Patents

Literature

451 results about "Ternary compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In inorganic chemistry, a ternary compound is a compound containing three different elements. An example is sodium phosphate, Na₃PO₄. The sodium ion has a charge of 1+ and the phosphate ion has a charge of 3-. Therefore, three sodium ions are needed to balance the charge of one phosphate ion. Another example of a ternary compound is calcium carbonate (CaCO₃). In naming and writing the formulae for ternary compounds, rules are similar to binary compounds.

Vapor deposition method for ternary compounds

InactiveUS20100102417A1High resistivitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogen plasmaGas phase

Embodiments provide a method for depositing or forming titanium aluminum nitride materials during a vapor deposition process, such as atomic layer deposition (ALD) or plasma-enhanced ALD (PE-ALD). In some embodiments, a titanium aluminum nitride material is formed by sequentially exposing a substrate to a titanium precursor and a nitrogen plasma to form a titanium nitride layer, exposing the titanium nitride layer to a plasma treatment process, and exposing the titanium nitride layer to an aluminum precursor while depositing an aluminum layer thereon. The process may be repeated multiple times to deposit a plurality of titanium nitride and aluminum layers. Subsequently, the substrate may be annealed to form the titanium aluminum nitride material from the plurality of layers. In other embodiments, the titanium aluminum nitride material may be formed by sequentially exposing the substrate to the nitrogen plasma and a deposition gas which contains the titanium and aluminum precursors.

Owner:APPLIED MATERIALS INC

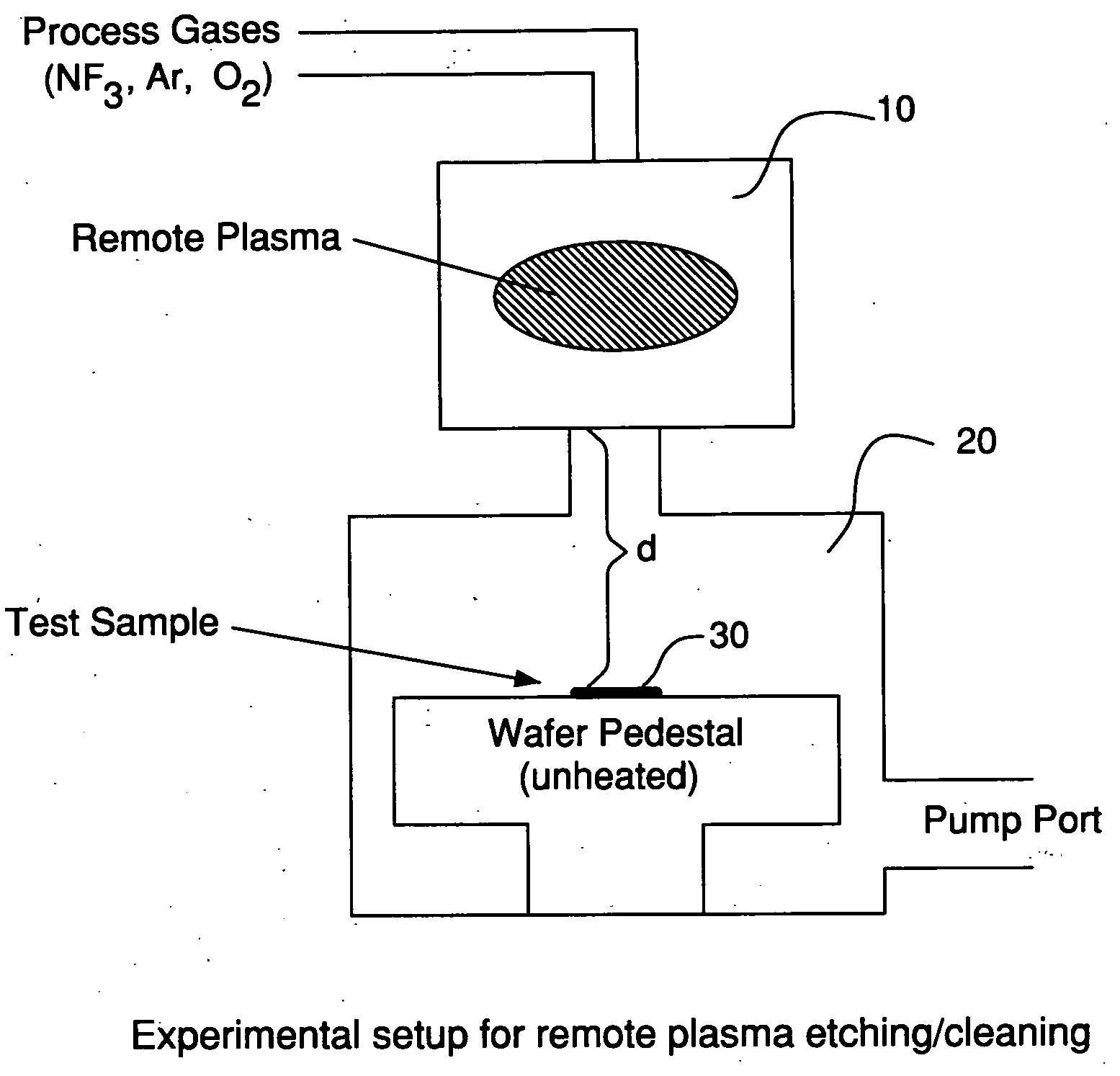

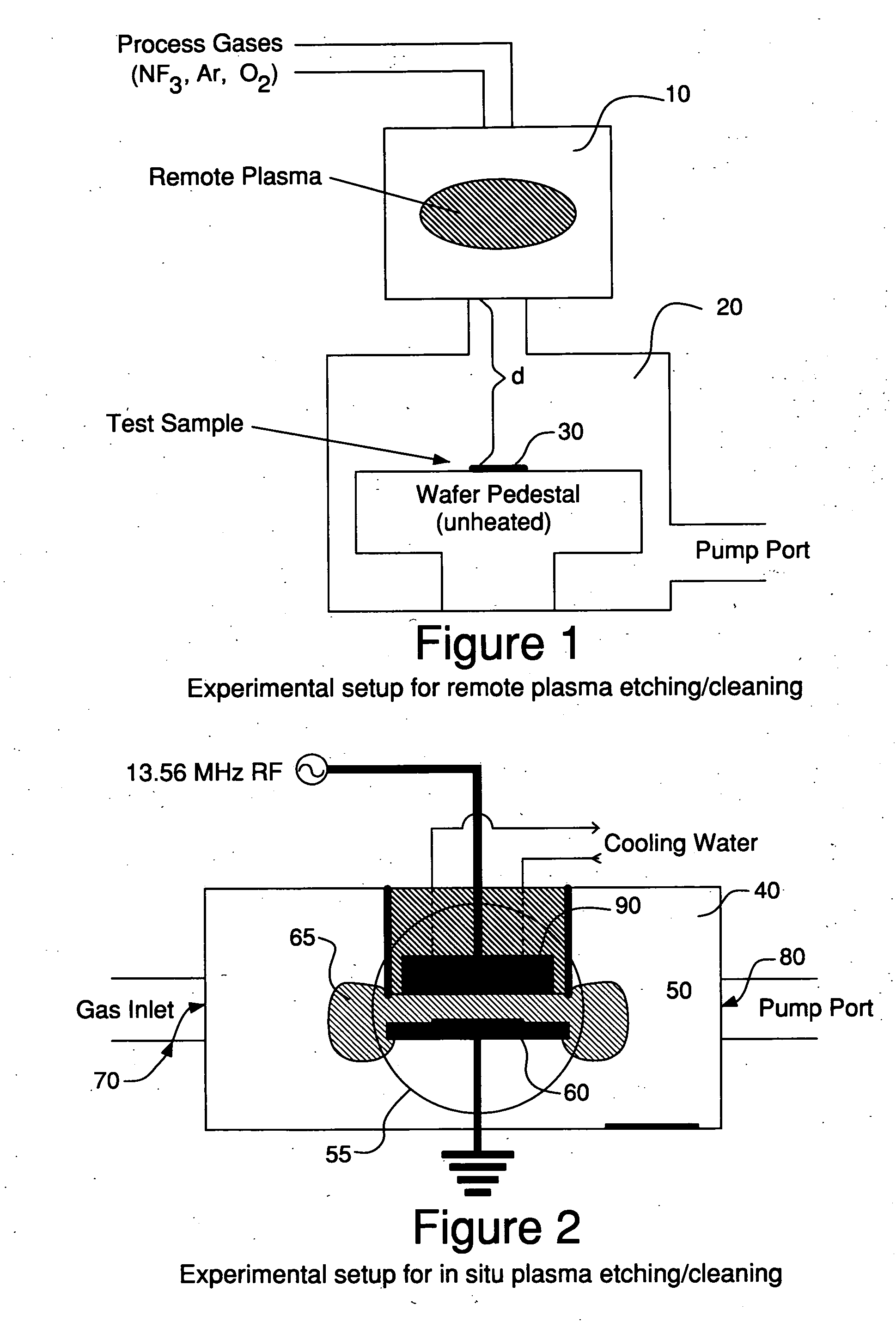

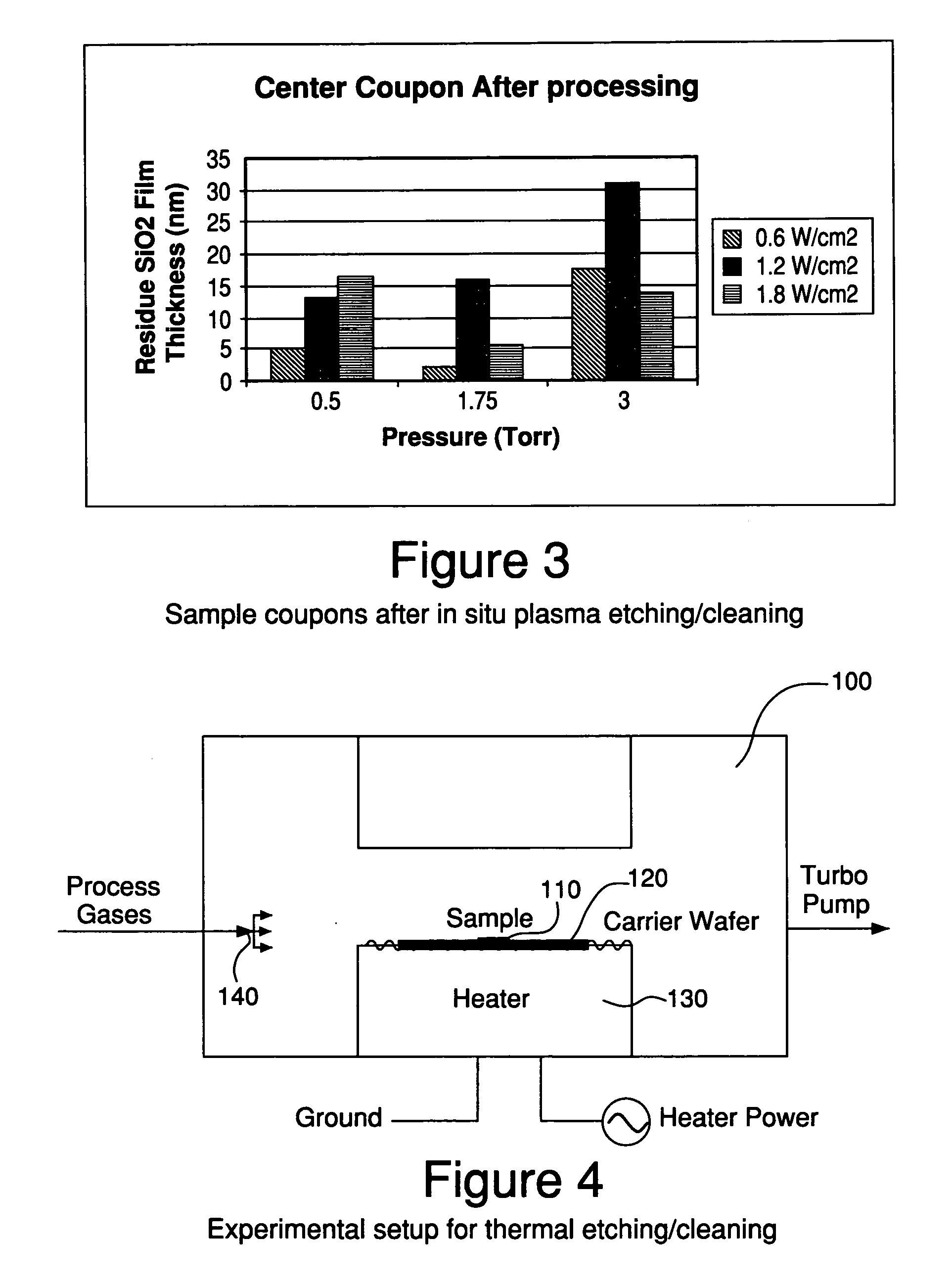

Removal of transition metal ternary and/or quaternary barrier materials from a substrate

InactiveUS20050112901A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCompound (substance)Quaternary compound

A process for the selective removal of a substance from a substrate for etching and / or cleaning applications is disclosed herein. In one embodiment, there is provided a process for removing a substance from a substrate comprising: providing the substrate having the substance deposited thereupon wherein the substance comprises a transition metal ternary compound, a transition metal quaternary compound, and combinations thereof; reacting the substance with a process gas comprising a fluorine-containing gas and optionally an additive gas to form a volatile product; and removing the volatile product from the substrate to thereby remove the substance from the substrate.

Owner:VERSUM MATERIALS US LLC

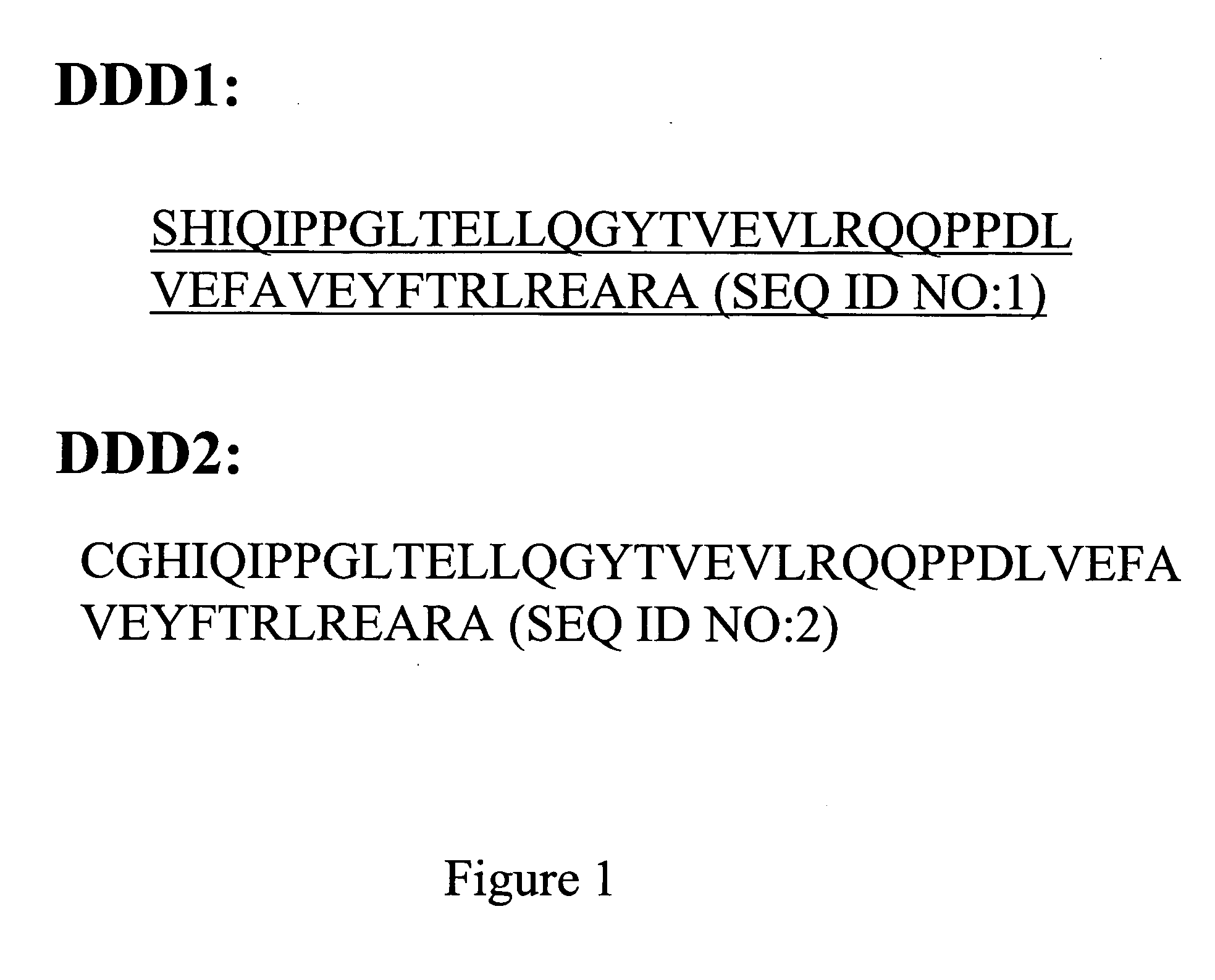

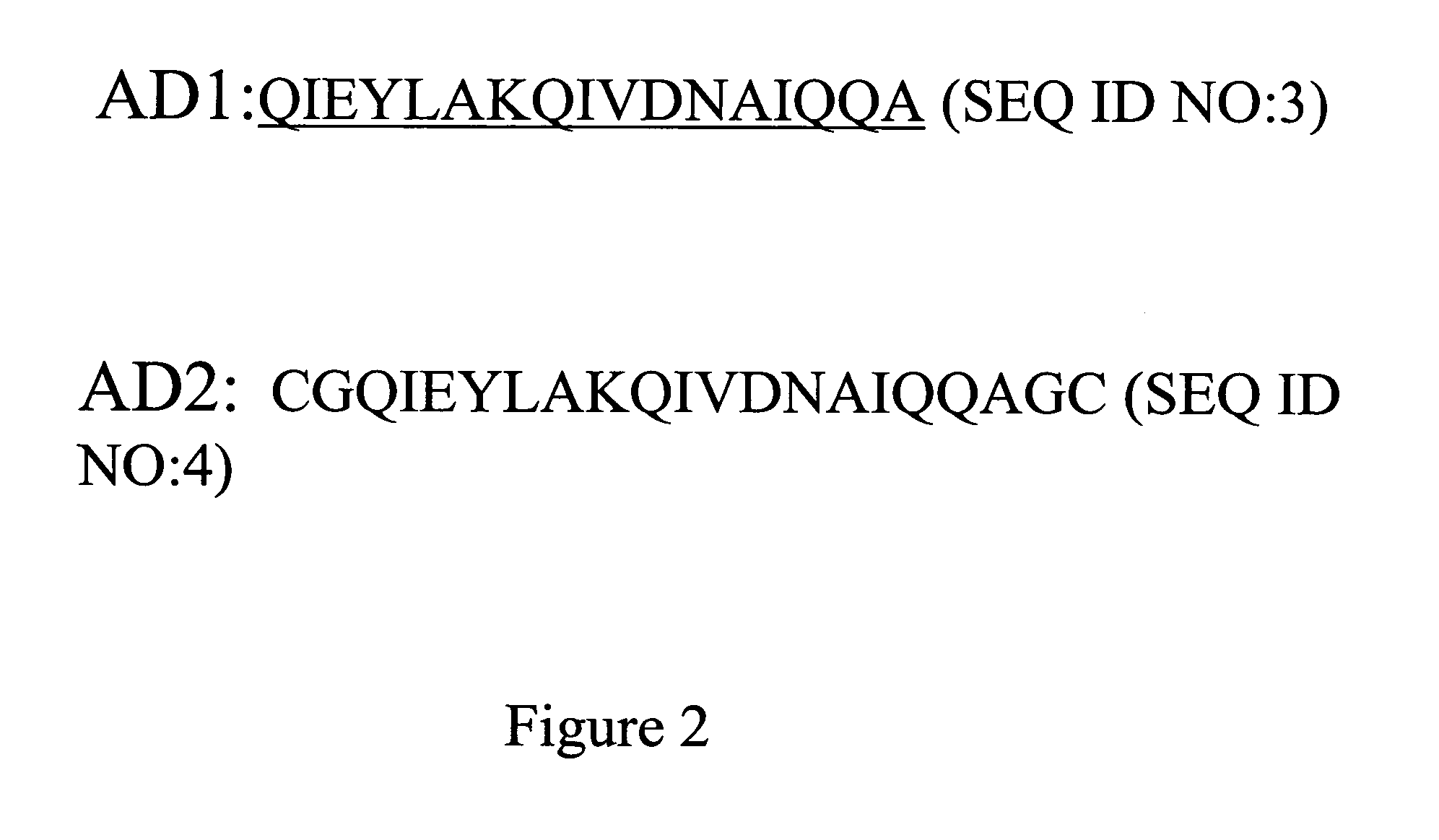

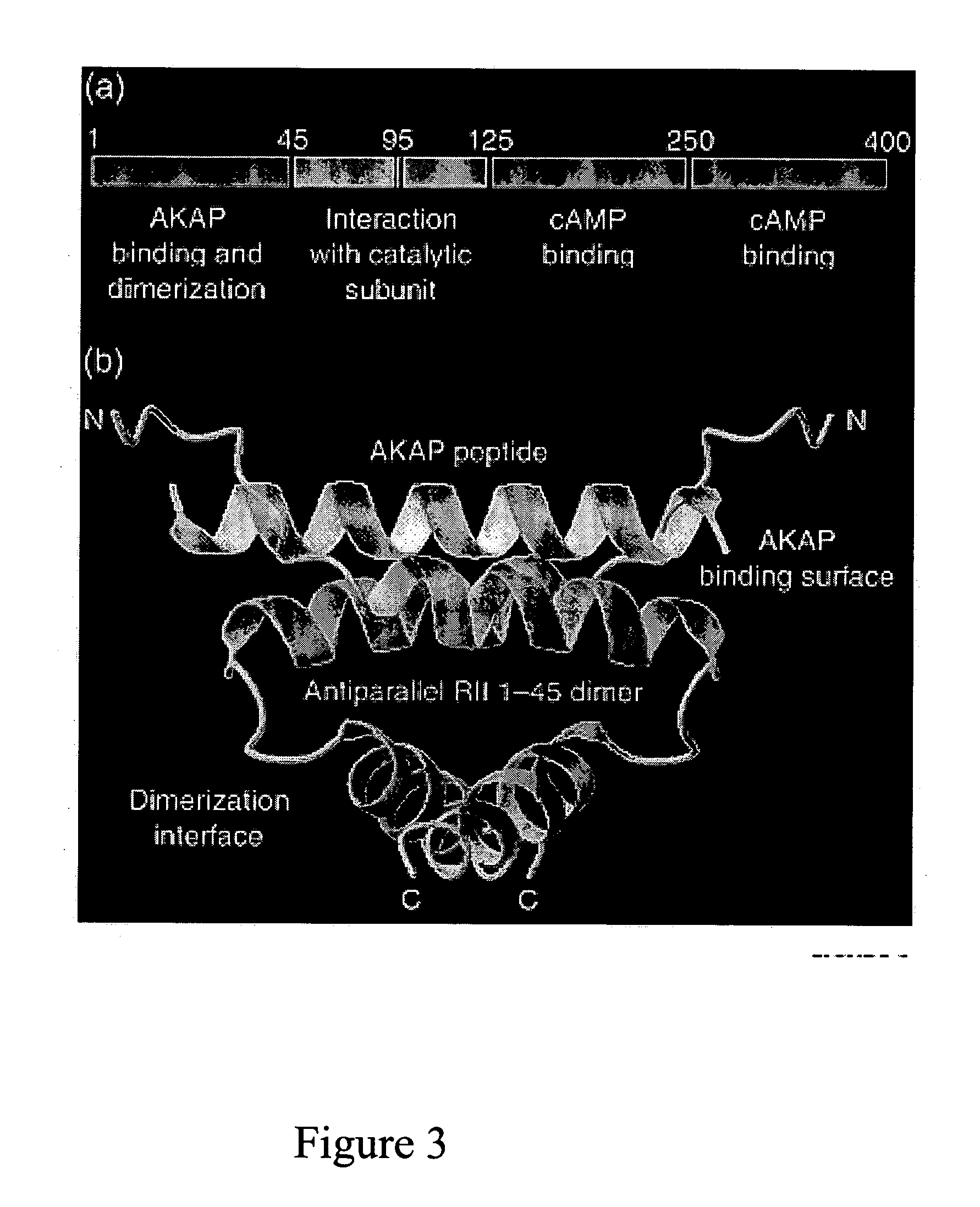

Stably tethered structures of defined compositions with multiple functions or binding specificities

ActiveUS20060228300A1Reduce exposureReduce deliveryAntibacterial agentsSenses disorderAntibody fragmentsBinding peptide

The present invention concerns methods and compositions for stably tethered structures of defined compositions with multiple functionalities and / or binding specificities. Particular embodiments concern stably tethered structures comprising a homodimer of a first monomer, comprising a dimerization and docking domain attached to a first precursor, and a second monomer comprising an anchoring domain attached to a second precursor. The first and second precursors may be virtually any molecule or structure, such as antibodies, antibody fragments, antibody analogs or mimetics, aptamers, binding peptides, fragments of binding proteins, known ligands for proteins or other molecules, enzymes, detectable labels or tags, therapeutic agents, toxins, pharmaceuticals, cytokines, interleukins, interferons, radioisotopes, proteins, peptides, peptide mimetics, polynucleotides, RNAi, oligosaccharides, natural or synthetic polymeric substances, nanoparticles, quantum dots, organic or inorganic compounds, etc. The disclosed methods and compositions provide a simple, easy to purify way to obtain any binary compound attached to any monomeric compound, or any trinary compound.

