Patents

Literature

886 results about "Zirconium oxychloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

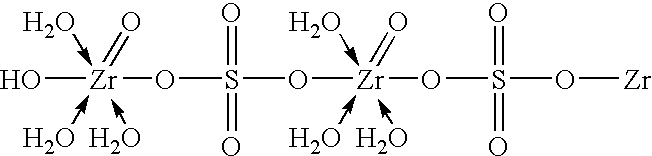

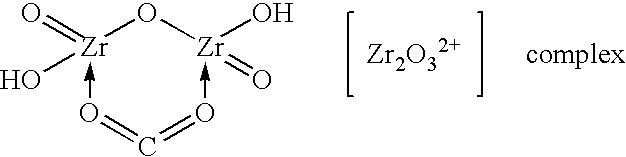

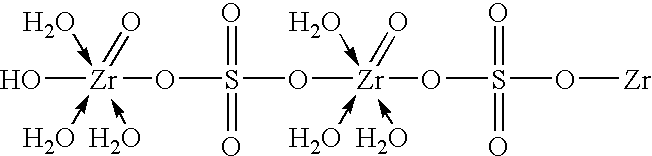

Zirconyl chloride is the inorganic compound with the formula of [Zr4(OH)8(H2O)16]Cl8(H2O)12, more commonly written ZrOCl2*8H2O, and referred to at zirconyl chloride octahydrate. It is a white solid and is the most common water-soluble derivative of zirconium.

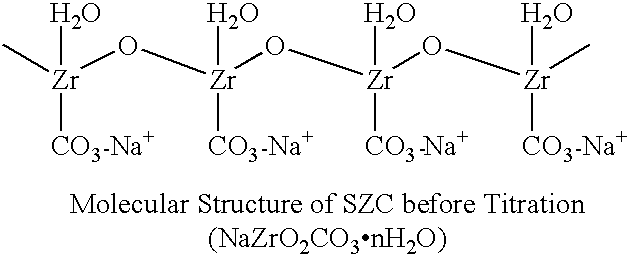

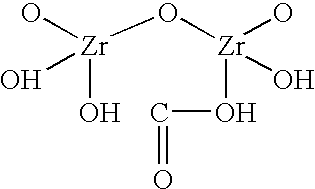

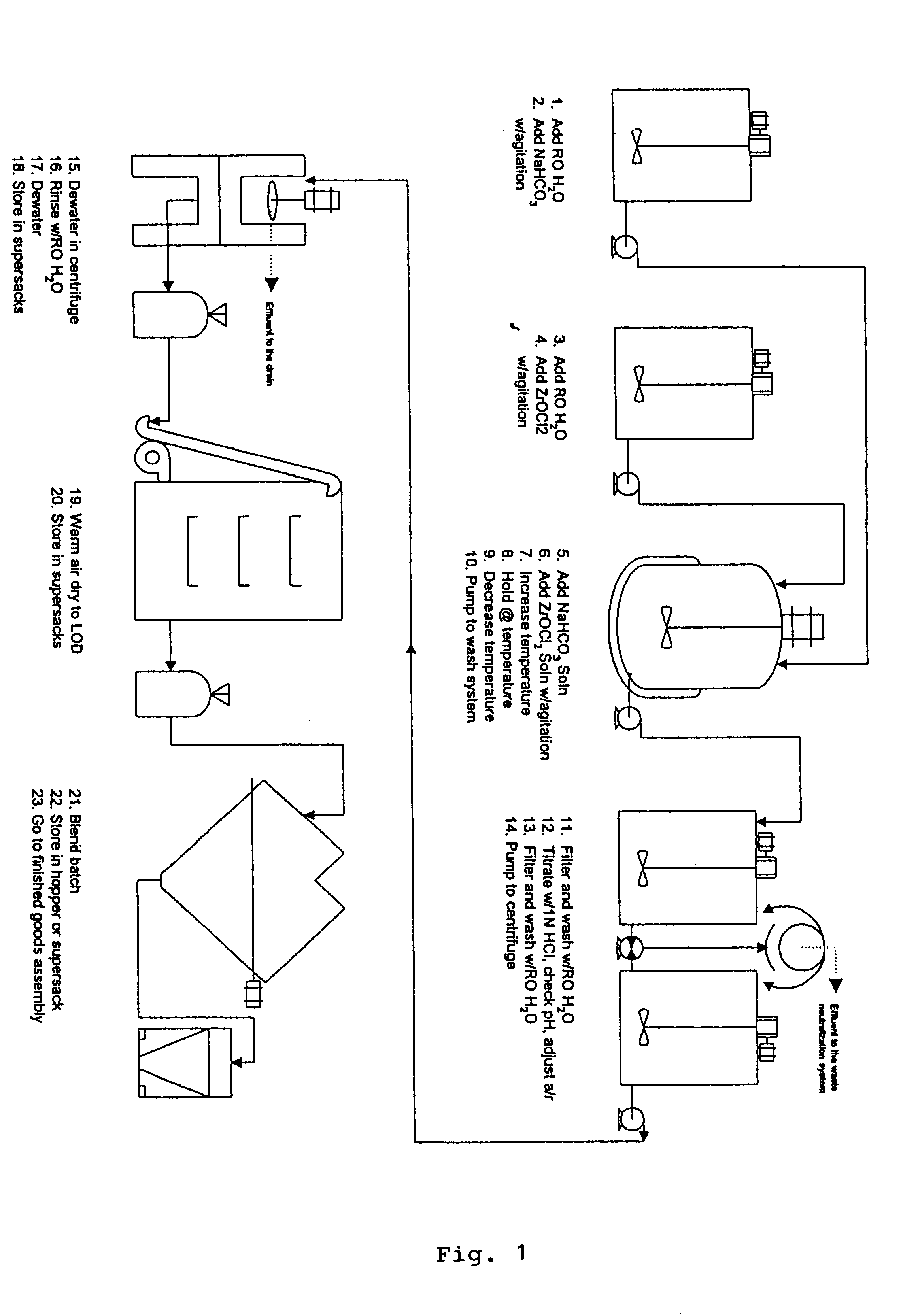

Sodium zirconium carbonate and zirconium basic carbonate and methods of making the same

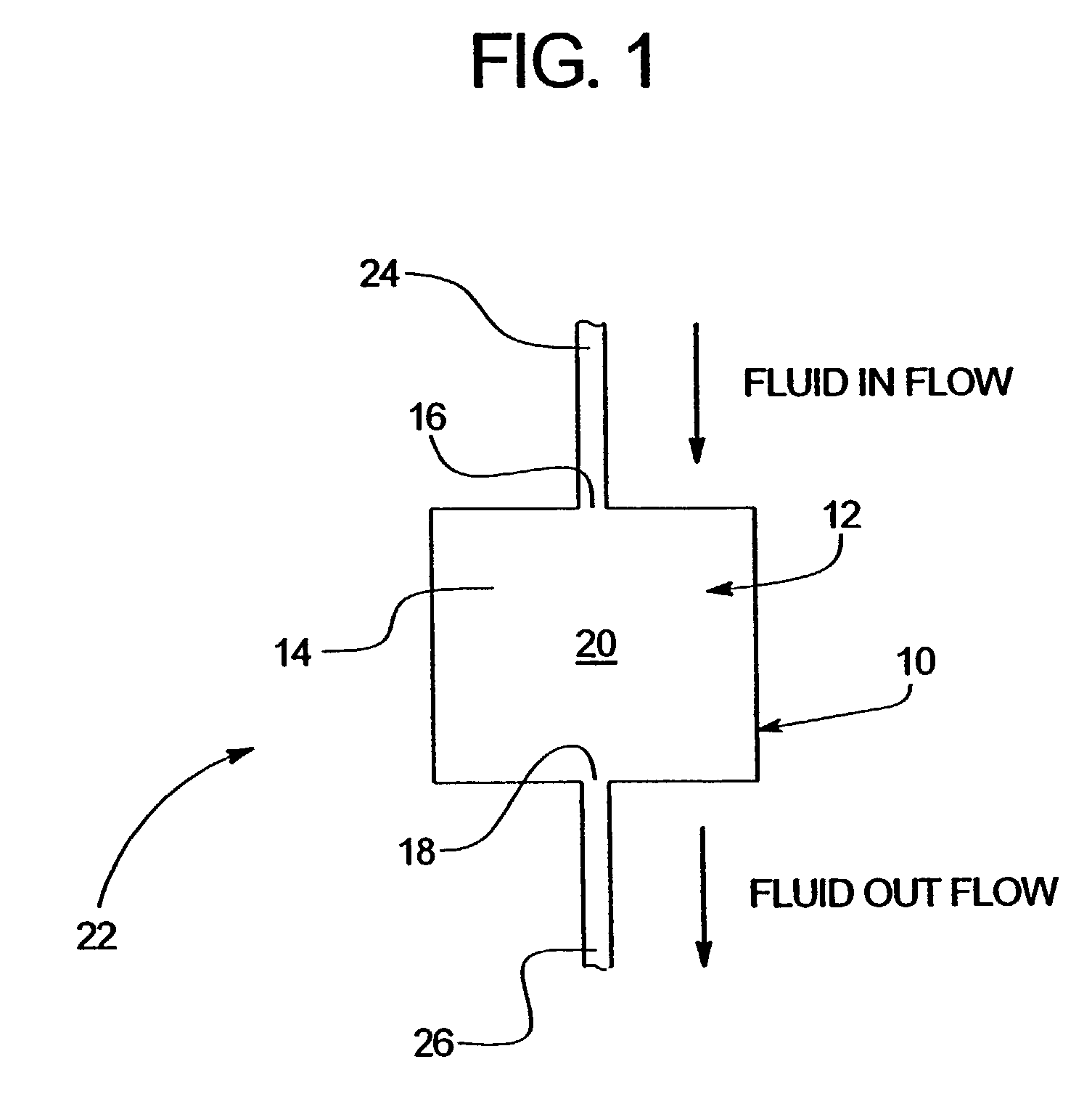

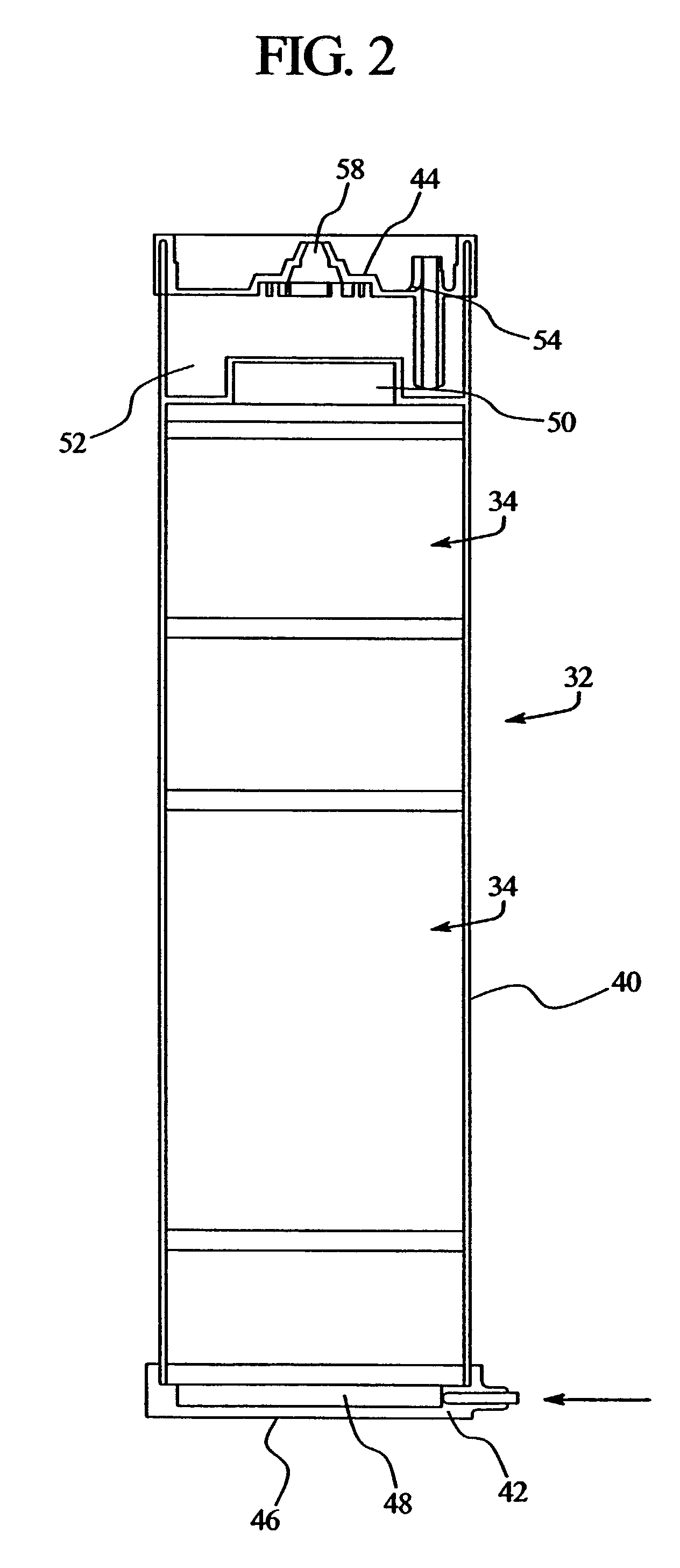

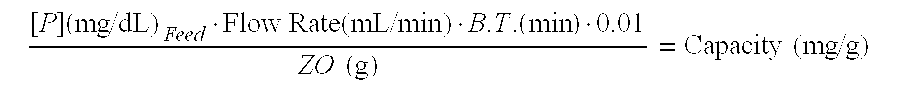

InactiveUS6627164B1Quality improvementImprove adsorption capacityHeavy metal active ingredientsOther chemical processesSufficient timeFiltration

A method of making sodium zirconium carbonate is described which involves forming a mixture of zirconium oxychloride with soda ash and then heating at a sufficient temperature and for a sufficient time to form the sodium zirconium carbonate. Subsequent washing and filtration steps can further form parts of this process. A novel sodium zirconium carbonate is further described which contains from about 2 wt % to about 5 wt % Na<+>; from about 44 wt % to about 50 wt % ZrO2; from about 12 wt % to about 18 wt % CO3<2->; and from about 32 wt % to about 35 wt % H2O.

