Patents

Literature

206results about How to "Improve impregnation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

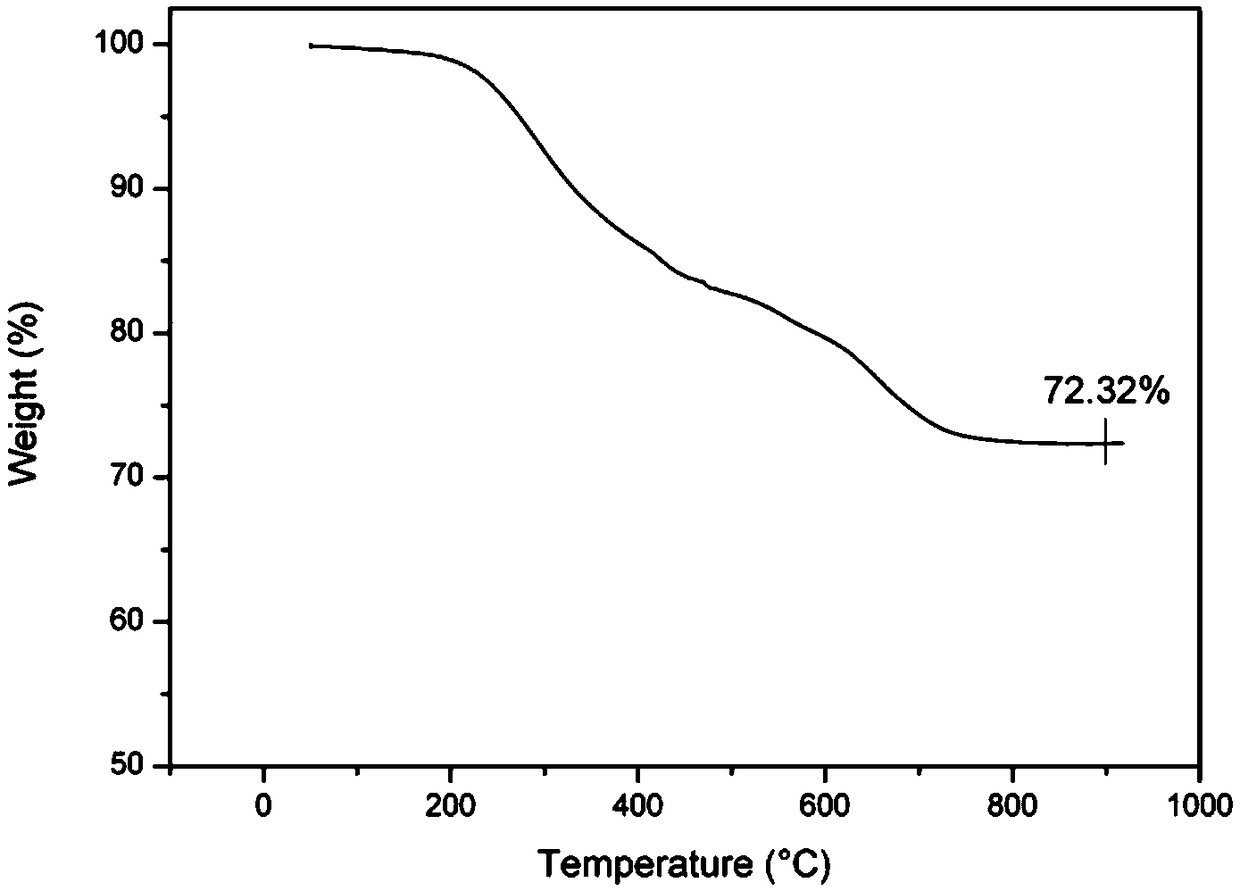

Novel liquid polycarbosilane as well as preparation method and application thereof

The invention discloses novel liquid polycarbosilane which is low in viscosity and high in storage stability and is crosslinkable, a preparation method of novel liquid polycarbosilane, and an application of novel liquid polycarbosilane. Polycarbosilane is prepared by adopting chloromethyl alkoxy silane or mixtures of chloromethyl alkoxy silane as raw materials by virtue of Grignard coupling reaction and reduction reaction, and the structure of polycarbosilane is shown in a formula (I) in the specification. The structure simultaneously contains Si-H bonds and unsaturated bonds such as C=C bonds, can be subjected to self-crosslinking and curing under a certain condition, has relatively high ceramic yield, and can be used as a silicon carbide precursor of a polymer precursor impregnation pyrolysis (PIP) process. Polycarbosilane disclosed by the invention is adjustable in structural composition, good in storage stability, low in viscosity and relatively low in boiling point, and has the utilization potentiality of being used as a silicon carbide ceramic precursor for chemical vapor deposition / chemical vapor infiltration (CVD / CVI). In addition, polycarbosilane can also be used for replacing commonly-used divinyl benzene to serve as a crosslinking agent of solid-state polycarbosilane (PCS).

