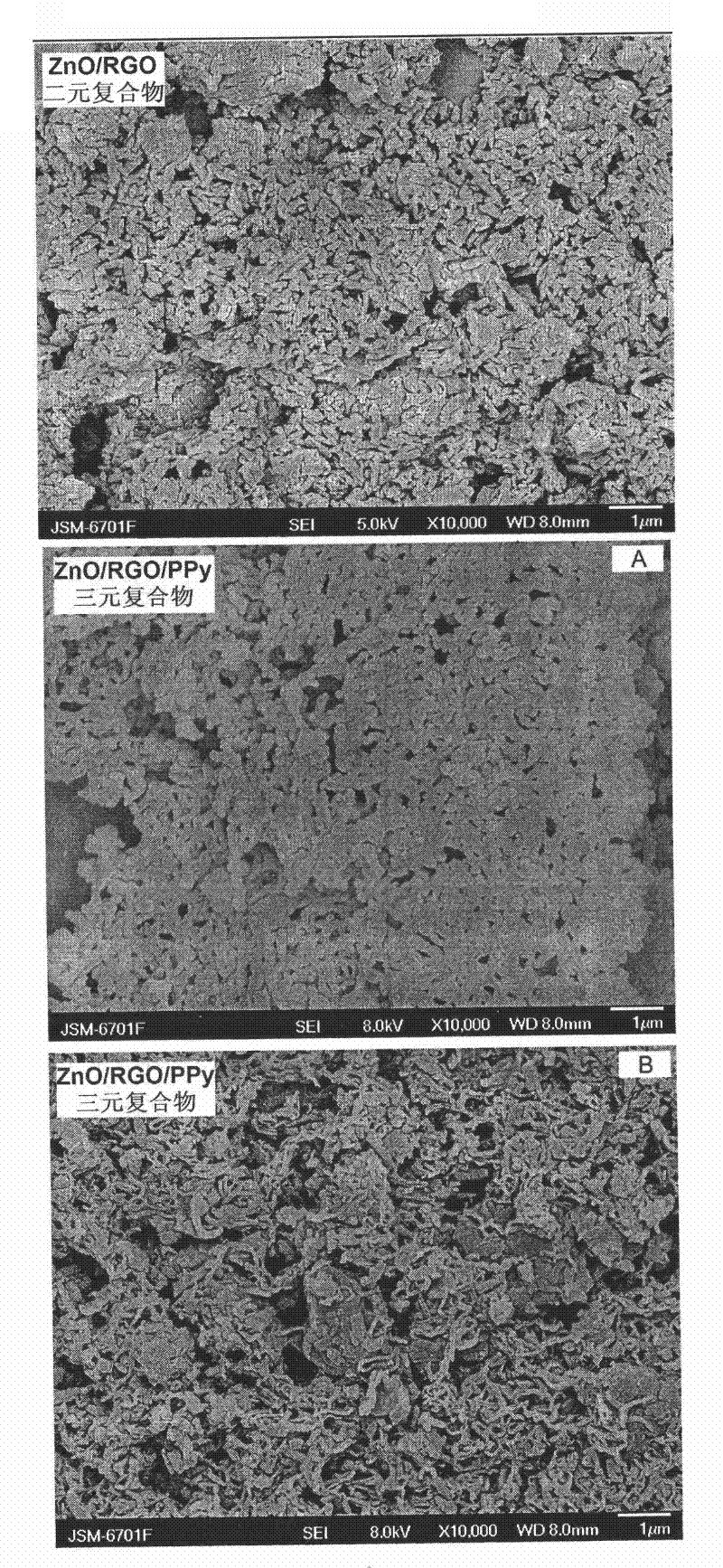

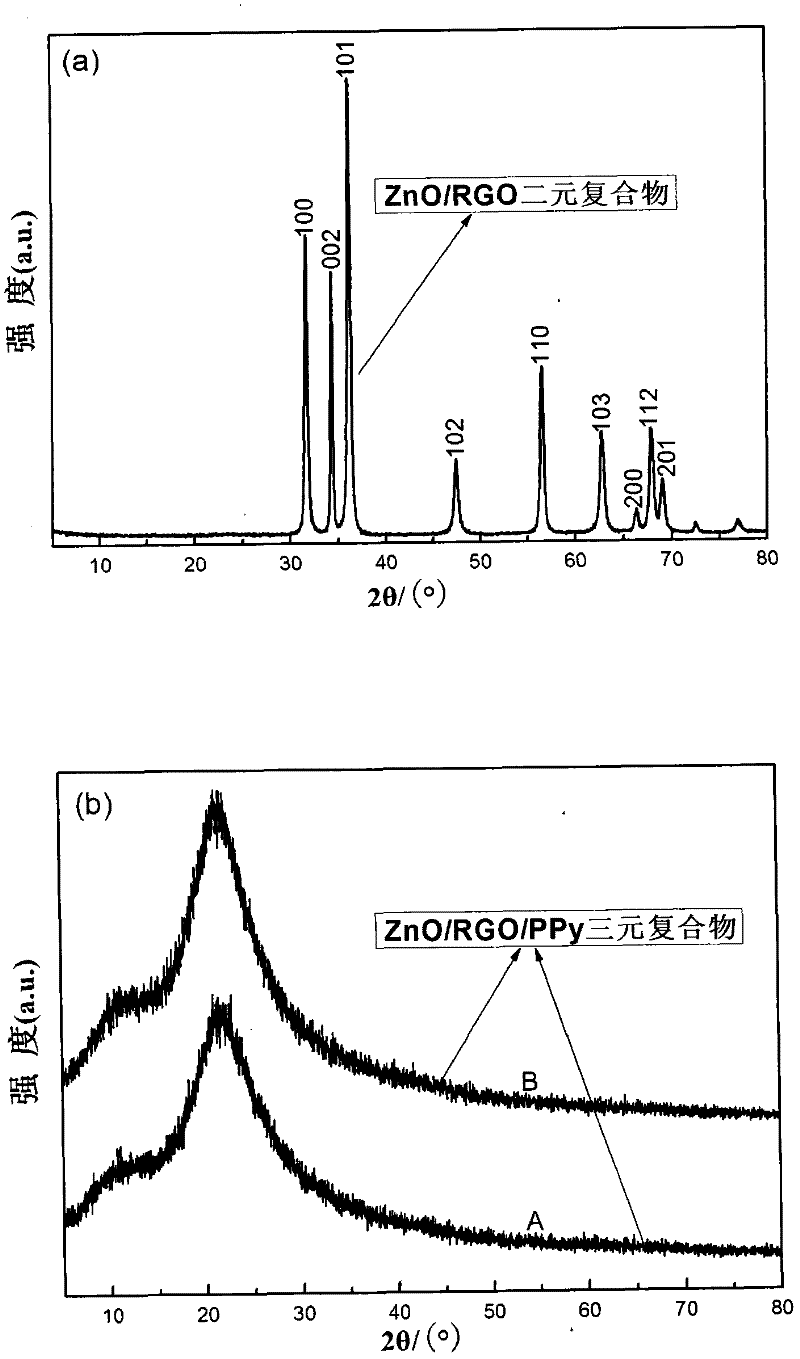

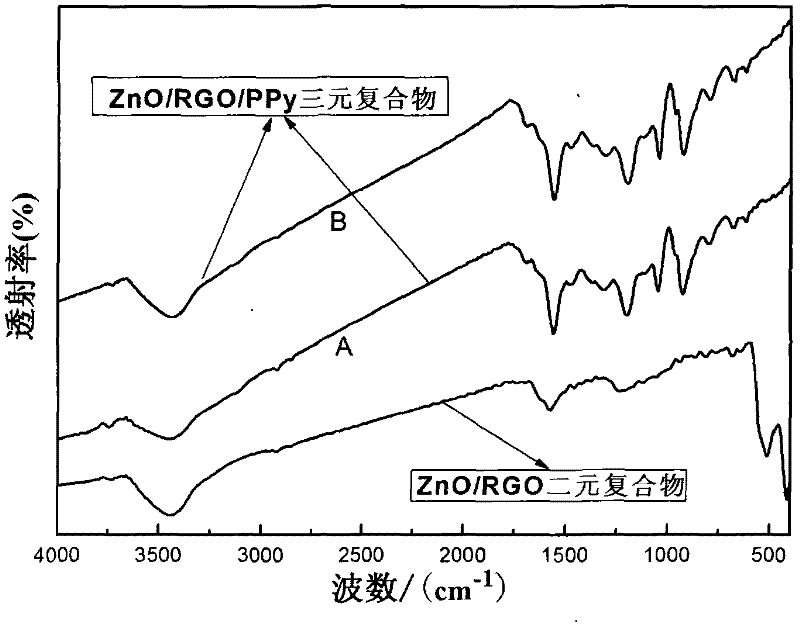

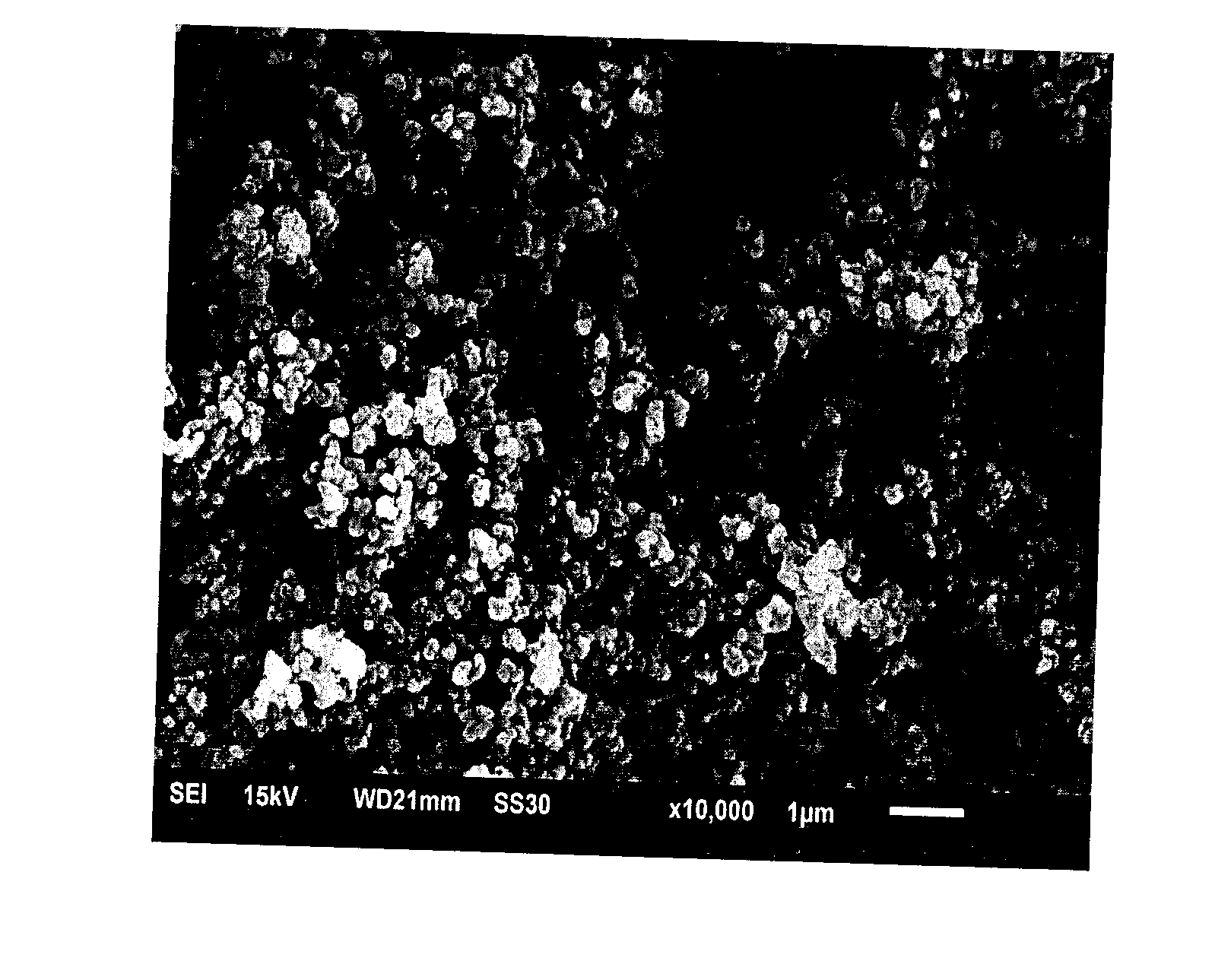

ZnO/reduced graphene oxide/polypyrrole ternary composite material preparation method, and application of the ternary composite material

InactiveCN102543464AImprove Capacitive PerformanceUniform shapeHybrid capacitor electrodesElectrolytic capacitorsPolypyrroleHigh energy

The invention discloses a zinc oxide (ZnO) / reduced graphene oxide / polypyrrole (ZnO / RGO / PPy) ternary composite material, which belongs to the technical field of composite material. The ZnO / RGO / PPy ternary composite material is prepared by a two-step method, including preparing a uniformly-dispersed binary composite material ZnO / reduced graphene oxide (ZnO / RGO), and polymerizing pyrrole (Py) monomer by chemical oxidation method by using the binary composite material as a template to obtain the ZnO / RGO / PPy ternary composite material. The ZnO / RGO / PPy ternary composite material prepared by the invention has both the electric double layer capacitance characteristics of RGO and pseudocapacitor energy storage characteristics of ZnO and Ppy, so that the composite material can show high electrochemical capacitance behavior, excellent rate capability, good circulation stability, and has high energy densigh and power density, , and can be used as the electrode material of a super capacitor.