Owner:RENAL SOLUTIONS

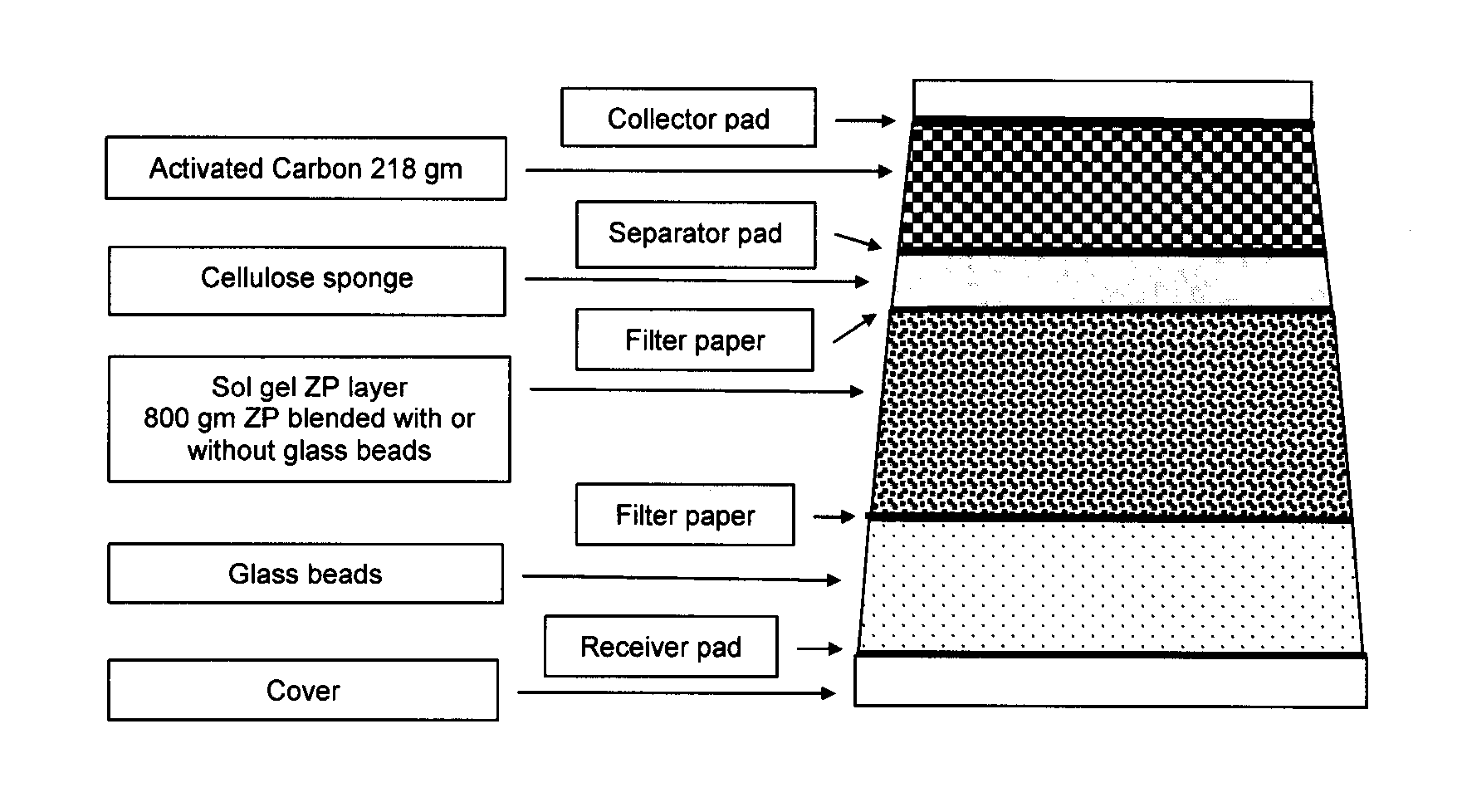

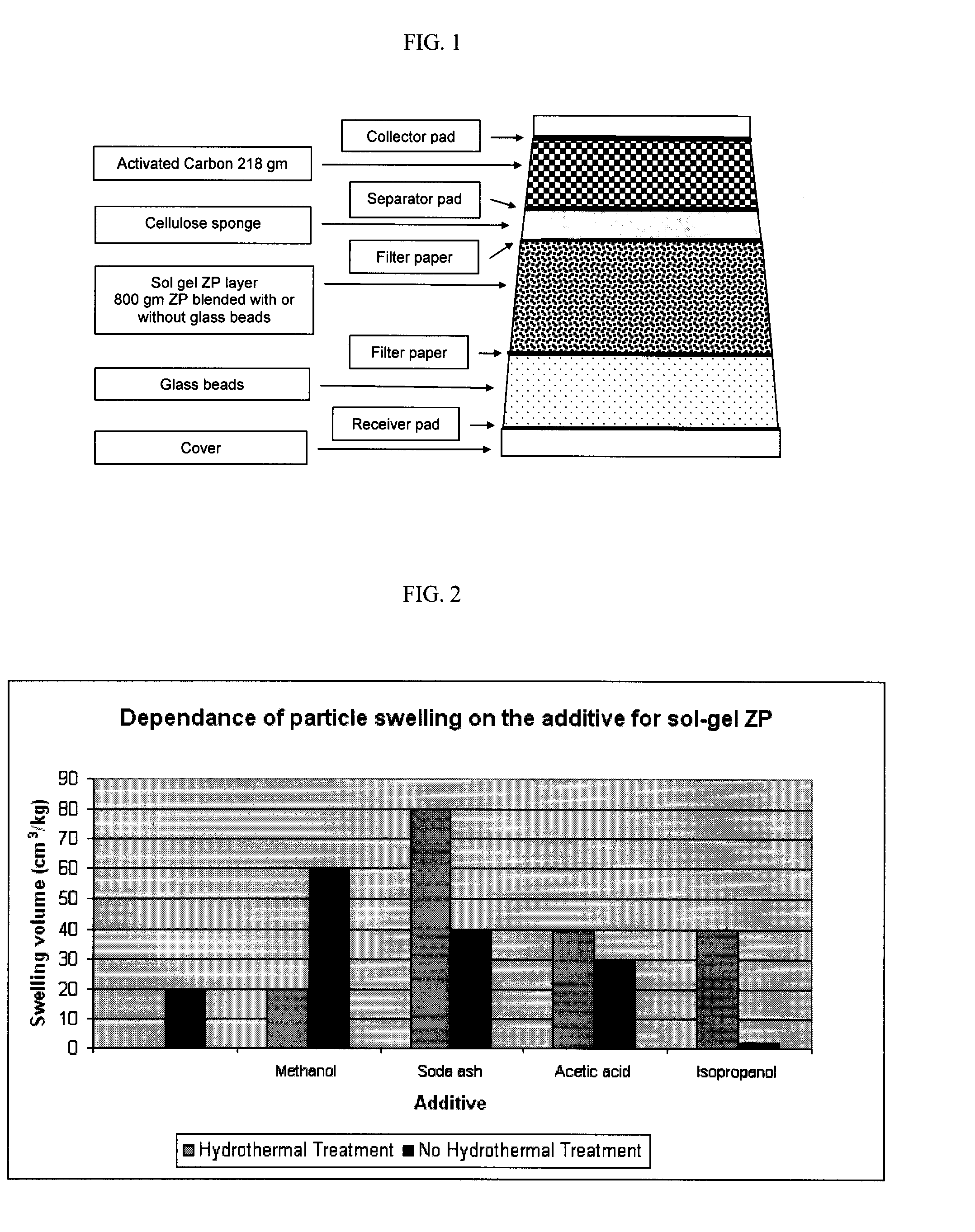

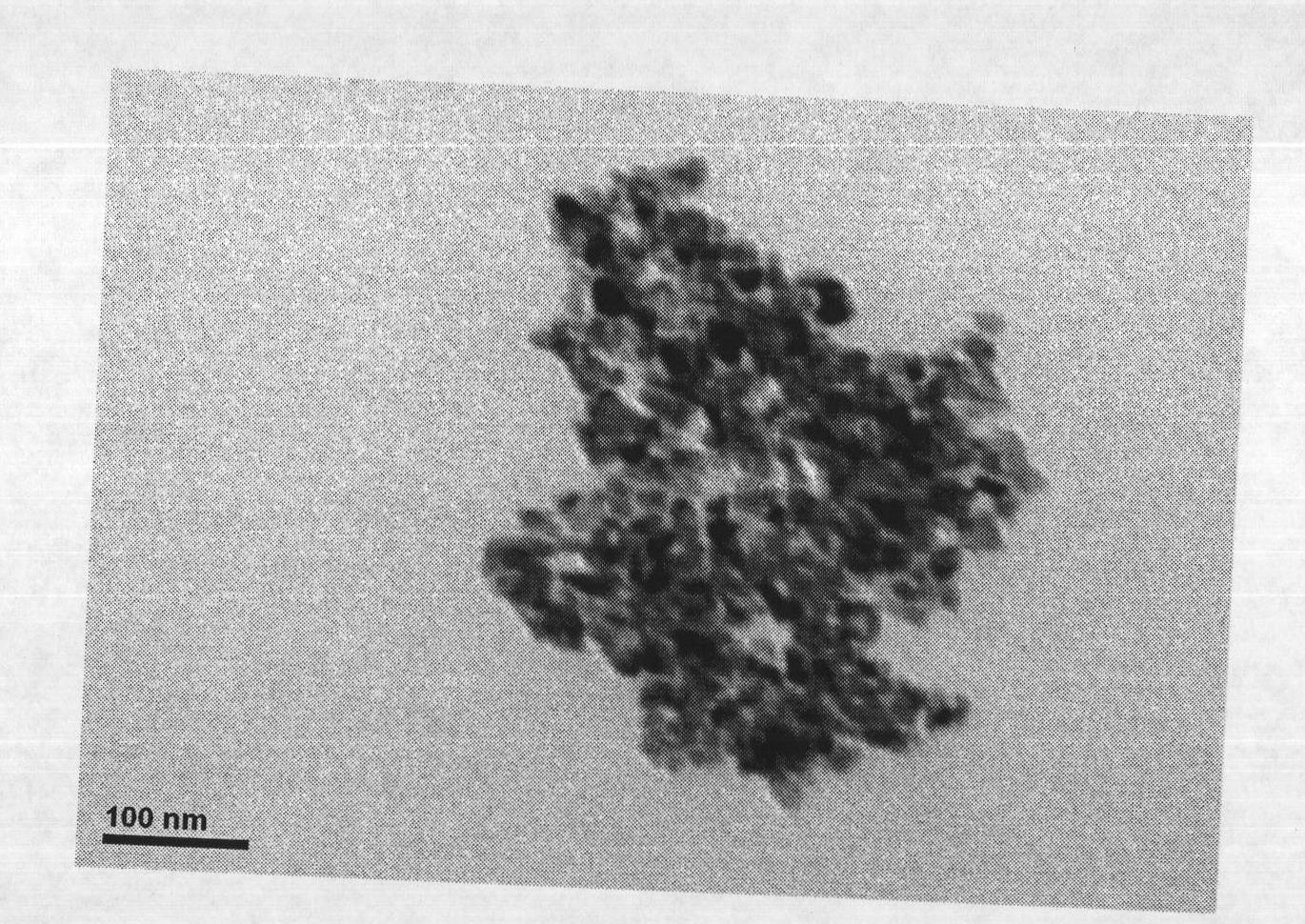

Method of synthesizing zirconium phosphate particles

InactiveUS7566432B2Inhibition of agglomerationReduce moistureSemi-permeable membranesPhosphatesO-Phosphoric AcidZirconium oxychloride

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one oxygen-containing additive to the solution, the oxygen-containing additive being selected to form a complex with zirconium ions in the solution of zirconium oxychloride and thereby reduce hydration of the zirconium ions, and combining this solution with phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:RENAL SOLUTIONS

Zirconium Phosphate Particles Having Improved Adsorption Capacity and Method Of Synthesizing The Same

InactiveUS20100084330A1Avoid disadvantagesHigh porosityPhosphatesDialysis systemsPhosphoric acidOxygen

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one low molecular weight, oxygen containing, monofunctional, organic additive to the solution, and combining this solution with heated phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Method of synthesizing zirconium phosphate particles

InactiveUS20060140840A1Avoid disadvantagesInhibition of agglomerationSemi-permeable membranesPhosphatesPhosphoric acidSolvent

Zirconium phosphate particles are synthesized by providing a solution of zirconium oxychloride in an aqueous solvent, adding at least one oxygen-containing additive to the solution, the oxygen-containing additive being selected to form a complex with zirconium ions in the solution of zirconium oxychloride and thereby reduce hydration of the zirconium ions, and combining this solution with phosphoric acid or a phosphoric acid salt to obtain zirconium phosphate particles by sol gel precipitation.

Owner:RENAL SOLUTIONS

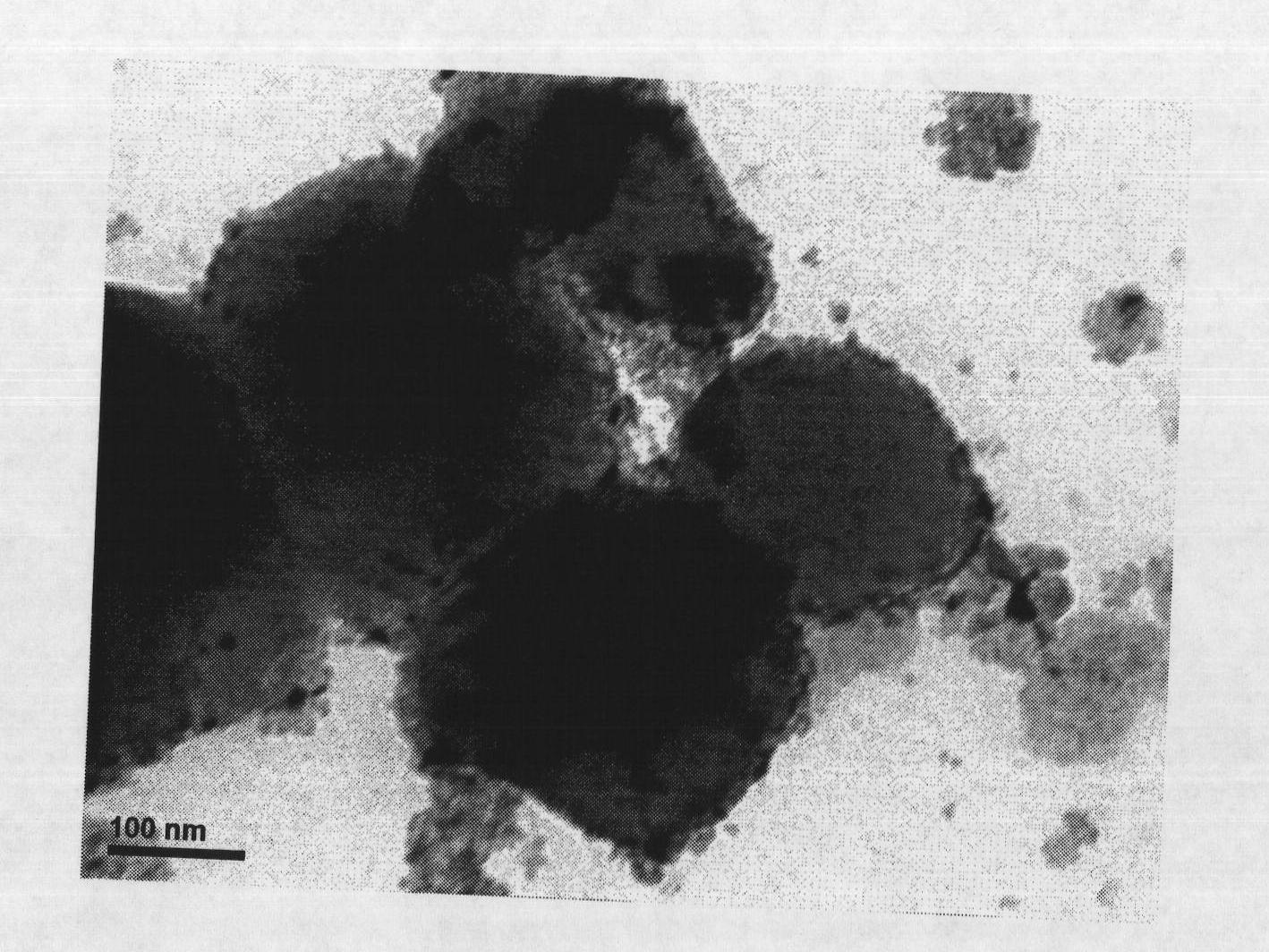

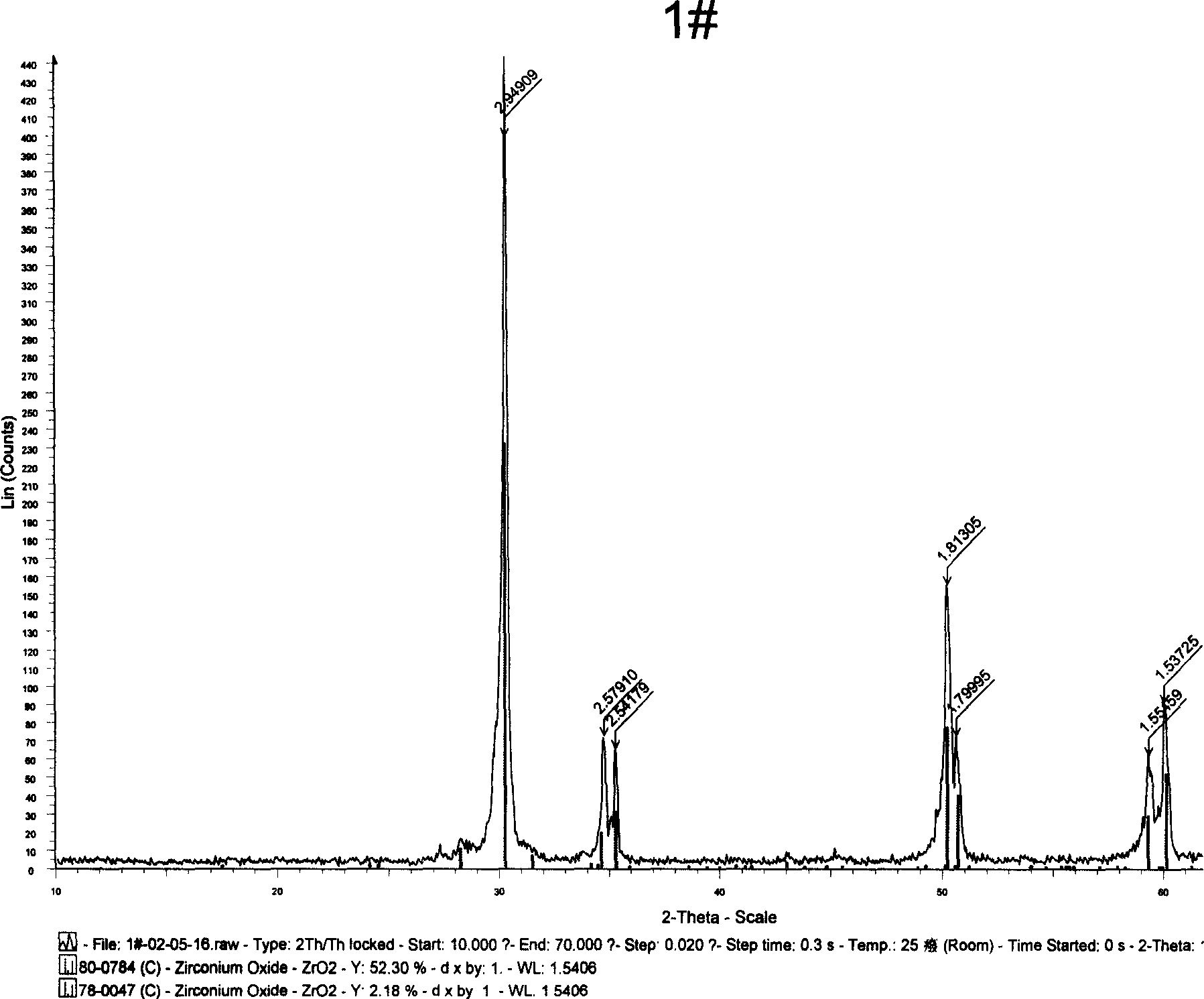

Method for processing a zirconium oxide composition in crystalline form

ActiveUS7135156B2Simple methodImprove adsorption capacityTitanium compoundsZirconium oxidesZirconium oxychlorideHydrolysis

Methods of producing zirconium oxide compositions and using same are provided. The zirconium oxide compositions in crystalline form can be prepared by a synthetic process wherein the hydrolysis of zirconyl chloride and particle formation can be achieved simultaneously. Alternatively, the particle formation can occur first and then followed by hydrolysis with a base solution. The processes utilize a zirconyl salt solution that includes a zirconyl salt in isopropanol and water.

