Patents

Literature

633results about How to "Inhibition of volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

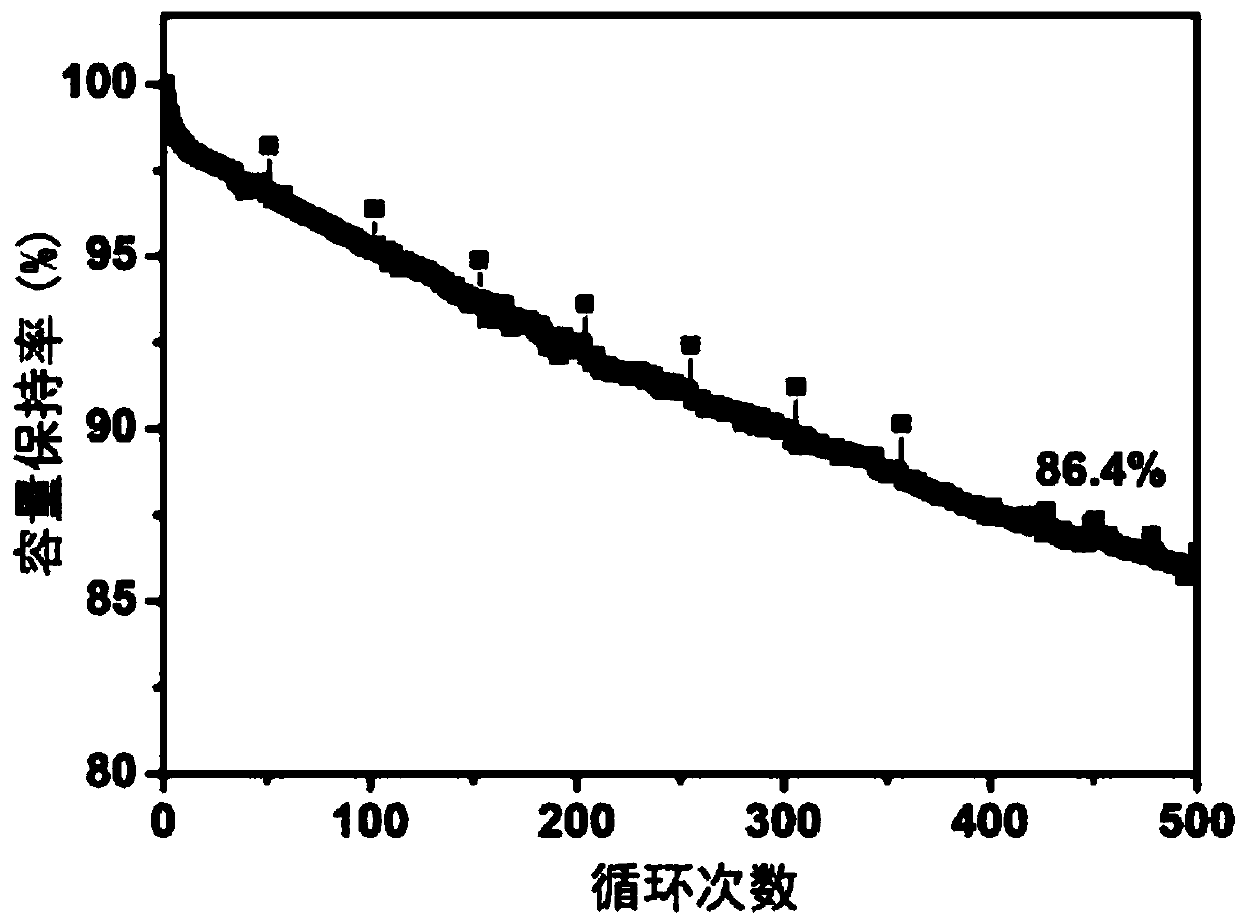

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

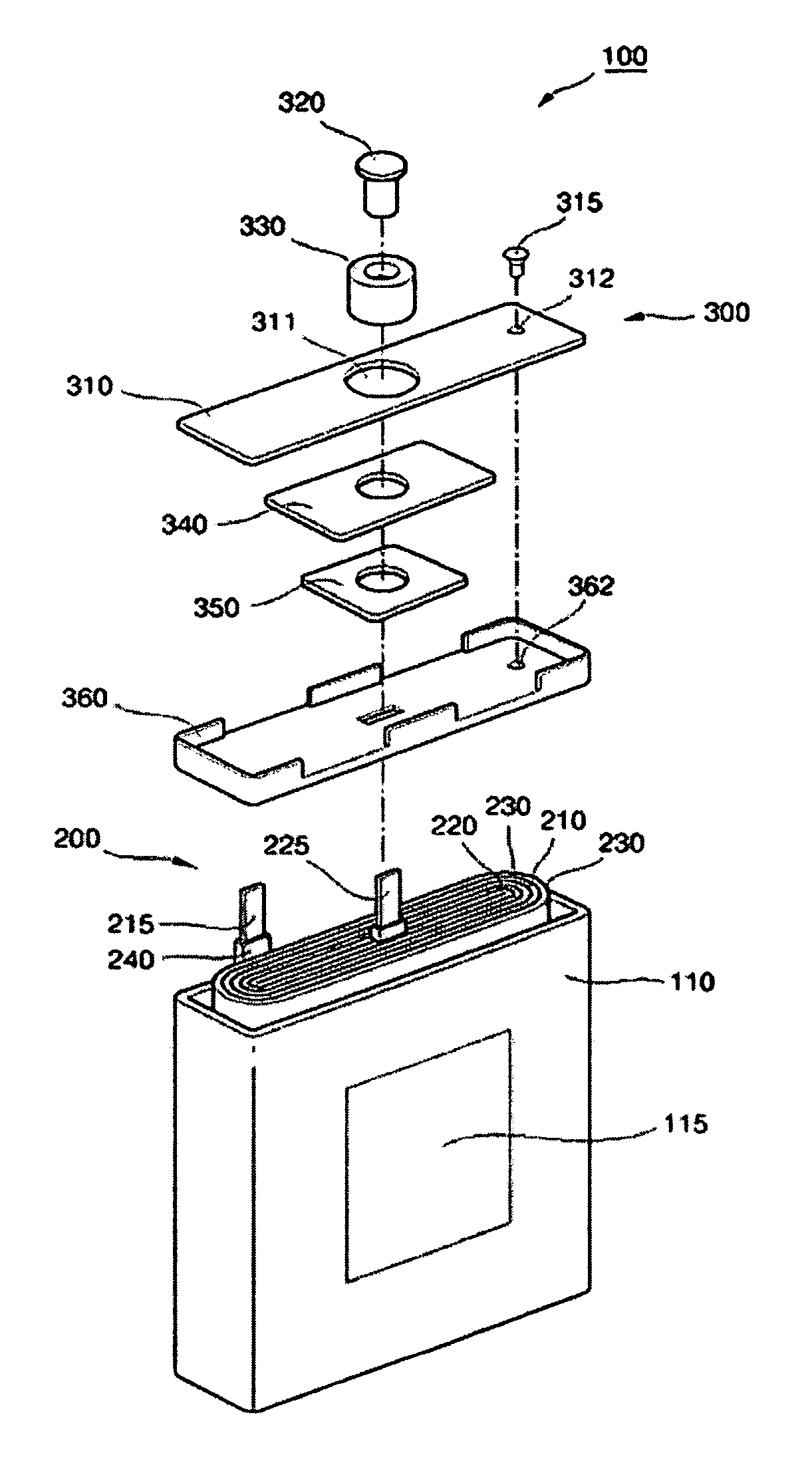

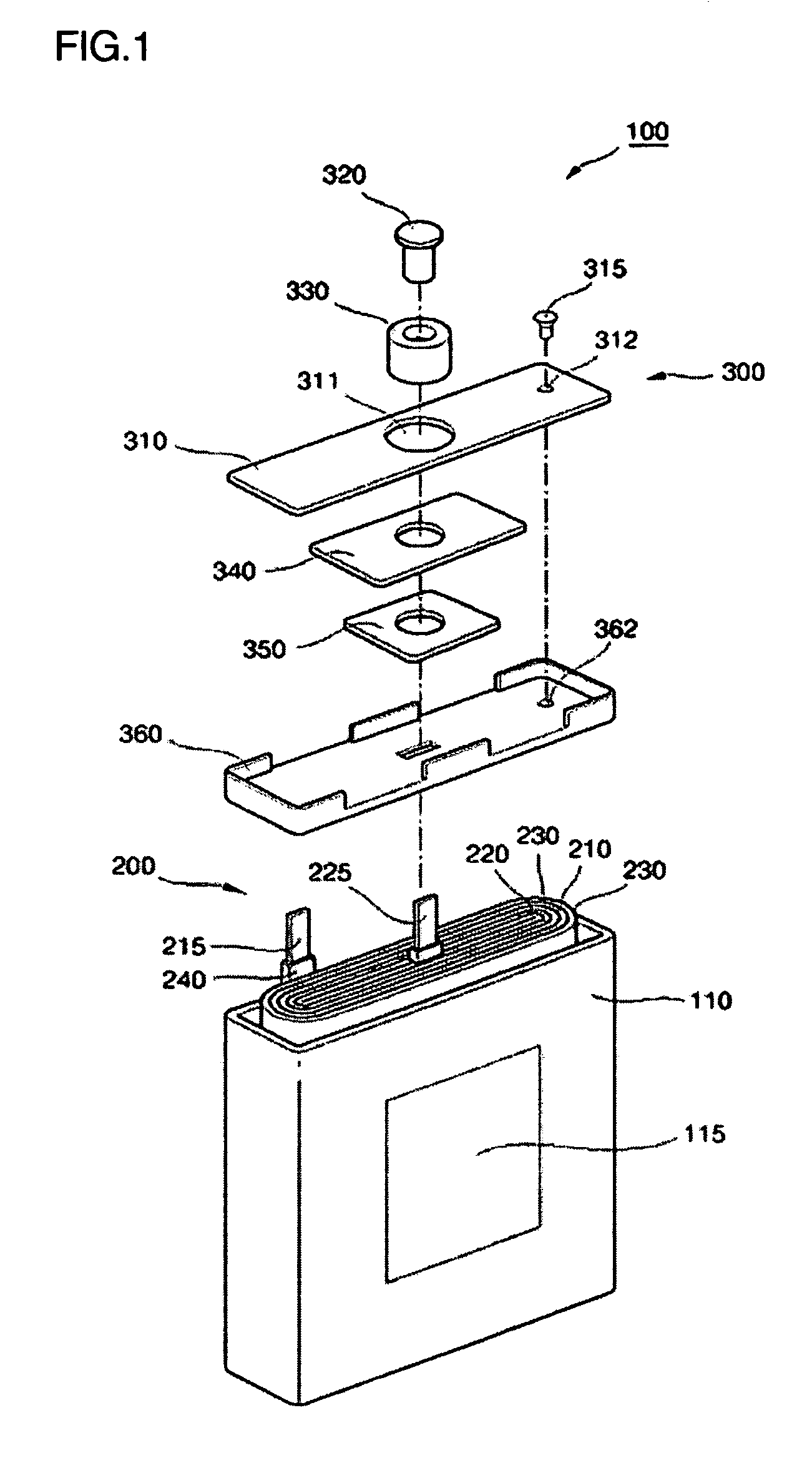

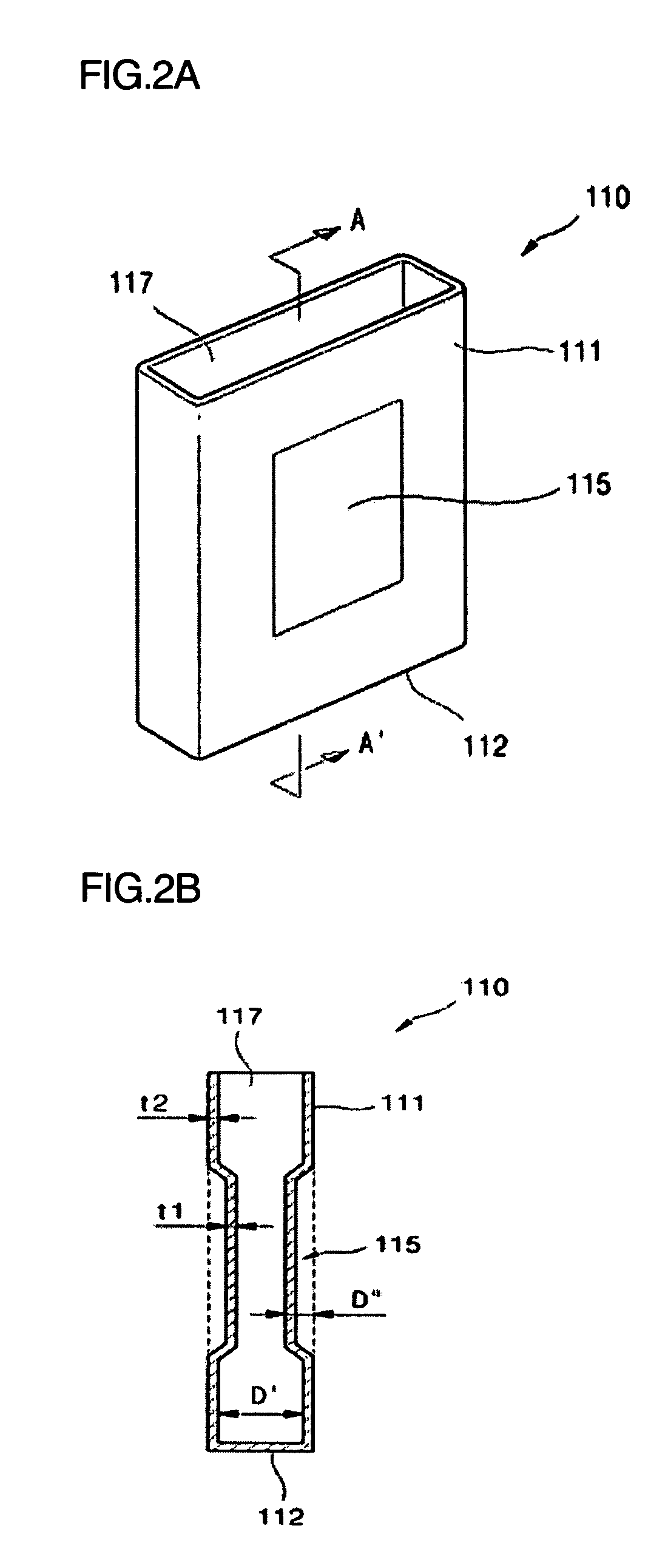

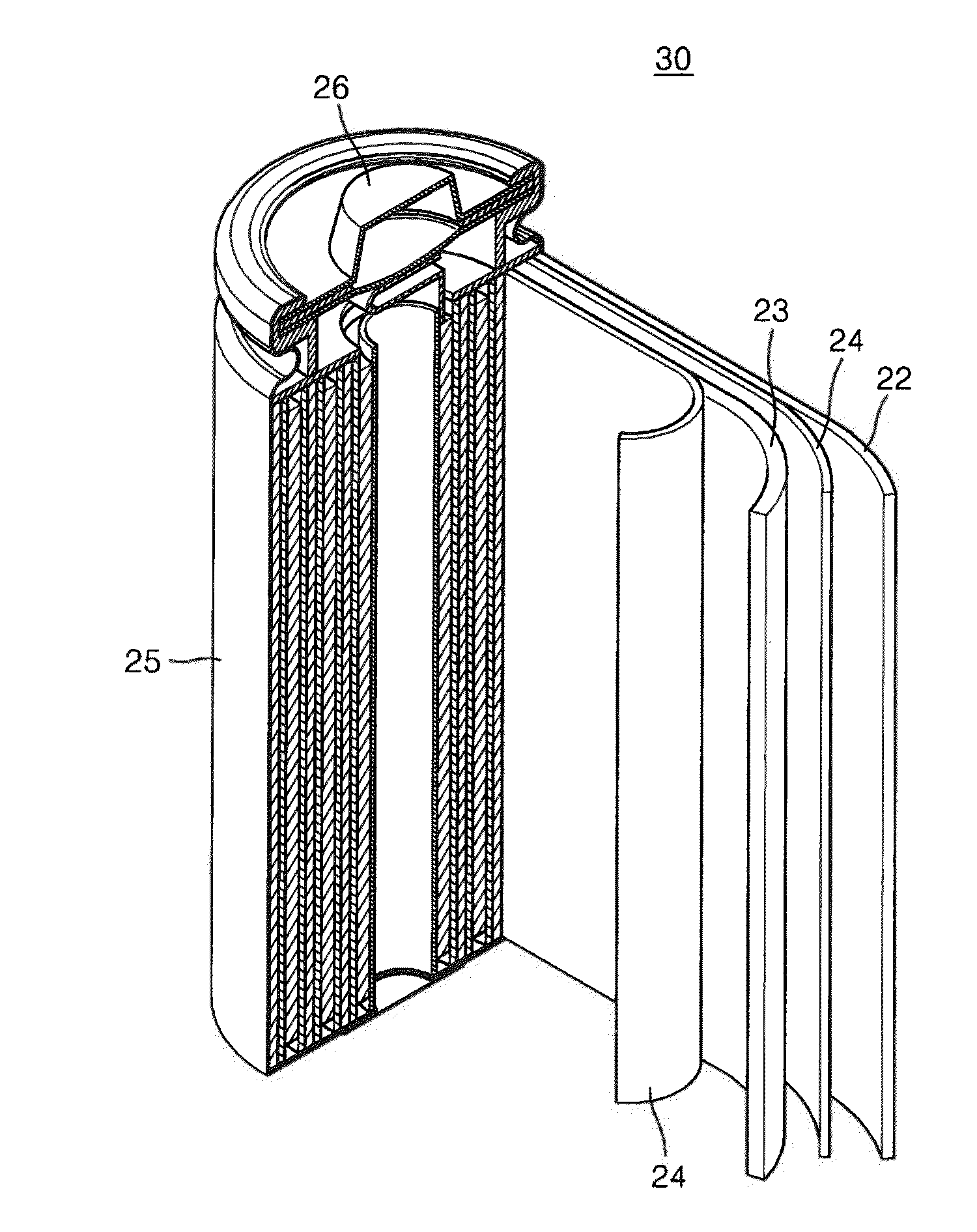

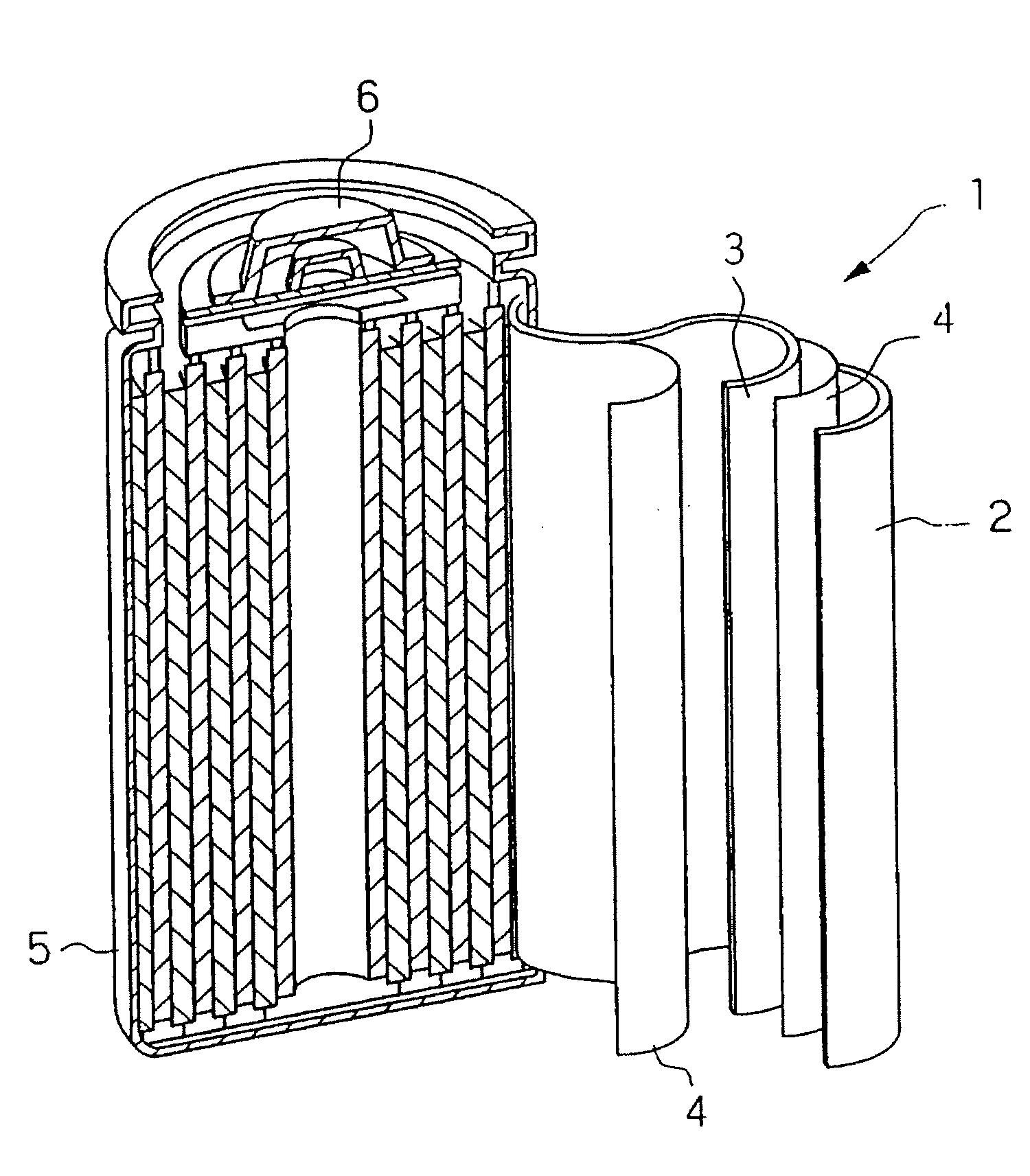

Secondary battery

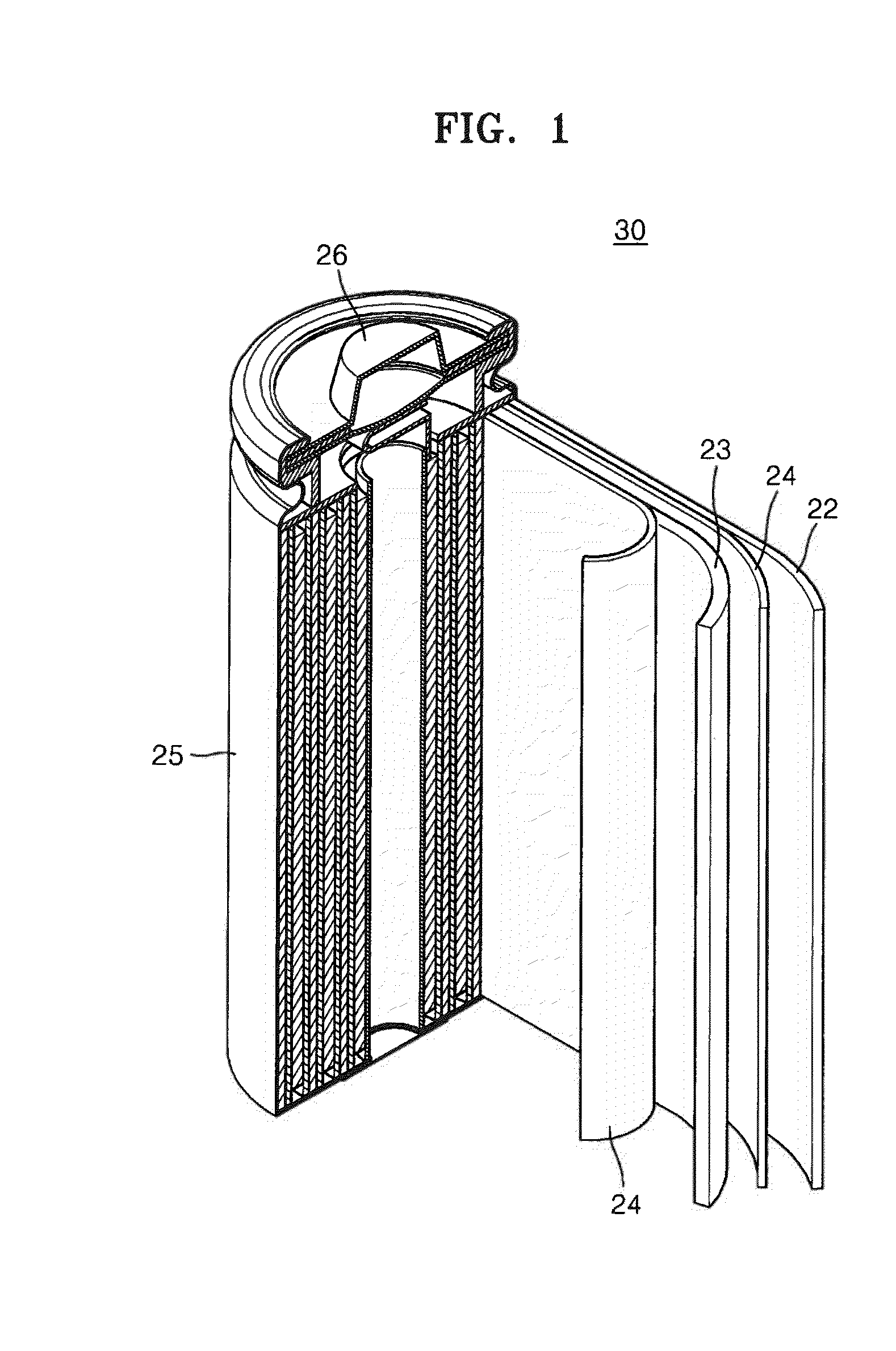

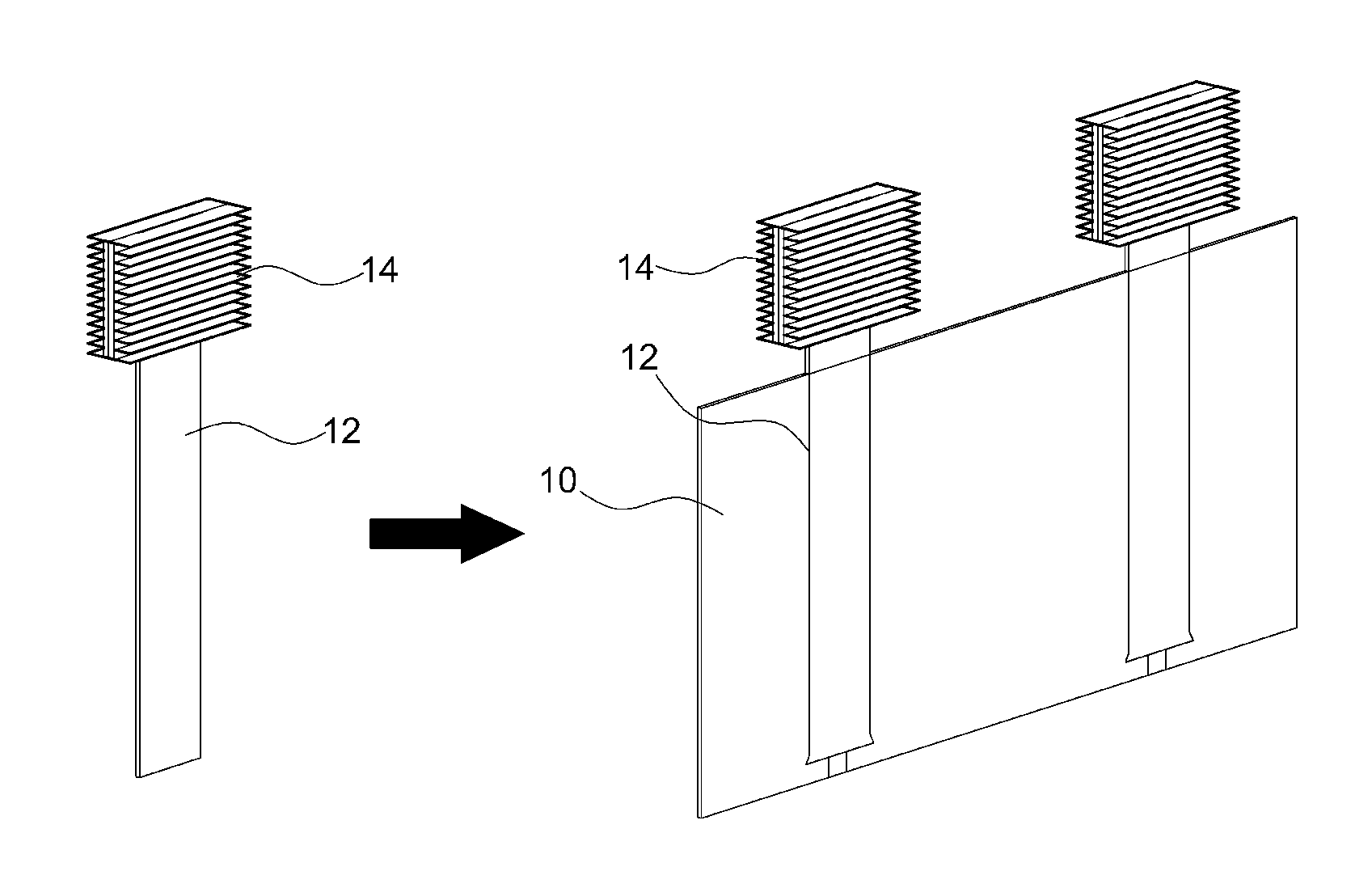

InactiveUS20060051666A1Inhibition of volume expansionAvoid assemblyNon-aqueous electrolyte accumulatorsLarge-sized flat cells/batteriesInternal pressureElectrical connection

Disclosed is a secondary battery having a element for compensating for and preventing volumetric expansion during charging / discharging of the battery, in order to prevent the electrode assembly from deforming due to rising internal pressure and compensate for and prevent the expansion of the secondary battery case. The secondary battery includes an electrode assembly having positive and negative electrode plates having active materials formed on at least one surface of positive and negative electrode collectors and a separator interposed between the positive and negative electrode plates, a case having a space for containing the electrode assembly and at least one element for compensating for and preventing volumetric expansion, and a cap assembly adapted to be coupled to the case and seal it and provided with a terminal portion in electrical connection to the electrode assembly.

Owner:SAMSUNG SDI CO LTD

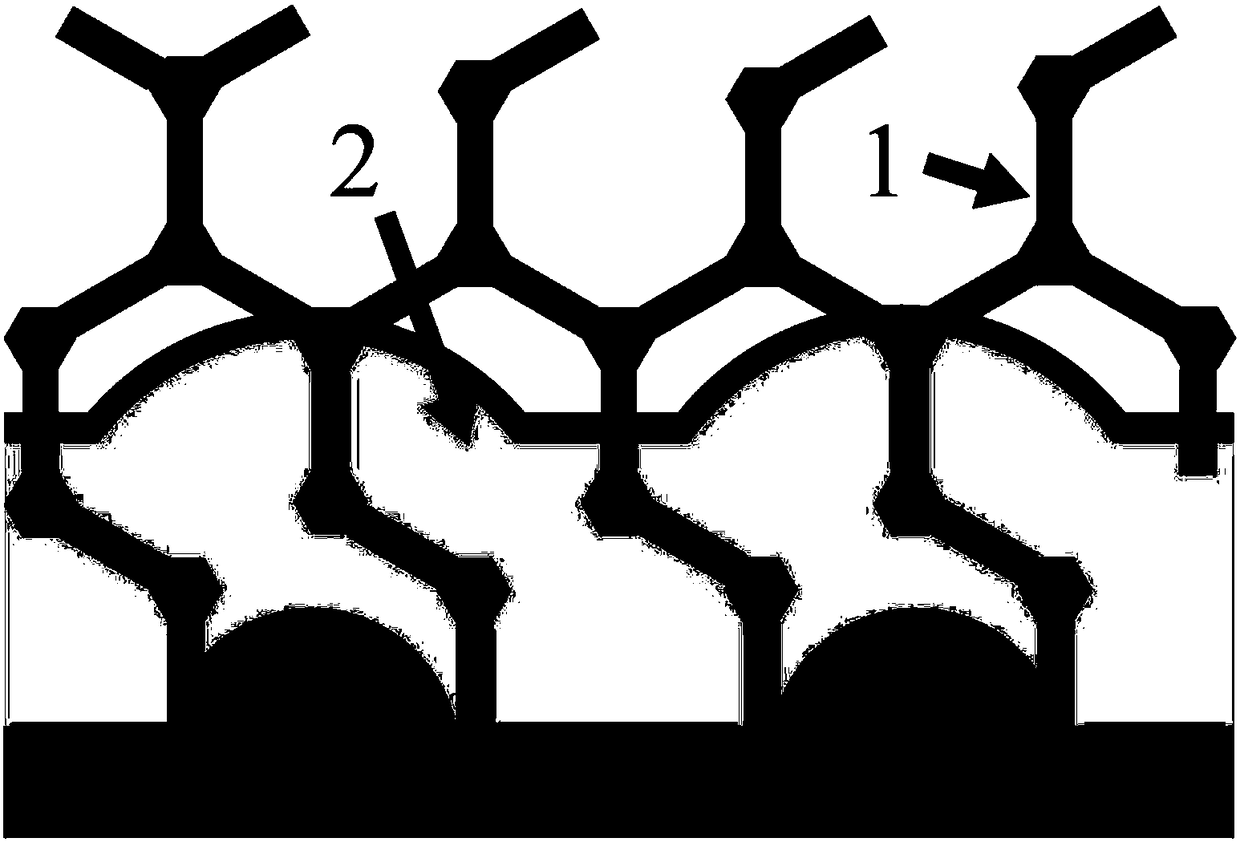

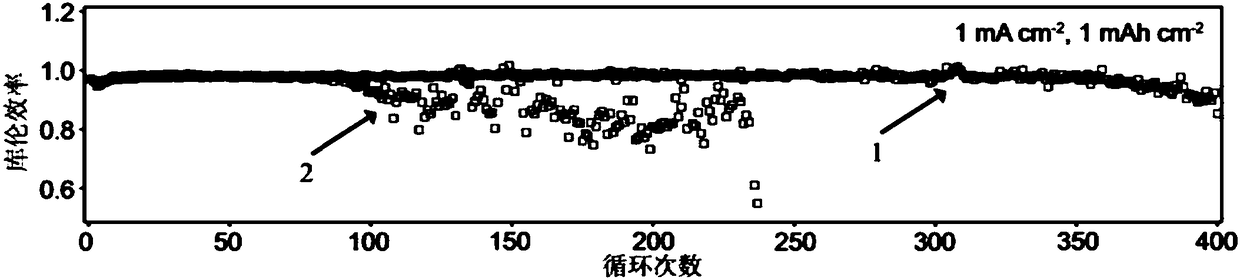

Anode material for lithium metal battery as well as preparation method and application of anode material

