Positioning device for a color measuring head

A technology of positioning device and measuring head, which is applied in the direction of measuring device, machine/structural component testing, printing, etc., and can solve the problem of not being able to provide individual measurement positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

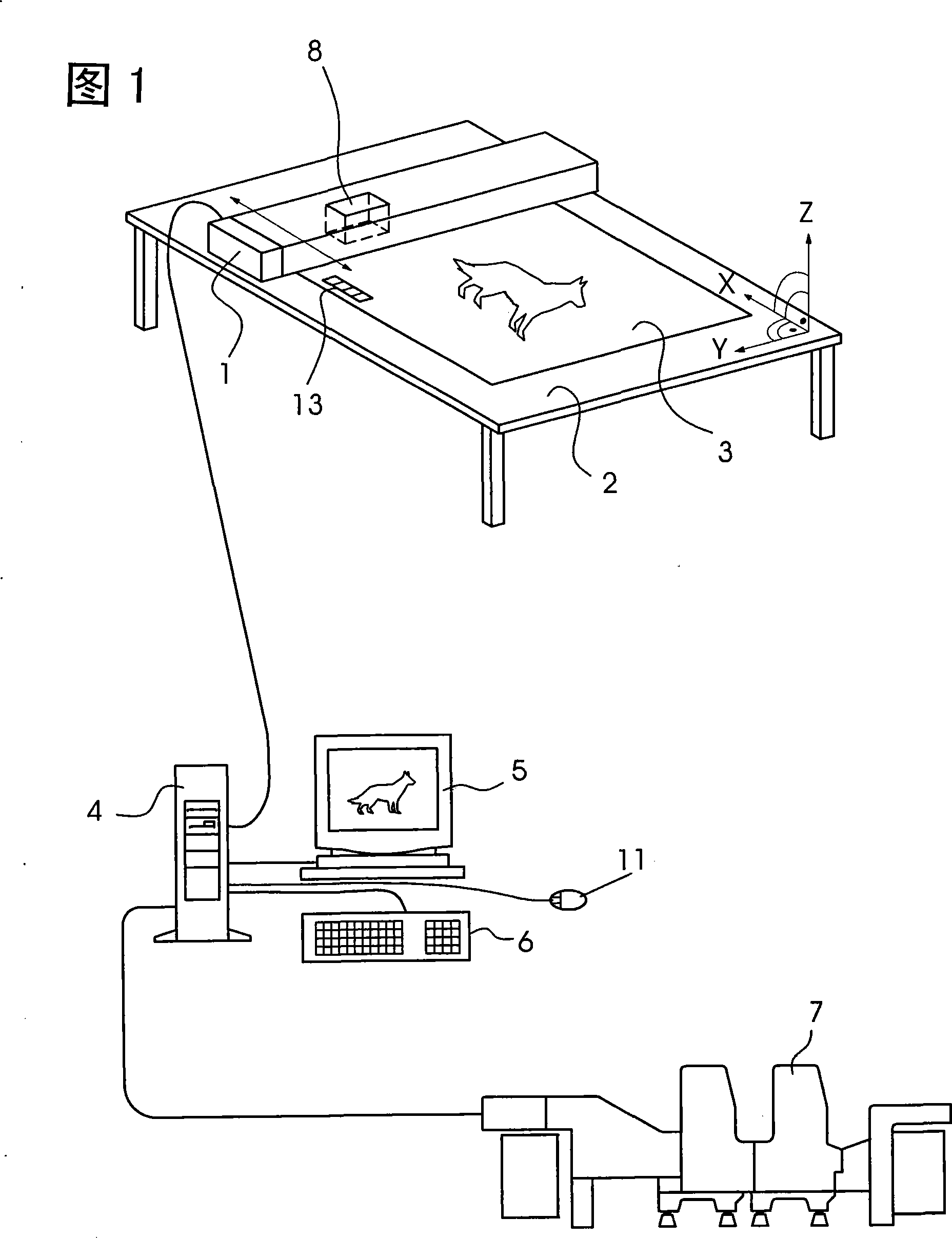

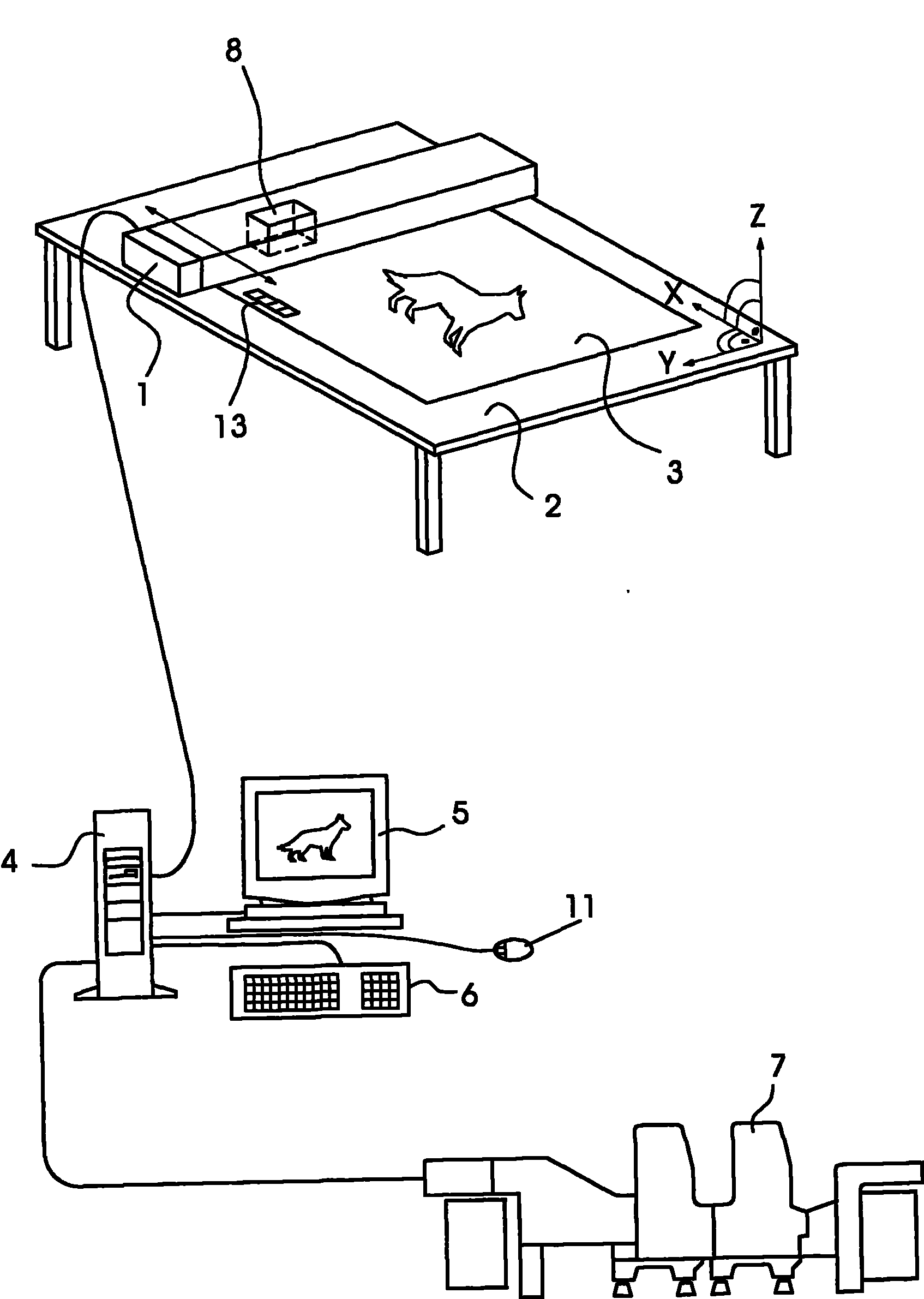

[0016] FIG. 1 shows a color measuring device which is connected to a computer 4 . The color measuring device consists of a measuring table 2 on which a produced printing material 3 can be placed. The placed printing material 3 can be measured, for example with respect to color, by means of the measuring beam 1 . The measuring beam 1 is displaceable in the X direction in FIG. 1 in order to be able to traverse the entire length of the deposited printing material 3 . The measuring beam 1 in turn has a measuring head 8 that can be moved in the Y direction, by means of which it can be moved in a targeted manner to individual measuring points on the printing material 3 in order to measure these measuring points with regard to color. Furthermore, for example, a color measuring strip 13 on the printing material 3 can be detected, detected and measured by means of the measuring head 8 . The data sensed by the measuring head 8 are sent to the computer 4 and can be represented on a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com