Owner:IBC PHARMACEUTICALS INC

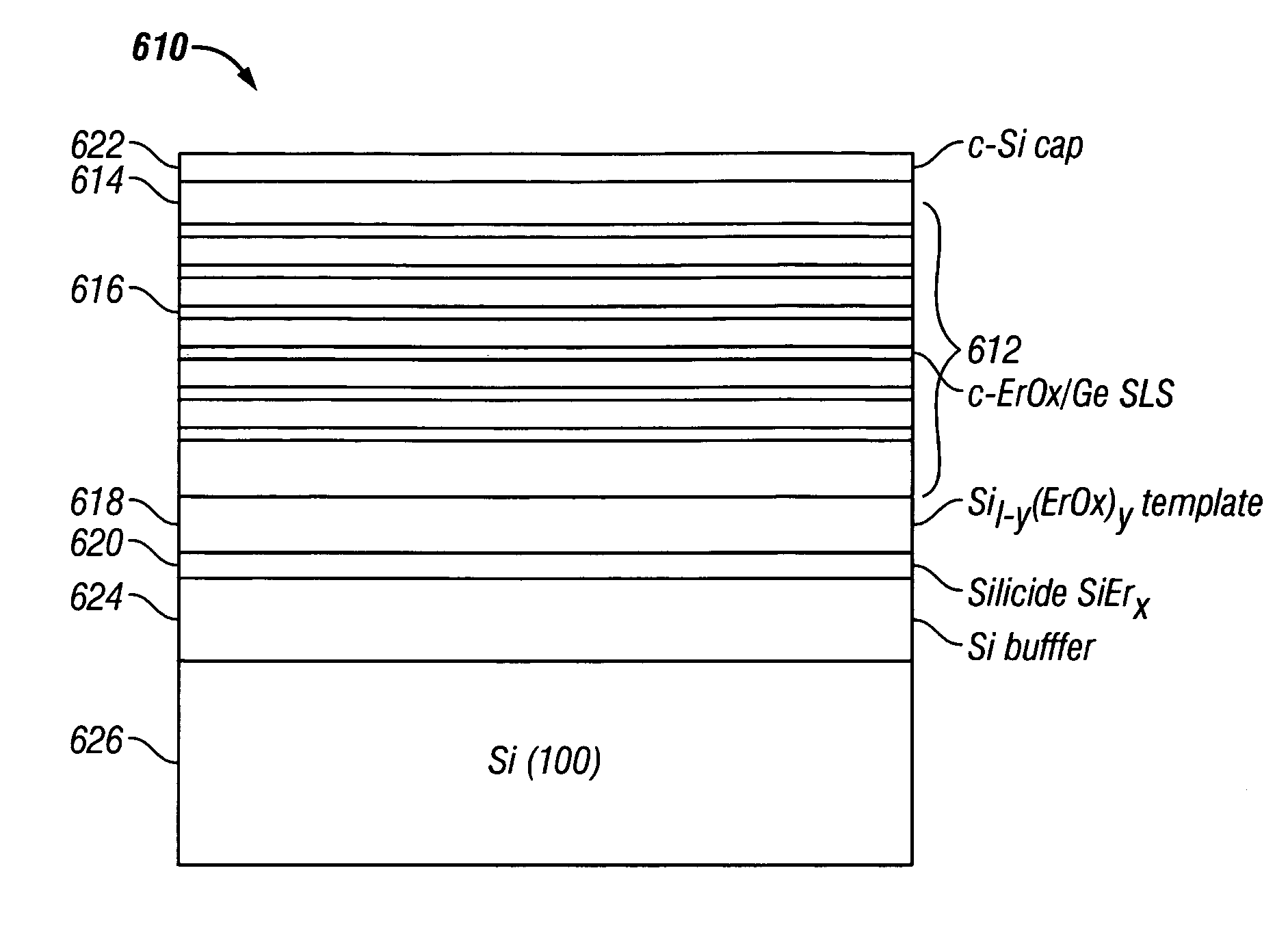

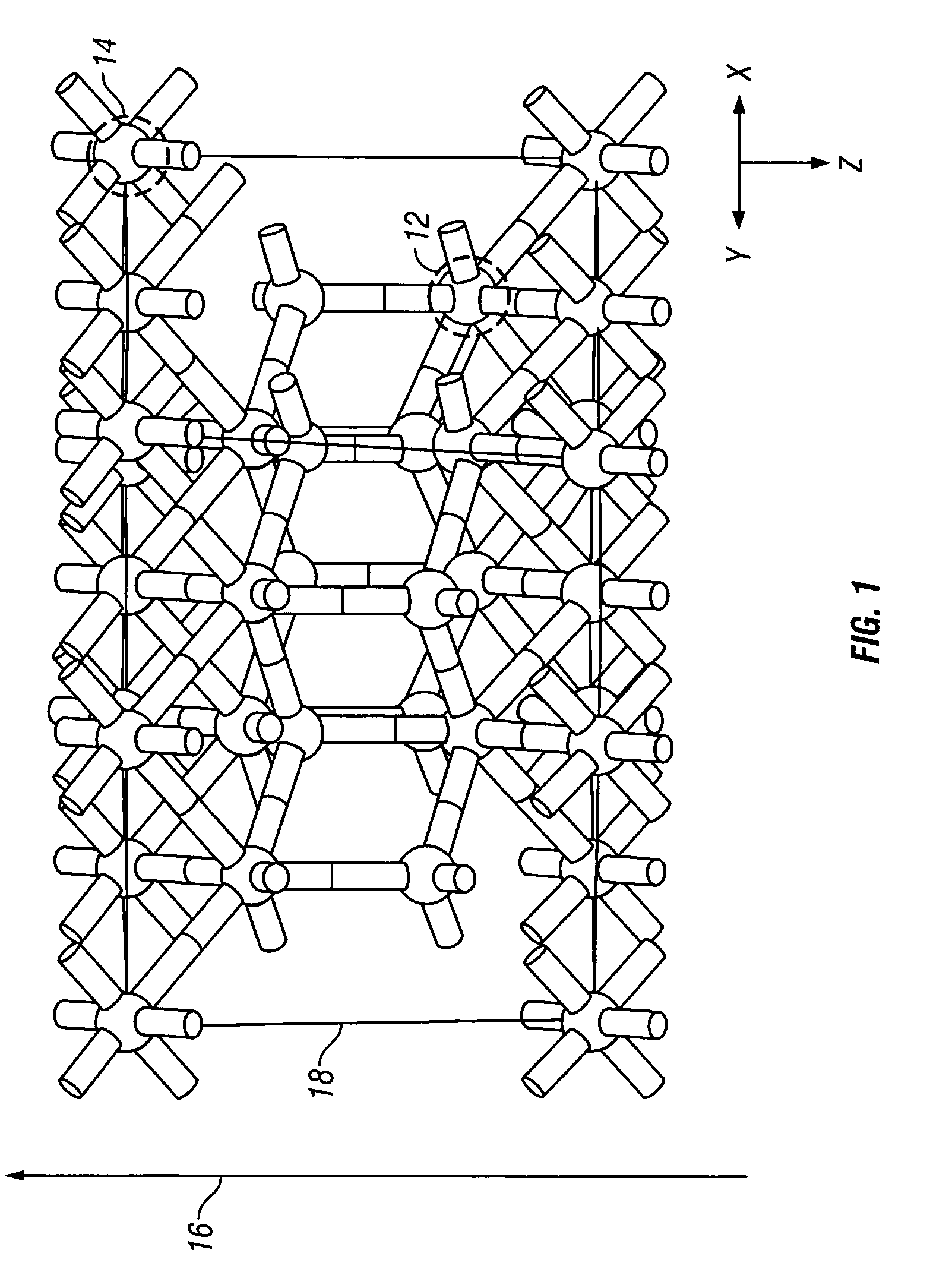

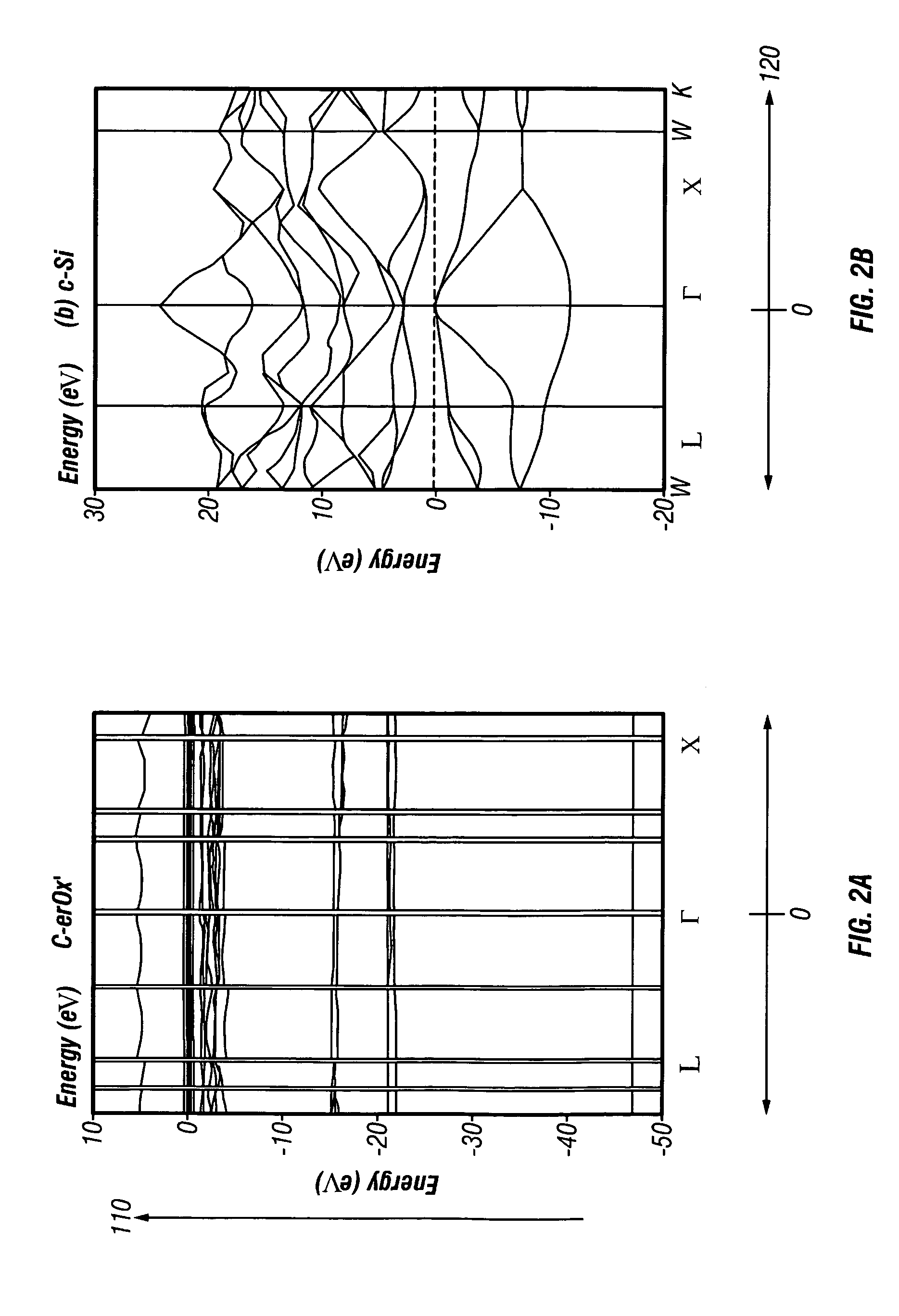

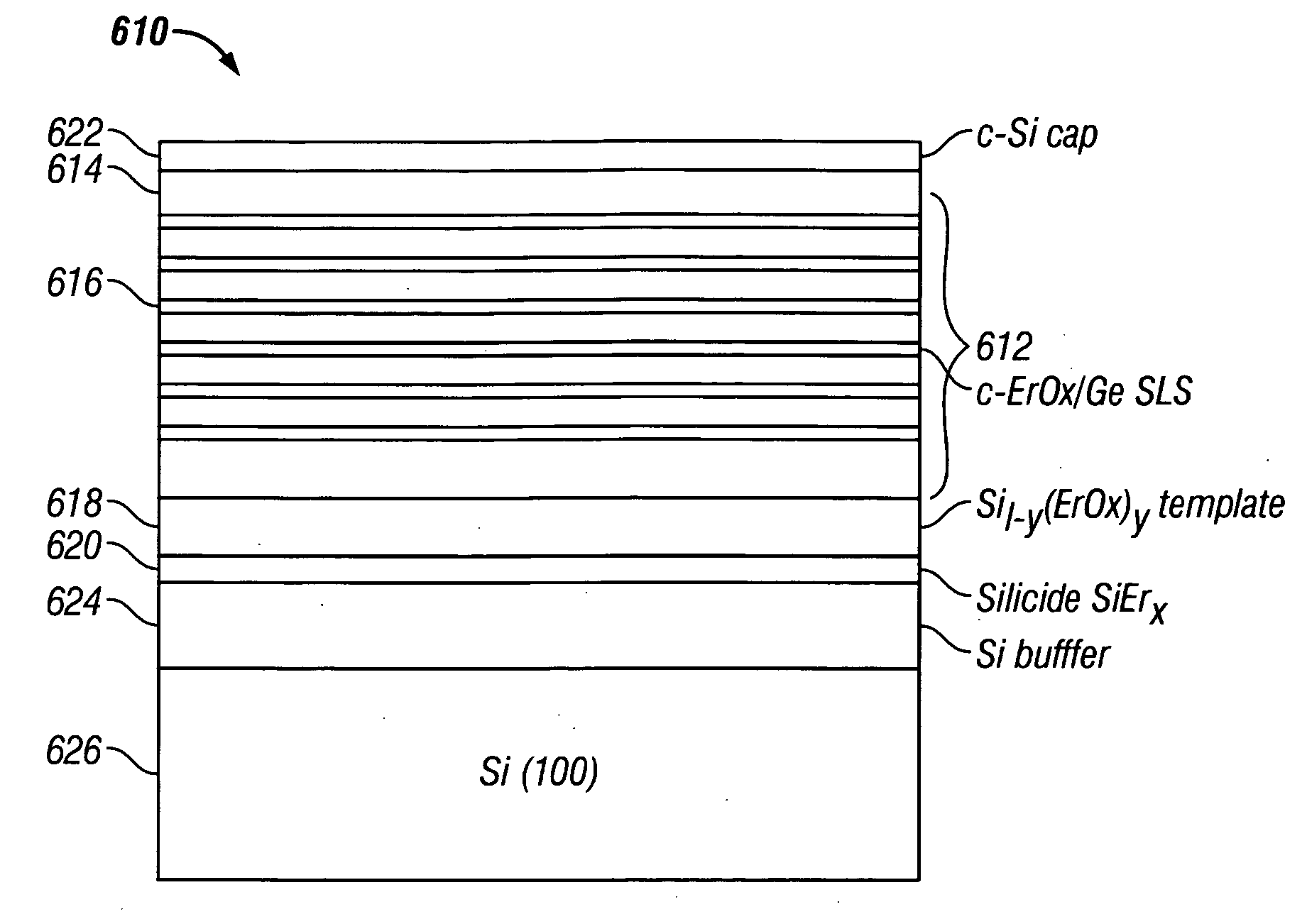

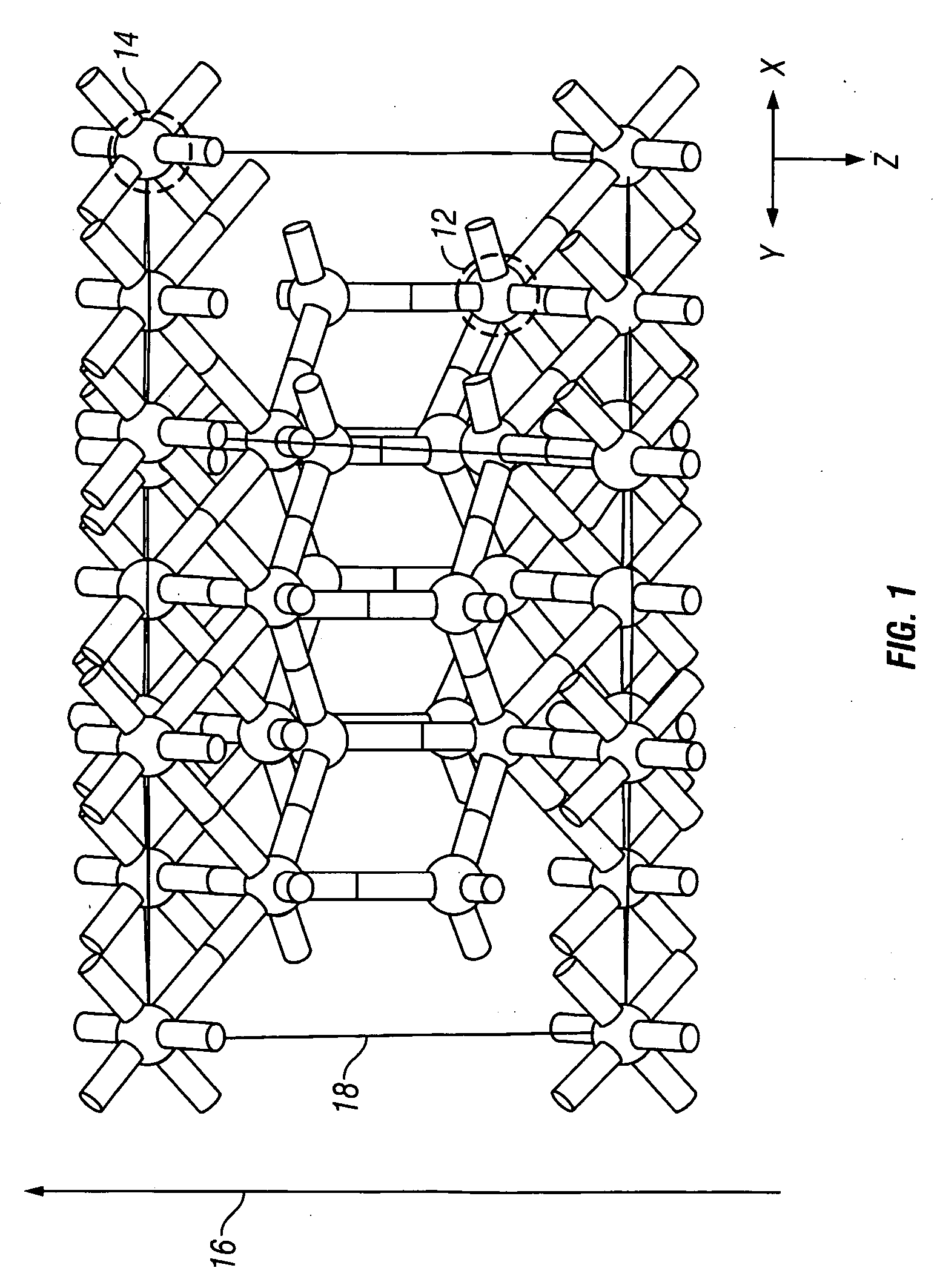

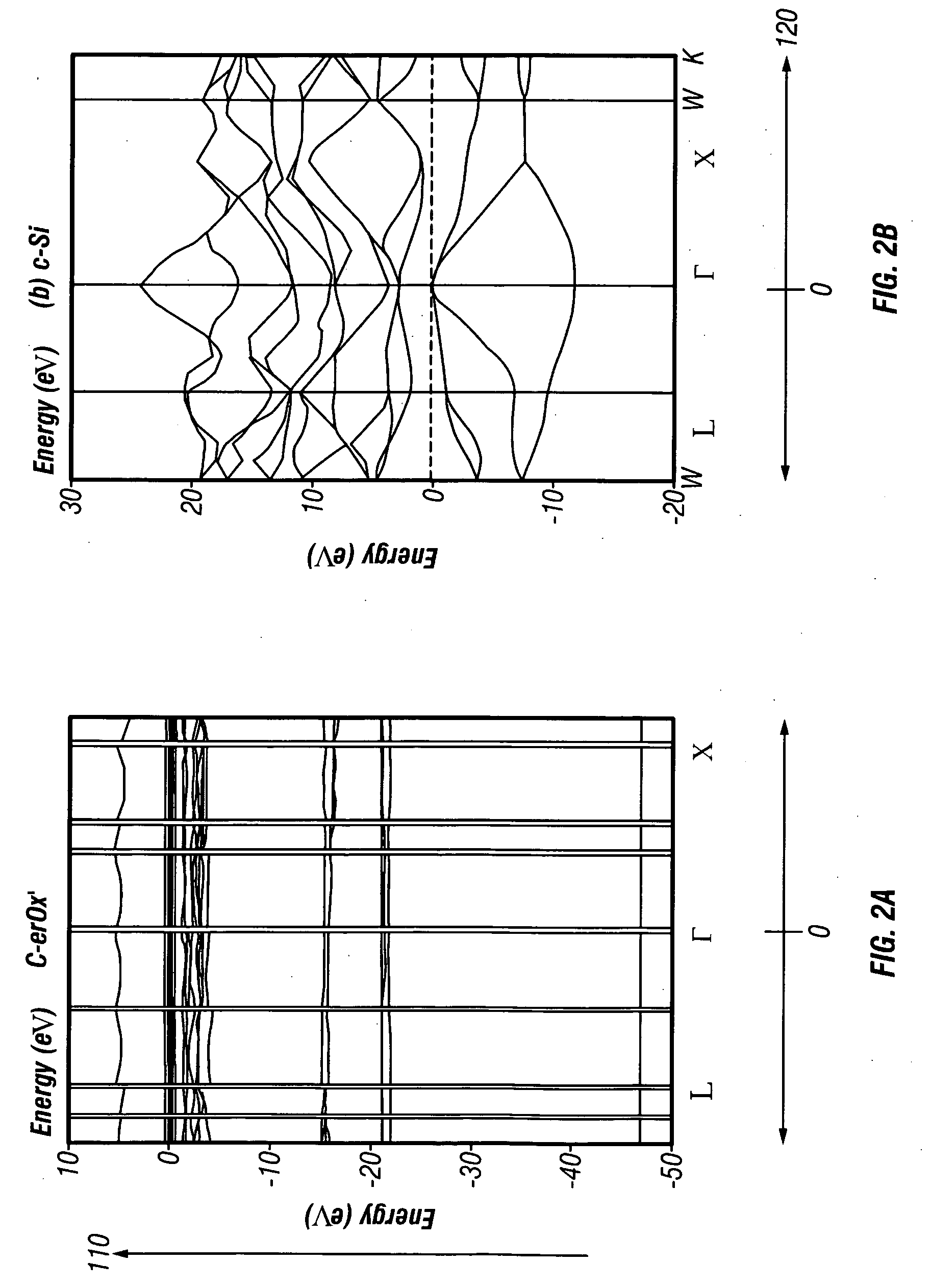

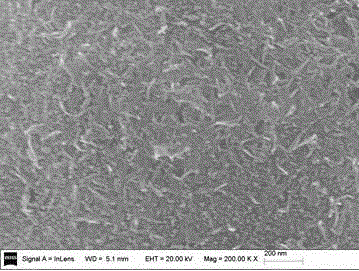

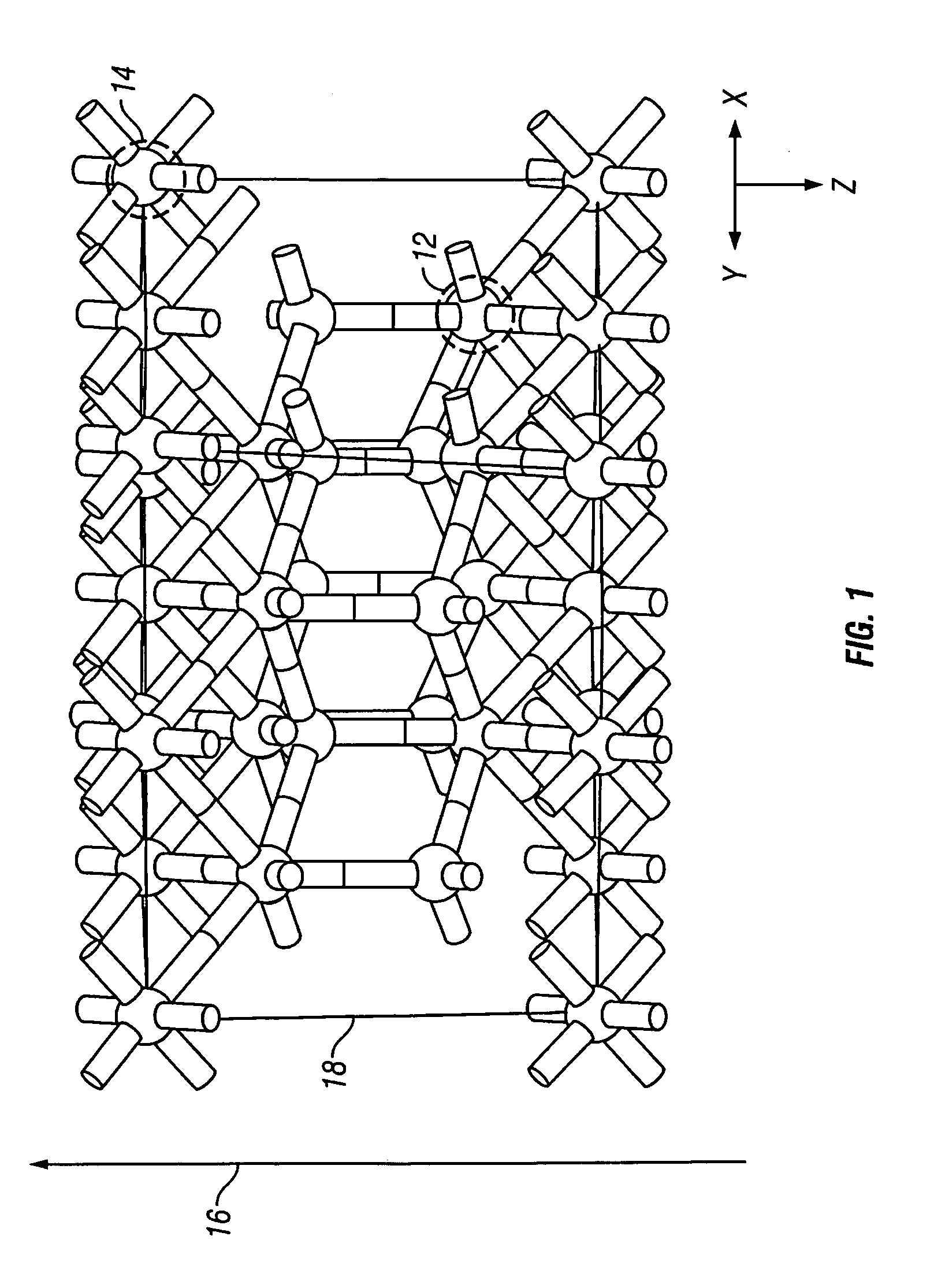

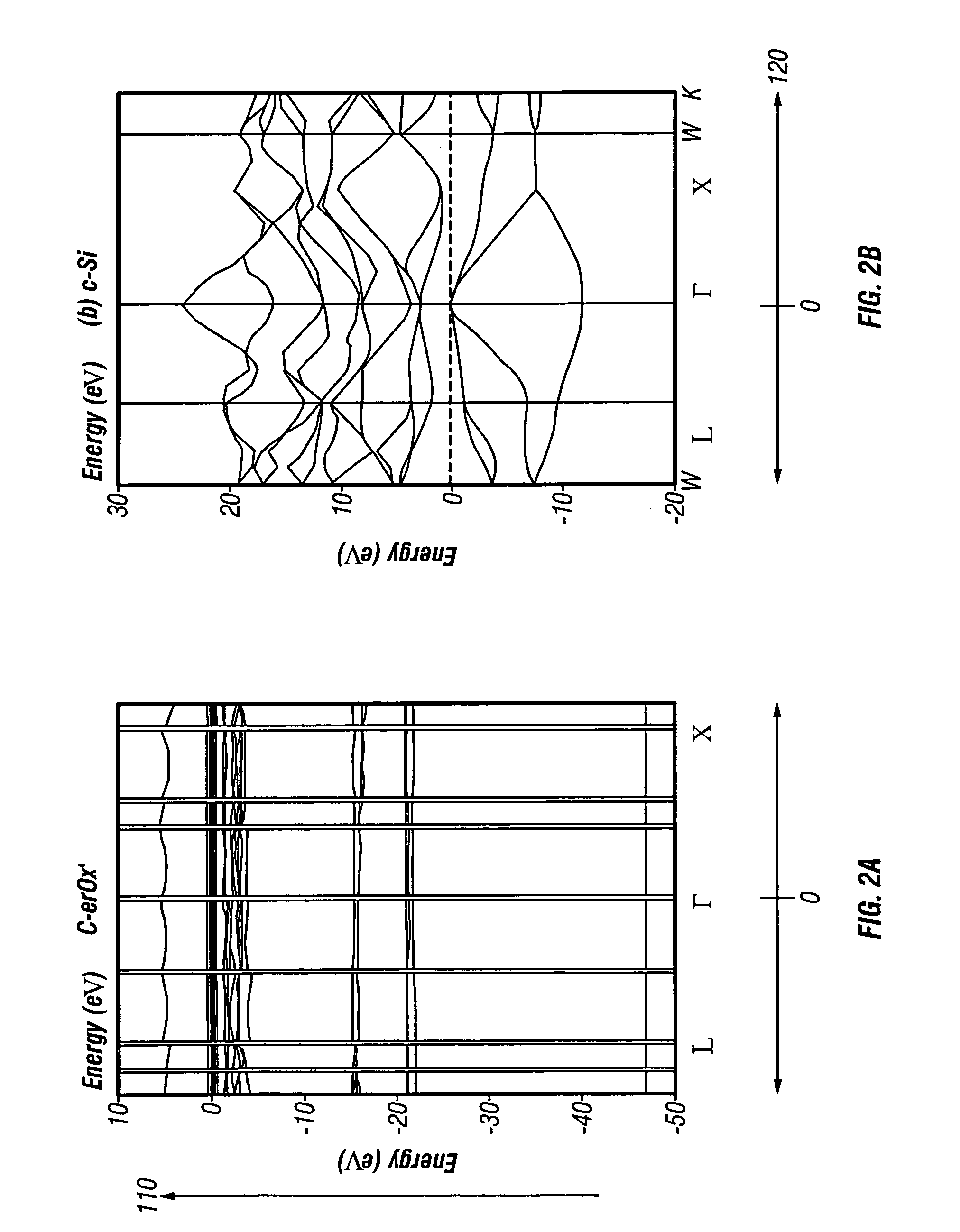

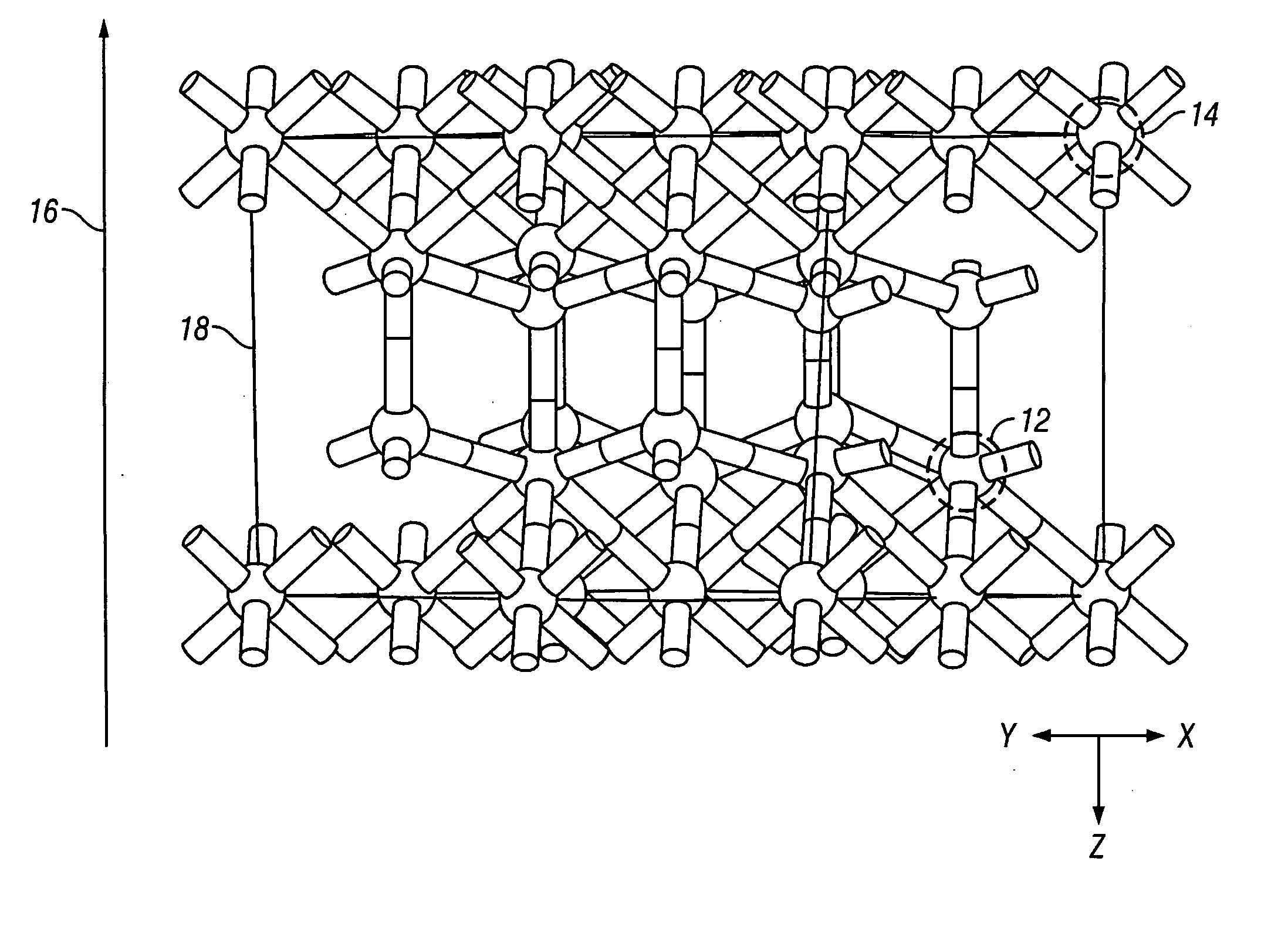

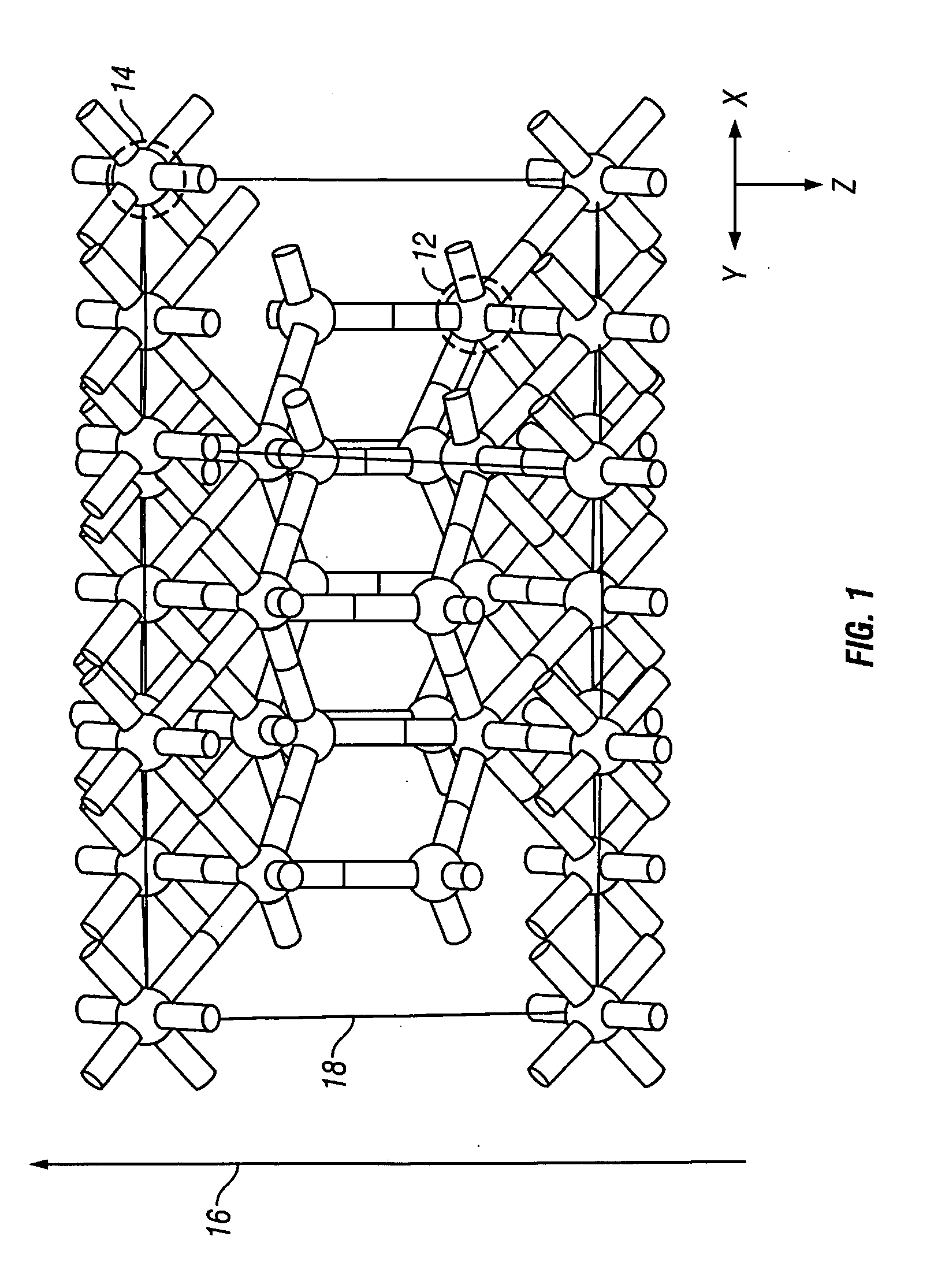

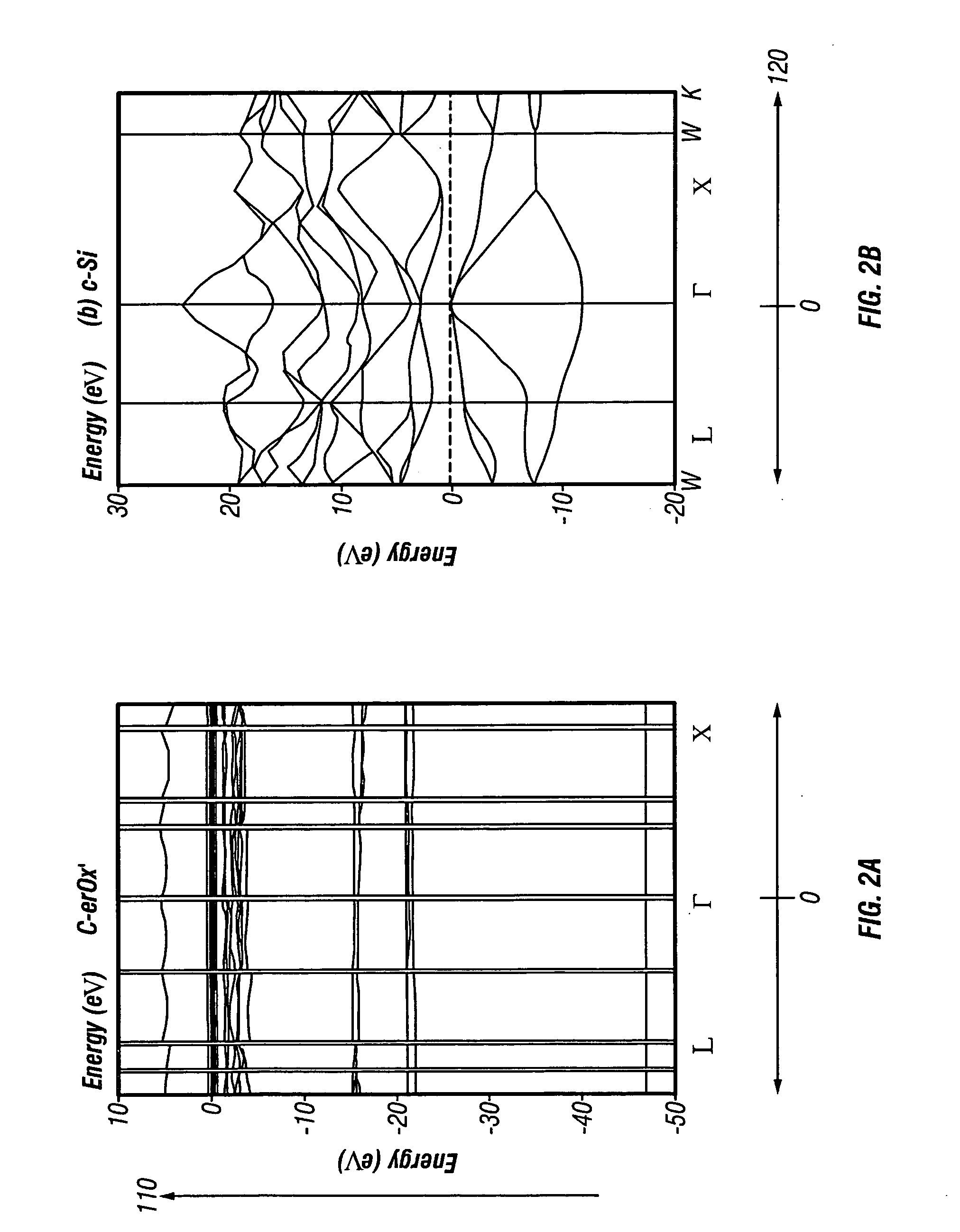

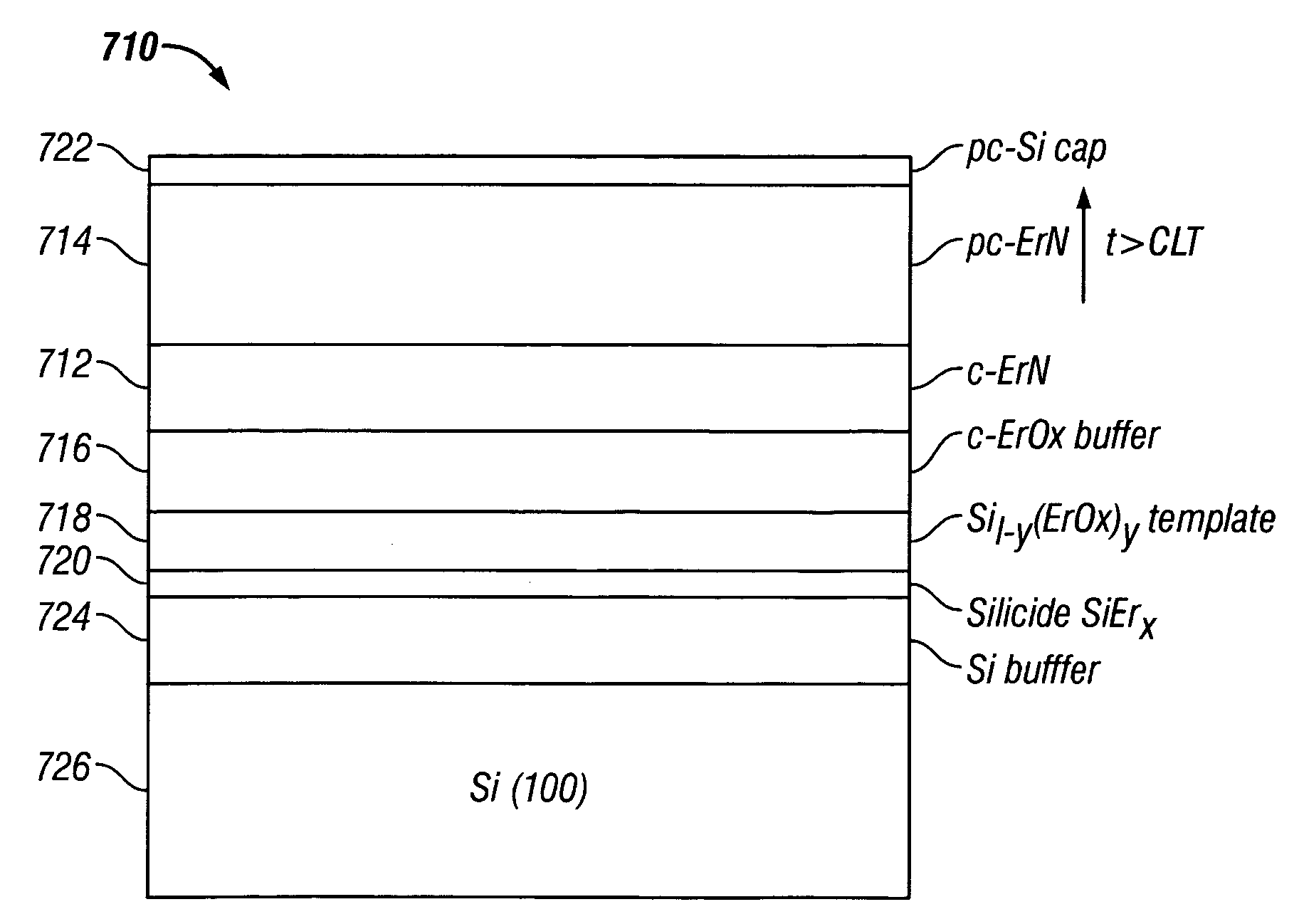

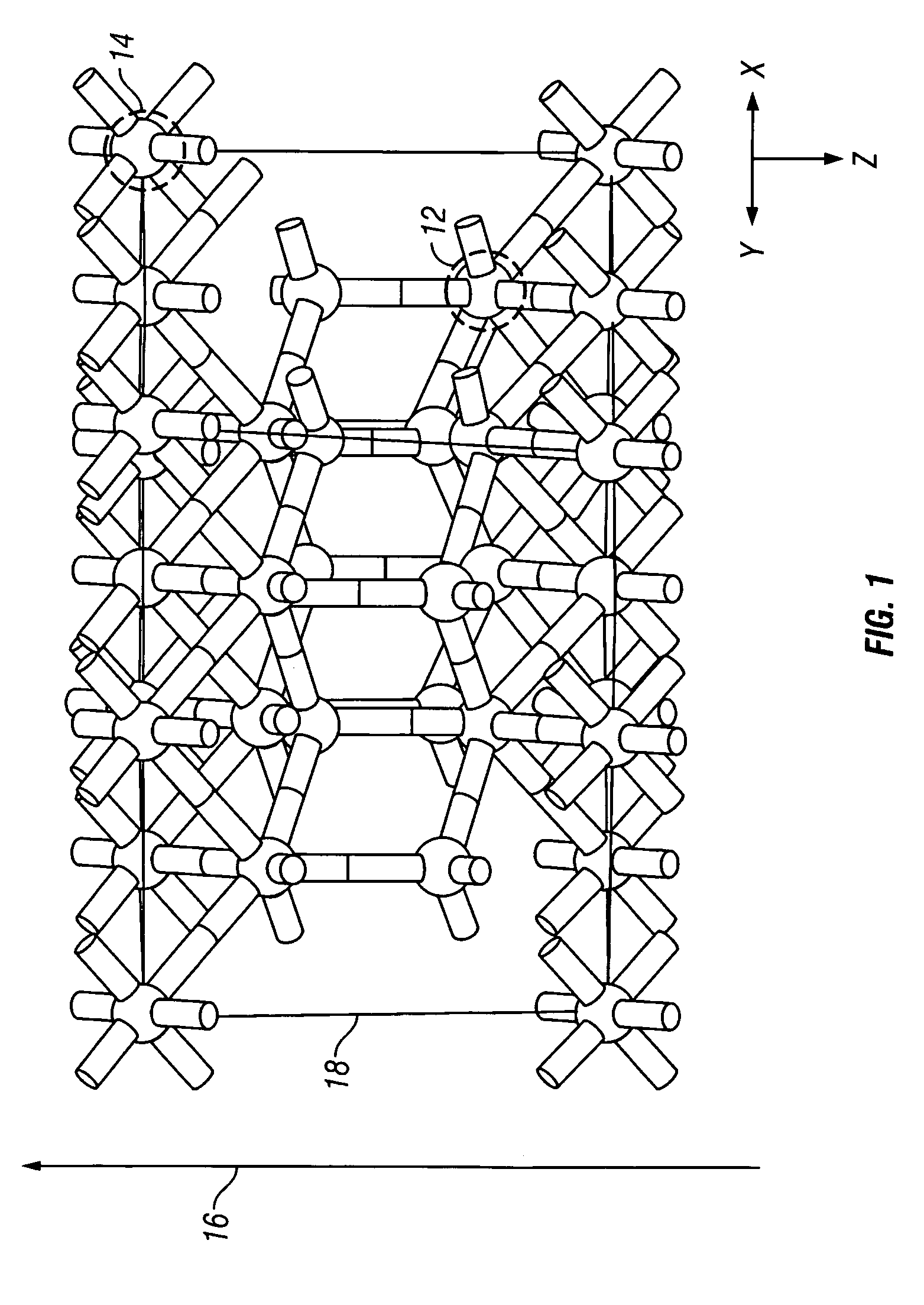

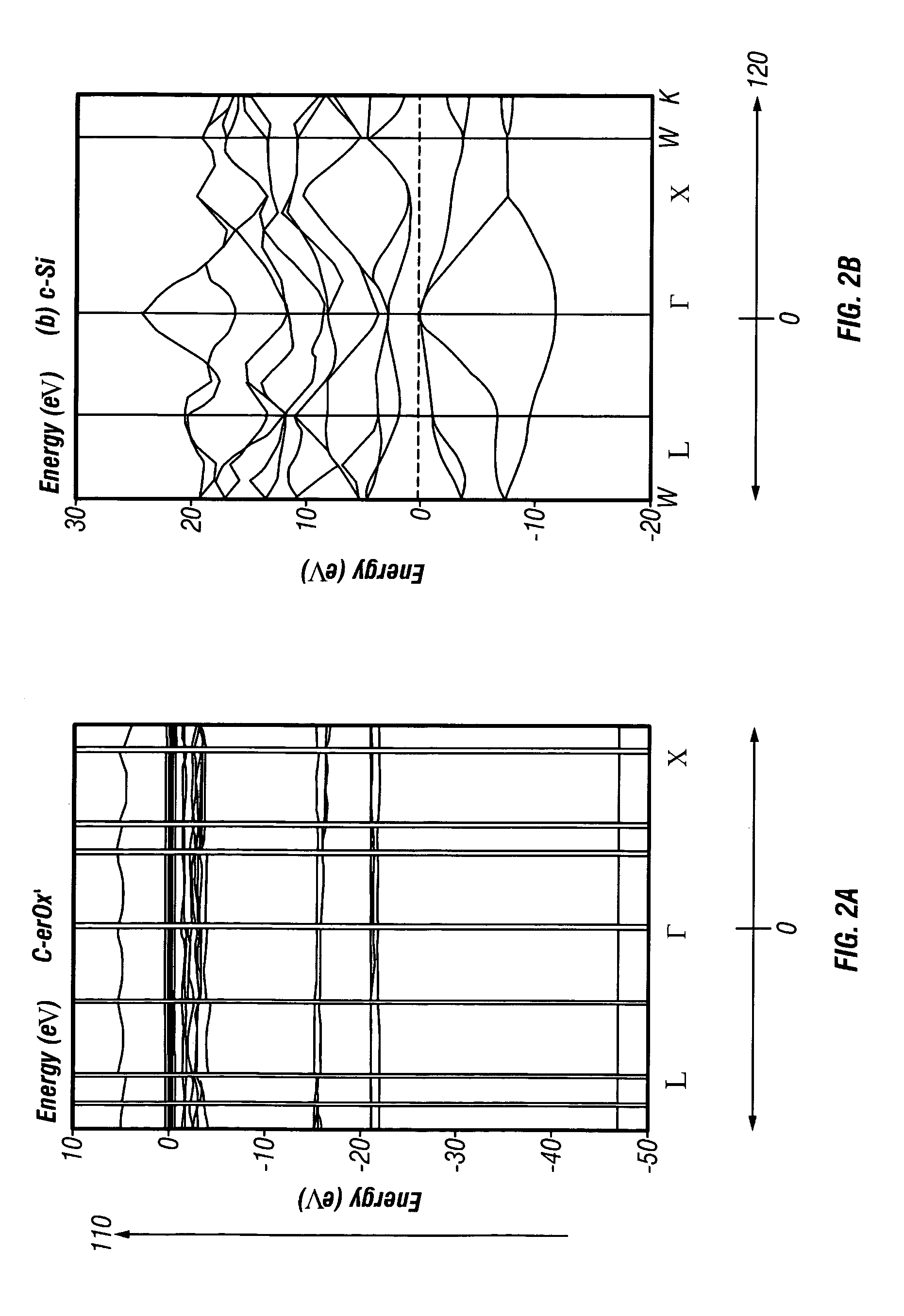

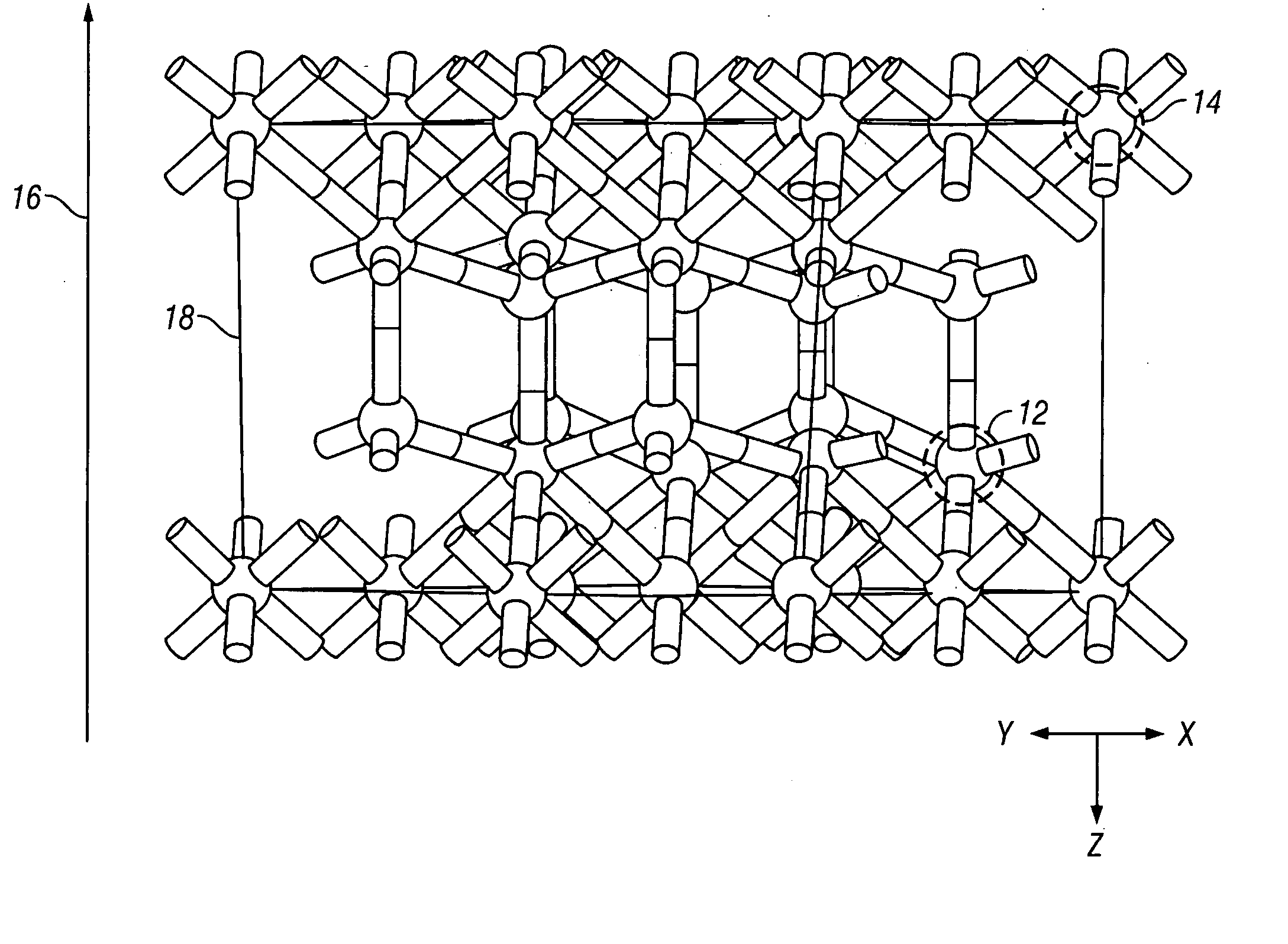

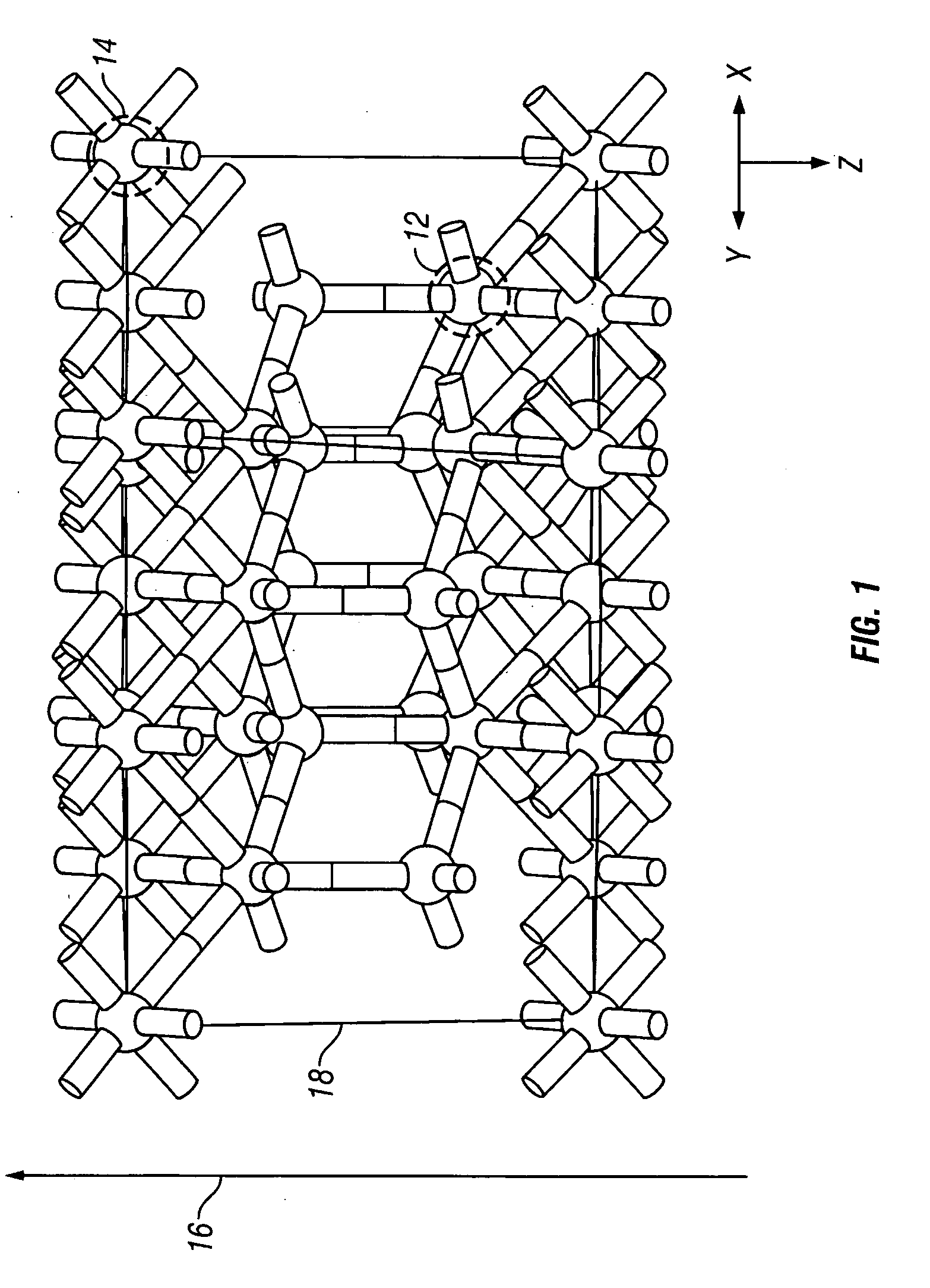

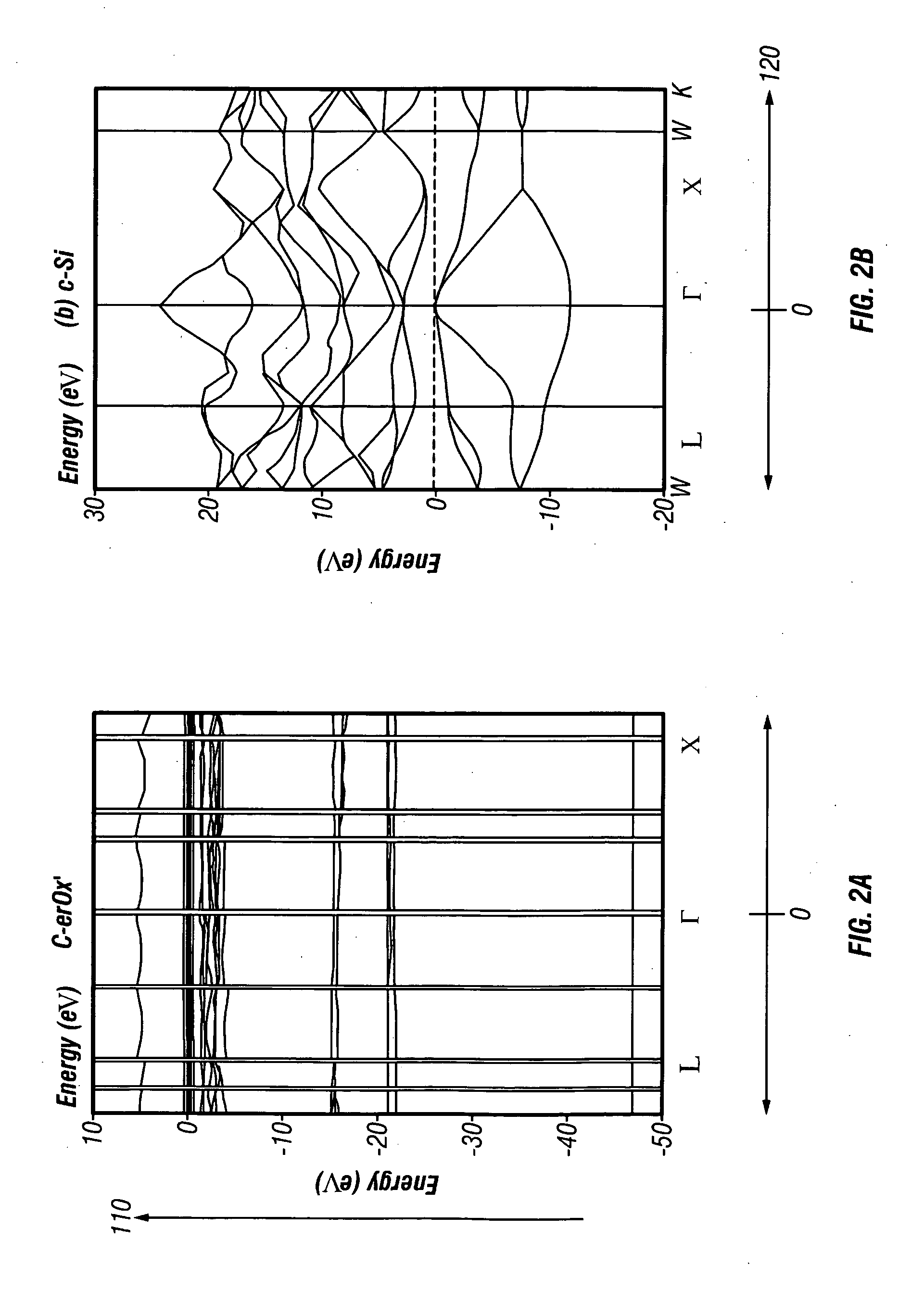

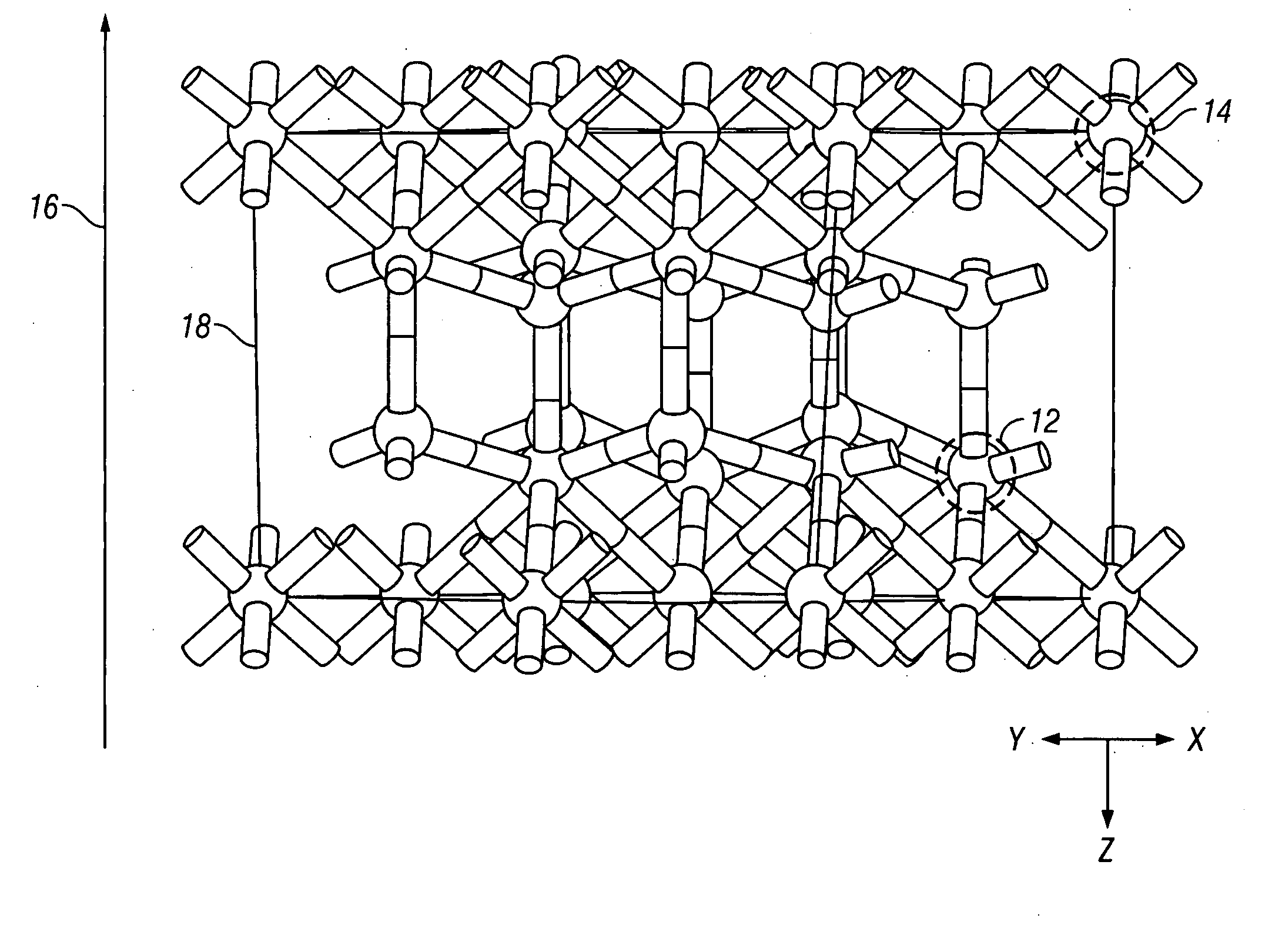

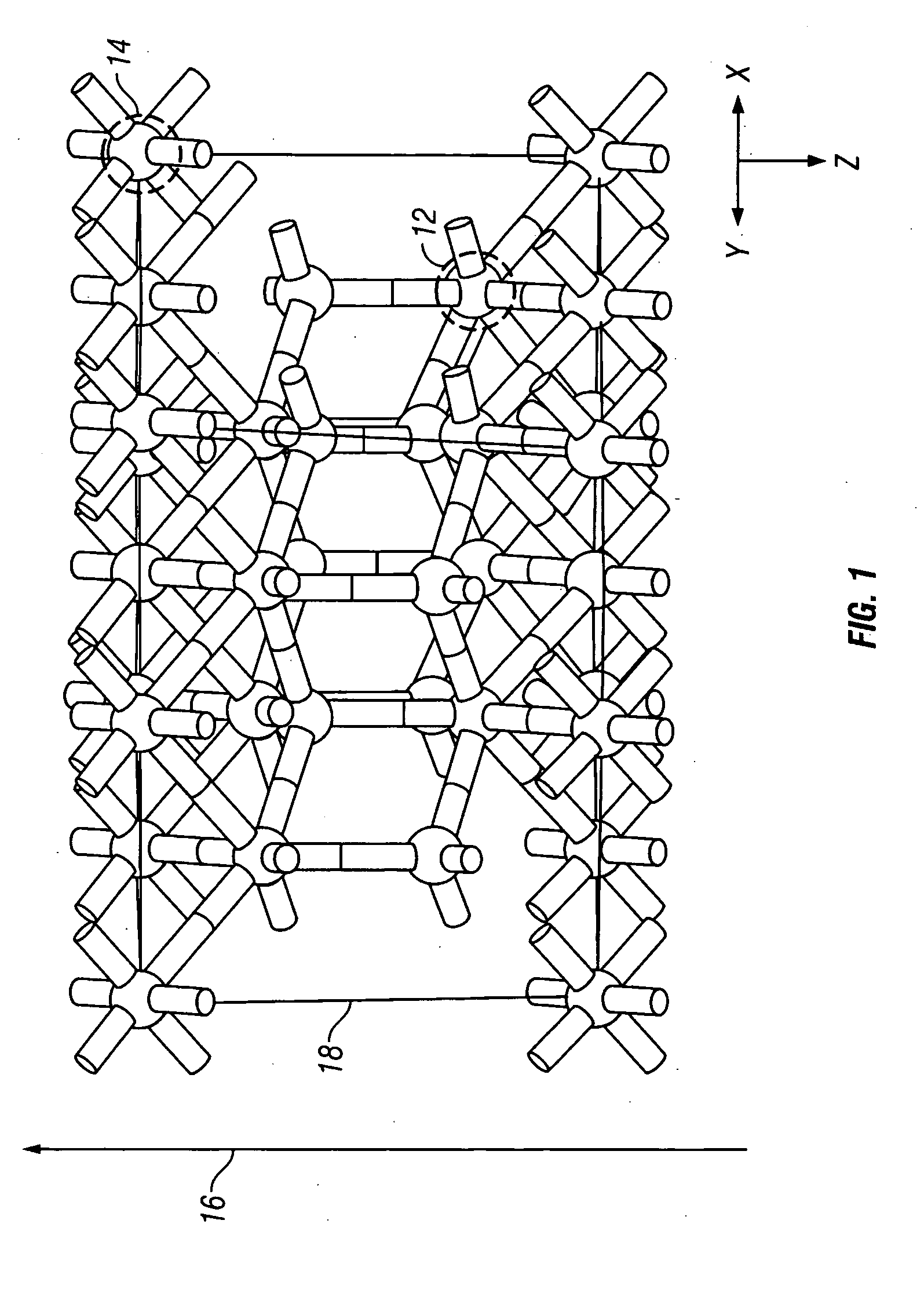