Owner:BAXTER INT INC +1

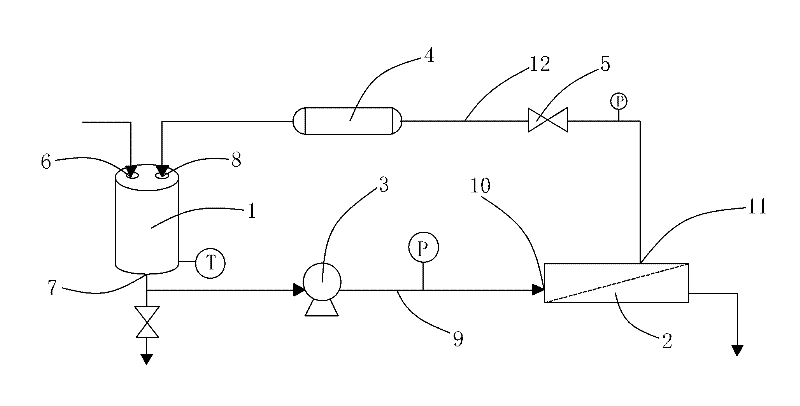

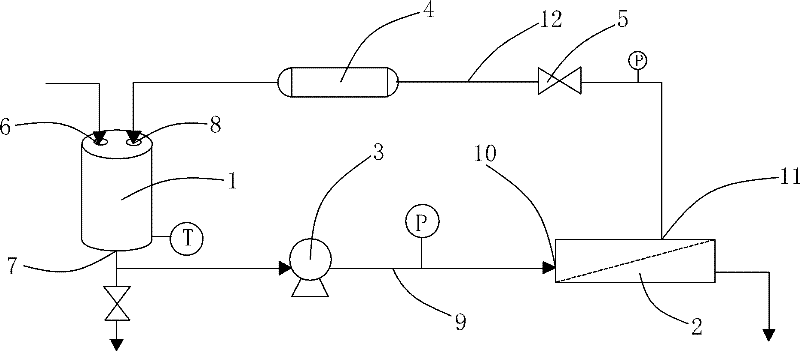

Method and equipment of preparing high performance zirconium oxide continuous fiber

InactiveCN1459418AGood effectHigh molecular weightInorganic material artificial filamentsZirconium oxidesFiberStructure and function

A process for preparing high-performance continuous fibre of zirconium oxide includes such steps as synthesizing acetylacetone-zirconium polymer as precursor from acetylacetone and zirconium oxychloride as main materials, dissolving in methanol to obtain the spinning solution, drying spinning to obtain continuous fibre of precursor, heat treating in a multifunctional sintering furnace by special atmosphere and high-temp. airflow spraying for stretching. Its advantages are high tensile strength (over 2.6 GPa) and long length up to several kilometers.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

Crosslinked acid sand fracturing acid liquor

ActiveCN101724389ALow viscosityCompletely broken glueDrilling compositionReaction rateZirconium oxychloride

The invention relates to crosslinked acid sand fracturing acid liquor, comprising the following components in percentage by weight: 0.7% of thickening agent, 1.5% of cross-linking agent, 1.5% of corrosion inhibitor, 0.5% of surfactant, 0.15% of stabilizing agent, 20% of hydrochloric acid and 75.65% of water, wherein the thickening agent consists of the following components by weight percent: 6.61% of methacrylamidoethyltrimethylamine hydrochloride, 3.22% of acrylamide, 1.25% of acrylic acid, 9.52% of 2-acrylamide-2-methylpropanesulfonic acid, 6.15% of sodium hydroxide and 73.25% of deionized water; and the cross-linking agent consists of the following components in percentage by weight: 1% of zirconium oxychloride, 80% of formaldehyde and 19% of glyoxal. The crosslinked acid sand fracturing acid liquor can be cross-linked in 20% hydrochloric acid, the temperature resistance reaches 100 DEG C, the constant of reaction rate of acid-rock is 1.3744*10-6 (mol / cm<3>)(1-m)*(cm / s), and the viscosity of the gel-breaking liquid is less than 10 mPa.s.

Owner:PETROCHINA CO LTD

Method for preparing nanometer zirconium oxide for thermal barrier coating

InactiveCN1757605AImprove thermal shock resistanceGuaranteed compactnessZirconium oxidesChlorideZirconium oxychloride

A process for preparing zirconium oxide nano-particles used for coated thermal barrier layer includes such steps as preparing the mixed solution of zirconium oxychloride and yttrium oxide (or chloride), adding ammonia water, washing for dispersing, hydrothermal reaction to generate Y-stabilized ZrO2 nano-particles, separating, coating by aluminium oxide, drying, granulating and heat treating.

Owner:SHANDONG UNIV

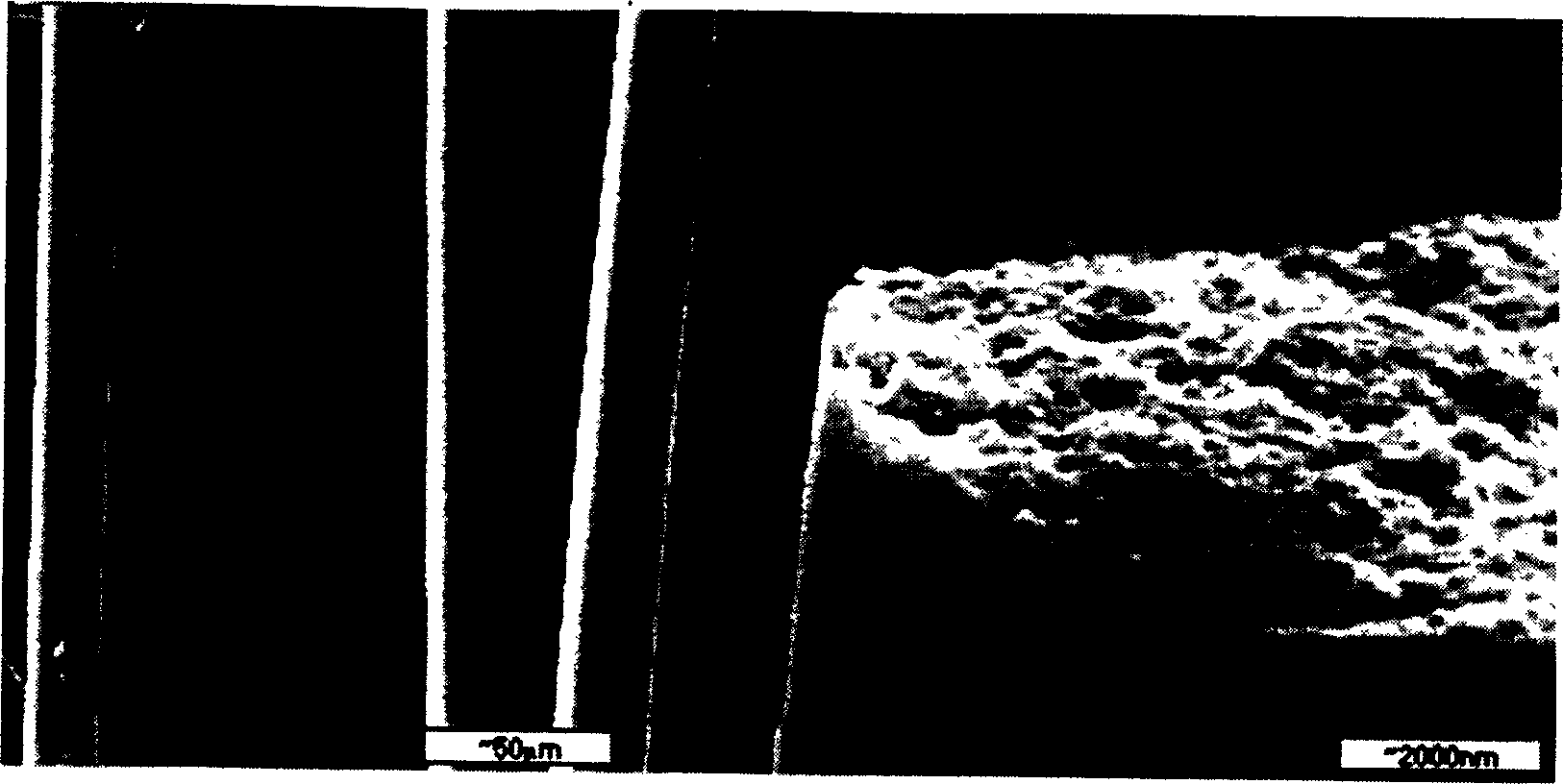

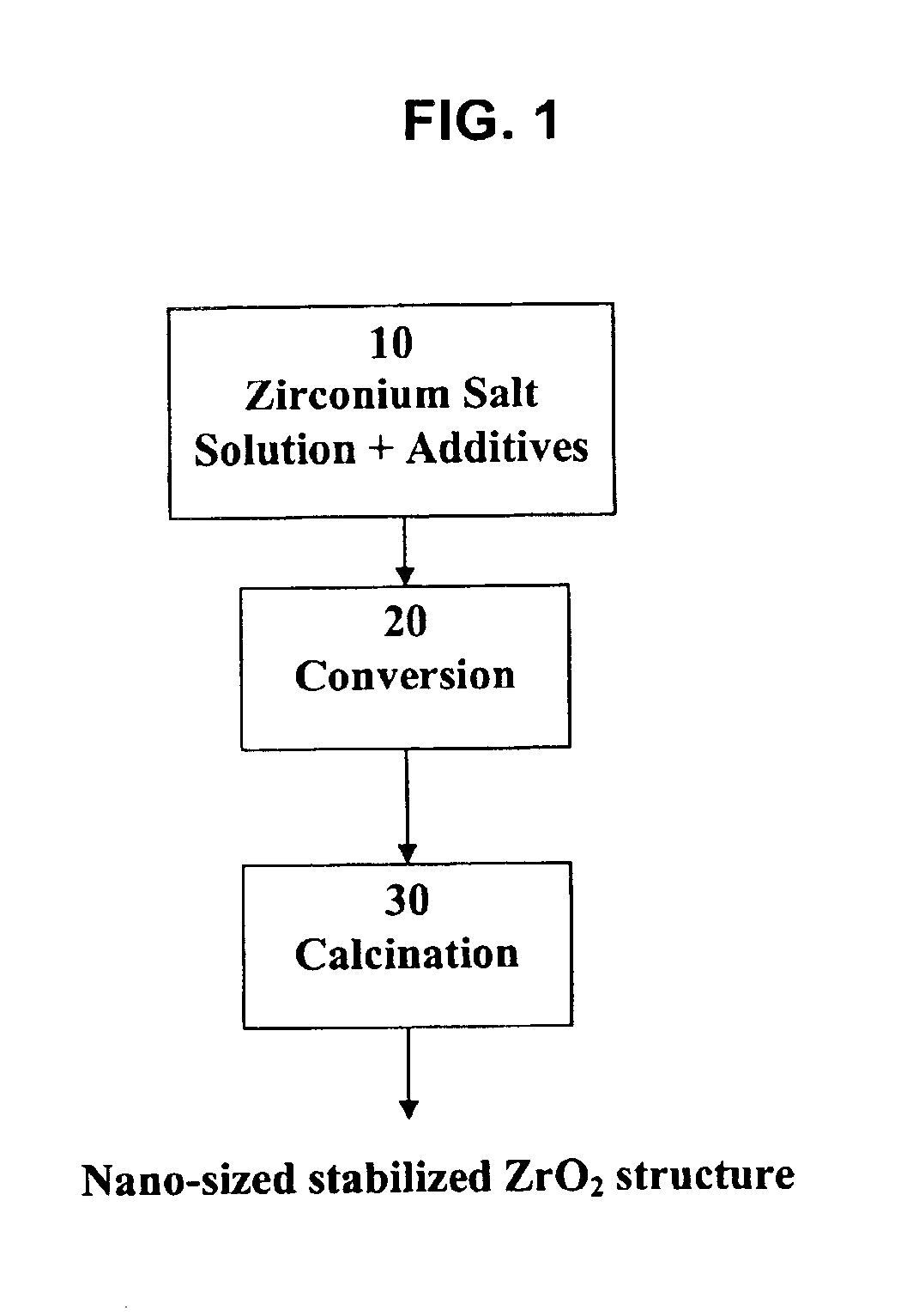

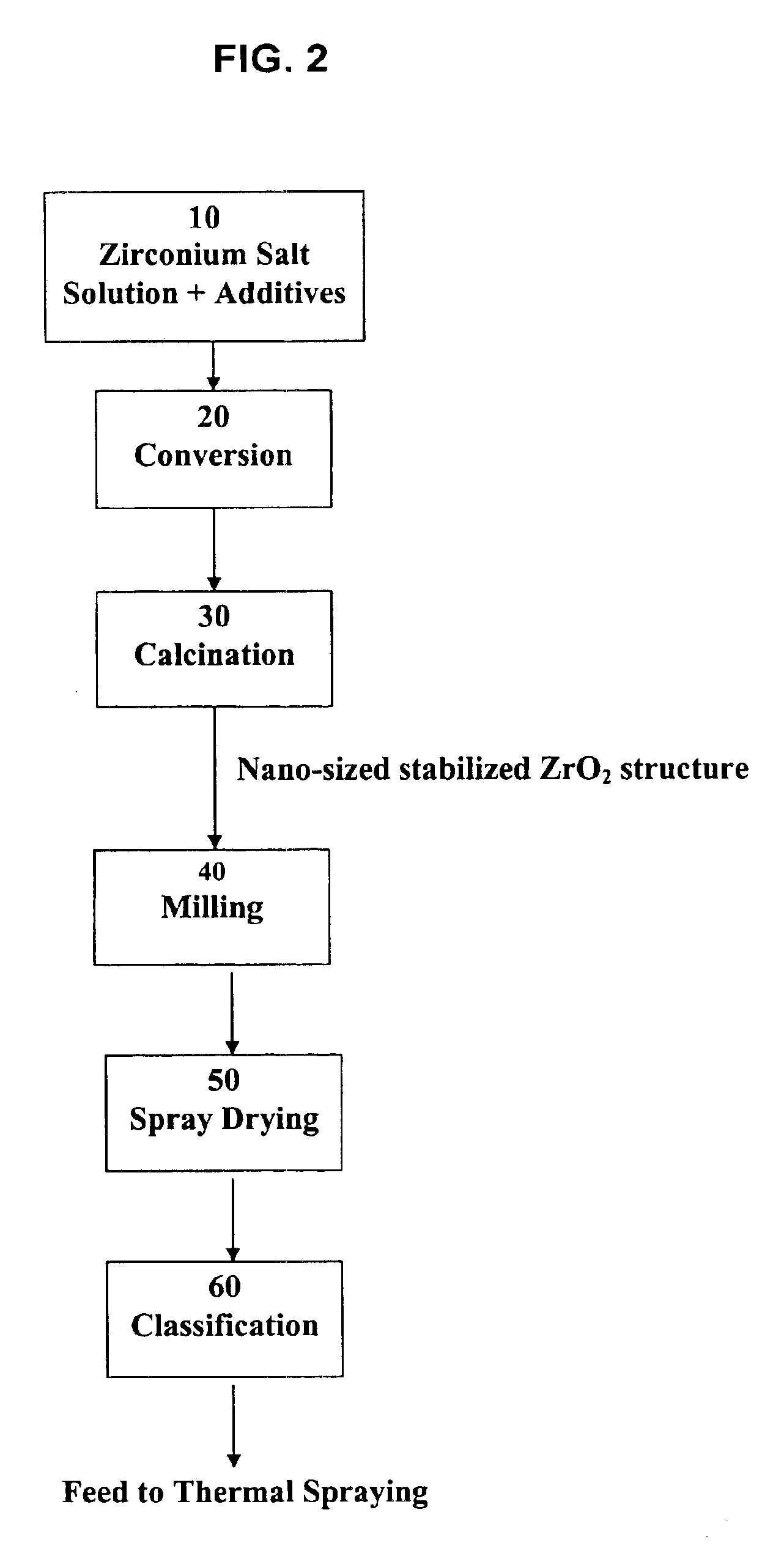

Process for making nano-sized stabilized zirconia

A process to produce stabilized zirconia from a solution of zirconium salt and a stabilizing agent. The zirconium salt may include zirconium oxysulfate, zirconium oxychloride, zirconium oxynitrate, zirconium nitrate, and other water-soluble zirconium salts. The stabilizing agent may include calcium, magnesium, yttrium salts of oxides and rare earth oxides. The process is conducted by evaporation of the solution above the boiling point of the solution but below the temperature where there is significant crystal growth. The evaporation step is followed by calcination to produce the desired nano-sized structure. Further processing by sintering may be applied to produce solid structures or by milling and classification to produce material for thermal spray coating.