PendingCN108232117AImprove Coulombic efficiencyImprove securityCell electrodesLi-accumulatorsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses an anode material for a lithium metal battery. The anode material comprises a current collector and a carrier which is in tight fit with the current collector, wherein the carrier has a three-dimensional framework structure; a gap of the three-dimensional framework structure is filled with lithium metal; the carrier is selected from at least one of polymelamine, polyacrylonitrile, polyaniline, polyimide, polyvinylidene fluoride and polytetrafluoroethylene. The anode material disclosed by the invention has the advantages that a nonconductive polymer with the three-dimensional framework structure is used as the carrier, and stable deposition of lithium ions is realized by using interaction of functional groups contained in the carrier and the lithium ions; meanwhile,volumetric expansion is inhibited, internal stress of the battery is relieved, and thereby the aim of inhibiting growth of lithium dendrites is achieved. The coulombic efficiency, the safety of the lithium ion battery obtained by assembling the anode material prepared disclosed by the invention is remarkably improved and cycle life is obviously prolonged.

Owner:ZHEJIANG UNIV

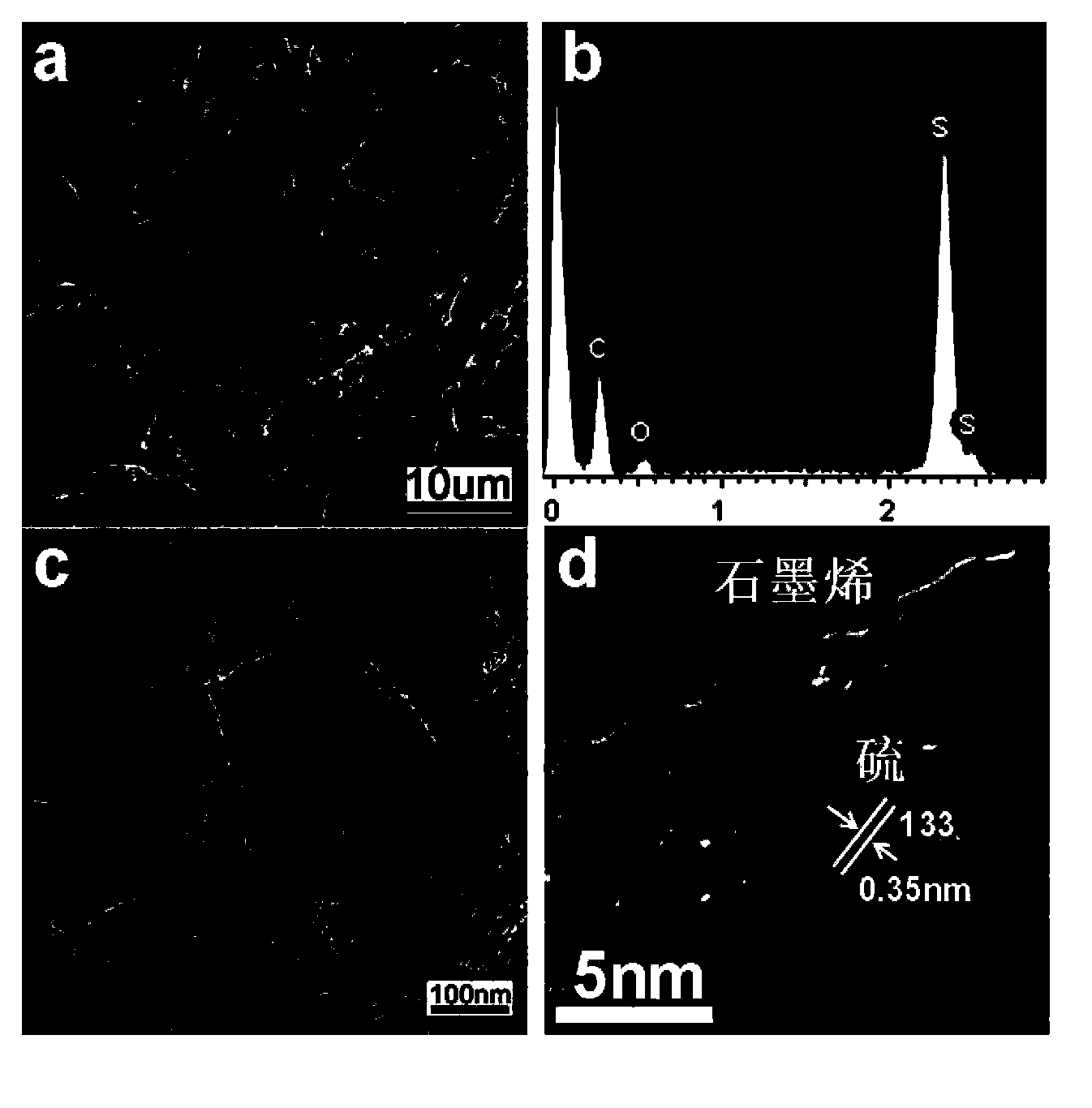

Preparation method of sulfur-active carbon/graphene composite material

ActiveCN106602013AWide variety of sourcesEasy to prepareCell electrodesLi-accumulatorsActivated carbonSulfur

The invention discloses a preparation method of a sulfur-active carbon / graphene composite material. The preparation method comprises the following steps of (1) pre-processing a biomass raw material; (2) mixing the pre-processed biomass raw material, graphene and an activating agent to form a solid mixed material; (3) performing activation, washing, solid-liquid separation and drying on the solid mixed material to obtain an active carbon / graphene composite material; and (4) combining the active carbon / graphene composite material with sulfur to obtain the sulfur-active carbon / graphene composite material. The composite material provided by the invention has the advantages of simple preparation process step, high efficiency and low energy consumption, and production on a large scale can be achieved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

