High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

A reinforced composite material and alumina fiber technology, which is applied in the field of high-temperature-resistant high-strength alumina fiber-reinforced composite materials and its preparation, can solve the problems that the preparation method has not been reported in detail, achieve excellent room temperature and high temperature mechanical properties, and improve impregnation Efficiency, the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the high-temperature-resistant high-strength alumina fiber-reinforced composite material of the present invention specifically comprises the following steps:

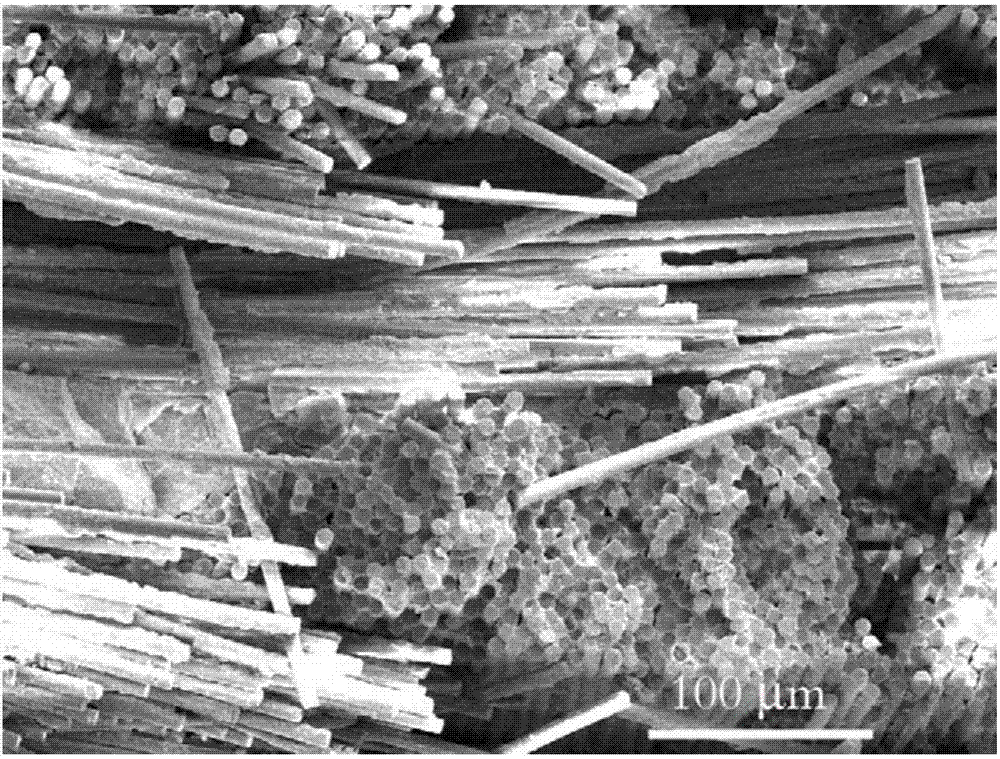

[0039] Step (1) The continuous alumina fiber prefabricated body stitched or woven by two-dimensional cloth layer, 2.5D or orthogonal three-way method is used as the reinforcement body, and the volume content of the fiber reinforcement body is 30-60%.

[0040] In step (2), put the alumina fiber prefabricated body prepared in step (1) into a muffle furnace for purification and heat treatment. The heat treatment temperature is 380-750° C. and the heat treatment time is 0.5-8 hours.

[0041] Step (3), after mixing nano-alumina powder and deionized water with a mass ratio of 30:100 to 1.5:100, add 0.05 to 6.0% dispersant, the dispersant is CELUNA D-305 (Zhongjing Oil Co., Ltd.), BYK-154 (ByK Chemicals) or BYK-191 (ByK Chemicals), ultrasonic 10 ~ 120min, until the formation of a uniform disper...