Owner:ALTAIR NANOMATERIALS INC

Preparation method of nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent

ActiveCN102239887AImprove antibacterial propertiesControl non-cohesiveBiocideDisinfectantsDisplacement reactionsZirconium oxychloride

The invention discloses a preparation method of a nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent. The preparation method comprises the following steps of 1, a nanoscale zirconium phosphate carrier preparation step specifically comprising that enough sodium dihydrogen phosphate aqueous solution is added into zirconium oxychloride aqueous solution to undergo areaction to produce nanoscale zirconium phosphate carriers, 2, an ultrafiltration step specifically comprising that the nanoscale zirconium phosphate carriers obtained from the step 1 are added into an ultrafilter membrane system for ultrafiltration and when a result of a detection adopting silver ions shows that there is not chloride ions in filtrate, the ultrafiltration is completed, 3, an antimicrobial metal ion adsorption and displacement step specifically comprising that nanoscale zirconium phosphate carrier sol precipitates are dissolved in pure water and then antimicrobial metal ion aqueous solution is added into the nanoscale zirconium phosphate carrier sol precipitate aqueous solution to undergo complete adsorption and displacement reactions, and 4, an inorganic antimicrobial powder preparation step specifically comprising that reaction products obtained from the step 3 are filtered by a pump and washed to form filter cakes and the filter cakes is dried by an oven, crushed slightly and calcined to form finished products. The preparation method removes an inorganic salt by-product from a zirconium phosphate synthesis process through adopting an ultrafilter membrane thus enables zirconium phosphate carriers to be utilized directly for adsorption and displacement of metal ions without high-temperature calcination.

Owner:SANDA FILM SCI & TECH XIAMEN

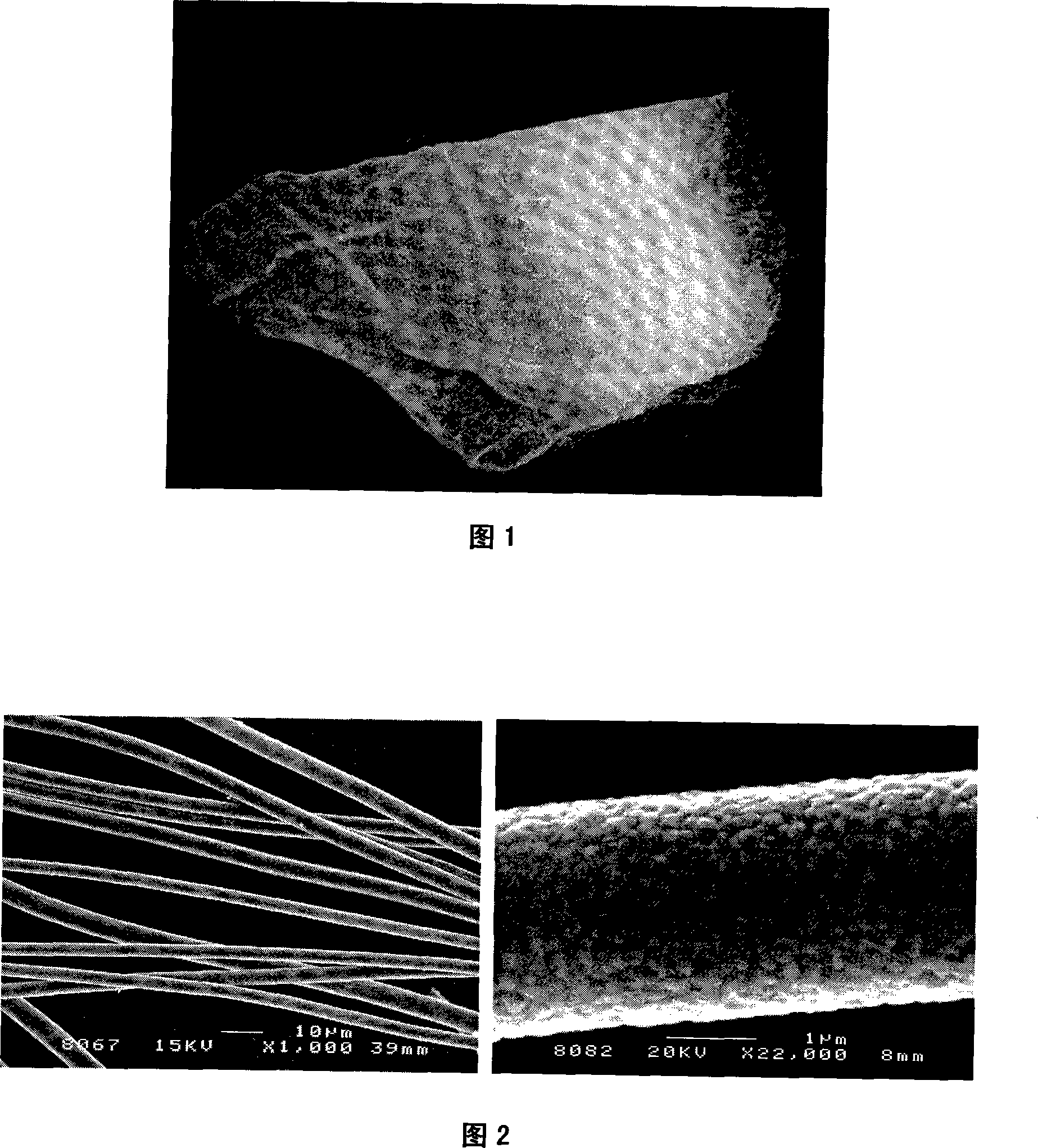

Method for preparing zirconium oxide refractory fibre

The present invention provides a method for preparing a zirconium oxide refractory fiber. The method adopts zirconium oxychloride, aqueous hydrogen peroxide solution, yttrium chloride or yttrium nitrate as raw material, the inorganic zirconium spinnable glue solution is made by reaction and compression, the gelatinous fiber can be obtained by centrifugal fiber forming, and after heat treating sintering the zirconium oxide refractory fiber which has the following advantages can be obtained: crystal phase composition with square phase and / or cubic phase zirconium oxide, purity up to 99.5% above, diameter around 5 mu m, length approximate continuous, soft and flexible property and without slag including sphere. The using temperature of the fiber is above 1600 DEG C, the material can be used as extreme temperature refractory, heat insulation material, protecting material, ablative material, satellite battery separator material and the like, used for the fields of aerospace, war industry and national defense, atomic energy and the like; the fiber can also be used as the flame-proof heat-insulating material of the extraordinary high-temperature electric furnace with temperature 1600 DEG C to 2200 DEG C, the oil or gas burning furnace and other extraordinary high-temperature heating mechanism, and is used for the fields of ceramic sintering, crystal growth, metal smelting, petroleum cracking, scientific researching and the like. The invention totally adopts the inorganic raw material, has the advantages of low cost, no pollution, simple technique and excellent effect.

Owner:山东红阳高温节能材料股份有限公司

Preparation of complete stable cubic phase zircite crystal fibre

InactiveCN101498063AGood effectSimple processFibre chemical featuresZirconium oxidesFiberPolymer solution

The invention relates to a method of preparing full-stable and cubic-phase zirconia crystal fibers, which mainly comprises the following steps: using zirconium oxychloride, acetylacetone and triethylamine as main raw material and using ethanol as diluent solvent to directly react at a temperature of 0 DEG C to 50 DEG C under a stirring condition so as to generate an organic polymer solution comprising zirconium; evaporating the ethanol and using acetone as solvent to dissolve soluble substances and filter and remove an undissolved substance of triethylamine hydrochloride; recycling the acetone, dissolving the obtained products and yttrium salt to the ethanol to prepare a spinning solution which is centrifugally flung at a high speed to obtain organic polymer fibers comprising zirconium; and carrying out heat treatment in a special atmosphere and ultra-high temperature treatment of the organic polymer fibers comprising zirconium. The invention has simple preparation technology and can recycle the solvent, and the prepared crystal fibers have single ingredients, high purity and stable high-temperature performance and can be used in a range from 1700 DEG C to 2150 DEG C for a long time.

Owner:SHANDONG UNIV +1

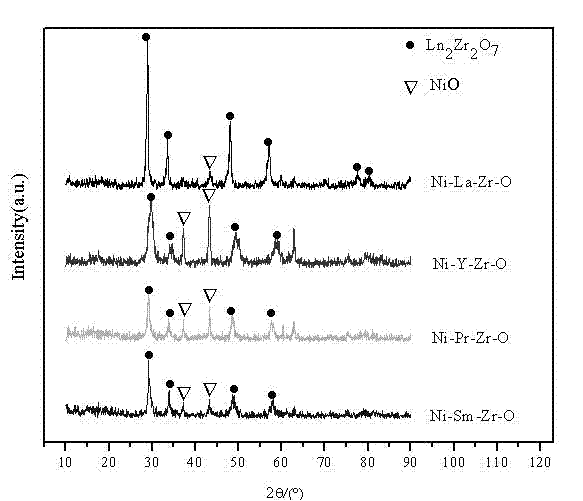

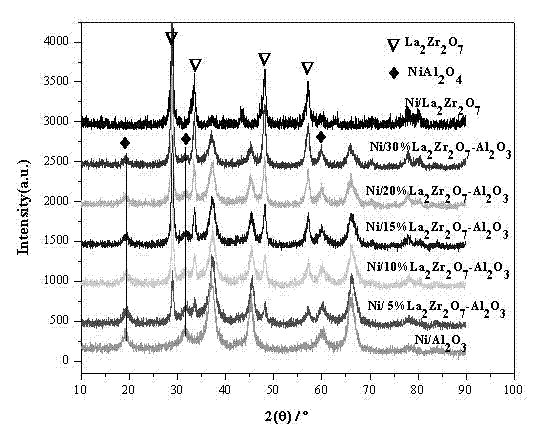

Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

ActiveCN103752319AMeet activityMeet service life requirementsHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

The invention relates to an anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and a preparation method thereof. By taking lanthanum nitrate, praseodymium nitrate, samarium nitrate, yttrium nitrate, zirconium nitrate, zirconium carbonate, zirconium oxychloride, and the like as precursors and taking ammonia as a precipitant, a pyrochlore composite oxide is prepared through using a coprecipitation method; and then the pyrochlore composite oxide is mixed with alumina by using a mechanical mixing method so as to obtain a pyrochlore alumina composite carrier. Nickel nitrate, nickel chloride, nickel sulfate, nickel oxalate and the like serving as nickel sources are loaded on the pyrochlore alumina composite carrier through direct immersion. The loading capacity of nickel in the catalyst accounts for 5-30% of the weight of the catalyst, the pyrochlore content of the catalyst is 5-50%, and the alumina content of the catalyst is 20-90%. By taking the pyrochlore alumina composite oxide as a carrier, the reaction activity and anti-carbon-deposition performance of the catalyst can be greatly increased; the preparation method of the catalyst is simple; and the catalyst has excellent catalytic activity and stability to methane steam reforming in a stationary bed.

Owner:NANCHANG UNIV +1

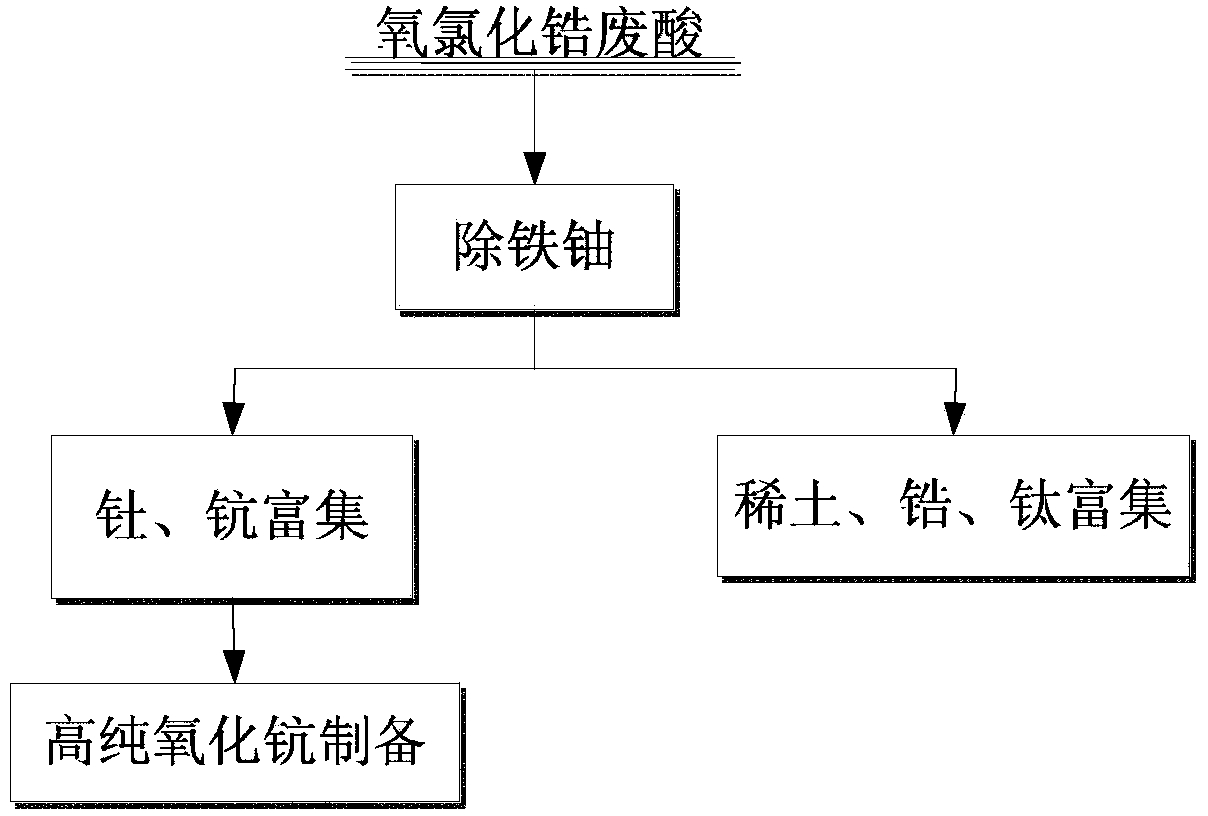

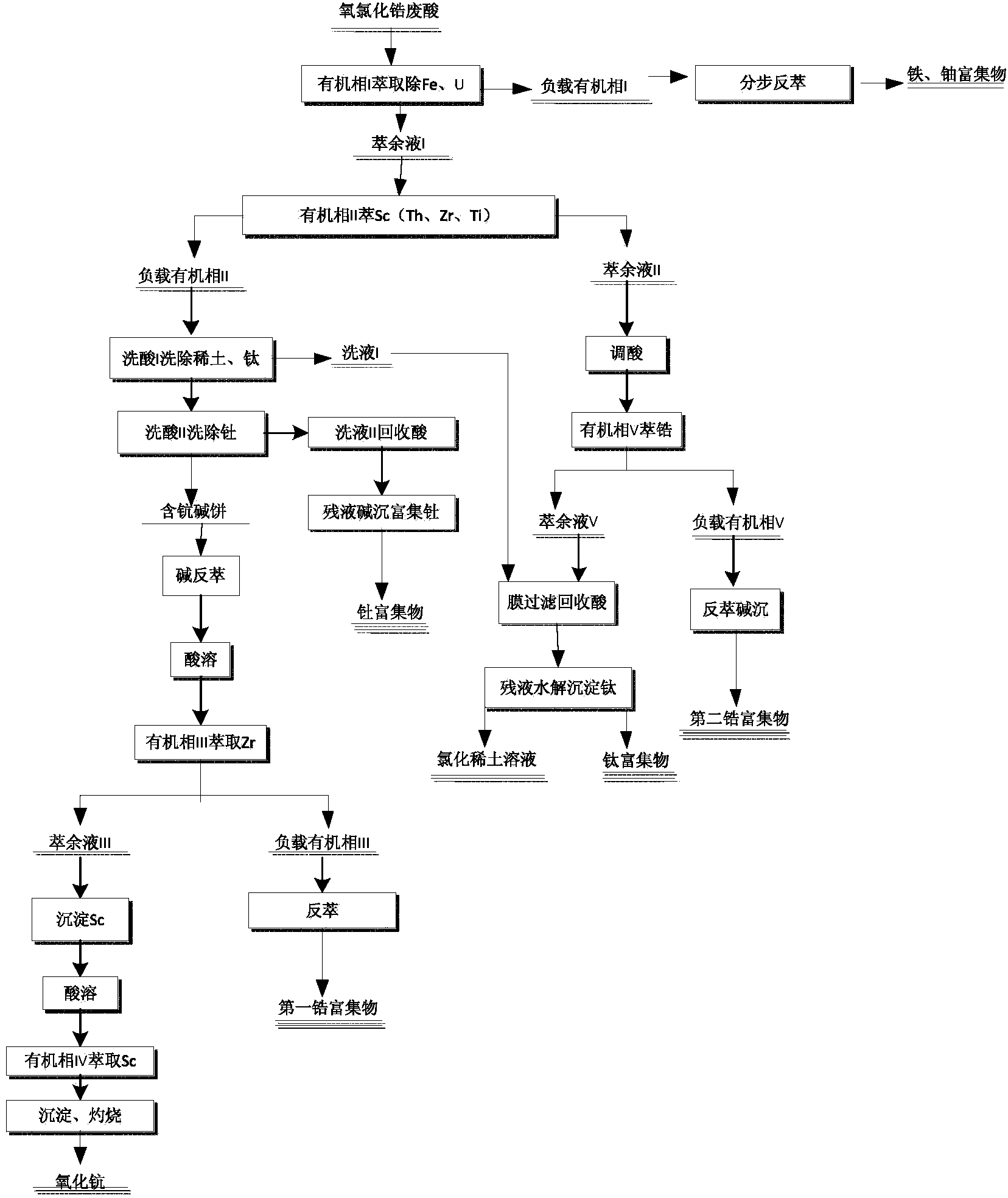

Method for comprehensively recovering multiple elements from zirconium oxychloride liquid waste

