Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

A positive electrode material, high-nickel technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability, low capacity and first Coulombic efficiency, and more residual lithium on the surface, so as to reduce residual lithium and improve initial Effect of improving discharge capacity and surface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

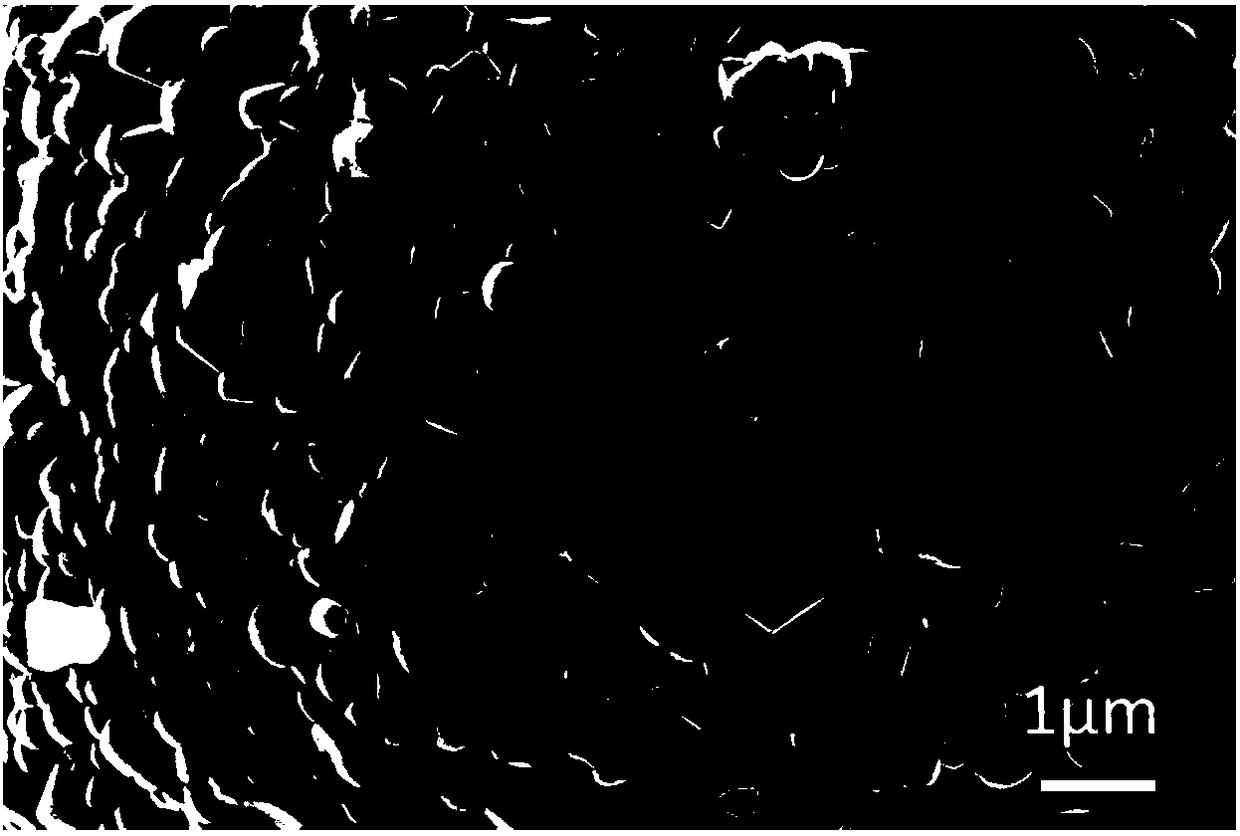

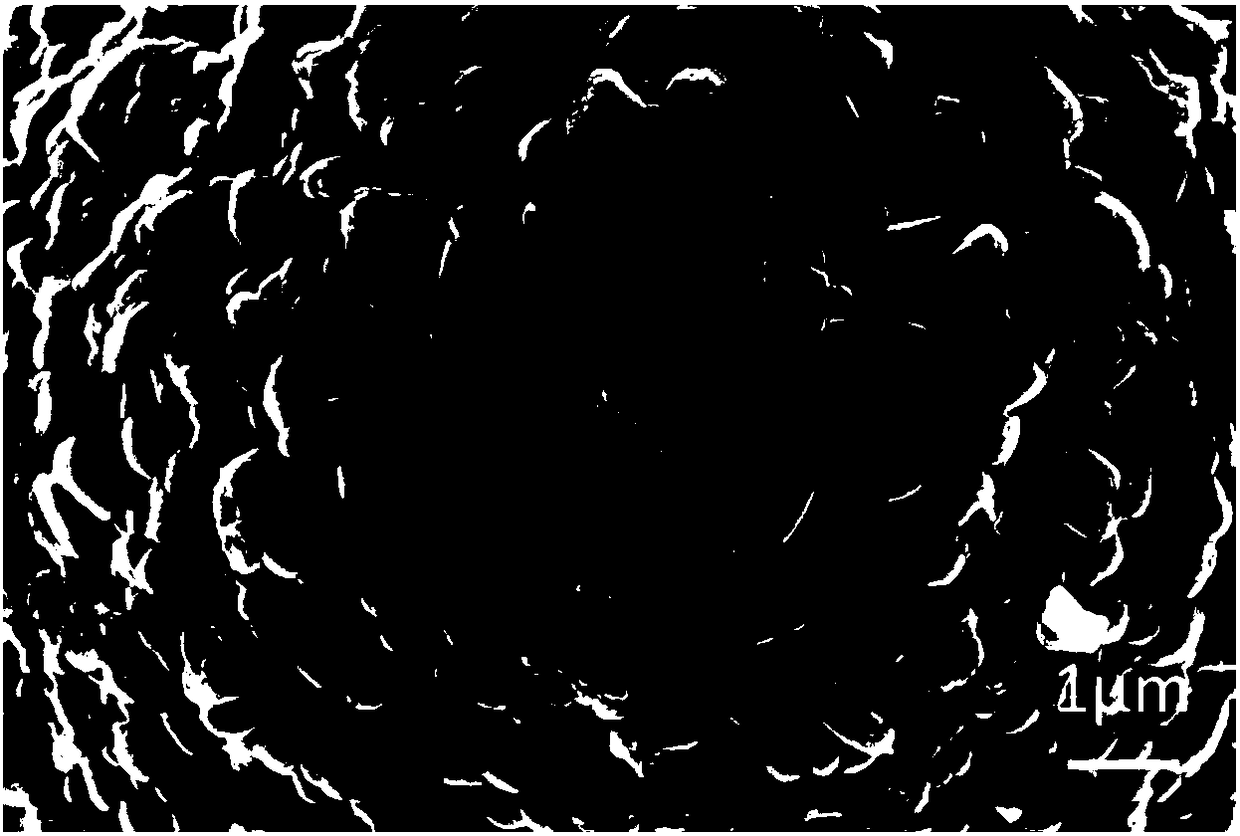

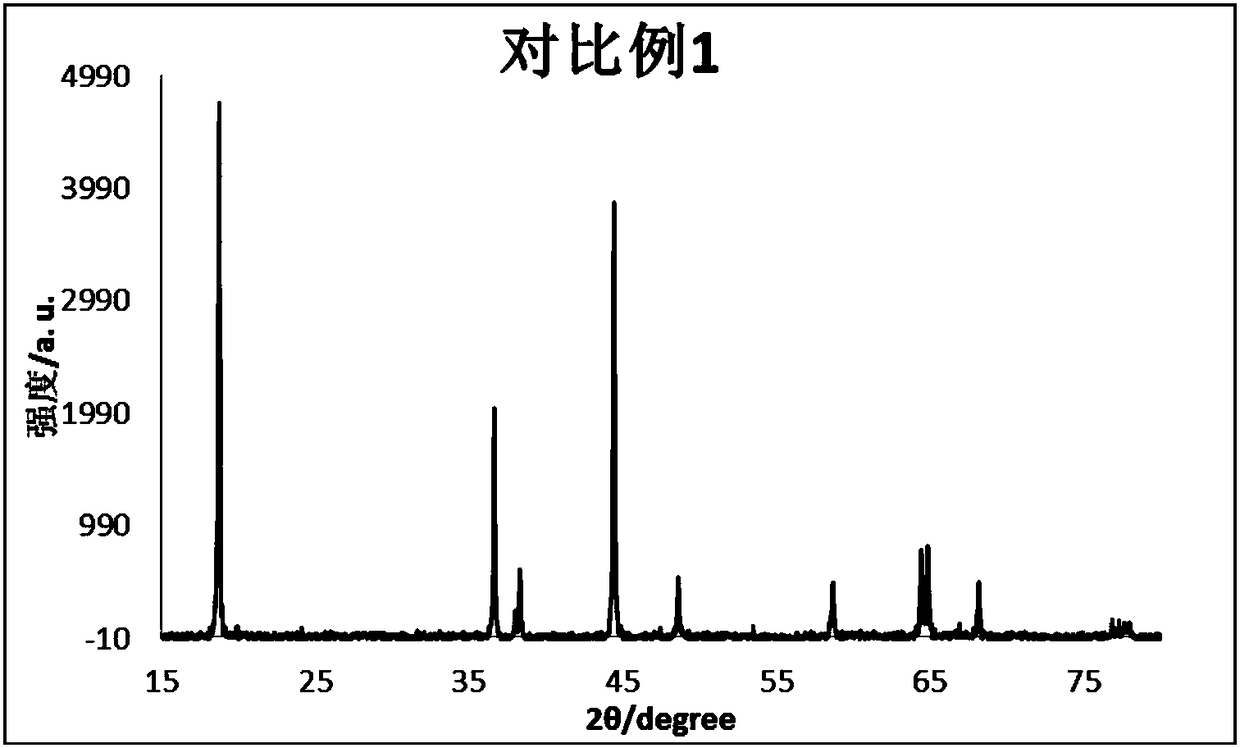

[0038] A modified high-nickel ternary positive electrode material coated with a fast ion conductor material (LLTO), wherein the high-nickel ternary positive electrode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , the LLTO cladding accounts for LiNi 0.8 co 0.1 mn 0.1 o 2 0.3wt% by weight, cladding thickness is 20nm, LLTO is Li 0.2 La 0.6 TiO 3 ; The SEM image of the modified high-nickel ternary cathode material is as follows figure 2 As shown, the XRD pattern is as Figure 4 shown.

