Preparation method of aluminium oxide-silicon oxide-zirconium oxide ternary compound aerogel

A ternary composite and aerogel technology, which is applied in the field of preparation of heat-insulating alumina-silica-zirconia ternary composite airgel, can solve the problems of poor infrared blocking ability, unfavorable industrialization, cumbersome operation, etc. Achieve the effect of good high temperature resistance, good agglomeration and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

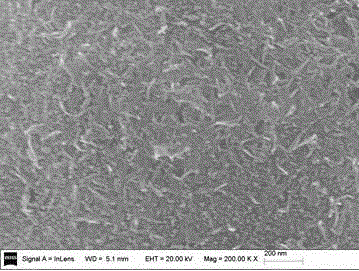

Image

Examples

Embodiment 1

[0030] (1) Preparation of alumina sol

[0031] Weigh 1.8g of anhydrous aluminum chloride as the precursor of alumina airgel, place it in a 100ml beaker, add 5ml of anhydrous methanol and 5ml of deionized water, and stir fully at 15°C to dissolve the aluminum salt until the formation of anhydrous color transparent solution.

[0032] (2) Preparation of silica and zirconia hybrid gel

[0033] Weigh 8ml of tetraethyl orthosilicate as the precursor of silica airgel and 0.4g of zirconium oxychloride as the precursor of zirconia, place them in a 100ml beaker, add 5ml of anhydrous methanol and 5ml of deionized water, at 15°C Stir well until a colorless and transparent solution is formed.

[0034] (3) Preparation of alumina, silica, zirconia ternary gel

[0035] Mix the prepared alumina sol with silica and zirconia sol, add 6ml of methyl propylene oxide, stir for 60 minutes to obtain a ternary sol, and let it stand to obtain a gel;

[0036] (4) Aging

[0037] The o...

Embodiment 2

[0042] (1) Preparation of alumina sol

[0043] Weigh 1.8g of anhydrous aluminum chloride as the precursor of alumina airgel, place it in a 100ml beaker, add 10ml of anhydrous methanol and 8ml of deionized water, and stir well at 15°C to dissolve the aluminum salt until the formation of anhydrous color transparent solution.

[0044] (2) Preparation of silica and zirconia hybrid gel

[0045] Weigh 0.4ml of methyl orthosilicate as the precursor of silica airgel and 0.54g of zirconia nitric acid as the precursor of zirconia, place them in a 100ml beaker, add 10ml of anhydrous methanol and 5ml of deionized water, at 15 Stir well at ℃ until a colorless transparent solution is formed.

[0046] (3) Preparation of alumina, silica, zirconia ternary gel

[0047]Mix the prepared alumina sol with silica and zirconia sol, add 8ml of methyl propylene oxide, stir for 70 minutes to obtain a ternary sol, and let stand to obtain a gel;

[0048] (4) Aging

[0049] The obtained te...

Embodiment 3

[0054] (1) Preparation of alumina sol

[0055] Weigh 2.5g of aluminum chloride hexahydrate as the precursor of alumina airgel, place it in a 100ml beaker, add 10ml of anhydrous methanol and 4ml of deionized water, stir well at 15°C to dissolve the aluminum salt until the formation of color transparent solution.

[0056] (2) Preparation of silica and zirconia hybrid gel

[0057] Weigh 0.8ml of methyl orthosilicate as the precursor of silica airgel and 0.63g of zirconia nitric acid as the precursor of zirconia, place them in a 100ml beaker, add 10ml of anhydrous methanol and 7ml of deionized water, at 15 Stir well at ℃ until a colorless transparent solution is formed.

[0058] (3) Preparation of alumina, silica, zirconia ternary gel

[0059] Mix the prepared alumina sol with silica and zirconia sol, add 9ml of methyl propylene oxide, stir for 80 minutes to obtain a ternary sol, and let it stand to obtain a gel;

[0060] (4) Aging

[0061] The obtained ternar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com