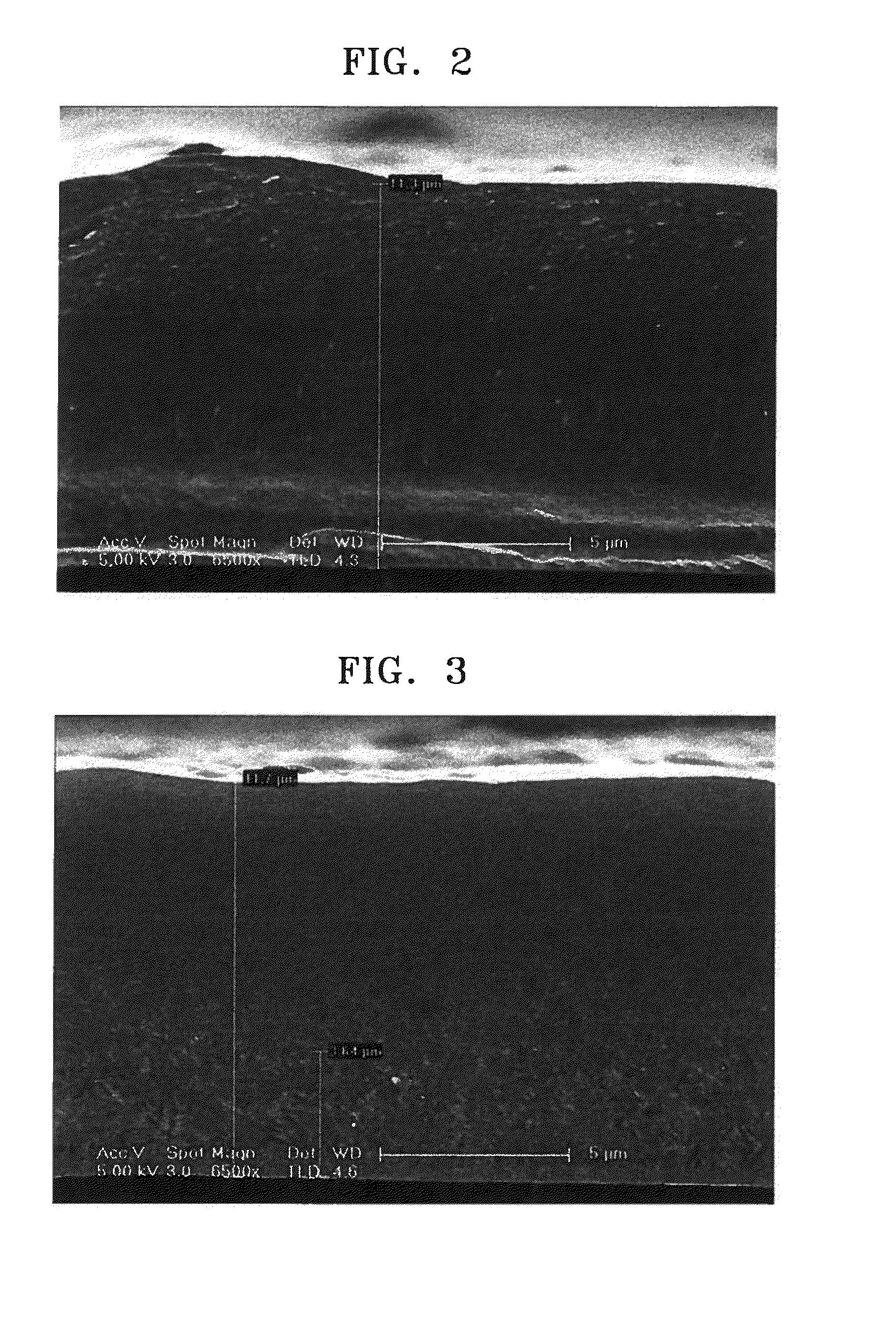

Negative active material, lithium battery including the material, and method for manufacturing the material

ActiveUS20130266865A1Increase capacityExcellent characteristicsFinal product manufactureNegative electrodesMetallurgySilicon alloy

A negative active material having controlled particle size distribution of silicon nanoparticles in a silicon-based alloy, a lithium battery including the negative active material, and a method of manufacturing the negative active material are disclosed. The negative active material may improve capacity and lifespan characteristics by inhibiting (or reducing) volumetric expansion of the silicon-based alloy. The negative active material may include a silicon-based alloy including: a silicon alloy-based matrix; and silicon nanoparticles distributed in the silicon alloy-based matrix, wherein a particle size distribution of the silicon nanoparticles satisfies D10≧10 nm and D90≦75 nm.

Owner:SAMSUNG SDI CO LTD

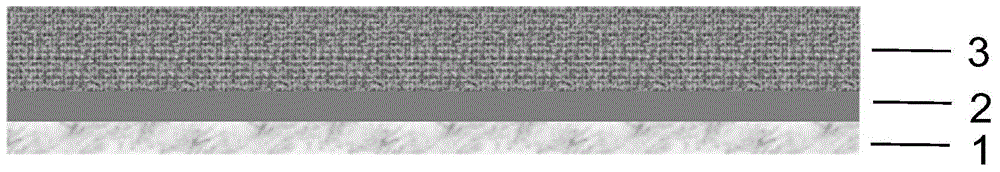

Integrated flexible electrode

ActiveCN104916809AReduce contact resistanceImprove flexibilityCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsIntegrated designSlurry

The invention discloses an integrated flexible electrode and belongs to the technical field of electrochemical cells. The integrated flexible electrode is composed of three layers which are successively a polymer layer, a graphene layer and an active material layer. According to the invention, the multi-component integrated design is realized. The graphene layer is formed by dispersing and coating graphene onto the polymer layer. The active material layer is formed by coating slurry onto the graphene layer. After drying, the integrated flexible electrode material is obtained. The integrated flexible electrode material has excellent flexibility and tensile strength and is applicable to flexible cells. A preparation method of the integrated flexible electrode is simple and easy to control, can be applied to various electrode materials and has potential application value. Mass and low-cost preparation can be realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

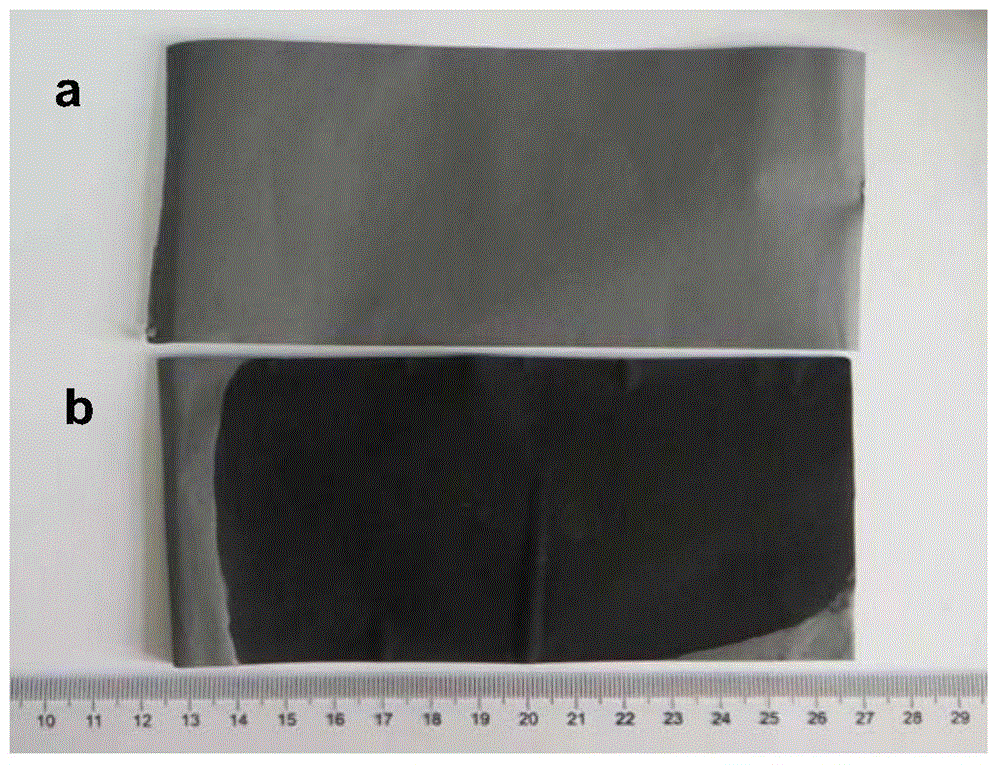

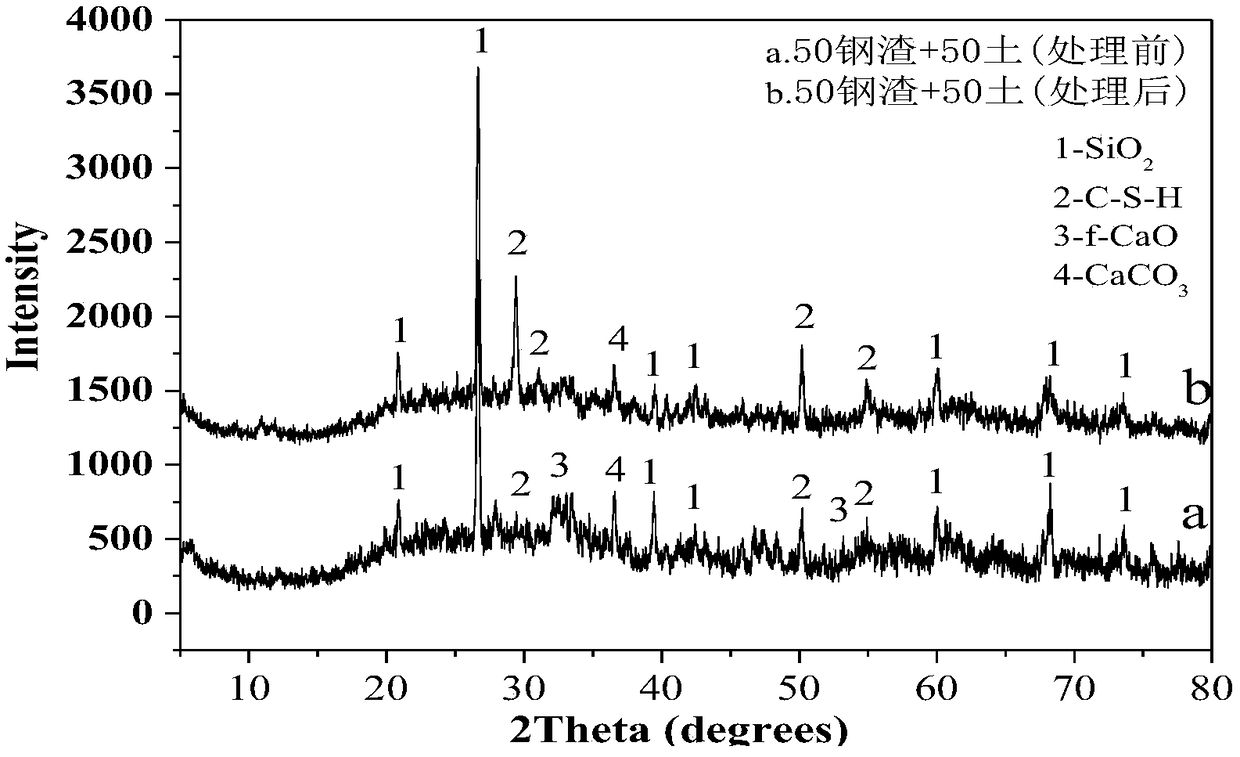

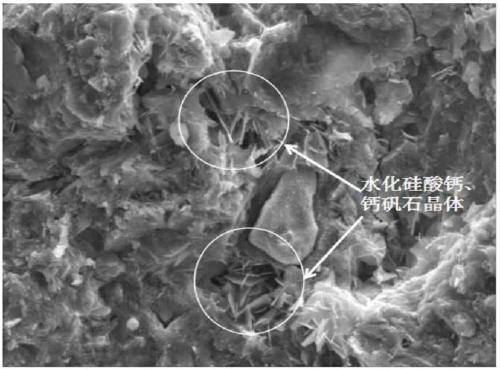

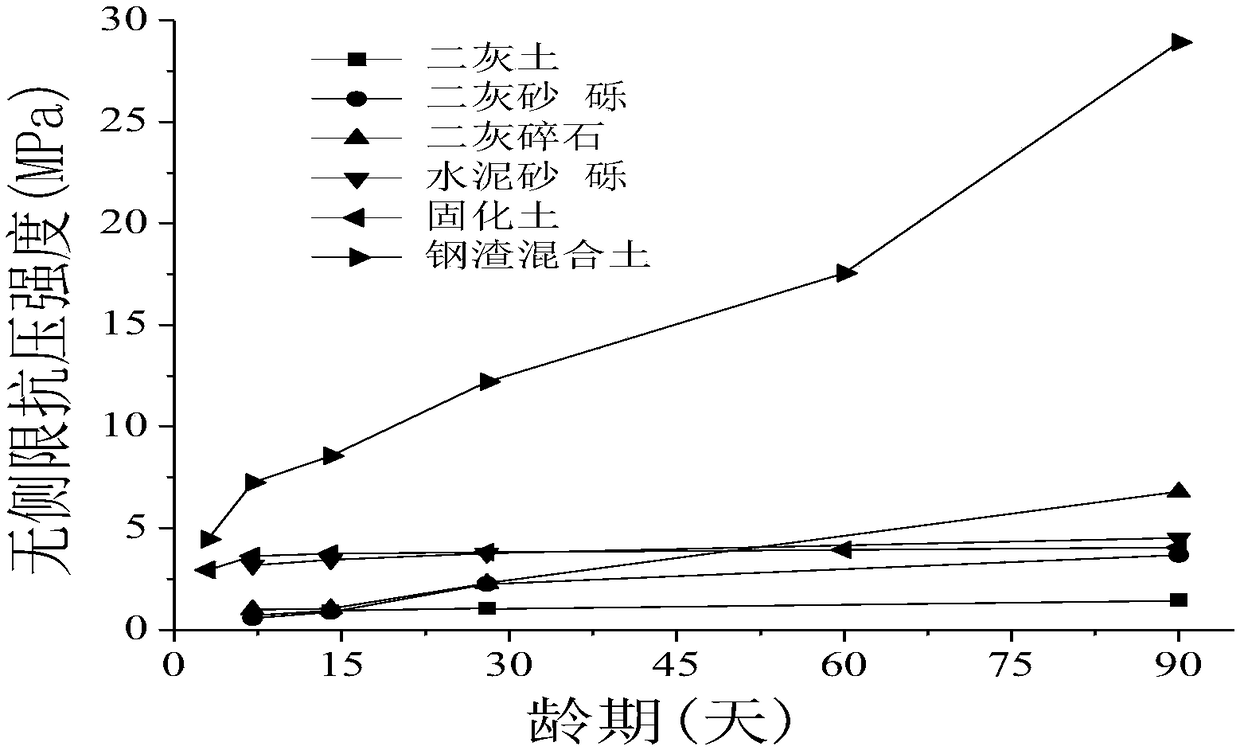

Novel steel slag composite soil road base material and preparation method thereof

The invention discloses a steel slag composite soil road base material and a preparation method thereof. The steel slag composite soil road base material contains the following materials in parts by weight: 0-15 parts of water, 40-80 parts of common soil, 20-60 parts of steel slag without ageing treatment, 5-25 parts of complexing agent, 1-5 parts of cement, and 0.01-0.05 part of modifying agent.The preparation method comprises the following steps: mixing the steel slag, the soil, the cement and the complexing agent and then performing a compaction test, and testing to obtain an optimal watercontent; smashing the steel slag; spraying tap water accounting for 50% of the total water amount, and sufficiently blending the steel slag with the complexing agent, to obtain a slag-powder mixture;spraying the modifying agent to the common soil and doping the redundant tap water, to obtain modified soil; blending and compacting the slag-powder mixture, the modified soil and Portland cement, toobtain a road base material. The steel slag composite soil road base material and the preparation method can sufficiently realize recycling of metallurgic solid water resource, and reduce pollution to the environment in the steel slag stacking and ageing process; also can effectively save the sandstone material, and avoid destruction of the ecological environment caused by sandstone material mining, and has remarkable economical and social benefits.