Owner:NORTHWEST NORMAL UNIVERSITY

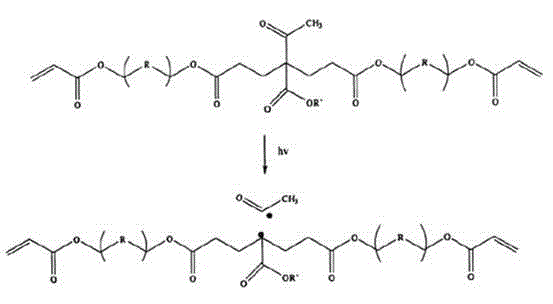

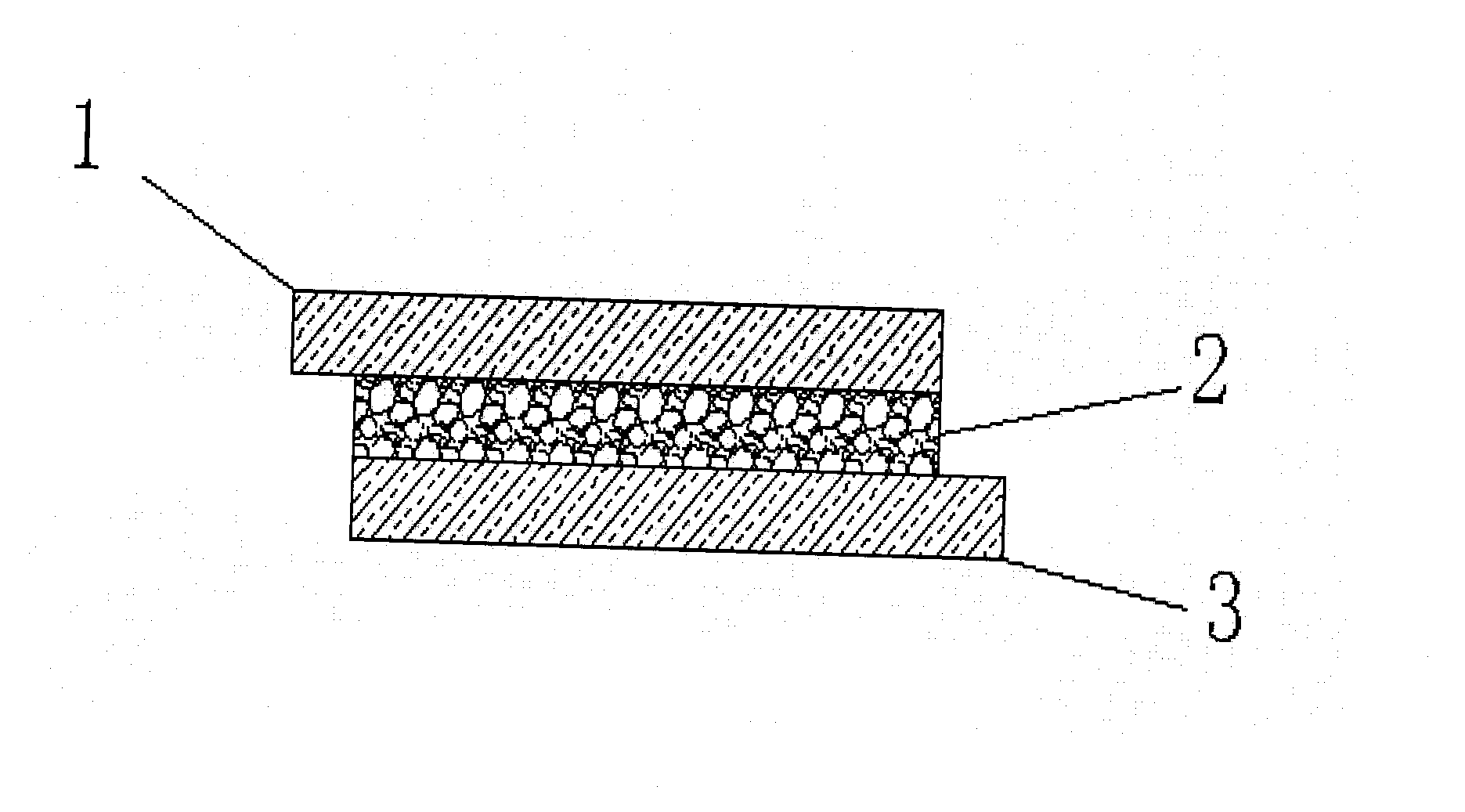

Fabric morphological polymer battery and preparation method thereof

InactiveCN103066314AUniform adhesionIncrease loadFinal product manufactureSecondary cells manufactureCapacitanceCharge rate

The invention relates to a fabric morphological polymer battery and a preparation method thereof, and belongs to the technical field of batteries. The fabric morphological polymer battery takes non-conductive fabric as flexibility base materials, conductive macromolecule is polymerized and deposited on the base materials, conductive fabric is obtained, and then the conductive fabric is used for machining two electrodes of a battery and is assembled to the battery with an electrolyte layer. Condition of the preparation method is easy to control, and the preparation method is simple in operation, low in raw material cost, small in energy consumption and suitable for large-scale industrialization production. The prepared fabric morphological polymer battery is light in weight, simple in structure, good in flexibility, pollution-free, high in safety, high in battery specific capacitance, good in circulation stability and rapid in charging rate. The fabric morphological polymer battery can be applied to certain flexibility electronic products and wearable electronic clothes.

