Calcium germinate nanowire and preparation method thereof

A calcium germanate and nanowire technology is applied in the field of calcium germanate nanowires and its preparation, and achieves the effects of high purity, low preparation temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

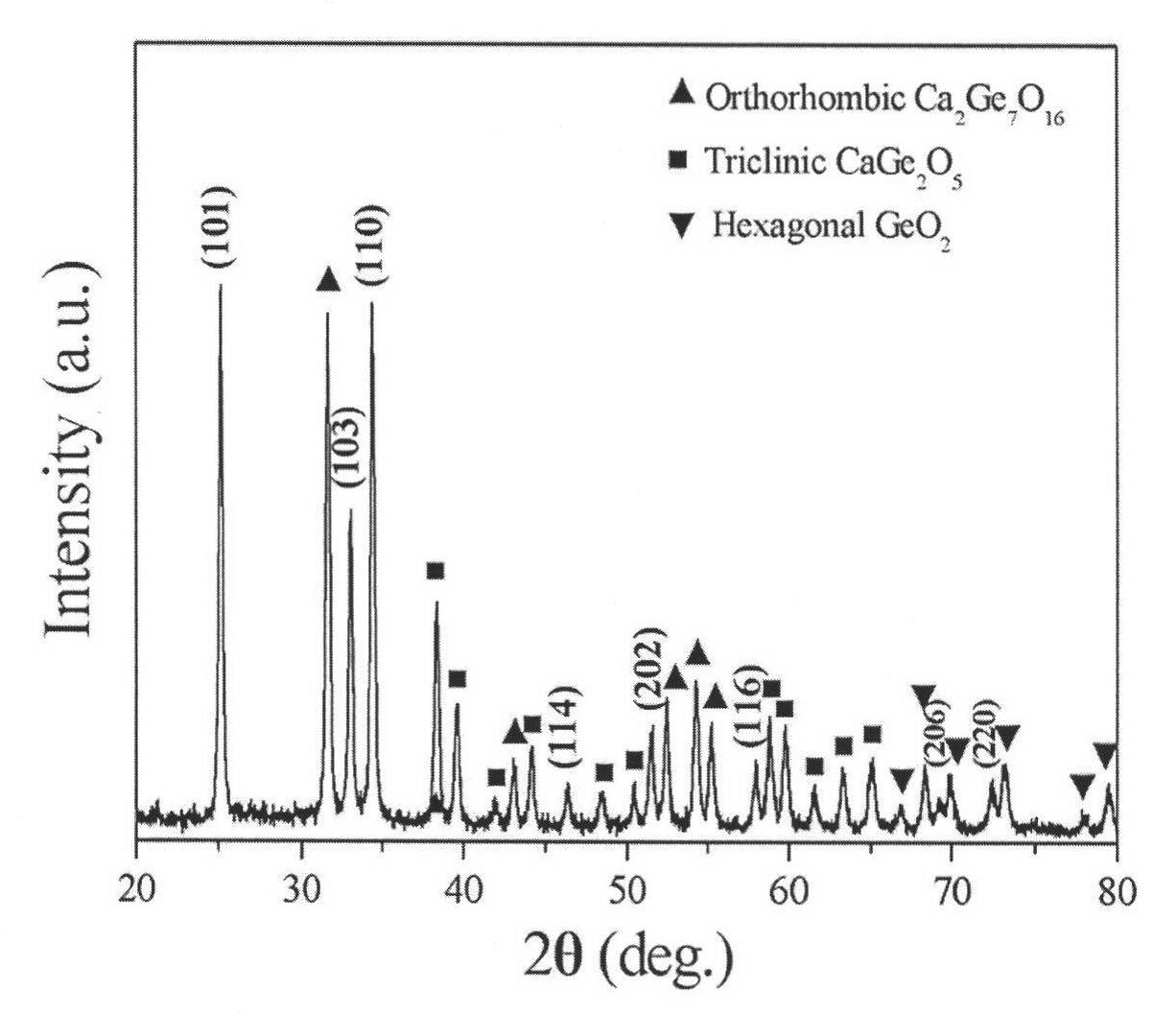

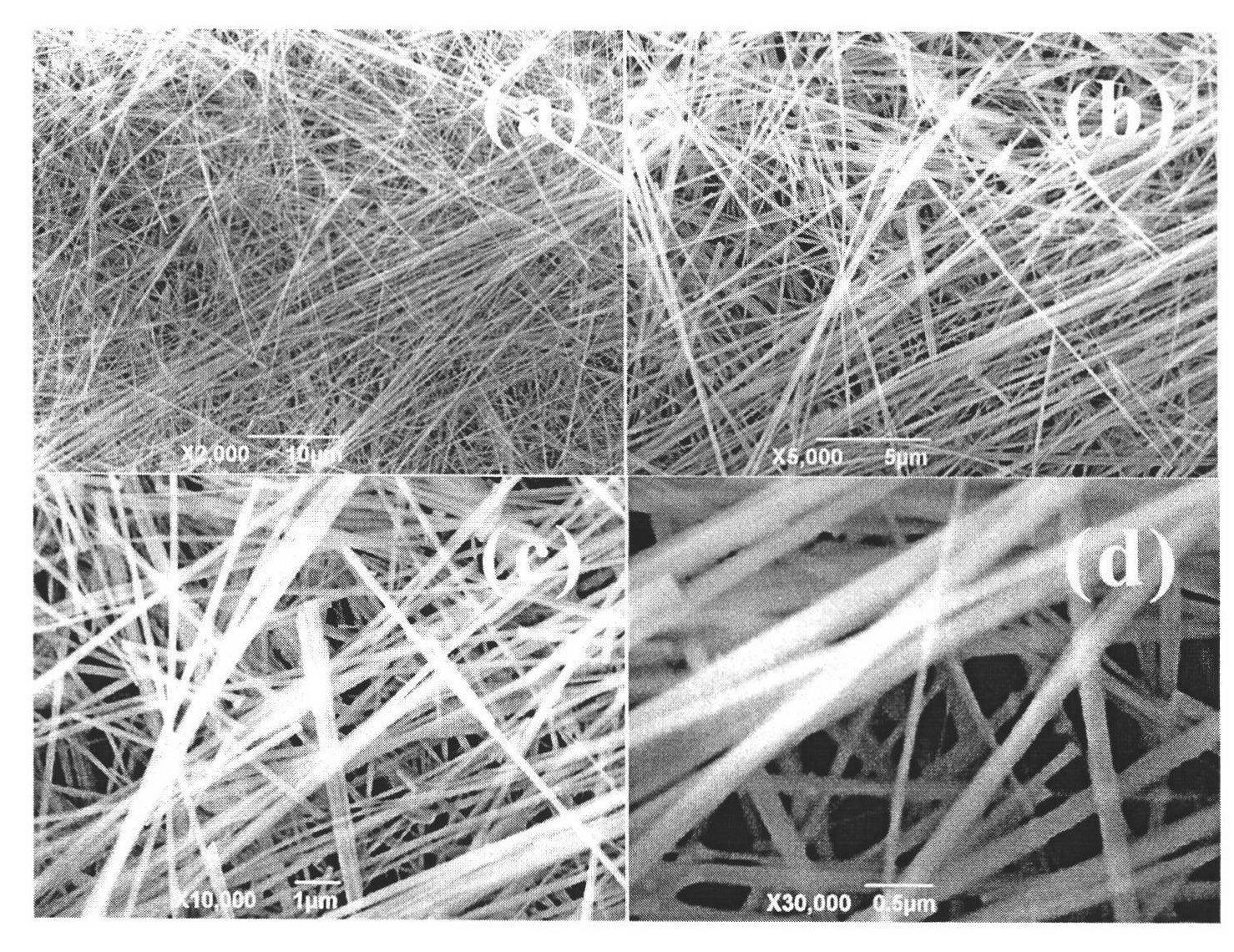

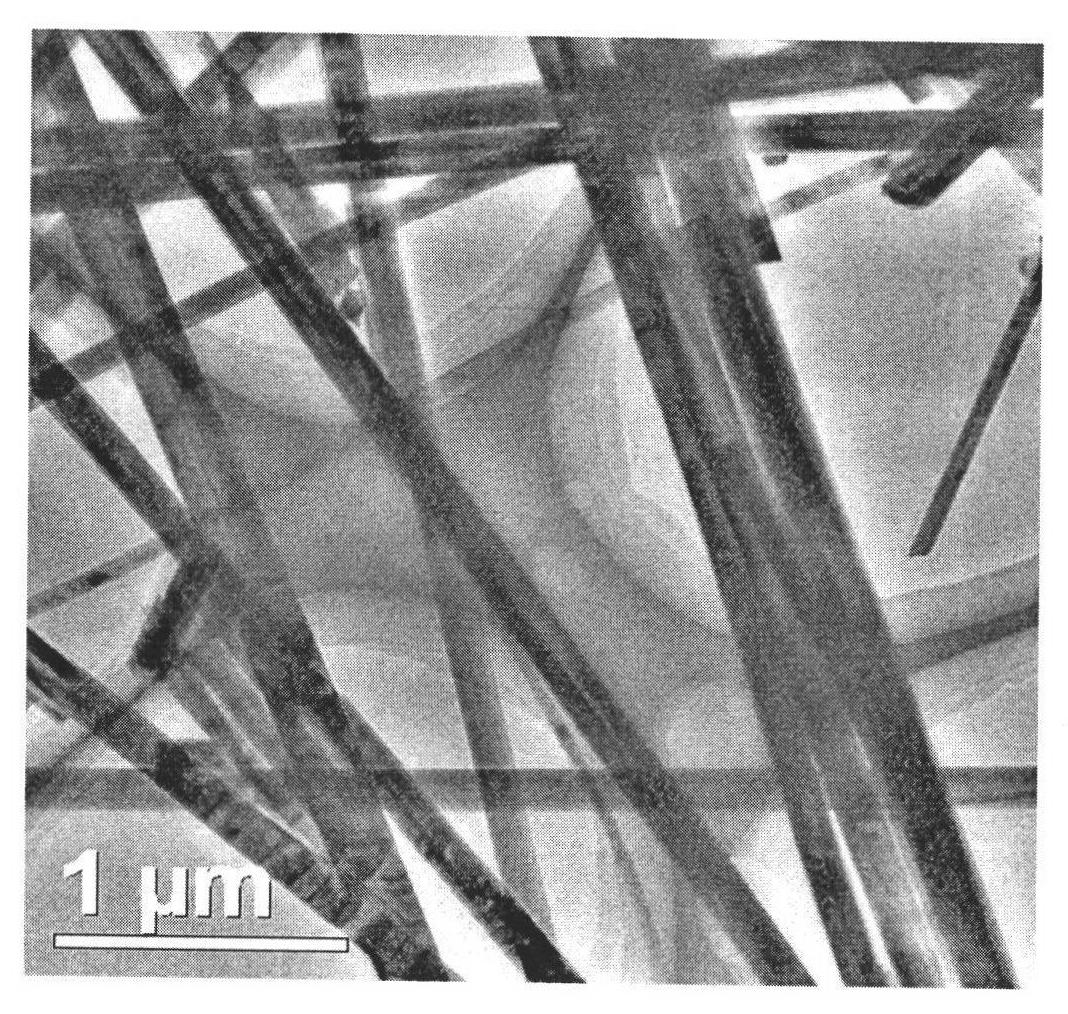

[0021] Example 1: Mix germanium dioxide, calcium acetate and distilled water accounting for 3% by weight of the water solvent and put them into a closed container. The total amount of germanium dioxide, calcium acetate and water solvent accounts for 60% of the closed container. It was then kept at a temperature of 180°C for 24 hours. Finally, a calcium germanate nanowire fluffy white product with a diameter of 20-100 nm and a length of more than 100 μm was obtained.

Embodiment 2

[0022] Example 2: Mix germanium dioxide, calcium chloride and distilled water accounting for 3% of the weight of the water solvent into a closed container, and the total amount of germanium dioxide, calcium chloride and water solvent accounts for 60% of the closed container. It was then kept at a temperature of 150°C for 24 hours. Finally, a calcium germanate nanowire fluffy white product with a diameter of 20-100 nm and a length of more than 100 μm was obtained.

Embodiment 3

[0023] Embodiment 3, after mixing germanium dioxide, calcium nitrate and distilled water accounting for 3% by weight of the water solvent, put them into a closed container, the total amount of germanium dioxide, calcium nitrate and water solvent accounts for 60% of the closed container. It was then kept at a temperature of 180°C for 12 hours. Finally, a calcium germanate nanowire fluffy white product with a diameter of 20-100 nm and a length of more than 100 μm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com