Preparation method of large-size yttrium iron garnet single crystal

A technology of yttrium iron garnet and large size is applied in the field of large size yttrium iron garnet single crystal material and its preparation, and can solve the problems of poor uniformity, small size of yttrium iron garnet single crystal and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

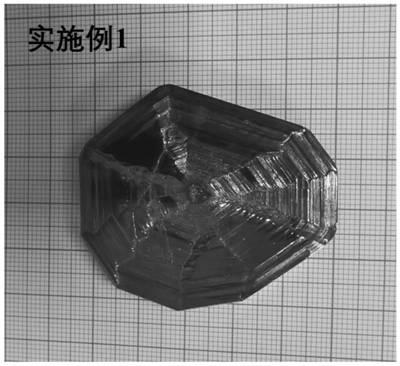

Embodiment 1

[0040] Embodiment 1 uses the top seed method to grow large-size yttrium iron garnet crystals:

[0041] The initial raw material Y 2 o 3 , Fe 2 o 3 And the composite flux is weighed according to the stoichiometric ratio to obtain the initial mixture, and the mass fraction of the composite flux in the mixed raw material is 73.78%. Among them, the composite flux includes Z1 component PbF 2 , Z2 component B 2 o 3 and Z3 component Bi 2 o 3 , and the molar ratio of component Z1, component Z2, and component Z3 is 6:2:1.

[0042] The initial mixture was thoroughly mixed in a mixer for 24 hours, and the obtained mixed raw material was loaded into a platinum crucible, and placed in a crystal growth furnace at 1050° C. for 48 hours to form the raw material. Use yttrium-iron garnet seed crystals to find the supersaturation temperature of the melt, introduce formal seed crystals at 990°C, and then slowly cool down to grow; the crystal rotation rate is 30rpm, and the cooling rate i...

Embodiment 2

[0043] Embodiment 2 uses the top seed method to grow large-size yttrium iron garnet crystals:

[0044] The initial raw material Y 2 o 3 , Fe 2 o 3 And the composite flux is weighed according to the stoichiometric ratio to obtain the initial mixture, and the mass fraction of the composite flux in the mixed raw material is 68.25%. Among them, the composite flux includes Z1 component PbF 2 , Z2 component B 2 o 3 and Z3 component Bi 2 o 3 , and the molar ratio of component Z1, component Z2, and component Z3 is 4:2:1.

[0045] The initial mixture was thoroughly mixed in a mixer for 24 hours, and the obtained mixed raw material was loaded into a platinum crucible, and placed in a crystal growth furnace at 1100° C. for 48 hours to form the raw material. Use yttrium-iron garnet seed crystals to find the supersaturation temperature of the melt, introduce formal seed crystals at the supersaturation temperature of 1040°C, and then slowly cool down and grow; the crystal rotation ...