Owner:WUHAN TEXTILE UNIV

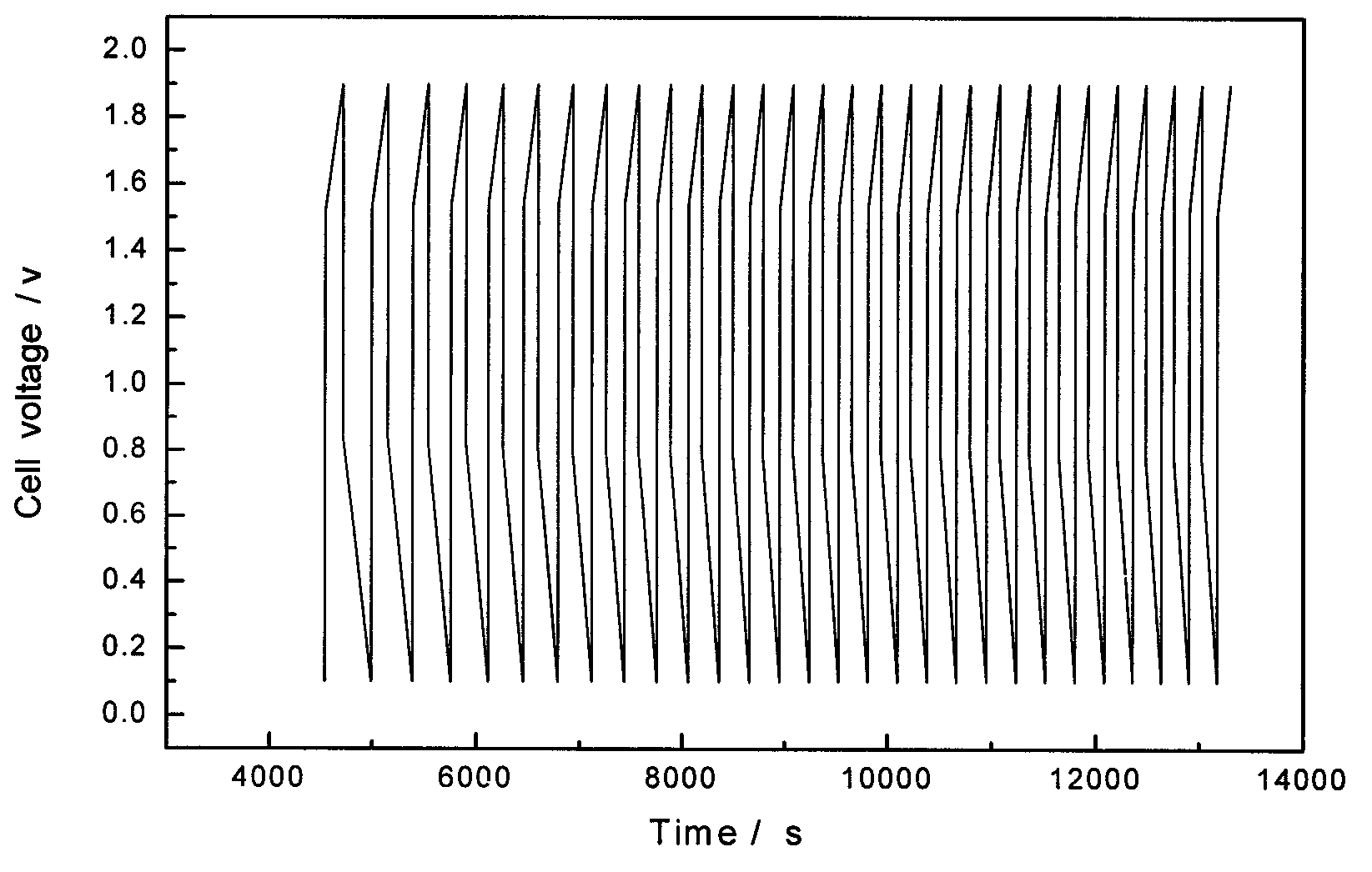

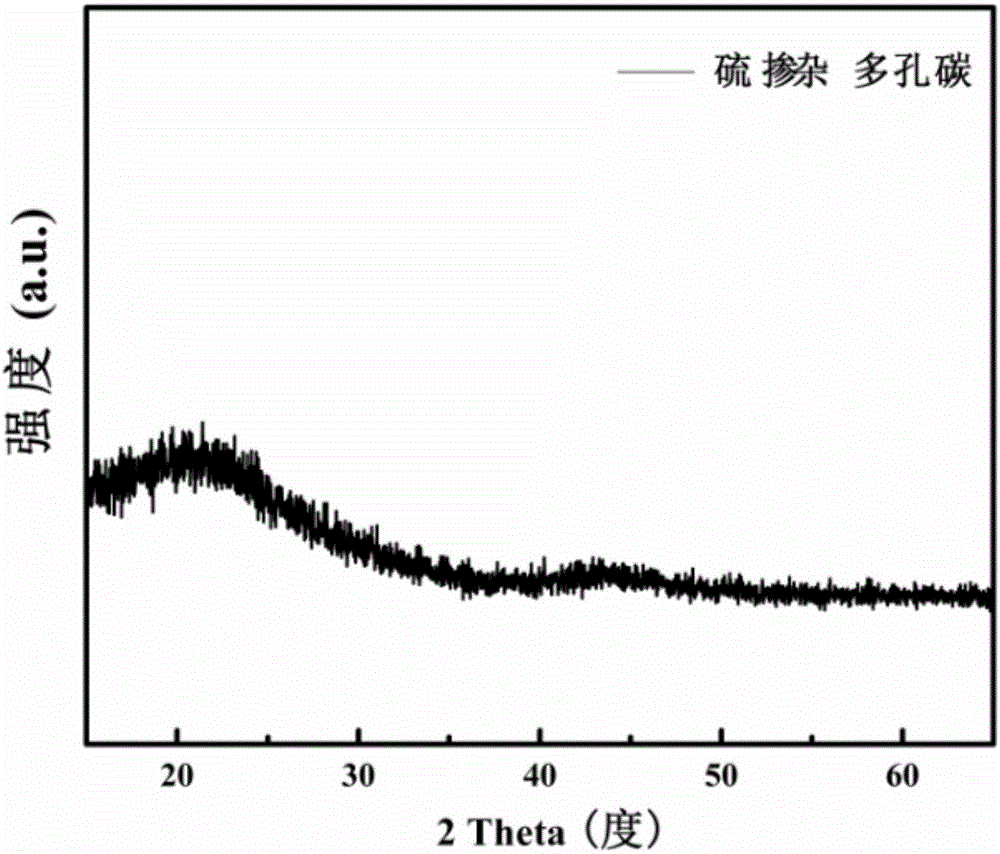

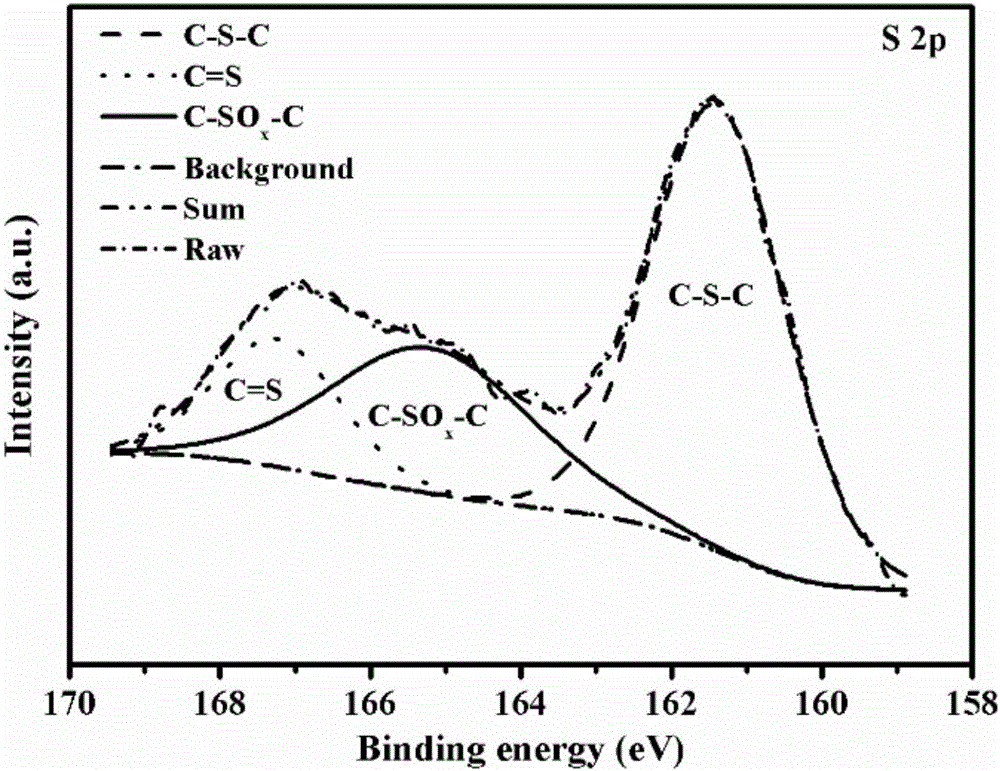

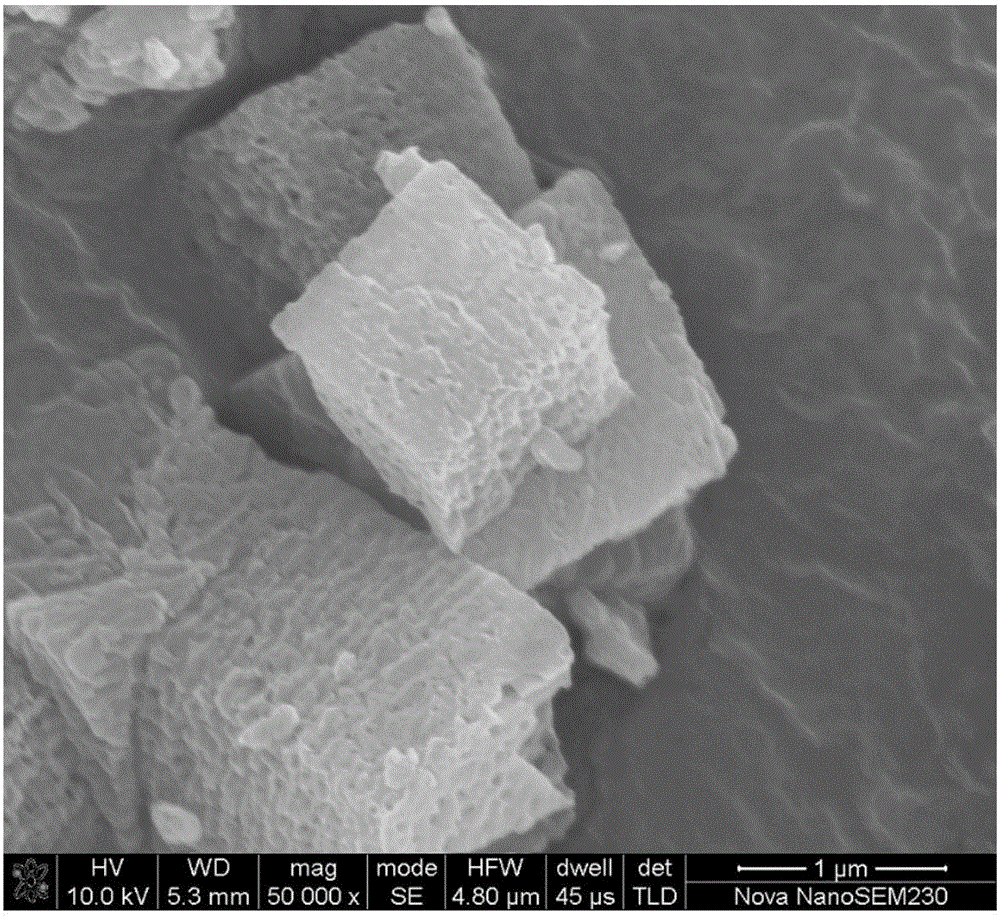

Sulfur-doping porous carbon material of sodium ion battery and preparation method of sulfur-doping porous carbon material

ActiveCN105810914AImprove cycle stabilityEasy to embedCell electrodesSecondary cellsInorganic saltsPorous carbon

The invention discloses a sulfur-doping porous carbon material of a sodium ion battery and a preparation method of the sulfur-doping porous carbon material. The sulfur-doping porous carbon material is formed by chemical doping of sulfur in a carbon material, and the carbon material has a loosen and porous spongy structure. The preparation method comprises the following step of preparing a metal organic frame material from a metal inorganic salt and an organic ligand by an in-situ growth method; and grinding and mixing the metal organic frame material and sulfur powder, placing the obtained mixture in an inert gas, carrying out low-temperature thermal treatment and then carrying out high-temperature carbonization on the obtained mixture, and washing and drying the carbonized product to obtain the sulfur-doping porous carbon material. The sulfur-doping porous carbon material prepared according to the method has excellent long-circulation stability, favorable rate performance and high specific capacity when taken as a negative electrode of the sodium ion battery; and moreover, the preparation method is simple, is low in cost and has wide industrial application prospect.

Owner:CENT SOUTH UNIV

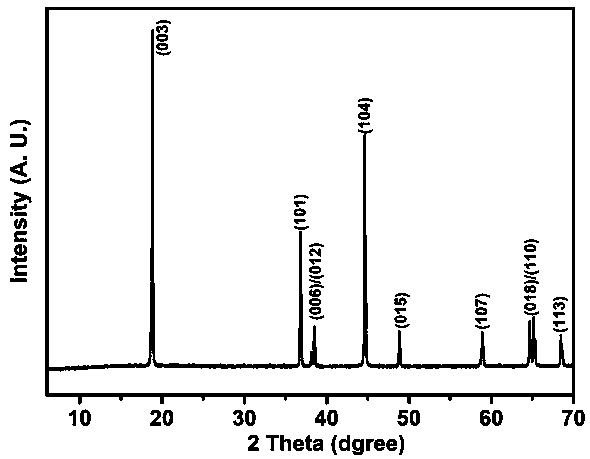

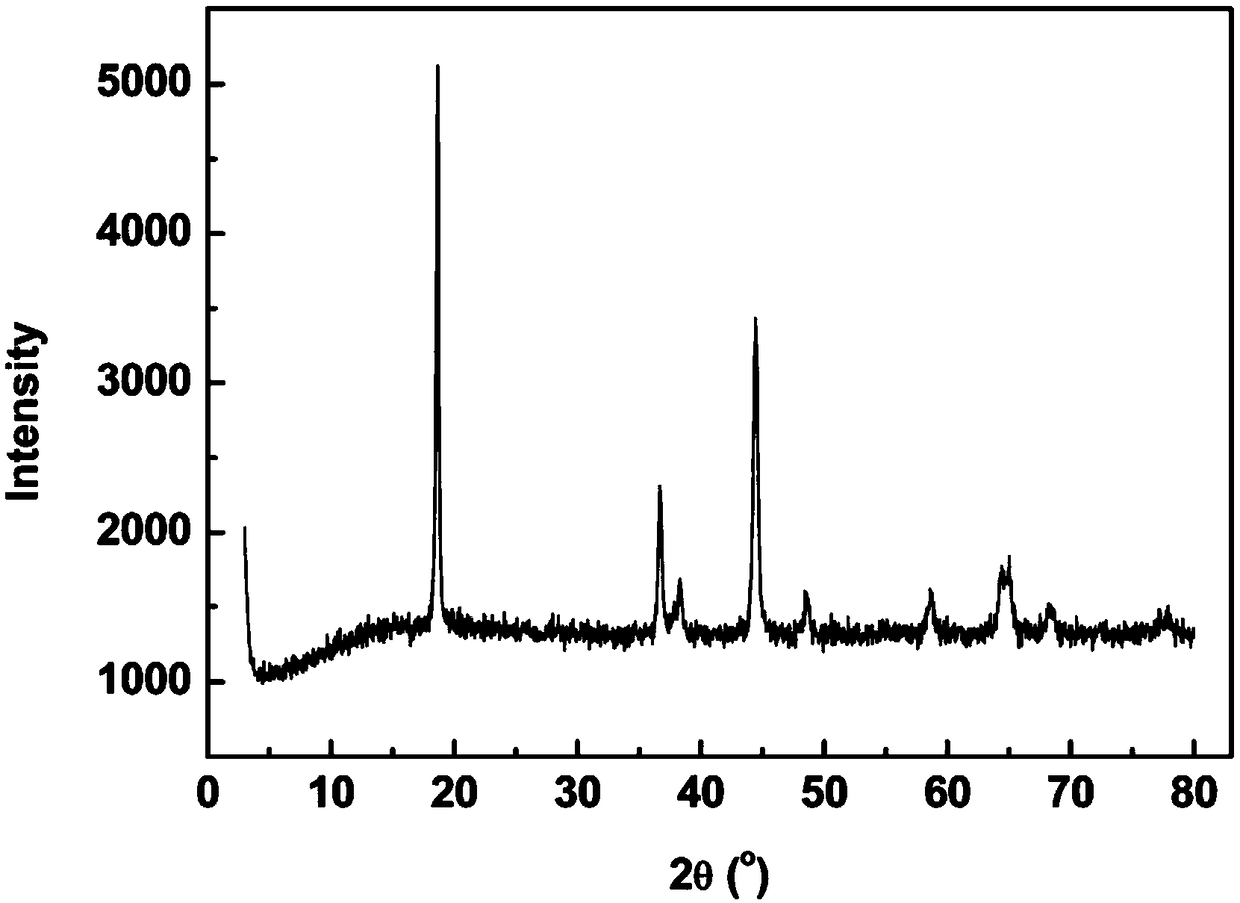

High-nickel and low-cobalt ternary cathode material and preparation method thereof