Owner:安徽马钢嘉华新型建材有限公司 +1

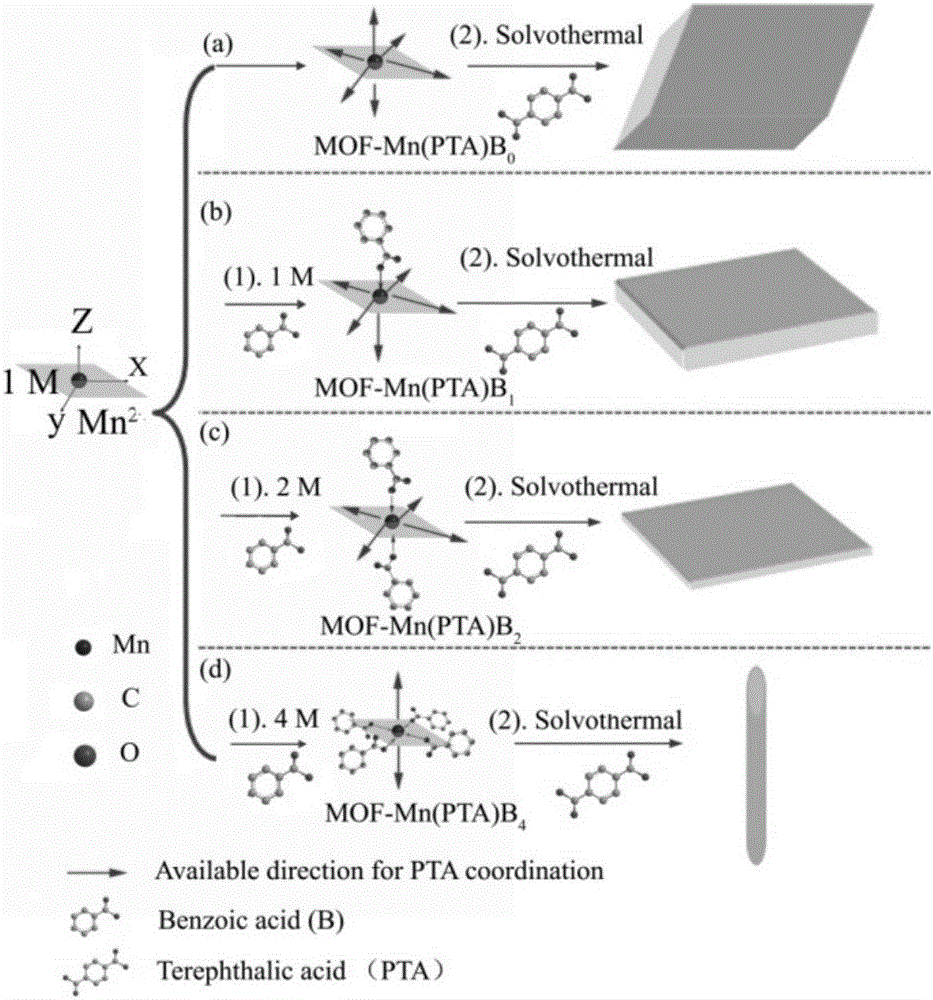

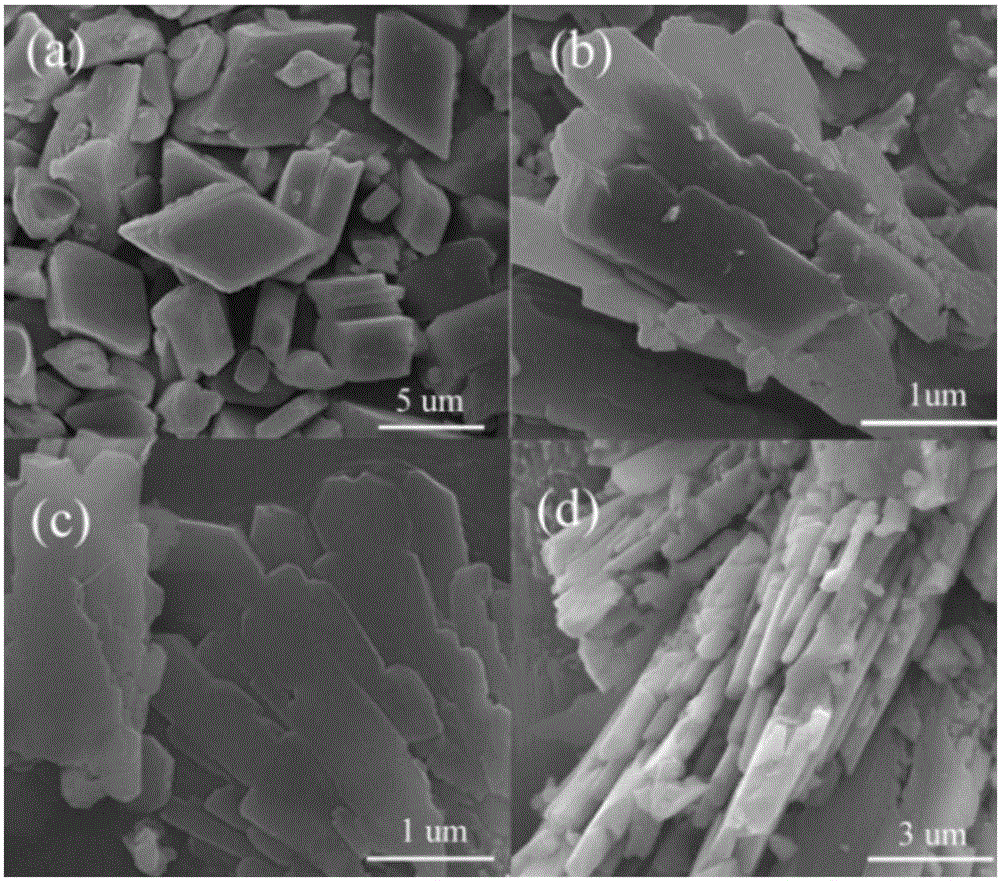

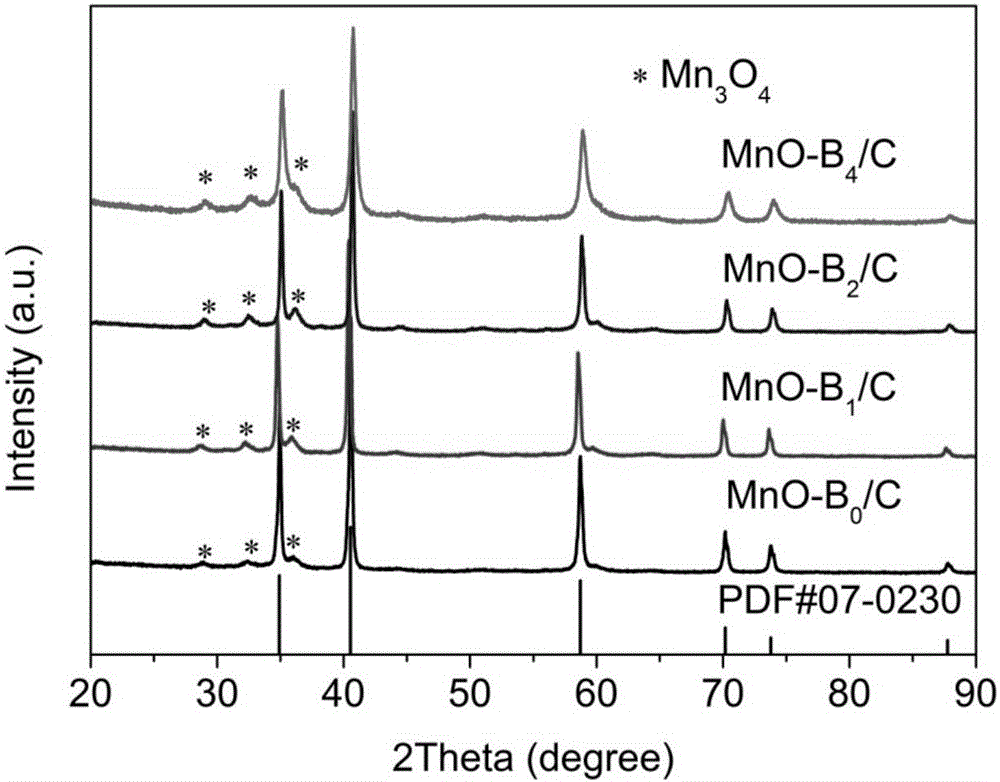

Morphological control method of metal oxide/carbon negative electrode material for lithium ion battery

ActiveCN106784658ALarge specific surface areaSimple processSecondary cellsNegative electrodesAluminium-ion batteryMetal-organic framework

The invention discloses a morphological control method of a metal oxide / carbon (MOx / C) composite material for the negative electrode of a lithium ion battery. The method comprises the following steps: adding metal ions and monodentate ligands with different proportions into a solvent, stirring for a period of time, then adding a multidentate ligand, and heating in a reaction kettle for a period of time to obtain the metal organic framework (MOF) precursor materials with different morphologies; and calcining the precursors in an inert gas atmosphere for a period of time to obtain the MOx / C composite materials with different morphologies. The composite materials disclosed by the invention have relatively high specific surface areas and rich pore structures, and have excellent rate performance and cycling stability as the negative electrode materials of the lithium ion battery. The morphological control method disclosed by the invention is simple to operate, easy to realize large-scale application, and can also be extended to other fields that focus on material morphology control.

Owner:CENT SOUTH UNIV

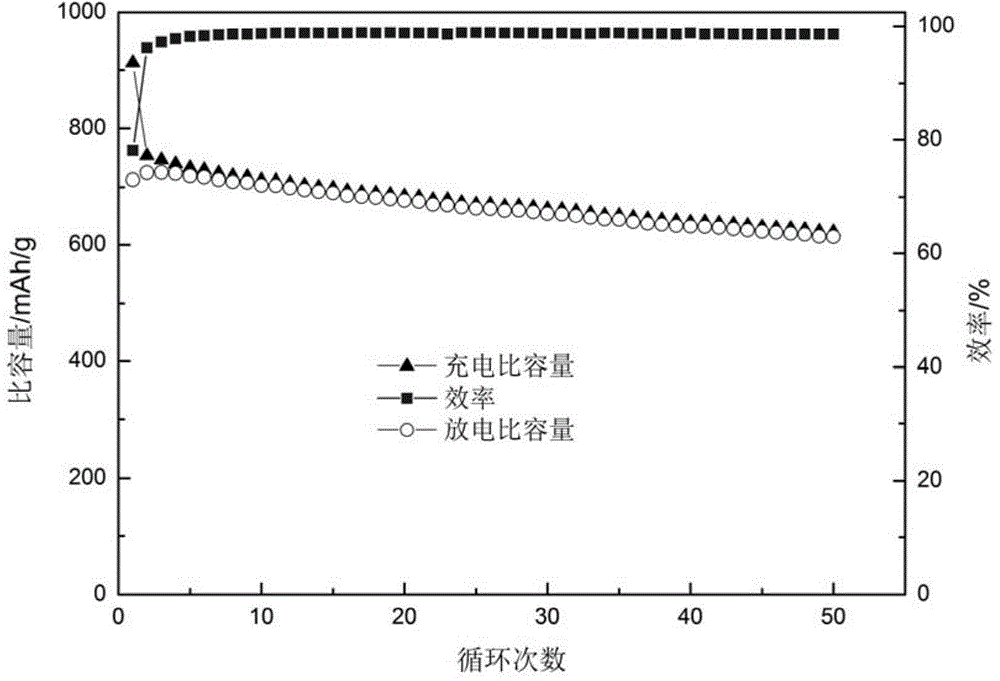

Anode material and manufacturing method thereof as well as lithium ion battery and negative plate thereof

ActiveCN102332572AHigh specific capacityIncrease capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesMetal particleSodium-ion battery

The invention discloses an anode material which comprises a stack layer of graphene sheets and tin metal particles, wherein the tin metal particles are embedded into the graphene sheets or distributed among the graphene sheets. The invention also discloses a manufacturing method of the anode material, and the manufacturing method comprises the following steps of: directly reducing tin hydroxide on the graphene sheets by adopting a one-step total heating reduction method to obtain the tine metal particles; and baking to obtain a tin-graphene composite material. The invention also discloses a lithium ion battery, and the negative electrode of the lithium ion battery is manufactured by using the lithium ion battery anode material. The lithium ion battery anode material is high in specific capacity, the first-time discharge capacity can reach 600-900 mAh / g, and the capacity can reach 550-820 mAh / g when the discharge is stable; the cycle life of the lithium ion battery anode material is long, and the number of cycles can reach over 1,000; and the lithium ion battery anode material is simple in preparation process, and is suitable for industrial production.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

Sulfur-activated carbon/graphene composite material and application thereof

InactiveCN106532026AWide variety of sourcesEasy to prepareCell electrodesGrapheneActivated carbonLithium–sulfur battery

The invention discloses a sulfur-activated carbon / graphene composite material and an application thereof. The composite material is formed by loading sulfur on an activated carbon / graphene composite material or a material; and the sulfur-activated carbon / graphene composite material comprises the following components in percentage by mass: 10%-90% of sulfur and 10%-90% of activated carbon / graphene composite material. The sulfur-activated carbon / graphene composite material is used for a lithium-sulfur battery, so that, on one hand, the weight of the battery can be greatly reduced, the internal resistance of the battery is reduced, the conductivity of an electrode material is improved and the specific capacity and the overall performance of the battery are improved; and on the other hand, the shuttle effect is reduced, the influence of volume expansion of the sulfur on the performance of the battery is reduced to a certain extent and the utilization rate of the active material is improved. Under the same test condition, the overall performance of the lithium-sulfur battery assembled by the composite material as a positive electrode material is obviously superior to that of the lithium-sulfur battery assembled by the similar positive electrode material as the positive electrode material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

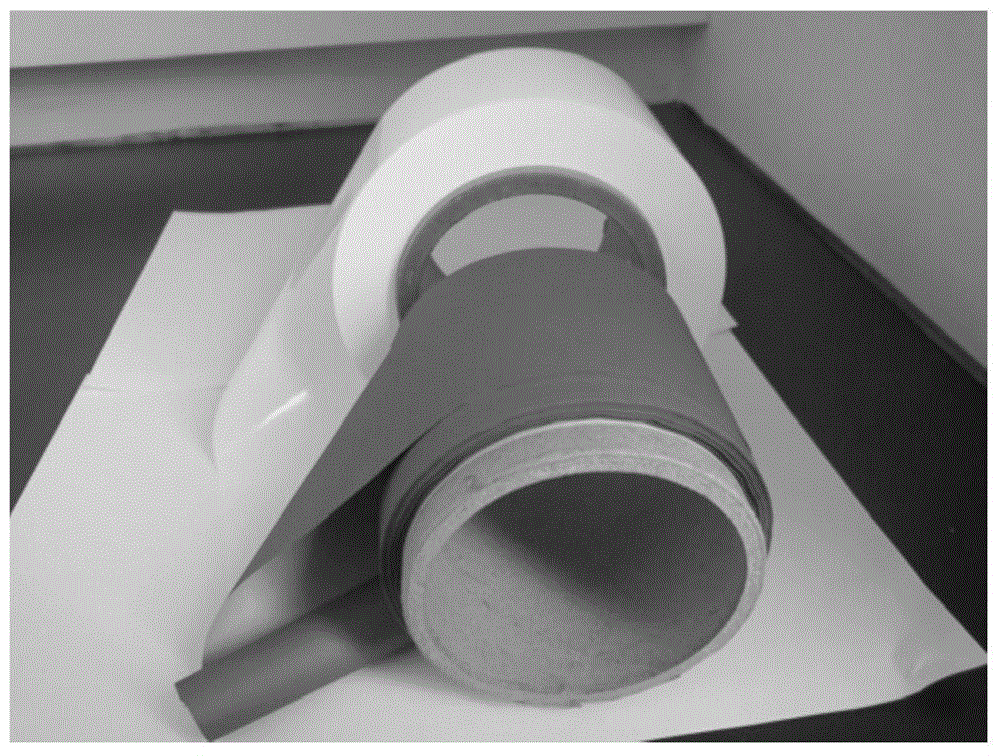

Preparation method of silicon-carbon negative electrode material for lithium ion battery

ActiveCN104538607AInhibition of volume expansionAlleviate volume expansionCell electrodesCarbon coatingHigh energy

The invention discloses a preparation method of a silicon carbon negative electrode material for a lithium ion battery. The preparation method comprises the following steps: high-energy ball milling, organic carbon coating, high-temperature carbonization and micro-oxidation, wherein the micro-oxidation step is carried out after the high-energy ball milling step and before the organic carbon coating step, and is carried out at least once after the high-temperature carbonization step. The previous and / or subsequent micro-oxidation treatment can ensure that a SiO2 layer is oxidized on the Si surface, and play a role of oxidation and pore-forming on graphite and pyrolytic carbon; a SiO2 electrochemical inert layer inhibits the volume expansion of Si to a certain extent, while the porous structure can relieve the volume expansion of Si to a certain extent, thereby improving the cyclic performance of the silicon carbon negative electrode material.

Owner:TIANJIN B&M SCI & TECH

High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

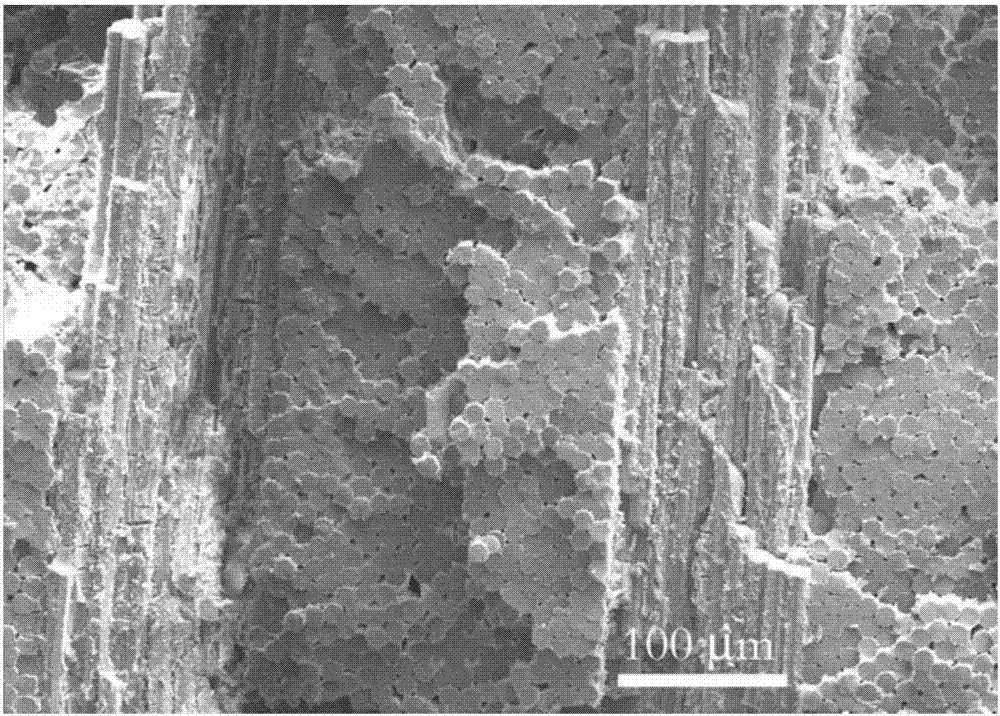

Graphene-sulfur composite electrode material, preparation method and application thereof

ActiveCN103811731AImproved magnification performanceLittle change in resistivityPositive electrodesLi-accumulatorsFreeze-dryingAdhesive

The present invention discloses a graphene-sulfur composite electrode material, a preparation method and an application thereof, and belongs to the field of electrochemical batteries. According to the graphene-sulfur composite electrode material, a uniformly-dispersed graphene oxide aqueous solution, an organic solution of sulfur, and a miscible solvent are subjected to mixing stirring, and then are subjected to a hydrothermal reaction to form a three-dimensional macroscopic body structure with sulfur nanoparticles uniformly distributed and anchored on the fibrous graphene surface, and low temperature freeze-drying is performed to obtain the graphene-sulfur composite material. According to the present invention, the electrode material is the microcosmic structure with sulfur nanoparticles uniformly anchored on the interconnected fibrous graphene surface; and according to the battery design, after the graphene-sulfur material is cut to obtain the corresponding thickness, the obtained material is pressed and then can be directly used as the lithium-sulfur battery positive electrode with no metal current collector, no conductive agent and no adhesive.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

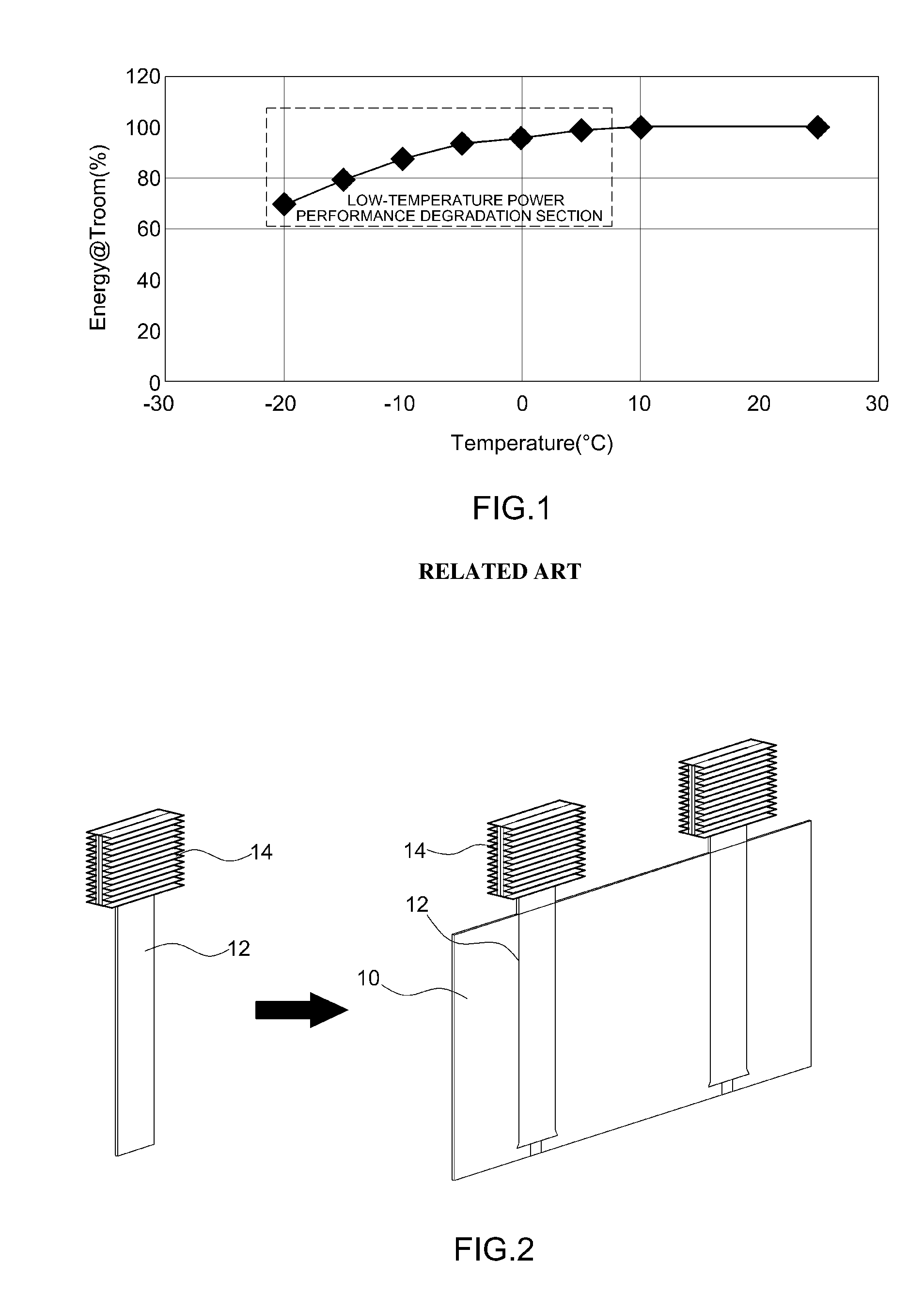

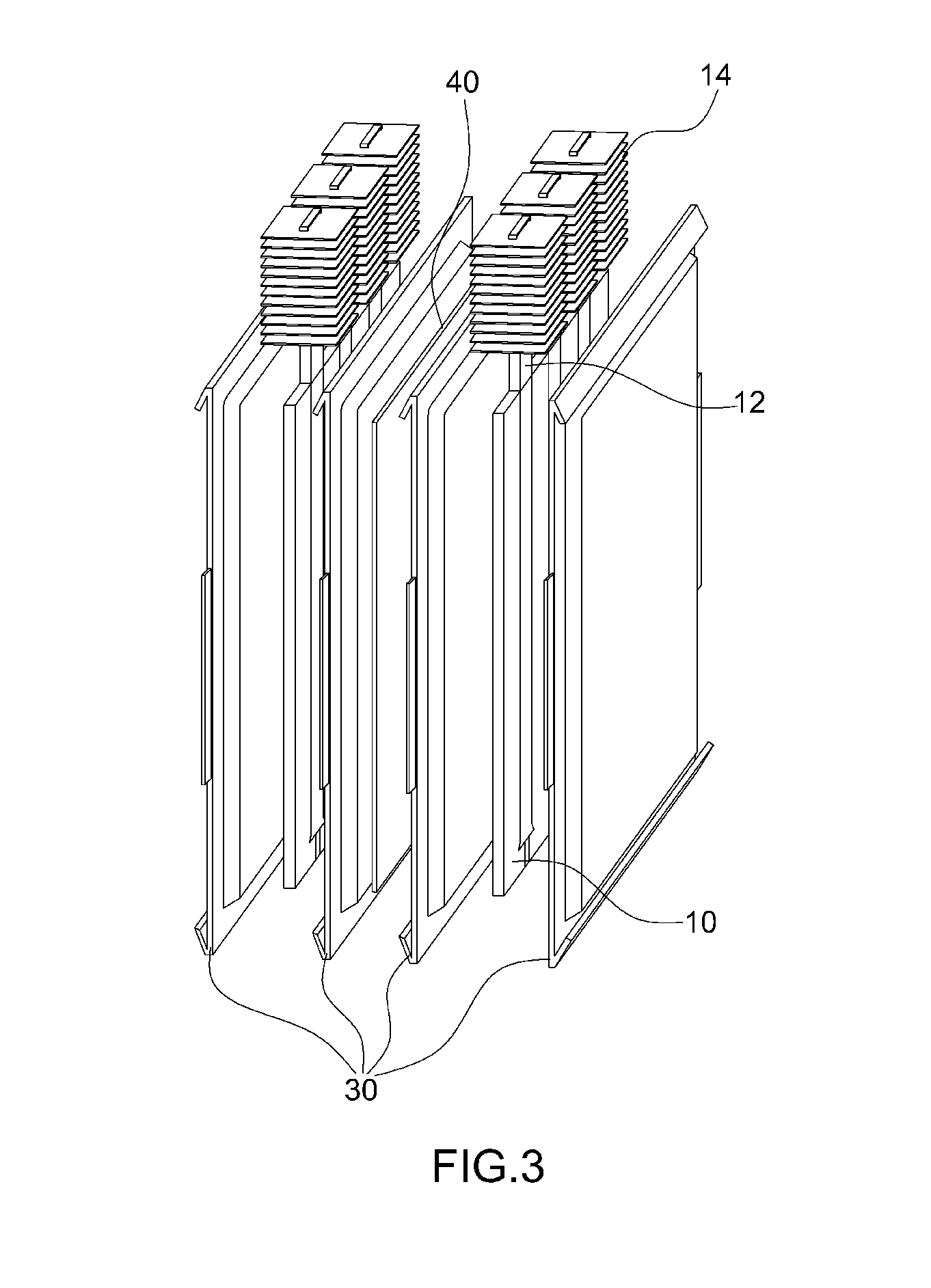

Device for indirectly cooling battery module of eco-friendly vehicle

ActiveUS20140318746A1Improve adhesionMaximizing heat-emission performance of batteryLiquid coolingCell temperature controlIn vehicleEngineering