Owner:淄博市临淄齐泉工贸有限公司

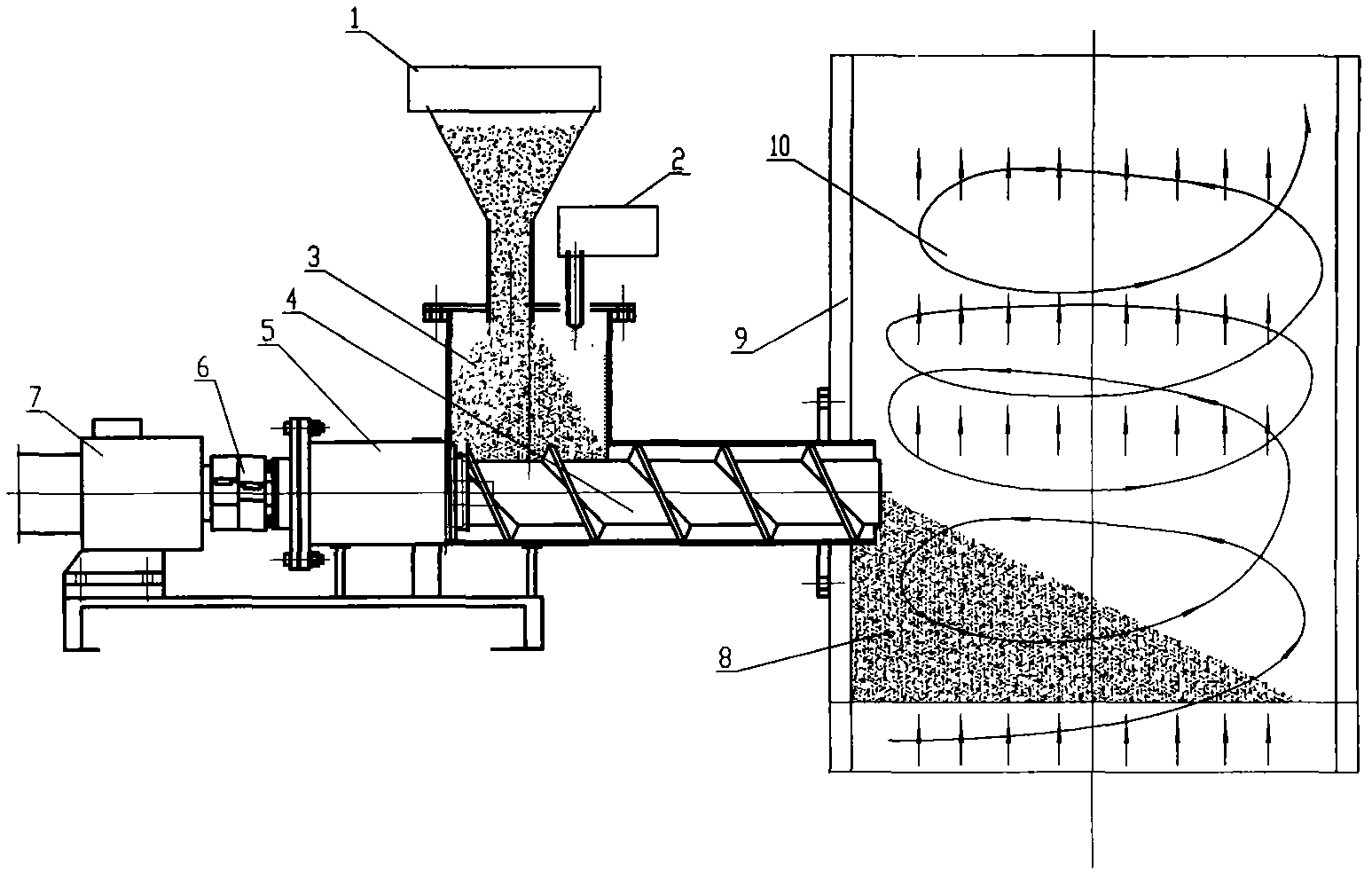

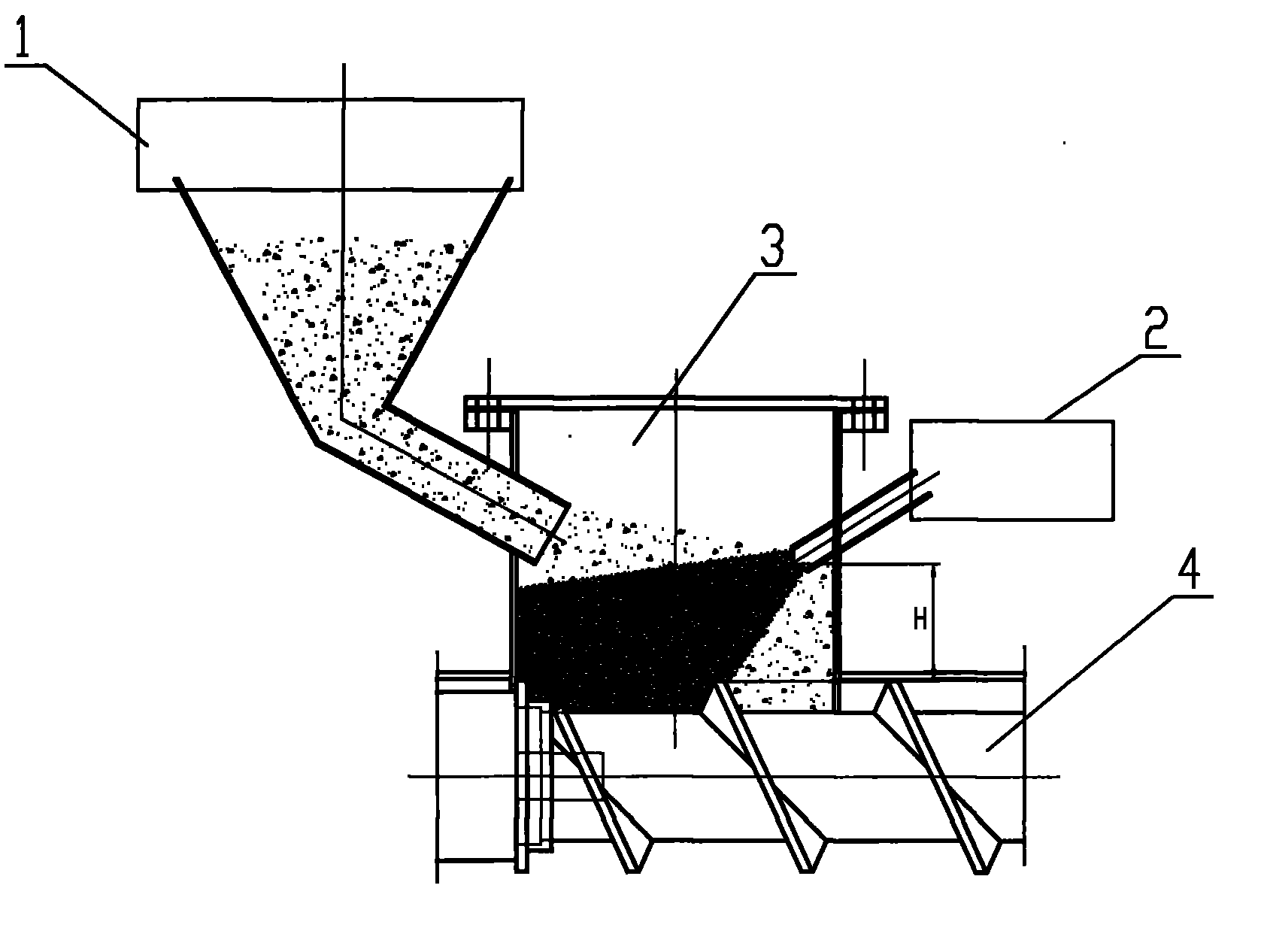

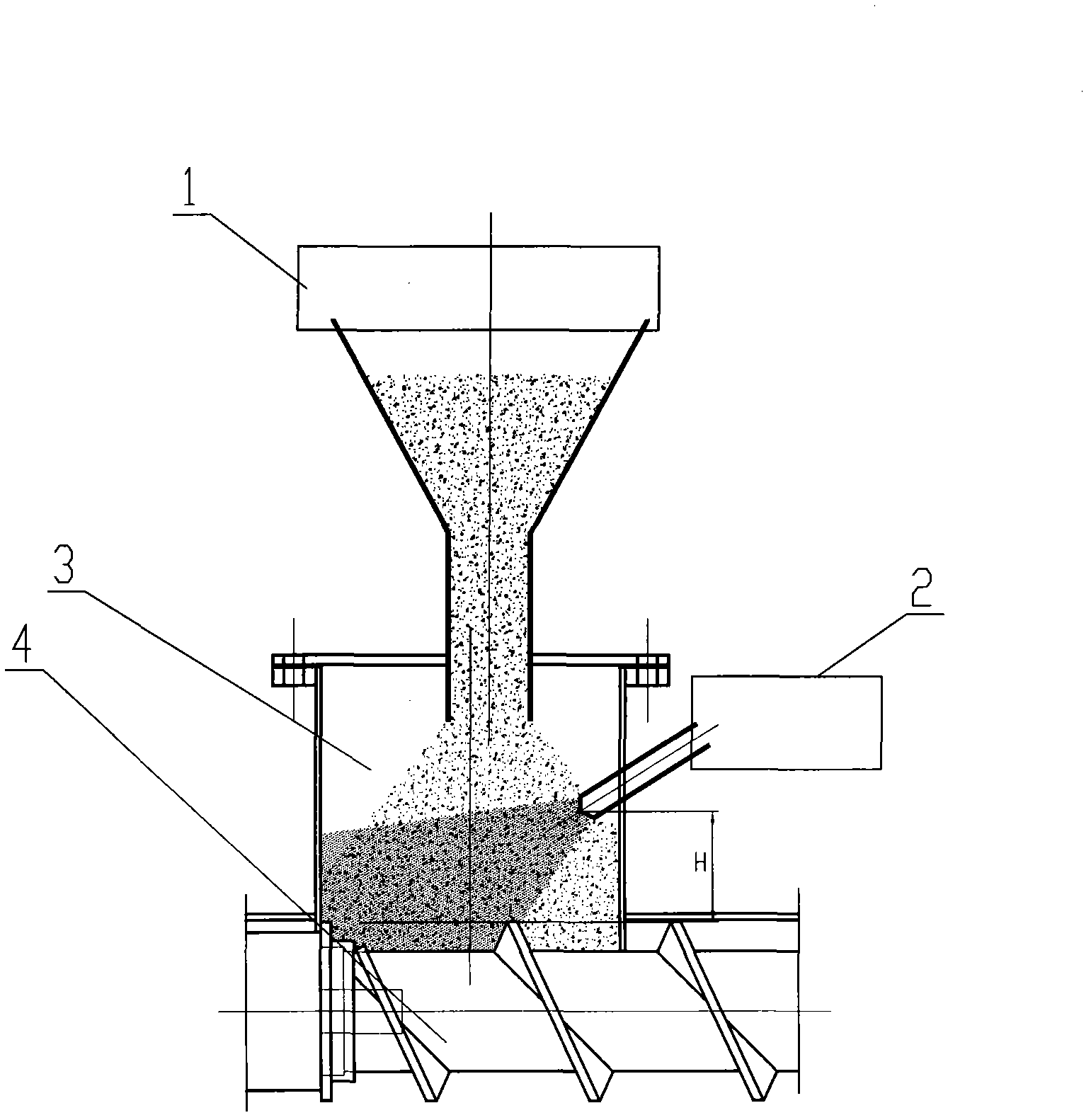

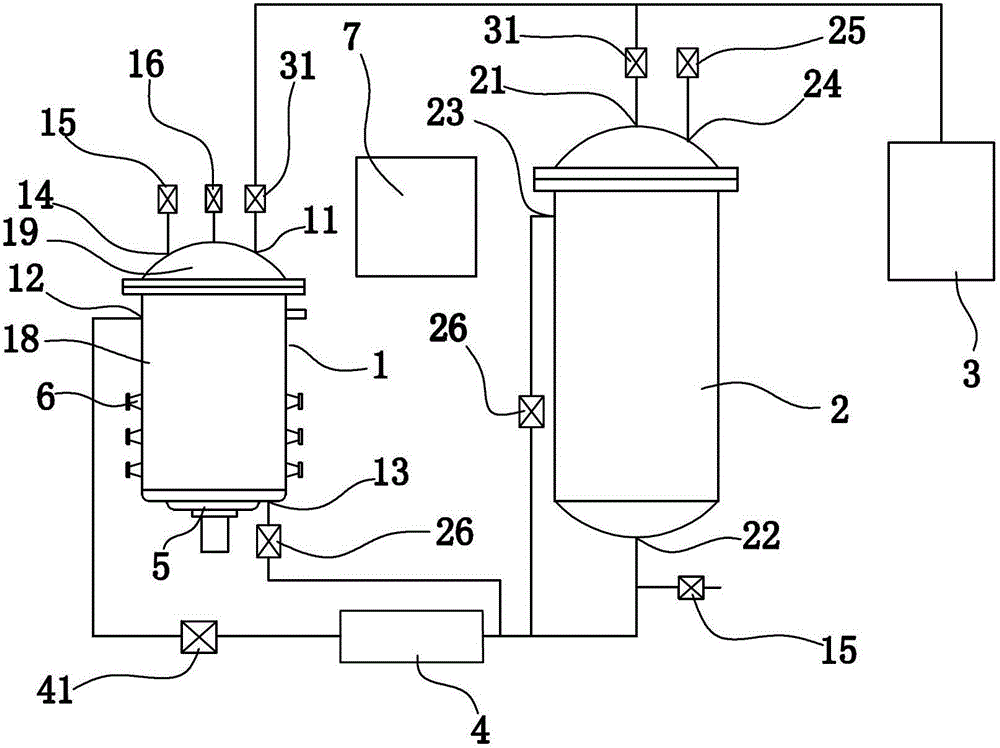

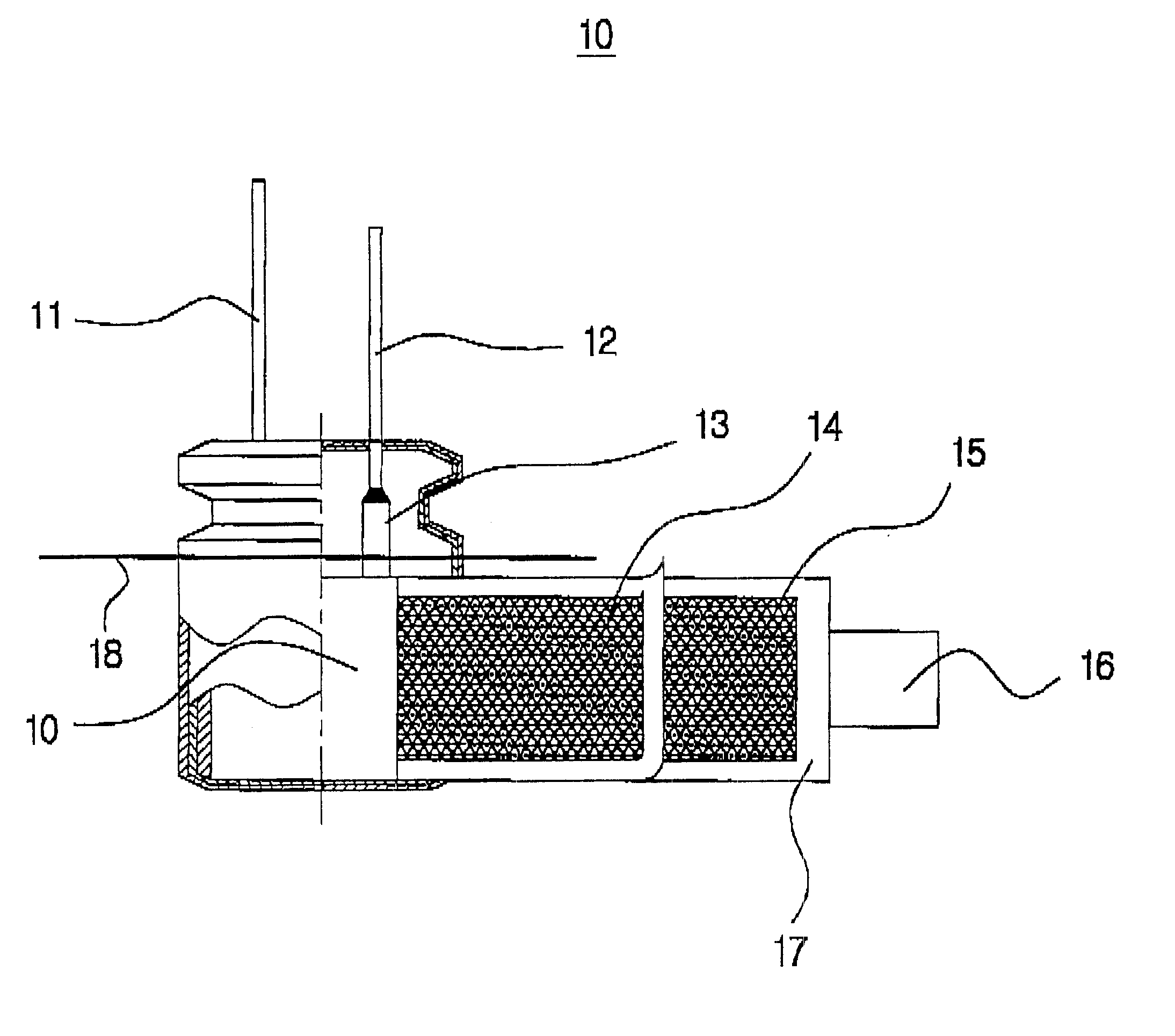

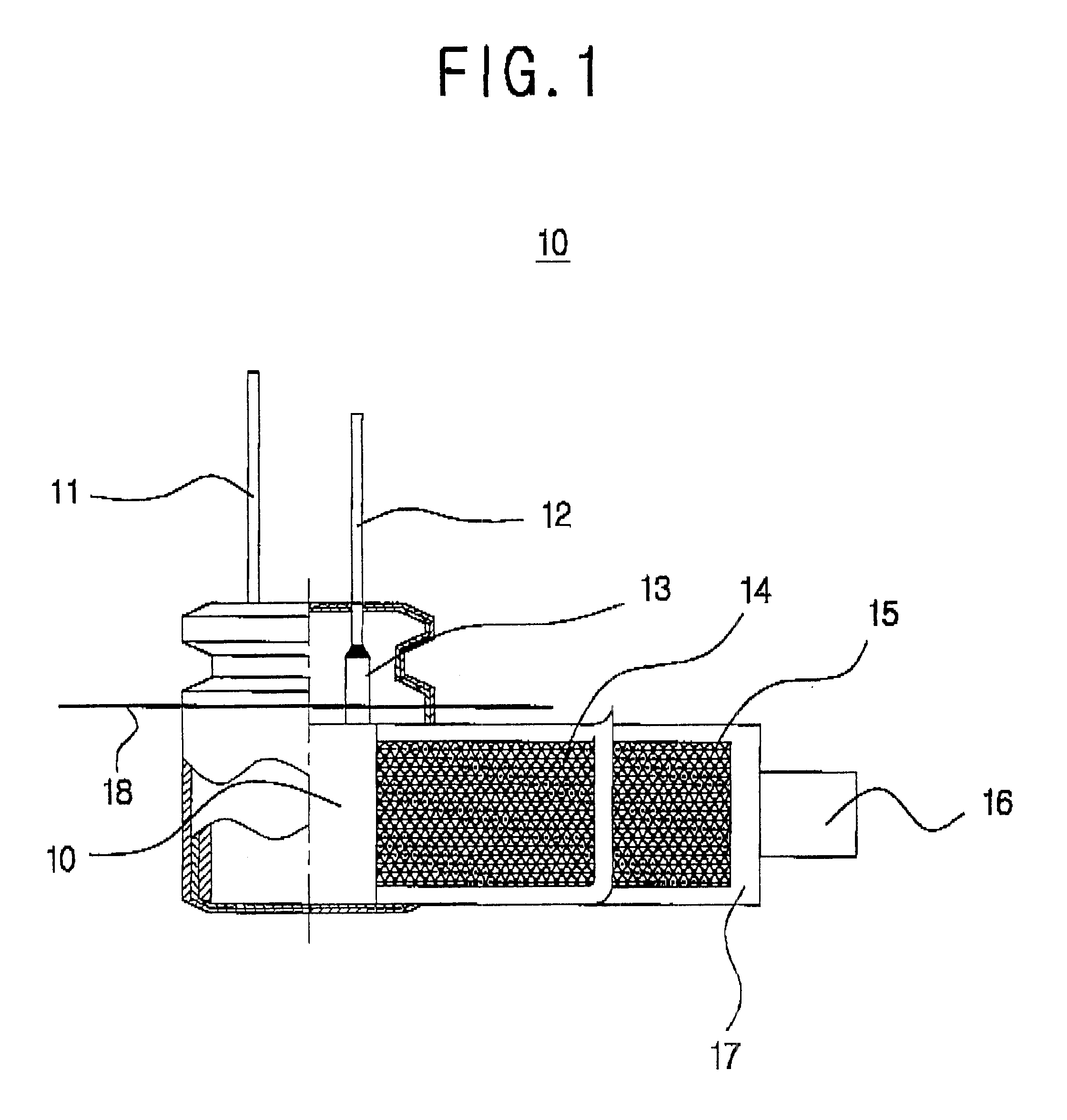

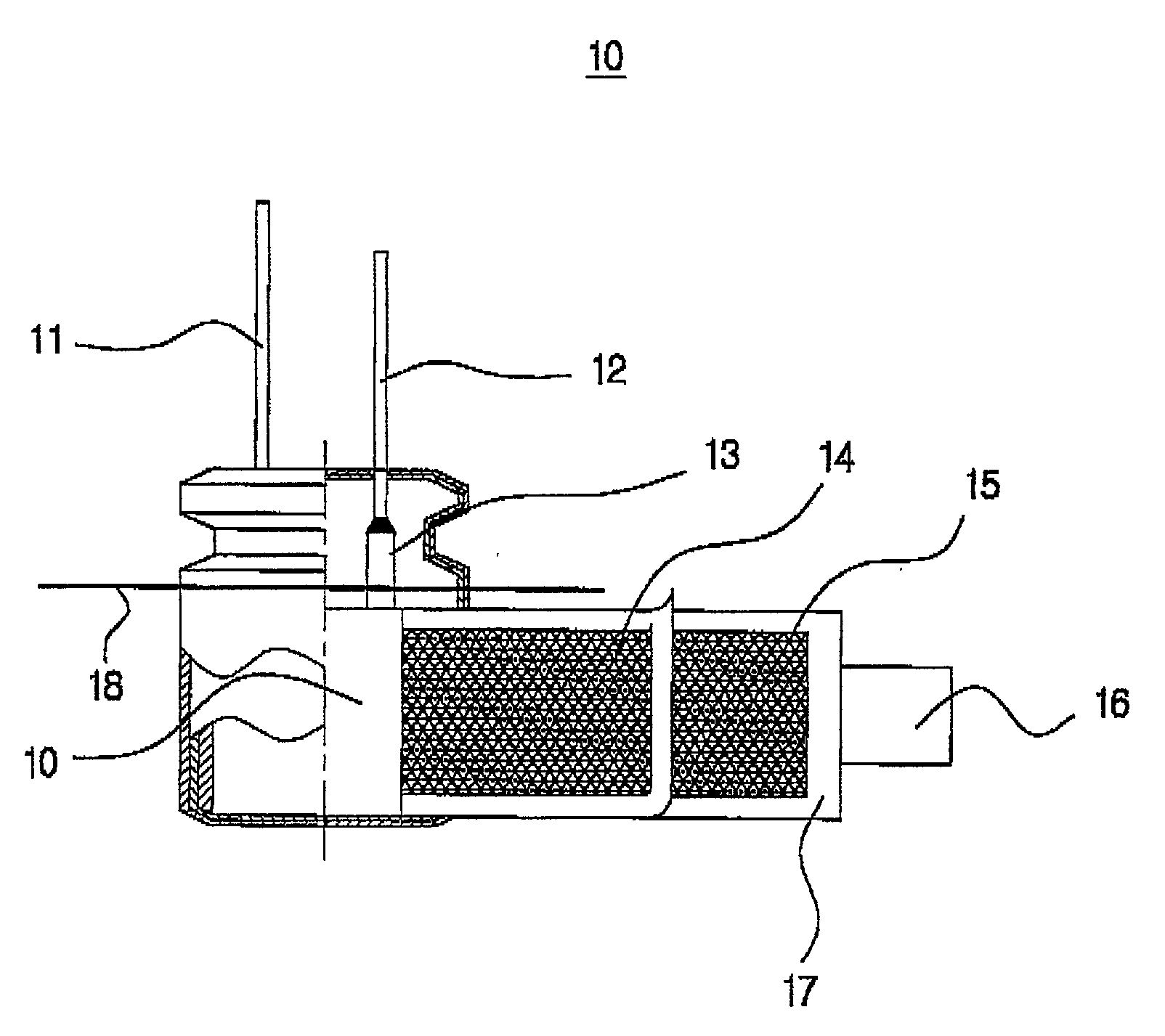

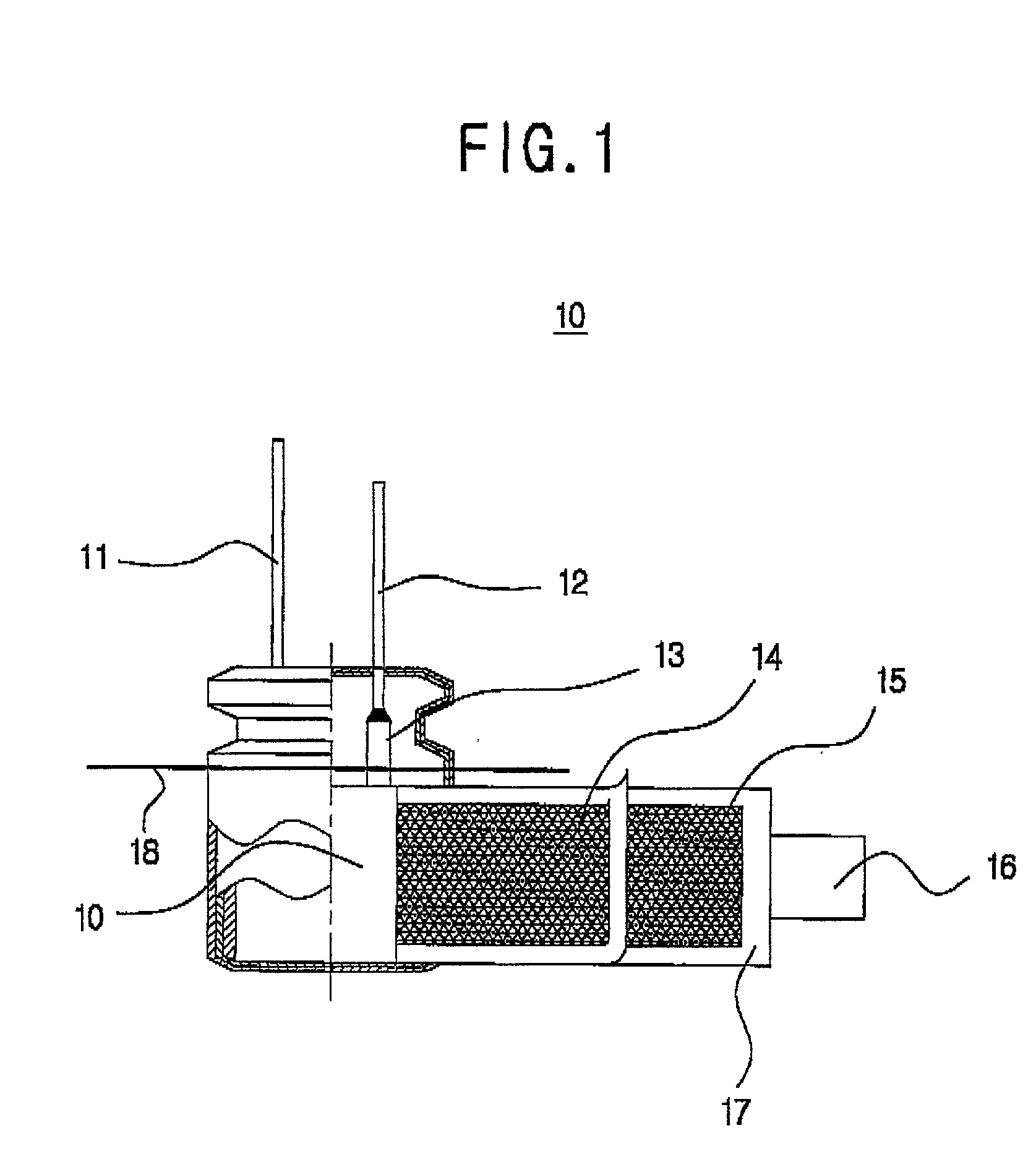

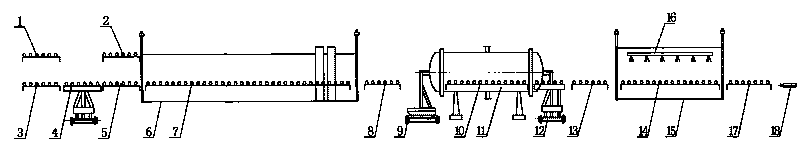

Catalyst successive impregnation equipment and method

ActiveCN102806109AImprove impregnation efficiencyImprove impregnation uniformityCatalyst activation/preparationEngineeringCatalyst support

The invention relates to catalyst successive impregnation equipment and a method. The catalyst successive impregnation equipment comprises a carrier continuous feeding system (1), an impregnation liquid conveying system (2), an impregnation chamber (3), a conveying part (4), a dryer (9) and a power system; the carrier continuous feeding system (1) and the impregnation liquid conveying system (2) are open in the impregnation chamber (3); the bottom of the impregnation chamber (3) is open at the initial end of the conveying part (4); the conveying part (4) is positioned between the impregnation chamber (3) and the dryer (9); an outlet at the tail end of the conveying part (4) is communicated with the dryer (9); and power is provided for the operation of the conveying part (4) by the power system. The invention also discloses the method applying the equipment. The catalyst successive impregnation equipment and the method which are provided by the invention can be used for carrying out catalyst carrier impregnation to prepare a catalyst; a catalyst carrier is continuously impregnated; the impregnation efficiency is high; the impregnation uniformity is good; and the catalyst carrier is crushed a little.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

High-temperature-resistant wave-transparent silicon nitride fiber-reinforced composite material and preparation method thereof

The invention relates to a high-temperature-resistant wave-transparent silicon nitride fiber-reinforced composite material and a preparation method thereof. The method comprises the following steps: by using a two-dimensional fabric laying or three-dimensional four-direction knitted continuous silicon nitride fiber preform as a reinforcing body, carrying out interface coating preparation on the reinforcing body fiber surface with a polyboron azane precursor by half-vitrification; compounding the precursor mainly composed of polyboron azane with an impregnation liquid to prepare a base; and carrying out vacuum pressure impregnation, desolventization, pressure crosslinking curing and cracking densification to obtain the final silicon nitride fiber-reinforced composite material. The preparation method greatly enhances the impregnation efficiency, enhances the material density by 18-40%, and finally obtains the novel wave-transparent material system with excellent high temperature resistance. The strength retention rate of the material at 1200 DEG C and 1500 DEG C is 70-94%. Compared with the silicon nitride ceramic material, the novel wave-transparent material has obviously higher breaking strain.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and preparation method thereof

The invention relates to a high-temperature-resistant high-strength aluminum oxide fiber enhanced composite material and a preparation method thereof. The preparation method comprises the following steps of: by taking a two-dimensional cloth paving layer and 2.5D woven or orthogonally three-dimensional woven continuous aluminum oxide fiber preform as an enhancer, preparing a matrix through a double nano composite impregnation liquid where silicon dioxide and aluminum oxide are uniformly mixed; and finally obtaining the aluminum oxide fiber enhanced composite material through the process of vacuum pressure impregnation, micro-positive pressure medium and low temperature pre-curing, micro-positive pressure curing and atmosphere temperature programming sub-sectional thermal treatment, wherein the mass ratio of silicon dioxide to aluminum oxide in the composite material is (19:1)-(12:8), and the volume content of the aluminum oxide fibers is 30-60%. The prepared composite material has a high-temperature-resistant property and a high-temperature mechanical property, and is high in compactness; the room temperature tensile strength of the material reaches 310+ / -30MPa, the tensile strength at 1100 DEG C reaches 135+ / -20MPa, and the tensile strength at 1200 DEG C reaches 90+ / -10MPa; and compared with a similar quartz fiber enhanced silicon dioxide oxide / oxide composite material, the performance is improved by 4-5 times.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Fiber bundle fuse dipping die head for producing long fiber reinforced plastic and dipping method

ActiveCN101695873AReduce frictional damageImprove impregnation efficiencyLong-fiber-reinforced thermoplasticFiber bundle

The invention discloses a fiber bundle fuse dipping die head for producing long fiber reinforced plastic and a dipping method. The fiber bundle fuse dipping die head comprises a die head shell, a contact fiber guiding roll and a non-contact fiber guiding roll pair which are arranged in the die head shell. The contact fiber guiding roll includes a coaxial drum body; the non-contact fiber guiding roll pair is a fixing roll or an automatic driving roll and has a round, polygon or multi-edge transverses section surface. The dipping method comprises the following steps: in a die cavity full of fusant, a fiber bundle alternately winds the drum body of the contact fiber guiding roll under the tension traction and penetrates through a gap between the non-contact fiber guiding roll pair, and the dipped fiber bundle is exported from a derivative channel. The invention can reduce the friction consumption of the single fiber, ensure that the fuse and the dipping of the continuous fiber bundle operate stably at high dipping line speed, improve the dipping efficiency and reduce the production cost of long fiber reinforced thermoplastic plastics.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

Fast impregnation method for capacitor core package and device thereof

InactiveCN102723199ANo pollutionEasy accessElectrolytic capacitorsDrying/impregnating machinesAtmospheric pressureMoisture

The invention discloses a fast impregnation method for a capacitor core package. The method comprises the following steps of putting the core package required to be impregnated into an impregnation tank, and sealing the impregnation tank; opening a liquid storing barrel, pouring the impregnation liquid into the liquid storing barrel; vacuumizing the impregnation tank through a vacuum constant pressure device; during vacuumizing, extracting moisture and air in the core package of the capacitor at the same time; injecting the impregnation liquid from the liquid storing barrel in the impregnation tank in a vacuum state; immersing the core package of the capacitor in the impregnation liquid, fast penetrating the impregnation liquid in the core package of the capacitor to be impregnated by the vacuum state in the impregnation tank, keeping the vacuum state in the impregnation tank; releasing the vacuum state in the impregnation tank instantaneously to be normal atmosphere, and penetrating the impregnation liquid in the core package of the capacitor to be impregnated by the atmospheric pressure. The invention further discloses a device for implementing the method. The method and device provided by the invention has the advantages of short impregnation time, high efficiency, good impregnation quality and low energy consumption.

