High-performance C/SiBCN composite material as well as preparation method and application thereof

A composite material and high-performance technology, which is applied in the field of high-performance C/SiBCN composite materials and its preparation, can solve the problems of low mechanical properties of C/SiBCN composite materials, and achieve the goal of improving impregnation efficiency, impregnation depth, and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method of high-performance C / SiBCN composite material in the first aspect, described method comprises the steps:

[0029] (1) Prepare C interface layer, SiC interface layer and / or (C / SiC) consisting of C interface layer and SiC interface layer alternately deposited on the surface of carbon fiber preform n Alternate the interface layer to obtain a modified carbon fiber preform; in the present invention, the carbon fiber preform, for example, can adopt a 3D structure porous carbon fiber preform such as a needle-punched structure, a two-dimensional carbon cloth laminated stitching structure, or a finely punctured puncture; In the invention, for example, the C interface layer, the SiC interface layer and / or the (C / SiC) interface layer can be prepared by a CVI process. n Alternating interfacial layers; in the present invention, the (C / SiC) n Alternate interface layer is denoted as C, SiC alternate interface layer;

[003...

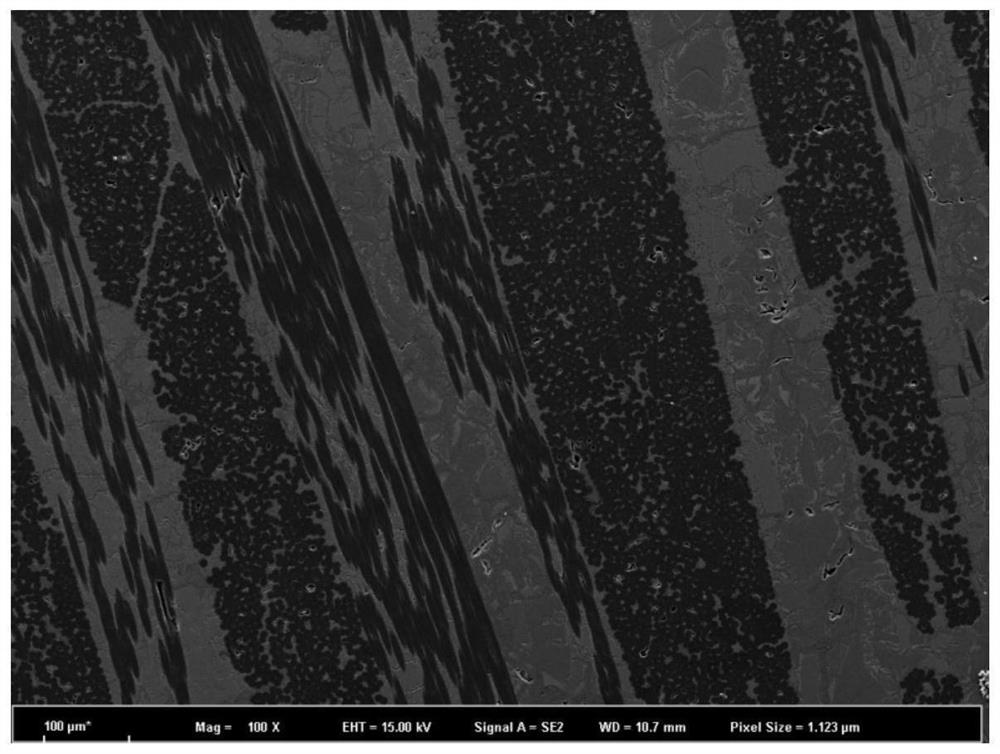

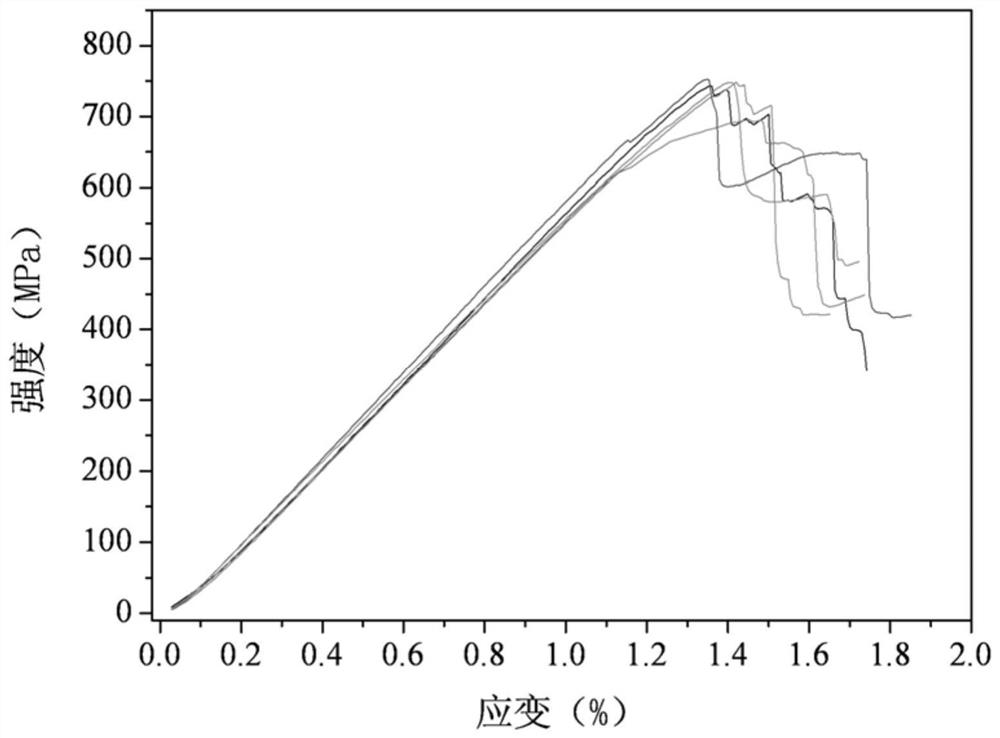

Embodiment 1

[0053] ①The carbon fiber prefabricated body with carbon cloth laminated stitching structure is adopted, and the density of the prefabricated body is 0.65~0.80g / cm 3 , using the CVI process (CVI) to prepare the C interface layer, the deposition time is 100h, and the modified carbon fiber preform is obtained.