The invention provides a method for comprehensively recovering multiple elements from zirconium oxychloride liquid waste. The method comprises the following steps: (1) removing iron and uranium on zirconium oxychloride; (2) gathering scandium and thorium; (3) preparing a high-purity scandium oxide; and (4) gathering rare earth, zirconium and titanium. According to the method provided by the invention, through reasonable configuration of the recovering order of various elements from the zirconium oxychloride liquid waste, scandium enrichment capable of improving the purity by a subsequent purification method can be obtained just by virtue of a cheap extracting agent; and the adverse effects on purity improvement of the subsequently obtained scandium caused by irremovable zirconium and titanium, and radioactive elements thorium and uranium are avoided.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

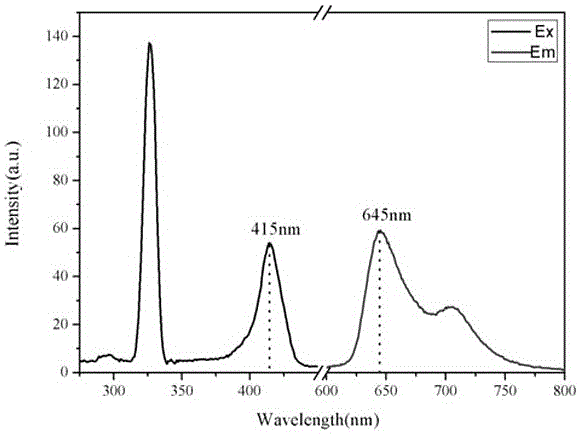

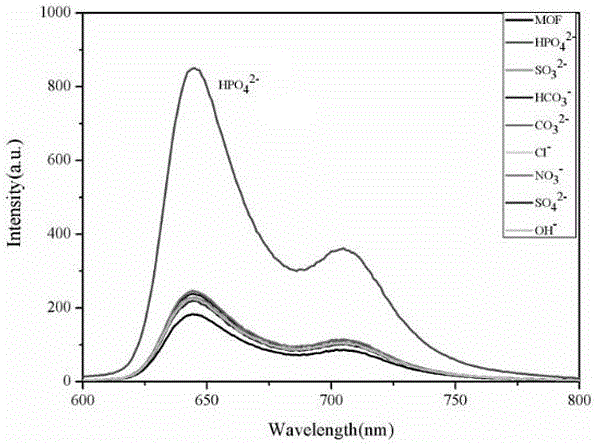

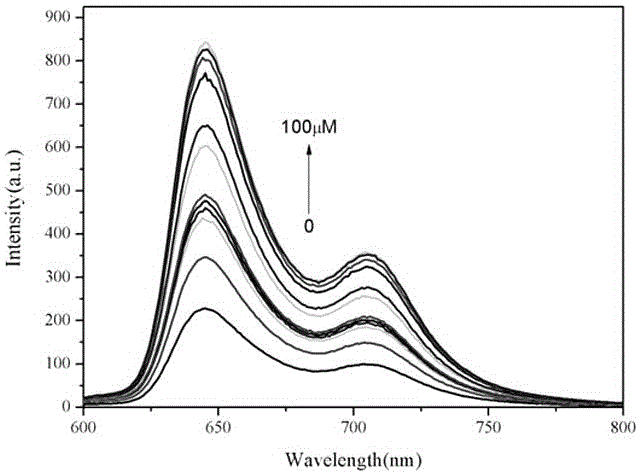

Application of zirconium-porphyrin metal-organic frameworks (MOFs) as fluorescent probes to detection of hydrogen phosphate ions

The invention discloses application of zirconium-porphyrin metal-organic frameworks (MOFs) as fluorescent probes to the detection of hydrogen phosphate ions. The zirconium-porphyrin MOFs are made by making 5,10,15,20-tetra(4-carboxylphenyl)porphyrin, benzoic acid and zirconium oxychloride react through a solvothermal method. In comparison with the prior art, according to the application, the zirconium-porphyrin MOFs are used as the fluorescent probes to detect phosphates; not only does the application have the advantages of being simple in method, being quick and being convenient to operate, but also Zr-O nodes in the zirconium-porphyrin MOFs have quite strong affinity interactions with the hydrogen phosphate ions; moreover, the zirconium-porphyrin MOFs have favorable dispersity in an aqueous solution and are easily recovered; thus, the detection on the hydrogen phosphate ions in the aqueous solution is realized.

Owner:临沂临联无机材料有限公司

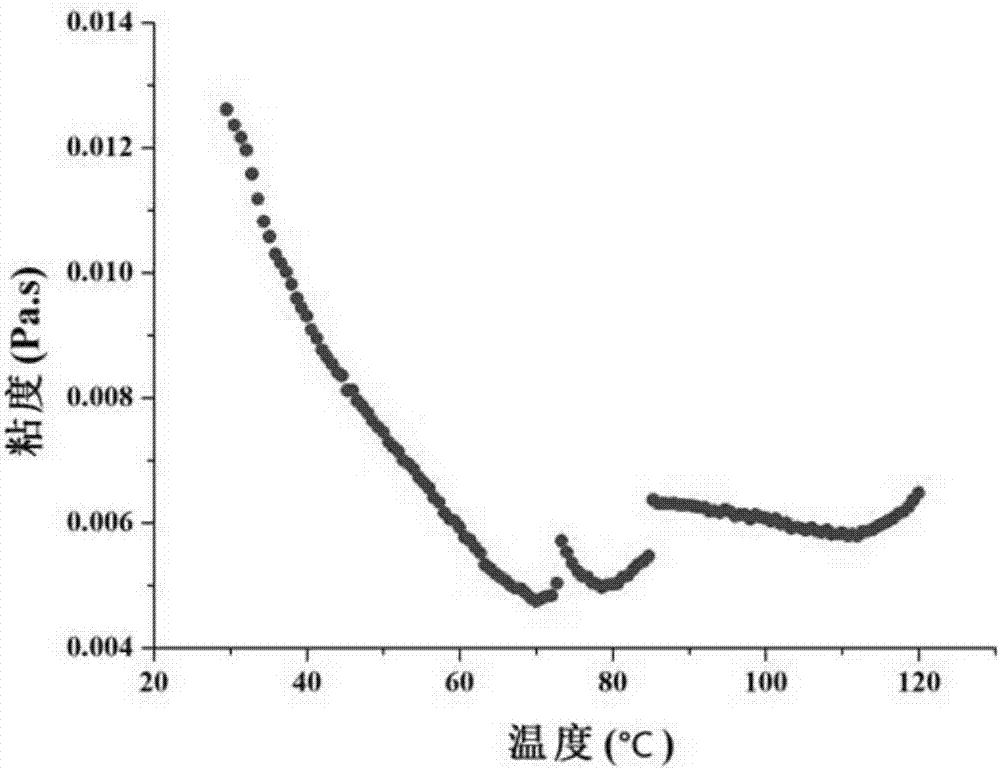

Ink for inkjet printing and preparation method as well as zirconia film printed by ink for inkjet printing

ActiveCN107151483AImprove flatnessImprove surface topographyInksPrintingPolymer scienceCoffee ring effect

The invention discloses an ink for inkjet printing and a preparation method as well as a zirconia film printed by the ink for the inkjet printing. The preparation method for the ink for the inkjet printing comprises the steps: (1) dissolving zirconium oxychloride in a mixed solvent to obtain a mixed solution, wherein the mixed solvent is prepared from ethylene glycol monomethyl ether and ethylene glycol in a volume ratio of (0.5 to 2) to (2 to 1)1; (2) adding PVP to the mixed solution obtained in the step (1), dissolving and standing to aging, and obtaining the ink for the inkjet printing. According to the ink for inkjet printing and the preparation method as well as the zirconia film printed by the ink for the inkjet printing, the polymer PVP is introduced in the process of preparing the ink for the inkjet printing, the viscosity and the dispersion of the solution are adjusted by due to the existence of the polymer, the system is more likely to generate gelatinization, and the flow of the liquid phase is restricted and the coffee-ring effect is weakened, so that the flatness of the surface of the zirconia film printed by the ink is improved.

Owner:SOUTH CHINA UNIV OF TECH

High purity ultra fine zirconium biboride powder and its preparation method

The present invention relates to a high-purity ultrafine zirconium diboride powder material and its preparation method. It is characterized by that the described powder material contains zirconium oxychloride, boron carbide powder and active carbon powder, their mole ratio is ZrOcl2:B4C:C=1:0.4-0.8:1.4-1.8. Its preparation method includes the following steps: firstly, mixing boron carbide powder, active carbon powder and water according to mixing ratio, regulating pH value to obtain mixed suspension; dissolving zirconium oxychloride in deionized water to obtain the zirconium oxychloride solution; mixing the above-mentioned suspension and zirconium oxychloride solution, adding ammonia water, making the zirconium oxychloride be fully hydrolyzed and precipitated; making suspension undergo the processes of solid-liquor separation, waster-washing, removing NH4+ and Cl-, drying and sieving; then placing the powder material into a vacuum furnace to make reaction synthesis, its synthesis temperature is 1500-1600 deg.C, heat-insulating for 0.5-4 h; grinding powder and sieving so as to obtain the invented powder material.

Owner:칭다오정왕철강수통제주식유한회사

Composite catalyst, preparation and application thereof

InactiveCN101829577AImprove stabilityExtended service lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsNitrateHydrogen

The invention discloses a composite catalyst, a preparation method and application thereof. The composite catalyst is used for absorbing and strengthening methane steam in a reaction for reforming and manufacturing hydrogen. The composite catalyst is prepared by compounding CaO using nanometer calcium carbonate as a precursor, active nickel component using nickel nitrate as a precursor, nano ZrO2 using zirconium oxychloride as a precursor, and an alumina carrier; the mol ratio of CaO: Al2O3: NiO: ZrO2 is 1: (0.05 to 2.0): (0.05 to 3.0): (0.005 to 1.0). The composite catalyst has a catalytic function and an absorbing function of carbon dioxide, enhances stability, prolongs service life, and can be recycled 20 times or above.

Owner:ZHEJIANG UNIV

Preparation process for superfine powder of zirconium oxide

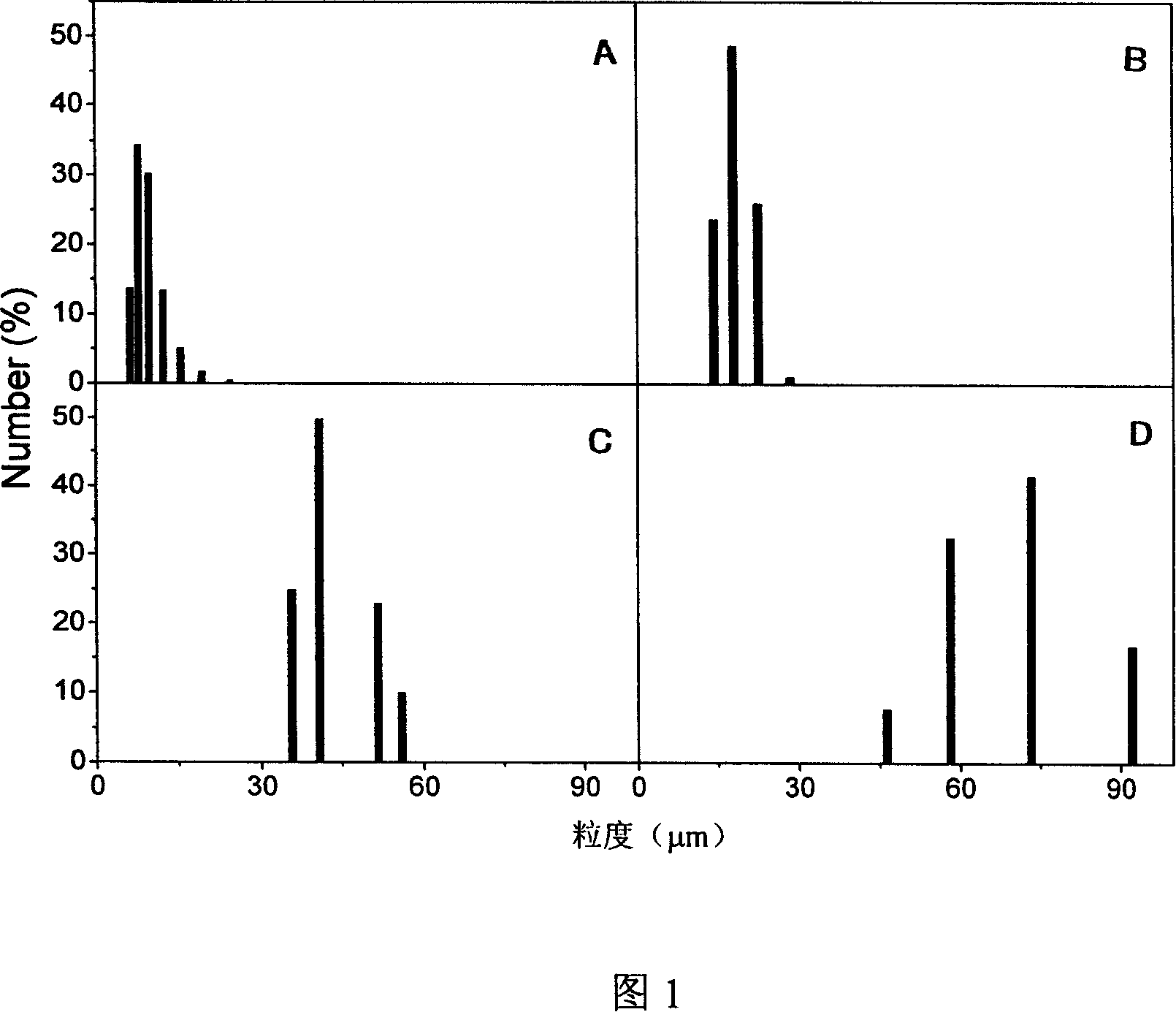

InactiveCN1559982AUniform particle size distributionNarrow particle size rangeZirconium oxidesGranularityMetallic materials

The invention relates to a ultrafine zirconium oxide (ZrO2) powder preparing method. ZrO2 is a high temperature-resistant, wearable, corrosion-resistant inorganic nonmetallic material, the proper-sized ultrafine ZrO2 powder is an important chemical raw material to prepare high-performance refined ceramics, like electronic ceramics, functional ceramics, structural ceramics, etc. and has increasingly wide applications in the technical fields of aviation, spaceflight, machinery, chemical engineering, electronics, automobiles, energy sources, etc. It adopts zirconium oxychloride and salvolatile as precursor raw material, uses uniform codeposition method to prepare wet ZrO2 gel, then drying at 100-150 deg.C at 0.3-1.0 MPa, and burning at 700-1000 deg.C to make ultrafine ZrO2 powder. It can obtain the ultrafine ZrO2 powder, particle size 0.1-0.5 mum, specific surface area 15-30 sq m / g and distribution range of particle size narrow. The ultrafine ZrO2 powder properly acts as the chemical raw material for refined ceramics.

Owner:HARBIN ENG UNIV

Preparation method of zirconium oxide colloidal sol

The present invention discloses a method for preparing zirconium oxide sol. Said method includes the following steps: using zirconium oxychloride as precursor body, using hydrogen peroxide as hydrolysis accelerating agent, utilizing strong oxidative property of hydrogen peroxide to make chlorine ions be reduced into chlorine gas and make said chlorine gas be overflowed so as to obtain the colloid whose particle size distribution is narrow. Said invention makes the zirconium oxychloride be dissolved in a proper quantity of mixed solution formed from alcohol, water and surfactant, uniformly mixes and stirs them, and selects proper surfactant, and utilizes a simple technological process to prepare high-purity and stable zirconium oxide sole whose particle size can be controlled and particle size distribution is narrow.