Owner:李玉祥

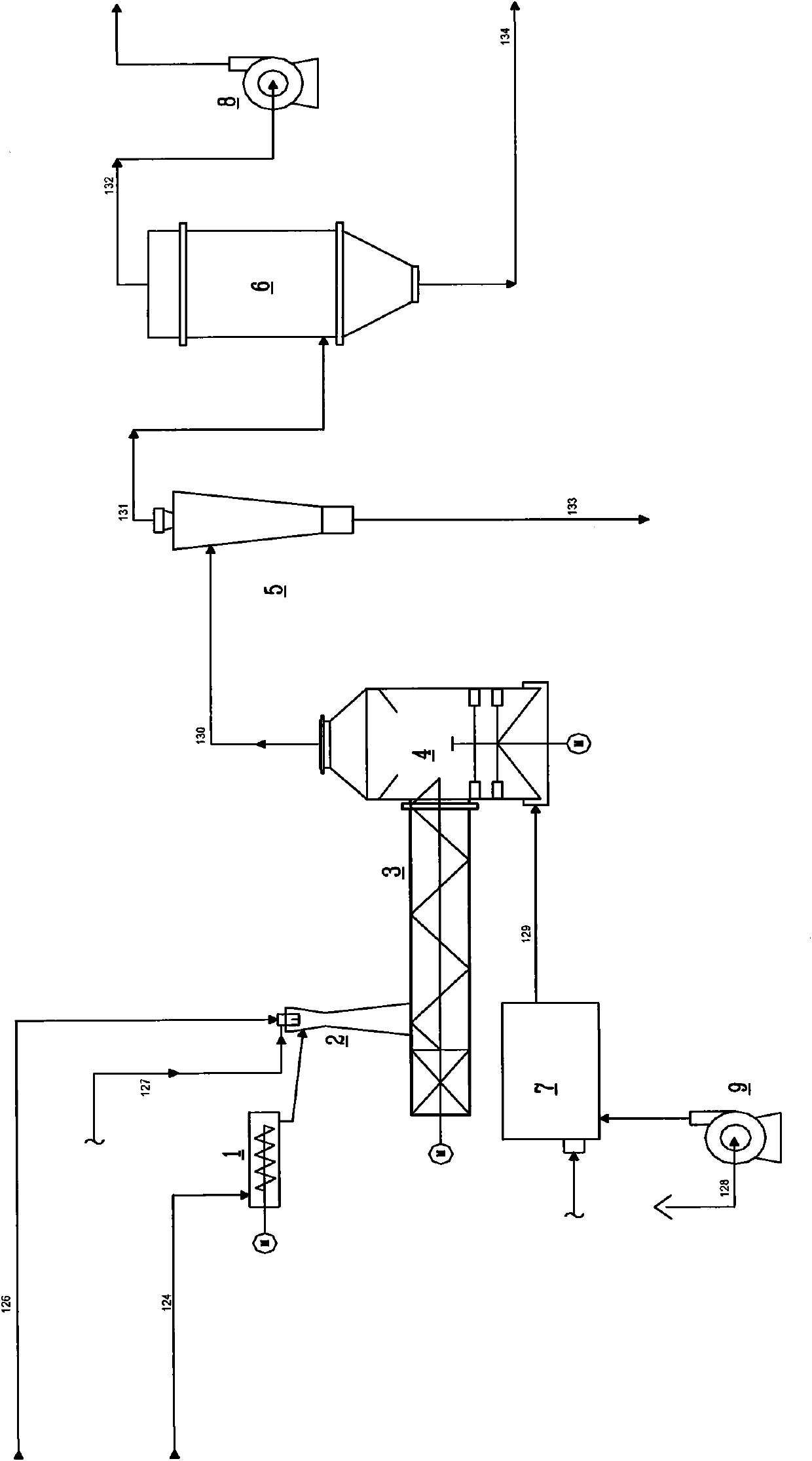

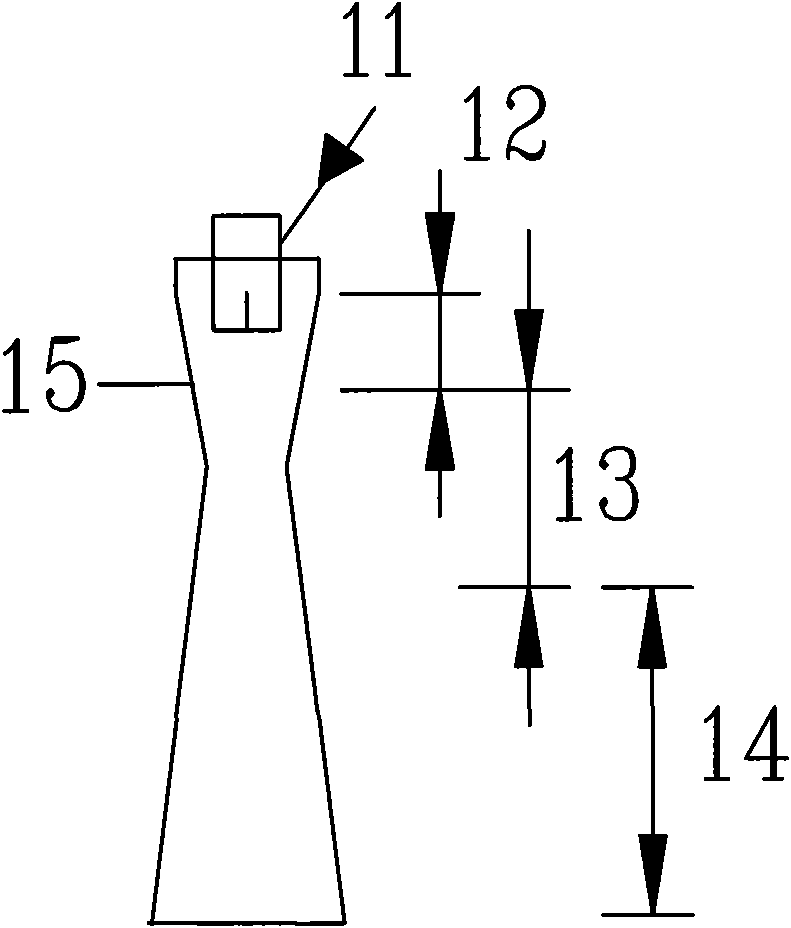

Continuous steeping method for grain carrier and equipment thereof

ActiveCN102019208AImprove impregnation efficiencyGuaranteed uptimeOther chemical processesCatalyst activation/preparationActive componentSorbent

The invention relates to a continuous steeping method for a grain carrier and equipment thereof. The continuous steeping method comprises the following steps that steeping liquor is atomized into drops through a nozzle and is jetted into an atomizer; carrier grains are led into the atomizer; the steeping liquor drops and the carrier grains are mixed in the atomizer to form a mixture; the mixture enters into a steeping mixer to carry out sufficient contact; the average grain diameters of the carrier grains are 40-90 microns; the average grain diameters of the steeping liquor drops are 0.5-1.0 time the average grain diameters of the carrier grains; and the ratio of the volume flow of the steeping liquor to the mass flow of the carrier is 0.30-0.60L / kg. The continuous steeping equipment comprises the atomizer and the steeping mixer which is connected with the outlet of the atomizer. The method can implement the continuous steeping process of the grain carrier and can make active component evenly distributed in the carrier, thereby ensuring the strength of an adsorbent finished product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pretreatment device for improving wood impregnation efficiency and wood impregnation treatment method

InactiveCN104416635AExpand the effective channel areaIncrease drug intakeWood treatment detailsWood impregnation detailsCavitationPre treatment

The invention discloses a pretreatment device for improving wood impregnation efficiency and a method for impregnating woods by utilizing the device. The device comprises a wood pretreatment chamber in which a cavity is formed, an ultrasonic treatment system and pretreatment liquid, wherein to-be-treated woods are subjected to ultrasonic pretreatment. The method disclosed by the invention comprises the following steps: pretreating to-be-impregnated woods by using ultrasonic waves under normal pressure, and getting through a liquid moving channel in the woods by utilizing a cavitation effect of the ultrasonic waves, so that the liquid permeability of the to-be-impregnated woods is enhanced, and the effective channel area inside the woods is enlarged; impregnating the woods, and impregnating a wood impregnation modifier into the woods, so that the absorption dose of the impregnated woods is improved, the agent penetration depth is increased, the impregnation period is shortened, and the impregnation effect is improved. The treatment device disclosed by the invention is simple, convenient to operate and is suitable for treating various woods, and process treatment conditions are controllable.

Owner:BEIJING FORESTRY UNIVERSITY

Flavored low-fat white mushroom crisp chip and preparation method thereof

InactiveCN103689552AImprove processing qualityGood colorFood freezingFood thermal treatmentMushroomFat content

The invention belongs to the technical field of food processing and specifically relates to a flavored low-fat white mushroom crisp chip and a preparation method thereof. The flavored low-fat white mushroom crisp chip comprises the following materials in parts by weight: 1000 parts of white mushrooms, 5-10 parts of konjac glucomannan, 10-80 parts of chitosan, 10-60 parts of salt, 60-200 parts of isolated soybean protein and 40-200 parts of a nutrition balancing agent. The preparation method comprises the following steps: pre-treating the white mushrooms, preparing impregnation liquid, carrying out vacuum soaking and ultrasonic coating, carrying out quick-freezing and slicing, carrying out vacuum frying and dehydrating, removing oil, and packaging. The prepared flavored low-fat white mushroom crisp chip has the advantages of being low in fat content, uniform in color, crisp in mouthfeel, full in nutrition, complete in product shape and almost free of fractures.

Owner:SHANDONG INST OF COMMERCE & TECH

Method for manufacturing solid electrolytic capacitor using functional polymer electrolytic composition

InactiveUS6454817B1Improve impregnation efficiencyEasily impregnatedHybrid capacitor separatorsHybrid capacitor electrolytesEpoxyElectrolysis

Owner:SAMHWA ELECTRIC

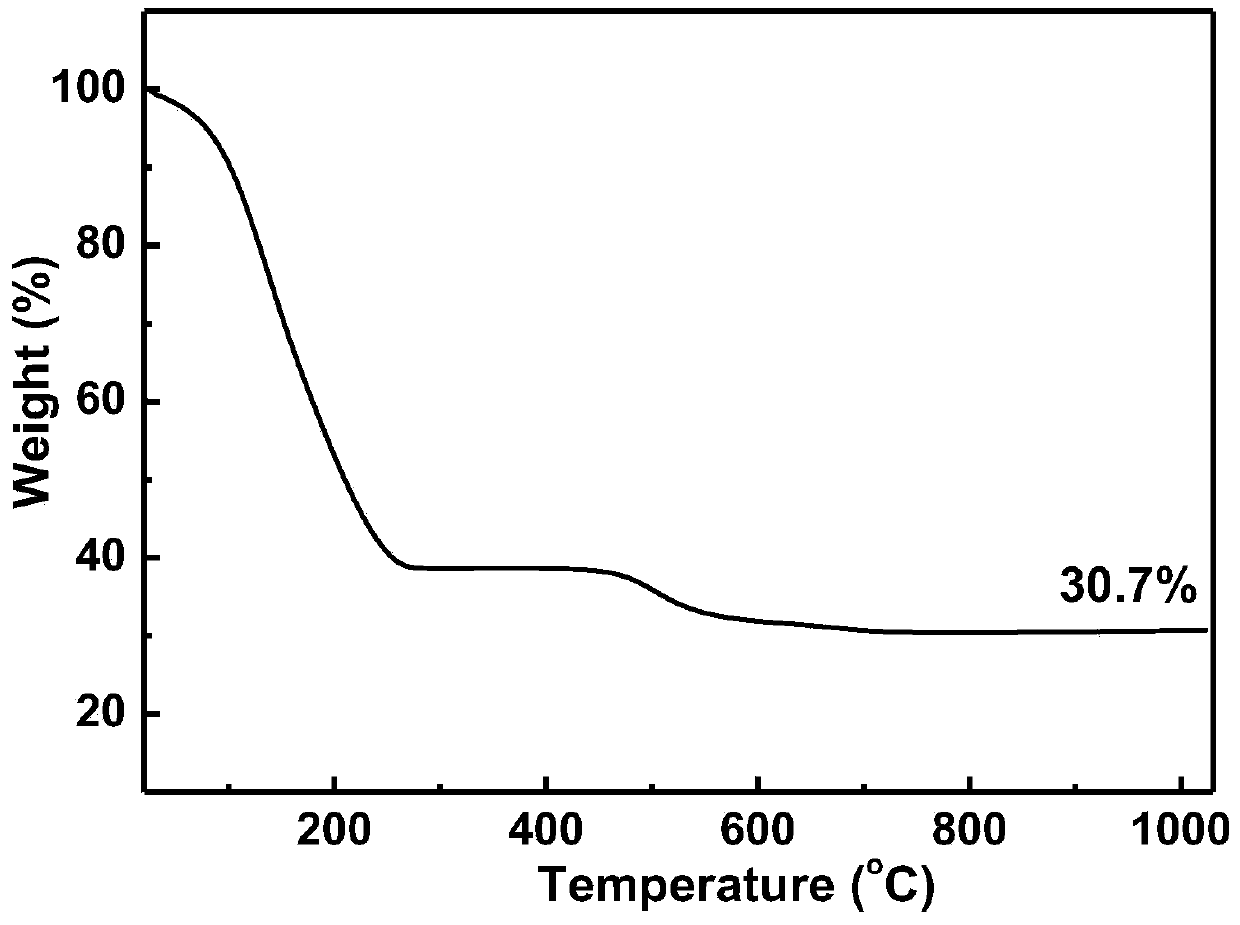

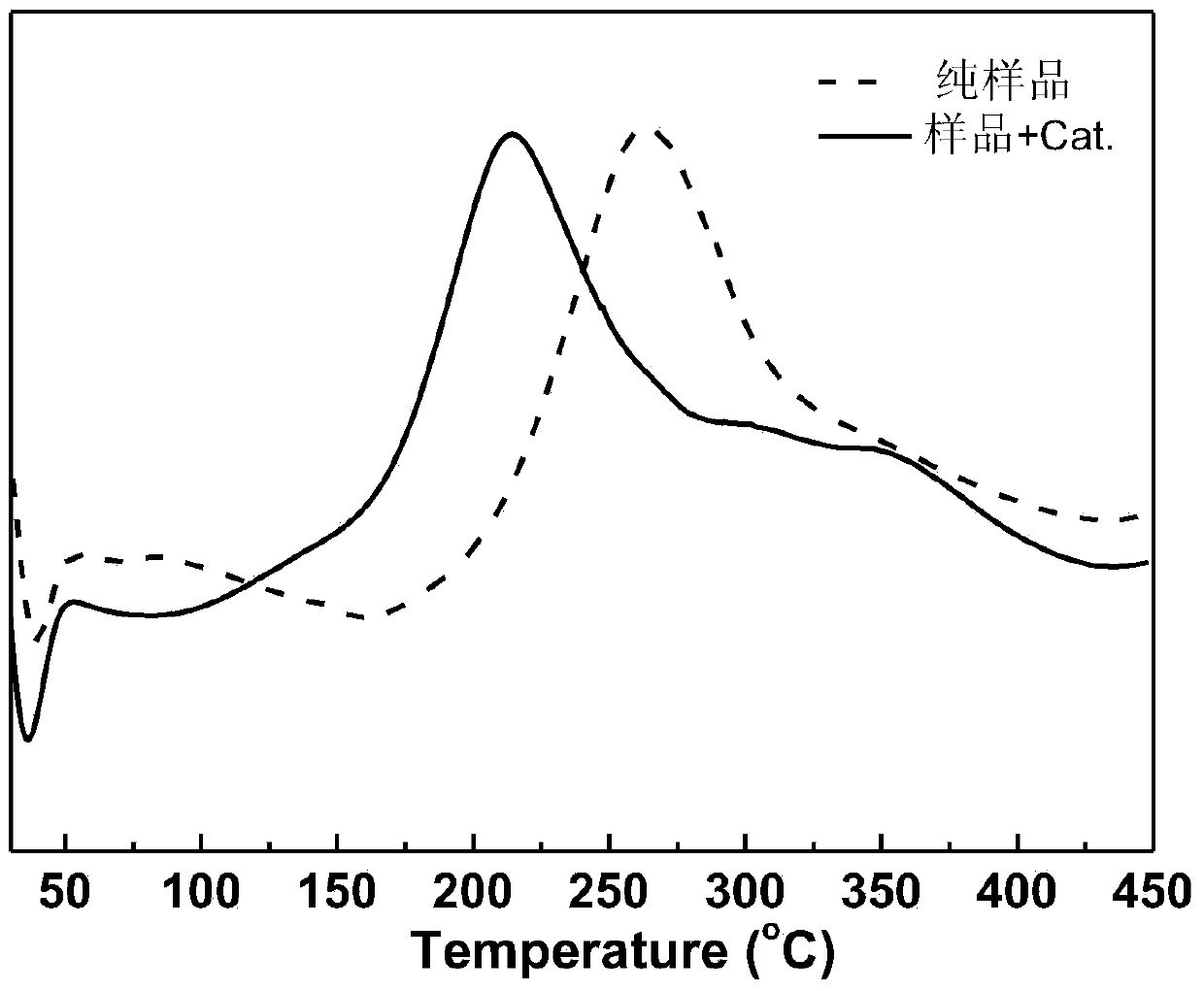

Preparation method of C/C-SiC composite material

The invention discloses a preparation method of a C / C-SiC composite material, and belongs to the technical field of preparation of C / C composite materials. The method comprises the following steps: putting a carbon felt of which the density is 0.4-0.55g / cm<3> into an impregnant to steep under a protective atmosphere; carrying out curing treatment and carbonization treatment; repeating vacuum impregnation, pressure impregnation, curing treatment and carbonization treatment and putting the obtained preform into a polyaniline methyl silane solution to steep after a C / C porous preform of which the density is 1.2-1.3g / cm<3> is obtained; carrying out curing treatment; repeating the steeping and curing technologies for 2-3 times, and then cracking under the protective atmosphere; and repeating the steeping, curing and cracking technologies until the C / C-SiC composite material of which the density is 1.9-2.1g / cm<3> is obtained according to the system of cracking once after steeping and curing for 2-3 times. The preparation method is short in preparation cycle, and low in cost, and the obtained C / C-SiC composite material is excellent in performance, and convenient to achieve industrial production.