InactiveCN108767239AStable internal structureSimple internal structureCell electrodesSecondary cellsCrystallinityCobalt

The invention discloses a high-nickel and low-cobalt ternary cathode material and a preparation method thereof. The chemical general formula of the material is Li[Ni0.975Co0.0125Mn0.0125]1-xMxO2, wherein x is mole percent and is greater than or equal to 0.01 and is smaller than or equal to 0.05; M is one or a combination of Sc, Y, Zr, Ti, Mg or Al. The preparation method comprises the following steps: preparing a precursor by adopting a co-precipitation method; then synthesizing a cathode material which contains excessive lithium and is doped with M ions by adopting a simple solid phase method; the cost of a product is low; the preparation method of the high-nickel and low-cobalt ternary cathode material has the advantages of simplicity and easiness in control, wide source of raw materialsand easiness in industrial production; the prepared material has the advantages of good crystallinity, no impurity phase, fine and evenly-distributed particles as well as high discharge capacity andexcellent cycle performance.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Battery diaphragm and lithium ion battery

ActiveCN110197887AReduce polarizationIncrease energy densitySecondary cellsCell component detailsTemperature resistanceLithium-ion battery

The application provides a battery diaphragm and a lithium ion battery. The battery diaphragm comprises a porous base film and a lithium-replenishing coating attached to one side of the porous base film. The lithium-replenishing coating comprises a lithium-replenishing material and a first binder. The lithium-replenishing material comprises a core and a coating layer on the surface of the core. The material of the core comprises a lithium ion compound. The material of the coating layer comprises carbon. The lithium ion compound has a first delithiated capacity greater than a first lithiated capacity, or the lithiated potential of a delithiated product of the lithium ion compound is less than or equal to 3V. The application further provides a lithium ion battery comprising a positive electrode, a negative electrode and a diaphragm, wherein the lithium-replenishing coating of the battery diaphragm is opposite to the positive electrode. The battery is prepared by forming the lithium-replenishing coating in one side of the battery diaphragm and arranging the lithium-replenishing coating of the diaphragm opposite to the positive electrode, thus, the battery capacity is greatly improved.Further, the diaphragm also has good mechanical properties and high temperature resistance.

Owner:BYD CO LTD

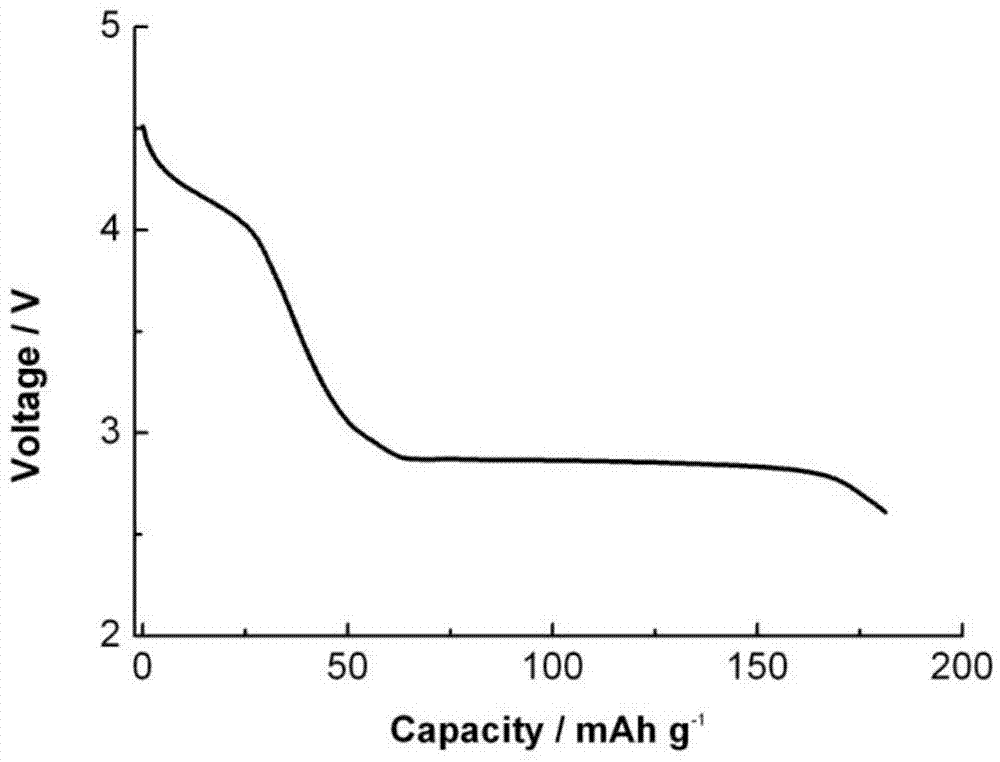

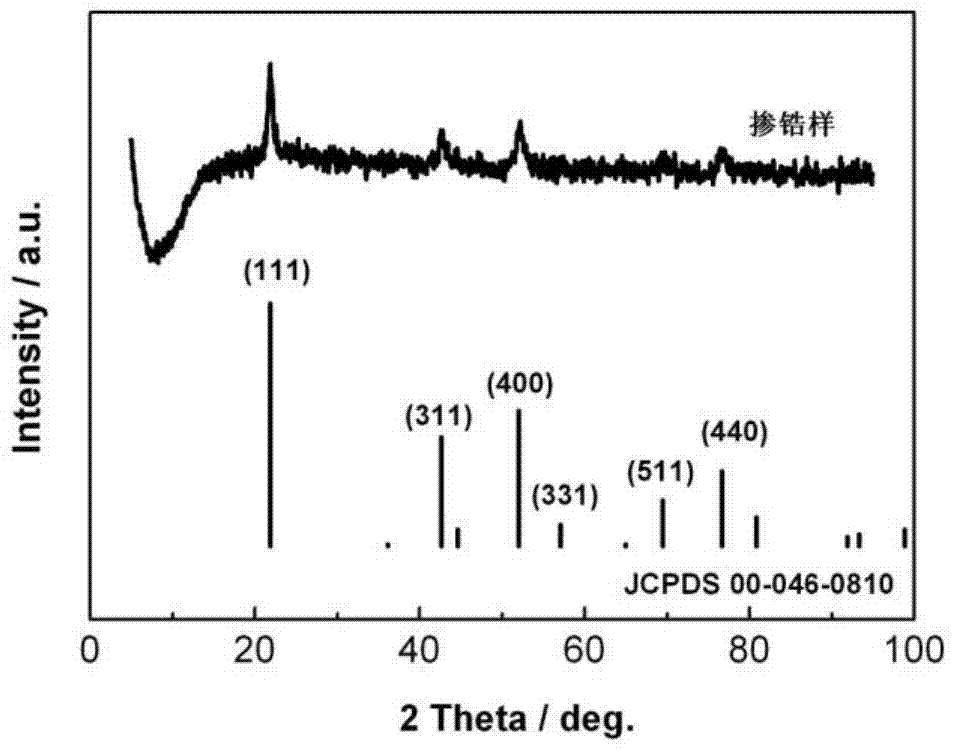

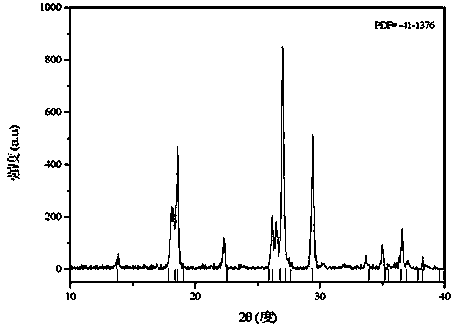

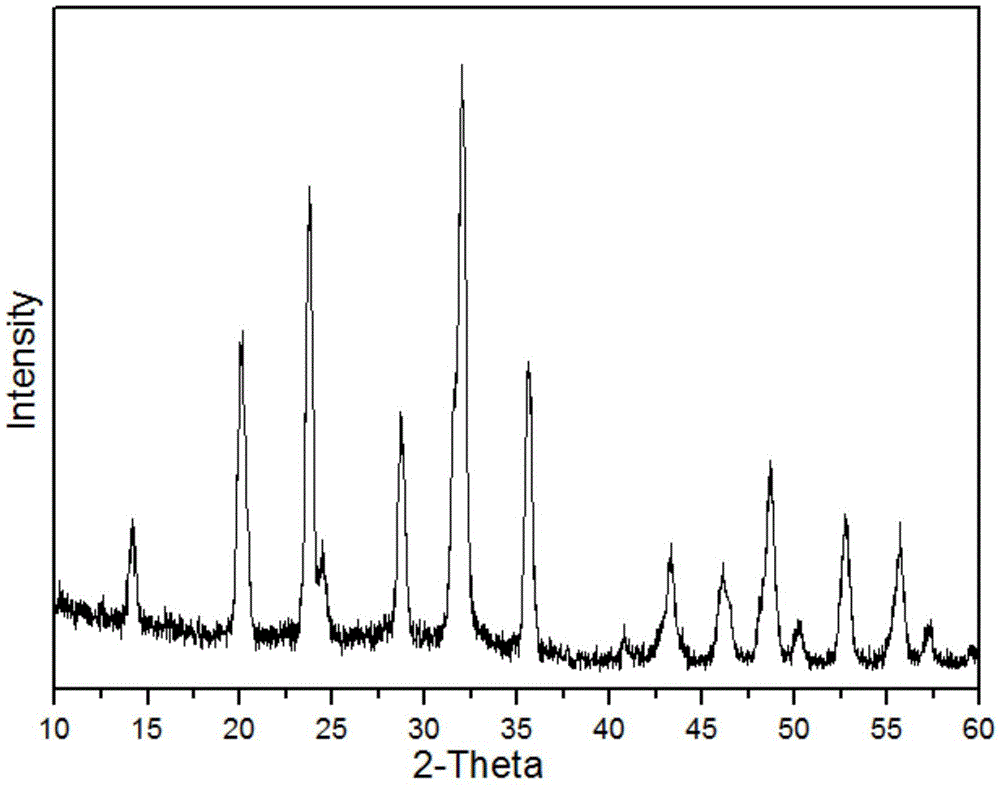

Method for preparing spinel-doped lithium-enriched lithium manganate anode material through doping zirconium

The invention relates to a method for preparing a spinel-doped lithium-enriched lithium manganate anode material through doping zirconium. The method is characterized by respectively weighing compounds of lithium, manganese and zirconium according to the fact that the mol ratio of lithium ions (x) to manganese ions (y) to zirconium ions (z) is (0.95-1.06):(1.05-1.20):(0.05-0.20); y+z is greater than or equals to 1.20 and is less than or equals to 1.25. The compounds of the lithium, the manganese and the zirconium are mixed and added with wet milling mediums to prepare a precursor 1; the precursor 1 is dried to prepare a precursor 2; the LixMnyZrzO12 spinel-doped lithium-enriched lithium manganate anode material is prepared by the precursor 2 through the two-stage sintering method. Zirconium-doped samples prepared by the invention are high in structure stability, so that the lithium ions are conveniently embedded in and released out when charging and discharging, and excellent foundation is laid for the industrialization.