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)-(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

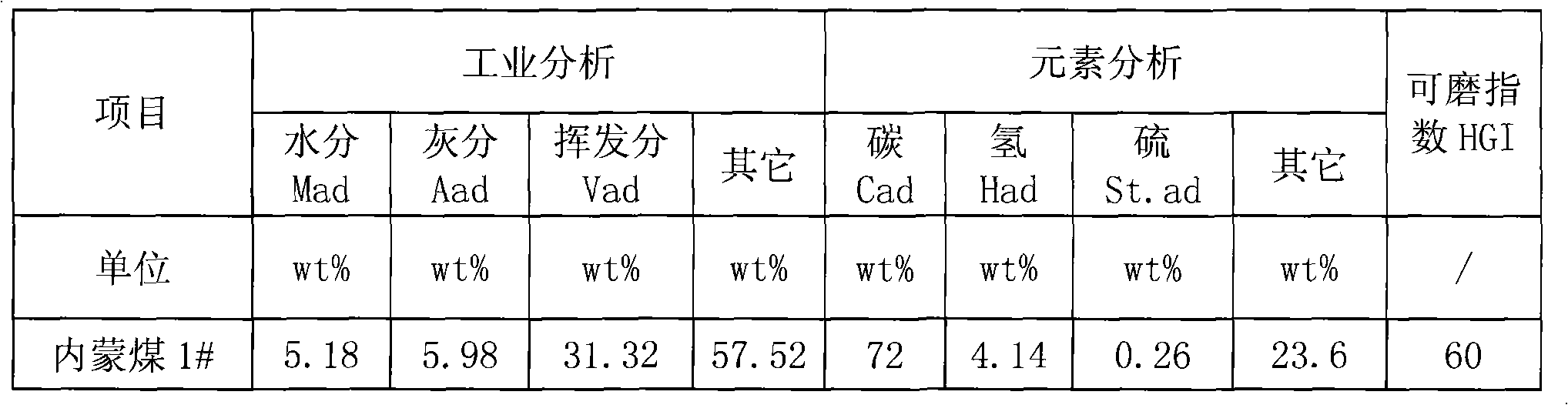

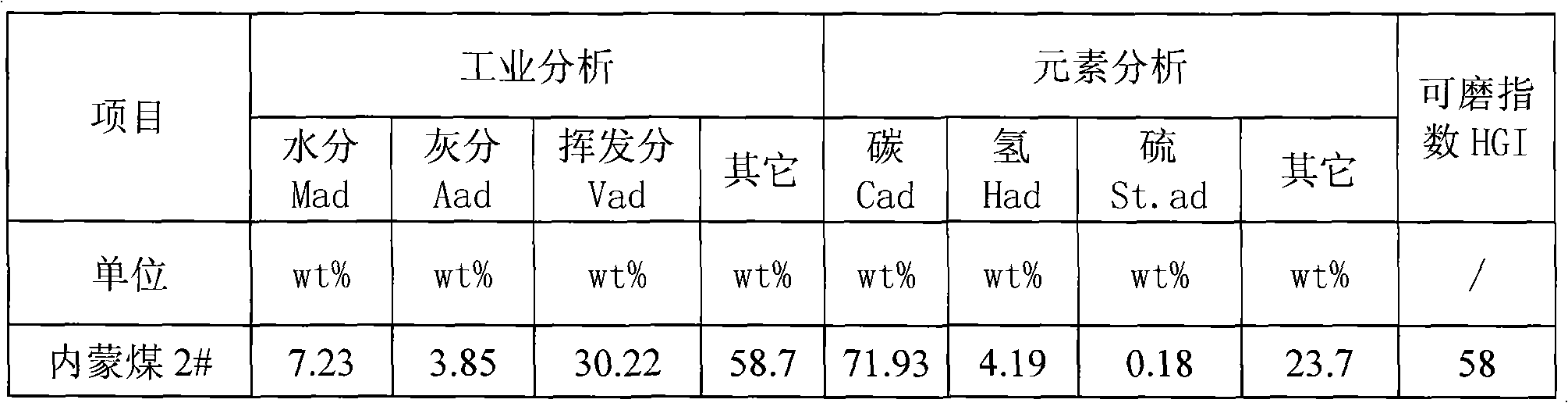

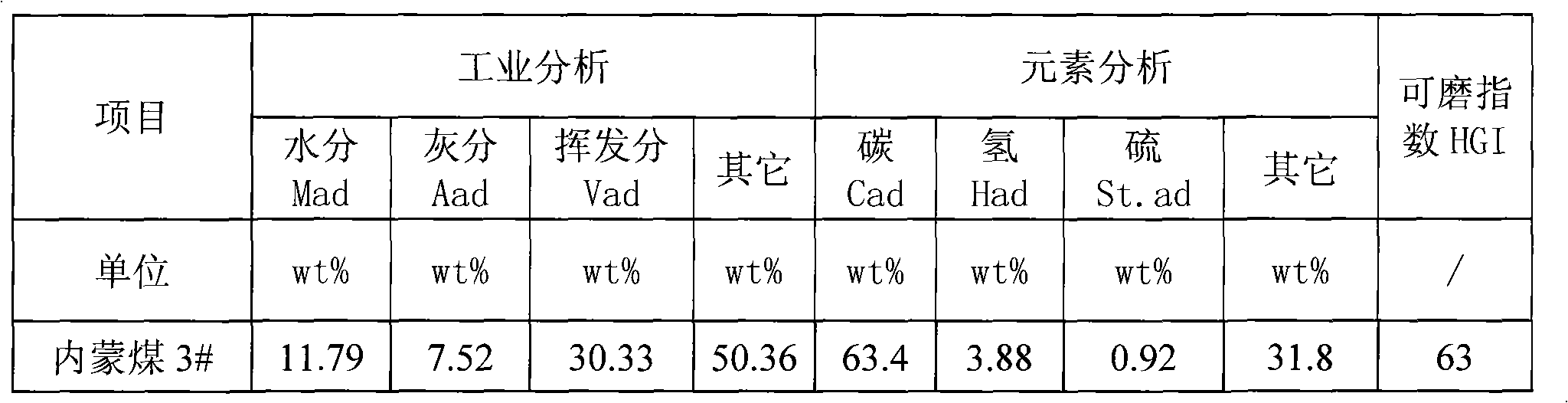

Water-coal-slurry additive and preparation method thereof

ActiveCN101550369AImprove hydrophilicityReduce viscosityLiquid carbonaceous fuelsAlkylphenolMethyl group

The invention provides a water-coal-slurry additive and a preparation method thereof. The additive is compounded by anionic surfactant naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and non-ionic surfactant alkylphenol polyethenoxy ether (methyl) acrylic ester according to mass ratio of 8:1:1 to 1:8:1. The invention uses the naphthalene sulfonic acid formaldehyde condensation product sodium salt, lignosulphonate and alkylphenol