Owner:湖南中坚科技有限公司

Three-dimensional fiber prefabricated-part enhancement mullite composite and preparation method thereof

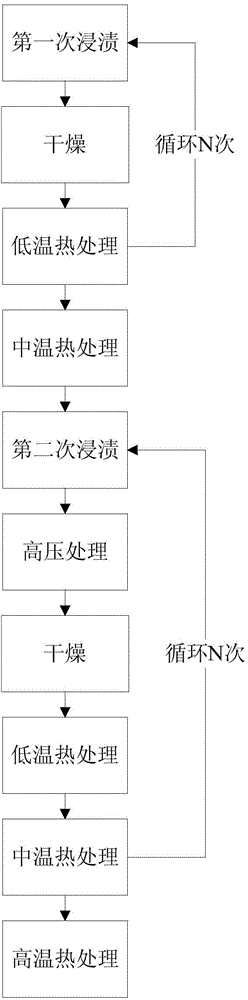

The invention discloses a three-dimensional fiber prefabricated-part enhancement mullite composite and a preparation method thereof. The preparation method comprises impregnating three-dimensional fiber prefabricated parts in an A1203-SiO2 composite sol to be impregnated, dried and subjected to low-temperature thermal processing to obtain the A1203-SiO2 impregnated three-dimensional fiber prefabricated parts; repeating the process till the weight gaining of the A1203-SiO2 impregnated three-dimensional fiber prefabricated parts is lower than 1% to obtain three-dimensional fiber prefabricated-part first intermediates, performing medium-temperature thermal processing, subjecting the medium-temperature thermal processed three-dimensional fiber prefabricated-part first intermediates to impregnation, high-pressure processing, drying, low-temperature thermal processing and medium-temperature thermal processing, circulation the process till the weight gaining is lower than 1%, and performing high-temperature thermal treatment. According to the composite and the preparation method thereof, by three-stage thermal treatment, the compactness of the three-dimensional fiber prefabricated-part enhancement mullite can be further improved, and the mechanical performance and the oxidation resistance of the enhancement composite are enhanced.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing charcoal/charcoal heating element of high resistance and high purity

The invention relates to a preparation method for a carbon / a carbon heating unit with high resistance and high purity; in the method, carbon cloth and short carbon fiber web fetus are adopted to be alternately laminated or wound into a cylinder to form horizontal fabric which is added with vertical fabric along the thickness direction by adopting a needling technique to prepare a prefabricated body of the heating unit with a three-direction structure; the prefabricated body is processed with furfural acetone resin or phenolic resin vacuum pressure impregnation and curing treatment, charring at normal pressure and other densification techniques until the density reaches 1.55g / cm<3> and then high-temperature vacuum purification is carried out below 2,000 DGE C and the carbon / the carbon heating unit with high resistance and high purity can be produced after mechanical processing. The carbon / the carbon heating unit of the invention has outstanding features of high resistance and high purity and has the advantages of short production period, low production period and long service life, which is mainly applicable to a U-shaped heating unit of a polysilicon hydrogenation furnace as well as a large cylindrical heating unit of a polysilicon pulling furnace.

Owner:XIAN CHAOMA SCI TECH

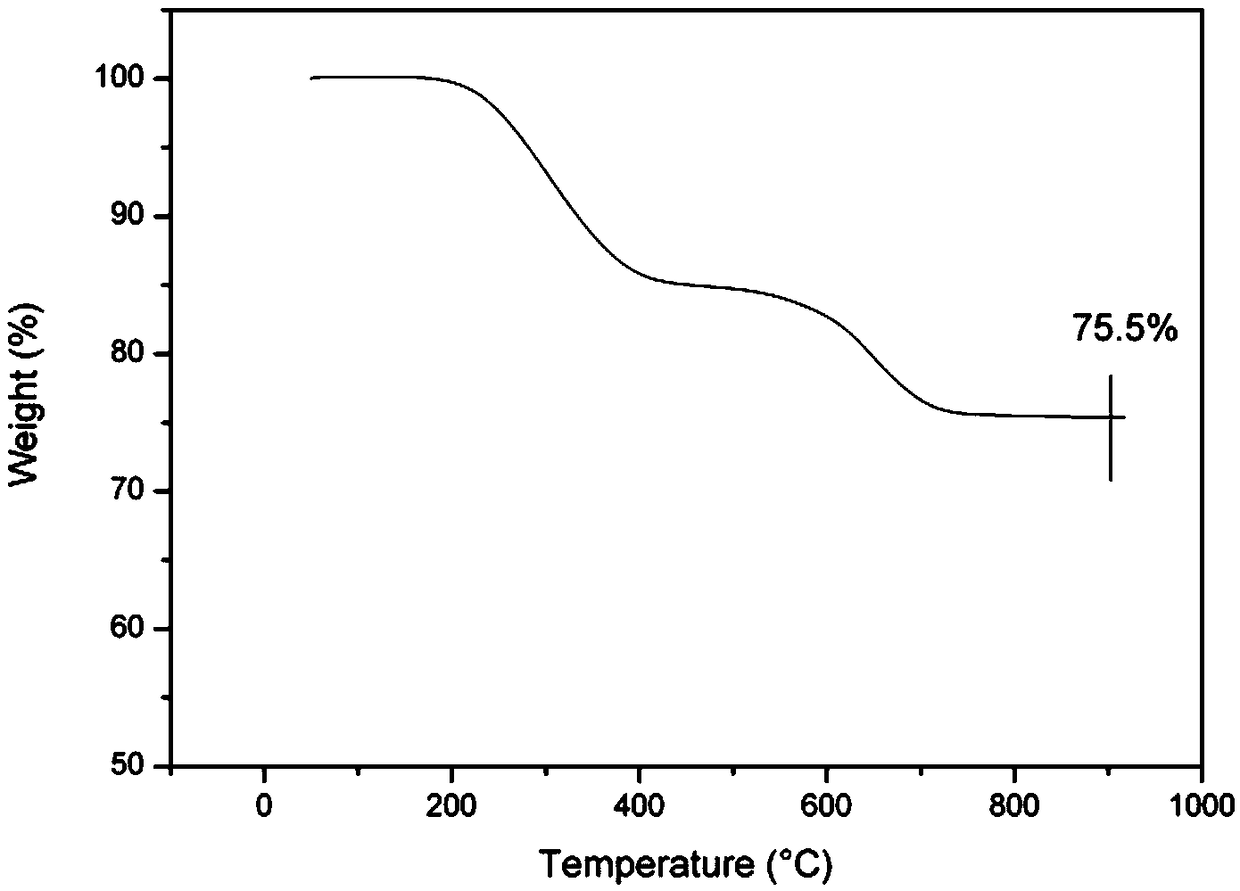

High-performance C/SiBCN composite material as well as preparation method and application thereof

The invention relates to a high-performance C / SiBCN composite material as well as a preparation method and application thereof. The method comprises the following steps: preparing a C interface layer,a SiC interface layer and / or a (C / SiC)n alternate interface layer, which is formed by alternate deposition of the C interface layer and the SiC interface layer, on the surface of a carbon fiber preform to obtain a modified carbon fiber preform; and with a liquid SiBCN precursor as an impregnation liquid, carrying out SiBCN matrix densification on the modified carbon fiber preform through a vacuumimpregnation / in-situ curing / medium-pressure cracking PIP process to obtain the high-performance C / SiBCN composite material. According to the invention, the proper interface layers are prepared, so atoughening function is achieved; an in-situ curing process is adopted, so outflow of the precursor in the curing process is avoided, and impregnation depth and impregnation efficiency are improved; and meanwhile, a medium-pressure cracking process is adopted, so SiBCN matrix cracks are reduced, the porosity of the material is reduced, and the mechanical property of the composite material is improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

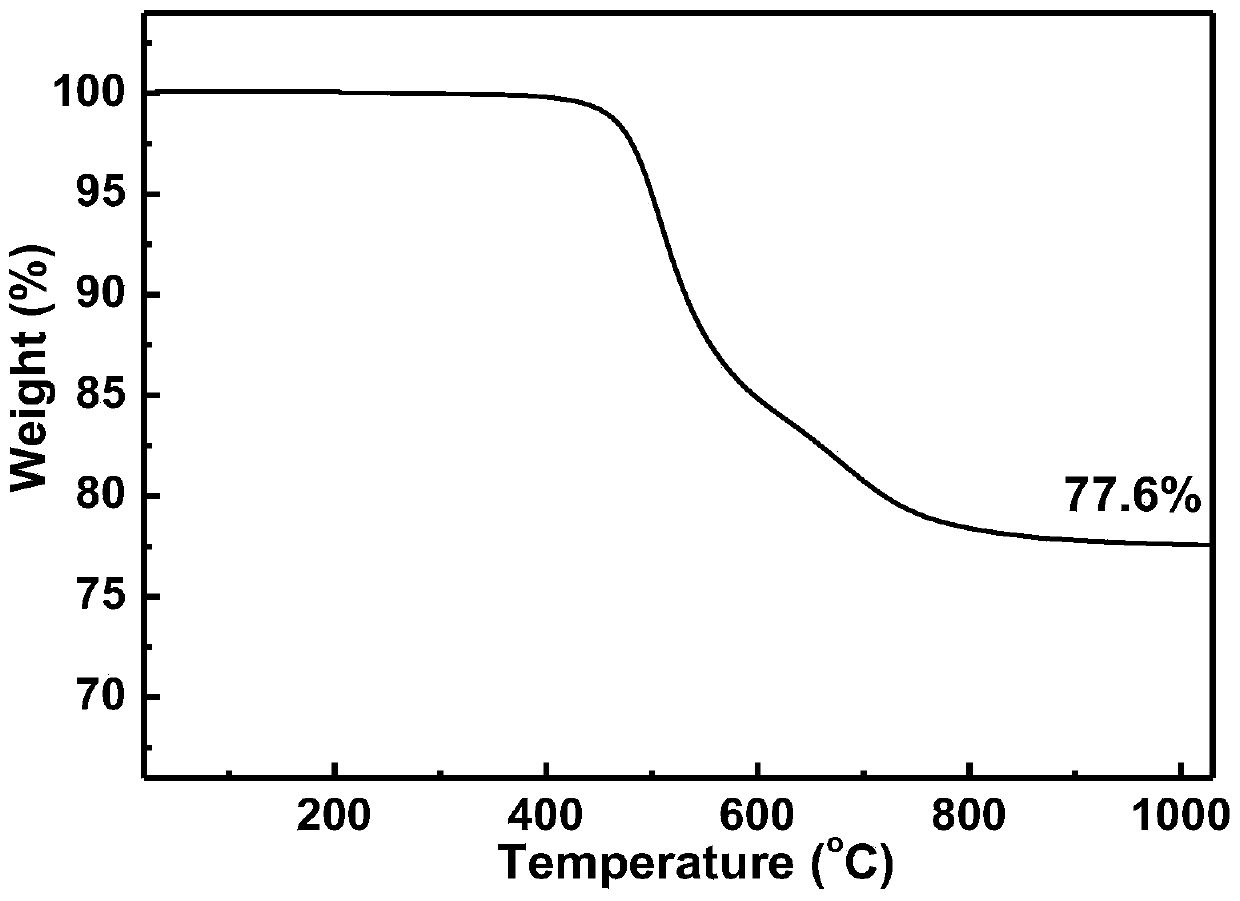

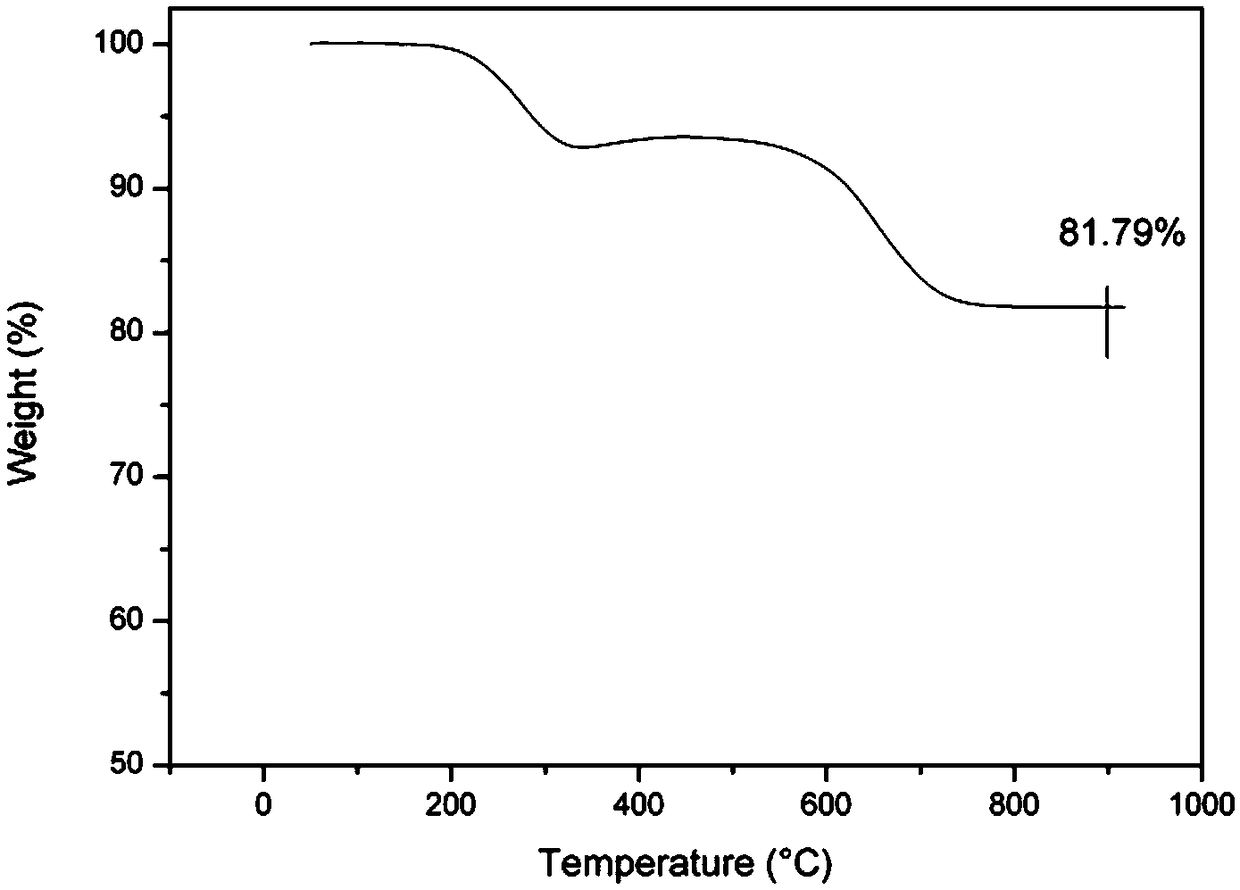

Novel liquid polycarbosilane and preparation method thereof

The invention relates to novel liquid polycarbosilane and a preparation method thereof, and belongs to the technical field of ceramic material synthesis. The novel liquid polycarbosilane has a chemical structural formula as follows: as shown in the specification, wherein m1, m2, m3 and m4 are all positive integers and more than or equal to 1. The novel liquid polycarbosilane provided by the embodiment of the invention can be adjusted in the viscosity from 10 to 1,000 cP, does not need to be used in combination with a solvent, has a certain degree of cross-linking between molecules, does not generate bubbles easily, is high in impregnation efficiency, and has a ceramic yield up to 81 percent.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Cf/MC-SiC composite material and preparation method thereof

The invention discloses a Cf / MC-SiC composite material and a preparation method thereof. The Cf / MC-SiC composite material comprises a carbon fiber fabricated part, an MC substrate and an SiC substrate, wherein M is Zr or Hf, the MC substrate and the SiC substrate are uniformly filled in the holes of the carbon fiber fabricated part, in the Cf / MC-SiC composite material, the volume fraction of the MC substrate is 10%-20%, the volume fraction of the SiC substrate is 20%-30%, and the percentage of opening of 2%-10%. The preparation method comprises the following steps that (1) a precursor is soaked and split for preparing a Cf / MC blank; (2) a Cf / MC-C blank is prepared; (3) the Cf / MC-SiC composite material is prepared with a gas phase siliconizing method. The Cf / MC-SiC composite material has the advantages that the material is high in content of MC substrate, low in porosity, high in heat conductivity, excellent in oxidation resistance, ablation resistance and mechanical property and the like, and the preparation method is simple in technology and easy to implement.

Owner:NAT UNIV OF DEFENSE TECH

Composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and preparation method thereof

ActiveCN105042219AImprove adhesionAvoid safety hazardsFlexible pipesLow-density polyethyleneCorrosive chemical

The invention discloses a composite rubber hose for conveying LPG, LNG and strongly corrosive chemical solvent and a preparation method thereof. Low density polyethylene, ultra-high molecular weight polyethylene and macromolecule cross-linked polyethylene serve as raw materials; after scientific compound and vulcanization of a rubber hose, a chemical substance with a good adhesive property is obtained for preparing a liner film; meanwhile, corona treatment is carried out on the bonding face of the liner film and the bonding face of the rubber hose, and fiberglass reinforcing fiber with radiation protection performance is compounded on the surface layer; therefore, the surface layer of the rubber hose has good radiation protection performance, hidden danger of conveying pipelines caused by ionizing radiation is avoided, and finally the composite rubber hose which has the firmly bonded liner film, and is high in radiation protection and capable of conveying LPG, LNG and strongly corrosive chemical solvents is prepared, the hose can absorb as much as 97.5% to 99.5% of X-rays, gamma-rays and various neutrons in nuclear radiation, and the adhesive force (N / 25mm) between the liner film and a rubber layer reaches 160-180.