A device for indirectly cooling a battery module of an eco-friendly vehicle is provided that cools the battery module using an interfacial plate into which a heat pipe is inserted to maximize battery heat emission performance and simultaneously prevent degradation of battery performance. A thermally-conductive interfacial plate in which a heat pipe is embedded by over-molding is disposed between battery cells and a heat sink, which is a condensation unit, integrally connected to an upper end of the heat pipe is disposed in a cooling air flow path to improve contact strength between the interfacial plate and the battery cells. A planar heat emitter is disposed between the battery cells where the interfacial plate is not disposed to heat the battery to a proper-level temperature in a cold-start environment and a low-temperature environment, thereby improving battery performance and preventing degradation in vehicle power.

Owner:HYUNDAI MOTOR CO LTD

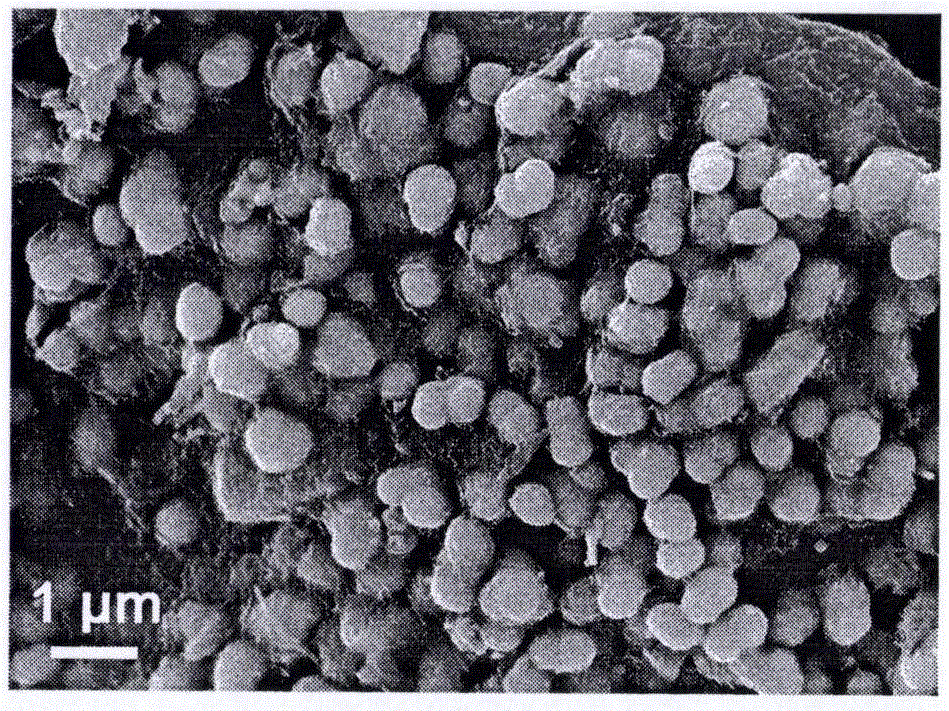

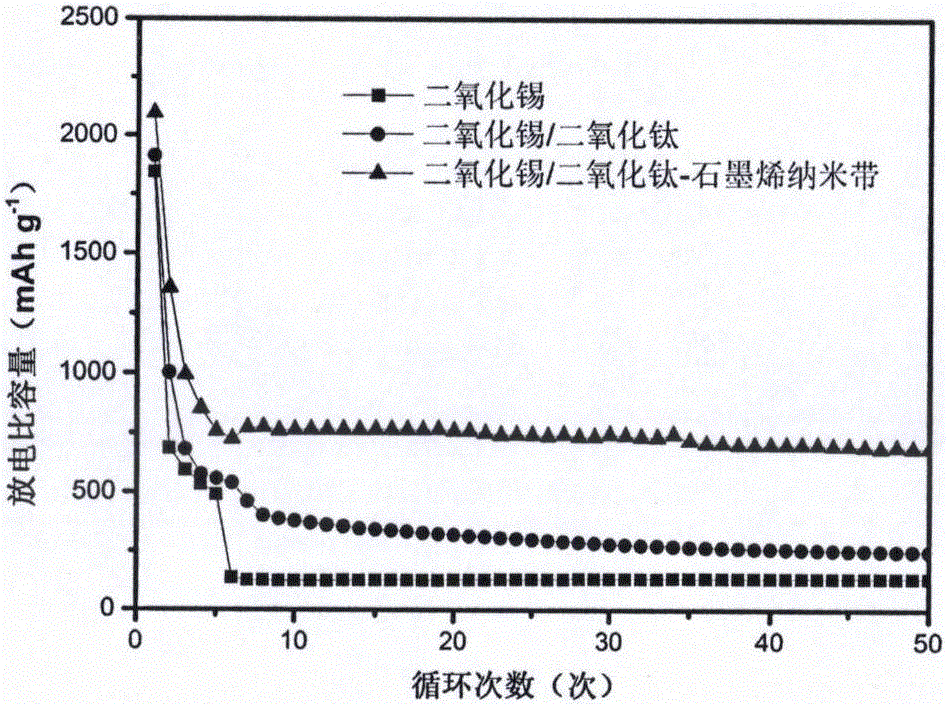

Preparation method of tin dioxide/titanium dioxide spherical particle and graphene nanoribbon composite material

The invention belongs to the technical field of lithium-ion batteries, and particularly relates to a preparation method of a negative electrode material for the lithium-ion battery, namely a preparation method of a tin dioxide / titanium dioxide spherical particle and graphene nanoribbon composite material. The method comprises the steps of employing potassium stannate and urea as raw materials, synthesizing tin dioxide hollow spheres through a hydrothermal process, and then mixing the tin dioxide hollow spheres with tetrabutyl titanate; preparing tin dioxide / titanium dioxide spherical particles through a sol-gel method; and finally mixing the tin dioxide / titanium dioxide spherical particles with a graphene nanoribbon dispersion liquid to obtain a tin dioxide / titanium dioxide-graphene nanoribbon composite material product. The operation is simple; the cost is low; the method is friendly to environment; and the prepared product has relatively high capacity and excellent cycle performance and can be widely applied to negative electrode materials for high-power lithium-ion batteries and super capacitors.

Owner:重庆锦添翼新能源科技有限公司 +1

Lithium secondary battery

ActiveUS20090181301A1Inhibition of volume expansionLarge capacityCell electrodesFinal product manufactureMetallic materialsLithium-ion battery

A lithium secondary battery includes a positive electrode, a negative electrode, a separator separating the positive electrode and the negative electrode, and an electrolyte. The negative electrode active material of the negative electrode includes a material that is capable of reversibly intercalating and deintercalating lithium ions and a metallic material capable of alloying with lithium. The electrolyte includes a chemical compound containing a nitrile (—CN) radical.

Owner:SAMSUNG SDI CO LTD

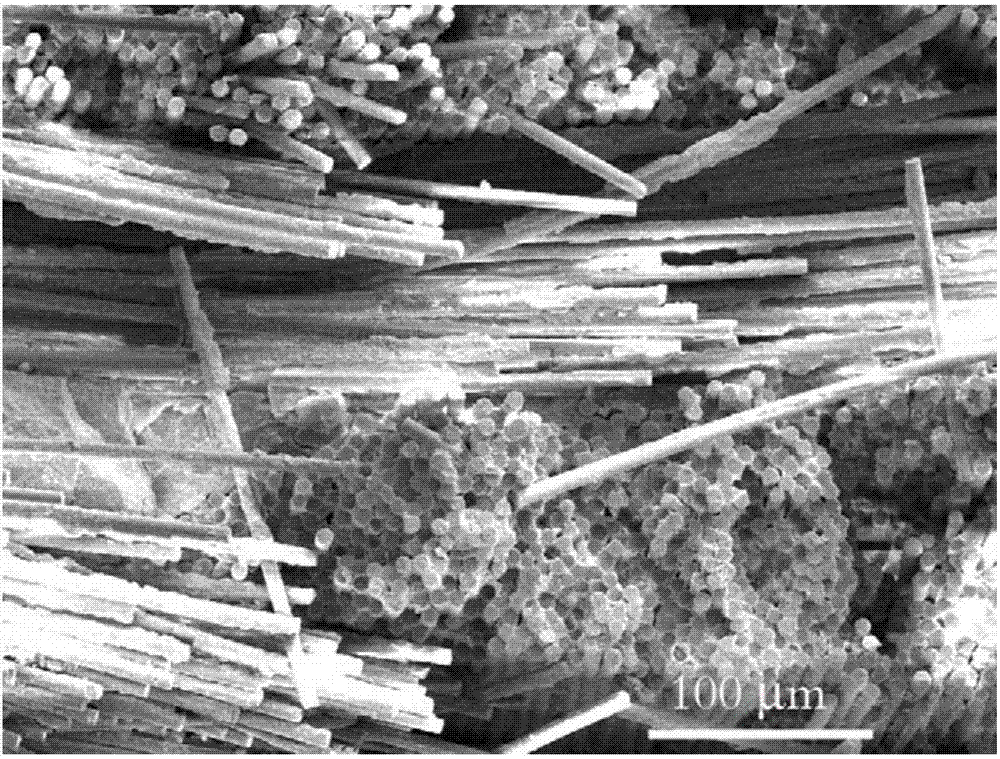

Bergmeal-based lithium sulphur battery cathode material as well as preparation and application methods thereof

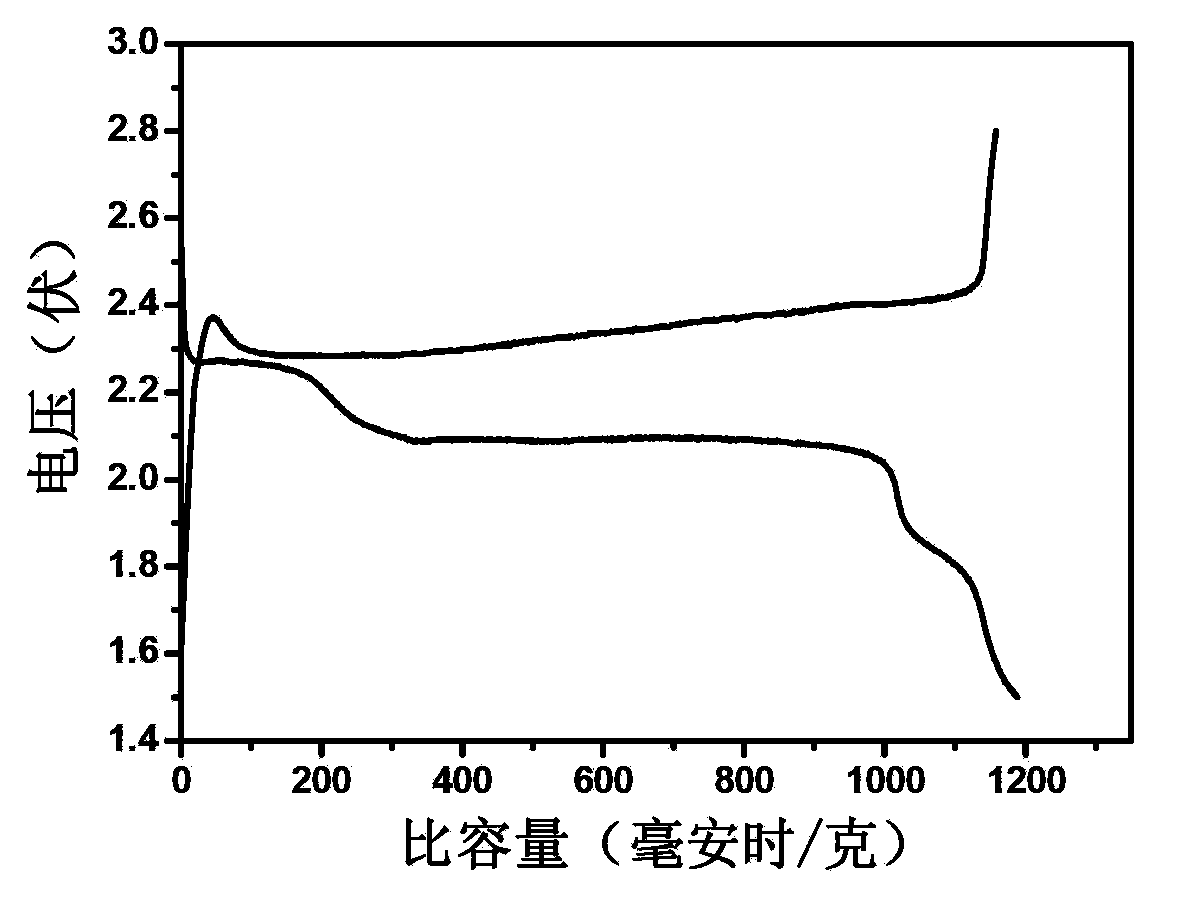

InactiveCN103730632AInhibition of volume expansionReduce solubilityPositive electrodesLi-accumulatorsLithium–sulfur batteryCharge discharge

The invention discloses a bergmeal-based lithium sulphur battery cathode material as well as preparation and application methods thereof. The cathode material uses bergmeal as the skeleton, and elemental sulfur is injected into the bergmeal, so as to obtain sulfur-bearing composite material, and then the sulfur-bearing composite material is coated with a conductive material. By adopting the bergmeal, the dissolution of polysulfide can be reduced and the volume expansion of sulphur during charge-discharge process is restrained, and the cycling performance of lithium sulphur batteries is improved. Conductive material is used for coating, so that the electrical conductivity of material is improved and the capacity of the lithium sulphur batteries is increased. The lithium sulphur battery cathode material is simple in preparation technology, and the bergmeal belongs to natural environmentally-friendly material, and is low in cost and benificla to the industrialization of the lithium sulphur batteries. Meanwhile, the introduction of the bergmeal also promotes the industrial transformation and upgrading of the nonmetallic minerals.

Owner:XIANGTAN UNIV

TiO2 coated sulfur/ordered mesoporous carbon composite cathode material and preparation method thereof

InactiveCN104269559ALower transmission impedanceImprove conductivityCell electrodesComposite cathodeHigh energy

The invention discloses a TiO2 coated sulfur / ordered mesoporous carbon composite cathode material and a preparation method thereof as well as the application thereof in a secondary aluminum battery. The cathode material consists of a sulfur active substance, ordered mesoporous carbon and TiO2 and is characterized in that the ordered mesoporous carbon has a highly-ordered three-dimensional pore structure, is provided with a conductive network and provides a large number of adhesion area for the active substance and a conductive channel; a TiO2 coating layer has a very effective shuttle effect of blocking polysulfide. The preparation method of the TiO2 coated sulfur / ordered mesoporous carbon composite cathode material comprises the following steps: compounding the ordered mesoporous carbon and sulfur and then TiO2 coating on an outer layer. The preparation method has the advantages of simple process, low cost, no toxic raw material used, environmental friendliness, high energy density and high sulfur utilization rate, and the rate performance and the cycle life of the secondary aluminum battery are greatly improved.