polyethenoxy ether (methyl) acrylic ester in the preparation technology of water-coal-slurry, and the additive has wide adaptability to coal, in particular to coal with low degree of metamorphism. When ternary compound additive reaches 0.1-1wt percent of the weight (dry basis) of the coal, the water-coal-slurry with the content of coal dust being 62-70wt percent can be prepared. The slurry has good fluidity, lower apparent viscosity and favorable steady state stability. The ternary compound additive is simple in production process, excellent in performance and wide in the range of applicable coal.

Owner:ENN XINNENG BEIJING TECH

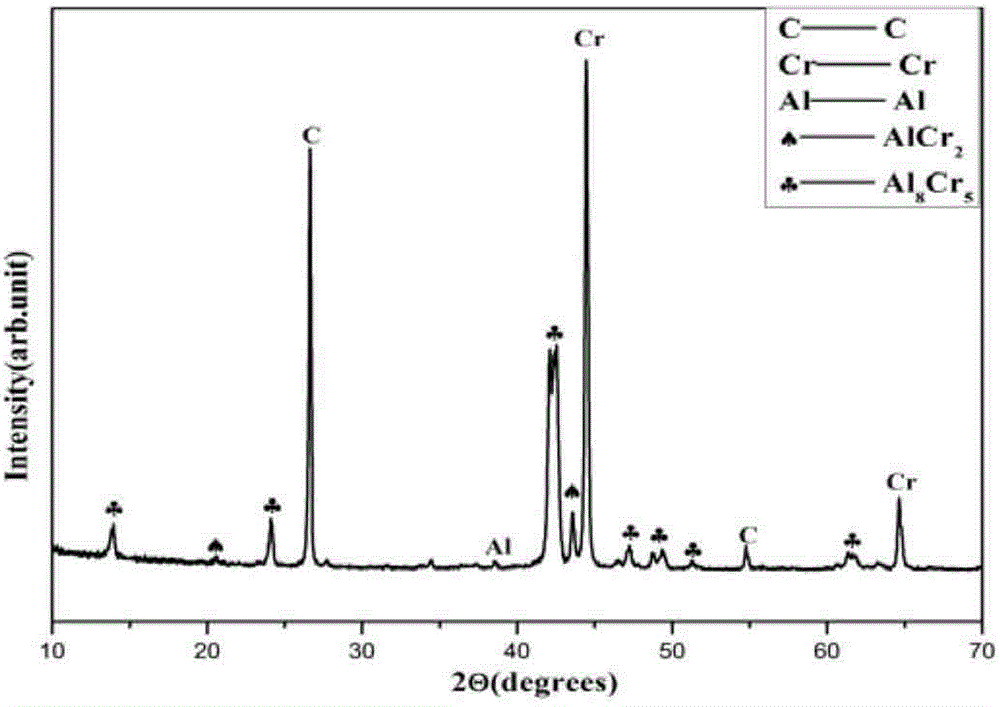

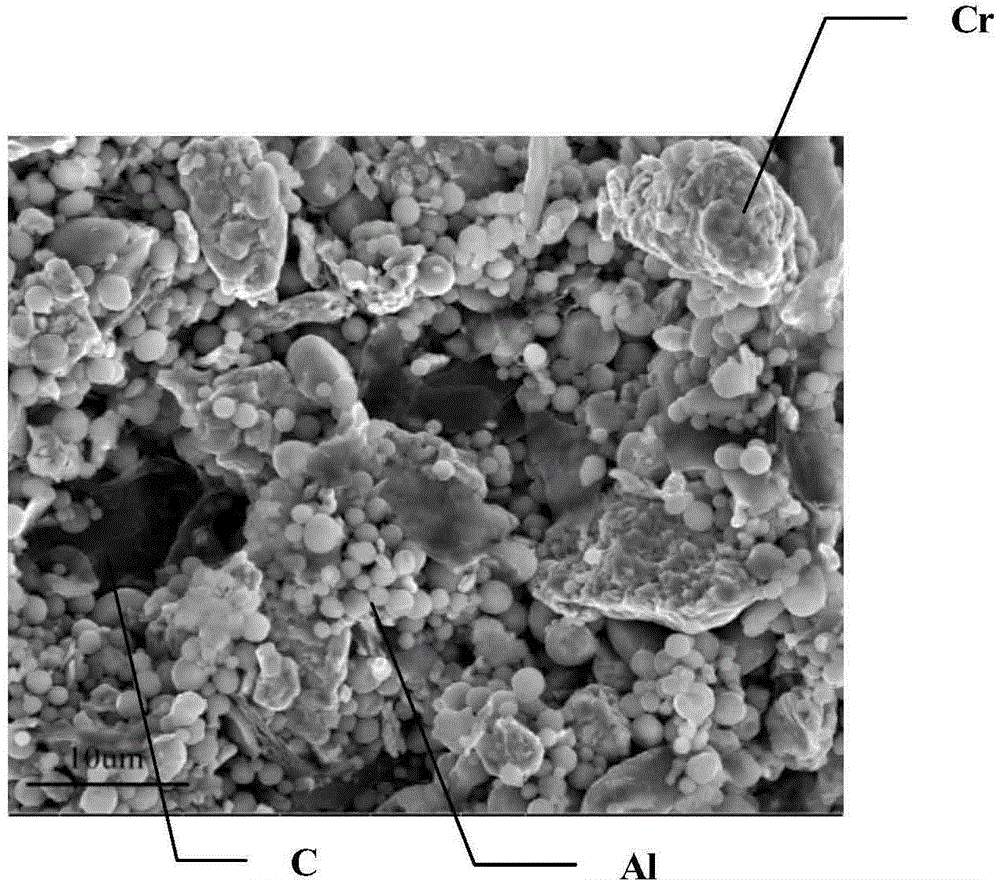

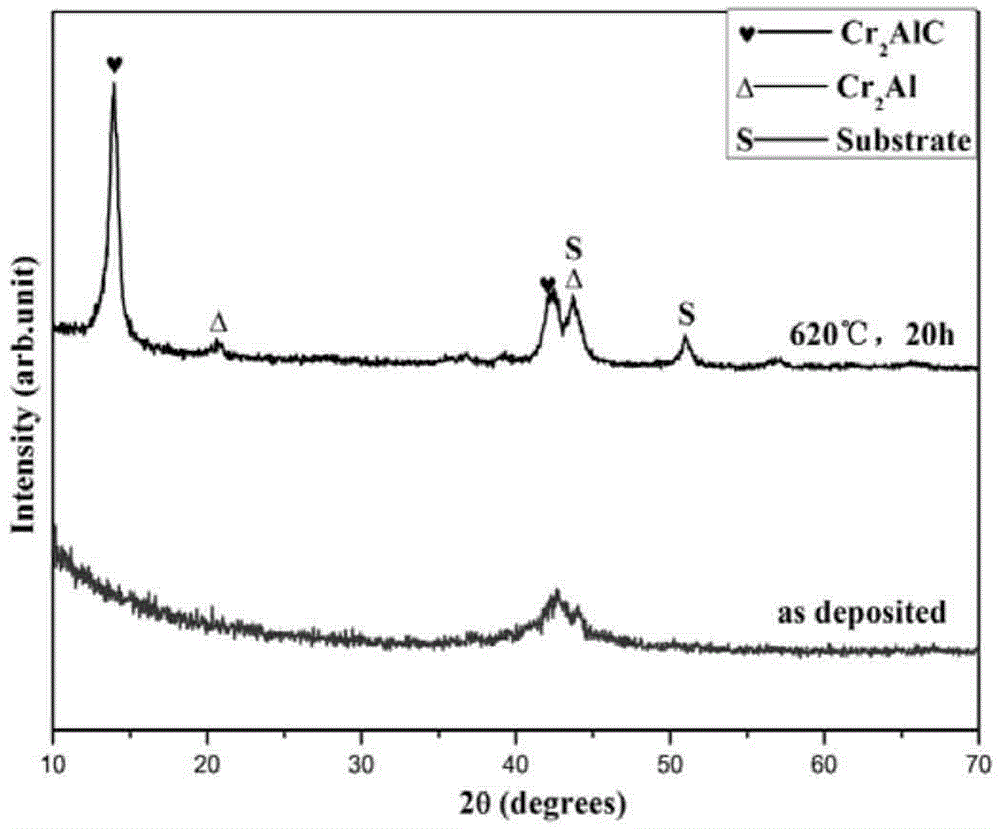

Method for efficiently preparing ternary laminar MAX phase ceramic coating layer at low temperature