Embodiment 1

[0051] (1), with 2.5D continuous alumina fiber prefabricated body as reinforcement, the volume content of fiber is 42%;

[0052] (2), put the alumina fiber prefabricated body prepared in step (1) into a muffle furnace for purification heat treatment, the heat treatment temperature is 700°C, and the heat treatment time is 5h;

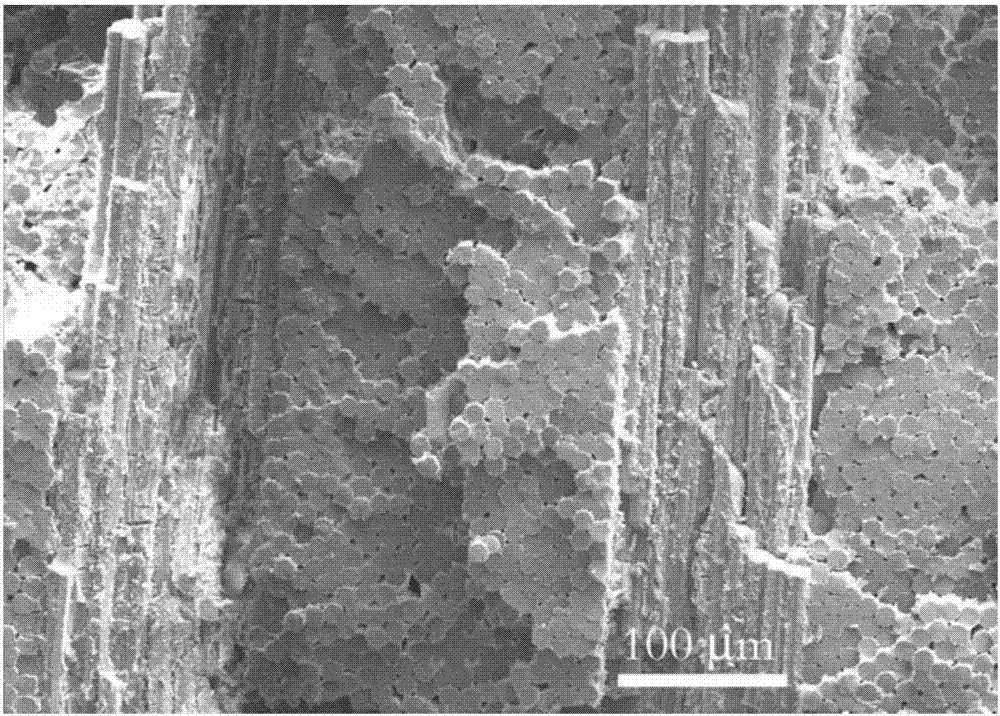

[0053] (3), after mixing nano-alumina powder and deionized water with a mass ratio of 28:100, add 3.5% dispersant CELUNA D-305, ultrasonic 100min, to form a uniform dispersion; 40% nano-silica sol and nano-alumina powder suspension are mixed according to the mass ratio of 1:1.5, and placed in a ball mill. The speed of the ball mill is 800r / min, and the ball milling time is 100min. 120mPa s;

[0054] (4), place the alumina fiber prefabricated body obtained in step (2) in the "dual nanocomposite impregnation solution" obtained in step (3), vacuum impregnate for 120min, and the vacuum degree is 133Pa, then carry out pressure impregnation, and the impregnat...

Embodiment 2

[0062] (1), the continuous alumina fiber prefabricated body of the two-dimensional cloth layer is used as the reinforcement, and the volume content of the fiber is 38%;

[0063] (2) Put the alumina fiber prefabricated body prepared in step (1) into a muffle furnace for purification heat treatment, the heat treatment temperature is 400°C, and the heat treatment time is 3h;

[0064] (3) After mixing nano-alumina powder and deionized water at a mass ratio of 15:100, add 2.0% dispersant CELUNA D-305, and ultrasonicate for 60 minutes to form a uniform dispersion; 40% nano-silica sol and nano-alumina powder suspension are mixed according to the mass ratio of 1:1, and placed in a ball mill. The speed of the ball mill is 600r / min, and the ball milling time is 60min. 50mPa·s;

[0065] (4), place the alumina fiber prefabricated body obtained in step (2) in the "dual nanocomposite impregnation solution" obtained in step (3), vacuum impregnate for 1h, and the vacuum degree is 100Pa, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com