Owner:NANJING ZHONGCHU NEW ENERGY

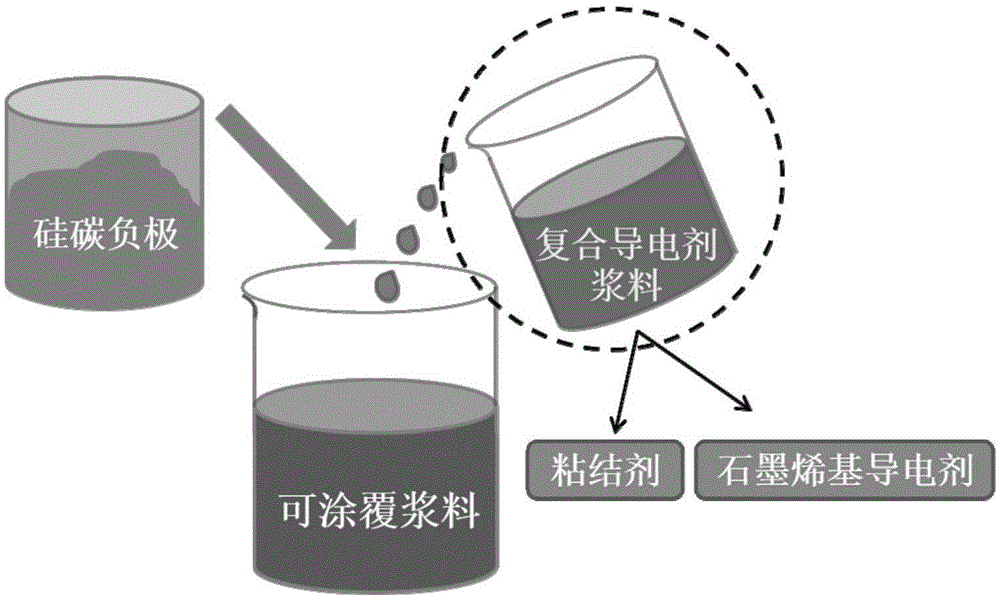

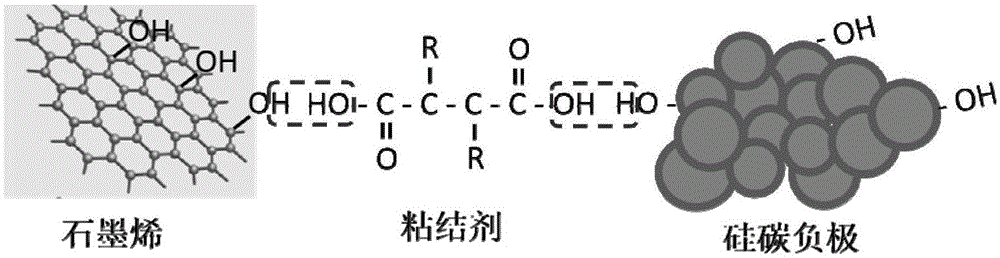

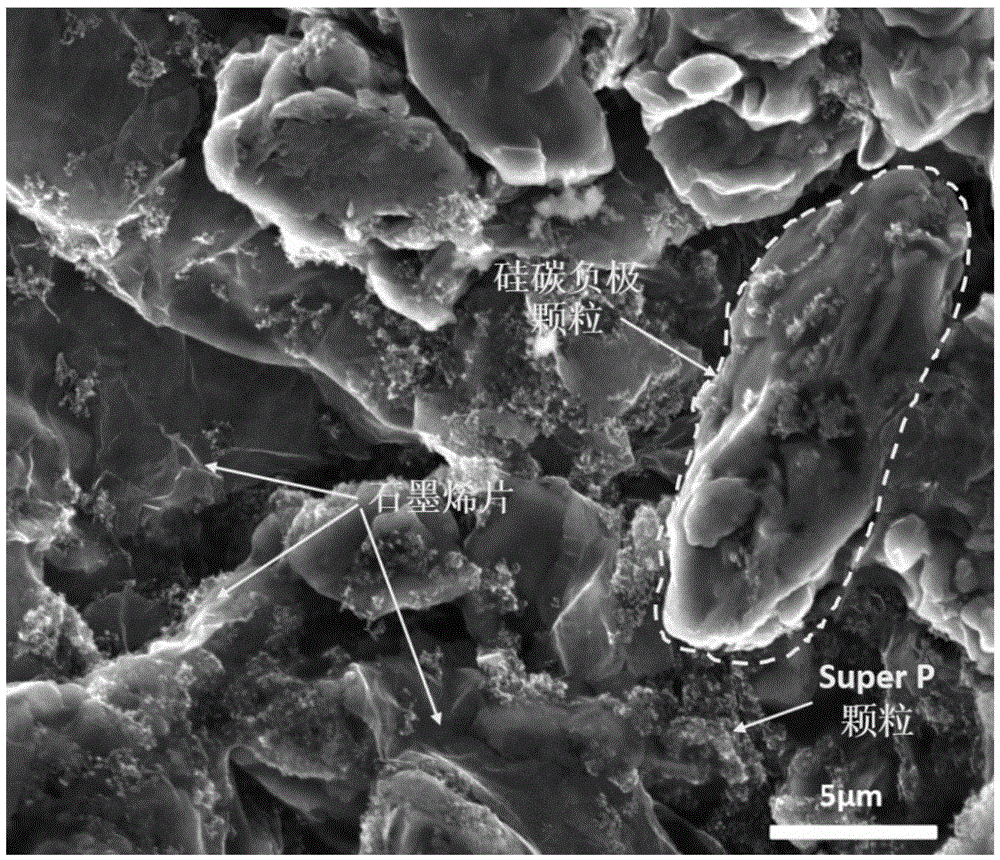

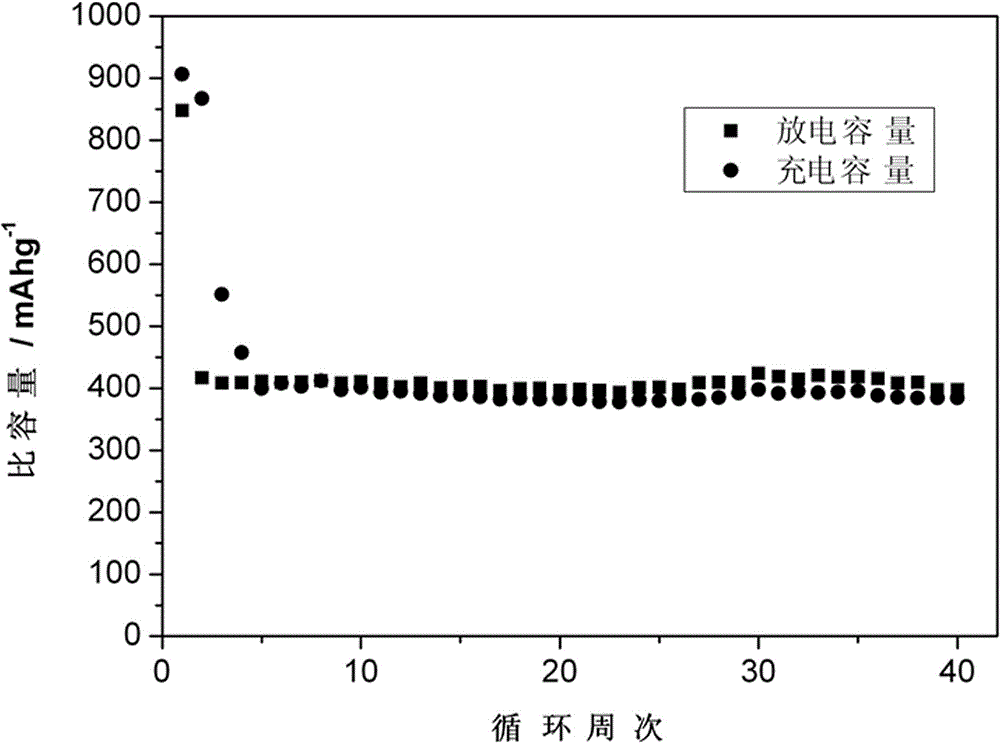

Composite conductive agent slurry for silicon-carbon anode and preparation method and application thereof

ActiveCN105576248AInhibition of volume expansionImprove conductivityNegative electrodesSecondary cellsInternal resistanceSlurry

The invention discloses a composite conductive agent slurry for a silicon-carbon anode and a preparation method and application thereof. The composite conductive agent slurry mainly contains a graphene-based conductive agent and a high-viscosity polymer binder provided with a specific carboxyl functional group. The graphene-based conductive agent and the binder have a synergistic effect, a stable conductive elastic inhabitation layer can be formed on the surface of the silicon-carbon anode, the volume expansion of the silicon-carbon anode material in the charging and discharging process is inhibited while the internal resistance of a battery is effectively reduced, stable cycle is achieved, heat dissipation is strengthened, and accordingly the overall performance of the battery is improved. The preparation method of the composite conductive agent slurry is simple in process, easy to regulate and control and capable of achieving large-scale low-cost preparation, and the obtained slurry is high in stability, can be directly mixed with a commercialized silicon-carbon anode material in proportion for usage and can be applied to multiple volume expansion type electrode materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Antimony sulfide negative electrode material with micro-nano structure for sodium-ion battery and preparation method of antimony sulfide negative electrode material

InactiveCN104600293AImprove cycle stabilityHigh specific capacityNon-aqueous electrolyte accumulatorsCell electrodesMicro nanoSodium-ion battery

The invention discloses an antimony sulfide negative electrode material with a micro-nano structure for a sodium-ion battery and a preparation method of the antimony sulfide negative electrode material. Materials with the structure such as a micro-tube, a nano-wire and spherical micro-nano level particles are prepared by a hydrothermal process and a precipitation method; the morphologies of the materials are regular and uniform; the first capacity exceeds 850mAh / g when the current density is 100mA / g; and the capacity is still 90% that of the second week after circulating for 40 weeks. Antimony sulfide powder with the micro-nano structure is synthesized by the hydrothermal process and the precipitation method; and according to the antimony sulfide negative electrode, the preparation method is simple, raw materials are available and the cost is low; the process is easy to control; and the prepared antimony sulfide with the micro-nano structure has excellent electrochemical sodium storage performance, and is a good sodium ion battery negative electrode material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Lithium-ion battery silicon monoxide negative electrode material, preparation method and application thereof

ActiveCN110767877AShorten migration distanceImprove poor conductivitySecondary cellsNegative electrodesSilicon monoxideChemical physics

The invention relates to a lithium-ion battery silicon monoxide negative electrode material, and a preparation method and application thereof. A method for improving rate performance and cycle performance of the lithium-ion battery silicon monoxide negative electrode material includes the following steps: S1: crushing silicon monoxide to silicon monoxide particles having a particle size of 100 to800 nm; S2: after mixing the silicon monoxide particles, a conductive agent, an organic carbon source, and a solvent to obtain a slurry, performing granulation to obtain spherical silicon monoxide secondary particles having a particle size of 4 to 8 [mu]m; S3: pyrolyzing the silicon monoxide secondary particles; and S4: performing secondary coating on pyrolyzed silicon monoxide secondary particlesto obtain the silicon monoxide negative electrode material. In the invention, pulverization, secondary granulation, pyrolysis, and secondary coating processing are performed on the silicon monoxide,on the basis of retaining original first-time coulombic efficiency to a large extent, thereby shortening a lithium-ion diffusion path, improving lithium-ion conductivity, limiting lithium-ion volume expansion, and having better rate performance and cycle performance.

Owner:乳源东阳光新能源材料有限公司

High-energy-density lithium ion battery and preparation method thereof

ActiveCN104134818AIncrease specific energyImprove Coulombic efficiencyFinal product manufactureElectrolyte accumulators manufacturePower batteryHigh energy

The invention relates to a high-energy-density lithium ion battery and a preparation method thereof. The high-energy-density lithium ion battery comprises a positive pole piece, a negative pole piece and a membrane, wherein an active substance on the positive pole piece is nickel cobalt lithium manganate, namely Li<1+a>Ni<x>Co<y>Mn<z>O2; an active substance on the negative pole piece is a silicon-carbon material. The preparation method of the high-energy-density lithium ion battery comprises the following steps: manufacturing the positive pole piece with the active substance, nickel cobalt lithium manganate, namely Li<1+a>Ni<x>Co<y>Mn<z>O2; manufacturing the negative pole piece with the silicon-carbon material as the active substance; coiling or laminating the positive pole piece, the negative pole piece and the celgard membrane to prepare a power battery core. The lithium ion battery provided by the invention is high in energy density, high in coulombic efficiency and high in cycling stability. The preparation method has the advantages of simple process, low cost and easiness for industrialized production.

Owner:CHERY AUTOMOBILE CO LTD

Silicon-based composite cathode material for lithium-ion battery and preparation method thereof

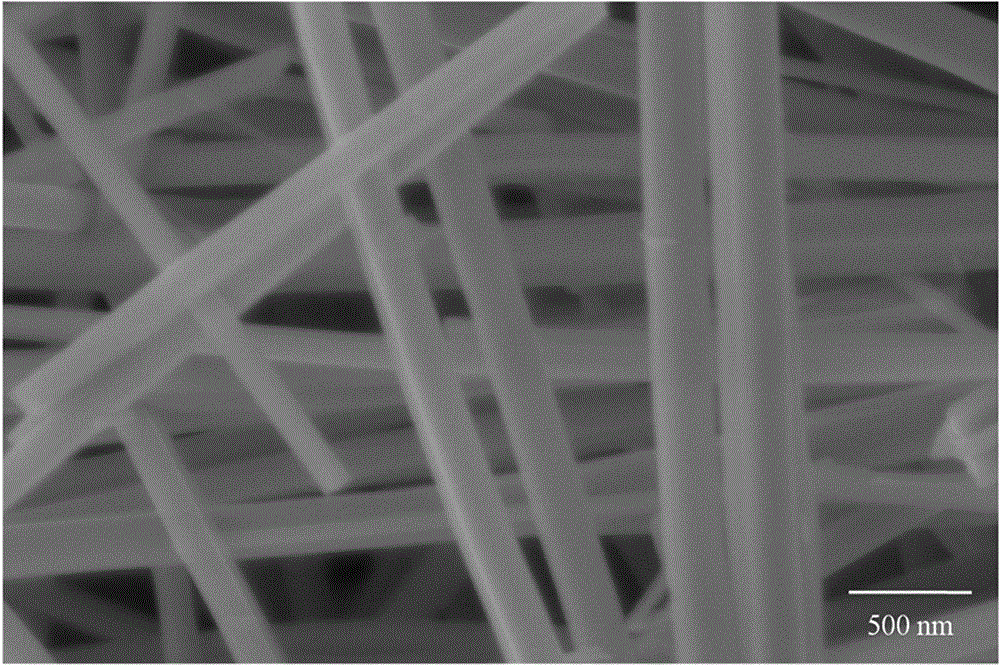

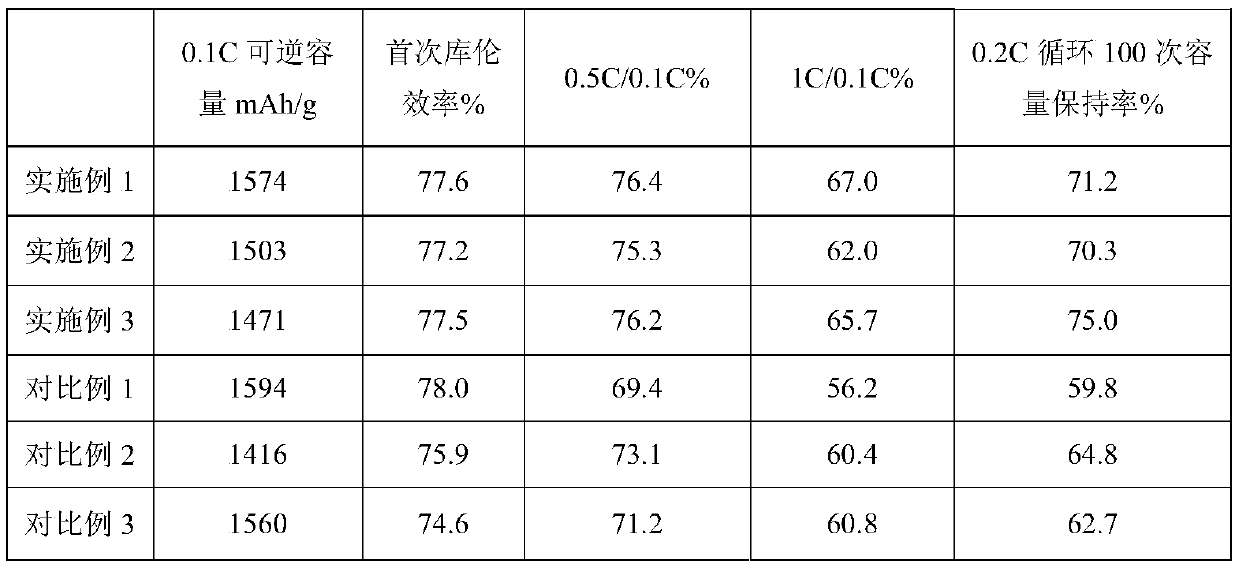

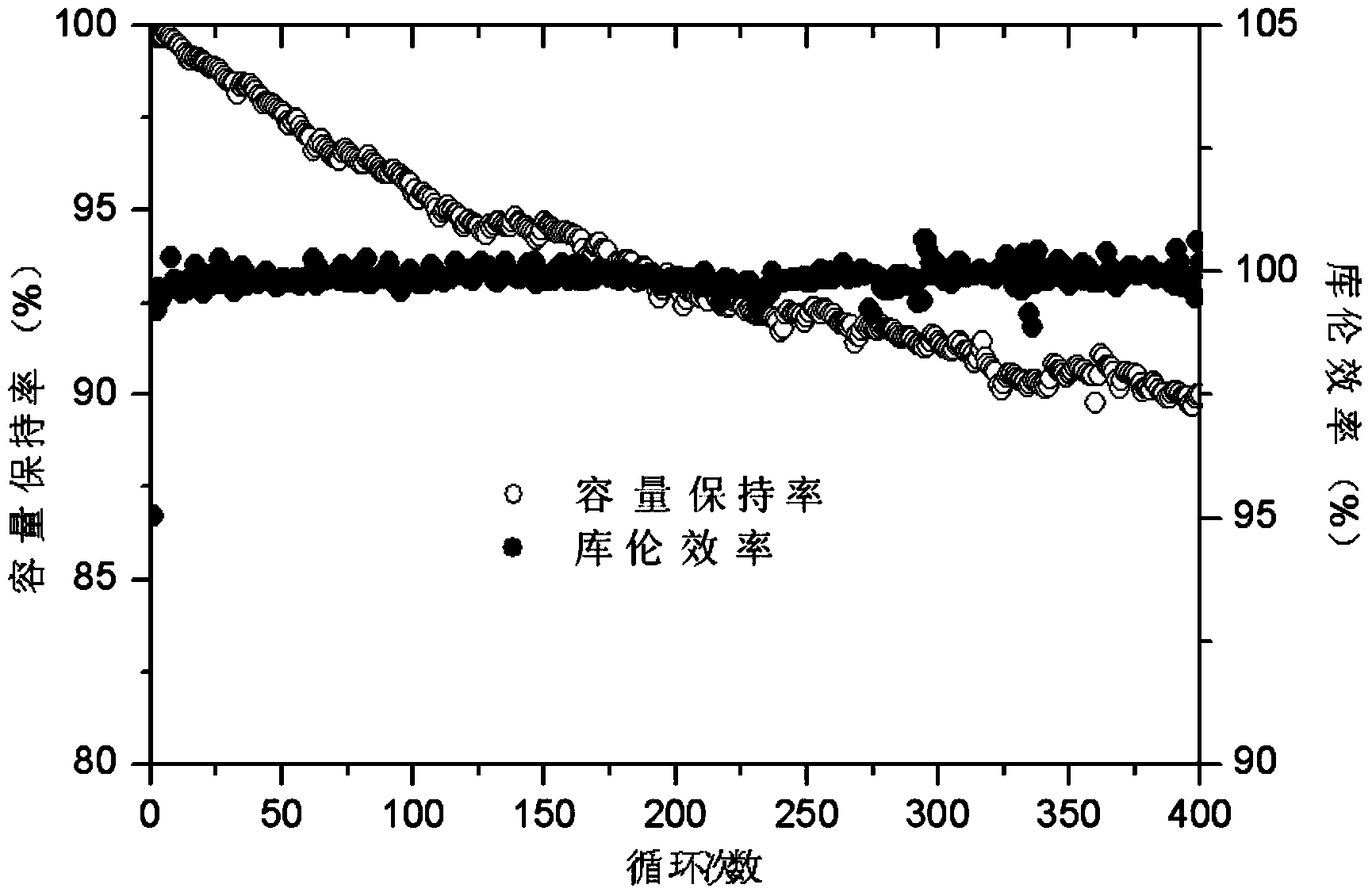

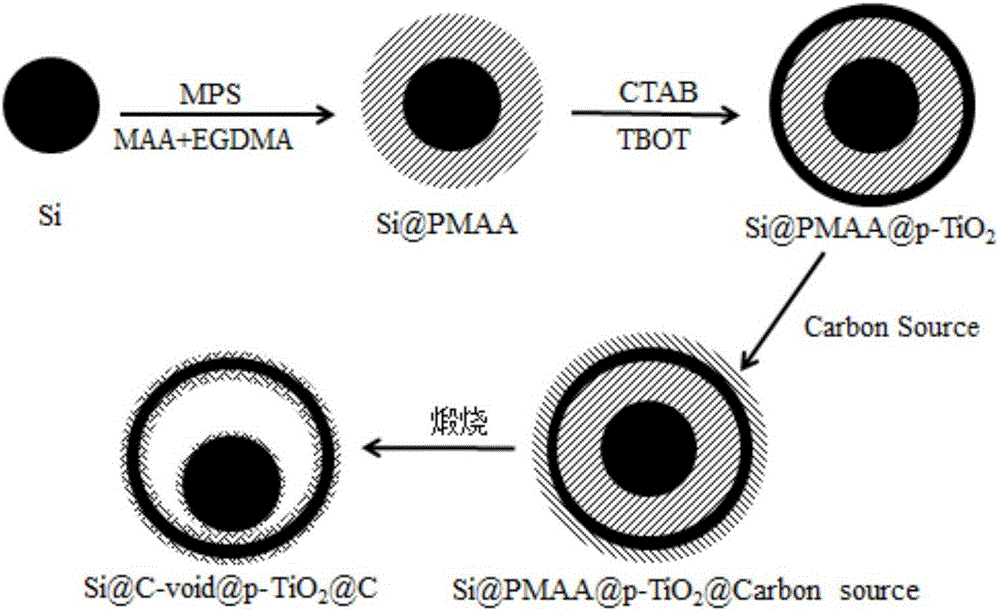

ActiveCN106784714AImprove efficiencyImprove cycle stabilityCell electrodesSecondary cellsCarbonizationLithium electrode

The invention discloses a silicon-based composite cathode material for a lithium-ion battery and a preparation method thereof. The silicon-based composite cathode material for the lithium-ion battery adopts a yolk-shell structure with nanometer silicon as the inner core and with porous titanium dioxide (p-TiO2(at)C), which is coated by pyrolytic carbon inside and outside, as the shell layer. The composite material Si(at)C-void(at)p-TiO2(at)C with the yolk-shell structure is prepared by using a precipitation-codistillation method to coat an organic layer on the surface of the nanometer silicon, using a soft template method to coat a mesoporous TiO2 inorganic layer on the surface of the organic layer in a hydrolyzed manner, coating an organic carbon source on the surface of the mesoporous TiO2 shell layer and carrying out high-temperature carbonization on the organic carbon source under the inert atmosphere. The prepared silicon-based composite cathode material for the lithium-ion battery has the advantages that the high capacity of the silicon material and the high stability of TiO2 are sufficiently utilized, the volume expansion of the nanometer silicon is effectively inhibited through a cavity core-shell structure, a conductive network is constructed within the material by using the pyrolytic carbon, and the first-week coulombic efficiency and cycling stability of the material are enhanced through the synergistic effect of the components; therefore, the silicon-based composite cathode material for the lithium-ion battery is an ideal lithium-ion battery cathode material.