Owner:河北泽邦塑胶科技有限公司

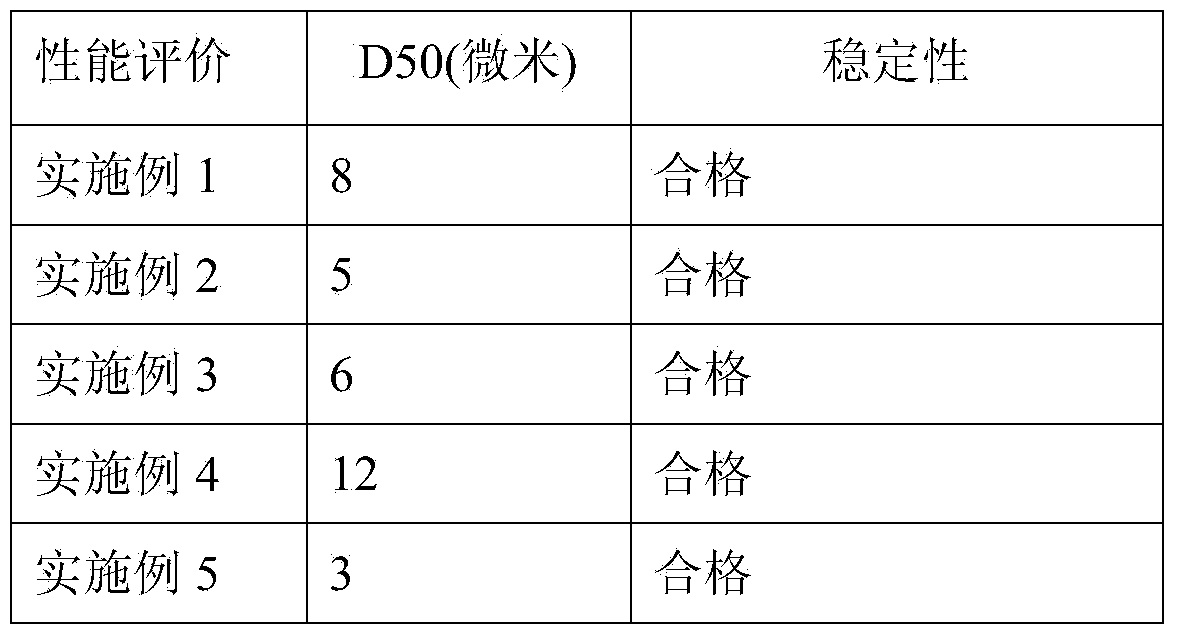

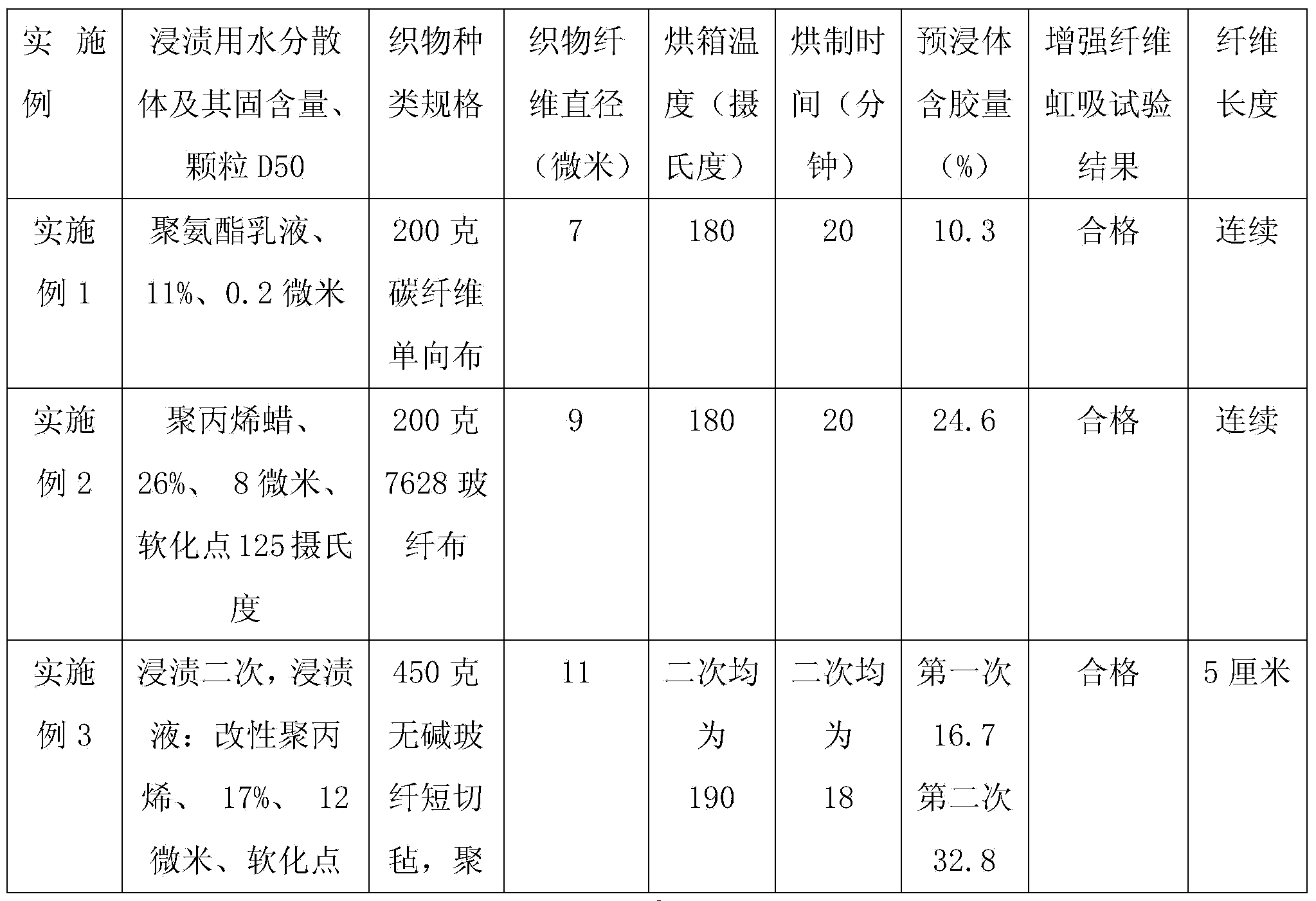

Method for preparing thermoplastic polymer aqueous dispersion

InactiveCN103613710AExcellent impregnationImprove tensile strengthFibre treatmentSynthetic resin layered productsPolymer scienceRoom temperature

The invention discloses a method for preparing thermoplastic polymer aqueous dispersion. The method comprises the sequential steps of A. uniformly mixing 100 parts by mass of thermoplastic polymer powder, 5-20 parts by mass of a reactive surfactant, 0.05-2 parts by mass of an initiator, 0-30 parts by mass of a grafting monomer, and 180-250 parts by mass of water, thereby obtaining a mixture; B. heating up the mixture obtained in step A to 85-99 DEG C, preserving constant temperature for 3-6 hours under the stirring condition, then reducing the temperature of the material to room temperature, or moving on to next step without cooling; and C. grinding the material obtained in step B till the grain size D50 is less than 13mu m, cooling to room temperature and discharging. The prepared thermoplastic polymer aqueous dispersion is convenient to recycle, and is beneficial to environment protection. The preparation method is simple and easy to realize, and has high production efficiency and low production cost.

Owner:南京彤天广元高分子材料有限公司

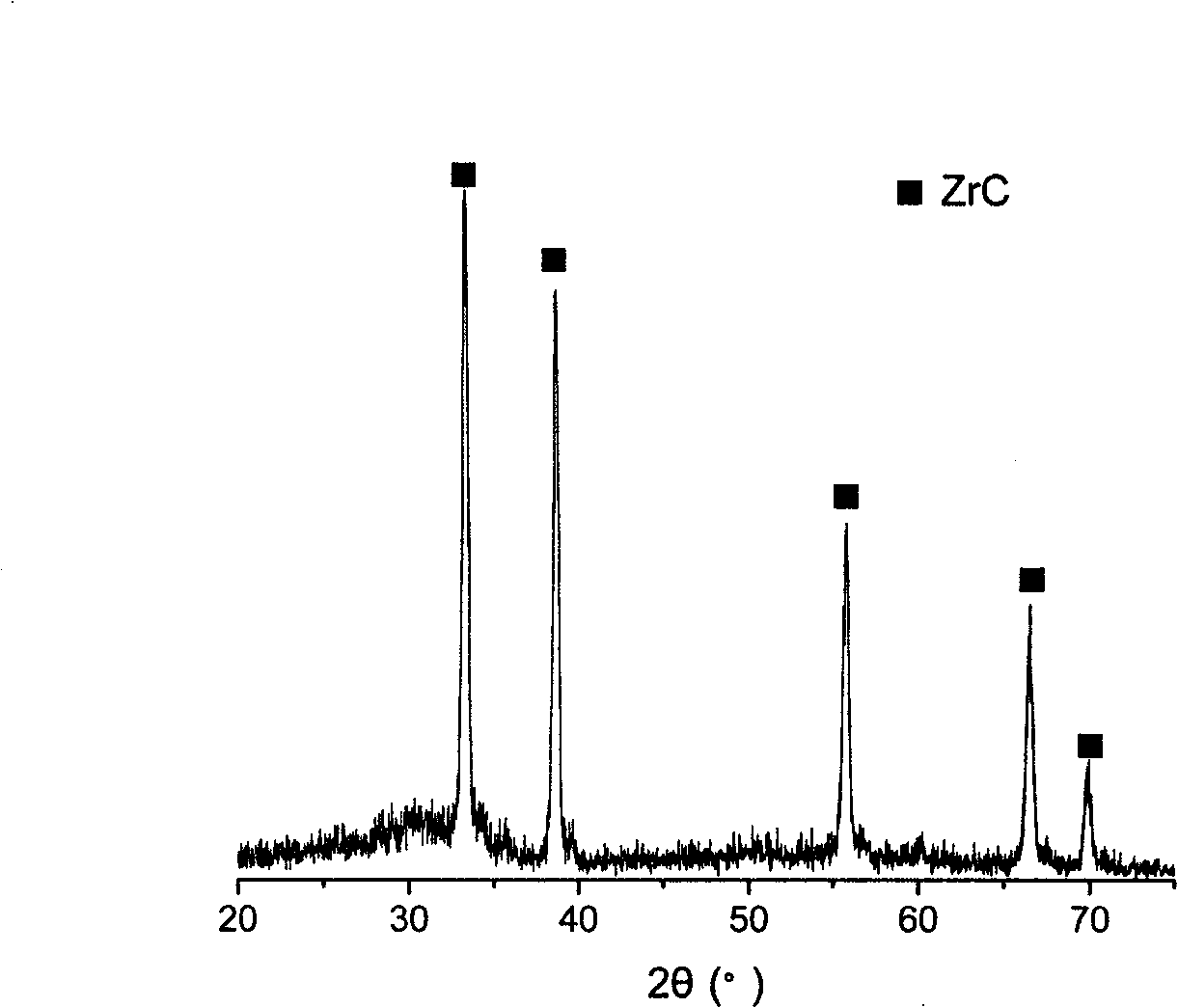

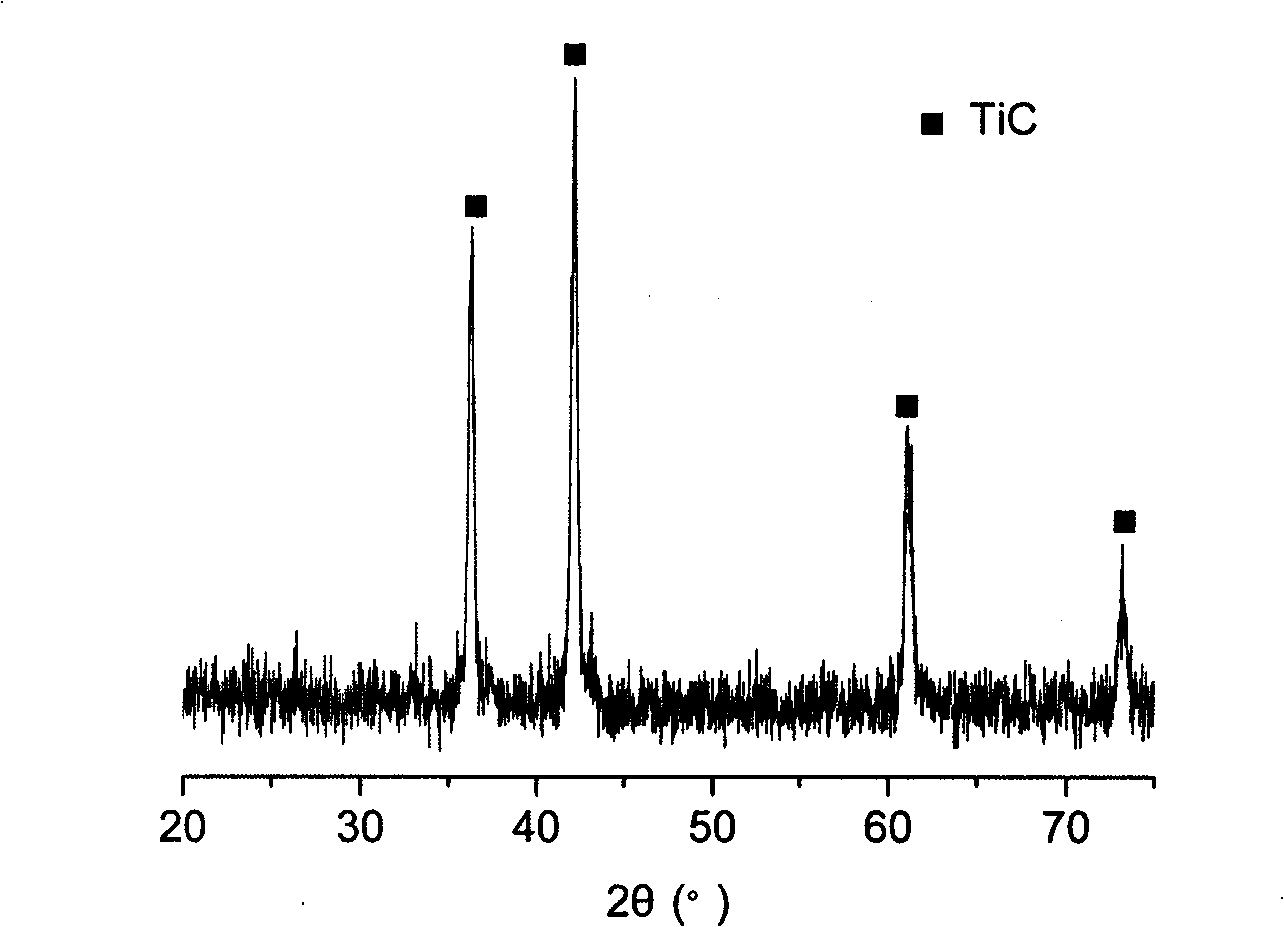

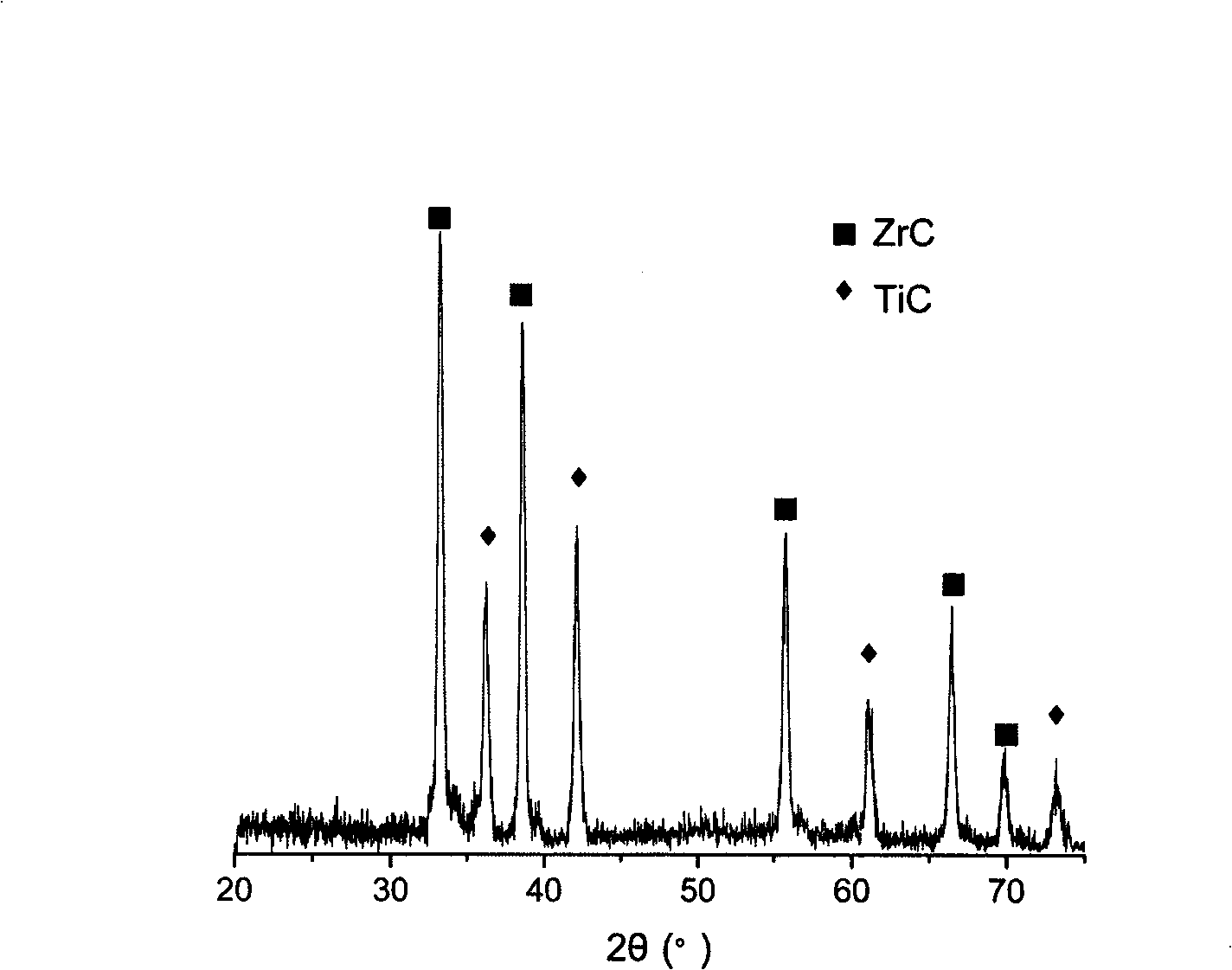

Precursor solution of carbide ceramic, carbide ceramic and preparation thereof

The invention discloses precursor solution for carbide ceramics. The precursor solution uses an alkoxy compound of more than one refractory metal as solute, and uses divinylbenzene, vinyl group acetylenyl benzene or diacetylene-benzene as solvent, and the molar ratio of the solute to the solvent is 1 to between 0.2 and 2. The invention also discloses carbide ceramics and a preparation method thereof. The method comprises the following preparation steps: the precursor solution of the invention is evenly mixed and heated to between 150 and 300 DEG C, and then is insulated for 0.5 to 4 hours; the precursor after low temperature crosslinking treatment is heated to between 1, 200 and 1, 800 DEG C in an inert atmosphere or under a vacuum condition, and then is insulated for 0.5 to 2 hours for high temperature pyrolysis; and the carbide ceramics is obtained after temperature reduction. The precursor solution has the advantages of low viscosity, good stability, simple preparation process, and so on. The method for preparing the carbide ceramics has the advantages of high impregnation efficiency, simple crosslinking process, high ceramics yield, and so on.