InactiveCN104894516AReduce manufacturing costSimple processVacuum evaporation coatingSputtering coatingGas phaseCeramic coating

The invention relates to a preparation technology of a ternary laminar MAX phase ceramic coating layer, and in particular, provides a method for efficiently preparing a ceramic coating layer with a ternary laminar MAX phase as a main phase at low temperature by a physical vapor deposition technology. M, A and X element powders with a certain mol ratio or electrically conducted binary and ternary compound powders are uniformly mixed and pressed to produce a cathode target at a certain temperature; the physical vapor deposition (multi-arc ion plating or magnetron sputtering) is adopted under optimized process conditions; and then, the crystallization heat treatment is adopted, thereby realizing the preparation of the ceramic coating layer with the MAX phase as the main phase by a two-step method. The method has the characteristics of deposition at room temperature, easy adjustment of target components, simple process, high deposition efficiency and low cost, has obvious advantages in the aspect of preparing the MAX phase coating layer, can solve the problems of high cost and complicated process in traditional preparation of the MAX phase coating layer, and promotes the large-scale industrial production of the MAX phase coating layer.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

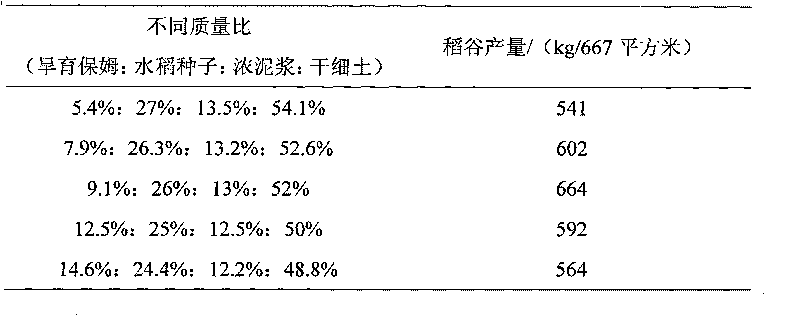

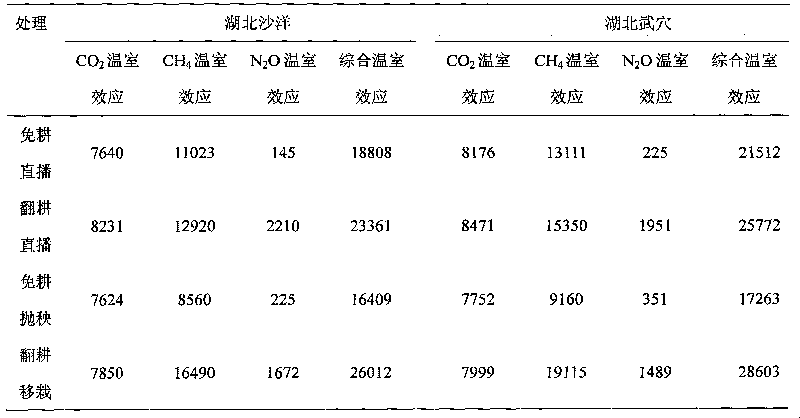

No-tillage seedling-throwing overall aerobic cultivation method for oil crop-medium rice fixed compartment ditch

The invention belongs to the field of rice cultivation, and particularly relates to a cultivation method suitable for no-tillage rice in a fixed compartment of an oil crop-medium rice field. The cultivation method comprises the following steps that: (1) rice seeds are coated by using dry-raised nurse, thick mud and dry fine soil serving as coating agents, wherein the components comprise 7.9 to 12.5 percent of dry-raised nurse, 25 to 26.3 percent of rice seeds, 12.5 to 13.2 percent of thick mud with 37 percent of water content and 50 to 52.6 percent of dry fine soil with 3 percent of water content in percentage by mass; the rice field is finished as required and the soil moisture is kept; and keeping the seedling age at 15 to 18 days; (2) the compartment width of the oil crop field is 1.2 meters, the width of the ditch is 0.3 meter, and the depth of the ditch is 0.25 meter; the rape seedlings are applied to the field; a ternary compound fertilizer of which pure nutrients comprise 15 percent of N, 15 percent of P2O5 and 15 percent of K2O is applied, and 30 kilograms of pure nitrogen is applied in each mu; 5.80 kilograms of zinc is applied in each mu; and 4.8 kilograms of boron fertilizer is applied in each mu, and the ditch is kept full of water; (3) rice seedlings with 50 to 100 grams of soil in each seedling in 15 to 18 days are directionally thrown according to a row space of 20 centimeters; and (4) the ditch is kept with water and the compartment surface has no water after throwing the seedlings till the heading stage, and dry and wet alternated cultivation is adopted from the grain filling stage to the maturation stage. Compared with the conventional method, the yield is averagely increased by 8.7 percent.

Owner:HUAZHONG AGRI UNIV

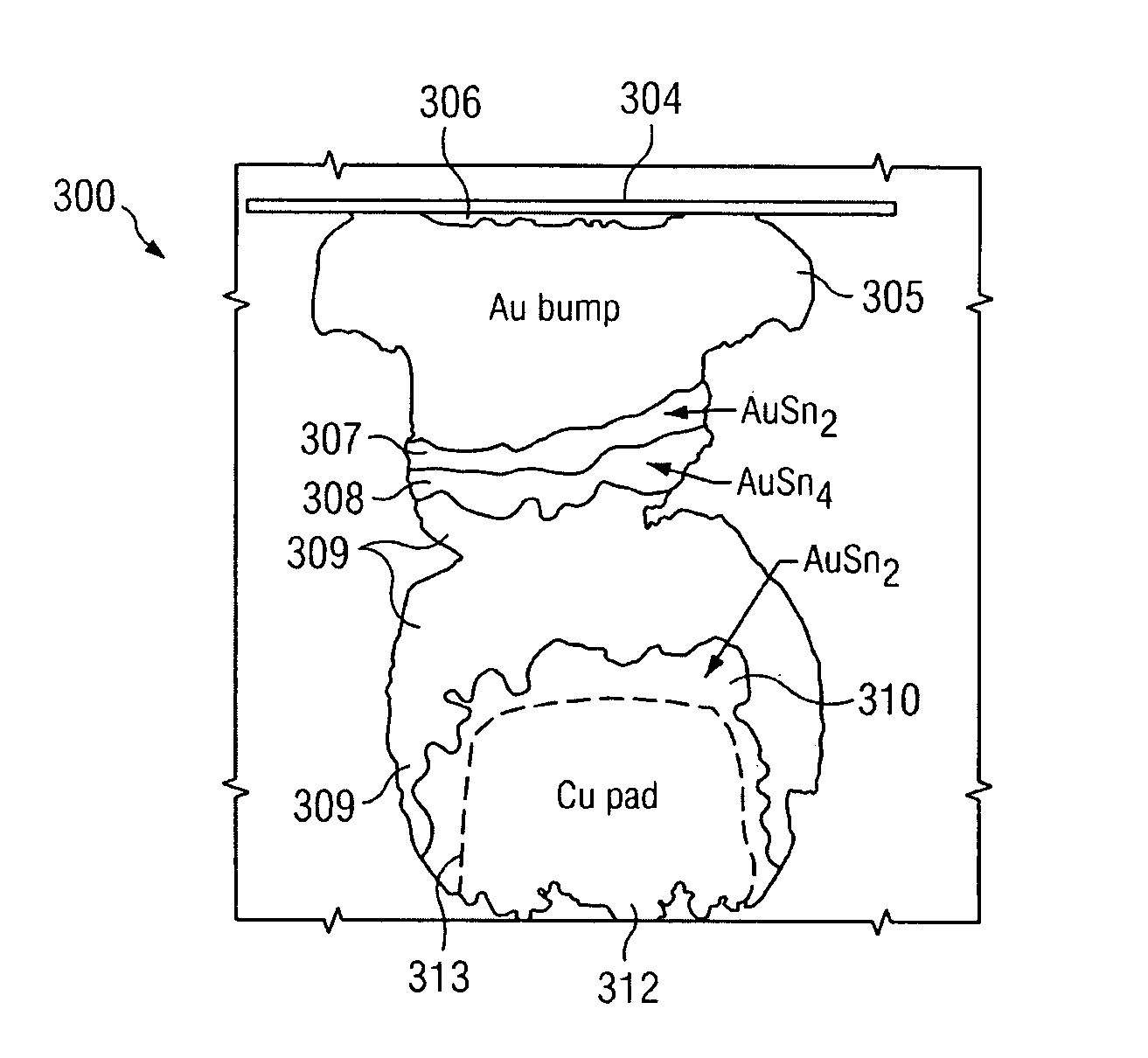

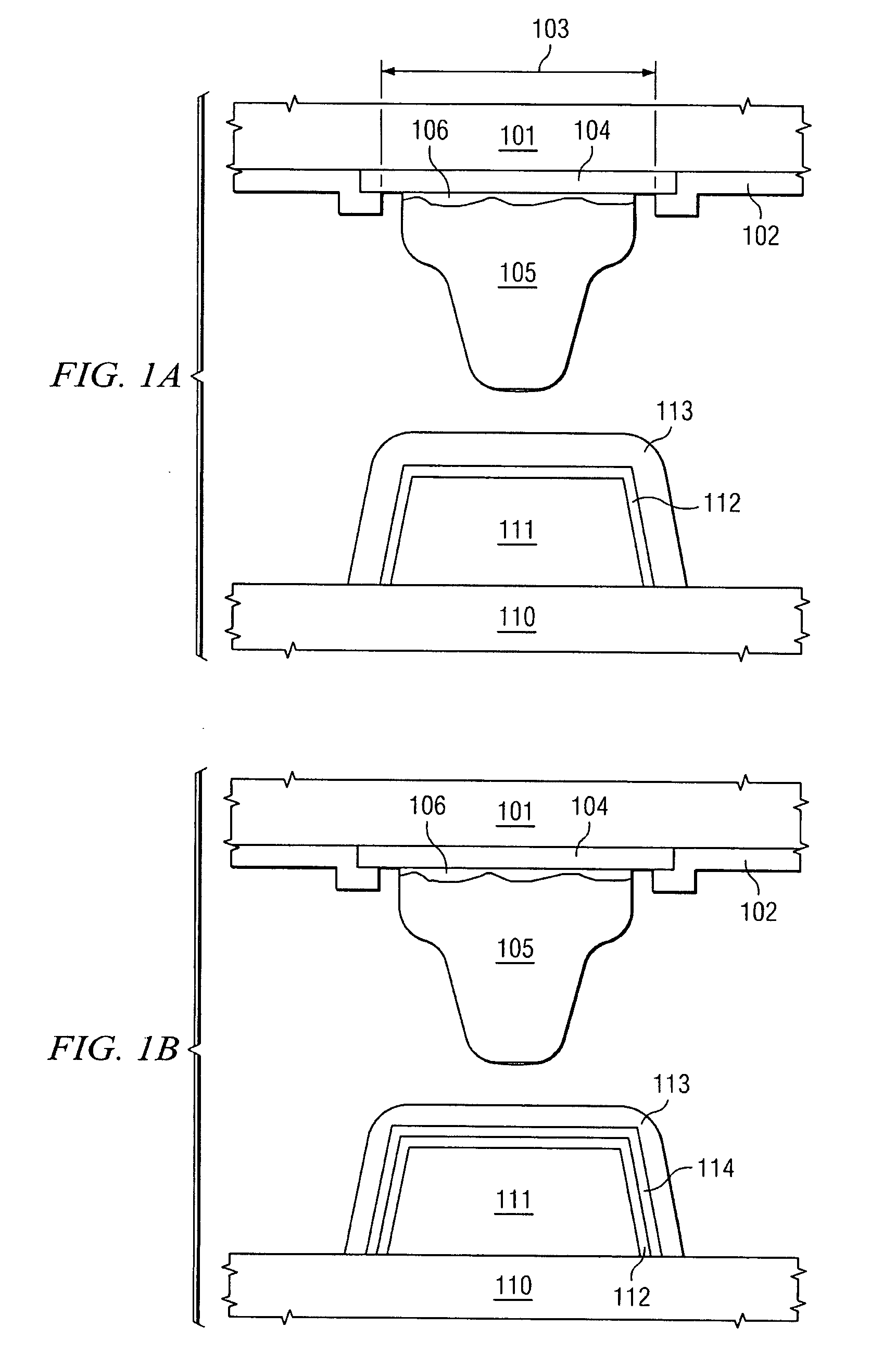

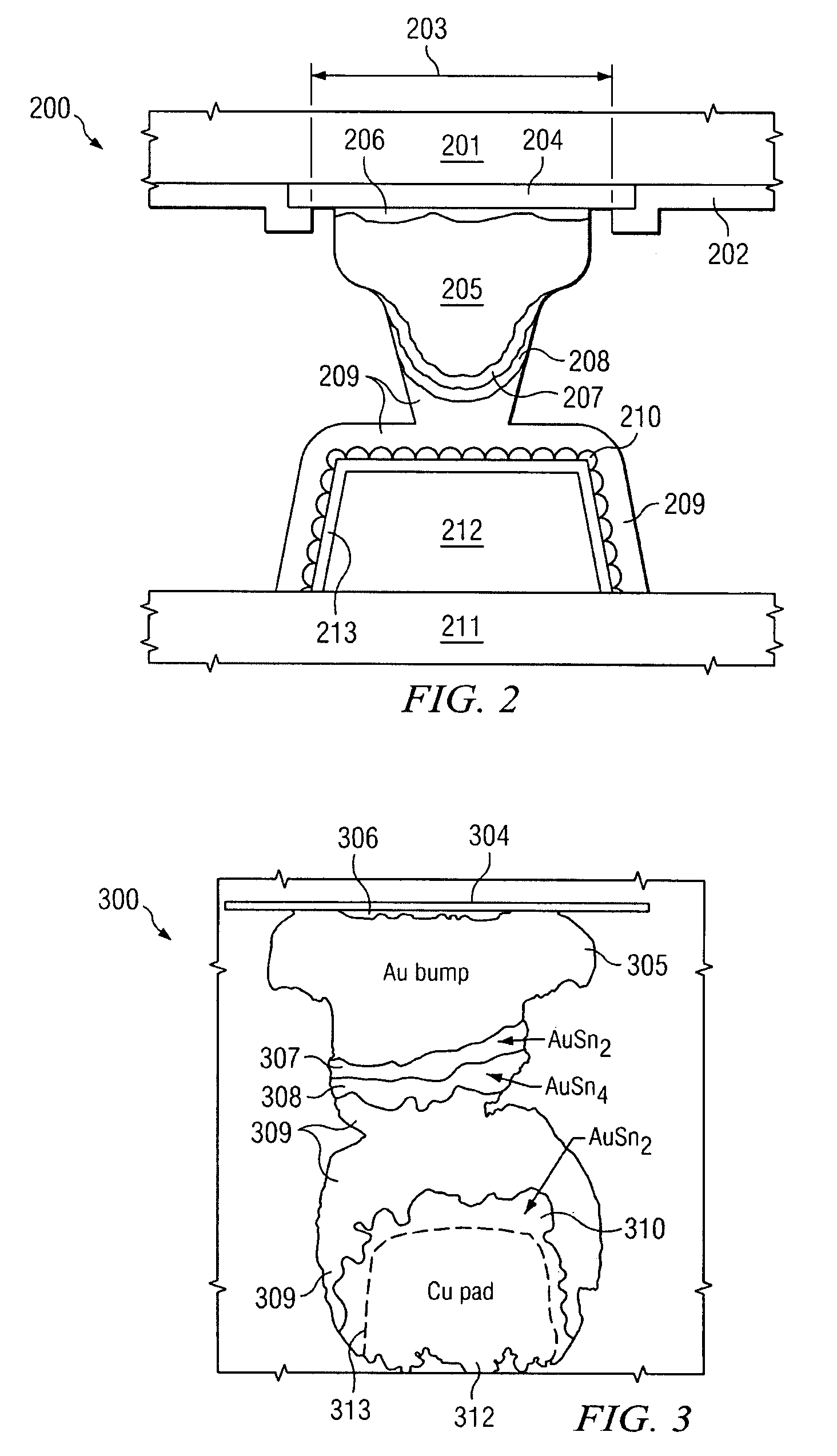

Stable gold bump solder connections

ActiveUS7939939B1High dissolution rateLess brittleSemiconductor/solid-state device detailsSolid-state devicesSolid solutionIntermetallic

A metallic interconnect structure (200) for connecting a gold bump (205) and a copper pad (212), as used for example in semiconductor flip-chip assembly. A first region (207) of binary AuSn2 intermetallic is adjacent to the gold bump. A region (208) of binary AuSn4 intermetallic is adjacent to the first AuSn2 region. Then, a region (209) of binary gold-tin solid solution is adjacent to the AuSn4 region, and a second region (210) of binary AuSn2 intermetallic is adjacent to the solid solution region. The second AuSn2 region is adjacent to a nickel layer (213) (preferred thickness about 0.08 μm), which covers the copper pad. The nickel layer insures that the gold / tin intermetallics and solutions remain substantially free of copper and thus avoid ternary compounds, providing stabilized gold bump / solder connections.

Owner:TEXAS INSTR INC

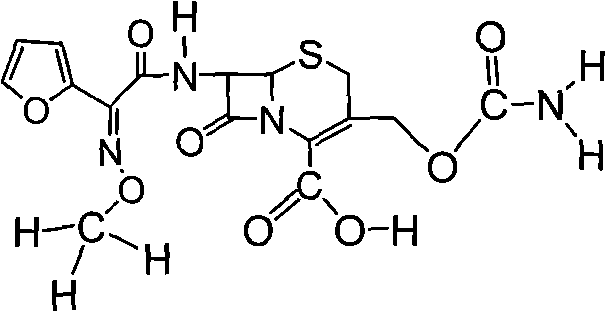

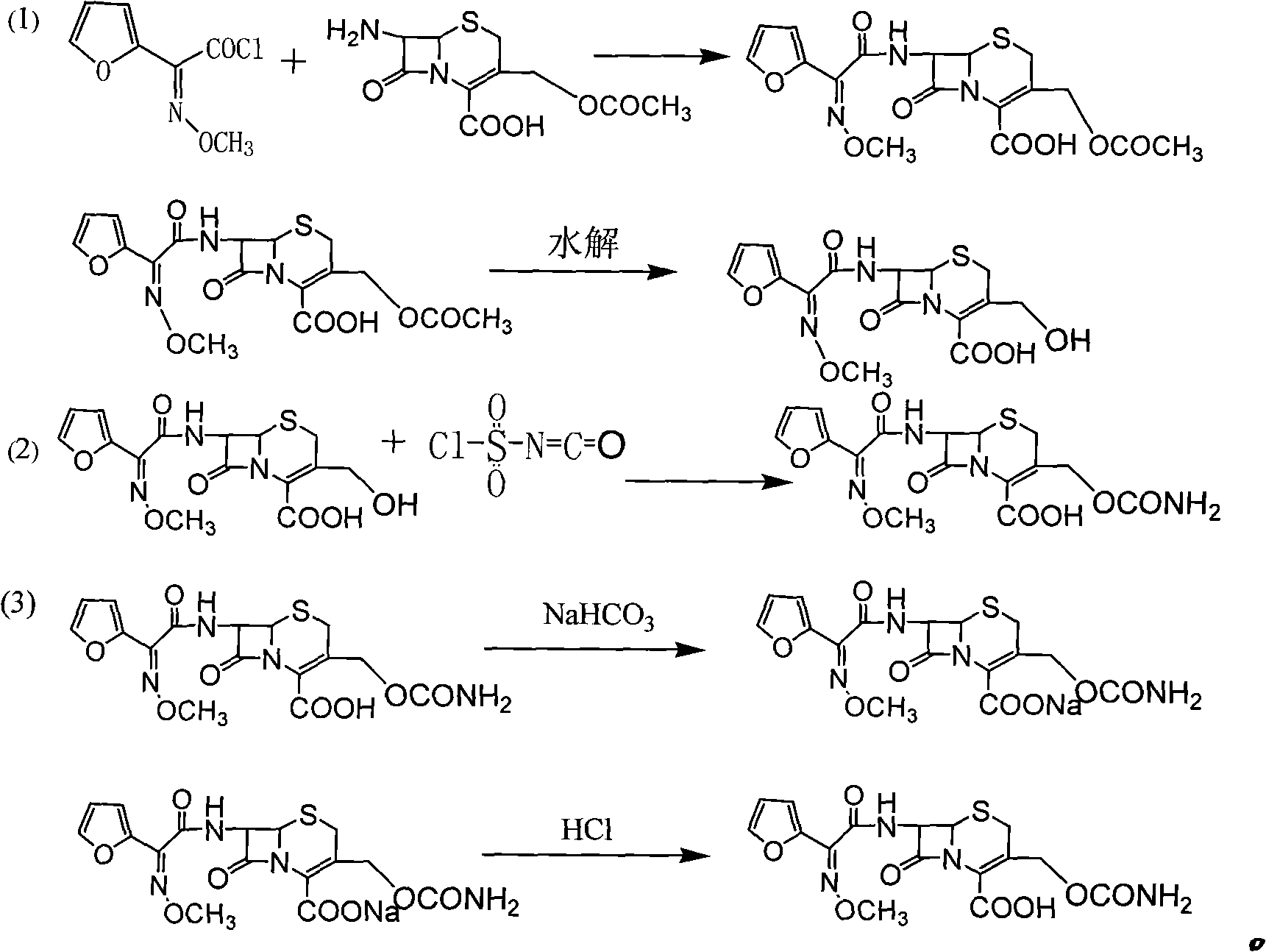

Preparation method of high-purity cefuroxime acid

The invention discloses a preparation method of high-purity cefuroxime acid which is an intermediate for synthesizing second-generation cephalosporins cefuroxime sodium and cefuroxime axetil. The preparation method comprises the following steps: based on 7-aminocephalosporanic acid (7-ACA) as a raw material, carrying out an N-acylation reaction on the 7-ACA and furoyl acetylcholine at the 7-position; at a low temperature, hydrolyzing 3-acetyl with a sodium hydroxide solution, crystallizing, filtering and drying so as to obtain the intermediate 3-deformamido cefuroxime acid (DCC); quantitatively adding the DCC in a tetrahydrofuran solvent, dropwise adding chlorosulfonyl isocyanate for a nucleophilic addition reaction so as to generate chlorosulfonyl cefuroxime acid, and adding purified water for hydrolysis so as to prepare a cefuroxime acid reaction liquid; adding sodium bicarbonate for salifying; removing by-reactant lactone and other unsaponifiable impurities in the reaction liquid with a ternary compound extracting agent of dichloromethane, ethyl acetate and tetrahydrofuran, layering, and adding hydrochloric acid in a water phase for acidification; adding the ternary compound extracting agent to extract and separate out the cefuroxime acid; and removing water-soluble impurities, crystallizing and filtering a distilled organic phase, and then drying so as to obtain the high-purity cefuroxime acid with the purity of more than or equal to 99%.

Owner:四平市精细化学品有限公司

Preparation method of aluminium oxide-silicon oxide-zirconium oxide ternary compound aerogel

InactiveCN104556968ALarge specific surface areaImprove high temperature resistanceSilicon oxideSolvent

The invention relates to a preparation method of heat-insulating aluminium oxide-silicon oxide-zirconium oxide ternary compound aerogel. The preparation method comprises the following steps: using inorganic aluminium salt, silicon salt, inorganic zirconium salt as precursors, an alcohol solvent and water as reaction solvents, and epoxide as a gel accelerator, performing supercritical fluid drying process to obtain the block-shaped ternary compound aerogel with excellent performance. The obtained ternary compound aerogel sample is low in density, good in elasticity and stable in performance; compared with single aluminium oxide aerogel, single silicon oxide aerogel and single zirconium oxide aerogel, the ternary compound aerogel can bear higher temperature and is more stable in quality; through excellent high temperature stability, the application range of the ternary compound aerogel is extended, so that the ternary compound aerogel can be used in the field of heat insulation.

Owner:BEIJING UNIV OF CHEM TECH

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

InactiveUS7273657B2Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Owner:IQE

Composite organism slow release fertilizer product and producing method

InactiveCN101054314AOvercome the disadvantages of easy exceeding the standardOvercoming pollutionAgriculture gas emission reductionOrganic fertilisersMoisturePollution

The present invention relates to a chemical fertilizer and a manufacturing method thereof, specifically to a composite biological slow-release fertilizer product and its manufacturing method. Said composite biological slow-release fertilizer product in accordance with the present invention comprises granular fertilizer cores and coatings packing outside of the fertilizer cores, wherein said fertilizer cores are grains formed by a mixture of ternary compound fertilizer and the slow-release components which are mixture of urea and humic acids. Said coatings comprises at least animal oil and fat, bone meal and bacillus components. By replacing steam for heat spraying granulation with urea and humic acids melting complexing liquor, the manufacturing method in accordance with the present invention resolves the problem of moisture exceeding standard in 'three (organics, inorganics and bilogies) in one' fertilizer production and achieves the goal of nitrogen slow-release. At the same time, by adopting animal oil and fat and bone meal which can provide food such as lipids to animalcules and are easy to degrade as bacillus preparation carrier, said method overcomes the problems that the mixing of bacillus preparation and other fertilizer components leads to bacterial agent pollution and bacterium poisoning phenomenna. The present invention provides a 'three (organics, inorganics and bilogies) in one' composite biological slow-release fertilizer product which exhibits quick results, slow results and long results integrally, and a manufacturing method thereof.