Owner:SHAANXI COAL & CHEM TECH INST

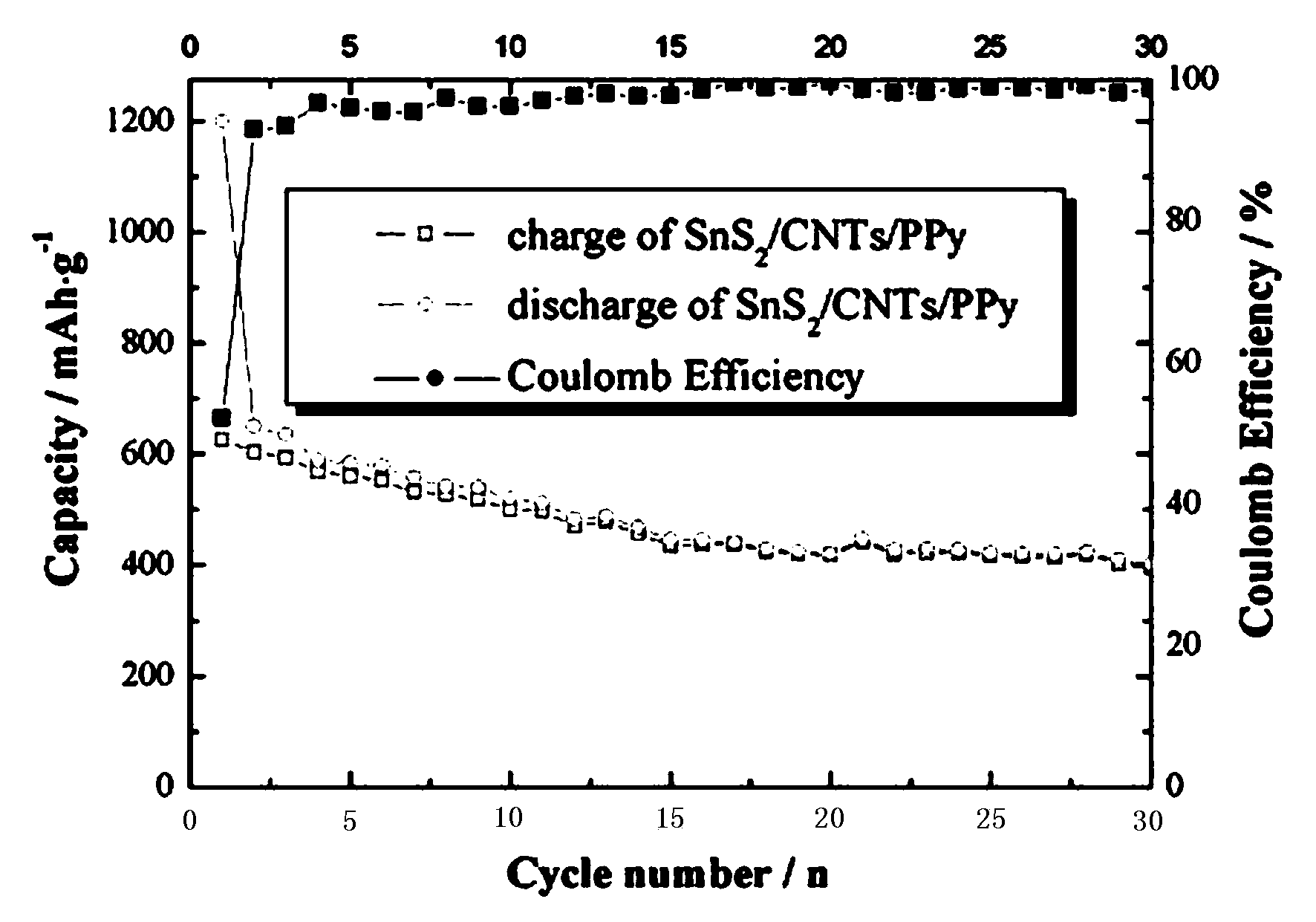

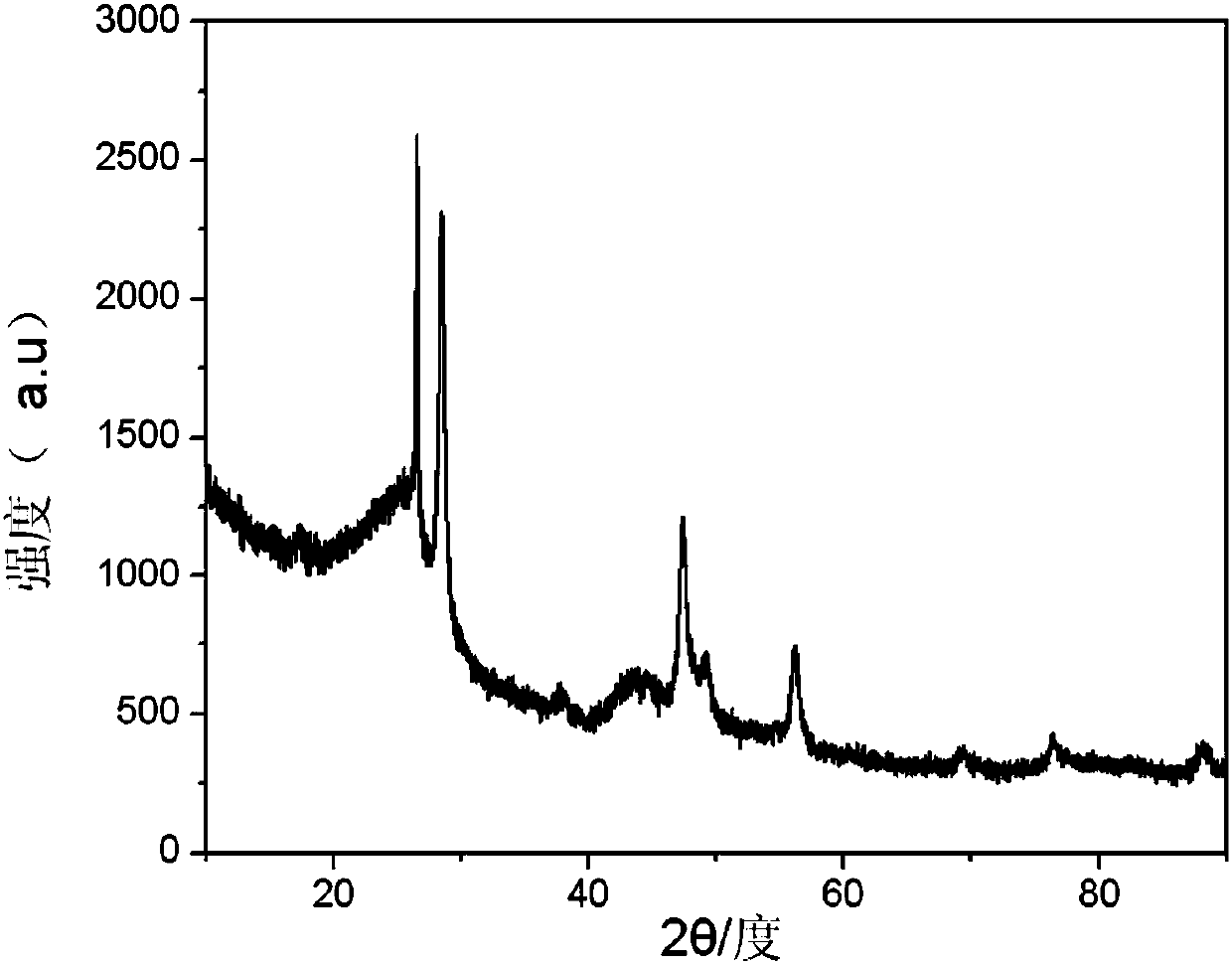

Preparation method of lithium ion battery SnS2/CNTs/PPy composite anode material

InactiveCN104319371AIncrease capacityImprove securityCell electrodesPolyethylene glycolCarbon nanotube

The invention relates to a preparation method of a lithium ion battery SnS2 / CNTs / PPy composite anode material. The preparation method comprises the following steps: Step One, adding SnCl4.5H2O and thioacetamide to a polyethylene glycol solution, and sufficiently and uniformly stirring; Step Two, adding a carbon nano tube to the solution, and carrying out ultrasonic dispersion for 60 min; Step Three, transferring the solution obtained in the step two into an automatic reaction kettle of polytetrafluoroethylene, and carrying out furnace cooling after insulation treatment; Step Four, carrying out centrifugal separation on the solution obtained in the step three, washing with deionized water and absolute ethyl alcohol, and carrying out vacuum drying; Step Five, dissolving an SnS2 / CNTs composite material obtained in the step four to the deionized water, uniformly stirring, adding lauryl sodium sulfate, adding pyrrole monomers and oxidizing agent, and stirring at room temperature for reaction for four hours; Step Six, carrying out centrifugal separation on the solution obtained in the step five, washing with deionized water and absolute ethyl alcohol, and carrying out vacuum drying. The anode material obtained by the preparation method is high in capacity and good in cycle performance, and has potential application prospects in the fields of portable electronic equipment, electric vehicles, aerospace and the like.

Owner:SHENZHEN POLYTECHNIC

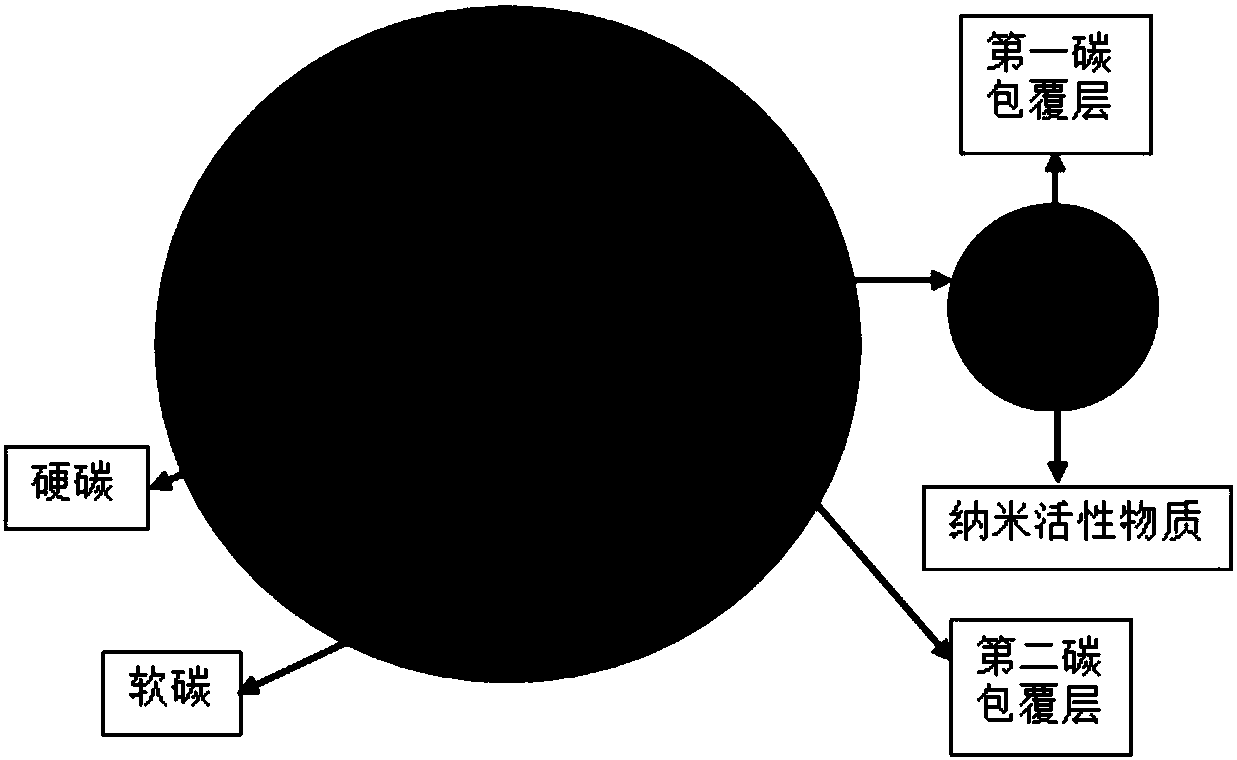

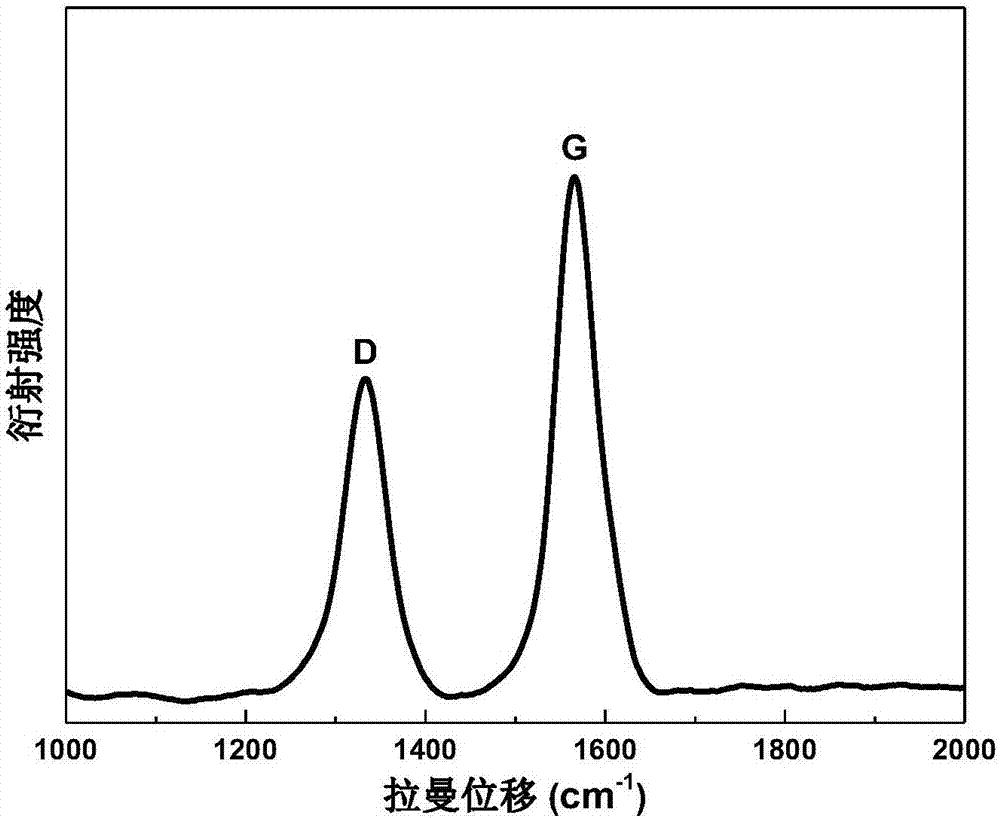

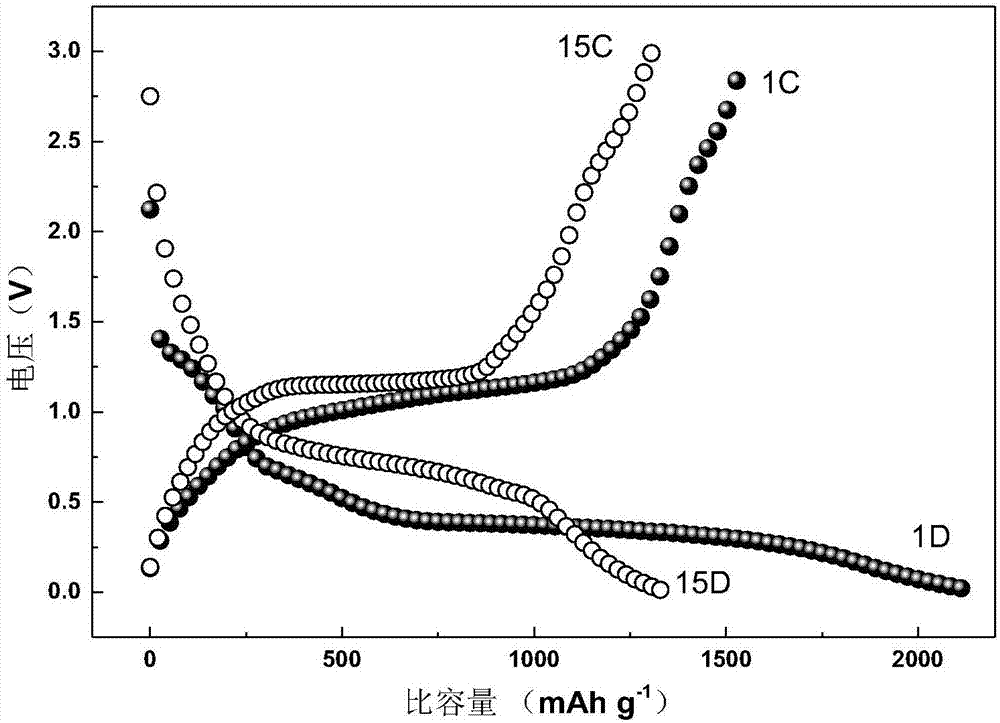

High-capacity ratio rate carbon-based composite material, preparation method thereof and application thereof in lithium ion battery

ActiveCN107768626AImprove Capacitive PerformanceImproved magnification performanceSiliconElectrode thermal treatmentCarbon coatingOrganic matter

The invention discloses a carbon-based composite material, a preparation method thereof and application thereof. The carbon-based composite material comprises micron-order soft carbon, micron-order hard carbon, a nano-active material, a first carbon coating layer and a second carbon coating layer, wherein the first carbon coating layer is coated on the surface of the nano-active material to form composite particles; the composite particles are dispersed on the surfaces of the soft carbon and the hard carbon and in the second carbon coating layer; the second carbon coating layer coats the softand hard carbon and the composite particles. The method disclosed by the invention comprises the following steps: 1) performing carbon coating on the nano-active material to form composite particles;2) dispersing the composite particles on the surface of the soft carbon and the hard carbon to form a first precursor; 3) performing coating modification by using an organic matter; 4) performing VC heating mixing or mixed kneading and molding; 5) sintering at a high temperature, thereby obtaining the composite material. The composite material disclosed by the invention is very suitable to serve as a negative electrode active material of the lithium ion battery, has high capacity and first charge and discharge efficiency and is excellent in rate capability.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for synthesizing TiO2/C (titanium dioxide/carbon) composite material on basis of MOF (metal organic framework) structure and application

InactiveCN107123803AImprove adsorption capacityInhibition of the shuttle effectCell electrodesLi-accumulatorsCarbon compositesLithium–sulfur battery

The invention discloses a method for synthesizing a TiO2 / C (titanium dioxide / carbon) composite material on the basis of an MOF (metal organic framework) structure and application. The method comprises the following steps: (1) preparing a Ti-MOF by virtue of a hydrothermal method; (2) treating the Ti-MOF in a tube furnace to obtain the TiO2 / C composite material at high temperature under the protection of inert gas; (3) mixing the TiO2 / C composite material and elemental sulfur, performing heating melting under the protection of the inert gas, and cooling to room temperature to obtain a TiO2 / C / S composite material. According to the method, the TiO2 / C composite material is prepared by treating the MOF at high temperature, and the C has high electrical conductivity, so that problems about the insulativity of the elemental sulfur can be well solved; in addition, strong Lewis acid-base actions can be achieved by TiO2 which serves as a cathode material for a lithium-sulfur battery and a sulfur polymer, thereby inhibiting the shuttle effect of lithium polysulfide and improving the overall electrochemical performance of the lithium-sulfur battery.