Owner:NAT UNIV OF DEFENSE TECH

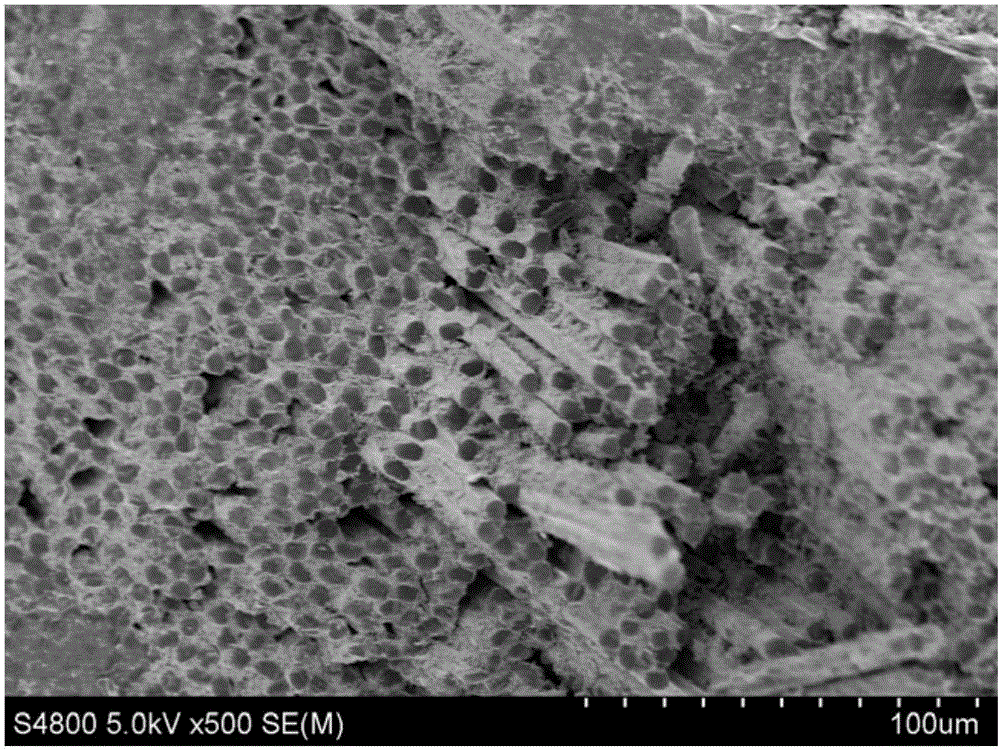

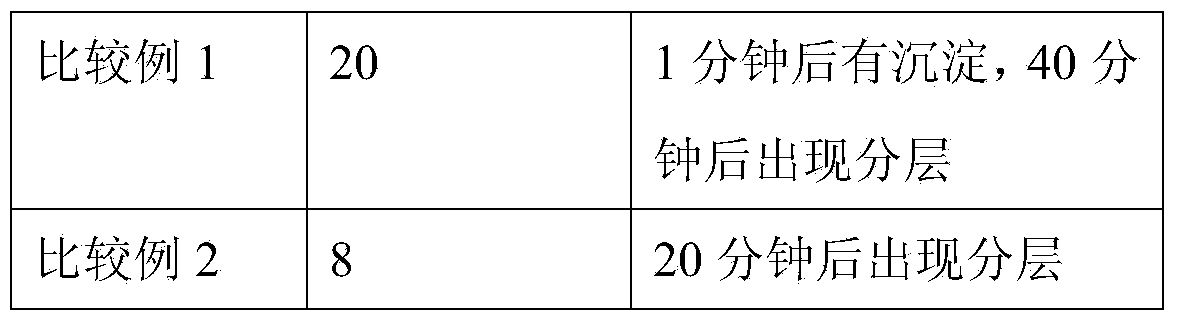

Thermoplastic composite preimpregnation body plate

InactiveCN103613775ASolving Effective Impregnation ProblemsGuaranteed to pass the siphon testSynthetic resin layered productsEnvironmental resistancePolymer science

The invention discloses a thermoplastic composite preimpregnation body plate, which is prepared by a thermoplastic composite preimpregnation body or is compounded by the thermoplastic composite preimpregnation body and thermoplastic polymer through hot melting. The thermoplastic composite preimpregnation body is prepared by steps of steeping fabric prepared by reinforced fibers in thermoplastic polymer aqueous dispersion, drying and dehydrating, melting the polymer, cooling and shaping, and the length of the reinforced fibers is more than 2cm. According to the preparation method of the thermoplastic composite preimpregnation body, an organic solvent is not used, water is taken as a dispersion medium, the aqueous dispersion of polymer substitutes for the organic solvent, so that the preparation method is environment-friendly; the aqueous dispersion used by the preparation method has low viscosity and is beneficial to steeping of the polymer on fiber bundles, the immersion treatment is convenient, the production efficiency is high, the production cost is low, and the problem of effectively steeping the reinforced fiber fabric by the thermoplastic polymer is solved; compared with the composite board prepared by the prior art, the preimpregnation body plate is sharply improved in tensile strength and deformation performance.

Owner:南京彤天广元高分子材料有限公司

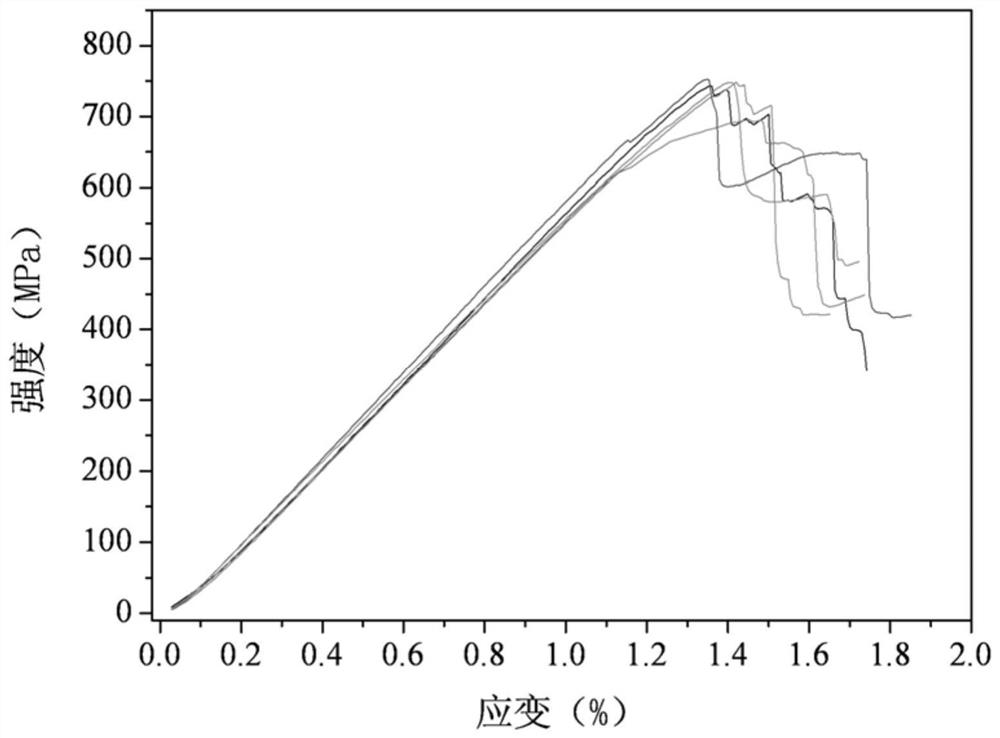

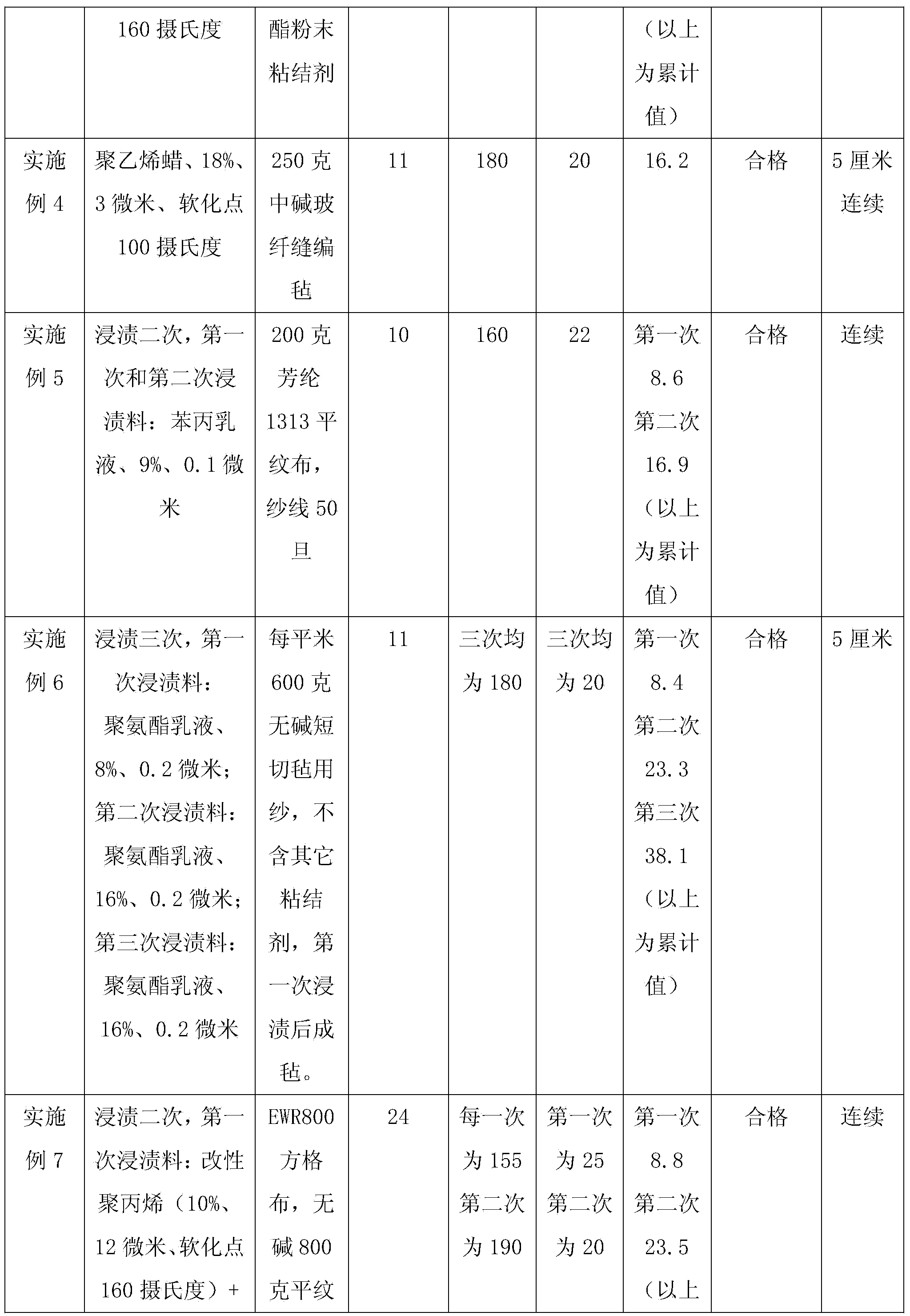

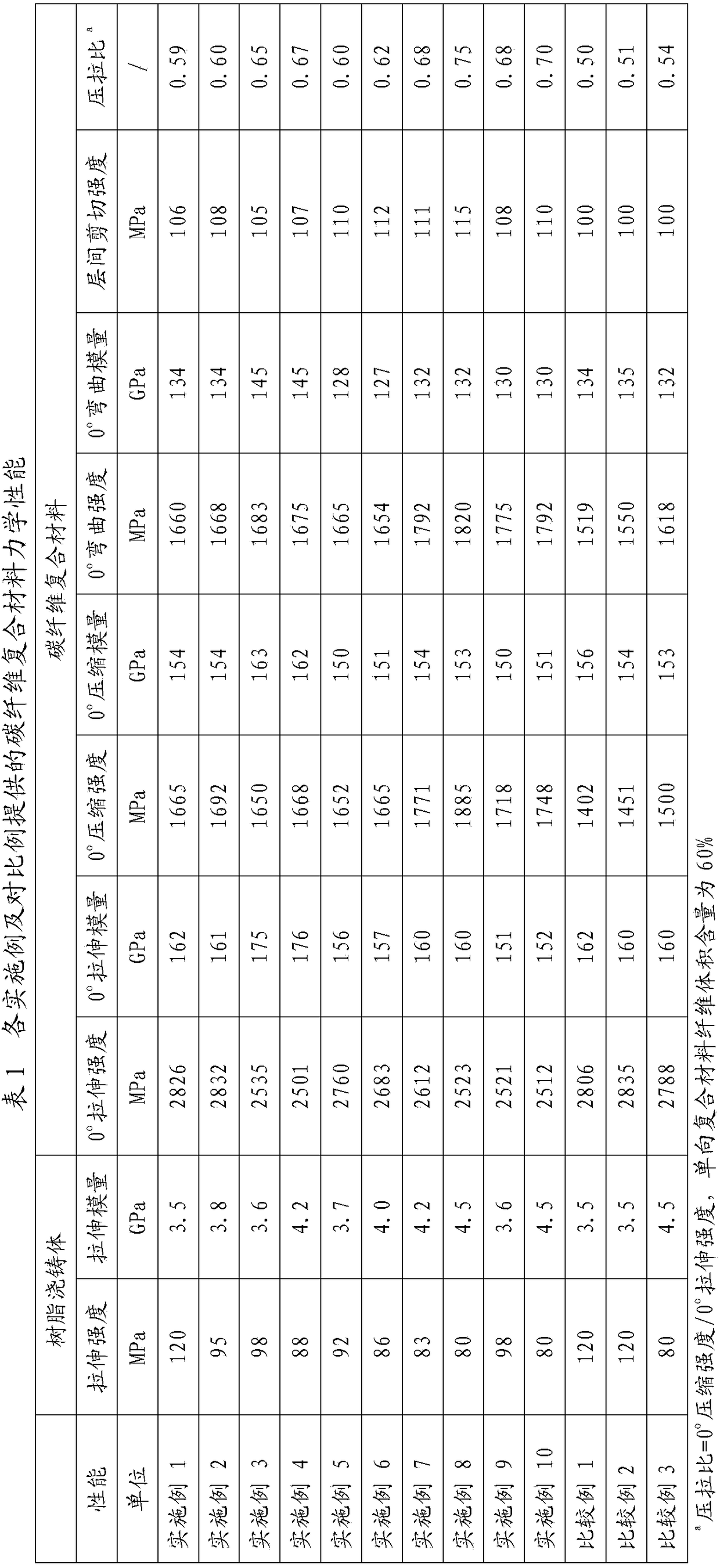

Carbon fiber composite material with high compressive strength and high-pressure draw ratio and preparation method thereof

The invention discloses a carbon fiber composite material with high compressive strength and a high-pressure draw ratio and a preparation method of the carbon fiber composite material with the high compressive strength and the high-pressure draw ratio, and belongs to the field of composite materials. The composite material comprises a resin matrix and reinforced fibers, wherein the reinforced fibers are carbon fibers of which the fiber monofilament diameters are 5.4 to 7.0 microns, the resin matrix comprises the following components in parts by mass: 100 parts of resin, 30 to 60 parts of a curing agent, 0.5 to 2 parts of an accelerator and 0.1 to 3 parts of inorganic nanoparticles. The composite material disclosed by the invention has excellent mechanical properties, especially the characteristics of high compressive strength and good pressure-tension balance, can be used for preparing main force-bearing structural parts of aerospace vehicles, and further can meet demands for the composite material with light weight, high strength, compressive strength and high-pressure draw ratio in the fields of high-speed rails, automotives and other industrial equipment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for improving high temperature mechanical properties of hollow turbine blade ceramic mold

ActiveCN103193508AImprove high temperature mechanical propertiesExcellent high temperature mechanical propertiesPotassiumAlloy

The invention discloses a method for improving high temperature mechanical properties of a hollow turbine blade ceramic mold. According to the invention, a yttrium-aluminum garnet high temperature strengthening phase is synthesized from yttrium oxide and alumina through high temperature sintering, magnesium oxide is utilized at the same time for inhibiting growth of an alumina crystal grain under the condition of high temperature sintering, and titanium oxide is used for solution strengthening of alumina so as to improve high temperature strength of an alumina-based ceramic mold; finally, an yttrium chloride ion solution is used for dipping of the alumina-based ceramic mold to allow yttrium ions to be uniformly distributed in the alumina-based ceramic mold with a complex structure, so on the one hand, chloride ions are enabled to react with impurity Na and K ions in an alumina ceramic material to form sodium chloride and potassium chloride under high temperature sintering, thereby removing the Na element and the K element, and on the other hand, the yttrium ions are enabled to react with alumina under high temperature sintering for secondary formation of the yttrium-aluminum garnet high temperature strengthening phase. The method provided by the invention can be used for improving high temperature mechanical properties of a core-shell integrated alumina-based ceramic mold for a hollow turbine blade and improves a qualified rate of a directionally solidified high temperature alloy blade.

Owner:XI AN JIAOTONG UNIV +1

Method for manufacturing solid electrolytic capacitor using functional polymer electrolytic composition

InactiveUS20020042976A1Improve impregnation efficiencyEasily impregnatedHybrid capacitor separatorsHybrid capacitor electrolytesEpoxyElectrolysis

Disclosed is a method for manufacturing a solid electrolytic capacitor using a functional polymer composition. The method comprises immersing the rolled aluminum electrolytic capacitor device in polyaniline solution with high electric conductivity to impregnate the device with polyaniline, drying the impregnated device in a drying oven which is maintained at constant temperature to fully remove the solvent, inserting the dried device to a capacitor aluminum can and then sealing with epoxy resin, to manufacture a solid electrolytic capacitor using a functional polymer. As such, the impregnation can be performed well at not only normal temperature and pressure, but also high temperature and reduced pressure. The solid electrolytic capacitor has the advantages of high capacity, low impedance and low ESR, and also, low manufacturing cost, simple processes and high reliability.