Owner:贵州唯特高新能源科技有限公司

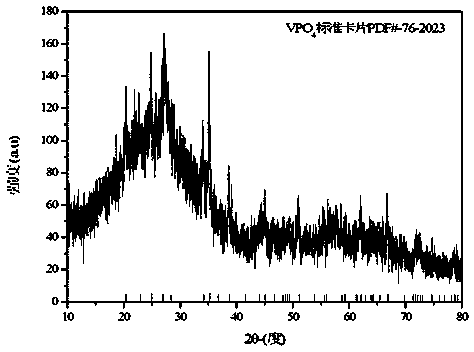

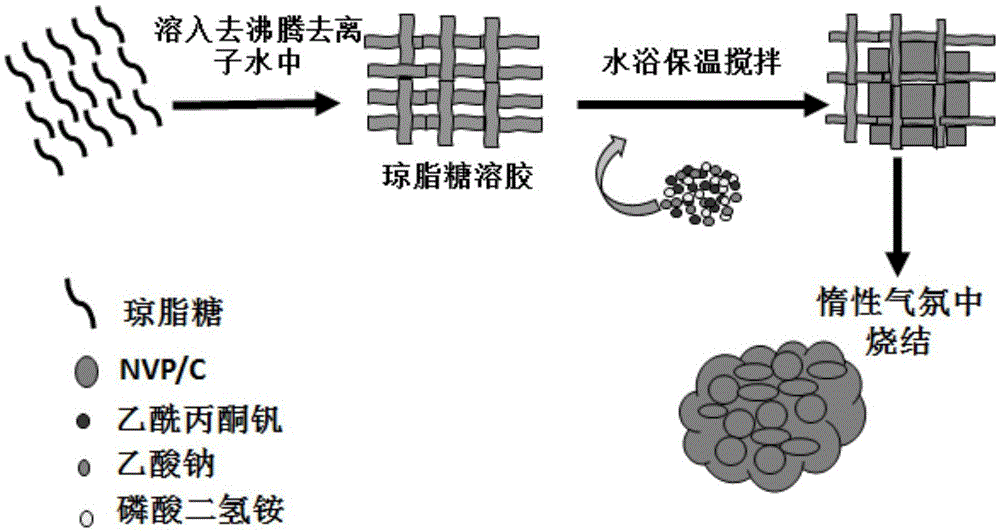

Preparation method for nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate

ActiveCN103840157AEasy to passEasy to embedMaterial nanotechnologyCell electrodesWater bathsLithium-ion battery

The invention provides a preparation method for a nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate. The preparation method comprises the following step: (1) dissolving a vanadium source, a phosphorus source and a reducing agent into water; (2) agitating in a water bath; (3) adjusting the pH to 2-12; (4) transferring the solution to a polytetrafluoroethylene tank; putting the polytetrafluoroethylene tank into a pyrolysis tank, and heating and reacting at 220-280 DEG C for 15-25 hours; cooling to a room temperature; (5) filtering and drying in vacuum; (6) arranging into an agate mortar to be grinded; then sintering under a non-oxidization atmosphere; cooling to the room temperature to obtain a crystallized-state vanadium phosphate precursor; (7) mixing the crystallized-state vanadium phosphate precursor with a lithium source and a fluorine source; uniformly grinding; and (8) arranging a mixture into a pipe type sintering furnace and sintering under the non-oxidization atmosphere; and cooling to the room temperature to obtain the nano sheet-shaped lithium ion battery positive electrode material fluorine lithium vanadium phosphate. According to the preparation method, the microcosmic appearance of the positive electrode material is in a sheet-shaped structure with the thickness being in a nano grade; the surface of a nano sheet is uniformly coated with carbon and the appearance of the material is special; the excellent electrochemical performance is represented.

Owner:CENT SOUTH UNIV

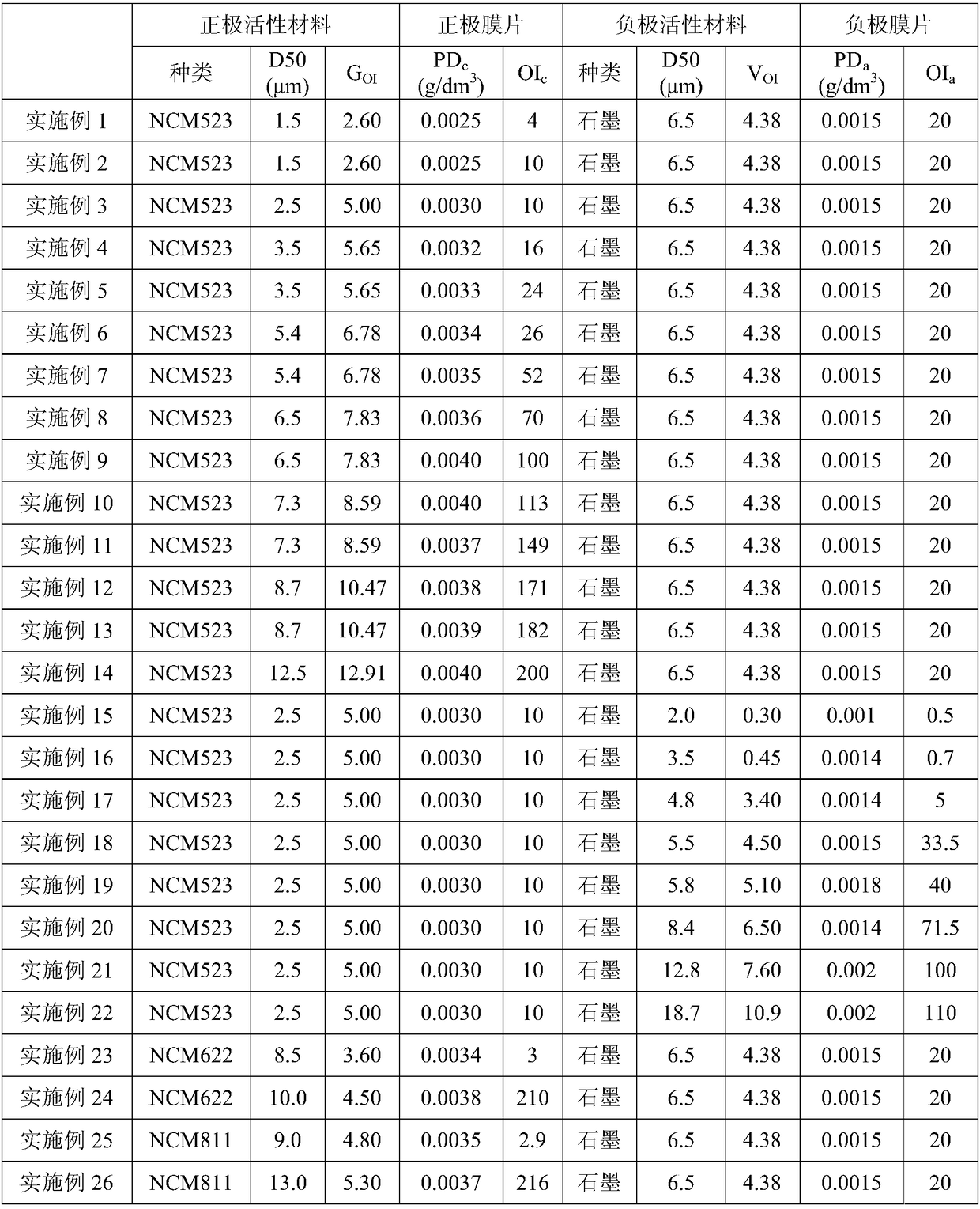

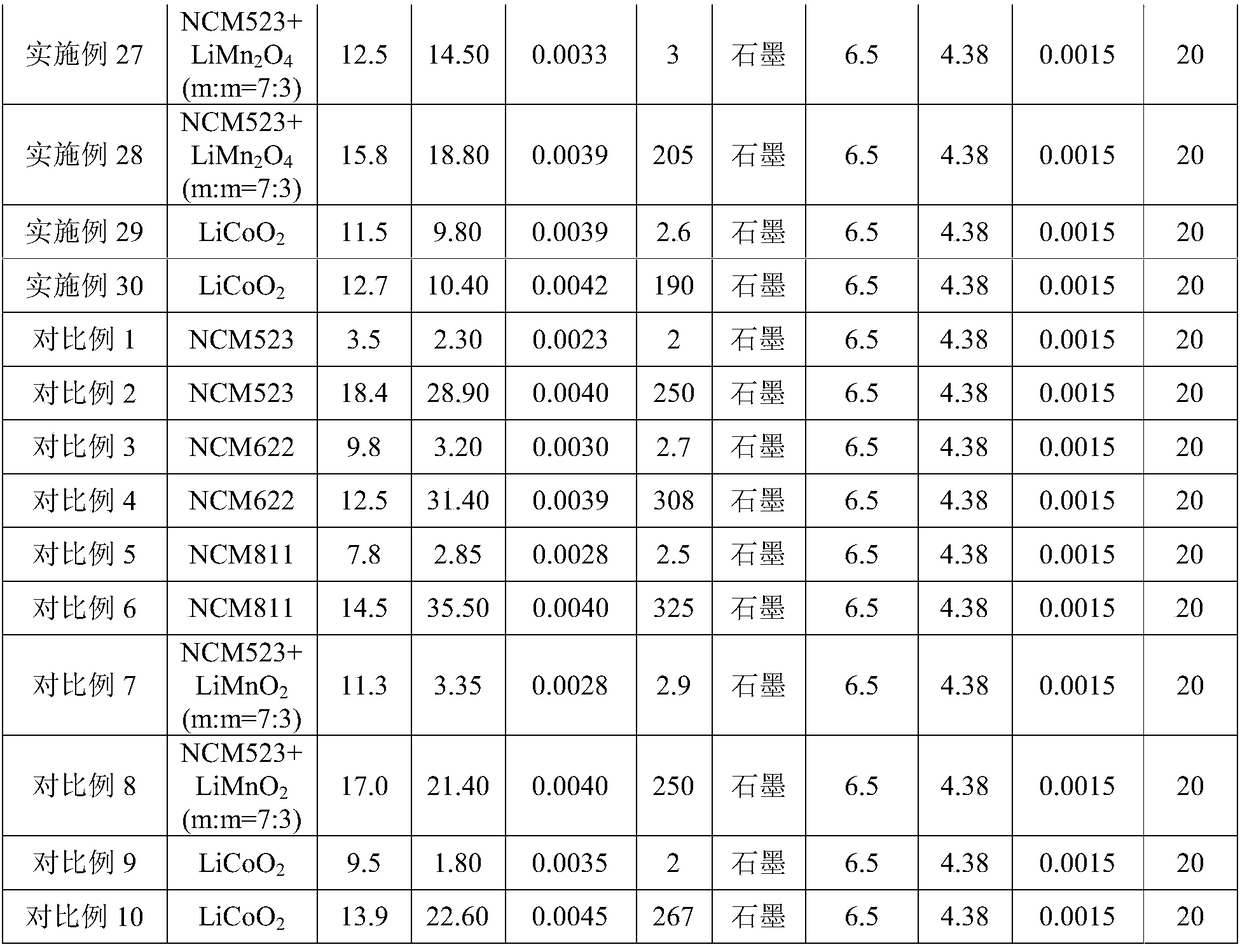

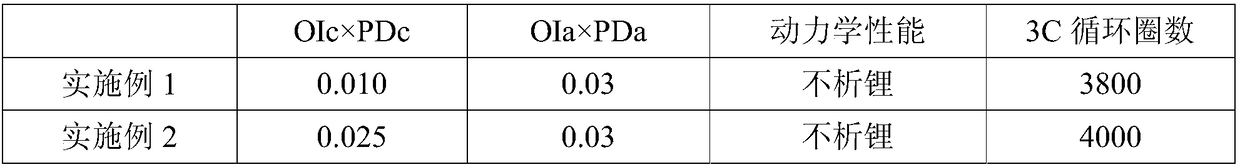

Lithium ion battery

InactiveCN108808072APromote prolapseEasy to embedSecondary cellsActive material electrodesLithium compoundLithium-ion battery

The invention provides a lithium ion battery which comprises a positive electrode piece, a negative electrode piece, an isolating membrane and electrolyte solution. The positive electrode piece comprises a positive electrode current collector and positive electrode diaphragms, the positive electrode diaphragms are arranged on at least one surface of the positive electrode current collector and comprise positive electrode active materials, the positive electrode active materials comprise layered lithium-containing compounds, and the positive electrode diaphragms meet the equation of 0.01<=OIc*PDc<=0.80. The lithium ion battery has less expansion and high charging ability and excellent circulation service life and safety when being rapidly charged for a long time.