Embodiment 3

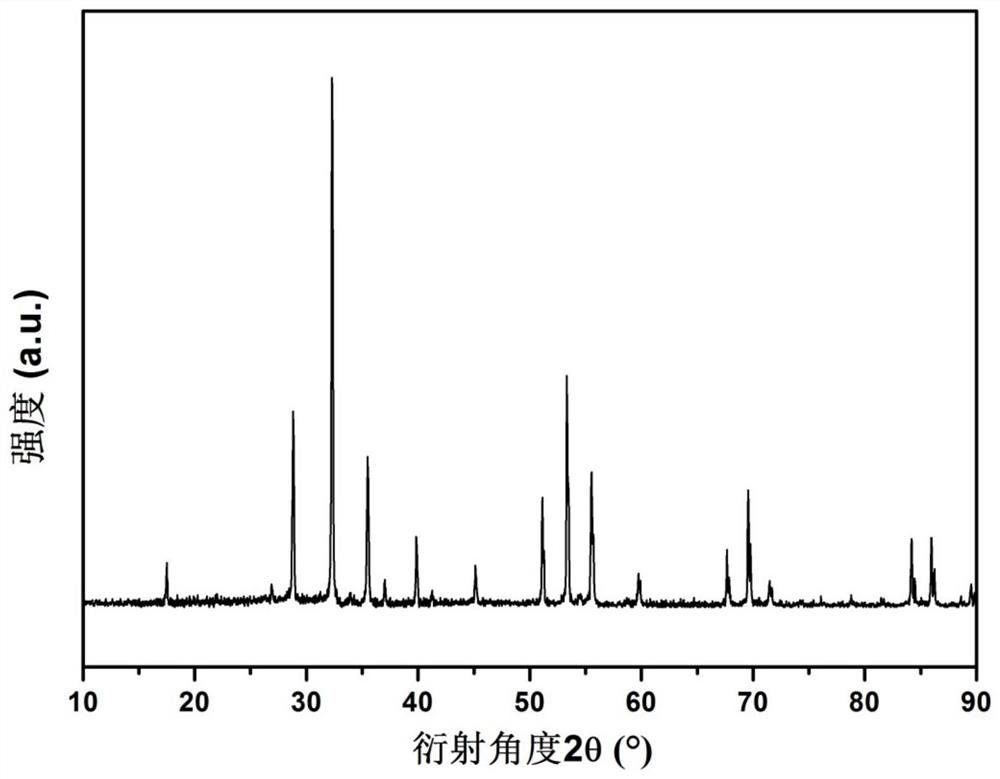

[0046] Embodiment 3 The yttrium iron garnet single crystal obtained in embodiment 1 is subjected to structure and performance tests:

[0047] (a) Cut the crystal into a small piece and grind it into a powder for XRD powder diffraction test. The powder diffraction spectrum of yttrium-iron garnet single crystal shows that the room temperature is a typical garnet-type structure, which belongs to the cubic crystal system (see figure 2 ).

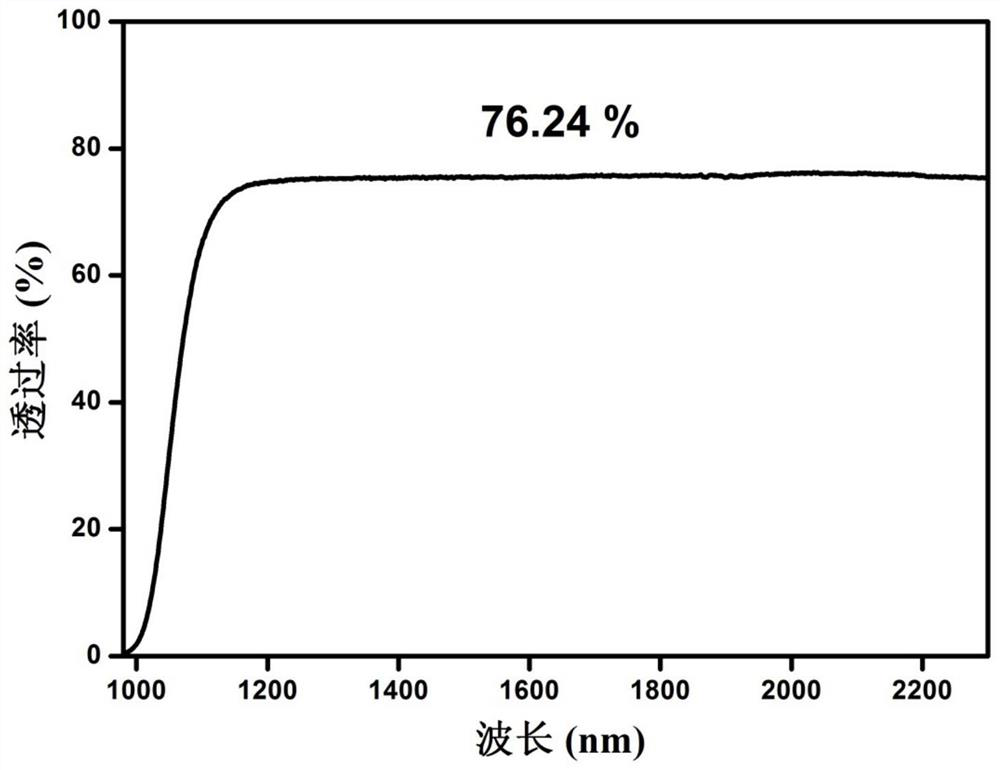

[0048] (b) Slicing the obtained yttrium iron garnet single crystal according to (110) or (211) direction, followed by fine polishing on both sides. The transmittance was measured with a UV-Vis-NIR spectrophotometer (Lambda950). The transmittance spectrum shows that the transmittance is as high as 76.24% in the 1200-2300nm band (see image 3 ).

[0049] (c) slice the obtained yttrium iron garnet single crystal according to (110) or (211) direction, then perform double-sided polishing and gold-plated electrodes. The prepared samples were use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com