[0054] ②Using the liquid SiBCN precursor (liquid polyborosilazane) as the impregnating liquid, the modified carbon fiber preform is densified by the PIP process of vacuum impregnation / in-situ curing / medium pressure cracking, vacuum impregnation, original In-situ curing and medium pressure cracking, this is a PIP process of vacuum impregnation / in-situ solidification / medium pressure cracking; the number of cycles of the PIP process of vacuum impregnation / in-situ solidification / medium pressure cracking is 6 times, obtaining High-performance C / SiBCN composite material; each PIP process of vacuum impregnation / in-situ curing / medium pressure cracking is as follows: the modified ...

Embodiment 2

[0057] ①The carbon fiber prefabricated body with carbon cloth laminated stitching structure is adopted, and the density of the prefabricated body is 0.65~0.80g / cm 3 , using the CVI process (CVI) to prepare the SiC interface layer, the deposition time is 100h, and the modified carbon fiber preform is obtained.

[0058] ②Using the liquid SiBCN precursor (liquid polyborosilazane) as the impregnating liquid, the modified carbon fiber preform is densified by the PIP process of vacuum impregnation / in-situ curing / medium pressure cracking, vacuum impregnation, original In-situ curing and medium pressure cracking, this is a PIP process of vacuum impregnation / in-situ solidification / medium pressure cracking; the number of cycles of the PIP process of vacuum impregnation / in-situ solidification / medium pressure cracking is 6 times, obtaining High-performance C / SiBCN composite material; each PIP process of vacuum impregnation / in-situ curing / medium pressure cracking is as follows: the modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com