Owner:CONTEMPORARY AMPEREX TECH CO LTD

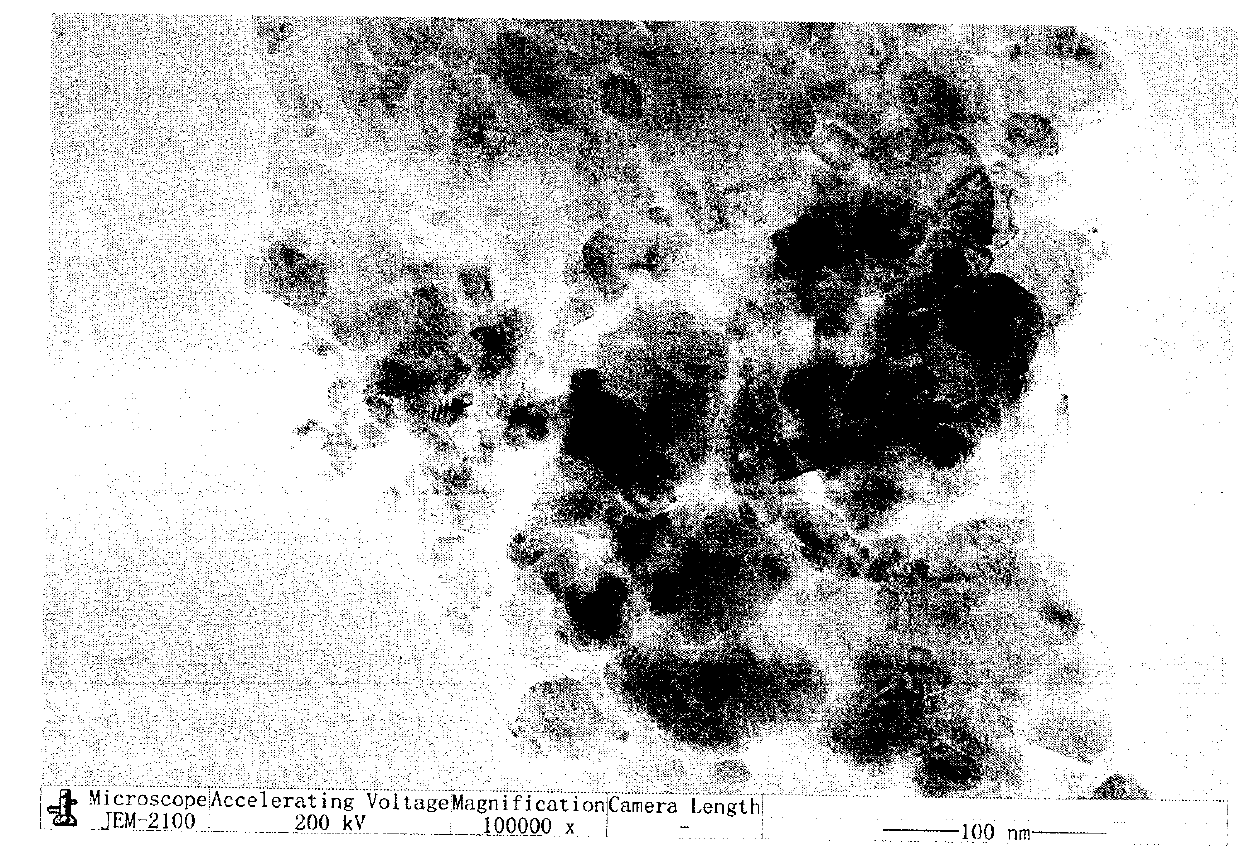

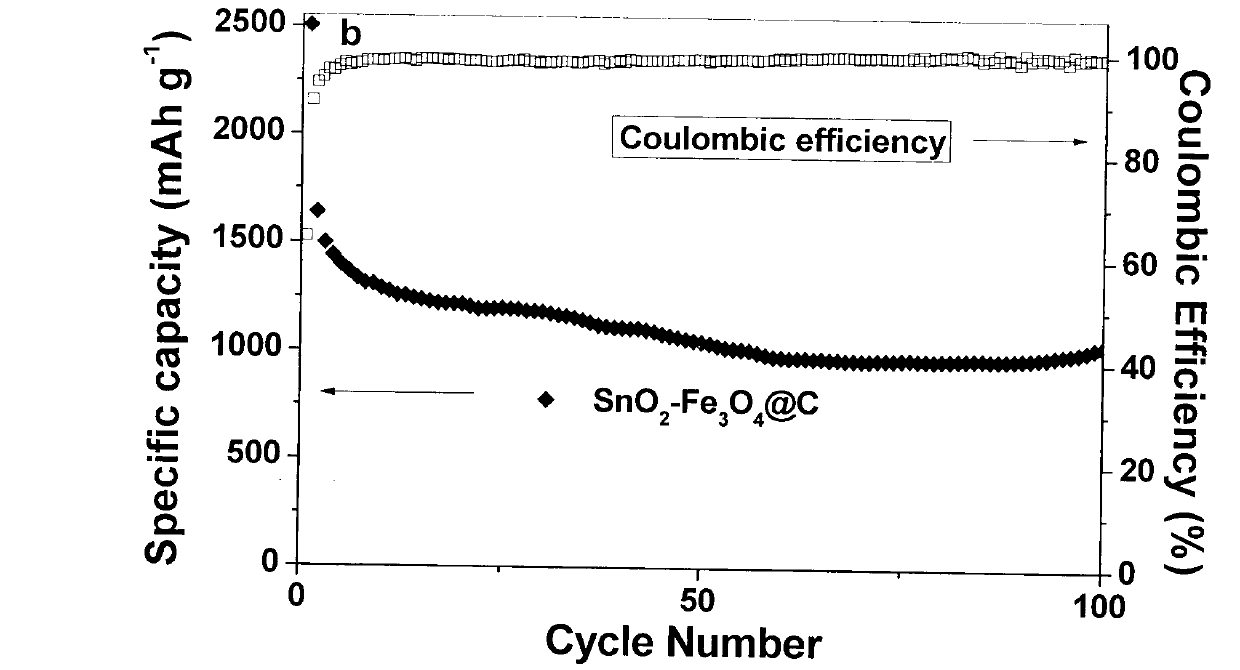

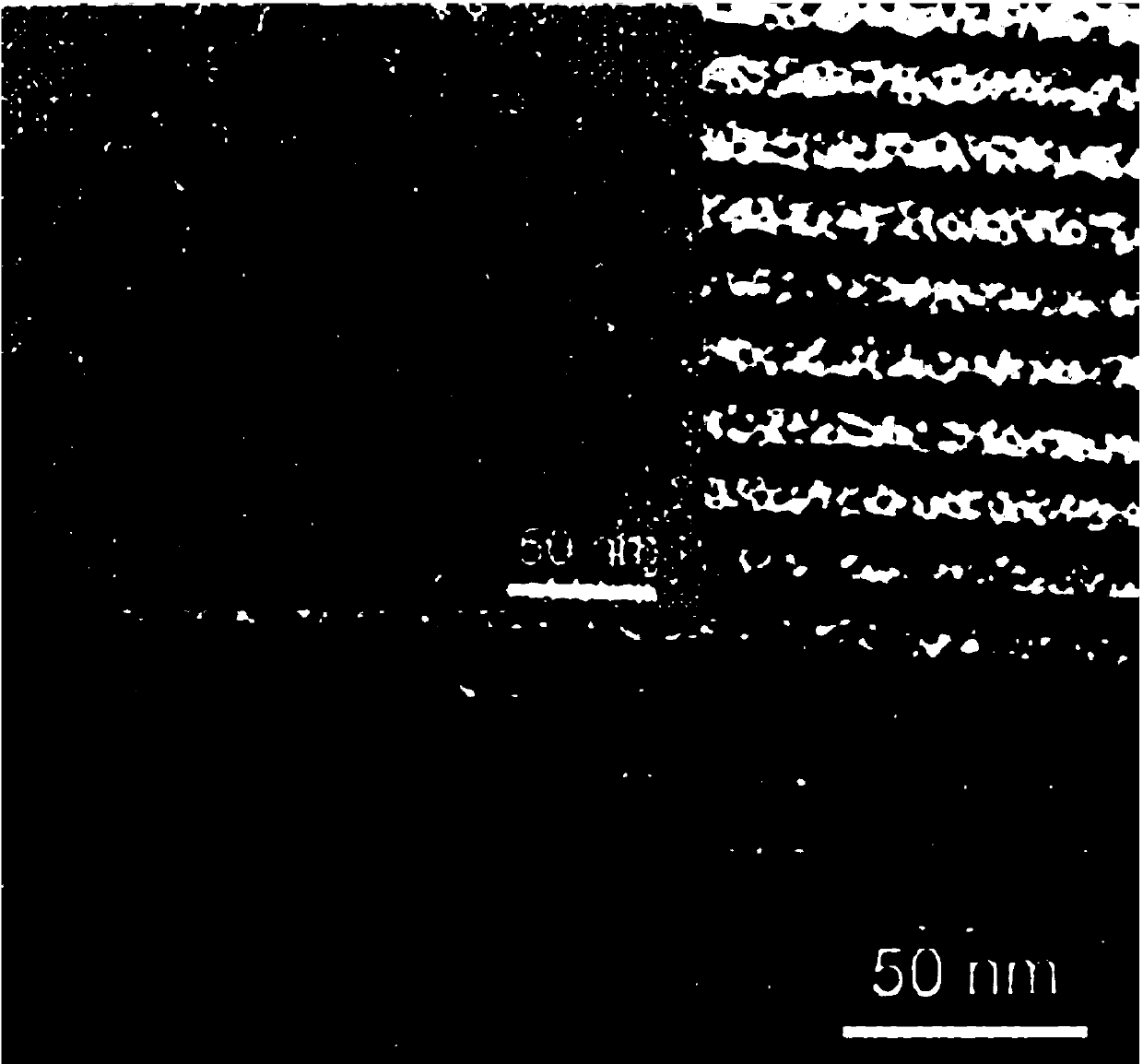

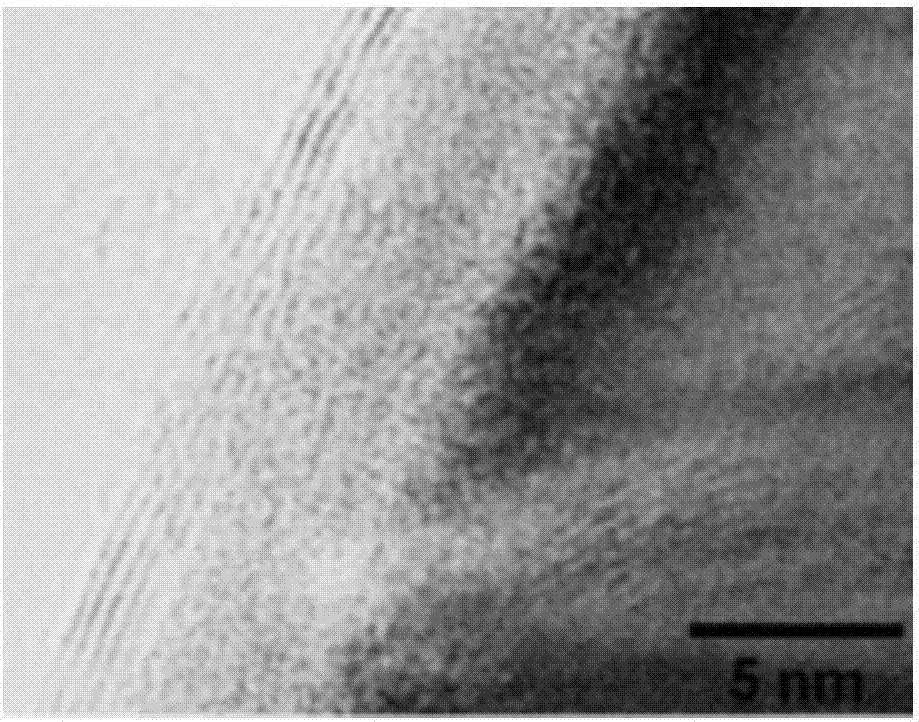

Preparation method for carbon coated composite metal oxide electrode material

The invention discloses a preparation method of a carbon coated stannic oxide (SnO2)-iron trioxide (Fe2O3) composite oxide material. During the preparation of the material, a polyaniline layer is introduced on the surface of a composite oxide by in-situ polymerization, and the carbon coated SnO2-Fe2O3 composite oxide material is obtained by a calcination method. The composite oxide material prepared by the method has the advantages of controllable particles, uniform thickness of a carbon layer; and the composite oxide material as a negative electrode material for a lithium ion battery has the characteristics of high lithium storage capacity and excellent cycling performance.