Owner:上海西源新能源技术有限公司

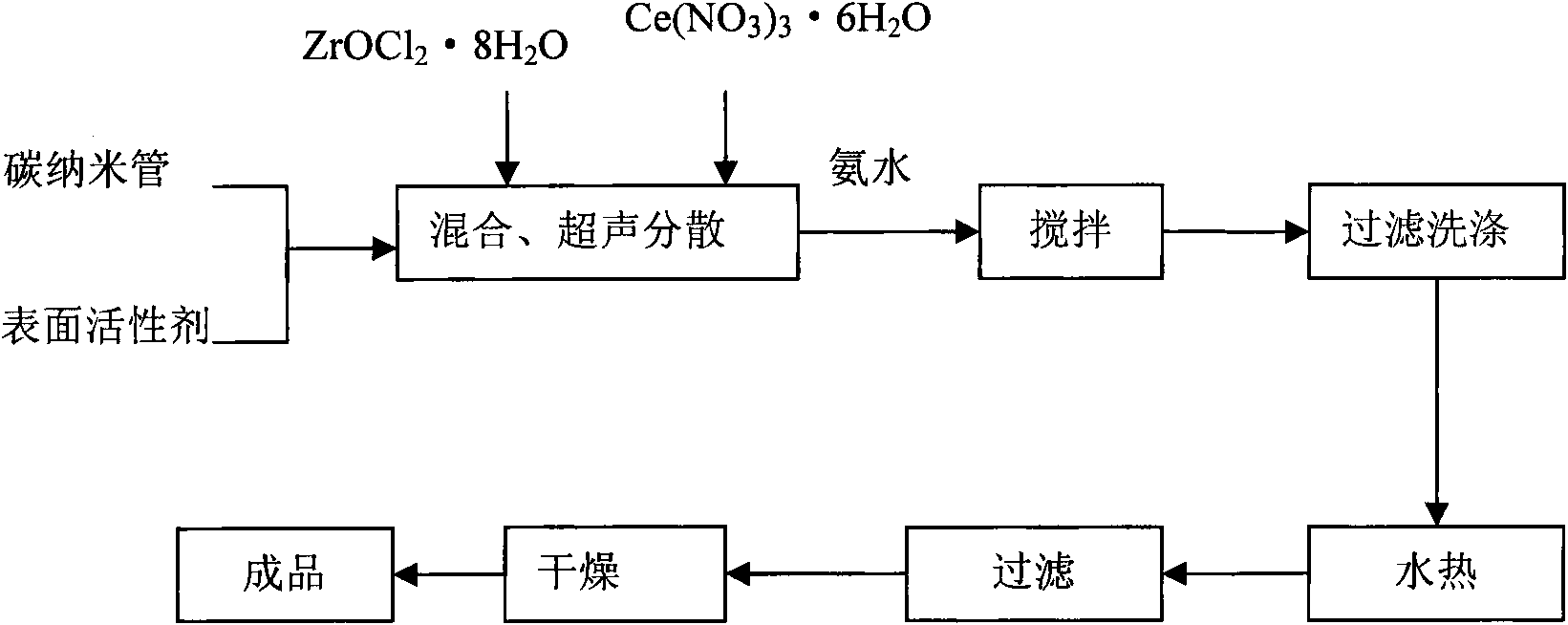

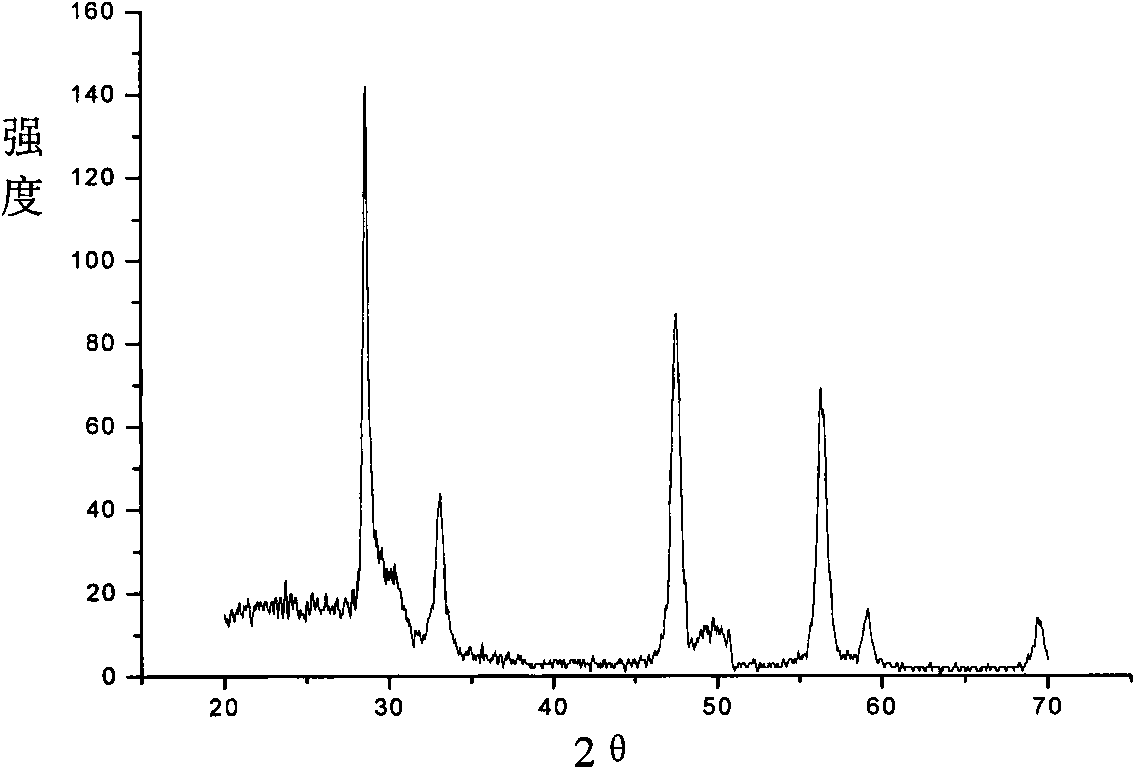

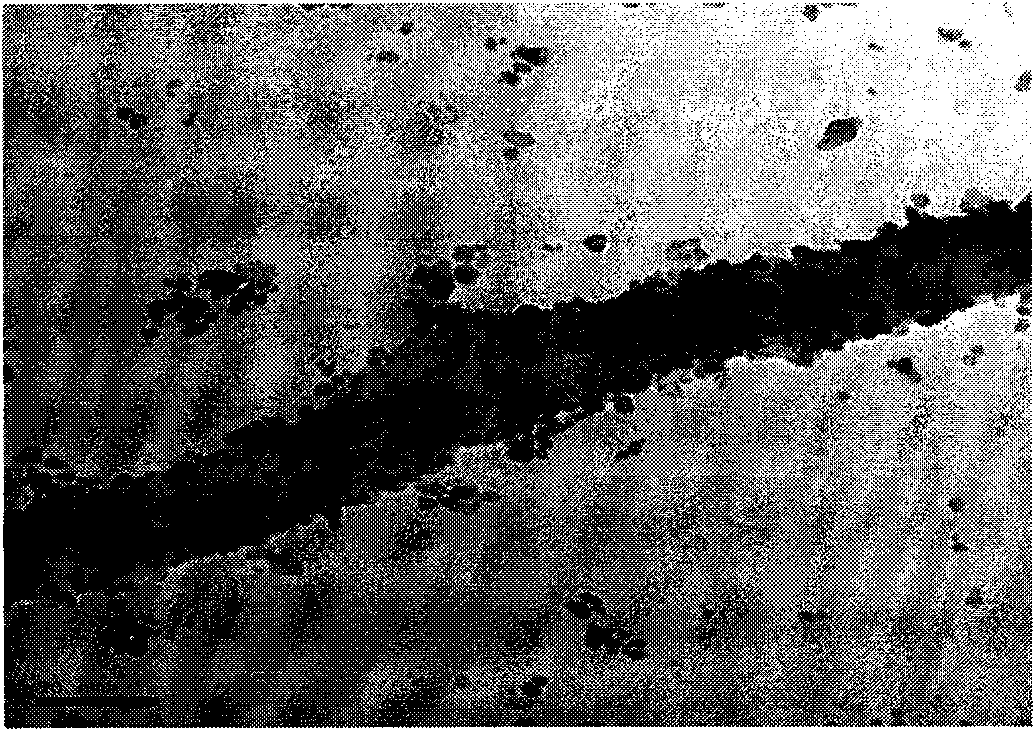

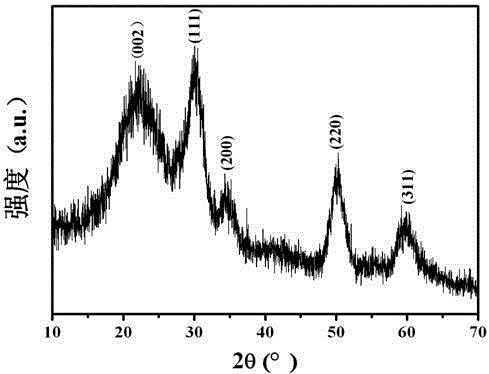

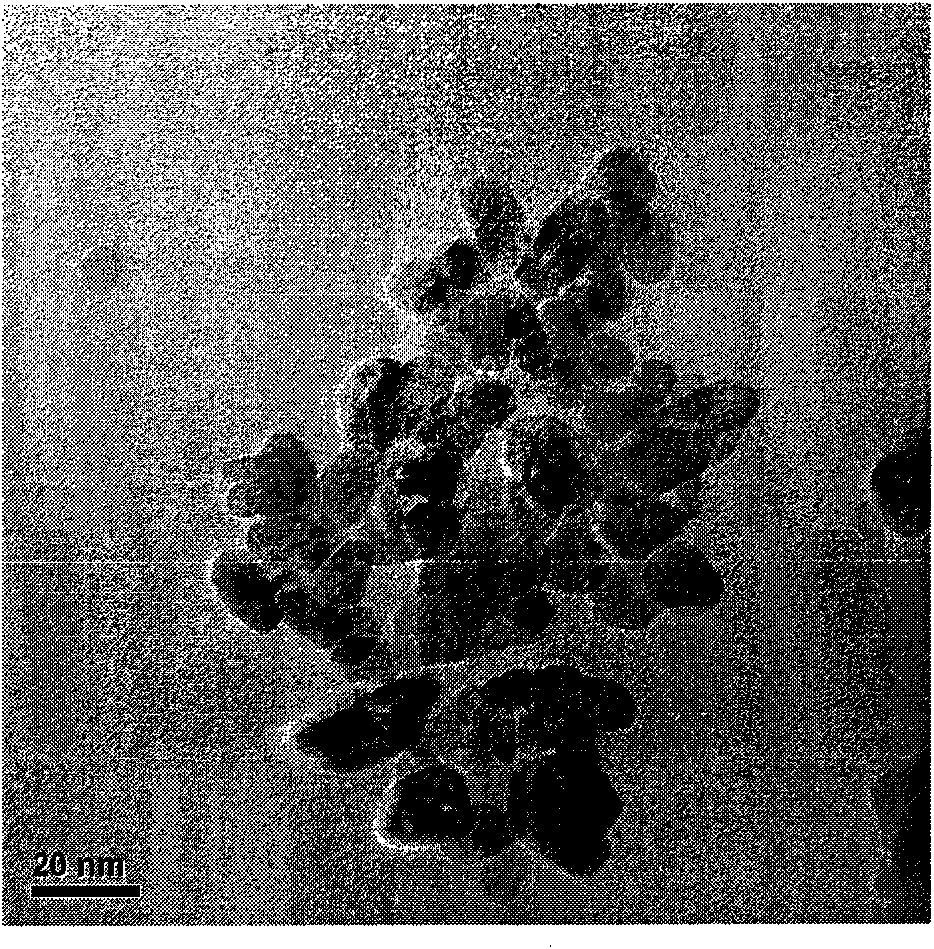

Method for preparing ZrO2-CeO2/CNTs composite nanotube by hydrothermal method

InactiveCN101767770AGood dispersionLarge specific surface areaNanostructure manufactureCatalyst activation/preparationCarbon nanotubeSurface-active agents

The invention discloses a method for preparing a ZrO2-CeO2 / CNTs composite nanotube by a hydrothermal method, which is a method for preparing a composite carbon nano tube based on nanoscale cerium oxide, nanoscale zirconia and a carbon nano tube. The preparation method comprises the steps of: sequentially adding the carbon nano tube, a surface active agent, zirconium oxychloride, cerous nitrate and deionized water which serve as raw materials according to stoichiometric ratio; performing ultrasonic dispersion to uniformly mix the raw materials; dripping ammonia water into the mixed raw materials until the pH value is 9.5; and performing hydro-thermal treatment to prepare a product, wherein the tube diameter of the prepared ZrO2-CeO2 / CNTs composite nanotube is between 50 and 80 nanometers, and a specific surface area reaches 70-150 m<2> / g; and the ZrO2-CeO2 / CNTs composite nanotube exists in the form of complete solid solution of a square / cubic system, the crystallinity reaches over 75 percent, and the ZrO2-CeO2 / CNTs composite nanotube is uniform in loading and has no agglomeration phenomenon. The method has the advantages of simple process, no need of high-temperature calcination, low energy consumption and the like.

Owner:GUANGDONG UNIV OF TECH

Preparation method of nanometer yttrium stabilized zirconia powder

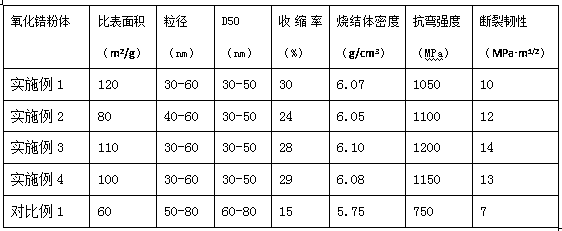

ActiveCN107628643AHigh sintering shrinkageHigh sintered body densityNanotechnologyZirconium oxidesEthylenediamineMass ratio

The invention discloses a preparation method of nanometer yttrium stabilized zirconia powder. The preparation method comprises mixing zirconium oxychloride, yttrium oxide and deionized water accordingto a mass ratio of (50-60): (0.8-1): (10-12), heating the mixture to 90-110 DEG C, carrying out heat preservation for 1-3h, adding plant gum into the mixture, then adding at least one of ethylenediaminetetraacetic acid or citric acid into the mixture, carrying out stirring for 3-5h to obtain a colloidal solution, adding an ammonia solution into the colloidal solution along with stirring for 8-10huntil pH of 10.0-11.0 so that white precipitates are produced, standing the white precipitates for aging for 24-48h, washing and filtering the precipitates, carrying out spray drying and fluid energymilling to obtain precursor powder, and calcining the precursor powder at 450-600 DEG C for 5-7h to obtain the nanometer yttrium stabilized zirconia powder. The zirconia powder has a high sintering shrinkage rate, high sintering density, good strength, good performances, small particle size and narrow distribution.

Owner:汉中市恒宝锆业科技有限责任公司

Method for preparing macropore-mesopore Ce1-xZrxO2 solid solution

InactiveCN101265100ALarge specific surface areaGood oxygen storage and release performanceCeramicwareMicrosphereCerium

The invention relates to a method for producing macroporous-mesoporous Ce1-xZrxO2 solid solution, which belongs to the technology fieldof multiphase catalysis. Currently, the synthetic Ce1-xZrxO2 solid solution has mesoporous structure only. Report on the production of Ce1-xZrxO2 solid solution with three-dimensional ordered macroporous-worm-like mesoporous structure is not available in domestic and abroad. The method comprises the following steps: preparing an ethanol solution of cerium chloride and zirconium oxychloride as metal sources and triblock polymers as soft template under room temperature; impregnating a polymethyl methacrylate monodisperse microsphere template with the solution; suction-filtering under vacuum; drying in room temperature air with a relative humidity below 40%; and burning to obtain the Ce1-xZrxO2 solid solution with three-dimensional ordered macroporous-worm-like mesoporous structure. The inventive Ce1-xZrxO2 solid solution is helpful for diffusion and has large specific surface area, and has good application prospect.