Owner:王怀欣

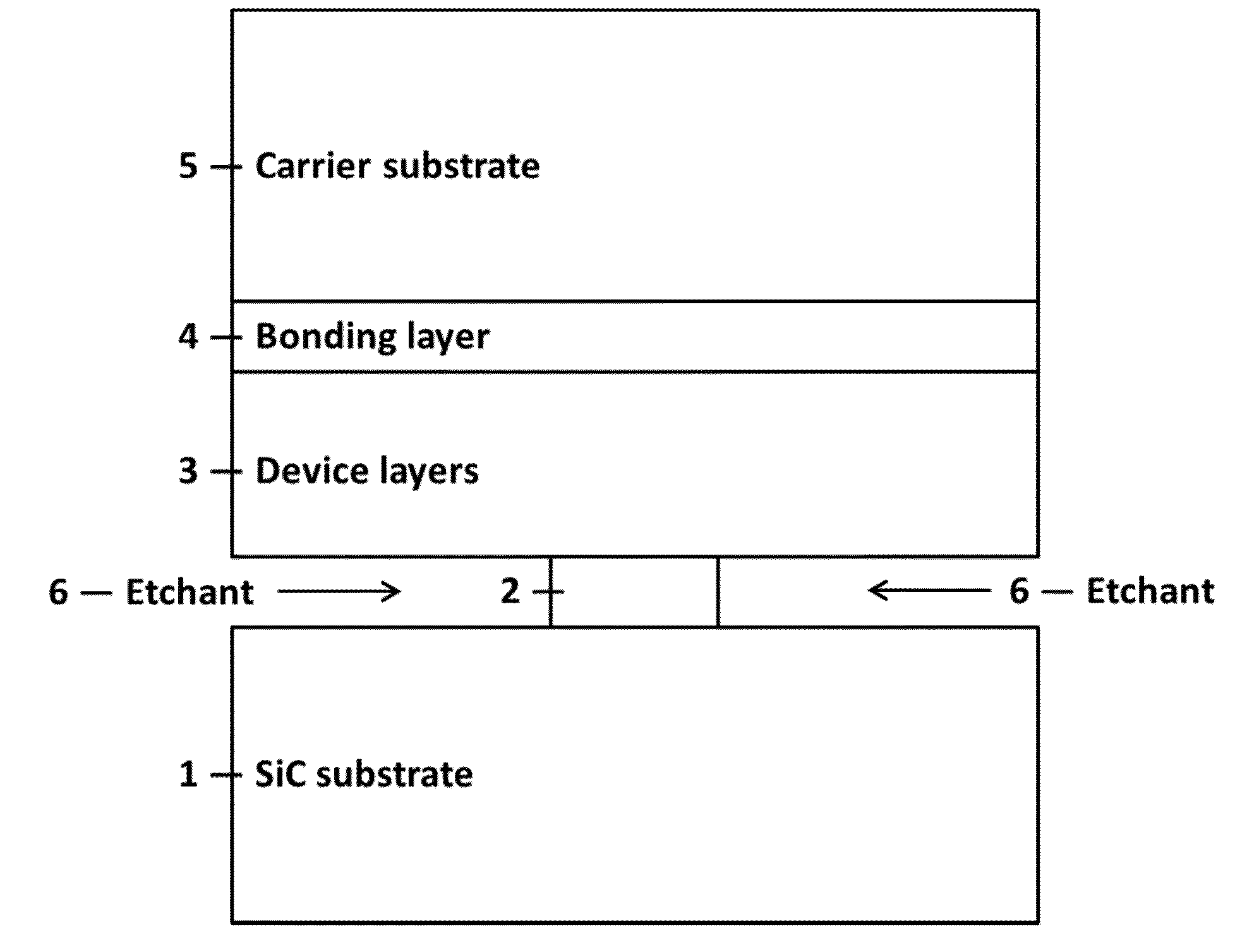

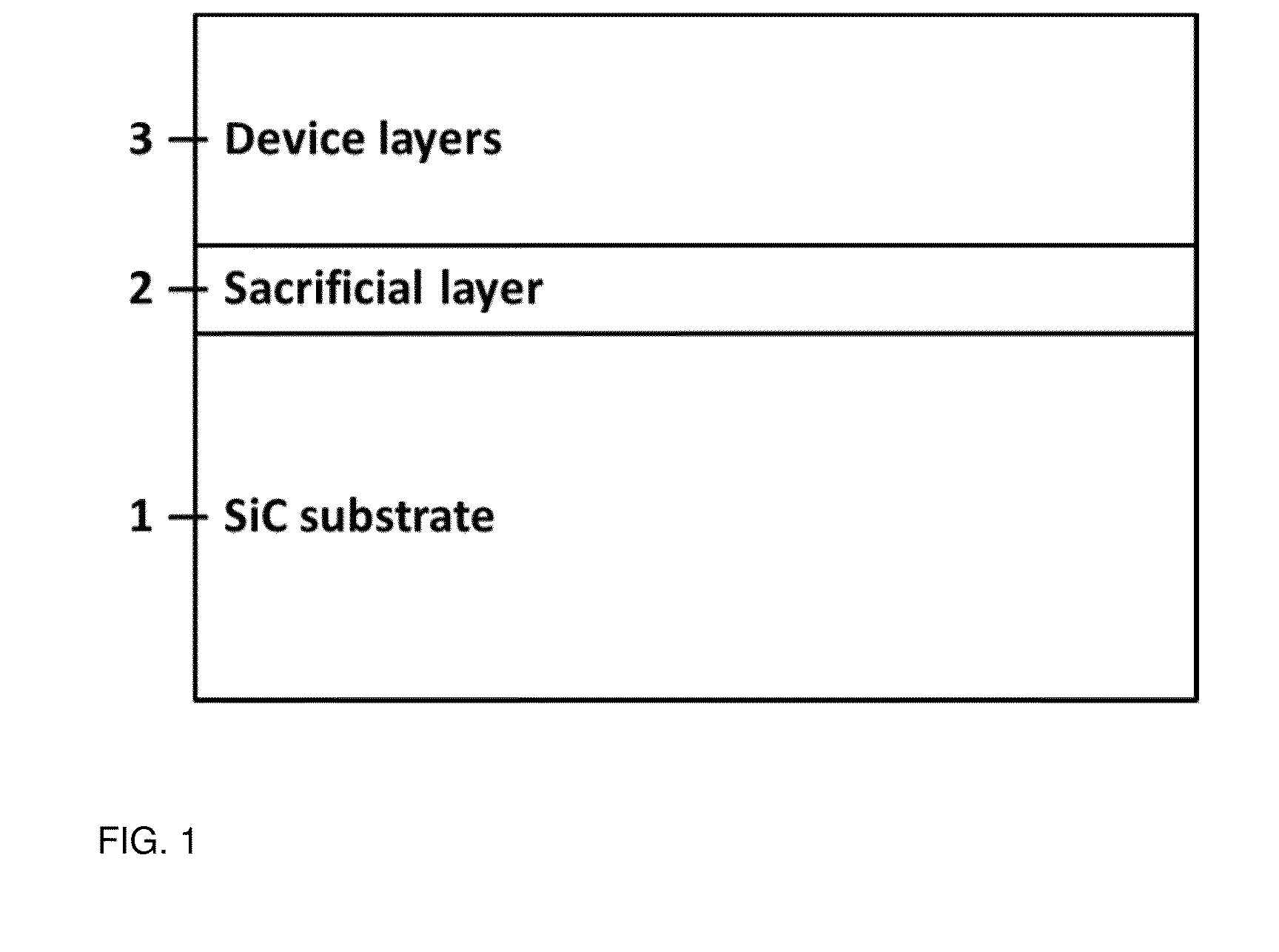

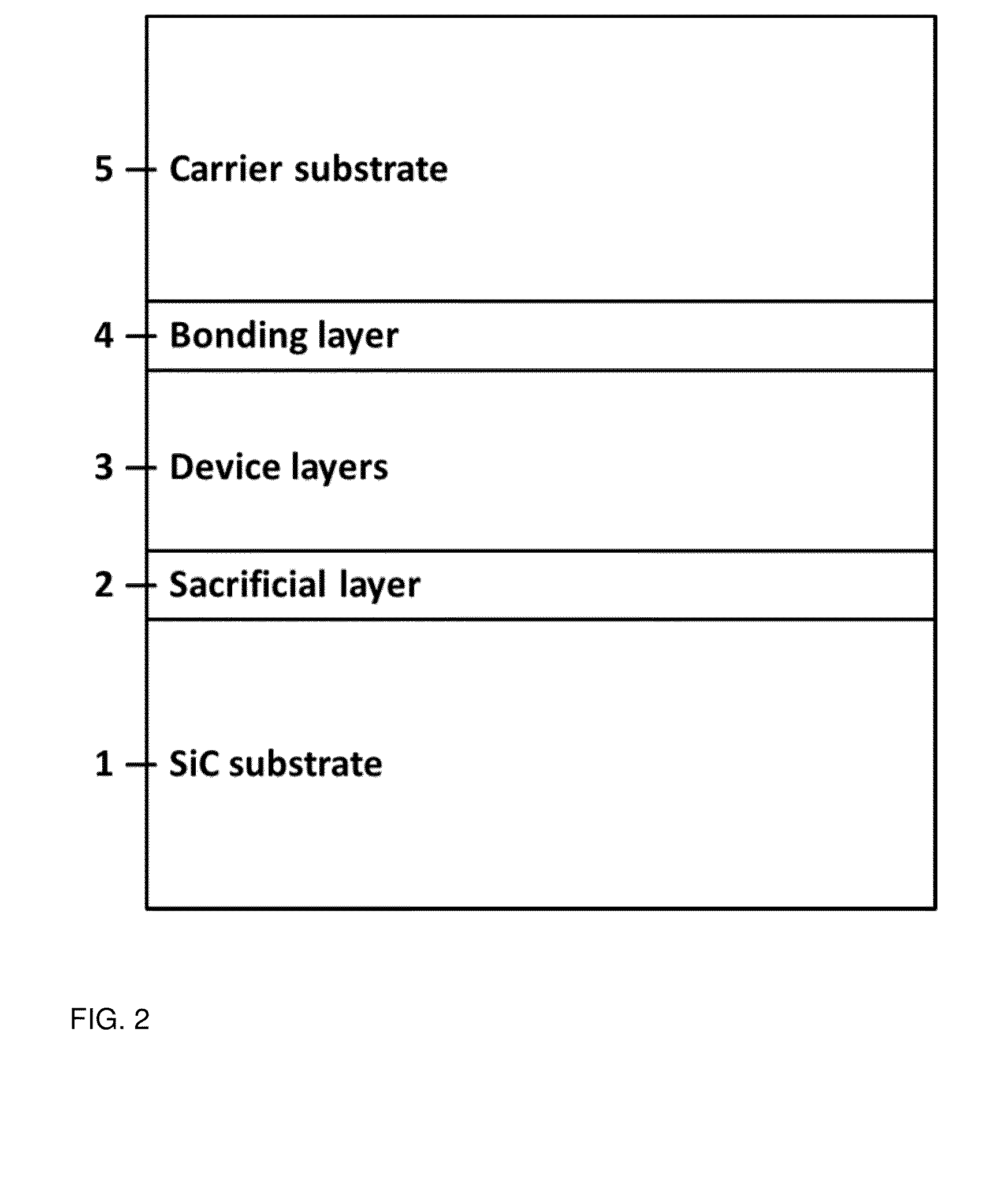

Lift-off of epitaxial layers from silicon carbide or compound semiconductor substrates

ActiveUS20150021624A1Minimal cleaningTimely controlSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsTernary compound

A method to remove epitaxial semiconductor layers from a substrate by growing an epitaxial sacrificial layer on the substrate where the sacrificial layer is a transition metal nitride (TMN) or a TMN ternary compound, growing one or more epitaxial device layers on the sacrificial layer, and separating the device layers from the substrate by etching the sacrificial layer to completely remove the sacrificial layer without damaging or consuming the substrate or any device layer. Also disclosed are the related semiconductor materials made by this method.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

InactiveUS20050156155A1Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

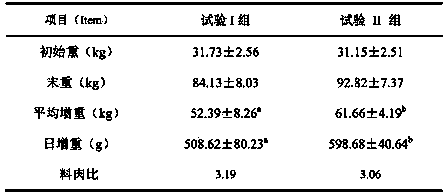

Ternary compound inoculant for fermentation bed for pigs

The invention provides a ternary compound inoculant for a fermentation bed for pigs. The ternary compound inoculant is prepared from a compound inoculant I, a compound inoculant II and a compound inoculant III, wherein the compound inoculant I is a starting inoculant and consists of trichoderma koningii, bacillus licheniformis and bacillus amyloliquefaciens; the compound inoculant II is a maintaining inoculant and consists of azotobacter chroococcum, enterococcus faecalis, bacillus laterosporus, bacillus amyloliquefaciens and bacillus subtilis; the compound inoculant III is a stacking inoculant and consists of aspergillus oryzae, streptomycete, azotobacter chroococcum, trichoderma koningii and bacillus licheniformis. The ternary compound inoculant provided by the invention is an efficient conversion flora system with complementary function and complementary enzyme system; the compound inoculant I is fermented to produce heat before entering; the compound inoculant II is subjected to biological deodorization, bacteria inhibition and waste transformation in cultivation; the compound inoculant III is decayed at high temperature after being discharged; nutrients are preserved in situ. The ternary compound inoculant system is collaboratively progressive, a continuous circulating fermentation process for cultivation of the fermentation bed is achieved, and healthy and clean production of pigs is facilitated.

Owner:JIANGSU ACAD OF AGRI SCI

Rare earth-oxides, rare earth-nitrides, rare earth-phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

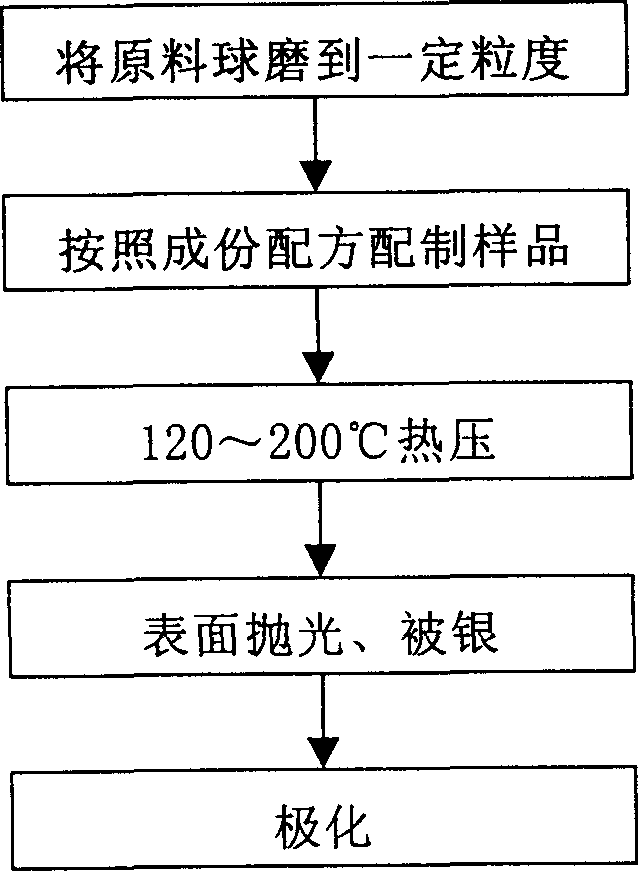

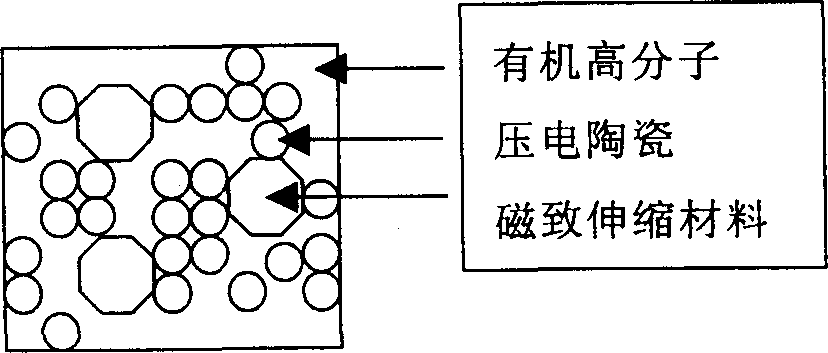

Three-component compound magnetoelectric material using organic polymer as adhesive and its preparation method

InactiveCN1395325AImprove mechanical propertiesHigh magnetoelectric conversion coefficientPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyLead zirconate titanateBarium titanate

The invention relates to the ternary compound magneto-electric material by use of the organic macromolecule as the agglomerant as well as its preparation method.With the organic macromolecule being as the agglomerant the piezoelectric ceramic(such as lead zirconate titanate etc.)and the magnetostriction material(such as terbium-dysprosium-iron alloy)are taken shape by hot pressing at low temperature.The magneto-electric compound material can be made by the method.Comparing the prior art,the invention possesses the advantages of simple process,good mechanical characters of the material and high magneto-electric transformation factor.The hotpressing technique provides the features of low pressing temperature(about 120-200 deg.C),easy to change the magneto-electric characters by changing the sequence for adding the constituent and the relative content.

Owner:TSINGHUA UNIV

Rare earth-oxides, rare earth -nitrides, rare earth -phosphides and ternary alloys with silicon

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Rare earth-oxides, rare earth nitrides, rare earth phosphides and ternary alloys with silicon

InactiveUS20050161773A1Quality improvementLaser detailsSemiconductor/solid-state device detailsRare earthOpto electronic

Atomic layer epitaxy (ALE) is applied to the fabrication of new forms of rare-earth oxides, rare-earth nitrides and rare-earth phosphides. Further, ternary compounds composed of binary (rare-earth oxides, rare-earth nitrides and rare-earth phosphides) mixed with silicon and or germanium to form compound semiconductors of the formula RE-(O, N, P)—(Si,Ge) are also disclosed, where RE=at least one selection from group of rare-earth metals, O=oxygen, N=nitrogen, P=phosphorus, Si=silicon and Ge=germanium. The presented ALE growth technique and material system can be applied to silicon electronics, opto-electronic, magneto-electronics and magneto-optics devices.

Owner:IQE

Attapulgite/carbon nitride/polyaniline desulfurization photocatalyst and preparation method thereof

ActiveCN105195227AAvoid reunionImprove photoresponsive areaOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsCarbon nitrideNitrogen

The invention belongs to the field of fuel desulfurization and particularly relates to a compound photocatalyst taking attapulgite as a carrier and a preparation method of the photocatalyst. Firstly, a raw material rich in carbon and nitrogen is added to attapulgite slurry to be mechanically stirred, then the mixture is kept at the temperature of 520-570 DEG C, and an attapulgite / carbon nitride binary compound is prepared; polyaniline is assembled on the obtained attapulgite / carbon nitride compound carrier, and the attapulgite / carbon nitride / polyaniline ternary compound photocatalyst is prepared. The prepared compound photocatalyst involves no metal or metal oxide catalysts, cannot cause secondary pollution to oil products and has the advantages of environment friendliness and the like.

Owner:常州纳欧新材料科技有限公司

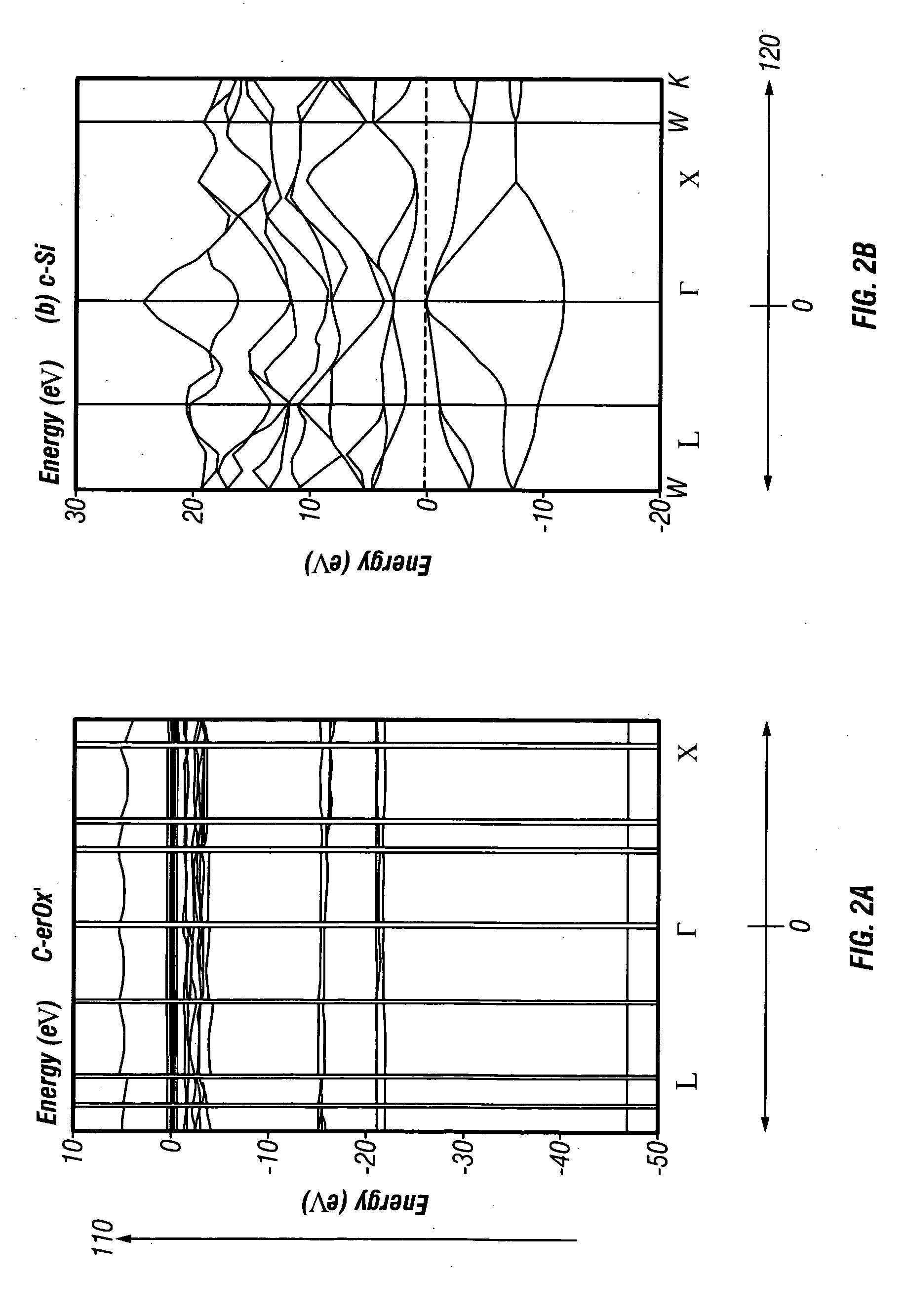

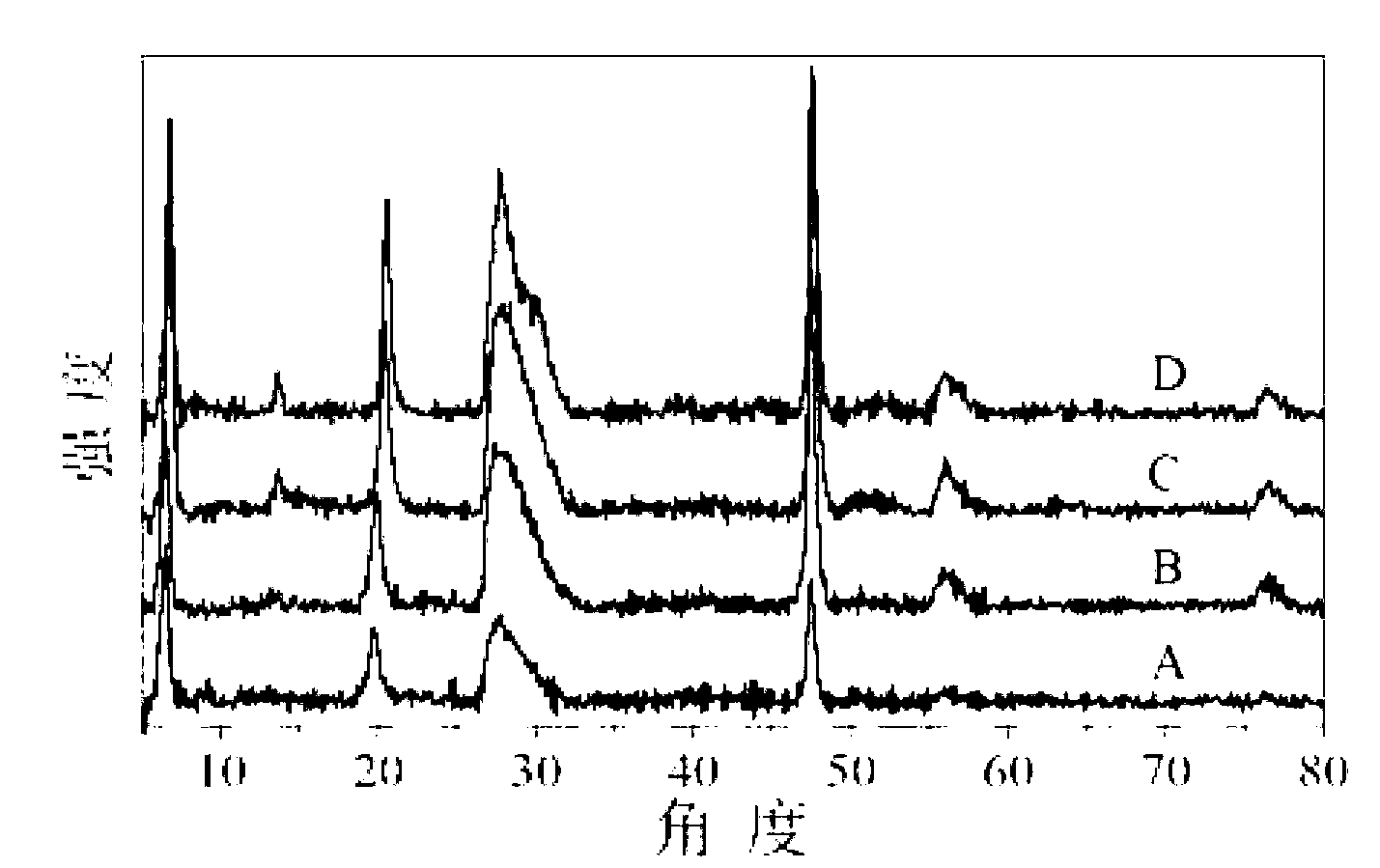

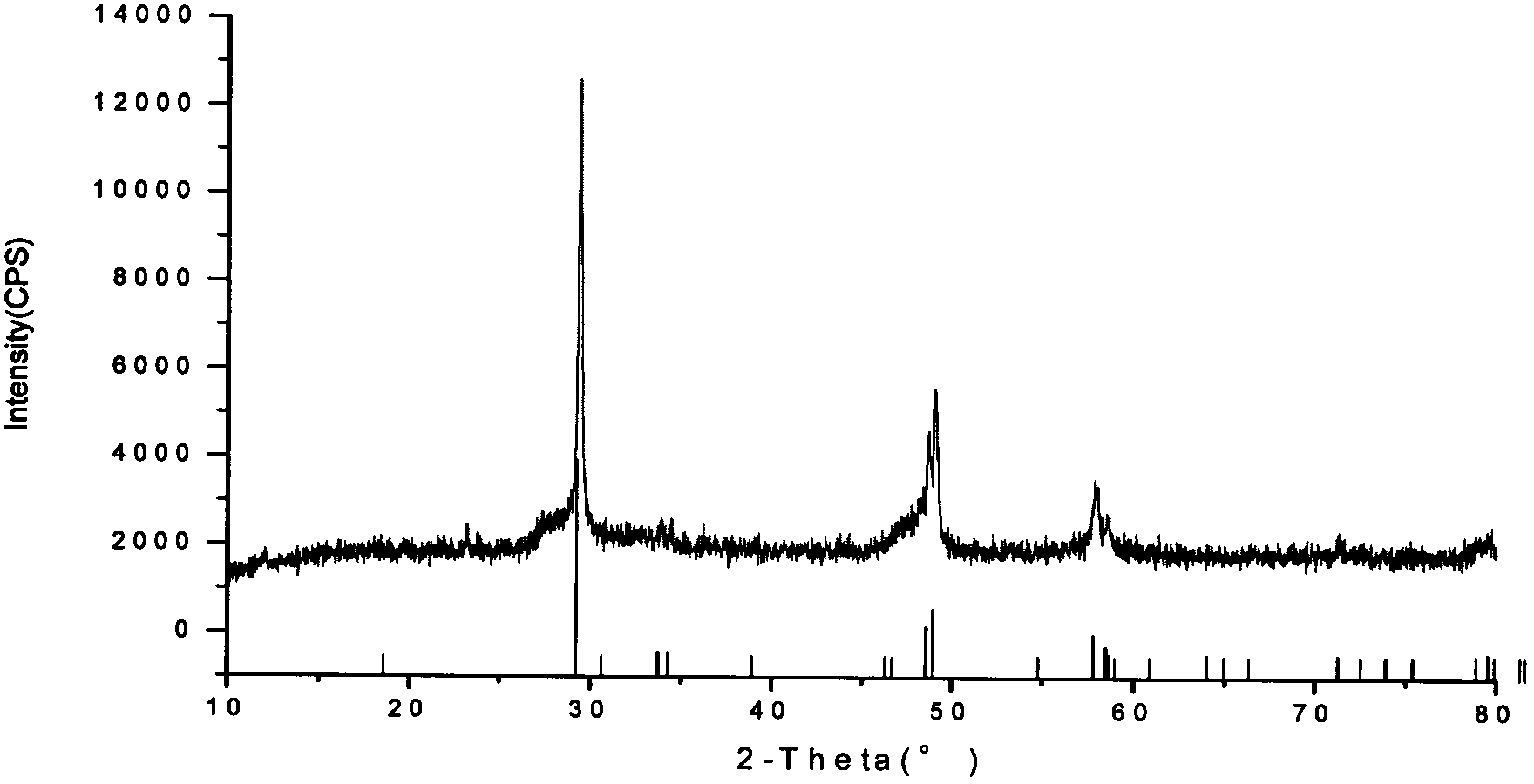

Ternary composite octahedrite type titanium dioxide photocatalyst and preparation process thereof

InactiveCN1927452AImprove adsorption capacityEasy to preparePhysical/chemical process catalystsIndividual molecule manipulationSorbentWastewater

The invention relates to a method for preparing ternary compound anatase titania photocatalyst. Wherein, it uses magnetic nanometer particle sol and active carbon whose mass ratio is 1:1-1:9; then puts the active carbon into magnetic nanometer particle sol, to be mixed; therefore, the magnetic nanometer particles are adsorbed by the active carbon; then separating them via magnetic field to be dried at 40-80Deg. C, to obtain magnetic active carbon whose carrier is titania; then emerging the magnetic active carbon in anatase titania sol, to make the mass ratio between the magnetic active carbon and anatase titania 1:1-1:5; mixing for 0.5 hour and evaporating the suspension into powder; said powder is the final compound photocatalyst. The invention can prepare porous active carbon with high adsorption ability.