Owner:HARBIN INST OF TECH

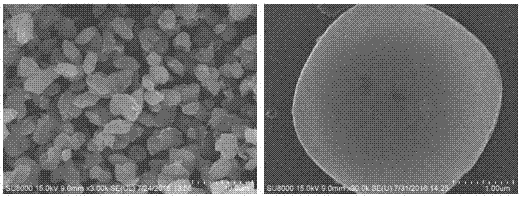

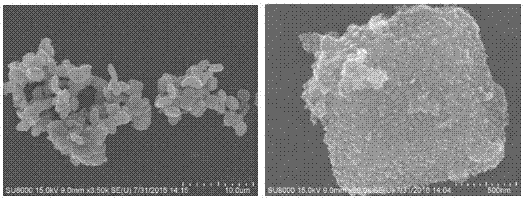

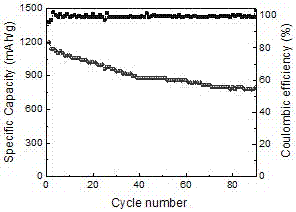

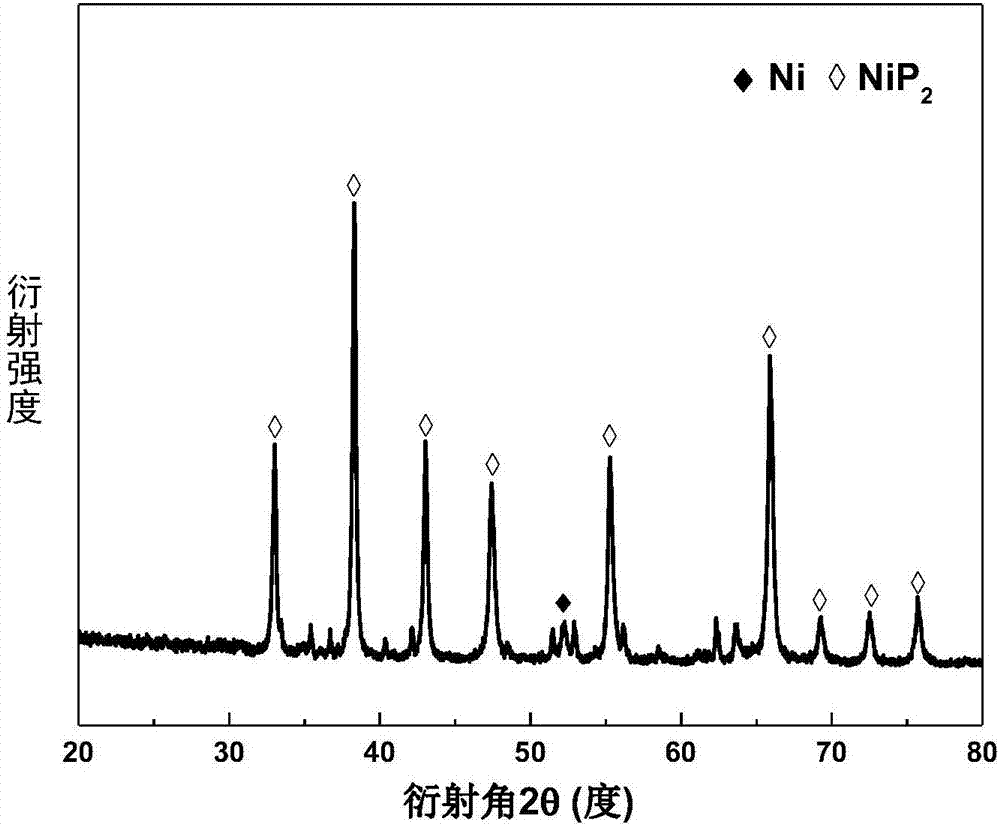

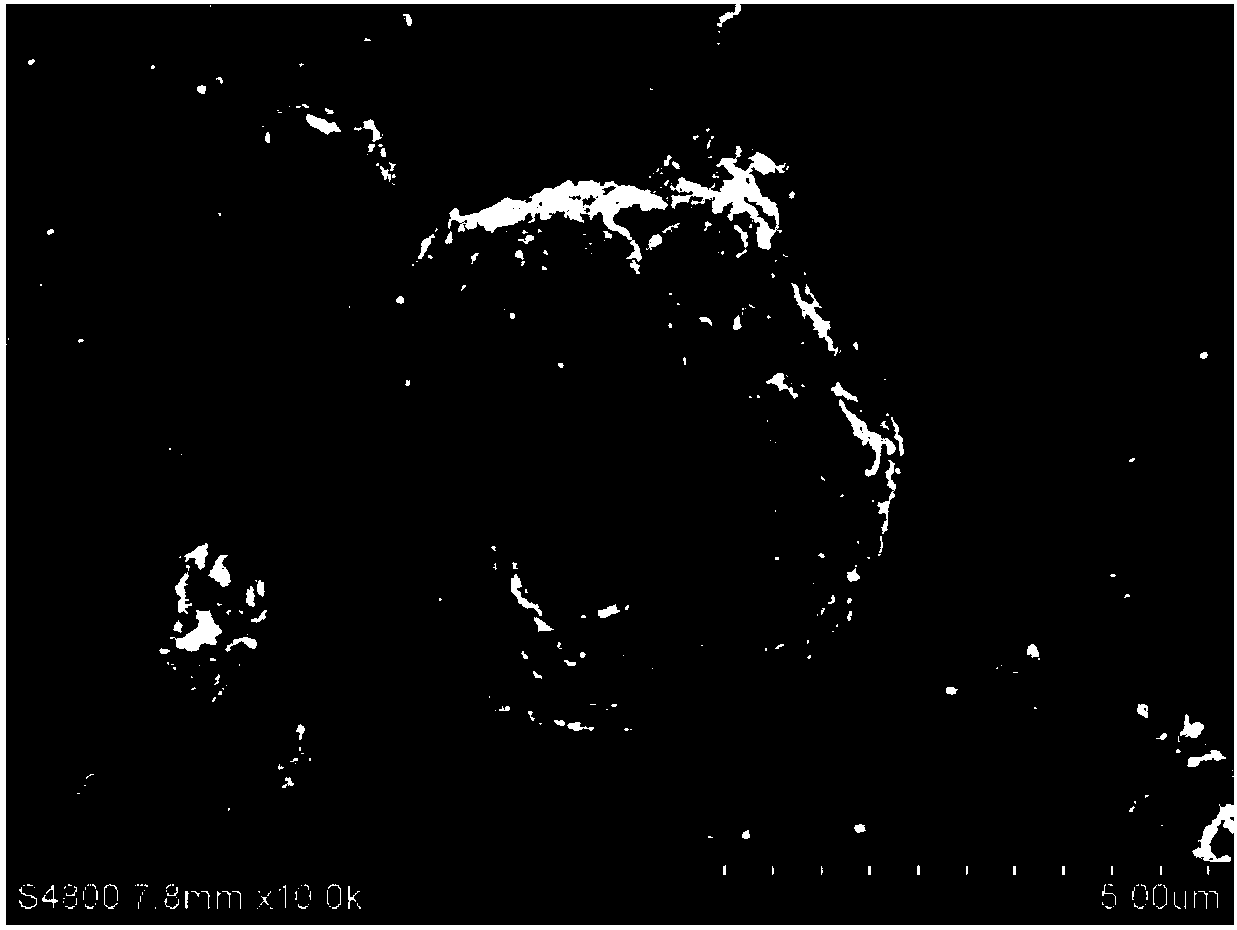

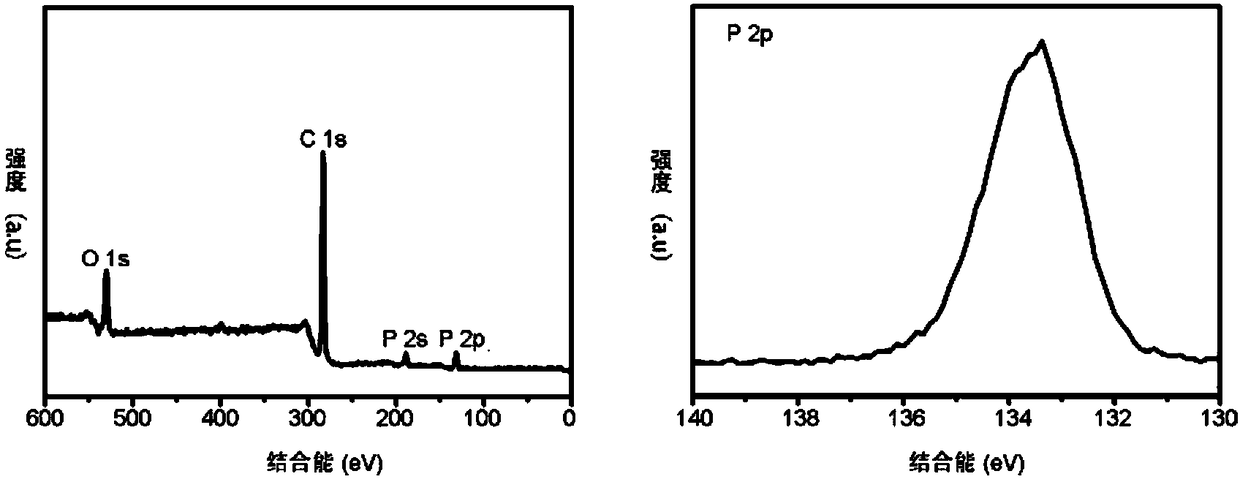

Preparation method and application of shell-core carbon-coated metal phosphide nanometer composite particle

InactiveCN107317008ALow costEasy to makeCell electrodesSecondary cellsAutomatic controlCarbon source

The invention provides a preparation method of a shell-core carbon-coated metal phosphide nanometer composite particle. The obtained composite particle is used as a lithium ion battery negative electrode material to be applied to the field of a lithium ion battery. The preparation method comprises the steps of adding a certain proportion of a substance containing a carbon source and inert gas into automatic control DC arc metal nanometer powder production equipment, and evaporating a metal raw material to obtain a carbon-coated metal nanometer particle precursor; mixing and placing the precursor and red phosphorus powder in a high-pressure sealing reaction kettle for thermal treatment to obtain a carbon-coated metal phosphide nanometer composite material; and fabricating a lithium ion electrode plate by taking the carbon-coated nickel phosphide nanometer composite material as an active substance. The preparation method has the advantages that the carbon-coated nickel nanometer particle synthesized in an in-situ way is used as the precursor, the carbon-coated nickel phosphide nanometer composite particle is obtained by low-temperature phosphorization, and the composite particle has relatively high intercalation / de-intercalation lithium capacity density and cycle stability, is low in raw material cost and simple in process, can be prepared on a large scale and is suitable for industrial production.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

Lithium silicon alloy material with surface modification layer, preparation method thereof, electrode and electrochemical energy storage device and negative electrode lithium-supplementing method

ActiveCN108565414AProcess stabilityImprove the first charge and discharge efficiencyFuel and secondary cellsCell electrodesSilicon alloyHigh energy

The invention discloses a lithium silicon alloy material with a surface modification layer, a preparation method thereof, an electrode and an electrochemical energy storage device and a negative electrode lithium-supplementing method. The lithium-silicon alloy material is in the form of particles, the particle size of the particles is 0.1 to 50 micrometers, and the lithium-silicon alloy material comprises lithium-silicon alloy particles and a surface modification layer which covers the exposed surfaces of the lithium-silicon alloy particles. The outer layer of the surface modification layer isused for preventing the lithium-silicon alloy from coming into contact with the external environment, so that the lithium-silicon alloy can be stably stored and used in the dry air, and the reactionbetween the material and the electrolyte during the electrochemical cycle can be effectively prevented, and the cycle stability is improved; in addition, the lithium silicon alloy with the surface modification layer can be used as the negative electrode alone, the first efficiency of the battery can be improved, and can also be used as an additive in other negative electrodes without lithium element to supplement lithium and reduce the loss of effective lithium, and a lithium ion battery with high energy density is prepared.

Owner:CHINA ENERGY LITHIUM

Nano microstructure silicon negative electrode material preparation method

ActiveCN108336345AInhibition of volume expansionEnsure structural stabilityMaterial nanotechnologyElectrode manufacturing processesLithiumNano silicon

The invention discloses a nano microstructure silicon negative electrode material preparation method. The preparation method comprises the following steps: 1) metallurgy nano silicon is dispersed in organic dispersion liquid; 2) HF-metal salting liquid is prepared as an etching agent, the etching agent is slowly added in silicon pre-dispersion liquid, and the nano silicon with the surface deposited with the metal particles can be obtained; 3) the nano silicon with the surface deposited with the metal particles is re-dispersed in the organic dispersion liquid; 4) a HF-H2O2 solution is added inthe silicon dispersion liquid, and the organic dispersion liquid is intermittently added; 5) porous silicon is immersed in a HNO3 solution to obtain the high-purity porous silicon; and 6) the high-purity porous silicon is subjected to ball milling processing with a controllable oxidation degree. The method employs combination of metal auxiliary chemical etching and ball milling with the controllable oxidation degree, and the nano microstructure silicon negative electrode material with the surface coated with a layer of compact oxide SiOx and having micropores inside can be prepared, a lithium ion transmission path is shortened, silicon volume expansion can be accommodated, and the method has excellent cycle stability.

Owner:湖南宸星新材料研究院有限公司

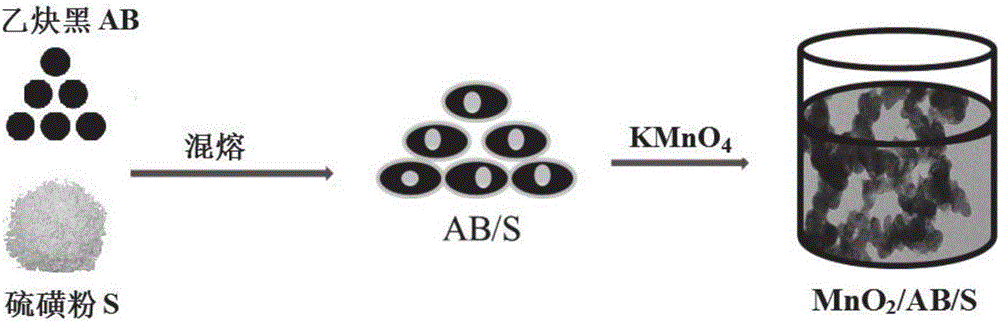

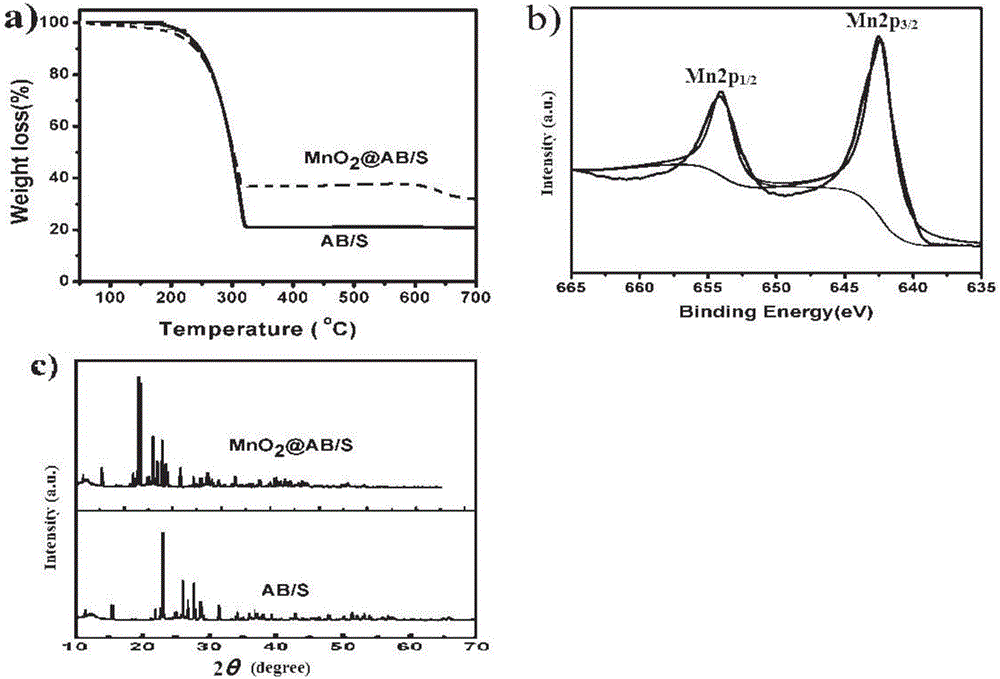

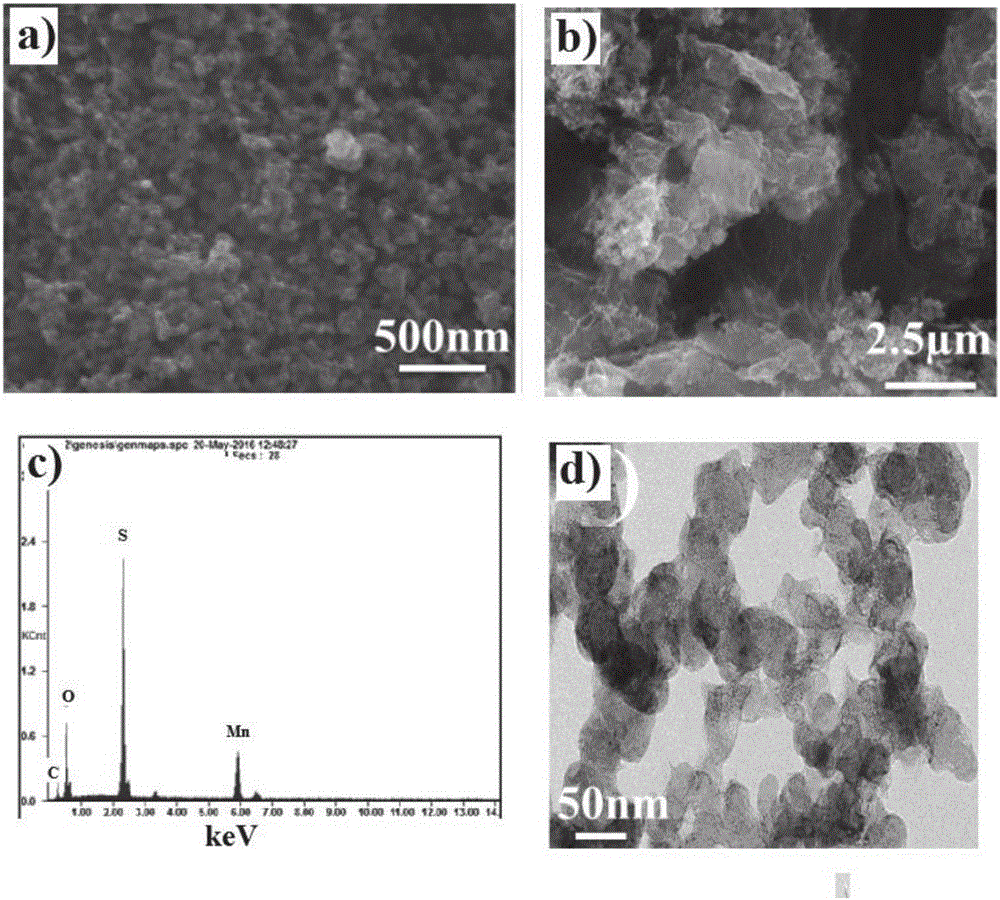

Manganese dioxide nanosheet coated carbon/sulphur compound, preparation method and application thereof

InactiveCN106129384AWrappedIncrease the speed of electron transferCell electrodesLi-accumulatorsSulphur compoundCathode material

The invention discloses a method for preparing a manganese dioxide nanosheet coated carbon / sulphur (MnO2@C / S) compound. The method comprises the following steps: firstly heating and melting a carbon material and sulphur simple substance to obtain a carbon / sulphur compound, then adding permanganate solution into aqueous phase dispersion liquid of the carbon / sulphur compound, heating, stirring, reacting, then carrying out solid-liquid separation, washing, and drying, so that the manganese dioxide nanosheet coated carbon / sulphur compound is obtained. Besides, the invention also discloses the manganese dioxide nanosheet coated carbon / sulphur compound obtained by adopting the method and application thereof. When the manganese dioxide nanosheet coated carbon / sulphur compound is applied to a lithium sulphur battery cathode material, and initial discharge capacity, cycle performance and rate capability of the obtained battery are respectively greatly improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com