Owner:SAMHWA ELECTRIC

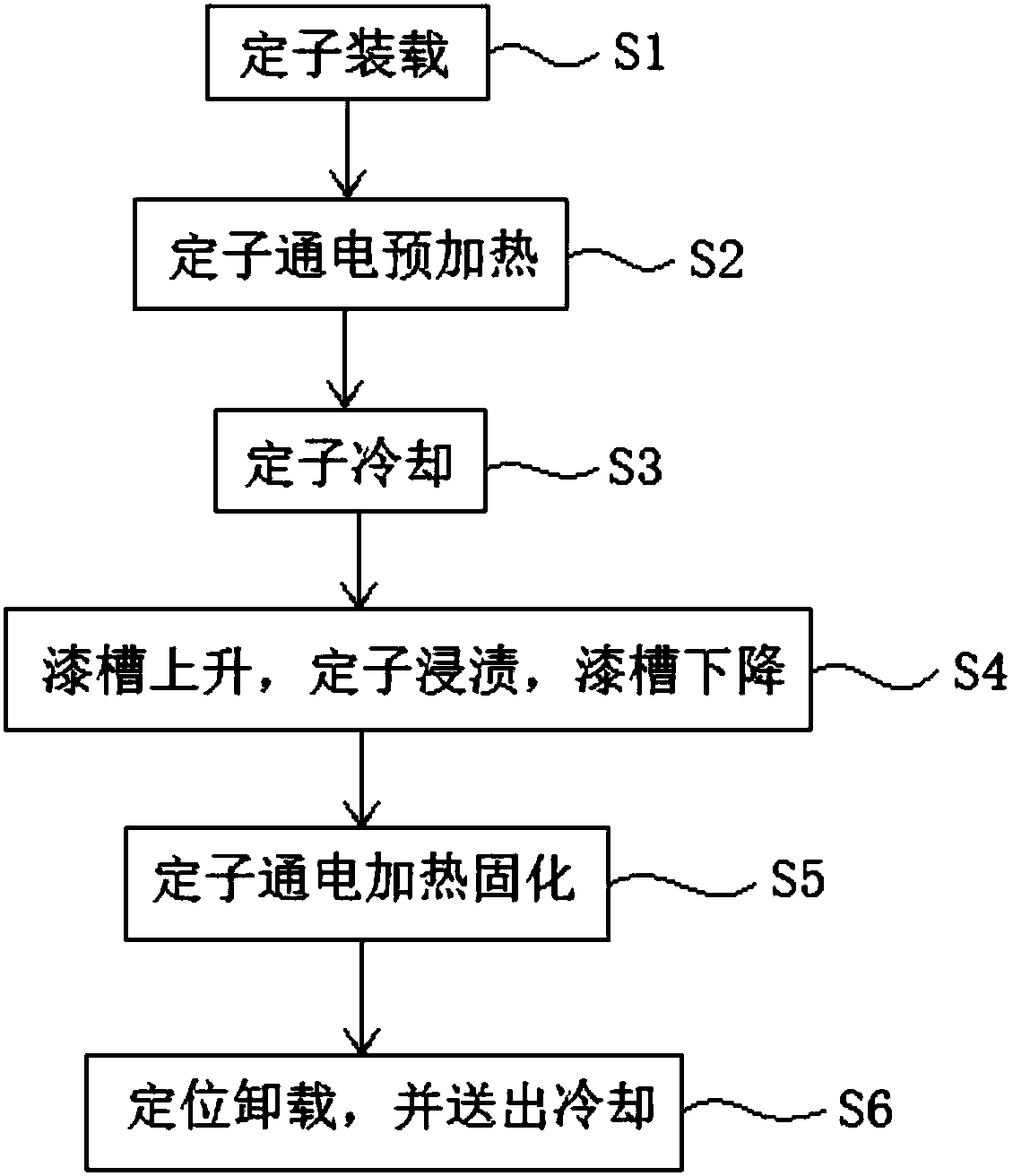

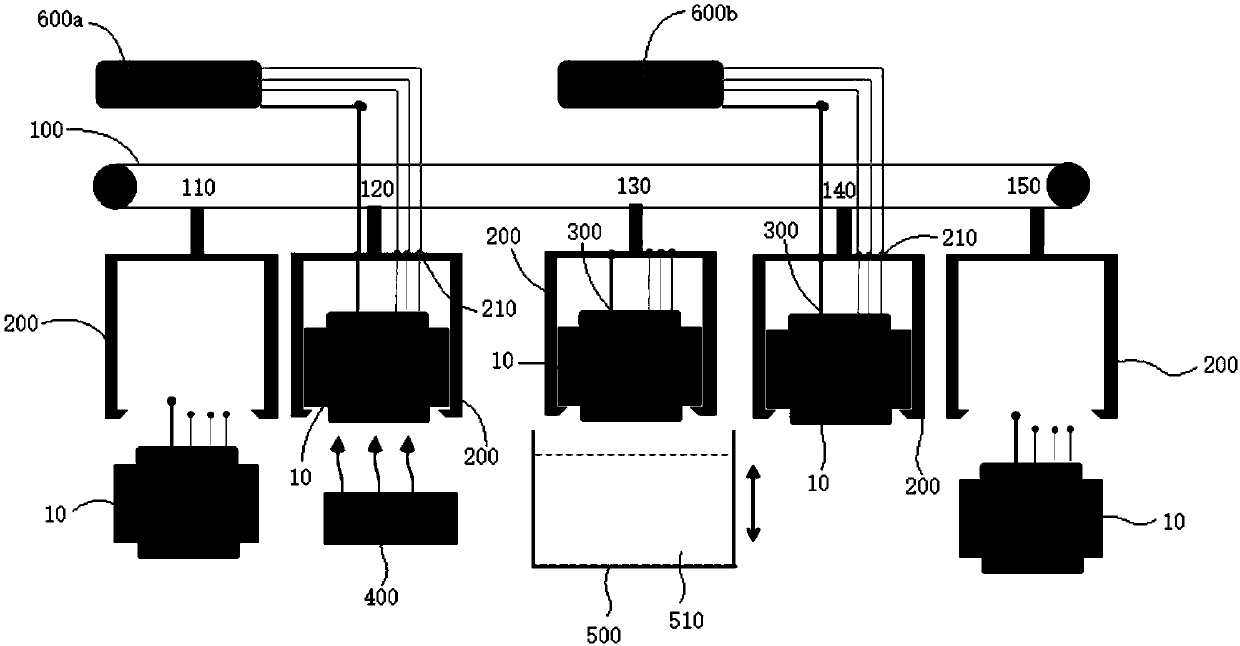

Insulating impregnating treatment technology of alternating current motor stator and treatment device thereof

PendingCN107742962AImprove processing efficiencyShort heating timeManufacturing dynamo-electric machinesElectric machineElectric current flow

The invention discloses an insulating impregnating treatment technology of an alternating current motor stator. The technology comprises the following steps that 1, the alternating current motor stator is loaded at an impregnating treatment station, and a three-phase winding of the alternating current motor stator is plugged into a three-phase alternating power; 2, the three-phase alternating current is applied to the three-phase winding of the alternating current motor stator, so that the alternating current motor stator is preheated; 3, the alternating current motor stator is cooled; 4, a paint tank is controlled to go up, so that the alternating current motor stator is soaked in the paint tank for impregnating treatment, and after impregnating treatment is completed, the paint tank is controlled to go down; 5, the three-phase alternating current is applied to the three-phase winding of the alternating motor stator to make paint of the winding of the alternating current motor statorheated and solidified; 6, the alternating current motor stator is unloaded, a wire between the three-phase winding of the alternating current motor stator and the power is disconnected, and finally, discharging is conducted. The invention further discloses a treatment device for achieving the insulating impregnating treatment technology of the alternating current motor stator. By means of the technology and the device, the impregnating efficiency is high, the impregnating filling effect is better, and energy consumption is lower.

Owner:CHUANGQU SHANGHAI NEW ENERGY TECH CO LTD

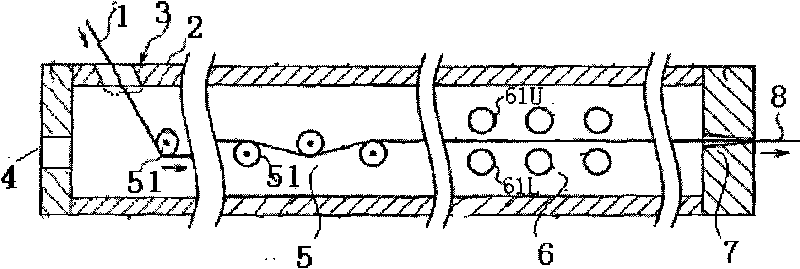

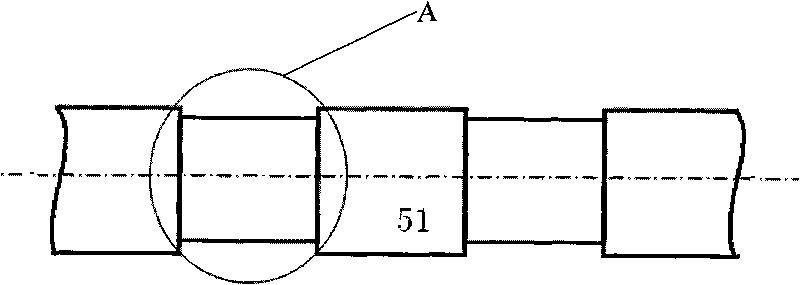

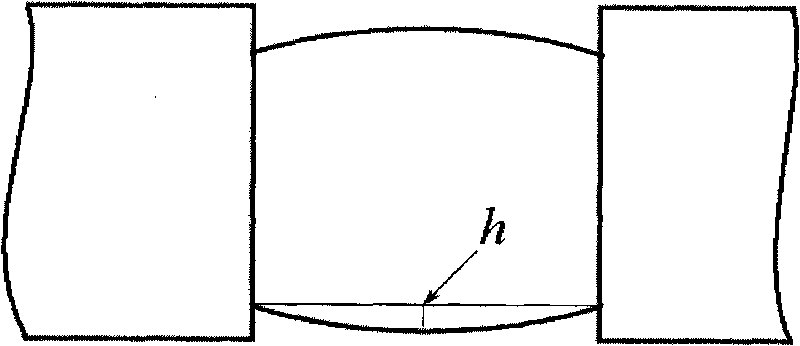

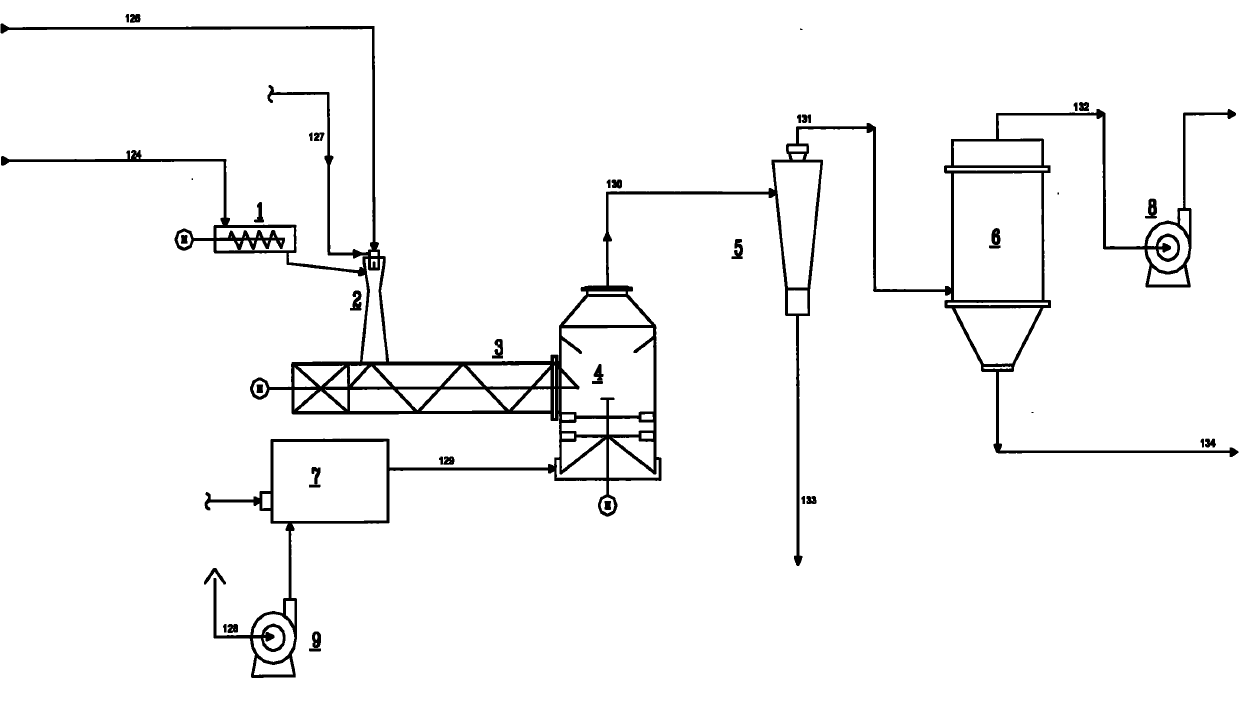

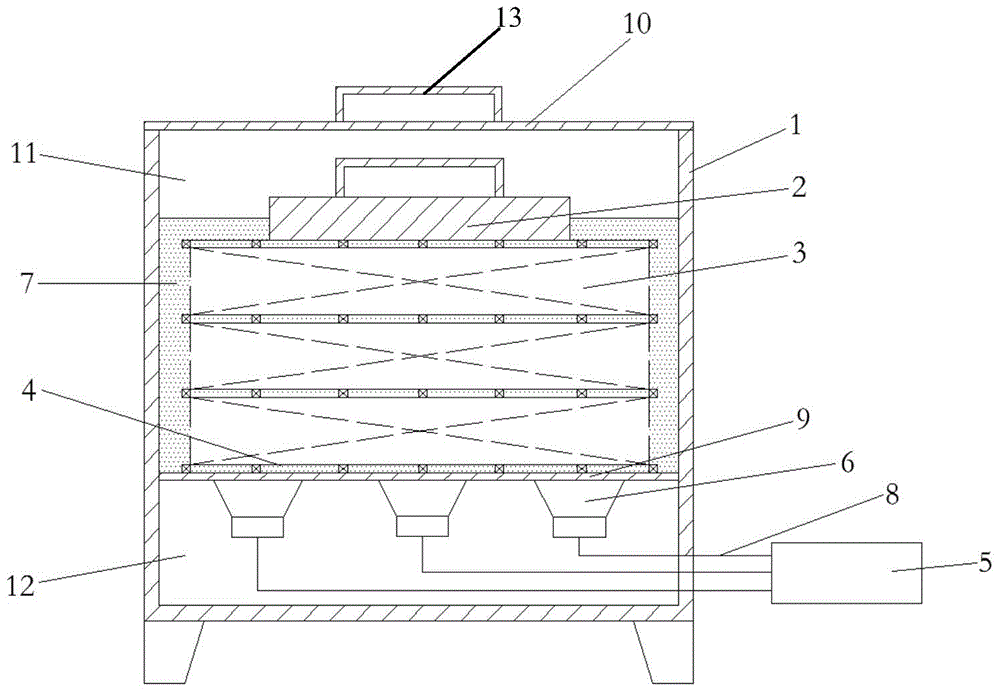

Continuous high pressure steeping device and method

ActiveCN101723703AEfficient use ofReduce labor intensityLiquid surface applicatorsCoatingsAutomatic controlCooling chamber

The invention discloses a continuous high pressure steeping device and a method, particularly to a continuous high pressure steeping device and a method suitable for industries of carbon, metallurgy and the like. A conveyer No. 4, a preheating chamber, a steeping tank, a cooling chamber, a conveyer No. 7 and a hooking and pulling machine are positioned on the same straight line and sequentially arranged in the continuous high pressure steeping device; trolleys No. 1, No. 2 and No. 3 are installed on a railway, and the trolleys No. 1, No. 2 and No. 3 and conveys, No. 1 No. 2, No. 3 and No. 4 are all provided with a pusher. The continuous high pressure steeping device and the method have the advantages and the effects that energy sources are effectively utilized, and the steeping efficiency is improved; the whole high pressure steeping process is continuously carried out, automated control is easy to realize, and the labor intensity of worker is lowered.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