Owner:QINGDAO UNIV OF SCI & TECH

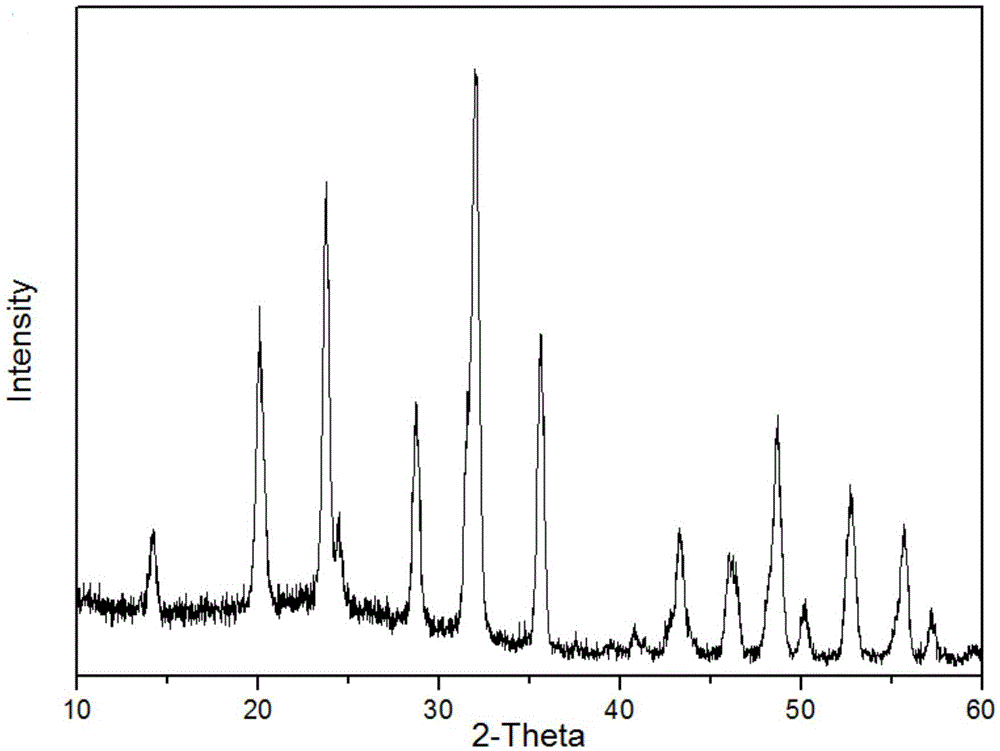

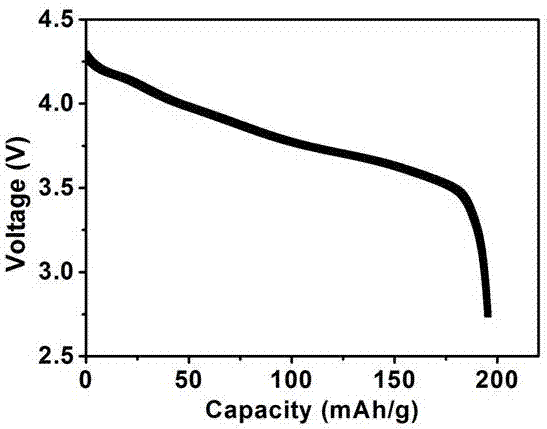

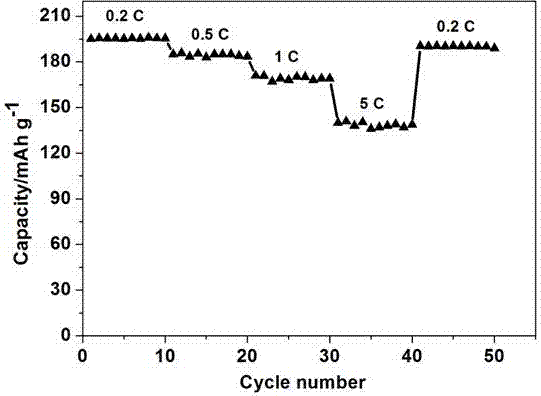

Method for synthesizing lithium nickel cobalt manganese oxide used as anode material for lithium ion battery by template method

ActiveCN104201324AEvenly distributedFacilitated DiffusionElectrode manufacturing processesSecondary cellsNickel saltPolyethylene glycol

A method for synthesizing lithium nickel cobalt manganese oxide used as an anode material for a lithium ion battery comprises the following specific steps: (1) lithium salt, nickel salt, cobalt salt and manganese salt are dissolved in water-organic solvent in a mole ratio to form a metallic solution, the mole ratio of lithium to nickel to cobalt to manganese is 1.1 to 1 / 3 to 1 / 3 to 1 / 3, and the mass ratio of water to the mixture is 10-40wt%; (2) a mixed aqueous solution of ammonia water, ammonium carbonate and polyethylene glycol is prepared; (3) a silicon dioxide molecular sieve is added into the solution obtained in the step (1), the mixed aqueous solution obtained in the step (2) is dripped into the solution under the condition of mechanical agitation, so that a precursor precipitate is obtained; (4) the precursor precipitate obtained in step (3) is washed and dried, so that a lithium nickel cobalt manganese oxide-SBA-15 material is obtained; (5) the lithium nickel cobalt manganese oxide-SBA-15 material prepared in the step (4) is agitated and washed, an SBA-template is removed, and thus the template-free lithium nickel cobalt manganese oxide material is obtained.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Anode material of high-magnification aqueous alkali metal electrochemical battery and preparation method of anode material

ActiveCN103441259APromote prolapseImprove electrochemical performanceAlkaline accumulatorsCell electrodesManganateCrystal structure

The invention relates to an anode material of a high-magnification aqueous alkali metal electrochemical battery and a preparation method of the anode material. The anode material is characterized is that the anode material is manganate with alkali metal of which the formula is AxMnO2, wherein A is one or two selected from Na and K; x is greater than 0 and less than 1; the crystal structure of the manganate with the alkali metal is of a layer-shaped structure. The anode material is of a nano-crystallized three-dimensional shape, the specific surface area of the material is increased, a conduction route for ions and electrons in an aqueous electrolyte is reduced, and the magnification property of an electrode material can be effectively improved.

Owner:ENPOWER ENERGY TECH ANHUI CO LTD +1

Battery diaphragm and lithium ion battery

ActiveCN110197888AReduce polarizationIncrease energy densityCell seperators/membranes/diaphragms/spacersSecondary cellsConductive polymerTemperature resistance

The application provides a battery diaphragm comprising a porous base film and a lithium-replenishing coating attached to one side of the porous base film. The lithium-replenishing coating comprises alithium-replenishing material and a first binder. The lithium-replenishing material comprises a core and a coating layer on the surface of the core. The material of the core comprises a lithium ion compound. The material of the coating layer comprises a conductive polymer. The lithium ion compound has a first delithiated capacity greater than a first lithiated capacity, or the lithiated potentialof a delithiated product of the lithium ion compound is less than or equal to 3V. The application further provides a lithium ion battery comprising a positive electrode, a negative electrode and a diaphragm, wherein the lithium-replenishing coating of the battery diaphragm is opposite to the positive electrode. The battery is prepared by forming the lithium-replenishing coating in one side of thebattery diaphragm and arranging the lithium-replenishing coating of the diaphragm opposite to the positive electrode, thus, the battery capacity is greatly improved. Further, the diaphragm also has good mechanical properties and high temperature resistance.

