Preparation method and application of graphene/sulfur/prussian blue analogue composite material

A technology of Prussian blue and composite materials, applied in the field of preparation of graphene/sulfur/Prussian blue analog composite materials, can solve the problems of poor cycle stability, low Coulombic efficiency, low sulfur conductivity, etc., and achieve good conductivity, good Effects of mechanical properties, unique electrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

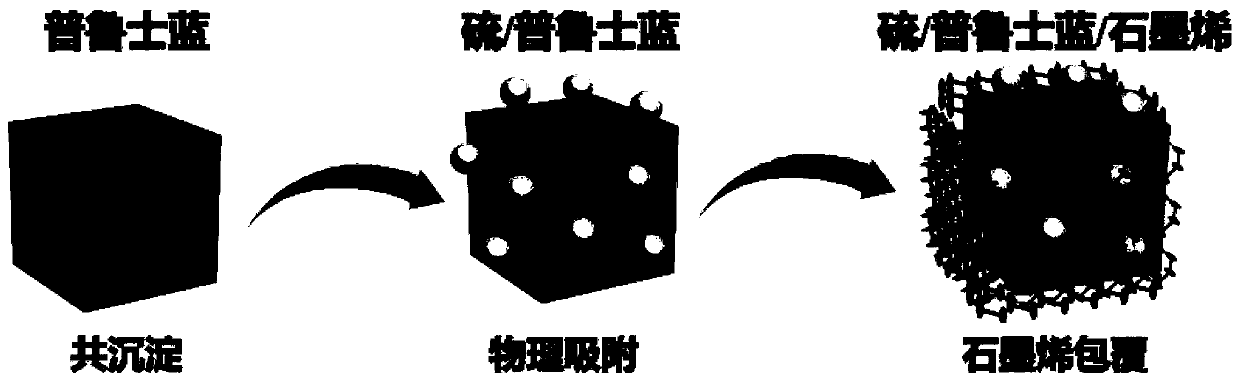

[0035] A kind of preparation method of graphene / sulfur / Prussian blue analog composite material, comprises the steps:

[0036]Step 1. Preparation of Prussian blue analogues: Weigh a certain mass of sodium ferrocyanide decahydrate and polyvinylpyrrolidone, add them to a certain volume of hydrochloric acid solution, stir evenly, and drop a certain volume of Cobalt chloride solution, after the dropwise addition, continue to stir for a certain period of time, then put it in an oven, react at a constant temperature of 80-90°C for 10-12 hours, filter after the reaction, wash the obtained precipitate with distilled water and ethanol, and dry it in vacuum to obtain Prussia Blue analogue, ready to use;

[0037] Step 2, preparation of sulfur / Prussian blue analog composite material: weigh the Prussian blue analog and sulfur powder prepared in step 1 according to a certain mass ratio, add it to a certain volume of carbon disulfide solution, stir evenly, and steam at a certain temperature ...

specific Embodiment approach 2

[0055] The graphene / sulfur / Prussian blue analogue composite material prepared according to the preparation method of the graphene / sulfur / Prussian blue analogue composite material described in Embodiment 1 is used as a cathode material for a lithium-sulfur battery.

specific Embodiment approach 3

[0057] A kind of preparation method of graphene / sulfur / Prussian blue analog composite material, comprises the steps:

[0058] Step 1. Preparation of Prussian blue analogues: Weigh a certain mass of sodium ferrocyanide decahydrate and polyvinylpyrrolidone, add them to a certain volume of hydrochloric acid solution, stir evenly, and drop a certain volume of Cobalt chloride solution, after the dropwise addition, continue to stir for a certain period of time, then put it in an oven, react at a constant temperature of 80-90°C for 10-12 hours, filter after the reaction, wash the obtained precipitate with distilled water and ethanol, and dry it in vacuum to obtain Prussia Blue analogue, ready to use;

[0059] Step 2, preparation of sulfur / Prussian blue analog composite material: weigh the Prussian blue analog and sulfur powder prepared in step 1 according to a certain mass ratio, add it to a certain volume of carbon disulfide solution, stir evenly, and steam at a certain temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge rate | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com