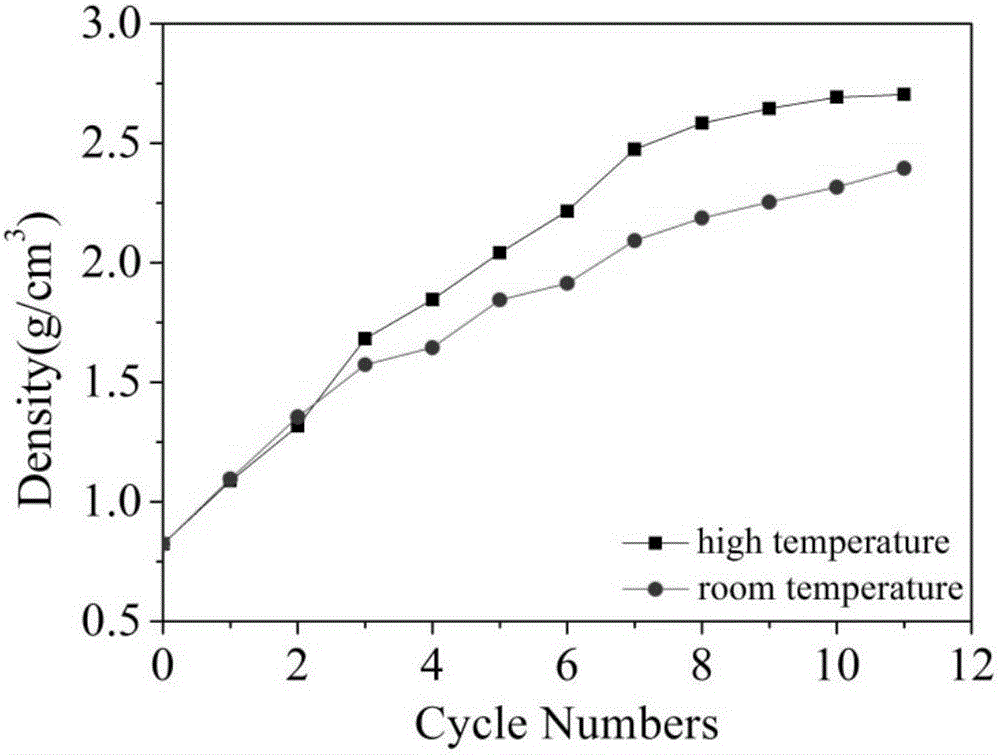

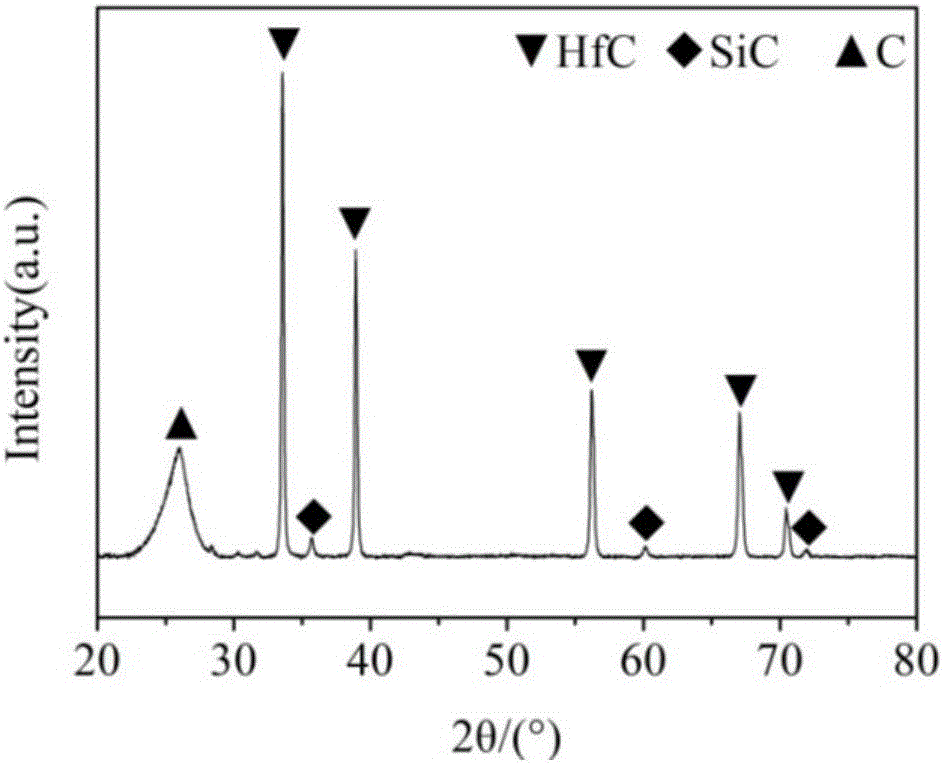

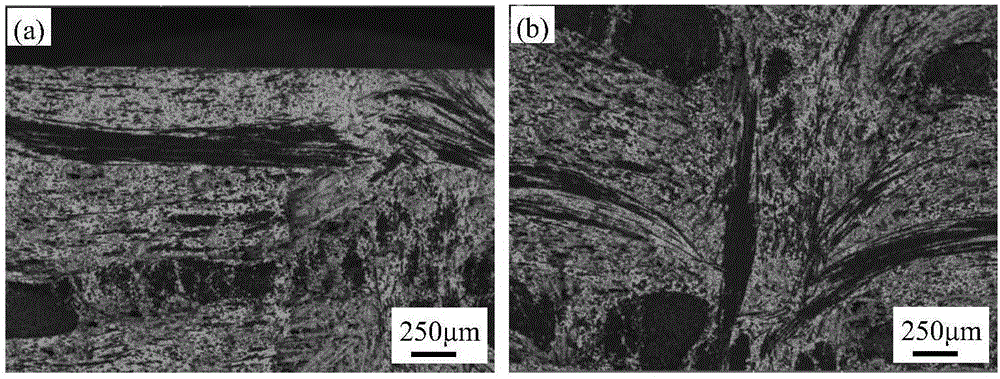

Method for preparing HfC-SiC modified C/C composite with high-temperature infiltration-pyrolysis process

The invention relates to a method for preparing an HfC-SiC modified C / C composite with a high-temperature infiltration-pyrolysis process. The method comprises the following steps: a carbon felt is cleaned and dried, and a low-density porous preform is prepared through isothermal chemical vapor deposition; an HfC precursor and polycarbosilane mixed solution is prepared to be taken as a precursor of an HfC-SiC ceramic phase, subjected to vacuum infiltration in an environment at about 110 DEG C and infiltrated into the preform, pyrolysis is performed, the high-temperature infiltration-pyrolysis process is repeated until the material gets densified, and the HfC-SiC modified C / C composite is prepared. The method has the beneficial effects as follows: based on the characteristic that the viscosity of the high-concentration polycarbosilane and HfC precursor mixed solution decreases with increasing temperature, the precursor mixed solution with high concentration is infiltrated into the porous C / C preform when the temperature is 90-110 DEG C, so that the porous C / C preform is filled fully faster, ceramic is uniformly and densely distributed in the preform, the final density reaches 2.4-2.7 g / cm<3>, the material preparing period is shortened, and the material preparing efficiency and the distribution uniformity of the ceramic phase in the material are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Lipophilic felt base cloth and production method thereof

InactiveCN108085873AImprove permeabilityImprove oil immersion effectSpinning head liquid feederArtificial thread manufacturing machinesPolyesterCrystallization

The invention discloses a lipophilic felt base cloth and a production method thereof. The production method comprises the following steps: successively carrying out crystallization and drying, screw extruding, melt filtering, spinning, cooling, drafting, wire placement and net pavement, needling reinforcement, hot rolling and chemical glue dipping and drying on polyester chips. Based on the totalweight of a glue solution, the glue solution for chemical glue dipping and drying comprises 6-8wt% of acrylate, 90-93wt% of water and 1-2wt% of a curing agent. The invention provides a production method of the brand-new lipophilic felt base cloth. According to the production method of the brand-new lipophilic felt base cloth, an acrylate solution which contains the curing agent is selected to be used as the glue solution to prepare the lipophilic felt base cloth, thus, the prepared lipophilic felt base cloth has good oil immersion property, and the problems that in a follow-up coiled materialproduction process, oil immersion uniformity of a coiled material is slightly poor, and the production efficiency is low are solved.

Owner:滁州天鼎丰非织造布有限公司

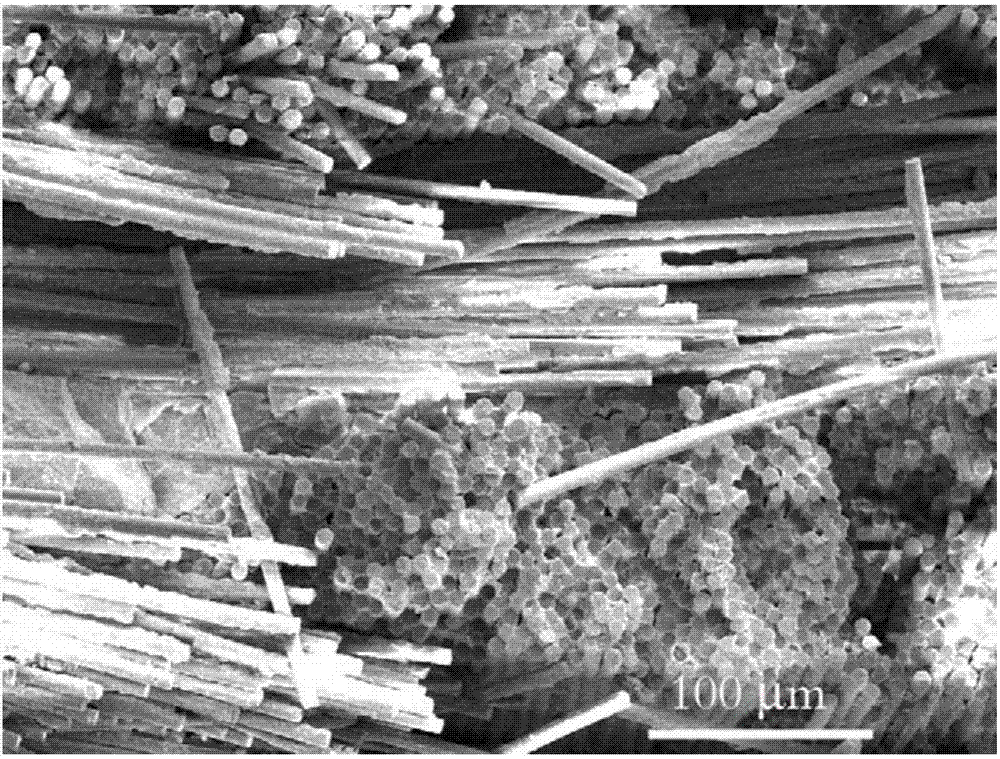

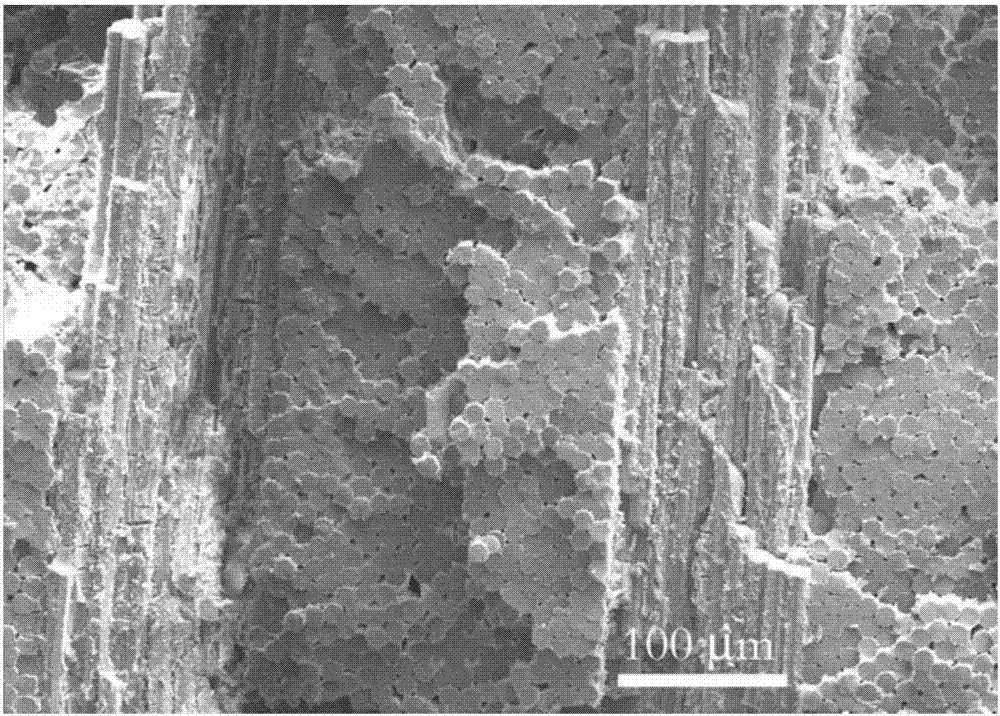

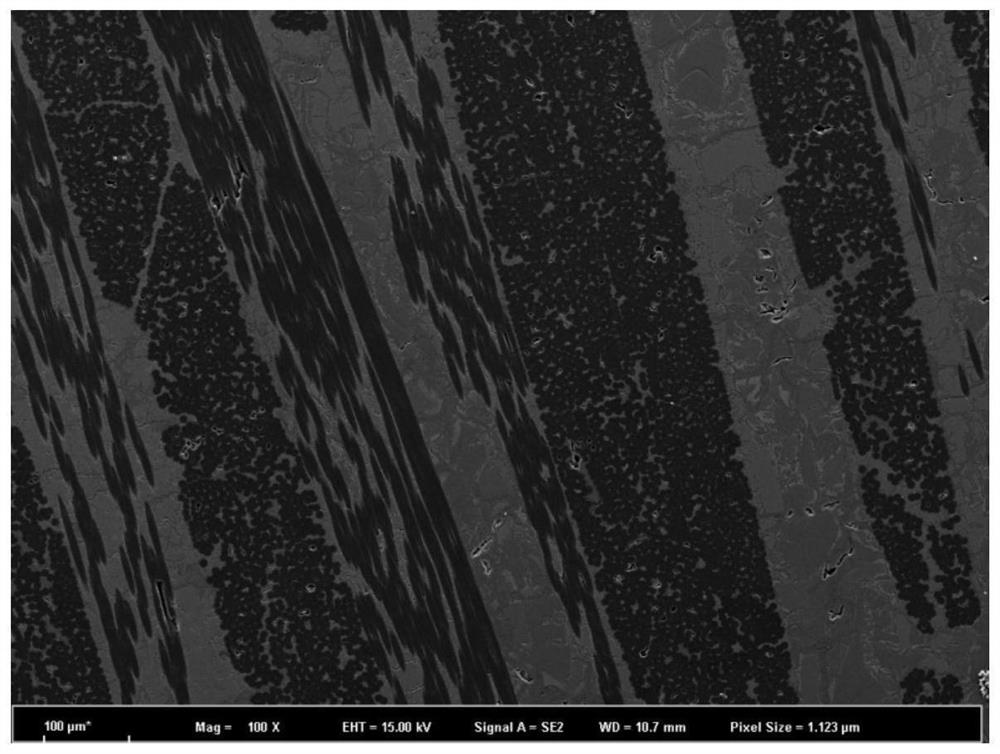

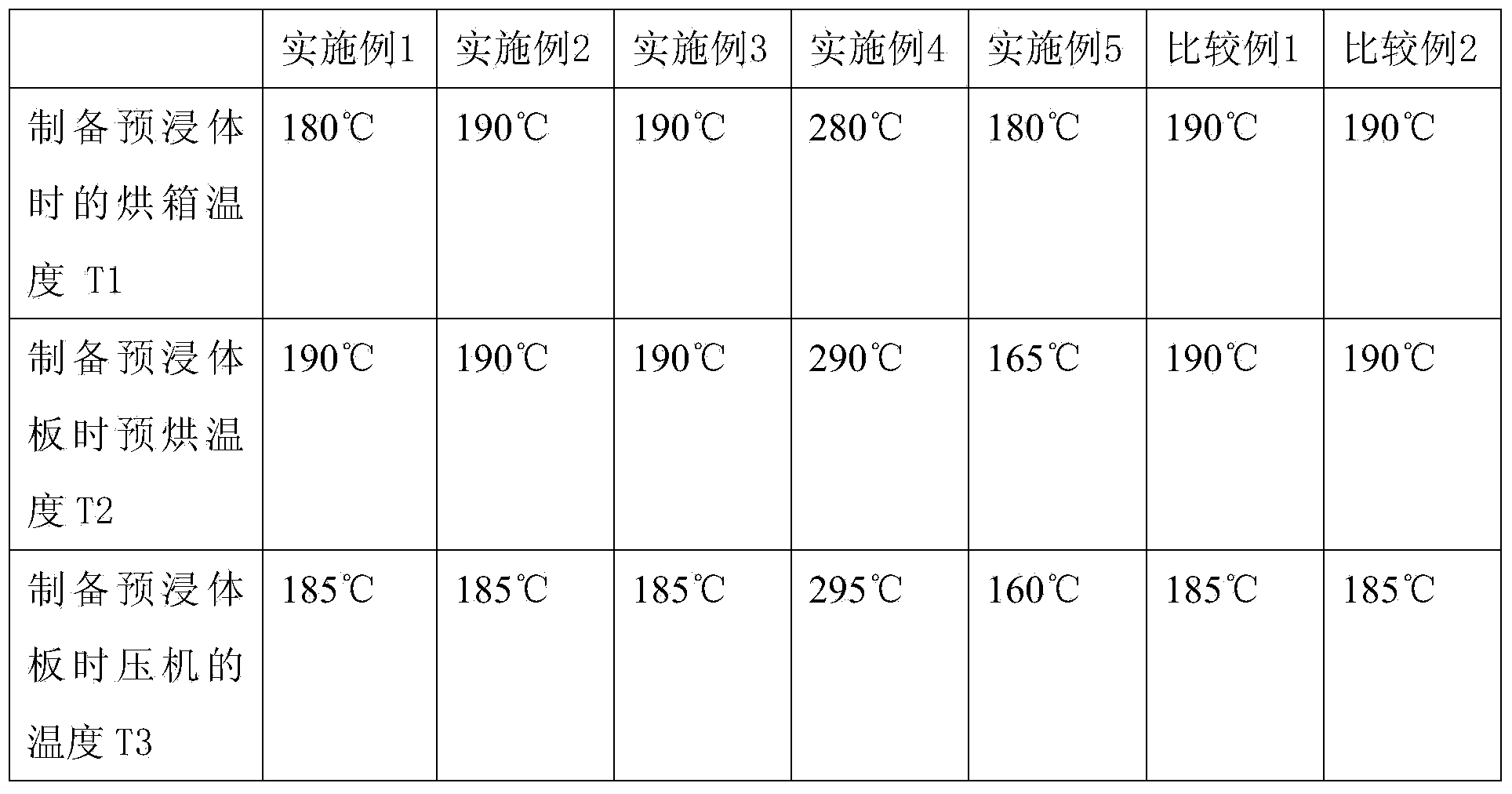

Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof

The invention discloses a Cf / Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof. The composite material comprises a carbon fiber fabricated part, an SiC substrate and an Hf[x]Zr[1-x]C substrate, wherein x is larger than 0 and smaller than 1, and the Hf[x]Zr[1-x]C substrate and the SiC substrate are uniformly filled in the holes of the carbon fiber fabricated part. One preparation method comprises the following steps that (1), a Cf / Hf[x]Zr[1-x]C blank is prepared; (2) the Cf / Hf[x]Zr[1-x]C-SiC composite material is prepared. The other preparation method comprises the following steps that (1), a Cf / Hf[x]Zr[1-x]C blank is prepared; (2) a Cf / Hf[x]Zr[1-x]C-C blank is prepared; (3) the Cf / Hf[x]Zr[1-x]C-SiC composite material is prepared. The Cf / Hf[x]Zr[1-x]C-SiC composite material has the advantages that the material is low in cost, ablative-resistant, excellent in mechanical property and oxidation resistance and the like, and at the same time, the preparation methods are simple, and the contents of the substrates are easy to control.

Owner:NAT UNIV OF DEFENSE TECH

Automatic impregnation method of capacitor core package

InactiveCN110010355ASimple and safe operationReduce manual laborLiquid electrolytic capacitorsDrying/impregnating machinesEngineeringCapacitor

The invention relates to the field of capacitors, and also relates to the field of impregnation methods of capacitor core packages, in particular to an automatic impregnation method of a capacitor core package. Prior to impregnation of a capacitor core package, impregnation time, vacuum relief time, pressing time, the electrolyte temperature and the vacuum degree are set, the whole impregnation process is completely intelligent, automatic and integrated, is simple and safe in operate, saves the labor force and effectively improves the impregnation effect and the impregnation efficiency of thecapacitor core package.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof](https://images-eureka.patsnap.com/patent_img/d1493a6d-d1c5-4680-925b-9ab2a0619944/HDA0000988282670000011.PNG)

![Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof](https://images-eureka.patsnap.com/patent_img/d1493a6d-d1c5-4680-925b-9ab2a0619944/HDA0000988282670000012.PNG)

![Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof Cf/Hf[x]Zr[1-x]C-SiC composite material and preparation methods thereof](https://images-eureka.patsnap.com/patent_img/d1493a6d-d1c5-4680-925b-9ab2a0619944/HDA0000988282670000021.PNG)