Owner:BEIJING UNIV OF TECH

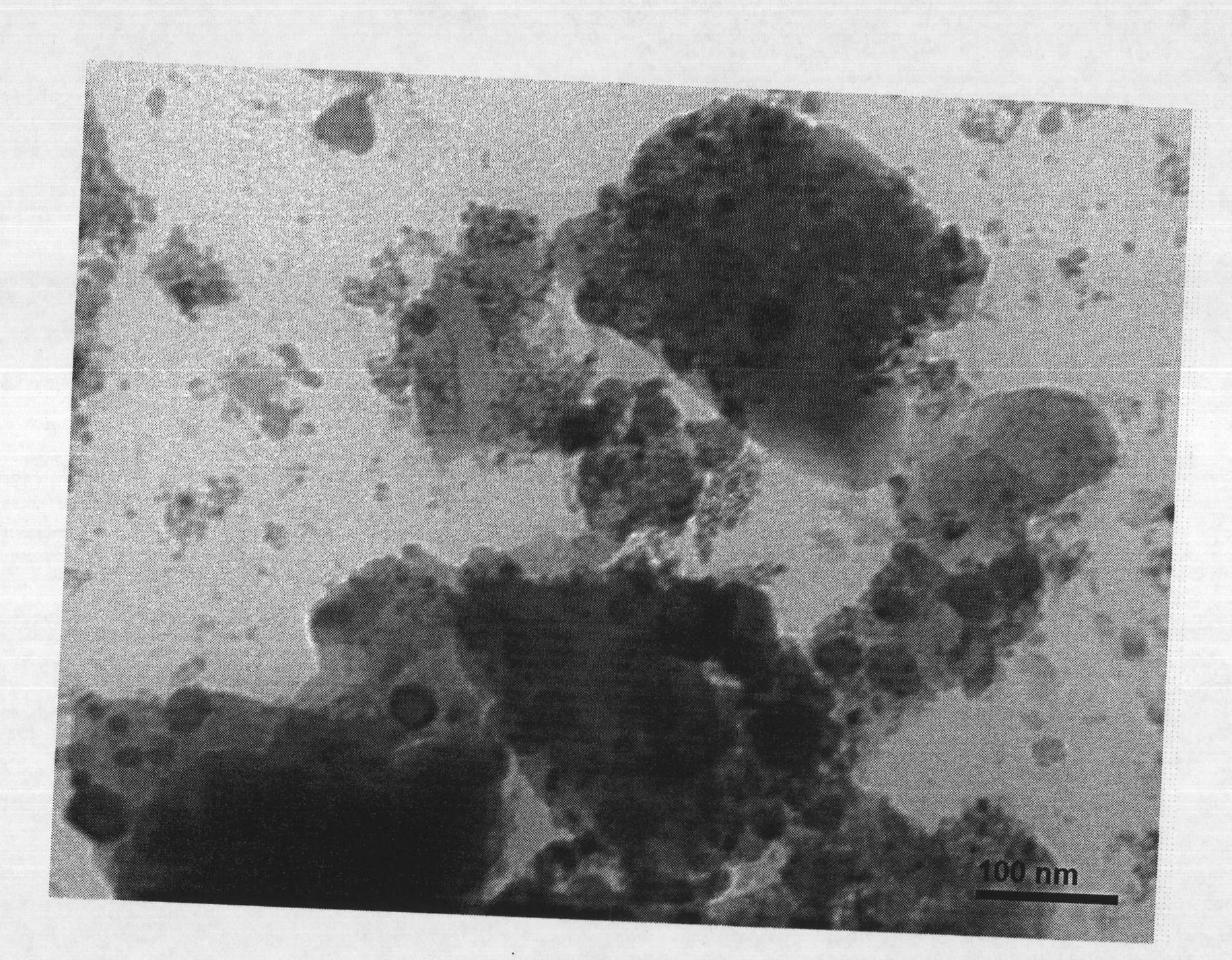

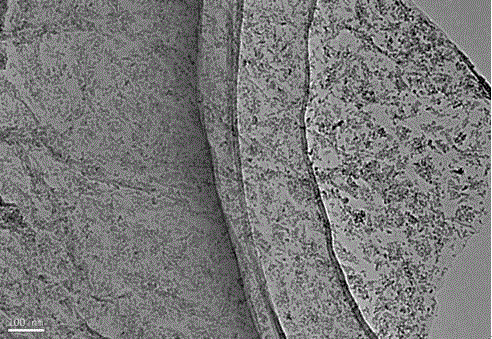

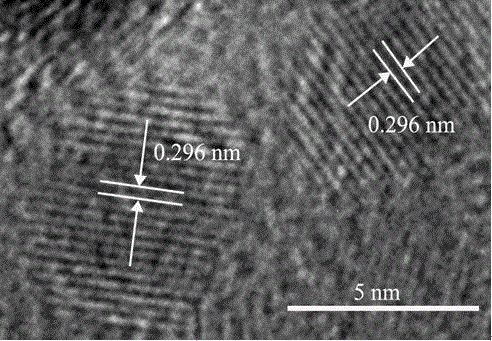

Preparation method of graphene/zirconium oxide nano-grade composite lubricating material

InactiveCN105219478ASimple processShorten the production cycleBase-materialsFreeze-dryingZirconium oxychloride

The invention discloses a preparation method of a graphene / zirconium oxide nano-grade composite lubricating material. The method comprises the following steps: a graphite oxide solution is subjected to ultrasonic treatment for 1-2h, such that a uniformly dispersed graphene oxide suspension liquid with thickness of 1-2 layers is obtained; the suspension liquid is diluted with ultrapure water; zirconium oxychloride octahydrate is dissolved in ultrapure water, such that a zirconium oxychloride solution is prepared; the diluted graphene oxide suspension liquid is mixed with the zirconium oxychloride solution, and the mixture is uniformly mixed by stirring; the mixture is subjected to ultrasonic treatment for 10-30min; hydrazine hydrate is added into the mixed liquid, and a reaction is carried out under a hydrothermal condition, wherein a reaction temperature is 150-220 DEG C and a reaction time is 18-24h; a black solid product obtained after the reaction is repeatedly washed with ultrapure water, and is subjected to freeze drying for 6-12h, such that the graphene / zirconium oxide nano-grade composite lubricating material with zirconium oxide nano-particles uniformly distributed on graphene surface is obtained. The preparation method provided by the invention has the advantages of simple process, easy operation, low cost, high product purity, and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Yttrium zirconium composite nano-ceramic powder

The invention relates to an yttrium zirconium composite nano-ceramic powder in the field of ultrafine ceramic and preparation method thereof. The components and molar percentage contents of the composite nano-ceramic powder are as follows: 5% to 8% of yttrium oxide and 92% to 95% of zirconium oxide; the preparation method includes the following steps: zirconium oxychloride is dissolved in ethanol, and then yttrium oxide is added at the temperature of 60 DEG C to 80 DEG C; cooling, sodium bicarbonate or potassium bicarbonate solution is added, acrylic ester is then added, ultrasonic washing is carried out for 20 to 30 minutes, and reaction is carried out after putting in a high pressure reaction pot; the power is taken out after the reaction is finished, and then washed, so that the yttrium zirconium composite nano-ceramic powder is obtained. The invention has simple preparation method and low cost, and industrialization production is easily realized; the yttrium zirconium composite nano-ceramic powder in the invention has the characteristics of good toughness and easy sintering; and the yttrium zirconium composite nano-ceramic powder in the invention rarely has crystal imperfection.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of marble composite polishing powder

InactiveCN102925060AFine and uniform particlesNarrow particle size distributionOther chemical processesPolishing compositions with abrasivesSlurryZirconium oxychloride

The invention discloses a preparation method of marble composite polishing powder and application of the preparation method in a polishing process of marble production and refurbishment. The method comprises dissolving 5%-18% of zirconium oxychloride in water, adding 50%-65% of aluminum oxide, adding 10%-22% of stannic oxide, adding 2%-8% of silicon dioxide, stirring to be slurry, adding 10%-25% of urea, conducting heating reaction, solid-liquid separation, drying and roasting, mixing with lead powder according to the proportion of 10-25:1, and then obtaining the marble composite polishing powder. The preparation process is simple, preparation methods are easy to control, production cost is low, and industrial production is easy to achieve. The preparation method is used for a marble polishing procedure, the marble composite polishing powder has good polishing effects, glossiness can achieve more than 98 degrees, scratches are fewer, evenness is high, and using amount of the powder is less.

Owner:UNIV OF JINAN

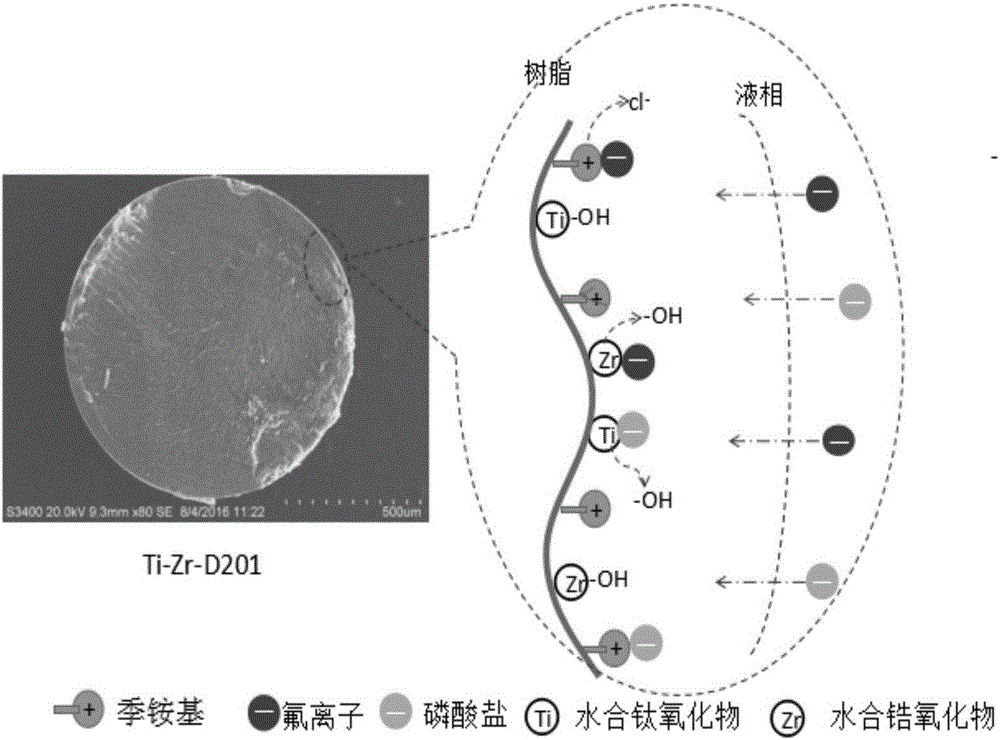

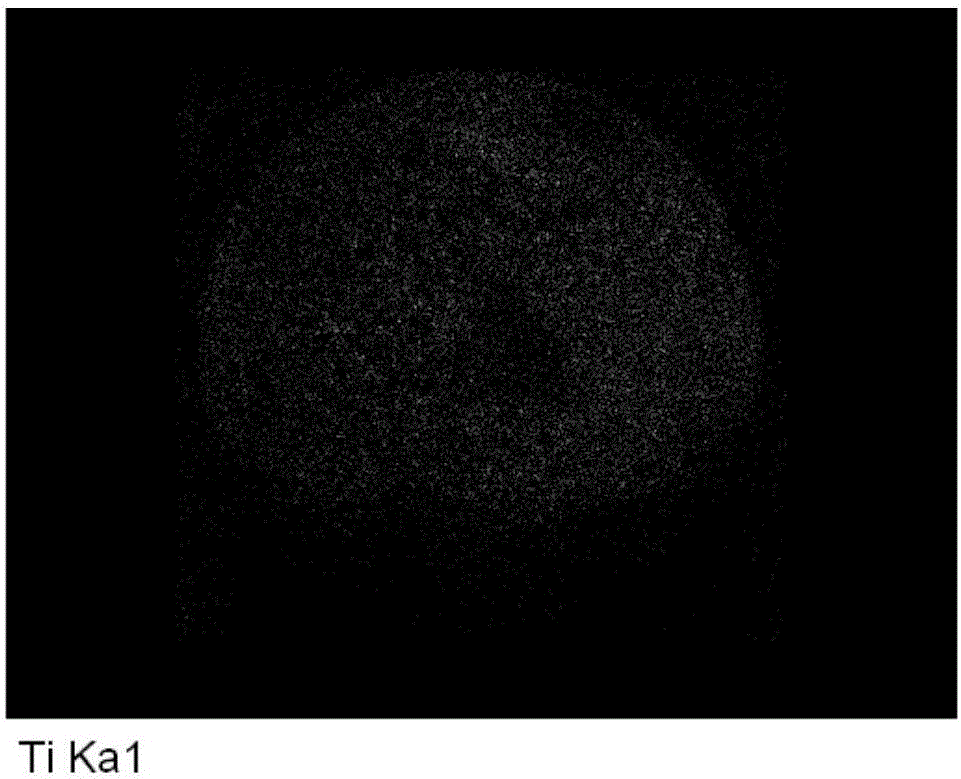

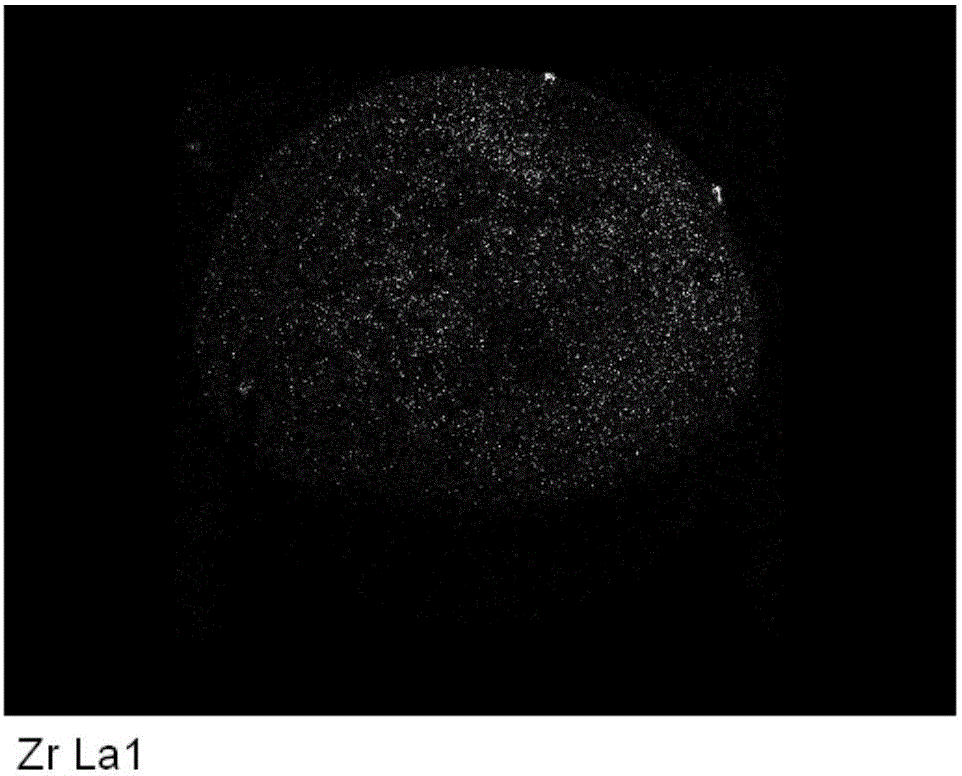

Resin-based composite adsorbent for synchronously and deeply remove phosphorus and fluorine in water and preparation method

ActiveCN106268701AImprove adsorption capacityHigh adsorption selectivityOther chemical processesWater/sewage treatment by sorptionWater bathsSorbent

The invention relates to a resin-based composite adsorbent for synchronously and deeply remove phosphorus and fluorine in water and a preparation method thereof. The preparation method includes: weighing resin, adding the resin into a prepared titanium tetrachloride-hydrochloric acid-anhydrous alcohol solution, stirring in constant-temperature water bath, filtering, drying, adding a prepared NaCl+NaOH solution, stirring, filtering, cleaning, rinsing, and drying; weighing zirconium oxychloride, adding into a a hydrochloric acid-alcohol-water solution, adding the resin which is dried to constant weight, stirring in water bath, filtering, drying, adding into a NaOH solution, stirring, filtering out, washing with water to neutral, using a NaCl solution and alcohol for rinsing, filtering, and drying to constant weight to obtain the resin-based composite adsorbent. A carrier of the adsorbent is macroporous anion exchange resin with quaternary ammonium functional group, and nanoparticles of titanium oxide and zirconium oxide are distributed on the surface and in pores of the carrier; the composite adsorbent has the advantages of high adsorption capacity, high selectivity and capability of synchronously removing phosphorus and fluorine and can be applied in deep phosphorus and fluorine removing treatment of drinking water and industrial wastewater.

Owner:NANJING UNIV OF TECH

Method for preparing zirconium oxide micro powder

A process for preparing superfine zirconium oxide powder includes such steps as reaction between ammonia water and Zr salt in solution to obtain deposit, washing, filtering, adding it to the solution of zirconium chloride oxide to generate sol, heating while hydrolyzing to obtain deposit, washing, calcining and grinding. Its advantages are controllable and uniform granularity, and low cost.