Owner:NANTONG SUZHONG TEXTILE +1

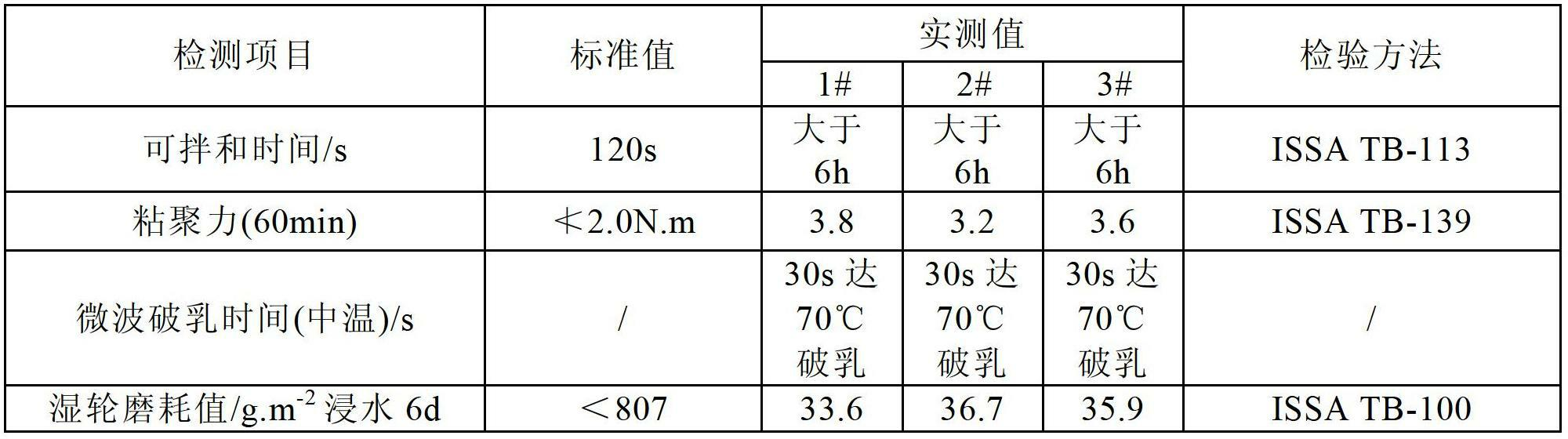

Demulsifying slow breaking and quick setting modified emulsified asphalt by microwave heating and preparation method thereof

InactiveCN102675890AExcellent slow cracking performanceWide adaptabilityBuilding insulationsMicrowaveEmulsion

The invention provides demulsifying slow breaking and quick setting modified emulsified asphalt by microwave heating and a preparation method thereof, adopts the emulsified asphalt emulsion by asphalt and a cation-anion-nonionic ternary compound emulsifier according to a certain ratio under an effect of high shear force, and solves the problem that conventional slow breaking and quick setting emulsified asphalt is uncontrollable in condensing speed and poor in adaptation of temperature and stone materials. The invention provides the emulsified asphalt which can be stably stored for a long time at normal temperature, is free from layered separation and demulsification, prevents demulsifying and condensing phenomena after being mixed with aggregates, and can demulsify and condense quickly when being heated to be at about 70 DEG C by microwaves, and the enough construction time is provided. The asphalt emulsion prepared by using the method is smooth and uniform in particles, and the enough mixing time in a construction application of slurry seal can be provided. According to the emulsified asphalt and the preparation method, the condensing speed can be controlled. The emulsified asphalt is generally adaptive to the stone materials, further the construction season is prolonged and the construction quality is improved.

Owner:CHANGAN UNIV

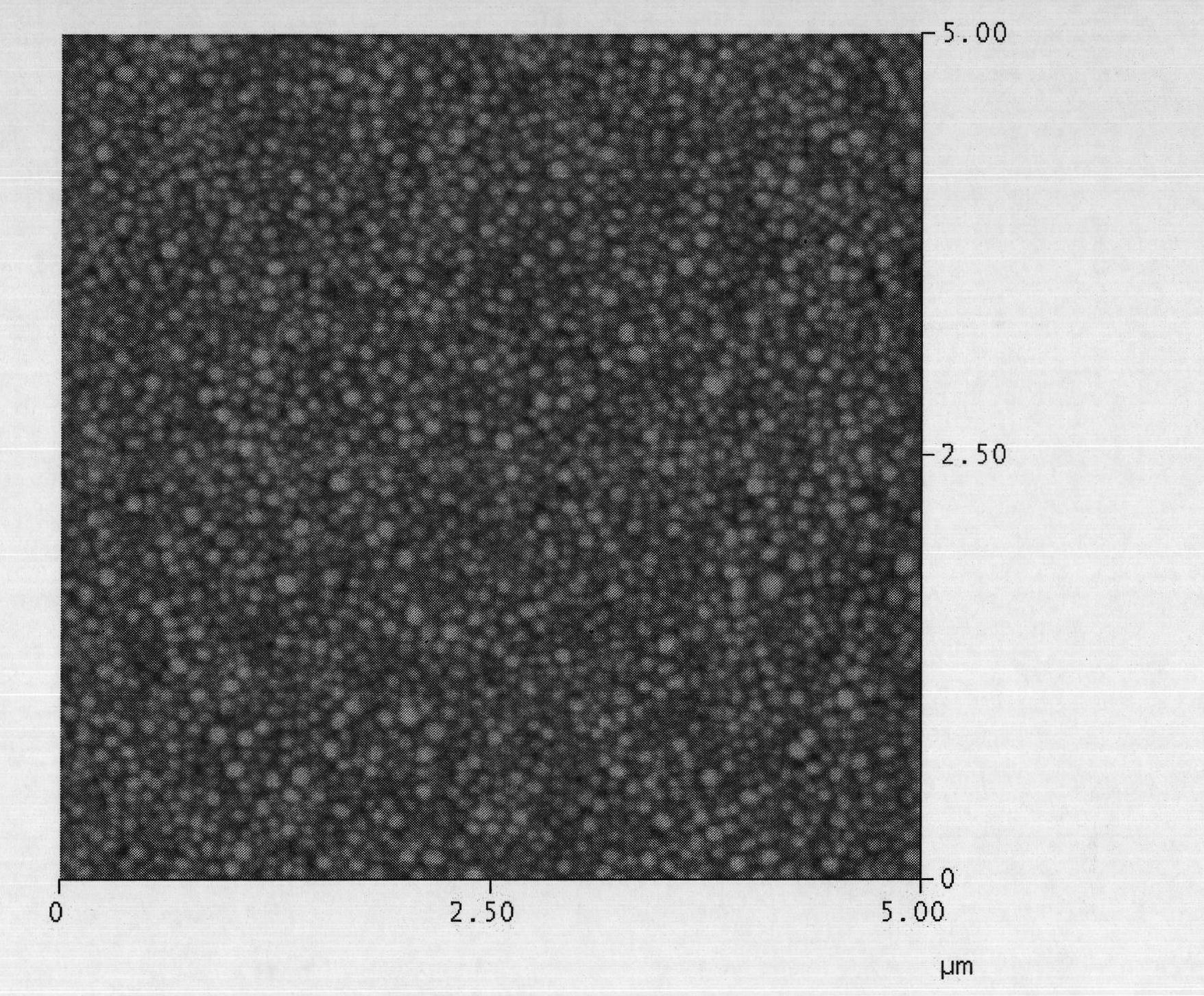

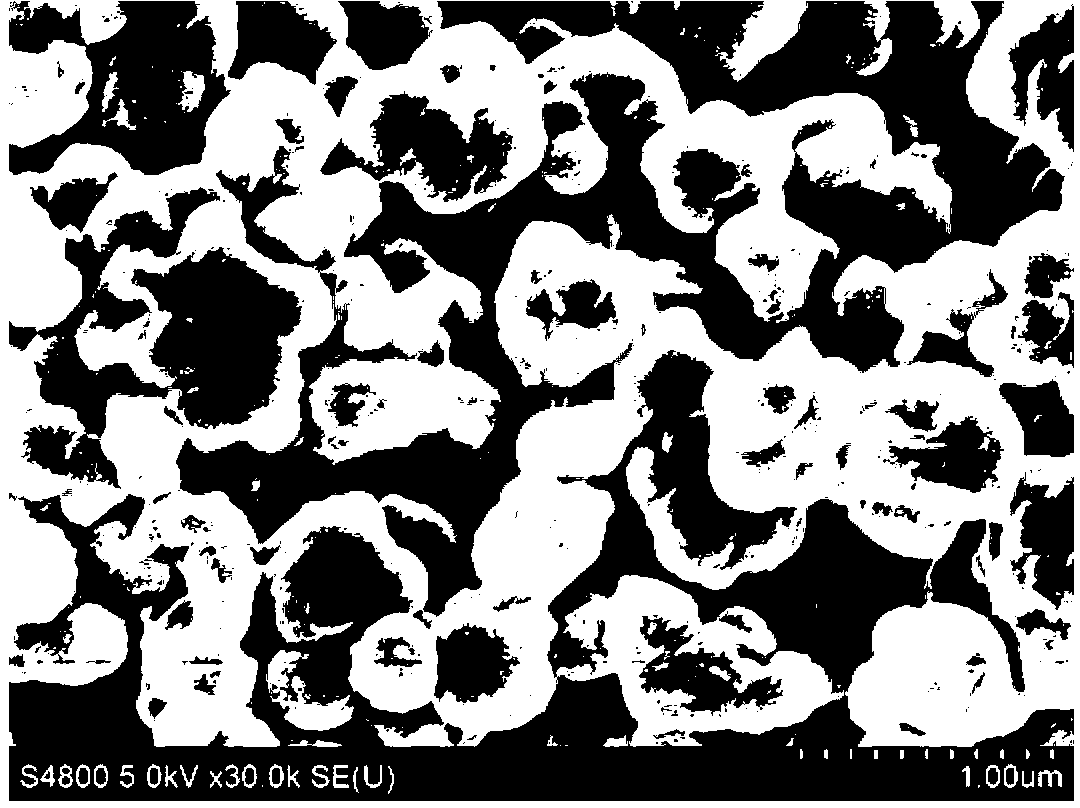

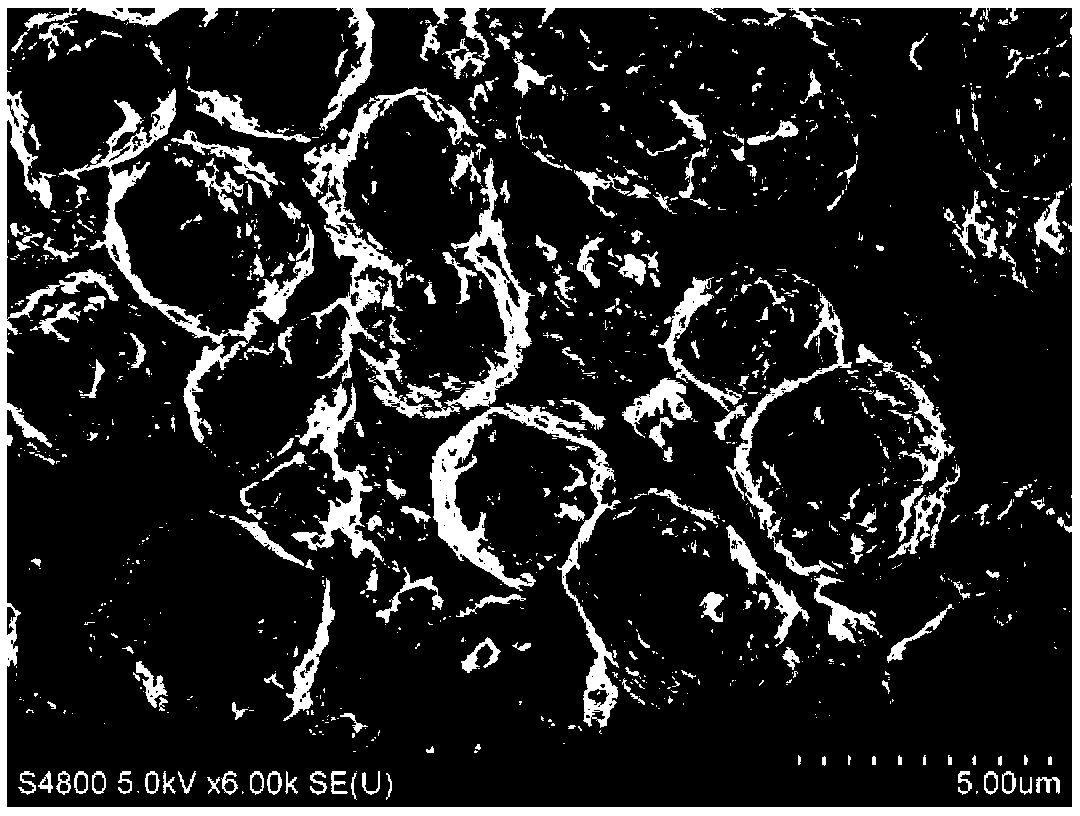

Chemical method for preparing nano mesh-like sulfur-indium-zinc ternary compound optoelectronic film on ITO conductive glass in situ

The invention relates to a chemical method for preparing a nano mesh-like sulfur-indium-zinc ternary compound optoelectronic film on ITO conductive glass in situ. The method comprises the following steps that: an ITO conductive glass substrate material with a nano indium-zinc alloy surface, monomer sulfur powder and anhydrous ethanol are put into a PTFE reactor, with the concentration of monomer sulfur powder of 0.001 to 0.015g sulfur / ml anhydrous ethanol, react for 12 to 24h at 160 to 180DEG C, are naturally cooled to room temperature after the reaction is completed; and finally, the product is sequentially cleaned by deionized water and anhydrous ethanol, naturally dried at room temperature, and the mesh-like ZnIn2S4 ternary compound optoelectronic film which comprises nano sheets is prepared on the indium-zinc alloy surface of an ITO conductive glass substrate in situ, wherein the thickness of the nano sheets is 20 to 30mm. The film prepared by the method is transparent, the nano mesh-like structure has uniform and perfect appearance, and the surface is very uniform and flat. Simultaneously, the method has the advantages of good low-temperature in situ growth repeatability, convenient operation, no further post-treatment, environmental-friendliness and convenience for industrial production.

Owner:XUCHANG UNIV +1

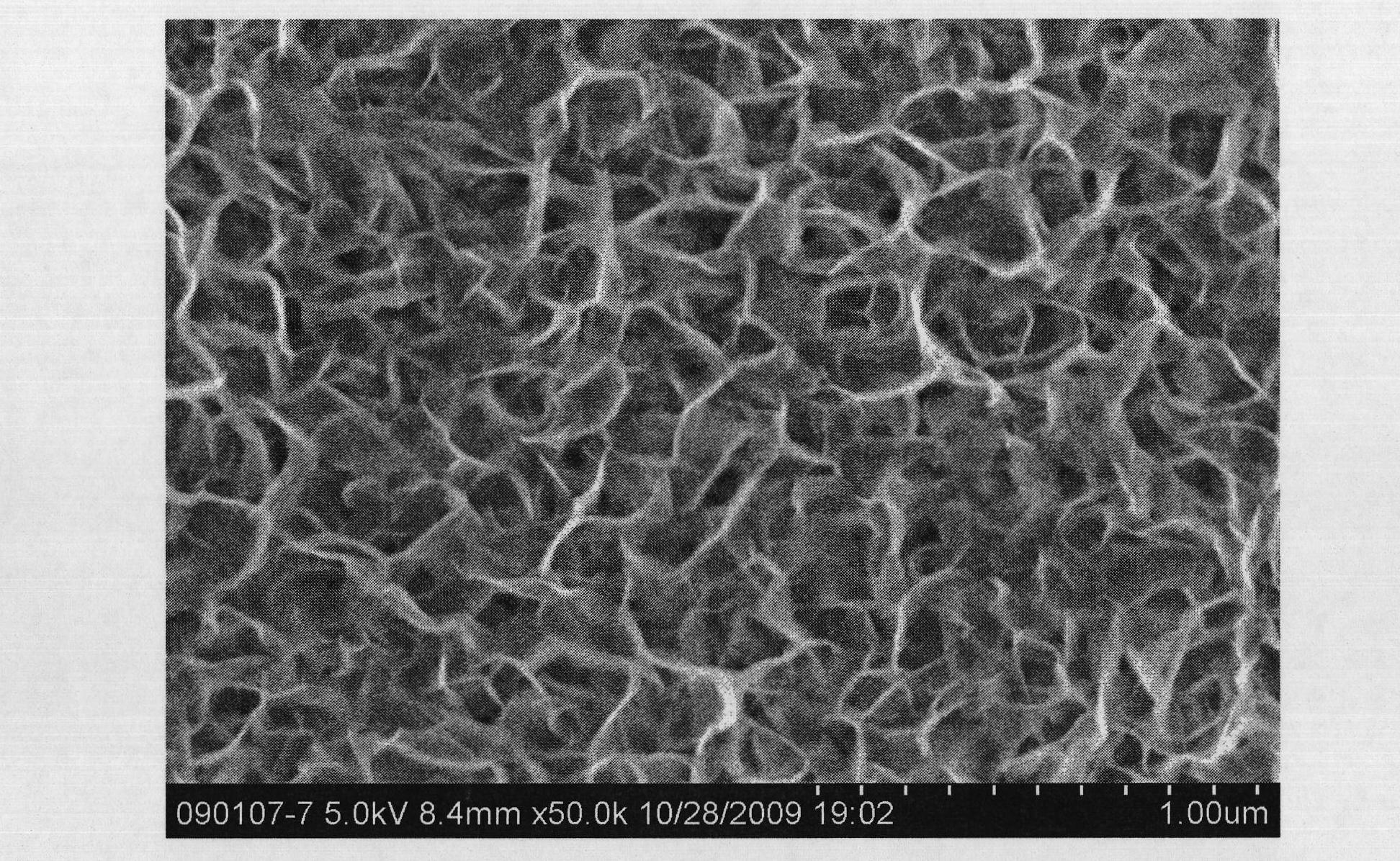

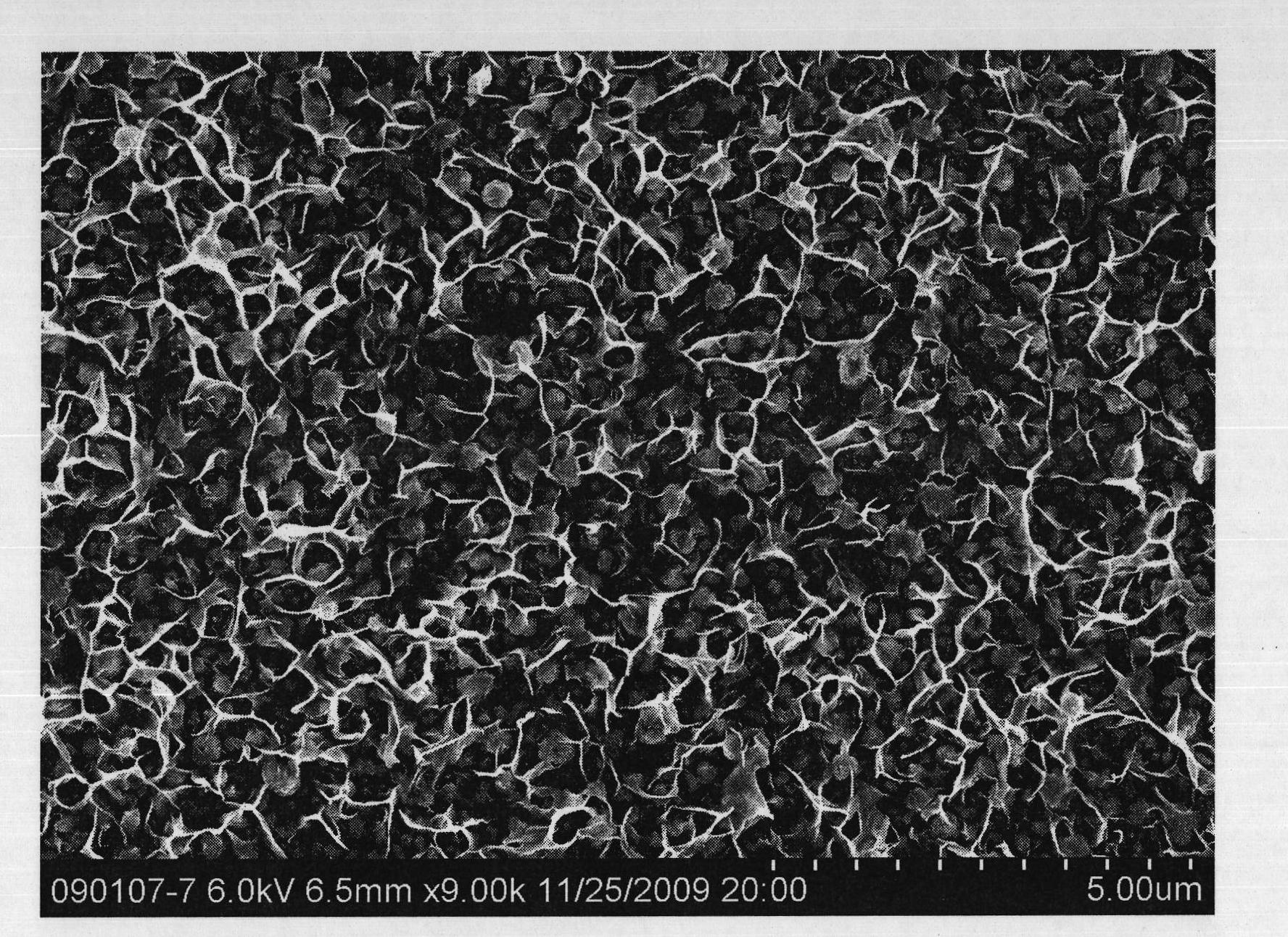

Method for preparing hierarchical floriform ZnIn2S4 ternary compound

InactiveCN102795661AHigh catalytic activityLarge specific surface areaMaterial nanotechnologyGallium/indium/thallium compoundsIndiumAlcohol

A method for preparing a hierarchical floriform ZnIn2S4 ternary compound relates to a method for preparing a nano-ZnIn2S4 ternary compound. The method provided by the invention aims to solve the technical problems of small specific surface area and low visible-light catalytic activity of the existing ZnIn2S4 ternary compound. The preparation method provided by the invention comprises the following steps of: firstly, adding an inorganic zinc salt to mixed alcohol solution, and then adding in an inorganic indium salt, and further adding in a sulfur source to the mixed solution and stirring after the inorganic indium salt is dissolved; and finally, arousing a reaction in a high-pressure reaction kettle lined with polytetrafluoroethylene, and then performing cooling, separation, washing and drying, thereby obtaining the hierarchical floriform ZnIn2S4 ternary compound. The preparation method provided by the invention is simple in process and low in cost; the obtained ZnIn2S4 ternary compound has a hierarchical floriform structure; the specific surface area of the ZnIn2S4 ternary compound is large, which is 71-98 m<2> / g; besides, the ZnIn2S4 ternary compound is tough in surface and thereby high in visible-light catalytic activity; and therefore, the ZnIn2S4 ternary compound can be applied to the fields such as solar cells, electrochemistry, environmental catalysis and the like.