[0039] The preparation steps mainly include: adding tetrabutyl titanate, lanthanum nitrate, and lithium nitrate into ethanol in sequence according to the element ratio of 1:0.6:0.2 in molar ratio, stirring for about 30 minutes until completely dissolved, and then putting the solution in a water bath heated to 60°C in a medium temperature and kept stirring to evaporate the organic solvent, dried the obtained solid powder in a vacuum oven for 12 hours, and finally sintered the obtained powder ...

Embodiment 2

[0041] A modified high-nickel ternary positive electrode material coated with LLZO, wherein the high-nickel ternary positive electrode material is LiNi 0.8 co 0.1 mn 0.08 Zr 0.02 o 2 , the LLZO cladding accounts for LiNi 0.8 co 0.1 mn 0.08 Zr 0.02 o 2 0.3 wt% by weight, LLZO as Li 0.2 La 0.6 ZrO 3 .

[0042] Its preparation method is the same as that of Example 1, except that tetrabutyl titanate is replaced by zirconium nitrate, and the solvent is deionized water. The final Li 0.2 La 0.6 ZrO 3 coated LiNi 0.8 co 0.1 mn 0.08 Zr 0.02 o 2 The material is assembled as a positive electrode material into a buckle for capacity and first-efficiency tests.

Embodiment 3

[0044] A kind of LMPO modified high-nickel ternary cathode material, wherein, the high-nickel ternary cathode material is LiNi 0.8 co 0.1 mn 0.1 o 2 , the LMPO coating accounts for the LiNi 0.8 co 0.1 mn 0.1 o 2 0.3wt% by weight, LiMPO 4 for Li 2 AlPO 4 .

[0045] Its preparation method is to add ammonium dihydrogen phosphate, aluminum nitrate, and lithium nitrate into deionized water in sequence according to the element ratio of 1:1:2 by molar ratio, and the rest of the steps are the same as in Example 1 to obtain the fast ion conductor Li 2 AlPO 4 coated LiNi 0.8 co 0.1 mn 0.1 o 2 , using it as a positive electrode material, assembled into a buckle according to the method of Example 1 for capacity and first effect tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com