Owner:BYD CO LTD

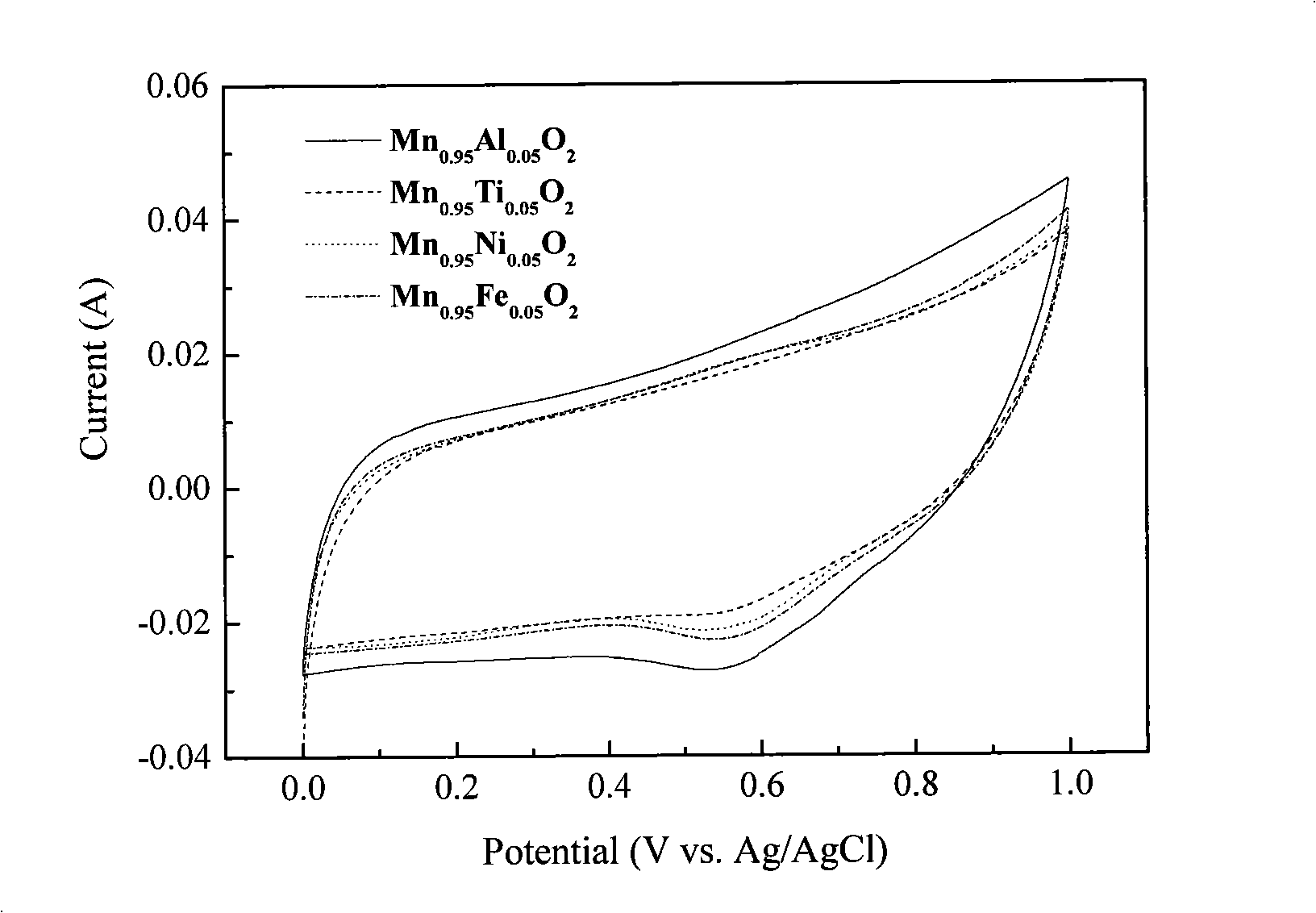

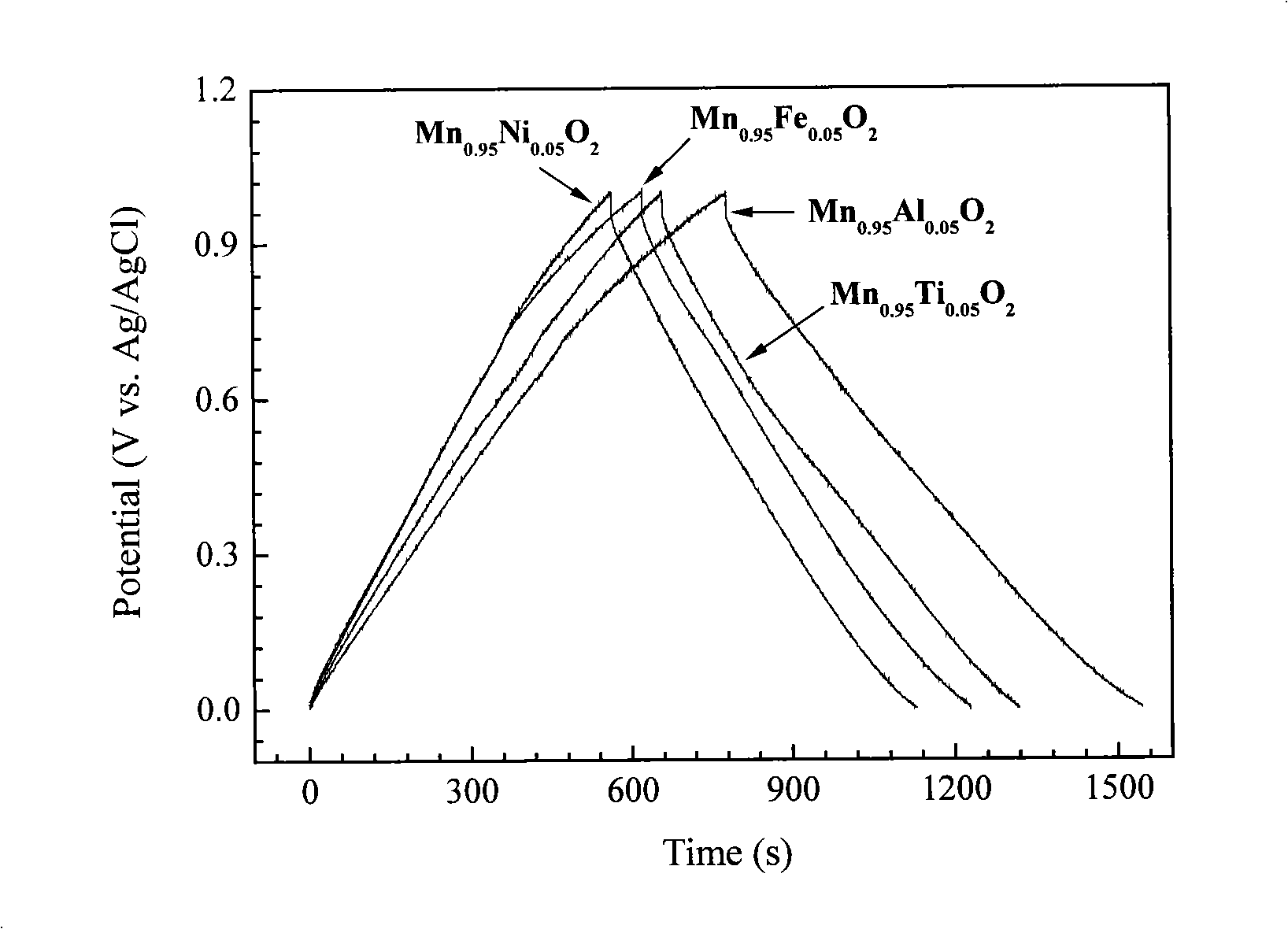

Preparation method for element-doping manganese bioxide electrode material for super capacitor

InactiveCN101409152AEvenly distributedHigh specific capacitanceHybrid capacitor electrodesElectrolytic capacitorsCapacitanceHigh energy

The invention relates to a preparation method of an element doped manganese dioxide electrode material for a supercapacitor; the preparation method is characterized in that the high-energy ball milling method is adopted to mix any one of Al, Ti, Ni and Fe with manganese atoms in manganese dioxide according to the ratio of 0.05: 0.95 and then the mixture is placed in a high-energy ball milling tank, a ball milling medium is selected from agate balls with the different diameters, ratio of grinding media to material is 20:1, ethanol is added for preventing the agglomeration, the ball milling speed is 250 turns / minute, the ball milling time is controlled to be 15 hours; products are taken out after the ball milling tank is cooled to the room temperature, the drying at the constant temperature of 80 DEG C is carried out in a drying box for 48 hours; the powder after the drying is ground in an agate mortar to obtain the element doped manganese dioxide supercapacitor electrode material prepared by ball milling. The preparation method has low cost and simple preparation technology, the obtained element doped manganese dioxide electrode material has uniform distribution, high specific capacitance and good cycle stability; the preparation method can be applied in occasions which need power supply with neutral electrolyte, high stability and high power density.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Sodium vanadium phosphate sodium ion battery positive electrode material and preparation method therefor

InactiveCN105552328APromote prolapseEasy to embedMaterial nanotechnologyCell electrodesCarbon layerCarton

The invention discloses a sodium vanadium phosphate sodium ion battery positive electrode material and a preparation method therefor, and belongs to the fields of an energy storage material and technology. The positive electrode material comprises a three-dimensional carbon framework and Na3V2(PO4)3 composite granules; the Na3V2(PO4)3 composite granules adopt core-shell structures, wherein Na3V2(PO4)3 is taken as the core part while a carton layer is adopted as the shell part; the thickness of the carbon layer is 1-4nm; the grain diameter of the Na3V2(PO4)3 composite granules is 20-200nm; and the Na3V2(PO4)3 composite granules are positioned in the gaps of the three-dimensional carbon framework. The invention also discloses a method for preparing the sodium vanadium phosphate sodium ion battery positive electrode material by adopting a sol-gel method and a ball-milling method. The preparation method is simple in process; and the finally-synthesized positive electrode material has the characteristics of large specific surface area, small grain diameter dimension and uniform carbon layer coating, so that the positive electrode material is excellent in the electrochemical performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of carbon nanotube/manganese dioxide hybridization supercapacitor electrode material

ActiveCN104201006AEasy to embedPromote prolapseHybrid capacitor electrodesHybrid/EDL manufactureGas phaseCarbon nanotube

Provided is a preparation method of a carbon cloth / carbon nanotube / manganese dioxide hybridization supercapacitor electrode material. According to the preparation method, a plasma chemical vapor deposition method is used for directional growth of orderly carbon nanotubes of great binding force on a carbon cloth, and a hydrothermal mode is used for completely coating the periphery of the carbon nanotubes with a layer of nano sheet-like alpha-MnO2 active substances. The hybridization electrode material prepared through the method is simple in structure and has a directional porous channel for facilitating the embedding, removing and diffusion of the plasma, thereby having the characteristics such as high capacity and high cycle performance.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method for preparing high-rate nickel cobalt lithium aluminate anode material

ActiveCN107093741AImprove performanceImprove cycle performanceCell electrodesSecondary cellsCyclic processHigh rate

The invention discloses a method for preparing a high-rate nickel cobalt lithium aluminate anode material. The method comprises the following steps: (1) preparing a nickel cobalt lithium aluminate precursor; (2) performing lithium-site doping and modifying on potassium ions; and (3) constructing a cladding layer of a lithium-containing compound. According to the method, the dispersing speed of lithium ions is effectively increased by lithium-site replacement of potassium ions, and the rate capability of a material can be improved; the lithium-containing compound layer constructed on the material surface can be used for reducing the content of alkali remained on the material surface and reduce later cell bubbling; side reaction can be effectively inhibited, and the material structure stability in the cycling process can be promoted; and the lithium-containing compound layer has high conducting performance for lithium ions, embedding and separating of lithium ions can be accelerated, the problem of poor lithium ion conductivity when conventional metal oxide is used as the cladding layer can be solved, and the cycling performance and rate performance of the material can be improved.

Owner:郑州中科新兴产业技术研究院

Porous carbon nanometer tubular material and preparation method and application thereof

The invention discloses a dual-layer porous carbon nanometer tubular material and a preparation method and application thereof. The material has a coaxial dual-layer hollow tubular structure, wherein a carbon material taking high graphitized carbon as main is arranged at an inner layer, and a carbon material taking amorphous carbon as main is arranged at an outer layer. The preparation method comprises the steps of preparing a transition metal nanowire by a hydrothermal method, coating an organic carbon source on a surface of the transition metal nanowire to obtain a precursor by a liquid phase deposition method, and carbonizing and pickling the precursor to obtain the material. The method has the advantages of available raw material, simple preparation process and good repeatability, and the prepared material has relatively large inter-layer distance, rich porous structure, large specific area and favorable conductivity, shows high cycle efficiency, high specific capacity and rate performance when applied to a sodium ion battery, and has wide industrial application prospect.

Owner:CENT SOUTH UNIV

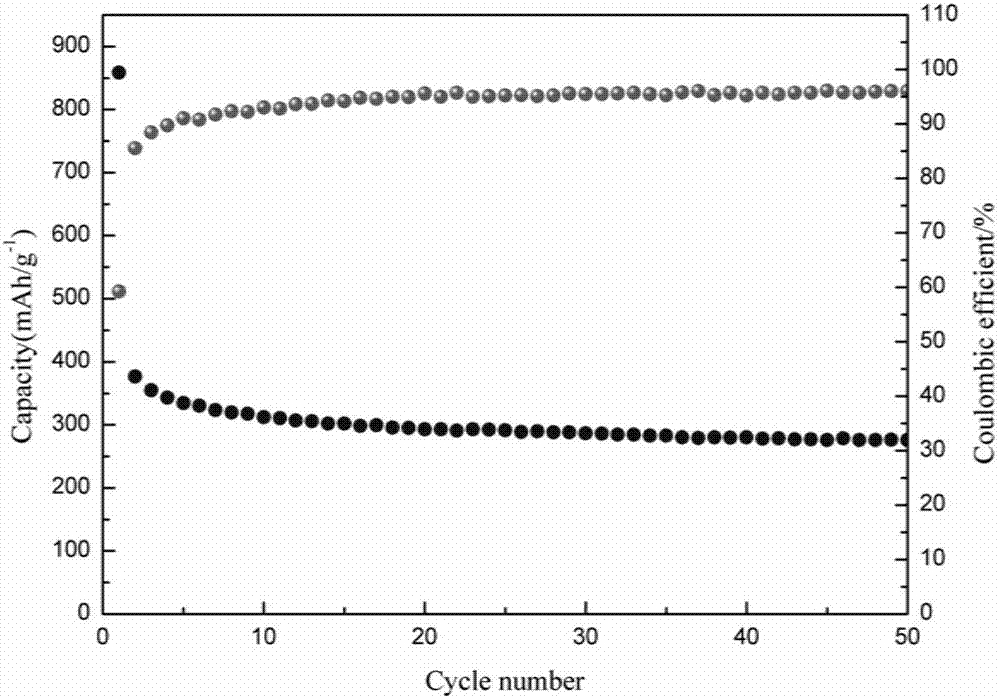

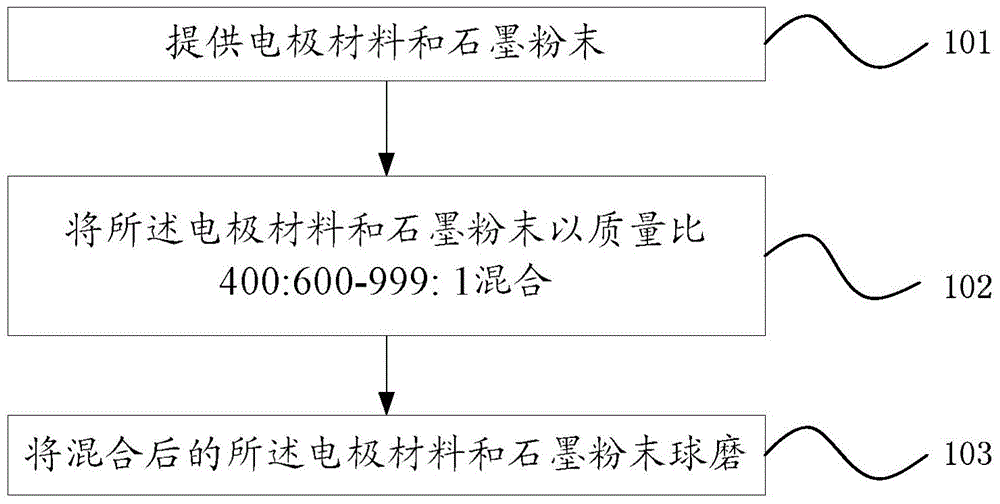

Graphene composite material and preparation method thereof

The present invention relates to a preparation method of a graphene composite material, and the method comprises the following stesp: providing an electrode material and graphite powder; mixing the electrode material and the graphite powder in a mass ratio of 400: 600-999: 1; and ball-milling the mixture of the electrode material and the graphite powder. In the preparation process, a few-layer-graphene-coated electrode material is formed to facilitate embedding and removal of lithium ions, conductive performance and cycle performance of lithium ion battery electrode materials can be improved, and the overall electrochemical properties of lithium-ion batteries can be greatly improved. At the same time, the graphene composite material is low in cost and is suitable for mass production and application.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com