Owner:HEILONGJIANG UNIV

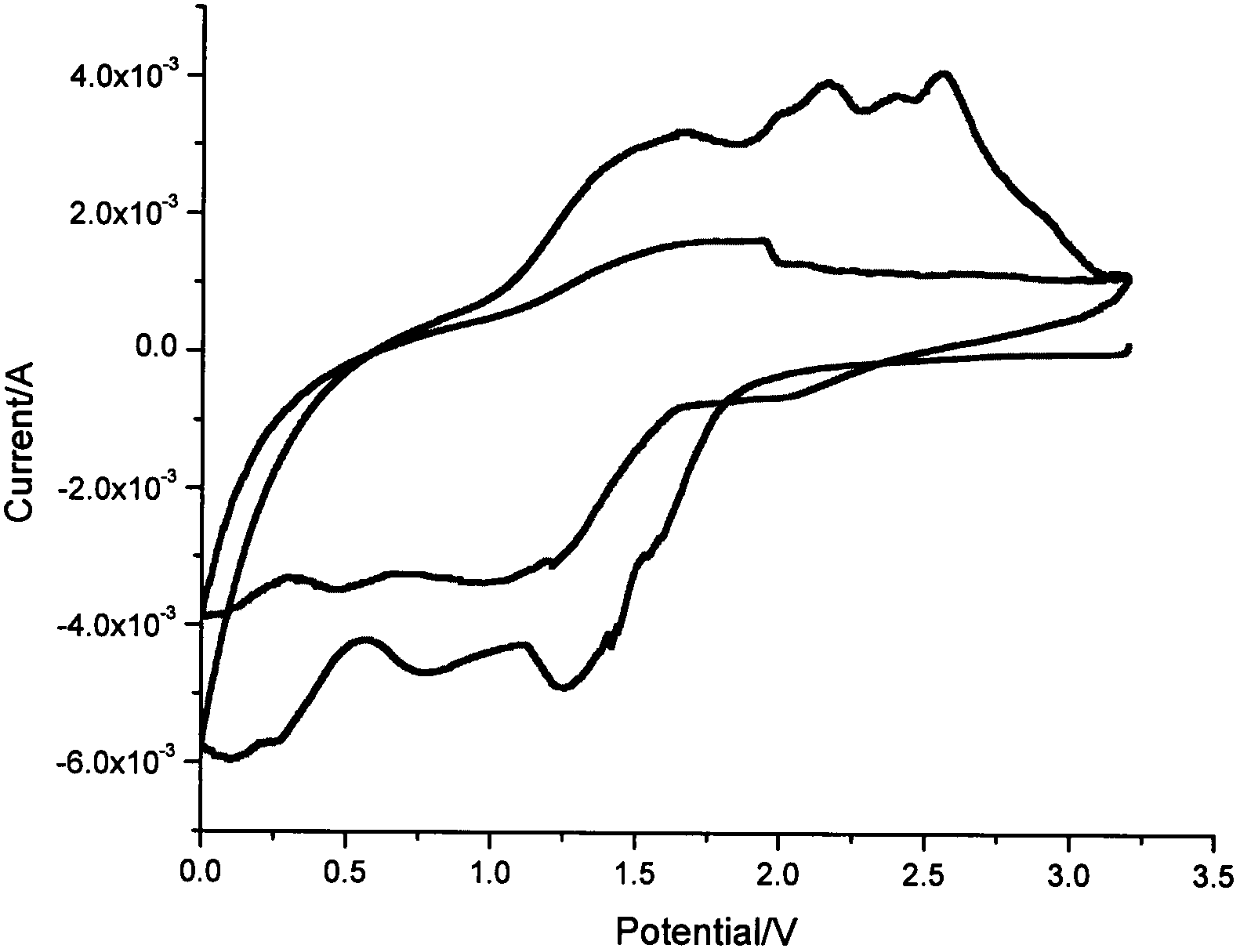

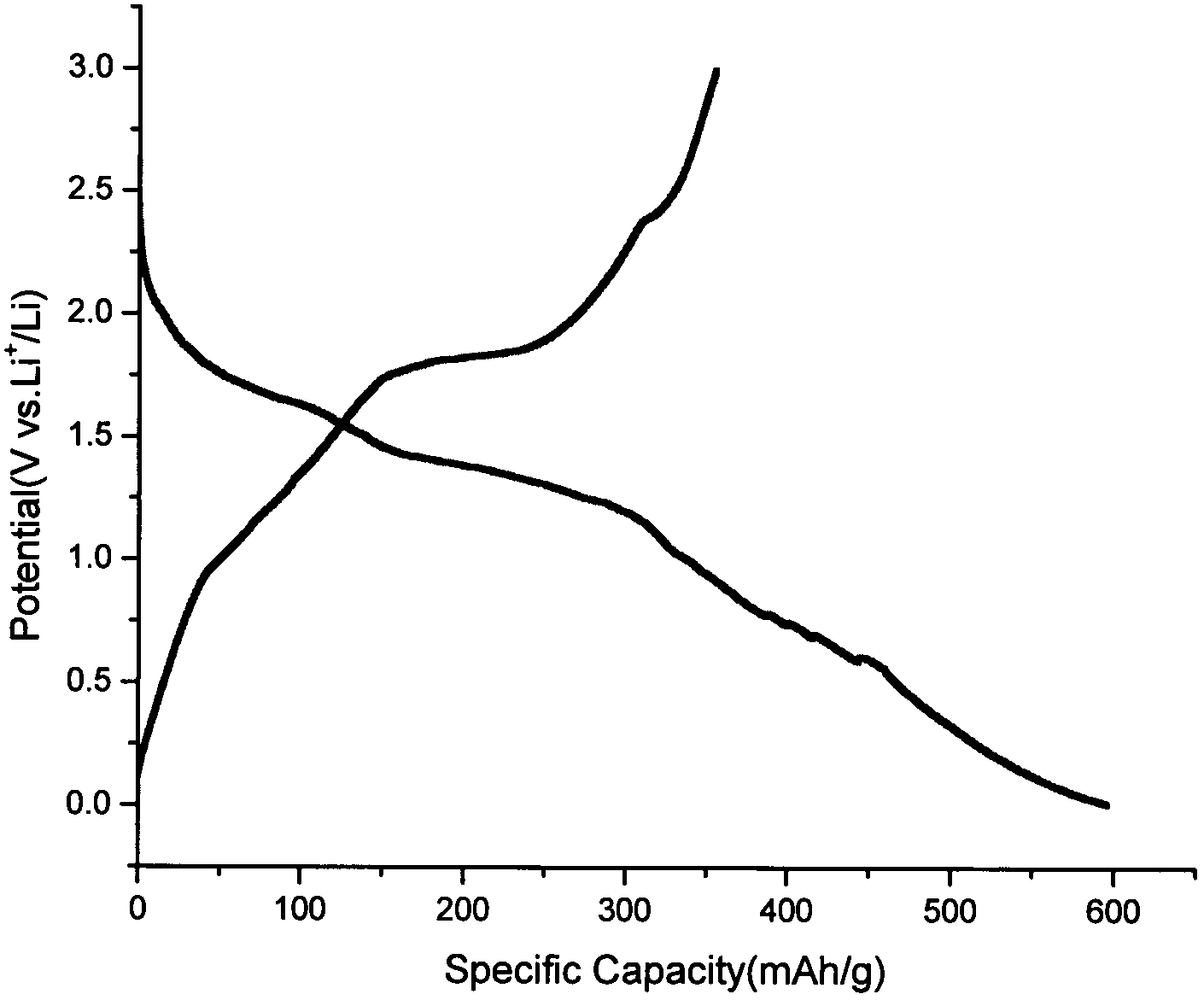

Cathode active substance for lithium ion battery, cathode material containing cathode active substance and lithium ion battery

InactiveCN102701160AHigher quality than capacityImprove conductivityTin compoundsCell electrodesAluminium-ion batterySodium-ion battery

The invention discloses a cathode ternary compound CuxMySz active substance for a lithium ion battery, a cathode material containing the substance and the lithium ion battery using the cathode material as a cathode. M in the chemical formula CuxMySz belongs to an IVB group, a VB group, a VIB group, a VIII group, an IIB group and an IVA group in a fourth period and a fifth period in periodic table of chemical element and is any one in metal elements of an IIIA group in third, fourth, fifth and sixth periods, such as Ti, Cr, Mo, Fe, Al, Ga, In, Tl, Sn and the like. The active substance has higher charge-discharge capacity which is about two times that of commonly used graphite material in the charge-discharge capacity, thereby being a novel lithium ion battery cathode material with good application prospect and high capacity.

Owner:EAST CHINA UNIV OF SCI & TECH

Process for extrusion casting piston blank of internal combustion engine with local feinforcing of metal base composite material

The invention is a craft which founds metal base compound local enhanced engine piston blank. It includes: (1) produces enhancing phase pre-component; (2) confects base alloy materials, the proportion is: silicon 11~13%, copper 0.5~2.0%, magnesium 0.4~1.4%, manganese 0.2~0.9%, vanadium 0.05~0.27%, the other is aluminum; (3) melts the base alloy; (4) refines it by eliminating the air: flows argon with pressure of 100~110mm mercury column for about 6~8 minutes, the temperature is 780~810íÒC; (5) Deterioration processing: adds in 0.013~0.016% Be, 0.04~0.06% Ti, 0.002~0.004% Te ternary compound deterioration agent; (6) prepares the mould; (7) founds the piston blank.

Owner:张强

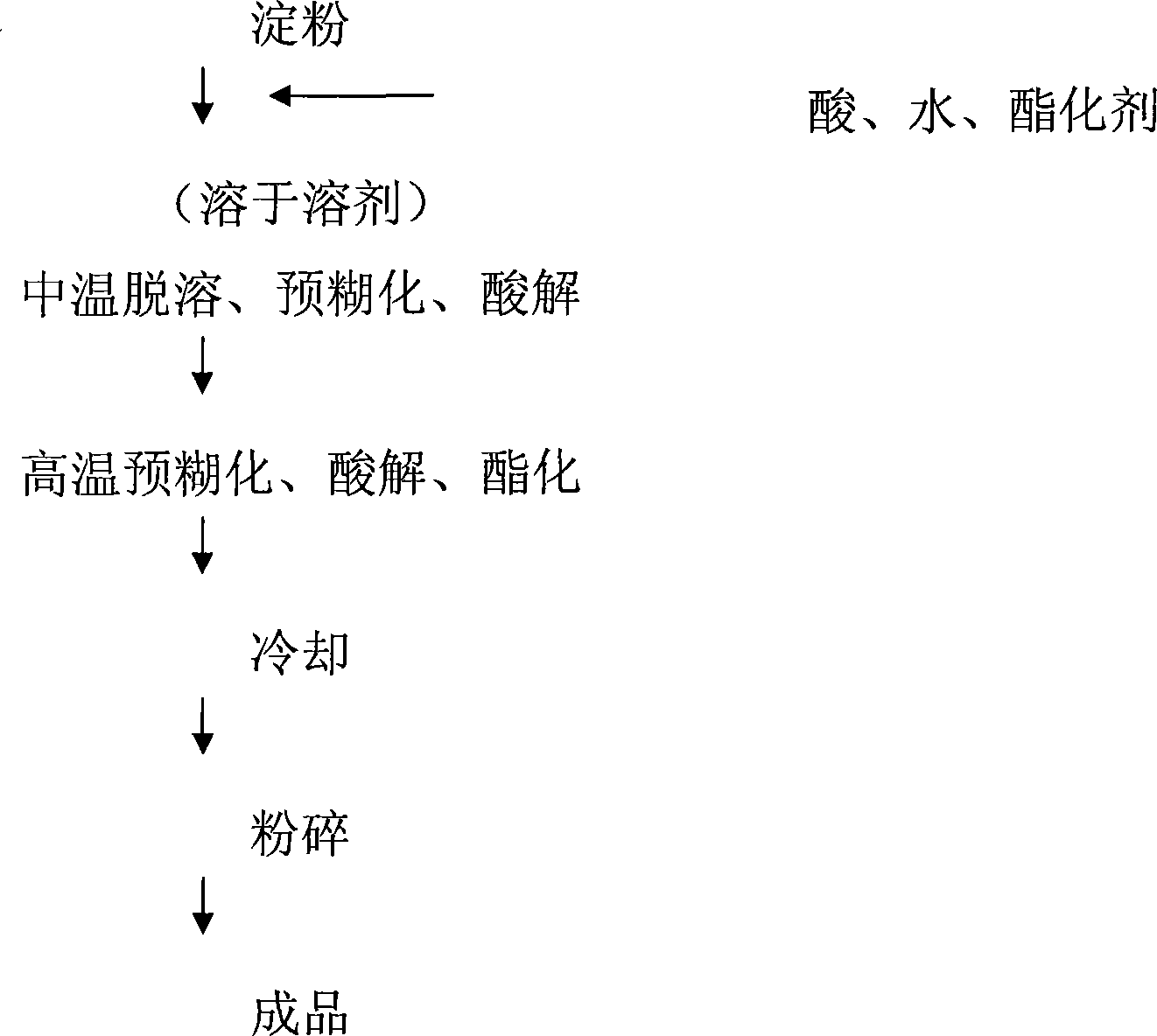

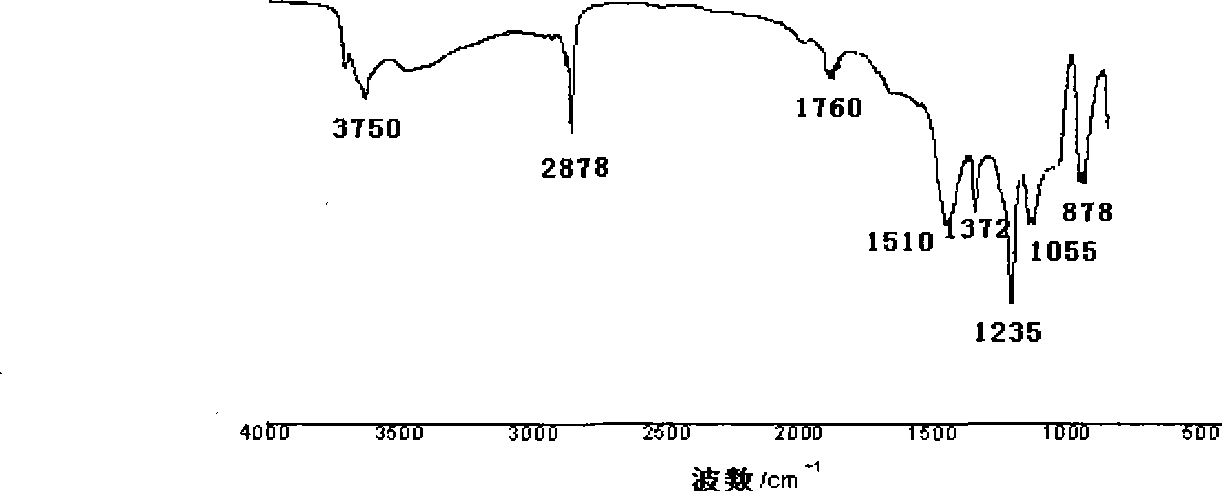

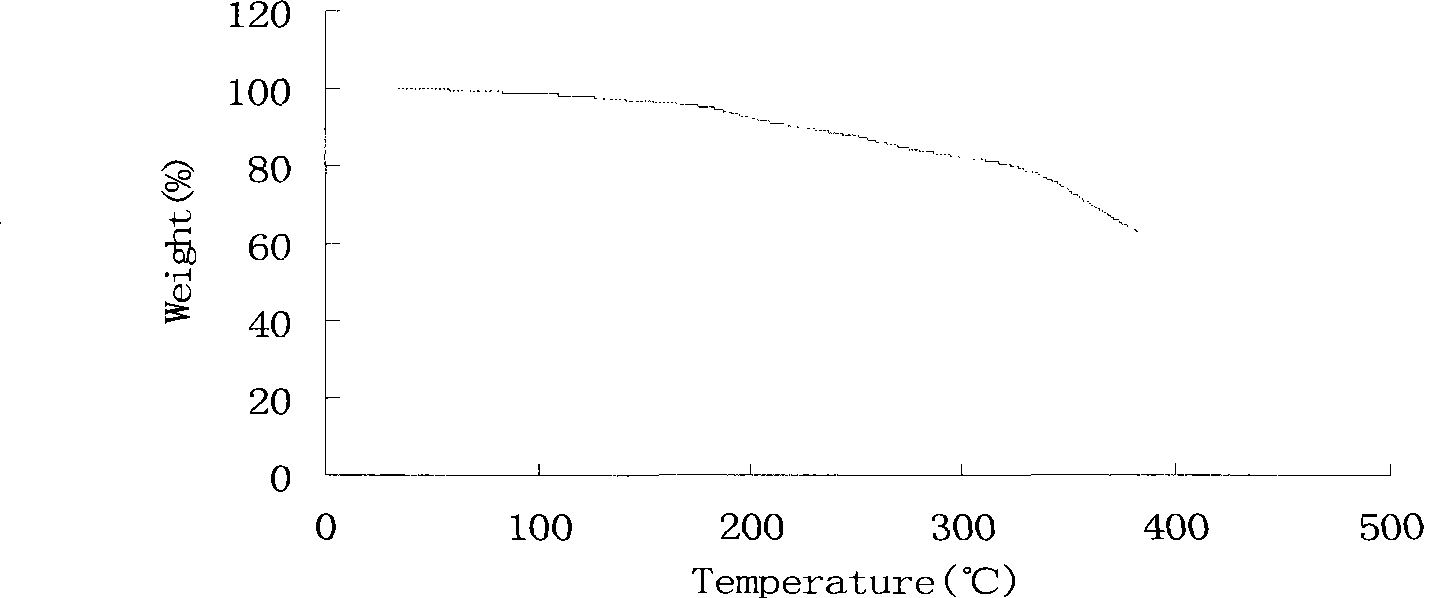

Method for preparing pregelatinization-acid hydrolysis-esterification ternary compound modified starch and use thereof

InactiveCN101456915AEvenly distributedFacilitate osmotic acid hydrolysisFood preparationPolymer scienceAlcohol

The invention relates to a preparation method for pregelatinization-acidolysis-esterification ternary composite modified starch and application thereof. The preparation method comprises the following steps: a, dissolving 2g to 4g of an esterification reagent in 120mL to 150mL of anhydrous alcohol with the temperature of 25 to 40 DEG C, then adding 0.05g to 0.15g of 38 mass percent hydrochloric acid, and adding 15mL to 30mL of water; b, taking 100g of starch counted on a dry basis, adding the starch into the solvent prepared in the step a, and stirring the starch evenly in the solvent to obtain even slurry; c, carrying out the moderate temperature exsolution of the even slurry prepared in the step b, simultaneously carrying out pregelatinization and acidolysis, and setting the exsolution temperature between 55 and 80 DEG C and the exsolution time between 0.5h and 2h; and then carrying out a high temperature reaction, carrying out the pregelatinization-acidolysis-esterification action at the high temperature, and setting the reaction temperature between 120 and 160 DEG C and the reaction time between 2h and 5h; and d, cooling down and crushing the product obtained in the step c so as to obtain the modified starch simultaneously having the multiple characteristics of pregelatinized starch, acidified starch and esterified starch.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

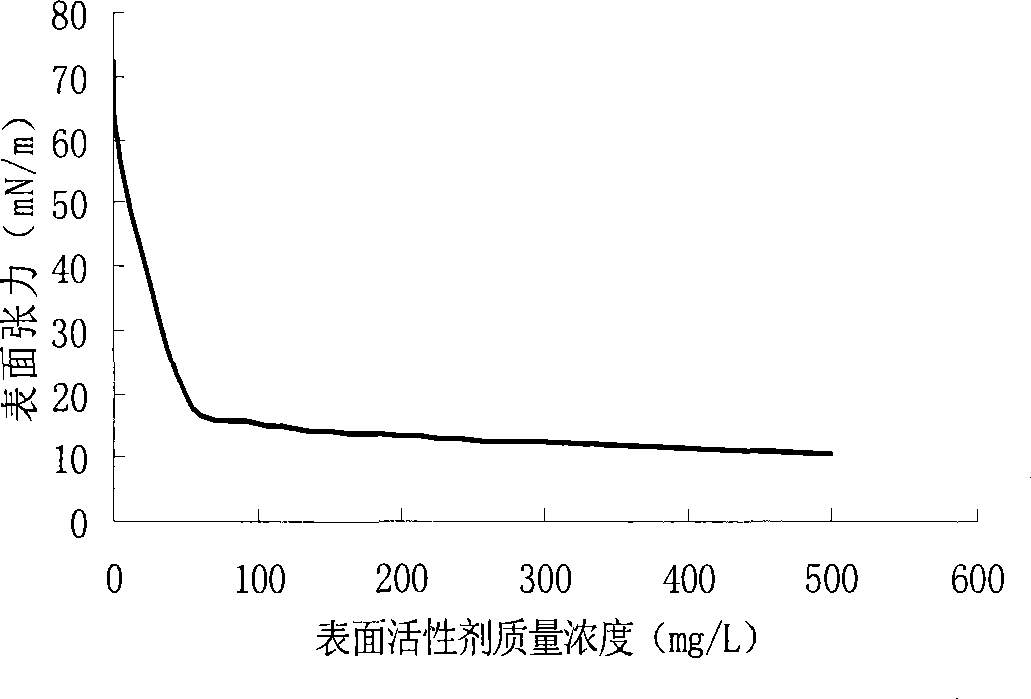

Fluorocarbon gemini surfactant as well as preparation method and application thereof

ActiveCN101502771AUse low concentrationReduce surface tensionTransportation and packagingMixingPotassium hydroxideEthyl acetate

The invention discloses a fluorine-carbon gemini surfactant for oil extraction and a preparation method thereof. The preparation method of the surfactant is as follows: 1) perfluorooctsulfunyl fluoride is dissolved in ethyl acetate, is firstly mixed with polyethylene polyamines and then reacts with potassium hydroxide after being heated to obtain diperfluoro octyl sulfamide; 2) diperfluoro octyl sulfamide is mixed with 2-chlorethanol in an organic solvent and reacts with potassium hydroxide to obtain N-N-alcohol diperfluoro octyl sulfamide; 3) N-N-alcohol diperfluoro octyl sulfamide is mixed with hydrogen peroxide and reacts with potassium hydroxide to obtain the target product. The fluorine-carbon gemini surfactant for oil extraction provided by the invention has comparatively low using concentration, can obviously reduce the surface tension of aqueous phase system, is excellent in temperature and salt resistance, can be used as a surfactant component in polymer-surfactant binary compound flooding and alkali-polymer-surfactant ternary compound flooding systems and can also be directly applied in surfactant flooding.

Owner:CHINA NAT OFFSHORE OIL CORP +1

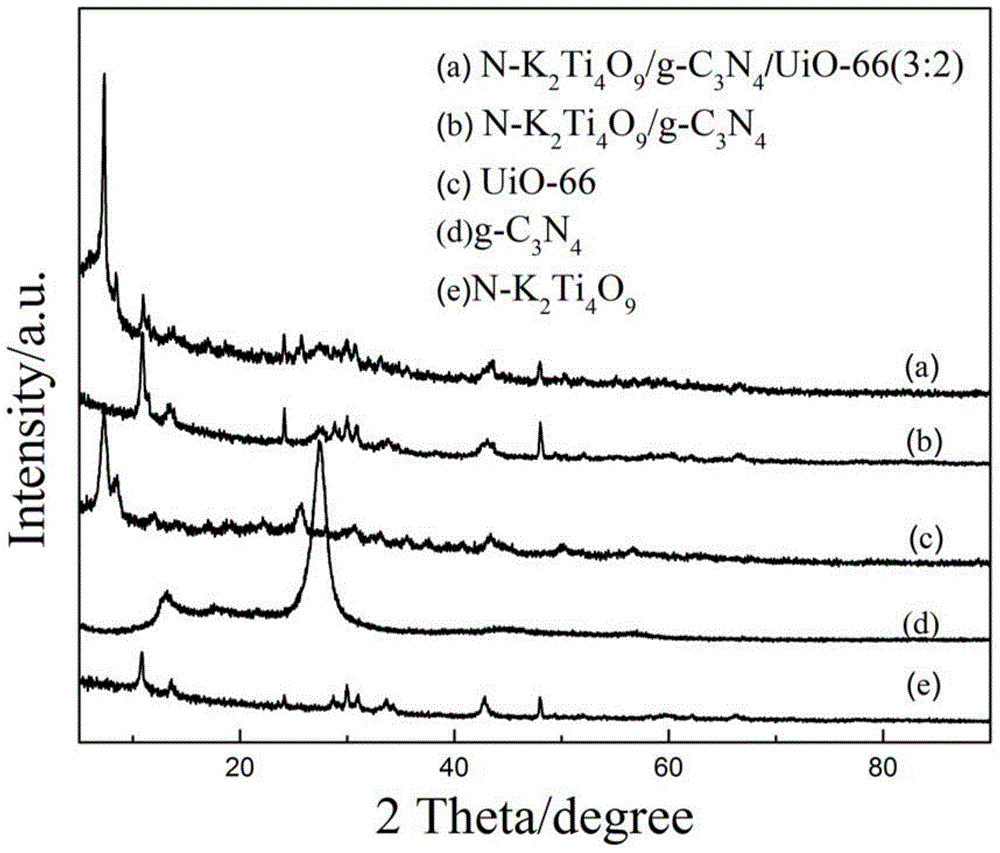

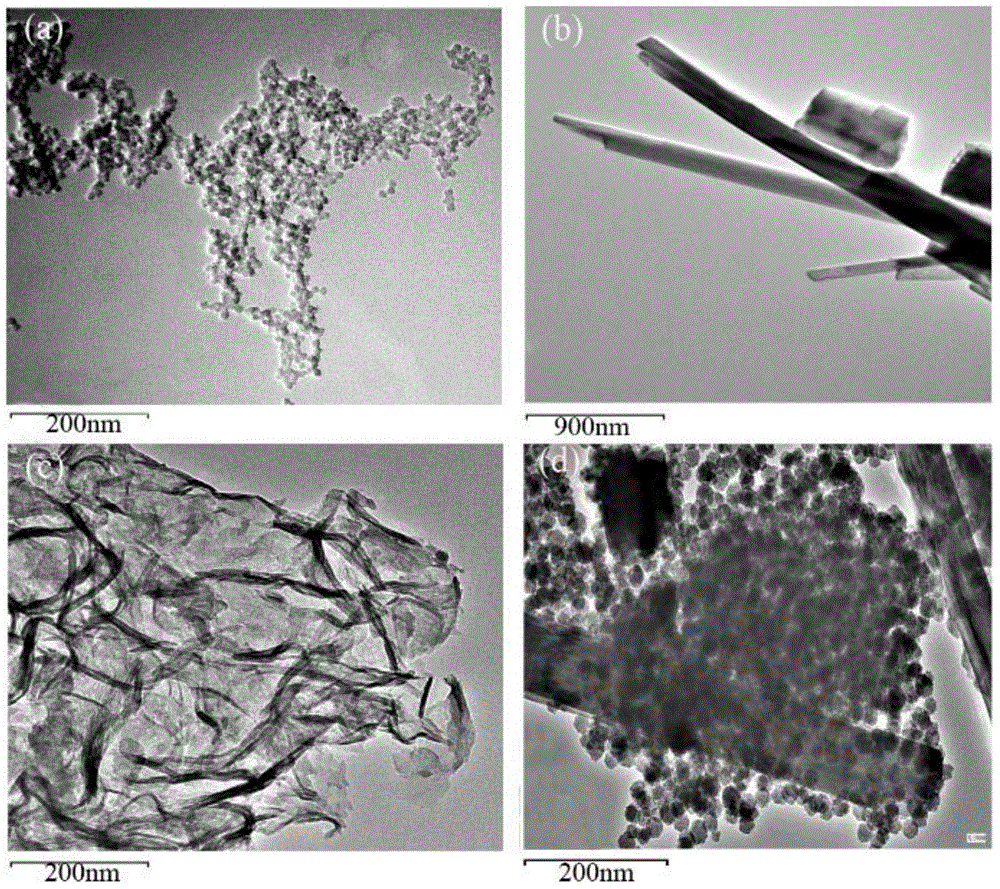

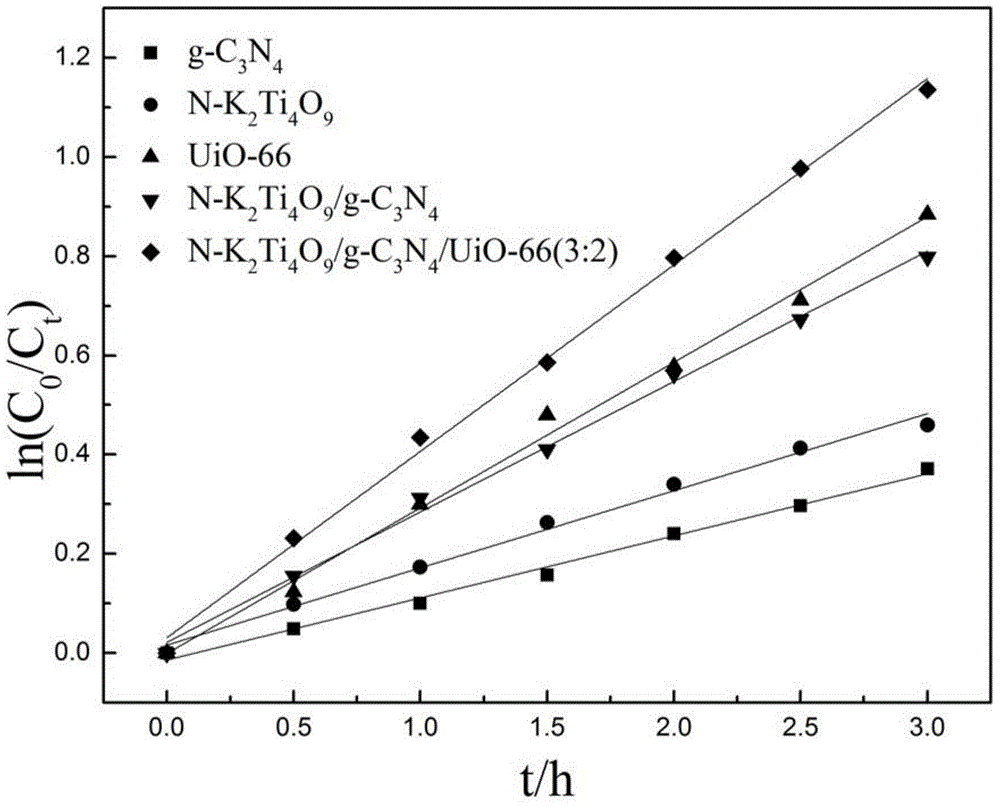

Ternary efficient compound visible light photocatalytic material and preparation method thereof

ActiveCN104888858ASimple manufacturing methodImprove photocatalytic efficiencyWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic dyeCharge separation

The invention discloses a ternary efficient compound visible light photocatalytic material and a preparation method and application thereof. The preparation method is characterized by comprising the following steps: preparing N-K2Ti4O9 and g-C3N4 by a forging method, preparing an N-K2Ti4O9 / g-C3N4 binary composite material via electrostatic attraction, and further synthesizing an N-K2Ti4O9 / g-C3N4 / UiO-66 ternary efficient compound visible light photocatalytic catalyst via self-assembling by a solvothermal method. According to the invention, the characteristics of good visible light response of N-K2Ti4O9, high conduction electron hole capacity of g-C3N4 and high MOF material adsorption amount of UiO-66 are utilized; the ternary compound light catalyst synthesized by integrating the advantages of N-K2Ti4O9, g-C3N4 and UiO-66 has obviously reinforced activity of performing photocatalytic degradation on organic dye under visible light under the effect of compound promoted photogenerated charge separation, and has wide application prospect in the field of photocatalysis.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com