Owner:河北恒博新材料科技股份有限公司

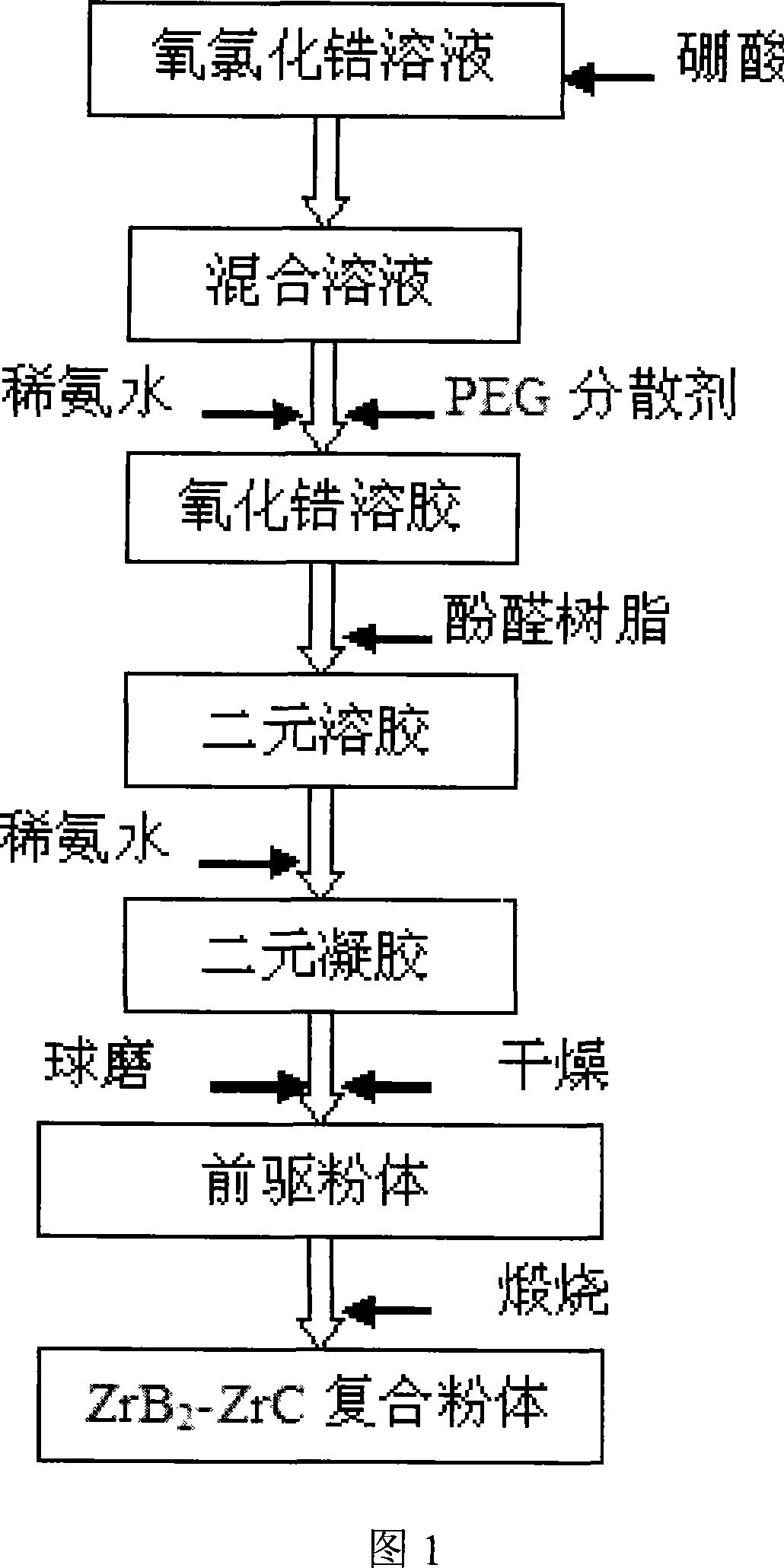

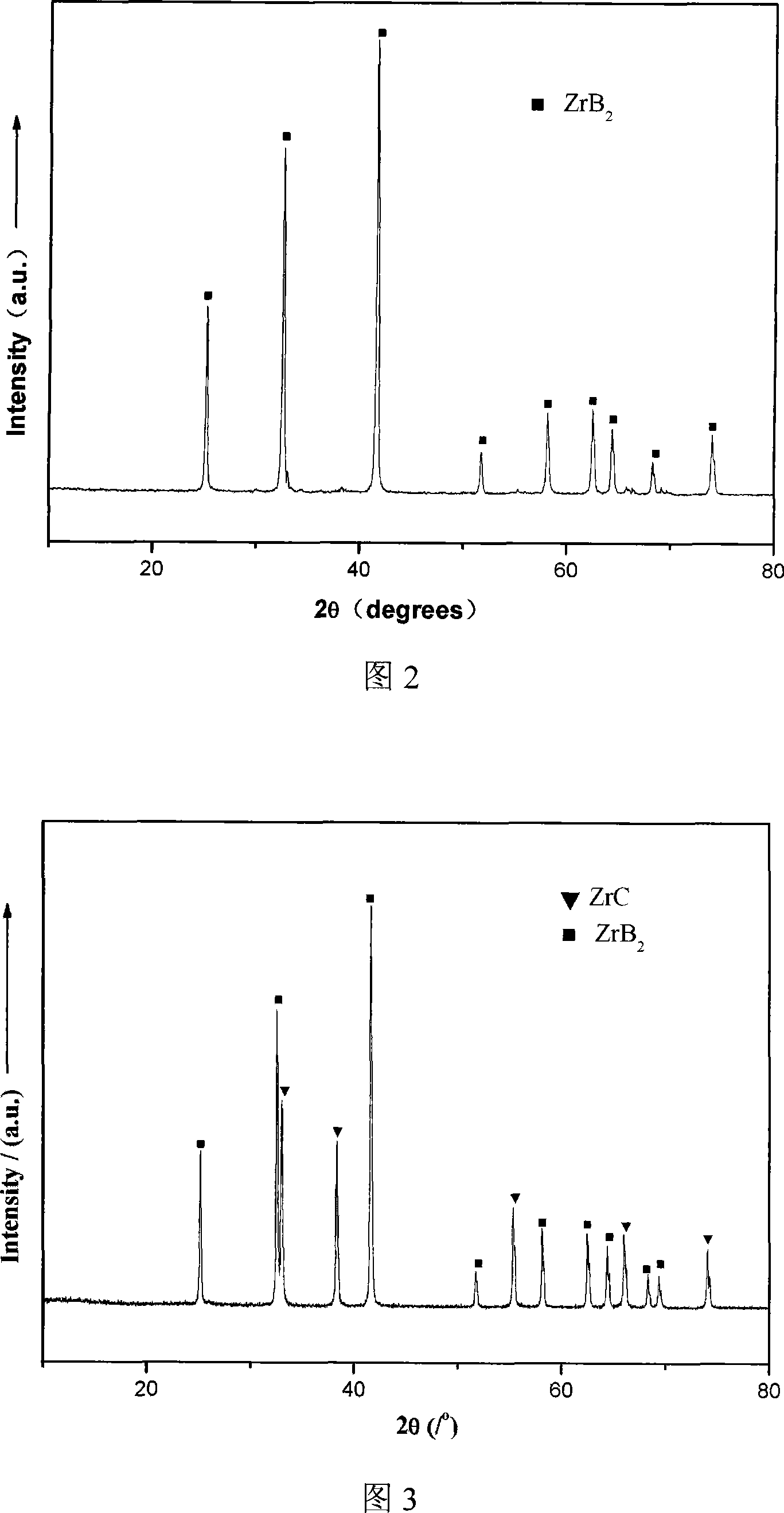

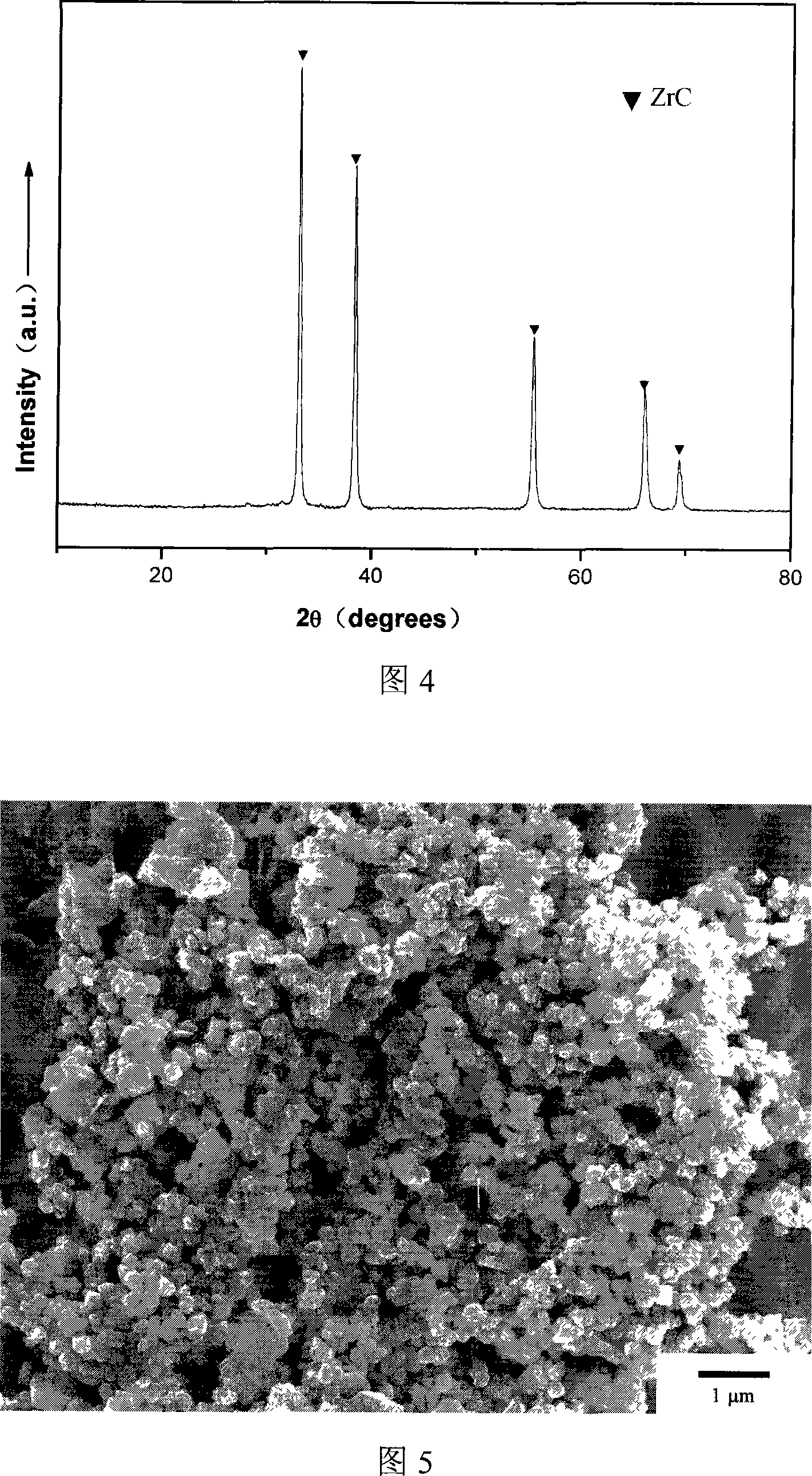

Method for preparing boron-carbon-zirconium material by liquid phase process

InactiveCN101205065AOvercoming is not easy to determine,Overcoming the disadvantages of toxic side effectsCalcium carbideMetal boridesZirconium oxychlorideElectron

The invention relates to a method for preparing boron carbon zirconium materials by liquid phase method, which belongs to the field of structural ceramics. By using carbothermal reduction as the basic principle and adopting zirconium oxychloride, boric acid and phenolic resin as the main materials, the method comprises the steps as follows: the phenolic resin is mixed with zirconia sol which is formed by titration of ammonia; then gel is formed by the titration of the ammonia; finally ball milling is carried out; after drying, screening and heat treatment, the ultrafine boron carbon zirconium materials can be obtained. The boron carbon zirconium materials which are prepared by the invention, with product granularity smaller than 200nm and excellent molding and sintering performance, can be applied to fields such as electron materials and refractory materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

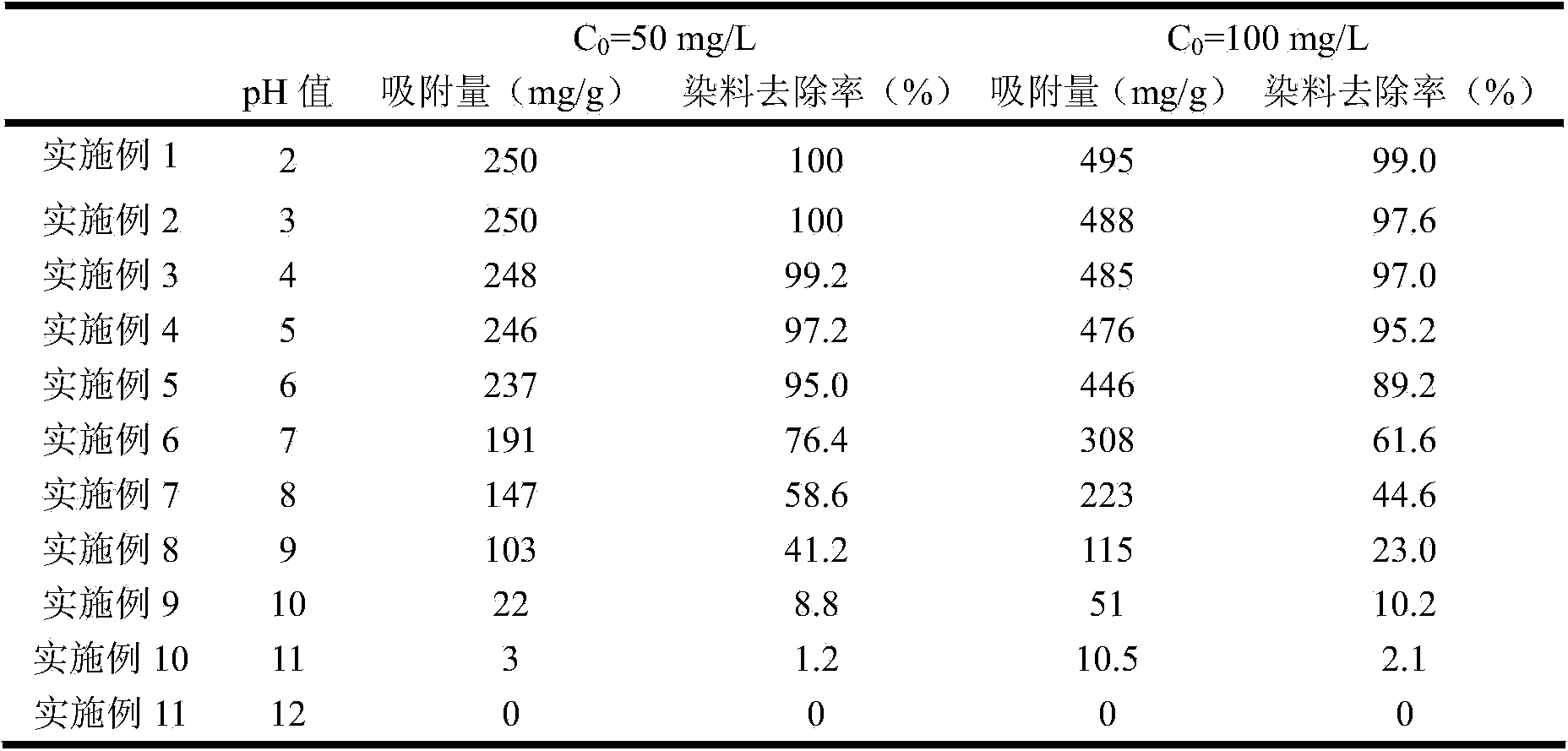

Dye adsorbent capable of effectively removing anions from wastewater and preparation method of dye adsorbent

InactiveCN103894159AEfficient removalImprove stabilityOther chemical processesWaste water treatment from textile industryCross-linkSorbent

The invention relates to a dye adsorbent for effectively removing anions from wastewater. The dye adsorbent is zirconium metal and chitosan composite microspheres. A preparation method comprises the following specific steps: dissolving chitosan powder in 2% acetic acid solution; adding 0.1mol / L zirconium oxychloride, stirring for 2 to 3 hours at normal temperature to form a uniform composite solution; spraying ammonia water or sodium hydroxide solution into the solution in a spraying mode and solidifying the solution to obtain a solidified solution; adding a glutaraldehyde solution with the mass fraction of 5 percent for performing cross-linking; stirring for 2 to 4 hours; putting the glutaraldehyde solution in the environment at 2 to 6 DEG C and continuously performing cross-linking for 10 to 14 hours; washing the glutaraldehyde solution to neutral by using deionized water after the cross-linking reaction; freezing and drying so as to obtain the zirconium metal and chitosan composite microspheres. The zirconium metal and chitosan composite microspheres adsorbent prepared by the invention has the high acid resistance and the high adsorption capacity; the density of the zirconium metal and chitosan composite microspheres adsorbent is greater than that of water; the natural sedimentation separation is realized; the preparation method is easy to operate, environmentally-friendly and low in cost, and has a good application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com